Turquoise Energy Ltd. News #119

covering April

2018 (Posted May 4th)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month

In

Brief

(Project Summaries etc.)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- 7CoreValues.org - Plastic beaches and oceans

- US Government: a failed democracy? - Guarded humour

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Chevy Sprint: got it running. (YAY!) Complications &

inspirations... Stereo & music - Controller & motor - Clutch

slipping - Another Try at "Sep Ex" Control - Take apart - Motor - Field

Drive DC to DC Converter? - Batteries - Headlights: fixing problems

from long ago - Moving along - Solar charging?

* PM Assisted Reluctance Motors, Improved Performance Unipolar Motor

Controllers(?) & Electric Transport

* Some Nissan Leaf Notes - EV Market

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Bandsaw Alaska Mill")

* "The Indoor Vegetable Garden" - Year round gardening with LED

Lights! (and other gardening)

Electricity Generation

* Hydro Power: Turbine Shaft & "Spiral Staircase" water wheel

* The Electromagnetic Spectrum, John Bedini & (V)HE Ray Energy:

Ideas and experiments

Electricity Storage -

Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc.

* Nickel-nickel: How good would it be?

April in Brief

Halibut Bight/Lawn Hill beach gratuitous image

having nothing to do with anything

Halibut Bight/Lawn Hill beach gratuitous image

having nothing to do with anything

from low tide looking toward my house (wherever it is).

The sand on the lower part of this unusual beach is always mostly

soaked

but it's only 1/4 inch deep or even between the sand grains -

those 'ripples' are actually patterns in the sand. On the upper part

the

rock and sand rearrange themselves with every tide -

in any place rocks one day, sand the next, or sometimes all gravel and

rock.

The Chevy Sprint - at the far side of the

acreage under its own power.

The Chevy Sprint - at the far side of the

acreage under its own power.

(Behind-right is the electric Miles truck, presently being kept under

the trailer shelter roof.

And behind-left is part of yet another pile of spruce branches that

hasn't been cleaned up yet.)

In April I did a considerable amount of work on the Sprint

car. I got

it to run right after doing the last TE News (as series wound motor)

and took it up Lawnhill road a way once, as well as across

the acreage a few times. I made several fixes or improvements. Now it

runs great "off road". But the

performance will need considerable improvement before hitting town

streets much less for highway cruising, and so far it's still "push to

back

up" - ugh!

But in the

process of trying to figure out ways to improve

it, I may have

hit on a potential technical breakthrough: in thinking of how to turn a

series

wound motor into a "separately excited" motor, I ran into a circuit,

simpler than others, that appeared to harness "HE" rays (apparently not

"VHE" rays), which might be used to supply more current to the field

coils. And from there the idea expanded in my head of potentially using

similar circuits to power other

electrical loads from these high energy "short space rays" that

continually shine(?) down on our planet, mainly from the plane of the

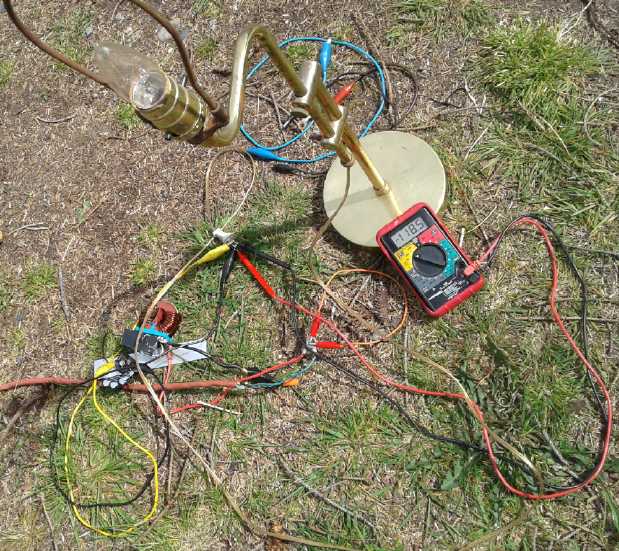

Milky Way. However, aside from better theory and in spite of a few

experiments with coils out by the car, I haven't got anything to

actually work.

But in the

process of trying to figure out ways to improve

it, I may have

hit on a potential technical breakthrough: in thinking of how to turn a

series

wound motor into a "separately excited" motor, I ran into a circuit,

simpler than others, that appeared to harness "HE" rays (apparently not

"VHE" rays), which might be used to supply more current to the field

coils. And from there the idea expanded in my head of potentially using

similar circuits to power other

electrical loads from these high energy "short space rays" that

continually shine(?) down on our planet, mainly from the plane of the

Milky Way. However, aside from better theory and in spite of a few

experiments with coils out by the car, I haven't got anything to

actually work.

I now had the 36 volt car

at least running, and I was reminded that Jim Harrington in Victoria

had a 2500 watt, 36 volt to 120 VAC inverter he didn't want. I bought

this from him and had it shipped up. It arrived in record time via the

post office. If there should be an extended power failure I can use the

car to keep the freezer and fridge cold and make coffee, using as many

solar panels as required to keep the batteries charged for these

essential purposes.

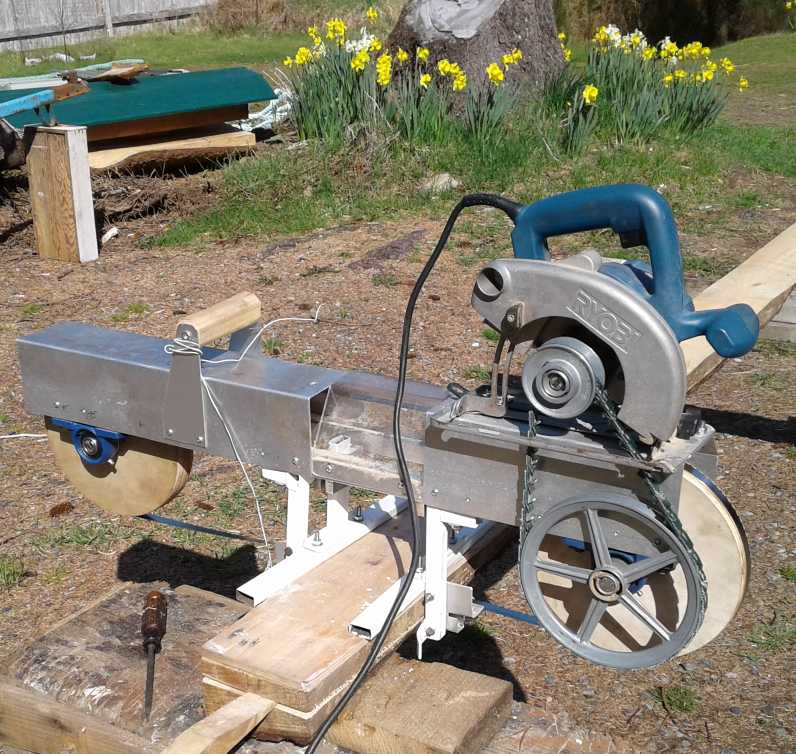

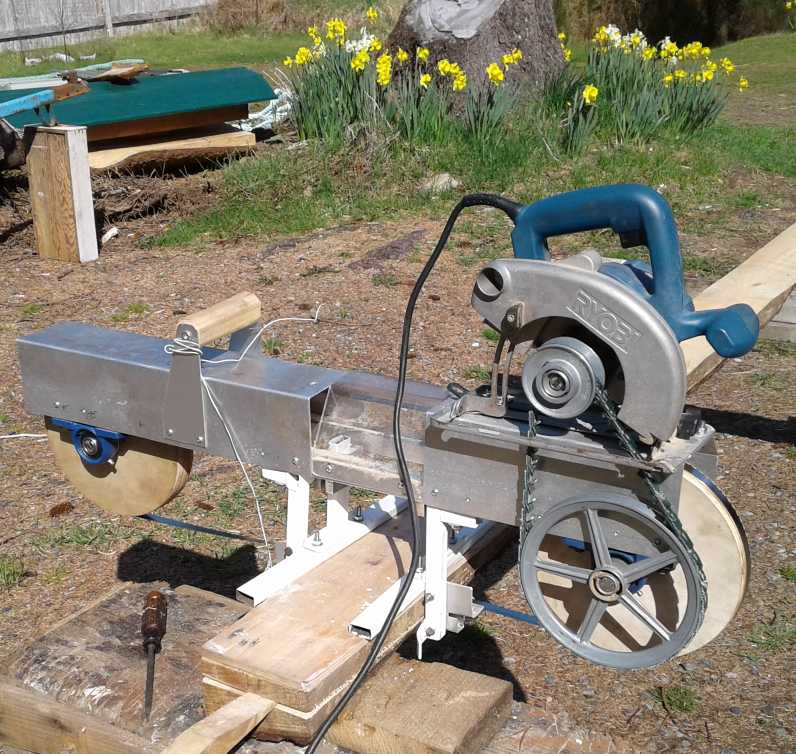

I made one

small stab at the handheld bandsaw mill and

finished the first adjustable band guide. It worked, but the other one

needs doing, and some other parts and mounts need to modified or made

stronger, before it'll be tackling real lumber cutting jobs. Adjustable

band guides are however the key. People say the trouble with bandsaw

mills is that you're always adjusting them. Instead of

trying to achieve what others have failed to do - make a small bandsaw

mill that doesn't need adjusting - the thumbscrew adjustments will

allow fine adjustments in a moment "on the go" in the middle of a

cut, without removing the saw from the work.

