Turquoise

Energy Ltd. News #105

covering October 2016 (posted November 10th 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Coming Next month (November):

*

Tesla

Turbine Windplant? * Hydro Power Wheel with Curved Blades? *

Plan for Floats for Floating Hydro Power Units --- I didn't have time

to finish these writeups, so I'll just note here that some interesting

ideas

have been thought of and are coming for next month.

Month In Brief

(Project Summaries)

- Late Newsletter, etc - Differential Torque Converter: Gear Cutting -

The Electric Suzuki Swift! ... Regen Braking ... Swift compared with

"ultra-efficient" Ideals - Big Oil is on its way Out - Personal Doings

& 'Business' Trip - Tidal Power in Haida Gwaii? - Building

Renewable Energy Mechanisms Workshop/Lecture Series?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Evolution of Democracy

- In Depth

Project Reports -

Electric

Transport - Electric Hubcap Motor Systems

* Electric Hubcap motor, Chevy Sprint & Differential gear Variable

Transmission:

- Gear Making

- Kelly Motor Controller Troubles

* Electric Caik Outboard Upgrade

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation

* Improved 750/1500 Watt Hugh Piggott Frictionless Axial Flux

Alternator?

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc. (no reports)

October in Brief

Well, this issue covering October is the latest TE News in years, if

not ever. Several factors conspired for delay. First was my trip to

Haida Gwaii on October 31 to November 3rd to look the island over, to

look at properties, and to assess the potential for doing 'green'

electricity generating projects there, including potential for

community involvement. Obviously the newsletter would be delayed until

the 6th or 7th. I liked it and hope to move there. Then I spent a day

looking for and at 8' x 20' shipping containers to pack my many

belongings into.

Then, a

bacterial bloom had started up in my tilapia aquarium which I hadn't

managed to change water fast enough to get ahead of. The days of the

trip were just too much. The water got too bad and one of the fish

died. That was the last straw on that. I set up a tiny 10 gallon

aquarium and moved the fish to it. With just a quart of water from the

first tank, the water tuned cloudy overnight! I think it all might have

something to do with chlorinated water, too, even tho I was putting

chlorine/chloramine removal drops in the water before adding it.

Then, a

bacterial bloom had started up in my tilapia aquarium which I hadn't

managed to change water fast enough to get ahead of. The days of the

trip were just too much. The water got too bad and one of the fish

died. That was the last straw on that. I set up a tiny 10 gallon

aquarium and moved the fish to it. With just a quart of water from the

first tank, the water tuned cloudy overnight! I think it all might have

something to do with chlorinated water, too, even tho I was putting

chlorine/chloramine removal drops in the water before adding it.

I set up a new 30 gallon aquarium that I had bought some

months previously when a pet store was going out of business. I dragged

water up the stairs from a rain barrel outside, bucket after bucket. It

has a great filter system and a faucet to drain water, which will be

much easier than siphoning it out. (But it won't clean the gravel.) And

a bright white or dim blue LED light. The two remaining fish finally

started perking up and hopefully eating again. And maybe I should

mention here that I left a cover off the pond outside and an otter (and

maybe raccoons) ate my 17 goldfish, which had grown from tiny to 4 or 5

inches long.

I'm not proving to be much of a fish farmer, and setting

up another aquaponics system is looking far off. Perhaps it's fortunate

that the tilapia haven't bred.

I set aside for next issue

a couple of 'idea' articles about floating hydro power and one about

wind power with a Tesla turbine, that I hadn't finished working out. I

had it about ready to go on the 8th, but when I got up from an evening

nap to finish up, there was water everywhere. My hot water tank had

sprung a leak after 19 years and 11 months of service, and of course

replacing it made itself top priority for another day. (Just a few more

months and it could have been somebody else's problem!) Usually they

last less than 10 years. I attribute its longevity to buying a better

than base level tank in 1996 and to having the hot water at 130°F

or less instead of the scalding 140°F most people have it at, which

would surely reduce the rate of corrosion.

Congratulations to the Americans on their election! Of the

available choices I think it was a good decision. The rampant

corruption within all the ruling structures including the

blatant propaganda news media, who all staked everything on Mrs.

Clinton winning when Trump won the Republican nomination, just might

take some sort of hit. While the "oligarchy", "corporatocracy" or

"shadow government" can be expected to spare no effort or expense to

hamper and discredit him from behind the scenes via the media

(hopefully further

discrediting themselves in the process), Mr. Trump certainly won't

start world war three or end democracy, which were potentially in the

cards. Whatever Clinton supporters feel, there are certainly some

nations breathing a huge sigh of relief and seeing a new light shine in

a bleak landscape.

Of course, no election result changes the fact that our

democratic forms are all very primitive and badly need to evolve to

forms that are suitable for increasingly enlightened people with so

many capable of contributing so much, in an age of advancing

communications and growing interconnectedness. We are gradually better

learning how this might look, and I will soon be posting another update

to http://www.HandsOnDemocracy.org .

Differential Torque Converter: Gear Cutting

Having conceived it and seeing it seemed the most

suitable, I decided to go with the "Asymmetric" Differential unit I

mentioned last month. On the 8th I got the rotary table and dividing

plates for gear cutting. Much of the physical project work I managed to

do in October was setting up the equipment and jigs, and cutting gear

teeth and sample gears for the asymmetric differential unit that is to

be a main component of the torque converter.

Perhaps I chose too large a tooth size, because the

smallest gears are pretty large in diameter. That forced me to shrink

the center gears and to have only 4 pairs of outer gears. I'm no longer

confident that plastic ones will be sufficiently strong at the smaller

diameters with fewer sets of teeth taking the loads. It looks like

it'll have a mix of UHMW plastic spurs and larger steel center gears,

but still, meshing against each other with low friction and no need for

lubrication.

"C" is to be connected to the front,

and "D" to the rear, side shafts of the differential.

"C" is to be connected to the front,

and "D" to the rear, side shafts of the differential.

The whole (brake drum) case, with an opposite side cover plate (yet to

be made), is the center element.

'Spur' or 'planet' gear "A" is double width and meshes with "D" and "B".

"C" is just enough smaller that "A" doesn't touch it.

"B" is the direction reversing connection gear between "A" and "C". It

is beside "D" and its shaft is outside from it.

"A" and "B" are to spin freely on metal shafts running across between

the two sides.

There are to be 4 pairs of "A" and "B" gears around the outside to

reduce the loading per gear tooth.

I also found poly-V-belt pulleys at Mac's Auto Electric,

to use on the motor shaft with two of the same poly-V-belts as the one

I've had all along, which will turn the rough outside rim of the 10"

differential drum, used as 'flat belts' at that end. With the single

variable pulley on a swinging arm with a fixed pulley on the same

shaft, running to large pulleys on the motor shaft and on the

differential input end, the main components are pretty much picked out,

leaving lots of little details about shafts, bearings and shaft

fittings, and the chassis to hold them all together while allowing for

all required belt tension adjustments.

Various further details are of course to be found in the In

Depth

Project

Reports - Electric Transport.

The Electric Suzuki Swift

On about the

13th a friend offered me an electric Suzuki

Swift, without batteries. It had been converted some years ago by

university mechanical engineering students under the tutelage of Randy

Holmquist of Canadian Electric Vehicles. It hadn't been on the street

since 2013, when the owner got a Mitsubishi iMiEV. This particular

vehicle had exceptional driving range, 65-75 Km, with just 9.6

KWH of batteries: 96V, 100AH. This is much farther than the Mazda

RX7-EV went, and with only 3/4 of the battery storage capacity. It was

of course a great asset that they were all lithiums rather than

lead-acid.

On about the

13th a friend offered me an electric Suzuki

Swift, without batteries. It had been converted some years ago by

university mechanical engineering students under the tutelage of Randy

Holmquist of Canadian Electric Vehicles. It hadn't been on the street

since 2013, when the owner got a Mitsubishi iMiEV. This particular

vehicle had exceptional driving range, 65-75 Km, with just 9.6

KWH of batteries: 96V, 100AH. This is much farther than the Mazda

RX7-EV went, and with only 3/4 of the battery storage capacity. It was

of course a great asset that they were all lithiums rather than

lead-acid.

Knowing what the owner had said about the car back when he

was driving it (as best I recall), it only used 120-140WH/Km

instead of the RX7's 170-200. Yet the owner lived in the country and it

was

around 50Km to and from town plus whatever driving he did in town, so

that range, plenty for most of my driving, was marginal for him. Hence

he purchased the

iMiEV with enough additional range to make the difference. But he also

complained about heavy steering, 'spongy' brakes, and that if one

accelerated too fast for very long, drawing over 350 amps, the motor

controller didn't like it and started a loud beeping.

