Turquoise Energy Ltd. News #121

covering June

2018 (Posted July 3rd)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features:

* Stable Zinc Electrodes, The "Holy Grail" of battery making...

hundreds have tried and (more or less) failed: Grail TAKEN by new

electrolyte!

(See Month in Brief,

Electricity Storage)

* New Bandsaw Mill Concept: Self-Correcting Band Angle always cuts

straight! (See Month in Brief, Other "Green"

Projects)

Month

In Brief

(Project Summaries etc.) - Band mill - Band - Batteries! -

"Electrafest":Portable 6 KW J1772 EV charger

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Battery Commercializations?...Useless SDTC Again-Changhong-DIY

Crowd-Factory? - Crystal Sponge? - Moles and hydrocortosone cream:

Update - Feeding the 9 Billion? - After the Thugs (bad poetry that

doesn't rhyme) - Age of World?

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (no reports)

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Handheld Bandsaw Alaska Mill")

- "railway" band guide wheels: Mounting, adjustments & Cuts

- Self Correcting Band Guides?

* Proposed New Electrical Standards "RFC": a new standard Voltage

(38/36 VDC) +

Standard Connectors for 12 VDC, 38 VDC

- Idea: If making 38/36 volt connectors, why not market 38 volt

lights and appliances along with them? - Other notes

Electricity Generation

(no reports)

Electricity Storage -

Turquoise Battery

Project (NiMn, NiNi, O2-Ni), etc.

* Zinc: notorious battery electrode substance, TAMED by the new

electrolyte!

* Nickel-Zinc Batteries - Compacting electrodes - Glue &

Jell - Why, suddenly, Zinc instead of Nickel?

* Manganese-zinc & Lead-zinc cells & experiments (They all

work!)

* Zinc Sheet Electrodes work great - Shaping Plates to gain More

Surface Area

* Mn-Zn cell from scratch: works great!

This month is mainly about battery

experimentation and development. Now that I'm having real successes it

seemed like a good thing to concentrate on and I spent most of the

month on it. (More below.)

Notwithstanding that, I did just a bit of work on the

bandsaw mill guide wheels near the end -- and on the 30th conceived of

what I believe will be a real breakthrough in band mill design: place

the guide wheel pivots in front of the blade (instead of behind it) and

have spring mounted adjustments instead of solidly fixed. Then the band

will continuously adjust its angle of attack to keep cutting straight

and never veer off up or down (even if the blade is dull), which is the

main and very serious complaint I've been hearing for all band mills

whenever the subject is mentioned. With a single stroke, this should

raise the general liking for band mills among those who've milled wood

from maybe a 3 to an 8 out of 10. It's going to "Wow!" people.

I also said I'd play my Supercorder (the flute instrument

I developed 2003-2006 - www.saers.com/craig/recorder/

) in a couple of songs with a small band on Canada day, July first.

Practice and daily rehearsals took up much time in the last week - with

a half hour commute each way (in the electric Nissan Leaf, of course)

adding to the time. They didn't want me to use sheet music in the

concert and I've never played a "fixed script" without reading the

music before, so they were trying to teach an old dog new tricks and it

didn't go very smoothly. Then in the concert things went really awry

when the sound guy came up and wanted to adjust my microphone while we

were playing, talking to me and breaking my concentration in my most

prominent song. I missed my entry and played some wrong notes in the

rest. But the audience seemed to like it anyway, and (from the movie

"Star Wars")... "It's not my fault!"

Batteries!

Assembling

nickel-zinc

cell

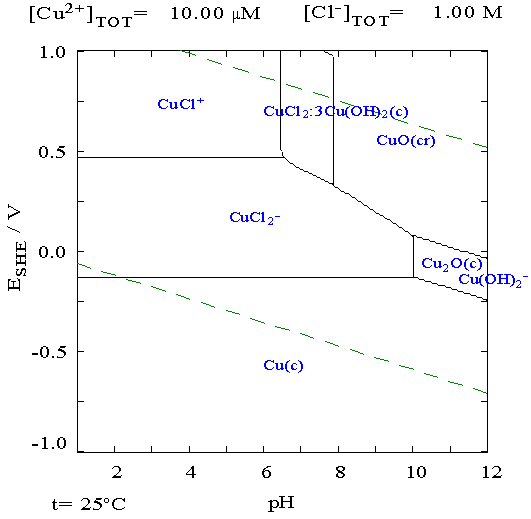

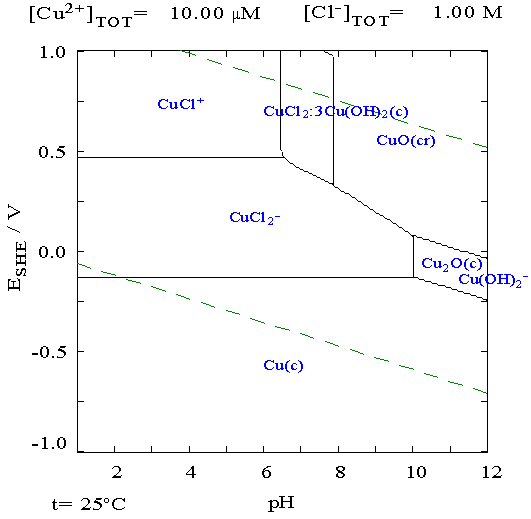

I started the

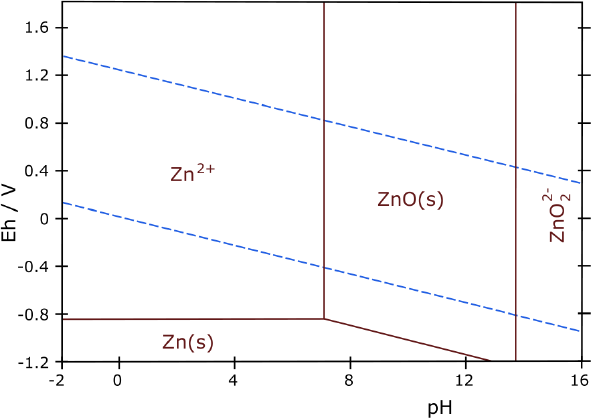

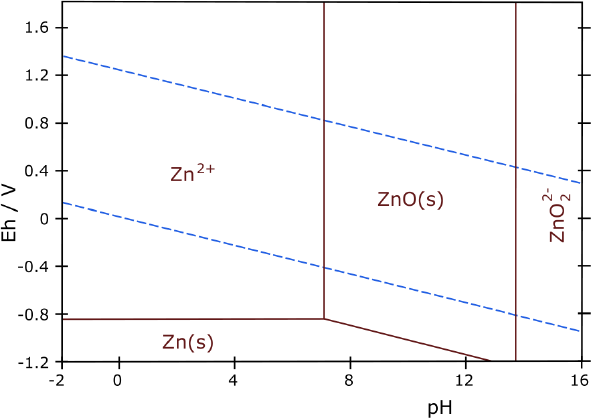

month by looking at some charts - Pourbaix

diagrams. I forget why. I hit zinc (just before zirconium) and suddenly

realized that zinc would work as

an everlasting negative electrode with the electrolyte I had come up

with. A long life zinc electrode has been a "holy grail" of battery

making ever since batteries were first made. Many have tried, but no

one has

had real success. Batteries with zinc are single use or

notorious for their short cycle life. Thomas Edison picked nickel-iron

instead of nickel-zinc to get a battery that would last, in spite of

iron's lower energy storage and poorer performance. A web search will

reveal many past and current attempts to make zinc electrolytes work,

or at least to last a few hundred charge-discharge cycles - mostly in

pH 14 alkali. For example, a Journal of the Electrochemical Society

article from 1991 cites ten previous articles on the subject and below

it is a list of 21 newer articles citing it.

I started the

month by looking at some charts - Pourbaix

diagrams. I forget why. I hit zinc (just before zirconium) and suddenly

realized that zinc would work as

an everlasting negative electrode with the electrolyte I had come up

with. A long life zinc electrode has been a "holy grail" of battery

making ever since batteries were first made. Many have tried, but no

one has

had real success. Batteries with zinc are single use or

notorious for their short cycle life. Thomas Edison picked nickel-iron

instead of nickel-zinc to get a battery that would last, in spite of

iron's lower energy storage and poorer performance. A web search will

reveal many past and current attempts to make zinc electrolytes work,

or at least to last a few hundred charge-discharge cycles - mostly in

pH 14 alkali. For example, a Journal of the Electrochemical Society

article from 1991 cites ten previous articles on the subject and below

it is a list of 21 newer articles citing it.

