Turquoise

Energy Ltd. News #115

covering

December 2017 (posted January 11th 2018)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features: A Decade in Review

Month In Brief

(Project Summaries etc.)

-

Internet - Shrinking World - Carmichael Mill ("Bandsaw Alaska Mill") -

Battery Lab & Nickel-Nickel Batteries - Hybridizing the Toyota

Echo... Wait, how about the Miles truck?

A Decade in Review

* What's been done?: Listing the projects

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Sea Foam is natural (Ooops!) -

Cryptocurrencies - Fraud in the Stock Market? - John MacAdam -

Carmichael

Projection World Map & Virtual Reality

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Craft: Fixing Lateral Stability Problem

Other "Green"

Electric Equipment Projects

* "Carmichael Mill", a "Bandsaw Alaska Mill" - Meat cutting band is

better(?) - Building It, continued - Home Sheet Metal Tools - Motors

and Duty

Cycle - Drive Belts

* Power Supply: Photos Simplify Repair. But is it worth it?

Electricity Generation

* Tiny Solar Cells (purchased)

* A couple of VHE Ray Energy Notes

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc.

* Another round with Nickel-Nickel chemie: in oxalic acid - Battery Lab

- Chemistry - electrolyte - Building a Cell - Expectations: The

Reactions - Testing & Observations - Conclusions - Next

Electrolyte: Potassium Oxalate? - Cell with KH(C2O4)? - Positive

Electrode Characteristics (seemingly Favorable: with slightly lower

voltages)

December in Brief

Here's another late newsletter... so much to do, so

little time! I spent a couple of weeks in Victoria with family for

Christmas, which definitely ate into December's project time. Then at

home there were things to catch up on. Then after 10 years, it took

quite a while to look through the TE News indexes at all the tables of

contents just to find and list all the projects - successful or

unsuccessful, one time or ongoing, and finished, unfinished, barely

started or just envisioned. (My multi-millions "dream list" budget that

would really get things going will come next month.)

Internet!

My friend Tom, having moved to Skidegate, managed to get

internet via a radio link from Gwaii Communications. (My place is out

of

range of their system.) I visited him a lot to use it, and especially I

left a computer there for well over a

week and got my bitcoin wallet

updated after 7 months off line. Then I sold the last of my bitcoin at

what seemed like a great price, just before it doubled again and more.

People in China have been getting into it in a big way, and there are

1.4 billion of them. And there are many others as well, especially in

those lands where the local currencies have been proving most

untrustworthy.

I finally figured out a means to get basic internet at

home and

got it working in late November or the start of December. In October(?)

I asked my next door neighbor, thinking he had satellite internet, if

he would share it via WIFI in exchange for splitting the monthly

charges. It turned he just had the satellite dish left over from when

he had had it, still mounted on his house. I bought the dish off him

and phoned to ask about getting satellite internet installed (now that

I had one of the costly pieces). Somehow I got no reply to my

message.

In the meantime, I aimed the antenna dish two acreages

over and

put a WIFI repeater in its focus. I found I could pick up the closer of

this person's two satellite systems. I had internet!... sometimes... If

the

WIFI gods were smiling. But at least

sometimes

along with everything else internet does, I could search and

order things on line from home again and do research on

line again. In mid December I was in

pursuit of chemical information in attempting to make nickel-nickel

batteries.

After Christmas I put the dish in a new location and it

seems to be working better. I also discovered one of my computer

tablets was frapping out and saying it was off line, which of course I

had been attributing to loss of signal at the repeater.

Shrinking World

When I worked for the federal government ministry Transport

Canada in the late 1970s, electronic technicians were still often

posted at isolated northern posts to maintain equipment,

and one got "isolation pay allowance" for working at one. I think

Sandspit airport was one such place. And even in Victoria, a fair size

city, electronic components could be hard to come by. (Someone tells me

one can still get income tax advantages for living in a "semi isolated

locale" such as this one, including for moving to one for work. If I

can write off my moving expenses I will certainly owe no income tax for

2017!)

Today with the internet, one is much less isolated in "out

of the way" places than in those times - which were doubtless better

than still earlier times. From anywhere electronic parts can easily be

ordered on line from several major sources who will have everything in

stock. But I've done that before. I really felt less isolated when I

started ordering mechanical parts for the bandsaw mill. I started out

very apprehensive about being able to get them. Then I went to

PrincessAuto.ca and found I could get everything on line that I could

at

their

store in Victoria, and probably more as the mail order depot was less

likely to be out of stock on any item. It would arrive in a week or so

by mail (as fast as any mail gets here). I was however glad that I had

seen all those actual parts in their Victoria store and knew just what

they were and what to order. I also know there are other common

mechanical

parts that they don't have, and when I need these they may be harder to

track down. (Small ball bearings, for example. I didn't find a Canadian

source and finally had to order

some from VXB bearings in the USA again. But then I found some more at

"Mac's Auto Electric" when I went to Victoria for Christmas.)

If ever practical ground effect craft are made and put

into service, such vehicles (unless supplanted by something even better

like

anti-gravity flying craft) could make mountainous coastal areas and

isolated islands, such as abound in northern BC, still more accessible.

Carmichael Mill ("Bandsaw Alaska Mill")

I explored and ordered "meat cutting bands", which proved

to be substantially thinner than "wood cutting bands" (and seemingly

much resistant to rust), and hence should cut more easily, giving

perhaps 3 HP-like performance from a 2 HP motor. This could make

considerable difference in the viability of the plug-in electric model.

To my surprise the price was similar, and I started wondering why they

make the thicker "wood cutting" ones at all.

I worked on it until the 9th and the assembly was well

underway.

Then I went to do small

ball bearing races as little guide wheels. I needed 6 and had 3. They

didn't arrive and didn't arrive (and in fact came after the new year).

It got a little frustrating. I did get the meat cutting bands and I put

one on.

The next question was a motor. I had meant to just mount

the Ryobi skill saw on top, but a company on line was advertising BLDC

motors that sounded suitable. These would give the most mechanical

power from the electrical power available in a wall plug. It sounded

like it might cost 500$ or so, and would

be worth waiting a bit for. I wanted to give the new saw all the best

advantages I could since I not only want to try it out, but actually

put it to work milling some spruce lumber, and if possible attract

investment to make and sell them. Best not to needlessly make it look

underpowered.

But they didn't reply and I started

considering whether to take my own Electric Caik BLDC motor off the

outboard and put it on the saw. (I don't want to spend time making

another one - unless I can see how to improve the cooling for higher

and sustained power.) It could (for a time) put out as much power as

any plug-in motor, using 60 amps from a 24 volt battery. That could be

advantageous if one wanted to cut where no power was available. (Or a

generator could work too, and unlike the gas chainsaw it could be

placed downwind at a distance from the miller.)

Battery Lab & Nickel-Nickel Batteries

On the 10th, waiting for parts to continue the mill, I

started setting up my battery lab in the small laundry room. It was

cramped but it would have to do. I had to store a lot of whatever I

wasn't immediately using on shelves out in the workshop.

I

decided to pursue the "nickel-nickel" battery chemistry

again. This time I would try oxalic acid as the electrolyte. It seemed

to work for a nickel-zinc test cell long ago, and potassium chloride

didn't work with a nickel negative side. So, instead of "lead-lead" in

sulfuric acid, it would be "nickel-nickel" in oxalic acid.

I

decided to pursue the "nickel-nickel" battery chemistry

again. This time I would try oxalic acid as the electrolyte. It seemed

to work for a nickel-zinc test cell long ago, and potassium chloride

didn't work with a nickel negative side. So, instead of "lead-lead" in

sulfuric acid, it would be "nickel-nickel" in oxalic acid.

