Turquoise Energy Ltd. News #126

covering

November

2018 (Posted December 3rd)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month

In Brief

(Project Summaries etc.)

- Milling Trouble - New Chemie Batteries - A Better conductive

Paint - Vertical Axis Wind Turbine Etc.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- America at the Crossroads: Restart and Fresh Progress, or a New

Dark Age? - NO MORE WARS! NO MORE VIOLENCE AGAINST SYRIA! -

"Proportional Representation" and the Third Stage of Democracy - The

Exponential Function & Global Growth - More California Fire

Oddities - Qualifying to Run for Office - CIA: Rogue from Day One -

Coffee Roasting - ESD etc.

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Just a bit of work on the reluctance motor

Other "Green"

Electric Equipment Projects

* Carmichael Mill Handheld Bandmill (more operating than building this

time) - Bonus Tip: stack firewood under a tree to dry

* Recycling Scrap HDPE (or UHMW, or PP?) Into Useful- (millable) Shapes

- plus: Who needs to Have a Kitchen Stove?

Electricity Generation

* VAWT Designs: A bewildering variety of blades, vanes, shapes and

designs. What's really best?

* Magnetic Flipping HE Ray Energy?

* A Water Wheel Hydro Power Project

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Oxalate electrolyte)

* Conductive Polyurethane Paint: Painted Copper MnO2 Pocket Electrode -

New MnO2-Zn

cell tests

November in Brief

It seems a picture of me with the Nissan Leaf

made the Haida Gwaii Observer

It seems a picture of me with the Nissan Leaf

made the Haida Gwaii Observer

newspaper's article on the Swiilawiid Energy Symposium at the

end of September.

It always seems I have more projects than time to work on

them. OTOH lately I was getting some lumber milling done with my

"Carmichael Mill" handheld bandmill. -- part of September and much of

October up until the first week of November. And I'm going to want the

lumber if I decide to put walls on the roof over the travel trailer.

Sawing up a cant of wood (6" x 1.5" boards x

12') Nov. 7

Sawing up a cant of wood (6" x 1.5" boards x

12') Nov. 7

It was

working great until the gear teeth in the Ryobi skillsaw that was

powering it wore out. There's no way to know that the grease was

essentially gone inside the 'gear box'. Otherwise I'd have regreased it

earlier. Skillsaws are quieter than chainsaws, but they're still so

noisy you don't hear any clues. So milling came to a halt for most of

the month until I got another motor - another skillsaw. And then it

stayed halted because the weather wasn't very nice, so I didn't bother

to fix the mill until late in the month. And then I was out of sharp

bands. I started in on adapting the band sharpener, but as I feared I

didn't get the new offset cam bolt hole in the right place - twice. It

sort of worked on December 1st. The sharpened band cut better than

dull, but not well. On December 2nd I made a change and it was better.

On the 7th I started on "clean energy" projects again.

I've lost track of the timeline after that, but here are the projects:

New Chemie Batteries - A Better conductive Paint?

Leonardo sent

me a link to a site where someone showed how

to make conductive ink with graphite powder in gum arabic. The

application to battery making was spoiled by the fact that gum arabic

is water soluble, but right at the end of his video he remarked that if

one wanted a waterproof ink one might try a similar thing with

polyurethane paint. That seemed like a great idea. My quart of yellow

PU paint was "water clean up" and could be thinned with water, but

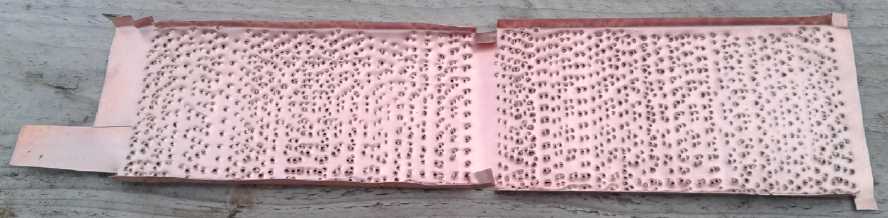

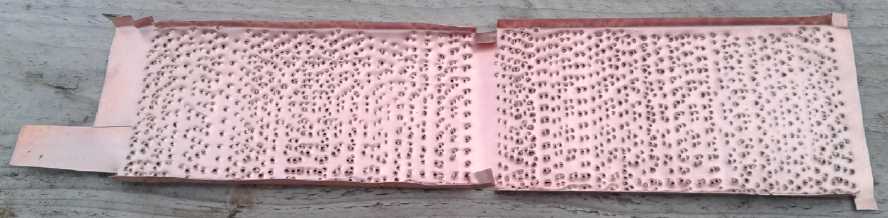

after it dried it was waterproof. I made a copper electrode pocket,

then painted it with the PU paint after mixing in some conductive

carbon black and thinning it. To my surprise, while it clogged the

perforations in the pocket when I painted it on, they seemed to all

open up again as it dried. It came out quite thin in most areas, kind

of like an ink. One could see the copper undertone beneath. It's

probably almost ideal, and easier than the osmium doped film. Then I

filled it with MnO2 salvaged from dry cells, and crimped the edges with

a hammer and screwdriver while pressing it flat in the hydraulic press

with only a couple of tons of pressure. Somehow these little jobs to

make it were spread over much of the month.

Leonardo sent

me a link to a site where someone showed how

to make conductive ink with graphite powder in gum arabic. The

application to battery making was spoiled by the fact that gum arabic

is water soluble, but right at the end of his video he remarked that if

one wanted a waterproof ink one might try a similar thing with

polyurethane paint. That seemed like a great idea. My quart of yellow

PU paint was "water clean up" and could be thinned with water, but

after it dried it was waterproof. I made a copper electrode pocket,

then painted it with the PU paint after mixing in some conductive

carbon black and thinning it. To my surprise, while it clogged the

perforations in the pocket when I painted it on, they seemed to all

open up again as it dried. It came out quite thin in most areas, kind

of like an ink. One could see the copper undertone beneath. It's

probably almost ideal, and easier than the osmium doped film. Then I

filled it with MnO2 salvaged from dry cells, and crimped the edges with

a hammer and screwdriver while pressing it flat in the hydraulic press

with only a couple of tons of pressure. Somehow these little jobs to

make it were spread over much of the month.

Then I made another zinc electrode (started in September).

This time I cleaned it in solvent to be sure there was no chloride left

on it after etching it in ferric chloride. I sprinkled just a bit of

zinc powder inside the pocket to help ensure there was something like

enough to match

the 22 amp-hours or so of the MnO2.

I put them together and filled the cell, and did a couple

of other things after that. It was better made, but it didn't behave

much differently than with the previous electrodes. So I started to

think it must be the zinc side that was the main problem. But why? I

thought zinc electrodes were pretty much foolproof. The

month ended with the questions still unanswered.

Vertical Axis Wind Turbine Etc.

I started

studying the VAWT idea again. I hadn't been

impressed with the "wind scoop" vane profile

performance on a VAWT. What was really the best vane shape? I saw a

video, a youtube suggestion, of a VAWT

with 8 straight vanes mounted at 45°. It seemed to turn excitedly

in what the maker said was a 1 meter per second breeze. It looked like

it was turning backward compared with what I expected. I looked up a

few more and "V" shaped vanes seemed like a good idea, which I tried

out.

I started

studying the VAWT idea again. I hadn't been

impressed with the "wind scoop" vane profile

performance on a VAWT. What was really the best vane shape? I saw a

video, a youtube suggestion, of a VAWT

with 8 straight vanes mounted at 45°. It seemed to turn excitedly

in what the maker said was a 1 meter per second breeze. It looked like

it was turning backward compared with what I expected. I looked up a

few more and "V" shaped vanes seemed like a good idea, which I tried

out.

I also had an idea to use vanes - airfoils - shaped like

venetian blinds similar to my water wheel idea from a couple of years

ago... and then to make them flat on the inside from log outside

cuttings

or "plywood peeler" boards, with a profile of a thin |) . If the

angle was 45° I could cut spoke pieces at that angle, screw them to

the

"spokes" in my center assembly, and screw the vanes, flat or "|)", to

those. That too seemed like a simple thing to do to see what would

happen. But since the whole VAWT idea seemed more and more like an

unproductive diversion, I turned to other things.

I had contacted a couple of

people in October about

support for the tidal flow power unit. Neither replied. Probably I'm

remiss in not trying a few more people, but it seems to me I've

been here before. I set it aside to work on HE ray energy

instead. I could do that without help, and if I could get something to

work, it would be the more valuable.

