Turquoise Energy News #132

covering May

2019 (Posted June 3rd 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In Brief

(Project Summaries etc.)

- Lower Power Hot Water Tanks - Under Kitchen Sink Solar Hot

Water Tank - Air Injection Iron Filter - Pipe Battery Assembly

Improvement - Biggest Mistake in Solar: Not Going Solar? - Batteries

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- More on Time Zones - The Weather and The Corn - American Armyworm Invades China - The Sudden Drop in the US Crime

Rate: Many Misattributions and the Real Reason - ESD [Eccentric

Silliness Dept.]

- Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle: Multiple Ducted Fans? - Selecting

Ducted Fans for the RC model

* Seen on youtube: a very large Fully Electric Ferry and a Solar

Electric Passenger Train.

Other "Green"

Electric Equipment Projects

* "Off Grid" (etc) 36 volt DC Infrastructure - HAT clay socket

- "DIY" Blades for High Power HAT36V-50A Plugs? - Kitchen Solar Hot

Water Tank: Plumbing & Wiring (Yay, instant hot water!) - Solar Hot

Water Panel(s) Versus Solar-Electric Water Heating - Badderies - Fried

Charge Controller- Oops - Charge Controller Vagrancies

Electricity Generation

* [In?]Efficiency of 1000 Watt Y-Solar Microinverters - More solar

trivia - Lots of cloudy days make for low power generation - Miles

truck charge controller goes berserk, doubles house power usage for

10(?) days (see May 25th) - Extra Solar Panel on Lawn ups production

* Beach-Launched Tide Power: the Beach

* Off Grid Solar Installation for a neighbor

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Methyl

Hydroxide electrolyte)

* Electrode "Pocket" with Nafion Ion-Selective Membrane Face

* "Mounting" NiMH D cell Tube Batteries

Me on the beach

I was again frustrated in May at how little work I was able to do on

any "cutting edge" green energy projects. I seem to be more and more

occupied with the more mundane things - and with getting the garden in.

On the first of June there were still a couple of unplanted areas, and

I know I won't have enough peas to freeze some.

I was again frustrated in May at how little work I was able to do on

any "cutting edge" green energy projects. I seem to be more and more

occupied with the more mundane things - and with getting the garden in.

On the first of June there were still a couple of unplanted areas, and

I know I won't have enough peas to freeze some.

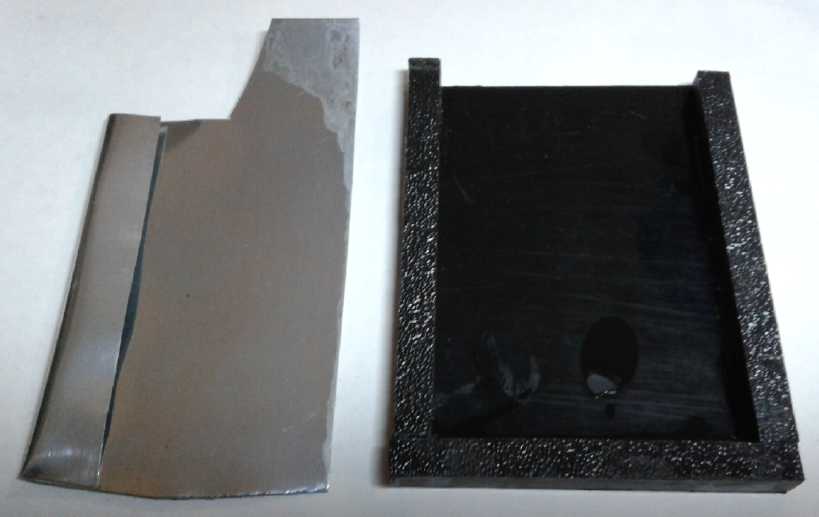

Insofar as I went, I

continued my push to create

infrastructure for 36

volt "off-grid" and solar power systems. I figured out how to 3D print

and manually smooth and

shape a workable (if crude) plastic mold to shape clay for ceramic 50

amp HAT36 sockets, did it, and made the two halves for a socket. But

the raw clay has to sit until I fix my long-broken mini-kiln - one more

little project I didn't get to.

(Hmm... I should make more than one shell before I do the firing? ...or

wait and

see if any changes are needed?)

3D-printed mold and red clay ceramic socket

pieces formed in it

3D-printed mold and red clay ceramic socket

pieces formed in it.

I spent part of the month including the last few days

doing solar work for other people - the ones for the tug boats and an

installation for a lady across the highway in her 70s who has lived

without electricity most of her life. Even this little system with two

90 watt solar panels and a 12 volt battery for LED lights and to charge

her cell phone, and to occasionally run a vacuum cleaner with an

inverter, should be a big plus for her.

Lower Power Hot Water Tanks

Hot water tanks are essentially mysterious creatures. We know

they're there. We know they're using energy - more than anything else

in the home except electric heat and perhaps electric car charging. But

there's usually no way

to see or measure it. They're hidden away in some closet or basement,

and even when seen still betray nothing of their activities - whether

they're doing nothing or drawing 3000 watts of electricity. How much

electricity is it using? The wiring is carefully set up so even if you

want to, you can't get an ampmeter on them without disassembling

something. It's about the one thing that still gets directly wired in,

without a plug and socket. How much electricity is being wasted when we

have to run the hot water

for a while each time before we get a cup of it to wash our hands? The

simple fact that they take so much power when they're on, and that

they're hard wired in with 240 volts (ooh!), makes us apprehensive. It

says "Don't Touch!"

Yet when I changed mine from 240 volts, 3000 watts to 120

volts, 750 watts by simply moving one wire in the house breaker box, I

found no difference. Hot water is always available when I want it. But

there is one difference: My 10 solar panels put out over 1500 watts in

sunshine - a few hundred even in clouds. But it would take 20 or 30

panels to supply 3000 watts. So now if I use hot water when it's sunny,

the

grid electric meter doesn't move, instead of jumping up rapidly by the

majority of what was needed to reheat the tank. So that's a keeper.

With the kitchen sink now having almost instant hot water

from its own solar tank, I prefer to go there even to wash my hands,

and the big tank is now used almost entirely for showers, laundry and

baths. (Why do I always want my baths at night?) 3000 watts is probably

needed for a family of four or five. Likely not for a

single person or a couple - which is the occupancy of the majority of

homes these days.

Under Kitchen Sink Solar Hot Water

Tank

I've always said "No level of scalding hot temperature can

atone for the hot water taking so long to get here." In this house, to

get hot water at the kitchen sink took a minute or more, and 4 liters

of hot water wasted in the pipe. The answer I have

long wanted to try, a tank right by the sink, I finally did.

I must have had the 15 liter hot water tank for the

under-sink hot water for the kitchen for well over a year now,

but with the new "chemical-free iron filter" for my house well water

system, I wouldn't need to connect it to rain water to get un-stained

dishes. So by putting it off so long I saved myself a lot of work that

now

wasn't needed.

The Dernord 36

volt water heating element in the

15

liter

under-sink hot water tank. I found 250 watts was

plenty.

But the soft silicone(?) gasket supplied (white, under hex top)

squished

out

under pressure, causing a flood in the kitchen. Get an "O-ring" or a

stiffer gasket.

The 36 volt

water heater element having arrived, until the

8th I made up pipe assemblies for it. On the 11th after a

couple more trips into town for parts, I did the plumbing and installed

the

36 volt heater element

in the tank and the tank under the sink. Then I ran a cable across the

house through the crawl space (ugh!) to connect up the 36 volts. On the

12th I

hooked

it up and (not without some troubles and a flood first) got the water

hot. It seemed to heat surprisingly quickly even with just 265 watts of

heating applied. (I wired two ~500 watt elements in series with the

third disconnected.) It was hot

for dishes in under an hour. I also found the small 15 liter tank

seemed to

cool surprisingly quickly. There was only warm water in the evening and

quite cool late at night. But soon I found that it actually seems to

spend most of its

time shut off, so I started leaving it turned "on" at night to run on

the batteries.

The 36 volt

water heater element having arrived, until the

8th I made up pipe assemblies for it. On the 11th after a

couple more trips into town for parts, I did the plumbing and installed

the

36 volt heater element

in the tank and the tank under the sink. Then I ran a cable across the

house through the crawl space (ugh!) to connect up the 36 volts. On the

12th I

hooked

it up and (not without some troubles and a flood first) got the water

hot. It seemed to heat surprisingly quickly even with just 265 watts of

heating applied. (I wired two ~500 watt elements in series with the

third disconnected.) It was hot

for dishes in under an hour. I also found the small 15 liter tank

seemed to

cool surprisingly quickly. There was only warm water in the evening and

quite cool late at night. But soon I found that it actually seems to

spend most of its

time shut off, so I started leaving it turned "on" at night to run on

the batteries.

I left the top of the tank with two wires

sticking out that could be connected to the thermostat giving either

~260W (drawing 6.5 amps) or ~500W (almost 13 amps). The water heats so

fast with 260 I don't expect to use the 500 at all.

