Turquoise

Energy Ltd. News #102

covering July 2016 (posted August 1st 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries)

- Sprint/Variable Transmission - Ocean Wave Power - New Chemistry

Batteries (Air-Nickel) - Solar Panels for

the Miles Electric Truck? - Hydro Power from

Small Creek on the Cheap (a Video)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Rising Sea Levels? Not so fast! - Platinum Gets Rare - Turkey

Shoot - Violence Starts with Ruthless People - More

Lawlessness - Where are the VHE/Lambda Ray/"free energy"

Collectors/Converters?

- In Depth

Project Reports -

Electric

Transport - Electric Hubcap Motor Systems

* Electric Hubcap motor, Chevy Sprint & Variable Transmission:

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation

* Solar Panels for the Miles Electric Truck?

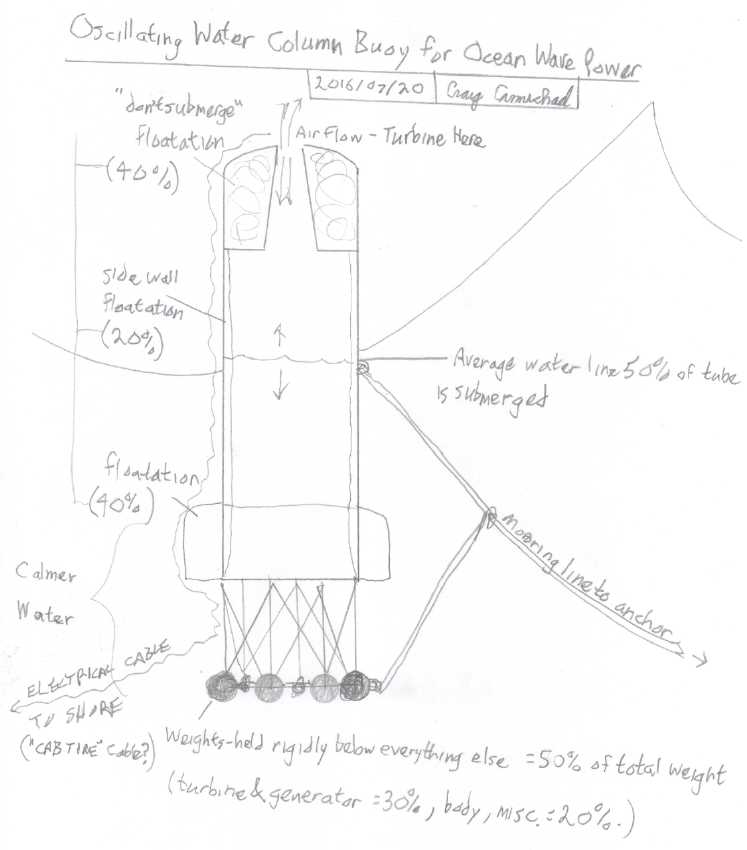

* Oscillating Water Column (OWC) Ocean Wave Power Buoy Drawings

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc. (no reports - see month in

brief)

July in Brief

Sprint/Variable Transmission

As in June, most of the month's project work that I

managed to get done, which wasn't very much, was on the variable torque

converter for the Chevy Sprint.

After not getting the last newsletter off until July 8th,

it was another couple of days before I finally got a bit of project

work done: part of one of the pulley sides. By the 14th in spite of

minor challenges I had two sides done and the lower pulley together,

and on the 15th and 16th I did the other one. Shaping the sides on the

lathe and cutting the bolt holes and getting everything to line

up occupied

considerable time.

Then the drive shaft wasn't quite long enough as I already

knew, and when I

finally tried to test the system, the pulley came off the end. There

was nothing for it but to make a new shaft. I also got 'joy' couplers

to connect the motor to this shaft, and I had to cut the sun gear off

the motor shaft. I was very reluctant to do this, but nothing else

worked, and I was even more reluctant to disassemble the motor so I

could press it off in the hydraulic press or replace the whole shaft.

Since the drive shaft was now connected to the motor at one end, it

should only have a single "steady" bearing at the other, so I took off

the cut-down trailer wheel hub with its two bearings and replaced it

with a single press-fit mounted needle bearing. Luckily I saw how to

mount it very easily with the same bolts as the hub, just by grinding

and filing the outside edge a little so it became an exact, locked in

fit.

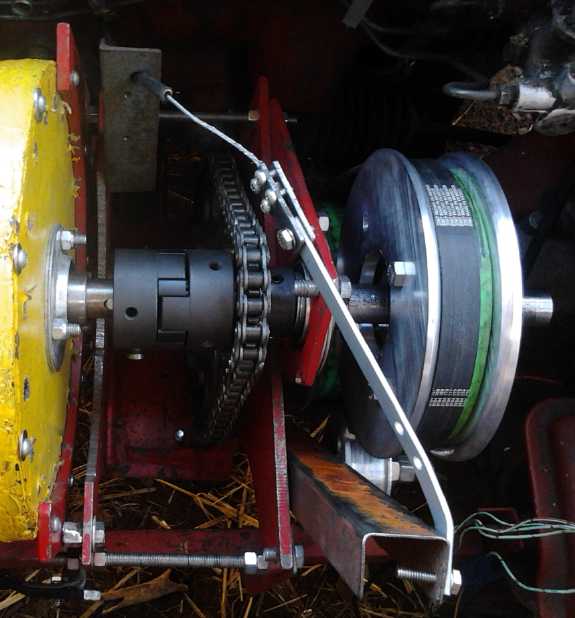

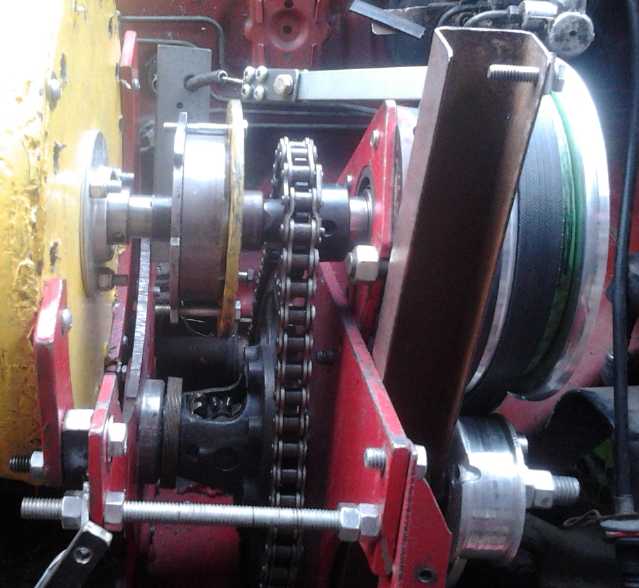

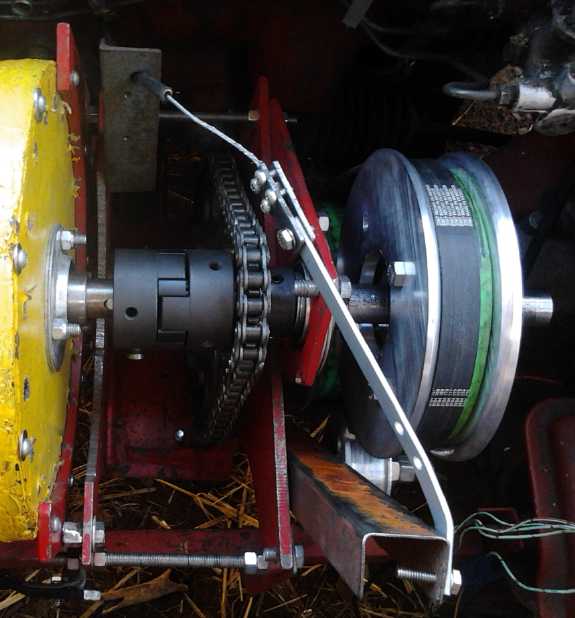

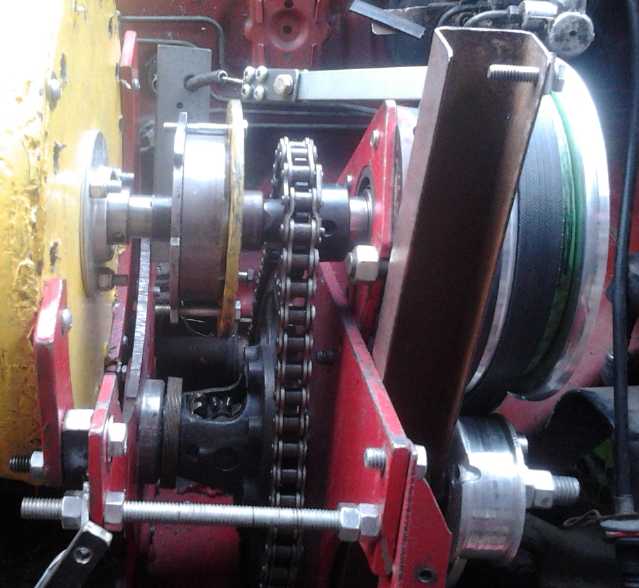

L to R on shaft: Motor, Joy (flexible)

coupling, chain drive to differential

L to R on shaft: Motor, Joy (flexible)

coupling, chain drive to differential

center, needle bearing, slip-belt pulley to differential left (port)

side.

