Turquoise Energy Ltd. News #2^7 (= #128)

covering

January 2019 (Posted February 1st 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month

In Brief

(Project Summaries etc.)

- Battery Project - When EV's were "Killed" - Carmichael Mill -

Lumber Cutting - Ground Effect Vehicle Improvement? - Expanding my

Solar Power System - NO Tidal Power project

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- World's Most Costly Garbage Pickup Service? - Sardine Tins and

Bathtub Designs - Clinton & the "Deep State" - Why They

REALLY DON'T Want the US-Mexico Border Wall - Yellowstone

Volcano: ready, set, ...? - Coming Collapse:

Contempt & Disdain - Cryptocurrency Exchange Failure? - ESD

(Eccentric Silliness Dept.)

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle - New wing profile & restart of design -

Trying out RC components

Other "Green"

Electric Equipment Projects

* Carmichael Mill ("Bandsaw Alaska Mill")

* Mining Beach Sand?

Electricity Generation

* Expanding My Solar Power System - grid ties - 36 volt DC LED lights -

Solar Hot Water? - Batery consreving controls? - Putting up some of the

New Solar PV Panels

* Magnetic Flipping HE Ray Energy?

* Woodstove Thermoelectric Generators (TEGs) (Didn't get very far...)

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Oxalate Methyl

Hydroxide electrolyte)

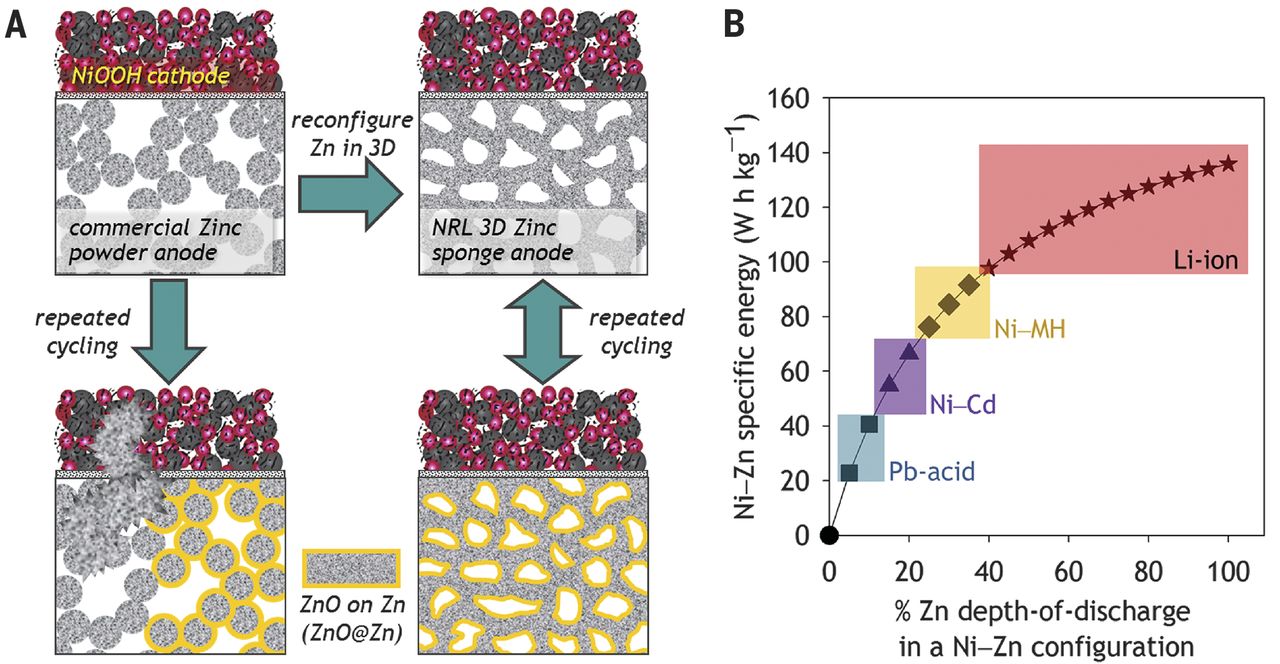

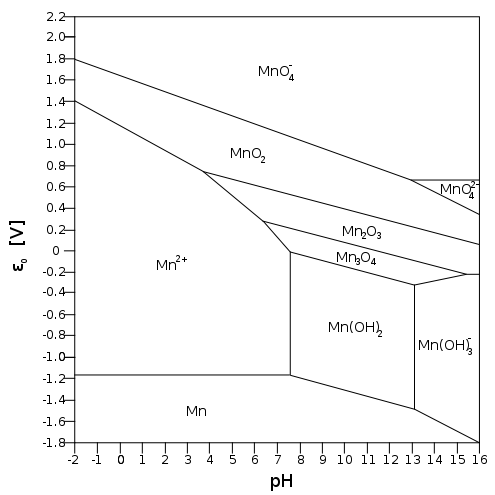

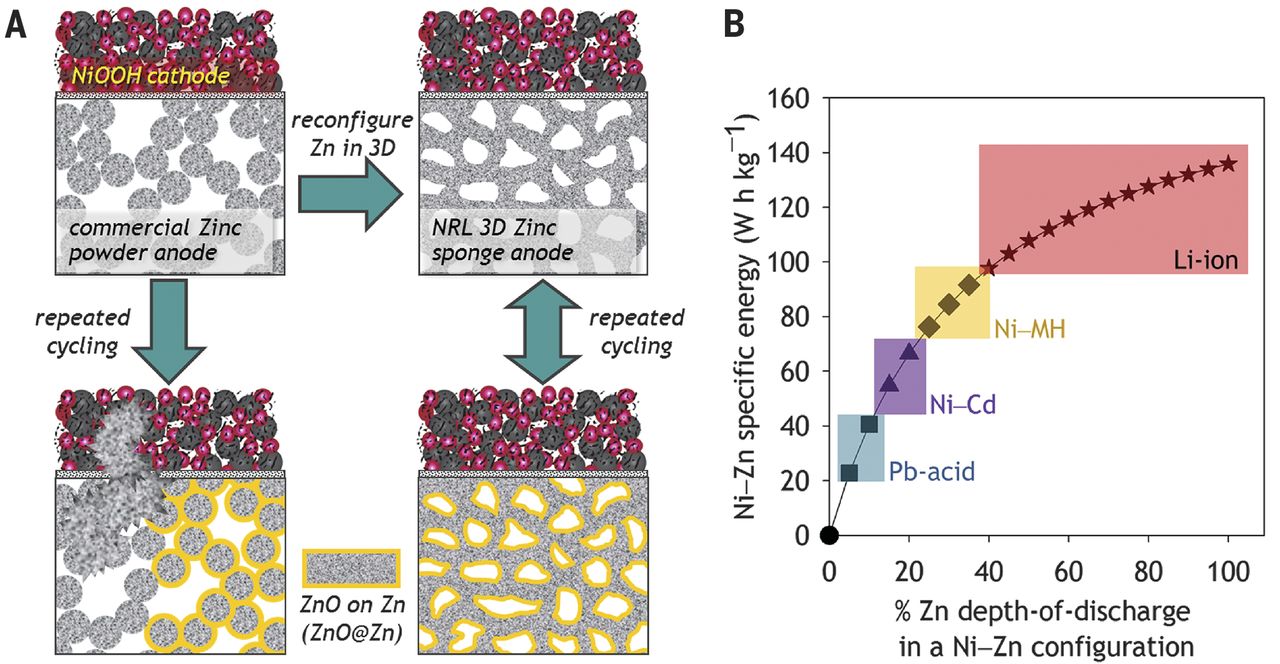

* Experiments mostly with Mn-Zn... - Attempts by Others to use Zinc -

Oxalate Electrolyte or Not? - Lead-Zinc in Oxalate (with commercial

lead oxide electrode plates) Again (Jan 9th - Aborted) - Totally Common

Ingredients!?! New Mn-Zn Cell With Very Weak Potassium Hydroxide - Was

it the Water? - Thicker KOH Electrolyte: Finding Solutions - Sodium

Oxalate - Alcohol: Methyl Hydroxide - Proton Membranes

New Chemie Batteries

I spent a lot of time on battery experiments and research

this month. Too much! It took time away from everything else. I've

always just wanted some simple to make, lower cost, long life

batteries. Of course, so does everybody else and no such "ideal"

batteries have appeared

in over two centuries of battery research. There

are a lot of elusive "almosts" and short cycle life solutions. After

all this time and with all the ideas I've had, nothing I've done has

actually made any that have been practical.

This month new ideas were suddenly springing up left and

right, and my only sure conclusions are that what I've tried so far

hasn't worked out... and that in some ways I'm still out of my depth. I

keep finding out about things that that have been causing me unknown

problems that others already know.

Oxalate electrolyte didn't seem to work like I had confidently expected

it would.

It all got rather discouraging.