But then I did a bit more reading. And I thought of

Yourbrook Energy's present plan to build an upper and lower reservoir

with a hydro turbine between them. Their tidal power unit pumps water

directly, and would pump it from the lower to the upper reservoir by

tidal power. Then the turbine generates electricity at a rate where the

upper reservoir won't run dry at slack tides, providing continual power

via energy storage as elevated water.

I started thinking of all the intermittent energy sources

that are not the favorites of power companies. If an electric pump were

installed, extra power from any source anywhere on the entire grid

could be used to pump water into the upper reservoir, which could then

be drawn on demand for power to even out with high load and low

production times. If water was running low, there'd be lots of time to

warm up another diesel and bring it on line.

The amount of water needed to make such a system practical

needs to be figured out. Eg, it would need at least 16 hours storage if

there were a lot of solar panels, only 4 or 5 for tidal, but ideally

far more for wind. But if it is practical, it could be a model for

other places. For example, in Australia (Queensland?) the power

companies were compainlng there was "too much solar", working in the

day when demand was low and cutting out just before everyone started

making supper, so their generators needed just as much capacity as

ever. There a good way to store power even just into the evening hours

would make a big difference.

I made a couple of changes to the "magnetic switching" HE

ray

unit. I tried it out with essentially no results and went no further.

"Magnetic Switching" HE ray power unit

"Magnetic Switching" HE ray power unit

Reluctance Motor

Having decided

to try welding the "salient poles" onto the

rotor (iron powder toroid cores matching the ones on the stator)

I figured I could at least get that done. I thought it went pretty well

until I discovered one of them was visibly crooked. It must have caught

and "hung up" somehow. I'd have to grind it off and try again.

Having decided

to try welding the "salient poles" onto the

rotor (iron powder toroid cores matching the ones on the stator)

I figured I could at least get that done. I thought it went pretty well

until I discovered one of them was visibly crooked. It must have caught

and "hung up" somehow. I'd have to grind it off and try again.

So I

might as well weld some "optical interrupter" bits or arcs of metal on

at the outer rim at the same time next time I get out the welder. So I

have to make those first.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

America at the Crossroads: Restart

and Fresh Progress, or a New Dark Age?

I have for some time been

following the attempt to "drain the swamp" in the USA, on Youtube where

real journalists make their real investigative reports to the minority

who listen. [X22 Report, SGT Report, USA Watchdog, Dr. Dave Janda, and

many others do real political reporting in and on USA.]

In February 2017 (IIRC), president Trump announced that

corruption was a "strange and unusual threat" to the country, of such

monumental proportions that he declared it a national emergency. An

executive order was signed and further steps would be taken. (You

didn't hear this most monumental announcement by none other than the

President of the USA!?! Such is the level of corruption within the news

media establishment itself that they choose not to mention it, then or

any time since. But apparently the corrupt are all scared out of their

wits.)

In fact, steps to fix it were doubtless charted out well

before that. It's been said that Trump has the support of the military.

What may be closer to the truth is that some high-ups in the military

got fed up with fighting wars for the corrupt "status quo" on behalf of

the banks, big oil and arms merchants, and they resented Obama's purge

of their ranks. They recognized that the top villains were all in

cahoots, and were occupying all the high positions of economic and

political power sequentially, so that it was impossible for an outsider

to be elected to high office and reverse the trend. The highly paid

off, corrupt news media (virtually all owned by 6 or so persons and

under the direction of the CIA) paints these people in glowing terms

without reporting their heinous acts that make Watergate look like a

tiny blip, while trivializing and demonizing all their opponents. So

the public was mostly lulled to sleep and had - and still has - no idea

what was and is going on. (Dec. 2nd: a middle east fleet commander has

been "found dead in his residence", and days earlier a government

whistleblower's home was raided by the FBI in contravention of

whistleblower protection laws - are they getting rid of and

intimidating witnesses?)

How to end it all and save democracy? Rather than stage a

divisive military coup that would likely end in civil war and blood in

the streets, the military came up with a brilliant plan. They would get

an outsider elected, someone with no more love of these people than

they had, who could get the whole machinery of the nation behind

cleaning it up. They asked Trump, who had never been in politics, to

run for president. Some say he had more than their backing: he was

chosen by them and his running for president was their idea. I marveled

that he got the republican party nomination. When Ron Paul tried in

2008 he drew huge crowds like no one else and won many votes in the

first state primaries. The news media pretended he didn't exist. One

person came first, others came third and fourth. No one came second.

The extent of the insider racket was revealed when Jebb

Bush, losing in a debate to Trump in the 2016 primaries blatantly said,

"Yah, but I'm going to be president and you're not." It was revealed

again on election night, when the corrupt TV media personalities,

supposedly covering in a fair and unbiased manner a supposedly fair and

honest election, were visibly dismayed and almost distraught as Trump

won state after state. They wouldn't announce him as winning a state or

the election until there weren't enough votes left to swing it even if

they were all for Clinton. It was in fact supposed to be all scripted,

but somehow it just wasn't going according to the script! And these

"unbiased" presstitutes have unceasingly attacked their new president

ever since. To them he is just an arrogant oaf who acts solely out of

impulse and can do nothing right, who some "useless eater"

"deplorables" somehow put into the white house by mistake. What

they are most afraid of is real, rule of law justice.

Notwithstanding that enough people, sensing that all was

not as it was being painted out to be, voted for "egoist" outsider

Trump given the "queen of corruption" alternative, how did he ever get

into the position where he could be voted for? And how does he even get

the support of corrupt republicans in the senate? I now expect there

must have been much pressure put on various people behind the scenes,

probably by military figures and their supporters. No one gets to the

white house simply on merit, or achieves anything good while there,

without

powerful support! It's been half a century since anything much

favorable to the hardworking American people has been done by their

government.

But that's just background info. Back to the plot. When

Trump announced the national emergency, almost special 500

investigators were put onto the case to get the real scoop on all the

corruption - as well as the pedophelia and human trafficking that many

of the same people were involved in. They came up with over 60,000

indictments, which remain sealed until the time to make arrests comes.

Those are the people who were in complete control of America until the

unexpected election result and who

are now fighting Trump tooth and nail. At that time, all available

forces are to be called out to impose 72 hour martial law and make the

arrests. There's the reason Trump has been revamping "gitmo" and some

of the closed "for profit" jails. And at least the most treasonous top

people if not all of them are evidently to be tried by military

tribunal.

It is suspected by some that the time for the arrests was

supposed to have already come. There are so many judges in on the

corruption that no move was to be made until some were replaced, and

Kavanaugh was confirmed -

a majority who would convict the guilty in accordance with rule of law

was required on the supreme court. Digging up accusers from under

rotten logs who would perjure themselves to accuse Kavanaugh of rape at

the most opportune moment was another desperate ploy by the guilty.

They

hoped public opinion would convict Kavanaugh and force him to step

aside. If you were in a position to have to confirm appointment of a

judge who you expect will sentence you later for your crimes, wouldn't

you try anything to block his appointment?

With Kavanaugh's confirmation delay the arrests were thus

delayed until after the November midterm elections. Score one for the

corrupt "deep state!" The more they can delay, the more tricks they can

pull to try and weasel out of everything and get back in control. OTOH,

the republicans secured their hold on the senate in that election,

which plays into the hands of the plan. The house is needed to pass

bills, but the senate controls the judiciary. Bills aren't needed to

arrest and try people. The judiciary is. So perhaps Trump too decided

it would be best to wait until after - and not just to avoid it giving

the impression of interfering with the elections.

[per Dr. Janda interviewed on Silverdoctors, whose father

did construction contract work for Trump, but in my own words:] Trump

has built a number of very large buildings. If anything goes wrong in

one of those, it can be a complete disaster. He asks for all the

information, not just the bullet points, and he surrounds himself with

talented people who don't hesitate to disagree with him if they think

he has something wrong, and he asks many questions. He gathers all the

information he can get. His planning is thorough and methodical, and I

would presume no foundation is dug until every detail is ticked off as

ready.

Let us hope that is the case here as well. It sounds like

such a huge operation could hardly be in better hands.

Paying for caravans of migrants and criminals to come up

from Central America was another corrupt "deep state" tactic. They

hoped that the violent agitators among them - probably pushing the

women and children in front of them - would rush the border and force

the military to respond with violence, perhaps open fire on the crowd.