But in my pH 12 electrolyte zinc should last forever. Zinc

has high

voltage and energy per kilogram. In developing the pH 12 electrolyte

with oxalate to use with nickel (or possibly manganese), I had taken

the grail without realizing it! In fact, the electrolyte is

key to a number of potential better chemistries, mostly best using zinc

for a negative side.

So I made a zinc electrode with nano-zinc flake/powder and

traded out the nickel negative electrode for it. But the voltage being

higher meant that oxygen had to be kept out of the cell, or it would

spontaneously convert ("discharge") the zinc to zinc oxide. And I

wanted to get better

compaction on the plus electrodes. I found a compactor I had made

previously that would do that. It made square electrodes instead of

round. So next I made a whole new, square battery cell. (I could use

the 3D printed cases I developed quite a while back along with this

compactor.)

Concurrently with these great chemical finds and results,

I started

putting "stuff" into the electrodes to help hold them together as

thickeners, binding agents and gels. With successful electrodes to

compare with I could tell if the additive(s) were causing a problem.

They helped.

There was still a self

discharge problem in each cell I made, including in the manganese-zinc,

and that chemistry is noted for low self discharge. So it could hardly

be inherent in the electrode chemistry. By process of elimination with

the various cells I made, it finally seemed it must be my cheap

"pottery supply" calcium carbonate, converted by me to calcium oxide in

my mini kiln 6 years ago (TE News #47, #66). It pretty much had to be

contaminated, probably with nitrates. I ordered some guaranteed pure

stuff from Westlab chem/lab supply. I look forward to batteries that

hold their charge for weeks or months instead of hours. (How many years

has this been an ongoing concern of mine, which I've attributed to

other things or had no explanation for? Finally the light dawns...)

But the main thing was I had a great working chemistry

[and soon three of them] that

could be produced one way or another. Fantastic! Now, how to get

production happening?...

On the 5th I e-mailed SDTC (Sustainable Development

Technology

Canada) to tell them Canada could freely have this fabulous new

"created in Canada" battery

chemistry. But Canada didn't want this once in a lifetime opportunity.

An inventor with an invention, however Earth-shattering, doesn't

fit their Procrustian profile of a "well organized and supported

innovative

company" for funding. They don't even pay lip service to inventions and

they don't want to talk to inventors. Is that how to foster development

of new sustainable technologies? I have written of how they put the

cart before the horse before in TE News #80, and I've written more

again below in In Passing.

The next day I e-mailed to Sichuan Changhong Batteries in

China (to "the president") and pointed out the new chemistry they could

freely have. Given their current obsolescent line of flooded alkaline

cells - nickel-iron, nickel cadmium and nickel-metal hydride, made on

their production line bought from Varta in Sweden or Germany many years

ago when they ceased production there, I felt this was one company that

might be in need of

a new battery like this. They would be much more likely to adopt it

than

a lithium or lead-acid battery maker (who would more likely just wish

it would go away!), and their "green" markets

would really appreciate them. (Of course, their markets would then

start expanding, too, instead of shrinking!) So far I have received no

reply. They'll get a pointer to this newsletter, too.

Nickel plus electrodes would be great for a mass

production line, but so far seem hard to do for a homemade battery

because of

their

high voltage. (more experiments!...) So, what about other elements? The

ones that come readily to

mind are lead and manganese. I soon had a battery that worked well

using the manganese electrode of an old "F" size dry cell (found in 6

volt

lantern batteries). And I bought a new lead-acid battery to

get lead positive plates from. I got some good results from these with

zinc negatives in the new electrolyte.

L: Remaking manganese-zinc "F" cell with new

zinc nano powder electrode and the new oxalate electrolyte

R: Testing first lead-zinc cell in original

lead-acid battery case

L: Remaking manganese-zinc "F" cell with new

zinc nano powder electrode and the new oxalate electrolyte

R: Testing first lead-zinc cell in original

lead-acid battery case

Manganese-zinc flat plates

cell from scratch.

(Outside padding is because cell didn't fill case.)

This worked very well and will probably be

the pattern for battery production - if I do it.

But I started thinking rechargeable, "everlasting" Mn-Zn

would be the batteries to make at home. Much the easiest to make, CHEAP

materials, and higher energy density than lithium types. It would seem

that all that's been missing for 150 years to have a lightweight, high

energy, low cost and long cycle life battery was an appropriate

electrolyte. And I probably wouldn't have found it either if it hadn't

been for someone giving me an old kid's chemistry set with a small

bottle of oxalic acid in it. I started with that name, years ago.

But I started thinking rechargeable, "everlasting" Mn-Zn

would be the batteries to make at home. Much the easiest to make, CHEAP

materials, and higher energy density than lithium types. It would seem

that all that's been missing for 150 years to have a lightweight, high

energy, low cost and long cycle life battery was an appropriate

electrolyte. And I probably wouldn't have found it either if it hadn't

been for someone giving me an old kid's chemistry set with a small

bottle of oxalic acid in it. I started with that name, years ago.

I put this out on two "DIY"

battery related e-mail lists, and I'll post a link to this newsletter

as well.

But maybe,

since most people obviously would rather buy batteries than make them,

I should set

up a small production plant here? Along with the regulated voltage

chargers they would need. "Prismatic" cells made with multiple plates

stacked end to end (similar to lead-acid batteries) yielded excellent

results in my experiments. They would be 1.5 volts. A factory is easier

to

accomplish with funding. And someone tells me he saw on BBC that

battery factories are presently the world's biggest factories. There's

stiff competition even if one has the "better mouse trap". It would be

typical these days of well established companies to pull some sort of

hi-jinks (bribing government to pass some prohibitive regulation or tie

the company up in court on some pretext with a "stop work" order in

place, devious legal and business maneuverings, criminal threats and

violence in various forms...) to have such an upstart shut down before

it got far onto the public radar screen.

But one can't worry too much about such possibilities.

Hopefully nothing will happen. I'll fill out an application with a

place in BC that has "Executives in Residence" to help manage a new

business, and see how far I get with that.

Saltspring Island "Electrafest" & Portable 6 KW Charger

In other news, Tom Sawyer sent me pictures from the "Electrafest"

electric transport gathering on Saltspring Island. He said an entire

ferry trip to the island was fully booked with electric cars and not a

single gasoline vehicle. He also says that the price of a 2015 Nissan

Leaf like mine has gone from 18000$ to 23000$ (in 6 months). People are

catching on

and there are few electric cars to be had at the dealerships. Mostly

they're pre-sold, right into next year. Of course, in Victoria driving

distances are generally pretty short compared to on the sprawling

mainland so they're more practical. (When the better batteries start

being incorporated into cars, the continent will want them too!) On

Saltspring Island, from the sounds of things most everybody has an

electric car; mostly Nissan Leafs.

In other news, Tom Sawyer sent me pictures from the "Electrafest"

electric transport gathering on Saltspring Island. He said an entire

ferry trip to the island was fully booked with electric cars and not a

single gasoline vehicle. He also says that the price of a 2015 Nissan

Leaf like mine has gone from 18000$ to 23000$ (in 6 months). People are

catching on

and there are few electric cars to be had at the dealerships. Mostly

they're pre-sold, right into next year. Of course, in Victoria driving

distances are generally pretty short compared to on the sprawling

mainland so they're more practical. (When the better batteries start

being incorporated into cars, the continent will want them too!) On

Saltspring Island, from the sounds of things most everybody has an

electric car; mostly Nissan Leafs.

A donated Chevy Firefly (2 door version of my

Sprint)

A donated Chevy Firefly (2 door version of my

Sprint)

converted to electric by Saltspring Island high school class.

I'm not sure about the motor but it looks like they've

kept the original manual transmission and gear shifting.

Back seat removed - lead-acid batteries

are heavy and take up a lot of space.

Probably the most

interesting thing

there was a 6 KW EV charger that instead of installing, one plugs into

a 240 volt dryer plug. I'm not sure I want to buy one because those

plugs aren't everywhere and are usually hard to get at. But if there

was one available anywhere in Masset, perhaps at the town hall, I'd be

able to drive there in the Leaf, charge a while while I did my shopping

or business, and then have the range to return home. Then they would

only need to buy the unit - no electrician and costly retrofit

installation.

(And maybe I could drop the insurance on my Toyota Echo

for part of

the year - bigger savings on this "administrative" item than on fuel.