After doing the paperwork, he drove it to my house and I

drove him home. The 25Km from Metchosin to my place used about 33% of

the range, according to a "% left" meter. It was well equipped with

meters -

except for the one I consider most informative as to state of charge, a

voltmeter. There was even one of those, a multiple meter of some sort,

but it hadn't been installed (yet). He

left me the batteries for the time being, so I can compare it with

before and after changing them. Personally I thought the steering was

fine. As a front wheel drive it was much lighter than the rear wheel

drive RX7. But then, I rarely drive a vehicle with power steering. The

brakes had no vacuum assist, and they did take much more push

than one expects or desires. Nevertheless, pushing hard enough does

make

tires skid. When I drove it accelerating up a hill I was favorably

impressed with the power - for a few seconds until the controller

started beeping. But the batteries as well as the controller are

probably stressed by supplying

that much current. I backed off a bit (ampmeter then read 200) and

after a few more seconds it stopped.

1998(?) Suzuki Swift.

1998(?) Suzuki Swift.

In 2010 (just 6 years ago!) there were very few electric cars on the

road,

and those who converted it were justly proud to paint "Electric

Vehicle" on the back.

I could put in my 11

lithium cells (36v), which were

apparently the same as the 30 being removed, and 5 NiMH batteries, each

12v, 100AH for the other 60 volts, making up the 96 volts at the same

theoretical capacity. They certainly weren't going to fit in the

battery box that had been welded together under the back seat for 30

compact lithium cells. I figured I could sacrifice the bottom of the

small rear cargo space, or 1/2 the back seat.

Toward the end of the month I bought several 12 volt

battery chargers for the NiMH batteries. In the meantime I was doing

nearly all my driving in it with the original batteries and getting a

good feel for it. It seemed to be using around 135-150 WH/Km, about 'as

advertised', and that in cooler fall weather.

Regen Braking

Like the Miles electric truck, this vehicle has an AC

induction motor and regenerative

braking, engaged simply by lifting one's foot on the 'gas' pedal. (They

don't have the torque of the RX7's DC motor from a

stop, but it picks up quickly once it gets moving.) There being an

ampmeter, again I note that the amps being

returned by the braking are far less than those being put in during

acceleration. I checked it on a hill. The downhill test (both tries!)

was shortened or distorted by someone pulling out right in front of me.

Anyway I got that going up at 50 Km/H took around 200 amps. Going back

down at 50 Km/H seemed to return only around 40 amps in the brief times

I was able to maintain that constant speed. When I noted the large

difference before, some interpreted my remarks as indicating that I

didn't think regen braking was worthwhile or useful. Not at all. What I

was pointing out was that to get those very different figures between

acceleration and similar deceleration showed

how many losses there were through a car's drive train: through the

usually lossy automotive transmission, the differential, the wheel

bearings, and the tires on the road. Plus wind resistance and any

electrical losses within the motor and controller. If one calls it 200

amps and (being generous) 50, the middle would be 100 amps, suggesting

a 50% loss of the power applied and 50% loss of the power returned. The

actual figures thus give us a rough idea of how much room there seems

to be for improvement in vehicle efficiency - even for electric

vehicles. (The Mitsubishi iMiEV is reputed to have exceptionally

effective regen braking. Perhaps it simply has lower drivetrain losses.)

Perhaps it's also

worth noting that radial ply tires, which decades ago became an almost

universal standard, have about 10% less rolling resistance than the

bias ply tires that were previously the norm. The difference between

power applied and regen regained, as well as the total power needed to

drive, would only be worse if we still used bias ply tires. We also

know

that tires with low air pressure have noticeably higher rolling

friction than well inflated tires. This suggests that the most

significant areas to focus on improving are the transmission (as I've

been doing) and probably, still, the tires. (Think how easily a rail

car with almost frictionless steel wheels rolls compared to a car with

rubber tires.)

Mea culpa!... I got a good demo of the effect of tire

inflation. On November 7th I finally went to inflate the air suspension

units on the back of the Swift, added because of the battery weight.

They were completely flat and I put in 25 PSI. Then I thought to check

the tires. Three of them were down around 15 PSI. (The other had gone

completely flat recently and had been replaced by the previous owner.)

I pumped them all up to over 35 PSI. Now I'm not sure if the ride is

softer with the suspension inflated or harder with the tires inflated.

But it takes palpably less power to accelerate and more energy is

returned (or it slows less quickly) with regen braking. Sure enough, in

considerable driving around town on November 9th related to the hot

water heater, the Swift only used 120 WH/Km. That's excellent economy

and perhaps a 15% improvement over having 3 low tires!

Motor and controller efficiency also plays a roll. Even an

88% peak efficiency induction motor is also 12% minimum losses, so the

Electric Hubcap motor at perhaps 95% peak efficiency is some modest

improvement.

Compared with "Ultra Efficient" Ideals

My 'ideal' target for an "ultra efficient" drive system

has been 100 WH/Km. Realistically, while my Sprint is still small and

light, it's the somewhat larger 4-door version of the same car design

as the Swift, and perhaps I won't improve much on what the

2-door Swift

already does. At least, perhaps not without one of those new "permanent

magnet

assisted" or "electro-permanent magnet" motors that apparently can give

seemingly miraculous performance. (Another sidetracked project, but one

can only do so much at a time!) Still there's that reputed 30% loss in

automotive transmissions, that might favorably surprise us if

eliminated.

Even counting that, I'm guessing that for general

driving around town, I'll probably want two Electric Hubcap motors

rather than one for acceptable (and still not powerful) performance.

People said one wouldn't be enough power. I reserved my judgment, but

it looks like they must be right. On the prairies with flat ground one

just might do it, but here

one is always going up and down hills. Or if there was no gasoline

available (or it costs too much) and nobody cares if a car is sluggish

as long as it runs, one

might do.

For those interested in such details, here's my take on

"power

required" based mainly on seeing the ampmeter in the Swift and knowing

it's 96 volts, and that hence, about 100 amps means it's using 9.6 Kw -

about 13 horsepower. The "ultra efficient" case figures in the table

below would be for a car the same size and weight, assuming an "ideal"

30% higher transmission/drivetrain efficiency.

Power Required

|

Swift: Amps = KW, HP

|

Ultra-efficient Ideal: 30% more

efficiency - KW, HP

|

Constant speed driving, Downhill Grades

|

0-50 = 0-4800, 0-6

|

0-3360, 0-4.5

|

Lighter Acceleration, Uphill Grades

|

100 = 9600, 13

|

6720, 9

|

Stronger Acceleration, Steep Hills

|

200 = 19200, 26

|

13440, 18 (2 Electric Hubcaps)

|

Very strong Acceleration

|

300 = 28800, 38

|

out of reach - (3 E.H. motors?)

|

Moderately Strong Regen Braking

|

0- -50 = 0- -4800, 0- -6

|

0- -4800, 0- -6

|

In the regen braking case, I used typical figures for the

Swift, then considered that lower transmission losses for the 'ultra

efficient' means more power is returned in order to attain similar

braking effect, making the regen braking more effective compared to the

figures for thrust.

(The table was based on Swift figures as seen with low

tire inflation. When they were properly inflated, currents & power

went down perhaps 15%, and the regen similarly went up. So "Lighter

aceleration, Uphill grades" might now translate to "Moderate

acceleration, Moderate hills". Etcetera.)

Big Oil is on its way Out

A new article on RT.com said that analysts at BHP

Billiton (whoever they are) said that 2017 will be the year the

electric car revolution really gets started. In 2016 550,000 electric

cars were sold - no longer trivial numbers, and in Japan there are now

more charging stations than gas stations. The number of EV.s on the

road has risen sixfold even since 2014. What a change that is from 2008

when I started on trying to make a motor to add onto a car wheel, or

even since 2010 or 2011! Then, the only electric cars were

home-converted gas cars, and there was no such thing as a dedicated car

charging station.

But the International Energy Agency (IEA) said that

electric cars won't make much difference to oil consumption or stop it

from rising - that most of it is consumed by ships, planes, trains and

trucks. I think he's simply trying to downplay the significance. Also

BYD is now making electric freight trucks, and we could easily

electrify the railroads. With electrified railroads, cross-country

freight wil be so cheap and fast that people won't want to ship larger

items by air, and the reduction in air cargo will further curtail the

air freight service. And there are even small electric (manned)

aircraft, and electric boats that run straight off solar panels, which

have the potential to go bigger.

And this is disregarding technology advances and

innovations which will doubtless occur. Even years ago there was a

"sail assisted" freighter ship, which not only used less petroleum, but

was nicer to be on because the sails damped out most of the usual

rolling motions caused by waves.

Personal Doings & 'Business' Trip

My personal big news for October is that I

made up my mind to sell my house and move to Tlell on Graham Island in

Haida Gwaii. With the "housing bubble" in

Victoria, I should be able to sell my house for an exceptional price.

