Turquoise Energy Ltd. News #130

covering March

2019 (Posted April 5th 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In Brief

(Project Summaries etc.)

- Finishing the solar PV system infrastructure - 36 volt HAT

Plugs, sockets, wall plates and driving any lower voltage appliances

from 36 volts - Thermal Pane Window disassembly & glass cleaning -

Gardening and greenhouse.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- The Value of Social

Ratings

- Self, Other and Together

Interest - Climate Disasters, Chapter One - On and Off Beefs - More on

Recycling Plastics into Valuable

Products, Recycled Transparent Plastic for Greenhouses? - ESD

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle (R/C Model): Beginnings

Other "Green"

Electric Equipment Projects

* "Off Grid" (etc): 38 (33-45) Volt DC "HAT" Plugs & Sockets ...and

other 40 volt components.

- Instructions for making plugs, sockets, wall

plates (with 3D printer) - Revised HAT plugs and sockets - Wall Triple

Outlet & Cover - 36-40 V DC System Breaker Box - Special Duplex

Outlet with Switch - Hole Caps and Glands with 3D printer - Power

Monitor - Anderson

Connectors (70 Amp) - More Wall Plates - Weak NiMH Battery Repairs

* Disassembly and Cleaning of Thermal Glass

- Disassembly: "Success by 1000 Cuts" - Cleaning: Magic Baking

Soda

Electricity Generation

* My Solar Power System - Crappy Alligator Clips! - Energy collection

readings for March - Winter Solar Panel Reflectors? - All the Angles -

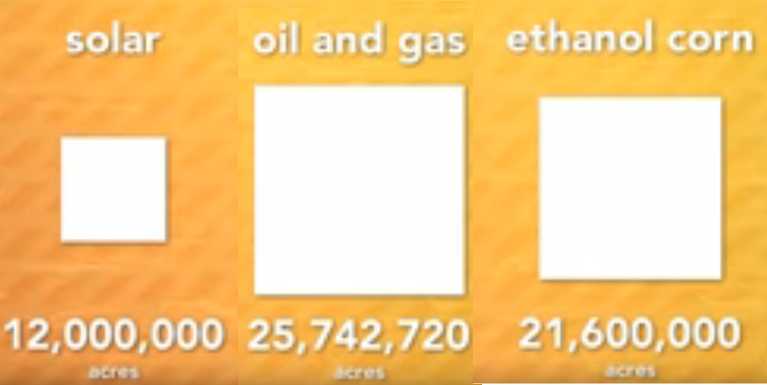

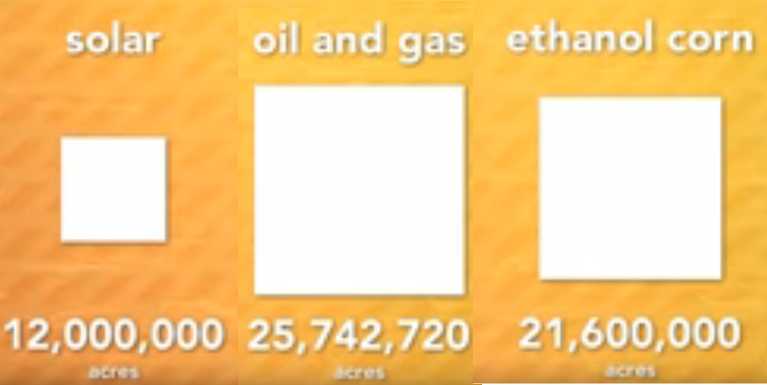

Power Outage Power From Grid Tie Inverters? - For America to go 100%

Solar...

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Methyl

Hydroxide electrolyte) (no reports)

The weather continued on from February, sunny and right

around freezing without let up. In late afternoon on the 8th it clouded

over. On the 9th it stayed cloudy and the temperature broke +5°C

for the first time since January.

I monitored the solar panels daily all month. Often they

still

collected around half as much through the clouds as in the sunshine,

but occasionally they were quite low. The 10th in particular had rain

and heavier cloud and the collection went to under 10%; .8 KWH instead

of 8+. As spring progressed, total daily energy collection rose from 8

to over 12 KWH per day when it was sunny. Power hit 1.95 KW at noon on

one sunny day. The mornings lengthened, but afternoon cutoff stayed at

around 4 PM (PST) owing to tree shadows. It's somewhat irksome to see

that the sun is still in the sky, but behind the trees. for the garden

as well as the solar. ...cut down the forest to the west of the house?

But there is only one row of nice spruce trees, near the house. Behind

that is just thin, densely packed alders because it was all clearcut in

the 1960s. No sign of sustainable forestry in that!

Naturally I wanted to get on with the new battery

development, the ground effect vehicle, the reluctance motor and

controller for electric cars, HE ray energy, and maybe a large VAWT

(must wind new stator coils for higher generator voltage at lower RPM)

and

a CNC garden digger-upper, and solar panels on my electric Sprint car

and Miles van vehicles. Not to mention milling more of my spruce and

getting the greenhouse up and beds dug and vegetables planted. As a

precursor to some of that and to plastic

recycling, I wanted to get my CNC router/drill/plasma cutter up and

running.

But having started in on the solar power and some home

infrastructure for it, it seemed advisable to finish that to a

relatively completed state.

What had been done in previous recent

months (see previous issues) was:

* I argued that 36 volts is the best voltage for a DC power system for

RVs, boats, off-grid homes, etc. The logic was that it's about the

highest "human-safe" voltage, wiring only needs to be 1/3 as heavy as

for 12 volts, and it's a good "in between" voltage, being about 3 times

12 volts and 1/3 of 120 volts. (One recognizes that this an unregulated

"nominal" battery voltage.) Cheap DC to DC down converters can turn it

into 12 volts as needed - or any other lower voltage like 5, 18 or 24.

* 4 (last summer) and then 6 more (total 10) solar panels were

installed in two roof

sites, providing 1.6 and 1.2 KW nameplate capacity - or 1.2 + .9 = 2.1

KW with the 75% "realism" factor. (Owing to the low angle of the roofs,

collection may not even hit 75%. It's over 60% now.)

* The 10 amp programmable DC to DC converter/charge controller was

connected and programmed to provide 41 volts to charge a 36 volt DC

system. (I've been calling it "38 volts +/- 15%" but that's probably

just confusing and I should stick to calling it "36 volts" like

everybody else. But really by the time three 12

volt NiMHs or lithiums are down to 36 volts, they're largely drained of

their energy.)

* Three 12 volt, 100 amp-hour NiMH batteries made up of "D" cells gave

some storage capacity. But two of them, and especially one, seemed

surprisingly weak. This month I checked them over and replaced 18 bad

or weak cells - 13 of 100 on the weakest one and 5 of 100 on the other.

One cell was actually shorted, 0.0 volts.

* Plug-in grid tie inverters ensured that excess power didn't go to

waste. (even if I was giving much of it to the power company for free)

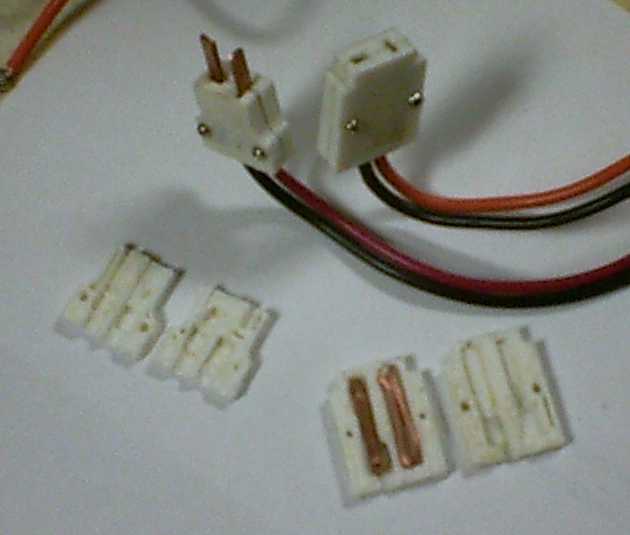

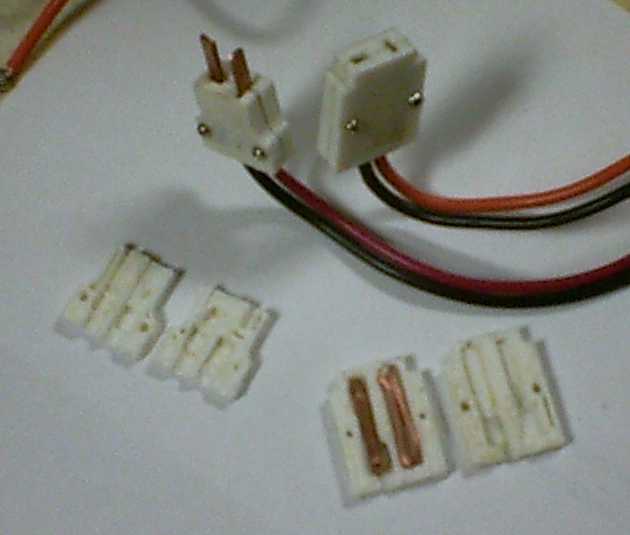

* I designed and made 36 volt "HAT" plugs and in-line sockets. (Plastic

shell designs to be uploaded to "thingiverse.com" for 3D printers.)

Lack of standard plugs and sockets has held back development of both 12

and 36 volt systems, so now there are 12 V "CAT Std." and 36 V "HAT"

plugs, sockets, wall plates, etc.

* I wired a low cost, compact little adjustable 5 amp DC to DC down

converter with a HAT plug to accept 36 volts and a CAT socket to power

the more common 12 volt DC equipment. Being well regulated they can

power 12 volt electronic and computer equipment that you might not dare

to power from an unregulated 12 volt battery system. And

being completely adjustable a single stock unit can replace most every

"wall wart" 120 VAC power adapter, reducing the headaches for finding

the right one. They can be adjusted to 5 volts with a USB socket

output, or to 18 or 19.5 volts for laptop computers with a round

socket/plug.)

So... now, ALL KINDS OF THINGS can be powered from 36

volts DC with its much thinner distribution wires than 12 volts would

need. And the HAT and CAT plugs and sockets make it easy to connect

things up. No wiring - everything plugs in. That is of course once the

appliance cord has the plug on it.

After realizing all these good points, I found the

converters I bought ran rather hot driving any considerable 12 volt

load, and this month I ordered some similar but higher power capacity

units with good heatsinks for twice the price - 5$ instead of 2.50$.

