Turquoise Energy Ltd. News #127

covering

December

2018 (Posted January 7th 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month

In Brief

(Project Summaries etc.)

-

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- No Clean Air Anywhere - Hybrid Potatoes? - Yikes! More California

Fire Stories? - Wonder Weather - BC

Referendum on Proportional Representation Results - ESD

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (no reports)

Other "Green"

Electric Equipment Projects

* Carmichael Mill Handheld Bandmill (more operating than building this

time) - Bonus Tip: stack excess firewood under a tree to dry

Electricity Generation

* Solar: Storage & Going Off-Grid, CAT & HAT plugs &

sockets - Real Life "Off-Grid" Tests during power failure

* Magnetic Flipping HE Ray Energy? - Dual Frequency Pulses - more tests

and trials

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Oxalate electrolyte)

* Ugh! Zinc hydride!

* Hydro - water storage

* Problems charging oxalate - JUST calcium hydroxide as electrolyte?

New Chemie Batteries

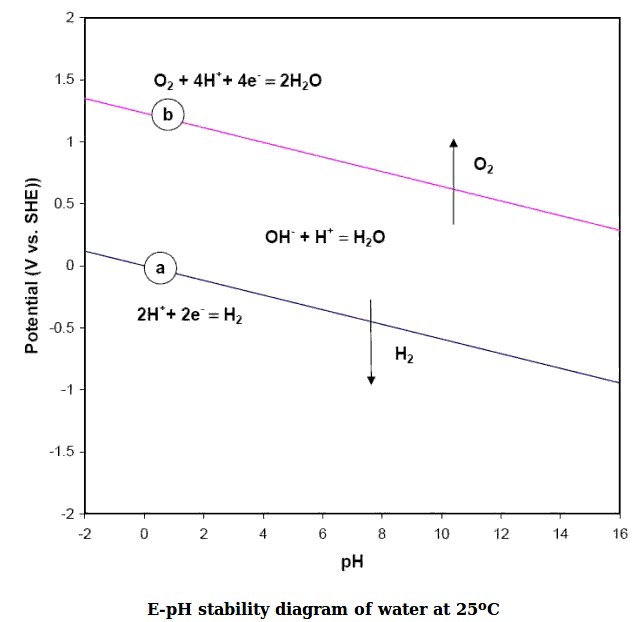

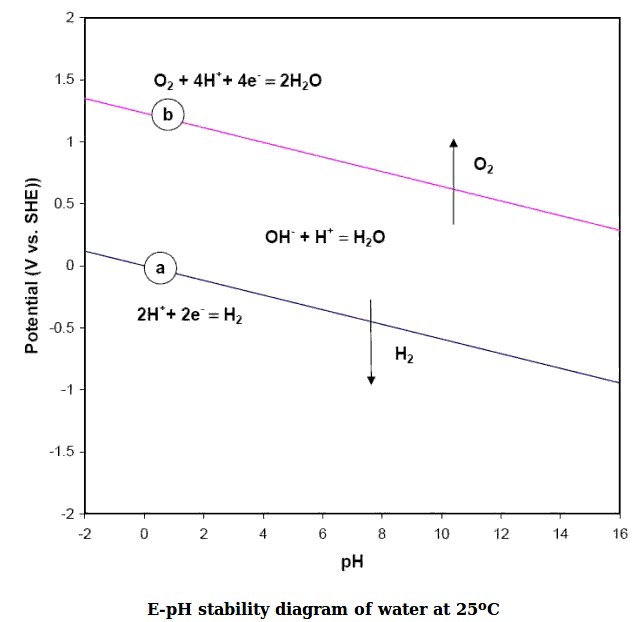

December's battery experiments disclosed several things I

hadn't understood or figured out before. First, it looked like the

whole oxalate idea just might have to be

thrown out the window. Whatever its other properties, oxalate seemed to

keep both nickel and manganese oxides from charging. (What did it do

with lead oxide? I can't remember and

can't be bothered to look back at that issue.)

What might I use for an electrolyte then? I was and am

very loathe to go to potassium hydroxide. After all its pH 14 solutions

are what causes zinc electrodes to degrade. The pH 12 where zinc

doesn't (according to the table) form a soluble ion had the promise for

long life, even everlasting, zinc electrodes. It finally, after all

these years, occurred to me to try just calcium hydroxide. That

had seemed like a silly idea because it's so little soluble. In fact,

that's why it's pH 12 instead of 14. But the result of very low

electrolyte concentration is just low current capacity per square

centimeter. Perhaps the best

answer to that is just to have more square centimeters. That's

certainly what's done with lithiums, which are made of very thin folded

up

sheets.

However, I'm going to try sodium oxalate before I give up

on the oxalate idea - either by itself or as an additive with the

potassium oxalate. Sodium-hydrogen sulfate seems to work wonders with

lead-acid batteries, so the sodium ion may act as a catalyst of sorts.

By itself it's not as soluble as one might hope, but 20 times more so

than calcium hydroxide.

Everything Else

Much of the month was pretty cold or windy and rainy,

which precluded working too long in the workshop or outside.

I wanted to continue (however slowly) with the reluctance

motor, but I only got as far as grinding off November's crooked weld-on

of one "salient pole" on the rotor.

I set things

up better and did a couple more experiments

with the magnetic flip HE ray

converter, still without notable results, but I did learn a couple of

things. The oscilloscope showed I

had had some things wrong in my perceptions of what was happening with

the pulses. Now... perhaps an L-C tuned circuit can get some better

higher voltage switching happening?

I set things

up better and did a couple more experiments

with the magnetic flip HE ray

converter, still without notable results, but I did learn a couple of

things. The oscilloscope showed I

had had some things wrong in my perceptions of what was happening with

the pulses. Now... perhaps an L-C tuned circuit can get some better

higher voltage switching happening?

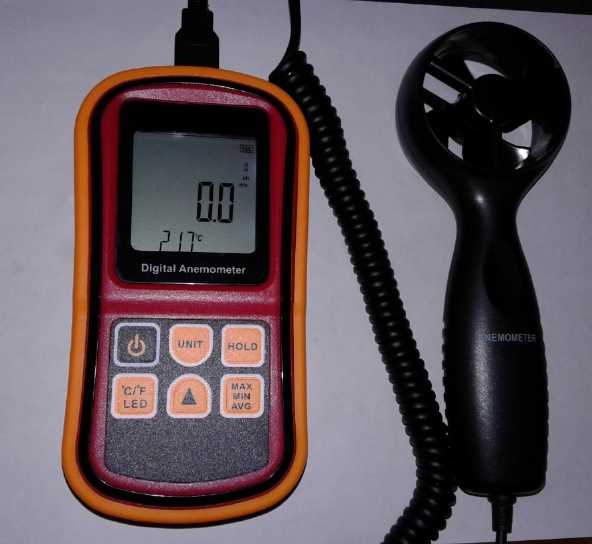

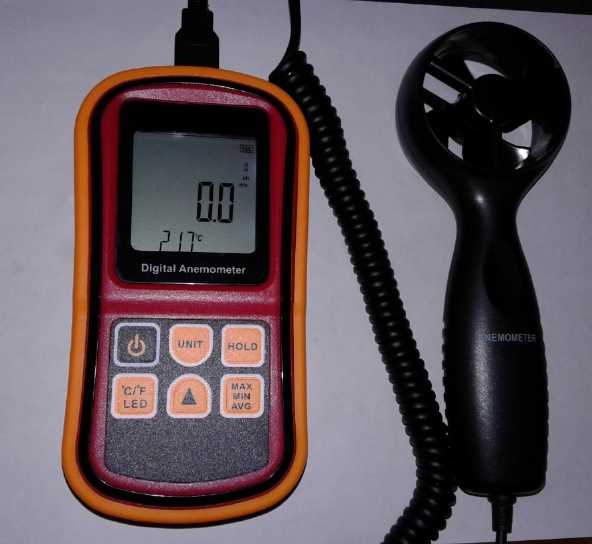

Being unable

to find either of my two anemometers for months, and even finally when

I

wanted to measure wind speed while I was trying out the VAWT, I ordered

another one. Quite a nice one this time, and I could take the

measurement part and tape it to a pole to check wind higher up while I

read

it from the ground. (The cable, whatever each wire actually did, had a

"USB" plug into the meter so I could add on a USB extension cord for

more length. I have trouble believing the reader unit actually sends

USB.)

Being unable

to find either of my two anemometers for months, and even finally when

I

wanted to measure wind speed while I was trying out the VAWT, I ordered

another one. Quite a nice one this time, and I could take the

measurement part and tape it to a pole to check wind higher up while I

read

it from the ground. (The cable, whatever each wire actually did, had a

"USB" plug into the meter so I could add on a USB extension cord for

more length. I have trouble believing the reader unit actually sends

USB.)

