Turquoise Energy Ltd. News #122

covering July

2018 (Posted August 4th)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Feature: Bandmill Design Breakthrough: Self-Adjusting Band

Guides for reliable straight cutting

(see Month in Brief, Other "Green" Electric Equipment Projects)

Month

In Brief

(Project Summaries etc.)

- Scenery! - Batteries - Solar - Reluctance Motor - Development

Centers - Bandmill breakthrough

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Election Reform: Corrupting Influence - Keeping/Restoring Your Hair -

A Hydrocortisone Cream Healing -

Bad Grammar: "Mine" versus "Yours" - Peace Between USA and Russia -

Quinoa as an emergency food grain? &

Vegetable

Gardening - Birth Control: Helping Ourselves by Helping Underdeveloped

Countries -

South Africa: No genocide after all? - More on Bankers Creating the

Money Supply, by a banker - What is News? - Double Agent Strzok

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

*

Revisiting Reluctance Motors and Unipolar Motor Controllers -

Considering the 2015 AFSRM Motors &

Studies - Note: Current density - First project: Back to the old Motor,

with new "Rotor Poles"

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Handheld Bandsaw Alaska Mill")

- "Front Pivot" Self Correcting Band Guides - blade protector -

Conclusions (in short: yes, it works!)

Electricity Generation

*

Solar Panels Installation - nasty cable run job - Grid Tie Inverter:

NOT as advertised! - - - Synchronous

Rectification?

Electricity Storage -

Turquoise Battery

Project (Now Mn-Zn, Ni-Zn or Pb-Zn)

* Mn-Zn rechargeable 50/75 amp-hour cell with ABS sheet plastic case

(1.5" t x 3.25" w x 5.75" h)

* Pocket Electrodes: Perforating Sheet Metal with a "Bed of Nails"

* Lead-Zinc Cell From Scratch With Rolled-up Sheet Metal Electrodes

(not finished)

I had friends visit for a

week and took a bit of a holiday myself.

Tow Hill on the north coast of Graham

Island, from the beach.

Tow Hill on the north coast of Graham

Island, from the beach.

It's a "volcanic plug" the center core of lava that came up,

while the softer outer parts were washed away by the ocean.

Similar hexagonal columns can be found at Fingal's Cave in Scotland.

On the land side it can be climbed.

View from the top looking west toward Masset.

View from the top looking west toward Masset.

I did some work on the

bandmill, which (at that point) didn't seem to cut

as I'd expected. I didn't get very

much else started until the 10th, when my guests left, the [pure]

calcium oxide arrived, and I did some more battery experiments.

The components of a new Mn-Zn Oxalate cell with

"pocket" electrodes.

The components of a new Mn-Zn Oxalate cell with

"pocket" electrodes.

Apparently there weren't enough perforations in the "pockets" to conduct

the electrolyte freely, greatly limiting the current capacity in a cell

that

should have had at least a few amps and 25 amp-hours capacity.

(and later I'll add more electrodes to double that.)

In the middle of the month I put four of my solar panels

on the roof of the house (1000 watts). I thought of simply wiring them

to a grid-tie inverter. But that won't help in a power failure. I'd

rather have a separate system - especially if it can have good, high

capacity rechargeable batteries that last forever to store the power.

But I had a grid-tie inverter and I tried it out. It proved to put out

only 400 watts. It was advertised as, and said on it "1000

Watts". I think I was gypped. So it was effectively using only two

panels. I discovered it might take about 8 panels (2 KW, with 2 KW of

inverter(s)) to put things in reverse and stop the utility company

meter from racking up KWH on my bill, even on sunny days in the summer.

But when it got cloudy, the panels only put out 200 or 300 watts anyway

and the inverter was big enough.

I climbed the left ladder, which was tied to a

hook.

I climbed the left ladder, which was tied to a

hook.

I hauled the panels up the right one with a rope.

(Setting them on the block of wood kept them from snagging under the

bottom of the ladder.)

I'm not happy that I still can't drive the Chevy Sprint

car on the highway. I started thinking about reluctance motors again,

with their good torque and very high RPM capacity. A reluctance motor

could be the best solution to outboard motor conversion as well as for

cars. Gas outboards gear down too much at the propeller shaft, so they

need a higher RPM electric motor and a reluctance motor should be

ideal. At first I decided to more or less copy the layout of the axial

flux, two

rotor design done in Guelph, Ont. in 2014. In addition to the Sprint

under-hood motor and an outboard that could make a small boat plane, if

enough power can be packed into a light enough unit, the "Electric

Hubcap" wheel motor plan (with a compact planetary or fixed gear

reduction) could be "on" again. And what about for a ground effect

craft? Surely the ducted fan design needs a higher RPM than a 'regular'

airplane propeller?

Finally what I

took away from the papers, which I read more carefully than in 2015,

was that (a) the axial flux motor is the right layout and (b) - what

I'd missed - that it needs, bug, chunky iron magnetic components for

good force, not the fine stuff I made in 2015. (After all, it's much

harder to pull a big wrench off a supermagnet than a small

screwdriver.) Ideally for the car,

"slice of cake" coil cores might be 3 inches thick, and similar shape

"rotor poles" maybe half that thickness, with thick "back iron" behind

them all.

Finally what I

took away from the papers, which I read more carefully than in 2015,

was that (a) the axial flux motor is the right layout and (b) - what

I'd missed - that it needs, bug, chunky iron magnetic components for

good force, not the fine stuff I made in 2015. (After all, it's much

harder to pull a big wrench off a supermagnet than a small

screwdriver.) Ideally for the car,

"slice of cake" coil cores might be 3 inches thick, and similar shape

"rotor poles" maybe half that thickness, with thick "back iron" behind

them all.

I decided to try first the motor I'd made in 2015 with its

6

donut coil cores, but to match that with a rotor that used the same

iron powder cores as "rotor pole" elements. I found I could use the

same rotor by

cutting some bits out and inserting the cores, another good

simplification for a test. And it just might have the power to

run the outboard once it was working well.

On the 19th I took a day off and drove over the rough

logging roads to Rennell Sound on the west coast near the south end of

Graham island. The scenery was rugged and spectacular. The road rose so

steeply from the waterfront into the mountains that I had to drive the

Toyota Echo in first gear part of the way to climb out!

Rennel Sound, opening to the west coast of

Graham Island (looking SW)

Rennel Sound, opening to the west coast of

Graham Island (looking SW)

There was a camping area with a boat ramp

(looking NW)

There was a camping area with a boat ramp

(looking NW)

and a little farther on, a "log op" - with

warnings to wait and follow a truck with a radio to avoid running into

logging trucks (you'll come off worst).

and a little farther on, a "log op" - with

warnings to wait and follow a truck with a radio to avoid running into

logging trucks (you'll come off worst).

This is a small island. You run into people you know...

A friend from Tlell who runs big machines got a job working here

later in July.

(looking W)

On the 22nd I finally decided to send an application to

ForesightCAC.com, "cleantech accelerator centre" in Burnaby BC. But did

I

really want to apply as a cleantech startup business? When after quite

some length I had finished filling out the online form which had many

involved business questions, I hit "send" and it said "failed". Then it

said "Prove you're not a robot", but there was nothing to click on or

type for that purpose. It said "failed" again, and I lost all my work,

which was considerable.

So the next day I telephoned. I had to leave a message,

and I said I had created new and 'better than lithiums' batteries and a

breakthough in bandsaw mill design among other things, and that "Now I

want to get them commercialized." That bit of grammar I stumbled

on is really exactly what I want. I don't really want to convert myself

from a talented inventor and product developer into a mediocre

entrepreneur. ("It's too bad we have to buy it this Canadian

technology from China. He had some great products but he sure didn't

know how to run a business!") Surely they must be in touch with

talented and enthusiastic entrepreneurs looking for products who would

be delighted to have some great newly developed cutting edge

technology(s), theirs to make and sell?

I managed to put this across quite well to the person who

returned my call. I hope they may manage to find a way to help get

things going.

I don't know how in our society that helps inventors to

put food on the table when patents seem to be worse than useless to

inventors (exactly who they were theoretically created for) and there's

nothing else, but

division of labor is a fundamental principle of advanced societies.

Perhaps there's something to be learned from the music industry where

those who write music as well as those who perform it and record it are

entitled to royalties whenever that music earns commercial

revenue. The composer/songwriter doesn't have to sell the rights to his

work for peanuts before someone will perform it and then perhaps it

becomes a top hit. Or defend it on his own budget in court against

those who've

used it without telling him.

