Turquoise Energy Ltd. News #123

covering

August

2018 (Posted Sept 4th)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlight: Carmichael Mill cuts beautiful, straight

lumber with little waste sawdust (see Month in Brief, Other Green"

Projects)

Month

In Brief

(Project Summaries etc.)

- Concert - Swiilawiid Sustainability Society talk? - Carmichael

mill - Batteries - Reluctance motor -

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Electromagnetic Induction Arson: Burning the world!

- "By Prescription Only": Overregulation is Causing Shorter,

Less Healthy

Lives

- Democracy Denied in California - South Africa: White

farmers

want to flee en-masse to Russia - More Hypocrisy from the Main Stream

Media (MSM) & Extension of Censorship - Big Oil Subsidies -

Changing Language... All well and good (unwell attempted humor)

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Jim Harrington's 2.5 HP Electric Outboard

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Handheld Bandsaw Alaska Mill")

- Various improvements and changes, blah blah blah - Finally:

Good Results! - Dulling Bands

Electricity Generation

*

Solar Panels

* Tidal Power Project on Tlell River?

* Scot Power Floating Tidal Power Vessel: 3 GWH in first year!

Electricity Storage -

Turquoise Battery

Project (Now Mn-Zn, Ni-Zn or Pb-Zn)

* Lead-Zinc Cell From Scratch With Rolled-up Sheet Metal Electrodes (as

made it was a flop)

On the 4th, after I

posted the last newsletter, our band of five "The Huckleberries" played

at an outdoor potluck party. People liked hearing my "supercorder",

something besides the usual guitars and percussion. (longer version in

"In

Passing".)

On the 5th I went to the Tlell fall fair, where I found a

"Swiilawiid[.org] Sustainability Society" booth and volunteered to talk

about

renewable energy things at an upcoming symposium on that subject in

September. (I had been meaning to send an e-mail for a few days.)

Carmichael Mill/Handheld Band Mill

This was

certainly the project of the month. I finally put

in a simple tube with a sponge to wet and cool the band as it went by.

As I surmised by the time I wrote the last newsletter, the self

adjusting band guides system is far superior to any previous bandsaw or

bandmill setup. But this wasn't as immediately demonstrable as

expected. The worst problems I was having were due to a dull and,

worse, unsymmetrically bad band that really wanted to cut circles

rather than straight. Later wavy boards were traceable to bad guide

alignment and then mechanical problems keeping the band from pointing

the direction the guide wheel was aiming it - from two different guide

mechanisms. The second one intended to cure the problem didn't - but

only, as it turned out, because a spring was too light.

This was

certainly the project of the month. I finally put

in a simple tube with a sponge to wet and cool the band as it went by.

As I surmised by the time I wrote the last newsletter, the self

adjusting band guides system is far superior to any previous bandsaw or

bandmill setup. But this wasn't as immediately demonstrable as

expected. The worst problems I was having were due to a dull and,

worse, unsymmetrically bad band that really wanted to cut circles

rather than straight. Later wavy boards were traceable to bad guide

alignment and then mechanical problems keeping the band from pointing

the direction the guide wheel was aiming it - from two different guide

mechanisms. The second one intended to cure the problem didn't - but

only, as it turned out, because a spring was too light.

I continued cutting with both the bandmill and chainsaw

"mini-mill". The boards were good enough for rafters for a lumber

shed... and the cants were sitting where I wanted to make that shed,

and had to go. Cutting them into boards seemed like the best way.

I order some slightly heavier bands, and when they arrived

and a heavier spring was installed, I cut 100 feet of nice straight 6

inch wide boards on the 29th and 30th.

It seemed the bands would need frequent sharpening, but I

finally realized there wasn't enough cooling water coming through the

sponge in the new mechanism and they were overheating when the going

got tough, causing the teeth to lose their tempering and dull quickly.

(Well, duh! I could feel that they were too hot!) A cordless drill (or

'dremmel' tool on slowest speed) with a 1/8" diamond cylinder bit

sharpens pretty fast, but 279 is a lot of teeth, and they don't stay

sharp long if their temper is gone. Maybe I can get a band maker to

produce 2 TPI (or less), .025" thick bands for milling (186 teeth or

fewer).

I could see

better ways to do various things with experience as time passed. Some

of them got done. The "skis" that sat on the guide board were changed

to crosswise "skids", a much better arrangement.

I could see

better ways to do various things with experience as time passed. Some

of them got done. The "skis" that sat on the guide board were changed

to crosswise "skids", a much better arrangement.

As I worked through the problems one at a time

results improved. By the time I was on the fifth band it looked like I

might stop wrecking them so swiftly. It was cutting nicely by the end

of the month in spite of still needing a proper band tensioning

mechanism.

By the end of the month I conceived that a "changes and deficiencies"

list was needed for all the little details to apply to a production

model.

Most of the cuts were in spruce and about 6" wide, plus a

few 7-9" mostly in alder.

But on September 3rd I set the width to 13"

and used it to cut up another 10 foot section of alder log in a little

over 2 hours, making ten "perfect" 1 inch thin boards with most cuts

being 8

to 10" wide. (good siding lumber?) With the sponge letting through a

bit

more water, the band never even got warm, and all the cuts went very

well. I was surprised. It was, like... industrial!

The saw will adjust to 18" cut width (potentially 21"),

but I suspect it

will be tough slogging at such widths. Certainly it's perfect

for cutting large cants into boards with almost no waste, and the last

session demonstrated that it can slice up small

whole logs. Cutting large logs into cants is probably still better done

by

chainsaw milling.

Like

the oxalate battery electrolyte, the self adjusting band guides are a

fundamental advance to the state of the art and yet something so simple

that in the future

everyone

will say, "Well obviously. Why would

it have been done any other way?" And yet, for well over a century

before that, since the first batteries and the first bandsaws, everyone

was groping in various directions and no one had a really satisfactory

solution. The electrolyte didn't come to me without a decade of

trying to make better batteries. The band guides inspiration only took

months.

---

I finally sent an e-mail to Swiilawiid on the 17th with a

description of all the things I could talk about if they liked them and

gave me time. The last item on my list is a pitch for a floating

hydro project at the Tlell River, which site I had just

identified as being a good place a week previously. The river is slow

and flat, but near the mouth a lot of water flows both directions at up

to 2 meters per second, in

and out with the tides.