That's still cheaper than most AC adapters - or even a replacement AC

appliance plug in a hardware store. And there are still other DC to DC

converters on which both the voltage and the current limit are

completely adjustable - better for LED lights and for charging

batteries.

What was done this month, March, was:

* I improved

the shells for the HAT 36 volt plugs and sockets a little.

* I improved

the shells for the HAT 36 volt plugs and sockets a little.

* I designed

and made on the 3D printer HAT triple receptacle wall plates for house

wiring, and a special duplex one to cover a round hole. They seem to

work well and so the specs for HAT plug

pins and spacings from last month may be considered final:

* I designed

and made on the 3D printer HAT triple receptacle wall plates for house

wiring, and a special duplex one to cover a round hole. They seem to

work well and so the specs for HAT plug

pins and spacings from last month may be considered final:

HAT Plug Blade Specifications (36 volts nominal, maximum 15 amps)

Thickness: 1.35 mm +/- .15 mm (1.2 to 1.5 mm)

Width: 3.75 mm +/- .25 mm (3.5 to 4.0 mm)

Length: 10.0 mm +/- 1.0 mm (9 to 11 mm)

Pins Center Spacing: 7.5 mm

Negative pin is "in line" (lower pins in image), positive pin is

"across" (upper pins).

Just as with 120 volt plugs and sockets, there can be a wide variety of

designs as long as the blades/pins matching this size and spacing fit

in and connect. See TE News #129 for construction details of basic

plugs and sockets with 3D printer printed shells.

I intend to put all HAT connector OpenSCAD designs onto www.thingiverse.com

for anyone with a 3D printer. (The CAT 12 volt designs are

already there.)

* I assembled

a breaker box with "Blue Sea Systems" type circuit

breakers for the 36 volt house distribution system. Of course I used

the breakers and box I made previously in Victoria, but with

modifications. In it I installed:

* I assembled

a breaker box with "Blue Sea Systems" type circuit

breakers for the 36 volt house distribution system. Of course I used

the breakers and box I made previously in Victoria, but with

modifications. In it I installed:

- a 50 amp main breaker from the batteries (biggest breaker I

had)

- 6 branch circuit breakers: 40, 20, 20, 15, 15, 5 amps

- an LCD digital DC voltage, current, power and total energy use

meter on the front panel. And for this, a 100 amp shunt "resistor"

(.00075 ohm) inside, on the "-" side.

- a duplex HAT socket with a small switch on one outlet. (on the

5 amp breaker.)

- One 15 amp breaker went to the wire crossing the house to far

end of the

(huge) living room, where the triple HAT outlet plate was connected.

(Still to do: another outlet in the bedroom and one in the livingroom

by the computer tables.)

- a 70 amp Anderson APP connector, "+" and "-" (on the 40 amp

breaker - especially to power the 36 V to 120 V or the 36 V to 230 V AC

inverters [2500 W for the well pump]).

* Some Anderson plug cables were made up to connect the Sprint car (11

KWH @

"36" V batteries), the 35 V to 120 V inverter. (Still to do: One APP

"extension cord" to connect the car to the breaker box.)

* As mentioned I repaired

two 100 AH, 12 V NiMH "D" cell box batteries

by replacing bad or weak cells. Then I started delving into the 12 V

pipe batteries, finding the good ones and replacing bad cells in

others.

Then adding them into the system for more energy storage. It should

total at least 160 AH, ~6 KWH when they're all done.

* As mentioned I repaired

two 100 AH, 12 V NiMH "D" cell box batteries

by replacing bad or weak cells. Then I started delving into the 12 V

pipe batteries, finding the good ones and replacing bad cells in

others.

Then adding them into the system for more energy storage. It should

total at least 160 AH, ~6 KWH when they're all done.

* I ordered a 60 amp charge controller. 10 amps won't be enough in an

extended power outage since it would take over 16 hours to charge 160

amp-hours of batteries. Just the four old solar panels should do over

30 amps.

Since I haven't made a high amperage HAT plug and socket

yet but

didn't want to hard-wire everything together and limit versatility, the

70 amp Anderson connectors were really the only choice for the high

current stuff. And they are versatile because the "plug" and the

"socket" are identical. This means I can plug in a 36 volt, 1.7 KW

inverter as a load (to run, especially, the fridge and freezer, or the

well water pump), or perhaps the "36" [AKA 40] volt Sprint car

[batteries]

either to charge them or to supply the system from them. One might also

plug the inverter into the car batteries, completely separate from the

breaker box.

They are also dangerous in that being all the same, one

can easily plug in incompatible things. Like a 12 volt appliance into

36 volts -- or one appliance into another appliance -- or even a 12

volt

battery into a 36 volt battery. And you can clip the two single pin

housings together backward and fry valuable equipment with reverse

polarity. They aren't for household use where someone who may not know

exactly what they are doing may do something wrong.

Since no one else had done it, this is why I made the CAT

12V and HAT 36V connector

systems with defined voltage specs for house, boat, RV... wiring. I

hope 36 VDC will become a standard wiring voltage.

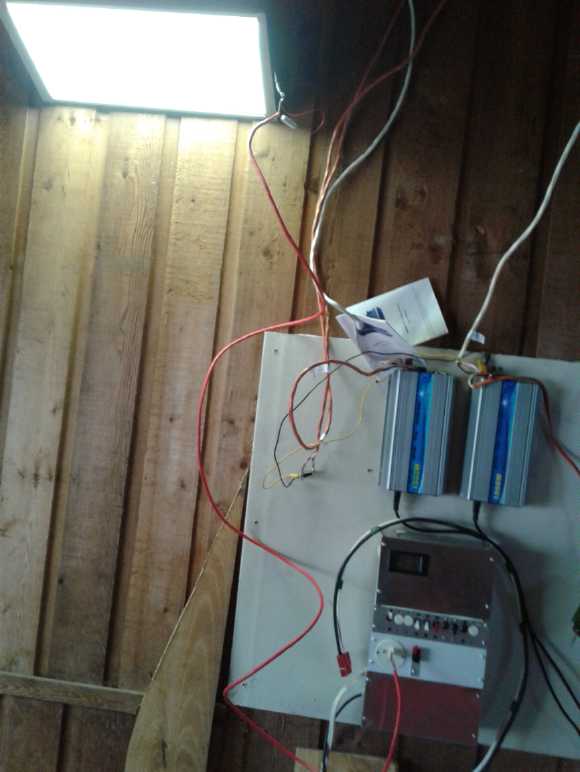

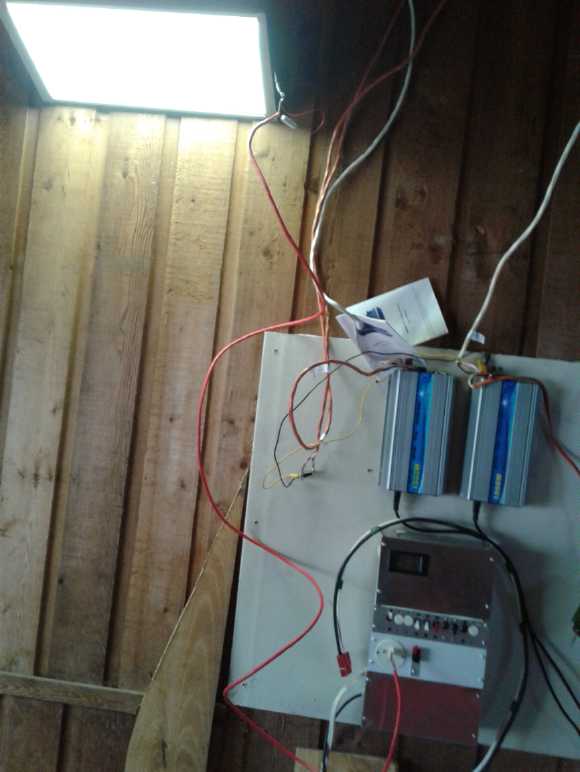

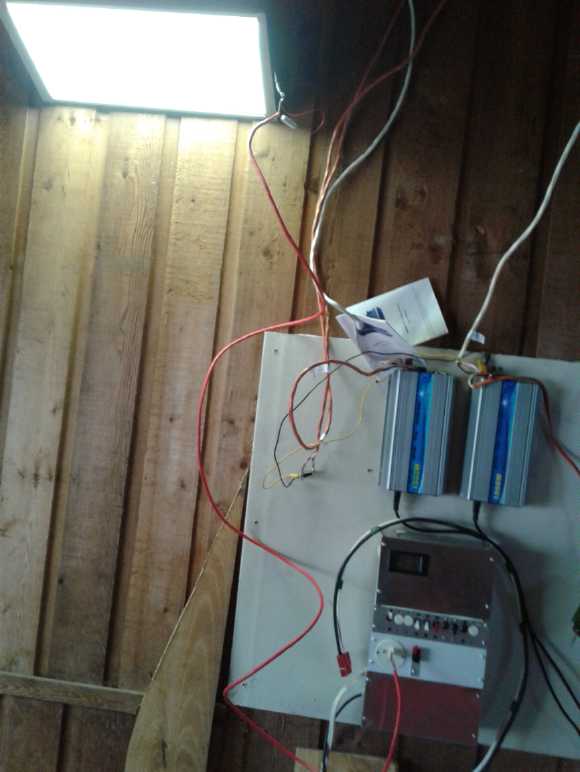

* Later I put a 36 volt

panel light on a bracket on the garage wall to light the solar

equipment area. I put a HAT plug on its cord and plugged it into the

switched outlet on the breaker panel, so putting in the switch came in

really handy.

* Later I put a 36 volt

panel light on a bracket on the garage wall to light the solar

equipment area. I put a HAT plug on its cord and plugged it into the

switched outlet on the breaker panel, so putting in the switch came in

really handy.

I had thought to finish the

DC power and solar systems up

in the first half of the month and then get to battery experiments

again, but I was also determined to do a decent job of it and finish

each

individual part "properly". On the 18th I was still working on

various aspects.

Then I got a small job to make angled mountings and

wire up 100 watt solar panels for two tug boats. I didn't even get to

that until near the end of the month, when I put one together, a

30-60-90 triangle, with plywood. I took it to the customer's house to

make sure it was what he wanted, but he was at sea. It is so now I have

to do the rest of the work - the second one, painting the plywood, the

wiring on the boat...

A triangular 100 watt solar panel frame.

A triangular 100 watt solar panel frame.

