Turquoise Energy Ltd. News #118

covering March

2018 (Posted April 3rd)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month

In Brief

(Project Summaries etc.)

Special Feature:

The Fantasy Budget!

What if someone offered me a fortune for the purpose of helping to

improve the world?

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- The need for teaching the core values of social sustainability

- Inbread humour?

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Chevy Sprint: Battery placement - Motor Controller

* A BLDC Motor Disassembly

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Bandsaw Alaska Mill")

* "The Indoor Vegetable Garden" -

Year round gardening with LED Lights!

(and other gardening)

* LED Light Making Update (how the ones I made some years ago are

faring now - dimming - repairs)

Electricity Generation

* Small Creek - And Larger - Hydro Power Units? - The spiral staircase "Turbine

Pipe"

with "Intake Head"

Electricity Storage -

Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc.

* Doped conductive coating separates graphite current collector

from electrode

* Ethaline DES with potassium oxalate and calcium hydroxide

electrolyte

* Nickel-Nickel test cell seems to work!

(real, practical cells for EV.s now seem possible)

* Use NO Graphite or conductive carbon black powder - It caused

the self discharge in all those previous cells

For this newsletter I've done something I should probably

have done quite some time ago as the newsletter length grew, and put

links from the table of contents to each section.

"reflective" white wall paint; blueberries and

strawberries planted

"reflective" white wall paint; blueberries and

strawberries planted

Whereas most of February was too cold to work out in the

shop, March got warm and sunny on many days and seemed ideal for

outdoor work and

gardening - so I still wasn't in the shop much and I didn't get the

bandsaw mill done. I picked away at the

Chevy Sprint electrifying project on many or most days (along

with yard work and other things), for some time mostly just figuring

out where the

batteries could go. And I wrote up a "dream budget"

so as not to be

caught by complete surprise just in case some wealthy philanthropist

should ask me how much was needed and what would be done if he gave me

some money to pursue groundbreaking projects and products in a big way.

Before mid month I was doing a lot of stuff outdoors and "project time"

continued to suffer.

Nevertheless, March saw some interesting and even exciting

developments.

- I thought up a new design, the turbine pipe, as a base

for flowing water hydro power production, especially for either small

creeks or floating hydro units.

- Jim Harrington and I had both been experimenting with growing

vegetables indoors with LED lighting. We had concentrated on the

lights. But now that I've been eating lettuce started in January and I

see what actually works and is needed, I started thinking it would be

ideal to offer a "complete solution" LED Indoor Garden. I

started to realize there's potential for selling literally millions of

them, so erstwhile indoor gardeners don't have to "re-invent the wheel"

to start growing their greens indoors in the winter.

- And then, the very occasional formulation and testing I've been

doing has at last apparently yielded nickel-nickel batteries that hold

a charge, with all the potential that holds for electric transport and

other battery uses.

These developments and other thoughts had me revising the

"fantasy budget" several times.

Carmichael Mill

Along the way

I ran across some great parts I could adapt

for making adjustable band guides on the "bandsaw alaska mill", so the

band could be carefully aimed, adjusted with a thumb screw as required

to cut straight,

without removing the saw from the cut. They were a particular model of

pickup truck "canopy clamp" with a pivot hinge. I started adapting the

first one on the 11th then got sidetracked.

Along the way

I ran across some great parts I could adapt

for making adjustable band guides on the "bandsaw alaska mill", so the

band could be carefully aimed, adjusted with a thumb screw as required

to cut straight,

without removing the saw from the cut. They were a particular model of

pickup truck "canopy clamp" with a pivot hinge. I started adapting the

first one on the 11th then got sidetracked.

Small Creek... or larger... Hydro

Power Units?

I had puzzled at how one might extract electricity from

the

shallow creeks nearby, and I finally came up with an idea, and one

thought led to another. The final version was, Why have a floating unit

in such shallow

water?; use a screened funnel upstream entrance to keep crap out and

concentrate more water; that would feed an enclosed "turbine pipe" with

several

"spiral staircase" propellers along its length. Surely one could come

up with some sort of

small, portable low voltage unit, easily set into place in rapids on a

creek bed?

The (12 volt) power cord would be tied to a tree or

whatever

both for connection and to ensure the unit can't get washed away if it

comes

loose. Then it would be carried into the rapids and set down. Any

rocks holding it out of the water could be shifted, ideally setting it

down low, perhaps even forming something of a trench. Rocks could be

set on

flanges at the intake funnel, or on the pipe, to hold it in place, or

stakes pounded in. The steeper the pipe can be angled from intake to

outlet, the faster the flow will be, hence the deployment in "rapids"

or a fast flowing place.

Sticking to a very small, basic unit, this could be a

fairly quick and simple demo or an off-grid home power project.

Over the next days I thought of more and more variations

on the design. The generator could sit on top of the pipe, connected to

the shaft with pulleys or by a "U-joint" at 45°.

This configuration with the "turbine pipe" and a water

concentrating intake soon became the center of my thoughts for any

hydro power unit, small or floating, and whether the pipe was 4 inches

diameter by 3 feet long for a creek or 4 feet by 30 for a substantial

river. For a floating unit, the floats merely had to keep the pipe at

or near the surface and prevent it from spinning, making their design

and construction simple. (See the long

version under Electricity Generation.)

Chevy Sprint Electrification

On this I

first figured out where to mount the batteries. I made a battery shelf

for 12 cells under the hood and a level styrene foam cushion for the

spare tire well for 24 cells in the rear. Then I did a "cargo floor" -

a cover over the batteries in the rear, and I set them in place and

(having two types of somewhat different shaped lithium ion cells)

figured out optimum positioning.

On this I

first figured out where to mount the batteries. I made a battery shelf

for 12 cells under the hood and a level styrene foam cushion for the

spare tire well for 24 cells in the rear. Then I did a "cargo floor" -

a cover over the batteries in the rear, and I set them in place and

(having two types of somewhat different shaped lithium ion cells)

figured out optimum positioning.

On the 21st the motor controller and programmer arrived

and I started wiring the controller up. I used the plate with circuit

breaker, contactor relay, car key relay et al that I had made for and

used with the Kelly controller, but I decided to put it inside the car

behind the firewall. That complicated things a little, but it won't get

road dust, water and de-icing salt in it! Then I turned it around for

better access and wire routing... and had to redo the heavy wires. In

the last two days of March I got it wired up and tried it. But

something isn't right, as the controller keeps shutting the power off

when I try to drive.

Nickel-Nickel Batteries

I found my old bottle of acetal ester and doped some with

osmium powder to try out for thin-film positive electrode current

collector coatings so the current collector substance (whatever may be

used?) wouldn't corrode away or cause self discharge, and painted it

onto the graphite foil. (If there are any gaps, at least graphite won't

corrode away like metal would.) I finally got the cell back together to

try it out on the 25th, which of course got me working on the project

again. After adding some more potassium oxalate and ethaline DES, it

seemed to hold a charge! And with a couple of other steps in the next

days, performance improved. But when I added some "conductive carbon

black" it started having the same nasty self discharge as my previous

cells. It was a graphic demonstration of the deleterious effect

graphite and carbon had been having on my cells. With the monel "solid

solution" mix it can work without the graphite. So, with the osmium

doped conductive film to separate the graphite current collector from

the electrode, the positive electrode mix I made a long time ago,

potassium oxalate and calcium hydroxide electrolyte in ethaline DES, I

finally seem to have a working formula for nickel-nickel batteries.

There don't seem at this point to be any remaining important

problems. Real, practical batteries then should be just a few steps

away, really for optimization. They should be better (and cheaper) than

lithium types.

But it all takes time. I may try making one cell with

properly compacted powders sometime to be really sure it works as well

as the test cell seems to.