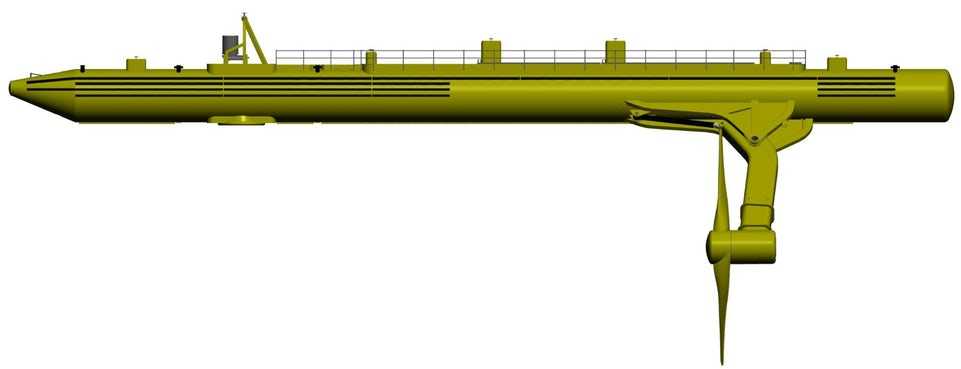

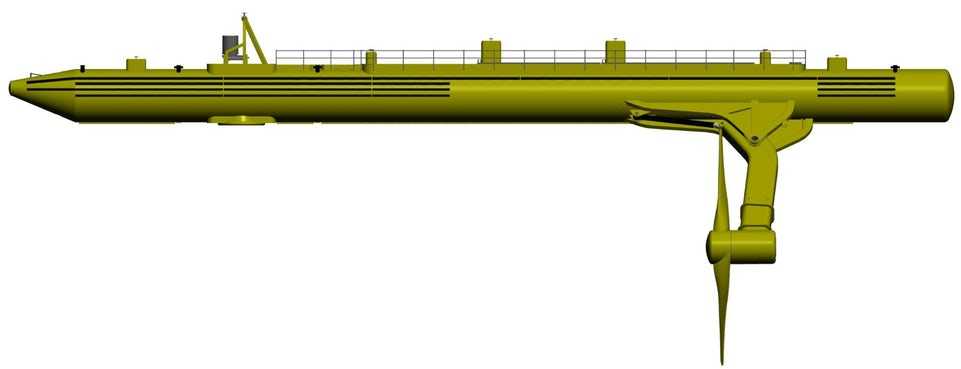

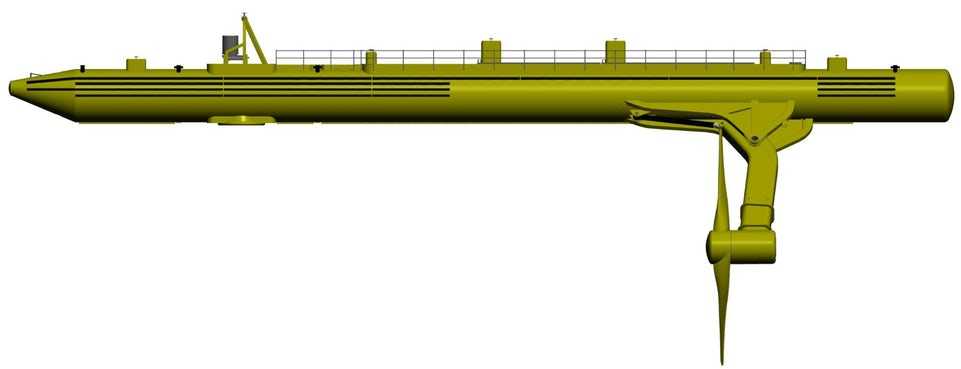

But...

speaking of simple and obvious "why do it any other way?"

designs... on the 22nd a friend sent me a link to a

tidal power project that looked better than all the others and had in

fact made 3 gigawatt-hours of electricity in its first full year of

operation - more than all other previous tide and wave power projects

put together. This seemed very promising. I finally decided that a big

project using that design right in the channel of Masset Sound instead

would be far more worth doing. The design has been proven and it has

the potential to drastically curtail diesel fuel usage on the north

grid of this island.

But...

speaking of simple and obvious "why do it any other way?"

designs... on the 22nd a friend sent me a link to a

tidal power project that looked better than all the others and had in

fact made 3 gigawatt-hours of electricity in its first full year of

operation - more than all other previous tide and wave power projects

put together. This seemed very promising. I finally decided that a big

project using that design right in the channel of Masset Sound instead

would be far more worth doing. The design has been proven and it has

the potential to drastically curtail diesel fuel usage on the north

grid of this island.

Some people

dropped by looking for advice on batteries, and I decided I

should get back to doing a few more battery experiments. Lots of people

want them and need them, and what's available is either short lived and

very heavy, or very expensive. We need the new types the oxalate

electrolyte enables. A lead-zinc cell with rolled up sheets for

electrodes performed very poorly. While one may perhaps get 5-10% of

theoretical capacity or better out of zinc, it would seem one gets very

little out of a thin sheet of lead. Most materials have to be in

particle form to get enough surface area to be of use. Also it soon

shorted out, and then again, and I decided to give up on thin paper

separators and stick with the more robust liquid filled battery design

with "pocket" type electrodes. But with all the other things to do I

didn't get any further.

Some people

dropped by looking for advice on batteries, and I decided I

should get back to doing a few more battery experiments. Lots of people

want them and need them, and what's available is either short lived and

very heavy, or very expensive. We need the new types the oxalate

electrolyte enables. A lead-zinc cell with rolled up sheets for

electrodes performed very poorly. While one may perhaps get 5-10% of

theoretical capacity or better out of zinc, it would seem one gets very

little out of a thin sheet of lead. Most materials have to be in

particle form to get enough surface area to be of use. Also it soon

shorted out, and then again, and I decided to give up on thin paper

separators and stick with the more robust liquid filled battery design

with "pocket" type electrodes. But with all the other things to do I

didn't get any further.

I reluctantly decided to leave the reluctance motor until

winter. But I decided to plane some of the wavy lumber I'd been

cutting and make a large new workbench in my electronics lab to work

on the motor and controller there. My test equipment and electronics

components for the motor controller are there and it's indoors. And

along those lines, as I perhaps belatedly realized the summer was

drawing to a close, on the 22nd I started in on construction projects

like putting up eavestroughs on the big roof over my travel trailer

(which had been up for a year - took 5 days). The lumber storage shed

was to

be next, but I decided to put it off and use the spare gravel space

under the travel trailer roof for lumber this winter. I could get more

of the

wood cut up instead. and do the bandmill spring tensioning system.

Another two days was consumed shifting things around and moving the

wood, which had been accumulating in an untidy pile.

I also planed

a

few boards of alder (for the workbench?) and then a couple of spruce,

after installing a new pair of blades in the planer, which set has

escalated from 40$ to over 100$ in the 10 years since I bought it. The

second spruce board had a broken off screw in it, which wrecked the

brand new

planer blades: now they leave a narrow ridge in the middle of a planed

board. I remember one screw breaking, but I cut the end off that board

- this was a different one I missed or forgot about. That's also what

happened to my last pair

of planer blades - a cut off nail or something when they were almost

new. I can turn them around

and use the second side, but things aren't looking good for making

lumber to sell! I ran a metal detector on a couple of boards I thought

were suspect before

using the bandmill on them, and I think I'd best do the same for

anything I'm going to put through the planer. A bit late tho!

I also planed

a

few boards of alder (for the workbench?) and then a couple of spruce,

after installing a new pair of blades in the planer, which set has

escalated from 40$ to over 100$ in the 10 years since I bought it. The

second spruce board had a broken off screw in it, which wrecked the

brand new

planer blades: now they leave a narrow ridge in the middle of a planed

board. I remember one screw breaking, but I cut the end off that board

- this was a different one I missed or forgot about. That's also what

happened to my last pair

of planer blades - a cut off nail or something when they were almost

new. I can turn them around

and use the second side, but things aren't looking good for making

lumber to sell! I ran a metal detector on a couple of boards I thought

were suspect before

using the bandmill on them, and I think I'd best do the same for

anything I'm going to put through the planer. A bit late tho!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Electromagnetic Induction Arson:

Burning the world!

Note: I thought this would be a

few paragraphs and a few pictures. But

apparently I'm incapable of writing anything briefly to make a point

and it got longer and longer. I hope it's at least a good story.

This is so incredible it's hard to know whether to even

believe what

one sees in the photos in the reports. Unfortunately it's all starting

to form coherent patterns of vast wanton destruction for the purposes

of

sabotage and theft on the grandest scale. It has the appearance of a

plot so twisted

and diabolical that one could hardly invent it for a movie.

In a wildfire the first things to burn are the dry grass

and leaves,

and twigs and branches of trees. All this is the 'kindling' that

spreads the fire.

A lady in

California brought attention to it on youtube

("intruthbygrace"). In a news

report about "wildfires" she saw on TV, she noticed what most of us

missed: that the

wrong things had burned. An

entire highway crash fence had caught fire, all the posts and the

protruding 6"x8"s that held the metal guard rail, and left the guard

rails lying on the ground at the edge of the highway. (Both sides of

the highway?!?) But the dry grass

and leaves everywhere around it weren't burned, and neither were the

trees nearby. And somewhere a metal

sign had

burned off its two posts, lying on the ground. And

again, the grass, shrubs and bushes near the sign were untouched.

A lady in

California brought attention to it on youtube

("intruthbygrace"). In a news

report about "wildfires" she saw on TV, she noticed what most of us

missed: that the

wrong things had burned. An

entire highway crash fence had caught fire, all the posts and the

protruding 6"x8"s that held the metal guard rail, and left the guard

rails lying on the ground at the edge of the highway. (Both sides of

the highway?!?) But the dry grass

and leaves everywhere around it weren't burned, and neither were the

trees nearby. And somewhere a metal

sign had

burned off its two posts, lying on the ground. And

again, the grass, shrubs and bushes near the sign were untouched.

