Turquoise

Energy Ltd. News #100

covering May 2016 (posted June 3rd 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features:

* Planetary Gear Variable Torque Converter is The Ultimate

Automotive Transmission! (see Month in Brief, Electric Transport)

* Permian Period Revisited: The Age of Evolving Amphibians, not

Reptiles (Special report)

Month In Brief

(Project Summaries)

- Variable Torque Converter Transmission... & crab fishing -

Permian Period Revisited - Commercializations?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Mexican Silver Money - Financial Collapse Timeline?

- In Depth

Project Reports -

Permian Period Revisited: The Age of Evolving

Amphibians, not Reptiles

Electric

Transport - Electric Hubcap Motor Systems

* Electric Hubcap motor, Chevy Sprint & Variable Transmission -

Conclusion: PGTC looks like the ultimate auto tranny, May's

frustrations solved... I think - miswired phases - better planetary

gear?... buy it! - Stronger Spring - Various experiments and

adjustments with springs and mountings

* A small note on permanent magnet assisted motors: just by luck I made

the ARM motor that can be converted

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation (no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc.

-

Source of Electrolyte - Oxidizing Graphite for the Positrode - Nickel

Ion Battery: another form of nickel-nickel cell

No Project Reports on: I'm

dropping this section. In theory I've felt it's good to be able to see

quickly if there's been no activity in an area of interest rather than

to have to read through to find it's not there by omission, but it's

probably more confusing than anything... especially to me to decide

what to include as projects and project ideas evolve and morf. I now

put what is covered in "Month in Brief" in the contents under that

heading, so if something is even briefly written about anywhere it'll

appear somewhere in the contents above.

May in Brief

My work at AGO continued to eat into project time until I

finished the jobs

in mid May.

Planetary Gear Variable Torque Converter (PGTC) Transmission in

Chevy Sprint

Other than that I persevered rather doggedly with the

frustrating Sprint Car transmission project. It soon became evident

that the PGTC system actually worked just fine from a stop. Nothing

else is needed to get the car rolling, and the 'final drive ratio' to

the wheels following the converter is almost irrelevant.

What was relevant, the missing point I finally figured out

about the end of the month, is that the maximum torque out is dependent

on the maximum speed of the slipping gear, so with a lower PRM motor,

getting the most is dependent on configuring it with the slipping gear

as the fastest turning gear. Instead I had the motor on the fastest

gear, so everything else ran more slowly, and the torque conversion was

at a disadvantage. As configured it's a demo.

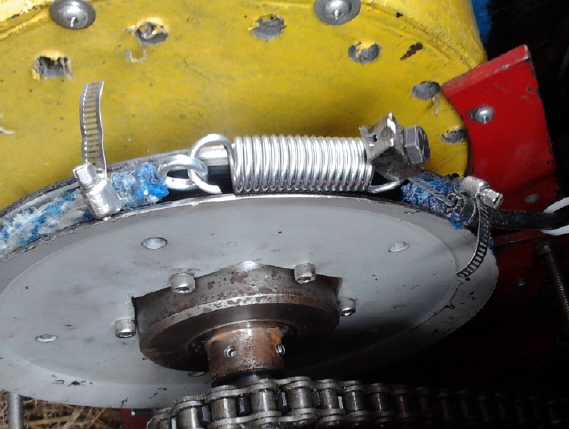

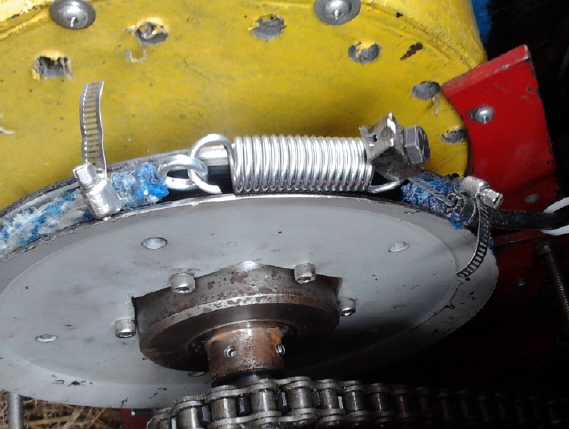

Sprint with torque converter et al. New is the

mounting bracket and lever

Sprint with torque converter et al. New is the

mounting bracket and lever

for the tensioning cable to better pull the tensioning rope.

Newly realized is that for maximum torque, the slipping pulley with the

rope should

be on the sun gear instead of the planets assembly, to turn at a higher

speed.

Until then it was a perplexing mystery why the car worked

fabulously at lower torques, but simply seemed to jam up with friction

on higher ones - if it needed more than about 20 foot-pounds of torque

at the mechanism's output shaft. That meant it wouldn't climb hills and

couldn't be taken out on the road.

I thought it seemed perhaps to have something to do with

the spring in the tensioning system. By the 17th I had a stronger

spring and was ready to install it.

But just before I

started working I was invited to go crab fishing. Here on the coast

that might be a valuable life skill at some point if food gets scarce,

so that day I bought a "clamshell" crab trap (16$ at 'Capital Iron' in

Sydney) and a fishing license and learned how to fish for

and identify crabs. I caught the allowed limit of 4 male

rock crabs off a wharf. In fact, we continued fishing and I threw the

two smallest ones back and kept two larger ones. (Grab them by the rear

legs so they can't pinch your fingers with their claws. I'm sure that

would really hurt.)

With the new spring it seemed to work a little better.

Then I made a 'proper' mounting for the slipping gear pulley tensioning

system. It still did up to 20 foot-pounds very smoothly, but still

jammed above that. I ran the car a couple or a few times most days and

scratched my head over the problem. What, what, could be wrong?

On the 25th I discovered that the pulley was being pulled

off-center by the tensioning rope, and I thought for a while that that

was the main problem. Perhaps at higher torques perhaps it was more or

less jamming the gears together, creating high friction.

But in looking for a more suitable commercially made

planetary gear and thinking of how to configure it on the 31st, I

finally realized what I believe is the actual problem. A certain amount

of torque slips the slipping gear, depending on rope tension. The

torque available at the output isn't infinite. It depends on the

slipping torque times the relative gear ratios of the slipping gear and

the output gear. The motor only runs so fast, so the slipping gear only

turns so fast, and at top speed, only 20 foot-pounds is available at

the output. More tension only slows down the motor and hence the

slipping gear without increasing the available torque, so if that same

torque won't budge the car, everything grinds to a halt. The means to

increase torque then is either to have a faster motor, or to have

higher intrinsic gear ratios, even tho any ratio above the fixed ratio

can theoretically be obtained. If the sun gear was the slipping gear,

the pulley would spin much faster and it would probably work up to a

much higher torque.

Apparently that has been the main problem with the

Planetary Gear Torque Converter (PGTC) since I first made it in 2012.

Why didn't I try other configurations earlier? It will be darned hard

to change it - a complete rebuild. I may set it up using the best

planetary gear I can find, with CNC waterjet cut metal chassis parts.

Assuming it works the experiment would double as the first pass at a

production design.

Then I started to think that with the slipping (sun) gear

shaft sticking out one end and the motor (planets) shaft sticking out

the other, and the ring gear in the middle with the chain drive

sprocket (or the original gear) to the differential, I might be able to

use the original transmission chassis, hacking it as required and

replacing all the crap inside with a single planetary gear. Then it

would be sealed to have gear oil and so solve the gear and chain

lubrication problems, keep the dust out, and it would fit some of the

original mountings.

When the torque has been within limits, I've now seen what

an amazingly smooth running variable system it can be. I think it'll be

"the ultimate auto transmission" when configured properly. All that's

needed is for the gear to be configured right.

The Permian Period Revisited

Starting in April but especially for most of May I stuck

my nose into paleontology,

where I wanted to find out more about the evolutionary transition from

amphibians to reptiles. I've never felt I had much to offer on this

sort of subject before, but as I delved into it, it gradually became

clear to me that important parts of the story had become confused by

past mistakes and that the Permian virtually needed a fresh start, a

re-evaluation, to clear them away.

Until perhaps the 1960s(?) there was perhaps little

distinction in most peoples' minds or in scientific nomenclature

between what then became known as 'amphibians' and reptiles, and this

surely played its part in creating the confusion. Prior to that,

"amphibian" was purely a functional term, and otters and seals were

called amphibians because they lived in water and on land.

Small reptiles were being assumed to have existed long

before the

fossil record showed any large ones, which somehow then evolved rapidly

into many types. But there is every reason to expect that reptiles

would have become large as soon as they differentiated from amphibians.

It started to become evident that all the presumed "reptiles" up until

the very late Permian were in fact amphibians or at least

"pre-reptiles". I noted that very heavy breast bones, sternum and

clavicles, seemed to distinguish large amphibians from reptiles. This

was well supported by mentions in Wikipedia articles of 'bone

microanatomy' suggesting low metabolic rates and aquatic or amphibious

lifestyles in those very same creatures.

Wikipedia articles showing 2, 3 or 4 possible 'clade' (family tree)

diagrams for various species and families seemed to illustrate that

there is as

much speculation as relatively clear knowledge.

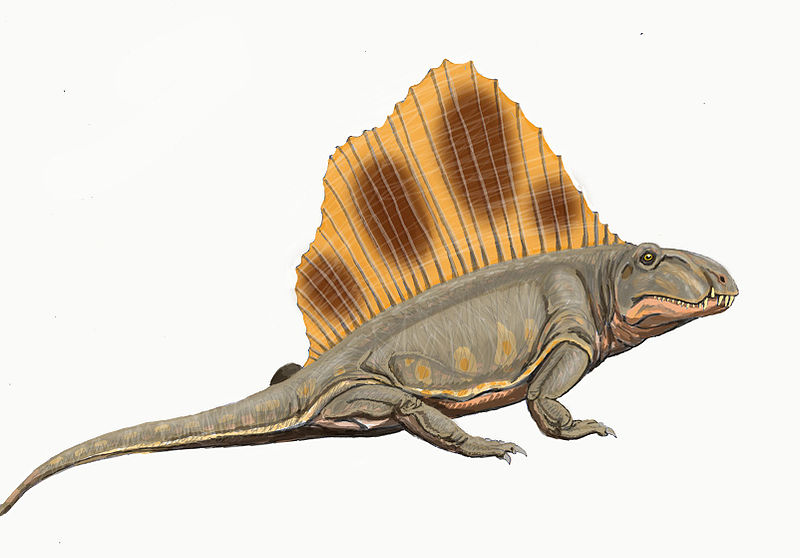

I started writing with

what I feel is a convincing theory about the unsuspected purpose of the

sails of Dimetrodon and Edaphosaurus (the

"parareptilian" Pelycosaurs): they added skin surface for

amphibious respiration. This evolved into a revised

(but by no means complete or definitive) version of the history of the

Permian period as a whole.

