Turquoise

Energy Ltd. News #111

covering April, May, June, July and August 2017 (posted

September 15th 2017)

Haida Gwaii, BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries & short project reports)

- House Move - Project Selections - Electric(?) Ground Effect Vehicle -

Lambda Ray Converter - Upgraded Electric Caik Outboard Test ...&

the next "Hubcap" type motor improvement - A Nickel-Air Battery Note -

LED Lighting - Suzuki Swift: Burned an EV (Yow!) - Miles Electric Truck

Chain Drive

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Haida Gwaii (AKA Queen Charlotte Islands) - The Move - A Trip Back to

Victoria - Antigravity in a Dream? - Time of day - Sigh, Chem Trails

Again! - Possible Health Ideas: Cyst and maybe Mole Removal or

Shrinking? - Easier Shelling of Peas and Beans?

- In Tedious

Depth

Project Reports -

Electric

Transport - Electric Hubcap Motor Systems

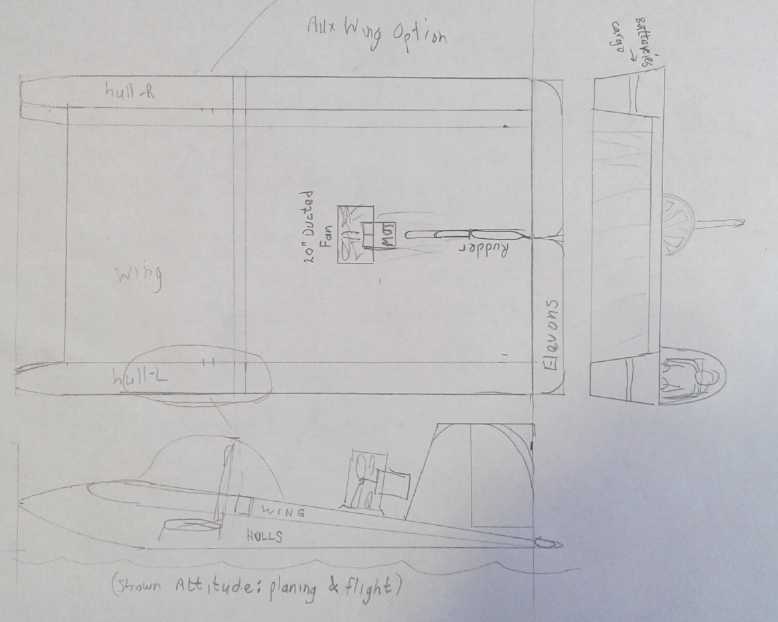

* Electric Bixel Ground Effect Vehicle: - Ducted Fan etc. - The "paper

airplane" delta wing design - back to Catamaran design

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation

* New Water Flow Turbine Design Thoughts

* Ocean Wave Power Thoughts

* Short Space Ray/Lambda Ray/VHE Ray Converter: - Circuit Board is

working - Programming - How it Works: A bit of speculation

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc. (no reports)

April... May... June... July... and August in Brief

I was very busy all spring and summer with the move to Haida Gwaii and

setting up home and shop there, and there is still a lot to do. I wrote

a lot about that, then decided it was mostly of interest to friends and

relatives, and here I include just a bare outline, in the "In Passing"

section. I found it was harder to get

internet up here than I had expected, and without internet at home I

couldn't post newsletters. It has been a challenge getting all my

stuff moved, and I was without the computer I usually write the

newsletters and edit the pictures on. I was missing parts and tools for

working on almost any green energy project. I typed article text on a

combo-tablet that had a keyboard. Meanwhile the months rolled on. I

wrote haphazardly on two different machines, and it became a

hodge-podge that took considerable editing to merge into organized

texts. And there were dozens of pictures, taken over 4 months.

Luckily there is cell phone service in my area. (Some

areas don't even have that.) Late in May I got a new cell phone, one

that I could use

as a "WIFI hot spot" and get on the internet. (The price for using that

very much is steep, but at least I could get on line from home

occasionally.) Late in July I got my trailer which had been stored in

Cache Creek and which had much of my computer equipment in it including

the one I do the newsletters on, with the subscription list. Now I

could upload and edit all those pictures I'd taken - but with so much

to do I didn't get around to it. In mid August I

bought a "WIFI Range Extender" which also had an ethernet connector so

I could connect that old desk computer via WIFI. (Similar WIFI items I

had ordered from

China in June or July finally arrived on September 11th.) So I finally

wrapped up

this TE News, #111, which had become more than plenty long with a lot

of loose ends. But it didn't work. While the physical connections are

there, these WIFI devices expect the LAN to be on the ethernet and the

computer(s) to be on the WIFI instead of the other way around.

I saved a lengthy and revealing In Passing article

about World War Two, based on the works of Victor Suvarov, for next

issue. (and you thought you pretty much knew what that war was about?

So did I. Hah!)

In these months I couldn't do much with green energy

projects except study and plan. I first considered the tidal power

project at Delkatla estuary, and the Differential Variable

Transmission, and a couple of other projects. But there seemed to be no

local interest in actually doing the Delkatla project - at least none I

managed to get in touch with. Finally I decided to concentrate on two

projects that seemed to me to be more valuable than any of the others.

Electric(?) Ground Effect Vehicle

Ground effect vehicles seem to me to be the best way to

open up transportation to islands, between islands, and along

inaccessible coastlines, especially mountainous ones cut by fjords and

inlets where road building is circuitous or impractical. Today's

options are usually airlines (costly) and ferries (slow). The subject

has become of great interest to me since I now live on an island rather

remote from the main stream of human activities, which would become

much more accessible with such a craft.

The ground effect vessel flies over the water at very low

altitude with the speed of an aircraft, with less special 'pilot'

training and 1/3 the energy cost, a "sea bus" enabling many local or

intermediate distance routes to be traveled quickly and economically.

In scale it could be anything from a personal "sea car" to a ferry

carrying vehicles.