Of course, I don't always know in advance when I'll want to pull a

trailer. ...Maybe I should ignore recommendations and put a hitch on

the Leaf for my lightweight trailers? Insurance for two vehicles, one

of which is hardly ever used, really costs.)

Also remember that dryer plugs and 240 volts can be

hazardous.

People get electrocuted plugging/unplugging dryers in damp laundry

rooms. That's another reason not to carry one around in the car: if

they get condensation on them around the plug they could be lethal.

It's best if they're kept in a dry, heated space. And this of course is

why

the J1772 charging plug was created in the first place. The power

doesn't come on until and unless the socket is securely plugged into

the car, and there's a ground fault detector. (It still galls me that

there's no neutral provided for plugging in 120 volt chargers. It can

probably be tricked, perhaps by using the metal box or actual ground as

a neutral.)

Maybe I'll volunteer to put up some of the money for

Masset to buy one for the town hall or other conveniently situated

building.

"Portable" J1772 - 6 KW charging unit plugs

"Portable" J1772 - 6 KW charging unit plugs

into 240 volt, 30 amp (dryer/welder) wall outlet.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Battery Commercializations? - Useless SDTC Again - Changhong - DIY

Crowd - Factory?

Regardless of my own troubles making nickel electrodes,

I'm sure

there are people out there who know the best ways to make them, and

also how to set up mass production lines (actually I know someone).

With funding one can hire talent. The chemistry worked, and everything

else would surely come together as needed if there was commercial

interest. But putting that together by myself seemed beyond me.

On the 5th I e-mailed SDTC (Sustainable Development

Technology

Canada) to tell them Canada could freely have this fabulous new battery

chemistry and technology, created in Canada. But the chance of a

lifetime for starting a

fine new

Canadian industry ahead of the world was passed up on a technicality:

An inventor with an invention, however Earth-shattering it is, doesn't

fit their profile of a "well organized and supported innovative

company". I said I could help set up the production facility, but that

I was an inventor, not an entrepreneur. But they don't want inventions.

It is my belief that to do this sort of thing is exactly why parliament

created SDTC in the first place - the very sort of thing the

legislators had hoped would happen, and that parliament probably left

them a pretty free hand as to how to go about it.

Their self-imposed (I believe) rules don't allow them to

simply say (after evaluating the technology, of course), "Parliament

created us for the purpose of seeing that sustainable energy

technologies are developed and commercialized within Canada. Here is a

fine new invention

that Canada should want. Let's make it happen!" If they won't do that,

99% of sustainable energy inventions will simply not be developed, or

commercialized if they are, just as was the case before SDTC existed.

With a new

enterprise the funds can certainly be committed piecemeal based on

progress, so

large sums aren't being gambled on a single impression. And once an

enterprise is profitable, the funding can be repaid directly or through

taxation of an industry that wasn't there before.

In fact, why are they not out there simply hiring the

people for a "technology development park(s)" to move desirable

sustainable energy technologies forward from ideas to prototypes, so

they can then go to production? Their funds would go toward product

development; their staff would have inventors, innovators and engineers

who could work together to accomplish more, instead of just

bureaucrats. This would soon attract a retinue of business people,

investors and entrepreneurs looking for a product or products to base

new businesses on and invest in. Instead the agency has no goals or

road map, no plan... no clue. It doesn't foster development of

desirable technologies or recognize golden opportunities when they are

shoved in its face. SDTC is supposed to take the lead for fostering

renewable

energy in Canada, but not a trace of leadership seems to emanate from

it.

I have written of this before, especially in TE News #80

after

attending an SDTC seminar that supremely disappointed a whole room full

of some of Victoria, BC's most innovative and active green energy

inventors and product developers. To meet their criteria for funding,

it seemed one would have to have a million dollars to start with, and

would be blowing money out the windows left and right to maintain a

facade of a prosperous company, a "going concern". The truth is it

isn't a "going concern" until the product is for sale. The funding (as

I've

seen happen before) would be used up creating and maintaining the image

complete with

superfluous

office staff, without the proponent ever being able to put it to its

intended use of developing the product. Most of the room would have

felt it was a dream come true if they had anything like a million

dollars to develop their product, and would have been off working on it

instead of attending a funding seminar in the vain hope that someone

might

actually provide even a little seed money.

In spite of a few improvements since that time, SDTC is

then merely a supplemental funding source for

large established companies, from which tens or even hundreds of

millions of

dollars may be sucked by having a "rent seeking" department to put

together carefully tailored fund seeking proposals for

things the company was probably going to do regardless. Is this good

use

of our

tax money? It certainly uses it up in bulk for the benefit of just a

few projects that already have other funding.

The best the contact I reached at SDTC could do was point

me to a

couple of other groups. I checked out one, a "green chemistry" group.

It was set up with pretty much the same vague, undefinable goals as

SDTC: it would help connect "academic research" with "innovative

companies". Again not even lip service was paid to inventors or

inventions or

to getting a new invention from prototype to market stage - the

"pre-corporate" stage of development. Pathetic!

The slow, flaky

internet here somehow deserted me each time I tried to check out the

other

one, 2 or 3 occasions. I finally got there on the 24th. By then I

wasn't expecting much, but in fact it looks potentially promising.

(ForesightCAC.com - Foresight Cleantech Accelerator Center) So I sent

off an

e-mail.

No doubt agencies such as SDTC and NRC would have been

proud to support an

"innovative company" like (as an on topic example) Cobasys (AKA

"Ovonics" - the name seems to flip-flop). But "Cobasys"

didn't invent the good nickel-metal hydride car batteries that made the

GM EV1 and other EVs of the time fabulous. Stanford Ovshinsky did...

after

he retired, living and funding the project just on his pension. The

whole basis for the company would never have existed without first the

individual inventor - working in his garage after retirement for want

of

any outside support. Then Cobasys was organized. (No doubt

Ovshinsky had to do that pretty much by himself, too, before he could

get any help.) No amount of money then thrown at Cobasys would have

changed

the fact that the chief "innovation" of the "innovative company", the

one that gave it its reason to exist, had

already taken place beforehand. The time funding was most needed was

when he was working in his garage to develop the product, the

"pre-commercial" period. He might well have got there sooner. That this

was the intent of parliament in creating SDTC, is shown SDTC's

own graph:

The time there's no other funding available

("pilot to full scale"),

The time there's no other funding available

("pilot to full scale"),

the time of "Development and Demonstration:", might in most cases

be better described as "development of an elaborated concept to a

production prototype". The "D" of "R & D" - where it takes place

at all - is usually done in peoples' garages and basements owing

to there generally being no funding from any source.

STDC has done nothing to address that.

By "elaborated concept", I mean that it isn't just a fuzzy

idea or one that can't be explained clearly and understandably. It's

one in which the parameters and plans are reasonably well defined, and

perhaps some preliminary work or study has been done, and there seems

to be a reasonable chance that the development if pursued long enough

through the vicissitudes of various trials and some inevitable failures

will lead to a successful outcome.

SDTC in its

current form (and ditto for most funding agencies as currently

constituted) would have been proud to have funded "Cobasys" -- but it

would

never have funded Ovshinsky the individual inventor to do his battery

development or to get Cobasys started. And that notwithstanding the

fact

that Ovshinsky had already blessed the

world with the thin film transistor (TFT) and LCD advances that has

allowed us to trade

in our picture tubes for hi-rez flat screens and quite a number of

related and other advances to computer and energy technologies. The

stupendous benefits already accrued

to everyone from these entitled him to nothing. Credentials and

accomplishments in the inventive world count for nothing when trying to

start the next project. It has to be

a "business corporation" that already has money coming in to qualify

for funding to develop a product. Why on Earth does one have to put in

money to qualify to receive funding? Who is supposed to be funding who?

Does anybody not think this is putting

the cart before the horse? And are corporations not composed of

individuals? Why not support the individual inventor, especially those

with proven track records, the rare and key player in new technology,

even just for the lowest

cost so he can eat while he develops the product when there is no other

support available to him, instead of trying to

simply add support to a whole corporation that already has products and

production in the two last stages of the SDTC chart?

And Cobasys is Ovshinsky's success story. Far more often

the inventor is left out in the cold after all his time and energy have

been spent. Either the invention is never used or corporations pick up

on it and have no reason to

tell the inventor they have done so. He can find out when he sees it

for sale in big box stores, and having

spent his funds in development and having never made any money off of

it, he can try at his own expense on his own time and his own burden of

proof to sue

the perhaps large, well funded transnational company or companies that

have adopted his technology, who can use some of their profits from the

invention to have lawyers do

their work in court -- without those who made the decision to use

without

a contract (steal) the usually patented invention having to spend any

of their time on it, answer embarrassing questions or face personal

criminal prosecution. That's not worth trying!