I still want to install a 50 amp socket and plug rather

than a 15 amp, because I want to be able to unplug the heater and plug

in a 36 to 120 volts

inverter to run the fridge in case of a power failure. I connected the

tank with "wire nuts" until I've made the socket. I wouldn't have dared

put the connection down there where it might get wet (and already has)

if the power was 240 or even 120 volts... or maybe even 60. 40 or

less is different.

(There are "on demand" sink water heaters that don't need

to keep a tank

of water hot, but they need sudden very high power that is sort of

counter to the way solar wants to work. Someone on Youtube also said

that they aren't very reliable and he's on his third one at his sink.

But I confess they weren't even on my radar screen and I had never even

thought about the idea until I saw that video, and I don't know what is

available. I'm very

happy with the new tank. It's great!)

From the 13th

it

was a real pleasure to have almost instant

HOT water (~2 seconds with the tap full on) instead of over a minute to

get tepid water from the distant main tank.

From the 13th

it

was a real pleasure to have almost instant

HOT water (~2 seconds with the tap full on) instead of over a minute to

get tepid water from the distant main tank.

In several short sessions

(my preferred way but previously impractical) I did dishes that had

been piling up for 3

weeks and cleaned up the counters. After that I could do dishes

right after I

used them and kept the place tidy[er]. I'd always wanted to do it that

way,

but especially here I'd also always been loathe to run a gallon of hot

water from a

distant tank to get a cupful or two. Now it's just a cupful extra in

the pipes.

(Anywhere I can shorten the pipe or tube? I guess not unless I move the

sink drain pipes. NO!)

Air Injection Iron Filter

"The 24th of May is the Queen's birthday. [British queen

Victoria

18??-1902(?)] If you don't give us a holiday we'll all run away!" (How

is it the holiday Monday falls on the 17th to 23rd then?) It was on the

21st

after the long weekend that I finally installed the new filter. I

wanted to start in the morning on a work day so that if it didn't go

well I could drive into town for parts. (The hardware store had been

closed Saturday! Why would I trust them for Monday?) I had all the

parts I needed, but it took most of the daytime anyway before it was

finally in and working.

On later observation it seemed that the water was just

slightly

orange instead of clear. But it didn't get any worse. With just the

sand filter, the water started clear and then turned more and more

orange and brown. And now it didn't seem to leave a stain behind it.

Previously just one bath left a very visible ring in the bathtub. It

was so thick and hard to scrub I had given up and just sometimes did

one section of the tub, which was all brown stained again by the time I

had worked my way around to the same place again. Or I would clean a

few wall tiles. I had long since taken to using a squeegee after each

shower to keep them from darkening so fast - not something I had ever

bothered with before.

Pipe Battery Assembly Improvement

Pipe Battery Racks for the solar,

and Air Injection Iron Filter for the well water

Putting NiMH

"D" cells into long pipes of ten for 12 volts

had made it practical to use them for big batteries by amalgamating 10

cells into a single physical unit. But the pipes themselves had always

formed unwieldy

groups, wired together but not forming a physically solid piece. The

Honda hybrid batteries stacked onto little "racks". That gave me the

idea. On the 16th and

17th I printed "racks" for the "D" cell pipe batteries on the 3D

printer. One could make a rack of 3, 6, 9 or 12 pipes stacked 1, 2, 3

or 4 rows deep. I decided to make three sets of 6 pipe batteries to add

capacity to the solar storage. (I even had to make 2 more pipes to do

that. But I still had extra cells (the better part of 100 bought in...

early 2016?) which might as well be put to use. And even extra pipes

and ends all cut.

Putting NiMH

"D" cells into long pipes of ten for 12 volts

had made it practical to use them for big batteries by amalgamating 10

cells into a single physical unit. But the pipes themselves had always

formed unwieldy

groups, wired together but not forming a physically solid piece. The

Honda hybrid batteries stacked onto little "racks". That gave me the

idea. On the 16th and

17th I printed "racks" for the "D" cell pipe batteries on the 3D

printer. One could make a rack of 3, 6, 9 or 12 pipes stacked 1, 2, 3

or 4 rows deep. I decided to make three sets of 6 pipe batteries to add

capacity to the solar storage. (I even had to make 2 more pipes to do

that. But I still had extra cells (the better part of 100 bought in...

early 2016?) which might as well be put to use. And even extra pipes

and ends all cut.

Then, using the Honda batteries - for anything - had been

awkward because of them being welded into tubes of 6 cells, and because

there were racks only for 3 rows. I had been given the battery from one

Honda Insight, but then I bought some more sets cheap on eBay, so there

simply weren't enough racks. The one way to get a "standard" voltage

out of them would be to pile them 5 rows deep to get 30 cells, 36

volts. So on the 18th I changed the dimensions of my previous racks and

printed 12 more pieces to do two top rows on the Honda batteries. But I

didn't get anything more done with them.

The 3D printer - and I'm still using my old RepRapPro,

having not yet successfully downloaded and installed the "Cura" slicer

software for

Ubuntu - is a wonder. Each of these 30 total pieces took nearly an hour

to print, and the printer chugged away hour after hour for days, the

print head and the bed whipping back and forth at rapid speeds, without

anything coming loose or failing.

Biggest Mistake in Solar?

A solar company put a video on youtube, 8 Costly Solar

Mistakes to Avoid When You Design Your Solar Panel Kit. One of them

was

a little surprising: Mistake #4: Deciding Not To Go Solar. Here it was

pointed out that solar soon pays for itself and is then a continued

gain for many years, especially as electricity prices keep rising. We

may not have an ideal climate in the "Pacific Northwest", usually with

plenty of cloud cover in winter, but if our electricity wasn't being

subsidized here on Haida Gwaii (same rates across the whole province),

seeing the price of a couple of solar

panels on each month's bill would surely cause solar panels to be

covering rooftops at a rapid pace.