Those would make great video clips for the headline news! What an ogre

that Trump is, shooting innocent women and children! Maybe they could

get him impeached? Or they would be let through and Trump's policy

would be seen as a failure. The media would never let either story die.

Realizing what was doubtless intended, putting up barbed wire to

prevent people from rushing the border was a good response.

Having failed so far to murder him or disgrace him,

impeachment is definitely on their minds when the new "democrat" (it

hurts to have to use such a word to describe dictatorial oligarchs)

controlled house opens in January. Any excuse will do.

And therein is the crossroads. If the arrests aren't

carried out before the new year, Trump may be impeached and

escorted from the white house in disgrace and the whole plan will be

scrapped. If they can further delay the day of reckoning, they may put

it off forever. If that happens even the semblance of democracy will

soon be dropped. If they restart the wars they are still adamant about

in the middle east, the conflict can hardly escape becoming global. In

the next article below I speak of one of the current plans. A new dark

age will have descended, perhaps with very few people in it - or even

extinction of life. (If Clinton had been elected, we might well be

there

already.)

But postings by the obviously highly placed "Q" - who may

simply the codename mouthpiece for the military and Trump and perhaps

not even a single person - indicate that December 5th is going to be a

big date, and that "nothing can stop it." But is it the main event?

Probably not. It's probably the release of the unredacted documents of

illegal and treasonous dealings already demanded: the FISA warrants and

a couple of others. But it will be a big step in awakening the American

public to how underhanded the dealings of their elected and

appointed officials have been, and thus to helping to prepare them for

what is (hopefully) to come.

If the corrupt are all arrested en masse and thus "the

house is cleaned", "the swamp is drained", it doesn't solve all the

problems. Without advancing democratic governance to a more evolved

status, the swamp would gradually refill and be repopulated by new

swamp creatures, or even some of the same ones. And indeed economic

collapse, monetary collapse, plagues, famines, climate cataclysms and

Earth disasters complete with heavy population reductions are just

around the corner regardless. But at least for the time being, when and

as those strike, rational people will be at the helm instead of those

bringing senseless war, trying to micro-manage and control everyone,

and trying to

make life as miserable and unfulfilling as possible for everybody.

I have considerable confidence or at least high hope that

the cause will not fail and the light of freedom on Earth will

not be suffered to be extinguished for 1000 years. We will be granted

the time to evolve our systems to the point where ruthless dictators

won't have access to the halls of power, where social continuity,

social stability and finally social sustainability can take root and

flourish, never ever to be uprooted again.

How can we help in these monumental dealings over which

most of us have no influence or control? Pray for president Trump that

he isn't murdered, removed from office, or the plan is otherwise

derailed. These are critical times. Anyway there probably won't be much

longer to wait.

NO MORE WARS!

NO MORE VIOLENCE AGAINST SYRIA!

This is a special message to

certain members of the US/Washington DC "Deep State" and all others

involved just in case any may somehow chance across these words and be

moved to read them. You know who you are. As many Syrians displaced by

your years of ruthless bombing and proxy wars start to return home, and

the world starts to breathe a huge collective sigh of relief, I hope

and I pray that forces of peace, goodwill and sanity in America will

prevail over you.

But if you should manage to destroy Damascus and

mercilessly

slaughter people with a nuclear bomb - one and a half million

immediately and with millions more even into Iraq and perhaps Iran are

doomed to painful, lingering deaths - a collective insanity will surely

engulf America. It won't help to have your Israeli puppets carry out

the

actual deed - your evil designs are already known. Americans and the

world have put

up with a lot from you and your ilk for a long time, but you will have

crossed a vital threshold in the collective consciousness. Do not count

on the American public, or the rank and file in your many "security"

agencies

and your military to continue to take orders from you. Tens of millions

of

Americans will die in the ensuing confusion and chaos, and

a special vengeance will doubtless be extracted on those who are

thought to have had anything to do with the heinous act, and perhaps

on

their families, friends and associates. God Forbid... You May Not

Bomb Damascus!

Pause to consider Judas Iscariot. He was thrilled to

betray his fellows

imagining great rewards and honors, but after the deed, when he saw the

horror of what he himself had done no one had to bring him to

justice - in his utter disillusion and despair he killed himself.

Examine your motives and your prospects. Why are you

fighting to

restart a potentially globally suicidal war just to enable a gas

pipeline across Syria when the gas will soon no longer even be

wanted in Europe? How much longer

do you expect to delay the common utilization and commercialization of

free energy, known for many decades if not over a century and better

understood by more and more people each year in our new information

age? How much of your greed and ill will do you wish to have paraded on

public display at the expense of your own lives, your childrens'

lives... and your own immortal soul? How much more of Earth's natural

resources do you hope to squander today at the expense of your

grandchildren and all future generations? Peace and goodwill, or

widespread chaos, death and destruction in America, and personal

violent liquidations for yourselves one way or another - what do you

want?

The whole world is praying that either you change your minds or are

removed

from positions of influence. Think about it.

The

Exponential Function & Global Growth

20 Years ago the world looked rosy: Why are times

getting so tough so

fast?

I've mentioned overpopulation

before. If the population is low enough, isn't there plenty of land,

housing and food for everyone? Don't we all live like kings? But if the

population is double an "optimum level", then for only 1/4 of the

people to have optimum resources for a good life, they need half of

everything, leaving the other 75% with the other half - an average of

1/3 of the optimum per person. If it grew to triple the "optimum", the

figures get dramatically worse. And thus as population grows there is -

or will be, if one doesn't think there is now - fierce competition to

live well, damaging the core values of social sustainability: Equality,

Growth, Quality of Life, Empathy, Compassion and Love of Humanity...

and even Life itself for masses of people comes into in jeopardy.

I know there are a lot of people who presently don't think

the

world today is overpopulated, that our problems are strictly social and

political. Technology and new energy sources will solve everything. Al

Bartlett (1923-2013) was a University of Colorado (Boulder) physics

lecturer who

laid out the problems of continued uncontrolled growth on a finite

planet in terms

of simple arithmetic, with real world examples, starting decades ago.

Even if eight billion people isn't too many, the presenter shows us how

close to the brink we must be. How uncontrolled growth hurts us, how it

destroys democracy and cheapens the value of life - which causes the

social and political problems.

When I was young there were less than 3 billion people.

That figure was thought excessive by some - "How will we feed them

all?" If eight billion

people today isn't too many, and if then the population keeps doubling

every 40 years, will 16 billion be too many? Many now living will still

be here then. In 80 years, will 32

billion be too many? How about 256 billion in 200 years? or 8.192

trillion in 400 - a thousand people for every person today? How many

before we are all standing shoulder to shoulder everywhere? At just

what level would you expect "the population bubble" to collapse?

The video I watched

on Youtube was called:

Arithmetic,

Population and Energy - a talk by Al Bartlett

(Search for it.) Bartlett lectured on these topics over 1600 times,

almost to age 90, and a number of videos are available.