LED Indoor Garden

After making

my "LED light table" in early January, before the end of the month I

had planted leaf lettuce. In mid February I planted another box, this

time with romaine. By early March I was eating lettuce from the first

box. But not before putting the boxes on wheels for access and adding a

fan to prevent mold from growing on top of the dirt. In mid March I

planted a third box with spinach and another variety of romaine. In the

last day or two I started including a leaf of romaine in sandwiches. In

addition I started some seedlings in seedling pots and some tomatos in

a big pot.

After making

my "LED light table" in early January, before the end of the month I

had planted leaf lettuce. In mid February I planted another box, this

time with romaine. By early March I was eating lettuce from the first

box. But not before putting the boxes on wheels for access and adding a

fan to prevent mold from growing on top of the dirt. In mid March I

planted a third box with spinach and another variety of romaine. In the

last day or two I started including a leaf of romaine in sandwiches. In

addition I started some seedlings in seedling pots and some tomatos in

a big pot.

I started to get the idea that this could be a fabulous

product - not just the lights but a complete, ready made "LED Indoor

Garden - just add dirt, seeds and water for year round greens." One

could optimize it as lessons were learned, and people could start

growing without each one having to figure everything out for

themselves, find all the parts and do their own wiring. I added it into

the "dream budget". On the 24th I took a head of lettuce down to the

farmer's market just to show. People seemed suitably impressed. It

started to dawn on me that literally millions of people might want

them. One lady thought schools would buy them as a classroom

educational tool. Exciting idea! And another whole market!

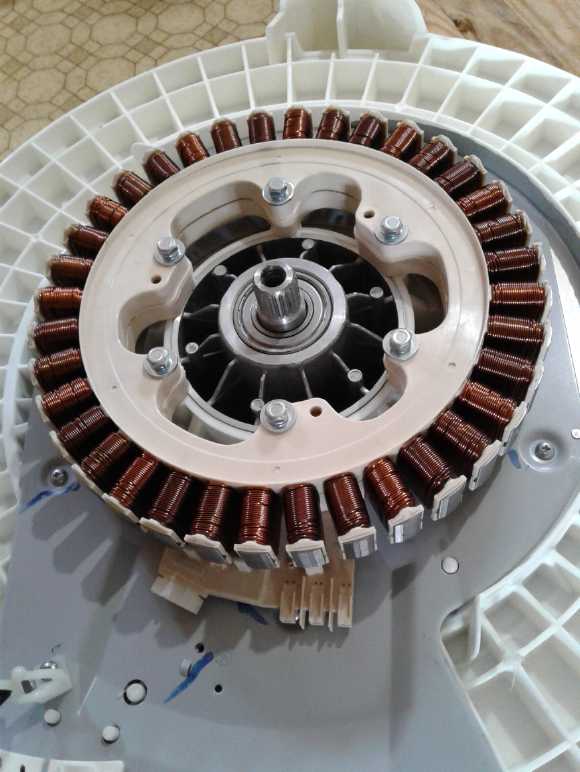

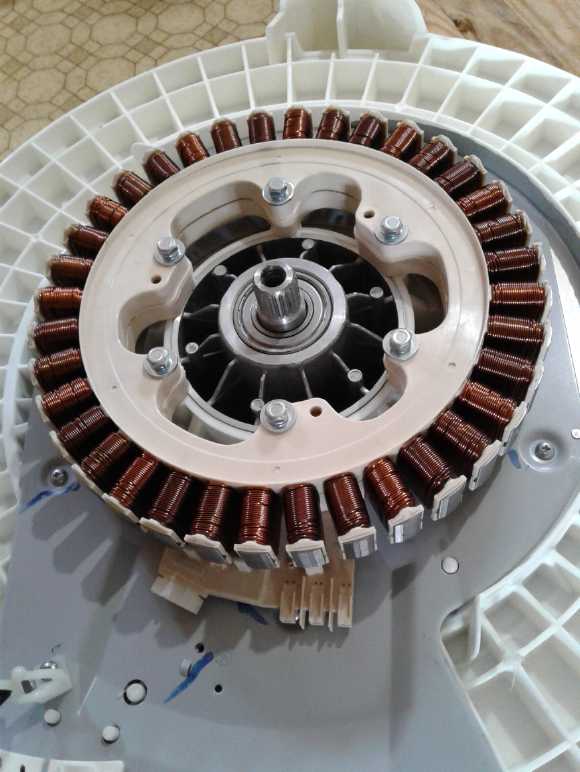

Somewhere in

there I fixed a couple of LED lights I had made some time back, and on

April 1st I took apart a BLDC motor and had a good look at it - my

quite new washing machine had broken and had to be completely

disassembled.

Somewhere in

there I fixed a couple of LED lights I had made some time back, and on

April 1st I took apart a BLDC motor and had a good look at it - my

quite new washing machine had broken and had to be completely

disassembled.

The subject came up

late last year to consider what a person involved with plans or

projects for advancing civilization in some way would

do if some

philanthropist multi-billionaire decided that some of his fortune

should be invested in improving the future of the planet, and offered a

virtually unlimited budget to give effect to a program of

implementation. The terms

would be that the money must put to productive use for the program, the

recipient would take only a fair and reasonable salary and not

otherwise help themself personally the money offered or to any

profits that might accrue. Would we ask

for 10 million? 100 million? half a billion? or a whole billion?

If we asked for too little, it would limit our potential

contributions to humanity. If we took more than we could productively

use, everything would be subject to cancellation for being wasted. Are

these various ideas and projects not priceless, worthy of such an

investment? Furthermore, with some of the projects having the potential

for swiftly becoming revenue generating, the seed money supplied would

surely turn into a self sustaining enterprise and return manifold more

fruits than the initial amount.

Wow - to have the resources to be able to get talented

people together as

required to go at each project full bore, and to have several things

proceeding

simultaneously? The ability to develop my ideas multiplied many times

over? Wouldn't that really kick-start everything! All those

development and research projects that I probably couldn't perfect in

my lifetime could rapidly be completed and commercialized! Useful

new products and technologies for everyone's

benefit!

Capital to commercialize projects with, and even to get a

reasonable salary for what I do, has been beyond my expectations for

many years now. The idea of having an unlimited potential budget to go

about several things or

even everything in a big way I shoved out of my mind. The possibility

just seemed so far off the radar screen. Perhaps it still is, but one

can hope! The last time I

had a salary and a decent budget even to

order

whatever parts and materials I needed for a project was over 30 years

ago (1985-1989),

when the facilities manager of the Victoria BC school district, Keith

Hawkins, had me hired. There I designed, built, installed

and programmed computers to control heating, ventilation and other

functions in the schools, when commercially available products were

pretty primitive.

Should this sort of fabulous offer be made to me, where

would I even

begin to guess how much money to ask

for, and how

to best put it to use? I decided to focus in on technical and

sustainable energy projects and products rather than those ideas for

improving democracy

and societal concerns. (not that setting up a web site or two for some

of

those programs might not be equally valuable!) Then I would break it

down into

very, very rough budgets for each separate project.

I should point out that all these projects are described

in past issues of Turquoise

Energy News going back a decade and are not brand new ideas that

have recently popped out of my head without having been thought out in

some considerable depth for some time, and in most cases have had some

actual development to some degree. Many projects have continuing

development, physical or conceptual, moving forward from their origin

even to this issue. Some projects I have left out as they seem to me to

be less valuable or lower priority than those selected.

