Turquoise Energy News #133

covering June

2019 (Posted July 3rd 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Feature: "No Dendrites!" Coated Zinc Electrodes for

Long Life

Nickel-Zinc or Manganese-Zinc Batteries

(See Month in Brief, Electricity Storage)

Month In "Brief"

(Project Summaries etc.)

- "New chemistry" battery Breakthough and Progress - Beaten to

it!: an "Ultra Efficient" Electric Car! - the Lightyear - Workable

Unipolar BLDC Motor Concepts (at long last)! - Better Variable

Transmission Concept

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- World Unity - Witch Hazel & Red Spots - "Rivers from the

Sky"? - ESD... egg whites for burns?

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle ("GEV") (scant progress)

* More Unipolar BLDC Motor Ideas

* Jim Harrington's Latest Electric Outboard Motor

Other "Green"

Electric Equipment Projects

* 36 Volt DC Wiring & Infrastructure

* Laser Engraver

Electricity Generation

* Solar Car Charging Trailer(!)

* My Solar Power System: Monthly Solar Production log et cetera

Electricity Storage -

Turquoise Battery

Project (Mn-Zn, Ni-Zn or Pb-Zn in Methyl

Hydroxide electrolyte)

* Electrode "Pocket" with Nafion Ion-Selective Membrane Face - What

Next? - Making Barium Hydroxide? - Nafion Delamination -

Film-On-Electrode? - Lead doesn't work in alkali! - Nickel-Zinc in KOH

- Some Conclusions... and some Dissolved Oxygen? - Nafion Versus Osmium

Doped Film - The Filmed Zinc Electrode - Next: jelling the electrode...

egg albumen?

Where do the days go? Increasingly it just seemed impossible to get

anything done on projects. I don't have the drive any more for 3 work

sessions a day, and the one or two that I do are somehow consumed with

other things. Then (having finally planted it all) there's watering the

garden and greenhouse. And just driving around. Where does the rest go?

For a few days I started writing it down ("Diary" below). It seems most

days I actually wasn't idle after all. Then I seemed to start finding

times here and there.

June was literally a very dull month. By the 20th there

had only been a total of maybe an hour or two of bright sunlight, on 3

or 4

days when the overcast had a few gaps in it that happened to cross the

sun. And a couple of clear nights. There was some rain, but not a lot.

Mostly just clouds and overcast. It didn't do the solar power any good

as the daily readings show. (see Electricity Generation)

And, how

are crops supposed to grow without light? I was almost ready to start

up the "indoor LED garden" - in the summer. Finally from the 20th on we

got some sun - even 3 or 4 whole sunny days.

But soon June did become especially interesting because I

did

manage a few battery experiments, one of which looks like a

breakthrough - a real winner. Whatever possessed me to keep trying new

things after 11-1/2 years of not coming up with a practical cell, I'm

not sure. But this time there was a good result, and the focus will

shift to how to hopefully improve, optimize and maybe even produce the

fabulous new cell. It's not

that there aren't probably other good combos of things that might work,

but having got an excellent one to actually work well, it'll do just

fine!

A Breakthrough?

My mother thought I should patent it. I explained that the

chief use of patents is to scam them off the inventor by business ruses

or if necessary to buy them up, to kill new technologies so they won't

compete with existing products that the invention makes obsolete. I

don't want that no matter what I might be paid. Or else, a big company

will see the patent, use the invention, and not tell the inventor.

After you find it's in the big box stores, no one will help you try

to collect anything from the big corporation that has more money than

they'll ever need to stall and fight you forever in court - partly from

selling the product you invented.

Then she thought I shouldn't put it on line; that I

shouldn't put it in the newsletter. As with the majority of inventors,

my number one priority in inventing a better product is that it be

used, that it will in some way contribute to a better future. What's

the point of spending years on a project, succeeding, and then hiding

it under a pillow? Those who think most inventors' primary motivation

is financial are mistaken. Getting a good sum of money is always in the

mind

because everyone needs money to live, and they've sacrificed time and

energy to get to where they are and new inventions don't happen every

day. Obviously any sense of fair play says a successful inventor should

be fairly and generously compensated for risking years of his time -

that may yield nothing valuable - to make the world a better place.

Unfortunately there is no mechanism for that in today's society and

over 99% of inventors never do well off their inventions. Even Nicola

Tesla who (among several other things of note) invented the electrical

machinery to create the whole ubiquitous power grid we all enjoy, and

the principles and techniques of radio that his one-time apprentice(?)

associate(?) Marconi used to send the first wireless signals across the

Atlantic, died, and mostly lived, in poverty.

Then she thought I should start making and selling them.

That I hope to do. A fellow who moved up here about the same time I did

once ran the first recycling business in Calgary where he created

various production jigs and tools. He is very interested in solar

energy and electric transport, and in helping and seeing these

batteries being produced. The biggest challenge is to automate each

process so the batteries don't each take hours of labor to make.

My other thought is that should some person of means ever

take an interest in my work or in any one of my creations, it will be

because my works get known and come to his/her attention. I promote my

work - whether badly or well - by publishing everything I do in this

newsletter, "open source" as it were. When I come up with something the

entire process of getting there is well documented. It seems to me such

a person is

most likely to come to the one who's been doing it all along as being

the person most likely and most motivated to be able to use the funds

most effectively to take the same products from design or prototype

stage

to production.

While I have uncovered a key, I also have in mind further

important improvements before producing batteries. Would a potential

investor be wise to invest instead in someone else, or in some company,

that hasn't been thinking through the various aspects for years? Well,

maybe if they're in China... Either way, let's have better batteries

become available. EVERYBODY has wanted really good, lower cost

batteries, for SO LONG!

Very Long Life Nickel-Zinc Batteries!

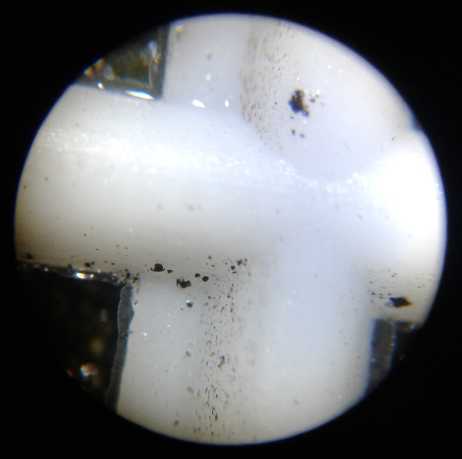

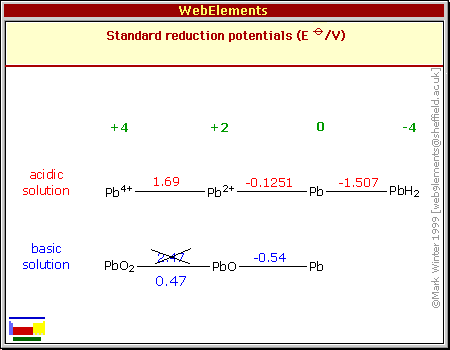

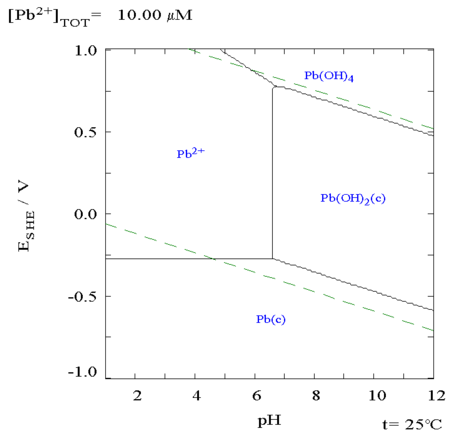

I wanted to try out the nafion "ion selective

membrane". I tried it with the methyl hydroxide electrolyte, with

a lead-zinc cell. It didn't seem to work. And the nafion delaminated

into 3 thinner sheets. Apparently it didn't like alkaline! When I did

some

re-reading I realized nafion allows "+" "cations" to pass but not "-"

"anions". Wasn't that really the opposite to the desired effect in

alkaline

solution, and to block zinc "Zn++" ions from migrating?

I tried it without the nafion, as a straight lead-zinc

cell. It still didn't work. I thought the electrolyte must be at fault,

so I tried potassium hydroxide (KOH). Contrary to all expectations that

didn't work either! I discovered it was actually lead dioxide (or lead

tetrahydroxide) that doesn't work in an alkaline environment. It

dissolves or sheds off as particles into the electrolyte. When it

touches the zinc, it turns to metallic lead and plates itself coarsely

on. How blind I've been! I had seen crud on the zinc in previous

experiments

but I didn't catch on to what it was or what was happening.

Since I was using KOH anyway I broke open a dead NiMH "D"

dry cell and stuck in a convenient piece of the nickel hydroxide

electrode for a

positive. (And I almost took the trash with dozens of them in it out to

the road for pickup, just days previously!) It worked but the (also

new) zinc electrode collected more

lead crud. And it had my usual much-too-high self discharge. At least

it worked!

If the nafion was an ion selective membrane intended for

an acid environment, what I needed was an ion selective membrane that

would work in an alkaline environment: The osmium doped film. But what

to paint it onto/into? Cellophane maybe. But again unless whatever it

was was very well sealed

around the edges, the zinc ions would get past it and build dendrites.

Maybe wrap the cellophane all around the zinc electrode?