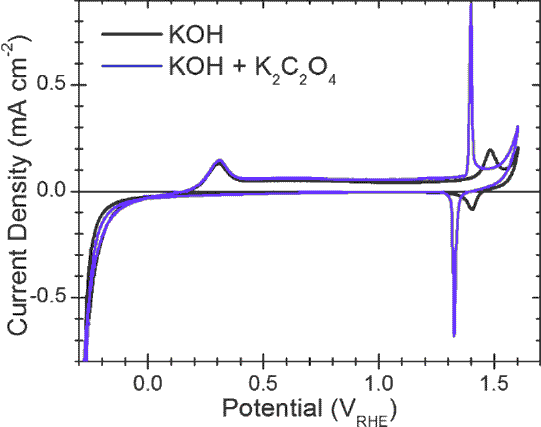

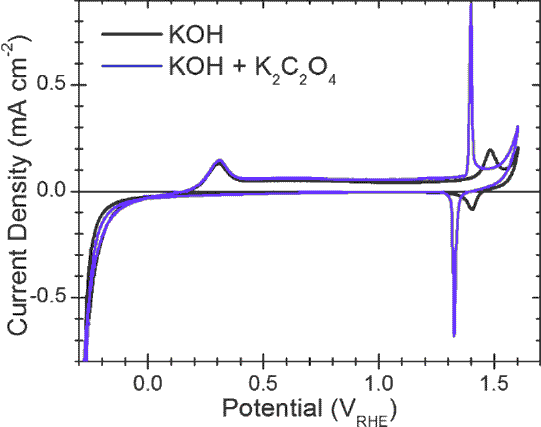

But the experiment showed the oxalic acid unexpectedly

attacks metallic nickel spontaneously, and while the reaction product

isn't soluble, it does separate from the metal plate and precipitate

out. Perhaps instead of the acid an oxalate salt could be used -

potassium hydrogen oxalate or potassium oxalate - both of which are

said to form alkaline solutions. These can be made from oxalic acid (I

had to order more), and potassium hydroxide (which I have lots of). In

alkaline solutions I expect the nickel is less likely to react

spontaneously than in acid. On reading a research paper it looked like

adding still more KOH would give a mix of KC2O4 and KOH for a pH 14

alkaline battery, where the KC2O4 just might render metallic nickel

oxidizable in the KOH. This formula also might make a good electrolyte,

so there are several things to try out.

Somehow creating a new and better battery chemistry and

making better batteries (and ultimately production) has always seemed

to be just a hop, skip and a jump away, but so far I haven't hit a

magic combo with everything right. I am rather optimistic about

oxalate, however. It seems like just the right ion. It lowers the

reaction voltage of a nickel positive electrode just a little, quite

possibly just enough to solve my "bug-a-boo" self discharge problem.

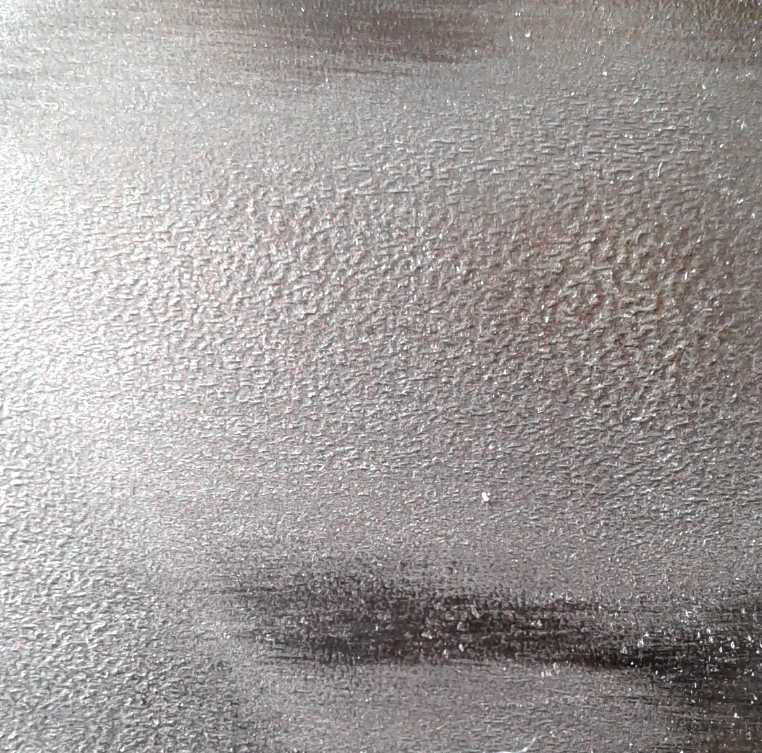

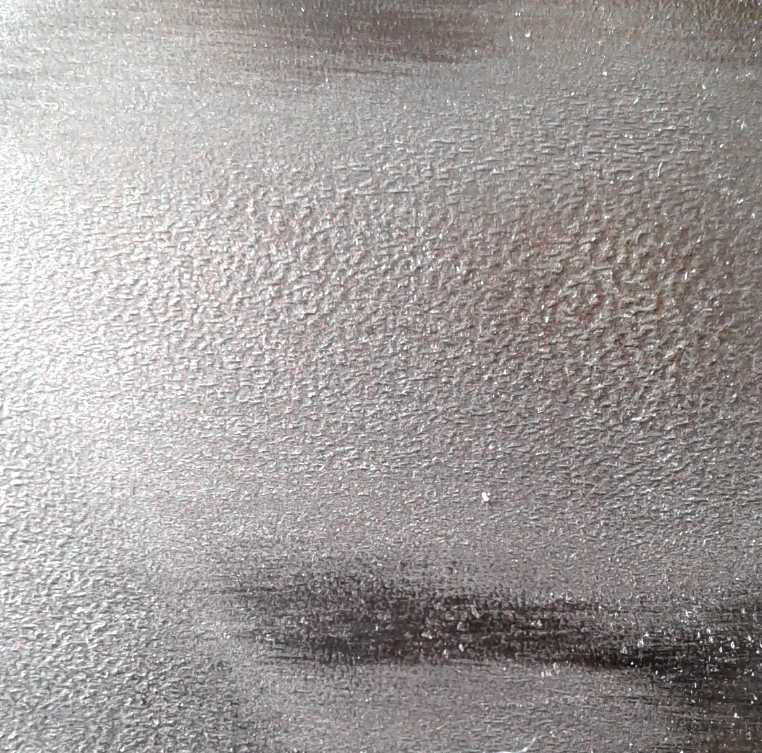

The cell and electrode

plates after adding electrolyte and

attempting to charge it for a while.

Hybridizing the Toyota Echo...

Wait, how about the Miles truck?

The last parts I thought I needed arrived in early

December. But as I thought about hybridizing the Toyota Echo I decided

to exercise the better part of valor and chickened out. It was

currently my only road vehicle and it was a long way to anywhere by

bicycle, and to make it all work there were a lot of parts to install

and wire up, besides just the motor

and transmission parts.

That didn't mean abandoning or further delaying the

project and

its main intent. If I did the Miles truck instead, it was already

electric and all that was needed was the basics: move the motor,

install the transmission stuff, and remove the original transmission

and drive shaft. I could work on it at leisure in the garage without

worries about getting places in the duration. I hoped to improve the

power and

substantially improve the range of the truck with this new

configuration, and hopefully it would be fit for the lightly trafficed

highway here even if it would slow down going up hills. Then I would

have both a small car and a small electric truck.

The two electric drive parts that had been destroyed in

the Swift fire were the meters above the dash. I was passing by

Canadian Electric Vehicles during my Christmas holiday. We determined I

didn't need one of them because of a meter I had that would do the job

(it had come with the Swift but hadn't been installed). The other one

was over 400$. Yow! Since I wanted it and wouldn't be passing by again,

I bought it anyway. But I wondered if I needed a sanity check to spend

so much on one little part.

On the 18th I was still waiting for bearings for the

bandsaw mill, and then for oxalic acid too. At least, I couldn't find

my tiny bottle of it. I may have already, before I moved here, mixed

the

last of it into the solution I was using, now virtually empty. Then

everything had to come to a halt anyway because I was going to Victoria

to see my family for Christmas, departing here on the 20th and

returning on my 63rd birthday, January 1st.

A Decade in

Review

I

first visualized

and started in on the car hybridizing projects in January 2008, so

December 2017 completes an entire decade. The objectives when I

started were a wheel motor to mount on the outside of a car wheel, a

motor controller to run it, and some sort of as yet undefined new

battery chemistry that would be cheaper to produce and better than

lithium for electric transport - preferably with indefinite cycle life.