I would start with projects I think are most certain to

quickly

start generating revenue, returns on the

investment: the Bandsaw Alaskan Mill, the Indoor LED Garden and the 12

Volt DC plugs and sockets system. But there would be no pause before

initiating the various projects that need more development and

research. Having multiple projects

running at the same time would be a

major advantage. Everything could be housed in one facility, or a

very small number of facilities next to each other to better utilize

resources and minimize fixed costs. There would be one head office and

one accounting department for all of them to split these overhead costs

between all the projects. And if one project needed

more resources (monetary or human) than budgeted, it might borrow

persons or funds from another budget as long as everything balanced

out. Usually, when a single project start-up business needs more

resources than allowed

for - as so often happens - it may go broke without success, or

dissipate

its efforts and "sell the farm" looking for supplementary funding, with

progress set far behind. With multiple projects, when one

becomes commercially successful, its revenue stream can help the

others. If one is seen to be unviable or no longer very valuable in

light of

other developments, or is not progressing well enough, it can be

terminated and its

resources and probably valuable personnel shifted to other projects.

The enterprise as a whole can become self sustaining before the the

initial capital runs low, while R & D for the next products is

ongoing.

The budget amounts

are the vaguest of estimates. I decline to write up

phony "business plans" that pretend to know in detail how much

everything will cost, how long it will take, and how much revenue will

be generated and how soon. (Apparently many forward looking investors

find formal business plans rather passé now anyway and use other

criteria to formulate their decisions.) The total budget is 22 million

Canadian

dollars. If that figure seems small compared to 100 million or a

billion, it's still a lot of money and a lot of good work can certainly

be done with

it!

Here is the "Table of Contents" short list of the potential

projects that I'd like to fund:

Bandsaw Alaskan Mill ("Carmichael Mill"): Manufacturing Business: $5

million

Standardized 12 VDC Plugs, Sockets, Wall plates, Adapters: Production

and Marketing: $1 million

Textured Solar Panel Glass to Improve Overall Collection: Development

and Production: $1 million

New Chemistry Battery(s): Development: $1 million

Permanent Magnet Assisted Reluctance Motor and Unipolar Motor

Controller: Development: $2 million

Ground Effect Aircraft for Islands and Inaccessible Rugged Coastlines:

Prototype Development: $4 million

In-Stream "Turbine Pipe" Hydro Power Generators: Development and

Production: $2 million

Indoor LED Garden Kit: Development, production and sales: $4 million

Contingency & Optional Projects Reserve: $2 million

Total $22 million

Here are Short Descriptions of each Project or potential

Product

Carmichael Mill ("Bandsaw Alaskan Mill"): Manufacturing Business:

$5 million

There are a lot of "knowns" in the bandsaw alaskan mill

project with

the "unknowns" being relatively few. We know chainsaw alaskan mills

work well. We know that bandsaw mills on tracks work well. Combining

these into a "Bandsaw Alaskan Mill" is therefore a matter of getting

everything right to constitute a good, practical tool rather than

explorations

into unresearched or undeveloped territory. I've already proven

that the first

prototype cuts well and is pleasing to use. Business,

production design (safety is of course paramount with any saw. This one

should be intrinsically safer than a chainsaw mill) and

marketing aspects will then be the main focus.

In the 1990s more than one person estimated (independently

of each

other) that it would take 5 million dollars to start up my computer

operating system business. Here product

development will be much faster than in a new software business, but

then this will be a manufacturing

business requiring a lot more space as well as equipment and the cost

of the actual parts inventory for the mills. So it might work out

around even. Notwithstanding considerable inflation since then,

administrative costs are shared between all the programs. So I'll call

it 5

million.

I believe the market for such saws will be large enough

that the

initial investment will be recovered in, say three years from the time

the first batch of saws is out there and people are seeing them at

work. That may be a couple of years from starting up, so give

it five years. (Making and selling 7000 mills netting $700 above cost

each would just about do it.)

I think this mill will both open up new markets (people

who wouldn't

have bought a full-fledged sawmill just for a few logs or even one

special one) and replace purchases of the smallest "low end" bandsaw

mills on tracks,

by being more practical: portability and milling logs without moving

them

to a sawmill, a lower purchase cost, low maintenance time and cost,

and

taking up little storage space when not in use.

CAT Standard 12 VDC Plugs, Sockets, Wall plates, Adapters:

Production and Marketing: $1

million

I think there's a big market for something similar to the

ubiquitous NEMA standards for 120/240 volt AC plug, socket and wall

plate systems,

created similarly for DC

battery systems for off-grid and portable applications. It's an area

with

much need and with a gaping vacuum of standards and parts availability.

I've created a couple of "standard" 12 Volt DC sets based on "AT"

automotive fuse pin and socket

design, and I make them on a 3D

printer. Real production and marketing would spread their use and make

them

a real, adopted standard. 24, 36 and 48

volt standards can also easily be created and produced. No one else so

far has

taken the initiative to create such a thing and manufacture and market

the products. With capital, it could easily be done and should be

effective. For 12 volt use, adapter plugs can easily give it both-ways

backward

compatibility with "car cigarette lighter" plugs and sockets, so

migration to the new system should be simple and painless. Such 12 volt

wiring for buildings can also utilize common and proven electrical

boxes (which the faceplates fit on), wire and

wiring components and techniques.

Textured Solar Panel Glass to Improve Overall Collection:

Development and Production: $1

million

The nanocrystalline titanium dioxide borosilicate glaze I

created

some years ago could be developed into a pebbly textured front surface

solar panel glass that would increase light collection, especially from

scattered and low angle light. The pebbly (little lenses) texture and

the high refractive index of nanocrystalline titanium dioxide reduces

reflections and bends more light straighter through toward the

collector

elements. This would increase effective solar

collection over a day, including in cloudy conditions when collection

is low, making any solar panel more effective overall. Since it hasn't

been tried the percentage

improvement is hard to determine. It could be

anywhere from 10 to 30%. 10% could make it worthwhile; 20% or more much

more so.

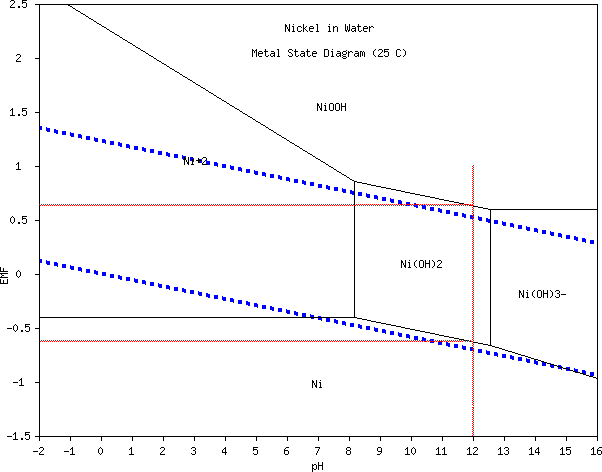

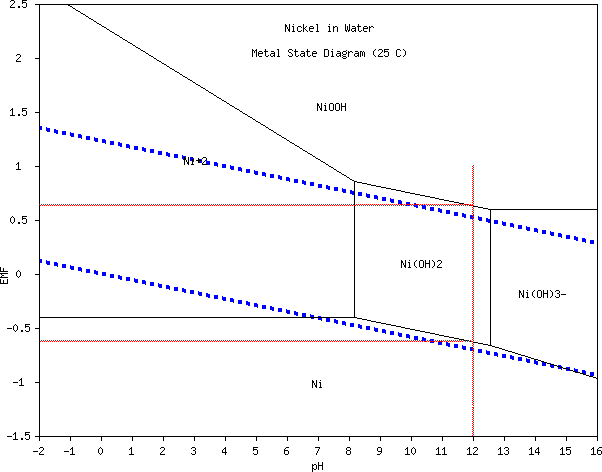

New Chemistry Battery(s): Development: $1 million

With capital, a full time real chemist could take my ideas

and

designs much farther and faster than I have been able to do. In

exploring "mildly alkaline" novel electrolytes, I seem to have

uncovered not

one but several potentially valuable new "better than lithium" battery

chemistries

that can

be worked out. For example using trace additives I got manganese to

hold its -1.5 volt metallic charge (world first!) to make

nickel-manganese

2.5 volt cells.

