Turquoise Energy Ltd. News #125

covering

October

2018 (Posted November 3rd)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month

In Brief

(Project Summaries etc.)

- Solar Rewiring - HE Ray Energy - Bandmill Improvements &

More Milling - VAWT

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Putting up the Beveled Siding - Home Milk Pasteurizing -

Treating

Foot Corns - The Moral Dilemma of Uninvited Migrants - Be Prepared for

Economic Trouble - A Minor Service Sector?: the Average

Financial Salary in New York 431,000 $US - Orange and Red Peppers from

the Greenhouse & Indoors - Metric System Length

Problem: the real reason English/Imperial measures are better - Black

Flamingo Event

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Electricity is cheaper than gas - but it does go on your home power

bill (duh!)

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Handheld Bandsaw Alaska Mill") - Band

Sharpener - New Bands, Cutting & More & More Cutting -

UHMW Main Wheels & more cutting - Production Model Design?: As is!

- Sell the special components as Kits!

Electricity Generation

* How Not to Build a Vertical Axis Wind Turbine (VAWT) - Initial

Theories - Construction and Testing

* Solar Panel Rewiring

* Tidal Flow Power Unit: Cheaper, Better! - Cheap Floating Power

Vessel Hulls? - Ducted Fans and Venturies

* Short Space Ray Energy: a new design?

Electricity Storage -

Turquoise Battery

Project (Now Mn-Zn, Ni-Zn or Pb-Zn)

* Another idea for a Conductive Graphite Material?: Conductive

Polyurethane Paint

I must have been a bit burned out after the Energy

Symposium on September 29th and 30th. With no other special task to do

it took me 6 days to get out the last newsletter and then turn to some

other writing I'd been neglecting for a couple of weeks.

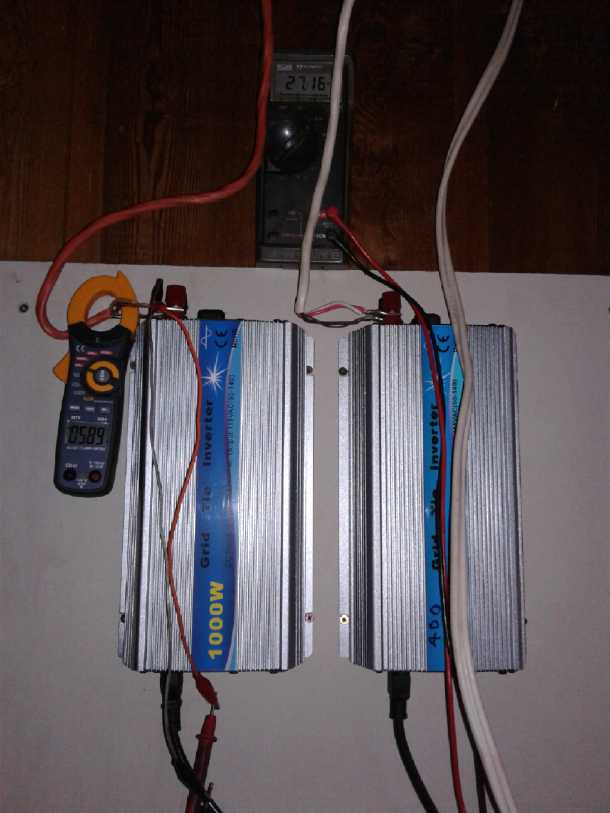

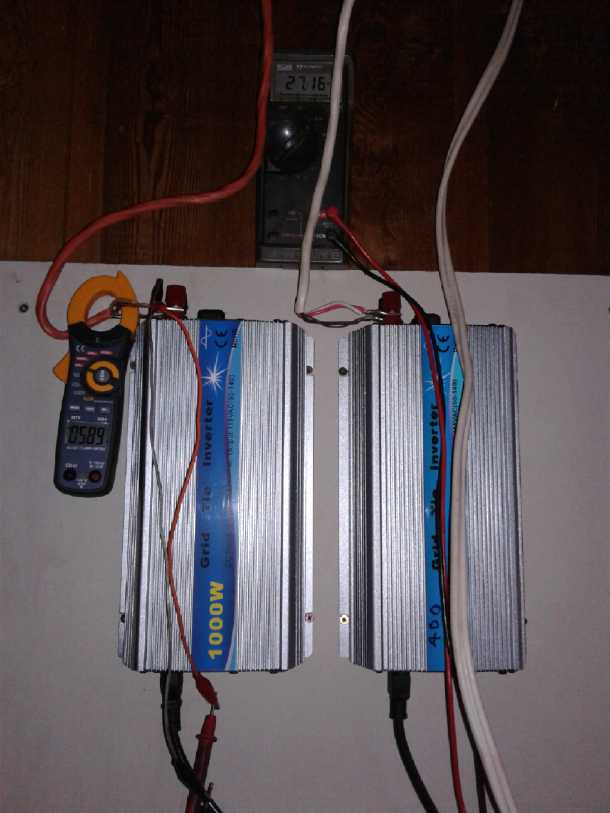

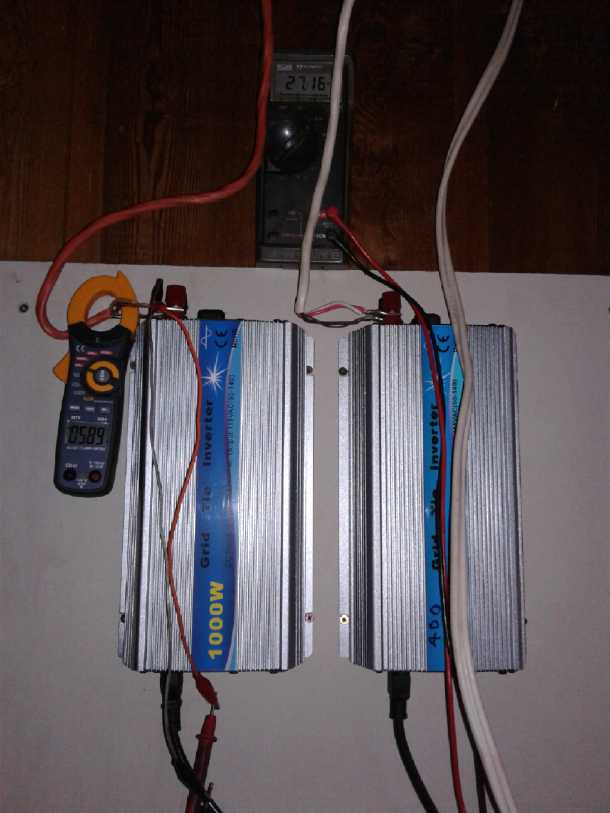

But I did

rewire the rooftop solar panels on the third and fourth. I split them

into two pairs for 500+500 watts, each with their own wire and (for

now) their own grid tie inverter. With two inverters I finally got over

400 watts output - but not much over 500, and with lengthening winter

shadows, that much only for a couple of hours in the afternoon. And

only if it was sunny. There were some power failures in high winds

toward the end of the month, and very little power output in clouds and

rain. Reliable tho they were proving to be, I turned off and unplugged

the inverters to avoid any problems or failures in potential "brownout"

or power line voltage spike conditions.

But I did

rewire the rooftop solar panels on the third and fourth. I split them

into two pairs for 500+500 watts, each with their own wire and (for

now) their own grid tie inverter. With two inverters I finally got over

400 watts output - but not much over 500, and with lengthening winter

shadows, that much only for a couple of hours in the afternoon. And

only if it was sunny. There were some power failures in high winds

toward the end of the month, and very little power output in clouds and

rain. Reliable tho they were proving to be, I turned off and unplugged

the inverters to avoid any problems or failures in potential "brownout"

or power line voltage spike conditions.

On the 6th I made use of

the beveled alder siding I cut a month previously. (Pictures, see "In

Passing".)

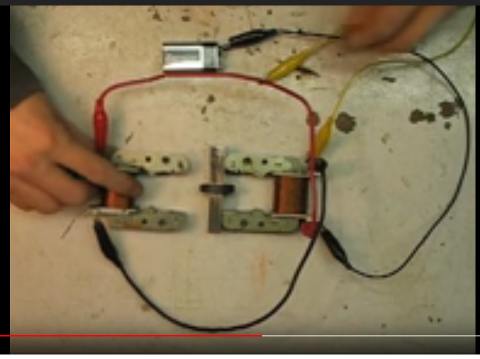

I talked with

someone about HE ray energy, which inspired me to look up some circuits

again, printed and on youtube. I

saw an interesting magnet demo, and found radiant energy devices that

seemed to use that effect.

Magnet Switching Demo

Magnet Switching Demo

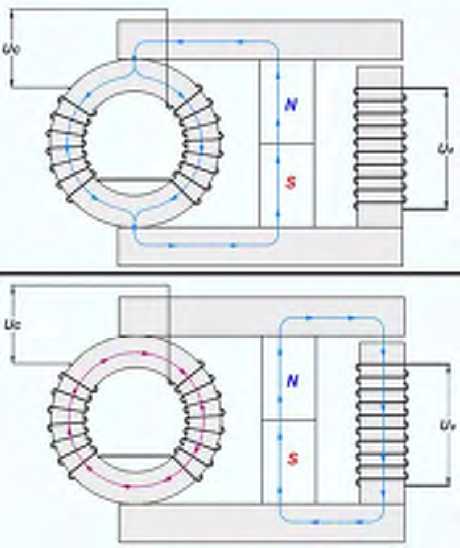

Whichever "U" of iron is brought next to the center "bar"

permanent magnet first, "sticks" to it.