On the 25th an e-mail from United Inventors' Association

in the USA said they are trying to have passed a new "Inventor

Protection Act". I applaud this effort! If successful inventors

can make a living, there will be more of them, and new products and

technologies to take us off fossil fuels.

To conclude this topic, on August 2nd I had an inspiration

as to how an inventor, even me, might after all get paid for his

discoveries and all the work that usually went into finding them. As

it's a brand new thought and as it involves others it may evolve

rapidly, so I'll leave off explaining it until next month. I've been

groping for something for 10 years, not to mention for another decade

before that. Maybe this is it.

26th: I note that I seem to be spending more and more time

writing - seemingly more than I spend on the projects these days. Does

writing more make up for not getting projects done? I've known what I

want to do on the bandmill for a couple of weeks now, but never seem to

get to it. Hmm. Not that nothing is happening!

Near the end of the month it didn't just get warm. It got

hot. There were much warmer days than any last summer, and lots of

them. The garden needed watering every day, or things started to wilt.

Temperatures approached or exceeded 30 °C in the shade. Smaller

creeks stopped

flowing. I actually appreciated having a real summer after the cool and

wet of last summer. But I know people over most of the northern

hemisphere this summer won't raise their eyebrows over our little "heat

wave" here. (It ended August 1st.)

In the last 4

days of the month I got back to the bandmill. The cuts kept veering

upward in spite of the band being aimed downward by the self-adjusting

configuration. Finally on the 31st with a strong magnifying glass I

found a problem if not the problem: in addition to being dull,

the 'set' of the lower teeth was zero, no clearance at all. I did some

rough sharpening and tooth setting. That evening I finally cut a 6"

wide board, 13' long, that wasn't bad. And for once, without making any

adjustments either before or during the cutting.

In the last 4

days of the month I got back to the bandmill. The cuts kept veering

upward in spite of the band being aimed downward by the self-adjusting

configuration. Finally on the 31st with a strong magnifying glass I

found a problem if not the problem: in addition to being dull,

the 'set' of the lower teeth was zero, no clearance at all. I did some

rough sharpening and tooth setting. That evening I finally cut a 6"

wide board, 13' long, that wasn't bad. And for once, without making any

adjustments either before or during the cutting.

I finally added a cooling water system on August 2nd to

keep the

band from heating up and thus expanding and getting slack. With that I

cut a couple more boards even with the dull band. A new blade/band will

probably help a lot.

Reorganizing SDTC to meet real needs?

Early in the month I e-mailed SDTC with a link to my

uncomplimentary piece

about

them in the

last newsletter. I got the idea of writing my MP to suggest that SDTC

needs to be completely reorganized on a new basis since it doesn't do

what it was created to do - support sustainable energy inventions and

new product development - or else be scrapped altogether as being a

poor use of citizens' money. Then I started thinking that perhaps

several of us who were doing sustainable energy projects and getting no

support from them should get together and write to parliament instead

of just me.

Then I thought it would be even better if we can get a few

people together - a social sustainability design team - and work out

how we would set up the organization to meet the real needs for

fostering development of sustainable technologies. A plan sketched out

in

some detail for recommendation to parliament would probably be better

than just

criticism or even vague suggestions. My now rather remote location

works against organizing and meeting with people, unless it is done by

e-mail and perhaps conference calls.

Any takers on this? I welcome ideas and suggestions along

these lines,

especially from fellow inventors and product developers in Canada (but

also

anywhere), and especially from those with any sort of experience with

organizational structures, who think they might have good ideas for how

such an organization might ideally be put together.

And what does anyone think of the idea of having them run

a "Sustainable Technology Product Development Park" or even 2 or 3 or

more across the country? Look how we got the graphical user interface

and the whole workings of the internet from Xerox's "Park Pacific"

technology park. (Xerox didn't even understand what they had achieved

or know what to do with the results.) One technology park for a few

short years. What fabulous advances could we get from an ongoing one or

more than one?

This/these park(s) would hire creative people and guide

them as to what was to be created, instead of just waiting for whatever

off-target, high budget proposals drift

their way from well established corporations who meet some Procrustean

organizational criteria. They could hold patents on behalf of the

inventors, and being an organization of government instead of one

pretty defenseless inventor, should be able to successfully extract

royalties from all manufacturers both for the inventors and to become

a self-sustaining organization itself.

If a few people are interested it's not impossible we

might get

something useful done.

---

"Don't worry about people stealing your ideas. If your ideas are any

good you'll have to ram them down peoples' throats."

- Howard Aiken [Mathematician, physicist & computer pioneer]

A nest of swallows messing up my front door

light.

A nest of swallows messing up my front door

light.

Just about ready to 'fly the coop' I should think (Aug 2nd).

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Election Reform: Corrupting Influence

In Canada we were promised a new electoral system by the

present government if we elected them. Then they held meetings across

the country to help decide how best to set it up. I went to the one in

Victoria, and the one thing that was abundantly clear was that few

people who attended liked our current "illiterate's 'X'" single mark,

single ballot

system. When those meetings were done, they dropped it and will make no

changes. And apparently this has happened at least a couple of times in

the past

in Canadian history.

In BC we are now to vote on a new two-question

"proportional representation" system referendum in the next election.

While I'm not entirely happy with the choices being made available,

almost anything would be better than what we have. As soon as the BC

government announced it, a lawsuit was taken out to try to have the

referendum blocked, complaining about almost every detail. And Google

ads started appearing telling us that our present system is great and

"proven*", the new one (regardless of what is chosen?) would be a

disaster, that once we changed it we would be lost forever, and so on.

The .01% of corrupt, selfish, filthy rich and

anti-democratic people don't want a

system they can manipulate so easily and buy politicians to help them

get their way to be replaced with one that would make it hard for them,

and will spare no effort or expense trying to nip it in the bud. I

suspect they will

succeed again, as they have for over a century and most recently

federally. There are just so many apathetic people who won't take the

time to see and to think and perceive and make up their minds for

themselves, who will let their minds be made up for them by those who

squawk loudest - those with the money to hire PR firms and run plenty

of ads. (One of their complaints in the lawsuit was about the

campaign financing rules - because the government supplied a little

money to counter

their smear ad campaign!) Having given it no prior thought, all many of

these people may

remember at the voting booth when they are surprised to see these

questions actually there to vote on is all the negative ads warning of

doom and gloom should they vote for change, and reminding them of how

rosy the present system is - the one that keeps people rising up in

ineffective protest against its repeated unilateral acts, its giveaways

of public assets and its free-spending management of the public's money.

My own views on what sort of systems of governance might

be best are

laid out in detail at HandsOnDemocracy.org

* "Proven" only to be unfair to all and

socio-politically polarizing.

Keeping/Restoring Your Hair

A couple of

years ago there was a piece of "click bait"

going around that showed a picture of a man brushing his partly bald

head with a brush, with the words something like "To keep or restore

your hair, do this daily." In fact this was complete within itself,

because brushing with a brush to stimulate the hair follicles is

exactly the right thing to do in (I believe the majority of) cases of

thinning hair or baldness as we age. Doubtless the makers were sure no

one would

believe it was so simple and would follow the link. (Or they may have

given some finer details in the links.)

A couple of

years ago there was a piece of "click bait"

going around that showed a picture of a man brushing his partly bald

head with a brush, with the words something like "To keep or restore

your hair, do this daily." In fact this was complete within itself,

because brushing with a brush to stimulate the hair follicles is

exactly the right thing to do in (I believe the majority of) cases of

thinning hair or baldness as we age. Doubtless the makers were sure no

one would

believe it was so simple and would follow the link. (Or they may have

given some finer details in the links.)

Now I've found a brush in a dollar store (4$ ... yay, we

now have a dollar store!) that's much

better than any other I've tried. I could feel the difference the first

time I used it and since. And after 3 or 4 months, I can see (in two

mirrors) that the thinning hair at the top-back of my scalp has gotten

thicker and if not "perfect" (yet?) no longer looks half way to bald.

And that's where I most felt that it had a very good stimulating effect

where other brushes I've tried (which I admit isn't very many) had

seemed pretty listless by comparison in that area.