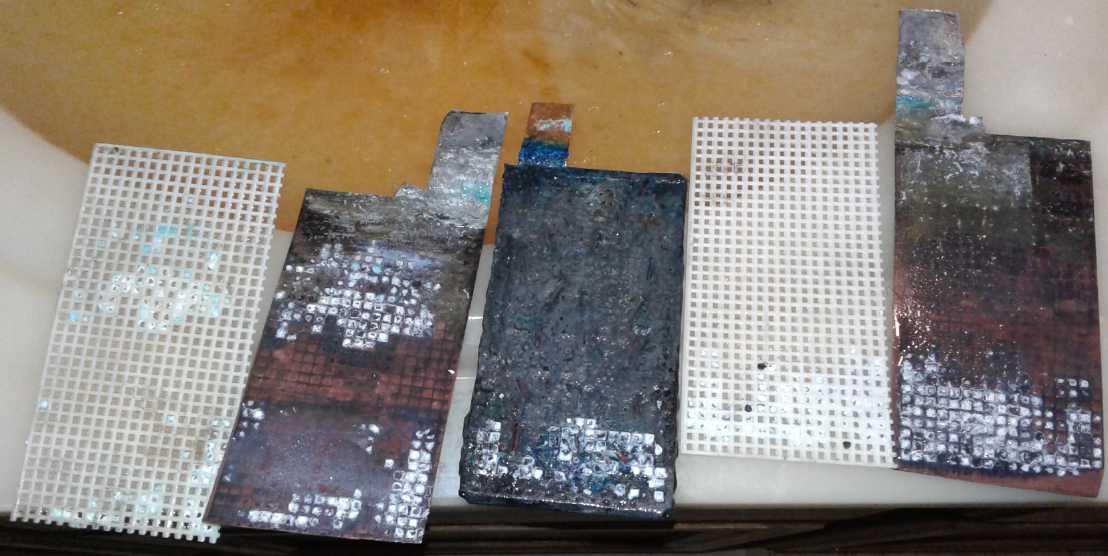

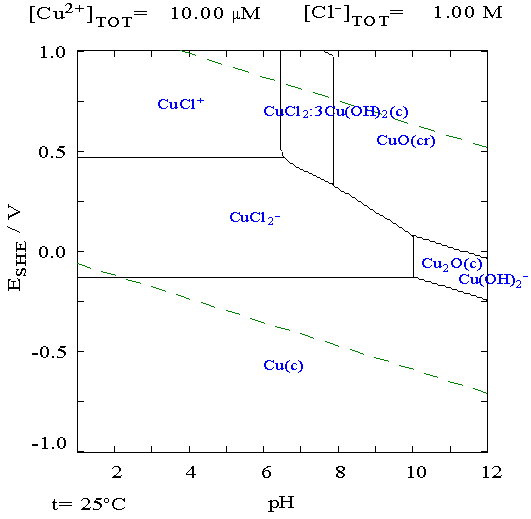

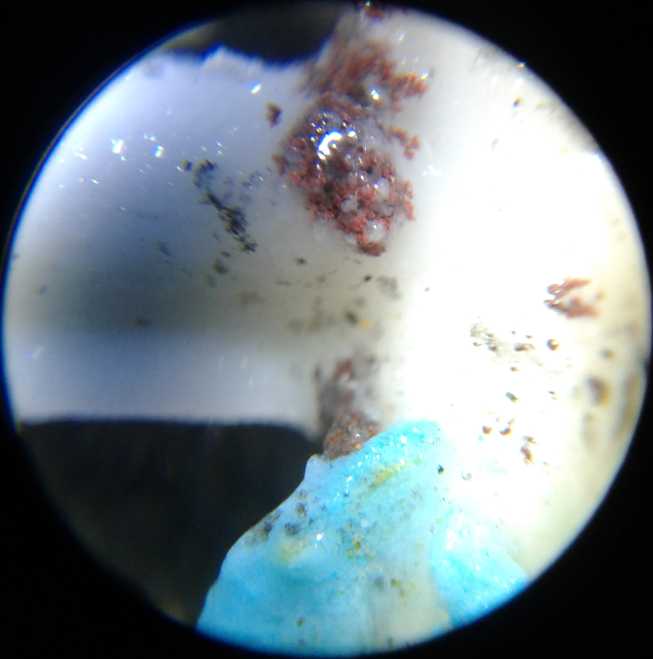

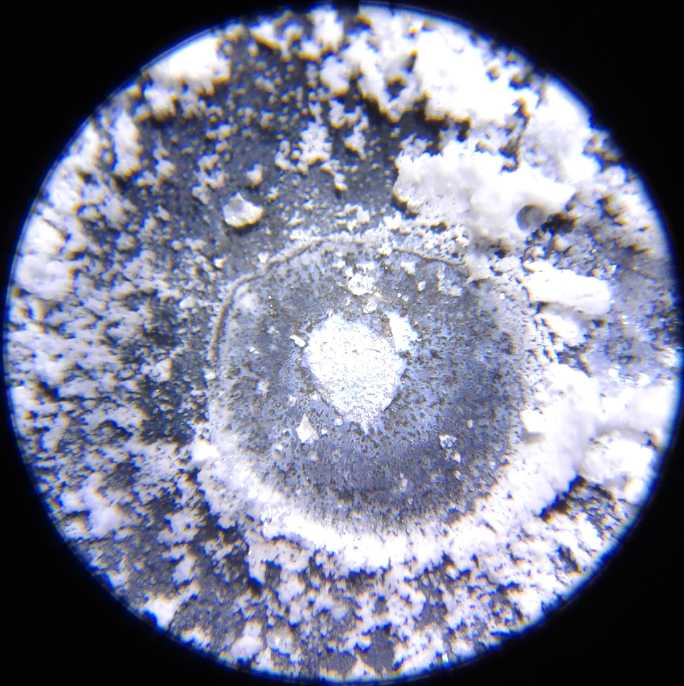

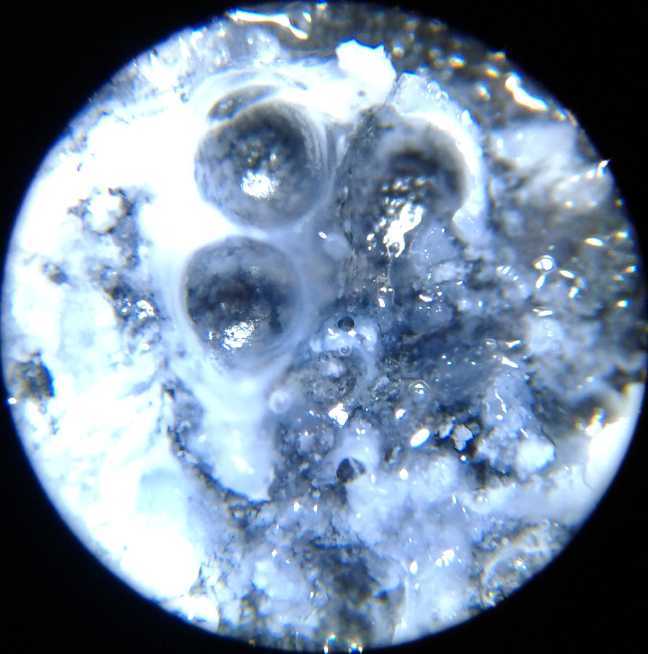

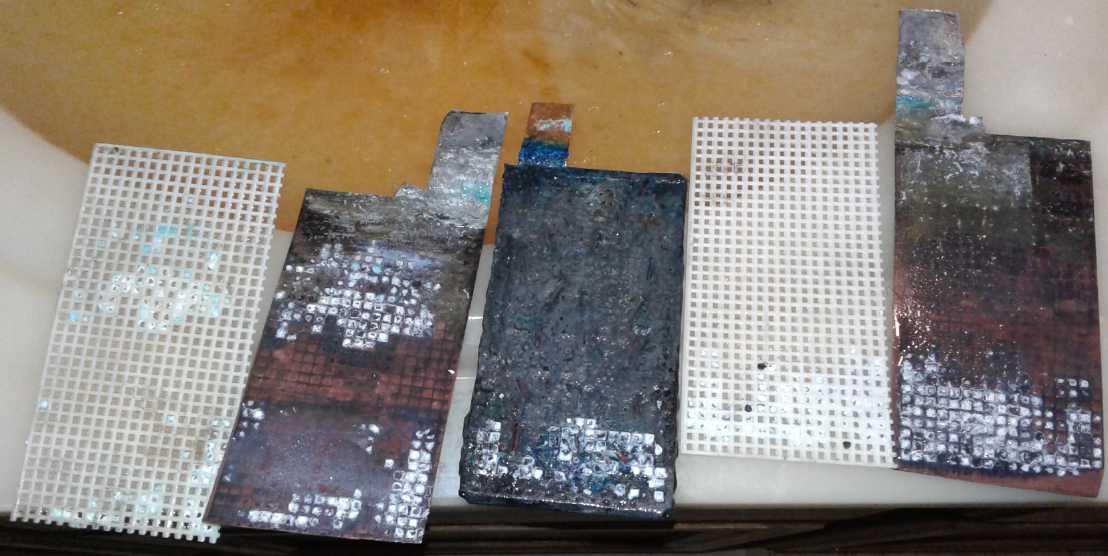

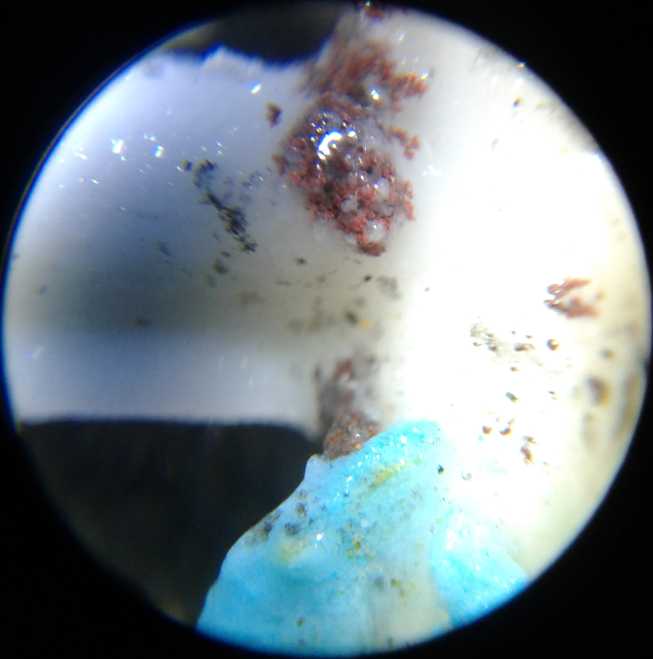

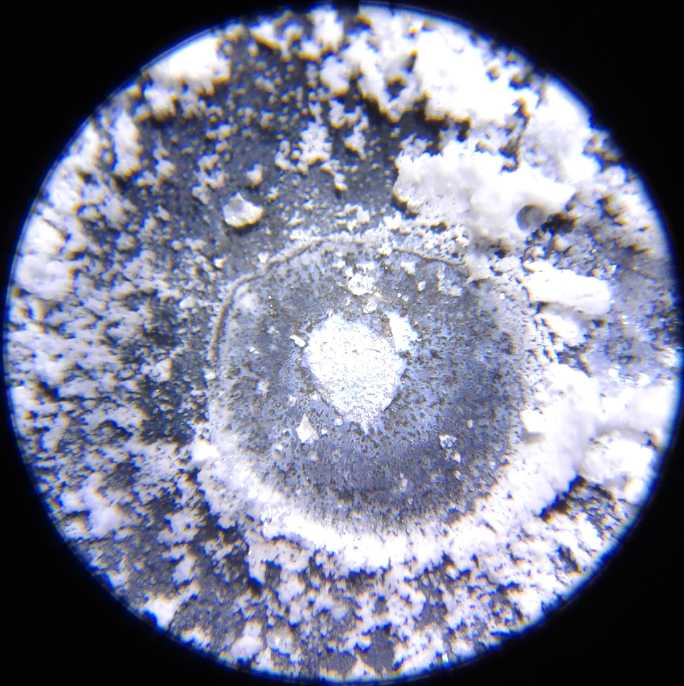

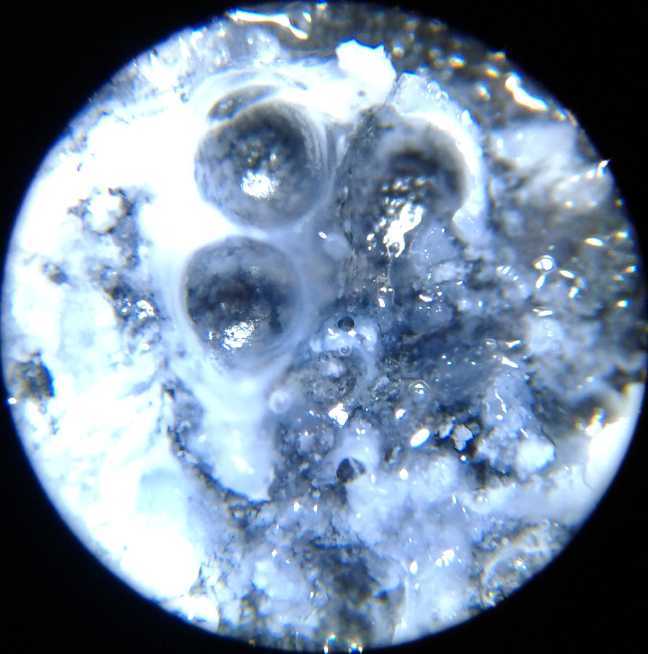

Copper dendrites shorting

out the cell across the separator grille, under the microscope

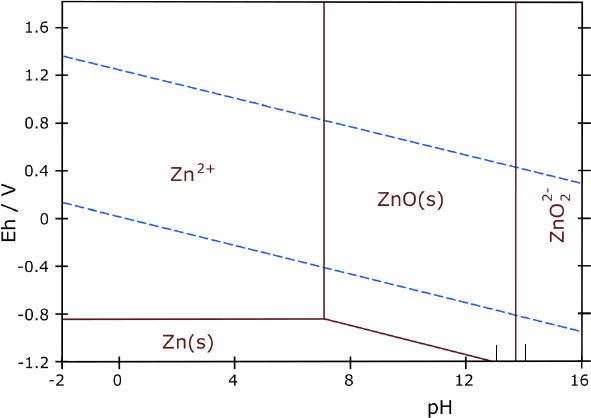

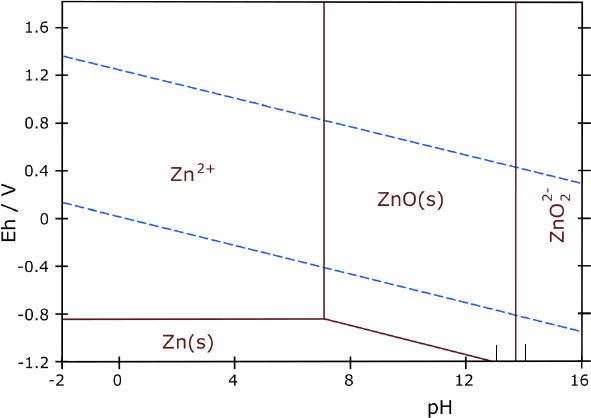

One especially bright spot was a "new" hydroxide electrolyte I

somehow found but glossed over and forgot a decade ago. Hydroxides seem

to be what really work

best and don't dissolve electrode substances - except especially zinc,

which gives

the best energy and conductivity but gradually dissolves during

discharge at the pH 14 of the hydroxide electrolytes. But the

organic substance methyl hydroxide, CH3OH - AKA methanol,

AKA wood alcohol,

AKA methyl hydrate, AKA methyl alcohol (I think all the names confused

me) - is a soluble hydroxide that is (evidently) mildly acidic instead

of pH

14. By mixing that with a small amount of pH 14 hydroxide, one should,

presumably, be able to get a hydroxide electrolyte of any desired pH. I

ordered some from Westlab.com. Then I realized I already had some,

hardware store variety, that (IIRC) my mother gave me about 40 years

ago and I didn't know what to use it for. On my first try I didn't use

enough KOH and it was apparently too acidic. On recharging the

electrodes shorted out with both copper and zinc dendrites. These were

clearly visible under my new microscope, a valuable piece of equipment

I should have bought long ago.

One especially bright spot was a "new" hydroxide electrolyte I

somehow found but glossed over and forgot a decade ago. Hydroxides seem

to be what really work

best and don't dissolve electrode substances - except especially zinc,

which gives

the best energy and conductivity but gradually dissolves during

discharge at the pH 14 of the hydroxide electrolytes. But the

organic substance methyl hydroxide, CH3OH - AKA methanol,

AKA wood alcohol,

AKA methyl hydrate, AKA methyl alcohol (I think all the names confused

me) - is a soluble hydroxide that is (evidently) mildly acidic instead

of pH

14. By mixing that with a small amount of pH 14 hydroxide, one should,

presumably, be able to get a hydroxide electrolyte of any desired pH. I

ordered some from Westlab.com. Then I realized I already had some,

hardware store variety, that (IIRC) my mother gave me about 40 years

ago and I didn't know what to use it for. On my first try I didn't use

enough KOH and it was apparently too acidic. On recharging the

electrodes shorted out with both copper and zinc dendrites. These were

clearly visible under my new microscope, a valuable piece of equipment

I should have bought long ago.

Another potential improvement was nafion ion selective

membrane. This lets hydrogen ions - protons - pass through but not much

else. It might be used to prevent dissolved ions from passing from one

electrode to the other, and would potentially allow having one

electrolyte for

the plus electrode and another for the minus. Costly as it is, I

ordered a piece of that, too. Then I found that attaching it so nothing

gets around the edges has its own set of challenges, usually involving

barium metasilicate.

When EV's were "Killed" (not for the first time)

Many will recall the

documentary Who Killed the Electric Car, about

the GM EV-1 produced in the late 1990s, which was an exciting electric

car with the nickel-metal hydride flooded batteries that were such a

huge advance over lead-acids. (It was some years before more recent

cars with lithium batteries equalled its driving range capacity.)

Many will recall the

documentary Who Killed the Electric Car, about

the GM EV-1 produced in the late 1990s, which was an exciting electric

car with the nickel-metal hydride flooded batteries that were such a

huge advance over lead-acids. (It was some years before more recent

cars with lithium batteries equalled its driving range capacity.)

At the same time other car companies made

some very nice electric vehicles, most of which were likewise only

leased and

not sold, and were crushed when the greedy got control over the

California

government and had the mandates for clean cars repealed. One exception

was the Toyota RAV-4 EV. Some of those were sold. Of course, once

Chevron was given control of the batteries, it became impossible to get

replacements. But many of the flooded NiMH batteries still work

passably well, or did until fairly recently and some may just need the

electrolyte replaced.

A friend in Victoria BC, Eric, got together with someone

else and

they have now brought up from California and put together two revamped

RAV-4 EVs from about 1996 to 2001 with batteries from three,

re-outfitting

them to plug into today's charging stations.

Here is Eric's beautiful

"new" 2001 RAV-4 EV, always kept in a garage in California. It had a

remaining range of just 5 miles, but is

being outfitted with refurbished NiMH cells to bring it back to 100(?)

miles.

...Not bad for 500$US! (Well... plus substantially more than that for

shipping.)

In the back is the original charger.

In the back is the original charger.

Carmichael Mill - Lumber Cutting

The handheld bandmill is basically finished and continues

to perform

well. I uncovered - and fixed on the lathe - a minor problem with the

guide wheels being a little too wide, which caused them to gradually

pinch the "set" off of the inner teeth and cause "cupped" and wavy

cutting.

The biggest news for me was that I finished milling up the

big cants of spruce that were blocking my driveway, except one that I'm

saving. After

some clean-up I drove the Leaf through the previously blocked space for

the first time since summer 2017.

When the last cant is gone (or shoved off farther to the side after

some more clean-up of branch piles that were formerly trapped

underneath the cants of wood), I'll have back the whole circle driveway

that came with the house before I had the trees cut down! Yay!

But I've still only cut up half of the spruce - the rest

just isn't blocking the driveway.