As I found, for wind power nothing is as important as

finding where the most wind is.

Where would I keep this one so I could find it when I

wanted it? I decided to put it on the shelf with my various voltmeters.

On the back of that shelf I found the better of the two missing ones.

The same

day the other one turned up in a messy drawer I had already looked in.

Sigh!

And speaking of wind power

I found yet another VAWT video, by "New Forest R & D" that claimed

to be the world's best. It was a sort of a self-starting Darius rotor

that spun faster than the wind speed. It certainly seemed to spin well.

Unfortunately one couldn't make out the airfoil shape from the video.

(Someone commented on the silliness of making "tilted" blades, which

showed his own ignorance of how the unit is turning and has rotated

farther by the time the digital camera scans from the top to the

bottom. It would be easy to be fooled like that if I hadn't just seen

the effect in photographing my own rotor.)

And speaking of wind power

I found yet another VAWT video, by "New Forest R & D" that claimed

to be the world's best. It was a sort of a self-starting Darius rotor

that spun faster than the wind speed. It certainly seemed to spin well.

Unfortunately one couldn't make out the airfoil shape from the video.

(Someone commented on the silliness of making "tilted" blades, which

showed his own ignorance of how the unit is turning and has rotated

farther by the time the digital camera scans from the top to the

bottom. It would be easy to be fooled like that if I hadn't just seen

the effect in photographing my own rotor.)

If one could estimate the "wing" airfoils for optimum

lift/thrust, this one, perhaps a two-tier version, might be more worth

building than the simple "windjammer" Savonius types I've been trying

out.

On the 15th

there was a big windstorm that blew down trees

across the highway and across the power lines in several places. On the

evening and next day while the power was out I finally installed some

of the solar power equipment that was sitting around and this is

written up as a project below. I was glad I had at least put the solar

panels on the roof last summer. Now necessity induced me to install the

charge controller and the 36 volt, 100 amp-hour NiMH batteries formerly

from the Mazda RX7-EV.

On the 15th

there was a big windstorm that blew down trees

across the highway and across the power lines in several places. On the

evening and next day while the power was out I finally installed some

of the solar power equipment that was sitting around and this is

written up as a project below. I was glad I had at least put the solar

panels on the roof last summer. Now necessity induced me to install the

charge controller and the 36 volt, 100 amp-hour NiMH batteries formerly

from the Mazda RX7-EV.

Using the 36 to 120 volt inverter wired to the Sprint EV

car, I ran the fridge and the freezer toward the end as the ice cream

had

started to get very soft if not to melt. I was especially concerned

that the well pump was 240 volts and I have no 240 volt inverter. I had

to forgo a shower even while the water in the tank would still have

been hot. But later in a store I found all the well pumps seemed to be

240 volts, so I guess I need to get an inverter for 240 volts. Keeping

the hot water hot in an extended outage is a problem for which I see no

simple solution. A water loop to the woodstove is a big plumbing job,

and the extra tank needs to be placed somewhere.

I got a fair

bit of lumber milling done with my

handheld "Carmichael Mill" in spite of cold and rain, and I got the

automatic band sharpener working pretty well. Milling after the last

sharpening seemed as good as with a new blade.

I got a fair

bit of lumber milling done with my

handheld "Carmichael Mill" in spite of cold and rain, and I got the

automatic band sharpener working pretty well. Milling after the last

sharpening seemed as good as with a new blade.

After one more cant, I'll be able to clean up a part of my

driveway and drive around the circle, for the first time since I had

the trees cut down shortly after I bought the house. Wow!

The last 1/3 of the month

was a "write-off" - for energy

projects - as I went to my Mom's in Comox and then to Victoria for

Christmas visiting and some shopping. In that shopping I did get a 6

foot (x 1 foot) roll of .005" copper sheet/foil at Metal Supermarket

for making battery electrode pockets from in case I manage to make

working cells. (I hope that's not too thin. Their next choice copper

sheet was way thicker - .032" or something.)

I got back on January 2nd and didn't get going on

finishing up this newsletter until about the 4th, and even then not in

any hurry. (Do I have a deadline? well, I usually try!)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

No Clean Air Anywhere

From what I've read

lately it appears there is now no clean air anywhere on the planet.

There is a considerable and increasing aggregate global level of

combined "EO-TOX" toxins we all breathe. At this point the Earth can't

clean its air of some of these without human intervention. That will be

a long,

slow process requiring new technologies to be developed. Even then for

that to work, first we have to stop polluting. Period!!!

The aerosol spraying program, now running evidently for

around 30 years, may not have made the world cooler, but it certainly

is helping to destroy it and poison the inhabitants. With the aluminum

and barium particles now in the air along with all the rest of the

eo-toxins being pumped into it from cars and trucks, factories, fossil

fueled power plants and heating systems, fertilizer and pesticide

spraying, nuclear

plant "exhaust" and other sources, apparently poor air quality has

become a recognized or

unrecognized contributing factor directly or indirectly in maybe 1/3 of

all deaths each year.

There are even still radioactive particles in the air from atmospheric

atomic bomb tests of the 1950s. (As a kid I remember we had to send off

our baby teeth for analysis when our adult teeth grew in because the

damage of these tests was being recognized. The Earth's Van Allen belts

grew stronger after each test, IIRC, and only very gradually subsided.)

Furthermore the ozone layer is evidently still getting

thinner. So

far it means increasing skin cancer levels, and is perhaps a factor in

some of the mass die-offs occurring around the globe. At some point

plants everywhere might start dying of short UV ray radiation and then

the deterioration of the atmosphere could become irreversible and

extinction of life would follow. I don't think we're there yet, and the

collapse is coming to help bring about an end to some of our

destructive ways, so, surely, it won't progress that far.

I myself had no idea things were this bad. Why did I

start reading along such subject lines? Maybe better not to know?...

but then again, maybe it helps explain my occasional coughing fits in

the last couple of years. After all I don't smoke... or do I? In this

and every remote corner of the world they chem-spray.

I bought an "air purifier" with a washable filter for the

house when I went south for Christmas. My present woodstove smokes

badly whenever the door is open - more pollution generated right in the

house. (I'll be replacing it next winter.) It said "whisper quiet" but

as I feared it turned out to be sort of an industrial sounding WHISPER! Noisy fans are everywhere!

So I run it at night on low at the opposite end of the

house from my bedroom. Hmm, I think it might be helping.

Hybrid

Potatoes?

I left my potatoes from last

summer in the ground because they seem to keep better there. No doubt

if the ground froze very deep down, or perhaps if the soil had some

composition other than very sandy, that wouldn't work so well. I'm not

a big potato eater. I dug up a few on January 3rd after returning from

Christmas in Comox and Victoria.

I left my potatoes from last

summer in the ground because they seem to keep better there. No doubt

if the ground froze very deep down, or perhaps if the soil had some

composition other than very sandy, that wouldn't work so well. I'm not

a big potato eater. I dug up a few on January 3rd after returning from

Christmas in Comox and Victoria.

There's white and red skinned potatoes with white flesh,

yellow "yukon gold" potatoes with yellow flesh, and here we have purple

"haida" potatoes with purple flesh, light or very dark purple. The last

bunch I dug up were "haida". This time I just dug up 3 from a different

part of the garden for supper. Whatever are these? They have white

flesh.

I thought I had grown all my potatoes from the previous

year's potatoes, but with this skin they seem to be a hybrid or

something. Perhaps

some potatoes seeded themselves from the flowers and cross pollinated?

Anyway they're quite colorful potatoes! (Hmm... somebody might actually

pay extra for the colors!)

Yikes! More

California Fire Stories?

In a video (again by "aplanetruth") the author mentions

the population of Paradise, California as being well over 50000 people

going on more than one source. And the Weather Network said 18000

structures were destroyed. (Oops, was that in the Camp Creek

Road/Paradise fire, or overall for the state?) The media said the dead

were under 100,

and the "unaccounted for" peaked at 1200 but dropped to just 25 after a

couple of weeks. That sounds so good until it's turned around and the

people accounted for are counted instead, along with knowing

there were so many thousands of houses destroyed.

The author said he went around and found around 600 people

at the refugee camps. Doubtless some people would have driven off and

found other accommodation - friends, relatives, motels... That

might account for one or two or three thousand people. But say it was

5000... what happened to the other 45000

people? And in the surrounding area - more thousands?

The fire came on so fast and ignited so many places at

once that the main road in and out - with mountainous flames on both

sides and covered in dark smoke - was quickly jammed with vehicles.

There are a number of videos (dash cams?) from people who drove through

this inferno and made it out. Others abandoned their gridlocked,

burning cars and ran, but where could they go? The entire town was

obliterated. How could most of the population possibly have got out? A

tow truck driver said he counted over 200 bodies on a short trip in.