I knew there was a difference between combs and brushes,

but I didn't realize brushes could be so markedly different. I don't

know what it is about this particular brush that makes it seem so good,

but here's a pictures of it. (I bought an extra to send to someone.)

A Hydrocortisone Cream Healing

Something I missed last month writing about applying

hydrocortisone cream... When I was maybe 12 I was trying to hacksaw

something. The piece wasn't held well and in the vibration the saw

suddenly jumped up and over as I cut, and cut into the back of my

thumb. Trying again brought a second slice. I didn't think much about

these at the time. Weren't they just cuts that would heal? But they

never did heal properly. The hacksaw teeth had ripped up the skin

pretty well and it hadn't gone back into place. They were always two

rough, scaly lines across the top of my thumb.

In rubbing hydrocortisone cream onto all the moles and a

couple of cysts, I started applying it to those rough lines too. They

seemed to get worse at first and irritated, then - after 50 years -

they healed over. They are smooth and just visible as slightly raised

lines. Wow!

(I never thought to take any "before" pictures, and

"after" there's nothing anyone would notice.)

The labels on hydrocortisone cream tubes all seem to say

to 'discontinue after 7 days'. But these sorts of skin healings - the

cuts and especially the cyst (never mind keeping the moles light)

required continuing

application over much longer periods of time.

Bad Grammar: "Mine" versus "Yours".

Somebody's "cutesy" but crazy idea from the 1980s(?) has

got parroted by all sorts of organizations. Even the government (CRA)

speaks of "your my account", a complete oxymoron in three words. It

bothers me that any organization should think it somehow enhances

customer or public perception of them or makes them seem friendlier or

more sophisticated to

perpetrate such confusing misuse of language. Since I wrote the

following

almost 20 years ago things have only got worse, and now I've had the

urge to dig it out of my e-mail records and reprint it.

---

Dear xx Bank VISA:

Our use of the words 'I' and 'my', and 'you' and 'your' in the new

cardholder's agreement which we sent you do not make sense to you!

It is common ground, implicit in grammar in every language that the

word 'you' refers to the person intended to read a document, and 'me'

or 'us' refers to the party which wrote it.

But we have elected to reverse the meaning of these common words,

which, of course, makes our cardholder's agreement difficult for you to

read. If you had written the agreement, there would be no need for us

to send it to you to read, would there? Instead, we there at VISA would

be the ones to have to receive it, check it over and see if your terms

were agreeable.

And we are not even consistent in our approach, since all the

correspondence we send to you, including the cover letter "Special

Notice To Cardholders" on the very same piece of paper as the new

agreement, says 'WE are writing to tell YOU', instead of 'YOU are

writing to tell ME'! Because if we did that, our letter to you would be

even more confusing than your cardholder agreement, would it not?

Who on earth writes our stuff, anyway? I should be shot!

You would be greatly relieved if we chose to restore these words to

their proper meanings in the future. Thank us very much.

Mine truly,

VISA cardholder

Peace Between USA and Russia

In mid July, US president Donald Trump met with Russian

president Vladimir Putin in Helsinki, Finland. Trump said relations

between the two countries 'have never been worse', and that that was

thanks to stupidity in Washington. He wanted to improve them and to

have peace between the two democratic republics.

Trump was attacked for this, not by Russia but by his own

country. He was accused of "being in Putin's pocket" and "what did

Putin have on Trump that he could be blackmailed in such a way?" One

malcontent said Trump's promotion of peace between them was "the

highest treason". The funny thing is, Trump said before the meeting

that regardless of the outcome that is what would be said of it. And

that no possible outcome would be good enough to satisfy these critics.

But one notable person said Washington had "criminalized diplomacy".

The "deep state" - largely the civil service bureaucracy

including the military and the many security agencies, as well

"cross-connects" from the largest corporations - that holds real

power hidden away in private from public scrutiny isn't used to having

a president who, whatever his faults may be, is trying to make state

policies in public and apart from their lies and conniving back room

deals to

keep the military-industrial-banking-oil-monsanto-pharmaceuticals

complex in business and receiving way over 50% of the US national

budget, regardless of the needs of the people and the potential for

peace in the world. They will discredit him with any lies and

unfounded insinuations they can think of, and they dearly wish someone

would

shoot him and get him out of their way. In fact some of them are

actually advocating it - real treason not only against the peoples'

chosen leader but against democracy itself. And they will feel the same

way about any president who follows him who has the temerity to try to

lead the nation instead of to follow their dictates.

Dwight D. Eisenhower warned that the need to maintain a

large "military industrial complex" after world war two was itself a

grave threat to American liberty. Liberty and equality minded John F.

Kennedy was shot to get rid of him, apparently by the mafia but with at

least complicity by federal agencies. (See "Oswald's last phone call"

on youtube.) Robert Kennedy was shot beforehand to prevent him from

ever taking up the reins. Then Richard Nixon was thrown out. Why? After

being a perfect "deep state" stoogie for several years, Nixon got fed

up. He ended the Vietnam war, Accorded China long overdue diplomatic

recognition, and started nuclear arms limitation talks with the Soviet

Union. That was why the Watergate manipulations, in which he had of

course played a part, suddenly came to light: deliberately to arouse

public indignation to get rid of him. Dr.

Paul Craig Roberts says they repeatedly tried to block Ronald Reagan in

most everything he tried to do in the 1980s, including rejecting or

stalling on approval of his chosen appointees (as with Trump),

"Reaganomics" (of

which Roberts as assistant treasury secretary was the co-author), and

most especially of his trying to end the cold war. After his second

election Reagan became senile, and instead of promoting the

vise-president it was covered up for the rest of his term. What a

perfect president to let them have their way with no argument! (The

senility was just fortuitous... right?)

I know Nevil Chamberlain once said this and was quickly

proven wrong, but personally I don't believe any important nation in

the world today wants war... apart from the US 'deep state' actors. If

it was up to them, the world could well be a desolate radioactive

wasteland by

now. Unfortunately these types of people too often get their way. They

won't take "NO!" for an answer and will keep trying different tactics

until they do. But

here, finally there is just too much at stake to let them and they

haven't.

Which brings up another topic... One of the worst problems

(besides overpopulation) is that our justice systems are so gutless (if

not corrupt). Some of the worst of the selfish people in government and

in corporations who commit egregious crimes, predating on and working

against their own people year after year and decade after decade should

be given an overdose of morphine and be peacefully removed from the

planet to get them out of high places and to demonstrate that society

will not give in to crimes of betrayal against itself that prejudice

the whole future of civilization and freedom. It's not that "jail is

too good for them": it's that they will simply continue to predate

whenever they are free to do so and that many of them can call on their

friends or henchmen to bribe, threaten or do away with those who are

causing them trouble even while they are in jail. Someone is going to

die: should it be the troublemaker, or whoever opposes the

troublemaker? Gutlessly allowing the latter course to occur leads to

problem after problem and often victim after victim since the source of

the trouble is still there.

Just for one familiar example, how different might history

have been if Adolf Hitler had been executed for attempting to violently

overthrow democratic government in the "beer hall putsch", instead of

simply being jailed for a time? There are many and various other

examples of ways in which the world has been markedly damaged by single

individuals who should have been permanently stopped, but the

consequences of that one particular failure to act resolutely at the

critical moment are the most stark. Civilization was shaken to its core

and tens

of millions died.

The only two ways people are safe are (a) knuckle under to

unreasonable demands and conditions - and ultimately live in a

totalitarian dictatorship or (b) eradicate the predators. The only way

the network of associates and henchmen won't bribe or threaten or

murder is if their boss is no longer there to give the orders and to

pay them and protect them from the law themselves. Not there to ensure

there are no investigations into briberies or threats, or that the

suspicious death of an opponent will be deemed a "heart attack",

"suicide" or "accident" likewise without any investigation. How many

judges, prosecuting attorneys, witnesses and others have been murdered

by those they sent away for more limited punishment? It makes

obvious sense: only one person, the predator, is killed instead of

potentially

numerous innocent and usually upright victims who try to stand up to

him, know too much or just get in the way. We will not have social

stability, much less sustainability, while people are, with good

reason, afraid of violence.

The media is now owned and paid for by the same "deep

state" that holds the real power hidden away in the back rooms and they

trumpeted this "Trump's treason" nonsense to the American public. I'm

not sure how many are still buying it. But no major station or network

(all owned by the same 5 or 6 people) will depart

from those narratives.