I made one

small stab at the handheld bandsaw mill and

finished the first adjustable band guide. It worked, but the other one

needs doing, and some other parts and mounts need to modified or made

stronger, before it'll be tackling real lumber cutting jobs. Adjustable

band guides are however the key. People say the trouble with bandsaw

mills is that you're always adjusting them. Instead of

trying to achieve what others have failed to do - make a small bandsaw

mill that doesn't need adjusting - the thumbscrew adjustments will

allow fine adjustments in a moment "on the go" in the middle of a

cut, without removing the saw from the work.

I would like to get it really working well and cut the

spruce cants blocking my driveway into lumber and put them away before

they start to deteriorate.

On May first someone said there is already such a thing as

a "handheld band saw". I'll be looking up that term to see what I can

find. I certainly came up blank in previous searching, but sometimes

it's a matter of knowing the exact term.

The indoor garden has

continued to bear fruit... I mean vegetable greens... from the January,

February and March boxes but I didn't plant a new box in April, only

garden and greenhouse seedlings, and tomatoes. It's getting to the time

of year one can grow crops in the greenhouse and outside. I may make an

improved version indoor garden for next fall.

The LED indoor garden April 20th with January

(leaf lettuce... and a potato), February (romaine) and March (spinach)

The LED indoor garden April 20th with January

(leaf lettuce... and a potato), February (romaine) and March (spinach)

box plantings, as well as tomato pots and remaining seedlings not yet

planted in the greenhouse or outside.

The lettuce has good flavor.

In monthly conference calls I've been following the

progressing documentation work on "planetary management", "evolution of

democracy", "social sustainability" and "the seven core values of

social sustainability". Two of the participants have just created a web

site called 7CoreValues.org .

(I got invited because of my "HandsOnDemocracy.org"

web

page.)

As the weather improved I also did a lot of work cutting

up and burning branches from the fourth spruce tree, cut down last

fall. The larger branches seem to make good firewood - I'm already

burning

those from the other three trees, which were cut early last summer. But

I heavily discounted the time it would take to clean everything up.

It's good exercise

and once a branch pile is burning it seems irresistible to keep cutting

and feeding it day after day until the branches are gone from an area,

but while doing that I keep thinking of the projects, gardening,

housework, paperwork

and other things getting farther and farther behind. It will be nice to

get a year ahead on firewood at some point so I'm burning wood that has

had a year or more - two summers - to dry out.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

7CoreValues.org

I've mentioned the new ideas of the core values of social

sustainability before - values that everyone in every culture could

agree on as being primary over other values. From these a morality (set

of rules of human interaction) will gradually develop and ethic

statements or principles (the "how to" for fulfilling the rules or

morality) will be derived to serve individuals, families,

organizations, societies and global civilization. Now there's a web

site

being

put together with them, per the title. Someone is putting together a

postcard with a slogan to introduce it:

"It's not hard to make decisions once you know what your values are.

"LIFE - Quality of Life - Growth - Equality - Empathy - Compassion -

Love of Humanity"

So far the site has just basic introductions to Planetary

Management, Social Sustainability and Values Based

Design Teams. There is a page with a few links to resources. Many

additions are intended or in the works. The family will be a prime

focus as the home is the basic institution that carries forward what is

learned and the values from one generation to the next.

If it is new and may attract little interest at the

present time, in coming years and decades people will be scouring the

web for info to help solve a perplexing array of societal, political

and economic problems. They will eventually look here and find some

positive values, approaches and other answers.

Plastic Beaches and Oceans

Apparently I am neither the first nor the only local

resident who picks up plastic off the beach. I'm told it's not nearly

as bad now as it was after the Japanese Tsunami of 2011. Also that the

west coast of the island - open to the Pacific and with no one living

there - is much worse than here on the east coast. Might we dare

hope some of those islands of floating plastic "the size of Hawaii" in

the middles of the oceans are shrinking too? But no one is out there

cleaning them up, so it depends whether the currents ever unlock them

and send them to some shore - like our west coast.

Is anyone in Charge?

One day in April US President Trump said what most of the

world so wanted to hear: That the USA had accomplished what it set out

to do [whatever that was] and would be withdrawing from Syria, to leave

the tangled affairs of the middle east to others. No more American

blood would be spilled. He was then reportedly incensed when his top

general told him it would take over a year to exit that country. (2000

troops was it? - about the number of people transported, with their

hundreds of vehicles and freight, every two hours by each BC Ferries

vessel?) If the president is really the nation's leader and your

commander in chief, this was pretty

blatant refusal to obey an order and tantamount to treason.

On cue there was then a reported "chemical gas attack" in

the last remaining rebel held area near Damascus, which everybody from

everywhere as soon as they went there and checked it out quickly said

there was no sign had ever taken place - no bodies, no hospital

patients, no chemicals. In the USA this (this... what?) was immediately

pinned on Syrian president Assad. (After all, Assad must be doing these

inflammatory, pointless attacks on his own citizens, all in rebel held

areas, to have been baselessly accused of them three times! It's the

stock narrative!) And what possible result could they have had? Only to

keep

the USA from leaving Syria in peace! (Most of the rebels in this

last enclave had already surrendered and were being bussed to another

part of Syria per the surrender agreement. A last small group held out

long enough to fake this little stunt. Now, Quickly, Attack Assad

before any more inconvenient facts leak out!)

The USA responded with a real (but forewarned) missile

strike against Syria, Trump tweeted against "that murdering ___,

Assad", and it was said that it would be a long time before the USA

would pull out of Syria. Conveniently a fleet of warships had just

arrived in the Eastern Mediterranean just in time to

launch the strike. The situation is perhaps confused by the amazing and

also conveniently timed and co-ordinated French and British

participation. But no real explanation

for the apparent abrupt reversal of stated US policy by its elected

leader has been offered so far.

Is the USA a failed state? Or at least a failed democracy?

The elected leader, whom we've long suspected isn't really in control,

has just demonstrated it by giving a direct order which was disobeyed

or circumvented, and then by changing his mind or having had it changed

for him - caving in. A bunch of brazen faceless, unelected, tinfoil hat

wearing civil service boss wackos with various conflicting agendas

appear to be in charge of what is laughingly called "US foreign

policy". GW Bush said on the initial invasion of Iraq "It's not about

the oil", but when Trump said the USA was going to pull out of Syria,

someone of note

said "We took the oil! We've got to keep the oil!" If it's an affront

to all decency, at least some honesty is coming out after 15 years. And

what's it all for anyway? In another 25 years we'll be using very

little of the stuff compared to today - mostly for plastics - much to

the relief of the environment and the populace.

Or was Trump even serious about getting out of Syria and

the Middle East in the first place? Whatever... along with their

victims, the people of the USA apparently aren't going to be permitted

to

live in peace until their government falls apart. perhaps until there

isn't enough of a productive public left to carry on giving all their

first fruits (over 50% of the entire US government budget) to the

military while everything domestic is permitted to fall apart through

neglect. How would 30 years of peace and relative tranquility

transform that nation? They certainly haven't had it in a century. And

what country would really attack a peaceable

USA? Its existential threats are indeed from within.

---

Funny, it seems "slaughter" is just "laughter" with an "s" on it. [per

Benny Hill, "The Film Editors" - youtube]

Is this why those who order deadly attacks think so lightly of doing it?

Can you send your regards without first sending your gards?

Do

choices have percussions before they have repercussions?

When cancer is in remission has its original mission ended?

(Well, we always hope so!)

People wish to fulfill their aspirations, but to filfull their morning

coffee cup.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get

into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and often, of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in

writing of

those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Chevy Sprint

Car - Forklift Motor & Fixed (8.9:1) Reduction

Aside from getting the car to

run, one pleasant thing that happened when I connected 12 volts and

brought the car's electrical system back to life was that the stereo

(after releasing and plugging in the removable faceplate a number of

times) was

very nice. This 1990 car's stereo had SD card and USB memory stick

plug-ins. That's pretty impressive when USB 1 wasn't created until

maybe

2002. I copied some files of instrumental music I'd written and played

from

1999 until about 2003 and played them in the car while I worked.