The second one then won't stick, unless the first one is pulled away.

Then there was an electrical demo:

If momentarily pulsed one way, one "U" electromagnet (permanently)

"sticks" to the center

"bar magnet". If pulsed with the other polarity, the other "U" sticks

and the first one lets go.

Never do both "U" bars stick to the magnet as one might suppose they

would.

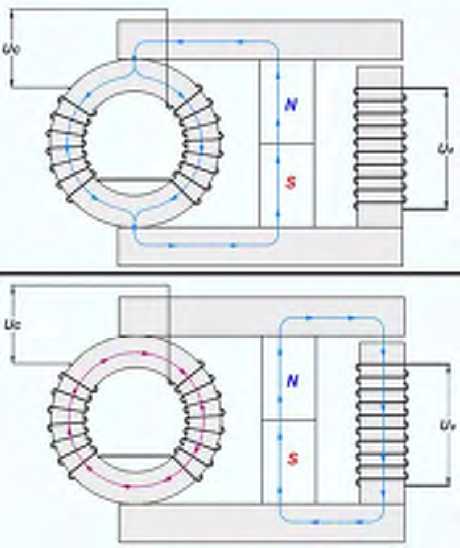

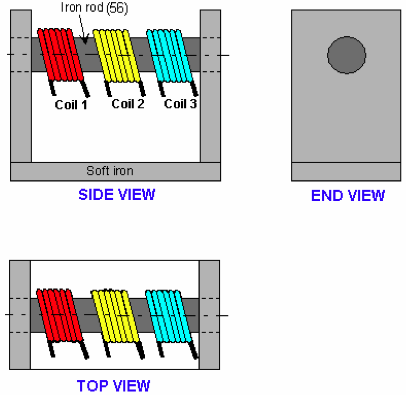

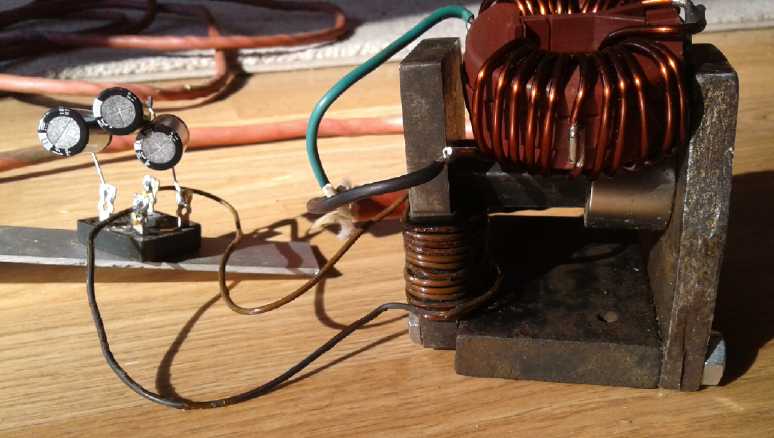

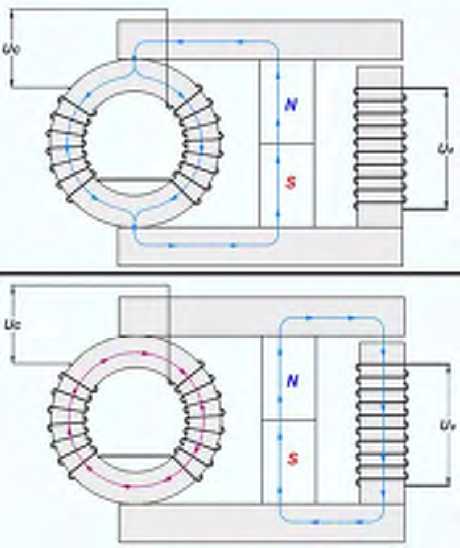

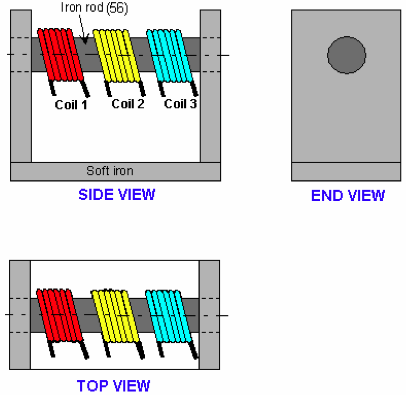

One device seemed to have some similarities to the

toroidal one I had been working on, plus it had features reminiscent of

the magnet demo. Presumably when power was applied to the left hand

coil, an electromagnetic circuit flowed around the left side of the

unit through the permanent magnet. Then when it was turned off, the

flow would "switch" to go through the right hand coil. As previously

noted it appears that HE rays discharge their energy as they pass

through a suddenly switched electromagnetic field, and into that field,

making it stronger than the original impulse. And this seemed to be a

good way to get suddenly switching fields. It would probably be a

momentary field, on and then off again because (all else being equal)

the gap would favor the field staying on the left side.

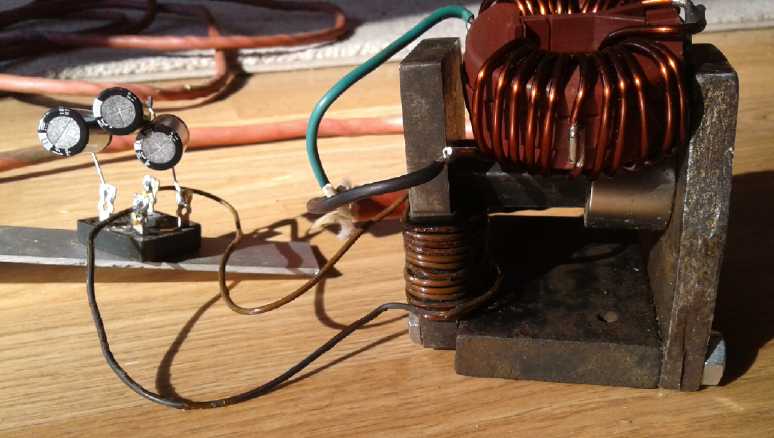

I cobbled something together, but I got no output at all.

Perhaps this type needs different pulses: much lower frequency because

of having an iron core, and pulses powerful enough to saturate that

core. I didn't get into designing a circuit to do that. I also put the

gap on the toroid side. (shouldn't that work just as well?)

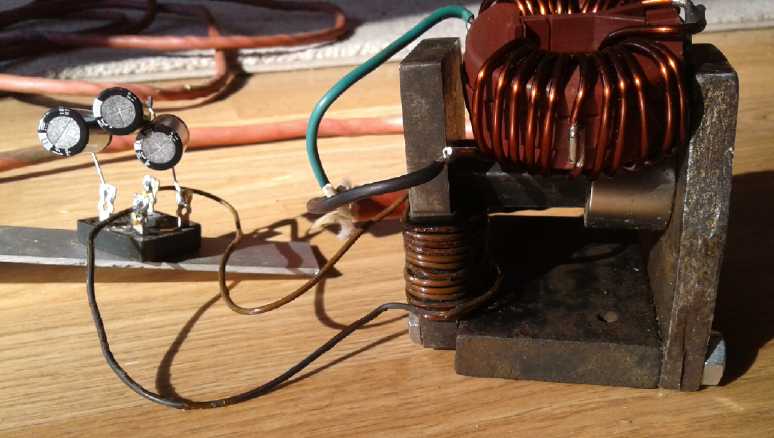

Sort of a "stood on end" version of the above

in regular steel.

Sort of a "stood on end" version of the above

in regular steel.

I wanted to

get back to milling lumber with my handheld

bandmill, but a want of sharp bands and reluctance to tackle conversion

of the band sharpener to suit my bands kept me from it until the 13th

when my order for 5 new ones arrived. Following that I started cutting

more of the spruce and finally cleared up one of the dozen areas

cluttered with spruce logs and cants. Finally! Then I tackled the

next area and finished it up. At the same time I made a

UHMW- polyethylene main wheel for the undriven wheel. It worked well

and

the slippery UHMW didn't get a buildup of sawdust on it like the

plywood wheels. Then I made another one for the drive wheel. I was

afraid it would slip, but provided there was sufficient band tension it

worked. The UHMW wheels solved the problem of sawdust buildup that

caused the band to mistrack forward, which would get the teeth trying

to cut metal in the saw and dull them. The bands started lasting much

longer without having to keep a watchful eye on the wheels and keep

scraping the sawdust layers off them.