This might be useful in a number of situations where a panel might be

carted around to get the best sunlight.

In addition to being turned during the day to keep pointed at the sun,

it can be set more vertical in winter and more horizontal in summer.

Then I was offered another

small

installation job at a nearby off-grid house. When will I get to that

one?

---

In the meantime near the end of the month I was inspired

to do just a bit of work on the radio controlled model for the ground

effect vehicle, intended to cross open water at aircraft speeds. I cut

out the sides for the hulls from 2" styrene foam, and then split them

down the middle on the bandsaw. (To my surprise they warped more than

any board when split.)

In view of the vast flooding of the center of America with

the vast loss to water of stored grains (and a million(?) drowned

calves) and indeed of the high percentage of bankrupt farms which

may not reopen for years and then under new ownership, and the

inevitable vast crop failures for at least

two or three years to come - along with all the other huge global food

disasters - I started thinking food might become a

priority and worked some on the redoing of the greenhouse. It wasn't

much good with half the walls wide open. I planted a few things indoors

(but not enough either in variety or in quantity). I bought some

chicken feed while it's still available looking ahead to getting a

chicken or two. (I also bought extra flour and groceries on "sale day"

at the co-op grocery.) I wished I had the CNC gardening machine done to

turn

some lawn into a small wheat or barley field. And some more fence to

keep the deer out of a larger growing area. (Perhaps I should go buy

that?)

And I finally dug up the bulk of last year's potatoes. On

the 25th, with the main patch done, I weighed just 12 Kg of small

potatoes - red, purple & white skin, white, and purple haida. I

might have

eaten another Kg or two over the winter, and there were a few soggy,

spoiled ones from near or on the surface that had got frozen in the

cold a month earlier. And a small patch I hadn't dug up yet. Maybe 40

pounds total? Not a huge crop considering the area devoted to

them, but decent considering the very sandy soil. (Some red potatos at

one end were a good size. Better variety for the climate? Better spot

with

a bit more sun? Better soil? I dug a little deeper so as not to cut

up potatoes with the shovel, and I was turning up pretty much pure

sand. Thinking

back, it was mostly sand when we started in 2017. Tom brought several

wheelbarrow loads of black organic dirt from the forest when we were

starting, and I've added spruce sawdust from the milling operations,

eel grass from the beach, and some crunched up clam shells for

calcium/lime. I should probably do some more before I plant again.

Potatos are easy to grow, but now I hear (on youtube) are heavy feeders

to get good size spuds.

Here's my hard luck story with yukon

yellow potatoes. (What, you don't care? Well, just skip to the next

heading.) The stores were always sold out when I happened along. "Oh

well, next year."

In 2016 in exasperation I finally bought some at a grocery store, but

predictably they had been treated not to grow. Finally some of them

started

coming up toward the end of the summer, and I hoped for at least a few

small but good seed potatoes for the next year. But a deer came along

and ate

the tender late stalks, especially picking them out.

I finally found some yukon seed potato in spring

2017. (As I recall I was

barely lucky even then - it was the last bag or one of only 2 or 3

left.) Why are they SO hard to get? I brought them up to Haida Gwaii

with me. Tom and I planted them. But in fall 2017 as he harvested, his

wife Tess cooked them all up (in preference to all the other varieties)

and we had eaten them all before I realized there were absolutely none

saved for seed or still in the ground. So I had none in 2018. AWRG!

But having thought of it, I put yukon seed potatos on my

shopping list. There were LOTS at "Funk It", the garden store. I got

some, and then

at the health food store they had yet MORE - and also "french

fingerling" seed potatos (and other unusual varieties). These are

reputed to be sweeter than most, so I got some of them too. So this

year I'll have white, red, purple with white eyes & white flesh,

purple with purple flesh haida, yellow fleshed yukon and french

fingerling. Not

actually being a big potato eater I decided to try and recoup some of

the 25$ or so I had spent on seed potatos by taking several 1 Kg bags

of my small harvest to someone to sell at the farmers' market. But she

didn't answer my message and it turned out she hadn't done the market

that week.

Take Apart of a Sealed Window

Somehow related to

planting... I tackled an interesting and perhaps unusual project on the

31st. A thermopane window sitting in my basement was just the right

size for the greenhouse I've been putting together. It was fogged on

the inside, and anyway double glass doesn't let as much light through

as single. Plus, it was just right for that whole wall section if there

were two of it. So I looked on line for sealed window disassembly

instructions. To my surprise there weren't any. It seemed no one ever

does it. I guess that explains why you can get them free or cheap if

they're fogged up inside.

Somehow related to

planting... I tackled an interesting and perhaps unusual project on the

31st. A thermopane window sitting in my basement was just the right

size for the greenhouse I've been putting together. It was fogged on

the inside, and anyway double glass doesn't let as much light through

as single. Plus, it was just right for that whole wall section if there

were two of it. So I looked on line for sealed window disassembly

instructions. To my surprise there weren't any. It seemed no one ever

does it. I guess that explains why you can get them free or cheap if

they're fogged up inside.

I did it before, years ago, with somewhat unsatisfactory

results. I sawed through the aluminum edge spacer with a jigsaw to get

the panes apart. Trying to get that awful aluminum oxide off, I

somewhat scratched the glass with "scotchbrite". It was better than the

fog.

This time I came up with much more satisfactory means both

to open and to clean them [baking soda], which are written up below

under "Other Green Projects". I have also done a video which I'll

upload when the internet is working a lot better than it is right now.

(They're the two panes next to the door of the greenhouse below.)

I finally got

the greenhouse almost as sealed up as I wanted it to be on April 3rd.

Last year I grew nice greenhouse tomato plants that got almost no

tomatos, and those few very late. This year I hope pollinating insects

can get in and out, while inside it still gets warm in the sun. I put

in a first row of peas by transplanting some that had fallen last year

and had now taken root here and there and grown a few inches. (I don't

know what variety(s) they are, but they're bound to produce sooner than

seeds I start now.) Now to do a bit each day or two until it's all made

into beds and planted. Fresh peas! Tomatos! Cucumbers! Asparagus!

I finally got

the greenhouse almost as sealed up as I wanted it to be on April 3rd.

Last year I grew nice greenhouse tomato plants that got almost no

tomatos, and those few very late. This year I hope pollinating insects

can get in and out, while inside it still gets warm in the sun. I put

in a first row of peas by transplanting some that had fallen last year

and had now taken root here and there and grown a few inches. (I don't

know what variety(s) they are, but they're bound to produce sooner than

seeds I start now.) Now to do a bit each day or two until it's all made

into beds and planted. Fresh peas! Tomatos! Cucumbers! Asparagus!

Oh wait... first the wall inside needs to be painted white so it

doesn't absorb half the light. (Half done as of newsletter final edit.

Ran out of white paint.)

At the other end, I used a scrap shower door

and a couple of small windows that open.

At the other end, I used a scrap shower door

and a couple of small windows that open.

(Yes it's a two-door greenhouse!)

When I've found more windows I hope to match the two halves of the

greenhouse at the front and

eliminate some of that shady "Solexx" plastic. Plants grow huge leaves

in there trying to get enough light.

A row of peas - pretty good for "just

[trans]planted yesterday!"

A row of peas - pretty good for "just

[trans]planted yesterday!"

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

The Value of Social Ratings

Not to be confused with the now

defunct "Social Credit" political party in Alberta and BC, it seems

China is now creating a "social credit" scoring system to rate each of

its citizens. This would appear to be more of an onerous "social debit"

system, since people

scoring lower, with black marks against their name, are being

denied basic services like transportation. This will make life

unlivable, which can only end in some kind of blow-up and change of

government. There's a North American "no

fly list" too. You don't even know if you're on it or why, or who

decided you should be on it, until you try

to take a flight and can't. And there is no appeal process.

And of course, much is being made in the west of

government and corporate data collection on citizens from their on-line

activities, telephone conversations, GPS tracking, public area security

cameras with facial recognition software in city areas, and so on.

But there are benefits to fairly rating people based on

their deeds, too, provided such ratings are not used to destroy liberty

and opportunities - to make people unequal. And they may start to

outweigh the problems. In the

past, a

person's reputation was important. In the modern world before the

internet, there got to be so many people that one inevitably deals a

lot with strangers, whose reputation is unknown. If one's misdeeds and

lies started catching up with one, one

could always go somewhere where they weren't known and begin the same

shady lifestyle again. Things are changing.

On eBay and Aliexpress, customers rate merchants in accord

with how they feel they've been dealt with. Those who don't represent

their products realisticly or who give poor service, will pretty soon

have some low ratings. One can imagine that they soon will not get much

business any more.

Imagine if you could look up such ratings for the used car

salesman who is trying to sell you a car. You could see if he presents

things honestly to customers, or if people feel they had been "ripped

off", or pressured into a poor choice or sold a "lemon", and would

rather never deal with him again. Might that be helpful? Might he

himself be more inclined to honesty?

Now imagine you could look up ratings of those running

for political office. Today we can usually only hear the

propaganda media's opinion of what those running stand

for. We don't get to hear the candidates' platforms, and rarely even to

hear them speak, except perhaps a for

brief sound byte taken out of context for purpose of furthering a

preset narrative - often of making the establishment's choice candidate

sound noble, or of "demonizing" some upstart "not in the club" who

thought he could make a difference if he was elected to that office,

and that he had a realistic chance at it.

With a good rating system that can't readily be "gamed",

we would start finding out the reality behind the façade, the

upbeat - or downbeat -

"public image" that we are being presented with. Do they mean it, or is

it just hypocrisy? Does their track record say they try to keep their

promises? Do they treat voters with disdain once elected? Have they

taken favors from big corporations? Are they on the board of one? Do

they have other conflicts of interest?

a criminal record? do they intimidate others or pull dirty tricks to

make opponents look bad? Have they ever done anything worthwhile for

their

society and community? Are they honest and forthright in their

dealings? Are they a team player with real leadership qualities? Do

people who know them like and trust them?

Here is an opportunity to know more of the real person, in

order to start electing those who are sincere, honest and capable.

Unlike today, those who are crafty and designing, and in it for their

own power and self-serving personal gain, will be found out and won't

get the votes. Could Hitler have won the votes to gain office in 1933

if it had become widely known that Goering had said something to the

effect that "We're having a hard time getting into office, but once

we're there, the only way we will leave it is when they drag out our

dead bodies."? The public only heard what the Nazis wanted them to

hear, on the radio. Today we have means of "peer to peer"

communication, and if and as we start using it, a lot will change.