The

second property I had looked at in Haida Gwaii just up the road from

the first, was very economical at 180,000$, with a cabin having rental

income. It had a 12'x18' outbuilding that might make a decent shop, but

I hope to build a bigger one.

On the sensible advice of everyone, I went up to Haida

Gwaii on

October 31st, and flew back on November 3rd. (Hence the late

newsletter) I could see from the air that in contrast to most of the

mountainous west coast, much of the island was flat and even boggy. It

seemed like a cross between Alberta prairie and the less populous

Vancouver Island of decades ago. I think it will thrive in the future,

and also pass through troubled financial and economic times relatively

undisturbed.

A typical section of highway from Masset to

Port Clements, October 31 2016.

A typical section of highway from Masset to

Port Clements, October 31 2016.

Between Masset and Tlell I met no traffic going my way and passed only

about 10 vehicles going the other way.

I decided I didn't especially like the layout of this

property. That realization alone of course made the 1500$ trip worth

while. There was a third prospect just two places over - south of the Crow's

Nest

Country

Store and Cafe instead of north of it: a

large but dumpy looking house on 15 acres of mixed clearing and forest.

I thought there must be something wrong with the house for the price of

220,000$, that perhaps it was rotting into the ground. The real estate

ad images betrayed no hint that it might have much value. But in fact

it had solid

looking concrete foundation walls. We (the owner of the first place

accompanied me)

found the door unlocked and walked through it, and (tho without being

able to inspect underneath) it seemed perfectly sound and solid. It

seemed like the opposite of most houses where a great looking paint job

distracts the viewer from noticing many problems: it seemed it really

only (and badly) needed

some painting, staining and varnishing, and some cracked windows

replaced, to be very nice. Soon she said what I had just started

thinking myself: "I think this might be better for your purposes than

my property."

House in Tlell.

House in Tlell.

I had a different impression on actually seeing it than I did from the

pictures: As far as I could tell it seems

basically quite sound and up to modern standards, and has some nice

features and almost 2000 square feet.

Obvious problems were ugly (IMHO), dark paint colors inside, virtually

vanished paint or

stain outside, missing eavestroughs and cracked windows. These aren't

major work to fix.

The big question is: can I buy it? The

owner, after (he said) 12 years trying to sell it, was just in the

process of signing an agreement with a buyer. After all that time, was

I

just weeks or even days too late? If so, I'm deeply

disappointed, having thought I had found pretty much just what I wanted

at a price I could afford, and I'll have to keep looking, because I'm

still going to sell my house while the prices here are so high. It

makes financial sense "looking toward retirement" if that term still

applies in a collapsing economy where there are getting to be more

people in the "retired" age groups than in prime working ages.

In addition to that, I toured Graham Island pretty much

from one end of the road to the other, from Masset and the north

beaches to Queen Charlotte city (small town) in the south, and peered

down Skidegate channel. Without changing my general view of how to

proceed, I noticed there were more little stores and services here and

there than

I had feared.

My last dinner there was by prearrangement with the owner

of the property I'd gone up to look at, and the main course consisted

entirely of local food. It turned out she knew my sister in law! And

the freezer at the DIY B & B I stayed at was stuffed with salmon.

In spite of cost my plan is to ship almost everything I

have up there

including most of the tools, equipment and pieces for all my projects,

since not too much beyond basic living

and building supplies is available locally

and everything will cost plenty to buy there or to ship in if purchased

later.

There's still the possibility of sneaking a wire under the highway and

doing ocean wave power if I get some funding for that. I plan to take

the

electric vehicles up there. They couldn't be driven up along many

hundreds of miles of highway, but they have enough range to go between

towns on Haida Gwaii and will be especially valuable up there.

(Gasoline was 1.52 $/liter where I filled up.)

Tidal Flow - and River Flow - Power in Haida Gwaii

I read in the news that someone is doing a "tidal

power" experiment somewhere up there. A floating paddlewheel type unit

is

supposed to pump water up into a reservoir, and a regular sort of

hydroelectric turbine is to use the water to make electricity. The

floating paddlewheel itself is a good idea because it simply floats up

and down with the tides, maintaining the wheel's optimal depth. But the

overall plan

seems complicated and costly for attaining the desired result.

It really requires three separate projects: - the paddlewheel unit in

flowing

water, perhaps in the channel into Masset inlet, a large artificial

reservoir for sea water at some good elevation, and a hydroelectric

plant.

Their unit could be substantially more effective at

capturing the flow of water, too. The squareish, flat paddles are a

poor

shape: I'll have an article next month in the Electricity Generating

section about a 'venetian blind slats' curved 'wing' shape of blades on

a paddlewheel unit. (And since thinking up this "original" idea, I've

seen a couple of wheels with that shape of blades in videos on Youtube

on November 7th.) When I visited

Port Clements, I actually saw this unit tied up at the wharf. I can't

help but

think all those elaborate water pump fittings visible at the sides of

the wheel must have cost far more, and were far harder to make and

install, than a generator. (They probably pump more water than the

simple "pipe coil" pump units on Youtube, but those could simply be

multiplied at low cost to pump more.) And the vessel seemed to be much

larger and more elaborate than it needed to be for its simple purpose.

I suspect they would have changed a things substantially if they had

done some on-line research before building.

Tidal Flow Power Unit at Port Clements wharf.

Tidal Flow Power Unit at Port Clements wharf.

The paddle wheel is about 6 feet wide.

Another view.

Note the many elaborate connections in the water pumping system,

apparently duplicated on both ends.

It would be far more practical in my view - and I have

lately been considering such a

project (more details next month) - to start much smaller, and to have

multiple paddlewheel units each turning a generator

directly - along the lines of the successful (if crude looking) Zambezi

River project shown on Youtube and mentioned in TE News a month or two

back. Such units in tidal flows

would each of course provide intermittent power, nothing being

available

when the tidal flows are slack. However, in addition to Masset inlet

fed through a long, narrow channel off the north coast, there's the

narrow Skidegate channel between

Graham and Moresby islands on the south coast. Without having

studied the tide charts, I suspected there was at least an hour

difference

between the tidal flows. Someone up there told me it was several hours.

Perfect! When one current was slack the other would be streaming away.

One hitch is that there are no power lines connecting the northern and

southern halves of the island. But there are tall poles there, with

only

telephone cables half way up, all ready to wire up power lines to at

the top.

Looking at the terrain on Google Earth on November 7th, I

spotted a considerable inlet off the south of Masset inlet, fed by two

very narrow channels. It was plainly visible in the image that water

was just ripping through one of them in a very fast tidal flow. The

energy is thus much more concentrated than in the broad channel into

Masset inlet. It wasn't named on this map, but I'll call it the

"Justkatla Inlet" and "Juskatla Narrows" in honor of the only thing

nearby showing a name and having a road to it. Making several floating

power units to harness this energy could be a community project that

might potentially even supply power to the whole island when the tides

run - probably well over 1/2 the time. (A private project wouldn't be

feasible because a couple of kilometers of power line will be required

to send out the electricity.)

Even in addition to tidal flows, there are many small

rivers

on Graham Island, draining a lot of interior wetlands. The very same

(smaller size) paddlewheel units could be moored in rivers, which would

provide continuous flow.

Unfortunately for that idea, the flows seem to be pretty leisurely in

most

areas. It would be a question of finding fairly deep but rapidly

flowing points, close to existing power connections.

Again I think that on the small scale, using BC Hydro's

"net metering" program and selling power from small installations, with

approval and co-operation from the community and riverfront property

owners, would be the way to get it started. Juskatla would come after

experience gained with the smaller installations.

Building Renewable Energy Mechanisms Workshop/Lecture

Series

I met with the owner of Haida Gwaii Trader magazine

(HaidaGwaiiTrader.com), just after seeing the tidal flow machine at the

wharf and thinking how awkward parts of their plan and design looked. I

told her I

had been doing electric transport and sustainable energy projects for 8

years, and that I could have had a couple of suggestions for the tidal

flow power

project.

She told me that despite often favorable wind speeds, the

island community had rejected doing wind power. But, I asked, what had

they rejected?... Of course what they didn't want was big propellers

going whoop, whoop, whoop, making an unpleasant environment, unsafe for

birds and giving people headaches from their low frequency sonic or

subsonic effects. I said there were other ways to do wind power, and

that I had a couple of VAWT designs including one with a Tesla turbine

that had no external spinning parts (more details on that next issue).

I did very much like hearing again that there is

an island community, making decisions of that nature for itself,

instead of having them imposed by some somewhat 'out of touch' 'higher'

level of government centered elsewhere. It's easier to achieve in

isolated areas with small populations, but this is what needs more

development for social sustainability in communities around the world.