I first put it in the In

Passing section, but as I wrote more and more and added more and

more images it made the e-mail pretty large, and since many regular

readers may not be especially interested in the topic, I made it a

special project report in its own section for the web posted 'full'

version of the newsletter. [ http://www.saers.com/recorder/craig/TENewsV2/TENews100/TENews100.html

]

Permian Period Amphibians:

Permian Period Amphibians:

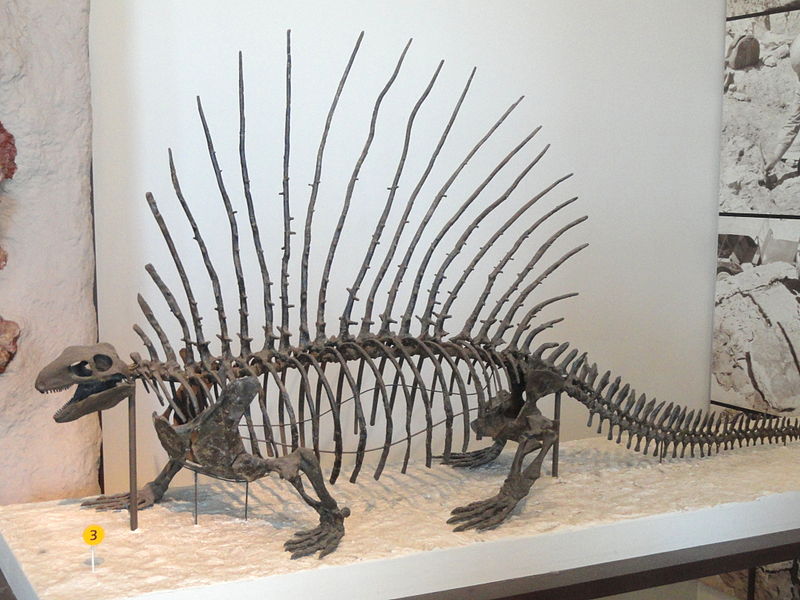

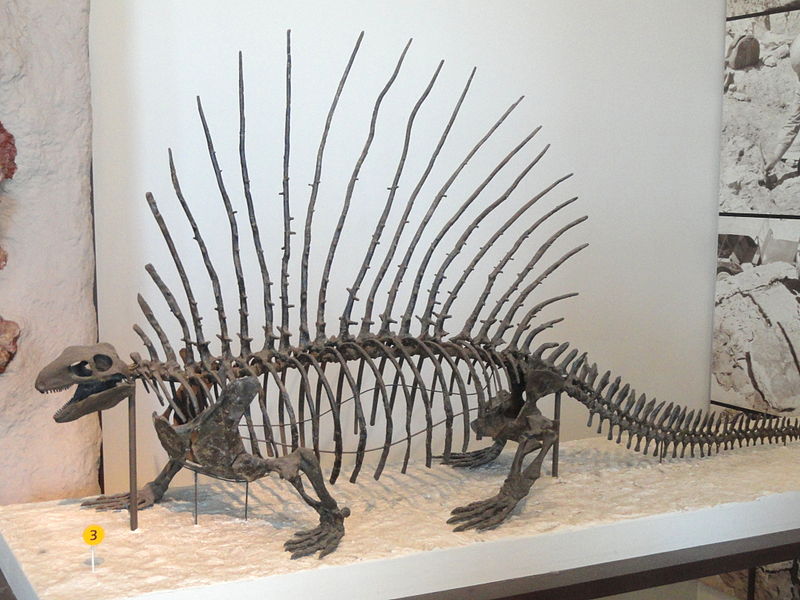

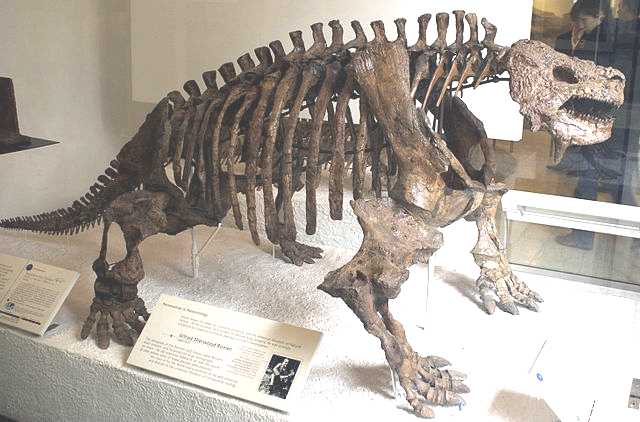

Skeleton of the Pelycosaur Edaphosaurus:

Not a "lizard" at all but a giant (~3 meters long) "salamander".

Note the heavy sternum and clavicles that anchor the buccal breathing

muscles.

The sail adds greatly to its soft, moist skin area -

skin surface is an important component of respiration in amphibians.

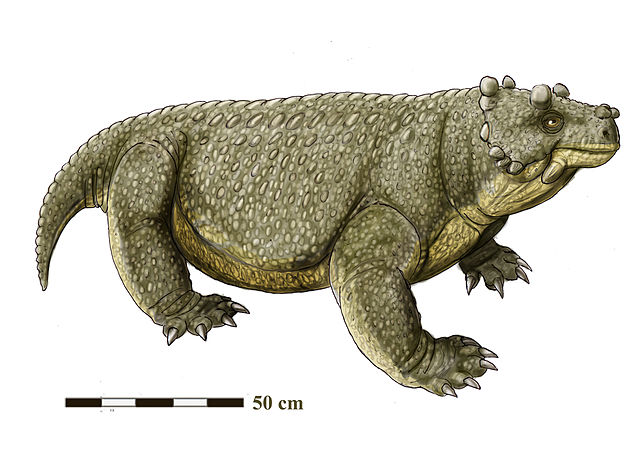

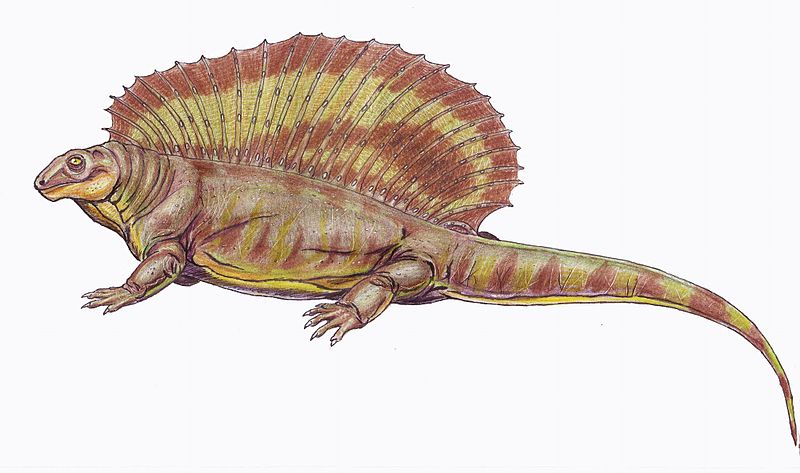

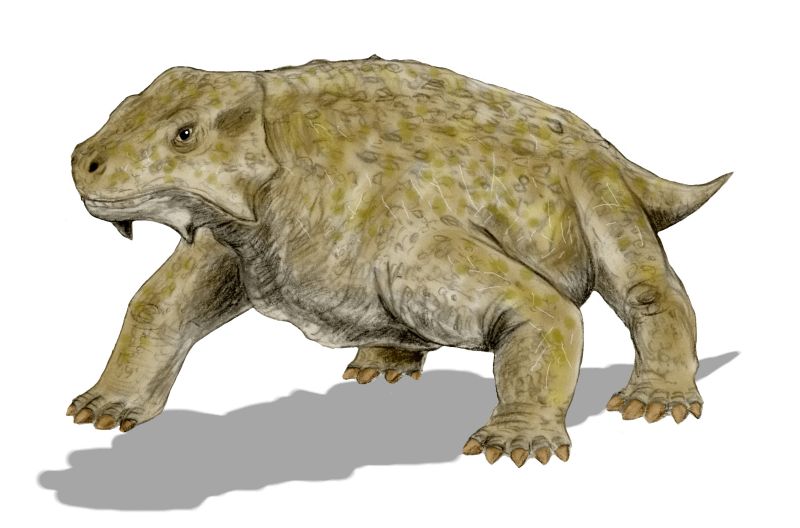

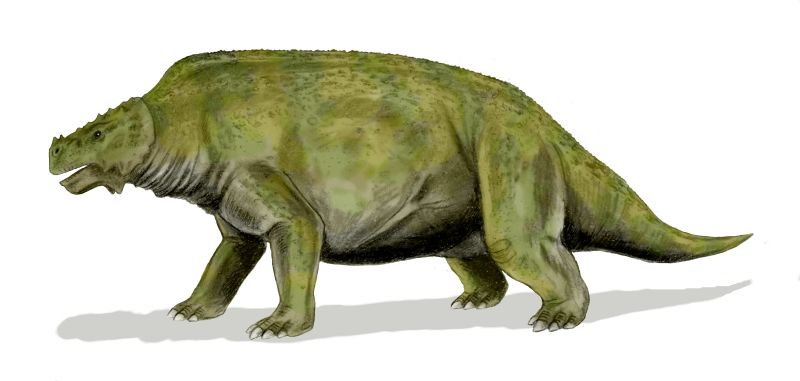

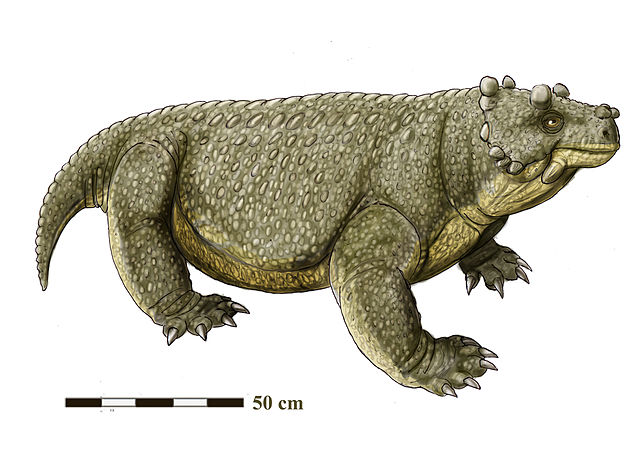

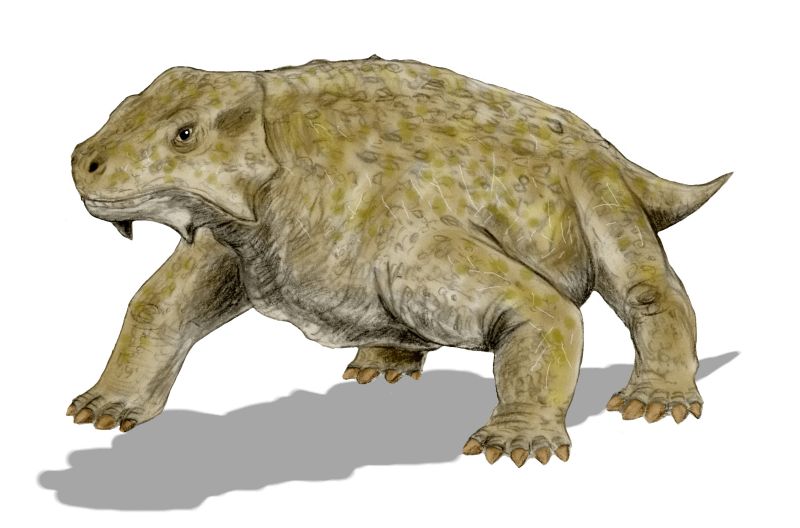

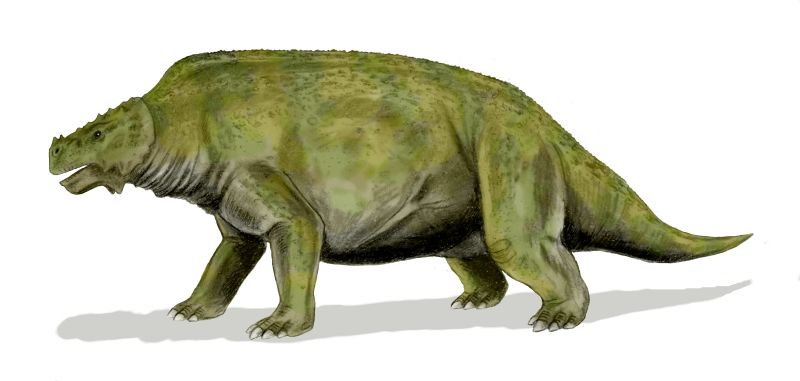

Artist's rendition of the Pareiasaur Bunostegas:

Artist's rendition of the Pareiasaur Bunostegas:

Not a "lizard" or an "ancestral turtle" after all, but rather a giant

"frog" or "toad".