I incorporated Turquoise Energy Limited in March to help pursue these

projects and then hopefully commercialize the results. Without any real

timeline in mind, I initially thought developing such things might take

a year or

so. While I made an "outside the wheel" motor and controller that

(barely) moved my

car by October, I gradually started to realize that it was going to

take substantially longer to develop tried and tested products that

were reliable and safe beyond being (at least, I hoped) "cutting edge"

conception

prototypes. I started thinking in terms of three to five years. Little

did I realize I was in for a dazzling decade long string of novel and

exciting "green energy" projects, but always on a shoestring budget and

with only glimmering hopes of ever commercializing any of them.

I

first visualized

and started in on the car hybridizing projects in January 2008, so

December 2017 completes an entire decade. The objectives when I

started were a wheel motor to mount on the outside of a car wheel, a

motor controller to run it, and some sort of as yet undefined new

battery chemistry that would be cheaper to produce and better than

lithium for electric transport - preferably with indefinite cycle life.

I incorporated Turquoise Energy Limited in March to help pursue these

projects and then hopefully commercialize the results. Without any real

timeline in mind, I initially thought developing such things might take

a year or

so. While I made an "outside the wheel" motor and controller that

(barely) moved my

car by October, I gradually started to realize that it was going to

take substantially longer to develop tried and tested products that

were reliable and safe beyond being (at least, I hoped) "cutting edge"

conception

prototypes. I started thinking in terms of three to five years. Little

did I realize I was in for a dazzling decade long string of novel and

exciting "green energy" projects, but always on a shoestring budget and

with only glimmering hopes of ever commercializing any of them.

At this

point, there have been so many projects - successes, failures, and

those taken to various stages of completion or incompletion short of

definitely fitting into one of those categories, that I will here

simply list them, sometimes combining multiple segment

projects into one title. The projects seemed to need some basic

explanations, but for so many projects, the list started to get really

long by the time I was half done, in time spent as well as words. I

decided to save most of the descriptions for the newsletter indexes,

and I'll have to refer the reader interested in a particular title to

those (once I've done them) as well as to the newsletters themselves.

- Ocean Wave Power (the original project started in 2006)

- a small Pivoting Blade Electric Sawmill (built and cutting

hardwood lumber in 2006)

- Electric Hubcap axial flux BLDC 'pancake' motor. More than any

other project, this evolved from "golly it works", first into a highly

efficient motor, then into a safer, more reliable unit that might

actually be approaching one that could be produced and sold. Later, new

types of motors with amazing promises started to cross my path, and I

started diverting efforts into them.

- 'Turquoise' BLDC Motor Controller, for the motors.

- 'Turquoise Battery' (chemical ideas initially only vaguely

defined). Ni-Mn; Ni-Ni; Ni-Air;

nickel-manganates "+" electrode. Trying to create a viable new battery

chemistry has been an ongoing project throughout, and a number of

promising developments have taken place.

- Some lead-acid battery explorations: sulfate salts & "pulse

charging".

- A Variable Torque Converter/Transmission (only the objective

was defined - it sounded simple enough!). Like the new battery

chemistries, this has been an ongoing focus and many novel ideas have

been tried out over the years. Some of them are undoubtedly

improvements, but my constructions to date have not been robust enough

to put a car on the street with.

- EV Fan-Heater(s) to defog windshield quickly (nothing very

special here)

- Micro- or nano-crystalline coil cores

- Nanocrystalline titanium dioxide borosilicate "pebbly textured"

Solar Cell Cover Glass Project to collect more of the light (Cores

project above morphed into this, plus a couple of new ideas for dye

sensitized solar

cells!)

- Electric Outboard motor project with Electric Hubcap prototype

motor. (Later changed to Electric Caik motor outboard.)

- Pulsejet Steel Plate Cutter (Probably a good idea for CNC

cutting, but I didn't finish it.)

- Giant "Electric Weel" motor project, perhaps to drive car

wheel(s) without gear reduction (as built with similar techniques to

"Electric Hubcap" the case was too flexible - and it didn't work well

as a

generator.)

- I bought a Chevy Sprint, at first intending to do just a

'regular' conversion to EV to drive electrically. But soon I started

trying to apply my torque converter ideas instead so it would have

better range, and have never yet got it on the street.

- LED space & grow Lighting projects. (Globe lights, lamps

& flat panel lights - started in 2012 when LED lighting was

virtually unavailable).

- I dabbled in 'magnetic drives' but failed to make anything very

interesting or that powered itself. (I'm not convinced it can't be

done.)

- I came up with a way to use magnets with the Earth's field to

orient and accelerate an orbiting spacecraft, but didn't convince

anyone to put them on a small satellite that was being made.

- I put up some solar panels and made a 12 volt system. In that

project, I came up with a line of 12 VDC plugs, sockets, wall plates

and more for any sort of 12 V wiring. I called it the "CAT standard" -

Connectors based on AT fuses.

- I also made a "super insulated" peltier module shallow chest 12

volt fridge, about 4 cubic feet.

- I then dabbled with magnetic refrigeration using gadolinium -

thought I had a better, simpler design - but then figured better

peltier modules would soon be made and make it obsolete.

- I made custom plastic cases (3D printed) to hold 10 D cells,

which in NiMH makes a 12 volt battery.

- I conceived a CNC farming or gardening machine. (But haven't

made it.)

- The Electric Caik motor extended the Electric Hubcap

motor family down in size instead of up, with 2/3 of the internal power

components and running at 24 volts instead of 36. It was originally

conceived for electric motorbikes, but the prototype ended up running

the electric outboard.

- A bicycle wheel rim motor was conceived to power bicycles and

also using 6 of the same coils, but was never built.

- I put together a "Reprap Pro" 3D printer kit and got it

printing.

And all the above, with various overlaps in the narrative

and project time spans, covers the first five years, as detailed in

Turquoise Energy News #1 to #59.

- I tried making an evacuated tube heat radiator for the fridge.

Such a device transfers heat much more rapidly than copper or aluminum,

which might render a fan unnecessary. I couldn't get sufficient vacuum

in the tubes.

- I bought some thermoelectric generator modules (pretty much the

same as peltier modules, but instead of electricity in, different

temperatures out, different temperatures in generate a voltage. I

investigated using these for a woodstove thermoelectric generator.

- I thought that with peltier modules one might make a house or

electric car solid state heat pump using less electricity than with

radiant heating. If one could achieve a coefficient of performance of

1.0, and add that to the heat directly radiated by the electrical

inefficiencies, one might get double the heat. Attaining good results

looked less and less promising.

- I got an electric converted Mazda RX7 EV and tried mixing

battery types in it, charging each 12 volt section separately. Worked

well.

- I got a setup working to program TI's MSP430 line of

microcontrollers in assembly language. I conceived of several uses for

microcontrollers.

- I started investigating "bladeless" Tesla Turbines as well as

vertical axis wind turbines (VAWT.s). It seemed to me possible one

might put together a better VAWT, quiet and with the moving parts all

inside a housing, with the Tesla system. I took (not for credit) a

"coursera.org" course on "Wind, Waves and Tide" power from University

of Toronto an learned much about Earth's wind systems.

- I made an axial flux "switched reluctance" motor ("ARM" motor)

and a new type of "simpler" motor controller for it with only 3 drivers

(low side only) instead of 6. With solid steel rotors and almost no

back EMF, reluctance motors can turn at fantastic RPM.s safely and

easily, eliminating all need for variable gearing - a fixed reduction

will do fine. I didn't get it running very well (motor controller needs

work) before more promising new ideas started pouring in.

- After starting on the ARM motor, I heard about a "transverse

flux" BLDC motor. One coil per phase is wound around the entire stator

- so simple! It looked even more applicable to the reluctance motor

type than to PM motors.

- If seemed "Bedini" (or should it be "Houdini"?) unipolar motors

somehow got more out than was put in, a "Coefficient Of Performance

(COP) greater than 100%. It also seemed there were "Zero" motorbikes

that got fantastic range from their batteries, which seemed to indicate

it wasn't just hot air. It seemed short pulse driving was the key,

which would require more changes to a motor controller to accomplish.