Then again, today people fear they may be dragged into

court and

impaled (or at least fined) for minor infractions that formerly meant

little and were forgotten minutes later, but which will now inevitably

be

detected and permanently recorded by computerized spying. Will one

start being persecuted

for small indiscretions or mistakes of long ago... because one has now

developed a political agenda different than those presently in power?

for having a new product that would disrupt an existing major business

or "status quo"?

Today these are real concerns.

But who really has the most to lose? We have the

incriminating e-mails even of "top" people like Clinton and Podesta,

Comey,

Wasserman-Schultz: the top ranks of the FBI, the CIA and the

"Democratic" party,

and so on, all in on plotting child sex trafficking, murders and

treasons. Before the 2016 election they all thought they were in an

"elite" club, always in power and "above" the law. To these

"despicables", the public were just "deplorables" to be lied to during

elections and then ignored. A billionaire with his own security force

and resources crashed their party.

Since then they've

tried everything to cover their tracks, but when their e-mails were

sent

they were

recorded by those same spying agencies the public so much fears. Their

cell

phone conversations may also be of record and might be of great

interest to the courts. Even the plottings of 2001/9/11 are belatedly

coming under court scrutiny. We will see whether and who is brought to

justice - or not - but notice is given that from now on it will not be

possible to sweep ones' nefarious activities under the rug to be

forgotten by everyone in a few weeks. The black stains on the records

of the bad actors are increasingly coming into the light.

Since that election the spate of "retirements", "not

running again" (for senate or congress, etc.), firings and resignations

has

evidently been astonishing, along with many charges being brought to

bear of pedophilia and child trafficking that was formerly kept well

hushed up. "Democrat" lawyer Michael Avenatti, who apparently still

thought he was above the law, has been arrested for trying to blackmail

the Nike company. Hopefully people of such ilk are now at the very

least becoming unelectable, and unemployable

in high level positions.

It seems inevitable that more and more of what we do and

who we are will be recorded and known. But for this very reason,

increasingly we should start to have have reliable, understanding

people in the high

positions that corrupt sociopaths occupy today. Then the public will

have that reason to celebrate, and

little to worry about.

Self, Other and Together Interest

"Self interest" is a

common term. "Other interest" is less common. We may often

speak of "altruism" with similar meaning. There's also "mutual

interest". The usual connotation of

"mutual interest" is still limited to it being "your and my interest".

But not other peoples' interest. "The public interest" is often used by

politicians. Usually it's used to deny consideration to a smaller group

that is being harmed by an act that supposedly benefits the majority.

A new term is "Together interest", which includes both the

self and others. Perhaps it may also be expressed as "Realism".

"Together interest" is a more general idea

that it is in everyones' interest - not excluding others, not excluding

the self. The concept has also recently

found expression on the

internet as a new term "WWG1WGA" - "Where we go one, we go all."

What is in the true interest of everyone is usually also

in the

interest of the individual, and what is in the true interest of the

individual is usually in everyones' interest.

"Together interest" is in accord with the seven core

values starting with equality. It seems to me is a valuable philosophic

concept

towards establishing and maintaining social stability and

sustainability.

Climate Disasters, Chapter One

The prologue is evidently over. The much anticipated

climate disasters are upon us in force. Without disregarding the many

other "record", "once in a thousand years" and "unprecedented" weather

events and local or regional disasters around the globe, it would be

hard to overstate the magnitude of the colossal catastrophes

that have taken place this month in Mozambique and in the center of

America.

In Mozambique the floods have made almost a clean sweep in

many areas including major cities. roads are destroyed. the power is

gone. the homes and buildings are gone or badly damaged. Mozambicans

are going to need help on a gigantic scale that is probably not going

to be forthcoming from South Africa or any other quarter. What will

happen to all those people? Many are likely to start migrating.

especially if it happens again when some have started rebuilding.

In America, the crop losses alone from the "bomb cyclone"

that rampaged through the heart of the country's agriculture are

staggering. 6.7 billion (was it?) bushels of stored wheat, soy and corn

grown in

2018 have been flooded out, ruined. This is half of America's food crop

production and the source for the whole "just in time delivery" supply

chain. The land won't be dry enough to plant this spring with continued

inundation projected into May as the heavy snows melt and make their

way down the swollen rivers. So that's two years of half of the USA's

crops lost. Owing to top soil damage - what hasn't been simply washed

away - it may even take several years for some land to be restored to

good productivity. What are Americans going to eat in the meantime?

(Evidently a million calves have drowned, and what food is there for

the rest of the cattle. Australia's gigantic flood in Queensland also

drowned staggering numbers of cattle, while elsewhere the drought is

ruining Australian agriculture.)

And who will farm it? For some time now most farmers have

increasingly been the elderly, and they have been pressed to the limits

by previous

disasters of recent years. With this new calamity many are now

bankrupt. It sounds like only half

of them are likely to even try again in spring 2020 - if nothing else

happens by then. Then too, much infrastructure has been destroyed.

Major highways, roads and bridges have been washed out and some have no

way to

drive anywhere. No doubt power outages are widespread with many and

major repairs required to restore it. A week later further drone

footage by a Nebraska resident [youtube channel "farm dad word barf" -

where do

people get these names?] showed the water had receded a long way, but

the prospect remains for much curtailed crop production for the USA

this year.

Once the mass of the general public realizes what has

happened, it may be too late to start storing up some food that keeps.

It either won't be available or it'll cost too much. Will the price

hikes be coming in weeks, or will they take months to filter through?

There can certainly be no doubt they're coming. And then, will the high

prices kick off unrest as people already stressed can no longer afford

to eat? And will rising food prices kick off hyperinflation and the

death of our "pyramid scheme" debt-based money system, created by

bankers to make

bankers rich? And will the generally deteriorating conditions help kick

off a sudden pandemic that kills billions of people in a matter of

weeks or months? WHO and CDC have already been telling us a pandemic is

a matter of "when" not "if". And how many more devastating climate and

geological disasters may we expect in the next decade or two or three?

I am

certain this is only "Chapter 1" and more is in store.

And we need to remember that except for volcanos and

earthquakes, these problems are almost entirely man-made, including the

weather and sea level rise and all that these changes entail, via a

century and more of burning fossil fuels (esp. coal) and lately,

misguided and huge geoengineering projects. And even more, we have

permitted the

"population bubble". There are simply far more people on the planet

than can have a good quality life and grow into their full potential -

almost four times as many as just 100 years ago.

When the appearance of "normalcy" begins to vanish - and

for many it already has, the

world will never return to "normal" as we have known it. Disasters

other than continued sea level rise will start to wane after 2 or 3

decades with the end of the geoengineering programs and population

reduction, but things may not settle down socially for 1000 years. In

that time people will be building a new world and a new, and this time

sustainable, civilization. from the local community level up.

---

Here on normally soggy Haida Gwaii we seem to have an

unusual problem - dryness, not to say drought. It started last summer

and there hasn't been much rain this winter or spring. On the 27th I

lit a pile of branches I wanted to burn for fear there would soon be a

burning ban. While I was away for a couple of minutes gathering more

branches, the grass caught fire around my fire and it started

spreading. It went out easily when I played the hose on it, but I'm

glad it didn't have a few more minutes to spread! I've been burning

daily since, as those piles may themselves become a fire hazard if it's

dry enough. (They are, at least, shrinking.) I suppose we'll get

our disasters here - perhaps not in the form of an earthquake, volcano

or tsunami but

instead a forest fire(s), like so much of the BC interior has been

having

(not to mention California). One here might well threaten my house.

(Gosh, should I take out my row of spruces that edges the forest beside

the house?)

On and Off Beefs

When most every appliance had a power switch, it was

pushed one way for "off" and the other way for "on". There was no

question about whether an appliance was "on" or "off".

Whose crazy idea was it to replace the power switch with a

single button that reversed the state every time it was pressed - even

when there is insufficient feedback to know which state one has set

something to?

Often there is some sort of display, but even then one

can't just go turn something off without pausing to make sure that is

what happened when the button was pressed. Even then it may be unsure

because some devices don't respond fast enough, and it may come back on

once your back is turned.

Worse is when there is no feedback, or it is too slow.

Such as with sound and video players. I've often tried to pause a

youtube video during a dropout, only to have it start up again after

I've walked away to do something. Then I have to come back and hit the

play-stop button

again, and back up to get to what I missed. Or even the video plays to

its end while I'm gone. The button shows "||" [pause] when it's playing

and ">" [play] when it's paused, too. But after a couple of presses,

the

button stops showing the actual state. WHY is it the same button for

both? We pay for data/bandwidth here!

Another case is new cars. One button to start the car. The

same button to stop it. But the button does different things at

different times. When my Nissan Leaf is plugged in, it takes two

presses to get the instruments on - when all you want to do is see how

much longer it'll take to charge. And then they don't go out like usual

when you turn it off. Since it doesn't appear to be off (I'm still not

sure it really is), you hit it again and go around in a vicious circle,

to the point I'm not actually sure how many times I'm supposed to hit

it. I only know it's off if it doesn't start beeping at me when I open

the dorr to get out. And a car I rented kept starting the engine again

when I was trying to turn it off. I've always turned off the key first

to get the car to stop polluting, then put it in park. Not with a new

car! The one I had wouldn't turn off. Hit the button again and the

engine restarted. No, no, it wanted you to put it in park before

turning it off! Why? electronic automatic gearshift: if you turned it

off, you wouldn't be able to put it into park!

I have no doubt that these modes would be much less

confusing if there were separate "on" and "off" buttons. Then at least

there could be no misinterpretation of what the user wants to do.

Then there's the telephone "mute" button. There is no

feedback. In long conference calls, I eventually lose track of whether

my mute is on or off. Then either everyone is listening (unknown to me)

to my coughs and rustlings around, or I have something to say

and some "rude" person breaks in right while I'm talking -

because I'm not being heard. (And occasionally someone else is making

distracting noise, probably thinking they're muted.) Many times I'd

like to press a button again to confirm being muted or live. What

insanity that the same button goes between mute and unmute, with

absolutely no way of telling which state it's in! And the conference

call system we use does exactly the same stupid thing - "4*" both mutes

and unmutes your line, again with no way to tell what state it's

presently in.

(Having written this, I took a look at the phone. The

display says "mute on" or "microphone live". Since the phone is up to

my ear when I'm on it, in 3 years of occasional conference calls I've

never seen that before. If I take it away to look, I'll miss something.