Back to making electricity... I thought that what was

really needed now was less theory (not of course

to belittle theories, calculations and new ideas!) and more building

and

installing of working projects.

Somewhere in all those thoughts and about the time of the

meeting, I got the idea,

with all my experience at building green energy devices (whether

successful or

not!), to give a series of workshop-lectures on how to

actually design and put together working equipment. I would cover

generators and turbines and their construction, and ideas for various

wind and water electrical generating products and potential practical

construction techniques.

But also I would cover the mechanical details of shafts,

keys, bearings, fittings, chassies and so on, and what all the various

options are for various types of fittings, and what all the little

parts are called, how they fit together, and where to buy or order

them. And importantly, I would talk about means for connecting smaller

electrical sources

to the power grid via the "net metering" program with induction

motor-generators and grid-tie inverters.

Those are the things that most people trying to start their great

little green

energy project know little to nothing about - as I didn't when I was

starting out in 2008. All the lectures would be done with samples and

examples of the devices and components being talked about, for people

to touch and fit together for themselves. Essentially, the series would

be piles of the more useful stuff from all the issues of TE

News, all concentrated into one set of lecture-workshops.

If I do that, and capture imaginations (which must surely

already

be fired up for people to want to attend), there might soon be many

green energy generation projects built than I could ever get working

myself. I might try in Victoria, but I'm also sure there must be eager

students in Haida Gwaii. In Haida Gwaii, I have good hope that

fortuitously situated property owners and the community would be happy

to be involved

with the green energy builders, and that builders would get together,

so that power projects could be joint ventures sanctioned by the

community instead of one person

needing to have everything including all the requisite tools and

the target energy source, and to build everything himself. And I would

like also to discuss with participants, ideas for how to equitably

split electricity revenues between land owners, the builders, and

anyone who invests money into the projects. But

anywhere, useful things would be likely to be built following the

lectures.

Gosh, maybe someone could record the lectures and they

could go up on youtube and a web site. Wouldn't that spread these

essential knowledge

tidbits quickly? No longer would one have to 'be where the action is'

to uncover the 'industry secrets', or really industry specialized

knowledge. They'd be up there for all!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Evolution of Democracy

A constitution may perhaps be a marvelous document. But

while the American constitution was a radical and progressive document

when it was written, the founding fathers could never have imagined the

world as it is today, nor would we fit happily into their world. In 240

years, most everything has changed. The world is always changing and

adapting - evolving. The fathers were happy to have created a way to

change governments without death of a monarch or a revolution. They

didn't consider that needs are ever changing and so failed to put

provision for evolution into it. It gradually became ossified and

obsolete, and for a long time now has not been well serving the public

good. Without consideration of the core values in decision making,

"social creep" gradually allowed, then fostered, narrow predatory

interests to come into positions of social, political and economic

dominance.

There are better ways of doing things. They just need to

be dreamed of and tried. In the town of Nelson, BC, Canada, the great

"status quo club" (or "oligarchy" or whatever name one chooses to call

it) pulled out

and left the town in economic ruin. A university, an art school, a mill

and other sustaining institutions were all shut down within a short

period - almost all at once. However, the workers at the lumber mill

purchased the mill and started to run it for themselves. I don't know

the exact arrangements, but without profits from the mill being sucked

away, the workers did better than ever before, spent much of their

money locally, and the town regained its economic health.

But this story is exceptional. Quite often, and especially

in the USA, when some new endeavor outside of the "status quo club"

prospers or threatens to become prosperous, it is usually attacked and

ruined by interference from the government that ought to be ensuring a

level playing field for all. The "American dream" is permitted only to

"oligarchy" members, and then only if they don't "make waves" and only

see the "bottom

line" as being monetary gains. For them, the government will do any

favors,

bend over backward to help - because so many of the same people who run

them also run the government. (I mentioned David Quintieri's video on

these conflicts of interest in a recent issue.)

There needs to be an intention first to evolve new

democratic forms and systems, and then in that evolution to put the

core values first.

Today with modern communication including the internet, it

is both practical and necessary to have means for citizens to have the

means for even daily communication with the elected, to make those

interested in an issue active participants in the decision making

process. Electing a representative every few years and expecting them

to act as desired on whatever issues may arise in our fast-paced modern

society is ludicrous.

The universal core values: Quality of Life, Growth, and

Equality; overlie many subsidiary values, which have often mistakenly

been put first as part of an ideology. There are underlying assumptions

when secondary values are promoted, for example when espousing that

socialism or capitalism is the "ism" to base society on... because,

implicitly, it is supposed that it will improve peoples' quality of

life, provide growth opportunities, and help attain toward equality.

But basing societal (and even family) decisions on

secondary values instead of directly and explicitly on the primary ones

results in a "social creep" away from the primary values as decisions

are made, one after another, over time. Adherence to any "ism" prevents

seeing clearly what is truly needed or best in each given situation,

for ongoing social sustainability. It gradually subverts progress and

social evolution and leads to eventual collapse, which has been the

final outcome of every civilization so far throughout history.

It need not be so. Social sustainability design teams can

explicitly consider: Does making this decision improve quality of life

for each person?, does it provide for growth?, and does it provide for

more equality? Society today is better equipped than ever before to

create socially sustainable families and communities, followed by

regions, nations and finally - when democratic systems have evolved in

accord with the core values, considered and administered in empathy,

compassion and love, to the point where it will be a blessing to all

mankind instead of a global tyranny - the world.

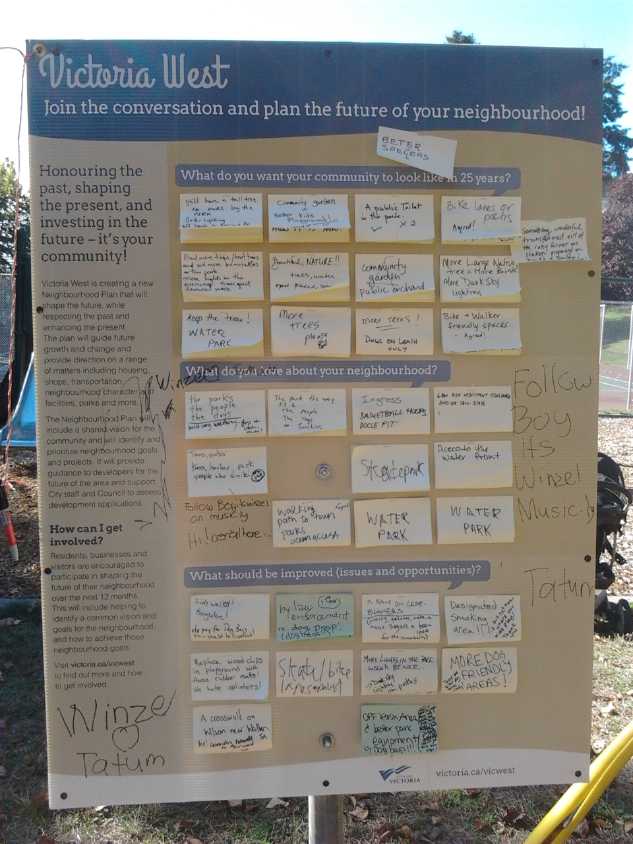

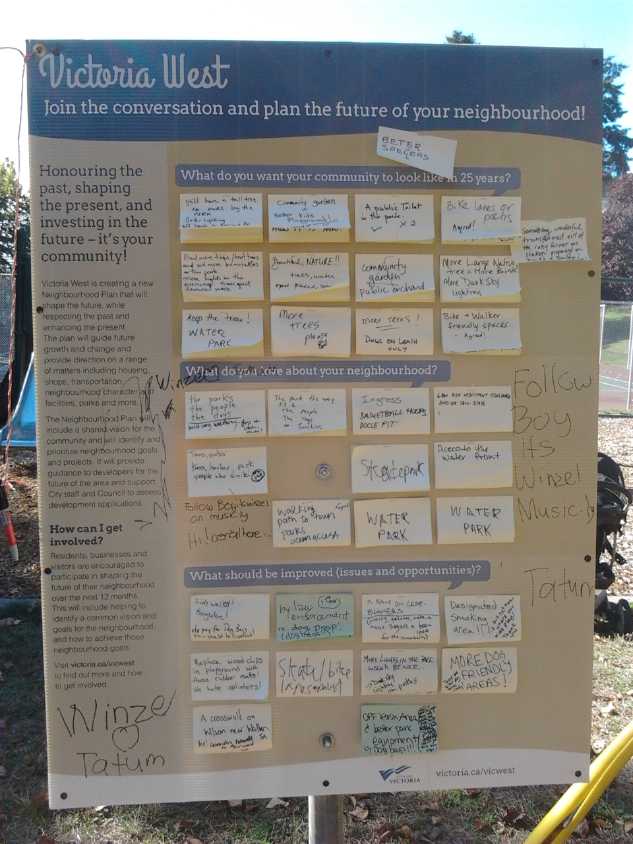

Here is an idea fom the City of Victoria BC for gethering

public input: a billboard with "post-it" notes for people to write

ideas on. I see merit in this, even while it is being abused by the

thoughtless and can't be considered any sort of complete solution.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Electric Hubcap Motor Systems - Electric Transport

'Hubcap'

motor, Chevy Sprint & Infinitely Variable Transmission

Differential Torque Converter in the Sprint?