With much time taken up in the first half of the month and being

determined to solve the mysteries of the PGTC in the second, I didn't

touch the 2015 tax report until the night of the 27th, when I wrote up

the points for that project. After that I continued almost daily with

some little but or other. Nor did I get any farther on the promising

nickel-air battery, the permanent magnet assisted ARM motor, or any of

the other projects.

Commercializations?

There were some indications of interest in energy

production projects, including interest from Australia in setting up an

ocean wave power system. I could see devoting time to that in some

administrative/oversight role, so long as there is development money

and I'm not the one doing the exact mechanical design drawings or much

of the fabrication or labor. It is by no means a one person project

anyway, and will have to be mostly done by paid help. Given the basic

design from the sketch in TE News #80, it becomes more a marine

engineering project than inventing. I think it should be worthwhile.

Money for employees and access to a wavy beach to build the structure

on are the key requirements, and access to power lines to send the

power to if it's to be more than an experiment or very local system. So

far I haven't even found time to send an e-mail that I probably should

have already sent.

And with a better understanding of the variable PGTC, and

seeing how smoothly it works once it's working, designs are developing

in my mind for the manufacture of PGTC transmissions for EV.s,

including under the hood types and the add-on wheel motor drive. Any

suitable motor that fits in the available space can be attached.

(allowing, eg, later upgrade to a 'permanent magnet assisted' motor)

Per the latest plans, a wheel motor would mount under the car behind

the rear wheel and connected to it by a toothed belt.

A source of funding for any or many of the projects would

help open them up. Otherwise, I think small scale PGTC transmission

manufacture might be attainable with a local partner, and I'll keep

plugging away at the rest as time permits.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Mexican Silver Money

Mexico mines more silver than any other country. I

recently heard that in Mexico they are using silver coins for currency.

In the USA and Canada we stopped doing that in the 1960s, as inflation

made the face value of the coins worth less than the value of the

silver they contained. (In fact, it presently costs about 15$ to buy

one dollar of face value in old Canadian silver coins - .6 troy ounces

of silver. So a dollar is worth 7% of what it was in 1967 when they

stopped putting silver in them. The other 20% was copper and maybe some

nickel to make the coin harder so it would last longer. A USA dollar

had .72 ozt as it was was 90% silver. Being the same size, the US coins

were slightly heavier overall because silver is denser than copper or

nickel.)

As I imperfectly understand it, Mexico has a new system.

The coins have a weight of silver, not a face value. Every day the

day's value of a gram of silver is posted on a government website. If

for example it was 11.35 pesos, a purchaser could go into a store and

buy a 5 peso item with a one gram sliver coin, and would receive 6.35

pesos in change. (In this system one probably sees the hand of Hugo

Salenas Price?) While fiat currency gradually inflates away, the silver

coins will retain their value. "Gresham's Law" states that bad money

drives better money out of circulation. Ie, people will spend the paper

if they have any and hang onto the silver. If Mexicans are saving in

silver, they may be better off than most of us when faith is finally

lost in fiat, as it must soon be with the lavish, unending money

printing -- first the dollar, then the yen, now the euro, next will be

the dollar again.

Financial Collapse Timeline?

Well, along with many I've been early on the collapse

timeline. Apparently some have expected it imminently even for 10 years

- and it hasn't happened yet. But Venezuela, where (in case you missed

it) people are now eating pets, looting, rioting, starving, murdering

and dying in droves, including in hospitals with no power or medicines,

will soon be coming to a country near you. Just as there, if one is

paying attention, one sees everywhere an inexorable creep toward

disaster which no one is attempting to address.

There are those who have been saying it'll happen "within

the next year" for some time. There are now more of them and some day

they'll be right. In the meantime, many of the cooler heads who were

saying "It's still a few years off." are now talking about 2017 and

saying "We're in the end-game."

But anybody who stocked up on food and supplies in

Venezuela, even if it was 5 or more years "too early", is doubtless

really thankful now that they did! I now have a vegetable garden and

chickens. And with solar panels, an EV and a trailer hitch I can go out

and fish, using the Electric Hubcap outboard in my aluminum boat. (must

get some more fishing tackle!) I am, I hope, much better prepared than

I was five years ago. Still, one never knows for sure what the future

holds for oneself.

What warning signs might we expect? First, credit

tightening up. Too many banks have too many bad loans outstanding, and

are becoming reluctant to make more of them. This is already starting

as business loan payment delinquencies rise precipitously. Then,

businesses that have hung in there until now will be going out of

business in droves - partly because of lack of customers who can afford

to buy things besides food, and partly from the credit freeze-up. Also

banks and governments, in collusion, can be expected to steal money

from everybody's pension plans and accounts one way or another to keep

themselves afloat. And food prices are expected to rise notably month

after month - probably starting this fall. When you see these late

warning signs, the collapse is just around the corner.

Whether physical gold and silver become unavailable

leading up to the bank failures or at the same time is unsure. More and

more people worldwide are now buying them to protect their wealth, but

the annual supply isn't growing. (A bank teller has noticed the rising

interest here.) It's still a good time to buy.

Now the finance guy on Next News Network (youtube)

about the start of June noted that there have been major crop failures

or setbacks in North America and Europe already this summer owing to

the many climatic disturbances such as the record droughts, record

floods, and unseasonal snow and hail (all brought on to a large extent

by 'geoengineering', I'm sure). He expects food costs to rise sharply

this fall for that reason, again bringing us everywhere closer to the

Venezuela situation.

The collapse, as I've said before, will remove the power

base of the corrupt (who all work through the financial system) and

wake people up, a great intellectual, philosophical and spiritual

awakening. Those who live, and those who come after we're gone, will

examine what happened and make vital changes to society that wouldn't

happen - wouldn't be permitted - in a thousand years if everything just

drifted along as it has been going. Change will start with local

communities and grow from there. The new world will take form over

decades, and it won't settle down for a millennium. After that I'm sure

we wouldn't even recognize it. The planet has a glorious future.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Permian Period

Revisited:

The Age of Evolving Amphibians, not Reptiles

by

Craig Carmichael

May 2016

Who having an interest in dinosaurs and early life hasn't

seen images, and perhaps plastic models, of 7 to 12(?) foot long

Dimetrodon and probably wondered about the purpose of the enormous

sail on its back? There has been no convincing answer. I was doing

some study into possible

transition stages between amphibian and reptile, and came across a

lengthy thesis about "Modes of Ventilation in Early

Tetrapods: Costal Aspiration as a Key Feature of Amniotes" [ie, how

early land creatures breathed] by

Christine M. Janus & Julia C. Keller.

As I was reading in this, the reason for the sails clicked

on

like a light switch. In fact, I thought the authors were about to

propose it themselves in the next paragraph or two, but they took

another path. If even these obviously knowledgeable authors didn't

mention it there, it had surely never before been suggested. This got

me started on a path were I came to realize that much about the animal

life of the Permian period appears to have been substantially

misinterpreted.

Misconceptions have always abounded in paleontology, where

everything must be guessed about an unknown fossil. "Basilosaurus"

should have been named "Basilocetus" because it was actually a

mammalian whale, not a reptile. Entelodont was first thought by the

strange jaw and teeth to have been some sort of crocodile, until

someone realized it was a giant pig - a very different animal. Ideas

right and wrong get passed on as being facts unless someone notices

inconsistencies and figures out a scenario more in line with facts that

have emerged. The mistakes are thus gradually corrected. I believe what

I've written below will prove to be a good step in clarifying the

Permian period.

Dimetrodon and Edaphasaurus appear to date from the early

Permian period, or perhaps the late

Carboniferous. Their fossils have been found in

North America and in Europe so far. (All the continents were connected

together with land bridges in the mid Permian.) An explosion of mid

size to large reptiles

appeared at about the beginning of the Triassic. It seems to have been

presumed

that small reptiles existed long before that, even in the late

Carboniferous, and also that these two unique Pelycosaur

genuses were reptilian. It wasn't at all clear to me that a

good case had been made for either of these ideas. Would small reptiles

have developed so soon after amphibians first crawled out on shore -

almost contemporaneously? Even before frogs? It would seem

logical that reptiles, once they appeared, would quickly evolve into

large sizes and dominate the environment. Why would they start off tiny

and long live in the shadow of land dwelling amphibians?

So, were the Pelycosaurs actually reptiles, or amphibians?

or

more advanced large amphibians? Recently paleontologists seem to

be calling them "parareptilian".

