Turquoise

Energy Ltd. News #42

Victoria BC

Copyright 2011 Craig Carmichael - August 2nd 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Spotlights:

* Advanced "Current Ramp Modulation" Brushless Motor Controller made

and tested

* "Battery Sticks": Stacking dry cells in pipes makes using a

zillion of them for big (EV) batteries more practical.

Month

In Brief

(actually pretty brief this time - lots of pictures)

Electric Hubcap System

* 'Final' version Hubcap

motor: "the kit" parts photo, assembled, runs great

* IR2133 Motor

Controller Works Great (Yay!)

* Advantages of "Current Ramp Modulation" ("CRM") over "Pulse

Width Modulation" ("PWM")

* Finally a great controller (tentatively $499) for a great motor

(kit $499!)

* Regenerative Braking control! (a simple add-on control

circuit)

* Zinc undercoat: spray it on, heat treat it in oven, then spray

paint finish coat over it. Forget powder coating!

Nickel - Metal hydride Battery Project (focus:

Battery Cases)

* NiMH Battery Update: bought a pile of D cells, NiMH

prices, sold a

car battery

* Stressed solder joints fatigue with road bumps & vibration.

* New Case Design: Battery Sticks! load NiMH D

cells into Plastic Tubes. Fast. No soldering.

* Motorbike tests, with new controller... and battery sticks.

* 6V (5 D cells), 10 AH, 1 foot sticks, and 12V (10 D cells), 10

AH, 2 foot sticks: 14-20$ - batteries not included.

Electric Weel Motor Project (Electric Wheel

Motor... Rim Motor...)

Torque Converter Project

LED Lighting Project A little

energy efficient home lighting, anyone?

* The kitchen lights: 20 watts replaces 200.

* LED PVC pipe & mushroom diffuser table lamp (Similar lamps

from me: $95)

* Bedroom: Installed ceiling LED globe or mushroom Lights: Simple

- almost trivial!

* My LED table lamp seems to outshine four Wallmart LED

lightbulbs. (YES!)

DSSC Solar Cell Project

* Overall & Latest Concepts overview... but no actual work.

Turquoise Battery Project (no

report)

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor

- Turquoise Motor Controller

- 36 Volt Electric

Fan-Heater

- Nanocrystalline

reflective rear electrodes to enhance DSSC Solar

Cells

- Simple Spot Welder

for battery

tabs, connections

Products:

- Electric

Hubcap Motor Kits, Parts - Build your own ultra-efficient 5 KW

motor!

- Sodium Sulfate

4x

longevity additive & "worn

out" battery renewal.

- NiMH Dry Cell Car

Batteries (please e-mail me to order batteries)

- NiMH Custom Batteries (EVs, E-Bikes, Scooters, etc. - eg, 10 AH

36V $275)

- NiMH individual Dry Cells (D - 10 AH, $10 -- AA - 2.5 AH, $2.50)

- Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

July in Brief

July saw valuable new ideas for easily making large dry

cell

batteries and LED lights, and important electric drive components

finally

starting to come together.

I finally assembled an Electric Hubcap motor in

the planned 'production kit' form, and ran it with the newly designed

and made IR2133 motor controller. The motor ran great, but the

controller

still had some "glitches".

The parts of the Electric Hubcap motor kit

(body 'ring' parts were drilled & painted shortly after photo,

coils were redone with ilmenite)

The

motor/controller set is key to moving cars regardless of everything

else, so I then focussed on the controller. It had the very same

troubles with spurious very high currents as previous types. Re-reading

IR's app notes on driving high

power

MOSFETs led to a minor change

to the power MOSFET wiring... which cured the problem! Since then it's

been stable even at the full 42

volts with heavy loading and high stress tests. Evidently nothing more

than unshielded

MOSFET gate wires 2 or 3 inches too long caused much of the grief and

many of the blown MOSFETs and chips over the past couple of years.

But the new IR2133 controller is the best. With it I was

finally able to

verify that regen braking is done

simply by reversing the motor thrust. This causes it

to pump current back into the batteries as it slows down. A simple

add-on circuit tied into the brake pedal will activate this process.

At last I seem to

have a fine

controller, with the superior "current ramp modulation" and regen

braking, to go with the

fine motors!

'Production kit' version Electric Hubcap motor

Motor controller with IR2133 as controller chip.

Longer gate wires became twisted pairs for shielding.

Other things inevitably got neglected. The promising

[Mn/Ni]-Ni battery went untouched, as did the torque

converter.

I did do some work on the Weel motor: I put

the polypropylene-epoxy skin on the stator parts, painted the metal

center, and entered drill co-ordinates for the CNC machine. For 162

hole positions, I finally thought to use a spreadsheet to generate the

numbers instead of a hand calculator, making what would have been a

very tedious job manageable, and I got the holes drilled.

And with a dozen bright Cree XM-L-H LED emitters, I did a

few more LED house lights. And I've ordered some

more LEDs and components - this time a greater variety to try out, and

some LED drivers -

thinking also of how much fuel LED lights could save in gas cars, and

the increase in range (however slight) for electric vehicles. After

mid-month, I realized I was turning on LED house lights without even

thinking about it. I was already used to the whiteness of the light and

it seemed normal. This played some small part in getting my lowest

electric bill in decades.

Kitchen Counter Hanging Globe

2 Emitter PVC Pipe Mushroom Diffuser Table Lamp

Bedroom Globe at peak of sloped ceiling - 2 emitters pointing down

Unfortunately, no one seems to make receptacles that fit the electrical

boxes used for lights. Instead,

I had to install a light socket and put in a screw-in receptacle for

the power

adapter, after removing an unsuitable old fixture.

Typical LED light circuit

I also got some more NiMH D

cells, "on sale" at the lowest

price yet - 365 US$/KWH list. I made and sold a NiMH car battery

($275),

and I now have

250 cells available - 3 KWH - enough for

35-40 Km range with only 100 pounds of weight and for about $1500.

Unfortunately, prices (no doubt for all batteries) went up

substantially before the end of the

month, D cells (in quantity) suddenly going from about $5.80 list to

$7.20.

(A bit of a shock.) I

also note supermagnets have tripled in price and more since February.

Seems I got my supplies at the right time, and I wish I'd bought more

of everything! These things are made in China. It would seem western

society really needs to tear down

the barriers erected by corrupt vested interests to making such hi-tech

things here,

and start learning how to produce our own.

12V NiMH battery in Honda Insight

I took the

battery out of my car and checked it. On the bottom side, some solder

joints had

come loose. The weight of nearby cells was stressing some of the

joins apart on road

bumps.

I'm now trying out an entirely different construction,

putting them end to end into tubes such as 5 cells (6 volts) or 10

cells (12 volts), with tube ends that press them together for good

contact, and links between tubes. That seems to eliminate all the

problems... and the soldering... to make for cheap, reliable car

batteries. Any number of small cells are now easily employed to build

huge (EV) batteries.

And I can just sell cases and let people find their own D cells

(or AA or C?) to fill them with.

And, I wrote up my latest

thoughts on a design of DSSC

solar cells using the borosilicate glaze/glass with nanocrystalline

titanium oxide that I developed. If I have no time to work on it,

perhaps it can

at least point directions for future experiments, by me or others.

There

would be no

expensive ingredients in these solar cells, so they could potentially

become 'dirt

cheap' and solve a lot of clean power generation problems.

Electric Hubcap Motor System

Electric Hubcap motor - kit version, parts, assembly

I could have put a

motor together fastest in one of the

three first, larger diameter cases - two of them are ready to use

except for paint and

some hole drilling. But I wanted to do one in the new production size

case -- the first one to be done just as I wanted to sell as kits.

I made the first

flat plate magnet rotor in June. Now

I made the outer edge cover of the rotor compartment. I wrapped a

couple of winds of 2" PP strapping around the rotor end cover and

epoxied it, using the UHMW polyethylene disks from the molds to hold

the shape and diameter. After it set, I wrapped and epoxied a couple

more winds of

1.5" strapping on the inside. This gave a rotor outside edge almost

1/4" thick, with a flat to set the center ring/cover on and a lip

around the

edge to hold it centered. (It would have been more ideal if it made the

rotor compartment

about 1/8" or so wider. But I can't seem to find 1-5/8" and 2-1/8"

strapping.)