My complaint stands.)

And as long as I'm here... Why won't video players - even

video editors - let you go forward or back frame by frame? Sometimes

something valuable is caught in just one or two frames, and it can be

not just frustrating but

impossible to pause at just the right spot. Often it ends up playing

a little farther - or just playing on - just when you finally hit

"pause" in exactly the right place! Videos are played frame by frame

anyway. Just how hard could it possibly be to let the user page through

them?

More on

Recycling Plastics into Valuable Products

Plastic Building Materials - Tiles Etc.

On the 3rd, the day I sent e-mails saying TE News #129

was posted, with its ideas for plastic recycling, my friend Tom told me

about a Russian youtube video about making patterned tiles from

recycled plastic. I searched youtube for "making plastic tiles" and got

dozens, maybe even hundreds, of results for recycled plastic floor

tiles, roof tiles, paving tiles, decorative tiles, extruded plastic

slabs, plastic cubes, plastic bags into decorative blocks, and on and

on and on.

It's being done in India and Africa - people all over the

world are realizing the potential of a valuable raw material. Just go

onto youtube to get almost countless ideas on what to do and how.

That's what I'm going to do, because...

...that seems like a perfect - and free - material to to

use for floor tiles - and maybe other parts (ceiling tiles?) - if I

should ever decided to turn the roof over the trailer into a building.

A major caution in using plastics as building materials is

to consider fire safety. Will they, for example, burn if a match is

dropped on them? (I doubt it, but I will certainly experiment before

constructing anything! If plastic tiles ever did get burning, look out!

What would it take to ignite them? wood embers? a propane torch?) I

wouldn't use them on the roof of a building that has a woodstove for

fear sparks and hot stuff from a chimney fire might ignite them.

Info On Line

One youtuber whose channel especially attracted me is

DaveHakkens, of PreciousPlastic.com. In the past 5 years he has done an

entire excellent, professional series of videos on recycling plastics,

going into all the details of types of plastics and how to sort and

separate them, types of machines and how to make them, and various

techniques and molds.

(We learn that some plastics float, some sink. Some float,

or float

better, in salty water!)

Shredder

As I had surmised, the first piece of equipment in the

series is a shredder, and he has instructions for making one. There's

CNC files for cutting out some of the shredder parts including the

rotating cutters with (eg - ready for this?)

a CNC plasma cutter. (I'm abandoning my 1991 CNC driver box, which

turns out to have only two stepper motor drivers. To replace it I've

ordered a "Gecko Drive" quad stepper motor driver to get started on

this project.) Another

homemade shredder in video by someone else seemed pretty "Mickey Mouse"

compared to Dave's. One can

see Dave's will last and last, and does a better job. Various

sieves can be attached to keep bits circulating until they're small

enough to fall through.

Extruder and Molds

While I had been content to think of pressing plastic into

blocks in molds, Dave has instructions for a homemade plastic extruder

and shows homemade molds for extruding into to make various forms. (He

does do some welding to make these things.) An

interesting feature was a threaded pipe fitting on the output of the

extruder. Every mold to use it had the matching pipe fitting welded to

it for the plastic to come in through, and for use it was screwed into

the extruder. Of course the pipe fittings attach the mold securely to

the

extruder.

He had long steel tubes for extruding plastic beams and

rods into. (His were different lengths with an end on the tube. (I

question that one needs an end on the tube. If the tube is long enough

for the plastic to cool and harden some, couldn't it just extrude

continually and then the product be cut to any desired length? I

suppose I could check out his forum and ask if it hasn't already been

discussed.)

Other Plastic Working Tools

I could see there were other videos on vacuum forming,

blow molding and other techniques. Doubtless he showed how to make

these tools as well as use them. His web site and videos appear to be a

gold mine of info on plastic recycling.

I found out that a friend now living in Queen Charlotte

had

been involved in the recycling business in a big way in prior decades

and knew a

lot about it. He showed me a simple device he had made to extrude 3D

printer filament.

Reuse Before Recycle: Transparent Plastic for Greenhouses?

Last winter I purchased seven "corrugated" 2' x 10'

polycarbonate sheets for my greenhouse roof and they were well over

500$ on this island. I was looking at some transparent food containers,

PETE and PS, and wondering about making them into plastic panels or

sheets for greenhouses. Would it be hard to do? How long would they

last? I mentioned the idea to someone and he asked if I meant to

re-melt them or to use as-is. That gave me the idea to just cut some

flat pieces out and use them as-is to fill in some narrow gaps. All I

needed for that was scissors and a stapler. And in a couple of years

one question would be answered: Would they last? If they ripped in the

wind in the second year, it wouldn't be worth making and installing

PETE or PS panels. But if they were still strong, it might be. Perhaps

one would last better than the other?

On looking them up, it seemed PETE needed more heat,

didn't hold up well in sunlight, and in fact turns markedly yellow. PS

lasts well and melts at a lower temperature. It sounds like clear PS

food containers are the plastic to start with.

I remembered back to when I was 4 or 5, and my dad and his

brother and a friend decided to make polyethylene tents for ice

fishing. (I'm sure in 1959-1960 PE was a pretty new thing.) They took

mom's iron and (IIRC) put some aluminum foil over the hot part. They

cut the PE and overlapped it where they wanted seams. Then they put

cellophane over it and ironed it. The cellophane protected the plastic

and the iron, and the seams were melted and fused.

What would

happen if I cut the corners out of the PS

packages so they would flatten out, overlapped any voids thus created,

and ironed them with a cellophane barrier? Could I melt them down flat

and have the seams melt and join? (preferably "seamlessly?") I had some

cellophane, so that was easily tested.

What would

happen if I cut the corners out of the PS

packages so they would flatten out, overlapped any voids thus created,

and ironed them with a cellophane barrier? Could I melt them down flat

and have the seams melt and join? (preferably "seamlessly?") I had some

cellophane, so that was easily tested.

It worked, but badly. The polystyrene softened and

flattened out as it got hot, but it also shriveled quite a bit, leaving

holes and generally looking really ugly. One could fill the holes with

another piece, making it even uglier. And the fragile cellophane stuck

just enough that it was soon ripped into pieces too small to guard the

iron. Clearly another technique would be required, probably involving a

complete melt and re-extrusion. Substantially thicker panels would

surely be much better anyway.

...or maybe press some between two sheets of aluminum in the oven?

(Cellophane is clear too. Could thick and hence durable

panels be made of cellophane? Or would it rip almost as readily as the

thin sheets? Well, even if that works it's not going to recycle much

plastic!)

ESD

(Eccentric Silliness Department)

There was a hurricane outside, but all was comm at the radio station.

It was also.com at local websites.

Swiss chard should be eaten raw, boiled or steamed, not charred. It's

already chard.

What's with the word "palindrome"? Shouldn't it be "palinnilap" or

something?

Why does "touch" end with "ouch!"? Not everything you touch is hot or

sharp.

Those who plant light bulbs will surely have a brilliant garden.

(Alternative: Those who plant light bulbs aren't very bright.)

Why do they want Maduro out? Hmm, the last thing the US did in action

in Syria was steal the gold, just like from the basement of the world

trade center, and from the Ukraine and from Libya. Maduro tried to

withdraw some of Venezuela's gold from the bank in London. They asked

what he wanted it for! That's none of their business. They're stalling.

Maybe they're trying to oust him with a coup before they have to admit

they sold Venezuela's gold with the rest and that the vaults are empty?

Some write memoirs. Here's a couple of stories from the 1970s.

You know you're in good hands (1976?)...

Fishing Boat: "Mayday! Mayday! I'm sinking off the northern tip

of Cormorant Island!"

Alert Bay Coast Guard Radio Operator: "Cormorant Island, where's

that!?!"

(Alert Bay is on Cormorant Island.)

Some bureaucrat in Ottawa noticed that this same Alert Bay

Coast Guard Radio station didn't have CW (morse code radio

communication

- 1978?). And, for such stations, the rules said radio operators were

supposed to only be rated RO-1s instead of RO-2s. But it was hard

enough to get people to want to move to isolated small island Alert Bay

without asking them to take a pay cut too. Not very fair to get

different pay depending where one got stationed, when the job wasn't

that different. (The radio operators, it seemed to me, already did the

most work for the lowest pay of those I worked with and around.)

This was after I had moved to Victoria. My supervisors

decided to correct the situation as fast as possible by sending a young

electronics tech (me) north in the van to install a CW transmitter in

the transmitter building at Alert Bay. It was an old 6 foot tall, 19

inch rack vacuum tube unit that had been removed from Tofino. As all

suspected, I didn't have enough time for all the travel first to Tofino

to pick it up, then up to Alert Bay to get it installed and working,

and then to return. But they had anticipated that. I got it set in

place

in the transmitter site, but I didn't get much farther than that before

having to get the ferry back out and then head home.

It was enough that they told Ottawa, "Oh yes, that was

just an omission. There is CW at Alert Bay."

---

The new "5G" cell phone system is supposed to be much

faster than the present system. This is a very exciting prospect. If I

can get people off the phone in half the time, I can get more done!

(But I must remark that 5G is powerful enough in the

millimetric (...why is it called "micro"wave?) band to raise

substantial concerns for the

health of birds going by and people living too close, and yet no

health

studies

have actually been done on it. For the whole world

to be the guinea pigs in this is not comforting. Human adults can

probably take it if the antenna isn't right outside their window. But

where are the studies

on chickens or whatever, showing that there are no adverse effects on

the offspring after 3 or 4 generations of exposed chickens and embryos?

The last thing we need is damaged children being born - something like

the thalidomide

crisis all over again, or young children becoming damaged as they grow.)

---

AHA! I've found the culprit! Evidently it was the great

inventor and experimenter Benjamin Franklin, who got it wrong. He

ascribed one direction of electrical charge as being "negative" and the

other as "positive". What he didn't know was that the direction he

arbitrarily assigned as being "negative" indicated an excess of

electrons rather than a deficit of them. (The more money in your bank

account, the more negative your balance. ...say, is that the trouble

with the financial system?) Would we then say that the

Franklin Stove, the forerunner of the modern wood stove (and still

produced up to about the 1960s?), was Ben's "most negative"

contribution

to improved quality of life?