Ground Effect Vehicle Improvement?

I watched a

video of a model ground effect craft. It was

very short, of a primitive model launched across the floor by a rubber

band, but it got my attention. Like some others it was "catamaran" in

form, but the wing profile seemed unusual. (The closest thing I've seen

to this

profile - and not very close - was something called the "Flugboat"

which can also be found on youtube.) The maker explained to me that the

unusual shape shifted the wingtop "vacuum" lift toward the rear of the

wing, while the ground effect "compression" lift underneath was

greatest at the front. Since only the ground effect lift decreases with

altitude, this profile gives the longitudinal "level flight" stability

for the craft to find its optimum altitude and attitude based on the

speed and

weight, without the lower lift and high attack angles of the Bixel flat

wing that required extra high takeoff speeds. It *might* not even need

a controlled elevator. The bottom is actually pretty flat. It's the top

shape that is novel.

I watched a

video of a model ground effect craft. It was

very short, of a primitive model launched across the floor by a rubber

band, but it got my attention. Like some others it was "catamaran" in

form, but the wing profile seemed unusual. (The closest thing I've seen

to this

profile - and not very close - was something called the "Flugboat"

which can also be found on youtube.) The maker explained to me that the

unusual shape shifted the wingtop "vacuum" lift toward the rear of the

wing, while the ground effect "compression" lift underneath was

greatest at the front. Since only the ground effect lift decreases with

altitude, this profile gives the longitudinal "level flight" stability

for the craft to find its optimum altitude and attitude based on the

speed and

weight, without the lower lift and high attack angles of the Bixel flat

wing that required extra high takeoff speeds. It *might* not even need

a controlled elevator. The bottom is actually pretty flat. It's the top

shape that is novel.

It seems like a brilliant idea. He also had a video of an

earlier radio controlled model ground effect craft with a "regular"

wing design. He doubtless found it unsatisfactory and that led him to

come up with this new wing profile. (Below: Front is at the left.) One

can visualize that, if it wasn't in ground effect range, the back of

the wing would want to lift and aim it down.

Come to think of it, this would be a rather similar effect

to the "wingfish" with its "inverted delta" wing shape and a separate

elevator high up. But this form allows the catamaran design with better

lift-to-drag potential owing to the hulls virtually eliminating wing

& elevator tip vortices. The catamaran shape will surely also be

much

easier to dock at a wharf than something with a fragile wing sticking

out both sides.

With this one last item seemingly solved in a more

satisfactory way than I had found earlier, I started working on the

design of the model again. And I got out the radio control components

and tried them out for the first time. Except for the ducted fan

propeller rubbing a bit on the duct housing (the motor and the fan

weren't made to mount together) and unsatisfactory "backward" control

of the throttle, it seemed to work well.

Expanding my Solar Power System

After initially installing the "off-grid" power system in

the December power outage, I gave it some more thought this month, and

did a bit more on it. Two panels seemed to be enough for that as I was

using it - mostly just for one light - and I moved two of the panels

back onto one of the grid tie inverters.

I want to make the 36-40 volt house wiring system. I

ordered various LED lights and LED emitters to make 36 volt lights with

- mostly 12 volt emitters in sets of three. I ordered several varieties

of 12 volt "cob" lights, a set of three 30 x 60 cm flat panels, and

some screw-in "bulbs" that are supposed to work from 12 to 72 VDC

instead of 120 VAC. They're all on their way on the slow boat from

China.

I gave some thought to a kitchen solar or solar assisted

water heating system (it takes much too long to get hot water in my

kitchen), and controls to run things when the sun is out but shut off

if draining battery power, or if the batteries are getting low.

On the 29th

and 30th I put up and ran wires to two of the new 305 watt panels that

are supposed to be better in low light. I hooked them to the other

grid-tie inverter. Performance in the clouds, mist and drizzle was been

poor, but on February first the sun made an appearance and at one point

the two panels ("610 watts") were giving about 270 watts - about all

one might expect from the low angle of the winter sun. They will

improve bit by bit until they're somewhere near their full rated power

in the summer.

On the 29th

and 30th I put up and ran wires to two of the new 305 watt panels that

are supposed to be better in low light. I hooked them to the other

grid-tie inverter. Performance in the clouds, mist and drizzle was been

poor, but on February first the sun made an appearance and at one point

the two panels ("610 watts") were giving about 270 watts - about all

one might expect from the low angle of the winter sun. They will

improve bit by bit until they're somewhere near their full rated power

in the summer.

Doubtless it wouldn't hurt to put up two more.

(The white wall paint is so the garden vegetables get some light

reflected from the north. When it was dark brown they all leaned away

from the house. The wire fence is to keep the deer out of the garden.)

One place that is going

solar in a big way is Puerto Rico. After hurricane Maria power was out

for ages. It's still only been restored in some areas. A whole island

lost its undersea power cable and it's never been reconnected. People

died. Panels and huge battery storage units have proliferated. The

island uses far less petroleum for power now and will never be wholly

without power again. But Puerto Rico gets a lot more sun year round

than Haida Gwaii does in the winter months when power is most needed.

So far what would work best here is tidal power, with the continual

flows churning in and out of long Masset channel between the ocean and

the shallow inland sea.