Then from there I got the idea to coat the zinc electrode plate itself

with the

osmium doped coating. Would that work? It's implicit in battery design

that the electrolyte has to

be in contact with the electrode for it to work. ...But if it worked

right the film should pass "OH-" ions directly to and from the zinc.

And if the electrode isn't in contact with the electrolyte, it can't

dissolve into it. I've said it before: a zinc

electrode that doesn't degrade is the "holy grail" of battery making.

It would change the whole ballgame. Here might be a wholly new means of

accomplishing that. It was worth a

try. (and I still don't understand what if anything was wrong with the

previous "moderately alkaline" pH technique!)

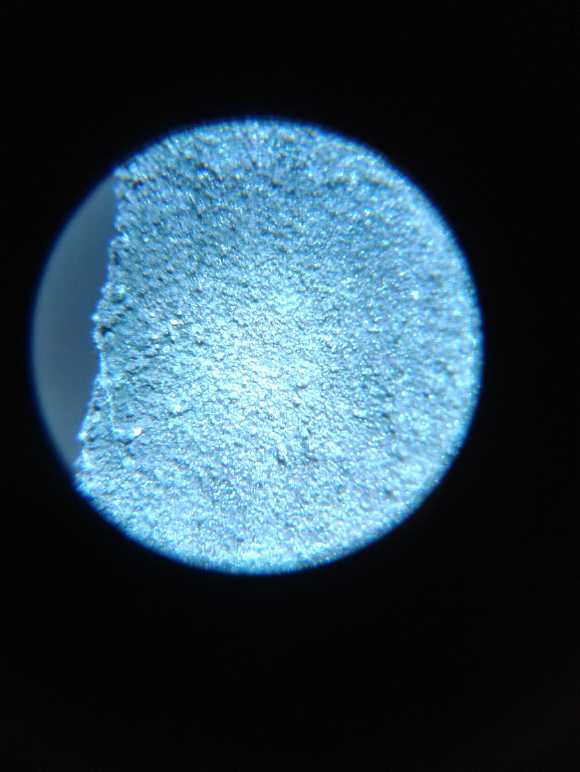

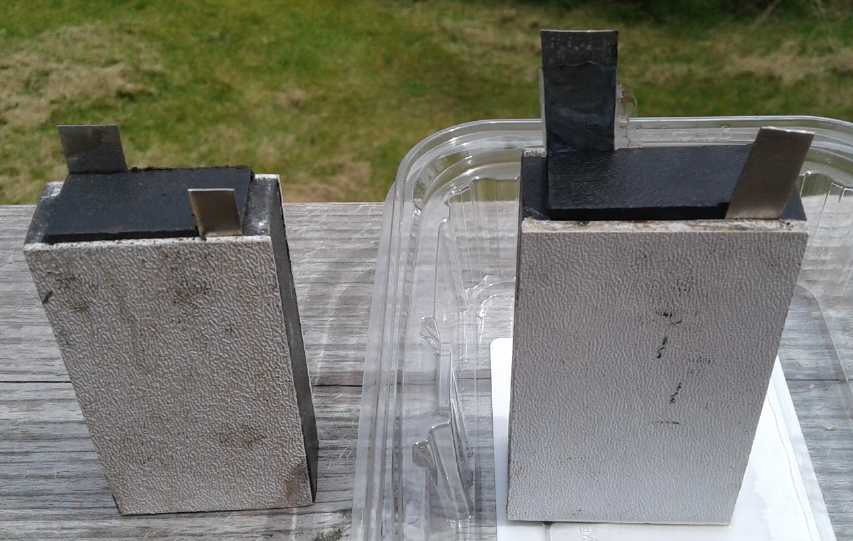

I

made

a

new small cell (in an old ABS plastic case with a

new,

better fitting lid) with fresh (KOH) electrolyte. Again I used [some

other] chunks

of the "D" cell for the nickel oxides side, with a piece of

cupro-nickel sheet as a current collector plate. I painted the osmium

doped

film on the zinc with a small brush.

I

made

a

new small cell (in an old ABS plastic case with a

new,

better fitting lid) with fresh (KOH) electrolyte. Again I used [some

other] chunks

of the "D" cell for the nickel oxides side, with a piece of

cupro-nickel sheet as a current collector plate. I painted the osmium

doped

film on the zinc with a small brush.

The cell worked! And it had very good current for the size

of the electrodes. So either the coating worked great, or it had

dissolved in the caustic alkali. Furthermore the self discharge was

quite low -

probably the good fitting lid was keeping fresh oxygen out.

Next the

question was what would the cycle life be? Would the zinc grow

dendrites and short the cell as usual, or did the film keep it out of

the electrolyte entirely?