Idler pulley is seen below, mounted on steel "U" arm, with hinge pin

at the bottom and tensioner from shift cable at the top of the arm.

When I finally had it all together, testing didn't go

well. The thin steel "U" piece I'd used to mount the idler pulley, tho

just the right size, flexed a bit and the idler didn't get a lot of

tension. When it got enough, the 'poly-V' belt melted poly-V

grooves into the ABS pulleys. The belt was pretty warm and I could

smell the hot plastic. I turned the belt inside out with the flat face

against the pulleys. It took so much pressure on the belt to force it

to engage that I ran a bungey cord to the driver's door and pulled on

that as well. Then the adjustment screw in a slot, strongly tightened,

slipped and the belt slackened. Later I noticed that the smooth face of

the belt was also quite slippery compared to the textured poly-V

face.

In all the testing, the car moved: only backward, 3 or 4

times, a foot or two, and only if it started from a position where it

wouldn't

take much of a push to start it going. I wondered if the reduction

ratio was sufficient even with the slipping belt, but I wasn't really

sure it ever got a fair test, either. And it seemed the idler would

have to be on the back side instead of the front to drive forward. Two

idlers?

On the 30th I went to Princess Auto to get another idler

pulley to install on the back side. I noticed they had a wide, fat belt

from a variable torque converter such as is used on small motorbikes.

I thought that if a fat belt like that would grab at the

edges of the pulleys like a big V-belt, it should take far less

force to get sufficient friction for things to engage as desired.

Finding such a belt was another problem - theirs was too short. I

started thinking of somehow using multiple strands of rope to create a

wide belt. Or maybe single ropes in double V-belt pulleys? What, change

the pulleys back to V-belt?!? Or maybe a couple of layers of PP

webbing/strapping the full width of the pulleys?

Ocean Wave Power

In saying what project I actually worked on, I can't omit

a thing I actually spent far more time on: considering ocean wave

power

and discussing it with potential funders and participants in Australia.

Someone pointed us to Wikipedia, an obvious source of information we

all should have thought to check earlier but of course didn't.

That made me think of youtube, and I started watching

videos. At first, my contention that the rope and pulley system with

all the floats tied into a tower on the shoreline was better than one

done with hydraulics seemed to be gaining sway. Then I found a video

about a floating machine using the oscillating water column (OWC)

method of extracting the energy. I had long ago heard about the one in

Scotland - a big cement structure on a steep bank - and I thought (ie,

without thinking) they had to be made like that.

Seeing the floating one revolutionized my thinking. Large,

heavy floats are ponderous. It takes time to get them moving. If the

waves are large that's okay, and large floats can extract more energy,

but if the waves are too small large floats won't move much to extract

even what energy they have. A water column in an open bottom tube buoy

reverses this inertia problem, immediately rising or falling with each

wave of whatever size, and exhaling or inhaling air through an air turbine covering a hole at the

top of the tube. It can extract the max from small or mediums waves,

but will start to follow large ones up and down, reducing stress in

storms. I drew 3 diagrams and sent them to the group. I've included

them in the "detailed report", which actually has just the drawings.

Someone else did a presentation in LA, CA, USA about wave

machines in general and what crappy designs there were out there (eye

opening in itself), and then showed his version of a floating OWC

machine, and how it would generate electricity for 2¢/KWH. It was

different in that it used a water turbine rather than air, in a venturi

under the water column's surface.

At first I thought this might be as

good as or better than the air turbine. Then I thought it wouldn't.

Then I realized it was his buoy design I didn't agree with, and decided

that if the buoys were similar, its performance would also be pretty

similar. (depending on relative turbine setup and efficiency.) But

moving parts

under the sea would corrode faster, and furthermore, a single air

turbine-generator unit could be more easily unbolted from the top of a

buoy and removed for servicing. So I went

back to thinking the air turbine was the better idea.

If he continued his experiments he would probably come up

with good units. But like most of us

working in green energy, he ended by saying he needed money to get any

farther. Big oil and even (now totally uneconomical) nuclear energy get

subsidies. Green energy gets the

cold shoulder or even sabotaged. (How did we ever even get river hydro?)

The air turbine model too (as I visualize it) needs mass

if it is free-floating, but in this case we don't want it to

rise and fall, so it works the other way, reducing power output

efficiency as the waves get bigger, while making the most out of the

small ones. I think that's the way to get the most and steadiest power,

including during those many calmer months when swells are a meter or

two instead of 3, 4, 5 meters or more. The motions it does make *might*

actually be helpful in amplifying wave effects. I could see it getting

up to 3 times as much average power over a year as non-OWC systems.

At both ends of the Pacific, we figured that 'politics'

and 'bureaucracy'

was probably going to be a harder problem than the actual project. I

was sorry

to hear it sounding like Australia would be as bad as Canada.

The first wave power unit to actually go on the European

power grid is one mounted on a wharf in Gibraltar. Another that is said

to

be going on line next year is in Denmark. Note these places: the

decisions permitting the projects were doubtless made locally. In

larger countries, the entire shoreline is government property and

bureaucracy makes everything so difficult

that no one can get anywhere, so the first success was Gibraltar rather

than Germany, France, Britain or Spain, with all the resources any of

these

could potentially throw at it. And as I may have said in 2008 in some

of the first issues of TE News, trying to get anywhere with anybody

here in BC seemed like rowing up a waterfall.

There are no little countries or duchies in North America

nor in

Australia where one might skirt the big bureaucracies. But there are a

few little out of the way islands and isloated places. I'll leave that

thought for now.

On the 24th a news article about making drone engines with

3D printers in Russia reminded me of that process. Maybe I could more

easily make the smallest wave power turbines for testing buoys - and

for comparing turbine types - from

plastic on the

3D printer? I continued to think of cutting the bottom off an old hot

water tank, and cutting a square wind hole in the top and outfitting it

to be a wave power buoy. I would cut pieces of 2" styrene foam as

floatation and glue it on with canned spray foam - a technique I

learned while making the peltier module fridge.

On the 29th I went out to the garage and tracked down a 24

volt lawnmower motor I mentioned many newsletters ago as a potential

low power generator. That might handle what the water tank can put out.

For more power I'll have to either sacrifice my 12 amp, 120 volt mower

(I loaned out the other one - sigh!) or else convert an alternator to

permanent magnet armature.

On the 31st I looked for "air flow turbines" and finding

nothing for sale, ended up reading about OWC design and theory on the

web, complete with all the funny greek symbols in complex equations. I

started to think that a "common sense" estimate of everything might

work out just as well as getting lost in a maze of formulae.

On August 1st I ground the welds off my 2007-8 attempt at

wave power, lurking in the bushes in a corner of the yard for nearly a

decade, to liberate the two rusty old hot water tanks. Now each tank,

all by itself (with hanging weight, foam floatation, and a turbine and

generator on top) could be its own wave power unit that would doubtless

capture more energy than the entire 2007 unit that included both tanks,

welded joiners and various mechanical parts and supporting stucture.

2007-8 wave power attempt; rusty water tank:

Cut off bottom and outfit as

a wave power buoy?