Save the Music!

As a side note, that inspired me to boot up the old Mac OS

9 system and turn all my music, written in the now unavailable

"Overture 2" music notation software, into MIDI files which, if they

lose text and many nuances, can at

least be imported by other notation programs. While there was never any

particular urgency, it was important to do this before I lose my last

computer that will run Mac OS 9 & Overture 2 and hence lose most of

the music I wrote, mostly from 1999 to 2004. I don't have printed

copies of some of it. They're now on a USB

stick. Now I must upload them to the web!

Most of Antonio Vivaldi's music survived until the 20th

century only by the scores being thrown in drawers in some back storage

room in a church for 2-1/2 centuries. Someone checked somewhere with

someone before throwing them out and somebody bought them all... and

what fabulous music it is! (Actually I think there was a second stash

found after that, and an occasional other score has turned up now and

then.) Vivaldi's music was very popular while he

was alive. He was JS Bach's inspiration. No doubt all I have to do

today to have Craig Carmichael's instrumental music preserved is get

around to uploading my music to some archive. I might have become

popular if I'd kept at it, but I had a hard time getting players

together and I turned to other pursuits.

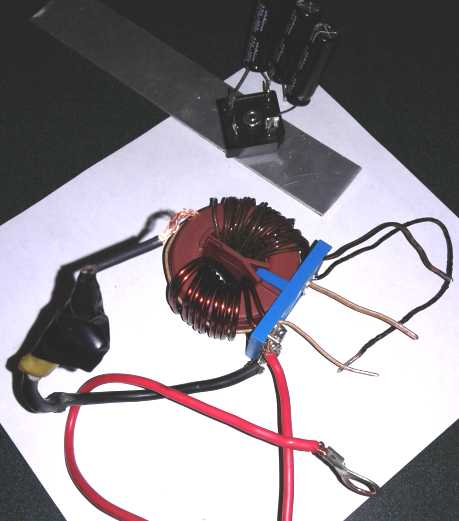

Motor Controller and Motor

The motor controller

assembly just sitting on the center hump

inside the car. (It needs fastening down and a cover.) Right

behind is a big hole that the gear shift stick went down into,

which was convenient for running the heavy wires through.

(A coffee cup holder will cover that hole.)

The red button is the obligatory circuit breaker trip within

reach of the driver - perfect!

Somehow I had

got the idea that a "series wound" type of

motor with four terminals, 2 for field coils and two for armature

coils, was pretty much the same thing as a "separately excited" motor

also having four terminals. The motor controller however didn't think

so. I couldn't get it to play ball. The resistance of the "series

wound" motor's field coil was so much lower than that of a 'regular'

separately

wound field coil that the controller had trouble modulating it and

considered it a "short circuit". It accordingly went into error mode

and shut off the power. The same reason both types of motor had four

terminals was so the field could be reversed without reversing the

armature, to get it to run backward. And (I assume) they are really the

same

except for the size and number of windings in the stator (field) coil

being drastically different.

Somehow I had

got the idea that a "series wound" type of

motor with four terminals, 2 for field coils and two for armature

coils, was pretty much the same thing as a "separately excited" motor

also having four terminals. The motor controller however didn't think

so. I couldn't get it to play ball. The resistance of the "series

wound" motor's field coil was so much lower than that of a 'regular'

separately

wound field coil that the controller had trouble modulating it and

considered it a "short circuit". It accordingly went into error mode

and shut off the power. The same reason both types of motor had four

terminals was so the field could be reversed without reversing the

armature, to get it to run backward. And (I assume) they are really the

same

except for the size and number of windings in the stator (field) coil

being drastically different.

After days of puzzling, I finally suspected this was the

problem on the evening of the third. I

disconnected the field wires at both ends, and wired the motor with the

coils in series - just as it had been when it pushed the car, connected

straight to batteries. The armature drive now drove the whole motor. It

seemed to spin okay and I took the jack out from under the wheel. I

pushed the car to the front of the garage, got in, and pressed on the

pedal. It backed up smoothly to the far end. Finally it ran nicely!

I don't know why but I'm somewhat amazed that my

slide-button-potentiometer 'electron pedal' made years ago now has been

working flawlessly, as shown on the smooth "throttle" readings on the

programmer as well as there being no power glitches during driving.

At least (and at last) it was running. But the plan had

been to use the

motor controller's field drive to select forward or reverse. I was left

with having to change the wires at the motor to change direction. It

could go forward or backward, but not both. Well, one could always be

sure to park facing uphill so the car would roll back out of its

parking spot. That or "push it to go backward" sounded easiest! (Keep a

peevee in the car to pry it with. Or a wrench to rewire the motor

twice.)

First I tried to open the motor to see about changing

things inside. Instead I almost wrecked it. Later I tried to come up

with plans to make it work like a

"sep-ex"

motor without actually changing the motor.

Project Slipping Backward

(April 4th) I backed the car out of the garage. A separate

problem

presented itself. When it went to climb a bump, something was slipping.

I could hear the motor turning but the car wasn't moving. This had

happened before I got the right Lovejoy connectors and I shrugged it

off as being one must have come loose and been slipping on the shaft.

Now they were

solidly in place, spline on one and keyed slot on the other. What could

slip? It finally hit me: my jamming up of that internal clutch in the

transmission had been inadequate. Evidently just because I couldn't

budge it with a big screwdriver with good leverage didn't mean it

couldn't slip once the transmission was full of oil and the load of a

whole car was on it. Could using heavy gear oil instead of "automatic

transmission fluid" have been a mistake? Maybe that was formulated

specially to make the internal clutches stick? Or was it just not

jammed stiffly enough? It looked like I'd have to take the whole thing

apart again. A big setback from a small cause!

Another Try at "Sep Ex" Control

I wasn't entirely convinced that the "sep ex" control

method couldn't work. Perhaps one could put a small resistor in line

with the field coil so that the controller wouldn't see it as a "short

circuit"? How about .1 ohms? 25 A ^2 = 525. 525*.1=52.5 watts. Ouch!

The "small" resistor would have to be pretty huge! Maybe instead of

running heavy (#10 AWG) wires cut as short as possible (5'), I could

run skinny wires, a long length coiled up? Maybe a long chunk of #16

gauge cord? Would the extra inductance from a coiled wire fry the

controller? Well, it was already driving a motor coil - an inductor.

Should be safe, then?

So I found a 19 foot piece of #16 extension cord and tried

it out. Nope. It still tripped off just the same, using either set of

coils as the "field". I measured its resistance. (by shorting one end

together and putting 1.00 amps through it from one terminal to the

other at the open end, and measuring the voltage.) It was 247 milliohms

- 0.247 ohms. The field coil was only 13 milliohms; this was 20 times

higher. Just how high, in miiliohms, do you have to go before it

doesn't register as a "short" in the controller?!? I should have

checked the "motor resistance" reading on the programmer.

Now, what about that clutch? Ugg! I put the motor wires

back at "series wound" and "forward". Between the slipping motor and

pushing with the other foot where it slipped I got it back into the

garage.

But I wasn't quite done. I returned to the "sep ex"

experiment in the evening. I put the "field" drive wires on the

armature. It read "100" - a whole ohm. It had gone from reading "0" to

a higher figure than was real. It should have been under 1/2 an ohm. I

turned the "Max Field" current down from 25 to 15. This time when I

pressed the pedal, it didn't quit. But the drive was feeble and the car

only sort of wanted to move. I changed it to the "field" wires on the

"field" coils. Here the resistance read "0" again, even tho I knew the

wires were 1/4 ohm. It worked just a bit better, if at all. I upped the

"Max current" to 20. Here the car would roll feebly back and forth on

the level cement, with very high armature currents. I went up to 21...

22... 23 amps, and here the controller tripped off again.

Then it started saying there was no contactor relay. The

voltmeter confirmed that sure enough, with all the tripping off of the

contactor while the highest of currents were flowing through it, no

doubt there was a lot of arcing inside, and the contacts no longer made

contact. Yet another thing to fix or replace before I could get any

farther! (The next morning the relay was okay again. But for how long?

Oops, not long - it quit again.)

I suppose that if the controller would put similar amps

into the field coils as into the armature coils, it would work fine. If

it would put in even 40 or 50 amps (reliably) instead of 15 or 20, it

might do it. That gave me the thought of a way that might just

conceivably make it work. That would be to open the motor and see if

either set of coils - those of the stator or of the rotor - were made

up of multiple identical coils connected in parallel.

If there were for example four wires inside going to each

of the field connection terminals, then they must be wired in parallel,

and they might be rewired in series.