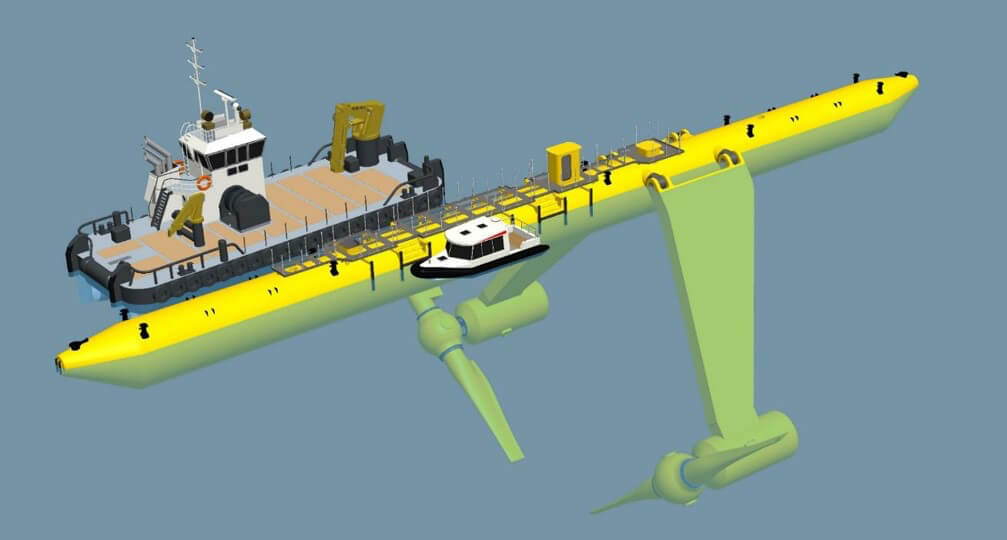

NO Tidal Power Project

Someone offered to administer a tidal power project if I

wanted to do it - to make the phone calls to look for funding and find

supporters, workers, co-ordinate with BC Hydro, etc. I thought I had

great floating power vessel designs and a great plan to do everything

pretty

much all from shore at low tide, by giving the vessel a "smart" rudder

to position itself into the strongest current (and return to shore when

necessary at high tide for maintenance access at low tide), but having

started working on the ground effect vehicle, somewhere during the

month I decided it was just too much for me to tackle.

Then for a short time I thought

maybe to do just a small 'pilot' or 'private power' project that I

could handle myself without so much outside help, probably to deploy at

the mouth of the Tlell river where there was easiest access to a good

flow. I went to

Coastal Propane, but I hadn't realized their old (free) 80 gallon tanks

were still too big to fit into the car. I could have come back another

time with the trailer, but I finally decided I had better drop tidal

power entirely. It's not that it wouldn't be a great project (and the

small one could put my fine "Improved Piggott" generator to the test),

but I'm already flitting from project to project and getting only bits

done on each one. It needs some other champion to move it forward.

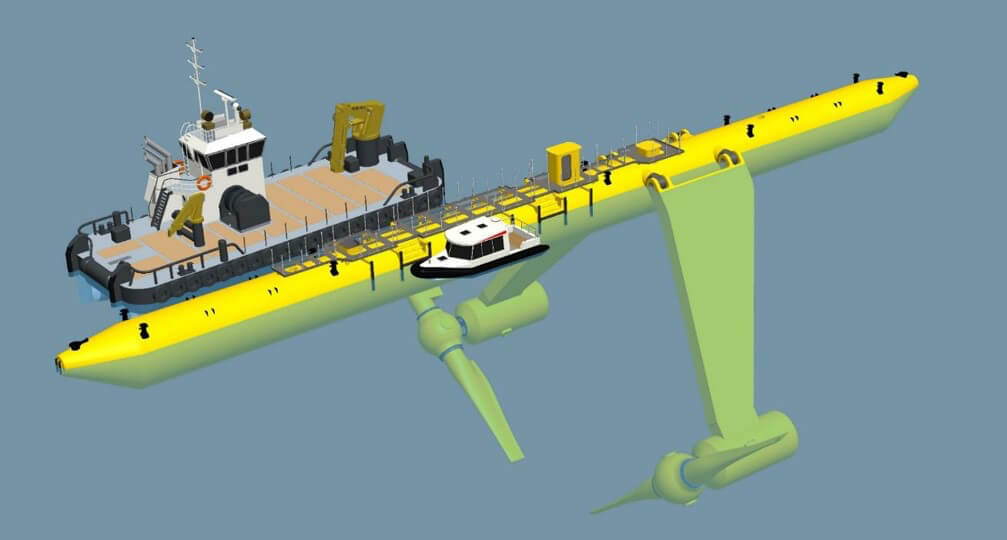

FloTec (formerly Scot Renewables) latest 2 MW

tidal flow power design.

FloTec (formerly Scot Renewables) latest 2 MW

tidal flow power design.

Their units are helping to power the Orkney Islands off the north coast

of Scotland.

In a few years their units may be for sale globally. In the meantime,

why

can we not make our own - and even play a leading part in a new

industry?

And as usual, I've voiced some opinionated opinions on

various

miscellaneous topics, below.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

World's Most

Costly Garbage Pickup Service?

I got a bill in the mail. It was for garbage pickup. I

conserve. I reuse. I recycle. I burn.

What's left goes into the garbage can along with crap I've picked up

off the beach. I take the can out to the road for Thursday pick-up

about once every six weeks or so. I mentioned that to the garbage man,

Paul, in a cafe. He thought for a moment and said "If that." So that's

maybe 7 or 8 cans per year. I would

happily take them to the dump myself on my way by when I need to. The

bill

was for 288$. That's 41$ or 36$ per can - or often half a can.

Yet there it is: a flat rate bill equal to those of careless families

of five who thoughtlessly toss everything they don't want into the

street garbage without

sorting it or worrying that someone else has to deal with their mess,

and who complain that they should be permitted more cans each week.

Why should I be subsidizing the wanton carelessness and

indifference of others? Is that equitable? For the service I get out

of it, I think it's highway robbery. I could buy two or three

garbage cans, per pickup, for that sort of price! It shows a need for

several things:

1. A citizens' social sustainability design team to study the issue and

make recommendations to government. I suspect the following

recommendations will likely be forthcoming:

2. Education of the public about recycling, composting and minimizing

trash.

3. Options for a low basic rate with pay-per-can for anything more than

very

minimal usage. (Others may think of other options, eg, for absentee

owners, who are presently dinged the same high rate for no pickups at

all!)

4. Enforcement of anti-dumping laws. (I can already hear "But people

will just dump their garbage anywhere if they have to pay per can." as

an excuse to not change it.) IF there are offenders, make it

too hazardous for them to dump their trash 'anywhere'. Video cameras

can be set up where such offenses seem to be occurring. Likelihood of

being caught is always the best deterrent. (A decade or two ago, car

thefts

were rampant in BC. Then the police set up "bait cars". After catching

a mere handful of car thieves in a few weeks, the whole epidemic came

to a halt. Either it was all being done by just those few

individuals [probably], or else the arrests scared everyone else off.)

My next door neighbors Stan and Louise spend half the year

in Lac la Hache. They still have to pay the whole 288$ here. And Stan

told

me that in Lac la Hache, there is no fee at all, nor pickup. They take

their garbage to the refuse transfer station, and there is a "swap

table" there where one can pick up anything that looks useful that

others have discarded. (He said Louise sometimes came back with more

than she took!)

What a difference! With very little income and so often

spending so much on R & D materials, suddenly I have to come up

with another 288$, too, but in Lac la Hache I'd have had no problem.

Bathtub Designs

My first question is: Who are all the sadists that create

all the

bathtubs with no slope to the

back end so you can relax in it? The other question is its companion:

Who are all the masochists who buy and install these tubs? Once a tub

is purchased and installed one is stuck with the choice for years or

maybe even a lifetime. (My previous house in Victoria BC still had the

antique cast iron bathtub it came with when I left. That's more than

one lifetime! I soon moved it over to a corner and tiled it in for

showers like any newer bathtub.)

My best guess on the first question is that less thought

goes into a bathtub's design than a tin can's. All those old cast iron

bathtubs from the 1800s at least have sloping backs. The trouble with

them is the thick cast metal is a big heatsink and if you lean back,

your back gets cold even while the water is hot. And of course all the

water cools more quickly. My best guess on the second question is that

contractors build the majority of houses, and they want nothing but the

cheapest - er, I mean the finest - to go into the houses they are

building not to live in but to sell, and again little thought is put

into the tub purchase decision. Or perhaps the contractor may even be

afraid to

put in a tub that might attract notice.

But even examining the cheapness aspect, it is surely

easier to punch out a formed sheet metal bathtub with sloping sides and

ends than straight. We must then go back to the first supposition, that

little thought goes into the design. This hypothesis is reinforced by

them mostly having level, or even (as in my present tub) slightly

convex surrounds. Any water that gets up onto the sill doesn't run back

into the tub as it would if they were, more logically, slightly sloped

inwards. On mine it actually pools up against the wall, and runs down

the outside onto the floor. I finally had to caulk a substantial

silicone ridge "dam" onto the shower curtain side of mine to keep water

from

running around the corner, behind the curtain, and soaking the floor

and bath mat during every shower.

But I somehow get red spots on my legs that seem to be

best treated by immersion for a time in a hot bath, so I don't always

just shower.

Obviously I am never going to divert from my many other

projects to design a bathtub. But I can imagine things I might do or

try if I was in that business. Here are some hypothetical designs - and

things I will look for if I ever have the occasion to be shopping for a

new bathtub... which would probably be because I hate this "typical"

one so much I would like to rip it out and replace it.

1. The aforementioned sloping head end for comfort. It probably doesn't

need to be as sloped as the old cast iron tubs, but enough for

leaning-back comfort.

2. Do they have to be so wide - 24-25" on the inside? It seems to me if

they weren't such big, square tanks it could take a lot less water to

have a bath.

a. First, they might be wide in the middle but taper toward both

ends, say to 18" at the feet and 20" at the head. Maybe even thinner.

Anyway there should be some compromise somewhere between being too

extreme for comfort and using so much water.

b. Vertically, they might be more sloped on the sides as well as

the ends. The 24" or more toward the top might be again say 18" at the

bottom. I've seen a tub with contours - "armrests" - on the sides at

about the high water level, which seemed rather nice.

3. The drain might be at the head end instead of the foot. (in a

corner? or slightly recessed?) That would put the deeper part of the

tub at the head end and it would take substantially less water to cover

to the depth

of the thighs. (If I turn around the "wrong" way in this tub, it's

definitely deeper at my body end; shallower at the toes.)

When the person takes up a higher percentage of the total

volume of the tub, the water will rise up higher when they get in, so

shrinking the volume makes for proportionally more water savings than

than just the reduced cubic tub measurements considered alone would

indicate.

4. Some compromises might be necessary to ensure a good standing area

for showering.

5. Textured non-slip patches on the bottom for safety in the shower

standing area. I've seen a tub with this nice feature in the bottom

enamel. Just enough texture, still not a dirt accumulator. No ugly,

dirt trap rubber mat needed.

6. A "lower entry" area on the outside for best access by the elderly

and the physically handicapped.

Let us be done with these 20th century square "sardine

tin" bathtubs!

Having written this on my old iMac with no WiFi and not

even physically connected to the internet, mind reading Google put up

an ad for

"bathtub inserts" when I was watching youtube on another computer.

Unfortunately this was from a contractor who installs them. I didn't

think much of my chances of getting them up here to do mine for any

sane sort of price (much less getting just what I wanted) and I didn't

follow it up. But I will do a search and see just what "bathtub

inserts" might be

available.

Clinton &

the "Deep State"

I understand Hillary Clinton said this month "If I'm

indicted there'll be civil war." Would an innocent person not have said

something more like "Good! Let them indict me, I've done nothing wrong

and it will at last clear my name."? So we can seemingly read into her

statement, petulant defiance, a threat and an implicit admission of

having willful and significant wrongdoing.