It takes a long time to burn through heavy posts. They

should be

pretty much the last thing to go in a fire, not the first, kept lit by

the heat around them. But trees are cleared away from the edge of

highways. What lit

them on fire

if even the 'kindling' all around them wasn't burning? And, each post

is

well separated from the others, so what could cause the fire to spread

from post to post with no fire in between posts, to bring down the

entire crash fence? What do the posts have that the grass and leaves

don't have? Seemingly the answer is they have bolts in them, which

could be

heated electromagnetically or by microwaves.

Then other people have

noted trees that seemed to catch

fire from

inside, sparks and flame bursting out from the interior while the bark

is still

hardly touched. Apparently the US government had some bizarre

explanation handy

for that. (Happens all the time... really?) But... burning from the

inside? Aren't microwave ovens

described by the term "cooks from the inside"?

And what about the "fire tornadoes" so many have seen,

wildfires

that burn faster and hotter than any ever before, spreading with

record-breaking rapidity? Lighting up "everything at once" sounds like

the best way to achieve such results, which are reminiscent of the

firebombing of Dresden or Tokyo during the second world war.

And why have there been SO many fires burning all across

the west?

Sure, it's

dry, but it seems nobody knows how most of the fires, at least those in

California, started. They are evidently not mostly lightning strikes.

They are mysteries. But many people have started saying owing to the

suspicious circumstances that they must be being started by some

"directed energy weapon" ("DEW").

California. What kind of wildfires repeatedly

leap wide paved areas to utterly devastate widely separated buildings,

California. What kind of wildfires repeatedly

leap wide paved areas to utterly devastate widely separated buildings,

while leaving the vegetation seemingly intact? Arson is the word that

comes to mind.

But what kind of arsonist could do so much damage without being

apprehended and stopped, and so fast?

Even before recognizing the suspicious causes and

suspicious nature

of so many of the fires, people had been calling it a "federal land

grab". The US government has seized possession of the burned out areas

as they occur and deemed them federal property, apparently without

even offering

compensation to the owners, who are left homeless or businessless

without a thought as

to their wellbeing. Outright theft!

So there's a motive to explain the bizarre events

behind this bizarre story.

Perhaps some of the huge number of fires in BC as well as

in Washington and Oregon states may be "camouflage" so the huge number

of California fires seems less suspicious, and to keep firefighters too

busy to analyze, seek causes and ask questions.

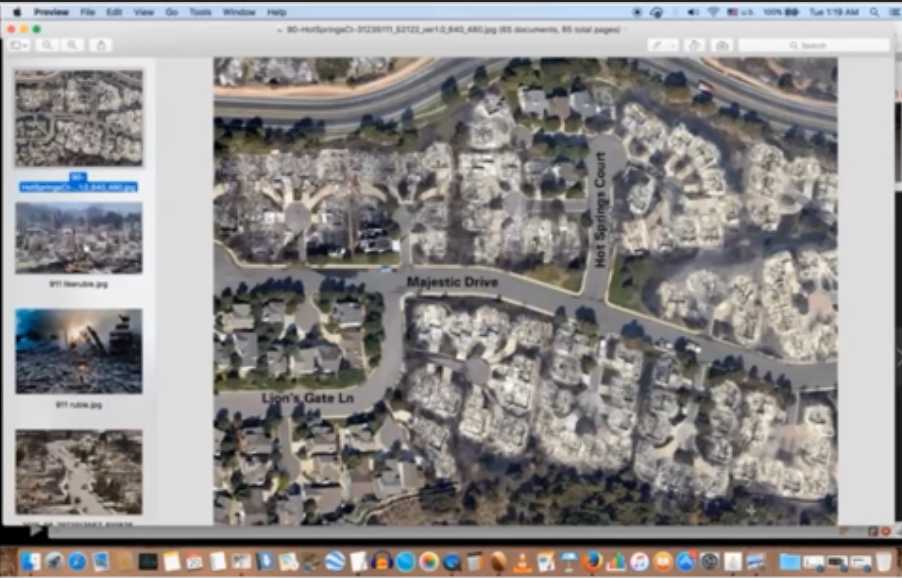

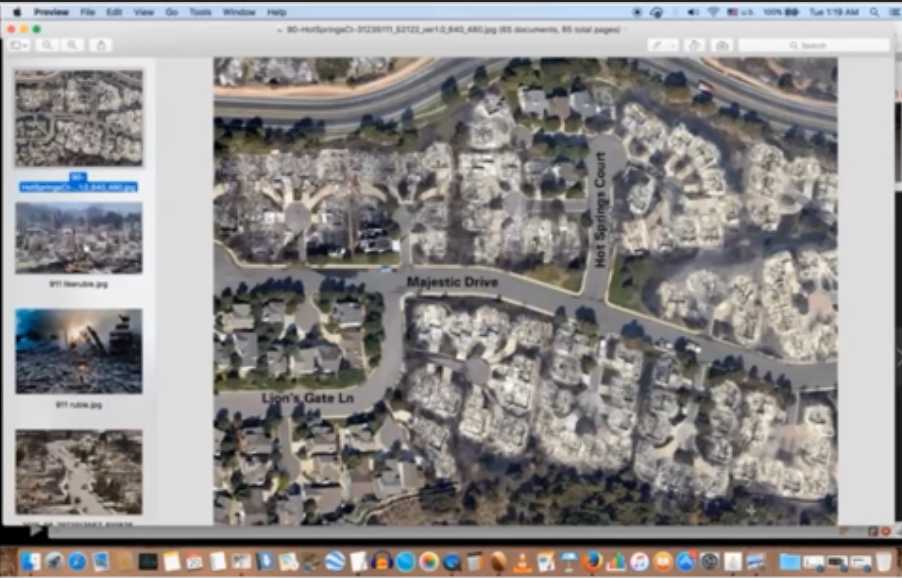

Fort McMurray, Alberta, May 2016.

Yellow is said to be "hot", white is "still burning".

Now let us go

back to May 2016. In spite of it being

spring and

probably not too dry, "forest fires" sprung up around the largely new

"tarsands

oil town" of Fort McMurray, Alberta. An infrared satellite image gives

the appearance of the town being very selectively targeted by fire,

does it not?

(According to the description yellow is hot, white (all those houses?)

is still burning.) The fires and heat seem to be all around the town in

a

rectangle.

Nowhere else.

Now let us go

back to May 2016. In spite of it being

spring and

probably not too dry, "forest fires" sprung up around the largely new

"tarsands

oil town" of Fort McMurray, Alberta. An infrared satellite image gives

the appearance of the town being very selectively targeted by fire,

does it not?

(According to the description yellow is hot, white (all those houses?)

is still burning.) The fires and heat seem to be all around the town in

a

rectangle.

Nowhere else.

What happened IN town,

probably

right after the evacuation, appears to defy natural explanation.

Another

youtuber as well

("intruthbygrace" and "PlaneTruth") shows us aerial photos of the town

after the fire. Whole

streets of houses are burned up to a crisp, not even any walls left

standing; no wood left to be seen anywhere. (Even a house that caught

fire in Queen Charlotte this

summer, and then exploded because the owner was storing dynamite and

blasting caps in it, had part of a wall

left standing.) These various streets in "Fort Mac" where everything

was razed

to the ground, are ringed by seemingly untouched trees. And around

those are

other untouched streets with untouched houses. How did the fires get

into

and utterly destroy these various interior streets or even individual

houses, with no apparent fire path or damage around them?

The haste with which everyone was evacuated to distant

points from a fire that was only right around the town seems

reminiscent of some wartime ruse to cause an army to flee without a

fight.

This one looks like it was taken in autumn,

some months after the fire.

This one looks like it was taken in autumn,

some months after the fire.

Still, it doesn't look like the fires did the trees much harm.

Most of the ash seems to be rings around house

foundations

Most of the ash seems to be rings around house

foundations

Some trees burned here.

Some trees burned here.

But how did the handful of trees behind the front row torch all those

houses?

Or did the houses burn first?

Masonry and metal: scarcely a board seems to

remain of the houses (here

Masonry and metal: scarcely a board seems to

remain of the houses (here

some townhouses?), while

the trees nearby are untouched or recovered quickly.