2007-8 wave power attempt; rusty water tank:

Cut off bottom and outfit as

a wave power buoy?

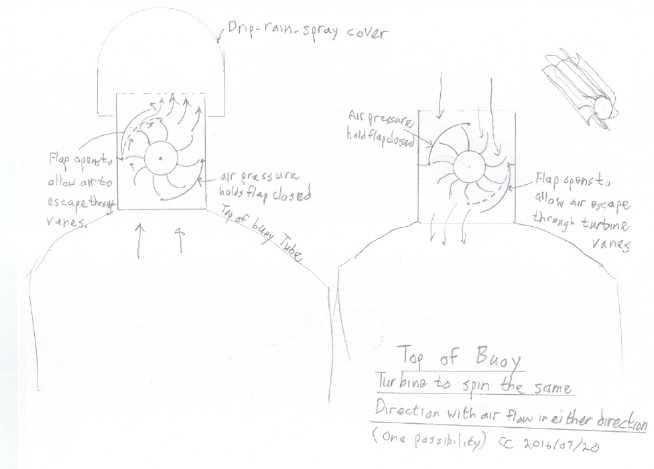

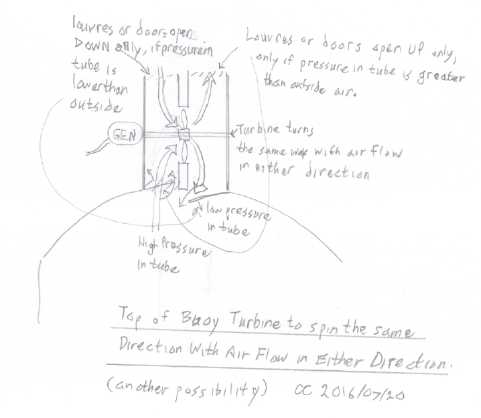

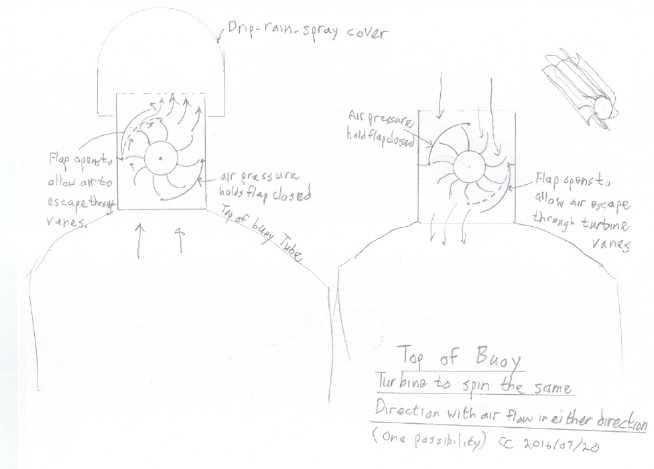

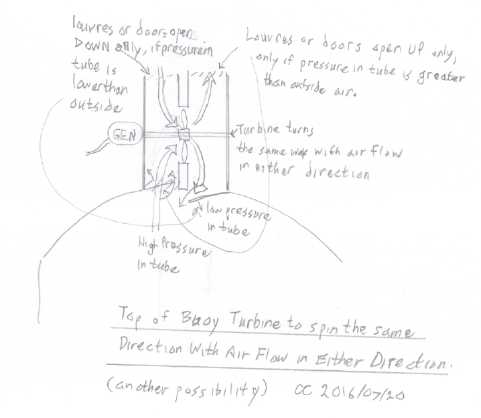

Much was made of the need for airflow turbines/fans that

would turn the same direction with air coming from either direction.

The standard seemed to be the Wells turbine, but a youtube video

compared that to a modified wells turbine with blades that flipped

back and forth

depending on the air direction, which seemed to perform much better.

But even that isn't the optimum wing/propeller airfoil shape. I struck

me as the wrong approach. I think

it might be better to use one-way louvers or flaps so that the air

always hits the turbine from the same direction, regardless of whether

it's going into or out of the buoy, and make an optimum turbine.

A 'DIY turbine' in a youtube video reminded me of computer

fans. I got out my largest one (120x120mm), 48v @ .15a or 7.2 watts.

Spinning it with the vacuum cleaner on "blow" I got (aside from some

funny and inconsistent much higher voltage readings) about 7v o/c and

.06A s/c. for a maximum possible .42 watts. That could light a bright

LED. I think that would make a disappointing demo. On the other hand,

one facing each way, each with a flap, seemed a simple solution to the

bidirectional flow dilemma.

New Chemistry Batteries - Air-Nickel

On the 19th I stuck the nickel-air cell (now sitting on

the counter for about 2 months) into a jar of water. I pulled it out to

drain and changed the water, several times over several days, to

hopefully dissolve out impurities. All that beeswax that seemed so

sticky came loose all the way around the edges. And the top bulged up

like a big bubble. And then I started cleaning up the

counter instead of working in a mess... and didn't get any

farther. Sigh!

Solar Panels for the Miles Electric Truck?

I started driving the truck more in July. Where it had

been able to do 30 MPH with the original bad or intermittent motor

rotation sensor, after the repair it would only do 25. Ugh! So I stick

to short very local

trips. The puzzling thing is the Miles vehicles are supposed to be

fully road safety rated, so why are their electric ones, only, with the

same frame and cab as the gas ones, deliberately so limited

in speed?

I had been

thinking of using two 90 watt solar panels in series as a possible

charging system for the 36 volt Sprint. The maximum open circuit

voltage per the specs is 22.3, so two would be 44.6 - theoretically

enough for a 42 volt float charge on 36 volts NiMH.

The

truck is 72

volts. On the 23rd I set the two panels on the truck and measured about

39 volts.

For charging a 36 volt segment, that would be 13 volts per 12

volt section - a good minimum float charge voltage for lead-acid. 1/2

of the batteries initially measured 38.3 volts. Clouds came on and off,

and the charging current varied between 50mA

and 330mA; at one point .4 amps. The panel will supply about 3 or 4

amps (4.9A at

MaxPowerPoint) if the batteries need charging.

The

truck is 72

volts. On the 23rd I set the two panels on the truck and measured about

39 volts.

For charging a 36 volt segment, that would be 13 volts per 12

volt section - a good minimum float charge voltage for lead-acid. 1/2

of the batteries initially measured 38.3 volts. Clouds came on and off,

and the charging current varied between 50mA

and 330mA; at one point .4 amps. The panel will supply about 3 or 4

amps (4.9A at

MaxPowerPoint) if the batteries need charging.

After 20 minutes the voltage was 38.6. But an isolating

diode is needed to prevent the batteries feeding back into the panels

when their voltage is lower (ie, no sunlight). And as panels warm up,

their voltage drops a few volts. With them already marginal, I begrudge

another 1/2 a volt diode drop loss.

After considering various "almost works" choices, I

decided

maybe the best solution (and only since they are

6V lead-acid batteries) would be to use the four 90 watt panels as four

18v

charging sections, and design my own oscillator circuit to drive some

switching

mosfets, to switch the connection (the minus side) on and off at high

speed to give "pulse

charging", which will automatically weaken to "not much" as the

batteries reach full charge... if it's sunny... in the summer. This

would

also incorporate a

shutoff for when the panel voltage is less than the battery voltage.

And the mosfets would act as "active rectifiers" without the loss of

over 1/2 a volt for passive diodes.

The real voltage from the panels is a little too low to

float

charge NiMH. The Sprint with NiMH and or lithium cells will need

another plan.

---

Then I think in the cab I should put four 18 volt meters

on the dash to show the state of the battery charges of each section.

If a battery is dying, one can isolate it to one of the four

sections and replace those 3 - and keep the two still good ones

for the next dud, maximizing use of every battery and keeping cost

down. The immediate problem with that is that the present batteries are

only 180 amp-hours instead of the usual 220-260 amp-hours of most 'golf

cart' batteries. New ones with more capacity will upset balance

when charging from 120 volts, and one might want to replace the lot to

increase range anyway.