I'm not much worried by the threat. If she had been

indicted a year or more ago while her cronies - who were also Bush's

and Obama's cronies - were still running the FBI, the CIA, the DOJ and

the supreme court and when the public understood almost nothing of what

sort of

entrenched cabal they were being run by, this could have been a

potential. Not now.

"The Most Highs rule in the affairs of men." - Bible. Or as the

Urantia Book puts it, They rule in the affairs of nations. We live in a

time of a great moral and spiritual awakening, which, we trust, will

not be

permitted to be extinguished and delayed by a new dark age.

"Better a deplorable than a despicable." - me

And how is it that so many people, known very bad actors

of various ilks, walk freely, while president Trump's team members are

indicted one after another? According to attorney Harvey Silverglate in

his book Three Felonies a Day: How the Feds Target the Innocent,

there

are

so

many

laws

that

everyone

over

the age of 18 unknowingly

commits around three felonies a day against laws they were unaware of

such as "Dogs within 200 feet of a federal building must be on a leash

six feet or shorter". Did you dig a hole in your back yard without

complying with some EPA requirement? There are over 5 million felony

laws - no one can count them all. No one over age 18 hasn't violated

some of them. There is no requirement that you had to have willfully

and knowingly violated a law with evil intent. "Aha! You forgot to fill

in this box on your income tax form in 2012 - and we don't like you -

so you're going to jail for income tax fraud." On the other hand, the

"deep state" and connected actors, mostly all as criminal as each

other, simply choose not to prosecute each other, even for murder,

theft of billions, child sex trafficking and "crimes against humanity".

Working for president Trump is in their minds the real crime - or at

least the real threat - because he's trying to "drain their swamp".

Here's another Churchill quote: "If there were 20,000 laws, people

would lose their respect for the law." Now it's more a case of "the

law" has no respect for the people.

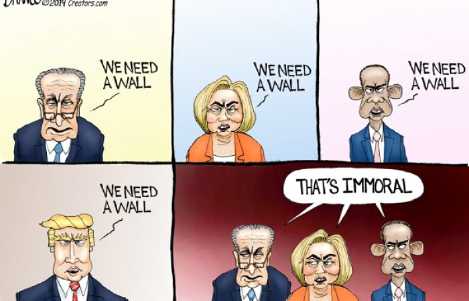

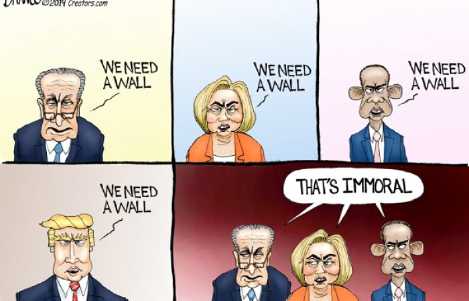

Why They

REALLY DON'T Want the US-Mexico Border Wall

Finally I think I understand. I watched a video, but it

was the

comments from a viewer underneath that finally told a story that fits

the facts and explains the seemingly absurd obstinacy of the

opposition.

"Follow the money."

The wall, a one-time expense, will cost 5 billion dollars

(or whatever).

Of course we'd all love to have that much money, but it's pocket change

compared for example to what the US spends on

"foreign aid" each year. What it's also pocket change compared to is

200 billion dollars of drug smuggling and who knows how many tens or

hundreds

of billions in human trafficking annually. With a border wall, all this

illicit commerce will doubtless suddenly become far more difficult and

will

surely be drastically curtailed. Where will all the untraceable money

come from for all

the secret "black ops" and unregulated "deep state" activities that

congress has no oversight or control over?

from USAWatchdog.com (Greg

Hunter)

Those now

opposing the wall gave it lip service in the

past, saying one was needed and actually voting for it, but in fact

doing nothing. Now that one is actually to be built, the same

hypocrites

are dead set against it. Truly they

don't care beans about floods of

illegal immigrants destabilizing the country and destroying its quality

of life, and that these have to be supported

by broke taxpayers or take their jobs, or about the immigrants

themselves -- or much about any societal consequences to anyone. As

long

as their institutionalized cash machine continues to function and fund

their dark budgets, they will let the country rot. The CIA truly is the

Cocaine Importing Agency of

the "deep state". The wall is surely a fundamental threat to the whole

unelected,

underground, shadow government whose tentacles wrap around the entire

US political machine. So is withdrawal from Afghanistan, where the

opium comes from.

Those now

opposing the wall gave it lip service in the

past, saying one was needed and actually voting for it, but in fact

doing nothing. Now that one is actually to be built, the same

hypocrites

are dead set against it. Truly they

don't care beans about floods of

illegal immigrants destabilizing the country and destroying its quality

of life, and that these have to be supported

by broke taxpayers or take their jobs, or about the immigrants

themselves -- or much about any societal consequences to anyone. As

long

as their institutionalized cash machine continues to function and fund

their dark budgets, they will let the country rot. The CIA truly is the

Cocaine Importing Agency of

the "deep state". The wall is surely a fundamental threat to the whole

unelected,

underground, shadow government whose tentacles wrap around the entire

US political machine. So is withdrawal from Afghanistan, where the

opium comes from.

Also: Along with a good majority of all

in border states, lots of Latino citizens in the USA, whether their

ancestors got there legally or illegally, support having the wall.

With the organized

migrant caravans stopped south of the

US border at this time, it appears many Mexicans too, especially

businesses, are getting

fed up with their presence and their needs harming the economic life of

their communities. Perhaps they too will want a wall on their southern

border? It would be shorter.

Today's caravans of thousands will soon become migrations

of millions as conditions worsen. North America will lose its educated

society, culture and civilization and become a chaotic mess if the

process is permitted to proceed unabated.

And if the USA would stop sabotaging South and Central American

affairs, there would surely be fewer migrants whose lives and

livelihoods have been trashed, who flee to try and find a decent life.

The campaign to destroy Venezuela in order to get them to virtually

hand over their oil fields

to American interests for free is disgraceful. The deplorable situation

in Venezuela largely came about through US sanctions and seizure of

Venezuela's funds. (Funny we hear no sympathetic calls to donate to aid

the

poor, starving Venezuelans.) Instead 20 billion dollars of "aid" is to

go to try to overthrow Maduro and install some dictatorship

more to America's liking.

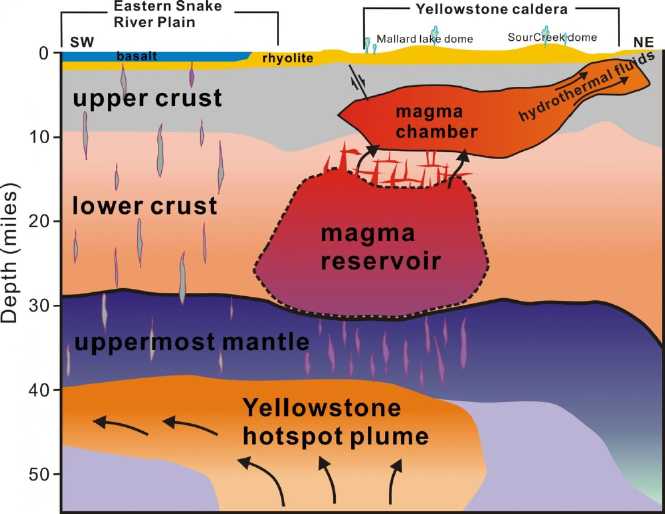

Yellowstone

Volcano: ready, set, ...?

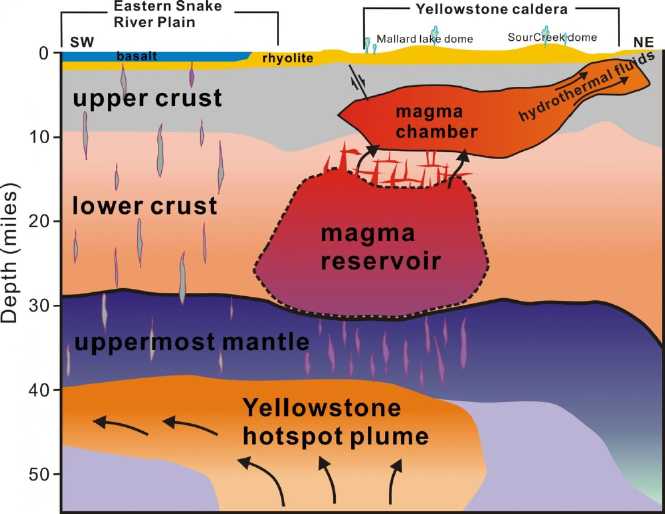

Many have said, and have said for some lifetimes, that the

chance of the giant Yellowstone volcano going off "in our lifetimes" is

trivial. Given that last major eruption was 600,000 years ago, this

seems like an awfully safe bet. But then its big

eruptions have been at 600,000 year intervals. At the other end of the

spectrum are those observing it like Mary Greeley (youtube), mostly

since mid 2018, saying that it looks like it's going to go off very

soon. The ground has been bulging up, geysers have become more active

and there are new ones, and some have started spewing rocks as well as

steam. And there have been some earthquake swarms - which were the last

signs before Mount Saint Helens erupted in 1980. So much sulfur dioxide

is coming out of the ground it's killing the forests around the caldera.

If the Yellowstone "supervolcano", with a caldera 35 by 45

miles, did blow in a major eruption, it would dwarf Mt. St. Helens. The

more excitable have said that the ash cloud would "destroy the United

States", "make humans extinct", or at least cause the economy to crash.

It is certain there would be vast disruptions to transport, deliveries

and food production in North America - especially to air travel and

possibly for two or three or

four years. More locally lava and pyroclastic flows could devastate

- bury - vast areas up to 100 or 125 miles away. I am very glad I don't

live in

that "kill" zone.

If the Yellowstone "supervolcano", with a caldera 35 by 45

miles, did blow in a major eruption, it would dwarf Mt. St. Helens. The

more excitable have said that the ash cloud would "destroy the United

States", "make humans extinct", or at least cause the economy to crash.

It is certain there would be vast disruptions to transport, deliveries

and food production in North America - especially to air travel and

possibly for two or three or

four years. More locally lava and pyroclastic flows could devastate

- bury - vast areas up to 100 or 125 miles away. I am very glad I don't

live in

that "kill" zone.

We have little experience with such huge volcanoes. One

geologist thought that it might go off with as little as two weeks

notice.

My question is, if people looking at the Yellowstone

seismic

monitors on line and reporting all these signs on youtube and the web,

are we already looking at the warning signs? Geologists were expecting

Mt. St. Helens to erupt, but even so it blew before they thought it

would. How much warning will all those people really have before the

real event, should it occur? If the signs only gradually get stronger

and stronger over the months, will everyone get complacent and ignore

it until it actually goes?

Coming

Collapse: Contempt & Disdain

People have been talking about a collapse for perhaps this

whole decade - apparently prematurely. (Including me.) While things

have been gradually

deteriorating in many ways, nothing monumental has happened to most of

us yet in

the western world. Someone has stated that people have become not

merely complacent, but actually dismissive and contemptuous of the

idea of a

major collapse. With all the predictions that have not - yet - come to

pass, they feel that anything untoward that happens will surely be

papered over by "the

powers that be".