- Then I heard of the idea of "electro-permanent" AlNiCo

permanent magnets. The motor controller would pulse the coil once to

"permanently" magnetize it, so the rest of that part of the cycle would

be two permanent magnets attracting or repelling each other. At the

correct points of rotation, pulses would magnetize, demagnetize or

reverse magnetize each coil. This seemed to have tremendous potential

for using less electricity to run a motor. (Perhaps the Bedini made use

of this.)

- Before I built anything using that idea, I heard about

"permanent magnet assisted" coils. Here there is a permanent magnet and

an electromagnet in each coil. If no current is applied, they short

magnetically through "keepers" and there is no external magnetism to

the rotor, but if the coil is energized to the same strength and

polarity as the magnet, they add together and the field is doubled

using the same amount of electricity. This seems to be a really neat

trick for cutting the electricity required in half. I planned how to

convert my reluctance motor to this system since it was readily

applicable. I didn't get that done either, but it holds tremendous

promise.

- I added opposite polarity magnets to the "unipolar" BLDC motor

between the other magnets, giving it 4 magnet poles where a regular

BLDC rotor would have 2. This enables it to be run from the (more

reliable?) "unipolar" motor controller instead of a regular BLDC

controller. I called it the 4:3 BLDC motor.

- I delved into aquaponics (with LED grow lighting), in which

fish eat fish food and their waste is pumped out to feed a vegetable

garden, which sends clean water back to the fish pond. For minimal

input one gets both fish and vegetables. It has great potential for

feeding people form a smaller space.

- I found there is a much higher top end to the electromagnetic

spectrum than gamma rays, identified in 2007, which appeared to be how

various people have pulled "free energy" out of the air, starting if

not with Nicola Tesla then with Thomas Henry Morray whose energy

machines in the 1930s or so have many testimonials from knowledgeable

people and government officials, and who recognized this higher

frequency band as being the source of the energy. When scientists

identified them in 2007 they were calling them "Very High Energy Gamma

rays" or "VHE gamma rays". Since it is far beyond the gamma ray area of

the spectrum and the effects are qualitatively different, I felt this

was a misnomer and I started calling it "Lambda" rays. But I could go

for "VHE rays" without the word "gamma" attached. (The space scientists

seem to have never entertained the idea that real energy can be had

from these "Very High Energy" rays.)

- Having recognized the energy source and some basic principles

for generating electricity from the rays, I started trying to do so. I

have worked on it at 3 different times and I expect I'm not so far off

from good results, but I seem to keep getting diverted by other

projects.

- I also briefly looked into atmospheric charge energy, but in a

couple of experiments it seemed less than promising.

- Converted a car alternator into a PM alternator by replacing

the rotor coil with a big NIB ring magnet.

- I designed an improved version of the Piggott virtually

frictionless PM alternator, and started to build one. It can have much

higher power than Piggott's by virtue of much better internal cooling,

and multiple units could be made in one case on one shaft for still

higher power.

- I discovered ground effect craft, which fly just over

the water at aircraft speeds using far less fuel. I looked at various

types and came up with a somewhat new design that has some 'hovercraft'

like attributes that would get it off the water at low speed with its

ducted fan blowing air under wings with air flaps, the flaps folding up

with conversion to aircraft lift as it accelerates. Symmetrical wing

profile improves longitudinal stability and an extra forward 'shark

fin' provides better lateral stability. Such craft could better open up

many islands and mountainous coastal regions that are presently

difficult of access, such as the BC northern coast, Alaska, Norway and

interconnection of island chains such as Hawaii, Canary Islands and so

on.

- I came up with new ideas for river or tidal flow power using

floating platforms, and a couple for ocean wave power with oscillating

water column buoys.

- Finally, in milling up some trees with a chainsaw Alaskan mill,

I came up with an idea for a bandsaw Alaskan mill. Since this

had immediate valuable application for me I started making one and I

should be testing it in the next month or two.

- To flourish, plants need LIGHT,

not just light. Over Christmas while in

Victoria, I bought 48 LED light "bulbs" in two boxes, one of 5000 K

("daylight") and one of 2700 K ("orange" IMHO), and five "bathroom"

fixtures of four light sockets each: 20 lights. This, along with a 1' x

2', 6500 K, 30 W flat panel light, I made into a 200 watt LED "grow

light" stand for growing seedlings and probably whole vegetables

indoors. But in this I'm impinging on 2018.

As to the many "incomplete" or "didn't build it" projects

or project ideas... well, there's only one of me. Imagine what could be

done with a person for each project, or still more with teams of people

to build and commercialize them in a big way.

Before and during World War Two governments spared no

expense on research and development just in case something might give

them an edge, and tremendous technological breakthroughs were attained:

sonar, radar, radio navigation systems, jet engines, space rockets,

television, the digital computer and (unfortunately?) the atomic bomb

to name some prominent ones. These set the stage for a materially

better world.

Governments then turned to rebuilding shattered

infrastructure and stopped funding most R & D - especially "D",

development. With no programs of social sustainability to set national

goals and priorities, promising new developments and developers were

pretty much left in the lurch. The budgets to do great things were

modest in terms of national budgets, but except for less capital

intensive ventures where profits also glittered on the horizon, many

possibilities for valuable advances have since been thrown under the

bus. (A major exception to this trend were the Russian and American

space programs. Governments pursued the goal of sending men to walk on

the moon with great vigor and expense until it was accomplished almost

40 years ago. At least in the west they have set few worthy national R

& D goals since.) Government funding of R & D, with no clearly

defined national goals or directions by which to measure progress, sees

little in the way of integration of inventive projects into society and

into the economy.

(As I think about it, I think I would call my company a D

& R company. Development of ideas is primary, while "pure Research"

is what is often required in order to develop ideas into products.)

Increasingly as I went along I made comment in Turquoise

Energy News on social issues that seemed to be hobbling and hampering

attainment of clean, renewable energy and electric transport on any

sort of commercial basis. As my understanding of these problems grew,

ideas evolved to the point of my doing

a large write-up with about a dozen proposals for how we might better

place the direction of governance into the hands of the people - and

especially those of the people who take an interest in such things and

who have ideas for things that they think the majority would like to

see done. This may be found as http://www.HandsOnDemocracy.org

.

One of the earlier ideas was for a government "Department

of

Progress", which would define and attempt to clarify what society

desired to become, and then oversee the work required to attain those

goals,

whether by funding inventors and product development or by testing out

and recommending to the legislature democratic and other social reforms

that would improve society. Put another way, it would turn government

into a "learning institution" that can evolve and adapt as society

evolves and changes.

This might be a potential application for Daniel

Raphael's writings about "the seven core values of social

sustainability" and "Planetary Management", implementations of

educational segments of which are now in formative stages. The problem

of "constitutions are fixed while society continually changes" were

already noted by the early 1800s. With impassioned and cogent arguments

and the possibility of a "French Revolution" looming, the UK's Reform

Act then to give most men the vote (instead of just the few wealthy

landholders) passed by one vote in the British parliament, but nothing

was done about the problem of institutions being static in general.

"Social Sustainability" as explained by Raphael, will keep

family

values and the various institutions of society in line with evolving

needs generation after generation in perpetuity. This is quite a new

concept

compared to physical or technological sustainability, which has been

increasingly recognized as a need for at least half a century. Social

sustainability is the only way to prevent civilizations from rising,

peaking, declining and finally failing as every one has done so far.

Today we head for the failing point for our present civilization with a

rising crescendo of increasingly serious crises which are mostly being

created by humans and overpopulation.

( https://sites.google.com/view/danielraphael

)

But back to technologies for the future... I am about to

tackle the perhaps whimsical task of figuring out how much money I

could productively put to use and in what areas if I somehow "won the

lottery" or some philanthropic multi-billionaire decided to put some of

his wealth toward improving the future of the world by investing in me

to build teams to develop and commercialize some of these projects.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Sea Foam is natural (oops!)

After I wrote last month thinking foam on the beaches was

probably man-made pollution, someone wrote and said sea foam is a

natural occurrence. I

asked a long time resident who lives by the shore, and she said the

winter sea foam and "foambergs" I wrote of have been

happening for 40 years since she's lived here, and that some years

there's been more than this year. So it would seem I was jumping to

conclusions. (Not like me to jump to unwarranted conclusions, oh no!)