But many were burned until hardly charred bones or even just ash

remains.

The author said there are plenty of residents who aren't

posting to facebook and twitter any more, and he is starting a web site

hoping to find out what happened to them all. One starts to get the

impression of deaths on a similar scale to the nuclear bombing of

Hiroshima (50000).

In another video, a person recounted how he had been

through a big California fire before many years ago (he named the fire

and date)

in similar dry conditions, and how in spite of the wind it took hours

for it to spread from where he saw the first smoke to threaten the

town. This fire was completely different, he said. Even while the fire

seemed far away and there were no obvious flying embers reaching the

town,

pretty soon his house and the whole town was engulfed in flames. So he

ran to his car and left, within two minutes of first seeing fire. He

said he luckily had oxygen in the car, and that if he had taken two or

three more breaths he'd probably have died of smoke inhalation.

Apparently he got out before the gridlock hit, or missed it somehow. Do

we suppose his neighbors all got out okay?

There are some videos of the burned town, but evidently

the military has now taken over and no one is allowed in. Is there

something to hide? Where are the 50000 residents who want to see what's

left of their homes? Given the seemingly impossibly small 'casualty'

and

'missing' figures being spouted by the media, are they there to hide a

mass genocide? And "aplanetruth" is not the only one

calling it "mass murder". (The names, the names... Where would be a

copy of the Paradise phone book?)

I'm leaning toward to the conclusion that several

presenters are

right and that it's being done with "directed energy weapons" ("DEW"s)

- infra-red lasers or something similar - from aircraft. It would also

explain the "two sides of a rectangle" Fort McMurray fire perimeter

quite well.

Inventor Nicola Tesla offered the US military a "death

ray" of some sort during world war two, and his papers were seized by

the government when he died. And apparently they have been developing

"DEW"s since about 1998 with a budget of several billion dollars, so it

would be almost more surprising if they haven't come up with anything

than if they have. If this is really what is happening, perhaps we

should be grateful they're now using them on their own people instead

of on others, which could spark a world war.

But there are also some less bizarre aspects to these

fires; the ones that leave you saying "Well, that figures." With

housing so costly in and around the big cities, notoriously San

Fransisco, new

communities have been permitted to sprout up on "interface" border

lands between the urban and the seasonally very dry woods. They are

designed to lax standards with meager road access and laxly enforced

building codes and fire safety regulations. In short, they're thrown

out there into iffy zones previously thought to be unsuitable for

housing, because of population pressure, which makes them "accidents

waiting to happen." -- another result of the planet being

overpopulated. Then again, what about images like this? (here, in

Malibu):

Forest fires burn down houses and leave

the trees?

Forest fires burn down houses and leave

the trees?

(...But how long after the fire was the picture taken?)

I'm definitely going to have to stop watching these

disturbing California fire videos! Just as with VAWT and many other

video topics, once you've watched a couple, Youtube keeps putting more

and

more of them in front of you as "suggestions".

Instead, maybe let's

follow the main

inhabited part of Alaska, where the ground has not stopped shaking

since the November 30th 7.0 quake? (but Alaska Earthquakes Center says

it isn't unusual - and okay, it finally looks a little more solid with

the

new year.) High waves and extensive coastal flooding are in store

for California this winter according to NOAA. If the worst predictions

for

much of the state sinking into the sea hold out, fires however started

may soon be the least of their problems.

From one video (by "Suspicious Observers", who

have a good record for earthquake prediction based on solar magnetism

patterns) I found out a theory for why there might be more flooding

than

just sea level rise would account for. It seems that (as I understand

it) as the ice sheets retreat

in Greenland and Alaska, the pressure on the mantle under those areas

is reduced, and the crust rises up. The mantle flows (seemingly from

especially the eastern and western seaboards farther south), causing

coastal California as well as South Carolina and most of Florida to

subside under the oceans. It is well known that Miami and New Orleans

will have to be abandoned just from sea level rise, but people there

are "in denial"; still

erecting new buildings in Miami and trying to improve protective

earthworks in New

Orleans.

Or how about the smoldering

Yellowstone supervolcano, its caldera 35 by 45 miles across, where new

geysers are chewing up the

walkways and roads and perhaps even the monitoring equipment? Is a big

eruption far

off as many insist, or it could blow very soon as some think. Mount

Saint Helens (its eruption in 1980 was heard from my house in Victoria

BC) was an anthill compared to Yellowstone.

Maybe some old British comedy shows would be a better

viewing choice?

Wonder Weather

But no, I had to check out

some more shows, on weather, and found the nastiest hail storms ever

recorded, from this last summer. In

South Africa (IIRC) one broke trees and killed cattle. One in Australia

only

killed

sheep (oops, and kangaroos). So in addition to the usual "once in 1000

years" droughts and floods, record high temperatures, record low

temperatures

and record breaking hurricanes, we now have nasty hail storms that

rain ice balls the size of golf balls and even base balls.

Hail Storm in South Africa as seen from the

outside

Hail Storm in South Africa as seen from the

outside

It did this to this piece of forest (saplings?)

and it killed cattle

On Haida Gwaii we've had no snow (or hail), but one morning I

found a

strange "frost forest" covering the ground and on my car.

BC Referendum

on Proportional Representation: Results

Well, I guess there really are a lot of "sheeple" out

there.

Everybody complains about autocratic, dictatorial government decrees,

but the

proposal to reform our primitive, unfair and polarizing voting system

was rejected by 61% of BC voters (of the less than 50% who bothered to

mail in their post-paid ballot).

Reading some reader comments under the news story was

disheartening. I began to see the low levels of social awareness of the

general

population. To me, most of the "reasons" for voting against the

proposal seemed to be "cop-outs" - illogical rationalizations for

deciding not to take the trouble to give the matter any thought. Just

be negative

and nothing will change. That way it's impossible to make a worse

choice than the existing one. (It was impossible to make a worse choice

than that anyway.) Some thought it was just a waste of money. Some said

it was "too confusing", that "too many options" had been offered, so

(in spite of the option to simply vote "yes" and let others decide

which option to pick)

they just voted "no". Many voted against this measure to improve

election of governments just because they "don't trust the

government" - so "it must be some kind of trick" to get more money or

take more freedom from us! Premier Horgan and others in the new BC

government expressed disappointment with the result of what they had

championed as a means to change our polarized politics.

The one argument that seemed to me to have some merit was

that if a "majority government" isn't elected, it's hard to govern.

Decisions get bogged down in partisan bickering.

An unfair electoral system is the only way to get majority governments.

("Majority government" meaning over 50% of the entire legislature are

all from

just one political partisan sect ("party") - so much for the ideal of a

legislature being "a representative cross section of the society")

But that just highlights the need to separate the

executive branch from the legislative so that governing is separate

from legislating. Ideally both improvements - electing a 'governor'

separately from electing 'legislators', and picking a fairer electoral

system - would be adopted simultaneously.

We will not get another chance to make even this small

improvement to our governing systems before governments as a whole

start to lose cohesion and nation become largely ungovernable. And

obviously we'll need improvements to be offered

and promoted by local social sustainability design teams before the

general public will think proposals for improvements have credibility

and aren't something being foisted on them by corrupt leaders wanting

more control.

ESD

(Eccentric Silliness Department)

* Ducktors are just a bunch of quacks.

* Just when did "cocoa butter" become "white chocolate"? And when did

cadmium (as in screw and bolt plating) become "yellow zinc"?

* Russian anti USSA propaganda? "For 50 years, we wanted to live like

you. But no longer!" - Margarita Simonyan, head of RT.com . Maybe

it's because we don't have that life any more either. "The free world"

seems to have shifted markedly to the East.

* How many Microns in a Macron?

* The above mention of lax building standards in California raises

further questions...

- Can you relax without first having laxed?

- Can you relax when flying into LAX in a malfunctioning airplane?

- Are LAX (Laxton's Progress) peas better than Green Arrow peas?

- Do Green Arrow peas fly straighter than that airplane you're on?

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Other "Green"

Electric Equipment Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

[ 20 minute Video: "Carmichael Mill Update" https://www.youtube.com/watch?v=P7r6hQF3yg8

]

Other than

modifying the automatic band sharpener to get

it to work for my type of bands, which are lighter and have much finer

teeth than most bandsaw mill bands (3 per inch instead of about one),

there were no new developments in this project except the "Carmichael

Mill Update" video posted to youtube.

Basically it's a prototype that's working well and cuts

good, if often somewhat wavy, lumber. (More band tension and using

sharp bands minimizes waviness.)

Other than

modifying the automatic band sharpener to get

it to work for my type of bands, which are lighter and have much finer

teeth than most bandsaw mill bands (3 per inch instead of about one),

there were no new developments in this project except the "Carmichael

Mill Update" video posted to youtube.