But the economic news looks more and more bleak with polls

suggesting that now over half (58%) of Americans and Canadians are

living paycheque

to paycheque with record levels of debt and no savings to speak of, up

from

40% a year or two ago. Now even seniors are declaring bankruptcy. Plus,

the sea level rises are just getting going with Antarctica now joining

Greenland and starting to melt in earnest, and weather and geological

calamities are growing ever stronger and

more frequent, causing crop losses our heavily populated planet can

hardly

afford which in turn will lead to unaffordable food prices in

the stores if not empty shelves. Diseases are on the rise and some

antibiotic-resistant thing is likely to break

out in our crowded cities and spread around the globe. Humongous

die-offs of every sort of plant and animal species are being reported

daily from all over the world - even Antarctic krill and ocean plankton

are in peril.

All of this ongoing devastation has become so common most

of it

doesn't make the news any more. Many things that are being done that

are unsustainable are drawing toward their inevitable endings. Chris

Martenson [PeakProsperity.com] says collapse is already happening, that

it's a process, not an event.

But there will probably be some climax to

all this - or at least to some "straw that will break the camel's back"

- (Yellowstone erupting might be a fitting climax?) and it's likely

over another decade or two this will become a dramatically

changed world with a lot fewer people in it. That population

reduction will be highly beneficial to those who remain. Gradually the

quality of life will become vastly better, and people will look back

and say "what

went wrong?" and turn their attention from physical sustainability

projects to those that will ensure social sustainability for the future

of the world.

Those who are discerning the signs of the times will be

more ready in many ways, mentally and spiritually as well as

physically, than "couch potatoes" who dismiss it all as "fear porn" and

do nothing. Physically, many have said it's just good insurance to be

prepared

with a food supply, some "redoubt" prepared to go to outside of cities

in case (for example) you hear of a serious disease spreading in yours,

enough gas

always on hand to get there, and hard cash or real silver in hand for

if the banks are off-line or fiat paper notes aren't being accepted any

more. And it's still true as some have said, that it's better to be

prepared years too early than a day too late. Mentally and spiritually,

are we prepared to contribute, to help ourselves and others when times

of great need - and great opportunities for service - arise? We are

living in, surely, the most unique period the world's history will ever

record.

Cryptocurrency

Exchange Failure?

They say not to leave your cryptocurrency on an exchange

because they get hacked. It's much safer in your own wallet. Oops. With

the poor internet service around here I got complacent. I had left

some etherium on the QuadrigaCX.com exchange for quite some time. I

thought occasionally about withdrawing it to my wallet. But I was

having trouble with the wallet, and I kept putting it off. One day I

went onto QuadrigaCX and transferred the majority to my wallet - or at

least I hope I did. (Once I get into my wallet I'll be sure. I seem to

have done something to the password and will probably need to reset

everything to get back in.)

The price of etheriums being way down from where I bought

them, I thought I would "double down" and get some more. Options for

transferring funds from a bank to this exchange had become quite

limited. Perhaps I should have been suspicious.

I got a "prepaid credit card" at the post office. When I

went

back to the exchange the next day it said "site down for maintenance".

It still said that 3 days later, so finally I checked around. It turned

out that the exchange was mostly a one-man show, and the owner had died

unexpectedly in December. Everyone had been unable to withdraw $money

from it since then. His wife doesn't seem to have any idea how to run

it. I may (I pray) have got my etheriums out just in time - not a day

to spare - and the remainder I left on the exchange in case I wanted to

sell some may well be lost. Until then it was a great exchange. All

quite

distressing.

Assets that are nothing but numbers on a computer screen

at a bank can be lost, too. Paypal is a huge outfit, and it doesn't

lend your money out, so it's probably about the safest place to have an

account. But

QuadrigaCX where I've dealt for several years going down without

warning (as far as I knew) certainly took me by surprise.

ESD

(Eccentric Silliness Department)

Here's a quote I should have had for the article on

the BC Referendum

last month, which appeared to suffer from the same contempt and disdain

as the subject of collapse: The first attempt to change things was in

2008

(which "failed" with 59% approval but a mark of 60% required), and

since then people just didn't want to think about it again, good or

bad. The quote:

"The best argument against democracy is a five-minute

conversation with

the average voter." - Winston S. Churchill

---

WARNING: Really bad puns ahead

---

Q: Ding-dong. When does the SHTF?

A: When the bell over the fan has dung.

---

"Have you heard of lamas?"

"Neigh, but I have herd of horses.

"And flock of flying sheep." (Methinks he's telling yarns!)

Sheep of a fleece may flock in peace.

---

Long drives on vacation with my parents and my two brothers, ca.

1968-71:

Dad: "Oh, here's a White Spot. I guess that'll do."

Somehow it never occurred to me back then that there actually were no

restaurants called "Black Spot" or "Brown Spot".

But I can be pretty dense. Once there were several people were at a

table. In introductions one guy said he ran a filling station and

everybody but me immediately understood he was a dentist.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls.

Electric Transport

Ground Effect

Vehicle

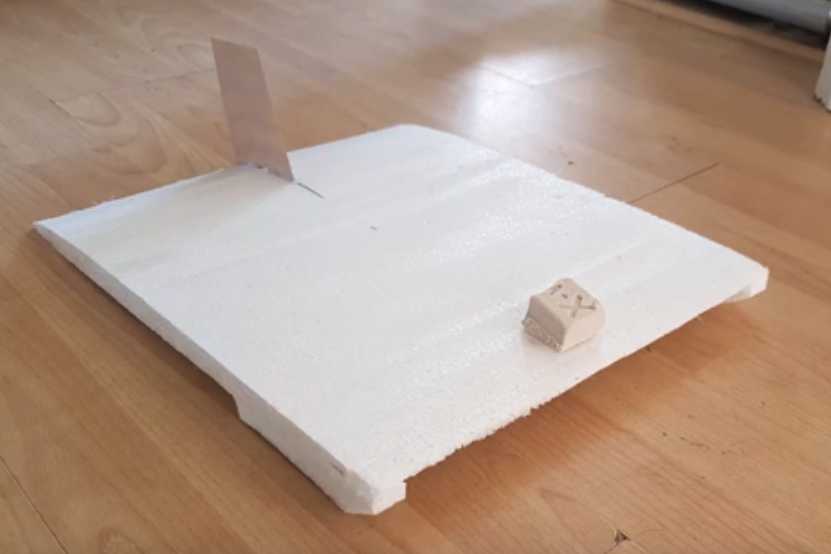

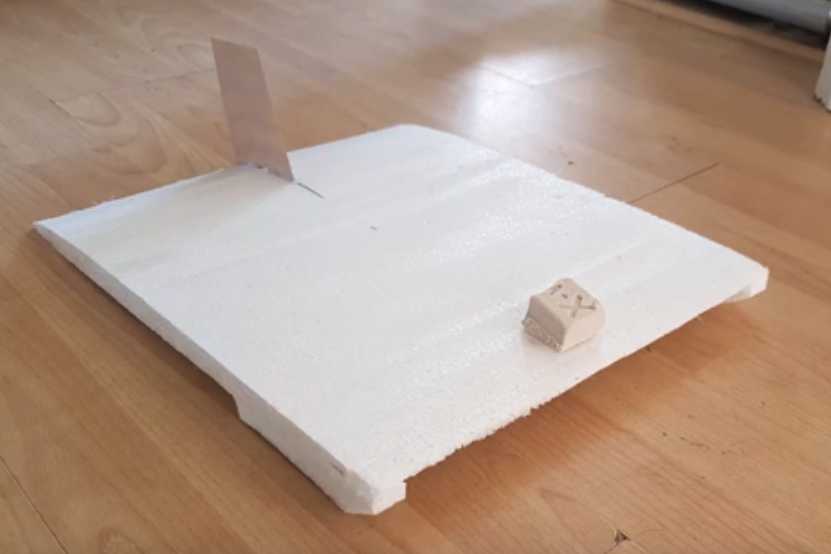

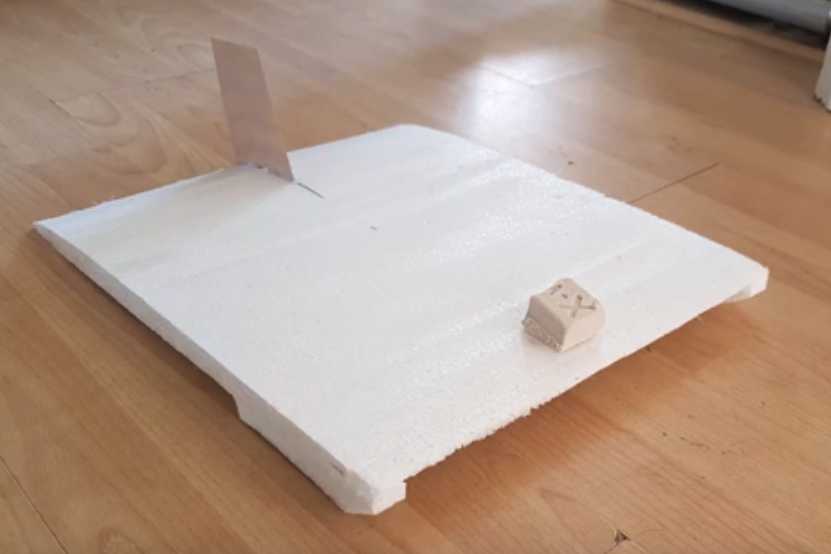

Youtube put up

another ground effect craft video suggestion. It was just a short 1.5

minute video of a square model launched by rubber band across a floor,

but it got my attention. The wing

profile was different than any other I'd seen. The model

seemed more stable than others, including with different weights placed

on the

nose. (lighter, right; heavier, left below) I ended up in e-mail

contact with the maker, John Ryland of

RylandResearch.co.uk . He seemed to also have some interesting robotics

projects including a fire-fighting robot.

Youtube put up

another ground effect craft video suggestion. It was just a short 1.5

minute video of a square model launched by rubber band across a floor,

but it got my attention. The wing

profile was different than any other I'd seen. The model

seemed more stable than others, including with different weights placed

on the

nose. (lighter, right; heavier, left below) I ended up in e-mail

contact with the maker, John Ryland of

RylandResearch.co.uk . He seemed to also have some interesting robotics

projects including a fire-fighting robot.

The wing was

designed with the curve on the top side more

evenly distributed front to rear, in fact with more curve toward the

rear instead of the front, so that the center of the vacuum lift

on the top

was more toward the rear of the wing instead of concentrated toward the

front as in most aircraft wings. It almost looked like it had "flaps"

partly extended. This lift is independent of ground

effect. He said the relatively more flat underside kept the ground

effect compression lift underneath, which decreases

with altitude, more toward the front. Thus if the nose rose up, the

front lost [ground effect] lift while the rear maintained its [suction]

lift, which would tend to lower the nose. This should work to keep the

vehicle in more stable, level ground effect flight.

The wing was

designed with the curve on the top side more

evenly distributed front to rear, in fact with more curve toward the

rear instead of the front, so that the center of the vacuum lift

on the top

was more toward the rear of the wing instead of concentrated toward the

front as in most aircraft wings. It almost looked like it had "flaps"

partly extended. This lift is independent of ground

effect. He said the relatively more flat underside kept the ground

effect compression lift underneath, which decreases

with altitude, more toward the front. Thus if the nose rose up, the

front lost [ground effect] lift while the rear maintained its [suction]

lift, which would tend to lower the nose. This should work to keep the

vehicle in more stable, level ground effect flight.

I had been told or had heard that the Bixel flat or

symmetrical wing,

while more stable, needed too high of take-off speeds, and too high an

angle of attack while flying. It seemed to me this new wing profile

might solve or

at least ameliorate the problems, providing stability and more lift at

lower speeds.