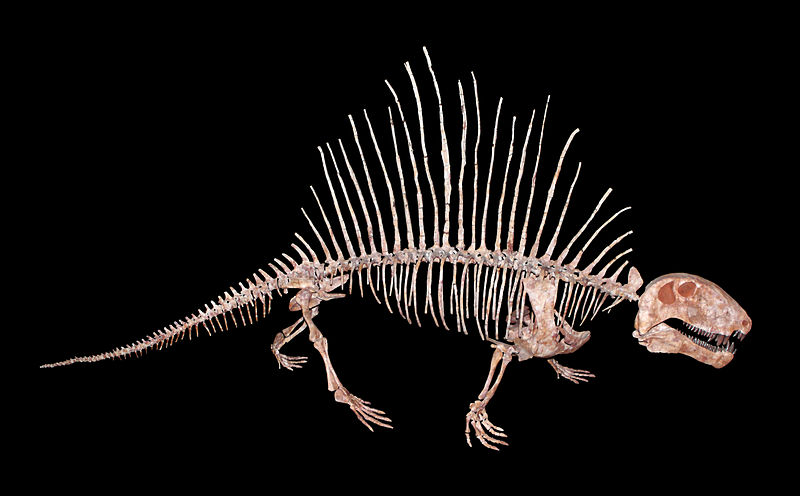

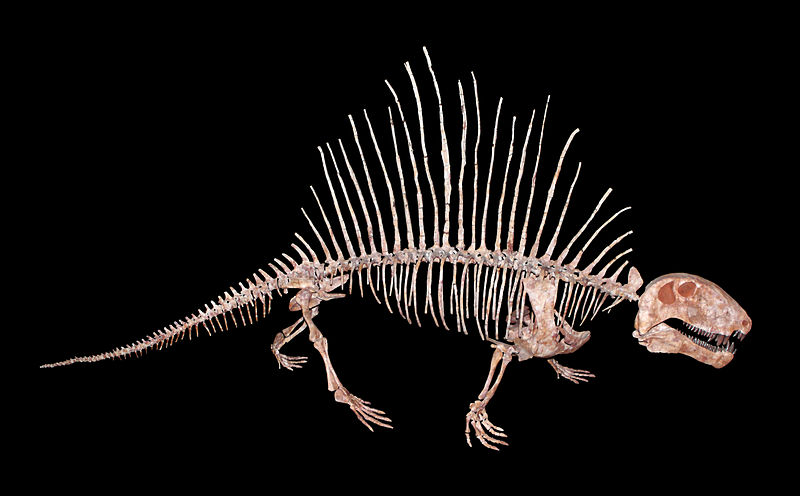

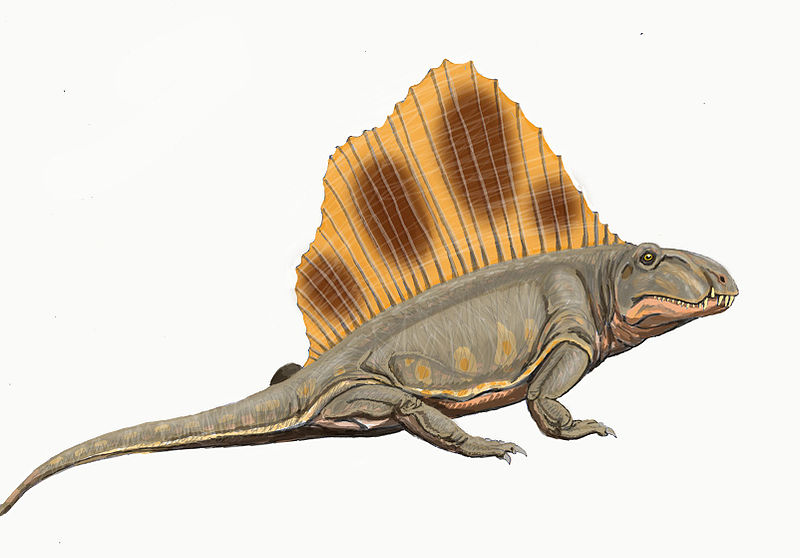

Dimetrodon Skeleton (images are

from Wikipedia or from Paleos.com . Proper attributions can be found

there.)

Apparently scientists seem to believe the Pelycosaurs practiced the

more advanced "costal

respiration", the chest muscle and diaphragm breathing common to modern

reptiles,

birds and mammals. Since no modern amphibians do this, we might

naturally assume that they were reptiles. But I

looked for more information, and it all seemed to suggest they were

amphibious.

Could they have been a "missing link", a stage between amphibians and

reptiles? Or even just plain amphibians?

Apparently scientists seem to believe the Pelycosaurs practiced the

more advanced "costal

respiration", the chest muscle and diaphragm breathing common to modern

reptiles,

birds and mammals. Since no modern amphibians do this, we might

naturally assume that they were reptiles. But I

looked for more information, and it all seemed to suggest they were

amphibious.

Could they have been a "missing link", a stage between amphibians and

reptiles? Or even just plain amphibians?

Today's amphibious anamniotes (creatures without an

amniotic sack - fish & amphibians that must lay eggs in water)

practice

"buccal breathing". As the whole bottom of the frog's or newt's mouth

or throat goes up, it closes its nostrils and air is pumped into the

simple

lungs. There are no muscles in the

chest pulling air into the lungs. Because of

this buccal breathing, frogs and toads generally have short necks and

large, flat heads, in order to have a larger lower mouth/throat/buccal

area compared to their body size. Newts and salamanders have smaller

heads but breathe the same way.

The Pelycosaurs' short newt-like neck as presented in some

images, and their slow metabolisms, seem to me to support the buccal

breathing idea.

Could the idea they used costal respiration be simply

an assumption, made early on and never challenged? The murkiness of the

subject was such that it

wasn't until the 1960s(?) that the whole order "amphibia" even had

their own name as distinct from reptiles.

(...-Fish-Amphibians-Reptiles-Birds-Mammals) Before that, the word

"amphibian" was mostly used as a functional term, and seals and otters

were described as "amphibians" because they live in and out of the

water. A creature that hatched as a tadpole in water and then grew into

a land dweller might easily be called a "reptile" - a salamander was

considered to be a species of lizard.

But in addition to throat breathing, amphibians make use

of their soft, moist

skin

for a considerable part of their respiration, especially to expel CO2.

Elimination of CO2 (according to the 'Modes of Ventilation' thesis) is

the harder part of air

breathing. Intake of oxygen is the easier part. And in the

Carboniferous probably through into the early Permian, there was still

some gradually decreasing CO2 remaining in the atmosphere, compounding

the problem. But the

larger the creature, the less skin area it has per volume of body, so

only very small animals respire just through the skin - mostly insects,

and a few small salamanders.

About the largest land-dwelling "typical" newt-like amphibian was the

Permian

Eryops, about 6 feet long.

Perhaps you too have just guessed it: I believe the

Pelycosaurs with their low metabolic rates were amphibious, and their

soft, moist skin would have been an

important part of their respiration. The sail greatly increased the

skin surface respiration area to enable a much larger

body size. At up to maybe 12 feet long and 150Kg weight for both

genuses, they were much the largest land

animals up to that time and would have dominated the environment by

virtue of that great size. The sail made this possible, especially in a

still less than ideal atmosphere.

In this and other images, Dimetrodon seems

reminiscent of a giant salamander.

In this and other images, Dimetrodon seems

reminiscent of a giant salamander.

If it was a buccal (throat)

breathing creature like a salamander or

frog,

which also utilizes skin respiration as a vital part of its total

respiration,

the sail would have greatly increased its skin respiration surface

compared to its body volume, allowing the Pelycosaurs to grow

to be the largest land dwelling amphibians up to that time.

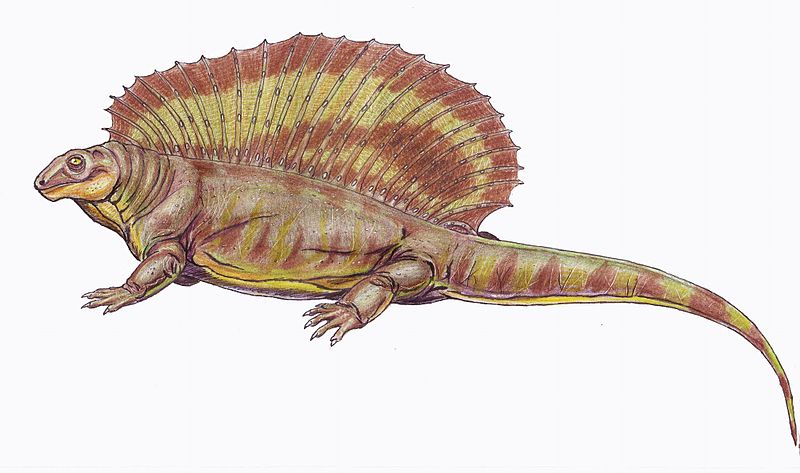

An Edaphosaurus skeleton.

An Edaphosaurus skeleton.

A short-necked Edaphosaurus image again

potentially suggestive of buccal (throat) breathing.

A short-necked Edaphosaurus image again

potentially suggestive of buccal (throat) breathing.

(I wonder what a swamp full of croaking Pelycosaurs would have sounded

like?)

Other info I found indicated that contrary to much art

depicting them in dry places (such as in the BBC series "Walking with

Monsters - Before the Dinosaurs"), it is said of both types that

they lived in swampy and wet areas -- typical for amphibians. Another

site indicated it had similar tastes in habitat to Eryops, a 6 foot

amphibian. (And

there were in fact at least a couple of smaller early amphibian

genuses, Ianthasaurus and Platyhystrix that also had

sails on their backs,

which line may perhaps have evolved into the Pelycosaurs.)

Then, one source said specifically that no Dimetrodon eggs

have ever been found. I found no mention of Edaphosaurus egg fossils

except that they were 'presumed to surely have been hard shelled',

which also implies that none have ever been found. Is that lack of eggs

just bad

luck, or could it be that Dimetrodon and Edaphosaurus laid soft shelled

eggs in the water and perhaps had a tadpole larval stage? Hard shelled

eggs, if they did exist, wouldn't preclude the 'amphibious' or

'prereptilian' breathing skin, but that none have been found does add

fuel to the idea.

(Afterthought: How would a reptilian male mount a female with a sail

for procreation? The sail would be much less of an impediment to

procreation in an amphibious species laying eggs in water, where the

male comes along and fertilizes the eggs after they're laid by the

female. Oh well, Stegosauruses must have done it somehow!)

A question that might have an answer or might someday get

one is: Have quite young Pelycosaurs been found, or only relatively

mature adults? Different size specimens found correspond poorly to

different ages, according to Wikipedia. Would a fossilized tadpole

Pelycosaur be recognized as such? Tadpoles attributed to Eryops have

been found.

Another web site mentions that Dimetrodon skeleton

microanatomy indicates it had a "low metabolic rate", with relatively

few channels for oxygen carrying blood. This too would be in keeping

with it being amphibious and a buccal breather.

This is mostly rather circumstantial evidence, but that

may be about the best we have for now about this far-off time. But a

picture emerges of a more orderly evolutionary timeline: Amphibians

emerged from the water sometime in the Carboniferous period as the

carbon

dioxide content of Earth's atmosphere became reduced enough to support

higher land animals. They evolved into the two probably amphibious

Pelycosaur species at least by the early Permian.

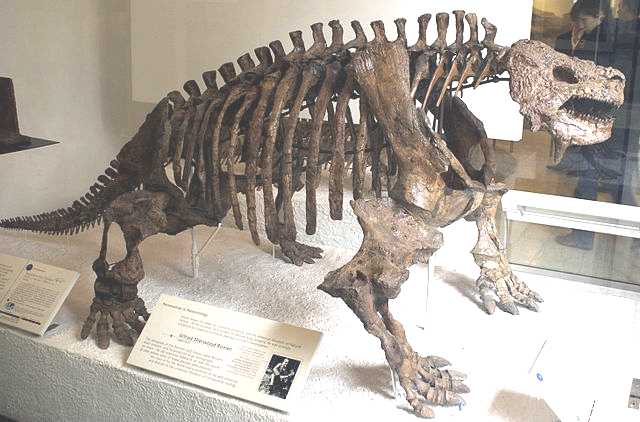

I noted the very heavy clavicles and sternum in the chest

behind the throat, seemingly fused or closely bound together. This

seemed like an ideal heavy attachment point for buccal breathing

muscles. I started checking other skeletons as further evidence for the

Pelycosaurs being buccal breathers. Yes, that was similar to known

amphibian Eryops's skeletal build.