Basically it's a prototype that's working well and cuts

good, if often somewhat wavy, lumber. (More band tension and using

sharp bands minimizes waviness.)

I cut the largest 16 foot long

spruce cant into eighteen 1"x8" x16' boards in the single digit days of

December. A chainsaw mill would have only made 12 or 13 boards and the

rest would have been sawdust. I put them up temporarily on the trailer

shelter walls with

deck screws, to block the wind and rain. (I screwed on the vertical

stick

seen in front and slipped the right end of the top two boards in behind

it

as they were too heavy for one person to lift and hold in place from

one end while screwing them on from on a

ladder. ...Left side: wall studs on 16 foot centers?) Everything held

in the big wind storms. It would be drier underneath if they covered

all 24 feet of the windward end, and from bottom to top.

I started on the cant that was

underneath that one on the 12th.

While the sharpener took the better part of an hour sharpening each

band, and each one cut only 3 to 5 of the wide boards in the

tough-milling spruce, at least I didn't have to do the tedious

sharpening by

hand. It

allowed me to keep cutting instead of running out of sharp bands. One

band, sharpened 3 times, didn't seem to stay sharp long after the third

go. I switched to another one and once into the narrower cant, I got

quite a few good boards with it.

I started on the cant that was

underneath that one on the 12th.

While the sharpener took the better part of an hour sharpening each

band, and each one cut only 3 to 5 of the wide boards in the

tough-milling spruce, at least I didn't have to do the tedious

sharpening by

hand. It

allowed me to keep cutting instead of running out of sharp bands. One

band, sharpened 3 times, didn't seem to stay sharp long after the third

go. I switched to another one and once into the narrower cant, I got

quite a few good boards with it.

A guest watched my video and thought the mill could be

mass-produced to sell for 400$. He's probably right. I've thought about

making them, but I seem to be on to other things - except for cutting

up my own spruce. I'm thinking I may, after all, someday get through to

the

end of the ones blocking the driveway and be able to drive around the

circle again. 2-1/2 big cants to go (and one to sell as-is for a big

beam) as of the 13th.

One

development perhaps of note: I finally got the automatic band

sharpener working well.

One

development perhaps of note: I finally got the automatic band

sharpener working well.

Earlier I put a bolt in closer to the center so the pusher

would

only push one tooth through at a time instead of two or three, and I

moved the rod from the

grinding wheel closer to the hinge so it went up and down less. Even

so, this month there was another thing: I put in a piece of sheet

aluminum on the turning cam so the grinding wheel travelled up and down

still less for each tooth. Then it didn't dig crazily far down in the

gullies between the teeth.

The next band cut like new again! The bottom of the cant

took about 4 minutes per cut for all three cuts, instead of 8 minutes,

10 minutes and 12 minutes with each cut being slower than the previous

one.

I may not report on the mill again unless there's some

interesting development, or if I'm especially proud of something I've

done using it. It's sure nice, with so many puzzling failures and

setbacks in other projects of potentially priceless value that I just

never seem able to finish, to have one nice one that I can say is done

(in

just one year!),

works great and I'm using it heavily, and which has advanced the state

of the art in

something. (Self-adjusting band guides seem to have never been thought

of before.) It cuts using less power and turning a thinner kerf into

sawdust than any other mill anywhere.

The mill (from the front) near the start of

January.

The mill (from the front) near the start of

January.

The original skillsaw's gears wore out - their

grease was gone - and it had to be replaced.

(Must open this one up and check the grease occasionally!)

Solar: Storage

& Going Off-Grid,

12 & 36 VDC, CAT & HAT Plugs & Sockets

I still had the Honda

Insight batteries, a total of 32 sets of 6 NiMH super-high-current

cells welded together.

They had proved to be a frustrating setup, yielding as I saw it a

nominal 7.2, 14.4, 21.6 or 28.8 volts, which were all too far off to

use for 6, 12 or 24 volts. But I should have gone one further: 5 sets

in series makes 30 cells for 36 volts nominal, which is the voltage I

was saying

earlier is an optimum DC power voltage: 1/3 the current and wire size

of

12 volts, yet low enough voltage that no one will be electrocuted from

touching it. And it fills the gap right in between: at three times 12

volts it's also 1/3 of 120 volts common AC grid line voltage. (I

"officially" defined it as

38 volts with +/- 15% tolerance: 33-43.7 volts, which allows for all

the common "12 volt" battery types in all states of charge including

being under

charge. [Except high voltage pulse charging. If that is in use, the

power may need to be filtered to protect appliances/equipment.])

6 sets of 5 cell stacks, which are either 6.5 AH or 8 AH,

would give 39 or 48 AH of very high current capacity storage. They

would have no trouble running high load appliances, like perhaps the 36

volt to 120 volt inverter as it turns on the fridge or freezer. To that

could easily be added 100 AH in the form of my three 100 AH regular

NiMH D cell batteries for more storage capacity. And about another 100

AH of miscellaneous NiMH D cells if I wanted to add them in. These are

all surplus since I took them out of the Mazda RX7 EV some time ago and

with sufficient solar panels could tide one through a very long power

outage - at least in the summer.

Real Life Off-Grid Tests

Well, on the 15th came the opportunity - in fact the need

- to test things out. There was a strong wind storm up to 120 Km/Hr or

higher. I

went to a cafe for lunch. The road was cluttered with small branches.

The whole building shook. It was predictable: At about 4 PM the power

went

off. At 8 PM it came back on for a short time (10 or 15 minutes?) and

then went off again. At about 4:30 PM the next day, 24-1/2 hours later,

it came on and stayed on. I wondered how many

trees fell across the power lines in the tempest? A couple of days

later I saw a couple of pairs of them on a trip into town:

Looking south; Hecate Strait [ocean] to left

Looking south; Hecate Strait [ocean] to left

Another spot, Looking north

Another spot, Looking north

The outage demonstrated

that I was less prepared than I

thought. One thing I did have was of course the woodstove and

firewood, so there was no interruption to the heat. (And I had just

noticed a video suggested by youtube from Canadian Prepper: "You won't

last one off-grid winter without one of these.", with a picture of a

wood stove. Those living in regions with cold winters should take note

as people here and there have been without power for extended periods

recently.)

People talk of cooking on a woodstove, but my experience

is that the top of any newer "high efficiency" model is never really

hot enough to boil water. For coffee I put water on the stove for

hours, then I brought in my propane camp stove to get it boiling. It

didn't take much propane that way. In the morning I very, very

gradually cooked a pancake directly on the wood stove.

Electrically was where I wasn't so prepared. I had all the

pieces, and 1000 watts of solar panels sitting on the roof, so I was

surely far more prepared than most - but nothing was hooked up. It all

had to be installed and wired. In the gathering gloom I couldn't find

the 3 KW, 36

volt DC to 120 volt pure sine wave inverter. The just charged Honda

batteries

weren't all wired together for 36 volts yet. All my other big 12 volt

NiMHs proved to be pretty discharged, and they were the ones with 12

volt CAT sockets wired on so you readily could plug 12 V lights in. I

was hard pressed to put on a couple of low power lights for a few hours.

I thought I'd like to try two 12 volt LED globe lights

with round "power adapter" sockets on them. I found a wire with a

"power adapter" plug on one end, but I had to put together a CAT plug

for the other end. For that I had to find another battery that would

power an inverter so I could run the soldering iron. I also had to

grind the

few roasted coffee beans that I had to brew a small pot. (I keep

telling myself to keep some ahead in case of a power failure, but they

always seem to be all gone before I roast more.) I left the inverter

turned on but running nothing and within 1/2 hour its low voltage alarm

started going off - it had sucked what little charge that battery had

out

all by itself powering nothing. Making the cord paid off because one of

the globe

lights in low power mode drew only 90 mA - barely over a watt, yet it

was enough to see by. Surprisingly bright. I could leave that on all

evening even with the low batteries. (The 15 watt 12"x12" square flat

panel light was way more light, eg for reading, but drawing 1.25 amps,

the batteries wouldn't have been up to it for very long.) As always I

had my 6 volt bedside light with 5 D cells, which I do use and usually

keep well charged. Another 12 volt light sufficed for the kitchen to

make coffee and food.

The most problematical thing of all, which had been

preying on my mind ever since moving here, was that the well water pump

is 240 volts. I couldn't run it without grid power, period. If I ran

much water, the pressure would be gone and there would be none. I saved

it for toilet flushing and short bursts of running sink faucets. The

shower I'd meant to have had to be put off even though there was plenty

of hot water in the tank.