Of course in rather shallow, choppy Hecate Strait there's

also "sponge reefs", apparently extinct since dinosaur times everywhere

else on the planet. (Ahem. Were all those paleontologists jumping to

conclusions when they claimed they were long extinct?) Bits of sponge

("crystal sponge"?) wash up on

the beach here in summer. So it's a somewhat unique environment.

And after writing I noticed thick foam in a creek. It's

brownish when it dries out, and a neighbor said one alder leaf will

turn a whole bucket of water brown. So my next theory is that alder

leaves and other organic material from the swampy parts of the island

decay and make their way to the ocean in the rains where the brackish

water with its, um, nutrients, is churned up by the waves into foam. A

distinct line separating brownish runoff water near shore from

clear ocean water farther out is sometimes visible during rainstorms.

Hah, maybe the sludge from the swamps of Haida Gwaii

provides the nutrients that grow the sponge reefs?

Cryptocurrencies

Bitcoin transactions have been slowing down. Occasionally

transactions

can take as much as days instead of under an hour. Some of the bitcoin programmers proposed the

solution of increasing the block size so each block could handle more

transactions. The majority refused to accept the change, and bitcoin is

a democracy. That means bitcoin can't adapt and has become

unsustainable. The developers who saw the need for it to adapt created

"bitcoin cash" from bitcoin, and whoever had 1.234 bitcoins on August

1st now also had 1.234 "bitcoin cash". (At least theoretically. I still

haven't figured out how to get mine.)

I sold my remaining bitcoin at a staggering 10,250$. And in about 3

weeks the price doubled again and then went up further! (If only I had

kept all 24! But I used them up when they were 700$ to 1600$ financing

my move to

Haida Gwaii.)

It appears "Etherium" is being

considered or adopted by some large businesses in their programming,

which should

make it a "rising star" as some have said. Last January I could have

bought some etherium for under 10$. Earlier in December it was over

600$, and now (Jan. 10th 2018) it's about 1600$. I bought some after I

sold the

bitcoin, but after seeing other "alt coins" do not much and expecting

etherium was just another fad, I missed a huge chance there last

spring. I bought some cheap "Quark coin" last winter

instead and

it appears to be a dead horse. (Well, I should check it before I say

that - I haven't done so in months.)

Not having had internet all these months, these things got

ahead of me.

I bought a "Ledger Nano S" hardware "wallet", a USB device

with

its own little LCD display, which is supposed to be very safe against

theft by hacking because it's all done internally and not in the

computer. It can be used to hold bitcoin, bitcoin cash and etherium.

and probably others. You write down 24 words it gives you and you can

recreate the wallet from them if you lose it or it quits working. (So

can somebody else steal your cryptocurrency if they get hold of your

list of words!) Then I lost the "wallet". Probably I put it somewhere

"safe" before I went on my Christmas holiday. Now I can't remember

where I put it and I've searched for it. To all intents and purposes it

appears to be gone.

Fraud in the Stock Market!

Certain members of the alternative media have been saying

for some time that stock trades are not being properly cleared and

registered. They say that if you don't hold the actual piece of paper

saying "1000 shares XYZ", you don't own it, and not to buy unless

you can get it. But the brokerage through which you purchased the

stock probably doesn't have the actual printed shares either. In fact a

company that is supposed to register all shares in New York is

completely

overwhelmed by all the trades, especially computer handled high

frequency trading and "front running" of stock purchases.

The front running entities purchase high speed fiber optic

links to the big Wall Street stock exchanges. If you decide to buy 5000

shares of stock

"X" and send a signal to the exchanges, the first transaction of, say,

100 shares gets transferred into your name. With their faster than

lightning connections, the front running company's computers then buy

the

rest of the available shares in milliseconds, and raise the

price a little. By the time your broker's computer has connected, you

are forced to buy the other 4900 shares at a

slightly higher price, which is profit to the front running company and

loss to you.

There are no laws against it. How can the clearing agency keep up with

that, with thousands of transfers of ownership and double transfers or

more going on every second?

It gets better. A company trading shares delays sending in

the registration for shares sold, and so "still holds" shares it has

theoretically sold. Then perhaps it double sells them. Enron and Bernie

Madoff move over!

Now companies are taking advantage of "free money"

(practically zero percent interest rate loans) to buy back their own

stocks. As they buy the price goes up, so they're "making money" for

their (remaining) shareholders - more than by their actual

business operations. Now combine that with the above double selling: It

has been

reported that one company has now

purchased back all its outstanding shares --

only to find their stock still trading briskly on the exchange the next

day!

Of course, the stock market is full of scams so that many

people

who think they might do well lose money in it, even as the DOW ascends

to

ever higher new highs. Here's a great example from last spring.

One person who

thought his stock market investments were doing pretty well, on

"shorting" a stock, overnight lost

140,000$ from 35,000$ invested, because of a single transaction of well

under 35,000$. He didn't know it was possible to lose more than you had

invested. He had to sell his and his wife's retirement savings to pay

it. The head of the company he shorted had just announced something

along the lines

of "Well, doesn't look like much future here. I guess we'll be winding

down operations and closing down in the next couple of months." Would

any company really admit (let alone proclaim publicly) it was worthless

and going out of business, prematurely and to everyone? It stinks!

After all sorts

of gullable

investors had heard this and "shorted" the stock, by some "miracle" a

major corporation invested heavily in the company and suddenly the

future looked

bright. Instead of going out of business, the stock jumped

[something like] 1000% overnight. Bad

luck for the shorters? Maybe call it "outsider trading"!

Knowing what had publicly been said, if everything was "on

the level" the "angel" company that "invested" in it could have bought

it for a song and then invested when it was theirs, so the action made

no business sense -- except in collusion, as a means to grab fortunes

on the stock

market by duping people into shorting the stock. This little caper

probably didn't even rate a blip on the "major new

fraud every 4 days on Wall street" radar, but it doubtless extracted

life savings from a lot of unsuspecting, hard working people.

A society increasingly based on accumulating massive

fortunes by an organized so-called "elite" via theft from the majority

cannot last. The seeds of revolution have been sown. May it be a

non-violent one that leads to progress, social stability and for the

future, social sustainability!

John McAdam

Around 1790 England had a few left over Roman cobblestone

roads, but everything else was dirt (i.e. mud) roads, and travel

anywhere was slow and laborious. John McAdam discovered that if road

surfaces could be kept dry, they didn't form ruts and mud. And that

crushed stone and a layer of gravel would be compacted down by horse's

hooves and carriage wheels to form a hard, dry, durable surface. This

must have been less intuitive than we would think today - apparently no

one had tried it before. So it would seem he invented the gravel road.

Cheap and easy compared to cobblestones. Soon roads crisscrossing

England and Southern Scotland had been "macadamized". Travel time from

London to Edinburgh was reduced from 10 days to less than 2, at speeds

of up to 15 miles per hour. Later asphalt was added, making them

"tar-macadam", or "tarmac" for short.

[Source: How the Scots Invented the Modern World (page

280) by Arthur Herman, 2001]

Carmichael Projection World Map & Virtual Reality

I

hit on this new type of world map one day long ago, when

peeling a mandarin orange. It has the least surface distortion from

projecting the sphere of the world onto a flat surface of most any

projection.

I

hit on this new type of world map one day long ago, when

peeling a mandarin orange. It has the least surface distortion from

projecting the sphere of the world onto a flat surface of most any

projection.

It does suffer from a few faults:

- finding most anything other than the north pole and the south pole

- figuring out what you're looking at

- figuring out where any two map edges meet

- figuring out how to get from point "A" to "B" if they're not visibly

in line with each other.

Okay, so really it's dumb and totally useless! Go on line

and use Google

Earth. Better still, with the "virtual reality" goggles version you can

pick a town or area and view it in 3D from any angle or height and

facing any direction. There I was at a village in the Alps, as if I was

really there hovering over it. Later I went to an Italian town (sorry,

I forget the names) and looked at a couple of interesting old

buildings, then went down ("street views") actually inside the

municipal art gallery and saw the paintings on all four walls of a

room. It was the stuff of far out science

fiction, now techno avant guard (my nephew James), tomorrow it will be

commonplace.