Then 20 amps would flow through all four sets instead of 5 amps through

each. (And the motor controller field driver would probably handle 4

times the resistance better.) Then 20 amps would give the same magnetic

effect as 80 amps does now. That might make it reasonably

similar to what one would find in a "separately excited" motor.

Or if not the stationary windings, how about the armature?

This motor has 4 brushes instead of 2. Could there be in effect two

sets of armature windings electrically in parallel? If one could rewire

them in series and drove them with the field drive, then the magnetism

would double for the same current (which would be attained at twice the

voltage). 20 amps would be like 40. Might that be enough?

Take Apart

By evening of the 5th there were three compelling reasons

to take everything apart:

* The slipping clutch inside the transmission needed to be made solid.

* The poorly functioning contactor, doubtless with burned contacts. I

hoped I could fix it.

* The motor would be examined to see if any beneficial rewiring was

possible. (Without rewinding half the motor coils!)

and

* While I was at it, the Lovejoy coupler on the motor was rubbing a bit

on the motor plate, making noise. While it was off I could turn it down

just a bit more on the lathe.

* And I had missed putting the rock shield back under the transmission

oil pan - good time to do it.

That wasn't going back to square one, but it was certainly

a few squares back! I wasn't looking forward to reopening the

transmission that I had filled with 2 liters of heavy gear oil. Perhaps

it was time to switch to another project for a while? In a fit of

determination or desperation, I disconnected and disassembled

the whole front end in an hour before bedtime: motor, batteries,

battery shelf, motor plate, and transmission. Maybe it wouldn't be so

bad. And maybe I could just tip the transmission up so the oil stayed

at the back while I took off and pulled out all the pieces?

I tackled the

transmission the next morning. The oil stayed in the pan at the bottom.

But I could see it had wetted the gears and interior. That was

reassuring. I pulled out the clutch plates and drilled two holes

through them all (carefully aligned and held with C-clamps), then put

two #8-32 machine screws in through them with locking nuts.

I tackled the

transmission the next morning. The oil stayed in the pan at the bottom.

But I could see it had wetted the gears and interior. That was

reassuring. I pulled out the clutch plates and drilled two holes

through them all (carefully aligned and held with C-clamps), then put

two #8-32 machine screws in through them with locking nuts.

Rear of Transmission with bolted clutch plates.

The circlip ring to hold it in place wouldn't go back in

the same slot because of the bolts and nuts, but there was another slot

just a little farther out and I more or less got it in there - except

in a couple of places. I didn't want to "cludge" it like that (any more

than I had wanted to "cludge" the clutch closed in the first place),

but

there wasn't room to do much else. (Which is also why I didn't use

bigger screws.)

The circlip ring to hold it in place wouldn't go back in

the same slot because of the bolts and nuts, but there was another slot

just a little farther out and I more or less got it in there - except

in a couple of places. I didn't want to "cludge" it like that (any more

than I had wanted to "cludge" the clutch closed in the first place),

but

there wasn't room to do much else. (Which is also why I didn't use

bigger screws.)

With the transmission out in the light I could see the

Lovejoy connector could be moved in another 1/2" along the shaft, which

would move the motor in 1/2 inch and should take care of the rubbing. I

put the rock guard on the

bottom and put the transmission back in the car by mid afternoon.

7th: I disconnected and removed the contactor relay, and

took it in the house. Once I had it at the bench I noticed there were

two screws holding a cover over the contacts. All I had needed to

do was open the cover, without dismounting it. The contacts looked like

new. I guess the controller shuts off the motor drive currents just

before it opens the contactor. Then I realized the problem was that it

had a 36 volt activation coil and I was still running the car at 24

volts for testing. It didn't have enough pull to be reliable. If I left

the cover off

and pushed just a bit with my finger as I turned the controller on,

it would click into place.

Motor

At this point a sane person would have just put the motor

back on the

car and ordered a giant DPDT contactor relay to reverse the motor

direction

for backing up the car. But not me. Oh, no, I had to see if it could be

done better, if there was some way to make it from a plain "series

wound" into a superior "sep ex" type motor. It's

impractical to do regen braking with series wound, whereas it was

built into the sep-ex controller by driving the field coils in reverse.

I put it on the bench in the shop and tried to get it

apart. I got the ends unscrewed (one bolt broke off in the hole - 3 out

of 8 now with someone else's previous breaks), but I couldn't get the

bearing off one end nor the fan off the other, so I couldn't pull the

rotor out. I could sort of see inside. There's "flat" and "oval" wire

as well as round, but I'd hardly call this wire. More like flat copper

bars bent to the desired shapes. I could see why it was said these

motors could take a lot of abuse. There were indeed four stator

("field") coils. The question was then whether they were in parallel

and could be changed to series, or if they were already in series.

There only seemed to be one copper bar connected to each terminal. That

suggested they were already in series. Rewinding those heavy coils with

regular wire seemed like a poor prospect.

Each of the four coil cores seemed to be held onto the

inside

of the "can" with two bolts. I could remove those and the fan and all

would slide right through... everything would work except for the two

terminal bolt heads connecting the "wires". I took the nuts off one,

but

I couldn't seem to get it out. I had the impression the wire was welded

on. Doubtless easy to remove without the rotor, but

then getting that out was the whole problem.

Then I thought if I put the motor on the hydraulic press I

could press the end bearing out via the shaft. Since the end bell would

be supported

all around, nothing would break. Unfortunately... wrong! As I increased

pressure I heard a couple of noises and thought the bearing must be

starting to come out. In fact, the entire end bell was caving in. When

I noticed its concave shape, I released it. It didn't quite come

completely back out. The noises were the

brush holders cracking. Somehow the brushes were still held, but they

were no

longer flat against the commutator. Yow! And then I found a piece of

the rim of the fan had broken off somewhere in the madness. Now if the

RPM gets too high the fan just might fly into pieces. I put it back

together (cleaning and oiling the remaining bolts) and onto the car. I

reconnected the batteries. It still ran. At least now the car ran

without slipping -

Hurrah! And the rubbing sound had quit. But I now have misgivings about

the motor's reliability, efficiency and longevity.

Moving along, I checked currents on the 10th. A slow roll

on the level garage floor said around 100 amps of motor current (as

read by the programmer on "monitor"), which measured as around 25-30

amps of battery current (clamp-on DC ampmeter). If I stuck a 2x4 board

in

front of one wheel, it couldn't quite climb over it without just an

inch or two run at it. (This should improve when I raise it to 36

volts?) This stall involved around 180 amps in the motor or 84 amps

from the batteries. (I limited the motor current to 200 amps in the

controller programming.) Since the battery was just ~25 volts, these

translate to 25*25=525 watts (3/4 HP to 1 HP) to roll and 2100 watts

(2-3/4 HP) to stall at or climb over the 2x4.

That's probably not too dissimilar to performance I was

getting with the

Electric Hubcap motor with the clutch and flywheel when all was going

well with that setup in 2016. But then I had no level concrete, just

hilly

lawn, so it's hard to compare. And on this one I haven't yet gone from

24 to 36 volts yet.

Take 2: About the 14th I started thinking that I hadn't tried very hard

to get the field coil connection bolts out before I tried

unsuccessfully pressing out the bearing. If those bolts could be

knocked loose, the insulator might come loose and allow the bolt to be

turned sideways and removed. Then the fan would fit through the body

and it would all come apart.

Maybe to make it a "sep ex" instead of a "series wound"

the field coils could be rewound to have, ideally, say 6 times the

length of wire of 1/6 the cross section. That would mean 20 amps -

which the field drive in the controller can manage - would give the

magnetism that 120 does now. If I can get it apart. Then if nothing

else, the car would at least back up. But I suspect there would also be

improvement in performance.

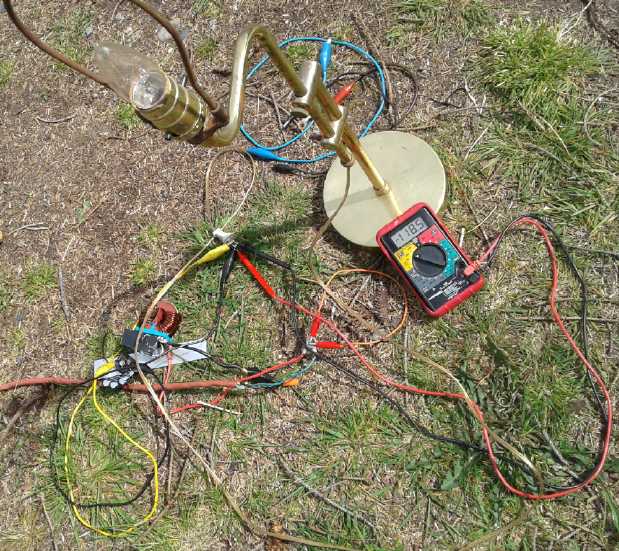

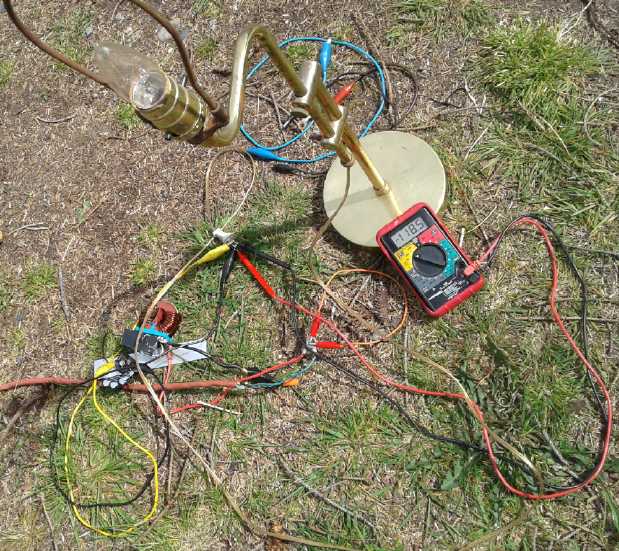

Field Drive DC to DC Converter?