That's even higher voltage than lead-acid and high enough for digital

circuits and to drive LEDs, so

one rechargeable "button" or "AA" cell

could replace two other cells for many small products, and larger cells

should have very high watt-hours for their weight.

Nickel-nickel

has the promise of very high current capacity as well as high

watt-hours per

weight for electric transport.

Nickel-air, if it can be made to work,

could bring a whole new level of light weight electric transport

batteries - a car might

run for days before recharging. Nickel has advantages over other metals

(eg zinc, iron) for a rechargeable air cell, but the electrolyte is

again a key since it won't work in a regular pH 14 alkaline cell.

Novel chemical developments or ideas to date include the

~-1.5v manganese negative electrode, potassium oxalate for a less

alkaline (less caustic) electrolyte (along with calcium hydroxide),

possible use of ethaline DES as an electrolyte base with a higher

breakdown voltage than water, thin film conductive layer (osmium in

acetal polyester) to protect positive electrode current conductors (now

testing; looks like it works), chelation of active metals to prevent

gradual deterioration with cycling (for everlasting cycle life).

Taking the

chemical techniques developed or attempted so far to practical cells

for

production and market may well cost substantially more than this

budget, but,

anticipating a

delay before they're developed and ready for production, it might be

financed with

profits from more immediately salable items. (Or production might be

contracted out... to China or ?.)

And late this very month, I got a nickel-nickel test cell

working (here), demonstrating the above theories

work. I'm sure this is the chemistry to concentrate on for electric

transport. It should be cheaper and better than the lithium types

presently in use, and should have higher energy density. Rather than

add to the budget, contingency money might go toward setting up for

production if it seems warranted.

Permanent Magnet Assisted Reluctance Motor and Unipolar Motor

Controller: Development: $2 million

Here are opportunities to revolutionize the motor industry

with exciting new but little explored developments. Different motor

types use different types of solid state motor controllers, and the

novel reluctance type should be developed along with a controller for

it, as a pair.

The permanent magnet assisted motor has coils with

permanent magnets in them as well as electromagnets. Perhaps amazingly,

there's no external field if the coil isn't energized, but if it is,

the permanent magnets add their field to the electromagnet field,

providing more magnetism with less current and power than with an

electromagnet by itself. The ultra-efficient operation this provides

can drive electric vehicles with less applied electrical power under

heavy load conditions, potentially yielding much greater driving range

even with present batteries. My "axial flux" reluctance motor designs

with large diameter thrust bearings allow for very small gaps between

rotor and stator, a critical parameter of effective reluctance motor

operation. They are also easily produced, with CNC waterjet cutting of

the main metal parts.

The unipolar motor controller for reluctance motors is a

simpler and more reliable design of mine, with half as many active

mosfets as other controllers - allowing both forward and reverse motor

operation with single ended transistor drivers. Cost is thus

intrinsically lower and it should have fewer "failures per zillion

hours" of use. And the reluctance motor can run safely and efficiently

at very high RPMs, eliminating the otherwise valuable use for variable

transmissions in electric vehicles.

(If development goes smoothly, there

might be some capital left over to put toward production.)

Ground Effect Aircraft for Islands and Inaccessible Rugged

Coastlines: Prototype Development:

$4 million

This is among the potential things to make more of the

world more habitable, by making some isolated areas less isolated. The

ground

effect (or "surface effect") provides much more lift with much less

drag and so the craft flies low over water using perhaps 1/3 of the

fuel

or energy of a regular aircraft. It goes where a boat or ship goes and

isn't used over land. The main problem with commercializing

ground effect craft has been stability. It's extra critical when flying

just over the surface. Some promising testing of "catamaran" types has

recently been done by radio control model aircraft builders (see

youtube). But features of my "catamaran" designs (which would again

first be tested with radio controlled scale models for safety and at

low cost) would improve both lateral and longitudinal stability over

other types, with a high degree of confidence a practical craft will

result.

The design traps air under itself like a hovercraft. The

rear of the

central wing and the catamaran side bodies meet at the waterline to

form 3 sides of

a box, and a retractable flap at the front of the wing extending down

the same distance makes the 4th side. Some of the air from the ducted

fan propeller is directed into this box. This allows much lower power

take-offs, the craft lifting up at low speed like a hovercraft. It

starts to fly

like a ground effect airplane as it picks up speed (already

"airborne"), with the front flap

folding up under the wing.

Developing a practical, safe manned prototype of this sort

of

larger, more complex product will obviously cost more than for the

small items.

If this budget takes it only that far and successfully proves the

designs involved are practical, it will inspire and should be

considered a

success. If we can then

produce a multi-passenger model for more extensive trials and perhaps

to ply a formerly long and tedious commercial ferry route or two, or

even a long route where no ferry runs now, that would be marvelous!

Seeing

them in use might bring in orders for more and larger craft for various

such routes. (BC North Coast, between Hawaiian Islands, Norway Coast,

Azores Islands, Canary Islands, East Asian coast, Thailand,

Philippines...)

In-Stream "Turbine Pipe" Hydro Power Generators: Development and

Production: $2

million

There are designs,

computer modelings and a few successful individual

projects for making electricity with floating "catamaran" style

generators with paddle wheels anchored in rivers. The idea has

tremendous potential but no easily replicable or

production designs have ever come out. (Wind power was commercialized

in

Denmark and they soon became the major manufacturer. Flowing water

provides

continuous power - why should it not be done?)

This design would do even better. In the "turbine pipe"

(written up in this very issue of Turquoise Energy News), the main body

of the generator is a length of pipe with a center shaft holding a

number of propellers along its length - a "spiral staircase" of

propellers. An experiment (youtube) using such a system for a wind

plant has shown that this should give "the most bang for the buck" -

the most energy from a column of flowing water. The enclosed pipe

design along with a screened "funnel" intake also addresses various

concerns such as low water operation, ice, debris in the water, fish

safety, longevity and durability.

Small, easily deployed units could be manufactured and

sold. The smallest could be deployed even in relatively small streams.

Large units could potentially take the place of hydroelectric dams,

making as much electricity or perhaps more from the same water energy,

but deployed as floating units spread up and down the river instead of

everything being housed at a single costly dam site (with its potential

for eventual catastrophic failure).

The smallest units, perhaps a few inches in diameter and 3

or 4 feet long, for use typically in rapids in very shallow

streams, would simply rest on the stream

bed, held in place with weights or rocks, with the screened "funnel"

inlet potentially somewhat upstream and feeding through a hose to give

more pressure and flow to the turbine pipe. Larger installations, feet

in diameter and proportionately longer, would be anchored in a fast

flowing section of a river or a tidal flow, and would include

sufficient flotation for buoyancy and stability.

This project would concentrate on the small end of the

scale (starting with retail units of 12 volts, under a kilowatt?).

Assuming marketing these products brought more interest, later

designs would scale up to "industrial" size models for small community

and larger "on grid" power projects.

Indoor LED Garden Kit: Development, production and sales: $4

million

In temperate climates vegetables can only be grown "in

season" for part of each year. A greenhouse can extend this season but

much of the winter is still "out", with increasing winter cold and

reduction of daylight hours with latitude. This idea in its essence is

a pretty obvious application of LED lighting technology, which has

lately become "mainstream". Before LED lighting existed - and then

became "cheap" in big box stores - it wasn't realistic to grow

vegetables beyond the seedling stage indoors with artificial light. It

took hundreds of watts of lights making excessive heat to light a small

area. This LED vegetable growing idea has been successfully tested just

this year - indeed it has just been written up in the last issue of

Turquoise Energy News (#117) and this one, with lettuce started in late

January growing well and being eaten by early March.

In the process some less obvious things were discovered.

