Turquoise Energy Ltd. News #131

covering April

2019 (Posted May 6th 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In Brief

(Project Summaries etc.)

- Greenhouse and Garden - HAT36V-50A Plugs and Sockets - The Last

of the Month - Shingles! - Chemical-Free Iron Filter for Domestic Water

- Solar PV Hot Water Heating - To make the Main Hot Water Tank Grid

Plus

Solar - Turned the hot water tank to 1/4 power - Tugboat Solar Panels

- Ground Effect Craft (R/C Model) - Tesla 3 versus 2019 Nissan Leaf

(video) - Cigarette Lighter: 120/240 Volts AC Power From Any Electric

Car?

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Hearing Improvement - Shingles - The Weather - ESD

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle (R/C Model): Snail's pace but moving

* Car Charging Mystery Solved: There is no such thing as a 3 KW

charging station (they're 4 KW!)

Other "Green"

Electric Equipment Projects

* "Off Grid" (etc) 36 volt DC Infrastructure

* High Current HAT - 50 Amp Plugs & Sockets

* Today's AC Wire Color Conventions NEED TO BE CHANGED! and

unified with DC conventions

* Solar Water Heating: 36 volt water heater elements

* Hybrid system?

* Regular Hot Water Tank as Combo Solar 'preheat' and Grid Water Heater

* Chemical Free Iron Filters for (eg) Well Water

* Need for voltage controlled operation... & Components for that

* "Custom" Heatsinks for LED Lighting

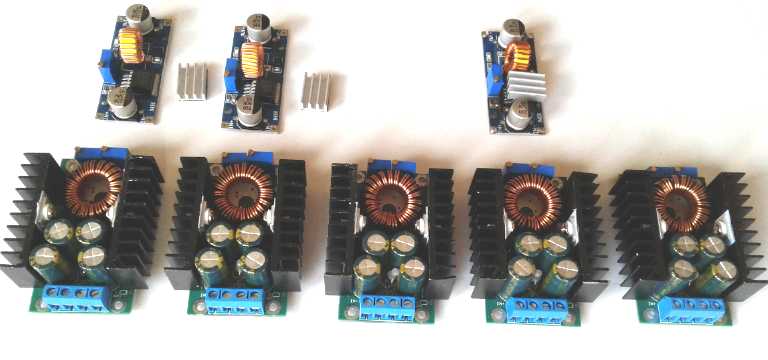

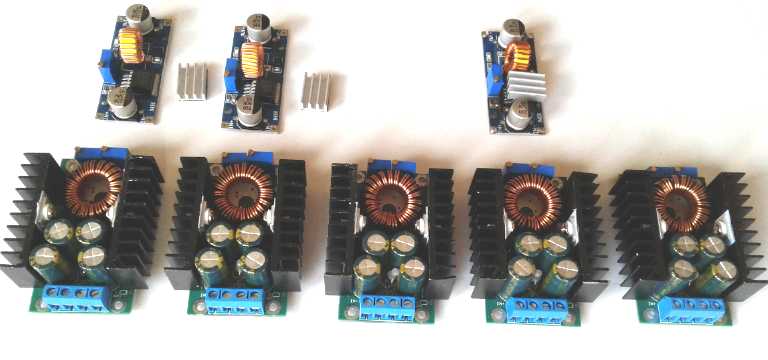

* DC to DC Down Converters to run 12-24 Volt Equipment From 36 Volts

Electricity Generation

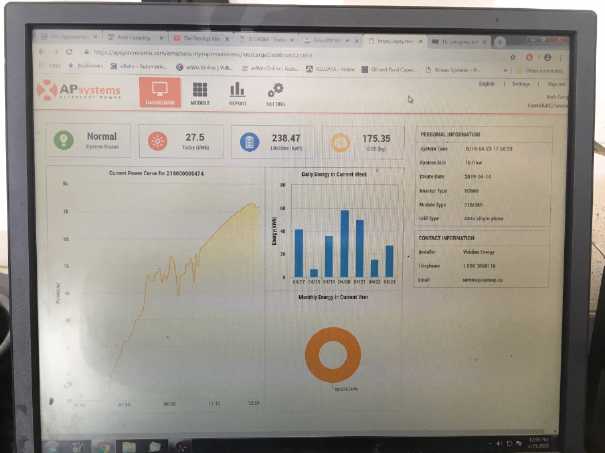

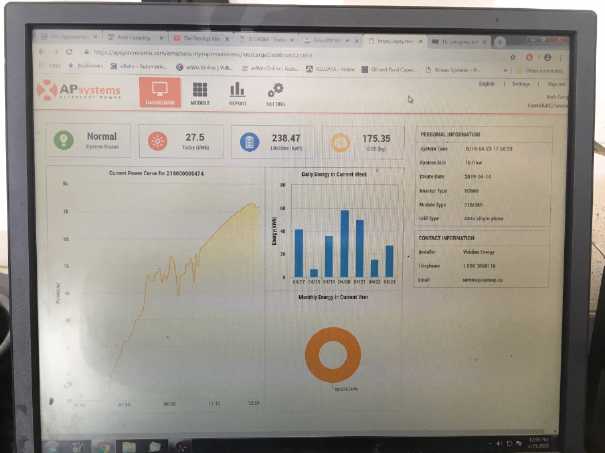

* Another month (April) of solar collector performance logging

* Another palette of solar panels ordered - watts, efficiency are still

creeping up: 315 W.

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Methyl

Hydroxide electrolyte)

* Nafion & Osmium Doped Acetaldehyde film Notes

* The Continuing Saga of the NiMH Dry Cells Car Starting Battery (a

little

repair and it still works great! - 7-1/2 years old now)

Sometime in April I got a little boat ride from Queen

Charlotte out to check a crab trap. There weren't any crabs, but I got

a couple of pictures of the town looking north from the water - a

little westward, and a little eastward. It's quite a "vertical" town

without extensive level ground anywhere and even steeper hills behind,

and so it's very much spread out east to west along the waterfront.

Greenhouse and Garden

I

finally got my greenhouse into "operable" shape at the start of the

month. In view of the food scarcity crisis now so obviously

looming for the next few months and a year or two (and even then, only

if there are no more catastrophes in the meantime - hah!), I spent a

lot of

time in April prepping beds in the greenhouse and the garden and then

planting things. (My garden dirt is largely beach sand except for

whatever I manage to fortify it with, so prepping it is extra

important.)

I

finally got my greenhouse into "operable" shape at the start of the

month. In view of the food scarcity crisis now so obviously

looming for the next few months and a year or two (and even then, only

if there are no more catastrophes in the meantime - hah!), I spent a

lot of

time in April prepping beds in the greenhouse and the garden and then

planting things. (My garden dirt is largely beach sand except for

whatever I manage to fortify it with, so prepping it is extra

important.)

I was afraid cold weather and dryness in the greenhouse

had killed my asparagus, but with warmer weather and some watering some

thin stalks started springing up. Nothing like a good eating size, but

at least some were alive. My apricot tree in the garden

looked dead, but it finally started budding by May. The other one, in a

large pot, started flowering early and may actually get fruit, along

with

the fruit trees I had planted north of the house when I first moved. I

had already been eating swiss chard still growing from last year, and

some spinach from the indoor LED garden. But other than potatoes, what

did I really have to make a meal of except some greens? My garlic

planted last fall was up, but all the "winter wheat" was a no-show. I

put in a small patch of barley in March where the quinoa had been last

year. At least that sprouted! I planted corn, but it hadn't done well

last year. I originally was going to plant it in the greenhouse, but

that was probably going overboard. It didn't fare well - I put it

outside too early.

Then I rototilled up a fair patch of grass (10x10 feet?)

and moss clods well outside my regular garden area. It was tough going

and I had to stop and strip the grass out of the tines a few times.

This was the sort of thing I wanted the CNC gardening machine for. But

it might not have handled it anyway.

I was going to plant barley there too, notwithstanding

that the deer might eat it. I couldn't find the barley seeds

(I can misplace anything, anywhere, anytime, better than most anybody

else.) so I dug up some from the small sprouting barley bed to thin

them at the same time. After transplanting to make two rows, it

occurred to me

that corn might be the best thing to plant there. I figured the deer

were unlikely to eat corn, and if I had a good amount, the raccoons

probably wouldn't manage to mutilate too many. (There seem to be far

fewer raccoons here than than in the city in Victoria. In fact I've

never seen any near my house.) So the rest of the bed got corn. A

day later three deer were wandering around the area munching. They'll

probably leave the barley until the grain is ripening, then gobble it

down. Hopefully the corn won't attract them.