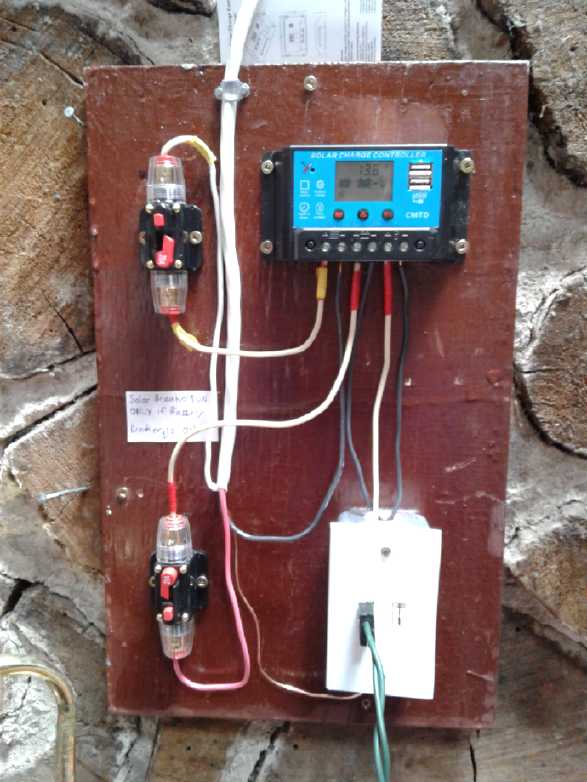

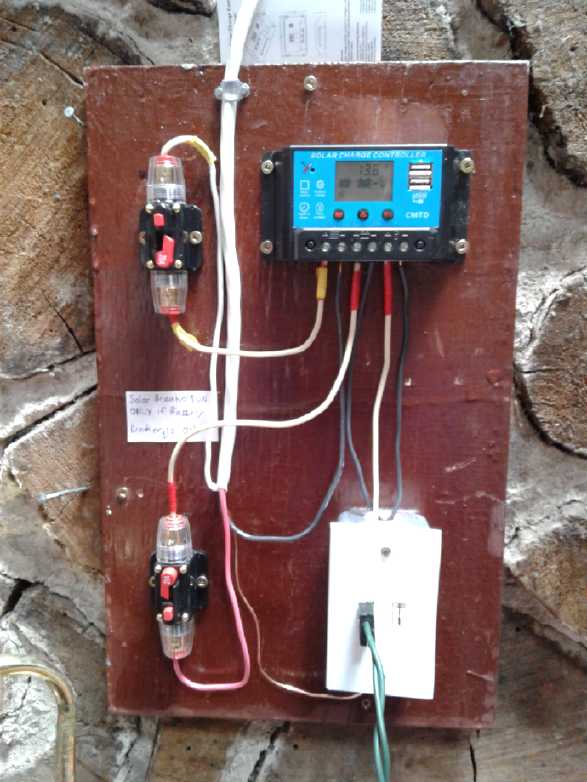

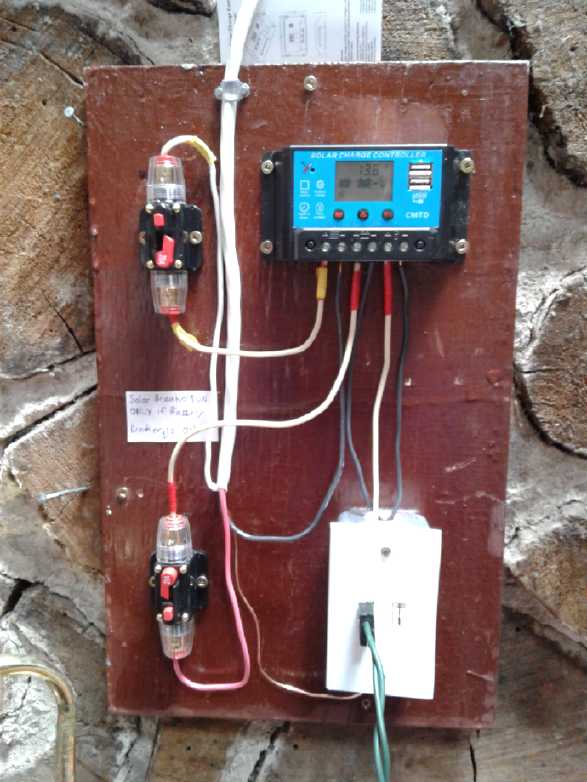

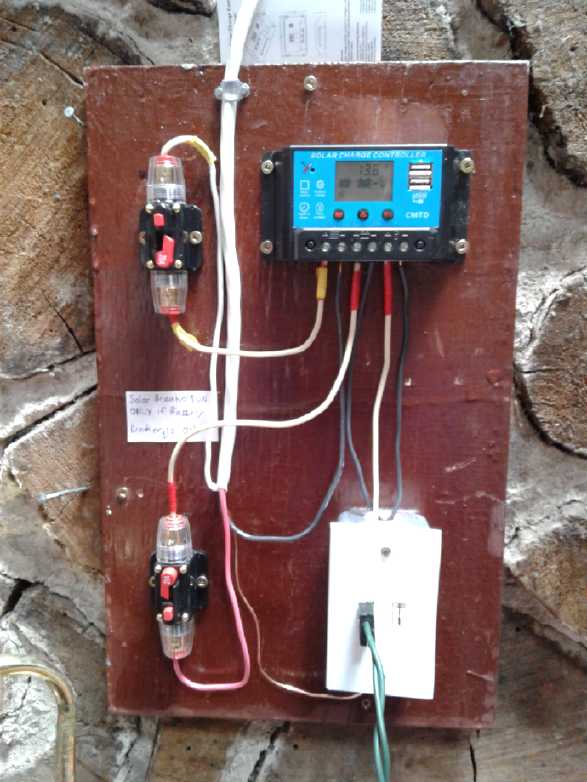

Solar Power for a Neighbor

As mentioned the end days of the month were occupied with

putting in solar electricity for an older neighbor who has lived

without electricity for much of her adult life. Just a 12 volt system:

two 90 watt panels on her roof, a "frame 27" size 'deep cycle' battery

just outside, and a PWM charge controller on an inner wall.

Two 90 watt solar panels, facing south and ESE.

(The west side is shaded by a nearby tree in the afternoon.)

Inside near the battery went a 1500 watt

inverter mainly for vacuuming.

Inside near the battery went a 1500 watt

inverter mainly for vacuuming.

The 100 amp circuit breaker behind is for emergency shutoff.

The battery is just visible outside the window.

Plywood panel with charge controller,

solar &

battery breakers, CAT12V duplex socket

The duplex

"CAT12V" receptacle will allow plugging in LED lights. (I loaned her a

lamp with a multi-voltage DC light bulb for now.)

The duplex

"CAT12V" receptacle will allow plugging in LED lights. (I loaned her a

lamp with a multi-voltage DC light bulb for now.)

Something was wrong and I was still troubleshooting

into June. It turned out that the

charge controller was "positive ground" rather than the virtually

universal standard negative ground. Solar panel "minus" couldn't be

grounded with all the other minuses. (The last item I've even heard of

having

a positive ground - much less seen myself -

was some British cars of the early 1960s.)

If the instructions had simply mentioned this important

and unexpected fact, it would have save me a lot of trouble. And the

battery wouldn't run the vacuum cleaner after being so badly

overcharged.

Battery Development

I made a

battery pocket with nafion ion membrane covering one face to test out

the idea of preventing metal ions - especially zinc - from traveling

between electrodes. I haven't had a chance to test it yet. Again I am

frustrated with how little time I've been able to devote to such

projects with so much potential.

I made a

battery pocket with nafion ion membrane covering one face to test out

the idea of preventing metal ions - especially zinc - from traveling

between electrodes. I haven't had a chance to test it yet. Again I am

frustrated with how little time I've been able to devote to such

projects with so much potential.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

More on Time Zones

It has

evidently been noticed that people living in the west end of time zones

are more often more deprived of sleep than those living in the east

ends. It seems that's because the sun goes down up to an hour later. It

also comes up up to an hour later, but the clock times scheduled for

starting work are the same. So those in the west ends of the zones tend

to go to bed at the same actual time of day by the sun, but they have

to get up, by actual sun time, up to an hour earlier to go to work than

those at the east ends.

It has

evidently been noticed that people living in the west end of time zones

are more often more deprived of sleep than those living in the east

ends. It seems that's because the sun goes down up to an hour later. It

also comes up up to an hour later, but the clock times scheduled for

starting work are the same. So those in the west ends of the zones tend

to go to bed at the same actual time of day by the sun, but they have

to get up, by actual sun time, up to an hour earlier to go to work than

those at the east ends.

Then there's where I'm living now, Haida Gwaii, where the

clock is almost a whole hour ahead of the sun... an hour and a half

ahead of those at the eastern end of the Pacific time zone. And then it

gets moved another hour ahead for "DST" most of the year. What

insanity! Only real

early birds need apply for 8 AM start jobs around here,

because it's really 6 AM! Even employees in stores opening at 10 AM are

actually getting up quite early to make it to work on time.

(Even regardless of time zone position, I call DST

"afternoon losing time" because that's usually my most productive

outdoor working

time, and when there's anything scheduled in the evening it starts an

hour

earlier and I have to cut the afternoon an hour short.)

(I might also mention western France as being in a similar

situation to Haida Gwaii. Apparently Germany won the war, because in

spite of being a time zone and more to the west, all of France has been

on central European time since 1940. But at least France doesn't

go on "daylight savings" time as well.)

My tentative conclusion is that Newfoundland has it

right... the world should be divided into 48 time zones 1/2 an hour

apart to limit the disparity of what "the time of day" means across the

zone. And surely to God we can do away with "phony time" DST, which by

the only available statistical evidence costs extra energy not

withstanding that "energy savings" is often cited to justify adopting

it.

The Weather & The Corn

By early May the drenched US "midwest" was raining again.

The Mississippi was flooding 8 feet higher than ever before for longer

than ever before (41 days as of May 6th), with projections that there

could be no crop planting in many areas even in June. Near the end of

May, just 40%

of US corn land had been planted. And evidently, planting so late risks

getting frost before the crop is in. (And who knows these

days - maybe snow?) And evidently some of it was "wet planted" - seed

sown in the soggy ground or water with no hope of a crop, before June

in order that "crop

insurance" will pay out in the fall.

For the latest gruesome stats on crop failures around the

world see "Ice Age Farmer" and "Adapt2030". For graphic footage of all

the horrible weather and other calamities from around the world from

South America to Soggy Arabia to places I've never even heard of, see

"Nared King" and "World of Signs". All on Youtube.

I planted my own garden corn early, but it didn't come up.

Hedging my bets, I put a bunch of seeds in a tray of potting soil

inside. These

sprouted. I transplanted them outside, replanted the rest of the rows

outside, and planted

another tray inside. But the tray was a half-hearted effort - there

were nothing like enough plants to fill my little corn field. Again

nothing came up outside. No frost, but probably just too cold for corn

seed germination. Again

the tray of seedlings inside sprouted and I relocated them outside,

where the first ones were at least growing a little. I did a third

tray which only sprouted gradually here and there (I think I used some

older seed), and by the time some of those came up it was almost the

end of

May, and there was still a whole row (of four) with no corn. While

things are warming up with spring proceeding, there have only been a

very few nice, warm sunny days. (The solar power records under

"electricity generation" below show how few sunny days.)

There probably won't be any frost to summarily end the

growing season here. Much less snow. It will probably just peter out

with the days getting too cold and dull for plants to grow further.

Then tomatos and things will start to go mouldy.

Next year I will know to start enough corn indoors under

LED lights for whatever cornfield I decide to grow.

I had the theory that the deer wouldn't eat corn. The

plants were too tough, and they wouldn't know to eat the cobs. If there

were enough, the raccoons wouldn't get too many. So I planted them in

the field outside the garden fence. But on the 29th I found that a deer

had "sampled" the first four small corn plants in one row. Fooey! Do I

need to fence off EVERYTHING? I bought a roll of fencing on the 31st.

But my mom says to mix up an egg, vinegar, hot peppers and water and

spray it on the plants. The deer evidently do have some limits to what

they'll eat. (No more had been eaten in spite of doing nothing by June

3rd.)

Gratuitous picture of the expanded greenhouse.

Gratuitous picture of the expanded greenhouse.