It reminds me too of the company "Taligent", created by

Apple, Motorola and IBM to write a BIOS and operating system for their

new "Power PC" CPU chip. (1994?) I looked at their website. Management

wanted the prestige of hiring only university trained "computer

science" graduates. These are people who can put an operating system to

use with application software, not build one. It had no clue what

needed to be done to accomplish the simple things they needed, and they

weren't hiring anyone who did either. They wanted a "sophisticated"

image. They didn't want the real "creative hackers" who could have

easily accomplished what they wanted. They would never have hired Steve

Wozniak, without whose technical genius Apple would never have existed,

nor even the people who designed the Power PC chip itself who would

have had a very good grasp of what was needed at the base level.

Instead the whole clueless company failed to even begin to create the

simple operating system (their raison d'etre) for a marvelous chip, and

was finally dissolved. One person, the right person, could have got

them well underway in a matter of weeks. SDTC too has failed to acheive

the simple results for which they were created, but lumbers on year

after year on taxpayers' money.

The net effect of everyone closing the door in the face of

society's small elite of even the most gifted inventors when they have

a

good and practical plan - or even a developed prototype - for something

people would want is not to

foster vital progress and innovation but to prevent them from taking

place. One way or another seed money is needed - sometimes even just a

"pension" to live on so they can do the work instead of taking some

mundane job. How many potential inventors with paradigm changing

product ideas are out there who haven't got the luxury of both time and

income to pursue them? Why not fund a few of the best who seem to have

the most promising plans with the greatest potential for changing the

world in desired directions -- or directly employ them to do their

work? They are certainly entitled to pick and choose the most

promising. (This brings us to management having to determine what the

"desired directions" are - what are the intended outcomes, preferably

in accordance with the seven core values. What should Canada be working

toward? Without there being aims and intentions, organizations can only

drift. That's another whole subject.)

We all know not every plan works out. But the ones that do

can change the world. That should be duly noted on the web site so as

not to provide fuel for the adversarial elements of society who would

use anything as an excuse for bad publicity. As one corporate

president (?Toyota? ...it was before the internet) once said: "90% of

my advertising budget is a complete waste. If only I knew which 90%."

That didn't stop the company from advertising. Likewise, we don't know

which projects will bear fruit and which won't. Past accomplishments of

the inventor presenting the plan might give some indication of the

prospects for success. For the pittance of the fraction of 1% of the

GDP it would cost, the inevitability of some percentage of failures

shouldn't stop us

as a society and a nation from having some promising developments on

the go instead of supporting none.

---

Following this summary dismissal by my native

Canada I e-mailed to Sichuan Changhong Batteries in

China (to "the president") and pointed out the new nickel-zinc

chemistry they could

freely have. Given their current obsolescent line of flooded alkaline

cells - nickel-iron, nickel cadmium and nickel-metal hydride, made on

their production line bought from Varta in Sweden or Germany many years

ago when they ceased production there, I felt they might be in need of

a new battery like this and would be much more likely to adopt it than

a lithium or lead-acid battery maker, and that their "green" markets

would really appreciate them. (Of course, their markets would then

start expanding, too!)

About 10 days later, having come up with the simpler

rechargeable manganese-zinc and lead-zinc ideas, I wrote to two "DIY"

(Do It Yourselfers) e-mail

lists, "Edison NiFe cells" and "BatteryConversions" (@yahoogroups.com)

and let them know about them. I'll follow up with a link to this

newsletter, and mention the other two possibilities to Changhong.

Mostly it's the electrolyte that enables all these things. That's the

big thing that's been overlooked for 150 years.

There are still ways I might start manufacturing

batteries. It's a lot harder with no support and one must start at the

smallest scale to make basic production equipment. Do I want to do it?

I've achieved the breakthroughs and can add them to my resume of

inventive accomplishments that gives me no credit or 'in' with anyone

and no entitlement to any sort of funding for accomplished or present

work for future benefits to society. Others can put the advances to use

for their corporate profits if they so choose, or it can sit on the

shelf for a century and be of no help to anyone. In our western society

it seems inventors are supposed to be satisfied with that.

Or let's go back a little farther, to 2006... Should I

have kept up making and selling my new 'Supercorder' woodwind

instruments and never have started doing renewable energy stuff? I

might have become well known in music circles for it and I would

probably have been making a decent or even a good living over the last

decade. No green energy developments. No Turquoise Energy News. No

battery breakthroughs. No bandsaw mill breakthrough. No potential

future breakthroughs (eg, projects as detailed in my "Fantasy Budget"

in TE News #118). But I have no rooms to rent now. Canada Revenue's SR

& ED tax credit program won't work for me any longer, and they've

even denied my 10000$ 2016 application, which money I was counting on.

How long can I go on with no real income? Not much longer I expect.

(Next step: I've applied for a reverse mortgage on my new house, having

already liberated - and used up - nearly half the value of my old house

by selling it and buying this one. Sigh!)

Crystal Sponge?

Some years ago

an oceanographic survey found a "sponge reef" in Hecate Strait.

Something different than a "coral reef", in water too cold for corals.

This caused quite a stir in paleontology as it had been thought that

sponge reefs had been extinct since the days of the dinosaurs.

Some years ago

an oceanographic survey found a "sponge reef" in Hecate Strait.

Something different than a "coral reef", in water too cold for corals.

This caused quite a stir in paleontology as it had been thought that

sponge reefs had been extinct since the days of the dinosaurs.

Now I'm going on memory, but it seems to me the sponges in

question were called "crystal sponges". These things wash up on the

beach here during the summer. I suspect this is the creature here. Is

this what all the fuss is about?

Moles and hydrocortosone cream: Update

Some months ago I mentioned the idea of putting something

on moles and other similar skin blemishes that would treat them as

injured skin

that needed to heal rather than as a foreign entity that needed to be

eradicated. (TE News #111, April-August 2017) I tried it out and said I

would write an update if I got

any results.

Attacking the blemish is what one thinks of first,

but it rarely works out well. (Usually it's best to leave them

alone, although this is not invariably true and it can occasionally

mean life or death to make the right choice. It's best to

consult a doctor if something on your skin is changing and you are

concerned.)

But I decided to try putting something on them to see if

some moles or other blemishes might be coaxed to heal. The only

substance I know of that helps to heal instead of

attacking is hydrocortosone cream. I very gradually shrank a cyst on my

arm since childhood from a considerable lump and irritant to almost

nothing with it.

It's still shrinking with application, but so far has refused to

entirely disappear.

At first I applied the cream every evening, but not

noticing any results, I soon dropped that to every 2nd (even numbered)

evening. I did

that for the many months it's been since I first wrote about it, and

wasn't seeing much change. Then a few weeks ago I stopped. At first I

didn't see any change, but then a few of them started getting dark

spots and crusty on the surface. Then I remembered that these had been

that way previously. The lightening and softening had been so gradual I

hadn't been

aware of it. Only a very few moles with a smoother texture had stayed

dark. So applying the cream had eliminated the dark

crusty spots and prevented them from reappearing as long as I was using

it. They stayed relatively soft and light in color. It's not a cure,

but I'm sure it's significant. It's at least a healthy and innocuous

general treatment that can be applied to moles where there hasn't been

much of one of any sort available that I've heard of.

I presently plan to keep it up one day a week, Saturday or

Sunday. I'll increase that if the crusty and dark spots don't go and

stay away.

I'll think of it as something that just needs to be done for better

health,

like brushing

and flossing your teeth.

I hope that some day someone will invent a cream (or

something) that

actually heals such things and makes them vanish. That would be a

factor in people starting to live 2 or 3 hundred years in the coming

decades and centuries. Today people already live substantially longer,

on average, than they did 70 or 80 years ago, when the percentage of

the population over age 65 or 70 was very small. (whether because of

improving living standards and medicine since then, or just because

everyone smoked tobacco back then...?) Go back just 300 (or maybe a

little farther) years and living to 50 was an accomplishment not shared

by the

majority. In principle the potential for cultural improvement goes up

with life span, as more people gain time to learn and understand what's

better and have opportunities to apply and share that knowledge before

they exit the planet. (And now we can share much better, via the

internet.)

Feeding the 9 Billion?

