Turquoise Energy Ltd. News #129

covering

February 2019 (Posted March 3rd 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Special Report: The Second Industrial Revolution:

Exciting New Machines for Local and Home Manufacturing

(Report follows "In Passing")

Month In Brief

(Project Summaries etc.)

- Better LED Lighting - Expanding My Solar Systems - Solar

Electric Hot Water Experiments - HAT 36-40 Volt Plugs and Sockets - New

3D Printer - Amazing New

Production Machines - My CNC Router... and Plasma Cutter - Tidal &

Wind power notes -

Ground Effect Vehicle

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Oceans Tell of Global Warming

- Jet Streams & Global Circulation Patterns - Recycling Plastic

LOCALLY - ESD

(Eccentric Silliness Dept.)

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

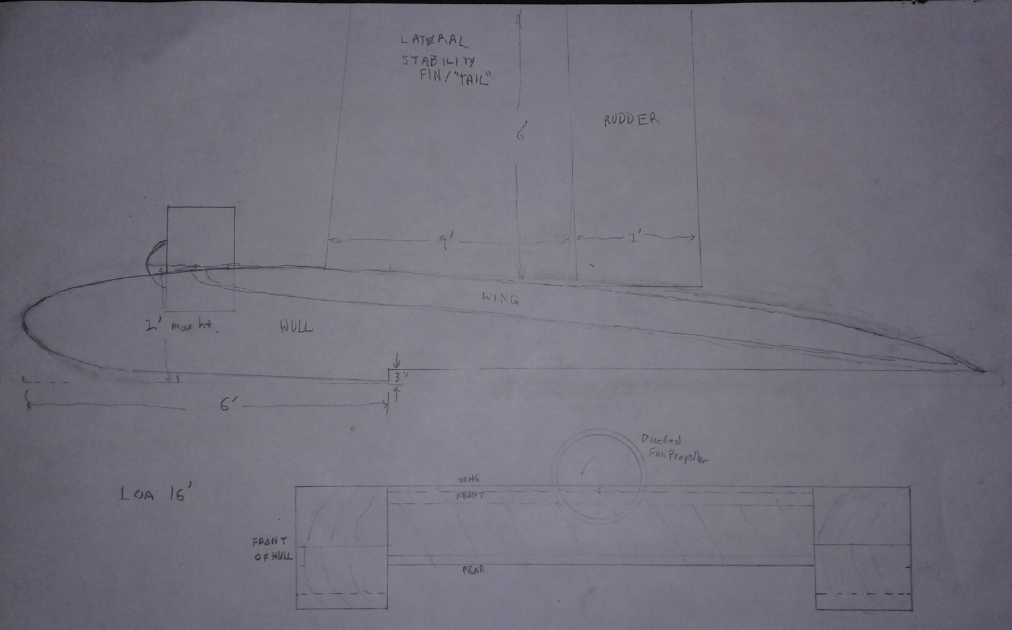

* Ground Effect Vehicle (not a lot to say)

Other "Green"

Electric Equipment Projects

* "Off Grid" (etc): 36-40 Volt "HAT" Plugs & Sockets - New 3D

Printers

* New 3D Printer: Anycubic I3 Mega

* Better LED Lighting & Plant/Grow Lighting

* CNC Router & Plasma Cutter

Electricity Generation

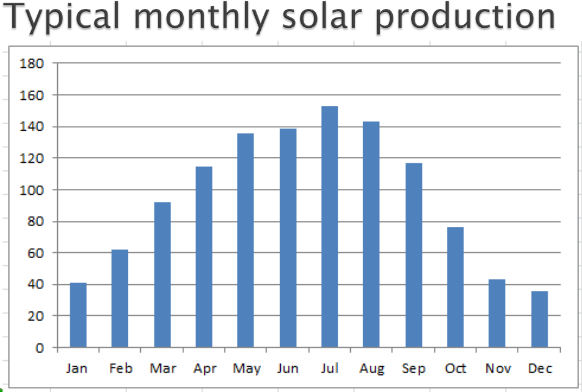

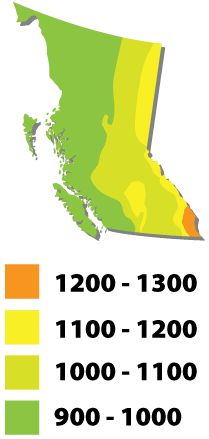

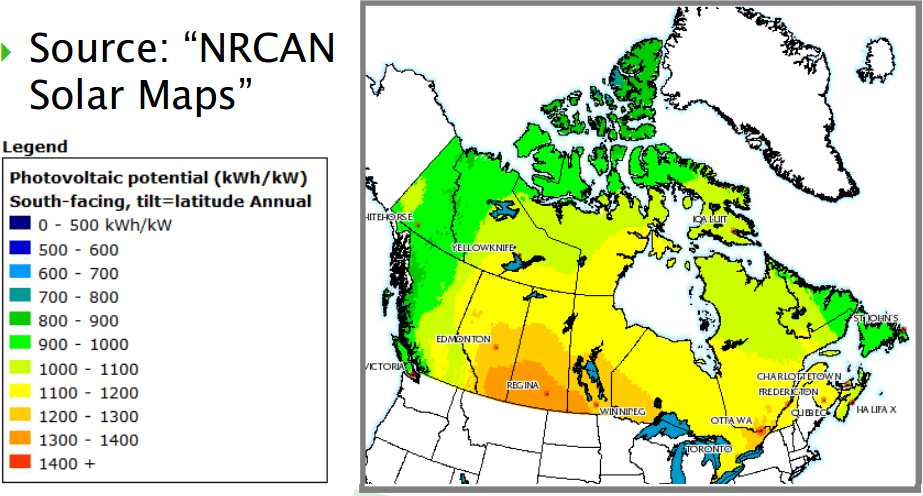

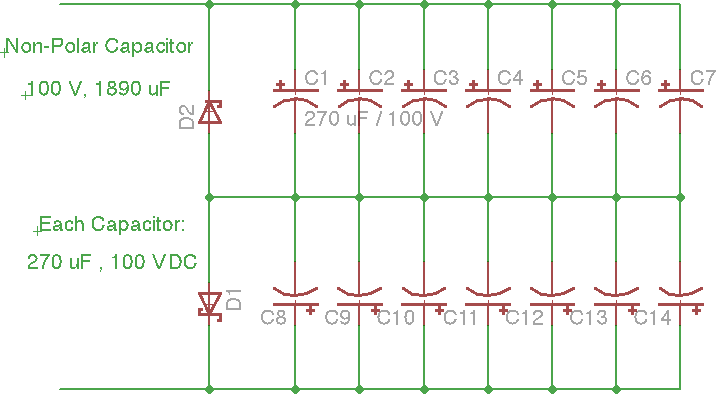

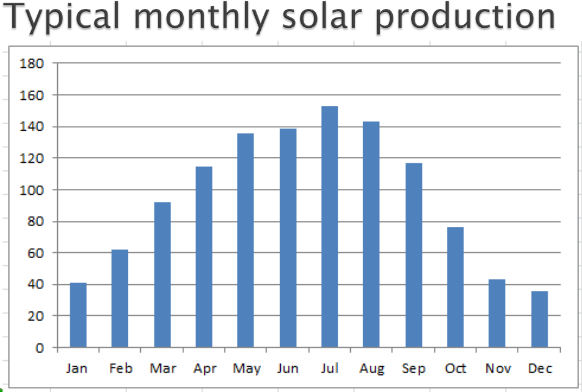

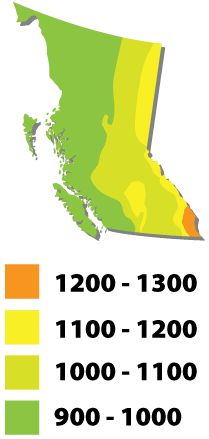

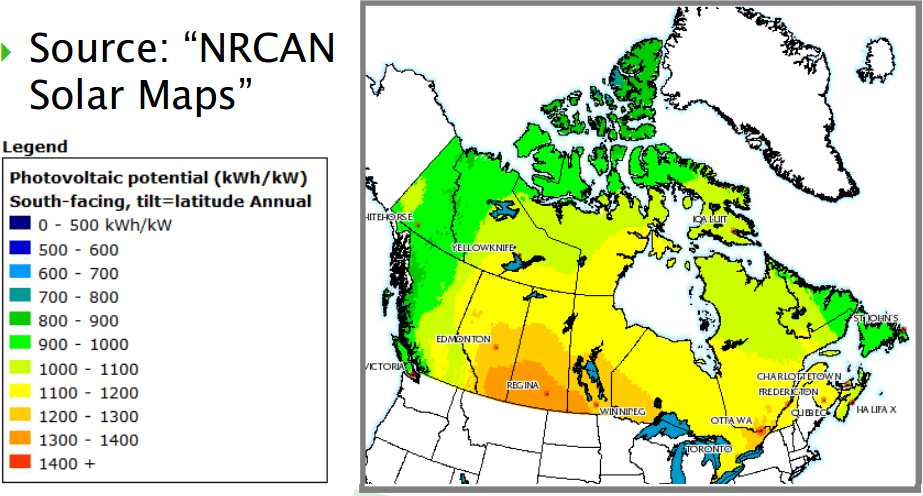

* Further Expanding my Solar System - How many watts are those panels,

again? Never full nameplate

power: 75% seems to be a practical figure - Panel Efficacy: Crap in

winter as expected - Still More Solar Panels - and Monitoring Output.

* Solar Hot Water Panels: simpler to make than ever

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Oxalate Methyl

Hydroxide electrolyte)

* Thinking of Options with Nafion Membranes (no actual project work)

February brought winter with it. Whereas we had so far had

only some frosts, Saturday morning the 2nd it was -7°C. It went up

to -2 then dropped back to -7 overnight. Sunday it hit -3.5 and that

night went up to -2.5. It was too cold to work outside and almost too

cold inside. Better to sit in

front of the woodstove and feed it as much wood as I dared. Around the

18th it went up to +2

to +4 during the day for a few days, but that didn't seem to thaw out

all the frozen ground and the ice in my rainwater barrel. Then it went

down to freezing again for the rest of the month. There was a little

snow on parts of this island, nothing that stayed long in my area.

But by the end of the month that seemed mild compared to

farther south where the whole west coast got heavy snow, from Vancouver

Island through Oregon and a bit even as far south as Los Angeles.

The fine line dividing warm and cold on many

days this February:

The fine line dividing warm and cold on many

days this February:

Wherever the sun hit, the frost melted and the hoses ran.

Wherever it stayed in shadow all day, it all stayed frozen.

The month thus seemed to start out pretty slow, but

somehow by the end I seemed to have done quite a few pretty cool things

and found a lot to write about - even too much. Maybe it was partly

because it was too cold to mill lumber.

I wanted to get this newsletter out on the 1st of March.

I'd have had a couple more days if some deranged person or

persons long, long hadn't decided that February should be the only

month to have only 28 days. Why wouldn't January, February, March and

April all have 30 days? It's the same number of days either way - 120.

(Surely it must have been decided by a committee!)

Better LED Lighting

Now the fluorescent holes need insulation,

gyproc and all the things that go into making gyproc smooth.

Now the fluorescent holes need insulation,

gyproc and all the things that go into making gyproc smooth.

(I'll probably put in a second LED panel too.)

I

pulled out a ceiling-flush fluorescent fixture and

put up an LED panel light in its place in the dining area on the 3rd.

Then I did two more

in the big wooden light fixture in the kitchen ceiling on the 8th when

I

realized how easy it would be if I just left the fixture and the

fluorescent lights within it in place. With

two 24 watt LED ceiling panels, even with the morning sun coming

through the window switching them on markedly brightened the room and

vanquished the shadows. There'll never be another dull day in the

kitchen!