Hopefully it will become much greener as summer progresses.

Typical of waterways along the east coast of

Graham Island, "Jungle Creek" flows north

Typical of waterways along the east coast of

Graham Island, "Jungle Creek" flows north

parallel to the coast for a long ways before it finally turns and heads

down to the sea.

(It even ran another kilometer from here behind me before the highways

department

put in big rocks and "rip-wrap" and diverted it down onto the beach at

this point.)

The water and the flow is very low, especially considering that it's

spring.

American Armyworm Invades China

The American Armyworm some years

back jumped continents and hit Africa, with none of its natural enemies

accompanying it. It has been decimating food production ever since. It

has spread across Asia and has now reached China, where it is wreaking

havoc. It is so severe it has been said it threatens economic and

social stability. (Adding to the African Swine Fever problem and the

crop-wrecking weather in general.)

When migrant Winter Moths hit Victoria BC in the 1970s

they

defoliated all the fruit trees and some other broad leaf trees every

spring. Healthy

trees grew a second set of leaves later, but some died and there was no

tree fruit

anywhere, for some years. People tried various things to kill them or

keep

them out of

their trees, to little avail. In about 1980 biologists had located and

imported the moth's enemies, a parasitic mini-wasp that injected eggs

into the leaf-curling caterpillars, and a fly that laid eggs on the

leaves for them to eat, which hatched out inside. The next year - in

just one year - this horrible

pestilence was gone and while the caterpillars and moths could be found

occasionally ever after there

was never any more serious trouble from them. (Next in the later 1980s

came infestations of tent caterpillars, which I was familiar with as

they had infested the poplar trees in the Edmonton, Alberta region in

the 1960s when I was

growing up there.)

The article I read made no mention of trying to find and

bring in

the armyworm's enemies, only the despair and the woes they were

causing. As if there

was no solution. This seems very puzzling. Is no one even trying to

solve this biological catastrophe?

The Sudden Drop in the US Crime Rate:

Many Misattributions and the Real Reason

from Freakonomics by Levitt and Dubner

In the late 1980s there was

a lot of violent crime in the USA and the rate was rising year after

year. Everyone looked at statistics and

said it was going to be a worsening, horrible blight on society. No one

predicted anything else. Then rather abruptly the violent crime rate

started to fall substantially. It got better and better year after year

and stayed down. (For example, murders in New York 1990: 2,245. 2003:

596.) This was variously attributed by the former gloom and doom

predictors to a 'roaring' economy, better education, gun control

programs and innovative law enforcement tactics. Except for a

quadrupling of the incarceration rate (2 million Americans living in

prisons) which probably accounted for 1/3 of the improvement,

decreasing profits (and hence decreasing turf wars) from selling crack

cocaine (another 10%?) and an increase in the number of police

(effective where it occurred) most of these actually had little effect.

While all the agencies

were patting themselves on the back for 'solving' the problem,

economist Steven D. Levitt figured out the main reason.

In 1973 was the case of "Roe versus Wade". By almost a

century before that,

abortion had been made illegal in most states. Afterward it was legal

and

affordable. The number of unwanted children being born into adverse

family environments to (take your pick) poor, uneducated, foolish,

alcoholic, drug

abusing, unwed teenage mothers dropped sharply. In under two decades

the crime rate

followed suit. The pool of the statistically most likely potential

criminals entering their criminal prime had dramatically shrunk. (At

the same time, so had the pool of young girls statistically most likely

to have unwanted families, so the effect was and is multi-generational.)

Levitt

connected cause and effect. Of course birth control is highly

preferable and was just coming into wide availability around the same

time. But as ugly as abortions may be (and we may hope it's done as

early in the pregnancy as possible) here was a huge positive result of

restoring

personal freedom. The high crime rate was an unseen result of foolishly

coercing

women, not all of whom were ready to, or in a position to, or capable

of raising a healthy, functional family, into having one anyway.

Freedom works better than government trying to control peoples'

lives.

"Know the truth, and

the truth shall set you free." - Jesus

Now imagine all children, in numbers just sufficient to

maintain a stable and healthy population, being born wanted into

loving,

caring, well functioning families that are living the morality and

ethics of the seven core values of

Life, Equality, Growth, Quality of life, Empathy, Compassion and Love

for humanity. In a couple of generations would the world not be a

wholly different place? This is coming in the decades ahead and will

become a permanent quality of our planet's civilization.

ESD

(Eccentric Silliness Department)

(with a little filosofy mixed in?)

* A website, FootprintCalculator.org , reportedly figures out how big

the Earth

would have to be to sustainably support the global population based on

usage of materials and resources. In 1971 we evidently hit 1.03 Earths.

Last year it was 1.71 Earths. Unless we become more frugal and austere,

or drop the population, the Earth will need to grow quite substantially

to maintain its existing population for much longer. The mounting daily

mass die-offs and the horrifying numbers of species going extinct

probably indicates that the oceans have been essentially fished out and

poisoned with plastic, and the land is faring almost as badly.

Isn't that just another view of what more and more have

been

saying when they suggest we should prepare for a lean time and that the

population bubble will soon burst?

* No amount of hours spent driving in the car makes up for the missed

exercise of

not taking a 20 minute walk.

* Politics and Peace are opposites. Ultimately politics is separation;

peace is

everyone in harmony together. Politics comes about when people won't

work together and compromise to find the common good and the best path

forward. Bipolar politics is "my way or the highway." We won the

election

(51%); you lost (49%), so get lost. Your view is worthless. Peace comes

when all views are taken into account and there is co-operation instead

of competition and strife.

* In mid May big game hunting season opened. The big game hunters came

out in swarms:

carnivorous blackflies, midges ("no-see-ums") and mosquitos.

Best to stay inside in the evening.

* Why do Christians hate Muslims? No doubt because mosques must surely

breed mosqu[ito]es - and nobody likes mosquitoes.

* The hardware/building supply store in Queen Charlotte is called

"AMS". According to the store that's short for "Aaron-Mark Services".

According to most everyone else it stands for "All My Savings", as in

"I took in all my savings and bought something at AMS."

* HOW many functions with ONE button? The LCD DC power meter I put on

my solar electricity system has only one button controlling several

features. But I couldn't figure them out... When the watt-hours reading

passes 9,999 WH, it says 10 KWH. Eventually it goes to 11 KWH. This is

a sudden 1000-fold loss of precision. Hard to track a few hundred

watt-hours per day, let alone activity within the day, with that! I had

to go back to AliExpress and read the instructions, a couple of times.

If you click the button, it turns the LCD backlight on or off. If you

hold it longer, it suddenly says "SET" and allows setting of alarm

points. (What good an alarm is on something that doesn't have a beeper

I don't know... but apparently the backlight flickers.) Here Patience

is the key: KEEP holding it down. In a few more seconds it goes from

saying "SET" to "CLR". At this point release it, and the WH/KWH

reading flashes for a few seconds. While it is flashing, click the

button again to set the WH/KWH reading back to zero. (If you hold it

down even longer you can change the setting from "100 amp shunt" to "50

amp shunt". That would require changing the actual current measuring

shunt resistor too.)

* Microwave ovens heat things up in 2 or 3 minutes. In 20 or 30

minutes... the item is completely cold again.

Headline February 7th, 2057:

Using poultry embryos and advanced Crispr25.9 gene splicing technology,

Scientist Recreates

a Phorusrhacid, an Extinct Giant Flightless Bird.

June 3rd,

2057:

June 3rd,

2057:

"You called the pound, sir?"

"Yes, it's my next door neighbor. Her chicken is eating my dogs!"

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground Effect

Vehicle (first the R/C Model)

Multiple Ducted Fan Propulsion

A friend, Rick Peterson,

sends me various links to what

are sometimes very interesting articles about green energy stuff. He

sent me a link to an article about a VTOL

[vertical take-off & landing] "electric jet" aircraft from Germany

for "urban" use, the "Liliam". I couldn't think what an "electric jet"

might be but a ducted fan such as I intended to use, and so it turned

out to be. A feature of special interest was that it had 32 of them: 12

on the flaps on each wing and 6 on each side of the elevator (elevons?)

of a front canard. Instead of a rudder, it used the differing thrust of

the motors to steer.

The design was perhaps not so strange for some radio

controlled craft, but mind bogglingly different in many ways from any

other real aircraft for carrying passengers that I've seen.

The design was perhaps not so strange for some radio

controlled craft, but mind bogglingly different in many ways from any

other real aircraft for carrying passengers that I've seen.

VTOL was attained by the ability of the control surfaces

to point the motors straight down. (Step aside, Harrier fighter jet!)

Ducted fans doubtless gave it

sufficient static thrust with less power. And they said they made it

far less noisy than a regular aircraft, much of whose noise besides

engine roar is propeller tip vortex noise. In 2017 Lilium[.com] got 90

million dollars funding to make the prototype 5 seater craft (the

intended full size) after demonstrating their smaller two-seater could

transition smoothly from hovering to forward flight. (How do other

people seem

to get immense levels of R & D funding? I haven't managed a penny -

not even SR & ED tax credits since 2015. Even my "Fantasy Budget"

for all projects combined was only 1/4 that much. Ah well...!)