This lecture was in 2002. Perhaps somewhat prophetically for that time

he mentioned that he thought

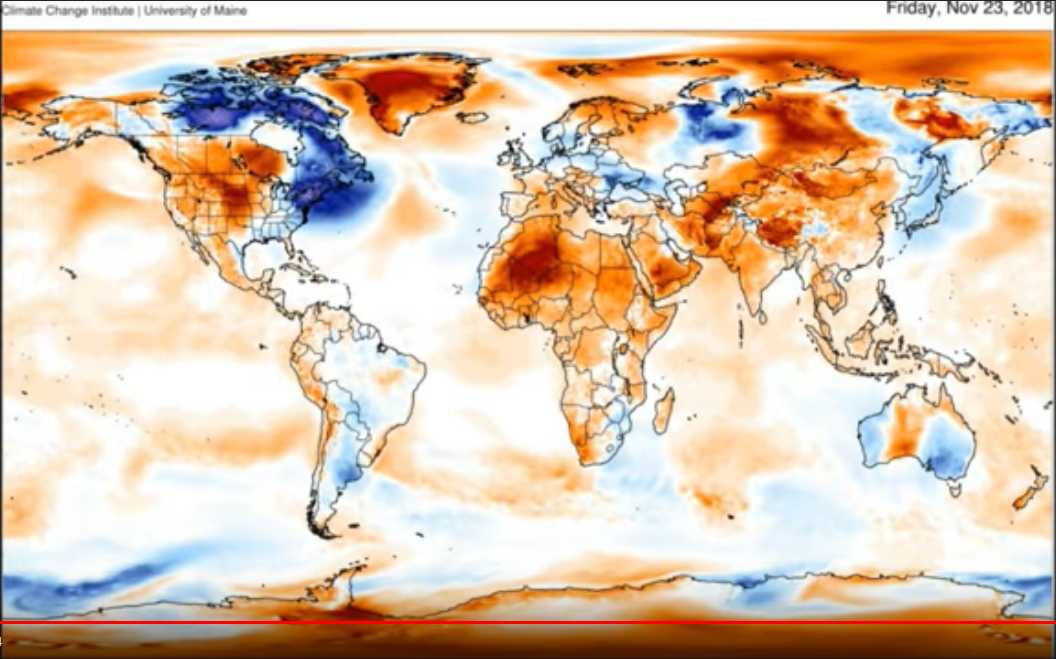

that global warming would become the biggest threat. Bizarre

weather and climate catastrophes certainly are becoming huge problems

for life and food production today, with globally severe crop losses

this year and apparently worse to come. And this in spite of the

overall increase in heat (especially in the arctic per TE News #109 -

the cold temperate winters in some areas are also a result) being

somewhat mitigated by the developing solar minimum (a slight reduction

in

the sun's output over a span of years or decades).

And there are many other

insights in this 75 minute video that illuminate and throw a broader

perspective around the problems we are having - and how the less people

knew and the less they examined the problems (2002 - especially

officials and 'experts'), the more confident they were - and many still

are - that all problems could somehow be overcome... without limiting

population growth.

But here is a related thought: When populations get too

crowded, diseases strike. That doesn't only apply to human populations.

When interior BC forests were logged and replanted with pine trees

everywhere (known in farming as "crop monoculture") a normally minor

pest, the pine beetle, became a huge epidemic and killed them en-masse,

province-wide.

And once upon a time, potatoes were brought from the

Americas to Europe. They were planted everywhere, especially in Ireland

where they grew well. With such dense populations of potatoes, a great

new food source, the human population grew, but when a potato blight

struck it quickly spread everywhere. This caused the "Irish Potato

Famine". Over several years millions starved and many millions more

emigrated to find food. (Perhaps they were modern history's first mass

economic migrants?)

Today to support humanity's many billions, food crops

cover nearly all the planet's arable land. (And today's farming

techniques aren't sustainable to start with.) Wheat fields cover the

Canadian prairies, and corn farther south in the USA. Is it not

possible, even inevitable, that such huge crop monocultures will be hit

with a plague or plagues, such as some new strain of "rust" to which

the wheat isn't immune, and it will quickly spread over the all those

connected fields to everywhere? As in Ireland but on a continental or

even global scale, devastation of vital wheat, corn, rice or other

major "everywhere" crops will not allow the present much increased

human population levels to be supported. As with Selkirk wheat, new

strains resistant to the new rust will be found or developed, but today

a gap of several years in commercial production will pose a severe

problem on top of all our other serious problems.

To underscore the above written earlier, on the 22nd I saw

a Youtube video by "Ice Age Farmer" showing an agro-insurance website

where the title was "Ontario Farmers Facing 'Catastrophic' Disease

Outbreak in Feed Corn". "DON"(?) mycotoxin had ruined 50% of the crop.

This was mentioned among all the other serious to severe global crop

losses.

And a dense urban, hungry populace is one itself

susceptible to epidemics. On the same evening (22nd) a "Full Spectrum

Survival" news video detailed at least three serious diseases, one of

which, Prion Disease, especially might be unstoppable if it gets going.

(also mentioned: Ebola is spreading in DR Congo; and H1N1 Swine flu: it

kills the healthy as much as the weakened.)

All these plus climate and geologic cataclysms will reduce

the present crowded human population to a much smaller figure in the

next two or three decades. Then the term "population management" will

become well known and much studied globally for the first time.

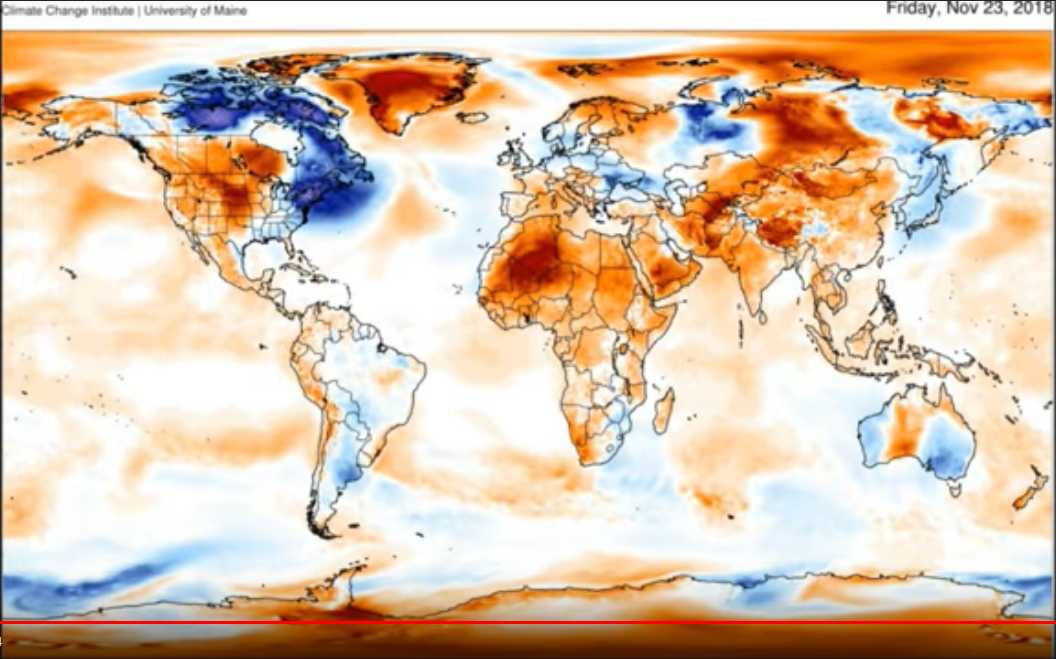

Those in the East of North America might

perhaps be excused for thinking in the winter that

Those in the East of North America might

perhaps be excused for thinking in the winter that

"global warming" must be a myth and that in fact a "mini ice age" is

coming with the solar minimum.

Chaotic as the climate has become, globally there are more "above

average" temperatures than

"below average", and recent summers have broken many high temperature

records in many lands.

"Proportional

Representation" and the Third Stage of Democracy

The first place I heard of the present British

Columbia (BC), Canada provincial referendum on proportional

representation was Google ads saying how "great" our present electoral

system is, how it "works so well" and how terrible things will happen

to us if we change it, from which there would be "no going back". How

on Earth could any group with the money and organization to launch an

ad campaign be so convinced that the present unfair system that

generates so much political and social polarization and trouble works

well?, and why would anyone think that if we didn't like something, we

would somehow be stuck with it forever?

But that would seem to be the very situation we have now,

stuck with an unfair voting system where somehow all attempts at

progress and change have been thwarted for a century! (...like the

present federal government's solemn promise for electoral reform during

the last election, that was dropped once they won it, with some public

meetings about it apparently just to fool the public into thinking

things were moving forward for a while and to dilute and wear down the

critics. Justin Trudeau, unlike his father Pierre Elliot Trudeau, is

proving to be just another "deep state" puppet with no will to lead of

his own.)

Yet apparently only 3 democracies still use the

rudimentary and inherently biased toward polarization "first past the

post" voting system: Canada, United Kingdom and United States.

To me the "attack ads" reeked of well funded hypocrisy by

vested

interests who gain something from the present unfair system: the

behind-the-scenes hand of the rich and powerful trying to prevent

democracy from working and evolving, here by trying to manipulate the

public's opinions through misrepresentation and fear.

Later I found out that the opposition did indeed consist

of some of the very few richest and most powerful figures around BC.

Names of the individuals were given. They had tried first to prevent

the government from holding the referendum at all by trumped-up court

challenges. These failed. So now they have been trying instead to make

the BC public afraid to vote for any change. Will it work? Are there so

many "sheeple" to be herded back into the pen by the command of their

rich "overlords"? We shall see. (If the referendum passes, will there

be threats or inducements to the premier and individuals in the

government to "forget about it" without enacting it?)

