Turquoise Energy Ltd. News #124

covering

September

2018 (Posted October 4th)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlight: "Improved 2 KW" ultra-efficient Piggott

Generator built and works great!

(See

Month in Brief, Electricity Generation)

Month

In Brief

(Project Summaries etc.)

- Milling - Nails - Water Pump - Ordered 305 W solar panels -

Piggott Generator - Sprint 36 V car charging - Swiilawiid

Sustainability Society Symposium - Energy Co-op for Tidal Power?

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Red Quinoa

- HOW Much Money?!? - Monsanto Sellouts: Justice Served?

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Solar Battery Charging for the Electric Chevy Sprint and Miles Cargo

Van - a better plan

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Handheld Bandsaw Alaska Mill") - Milling

Alder - Spruce: Nails - Automatic Band Sharpener - 1295 $?

Electricity Generation

*

Improved Piggott Axial Flux PM (permanent magnet) Generator - magnet

rotors - coil winding - case - assembly - testing - What to use it for?

- VAWT, Tidal Experiments - Saving Mixed Epoxy for Later - commercial

prospects: 1295 $.

* A very small hydro project using Sprint car alternator I converted to

PM generator in 2016

* Tidal Power Project: 100 KW Floating Tidal Power Vessel - Smaller

Propellers in Venturis? - Self Steering to Optimum Position in Stream,

collision avoidance, "return to shore" for maintenance

Electricity Storage -

Turquoise Battery

Project (Now Mn-Zn, Ni-Zn or Pb-Zn)

* Manganese-Zinc Cell

On the 3rd and

4th I finished cutting up the alder log I had felled - three sections 8

to 10 feet long. I cut it down to compare milling something else -

almost anything else - with the spruce, which has interwoven grain and

seemed like really tough stuff to mill. Having not tried anything else

though, I wasn't really sure. Sure enough, the alder cut like a dream

compared to the spruce and I cut the tree into lumber in about 3

sessions.

On the 3rd and

4th I finished cutting up the alder log I had felled - three sections 8

to 10 feet long. I cut it down to compare milling something else -

almost anything else - with the spruce, which has interwoven grain and

seemed like really tough stuff to mill. Having not tried anything else

though, I wasn't really sure. Sure enough, the alder cut like a dream

compared to the spruce and I cut the tree into lumber in about 3

sessions.

The last and widest section I cut into beveled siding with

a "live" (bark) bottom edge. I thought this would look interesting.

On the 6th I

went back to the spruce and the saw found nails embedded in one of the

pieces. These dulled my last two bands and cutting was over for the

month. Trees near houses are prone to having nails. People will nail a

fence or something to it or up a put a clothesline, then later the tree

grows over the forgotten nails.

On the 6th I

went back to the spruce and the saw found nails embedded in one of the

pieces. These dulled my last two bands and cutting was over for the

month. Trees near houses are prone to having nails. People will nail a

fence or something to it or up a put a clothesline, then later the tree

grows over the forgotten nails.

A supermagnet found yet a third nail buried

just under

A supermagnet found yet a third nail buried

just under

the surface still farther up the length. By this time I

had cut about 2 feet off the end.

I

had been noticing people liked

my Nissan Leaf - especially the color - but didn't even realize it was

electric. "Electric Blue for the electric car!" I tell them. I think

the car companies still only sell electric cars reluctantly and don't

want to enlighten other drivers that perhaps they don't need to be

burning gasoline. Tom sent me up an "Electric" sticker from Victoria

and I stuck it on the tailgate.

I

had been noticing people liked

my Nissan Leaf - especially the color - but didn't even realize it was

electric. "Electric Blue for the electric car!" I tell them. I think

the car companies still only sell electric cars reluctantly and don't

want to enlighten other drivers that perhaps they don't need to be

burning gasoline. Tom sent me up an "Electric" sticker from Victoria

and I stuck it on the tailgate.

Trouble at the Pass - water pump clogged up

On the evening of the 8th my water pump clogged up. Black

sludge and soon nothing at all came out of the taps. I shut off the

power to the water heater. Luckily my neighbor, one of the family of

previous owners of the house, knew a lot about wells and pumps and had

in fact set this one up. He explained that one needed a four foot

section of 3/4 inch threaded steel pipe. This was inserted down to

where the water line/pipe went through a special fitting to pass

through the body of the 6" well pipe about 2 feet under the ground, and

screwed into the special fitting there. (That's below the freezing

level. Otherwise the top of the well would have to be in a heated

enclosure to prevent a pipe coming out the top from freezing.) Wiggle

it and lift, and the fitting slides apart and the plastic pipe lifts

up. Then the entire pump with its 2" plastic hose, power wires and rope

is pulled out of the ground -- in this case 60 or 70 feet of black PE

plastic pipe. I had to drive to Masset at the far end of the island to

buy a piece of 3/4" pipe as neither of us seemed to have one. I found a

short piece and a coupling to 1/2" pipe, which I did have a short piece

of, to make a long enough piece.

Well, there's more than you - or I - ever wanted to know

about deep wells and pumps - and a round about way of saying I didn't

get to too much project work on the 9th and 10th. We chopped off 4 feet

of the plastic pipe so the pump would hopefully hang well above the

sludge, and put it back. That was still way below the water level

inside the well. It was well there two of us to pull the plastic pipe

out of the well pipe, and to do it without kinking it. It pumped, and

after a while the black-as-oil water started clearing. Maybe I'll have

better water now, without periodic bouts of black water from the taps?

Improved Piggott Generator

So after the 6th and 7th it must have been from the 11th

or so that I got back to work on the "Improved Axial Flux Piggott

Alternator". I finished the rotors and then wound the stator coils.

Then I screwed the coils by their winding centers to the stator mold,

wired them, and filled the mold with epoxy.

A finished rotor, magnet side down. (2nd coat

of epoxy setting)

A finished rotor, magnet side down. (2nd coat

of epoxy setting)

Wiring the Stator

Wiring the Stator

Finished molded epoxy stator

Finished molded epoxy stator

Generator in wooden chassis. The outer rotors

with magnets spin past

the stator, a cast ring of epoxied copper coils, which remains

stationary.

The magnetism from supermagnets on both sides provides very large

electro-

magnetic interaction even with no iron in the stator coils and at very

low RPMs.

On the 20th I made a case from birch plywood. I finished

the unit in September before the symposium except for a few finishing

touches like air flow holes in the case and flamproof paint on the

plywood. I tested it by running it with a pulley from my 2 HP radial

arm saw motor, and got some very good results - voltages to charge

batteries and 62 amps short circuit current between two phases at 270

RPM. It looks like when I get some high current diodes to convert it

from 3-phase to DC, it should meet the top lines in Piggott's

performance graph from his book How to Build a Windplant, and

extend them out to 2 KW (maximum power point - MPP) at 600 RPM:

I'm glad I took a bit of

time to do the testing. It gave me much more confidence in speaking

about the unit.

A Crate of Solar Panels

HES Home Energy sent out a new price list, and then a new

sales rep at the Victoria office sent an intro e-mail. I looked at the

price list. The best deal seemed to be Hanwha 305 watt(!!!) 60 cell

panels for only a little more than 265 watt panels. (And there were 345

watt, 72 cell panels for not so much more than that! They just keep on

getting better!) I got the idea to order a palette of them to sell at

the Swiilawiid Energy Symposium on the 29th and 30th and I e-mailed

him. (Pronounced "sweeluweed". Not as bad as "quinoa" - "keenwah", I

suppose.)

I thought there might be 20 panels on a palette, but it

turned out there were 32 in a crate, for what would be about 8500$ by

the time I got them. But an extra 5% discount for a whole crate on top

of 30% for wholesale, and being crated and stored in Vancouver I could

ship them (insured) on the North Arm barge for arrival in late October,

which I'm pretty sure is substantially cheaper than by truck. On the

20th I bit the bullet and ordered them. Nobody seemed interested at the

symposium. There was a lady there who does approved solar panel

installations who also buys from HES. (Very knowledgeable.) Hopefully I

can sell them with ads on line (HaidaGwaiiTrader.com) to pay for the

five or so I've decided to keep. I'd better!

36 Volt Chevy Sprint EV Charging

On the 21st I took the Sprint out for a spin around the

acreage for the first time in a while and as I suspected the batteries

were down a bit. I still hadn't installed a proper charging system. The

lead-acid battery chargers should raise the voltage

up to 14.4 volts - a little much for lithiums - before they would

decide a battery was charged and shut off. I had decided to put a diode

in series with each of the three chargers (12+12+12=36 volt car) so the

battery voltage would actually be .7 volts less than the charger

thought it was.