If I bought a 240 volt inverter, it would be just for the

pump. And if it failed, I wouldn't have any other to use. I have

several inverters for 120 volt appliances. Plus the pump was wired

straight into the sub panel in the shop: even if I had the inverter,

I'd have to un-wire the pump and reconnect it, with the cover off the

panel. I added "120 well pump" to my shopping list. I'd wire it

plug-in so it can be plugged into an inverter if the wall is dead. But

in Canadian Tire on my Victoria shopping trip, I only found 240 volt

well pumps, and they were 300$ and up. Perhaps a 240 volt inverter is

the thing to get after all.

The next morning I disconnected the grid tie inverters

from the solar panels and put on the programmable DC to DC charge

controller. I set it to 42 volts and dragged in the 'pretty discharged'

100 AH - 12 V NiMH batteries, and set them in series. Over the course

of the cloudy, rainy day, the power from the 1000 watts of solar panels

went from 10 watts around 11 AM (or whenever it was I'd got it all done

by) up to almost 80 for a couple of hours and back to 10 by 3 PM. Short

cloudy northern days with the sun at a low angle aren't optimum for

solar. The controller said it had put a whopping 2.1 amp-hours into the

batteries, which just hit 39 volts.

I took the two pairs of wires, each coming from

two

solar panels, and tied them together.

I took the two pairs of wires, each coming from

two

solar panels, and tied them together.

(The screw terminals on the grid tie inverters are too short to put in

more than one wire,

the MPT7210A only takes one skinny wire per connection, and I didn't

have a heavy

terminal strip, so the connections are hanging in the air tied together

on two bolts - Ugh!)

The charge controller, set to charge to 40.5 DC

volts at up to 10 amps.

The charge controller, set to charge to 40.5 DC

volts at up to 10 amps.

I could float charge them up to 1.40 x 30 cells = 42.0 volts, but there

seems

no

reason to push them to the max if they'll be charged every day and not

much used.

(Solar panel input is usually 32 volts open, 29 volts charging, but it

was just getting dark outside.)

This unit works well, but the instructions are so inadequate for

setting up its many programmable

features that people have put up youtube videos that explain how to get

it to do what you want.

The solar panels are 1000 watts, but in the cloudy winter weather

with the low sun angle I

don't think it's hit 100 watts charging yet.

Three 100 amp-hour, 12 volt NiMH batteries to

make 36 volts.

Three 100 amp-hour, 12 volt NiMH batteries to

make 36 volts.

(Beside them are some 12 V, 10 amp-hour tubes. I'm connecting and

charging one each day

since I haven't got enough wires made up to connect them all together.)

Breaking the narrative here, Jim Harrington of AGO gave me

a link to the MPT7210A programmable charge controller and I got

two because they sounded like they would do just what I wanted. Now

from the many youtube videos about it, it sounds like this is in fact the

one to get for many purposes. It has a zillion ways it can be set up,

and even multiple setups can be programmed in. The biggest complaint is

the fan noise, which is terrible, and it blasts away regardless of

temperature. The speed is supposed to be programmable, but doing the

same thing that seems to work in a video does nothing on mine.

The other complaint is the complexity of operation. How to

use it goes from poorly explained to just not explained in the brief

manual. And there's nothing intuitive or simple to setting it up.

That's the main reason there are so many videos about it. There are

just four buttons, but they do many different things depending whether

the unit is charging or not, which one is pressed first, whether it's

held down or pressed quickly, and the entire sequence.

For example, to set it to auto-on when the sun comes up

and it powers up: 1. Hit "OK" to turn off charging. 2. Hit set about 4

times until "Amps" is highlighted. 3. Press and hold "Set" again a few

seconds. 4. Hit "Set" again 3 or 4 times until "OFF" is highlighted. 5.

Hit "up arrow" so it says "ON". 6. Hit "Set" again. 7. Hit "OK". Then

you can turn it on again by hitting "OK". The manual doesn't explain

this. I had to watch part of the video, go out and do the first steps,

then watch the rest of it and go out and finish it. I can't help but

think it could all be made a lot more intuitive even with just the same

four buttons and the same display. Meanwhile, back at the ranch...

By early afternoon the ice cream in the fridge's freezer

was melting or at least very soft, and the small chest freezer was up

from its usual -22°C to -10 under the lid, notwithstanding that the

room/garage it was in was probably only 7 or 8 degrees. (It was

probably colder down lower in the mass of frozen food.)

I got out the 36 VDC to 120 VAC inverter (I did eventually

find it) and connected it to the 36 volt, 300 amp-hour Sprint car -

half the storage of the Nissan Leaf, but accessible. I had been

keeping its batteries pretty well charged, and of course lithiums don't

self-discharge as fast as NiMHes. (How was it that I had to attach

wires

by removing nuts and hard-wiring up the inverter to the car instead of

just plugging it in somewhere?) I ran a 100 foot extension cord to the

house. I put in the Canadian Tire appliance power meter and plugged in

the fridge. It was using about 170 watts, which gradually dropped to

under 140, drawing around 5 amps DC from the batteries according to the

clamp-on ampmeter. I ran it an hour or more until it stopped. It soon

started again, but I unplugged it and plugged in the coffee roaster

(popcorn popper) and roasted one batch, taking about 3 minutes. The

1500 watt roaster would have used in 3 minutes what the 150 watt fridge

does in half an hour. After that I plugged in the chest freezer, which

drew just under 100 watts. By this time it was mid to late afternoon.

After an hour of that the power thankfully came back on. The car's

batteries had started at 39.6 volts. They soon dropped to 39.0, but

stayed there for the rest of the event. (Except when roasting coffee

they dropped a little farther, but came back up to 39.)

My conclusion is that while not much happened during a one

day off-grid event (other than frantically setting everything up and

wiring it, and missing a shower), a longer period would bring serious

hardships as things are

set up now. OTOH it was a good day to run around setting things up...

there's a whole bunch of other things one can't do anyway if there's no

power!

First and foremost, I definitely need a well water pump

that I can plug into a 120 VAC inverter (or else a 240 volt inverter).

Then,

for a period more than

two or three days, I need more power generation for lights, fridge and

freezer. The Sprint car, if kept charged, can run them for a while, but

not

more than a week or so. After that it would depend on the sun coming

out to recharge the batteries. And it would take still more available

power to

keep a computer or two running. Milling with the electric band mill is

out. Firing up the gasoline generator for fridge and freezer is a

stop-gap

solution for a few days. Combining the wood stove and the propane

camp stove for heat should suffice for meals and coffee for a very long

time. The woodstove would have to do for hot shower water, too. Ugh!

A 20 to 50 watt thermocouple generator to put on the wood

stove, that would run 24 hours a day, starts to sound like a good idea

again, if that's all that can be had out of solar panels in the winter

anyway. If the modern woodstoves don't get so hot on top as the old

ones, perhaps it could be done with TEGs ("Thermo Electric Generators"

- higher temperature Peltier

modules) without any special overheat protection needed. The number of

modules could perhaps be selected to send a voltage to the solar

controller similar to that of the solar panels - but it would work all

day and night.

And if I'm going to have my "optimum line voltage" 36-40

VDC system, I need to start looking for some appliances that use that

voltage. All I have presently for that voltage is the Sprint car and

the inverter. Maybe I can put three 12 identical volt LED lights in

series? It'll probably work, but it's a makeshift solution.

And I need to finalize the design and start producing the

"HAT standard" 38 volt

wiring products: Plugs, Sockets, electrical box Wall Plates, and so on.

In the meantime, I had the CAT plugs and sockets. After

doing some 12 V wiring I decided after all, there was little point in

changing the standard. CAT is quite good, fine as it is. There would be

no RAT (Revised CAT) standard. Changing it poses two problems. One is

that any little bit of traction it might have gained as an adopted

standard so far will be broken. It was probably even a mistake to say I

would change it some issues back. The other is that I haven't had time

even to set up the 3D printer. How much time do I have to redo what's

already done?

I had planned to make the 36-40 volt HAT standard plugs

and sockets about the size and shape CAT is now. What I do need to do

instead is make it different enough so that you can't accidentally plug

the one into the other and underpower 36 volt equipment on 12 volts or

blow up 12 volt equipment on 36 volts. Perhaps the thing to do would be

to make the proposed "RAT" standard, or something close to it, into the

"HAT"

standard. I guess nothing will be settled on HAT until I get on the 3D

printer and start making something.

I managed to cross voltages without HAT plugs. I had the

36

volt battery system on the solar panels, and during the power failure I

had connected one 12 volt battery of it to the wire running across the

house to the closet by the living room. I wired in a CAT duplex

receptacle there and ran 12 volt lights off it in the living room.

Later I had been charging some other batteries and used the alligator

clip jumper leads. When I reconnected to the wire, I absent-mindedly

connected it across all 36 volts instead of just 12.

When I turned on one of my 12 volt homemade LED lights, on

"low", it was amazingly brilliant for about one second, then it went

out. Oops, the "12" volts was 39! I moved the alligator clip wire.