I admire that the BC government is holding this referendum

which they apparently will enact if it passes, and equally how they

framed it. Commonly the several options would be presented - there are

many opinions on what would be most preferable - and one of the options

would be to keep things the way they are. Mark an "X"! This is the same

way "first past the post" elections are presently run. Since the

various options would "split the vote" of the majority who wanted

change, the substantial minority who were afraid of change and were

unwilling to open their minds and think about it or choose between

systems - and the tiny minority who think they benefit from the way

things work now - would win. The more options for change that were

presented the more certain it would be that the largest minority of

votes would be the one for "no change".

Instead, it was split into two questions. The first one

is: Do you want a proportional representation system:

yes or no? This question uses the present "first past the post", "mark

an 'X'" question that has to pass - but here it is fair as there are

only two options.

Then the second question is: What kind of

proportional representation system do you want? For that the

government gave three voting system options. Since the second question

only matters if people asked for change, they were free to pose it as a

more advanced Choice Ranking ballot. Instead of just marking

the "illiterate's 'X'" for one "first past the post" choice, voters

rank them 1, 2, 3 - 1st, 2nd and 3rd choice. If one choice doesn't have

over 50% of the vote, the votes for the least popular choice will be

"transferred" to those voters' second choice. Thus the winning choice

will have been approved by over 50% of the voters - no more minority

choice wins; no more can the less popular choices on a ballot

(whichever ones they prove to be) tilt the final balance in favor of

one or the other of the most popular.

Third Stage Democracy

It's great that the premier and the government has decided

to hold this referendum. But it is still top down - authoritarian. It

has been brought to the people by their government representatives.

If citizens had a venue for getting together and thrashing

out political ideas at a grass roots level, we would long since have

addressed this issue and come out with a consensus for a better system

- probably better than any of the present proposals. Since it would

have come from the whole public-at-large as a single recommendation, it

would have been passed by the government - or by the next government

that replaced the one that was unwilling to do the public's will. Now

that we have the internet, such a social sustainability design team

mechanism can come into play in the coming years. At some point such

local teams will surely "go viral" as the expression goes.

When they do, we will be able to start tackling all sorts

of issues that can't be dealt with by the top-down approach. Presently

local and community issues are subject to national regulations and

national decisions from the national leader. Since the national leader

doesn't have time to be informed about and deal with local issues all

across a nation, they simply are left in limbo. When instead decisions

are made at the local level and only feed up to the level that's

warranted, they can be appropriately dealt with.

More

California Fire Oddities

One clear thing emerges from the California fires: that

much of California is not only even more bone dry than usual, but that

it's littered everywhere with kindling to spread any fire out of

control, however it starts. especially in high wind conditions. But was

this in fact planned in advance, premeditated?

I understand that in 2016, with a major wildfire actually burning,

California state legislators passed a bill to help to get some of the

tinder dry chaparral & brush areas cleared off and make fire breaks

to limit damage that might be caused by future fires. It passed both

houses unanimously. Governor Jerry Brown vetoed it. This is the same

person who probably also ordered a truckload of petitions to be "lost"

so there weren't enough of them left to cause an [anti compulsory

vaccination?] initiative to be put to a public vote.

How does he get away with these things? Who is he working

for and are the elections that keep binging him back rigged?

People have noted that a "typical" house fire is about

1100°F. But metals that require much hotter temperatures have

melted in recent California house fires. There seems to be remarkably

little left.

Unusualities: a house 3/4 demolished and the

other 1/4 almost intact?

Unusualities: a house 3/4 demolished and the

other 1/4 almost intact?

and a truck, apparently bizarrely burned and

the steel door melted?

and a truck, apparently bizarrely burned and

the steel door melted?

(hmm... the whole picture seems rather bizarre)

Oh well, those who get out of California now may be the

lucky ones. There are predictions that large parts of Alaska and

California will sink into the sea in the upcoming years, Alaska first.

The BC coast will suffer too, but not so drastically except in the

north near Alaska. But with all the earth movements and rising sea

levels there should be plenty of nasty tsunamis and inundations for

everyone along the whole Pacific rim and islands.

Qualifying

to

Run

for

Office

A new American

congresswoman, Occasio-Cortez(SP?) was asked "What are the three

branches of government?" and she couldn't answer it. This must be a new

low in American politics. It underscores my idea that one should have

to pass some basic tests to qualify to be able to vote, and a bit more

in depth to qualify to run for office. I have no doubt that

Occasio-Cortez would be capable of passing the tests with a bit of

study, but no one should be in government while ignorant of most its

basic structures. We aren't even allowed to drive without studying up

on and learning the basic rules; why should we allow people to drive

the country without the same sort of preparation? (Hmm... the CIA, the

FBI and the IRS? ...or are those three "tentacles" of government rather

than "branches"?)

CIA: Rogue

from Day One

Quoted from a "Zerohedge.com" story Dec. 1:

>--- [begin quote]

One month to the day after President Kennedy's assassination, the

Washington Post published an article by former president Harry Truman.

"I think it has become necessary to take another

look at the purpose and operations of our Central Intelligence

Agency, CIA. At least, I would like to submit here the

original reason why I thought it necessary to organize this Agency

during my Administration, what I expected it to do and how it was to

operate as an arm of the President."

Truman had envisioned the CIA as an impartial information and

intelligence collector from "every available source."

"But their collective information reached the

President all too frequently in conflicting conclusions. At times, the

intelligence reports tended to be slanted to conform to established

positions of a given department. This becomes confusing and

what's worse, such intelligence is of little use to a

President in reaching the right decisions.

"Therefore, I decided to set up a special

organization charged with the collection of all intelligence reports

from every available source, and to have those reports reach me as

President without department "treatment" or interpretations.

"I wanted and needed the information in its "natural

raw" state and in as comprehensive a volume as it was practical for me

to make full use of it. But the most important thing about this move

was to guard against the chance of intelligence being used to influence

or to lead the President into unwise decisions, and I

thought it was necessary that the President do his own thinking and

evaluating."

Truman found, to his dismay, that the CIA had ranged far afield.

"For some time I have been disturbed by the way

CIA has been diverted from its original assignment. It has become an

operational and at times a policy-making arm of the Government. This

has led to trouble and may have compounded our difficulties in several

explosive areas.

"I never had any thought that when I set up the CIA

that it would be injected into peacetime cloak and dagger operations.

Some of the complications and embarrassment I think we have experienced

are in part attributable to the fact that this quiet intelligence arm

of the President has been so removed from its intended role that it is

being interpreted as a symbol of sinister and mysterious foreign

intrigue - and a subject for cold war enemy propaganda."

The CIA lies with astonishing proficiency. It has made an art form of

'plausible deniability.' Like glimpsing an octopus in

murky waters, you know it's there, but it shoots enough black

ink to obscure its movements. Murk and black ink make it impossible for

anyone on the outside to determine exactly what it does or has done.

Insiders, even the director, are often kept in the dark.

--->[end quote]

Why is it that time after time, presidents and other

public figures only realize or acknowledge the damage they've done

after they no longer have any power to influence events or undo what

they've done? And the

present occupier of the position never takes action to correct the

problem either?

Coffee Roasting

Coffee Roasting

Coffee Roasting

Perhaps some may be interested? It's simple to roast

coffee. I buy "green" (raw,

unroasted) coffee beans in bulk (at GreenBeanery.ca), and roast them as

needed in a hot air popcorn popper. I like a pretty light roast, and

it's hard to buy that anywhere. I keep the green beans in a cool place.

They keep for ages - I haven't bought any in almost two years and

they're still fine. And it's cheaper than buying good coffee in a

grocery.

Required:

* Coffee. My favorite is "Nicaraguan SHG Fair Trade Organic". "Coffee

connoisseurs" have remarked what good coffee it is and where do I get

it?

* Popcorn popper (I don't use the lid) - the beans "crack" as they

roast

but they don't pop out. (For light roast, only a little "cracking". But

if it's too light it's hard to grind.

* Coffee container, measuring scoop.

* Minute timer unless you want to stand there and watch (time varies by

popper from 2 minutes to 8 and gradually gets shorter for some reason.

Since I started (10 years?) I've gone through 3 or 4 poppers.)

* Things to dump the coffee into. It's hot, and it smokes during and

after roasting, so it's usually done outdoors.