Assuming somebody has the means, do we have a motive? The

tar sands

was (and probably again is, at terrible environmental cost) supplying a

lot of crude bituminous petroleum. The price of oil dropped to the

point where all the newly created "fracking" oil seams in the USA were

losing

a lot of money. And so the banks that loaned them billions of dollars

were also

losing.

If a major source of oil like the tarsands could somehow

be shut down without arousing suspicion - or at least without anyone

being able

to point a finger directly at someone - the price of oil would go up

and help

all those banks and rich people with shares in them and in the

"fracking" industry

to make money instead of losing it. What more natural thing could

happen than a big forest fire... which just might happen to pass

through the town where all the workers lived? The timing (Wait... at

the start of May?!?), the location and the rapidity of the spread are

suspicious, and the effects of the - multiple individual fires - inside

and

outside the town

still more so.

There is a revolving door between the big banks in the US and the

government, with things like last year's treasury secretary (or

watchdog over the big banks) becoming next year's Goldman Sachs Bank

chief executive and vice versa. This has been going on ad nauseum for

decades now. And it has been said that there is a new major fraud

averaging every four days on Wall Street. The corruption seems almost

total. But are they really heartless enough to pull such an egregious

caper? They start wars in the name of profits. Did they not blow up the

World Trade Center? This would be nothing to them.

So the next question would be, HOW could this possibly be

being

done? I suspect theories of "directed energy weapons" shooting down

from the sky

might have some problems with physics. There are however

inductively heated cordless kettles and kitchen stoves. They heat

the metal of the bottom of the pot inductively. My theory is that there

is some big truck with powerful electromagnetic, or alternatively

microwave, heating equipment in it. It drives down the highway or

street or trail turning everything metal red hot behind it as it passes

- including

the bolts

in sign posts and guard rail posts, and the nails in house walls. The

wood ignites from the red or even white hot metal embedded in it. Maybe

it's disguised as a fire engine to explain away its otherwise

suspicious presence near fires.

That would describe the nature of the fires pretty well.

In general they happened next to roads. It's easy to visualize a truck

driving

down the highway, turning the bolts and guard rail red hot and thus

lighting up each post of the guard rail as it passes by it.

In Fort McMurray, the patterns of destruction could

indicate that

they drove down some back alleys (a common Alberta municipality layout

feature),

lighting up the homes on both sides of the alley. With red hot nails in

all the

walls, the entire house burns to the ground - no wall left standing and

indeed little wood remaining

because the fire didn't simply progress from where it started to other

parts of the house:

the whole house lit up, and all the houses in quick succession. The

trees around, and the houses across the street, seem untouched or at

least soon recovered because

the "firenado" of the hot, fast fires from the houses sent the most

intense heat upward

into the sky. Apparently they burned too fast to start catching nearby

flammable material on fire. It was only May. The trees were too green

and the houses across the streets were too far away.

We know some fires start naturally or by accident. A quick

question, easy to ask but not easy for me to answer: WHERE

have most of the bizarre looking California fires started? and WHERE

are most of the many

forest fires currently burning in BC starting? Is it near roads or

possible vehicle access points of any sort in most cases? If so, that

would be a smoking gun. But someone has pointed out that the 2018 fires

have been small and numerous, and no one knows how most of them

started. They joined each other to become larger conflagrations as they

grew, there being too many starting too fast to put them all out in

time to stop them.

In the above image from the Fort McMurray fire also, there

appear to be numerous separate small fires upwind of the town rather

than one conflagration spreading through a wide area. Here's a

potential scenario, with Fort McMurray as "practice" before the

California events:

* The above fires might well have been started with incendiaries from

an airplane - this pass south of town and at least one other west of it

per the satellite image quite a way above. Note the nearly straight

line the upwind

points form... as if under a flight path. In this wide country with

hardly any roads it's not likely anyone would be out in the woods and

close enough to witness it.

* The wind blew the smoke over the town and perps went in and said

"It's a big forest fire, moving fast. Everybody has to evacuate."

* The residents evacuated.

* A "fire truck" previously hidden in town in some garage went out in

the deserted streets under cover of the smoke and electromagnetically

lit many houses on fire.

* Some more forests were lit on fire in Alberta and in BC (more

incendiaries?) as

"camouflage" and to keep firefighters busy so they wouldn't have time

to investigate carefully.

I admit that sounds pretty wild. OTOH the whole event just

seemed crazy. Especially in the spring. (Hardly had people started

returning when there were heavy rains and flooding.) And the California

fires are equally bizarre and similar.

I suspect that if you can find the trucks and the weird

equipment they must have - probably including large generators to power

the heating equipment - you'll have found the arsonists. (Or maybe

not... how

to harness HE ray energy has been known to the "deep state" for at

least well over a decade, even if they won't release it to the public,

and

it could explain where the high power that would be needed for this

comes from.)

Finally who could and would be doing it? All I can come up

with is the lawless banks and corporations and the lawless "deep state"

together. Observant people have noted for a decade now that the banks

have gone from being parasites on society to being a terminal cancer.

The government does nothing because the banksters and corporations own

it and control it through deeply woven interconnections. Every year the

crimes and thefts have become more egregious. No one has ever stopped

them, punished them or (better) "dispatched" any of them and they get

bolder

and bolder. These crimes "take the cake" as it were... or is there

worse

to come? (Did you know that with legislation over the last decade

depositors have gone from being the "top of the list" creditors of the

banks to the bottom should the bank have gambled away your money and

become insolvent? All these "zombie banks" are kept afloat by money

printing, fraud and theft. Should any one big bank go under, much less

all of them, deposit insurance plans will be bankrupt. Or the

government will print so much money to cover it that the money will

become worthless, like in Venezuela where today heaps of bills even

with huge

denominations are being tossed into garbage cans for disposal.)

And this is only part of a broader picture. Over the whole

world everyone is starting to sense that something has fundamentally

changed. The sociopaths "at the top" no longer have any regard or

respect for the populations they supposedly lead. Much of the world's

weather is now being controlled artificially. Droughts and floods are

becoming deliberately created phenomena. Since the early HAARP and high

altitude aerosol spraying, weather modification and weather creating

technology has advanced considerably. I'm not even going to touch on

this here except to say that many if not most of the horrible

things we're seeing today appear to be man made - deliberately, but not

with any

coherent overriding plan or theme (or even recognition of cause and

effect) unless it's just to spread chaos and

destruction and kill people in vast numbers. (The increasing

earthquakes (other than those caused by fracking) and volcanoes are no

doubt natural, but somehow fit well into the overall temper of the

times.)

The chief perps think they'll be immune to all this in their bunkers

and

island retreats, but the Most Highs rule in the affairs of men, and it

has been promised that those that remain when the time comes for

cleansing the planet and not reformed themselves by then will all one

way or another be removed from the planet. (That will probably be given

effect to by men, too.) Their callous and wanton

disregard for the lives of others will come back to haunt them. People

will be making decisions in the not distant future that they never

thought

they would have to make, to be a contributing part of the future as the

old

society collapses, or to emotionally and mentally separate themselves

from mankind and live selfishly. Let us pray for everyone and for each

other in this trying time.

I can hardly see all these horrific happenings as being

anything but the death throes of corrupt 20th century civilization.

Obviously with all these weather manipulations, electromagnetic arson,

financial slight of hand and other tricks to try to steal everything

from everyone, it's going to get much worse before it gets better.

For how much longer will orderly commerce for goods and supplies be

available as there's more and more piracy, theft and disruptions? It

would seem to

be appropriate now or soon to get your stored food and supplies

together to

maintain life and limb!

From another even broader perspective, the world is

overpopulated and

this is soon to be corrected. Think of the inequity this way: if the

world has two times too many people, for 1/4 of the population to live

well they need half the resources. The other 3/4 of the population is

then obliged to live on the other half, so they only have - on average

- 1/3 of what is desirable. Only a minority can live well to grow into

their full potential for development. With three times too many people,

then for 1/4 of the population to live well they would consume 3/4 of

the resources and the other 3/4 of this huge population would have to

live on the remaining 1/4, leaving them each with only 11% of what a

good living entails. Since those "with" will have to guard it and

struggle to keep it, and it won't be safe to walk down the street,

really almost no one would have a good quality of life.