Interviewees (and even news announcers) saying the wrong thing have

been known to be cut off in mid sentence as the network "has technical

difficulties". The CIA has an agent now in every major newsroom to vet

what stories must, may or can't be aired.

But they haven't been able to

stop the internet. Trust in the western mainstream media is more and

more being eroded as more and more people start to realize they're

being fed crap that doesn't match facts and leaves major issues

and events uncovered. And as opposing information, opinions and

viewpoints from many lands present themselves on the internet. In spite

of accidental or deliberate misinformation here and there, a

different and more coherent picture of events is starting to be

discerned by

increasing numbers of people. The 'establishment' wages real, serious

war on real journalism as exemplified by The car booby-trap murder of

Michael Hastings and Hillary "Can't we just drone strike him?" Clinton

regarding Julian Assange as well as the whole Wikileaks organization.

They seem to have cowed Equador into agreeing to turn Assange over to

their tender mercies.

Russia was once the home base of communist zealots who

thought the world would be a better place if they ruled it in

accordance with their ideology and who thought any and all means to

achieve that end including violence and war was justified. They ended

up dictating to the whole of eastern Europe for decades. (And if Victor

Suvarov is right, the rest of Europe and perhaps the world got off

lucky.) Today

Russia is a democratic republic where there is probably more freedom

than in North America, which since 2001 is rapidly becoming

increasingly unlivable by government decree. (Toronto psychology

professor Jordan Peterson [see on youtube] has attacked one

Canadian 2016 bill in particular as giving the government sweeping

power pretty much to prosecute - persecute - anybody they decide isn't

being "politically correct" or is saying things someone disagrees with

even if it's an honestly held opinion. People have become afraid to

voice disagreement about anything, however disagreeable, for fear of

official retaliation without recourse: fines, loss of job, loss of

rights, eg, to fly or

leave the country, even jail. Freedom of speech and freedom in general

is under increasing assault.) Even Iran, another special target of

American venom, has an elected president, who was peacefully changed

without so much as honorable mention or a hiccup in the "Iran needs

regime change" rhetoric.

Get over it!

Look to home for where "regime change" is really needed.

We have democracies. We need better communication channels with our

elected representatives in order that they do our collective will

instead of that of corrupt special interests or vocal minorities. And

we need to better know who we are really electing. What have been their

past actions and activities? Are they capable, experienced, honest,

sincere? Or are they a social predator in disguise? Knowing like Hitler

how to present themselves in public as being good and reasonable,

knowing how to tailor their "beliefs" and "principles" to

the audience, makes them more dangerous unless they are exposed, which

to date rarely happens.

And whatever most people who aren't themselves a special

target of some social predator may think today, we desperately need to

have a death penalty and we need to use it on those who prey on us all

and it has become a long continued, habitual pattern for them or a

present menace to the future of society. Permitting social predation

sets the stage to wreck the future. The tentacles start spreading

pretty soon after the unpunished, uncorrected crime, and encourage more

and more and larger and larger such crimes. (Anybody remember what

happened to Hitler after he got out of jail? Did it reform him and he

went about doing good? He just changed his tactics that hadn't worked

to ones that did.)

We are all tacitly or indirectly responsible for decisions

by leaders. Employees and shareholders of corporations are at least

tacitly complicit in immoral decisions made by management. When the

great majority plays their part, each person helping to prevent wrong

things including the wrongs behind the other wrongs, or to "regime

change" what has already gone wrong, we will we have peace and

stability - and perhaps even continuity and social sustainability.

Quinoa as an emergency food grain? - Salal - Vegetable Gardening

Quinoa, mid July. By the end

of the

month it was taller and bushier, and buzzing with pollinating

insects, flowers with seeds forming and growing everywhere.

Potatoes is still the easiest way to get calories from a

garden. If I plant wheat here in a large enough patch to be

useful, that would be too large for a tall fence and the deer would

probably eat it all. But here's something else where wheat (etc) may be

impractical for a home gardener. A couple of years ago I grew just 5

plants of quinoa in my garden in Victoria BC. They grew tall and bushy

and produced a whole jar of seeds. This year I'm trying a larger patch.

Potatoes is still the easiest way to get calories from a

garden. If I plant wheat here in a large enough patch to be

useful, that would be too large for a tall fence and the deer would

probably eat it all. But here's something else where wheat (etc) may be

impractical for a home gardener. A couple of years ago I grew just 5

plants of quinoa in my garden in Victoria BC. They grew tall and bushy

and produced a whole jar of seeds. This year I'm trying a larger patch.

Only one of the 6 seedlings planted early indoors survived

outdoors. I planted a bunch of seeds in the garden - twice - and for a

while things looked rather sparse and unpromising. I even planted beans

and things between the rows in case the quinoa didn't do anything. The

one from indoors is still the largest, but others finally started

catching up, and in spite of some being eaten by slugs when they

were small, it now appears they are pretty crowded (just one notable

bare spot could have used another plant) and I should have followed the

spacing guidelines or thinned them. But it looks like there'll be a

good crop.

Since quinoa is rather grainy unless soaked, on the 24th I

tried grinding up some into a flour in the coffee grinder. It's

probably more

like rice flour than wheat flour. It added some grittiness to a cake

and cookies, but not so crunchy as the whole seeds. A real flour mill

would doubtless make it quite smooth.

Salal, Aug

1st. Hmm... Picking season is hardly starting...

but these ones growing near a creek have some notably bigger berries,

already ripe.

Maybe I should water mine?

I also

(finally) read up on salal,

a berry native to the west

coast of North America from about Washington state north to the

southern islands

of Alaska. It didn't seem to be related to anything, but I discovered

it's a member of the heather family and has been imported to the UK and

Europe. It's very plentiful in my neighborhood, especially in an area

of my field and by the highway. Stems with leaves are very popular in

floral

arrangements. It has a small blue-black berry that makes good pies and

jam. Being so small, they're as tedious to pick as wild blueberries,

huckleberries or saskatoons; maybe more so. Then usually you have to

pick out bits of stems and petals before using them. So far it hasn't

been available

commercially, but after picking saskatoons wild in Edmonton over half a

century ago and hardly seeing them since, I never expected to see them

available commercially either. (The wild ones are bursting with flavor.

I've been unimpressed by the commercial offerings except the last jar

of commercial saskatoon jam I had was very good.)

I also

(finally) read up on salal,

a berry native to the west

coast of North America from about Washington state north to the

southern islands

of Alaska. It didn't seem to be related to anything, but I discovered

it's a member of the heather family and has been imported to the UK and

Europe. It's very plentiful in my neighborhood, especially in an area

of my field and by the highway. Stems with leaves are very popular in

floral

arrangements. It has a small blue-black berry that makes good pies and

jam. Being so small, they're as tedious to pick as wild blueberries,

huckleberries or saskatoons; maybe more so. Then usually you have to

pick out bits of stems and petals before using them. So far it hasn't

been available

commercially, but after picking saskatoons wild in Edmonton over half a

century ago and hardly seeing them since, I never expected to see them

available commercially either. (The wild ones are bursting with flavor.

I've been unimpressed by the commercial offerings except the last jar

of commercial saskatoon jam I had was very good.)

If you suspect there'll

ever be food supply problems, the

time to learn how to garden vegetables is before it happens. A sort of

insurance, but it does take a certain amount of know-how. It's easier

to expand if necessary by already knowing what's needed than to start

learning to recognize a weed from a cabbage seedling when hunger is

around. And you'll need some basic seeds and supplies in advance too.

And

of course you always get the best, freshest and most nutritious

vegetables when

you grow them. Commercial frozen peas don't have the flavor of 'real

ones' fresh from the garden.

And various things to learn are different in different

areas. Despite still being on the coast I note that the bugs buzzing

around the flowers here are much more like the ones in Edmonton AB than

those of Victoria BC. (must be a latitude

thing?)

And slugs were never a real pest in town in Victoria. I never bought or

needed "slug

bait" there, but here they can eat whole rows of seedlings and I

lost lots of crop "in the bud" last year before I caught on, and still

some

this year. (Must stock up on slug bait in advance of any supply

disruptions!)