I

pulled out a ceiling-flush fluorescent fixture and

put up an LED panel light in its place in the dining area on the 3rd.

Then I did two more

in the big wooden light fixture in the kitchen ceiling on the 8th when

I

realized how easy it would be if I just left the fixture and the

fluorescent lights within it in place. With

two 24 watt LED ceiling panels, even with the morning sun coming

through the window switching them on markedly brightened the room and

vanquished the shadows. There'll never be another dull day in the

kitchen!

They were so nice I ordered another set of 3, and I just

might even go for a third trio. As a bonus the power supply is external

and they can easily be run off the 36-40 volt DC solar power instead if

required.

Expanding My Solar Systems

Toward mid month

temperatures hovered around freezing. Having sold no solar panels, on a

sunny day I put up three on the roof over the travel trailer, which I

had discovered got more winter sun than anywhere else. The results

being good, on the 20th I added a fourth one to more fully utilize the

1 KW plug-in grid tie inverter. At this point I'd used 6 of the new

panels and even if I sold all the rest I wouldn't be making any money

from the palette of panels. But I still want (probably come summer) to

put a

panel on the converted Chevy Sprint EV and two on the Miles electric

truck. That would make 9 of the new 305 watt panels (instead of my

intended 5), plus the four ~250 watts I'd brought from Victoria, plus a

bunch of 100 watt and a couple each of 90 and 208 watts - for sale but

no takers. Then on the

19th someone bought 8 of the 305 watt and on the 27th another 6 went,

so I could finally start repaying the bank line of credit... or use

some of the cash for other things. I had already ordered a plasma

cutter and a new 3D printer. I had finished off the several thousand

dollars I had put into my Paypal account a year ago and dug into my

bank account when I ordered the plasma cutter. It had felt like "free

money" for the last year whenever I could pay for something with

PayPal. I put some more money back in my PayPal account. (probably

safer than in a bank anyway.)

Near the end of the month there was quite a bit of sun and

now 10 panels well engaged, and the solar started putting out good

energy, doubtless lowering my power

bill a bit. That's great, but mainly I really want to be ready for

future potential extended power outages. All we need here to have that

is for some disaster like a tsunami to disrupt Masset and close the

fuel oil barge receiving facilities there for an extended period. Or in

common with everywhere, to have some other national or international

fuel supply disruption - a financial system disruption could bring

things to a halt since everything runs on credit. The south grid will

have hydro power whenever it rains enough. Any "on grid" time then will

be that little bit longer the more the solar panels that are

contributing to conserve the lake water. My panels will be diverted to

personal use if or when the grid power is off. In fact, if there were

enough solar panels or wind power, the south grid is well positioned,

because the hydro can supply as needed and the alternate sources can

help keep usage of the lake water low.

The north grid is almost

wholly diesel, with 3 or 4 good solar installations on public

buildings. They'll be out of luck unless some serious alternatives

are put into place. The pace for that so far is underwhelming, and if I

myself do a tidal project at all, at least at this point, it'll be more

of a demo than an immediate significant contributor.

Solar Electric Hot Water Experiments

Some time back I bought a

small hot water tank for under the kitchen sink. It takes far too long

to get hot water there and in common with the rest the iron rich water

stains everything brown including my dishes. A hot water tank right

under the sink filled

with rain water sounds marvelous. But I still haven't installed it.

Someone on youtube compared solar electric panels to heat water in a

tank versus an actual solar hot water pumped system. He had two or

three PV panels to get enough voltage to heat the tank.

Some time back I bought a

small hot water tank for under the kitchen sink. It takes far too long

to get hot water there and in common with the rest the iron rich water

stains everything brown including my dishes. A hot water tank right

under the sink filled

with rain water sounds marvelous. But I still haven't installed it.

Someone on youtube compared solar electric panels to heat water in a

tank versus an actual solar hot water pumped system. He had two or

three PV panels to get enough voltage to heat the tank.

I decided to try my little tank with just the 36-40 volt

solar system and hooked the tank up in the garage to the hose and the

DC solar power system. It worked, more or less, eventually. I got very

carried away with taking readings over time for several days and the

report is

down near the bottom under Electricity Generation.

I also looked at a new idea in solar panels: a simple coil

of pex pipe. It looked so easy to make I bought a 100 foot coil of pex

pipe and made part of a collector box. (no report or picture on that so

far.)

HAT 36-40 Volt Plugs and Sockets

HAT 36 VDC plug & CAT 12 VDC click-

lock socket on 36 to 12 volt converter

I (finally)

brought my 3D printer in from the shipping container and started in

designing plugs and sockets for 36 volt wiring and appliances. I didn't

get too far and went on to other things.

I (finally)

brought my 3D printer in from the shipping container and started in

designing plugs and sockets for 36 volt wiring and appliances. I didn't

get too far and went on to other things.

Near the end of the month some simple 36 volt to 12 volt

DC to DC converters arrived. (actually "from" and "to" whatever you

want, as set by a trimmer potentiometer, as long as the output is lower

than the input. 5 amps max.) It made sense that they should plug into a

36 volt HAT plug on the input, and have a 12 volt CAT socket to plug

something into on the output. But I had to solder alligator clips on

the input. I don't much like that because they are prone to miswiring

and to coming off.

So I went back to designing the HAT plugs and sockets. I

got one pair done and used them for it, but I wasn't satisfied. They're

not quite ready for prime time. Maybe next month.

HAT Plug & socket with blades and

(?)receptacles inside, mated together.

HAT Plug & socket with blades and

(?)receptacles inside, mated together.

When I soldered wires on the shells were pretty

cramped inside and wouldn't close very well.

And they might look better if done on a better 3D Printer.

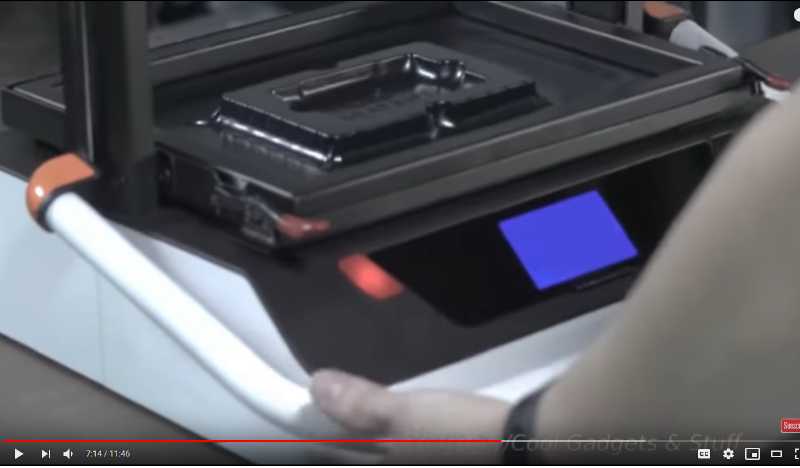

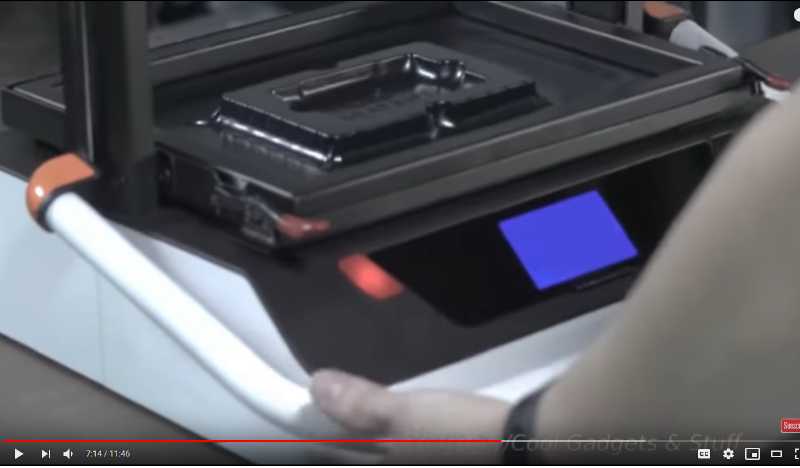

New 3D Printer

I had some

trouble with the 3D printer, and it occurred to me that new ones were

probably pretty cheap and better. I ordered an AnySolid I3 Mega

for around just 350$C. It arrived on the 26th and I set it up on the

27th. It came with tools and a spare extruder (my problem part in the

old printer) and a couple of other spare parts.

I had some

trouble with the 3D printer, and it occurred to me that new ones were

probably pretty cheap and better. I ordered an AnySolid I3 Mega

for around just 350$C. It arrived on the 26th and I set it up on the

27th. It came with tools and a spare extruder (my problem part in the

old printer) and a couple of other spare parts.

I did the supplied test print "two owls". (One didn't

stick to the bed and fell over during printing - ouch! The other came

out well.) The beads are considerably finer than on the RepRap Pro

Mendel, but the catch is it prints much slower. Now I suppose will

come the learning curve with the new software.

In addition to better looking parts, I hope to be able to

print some "porous" electrode

parts for batteries that I couldn't do with the old one.

Amazing New Production Machines

I spent some time writing up the Special Report

(below the In Passing section) on a number of exciting new

machines I saw in videos for home production of various things. There

were so many for so many purposes that I started thinking that the

whole face of the production of goods might be about to undergo a major

change to more local levels.

My CNC Router... and Plasma Cutter

One of the videos showed a home CNC plasma cutter. This

could make

nice cuts through steel sheets and plates. It's what I was trying to be

able to do with the "pulsejet steel plate cutter" that I never finished

making in around 2010. I discovered home plasma cutters are now common

and I ordered a 120 volt unit from PrincessAuto.com . Perhaps a bit of

a lightweight, but easier to plug in than a 240 volt unit I have no

outlet for. It came

on the 28th.

Then I looked

at the 30x30" CNC table I had and the controller that came with it. It

was old stuff (1991), but the table seems good. I thought the

controller would only be trouble with an old "parallel printer port" to

connect to the computer (predating USB by over 10 years), but then I

looked on eBay and found that new ones have all the very same plugs!

Then I looked

at the 30x30" CNC table I had and the controller that came with it. It

was old stuff (1991), but the table seems good. I thought the

controller would only be trouble with an old "parallel printer port" to

connect to the computer (predating USB by over 10 years), but then I

looked on eBay and found that new ones have all the very same plugs!

Underneath, eBay "suggested" several "USB to parallel

printer port adapters". I had some time back been told that "those

never work right", but if that's the way everybody is doing them, I

assume they must.

I used to have one - for a printer I used to have - but

couldn't find it. So I ordered one off

AliExpress.com, for under 2$. Now I just need to find the DB9 connector

pinouts and make cables to connect the controller to the stepper

motors. There seemed

to be a vexing lack of information on line for this simple thing,

considering they seem to be the same connectors as on new units.

It would be very nice to have a working CNC router again,

and with

a water bed and steel slats placed on the table, it should work for a

plasma cutter as well. I'm hoping to use my "general purpose" CNC table

to gain the functions of a couple of the other machines I saw in videos

as well. Especially I hope it can do printed circuit board making with

a miniature router and drill, which is very fine work to accomplish.

Tidal Power, Wind Power: A couple of Design Observations

I previously mentioned the idea of launching a tidal

power unit from the beach at low tide and maintaining it on or

retrieving it from the beach as well, with an automatic rudder to steer

it out into the channel at high tide and into the best current for

maximum power

generation.

But with the craft tethered from the bow and with it

pulling toward the shoreline, it occurs to me that the rudder action

will be different. The rudder will need to be at or near the bow - near

the tether, and it will be steered the opposite direction to how a

free-sailing boat would point. To stay away from shore while tethered

there, it has to

counteract the shoreward pull of the rope at the bow. This is similar

to towing a log with a small boat: one steers the outboard the opposite

direction because the drag of the log is the overriding factor. (Gosh

it's been a LONG time since I've done that! 1976.)