ESD

What is ESD? Eccentric Silliness Disorder

What causes ESD? Electrostatic Discharge while having Egg

Salad Dinner

When does it strike? Every Second Day during Easter,

September and December

Where does ESD strike? in Europe, Spain and Denmark, with

very isolated cases on Europa, Saturn and Deimos

For more information on ESD,

contact your local government branch of the Egregious Sarcasm Department

---

I Pulled a can of evaporated milk out of the fridge, and dropped it. I

grabbed it almost as soon as it hit the floor, but I turned it upright

the wrong way so it was upside down and still spilling. (the usual

result of a 50-50 chance) Dam, dam, dam dam! Is there any use cursing

over spilled milk?

---

Notice: Owing to changes in regional politics and weather

patterns, the name "Saudi Arabia" is henceforth changed to "Soggy

Arabia". (Can camels swim?)

---

Did you know?: Chordless phones can only play one note at a time.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Electric

Transport

Reluctance Motor

While the "piece of pie" shape is probably the best for an axial flux

reluctance motor's coils and salient poles, at least the iron powder

toroid version which is presently easiest for me to make gives the

effect (and better) of steel laminations

versus my only "homebrew" alternative, solid steel chunks.

I thought I was going to make a table for my electronics

lab before resuming this project. But there were things to do before

setting motor and controller up on a bench, and I was sorry this

project was falling behind any sort of schedule.

I decided to

weld the "salient pole" toroids directly to

the rotor plate - assuming that would work. It would solve a lot of

confusion about how best to do it, while actually being best. But since

I don't really know how they're made, it might not work. They kind of

look like they're made of sintered together iron particles, but then

again they might be glued together with epoxy.

I decided to

weld the "salient pole" toroids directly to

the rotor plate - assuming that would work. It would solve a lot of

confusion about how best to do it, while actually being best. But since

I don't really know how they're made, it might not work. They kind of

look like they're made of sintered together iron particles, but then

again they might be glued together with epoxy.

On the 25th I put them on the lathe and

turned/scraped/filed off the epoxy outside coating. Now there was bare

metal (if such it was) to weld to. Magnetically the tops should be

flush with the top of the rotor, but I'll have them stick up a little

to be sure they can be solidly welded into place even if things aren't

perfect. (My welding is much less than perfect at best!) I wasn't going

to weld indoors, so what I needed next was a nice day. Those were

getting rare near the end of November. I was already waiting for one to

resume lumber milling. But one finally came along and I did the

welding. Unfortunately one is crooked and will have to be ground off

and redone.

The rotor would have to be

raised up by the amount the

toroids stuck down, and I figured out what to do about that: I would

put another "weld-on hub" the same size but with a slightly larger

center hole onto the bottom plate of the motor. (I even have it!) I'll

turn it on the lathe to get the exact height and fit for the bottom of

the 70 mm thrust bearing. The outer needle bearing can stay in its

original place.

I could still use the sameunipolar motor controller.

I had it all figured out... oh, wait... I have to make some new optical

interrupter, four slots and four solids around the outside rim somehow.

But soon I had a plan for that too. It involved some more welding and a

bit of grinding. Oh, and new mountings for the optical interrupters.

And once it's turning, a new outside rim and top.

Other "Green"

Electric Equipment Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

Sawing up a cant of wood (6" x 1.5" boards x

12') Nov. 7

Sawing up a cant of wood (6" x 1.5" boards x

12') Nov. 7

As I said last month, I had taken footage to make a video

about the bandmill. I made it and here is the link:

https://www.youtube.com/watch?v=P7r6hQF3yg8

The mill was cutting well

with remarkably little trouble. But somehow the blade always seemed to

have trouble cutting the last board or two off a cant. I cut one large

one on the 7th and 8th, getting

nine 12 foot 2"x6"s and one 8 foot from it. Again it seemed the band

was dull by the last couple, and they were hard going. Well, the band

had cut over 50 square feet of surfaces. Perhaps that's as good as it

gets?

But I figured that cutting at the bottom, as there was

less "cant" remaining in some sections than the material in the board

being cut off, the remainder under the board often wasn't very stiff

and was bending and closing up the cut. Perhaps that was why it always

seemed dull by the time it was at the bottom? However, putting wedges

in the cut behind the saw only seemed to be a partial solution.

This time (11th - being out of new bands anyway) I decided

to try using the same seemingly dull one to start the next cant. It

went okay if a bit slowly. But by the time I finished there seemed to

be some vibration. I started on the second board but it was getting

worse. At first I thought it must be the bearing in the saw. Then I

discovered that the bolt holding the pulley on was loose. But

tightening it didn't help. I took the saw inside and found the bolt was

again or still loose. Again tightening it didn't help. Perhaps it came

loose again because of the vibration rather than being the cause of it.

Motor Madness

The spindle of the saw

came off with four bolts, and I saw that a

small gear on the motor turned a large one for the blade. I thought it

was probably the gears. They looked fine to me, although there didn't

seem to

be any grease left on the teeth. I ran the saw motor without the

spindle and

it seemed smooth. Apparently with some kind of mental disconnect, I

took the smoothly running motor apart. I couldn't get the bearing off

that end by pounding on it, but I did somehow make it not turn

smoothly. Something seemed to be hitting something five times per

rotation. The plastic fan had five "spokes" on the side I could see,

and a sheet metal plate wasn't sitting quite flat. Probably it was

hitting five more spokes on the other side.

The spindle of the saw

came off with four bolts, and I saw that a

small gear on the motor turned a large one for the blade. I thought it

was probably the gears. They looked fine to me, although there didn't

seem to

be any grease left on the teeth. I ran the saw motor without the

spindle and

it seemed smooth. Apparently with some kind of mental disconnect, I

took the smoothly running motor apart. I couldn't get the bearing off

that end by pounding on it, but I did somehow make it not turn

smoothly. Something seemed to be hitting something five times per

rotation. The plastic fan had five "spokes" on the side I could see,

and a sheet metal plate wasn't sitting quite flat. Probably it was

hitting five more spokes on the other side.

Then I inserted a screwdriver through the fan blades and

tried to pound out what I thought would be a sealed bearing that held

the spindle. I succeeded in punching a hole in the piece of metal, and

then pushing an integrated needle bearing race out a bit. The needle

race was a separate piece, and it seemed all it needed to get it out

was some little hook under it.

The motor didn't seem to need to be apart so I put it back

together except for the spindle and ran it again. It was as always so

noisy

anyway I couldn't even hear if there was any extra clicking from the

spokes. (And since I didn't have the gear connected, apparently all

that noise was just from the brushes and the fan.)

Getting a hook under the bearing race didn't work. But the

bearings on the spindle seemed smooth enough... I put the spindle back

on, and it seemed to run just as rough as before. Finally I took the

spindle inside and looked at the gear through a strong magnifying

glass. There, it did become obvious it was quite worn. The gear teeth

were pitted and worn to a pointed shape at the outside on the driven

face. All that hard milling, plus (seemingly) no grease. If I continued

the teeth would surely fail completely, probably destroying the gear on

the motor as well.

So once again, milling came to a halt to await parts for

the mill. True, milling could go faster if the mill had a little more

power, but the idea of changing everything that had been working so

well and putting my Electric Caik motor on just wasn't very appealing.

Doubtless I could order a whole new saw. Could I order just the gear or

spindle or output shaft assembly?

The next morning I decided

to give up on the idea of

fixing the saw. If I found the part and replaced the one gear, there

was no guarantee the other wasn't too worn as well. I've tried fixing

angle grinders with worn or broken gears. It's usually not worth it. I

went on line to Home Depot and as I hoped I found the 13 amp Ryobi saw

for 60$. But I also found a 15 amp Ryobi saw for 90$. One wouldn't

think there'd be much difference, but a neighbor had said 15 amps would

be better - and there it was: "a little more power". A very little bit

more; 15%. But if it would make milling go even 10% faster, or make an

extra inch width easier to cut, would it not be worth it? So I went for

the extra.

At the same time, I had been thinking for a long time that it would be

nice to have a handheld power planer. The thickness planer was great as

long as the boards were under 12.5" wide. A wider slab can't be done at

all, nor with the 6" jointer. There was a Bosch planer with "reversible

micrograin carbide blades" for "a mere" 170$. and extra blades for 25$.

It also had adjustable guides on the side. So with a straight edged

guide one could plane a wide slab, doing one straight 3.25" row at a

time. (Well, hopefully that would work - I've never used a handheld

planer before or seen whether the edges of the joins would dovetail

smoothly.)

They sent them UPS! I figured I'd have them before

Christmas. When I mentioned the problem to someone he gave me an old

Mikita skillsaw with no brushes and a bent blade guard.