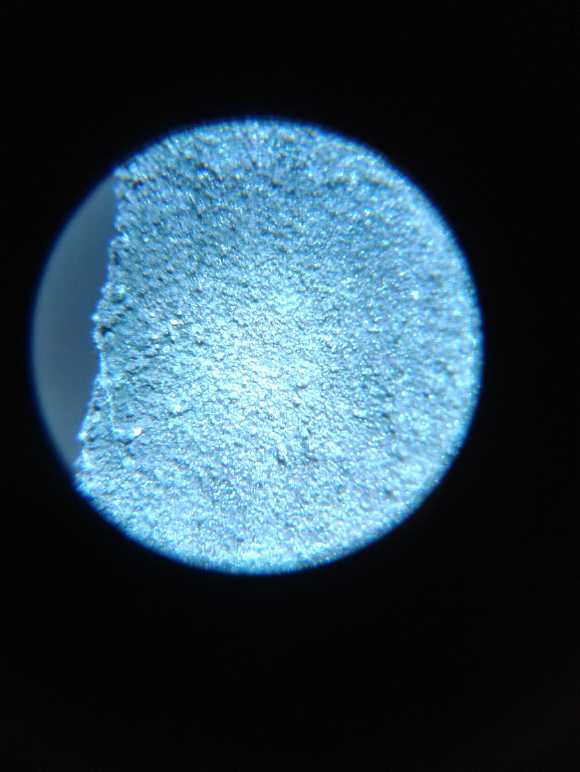

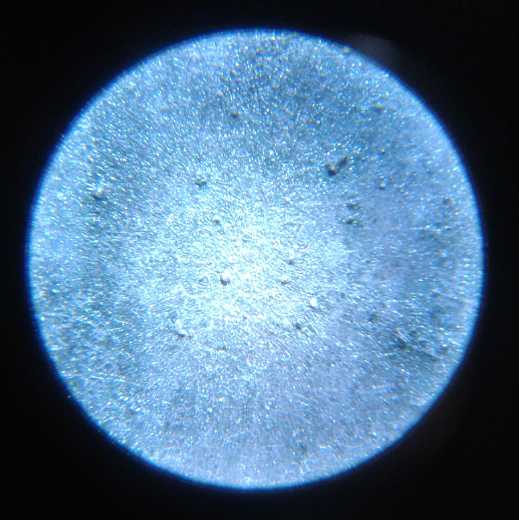

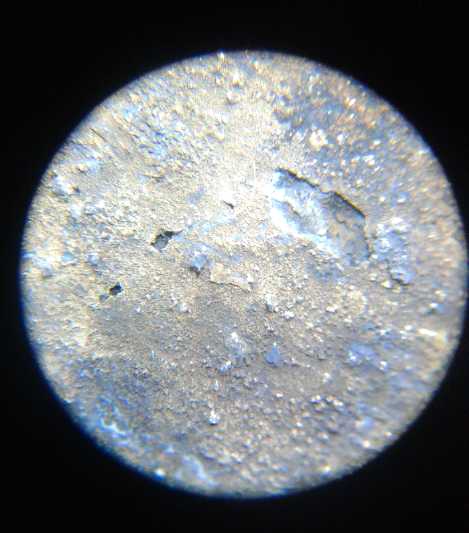

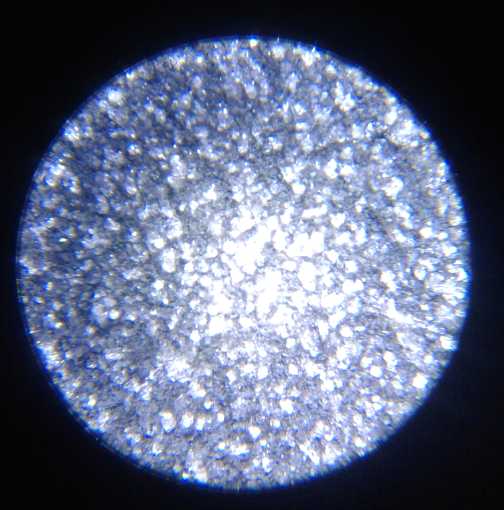

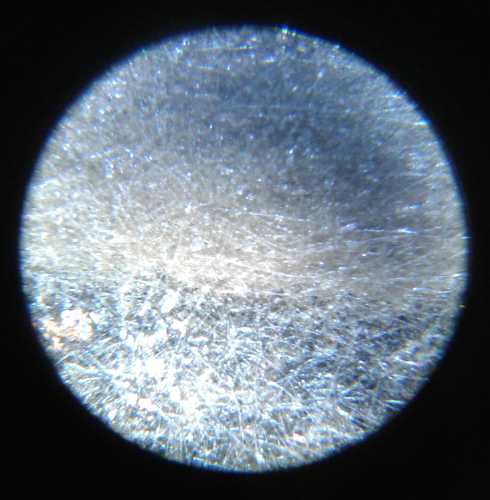

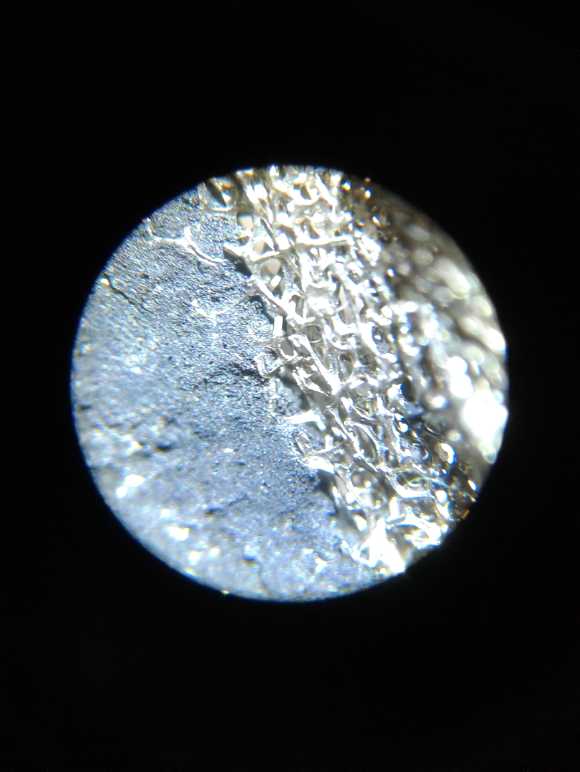

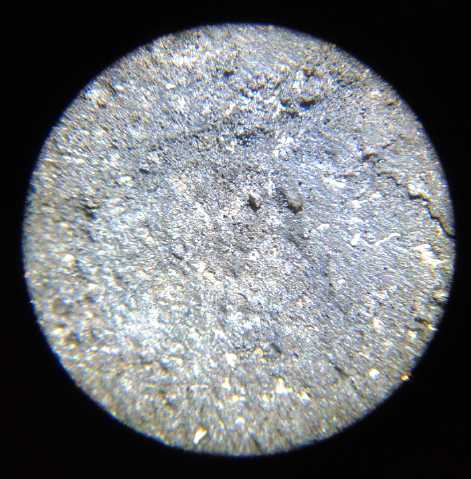

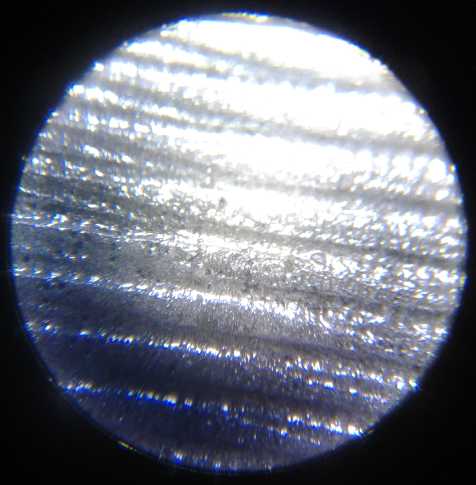

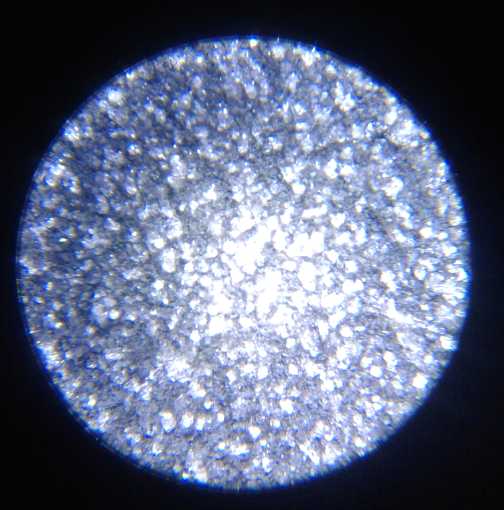

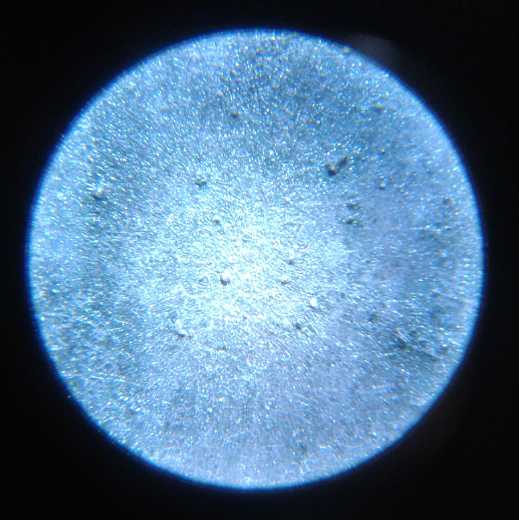

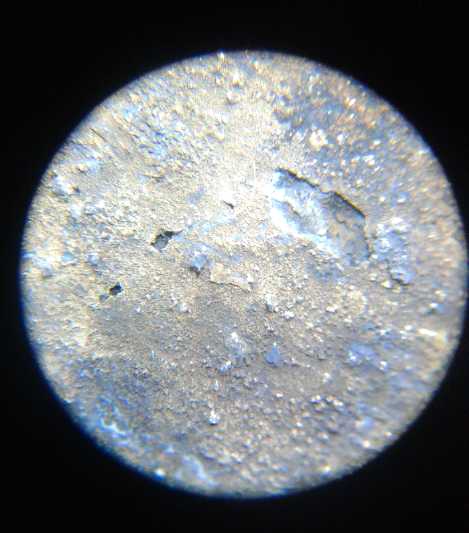

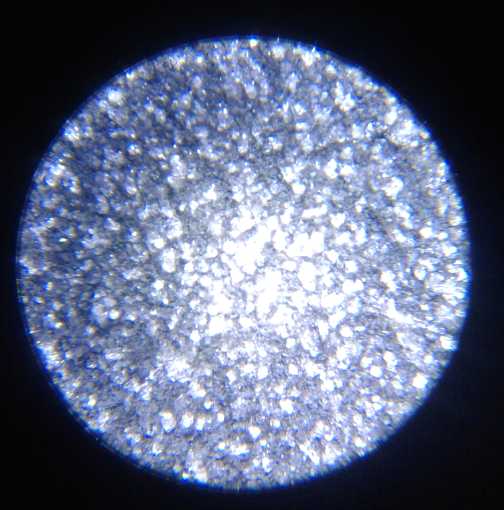

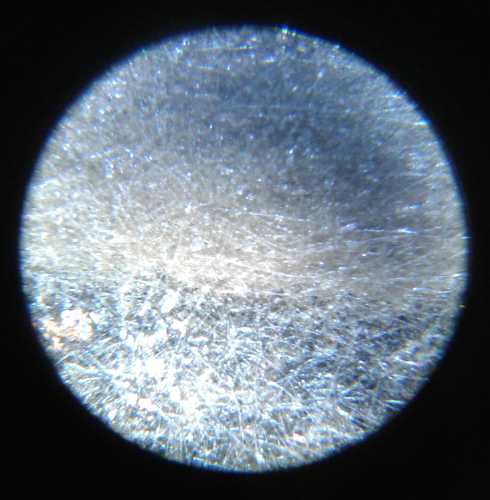

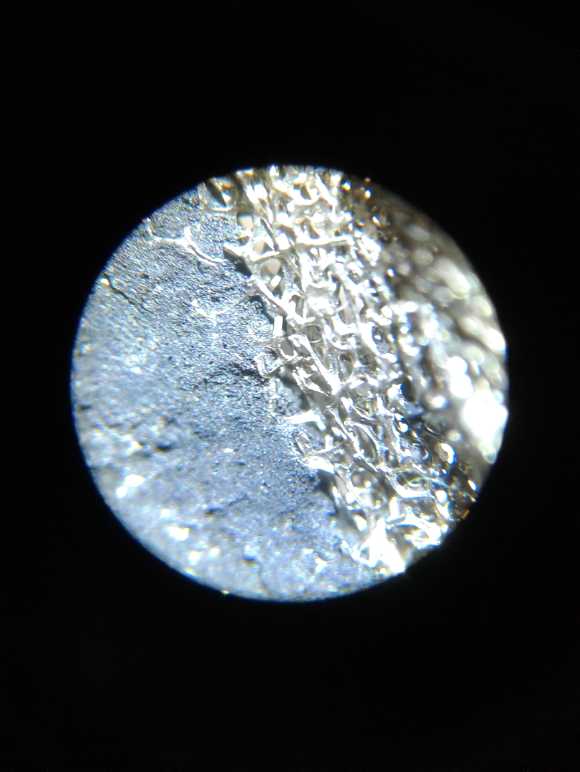

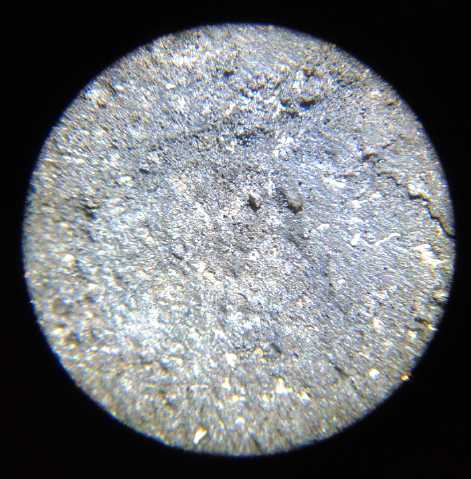

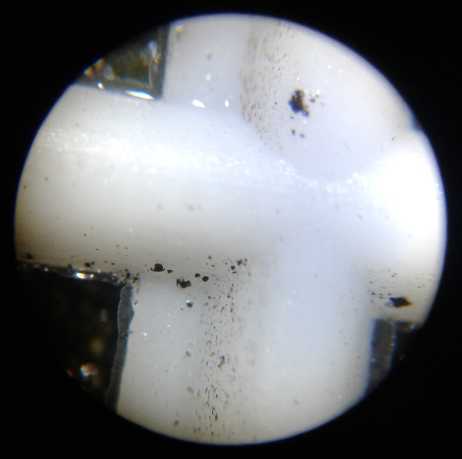

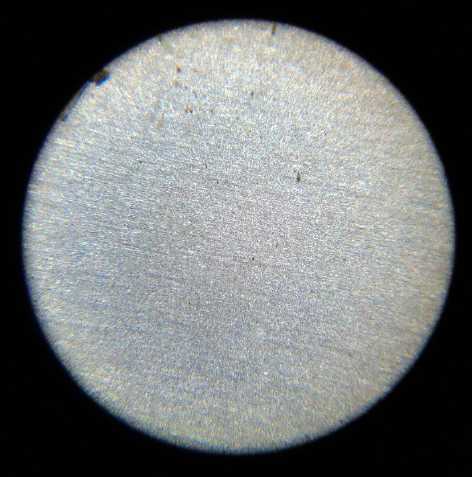

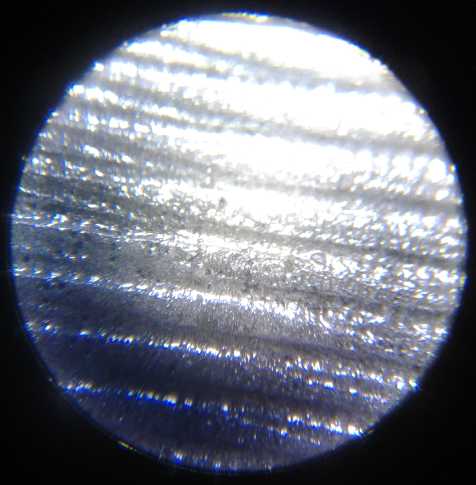

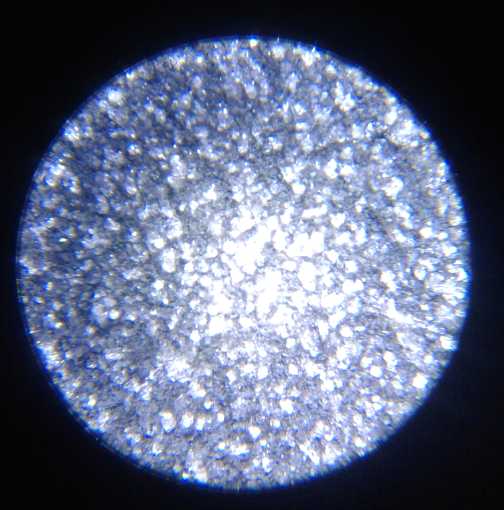

Seven charge-discharge cycles worked without dendrites

shorting the cell. That was more than I ever got before. After the

fifth and eighth charge I opened the cell and inspected the separator

grill and the zinc electrode under a microscope. No dendrites! And the

cell continued to work.

It looked like a winner! And after all these years and all this

research, the

only thing different from so many other short-lived or relatively short

lived nickel-zinc cells was the coating on the zinc - which I had

formulated a decade ago but not put to its best use! I may still

experiment occasionally with milder electrolyte and different metals.

There may be a number of things that will work well. But even if

nothing comes of anything else I try, this seemed to be an excellent

cell!

But the zinc, while not forming dendrites, still degraded.

Eventually the first one disintegrated at the water line. Next will be

figuring out what to use to jell the zinc electrode to prevent that, to

make it "permanent".

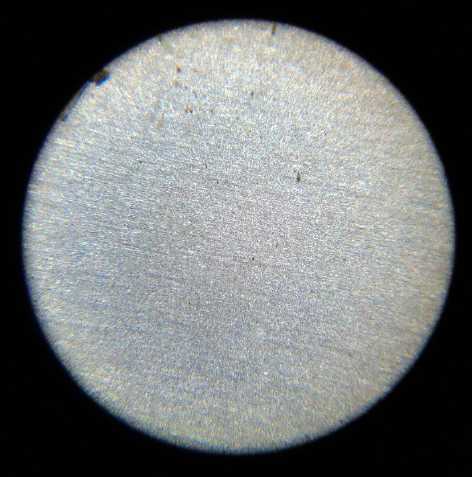

I took many pictures of the several surfaces under the

microscope during making, before use, and after being used, to the

point that when I came to use them, I had lost track of what many of

them were.

A "fluffy" electroplating of porous zinc on the

zinc electrode to give it

more substance and surface area came out much thicker near the edges

than in the middle, so improvements are needed to the plating process.

Once the design - every aspect of each component of the

cell - is optimized, fast and automated manufacturing techniques and

production will become the main focus.

But in spite of the progress, somewhere heading toward the

end of the month I must have "burned out" on chemistry & materials

sciences. I did some studying, but didn't get any more actual work

done.

Misc

Of course one continually learns more about topics

previously mentioned. I wondered in a recent issue why it seemed to

take more energy to recharge the car than the indicator said it had

used. One reason: it was mentioned in a video that recharging a car

with a lithium battery is only 90 even down to 80 % efficient. Lower

charge

efficiency would account for a good share of the discrepancy.

---

There was something odd with the solar panel system I had

put in for the off-grid lady across the road, which was supposed to

have been finished in May. When I first tried it, the 1500 watt