Now apply these ratios

to a comfortable 3 billion - versus 6 billion - versus 9 billion - for

a rough estimate of

where we are today at around 7.5 billion, and we see why nearly

everyone is less and less well off with each passing decade as the

population grows, and why millions of refugees are on the move to seek

a

better life or even continuation of life, and why things must soon

collapse. It doesn't excuse

egregious actions against one's fellows, but it does make them more

understandable. Overpopulation is the underlying problem behind all the

other

problems.

When the worst is over, the remaining population, which is

expected to be well under 3 billion or even 2 by 2050, can get on with

building new

and lasting societies based on the core values of life and the enhanced

moralities that will spring from those. [7corevalues.org] The need to

manage

global population will have become abundantly understood by the

discerning majority.

And at some time during all this turmoil, it has been said

that a

new divine son is to

appear. He will not be born a babe like Jesus was but will appear as a

full fledged adult complete with his staff. His divinity will be

readily

apparent

to all who see him. He is to remain on this world for 1000 years to aid

and assist us in helping ourselves, by which time the last vestiges of

the ancient Lucifer rebellion will have been effaced and the planet

brought back into the main stream of universe evolution for the

establishment of the beginnings of the era of light and life.

There are various youtube channels covering the induced

fires and the incredible patents and weather modification machines

created - and deployed - in the past decade. I've only looked at a very

few videos myself. Look them up if you want to know more:

aplanetruth.info - mental_boost - intruthbygrace - neverlosetruth ...

The following quote can perhaps be applied equally to individuals or to

whole societies, at any point in history.

"By their fruits you shall know them. Do men gather grapes from thorns

or figs from thistles? Even so, every good tree brings forth good

fruit, but every corrupt tree bears evil fruit. A good tree cannot

yield evil fruit, neither can a corrupt tree produce good fruit. Every

tree that does not bring forth good fruit is is presently hewn down and

cast into the fire." - Jesus

"By

Prescription Only": Overregulation is Causing Shorter, Less Healthy

Lives

Note: Well, here's another topic that I thought I'd write a few

paragraphs about, and somehow over the month it's turned into a booklet

instead!

Caveat: I've tried to be factual but I didn't have time to

properly research every regulation and every substance in detail. I've

done a lot by memory, and memory is notoriously fickle, especially as

to finer details. Doubtless there are mistakes. The overall deleterious

patterns of authoritarian tyranny as related to this subject are what I

want to show.

---

There are some very good and useful medications out there,

which can be obtained by prescription only. Because of the fact that

they are prescription, you haven't heard of most of them, and there are

probably lots I haven't heard of, either. And for most of them, neither

you nor I can get them - at all - whether or not they would be

beneficial

to us. Your doctor isn't permitted to prescribe them except under

certain conditions for fear of losing their medical license, and that

means some of them are virtually never prescribed. Put simply, they are

banned.

It isn't just you that is being denied freedom of choice, freedom to

use your own best judgment about what might be helpful to you. Even

your doctor has been denied the freedom to evaluate and judge what

might in their patient's best interest. And you thought you lived in a

free country?

DMSO

Take the case of DMSO, dimethyl sulfoxide. [ (CH3)2SO

]

Never

heard of

it? Not a surprise. It's actually a simple solvent, not specifically a

medication at all. Once it could be freely bought and sold. In medical

use,

it seems to cause absorption though the skin of whatever is added to

it. Thus it can be a means to get medications or beneficial substances

into the body via the skin, which can be useful to get specific things

absorbed into specific problem areas rather than just ingesting them, a

route through which it becomes modified through the digestive system

(and perhaps ruined as to therapeutic effect) - and then diffused

through the

body, instead of being concentrated at the problem spot. Astute people

were having good success treating various conditions, especially

certain skin

conditions, that the medical

establishment wasn't doing very well at.

An existing solvent couldn't be patented, and perhaps it

was beneficially replacing some prescription medications(?) The

pharmaceutical companies raised a fuss. When just one person in Ireland

who had

been known to be using DMSO died, from causes which were never

determined much less blamed on the DMSO, it was

seized on as an excuse to make this common solvent available "by

prescription only". (Compare that to 50,000 deaths per year from

acetaminophen ('Tylenol'), by accidental overdose because various

medications with different names contain it, or because it damages the

liver if combined

with alcohol - where are the warnings? Still not "prescription".)

Thus

almost as soon as DMSO was discovered to have medical value it

disappeared from the shelves and, because it isn't specifically a drug

itself and almost no conditions had yet been established for which it

might

be prescribed, it is "by prescription only" yet doctors are not

permitted to prescribe it, even when asked for

it point blank by a patient who knows what they need it for and how to

use it. You can buy any number of harmful solvents, but a rare

one useful to health has been banned. (It occurs to me that perhaps

DMSO

just might hold the key, or part of the key, to healing moles on the

skin.

How will anyone ever find out?)

And you thought you lived in a free country?

Sumatriptan

The variants of sumatriptan - brands Imatrex, Maxalt and

whatever - are the one thing that will take a migraine - that has

perhaps laid someone low with pounding headache and vomiting even for a

whole

day or more - and simply make it go away, or greatly alleviate it, in

an hour or so. I've heard that in Britain and Sweden

it is freely sold on store shelves along with aspirin, advil, tylenol,

ibuprofen etc. Here in North America it is "by prescription only". What

that means is no one hears about it. I even know people here who've

gone to

hospital for help because their migraine is so bad and has

lasted so long - and they still aren't told

about it! They go in there for relief, and are given who knows what

worthless treatment when the whole staff must - surely? - know full

well

what the simple and effective remedy is. (It's also available as an

injection that apparently provides relief in ten minutes! Also note

that the sooner the pill is taken when the headache is coming on, the

less is needed, and that it lasts maybe 12 hours or more, so usually

one dose is all that's needed.) If perchance the staff of this small

town hospital somehow doesn't know there's a remedy for

migraines, how much more does that say the pharmacies should be selling

the medication on the shelves for people to find for themselves instead

of hiding it away?

According to Wikipedia, serotonin levels "often become

extremely erratic" at the onset of a migraine. Sumatriptan "is an

agonist for serotonin which it is structurally similar to", and binding

to it causes constriction of the dilated [inflamed?] cranial and

basilar arteries. (Might we then suspect that the migraine causing

action from migranous foods is to somehow disrupt the normal serotonin

levels in susceptible people?)

I eventually learned that certain foods always (MSG, lemon

peel, yogurt...), and certain other

foods unless they are very fresh (milk [eg, even beyond one

day open in the fridge], chicken...), are the cause of my

migraines. That understanding, which I gained in my 30s, has saved me

from many migraines. Still, eating is still often like 'Russian

roulette', since food

that isn't fresh enough still tastes fine, and unless you made it

yourself at home often you don't know what some of the ingredients

are. (I recently dared to eat some canned chicken. To my relief it was

fine. So gladly I had some from another can of the same chicken with a

somewhat later expiry date. It gave me a doozey of a migraine, which

required way over 100 grams of sumatriptan taken perhaps "not enough

at a time" over quite a few hours to more or less subdue - an

unpleasant day. (At least I wasn't in bed "comatose" for the day like

before sumatriptan.)

Probably the chicken

wasn't fresh that day when it was canned. And I've had migraines from

many canned foods.)

Sumatriptan has been available since 1991 - 27 years. Yet

it seems to

be a well kept secret. The spelling checker here is underlining it and

all of the words related to it. To whose benefit? After too many years

of having too many 'lost' days of serious suffering, my brother gave me

a pill, and said to bite off just 1/3 of it. For the first time, the

vise squeezing my head simply vanished within an hour or so. I don't

know where he found out about it. My doctor

had never told me about it.

Can anyone imagine this senseless lack of information to

migraine sufferers existing if sumatriptan tablets were on the shelves

with the rest of the pain medications? Making it "by prescription only"

has effectively kept it out of the hands of most migraine

sufferers, for whom it is the only remedy so far that has ever really

worked.

And of course one has to make a needless visit to a doctor

each year

to get the prescription, needlessly costing the medical system, and

then pay through the nose - 10 to 20 $ per pill - over 200 $ at a crack

- to get it. It's worth

it if you have a migraine, but I can't help but think that I'm paying a

ransom, and that it must be cheaper in Europe. And surely the makers

there make more money not less because migraine sufferers know what it

is and

can readily buy it when they need it.