The rest of the newsletter is "in depth reports"

for

each project. I hope these will help anyone who wants to get

into a simliar project to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and often, of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in

writing of

those thoughts. They are thus something of a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Electric

Transport

Ground Effect

Craft: Fixing Lateral Stability Problem

This is just a quick design thought; I doubt I'll be

resuming work on this in the near future. As I noted, one radio

controlled

'catamaran' shaped craft especially had tended to fly diagonally

whenever it

turned, and even to some extent in straight flight. I also recalled

Bruno mentioning that the catamaran shape had poor lateral stability

without outside-the-hulls wings. Plus, ground effect craft have trouble

with turns anyway. On a regular airplane, lateral instability is easily

compensated for by using the ailerons to bank the craft into the turn.

On the low-flying catamaran ground effect craft, banking is apt to dip

one hull into the water. So it's better if it is able to turn without

banking very much; indeed, to stay relatively flat and turn without

ailerons at all.

I gave this some thought, and decided the way forward

would probably be to put a vertical "fin" sticking up from the front of

the wing at the center - maybe 25 square feet for my small craft. This

forward fin

would force the craft to stay properly oriented, or to say it another

way, to quickly and accurately change course to wherever the

rudder/tail fin at the back points it.

(And you could shape it like a shark fin and paint teeth

and eyes on the bows!)

Other

"Green" Electric Equipment Projects

"Carmichael

Mill" - a Portable Bandsaw "Alaska Mill"

A Better Cutting Band?: Meat cutting bandsaw band has less bone

Meat Cutting Bandsaw, exit guides detail

The wheels on this saw had a ridge on the

back edge, so no rear guides were required.

For

some strange reason I had bought a meat cutting

bandsaw a couple of years ago. It was just some hunch that I would need

it, when I had no earthly reason at the time. I hadn't even thought of

it when I wanted bandsaw parts for the mill. It was still stashed in

the shipping container. When I did think of it, I remembered that meat

cutting bands seemed to be even thinner than regular wood cutting

bands, and seemed to be made of stainless steel (or something) instead

of rust covered blue steel. On the 3rd I measured the bands to verify

this impression. Wood bandsaw band: .9 mm thick (1+ mm if rusty). Meat

bandsaw band: .5 mm. What about the actual cutting thickness, with the

set

of the teeth? It was harder to measure that, but the wood saw seemed to

be around 1.2 mm and the meat one about .75 mm. It would have less

kerf, make less sawdust. And the clearance behind the cut? Wood saw:

1.2 mm - .9 mm = .3 mm; meat saw: .75 mm - .5 mm = .25mm. So, the meat

saw had almost as much clearance as the wood saw. Should it not cut

wood just as well?

For

some strange reason I had bought a meat cutting

bandsaw a couple of years ago. It was just some hunch that I would need

it, when I had no earthly reason at the time. I hadn't even thought of

it when I wanted bandsaw parts for the mill. It was still stashed in

the shipping container. When I did think of it, I remembered that meat

cutting bands seemed to be even thinner than regular wood cutting

bands, and seemed to be made of stainless steel (or something) instead

of rust covered blue steel. On the 3rd I measured the bands to verify

this impression. Wood bandsaw band: .9 mm thick (1+ mm if rusty). Meat

bandsaw band: .5 mm. What about the actual cutting thickness, with the

set

of the teeth? It was harder to measure that, but the wood saw seemed to

be around 1.2 mm and the meat one about .75 mm. It would have less

kerf, make less sawdust. And the clearance behind the cut? Wood saw:

1.2 mm - .9 mm = .3 mm; meat saw: .75 mm - .5 mm = .25mm. So, the meat

saw had almost as much clearance as the wood saw. Should it not cut

wood just as well?

All else being equal, the meat blade should use not a lot

over half the power to mill wood. That depended on it cutting straight

and not jamming, and on the teeth staying sharp. The teeth just might

dull faster, but the fastest dullener is heat, and the mill will have

water drip cooling on whatever band it's using. Something not equal was

that the teeth were finer, 3 per inch instead of 2.

I looked at the band guide blocks in the meat saw. They

were somewhat different than in the wood saw. The lower ones seemed to

be made to deflect meat and bone bits away to keep the band from

clogging up - just as I had been thinking about for bark and chips. And

they were staggered, the left and right ones at different points

instead of across from each other so if a wedge of bone did get in, it

could push past without jamming the blade. That seemed like a fine

improvement too.

The aluminum wheels were also different from wood bandsaw

wheels. They were small (just ~8.5"), flat rimmed with no tires, with

in-line grooves where the blade ran, and had a ridge on the back to

stop the band from riding off when cutting, instead of rear blocks near

but between the wheels. (That just might run a little more freely, less

heat - or keep the band running more straight?)

The thin band was a very exciting find. Using less power

to cut should be like having the under 2 HP motor perform as if it was

3

HP - without any added weight or using any more electricity. It should

make the plug-in electric model that much more practical and faster

cutting. And the thin blade will obviously bend freely around "big" 10"

wheels.

It seemed well worth trying, and even having on hand for

when the mill was ready. The band in my meat saw was way shorter than

the 93" wood band. On this mill I can move a pulley in to accommodate

short bands, but it wouldn't have much cutting width. It would probably

cut boards from a 6" wide cant, but not much more. (With the small

wheels, the meat bandsaw had virtually a 10" vertical cutting capacity

even with the short band.) But it's the wide cuts where more power

(easier cutting) would be the most helpful.

On line I found Dimar Canada (manuacturer of many saw

blades and bands) has them with 3 or 4 teeth per inch ("TPI") and will

cut them to any length. There being no shop tool dealers around here I

asked about mail ordering two, 93" long, 3 TPI. The next day they sent

me a link to a list of dealers in BC that do mail order. I went to

Skukum Tools in Victoria, since I had bought saw blades there when I

lived in Victoria. I thought they would be costly, but they were about

the same price as wood bands. I ordered three, 93" x 3/4" x 3 TPI,

.022" thick (.56mm).

Building, continued

Still on the 4th I went into town and got a bunch of nuts

and bolts. Amazing how you can have a big selection and still not have

the ones you need! With the angle grinder & zip disk I cut up two

pieces of previously welded up 3/4" square steel bracket assemblies to

use as arms to hold the band guide blocks. Once cut they had the 3D-"L"

shape I wanted without doing any welding myself. I wire brushed the

rust off (bench grinder with wire brush wheel) and drilled mounting

holes, and fitted them on.

Next I looked for a way to mount the Ryobi skill saw. At

first I thought the best thing would be two "U" bars (more like "["),

3" tall by about 1" top and bottom. Bolted to the main bars the tops

would be above the wheel about 1/2", and the four corners of the saw's

bottom plate could be bolted along the top. Checking more closely, for

the saw pulley to line up with the mill's pulley, it didn't fit so

neatly over the two bars, but was off the front one entirely and

hanging a good way over behind the rear one. It seemed to defy finding

a simple, sturdy solution. Then I realized that a 4" x 5.5" x 4" upside

down "U" could form a cover over the whole thing, and that the saw

could be

bolted to. I also realized that meant the cover would have to be

unbolted to get cutting bands on and off. Oh well!

The Ryobi would be in a very awkward position to hold its

switch on while cutting. I had intended to tape the switch "ON", and I

looked on line for a pistol grip switch to put in "upstream". It wasn't

proceeding very well. I could find trigger switches, but they still

needed to be mounted in something. Then I figured if that was the case,

I might as well take the one out of the Ryobi and extend its wires.

Then re-mount it in some sort of pistol grip, perhaps made on the 3D

printer.

These things now had good plans to be worked out and I

retired for the night happy with the progress.

The 5th started out well enough, as I figured (a) that I

should use roller bearings instead of blocks for all 6 surfaces and

then (b) how to mount at least 4 of them. I picked out bearings that

would go on a 1/4" bolt as a shaft. But I only had 3 and I needed 6. I

went into town and at the NAPA store, which had told me they had them,

the clerk found one the same. I said I would take 10 and he said they

only had the one, and it was 55$. I should have got the bearing number

off him. I went on line to Princess Auto, but the ball bearings were

mixed in with all the other bearings and bushings in an apparently

random order. Every one that said "ball bearing" used the same picture,

with no info about the size or anything. With nothing to go on in

random order amongst about 270 bearings and bushings, I never did find

any close to what I wanted. Chinese stores didn't seem to have any.