A news article asked how we were going to feed 9 billion

people "by 2050". I came up with two possible answers which may be seen

by some as impractical:

1) Start feeding them now. You'll have fed them all long before 2050.

2) Deposit food in a food bank. By 2050 everyone should be able to eat

off the accrued interest.

Well I might be more concerned if I thought there would

ever be that many people. Signs of a crash well before mid century are

all around us. 47% of Americans are now having trouble paying for food

and rent. Most will never own their own house, and most of those who do

have a huge mortgage on it - banks and investors have bought them all

with 'free money' - wealth transferred from citizens to the financial

'services' community mainly via unprecedented new money printing, which

will sooner or later cause hyperinflation. The whole middle east is in

turmoil. Venezuela has crashed. Brazil and Argentina are crashing.

China is in bad shape. More refugees than ever before in history are on

the move or stuck in refugee camps, and they are destabilizing Europe

too. The heat keeps rising so gradually people don't notice it. The

"news" doesn't cover it. And now the environment and the climate are

bringing natural disasters (some of them actually man caused, I'm sure)

into the picture and there are predictions for famine and devastating

epidemics. Food production today is adequate at the best of times, but

is being hit by climate change, and things beyond human control are

happening with increasing frequency and severity. Consider if for

example a volcano should darken the skies for a year or two as

occasionally happens, it would spark a major catastrophe in food

production.

We are surely on the eve of the gigantic collapse

predicted as the inevitable outcome of uncontrolled growth on a finite

planet ever since the earliest computer modeling in the 1960s. And the

more people there are, the lower everyones' quality of life. Most of

our problems have their root in overpopulation. If we were suddenly

down to 2 billion people (as we just might be by 2050), there would be

almost four times the resources to support each person as there are

today. Imagine the relief to the environment. Imagine how the cost of

housing would drop if the population was gradually shrinking instead of

gradually expanding. In a rapid drop in which homes are not destroyed

en masse too, there will quickly be no more homeless people. What is an

optimum population for this planet? Surely under half of what we have

today (ie, 3.5 billion) and probably closer to 3 billion, or even under

that.

It has been predicted that even a single year may come

when the "world as we know it" will be there at the start, but will no

longer exist after it. It will be incredibly transformed. The aware may

sense that year approaching... or not!

---

After the Thugs

When the thugs have come to rule the roost,

when psychopathy is the most rewarded trait,

And those in economic power, behind the scenes,

grasp control from the people the reigns of political power

to manipulate them for selfish ends,

and now resent attempts to address imbalances,

or to improve the static status quo,

When the rights and interests of the citizens take a back seat to

everything else,

and their attempts to participate in decision making are repeatedly

rejected

with indifference, or they are beaten by police,

When a few live beyond the reach of the laws imposed on everyone else,

Such a society is doomed.

And this becomes the best outcome,

because it would never be possible to start again

unless these covert kings were toppled from their hidden thrones,

with the tilted cards laid face up on the table and in the light for

all to see,

and the people exercise their democratic rights,

to fairly distribute new cards, change the games and level the tables,

in favor of the seven cosmic values of Social Sustainability

to sustain families and society, everyone equitably, for all future

time:

Life, Equality, Growth, and Quality of Life, all executed in

understanding Empathy, Compassion and Love for humanity and the world.

And with these

to create sustainable moralities anew in each progressing generation,

the planet and its peoples,

with an ever advancing populace and society, and a stable population,

headed toward light and life instead of away,

towards our cosmic evolutionary destiny of Universal Perfection,

even as the Father in Heaven,

the first source and center of infinity and reality,

is Perfect.

---

We know from the Bible that the world is only 6000 years

old. (um, where does it say that, again?) Therefore those early

Christians who

first postulated that the world is 6000 years old were wrong, since it

must have

been less than 5000 years old back when they did!

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get

into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in

writing of

those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Other "Green" Electric Equipment Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

Band Guides - Adjustments & Cuts

After spending the whole month on one exciting (and mostly

successful) battery experiment after another, I finally mounted the

"railway wheel" band guide wheels on the saw on the evening of the 27th

.

On the exit

side I did the simplest thing: I used the main wheel as the 'other'

guide wheel by not putting the new one exactly in line with it, so the

band went over it in a very slight arc. (Okay very slight.)

On the exit

side I did the simplest thing: I used the main wheel as the 'other'

guide wheel by not putting the new one exactly in line with it, so the

band went over it in a very slight arc. (Okay very slight.)

On the entry

side I figured that wasn't good enough and put in the offset wheels

design as planned in the last issue: The "railway" wheel in line with

the main wheels and the offset wheel pushing the band down a bit

against it, again the band making a slight arc over it. (When tension

was put on it it swiveled a bit and again the arc was very

slight.)

On the entry

side I figured that wasn't good enough and put in the offset wheels

design as planned in the last issue: The "railway" wheel in line with

the main wheels and the offset wheel pushing the band down a bit

against it, again the band making a slight arc over it. (When tension

was put on it it swiveled a bit and again the arc was very

slight.)

The attack angles to aim the blade up and down are again

both adjustable by the hinged assemblies with springs.

This brings up the idea of

possibly changing the design a bit: The main wheels could be any size,

eg, 9 inches, with the guide wheels lower and the band arched under

them, making it a "four wheel bandsaw". With the guide wheels lower

than the main wheels they can make extra cutting depth. On the minus

side, to change the cut width the band would have to be slackened off

and retensioned.

The next morning I tried cutting. I hadn't got the

positions set very well. There wasn't enough bend in the band on the

entry side, and if it decided to go up, it pulled away from the main

wheel entirely. That pretty much upset the applecart. The band would

then also pull completely away from tracking on the exit wheel - which

also didn't form enough of a bend in the band to be secure. After one

crappy board and starting in a couple of feet into another it started

raining, plus I had other things to do (band rehearsals).

But the fixes were in my mind. Both sides would have

accompanying top wheels, and they would both cause more bending of the

band so a good arc was stretched over each 'railway' wheel. Either

that, or I should set both guide wheels down lower per the potential

design change above. But if I did that, the guide wheel adjustment

springs were upside down. They would have to push up instead of down,

with a solid adjustment for pushing down, since they would then be

operating against the band's tension.

On the 29th I

fixed up the entry side. I had been having problems from the start with

the threads being stripped in the adjustment hole. I had bashed the

thin end to squash the threaded hole down a bit more than once, but now

again to my surprise, the bolt just skipped threads when I tried to

tighten it beyond "easy". It occurred to me to make another threaded

hole in my add-on piece, and let the bolt come right through into that.

Using that hole as one support as well actually made it easier to make.

But once again by then it was getting dark. I didn't get to doing

anything with the exit side.

On the 29th I

fixed up the entry side. I had been having problems from the start with

the threads being stripped in the adjustment hole. I had bashed the

thin end to squash the threaded hole down a bit more than once, but now

again to my surprise, the bolt just skipped threads when I tried to

tighten it beyond "easy". It occurred to me to make another threaded

hole in my add-on piece, and let the bolt come right through into that.

Using that hole as one support as well actually made it easier to make.

But once again by then it was getting dark. I didn't get to doing

anything with the exit side.

The next evening (30th) I took the saw out and tried

cutting. For some reason it seemed the guide would adjust too far down

or even farther down. The spring was fully compressed. (maybe at the

top it was about centered.) And I couldn't understand why it seemed so

hard to push the saw, even while the cut seemed about right... and the

band didn't stop instantly when I released the switch. Finally I

realized that the rough cedar board had a lot more friction because it

was damp. There was nothing wrong with the cutting, it wasn't the

friction. I got a washer and inserted it so the whole adjustment

mechanism was aimed up a bit higher. It seemed I goofed on that because

when I went farther the cut was veering up. Then it seemed very hard to

get it to go level. Then I started cutting slower, and the cut started

going straight. I didn't think I was really pushing it before, but

slowing down definitely helped.

When the cut was veering up, the exit side wheel, being

just a single wheel, simply let it lose contact and go up. That was

actually useful to see when it wasn't going straight. This board didn't

have any of the side to side bow shape of many of this saw's cuts, from

poor adjustment. But then also I had considerably tightened the band,

which doubtless made a big difference.

I started thinking maybe my

neighbor was wrong about the band speed being too high. There's

probably a relationship between band speed and the speed you can push

the saw without it starting to veer off up or down. If the relationship

is as it seemed to be this day, it should go faster so you can cut

faster, instead.