Helping Ourselves by Helping Underdeveloped Countries

I've always thought it was irresponsible of all those

undeveloped countries to keep having so many children when they can't

feed them all. In the "developed" nations we have been

having children under the rate needed to maintain the population

for decades now. This

problem continually comes to light as people from more crowded places

with few opportunities keep flooding into the lands that should be

enjoying a great standard of living for everyone, keeping them pressed

to support growing populations. This influx of mostly unwanted

immigrants is reaching crisis proportions. We are everywhere hitting

the limits. We can't maintain our quality of life as long as the

population keeps growing, especially when the migrants don't have our

culture and values or even language, and so are a drain rather than a

benefit for quite some years after arrival. Opportunities even in the

developed nations are shrinking to the point of vanishing especially

for

the young, and inequality has become egregious.

Now it has come to my attention that it's not that the

undeveloped regions want all those children. But people

everywhere do want sex. The problem boils down

mainly to just one thing: in the more developed nations we have ready

access to birth control products. In the less developed places they

don't. So we don't have babies unless we want them, whereas in the more

primitive places the babies keep coming, wanted or not.

Instead of sending food or other immediate material aid,

we would surely do ourselves as much as them a much greater service by

offering to send free birth control products so the people there can

choose not to have more children than their land can support. Solving

the refugee and migrant problem is worth the price - especially when

the aid won't simply be fostering a larger and larger population who

then need more and more aid, and people who are compelled to migrate to

seek meaningful lives.

South Africa: No genocide after all?

In a later news article, the president of

South Africa seems to have backed off on his earlier "get rid of the

whites" stance, saying that they weren't out to kill off the whites and

other minorities after all. Hopefully and likely some voices of reason

even from within the black community have induced or forced him to

change the attitude of a few months back, and hopefully this improved

attitude will continue. Perhaps they look next door to Zimbabwe where

the whites were killed or driven out and the country has become

primitive and barbaric. "Is that really what we want?" Still from what

I've heard South Africa is a relatively violent place and I'm glad I

don't live there. Doubtless so are the 15% or more of the entire white

population which has already departed.

More on Bankers Creating the Money Supply

"Banking was conceived in iniquity and born in sin. ... Bankers own the

Earth. Take it away from them but leave them the power to create money,

and, with the flick of a pen, they will create enough money to buy it

back again.

"Take this great power away from them and all the great fortunes like

mine will disappear and they ought to disappear, for then this would be

a better and happier world to live in.

"But, if you want to continue to be a slave of the bankers and pay the

cost of your own slavery, then let the bankers continue to create money

and control credit."

- Josiah Stamp, director of the Bank of England, 1928

Just how much longer are we going to let this admitted

pyramid scheme continue? Why don't nations simply say "Our treasury

department will print whatever new money is needed, and the public then

won't owe it - with interest - to anyone." Admittedly the bankers kill

or try to kill any national leader who tries this approach and perhaps

it's small wonder our politicians seem to have no courage. As I

understand it Argentina was letting its provinces print their own money

some years back and having an economic boom, then the IMF stepped in

and told them the nation had to trade in all these local currencies for

national currency (wait for it...), borrowed from the IMF. I don't know

what coercion was used but it probably involved some pretty serious

threats. No such prosperity making alternative was to be permitted.

Today Argentina's currency is inflating away and the nation is in a

depression again.

We need people everywhere in lesser places too to say

"Whatever happens, even to our leader, the new money policy will still

be law and the nation will never again borrow money created out of thin

air by a bank instead of creating it itself."

What is News?

On TheWeatherNetwork.com was a headline about a teen

infested with hookworm parasite while playing on a beach. Such a thing

catches our eye. But why? And why include such a story in national news?

Where was it? Most likely far, far away from you or I.

Unfortunate though it was, just for example, millions die annually of

cancer, and in our own neighborhoods. Wouldn't it be more useful to

talk about how you can cut your chances of getting cancer at least in

half by getting either vitamin D or some sunshine daily or at least

very frequently? Cite some study or a bunch of them - they all say it.

That gives people good news and something positive they can do, instead

of just making them needlessly anxious over something that virtually

never happens to anyone. (Okay... just had to look... it was Memphis

TN, and he didn't just walk across something bad in bare feet, he had

been buried by friends in the sand, where the hookworms apparently

lived. (I bet it looked dirty, too.) And TN is inland, so it was a

freshwater beach, not ocean. I.E: this will never, ever happen to me or

you.)

And if one wanted to focus on bad news, there was plenty

of more newsworthy bad news without dragging in such drivel.

Double Agent Strzok

Hah! He was supposedly an FBI agent, now it seems Peter

Strzok was actually a CIA agent planted in the FBI! Impersonating an

FBI agent is a federal offense. So is espionage against the government,

and so is CIA activity within the USA. So is he classed as a foreign

spy or a domestic terrorist? How many more are infiltrating how many

departments? Does the FBI infiltrate the CIA? Does the IRS know Strzok

is collecting two paychecks? Who should investigate this clearly

illegal activity? Does the IRS infiltrate the CIA? Does the CIA

infiltrate the DHS? Is the snake eating its own tail?

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get

into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in

writing of

those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Electric Transport Projects

ARM Reluctance

Motor & Unipolar Motor Controller

I was working on my "ARM" (Axial flux Reluctance

Motor) and "unipolar motor controller" in 2014 and 2015, then other

things

caught up with me and I stopped. Now

having spent some months to get new chemistry batteries more or less

created and 'tamed' so to

speak, I thought

that getting a good reluctance motor and controller working would give

the best of everything:

* It would in and of itself be a superior motor, and it would

(presumably) provide a

motor controller for various reluctance motors.

* It would provide a platform for trying out the "permanent magnet

assisted" motors idea, since I already had some magnets the right size.

* It would get the electric outboard going without trying to solve the

cooling problem of the present Electric Caik BLDC motor. And it

would be better because it could exceed the RPM of the original

gasoline engine removed from any outboard where most electric motor

RPM.s limit boat

speed.

* It would provide a motor to get the Chevy Sprint - and by extension

most any light car - on the road and on the highway, efficiently with

simple

fixed ratio gears.

Note: I have recently found there are two entirely

different types of "PM assisted" reluctance motors. In one the

permanent magnets are in the coils as previously described. In the

other they are in the rotor. I haven't come to grips with how this

second type works yet myself.

So I decided to locate the components of the project and

pretty much start again, but with certain things already made. I would

try out the same unipolar motor controller and the same motor stator,

but with a new "more conventional" reluctance rotor on the motor. My

attempted

"flower" pattern rotor matching the donut coils ran, but it was

nothing like it was intended to be,

perhaps at least partly because when made, the "rings" didn't

seem to line up quite the same as when I had cut them out of cardboard

and simply set them in place for a rough estimate. As it was, there was

some

braking force as well as the forward force at certain points of

rotation.

In some reading I found out also that the rotor poles each

need way more iron for the stator to attract. That's probably the

biggest key to getting a motor with good torque. Changing the toroidal

coils to rectangular or pie shaped ones to

maximize the magnetic attraction along a rotary line of force would

also be very useful.

But the first question was, where? My electronics lab here

is tiny. The big workshop seems not very suitable. But it's summer and

the workshop is probably the place until it gets too cool to work out

there - if I can figure out how to set up a good workstation somewhere

- and get to the project.

I started by

freeing up some space by the only wall without shelves built in in

front of it - by installing the solar panels leaning against it.

Then other things caught up again. By the 16th I

thought I had decided to start afresh on the motor and just use the

controller. I

would look up a few more reluctance motor projects by others on line,

and perhaps find a pattern of coils and rotor design that "meshed"

really well together. Donut coils were great for BLDC motors, but

without supermagnets on the rotor, merely soft magnetic material,

reluctance motors require far closer and more exact magnetic coupling

to get high torque - or even "good" torque. Practically everything that

could contribute to that coupling seemed worthwhile incorporating into

the design.

In the evening I tried to find more info on line but I

wasn't finding much besides things I already knew. Finally I thought of

the two papers on axial flux reluctance motors I'd downloaded in 2015,

and finally I found the folder I'd put them in.