Eryops skeleton with similar heavy clavicles

and sternum

Eryops skeleton with similar heavy clavicles

and sternum

Then I started checking some known early reptiles:

Postosuchus,

Lystrasaur, Placerias... Sure enough, their chest bones were much

lighter. But I also noted that those I found were listed as being

"early

Triassic".

Postosuchus

Postosuchus

Lystrosaurus

Lystrosaurus

Both early reptiles were much lighter in the breast area than the

amphibians.

Then I came to Scutosaur, supposedly a reptile from the

late Permian. It had the heavy breast bones, similar to the Pelycosaurs

and amphibians.

Scutosaurus Skeleton

Scutosaurus Skeleton

That appeared to shoot down

what had seemed like a fine piece of evidence - but only for a moment.

Scutosaur was listed as

being Pareiasaur genus, a member of the "Synapsids" once

known as "mammal-like reptiles". Some paleontologists have thought it

might be an ancestor of the turtle. But in the description was a most

revealing statement, in fact, a bombshell:

"Most authors have assumed a terrestrial lifestyle for

pareiasaurs, but bone microanatomy suggests a more aquatic, plausibly

amphibious lifestyle." [Wikipedia, 'Pareiasaurs']

If the Pareiasaurs (including for

example Bradysaurus, Scutosaurus and Bunostegos) were actually

prereptilian amphibians, the seemingly contradictory skeletal form

evidence was actually

virtually conclusive support! Bunostegos is explicitly denominated as a

"pre-reptile" in Wikipedia.

And from their

essential forms and proportions, to me it looks like they are probably

closely

related to - evolved from - frogs. (Frog skeleton images too seem to

show heavy breast bones relative to the whole skeleton.) We might

perhaps suspect two somewhat parallel strains of evolution, in size as

well as probably in increasingly sophisticated anatomy: from

'salamanders' to Pelycosaurs, and from 'frogs' to Pareiasaurs. The

Pareiasaurs appear to have evolved in Africa, where many fossils have

been found. But they seem to have spread over the world from there,

with all the continents being connected at the time.

Bradysaurus.

Bradysaurus.

The form might suggest it evolved from a frog.

Scutosaurus

Scutosaurus

(The skeleton above looks far more froglike than this particular

rendition,

perhaps revealing how much may depend on the artist's preconceptions.

In fact, some of the form doesn't seem to follow the skeleton at

all.)

Bunostegas, another Pareiasaur,

again looking like an overgrown frog or toad

(one "the

size of a cow"),

Bunostegas, another Pareiasaur,

again looking like an overgrown frog or toad

(one "the

size of a cow"),

and as with the others, having a "lumpy" skin with more

respiratory surface area than smooth skin would have.

(Apparently it was also the first creature with all four legs

essentially vertical, rather than sticking out to the sides. Evolution!)

Really, with all the similarities...

were these all just varieties of one species?

Most of the Pareiasaurs

were big, from .6m to 3m long, and considering the bulk and short tails

seem larger than Dimetrodon and Edaphosaurus, yet they had no sails.

How could they be so big, and evidently buccal breathing, yet

apparently with much less respiring skin area per volume? First, they

had wider

more frog-like proportions and so probably lung-breathed better than

the

newt-like Pelycosaurs with their narrower heads. Then, the atmospheric

CO2 level had dropped to insignificance, where it has since remained.

Then, as "prereptiles" they might have evolved more complex lungs.

Evidently the rest

came down to the skin texture. The Pareiasaurs had scutes, knobs,

folds, and lumpy skin textures. On a fractal level, all this could

bring about a much increased respiratory surface area over what

flat, smooth skin would provide.

On a further note, in both the Edaphosaurus and the

Scutosaurus skeletons shown above (but not necessarily in all

amphibians) we observe longer ribs extending back almost to the rear

legs. I suppose that with buccal breathing, the abdomen doesn't need

the flexibility it does for costal respiration.

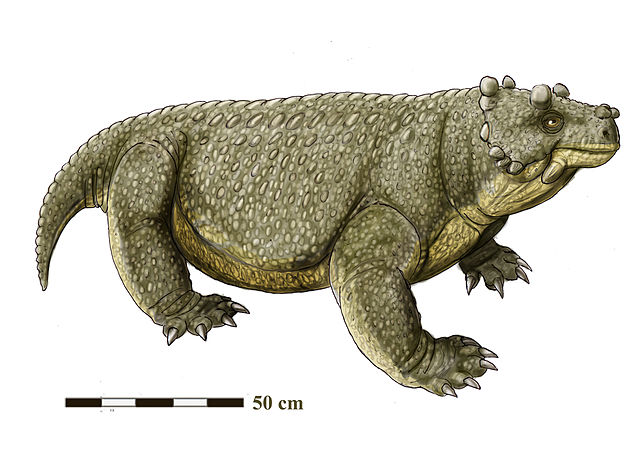

Looking more

deeply into creatures of the Permian on a site called http://palaeos.com/, I found the

mid-Permian Dinocephalia family. They also had very heavy

breastbones, and they seem to look a lot like the Pareiasaur "overgrown

frogs" above. Pictured is Estemmenosuchidae Uralensis. Again

they were said to be swamp dwellers, and were thought to be largely

vegetarian.

Looking more

deeply into creatures of the Permian on a site called http://palaeos.com/, I found the

mid-Permian Dinocephalia family. They also had very heavy

breastbones, and they seem to look a lot like the Pareiasaur "overgrown

frogs" above. Pictured is Estemmenosuchidae Uralensis. Again

they were said to be swamp dwellers, and were thought to be largely

vegetarian.

It started to look like all of the so-called "reptiles" of

the Permian period were in fact amphibians or at least prereptilian.

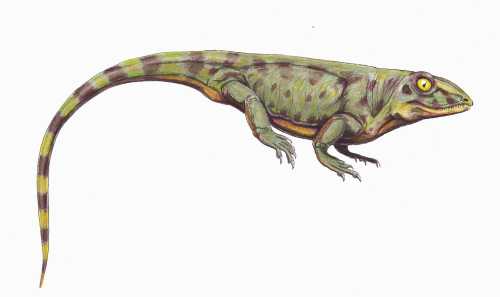

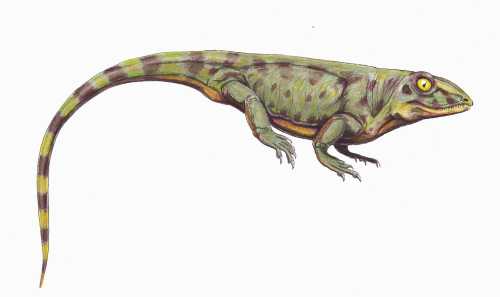

Another area I briefly

explored reinforced this view. Many of the early Diapsids, a

broad group presumed to be small early reptiles, again sounded like

they had

suspiciously amphibious lifestyles. I couldn't find any photos of

skeletons showing the chest area, just a couple of side view drawings.

In these they seemed to have the heavy breast bones, but it was hard to

be confident of it. Some were of salamander- or lizard-like formation.

Another area I briefly

explored reinforced this view. Many of the early Diapsids, a

broad group presumed to be small early reptiles, again sounded like

they had

suspiciously amphibious lifestyles. I couldn't find any photos of

skeletons showing the chest area, just a couple of side view drawings.

In these they seemed to have the heavy breast bones, but it was hard to

be confident of it. Some were of salamander- or lizard-like formation.

But might some of them actually be primitive frogs? In the

artists' images, many of the large rear feet and legs looked to me like

frog feet and legs. Would they not have been webbed? This considerable

size difference commonly found between rear and front legs was also

noted in writings. (Oops... I've lost the link to the item where I

first read

this and about the 'aquatic' or 'amphibious' habits of many types. And

where is the bone microanatomy analysis?) It

was thought that the long rear legs would be for 'bipedal' locomotion,

but they could

instead be for jumping, or lunging forward at prey. Some seemed to have

shorter tails, but it

didn't seem that any had no tails. Juvenile frogs have tails, and

perhaps adult primitive frogs might still have had tails. Even the

pareiasaurs had short tails. The rear end anatomy doesn't look like

modern frogs, but perhaps primitive frog ancestors might have used

their front limbs to assist in launching, and their tails for balance

in the air. But whether salamanders or frogs, it looks to me like yet

another case of amphibians having been misidentified as reptiles, again

no doubt

starting in past times when there was no distinct scientific

classification called "amphibia".

Here's a related note: Two broad

divisions of Diapsids have been

identified: the Lepidosauromorpha and the Archosaurs.

In one text the Lepidos are described as having a heavy sternum (and in

Wikipedia as having a 'primitive sprawling gait' - legs to the sides).

Since the heavy sternum seems to be a distinguishing amphibian

characteristic, perhaps the two classifications have unwittingly

divided the amphibians from the reptiles. (But I have not checked this

out.) If that's the case, the Lepidos probably evolved into the Archos.

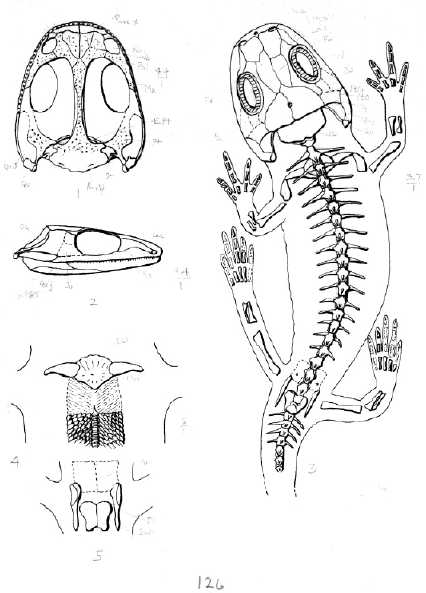

Then I did a search specifically on "frog fossils". Based

on lack of earlier fossil finds, frogs were long thought to have first

evolved in the Triassic period. Recently frog remains from the early

Permian have been found, which puts a different slant on things. (Now

where was that link?) Also the wide divergences in finds from later

times is said to indicate that frogs and salamanders likely radiated

away from each other in the Carboniferous. Amphibamus is a late

Carboniferous creature said to be "froglike", yet with a tail. Even so,

in the absence of any reptiles, earlier Permian frogs certainly might

well have become later Permian Dinocephalians and Pareiasaurians, which

after all have short tails themselves.