The $500 Electric Hubcap motor kit: all the parts spread out on the

workbench.

(Magnet rotor without magnets is shown - supermagnets and epoxy for the

rotor aren't supplied with the kit.)

At the time of this image, the body pieces still needed painting and

their holes drilled.

The coils were a reused set, from a recently disassembled motor.

From Top-Left: Magnet sensor board on inner ring, rotor

compartment cover with bearing holder & bearing,

1" axle/shaft with SDS taper-lock shaft bushing to hold magnet rotor,

plastic bug

screen, 2" wide PP strapping to hold magnets, magnet rotor,

some spacers, APP power plug housing, coils & bolts, outer stator

ring, bearing holder pieces with spacer, bearing & bearing 'cup'.

Next I spray painted the PP-epoxy parts with Dolph's

polyurethane insulating spray paint (color choice: brick red only -

source: Troy Electric motor shop) to make the surfaces heat resistant.

Then I put the bearing and bearing/planetary gear holding plate

on the

rotor side, and assembled the axle (the one set up for attaching the

sun gear) and rotor.

Next day (12th) I fired up the CNC machine and drilled the

stator holes in both pieces, and in the ones for the three larger

diameter motor cases as well.

I also took the 'used' coils apart and

dissolved off the rutile/sodium silicate, which didn't work as well as

ilmenite does. I found some of the sodium silicate seemed to have

become insoluble all by itself and there were a few sections I couldn't

get off. Perhaps if it's left dry long enough, it will all gradually

become permanent. Then I spent time sanding the coils, hoping the

ilmenite would stick better and not flake off. (It didn't seem to help.)

On the 16th I spent some hours trying to get washers for

the coil bolts. The ones I had were too thin, and when tightened turned

dish shaped instead of spreading the force. I had tried before in

passing to get some, but Rona and Capital Iron both had only the thin

ones. I knew where I wanted to go: Fastener Force. But it was Saturday.

I would have had to wait until Monday. I finally found some thicker

'metric' washers at Canadian Tire View Royal. At the end of the day I

finally had the motor together.

The next day I tried to run it out at the car. It ran, but

it didn't seem I had the phases connected right. (There are two "wrong"

ways out of six where it seems to run but draws way more current going

one way than the other, three where it won't run, and one right way. I

haven't found a system... yet... to figure them out on a new motor

besides trying them out.) While swapping wires around, the controller

made some alarming noises a couple of times, and the currents shot way

up. Then on one try it blew. Sigh!

Finished Motor, 32 pounds all up.

(finished except for bug screen - must be a better way to fasten

it than staples!)

The new motor ran

great with the new IR2133 controller on the 18th, though the

controller still had some glitches.

At about 16 volts, I

got

no-load readings of 2.2 amps at a steady 500 RPM (35 watts) and 4.7

amps at 1000 (75 watts). These are fantastic figures for a 5 KW motor!

As an indicator of how far things have come, the earlier Electric

Hubcap

motors used 250-500 watts no-load at 1000 RPM.

Recapping the big improvements:

- the PP-epoxy composite stator rings replaced the metal (disk brake

rotor) plate, reducing

magnetic drag

- the very low loss iron powder coil cores replaced the iron laminate

cores, reducing drag & current

- the ilmenite in sodium silicate coil coating creates a low

magnetic resistance path that bends 'wasted' lines of magnetic flux

around into the core, providing more flux with the same electrical

current. This innovation of mine gives it an edge over every other

motor.

IR2133 Motor Controller

After it gradually

dawned on me that low low-speed torque from the MC33033 controllers

was a big

part of the reason the car wouldn't move regardless of mechanical

designs, and after all the failures of

the

A3938 controllers I'd been trying to make since last fall, I designed a

new one around the IR2133 chip -- taking

the design back almost to 2008 when I actually got the car to move with

the IR2130 controller, but with important improvements, especially

including the variable frequency 'current ramp modulation' ("CRM", with

its

implicit overcurrent protection), and needing

only

two

chips instead of four or five.

The

IR2133 can be used as an

advanced single chip brushless motor controller. I used certain signals

and

features in (surely) unexpected ways to achieve that, not as suggested

or

implied in the datasheets, and along with the missing forward/reverse

function - one missing pin requiring a whole second chip to replace - I

have little

doubt that the maker, International Rectifier, has no inkling that it

can be so used.

The variable frequency CRM

does three things that PWM doesn't:

* From motor start and at low RPMs current ramps up quickly and the

peak allowed current is rapidly reached. With PWM when the peak current

is reached, the rest of the fixed frequency cycle is "shut off" to

prevent overcurrent, and there's no more torque until whenever the next

PWM cycle begins. With CRM The motor is only shut off for a short fixed

off period (lower 10s of microseconds), then the next cycle commences,

so (unless the PWM frequency is set high) the average current is much

higher.

* As the motor speeds up, it takes longer for the current to rise

(owing to back EMF - generated voltage - reducing the effective voltage

to the motor.) A fast switching fixed frequency PWM is then wasting

energy and making heat in the controller with unnecessary switching.

The CRM frequency will naturally drop as the current takes longer to

rise to the setpoint.

* Current lags voltage in an inductor (a motor is an inductive load),

so using current control instead of voltage control also helps correct

the phase angle of the current with respect to the actual positions of

the magnets, again improving torque. When the commutation switches as

the magnets rotate, the very first modulation stays ON until it brings

the new set of coils up to the selected current and torque using the

full available voltage. Only a control that anticipates changes of

commutation, or magnet sensors advanced from the switching mid-points,

can improve on this timing... and such measures are pretty much

academic at the Hubcap motor's speeds. CRM is simple and effective.

Sometimes I've wondered why I was bothering with my

own

design when there are

commercial controllers out there. I guess it was the lure of

potentially coming up with something better - or simpler to make - than

what exists. I think the layout is

excellent, and the "CRM" will prove better than

"PWM", which is what other controllers are probably

using.

Certainly the Electric Hubcap motors have turned out to be

exceptional, and people certainly were asking,

"Why are you bothering? There's lots of motors around." And a year ago

my only real answers were "To get that 'pancake' shape, and an easy to

build motor."

On the other

hand, after 3 years until this month I was still struggling to come up

with a controller

that really worked well at all. Certainly I - an experienced (if

somewhat dated in practice) computer and interface circuits designer -

didn't quickly understand the rigorous requirements of every detail in

multi-kilowatt power switching control circuits. I suppose while I was

grasping the basics, I glossed over some finer points in my mind -

particularly the need for short gate drive wires, and the need for

driver chips to be able to handle heavy voltage spikes in the phase

sense lines without damage.

Near the start

of the month I polished up the circuit design and board layout as best

I could think of, and

e-mailed it off to APCircuits[.com] to get the boards made.

Then I ordered the actual IR2133s and a few other parts, and was happy

to think of setting it aside for a while. The parts

arrived within 24 hours of hitting "purchase" on the Digikey.com web

site! The boards arrived the following day. No rest for the wicked! In

another day I had put the

controller together.

Motor controller with the new IR2133 two-chip controller board

But I

got my respite. I wanted to try it on a motor in the shop under

controlled

conditions, and for that I needed to put together another motor

(above). And I wanted it to be a

'final version' motor. I didn't have it

together until the evening of the 16th.

On the 17th I tried the new motor on the car's MC33033

controller. The

motor ran, but while trying to get the phases the right way around,

that controller blew, too! Now the only controller that might work

(without repair) was the new one.

In the new controller (new IR2133 PCB replacing the

MC33033 PCB) I found four blown mosfets before

even starting. No doubt a legacy of the last try on the motorbike. When

that was fixed, I found a solder blob short on the circuit board (power

to ground), and

then a

resistor that hadn't been soldered on one end. My eyes aren't

what they used to be. I did inspect the board as carefully as I

could when I assembled it, using a magnifying glass.