---

Evidently the name "Witch Hazel" has nothing to do with Margaret

Thatcher et al. Wikipedia indicates that

it only got the "w" in later times, replacing "y" or a vowel in some

Gaelic word. In view

of its purpose then, might it not be prudent to drop the "w" and call

it "Itch Hazel" instead? One would immediately get the idea it's

for skin care. (Now as for that second word... is it derived from

hazelnut trees

or some relative thereof?)

Which word is out of place?: Sing, Sang, Song, Sung. (Well, three are

verbs, one is a noun.)

"Odd" has only two sounds in it, but three letters. That may seem odd,

but it couldn't be spelled "od" because that would be even.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground Effect

Vehicle (R/C Model): Beginnings?

Mentioning how great it would be to have ground effect vehicle

coastal/islands/ocean transport to someone inspired me to do just a bit

of work on it. I marked out and cut the side profile for each hull from

2" extruded styrene foam. According to the plan the hulls should be

4.5" wide. And I actually did want hollow space in them for batteries

and electronics.

Mentioning how great it would be to have ground effect vehicle

coastal/islands/ocean transport to someone inspired me to do just a bit

of work on it. I marked out and cut the side profile for each hull from

2" extruded styrene foam. According to the plan the hulls should be

4.5" wide. And I actually did want hollow space in them for batteries

and electronics.

I decided to split them with the shop bandsaw and put 1.5"

wide foam on the bottom between to make them into the two sides for

each hull. Much to my surprise the foam warped worse than any wooden

board when it was split down the middle. It'll take some stiff clamping

to straighten them out when the bottoms are glued on!

The ducted fan on the coffee cup is the approximate

intended position, about at the front of the wing and vertically in the

middle, blowing some air under the wing and some over.

The hulls top shape of course matches the upper surface of

the special wing profile designed to provide good ground effect lift

with maximum stability.

In an aircraft there's usually a heavy spar toward the

front of the wings at the center of lift that provides much of the

strength. But if this wing has more suction lift toward the rear as

well as compression lift more front to center, should that be broken

into two or three smaller spars?

Rather than aerodynamic considerations, the width (the

length of the boards) is 2.5 feet in the 1/4 scale model, making 10

feet in the full size version, which (I believe) is maximum legal

regular trailer width on the highway. The length of 4 feet (16 feet)

was chosen as making it a good profile with the 10 foot width.

I think the length and width of the hulls should provide

sufficient buoyancy. The wing length is about 3.125 feet (12.5 feet).

Since there will be 7 feet between the 18 inch wide hulls, there's 87.5

feet of wing area. I believe that should be a good value - but it's a

good reason to build the model first and run it with various weight

loads to see how well it works before attempting a full-size human

carrying craft.

Other

"Green"

Electric

Equipment

Projects

"Off Grid"

(etc):

36 Volt DC "HAT" Plugs & Sockets

...and other 36 volt components.

Use of 36 Volts as a House Distribution Voltage

I've discussed before (if not ad nauseum) what makes "36

volts" (or

a few more) seem to be the best compromise DC distribution voltage for

off-grid home (or RV, boat, etc).

- Highest "human safe" voltage. It

starts getting incrementally more dangerous to go higher. In saying

this we must take into consideration that up to 15 volts is used to

charge lead-acid 12 volt batteries, so a nominal "36 volts" could be as

high as 45 while it's charging. Nominal "48 volts" can be as high as 60.

- It has 1/3 the current and hence

1/3 the distribution wire size of 12 volts for heavy loads. The cost of

copper wiring being large, thinner wire can save a lot of rather

needless installation

cost. And it's lighter. and easier to work with.

- Voltage drop with current loses a

high percentage of total power at 12 volts. (eg, a 1.2 volt drop is

10%) With 38 volts, currents are reduced by 2/3 and the same voltage

drop is 1/3 the loss. (eg, a 1.2 volt drop is 3%, and with lower

current the drop itself

may be less than a similar appliance with 12 volts.)

My optimism that 36 volts may eventually be adopted as a

standard inside distribution voltage has recently increased with two

factors:

- Finding the simple little single

chip, potentiometer adjust, DC to DC down converters for under about

3$; 5$ for higher power rated ones.

- Simply the making of the HAT and

CAT connectors. A HAT plug allows the DC to DC converter to easily be

plugged into a 36 volt wall socket, and a 12 volt device - the most

common appliance voltage other than 120 VAC - can then be plugged into

the

converter's CAT socket.

The subject reminds me of

the fight between DC and AC power distribution at the beginning of

electrification. Once the diode had been invented to convert AC to DC,

the battle was over because AC could be converted to DC for appliances

(electronics) that needed DC. Once we had reliable DC to AC inverters,

it became still less of an issue. Now we have small, cheap, adjustable

DC to DC

down converters to readily get 24 or 18 or 12 or 5 volts from 28 to 40.

And that's well regulated voltages for computer power supply, etc, not

a raw "somewhere around there" battery voltage as with a 12 volt

battery.

Now the 12 versus 24 versus 36 versus 48 volts and higher

issue can be argued along lines of distribution wire sizes versus

safety.

Presently 12 volt appliances are next most common to 120

volts, but with standard HAT type appliance plugs, sockets and wall

receptacles

to facilitate adoption of 36 volts, that may easily become preferred,

and certainly preferred over 24 or 48(+) volts. (I recall a major auto

company (Ford?) had created a 36 volt gasoline car maybe 20 years ago.

It seemed curious at the time. They thought it would be better than 12

volts probably with reasoning similar to mine. But apparently it never

got onto the market. A pity!)

About mid month I noticed that with the 12 volt

"night-light" on "high" (a

whopping 10 watts or so) the little DC to DC got pretty hot. I ordered

some beefier adjustable DC to DC down converters with substantial

looking heatsinks. They were something like double the price - 5$

instead of 2.50$ area. Double insignificant is still not very

significant.

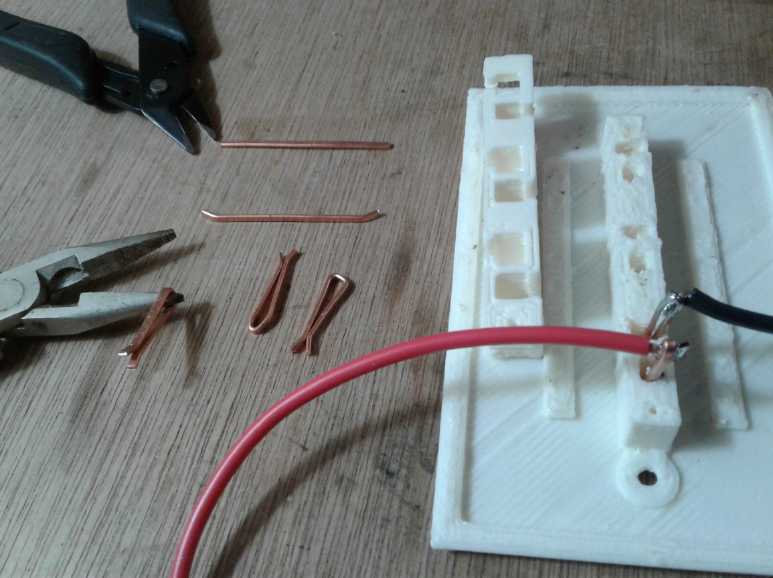

Instructions

Before delving into the diary of the development, here are

some instructions for making the sockets and electrical

box wall plates. Also and for the plugs, see the illustrations in last

month's issue, TE News #129.

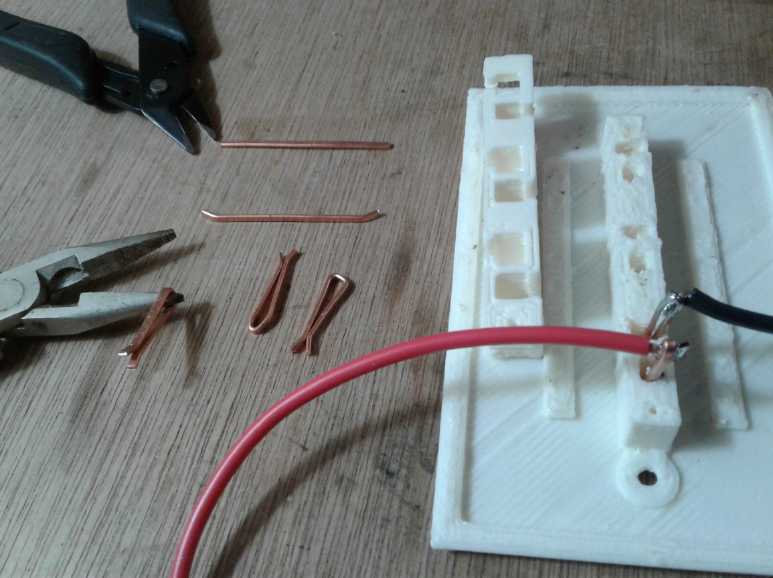

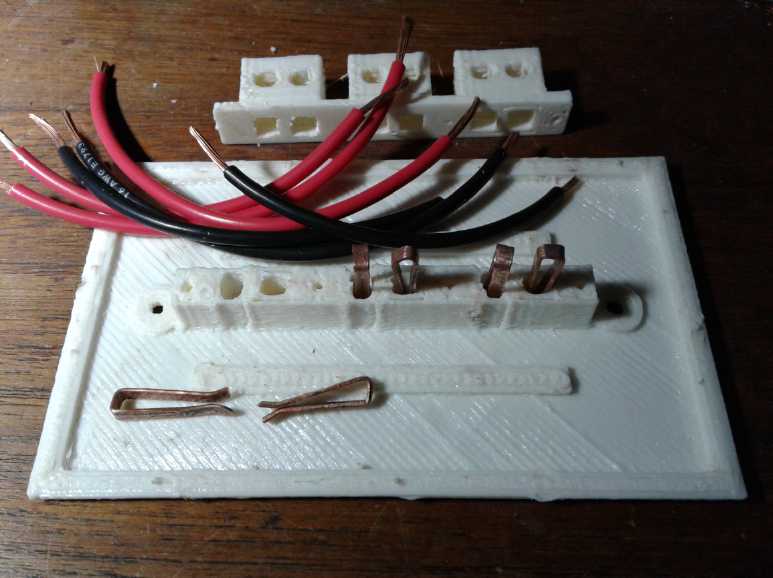

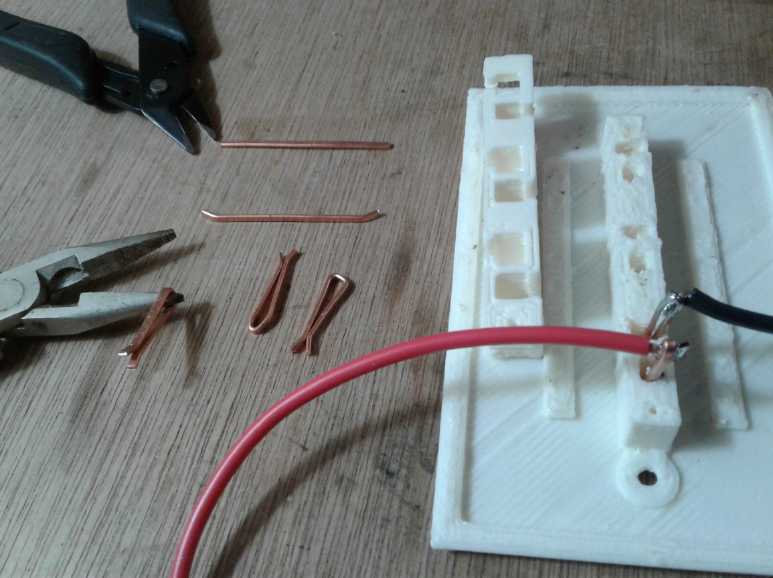

Socket "Hairpins"

1. Flatten a piece of #14 AWG (or #12?) with a hammer on some sort of

anvil.