inverter had run her 1000 watt 'shop vac' vacuum cleaner. Then it

wouldn't. I attributed it to the initial overcharging of the 'frame 27'

lead acid battery I had given her (owing to the charge controller

unexpectedly being "positive ground"). I finally brought over a four

100 amp-hour lithium cells battery, a spare from the old Suzuki Swift

EV. It still wouldn't run! It was all the same: turn it on and after

about 2 seconds the low voltage alarm would go off on the inverter. In

a couple more seconds the 100 amp breaker I had put in for safety would

blow. I realized the #10 wires I had used, tho quite short (2 feet),

were pretty light for such a heavy load and replaced them with #6. No

change! I finally thought: it worked the first day.... what?... until I

had installed the safety breaker. I took it out and taped the wires

together. Sure enough, it worked fine! The 100 amp circuit breaker

itself was

high resistance. I found the in-line battery fuse from the old Mazda

RX7-EV and installed it where the breaker had been, and sold her the

spare lithium battery, which would doubtless run the vacuum cleaner

longer in a session, and last longer in years, than

the old "27" lead-acid. (notwithstanding that I had put sodium sulfate

in the "27" in 2016 to make it last longer. I got it as a scrap battery

about 4 years ago and it's still fine.)

---

Toward the end of the month, on the 24th, I returned to

milling my spruce after neglecting it all winter and spring when it was

cold and

the days were short. I had purchased an Alaska mill off Amazon for my

big chainsaw. (one might say belatedly - previously I had borrowed

one.) After much assembly, setup and chainsaw issues (putting on the

very

dull chain that had hit a screw... on backward at first, a terminally

dull chain sharpening file, mixing gasoline...) I sliced into one of

the smaller logs now lying there almost two years and made a couple of

slabs. It was hot, loud, stinky and exhausting. I had to repeatedly

stop to step back and breathe some clean air. Oh well, just a few

chainsaw cuts to make it into big cants, and then I could use the fine

electric handheld bandmill I had invented last year [TE News issues of

2018] to make lumber. It made eleven 12 foot 2"x6"s and one 2-1/2"

thick slab.

As I worked, woodbugs and termites and millipedes were

trying to find

new places to get back under the bark. The wood was spalted. And it had

cracks (but they were likely formed when it was felled). Yes, it was

high time to get the rest of the spruce milled up. Another winter and

it might not be worth milling.

---

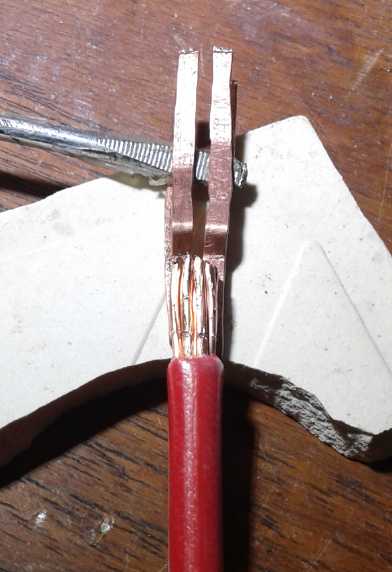

Wiring the

HAT35V-50A Ceramic socket

I could see the

ground effect vehicle, sitting there

waiting

all month, wasn't going to get its wing in June! And I fired the

ceramic HAT36V-50A socket in the kiln and wired it, but I hadn't even

made

the HAT36V-50A plug to plug the kitchen water tank into it.

I could see the

ground effect vehicle, sitting there

waiting

all month, wasn't going to get its wing in June! And I fired the

ceramic HAT36V-50A socket in the kiln and wired it, but I hadn't even

made

the HAT36V-50A plug to plug the kitchen water tank into it.