Or maybe the mooring line shouldn't be at the bow? Maybe

it would be better if it was amidships somewhere? Along with the

rudder. Or maybe it needs two rudders to keep it out in the flow and

also best lined up into it.

I watched a video on youtube about a vertical axis wind

turbine model with 3 "hybrid blades" that was for sale commercially for

mounting on houses. The blades seemed to be propeller shapes at the

front, but with the tail end chopped off. I surmise the "open" tail

ends ensured it would start spinning by providing something for the

wind to push on when it wasn't.

Otherwise it looked like many other VAWTs until I saw the

dimensions: 3 meters tall and 3 in diameter. My little experiment was

only about 1/2 a square meter. This one was 9. Greater efficiency is

good. Catching 18 times the cross section of wind is much better! I

started to think in those terms if I was going to try again - make it

more of an engineering project, and find the windiest spot for it. And

another way to get the generator spinning faster, to get more voltage

without winding a new stator, would be to gear it up. A flat belt and

pulleys, or maybe a couple of those plastic gears I made in 2016?

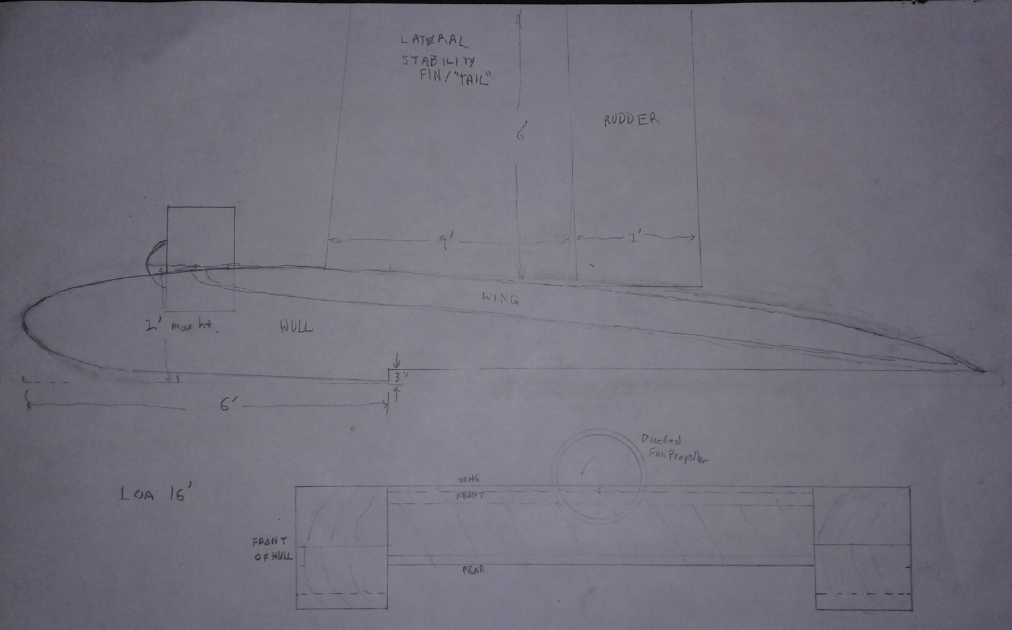

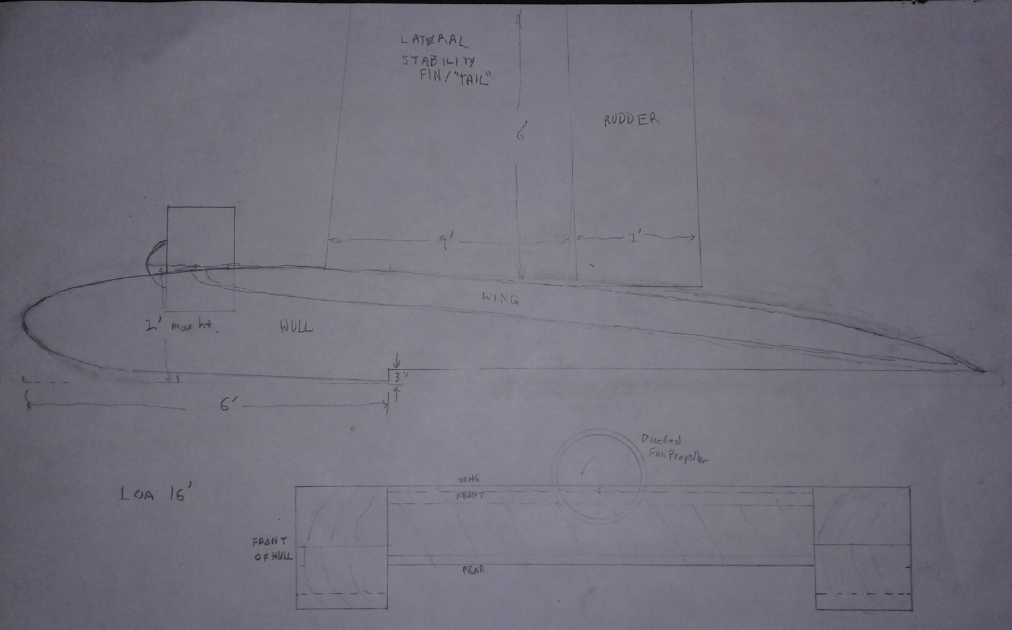

Ground Effect Vehicle

One would think that with it being too cold to work

outside except in brief bursts I'd have been working on this. In fact,

I only very lethargically picked away at a drawing. One notable change

was that if there was going to be a "tail" in the middle for lateral stability, then I would attach the

rudder to that instead of having another tail at the back. Owing to

that position, I also made it quite large. It's an unusual arrangement,

but

I think it should work.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

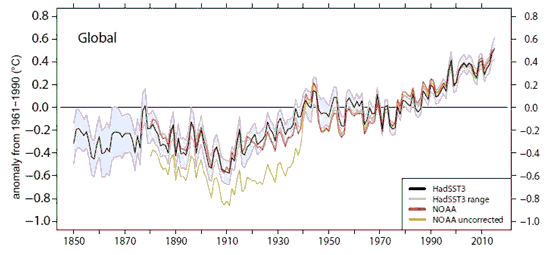

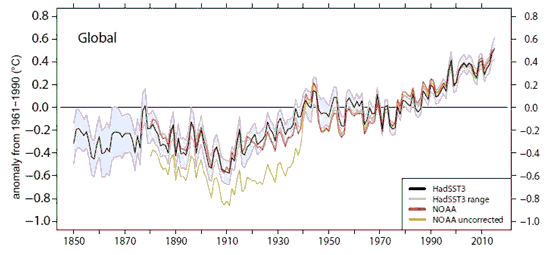

Oceans Tell of

Global Warming

Record cold winters have many people reasonably questioning that

there's

global warming, with much speculation about a coming "mini ice age".

But at the same time there's been record heat in parts of Autralia. I

suspect the next northern summer may change many minds, but in

the meantime, someone mentioned that the oceans are a more reliable

measurement of trends because they hold so much more heat than the air

does.

Record cold winters have many people reasonably questioning that

there's

global warming, with much speculation about a coming "mini ice age".

But at the same time there's been record heat in parts of Autralia. I

suspect the next northern summer may change many minds, but in

the meantime, someone mentioned that the oceans are a more reliable

measurement of trends because they hold so much more heat than the air

does.

They seem to show a slow but definite trend over the last

three decades. Unless that unexpectedly reverses, expect significant

sea level rise. Polar ice is melting at an increasing rate, and as

water warms it expands. As ice melts on Greenland and Antarctica they

become lighter and will probably rise up, displacing still more water.

Then as water encroaches over the land in other places, that land may

become heavier and will tend to sink, compounding the effect.

Current advise has it not to buy a home at an elevation of

under 50 feet, but this generalization will obviously vary by region.

My own house is just 25 feet above the high tide mark, but it's not

wide open to the Pacific. It seems quite unlikely there'll be any big

storm surges or tsunamis in Hecate Strait. (...And if you're in

Greenland, you're probably pretty safe.)

Jet Streams & Global

Circulation Patterns

My earlier analysis

of what was happening with the circulation patterns of Earth's air was

incomplete. In TE News #109 I noted that the aerosol spraying at high

altitudes makes high altitude clouds that blanket the atmosphere up to

those altitudes, perhaps 25000 to 40000 feet. To oversimplify, the

whole vertical layer

of blanketed atmosphere is all ground-level warm. It doesn't have the

vertical temperature gradient that drives the Earth's predominant

circulation patterns.

One thing I missed was that the temperature gradient still

exists. But now it starts above those clouds. We now have a relatively

less

active layer of air going up 5 to 7 miles before we hit the more usual

vertical circulation driving patterns. Of course the air is far thinner

up there, so the forces driving the circulations are weaker. The jet

streams are now at a much higher altitude than historically.

The other thing I didn't note is that with the sprayings

being quite inconsistent, some places on some days may have normal

circulation

gradients from surface levels, while other places and other days there

will be only the high altitude drivers. This is probably why the jet

streams often become broken up and chaotic.

But if the circulatory forces are weaker, they are also

farther up from the ground and so less coupled to it. Recently a

commercial airliner set a new time and speed record going from (IIRC)

Los Angeles to London. It broke the sound barrier at (?)800 MPH with a

(?)300 MPH jet stream tail wind.

Recycling

Plastics LOCALLY

Along with being

able to manufacture with plastics, the potential grows for local

plastic recycling. More and more, the imagination is the limit to what

can be done to solve our many longstanding problems of waste and

pollution and create a better future.

First my grievances with

the egregious annual garbage collection fee led me to think that since

this is

a remote island, we should recycle our own plastics. I remembered the

video of a guy who cut his scrap plastic into little pieces, then

heated them in a waffle iron until they melted into multi-colored slabs

of solid plastic. In Victoria I was paying (probably overpaying) up to

40 $/sq.ft. for 1" thick UHMW to use for motor molds. Could I have made

my

molds - and made them much thicker - with plastic scraps and a

large "waffle iron"?

To recycle plastics locally one would need pretty minimally:

(a) to get people to bring CLEAN plastic and sort it into the right

bins: LDPE (plastic bags), HDPE, PP, PETE... maybe PS, and "other".

Those named

would account for most of the material.

(b) a washer to clean them better anyway - depending on type, use and

shape of items.

(c)

a

chipper/shredder to break the plastic into bits. (It might be

washed after chipping it up instead of before. Solves trying to clean

inside of bottles

with thin necks or other awkward shapes.) The shredder might be the

trickiest piece of equipment to buy or make, but it could surely be

done. Where quantities warrant, there could be different chippers for

different types of plastic. Otherwise, different types would be done in

batches.

(d) a giant "waffle iron" or two. This would be two plates of heated

metal that would come together, with a rim all around, to melt the

plastic into sheets or bars. 2"x2" angle iron, or square tube, might

make good sides. The metal enclosure would keep air out as much as

possible. The video presenter's waffle iron seemed to work pretty well,

but I remember much of my polypropylene rope material vaporizing(?)

when I melted it in open air. Again plastic extruders are also a

possibility. (One to extrude filament for 3D printing would be nice!)

I'm pretty sure that could all be bought or made for quite

minimal

cost for small scale use. In the cities bigger units and more of them

would be required. In the long run it would surely be much cheaper

everywhere than finding more landfills or sending plastics to China for

recycling.

The thickness of finished pieces would depend on the

amount of material placed on the bottom (rimmed) plate. It could be

1/16" or less to 1" or more to make different sorts of products. There

could be a long

heater maybe 6" wide to make plastic "boards", and a short but wide one

to make fat slabs for various purposes and multi-colored butcher

blocks. Or perhaps any length "boards" - or thinner sheets - could be

extruded out one end of a press? (Doubtless trickier, but might be

practical - if not here, then in cities where there is more material to

process.)