Another possibility I though of for design change would be

to have the guide wheels fixed in position (if it's possible to align

them very exactly and alike), and have the 'skis' (or whatever part of

the saw rests on the board) adjust front to back, so the whole saw

angles up or down a bit until it's cutting straight. That would also be

the easiest and most obvious thing to adjust from an operator's point

of view.

Then I had a whole new inspiration that changed

everything...

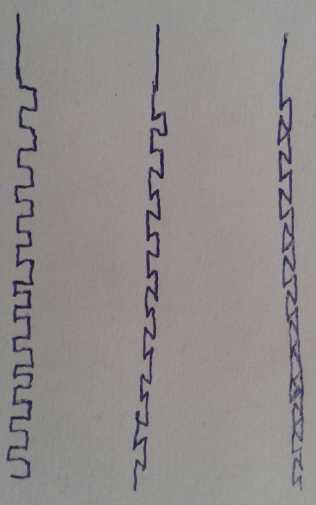

Self Correcting Band Guides - Concept

Most people, including me, just copy what has been done

before. We "innovate" but within the existing basic framework. Only

occasionally do we manage to step back outside that box and see that

the box itself is the problem. Then we "invent".

Finally, on the night of the 30th, I thought that the cut

direction of all bandsaws - all the ones I've ever seen - has a positive

feedback loop in it: Once it starts veering off the line, the farther

the band strays from the intended cut line, the more it wants to veer

still farther off. Freehand in a shop, the operator can compensate by

moving the back of the board left or right as he feeds it. On a mill or

saw where the saw to board cutting angle is fixed, once it has veered

off the line far enough, the back of the band tries to stay on target,

while the front leads the way off target and the tilt or attack angle

of the band gets worse and worse. The board is ruined, and finally the

saw jams.

A negative feedback loop leads to stability. How

to get that? Instead of manual adjustments, the band angle needs to

adjust itself to straighten out the cut as it cuts.

What if it was made so the front of the guide wheels, at

the front of the band, was the pivot point and the back of the wheels

could be moved up and down, instead of the pivot point being behind the

band or at best in the middle with guide blocks? Instead of trying to

carefully fix the band aim as a solid constant, there should be some

way to make it so that if the cut was going above the set line, the

back of the band would be pushed upward further than the front was up,

and if it was below, the back would be pushed downward more than the

front. Thus instead of veering off and going off worse and worse the

more it veered, the band's attack angle would adjust to compensate.

Instead of being a finicky adjustment, the cut direction would be self

correcting. In fact, if the pivot point was a little in front of the

band, this correction effect should be attained smoothly and

automatically with little deviation from the path.

The one manual adjustment point would be to set the

springs to hold the back up so the blade enters the wood level at the

beginning of the cut.

Here, I think, is a real breakthrough in bandsaw mill

design. I could see this one being the first handheld band mill that

will be commercially successful, and wanted by everyone. The serious

objection to all band mills, that the cuts sometimes veer off, the one

that keeps people looking for a better mill even after they have a band

mill of some sort, would be eliminated. In retrospect it seems like a

stupidly simple idea - as so many good ideas do in retrospect - yet as

far as I've discovered no one ever seems to have made such a guide

system for a bandsaw or bandmill before. (This will be fantastic!

Now... how to build it?)

On July 2nd I went and looked at the Woodmizer mill again.

I remembered some unusual and elaborate things about how it held the

guide wheels. Could I have possibly come up with something that already

exists? But no, the elaborate things were to hold the wheels as stiffly

and as precisely as possible, not to make them self correcting. If

Woodmizer, the premium maker of bandsaw mills, hadn't figured it out,

no one had.

Woodmizer band guide wheels and mountings.

Woodmizer band guide wheels and mountings.

Note the elaborate means provided for fine up-down and left-right

adjustments,

and for keeping the adjustments solidly in exact place once made...

nothing for self-correction of the cutting path.

Proposed New Electrical Standards:

A Low Voltage Standard (36/38

volts DC) and Standard Connectors

I got no feedback on my

ideas from last month. I don't suppose people (even most TE News

readers) had or have given such an area much thought. A new idea that

occurs to me for the 38 (AKA "36") volt standard is to make not only

plugs, sockets, wall plates and other connection components, but to

also make (or more likely have others make) 36 volt appliances sold

with these connectors - especially LED light fixtures and lamps. Such

products would kick-start that voltage as a new standard. They would be

marketed to solar and off-grid equipment suppliers and distributors.

(BTW I vaguely remember some new car a few years ago that

was going to use 36 volts for the lights and all. (At least, I think it

was 36... lights, starter, alternator, fans, stereo...?) I wonder if

that was ever produced, and what 36 volt equipment might have become

available? Or did they change their minds because of the lack of

available 36 volt equipment?)

Something I didn't think to remark on in the last issue:

When I ran the coffee maker from a 36 VDC to 120 VAC inverter, I had to

wire the inverter to the car batteries. If the coffee maker was 1500

watts and thus took 12.5 amps at 120 volts, it must have drawn about

39.5 amps at 38 volts. Thus a 40 amp (or maybe it should be 50 amp?)

HAT standard socket in the car and matching plug on the inverter would

have made for a simple plug-in solution - no wrenches and no chance of

miswiring or shorting something out, which often destroys inverters

among other potential problems.

On further consideration, it might be worth making the

40/50 amp sockets all "click-latch" type. Sudden loss of power from the

supply coming unplugged is another cause of delicate equipment failure,

and latching plugs to sockets should eliminate that. For simple

equipment where it might be a nuisance the plug need not have the

latch. (Which gets me to the thought that I haven't defined the

latching spec. For now see the CAT standard click-lock plug and socket

designs on thingiverse.com .)

Another thing I might remark on is that a 12 VDC to 120

VAC inverter would have drawn 125 amps from the 12 volts. That's pretty

serious current needing very heavy wires, and a 1 volt line drop is 8%

power loss. 38 volts DC is a much better voltage for things needing any

significant amount of power, yet it still doesn't need a big bank of

batteries to attain and no one is in serious electrical danger.

Rechargeable

Battery Making

with oxalate electrolyte:

* Nickel-Zinc *

* Manganese-Zinc *

* Lead-Zinc *

I consider that after 10 years I finally achieved the main objective of

the whole "better battery" project when I got a nickel-zinc cell to

work almost at the start of June.

However, that particular chemistry seems rather hard to

make at home, and I thought it would be nice to find some means for

home battery making, or at least for making them with a minimal

production setup. So I continued experimenting. Making good electrodes

has always seemed to be a difficult and obscure problem beyond the

chemistry, and I started coming to grips with that in June.

It's the Electrolyte

Perhaps the most exciting invention has been the

electrolyte rather than any particular electrode or electrode

developments. Realizing that an everlasting zinc

negative electrode is enabled by this electrolyte is certainly the

second

most prominent development. Then three fine possibilities appear for

positive electrodes: nickel, manganese, and lead.

The voltage of the nickel, or mixed valence nickel

manganates, at pH 12 instead of 14 is such that it appears special

techniques must

be employed to use it, but the cells have the highest voltage (~1.8v)

and energy. I may experiment further, but it looks right now as if it's

best to leave this to commercial battery

makers.

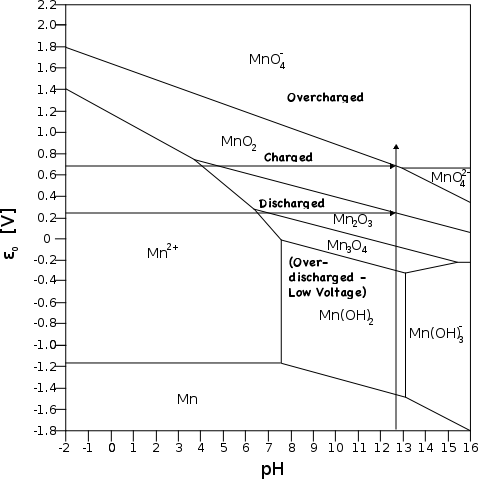

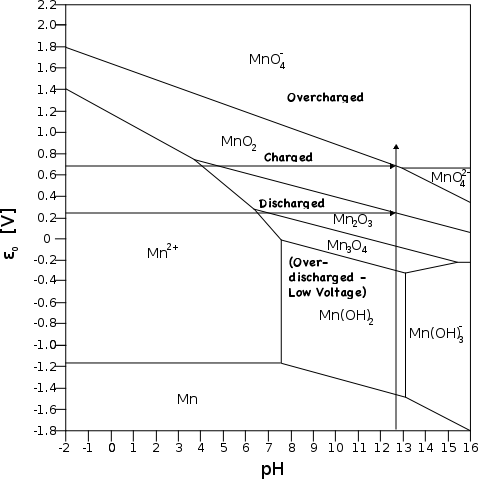

Manganese (1.4-1.5v cells) is simpler. Much has been made

of

manganese forming permanganate and dissolving, limiting cycle life, but

at pH 12 there's a .45 volt spread between MnO2 (manganese dioxide) and

KMnO4 (potassium permanganate), and I think it's just

a matter of strictly regulating the charge voltage to stay about 1/4

volt below the permanganate forming threshold. An everlasting

manganese-zinc battery would be very exciting because it's so low cost

and

such high energy - substantially higher by weight than lithiums. And if

there was ever a battery that might be made from scratch at home, this

is probably it. I made one that, while not perfect, worked well before

the end of the month.