Hydro Power from Small Creek on the Cheap - Video

I've watched this video a couple of times now: Water

Wheel

Generator by Off Road/Off Grid youtube channel. With a

very small creek, a chute of a few boards, a big old wire drum/spool

made

into a water wheel, a bicycle wheel as a big pulley and an alternator

converted to a permanent magnet armature, this fellow has made a hydro

power plant for his country mobile home. With a very low head, it puts

out about 40 volts and is probably well under 100 watts if not under 50

(he didn't say -

maybe he doesn't really know, and of course it would vary with water

flow in the creek). But of course it runs continuously, which is better

than most alternative energy sources.

He uses it with a modified charge controller to charge

some old 12 volt batteries. The batteries feed a 1000 watt inverter.

Thus when he wants power, even hundreds of watts for a while, he has

it, and recharging starts as soon as the load is turned off.

I got a call from AGO on the 27th. They finally had

all the parts to make more ships' winches slip rings, and needed two

made ASAP. Considering how little I'd got done in July on projects, I

figured that would probably pretty much end the month. Ah well, a

little extra income doesn't hurt! Anyway, I didn't get them finished

before the August 1st long weekend, and I did do a bit more project

work.

For August I hope to do a bit more variety of work than

just the variable transmission, whether it's battery development, wave

buoy construction, or just the solar panels for the truck.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Rising Sea Levels? Not so fast!

Last winter I wrote of unusually high water levels which

several times flooded the lowest parts of the sea walkway near my house

at high tide. Such flooding had only occurred once before, perhaps a

decade previously. I took this to mean the expected rise in sea levels

had become perceptible. However, these episodes weren't repeated and

there have been some pretty low tides this summer. Then I heard that

ocean levels have risen by only about 2cm - less than an inch. NOAA has

this to say: "Since 1992, new methods of satellite altimetry (the

measurement of elevation or altitude) indicate a rate of rise of

3 millimeters or 0.12 inches per year." This figure

indicates a rise of nearly 3" from 1992 to 2016. Not huge, but not

insignificant, either.

On top of the 3", the extra high waters here last winter

may have been a combination of factors which would have included El

Niño, heavy rainfall on the mainland gushing out the Fraser

River mouth, and "super moon" especially high tides.

The 3" however is sure to continue growing.

Platinum Gets Rare

Okay, so you already knew it was rare. Until the last 3 or

4 years, for decades platinum has cost substantially more than gold,

even double. Now it's substantially less. Like gold and silver it's

considered a monetary metal so there's no sales tax. I decided to buy

some platinum since it'll probably revert to its usual higher price as

the manipulations end and all the precious metals rise.

I have been having a bit of trouble getting it. I ordered

a bar and it came immediately. I ordered another one later, and it took

almost a month, with the usually prompt supplier (SilverGoldBull.ca)

eventually e-mailing and apologizing for the delay. On the phone, a

lady said a shipment they had expected didn't arrive and they had

run out. It was perhaps "on allocation". (limited quantities to

dealers) There have been times platinum (and sometimes palladium)

simply isn't on the shopping list at on-line dealers - as was again the

case for the platinum bars for a while before my order arrived. I've

never

found any locally.

Demand for gold and silver are continually rising as

people lose trust in paper money and blips on banks' computer screens

(conjured up out of thin air). Soon they too will be more in demand

than there is stored metal plus new supply, and there will be waiting

times and the prices rises already happening will accelerate.

A diminution of precious metal price

subsidization started to happen in June. By August 1st platinum

(retail 1 ozt bars) cost 1600 $Canadian versus 1330 $ in mid June. The

western world's

vaults are said to be about empty, and the scheme can't be continued

without at least some real metal backing the unbelievable amount of

paper futures contracts for metals that will never be delivered. (I'm

sure the guards at Fort Knox are only there to prevent anyone from

finding out!) Why are they doing it? Because if gold and silver were

continually rising in price in a free market, the decline in purchasing

power of fiat currency would become more glaringly evident than it is

at the grocery store. Then many people would start buying metals

as

a hedge against inflation, accelerating its fall. Now they can't hold

the beachball under the water much longer. (While precious metals have

gone down since 2011, people are telling

me unbidden they are paying double for food what they were a couple of

years ago. Surely it isn't that bad yet, is it? I'll get there and

more... but whoa!, I covered that last issue.)

Turkey Shoot

The attempted coup in Turkey was apparently fomented by

the CIA and other American/corporate/financial interests. A Turkish

woman living in the USA predicted on Corbett Report many months

previously that she expected the CIA to attempt such a coup.

The plan apparently was to kill Erdogan, get rid of the

Turkish prime minister and parliament, and install the

ultra-influential Moslem guy living in Pennsylvania as a dictator. (I

forget his name - he was already wanted in Turkey before the CIA

spirited him out of the country.)

Omitted in the media demonization of Erdogan with much

groundless name slinging like "tin pot dictatorship" and then how

"Erdogan" was maltreating thousands those involved in the failed coup

and that he was bringing back the death penalty for them, has been that

he was democratically elected by the people of Turkey. So was the

parliament. The justice department of Turkey is the body rounding up

the coupsters and those involved in groups which had been known for

some time as having violent anti-government leanings. True, Erdogan

said in an exclusive Eljazeera interview (youtube) that if parliament

passed a bill to bring back the death penalty, as was being demanded by

the people, he would sign it.

The coup was timed for the middle of the night when

everyone would be asleep, and by morning when everyone woke up, it was

supposed to all be over - fait accompli. Some factors that led to

its failure: Erdogan got warning in time to be elsewhere than his hotel

room when they stormed it to kill him, and likewise to warn others in

the government. Social media spread news quickly that something was

happening. (Also spreading lies that Erdogan had fled the country and

the coup had succeeded.) Erdogan asked the citizens of Turkey to go out

in the middle of the night and occupy the town squares and government

buildings. This they did, even climbing onto tanks, and 270 lost their

lives. The police went out and arrested many of the military

participants - even tho these were wielding powerful military assault

weapons which they could not match. (Many of the military were told

they were simply taking part in an "exercise".) All these courageous

acts indicate that people prefer an at least nominally democratic

government to a dictator installed by a foreign coup, a process that

doesn't seem to have worked out very well for the people of Ukraine.

Violence Starts with Ruthless People

In the USA lately, some policemen shoot innocent people

and are acquitted. In fact, there have been more annual

gun

deaths by the police in the last 2 or 3 years than by everyone else put

together, and more robberies by the police from persons or from

vehicles ("redistribution of wealth"

or "civil forfeiture") than by everyone else.

Then we have the topper: After a chief witness against

Hillary Clinton, no less than a former Secretary General of the UN,

turned up dead with his throat crushed (they tried to say it was a

heart attack, but the real cause got out - now it's "from exercise

weights in his gym"... let's see: he was weak enough to be in danger of

a heart attack, but he was exercising with crushing weights?), the

head of the FBI read off

a litany of her crimes as Secretary of State on TV... and he ended up

by saying she won't be charged (but he said that if you try the same

things, you will be). He carefully phrased things to leave out typical

incriminating words, such as saying "reckless" instead of

"criminally negligent". Perhaps he and his family were

threatened. Likewise, Attorney General Loretta Lynch, after meeting

"secretly" (it got out) with Bill Clinton, pursued no charges.

It is now plain to all that rule of law is dead at all

levels, and that even the biggest predators - especially the biggest

predators - are free to continue their predations.

A result this summer is a growing struggle

between those most oppressed and the authority of the state as embodied

in its increasingly corrupt police forces. Caught in the middle are

society at large as well as the good police, who will be targeted just

as much as the bad just for wearing their uniforms.

Many Americans are pointing to this as "The Day the

Republic Died." Some say "Republic" now has to be preceded by "Banana".

But it has been in decline for over a century. I might rather point to

November 1963 when president John F Kennedy was shot and killed.

Kennedy was a beacon of hope to a nation that had already been

increasingly darkened for decades by private and corporate agendas that

went against the public good. He tried to eliminate government secrecy

and corruption, harness tidal power for virtually free energy, have the

US treasury print money directly instead of via the private "Federal

Reserve", stay out of wars and disband the CIA, and expose hidden

agendas, and for these things he was hated by most every special

interest group. Only the public loved him, and that wasn't enough

support.