(e) On the 14th (Happy Valentine's Day!) I found a video

showing a desktop vacuum forming machine, Vaquform. (5 Incredible

Machines For Manufacturing at Home #2) Again we find new ideas and

products that can change the whole way we do things and what we are

able to

dolocally, even at a very small scale. If one made thin recycled

plastic sheets, they

should be amenable to vacuum forming. The colored sheets from scrap

could then turned into things - like back into food containers. This

would result in the same plastic being recycled and used over - and

over - again

locally.

Why should these practices not now be adopted locally

everywhere? All the rope and fishnets (good PP!) and other plastic crap

littering the beach (not to mention drifting across

the oceans) might start to be seen as valuable raw material instead of

as a gargantuan clean-up problem.

I wonder if anyone in authority here would go for that and

if it would be

economic enough to pay someone to do it? No doubt here it would only be

a part-time or one person operation. Or could colorful plastic products

even be

exported from Haida Gwaii? Could they be a "Haida Gwaii signature"

product?

One must inject a bit of caution of course. Plastics do

degrade in

the sun, and perhaps gradually with reprocessing. Garbage in, garbage

out. At some point the plastic must find a "permanent use" out of

sunlight or be completely reprocessed. Obviously polyethylene sheets

used for greenhouse coverings for a year or two, which then rip to

shreds easily, won't be readily turned into a strong, durable product.

But I expect most plastics used for most things can be reused many

times.

ESD

(Eccentric Silliness Department)

I accidently typed "bug" instead of "big", and later noticed it. The

spelling checker didn't catch it. There must be a bug in the spelling

chequer.

2B ... or something else ... that is the question, when selecting a

pencil.

Some have said "Doing the same thing over and over and expecting

different results is the definition of insanity." But in music and

theater it's known as "rehearsal" or "practice".

It used to be that you had to unlock something and get in before you

could swipe anything. Now you have to swipe something in order to

unlock and get in.

Does your area suffer from "crunchy ground syndrome"? The cause is

generally outdoor temperatures below 0°C. Help Global Warming

is hoping to secure sufficient funding to fix the problem by leveling

all the mountains and highlands into the oceans, thereby also adding to

global real estate with sales to help offset costs. When the land is

all flat, boring lowlands, the ocean breezes will blow freely over the

continents and return them to the salubrious oceanic climate Earth

enjoyed in the Carboniferous period before the Permian highland and

mountain building era made the climate arid, cold and continental, and

killed off most species of life. Please donate generously to HelpGlobalWarming.con

and together we can cure crunchy ground syndrome.

"Witch Hazel" was recommended for a skin condition. There seemed to be

several choices. I just bought the most basic one because I didn't know

which witch hazel was which. (Q: Which hazelnuts come from witch hazel?

A: Witch hazelnuts.)

Irregular English Verb Irregularities

Past tense of throw: threw - "The team threw the ball game"

Past tense of blow: blew

Past tense of snow: snew - "In

the blizzard the wind blew strongly and it snew heavily."

Past tense of show: shoe - "I

shoe him where his grammar was bad."

Past tense of grow: grew

Past tense of glow: glue - "The room grew brighter as the lamp

glue more strongly."

"Dr. Suessingston, I presume?" In the fall, leaves leave

the trees and fall,

leaving fallen leaves in the eaves. Some rake leaves in fall, but when

the raker leaves, more leaves fall. So I prefer to leave them. At the

electric car dealership, some leaves fall onto Leafs. Relief comes in

the spring when

the fallen fall leaves have left and the trees

spring to life

and releaf.

Why would anyone think spraying lice-all would kill germs? Lice don't

eat germs.

Special Report

The Second Industrial Revolution:

Exciting New Machines for Home and Local Production and Recycling

As I watched some youtube videos about new

production machines, it dawned on me that a new industrial revolution

is unfolding before us. The first one,

while greatly advancing technology, increasing productive capacity and

improving quality of life,

brought us centralized "mega factory" production facilities and locked

the average person out of the mainstream of being able to turn ideas

into new commercial products.

Then very recently we had the computer revolution and then

the internet revolution, bringing

powerful computing power and the world's information to our fingertips.

This has accelerated the spread of new ideas and by the way enabled the

"second industrial revolution" - a revolution in producing things.

I remember the first time I heard of some sort of printer

that could create a solid object out of thin air (around 1987 as best I

recall - before the internet). I heard it from a person who was always

well ahead of everyone in the new technology knowledge curve. Of course

as a newly invented device for industrial prototyping it would

obviously be far too costly for an individual and I never expected to

have any such thing in my lifetime.

The next time I heard about it was on the internet or in

the news over 20 years later, when someone in London had created a 3D

printer the average person could afford, the "RepRap" ("replication

rapid"). The technology itself had enabled the replication of the

special plastic parts it itself needed without costly injection molds.

The 3D printer could print 3D printers! Some enterprise and the

internet made it available worldwide, to anyone who wanted one. I spent

850$ and two weeks to put mine together. Just this month I bought a new

one from China for 350$ assembled, which does much finer detail (and

prints correspondingly slower).

But 3D printers, it turns out, are just one of many new

production machines now making their appearance.

The second industrial revolution builds on the previous

revolutions to bring multiple custom

machine production and fabrication capabilities to our fingertips.

Videos reveal a wide array of exciting new developments in tools

and equipment for making things, within the budget reach of individuals

and very small groups. It becomes apparent that computer controlled,

fast, precision manufacturing can and likely will become more and more

local, less and

less concentrated in giant factories situated wherever labor is

cheapest.

That's not to say that everyone will want to have all the

tools and

to learn how to do everything to produce whatever they want, but that

at some point there'll come to be various people in town who will make

a business of providing many things locally that presently are perhaps

made in China or wherever and transported around the world. Presently

these technologies are either quite new, or newly available at

personally affordable prices. So far there's no culture of local

production. There's no

local "AliExpress.com" umbrellas for home manufacturers to help clear

away the daunting overhead tasks of doing small individual

transactions:

marketing, sales and deliveries, and for complying with onerous

government regulations.

One thing I seem to be spending considerable time at is

watching videos,

and now sometimes spending further time commenting below them hoping to

broaden peoples' perspectives. This is what brought me to this topic.

Youtube is always suggesting

videos, which suggestions are sometimes actually valuable, and you

discover things you would never have guessed existed without them. On

about the 14th I found 5 Incredible Machines For Manufacturing at

Home #2.

In the middle of that, an ad cut in for a "CNC plasma cutting machine",

yet another incredible machine which I actually found more interesting

than the video and looked it up. I did a separate article about it,

below.

Then I finished watching the original video, and I also found Incredible

Machines videos #1 and #3 - a total of 15 devices. I

particularly noted the following devices.

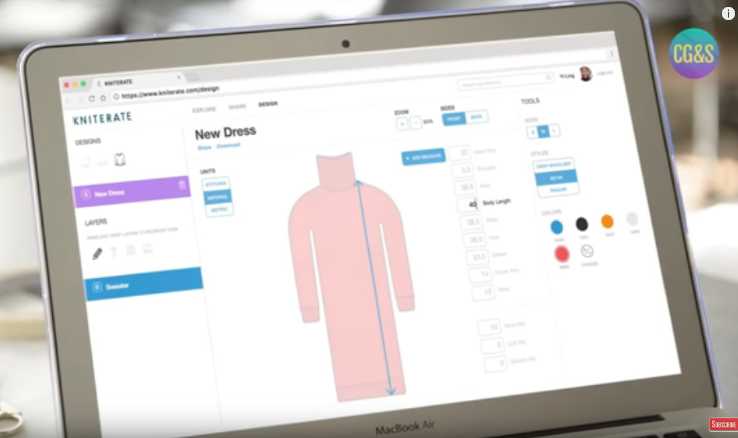

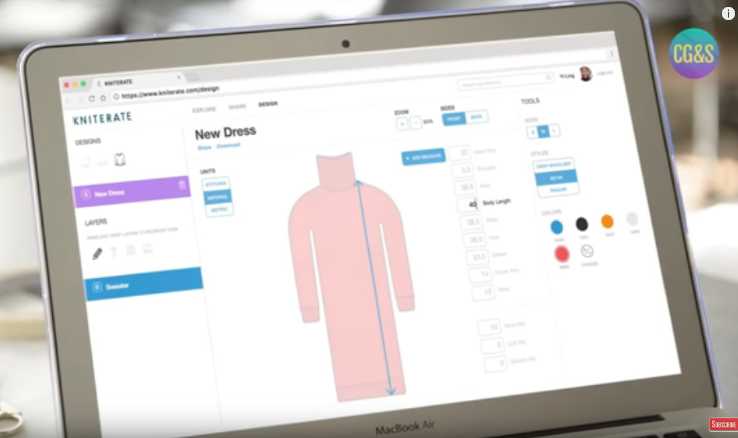

Kniterate

An automatic knitter that will make your own custom

designed, custom size, custom colors clothes. From wool, acrylic or

cotton yarns. There were clothes designs for it on line. When I was

little my Mom used to knit us warm woolen winter wears by hand.

Scarves, sweaters, tuques... She spent hours at it. (Even fur lined

moccasins one year!) I don't suppose many moms would know how these

days. Now it can be automated! (Except for the moccasins.)

Kniterate. Do we now have the potential to

easily design and make whatever clothes we want?

Kniterate. Do we now have the potential to

easily design and make whatever clothes we want?

Hi neighbor, can you do me a new tee shirt please? How

about that pattern but in tan and brown? Cotton acrylic blend. Make it

with a little extra room at the shoulders. Sleeves ending a little

above the elbows. Noo, a vee neck please, and a breast pocket. That's

it, thanks! Can I pick it up tomorrow? Great!

What will happen to the big department stores? What will

happen to the Asian clothing sweat-shops?

Wazer

In video #1

there was a CNC abrasive waterjet cutter. That was quite exciting, but

it was more limited than industrial waterjets. While it would do thick

plastic and 1/2" aluminum, it said it wouldn't do 5/16" or even 1/4"

steel, which would be my minimum for cutting motor rotor type parts. So

the plasma cutter is still a go. The other thing that ruled it out was

the price: 7500 $. Presumably US$, so 10000 $C. But we can be sure they

will only get cheaper and better.

In video #1

there was a CNC abrasive waterjet cutter. That was quite exciting, but

it was more limited than industrial waterjets. While it would do thick

plastic and 1/2" aluminum, it said it wouldn't do 5/16" or even 1/4"

steel, which would be my minimum for cutting motor rotor type parts. So

the plasma cutter is still a go. The other thing that ruled it out was

the price: 7500 $. Presumably US$, so 10000 $C. But we can be sure they

will only get cheaper and better.

In 2008 I had never heard of abrasive waterjet. By 2010(?)

I knew of it but couldn't find a place that would do it. By 2012 I had

found a place where I could get it done, and not long after, more than

one place.

Now there's the "home unit". If I'm making things long

enough, some day I may want one of my own.