Near the end of the month, I put a table inside the

greenhouse and painted the boards and plywood for the tugboat deck

solar panels. It was warm and the paint dried well instead of taking

days. I managed to avoid stepping in my asparagus, if only barely.

HAT36V-50A Plugs and

Sockets

HAT36V-50A Plugs and

Sockets

All this gardening was good exercise and may well pay off

later in the summer and fall, but naturally, it

ate heavily into energy project time, which seems to be in shorter and

shorter supply. I managed to design and make 50 amp HAT36V plugs and

sockets, but only by working on them late at night. And after designing

the sockets in 3D printed plastic, for such high currents that will get

very hot if there's a poor connection, I wanted ceramic socket shells.

That means making molds... and fixing the mini-kiln's burned out

element. The first mold didn't go well. I have a couple of possible new

plans. Later I started thinking that lacking the high temperature

plastics used by electrical manufacturers, even the 15 amp sockets and

wall plates should probably be ceramic. This will be a challenge!

The Last of the Month

I woke up on the 21st realizing that virtually 3/4 of the

month was gone with so little to show for it. All I had managed for

energy projects was the HAT36V-50A plugs and sockets. Where does all my

time go? I shifted focus and didn't get much more gardening done.

Shingles!

I felt something on the top of my head, but I couldn't see

anything under my hair. A minor bruise? A couple of days later I

couldn't

understand why it wasn't going away. In fact, had it spread? On the

24th there

were red blotches all over my forehead on the left side. It was

shingles. I

saw the doctor and got some "anti-viral" pills. I rubbed some butter on

the splotches. I'd heard it was helpful or at least soothing. After

that I mostly stuck around home as I was apparently contagious for

chicken pox

- same virus. I went out occasionally for groceries and mail. (Long

version see "In Passing")

Chemical-Free Iron Filter for Domestic Water

But I saw my neighbor (he'd already had chicken pox), and

he mentioned finding out about air injection filters that would get rid

of iron from water without added chemicals. What commonly happens in

many areas (eg, all around this area and in Tlell) is that iron-rich

well water looks clear, but it has dissolved iron II (ferrous) ions in

it. These soon change to insoluble ferric (III) form after they come

out of the tap into air - yellow to red rust - and stain everything.

That's why I've wanted to catch and use rain water for dish washing.

These new(?) filters inject air as the water comes up from

the well pump. So it (mostly) converts to ferric form there, before the

main filter. This is filtered out in the regular sand filter instead of

entering the house water. It seemed "Rainfresh" was a good brand. I

ordered one to pick up in-store at Home Hardware in Masset. (Best

price, too: ~1000 $. Still, there go my savings from not being on

pricey city water any more!)

Solar PV Hot Water Heating

1200 Watt, 36 Volt Hot Water

Tank Heater Elements with

1", 1.25" threads. The multiple elements can be separated.

One is thus 600 or 1200W and the other is 400/800/1200.

That was a thrilling discovery. It changed the

way I want to do the solar water heater for under the kitchen sink.

I'll just connect the 4 gallon tank to the regular house plumbing and

not to rain water barrels - a great simplification!

That was a thrilling discovery. It changed the

way I want to do the solar water heater for under the kitchen sink.

I'll just connect the 4 gallon tank to the regular house plumbing and

not to rain water barrels - a great simplification!

Making the Main Hot Water Tank Grid Plus Solar

And now I'm starting to have the ambition to disconnect

the lower element in the house hot water tank and replace it with a 36

volt, lower wattage heater. Thus the bottom half of the regular tank

replaces the usual "solar water preheat tank", and is heated by solar.

If that doesn't heat it enough, when hot water is run and the cooler

water moves upward, the top element will ensure there's 1/2 a tank of

hot water. That way that project involves no plumbing except installing

the new heater element.

The problems with the present arrangement are: (1) With

3000(?) watt elements and only 1900 watts max solar power for all

purposes (on a sunny day), most of the water heating is done very

quickly without much time for the solar to help. If I could even find a

low wattage 240 volt element, the grid tie inverters could supply much

more of the slower heat without changing anything else or adding

wiring. (2) If the power goes off for quite a while there'll be no hot

water for the shower. (I don't fancy carrying buckets from the kitchen

sink.)

Setting the hot water tank to 1/4 power

As I was

editing the above paragraph (on May 4th) an

interesting thought occurred to me: In the breaker panel, disconnect

one wire from the double breaker and connect it to neutral. Then the

tank would get only 120 volts instead of 240. Since the only things in

the tanks are the thermostats and the heaters (no electronics, etc),

these would be running well below their maximum ratings. I couldn't

think of much that could go wrong. The elements would run at 1/4 power:

750 watts each instead of 3000. If there's solar power available, it

should easily supply 750 watts instead of 1500 to 2000 of the 3000

coming from the utility. The water will (eventually) get hot

regardless. That seemed so simple I did it that day.

As I was

editing the above paragraph (on May 4th) an

interesting thought occurred to me: In the breaker panel, disconnect

one wire from the double breaker and connect it to neutral. Then the

tank would get only 120 volts instead of 240. Since the only things in

the tanks are the thermostats and the heaters (no electronics, etc),

these would be running well below their maximum ratings. I couldn't

think of much that could go wrong. The elements would run at 1/4 power:

750 watts each instead of 3000. If there's solar power available, it

should easily supply 750 watts instead of 1500 to 2000 of the 3000

coming from the utility. The water will (eventually) get hot

regardless. That seemed so simple I did it that day.

Before I closed the breaker box (what neat wiring), a

clamp-on ampmeter read

about 6.15 amps. 6.15 A * 120 V = 738 W. Well, that certainly was the

simplest of projects! With only one of me living here, I can't see

running out of hot water in spite of the slow recovery it will have.

(I'll find out soon enough if I'm wrong.)

The difference now between this and rewiring the bottom

element with a 36 volts specifically solar circuit is that the solar

circuit would heat the bottom half of the tank only with

available solar power, even if it means leaving it cold all night. But

it would also heat the tank even if the grid was off.

Tugboat Solar Panels

On the 25th and 26th I nibbled away at the triangular

holders for the solar panels for the tugboats, to keep their batteries

up and the bilge pumps working. I should have finished that - at

least - 2 or 3

weeks previously. It was mostly a wood construction and painting

project. That didn't enthuse me much. Installation - wiring to the

charge controller and

battery below - shouldn't take very long.

Ground Effect Craft (R/C Model)

On the 26th I (finally) cut some 2-1/2" wide pieces of

styrene foam for the

bottoms of the hulls of the RC model ground effect vehicle, and on the

27th glued them together. Then I managed to cut and glue some more

pieces at the front and back. The beginnings of a shape are finally

starting to emerge. Next: the spars for the wing, which is also the

"deck" between the two hulls.

The two hulls for the ground effect vehicle

model take shape,

The two hulls for the ground effect vehicle

model take shape,

from polystyrene foam glued with epoxy resin. - Bottoms

Right way up with fronts filled in.

Tesla 3 versus 2019 Nissan Leaf - video

A father and son team with a garage, decided to compare

two new electric vehicles, Tesla 3 and 2019 Leaf, by taking them on the

same trip 75 miles

each way on the highway including up and down a mountain in

Colorado. The longer range Tesla was charged to show the same number of

miles of "range remaining" as the Leaf. Off they went. "Dragging" from

a stop light

up to the speed limit of 55 MPH, the Tesla pulled way ahead of the

Leaf. (They have scary power!) Both cars left all the gas cars far

behind.

The Tesla seemed to have everything calculated out for

mileage. As they went up the mountain, its "remaining range" indicator

dropped a mile per mile driven. The route was plugged in and it knew

the car would come down again. The Leaf just calculated by power being

used, and the "remaining range" reading ("at the rate you're using

power...") dropped 2 or 3 miles per mile driven. By the top of the

mountain pass, it said only 80 miles left - hardly enough to get back.

Going back down, the Tesla continued to drop mile for mile, but the

Leaf's range estimate was rising (to well over 100) as the power

regeneration refilled the batteries. (As a Leaf owner myself, I was

sure it

would.)

The comparisons when they got back to the shop were

interesting: Both vehicles said 82 miles range left. Both said "20

hours to charge". And both had used 272 watt-hours per mile. (The trip

being high-speed highway driving up to 70 MPH, a lot of the power would

have gone to wind resistance. Slower speeds would have used less power

per mile. An EV-1 with its extra low wind profile would also have used

substantially less.)

Cigarette Lighter: 120/240 Volts AC Power From Any Electric Car?

I have the 36 volt converted Sprint ready to plug into the

house solar system, either to charge it, or as extra stored power if

needed. With a commercial electric car it's trickier. No doubt the car

makers don't want the batteries risked in unknown "off-grid" power

applications, and they don't provide a means to use them that way. But

here's a way

that should work with most any electric car: You can get small power

inverters that plug into the car's lighter socket, to provide 120

volts.