Since Kennedy, corrupt private interests have seen to it

that no such president was ever again elected, including by murdering

his brother Bobby in 1968 when he tried to run for the office. Hope for

a brighter future died with the Kennedys. The last vestiges of real

public control over national affairs were dead.

Of course, my own ideas on how to take back full control

of our affairs are at http://www.HandsOnDemocracy.org

. It wouldn't be that hard if people were awake and realized that they

can't simply hand over their own political power and authority to

others, avert their gaze from the political "black box" machine for

four years, and expect good results. The internet can be a powerful

tool

for making sure that what goes on in government is known publicly

and is what people really want to have happen, and that people who

wish to serve rather than to rule can be chosen for public offices.

We are today seeing that when ruthless predators are

allowed to run amok, not only does it make things worse for everyone,

but that society eventually cannot survive at all. In the future, if we

are to have socially sustainable societies, we must have the temerity,

audacity and nerve to stand up to ruthless people who prey on the

innocent when once we recognize their crimes as such -

people like the original Rothschilds, the David Rockefellers,

the JP Morgans, the Alfred Sloans, some of the 'big oil' and bank

executives, the Clintons, probably many or even most of the 65 people

who have as much wealth as half the planet's population, and, well, the

list could go on and on and on. We will need to arrest such people, try

them

fairly and impartially by a judgment group, and execute the guilty,

rather than have them return to society at any later time to take

revenge and resume their manipulations, robberies, abuse and killings

so many unsuspecting souls, and to continually decimate our most

progressive social, intellectual and creative elites when they try to

make progressive changes. They sideline progress, generation after

generation, nowhere more than in energy, finance and governing

institutions.

The "mainstream" media is on their side - paid lackeys,

who will lose their jobs or their broadcasting licenses to 'go against

the narrative'. They demonize those the corrupt don't like with lie

after lie. One would believe from the "mainstream" news that Trump,

Putin, Assad, Erdogan and others are the most evil of people. I have

heard people say that if Donald Trump is elected, he'd start World War

Three. Really??? The man who said Putin is a great leader, and that he

could work with him? It is in fact Hillary Clinton who said that a

nuclear first strike against Russia is not off the table. So by

their own words: Is it Trump who is likely to start world war

three? Putin himself praised Trump in return, and warned that if

Clinton

is elected, the world is headed towards war, and (to

western reporters) "It really worries me that you seem insensible to

the

danger."

Another person said "Don't let them undermine or

federalize your county sheriff's office." In the USA sheriffs are

elected and are not accountable to those in any other political office,

only to the public by election. They represent only the enforcement of

law and order. This was a brilliant move on the part of whoever set it

up. The sheriffs may soon be the only people standing between civilized

society and slavery or civil war, anarchy. If or when the time

comes, when the crimes are seen to have caused a horrendous economic

collapse, the local sheriffs are not employees hired by the rest of

government. The politicians don't have authority to give them orders or

to fire them. They will have the authority to arrest all these corrupt

politicians and all their corrupt associates - lawyers, judges,

bankers, anyone - and lock them up pending trials.

When the old system has definitely failed and everyone is

looking for answers, they will be ready to try out ideas like Hands On

Democracy, and to build socially sustaining communities embodying the

six core values of Quality of Life, Growth, Equality, Compassion,

Empathy and Love, starting at the local level.

More Lawlessness?

Here is some heresay from a video on youtube. I think

I mentioned a while ago that police in the

USA have been searching cars and relieving people of any cash they find

- "Prove it wasn't drug money." or some such nonsense.

Now (it says) Oklahoma has apparently

carried the program to a whole new level. The video I saw said they

have devices that will

scan your debit card and prepaid credit cards and take the credit or

the money from your back account. However, if they are real, I haven't

heard any stories

of them being used for such theft - yet.

This source thinks law enforcement are stealing a

hundred billion

dollars a year now from innocent motorists who will never be charged

with a crime, but who have nonetheless been relieved of their money by

highwaymen, er, highway patrols. Evidently truck drivers are a

particular target because they may have large expenses, and hence carry

more cash. (I used to hear tales of Mexican

police wanting $20 if they pulled over a "rich American tourist". They

were being modest and polite!)

The same video also says the federal government got

scared by how much they were "raking in" and quit, but now many

desperate states are in on the game. (And

here I thought it was just crooked cops!)

Whoever is behind it and however widespread it is and

however much is being taken, the CBC news, usually a pretty reliable

source, warned Canadians traveling to the USA about the robberies a

couple of years ago, with a couple of disturbing motorists' tales of

losing, for example, the money given a student by his parents to go to

university with. If more and more people hear

tales from people in their circles about being robbed by police,

doubtless many more

Americans likewise will start fearing to go on the road -- especially

truck

drivers, even out of proportion to the amounts stolen. Ultimately that

can only lead to the breakdown of the delivery system and social order

as a whole. Unless all this isn't true,

in

a culture of increasing lawlessness there are doubtless those who will

now flee from the police just because they're carrying their

own money -- and

perhaps some who will open fire on them if they can't get away.

Civilization is built on rule of law and trust that that law is

properly and

equally applied to all. How can it possibly survive

such an onslaught? Look for new stories of high speed police chases

and be sure to wonder why the 'suspect' was fleeing from police.

Where are the VHE/Lambda Ray Collectors/Converters?

I have written about VHE (Very High Energy) or (as I

called them) "Lambda" rays, recently at last identified beyond the

gamma ray spectrum, and theory for how to turn them into electricity.

Others have made these exciting and astounding discoveries long before,

even without having the whole theory. I have written how in some of

Steven Mark's last e-mails he said he was being threatened by the US

government with jail if he didn't shut up about it. (Yes, they had all

his e-mails - spying without a warrant. Think government spying is

benign or is used against "terrorists"?)

Then there were the two people in Brazil who had Brazilian

patents for free energy devices, did a youtube video about them and

offered to sell them locally, and who then vanished from the radar

screen, after having been arrested once on trumped up charges and then

released.

I don't watch "Dragon's Den", and can count on 2 or 3

fingers the number of pitches I've seen. But one of those, as I channel

surfed by, definitely caught my attention. Someone brought in a free

energy device, placed it on the floor, and turned on some incandescent

light bulbs powered by it. He said something to the effect that there

were no batteries in it and that the light bulbs would stay lit as long

as anybody wanted.

It was quite a short presentation. After a few moments,

one of the "dragons" jumped up, walked over and shook his hand, and

said "If the technology works, I'm in." As usual, rather than changing

the world, that was the first and the last I ever heard of that.

A Malaysian Airlines plane (called 'Flight MH370' IIRC)

disappeared over the ocean some time later. It suddenly and

mysteriously vanished with no distress call and it was never found...

but it seems a damaged piece of the elevator appeared a year or two

later on an island in the Indian Ocean. I hardly remember the details,

but it seems to me some thought some dents or holes indicated a bomb

had gone off on the plane.

It's somewhat 'common knowledge' that when those in the

top positions of power and influence want to get rid of someone, a

plane crash is sometimes used. That anyone having wealth and influence

could be so evil, so utterly lacking in conscience and moral nature, as

to sacrifice a whole plane full of innocent people to kill one innocent

person they don't like stretches most peoples' credulity, and so his

death would have to be seen as an unfortunate accident, not as a

targeted killing. Yet, "collateral damage" - violent death of multiple

innocent people in pursuit of a violent agenda - appears to be quite

acceptable in some circles. A bomb on a plane? Well then, it must have

been terrorists.

I heard a rumor shortly after the crash that there was a

small group of people on board who had gone to Malaysia or to Singapore

to arrange for manufacture of a free energy device. I have always

wondered if this was connected to the Dragon's Den episode.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Electric

Hubcap

Motor

Systems

-

Electric

Transport

Electric

Hubcap motor, Chevy Sprint & Variable Transmission

Differential Variable Transmission

with Slipping Belt that Returns Power to Motor Shaft

On the 10th I finally got

a bit of project work done: part of one of the pulley sides. The

splined center piece that went on the shaft was a bit too wide, and

held the side away from the pulley. On the 12th I did some more, and I

figured out that if I machined a 'bowl' in the center of the inside

side as deep as the offending extra width, it would

fit. But it didn't fit in my small lathe to be able to dig it.