This "work hardens" it as well as flattening it,

making it somewhat springy instead of limp.

2. Cut it into pieces about 44 mm long. If you're going to squeeze the

wire in (6), make it 40-42 mm.

3. Bend the ends over a little, about 4 mm long. This will end up as an

entry for the plug blade.

4. Bend it around a pair of needlenose pliers until the ends meet - the

"hairpin" shape.

5. Squeeze it just a little more with the pliers so there's a good

spring tension when a 1.25 mm flat blade is inserted.

6. Solder the wire into the inside of the fold.

The '-' wires have to

do a 90° bend right where they attach, best done before soldering.

You can squeeze the hairpin

turn around the wire to help hold it, but be careful solder doesn't

flow down the pin and close the gap.

The '-' wires have to

do a 90° bend right where they attach, best done before soldering.

You can squeeze the hairpin

turn around the wire to help hold it, but be careful solder doesn't

flow down the pin and close the gap.

7. Insert both/all hairpins into socket.

Close socket

and screw it

together or screw plate rear cover on. The hairpins & wires should

be slightly loose.

If they're tight, they can hold the rear cover off its seat or

cause bad connections. They can be trimmed a bit

shorter if necessary.

Close socket

and screw it

together or screw plate rear cover on. The hairpins & wires should

be slightly loose.

If they're tight, they can hold the rear cover off its seat or

cause bad connections. They can be trimmed a bit

shorter if necessary.

Now back to the month's sequence.

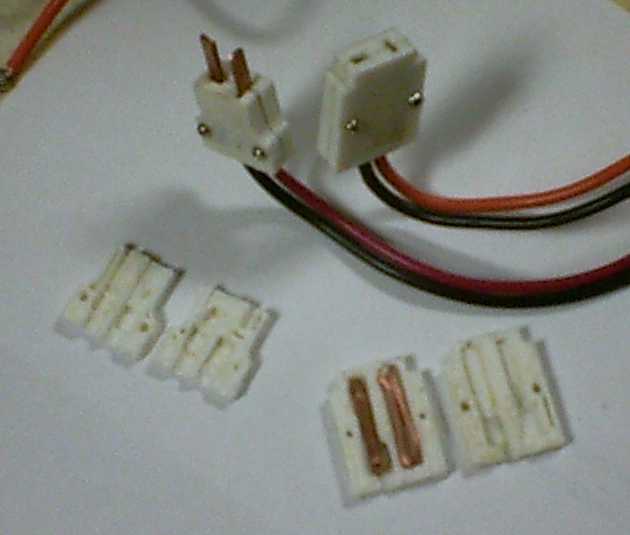

Revised HAT plugs and sockets

On the 5th I went at the revision to the shell design (not to the HAT

connection specifications themselves), to make more room for

the wires inside the shells. I decided to keep the 7.5 mm pin centers

spacing. I printed a socket, then a plug which looked good. The socket

had a misalignment so I went to reprint it. Try as I might I couldn't

get a good print. The piece kept coming loose from the bed. It was like

when I had first got out the printer in February and couldn't get it to

work.

I tried again on the morning of the 6th with the same

results. Suddenly I realized: I had put a new spool of plastic on. I

had thought it was PLA but it must be ABS instead. That explained

everything. ABS needs a higher extrusion temperature, and a much higher

bed temperature to stick on. I must have had ABS when I first tried,

too, and then for some reason I must have changed spools and got PLA,

and that's when it "mysteriously" started working. The first plug and

socket that I successfully printed were red PLA, which as I recall was

not the color originally in the printer. Now I wanted white and changed

spools - obviously back to ABS.

I should have paid more attention when I was buying them

that the spools weren't labeled. I could have labeled them then because

I knew what I ordered each time, but now they were all in one big box.

Printing ABS on the RepRap is a little frustrating because the bed

barely gets hot enough - usually not even quite up to the 110°C

setpoint,

and only very, very slowly. Then I remembered that putting a sheaf of

paper on the glass helps it warm up quite a lot. (Heating paper indoors

- yow!) If it's not hot enough, the piece comes off during printing.

And the printer immediately turns off the extruder and bed heat when a

print finishes, so if you're not right there to turn it back on, it

makes for another lengthy delay before the next print - before each

print.

Perhaps the new printer will do a better job of ABS? In

the meantime, it's too much trouble to figure out the software for the

moment. I just want to make some things, so the old printer it still is!

I

put on a print of 4 plugs, and made 5 plugs and 4

sockets total by the 6th. I can doubtless design better looking plugs

and sockets - and better CAT plugs and sockets - but for now these work

fine.

I

put on a print of 4 plugs, and made 5 plugs and 4

sockets total by the 6th. I can doubtless design better looking plugs

and sockets - and better CAT plugs and sockets - but for now these work

fine.

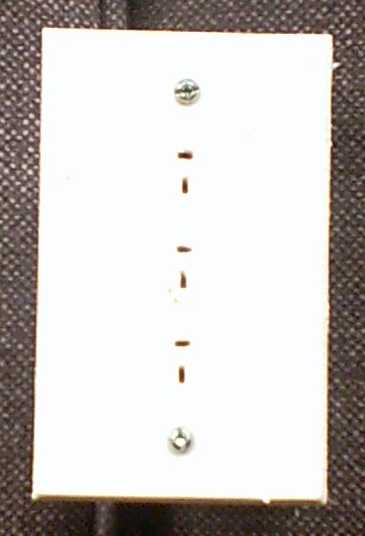

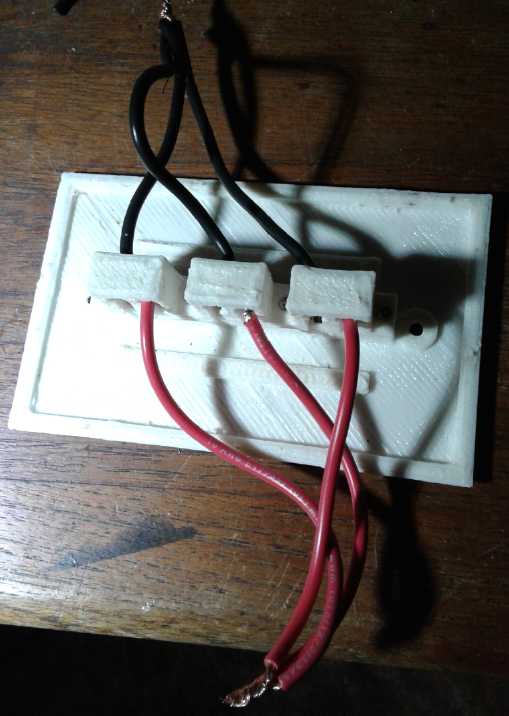

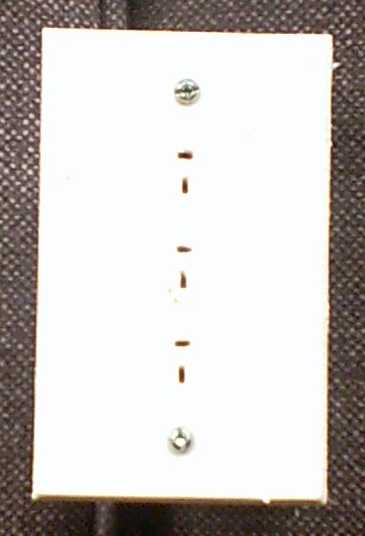

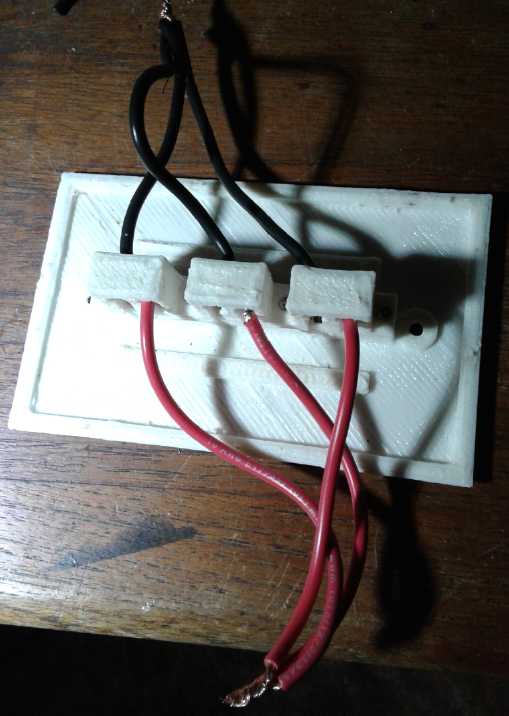

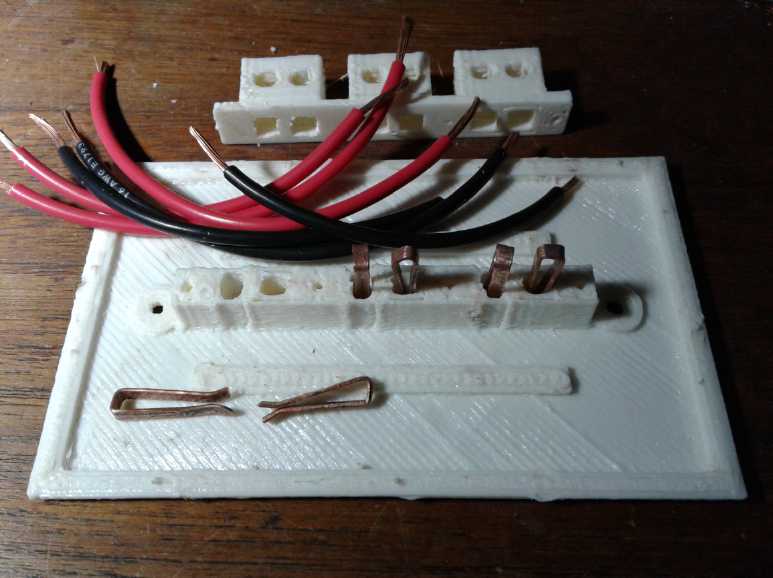

Wall Triple Outlet & Cover

Next the wall plates! Duplex? Triplex? Quadplex? Hexplex?