And beyond the price, with them being made so hard to get

at the best of times, it's almost impossible to "stock up" on any

prescription medication for times of delivery and

service disruptions. "By prescription only" of almost anything means it

will unavailable and useless to all when hard times are upon us.

Having put aside some emergency food and being on an island where many

seafoods are relatively abundant, it's things like sumatriptan that I

am

most apprehensive about running out of.

Metformin

Metformin was first formulated in about 1920. It was soon

put to

effective use for type 2 diabetes. But in recent decades and especially

in this century quite a few studies have found a surprising number of

other healthful

effects. It's anti obesity, anti Alzheimer, anti cancer,

anti diabetes and a number of other things. Not only can it make older

people

healthier, recent findings have indicated it might extend life even by

up to 40 years, or even 'to age 140'. These estimates by its

enthusiasts may be wildly optimistic. But even if it's only five

or ten years, or even just healthier years, is it not worth taking? If

it was on the store shelves this would become widely known, and it

is plainly obvious that then many people would start living longer and

healthier lives.

None of the usual reasons given for a drug to be "by

prescription" apply to metformin:

- It's cheap, old and well known,

easy to make (in a proper facility, of course).

- It's not dangerous - it has few

and minor side effects if any, especially at the low doses healthy

people might take to get beneficial effects. (eg one 500 mg pill.

People with diabetes commonly take up to four pills, 2000 mg per day.

From what I could find out, potential side effects were 'digestive

upset' and 'gas' -- it sounded about the same as from having a large

bowl of chili.)

- It cannot lead to antibiotic

resistant bacteria or other undesirable long term complications.

- Does no environmental damage.

So it's pretty much like

taking a vitamin. But once again in our "control freak" society, it

can't be had without a prescription - and our doctors aren't

allowed to prescribe it unless you have diabetes. Once it could be

ordered at high cost through the mail from abroad, but now the

company says it can no longer ship drugs to Canada because most of its

shipments are being stopped by customs and returned. The only way to

get any now would be to bum it off a diabetic. And I suppose if a

diabetic were caught taking money from you to recoup his cost,

he would be charged with illegal drug dealing and be

liable to fines or imprisonment. No such thing as it being "between

consenting adults". So here we have something that does no

harm and apparently a lot of good being ruthlessly kept out of

citizens' hands. No amount of effort or money is too great to enforce

each nit-picky little law. It doesn't matter how much harm the law is

doing and that it is doing no one the slightest earthly good.

I complained to my Member of Parliament nearly two years

ago about this, predictably to no effect. I don't think anyone in our

government or even the Canadian government as a whole is actually able

to right wrongs or to undo wrong or obsolete restrictions however

stupid once they have been made. They're not on anybody's agenda, and

nobody feels qualified - or is permitted - to make a new decision

however much sense it seems to make and no matter how long ago, how

uninformed or misinformed or how lacking in perspective the original

decision had been.

And you thought you lived in a free country? It has

become highly dysfunctional and is creepingly more autocratic,

dictatorial and hard to live in every year.

Antipsychotic Medications

Unfortunately there are people born into this world who

develop chemical imbalances that start to affect their brains as they

mature. From what I've seen (and I'm certainly no expert), it often

seems to relate to extraordinary stress when their mother is 4-5 months

pregnant as the brain is developing: eg, serious illness, toxic

relationship with their spouse, and so on.

There are medications to help control the imbalances, and

they are prescription. Perhaps in this case it's best that precautions

be taken, because no one of normal chemical balance should buy and

consume these pills by accident. But being prescription, the patient -

or their caregiver in the more serious cases - isn't permitted to stock

up. This probably causes trouble today, and it's doubtless going to

cause real trouble in times of uncertain

deliveries. There will be people becoming really insane, needlessly.

(Of

course, there will be people going hungry because they haven't stocked

up on food, too. What to do?)

Antibiotics and Nano-Sliver

The argument that antibiotic use should be carefully

controlled so that bacteria don't develop an immunity to them was a

good

one. But there's a huge flaw: Antibiotics are wantonly added to animal

feed from chicken pellets to farm fish feed to prevent epidemics in

overcrowded flocks, herds and schools. This use doubtless far

outweighs all human medical use and tests show that antibiotics have

become ubiquitous in the environment. No, it's not because someone

carelessly

flushed some pills down the toilet! When seen in this context, it might

be understood how little effect making antibiotics for humans

"prescription only" really has had at preventing antibiotic resistant

bacteria from developing. The feed for your chickens is loaded with

those same antibiotics that you have to beg your doctor for a small

bottle of. In some jurisdictions one can freely buy the very same pills

at a pet shop that are impossible to buy to have some on hand from a

pharmacy - to put in your aquarium or give to your dog.

As feared and not surprisingly, bacteria are becoming

resistant to them.

Antibiotics that were once so effective, like penicillin, now are

effective against few diseases and new antibiotics have been rolled

out. But more and more disease organisms are becoming and will become

immune to all of them. The "elephant in the room" of animal feed

antibiotics

overshadows all. Human medical use, underdosage or overuse has

almost no bearing

on the problem. So why not put them on the drug store shelves?

A doctor is likely to know best whether you should take

one, which type is best, the recommended daily dosage and the

number of days for each individual type. But a doctor will have that

knowledge and can make a good recommendation whether the

medication is "prescription only" or "on the shelf". And today many

patients are quite

capable, if they choose, to look on the web and make a reasonably

informed decision for themself, or may have a condition that requires

occasional use with which they are familiar without going to a doctor

each time. Or a

pharmacist might be able to make a recommendation for a particular

common

case without referring to a doctor. They often know more about them

than the doctor. But when it's prescription, the pharmacist can't sell

it (or apparently even suggest it) without a doctor having specifically

prescribed it.

How controlled do we want to be versus how proactive about

our health? Occasional decisions about antibiotics that are less than

optimal would inevitably be made. They are anyway. But at lower overall

cost to every

other patient and to the medical system. I needed antibiotics a year

ago for a tooth infection, but if I

hadn't remembered while in the office from a previous occasion long ago

that

I have a bad allergic reaction to "_cillin" types, the doctor would

have prescribed me one of them. I'd have seen a doctor anyway, but I

suspect the pharmacist could probably have told me a good one to use.

Further, they always say to take the

whole course, but when the problem goes away in a day after one or two

pills, a few more is plenty and it's plainly pointless to take dozens

for another 12 days (or whatever). But the doctor doesn't know because

he's not there. Stopping sooner means less antibiotic use instead of

more. We all have discernment and should be able to take some

reasonable level of

responsibility for our own health if we are pretty sure of what's best.

We are each

ultimately responsible for our own health anyway.

Nano Silver

The decreasing effectiveness of antibiotics brings us to

the antibacterial effects of silver

nano-particles, which hasn't deteriorated over time. It's not that

silver was ever made "prescription" or banned as an antibacterial

agent. It's used in

dressings and bandages for that express purpose. Other than that, it's

simply been forgotten. Back when its use was common, no one understood

what it was doing. Why did babies fed with a silver spoon or drinking

from a silver

cup seem to be healthier than others? Besides magic

or superstition, why did a piece of silver tossed into a cask of

drinking water on a ship make it safer to drink later? No one knew.

"Nano-particles" was not in the vocabulary. Nor was "bacteria".

("Surely

nothing too small to see could affect our health!")

As antibiotics lose their effectiveness, silver will

reclaim

its proper place in health and medicine. Silver, once called "the

devil's metal", is starting to be rediscovered as "the angels' metal"

(which - ahem - doubtless explains its chemical symbol, "Ag" for

"Angelium"). One can buy "colloidal silver" or make it (various

instructions on the web, I'm sure) if one has some pure silver metal --

those same silver coins and bars so many are saying to have in hand for

barter when (not if) the currency of your country hyperinflates or the

banks or government steals your savings from your account(s). (Cypress:

stolen; Venezuela: hyperinflated away; Argentina, Brazil, Turkey:

hyperinflating now. Canada: not

yet; USA: may be last? but will not be excluded.)