On the 10th I finally got

a bit of project work done: part of one of the pulley sides. The

splined center piece that went on the shaft was a bit too wide, and

held the side away from the pulley. On the 12th I did some more, and I

figured out that if I machined a 'bowl' in the center of the inside

side as deep as the offending extra width, it would

fit. But it didn't fit in my small lathe to be able to dig it.

I took

it down to AGO where a new machinist did it for me after the piece he

was presently working on. Marvelous! In the meantime, I had

done the other side for the same pulley. The edge rounding, to

keep the belt from rubbing on a sharp corner and wearing rapidly or

even

jumping off, didn't match. Oh well! I also had to trim the outer

diameters down a bit, as fitting it on the car showed that the sides of

the two pulleys were going to collide - I wouldn't be able to

get both pulleys on. I hadn't thought they were that close together;

apparently less than 7"!

The first pulley was the bottom one, and only a 1/4" bolt

with small split washer that just might bend and slip through holds it

into the differential left side. There's no room inside the

differential for anything bigger and better. The second one was the

top, and the drive shaft, pulled out as far as I could, was a

little short, so it was only gripping at one end of the SDS bushing.

These things weren't satisfactory, but the bottom seemed almost

problematic, and changing the top shaft would be a fair bit of work.

The first pulley was the bottom one, and only a 1/4" bolt

with small split washer that just might bend and slip through holds it

into the differential left side. There's no room inside the

differential for anything bigger and better. The second one was the

top, and the drive shaft, pulled out as far as I could, was a

little short, so it was only gripping at one end of the SDS bushing.

These things weren't satisfactory, but the bottom seemed almost

problematic, and changing the top shaft would be a fair bit of work.

By the 19th I had everything together and on

the car,

having done the idler wheel tensioning arm and its connection to the

shift lever that day and the previous. I found a piece of "U" shaped

channel steel for it that was the perfect shape. However, the thin

metal proved more flexible than I'd hoped, twisting to the side

some when pressure was put on the idler pulley.

By the 19th I had everything together and on

the car,

having done the idler wheel tensioning arm and its connection to the

shift lever that day and the previous. I found a piece of "U" shaped

channel steel for it that was the perfect shape. However, the thin

metal proved more flexible than I'd hoped, twisting to the side

some when pressure was put on the idler pulley.

With these three deficiencies my level of confidence that

it would actually work on the first test was about 2%. Sure enough, the

twisting arm didn't seem to put enough pressure on the idler pulley,

and after a few moments the upper pulley fell off the end of the shaft.

First order of business would be to make a shaft about 2" longer. Then

somehow stiffen the arm. Then would the bottom pulley hold okay?

I considered making a very long drive shaft that would

be the motor shaft and run all the way across the transmission

(~17"), but then I considered that then I couldn't take the motor off

without disassembling several things, and the transmission with the

motor would be too heavy to handle. The motor with the 13 pound

flywheel was now ~42 pounds all by itself. Better to put in a coupling.

I milled the required keyway slots in a 9" piece of shaft

on the 23rd. None of the 1" shaft parts would fit on the '1"' shaft -

it was slightly oversize, and a bit oval. It also wouldn't fit into the

1" center hollow in the lathe chuck. On the evening of the 24th I took

it out to the somewhat larger lathe at Victoria Makerspace and trimmed

it down - the first use I'd made of my rather pricey membership in well

over a year. It worked much better than mine for this job, the whole

head having a center hollow bigger than 1".

The next day I started trying to assemble and

fit

everything. I decided to get rid of the shortened trailer wheel hub. It

pushed the top

pulley out about 1/2" over from the others. And with the joy couplings,

what was needed now was a single bearing that could be twisted a bit to

line up with the motor shaft, wherever it was: a pressed needle

bearing.

I found it would be very simple to grind 3 semicircle crescents for

bolts in the extreme outside of the press fitting, and then it would

fit securely, held by the same bolts that had held the trailer hub on.

The next day I started trying to assemble and

fit

everything. I decided to get rid of the shortened trailer wheel hub. It

pushed the top

pulley out about 1/2" over from the others. And with the joy couplings,

what was needed now was a single bearing that could be twisted a bit to

line up with the motor shaft, wherever it was: a pressed needle

bearing.

I found it would be very simple to grind 3 semicircle crescents for

bolts in the extreme outside of the press fitting, and then it would

fit securely, held by the same bolts that had held the trailer hub on.

I was very reluctant to cut the sun gear off the motor

shaft, but nothing else worked (even with a propane torch), and I was

even more reluctant to disassemble the motor so I could press it off in

the hydraulic press, or replace the whole shaft. If I ever go back to

the planetary gear, I'll regret that.

The joy couplings had only one set screw - where the key

was. I remembered how the electric Caik outboard had been messed up by

one of those working its way up the shaft with the key until it had

forced the motor shaft and rotor up and it jammed against the stator

compartment wall. So I took the two couplers and drilled set screw

holes

at 90° to the originals for a proper lock onto the shaft. Then I

hunted around for 5/16" set screws but couldn't find any. I thought I

had at least one! I finally got some bolts for temporary use, only to

discover that I had now somewhere misplaced one of the couplers. After

everything else was mostly done, with it still not found, I quit for a

while. Later a fresh search found it still in the vise from threading

the new set screw slot. I'd looked on my messy workbench all around it.

I took it out to the car and somehow found that I had now misplaced the

rubber cushion piece that goes between the two metal ones. Another

search all over, a coffee and some other things... Finally I rolled the

car back a few feet in case it had somehow fallen under it. Sure

enough, there it was.

I had to carve a small 'V' out of one side of the

transmission box body because it was in the way of a bolt - just a bit,

and I had to carve a bit of a motor mount piece that wouldn't quite

adjust to where I now needed it. Then I couldn't move the new shaft out

quite far enough because the key for the chain sprocket went

just a bit too far that way.

The next day (26th) I took it apart, cut off a bit of the

key, and put it all together. With the new bearing arrangement, the

shaft was about 3" longer than it needed to be. I could have just used

the old one! The car wouldn't move, but it didn't seem the idler pulley

got very tight. I put a bungey cord on it that I could pull from the

driver's door. I operated with one foot outside, one on the electron

[gas] pedal, and one hand pulling the cord. Not an arrangement for

going very far!

The car would go backward from a level to "almost rolls by

itself" slope, but not uphill. It did go smoothly. It wouldn't go

forward. Evidently it needed a second idler wheel around the rear for

that, or extreme tension on the front one. The ABS plastic pulleys and

or the drive belt very soon smelled quite hot, much sooner than the

motor started getting hot. Somehow I hadn't considered that at any time

before or since making ABS pulleys on the 3D printer. I can see some

changes will be needed to the materials being used and of course to the

idler wheel mounting, as already noted. Maybe once those are done it'll

start moving more robustly? - I sure hope it's much more!

The next morning (27th) I tried again and this time the

belt jumped off the pulleys. It was really a poly-V belt, and it had

melted poly-V grooves into the pulleys, which reduced the effective

pulley diameter and loosened it. I turned it inside out, flat side out,

but somehow that was even looser. The chain needed another link to

get the pulleys a little farther

apart. But obviously those pulleys weren't going to last. After all

that work on them!

Either I could make some the same of another material, or

I could change the sizes entirely and have sizes that wouldn't spin the

differential so fast once it was in sync. And since the car movement

had been less than robust, I should probably size them for a greater

speed reduction to the wheel, per the tables in last month's TE News.

If I made one smaller pulley, the slip would be on it. Then I could

keep the lower pulley without it quickly melting. Of course, it would

need a shorter belt. I guess I'll have to make one from a polypropylene

strap, melting the ends together per an issue of TE News a while ago.

Perhaps better still, I could line up the ends flush, and bridge them

by melting a second piece onto the outside.

But making new pulleys and changing setups is time

consuming. Perhaps I should try the flat side of the belt (adding

another 1/2 chain link), and just replace the idler mounting for

now, and see how that works? After all I'd hardly run it and I might

find I want to change other things or do something differently once I

had this working as best it may as it is. (And if the belt was tight

enough when loose, maybe the idler mounting will work 'as is' too.) I

added the link, made the adjustments, and tried again with similar

results - the car would only go backward from an easy spot, and stalled

when the going got tougher.