Before connecting

the power leeds to

the motor I checked all the voltages and signals I could think of -

uncovering a wrong value resistor and a couple of

things that needed changing.

I found that

although the datasheets said the 10 to 20 volt IR2133 inputs could

handle logic voltages "as low as 2.5 volts", it seemed they couldn't

handle any higher

than 5 volts! Higher voltages were dragged down to 5.6V. They might

have mentioned that! Admittedly there was a

clue in the "recommended operating conditions" being 5 volts max, but

"absolute max" said 15V. I did wonder why it wasn't 20 or 25V like the

rest of the chip. Had I been more cautious, I'd have e-mailed IR

tech support for clarification. I designed

the whole board around 12 volts. Now it seemed some things would have

to be

redone and a 5 volt supply added for no other reason than to satisfy

this silly

5V logic input voltage limit on a 20 volt chip. For now, I would simply

bend up

the output pins on the CMOS XOR gate and put in diodes in series to

make the gates "open drain", and allow the IR2133 to drag pull-up

resistors

down to 5.6V. That meant unsoldering the 4070. I had

socketed the IR2133 (yay for socketable DIP chips!), but not the 4070,

which seemed unlikely to blow. I

didn't have the stomach for it that day, so I made an LED light for my

bedroom -- something that was highly likely to (and did) work without

any special

trouble.

When I did connect the motor, it was through three .47 ohm

resistors. Once I had the phases right, it ran! The current ramp

modulation seemed to work great, the signals oscillating more or less

as they

should! After a few more tests, I couldn't see anything amiss or think

of anything else to do. I very reluctantly removed the

resistors before they got fried. After all the A3938 failures, I could

just see the IR2133 now going up in smoke the same way, inevitably

taking out a few mosfets with it. It didn't. Hurrah for International

Rectifier's great high voltage MOS driver chips!

After all the troubles, I was cautiously

optimistic that this controller would work well and reliably. But 16

volts

wasn't 36 or 42, and 22 max amps DC wasn't 127. So I went through a

checklist sequence:

Checklist:

- check and decrease 'short fixed off period' with smaller capacitor -

it's long

- view the currents on the scope and see what the real instantaneous

MAX current is

- try higher voltages: 24, 36, 42 volts

- permit higher currents to the desired max...

then (if all is still going well)

- try the motorbike!

Results:

- Off period is variable and short enough as is. (I wish there was some

way to add a little hysteresis to the switching - that should probably

give more uniform results.)

- looked like there were very short transient pulses uniformly of 100

or so

amps - these were no doubt

transient switching spikes. It looked like currents might be increasing

as the control was turned up - or did high currents simply get more

frequent? There was lots of hard to figure stuff on

the scope, including what looked like some RF oscillation. The

oscillation

could be seen simply by having the scope probe near the

controller with the motor running. Nothing looked really neat and

clean... except maybe the motor coil signals. I think a

recording/graphing scope would be useful.

- 24 (actually 27) volts: 40 amps, works fine

- 29 (32) volts: 45 amps, works fine

- 36 (40) volts: worked for a while, but there were some very high

currents with the

control pot turned up even part way. I saw the meter say "150 amps" and

then it

malfunctioned.

Here again, the higher voltage caused problems and major

current spikes. This time nothing blew up (luck?) - it just quit

working. It

seemed one(?) phase still worked but not the other(s), and the motor

came to a stop. When depowered

and repowered at 24 volts, it worked fine again. Seemed suspiciously

like CMOS latch-up. Prime suspect: 4070 CMOS XOR gate, even though it

shouldn't be getting anything but simple logic voltages. On the other

hand, its signals come from the hall sensors in the motor, near

the coils. In the last controller design, I had put in some

filtering... this one I didn't bother.

Another possibility was that the power mosfet maximum

voltage had been transiently exceeded and caused some sort of latch-up.

The IRFP3260s are rated for 60 volts - should I switch to 70 volt rated

IRFP3207s? That seemed less likely, though.

But on going over more of IR's AN978 application note, I

became more impressed with the need to keep all the connections short

and straight. It said "gate connections 2 inches max" - a figure I'd

long since forgotten if I even noticed it on first reading. If it's

longer,

it's an antenna. But the mosfets need to be

spread out on a heatsink for cooling. Even the driver chip itself is

1.6

inches long. This

requirement is impossible. But evidently twisted pair gate wires can

help for longer runs - the twisted pair gives common mode rejection of

induced voltages.

Evidently also, negative turn-off spikes on the mosfet

source

leeds (as well as other induced voltages) can cause the gate to become

positive compared to the source, spuriously turning the mosfet on at

the wrong time.

Spurious switching would explain much of the trouble I've

had. I

decided to shorten the gate leeds if possible, and to run twisted pair

gate wires as recommended in AN978 to all the gates. Not much I could

do about the length of traces on the circuit board, or about having the

mosfets spread out for good heat dissipation, which is just as

necessary.

-

There seemed little need to increase current limiting. If it was to

be increased, I would increase it by upping the voltage to the control

pot and having higher voltages with more noise immunity, rather than by

reducing the 'sense resistor'.

In fact, I might allow 3mV per amp with a 3 mΩ sense

resistor, and set the pot voltage to 381mV for 127 amps instead of

127mV. The noise immunity on

the current sensing should be better. But that sense resistor - 4" of

#8

nickel-brass wire - would get warm if not hot!

Next Steps...

Having similar

runaway current problems at the same voltages as the MC33033 controller

seemed to

indicate that the layout was at least a part of the problem. With the

high currents being switched, every piece of wire must be viewed as an

antenna: an

inductor, capacitor and resistor all at once. My MOSFET layout is set

up not only to keep the transistors apart for heat dissipation, but to

make for short, straight runs on all the high power signals. This is

good, but the gate leeds must reach everywhere.

Evidently the thing to do was to use a twisted pair of

wires, and run the gate

driver to the gate and also the mosfet 'source' signal to the common

return (low side) or to the

phase output (hi side). Any spike on the source is coupled to the gate,

and external

signals are "common mode rejected" - actually coupled to both leeds at

once, canceling the effect at the mosfet.

Consider the spark you get when you touch and remove a 12

volt

battery leed from a coil - it can take a notable chunk out of a

lead-acid battery terminal post. These are the sort of forces the

controller

is dealing with continuously, and it's a miracle any solid state

controller can work at all! I guess it should be no surprise that some

things you wouldn't even think about, like a few inches of skinny

wire, turn out to be quite critical.

I twisted another wire around the longer gate wires

including the 1.5" runs between transistor pairs and soldered them at

the appropriate points, ignoring only a couple of 1" runs to phase "B".

Another problem was the motor sitting there and not even

drawing current when it was supposed to start turning. Flipping the

direction switch and starting the other way usually worked. It seems to

be some problem with not getting

the floating hi-side supply charged, and I had it in 2008 with the

IR2130 too. The one advantage to having the low side transistors stay

on when the high side turns off is that the coils are pulled to ground,

charging the floating high side supply with each modulation. I've

already put in 10KΩ resistors to tug the motor lines towards ground so

the floating supply capacitors charge. So a second mod was to try 1uF

ceramic bootstrap capacitors

instead of .47uF to hold the voltage longer and get the motor to start

turning. Once it's turning, commutation brings each phase to ground

(low driver on), repeatedly charging its high side supply capacitor.

But it has to start turning first...

In IR's app notes, they talk about using "ultra fast recovery diodes".

But then they use some weird numbered diodes that aren't even nearly as

fast as a common 1N4148 fast signal diode. That's puzzled me ever since

I started, but I finally figured it out: they're selecting high voltage

diodes for line voltage motors, and the 1N4148 is only good for 75 or

100 volts. Under about 50 volts, the common 1N4148 is in fact the best

choice.

A third next step was to increase the sense resistor

from 1 milliohm to 3mΩ, making the voltage rise at 127 amps .381 volts

instead of .127. That provides more noise immunity for the current

sense. Thinking a 12"

piece

of copper wire was really long, I used a piece of #8 nickel-brass (aka

"nickel-silver") wire. Measuring the voltage drop with a 1.0 amp

current, it turned out a 4" length was .003 ohms. I didn't immediately

replace the resistor supplying the speed control pot, so the peak

current would be limited for the time being - theoretically - to around

45 amps.