(or I presume 240.) At least for the Nissan Leaf, the car must be

turned ON so that the main batteries will keep the 12 volt battery

charged.

I don't suppose cigarette lighter inverters are very high

watts, so heavy loads are out. And I don't know how

much the car uses for itself sitting there turned on. But it's

something that could presumably run small 120 V items away from mains

power if

needed, and no doubt for a very considerable period of time before

killing the batteries.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Hearing Improvement?

It is generally accepted that hearing deteriorates with

age, and that there's nothing that can be done about it except to avoid

loud noise. Was that really true? On the face of it it seemed to be.

I've never heard anyone say, "Oh, my hearing was pretty poor, but it

got better in my fifties." From past hearing tests I know my own

hearing has deteriorated over the decades. I know from my last hearing

test (I think it was 2012) that I had lost more from making and tuning

recorders (the

flute instrument) between 2004 and 2007. My hearing somewhere around

the 2000-8000 Hz

range - the range for hearing what people are saying - had gone from

one step above to the top of "impaired".

However there are many things that we are told and that we

accept without question, which turn out not to be absolutes. Arthritis

and osteoporosis, "incurable" bugaboos of "old age" until recently and

even now among the many who haven't heard, were discovered to be mostly

caused by boron deficiency, and taking borax cures it like vitamin C

cures scurvy. (There are various rather similar water-with-borax

formulas on line.)

If you don't look for answers, you're not likely to find

them, especially if few others have searched either, so any knowledge

there is is not being shared. I searched on something like "hearing

improvement" on youtube. That brought up an

odd video with synthesized voice that said to put drops of garlic juice

mixed with oil in your ears. It was pretty vague on details, but

somehow I got a sense that they might be onto something. How might one

more directly affect the ears than by putting something in them? Was it

like a vitamin? Did the oil give the little vibrating hairs a rest? Did

it clean the wax out? I decided

to try it out in my left ear, which if anything seemed to be poorest.

The video said nothing about time or applications. One

application certainly did nothing. Disappointing

perhaps, but to be expected. If it worked like that, everyone

would be raving about it. Like arthritis, one doesn't (normally) get

bad hearing ovenight, so why would one expect to cure it overnight?

After crushing garlic and mixing the juice with oil

a couple of times, I dispensed with the garlic. For a while I used

peanut oil, then I switched to olive oil. I don't know if one oil is

better than another. The peanut oil seemed to drain out a bit more

readily.

You have to find just the right place at the back at the

top where the dropper can be put in farther (just a little

farther, no more!), and the oil goes right into the ear. I just squeeze

the dropper slowly until it sounds like I've gone underwater. It's just

a couple of drops. Then sometimes I roll up a bit of tissue and put it

in my ear, and often I get some oil on it. Then I just let it drain

out. If I put my little finger into my ear, even hours later, it often

comes out oily. I've now been trying it for probably 3 or 4 months,

usually once or twice a day but missing sometimes. (Rats, I've kept no

record of when I started.)

In recent weeks I started noticing frogs croaking. They

have a high pitched sort of "chirping" to their sound and they go on

and on (until they all suddenly stop at once for a while, for no

apparent reason), so it makes a good test. First I noticed it lying in

bed with my left ear up. Was I hearing this faint sound from outside

more than usual? I turned over and I had the impression that the higher

parts of the sound - where the tests had said my hearing was poor -

were more subdued with my right ear. I continued with the oil and by

the end of April I think I can pretty safely say that if I plug

my right ear and listen with the left, the sound has more treble

"presence" than through my right ear alone. I have the impression I

hear more frogs, some from farther away. Listening to a couple of other

things, power pole transformer hum seemed no better in my left ear, but

some heavy machinery in the distance was definitely clearer.

I probably lost my several hearing test result cards from

the late 1980s and early 1990s and the one from 2012 when I moved to

Haida Gwaii. At least, I've looked in the drawer where I once kept them

(so long ago) and have no idea where they went. (I wonder if they're

still on record at Island Acoustics?) But I have a fair memory of what

the charts looked like. They weren't very good, and the one from 2012

was worse as mentioned. If a test would show the left ear improved over

the previous test, and over the right ear, that would be definitive

proof. As it is, it's what and how I think I hear - subjective

evaluation that's says "I seem to hear better" and I think

I know roughly what a chart would look like, but it can't be quantified

in decibels and I'm not absolutely sure it's any better at all.

One disappointment of note: So far I have not noticed any

change to my tinnitus.

I called the clinic. If they do hearing testing it would

be silly to not check it out. An audiologist periodically comes to the

Skidegate Medical Clinic. He had just been there. I can book an

appointment for next time, in August. Well, that gives over three

months to apply more drops in just my left ear, to have an even more

certain idea that it's improving.

Shingles

The virus that causes Chicken Pox usually hits when one is

young. (It is in fact more serious if it strikes when one is older -

notably it can cause sterility.) Once you've had it, you're immune. You

don't get it again. But they never completely die off. Apparently they

eek out a living in the skin or away from the body's main immune

defenses. And they can cause "Shingles" later in life - nasty red

splotches that hurt like heck. Variously, they tingle, feel like you've

been stung by a wasp or have been hit with something. And in fact the

skin all around seems to all be sensitive to an extent even where

there's no splotch. They somehow follow a nerve, and affect the skin

only where that nerve surfaces. This is good, because I'm sure it would

acutely serious to fatal if they spread everywhere. One area is plenty

bad enough. I've heard it can stick around for months. And if it gets

in your eye, it can blind you.

None of this was on my radar screen. One day my head hurt

in a couple of places, but I couldn't see anything under my hair and I

payed it little attention. I had bumped my head a couple of days before

- lightly I thought. Must be a bruise? taking so long to start hurting?

This went on a couple more days and I started to wonder. And had it

spread? The next morning there were red splotches all over the left

side of my forehead.

I still had no idea what it was. I went to the pharmacy

and the pharmacist thought it looked like shingles and that I should

try to see a doctor. Luckily the nurse decided I'd better see the

doctor on duty before she went home after she finished with two or

three emergency patients. So I waited. The doctor was very concerned

because it was so close to my eye, and did a retinal exam. She

prescribed me "anti-viral" pills, which I had never heard of before.

These apparently are specific to various viruses (and yes, there seem

to be some for flu, but dubiously effective). They stop the virus from

multiplying rather than killing it outright. Herpes and shingles have a

certain enzyme targeted by the pills. If I had taken them sooner the

whole thing might have been much milder. I got back to the pharmacy

just in time to get the prescription before they closed.

Somewhere I had heard of putting butter on the splotches.

I started doing so. I thought it might merely alleviate the pain. But

I'm starting to think there's more to it. The virus can't give you

Chicken Pox twice because your body has built up an immunity. So to

cause shingles the virus is recurring at some weak point in the body's

defenses, which somehow involves the skin and a nerve. On the outside,

the virus has access to the air, away from the body's defenses. By

greasing the skin, that access is blocked. Some sorts of skin nasties -

mites?, scabies?, bacteria?, fungus?... and shingles/chicken pox virus,

might just be suffocated or "drowned" by or in butter. What besides

butter might work? Oils and margarine would probably soak into the skin

and have no lasting effect. (Who would want to use automotive grease?)

Maybe lard, or vaseline? Butter is probably pretty neutral and mild,

and it washes off easily with soap or shampoo. Perhaps it's unique?

Later someone told me there was a special cream for shingles, Capiscum.

(Why wasn't I told about it at the clinic or pharmacy?) From the

description it sounded a bit harsh.

The rubbing to apply it hurts, but is probably helpful in

itself. (Brushing or combing my hair, or even anything touching the

left side of my head, is excruciatingly painful. Improving by May 6th.)

The doctor had me come in the next morning for another

retinal exam, which seemed okay - somehow better than the previous

evening. She said something about some eye drops, Polysporin with

antibiotic. But the lowest splotch was above my eyebrow. I didn't think

that was close enough to worry. Over the weekend a new red splotch and

some swelling appeared right over my eyelid. On Monday morning I drove

into town and got the Polysporin and immediately went into the washroom

and dropped in the drops. I should have bought it in the first place,

just in case! No doubt I should have been taking them regardless of

where the shingles was. Anyway, nothing seems to have happened. I went

into the post office to get my mail, and a lady waiting there for

something told me a horror story of someone who had got it in their eye.