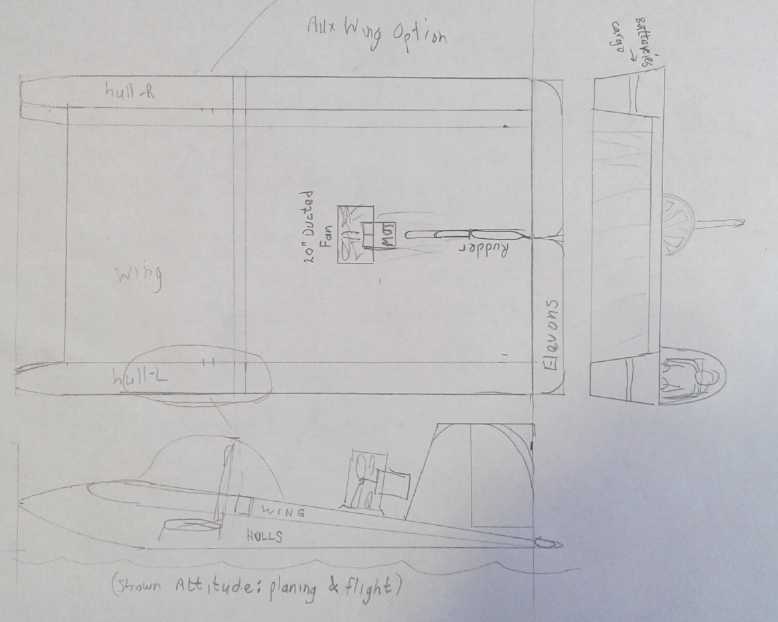

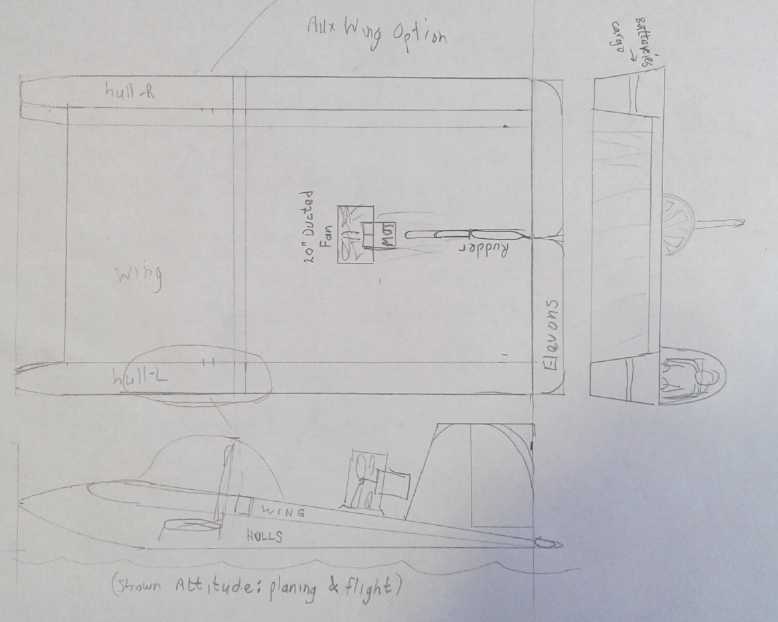

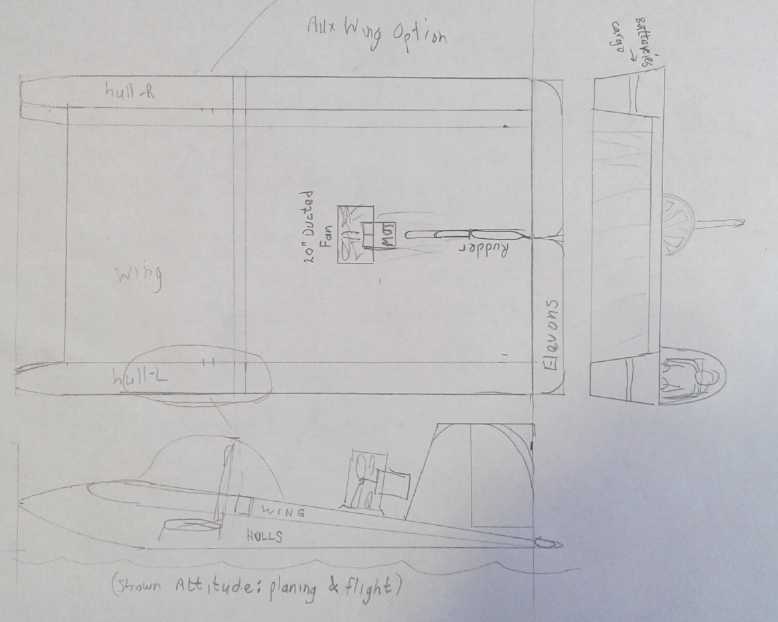

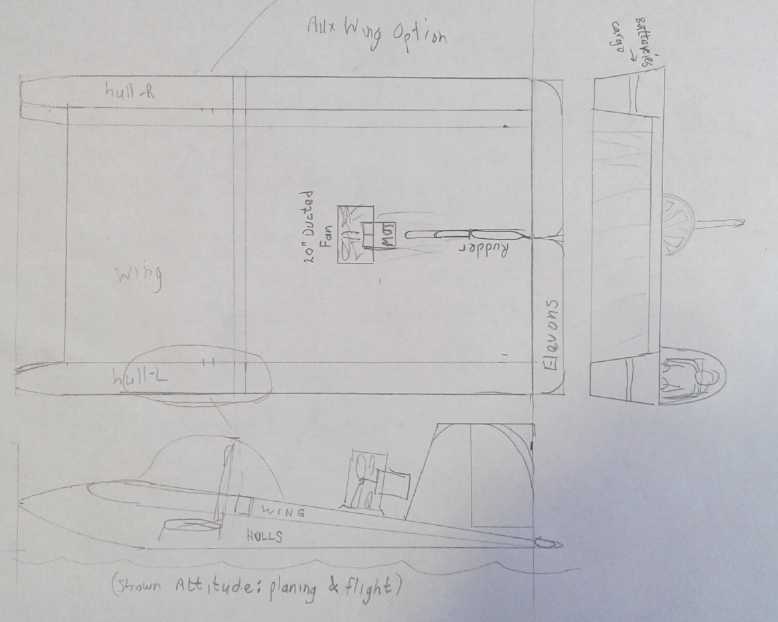

Mock-up of the delta wing shape - imagine the

center as a solid hull instead of just an outline.

But the catamaran shape seems more practical.

My idea of the best form for the ground effect vehicle

metamorphosed from a catamaran with optional stubby outer wings to a

"paper airplane" delta shape... and, on reviewing some videos, back

again.

The paper airplane flew well and the delta wing shape seemed "cool",

but it seems two outer hulls with a

main wing between them traps air at the sides as well as the back, so

the air scooped in the front under the wing has nowhere to go except to

lift the vehicle out of the water. So this rather "boxy" looking shape

is almost inevitably going to give the best performance, stability

and fuel economy. And it would be easier to dock and to embark

and disembark. But one radio control modeler said when he added stubby

wings to the outside of the floats, it worked better. And that's the

configuration Bixel seemed to use and showed in his patent drawings. I

tend to think simply making the catamaran wider, even square viewed

from above, could accomplish the same thing.

My idea of the best form for the ground effect vehicle

metamorphosed from a catamaran with optional stubby outer wings to a

"paper airplane" delta shape... and, on reviewing some videos, back

again.

The paper airplane flew well and the delta wing shape seemed "cool",

but it seems two outer hulls with a

main wing between them traps air at the sides as well as the back, so

the air scooped in the front under the wing has nowhere to go except to

lift the vehicle out of the water. So this rather "boxy" looking shape

is almost inevitably going to give the best performance, stability

and fuel economy. And it would be easier to dock and to embark

and disembark. But one radio control modeler said when he added stubby

wings to the outside of the floats, it worked better. And that's the

configuration Bixel seemed to use and showed in his patent drawings. I

tend to think simply making the catamaran wider, even square viewed

from above, could accomplish the same thing.

Unexpectedly I have a

complete electric drive system that will run at 10 or 15 kilowatts,

with 30 KW briefly for take-off, and (while realizing it won't cover

long cross-ocean routes) I now hope to make the prototype manned craft

electric instead of gasoline. But before that will come the electric

radio controlled ("RC")

1/4 scale model.

In order to maximize thrust for take-off using

the least amount of power, I'll be using a

ducted fan propeller, as they have more static thrust per

horsepower. And perhaps the unit can be mounted at the front with the

air aimed or further ducted to blow under the wing instead of over it.

That should increase lift for take-off at a lower speed. For the model

I found a 5" plastic ducted fan at "Hobby

King". I don't know where I'll get a 20" or larger one for the full

size

craft. The "turbofan", the common jet aircraft engine, is a ducted fan

propeller turned by a turbine.

In order to maximize thrust for take-off using

the least amount of power, I'll be using a

ducted fan propeller, as they have more static thrust per

horsepower. And perhaps the unit can be mounted at the front with the

air aimed or further ducted to blow under the wing instead of over it.

That should increase lift for take-off at a lower speed. For the model

I found a 5" plastic ducted fan at "Hobby

King". I don't know where I'll get a 20" or larger one for the full

size

craft. The "turbofan", the common jet aircraft engine, is a ducted fan

propeller turned by a turbine.

I didn't get the radio control parts from storage until

the start of September, and without knowing how it would all fit

together I held off building more than a "mock-up", and that was of the

delta wing design.

In the catamaran design, air scooped in under

the front of the wing has nowhere to

In the catamaran design, air scooped in under

the front of the wing has nowhere to

escape out the back and sides except by lifting the craft out of the

water.

At the start of September I conceived of the ducted fan

being at the front and blowing air under the wing instead of over it

for still more lift and lower take-off speed. Others have done that

with models, but it looks more practical with a small diameter ducted

fan than with a big propeller.

VHE/Lambda Ray Converter

The other especially useful project was one item that did

arrive in the shipping container in April before

I did. It was a cardboard box labeled "Lambda", which had the parts and

pieces related to the project. It seemed to be one project I should be

able to work on - at least, once I got my computers back. If I could

get it to work, it might replace any and all other means for generating

electricity that I might work on. And it could even make battery

storage and hence better batteries much less important. It would be

relatively easy to duplicate units and I could do it without help and

interest from others, which seemed to be lacking.

So the on again off again

converter project was on again as of late July when I got my computers

back, with the control board schematics and the software development

system for writing

MSP430 microcontroller software. This time I hope to get as far as a

fairly well built coils/antenna unit in a "bread pan" steel box, a

working microcontroller based coil pulse control board, and trying out

what might be a viable software strategy for turning the rays into

electricity via those circuits.

In August I got the circuit board that I made a year and a

half ago working (at least, the microcontroller ran - not without some

initial trouble and confusion), and I made

much progress on writing the software. Sometime earlier I realized I

had the IRF7307 predriver chip connected wrong

and I fixed the design for the present circuit board. But going back to

the earlier

experimenters' schematics, which I had copied the much of the driver

circuit from, I found they all used the same circuit and they all had

it wired wrong,

identically! My own original

mistake was in copying the original mistake! Everyone had simply copied

the

first person's cludge job assuming it had been properly designed, and

so they were all working under a considerable handicap with poor and

uncertain drive to

the power mosfets and hence to the coils. This may help explain why

they got unpredictable results and no successful converters. In August

I finally realized it was a poor choice of chips to start with - there

are lots of more suitable ones.