I wanted to

get back to milling lumber with my handheld

bandmill, but a want of sharp bands and reluctance to tackle conversion

of the band sharpener to suit my bands kept me from it until the 13th

when my order for 5 new ones arrived. Following that I started cutting

more of the spruce and finally cleared up one of the dozen areas

cluttered with spruce logs and cants. Finally! Then I tackled the

next area and finished it up. At the same time I made a

UHMW- polyethylene main wheel for the undriven wheel. It worked well

and

the slippery UHMW didn't get a buildup of sawdust on it like the

plywood wheels. Then I made another one for the drive wheel. I was

afraid it would slip, but provided there was sufficient band tension it

worked. The UHMW wheels solved the problem of sawdust buildup that

caused the band to mistrack forward, which would get the teeth trying

to cut metal in the saw and dull them. The bands started lasting much

longer without having to keep a watchful eye on the wheels and keep

scraping the sawdust layers off them.

In fact, the whole mill was now performing quite well

and without having to keep adjusting anything or watch out for anything

special other than the band cooling water tube running dry. I cut a

couple of sections (10'+10') from the small end of the so far uncut big

log by month's end. (The butt end is seen 'far away' at upper right

with some metal roofing pieces on it (plastic draped down at the

roofing joins). Someday I'll get to it!)

In fact, the whole mill was now performing quite well

and without having to keep adjusting anything or watch out for anything

special other than the band cooling water tube running dry. I cut a

couple of sections (10'+10') from the small end of the so far uncut big

log by month's end. (The butt end is seen 'far away' at upper right

with some metal roofing pieces on it (plastic draped down at the

roofing joins). Someday I'll get to it!)

On the 23rd it

was raining in the morning and I decided to

try making the vertical wind turbine (VAWT) with the rotor blades made

from scrap PVC pipe so long ago. In a day I had it done, and I mounted

it on top of the Improved Piggott Alternator I made in September. But

it didn't perform well. I tried various angles of attack for the

blades, but in the howling gale, it never got turning faster than LP

phonograph speed, about 33-1/3 RPM. I looked at the one on youtube I

was trying to copy in 2013. I had the vanes inside out, so I turned

them around. It didn't help. I'm sure there are better designs.

On the 23rd it

was raining in the morning and I decided to

try making the vertical wind turbine (VAWT) with the rotor blades made

from scrap PVC pipe so long ago. In a day I had it done, and I mounted

it on top of the Improved Piggott Alternator I made in September. But

it didn't perform well. I tried various angles of attack for the

blades, but in the howling gale, it never got turning faster than LP

phonograph speed, about 33-1/3 RPM. I looked at the one on youtube I

was trying to copy in 2013. I had the vanes inside out, so I turned

them around. It didn't help. I'm sure there are better designs.

But two things made real difference to performance: (a)

putting a wind block in front of the side moving into the wind, and (b)

finding a better location. My driveway seemed to be something of a

"wind funnel" and a steady breeze blew up it from the ocean. The unit

hit 90 or 100 RPM, but it didn't make much power. To get much voltage

at that speed the generator would have to have far more turns of far

finer wire.

Definitely even with a vertical axis turbine if you don't

have a good location you've got nothing. I may buy a new cheap Chinese

anemometer with a detachable sensor for remote reading (having lost or

misplaced the old one - grr!) and stick it on the end of a long pole to

try out some different spots.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Putting up the Beveled Siding

If cutting lumber with the new handheld bandmill is

straying a little far from being a "green energy" project, using that

lumber is even farther off. But on October 6th I used the alder "one

live edge" beveled

siding I cut on September 3rd (now "well seasoned" - hah!) on the

windward gable end of the roof over my travel trailer. Why I picked the

first rainy day in a while to do outside construction work on ladders

I'm not sure. except that the internet wasn't working and I was unable

to post TE News #124 until evening.

Like I said last

month, if I'd had this planned I'd have cut the log section a little

over 12 feet long so the boards would go from one side to the middle of

the building. (25 feet, across the entire face, might be even better!)

As it was, I cut them shorter and had a seam in the middle except for

the top few where it narrowed toward the peak. I used all but one, 8 I

think it was. There were a lot of waste scraps. I cut the first one a

bit too short. So I unscrewed it, but soon had to use it anyway. If -

when - I make more, I can change it. (I put in the screws a little

lower so they aren't under the board above.)

I decided I'll cut down

a few more alder trees to make

similar siding for the rest. At least for a wall or two. Some of the

scraps might fit beside windows.

I'm wondering if there's some way to seal around the edges

besides putting up plywood or wallboard of some sort under the siding.

(Ty-Vec?)

Home Milk

Pasteurizing

The countertop

milk pasteurizer I ordered from Czech in August arrived in

September. On October 7th I got 3-1/2 quarts of raw goat milk from down

the road to try it out. It seemed to work well. I poured in the milk

and ran "hot" water in from the tap through the hose until it was

coming out the top tube. I plugged it in and pressed "heat". It heated

the water in the outer jacket up to 84°C and then maintained that

temperature. (It was adjustable, but that default seemed like a good

setting.) I stuck in the thermometer a couple of times - and used it to

stir the milk - until the milk soon hit 80°, and then I shut it

off. Then I connected the cold water tap and started running cold water

through the jacket. After a while the water coming out, very hot at

first, was down to 12° and the milk continued to cool. When it was

down to about 15° I used a funnel to pour it into a 4 liter jug.

The countertop

milk pasteurizer I ordered from Czech in August arrived in

September. On October 7th I got 3-1/2 quarts of raw goat milk from down

the road to try it out. It seemed to work well. I poured in the milk

and ran "hot" water in from the tap through the hose until it was

coming out the top tube. I plugged it in and pressed "heat". It heated

the water in the outer jacket up to 84°C and then maintained that

temperature. (It was adjustable, but that default seemed like a good

setting.) I stuck in the thermometer a couple of times - and used it to

stir the milk - until the milk soon hit 80°, and then I shut it

off. Then I connected the cold water tap and started running cold water

through the jacket. After a while the water coming out, very hot at

first, was down to 12° and the milk continued to cool. When it was

down to about 15° I used a funnel to pour it into a 4 liter jug.

Basically I did for a few liters what Island Farms Dairy

Products does for millions of liters using millions

of dollars of equipment. Maybe not quite as exactly, and probably

it cooled more slowly, but close enough. Of course, you can always just

heat

milk just

until it starts steaming in a pot on the stove, too. (A thermometer

would be the biggest plus for that.) But I'm sure the pasteurizer gives

more

consistent results, and without overheating the milk at the bottom.

Then, being susceptible to migraines from any but the

freshest milk, and using up milk pretty slowly myself (mostly with

cereal), I did what I

usually do with milk: I poured it into little plastic drink bottles of

around a cup each (17 of), screwed on the lids, and put most of it in

the freezer

for future use. Frozen, it stays good for ages.

When I want some I get out a container and put it in a tub

of hot water to thaw out, which is under 10 to 20 minutes depending

partly on whether you shake the bottle occasionally. (I don't use the

microwave because the containers warp and shrink.)

Treating Foot

Corns

As I was preparing to move from Victoria to Haida Gwaii a

couple of years ago, I noticed an irritation in the outer ball of my

right foot. I had been wearing the same sandals for some time. I

thought maybe a sliver of metal from the shop had got in there. I

looked at the sandal and saw nothing. But it seemd to persist and I

looked again. This time I saw a sliver of metal sticking up. Aha, that

must explain it! I took it out. But my left foot now seemed to be

having the same feel, like something was stabbing it. There was nothing

there. This feeling in both feet continued.

After I had moved I had stopped wearing those sandals, but

my left foot had a bump there. It was a corn. I had never had such a

thing before. And I could feel but not see something there on my right

foot too. Those sandals had on the top of the sole a square "grille"

pattern of plastic sticking up. There was a pretty thick pad on top

of that, but obviously as the sandals became more worn, it wasn't

enough. Where my feet pressed most heavily they were stressed over an

edge of one of the ridges. This appeared to be the cause. There were

two spots, a large inner corn and 1/4" away farther toward the edge of

the foot, a small outer skin

disturbance.

I looked in Wikipedia to see more about corns, but it

didn't explain what they were or the root cause(s). It didn't seem like

there was anything foreign there, like the virus(es)(?) associated with

warts. I had occasionally had ingrown hairs. The corn, I figured, was

like "ingrown skin", where confused convolutions caused by uneven

pressure made the dead skin

layer go inside instead of being on the surface. So it didn't seem

right to try "killing" something with freezing or wart remover. The

skin had to be turned the right way out again. If this hyposthesis was

right, it meant that the corn would probably spread out and become

seemingly worse before it could get better.

I adopted a three-pronged approach. I'm sure all three

parts were important. Since they were on the bottom of my feet and were

being aggravated just by walking, the first and most obvious one was

to wear thick socks and the most padded shoes I could find.

The second part was to shave off the thick, dead outer

layer of skin, the lump that stuck out. This both reduced the pressure

on the

corn when I was walking and thinned out its outer "shell" to make the

third treatment more effective. I used an ordinary disposable shaving

razor. At no time was there any pain, sign of blood or any other

indication that I had cut into living tissue or irritated anything. I'm

sure that would have been quite counterproductive.

The third part was a "folk treatment": Paprika, carried in

butter to make a "paprika cream". This I rubbed on the corns. Ideally I

think it should have been a couple of times a day if not more, but I

usually only did it once, and as they got better, less and less.