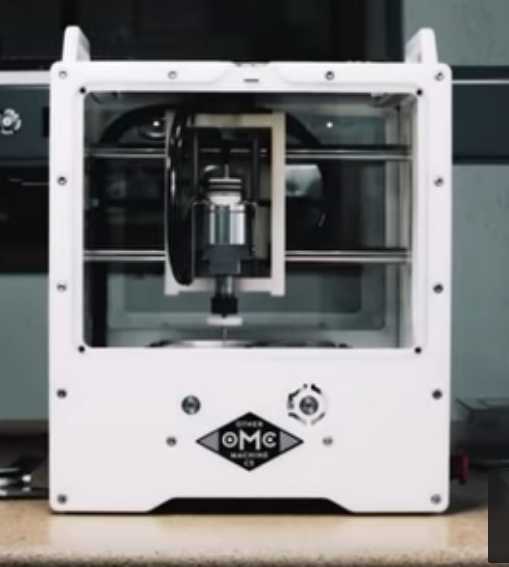

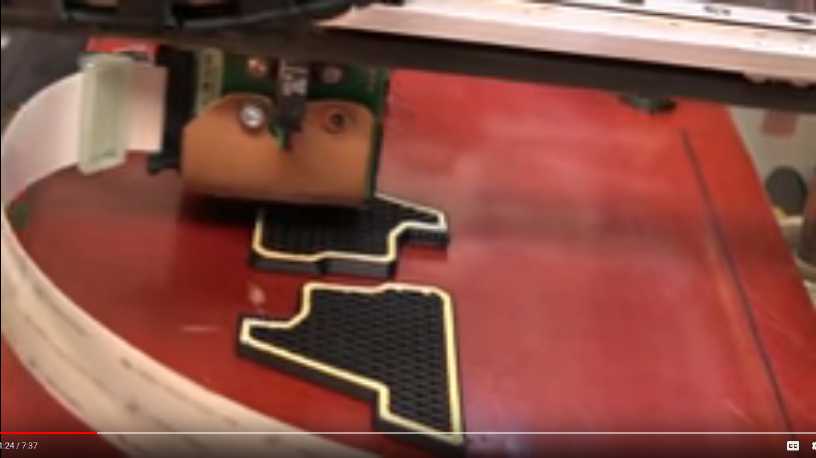

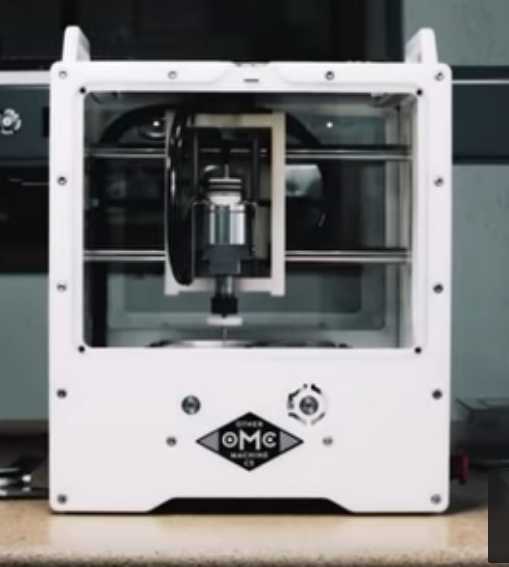

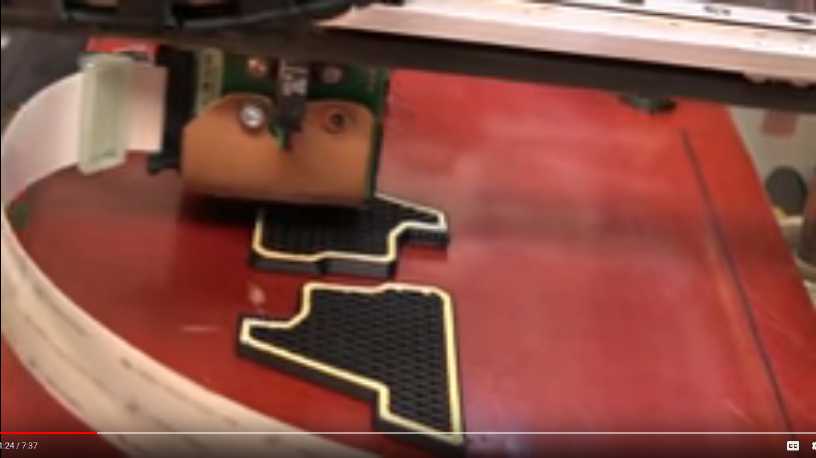

Other Mill

A PCB

router/driller for doing single and double sided circuit boards

by routing away the unwanted copper areas, leaving the desired traces

and drilling the holes. It would work from the same PCB CAD generated

files that PCB making houses use. Ooh, that would sure be nice to have!

I wonder how much it is?

A PCB

router/driller for doing single and double sided circuit boards

by routing away the unwanted copper areas, leaving the desired traces

and drilling the holes. It would work from the same PCB CAD generated

files that PCB making houses use. Ooh, that would sure be nice to have!

I wonder how much it is?

...Or, can I do the same thing on my general purpose CNC

table with a "dremmel" router and bits?

Vaquform

A small plastic vacuum forming table/machine. With this one could

make many typical food packages and things. That would make a good way

to

turn locally recycled plastics back into useful products! (I also saw a

video suggestion for doing a home made one, but didn't get to it.)

A small plastic vacuum forming table/machine. With this one could

make many typical food packages and things. That would make a good way

to

turn locally recycled plastics back into useful products! (I also saw a

video suggestion for doing a home made one, but didn't get to it.)

Vacuum forming a plastic packaging part from a

sheet of flat plastic.

Vacuum forming a plastic packaging part from a

sheet of flat plastic.

A great way to re-use locally recycled plastic?

DobotM1 and MakeArm

These were desktop robotic arms that could take multiple

attachments for 3D printing, PCB

routing, drilling and pick-and-place parts placement on printed circuit

boards, among other functions. To move a tool in a straight line,

obviously there must be a lot of trigonometry, but of course it's all

automatic. My mind isn't getting around what they're really capable of

and I didn't check out prices. Their reach would be limited compared to

a CNC table machine. No doubt we shall see what uses people put them to!

Dobot M1 and Make Arm

Dobot M1 and Make Arm

(Oops, I got Make Arm's top arm straight on - not the best illustration)

Mazlow

A CNC router that can work on 4' x 8' sheets of plywood stood on edge.

Steel cables and pulleys move the router around instead of the

usual long screws. It doesn't take up 1/2 the shop space of a

horizontal

unit. And it was supposed to be substantially cheaper as well.

The creators of Mazlow with their space and

cost saving wood routing machine

The creators of Mazlow with their space and

cost saving wood routing machine

Stoneflower

A 3D printer (or was it a clay extrusion head for 3D printing?) for

extruding clay or other materials of similar texture. Wow! I could see

attaching such a head to a general purpose CNC table and making pottery.

Stoneflower 3D printing clay pots for ceramic

or porcelain.

Stoneflower 3D printing clay pots for ceramic

or porcelain.

Can it do cups, plates, bowls, serving dishes?

...Porcelain mouthpieces for my Supercorders?

3D Printer for Making Sintered Metal Parts

Another notable product was a 3D printer to make small metal parts.

(Somehow I have forgotten the name. But it was called "Atomic Diffusion

Additive Manufacturing".) It

works like a regular plastic extruding printer, but the plastic strand

has metal powder embedded in it - probably to the maximum point at

which

it'll still extrude well. Any metal or alloy may be printed.

Another notable product was a 3D printer to make small metal parts.

(Somehow I have forgotten the name. But it was called "Atomic Diffusion

Additive Manufacturing".) It

works like a regular plastic extruding printer, but the plastic strand

has metal powder embedded in it - probably to the maximum point at

which

it'll still extrude well. Any metal or alloy may be printed.

This was an "industrial machine". (Industrial today - Home

making tomorrow! ...But you do need to melt the metal, etc.)

One first prints the part as normal, but 20%

oversize. Then much of the plastic is dissolved in a solvent, leaving

just enough to hold the particles together. Then the part is heated in

an oven. The plastic melts away and the metal particles fuse

together, and it shrinks by 20%. It is said to give accurate, complex,

strong parts made to order, in a day or so.

Sintered metal isn't wholly solid. It has minute air

spaces, but it's (apparently - in this case) about as solid as cast

metal, which also has air spaces.

I must say this seemed really exciting! If I thought I

could make metal parts with this, I might be sorry I ordered the plasma

cutting torch.

I do have a question (which could probably be easily

answered on line). Why can't one just buy and use the metalized

filament in an any old 3D printer?

The same company also had a separate composite plastic

printing process with chopped carbon fiber plus a continuous filament

carbon fiber, that make a non-metallic part much stronger than a simple

plastic printed one. Having tried "conductive plastic" with chopped

carbon fiber in it and had it clog up my print extruder, I think I'll

have to pass on that myself. But why would one not print polypropylene,

by itself or with something else. It must have good strength?

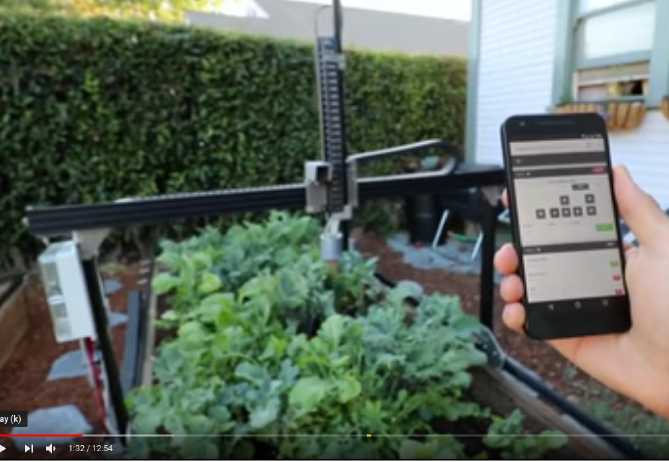

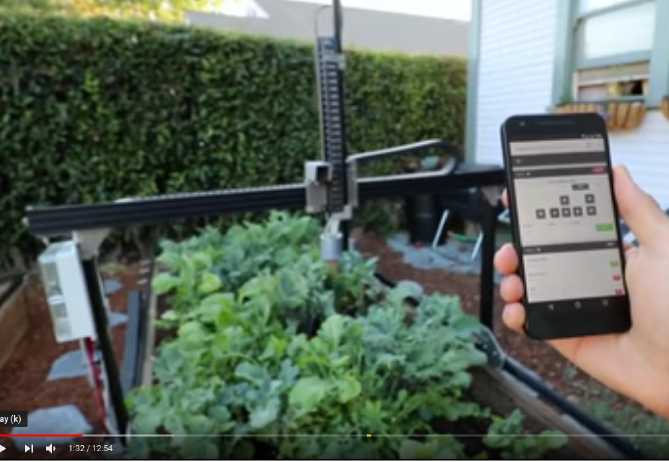

FarmBot

When you know exactly where

you planted each plant, you know exactly where to

water.

A CNC gardening machine. I

should have known somebody else would

think of this, when I still haven't got around to making one in several

years. It

comes in two sizes - roughly 1-1/2 meters by 3 and double, 3 x 6 m.

A CNC gardening machine. I

should have known somebody else would

think of this, when I still haven't got around to making one in several

years. It

comes in two sizes - roughly 1-1/2 meters by 3 and double, 3 x 6 m.

It's somewhat

different from my concept. Instead of riding on rails on each side of

the garden, it works on a garden plot framed with wood boards. It is

much lighter and wouldn't do the

grunt work of tilling the soil and prepping the plot for you. Mine was

intended

to [hopefully] be able to convert a lawn or other ground into a

prepared garden

plot, picking up the grass/weed clods and dumping them in a pile or in

a wheelbarrow. And other heavier jobs - perhaps spreading compost and

mulch and so on. (But one reason I haven't made mine is because it

would be a pretty ambitious project.)

It did however plant seeds, water and stomp out weeds, and

it had some good

software and some good tool attachments for those purposes, which were

said to be

3D printable. (I haven't followed them up yet.)

It would seem there's still room for my idea, which would

make it

into a pretty complete gardening solution. It could be scaled up even

for

farming on a very substantial scale, replacing tractors and combines

and harvesting the crop along with the other functions.