Nineplex? The only trouble with getting carried away is the need to

make contacts and wire all those sockets. Other then that, putting more

than two in a receptacle could, if one had enough devices needing

power, save a lot of power bars. Maybe a triple outlet would be a good

place to start? I got that made on the 8th. It just took a couple of

tries to get everything reasonably optimized, but before that it took

several hours defining every detail before trying. Then each print took

over an hour. So I only made one good one.

Next the wall plates! Duplex? Triplex? Quadplex? Hexplex?

Nineplex? The only trouble with getting carried away is the need to

make contacts and wire all those sockets. Other then that, putting more

than two in a receptacle could, if one had enough devices needing

power, save a lot of power bars. Maybe a triple outlet would be a good

place to start? I got that made on the 8th. It just took a couple of

tries to get everything reasonably optimized, but before that it took

several hours defining every detail before trying. Then each print took

over an hour. So I only made one good one.

I looked at it and thought it would be very easy to get

the plus and minus wires reversed. In fact, it would be a natural

because the shapes were opposite to the front: the 'plus' was in-line

and the 'minus' was crossways. I decided to to modify the design with

indents in the plastic: "-" and "+" signs on both sides of each socket.

The next afternoon I wired up the one I'd already printed. I

couldn't get the wires in and had to turn the wire holes into slots

with a hacksaw.

The next afternoon I wired up the one I'd already printed. I

couldn't get the wires in and had to turn the wire holes into slots

with a hacksaw.

At last it was all together and I

connected it to the

(disconnected) across-the-house line that was to be 36 volts instead of

12. I plugged

the DC to DC converter into it to check the fit. Then I went in the

garage and connected it the power. I went in the house and instead of a

working unit with a lit LED, there was the smell of fried electronics.

It was the DC-DC, which I hadn't unplugged. I checked the wiring for

reverse polarity. Nope. Nope. Aha! It was the wall plate itself. I had

fallen for the very trap I had envisioned and put the pins with the red

and black wires attached in the wrong holes!

The wall plates fit on standard "1110" type

electrical boxes.

The wall plates fit on standard "1110" type

electrical boxes.

(The one that's actually in use so far is behind furniture and anyway

just hanging in the air.)

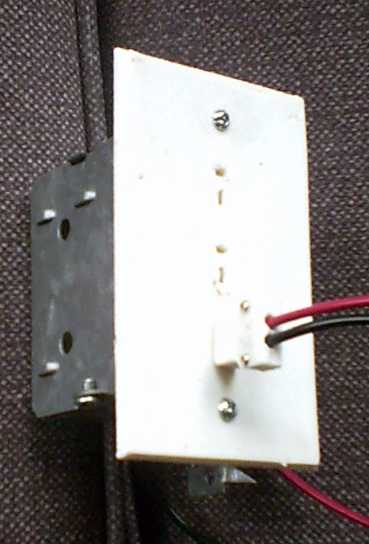

36 V DC System Breaker Box

But the wiring problem reminded me there was something

that should take precedence. There wasn't a single fuse or circuit

breaker between the batteries in the garage and the lamp plugged into

the DC-DC converter.

But the wiring problem reminded me there was something

that should take precedence. There wasn't a single fuse or circuit

breaker between the batteries in the garage and the lamp plugged into

the DC-DC converter.

The simple thing to do would be to install the same

breaker box I had used in Victoria, and which I still had and indeed

now had lying on the garage floor under the solar equipment. If it was

to be used for 36 volts instead of 12, it needed a few small changes.

Most notably, the 0-15 volt analog panel voltmeter would have to go.

(Why did I get that anyway?)

I had originally thought to put all the electronics in the

breaker box. Now the solar panels went to the programmable DC to DC

converter/charge controller and then to the batteries. It seemed

simpler to now just connect the breaker box to the batteries. The only

"extras" I put into the breakers box itself were a power monitor, an 70

amp Anderson "APP" connector to the 40 volt main, and a HAT duplex

socket with an ON-OFF switch on one. I'm sure the box is twice the size

it needs to be to easliy fit everything.

So: the 36-40

volt battery connects (-) through the current

measuring shunt to the main grounding block and (+) to a 50 amp circuit

breaker. This breaker's output goes to the main "bus bar" that all the

rest of the breakers connect to. There are presently 6 breakers

connected to that: 40, 20, 20, 15, 15, 5 amps. The 5 amp one goes to

the front panel HAT connector. The 40 amp one goes to the Anderson

connector. The rest are left for house circuits.

So: the 36-40

volt battery connects (-) through the current

measuring shunt to the main grounding block and (+) to a 50 amp circuit

breaker. This breaker's output goes to the main "bus bar" that all the

rest of the breakers connect to. There are presently 6 breakers

connected to that: 40, 20, 20, 15, 15, 5 amps. The 5 amp one goes to

the front panel HAT connector. The 40 amp one goes to the Anderson

connector. The rest are left for house circuits.

On the 11th I finished wiring the front panel stuff, and

mounted it on the garage wall. I plugged in the 36 to 12 volt converter

and a lamp with a 12 volt "corn cob" 'bulb', and the display showed it

used about 4-1/2 watts. I hooked up the wire to the livingroom as a 15

amp branch circuit. Then I plugged in the 12 volt adapter in the

livingroom. Then I plugged in 3 different 12 volt lamps sitting there,

and found their wattages. I had set the DC-DC to 13 volts, and I found

two 12 volt lights operated at far above their rated power: My homemade

lamp was 3.2 watts on "low" (my night-light), but 20 watts instead of

10 on "high", and a 15 watt flat panel was 30 watts. (They did however

give lots of light!) Only my own flat panel with the current control

circuit ran at about its rated 11 watts, and probably would have even

up over 15 volts. (Perhaps I should set the DC-DC to 12 volts instead

of 13? But "12 volt" lithiums would put out 13, as would well charged

NiMHs. Later I set it to 12.5 V and my lamp drew its rated 10 watts.)

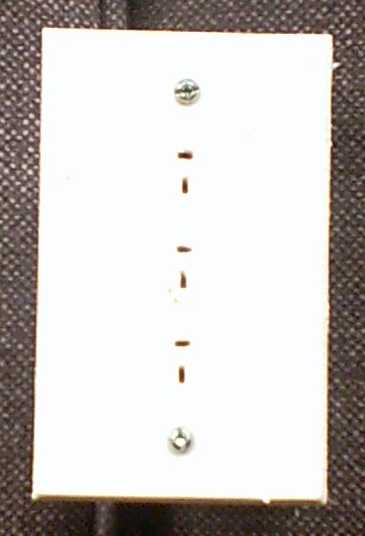

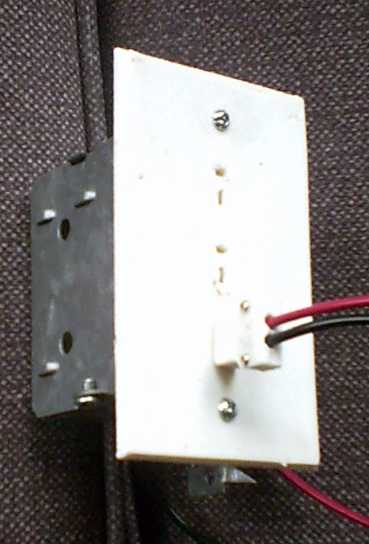

Special Duplex Outlet with Switch (as seen on breaker box, above)

Removing the analog meter from the breaker box plate left

a 2" diameter round hole. I thought of making a new plate and tossing

that one, or making a sheet metal plate to cover the hole. Then I

thought

that since I wanted a 36 volt HAT socket outlet on the breaker box

anyway for convenience, I would simply

make one with a round shape and use that hole. I spent over 2 hours at

it, but the print worked on the first try, and I had improved on the

design with the aforementioned wire slots. In doing this one I also

made it easier for

future wall plate designs to place individual outlets anywhere on any

plate.

When I went to wire this socket on the 11th, the positive

side was fine. But I had a very hard time fitting in the negative

wires. The negative socket "hairpins" made the soldered wire come out

in-line, and so it needed to be bent 90° in a very small space to

come out the side. The wiring spaces needed to allow for this with

space on the end and offset wire exit slots. On to "receptacles version

4" and another day of development! (Done.)

The switch

proved to be very useful. Later I mounted a panel light on the wall to

light the area better. If I had put a switch on it, it would have been

too high up to reach. So having the switch right by the plug proved

very convenient.

The switch

proved to be very useful. Later I mounted a panel light on the wall to

light the area better. If I had put a switch on it, it would have been

too high up to reach. So having the switch right by the plug proved

very convenient.

(It was a 24 watt panel, but I put in a resistor that was

a bit large and it used about 10 watts. It's pretty bright at that.)

Hole caps and glands

3D Printed glands and hole covers.

3D Printed glands and hole covers.

(The top left one is covering a larger hole in the top of the box.)

For ages I've bought plastic caps and through-hole glands

for wiring boxes. They never seem to come in the right sizes and you

never have the right ones, or enough of the right ones, for whatever

you're doing. So you leave holes with no caps on them, or stuff

wires through the bare metal holes with their sharp edges, meaning to

come back later and, by clipping it somewhere, flex a gland over the

wire and then into the hole.

I decided to do the breaker box up right. There were holes

with no circuit breakers in them. Enter the 3D printer and the brain.

Having done things one way all these years, it now occurred to me to

try the 3D printer. It was just the thing! I spent some hours at it,

but I covered all the holes with caps or glands. (which are almost the