Finally as they pretty much ceased to irritate my feet, many days would

go by when I wouldn't think about them at all. This surely much delayed

their final disappearance, because they didn't improve except with the

treatments, even when they had become pretty insignificant. Finally,

after all this time, perhaps two years, I'd rate the left one as being

'gone', or at least virtually undetectable, and the right one isn't far

behind. I decided I wouldn't write about this treatment until (and

unless) I could declare it successful. They were almost done many

months ago, but I only finally got some more paprika and butter and

started going at them again and polished them off in the last few

weeks. I've been keeping it in a shallow plastic tray, which has saved

the

little cat food tin of paprika from being spilled on the floor more

than once.

My theory about them getting worse on the surface first -

as they actually started improving inside - seemed to be borne out. The

first thing that happened after I started treating was that the

heretofore invisible sore spot on my right foot now erupted into a

mirrored carbon copy of the corn on the left foot. I had hoped that

wouldn't happen, but apparently the damage was already there inside.

Then the small outer blemishes became corns too, both feet

now about the same. Then the space in between the large inner and small

outer corns filled in and they became single elongated corns over 1/4"

long. Doubtless this was along the edge of where the ridge in the

sandals had been. And there were days when they must have grown worse

because of overmuch aggravation from walking and working while on my

feet,

but in general they very gradually shrank with treatment - when they

got treatment. They probably could have stood to be treated 3 or 4

times a day, and would doubtless have been gone far sooner. But for

that one would have to interrupt one's day, take the shoes and socks

off, and go off to get the paprika paste and razor. I probably did that

occasionally when they were at their worst and most irritating. I don't

really remember now. But mostly it was once or twice a day, then less

as they improved.

The Moral

Dilemma of Uninvited Migrants

There are already more refugees on the move or living in

temporary camps than at any previous time in human history. Yet what we

have witnessed so far is only the beginnings of vast migrations even of

whole peoples. Economic conditions are becoming desperate in many

lands. War has played its part, especially in the destruction of Middle

Eastern countries and North Africa. Whites are fleeing persecution in

South Africa. The Sahel continues to dry out and the Sahara Desert to

expand, so people are fleeing that region. Europe has been bearing the

brunt of this so far, with Italy and Greece becoming overrun with

migrants mostly from Africa. ("Palermo is no longer an Italian city."

said its mayor in early 2017.) Australia has been working for some time

to quietly repulse shiploads of southeast Asian migrants. So far lesser

troubles have started to be felt in North America.

But populations in many lands without ready access to

birth control products are starting to exceed levels that can be borne,

much less supported with a good quality of life. Notwithstanding

doubtless politically motivated factors in the present "caravan" mass

marches and bus rides en route from Honduras to USA, this is probably

what we are just beginning to see in migrations to North America from

Central, and maybe soon South, America.

And soon, as sea levels rise due to global warming, and as

storms and storm surges get worse with rising sea water temperatures,

there will be more migrants moving from flooding coastal lowland

regions to

higher ground. Sea level rise has been measured to be accelerating

exponentially in recent years. Oceans may be up a meter by mid century,

with storm surges inundating as high as 50 feet. Enormous numbers of

people living at low elevations will be flooded out. In Bangladesh

where there are elevations of only ten feet even 100 miles inland, we

are likely to see one hundred million people looking for new homes.

Other

changing conditions will doubtless uproot more people. (Hmm... My house

is on a little "hilltop" about 50 feet up from the high tide mark. How

fortunate it may soon

be that I didn't get one of the low lying ones I originally wanted to

buy!)

Naturally many coming from desperate circumstances will

want to reach the various fabled lands of freedom and democracy to find

greater opportunity - or even opportunity to preserve their life. Huge

influxes of refugees of other languages, other cultures and generally

with less or even little education would impose an enormous tax and

social burden on the citizens of destination countries. Australia could

be easily overwhelmed by more incoming migrants than it has present day

citizens. With "open doors" policies European and North American

societies and culture could potentially go down the drain too. The

future quality of life in these lands will to a great extent be

determined by the quality of the peoples that are permitted to enter -

and mass economic migrants may be by and large those who weren't

"making it" in their own lands. White people, having created birth

control products, are quickly becoming a

minority everywhere. IMHO it would be better to have some lands

remaining and progressing as an inspiration and a model to the rest or

the world than for it to all become homogeneously "slower to progress"

nations. I think that would tremendously retard planetary progress

toward Social

Sustainability and the Days of Light and Life.

This book goes into details:

Answering the Moral and Ethical Confusion of Uninvited Migrants

https://sites.google.com/view/danielraphael/free-downloads

Boiled down to essentials, one can and certainly should be

sympathetic toward neighbors in difficulty, but that doesn't mean

you're obligated to invite them to come and live in your own house. Or

especially to take them in uninvited!

Be Prepared

for

Economic Trouble

Okay, I've been saying there's a collapse coming for some

years now. Some might say nothing has happened, but in some countries a

collapse has happened or is in

progress; in others, the signs of

serious trouble are there beneath the surface, such as nearly 1/2 of US

households having trouble simply making ends meet and having unpayable

mortgages, student

loan debt, credit card debt and no savings.

I'm led to repeat the warnings which are coming now from

every

direction (except perhaps the so-called "mainstream media"). A 50-70%

drop in

stocks will hurt retirement funds, which are heavily invested in such

risky assets seeking to get enough yield to remain solvent. A "perfect

storm

financial crash" (as one analyst puts it) seems inevitable as the

"Everything Bubble" starts to pop. The US

federal reserve is quickly drying up global liquidity in our "Ponzi

scheme"

financial system. The causes are obvious, and the cures are not

unknown, but it would seem there's no leadership anywhere willing to

tackle the

problem. It is unlikely to end in complete dystopia, but we are heading

into a time when no assets are

entirely safe. Real wealth doesn't disappear, but tremendous transfers

of wealth are sure to take place.

On top of that are the ever increasing climate

catastrophes. Annual crop losses are reaching levels of "severe". If

you were on the coast in the affected areas of the

Carolinas, Florida or Texas, where are you now? Is your home still

there? Were your preparations suitable and effective? Will the next

hurricane be even bigger? Or, has your area lost crops in prolonged

droughts with

occasional severe flash flooding? hailstones that are killing crops and

even

sheep? forest fires? volcanoes or earthquakes or tsunamis?

No preparations are suitable for everyone. Personal and

environmental circumstances differ widely. Repeating myself perhaps ad

nauseum but in line with many others, in general have some

real assets - loss of trust in currency can erode its value rather

suddenly. Food stores and silver bullion come

highly recommended. If you're thinking you might retreat to a safer

place if things get rough, do you know where, and do you always have

whatever you need to get there? (eg, enough gasoline.)

And anything else you're likely to need over a few rough years as

applicable. Diversify your portfolio: Paypal and other non-bank

financial institutions may be better places to deposit some currency

than

banks in a banking collapse or bank "bail ins". Have some cash so you

can still buy things if there are "bank holidays".

A Minor

Service Sector?: the Average Financial Salary in New York is

431,000

$US

The financial services sector should be a very small part

of the economy. Ideally they hold and prudently lend other peoples'

deposited money as

capital for those who wish to do worthy real things but can't afford

the whole

price up front. For that they charge a small fee; interest.

Instead, under "10% fractional reserve banking", for every

1 $

on deposit the banks can essentially lend out 9 $ that doesn't exist.

Then when

those who receive the

borrowed money put that same 9 $ into their own bank accounts, the

banks can

lend out another 81 $ based in those deposits - rehypothecation of

money. Thus it is seen they are essentially

'printing money' out of thin air, all created as loans with interest

owing.

Therefore inflation - slow robbery of savings - and more

loaning, ever expanding indebtedness, must continue, otherwise there is

"deflationary debt collapse",

since there is nothing like the amount of actual money in existence to

pay

off debt as there is debt.

If your original dollar gets paid back to the bank as

interest on all that debt, or even if you simply take your dollar out

and put it under your mattress (BTW that really is where thieves look

first, then your dresser drawer, etc - your most personal spaces), the

base enabler for all that other money vanishes. With the original

dollar gone, there's just the 90$ created as debts.

That's where lack of "liquidity" created by the US Federal

Reserve - globally since the US dollar is the world's "reserve

currency" - by un-loaning even a relatively small amount of cash to

"shrink its balance sheet" makes it hard for those with debt to make

their payments.

The "fractional reserve" process has allowed the financial

services sector to grow

far larger than the total actual economy - the 90$ from the original

1$. Society has apparently no control over this cancer; the banksters

take what they please. Here are levels of

salaries and bonuses that make history's biggest and

most famous heists and robberies look like pocket change. The average

financial services executive in New York receives the amount shown in

the title

annually, and it is a far larger average than the compensation to those

who produce real goods or provide real services that contribute to the

economy

instead of sucking it dry.

(And all this while the banks they run are essentially

broke!

"Help, bail us out!" Is this fair and equitable to all?)