Recognizing these rather basic electronics flaws was

actually inspiring. Notwithstanding Mark's safety warnings and emphasis

on the difficulties, it gives me good hope that, using the flexibility

and precision control gained by using a microcontroller instead of

simple discrete circuits and oscillators, it just might be easier than

it seems - or even "pretty simple" - to convert VHE rays into

electricity.

I seem to have cludged my board to where it'll probably

work, but

owing to the poor choice predriver chips (even when connected right)

compounded by

power supply issues, I'm already wanting version 2 of the board to

improve the power mosfet drive while also getting the MSP running

within its specified voltage. I picked another mosfet gate driver chip

and ordered a few from Digikey. Meanwhile it is most helpful that the

MSP hasn't blown up yet at 5.2 volts, when

its "absolute maximum" rating is 4.1 volts.

On reading one experimenter's report I realized it would

be just as

necessary to varnish or epoxy all the coil wires solidly into place on

this unit as it is on an electric motor, or the wires would vibrate

until they shorted or broke.

I also started to dimly see an important aspect of the

operation. When the control coils pulse their high voltage pulses and

the sudden change in voltage triggers the lambda rays to release their

VHE electromagnetic energies, those energies don't simply appear in the

"collector coil". Instead, they are transformed into far lower

frequency radio (and or other wavelengths) energies in the areas around

the coils. These are in turn induced by electromagnetism into the

collector coil in the same way as into the secondary of a transformer

or perhaps more akin to lighting an unconnected light bulb near a radio

transmitter antenna. Here we may begin to appreciate why there may be

strange glows or electric arcs around the unit, how people can get RF

or radiation burns to their hands from them, and how Mark's earlier

transistorized versions didn't work because there was too much

electrical interference in the air, getting into the delicate circuits.

In some ways, I find lambda ray conversion to be a boring

project. There's no exciting spinning parts and not much machining or

fabricating to do. There's a fair bit of microcontroller programming,

but I've already done more programming than anyone should in a single

lifetime, and nowadays I can hardly stomach sitting down at a computer

to do it. Of course, a bit of success could go a long way to making it

more interesting!

While those were to be the two main projects for the time

being, other things deserved putting a little effort into on the way,

too.

Upgraded Electric Caik Outboard Test (Continued from TE News #104

& 105)

...& the next "Hubcap" type motor improvement

One thing I'd been wanting to do for a long time was to

test the Electric Caik outboard motor, repaired and with its

rotor upgraded for higher RPM.s almost a year ago. But somehow I'd

never managed to get the boat in the water. On September 6th, with my

14 foot aluminum boat and all finally at my new abode, I did some

repairs to the trailer (maybe lucky the boat made it up here without

falling off!), mounted the outboard and equipment in the boat with

eight 100 amp-hour lithium batteries (about 25 volts), and by the next

afternoon, the 7th, I turned it on. Everything worked properly on the

first try, so I hitched it up and drove down to the boat launch at

Queen Charlotte. Aside from stupid little things like leaving the drain

plug out of the boat when I launched it, and not bringing a bailing

bucket along, the trip went smoothly.

The outboard was rather noisy instead of virtually silent, which

experience says indicates downward pressure from the motor onto the

drive shaft. (Why?) But not loud like a gas outboard! There was a fair

crosswind but I seemed to have navigation - ie, I could steer anywhere

without the wind blowing me back - at only about 10 amps. Running at 25

volts instead of 16 or 18 helps. I ran it at different amperages (as

redd on the cheap Chinese shunt meter - not very steady readings and

probably just a little lower than the actual current) and got the

following results:

Amps - RPM

20 - 1530

30 - 1800

40 - 2000

50 - 2100

60 - 2250

At 50 amps the breaker blew after a bit. (25v*50A=1250

watts.) Well, it's a 50 amp breaker, and maybe it was really 55(?) amps

or so. Of course, it took me by surprise "Groan! Something's fried!",

but only for a moment before I realized what it was. Reading 60 amps it

blew pretty soon. With the improved rotor I wasn't worried about rotor

magnets potentially flying off when going to higher RPM.s, but about 60

amps and 2250 RPM was 'full throttle'. I was a bit surprised by this as

I thought it would go higher. But the limits are set by the shunt wire

in the controller. If I changed that, it could do more... if it didn't

blow the controller or overheat the motor.

Later, I found the control, which I contrived to mount

inside the arm of the outboard when I first did it in order to use the

original twist grip 'throttle', was acting up. It may not have been

reaching the end of the travel of the potentiometer and hence full

speed. But now I'm not sure the twist grip in the arm is actually the

best place for a speed control. It's arguably best for starting a gas

motor and for maneuvering, but in steady travel you're always turning

it by accident and it's hard to keep a steady speed unless it's at

maximum, and even there you're trying to twist it extra so as not to

inadvertently slow down. A control one can set and leave would probably

be better, especially when it'll often be run at part speed to conserve

battery power, and I think I'll convert it to that setup.

The boat didn't get up on a plane, but as there wasn't too

much weight in it, it probably wasn't too much short of a soft sort of

plane. From driving lessons when I was 18: 60 MPH is 88 feet per second

- close enough to 90. So 6 MPH is 9 FPS. So 15 FPS, my best very rough

estimate at 60 amps and 2250 motor RPM, is about 10 MPH. So assuming

proportional RPM to speed: 2100 RPM is 9.3 MPH, 2000 = 8.8, 1800 = 8,

and 1530 = 6.8. Note that the speed at 1/3 power (20 amps) was 2/3 of

the speed at 60 amps. One sees how with a displacement hull, power

consumption increases dramatically to gain just a bit more boat speed.

I guess I must

have run it longer and harder than on previous occasions. I forgot to

connect a meter to read the temperature, but afterward the motor was

certainly hot. I wouldn't want it much if any hotter. I was rather

disappointed after it had seemed to stay so cool on previous tests with

similar currents. I guess the "continuous duty" rating would be

somewhere around 1200 watts or 2 horsepower, and nowhere near my

evidently overrated thoughts of 3000 or more. But I'm not surprised,

having in the meantime seen how fast the Electric Hubcap motor

coils could get hot in the Sprint car when supplied with up to 150 amps

(*36 V = 5400 W) from the Kelly BLDC motor controller. The heads of the

(metal) coil clamping bolts (electromagnetically heated by the spinning

rotor magnets, with no electrical or good thermal connection to

anything else) were especially hot, to no benefit. I thought I had

replaced those with nylon bolts... but I guess that was in the next,

unipolar, version of the Caik motor. There might be some gain from

replacing them, and also by taking the hood off the outboard to get

better air circulation to the motor - the hood must certainly trap the

hot air.

I guess I must

have run it longer and harder than on previous occasions. I forgot to

connect a meter to read the temperature, but afterward the motor was

certainly hot. I wouldn't want it much if any hotter. I was rather

disappointed after it had seemed to stay so cool on previous tests with

similar currents. I guess the "continuous duty" rating would be

somewhere around 1200 watts or 2 horsepower, and nowhere near my

evidently overrated thoughts of 3000 or more. But I'm not surprised,

having in the meantime seen how fast the Electric Hubcap motor

coils could get hot in the Sprint car when supplied with up to 150 amps

(*36 V = 5400 W) from the Kelly BLDC motor controller. The heads of the

(metal) coil clamping bolts (electromagnetically heated by the spinning

rotor magnets, with no electrical or good thermal connection to

anything else) were especially hot, to no benefit. I thought I had

replaced those with nylon bolts... but I guess that was in the next,

unipolar, version of the Caik motor. There might be some gain from

replacing them, and also by taking the hood off the outboard to get

better air circulation to the motor - the hood must certainly trap the

hot air.

Improving the motors

In most motors, the copper wires are close enough to the

iron that some heat is carried off through the iron, and heat radiates

off everywhere. With my largely plastic motors, only air cools the coil

wires. Now I'm thinking of modifying the mold design for all my

"hubcap" type motors to get air flow over more surfaces of the coil

wires - exposing the bottom (and if possible the top) of the donut as

well as the outside edge. The problem with exposing the top is that the

flux gap has to be larger, and it may become too large. I've been

making my motors occasionally since 2008 and probably achieved

excellent efficiency about 2012 (IIRC), and it's amazing that I keep on

discovering very significant ways in which they can be improved.