But actually the new saw (only the saw) soon arrived. I

did other things until the 26th. That day (finally) was nice out, so I

drilled a couple of bolt holes and mounted the new Ryobi. The next

problem immediately reared its head: I had no more sharp bands. I cut

into the 16' cant and it didn't go well at all. I changed to another

band that looked better. But it was nothing like new. I eventually got

to the end with a lot of zig-zagging and the band heating up. It was a

nice but hard won 1" x 8" x 16' board. I wasn't about to try for

another one. Whether the 15 amp motor was better than 13 amps I

couldn't tell.

I wanted to see if the old Ryobi brushes would fit in the

(13

amp) Makita. It would be nice to get a skillsaw out of all this! But I

didn't find the time.

To set this 24"x8"x16' cant on edge I had to

use a big "jackall" jack

To set this 24"x8"x16' cant on edge I had to

use a big "jackall" jack

When a band gets dull enough, sawdust sticks

to the teeth.

When a band gets dull enough, sawdust sticks

to the teeth.

I eventually got to the end of the board.

I eventually got to the end of the board.

After that one, I got the band sharpener working, first

try not the best, second try not so bad (but can probably be improved).

Bonus Tip: Someone told me that firewood stacked against a

tree would stay relatively dry, because the rain tends to drip down at

the outside of the branches, not near the trunk. My firewood shed being

full, I decided to try it out.

Handheld Bandmill Troubleshooting Guide

I figure if there are going to be saws or kits for sale, it needs a

troubleshooting guide, so here is the start of it:

Band comes off the Wheels:

* Wheel alignment is off

* Band tension is too low

* Sawdust buildup on band or wheels (This is why the wheels are now

slick

UHMW!)

Band slips:

* Band tension is too low

Saw is jammed in the cut:

* Back it up 1/8". The teeth get stuck in wood at the end of the cut.

* Put in a wedge(s). The wood could be closing up on the kerf.

* The cut has gone off line and may be "bowed" inside the board,

owing to a dull band, insufficient band tension, tilting the saw while

cutting, lifting of the back end of the saw, or wood irregularities

(esp. knots). Back it off several inches or until

a position where it turns freely.

* At or very near the end of the cut, the top board can drop down onto

the

band. If the teeth are visible across the end, it may be possible to

pull the saw out or to pull the board back away from the saw.

Otherwise, a wedge or two in the cut behind the saw may be needed.

(Putting wedges in before reaching the end of the cut can help it

finish smoothly.)

The board(s) have bend(s) in the cut at the point where a wedge is

being inserted:

* Don't wedge the cut open too wide.

Band Gets Dull Fast

* Steel band teeth don't stay sharp as long as carbide saw blade teeth

- Relatively frequent band changing and sharpening is a normal part of

steel tooth bandsaw milling. Expect to make under 100

square feet of cut surfaces before changing or sharpening the band,

depending on species being cut and other factors such as where it was

grown. An automatic band sharpener is recommended if there is a lot

milling to be done. There are plans for homemade sharpening jigs on

Youtube etc.

* Cooling water has run out during a cut or is not flowing fast enough

to keep blade cool. The sponge in the water system gets clogged and the

sawdust, etc, needs to be occasionally squeezed out. Badly overheated

blades may dull almost immediately even if resharpened, if the

tempering/hardening has been lost from the tooth tips owing to heat.

(This also applies to overheating the tips during sharpening, as with

using a

"dremmel" tool running at a high speed.)

* Minerals or sand in bark and or wood. It is best with some species,

or trees grown in some locations (eg, near a sandy beach in a windy

area) to remove the bark before cutting. My method is to use a flat

blade shovel, with the end sharpened on a grinder. Hammer and chisel

has also been used. Debarking may be easier if the tree has been down a

while.

* Nails, lag screws or other metal pieces in the wood. This happens

mostly but not exclusively with trees near houses, where they may get

clotheslines attached, be used as a fencepost or children may drive

nails into them for fun. Later the pieces are forgotten and the tree

grows

around them. (I've even seen pieces of clothesline wire complete with

the pulley,

and electrical wires, completely grown into a tree or large limb.) If

suspicious, a metal detector or rare earth supermagnet may be tried to

detect them, but in my experience results are not usually certain.

Rough Running

* You're cutting into metal?

* Tracking is off.

* Pulley on saw motor is loose.

* Something else is loose or a bearing is bad.

* Gear teeth inside spindle of motor are worn out. Motor needs

replacement or repair. (Preferably, occasionally open the four screws

and grease

it inside while they're still good.)

* Brushes on motor are worn out. (Congratulations on having done so

many hours of milling!)

Recycling

Scrap HDPE (or UHMW or PP?) Into Useful (millable) Shapes

In my youtube wanderings I found a video, How to

Recycle HDPE Plastic (High Density Polyethylene) - a simple method,

which

relates

to

my

putting PP (Polypropylene) rope in a pot and

melting it down into a block of PP last January (TE News #116). This

person got a bit more clever and used a sandwich toaster and colored HD

polyethylene food containers to make flat sheets or blocks of plastic.

He had a figure for best temperature to soften and mix HDPE pieces:

about 180°C or 350°F. I expect it could be done in an oven

using a few flat metal plate clamping pieces and C-clamps, too. I hope

it can be done without cutting them up into such tiny bits as he did!

(I think part of his aim was to get the kaleidoscope of decorative

colors.)

I've cut thick, flat pieces of UHMW polyethylene using a

CNC router to make molds for motor parts, etc, per various TE News

issues mostly around 2010 to 2012. (How about bandmill wheels?) A "one

board foot" (12" x 12" x 1") piece of UHMW cost around 40$ at a store

in Victoria, so to make it oneself from scraps seems like an attractive

proposition. Perhaps to stick with UHMW one could use small and large

scraps of that (and I saved some milling shavings perhaps for this sort

of purpose... if I can find them). Or perhaps HDPE would work fine for

epoxy molds too.

Obviously from the video it works well with HD-PE.

(Presumably UHMW-PE would be similar.) I've previously softened and

bent ABS and PVC plastic pieces in the oven at 250°F. Whether or

not this "sort of" melting down at 350°F would work with PP would

be interesting to try. But if it needs a higher temperature and smokes

like my "melting down PP in a pot" experiment, I wouldn't want to do it

in the kitchen.

Who needs to Have a Kitchen Stove?

On an almost unrelated note, I went into the Home Hardware

store in Masset looking for a new coffee maker, and in looking around I

found a flat-top "inductive heating" hotplate, and an "air cooker". The

inductive hotplate could be temperature controlled, and it might be

used for melting the plastic--? But I bought it

because it had a timer and could be told to shut itself off (eg, after

the rice was done, while I was outside doing something else) whereas

stove burners will continue to fry it to a crisp and a house full of

smoke, and I wondered why I had recently purchased a new kitchen stove.

Two hotplates would be two burners (one more than I usually use), the

air cooker sounded better than an oven, and the total price for all

three was less than 1/2 the price of the stove. In addition,

potentially a burner/hotplate (or even both) could be put away to free

up counter space.

If you set the hotplate on the stove... well, just don't!

When you accidentally turn a burner on underneath it instead of the

hotplate the bottom plastic melts and smells terrible. and might start

a fire. (I think that's the only time I've used a stove burner since I

got the hotplate.)

Wind:

VAWT Studies

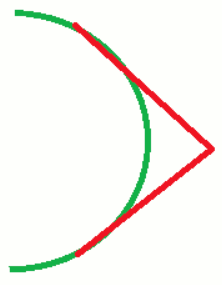

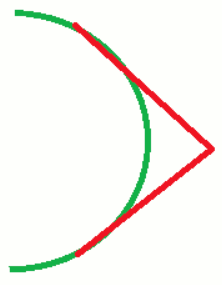

In looking at all

the VAWTs on youtube, there are lots of very different designs and they

all seem to turn. One interesting video titled vertikalis

Winrad RH2015-01, vertical axis windturbine, Germany had "V"

shaped blades. The pointy end cut through the wind going into it, while

the broad open end would catch it on the way downwind.

But which design, or which style of designs, can output

the most power from a given wind? This was the part that was

frustrating. Surely there had to be a known optimum shape of vanes and

density of vanes? Or at least, surely there must be some way to compare

them?