I'm not so sure an aircraft to take off and land on

special pads all over town and just to cross town is practical. It

might however be

productively employed for hops over water, replacing slow foot

passenger ferries, or in extreme terrain (swamps, jungle, canyons...)

where distances are too far or it's impractical, or the

volume of travelers is too small, for a bridge.

However, such a high speed

service over water could also

(and I trust better) be provided by a ground effect vehicle using much

less energy per kilometer, greatly increasing the range or the carrying

capacity

of a given size craft/vessel. The multiple ducted fans is

certainly a fine new idea and a timely one as I was just about to start

making the wing, which will hold the motor(s). Multiple fans should

be able to solve at least two design issues that have been in my mind.

1. Having the thrust above the wing tends to push the nose downward.

Yet if the propeller is large, to put it lower puts it into the water.

Land aircraft have long wheel struts to keep their low propeller(s)

above the ground.

Thus "amphibian" aircraft with floating bodies (including the electric

one shown in last month's issue) have the propeller back by the tail to

minimize the nose-down effect. But for the ground effect vehicle, to

blow some air under the wing for additional lift means putting the

propeller at the front of the wing, as low as possible. Multiple ducted

fans of smaller diameter would allow the thrust to be down lower, still

with

water clearance. Additionally, the vertical aim of the thrust might be

adjusted with pivoting fans.

2. I have seen 'catamaran' shaped R/C models flying diagonally for a

considerable distance before straightening out when the rudder is

employed to make a turn. Keeps going straight on when turned... the

collision stats will start mounting up! I was going to have a large

central "tail" ("dorsal?") fin sticking up for lateral stability

especially when turning. That would be fine on the model. On the

piloted version it would have to be made of transparent material or

something to

prevent a serious blind spot in the view to one side that would make

"taxiing", maneuvering and docking extra challenging.

Multiple fans, especially if they could be aimed left to

right, might take the place of the fin (or at least reduce its size).

Selecting Ducted Fans

Previously I was wondering if the 5" ducted fan was large

and powerful enough. Then

I started thinking of 4 (or even 6?) smaller ones, perhaps 3 inch

diameter.

I'm thinking of mounting them under the front of the wing, where they

would all contribute to "blowing up the bubble" under the craft that

will help it lift off as well as providing forward thrust.

So at this point, the next thing to do was to look on line

and see what's available in the 3" size. Surely there were some better

ones than the 5" one I have, which is the largest available but by no

means aerodynamically optimized. Then I'd need a motor and

controller for each one. More minimally, just getting another 5" fan

and having two would fulfill the essential requirements, at least for

the model.

On the 25th I sat down to look. I already had a browser

window

open to AliEpress, and I just did a search there. Sure enough there

were many pages of results. It wasn't that I didn't spend a little time

looking over a couple of pages of other choices. But at the top left

hand corner, the first result, was the biggest size, a 90mm ducted fan

with 12 blades.

3-1/2 inches. It looked very good. It looked powerful. "for model

jets".

You could buy it with a recommended motor already installed. I wasn't

prepared for the prices, thinking of 30 or 40 $. With motor it was 130

$C.

But considering the alignment problems I've had with the 5" one,

getting them already assembled sounded like a good plan.

Then they needed BLDC motor controllers, "ESC"s

("electronic speed controls") in hobby

parlance. 120 amps was recommended. The store didn't have one! I

searched again and found a store that did, a "Sky Flight" controller.

Another 40$ each!

I sat a few moments looking at my on-line "shopping cart".

Two of each, left and right. That was the minimum. I wasn't

going to go for four at those prices,

and it sounded like two would have plenty of power. Was I really going

to do this? I decided that if I was serious about the ground effect

craft, I needed

to. It has such potential! I clicked "purchase". There went yet another

350$ I didn't have. I get Canada Pension starting next year. I wonder

when money will start hyperinflating? Not something to count on when

incurring debts! (I got the solar panel system done for the off-grid

lady across the highway by the 31st... oops, June 3rd. That will pay

for them.)

Let's see... 120 amps at 22 volts is 2640 watts: 3-1/2

horsepower! Each! And in total 16 pounds of static thrust! Put it

nose up and it could probably lift off vertically! It starts to dawn on

me that having not just "sufficient" but "impressive" or even

"excessive", power will make for not just working but impressive demos

that can create the sort of enthusiasm needed to attract funding for

more development or perhaps even commercialization.

Then, what to use for the full size manned craft? Twenty

of the very same ducted fans? Those should actually fit across along

the front under the wing. That would be 160 pounds of thrust. This

would seem to be the approach of the VTOL "electric jet". But I suspect

bigger ones will be needed.

What part to build next if I wasn't sure how the fans

would mount on/in/under the wing seemed to be an academic question

since I didn't have time for building much of anything. (It's early

June and there's still areas of the greenhouse that aren't planted

yet!) I guess I'll wait for the parts to arrive. Before the end of May

however I decided to just make the whole wing and mount the

motors on top, in "amidships" on each side. It should have lots of

take-off power without blowing the air under the wing, and the small

diameter ducted fans wouldn't do much forward tipping.

From the 90mm 12 blades Ducted Fan Order Page:

It looks better made than the 125mm one I

bought

before.

It looks better made than the 125mm one I

bought

before.

It has a bit of a front rounded 'scoop' to bring in more air.

12 blades. (and a spare fan.)

It has a center streamlining piece at the back.

It comes with recommended motor, assembled and aligned.

Description:

Brand Name: FMS

Item Name: 90mm 12 blades Ducted Fan

Motor: 3546 KV1900(the diameter of the shaft: 5mm, the length of the

shaft: 27mm, the max power:3000W , banana plug: 4mm)

Weight: 327g

Usage: Suitable for RC Airplane

Recommended setting:

6s 22.2v 5500mAh 35C Lipo battery (not include)

ESC: 120A (not include)

Features:

- All composite materials processing and injection molding processing,

light weight, power system 327 g, has ultra high rigidity and toughness.

- First-class mold design,ensure the blades perfect dynamic balance,the

blade cooperates the duct in place,sound effect and efficiency value

are comparable to all metal duct on the market.

- FMS pioneering thermal design,in does not affect the efficiency of

the case,ensure the motor's normal working,no need to worry that the

motor heating will affect the life and performance.

- Reasonable structure design,you can arbitrarily choose different

manufacturers motor,this item can e assembled to all the 90 ducted

airplane,no need to make too much manual changes to the aircraft.

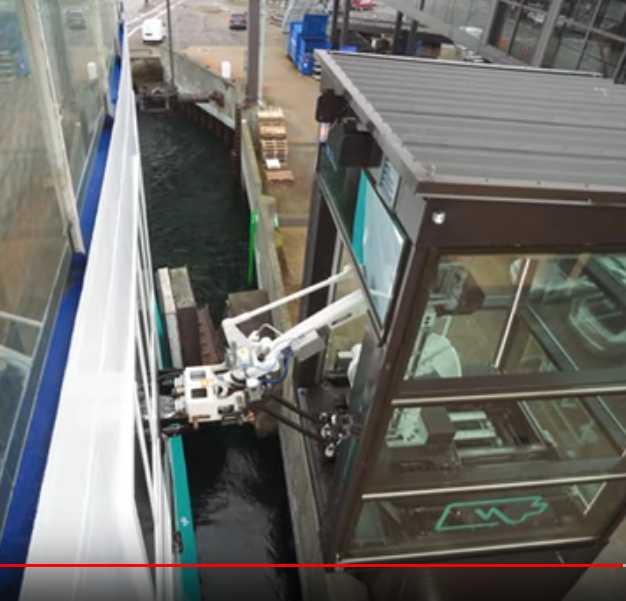

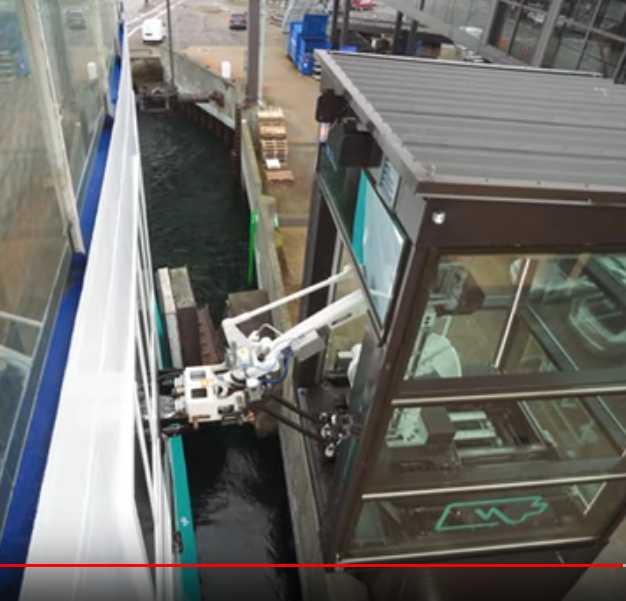

Electric Ferry

Danmark to Sweden

I've noted a couple of small electric ferries operating in

Norway. Here's a very large one plying a 4 Km route between Danmark

(Hey, that's how the Danes spell it) and Sweden. This one was converted

from diesel electric to plug-in electric by adding sheds full of

batteries on the top deck. Evidently the conversion is a plus in every

way.

https://www.youtube.com/watch?v=rE_M1n-ClOA&feature=youtu.be

Sweden to Denmark

Batts: 800 V 4,200 KWH

4 propulsion Motors 1.5 MW each.