Later I started taking the lamp apart hoping I could repair it. Wait!

There was a fuse! What a clever idea! Amazingly the 2 amp AT fuse had

blown and protected the lamp. I put in a new one and

it worked again.

But if I had connected the wire with a CAT plug to a CAT

socket - already present on each of the three batteries - instead of

with jumpers, the incident could never have happened. This just

underlines the need for proper and unique plugs and sockets for each

voltage: IMHO: 12 VDC, 36 VDC, and the existing ones for 120 VAC and up.

On the 19th I wired up my indoor garden fan, a battery,

and a 10 W solar panel with CAT plugs and socket. (Since the panel is

just 10 watts, I don't bother with a charge controller. I put a diode

in series next to the plug so it can't draw charge back when it's

dark.) Why had I been using aligator clip leads that keep breaking and

falling off for this little system all this time?

And I found the need for a couple more CAT type products.

First, If the solar panel is a power source rather than an appliance,

it should have a socket rather than a plug. But if it does, how do you

plug it into a battery that also has a socket? Apparently a plug-plug

"cheater" adapter is required. Second, I wanted to plug both the fan

and the panel into the battery at the same time. I have before put two

CAT sockets onto

a battery, but this time I thought it would be nicer to have a splitter

with a plug and two or more sockets on it, similar to those that grace

so many

120 volt wall receptacles because there are never enough of them.

Then, not to get too carried away, a very useful device

for off-grid power would be an in-line power meter with a plug and a

socket, to show the voltage and current. ...a low power one with an LCD

display that wouldn't itself drain the battery.

Finally after having them in use for a couple of weeks, I

am reluctantly forced to conclude that the 100 AH NiMH batteries are

rather worn out. One of them discharged itself from 13.5 volts to 12.7

overnight (about 17 hours) without a load. I think it was the continual

float charging in the RX7-EV that gradually wore them out. Better to

just charge them at a good speed and then turn it off and let them

rest. And they are several years old now. Of course they're also being

float charged all day on solar. For now in the dead of winter that's

only about 6 hours, and I turned that float down from 1.40 volts per

cell to 1.35 - total 40.5 instead of 42.0 volts. I expect the lithiums

take a float charge better because they stop drawing current once

they're charged.

But it all makes me the more determined to come up with

better, cheaper batteries. There's no way batteries should cost the

sort

of money they do. I keep thinking there can't be much more in the way

of getting a better, cheap chemistry to work as expected, after all the

progress I've made and all I've learned.

Magnetic

Flipping HE Ray Energy?

Okay, nothing

happened in my one try at powering the device up in November.

What else could I try?

* Dragging out the oscilloscope so I could see what's going on - actual

waveforms and voltages at various points.

* an antenna (Moray's earlier devices had one)

* a ground connection (Moray's devices all needed one, as I recall)

* Putting Diodes in series with the pulse source. 36 volt pulses are

nice, but since the motor controller doubtless

has rectification to capture the return energy, the big

spikes across the coil will be damped out. The big spikes

at turn-off of the pulse were a requirement. (How could I

have put that out of my mind?) If I put diodes in,

they can isolate the coil and let it fly. (When one works

it out, this was a mistaken assumption. The spike's reverse voltage

makes the diode forward biased anyway.)

On the 12th I thought, what was the real problem with

working on it and running tests? I started out in the summer with the

car out on the lawn. Now as long as I was using the Sprint car's motor

controller as the 36 volt pulse source, I was working on the floor of

the garage. It's winter and it's cold out there. Plus it's cluttered.

In fact, it's cluttered almost everywhere I work. Perhaps these were

the things I should deal with first.

Two things I could remedy quickly I did on the 13th: I

cleaned up the corner where I had been working, and I cleaned up a bit

of wood clutter by making it into a work table (long planned - just

needed legs), which I then set in the corner and picked the experiment

pieces up off the floor.

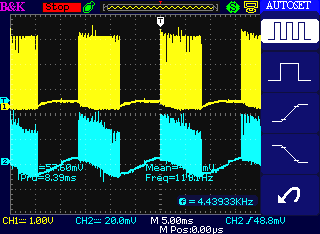

Dual Frequency Pulses

Having a table to set it where it was high enough up to see the

screen and where I wouldn't step on it or kick it, I brought out the

oscilloscope and checked just what pulses were coming from the motor

controller. It was set to 1.6 amps, the minimum, and I found it had two

components: a

low frequency "square wave" with the "high" part being composed of high

frequency pulses. The low frequency was 8 mSec of the spikes then 8

mSec off: 16-17 mSec. (60 Hz). The narrow spikes were about 3 uSec. If

I turned it up to 2 amps, then 2.6 amps, the pulse width increased to

about 4 and 5.5 uSec, but the overall pulse rate remained the same -

straight PWM at 16000 Hz.

I had connected a wire to one side of the input as an

"antenna". The unconnected scope probe picked up the pulses from being

near it, but nothing was obtained at the DC output (which I only

metered with a voltmeter) except a voltage that gradually rose from 0

to .15 volts over

a couple of minutes. I also tried reversing the pulse leeds in case the

pulses were the wrong polarity compared to the magnet.

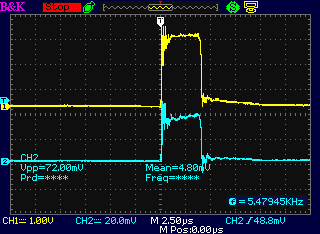

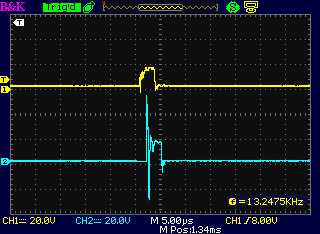

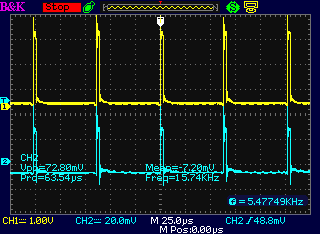

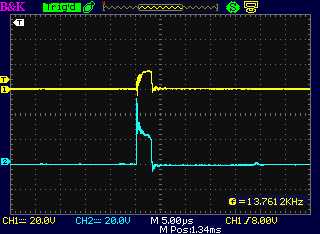

Zoomed out, a bunch of high frequency pulses is

followed by

quiet, each 8 mSec for 16+ mSec periods (about 60 Hz)

Zoomed out, a bunch of high frequency pulses is

followed by

quiet, each 8 mSec for 16+ mSec periods (about 60 Hz)

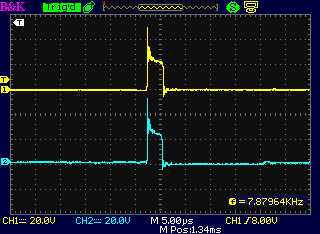

Zooming in on the pulse areas, each one is composed of short pulses

with about 62.5 uSec period (16000 Hz)

Zooming in still further, each short pulse is about 2.5 uSec.

As to amplitude, the scope probe on Channel 1 is x10, and it's driven

from ~40 V lithiums.

But it's a heavy load and a long, thin wire, so we see around 30 volts

(says ~3 V @ 10x scope probe).

(Channel 2 is only picking up noise from the "antenna", so the

amplitude

depends only on the pick-up. I should have turned it off.)

Perhaps interesting: the ground clips of both probes were unconnected -

I wasn't sure where there was a ground -

and the car should have been floating, yet solid readings were attained

on Channel 1.

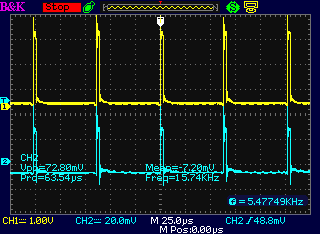

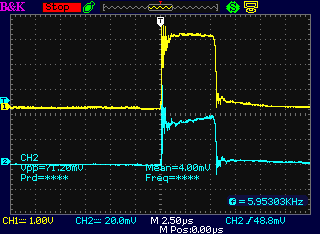

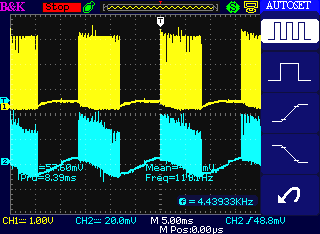

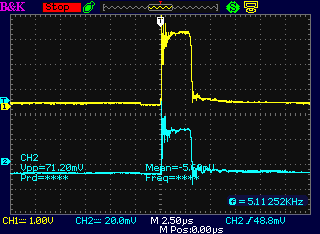

Increasing the current setting increased the

width of the pulses.

Increasing the current setting increased the

width of the pulses.

But the 16 KHz and 60 Hz overall frequencies didn't change.