With the special-job tools

already designed by Farm Bot one could possibly take it farther,

faster. I doubt I'll

ever find the time, but this is surely the future of crop production.

Doing something remotely with cell phone app

Doing something remotely with cell phone app

The seeding tool at work.

The seeding tool at work.

How far are we from dialing in the date and the vegetables

(with the growing locale pinpointed by Goggle or something and a tie-in

to the weather predictions), and just watching everything grow, coming

back at dinnetime on the day it says something

is ready?

With all these new, decentralized production tools, are

there still going to be big factories for making automobiles, trains,

washing machines, solar panels, and so on? There may be. A solar panel

factory in China says they have 10 production lines going full time.

(or was it 30? Memory, ugh!) But already many automotive factories are

closing. It is getting easier and easier to produce whatever is wanted

on a smaller and smaller scale. Is there a real economy of scale having

10 (30?) production lines in one place, or might they better be

separate plants closer to where the solar panels are to be used? Maybe

the

silicon wafer production should be centralized but not the heavy

tempered glass

panel production and final assembly? I don't pretend to know just how

all this will develop or should develop, but it seems obvious that

change is in the wind.

And then, how much value is there in having sprawling

cities? For at least a century, the greater the concentration of

population, the more and more varied the services that could be offered

to

the citizens. But now even in a remote location I can order whatever

specialty things I want on line more easily than I could obtain them in

medium-sized Victoria city 40 years ago. Living in a city is less

valuable than it used to be. And cities grown too large are

prone to contagion. It has been suggested that for reasons of both

local food supply and sanitation, cities should be kept to under about

1/2 a million people. (Obviously that can only happen after the

population has been reduced - which it will be partly by diseases

sweeping through huge cities. Then it needs to be kept managed.)

Again I won't pretend to know how things will work out,

but the potential for change and decentralization without accepting a

drop in living standards is greater than it has ever been before since

we've had

modern living standards.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric Transport

Ground Effect

Vehicle

This project keeps

is another that keeps getting pushed to the side. I did however at

least do part of a drawing of how I hope to make the radio controlled

model, using the new wing profile intended to provide the craft better

longitudinal stability. (And there's always the "Stealth" aircraft

approach of last resort: high speed computer controls sensing and

minutely controlling the rudder and elevator to damp out tendencies to

instability.)

"Catamaran" layout ground effect vehicle with

ducted

"Catamaran" layout ground effect vehicle with

ducted

fan propeller, 16 feet long (model to be 1/4 scale, so 4 feet).

Width is to be 10' or less to be trailerable without disassembly.

Details like the take-off "step" hulls and combining the lateral

stability fin with the "tail" and rudder are being thought out

for trials on the model before trying a person-carrying 'vehicle'.

Other

"Green"

Electric

Equipment

Projects

"Off Grid"

(etc):

38 (33-45) Volt DC "HAT" Plugs & Sockets

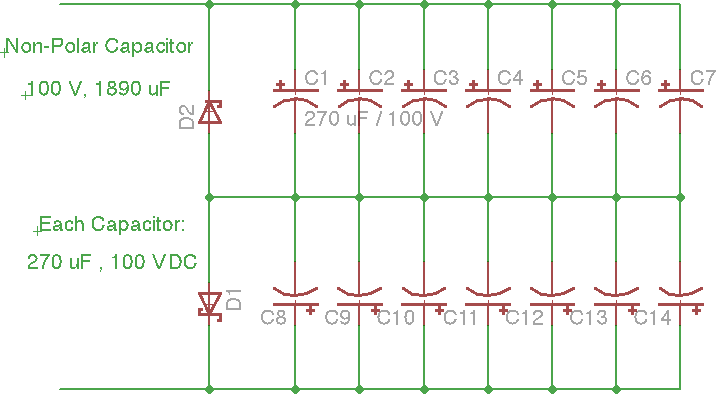

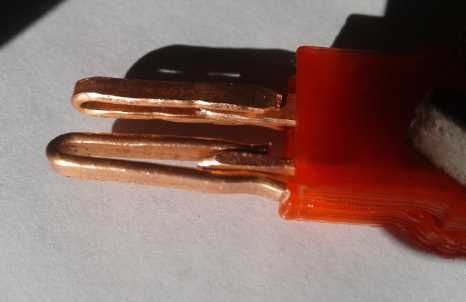

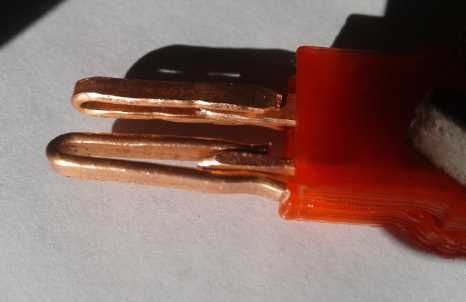

On the 10th I finally decided to tackle this project. With a hammer I

flattened a #9 AWG solid wire to what seemed like a good shape for

blades. I ended up with 1.5 mm x 4.0 mm. It was a substantial cross

section and different enough that it couldn't be plugged in crosswise

to what was intended, so plugs couldn't be inserted backward.

To be more sure of getting good

connections, I decided the blade length would be 10 mm instead of 8.

Then I went into OpenSCAD and made HATPlug.s and HATSocket.s

from CATPlug.s and CATSocket.s and started modifying

dimensions. I put the pins a little closer together and didn't leave

room for a screw in between them as I had with the 12 volt CAT design.

This would mean one couldn't accidently plug into the wrong voltage

outlet. As the pins were also 4 mm wide instead of 5.5, the whole

plastic plug shell ended up smaller in all dimensions. This was

agreeable - even if it was just plugs, there's no use having needless

extra bulk. The socket was a little longer since it needed room for 10

mm pins inserted instead of 6, but was likewise thinner and narrower.

Since I still intended to screw these shell halves

together (with this design of shell), I extended the little

grips on the outside edges to be big enough to hold tiny screws and put

holes through them, so there would be one screw on each side, which

would actually be better than just one screw in the middle even if

slightly more work to assemble.

Of course, it's possible to make shells differently. Just

look at all the different plug shells and sockets for 120 volt plugs,

and they (mostly) all work together. Another design I may try sometime

is to have the 'front' attach to the 'back' rather than the top half to

the bottom half. And they can be made to glue together instead of bolt.

Or molded of cast rubber or plastic...

Every time you change a number in OpenSCAD, you can hit F5

to have it redraw the plug 'instantly' with the change. So you see the

progress as you go and it gets mesmerizing. I worked on it much too

late into the night.

The next day I finished the plug design and got out the

ReprapPro 3D printer. I hadn't used it since I moved in 2017. The bed

was way out of adjustment. Adjust as I might, I couldn't get the PLA

plastic print to stay on the bed and make anything. And in trying to

clean the nozzle, I seemed to mess up the extruder temperature reading

and things went haywire. I finally had to quit.

Next day I went back and tried

again. If the bed was hotter, wouldn't the plastic stick better? I

turned it up from the 55°c default for PLA to 65°. I poked

around the extruder wires with needlenose pliers, pushing and pulling

the thermistor and the heat resistor, and it started working. Then it

seemed to read the temperature, but wrong, and I could smell the heat.

I poked some more and suddenly it read 350°c instead of 205°.

It gradually cooled off, and for the moment seemed to be working. I had

set it up in a room with no window that opened for fresh air and I was

sorry for that after the extra high temperature, which probably

vaporized some plastic.

I designed a small test cube and printed it. It worked! So

I tried the plug again. That worked too. Then I shut it off. The

plastic was stuck solid to the glass even after it was cool. I had to

pry the pieces off with a knife. Other than laying the plastic on a

rather thick it seemed pretty good. (It was the default setting, but it

needs adjustment for slightly different plastic spool wire diameters.)

I saw a couple of minor mistakes, but mostly it just needed the plastic

to print more thinly so things would fit as designed.

Next I went out to the garage to make and bend the copper

pins. I flattened some more of the same wire. But the fatter - and work

hardened - copper wasn't amenable to being bent how I wanted. One piece

broke at the bend. It obviously wasn't going to be practical with the

thicker pins. No doubt it could be done, but each pin would be a

struggle. There had to be another way to make pins that wouldn't slide

in and out of the housing.

At first I thought to try further flattening the inside

ends, spreading them out more and then bending them around to form a

crimp connector. That would make the inside too fat to slide through

the slots, and at the same time would allow crimped-on solderless

connection. Then I realized they wouldn't bend around to crimp unless

they were annealed with a torch. That too seemed like much trouble. (If

you did a whole bunch at once it wouldn't be bad. My usual mode is just

to make what I need for the moment, which is usually just two.)

To use simply

straight line pieces of copper that didn't

have to be bent, I could either have the printer make plastic alignment

"pins", and drill alignment holes in the copper blades, or else file

slots in the sides of the copper blades and print larger rectangular

alignment blocks to occupy the space of those side slots. With blades

only 4 mm wide, the holes would have to be pretty small and I figured

the plastic would break, so I decided to go with the slots.

To use simply

straight line pieces of copper that didn't

have to be bent, I could either have the printer make plastic alignment

"pins", and drill alignment holes in the copper blades, or else file

slots in the sides of the copper blades and print larger rectangular

alignment blocks to occupy the space of those side slots. With blades

only 4 mm wide, the holes would have to be pretty small and I figured

the plastic would break, so I decided to go with the slots.

Then I thought instead of bending the blades in the

middle, I could bend a single 90° corner at the inner end, and the

short end piece would lock it in. Then I moved on to other things. I

got back to it on the 25th after finding that I needed them. Again

figuring that, since it was a new size and many people would have to

bang a piece of wire flat with a hammer to make the pins, and since the

fattest common solid wire is AWG #10, I ended up with the following

specs for pin dimensions:

Thickness: 1.35 mm +/- .15 mm (1.2 to 1.5 mm)

Width: 3.75 mm +/- .25 mm (3.5 to 4.0 mm)

Length: 10.0 mm +/- 1.0 mm (9 to 11 mm)

Pins Center Spacing: (7.5 mm but subject to change in March or April.)

#10 wire is rated for up to 30 amps in house wiring and is

good for more in such a short length, so that was plenty of cross

section for 15 amp plugs and sockets. The reasoning behind picking this

exact size may be considered as somewhat trivial, and meaningless in

any production situation, but it's as good as any other nearby size.

(Except for me: the #9 wire I have, if flattened in the jewelers

rolling mill, stretches in length and comes out that same size.)

How anybody else may design their shells and pins is their business -

there are many ways to skin a HAT. Unlike the CAT pin thickness of .64

mm, 1.35 is too hard and thick to bend readily by hand. Thinking of how

3D printed shells might hold straight pins, I finally decided to file a

notch in them that would be filled by a piece of the plastic. With a

hole to solder a wire into they ended up per the image, and the first

plug also as shown.

It was a little smaller in all dimensions than the CAT

plugs. One might coerce one into a CAT socket, but the pin spacing was

a little smaller, and the blades twice as thick, so it wouldn't be easy.

But I wasn't

sure yet that this was the final size. I

still had to make a socket, and the shells inside to receive the plug

pins had to be far enough apart not to be in any danger of touching

each other. Now, what were those going to look like and how would I

make them?

But I wasn't

sure yet that this was the final size. I

still had to make a socket, and the shells inside to receive the plug

pins had to be far enough apart not to be in any danger of touching

each other. Now, what were those going to look like and how would I

make them?