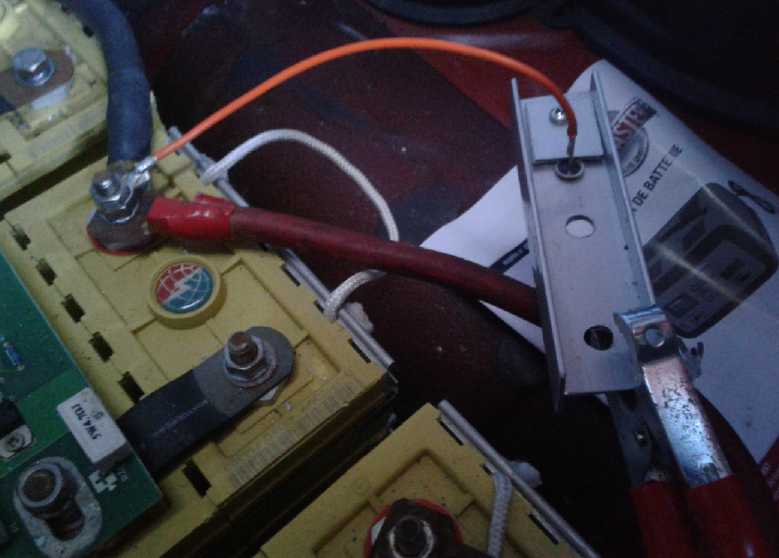

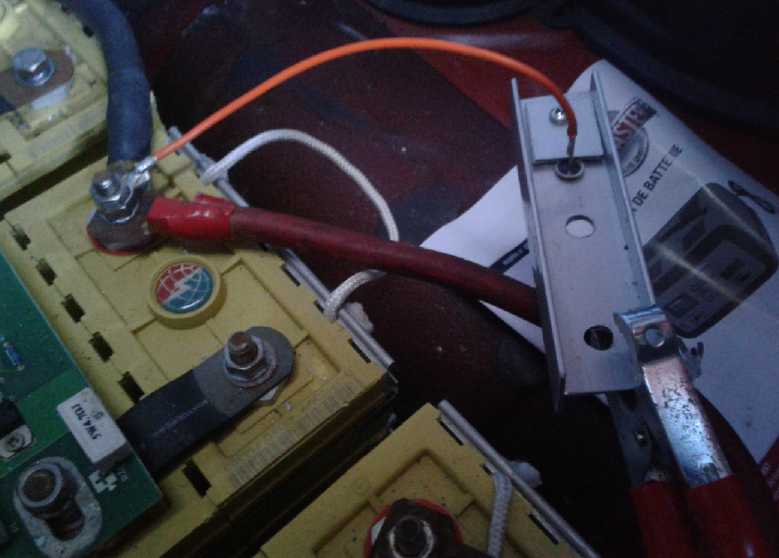

But the diodes

would dissipate up to 7 watts and needed heatsinks. I looked on the

shelf and there was a length of aluminum "H" bar. I cut three pieces 5"

long, found 3 car alternator diodes, and assembled them with a #14 wire

to connect to the battery. The charger connected to the aluminum bar. I

put them in the car and put it on charge. Each "10 amp" charger put out

6 to 8 amps. The heatsinks got quite warm but not hot. The "8" was the

one at the front under the hood, that powered the car 12 volt circuits

as well as the drive motor. Presumbly it was a little more discharged.

But the diodes

would dissipate up to 7 watts and needed heatsinks. I looked on the

shelf and there was a length of aluminum "H" bar. I cut three pieces 5"

long, found 3 car alternator diodes, and assembled them with a #14 wire

to connect to the battery. The charger connected to the aluminum bar. I

put them in the car and put it on charge. Each "10 amp" charger put out

6 to 8 amps. The heatsinks got quite warm but not hot. The "8" was the

one at the front under the hood, that powered the car 12 volt circuits

as well as the drive motor. Presumbly it was a little more discharged.

But these lead-acid chargers didn't shut off at

14.4 volts like one would expect. They wanted to charge, apparently,

by higher voltage pulses until the current dropped to near zero

regardless of voltage - just like the one that had burned up the Suzuki

Swift up with that same unexpected operating mode. If the current

didn't drop for whatever reason, they would continue pumping charge in

until something blew up. When I checked them 3 hours after starting,

they were frying the life out of some of my lithium batteries! In spite

of the diode losing .7 volts the batteries were up well over 14.4 volts

meaning the charger thought they were actually above 15.1, and yet with

this red flag waving "DANGER!" it continued charging full bore! Some of

the cells in the increasingly unbalanced arrays - formerly the "lesser

voltage" ones in the balance - were up to 4.4 volts or more. The

absolute limit for lithium ion cells is supposed to be 4.2 volts, so

they were perhaps headed for an explosion or another car fire in the

garage! And I had bought 6 of these arsonist chargers, expecting

them to work like most basic chargers do! You just don't know what

you're getting any more. The manual said nothing useful or

enlightening. Nothing about them using an unusual charging strategy,

pulse or PWM charging, much less explaining it. I won't be using these

unless it's with an external automatic shutoff. Or of course with

lead-acid batteries, with which they should - theoretically -

be okay. So now, with only two normal chargers, I still need one more

for the 36 volt car while these six will be deep sixed. (Or maybe used

in the Miles EV van which has just enough lead-acid golf cart batteries

to want all six chargers.)

While on the subject, it appears that I could fit one 305

watt solar panel on the roof of the Sprint and two on the cargo van.

They are a little more compact and would fit better than multiple 100

watt panels. About the same time, Jim Harrington of AGO sent me links

to a completely programmable 15-90 volt DC to DC converter/battery

charge controller with a good LCD display that took input voltages

compatible with the solar panels. (Aliexpress.com ~42$) Between them

the panels and onverters opened up a simple, practical way to charge

the vehicles by

solar power, which I plan to install.