On the 17th after the test drive on the road, a new idea

occurred to me. The objective of rewinding would be to attain the same

magnetism with lower current and higher voltage. But it would be

essentially the same power; it was just in how it would be used.

How about a DC to DC converter? The field drive already

produced pulse width modulated (PWM) pulses of current. Let the outputs

from the field drive build up a higher voltage, then when it was enough

convert that down to lower voltage, from which the motor field coils

could draw their higher current. Could it be done bidirectionally?

Could it be done with passive components? Feed the pulse drive through

a coil. Coils allow voltage across them instantly and then current

"gradually" starts to flow, opposite to a capacitor where current flows

before voltage can start to "gradually" build. Both devices can store

energy.

The motor coils measured 78 microhenries (field) and 124

uH (armature). I had a 570 uH double coil (bought for the unipolar

motor controller). Presumably then the coil could store 570/78 ~= 7.3

times as much energy as a magnetic field than the motor field coil -

almost the 6 to 1 ratio I had thought might be ideal. It didn't seem to

help.

A DC to DC down converter usually puts a pulse through a

coil. The coil separates the input voltage pulses from the lower output

voltage to prevent excessive "short circuit" current

draw from the (higher voltage) pulses across the voltage drop to the

(lower voltage) output. The current from the pulses/coil then goes into

a capacitor that builds the output voltage to the desired level. A

feedback circuit of some

sort tells the pulse maker when the output (capacitor) voltage is too

low so it will provide another or longer pulse(s) of current to bring

it up to

the desired level. The motor controller field drive already puts out

pulsed current. We're not too concerned with feedback or the exact

output voltage being attained. And here (ideally) it has to be

bidirectional. So coils

and capacitors by themselves might just do the job.

With the coil by itself not appearing to do much, I hunted

down a non-polar 115 uF ("motor start") capacitor to 'hold the output

voltage', put

wires and lugs on it, and put it across the motor field, with the 500

uH coil in series. It seemed like the car was just about to start

moving - in either direction - when the field drive, tho now limited to

15 amps, would shut off the controller. Was it a little better, or was

that just my imagination? 115 uF was pretty tiny for storing energy

compared to the heavy load of the motor coil. Might I have some much

bigger capacitor

that wouldn't quickly blow?

And might a bigger coil prevent the controller from

tripping off? I wired up the double 570 uH coil pair in series. In the

weird world of inductors it read 1800 uH (1.8 mH) instead of about 470

on my meter. The programmer still said "0" ohms. It still tripped off

before the car would start to roll. To limit the current, the inductor

has to match the pulse frequency. If it's too small for the

frequency it acts like a short circuit. Options are to raise the pulse

frequency (or decrease the pulse width) - not an option here - or to

use a

larger inductance. Perhaps a millihenry or two were way too small for

the frequency? Maybe it needed 50 or 200 or 1000 millihenries?

Next day (21st) I thought I'd try something else a bit

radical. I put the coil in series with the armature coil and drive.

Again the car only almost seemed to want to move - not much change

there. But very soon, smoke came out from under the hood. One of the

wires to the coil, selected long ago for another purpose, was only

about #16 AWG and the insulation was burning off of it. I should have

been

able to predict that in a 200 amp circuit, but I thought it would last

through a quick test. (Somehow that seemed to end that line of testing

despite a new, fatter wire.)

Batteries

I got the batteries mounted some time in the early part of

the month. I covered the details of figuring out the arrangements last

month. The front ones still need a proper cover and tie-down, and they

all need their chargers installed.

The lithium cells really

put out about 3.2 volts under

load. So a "12 volt" lithium battery is really about 12.8 volts until

it's getting low. So I variously call a "24 volt" lithium battery 24,

25, or 25.6 volts, and a "36 volt" one 36, 38, or 38.4. All depending

how exact or explicit I mean to be. The "96 volt" Swift was really a

little over 100 volts (102.4) and as much as 109 on the voltmeter while

driving when well charged. For simplicity I call it 100. (The Sprint

has been measuring around 40.0 standing and 38.9-39.1 in motion.)

I started thinking about all those sessions drawing many

tens of amps if not 100 out of the lithium batteries. Some were still

unconnected, but they had been shuffled around so I wasn't sure which

had been used. I took the four

chargers handy nearby and started charging some of them. After enough

time I checked voltages. A lot of the cells were around 3.3-3.4 volts.

But I found one at 4.0 and one at 4.25. They're supposed to stop

charging when they hit about 3.8, but they weren't balanced. Generally

a lead-acid charger will stop at

14.4 volts, which should be 3.6 volts per cell. But I was beginning to

suspect that there were not just two but many cells that would refuse

to rise above about 3.35. If 3 cells wouldn't rise out of 4 in a 12

volt battery, then the fourth cell would hit 14.4 - 3(3.35) = 4.35

volts or even more. Over 4.2 volts it could be ruined - or worse, catch

fire or blow up. So even for 12 volt charging those little BMS shunt

circuit boards were really a good idea. And what if none of them would

rise up and they all stayed at 3.35? How would the charger know when a

battery was charged if it wouldn't rise up to 14.4 volts? Wouldn't it

just keep pumping juice in until something blew? There were some

pairs of wires connecting all the cells and BMS boards together in the

Swift. Somehow they must have told the charger when to shut off?

I wasn't liking this. I set a timer to remind myself to

check every 1/2 hour while the chargers were on. None of them said

"finished" and shut off by itself. If I told them to charge at 2 amps

instead of 10, the voltage of the cells actually dropped and stayed

lower.

I opened one charger up to see if there was an adjustment.

If they would shut off at, say, 3.5 volts per cell they should be

pretty well charged without risking one cell going over 4.2 volts.

Nope, no adjustments. (I wish I had bought more of the type that had an

adjustment trimpot that Canadian Tire used to have, which I set to 14.2

for NiMH batteries. You don't know whether they have one when you buy

it - you only find out later when you open it and try it, and by then

they're gone from the stores. But then those ones were

only 4 amps.)

I turned on the 12 amp charger for the lower 12 volts in

the hood compartment again on the 10th. Last I checked most of the

cells were at 3.33 to 3.42 volts. But one on one battery was 3.8 and

one on the other was 3.7. These are about as high as you'd like them to

get, but the limit is 4.2, so I left it on. I didn't check for a while

while I was working in the car, and when I did, the charger had shut

itself off. Yay! The two high cells had gone down somewhat after the

charging was finished. I hope none

got above about 4 volts before the shutoff. (Come to think of it, I was

measuring 13.6-13.8 volts at the headlight switch in the car when

checking it.) The next time I charged it the cells seemed more even.

Perhaps they mostly just needed some equalizing after sitting around

for months? Some would doubtless have higher self-discharge than others

and so would be lower.

Charging on the 15th with all nine batteries installed, as

I

checked I added a BMS circuit board to each battery that seemed to be

going to a notably higher voltage than others in the same set. There

weren't enough to go around, but that should probably do the trick.

But it seemed senseless to have the chargers blasting out

and

heating up BMS board resistors until you could smell the heat, just to

get up to their arbitrary 14.4 volt setpoint when the cells were

already all charged. Then it occurred to me that one could drop the

voltage by .6 volts or so with a diode. That with a resistor across it

so the chargers would sense that a battery was present. (Hmm... those

10

amp chargers don't need the resistor - big sparks if the clips touch.

The 12 amp ones do.) Car alternator diodes with big heatsinks should do

the trick.

While on the subject, I somehow had the impression that

the small 40 AH lithium cells were lighter for their storage than the

100 AH

ones, which weighed about 31-32 pounds for a set of four making 12

volts. So I finally weighed a set of the smaller ones. 13 pounds.