Furthermore, the idler pulley needed a lot of

tension to engage the belt sufficiently, and it seemed the bolt

adjusting the height of the bearing, and hence the tension on the chain

and on the belt, had slipped down in its slot, in spite of being

tightened as much as I could. Thus, the belt loosened off as it went. I

think that probably happened before too, and was probably part of

the problem with getting the car to move and to keep moving. Something

will have to be added or changed to lock the adjustment securely in

place.

Later I realized the smooth surface of the belt was much

slipperier than the other side. And when I went to buy a second idler

pulley for "forward" I saw a torque converter belt used in small

motorcycles. If I had a belt that gripped the edges of the pulleys, it

would take a lot less pressure for it to have the required grab on the

pulleys. Finding one that would fit is another matter. Perhaps I can

make something out of ropes or multiple layers of polyproylene

webbing/strapping?

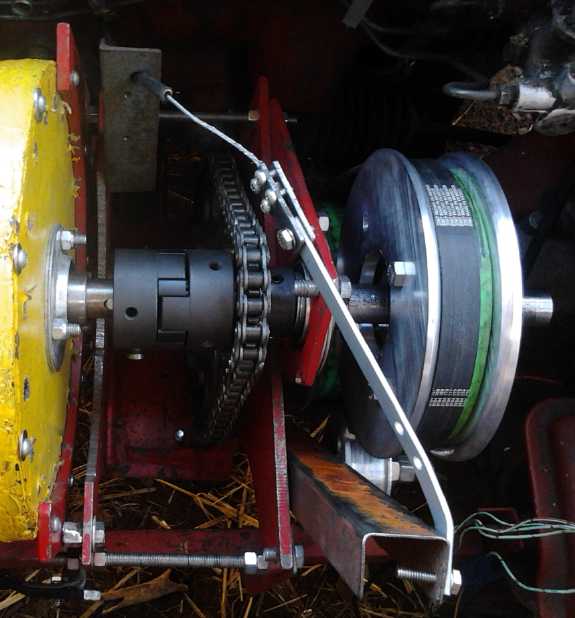

New Idler Pulley

New Idler Pulley

Let's see... on the motorcycle, there's a cam wheel with

indents set at different places. When the chain is adjusted, rotate

that

wheel as far as it'll go and lock it there. The chain slot can't slip

without the wheel moving to a lower position. Something like that to

keep the adjustment from slipping...

Electricity

Generation

Solar Panels

for Charging the Miles Electric Truck?

I started driving the truck more in July. Where it had

been able to do 30 MPH with the original bad or intermittent motor

rotation sensor, after the repair it would only do 25. When it hits 26

the motor switches off or even to braking to keep the speed down.

That's disappointing, because I'd be embarrassed to accumulate

a line up of traffic when I drive. So I stick to short very local

trips. The puzzling thing is the Miles vehicle frame, used for a number

of similar vehicles, is supposed to be

fully road safety rated, so why are the electric ones, only, limited

in speed? All I can think of is that the motor would be over-revving,

beyond its specs, above 25 MPH. It certainly does wind up! If it wasn't

for the fact that it might have trouble starting up from a pothole or

whatever, I'd think it would generally be better if they'd stuck it in

3rd gear instead of 2nd. A "2-1/2" gear might have been ideal.

The

truck has a flat roof over the cargo box, and on the

23rd I decided to try an experiment. I had been

thinking of using two 90 watt solar panels in series as a possible

charging system for the 36 volt Sprint. The maximum open circuit

voltage per the specs is 22.1, so two would be 44.2. The truck is 72

volts. I set the two panels on the truck and measured about 40 volts.

For charging a 36 volt segment, that would be 13.33 volts per 12

volt section - a good float charge voltage for lead-acid. I connected

them to 1/2 of the batteries, nominally 36 volts. They initially (after

connecting them for a few seconds before I remembered to check)

measured 38.3 volts. They'd have been lower if they had needed

charging, below 38. When I checked before connection, the panels said

39 volts.

Clouds came on and off, and the charging current varied between 50mA

and 330mA. The panel will supply about 3 or 4 amps (4.9A at

MaxPowerPoint at 36.2 volts) if the load has a lower voltage - ie, if

the batteries are low. Well, they could keep

the charge up, and on sunny days could do much of the charging if one

was patient. (Maybe all of it for the amount I drive it!)

The

truck has a flat roof over the cargo box, and on the

23rd I decided to try an experiment. I had been

thinking of using two 90 watt solar panels in series as a possible

charging system for the 36 volt Sprint. The maximum open circuit

voltage per the specs is 22.1, so two would be 44.2. The truck is 72

volts. I set the two panels on the truck and measured about 40 volts.

For charging a 36 volt segment, that would be 13.33 volts per 12

volt section - a good float charge voltage for lead-acid. I connected

them to 1/2 of the batteries, nominally 36 volts. They initially (after

connecting them for a few seconds before I remembered to check)

measured 38.3 volts. They'd have been lower if they had needed

charging, below 38. When I checked before connection, the panels said

39 volts.

Clouds came on and off, and the charging current varied between 50mA

and 330mA. The panel will supply about 3 or 4 amps (4.9A at

MaxPowerPoint at 36.2 volts) if the load has a lower voltage - ie, if

the batteries are low. Well, they could keep

the charge up, and on sunny days could do much of the charging if one

was patient. (Maybe all of it for the amount I drive it!)

After 20 minutes the voltage was 38.6. But tree leaves

started shading one of the panels, and it was soon down to 38.1. It

seemed the batteries were feeding into the panels, so an isolating

diode would be needed. With the voltages already marginal, I begrudge

another 1/2 a volt loss. Maybe it should be active rectification with

mosfets?

The next morning there was a clear blue sky (no clouds, no

chemtrails - a bit of luck), and around 10:30 DST there were no shadows

on the truck. I took the panels back out and set them on top. They read

41.0 volts. I found an alternator diode and again connected the panels

in series to 1/2 the batteries, through it. I got 40.0 volts open

circuit. (As panels warm up, their voltage drops.) When connected, the

panels dropped to 39.2 and on the battery side of the diode, 38.4.

Inserting the current meter, it showed .40 amps.

Well, that seemed to work nicely - on a sunny day with no

shadows on the panels. There's lots of room for 4 of those panels on

the square roof if they overhang the cab a little. In fact the panels

are 22" x 46", and the space per panel is 27" wide, or 29" if that

silly vent wasn't in the way. Should I get 2 more of the 90

watt panels, or should I get the biggest ones that will fit with that

voltage spec, perhaps 140 watts? Two more 90 watt panels is

definitely the cheapest option (~400$) since I already have two, that

have been sitting around unused for a couple of years now. They would

provide a rated 360 watts. The 140 W panels, which would make 560 total

rated watts for about 1000 $, were a good width at 26.4", but they were

almost a foot longer and would need a "roofrack" over the cab to hold

the front ends steady. I decided, if I was doing this configuration, to

stick with the 90s.

Then I thought that perhaps a better option would be to

find 3

somewhat shorter "full size" panels of over 200 watts, and use three 24

volt charge controllers. Two panels could go sideways over the box. The

third one would need a "roofrack" frame to mount over the cab. These

could charge with over 600 rated watts, even 1/2 the speed of the

plug-in charger. At well over 1000$ this

would also be the costliest option. But since the charge controllers

would be pulse chargers that should improve battery life, it would

replace my present desire to replace the existing 72 volt charger with

six 12 volt pulse chargers each costing 140$ + taxes, a theoretical

saving of 940$

plus all the electricity eventually saved.

My search eventually disclosed that panels are made

with 36, 60 or 72 cells. I have two 54 cell panels on my roof from

2012,

but HES says these are no longer made. They're the voltage and the size

I want for the truck for the three banks of 24 volts, but I only have

two of the three needed, and I would also have to extract them

from my high, steep roof (and replace them with others).

With existing choices then, I can't fit the three panels I

need to get the 24 volt charging systems. I don't want panels that

stick out past the box (back or sides), because the first time you get

the truck too close to something, instead of a near miss (or perhaps a

dent) you'll hit with a solar panel and probably break

it.