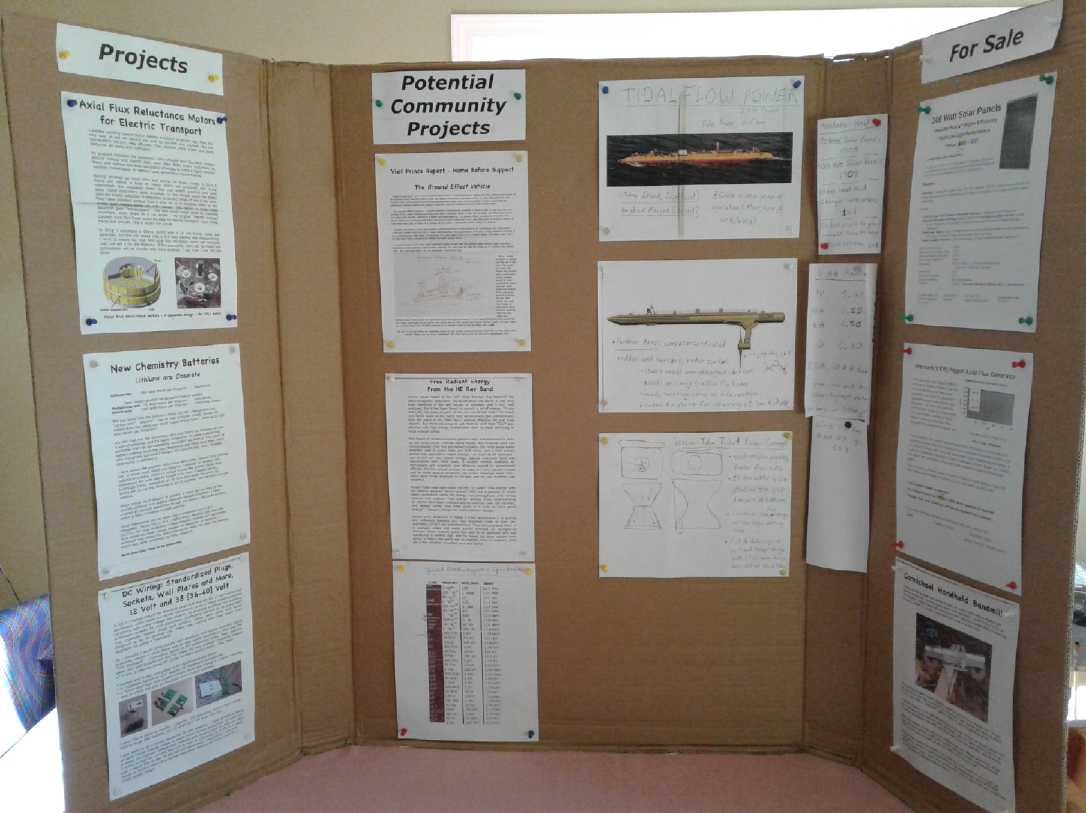

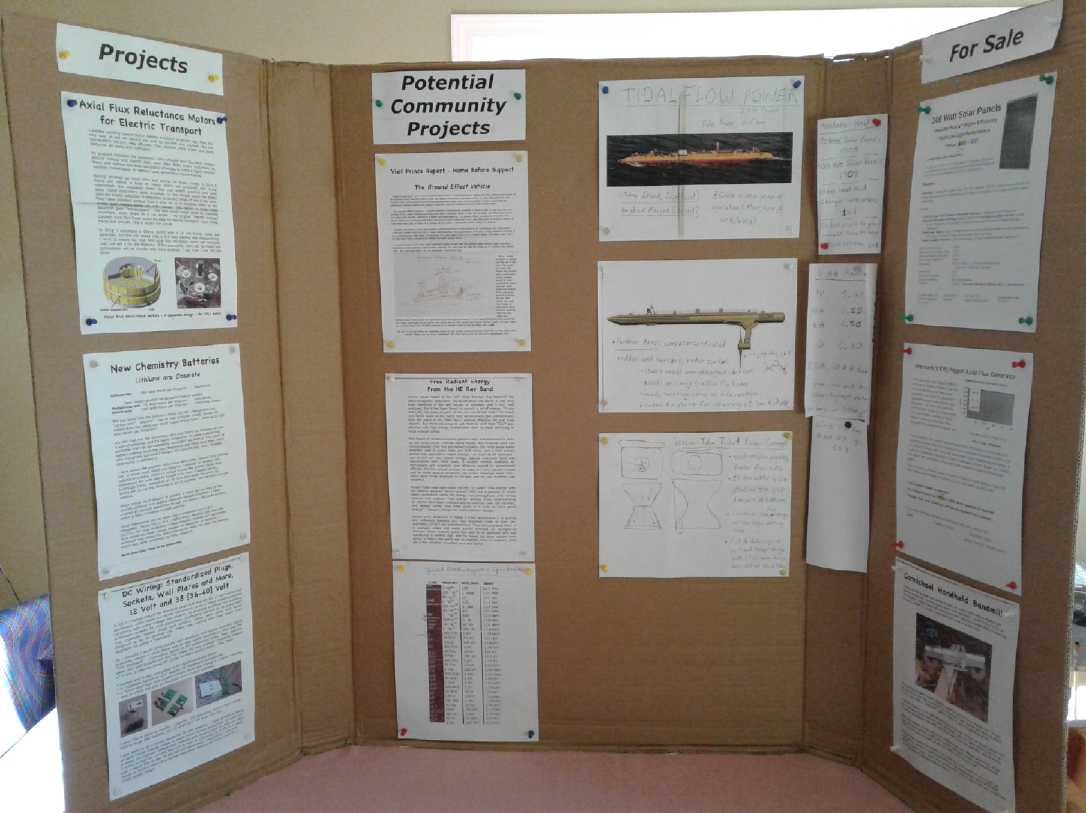

Swiilawiid Sustainability Society

Energy Symposium

In the last week I was occupied doing posters and writeups

of various projects and potential projects for the Swiilawiid Energy

Symposium. I could see a table wouldn't have room for them all, but I

found that the cardboard box for a 100 watt solar panel made a perfect

display board. The sides folded around so it would stand up on the

table to read easily from standing height. People pay good money for

custom display units like that!

But the event was really about networking and learning.

Only one person said he'd call about getting some solar panels, and so

far he hasn't.

The

first

talks on Saturday, viewed from my table in the "trade show"

area.

On the 29th

the event finally started. Sometime after it opened I counted about 66

people present. But more drifted in and by lunch time or so it was

announced there were 115. Considering the island has around 4500 people

total and this was at the extreme north end, that indicated a high

level of interest in the subject. Someone from elsewhere said he hadn't

seen such combined interest from native and non-native groups in

co-operation elsewhere in Canada, and that the bureaucrats in Ottawa

evidently try hard to keep us separated. He thought it was a model

for the rest of the country if not the world.

On the 29th

the event finally started. Sometime after it opened I counted about 66

people present. But more drifted in and by lunch time or so it was

announced there were 115. Considering the island has around 4500 people

total and this was at the extreme north end, that indicated a high

level of interest in the subject. Someone from elsewhere said he hadn't

seen such combined interest from native and non-native groups in

co-operation elsewhere in Canada, and that the bureaucrats in Ottawa

evidently try hard to keep us separated. He thought it was a model

for the rest of the country if not the world.

But we have a common goal. On

an otherwise pretty environmentally sensitive island we all want to get

rid of the diesel generators. It seemed the the north grid has up to

6.5

megawatts of diesel generated power. The south grid is larger but in

rainy months uses a hydro power system. When the water runs out by

summer the diesels take over, and between them they burn 30 million

litres of the future's oil supply per year. Another 20 million litres

goes into vehicle fuel tanks, with all the tiny communities being so

spread apart. Evidently it costs BC Hydro around 50¢ per kilowatt

hour to

generate the electricity by diesel (OUCH!), which is subsidized so we

pay the same rates as the rest of the province. (10¢ + tax;

17¢ if you go above a certain threshold per billing period, which

I apparently have not yet hit.)

Reviewing Results/Findings/Conclusions from

Participation Focus

Groups on Sunday, Sept 30th.

Reviewing Results/Findings/Conclusions from

Participation Focus

Groups on Sunday, Sept 30th.

Oops, I neglected to take a picture of my own

display!

Oops, I neglected to take a picture of my own

display!

Anyway here's the "display unit" of posters I had on my table.

(My color laser printer has been making lines across the paper, but

it's not like there's anywhere here to run out and buy a new one!)

The Haida have an interesting history. While many 'red'

and west coast native features are present, it's been said that they

have some Polynesian blood in them, I'm guessing probably dating back

from some Polynesian expedition that chanced to land there, perhaps in

the vicinity of 1000 AD. Evidently in more recent times they used to

raid up and down the west coast of the continent for slaves. But in the

1880s (three centuries after most of North America) 90% were wiped out

by smallpox and only 500-600 remained. Today while there are certainly

some very native looking people there, many of them hardly differ from

white people except culturally. I think I'm pretty white and it's

amusing to have been asked at the Skidegate Co-op Grocery till...

"Co-op number?" "8604." "Do you have a status number?" ...or "Are you

in the band?" (I replied no, I was kicked out because they didn't want

a flute player any more.)

I drove there Saturday in the electric Nissan Leaf. By the

time I had driven the 88 Km to get there, the batteries were getting

down there, and there was only a 120 volt outlet to plug into. I did it

because I knew I had 7 hours to recharge. But the dash

said it would take 14 hours to completely recharge the car. Only a

couple of people went out to look at it, but at least when the M/C, a

lady who must have been a school teacher, asked for a show of hands who

had come by electric car, I was the lone hand. That at least got the

idea into peoples' consciousnesses that electric cars actually exist

and are used. When I went to leave, the dash said seven more hours to

charge, and the estimated range said just 113 Km, which I knew would be

substantially high for highway driving. So I drove home at around 65

KmPH to conserve energy, taking an hour and a half and pulling over a

number of times to let about a dozen other vehicles go by. (Not a good

advertisement for EVs!) I made it with about 21 Km estimated remaining

- a kilometer left before the numbers would start flashing red. That

was a little nerve racking, so on Sunday I drove the Toyota Echo. I was

given a 25$ voucher for gas at Skidegate as a thank you for coming and

bringing all

my display stuff all that way.

Co-op Tidal Project?

There were ideas about "democratic ownership" of energy

production. But the thing that got my attention was a "renewable

electricity generation" co-operative from Vancouver,

"SolShare", in which people could buy shares in a larger solar project

such as putting a large array of panels onto a large building roof, for

500 $/share. They then collect royalties from the power generated. I

wonder how that would work for something more experimental like a tidal

power unit? My thought is that I'd like to try it. Not huge like the

Scottish one. Not a small "demo" project. Perhaps a 100 KW

unit in the north end of the channel near Masset.

At 10 ¢/KWH that could be around 50000-65000 $/Yr.

But because of what BC Hydro pays for diesel power (said to be 50

¢/KWH), it's likely that they would pay 20 or 30 ¢, doubling

or tripling those figures (up to about 200000 $/Yr). Royalties to share

owners would come out of that. Some kind of cost estimate for building

it would have to be created. Shares might be sold on "participate in

promising new technology" as much as for potential returns on

investment. The successes of the Scottish units will be a big help in

selling it since it has now been demonstrated that such designs do

work. If it went well we could continue and do

another one at the other end of the inlet.

Perhaps a two-prong approach would be best: approach the

co-op and see if investors come forth, and

at the same time do small scale experiments with a venturi type unit

towed behind a boat running my "2 KW Piggott" generator. If that looks

promising, do it, and if not, just

go for the large propellers already proven to work. (Hmm... it could

even have a propeller on one side and a venturi on the other for

performance comparison.) And of course press the idea of the

automatic and radio controlled rudder as a unique and valuable

improvement - which it would be. Steering into maximum current

maximizes

power generated, and being able to have the unit come to shore at high

tide so it's beached at low tide should reduce maintenance and repair

costs dramatically compared to having to reach it in a vessel. (See

project details under "Electricity

Generation", below.)

I tried to visualize the size of that Scottish

210 foot

I tried to visualize the size of that Scottish

210 foot

long, 2 megawatt tidal power vessel on the beach. BIG!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Red Quinoa

A bouquet of red quinoa

A bouquet of red quinoa

As it got colder out I brought some of the quinoa stalks

in and put them in a bucket of water. At first the ones still in the

garden kept growing and turning red as well as those I had brought in,

so it probably didn't make much difference. But it was a nice

September. Later I brought in potted peppers and tomatoes from the

greenhouse.