Multiply by 2.5 since they were .4 of the amp hours: 32.5 pounds -

virtually the same energy density!

And BTW, what happened to lithiums having energy densities

of over 100 WH/Kg? I get 12.8v*100 AH= 1280 WH. 1280 / (31 lbs / 2.2046

lbs/Kg) = 91 WH/Kg. Well that's actually pretty close, and supposedly

over double what lead-acids have.

The 100 AH, 12 volt NiMH.s were about

40 pounds, making them 66 WH/Kg - about 4/3 heavier; for the Sprint

they would have been 400 pounds instead of a bit under 300. Six ~~380

AH lead-acid golf cart batteries for similar or less effective storage

would have been around 700 pounds.

I wondered also how nickel-nickel would fare, and trying

out a

few fuzzy redox calculations I decided that in practice it might be

roughly

comparable to lithium rather than higher energy per weight. But in

principle they should be cheaper, safer and less finicky. And last

forever. (If one

could get nickel-air to work, they would be really fantastic - double

to triple the energy density.)

Headlights: fixing problems from long ago

Long time diligent readers of TE News with great memories

may recall that I

took apart the dash console to change the wiring of the headlights some

years ago. The common connection to high and low beam was +12 volts

instead of ground, and the low and high beam drives thus both went to

ground. This was reverse polarity for LED headlight 'bulbs' I had

bought. (I suppose they didn't think polarity mattered in 1990 before

bright LEDs were invented.)

It was an endeavor I soon regretted. A "daytime running

lamps control unit" ("DRL") circuit that wasn't supposed to be in the

1990 Sprint according to the Chilton shop manual (and wasn't

mentioned at all in the Hayes one) kept the rewiring from working

properly. I put the halogen bulbs back in and tried to wire it all back

the way it was. But that didn't seem to help either. I assumed I must

have fried the "DRL" circuit, but I didn't know where it was. The

console has been apart ever since. Now that I was getting the car

going, I decided it was time to try and get it working again.

But this one time when I tried it, the headlights came on

when

the key was turned to "run" position. Apparently the "DRL" circuits

were working after all. But nothing happened when you pushed the

"headlights" button, and the high beams only came on when you pulled

the lever to "flash" them. I started thinking that might be good

enough... because the lever was sticking in the "flash" position to

keep the high beams on. But the

next day I tried again, and as before there were no headlights at all

except high beam "flash".

I started with the "headlights on" button. It made a

ground. Finally I got a paper clip and stuck it into the connector the

light switches plugged into. Ground when on. On the other side of the

same connector, same pin... no ground! I unplugged the connector

(looked fine, no corrosion) and plugged it back in. This time there was

ground on both sides. Success... except still no headlights!

I went back to the manual and looked at the DRL circuit

"black box" again. The parking brake switch went into it, but it didn't

run the parking brake light. Why was it there? Suddenly I suspected and

checked: sure enough, if the parking brake was on, the headlights

turned off! (I much prefer "parking brake on, car won't move",

confusing tho that can be. More easily done with electric than gas!)

Luckily I had had the parking brake off the previous day so it had

worked,

or I'd never have figured it out!

So, it would minimally "work" as it was. (Of course, the

sticking "flash" switch would probably pop out with road bumps.) But

surely it was

just one wire somewhere? The one that I had just "fixed" at the

connector. From there it went into that almost inaccessible high-low

beam switch on the steering column. But the wire there was a different

color, so there had to be another connector somewhere in between.

Finally I realized the biggest problem. It wasn't that I

was working in a poorly lit garage. It wasn't that I was inside a dark

car in that garage. It wasn't that I was under the dash where there was

almost no light. Well, it was all those, but it was also that

everything was colored the darkest blue-grey or black. I had a table

lamp in there with me (bare LED bulb - I must have dropped it, knocked

it or picked it up by the bulb over a dozen times by now - not to

mention leaving it with the bulb touching plastic or lying on the

upholstery -- try any of those with incandescent!), but one

could only see what it was shining directly onto. All else was dark

shadow or glare in the eyes. Finally I picked up the light and instead

of trying to find a

better spot to set it, I moved it around to see as I traced where the

cables from the steering column went. The molded nylon fuse block also

had a bunch of connectors around the edges, and the high beam switch

wires went to one of these. I pulled it out and found one badly

burned connection pin with melted nylon surround. Somewhere in the

attempt to change things long ago I must have shorted it and got it

hot. I tried to poke in a jewellers screwdriver and scrape the

contacts. I doubt I did much but when I plugged it back in the

headlights worked.

So at long last I put the console on the dash back

together, and called it a [wasted] day. I had some thought of going on

into the instrument panel while it was all apart and putting the Curtis

"multifunction" display into it where the "engine temperature" or

"fuel" gauge was. But it was probably safer just to mount it up on top

somewhere. Anyway I don't have the right socket to plug it into yet.

And it was a relief to finally have the dash back together.

The better part of valor, way back then, would have been

to try to take one of the LED headlight "bulbs" apart and see if I

could swap the wires inside (I still might) rather than try to change

the "upside down" car wiring, which turned out to be much more involved

and difficult than expected owing to the "DRL" circuit.

Moving along: power, friction, clunking CV shafts, 38 volts,

invidious comparisons, license & insurance

On the 11th I found a 12 volt "hot in Run'" power wire

under the hood and (rather than try and trace it back under the dash

and make a connection at its source) I cut it and joined it to

another wire and routed it back into the cab to activate the power-on

relay to the motor controller. The motor controller drive system now

comes to life when

the car key is turned to "run". Wow! Just like a real car!

I pushed the car back and drove it forward again a couple

of times. I had been noticing it seemed harder than it should have been

to roll the car and to keep it rolling. I jacked up the back left

wheel. It spun quite freely (yet it was the one making a periodic

audible brake rubbing noise at one point of its turn). Then the back

right. It dragged a little (no noise), but not much. The front wheels

were both the same: hard to start turning and didn't spin long. Of

course the motor would spin too. The transmission would shift position

up or down a bit depending on the direction. It seemed the friction in

the motor and drivetrain was multiplied by the 8.9 to 1 reduction ratio

to become quite a substantial drag when applied back through it.

Later I pushed it back out of the garage and drove it back

in. Somehow it didn't seem very smooth. Maybe the motor needed a couple

of supports besides just two bolts that held it in and kept it from

spinning but didn't hold it solid?

12th: I found

two items (SDS hubs) just the right length

to use for spacers/supports and put them on the motor mounting bolts.

Lo and behold, the car rolled easily again. The currents to drive it in

the garage were also at least 25% lower, and it was smoother. But not

entirely smooth.

12th: I found

two items (SDS hubs) just the right length

to use for spacers/supports and put them on the motor mounting bolts.

Lo and behold, the car rolled easily again. The currents to drive it in

the garage were also at least 25% lower, and it was smoother. But not

entirely smooth.

I moved the Nissan Leaf out of the way, pushed the Sprint

out of the garage, and drove it along the driveway a ways. At the end

the driveway went steeply downhill to the highway. I could push the car

backward to start turning it around, but if the wheels straightened

themselves out it would back straight down and across the highway at

considerable speed! So I turned it off and pulled the key out to lock

the steering in a sharp turn. That worked, putting the car crosswise on

the hill, but the turn took it farther down than I expected. It

wouldn't climb out with the pedal floored, drawing 100 amps from the

battery and probably with my set limit of 200 amps flowing in the motor

- or reading close to it anyway. (Was it going to do better with 36

volts other than the battery current being 67 amps, if I didn't allow

more than 200 amps of motor current?) But I stopped and let it roll

back until the rear wheels had gone as far up the other bank as they

would go, floored it again, and it - barely - crawled out of its "hole"

and onto leveler ground. As I drove across the yard and back it got

clunkier and clunkier. I drove it back into the garage, and put the

batteries (four for 200 AH at 24 V) on charge. I checked for loose

wheels, loose CV drive axle nuts. Nope. Evidently, as usual, something

in my mechanical work was inadequate.

That night I thought of something. The inside ends of the

CV drive shafts had each had a little "C" circlip on them that made

them

sort of "click" into the differential. Those made them hard to get in

and out, and anyway there was no way the shafts could come out once all

was in place - there wasn't room. So I had removed them through all the

years of transmission experiments. Sure enough, the shaft on the

driver's

side had pulled out about 1/4 inch. I worked it back in. Driving one

turn

of the wheels in the garage it was hard to be sure, but it seemed to

eliminate the clunk. Was that the cause? - just enough play in the

shaft to make a "clunk"? I looked in the ashtray and there were the

circlips, still there after these several years and some of the last of

the many bits that had been in there. I had forgotten what they were

for.