In the whole aerodynamic design, the wing profile was the

remaining detail I had been rather uncertain about, and hadn't figured

out a solution for that I was confident would be satisfactory. It

seemed like a good time to draw up the design for the RC model, e-mail

it

to John for comments, and if it

seemed good to both of us, to build the model.

John mentioned that for water take-off it would need a

"step" in the hull. Steps are commonly used in "V" planing hull shapes

to effectively reduce the length of the hull in contact with the water

and hence the drag. They are ubiquitous on water takeoff aircraft. But

should I use them with the narrow but flat bottom hulls I had in mind?

I had thought not, but now I decided that I should: whether flat or "V"

bottoms, a step would still reduce waterline length and hence the drag

once

planing at higher speeds for takeoff. I put a 3" step in the design, 6

feet from the front out of the planned 16 feet overall length. (Scale

to 1/4 size for the model.) Hopefully 3" rise

wasn't going to make much difference to the "hovercraft box" effect --

if that was needed at all. Also I put the back of the wing another few

inches above the bottoms of the hulls - and a little ahead of the

backs. Better, I hoped, that the wing didn't cause drag in the water in

small waves. Also if the elevator was pointed down, it would cover that

space.

I think I'll start by hoping my earlier hovercraft effect

idea with flaps at the front of the wing to make a complete "hovercraft

box" underneath for take-off at low speed isn't

necessary. And why was I actually concerned about that, anyway? First,

there was the reputed high speed needed for take-off of the Bixel flat

wing, ...and almost

subconsciously, it was that I wanted to use the electric motor from the

Swift in the full-size craft. For anything else, for the model or with

a gasoline engine on the manned vehicle, I could just up the motor or

engine size until it had sufficient power. I should just design for a

typical(?) takeoff without thought of the electric motor, and then if

it had enough power,

great - otherwise forget it and just do gasoline. Gasoline power would

give it much

greater travel range anyway (in case I ever actually got up the nerve

to try flying 170 Km to Prince Rupert). Especially if better higher

energy

density batteries don't come along. As long as take-off doesn't require

a

scary speed regardless of power, it should be fine.

I picked away at the drawing now and then. I used paper

and pencil. I suppose it could be better done in LibreCAD or something

on the computer.

On the 24th I assembled the motor and the 5 inch ducted

fan propeller together. It wasn't simple as they definitely weren't

made to fit each other. The prop rubbed a little on the duct -

depending on the orientation. I

hope the motor is powerful enough to turn the fan sufficiently. And I

hope the fan

is big enough to power the large RC model. I note that the duct doesn't

have the curved lip on the front that a video showed was optimum

aerodynamically for greatest thrust. Sigh!

The next day I wired things up and (almost two years after

buying them) tried them out. I found which joystick on the

transmitter/control went to which 3-pin plug on the receiver by

plugging a servo into one at a time. It worked without having to set

anything up. The receiver was apparently tuned to the same frequency as

the transmitter, said to be 2,400,000,000 Hz (ugh, microwaves!*)

although they were sold separately. I don't understand how one would

keep different model aircraft from interfering with each other.

The motor turned the right direction, but it seemed to

work backward. It was "off" if the stick was pushed all the way forward

and "on" when it was pulled back. Furthermore, when I turned off the

transmitter, the motor revved up full and the ducted fan pulled the

whole all-wired-together web off the hard table onto the floor. Even if

I reversed the wires inside the control at the joystick to make it the

right way around, it would still go to "max" instead of to "off" if it

lost contact with the controller. I'm not fussy about that sort of

arrangement! Is there an analog "inverter" option somewhere? If not I

may have to make one. (Or was there some way to reprogram the "ESC"

BLDC motor controller for that?)

The tests were with 6 volts, with which it barely

functioned and the motor "crapped out" if accelerated very fast. It

should pull pretty well with 12 volts.

* Actually about 14 cm wavelength. Why they're called "microwaves",

implying sub-millimeter wavelengths, I don't know.

Other

"Green"

Electric

Equipment

Projects

Carmichael

Mill ("Bandsaw Alaska Mill")

When I re-sharpened the band I was using for maybe the fourth time, it

didn't cut very well. It didn't seem to have much "set" to the teeth,

that is, one sticking out a bit to the left, the next to the right, and

so on in a repeating pattern. If there's no set, the cut is no wider

than the band or blade, and it binds.

I took a small pair of blunt nosed pliers and bent the

teeth out by hand. It only took 10 minutes. I got three more cuts out

of the band and then it was plainly dull. When I took it off, there

seemed to be little set to the inner teeth while the outer ones were

still fine.

This uncovered a

problem with the mill. I had noticed this before when I took a dull

band off. I finally realized that what it was was that the guide wheels

were just a little too wide. Not the tips but the more base part of the

teeth went over them and it gradually flattened them out so they didn't

point slightly up. This would also explain why, when a band was dull

and the saw cut 'bow' shapes across the cut, it was always convex - the

outer, bottom teeth cut better.

So I took the band guide wheels and turned a little off

the edge on the lathe. In doing that, I noticed that on one of the

wheels, the rim was worn very thin - like to 1/4 of the washer's

original thickness. For now, I just swapped the wheels so the other one

would wear instead. (They aren't aligned quite the same - hey it's a

prototype!) And I'll oil them before each use. It might help.

Mining Beach

Sand?

I got a gold pan at

Christmas time. I shoveled up some beach sand and tried to pan it. I

didn't see anything special. Then on the 15th my microscope arrived

from Westlab.ca (.com?) and I put a bit of the sand under it. It looked

like there were a very few microscopic grains of gold, but more,

nuggets of

what might be platinum the size of small grains of sand. At least, with

the light from above, they looked like pictures I've seen of platinum

nuggets, aside from being almost microscopic. (Iron would surely have

rusted away in the salt water.) Lit only from below under the

microscope, they looked dark - opaque - contrasting with the

translucent grains of quartz sand. If there was some way to separate

them in bulk, it just might be worthwhile (monetarily) to do.

I went on line and looked, but I wasn't liking what I was

seeing. It seemed to be all nasty acid chemical processes with "Don't

try this at home!" sort of cautions. And "highly poisonous with effects

showing up months or even years later." so you might not even know you

were hurting yourself. Sort of like speeding ticket cameras where the

ticket - or multiple tickets - shows up in the mail after the drive is

long forgotten. And one needed to similarly dissolve the element as a

salt to "electro-win" it, too.

Let's see... First, if there was anything magnetic, it

could easily be separated out for disposal (or separate processing if

it was worthwhile), with a supermagnet.

A few years ago in my experiments I melted copper and

silver on a kitchen stove burner. (See TE News #__) I wanted to tin

plate pieces of copper. I melted solder on the stove and threw in the

copper pieces. Much to my surprise they came out shrunken and misshapen

or not at all. If stirred they disappeared quickly. Alloys melt at a

lower temperature than any of the individual metals that compose them.

The copper formed a surface alloy with the solder, which then melted

into the pot, exposing more and more copper, until it was gone if it

was left in long enough. It worked with silver quarters too. I got a

lump of solder up to about 10% silver. And since they were melted at a

low temperature and submerged in the tin, they didn't oxidize. Could

this process somehow be used on the beach sand to get the (what looked

like)

microscopic metallic nuggets out of it? Perhaps one could end up with a

lump of precious-metal-rich tin? Probably one could send that somewhere

for processing to refine out the various elements, whatever ones were

found to be worth

doing.

The trick would probably be how to separate the quartz

sand grains (maybe 95-99%) from the metal (1-5% precious, plus the tin,

which

would have to be enough amount to submerge the sand being processed). A

fine

metal screen... would likewise dissolve. The quartz would probably be

lighter than the metal.

Someone told me what I needed to do first was to send some off for a

"fire assay" to see if it was in fact worth doing anything with. If it

is, then I should think further about how to process it.

Extending My

Solar Power System

Mounting the charge

controller with a fan on the piece of fire-stop gyproc against the

garage wall turned out to have one flaw. That wall was the other side

of my bedroom wall, right next to the head of the bed. In the morning

as it got light I could hear it buzzing through the wall. I tried

cushioning it, without any apparent improvement. I took out the screws

entirely and left it dangling by its wires. That helped. I could still

hear it from in bed, but only a bit. Hmm... do I just leave it like

that?

DC LED Lights

One day in early to mid

January, I went on line to Aliexpress.com and ordered a bunch of DC

powered LED lights. Perhaps the most interesting ones were some that

screwed into regular light bulb sockets and would run on 12 to 72

volts DC. At last, something I could run off my "ideal house wiring

voltage", the 36-40 volt solar system! Other selections included a

batch of 30x60 cm ceiling panels (just 94$C for three - 31$ each!) and

some so-called "cob", "12

volt" flat LED emitter arrays. Those I also intend for the off-grid

system, with sets of 3 in series for the 36-40 volts. I also found some

adjustable drivers, simple, flexible units with two potentiometers,

which could be adjusted as desired for any constant current or any

constant voltage (within their limits of course). Those should be ideal

for LED lights. (Later I found the order I placed was for the wrong

ones, and I couldn't find the right ones again!)

The first lights to arrive, on January 31st, were the

30x60 cm ceiling panels. They were very thin and light - even "flimsy",

but once mounted on a ceiling who would care? A bigger problem, the

description on the web site said "85-265 volts", but the power supply

modules said "155-265 volts" and the light didn't light when I

plugged the wires into a 120 VAC wall plug. This was discouraging.

Then I tried running one straight off DC from a power

supply. At the full 30 volts the panel lit up. Could they be run off of

36 to 40 volts? They were supposed to be 24 watts. That would be .62

amps at 38.9 volts. I hooked it up to the full 38.9 volts of the solar

system with resistors to limit the current. With 22 ohms it was .22

amps with a moderate light. With 5 ohms it was .42 amps with quite a

bright light, and with 1.5 ohms (or was it 1.0 ohms?) it was .62 amps

and very bright. Nice light, fairly even across the panel face, with my

favorite 4000°K color temperature. Only

with no resistor was the current too high at .73 amps. Of course if I

was going to keep it simple with a fixed resistor, during the day with

the sun shining and up to 42 volts on the system, 5 ohms might be a

good minimum to ensure current stayed under .57 amps. (24 W / 42 V)

If I ran them all off the DC system, the wrong-voltage

power supplies wouldn't matter. But I decided to complain because I

wanted one or two of them in my dining area to run off the AC. I wrote

a letter to the company. Then before I clicked "Send", I decided to

make really sure they didn't work. I stripped off a bunch more

insulation and again stuck the wires into the wall socket. To my great

surprise, the light came on! In spite of them saying "155-265 volts",

all was well. I'm glad I didn't send the letter. I deleted it and

clicked the "Confirm Goods Received" button instead.

I lucked out. They seem like pretty much perfect lights

for 36-40 VDC power as well as good on line power. I may put in 3-way

switches so they can be "bright" (5 ohms series resistor - sucking the

life out of the batteries) or "subdued" (50 ohms - power conserving).

I was tempted to order another 3, and on February 1st I did. I'm sure

they're as salable as the rest of my solar equipment that isn't

selling. Now I need a bunch of 10 watt resistors from Digikey for the

simple

36-40 VDC power solution.

Off Grid and Grid Tie

After I connected up

the "off grid" solar system, while still having grid power, it seemed

about the only thing I was using solar/battery power for was a

nightlight. It was my four "Cree" LED light, and it was actually quite

bright on "high", but I kept it on "low" for the night for fear of

running down a set of batteries.

One sunny day that seemed like a waste of available power,

and I split it: two panels to charge the batteries, and the other two I

hooked back up to a grid tie inverter.

On the 25th I was reminded that the 305 watt

"monocrystalline" panels were supposed to be better in diffuse light.