---

The first paper was (Sorry, I don't have the URL) [Hmm,

extra words appeared when I copied and pasted the text of the title and

authors!]:

Preparation of a Formatted Technical Work for the ICEM [the above words are not visible on the page]

A Design of Axial-gap Switched Reluctance Motor

for In-Wheel

Direct-Drive EV

by J. W. Haggle,

L. L. Grigsby [the above names aren't

visible on the page] Tohru Shibamoto,

Kenji Nakamura, Hiroki

Goto and Osamu Ichinokura Elec. and Comm. Eng. Dept., Tohoku University

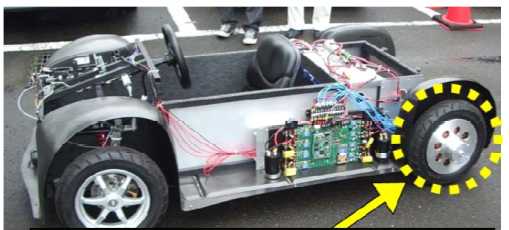

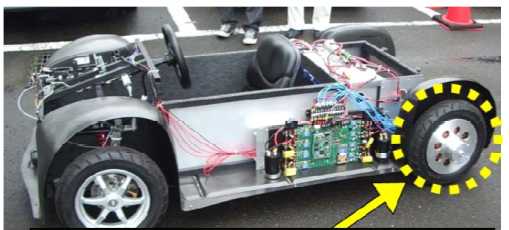

This motor was very high torque, but it had a problem that

the torque dropped off much too quickly with RPM above 200. The graph

stopped at just 800 RPM. I thought reluctance motors were supposed to

be able to easily spin really really fast? What about 8000 RPM? Was

this steep torque drop-off inherent, or was it programmed in as part of

the operating characteristics they desired for their specific "in

wheel" motor

in their specific test car? (I confess I don't think I'd want to be

doing highway speeds in it. Aviator goggles required!)

OTOH, they actually built and tested this motor. It turned

out the other

paper from U of Guelph was just a theoretical study.

In what they actually

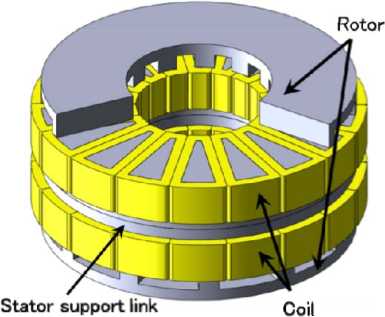

built, their "stator support link"

looked in the diagram like a solid steel plate with a coil above and a

coil below. If that was

so, wasn't it just two mirror image motors with a common shaft? Then

wouldn't a single motor with one rotor perform just as well?

---

The other

paper was:

Machines 2015, 3, 27-54; doi:10.3390/machines3010027

machines ISSN 2075-1702 www.mdpi.com/journal/machines/

Article

A Novel Approach to the Design of Axial-Flux

Switched-Reluctance

Motors

Tim Lambert *, Mohammad Biglarbegian and Shohel Mahmud

School of Engineering, University of Guelph, Guelph, ON N1G 2T6,

Canada;

OPEN ACCESS

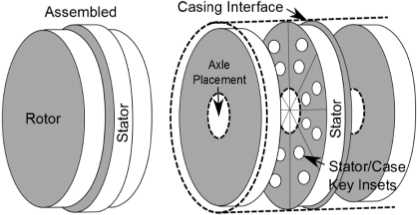

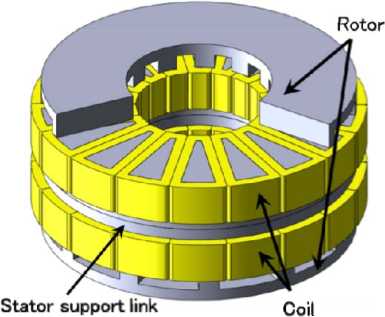

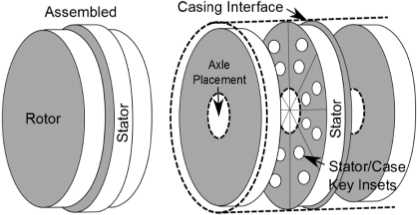

Both papers said that with reluctance motors, axial flux

gave best performance. Their motor was pretty similar, but with fewer

coils

and

apparently a different scheme for attaching the stator. (Some things

weren't clear and I started thinking of the "Stator/Case Key

Insets" as perhaps being slippery plastic bits that the rotors would

hit during vibration and jarring suspension changes. But that's

probably wrong. I don't have a clear picture in my head of how

they intended to attach the stator. A problem with a theoretical study

where nothing was actually built is that they may not have thought it

through completely themselves.)

---

Both motors had two rotors, one on each side of the stator. There,

apparently, was a chief key to maximizing torque, more or less doubling

it over one rotor, as well as supposedly improving energy conversion

efficiency. Each stator

coil core was a pie shape with the edges radial to the axle. The rotor

poles of this motor appeared to be similar, but of course there were

fewer of them. All very well, but...

With a rotor on each end, it looked to me like it would be difficult to

mount the stator coils. (Gosh, just like the axial flux generators with

two rotors!) The Tohoku motor showed a single stator in the initial

diagrams, but apparently when built was made pretty much as two stators

with a plate ("link") between them, which was required for sufficient

stiffness to handle the calculated magnetic forces. Would it not

then perform just like two single rotor motors? That would certainly be

easier to

make and to mount, even if it had to be a little bigger and or be

geared down more.

I thought of an alternative: putting "horseshoe"

electromagnets around the

outside, whose arms would equally attract the top and bottom the poles

of a single central rotor. But it would need very fat "arms" going to

the stator to carry the flux. These authors seem to refer to that as

"the double stator" layout. Their main complaint was it took extra

volume.

At first, knowing so much (ie so little) about all this, I

decided that the best thing to get the highest torque was to more or

less copy designs that worked. The axial flux seemed to be superior,

but the two rotor design seemed superfluous or difficult. I e-mailed

the authors of the paper in case any of them might still be reached at

U of Guelph. But somehow I hadn't realized at that point that theirs

was merely a

theoretical paper and nothing had been built. There was no reply. And

only the Tohoku one had

actually been made and tested.

What about the number and size of the active

components? I figured that the fewer poles there were, the higher the

RPM could likely be, so 6 or 8 coils should be better than the large

number in the Japanese design. If I made it 8 like the Ontario design,

it would need a 4-phase motor controller instead of 3-phase and I'd

immediately have to do a new motor controller as well as the motor. I

expect a microcontroller based motor controller is the way to go, and I

may end up doing 4 phases if I don't like the behavior of the 3-phase

motor, but for now the working controller, which I also wanted to test

further before starting a new one, made 6 coils the simple choice.

Also, the fewer poles, the fewer the magnetic reversals

for a given RPM, and so the lower the hysteresis losses in the rotor.

(Remembering that I already tried like poles and to avoid magnetic

reversals in 2015, and the motor had even less torque. That could

change with two rotors, with the flux going through the axle, but for

now I'll assume it won't.) Note that only the rotor poles reverse

polarity, not the stator coils, which already avoids the bulk of the

hysteresis losses. This is another advantage of the simple 3 phase

design: the coils have no reason not to actuate in pairs, the same

pairs each time, and so polarity doesn't matter.

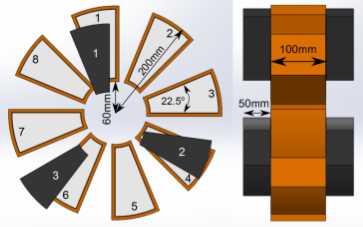

I started thinking about actual dimensions and placements:

Phases: 3 (6 coils, 4 rotor poles)

Stator Thickness: 3" --- 1"

made enough flux depth for coils for supermagnet rotors, but we need

much more flux with just a steel rotor.

Without going completely nuts, why not

greatly increase the depth of the field?

Rotor Salient Pole Thickness: 1/2" plus rotor disk --- (Or should

it be thicker, in keeping with increased depth of field?)

Rotor/Magnetic Diameter: 7" --- We get to go very high RPM, so why use

a very large diameter? Keep it compact.

7" should do it? (Or maybe 7.8"/200 mm, and

then I can use Princess Auto "brake rotor disks"?)

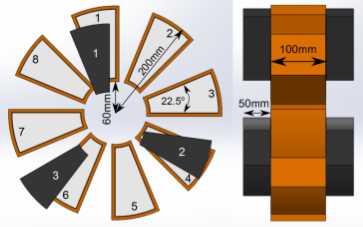

I

found

that

the

U of Guelph motor said 100 mm stator thickness

(4") and 50 mm rotor thickness (2"). The diameter is a very large 400

mm (16"). In spite of intending a "wheel motor", it seems a bit of a

monster

at 40 Kg. I wouldn't want that as unsprung weight on my car

wheel!