Hidden Products - "Shadow Banning"

Then there's rubbing alcohol, isopropyl alcohol, iodine

solution, and model airplane (styrene plastic) cement... sometimes

matches... and who knows

what else? My first experience was being unable to find

model airplane

cement. It seemed that a few foolish kids somewhere had been sniffing

the stuff and doing themselves harm. Instead of asking schools to

educate

about the dangers, the government apparently forced the stores to keep

it behind the counter. What exactly does that mean? Are the stores

supposed to educate the customers or vet them and decide who may buy

it? Is the store

liable if someone buys it, sniffs it and does themself harm? What about

the millions of others, who can't find it when they want it for more

constructive purposes? But at least customers will ask, "How are you

supposed to glue these models together?" - and will presumably be given

the glue. If the clerk knows.

But with that precedent, it seems pharmacies are now

required to

hide a whole host of things behind the counter. I went into a Shoppers

Drug Mart one day to get some iso alcohol. It seemed they were out of

it, as well as rubbing alcohol. Other stuff was in its place on the

shelf. Every time I went back, they still seemed to be out of it. I

finally asked when they would be getting some in, or if for some reason

they didn't sell it any more. They had it, all along! It was behind the

prescriptions counter - for the asking. Later I found the same thing

with iodine solution. And you can't just ask for "iodine": you have to

know it's called "Lugol's solution". They won't tell you. A more

cryptic name can hardly be imagined. (Yes, more than a few drops is

toxic, but a couple a week can be a healthful supplement. That's why

it's added to salt.) Now you have to

know all these things exist, what they're called, and beg for them from

the staff.

And was the point - to make people suspicious? Now I'm

wondering

how many other things are hidden behind the counters, that they can't

sell me or even tell me about unless I know they exist and exactly what

they're called? How

will new things be introduced if no one is permitted to see them?

What this is quite obviously going to cause, quite aside

from aggravation for all, is younger people - meaning all future

generations - aren't ever going to know where to get any of these

things, because they've never seen them for sale. They may have heard

of rubbing alcohol, but they won't know that people still use it. It

will be considered to be something out of old folk medicine, not

something

that might be useful to them. Otherwise it would be available in the

drug store, right? Various things that used to be freely

available on the shelves they will have never heard of. And then the

stores will stop ordering them because no one is buying any.

Effectively, these things are being banned without cause - and surely

without conscious intent to do so.

"You can't cure stupid." is a saying that we might apply

both to those very few individuals who harm themselves with substance

abuse (educate, educate!), and to arbitrary government regulators who

seem rarely to consider the real results to most everyone when they

make some idiotic restrictive law to try to cure stupid with more

stupidity.

"Controlled Substances"

There are other banned or "controlled" substances. I'll

just mention a couple.

Potassium permanganate has long been used by nurses for

skin poultices (I forget what the conditions are for applying it). It

is also used to help remove iron and rust from water in water and

swimming pool systems. I wanted it for new chemistry batteries. Now you

can't get it except at a water treatment

store, and you have to give your name and identification and the reason

you're buying it. Why? Why is every customer a suspect. And of what?

I understand sodium hydroxide ("caustic soda") used to be

readily available at groceries or drug stores. I suppose somebody

decided it was too hazardous to allow the public to have. Now you can

buy sodium hydroxide as various products such as photo developer and

"Easy Off" oven cleaner. But now you don't know it's sodium hydroxide

except by reading the fine print, and then you don't know whether

you're getting pure product or if there are additives, nor how

concentrated it is. It's still just as hazardous. But as long as it

doesn't have a descriptive "chemically" sounding name, it's okay to

sell. You have to go to a "soap making" supply to actually buy the pure

powder, whatever the actual use will be.

When I was growing up a friend of mine got a chemistry

set. His first projects were of course small "pipe bombs", but he was

careful with them, and soon he became quite knowledgeable about

chemical things in practical "how to" terms, well beyond anything

taught in chemistry class in high school.

I [eventually] came up with using potassium oxalate for

battery electrolyte because someone gave me an old kids' chemistry set

in about 2009 (seemingly dating from the same era - late 1960s - the

bottles looked

the same as my friend's) and one of the bottles was oxalic acid. If it

wasn't for that, I doubt if I ever would have looked up "oxalate" and

found that most oxalates including nickel and zinc are insoluble - a

key consideration for a battery electrolyte and evidently almost unique

to oxalate and hydroxide. Today I don't think you

can buy a "chemistry set". I've never seen one for sale. The government

probably doesn't permit them.

How are new generations supposed to get interested in and learn

chemistry? Could lack of overall chemistry perspective be part of the

reason why today most research is focused in the area of lithium

batteries while all other battery chemistry possibilities get

sidetracked or ignored?

Laetrile

Edgar Casey said anyone who would eat two or three almonds

a day need never fear cancer, and that they contained iron and

phosphorus in the right proportions and the most digestible forms to

inhibit tumor growth. "need never fear" is doubtless an overstatement,

but it's perhaps valid if one gets enough sunshine and if the diet is

otherwise healthy, as it commonly was back when that was said. (Pine

nuts

are said to be as good, but I doubt they were being harvested and sold

back then.)

So when I heard about Laetrile, and that it was made from

bitter almond or peach seeds, I wasn't too surprised. In 1830 amygdalin

was isolated from bitter almond seeds,

and it was used as a cancer treatment until the 1920s. The synthesized

version, Laetrile, was patented in 1961.

I remember the furor on American television when Laetrile

was banned in the USA apparently mainly by "big pharma" along with the

government. Their arguments as best I recall were that it hadn't

undergone countless millions of dollars of testing and development like

their products and claims seemed to be unsubstantiated, that

'charlatans' were charging high prices for a "quack" remedy, that one

shouldn't give terminal cancer patients "false hopes", and that it

contained toxic levels of cyanide. (Gee... charging big money... for

giving faint hopes... unhealthy or toxic treatments... that doesn't

sound like established cancer treatments?) But some cancer

patients claimed

that Laetrile had saved their life when they had been written off as

"terminal" by mainstream medicine. I could be wrong, but I pretty

distinctly remember the outlawing as being the spring of 1969 when our

family was in Upland, California. Wikipedia gives a later year for its

banning, 1977. Many individual states reversed the ban, but it seems

it's not legal to transport it across state lines, so no one can open a

factory for wide distribution. Sometimes people with terminal(?) cancer

who still remember about Laetrile go to Mexico to get it.

Since the source apricot, bitter almond or peach seeds and

Laetrile itself contain hydrogen cyanide, Laetrile

is probably in want of further research and development to be safer and

more effective. Meanwhile, have lives have been shortened and sickened

over the

decades by its banning? Has valuable progress and improvements been

stifled? Will we ever find out?

Myself, I prefer the preventions instead of waiting for

cancer to strike. By the time it's diagnosed it's so often already too

late: the daily almonds

without the cyanide, nutritious berries like strawberry jam, and most

of all

vitamin D, which cuts the risk of cancer in half regardless of

getting sunshine - and perhaps more than in half here on the commonly

cloudy

west coast where cancer is so epidemic. I strongly suspect I'd have

been gone 15 or 20 years ago now if I hadn't started daily tanning

through my office window whenever there was sun in the winter (luckily,

it had a

thin old single pane glass window facing south), and later started

taking vitamin D.

Milk

What, how on Earth is milk banned or controlled? It's in

every grocery! But it has been illegal in BC for some decades now to

sell "raw milk" straight from the cow. (In 1972 when we moved to

Vancouver Island we started buying it from someone down the road, but

in that same year the government enforced a stop to it everywhere.

Anyone

with a cow ever since has been forbidden to sell milk to their

neighbors.) Since a cow is a rather large animal that eats a lot and

makes a lot of milk, it's not practical to keep one just to get one's

own family's milk products. (They're also too big to hide from busybody

government regulation enforcers.)

While we all appreciate the safety of

pasteurized milk, is having pasteurization equipment for a cow or even

a herd of

cattle impractical? ...Or is it regulations that make it

impractical or even illegal? (Homogenization is not universally

appreciated for several reasons including that the finely emulsified

fatty particles absorb without being properly processed and cause

calcium buildup in the arteries leading to high blood pressure,

arteriosclerosis and heart disease.) Doubtless many lives and countless

bouts of illness have been saved over the decades by pasteurization.