Getting back to getting the Sprint going, I thought about

how a misaligned chain would jam up, and then again about the V-belts

that just slipped. I was pretty sure the V-belt pulley alignment wasn't

quite as critical as the chain sprocket alignment.

What if I put the so-called 12" (11.75" O.D.) V-belt

pulley, the largest one that would fit in the space, on the end of the

differential? That would need just 66% of the torque that the 7.75"

pulley needed, and it would have more surface gripping the belt. Also

it could be sanded to make the surface rougher, plus I now had the

wedge to keep the tension adjustment from slipping looser - factors

further increasing the grip. If I used the 5.75" pulley on the control

arm shaft, that would be about 2.04 to 1 reduction. Thus to get near

the 1.5 to 1 reduction idle point, the variable pulley section would

have to speed up instead of slow down, also reducing the torque it

would

have to handle.

The first thing to do if they would fit would be to try it

with two fixed pulleys on the two shafts, both larger than the ones I

had tried before. With the 11.75" pulley on the bottom, a 6.75" pulley,

if I could find one, would be ideal for the top, making a ratio of

1.74:1.

12" Pulley on Differential Left.

12" Pulley on Differential Left.

Oops, not enough space to the drive shaft for the other desired pulley.

Of the pulleys I had, the 5.75" would make too high a

"gear"

for low speed car motion (6 or 7 to 1), while the 7.75" one would be

awfully close to the 1.5:1 idle point (1.516). But the two shafts were

a little too close together to fit even the 5.75" with the 11.75". Did

I really want to go out and buy a 10" pulley and belt to try? All these

parts - pulleys, hubs and belts - just for experiments add up, and with

the store being somewhat distant, the shopping takes up time. The ratio

worked out nicely for a 'low gear', 1.7:1, which should make a final

drive of about 12:1, motor to wheel. But how much less torque did it

need than the 8" pulley? Might it just slip like the first one?

The next day I decided to buy them, but I got a pressed

metal pulley and 1" weld-on hub instead of a pulley to fit the "H"

taper-lock bushing that I had bored for the differential end shaft.

This was because I started thinking about the configuration with the

third shaft. If there was a 10" pulley on the motor shaft and a 12"

pulley on the differential, the third shaft could have two relatively

small pulleys (one variable) and spin much faster, without needing a

whole lot of torque.

However, this left the experiment in limbo. Either I

should have bought two pulleys to have one that uses "H" bushings for

the experiment (the costs add up!), or I would have to do some welding

and un-welding to have a 30mm center for the experiment and then

replace it with a 1" center for the motor shaft.

Then again, if I was to make the third shaft - the

reduction control shaft - it would have to be aligned 'perfectly' to

the differential anyway... so why not have the chain drive instead of

the

V-belt? But this could be done similarly, with a big sprocket on the

differential (minimizing the pull required to get sufficient torque)

and a small one on the third shaft, sized to match the big-small

variable pulley system coming from the motor. If I used a 72 tooth

sprocket on the differential instead of 36, the chain pulling radius

would be double and so the force on the chain would be cut in half. It

would have less tendency to jam.

There's room for that if there's a relatively small sprocket on the

control shaft.

Unlike on typical configurations of two-variable-pulley

drives there's no centrifugal clutch. I note here that it would

doubtless be hard to force the variable pulley halves apart by pushing

the third shaft away from the first, if the mechanism isn't turning. So

if it needs to be apart to get to "low gear" and get it turning, there

might be problems getting it started. But slacking off the pulley to

allow the halves to come together would cause slack in the belt. In

that case, either spontaneously or by trying to go, the belt would

surely pop out a bit and allow the spring to push the halves together

until there's belt tension again. So the "lowest gear", to get the car

moving, should be had with the pulley at its maximum diameter and the

control lever slack. The other way, just as good in theory, would

likely prove troublesome. Pulley sizes and configurations need to take

that into account.

Thinking about how and what to do was as far as I got.

Kelly BLDC Motor Controller Repair

When I had assembled and tested the Electric Caik

Outboard, I took it out to the Sprint car, disconnected a battery to

have 24 volts instead of 36, and hooked it up. When I had finally

figured out the correct phase connections (made more difficult since

the controller wasn't working right), I found there were still

rotational positions that the motor wouldn't start from. My fears were

confirmed: The Kelly BLDC motor controller must have some blown

drivers, the lows or the highs of one of the phases, and so only 4

positions in the rotation sequence of 6 were providing power. It wasn't

some additional unseen fault in the Electric Hubcap motor.

The next question was, could blown power mosfets simply be

replaced, or did the trouble extend back into the gate drive circuitry,

requiring sending it back to Kelly for more extensive repair or

replacement?

I disconnected and dismounted the controller and brought

it into the house. I opened it and saw (and smelled) the burned spot

where the magic smoke had escaped from. (Electronic devices don't work

if the magic smoke trapped inside the components escapes.) I looked

at all the screws that had to be removed just to get at the circuit

board, and the inaccessible screws sandwiched behind other plates to

remove the power transistors. This unit was definitely not designed and

made for serviceability. I didn't get any further in October.