I don't know what led me to want to try the car's motor

controller as a 36 volt pulse source. Somehow it just seemed like the

thing to do. Now I see a potential advantage to it over any pulse

generator I would have made for myself: I don't think a steel/iron

"core" material will respond well to a higher frequency like 16 KHz.

But it should turn on and off at 60 Hz just fine. A single frequency

pulser would have to put out the same microseconds-short pulses at, eg,

60 (or perhaps 100 or 120) Hz, which wouldn't put much energy into the

field.

So this dual frequency of pulsation just might be a good

key to getting such a unit to work with an ordinary iron core instead

of some of the more exotic core materials others have used. (And such a

setup, providing an absolute maximum 50% duty cycle with 1/120th of a

second rest periods, probably would keep my motor controllers from

blowing up, too! That may be why Curtis adopted it. I'll try that on

the reluctance motor controller in future tests. Something else I've

been missing all this time! My first motor controller was very low

frequency, but I never got the idea for combining high and low

frequencies. Nothing in any of the motor controller chip data sheets

suggested such a thing, either.)

Now that I understand that the pulses are of this special

special nature I can make a driver to generate similar pulses and

variations on them. In fact, I can use the circuit I already designed

with the microcontroller - eliminate two of the three coil drivers and

change the MOSFET driver to one of the better ones I bought. Then the

whole thing can move indoors. I should have looked at the pulses last

summer! I suppose again working on the ground made me subconsciously

reluctant to bring the oscilloscope out.

[At some point here I noticed one could set the oscilloscope for "x10"

probes in a menu so the numbers shown on the screen would be correct.]

Before doing

that, the next thing to try was to block the

suppression of the flyback at turn-off, by putting a high voltage,

fairly

high current diode in series with the pulse source (instead of across

the coil to damp it when it shut off). I tried on the 18th. I found I

only had lower voltage diodes, but I had an IRF840 Mosfet good for up

to

500 volts. Its body diode was good for a fair number of amps, so I

soldered

the gate to the source so it would never turn on, and soldered two

wires

to it.

Before doing

that, the next thing to try was to block the

suppression of the flyback at turn-off, by putting a high voltage,

fairly

high current diode in series with the pulse source (instead of across

the coil to damp it when it shut off). I tried on the 18th. I found I

only had lower voltage diodes, but I had an IRF840 Mosfet good for up

to

500 volts. Its body diode was good for a fair number of amps, so I

soldered

the gate to the source so it would never turn on, and soldered two

wires

to it.

I checked it out on the oscilloscope and found there

didn't seem to be a very notable spike. It seemed to me the coil should

have far more turns, of finer wire. (Channel B goes straight to the

motor controller. Channel A goes through the 'diode'. I thought it was

thus free

to spike as far negaitve as it wants, but it only did a few volts.) One

of the problems with energy device documentation is that it seldom

seems to give the size, characteristics and number of turns of the

coils.

Let's see... there are presently (were) 16.5 turns on each

half of the coil. If that little turn-off spike is maybe 9 volts, and

we want 100 volts, we need 11 times as many turns, or 183 turns (give

or take a couple of dozen). Let's see... unwinding one, it's less than

4 feet of wire. So make it 45 feet to be safe. That's probably more in

keeping with typical wiring for that sort of voltage... but much harder

to thread through a toroid, and to keep count while doing so! I found

some #19 AWG wire. That was about the thinnest I had much of without

going really fine. I wound it, but I'm not sure why I continued after a

certain point. It was obviously too bulky. Even #22 would have been a

dubious fit - 24 or 26 would have been better.

Let's see... there are presently (were) 16.5 turns on each

half of the coil. If that little turn-off spike is maybe 9 volts, and

we want 100 volts, we need 11 times as many turns, or 183 turns (give

or take a couple of dozen). Let's see... unwinding one, it's less than

4 feet of wire. So make it 45 feet to be safe. That's probably more in

keeping with typical wiring for that sort of voltage... but much harder

to thread through a toroid, and to keep count while doing so! I found

some #19 AWG wire. That was about the thinnest I had much of without

going really fine. I wound it, but I'm not sure why I continued after a

certain point. It was obviously too bulky. Even #22 would have been a

dubious fit - 24 or 26 would have been better.

So I went to

look for the fine magnet wire that Jim at

AGO, having had no use for it for quite some time, had virtually thrust

upon me. I didn't think I could possibly use it, winding lower voltage

motors as I was at the time, but this is the use! There was a spool of

#28 AWG and

one of #30. I used the #28. Thanks Jim!

So I went to

look for the fine magnet wire that Jim at

AGO, having had no use for it for quite some time, had virtually thrust

upon me. I didn't think I could possibly use it, winding lower voltage

motors as I was at the time, but this is the use! There was a spool of

#28 AWG and

one of #30. I used the #28. Thanks Jim!

And I was thinking, that if the pulse widths were wider,

the spike voltage would be higher. So I decided to wind just 100 turns

on each side. If the voltage was too low I could widen the pulses to

put more energy into the coils. I don't know what a good voltage is

anyway, just that it's a lot higher than single digit volts.

The outer diameter of my pipe "toroid" was 45 mm, the wall

thickness was 3 mm, and the height (pipe length) was 19 mm. It took

over 14 feet of wire to do each side. (according to my calculator.)

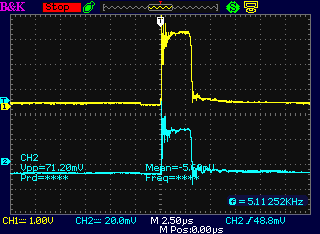

On the 20th I wired it up,

took it out to the garage, and

connected the motor controller and the 40 watt lamp. This time, the

pulses looked nothing like the previous ones. There was no 60 Hz, just

continuous 16 KHz pulses, and instead of being a very low duty cycle,

they were around 90% ON. Apparently the controller was unable to put

the set 1.6 amps into the (effectively) 50 turn coil of #28 wire, so it

was putting out all the voltage it could, trying.

I tried taking out my two 22 ohm, 10 watt resistors, to

provide a load. In parallel, (11 ohms) the controller kept saying

"field coil output shorted". With 44 ohms it worked sometimes, but it

was still long pulses with no 60 Hz 'off' times. And the resistors got

very hot pretty fast. With 22 ohms, it mostly said "shorted" but worked

one time and still had full pulse width and no 60 Hz. Apparently the

car's pulse generator was expecting motor field coils for a load and it

wasn't going to give me what was wanted now that my coil was probably

close to what was needed. Unless I managed to load it down just about

the same way it was before, and connect the unit in parallel with that.

Thinking of that, I got

out the original coil from last summer and did that. It worked - at

least, sometimes. (The other times, the motor controller says

"shorted", which has been happening all along.) When it did it gave the

desired pulse forms: short

pulses at 16 KHz going on and off at 60 Hz.

Thinking of that, I got

out the original coil from last summer and did that. It worked - at

least, sometimes. (The other times, the motor controller says

"shorted", which has been happening all along.) When it did it gave the

desired pulse forms: short

pulses at 16 KHz going on and off at 60 Hz.

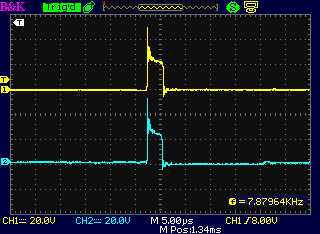

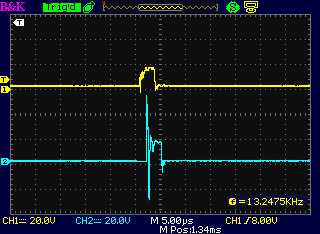

Probe "A" was mistakenly on the "+" side of the drive,

before the diode. "B" was after the diode, on the anode. Instead of a

spike at turn-off, the big spike was immediately at turn-on. Why? It

was around 95 to 125 volts from peak to peak as it went negative in

less than a microsecond.

This is probably about the right range. The only problem

was that there were still no results. No output.

As it got dark I went inside and drew it out on paper.

There were so many things that could be one way or another - so many

binary "1" and "0" choices... Diode polarity. Magnet polarity. Drive

polarity. And there was another one: polarity of the two coils, one on

each side of the 'toroid'. I had connected them opposite since they

were on opposite sides of the toroid. But that was wrong, wasn't it?

With the drawing there I realized that instead of both sides pushing

the magnetism from the magnetically connected end toward the gap end,

one was pushing one way and one the other, around in a circle. Net

result out into the iron horseshoe: zero. I swapped the two ends of one

of the coils.

The next day I went out again and figured out some more.

The spike at turn-on instead of turn-off was because the diode was the

wrong way around.

The rise was simply the turn-off time of the diode, and the fall was

because the diode stopped conducting, so it was like "turn-off". But it

was just stray transients. There hadn't been much time for energy to

accumulate in the coil, so there would be no notable magnetic output.