I decided to look for something outside of Youtube and

found a study by several Worcester Polytechnic Institute students in

pursuance of their Bachelor of Science degrees, from 2013: Vertical

Axis Wind Turbine Evaluation and Design. After plowing through all

the background information (AKA academic "mumbo jumbo") I selected the

following interesting information - partly from their results but more

from their conclusions. In their Results:

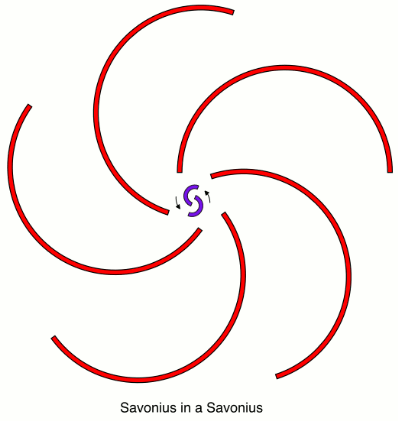

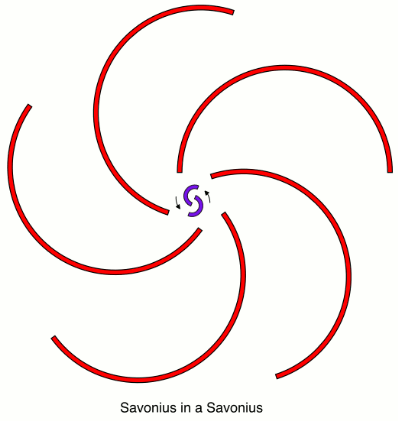

1. The Split Savonius Rotor (two half barrels, slightly overlapping)

performed a little better than a four blade airfoil design.

2. Either unit performed much better with a shroud blocking the wind

from the unwanted direction or shifting its direction. RPMs went up as

much as 65%.

3. The best shroud design very much depended on the type of turbine it

was shrouding.

4. Their small units didn't make much power. Nowhere did they get even

1/4 of a watt. Their generator was doubtless less efficient than my

Improved Piggott one (oversize tho it is for this featherweight

application), and had cogging that prevented turning with light forces.

It was hard to judge the forces because they used a wind tunnel with

wind speed measured in "hertz", which was nowhere explained for

conversion to understandable units.

In their Conclusions (which also included considered speculations):

1. The better performance of the Savonius "split barrel" design was

attributed to the large surface area of the vanes catching the most

wind.

2. The semicircular barrel

shape would probably be better with a "V" on

the outside to deflect wind when traveling upwind. I was surprised to

see this, so soon after watching the German VAWT video with that very

shape of vanes. (I don't suppose the shape of the wide end matters very

much, so the simple "V" might be just as good as the Savonius "half

barrel" with a "V" on the outside.

2. The semicircular barrel

shape would probably be better with a "V" on

the outside to deflect wind when traveling upwind. I was surprised to

see this, so soon after watching the German VAWT video with that very

shape of vanes. (I don't suppose the shape of the wide end matters very

much, so the simple "V" might be just as good as the Savonius "half

barrel" with a "V" on the outside.

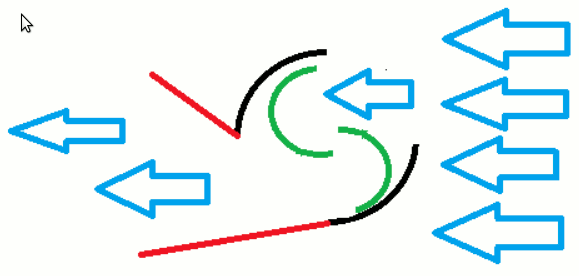

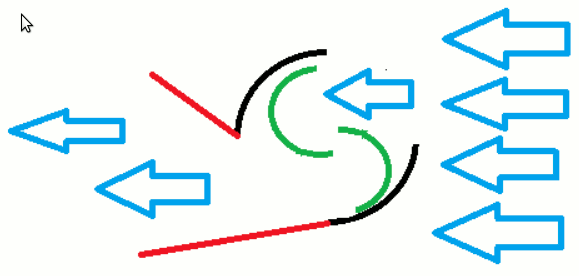

3. The "Reverse Funnel" concept. A funnel

trying to push air into the

side of the unit moving downwind to increase the velocity didn't seem

to work very well. But they noted that Japanese (and earlier)

researchers used a "reverse funnel" in tidal power units to create a

low pressure region that would increase water flow. They drew a

two-dimensional

version of that should pull more air in.

3. The "Reverse Funnel" concept. A funnel

trying to push air into the

side of the unit moving downwind to increase the velocity didn't seem

to work very well. But they noted that Japanese (and earlier)

researchers used a "reverse funnel" in tidal power units to create a

low pressure region that would increase water flow. They drew a

two-dimensional

version of that should pull more air in.

The students concluded that they hoped their work might help future

research. Thank you!

I noted the reverse funnel concept last month, and that an

"outside rounded" entry side also helped the flow. But I still think

the full venturi form with larger entrance as well as larger exit would

be optimum - assuming one is going to go to the trouble of building

such forms around the outside of the rotor. The low pressure caused by

the exit funnel will cause the air to suck into the entrance funnel for

maximum effect. To be applicable to shifting winds, it would have to

rotate to face the wind. But then one should get the performance of a

unit with a much larger rotor than it actually has.

That's really pretty similar to the tide power ideas.

A conclusion of mine - for "Savonius Vanes" rather than

"propeller" or Darius "Airfoils" - It's basically the wind pushing on

"X" amount of surface moving away from the wind, below the wind's

speed, that determines the available power. Subtract from that the wind

force trying to slow down the other side of the rotor that's coming

back upwind.

Considering that, the most important features are the

surface area catching the wind while going downwind, and the

effectiveness either of the shrouding or of the vanes to shed the wind

going back upwind. Going downwind, the vane's shape is much less

important than its effective area, provided it doesn't "spill" much

wind. Going upwind, for fixed vanes, I think the point of the "V" cross

section seems like the best shape to spill the wind. And the broad end

of the "V" isn't going to spill much wind going downwind, so it's

probably the best overall profile.

I'm also wondering (again/still) about pivoting vanes. In

this case, if the inside of the "V" was free to flap closed against the

outside, it would snap closed when it pointed straight into the wind

toward the end of the downwind leg, and turn the vane from a "V" into

an angled flat vane ("/") going around the downwind side. After a short

segment of mild reverse thrust (depending how wide the angle of the "V"

was - at 90° or wider there would be none), this would be angled to

push wind and then have actual lift to propel it through more of the

rotation, then it would point straight downwind to cut in half the

upwind leg drag. As it came toward the upwind side, it would gradually

open, and assume the "V" shape again for the push from front to back

again.

A bonus feature is that if the unit was spinning too fast,

the "V" would be pressed against the outside by centrifugal force and

wouldn't open readily, reducing power.

So there are two similar concepts and one rather mutually

exclusive that might perhaps be profitably explored:

1. A rotor with "V" vanes might be the most effective simple fixed vane

'Savonius' VAWT. Whether this would optimally be vanes on the outside

of "spokes" or big vanes in the overlapping Savonius configuration

might have to be tried to find out.

2. A rotor with inside-face folding "V" vanes (on spokes...?) should be

still more effective, and partly or even largely eliminate the value of

an outside shroud.

3. An outside shroud that forms some sort of venturi, shaped to feed

and to extract air from the proper sides of the turbine, with "funnels"

as in the Worcester drawing above, but both in front of and behind the

turbine. Does it matter that "Savonius" rotor speed is less than wind

speed if the venturi has accelerated that speed 2 or 3 times where it

hits the vanes?

Of course this adds a big cumbersome structure which would

have to rotate to orient to the wind direction, but the power is taken

from the wind across that whole structure instead of just from the size

of half the spinning turbine, so the potential power is as great as

that of a a much larger simple rotor.

If one has gone that far, the rotor might as well be

entirely enclosed in the venturi housing. (with screens to keep bug and

birds out?) And then, might a Tesla Turbine (see TE News #106, Nov.

2016) not be better inside the arrangement than a turbine with vanes?

We see here that we have moved completely away from the simple savonius

VAWT to some much more sophisticated type of wind power system.

Optimized entry and exit funnels of the venturi would

probably not be the same size and profile. If the design could be made

to swirl the air inside in the direction of rotation on its way

through, the greatest gains might be made. I think that's what the

Worcester authors were getting at in the drawing below. (Was this

outside section supposed to be stationary, or a 6-blade rotor? You