46 crossings per day - every 15 minutes

4 Km

10 KV charging in 10 minutes / 6 minutes.

Inside one of the battery containers on the top

deck

Inside one of the battery containers on the top

deck

An automatic arm comes out from a tower to

recharge the ferry when it docks.

An automatic arm comes out from a tower to

recharge the ferry when it docks.

No human intervention - they need to charge fast during

the short docking while cars are unloading and reloading.

Solar Train

Also from the "Fully

Charged" Youtube channel that did the ferry video... In someplace

called Byron Bay in Australia, a short railroad between the town and a

resort was converted to solar electric. It's a level track so it

doesn't take much power. The train, fully restored and converted

"historic" units, has some solar panels on the roof (flexible ones to

match the original curved roof), but mostly it recharges at

each station. (through the rails, perhaps?)

Other

"Green"

Electric

Equipment

Projects

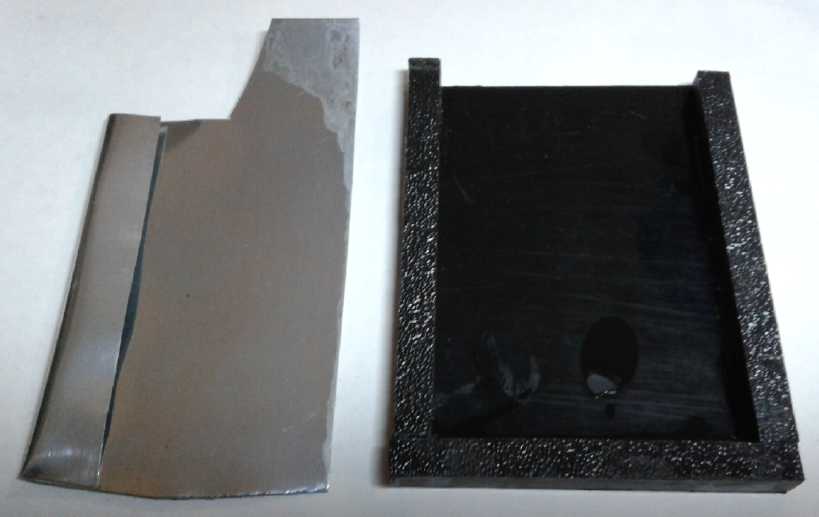

36 V DC "Off

Grid" Infrastructure

HAT36V-50A Ceramic Sockets

I printed the "bottomless" mold on about the 7th and tried

it on the 8th. The clay didn't come out very well, but it was much

better than with the previous mold. So I went about fine tuning this

one. Someone named Eric who I've never met said the walls should be

sloped 3 degrees to make it easier to get the clay out. That seemed

reasonable. Trying to program that in with OpenSCAD would be a daunting

task, I'm sure. I needed also to smooth the side walls, so on the 9th I

filed them and put a slope into them that way. After I was reasonably

satisfied that I had smoothed it off as best I might without going to

exacting lengths (both halves), I then coated it with the liquified wax.

The mold with smoothed and slightly angled

edges, and the clay pieces made.

The mold with smoothed and slightly angled

edges, and the clay pieces made.

That night I stuffed fairly stiff clay into one side.

Pushing on the bottom sections carefully, one area at a time, the clay

suddenly fell out. It looked workable! So I did the other half. Then I

did some edge trimming, then dug out the bolt holes with a small piece

of brass tube. After it dried I would need to fix my mini-kiln to fire

it. Somehow that didn't happen during all the rest of May.

That night I stuffed fairly stiff clay into one side.

Pushing on the bottom sections carefully, one area at a time, the clay

suddenly fell out. It looked workable! So I did the other half. Then I

did some edge trimming, then dug out the bolt holes with a small piece

of brass tube. After it dried I would need to fix my mini-kiln to fire

it. Somehow that didn't happen during all the rest of May.

"DIY" Blades for High Power HAT36V-50A Plugs?

The spec for the blades is 2mm x 8mm x 20mm. There are no

common solid wire sizes that will flatten to 2x8mm. It's not even

a very common thickness of copper sheet to find. However, 1/2" copper

plumbing pipe has about 1mm thick walls, and 1" pipe has about 2mm. So

one could slit a 1" pipe, pry it open and flatten it down to get 2mm

thick sheet copper. Alternatively, one could slit open a 1/2" pipe,

flatten, and cut it 8mm wide by double the desired length. Then fold it

in half. The closed end is the outer end, to be inserted into the

socket. Perhaps most ideally, the other end can be shaped to hold the

wire between the two pieces. Be sure it fits in the shell before

soldering.

Kitchen Hot Water Tank - Plumbing & Wiring

I've always said "No level of scalding temperature atones

for the hot water having taken so long to get here." The answer I have

long wanted to try, a tank right by the sink, I finally did. It's great!

Near the start

of the month I put together a rather

complex set of pipes and fittings to connect the hot water tank under

the sink. Then I remembered that since I had done any plumbing decades

ago, people had switched to using flex tubes with threaded fittings on

both ends to connect faucets to the rest of the plumbing. I supposed

that the fittings on faucets were some special size, but when I took

the one off the hot water tap it proved to be the most common size,

"1/2 inch NPT" - the same size as the hot water tank. So the tubes

would be too. When the flex tubes were created, they were quickly

adopted and everything else was cast aside. They are not only flexible,

but the nuts are loose and can be screwed on without turning the tube,

giving threaded connections without the need for "pipe unions" having a

loose nut.

Near the start

of the month I put together a rather

complex set of pipes and fittings to connect the hot water tank under

the sink. Then I remembered that since I had done any plumbing decades

ago, people had switched to using flex tubes with threaded fittings on

both ends to connect faucets to the rest of the plumbing. I supposed

that the fittings on faucets were some special size, but when I took

the one off the hot water tap it proved to be the most common size,

"1/2 inch NPT" - the same size as the hot water tank. So the tubes

would be too. When the flex tubes were created, they were quickly

adopted and everything else was cast aside. They are not only flexible,

but the nuts are loose and can be screwed on without turning the tube,

giving threaded connections without the need for "pipe unions" having a

loose nut.

I would still need the rather complex little assembly with

two shutoffs I had mostly already put togther to split the hot water

off from the cold and then reconnect the cold, but the connection from

there to the tank, as well as much of I had meant to use from the tank

to the hot water tap, could be replaced with two flex tubes. Pfew! But

I couldn't find one long enough so I had to make an "L" piece so the

tube would reach.

Having finally done everything, I found the old valve I'd

used leaked to the outside world. The "O" ring rubber was perished. I

didn't

have any the right size. So on the 9th I had to go into town, for the

fourth day in a row, and get a new one. Since I would have to shut the

water off, I wanted to start the job in the morning just in case

something didn't work out and I had to run out yet again and buy some

other part before I could turn it on again. The 10th was out. That

meant waiting until the 11th. Rats! How long was this going to drag out?

On the 11th I

finally got the main pipe assembly in. It took a couple of hours and

two tries. It looked like a solder join leaked... then it didn't. I had

to cut the original plastic cold water pipe. I really

hated to do things that were irreversible in case something didn't fit

right in the new assembly. Plastic "pex" pipe had replaced the plastic

pipe type used when building the house in 1988 and there was almost

nothing that fit it. The selection of plumbing parts on this

island is pretty limited if I needed something else. It could mean no

water... for how long? But there was no choice. Happily the parts I

thought would fit did.

I found the

Dernord element was (after all) the right size

for the threaded hole in the tank and I put it in. I disconnected two

of the three 400 watt elements, leaving 400. Then it occurred to me I

could put in a switch and switch it to 400 or 800, or even two switches

and have 400-800-1200.

I found the

Dernord element was (after all) the right size

for the threaded hole in the tank and I put it in. I disconnected two

of the three 400 watt elements, leaving 400. Then it occurred to me I

could put in a switch and switch it to 400 or 800, or even two switches

and have 400-800-1200.

The original thermostat went into a special tube in the

original element assembly, so I couldn't use it. Another hot water tank

thermostat I've had kicking around for decades turned out to have at

least two problems. It was junk. (And I threw out several others when I

moved - rats!)

So I made a hack job of putting the original thermostat up

against the side of the tank, inside the insulation. It might not

respond as fast or as well - and it sure wasn't proper - but it should

suffice.