Two days later on May 1st (after a week) I ran out of the

antiviral pills, and the shingles, while somewhat improved, definitely

wasn't gone. (and it looked like so many pills... but the dose was two

at a time, three times a day, so they disappeared fast.) Being pretty

sure they were helping, maybe a lot, I went back and got the

prescription renewed. I know at least with antibiotics you shouldn't

quit taking them in the middle, and I could see the virus coming back

with a vengeance with no more antivirals, to last for the reputed

months of shingles - with the ever present threat of getting some in

your eye(s), perhaps by rubbing or scratching your affected skin and

then rubbing your eye.

As of May 2nd, the red splotches were shrinking. A couple

of people asked why I hadn't had shingles vaccine. I had never given it

a thought. One person was currently one needle into a two needle

immunization. She didn't know if she had had Chicken Pox! Can they

really give you shingles vaccine safely without you first having had

that? But apparently the shingles vaccine is only good for a limited

time anyway, albeit for some years. And there's no point having it for

a year or so after having shingles.

The Weather

The weather is everywhere - globally - heading into

extremes. Although poorly reported on the mainstream media except

locally, weather stories saying "record breaking" and "unprecedented"

are all around us. The more than severe flooding in the central USA,

Queensland (Australia) and Mozambique was repeated in Iran,

Argentina, South Africa, and Ontario (Canada). Elsewhere there are

droughts, snow, record lows, record

highs, hurricanes, tornados and hail storms with pellets so huge they

kill both small and large animals.

IMHO the major cause of all this is geoengineering and

especially the "chem spraying" - the huge project making of cloud cover

at extra high altitudes all over the world. In most any outdoor photo

anywhere nowadays one can see spreading jet trails in the sky in

the background. The climate will probably just continue to get worse

until this absurdly unsound attempt to reflect sunlight away "to

reduce global warming" is ended.

Then we note mass die-offs of life daily or even more than

one daily around the globe. And it's not just fish, sea birds and

dolphins now. Insects are under threat with the monarch butterfly in

danger. "Colony collapse disorder" is happening to honeybees and

biologists have become worried that the entire genus "bumblebees" may

become extinct. Nicotinoid insecticides appear to be largely to blame.

Then, the numbers and variety of amphibians has shrunk to half globally

and

is still shrinking rapidly. They are being called "The canary in the

coal mine." I don't even remember the horrific estimate of the number

of species of life going extinct.

Who would have suspected that life on Earth as a whole

might become so endangered without a nuclear holocaust?

Here on Haida Gwaii pretty normal rains come down ("drier

than usual" is actually more pleasant here as long as it doesn't extend

to drought and forest fire). The bumblebees buzz in the dandelions

and in almost a swarm in my big flowering currant bush, and the frogs

croak up a storm all

evening in a nearby swamp. Chemtrails only dull some otherwise sunny

days. The location out

in the Pacific ocean is probably favorable. Then there's the fact that

there is no "big agriculture" with pesticide and herbicide spraying

here, and the small population is not making every possible speck of

land ideal for humans or crops at the expense of everything else. And

the

Haida having taken much local control of the fisheries, the sea is

probably better managed here than most places. They've closed even some

of their own favorite fishing spots to make safe places for marine life

to reproduce and thrive. Some of the global die-offs of starving marine

creatures and sea birds probably indicate that the whole ocean is being

seriously fished out,

but fishing is good here.

ESD

(Eccentric Silliness Department)

Philosophy: There's no point getting up on a ladder and cleaning your

gutters if it isn't pouring rain.

Someone said "preppers" are keeping the economy going. The economy is

so bad they're the only ones in the lower 75(?)% of the population

still buying things they don't immediately need.

Failed company slogan (it came back to bite them): "At Eclar fresh

produce, we put the asp in asparagus"

Instractions: instructions that distract the mind from actually getting

the job done. (eg: wading through the first five pages of safety

warnings.)

Neighbot: the robot horse next door. (Ooh those typos!)

Prepeat: Hmm, this one-word oxymoron just seems to defy definition. The

time just before hearing the same story over again?

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground Effect

Vehicle (R/C Model)

A catamaran doesn't look

much like an aircraft. Yet one can find videos of radio controlled

(R/C) models of this sort flying - mostly just above the ground, but

also up into the sky. For real life transportation, I don't think we

even want something capable of flying up into the sky. I'm hoping this

won't even need an elevator, although I'm putting one on the R/C

prototype. Ideally it will just be that if the throttle is pushed far

enough forward, the vehicle will rise and float over top of the water

instead of in it, at very high speed because of the reduced friction.

(I would be unhappy with less than highway speeds, with very low energy

consumption.) "Landing" is just lowering the throttle until it settles

back down. No aircraft pilot skills should be required. (And we

certainly don't want to attract the attention of federal aircraft

regulatory agencies!)

I finally got

back to this

near the end of the month. On the 27th I mixed epoxy and glued on the

bottoms of the hulls.

I finally got

back to this

near the end of the month. On the 27th I mixed epoxy and glued on the

bottoms of the hulls.

The "step" hull is ubiquitous in water take-off craft. As

speed increases the whole rear end lifts out of the water and more and

more the craft is planing just on the area in front of the step, with

less and less water friction until take-off. Then, flat bottom hulls

pick up speed and plane on the water considerably more easily than "V"

hulls. It's just my own supposition that this will make for easier

take-offs with less power.

In an aircraft the bottom profile behind the step gets

higher (farther from the water) toward the rear so it can "nose up"

without them hitting the water. In this design, the rear of the wing

almost touches the water too, which will lift the rear. In fact, the

back of the wing will surely be immersed before starting the takeoff

run. Here we don't want it to fly up into the sky, only to get it

"floating" above the water's surface.

Piecing the Pieces

Piecing the Pieces

Epoxy curing in the warm

greenhouse

The following

night I cut a bunch of little

pieces to do the curves around the fronts and along the tops to where

the

front of the wing starts. And a couple of pieces to fill in the backs

of the hulls to the point where

the wing becomes the elevator. This was all made with styrene foam. On

the 29th I glued the pieces to the hulls.

The following

night I cut a bunch of little

pieces to do the curves around the fronts and along the tops to where

the

front of the wing starts. And a couple of pieces to fill in the backs

of the hulls to the point where

the wing becomes the elevator. This was all made with styrene foam. On

the 29th I glued the pieces to the hulls.

The hulls are

to be covered with a thin sheet of epoxied PP cloth. (This needs to be

done if only to cover up that smug "pink panther" picture printed on

the foam.)

The hulls are

to be covered with a thin sheet of epoxied PP cloth. (This needs to be

done if only to cover up that smug "pink panther" picture printed on

the foam.)

Epoxy Techniques: I mixed the epoxy and painted it on in the rather

cold shop. (13°C?) One can be sure the epoxy did very little

setting in there. Then I put the pieces out in the warm greenhouse with

the sun

on it (yay, there's sun!) to set in a reasonable length of time.

(25°C?) For the bottoms I left them overnight with weights on them.

I wanted it all securely hardened into place since the sides wanted to

warp into curves and would probably peel off with the slightest

opportunity.

The unused epoxy and the brush go in the

freezer between sessions. At -18°C they only last a day or two. In

my present freezer at -22° to -25, they last several days.

The spars for the wing, which also hold the two hulls

together, would be spruce. I didn't get started on that part. I needed

to figure out how tall (wide) each spar should be to make the right

wing profile as well as how many spars to put on. And it must be

remembered that unlike a deck, the wing will be lifting the whole

vehicle, not just sitting pressing down on the hulls. That will require

different reinforcement - especially in the full size vehicle.

On May 3rd I measured the wing thickness off the diagram,

which was based on printing out the profile sent to me by John Ryland [

RylandResearch.co.uk ], and came up with a table:

Inches from

Front - wing thickness/spar width

00" - 0

0.5"- 0.84"

01" - 1.29"

06" - 1.56"

12" - 1.65"

19" - 1.80"

25" - 1.70"

32" - 1.35"

Behind 32" (to 38") is the back of the wing and the start

of the elevator. I was surprised by how wide the spars were to be. I

guess the key to lightness is to keep them thin front to back.

An Electric Amphibious

Aircraft - New Design (Let's see... if I put wheels on mine... you'd

still need to use a boat launch ramp

because you couldn't get over the fence to an airport. But maybe it

could be its own trailer?)

Is it even conceivable I could make anything that looks that slick? I

should probably at least try for that skin smoothness.

There are some

electric airplanes being made now including amphibious ones. One of

them is to be tried on the Victoria-Vancouver run. I salute that

effort! The whine and smell of the float planes all day was just a

small one of several things that were making life in Victoria less

pleasant and helped spur my moving to Haida Gwaii.

There are some

electric airplanes being made now including amphibious ones. One of

them is to be tried on the Victoria-Vancouver run. I salute that

effort! The whine and smell of the float planes all day was just a

small one of several things that were making life in Victoria less

pleasant and helped spur my moving to Haida Gwaii.