Perhaps it was time to put a couple of them up, either in addition or

to replace the two weakest ones. (232 w & 240 w with the other two

being 265, IIRC, but I don't know which panel is which. The labels are

on the undersides and of course they are bolted down.)

Solar Hot Water?

Some time ago I bought a small 120 volt water tank/water

heater that

I've been planning to install under the kitchen sink. But I want to run

rainwater to it from barrels instead of

the iron-rich water from the well that turns brown and turns dishes

brown too. (And it takes

approximately forever to get hot water at my kitchen sink anyway.) How

would it make out being run by the solar system, or even by a solar

panel directly? The trouble is, 40 volts is 1/3 voltage and so just 1/9

the

power of 120 volts. It certainly wouldn't heat the water very fast even

in the

summer sun. But it should work and it would put the solar power to use.

OTOH, it kind of makes a good case for a direct solar water heater with

pipes instead of electrical connections.

On the 26th I started coming up with a plan. Instead of

putting the rainwater barrel just under the eaves and having it gravity

feed to the electric tank, I would use the "submersible utility pump" I

bought at Christmas time in Victoria. The barrel would be on the ground.

For a pump system, one needs a pressure tank with air at

the top and a pressure switch to shut the pump off when there's enough

water under enough pressure. While looking at stuff in the building

supply, it occurred to me that I had a brass hot water tank that I

could use for two purposes: I could paint it black and put it in an

insulated box with a glass cover, sideways, as a solar box water

heater, and have it with air trapped in the top to make it double as

the pressure tank. Nowhere nearby got full sun for more than three or

four hours a day even in summer, but it could still help. (Hmm... up on

the roof, directly above the rest, would get more sun. It shouldn't be

too heavy for that.) The water would go into the electric heater

preheated, and the water in the tank would extend the rainwater storing

capacity of a 200 liter barrel to almost 300. And the (slightly)

pressurized water would come out of the tap with more force than just

gravity fed. To make it completely solar I could plug the hot water

tank into the 40 volts DC to top up the temperature. In the winter in

clouds and short days when the sun wouldn't do much, I could plug it

into the 120 volt mains.

The materials I'll need are just

whatever water tubing I can't come up with at home, and a pretty low

pressure pressure switch. Oh... and time to do it all.

Run When There's Power?

Something I keep finding is that it would be nice to have

an appliance that runs when there's solar electricity but doesn't when

the system is running off batteries. Like the water heater. There's

also the cases that one wants to run the appliance even off batteries

anyway at a certain point, usually going by the temperature. This would

be if the fridge or freezer gets too warm, or if water is going to

freeze or get colder than some limit.

Concentrating for now only only the first point, what's

needed is (a) an accurate measurement of the ON and OFF voltages and

(b) a time delay before retry.

With a charge controller, batteries will drop by

themselves below some voltage if they are not on charge, and must be

above the threshold in order to recharge. The ON voltage setting will

turn the appliance on. Since appliances draw current, the voltage will

drop a little when it does come on.

The time delay feature is required because the appliance

when turned ON may draw enough current (eg, if the sun isn't bright, or

the battery charge is too low) that the voltage drops too much and

turns it OFF again. Of course, as soon as the appliance turns off, the

voltage comes up to the turn-ON level again. A delay of maybe between 1

and 30 minutes before trying to power it up again gives the system time

to increase the power or charge available. So the device would be set

up with two trimmer potentiometers for ON and OFF voltage from about 10

to 45 volts (for 12 to 36 volt systems), and a DIP switch with two or

three selections for delay times. And perhaps there would be a preset

minimum ON time as well, for example 3 or 4 seconds for a fridge

compressor to start and get running at high current, after which the

current drops substantially and the voltage would rise above the

"power-OFF" setting.

When I was using the thermoelectric fridge I thought of

making a "smart" control for it that would take voltages and

temperatures into account. Here instead would be a universal power

control to hook into the power for any appliance, eg, plug it in and

plug a lamp into it, and when the batteries are too low, the light

would go out. The solar water heater would only run when the panels

were supplying power at a good voltage, not off the batteries at night.

When I used the 12 volt DC to 120 VAC inverter during the

power failure in December, it drew enough power even with no load that

it soon was sounding its "low voltage" alarm. I turned it off at the

switch and thought that would be that. But I didn't actually disconnect

it because I had used nuts to connect it (again an argument for

standard plug-ins for everything!) and I didn't have a nutdriver or

wrench handy. On January 27th I checked them and discovered to my

horror that they were down to 5 volts. Even with the power switch "OFF"

the inverter was drawing power and draining the batteries! Of course

this power shut-off device would draw a bit too. It would have to

itself be made micropower. But that can be done.

Another interesting way to make it, still pretty cheap to

make, would be with a microcontroller to turn the power on and off.

Instead of programming buttons, plug in a computer mouse. Use the mouse

buttons and roll it up-down or left-right to change the settings.

Putting up some of the New Solar PV Panels

One day someone mentioned panels that were better in

diffuse light, which jogged my memory that the new 305 watt

monocrystalline panels I had bought also claimed to be better in lower

light than others. After getting so few watts in December, perhaps I

should be comparing with these new ones? And anyway it was high time I

put a few of them to some use myself, even if no one had bought any

from me. On the 28th I broke open the crate by cutting the four tough

plastic straps wrapping it, two in each direction. Under the

polyethylene the "crate" proved to be cardboard (by now all soaking wet

in spite of the plastic and the metal roof pieces I had put on top), on

a wooden palette. Very minimalist, but it seemed to have worked. To my

surprise the panels were all on edge rather than laid flat, so the

height of the contents was the width of the panels.

I took two off

the side. Beautiful, new panels!

I cut four

flat aluminum pieces 1" x 2.5" and drilled a 1/4" hole near each end. I

put one end under each of four small slots on the bottoms of the panel

frames and bolted them on. This made four tabs about 1-1/4 inches long,

each with a hole, sticking out the sides to bolt the panel to the roof

with a 3" x 1/4" lag screw. But I had no lag screws and used up the

rest of the day going into town. I got them up the next day (29th).

Unable to think of a better spot, I put them below the two that seemed

to get the least shade. I got the wires run on the 30th and hooked both

panels in parallel to the other grid-tie inverter, but it was getting

pretty late in the afternoon.

I took two off

the side. Beautiful, new panels!

I cut four

flat aluminum pieces 1" x 2.5" and drilled a 1/4" hole near each end. I

put one end under each of four small slots on the bottoms of the panel

frames and bolted them on. This made four tabs about 1-1/4 inches long,

each with a hole, sticking out the sides to bolt the panel to the roof

with a 3" x 1/4" lag screw. But I had no lag screws and used up the

rest of the day going into town. I got them up the next day (29th).

Unable to think of a better spot, I put them below the two that seemed

to get the least shade. I got the wires run on the 30th and hooked both

panels in parallel to the other grid-tie inverter, but it was getting

pretty late in the afternoon.

The next morning continued cloudy with mist and drizzle

and there was little to no output. I checked about noon an found that

all the panels were supplying .93 amps AC to the line. .5 was from the

original (~500 W) panels and .43 from the new (610 W) ones. But it was

so dull out I couldn't tell if (as seems likely) there were more tree

shadows on the new panels as they were lower on the roof. On February

1st the sun finally made an appearance, and while it was still low, 1.6

amps was being supplied, .6 from the old panels and 1 from the new.

(1.6 A * 120 V = 192 W) 15 minutes later it was 2.2 amps: (1.0, 1.2) =

264 watts. In the best part of the afternoon it was 4.24 A (2.0, 2.24)

= 509 W... from about 1100 watts of panels. But each day is a bit

longer and

the sun a bit higher. It'll improve toward spring.

Magnetic

Flipping HE Ray Energy?

I decided I would

try to make a tuned circuit to "tune in" to the 16 KHz frequency from

the car motor controller. Since the inductor was (to my surprise with

so many winds) only 200 microhenries, that would need quite a large non-polarized capacitor - I

worked it out to around 1800 uF. I also wanted it to be good for at

least 100 volts. I thought about the capacitors I had, and realized I

didn't have anything at all suitable.

A trip to the websites of the usual electronic parts

supplies on the 20th wasn't very helpful either. The closest I could

find were motor start capacitors, but they were too small (still

requiring several to make up the capacitance) and too costly - over 20$

and up each.

Capacitors in series reduce the capacitance. If I took

some of my 270 uF, 100 volt capacitors (motor

controller power line filters) and put them in series in opposite

directions to make them "non-polar", it would take two to make 135 uF.

For almost 1800 uF, it would take 13 pairs, 26 capacitors. Appalling!

Then on the 21st I got an idea. If I put diodes across the

capacitors, it would prevent them from going into reverse bias (by more

than a diode drop, .7 volts), and the two sets of capacitors pointing

opposite directions wouldn't be in series with each other, since one of

the diodes would always be conducting. So 270 uF would be 270 uF. That

would cut the number in half to 14 - 7 for each voltage direction.

Still a lot, but I had them and wouldn't need to place a (yet another)

costly order. I wonder if anybody else has ever thought of that?

By the end of the month all I had managed to do was get

out the capacitors. Too many things to do!

Woodstove

Thermoelectric Generators (TEGs)

Having thought of

the subject in December, I thought it would be good to get a couple

more of TEC-TEG's very nice big heatsinks, which I had used in the

thermoelectric fridge some years ago, for use in a woodstove electrical

generator or other heatsinking purposes. I didn't see the heatsinks on

the tecteg.com web site so I sent a message via their web form. I

noticed they now had some ready-made woodstove generators. To my

surprise I almost immediately got a phone call from Gerard, the owner.

He said iron is a crappy heat conductor and woodstoves

would get much hotter if they could be made of aluminum or copper.

(Aluminum would surely melt and burn your house down. Copper probably,

and it would cost a fortune. Of course it's why old stoves had

removable round covers on the top for setting pots on to boil water.) I

said, ya, it seemed one couldn't even get water boiling... so maybe one

could just use ordinary peltier modules instead of TEG modules with

high temperature solder. He assured me peltiers wouldn't last long in

such an application - too close to the melting point of the solder

(137°c or thereabouts) and even below 100° they would flex and

break down. Considering they didn't seem to last all that long even on

the thermoelectric fridge, I believe him.

(He also said the manufacturers' claimed efficiency

ratings of woodstoves like "85%" are BS and that much smoke goes

unburned and much of the heat goes up the chimney. That too I believe.)

He suggested mounting the TEG generator on the back of the

stove on an aluminum plate, and putting some holes in the back to

transfer heat to it. (or was that just bolt holes to mount the plate?)

And to use water to carry off the heat from the cold side of the TEG

modules. That could be done with stuff I had already bought from him so

long ago and only used in a brief experiment or two... but I liked the

idea of putting it on the back, or a side. That should allow finned air

heatsinks to work quite well for convection cooling, which I was

concerned might not work so well positioned horizontally on top of the

stove. or maybe with small fans like the fridge used, if they still got

too warm. My desire for getting the heatsinks increased.

They also had their evacuated tube heat radiators shown,

but when I asked he said they had phased them out owing to cost. I said

I had tried making some something like that myself some years ago, but

that I couldn't get a strong enough vacuum with the steam technique for

them to work at the temperature range I wanted. He said I would need a

vacuum pump for that. A light went on in my brain... I have one of

those now! - yet another unusual but useful item given me by Jim

Harrington of AGO. I might give it another try with that. I still have

the peltier fridge, albeit stowed away. (Now where are those aluminum

finned copper pipes I made?)