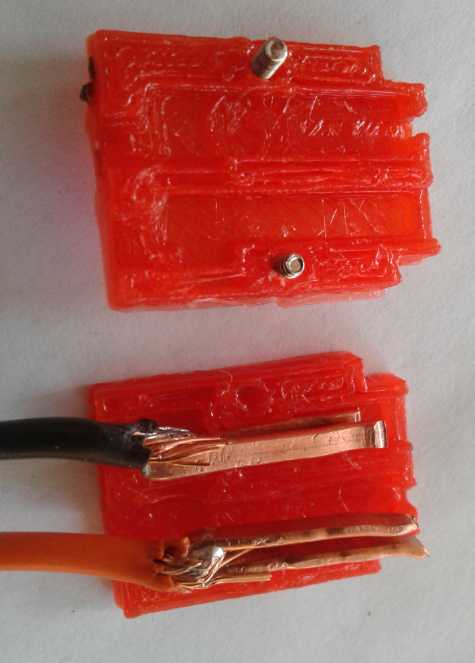

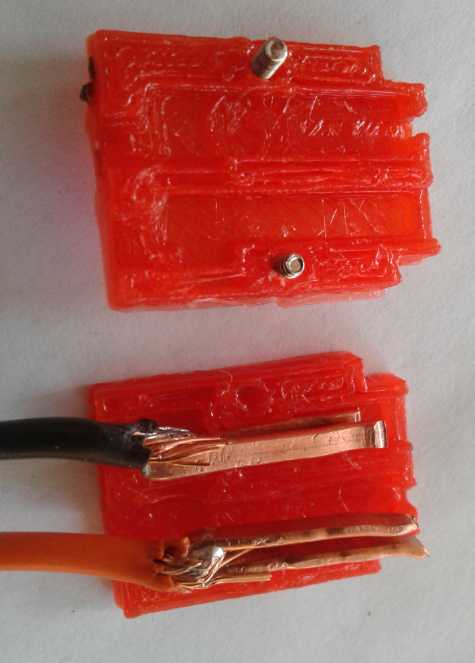

The simplest thing to do seemed to be to flatten a piece

of wire (#14), make shallow bends in both ends to guide the pin in and

pinch it, and then to fold it in half over a pin. The pin at the fold

made sure it would fit over a pin for its entire length, provided a

space to solder a wire into, and made the bend in the copper more

gradual so it wouldn't break. The resulting sockets seemed

satisfactory, the pins sliding in and holding with a good grip.

The fold was far enough away that it wouldn't loosen if a slightly

thicker pin was inserted. (Unlike those crappy Pico connector sockets,

which plague my CAT connectors. They bend and loosen and then connect

so badly that one once left my first electric Mazda RX7 EV dead on the

street and not knowing what was wrong!)

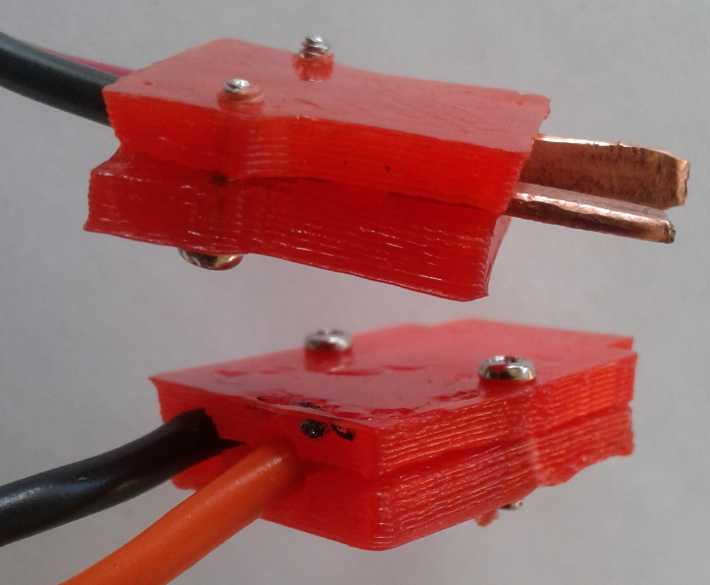

So next they needed

a shell. Back to OpenSCAD and the 3D

printer... I designed the socket shells and printed a couple, by now

rather late at night and after a small altercation with a loose drive

belt on the "Y" axis, caused by some loose nuts in the printer. The

first version didn't quite hold the copper pieces right. There wasn't

room for them to open a bit to receive the plug pins. The second

iteration was successful. The plug and socket seemed to mate and hold

well. After a couple of dozen insertions, they were looser but still

okay. Anyway they seemed much better than the Pico sockets.

So next they needed

a shell. Back to OpenSCAD and the 3D

printer... I designed the socket shells and printed a couple, by now

rather late at night and after a small altercation with a loose drive

belt on the "Y" axis, caused by some loose nuts in the printer. The

first version didn't quite hold the copper pieces right. There wasn't

room for them to open a bit to receive the plug pins. The second

iteration was successful. The plug and socket seemed to mate and hold

well. After a couple of dozen insertions, they were looser but still

okay. Anyway they seemed much better than the Pico sockets.

Of course it's a nuisance to have to make pins and

receptacle pieces instead of buying them and pulling them out of a box.

But it won't matter once they're in production. Some machine can spit

out any size and shape you want. With the CAT 12 VDC plugs and sockets,

I was trying to make something similar to AT fuses with a twist,

expecting to find existing blades and receivers for them. (But the

blades only existed on the fuses themselves.) With the HAT 36-40 VDC

ones I was

working for "optimum" instead of some nebulous "backward compatibility"

with existing hardware parts.

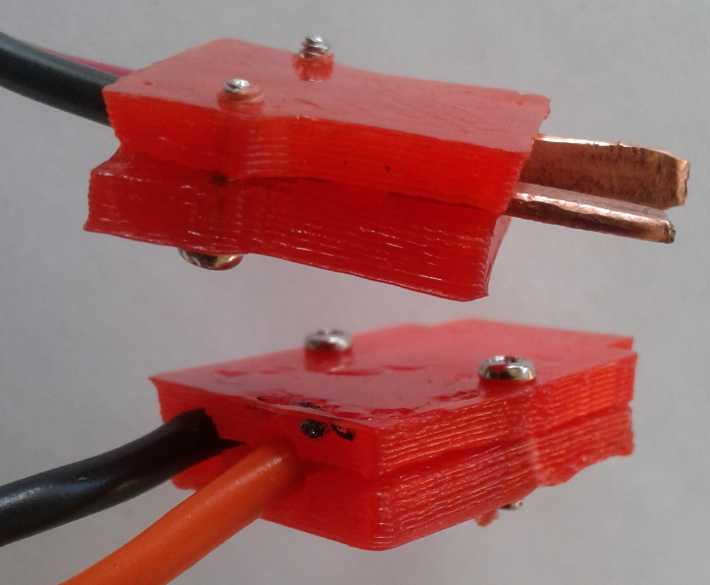

Plug & socket with pins, mated together

Plug & socket with pins, mated together

Trying to fit the wires.

Trying to fit the wires.

I found that when the wires were

added, the housings were

a little too small. I used the ones I made, but I'll expand the

housings a little to leave a good space for connecting the wires

inside. Once that's done I'll put the OpenSCAD [text] files for the

housings in TE News or link to them. Hopefully with wall plates as well.

I found that when the wires were

added, the housings were

a little too small. I used the ones I made, but I'll expand the

housings a little to leave a good space for connecting the wires

inside. Once that's done I'll put the OpenSCAD [text] files for the

housings in TE News or link to them. Hopefully with wall plates as well.

And I thought of a new design of sockets and wall plates.

The front end of the socket will be the wall plate itself. The blade

receptacles will be inserted into the plate, then the back ends will be

slipped on and screwed in to hold everything in place. These will look

much nicer, with the whole plate being the underside of the print, flat

against the printer bed. (I'll probably do a CAT socket plate that way,

too.)

New 3D Printer

My "ReprapPro Mendel" 3D printer is a commercial kit

version

of the original RepRap ("Replication Rapid") 3D printer made by the guy

in

London that started the whole genre - that first made possible low cost

home manufacturing of custom plastic parts. At the time, I was

astonished that one could buy a kit and put such a manufacturing tool

together for under 1000 $. It took me two weeks to assemble it, as I

recall. But with the ongoing intermittent troubles I

had long been having with the extruder head (even tho they were just

"minor" wiring problems, but in one small part of the printer but where

it was too hot for reliable solder connections), my confidence in the

printer continuing to

work reliably has become much diminished. And the pieces come out

pretty

coarse. I had been unable to make plastic battery electrode pockets the

way I wanted because the holes came out too big and let powder fall

through.

I also knew that there were new models out there even some

years ago. Especially useful would be those that had an enclosed and

heated printing space, which as I recalled was supposed to result in

much less warping of large parts.

I looked on line at AliExpress.com and found hundreds of

choices of seemingly dozens of models mostly for about 300 to 500 $

Canadian. WOW! There were lots of duplicates, the same machines being

sold by different stores (and even multiple listings by the same store

with somewhat

different prices listed and different shipping rates so that they all

ended up about the same anyway - Huh?), but it was still an astonishing

variety. For

those sort of prices it seemed almost foolish to continue to rely on my

old coarse-extrusion beast that warped larger pieces as it printed

them, when I could surely get something already assembled and reliable,

that works better and makes finer parts, for such a low price. Maybe I

could make the printed plastic battery electrode pockets I had tried to

make a

few years back?

I ordered one, an "ANYCUBIC 3D Printer I3 Mega Large Plus

Size Full Metal TFT Touch Screen". (I didn't see any that had the

heated print space. There was one that was enclosed, by the same

company, but it didn't say it was heated, so it would mainly just be

harder to

access things with no apparent advantage.) Perhaps the tendency to warp

had been improved without heated ovens? At 210 x 210 x 300 mm, it

had about the same bed size and could print taller than the RepRap. It

was also single extruder, where some could do colors or "wash-out"

extrusions. The latter allow for printing above spaces that turn into

large voids, without sagging, by putting the printed part in water and

dissolving away the water soluble parts after printing.

In addition to plastic extruding printers, there were a

couple of photo-laser resin-hardening printers for similar prices.

Those cost a fortune - tens of thousands of dollars - back when I was

first doing 3D printing!