(Warning: Digression! Much worse was

Telus

putting an equipment box with 24/7 ever-whining fans on my boulevard

right

outside my formerly quiet back yard in 2009. Did I have to live with

that for the rest of my life? And BTW they tried to rip me off - kept

billing me monthly and pretended not to know - when I switched to Shaw.

Even tho they cut the phone line off from their office. I found

out they were doing that to everyone, and of course most people

wouldn't know how to test the line and so couldn't dispute it with

them. People should have gone to jail for that scam and

betrayal of public trust (especially the CEO, I'm sure - these things

aren't authorized from the bottom!), but I'd be most surprised to hear

anyone did. But I digress.)

I'm becoming more keen on making the full size manned

vehicle electric. If it couldn't fly to Prince Rupert, there are still

a number of very

interesting local trips it could take. Seen flying around and videoed

it should be at least a demo of the potential and hence an inspiration.

Then again, if someone

can do a commercial electric float plane on the Victoria-Vancouver

route, or make an amphibious aircraft that can fly for an hour, and if

the ground effect vehicle really uses 1/4 or 1/3 of the energy of an

aircraft, perhaps the potential for a couple of hours flight to reach

the continent is

there even with present day batteries? Might it really float on the air

so effortlessly just above the waves?

Car Charging

Mystery Solved: There is no such thing as a 3 KW charging station -

They're 4 KW

After a trip the car dash would indicate numbers along the lines of:

"Time to Charge / 6 KW - 3:00 hrs / 3 KW - 3:30 / 120 Volts - 9:30".

Why should 1500 watts take more than twice as long to charge as 3000?

And why was there so little difference between 3000 and 6000 until the

car battery was very low?

I had assumed from the times shown that at 120 volts the

charge

was only at around 1000 watts (eg, the Miles truck is 1100 W). But when

I put a power meter on it, I found it was drawing the full 1500 watts

allowed on a regular 120 volt circuit. That's fully half as much as

3000 watts. Counting tapering off near the end of the charge, it should

be less than double.

Finally I looked online and found a table of charging

times for various vehicles with various chargers. There is no 3 KW

charger! The lowest one shown other than 120 volts, was "3800 watts"!

That explained the discrepancy. The used charger I bought had been sold

to me as "3 KW", and "3 KW" was what it said on the dash of the car.

Looking at some fine print on the side of the "3 KW" charger, it didn't

say anything about power, but it said it drew 16 amps continuous. 16 A

* 240 V = 3840 W. That's virtually 4 KW, not 3!

Based on the erroneous "3 KW" figure being bandied about

everywhere and nowhere contradicted, I had installed it with #14 wire

and a double 15 amp circuit breaker. It should have had #12 wire and a

double 20 amp breaker. I suppose the #14 wire gets pretty hot, and it's

a small wonder the breaker doesn't keep tripping.

I am appalled that this false figure is being perpetuated.

Here it has needlessly caused a reliability and safety issue, and

really I should rewire the whole thing. (Lucky I didn't refinish the

wall I had to rip apart to put it in.) How many other DIYers have just

accepted "3 KW" and done undersize wiring?

A new mystery now appears: The car takes more

kilowatt-hours to charge than it says it used. It might say after a

trip, for example, that the average was "7.2 Km/KWH". So if I

drove 55 Km, the car should have used 55/7.2=7.6 KWH. According to

that, the car should take a little over 5 hours to charge. Instead it

says "9 hours to charge" at 1500 watts. That's 13.5 KWH. Charging seems

to taper off in the last hour, so call it 13 KWH. Another reading says

"52% charge remaining" - from 24 KWH batteries, that indicates 11.5 KWH

used. Either way that's almost double what it says it used in the

"energy economy" section. I don't know if it takes 9 hours to charge,

but it certainly takes more than 5.

Other

"Green"

Electric

Equipment

Projects

36 V DC "Off

Grid" Infrastructure

Looking on the "Dernord" pages for low voltage water

heating elements I noticed that there was a "Number of Orders" below

each model. I tallied up the orders for all models of DC heater

elements on page 1 and found:

* 12V (445 orders) is incomparably the most common

* 24V (89) is next most common

* 36V (34) is the least common but by no means rare

* 48V (59) is third most common

There were no elements for any other specified voltages below 120 volts.

I'll take a guess that those running 36 volt systems are

those who are like me more prudent (or less sporting?) who wanted

higher efficiency but didn't want to go to the somewhat dangerous 48

volt level. Or perhaps they've noticed that you can readily buy cheap

DC to DC down converters for up to 40 volts input for running 12-24

volt equipment, but not for 48 volts.

Manual Method of Switching from "Regular" to "Grid Down" Operation:

Automatic versus Manual?

The day after posting TE News #130 with the idea for

powering the house or some extension cords using a pure sine wave

inverter to activate the grid tie inverters, I found a video by "altE"

("alternative energy store") called Adding Batteries to Grid Tied

Solar

in which that very topic is discussed.

Two different methods are outlined. Both require that you

make an "essential loads panel": a separate breaker box for freezer,

well pump, furnace fan and essential lights and plugs. When the grid is

down, only this panel will be powered and the main breaker box will be

dead.

For new construction this isn't a really big deal.

Installing wiring in open wall studs before the wall surfaces are put

on is pretty simple. But retrofitting a new, separate AC breaker panel

with diverse new outlets and circuits

in a typical existing house would be a prohibitive amount

of work.

The "AC Coupling" is about the equivalent of my idea last

month

of a power bar plugged into the pure sine wave inverter and having

extension cords to the grid tie inverters and to the appliances except

that it's all prewired permanently in advance. The driving inverter

apparently has to be of somewhat bigger capacity than the grid tie

inverter(s) it activates.

The "DC coupling" type evidently requires

there to be one big grid tie inverter instead of several "micro

inverters" like I have, and they talked about having several solar

panels in series making for lethal voltages, so I didn't pay it much

attention.

Having panels in parallel is valuable in many

installations of

which mine is typical: When some panels are in the shade, the other

panels still produce full output. If the panels are in series, having

one in shade kills the whole series string.

Later I found "smart" "Hybrid Inverters", which I confess

hadn't crossed my radar screen before. Here is how the "automatic"

works in installations where everything works "optimally" without any

manual intervention in any situation: sun or no sun, grid on or grid

off, all switched automatically. The most versatile units can draw

power either

directly from the solar panels or from the batteries, and also from the

utility grid as necessary. If the grid is down, solar is

off or insufficient, and the batteries are low, they will even start up

an automatic fossil fuel generator. They operate both as grid tie

inverters and off-grid inverters, switching their output from the main

line to the "essential loads" panel (disconnecting it from the rest) if

the power goes off.

The chief drawback as I see it is that this complexity costs a lot.

Solar done with all the official permits for grid tie and such

equipment, installed by those in the business, costs a lot more than

"basic solar" done DIY. To have a contractor come in one might start at

15000 $. Still, one can DIY and still follow approved

guidelines with lower cost hybrid inverters such as Conext MPPT 60 150

(still over 500$).

That is probably worth it in a "serious" new installation with 20 or 30

panels.

You can start solar for a very low price. A small panel

for 12 volts, a PWM charge controller and a 12 volt lead-acid

"RV/Marine" battery can be under 200 $ and will at least run an LED

light and charge a cell phone.

Moving up a step, four solar panels or so, a cheap charge

controller and a set of golf cart batteries might be under 2500 $ and

would do the essentials if the grid went down.

For myself I guess I've never taken doing a "proper"

installation too seriously. It grew very much piecemeal. I started by

putting up four solar panels for emergencies, then I thought I might as

well have a cheap grid tie so their output wasn't going to waste. Then

I put in a convenient little "boost" charge controller for 36 volts and

hooked up my collections of NiMH batteries. And somehow it grew to 10

panels on two roofs. Then I started adding 36 volt infrastructure,

which I prefer to 120 volts AC but which of course all needs wiring,

and wiring in existing buildings is generally a pain in the butt. (I

think even if I get HE ray electricity going, I would prefer to run

house wiring, if it will still exist, as 36 volts.)