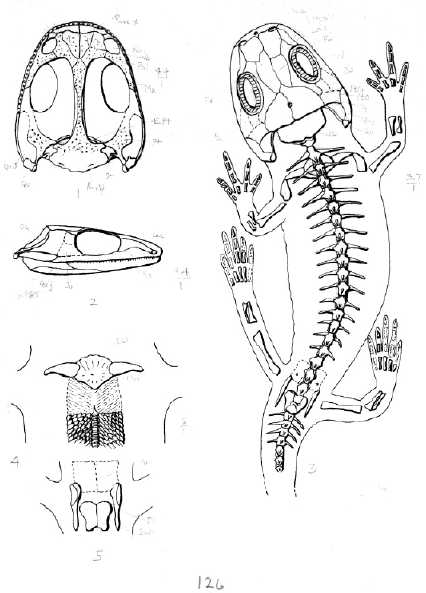

Amphibamus grandiceps Cope, textbook

drawing of the type specimen [georgesbasement.com]

Amphibamus grandiceps Cope, textbook

drawing of the type specimen [georgesbasement.com]

...20cm long Amphibamus, "a poorly understood prehistoric amphibian."

But much seems to be speculation and confusion about the Permian period

and amphibian evolution.

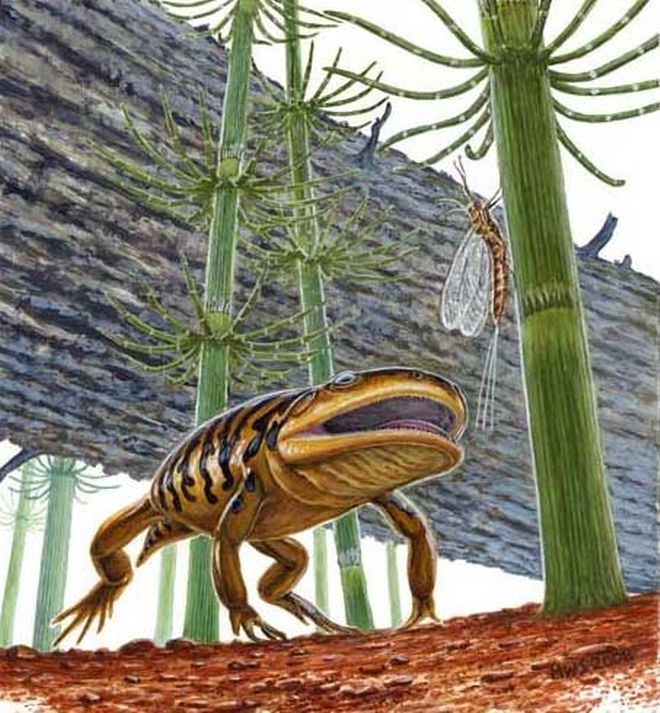

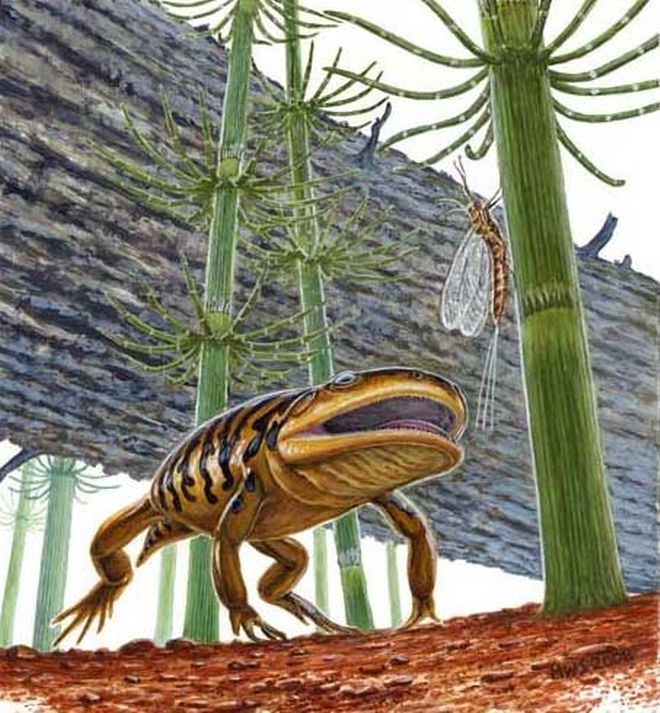

"Frogamander" from the early Permian

"Frogamander" from the early Permian

"In its Early Permian habitat in Texas, Gerobatrachus hottoni would

have lived on land and water where it could lunge after insects like

this mayfly Protoreisma. - See more at:

http://www.livescience.com/2554-frog-amander-fossil-fills-evolutionary-gap.html#sthash.YjIPrNN2.dpuf"

But groups of creatures from the late Permian such as the

Gorgonopsia and the Dicynodonts, didn't and don't seem to fit into the

otherwise neat scenario of the 'amphibious

Permian'. In the mid Permian the newly appearing seed bearing plants

began to provide a good food supply for land dwelling vegetarians, as

detailed on Paleos.com:

"While animals were undergoing a change so

were plants, with xerophyletic (dry-adapted) species of ferns,

seed-ferns, conifers and ginkgos coming into prominence. The

Glossopteris flora dominates in Gondwanaland. These new plants mark the

transition between the Paleophytic (the old spore-bearing moisture

loving coal swamp plants) and the Mesophytic (gymnospermous) era of

plant evolution. Significantly, whereas animal life has its big

transition at the very end of the Permian, plant life switches over to

a more modern flora some ten to twenty million years previous."

and

"But

now in the Kungurian [mid Permian] we see an environment dominated by

medium to large sized herbivores (the pelycosaur family Caseidae). This

very important event marked the shift from a food chain based on

detritus and carnivory (insectivore/ piscivore/ carnivore) to a more

efficient one in which plants as primary producers provide the main

input. The Lopingian Epoch (Late Permian) witnessed a succession of

impressive medium to large herbivores - caseids, estemmenosuchids,

deuterosaurs, tapinocephalids, and dicynodonts - with (apart from the

dicynodonts) each "dynasty" flourishing briefly then dying out after

only a few million years, to be replaced by a new wave."

So it would appear that land animal evolution hit an

accelerated pace once there were food plants, and this probably

fostered the transition from amphibians to reptiles. Then large,

sluggish amphibians who previously had the world to themselves would

have been easy prey for agile reptiles, so the transition once begun

could have been completed in a relatively short time.

The saber-toothed Gorgonopsids date to the late Permian.

Their form, skeleton (with light clavicles and sternum) and bone

microanatomy indicate they were terrestrial creatures having costal

respiration: reptiles. Certain bones had moved from amphibious

positions to form

the inner ear so they would hear best in air, again saying they were

reptiles,

not amphibians. Notwithstanding some "mammal-like" qualities and

outline, I

suggest from their late Permian timeline just before the Triassic

explosion of reptilian types, that they must have been the earliest of

reptiles. Scutosauruses were doubtless their easy prey, and when they

died out, so did the Gorgonopsids.

So it is possible that the late Permian (the "Lopingian

Epoch", or perhaps the last 15-20% of the period as currently

described), might better be described as belonging to the early

Triassic, if one would describe the Permian as a period dominated by

amphibian evolution, and the Triassic by early reptiles. At any rate it

seems to have been an age of rapid transition between the two.

In conclusion, herein I believe I've uncovered and

corrected what appear to me to be some large misconceptions about the

order of evolution and the nature of many Permian creatures. This

certainly doesn't clear away all the murk from this distant time, but I

think it's a good start!

Electric

Hubcap

Motor

Systems

-

Electric

Transport

Electric

Hubcap motor, Chevy Sprint & Variable Transmission

Planetary Gear Torque Converter

("PGTC") Works

Great, Starts Car Moving Great!

I'll start with an important conclusion: I was wrong in

2012 that the planetary gear torque conversion doesn't start working

until the vehicle is in motion. With a smooth, balanced

slipping/tensioning mechanism, it works just fine from a stop. In 2012

it was just too crude to work properly under many circumstances,

leading me to draw false conclusions. And in fact, a misconception

continued into May 2016.

For much of May I was puzzled that things worked great if

the required torque was under around 20 foot-pounds ("F-P"), but it

balked at much more than that. When the tension was directed more

evenly around the pulley so it didn't pull to one side, even with a

cable tie as a quick experiment,

this figure rose a little. But it wasn't the answer.

I started figuring that the output torque could only be

increased to a certain point for a given RPM of the slipping gear and

ratio between them. Probably there's a "maximum torque ratio" between

the gears as well as a gear ratio. If instead of the slow moving

planets assembly I use the fast moving sun gear as the slipping gear,

the torque should be multiplied much more, and the unit can have

perhaps ten or twenty times the maximum torque - plenty to put the car

on the road.

But now I've seen how smoothly the system runs when

working within its limits.

I'm finally convinced that this, the Planetary Gear Torque Converter

("PGTC"), must be about the 'ultimate' form of automotive transmission

one could come up

with. It needs to be set up right... and then produced for car

transmissions and add-on wheel drives.

A Better Planetary Gear?

I started thinking a large diameter UHMW planetary gear

several

inches wide with plastic planet gears that don't need lubrication would

be an ideal form of the gear for a car. UHMW would also have

the least possible friction with very low heat and losses. Aluminum

might be the best metal for the sun and ring gears. It's all about

spreading out the stresses so the lighter materials can handle them

even for a large, heavy vehicle.

Perhaps thus constituted they could also be straight gears

instead of helical for highest efficiency, without being noisy like

metal straight ('spur') gears are. Conceivably too, they could be

composed of

two or more planetary gears placed in parallel and bolted together,

with the teeth offset between units so that they were at different

points of engagement at any given time, spreading out any unevenness

caused by straight gears. Or with full width sun and ring gears, the

planets assembly might contain narrower planet gears, placed at offset

rotations. Such strategies might attain the general smoother,

quieter drive effect of helical gears, without having the helical gear

sideways thrusts and losses.

With such a planetary gear and a toothed or flat drive

belt instead of a chain, no lubrication would be required except for

greasing the bearings, which, with modern sealed bearings, is very

rarely needed.

One fly in the ointment is that cutting precision gear

teeth even in softer materials looks like a serious challenge, unless

they can be waterjet cut from thin pieces and built up into thick ones.

But, even if one chose larger, coarser teeth than might otherwise be

desired, would that be precise enough? I doubt my ability to do a

satisfactory job of it, even spending considerable time setting things

up.

On the 31st I looked on the web.

I found a planetary gear (Swiss company Gysin.com GPL120) that

looked like it would be notably better than typical automotive

planetaries, but it's a sealed (lubricated) unit with bearings, and

units with plastic planet gears. Presuming the price isn't out of

reach, why try to fabricate something difficult that someone else

already specializes in that's doubtless the best? It makes the prospect

of manufacturing transmissions a lot simpler! I sent off an e-mail to a

US distributor.

Another company makes gears to order, including from

plastic. So an option might be to take an automotive planetary gear and

make a housing that would give the benefits of the gysin housing, with

plastic gears replacing the steel ones to remove the lube requirements.

If they would handle the torque.

A couple of days later an inquiry found that there is a

company making still larger planetary gears 'for 4x4 offroading', right

here on Vancouver Island. But the prices were scary. Unfortunately it's

not near Victoria, but I may take a trip up there some time to have a

look.