I

found

that

the

U of Guelph motor said 100 mm stator thickness

(4") and 50 mm rotor thickness (2"). The diameter is a very large 400

mm (16"). In spite of intending a "wheel motor", it seems a bit of a

monster

at 40 Kg. I wouldn't want that as unsprung weight on my car

wheel!

Since my plan is just a motor to mount anywhere, not to go

inside a wheel, it can spin higher revs with less torque and doesn't

need to be as big. If I maintain the proportions with 3" (75 mm) thick,

the rotors poles should be 1.5" (37 mm) thick. Thus the motor is

already 6" thick (or 4.5" with one rotor. But if I use an effective

diameter of 200 mm instead

of 400, it has just 1/4 of the interface area. That shouldn't

going too small if it's geared down enough - eg, 4 times more.

BTW, the idea of allowing the rotor to move off center compared to the

stator so it can handle wheel suspension movements didn't work for me

in 2008. Instead of turning the rotor, the stator jumped around

wildly in front of the rotor (car wheel) with the magnetic forces. I

had to put in a

"lazy susan" bearing as a thrust bearing to keep them on a common

center. (how

little I knew about mechanical components and supply sources back

then!) I didn't see that this issue was dealt with anywhere in this

theoretical paper. How well did they really know what they were doing

as far as making a real, practical motor? All the forces in this motor

are attractive, none repulsive, and the stator is much heavier. Those

things might make a difference, but I have my doubts.

The control scheme, position sensing and flux paths are

markedly simplified in the 6 coil, 4 rotor pole design compared to 8

separate coils individually driving 3 rotor poles. For one thing the

coils simply come on in pairs making for just three phases instead

of eight separate activations. When the coils come on in pairs

with one magnetized 'north' and the other 'south', there is an even

strength flux path across the rotors between the two driving coils and

the four driven poles - two on each rotor at opposite ends.

I'd rather have a stationary case than a spinning one,

with only the shaft spinning externally. It seems to me a 3" thick

stator whose outside is the outside of the motor will also provide more

outside surface for cooling. Maybe some heatsink fins around the

outside? OTOH, if the outside of a spinning case was centrifugal fan

blades with the air drawn in through the ends by holes in the rotors,

that might do a good job of keeping the motor cool too. Then the stator

coils, and the motor itself, would have to attach to the

stationary center shaft.

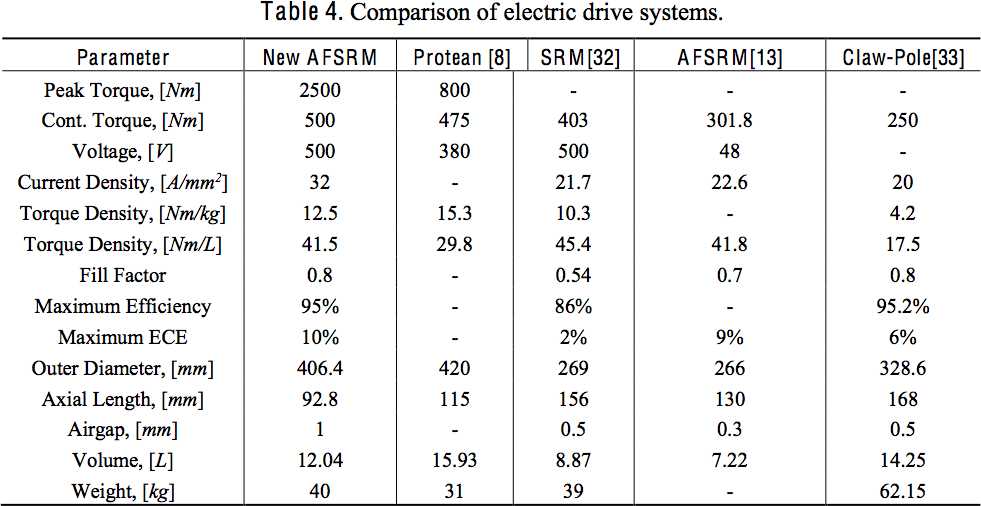

There was no reply from any of the U of Guelph team. The

lead author, Tim Lambert, seemed to have moved to a company selling

BLDC motors and equipment for scooters, etc. So it didn't sound like

they had made a real success of the axial reluctance motor themselves,

or they'd be for sale. (Well, if they never even built one!...) Here's

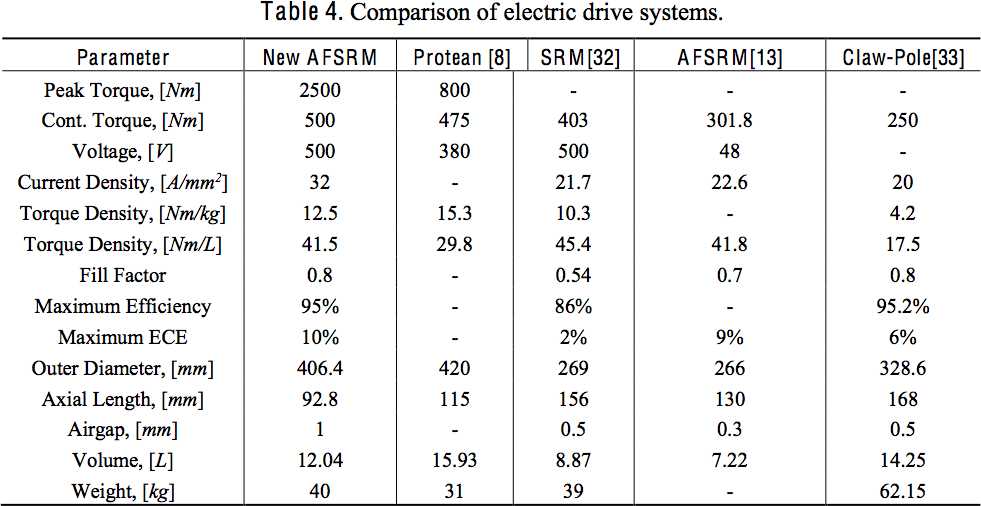

a last table from their paper:

The motor referenced as [13] is the one from

the Tohoku University paper (First paper above).

The motor referenced as [13] is the one from

the Tohoku University paper (First paper above).

It appears only the Japanese weren't using an insanely dangerous

voltage.

Note: Current density

How is it I've been making motors for so long and yet paid

so little attention to this parameter? How many amps does one want to

ram through what size of wire, as in the table above? Perhaps it's just

that I'd never taken note of what others were spec'ing, as in the table

above.

Of course in the absence of room temperature and above

superconductors, the more the amps, the hotter the wire will get.

[what's happened to those, anyway? somebody's research was getting

results a few years ago. For the first time ever, they had to raise the

temperature to find the superconducting point.]

My Electric Hubcap on the Sprint car, with the Kelly

controller, occasionally used up to 150 amps. It got hot fast. The

cross section of the #11 AWG wire I used is 4.17 sq.mm. If I restricted

current to the figure spec'ed for the Japanese motor, 22.6 amps/mm^2,

I

should have limited the current to 94 amps. 94 A * 36 V = 3400 watts

or 4.5 HP. (It still would have got hot pretty fast, I think.) I think

the U of Guelph team were unrealistic spec'ing 30 amps/sq.mm - that's

about like my 150 amps that got so hot so fast.

If I want the reluctance motor to have more horsepower at

the same 36 volts, it would appear I should wind two strands of #11, or

equivalent to keep it from getting too hot. As it is, the one I have

now with a single strand at 24 volts should be limited (again using the

22.6 amp figure) to (22.6 A/sq.mm * 4.17 sq.mm) * 24 V = 2260 W or 3

HP. And that's only if it has quite good cooling.

One can balance by putting coils in series or parallel. If

instead of having two coils of 21 turns (2 layers or wire) in series,

it had two of 42 turns (4 layers) in parallel, each coil would handle

94 amps current, total 188 amps. That's theoretically double the

available current and horsepower. (And it looks like there would

actually be enough room for the extra wire.) Of course, with four

layers of copper wire on each coil instead of two, each coil will be

harder to cool, so one may have to limit the current to a lower value

and the overall improvement, except perhaps for short burst capacity,

may be more limited than expected.

Or I could use two coils in series with ~32 winds (3

layers) instead of 21 and change it to 36 volts. There again is the

theoretical 4.5 HP but probably somewhat less than that in practice.