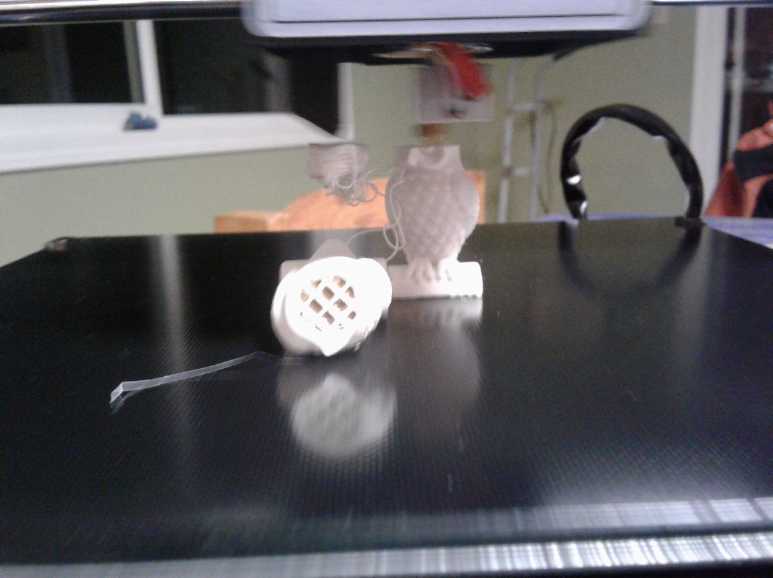

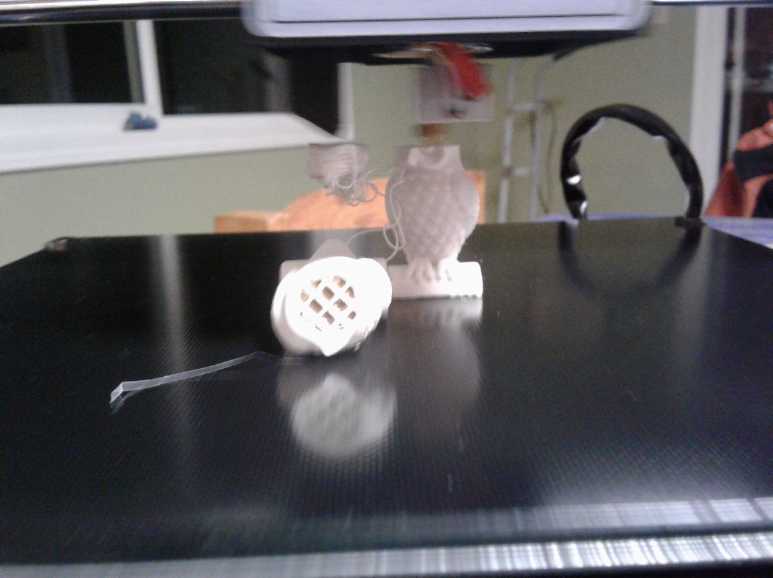

The machine

arrived on the 26th. I put it together and

tried the supplied test print. The detail was, as hoped, much finer

than the RepRapPro Mendel, with the extruder laying out a much finer

bead of plastic. But there was a tradeoff: The printing was also much

slower. It took 80 minutes to print the two little owls. And they were

tall on fairly small bases - one fell over 3/4 of the way through. The

bead came out into the air, making a mess. Yowr! But the other one was

still printing, so I let it continue. A couple of beads of plastic then

caught on the other owl and the first owl's head started printing

again, right in mid air! It moved around too much to make a good print,

but at least it stopped plastic from spewing everywhere. The second owl

came out very nice.

The machine

arrived on the 26th. I put it together and

tried the supplied test print. The detail was, as hoped, much finer

than the RepRapPro Mendel, with the extruder laying out a much finer

bead of plastic. But there was a tradeoff: The printing was also much

slower. It took 80 minutes to print the two little owls. And they were

tall on fairly small bases - one fell over 3/4 of the way through. The

bead came out into the air, making a mess. Yowr! But the other one was

still printing, so I let it continue. A couple of beads of plastic then

caught on the other owl and the first owl's head started printing

again, right in mid air! It moved around too much to make a good print,

but at least it stopped plastic from spewing everywhere. The second owl

came out very nice.

With that speed I can imagine my 5 hour prints of 10

D-cell battery cases might go to 15 or 20 hours. I won't be throwing

the Mendel out yet after all!

I noted that there was a new and doubtless useful feature:

the [noisy] fan blew air through a small slot directly onto the work

where the plastic came out of the extruder. (small black 'hood' duct

under extruder box) This would rapidly cool the

plastic. Perhaps this was the simple replacement for the heated oven,

which was thus rendered obsolete? I'll know if I print some larger

things with ABS and they don't warp.

I noted that there was a new and doubtless useful feature:

the [noisy] fan blew air through a small slot directly onto the work

where the plastic came out of the extruder. (small black 'hood' duct

under extruder box) This would rapidly cool the

plastic. Perhaps this was the simple replacement for the heated oven,

which was thus rendered obsolete? I'll know if I print some larger

things with ABS and they don't warp.

Another improvement was that the glass printing bed/table

has some texture and doubtless a superior grip to the smooth glass of the Mendel. (That

didn't seem to save the owl.) And it came with a spare extruder - the

very part I was having trouble with in the Mendel. If I had a spare

extruder for the Mendel, maybe I wouldn't have bought a new

printer now?

Next I'll have to delve into the slicing and G-code

software on the AnyCubic3D.com website. It would be too simple if I

could use the same stuff as for the Mendel. (...or are those on the

supplied USB stick or SD card?)

Better LED

Lighting

Ceiling Panel Lights

On the 1st I ordered

another 3 of the 300x600 mm panel lights because they seemed so nice,

and because I could so easily use them with the 36-40 volt DC power

system if the AC is off, since they were full brightness at about 38

volts.

On the 3rd I

mounted one in the ceiling of the dining

area, replacing a ceiling-flush fluorescent light. The dining area had

three of them and I removed the tubes from all of them. In theory I

replaced 6 old fluorescent tubes of 40 watts - 240 watts - with a 24

watt LED flat panel light, and it was just as bright. In practice three

of the tubes were 34 watts instead of 40, and one of the fixtures

wasn't lighting up anyway, so it was more like about 150 watts I

replaced - "only"

a six times power reduction.

On the 3rd I

mounted one in the ceiling of the dining

area, replacing a ceiling-flush fluorescent light. The dining area had

three of them and I removed the tubes from all of them. In theory I

replaced 6 old fluorescent tubes of 40 watts - 240 watts - with a 24

watt LED flat panel light, and it was just as bright. In practice three

of the tubes were 34 watts instead of 40, and one of the fixtures

wasn't lighting up anyway, so it was more like about 150 watts I

replaced - "only"

a six times power reduction.

Taking out the fixture with it freezing outside, cold air

blew through the hole in the ceiling, as it turned out the fixture

covered an uninsulated hole

into the unheated attic. I had to put in some wood to screw gyproc to,

insulation, and then gyproc with the cold air blowing down. Brr! (Now

that I know that, I really must do in the other two fluorescent

coldness holes!

They say one square foot uninsulated leaks as much heat as ten square

feet that are. Or was it even worse than that? This was almost 12

square feet uninsulated with cold-conducting metal fixtures - 8 more to

go.)

The LED light is 4000°K color temperature "natural

white", instead of unpleasant fluorescent "cold white" with its huge

retina-harsh mercury vapor spectral spike. Another bonus was

elimination of balast transformer hum. The only drawback was that the

light was now concentrated in one panel instead of spread out across

the ceiling. I may put up a second panel.

I put the power supply over the gyproc in the wiring and

put the short DC power cord through. I can easily access the plug and

change it to 40 volt DC power any time that seems useful (power is out

or ?) It will of course be easier if I get the 36-40 volt plugs and

sockets designed and make some, then run an actual 40 volt wire to a

wall socket, and make an adapter cable with about a 5 ohm current

limiting resistor to go to the light. There's the theory (it's

perfect!) and then the practical (it will take some work).

It wasn't until the 22nd that I got some drywall compound

and tape to "niceify" the ceiling.

On the 8th I

realized that the panel lights would fit

right into the "wooden box" light fixture

in the kitchen ceiling. So I disassembled the two 2-tube fluorescent

lights inside it (two 40 and two 32 watt tubes: 144 watts) and wired up

the LED power units. (I left the bodies of the fluorescents up rather

than disconnect the wires and pull everything out. They're doing no

harm and no one will see them in the closed box.) With two 24 watt

panels it was very bright. Even with the morning sun shining through

the window they brightened up everything except direct sunlit surfaces.

Dark shadows were vanquished. There would never be another dull day in

the kitchen! But with 48 watts I've only reduced power consumption

threefold. With 5, 8 and 17 watts LEDs, I've been leaving lights turned

on all over the place. Gosh, 48 watts is worth turning them off for if

I'm not in the kitchen!

On the 8th I

realized that the panel lights would fit

right into the "wooden box" light fixture

in the kitchen ceiling. So I disassembled the two 2-tube fluorescent

lights inside it (two 40 and two 32 watt tubes: 144 watts) and wired up

the LED power units. (I left the bodies of the fluorescents up rather

than disconnect the wires and pull everything out. They're doing no

harm and no one will see them in the closed box.) With two 24 watt

panels it was very bright. Even with the morning sun shining through

the window they brightened up everything except direct sunlit surfaces.

Dark shadows were vanquished. There would never be another dull day in

the kitchen! But with 48 watts I've only reduced power consumption

threefold. With 5, 8 and 17 watts LEDs, I've been leaving lights turned

on all over the place. Gosh, 48 watts is worth turning them off for if

I'm not in the kitchen!

I was finally rid of all the fluorescent light tubes

except in the garage. I may order yet another set of three panel

lights. Tubes of all types, even tungsten light bulbs and fluorescent

tubes, are quickly becoming a thing of the past, and as discovered by a

couple of friends, LEDs compared to

tungsten bulbs are probably a power savings equal to the extra power

used by the coming of electric cars.

Even with the sun coming through the window, the

Even with the sun coming through the window, the

kitchen is much brighter with the panel lights on!

Screw-In Plant Grow Lights

Even less connected to the solar system, I'll mention here that I got

five 120 VAC plant grow lights that screwed into ordinary North

American light bulb

sockets (officially named "E27" sockets). I had never heard of such a

thing, but Jim Harrington pointed me to a Chinese on-line store he

found called "BangGood.com" ("Good bang for your buck!") that had them.

Since I have the "indoor LED garden" with screw-in lights, this seemed

too convenient to pass up.

Even less connected to the solar system, I'll mention here that I got

five 120 VAC plant grow lights that screwed into ordinary North

American light bulb

sockets (officially named "E27" sockets). I had never heard of such a

thing, but Jim Harrington pointed me to a Chinese on-line store he

found called "BangGood.com" ("Good bang for your buck!") that had them.

Since I have the "indoor LED garden" with screw-in lights, this seemed

too convenient to pass up.

Since they were specifically for grow lights intended to

cast their

light straight down, they didn't have to cast light to the sides or fit

into the small profile allowed by most fixtures for

tungsten/incandescent bulbs. This allowed large flat lighting areas

pointing down, and with more cooling capacity provided by air slots in

the housings. Imagine almost up to a CD/DVD size with lights on one

face. Some types were out of stock, but I got five nice ones. I

appreciated that the largest ones had a few white LEDs to avoid that

weird look resulting from having only red (~670 nm) and blue/violet

(~450 nm) light colors. They were 30 watts, with 290 LED emitters: 190

red, 75 blue, 15 white, and 10 warm white. The smaller ones were 9

watts with 200 emitters: 166 red, 34 blue. (I thought grow lights were

supposed to have more blue than red. Obviously I'm mistaken.) Some of

the "too small" cooling slots in the 9W ones were blocked with remnant

plastic. The 30W ones had bigger slots, but of course they made more

heat too.

The screw-in plant lights installed in the

"Indoor LED Garden", replacing some of the regular LED "bulbs". I've

moved

The screw-in plant lights installed in the

"Indoor LED Garden", replacing some of the regular LED "bulbs". I've

moved

the whole thing into the livingroom where it's warmer. (Bonus: The sun

also comes through the window to the left.)

Note the horizontal strobe lines in the foto, indicating that at least

some of the lights actually flicker on and off at high speed.

(I've been remiss in my plantings:

Plants so far are just starting spinach and carrots. The lettuce didn't

come up.

Behind are 3 small coffee trees someone gave me. They didn't seem to

like the cold kitchen.

Anyway my confidence level that I won't have to buy coffee "beans"

(seeds) any more is quite low.)

A second box of E27 grow lights has yet to come. And I had

ordered a

few more still, but some were out of stock and I got a refund. At first

I thought I might order more to sell locally, but after an hour I found

both types run quite hot, so I think I'll wait a year and see how many

are still working.

CNC Plasma

Cutter

A video suggestion

showed up on youtube, 5 Incredible Machines For Manufacturing at

Home #2.

In the middle of it, an ad cut in. It was for an

"affordable" CNC plasma cutting table. That was interesting enough that

I didn't (at the time) watch the rest of the "real" video.

The table was 1500 $US; nice! But that didn't include the

torch. If I bought it all I'd be into it for over 3000 $C.

The plasma

cutting torch used with the table seemed very good. It seems to me it

makes obsolete and replaces the

pulsejet steel cutter I had started making but never finished in about

2010 or