I must have kept the stalks in the water too long - much

of September - because when I took them out the bottoms were starting

to rot and smelled like a swamp. That didn't seem to affect the seeds.

I got about 3 quarts from my 5' x 7', x 7' tall, garden patch. Once

they were dry, it was easier to roll the flowers between the hands to

get the seeds to fall out, but there was a lot more chaff in them than

in the seeds removed earlier. I may try a couple of things to blow it

out.

Later I brought the rest in. A few days later I

put it all out on plastic to dry.

Later I brought the rest in. A few days later I

put it all out on plastic to dry.

I think I convinced a couple of avid gardeners to try growing it next

year.

HOW Much

Money?!?

There are financial experts estimating that the USA has

secretly

printed between 21 and 30 trillion dollars

($21,000,000,000,000) over the years, mostly in this millennium.

Apparently it, or much of it, has originated in the "Exchange

Stabilization Fund" and has been filtered out through Department of

Defense contracts and (IIRC) Housing and Urban Development.

Of interest in this connection, on September 10th 2001

Donald Rumsfelt said there was 2.1 trillion dollars "unaccounted for"

by the Pentagon, and that this would be investigated. It seemed

surprising this should be announced on television even if it was true.

The very next day the Pentagon budget office where the financial

records were kept was hit by "an airplane" (by all evidence a missile)

and destroyed. It was claimed that no investigation then was possible.

What this means is that the money shouldn't be worth

anything like what it is presently valued at, because there's far more

of it in or entering circulation than publicly acknowledged and than

most of us know.

Take the 1928 (or 1929?) case of Portugal. To keep the

story brief, a gangster, Simon Riis, had been impersonating a Portugese

bank official, flying to the Bank of England where Portugal's actual

bank notes were being printed, and having them print reams of extra

money "for Algeria" (IIRC), which he brought

back in suitcases and used to buy up Bank of Portugal shares. Oddly,

the Bank of Portugal was responsible for charging anyone connected with

financial fraud. If he could buy the majority of the shares, he could

then choose not to prosecute himself. It almost worked, but as he

bought more and more shares their price went up and up. So he had more

and more Escudos printed. People became suspicious, but as they were

the real printed notes, no counterfeit could be found. And Portugal was

rich and prospering with all the extra money! It was the biggest scam

of the 20th century.

But in printing all the extra money as share prices rose,

Riis made a mistake

and a teller found two bank notes with identical serial numbers. They

had him! The Portuguese bankers realized what would happen if people

found out, and they were inclined to let Riis get away with it. But one

guy just couldn't let it go. He had Riis's wife thrown in jail on some

pretext, and Riis spilled the beans. When it was realized how much

unannounced extra money was in circulation, the Escudo was drastically

devalued, which sent Portugal into a deep depression well ahead of the

general depression of 1929 and the 1930s.

Today, those with first access to these tens of trillions

of secretly 'printed' (if that's the right word any more) dollars can

buy up everything with their much overvalued currency, and have been

doing so. One reason everybody else is poor because we're all selling

things including our labor much too cheap compared to the amount of

actual currency in circulation. Small wonder the US never runs out of

money for its huge military industrial complex and anything else the

"deep state" wants!

Certain things haven't gone up so much, yet. But anything

one can call an investment asset, like stocks, bonds and real estate,

has skyrocketed. The banks and wealthy interests have taken possession

of much of the real estate and rent it out to all those families who

can never, under present conditions, afford to buy a house. And those

who can buy will never ever pay off the gigantic mortgage, so it's much

the same as renting. Husband and wife must both work just to pay the

rent or mortgage, and even many employed people have to get food stamps

or go to food banks

to afford to eat. Half the country is having trouble just making ends

meet. The difference between Portugal then and USA now? Riis was

stopped and that was that. The USA can and will keep printing under the

table. The end result can only be loss of confidence in the money and

hyperinflation. As these multi-trillion dollar "dark money" figures

have only now started coming out into the open, we may be at the

beginning of seeing the dollar's slide into the same oblivion as every

other fiat currency in history.

On the bright side, the government simply creating money

out of thin air doesn't add to the national debt. It's how I've long

advocated that money should be created - for and by the people through

their government, not by a bank as a loan that is then owed back to

that bank with interest. Either way it's still created out of thin air.

If it's by the Federal Reserve or other central bank, or by fractional

reserve lending by regular banks, the money to pay off the interest

doesn't exist. If all the money

in the world were applied to paying down debts, no one would have a

penny except the banks, who would still have oodles of non-existent

money owed to them. So we all, from individuals to nations, become debt

slaves to the banksters.

And some of those with all this wealth, ill-gotten one way

or another, can see what's coming. Bulk bullion dealer Rob Kirby

(interviewed on Greg Hunter on youtube) says there's now "stupid"

amounts of money trying to buy physical gold and silver by the ton.

Bullion is the one investment asset whose price hasn't gone way up -

because

it's the one people measure the dollar against, so it's kept pushed

down at all costs. But there's little to be had. The banks and the

"deep state" have managed to hold the beachball under the water for

quite some time - to keep the best mines from closing, the coin shops

supplied with subsidized ounces and to "buy off" (or intimidate) those

who want to buy too much. But at some time it will pop out.

(Three of the world's top silver mines announced they were

closing 2 or 3 years ago because they couldn't make ends meet with the

current price. Oddly enough, the price of silver suddenly shot up from

14 to 17 $ per ounce, and the mines stayed open.

This month an interesting (if unrelated) story is that a

mining company (Australian?) on the verge of bankruptcy decided to

blast down to a certain strata and found it contained a whopping 70

ounces of gold per ton, an unheard of amount, including the biggest

gold nugget ever found!)

Monsanto

Sellouts: Justice Served?

People have been getting sick and gradually discovering

that it's from GMO foods, especially corn and corn meal products. To

start with, Monsanto invented "Glyphosate"(sp?) as a herbicide, for use

as a weed killer, sold as "Roundup". Then they created GMO strains of

corn that could tolerate glyphosate. Thus, one could spray glyphosate

on the corn fields and it would kill the weeds but not the corn. How

simple!

The trouble was that the "tolerate glyphosate" gene added

to the corn - and to wheat - is harmful to the human digestive system.

People are getting sick and gradually dying. And apparently the rapid

rise of "gluten intolerance" in recent years is also due to the

presence of this gene, and the same "gluten intolerant" people can eat

gluten fine when they visit a country that still has 'indigenous'

strains of wheat and corn. We are eating what might be termed 'tainted'

food. The scientists in the labs told them this would be the case. The

executives who made the decisions decided to go ahead

anyway. They told everyone it was safe. They bullied scientists into

saying it was safe. They got the FDA to approve it (probably in

exchange for money or favors to individuals, who are thereby

complicit). They doubtless reasoned that the eventual lawsuits would

cost less

than the profits from their "special" GMO corn seed and the glyphosate,

and

anyway would come later. They sold their souls for personal gain

without concern for the sickness, unhealth and even death their

egregious plan would inflict on people everywhere.

Now we hear that the Bayer company is buying Monsanto. But

who is selling Monsanto? Who is "getting out" so Bayer can "get

in"? The lawsuits are finally starting to come home to roost. The

individuals who made the egregious decisions of which the lawsuits are

the resulting "blowback" are doubtless the ones who are now "getting

out".

As the anger against Monsanto increases as the general public becomes

aware of what has been done, the perpetrators will doubtless have left

the company and will get off scot free, with all their ill-gotten gains

in their [offshore?] bank accounts. Let Bayer inherit the cauldron of

trouble they brewed up! (And Bayer doubtless has their own plan to

sidestep

it all, "It wasn't us" they'll say, and they're moving the headquarters

to Germany.)

In China, a company put melamine (? I have no idea why)

into baby food products a few years ago. Babies got sick and died.

Never mind the parents having to band together to litigate and sue the

company for eventually proven damages: Those individual

executives in the company who made the egregious decision to do that

were soon tried and convicted, and then stood up against a wall and

shot.

In one case the criminals were removed from the planet by

the authorities and will do no more harm. They will kill no more

innocent babies or hatch further "get rich quick" schemes. Others will

think long and hard before unleashing any similar deleterious program.

In the other the criminals, nameless and faceless to the public, have

walked away with their ill-gotten fortunes to set an example that crime

pays for others to follow, and are free to hatch another evil scheme

themselves. What a contrast! Public outrage and legal action is

mistakenly and impotently directed at the company which they were

running at the time of their crimes.

The future is being thrown to the wolves and the breakdown

of western civilization made certain as it permits all manner of such

sociopaths to continue to live and thrive among us - people with a high

degree of disconnect who have no cares, respect or love for the society

which nurtured them or for the people among whom they live.

-----

As a "bonus" we now find that pollinating insects like

monarch butterflies are dying in droves because of a chemical that is

ending up in flowers, making them poisonous to them. Nicotinoid

insecticides are even worse. Populations of bees are collapsing on a

widespread basis. This will have further serious repercussions to the

food supply.