After the spike, the voltage settled at about +20 volts - the same as

the

negative side of the drive.

But if I had the diode the right way around, my blithe

assumption that it would allow the coil to spike negative was wrong.

Just as the "+" drive rising to 40 volts pulled the coil to +40 volts

minus the diode forward drop, the "+" drive at zero wouldn't allow the

coil to go more negative than zero minus the diode drop, around minus

one volt.

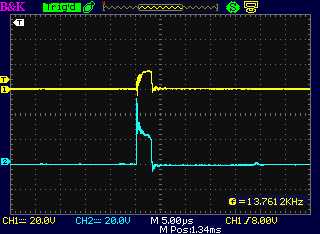

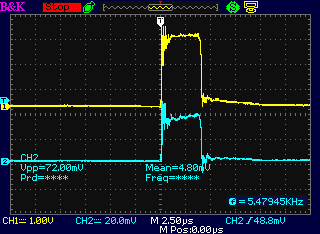

The drive from the motor controller as seen at

the dummy load coil, "-" side and "+" side.

The drive from the motor controller as seen at

the dummy load coil, "-" side and "+" side.

The "+" side of the drive (a) from the motor

controller and (b) following

The "+" side of the drive (a) from the motor

controller and (b) following

the diode at the unit's coil, with the diode the right way around:

Essentially the same less a diode drop (< 1 V)

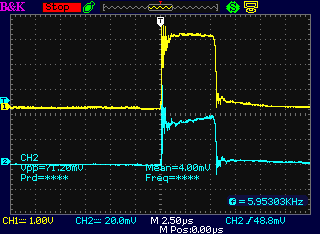

The "-" drive, and at the coil on the "+" side

following the diode, which was in backward.

The "-" drive, and at the coil on the "+" side

following the diode, which was in backward.

That's the only time a coil spike was seen, but it was at the wrong

time and with little energy.

(I'm not sure why a timing offset is seen. It seemes to be just in this

one trace.)

Okay, for someone trying to do groundbreaking work, I sure

made a lot of stupid mistakes. All a learning curve! I always take

comfort in what Roger the plumber said to me in about 1995: "The only

people who never make mistakes are the ones who never do anything."

So. Even with isolation diodes, was it possible to drive

the coil so that the turn-off spike wouldn't be damped off? It didn't

look like it. Maybe with a capacitor in series? Nothing like a tuned

circuit to maximize an oscillation! Time to refresh my memory of that

aspect of circuit design from BCIT in 1975. But it would have to wait

until

after Christmas.

The circuit... what circuit?

I had already been

thinking about and working on a pulse generator.

On the 18th and 19th I

spent some hours doing the revised circuit board for a microcontroller

based pulse generator. I printed out the finished board deign, then I

started thinking that the whole thing was pretty simple. While an LCD

display showing all sorts of info would be cool, why not just use a

couple of simple chips and forget the microcontroller? That would make

it much easier for others to duplicate and eliminate the need for

programming The programming requirement would add a level of complexity

beyond the grasp of many DIY builders. OTOH, for the prototype, the

easier it was to see what was going on, and the more the adjustments

and operating parameter possibilities it had, the more the things that

could be tried out simply by changing the programming instead of having

to modify circuits.

So the prototype should be run by microcontorller, and

doing the circuit hadn't been a waste of time. (Whew!) Once optimum

performance was obtained, a dedicated circuit could be created.

How to do a dedicated hardware circuit? Feedback would be

the filtered DC output voltage. That, after all, is the desired result.

One could modulate the pulse widths manually easily enough using a 555

timer and a potentiometer. But how to do it from voltage feedback? No

doubt it could be done.

But perhaps even that is a needless level of complexity.

It could be even simpler: If the voltage was below the setpoint, there

would be pulses. If it was above, there wouldn't. So: a 556 dual timer

providing the 60 Hz and narrow high frequency pulses, and an LM339 quad

voltage comparitor turning that on or off. But how to gate the pulses?

Use a second and third comparitor on the LM339 as switches to gate the

signals from the 556? Or add a CMOS logic triple 3 input AND gate: Low

frequency is high AND high frequency pluse is high AND voltage is below

setpoint will send the pulse to the coil driver. Or something like that.

I decided to continue using the car motor controller until

and unless I got some results. The idea of a tuned resonant circuit, if

it worked, or perhaps some other idea, might necessitate more changes

to the design, so I would wait.

Rechargeable Battery Making

... NOT with oxalate electrolyte?

As the battery performance

deteriorated, I started thinking it must be the zinc electrode that was

the problem. But how could that be? I looked at the old one. The

connection tab seemed almost

ready to break off where it came out of the case. With a little

touching, it did. This was something I has also noted with the

nickel-manganese cell negative electrodes with zinc current collectors:

where they

were not in contact with the Mn powder, they deteriorated and I ended

up switching to graphite current collectors. I didn't think it would

happen since I wasn't pushing it up to the -Mn (metallic) voltage. But

there it was.

I suspected it had something to do with hydrogen gas

bubbling off, but there are no electrochemical reactions shown to

combine zinc with hydrogen. Some reading on line on the 10th disclosed

that in flooded nickel-iron batteries, both the nickel hydroxide and

the iron absorb a large amount of hydrogen over the life of the

battery. In fact, the nickel hydroxide absorbed up to 22 wt% - four

times as much as a 2015 "target to aim for" for hydride storage. The

problem with using them as hydrides is they don't release the H atoms

under normal operating conditions. Surely then zinc electrodes will

also absorb hydrogen - and apparently in doing so become brittle and

break.

A big part of the problem is doubtless that I put in

charged (metallic) zinc and probably quite discharged MnO2 (Mn2O3,

MnOOH...). So as the MnO2 side charges (or is it to Mn(C2O4)2 in

oxalate?), the zinc side merely bubbles

hydrogen. I didn't think it could be absorbing it because there were no

electrochemical reactions shown for it, but turning it into a hydride

is what

these relatively new papers seemed to suggest. The second electrode

wasn't (yet) as brittle as the first one.

So my next

endeavor was to put 12 grams of yellowish ZnO

powder, which needs to be charged to Zn metal, into the (2nd) zinc

electrode. Another consideration was that my ultra-fine zinc (metal)

powder, at least the "flakes" jar, seemed to be so densely packed that

it kept electrolyte out and didn't work well. By putting in ZnO, when

it charged to Zn, there should be some spaces left over between the

zinc atoms for the water. At least, with little knowledge of

crystallography or how atoms behave, that was my theory.

So my next

endeavor was to put 12 grams of yellowish ZnO

powder, which needs to be charged to Zn metal, into the (2nd) zinc

electrode. Another consideration was that my ultra-fine zinc (metal)

powder, at least the "flakes" jar, seemed to be so densely packed that

it kept electrolyte out and didn't work well. By putting in ZnO, when

it charged to Zn, there should be some spaces left over between the

zinc atoms for the water. At least, with little knowledge of

crystallography or how atoms behave, that was my theory.

I sprinkled in the powder and smoothed it off with a

teaspoon.

Then I pressed

the electrode closed, then I put in ordinary

staples. It was tough going, but they went in. If I had used the

heavier staple gun, say with cardboard behind, I'd have had to bend all

the staple ends over. Finally I took a hammer and pounded the staples

flat anyway, which pretty much put some momentary pressure all across

the

electrode to compact the powder.

Then I pressed

the electrode closed, then I put in ordinary

staples. It was tough going, but they went in. If I had used the

heavier staple gun, say with cardboard behind, I'd have had to bend all

the staple ends over. Finally I took a hammer and pounded the staples

flat anyway, which pretty much put some momentary pressure all across

the

electrode to compact the powder.

12 grams of zinc oxide is 820 AH/Kg * (65.4 / (65.4+16.0)) = 7.9

AH theoretical capacity. Add to that the capacity of the degraded sheet

zinc itself? Surely over actual 10 amp-hours? A second electrode would

probably

be needed to get it up to 20 or 25 to match the plus side.

It was soon charging at 120

mA. Same sort of low currents

as before. I decided it was time to try some sodium oxalate to see if

that would help boost things. I combined some oxalic acid with some

sodium hydroxide. (I left it a little acidic in preference to having

free sodium hydroxide.)

It still had low currents, and it still had the same sort

of high self discharge as all my cells of any chemistry have always

had. Nothing I try seems to fix it. Why can any commercially made cell

sit there and hold its charge, but all mine bleed off? I have some

theoretically great stuff, all going to waste because I can't actually

say to anyone "Here's a great battery that will work well." What, what

am I doing wrong?

"In theory, there's no difference between theory and practice. In

practice, there's a great difference." - (I forget who said that).

Manganese-Metal Hydride cells?

A

thought occured to me... Sometimes my cells have quite a

few amp-hours but usually at voltages below a volt. Could that be from