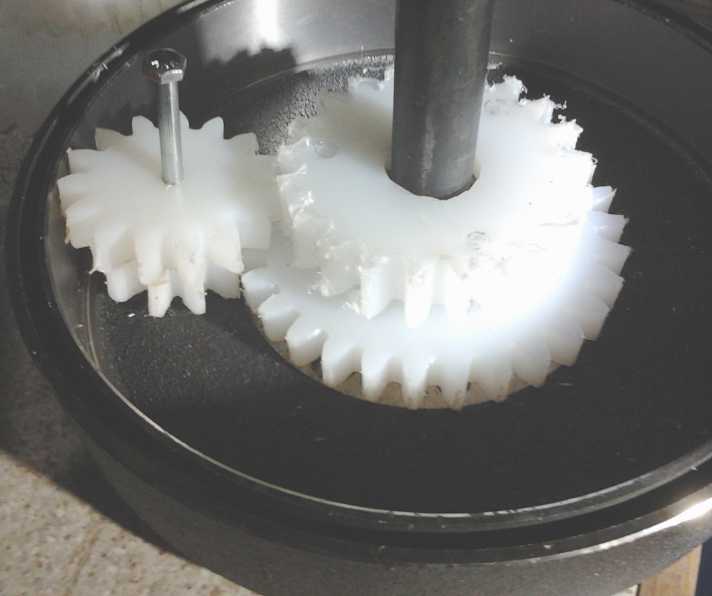

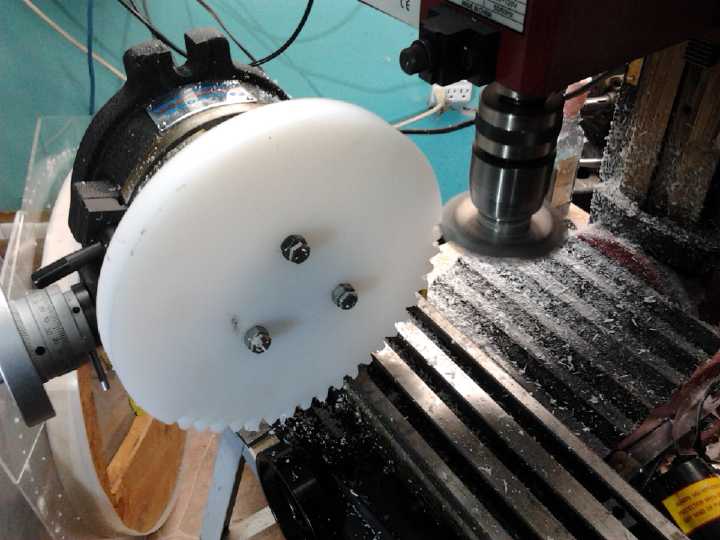

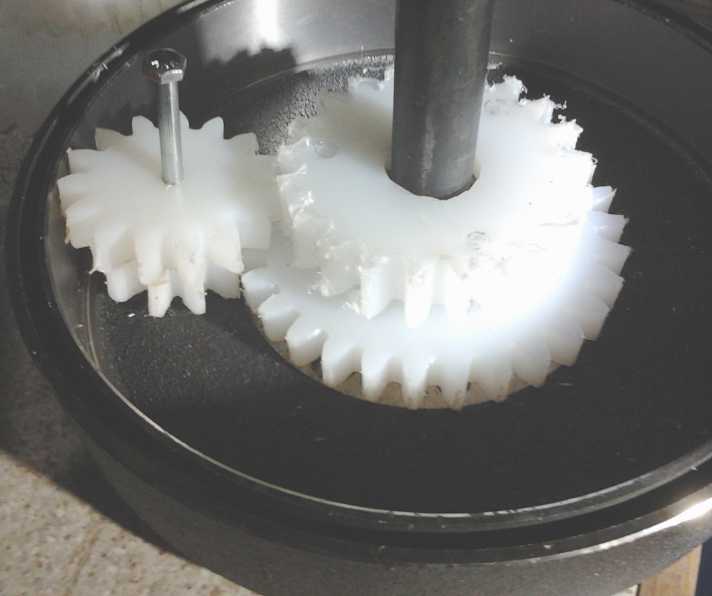

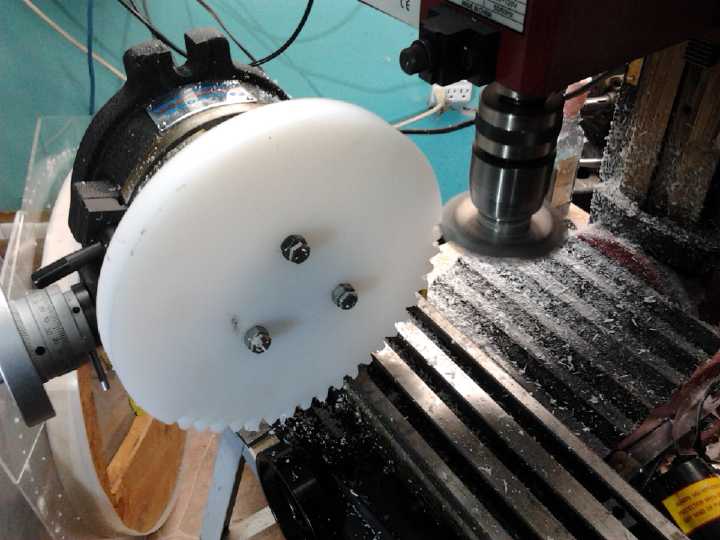

Asymmetric Differential with Spur Gears: Gears & Gear Cutting

On the 9th the rotary table and dividing heads arrived.

(Actually they said they had had them a week, but someone was on

holiday and they couldn't find the paperwork to call me.) After that,

gear making dominated the project work.

On the 12th I turned a sample gear to the diameter for 33

teeth. I used a disc of UHMW plastic that happened to have SDS mounting

holes drilled in it, and I went with that. I had already cut SDS

mounting holes in a plate for the lathe, so it was easy to mount it and

turn it. The rotary table also had 3 radial slots for mounting things,

so the "T" nuts could be moved in and out, 120° apart like the SDS.

"T" nuts usually have 5/16" or 3/8" threaded holes, but the SDS is

1/4", so I couldn't use regular "T" nuts. On the 13th I figured out I

could just use 3/4" wide steel bar pieces and pound them just a bit

wider so they fit exactly in the slots under the lips, and make 1/4"

threaded holes for the bolts. So the bolts went through the plastic,

through an SDS bushing (used as a spacer), and threaded into the holes

in the bars in the slots.

The rotary table was too big to mount directly on my

little milling machine in a position for the cutter in the chuck to cut

the gear teeth. I had a late nap and got up and made a plate to hold it

on the bed, then tried cutting the gear 33 tooth practice gear.

Somewhere I divided the depth by 2. I had just watched a video of a guy

using a dividing head, going about 1-1/2 turns between teeth. Mine was

a bit more than 1/2 a turn... but it should have been 2-1/2 turns, not

1-1/2. With the depth too small, and all the fuzz of plastic sticking

to everything, it didn't seem too bad until I had done quite a few -

15. Wait a minute, shouldn't I be 1/2 way around the gear by now, not

just over 1/4?

When I'd figured that out, I put the piece back on the

lathe and turned it down to the size for 30 teeth. Then I put it back

on the rotary table. This time TWO and a half turns per tooth!!! Well

of course that was wrong again, because that was angle for 33 teeth,

not 30. After just a few teeth this time I realized my mistake and went

into the kitchen for a cup of coffee. There I found the real problem:

the clock said 1 AM - midnight! (DST) I had no idea it had got so late.

I discovered years ago that when I worked too late at night computer

programming, in the morning I often returned and found I had made

numerous silly mistakes, and wondered what drugs I had been on. While

we may become "night owls", the brain nevertheless seems to lose focus

at night and one becomes something of a zombie on autopilot. I had only

planned to make the mounting plate, but I got excited about actually

being ready to do a gear. I should have checked the clock then, and I

certainly should have quit when I found I was doing the 33 teeth wrong.

By the evening of the 14th I had marked out out the 50

tooth gear and cut it on the bandsaw, drilled SDS holes in it, and

turned the outside smooth on the lathe. I then mounted it in the rotary

table and went to mill the teeth. There was no 50 - the dividing plates

went up to 49! And there was no 25 either: one plate went 21, 23, 27,

29. I would have to do it all manually without the plates.

360/50=7.2°. Let's see, that's 1-3/4 turns and another "12" little

marks on the crank wheel. Get any one wrong at any point, and the gear

was toast. I wrote down each of the 50 angles on a scrap of paper. I

thought the right cutting wheel was mounted, but I checked it to make

sure. I had to get mirror under it and then figure out the backwards

numbers. Nope, it was the "26 to 34" teeth wheel. (And why wouldn't it

be?) I put the right one on, "35 to fifty something".

Milling gears

is both tedious and nerve racking,

winding the wheel around to exact positions and then cranking the table

"X" back and forth to move the gear through the cutter, but I did it

without any mistakes on this occasion. "Tool depth" was supposedly 9mm

(2.25*m4). I

measured about 8.75 and thought that would be okay. When I meshed it

with the practice gear (on which tooth depth had come out only about

8.25mm) they meshed smoothly, but the gear disk centers were 163mm

apart instead of 160 and could come no closer. (30+50 teeth)* m4 / 2 =

160. Even with the teeth 1/4mm shallow, theoretically it should have

been 161mm center to center. Perhaps it's that plastic

cuts a bit differently and not as smoothly as metal. Obviously if one

is precision cutting the chassis with axle and bearing holes spaced

exactly "X" distance and they need to be "X" + 3mm apart, that's going

to be trouble.

Milling gears

is both tedious and nerve racking,

winding the wheel around to exact positions and then cranking the table

"X" back and forth to move the gear through the cutter, but I did it

without any mistakes on this occasion. "Tool depth" was supposedly 9mm

(2.25*m4). I

measured about 8.75 and thought that would be okay. When I meshed it

with the practice gear (on which tooth depth had come out only about

8.25mm) they meshed smoothly, but the gear disk centers were 163mm

apart instead of 160 and could come no closer. (30+50 teeth)* m4 / 2 =

160. Even with the teeth 1/4mm shallow, theoretically it should have

been 161mm center to center. Perhaps it's that plastic

cuts a bit differently and not as smoothly as metal. Obviously if one

is precision cutting the chassis with axle and bearing holes spaced

exactly "X" distance and they need to be "X" + 3mm apart, that's going

to be trouble.

There was another problem.

I had bought another 2767R

brake drum to use as the housing, but I hadn't actually sized up the

drum to see how the gears would fit. When I set the 50 tooth gear in

the drum it was obvious there wasn't anything like enough room on the

outside of it for the peripheral 'planetary' gears - the 30 tooth

practice gear was a better fit!

On the 15th I thought, wait a minute! The calculations

with metric "m" gear cutters are amazingly simple. For the m4 size I

got, you just need to size up the drum in millimeters, subtract 8 to

account for

the outer margins, and divide by 4 to get the total number of teeth

that will fit. It doesn't seem to matter which gear has how many teeth

as

long as they add up. It was 228mm, so 220/4=55. The smallest number of

teeth one could put on a gear is 12: the #1 tooth cutting wheel says

"12-13" and they go up from there. A 12 tooth gear is 48+8=56mm in

diameter - over 2"! I had been thinking they would be considerably

smaller than that, not to say half, but m4 is pretty big gear teeth. So

55 teeth would be 12+31+12=55, allowing for 12 tooth planetaries on all

sides of the center gear. In order to have a bit of outside clearance,

it would in fact be exactly a 30 tooth gear in the middle.