Motor Phases Were Miswired between

Cables

I noticed that the motor occasionally wouldn't start

spinning until it was run the other way or manually turned to a new

position. That seemed inexplicable. And I and thought of how it wasn't revving up very well in

reverse. On the 8th I disconnected the pulley rope so it was

free-spinning except for the flywheel. It still worked poorly in

reverse. Somehow, I must still - or again - have the drive phases

wrong! I hooked up a DC current clamp meter and started swapping drive

wires at the plug. Sure enough, they were wrong. When I had them right,

the motor started and spun freely in both directions and the motor

currents went

way down into the lower 10s of amps once up to speed. Instead of seeing

150 or more amps under load, it was down around 100 even while driving

forward. It explained why the motor had seemed to take substantially

more energy than with my controller, and of course it generated

considerably more heat - another problem explained!

How had this happened - again? I had the wire colors

clearly marked, but somehow they were wrong again. AHA!... Some hall

sensor wires had to be crossed between the handheld control box and the

driver's seat controls, so when I switched, the phases got switched at

the sensing side. That makes sense. If they were wrong in the handheld

control, it would also explain how it was that they were wrong earlier

when I changed from my controller to the Kelly. I've probably put them

back the way they were originally. (I may have cross-wired the Kelly

handheld control myself since it had the wrong plug for my motor, but I

knew I didn't like

Kelly's arrangement of having the motor sensor cable and the controls

cable both connected in the same "J2" plug in the controller! Thus

changing the operator controls means changing the motor sensor cable as

well. They have two different functions and should have separate

cables.) I'll say this for it: nothing blew up in spite of the fault,

even if the motor got smoking hot a couple of times.

So that cleared up some small mysteries and solved a

couple of problems, but it didn't make the car move any better,

including backward. Experimentally oiling the rope and pulley just made

them spin freely in spite of all tensioning.

Adjustments: Changing the chain

sprocket to a lower final drive ratio (3:1), and to a stronger tension

rope spring.

The spring was rubbing on the pulley and making a metal on

metal noise. Changing the spring to a smaller diameter should stop

that, and at the same time, any change there would be an adjustment,

with the possibility the car would roll better. or worse. or at least

that I'd learn something. Fortuitously I had recently found a spring

that seemed just right. But it proved to be weaker and I put the old

one back in.

Then, notwithstanding that it didn't have much torque, I

thought I would try changing the 4 to 1 final chain drive ratio to 3:1,

from a 12 tooth sprocket to 16, driving the 48 tooth one on the

differential. That would allow street speeds (not highway) without

over-revving the motor. In theory all that should mean was the

variable torque converter ratio

should change to compensate. I had a sprocket gear welded up, and

changed it on the 14th. Instead of an hour, it took all afternoon to do

everything and readjust it all.

The first results were perhaps predictable. Instead of 10

foot-pounds ("F-P" herein) or so to start moving at an easy to start

point, it required 1/3 more. Before, I could get the car to roll where

it needed 20, but this time it seemed to take more tension, and I

pulled the lever back until the spring clamp on the cable hit the cable

sheath, without getting enough to get the car moving at any time. The

motor would still start turning at this maximum tension, without moving

the car. It definitely needed a stronger spring.

On the 18th I

put a new spring in. The wire in this one

was 1.1" diameter instead of .85". It was even fatter than the old one

(3/4" O.D.) and so scraped even worse on the pulley. (For now, oh

well!) Much to my surprise, on pulling the stick back a little harder,

from an easy to roll position the car readily started and drove ahead.

As per the theory, the extra torque was provided by a higher ratio from

the planetary gear torque converter. In fact it seemed better than

before. (How far can this be taken - to 2:1, or even 1:1? If so highway

speeds should be attainable.) It even backed up a bit, if still not

very well. (It would have backed out of a level, paved parking spot -

yay!) But from a tough spot it still wouldn't go ahead and the spring

hit the end stop. So I torched another inch and more off the tensioning

rope and reattached everything. It helped, but it still wouldn't move

from that spot, which turned out to need almost 50 F-P (150 F-P at the

wheels). Again I was pulling the lever all the way back, and I got the

feeling an even stronger spring would definitely help.

On the 18th I

put a new spring in. The wire in this one

was 1.1" diameter instead of .85". It was even fatter than the old one

(3/4" O.D.) and so scraped even worse on the pulley. (For now, oh

well!) Much to my surprise, on pulling the stick back a little harder,

from an easy to roll position the car readily started and drove ahead.

As per the theory, the extra torque was provided by a higher ratio from

the planetary gear torque converter. In fact it seemed better than

before. (How far can this be taken - to 2:1, or even 1:1? If so highway

speeds should be attainable.) It even backed up a bit, if still not

very well. (It would have backed out of a level, paved parking spot -

yay!) But from a tough spot it still wouldn't go ahead and the spring

hit the end stop. So I torched another inch and more off the tensioning

rope and reattached everything. It helped, but it still wouldn't move

from that spot, which turned out to need almost 50 F-P (150 F-P at the

wheels). Again I was pulling the lever all the way back, and I got the

feeling an even stronger spring would definitely help.

I pulled the car a few

inches up the 'hill' to where it

"only" needed - if I recall correctly - about 35 F-P. (was it really

that much? - over 100 F-P at the wheels? I should have tried it again

to confirm that - I was probably mistaken.) and it did start, and drove

ahead until I stopped it.

It seemed it was approaching the point, at least the order of

magnitude, required to put it on the street. It seemed the stronger the

tensioning spring, the more torque the drive had available. Could it

really be that simple?

That was the strongest spring in the drawers at Capital

Iron. Somewhere I had to find a still stronger one, and I had to make

some sort of proper mounting so it didn't rub on the pulley. And

perhaps one

that would provide some leverage so one didn't have to pull the stick

so hard. It occurs to me that a 12" pulley would require lower tension

forces for friction than the 10" one. But I couldn't easily have fit

the larger size. It would have been in the way of the speedometer gear,

if nothing else.

Mounting Bracket for Tensioner Cable, Lever & Spring

Obviously I

was going to have to make another attachment

to the transmission - hopefully without complete disassembly again. On

the 19th I started looking - by no means for the first time - to see

how I might mount the cable for an even, smooth pull in both

directions. This time I came up with the idea of linking the two ends

of the tensioner rope with a short chain, and having the spring pull

the chain outward at right angles (upward). If there was just a bracket

sticking up above the pulley, it could anchor the cable sheath. The

cable could pull down on a lever, and the other end of the lever would

pull up on the spring. Two springs might easily be fitted to double the

strength of the tension, and the lever could hinge at a point nearer

one end to give the driver more leverage, too.

Obviously I

was going to have to make another attachment

to the transmission - hopefully without complete disassembly again. On

the 19th I started looking - by no means for the first time - to see

how I might mount the cable for an even, smooth pull in both

directions. This time I came up with the idea of linking the two ends

of the tensioner rope with a short chain, and having the spring pull

the chain outward at right angles (upward). If there was just a bracket

sticking up above the pulley, it could anchor the cable sheath. The

cable could pull down on a lever, and the other end of the lever would

pull up on the spring. Two springs might easily be fitted to double the

strength of the tension, and the lever could hinge at a point nearer

one end to give the driver more leverage, too.

I finally found what looked like a good piece of steel for

the bracket among my scraps, pre-painted yellow. I took the motor off,

estimated where things should be, drilled holes, and fitted it on. I

had to drill one hole in the body wall of the transmission. As I didn't

want to disassemble everything, I did it in situ with a cordless drill.

It took quite a while and tapping threads was also slow. It must

be harder than the usual "mild steel".

By the time I had it attached, I'd had enough and had

other things to do, and packed it up for the day without fitting

anything to it. At least at this point I had a pretty specific plan. On

the 20th I made a pivot piece and a lever to attach the cable to, and I

put an eye hook screw on the other end of the rope. Some chain links

connected the two eye-hooked rope ends together. More time had been

taken shopping for the bits (and then for unrelated things) than

making, and that was as far as I got.

On the 21st I got it all connected and replaced the motor.

It worked much the same as before, again with the car balking when

higher torques were required, the motor spinning without moving the

car. Again that seemed to be because I couldn't pull the spring as

tight as I wanted. This time it was limited swing of the lever, which

hit its end stop before the spring was tight enough to load the motor

down heavily enough. On the bright side, it was quieter without the

metal spring rubbing on the pulley, and it would now be easier to

change things. The cable sheath was firmly clamped on. The end stop

could be ground down a bit, the spring's position on the lever could be

moved up or down with another hole, and the spring could easily be

changed - or perhaps two of them could be employed.

The next day I ground down the end stop so the spring

could be pulled farther. That didn't seem to change much, so I went out

and got another spring. This time I didn't pull back very far on the

stick before the car started moving. But it still didn't like starting

to move if the required force was over about 25 F-P. I could tighten

the tension more now, but still if it was more than that, the motor

simply slowed down. It seemed it would do 30 F-P for a moment while the

motor and flywheel slowed, but not for very far if it had to be kept up.

The theory of course was that it would do twice the torque

at half the speed, but that still only seemed to apply up to 20 or 25

F-P.

That's the most yet, but it needs 50 or better (150 at the wheels) for

the road. Far from being "ultra-efficient", it was simply losing higher

torque than that to friction somewhere. The rope and pulley got very

warm. As the motor got hot.

Between the planetary gear and the chain reduction, the

motor had about a 5 to 1 reduction to the wheels. Really, it might run

as well or nearly as well just with any (working) clutch, without the

addition of the variable torque converter component. Where was the

theory not carrying over into practice?

Camera: View the workings?

I couldn't see into the hood from the driver's seat. I

decided I needed to mount a video camera right by the transmission. I

could run the car, then review the close-up video and see if there was

anything that might show what problem or problems there were with the

system. On the 23rd instead I got someone to hold the camera. In

reviewing the videos, it seemed the cameraman hadn't really got in

there where I wanted to see. I guess he didn't want to get run over.

However, the next day I did a little more driving. The

thrust bearing was loose again, and then I noticed that the set screws

on the ring gear were at a different rotation on the shaft than where

I'd set them. And this was the second time they seemed loose.

Apparently the ring gear could turn without the output shaft following

it! Since it was a splined tenon inserted over a 5-pointed "star"

shaft, this should have been impossible. Apparently not! The points

must have worn down. Well, it was always a 'cludjed' arrangement,

evidently another of my "not robust enough" pieces. One of the set

screws was now at the keyslot on the shaft, so I screwed it down into

the slot, which should keep it from sliding regardless of torque.

I thought that would have explained and solved everything,

but I still couldn't get the car to start moving if it took over 25

(75) F-P or so.

But I found I could stand with a foot outside the driver's

door and still reach the pedal with my other foot, once I had set the

tension lever to a desired point, and look at the shaft as I started

the motor turning. The ring gear may have twisted around the shaft

before, but it wasn't doing so now. Now what?

It's all in the adjustments? - Nope.