With more or less two separate small solar installations

and no "essential loads" panel wired in, I'm planning only a "manual

intervention method" switching of power with inverters and extension

cords to keep some lights, the fridge, freezer and well pump going if

the utility grid is down. But further DC capacity is planned. The more

things that can be run

off the 36 volts, the better. Water heating is usually a good use

because it's second only to heating for electricity use, and the

solar-heated hot

water will lower the electricity bill. Let's outline my setup - some

features existing, some projected for completion in the coming months:

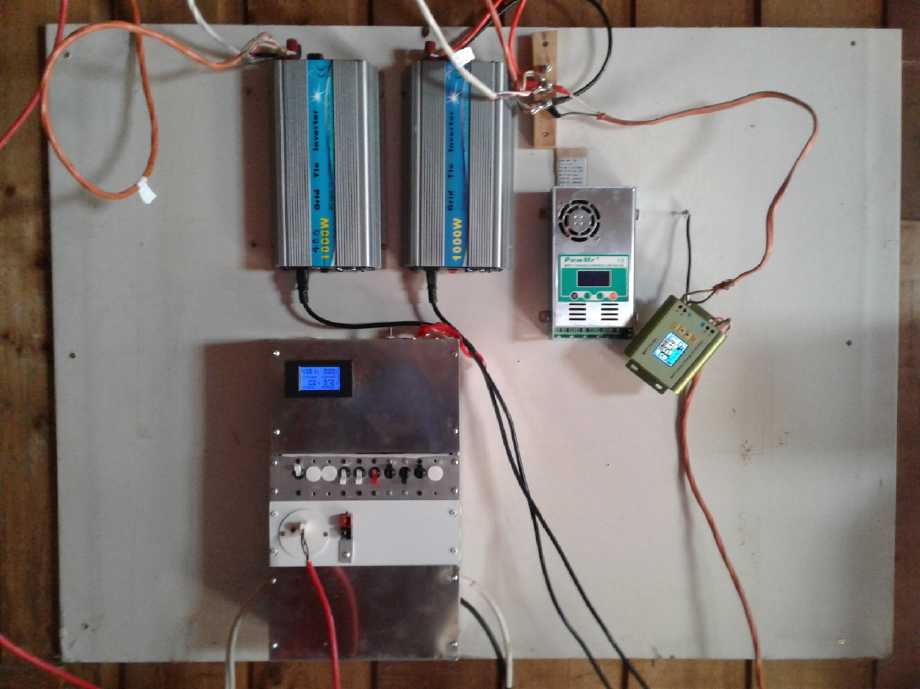

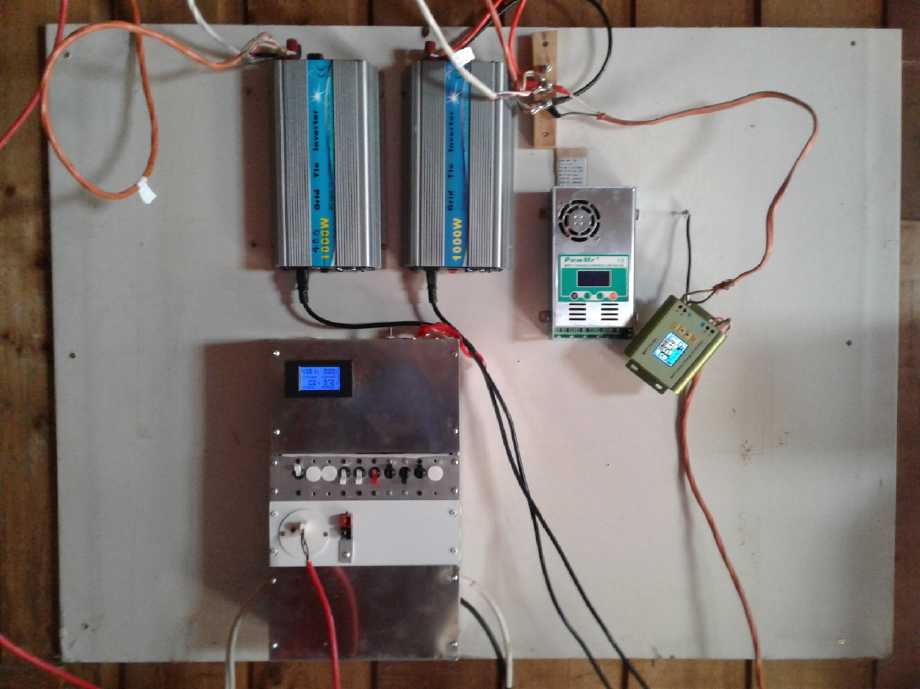

- 10 solar panels on two roofs.

- Six solar panels, 1800 watts go to two simple grid tie 1000 watt

"micro"-inverters.

- Four solar panels, 1000 watts go to a 36 volt, 10 amp "boost" charge

controller (and-or a grid tie inverter)

- A 36 volt, 60 amp "buck" charge controller is ready to switch in for

"grid down". (I can't find any higher power "boost" converters.)

- around 6 KWH of NiMH batteries.

- The Sprint car is also 36 volts and

can add over 11 KWH of additional storage by connecting it instead of

the other batteries.

- A 36 volt breaker box with "Blue Sea Systems" type DC breakers, and

with a voltage, current, power and power consumption meter.

- a few HAT36V wall receptacles in the house for lights (etc)

- a HAT36V-50A 50 amp one for the small kitchen hot water tank.

(drawing 11, 22 or 33 amps depending how many heat elements I hook up.)

I'll be running a very few (three or four?) "HAT36V" DC

outlets around the house from the DC/solar breaker panel in the garage,

and these could substitute - with some manual intervention. I would

unplug the small hot water tank [with the 36 volt DC element - see

detailed report] and plug in an inverter into the "HAT36V" 50 amp DC

outlet in the kitchen, and plug the fridge and freezer into this

inverter as required to keep them cold when the mains power was off.

Extension cords as required. (It just better not happen while I'm away!)

If it looks like a long outage, I have to disconnect the

MPT7210A 10 amp charge controller and connect the PowMr 60 amp one,

putting the two pairs of 250 watt panels in series. (I'll probably put

in a big DPDT switch for making this changeover. It would leave the

grid tie and MPT7210A connected to the two grounded, lower voltage

panels. These could be turned off or left on. If the MPT7210A was set

to charge at a slightly lower voltage than the PowMr)

I'll already be running LED lights from the DC outlets

(mostly 12 volt ones with the little DC to DC down converters), so that

takes care of 'emergency' lighting.

It's certainly not a perfect system. One minor aggravation

is high-power appliances. If I'm making 1500 watts and turn on the 6000

watt clothes dryer, I can't

spread the load out. It's "make the 1500 and buy the rest 4500

from the grid", and then go back to giving power to the grid free after

the dryer shuts off. Charging the car is normally at 3800 watts too,

but I

can plug in the 120 volt, 1500 watt adapter and spread the time out...

except that I'm usually getting home toward the end of the day.

Switching the water heater to 120 V / 750 W [see "April in Brief"]

should help spread the load and use the solar -- if I run hot water

during the day instead of at night. Anyway

even with 10 solar panels I'm not making enough power for my own daily

needs.

If the grid really goes down for a long time, hopefully

the trailer's extension cord can be plugged into the off-grid inverter

and that will bring its "grid tie" inverter to life so I can make use

of the trailer's output. Otherwise, it may use another PowMr charge

controller and 36 volts of 40 amp-hour lithium batteries that I have

for a separate trailer system.

That's at least enough to keep the lights on at night (if the trailer

is being

used).

High Current HAT - 50 Amp Plugs & Sockets

I thought it would be good to have the high-amperage HAT

connectors I had conceived of. If I ran a line across the house it

could go to the 36 volt water heater in the kitchen, or that could be

unplugged and the 36 volt to 120 volt inverter could be plugged in

indoors (warm and dry) to run the freezer and or fridge in a power

outage. The freezer is about 100 watts, and the fridge is about 140.

Theoreticly that's only 3 or 4 amps at 36 volts, but those compressor

motors draw a nasty surge current as they start. They may choke a 1500

watt inverter (= 42 amps at 36 volts) and not start up. My 1800

watt/2500 volt-amp pure sine wave inverter worked in the previous power

failure. It's probably just big enough.

What should I base the size and shape of a high current

HAT connector on? The vital part is the pins/blades. Everything else

depends on them. Of course I would use the same essential shape. A

target current would be a handy spec, too. 50 amps at 36 volts is 1800

watts - the same as 15 amps at 120 volts. That seemed like a good

starting target.

For comparison and contrast with what others have done:

Blades in a NEMA 30 amp 120/240 V [clothes dryer] plug measured about:

2.4 x 12.7 x ~30 mm, which is also (and probably specified

as) .10" x .50" x ~1.25". Cross section would be 30 sq.mm.

Pins for 30 amp Anderson APP connectors changed shape along their

length, but were pretty tiny compared to the NEMA plug.

Pins for 70 amp APP connectors had a cross section of about: 2.1 x 7.1

mm, cross section 14.91 sq.mm. (Call it 15.)