Test...

With these mods, I tried out the motor on the 24th at 17V

and everything went well. It started considerably better - it usually

started turning with no trouble... unless you turned up the control

very gradually and held it back by hand, in which case it would go one

step and then cease drawing current on the next one. Then if you turn

it off a moment and try again, this step works and it stops at the next

one, etc. But the mod has helped. On further trials I found that it

seems unstoppable if you just 'tromp' on the gas a bit instead of

taking it as slowly as possible.

If it proves necessary, I'll increase the capacitance as much as may

prove to be necessary for reliable, high-torque starting. I'm not

convinced further increase from 1uF is really necessary, but ceramic

capacitors up to 2.2uF are under 50¢ at Digikey, so there seems

little reason not to order some and use them.

Success - no spurious currents!

Then I tried it at 24 volts, 29 volts, 36 volts and 42

volts and had no problems. No current readings were seen above about 35

amps. In fact, currents dropped as voltage was increased. At 36 volts I

could hardly catch it above the 20s of amps as the motor gained speed

so fast; at 42 seldom above the teens. That's a far cry from suddenly

seeing 80, 120 or 150 amps 'randomly' flashing by on the meter at the

higher voltages. The twisted pair gate wires seem to have done the

trick.

Further Tests - Higher Currents, Regenerative Braking

I increased the control potentiometer voltage to

theoretically get 100 amps peak current. If I turned the control right

up and then switched the motor on, I saw actual (average) currents up

to about 62 amps with the control turned right up. This suddenly

applied maximum power at maximum voltage is the scariest test to do.

It's where any weak point is most likely to cause everything to blow

up. But everything ran smoothly, and the motor accelerated very quickly.

I also tried reversing the motor from high speed. As I've

suspected all along but never been certain of, the current flows

backwards - into the batteries - as the motor is forcibly decelerated.

Thus, a small external control circuit could enable regenerative

braking:

* If RPM indicates insufficient speed (perhaps under about 15-20 Km/H),

disable the circuit. (This is to prevent the car from trying to go

backwards after stopping.) If the circuit is enabled:

* If "brake" is on (signal from car brake lights), use analog switch to

switch from gas pedal pot to brake pedal pot, and reverse the signal to

the direction switch in the controller.

When the car has slowed enough, the RPM sensor will again

disable this circuit. Note that if your left foot rides on the brake

pedal and presses on it far enough to turn on the brake lights, that

will override the gas pedal and you'll be braking regardless of what

your right foot is doing.

Note: The MC33033 had an

undocumented

"feature" - if the motor was turning the "wrong" way, the low side

MOSFETs shorted it out to bring it to a quick stop. So The IR2133 is

the first controller I've been able to try out regenerative braking on.

On the 29th, after getting not much of a ride on the

motorbike, I reduced the resistor that sets the control potentiometer

top voltage, this time from 39KΩ to 30K, which would theoretically

limit current to the desired maximum, 130 amps. But that limits the peak

current, and the average will be less. At this setting (and 36 volts

supply), I saw currents on the meter (amp clamp) up to 75 amps as the

motor accelerated. I had to remove the motor from the electronics bench

and C-clamp it to a separate table as everything was vibrating off the

bench. I reduced it further to 22KΩ. This time I saw one reading of 103

amps and several in the 90s. The motor accelerates so fast that only

one high current reading flashes by before currents drop off with

speed. I may never be seeing the actual maximum. Then I tried reversing

it while it was accelerating at maximum power, full forward straight to

full reverse. I wouldn't have dared try this with any previous

controller. Everything worked normally - no problems or unexpected

effects. (!) I'll try it out on

the bike before increasing the current further - the currents

might already be hitting 127 amps, which will become visible under

heavier load.

As anticipated, the

current sense

resistor got very warm - almost hot in a short time. I may have to cut

it from .003 Ω to .002 and

drop the sense voltages by 33%. There was little or no heat evident in

the power MOSFET transistors, which are around that same resistance but

the average load is shared by six (x 2 - high and low sides) and they

are mounted on the heatsink.

It certainly appears

I finally have a reliable 5KW

motor controller. Theoretically

the doubled 120 amp MOSFETs can handle 240 amps

continuous, and momentary currents up to 1680 amps(!). I don't plan to

go anywhere near those values - a good safety margin is vital, and the

motor itself would overheat if driven too hard.

"Version 2" will

have a few changes to reduce gate drive runs on

the

board to the very

minimum feasible lengths. Also since 5

volts is needed anyway, I'll replace the 4070

CMOS XOR gate with a 74ALS86, eliminating any chance of CMOS device

latch-up. Other than those points and using a 9 resistor SIP pack to

replace several pullup resistors and save some soldering and board

space (for the 5V supply), it seems good to go.

Ultrasonic Noise

Following the main testing sessions, my tinnitus went

wild, a loud, high-pitched whistling in my ears being clearly evident

especially for a day or two. I had it before recently, too, but was

unable to identify the cause... it was probably when I increased the

frequency of the MC33033 controller. It will probably take weeks to

more or less fade away.

(And I've been so careful lately, wearing ear protection at the

computer and any source of continuing noise, too, trying to get some

peace and quiet back!) The motor coils 'sing' at the modulation

frequency increasingly with the current. There's an audible squeal, but

it doesn't seem very loud. However, paying close attention, I started

to sense at the top of my hearing range that there are very loud

harmonics to this 'innocent' squeal, and I'm sure these loud ultrasonic

sounds - 15, 20, 30... KHz - are ultrasonic earritants.

This is in fact a main reason I chose to use lower PWM frequencies when

I didn't realize it made a difference to operation: If there was

irritating noise, I wanted to hear it and know it was there.

And on a car, a certain amount of sound is actually desirable, as a

warning that something is coming. Only during one of the earlier tests

did I think to

wear hearing protection part way through, since I barely hear

anything... until later.

Fortunately, the motor goes on the outside of the car

(dogs beware!), or under the hood. But if a zillion cars are using high

frequency controllers switching powerful motors, might it be a bit like

car headlights? -- individually okay, but in mass traffic lines, at

times one can

hardy bear to look towards the glare of beams pointed almost straight

in the eyes. Muffling sound is of course possible if it should prove

necessary, but it's easier and the need for it is more obvious if that

sound can be heard.

But perhaps that whole concern is best left to a future

where people have finally overcome the many obstacles and are finally

driving in numbers under electric power! It's probably a good trade

because then the rumbling and bellowing combustion engines will at last

be following the rest of the dinosaurs to extinction.

Metal Parts Coating: Heat

Treating the Zinc and Spray Painting a

Finish Coat

I read a bit more about zinc coatings. It's a good primer

that paint adheres well to, but not a good finish. It also seemed

pretty soft. I heated the finished parts up in an oven to about

225ºC, about

the temperature used when putting it on as a powder coating primer.

That hardened it up considerably, though it could still be scraped off

with a thumbnail.

I spray painted some light beige paint over top of this as

a finish coat. This seemed to work quite well. It's probably as good

as powder coating except for a less perfect looking finish - depending

on the spray paint

used.

Nickel - Metal hydride Battery Project

The NiMH Battery Project is back, this time as an

exploration of the best ways to make NiMH dry cells into batteries

rather than covering electro-chemical aspects. The quality and

potential of the chemistry can now be taken for granted, and the

problem is we want car & EV batteries and we only have AA or D

cells.

A big leap in battery design concept was made: the

elimination of soldering, by stacking cells end to end in tubes with

screw-on ends. It simplifies (almost) everything.

Battery Sale - then a big price

increase

All-battery.com had a "Fourth of July" sale on NiMH "D"

dry cells, and I ordered 140 more of them - 1680 WH. I now have 250 D

cells available - 3 KWH, 95 pounds. That's probably 35 Km or more of

Electric Hubcap travel range, and all 250 at the sale price would have

been

about $1300 to my door. Similar range with lead-acid would weigh about

270-300 pounds, take up much of the

luggage space, cost $700 or more,

and they would hardly last half as long (if!) even with sodium

sulfate

added. (Price isn't counting putting heavier springs in the car's rear

axle.)