Knowing I couldn't scrounge any very long wire, I had

recently broken down and purchased a 75 meter roll of AWG #14-3 house

wire

cable "for solar projects". (146$ - I knew was saving money by

scrounging/saving wire!) I used about 20 meters to go from the solar to

the tank at the far end of the house. With the

bare ground wire, "#14-3" actually has four #14 wires. The black and

bare,

and the white and red, can each be doubled to make the equivalent of

two #11 AWG wires, which would be rated for 30 amps. 1200 watts at 36

volts is actually 33 amps. First, that doesn't seem like serious

overload. Second, I figured I'd probably never use all 1200 watts

anyway. I'll

start with 400 (11 amps) and see how that works out, and then go to 800

(22 amps) if that heats the water too slowly. (It turned out 2 in

series for 250 watts was plenty.)

I tried my best to arrange it so I'd only have to crawl

though each section of the dusty crawl space once, but such plans

rarely work out. The worst part is a long section only 16" high,

crawling on my belly on the concrete. I found a solid wall at the end

of that with nowhere to put the cable through. I called someone to help

me the next day, but he wasn't on the island. I decided by gosh I would

finish it that same day after all. I went back in with the drill. In

spite of good luck pushing the wire through that wall, I had to go in

to the other low section with a sand floor three times to pull the wire

up under the sink with a coathanger wire and tape - the cable came off

the first time. The next time I folded both the coathanger and a copper

wire around each other before I taped them together so I could pull

harder. I got out alive, if sore and tired and coughing up dust for a

while. An interesting thought is that while the water heater was under

the sink, if it had been 120 or 240 volts, I don't think I'd have

wanted the power connection to be under the sink where it can get wet.

Everything was ready for the hookup except that I didn't

have the first ceramic HAT36V-50A socket fired yet. Ah well... "wire

nuts"! Definitely time to call it quits. Plumbing, 36V heater element

installed in water tank, water tank installed, then a long wire run

across the whole house in the crawl space. That was lots of progress

for one day!

Next day (12th) I hung up the wire with some wire staples

in in the easier access places, hooked up the water heater, and hooked

up the other end of the wire in the breaker panel. I

was going to use the new surface mount breakers, but there was no place

to connect ground (B-) wires except inside the box. It would seem

there's a need for a surface mount grounding block for external

breakers.

Next day (12th) I hung up the wire with some wire staples

in in the easier access places, hooked up the water heater, and hooked

up the other end of the wire in the breaker panel. I

was going to use the new surface mount breakers, but there was no place

to connect ground (B-) wires except inside the box. It would seem

there's a need for a surface mount grounding block for external

breakers.

First problem: When I turned it on, it was only 275 watts

instead of 400. So I took the water heater cover off (not so easy being

all plumbed in now - it would have been impossible without the flex

tubes!) and checked it. I ended up hooking the power wires directly to

one element, and it was 460 watts. Bad connection in the thermostat?

(Later I noted that's the power with two elements in series. No doubt I

had it wired that way by accident.) I put it back with two wires

sticking out that could connect to the thermostat either one element

(which turned out to be about 500 W with full batteries) or two in

series (265W). Power seemed good. After a while the water was getting

warm, then hot. I did a few dishes.

Next problem: The MPT7210A was putting under 4 amps into

the batteries, while the tank on 225 W was drawing 6 amps. The MPT7210A

is supposed to be 10 amps, but now that it was actually being asked to

put out 6, it wouldn't! It wasn't drawing much from the solar panels

either - they were almost at open circuit voltage. The unit was running

cold, definitely not limiting itself because of overheating. It just

wasn't even trying. It was putting out 135 watts while the water heater

was drawing 250. The batteries were getting lower.

It turned out that if it's turned OFF and then ON again,

it wakes up and delivers the current, but I didn't know that at the

time. (And manual intervention certainly shouldn't be required!)

I decided to connect the PowMr 60 amp charge

controller. That meant some rewiring, which took quite a while. The

PowMr needs over 50 volts in to put out 40 volts, which meant taking

two

panels away from the grid tie and putting them in series with the other

two. That's well over 60 volts open circuit - my one beef with "buck"

controllers. I would rather they "boost"ed from 30 up to 40. (Don't

touch that, no! put the nut in the nutdriver and don't touch it while

putting it on! Only touch the handle of the nutdriver, not the metal

shaft!) At this point I did get to use a couple of the surface mount

breakers to disconnect the solar and the batteries. The PowMr and the Y

Solar grid tie inverter at this point seemed to fight over the two

panels still connected to the grid tie. Soon I gave up and turned off

the grid tie. The PowMr was however much more satisfying than the

MPT7210A: it was putting out 500 watts instead of 135, and recharging

the (now lower) batteries even with 235 W going out to the water heater.

Next problem: I went into the kitchen and found the floor flooding. The

soft plastic (silicone?) gasket that came with the Dernord heater

element was

surprisingly soft. I had wondered about it. Now it had squished out

from the join as the water got hot and the tank was spewing water - by

now cold again. I made a new gasket from a piece of hard rubber but it

leaked. I looked at the original element. It had a simple rubber "O"

ring. I put that on the Dernord and put it back on. Everything was so

wet I couldn't tell if there was some minor leak, but it seemed okay. I

put it back together (still minus the outer cover), connected the 400

watt element and turned it back on. With the batteries at full charge

that was doing 512 watts. There was still almost an hour before the

tree shadows would shade the collectors. Could I get some hot water

again? In 45 minutes it certainly felt hot coming out the tap. That

didn't mean the whole tank was hot. It was still heating at 500 watts.

And the PowMr was still putting out a similar amount and

keeping the batteries up. It certainly seemed to perform well. If set

to 40.5 volts, when the tank went on within seconds it would be putting

out as much power as was being used and even a bit more to keep it at

40.5 volts.

Next problem: The water got too hot. I don't like

scalding. I discovered that one set of contacts on the thermostat was

just "pass through", not a switch. I moved the wires to the other side.

There it switched on and off properly. While I was at it, if it was

going to heat that fast, I connected the wire with two elements in

series instead of the single element. The series pair drew about 265

watts with fully charged batteries. (137 W each. They should never burn

out!) I'm pretty sure I'll never want the full 1200 watts or even 800.

Probably not even 500.

The water was seemingly heating more than twice as fast as

in the experiment a couple of months back with 100-140 watts. I'm

putting that down to the element sticking into the tank from the top

instead of from the side near the bottom, and the Dernord element being

considerably shorter than the original. So it's probably not heating

the whole tank very quickly, just the top half. That is actually fine

with me if I don't run out of hot water doing dishes.

Solar Hot Water Panel(s) Versus Solar-Electric Water Heating

The other thing I would note is that I never got anything

like this sort of hot temperature when I was doing solar hot water with

a hot water collector and pipes around 1980. Notwithstanding all the

work installing it, this one has far less plumbing and was much easier

than putting in a hot water solar panel and a solar water preheat tank

- to feed an electric tank which would use grid electricity to finish

heating it. This was much simpler and more satisfactory. And once the

water is hot, the solar power is available for other things. I think

except perhaps for swimming pool heating, electric is the way to go

even for solar hot water.

For December when there probably won't be enough solar

power many days, I think I might just add on a battery charger that

plugs into the wall to keep up the 36 volts, and stick with using the

DC

system. Of course, only four

of my ten solar panels are on that so far.

Heat Loss

Aside from having the cover off the small tank, the pipes

coming out the top including the pressure/temperature relief valve,

were hot from the water. I had used some hot water, yes, but just four

hours after shutting it off, the water was hardly tepid. The pipes

seemed like major radiant heat leaks. Some pipe insulation was surely

needed. On a shelf I had a very fat (3" O.D.) piece that I cut and put

on before

bed, and a couple of thinner bits that I put over the flex hoses.

To skip ahead a day, the water was pretty cool again just

2 or 3 hours after I shut the power off as the sun went behind the

trees at 4:30 (PST). I guess with such a small tank (15 L) it's

probably inevitable it will cycle on and off frequently, and one just

can't expect it to keep the water hot for 8 hours.

The next morning (13th) was cloudy. I turned the water

heater breaker back on at 9 AM. It was using 265 watts. The PowMr

managed to put out 200, so it was usings batteries for the other 65.

But the solar power crept up as the sun rose - and then the clouds

lightened a bit - and soon it managed to equal the drain, and then to

recharge. By 9:45 the water coming out the tap was pretty hot and by 10

quite hot.

Hot Water! Clean Dishes!

It was a real pleasure to have hot water in the kitchen,

in 2 seconds, instead of tepid water after 70 seconds! I could wash

dishes as I used them, instead of letting them pile up for weeks then

spending an hour and a half at it, and still the "hot" rinse water got

cooler and cooler because I wasn't running it fast enough. This is how

I've always wanted to do it. Having a central hot water tank at a

distance has always been an obstacle, and this one was an extreme

example.

I cleared up much of the kitchen sink clutter by 10:15. I

filled a small metal bowl rather than the whole sink, but I mostly just

squirted a bit of dishsoap into whatever I was cleaning and ran hot

water into it. Before I was done the water wasn't as hot as it was at

first. But it had only been powered on 75 minutes at that point, at 265

watts. I picked away at the mess and wiped parts of the counter a few

times as I passed through, and before the end of the day, the kitchen

started looking almost habitable. Hot water any time you want it is

great!