The next day (13th) I pushed the car out of the garage

again and took another drive across the yard, taking a slightly

different route to stay more up the hill. This time backing up was

slightly uphill and I finally gave up with the peevee and blocks and

and changed the motor wires for "reverse" and backed it up. Then I

pulled on the drive shaft and it came out even farther than it had been

before. There was the clunking again. I pushed it back in and all was

well until I made a sharp turn into the garage, and it started again.

Also, after I had put the straighteners on the motor

mounts, the rubbing noise was back. Ugh! Evidently it was time to

uninstall the whole front batteries, shelf, motor and transmission

again. (And I had just about gone back to finish doing the band saw

mill's band aimer!) I took it all apart and got the circlips in. I

banged a finger when a wrench slipped putting the transmission back on,

and called it a day. Not before I shoved the drive shaft inner ends

'home' with a pry bar. (I get lots of banged fingers. But this one

raised a bump on the bone, still there and it still hurt two weeks

later whenever anything touched the spot.)

That just left the rubbing

motor. I could see from marks

on the lovejoy coupler where it was rubbing. It needed turning down a

little more. I did that on the 14th, but I didn't go far enough and it

still rubbed a bit (rats!). I pushed the car back and drove ahead... it

still seemed a little clunky. (?) Perhaps it was my shaft in the

transmission, which did after all have 1/8"(?) of end play. Either that

or the CV joints weren't very good. After all that's common on older

front wheel drive cars, and I never drove it on the street before I

took the engine out, so I had no sure knowledge that they were good

when I bought the car.

I drove it across the yard again. This time I 'booted it'

going back toward the garage, and it accelerated okay, drawing the

better part of 200 amps from the battery. (160 A * 25 V = 4000 Watts:

over 5 horsepower.) My confidence that nothing would blow up at least

while driving short distances is rising to dangerous levels.

It always seems a bit startling to see such high currents.

I had to remind myself that 400 amps in the Sprint at 25 volts would be

equivalent to just 100 amps in the now defunct Swift at 100 volts,

which

was what the Swift had used just going down the highway. So 160 wasn't

so much. High currents are inevitable if one is going to use a low

voltage. And of course once the Sprint is 38 volts (3/8 of 100 V), the

160 amps would have been ~110 (and 400 would be 267). Next question:

What would it do on the highway? That little motor wasn't going to like

267 amps for very long and it wasn't going to get it for long from the

300 amp motor controller. If it was going to work on the highway, it

would have to use less horsepower than the Swift had. (and the motor

and fan would have to stay in one piece.)

And then after I thought about that a while, I started

thinking that although the 10000 watts the Swift had used to go down

the highway, nearly 14 horsepower, was probably similar to the Leaf,

it's probably not the highest efficiency attainable. It shouldn't take

double digit horsepower to keep a small car running at 80 KmPH, so it's

just possible that the Sprint might do notably better. The Sprint is

the four door 'wagon' model instead of the two door hatchback, but the

transmission (as modified) is probably considerably less lossy and it's

an earlier year car, when they were made lightest with 12" wheels and a

3 cylinder 1.0 litre engine. That would best be put to the test by

putting the Sprint on the road. This is where I wish I was back in

town. The highway here is quiet, but the traffic that does come along

is all doing 80+ KmPH with lots of big trucks and there's hardly a

shoulder in most places.

Next day I switched to 38 volts and installed all 9

batteries for 300 amp-hours. In in-yard driving tests it seemed the

battery currents were lower - 3/2 the voltage, so 2/3 the current. (The

current in the motor was still limited to 200 amps by my setting.) It

only went much over 100 amps once, momentarily to 134 amps (if I read

it right in the quick glance) for 5100 watts. More typically 105 A * 38

V = 4000 W. So evidently the car is limited to half the power (max)

that the Swift used for its typical highway cruising. I think Sheldon

said the rating was 3.5 KW, so it probably shouldn't be pushed too much

harder.

In addition, with 3 batteries in parallel, 100 amps total

is only 33 amps per cell - much easier on them. That says the batteries

will last for a long drive. But does the car really have enough power

for the road? If the transmission as I had redone it only lost 10% of

the power instead of the typical 30%, that was 20% more

effective drive with the same watts, so 4000 would have the effect of

over 5000 in the Swift. (Hmm... stuck in second gear as the Swift was,

the input shaft was turning very fast and the losses in 2nd might be

well over 30%. That would help explain why it needed so much power.)

Another thing that didn't inspire confidence was that the

clunking indeed seemed to be coming from the CV drive shafts, because

it got worse with sharper turns, a typical symptom. Apparently the

typical failure sequence is that the rubber "boot" over the CV joint

bearings rips and splits into two pieces, dirt gets in, and they

deteriorate from there. Since the boots weren't ripped or split, I

assumed they must be okay. Nope! But then I've already had bitter

experience with so-called "rebuilt" drive shafts in my Toyota Tercel

when I had the clutch replaced. On mine the boots had split, so the

transmission place put in two sets

from different vendors and they were both crap. (The guy was surely

about ready to cry after the second set, and he soon sold the

business.) AFAIK all these

sleazy vendors do is put new boots and grease on them and nothing else

- no actual rebuild. So you install "rebuilt" ones to be safe when the

car is apart for something else, and they're worse than the ones you

took out. It's too hard to take everything apart again, so you're stuck

with them. Perhaps that's also what happened to the Sprint before I

owned it. I suppose I'd still have shelled out the 840$ for the car if

I had known.

But I would have got the right 'new' set from an auto wrecker while I

lived near some.

I do have the drive shafts from the Swift, as well as

another set from an auto wrecker, but they're all the lengths for the

manual transmission and won't fit with the automatic. (The left one is

longer and the right one is shorter, just by 2 or 3 inches.) So I'll

have to take them all apart and transfer good bearings to replace bad.

I hope that's doable at home. And of course it means taking everything

apart again again! again! to pull out the shafts. I wish I had figured

it out before the last time, but I just assumed it must be the circlips

since that was something I had done. I didn't think I had bought the

car with the shafts already bad. I suppose it can wait a while, but I

don't much like a "clunky" car. (And I was just thinking of turning to

other projects of more potential import for a while!) But (getting

ahead of the narrative) after the

next motor install it was okay, so it wasn't the driveshafts after all.

On Monday, the 16th, I decided to fix the sticking brake

on the Echo, give it a drive on the highway, and then transfer its

insurance to the Sprint so I could try it out on the road. My next door

neighbor has two connected driveways for "in" and "out". (And they're

away.) That's about 1/2 a Km test run with a half way parking place in

case of trouble - with no backing up. In the other direction and not so

much farther is Lawnhill road, a paved off-highway street for further

test drives.

The plan went bad when the Echo, now sitting in the

driveway with a wheel off, needed parts. It had only needed a little

pin last

autumn (I was going to make one from a nail), but somehow a rock had

got in (winter gravel & sand on the

highway - it was dirty like I'd been driving off-road) and chewed up

the brake shoes. I had to drive to town (Leaf), get parts and transfer

the insurance without the Echo getting its road trip, which it really

could have used.

I parked it at the far end of the yard, leaving the road around the

back of the house and across the acreage free.

So I drove the Sprint

around the whole yard, across the acreage, a .2 Km round trip. Other

than the clunking in

turns, the rubbing motor and pushing it backward to turn around, it

drove pretty well. I started to think that maybe nothing would suddenly

jam up and that sparks and smoke wouldn't suddenly come off the motor

controller

for no apparent reason or in hard going. It bumped along the rough

ground as fast as I was willing to go, but it was using 40-80% of the

'throttle' rather than 10-20% or 20-40%. It lost speed going

uphill and I doubted that it had the power for the highway. But somehow

I

had felt I should try with this motor in the first place, so best to

try it

out. (Upping the "max amps" setting from 200 to 250 or 300 should make

some improvement. But I'm leaving it for now.)

Before tackling the rubbing Lovejoy coupler (again), and

at the same time trying again to get the motor apart and look at

potential conversion to "separately excited", I decided to give the car

one road run just as it was. (17th) My worst suspicions were confirmed:

If it hit 20 KmPH with pretty high if not full throttle on the level

highway, it was just barely. I drove to Lawnhill road and turned up it.

I saw a neighbor in the window and stopped to talk to him. He had been

a mechanic and had tales of woe about trying to get parts to the

island, and the high cost, for any less common vehicles, and how he

thought no one would touch electric vehicles here. I was thinking that

that converting a car with more common parts and using

a low voltage was a big advantage for flexibility and serviceability.

Anything could be made to work. A production EV like the

Leaf might be harder for the uninitiated to deal with. Then a grader

came along plowing the

road (good grief; what timing!) and I had to jump in and drive off

before he got there.