The NEMA plug had big blades and was intended for just 30 amps. But the

common 120 volt, 15 amp blades are 1/2 the width and (again just via

measuring one) not much more than 1/2 the thickness, so 1/4 the cross

section for 1/2 as much current. As with the exactly .50" width spec,

everything suggested that the NEMA blade size was arbitrary and

substantially larger than actual current flow requirements. This belief

was further supported by the 70 amp APP plug pin having just 1/2 the

cross section of the 30 amp NEMA blades. 15 sq.mm would have a little

bigger cross section than #6 AWG wire. #6 AWG wire is rated for 55, 65

or 75 amps depending on the wire temperature permitted: to 60, 75 or 90

°C. (quite hot to really hot!) These ratings consider the heating

of a long length of insulated wire under heavy load. Plug and socket

pins are short and the wire itself (if thick enough) carries heat away

from the plug pins. (Of course, there's no help for the heat made by a

badly connecting plug and socket in any event.)

A 120 VAC, 15 amp wall receptacle opened up.

A 120 VAC, 15 amp wall receptacle opened up.

The grips for the plug pins are about the same size and grip as the

HAT36V "hatpin" grips,

and in fact they hold the HAT blades quite well.

(Oops, the 120 V plug with its big blades for comparison is just off to

the

right.)

I cut a piece

of 1.65 mm copper sheet/plate, 10 mm wide.

That seemed kind of wide. If I made my HAT blades 8 mm wide by 2 mm

thick (nominal), they would be 16 sq.mm. That should be sufficient for

over a 50 amp circuit. (Or should I call it "60 amps" just so it'll be

known as "2000 watts capacity".) I decided they should be about 20 mm

long. Again, just long enough compared to the width for a good grip

when plugged in. Just by eyeball after making a few socket shells, 12

mm seemed like a good spacing between pin centers. So those dimensions

become the specs.

I cut a piece

of 1.65 mm copper sheet/plate, 10 mm wide.

That seemed kind of wide. If I made my HAT blades 8 mm wide by 2 mm

thick (nominal), they would be 16 sq.mm. That should be sufficient for

over a 50 amp circuit. (Or should I call it "60 amps" just so it'll be

known as "2000 watts capacity".) I decided they should be about 20 mm

long. Again, just long enough compared to the width for a good grip

when plugged in. Just by eyeball after making a few socket shells, 12

mm seemed like a good spacing between pin centers. So those dimensions

become the specs.

36 volt, 50 amp HAT plug blade size specification:

Thickness: 2.0 mm +/-.25 mm (1.75 to 2.25 mm)

Width: 8.0 mm +/- .5 mm (7.5 to 8.5 mm)

Length: 20 mm +/- 2 mm (18 to 22 mm)

Blade center spacing: 12 mm (tolerance unspecified)

These pins are a little bigger in all dimensions than NEMA

120 volt, 15 amp plug pins. I don't think they should be any smaller. I

came up with 12.0 mm blade spacing after making some shells and finding

that 15 mm seemed to leave wasted space. 15 was what I had originally

thought just by setting the pins beside each other and setting them

what seemed a reasonable distance apart.

Obviously 2 mm x 8 mm copper blades aren't going to be

made on the spot just by flattening a wire with a hammer. But the pins

need to be large for high current. 2 mm sheet copper or 2x8 mm strip is

going to have to be obtained for the purpose.

Having that spec, how long would the actual pin be cut? I

decided to make it 40 mm. So 20 mm would stick out to connect, and 20

mm would be inside the shell to hold it in place and connect to. It

seems to me that 8 x 2 mm is wide and fat enough to put a machine screw

through to make a solderless connection. (But I didn't try it.) I cut a

couple of pins to that length. That was it for the 13th.

On the 15th I

I cut some flattened wire

"hairpins" for

sockets, 65 mm long. Instead of one, there would be two for each 8 mm

wide plug blade, 4 mm wide or less. Two springs would make a better

connection than a single point. I made two from #9 AWG wire. This

turned out to be quite hard to bend around. The other two were #11.

They seemed to grip just as well. Since #11 isn't very common, I

decided to try #10 and #12. (The thinner "under spec" 1.65 mm blades

gripped quite well too, not quite as strongly.)

On the 15th I

I cut some flattened wire

"hairpins" for

sockets, 65 mm long. Instead of one, there would be two for each 8 mm

wide plug blade, 4 mm wide or less. Two springs would make a better

connection than a single point. I made two from #9 AWG wire. This

turned out to be quite hard to bend around. The other two were #11.

They seemed to grip just as well. Since #11 isn't very common, I

decided to try #10 and #12. (The thinner "under spec" 1.65 mm blades

gripped quite well too, not quite as strongly.)

Next would be the plug

shell design. Since the pins were

thicker than the small HAT plugs as well as wider, a 50 amp connector

that could also accommodate a 15 amp plug seemed to be out of the

question. HAT would have to be like NEMA: in fact, different

incompatible plugs and sockets for each major current rating. Perhaps

that's for the best! Also there would probably only be two types, 15

amp and 50 amp, and the "50 amp" size might well be used with smaller

circuit breakers - 40 or 30 - according to the situation and the

wire size used. Of course I would keep the same shape, so the only

other question that counted for specifications was the distance between

centers of the blades. The thing to do was probably to start designing

on the 3D printer/OpenSCAD and see what worked well and looked

reasonable.

There were other questions of construction however. One

was safety. When something is drawing 50 amps, a poor connection can

make a lot of heat. Even my thermoelectric fridge drawing 8 or 10 amps

(with the crappy Pico .205" socket connectors) had somewhat burned one

of my CAT sockets. 120 volt AC plugs and sockets occasionally get

burned. I couldn't use some of the higher temperature plastics commonly

used in electrical connectors in the 3D printer. A very safe

alternative occurred to me on the 15th: ceramic. Less common today, it

has been used in light bulb holders and sockets. (I have an idea to

make

a single piece socket shell: The pins would slip in from the rear end,

and they would have a threaded hole for a machine screw. Two holes in

the sides of the shell would allow this bolt to be inserted into each

pin, which would both connect the wire and prevent the pin from sliding

in and out. Like the CAT socket shells, this could either be used

in-line or it would fit into a plastic wall plate.)

But I decided to do a two-piece shell in plastic on the 3D

printer and switch

to ceramic after I had a working design.

HAT36V, CAT12V: What's in a Name?

I also thought of a very important refinement on the

15th: if the CAT and HAT connectors manage to start getting out there,

they will attract more attention, but that will help them spread only

if people know what they're called. It's not like NEMA plugs and

sockets where everyone knows what they are and can find them in any

hardware store. I should print in the plastic on each and every one

something like: "HAT36V" or "CAT12V", or here, "HAT36V-50A". (At risk

of marring the appearance -- even on the face of the wall plates.) Then

when a guest comes into an off-grid house and asks "what is this wiring

system, I didn't know there was anything like this?" (s)he can see the

name and look it up instead of simply being told "Um, I forget what

that's called." Once they're in the hardware stores, the inscribed

labels can be dropped. (They aren't working out. Maybe I should use a

rubber stamp, stencil, or adhesive label.)

On the

evenings of the 15th and 16th I printed shells.

Each time I would think, "gee, there's some wasted space there", or

"those hairpins don't need to be so long". At one point I realized that

inside the space of the shell, if the open ends of the "hairpins" were

bent out a bit, they would hit the sides of their space, so toward the

center the hairpin was providing "double" pressure against the plug

blade, making a better connection. And that would prevent the folded

end from being spread apart and losing pressure, too. So I shortened

the hairpins, and hence the whole socket, some more.

On the

evenings of the 15th and 16th I printed shells.

Each time I would think, "gee, there's some wasted space there", or

"those hairpins don't need to be so long". At one point I realized that

inside the space of the shell, if the open ends of the "hairpins" were

bent out a bit, they would hit the sides of their space, so toward the

center the hairpin was providing "double" pressure against the plug

blade, making a better connection. And that would prevent the folded

end from being spread apart and losing pressure, too. So I shortened

the hairpins, and hence the whole socket, some more.

And somehow the shells on the 15th were 13 mm between

blade centers instead of 15. On the 16th I made one 15, and decided

narrower was better. With another adjustment, I ended up at 12.5 mm,

and decided that was a good size.

But that was all without having tried to wire the socket.

I always set aside the wire in my mind "It's just a skinny little

wire." Now I started to think that it would be hard to get fat wires

in. For 50 amps one would want to use #8 AWG wire, if not #6.

Hmm... no, those were definitely not going to go in. Either I was

making 30 amp connectors for maximum #10 wire - at most - or I was

going to have to scale up a bit.

Perhaps what I really needed was another way to connect

the wires to the hairpins? They really have to stick out from the end

of the hairpin instead of projecting sideways from inside the fold.