Orange and Red

Peppers from the Greenhouse & Indoors

I grew some peppers (mostly purchased

seedlings) in the greenhouse; some in the ground,

I grew some peppers (mostly purchased

seedlings) in the greenhouse; some in the ground,

some in pots. I've never grown anything but "green peppers" before,

because they never

ripen before colder weather sets in. This year I brought the pots into

the house in

late September. In mid October, almost in a day it seemed, the peppers

on one plant

all turned orange. I put the other one under the "Indoor LED Garden"

lights.

Late in the month, they turned red. On the 31st I cut the rest and

dumped the pots out.

(The last green one turned red sitting on the counter in the first days

of November.)

I also got a couple more good green peppers from a plant in the

greenhouse.

Metric System

Length Problem: the real reason English Imperial measures are better

yard / meter - 1 syllable

/ 2 syllables

inch / centimeter - 1 syllable / 4 syllables

mile / kilometer - 2 syllables / 4 syllables

foot / 30 centimeters - 1 syllable / 6 syllables

cup / 250 milliliters / (quarter liter) - 1 syllable / 9 or 10

syllables

/ (4 syllables)

quart / liter - 1 syllable / 2 syllables

gallon / 4 liters - 2 syllables / 3 syllables

pound / kilogram - 1 syllable / 3 syllables

---

(Give them an inch and they'll take a centimeter?)

---

"There you go, 10 liters."

"Okay. Is that French liters or US liters?"

Black

Flamingo Event

[No One Expects the Spanish Inquisition!

- Monte Python's Flying Circus; episode, ~1975]

We know that the financial system is so complex and

fragile that we can expect some "black swan" event sometime will throw

everything for a loop globally. (Can one expect a "black swan"

event?) Maybe: a 50-70% stock market crash is presently being forecast

by many financial experts (and before month's end seemed to be well

underway).

What no one could ever have expected was a "black

flamingo" event (2013?). The black flamingo was first seen in Israel,

doubtless colluding with the ever-plotting Israeli

government. Next it was seen in Cypress, and then the banking system of

Cypress collapsed. Just three years after Cypress joined the EU, it

apparently went from stability into financial crisis. Under the demands

of the European Central Bank, the Cypress banks "bailed

in" to bail themselves out. They took a great share of peoples' life

savings on deposit and then prevented them from withdrawing their

remaining money, all so trustingly deposited. That worked so well that

every 'western' nation now has similar legislation allowing potential

confiscation of funds on deposit at major banks. (How that fits with

"deposit insurance" I don't know.)

It isn't clear from its little known public activity

whether the

black flamingo played a role in the banking plot, or whether perhaps it

was the one who warned all the Russian account holders (only the

Russians) a day or more in advance to withdraw their money from their

Cypress bank

accounts while they still could. The flamingo mostly stayed out in the

water trying to mingle with the other flamingos (doubtless to avoid

reporters with questions). Some might insist it was all just

coincidence. (Hey, I'm not making all this up. Just check out "black

flamingo" on Youtube. [The other facts and events are of record

too.])

The Scottish Miser's Guide to Economy

*

You can wear your socks and underwear twice as long between washings if

you

turn them inside out after the first week.

(Well it's probably pointless to try and think up any more after

that one!)

---

More and more frugality (Victoria BC): "End of the Roll" discount

carpets

couldn't afford to keep their whole store open so they shrank it and

let one end of the building go. It became the bargain store "Excess

Cargo" where one could buy small appliances, some great "off brand"

electronics and various things at amazing prices. This store was very

popular. I bought many things there, but the whole chain went under.

One of the employees turned the store into "McFrugals" with a somewhat

different line of even lower cost products. In spite of its success (or

at least, payment of the rent) the owner of the building decided having

such a "low class" paying tenant wasn't good enough and he evicted them

to renovate so

he could charge more money in this backwater area. I've moved, but I

wouldn't be surprised if it's now yet another vacant storefront with

"for sale or rent" signs out front, of which there were no shortage

when I left.

The "retail apocalypse" proceedeth apace!

---

I can't quite place it, but there must be something ironic about this

road sign:

"No Overnight Camping on Skidegate Indian Reserve"

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Electric

Transport

Electric Charges: It's the EV!

My power bill for July and August was about 150 $. That

was 75 $/month. It seemed rather high for summer. I'd have expected

more like 35 to 50 per month. Then I remembered the extra 25-40 $/month

was

for charging the Nissan Leaf after driving it. If that had been

gasoline it would have been more like (just guessing) 150-250 $. Really

it wouldn't have been quite so much because I would have driven less. I

would have skipped many trips which weren't absolutely necessary, like

weekly lunch in Port Clements, and I'd have put off trips to town

until the need became pressing in order to combine more things into

fewer trips. With electricity the fuel bill is nothing much to worry

about - about 2 ¢/Km - even if I can't pin down what the exact

total is. (I suppose I could write down odometer readings.)

Almost everywhere I drive is a 50 Km or more round trip.

If I was still living in Victoria where everything is close by, the

addition to the bill would have been almost insignificant.

Other "Green"

Electric Equipment Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

After hitting two nails in

early September there was no more cutting until I had at least one

sharp band again.

Automatic Band Sharpener

This arrived near the end of September, but it was made

for wider bands with around 1" tooth spacing. In order to make it work

for 3/4" bands with 1/3" tooth spacing, I need to make a couple of

modifications. The first one was simple enough: I found some washers

the right size to put on the two bolts that held the band at the right

height.

Next, an offset cam moved the band too far and too fast

for the movement up and down of the grinding wheel, and also at the

wrong time. It would skip three teeth instead of one and the wheel

descended while it was moving instead of when it was stopped. I had to

drill a hole in a new rotation and closer the the center of a rotating

plate for the new offset cam that moved the band to the next tooth

while the wheel sharpened as it went. This mod made me nervous. I could

see about where it should go, but there wasn't much room, and if I was

off, the right place would overlap the one I drilled.

New Bands, Cutting & More & More Cutting

My order of 5 new bands arrived on October 13th. (.025" x

3/4" x 93", 3 TPI "meat cutting" stainless steel bands.) By the time I

was ready it was getting late. Nevertheless I put a new band on and

went out to cut. In about 20 seconds I was 4 feet though cutting a 2" x

6". It looked like I'd be done the 10 foot length in less than a

minute, but things started going funny about 2 feet from the far end.

On close inspection in the dimming light it appeared I had already cut

into this piece from the other end (over a month ago), and the two cuts

were meeting. So the board was nearly cut all along and was lying on

the band and jamming it. I put in a couple of wedges and finished

whatever bit was still holding the pieces together. That's probably

what I got for not waiting until morning when it was light out. It was

getting quite dark by the time I had everything put away. Amazingly the

cuts met so flawlessly I couldn't tell exactly where. The board's face

was nice and straight except near that end.

The next day I cut six 8' - 2" x 4"s and another 2" x 6".

The 2" x 6" was notably slower and I cut through some bark on it. I

suspect that dulled the band - maybe there was some sand in the bark?

because on the 15th I tried to cut another one and it didn't go well -

1/3 the cutting speed of the 2" x 4"s the day before and the band was

getting hot. And as it heated it cut even slower. After just 15 inches

I

decided to stop and change bands. If I didn't overheat this one I could

sharpen it later. Or maybe it just needs a new (or sharpened) band

every session, every few boards? After all, chainsaw mills do.

In the afternoon I changed the band. The old band appeared

to be gummed up with sawdust stuck to spruce pitch, which I also had to

scrape a layer of off the wheels before putting the new band on. Could

the old band be just gummed up? I wasn't putting it back on to find

out: I wanted to cut wood! The cutting went well and (at long last!) I

finally finished up the wood in the first area - out of maybe 10 or a

dozen stashes of spruce wood to be cut.

I kept most everything that was long and thin, as long as

it had a flat side or two. Usually I'd have considered much of that to

be firewood, but I may get some animals for the "ranch",

and I may want to fence in an area, maybe for sheep or goats. Anything

reasonably solid should make good, cheap animal fence boards.

(Let's see... that sounds like it could take many years to

get to the end of. But then, the cants sat all fall and I only started

the band mill construction project in January, and then I only got it

working fairly nicely by the end of August. A year! It needs further

improvements, but it's working and that lengthy experimental

development phase won't be repeated. And then I diverted and cut up an

alder tree - but that was worth it just to see how much easier alder

was to cut. Spruce I now hear is about the toughest wood to mill. And

having tried alder, I plan to cut some more of that attractive beveled

siding for my building. And if I cut enough alder trees down, the old

garden plot may just get enough sun to use again.)

I also came up with an easier way to push the saw, which

took a fair amount of pressure: with my knees! Not only was it easier

to get the pressure, but it was easier to get an even push to move the

saw smoothly along the cut. The one thing to be sure of as the piece

being cut from gets shorter is that the band isn't near one's feet. I

had my shoe touch the band a couple of times just when the cut was

finished and the saw was stopped, and I was pulling the saw away to set

it down. Perhaps the rear slide should be farther from the back of the

saw for the next model? Then the operator's legs would hit the slide

instead of

the body of the saw and the feet would be farther back.