And perhaps an appropriately ducted "computer fan" that

comes on whenever the motor is on, could be used to improve air flow.

The magnets acting as centrifugal fan blades seem to move air nicely,

but perhaps it needs to be flowing faster. A lot of electric car motors

that pack much power into a small size are liquid cooled. Partly

because of presumably high efficiency making less heat I don't think

I need to go to that extreme, but it's evident they would handle more

power with better cooling.

I may add a couple more battery cells for about 31-32

volts and try the boat again some time with this boost. OTOH, at least

at 24 volts I haven't yet blown my motor controller or burned out the

motor.

I didn't think to take any pictures or video until I was

back at the launch ramp.

A Nickel-Air Battery Note

The desire for lighter weight batteries for an electric

version of the low flying "sea craft" brought my thoughts back to the

potential for nickel-air batteries to fulfill that sort of role. A

metal negative electrode is light and compact compared with the

oxide/hydroxide based positive. Hence, using air to replace the heavy

electrode is an attractive idea that could potentially drop 3/4 of the

weight of a cell. Attempts to produce rechargable zinc-air cells do not

so far seem to have resulted in practical products. Seemingly few have

tried any other metal.

I've probably mentioned this before, but I'll bring it up

again: why would nickel-air be better than zinc-zir or most other

metals that might be tried with air?

1. The reaction voltage of nickel to nickel hydroxide (-.72 V in

alkali) is less than that of water to hydrogen (about -.83 V in

alkali). The nickel won't spontaneously oxidize in solution in the

presence of oxygen as do cadmium, iron, metal hydride and zinc. (hence

its well known corrosion resistance). Oxygen reaching the metal

electrode is hard to avoid in a cell that can't be sealed and where

oxygen is deliberately admitted for the air electrode.

2. Theoretical amp-hours aside, nickel has been determined by other

researchers to have the highest effective amp-hours per weight in

aqueous solution of most anything.

What special problems are there with making a nickel-air battery?

1. As everyone knows, metallic nickel, alone of all metals, will simply

not oxidize in pH 14 alkaline solution. Non-corroding nickel or nickel

plated current collectors for the positive electrode made making

alkaline batteries simple compared to salt battery chemistries. But it

precluded using metallic nickel as an active electrode element. For

that, a salt electrolyte must be used instead. The reactions are

nevertheless alkaline, but at a reduced pH, usually settling in at 12

to 13.

2. A chloride salt can't be used. KCl worked great with Ni-Mn with the

manganese negative electrode. But for reasons I don't understand (and I

have no formal training in chemistry) any cell I made with a metallic

nickel electrode underwent continuous self-discharge in chloride

solution and wouldn't hold a charge at all. Potassium sulfate seemed to

work much better. Oxalic acid also seemed to work. To use an acid

electrolyte one must choose an acid which won't dissolve the metal or

its reaction products. Neither nickel, nickel oxide, nor nickel oxalate

dissolves in oxalic acid. This is about the only common acid which will

work. Most acids will dissolve most lighter molecular weight metals and

so can only work with heavy ones like lead.

New House - LED Lighting

I brought what I thought was a lot of LED "light bulbs" to

my new abode, and three 4-foot, plug-in "fluorescent" style LED

fixtures. I immediately replaced the incandescent and compact

fluorescent "bulbs" in the house, buying more from the local building

supply (at a substantially higher but not outrageous price) when I ran

out.

I took the four fluorescent lights out of the workshop. In

two I put in receptacles and hung up two of the plug-in LED "fixtures".

For the other two I installed simple screw-in sockets and used the

"light bulbs". In one of these I put a "Y" and used two "bulbs" to

light the darkest corner. Now instead of 272 watts of "Super Saver" 34

watt fluorescent tubes, it has under 100 watts of LED lights and is

much brighter and more pleasant. The growling transformer hum

is gone and the room is quiet. One thing I would note is that some of

the 4' LED fixtures flicker at 60 or 120 Hz. That seems needless in

this day and age and with LED technology - cheapskates! How can you

find that out before you buy them instead of after? Some seem to

flicker somewhat but only dim-to-bright rather than on-off like old

fluorescents.

I also managed to change the fluorescent tube fixture in

the laundry room, but those in the kitchen and dining area are recessed

into the ceiling and are going to be a greater challenge. When

installed they were doubtless considered "deluxe", stylish, and "energy

saving". Now the elaborate settings just made it hard to change them

out for something better.

As an added benefit to LED lights, "LED" is much shorter

to type than "incandescent" or "fluorescent". Those long words will

mostly fade out of common use with their lighting types.

Suzuki Swift: Burned an EV (Yow!)

Embarrassing

to admit. With the Swift not having

quite enough range to get to town and back with a good safety margin, I

tried a battery experiment of adding 80 NiMH batteries, in series, to

the lithium ones. I thought that if I just made sure there were enough

NiMH cells that they couldn't be overcharged by the regular chargers in

the car, I could do it safely. But it seemed that however many cells I

put in the string (I was up to 83), the charger would up the anti and

put out a higher voltage. I didn't get much chance to figure out what

was going on before a day when I wasn't feeling well (a tooth) and I

had a long nap. Even before the nap the meter reading, another all-time

high voltage, should have triggered an alarm bell in my head. And

regardless I

should have come back soon to check.

Embarrassing

to admit. With the Swift not having

quite enough range to get to town and back with a good safety margin, I

tried a battery experiment of adding 80 NiMH batteries, in series, to

the lithium ones. I thought that if I just made sure there were enough

NiMH cells that they couldn't be overcharged by the regular chargers in

the car, I could do it safely. But it seemed that however many cells I

put in the string (I was up to 83), the charger would up the anti and

put out a higher voltage. I didn't get much chance to figure out what

was going on before a day when I wasn't feeling well (a tooth) and I

had a long nap. Even before the nap the meter reading, another all-time

high voltage, should have triggered an alarm bell in my head. And

regardless I

should have come back soon to check.

Instead, the

batteries were being

badly overcharged and the next thought of the car was 3 hours later

when the horn

started blaring. The car had caught fire and the interior was a blazing

mess. I put it out with the nearby garden hose through the open garage

door and through the broken windshield, and shortly Tom brought the

fire extinguisher, which sped the process up. The garage door above the

car was charred. Thank God, the horn going off saved the house! The

firewall stopped the fire so all the electric drive components under

the hood, as well as the lithium batteries in their metal box under the

back seat, were still fine, along with all the heavy cables which were

run along the floor. I had all the components to do another electric

car conversion except the meters that were mounted above the dash,

which had melted.

Instead, the

batteries were being

badly overcharged and the next thought of the car was 3 hours later

when the horn

started blaring. The car had caught fire and the interior was a blazing

mess. I put it out with the nearby garden hose through the open garage

door and through the broken windshield, and shortly Tom brought the

fire extinguisher, which sped the process up. The garage door above the

car was charred. Thank God, the horn going off saved the house! The

firewall stopped the fire so all the electric drive components under

the hood, as well as the lithium batteries in their metal box under the

back seat, were still fine, along with all the heavy cables which were

run along the floor. I had all the components to do another electric

car conversion except the meters that were mounted above the dash,

which had melted.

The loss of the Swift has already cost hundreds of dollars

in extra gasoline. Someone was interested in bringing Nissan Leaf

electric cars up to Haida Gwaii, which sounded great. Now he hasn't

answered his phone in recent weeks. But now another person, one who

lives here, is (evidently) a great mechanic, and is wealthy, wants to

bring some up and to build a garage and convert cars and boats

to electric here! Even better! If it pans out, the electric drive from

the Swift is going to be used for the ground effect vehicle for

"driving" over the water. And if it pans out, perhaps we'll be making

motors, controllers and differential variable transmissions.

One can

overcharge lithium batteries too. I hooked some of the ones I got from

an old Toyota Prius (which I initially thought were NiMH) to a solar

panel. If all 5 cells were good, they charged up okay. But if one or

two were shorted, the others charged to much too high a voltage. I

guess that makes gas, which swelled the cells up.

One can

overcharge lithium batteries too. I hooked some of the ones I got from

an old Toyota Prius (which I initially thought were NiMH) to a solar

panel. If all 5 cells were good, they charged up okay. But if one or

two were shorted, the others charged to much too high a voltage. I

guess that makes gas, which swelled the cells up.