And Youtube channel "Ice Age Farmer" shows various news

articles which show that owing to droughts, and cold weather into

spring and starting early in fall, the various major crop failures of

recent years have been much worse in 2018 - and have attained to being

a very significant percentage of total worldwide harvests. He says the

mainstream news laughs it off with articles like "Krisp Potato chip

famine in

Ireland", but the warning signs couldn't be any louder, that you need

to grow your own and become food independent. (Get your food stores

together!)

-----

The past tense of "sit" is "sat"

The present tense of "fit" is "fat" (as in, "it used to fit.")

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get

into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in

writing of

those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Electric Transport

Solar Charging for the Sprint Car?

and for the Miles Mini Cargo Van? - New Improved Plan

I had thought 100 watt solar panels would be a great way

to charge the Chevy Sprint and the Miles EV truck. If you put several

together on rails on the roof, you could get just the right voltage,

right? That didn't seem to pan out very well. The Sprint would need

2-1/2 to get enough voltage, and 3 was one too many to fit on the roof.

The Miles would need 5 or 6, which again was a tricky fit. And it

looked like I should make some circuit to shut the charge off when it

was full. So I hadn't actually got around to either project.

But after the 20th when I ordered a crate/skid/palette of

thirtytwo 305 watt solar panels, it occurred to me that one panel

had the same power as three of the 100 watt panels. It was also a

little smaller: 1 m x 1.67 m as

opposed to 3 * 1 m x .67 m = 1 m x 2 m. That would mean it could be

placed on the roof of the Sprint and not stick very far over the

windshield. Much better! The trouble was that as usual the 32 V MPPT or

40 V open circuit weren't quite enough to charge the "36 V" lithium

batteries, which in fact usually sit at about 40.0 volts when not in

use.

Jim Harrington sent me a link to a Chinese solar panel

charge controller/DC to DC converter with flexible input from 12 to 60

volts and a programmable output from 15 to 90 volts, for just 42$. And

a good LCD display to see what's going on. My preference would be to

charge each 12 volt battery as a separate unit, but for the solar the

charging currents wouldn't be too high, and doing the full voltage with

this unit should solve the problem. So I ordered two: one for the 36

volt Sprint and one for the 72 volt Miles.

Measuring showed that if one allowed the panels to stick

over the edge of the truck roof by ~10 cm (4"), the truck could hold

two panels for 400 watts of charging (counting a 2/3 effective

factor since the panels are mounted level and not aimed at the sun). If

it's sunny and you park in the sun, that's headed into some

good charging rate territory. The truck's regular charger only does

around 1100 watts. The charge controller said it was good for up to 600

watts of solar panels. Perfect!

The panels can not only save power grid electricity, but

they give peace of mind that you'll never be completely stuck because

the batteries ran dead. or if the mains power is out for an extended

period. ...at least in the summer.

Other "Green" Electric Equipment Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

I had a bit of an e-mail

conversation with someone where I bought the 3 teeth per inch, 3/4"

wide by .025" thick stainless steel "meat cutting" bands. Considering

the small wheels (10") he said thinner was best, and he thought I was

making the best choice of the limited selection available.

But if the saws get into production, I expect we can have

more optimal .025" bands with coarser teeth (2 teeth per inch or lower)

made to meet the new demands for a new type of saw. I'd rather the

bands can be bought in stores or broadly sourced rather than only be a

custom order from the bandmill maker.

As mentioned in the last newsletter, the 3rd and 4th were occupied

finishing cutting up the main two 10' sections of the alder tree I

felled in August. It was much easier to cut than the spruce and I was

quite pleased with the results and the performance of the mill.

Cutting lumber from the alder tree logs

Cutting lumber from the alder tree logs

Boards from the upper section

Boards from the upper section

Cutting beveled siding from the bottom section.

Cutting beveled siding from the bottom section.

The smooth edge started vetical at 90° but got more

and more angled with each angled cut.

Some of the beveled siding.

Some of the beveled siding.

If I'd had it planned, I would have made it 12' long instead of 10', to

make

siding for the roof over my travel trailer, which has posts 12' apart.

Well, there's lots more alder if I want to cut and mill it!

6th: After such good results with the alder, cutting up

two sections of log into about 20 nice straight boards in good time, I

returned to the spruce, to tackle the 10" wide cut I had set up

earlier. It went badly. The band cut inverted bowls and curves and got

hot. I tried a number of things to improve it. The only thing that

really seemed to work was increasing the band tension a lot. And even

that seemed to be a half measure. I tried starting again from the other

end, but it didn't go any better. I couldn't get through it. Not one

board! What a let down after cutting up a whole alder log into about 20

pieces of fine lumber in 7 hours! I finally went out again, determined,

and eventually got through it. What a wasted day.

So I conclude that there is indeed a great difference

between different species of wood. Also the alder was freshly cut down,

while the spruce had been down over a year. That too can make a

difference. I should probably stick to 4" and 6" wide cuts in the

spruce, while some cuts that went fine in the alder were 10" or even

11".

But there were problems. First, the blade was dull.

Second, a bearing seized in a guidewheel and had to be replaced.

Third the spring holding the plastic against that guidewheel managed to

spring over sideways so it wasn't strongly pressing the plastic against

the wheel. Once again a gap was opening up insead of the band tracking

properly. I replaced the bearing, and I drilled a shallow hole in the

aluminum bottom plate for the spring so it couldn't do that again.

What I seemed unable to do was sharpen the band very well. I got out a

magnifying glass and it showed that the diameter of the diamond

cylinder was a little too small. It was grinding up to but not quite

getting the dull cutting tip. Furthermore, the nylon had been chewed

off and the band had hit the bolt and the backs of the teeth just

behind the tips were flattened off. The backs needed to be filed down

to an angle again for it to work right, too, and I didn't manage that

with half of them. A diamond card I have wore out.

I wasn't very happy with the tube of little ball bearing

races I'd bought for the band guides. They seemed to be jamming and

breaking one by one. One thought is that thought they probably aren't

intended for transverse loads. With the "railway wheel" band guide

wheels, the band pushes on the bearings sideways, perhaps explaining

this broken one. But some that had never been used in those had broken

down or become hard to turn, too. Perhaps I should find some very small

needle bearings?

Someone later said that spruce was about the hardest thing

to cut, having criss-cross interweaving grain. If it could cut that, it

could cut most anything. On the 8th I tried again, this time taking a 2

to 5" slice off the edge of the same cant. It didn't cut well, so I put

on my last new band.

Two cuts, with the widths increasing as I went down, went

great! The new, really sharp blade was certainly what it needed.

Who named a big long block of wood a "cant", anyway?

Between "knot" and "cant", it all starts to sound pretty negative. A

more negative word however is "nail". 5 inches into the third cut. Now

that I was out of the city I thought there wouldn't be any, but there

it was inside with the tree having grown over it. Per my usual I not

only hit the nail, I had to be ripping it lengthwise. 3/16" higher or

lower I'd have blissfully missed it, perhaps none the wiser about its

presence. Now the fabulous brand new band, the last one of the three I

got, wouldn't cut anything.

I wouldn't be cutting again until (a) I ordered and

received some new bands, (b) I found a much better way to sharpen the

ones I had or (c) I could try the .032" regular band that I still have

from before I raised my shop bandsaw with a wooden block, after which

it needed 105" bands instead of 93". The "regular" .032" x 3/4" band

was 2 teeth per inch. I thought it was a little thick for wrapping

around 10" wheels instead of 14", but I decided it would be a good

thing to try out anyway, and see how it worked.

It became apparent that what I most needed was a practical

way to effectively sharpen the bands. On the evening of the 11th I took

two and inspected them under a magnifying glass. On one the edges of

the teeth were well rounded off. Definitely dull. (That's probably the

one I cut up the alder with, but I wasn't keeping track.) The other

looked pretty good to me. Why did I take it off? I put it back on the

saw. I also looked at a few ideas on line for how to sharpen bands.

There were simple things like "grind down the backs with a Dremmel

tool" (on slowest to minimize heat!), to elaborate jigs that moved from

one tooth to another with a powered ratchet as a grinding wheel touched

up all the faces of each tooth as it moved.

When I tried to saw another board it didn't go very well.

I was disappointed. It didn't seem to cut very well to start with, and

soon little sawdust was coming out as I tried to cut further. On this

band the teeth seemed to keep clogging up with sawdust. I used a wire

brush to clear them - three times - and eventually got to the end. When

I looked at the piece underneath I found the reason: just 3-1/2 inches

in, I had hit another nail! And again not just a nail: I had sawed

diagonally right through the head. So once again, unknowingly, I had

been cutting with a dull band. And it was the last one that seemed

pretty sharp.

I had already cut 6" off the end of the log with the

chainsaw. This nail was higher up. No wonder I couldn't figure out the

metal detector readings previously - there were actually two

nails near each other. Or were there even more?

This time I got out a supermagnet. As soon as I put it

next to the wood it jumped to another nail just under the surface! That

seemed to be it... three nails ...at least, near the surface. I cut

that piece off. My cant was a couple of feet shorter now. Of course if

I'd known I'd have cut it shorter before wrecking two bands.