On the 16th I whittled down another small collection of

logs. I sliced an long edge off with the chainsaw mini mill, leaving a

6" wide cant. It seemed to go better. I cut five 13' x 2" x 6"es and

another five irregular pieces one might call 4" x 4"s for fence posts

or whatever. These pieces had been lying in tall grass and not under a

piece of sheet metal roofing and the wood didn't seem very 'fresh' -

perhaps spalted or even starting to rot a bit. It even had a few boring

bug holes. Perhaps that contributed to ease of cutting. I spent more

time setting up, and carrying tools and lumber around, than I did the

cutting, which went smoothly. At one point the cooling water sponge

fell out. I found it jammed in the right guide wheel and put it back in

its tube. Only at one point did I notice that the band was tracking

forward into the band protector spindle as I started a cut. I stopped

and scraped gummed up sawdust off the rims of the plywood wheels and

everything was good again until the end of the cutting, when it needed

scraping off again. It would seem this is the main problem with the

band tracking forward and eating out the nylon protector until it hits

the bolt and dulls itself.

Seeing the deterioration of the unprotected spruce wood in

the pieces I had cut, I took some spare pieces of sheet roofing and

covered at least much of the big felled spruce tree still lying there

waiting to be cut. It looks like it'll sit out a second winter - ouch.

(and there are three more small uncovered logs to deal with ASAP.) But

as I cut some other wood and put the lumber under the roof by the

trailer, I should be able to liberate more metal roofing pieces to

cover more of the big one.

The next

morning I went after the last odd shaped lump of

wood. I trimmed some knots, put the guide board on top, and cut a

slice. Then it was flat on top and I decided to cut a 3.5" slab (not

really seeing anything "normal" in the shape - other than firewood). I

had to trim it some at the sides, and much of the cut was 11" with some

spots of 12" and even one of 13", the widest I could cut without making

longer skids. It was slow going, and I think an Alaska mill would have

been as fast or faster. But it cut it!

The next

morning I went after the last odd shaped lump of

wood. I trimmed some knots, put the guide board on top, and cut a

slice. Then it was flat on top and I decided to cut a 3.5" slab (not

really seeing anything "normal" in the shape - other than firewood). I

had to trim it some at the sides, and much of the cut was 11" with some

spots of 12" and even one of 13", the widest I could cut without making

longer skids. It was slow going, and I think an Alaska mill would have

been as fast or faster. But it cut it!

Then, again seeing nothing

better,

I cut another 3.5" slab similar to the first. (Ah, just the two ramps I

could really have used the previous day!)

Then, again seeing nothing

better,

I cut another 3.5" slab similar to the first. (Ah, just the two ramps I

could really have used the previous day!)

Just as I was finishing the

last cut it started to rain. I

put away the tools and the slabs. I thought that except for some

cleanup, I had now finished up two of the areas of logs. But later I

wandered over from another direction, "the wild side", and found

another cant buried in the tall grass, almost too big to flip with the

peevee, 20 feet away from the rest. It was certainly good for some more

lumber.

At least I had done two sessions of cutting with the same

band. That was more promising than usual! Was it getting harder to push

the saw? Probably.

UHMW-Polyethylene Main Wheels

With the

sawdust, gummed up with spruce pitch, sticking to

the main wheels I thought perhaps I'd try out UHMW wheels after all.

Not much of anything sticks to UHMW. I was afraid the band would slip

on the driving wheel, but it's a large surface area and it'd be worth

trying. And the undriven wheel would be fine regardless. (Presently if

the band is jammed the V-belt (a "link belt") from the motor slips.

That's probably about the best thing to have happen.)

With the

sawdust, gummed up with spruce pitch, sticking to

the main wheels I thought perhaps I'd try out UHMW wheels after all.

Not much of anything sticks to UHMW. I was afraid the band would slip

on the driving wheel, but it's a large surface area and it'd be worth

trying. And the undriven wheel would be fine regardless. (Presently if

the band is jammed the V-belt (a "link belt") from the motor slips.

That's probably about the best thing to have happen.)

I looked in my collection and found two round pieces of

UHMW about 9.9" in diameter. I could hardly believe my luck - how could

I ask for better? But instead of

being 1.5" thick they were only .85" - barely wider than the .75"

bands. It wouldn't take much mistracking for the band to come off those

wheels. But then, just possibly if it mistracked forward, it might fall

off just before the teeth hit metal and got dulled. That could be a

nuisance, but it would save bands! Being denser, the UHMW wheels were

almost identical in weight to the 1.5" wide plywood wheels.

Another thing about thinner wheels: In videos on youtube,

bandsaw experts were saying that the teeth should track just ahead of

the center of the "barrel" bulge on the wheels. What, then, was most of

the front half of the wheel for if the whole band was always to be

behind it? It just made sense that it wasn't needed. The wheel could

have its greatest bulge near the front, and most of the band should be

behind that. That should be as good as a wider wheel with the center of

the bulge in the middle.

I decided to

try one as the undriven wheel and see how

that went. (18th) I couldn't find anyone with a lathe and a chuck that

could hold a 9.9" piece from the outside. So I drilled four holes and

mounted it on a plate on my own lathe. That wasn't very good as I

couldn't quite get it centered. (How is it I keep ending up needing to

turn 10 inch rotors of one sort or another? At least it has a "gap"

that will actually hold 10" diameter, if only barely and usually with

contortions to get it mounted.) I had to turn it down another 1/8" or

more after I cut the center hole to get the outside concentric with the

center. It's not much, but it meant I had to put in washers under the

bearing holders to get the bottom of the wheel even with the band guide

wheels. Or at least it should have. When it was assembled I eyed

it up and decided it looked pretty close. (Was the previous wheel

actually a bit too big?)

I decided to

try one as the undriven wheel and see how

that went. (18th) I couldn't find anyone with a lathe and a chuck that

could hold a 9.9" piece from the outside. So I drilled four holes and

mounted it on a plate on my own lathe. That wasn't very good as I

couldn't quite get it centered. (How is it I keep ending up needing to

turn 10 inch rotors of one sort or another? At least it has a "gap"

that will actually hold 10" diameter, if only barely and usually with

contortions to get it mounted.) I had to turn it down another 1/8" or

more after I cut the center hole to get the outside concentric with the

center. It's not much, but it meant I had to put in washers under the

bearing holders to get the bottom of the wheel even with the band guide

wheels. Or at least it should have. When it was assembled I eyed

it up and decided it looked pretty close. (Was the previous wheel

actually a bit too big?)

I took the saw out to the big cant. I only cut a couple of

inches when the band came off. My first thought was that the narrow,

slippery wheel was just going to mistrack and be a lot of trouble. But

on closer look, it was still on that wheel! It had come off the plywood

wheel, and there was an unrelated cause. When I welded up the small

"railway wheel" band guide wheels, I had used one thick washer, and

being unable to find another, one thin washer. The thin one wasn't very

strong, and had worn some. Now it had partly ripped away from the

wheel, allowing the band to come off the back of the wheel. (I was in

fact surprised that the band hadn't snapped.)

So I had to

clean up the left guide wheel on the lathe and

weld on a new washer, then clean up the inside face again and put the

bearings back in. (19th, PM) The washer and hence the outside rim was a

little smaller, but thicker - now pretty similar to the other one. I

took the mill out and cut a couple of

slices off the top edge of the waiting cant. It cut well. It showed

little sign of mistracking and there was no indication the band might

come off. At one point it was tracking forward a little. Scraping the

sawdust accumulation off the plywood wheel fixed it.

So I had to

clean up the left guide wheel on the lathe and

weld on a new washer, then clean up the inside face again and put the

bearings back in. (19th, PM) The washer and hence the outside rim was a

little smaller, but thicker - now pretty similar to the other one. I

took the mill out and cut a couple of

slices off the top edge of the waiting cant. It cut well. It showed

little sign of mistracking and there was no indication the band might

come off. At one point it was tracking forward a little. Scraping the

sawdust accumulation off the plywood wheel fixed it.

The two cuts were a little wavy, which I realized was

partly because of big, hard knots, but more because the saw was still

set for 13" wide cuts and I was only cutting 6-8". So there was a lot

of band between the guides and the wood.

I cut the rest of the cant to 6" wide with the chainsaw

mini-mill, reset the saw for 6" wide cuts, and cut two more 2" x 6"es.

They too cut well, and I was still using the same second band from the

new box of five - for much longer than most, perhaps because I kept

scraping the sawdust off the wheels to keep them from tracking the band

forward into the nylon protector spindle, and into hard metal once it

had cut through that. And perhaps because there was no sawdust buildup

on the band. One reason for this might be that the wood was drier.

Finally it was plainly getting dull, but it had cut a lot of square

feet of spruce.

But there was no buildup of sawdust

on the UHMW wheel, while the plywood wheel had accumulated yet another

layer since the last scraping. And so another likely reason the band

had no buildup of glued-on sawdust was because one of the wheels was

helping to shed it. So it was definitely a keeper!

It seemed that if both wheels were UHMW the whole headache

of accumulation of pitch and sawdust, even on the band, would be

eliminated. That would definitely make the mill easier to use. It

seemed to be the wheel material of choice. I would definitely try the

other wheel too. Only if the drive wheel slipped would I not use it for

both.