I also have about .9 KWH in NiMH AA and 4/3AF cells if I

choose to employ them, for about 3.9 KWH total. But I'll probably stick

to using all identical cells, thought there's no important reason to do

so.

Significant for electric transport, the sale price worked

out to only 367 $/KWH, for the first time under $400. (US$ list price

before shipping, tax, etc.

Lithium types are about 500 $/KWH - straight from Thundersky.com in

China to the battery dealer - and up.) I hoped this sale was part of

the continuing NiMH price reduction trend and would be

repeated

and subceeded. (add to spelling dictionary.) Then NiMH

dry cell battery packs will become ever more

attractive and economic. Lead-acid may gradually become a thing of the

past and

electric transport more economical to purchase.

But near the end of the Month they went up substantially,

from under 6 US$ list to over 7. This probably applies to all batteries

and is part of the price trend of Chinese made products generally.

For range

comparisons: someone reports using around 100 WH/Km in his electric car

(a Canadian Electric Vehicles Suzuki Swift conversion, lithium

batteries). Another

electric car owner (self converted) with lead-acid batteries says he

only has about 20 Km range. But it gets him to work... at an auto

service shop.

I made and sold a battery for a

Honda Insight hybrid, which had (as usual) a lead-acid 12 volt battery

under the hood, that had gone bad. It had to fit in a vertical space,

and I

ended up making a plexiglass case. (an extra pound of weight, but looks

nice!) (I wouldn't be surprised if the unusual shaped lead-acid

replacement battery would have cost as much as or more than the NiMH.)

Ni-MH dry cell battery replaces lead-acid in Honda Insight.

Foam spacers can be seen filling in the empty spaces to keep it from

rattling around.

I also made a new frame to hold the

hexagon pattern I seem to be employing almost exclusively with D cell

batteries, which fits them into a smaller space.

Straight 5 x 6 cells holder for soldering "side 1" (behind)

and hex pattern holder for "side 2" (front).

For electric transport

batteries, I liked the Insight battery's vertical profile. One could

place several side by

side in a small space. I've looked all over the web for appropriate

cases - I can see having to make them. The acrylic is heavier than

necessary and considerable work. PP-epoxy?

All that of course is for new batteries. Cheapest (though

laborious and messy) course is still to scrounge old lead-acid

batteries (or buy

them cheap from a recycler) and renew them with sodium sulfate.

Another interesting NiMH thing I did was order eight 2 AH,

"10C" high rate AA cells. I used them in a new battery pack for the

cordless drill. The original packs were 1 AH high rate ("20C?") NiCd

cells that would put out as much as 20 amps (though that was pretty

much short circuit current). Since NiCd dry cells generally short out

after a while and don't last, the originals packs were long since

kaput. (To get the above specs, I tested an individual cell that was

still working.)

2 AH NiMHs supplying 10C is also 20 amps. Where the drill

had been underpowered with the regular NiMH AA cells I bought at a

store some time ago, these new ones gave it back the power it

originally had and was capable of. The double amp-hours of the NiMH

cells in effect doubles the "C" rating compared to the NiCd cells -

something that might not be readily apparent from a specs sheet. And

the drill battery was lighter and had considerable empty space in it as

the AA cells were smaller than the originals.

For electric drive, these cells would give you the most

power with the least battery on board. But they wouldn't take you very

far. For transport, 10 times as much substance at 1C rate with regular

cells gives lots of power, plus useful range.

Trouble at the Pass

Later, on two occasions I

had a short

dream just as I woke up that my car starter wouldn't turn over. Finally

one day I

took my own car battery out and had a look. On the bottom side, three

of the solder joints had come apart, and two more had weakened and came

apart when I

pulled it out of its case. The weight of the batteries was stressing

some of them on road bumps and they were working loose, and I was lucky

it hadn't stranded me somewhere.

These were soldered

quite solidly when I

made the battery in February - I tugged and twisted the wires with

pliers to make sure they wouldn't come loose - not without redoing the

occasional join.

I repaired the joins and put a piece of 1/2" styrofoam

underneath. This

should deform and help even out the weight. After the repair, the

starter

regained some zip

that said "better than lead-acid", whereas recently it had only seemed

"as good as". The fact that the car continued to start at all with

three disconnects vindicates my paralleling all the cells at every

second step to support any weaknesses. Perhaps I'll adopt stacking

cells

vertically as in the Insight battery to reduce the stress - lucky

that's the only one I've sold! Perhaps I should do even more, like put

in solid plastic supports for every cell.

New Battery Design!

Then I thought perhaps instead I should change the whole

design:

put the cells end to end in round plastic tubes (PVC pipes?) and

connect them at the ends. Someone had mentioned this being done in

hybrid car batteries. I had never considered this to be a viable

solution, automatically discarding it without due consideration: one

thinks of those unreliable little battery

compartments in tape recorders and flashlights, with inductors (coil

springs) on one end.

But the terminals at one end could screw in and clamp the whole string,

to securely tighten

the connection points and make the whole thing reliable. The plastic

ends would have just enough flex for thermal expansion and contraction.

That would eliminate all that soldering. Then, depending

on the end connections and pipe mountings, it would be simple to put

together batteries.

And it would be simple to replace individual cells or all of them.

For tubes with 5 cells - multiples of 6 volts:

* a 20 D cell battery (240 watt-hours) of 6, 12 or 24 volts, 12" x

2.75" x 2.75" (4 tubes of 5).

* a 30 D cell battery (360 W-H) of 6, 12, 18 or 36 volts, 12" x 2.75" x

4" (6 tubes of 5).

* a 40 D cell battery (480 W-H) of 6, 12, 24 or 48 volts, 12" x 4" x 4"

or 12" x 2.75" x 5.5" (8 tubes of 5).

For tubes of 10 cells/12 volts, there'd be half the tubes but they'd be

two feet long.

I got excited about this idea and spent much of the next

day, the 27th, shopping for appropriate tubes and fittings (instead of

trying out the motorbike with the new motor controller). It was only

supposed to be one short trip to Rona, but when you're trying to do

something new, anything can happen. First I looked all over without

being really satisfied with anything. I almost got some plastic

electrical conduit pipe at Torbram until I found out the price. I ended

up getting 1-1/4" ABS pipe and fixtures at Andrew-Sherret. But when

weighed, this seemed rather heavy. It would add the equivalent of 10

extra cells to a 30 cell battery - 33% extra weight. I had seen some

lighter PVC pipe at Rona, and I ended up going back and getting a

length of it and some PVC fittings. The batteries were an even sloppier

fit - oh well. It turned out that this pipe had a bigger I.D. but the

same O.D. as the others, so it took the same outside fittings.

I made up a 5 cell, 6 volt pipe with the PVC fittings,

then I realized the ABS fittings were substantially lighter and also

fit on this pipe. I made a second pipe, 10 cells, 12 volts, with the

PVC pipe but ABS end pieces. The ABS fittings used had a recessed PVC

screw-on plug, which made for a recessed electrode that can't easily

short to anything. This may be an advantage, or it may just make it

hard to connect over to other pipes. In many batteries that's done

simply with flat bars of metal with a hole at each end, but here a flat

piece won't fit on - unless an extra long terminal bolt (threaded all

the way) is used.

Construction was

simple and quick: drill 1/4" holes in the endcaps and put through a

1/4" x 1" stainless steel bolt, sticking out, for a terminal, check the

fit and cut the pipe to length, and glue the endcaps on. Slide in the

cells and screw on the removable end plug - hand tighten to a

reasonable pressure (preferably after the glue is set). They only take

10 minutes to make, and by the next evening I had 7 pipes, and nine

boxes of batteries (8 per) were loaded in. AA cell pipes would be about

the same with smaller pipe.

I'll temperature test them in a fridge, a freezer and in a

warm oven to ensure the contacts are reliable in any weather with

thermal expansion and contraction.