For example, a small fan (or fans) is required to circulate air to

prevent growth of fungus/mold on the surface of the soil. Flat rolling

dollies were made so the planter boxes could be pulled out from under

the rather low light table for access - watering, weeding and

harvesting. It would be easier to use if the lights were on a timer,

and perhaps an irrigation system could be provided to automatically

water - or a water bucket on top could feed a small hose to simplify

hand watering. This month it was realized that access would be easier

and less floor space would be needed if the entire light table pivoted

up and back like a freezer lid, with a latch to hold it open. For wider

units, that lighting lid might advantageously be angled left to right

or stepped (2 lids) to provide closer light on one side and more height

for taller plants on the other. And it or they might be adjustable

height lid(s). The unit could be raised up off the floor with storage

cupboards or drawers underneath for gardening supplies and tools.

The new part of the idea is to provide a whole "Indoor

Garden" product that is a complete solution, with all the features that

are found to be useful and practical well thought out and arranged.

That way anyone could start year round growing quickly and easily

instead of each person having to design and build their own from

scratch. There could be multiple sized models from "kitchen stove" size

to "large freezer" size for different needs and spaces, or perhaps

modular "kitchen stove" size units could fit together. They might pack

down into boxes for shipping and be assembled at home, as is so common

for furniture these days.

Contingency & Optional Projects Reserve: $2 million

However conservative the estimate, product development

usually takes longer and costs more than planned. Then, there

may be developments that go better than planned and may go into

profitable production earlier than hoped. For example a battery

experiment success or two (such as those this very month!) might mean

moving the project from "research" to "setting up for commercial

production" in weeks instead of months or a year or more. But some are

bound to lag behind. For example it might take much longer than

anticipated to solve some problem with the new motor or motor

controller,

and that would hold them both up. The reserve allows taking advantage

of the breakthrough on the one hand, financing lagging projects

longer, or both.

No doubt I could add to the "valuable projects" list, but

these seem

to me to be the most valuable items that I also have confidence in

because I pretty

much understand what needs to be done. I expect to hire self-motivated

talent that can be expected to proceed day to day with minimal

supervision and guidance. Still there's only so much one

person can initiate, direct and

oversee. I wouldn't want to spoil it by extending myself too

far -

not that I would want to absolutely preclude taking on a new idea or

project of great promise should one present itself!

And here already is such an example: the "LED Indoor

Garden" idea has made its appearance, with a prototype originally

intended just for personal use working since January and proving

lettuce (at the very least) can indeed be grown successfully in winter

with just 100 watts of LED light. Improved and commercialized it could

be a fabulous product used by millions, so it was added to the list.

Misc. Notes:

Apparently marketing via social media is now more

effective than

other techniques for introducing new things and someone good at that

would be

a valuable employee. As has been observed before, the trick to business

success is to hire people that are smarter, more talented and more

knowledgeable than you are. Or one might say, with different skill sets

in different areas.

In setting up an organization full of talented people (to

whit an innovative company with various departments), there may be

various opportunities to try out

"design team" approaches and new democratic systems in line with the

core values of social sustainability (Life, Quality of Life, Growth,

Equality, Empathy, Compassion and Love). With everyone understanding

that the financial "bottom line" is vital, it's possible the socially

sustainable approach could improve organizational adaptability and

contribute to long term success and an organization that continues to

learn and adapt and remain relevant through the centuries.

I think probably every department or project engaged in

development and research should contribute a monthly report. Turquoise

Energy

News would thus become considerably expanded. Since the

objective of the funding would be to improve the world, such reports

would make an excellent contribution toward further research by others

irrespective of the business success of each project. Even "failed"

projects would contribute to the human knowledge base, potentially

pointing better ways to future success by others, and so the money

would not

have been wasted.

Until "the ultimate best" technologies may someday be

created in all fields,

progress makes for obsolescence of existing technologies as new ones

are

created. For example antigravity craft will probably some day

make all

other types of aircraft including ground effect craft obsolete. (Things

do progress: When I was young, cell phones and the internet were beyond

science fiction!) As a "learning organization" this one should be in on

it as developments occur, phasing out production of ground effect craft

and working on potential commercial development of the new technology.

However, neither would it sit and wait for a

speculative unproven or virtually unknown technology instead of

developing technology (the ground effect craft) that

could be highly valuable in the present day and current conditions

probably for decades to come.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

The need for teaching the core values of social sustainability

It is disheartening that the government in South Africa is

apparently now following that of Zimbabwe where all the white farmers

have been tortured, murdered or driven out. (I in fact know a couple from Zimbabwe who were lucky to

get out with the shirts on their backs - they weren't permitted to take

any possessions with them.) All the core values of social

sustainability are being violated: love, empathy, compassion, equality,

growth, quality of life and even life itself are being extinguished.

It's not like black people take over the farms. They are

abandoned. Zimbabwe went from being a food exporter to needing food aid

in just a couple of years. And it's not like blacks are reclaiming land

that historically belonged to them in all cases: there were no blacks

in the Cape of Good Hope area when Dutch settlers arrived there to

start farming. Until about 1960 blacks were under 70% of the population

and whites around 20%. From 1985 four million Africans entered South

Africa while 640,000 whites left - 15% (and probably the cream) of the

white population. By 2015 blacks were 80% and whites 8%. Where are

those who just a few years ago were "tsk-tsk"ing apartheid and asking

how white people could be so cruel and why blacks weren't allowed to

vote? Surely, that was nothing like an ideal situation, but what about

now? It's as bad as the Jewish Holocaust in Nazi Germany, in a

supposedly Christian country. With a growing black population, and no

consideration for the core values by the larger group, it was

inevitable that the governing power would shift and the concerns and

influence of the white and other populations would be marginalized. So

this collapse into barbarism has been predictable for a long time.

South Africa, where Dr. Christian Barnard once performed the world's

first heart transplant, appears to be sliding from being the one bright

light in sub-Saharan Africa into the same sort of primitiveness as the

rest of it. Will the blacks continue to tolerate the Indians and mixed

races, or are they next on the hit list? (And how long will Australia

maintain its current culture and identity when a tide of more southeast

Asian refugees than its whole present population comes pouring in?)

Perhaps this situation could have been avoided if everyone

had had to study, pass tests and understand the responsibilities of

democracy before being permitted to vote. That could have been applied

equally to all the races in South Africa. Hostile, ignorant

demographics might have settled down to study and understand broader

viewpoints and principles in order gain the right to vote. And of

course there would be more advanced courses for those who actually

wished to run for office. That would have been my plan for ending

apartheid. Alas, nothing like this was tried, nor has it been tried

elsewhere.

Closer to home there are also daily outrages to law,

order, morality and reason, complete with lies drummed over the

"corporate media" so repetitively "it must be true" to justify them and

obfuscate the issues. One can pick an issue and try and fight it, but

by the time any slow progress might be made, other similar outrages and

many dissimilar ones have been committed. (Someone spent 12 years in US

court having the so-called "patriot act" struck down. Obama re-enacted

it in a moment with the stroke of a pen.) Finally good people simply

throw up their hands in despair - it's hopeless. And our legal system

is so gutless that many of the worst social predators are never dealt

with. They remain on the planet for their whole lifetime free, even

rising to high places to instigate bigger outrages that harm more

lives, sometimes of millions of innocent people, and society as a

whole. How can and why should one try to fight a brush fire while new

ones are lighting up on all sides until the whole forest of society is

burning - and no one stops those lighting the matches and setting the

fires?

And where do the matches come from? Like every

civilization so far, ours has come about without conscious planning. It

had and still has no overriding goals for where it wants to go and to

be in the future and there's no planning for social, scientific and

technological change. Mostly it just happens, haphazardly. A

constitution or framework of operation is set up that is appropriate

for the conditions of the day, with only vague allowance for

"amendments", which are to be pushed through only with the greatest

circumspection by overwhelming majority, virtually in the face of

potential revolution. But those who framed the American constitution

could hardly have dimly imagined today's world.