But another result, as an example, is that

on this rather remote island of 4500 people with not entirely reliable

ferry service even in normal times, there are only a very few dairy

cows, and those are owned by Mennonite farming families for their

own use. This

is probably pretty much true of most of BC. This regulation has taken

all milk production out of everyones' hands and concentrated it into

big conglomerates. There's probably an economy of scale, but it's

ubiquitous just because

it's the only way permitted.

All the milk for the whole province seems to come from a

couple of big dairy plants in the lower mainland and one in Victoria.

(It is impressive - I've toured it.) The dairy farmers all deliver

their raw milk to these plants, so they dairies are concentrated near

them. Thus

in just one more way, money is drained from rural and small communities

into the large cities. With various of these sorts of regulations

blocking small scale rural commerce and production, one starts to

glimpse why there is still an ongoing shift of population from rural to

urban areas and a continuing collapse of small communities.

And of course, all that milk then has to be distributed

from these centers to the rest of the province consuming fossil fuels

in transport. (An article I read says that the average gallon of

American milk travels 320 miles from udder to store shelf.)

There will be no milk products to be had anywhere in the north and

indeed in most of BC in the event of fuel shortages and delivery

disruptions, and the dairy farmers concentrated near the urban areas

will have to slaughter the bulk of their herds while at the same time

there aren't any

dairy cows to be had anywhere else to start local production and new

herds. So at that time yet another ill considered

restrictive regulation intended to improve health in the cities will

severely

contribute to everyones' food problems for an extended period.

Couldn't we create new types of small scale pasteurizing

systems? ...Or is

it that one must perhaps pay for a government inspector to inspect the

plant

daily or frequently, making small scale impractical? I don't know what

the regulations are. Whatever the problem is it

needs to be addressed so some milk production can be

decentralized and moved to local areas where it is consumed.

This topic turned into more research than I had

anticipated - and an unexpected development. Having asked those

questions, I took a look on line and immediately found small scale

pasteurization machines perhaps for a cow or two (3-14 liters per

batch), not very expensive - starting at 440 $US. It lacked

"turbulence" to make sure the milk is all the same temperature, but a

quick stir would cure that, and it came with a thermometer to insert

anywhere. When the heating was done, one runs cold water through the

outer jacket to rapidly cool the milk. [MilkyDay.com] Some of their

more costly ones made cheese and (bletch!) yogurt. I was more puzzled.

What prevents people from getting a cow and a low cost mini pasteurizer

and selling pasteurized milk products?

A further look showed "MilkyDay.com" was in the Czech

republic. A "legal" pasteurizer from the USA started at more like 6000

$ and they rapidly went up from there. They did "dairy herd"

quantities. One site said you could expect to pay 15000 $. An article

about a new one for a dairy herd that was "FDA Approved" ("LiLi") was

70000 $. And they all had temperature chart recorders for which special

paper was required and the charts were "legal documents" for when a

government inspector comes nosing around to check your (one-cow?)

"plant". Yep. That probably explains it. The economical Czech ones

seemed to be the only "kitchen appliance" types suitable for one or a

very few cows. They probably work fine and make the milk as safe as any

other. But they don't record charts and surely aren't "legal" in North

America. 6000+ $ for a way overkill machine makes the entry barrier for

keeping one dairy cow prohibitive. And maybe it needs a government

permit that is priced for a whole herd, too - and possibly may be

available only on a quota system. I didn't delve into these potential

legalities. But I suspect we're not living in a free country.

Thinking of those likely coming supply disruptions I

visited someone with goats. She gave me a liter of raw goat milk. It

seemed quite a lot like cow milk. Apparently it has even more fat.

Later I thought I'd make a small preparation and on the

31st I ordered the 440 $ pasteurizer (another 100 $US shipping). I

don't think I want to look after a cow, or even a goat, at this point.

Maybe a goat at some point. (Feta cheese is great!) In a crisis and if

there's demand I might just buy raw milk and sell pasteurized in the

neighborhood. Or if I don't use it, somebody else doubtless can.

I mentioned it to the lady with the goats and she said

Why? You can pasteurize milk on the stove. On the other hand, she said

she doesn't bother and she doesn't like the taste. I can well imagine

that doing it on the stove it gets a little burned, and it doesn't get

cooled down very fast.

She then went into all the trouble she goes to to make

sure the milk is clean: she throws away the first squirt that comes

out, and is very careful not to let her hands touch the milk as it

comes out. While admiring her care and technique, I began to appreciate

even more the value of pasteurization, with milk collected perhaps less

carefully being implicated in several diseases including tuberculosis.

Is milk pasteurization a main reason there's virtually no tuberculosis

today?

* * *

What's next? Will "big pharma" buy out the borax companies

and remove it from the grocery detergent shelves because it cures

arthritis cheaply, without a prescription? (since the main cause of

arthritis -

and evidently calcium buildup and osteoporosis - is boron deficiency.)

Will somebody figure out how to make vitamin D "by prescription" or get

it hidden behind the counter, unavailable on the

shelves?

You thought the west won the war and we beat the

dictators, and so you live in a

free country? Big Brother is watching over you, in collusion with Big

Pharma and Big Agra, deciding what you should want without asking you,

without allowance for your freedom of choice, geography or other

circumstances and without

bothering much about facts or the real best

interests of citizens!

When things do become a big enough mess and it becomes

apparent that "what is" will have become "what has been" but is now

gone, we'll have the chance to rewrite the playbook in

accord with the morals and ethics that develop out of the underlying

common values all people hold. [7CoreValues.org] I've seen an early

draft for another book by Daniel Raphael beyond Understanding

Social Sustainability

called Restoring the Greatness of Democratic Nations - A Radically

Conservative and Liberal Approach, which when completed should be

of

assistance in coming to grips with these new family, organization and

society building/rebuilding concepts.

Concert

On the 4th, after I posted

the last newsletter, our

band of five the "Huckleberries" played at an outdoor potluck dinner

party. My supercorder had parts in just a few of the songs, but those

were enough for me to have to memorize. People liked hearing

something besides the usual guitars and drums.

Somewhat to my surprise we seemed to be the musical

highlight of the evening and many people got up and danced. All that

rehearsing (with the one hour driving for each, cutting into my project

time) must have paid off. But after playing down on my knees to be by a

mic on

the stage I resolved to bring my own specially configured tiny mic and

amp next time. My supercorder is louder than other recorders; loud

enough without an amp - but not when everybody else is amplified! (For

over a decade now I've always stuffed bits of cotton batten in my ears

when I play, even unamplified, and while I have nasty tinnitus and some

hearing loss - especially from when I was making and tuning

Supercorders - after 40 years in jams, bands and orchestras I don't

need a hearing aid. Not yet, anyway. (unlike our drummer, who is

probably a decade younger than me.))

But later in the month they decided they didn't need a

flute. They were gathering to practice on a moment's notice and that

didn't fit with my 1/2 hour drive into town. And as that took up a

considerable amount of my time I'm just as glad. Time to try something

else, I guess. I bought a keyboard for a pianist to accompany me, and

we had a good playing session...but only one so far.

Democracy

Denied in California

Not long ago, there was a

"state initiative" for something

proposed in California. I forget what it was. To get an initiative - a

citizen proposed referendum - put on the ballot for the next election

in the state, one must get a very large number of signatures -

something like 400,000 in California - in a relatively short time, of

people who think putting it on the ballot is a good idea.

As I recall, it had something to do with health, perhaps

vaccinations, and "big

pharma" didn't like it. After enough people had signed, some of the

signatures were being carried in a government vehicle, from which they

were "lost". Without those signatures, there weren't enough others to

cause the "initiative" to be placed on the ballot - and it wasn't. Somebody

- who but the governor - or perhaps a federal official? (under orders

from whom... president Obama?) - put out the word that some signatures

should vanish. Those in subordinate positions wouldn't take such a risk

to their career. Somewhere, somehow, it was ordered or "authorized"

from "above".

Now someone else sponsored another "initiative", this one

to break California into three states. He spent 1.7 million dollars on

the campaign and got the required signatures. California is certainly a

large and diverse state by US standards, with a population as large as

all of Canada. But the state went to court to have it blocked and a