I made two 17 cell

pipes, 20.4 volts and 3-1/2 feet long. 14 of those could mount under

the ceiling of the station wagon (pretty much from behind the front

seats to the top of the tailgate), to provide my 3 KWH, at 41 volts,

for the Electric Hubcap system. Then instead of cargo space, they'd

take up only rear headroom that - with my usages - is rarely wanted,

and in any event is still adequate, if only just, for average adults.

The weight penalty is still 20% with the 10 cell pipe and

the lighter fittings. The 1-1/4" "irrigation" pipe and the fittings are

all a little

oversize, and the end pieces perhaps a little overkill in wall

thicknesses and strength.

There's no 100 PSI of water here. But I looked on the web for a source

for slightly smaller tubing closer to the battery diameter and found

nothing useful. Well, this pipe is good with appropriate wall

thickness. If I find lighter end fittings I'll use them, but the system

is servicable as-is. I'll replace my

current car battery, and (if all goes well with that for a few weeks),

the one I sold, and not have to worry about solder joins working loose

on the road.

So: Rather than making

and selling NiMH batteries, I'll simply make and sell D cell battery

PIPES, probably with "pipe racks"(?) to mount them.

Then people can make their own NiMH car, EV or other batteries. I'll

call them "Battery Sticks" - 12V, 6V or custom size. So simple!

Inventory will be minimal, and so will shipping costs.

On the 29th I finally tried out the motorbike with the new

controller - and with the three 12V "battery sticks". Currents hit 40+

amps. The cells are rated for 30 amp continuous, 50 intermittent. On

the first try I could soon smell

overheated plastic. I thought it was my thin jumper wire (a #10 wire

that I could yank off for a quick disconnect, there being no

breaker/switch), but it was

one of the tubes. When I made them I loaded the batteries before I was

sure the

glue was set, so I didn't tighten the ends. One got left that way, and

the poor connections heated the whole pack of batteries and the

terminal bolts going through the plastic endcaps. I

tightened the screw-on end, and it seemed to go a long ways. That was

because it was simply pushing the bolt at the far end right through the

softened plastic. On examination, I wondered if PVC would be better

than ABS. But then at the other end I found the bolt was half way

through the PVC

plug as well, so that was little or no better. Conclusion: be sure to

tighten them up before use! The enlarged hole now fit a 3/8" bolt, so I

put one in.

I got a bit of a ride on level ground. Then I got out a 6V

stick to get 42 volts, but it didn't even seem as good. I brought out

another meter (brand new - measures inductance!). The voltage measured

40 instead of around 45, and when I hit the throttle, it dropped to 31

and even 24. In a few minutes of running I had pretty much discharged

the batteries with such high currents.

(40A / 10AH = 4C = less than 15 minutes to discharge, and even less

owing to the high discharge rate - maybe 10 minutes or less total.)

In these further tests, none of the sticks seemed to get

notably warm despite the heavy currents.

I should use about 9 sticks to have 3 banks in parallel,

or the equivalent, ie the battery packs already made. But the sticks

got a good testing at high currents, and a weak point was revealed.

Melted end: the screw-on end wasn't tightened, making poor connecions

and heat.

Another test would be to compare voltages between a

soldered battery and a "battery stick" at similar high output current.

I tried that, using the "pentagon" headlights panel, and (after

measuring

voltages at the load instead of directly at the battery terminals the

first couple of times) came up with the following representative

results:

Soldered Battery (3 banks, 30 AH)

Vi=13.74, @ 40.1A after 10 seconds: 12.81V, 1' recovery 13.58V

Battery Stick (1 banks, 10 AH) Vi=13.74, @ 14.0A

after 10 seconds: 12.81V, 1' recovery 13.65V

It would certainly seem the conductivity through the

battery stick is as good as the soldered connections. If there were any

poor connections, the 12.8 volts would have been lower, perhaps

substantially lower. No telling about durability, but the soldered

joins aren't holding out well in moving vehicles, so my money's on the

battery sticks. If anyone else would like to buy one or some, I'll

happily make them. Batteries not included.

"Battery Sticks" 21 volt, 12 volt and 6 volt, recessed "+" electrodes

except on one 6V stick.

A number of possible end fixtures were found.

After making these two - 3-1/2 feet long - I decided to drop the 21

volters.

Higher current motorbike test with 6 tubes

I got six sticks mounted on a piece of plywood, 36 volts,

20 amp-hours, 60 amps rating. On August 1st I got that mounted on the

motorbike. With currents up to 60, 70 or 80 amps instead of 30 or 40,

it performed somewhat better, even managing to go slightly uphill. But

it was still a disappointing ride. (So I didn't post a video.) I

weighed the bike: 210 pounds all up. Add a 150 pound rider and the load

is 360 pounds. It did better when I got off and walked beside it, using

the throttle so I didn't have to push it uphill.

Higher currents for further performance improvement will

need 3 sets of cells in parallel, 30 amp-hours. The motor coils got

warm for once, but the transistors in the controller still felt cool.

The .003 ohm current sense wire was warm. The third set of tubes would

allow briefly pushing the motor and controller to their 127 amp design

limits.

Or a larger gear reduction (or a torque converter) would

improve performance. I wasn't measuring RPM but I expect it never got

very high. Twice the revs at the same bike speed would have given it

some good oomf.

20 AH, 36V Battery. 30 pounds for 60 cells - 38% extra over the cell

weight.

The pipes were plumbing, but the clamps were from the electrical dept.

Best easy way to mount the batteries I could see.

12 volt, 10 amp-hour, D cell Battery

Sticks (~2 feet long, 325g,

1950g full)

1 - 2 | 20 $

3 - 5 | 17 $

6 - ? | 15 $

6 volt, 10 amp-hour, D cell Battery Sticks (~1 foot long, 225g,

1045g full)

1 - 2 | 19 $

3 - 5 | 16 $

6 - ? | 14 $

(Now, must get those and the 95 $ LED table lamps onto the catalog on

the web site!)

Electric Weel Motor

On the 21st I applied the polypropylene-epoxy skin to the

first plywood stator ring, and the next day to the other one. I must

remark they seem pretty flimsy compared to solid molded PP-epoxy

composite.

Coating the rings with PP-Epoxy (non-woven PP 'landscaping fabric')

I had sprayed

zinc on the stator center plate in June, now I heat treated it. It

barely fit in the oven diagonally. (What will I do for the magnet

rotor,

which is considerably larger?) Then I spray painted it. I used up most

of a can of gloss yellow rust paint that I had on hand. It should be

much more rust-proof with the zinc undercoat, and it's a much thicker

coating.

I had marked off one of the stator rings for coil bolt

hole drilling, but I finally decided that although a CNC program would

take considerably longer to write than simply drilling by hand, it

would do a better job, and it would simplify making future Weel motors.

The waterjet places have software to automatically space

points and define lines spread evenly around a circle. My CNC system

has nothing, and I couldn't find a CAD program to download that would

do it. I could see spending many

hours with a calculator doing sines and cosines to figure out 162 X,Y

hole positions. But when I went to do it, it suddenly occurred

to me to use a spreadsheet. The coil bolt holes were listed in front of

me in half an hour. Doing the rest, and then copying and pasting them

to the CNC drill sequence programs for the two rings, took longer. It

was initially done in a morning, but there were three mistakes in the

formulas -- sine instead of cosine or "+" instead of "-"... and each

mistake was duplicated 27 times. The corrected numbers all had to be

copied, pasted, and rounded off to three decimal places again. But the

bulk of the anticipated long hours of tedium were

eliminated. I kick myself for not thinking of using a spreadsheet when

I did the

smaller motors! Within two days I

had the stator ring holes drilled. Until now I had considered the CNC

machine

to be "overkill" in size compared to my needs, but a 30" x 30" bed is

none too

large for a 28" x 28" piece - I had to shift the center point a couple

of times to get it to work!

Later I drilled and tapped the 27 mounting bolt holes in

the metal stator center piece (3/16" steel, 19" diameter). Wow, 27

holes in two separate pieces that all line up! That would have been a

painstaking manual job without the CNC machine. I didn't think to do

any bolt holes in the plate to mount the motor in a vehicle, or to

mount the triple motor controller on it - in fact, I haven't really

thought much about arrangements for them.