British parliament passed the reform act giving most men

the right to vote by just one vote out of hundreds cast in the face of

the working American example, the most cogent arguments and with the

spectre of a potential "French Revolution" in Britain staring everyone

in the face, in (?)1830. Even back then it was noted pointedly that

"constitutions are fixed while society changes", yet no thought was or

is even now given to the need for provision for government and its

institutions to ever learn and reform to keep abreast of developments

and needs.

As the forest burns itself out and nations fall apart and

perhaps little will be left of many beyond the local community level in

coming decades, a fresh start has become necessary. In order to build a

civilization that lasts into the indefinite future, the root causes of

forest fires must be understood and preventative measures taken in

timely fashion. The way to start, humble and almost trivial as it

seems, is at the personal and the family level, where children learn to

think in sound, moral and right terms - or in terms of avarice, greed,

power seeking and other aberrant ways of thinking and living. Children

have to be taught to think for themselves, and given the highest set of

values that will enrich their own intellectual and spiritual

development as well as the community and society around them.

No Earthly civilization so far has thought about needing

to have ongoing means for growth, to have its institutions change and

adapt as conditions change. The ruthless figure out how to "game" the

relatively static system to their own selfish advantage, the

civilization becomes corrupted and the contributing public on whom

everything depends become increasingly overburdened, neglected and

impoverished, until there is a general collapse, usually with great

loss of life. (Even in the relatively recent and relatively mild

collapse of the Soviet Union people did go hungry and even starved, for

some years.)

Again, the 7 core values for social sustainability are

Quality of Life, Provision for Growth, Equality, Empathy, Compassion,

Love and summing up, Life itself. Are these not the highest social

values? And values always underlie all decisions.

There are many worthy secondary values. They are

implicitly based on the core values but they tend to supplant them,

giving rise to many aberrant paths of development. Renewable energy is

good - but why? Because it improves the environment. And why is that

good? Because it enhances the quality of life. So what's wrong with

renewable energy as a core value? If a society puts renewable energy

first, it may for example decide to develop and employ renewable energy

even at the expense of quality of life. If noisy windplants are set up

around where people live, it deteriorates their quality of life and

sacrifices even their environment. Inequality and discontent are sown.

Renewable energy must fit into place in a broad spectrum of things that

together determine quality of life. If quality of life and equality

were the first concerns, a solution that would be more satisfactory to

all would be sought.

Or, tolerance of people who are different and who do

things differently or do different things than we would is a good

value. There are many beliefs, tastes and and ways of living. But

tolerance is again a secondary value: once society tolerates predatory

behavior as it does today, where one person is able to violate the

rights of others with any degree of impunity, disaster and collapse are

waiting. Quality of life and equality are higher values than tolerance.

Only by explicitly including these core values in teaching

youth, so that these future leaders may in turn explicitly incorporate

them into their plans for social, political or economic uplift, will we

see plans formulated in ways that benefit everyone, leave no one out

and permit no one to lord it over others - in socially sustainable

ways. Many of us will at some time or another encounter situations

where these values can be used for effecting improvement at a personal,

family or community level, or in the workplace. But in the broad

picture such values will take a couple of generations to instill in

youth who then grow up to become better decision makers themselves.

Then they can start becoming broadly effective in transforming the

whole world, eliminating the root causes of forest fires to bring us to

days of "Peace on Earth and goodwill among men", the beginnings of

"days of light and life". In a century great strides can be made. In

two we will no more recognize society than the American founding

fathers would know ours.

In order that a program that will take generations to

mature not be lost and forgotten before it has a chance to come to

fruition, and will be sustained into the indefinite future, a new

institution is needed: one that gathers together the world's collected

wisdom on raising children to become fully functional, contented,

contributing adults without developmental handicaps, and teaches

parents, prospective parents, grandparents and teachers how to raise

their children in accord with this wisdom, so that it may taught and

instilled in each new generation. The internet will make it much

simpler to have such a program initiated and adopted around the world

than it would have been in any previous time. One might almost say it

makes it possible.

It may seem to many that such things are impossible of

accomplishment - that such developments are just not in human nature.

But this discounts what is sure to be severe "fallout" from the

environmental, economic and epidemic catastrophes that are looming in

front of us on our present course. When the things that used to work

aren't working and one's very life is on the line, people become more

open to change. And even today there is a rise in consciousness

occurring with a decrease in national, racial and ideological "us

versus them" attitudes and materialism, indeed not in the war hawks who

seem to want to rip apart everything mankind has accomplished to

justify their existence and enhance their personal prestige, but in

general and especially in the young. It will become increasingly

manifest in the coming years and decades, changes occurring perhaps

even suddenly when tipping points or triggering events are reached. We

may soon see students on the streets and on campuses marching to

protest inequality, and this will help redefine public perceptions of

what is true wealth versus material wealth and especially material

wealth gained at the expense of everyone else.

Feeble attempts at humor

How many times in a row can a word be used properly in a sentence?

Consider the sign:

FISHANDCHIPS

One might well say that the spaces between fish and and and and and

chips are too small.

(Or properly punctuated: The spaces between "fish" and "and", and "and"

and "chips", are too small.

---

Or how about just words that sound alike?

"The train stops here for 4 minutes from 2 to 2 to 2 2." (for not too

long - 1:58 - 2:02)

---

Which word is out of place?

Ring, rang, rong, rung

Rong: it's the only word that's spelled rong.

---

Baking bread is similar to digital electronics except that

rise times are measured in hours instead of nanoseconds. (Fall times

are still measured in nanoseconds.)

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get

into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and often, of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in

writing of

those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Chevy Sprint

Car - Forklift Motor & Fixed (8.9:1) Reduction

Battery Placement

My plan was to make up the 36 volts in three 12 volt

sections in series. Each section would be charged separately, so it

wouldn't matter if all the cells weren't identical or even identical

types. (Four 3.2 volt lithium cells in series makes 12.8 volts. We're

still calling them "12 volts" and 12 cells in series makes "36 volts",

even tho it's actually 38.4.)

I had enough 100 AH

lithium cells to do an all lithium battery up to 300 amp hours at 36

volts: 36 cells. I had 45. (32 were from the Suzuki Swift. At least two

or three cells (not from the Swift) had the strange problem of not

freely going up in voltage from about 3.3 to 3.6 or more once they were

charged, which would doubtless cause charging problems even if they

worked okay otherwise. One cell had had that problem but when I tried

charging it a year later it was fine. Anyway there are a few spares.)

38.4v*300AH=11.52 KWH of storage capacity - not much more than the

Swift's 10.24 KWH and nothing like the Nissan Leaf's 26.4 KWH. A 400 AH

battery (15.36 KWH) would take 48 cells - a little out of reach. I

could also make it 340 AH by adding in twelve 40 AH cells I have.

(13.06 KWH) But I'd rather not mix them.

I could do 400 AH by using 32 of the lithiums for 24

volts, 400 AH, plus 400 NiMH "D" cells to make 12 volts, 400 AH. The

NiMH batteries are pretty much all put together anyway, so it wouldn't

be too hard to do.

But then

there's where to actually put all those

batteries in a car not designed for holding them. I looked it over on

the 6th and finally decided to

keep it simple and put them all in the cargo space behind the back

seat. In order to fit them I decided to go with just the 300 AH of

lithiums. And that would weigh about 280 pounds - also more than enough

weight for back there. I would put a solid cover over and around them

and there

would still be some cargo space above.

But then

there's where to actually put all those

batteries in a car not designed for holding them. I looked it over on

the 6th and finally decided to

keep it simple and put them all in the cargo space behind the back

seat. In order to fit them I decided to go with just the 300 AH of

lithiums. And that would weigh about 280 pounds - also more than enough

weight for back there. I would put a solid cover over and around them

and there

would still be some cargo space above.