(They're probably all made there anyway!) That seemed to leave VXB

bearings in the USA, which would mean extra expenses. I finally gave up

for now and picked some other less than ideal bearings that I already

had. By then it was getting late.

On the 6th I made a 12" x 14" piece of aluminum, bent in 3

places to go over the top to mount the Ryobi saw/motor on. It also

doubles as the guard covering 1/3 of the top of the band. Then, finding

a piece of pipe just the right diameter, that the motor shaft needed to

have around it behind and to support the pulley (the original blade

support being unsuitable), I got the small V-belt pulley properly

mounted on the motor.

Then I thought I'd do something simple and make a guard to

go the rest of the way across the top of the mill. When I got the sheet

metal bender, I'd been tripping over two pieces of acryllic plastic

that Tom had brought me from the dump, saying "you can always use

pieces of plexiglass." As I was cursing them and wishing he'd taken

them somewhere else besides my shop floor, I noted one of them was

folded at 90 degrees, and then it occurred to me it might after all

solve a problem. I wanted the user to be able to see the water drip

and know if it had run out of water while sawing. A guard of clear

plastic would do that. I found a piece of 3/16" lexan that might be big

enough to cover the rest of the mill if it was heated and bent to the

right shape. Lexan is tough and won't crack or shatter if it's hit by

flying bits flung off the band.

No, it wasn't good enough just to bend up some sheet

metal and make the guard. That would have been too simple! I had to try

another new thing, again

something I'd never done before - make folds in clear lexan plastic! I

decided to try out a 6" wide piece first to see how it would go. I

don't know how it's usually done except that you use heat. I put the

lexan in a small "angle irons" sheet metal bender with a piece of paper

above and below to keep the heat from being immediately lost into the

metal (oh, and to avoid scratches). Then I got out the hot air gun and

gently pried up the lever on the bender as I played the gun back and

forth to heat the plastic. After a while and then very gradually it

bent up. Three more bends and quite a while later I had the shaped 6"

piece, and it looked quite good for a first try except a couple of

places I guess I'd overheated had bubbled. I decided that I didn't want

to try doing a much wider piece than that with my technique. 26" to do

the whole rest of the mill in one piece was out. So, still wanting a

clear view place, I made some screw holes and mounted it on the mill.

I had hoped to be able to change the band without taking

anything apart, but the piece for mounting the motor on had to be

sturdy and held on both sides, and I wouldn't trust the plastic to be

mounted on only one side so it got screws on both sides too.

Originally I was just going to have a guard extend past

the band and bend down. But conceivably, one could carelessly grab the

guard to lift the saw and get their fingers into where the band was. So

I decided just to continue the same on the other half, fully covering

the entire top of the saw. These three covers all have to be removed to

change bands.

I took pictures outside before the light

faded too much and put in the last screws later. At this point the saw

weighed 22 pounds (10 Kg). That seemed to be about on target for 35-40

complete.

Operator's view

Operator's view

Log's view.

Log's view.

Upside down.

Upside down.

8th: I got the band guides

done on one end. It was a

lot of fiddly adjusting, filing and bending to get all three bearings

in line and straight. And when the whole piece is moved left or right

to adjust the cut width, it will have to be carefully set to the same

angle as it was at when I set it up at the end for the widest cut. If

the band doesn't go into the wood straight and level, it will try to

cut upward or downward and the mill won't work.

8th: I got the band guides

done on one end. It was a

lot of fiddly adjusting, filing and bending to get all three bearings

in line and straight. And when the whole piece is moved left or right

to adjust the cut width, it will have to be carefully set to the same

angle as it was at when I set it up at the end for the widest cut. If

the band doesn't go into the wood straight and level, it will try to

cut upward or downward and the mill won't work.

I started looking to see how the other end might be done

better to make it easier. The other end also needed to have the end

guide "ski" welded on. It sits below the band. The moving band will

pull the saw in that direction until it hits the end guide - or other

parts if there wasn't one. The "ski" bent front gets the mill smoothly

past bumps in the log or wood.

15th: I took the bearings off the leading side, and

and fitted made the pieces with them on the exit side.

I also got a

plastic jar for a cooling water container. Well, with a clear plastic

jar the amount of water left is clearly visible, so the clear plastic

view port to see the water spraying on the band was probably redundant.

But maybe not: it might be seen whether the water is

enough, too little or more than necessary, so the nozzle size can be

optimized. And of course it's still how to see if the jet has become

clogged, which having water in the jar won't indicate.

16th: The ferry came in in the morning for the first time in several

days and I went to the post office late in the afternoon hoping my

parts had come in, especially the bearings. But there was so much mail

and so many parcels the post office hadn't been able to sort it all

yet. Come back Monday! I only got the new, thinner "meat cutting"

bandsaw bands. I put one on the next evening. It seemed to run smoother

than the thicker, rusty "wood cutting" band, and I adjusted the

bearings it did have for the new thickness. I went back before closing

time on Monday (18th) and they still hadn't finished sorting Friday's

mail! This time I got nothing at all.

While two rollers clamp the band and keep it

from twisting,

While two rollers clamp the band and keep it

from twisting,

a third behind it keeps it from coming off the wheel

when wood being cut is pressing against the band.

There is one such assembly to the left of the cut and one to the right.

Home Sheet Metal Tools

Some may not realize that for cutting aluminum a regular

electric wood saw works pretty well. Even my bandsaw with coarse teeth

(3 TPI) does well. Finer teeth are better. If it won't fit in that, I

use my radial arm saw. Cut slowly and wear eye protection as well as

ear. So far I haven't had to resort to a skill saw, and I'm not sure

I'd want to.

Steel is tougher. There are metal cutting jigsaw blades

for steel. For sheet metal, use one with fine teeth; coarse teeth are

for thicker plate. Cut slowly and put on oil or water to keep the blade

cool. But for steel I usually gravitate to using a zip disk on an angle

grinder.

From schools

and shops where I've worked, I was originally

familiar with heavy floor standing sheet metal breaks to bend/fold

sheet metal. At best these are several hundred dollars and they go up

into thousands. And they take up valuable floor space.

From schools

and shops where I've worked, I was originally

familiar with heavy floor standing sheet metal breaks to bend/fold

sheet metal. At best these are several hundred dollars and they go up

into thousands. And they take up valuable floor space.

There are also benders that have a "V" slot and a bar that

pushes the metal into the "V". I've found these only seem to work on

the lightest of sheets - maybe okay for miniature furnace ducts or

something, but not for chassis thickness material. There are some

really small 2-piece ones that fit in a vise (eg, 4" wide). It seems

awfully hard to crank the handle on the vise to bend a small piece.

A rather

useful technique I've found for bending metal in

some situations, even pretty thick stuff, is to use a large crescent

wrench - maybe even 2 of them and sometimes a hammer and a vise. The

piece can be put in the jaw of the wrench, which is then tightened on

it. Sometimes a second wrench is needed to twist the first one, since

the handle is pointed in the wrong direction to get good leverage.

A rather

useful technique I've found for bending metal in

some situations, even pretty thick stuff, is to use a large crescent

wrench - maybe even 2 of them and sometimes a hammer and a vise. The

piece can be put in the jaw of the wrench, which is then tightened on

it. Sometimes a second wrench is needed to twist the first one, since

the handle is pointed in the wrong direction to get good leverage.

But to really do typical sheet metal folding at

home, the

best economical choice is what I call an "angle irons" type, which can

easily be picked up and carried. It consists of two long, heavy "angle

iron" pieces, with hinges and handles at the ends, and a loose flat

bar. The only brand I've seen is "Magnum". They come in 18" and 30"

sizes. (Now I see a 40 inch "Power Fist" one in a Princess Auto flyer.

Each size is heavier built and twice the price of the next smaller

model: ~ 50$, 100$, 200$.)

But to really do typical sheet metal folding at

home, the

best economical choice is what I call an "angle irons" type, which can

easily be picked up and carried. It consists of two long, heavy "angle

iron" pieces, with hinges and handles at the ends, and a loose flat

bar. The only brand I've seen is "Magnum". They come in 18" and 30"

sizes. (Now I see a 40 inch "Power Fist" one in a Princess Auto flyer.