I returned on

the 25th and did much the same. If the

pressure wasn't too much, one could see the slipping gear & big

pulley turn one way as the shaft turned the other, moving the car

forward. With the stick pulled tighter, the pulley turned less and the

motor turned slower, but again the car pulled ahead. It all seemed

smooth, predictable and according to theory.

I returned on

the 25th and did much the same. If the

pressure wasn't too much, one could see the slipping gear & big

pulley turn one way as the shaft turned the other, moving the car

forward. With the stick pulled tighter, the pulley turned less and the

motor turned slower, but again the car pulled ahead. It all seemed

smooth, predictable and according to theory.

I thought, well, the bottom anchor end of the tensioning

rope was very close to the pulley, while the other end being pulled had

somewhat more slack. That would mean the pulley was being pulled a

little off-center, and the higher the tension, the more off-center the

pull would be. Could that small factor make the difference when the

torque got too high? I put a cable tie between chain links and pulled

things tighter together. There would be more tension with the rope

lifted away from the pulley less.

The car pulled ahead, if grudgingly, from a

zone probably requiring 30 (90) continuous F-P. It seemed

the off-center pull was indeed the source - or at least an important

source - of friction that increased rapidly as the motive forces got

higher.

Before the mounting, the ends of the rope were simply

being pulled towards each other at the radius of the pulley. After the

ends were being pulled away from the pulley. At the far (bottom) side

of the pulley, the rope was held about 3/4 of an inch away from the

pulley. With the first system, the pulley was being pulled toward the

bottom when the rope was tightened. With the second, it was being

pulled toward the top, and the higher the torque, the more off center

it was.

I determined to replace the rope, which was now a little

short anyway with the cuts made, and make a noose that could be moved

in or out a bit with pipe clamps to adjust the height to match the

bottom.

At this point it appeared that the theory worked great,

and once again it was my somewhat flimsy construction with sloppy

tolerances that has been the problem. For a prototype, it'd have to be

excused.

But I got the pulley forces, I thought, more or less

centered without much improvement on the 31st. And, playing with a

spare planetary gear albeit not an identical one, it started to not

make sense - I could put sideways forces on it, and it still meshed

pretty smoothly. It still worked best under the magic 20 F-P.

In the meantime, on the same day I was considering buying

a planetary gear for a production prototype. As I did so, a better idea

of what the problem was came to me. Interactions with the slipping gear

turning a certain speed made for a certain maximum level of torque on

the output. That apparently was 20 foot-pounds. If that speed was

higher, the maximum torque would be higher. The speed could easily be

obtained by using the sun gear as the slipping gear instead of the

planets assembly. It seems to me the

Toyota Prius arrangement is that way. But that means changing pretty

much everything. I couldn't see using the same or another surplus auto

gear for a one-off

and then having to redesign it for production. I decided that for this

experiment I should buy a nice enclosed planetary gear and have the

chassis parts cut by CNC abrasive waterjet. If it worked, it would also

be the production prototype.

Then I started think about it more. If the shaft for the

motor stuck out one end and the shaft for the slipping gear the other,

with the chain sprocket to the differential being on the ring gear in

the middle, the whole unit could be enclosed in the original

transmission case, even if that might need to be hacked up somewhat. In

that case (bad pun!), it could contain a little gear oil for

permanent lubrication, and issues of using plastic gears would vanish.

It wouldn't be quite as efficient as what I've been visualizing, and it

would depend on getting the transmission from the same model of car,

but it would be good enough. All the regular gears and shafts inside

would be replaced by the one planetary gear. Solving the lubrication

problems and keeping dust and grime out are important.

On June 3rd I went out to the shed to get the transmission

housing, but a bunch of wasps came out of the cardboard box it was

under. Ugh, a hive! I decided to wait until dark and then pull the box

out with a long rope. Then I could take the garden hose to it.

"Permanent

Magnet Assisted" Unipolar Motor

Just a note

When I think that neo

magnets will fit into the existing toroidal core motor coils in the

"ARM" motor, it now seems fortuitous that I built it, and didn't get

around to doing the "Transverse Flux" reluctance motor idea. I might

now come up with some good way to put neo magnets into a transverse

flux motor, but it will require some design changes with some different

waterjet cutting patterns. The old motor would have turned out to be a

dead end, where the existing ARM motor can be "upgraded". I hope to

have the Sprint working in June (or maybe July) and so at last turn my

attention from

the variable torque converter to other things such as this.

Turquoise

Battery

Project

-

New

Chemistry

Battery

Making

Source of Electrolyte

I went to look for potassium chlorate as a strong oxidizer

to oxidize the surface of the carbon fiber, but I absently typed

"potassium sulfate" by mistake. I found it as a fertilizer for

agriculture, 0-0-50. That seemed too easy! I called a local supply to

ask if they had it. By the time the lady returned to the phone I

realized my mistake. Oops, how had I come up with the wrong chemical?

They did have it, and I thought I might get some for the

garden. Only after I hung up did I remember that potassium sulfate is

my battery electrolyte! That explains why I had absently typed the

wrong search term.

...A 25Kg bag for 54$. That sure has to beat mixing small

quantities of sulfuric acid and potassium hydroxide! Once again, if you

know where to look, you can probably find something. But it certainly

was an odd search sequence that took me straight to a cheap source!

I went there and ended up just getting a 2Kg box. It

didn't actually specify the chemical on the box, and I'm not sure of

the purity. It seemed better to get a little to try out.

Oxidizing Graphite for the

Positrode

When I typed the right chemical to search for, potassium

chlorate, in the search results was a way to make it using bleach and

potassium salt (NaClO + KCl), both of which I have. But it looked

complicated, and I decided instead simply to put some bleach in a pail

and toss in some carbon fiber cloth. That sat there the rest of the

month as I didn't have time to look at it.

The cell I made in April also sat for the month with a

small charge on it - the other method of oxidizing the positrode. It

didn't seem to have much current capacity. I added water a few times.

It didn't seem to improve with the charging. Finally on June 3rd it

occurred to me that there was no particular reason the carbon fiber

should be "battery purity" since that's not what it's made for. If it

had any nitrates or nitrites present in it, it would self discharge via

the "nitrate-nitrite shuffle". Or the Glycerin might produce something

as it oxidized. That these things didn't occur to me much sooner can

only be ascribed to having too many projects on the go at once, and

giving most of my attention to the PGCT.

The thing to do would be to flush out the electrolyte. The

beeswax seemed to have come off the far end. That simplified what I

thought would be tricky, as water could be run right through the cell.

Black powder (nickel or nickel oxide) came out, along with brown

liquid. I put it back on charge. Leter the discharge rate seemed to

have dropped in half, but it was still much too high. I suppose it

takes more than a quick rinse to clear out the water absorbed into the

separator sheet.

Nickel Ion Battery?

It seems that if one uses potassium sulfate in the

electrolyte, the nickel will stay

solid in all its oxidization forms. But according to the article below

(sent to me once again by Leonardo), if one uses instead nickel

sulfate, Ni++ ions coming off the negative will be dissolved and

migrate to the plus side. If something is made on the plus side to hold

all those ions, a battery cell is formed.

Secondary batteries

with multivalent ions for energy storage

Chengjun Xu1, Yanyi Chen1, Shan Shi1,2,

Jia Li1, Feiyu Kang1,2 & Dangsheng Su3,4

www.nature.com/scientificreports

See discussions, stats, and author

profiles for this publication at:

https://www.researchgate.net/publication/281779613

Secondary batteries with multivalent

ions for energy storage Article in Scientific Reports

· September 2015

Abstract:

The use of

electricity generated from clean and renewable sources, such as water,

wind, or sunlight,

requires efficiently distributed electrical energy storage by

high-power and high-energy secondary

batteries using abundant, low-cost materials in sustainable processes.

American Science Policy

Reports state that the next-generation “beyond-lithium” battery

chemistry is one feasible solution

for such goals. Here we discover new “multivalent ion” battery

chemistry beyond lithium battery

chemistry. Through theoretic calculation and experiment confirmation,

stable thermodynamics and

fast kinetics are presented during the storage of multivalent ions

(Ni2+, Zn2+, Mg2+, Ca2+, Ba2+, or

La3+ ions) in alpha type manganese dioxide. Apart from zinc ion

battery, we further use multivalent

Ni2+ ion to invent another rechargeable battery, named as nickel ion

battery for the first time. The

nickel ion battery generally uses an alpha type manganese dioxide

cathode, an electrolyte containing

Ni2+ ions, and Ni anode. The nickel ion battery delivers a high energy

density (340 Wh kg−1, close to

lithium ion batteries), fast charge ability (1 minute), and long cycle

life (over 2200 times).

Received: 18 November 2014

Accepted: 21 July 2015

Published: 14 September 2015

I'm not sure I want to tackle such an idea (having little

enough success with seemingly simple chemistries), yet it is an

interesting one. Again nickel is identified as the substance with the

most benefits of the metals considered.

http://www.TurquoiseEnergy.com

Victoria BC Canada

Apparently scientists seem to believe the Pelycosaurs practiced the

more advanced "costal

respiration", the chest muscle and diaphragm breathing common to modern

reptiles,

birds and mammals. Since no modern amphibians do this, we might

naturally assume that they were reptiles. But I

looked for more information, and it all seemed to suggest they were

amphibious.

Could they have been a "missing link", a stage between amphibians and

reptiles? Or even just plain amphibians?

Apparently scientists seem to believe the Pelycosaurs practiced the

more advanced "costal

respiration", the chest muscle and diaphragm breathing common to modern

reptiles,

birds and mammals. Since no modern amphibians do this, we might

naturally assume that they were reptiles. But I

looked for more information, and it all seemed to suggest they were

amphibious.

Could they have been a "missing link", a stage between amphibians and

reptiles? Or even just plain amphibians?

Looking more

deeply into creatures of the Permian on a site called http://palaeos.com/, I found the

mid-Permian Dinocephalia family. They also had very heavy

breastbones, and they seem to look a lot like the Pareiasaur "overgrown

frogs" above. Pictured is Estemmenosuchidae Uralensis. Again

they were said to be swamp dwellers, and were thought to be largely

vegetarian.

Looking more

deeply into creatures of the Permian on a site called http://palaeos.com/, I found the

mid-Permian Dinocephalia family. They also had very heavy

breastbones, and they seem to look a lot like the Pareiasaur "overgrown

frogs" above. Pictured is Estemmenosuchidae Uralensis. Again

they were said to be swamp dwellers, and were thought to be largely

vegetarian. Another area I briefly

explored reinforced this view. Many of the early Diapsids, a

broad group presumed to be small early reptiles, again sounded like

they had

suspiciously amphibious lifestyles. I couldn't find any photos of

skeletons showing the chest area, just a couple of side view drawings.

In these they seemed to have the heavy breast bones, but it was hard to

be confident of it. Some were of salamander- or lizard-like formation.

Another area I briefly

explored reinforced this view. Many of the early Diapsids, a

broad group presumed to be small early reptiles, again sounded like

they had

suspiciously amphibious lifestyles. I couldn't find any photos of

skeletons showing the chest area, just a couple of side view drawings.