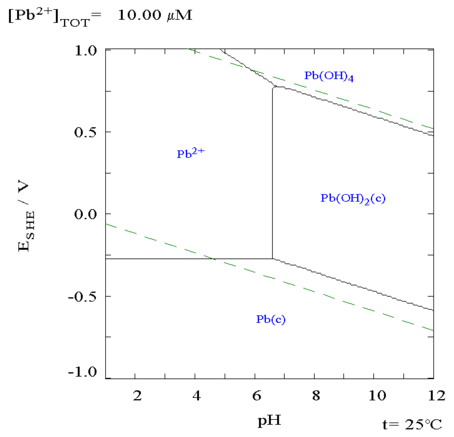

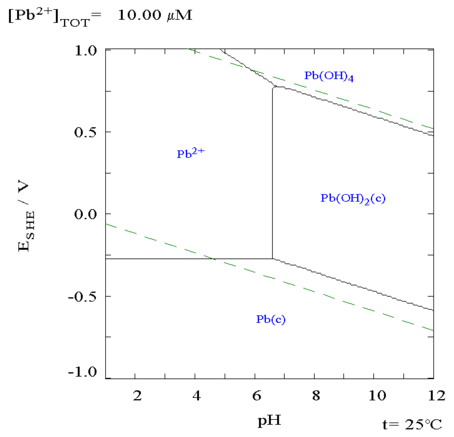

Lead (1.6v) is also simpler. If the permanganate turns out

to be a serious issue in spite of the various improvements, everlasting

lead-zinc could be a great alternative. The easy way to get lead

dioxide plus electrodes is to take them from a lead-acid battery, but

it should be a new battery that has never been filled with acid to

avoid sulfate contamination, or somehow the sulfates must be completely

removed. The energy density depends on how much

energy can be coaxed out of the lead electrode at good voltage compared

with its apparently much higher theoretical value. I also made more

than one such lead-zinc test cell that worked with lead oxide

electrodes taken from a new, unfilled lead-acid battery.

While I note that a metallic manganese negative electrode,

enabled by trace

additives (successfully made - see previous issues from 2011-2013) at

-1.5v has a higher voltage than zinc

at -1.2v and with a nickel plus makes cells of 2.4-2.6 volts, the zinc

is

easier to use and apparently yields a higher percentage of its

theoretical amp-hour capacity.

Zinc!

Almost since batteries were invented, a cell with a zinc negative

electrode that doesn't degrade has been a "holy grail" of battery

making. Zinc has soluble ions at any acid pH and also at the alkaline

battery pH of 14. There is a range of pH from 7 to 13.5 where zinc

doesn't inherently form a soluble ion, but in neutral salt electrolytes

such as the ammonium chloride of "good old" single use manganese-zinc

(AKA "carbon-zinc") dry cells, zinc chloride is soluble, so the zinc

still

dissolves. Acid has also been tried. In all cases the zinc electrode

deteriorates over time and

cycling, giving batteries with a zinc electrode a notoriously short

cycle life. Many have tried with no better than marginal success

to tame zinc for battery negative electrodes.

On the same day I put out the last newsletter I was also

looking at some Pourbaix diagrams. I looked at zinc and suddenly

realized I had done it, almost by accident. My electrolyte was about pH

12, and the diagram showed zinc didn't form the soluble zincate

ion below about pH 13.5. Furthermore, unlike zinc chloride, zinc

oxalate isn't soluble. The three forms the zinc might take then,

metallic zinc, zinc oxide and zinc oxalate are all solid, so the

electrode won't degrade. It would work just as well as nickel and has a

much higher voltage (-1.2 V versus -.5 V).

(This reminds me of creating my "Supercorder" alto

recorder. It could just as well have been created in the 19th century

when so many other woodwind instruments and their key systems were

being much improved, but nobody made a truly practical modern recorder

until I did in 2003-2006. Likewise, someone could have made this

electrolyte even 150 years ago (oxalate salts were known before

batteries), and we'd have had cheap rechargeable batteries ever since.

But nobody did. The grail was left to me in 2018!)

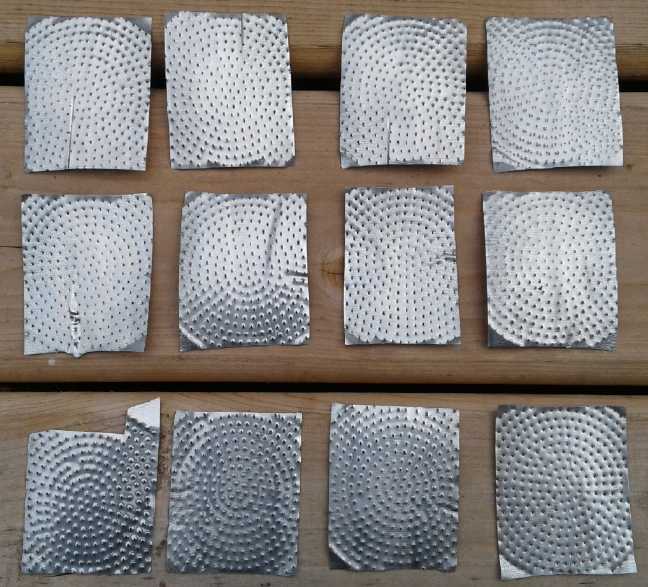

Positive Electrode Compaction

I was right onto this at the turn of the month and I kept

working on it and thinking about it. By the evening of June 2nd I had

realized that the only way I could get the extreme pressure that seemed

to be required

to condense the loose powder into an electrode "briquette" was to

hammer

heavily on a very small surface area. Say, the thickness of the

electrode instead of the width, and only a thin strip instead of a wide

electrode. Maybe 3 mm by 10 mm. It could be any depth because a little

powder would be poured in at a time.

Next morning I looked at an "edge loading" compactor I'd

made 3 or 4 years ago to make electrodes for my 3D printed

nickel-manganese cells, and started remembering details of its

operation. Its compaction using the hydraulic press had been

insufficient too, but far superior to most of my other results. The

cells at

least had something like an amp-hour (out of 5 or 6 expected) instead

of milliamp-hours, and could charge at and put out at least somewhat

respectable current.

I would fill it with powder and then compress it 5 or 6

times before it was filled. Each layer was thinner than the one below

since it fit less powder each time as it filled. And the resistance

measured much lower at the top of each layer than at the bottom, so the

material wasn't sliding along the sides of the compactor very well.

I conceived that the required compactor would have to be

made of

something tougher than mild steel, which was bound to bend and bulge

out, and sure enough this one was tougher 3/8" stainless steel. But it

had to be narrower to get the pressure, eg, 1 cm wide instead of 6.

Then I thought, what if I put in 6 narrow "plungers" to pound on, each

1 cm wide? If pounding on each one didn't make its neighbors bounce out

and just shift the powder back and forth, they could be pounded on

individually in sequence, more gradually doing the whole width.

Suddenly the whole plan started seeming more possible, at least for

test electrodes.

In practice I ended up cutting up an old file that was the

right thickness and using the three pieces as a bottom for the

compactor, a filler for one side, both filling in space to make it a

much smaller electrode, and the handle as the plunger to pound on. The

handle was wider than I had thought of, but it could do one side or the

other and it could be angled to hit harder on one corner than the other.

I also thought about different mixtures for this electrode

and whether some might need less pressure to compact than others. First

I measured out 30 grams of the mix I had been using (15 cc?) and added

3 cc of Veegum, then I weighed 30 grams of a nickel-manganese mix that

I found in the cupboard. This one was much less dense and filled 24 cc,

plus again 3 cc Veegum. I didn't use it. (The description of Veegum is

in TE News #21...