Each size is heavier built and twice the price of the next smaller

model: ~ 50$, 100$, 200$.)

At a glance they seem to be missing some pieces. The trick

is that you supply your own C-clamps to hold down the clamping bar with

the metal to be bent under it. (In order that it not occupy bench space

except when I need it, I also C-clamp the unit to the bench instead of

bolting it on - as I do with several tools.) Leave room behind the fold

point for the thickness of the material, and do the C-clamps up plenty

tight, or they'll slip.

The 30" break did my rather heavy aluminum covers, one of

which was 19" long, without much complaint. (Having done no chassis

making since I bought it, it is in fact the first time I've used the

larger one and I was pleasantly surprised. I think I would recommend it

over the 18" one for all but quite light work, even if the pieces won't

exceed 18".) If the middle area doesn't bend quite as far the the end

near the handle (slight flex in the "angle irons"), it is often

possible to reposition the work at the other end and the other handle -

or - use a big crescent wrench as an extra handle around the middle

where the break flexed most. To do multiple direction chassis folds,

use scraps of steel plate to make your own shorter clamping bars. With

some ingenuity, it's as versatile as the heavy, expensive breaks if not

more so. I made my aluminum motor controller chassies with one.

Motors & Duty Cycle

Someone mentioned that a skill saw motor was probably only

rated to run for short bursts, not for long periods as it will be when

milling. I had thought of that too but I cast it aside for the moment

and will see what happens when I start using the mill. OTOH it's also

probably not very efficient and for that reason too I've also been

casting around for other choices. I may try out the 12 amp motor from

my electric lawnmower. On the 7th I sent a message to "Transmag.com"

who make various BLDC motors that they say are more efficient and

lightweight than other types to see if they would recommend one of

theirs. I

suppose I could use one of my own "Electric Caik" motors, but it runs

on 24 volts, and I still have to figure out how to keep it from

gradually overheating. And I don't want to divert into making another

motor and controller at the moment. (But it might be a good option for

doing any milling necessary in the bush where there's no plug-ins, to

break down logs into movable pieces.)

Drive Belts

I thought of using a link-belt, as they are said to be

more efficient than regular V-belts. They are made up of short plastic

"links" that can be put together (and taken apart again) to make any

desired length of belt. There are two or three different belt widths.

Then I remembered that long ago I had tried one on my upright bandsaw.

It would slip when the going got tough and I had to replace it. The

going will always be tough on a mill.

Then I remembered the belts for variable pulleys, with the

"notches" in them. I dug them out and checked. Sure enough, they would

bend around a small arc much more easily than a regular belt. And I was

using quite a small pulley on the saw motor. Doubtless they were much

superior to the regular V-belts. But they were both too short. There's

yet another web search I'll have to do, and then I'll order one the

right length. Maybe even a small selection of them, and one for my

upright bandsaw. Considering how stiff regular V-belts are and how much

power they must lose, I wonder why they aren't all made with the

notches.

Power Supply:

Photos Simplify Repair. (But is it Worth Repairing?)

On the evening of the 14th I finally replaced the main

filter

capacitor in my "Circuit Test" 0-30 V, 0-10 A lab power supply. Circuit

Test used a 50 volt capacitor

that ran at 52 volts. In fact, there were a number of marginally rated

parts. But capacitors go bad, and from this low rating and the

symptoms, replacing it seemed like the best bet to fix the supply. I

got a new 22000 uF,

100 V capacitor a month ago, but it seemed like a dirty trick. The

pricey (22$?) part had screw terminals but came with no screws or tabs

to connect, and no clamp to hold it down. I had to go out and buy

#10-32 x 1/2" screws (I had lots of #10-24s) and a hose clamp. To

install it I

spent time bending some bits of aluminum to make tabs to hold down the

hose clamp and make it a capacitor clamp, and some copper tabs to

solder the wires to. Yetch! The rest was unsoldering and removing the

old capacitor, mounting and soldering in the new one, and then putting

all the wires back in, testing, and putting the case back together.

One thing I note simplifies electronics (and surely

mechanical)

repairs these days is the digital camera (AKA cell phone, tablet, etc).

When one had a complex device with a bunch of parts and wires to

disassemble, it used to be necessary or at least prudent to write down

where the nuts, bolts and pieces went and note the color and connection

of each wire before disassembly, in order that it might be reassembled

without mistakes. Today a picture taken with a digital camera shows it

all in its original condition. Words take time to jot down and can

later be

confusing; the picture is quick to take and unambiguous. There were two

white wires with black boots. I noticed in the picture one boot had a

bit of white writing on it. I had them backwards, and might not have

caught the mistake without that.

That seemed to fix it. The loud

buzzing

followed by destructive behavior didn't happen again. But the

supply was getting increasingly quirky. For some time the voltmeter

hadn't been reading. I hardly noticed because I had already connected a

little

2-wire self-powered DVM for more precise readings. But it also

did funny

things, putting out "random" high voltages until it was turned up to

about 2.5 volts, with the higher voltage relays chattering on and off.

Well, who would want less than 3 volts anyway? Now it wouldn't put out

above 2 amps even on the 10

amp range. And a wire had burned out a trace, and if reconnected it

made some sort of short - no

voltage could be had, just current limiting. I replaced a shorted diode

and it made no

difference. I couldn't for the life of me see how it could have worked

at all with that diode shorted. By then I had several hours into it. It

would

likely take several more to restore it completely. It seemed to work

well enough for 2 amps or less, but the real

solution, apparently, was to spend several hundred dollars and buy a

nice, tame,

predictable new power supply with digital displays. Sigh! (Next problem

was choosing. I found so many on line on the 16th that I didn't pick

out one that I liked and wanted to pay for, when most of them were over

1000$.)

The next day (17th) I decided I should get a small, rather

cheap one (200$) that I had seen, specifically for charging single

battery cells for those experiments. All along I've been using a cheap

power adapter that puts out a varying, unregulated voltage and current,

through a resistor that sets the current to the cell. And measuring the

voltage across the resistor to see what current is flowing. Suddenly

that seems senseless when I could so easily be using a regulated supply

to put out a constant current or voltage. But I was too busy to order

it.

On the 31st, while still in Victoria over Christmas, I

found and ordered a 16 volt, 5 amp supply from Digikey for just 130$.

(I knew it wouldn't be delivered until after new year's when I was home

again. It had not in fact arrived by January 11th - ouch!)

I figured that would do fine for battery experiments. It

would display current or voltage (not both at once), but it had an

indication

of voltage or current regulation. If the voltage stayed where it was

set, a known value, I only needed to see the current the rest of the

time.

If I need 30 volts at 10 amps I can either try to figure

out the problem or order a more costly supply. Or just use batteries.

Electricity

Generation

Nanocrystalline

titanium

dioxide

borosilicate glaze:

"pebbly concrete" glass surface for solar panels

Some years back I created a nanocrystalline titanium dioxide

borosilicate glaze - highly transmissive glass with a very high

refractive index. The idea is to grind it into a frit (glass powder),

sprinkle it onto a small piece of glass and heat the glass in the kiln,

partly melting the frit into it to make a tiny size "pebbly concrete"

glass front surface for a solar panel. This should bend light striking

from shallow angles into the glass to be absorbed by the solar cells

behind the glass, instead of reflecting it off, increasing collection

at low sun angles (increasing the hour of daily collection), and

collection of scattered sky light (especially on cloudy days) by a very

significant percentage. Conceivably each panel might make up to 35%

more watt-hours per day.

When I was originally making the glaze, I didn't realize

one could buy solar cells, and it seemed perhaps problematic to try and

test it. I let the project drop. But I still have a couple of pieces of

the glaze (formula #9) ready to try out.

Before moving here I ordered a pack of small solar cells,

each 20 x 40 mm. I finally opened it and discovered I should have

ordered the thin metal strips to connect the cells together and to an

external wires with, because there's really no other practical way to

connect them. Now those are on order and should arrive some day.

The wafers are very thin, and I also discovered that they

are very brittle. I accidentally snapped one in half with just a little

finger pressure. I don't know how 'flexible' solar panels are made and

hang together!