I decided to cut a planetary. The "SDS" bushing was out,

as the cutter would hit the mounting screws even if they weren't past

the

outside edge already. I looked at the center hole of the rotary table

and

realized it was a #2 morse taper. I dug into my lathe tools box and

found something I had made for turning pieces that mounted on a 1"

keyed shaft. I drilled a hole in the end and threaded it for 1/4" x 20.

It wasn't ideal as it already had a 3/8" hole there, so the 1/4" hole

started inside the 3/8" one. But it did the job - or seemed to.

I drilled a 1/4" hole in a piece of UHMW-PE, then roughed

out the disk on the bandsaw. I turned it on the lathe to the right

diameter, then moved it to the rotary table and milling machine.

Unfortunately, the holding piece wasn't quite long enough and the

cutter would hit the rotary table if it cut all the way across. I

decided to just cut the gear, and maybe turn it around and re-cut to

get the last bit. The jig must have slipped a bit on each tooth or on

some of the teeth, because one tooth ended up somewhat wider than all

the rest. (And it would have been hard to miscalculate 30.0° tooth

angles!)

It seemed like a great way to do it, but it wasn't quite

there. I decided to make another similar morse taper shaft, but with a

longer body for the cutter to clear the rotary table and holes to the

sides for pins. The pins would stick into the plastic gears so they

couldn't rotate on the shaft and the teeth would be even.

The new holder for small gears, both for the

lathe and the rotary table.

The new holder for small gears, both for the

lathe and the rotary table.

A nut and washer on the threaded rod ensures it doesn't come loose in

either device.

I checked out the fit in the drum. With the 30 tooth

practice gear in the middle, the 'planet' fit inside the outer rim in

any direction with about 2mm clearance as expected. (How about that!)

On the 19th I made a 27 tooth gear. It was the first

"perfect" gear, I thought, other than the teeth being about 9.4mm

instead of 9.0. Maybe I need one of those fancy digital position

readouts on the milling machine after all. Sigh! Later I noticed the

real problem: the disk hadn't been quite centered on the rotary table,

so the teeth were a bit deeper on one side and shallower opposite. They

averaged out to 9mm. Another refinement: on the lathe, when cutting the

outside circle, bore out the center to fit over the 1" shaft of the

same morse taper piece I was using for the small gears, to hold it

exactly centered. They have to be bored out some time for their shafts

anyway; I just hadn't bothered yet. Which was just as well, because

none

of the gears so far was usable...

I figured, each tooth smaller made the diameter 4mm

smaller. So a 27 tooth gear would be 12mm smaller diameter than a 30

tooth gear, and the teeth were 9mm deep, so the teeth of the smaller

gear would entirely clear those of the planetary of the larger. When it

was done I saw that they didn't. Duh! 12mm of diameter is only 6mm of

radius! It would have to be 25 teeth, 5 teeth and 10mm of radius less.

From 50 teeth down to 25, and now only 100mm effective diameter; 108 to

the outside. Tho they were still twice the diameter of typical metal

gears, this was starting to get pretty small in my estimation, when my

idea was to make very large plastic gears with low loading per surface

area owing to their size. I hadn't counted on the large m4 teeth making

for such a large minimum sized gear as to so much reduce the size of

the center gears. Perhaps I should consider steel gears for the two

not-so-large center ones. I wonder how much they might cost to buy...

versus how hard cutting steel teeth would be. The planetaries can still

be plastic so there are no steel gears meshing with steel gears, which

would require oil lubrication.

I started to think I should have bought m3 or smaller

tooth cutters. But then the smaller they are, the more there are to

cut, and this was tedious work! And, without really examining the

issue, I'm pretty sure bigger teeth are stronger and better for plastic.

On the other hand, as indicated in "Fixed Gear

Experiment?" below, maybe the thing to do is to keep the RPM up in the

transmission unit itself, even raising the output speed in the highest

ranges instead of lowering it, and then have a considerable final fixed

reduction before a car wheel drive. The gears and the belts would run

faster but with less pressure on them. Then they might be quite

adequate.

Up to this point I had been using 7/8" thick scrounged

plastic, but two of those wouldn't quite fit in the rim width. I could

do one that thickness, but at least one couldn't be more than 3/4" and

both 3/4" would be better. On the 19th all I got done was to buy a

small piece of plastic, 5/8" thick as they had no 3/4" handy, for a 30

tooth

gear and maybe a couple of planetaries. But really the 5/8" is probably

a better fit.

On the 20th and 21st I got a 25 tooth gear cut out and

lathed, with a 1" hole bored in the center, ready to cut the teeth. But

before cutting them, I wanted the 1" center axle described above, with

a #2 morse taper

that would fit in the rotary table and hold the gear for sure dead

center. I also wanted this to be the improved mounting piece for the

small spur/planetary gears, and I spent a couple of hours turning it

down to the taper and drilling and tapping both ends. I cut the gear

teeth on the 22nd. Then I drilled two holes in the 1" center near the

outside edge, cut two nails to fit, and put them in the holes with the

points sticking out. On this I mounted a 1.5" thick piece I had cut for

a wide 'planetary' to go across the main gears, turned it round, and

milled its 12 teeth. It was harder milling than the larger gears. Not

only was there a long distance, but the 12-13 tooth cutter seems to

take

extra power, and unless I cut very slowly the milling machine's motor

suddenly stalls and won't restart until it's turned off and on again.

The best technique to rapidly remove

most of the plastic fur seemed to

be to pluck it off with a small pair of pliers.

The best technique to rapidly remove

most of the plastic fur seemed to

be to pluck it off with a small pair of pliers.

Another result of the large size of the spur/planet gears

was that when I sized everything up (now having cut enough gears, good

or bad, to do so) it became apparent that only 4 pairs could be fitted

around the rim, at 90° angles. Of course one turns gears until the

teeth line up to put them together. As I went to bed, it occurred to me

that if there were 4 sets of planetaries, on the same two large gears,

all of them had to line up at the same time. If some were 1/2 a tooth

offset from others that were in line, the whole thing wouldn't work.

And in order to have quadrilateral symmetry, the number of teeth of the

large gears had to differ by 0, 4, 8, 12, etc. 25 teeth is different

from 30 teeth by 5. I tried the spacings to make sure, but there wasn't

room for 5 sets of planetaries around the rim. (3 could potentially be

fitted in the 5 spaces by having one of the side gears on the other

side.) With 26 teeth would hit the teeth of the larger gear. Next down

is 22 teeth.

So we now have "big" gears that are much smaller than I

planned, only 5/8" thick, and meshing with only 4 sets of planetaries

instead of 6 or 8. The only thing still big and robust is the tooth

size - and the peripheral gears. Everything could be fitted, but to

make it all more as I had originally envisioned it, the drum would have

to be more like 12-15" in diameter instead of 10. That would lead to

other fitting problems. Or the gears would have to have much smaller

teeth, which in plastic I think would be less robust. (But I'm

beginning to think m3 might have been a better choice.) It became more

and more apparent that the "big" gears, smaller and smaller than what I

had envisioned, would need to be steel. That still doesn't make the

objectionable steel on steel meshing since the spurs/planetaries are

still plastic, so it's probably better than needing a very large size.

Cutting plastic gears seemed okay, but I didn't have much

confidence in doing steel. I decided to order them. The 30 tooth one

was simple. It would be 5/8" or maybe 11/16" wide with a 1" keyed

center hole for a 1" keyed shaft. The 22 tooth one had to be on

bearings and able to turn independently round the other, meaning its

shaft would be a sort of a pipe over the 1" shaft with a bearing at

each end. I hadn't yet figured out the inner and outer dimensions for

that.

On the 27th I

tried to make a 22 tooth gear. Again the

calculations got more complicated. 360/22=16.363636 degrees/tooth. The

knob turns the table 4 degrees per turn, so that's 4 turns, leaving

.363636°. .363636*22=8. There wasn't a 22 indents setting on any of

the plates. 8/22=4/11. Nope, nothing less than 15 indents. But it's

also 12/33, and there was a 33 indents plate. So I set the divider to

traverse 12 holes per tooth. I neglected at this point to remember the

knob turns the table 4 degrees per turn, so I had 12/33 of 4 degrees

instead of 12/33 of one degree. It should instead have been 3 indents

forward per tooth. The gear came out with 21 teeth and uneven spacing

on the last 2 teeth, which I at least tried to even up by eye.

On the 27th I

tried to make a 22 tooth gear. Again the

calculations got more complicated. 360/22=16.363636 degrees/tooth. The

knob turns the table 4 degrees per turn, so that's 4 turns, leaving

.363636°. .363636*22=8. There wasn't a 22 indents setting on any of

the plates. 8/22=4/11. Nope, nothing less than 15 indents. But it's

also 12/33, and there was a 33 indents plate. So I set the divider to

traverse 12 holes per tooth. I neglected at this point to remember the

knob turns the table 4 degrees per turn, so I had 12/33 of 4 degrees

instead of 12/33 of one degree. It should instead have been 3 indents

forward per tooth. The gear came out with 21 teeth and uneven spacing

on the last 2 teeth, which I at least tried to even up by eye.