It took some puzzling to try and fit them in. It was as if

the batteries and the car were each designed to waste as much space as

possible to allow the smallest number of cells to fit. Each 12 volt

block of four cells was 5-5/8" x 11". So two were 11-1/4" x 11" and

turning

them sideways didn't really help. Four wide (22") wouldn't fit near the

bottom

of the spare tire space because of its gradual bends from vertical to

horizontal. But 3" higher up (read 3" less cargo space!) they would

fit.

Then for a second row behind the first there was... 10" - not quite

enough! All very frustrating.

Then I realized there was one trick left. The cells could

be electrically connected as blocks of four without being physically

stacked

together. If I put in just three cells per row, 10" was enough. So 7

sets of four would fit instead of 8. The remaining two would just fit

to the right, higher up, using up the cargo space on that side. (and

somewhat balancing out the driver left-right for weight?)

And there was one fortuitous thing about the 4-door

Sprint's layout: the tailgate didn't open to the floor. (I guess that

makes it a "hatchback" instead of a real "station wagon".) The

batteries, even the upper two at the right, would all be below the

level of the door. There was still room for groceries, etc, above the

batteries, as well as in the small remaining "full depth" space to the

left of them, and folding down the back seat still would make room to

slide in quite large items.

Continuing this subject, I spent some time on the 9th on

it. I cut some 2" extruded styrene foam, making rather

elaborate undercuts around the edges so it fit the spare tire well

well, and turned the batteries sideways to the way I'd had them. (Here,

saving 2 * 1/4" = 1/2" of length actually did help, allowing me to set

them an inch lower than the other way.) I could get in the seven 12

volt batteries, with just the rear one stretched out lengthways instead

of compact, and with little ventilation spaces between rows for

cooling. For the "balcony" at the right side (for the last two

batteries) I used 3/4" foam. (Say, shouldn't the cells be on spacers up

off the foam, so the bottoms get air for cooling? Maybe on a metal

grill or grid?)

The rear battery at the side was the thinner, wider shaped

cells of the same height (about the only place they fit well), leaving

just the 'malfunctioning' two cells of the original shape and seven of

the thin-wide ones as spares. (If I ever need any of the spares, I'm

not just sure how or if they'll fit.) But I spent a good portion of

this time cleaning dust and grime around the edges of the space with a

cloth and soapy water. (I thought I had already vacuumed and cleaned

the car?!? Ah... it was where I took out the plastic trim pieces in

fitting the cells. old car... road dust!) Let's see... a metal box for

the batteries? It had probably saved them in the Swift fire. If I left

the plastic trim off, the bottom, back, and right side, and the lower

part of the front, were already metal. I could bend up an aluminum left

side and a couple of pieces for the front, just behind the back seat.

3/4" plywood covers might be as good as anything, and would make a

solid cargo floor. Metal on the top is just an invitation to short out

battery connections. How about 5/8" firestop gyproc glued to the bottom

of the plywood? That would seem to have all the right properties.

With 250 pounds of batteries the rear springs were

definitely lower. But not bottomed out.

On the 11th I took a set of 4 cells apart and turned them

to make the thin, "stretched" battery. Now all were in place. But it

reminded me that where the radiator was was a thin space that I had

sometimes thought might be a good place for some batteries. I took it

up front and set it there. I measured the width for three such rows and

it was iffy - the innermost one was virtually touching the

transmission. But there was just a post in the way of putting them

farther forward. I disconnected the center link and nothing would

prevent putting the two halves of the battery farther forward, ahead of

the radiator grille area, except the horn. The horn could easily be

moved, or even its bracket simply bent to get it out of the way. I

could use the two sets of thinner, wider cells as well and save another

1/2 and inch, and have 4 of the "Swift" cells as spares for 28 in use

(excluding the two that charge funny), and 3 of the thin ones for 8 in

use.

On the 11th I took a set of 4 cells apart and turned them

to make the thin, "stretched" battery. Now all were in place. But it

reminded me that where the radiator was was a thin space that I had

sometimes thought might be a good place for some batteries. I took it

up front and set it there. I measured the width for three such rows and

it was iffy - the innermost one was virtually touching the

transmission. But there was just a post in the way of putting them

farther forward. I disconnected the center link and nothing would

prevent putting the two halves of the battery farther forward, ahead of

the radiator grille area, except the horn. The horn could easily be

moved, or even its bracket simply bent to get it out of the way. I

could use the two sets of thinner, wider cells as well and save another

1/2 and inch, and have 4 of the "Swift" cells as spares for 28 in use

(excluding the two that charge funny), and 3 of the thin ones for 8 in

use.

That changed everything. The first 12 volts, 300 amp-hours

battery could be on a shelf at the front of the hood. The 24 and 36

volt batteries would be at the back, in the spare tire well. That

definitely improved the weight distribution: 185 pounds at the back and

95 at the front.

In the event I managed to make the front shelf so wide I

could fit any desired batteries onto it - even the extra set of 40 AH

ones for additional 12 volt loads - headlights etc.

Then I remembered that I had to

put in the three chargers,

one for each 12 volt section. They added bulk and weighed 10 pounds

each. So much for the neat little box in the spare tire compartment -

the chargers needed the side shelves even without the extra cells. And

so

much for putting an extra 40 amp-hours of smaller lithiums on the

original battery shelf: the third charger had to go there. (The first

12 volts will have to supply the lights and other car circuits as well

as drive power. Owing to the low voltage I see no need for a floating

ground for the motor system, so 12 volts is 12 volts.)

Then I remembered that I had to

put in the three chargers,

one for each 12 volt section. They added bulk and weighed 10 pounds

each. So much for the neat little box in the spare tire compartment -

the chargers needed the side shelves even without the extra cells. And

so

much for putting an extra 40 amp-hours of smaller lithiums on the

original battery shelf: the third charger had to go there. (The first

12 volts will have to supply the lights and other car circuits as well

as drive power. Owing to the low voltage I see no need for a floating

ground for the motor system, so 12 volts is 12 volts.)

Hmm... and the chargers I had, heavy tho they seemed, were

only 10 amps. With 300 amp-hour batteries it could take a whole day to

charge the car! (At least if I put up some solar panels on the house it

could charge without overloading them when it was sunny.)

Carefully fitted plywood cover over the rear

batteries

Carefully fitted plywood cover over the rear

batteries

and chargers forms the new floor of the cargo space

AWG! I accidentally sliced into it. It looked

about the same as the

AWG! I accidentally sliced into it. It looked

about the same as the

regular plywood saw table where I had set it to glue a minor flaw,

and I set a board on top and cut it to length!

More...

The Lovejoy couplers arrived on the 5th. I took the motor

and plate off the transmission. Replacing the one on the

transmission was simple. The other was more challenging. The inner

spline was rough and didn't readily go onto the motor shaft. Filing it

a bit didn't seem to help. It seemed that I could pound it on, and the

hammering beat the rough projections out of the way. (Maybe a very

small wire brush?) But the bigger problem

was that the L110 size didn't quite fit through the hole in the

mounting plate. The choice was to grind or gouge the hole bigger, or to

turn the coupler down a little on the lathe. I decided on the latter.

At the same time I could turn the back down so it would fit on the

motor shaft without spacing washers - the back of the Lovejoy would

replace the washers to hold the bearing cone securely and at the same

time be a little better seated, the

spline on the Lovejoy being much longer than the motor shaft. A little

more of the splines would be coupled.

I did this turning on the 7th. I ran out of "Valcool"

special formula cooling water, which also evidently reduced friction,

to drip on the carbide cutting tool. I didn't know where to get more

locally and I didn't want to go to town in the middle of the job

anyway. Oil wasn't as good. Straight water would make rust on the cast

iron. I added soap and baking soda to some water. The soap might reduce

friction, and the alkalinity of the baking soda should inhibit rust.