Miles Electric Truck Chain Drive

Using the Miles electric

truck... to haul branches from a cut-down tree

The low speed

Miles electric truck has been

pretty useless

around here so far, with the driveway going straight onto a high-speed

highway. I didn't bother to renew the insurance for the

road. Quite some issues back I mentioned ways I had devised to attach a

motor to a vehicle wheel with a chain or toothed belt drive. I now

thought about doing so with the Miles. The idea would be that the extra

efficiency gained by going so directly from the motor to the wheel,

bypassing the lossy transmission and drive train parts (which I would

simply remove), I could use a lower reduction ratio, speeding up the

truck and increasing its range by perhaps 50%, with the same motor

speeds and powers.

The low speed

Miles electric truck has been

pretty useless

around here so far, with the driveway going straight onto a high-speed

highway. I didn't bother to renew the insurance for the

road. Quite some issues back I mentioned ways I had devised to attach a

motor to a vehicle wheel with a chain or toothed belt drive. I now

thought about doing so with the Miles. The idea would be that the extra

efficiency gained by going so directly from the motor to the wheel,

bypassing the lossy transmission and drive train parts (which I would

simply remove), I could use a lower reduction ratio, speeding up the

truck and increasing its range by perhaps 50%, with the same motor

speeds and powers.

I'm ordering a 120 tooth and 12 tooth sprocket set for a

10

times speed reduction, from Rebel Gears. 120 teeth, with #40 chain, was

the biggest that would fit on the back wheel. This is probably a change

from about 15 times reduction in the original drive train. (I'll try to

take the end off the motor so I can see it, and determine the actual

ratio before disassembly.) That should take it from about 40 max to 60

max KmPH and

similarly increase the range. It would still be more useful in town

than on the highway, but it should prove the point.

If the mechanical end of the project looked tough but

doable, the wiring for the motor moved to a new position in front of

the rear right wheel seemed like just as big a problem. I doubt it

would be wise to lengthen the three heavy wires from the motor

controller to the motor, so the controller will have to be moved from

between the two seats into the back of the truck. It has a plug with 34

pins with wires coming to it from various sources, and no extra length

of wire for any. I expect the only practical solution will be to cut

the whole cable and splice in another 6 feet of wire so it can reach,

for every wire in the cable.

Anyway, I'll order the sprockets, and then tackle this

project

some time when I have some time - or perhaps

hire someone to do some of it.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Haida Gwaii (AKA Queen Charlotte Islands) - BC, Canada

The whole archipelago of Haida Gwaii, situated on the

outer edge of the continental shelf of western North America, is about

the size of the island of Hawaii, which is home to some 100,000 people.

Haida Gwaii has under 5000 except in summer, when there is an influx of

tourists. Trout, and sea food from shellfish and crabs to halibut and

salmon, abound. There are no wolves, cougars or grizzly bears, and the

large black bears aren't usually aggressive. Small Sika deer, imported

a century ago, abound. With no natural enemies they are considered

pests and no one minds people putting one or even a few in their

freezer. I planted a garden, and it seems unlikely anyone will go

hungry here if the regular delivery chain is interrupted. But the

weather this spring (apparently unusually cold and windy) meant that

many things would only grow well in a greenhouse, and this may still be

true most years.

One can see that if the average temperature was just a few

degrees warmer, people would flock here to live. Cold winters are one

thing, but summers where one might wear a sweater much of the time are

considered desirable by few. Enter global warming. According to locals,

last summer this was Canada's warmest spot more than once. However

interesting and unusual, this occurrence was never mentioned in the

news. But this summer has been exceptionally cold and wet. At least we

have had no forest fires, hurricanes, floods or notable earthquakes.

Most of the people live on the largest land mass, Graham

island. The next largest, Moresby island, has just a village, Sandspit,

around an airport not far from the ferry to Graham island. The airport

is there, on the "wrong" island, because the large sand spit was a

simple place to build an airport.

The Move

The move to the house I bought on Graham Island didn't go

smoothly. Ignoring everything, I grossly overloaded the 20 foot "sea

can" shipping container and the truck couldn't budge it. Bill and I had

to hurriedly take out 1/2 the entire volume and 40% of the weight and

put it in the garage, which I had cleared of hardwood lumber only the

day before. We hurriedly shifted the rest of the weight to balance the

container, and the truck got the container off just in time to make the

April barge to Masset on Graham island. I then had to get two "U-Pak"

storage containers and store the remaining 8000 pounds of stuff. Of

course, there was no particular order to what was taken and what was

left behind. Bill refused to tow my 14' aluminum boat behind my Toyota

Echo, so I had to leave it stored at a friend's. I told him he could

sell it if he wanted.

Someone with a flat deck truck was supposed to pick up my

electric Miles truck, converted Suzuki Swift EV, and the Sprint project

car and take them to Vancouver to put on the barge. (I had them all

filled to the roof with stuff, too.) He procrastinated until they

missed the April barge, and indeed almost until I had to be gone, but

in the last couple of days he got them all, and they came up on the May

barge. It was just as well I didn't have to deal with them immediately.

On May 1st, days late, Bill and I headed out, he in the

Echo and I in the Dodge Caravan minivan towing a big utility trailer, a

converted tent trailer, with most of my remaining furniture including

my bed and sofa. Most of my clothes and personal stuff was in the

Caravan. There was a problem with the fuel pump assemblies on these

years of Caravans, and I ran out of gas 2 miles short of the first gas

station on the highway on the mainland, with the gauge still saying 1/8

of a tank remained. To make a long story short, this caused gunk in the

pump line to come loose and then the pump sucked air if the tank wasn't

5/8 full or better. This problem wasn't soon understood, and the

resulting confusion it caused led to storing the trailer at a storage

facility in Cache Creek, and later abandoning the van 40 Km south of

Quesnel and continuing with two of us in the Echo to make our ferry

reservation to Haida Gwaii on the 4th. This meant I ended up buying

clothes and furniture to make do (at unexpectedly high cost for the

furniture - double the 1400$ advertised price after shipping et al),

and huge expenses retrieving the two vehicles later on separate trips.

In the meantime, I sorely missed the items they contained. And all

summer I missed the many tools and items that were left behind in the

U-Pak containers.

There was certainly no lack of things to do around the new

house. One of my priorities was to have four huge trees near the house

cut down, and I spend weeks cutting up the branches, burning the bits

and stacking the substantial ones for firewood, which I'll need this

winter. It was like moving from the deep dark woods into an open field.

And many other things needed doing: planting the fruit trees,

unpacking, outfitting the workshop better, getting decent water from

the well or from the rain, fixing the dishwasher...

There are stores, but not many or large, and being out in

the country it's a 25 Km trip to Queen Charlotte, or 80 to Masset where

a somewhat different selection of good may be had. It should be a great

place for an electric car with sufficient range to go to either

destination, or even just to QC. But so far there's just one Nissan

Leaf (and my Miles truck) on the whole island, as far as I know.

Here are some pictures of the house and yard.

The south face of the house.

The south face of the house.

One of the trees being cut down, branch by

branch

One of the trees being cut down, branch by

branch

owing to limited space to fell it, on the north side.

Around the front, with the highway, my strip of

trees

Around the front, with the highway, my strip of

trees

along the waterfront, beach and ocean behind me.

The beach below my waterfront, looking south.

The beach below my waterfront, looking south.

The rocks and sand seem to be rearranged daily with waves and tide -

sometimes gravel, then sand, then rocks, at any given point.

looking north. Off to the right, about one day

a month it is clear

looking north. Off to the right, about one day

a month it is clear

enough to see some mountaintops of the BC coast on the horizon.

Looking up from the water's edge at low tide.

Looking up from the water's edge at low tide.

The highway and the house are hidden by the trees.

The big livingroom from just inside the bay

windows,

The big livingroom from just inside the bay

windows,

(before most of the furniture arrived).

The 24' x 24' Workshop

The 24' x 24' Workshop

I have much reorganizing to do.

A Trip Back to Victoria

A couple of plans to get the tons of equipment and parts

I'd left behind in two 7'x9'x7' U-Pak wooden storage containers in

Victoria delivered, didn't seem to pan out. Finally I took an airplane

to Vancouver and the ferry to Victoria (August 27th), rented a 20'

U-Haul truck, transferred everything from the U-Paks into it with the

help of a friend, attached my boat trailer behind, and brought

everything up, arriving September 2nd. I drove the length of Vancouver

island from Victoria to Port Hardy (500 Km), took the ferry from there

to Prince Rupert (16 hours), and then the one from Prince Rupert to

Skidegate on Haida Gwaii (6 hours). No more long hauls (1700 Km)

through the BC interior for me - the previous one ended up costing me

perhaps 6000$ when I ran into trouble with the minivan and then had to

retrieve it and the utility trailer with much of my furniture

separately from different areas. (Counting the extra furniture I

consequently ordered in June and the pickup truck I bought to tow the

trailer, more like 12000$.) This trip cost me about 5000$ - a bargain!