The Sprint crawled uphill on the gravel on Lawnhill at

10-15 KmPH (the speedometer works - yay!), again probably at full

throttle or close to it, drawing well over 100 amps battery current. I

found a driveway that went uphill on the left and pulled in and waited

for the grader to pass. Without much pushing I got the car turned

around and drove back down the road. I probably passed 20 KmPH here

with around 50-65 amps current. I took as much of a run at my own

driveway as I could (at "100% throttle"), but came within an ace of

'stalled' before I reached the top. I was glad I didn't have to tow it

the rest of the way up. The rubbing, for part of each rotation of the

motor, seemed to be getting worse, and I could feel it actually slowing

the car down. I opened the hood and found everything was still cold.

The mounted end of the motor was not quite as cold as the rest. The

batteries were also cold. Then I thought of the motor controller but it

too seemed quite cold. It certainly didn't look like there'd be any

overheating problems! I pulled back into the garage and the trip meter

said I'd gone just 1.1 Km. (I bet my Electric Hubcap motor could have

done as well, but it might have got pretty warm. Neither motor was

going to over-rev at the sort of speeds I've reached so far!)

The next

things to deal with were the rubbing coupler, to

tie up the wiring properly, secure the front batteries properly in

place, and a few other details. I tackled some of these individually in

the

midst of having other things to do over the next few days, starting

with the coupler. It was nice to drive across the field and back

without the rubbing noise.

The next

things to deal with were the rubbing coupler, to

tie up the wiring properly, secure the front batteries properly in

place, and a few other details. I tackled some of these individually in

the

midst of having other things to do over the next few days, starting

with the coupler. It was nice to drive across the field and back

without the rubbing noise.

I mounted the motor a bit better on the 21st - it seemed

to want to be 7/8" from the mounting plate now instead of 1-1/4". The

"clunking" in turns seemed to be gone! I drove across the field and

back a second time just to be sure. It seemed about as smooth as

driving in rough dirt gets. I guess the CV shafts are fine after all,

and it was probably the coupling shaft between the motor and the gears

doing the "clunking". (There must have been considerable end play -

3/8"(?), now probably reduced to under 1/16".)

Sometime I must drill holes in those aluminum spacer

pieces and put them onto the bolts so they can't possibly work loose

and fall out.

Whether or not the forklift motor just won't make the car

practical for the road I hope sometime to try making a better

reluctance motor that will run it with sufficient power and give it

lots of range (see below). Everything should stay the same except the

motor and controller.

Solar Charging?

Last month I mentioned the idea of putting solar panels on

the 36 volt Sprint for "continuous charge" anywhere, even while

driving. The problem was that two of my 100 watt panels didn't have

quite

enough voltage, while three didn't fit well. They either had to extend

way over the hood, which would block upward visibility, or over the

tailgate, which would interfere with

opening it.

But I thought that by having just two panels one might

achieve a trickle charge that would need no regulation. On the 29th I

rolled the car out into the sun and set a 100 watt panel beside it,

facing straight up as it would be on the car. A reading

across half the cells (6 cells for using two panels) said 19.9 volts.

A reading of the panel said 21.9 volts. If I connected the panel it put

1.2 amps into the cells. If I connected it across only 5 cells that

rose to 3.2 amps, and 4 cells ("12 volts") was 3.6 amps. So the trickle

charge idea would probably work, but one would get a lot faster charge

by

connecting across fewer cells.

One wants a diode to prevent the batteries from powering

the panel when there's no sun, and that dropped the panel voltage to

21.1 volts and the current across the 6 cells to .3 amps. Leaving that

permanently connected definitely wouldn't hurt the cells. But it wasn't

much charge, either, unless the batteries were way down. Connecting

just 5 cells

the current was down to

2.2 amps with the diode. With 4 cells it stayed up at 3.5 amps. After

charging four cells a while their voltage rose a bit, and then

connecting to

6 cells

again there was almost no charge at all. It seemed trying to trickle

charge the entire voltage was really a waste of solar panels that might

- eventually - give only 3/4 of a charge or less. And there

was no point trying to charge 5 cells per panel when there were 12

cells in series total and two would be left out. That left (a) having

two

panels

able to switch between battery banks, which would require a lot of

switches and manual intervention, or (b) somehow put up all three

panels, each one

charging a 12 volt battery section.

In the meantime I had come up with an idea for putting up

all three panels: put the front one over the hood with a hinge so it

could fold back and on top of the one behind it. (If necessary) when

driving, fold

it back; when parked fold it forward to charge. That seemed to be a

good compromise.

But now the fully engaged panels could easily overcharge

the batteries. I decided they would need a circuit to cut off the

charge when

a certain voltage (and or charging time) was reached, say for an hour

or until the

voltage

dropped to a considerably lower level. After an hour it could try

again, and if the

cells were still full, it would cut off almost at once for another

hour. I could try out some cheap solar charge controllers I bought for

hese "12 volt" panels and lead-acid cells, but I fear they would

probably

overcharge lithiums. So if I do decide to mount the collectors on the

car,

I'll also have to design and install the charging circuit. Unless I can

find some already made, made for charging lithiums.

PM Assisted

Reluctance Motors, Better Unipolar Motor Controllers & Electric

Transport

Referencing the Sprint car conversion article above and

the HE Ray ideas article below, before the end of the month my head was

swimming with ideas for improved electric motors that almost run

themselves, yielding higher driving distances from less battery power.

First I came up with a better reluctance motor configuration, for which

I could modify the motor I made in 2015 rather than start from scratch.

With the low back EMF and solid rotor allowing very high RPM.s to be

used easily, safely and efficiently, and the added efficiency of the

permanent magnet assistance, this should be pretty much the best

possible motor I can conceive of for electric transport. The high RPM

capability would completely do away with any need for a variable

transmission.

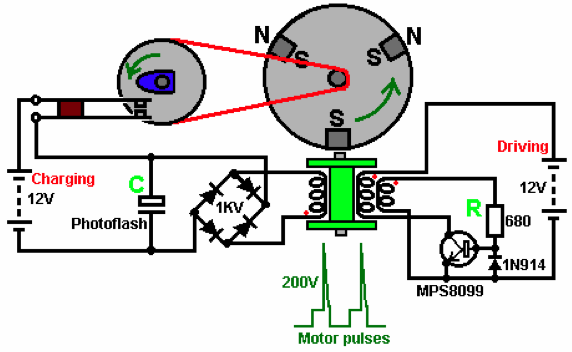

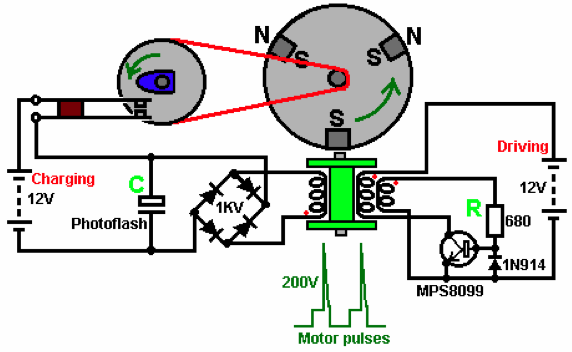

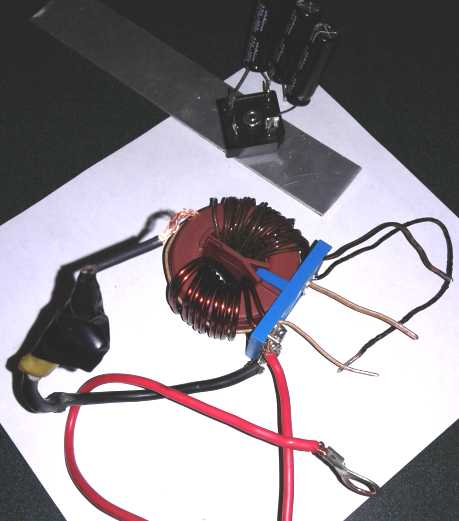

Then in the unipolar motor controller employed to run such

a motor, instead of discharging the motor coil turn-off spikes through

diodes as would be the usual design practice, the coils would be

allowed to build up the 100 or more volt spikes that could invoke HE

ray

energy conversion. When they hit that voltage (measured, or after a

very short pre-programmed time in which they would have hit it),

transistors would discharge them into the power supply line per the

existing choke coil isolation arrangement. In that way the HE ray

energy discharged into the magnetic field would help feed into the

system so the batteries would last longer. Or so went the theory.

The lure is there for getting that 500 mile vehicle range!

I would like to replace the forklift motor and present controller with

such new models (ones larger than the present test models) in the

Sprint. But working on my own, as I get older and seem to have less

personal energy to put into it, and a zillion other things to do, it

may be quite a long time before I am able to get all this put together,

if ever.

For the future, these are the sorts of developments

that will allow electric aircraft, ground effect craft, ocean vessels