Instant Firewood Shed

On the 21st, having disposed of the lumber, I cut and

cleaned up firewood. I was throwing it in a trailer box... but then

what? I told my neighbor I had nowhere to stack it, the wood shed being

full. He said he had seen someone simply stack firewood against a tree

making a ramp with the high end against the trunk. He said he thought

that was

odd, but the man pointed out that it doesn't usually get wet right

under a tree. The water mostly falls around the outside of the

branches. That sounded good to me and I stacked it against a spruce

tree behind the house. A fierce gale blew the whole pile over (many

short, irregular pieces) and I had to restack it - this time not as

high, in two ramps.

Second UHMW Wheel and (of course) More Cutting

The mill with its new "Racing Slicks" wheels

The mill with its new "Racing Slicks" wheels

On the 22nd I made the

second UHMW wheel and installed it,

along with a new band - the third one of the five. I tackled a 15 inch

diameter by 9 foot long knotty spruce log. On my first attempt what I

feared happened: an inch into the wood the driving wheel started

slipping, and then the band came off the wheels. But I thought it

probably didn't have enough tension and I tried again with more. This

time it worked well.

I cut off a bark slab and then another slab. The second

one was cuts of 9 or 10 to almost 12 inches wide and it went rather

slowly even with a new band. I was pressing the limits the farthest yet

do this diameter of log, but it cut it.

There was no sawdust collecting on the wheels (Yay!), but

the inside of the band got quite a layer, and notwithstanding the wide

cut, was probably part of the reason for the slow cutting. (I think

cutting the bark brings lots, along with goo to stick it on.) The

outside of the band was clear - nothing presses the sawdust against it.

I scraped it off with a chisel (a stiff brush did nothing) and then

squirted on some "Armorall" protective coating to make it slipperier -

again suggested by my neighbor. That seemed to help.

Then I turned it 90° and cut a second face. I hit it

just right, with just the tiniest bits of bark showing at the finished

corner.

What next? Hmm... tomorrow! I worked on the wind turbine

most of that day (23rd), but I did cut a couple of slabs having one

straight edge. The cuts got thicker and on the second one I was cutting

8" wide for half the cut and 10.5" wide for the rest. It was slow

going, but it went smoothly without incident. Arguably I should have

cut the other side of the log square and cut 2"x8"s with straight edges

- and with less width to cut. Nonetheless I finished it up with

bark-edge boards on the 25th: one more 9-10" wide board, and then four

6-7" boards by turning it the other way up after getting 3/5 of the way

through. Doubtless the cutting was getting a little slower. I figure

1.5 to 2 times as much power would be helpful once the bands become

less than "super" sharp with use - especially for wide cuts. But then

it wouldn't plug into a regular wall socket... and a cheap

mass-produced skillsaw wouldn't work for a motor. You'd be into a

custom motor of some sort for far more money. (One of my Electric Caik

motors still comes to mind for my own saw, but I don't think I want to

get into manufacturing them.) I made considerable use of the "zig-zag"

technique of moving one end of the saw forward at a time. And wedges

behind in the cut to keep it open seemed vital. Otherwise the cuts

often seemed to close in and finally jam the band. or at least make it

hard going.

Then I cut another 10 foot piece off the small end of the

big log and milled a flat edge with the big chainsaw in the

"mini-mill". (My potential customer wanted many 10 foot 2"x6"es.) It

seemed awfully slow going compared to the bandmill, and I had to remind

myself I was cutting 16(?) inches across instead of 6 to 10 inches. It

was also unpleasant breathing hot exhaust that was also almost burning

my hand. And it was hard pushing and the chain was exposed if my hand

should slip. I didn't much care for the arrangement. Maybe I'll at

least make an "Alaska" type mill from pieces of wood, as I've seen on

Youtube. (or borrow one again, as I did last year.)

I set up my video recorder on a tripod and took

footage to make a new video to

I set up my video recorder on a tripod and took

footage to make a new video to

put up on youtube. When it's uploaded it'll be called "Carmichael Mill

Update".

On the 28th a neighbor came over to see the mill in

action. In the course of things he said I should take the bark off the

spruce. When these trees were growing there weren't many on the other

side of the highway, and in high winds beach sand would blow across the

road and embed itself in the bark, and even get into the wood. That

would have a bearing on why my bands dulled rather quickly. I got out a

flat end shovel that I bought and sharpened the end of about 41 years

ago for scraping bark off logs (believe it or not), and used it. With

the trees having been

down for a year and a half, it came off easily in big chunks. We cut

into a big cant from the main pile, but the band seemed to be getting

dull - the cuts were getting wavy. (OTOH the waves were at big knots.)

The next day I changed the band and

finished it off, a total one might describe as seven 12 foot 2"x6"es.

With the new UHMW wheels there has been no notable

mistracking or other band or alignment problems. It works fine with the

rigid band tension adjustments that didn't seem to be good enough

before. In fact, it's cutting great! Most of my stopping is to put

wedges into the cut behind the saw because it's closing up and jamming

the blade.

Production Model Design?: Keep as is!

I had been thinking that for a production model I should

make it easier to change bands by having the axles go only one

direction to leave a space in the other for the band to slip through,

like on most shop bandsaws. But when I thought to try actually taking

the bearings off one side instead of unscrewing the covers in order to

change the band, I realized the band would also hit the assemblies that

held the band guides and the depth set glides. Removing those

would be more difficult than removing cover screws, and worse, it would

mean readjusting their positions on reassembly. Altering them would

involve the whole design of the saw - and make it weaker. So I decided

to

keep it as it was, and maybe reduce the number of cover screws a bit.

This doesn't mean I don't have a page long list of small

improvements to be made, a "deficiency list" in the sense that I've

thought of ways to improve various details and would make various

pieces somewhat differently next time.

One notable change I would make: The bearings for the main

wheels center about 1.5" below the "backbone" bars. I hadn't allowed

for the thickness of a guide board on top of the work, which may 2" or

more thick. This, plus the sideways skids adding another 1/2" of

material, reduces the available board cutting thickness from the

intended 4.5" to about 2" or even less. I would prefer to position them

about 2.5 or 3.0" below to allow thicker cuts. That also makes the top

covers over the backbone an inch (or 1.5") shorter. The top of the body

would still be 10" plus clearance above the bottoms of the main 10"

wheels.

I thought that the best way to do this would be to machine

some special bearing mounting pieces with more height. But it occurs to

me that it might just be simpler to use the store-bought "pillow block

bearings" (or "steady bearings", which I've just discovered are

virtually the same thing) and have 1" or thicker blocks of UHMW (or ?)

between them and the

"backbone" rails.

I've also found there are situations where, to get a

straight edge, it would be nice to cut down the width of a board, eg

6", rather than just the thickness. I think that would need some

redesign. Instead I have to use a chainsaw on the mini-mill.

Making most of these changes would be best done

on a

new saw. This one is cutting great, and I have a lot of cutting to do!

(And a

gear (plastic!) has broken on my milling machine. I hope I can get a

new one! Until then I won't be doing much machining.)

I ran across some lighter weight bearings for the main

wheels: "steady bearings" are like pillow block bearings but are made

of pressed metal instead of cast. They were similar high quality needle

bearings. They should take a bit of weight off the mill! Too bad I

found them right after getting an order at Princess Auto, but I ran

across a 1" size when I ordered and I got one. When I saw it I knew it

was what I wanted - four of 3/4" size for a mill. I couldn't find them

under "pillow block" bearings,

but I eventually dug them out with 3 or 4 searches. What I was missing

was the very different name, "steady bearing" instead of "pillow block

bearing". That's just confusing! So much of the difficulty in getting

the best parts to make things is in knowing where to look and its usual

unusual name.

They were on "clearance", presumably discontinued. I

wonder if that's because, like me, no one was finding them even when

they would have been the best choice? The store's web site isn't very

well organized.

The Kit!

I took the saw to show someone who uses many bandsaws and

specially made tools in his business on the 26th. He was impressed by

the saw but he didn't know of any better blades I might use with it

unless I made it bigger - bigger wheels and more power. If I made it

bigger, It would be too heavy to be handheld. But he had the great idea

that rather than making whole bandmills, I should just make kits of the

essential custom parts. Sell those components for less and let the

customer get the stock items and the skillsaw themselves. He thought

there'd be a great market for that, for people who wouldn't buy a

sawmill just because they occasionally had a tree to cut, but who would

love to mill it if they could. That sounded like about the market

I was aiming for when I designed and made it. But I hadn't considered

the kit idea.

A kit shifts main liability for injury from the

manufacturer to the person who put the kit together. If someone had an

accident with a new type of saw, in spite of doing my best to make it

safe I could theoretically end up penniless and homeless - or if I did

it under the auspices of Turquoise Energy Ltd, at least all my assets

(tools, equipment) could be seized. If I took out insurance it would

doubtless kill any revenue generated from even several saws. (Here's

another place where the already rich have it over someone trying to get

a new idea going. They would simply have it mass-produced in an

existing factory and would be able to afford any occasional lawsuits as

incidental expenses.) With a kit, that liability is largely shifted to

the kit builder, especially if I only supplied the plans and some of

the parts; the critical ones. And having put it together the user will

know and understand the tool better.