But it cost as much to take the boat on the ferries as I originally

paid to buy the boat in 1986. After I unloaded the U-Haul truck, I sent

it back "hossled" by BC Ferries to Prince Rupert (meaning driven on and

off the ferry by BC Ferries personnel so I didn't have to go myself)

and let U-Haul retrieve it from there.

Antigravity in a Dream?

Probably most or many people have seen a demo of a

gyroscope spinning at an angle on top of a rod or post, seemingly

defying gravity by not falling off the post, instead precessing around

and around it as it spins. Of course, one surmises that the downward

force on the post is equal to the weight of the gyroscope regardless of

its motions or lack thereof.

And perhaps many have once held a spinning object and

discovered that it strongly resists being turned in a desired direction

and instead tries to turn at right angles to the force applied.

If the precession of the gyroscope is forced to slow, I

presume it will start to drop until the axis is horizontal and it falls

off. Alternatively, if it were forced to speed up, would it not rise up

and spin more upright?

Some of the same properties may be seen in a pendulum,

which also has an uncentered pull on its axis of 'rotation'. (What

happens when a pendulum is forced to swing, or to rotate, faster or

slower than gravity would normally have it do? What happens if it's

pushed at right angles to its usual motion?)

Is there some unsuspected use for such properties to

counteract the downward pull of gravity? I have heard rumors of such a

thing, but I have been unable to form any concept of how it might

actually work.

Early on the morning of May 18th I had a dream. I was in

some sort of electronics products development place. Some stuff

happened that seems little relevant. Then my attention was drawn to a

rectangular-ish object perhaps 18" tall and a foot square, which slowly

levitated off the floor a couple of feet, moved over a couple of feet,

and came down again, all in a smooth arc.

I said, "You've solved the secret of antigravity! Wow,

that's a first! Or at least, the first time I've ever actually seen

such a thing." (other than rumors, I meant.)

I said, "You call it the Pendulum, but surely it has lots

of flywheels and gyroscopes in it?" (The idea of what it "must have

had" may have been merely my own preconceived notions of what such a

device "must have".) There was no verbal response and there was what

may have been a nod - or was it just a slight smile, perhaps

condescending? (Often the words of a dream bear little relation to the

scene and are the important part. In this case they seemed be

co-ordinate. But how did I know it was called "The Pendulum"? That term

was out of the blue. One suspects that if the dream may be taken at

face value, a pendulum or pendulums is or are a key component if not

the the key component.)

A small block of painted wood(?), like a child's

plaything, was levitated and set square on top of another similar one,

with a peg and a hole aligning them. [What was he meaning of this?...

It's child's play?!?] Then the original machine rose up and then moved

sideways horizontally owing to the antigravity vector being applied a

little off from the vertical axis, going across just above and then

settling on a counter top. There I awoke.

The dream seemed to come out of the blue. I had had few

prior thoughts about antigravity other than being sure it exists. My

only somewhat recent thought was that if it were discovered and

antigravity devices created in the near future, that would make the

ground effect craft obsolete, and therefore not worth developing.

(...not to mention all aircraft and hovercraft - maybe even commercial

ships)

In listening to the monthly ALTA web bot "predictive

linguistics" report summaries on youtube, Clif High's predictions of a

new field of "electro-gravitics" in the coming decades had set that

thought off in my mind.

Is it possible that somewhere in those right-angle acting

gyroscopic forces, perhaps acting in some timed pendulum fashion,

downward pressure can be converted to sideways and thence to up? I had

long since put those sorts of ideas in the "too hard" basket. Would it

take the same energy to lift an object up a foot that it does when it's

lifted from the ground, but somehow lifting itself by its own

bootstraps? Logic tells me that all the inertial forces must add up to

zero as seen external to the unit overall; that there would have to be

something more involved in order for it to work. Well, it was just a

dream. And maybe there was more to the machine than I surmised. Then

again logic can miss things, and there's the fact that something free

to turn can pivot on any axis gyroscopically without an external

fulcrum... and the seemingly gravity defying act of the gyroscope on

top of a post, turning downward force into a constant velocity

horizontal rotary motion.

In embarking on a new creation to solve a problem, one

must decide what project is most worth doing. Is it worth striving to

create some untested, perhaps nebulous device which will probably

consume a long development time and carrying a high risk of failure, or

would it be better to choose something whose principles are better

known, seeing a clear path from start to finish with a good prospect

for success if it is dilligently pursued?

In the infinitely variable torque converter, I saw no sure

and clear path, but was reasonably confident there must be some

practical way to do it. So I chose that path over conventional gearing.

Even so it took over 7 years to come up with a clear vision that can

surely be built as a practical and reliable design, and even now a

prototype hasn't been completed. But the Differential Torque Converter

may change transmission designs forever, which making something easily

envisioned with fixed ratios couldn't do.

For the subject of fast over-water transportation, so far

my thought is that barring an unexpected inspiration, the ground effect

vehicle is the path that can be built using known and certain operating

principles with existing materials and products. But the gyroscopes and

pendulums have been set spinning in my head!

Time of day

Growing up, I had always wondered, even before we started

using "daylight savings time", why the hours of sunrise and sunset

weren't symmetrical. If the sun sets (eg) at 7 PM (5 hours before

midnight), shouldn't it rise at 5 AM? Why was it more like 6 AM? In

Haida Gwaii this clock skew is highly pronounced.

In conjunction with my move, I found a minerological map

of BC that my brother had purchased around 1980. Among other things, it

had each degree of latitude and longitude clearly marked. I had noted

before that each Canadian western province was a timezone apart.

Alberta, for example, runs from 120 degrees west to 105 degrees:

exactly one time zone wide. I thought it was a clever arrangement by

design.

But this time I realized that the "prime meridian" time

zone doesn't run from 0 to 15 degrees. It runs from -7.5 to + 7.5

degrees. That means that the 120 degree line isn't the edge of the

"mountain standard time" zone, it's the center of the "pacific standard

time" zone. The whole western half of Alberta ought to be on Pacific

time! This explained the sunset-sunrise discrepancy in my home town of

Edmonton, properly at the edge of a time zone and not in the middle.

Likewise, the whole of northwestern BC (west of 127.5

dergees) ought to be a whole time zone west of "PST". My new location

on Haida Gwaii (132 degrees west) is just 12 minutes of time east of

the center of this next time zone - nearly an hour off from PST. It

would seem we are more on "DST" in the winter than almost half the

continent is in the summer, and that this effect becomes extreme when

DST comes into effect (now bizarrely for almost 8 months of the year).

To tell the real time of day to within the 1/2 an hour time zone

standard, the clocks on Haida Gwaii need to be turned back two whole

hours. Thus it's not proper to speak of the hours of 12 and 1 during

the day as "PM" (post meridian), when they occur before noon ("AM",

ante meridian). Noon is at almost 2 of the clock. But speaking of them

as "12 AM" and "1 AM", or of the night hours as "12 PM" and "1 PM" is

bound to cause confusion.

The net effect of all this compared to original "local

time" is that the clock has become less and less a consistent, reliable

indication of the time of day, and more and more a cause for confusion.

More and more it is an arbitrary shifter of diurnal cycles of sleep and

activity. When one hears of farmers of old rising to start work at 6

AM, here that same time of day would show on the clock as 8 AM. That

doesn't sound nearly as early, but the sun is in the same place. And

when a "night owl" retires at "midnight" (ie 12 PM) in June, does it

really mean what people think of, when it only got dark out an hour

before?

DST is based and has been extended further and further

through the year on the premise that it "saves energy", tho it seems

that the only actual evidence ever collected about that is that it

slightly increases energy consumption. It has also been assumed that

most people work daylight hours, and would like to have more of them

left to enjoy at leisure after they finish their workday. My most

productive time for getting things done outdoors is afternoon, and I

find that this period is curtailed. I need to quit earlier to prepare

for scheduled evening engagements, which are almost always indoors

anyway. So for me it is "daylight losing time", if anything - an hour

of sunshine cut from my afternoon. As for the daytime employees, they

had to get up an hour earlier to start work, and so are unlikely to

have much energy left to do interesting things afterward. The real way

to give them that extra hour is to shorten the work day, in accordance

with all the labor saving devices we've developed since the 8 hour day

became some sort of standard.