Apparently the first picture is a "find the

nail" puzzle.

Apparently the first picture is a "find the

nail" puzzle.

The next one is a supermagnet 'stuck' to an unseen third nail inside

the wood.

Automatic Band Sharpener

This was getting really discouraging! I looked at

bandsaw sharpening jigs and tools on line. There was a wholly automatic

one for 1300 $. It apparently only did wider bands with a longer tooth

pitch - around one tooth per inch instead of three. But it had many

adjustments and I thought it could probably be made to work. It might

skip every second tooth, but if so I could do it twice, offset by a

tooth the second time. The price was (I think) more than all I've spent

on the entire bandsaw project so far in all these months. (In fact,

it's more than the 1200 $ I spent making my entire pivoting blade

sawmill in 2006.) OTOH, I really need to be able to resharpen bands if

I'm going to mill lumber, and I don't want to spend half my time

sharpening them.

From a youtube video, it seemed this was the same

sharpener as the one sold by woodlandmills.ca . I looked there and they

were "only" 849 $ there. I ordered one. (total 933 $ with tax and

shipping. Yikes, did I really do that? I'm running short of money with

almost no income.)

On the 14th I visited someone who made arrow shafts. He

had several bandsaws and explained some details about bands and

sharpening and stress cracking. "Heat is the enemy of bands." A

reminder of what I already knew.

That evening, I tried sharpening another band with the

diamond bit in the 'dremmel'. It was one of the older thinner .022"

bands. It seemed to go on forever and I took a break in the middle. The

next morning I put it on the mill. It cut nicely for a couple of feet,

then started slowing down and cutting curves. It must have been one

that had been overheated and lost the tempering of the teeth, so it

didn't stay sharp long. There was a big waste of time - and one band,

at least, for the garbage can!

I ordered another 5 bands. The website said they would

take four weeks to produce. That was unexpected since the first ones

had only taken a week to arrive, and most unwelcome. By the time I got

them it would be November and cold and miserable outside. Maybe the

sharpener would arrive sooner. In the meantime, that was it for milling.

The sharpener arrived on the 27th. By then I was heavily

involved with preparations for the Energy Symposium and didn't even

have time to open the box.

Spruce shavings buildup on a dull band

Spruce shavings buildup on a dull band

Improved Piggott High Efficiency Axial Flux Alternators

With no iron in the stators and hence no iron losses and

absolutely no magnetic cogging or friction, and permanent magnets in

the rotor and hence no energy wasted in field current, and high

magnetic coupling for high output at low RPMs, I chose to build the

Piggott design because it appeared to be the absolute best of all

generators.

But Piggott said they were only good in homemade

windplants for around 500 watts (at only ~300 RPM!), or up to 1000+

watts (~425 RPM) for short periods. That didn't seem like much "bang

for the buck" for all the magnets and wire. The reason for the low

capacity however was not electromagnetic but simply that there was no

cooling designed into it. I thought that if it was supplied with air

cooling and the coils were better exposed to the air flow, it would

probably be good for at least 1500 and perhaps 2000 watts, still at

under 1000 RPM.

Making Rotors and Stator

Pursuant to getting the project going again, I was

gradually gathering up the parts and jigs and molds as I ran across

them in scattered places wherever they had been stored after I moved. I

couldn't find the stator mold. Finally I looked it up in TE News #108,

January 2017. The picture showed it was made of black speckled plastic,

not white like most of my molds. With this info, I soon located it

right where I had first looked. How fickle memory is for detail! Later

(8th) I looked there again to see how many turns of wire I had wound in

the coils. (21 but they took too much room so I unwound two turns,

making it 19.) It was the last project I physically worked on in

Victoria before I was out of time and had to get packing to move. I had

designed the stator and made the mold, designed and had four 30 cm

diameter steel magnet rotors cut by abrasive waterjet (for two

generators or one extended one), and wound 2 of the 9 coils. At the

bottom it said "To be continued at Lawn Hill." So here it is!

The mold was only about 10 mm thick. I started wishing it

was thicker and for the first time missed the CNC drill-router I had

left behind. I could have made another layer for it. As it is, I would

have to do all the work of setting up the new CNC router and finding

all the right sets of software for it before I can make anything more

like that. That would be another whole project - ugh!

Having not got to it for quite a while I had earlier

offered the parts to make one generator (I had enough for two) to an

off-grid farming family that seemed

very interested. I said all they had to do was send me pictures of the

construction and installation (micro hydro) for my newsletter. I said

they could work in my shop if they wanted and I would show them what to

do. Here, perhaps, was a chance to get others involved to finish this

one project, for their own benefit, and not have to do everything

myself. Somehow after visiting twice they seem to have let the idea

lapse. (I shouldn't have opened my mouth the second time and remarked I

might need one myself for a floating tidal power project. OTOH they did

say at the start they'd rather buy one than build it.)

Used supermagnets/NIB/NdFeB/rare earth magnets

epoxied onto custom steel rotor

Used supermagnets/NIB/NdFeB/rare earth magnets

epoxied onto custom steel rotor

On the 6th and

7th I got back to it and put the epoxied strapping on the magnet

rotors. I trust they'll be good for up to about 2000 RPM. It was extra

work to do the two rotors where

for my motors only one was needed. But it should be worth it to have

super efficient generators with no cogging or magnetic friction. One of

the rotors all ready to go (without hub) was 4143 grams.

On the 6th and

7th I got back to it and put the epoxied strapping on the magnet

rotors. I trust they'll be good for up to about 2000 RPM. It was extra

work to do the two rotors where

for my motors only one was needed. But it should be worth it to have

super efficient generators with no cogging or magnetic friction. One of

the rotors all ready to go (without hub) was 4143 grams.

Putting on the polypropylene strapping/webbing

Aluminum "U" pieces hold strapping onto magnets,

Aluminum "U" pieces hold strapping onto magnets,

and steel weights clamp them down magnetically

so it doesn't stick up.

Weights to hold down the strapping while the

epoxy sets

Weights to hold down the strapping while the

epoxy sets

A rotor done (magnets down)

A rotor done (magnets down)

Later I found that the

generator actually met Piggott's specs and realized it would never be

run over 1000 RPM. That made the strapping superfluous except as extra

tough magnet protectors. Basically it was a lot of extra work for

nothing, and it forced the magnets to be an extra 1/16" away from the

stator.

On the 8th I

wound a coil and on the 9th two more. It was a lot of extra work

winding three parallel wires instead of just one, as well as painting

each layer with epoxy as I wound. (And reusing old magnet wire

from an early Electric Hubcap motor also made it harder. I ran out of

that before I finished all the coils.) Oh well, 5 down and 4 to go!

Then I discovered that I had

done one wrong. I had made two sets of coil centers for winding them.

One was just 10 mm thick, the other was 1/2". I had decided to use the

1/2" ones, but somehow I accidentally used one of the thinner ones for

this one core. That made it bigger in diameter than the others to get

19 winds on it. Oh well, I'd see if I could get it to fit in. Otherwise

I had one more to wind. And with my winding setup I found I had coiled

one or two "counterclockwise" compared to the others. I decided no

matter, I'll just wind all three coils of that phase the same way.

On the 8th I

wound a coil and on the 9th two more. It was a lot of extra work

winding three parallel wires instead of just one, as well as painting

each layer with epoxy as I wound. (And reusing old magnet wire

from an early Electric Hubcap motor also made it harder. I ran out of

that before I finished all the coils.) Oh well, 5 down and 4 to go!

Then I discovered that I had

done one wrong. I had made two sets of coil centers for winding them.

One was just 10 mm thick, the other was 1/2". I had decided to use the

1/2" ones, but somehow I accidentally used one of the thinner ones for

this one core. That made it bigger in diameter than the others to get

19 winds on it. Oh well, I'd see if I could get it to fit in. Otherwise

I had one more to wind. And with my winding setup I found I had coiled

one or two "counterclockwise" compared to the others. I decided no

matter, I'll just wind all three coils of that phase the same way.

I wound another one on the 11th. Two more on the 12th and

the last one on the 13th. 6 coils in 6 days! I would definitely have to

find an easier way next time. Maybe I'd just use my heaviest (#11)

magnet wire, wind until it looked like the right size, and work with

whatever voltage came out - 1.5 times whatever this one was. Then

again, there's just one spool of #14 AWG, but I have lots of #15 and

#16 wire, and it's free until I run out!

On the 15th I screwed all the coil centers into place in

the mold complete with coils. Being wound mostly with used wire there

were slightly different sizes, and I contrived to avoid having to wind

a new one by putting the smallest coils on each side of the extra fat

one wound on the thinner center. The wires on those and one other coil

gap touched, so I put tarpaper between them.

I actually did it twice: once to make holes for the screws

in the right places, having marked them on the plywood in early 2017,

and then again with a sheet of polyethylene underneath so the finished

stator won't be stuck to the plywood.

On the 17th I

soldered all the wires together and arranged them as neatly as I could.