(Shoulduna used that camera for a close-up!)

The idea of putting up more solar panels remained just an

idea even tho I had the panels. I became aware of some obscure but

important safety considerations about HE ray energy and set that aside

while I consider whether or how to continue. Still, successful new

chemistry battery results atone for much lack of progress in other

areas.

But in a late night work session on the 27th I at least

cut foam ribs for the 'GEV's wing. (At the back they end where the

steerable elevator flap begins.) And the powerful 90mm ducted fans

("electric jets") had arrived - but not the "ESC" motor controllers for

them.

Beaten to an "Ultra Efficient" Electric Car! - the Lightyear One

On

youtube

and

in

news articles on the web I found the "Lightyear One",

a Dutch prototype for an ultra-efficient (their term as well as mine)

production vehicle complete with built-in solar panels, by the same

team that had won the cross-Australia solar powered car race a few

years ago against some big-name competition ("Honda" was mentioned). In

the video it went for its very first low speed drive. I saw them

pushing it backward - maybe like my Sprint in its current configuration

it doesn't back up yet!

On

youtube

and

in

news articles on the web I found the "Lightyear One",

a Dutch prototype for an ultra-efficient (their term as well as mine)

production vehicle complete with built-in solar panels, by the same

team that had won the cross-Australia solar powered car race a few

years ago against some big-name competition ("Honda" was mentioned). In

the video it went for its very first low speed drive. I saw them

pushing it backward - maybe like my Sprint in its current configuration

it doesn't back up yet!

It is expected to use 2/3 of the energy of a Tesla (or

Leaf, etc.) to go the same distance - a similar figure to what I was

trying to achieve for in-town driving. A big difference was that theirs

was designed and made with the efficiency goal in mind from the ground

up, whereas I simply had a car conversion in mind. They built it light,

incorporated the best solar cells right into the roof, hood and

hatchback, and made it extremely low wind drag. (As good as the GM

EV-1?) So its highway efficiency would no doubt be highest, and

doubtless better than a conversion could achieve. (But the Sprint was

pretty much the lightest mass-produced car, and not so much wind drag

either. I wonder if the original Suzuki equipment for manufacturing the

Swifts/Sprints/Fireflys is all rotting in some junk yard(s) somewhere?

But I suppose resurrecting that assembly line is a ridiculous idea!)

Perhaps I should just admit someone has (at long last)

beat me to it and give up. OTOH it's a prototype and they may not get

it into production. If they do it will be a very costly car. I couldn't

find

any info on the four in-wheel motors, but somehow it got me thinking

about ultra-efficient motors, controllers and transmissions again for a

few days. On July 1st I came up with inspirations for better solutions

for both unipolar BLDC motors and variable transmissions. They must

have been long festering in my subconscious mind to both pop up like

that on the same day!

Bonnet, lid and liftback

are all solar panels, all cells

independently contributing even if others are in shade.

(1.5 KW total solar? IIRC)

Solar on a car using many thousands of watts may sound almost trivial,

but it's always

charging and the makers estimate as high as 10,000 to 20,000 kilometers

free travel per year

owing to the solar recharging. (the higher figure is if you live

in a cloudless desert at lower latitude)

I suspect money helps get the layout and

cosmetic details looked after.

I suspect money helps get the layout and

cosmetic details looked after.

(What must all these custom components have cost?)

Unipolar BLDC Motor Concept

Any lingering thoughts of maybe getting the

newsletter out on Canada Day (July 1st) were dashed when that morning I

got to the "Unipolar BLDC Motors" idea section (Electric Transport,

below),

and

started

realizing

exciting new possibilities and exploring

them "on paper" as it were.

Any lingering thoughts of maybe getting the

newsletter out on Canada Day (July 1st) were dashed when that morning I

got to the "Unipolar BLDC Motors" idea section (Electric Transport,

below),

and

started

realizing

exciting new possibilities and exploring

them "on paper" as it were.

I hadn't been able to work out a unipolar magnet rotor and

stator design that would work properly before, but now I discovered

that if one went from "typical" 3-phase motor design to more phases and

activating coils individually instead of in pairs on opposite sides of

the stator, certain configurations appeared to work. If one could be

made to work well, it should be worth doing. Of course a custom motor

controller would be required too.

Even if I still came up with nothing I could manage to

build for a variable

transmission, with two such motors of maybe 8, 10 or 12 coils, each

driving one front wheel, together they would probably have enough

torque for fixed 3 to 1 ratio chains, belts or gears, allowing both

sufficient startup torque and highway speeds at safe motor RPM.s.

Perhaps that would be at least as worthy of pursuit as the

reluctance motor, given the "ultra-efficiency" of BLDC motors and their

high mechanical tolerance for small dimensional variations. And I've

already made good BLDC motors and controllers that at least work.

Variable Transmission Concept

Then toward evening (still July 1st) inspiration struck

for a better

variable transmission, too. This torque converter would combine two

previously used components: the planetary gear and the centrifugal

clutch.

What the planetary gear - or any variable ratio coupling

component - lacked was a means to control the third "control" element

to variably change the ratio between the other two elements coupling

the motor (ring gear) to the wheels (planets assembly). (That was where

I had tried using a rope around a large pulley. That wasted energy. But

it worked with a flywheel to transfer revved up motor energy into car

motion and get the car moving.)

A centrifugal clutch unit such as I had already made could

provide the means to control the control element: the faster the motor

(and centrifugal shoes) turned, the more stongly the centrifugal drum

would want to turn with the motor rather than just turn opposite to it.

By having the control element be the one that spun fastest with the

least torque (sun gear), the forces to slow the drum would be

maximized, which would provide highest torque to turn the output

element with the least torque on the drum.

Free spinning with the car stopped, the centrifugal outer

drum on the sun gear would turn around twice as fast as the motor

turned the ring gear with the centrifugal shoes on it. And it would

take 1/2 the torque to slow or stop it. (Ratio depending on the actual

planetary gear chosen.) So if the motor with the centrifugal shoes

turned 1500-2500 RPM, the drum if it was free-spinning would turn

3000-5000 RPM in the opposite direction, and the output gear wouldn't

move. But hopefully somewhere in that range we're looking at

speeds that will sufficiently engage the centrifugal coupling. As the

shoes engage the outer rim, the set would have a very large tendency to

want to slow the drum, which will turn the planets assembly and drive

the car ahead, slowly at first with highest torque and then graudally

increased speed and reduced torque.

While the ratio of the input (ring) to output (planets)

with the sun gear (drum) held stopped might be 1.5 to 1, the sun gear

goes from freely spinning before the centrifuge engages, to being

loacked and turning with the shoes and so all three gears turn in

unison, 1 to 1.

On the other hand (July 3rd - I'm trying to finish up the newsletter

but I can't stop thinking about it!)... a better way to do it would be

to have the motor drive the planet gears assembly, with the output on

the ring gear instead of the other way around. The centrifugal clutch

drum is still on the sun gear. That way, with the car (ring gear)

stopped, the drum wants to speed up to 3 times the motor speed instead

of 2 times, with only 1/3 as much torque required to bring it down to

motor speed. More importantly the drum also spins in the same

direction as the motor. That means that as the centrifugal shoes

contact the drum to slow it down, the rotating force tries to make the

motor speed up instead of slow down. The inertia of the spinning drum

works for us instead of against us. This is something I have been

trying to figure out how to achieve since 2012 too.

In theory if the drum were stopped the output/ring

gear/car would go backward at 1.5 times the speed of the motor. In

fact, the drum will never go slower than the motor, when it is fully

locked to it, and all three gears will turn in 1 to 1 unison as before.

Another possibility is to use, say, an idler wheel and a

belt between the ring gear (motor) and sun gear (control element).

Pulling the idler wheel tighter couples the two more strongly, so the

driver would have a stick clutch or something to do that. (That's close

to something I tried before, but applied a little differently.)

So there it is! The two components together, the planetary

gear to allow

variable ratios and the centrifugal (or other) clutch as the ratio

control

element, should make a fine variable torque converter. It seems it has

taken me a decade to figure this one out, too. I started on a variable

torque converter in spring 2009. This one should be more satisfactory

than any previous idea.

The variable reduction output would feed a further fixed

reduction to the differential, eg, 3 to 1, to drive the wheels.

---

I am now impinging on July, so it's time to wrap it up!

I'll call it June 31st, 32nd and 33rd. (Hah! - that means I got more

vegetables planted by

the end of June after all.) (January to June only has 181 days anyway,

while

July to December has 184. Like so many things on this planet,

the calendar isn't the first or last that 'just grew', piecemeal,

instead of being logically designed.)

Early June Diary: where does my time go?

1st to 3rd - Add photos/edit/finish up of TE News #132, and wrapping up

the solar installation across the road.

4th ??? Some other writing...???

5th - Another disappointing new chemie battery experiment.

6th - Fixed lawn tractor. It broke down at the far end of the field and

wouldn't move. I had to try and see what to do underneath in 15" grass,

then took a trip to town for the part. (Gasp! They had it in stock!)

7th - Writing up an article for Haida Gwaii Trader magazine for

July-August issue. (I said I'd do one every 2 months. It didn't seem

onerous when I volunteered. -- The last one was an update on the

completed Handheld Bandsaw Mill. Two others have been on aspects of

Planetary Management/Social sustainability.)