Last time I had noticed the energy meter on the DC panel,

it

read somewhere around 1000 watt-hours after some months of use mainly

just for the night light at 2.4 watts. But after a couple of days of

heating hot water in the daytime, I noticed it had now hit 3709. I was

finally making some substantial use of the DC power system!

The next day (14th) I turned it on and in a couple of

hours(?) it said 4333 WH. So 624 watt-hours to heat up the tank from

room temperature. I wasn't using much hot water in the kitchen (3 or 4

quick rinsings), and by 4:30 PM it said 4483. That meant that it only

came on very occasionally and had used just 150 watt-hours or so to

keep the tank hot all day, 8 hours. Maybe it wasn't such an energy hog

as I had been thinking after all! At that rate, all I had to do to save

the batteries yet have 24 hour hot water would be to not use very much

hot water in the kitchen at night. Even if I did some dishes after dark

they shouldn't be down too far by morning.

So I tried NOT shutting it off for the night. (What?!?

Actually USE the batteries? For more than a night light?) At 6:30 PM it

had gone up to 4578 - another 95 WH. At 7:30 it was 4641. Apparently it

uses around 50-70 WH for each "top-up" reheat?

May 14th, 15th, 16th

Time (PST) / Watt-Hours Reading / WH Used by water heater / Battery

Voltage

09:00 3709 0 40.5 Turned on circuit breaker -

water heated from room temperature to scalding.

11:00? 4333 [40.5 - being charged]

16:30 4483 150 [40.5] - (I turned the thermostat down a little at 11 AM

so it may not have come on for a while.)

18:30 4578 95 V??

(Didn't record battery voltage. It was well over 39 volts.)

22:20 4721 143 38.24

24:00 4768 47 37.61 (Voltage drop doesn't

look good! [but maybe it had just shut off?])

6:30 4982 224 38.6 (Too late to

see minimum voltage - it's already charging 3.2 amps)

8:30 5048 66 40.5

(Total 1339 WH - includes initial heat-up of 624 WH. Only a few rinses

of hot water use.)

14:30 5248 200 40.5

17:30 5311 63 40.5

18:30 5385 74 40.0 (I turned

voltage down to 40.0 - go easy on the poor old batteries. Ouch! Water

is hot! 817 WH in 24 hours.)

20:00 5452 67 40.0 (Sun

almost down - behind the trees - still getting 35 W of solar!)

21:00 5518 66 39.2 (Caught it in

the act - 235 W. Voltage dropped to 37.?? while it was running, but

recovered to over 39.)

24:00 5649 131 37.6 (again... 215 W and barely 36

volts while running. 891 WH over 24 hours.)

1:30 5718 69 ~37 (why

am I still up?)

4:30 5787 69 36.9 (Did I really get

up to do this? Batteries: 12.7, 12.6, 11.2 -- AHA! It's just ONE

battery that's the problem!)

9:30 5919 142 39.9 (~880 WH in 25

hours (= 845 in 24).)

Reading the voltages was a bit of a pain. If the meter on

the PowMr would say 14.2, then the one on the breaker panel would say

14.57. One voltmeter would say 14.3 and another 14.4. I finally started

using the one on the breaker panel at night. It was obviously a bit

optimistic, but the display always showed voltage, and it had a fourth

digit to decrease round-off error.

Next improvement would be to install the "chemical free

iron filter" so the well water doesn't stain everything brown. Then

it'd be perfect!

Oh yes, and then to install the 240 volt plug and socket

so I can unplug the well pump from the wall and into the 36 volt DC to

240 volt AC inverter instead, and so still have water if the grid power

is off. Then it'll be perfect. [Still not done June 3rd]

(Then can I move on to some more exciting project?)

On the 23rd I tried to chart how fast the temperature

rose, with

just a 250 watt (or thereabouts, depending on voltage) heating element

in the 15 liter tank. Considering how long it took to heat up with

around 120 watts in the experiment a couple of months ago, the

performance seems surprising. But again, it was probably heating the

top half of the tank, which only gradually conducted down to the bottom

half. The water was quite warm to start with, having been hot the

previous evening before I shut off the breaker (owing to

battery/charger problems) . (I didn't record the initial temperature or

the time I flipped the breaker on.)

~11:20? Start

11:30 37.2°

11:40 40.1°

11:50 42.0°

12:00 42.5° ...dropping battery (bad connection - fixed)

12:10 42.8° Huh? I think my measurement is using too much hot water.

12:20 43.1

Owing to there being almost no solar and the batteries

dropping, and so the power going down instead of staying constant, I

ended the test and shut off the breaker. Time to get to repairing the

main battery I had out! One problem with the test was that I was

actually running hot water to measure it at the faucet, and that the

temperature sensor took a long time to heat up, so I was actually using

a fair bit in order to measure it.

"Universal" Power Control?

Shutting off the breaker to the hot water for the night a

couple of time brought me back to the need for a voltage control. I

checked out the "output" circuit on the PowMr. Although I could set the

battery charging to various levels (thank goodness) the output shutoff

defaulted to 11.2 volts and could only be programmed up to 12.5

(*3=37.5V). I would pick at least 39 volts and probably 40. This

arbitrary maximum level would mean the NiMH batteries would be over

half way to flat before the load would shut off. I only wanted the

water to heat when they were fairly well topped up, ie, when the sun

was keeping everything charged. For the lack of imagination by limiting

its shutoff to this arbitrary low voltage, it couldn't be used for that

purpose.

At this point I'm thinking once again of designing my own

control. Now I'm thinking of using a microcontroller and a small LCD

display and making it highly programmable. Even with allowance for

voltage drop in the line. In fact, it might have 3 or 4 outputs to

control that many loads. One or two could be N-channel MOSFETs for

simple resistive DC loads, including high power loads. Another might be

a relay for anything. Another output or two might be a simple digital

output to control (eg) a solid state relay. Thus it could be a

controller for all solar and intermittent power purposes, installed at

the main equipment panel. Also it could have a temperature sensor

input(s) to control heating or cooling of any sort, in which case it

would probably run only one thing, installed at the equipment it would

control.

Another thing it could do in a central setting would be to

switch on another load "load B" when "load A" was satisfied. For

example, it could turn on a baseboard heater once the hot water tank

was hot.

That could be an actual valuable, salable product! (When

am I going to make it and program it, again?)

Arcing Thermostat

A reason cited by some for not using DC water heating was

that the thermostat might arc. That seemed to me to be a pretty paltry

reason. Surely an appropriate thermostat can be had! 120/240 volt AC

circuit breakers, when they bother to also give them a DC rating, seem

to be rated for about 40 volts DC. I figured a 240 volt water heater

thermostat should likewise be okay at 40 volts DC. I had ordered a

couple of high rated ones on line, but the one I had proving to be

defective, I presently had only the original 120 volt one from the tank.

At 10:50 (on the 12th), it having had another 1/2 hour to

reheat, I moved the dial to see how close it was to shutting off. When

it clicked, there was a green glow from within and a hissing sound. It

was arcing, and not shutting off! I did that a couple more times with

the same result. After a little bit I tried again and it shut off

normally. There was just a quick green flash. But it was certainly

disquieting! I hope the "240 volt" ones arrive soon! Meanwhile I

thought I'd better keep it shut off at the breaker when I wasn't home.

This would be a good place for the "universal" control above, set up to

measure the voltage and the temperature, and to switch the water heater

via a power MOSFET - solid state; no mechanical contacts arcing.

But I turned it on and off a couple more times, and left

it on while I was home, and it didn't do more than the momentary green

flash. I know it went on and off by itself at least once - probably 2

or 3 times. I decided it must be all right... for now. It continued to

behave itself into June.

Badderies

One fly in the ointment for the kitchen hot water was that

I didn't want the tank to run at night and drain the batteries. That

would mean manually turning the breaker on in the morning and off again

before the sun goes down. That increased my desire to make a "universal

power control" that will control most anything solar or even multiple

things, via flexible control schemes to be worked out by the

user/purchaser himself for various circumstances.

But after a couple of days my apprehension was relieved

when viewing the watt-hours meter on the solar breaker panel indicated

the tank (the only daytime load) only came on occasionally and would

use under half a kilowatt-hour overnight if I wasn't running hot water.

I shouldn't fill the sink at night, but quick rinses/washes with the

tap running slowly wouldn't make much difference.

The NiMH "D" cell battery bank however, while not

completely useless, appeared to be quite disappointing in actual use

after all the repair and replaced cells. They lost a lot more voltage

than they theoretically should have. At first I thought well, most of

them are 5 years old now and were used hard and perhaps abused in

charging in the converted Mazda RX7-EV. Still a 4.7 KWH battery bank

shouldn't drop from 40.5 volts (1.35 V/cell) to maybe 36(? - 1.2

V/cell) from supplying just 0.5 KWH of night time electricity. (How can

I ever find the time to finish my 'everlasting' battery experiments and

then get them into production?)

Then I got up before dawn with the hater heater turned on,

and checked on them. They were down to 36.8. That was getting toward

"flat" - not very good for 4600 kilowatt-hours of batteries having been

drawn down by less than 1/2 a kilowatt-hour. As soon as my head hit the