Electricity

Generation

How Not to Build a Vertical Axis Wind Turbine ("VAWT")

Whenever I did think about this project I had been all

along trying

to think how best to mount the 8 PVC vanes I had done long ago for a

VAWT. (TE News #68, Sept 2013) I wanted to be able to adjust the angle

of attack, because I didn't know what angle would work best. But their

curved shape didn't lend itself to mounting flexibility.

Having now made the Piggott alternator, and not wanting

the whole month to be almost entirely about the bandsaw mill, I had

been thinking about it again.

It would be simple to mount the generator on the roof with its axle

sticking up. The 22nd was blowing a howling gale (but no rain!) and I

wished that I

had already made it to see how it would do in a strong wind. As I

thought about this, I thought that I could screw

them to triangular pieces of wood or plywood, which could then be

screwed to a

central plate at a range of angles to see what worked best.

Another idea was that they might pivot dynamically. They

would be in

"least resistance" position as they came forward. Then when they passed

the center, the wind would push them around to "most thrust"

position. Around the back they would (suddenly?) return to "least

resistance". Another feature of this would be that as wind increased

and the unit spun too fast, the centrifugal force could overcome the

wind force and prevent them from retracting to "most thrust" position,

thus regulating the maximum speed. (Or vise versa, that centrifugal

force would keep them in "most thrust" position on the wrong side of

the turn; either way slowing it down.)

This idea required more sophistication than I was ready to

try out, and I haven't followed the blades around the circle to how see

exactly how it would work (I simply presume it could), but mounting the

blades on the separate pieces would be a

way to enable an upgrade later.

Initial Theories

The area of wind being captured would be: .56 m * .86 m =

.48 sq.m. Shall we call it .5? The total energy of a 14.4 KmPH wind

(see TE News #82 for more about wind power) would be:

W = .5 M V^3

where W is watts, M is the mass of a cubic meter of air in kilograms,

and V is the speed of the air in meters per second.

= .5 * 1.2 Kg/m^3 * (4 m/sec)^3

= 38.4 W/sq.m

Since it's 1/2 a square meter, that's 19.2 watts.

A Darius rotor is at best around 30% efficient. We'll call this one 26%

just for argument's sake. It works out to 5 watts. Of course, that's

the "cut in" wind speed. If the wind is twice that speed it would be 40

watts, and for triple, 125 watts.

Oh well, it's really just a demo. If I'm lucky the 14.4

KmPH wind will overcome the generator's bearing friction and it'll

turn. If I'm even luckier the vanes won't fold up or rip off in a high

wind.

The next day (24th) looked like a 135 watt day. The chart

in TE News #82 says a Savonius rotor should turn at about the speed of

the wind. How fast would that be if the wind was 12 meters per second?

* Circumference = π*D = π * .86 = 2.7 m.

* 12 m/sec / 2.7 m/Rot = 4.44 Rot/sec

*

4.44 Rot/sec *

60 sec/min

= 266 Rot/min

We know from the Piggott generator data from last month's

issue that the open circuit voltage output at that speed will be about

7.7 volts between any two phases. Multiply by square root of 3, or 2 *

sine 60° (= same number: 1.7320508), is 13.3 volts for the three

phases combined, which (IIRC) is also the DC voltage if they're all

rectified. Not very high! Especially if two diodes lose 1.3 volts from

it. Then just 12 volts DC. That should power some headlights for a

demo, but it wouldn't be charging even 12 volt batteries. For that it

should work okay in a howling gale!

Oh well... repeating myself, it's really just a demo!

Construction and Testing

On the 23rd it was raining in the morning and I decided

(instead of milling logs outdoors) to

try making the vertical wind turbine (VAWT) with the rotor blades made

from scrap PVC pipe so long ago. I had intended to cut a big plywood

center piece to attach

to the generator axle. I went out to the shop and there were the now

scrap

1.5" thick by 10" plywood bandsaw wheels with ready-made centers, just

replaced by the UHMW ones. Nice and fat! One of those would be just big

enough to screw eight 2"x4" "spokes" to if I cut the inner ends pie

shaped. These could hold the eight vanes.

The original axle fitting for the wheels was a 3/4" inch

"H" hub. The generator had a 1 inch shaft. I found a 1 inch "H" hub and

put it on one of the wheels. There was a whole job reduced to a few

minutes!

Rather than triangular pieces, I just cut eight 7"

rectangles

of 2"x6". On a corner of each one I placed a vane and drew lines where

to cut the curves with the shop bandsaw. Since the vanes were like

snowflakes (no two quite alike) I numbered them and the wood pieces

they matched.

Then I cut the "spokes". Without any particular plan I cut

them 13.75" long. Instead of cutting a 22.5° angle on each side I

made one 45° cut - easier to get the angle right. Since they didn't

come right to the center the overall diameter was 31". With the vanes

on the ends, it would be about 34".

In a day I had

it done, and I mounted it on top of the Improved

Piggott Alternator I made in September. But it didn't perform well. I

tried various angles of attack for the blades, but in the howling gale,

it never got turning faster than LP phonograph speed (33-1/3 RPM). That

was with the blades at about a 90° angle from what I had intended.

In a day I had

it done, and I mounted it on top of the Improved

Piggott Alternator I made in September. But it didn't perform well. I

tried various angles of attack for the blades, but in the howling gale,

it never got turning faster than LP phonograph speed (33-1/3 RPM). That

was with the blades at about a 90° angle from what I had intended.

At that speed it didn't put out enough voltage to consider

connecting any loads. (Of course, it did seem there was more wind in

the treetops than down at the ground. Predictions were for 105 KmPH

gusts, but I don't know what they really were, much less what they were

on my porch. I had a cheap handheld anemometer... somewhere. haven't

seen it in a year or more. Probably in some cluttered crevasse

somewhere.)

This blade angle, flat face out, worked better

- at least it turned!

This blade angle, flat face out, worked better

- at least it turned!

The apparent tilt of the blades is a camera illusion: they are rotating

counter-clockwise and as the

cell phone (camera) scans from top to bottom, they are turning a little

farther and farther.

About the only thing that seemed positive was that the

blades were easily detached. On the 26th I went back to youtube. I

found the VAWT I was trying to copy when I formed the blades in 2013. I

had them inside out - the concave face was supposed to go outside, not

inside. I checked over what would strike what in rotation and it was

fine: the blades would clear the corners of the generator and so it

would be simple to turn them around 180 degrees. So I

did that the next day. Again there was a good wind, but again results

were poor - perhaps worse. (Someone on youtube with similar blades who

also tried different angles thought it was a little better this way

out.) I taped over some of the holes in the plastic, without noticeable

results. But I wasn't convinced the location was

good.

Blades Reversed (screwed right onto to the

"spokes")

Blades Reversed (screwed right onto to the

"spokes")

I wandered around the yard and found there was a steadier

breeze

coming up the driveway. I moved it down there and got 30-40 RPM. Then I

put up a "wind shield" in front of the side that was moving forward,

toward the wind. That seemed to double the speed to 60-80 RPM.

Sometimes it would read 90 or 100. I also tried putting the wind shield

behind the unit, on the theory that the wind would have to stop either

way, but it was much less effective there. Some have put angled

deflectors around the outside of the spinning part and achieved similar

results. Those are probably better: my wind block would have to be

moved for different wind directions.

I should also note that the square 2"x4" spokes can't be

helping achieve good speeds - they're not aerodynamic at all!

The driveway seemed to be a "wind funnel"

The driveway seemed to be a "wind funnel"

At higher RPM the camera trick of "tilted

blades" (now rotating clockwise) was more pronounced

At higher RPM the camera trick of "tilted

blades" (now rotating clockwise) was more pronounced

Connections & Meters

At 60 RPM it put out about 1.5 volts AC across two phases.

(It was hard to tell - at 6 Hz the meter readings pulsed wildly up and

down.) That should end up at 2.6 VDC after rectification... not

counting losing ~1.3 volts in the diode bridge. If shorted it would put

out about 2.5 amps at first, but the unit would slow down after a few

turns until there wasn't much. A 1 ohm load brought the voltage down to

a volt and dropped the speed perceptibly. (The reduced voltage caused

the RPM/Hz counter to quit, so I couldn't tell how much slower.) The 1

W probably wasn't the "maximum power point", but

it seemed like a lot of bother for a watt or two!

The unit may be a meter wide, but it's only the segment

that's moving across or away from the wind that gives power. The other

half is just a drag. So presumably one must cut the wind frontage area

used for power calculations in half.

Some Conclusions

I found other VAWT videos by the same author, mostly from

around 2011. He kept changing them, experimenting. A couple of others

had vanes to redirect the wind, similar in effect to my wind shield,

and one of these he gave readings for had almost similar speed

increases over no vanes.

Moral: don't assume just because it looks well made and

professional, of welded stainless steel, and the builder was excited

about it when he did the video, that he had the best design. I hadn't

given it much study and was more interested at the time I made the

vanes in the fact that PVC and ABS plastics could be shaped by heating