Standard time zones were created by the railroads to help

co-ordinate activities of related areas. To a point they are valuable,

but when longitudinal boundaries are too much exaggerated the "time of

day" in such areas starts to have a different meaning than generally

accepted and expected usages. Contrary to what many elsewhere might

surmise, people are not lazy "slugabeds" on Haida Gwaii to open

businesses at 10 AM, when that's really 8:12 AM by the sun.

Sigh, Chem Trails Again!

In spring and early summer, the aerosol spraying seemed

even worse here than around Victoria. Whenever there was blue sky it

was fiercely attacked by jets and hazed over, from horizon to horizon.

Even the little sunlight we would have had was always dimmed; there was

never a bright sunny day. The moon and stars at night were similarly

washed out, only the brightest being sometimes visible. The first time

I saw a real night sky here was mid August. I was feeling personally

very cheated out of much fine weather by this insanity. And it seemed

futile to mount the big solar panels on the roof only to average 300

watts that varies sharply by the minute all day in the thin, patchy,

drifting haze, instead of 1000 watts steady in bright sunlight.

Thankfully, as summer wore on the program seemed to have

been considerably if not drastically curtailed - at least in this area.

In his monthly "ALTA WebBot" reports this spring, Clif

High was predicting unproductive crop yields this summer simply from

insufficient sunlight to the fields. With seven and a half billion

people to feed, this is a very serious prospect. It seems logical that

with the immense scope of the program, it is getting to be somewhat

like trying to grow crops in the shade, which generally isn't very

productive. I don't know the main result, but I've heard that with the

droughts - and perhaps the lack of sunlight - ranchers will be killing

off their cattle herds again as there's now insufficient hay to feed

them over this winter.

And aerosol spraying in the evening or at night seems to

make no sense whatsoever, even with the faulty idea that reflecting

away sunlight will cool the ground. What effect can they possibly think

they are attaining besides blanketing the atmosphere and preventing

normal night time cooling?

Possible Health Ideas: Cyst and maybe Mole Removal or Shrinking?

I've long had a cyst on my arm. Doctor's advice was to

leave it alone. By a decade ago it had grown much larger and was

getting irritated every time I rubbed or scratched my arm, or

accidentally brushed against it. At some point I got some prescription

hydrocortosone cream for a spider bite. There was lots left over. I

started applying it to the cyst daily. When that ran out I switched to

"over the counter" hydrocortosone cream in a tube. It seemed to work

too. The cyst shrank over the course of weeks and months from being a

growing concern to perhaps smaller than ever in my memory.

There are many types and forms of moles and mole-like skin

blemishes, and again for most of these the best medical advice has been

to leave them alone. But we always think in terms of trying to "kill"

or "get rid of" the apparent problem, and the things we try are along

those lines. What if instead of that, we think in terms of "making the

skin more healthy"?, that the cure is not to kill but to heal? So

instead of applying some acid or freezing to try to do harm to the

mole, we apply healing hydrocortosone cream to improve the healh and

resilience of the damaged skin?

I recently bought a new tube of hydrocortisone cream and

am trying it on the cyst again and on some moles and the like. The cyst

has shrunk further. It's barely visible now, tho a lump can still be

felt. Perhaps I can get rid of it entirely. What will happen to the

other things is entirely an experiment.

The instructions on the cream say to apply it sparingly

and to discontinue after a week. However, no reasons were given for

these injunctions. Even Wikipedia was unenlightening. Is there a valid

and convincing reason?... or is it just that it was conceived for bug

bites and other short term conditions and no one has done any studies

on effects of long term use? And so in fear of "malpractice"

accusations, they will not commit themselves to recommending, even by

omission of contrary (but equally unstudied) instructions, that it just

might be beneficial in situations requiring longer term application?

I certainly use it sparingly, but the idea of removing

moles and lesions is obviously a long term prospect, as was shrinking

the cyst and now maybe eliminating it. Long term use doesn't seem to

have done any harm around the cyst. The only apparent effect was that

the cyst has shrunk to a fraction of what it was when I started. It's

hard to imagine anything disasterous like moles flaring up and becoming

cancerous from this, which they certainly might from doing something

harsh.

So far after 2 or 3 months there have been no observable

results except two shrinking cysts (now doing one on my leg too), and

I've cut back application from daily to occasionally. If there are any

eventual results, I'll write again. One hopes that at some point

someone will figure out and create something that will work along these

lines.

Easier Shelling of Peas and Beans?

When we buy frozen peas or beans in a store in a big bag,

we give little thought to how they are shelled and processed. When we

grow them in the garden, it becomes apparent that we will not be

producing enough peas to sell shelled in bags by shelling them by hand.

So I did a search on line and found a couple of patents for pea

deshellers. One of them rolled the peas back and forth, squeezing them

a

bit, with the bottom of the roller being a screen that the peas would

fall through once they were free of the shell. Well, that might be a

bit complex for the small gardener to put together.

My present thought is to find a rigid screen, perhaps a

plastic one such as those sometimes used in fluorescent lighting, and

roll the pea pods over it by hand. If that still proves too cumbersome,

an

advance might be a textured flat plate to go over the top, so one would

be rubbing the pea shells between the plate and the screen by pushing

it back and forth, again with the peas falling through the screen,

which would be dumped as necessary to get rid of the pods. The texture

would be one that would grab the pods so they roll instead of slipping.

This was just ideas. I didn't get to try out much because

I only got a few peas and no beans this summer. When I finally got the

peas, I tried simply rolling them gently under my hand on a breadboard.

That did at least crack open the pods, and it did seem easier than

prying them apart and didn't harm the peas. It worked better with

'banana' shaped pods than with rather straight ones.

Misnomer?

Why is the leading brand of rat and mouse traps

called "Victor"? Shouldn't it be called "Victim"?

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Electric

Transport

Ground Effect Vehicle

As I thought about how travel times to places I might

otherwise rarely or never visit again would be sliced by a ground

effect craft, I started becoming more enthusiastic (or at least less

reluctant) about the idea of trying to make a "full size" manned craft

- of course after building radio controlled models

to test out configurations. Haida Gwaii to Prince Rupert in an hour or

two is

only one potential route along the coast. Victoria is either

prohibitive airfare for all but the rarest occasions, or else several

days travel with all costs for two costly ferries plus gasoline and

vehicle wear and tear - perhaps more costly in dollars plus a high cost

of

time. With a ground effect craft at 160 Km/Hr it becomes less than 6

hours - a single day's travel and obviously much less fuel than by car.

(That can be divided into less than 3 hours from Lawnhill, Haida Gwaii,

to Port Hardy at the north end of Vancouver Island, plus 1-1/2 hours

from Port Hardy to Comox, and 1-1/2 hours from Comox to Victoria.)

Vancouver BC, Seattle Washington, and Anchorage Alaska could likewise

become single day trips (one way) for lower cost and without the

increasing

complications and delays of air travel.

There are of course various complications. Some of them

stem from the fact that no facilities and rules or conventions are

prepared for such craft and no one will be expecting them. Much would

be

gained by establishing ferry routes with terminals for larger craft,

but that can't happen until smaller ones are built. Only then people

will start saying "How come a few people can flit about the Earth

freely while the rest of us are stuck with these cumbersome old "slow

boat to China" relic sea transportation systems?"

To that end, I gave a little thought to what such a

project might entail. First, what should the basic configuration or

form of the craft be? Before the Bixel design, the reverse delta wing

was said to be the most stable. Why was that, and did it still apply to

symmetrical wing profile types?

Let's see... as the angle of attack increases (slowing

down, or climbing), the cambered wing's center of lift shifts forward.

But if the front of the wing is higher, it gets less ground effect, so

the center of lift should move back. With the reverse delta, there

should also be less lift overall, because a smaller area of wing is

getting the same ground effect. Well, I'm not sure how much sense that

makes as far as creating a design.

With the flat or symmetrical wing, as the angle of attack

increases, the center of lift already shifts backward. The rise of the

front WRT ground effect can only add to this inherent stability. Why

would the reverse delta help?

A reverse delta would cause inconveniences in the design.

I wanted a long rear edge of the wings, that would be awash along their

entire length when floating in the water. Their buoyancy would

stabilize a craft and keep it from tipping sideways. This would allow

for a single hull rather than a catamaran arrangement. And the narrow

gap that would open up at the back of the wings as the craft increased

speed would (I expect) give the greatest ground effect lift during

takeoff. That should give it the lowest takeoff speed using the least

amount of power. (Craft taking off from water need substantially more

power than those using a runway on land. And if ground effect craft

need so little power to stay airborne, the only thing they need high

power for is takeoff.) More buoyancy to the rear should allow the

engine and propeller to be mounted behind the cockpit instead of in

front. Finally, if a wingtip should hit the water during a turn while

flying, wingtips at the rear would have the least leverage to try and

make the plane pivot and spin, and that more easily counteracted by the

rudder.