The wiring always take up more room than I bargain on. I left all 6

ends sticking out, 2 from each phase. That leaves the option of wiring

it "delta", or making the "Y" point "ground", if the voltages from "Y"

configuration are greater than desired. It was well that I did because

I had to reverse the ends of the phase wired counterclockwise. I drew

the waveforms - of course it mattered! Duh!

On the 17th I

soldered all the wires together and arranged them as neatly as I could.

The wiring always take up more room than I bargain on. I left all 6

ends sticking out, 2 from each phase. That leaves the option of wiring

it "delta", or making the "Y" point "ground", if the voltages from "Y"

configuration are greater than desired. It was well that I did because

I had to reverse the ends of the phase wired counterclockwise. I drew

the waveforms - of course it mattered! Duh!

Ready to Fill

Ready to Fill

The table

proved to be not quite level so I carefully leveled the mold by sliding

a couple of things under its plywood base. Then I poured epoxy into the

mold. The mold was only 10 mm thick and filled to about 9 mm, whereas

the coils were 1/2" - 12.7 mm. The next morning I looked. Should I

leave it like that? With some coil edges sticking out, the cooling

would be best. But it was pretty thin, and the wires were weak spots. I

wouldn't want it to vibrate magnetically while making power and perhaps

break.

The table

proved to be not quite level so I carefully leveled the mold by sliding

a couple of things under its plywood base. Then I poured epoxy into the

mold. The mold was only 10 mm thick and filled to about 9 mm, whereas

the coils were 1/2" - 12.7 mm. The next morning I looked. Should I

leave it like that? With some coil edges sticking out, the cooling

would be best. But it was pretty thin, and the wires were weak spots. I

wouldn't want it to vibrate magnetically while making power and perhaps

break.

I undid the

screws holding the outer mold and pried it up all around the edges,

working around the edges and inward with two chisels until it came

loose everywhere and was level with the tops of the coils instead of

the bottoms. (The coil centers were still screwed down, and as I hoped

the coils and the epoxy casting stayed right in place.) Then I mixed

more epoxy and filled it up so it would all be 1/2" thick like the

coils. I would have put in wads of polypropylene cloth to give it more

strength like on my motors, but there really weren't many places to put

it, and with no top on the mold to press them in it would have just

been a mess.

I undid the

screws holding the outer mold and pried it up all around the edges,

working around the edges and inward with two chisels until it came

loose everywhere and was level with the tops of the coils instead of

the bottoms. (The coil centers were still screwed down, and as I hoped

the coils and the epoxy casting stayed right in place.) Then I mixed

more epoxy and filled it up so it would all be 1/2" thick like the

coils. I would have put in wads of polypropylene cloth to give it more

strength like on my motors, but there really weren't many places to put

it, and with no top on the mold to press them in it would have just

been a mess.

It should perhaps be pointed out that the magnets on the

rotor spin around in the area of the white coil centers. The metal

rotor is farther away by the thickness of the magnets, leaving room for

the wiring to stick up a bit as it does.

Finished stator "side A"

Finished stator "side A"

Stator from the other side

Making a Housing

On the 19th, having made the rotors and stator, I finally

started thinking about a housing to put them in. The large diameter

(350 mm) end plates had to hold the bearings solidly in the middle,

especially if I used cup & cone "trailer wheel" bearings. I'd

probably be better off to use needle bearings. I started thinking about

making the plates out of plywood, and wished I had a lathe big enough

to turn 14" discs. But should they be discs? How about an upside down

"U" (or "n") shape, perhaps with mounting flanges sticking out the

sides? The cover could also be that shape, with a separate flat bottom

piece.

Then, the end plates would be out of the field, but a

metal cover over the center would cause magnetic drag and heating. It'd

have to be plastic. But plywood end plates with a coating of

"flameproof" paint seemed more and more attractive. One could even just

make it a plywood box. Why not? It would be in a room or in some sort

of outer housing with other components. It couldn't be waterproof or

streamlined or weather resistant and suck in cooling air too. End

plates sounded like a good use for my 3/4" birch plywood.

All I managed to accomplish that day was to buy a sheet of

1/4" birch plywood to match the 3/4", and dig out a 1" shaft and two 1"

center, press fit housing, needle bearings from a couple of cluttered

drawers. (Yay, I actually had them!) That meant I seemed to have pretty

much everything and all I had to do was figure out where to cut and

drill, and build it. I did that, except for a few finishing touches and

paint, the next day. I had intended the top half to be shaped, but when

I got there it looked like the simple thing to do was just to make it

square. The only thing I used the thin plywood for was the top cover.

(And later I thought that would be insufficient safety if a magnet did

fly off the rotor, and changed the top to 3/4" too.)

I made the

holes for the bearings with a hole saw that seemed about the right size

(1-3/4"?) and a tiny bit of filing at an angle made them perfect for

the pressed fittings. They weren't quite in line horizontally, but it

was level, and bearable. Later I figured out that instead of just

measuring with a ruler, I should have lined the two pieces of plywood

up one on top of the other, clamped them together, and drilled the

center bearing/shaft pilot hole right through both of them at once.

I made the

holes for the bearings with a hole saw that seemed about the right size

(1-3/4"?) and a tiny bit of filing at an angle made them perfect for

the pressed fittings. They weren't quite in line horizontally, but it

was level, and bearable. Later I figured out that instead of just

measuring with a ruler, I should have lined the two pieces of plywood

up one on top of the other, clamped them together, and drilled the

center bearing/shaft pilot hole right through both of them at once.

Holding the stator in place,

with one rotor, I spun it up to ~100 RPM by hand just by twisting the

shaft. I could feel the breeze coming off the rotor - a good sign for

cooling. It put out less than a volt AC from one phase. Might I end up

running it at a faster RPM than I thought? I shorted it and got 2.4

amps at about 50 RPM, which was as fast as I could get it to go with

the magnetic drag from the short. (Maybe I should make a crank handle?

But later I put a large V-belt pulley on it for real testing.)

Holding the stator in place,

with one rotor, I spun it up to ~100 RPM by hand just by twisting the

shaft. I could feel the breeze coming off the rotor - a good sign for

cooling. It put out less than a volt AC from one phase. Might I end up

running it at a faster RPM than I thought? I shorted it and got 2.4

amps at about 50 RPM, which was as fast as I could get it to go with

the magnetic drag from the short. (Maybe I should make a crank handle?

But later I put a large V-belt pulley on it for real testing.)

The finishing touches it still needed were ventilation

holes for the air flow cooling, and a flameproof paint for safety.

Later!

Assembly

On the 22nd I

tried putting together the two rotors with the stator in between. This

is a tricky operation because the rotors attract each other and if

given the chance will clamp together with crushing force. I had put in

three options for four bolts to have them thread together: four 1/2"

holes around a 4" diameter circle, four 12 mm holes in a 200 mm

diameter circle, and 3/8" holes also in the 200 mm circle, making 12

holes near the center spaced the same as car wheel lug bolts.

On the 22nd I

tried putting together the two rotors with the stator in between. This

is a tricky operation because the rotors attract each other and if

given the chance will clamp together with crushing force. I had put in

three options for four bolts to have them thread together: four 1/2"

holes around a 4" diameter circle, four 12 mm holes in a 200 mm

diameter circle, and 3/8" holes also in the 200 mm circle, making 12

holes near the center spaced the same as car wheel lug bolts.

I threaded the 12 mm holes to take 1/2" bolts, which I

made from 4.5" threaded rods with two nuts screwed together on one end.

I ground a 7/16" "hex head" onto the thin end so I could turn them with

a nutdriver. I put the rotor with the shaft in a vise so it couldn't

jump up at me when I brought the other one near, and held the one with

the bolts - with my fingers between the magnets and not on them, just

in case.

But when I tried to put them together, the nuts fit tight against the

SDS hub and the bolts wouldn't turn.

Then I thought it wouldn't matter: I could do it without

the nuts because the 1/2" bolts wouldn't go through the 12 mm

unthreaded holes in the other rotor. In this I was wrong again because

the bolts lined up with the 1/2" holes in the other rotor instead of

the 12 mm holes. Three of the bolts went through the holes, but for

some reason the fourth didn't quite line up, which prevented the rotors

from snapping together against the stator, which I hadn't actually

thought was possible... but still I held the rotor with my fingers

between the magnets. If they had snapped together, I'd have

been really thankful I took that precaution!

I started thinking of carriage bolts whose large heads

wouldn't go through any of the holes but which wouldn't hit the hubs,

but I didn't have any the right size. Then it occurred to me to line

the rotors up two magnets over. Then the bolts would be against the

3/8" holes instead. I got it put together and put it into the back of

the chassis with the shaft in the rear bearing. I put a couple of 3/8"

bolts through both rotors to be sure they couldn't twist against each

other and the 'outer' one jump over by two magnet places compared to

the one solidly attached to the shaft. (...that rotor I suppose should

have a shaft key, too. Sigh!)