Back to the old Motor, with a new Rotor

Well, double RPM makes up for half the torque via a

different gear ratio, so if there was actually little or no real

advantage to

having double rotors in practice, the stator plate I had made in 2015

should be as

good as any other. So before I got too carried away, I decided to try

the

previously unused four pole rotor I cut in 2015 with the original

stator, just to see what I might learn. On the 25th I found some

various washers and spacers that let me put that rotor in. That just

left mounting the optical interrupters. The spacings for those would be

completely different.

Then I thought about how fat the rotor poles were in the

other motors, and how at least in the Guelph design, the poles were the

same size and shape as the stator coils. A big chunk of steel is harder

to pull from a magnet than a small one. That made the thin 3/16" steel

of my rotor seem rather pathetic. In fact, whatever the other failings

of the 1/4" thick "flower petals" rotor, too little iron in the poles

was

doubtless the biggest one. If I was to use this motor with its 2" O.D.

round coil cores, probably what it should have for rotor poles was

something like 2" steel hockey pucks, at least 1/2" thick. That might

actually make a motor that would run the outboard. ...What about

using four of the actual iron powder toroidal cores? I wasn't sure the

rotor needed to be made of laminates, but these would be even

better than laminates. (Not physically stronger for high RPM.s, though!)

The diameters said these "pucks" would stick out slightly

past the outside of my rotor. So the next question was how to mount the

optical interrupter parts. It might be necessary to cut some pieces of

sheet metal and bolt them onto the outside of the rotor to make

"solids" and "gaps" or "slots".

Maybe I should use a different rotor after all?

In fact, it just might be worth getting another special

one cut for me at Victoria Waterjet.

And in the stator, I still have the cylinder supermagnets

and can still try out "permanent magnet assisted" configuration. That's

a valuable reason to pursue the existing motor design. So on the night

of the 26th I decided that was the plan.

Step 1: design another rotor and have it cut for me. I figured I'd put

the coils into four 2" round holes made for them. Then they'd be

aligned and I could center them vertically for ideal balance. I could

have two outer diameters for the optical slots and solids areas, 4

of each.

Then I looked

at a rotor with four cores sitting on it. A

big problem (all along) with using them was the there was nothing to

grip to hold them onto anything without having something extend past

the end. Well, really they were just iron powder with an epoxy coating.

What was the difference between that and sintered iron or cast iron?

Could I turn them on the lathe so they would have an inner mounting

surface that would leave the outside flush? How about a fat washer that

didn't stick out, with a flat head bolt? In spite of it being after 1

AM I took one out to the shop and turned it so it could be held in

place that way. It milled easily and it just took a minute.

Then I looked

at a rotor with four cores sitting on it. A

big problem (all along) with using them was the there was nothing to

grip to hold them onto anything without having something extend past

the end. Well, really they were just iron powder with an epoxy coating.

What was the difference between that and sintered iron or cast iron?

Could I turn them on the lathe so they would have an inner mounting

surface that would leave the outside flush? How about a fat washer that

didn't stick out, with a flat head bolt? In spite of it being after 1

AM I took one out to the shop and turned it so it could be held in

place that way. It milled easily and it just took a minute.

Great! That opened up new possibilities for using them.

Move to "Plan B": attach the "pucks" to this rotor

with four specially made "washers". Then make four pieces to

divide the edge into optical solids and gaps. Once the optical parts

were mounted and the flux gap was set by putting just the right

spacers on the shaft, it would be ready to run. That would seem to

be

the path of least reluctance. Too bad the coils were already made and

glued down - I could have done similar for the permanent magnet

"keepers". But first, I should get it to run as a simple reluctance

motor. The performance of that would be the benchmark.

Then I got the "flower pattern" rotor off the shelf. If I

just made a few cuts and did some filing, I could put the four "pucks"

into holes in it, all perfectly aligned. Okay, "Plan C". On the 28th I

did one using a

jigsaw with a metal cutting blade. That seemed good. Then I realized it

needed

support in both directions - it could slide either

way. If I turned off say 1/32" from the outside but only went just over

half way across, and left a bit more material in the rotor holes, they

could slide in to there and no further. Then they'd only need to be

kept from sliding out the way they went in.

Then I got the "flower pattern" rotor off the shelf. If I

just made a few cuts and did some filing, I could put the four "pucks"

into holes in it, all perfectly aligned. Okay, "Plan C". On the 28th I

did one using a

jigsaw with a metal cutting blade. That seemed good. Then I realized it

needed

support in both directions - it could slide either

way. If I turned off say 1/32" from the outside but only went just over

half way across, and left a bit more material in the rotor holes, they

could slide in to there and no further. Then they'd only need to be

kept from sliding out the way they went in.

Even better would be to turn that 1/32" deep channel 1/4"

wide (the thickness of the rotor) in the center so they couldn't move

either way. But that would take some special and larger cuts in order

to insert the donut. (It would slide into a bigger hole closer to the

center of the rotor and then slide out to where it was held securely. A

piece would be bolted on to prevent the donut from sliding back toward

the center and the bigger hole. Hmm...)

Anyway, on the 29th and 30th I cut and filed out the other

three holes. The rotor would be the "back iron" of the toroidal rotor

poles and one edge of them would be flush with its surface - never mind

ideal balance for this one. Then I

would mill a 1/8" holding ring slot just below and make four 1/8" steel

pieces to (a) hold the poles in place and (b) form outside "optical

solids" for the optical interrupters. The shape of these pieces to do

this will be easier to figure out by cutting some pieces of cardboard.

These will be bolted to the rotor plate. (...Or is that really how I'll

do it?)

Other "Green" Electric Equipment Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

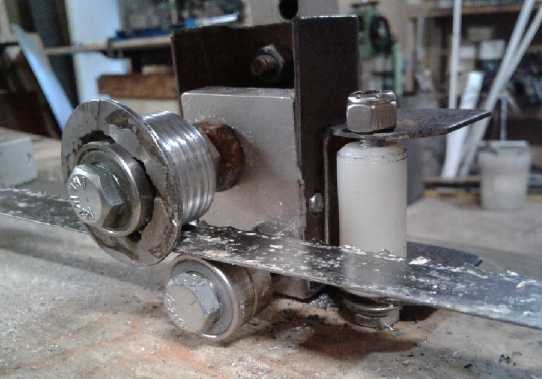

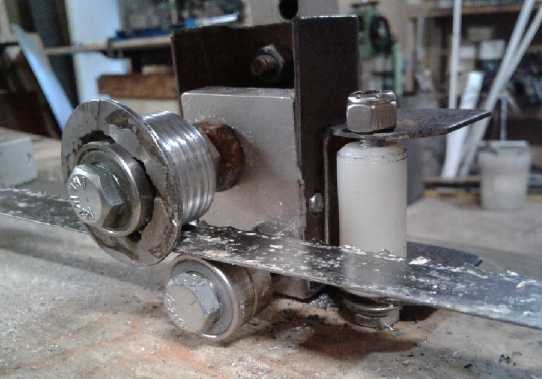

Front Pivot Self Adjusting Band Guides

After thinking

of this idea on June 30th, I made and

mounted them on the 4th and 5th. I wasn't quite sure how to do it. The

supports were behind the blade, not in front. Well... the saw was

somewhat symmetrical. I took the blade off, turned it inside out, and

put it on backwards facing the other way. Now the back was the front

and the motor was on the left instead of the right.

After thinking

of this idea on June 30th, I made and

mounted them on the 4th and 5th. I wasn't quite sure how to do it. The

supports were behind the blade, not in front. Well... the saw was

somewhat symmetrical. I took the blade off, turned it inside out, and

put it on backwards facing the other way. Now the back was the front

and the motor was on the left instead of the right.

The "pickup truck canopy clamps" now seemed unsuitable. I

made two bars of aluminum .5" x 1.25" x 2.5", each with a 1/4" hole

going across the width in the middle as the pivot point. A 1/4" bolt

went through the sides of a piece of 1.25" wide "U" channel steel,

holding the pivoting bar in the middle. I mounted the wheels and

bearings such that the band crossed over the center line along the

bolt. I drilled bolt holes in the "U" channel pieces holding everything

to match the holes already in the mounting arms on the saw. So I got

the guide wheels mounted nicely. As I was turning the saw to adjust the

band tracking, my finger discovered a sharp shard of aluminum on the

pulley. It cut a fair slit and I quit for the day to nurse it.

I tried the saw out the next morning (6th). I was pretty