Just ignore the parts of the project where I didn't know what I was

doing back then!)

I compacted the second substance first, adding a bit at a

time and a bit of the dishsoap here and there, and pounding it with a

20 ounce hammer until it felt like I was simply pounding on metal. It

made a nice "briquette". Resistance from the surface to the back was

around 70 kilohms. That's pretty high, but two orders of magnitude

better than 7 megohms. I only squeezed in about 60% of the powder or

maybe 18 grams to fill the space, about 4 x 40 x 40 mm. I did the

second one from the denser original mix and put in the whole 30 grams

to get the same size. I pounded pretty hard and was hoping for better

results, but it was again ones of megohms. I fear something would bust

or bend if I used the 6 pound maul. Then the other briquette started

giving very similar figures. Then this one gave the lower values.

Perhaps there's some ionic conductivity going on. Simply reversing the

test leads always gave widely different results, so one couldn't just

say "It's X ohms" as a repeatable figure. All very frustrating!

18 grams in (.4 * 4 * 4)cm = 2.8 g/cc

30 grams in (.4 * 4 * 4)cm = 4.6 g/cc

From these figures it can be seen that if the two powders give the same

energy per gram, the second one will make for a more compact battery,

with savings in space and case material. IIRC, both of them are higher

than I remember seeing for typical nickel hydroxide electrodes: 1.8

g/cc (or was it 2.2?).

Perhaps I should start experimenting with mixtures for

best performance, which would really mean lowest resistance with the

pressure I can attain.

Glue & Jell

Concurrently with the chemical and compaction trials, I

again started putting "stuff" into the electrodes to help hold them

together as thickeners, binding agents and gels. Pretty much the same

ones I was using years ago. With the successful

electrodes to compare with I could tell if the additive(s) were causing

a problem. They helped. As I proposed and later research also

discovered, jelled electrodes can last forever. (I wonder if they got

the idea to try it from Turquoise Energy News?)

(

See TE News #99:

http://www.theweathernetwork.com/news/articles/scientists-accidentally-make-batteries-that-last-a-lifetime/66934/

-- 200000 cycles with no deterioration, to the surprise of the

researchers.

)

The first was something called "Veegum", a powdered smectite

(bentonite) clay: Magnesium-Aluminum Silicate. I put in by volume maybe

15-20% Veegum into the electrode. It thickens and adds viscosity. The

powder is very light, so it wasn't much by weight. The next was

Sunlight original formula dishsoap as a "glue" or "gel" with its

organic

sulfate and sulfonate compounds. (I mentioned it from as early as TE

News #6 in 2008.) I just added drops of this as I compacted electrodes.

The clay seemed to help hold them together without

wrecking the electrodes chemically. I used both of these in

both the plus and minus electrodes. I considered using "CMC gum" as

noted by other battery makers, but I didn't add any. I note that in the

literature on "Veegum" there are several varieties, and "Veegum Plus"

has CMC gum as an ingredient, probably better dispersed in the clay

than by adding it separately.

Zinc !

Now I stared at zinc's very simple diagram. It showed no

soluble states

between pH 7 or so to over 13. When I had looked before I was

using

potassium chloride electrolyte which zinc could dissolve in. Now I was

using potassium oxalate, and zinc oxalate is insoluble. (That most

potential battery elements including zinc were insoluble as oxalates

was one of my original reasons for noticing oxalate, going through the

"solubility table" in Wikipedia. But I was thinking of oxalic acid at

the time.)

Many have tried to 'tame' zinc for rechargeable cells

without more than partial success. Some nickel-zinc "AA" alkaline cells

are (or recently were) available which claim they have 500 cycle

capacity (I suspect only

under ideal conditions). I finally concluded the researchers were

wasting their

time, and looked for other metals. But every reported attempt I've

looked at - several patents or studies - was in pH 14

hydroxide electrolyte except one. That one, in acid, had zinc

intentionally dissolve

as the cell discharged, and reform as it recharged. It still grew

dendrites.

Here is something quite different. As with nickel, I

don't think anyone else has tried oxalate or "mid alkaline pH" other

than chloride, with zinc before. Apparently zinc/zinc oxide/zinc

oxalate would stay solid at all times up to over pH 13. And higher

voltage negative

electrodes might be better in ethaline DES than in water, too.

Nickel-zinc-oxalate cells would give

around 1.8 volts. Whatever nickel's

extra amp-hours (as a negative electrode), it wasn't likely to match

the energy of zinc with this

high voltage when zinc is also a good energetic electrode. Nickel-zinc

would take

fewer cells to reach a desired voltage: probably 7 cells for 12 volts

instead of 8 or 9 or 10.

As an added benefit zinc is cheap, much cheaper than

nickel, which will mean, in principle, pretty cheap batteries.

So I started pondering: Would zinc insist on growing

dendrites and

deteriorate at pH

12 to 13 in oxalate? Or would it really last forever as this Pourbaix

diagram indicates it

should?

Since my cells are already just right in every other

respect I decided it would

definitely be worth an experiment or two with zinc powder instead of

nickel powder.

I decided to make a square cell just the size of the above

electrodes. I finally recalled that the positive electrodes, however

well they are compacted, swell up once wetted (at least in water - I'm

not sure about ethaline DES. Either that or it's with charging and

discharging.) In a cell the right size, they'd have little room to

swell. I used the 30 gram electrode.

The zinc electrode turned out to be just 20 grams, about

the same size because it was compacted in the same compactor, but I

nipped a bit off the edges so it would fit inside the paper basket, so

it was about 37 x 38 mm. (theoretically 20 g * 820 AH/g = 16.4

amp-hours... in such a tiny, lightweight cell? How well will that

actually be utilized? Prospects seemed good for high utilization

because the zinc powder, unlike most metal powders, seems to be of

"nano" size, providing potentially the highest surface area.) After

working with zinc powder I knew exactly how they gave the tin woodsman

his color in the Wizard of Oz movie. (Did you know the entire plot of

the book was a metaphor for the whole twisted financial system? "Follow

the Yellow Brick Road to the Emerald City"... does that not sound like

the promise dangled in front of everyone? The "silver slippers", silver

having been until recently the money of the common innocent person

(Dorothy), turned into "ruby slippers" in the movie. It didn't matter

because nobody knew the underlying plot anyway. After this book

families demanded more kids fairy tales about Oz, and the author had

found his calling. They are however apparently not as memorable as the

first. I only read one other, "The Land of Oz". It was okay but the

plot wasn't the equal of "Wizard of Oz".)

Making a New Cell

I went to put the new cell together and did everything wrong, out of

sequence. As a result, the plus electrode was pretty much broken up

into chunks and powder.

Here's how it ought to have been done:

1. Torch the positive electrode with a strong propane torch for

about 10 seconds to sinter the particles together a little better. (I

finally remembered about this. After so long doing no battery work I

had forgotten on the last cells.)

2. Make the case but leave one side and the top (front) face off.

3. Cut the graphite current collector

piece and paint it with the

osmium doped acetal ester. When it's dry, put it in. Put a small bolt

and washer through to the plastic support before the tab gets broken

off.

4. Slide the plus electrode into the case - easier with one side off

the case -

then glue the last side on with methylene chloride (or plumbing ABS

solvent glue).

5. Make a [watercolor, thick] paper

'basket' to cover the bottom

electrode and go up the sides so the electrodes won't short against

each other.

6. Put the zinc minus electrode in the paper basket.

7. Cut a piece of nickel mesh to cover

the back of the zinc electrode

for a current collector. (Unless the zinc electrode is totally

discharged to zinc oxide, the nickel will remain in metallic form.) I

made one with 3 folds and a fourth bit.

8. Stick a piece of cupro-nickel sheet

in for a tab. I tucked it under

the last fold in the mesh for better contact.

9. Fill in any remaining empty space in the cell. I used bits of

cupro-nickel sheet.

10. Take out enough bits to expose the

mesh and add a little calcium

hydroxide powder. Add some DES with potassium oxalate dissolved in it.

(Put the bits back in.)

11. Put the top/front face on. (I just held it shut with a C-clamp so I

could open it again. Later I put heat glue around the edges and the

terminals.)

Ready to charge!

After I torched the plus

electrode I couldn't get any

resistance readings. It was off the scale. I hoped it would improve

with charging and discharging. When I put the cell on charge, it only

took .3 mA at 2.2 volts. It was going to take forever (approximately)