8th - Picked up the new crate of 305 watt solar panels in two trips to

Masset - 4 hours just driving. Car and trailer were heavily loaded to

bring 16 each time.

9th - Someone phoned me before I was out of bed and yakked for almost 2

hours. I planted all the asparagus I wanted, then phoned someone to see

if they wanted more of the plants. They invited me to see their

shop-building project and then dinner. Well it was Sunday anyway!

10th - Finally I just HAD to put an ad in the Trader for solar stuff.

Why else had I brought solar panels et al up to this island and then

designed the HAT36V wiring and other infrastructure stuff? Well, I had

too much to fit in a

classified ad so I had to update the price list and make it HTML and

put it on my web site. The link

TurquoiseEnergy.com/SolarStuffPriceList.html only took me to the site,

not to the page. So I had to make a link from the main page menu. The

main page was way out of date so I spent some time editing that. Wrote

up two years "null" tax returns for Turquoise Energy Ltd. I haven't got

any R & D money

out of them since 2015 anyway. Nap time. But in the evening I finally

fixed

my mini kiln. (For once, a job that proved to be easy and went

smoothly!) Then I fired the ceramic HAT36V-50A socket.

11th - Made copper spring pins and wired the socket with short #8

wires. (But I didn't get to doing a plug.)

[12th - enough of this!]

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

World Unity

In times past,

transportation and communication were such that mainly it was close

neighbors that interacted, in trade and war. Even in 1700 it took over

a week to get from London to Scotland by horse carriage. Egyptian,

Greek and Roman civilizations centered around the Mediterranean Sea

because boat travel was better than land travel. These peoples

conquered those around them to exploit the resources and make slaves of

the conquered lands. There was no thought of the conquered people

having a culture and society that might have value which was being

destroyed, or that the people

there were spiritually equal with those who managed to conquer them.

Later mostly Europeans set sail in ships and conquered

around the world to exploit and enslave, to make an empire. The British

empire sought also to educate and left their forms of law and

government behind, but the primary motivation was still domination and

economic advantage. If there was to be unity, it was by the conquered

being forcibly united with the conquerors.

In the last 500 years the world has been entirely occupied

and settled. The attempts of one culture to dominate other more or less

equal cultures was rife throughout Europe and later North America over

the last millennium or so. Mostly little consideration was given to the

conquered. Then ending only a decade before I was born, the whole world

passed through the tremendous convulsion of world war two, a clash of

wills between several ideologies embodying mostly domination and

enslavement of peoples - starting with one's own country's peoples.

When I was young, countries were still much more separate

and

culturally isolated from one another. The so-called "United Nations"

had been formed, but "the international community" wasn't a part of

speech and

no one spoke much of "international law". Besides Europe, other

continents

were mystical

far-off lands that were (surely) of little concern to us in North

America.

"We all drink the

same water. We all breathe the same air." - John F. Kennedy

Trade and commerce started to change the world. Suddenly

everyone everywhere wanted to learn English as a means to be able to

communicate worldwide, to do business and open up their markets. I'm

not extolling English for its own sake, but it was the first

time everyone had, implicitly, agreed on one particular language as the

means to enable

international communication. Strange people speaking strange tongues

were suddenly no longer so strange or mysterious when they spoke in

your language, or at least one you too had learned.

We are politically separate, but through extensive trade

the world has largely become one economy. While we will retain our

cultural and racial identities for ages, the world will continue to

become more and more equal, more and more "all one people" as

international and intercontinental relationships are viewed. Wars,

refugee migrations and the fierceness of competition will be in the

past when the population has dropped (and is thereafter managed to

maintain stability) and there is material prosperity for everyone.

Witch

Hazel

&

Red

Spots

I had been been getting red spots on my upper legs for

some

time, which were proving intractable/chronic. They seem to be some kind

of mite - perhaps house dust mites? probably not even a millimeter

long. I have stabbed some with a needle and the spot goes away, but

more often I stab myself. I don't recommend it. I have recognized for

some time that they occur when something is pressed hard against my

leg, as in carrying in a pail of firewood or crossing my legs and one

is pressed against the underside of the desk. The area pressed is

exactly where

they occur. Apparently they can't penetrate the skin unless helped. But

then they seem to spread.

Antibiotic cream sort of helped. Daily baths sort of

helped. The witch hazel, applied lightly (hard rub bad), got rid of

them. And if a new spot should appear, a drop of it gets rid of it. And

Wikipedia says there's no proven medical use for witch hazel. Hah!

"Rivers

from

the

Sky"?

Here are a couple of good photos I ran across in a video,

showing what is said to be the "rivers from the sky" rainfall that has

never been seen until these last few years, which are now causing such

devastating flash flooding around the world.

To see each week or two's growing crescendo of calamities

from all around the world, go to "World of Signs" and "Nared King".

Calgary, Alberta

Calgary, Alberta

Mexico

Mexico

ESD

(Eccentric Silliness Department)

* I searched on eggwhite as something to put on burns, having heard of

it

and noticed that it wasn't mentioned in the Wikipedia article on

albumen. There were some hits where it was obvious that

it wasn't wholly in favor in the medical community. A lady on youtube

said,

with reasonable arguments, that it was an urban myth and that eggwhite

was no good for burns - and it might cause a salmonella infection.

But there were exactly 21 comments under the

video, 17 from people who had used it on various burns mild to

severe including

sunburn that said she didn't know what she was

talking about, that there was nothing better for burns than eggwhite.

Not one of the commenters supported her. One person said eggwhite has

the amino acids glycine and proline and that these give the body the

building blocks to build collagen when eaten, and that it seemed to

work well applied on burns too.

* The issue reminds me of "planting by the phases of the moon." This

doesn't fit with scientists' narrow logic, so they are quick to call it

"superstition". But apparently any farmers' almanac discloses that

there is statistically more rainfall at certain phases of the moon than

between them. (IIRC it was more around full moon and new moon.) The

moon makes atmospheric tides as well as oceanic. Depending on climate,

if you don't have running water for the crop or "anytime" irrigation it

could be important or at least helpful to plant according to the phases

of the moon.

* They say there's such a thing as "50-50" chance. When I open my

microwave oven door, the coffee cup handle is almost invariably rotated

around the back somewhere. It's been that way at least for a year or

two. But the last couple of weeks sometimes it's been at the front or

at the side. That's really spooky to find the coffee cup handle at the

front when I open the door! (Is the rotator platter in my microwave

wearing out? or am I just selecting the right amounts of time sometimes

now, instead of invariably the wrong lengths?)

* A store owner tries to guess what to order that he hopes his

customers will want to buy. With some items it's like throwing a dice -

people may buy lots, or none at all. That's why it's called

"merchantdice".

* People have said that the last living relative of the dinosaurs is

the tuatara of New Zealand. But they forgot the Thesaurus. Oh, wait...

that's probably extinct now, too.

* Something with four square corners is a rectangle. If one side gets

shoved too hard the corners buckle and it becomes four wrecked angles.

* Crazy English spelling conventions yield a seafood favorite: everyone

loves ghoti! ("gh" as in "enough", "o" as in "women", "ti" as in

"vacation")

* Nilliamps: current flows too small to measure.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection and consistency before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

(Note: Don't miss the Solar Car Charging

Trailer under Electricity Generation!)

Ground

Effect

Vehicle

(first

the

R/C

Model)

I didn't get much done on

it, but the 90mm ducted

fans arrived early in the month, and I did cut some styrene foam ribs

for the wing late at night on the 27th.

A control problem occurs to me: the "ESC" motor controller

I

have presently seems to have no control to put it into reverse and I

expect I'll be very lucky if the new ones (where are they?) have

reverse either. And the radio control also has no control for

reversing, much less for reversing two motors separately. By using the

"elevator" control it could thrust two motors separately. Then how do I

control the elevator? With the "ailerons" control?

It will be very tricky docking if one can't reverse the

thrusts. I'll have to either make some elaborate on-board electronics

or

accept that the RC model will have some aggravating limitations - all

in the

control system.

The ribs for the wing

The ribs for the wing

The left-and-right ducted fan "electric jet"

motors will mount just above,

The left-and-right ducted fan "electric jet"

motors will mount just above,

and may shrink (or replace?) the "dorsal fin" rudder idea.

The elevator goes behind the wing to almost the back of the hulls.

One might say the wing profile will be somewhat akin to a plane with

its "flaps

down".

More

Unipolar

BLDC

Motor

Ideas

I was closing windows on the computer screen when I ran

across

TurquoiseEnergy.com from editing it last month. The Electric Hubcap

motors were of course there, with the word "unipolar". I see a definite

advantage of unipolar as being reliability: there is no path

from B+ to B- except through a coil. Spurious turn-on of the wrong

transistor can't create a short circuit and blow up the controller. If

the permanent magnet assist idea works, reduces energy consumption,

then that will also be a major advantage. So far I have been unable to

test out that feature in a motor.

Unipolar coils can work easily for a reluctance motor

because

magnetic polarity doesn't matter - either the rotor metal is attracted

or it isn't.

But I thought

about how I had been unable to figure out a BLDC rotor magnet

& coil configuration that would actually work. There had to be

north and south

poles on the rotor and in the stator for good magnetic circuits, or the

thrust was much reduced.

Then, any arrangement seemed to reverse the drive half way around the

rotation. One would have to reverse the polarity of the drive to finish

the circle. Then it wouldn't be "unipolar".