Next would seem to be to coat the coils and wire them on.

But I've decided to put a second layer of PP-epoxy on the stator rings

to stiffen them up, so that comes first.

Torque Converter Project

In getting the motor controller running, I've done nothing

on the torque converter. But here's a little second hand report on

somebody else's attempt to improve the drivetrain.

They are developing a gear transmission especially for

EVs,

and

claiming it'll give 15% efficiency improvement. That's the right

direction, and the first time anybody seems to have tried to do much

about all the nasty drive train losses or awkward RPMs that sap

performance.

http://www.gizmag.com/...

[article link]

"the efficiency of electric motors still varies at different speeds -

they operate at a peak efficiency of around 90 percent but this can

fall to 60-70 percent, particularly at low speed. The question is

whether or not it's worth adding a multi-speed transmission to the EV

drive-train to optimize efficiency at all speeds. According to Antonov,

the answer is definitely yes."

But is it really so different from other gear

transmissions? Bypassing the

drive shaft and turning the wheel from the outside with a mechanical

torque converter should still be better in all respects, except for

sticking out from the wheel.

LED Lighting Project

Conclusions first...

I did some more LED house lights - the kitchen ceiling and

counter, a table lamp, and my bedroom ceiling. Here are my main

conclusions:

* BAD: Screw-in 120 VAC LED light bulbs seem to be an awkward solution

for LED

lighting. The ones in the stores now seem like toys - very expensive

toys - compared to the emitters I'm getting. LED lighting seems to call

for new solutions with

low voltage DC power. At this point, that appears to mean

buying LED emitters and

making your own lights. There are some LED emitters and 12 volt DC

designs locally at RV and marine places (Industrial Plastics has a good

selection), but the real solution for house lighting

seems to be to buy them off the web, eg, at ledsupply.com or

dealextreme.com, and run them with power adapters.

* GOOD: The best actual tiny LED

emitters made

for lighting have great quality white light and use next to no power.

Diffusers covering all directions are absolutely necessary as these

'point source' lights are so

bright they can damage the eyes. Aluminum heatsinks are also required

since all the power goes into that tiny emitter and electronics can't

run anything like as hot as light bulbs. In the course of doing several

lights, I've found a pretty decent 'standard' or 'general'

configuration using off the shelf parts.

* POWER: The bright lighting LEDs seem to drop about 2.9 volts, or 8.7

volts for the "triples". The simple and best way to power LED lights

from 120 VAC seems

to be with

DC power adapters. Specifically, 3, 6,

9, and 12 VDC adapters that will supply an amp or more are good for 1,

2, 3, and 4 single emitter LEDs. 9 VDC adapters rated for 350 to 500 mA

are good for triple emitter types.

Use a small series resistor (eg, 1/2 ohm, 5

watts) to set and limit the current. Keep the current below the

adapter's

rating, eg, maybe 800 or 900mA for a 1 amp adapter. At and above the

rating,

the power used from the AC line goes up sharply without supplying much

more current to the LEDs, reducing the efficiency and making the

adapter run hot. With most power adapters, an extra filter capacitor in

the circuit appears to be necessary to minimize 60 Hz flicker/strobe

effects.

* LED CURRENT: The emitters are most efficient and run coolest at 1/4

to 1/2 their maximum rating. And they'll probably last longer than you

will at those levels. The "2.9 volts, 1000 lumens, 10 watts" emitter

will supply considerably more than 500 of its lumens at 5 watts. I'm

running them at about an amp, which is only 3 watts but perhaps 400

(?) lumens or better. The 9 volt triple emitters use triple the

voltage,

1/3 the

current, for similar power and light output. The 'maximum rating' is

just the top end of where they won't quickly burn out (given a

sufficient heatsink), not a

recommended or efficient operating power level.

* LIGHT DIMMER: A 'universal' power adapter with a switch having

several voltage

settings makes a great 'light dimmer' where several lamp brightnesses

can be selected.

* THE PATH AHEAD?: LED

lights powered by power adapters can quickly be manufactured and

commercialized.

I'll even do one-off globe or mushroom diffuser LED lights

similar to those shown myself, for $95. The lamps are especially simple

to use: just buy one and plug in its power adapter. With an

external a power adapter, it needs no 120 VAC electrical safety

ratings. (Good

news for crafts lamp makers!) They still need the heatsink and should

have a fuse.

But retrofit

installed LED lighting is almost as easy, done the same way - as long

as a power adapter with a visible wire to the light isn't considered

too objectionable. The base, a 3" PVC pipe endcap, is simply screwed to

the ceiling or wall. The power adapter is plugged into the old light

fixture with a screw-in power receptacle, so it runs off the original

light switch. There's no wiring, so the light can easily be moved or

removed if desired, leaving only a couple of screw holes.

For new installations, eventually there'll be complete

light

fixtures with everything - power supply, LEDs,

diffuser - all built in. Or perhaps new buildings will

start installing low voltage DC wiring for lighting and drop the heavy

AC light

circuits entirely.

For installed lighting with external light switch, just drop the on-off

switch.

For three LEDs in series, use 9V power adapter.

(3V for one LED, 12V for 4)

When checking LED current at resistor, be sure emitters are facing away

from you or are covered.

I should probably mention that I like

brighter lighting than most people seem to. As far as I'm concerned

(and within reason),

the more light the better. I like to heat my office with lights and

have both warmth and brightness to ward off SADS on our overcast

Pacific northwest coast short winter days and long nights. Elsewhere,

and in warm weather, I

could save considerable energy with more efficient lighting.

I ordered a dozen more of the super bright LEDs. When they

arrived, I put 3 in series into the kitchen central light, powered from

a 9 VDC, 1 amp power adapter, again plugged into a power plug socket

that screws into the light bulb socket. A few days later I did 2 in

parallel for the light over the sink/counter with a 3 VDC, 2 A adapter,

this time hanging a small (6") frosted globe from the ceiling. In both

units, I ended up putting .47 ohm, 5 watt resistors in series with the

LEDs to limit the current to 1 amp.

The light is whiter than any other type of lighting. With

one LED in a room (4W) I call it "ultra bright moonlight", with

somewhat more it might be called "pale" light. In the literal sense

it's a cold light - you no that no matter how bright it is or close it

you get to it, it has no heat to it at all. My early impressions are

that I like it better than tungsten and much better than compact

fluorescent (CF). It may be better for preventing SADS, and I suspect

it's better for your eyes. Perhaps when it becomes common, fewer people

may end up wearing glasses?

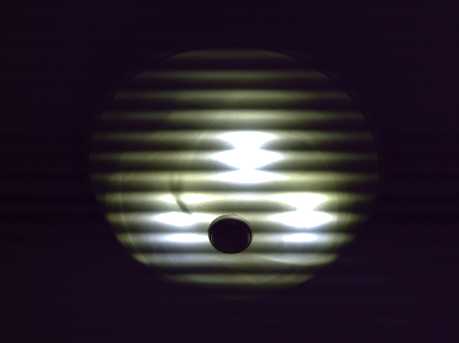

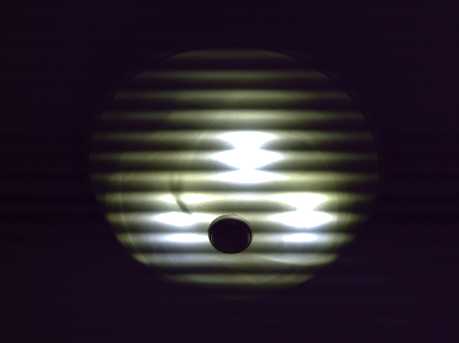

Kitchen Ceiling Center Light

As I expected, the patterned ceiling light glass in the

central fixture didn't diffuse the 'point source' LED's light as well

as the globe light did. It was good enough, but plain frosted gives

much better diffusion.

I noticed there was a

strong strobe effect, too - like old (or new) 60Hz fluorescent tube

fixtures. Evidently

that power adapter didn't have much of a filter capacitor in it to

match its one amp rating!