Next it needed some pieces to fasten and adjust the

position of the stator. It had to be held right between the two rotors

without touching either of them as they spun. And it had to resist

turning itself as the magnetism tried to drag it around. Since the

rotors spin from the center axle, the stator can only be held from the

outside, and I had sized the box so it came up to the top, bottom and

sides. I cut some small pieces of plywood to hold it and screwed them

into place. I ended up gluing a couple of bits in to adjust the

position. That needs a better system!

Finally it needed for the wires to come through the box

and preferably connect to a terminal strip. Since I didn't have such a

big terminal strip, they would just have to stick out. If it's to be

rectified to DC per the plan for this one, a six diode assembly on a

heatsink and screwed to the case can take the place of a terminal strip.

By evening

everything was assembled. It occurred to me that if Piggott generators

could do 500 watts at 300 RPM then they could do 2000 watts at 600 RPM

and 4500 watts at 900. There's no way (I don't think) the cooling will

be adequate for 4500 watts, so that means the top RPM can be limited to

under 1000; even to 800. For those speeds, it's probably superfluous to

have all that strapping on the magnets. Simply epoxying them to the

rotor should be sufficient, with maybe an extra coat over the top for

extra strength and to protect the magnets. I could simplify the rotors

with fewer and bigger cooling holes, making them that much simpler and

cheaper to have made, and more especially it would greatly reduce the

labor, making a production version seem more worth while.

By evening

everything was assembled. It occurred to me that if Piggott generators

could do 500 watts at 300 RPM then they could do 2000 watts at 600 RPM

and 4500 watts at 900. There's no way (I don't think) the cooling will

be adequate for 4500 watts, so that means the top RPM can be limited to

under 1000; even to 800. For those speeds, it's probably superfluous to

have all that strapping on the magnets. Simply epoxying them to the

rotor should be sufficient, with maybe an extra coat over the top for

extra strength and to protect the magnets. I could simplify the rotors

with fewer and bigger cooling holes, making them that much simpler and

cheaper to have made, and more especially it would greatly reduce the

labor, making a production version seem more worth while.

I wired it "Y" and got it up to about 120 RPM by hand. It

put out about 3 volts. So it should be 15 volts at 600 RPM. That seemed

a little on the low side. A single #11 AWG wire for the coils might

give about 28-30 turns instead of 19, so 23 volts at 600 RPM. Again for

production the single wire is much the easiest to wind. Or it could be

57 turns of single #14 AWG wire, making 45 volts at 600. If I'm

producing, customers can (within limits) have whatever they want. (But

I wasn't thinking... When all three phases were rectified to DC it

would be square root of two higher voltage, 21 volts DC rather than 15.)

I shorted two phases and managed to twist the shaft and

get around 4 amps. Lacking that handle, I put vise-grips on the shaft

and got up over 8. If I shorted all three phases together, it was hard

to twist the shaft. And when I stopped twisting, the generator came to

an 'instant' stop.

I might have run more tests, but that was sufficient and I

had to get ready for the Swiilawiid Energy Symposium.

Testing

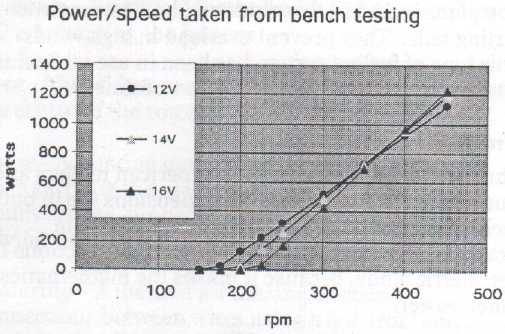

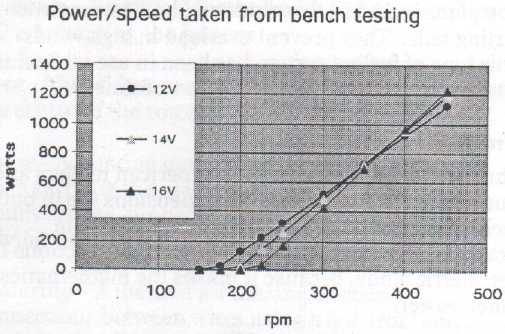

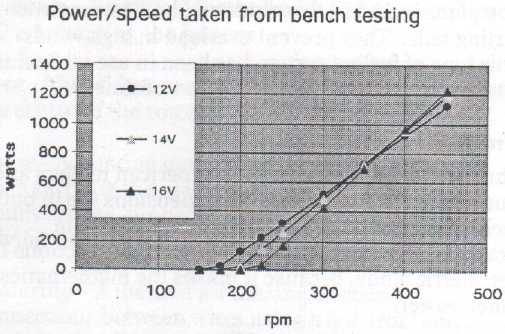

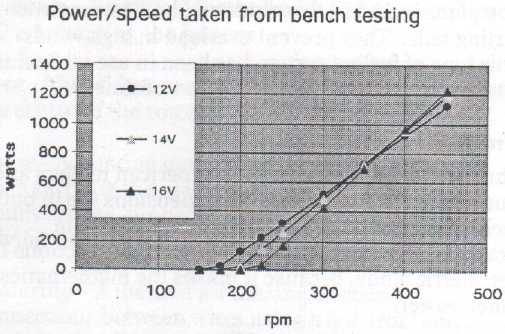

Generator Performance Graph from Hugh Piggott's

book, How to build a Windplant, 2004 edition

Generator Performance Graph from Hugh Piggott's

book, How to build a Windplant, 2004 edition

On the 25th

after making a few adjustments to stop things from rubbing, I put a 12"

V-belt pulley on the shaft, and a ~2" one on my radial arm saw, and

spun up the generator with the saw motor. It put out a whopping 7.2

open circuit volts AC from one phase, at 52 Hz. With 6 magnet reversals

per rotation, the speed would have been 52/6 * 60 sec/min = 520 RPM.

(The Hz reading times 10. Duh!)

On the 25th

after making a few adjustments to stop things from rubbing, I put a 12"

V-belt pulley on the shaft, and a ~2" one on my radial arm saw, and

spun up the generator with the saw motor. It put out a whopping 7.2

open circuit volts AC from one phase, at 52 Hz. With 6 magnet reversals

per rotation, the speed would have been 52/6 * 60 sec/min = 520 RPM.

(The Hz reading times 10. Duh!)

I connected the phases in "Y" and measured phases open

circuit A-B and A-C as 14.4 VAC. B-C however was 15.1 volts. That means

phase "A" is short a winding or two on one of the coils. I must have

miscounted, or I unwound a loop from the one that was too big in

diameter to fit it in.

Then I shorted between two phases and tried two clamp-on

ampmeters. They both said about 46 amps short circuit (I think it was

phases B-C). When I turned off the saw, everything stopped in an

instant. (That's how all those quick-stop power tools work - the switch

in "OFF" shorts out the motor.)

I thought I should try again and measure the RPM as well,

because it was probably lower. I used the third phase to get the

frequency. I was holding the V-belt tight by pushing back the saw

handle. I guess I pushed harder. This time I got 62 amps and 27 Hz -

just 270 RPM. The belt must have been slipping a lot. (If it hadn't

been it probably would have stalled my saw motor.) 62 amps? If it was

really 62 amps, even after a few seconds the alligator clip wire should

be hot. Sure enough it was still quite warm and one of the clips was

hot. I guess it really was 62 amps!

Of course with a proper load, the voltage would have been

loaded down and the current would have been less. and the RPM in

between. Open circuit voltage at 270 RPM would have been 270/520* 15.1=

7.8 volts. If we roughly estimate "maximum power point" would have been

6 volts and 45 amps, that would have been 270 watts. That's at the

lower end of what Piggott's graph shows at 270 RPM, but not far off.

Factors that could make it a bit lower are: 1. The steel

was bowed a bit so my rotors weren't quite flat, so they had to be a

bit farther away so as not to hit the stator, and 2. the polypropylene

strapping on my magnets also forces each rotor to be 1/16" farther from

the stator, and 3. my rotors are just slightly smaller in diameter, 300

mm versus 1 foot (305 mm).

But in writing the above paragraph there was something I

forgot: I'd only connected and measured between two phases. Once all

three phases are rectified to DC, the voltage will be square-root-of-2

higher with proportionately higher available DC current and power for

any given RPM. That's very encouraging. Apparently my original winding

calculations for useful voltage in 2016 weren't so far off after all.

So performance should be on the top line of Piggott's graph or even

exceed it. I didn't have time (or enough high current diodes) to try it

out this month. But it was gratifying to realize that the performance

is/will be "as advertised" in the performance graph that made me

originally want to make one; that my unit will achieve similar results

at around 300 RPM as the originals. And of course it should be able to

go up to 600-900 RPM and put out probably a couple of kilowatts - maybe

even more? - continuous. Even 1 KW continuous would make it the best

one ever built.

From now on I won't put the epoxied strappings on. It

isn't needed at such low RPM.s. Then it will do as well at even

slightly lower RPM.s.

What to use it for? - VAWT, Tidal Experiments

So I have perhaps the best generator ever, to connect to

any source of mechanical rotary power. Obviously a prime use for them,

for me, is to sell them. But before that, the first one should really