But that was with turning on coils in pairs, one north and

one south, across the diameter of the motor, and using typical 3

phase power.

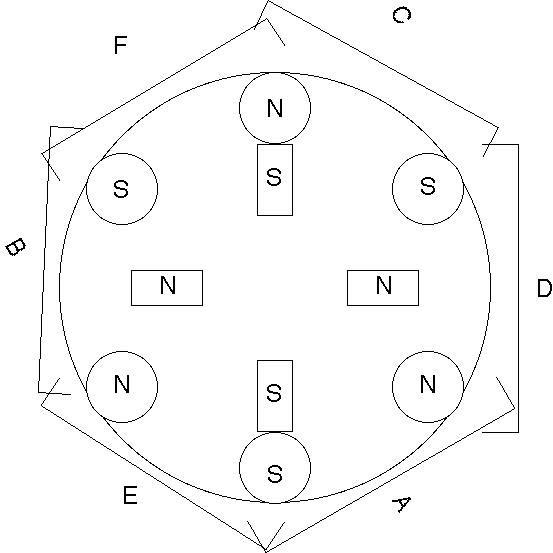

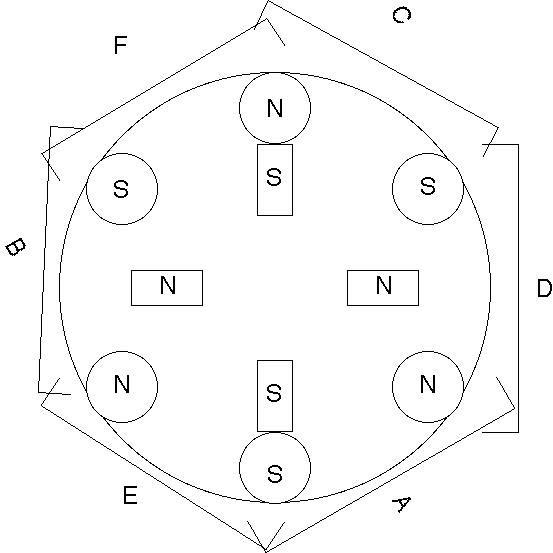

Out of the blue I thought I had an inspiration. By the

time I had drawn it all out and figured out how it would work, it

required a different and more complex operation of the coils, and very

specific numbers of coils and magnets, not the usual 3-to-2 of 3-phase

motors. But it

could use the regular Electric Caik motor. That would mean I

wouldn't have to make a new motor to try it out - just change the

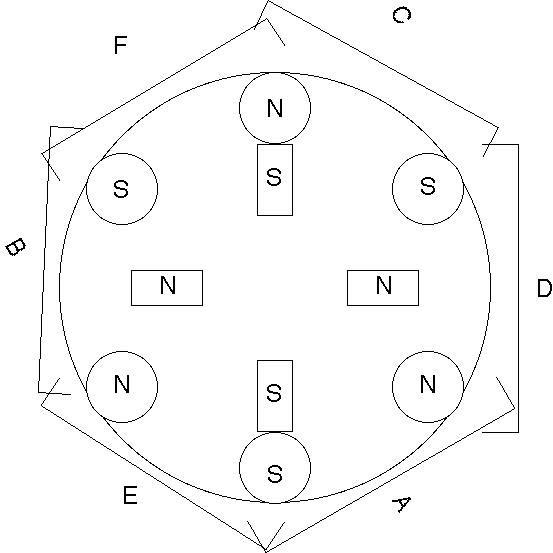

wiring in the Electric Caik and connect the unipolar motor controller. Instead of activating pairs of coils across

the motor from each other, each of the 6 coils

would be separately actuated. Half the motor would still have reverse

thrust at any given rotor rotation, but that half wouldn't be activated.

They wouldn't be actuated in fixed "pairs", but in

rotating pairs. Only two coils would be on at a

time. Thus to rotate clockwise, the coil pair activation sequence would

be: B, E, A, D, C, F - counter-rotating compared to the rotor.

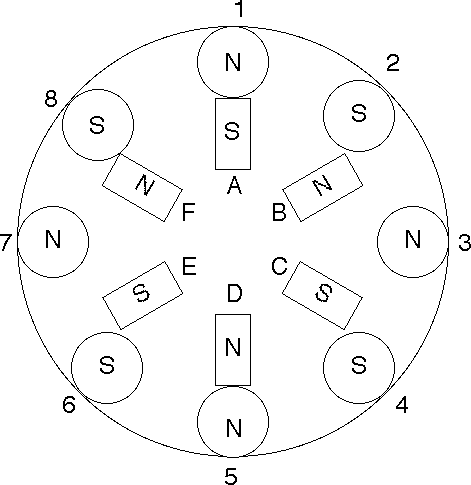

"Electric Caik" version

"Electric Caik" version

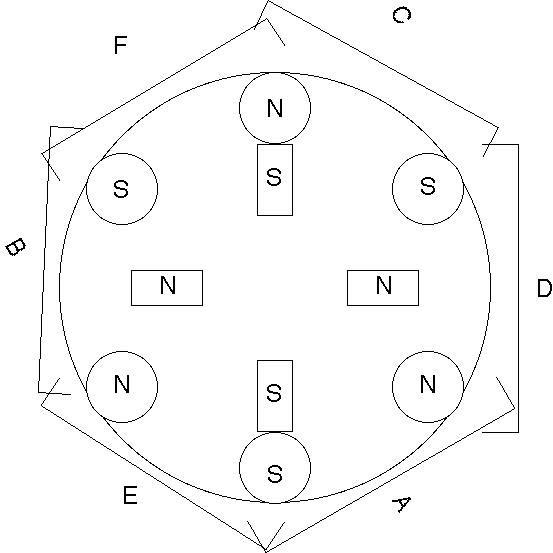

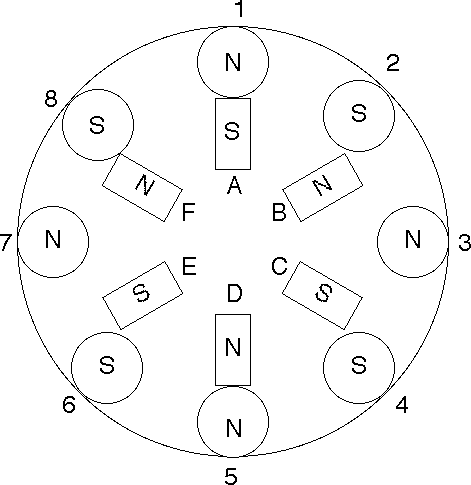

But an 8 coil, 6 magnet "Electric Hubcap" size motor would

probably be a more valuable unit. It would have more power and torque,

and instead of only two coils on at a time, it could have three or four

- up to half of them - to further increase the torque.

8 coil, 6 magnet "Electric Hubcap" size version.

8 coil, 6 magnet "Electric Hubcap" size version.

To rotate, individual coils are activated [always in pairs for magnetic

equality?]

Start: 6 & 7 are activated. If more torque is needed, 5 & 8 are

activated.

When magnet F reaches coil 8: coils 5 & 6; add 4 & 7 for more

torque.

Then 4 & 5, then 3 & 4, then 2 & 3...

But the 6 coil, 4 magnet, version looks like it should

work for a full rotation. That gives me hope that there must be

other workable combinations too. Obviously there must be an even

number of magnets on the rotor and an even number of coils on the

stator to avoid two in a row of like polarity. It looks like if the

magnets are N-S on opposite sides of the rotor, the coils opposite must

be N-N, or vice versa. I need to think further on that! Apparently it's

trickier

than it looks. I think I need to cut out a paper rotor and actually

turn it in a paper stator for each set of coils and magnets, to

properly plot out coil activation sequences.

With unipolar coils, one can try out the promising

"permanent magnetic assist" idea (in some 2016(?) issues of TE News).

There just might be some 'free energy' to be had in that!

Jim

Harrington's

Latest

Electric

Outboard

Motor

Jim sold his previous electric outboard and has

made/converted a new one. (3 HP IIRC) It is again a 3-phase induction

motor with variable frequency drive, running off 36 volts of batteries.

He says he ordered the components including the motor from China and

they cost far less. He isn't making innovative motors, controllers and

new chemistry batteries, but unlike mine his projects get done

and work in good time!

36 VDC to 240 VAC Inverter, and controls

36 VDC to 240 VAC Inverter, and controls

Other

"Green"

Electric

Equipment

Projects

36

V

DC

"Off

Grid"

Infrastructure

HAT36V-50A Ceramic Sockets

On the evening of the 10th I repaired my mini

kiln and

then fired the two clay socket

halves to 'cone 05', which my scribbled piece of paper said was the

temperature the kiln reaches after 75 minutes, after which time I

unplugged it. The red clay looked the same after firing as before, but

it had that ceramic "clink" to it when the pieces touched together.

Then I went hunting all over for the plug, on a long black cable. How

do I keep misplacing things? In this case the cable had kept me from

putting it in the "HAT36V" drawer and I found it draped over a chair in

the workshop. Somewhat to my amazement, it had shrunk to virtually the

ideal size in drying and then firing. (I had scaled the mold something

like 18% oversize - apparently a good guess... for this clay, at this

stiffness, at this firing temperature. I hope it's duplicatable.)

On the evening of the 10th I repaired my mini

kiln and

then fired the two clay socket

halves to 'cone 05', which my scribbled piece of paper said was the

temperature the kiln reaches after 75 minutes, after which time I

unplugged it. The red clay looked the same after firing as before, but

it had that ceramic "clink" to it when the pieces touched together.