Maybe a tab, silver soldered to the ends of the hairpins? More ideally,

a small pipe that could crimp down on the wire. Or more simply, perhaps

just different shaped hairpins with a tab bent right into the closed

end? Before bed, I pounded some #10 wire flat and snipped it at 70 mm.

Then I bent them into that special shape, using a 2.5 mm thick washer

to form them around. The wire could be soldered to the flat part and

hopefully would have enough room to come straight out the back.

Perhaps what I really needed was another way to connect

the wires to the hairpins? They really have to stick out from the end

of the hairpin instead of projecting sideways from inside the fold.

Maybe a tab, silver soldered to the ends of the hairpins? More ideally,

a small pipe that could crimp down on the wire. Or more simply, perhaps

just different shaped hairpins with a tab bent right into the closed

end? Before bed, I pounded some #10 wire flat and snipped it at 70 mm.

Then I bent them into that special shape, using a 2.5 mm thick washer

to form them around. The wire could be soldered to the flat part and

hopefully would have enough room to come straight out the back.

The 18th was again occupied with other things and I found

little time to get any farther. I did make another pair of the new

hairpins and soldered a #8 house wire onto them (40-55 amps), and a #6

(55-75 amps) onto the other pair. The soldering took a lot of heat and

a big tip on the iron, but it seemed like good joins could be made.

The 18th was again occupied with other things and I found

little time to get any farther. I did make another pair of the new

hairpins and soldered a #8 house wire onto them (40-55 amps), and a #6

(55-75 amps) onto the other pair. The soldering took a lot of heat and

a big tip on the iron, but it seemed like good joins could be made.

It was obvious that my shell arrangements were totally

inadequate for the wires. The hairpins were longer. The #6 wire with

its insulation was bigger than the connector pieces and would need a

very substantial space. Even the #8 insulation was a larger diameter

than the wire holes. It might even be better to have two designs, for

each wire size. But having the wires come straight out the back would

be a big improvement. On to shell design #5!

Before bed

seems to be about the only time I'm

getting to

work on this! On the night of the 19th I changed the shell to

accommodate #8 wires. I even made the wire holes small for a short

section with no insulation, and then larger for the insulated wire to

come out the back. I un-soldered the #6 wire and soldered on a #8 to

the other pair of clips, which is probably a bad sign that it's too

much work making the clips. It seemed to go together pretty well. It

took

substantial force to insert the pins, and without a plug to pull on, I

couldn't pull them back out except with pliers. They hold well and

should make good connections. I didn't see anything I wanted to change

offhand. The printer was warmed up and ready to go, so I just printed

another one the same.

Before bed

seems to be about the only time I'm

getting to

work on this! On the night of the 19th I changed the shell to

accommodate #8 wires. I even made the wire holes small for a short

section with no insulation, and then larger for the insulated wire to

come out the back. I un-soldered the #6 wire and soldered on a #8 to

the other pair of clips, which is probably a bad sign that it's too

much work making the clips. It seemed to go together pretty well. It

took

substantial force to insert the pins, and without a plug to pull on, I

couldn't pull them back out except with pliers. They hold well and

should make good connections. I didn't see anything I wanted to change

offhand. The printer was warmed up and ready to go, so I just printed

another one the same.

Next, the plug. I wasn't getting very far very fast on

this little project! But I managed to design and print a plug the next

day, Saturday the 20th. It seemed good. Noticed that the bed (still)

wasn't exactly level. I adjusted the right side up a bit, and put the

routine that printed "HAT36V" back in. I made one other small change

and printed another plug. This time, the lettering sort of came out. If

you got the light just right, you might guess that's what it said. I

spaced "H A T" a little farther apart so the printer wouldn't do weird

things between the letters, but I had had enough of 25 minute prints.

I'll assume the next one will be better rather than worse.

For the plug,

I came up with a new technique:

since the

wires (#8 AWG) were so fat, I picked a special fastening method and

used them as the means to lock the blades in, to prevent them from

sliding out. I drilled a hole in each blade. But the wire - #8 is

always stranded - was divided so half the strands went on each side of

the pin. The stripped length, about 5/8", was intended that the strands

ended just at the far end of the hole. I pushed many of the strands

into or through the hole from each side. Then when the wire was

soldered onto the blade, it had more than just surface contact,

improving mechanical strength.

For the plug,

I came up with a new technique:

since the

wires (#8 AWG) were so fat, I picked a special fastening method and

used them as the means to lock the blades in, to prevent them from

sliding out. I drilled a hole in each blade. But the wire - #8 is

always stranded - was divided so half the strands went on each side of

the pin. The stripped length, about 5/8", was intended that the strands

ended just at the far end of the hole. I pushed many of the strands

into or through the hole from each side. Then when the wire was

soldered onto the blade, it had more than just surface contact,

improving mechanical strength.

The final

result seemed quite satisfactory in operation.

Considerable force was needed to push the plug in or to pull it out.

But I don't consider it to be excessive. That force is going into

making a good, solid connection for the high currents these are

intended for.

The final

result seemed quite satisfactory in operation.

Considerable force was needed to push the plug in or to pull it out.

But I don't consider it to be excessive. That force is going into

making a good, solid connection for the high currents these are

intended for.

For the smaller plugs, I'd be finished here. Two parts

remain. First is that for such fat wires, distinct designs are required

for #8 and for #6 wire, so the #6 still needs to be done. Then the part

remaining is to make the socket shells out of ceramic instead of

plastic. I wouldn't want to burn someone's house down owing to heat

from a poor connection melting a plastic socket. This will be a

substantial project in itself.

I hadn't given

much further

thought to making molds for the

ceramic version, but it started to dawn on me that I could do them too

on the 3D printer, using the same design. On the night (again late at

night!) of the 24th I added a new block of plastic to completely cover

everything made before, and a "difference" command. This made it into a

big block with the socket design inside of it, "inside out" with spaces

where the solids would go and vise versa. Then I added "scale" by 1.15

times in each direction, to compensate for shrinking of clay during

drying and firing. I had to drop the lettering, which would have

printed in the air at the top. (But I could make it into a plastic

stamp to stamp into the outside face of the clay.)

I hadn't given

much further

thought to making molds for the

ceramic version, but it started to dawn on me that I could do them too

on the 3D printer, using the same design. On the night (again late at

night!) of the 24th I added a new block of plastic to completely cover

everything made before, and a "difference" command. This made it into a

big block with the socket design inside of it, "inside out" with spaces

where the solids would go and vise versa. Then I added "scale" by 1.15

times in each direction, to compensate for shrinking of clay during

drying and firing. I had to drop the lettering, which would have

printed in the air at the top. (But I could make it into a plastic

stamp to stamp into the outside face of the clay.)

The resulting mold looked rather rough and I could see it

needed a couple of changes, but I decided to try it out. I have a

feeling I'll have to scrape or sand some of those surfaces smoother,

and probably put a few holes in the bottom of the mold to push the clay

out from. If I got the slicer software for the new printer

installed, it would already be a lot smoother. (I would of course have

to remove the clay still damp, since it would crack if it shrank still

in the mold.)

On the 25th I tried it. I was

sure I would need holes to

push the piece out of the mold, so I drilled some in one side. I found

some clay that was rather too damp (no doubt had been a 'slip') along

with other bags that were too dry to work. It filled the mold nicely,

but when pushed, the spot right above the hole just bulged or opened.

On the 25th I tried it. I was

sure I would need holes to

push the piece out of the mold, so I drilled some in one side. I found

some clay that was rather too damp (no doubt had been a 'slip') along

with other bags that were too dry to work. It filled the mold nicely,

but when pushed, the spot right above the hole just bulged or opened.

Then I found

"Log End Sealer" (Bow River Craft Woods), an emulsified

wax solution, and painted some in to make the mold more slippery. Then

I tried some red clay that seemed like a good consistency, not too wet

or too dry. This time if I pushed on each hole, the piece started

coming out. But the edges in the thin slots broke away and stayed in

the mold. Looked like it wasn't going to work readily. Back to square

one.

Then I found

"Log End Sealer" (Bow River Craft Woods), an emulsified

wax solution, and painted some in to make the mold more slippery. Then

I tried some red clay that seemed like a good consistency, not too wet

or too dry. This time if I pushed on each hole, the piece started

coming out. But the edges in the thin slots broke away and stayed in

the mold. Looked like it wasn't going to work readily. Back to square

one.

The next idea was to make an oversize socket, file or

scrape everything as smooth as I could, then pour some flex mold

compound in it and fill all the spaces, then turn the whole thing over

and put it in a shallow box to make a mold, around 'actual' (oversize)

socket pieces. Hopefully the clay wouldn't stick to the flexible