Kitchen ceiling - center, LEDs mounted in the original fixture.

But using the original fixture seems to be the hard way to manufacture

LED lighting.

On: strobe effect interacted with camera to create this odd pattern.

Someone asked about

the efficiency of

using power adapters, so this time I checked it out: the AC power going

in versus the final DC power out to

the LEDs. But my DVM has two current ranges: 0-300mA and 0-10A. When

I put it on the high range, it read .16 (occasionally .17) amps. That

didn't seem like the best resolution, but when I put it on the low

range, it would flash "overflow"... and then instead of reading around

160mA, it read 32mA - 1/6 of the other reading.

readings:

120V AC: 160mA (19W) or .032A (3.84W)

9.0 VDC: 1.2 A (10.8W)

So we can believe

almost anything from

the transformer using up to almost 9 watts (so, only 56% efficiency),

to having it

magically deliver the 10.8 watts to the LEDs while only drawing 3.8

watts from the mains (281% efficiency - zero point energy!). For 100%

efficiency it would have drawn .09A.

I decided to check

it out with some other current meter before

drawing firm conclusions.

After several hours

the heatsink and the power adapter got pretty hot, and I decided to put

in a resistor and a couple more bits of aluminum for heatsink. (The

fixture would have more room without those silly lightbulb sockets in

it!) I used a 5 watt, .47Ω resistor. This time I measured the AC

current with an amp clamp on a split-wire extension cord. That gave:

120 VAC .09 or .10 Amps (11 - 12W)

DC: 1.0 amps (9W)

I neglected to measure the DC voltage, but since the power adapter load

current was reduced, and because I put in a 4700uF capacitor to stop

the flicker (it worked), it would surely have been no less than before

- 9 volts. So the resistor didn't reduce the output much, and the

efficiency seemed to be over 75% - perhaps partly the meter, and partly

because the adapter was now operating within its one amp output rating.

That's more like it!

Kitchen Counter Light

At first I thought I'd try fitting two or three plastic

dome lights over the kitchen counter, but the fact that they weren't

made for such mounting, plus the need to get the wires from one to the

other looked like it would be troublesome. In addition, I thought maybe

if the light was lowered, it would light the sink and counter better.

This suggested a hanging globe light.

I found a 6" frosted glass light globe at Canadian Tire,

and I got a white PVC plumbing pipe end cap for a cover. I put 3 screws

through the PVC to hold the glass on, and a 3" piece of 3/8" lighting

fixture pipe for the wires and to hold the works via the center of the

aluminum heatsink mount. I drilled 3 extra holes in the end (the top)

to let heat out. This globe I hung from the power adapter cord. The

power adapter was at the ceiling plug so only the 2 LEDs and their

current limiting resistors were inside the

globe.

Kitchen counter hanging 6" globe light

The two LEDs face down.

120 VAC: .09A (10.8W - amp clamp), 1.1A (13W - DVM)

3.38 V (unit), 2.90 V (an LED), 1.0 A - (6.8 W from adapter: 5.8 W

LEDs; 1W resistors)

Assuming the amp-clamp reading was right (given some weird

readings with the DVM), the efficiency was still only 54%. Evidently

the higher voltages with LEDs in series reduce the losses. There was at

least an extra 1/2W owing to the second resistor, and probably more

transformer losses owing to the higher current, with nothing gained by

the low voltage.

The light had some flicker, and I decided to pull it down

one more time and add a filter capacitor: if it's going to outlast me,

it should at least be done best.

Inefficiencies and all, now the entire kitchen was about

25 watts for light, with about 15 watts of actual light.

I couldn't decide if the kitchen was as bright as it was

before with two 100 watt bulbs - the difference in color of the light

made an exact comparison very much a subjective judgment. Adding a 100W

lamp on the kitchen table naturally brightened the room, but it did

before, too. This time the color difference with and without it was

also quite notable.

Store-bought 120 VAC LED Bulbs

Canadian Tire had a selection of ready made LED bulbs for

line voltage, from night lights to a 10 watt, 450 lumens bulb... for

$60. That's probably about as bright as each $9 emitter I'm using, and

it looks like their efficiency is under 50%. Somehow spending over $200

to

replace a $1, 1700 lumens, 100 watt bulb with 1350 lumens of LEDs in 3

bulbs seems uneconomic to me in spite of the 70 watt electricity

savings. The story was much the

same at Zellers. They seemed like toys - pricey toys at that.

Nonetheless, I

bought a couple of cheaper ones to compare.

One was a dull (60 lumens) decorative "candle" light for $15. Judging

by the shadows in a hallway chandelier, it seemed substantially

brighter than a whitish 7W CF bulb, but not as bright as a yellowish

one.

The other was a 2.2W 'spotlight' of only 100 lumens for

$20 - again not much 'bang for the buck'. I tried it over the kitchen

sink. It gave sufficient light over

the sink, but the dishrack to the right and the counter to the left

were left in relative darkness. My 5.8W globe gave brighter light even

on the sink, and this brightness extended in all directions.

Furthermore, the spotlight had the worst strobe of anything I've ever

seen - I think it must have been turning fully off as the AC crossed

zero. It was for that reason

unpleasant to wash dishes under.

I've heard the filter capacitors dry out and go first, but this bulb

didn't even seem to have one. And of course, there was no way to add

one to the sealed unit. The heavy glass construction seemed out of

place for a solid state, low voltage light that had almost no heat. Why

not lightweight plastic?

Screw-in LED bulbs will probably come down in price and

rise in brightness, but I

don't think they're a very appropriate format for LED lighting. LEDs

are inherently a low voltage, low power DC light. The power adapter

approach despite its inefficiencies appears to be the more efficient,

and it's more flexible: the power adapters can be replaced, replaced by

batteries

if required, or by low voltage DC wiring as desired. (I think it would

be worth considering putting in low voltage DC house wiring for

lighting for new construction.)

I think in general permanent LED house lighting fixtures

should be made complete with appropriate LEDs, rather than considering

the LED as an accessory to be screwed into place later by the user. But

as I tried things out, I discovered that making globe or mushroom

diffuser fixtures to replace existing light fixtures was simple to do

-- if one uses power adapters, no wiring is required.

LED Table Lamps

Doing the globe over the kitchen sink gave me an idea for

LED globe or 'mushroom' diffuser table lamps. A freestanding LED lamp

would simply have a power adapter plug on the side and a small power

switch. Here's a universally applicable idea, capable of infinite

variation by designers and crafts lamp makers!

I found that while the globe fit into the 3" PVC pipe

fittings that fit over the pipe, the lip of the mushroom's hole was

slightly smaller and fit into

the 3" pipe itself. This suggested that the simplest LED lamp structure

was a mushroom diffuser, a 3" pipe of the desired length, and a base of

some sort. A frosted plastic diffuser

could be better - then the lamp would be lightweight and not fragile.

But glass ones

are what's available, since plastic wouldn't take the heat of

incandescent bulbs. The only plastic diffusers I've found so far are

the small battery dome light ones.

* Take a length of 3" PVC pipe

* Mount the LED emitter(s) on a heat sink held showing above the top of

the pipe

* Drill holes for adapter plug

and switch, and wire it all up according to the diagram below

* put in 3 screws 1/4" from the

top about 120º apart, and mount the mushroom diffuser covering the

LED(s). (WARNING: Don't look at lit LED emitter without diffuser - it's

bright "like welding arcs"!)

* put it on a

table and plug in the adapter, and turn it on!

6" mushroom diffuser table lamp with switch

The two LEDs face left

and right, hence the darker band in the middle.

General LED lamp circuit with 2.9 volt LED emitters.

An installed light fixture doesn't need a switch if it's run from a

wall

switch.

I threw the first

'mushroom' lamp together with two emitters and a .27 ohm resistor, and

a power adapter plug at the bottom of the PVC pipe. The only suitable 6

volt, 1 amp power adapter handy was my 'universal' one with settings

from 3V to 12. It turned out that the different settings made for a

great dimmer switch with several brightness levels, each a little

brighter than the last!

It also showed how the power adapter's efficiency drops