(Perhaps there's a better formula I could look up on the web?)

(I couldn't seal the cup & cone bearing, and the

Lovejoy coupler was quite close fitted. Could grease be squeezed in, or

would the motor have to be dismounted and the coupler pried off to

grease it? Not the best arrangement for routine inspection and

maintenance!)

Connecting the splined-shaft motor to the

transmission shaft - the L110 Lovejoy Connectors

Connecting the splined-shaft motor to the

transmission shaft - the L110 Lovejoy Connectors

One on the end of the shaft in the transmission

One on the end of the shaft in the transmission

With the mating one in place, one sees that the

motor will stick out from the transmission

With the mating one in place, one sees that the

motor will stick out from the transmission

Steel strap (yellow) was added to support the right end of the motor

and transmission

Then I turned to

the missing right-side support for motor

and transmission in the car. With the motor off, I found another hole

at the very bottom of the motor plate. It seemed to have no purpose.

(Maybe for the manual transmission?) That was the lowest thing to run a

diagonal support from. I drilled a matching (3/8") hole in a bar of

steel and bent the end around to fit behind the plate and extend the

bar toward the original engine support. After deciding about how high

up to raise that end of the assembly I cut the bar to length and

drilled a hole at the other end. It'll pull to the side (and somewhat

forward) more than up, so it builds in quite a bit of stress, trying to

pull the plate off the transmission from the bottom, and at the other

end to pull the mount off the frame. But I decided 120 pounds of motor

and

transmission just isn't heavy enough to worry about. (Otherwise I could

try to balance it with a tube from the same engine mount to the top of

the plate, which would push instead of pulling. I still wouldn't call

that ideal, but I think it would be the best that one could do short of

welding in a new piece(s) of frame to hold a new cushioned mount

somewhere underneath - major work. I tried fitting the motor and was

relieved that the new bar passed by to one side (by about an inch) and

didn't hit it. (The 51 pound motor was too heavy for me. When I tried

to fit it into place by hand, I couldn't get it lined up and ended up

suddenly lowering it rapidly to the floor, almost dropping it. Next

time I wore

gloves, and put a big block of wood in place under it to hold it up

while I aligned it with the bolts. I'm sure 30 years ago I could have

done it by hand!)

On the 8th an L110 'spider' arrived in the mail, purchased

by a friend in Victoria at considerable cost. Good timing! I put it in

and pushed the second Lovejoy coupler into the hole in the plate. It

stuck out almost an inch. I was going to disassemble the tranny, take

out the shaft and cut an inch off it... then I thought it might be just

as good to have the motor sticking out farther instead of tight against

the plate. The mounting bolts were stiff, and long enough. It'd need

some spacers or something to hold it securely.

I securely mounted the plate on the tranny, then

remembered I hadn't tightened the set screws on the inside Lovejoy. I

took it off and tightened them, then I screwed in another couple on top

to hold these inner ones in place. I wrote on the Lovejoy "4 Set

Screws!" hoping the felt pen would last and that the note would help

anyone who couldn't figure out why it wouldn't come off with the

(outer) ones loosened.

I greased the bearing on the motor and tapped the splined

Lovejoy onto the shaft until it got to the bottom, to the bearing, and

stopped. The set screws on this one were almost an inch long, and 3/8"

diameter instead of 5/16". That was probably much better, and there

wasn't room left for outer ones. Then I attached the motor. It was

1.50" from the plate measured at both bolts. There was a small scraping

noise at intervals as I moved the car, as the motor turned. The motor

hung down a bit. I stuck a short piece of 2"x4" lumber (actually 1.5" x

3/5") under the lower side to even it up to 1.5" all around. Now it

scraped more of the time! It could hardly be anything but the Lovejoy

coupler rubbing on the plate. Evidently the "jaw" end, which I had

thought would be within the plate and left a bit wider, needed to be

reduced just a bit more to clear the hole.

With a battery connected, again the car moved "maybe" with

6 volts, slowly with 9 and faster with 12. (Perhaps it's ironic that my

Electric Hubcap motor probably would have done about the same if

connected to the tranny the same way - but its lower RPM would have

limited the travel speed even for city use, and it probably would

overheat in actual driving.)

Sometime I decided that the motor controller should go

inside the car, out of the weather and road dust. There wasn't much

room if one still wanted to be able to use the passenger seat, but the

shift lever was gone so was space in the middle from the parking brake

to the heater ducts. A controller just behind the firewall would still

have pretty short cables to the motor. Perhaps all the drive

electronics (circuit breaker, relay, heavy contactor, motor controller)

could go inside in a narrow "center column" enclosure, just leaving the

heavy cables to the batteries and motor out under the hood?

On the 20th I made a hole to pass the cable through to connect the

batteries at the back to the front. I had just one Greenlee hole punch,

1.18" diameter, purchased a couple of years ago at an electrical

wholesaler. The hole was just large enough to get the wire through with

little to spare. No room for a clamp or a gland. I came up with a

two-part solution: I rolled a piece of sheet steel and wrapped it

around the wire, and I put a pipe clamp around that. The steel stuck

out 3/4" from the pipe clamp. I worked the cable and the steel ring

into the hole and tightened the clamp. The steel would protect the

cable insulation in the hole and the clamp would both hold the steel in

place and prevent the cable end from being pulled into the hole.

On the 20th I made a hole to pass the cable through to connect the

batteries at the back to the front. I had just one Greenlee hole punch,

1.18" diameter, purchased a couple of years ago at an electrical

wholesaler. The hole was just large enough to get the wire through with

little to spare. No room for a clamp or a gland. I came up with a

two-part solution: I rolled a piece of sheet steel and wrapped it

around the wire, and I put a pipe clamp around that. The steel stuck

out 3/4" from the pipe clamp. I worked the cable and the steel ring

into the hole and tightened the clamp. The steel would protect the

cable insulation in the hole and the clamp would both hold the steel in

place and prevent the cable end from being pulled into the hole.

At the same time I checked

the size of the 100 watt solar panels versus the roof of the car. From

side to side, they only stuck out about 1/2" over each door frame, so

it's unlikely anyone would hit their head on one getting in or out.

There was easily room for two front to back, but a third one would have

to extend way over the hood. One wouldn't be watching the birds! Two

wouldn't quite provide a full charge if simply connected straight

across the batteries (with a diode to prevent discharge). The voltage

was a little too low. Maybe, gradually, a 3/4 charge. (OTOH it would

never overcharge - no precautions would be required. But this is where

one wishes some "non-standard" voltage panels were available to provide

just another volt or two - 23 or 24 instead of the ubiquitous "(~)21.6

open circuit volts" rating. OTOH "specialty" panels would surely cost

twice as much.) Well, maybe a DC to DC converter would be the best

answer. But that should come with a "full charge" detector and shutoff.

There the electronics start to become custom projects. The seemingly

simple idea of connecting solar panels to charge starts to get messy.

On the 21st the motor controller and programmer arrived.

(Also the now spare L110 Lovejoy rubber "spider".) The controller was

surprisingly small, smaller than the gearshift lever enclosure, and I

could see it would fit easily in the center column space. Then there

were the external components: 12V relay from car key, 36V main

contactor relay, circuit breaker, polarity protection diode and

controller fuse. These were almost the same as for the Kelly

controller. I had mounted them on an aluminum plate that attached under

the hood. Could they all go inside the car? I dismounted the plate and

put it inside. Part of the plate was in the way of the gas pedal. Then

I turned it sideways. If I cut off the part of the plate where the

Kelly controller had sat, and removed a terminal strip, it was close

enough to ideal. (I don't have to redo it from scratch? Really?!?) The

Curtis controller would sit 2/3 off the end of the plate, but sheet

aluminum could be bent up and around to form a top and back for the