I finally concluded that the best solution (and only since

they are

6 volt lead-acid batteries) would be the four 90 watt panels as four

18v

charging sections, and to design my own oscillator circuit to drive

some

switching

mosfets, to switch the connection (the minus side of each panel) on and

off at high

speed to give "pulse

charging", which will automatically weaken to "not much" as the

batteries reach full charge since that's the voltage the

panels are... if it's sunny... in the summer. And it would have a

shutoff for whenever the panel voltage is less than the battery

voltage. The mosfets would act as "active rectifiers" without the loss

of

over 1/2 a volt for passive diodes - a notable help with the marginally

high

enough voltage.

Then in theory if one battery gets weak earlier, I only

need to replace a set of 3 instead of all 12. Of course the other sets

will doubtless go soon enough, but it spreads out the expense and gets

more the maximum life out of each battery.

One caveat: I would have to park on the street to get the

sun. My yard is too shady. (Or cut down the old cherry tree, which is

actually long overdue anyway. But that would only be a partial solution

since the house itself shades the driveway much of the afternoon.)

---

To even just "float charge" nickel-metal hydride batteries

well, the open circuit voltage would have to be 42.0 volts (even

assuming low drop active rectification). The most I got in full sun was

41 volts, and even that soon dropped to 40.

I figured out why the open circuit voltage had gone down

the first day between readings: Just one of the several spec sheets I

looked at had a temperature graph. It showed lower voltages at higher

temperatures. The spec.ed voltage was 43.2v at 25°c. Theoretically

that meets my 42.0 volt requirement. But it dropped down to about 38v

at 50° and 34v at 75°. As my black panels sat out in the sun

they got warmer and their voltage dropped.

So getting near the highest rated voltage, to over 42.0v

for a NiMH float charge, sounded fine, but it was actually a

fantasy. The panels would have to be kept cool in full sunshine, and

they would have to be aimed at the sun. But really the only practical

orientation on a vehicle roof is flat. So my original plan for charging

the Sprint with solar wouldn't work. Like the Peltier modules, solar

panels could be made in just about any voltage rating in small steps,

but they're made either 22.3 volts or somewhere over 30 volts, 36, 60

or 72 cells, neither of which seems very convenient or efficient for

either 12 volt or 36 volt battery charging. (Maybe it helps them sell

DC to DC converting charge controllers?)

So the Sprint with NiMH and or lithium cells will need

another plan. Unless... if I used only 8 NiMH cells in the third "12

volt" battery, it would be 33.6 nominal volts instead of 36, and the

panels could put out 2.8 volts less for float charging: 39.2 volts

instead of 42.0. That could work, but it would bring its own set of

headaches, especially for charging the last one from three regular 12V

chargers.

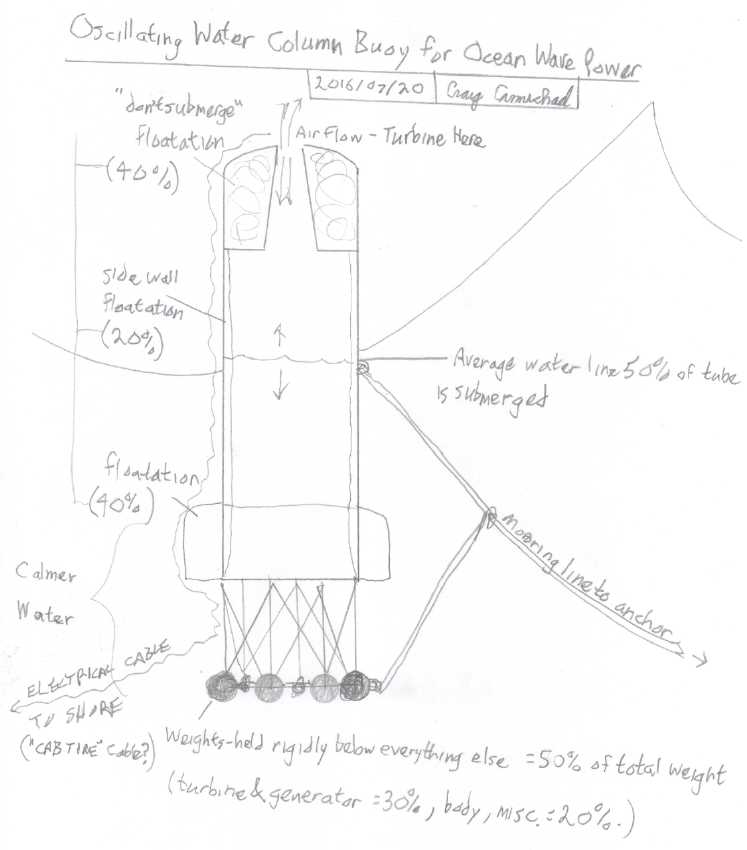

Oscillating Water Column (OWC) Ocean Wave Power

Buoy Drawings

Here are some drawings I did to illustrate how an OWC

sytem

for capturing wave power might be implemented. The design can be scaled

to sizes from "demo" to very large.

The open-bottom buoy

The open-bottom buoy

One idea for a turbine to turn the same direction with air inhaling or

exhaling

A propeller type wind turbine approach

http://www.TurquoiseEnergy.com

Victoria BC Canada

The

truck is 72

volts. On the 23rd I set the two panels on the truck and measured about

39 volts.

For charging a 36 volt segment, that would be 13 volts per 12

volt section - a good minimum float charge voltage for lead-acid. 1/2

of the batteries initially measured 38.3 volts. Clouds came on and off,

and the charging current varied between 50mA

and 330mA; at one point .4 amps. The panel will supply about 3 or 4

amps (4.9A at

MaxPowerPoint) if the batteries need charging.

The

truck is 72

volts. On the 23rd I set the two panels on the truck and measured about

39 volts.

For charging a 36 volt segment, that would be 13 volts per 12

volt section - a good minimum float charge voltage for lead-acid. 1/2

of the batteries initially measured 38.3 volts. Clouds came on and off,

and the charging current varied between 50mA

and 330mA; at one point .4 amps. The panel will supply about 3 or 4

amps (4.9A at

MaxPowerPoint) if the batteries need charging. On the 10th I finally got

a bit of project work done: part of one of the pulley sides. The

splined center piece that went on the shaft was a bit too wide, and

held the side away from the pulley. On the 12th I did some more, and I

figured out that if I machined a 'bowl' in the center of the inside

side as deep as the offending extra width, it would

fit. But it didn't fit in my small lathe to be able to dig it.

On the 10th I finally got

a bit of project work done: part of one of the pulley sides. The

splined center piece that went on the shaft was a bit too wide, and

held the side away from the pulley. On the 12th I did some more, and I

figured out that if I machined a 'bowl' in the center of the inside

side as deep as the offending extra width, it would

fit. But it didn't fit in my small lathe to be able to dig it. The first pulley was the bottom one, and only a 1/4" bolt

with small split washer that just might bend and slip through holds it

into the differential left side. There's no room inside the

differential for anything bigger and better. The second one was the

top, and the drive shaft, pulled out as far as I could, was a

little short, so it was only gripping at one end of the SDS bushing.

These things weren't satisfactory, but the bottom seemed almost

problematic, and changing the top shaft would be a fair bit of work.

The first pulley was the bottom one, and only a 1/4" bolt

with small split washer that just might bend and slip through holds it

into the differential left side. There's no room inside the

differential for anything bigger and better. The second one was the

top, and the drive shaft, pulled out as far as I could, was a

little short, so it was only gripping at one end of the SDS bushing.

These things weren't satisfactory, but the bottom seemed almost

problematic, and changing the top shaft would be a fair bit of work. By the 19th I had everything together and on

the car,

having done the idler wheel tensioning arm and its connection to the

shift lever that day and the previous. I found a piece of "U" shaped

channel steel for it that was the perfect shape. However, the thin

metal proved more flexible than I'd hoped, twisting to the side

some when pressure was put on the idler pulley.

By the 19th I had everything together and on

the car,

having done the idler wheel tensioning arm and its connection to the

shift lever that day and the previous. I found a piece of "U" shaped

channel steel for it that was the perfect shape. However, the thin

metal proved more flexible than I'd hoped, twisting to the side

some when pressure was put on the idler pulley.