On June 7th I made a paper airplane - a forward delta

shape. With side rudders, and 'elevators' pointing up a little, it flew

great. I decided the reverse delta was an unproductive approach, at

least with the Bixel flat or symmetrical wing. The paper plane would

fly with a small weight (I used a cup hook, screwed throu the paper) in

positions mid to rear.

For rough estimations I started out thinking that a

typical small plane has a wingspan of perhaps 20 to 30 feet averaging

maybe 5 feet wide - maybe 100 to 150 square feet. If the ground effect

gave 3 times the lift, that would be reduced to 33 to 50 square feet!

But the flat wing has less lift per area than the chambered wing, so

that might be raised to, say, 50 to 75 square feet. If the "paper

airplane" delta shaped wing was just 10 feet wide and 15 feet long it

would have 75 square feet of wing area, or somewhat less (55-65?) after

subtracting for the fuselage.

It seems to me 10' is also the maximum width for

trailering something on the highway without having an accompanying

"wide load" warning vehicle. Being able to trailer it would doubtless

be a tremendous advantage - instead of renting hangar space at an

airport or moorage at a marina, tow it home and put it in the garage,

where it will also be easiest to maintain and service.

All along I've been thinking of speeds like 175 Km/H to go

long distances quickly. But the thought of such high speed just over

the water is rather scary, especially if one has no radar, which I'd

probably have trouble fitting in such a small frame. But why would I

care to go so fast in a prototype? I think I'd be more comfortable at

80 to 120 Km/H, about the speeds one drives on highways. There's more

time to react, and the water, if hit, would be less hard. If the boat

becomes airborne at 65-75 Km/H that should work out well, and it would

need less power. (Of course it will be a great thrill if it actually

flys at all! But that's why I'm doing the RC model first, to make sure

the basic design... flys.) Higher speeds may be found desirable later

when the design becomes more refined and operation is more familiar.

Another aspect is the propulsion system. Taking off

from water in a float plane with a petroleum engine is a power hungry

affair. There might be stronger ground effects from having the rear of

the wings right down at the water, but still some considerable force to

get the speed up will be necessary. At first I thought a couple of

hundred horsepower or

more might well be useful. A big aircraft type propeller seemed

inevitable, perhaps 5 feet in diameter. Then I thought a ducted fan might be a better way to go. This gives up to double the thrust per

horsepower under high load conditions - like taking off from water. Or

of

course it can be the same thrust from a smaller diameter. Instead of

propellers of 8" to 10" diameter

for the model, later I got a 5"

ducted fan. That would translate out to just a 20" diameter for the

full size craft. (Could I actually find such a thing to buy? The most

common ducted fan type right now is the

"turbofan" - the jet engine -

where the multi-blade propeller in the duct

is turned by

a turbine.) Another benefit of ducted for the ground effect craft is

that the smaller the diameter,

the closer to the top of the wing it can be, making the thrust more

in-line.

In the paper airplane, bending the rear edge

'elevators'/'flaps' up or down was necessary to trim for changed weight

distribution when weights were added. So rear elevators are required.

The back of the wings seems like a good place for them, forming part of

the wing area, rather than in a higher-up separate elevator. I

originally thought ailerons would be unnecessary, but later it occurred

to me that propeller torque (ducted fan or not) - or an unbalanced

payload - might tend to want to make the craft tip sideways in

straight, level flight. If the right and left elevators were separate,

making them "elevons", any such tendency could be corrected. The

elevators are essentially the same. Only the controls and linkages get

more complicated. I bought one too few radio control servos to do

elevons, so I'll see what happens in the model without separating the

left and right elevators.

Then there's the hull or hulls. The models on youtube were

all catamarans And I thought it should have thin hulls for low

resistance in

water. But if the

flat/symmetrical wings are down at the water (at the trailing edge) and

buoyant (filled with foam), a single hull could be very thin and the

craft would still be

stable, not tippy.

Then too I read in the 1980s about small (even 12' long)

sailing catamarans with flat planing hulls that could outrace larger

traditional design cats. (I had been disturbed to read that, having

just barely completed making a boat with traditional hulls myself at

the time!) With a "paper airplane" shape and buoyant

wings, a single hull with a flat bottom - and a flat top - about 2'

wide and maybe 18' long, seemed to commend itself. Considered without

the wings, such a square cross section boat hull shape should get up on

a

plane quickly with relatively little horsepower. It could also be

aligned with the wings and be part of the lifting body. (The

pilot/passenger window canopy was going to louse that up a bit, but

maybe not badly.) With the boat up on a plane (or "on the step" in

aircraft parlance), the wings (touching the water at the back) would

be at the right angle for take-off, and every bit more speed would

reduce the contact of the boat and wing-rears with the water, which I

hope will mean it will lift off gently with a minimum of power; much

less than most seaplanes.

For materials I think the frame might be a quality

aircraft spruce such as was used in early aircraft. I hope to use a

very

large timber, a 4" x 6"

beam 10 feet long, as a strong

cross spar. (One doesn't want it

to fold up in flight!) If I can buy or rent a bandsaw mill, there is

very good sitka spruce

on Haida Gwaii, not excluding the four large trees I've had

removed from my own yard, with many more on the "back four" acres.

Back to the 1/4 scale, to start to turn the "mock-up" into

an RC model, I cut two triangles of 1" foam, 12" wide by 38" long for

the solid wing pieces. A 1" dowel, ripped in half, can sub for the

leading edge components.

For surface material I thought I would definitely depart

from

the old doped canvas or indeed any type of fabric. Perhaps

lexan/polycarbonate plastic might make a great, smooth, tough skin.

Otherwise some other tough plastic.

Then I thought of epoxied polypropylene... as a last

resort? Hmm, that was quite tough, and would be the thinnest and

lightest! Lightness

counts, so I decided on that: A single layer of PP-epoxy skin over

extruded styrene foam, akin to foam sandwich boat construction. That

should be pretty strong! I could use 2 or 3 layers of PP cloth on the

hull bottoms so it could better be run up onto a sandy beach after

landing. Well, I guess that would be a modernized version of doped

canvas after all. But with the foam underneath holding it flat.

The wing(s)... The foam could fill the wing solid, 4"

thick, with a semicircle front edge. (With gaps or holes where

wires or cables need to run through?) The rear would have the

elevator or elevons tapering from the 4" thickness down to a fine rear

edge. The PP-epoxy skin would wrap around the whole wing.

Another Design Revolution (Ack!)

On August 16th

I went to town to the library to get on

line and

order some parts at Digikey. Afterward I went to youtube, and a new

radio controlled ("RC") ground effect craft video was there. This one

was a rectangular shape with tall but very narrow "hulls" on the

outside and a wing between them. When it moved forward, air was trapped

under the wing by the two hulls at the sides and by the rear of the

wing. So it would fly with three sides almost touching the water (or

the ground in the video) and only the front was open, to scoop the air

in. Surely this must provide the greatest lift, with no lift-losing air

vortexes at the wing tips! And it looked like the

most wing area per overall size.

On August 16th

I went to town to the library to get on

line and

order some parts at Digikey. Afterward I went to youtube, and a new

radio controlled ("RC") ground effect craft video was there. This one

was a rectangular shape with tall but very narrow "hulls" on the

outside and a wing between them. When it moved forward, air was trapped

under the wing by the two hulls at the sides and by the rear of the

wing. So it would fly with three sides almost touching the water (or

the ground in the video) and only the front was open, to scoop the air

in. Surely this must provide the greatest lift, with no lift-losing air

vortexes at the wing tips! And it looked like the

most wing area per overall size.

When something did touch ground it seemed to be of little

consequence. Other than not turning very well and often flying somewhat

diagonally like a hovercraft, I decided it seemed to be a better plan.

It didn't look very glamorous - something like an overgrown snow sled

- but it was simple and should lift off the water at the lowest speed

with the least amount of power. Some of Bixel's drawings showed this

sort of shape but with stubby wings added to the outside, and some of

the RC videos had rectangular units with stubby wings. On one it said

they had been added later and that they improved the performance

considerably.

So, not being very far along yet anyway, I reverted to the

rectangular shaped catamaran form as it seemed to be the most

practical. Without stubby outside wings it would be a rectangle with

buoyant hulls at the sides - easiest to dock, embark and disembark. If

outer wings are being added to improve lateral stability, as seemed to