It did give me enough gears to start thinking about how

the bearings and shafts might fit together. I put in a center shaft and

a couple of bearings. That allowed it to actually turn the gears

against each other in the differential, if one held and turned the

small outer gears. I turned it to show someone how it all worked

together and he said it hurt his brain. (Well, I haven't seen this

combo anywhere before, so perhaps it's an invention within the overall

invention. It is thinner than a similarly constructed spur gear

differential as illustrated in Wikipedia. Maybe I'm some sort of

mechanical gear wizard after all? If a pretty amateur one.)

I then realized that even tho it was asymmetrical, if it

was used as a wheel differential, if the wheels were turning the same

speed, the gears inside would be motionless. I had been thinking they

would slowly turn, but that's not the case. (Not a mechanical wizard

after all.) What is different is that one wheel would doubtless have a

bit more driving force than the other, based on the difference in

center gear diameters.

"C" is to be connected to the front,

and "D" to the rear, side shafts of the differential.

"C" is to be connected to the front,

and "D" to the rear, side shafts of the differential.

The whole (brake drum) case, with an opposite side cover plate (yet to

be made), is the center element.

'Spur' or 'planet' gear "A" is double width and meshes with "D" and "B".

"C" is just enough smaller that "A" doesn't touch it.

"B" is the direction reversing connection gear between "A" and "C". It

is beside "D" and its shaft is outside from it.

"A" and "B" are to spin freely on metal shafts running across between

the two sides.

There are to be 4 pairs of "A" and "B" gears around the outside to

reduce the loading per gear tooth.

Here is my alternative to the

asymmetric differential, what I called the "double sun planetary gear"

Here is my alternative to the

asymmetric differential, what I called the "double sun planetary gear"

in previous TE News issues. The overall diameter needs to be a bit

larger (or the gears a little smaller)

because it has to accommodate the larger spur gear of the two, now

needing a few more teeth and

both turning tied together on the same axle. In the other unit,

the larger spur gear's axle is a little

closer to the center.

A functional difference is that the differential has a reverse

direction

of rotation - If one of the two

ends is rotated with the center stationary, the other end turns the

other way. In this configuration

they both turn the same way, at different speeds. Another difference is

that up to 8 (7?) of the single

axle spurs could be fitted instead of just 4 pairs, halfing the load on

each plastic tooth.

Fixed Gear Experiment?

On the 20th I got the idea to make fixed ratio plastic

gears and

drive the Sprint car with them, just to try out actually using the

plastic gear idea in a car. I visualized a small spur gear on the motor

and a great big one on the differential, with the left wheel's drive

shaft hooked up again. If things ran smoothly and easily, I still

figured it would take at least 8 to 1 reduction to reliably move the

car. Since the smallest gear has 12 teeth, the big one would need

12*8=96 teeth.

But there were problems with that idea: First, it would be

a lot of work. The whole box would have to be disassembled and the gear

put in, not to mention reconnection of the left drive shaft. Then,

making the gears. Then, a 60 tooth gear is about all that will fit in

the transmission box, and also about the largest the present tooth

milling setup can handle without modification. That only gives 5 to 1

reduction, so it would need 2 stages of reduction, by mounting another

shaft and having 4 gears. That seemed unpalatable just for an

experiment.

Or perhaps I could mount it on the left of the

differential and put something in to jam the differential so it was

essentially directly driving the right wheel drive shaft. Outboard a

12" gear could be fitted. That could be up to 74 teeth - still only 6

to 1, so it would still need 2 stages of reduction. That seemed to be

beyond what I wanted to make just for an experiment.

On the other hand, a smaller final drive gear would give a

closer approximation of how the smaller transmission final gears I was

now making would fare if they directly drove a wheel. I have a feeling

that they'll fall apart and will have to be made metal. Unless they are

run at higher speeds and have a 3 or 4 to 1 reduction before the final

drive shafts. The whole unit can make a speed increase or at least no

decrease in its "highest gear", which would then be followed by that

fixed decrease. Yah, that's the ticket, yah! So that 60 tooth gear

might just be a good size to try out right on the differential, driven

by a 15 or 20 tooth gear. And if it can't be any larger in diameter, it

could be quite wide, even a couple of inches, if 7/8" teeth don't like

the load. I set the idea aside for and kept cutting gears for the new

differential.

Electric Caik Outboard Upgrade

On the 10th I finished reassembling the Electric

Caik Outboard with the upgraded rotor. To make sure it ran okay I

brought in the motor controller from the boat and tried it out. It ran

fine. Furthermore I checked out the cheap ampmeter with the modified

shunt sensor that I use in the boat, against the clamp-on DC ampmeter.

It read a few percent lower but close enough for general use. And I

don't actually know for sure which is off, or if the truth is somewhere

in the middle.

I do know that with 16 volts from a lithium battery it

took almost 30 amps to spin full speed in air - 2250 RPM. The high

current

surprised me at first... but then it was only only 16 volts (so 480

watts). At 24 volts it would have been only 20 amps. In TE News #61 I

measured that friction in the outboard leg accounts for over 2/3 of the

power consumed, so the motor itself probably took less than 150 watts -

an unsurprising 6.25 amps at 24 volts.

(And of course with the darned gearing down in the foot of the

outboard, the propeller was only going around 833 RPM.)

The 2250 RPM @16V figure also indicates that the 0-3000

RPM

Caik motor could be slightly over-revved to 3375 RPM at 24 volts - but

only out of the water. In the water the drag from the prop would surely

slow it below 3000.

When all seemed to work fine, I took it outside to test

the Kelly motor controller in the Sprint car - which was the original

reason for tackling the Outboard project at this time. I wouldn't have

done it just to test the controller, but of course I also wanted to at

last upgrade and reassemble the Caik Outboard -- and try it on the

water to see what it would do. Getting the 14' aluminum motorboat

moving faster would be nice. Getting it up on any sort of plane would

be fantastic!

(I also have this ongoing desire to build a 20' catamaran

to run with an electric outboard. It would glide effortlessly through

the water, and

could carry wave power buoys (and their anchors) between the hulls

for deployment in the ocean, or tidal/river flow power generators could

be carried or towed. Hulls would be polypropylene-epoxy on

polystyrene foam sandwich construction with a few strategic wooden

spars - strong and lightweight. - - - Easy there, easy!

Enough new projects already!)

Somehow I didn't get the boat into the water by the end of

the

month. Rats!

Electricity

Generation

Improved

750/1500 Watt Hugh Piggott Frictionless Axial Flux Alternator?

On September 28th, thinking I just might get access to a

small

moving stream, I started thinking about an alternator. It might make

more power than my recently converted car alternator would handle. Or I

might want to put more than one floating unit in the water, each with

its own alternator. It would be better to be set up to make alternators.

The large

diameter Piggott/Scorag axial flux air core layout with a resin cast

stator was great, but it was said to overheat with more than about 500

watts continuous load. I had had

the same trouble with the very first prototype Electric Hubcap motor.

In spite of making some ventilation holes, I could soon smell hot

polyester resin. Of course, I was putting a lot of power into it and

the RPM was quite low. There seemed to be two factors contributing to

the overheating at what is a pretty low power for the size.

The first factor is that the stators are cast as a solid

block of resin, 1/2" wide by about 14" diameter, with no ventilation.

This might be improved by ventilation holes near the wires and by

making the surface rough rather than smooth, just with sandpaper.

I could also consider the

"heat conductive" epoxy resin right around the coils, but it was sold

in small containers and cost too much for general application. I

wonder how they make it "heat conductive"? Is there something I easily

add

to regular epoxy resin?

The second factor was that there was no ventilation fan.

Granted it was being used in a windplant, but sitting with a flat face

to the wind, it wasn't designed to take advantage of that. The

magnets were cast into a solid disk of epoxy with a steel backing,

which would circulate the least amount of air while blocking air flow

near the stators.

The fix for that is exactly the way I've been doing motor

rotors: Wrap a popypropylene strap around each magnet and epoxy it in

place. The rotors would be easily done by CNC waterjet complete with

all holes and strapping slots. The magnets then act as centrifugal fan

blades. If cool air is permitted to enter near the center, it gets

flung outward to cool the stator coils. (assuming there is somewhere

for the warmed air to escape, of course - vent holes around the

outside.) I figure one could surely increase the power output by 50%

without overheating. It might even be double. That would mean 1000

watts instead of 500. But I'll stick with the more conservative figure,

making it 750 watts. That's one horsepower. (1HP = 746.7W)

A unique aspect to the Piggott design is having no iron