Then I went hunting all over for the plug, on a long black cable. How

do I keep misplacing things? In this case the cable had kept me from

putting it in the "HAT36V" drawer and I found it draped over a chair in

the workshop. Somewhat to my amazement, it had shrunk to virtually the

ideal size in drying and then firing. (I had scaled the mold something

like 18% oversize - apparently a good guess... for this clay, at this

stiffness, at this firing temperature. I hope it's duplicatable.)

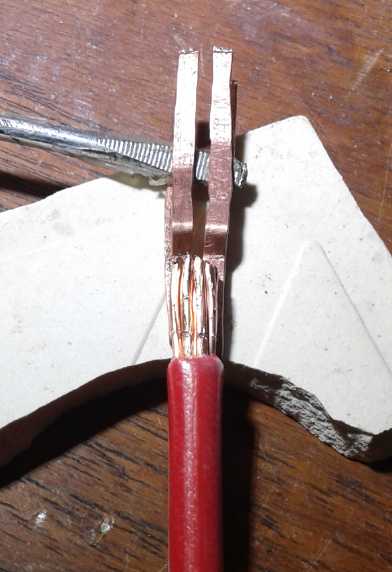

The next morning I made the "hairpins" and attached two

short "pigtail" wires. The plug seemed to fit pretty snugly.

How to hold the two 'hairpins' in line while

soldering the wire on?

How to hold the two 'hairpins' in line while

soldering the wire on?

Since it worked, I molded two more. I may

do a couple more yet before I fire them.

(My only #4-40 bolts are a bit too short, 1/2"

so I made the square indents.)

Another small 36 V solar water heater

An off-grid friend had bought some of my 305

watt solar

panels. I saw he had connected one straight to a ~15 liter hot water

tank that had come out of a travel trailer, now lying loose. I knew

from my own experiment that he wouldn't heat water very fast with a 120

volt

heating element with a panel under 40 volts. My next two Dernord 36

volt water heater elements arrived on May 31st and I took them to his

place on June 2nd. It turned out the 1 inch thread model fit his tank.

With considerable difficulty we (he) got the rustic old element out and

we put the new one in. (rustic = rust; ick!) I should have checked the

resistance/power of the old element. It didn't occur to me. It probably

wasn't even 1000 watts.

An off-grid friend had bought some of my 305

watt solar

panels. I saw he had connected one straight to a ~15 liter hot water

tank that had come out of a travel trailer, now lying loose. I knew

from my own experiment that he wouldn't heat water very fast with a 120

volt

heating element with a panel under 40 volts. My next two Dernord 36

volt water heater elements arrived on May 31st and I took them to his

place on June 2nd. It turned out the 1 inch thread model fit his tank.

With considerable difficulty we (he) got the rustic old element out and

we put the new one in. (rustic = rust; ick!) I should have checked the

resistance/power of the old element. It didn't occur to me. It probably

wasn't even 1000 watts.

He filled the tank from a hose and we hooked it up. There

was just one problem: it was raining and there was virtually no solar

power to be had. When we've had some sunny weather and I get a chance

to go up there again, I'll see how that's faring. (As of the 14th,

still not one nice sunny day.)

Near the end of the month I saw him and asked. He said it

gets "pretty warm". I guess for "really hot", especially on cloudy

days, one would want two solar panels instead of just the one he has

connected (which isn't well aimed, either - almost vertical against a

westerly wall, held in place with a rope).

Rong Inverter? ...Hmm, No!

I had got a 2500 watt, 36 volt to 230 volt inverter to run

my well pump if the power was off. I decided to order a similar 36 to

120 volt one to have one for the fridge and another (I already have)

for the freezer. It

arrived on the 10th but when I took it out of the box, it looked like

another 36 volt to 230 volt one! What to do... send it back? keep it to

sell? and then, order another one?

The next day I looked at the label on the bottom to see if

anything said the input was 36 volts. The tag had everything with boxes

to tick off.

The numbers ticked off were 36 VDC, 120 VAC, 60 Hz, 2500 watts. Huh?

120 volts with a 230 volt socket? Did I need to make an adapter?

I looked at the rather odd socket again and discovered it

was cleverly made with extra slots so you could plug either a 120 or a

230 volt plug into it! It had pins for both! Wow! That defeats the

whole purpose of having different plugs for different voltages! Perhaps

only the Chinese would dare do that! (I've seen another such plug

since, also on a unit Made in China.) I could plug a 120 volt appliance

into the 230 volt inverter or vice versa - especially as they were

identical on the outside except for the tick marks on the tiny label on

the bottom. The

top said simply "Power Inverter / 2500 Watts / Pure Sine Wave". That

applied to every model. (I wondered if the components inside were

actually different or if one merely changed jumper wires - or even just

programming - for the

different specs. But for that much power one suspects they'd have

different spec power transistors, capacitors, and a couple of other

components for

the different input and output

voltages. The rest might well be the same.)

I took a felt pen and printed "120 V" on the one and "230

V" on the other on top near the socket end. And "36 V" near the input

end of both for good measure. Now you can only get it rong if you space

out. The trick will be to mount the 230 V one near the well pump plug.

(Yet to be installed.) Then the position will indicate what it's for.

It seems to me the manufacturer could fix the socket

pretty easily by inserting one of two plastic plugs, flat on the

outside, that would

plug in and block the wrong holes so that only the right plug would

fit.

That could be easily defeated by removing it, but why would one do so?

Laser

Engraver

I was given a very small laser

engraver. (NEJE model DK-8-KZ) The owner couldn't get it to work for him. It specifically

prints black and white images (no grays) of size 520x520 pixels, at 350

pixels per inch. Each pixel is either burned or not burned. Burn time

for each pixel can be set from 0 to 230 - I think that's milliseconds.

I was given a very small laser

engraver. (NEJE model DK-8-KZ) The owner couldn't get it to work for him. It specifically

prints black and white images (no grays) of size 520x520 pixels, at 350

pixels per inch. Each pixel is either burned or not burned. Burn time

for each pixel can be set from 0 to 230 - I think that's milliseconds.

I understand the size is because it's made with obsolete

hard drive stepper motor systems. Clever to find such a cool new use

for them instead of the garbage can!

I spent much of the 20th and got a computer set up to run

it. (Why are these things never simple?) I recall that once upon a time

I got laser

diodes and was going to set up my CNC machine to burn holes to

perforate plastic for plastic pocket battery electrodes. I never got it

set up. This might do that job if I ever want it done.

The only present use I can see for this machine is to

engrave labels onto things like my HAT series plugs and sockets. (and

it doesn't seem to work on white ABS.) Perhaps something more in

keeping with its suitabilities will come along.

Someone on youtube said

he tried painting a printed circuit board with (?)black nail polish(?)

and burning it off the parts of the board that were to be etched. It

wasn't successful, but he hadn't yet tried a longer burn time or going

over it twice or more, which (looking at his board) just might

make the difference. (I wonder what other coating might work. Black

spray paint?) It might be a cool technique, but the board size would be

quite limited. 520 pixels at 350 pixels per inch is only about 1.5

inches square.

I view this software

installation as practice for getting the ANYCUBIC I3 MEGA 3D

printer software working as well as the GECKODRIVE CNC Table

Stepper Motor Driver. So many things to do!

Solar

Car

Charging

Trailer

Jehu Garcia is a solar and EV buff who

reports everything

he sees and does

to Youtube. He has a LOT of videos. He went to the 2019 EVWest EV show

and found a trailer with fifteen big 72-cell solar panels, batteries,

charging system electronics, a wind sensor and a sun tracker. The panels are in 3 rows. The middle row of 5

panels is the roof of the trailer, fixed in position. The sides of the

trailer hinge up from the top to make the outer two rows. These track

the sun to unfold to the best angles. Sometime during the show it was

charging a car at 4.2 KW. It seems like a great system!

Jehu Garcia is a solar and EV buff who

reports everything

he sees and does

to Youtube. He has a LOT of videos. He went to the 2019 EVWest EV show

and found a trailer with fifteen big 72-cell solar panels, batteries,

charging system electronics, a wind sensor and a sun tracker. The panels are in 3 rows. The middle row of 5

panels is the roof of the trailer, fixed in position. The sides of the

trailer hinge up from the top to make the outer two rows. These track

the sun to unfold to the best angles. Sometime during the show it was

charging a car at 4.2 KW. It seems like a great system!

It's a pity commercial EVs have no facility to allow

charging while driving. Even the 5 roof panels might let a car drive

for free in city traffic.

From it I have the idea (a) to do something similar with

my utility trailer, or (b) to put three panels on top of my Chevy

Sprint instead of one, and have two of them unfold to the sides. The

downside would be that they probably couldn't charge the car while

driving, which I would arrange for with a single panel. Furthermore

there are lots of places one would be unable to unfold the panels. Then

again, many arrangements are possible both physically and electrically.

Perhaps it could charge with one panel while driving or parked without

room to deploy, and with all three when parked and unfolded. (I was

just going to have them facing up and not try for the solar tracking

either automatic or manual.)

Am I headed into "impractical" territory here?

My

Solar

Power

System

Observations of System Operation

On the 4th the rain stopped and the sun came out for a few minutes. Of

course the solar panels were still cold. I happened into the garage and

saw that the house panels alone (6 plus the 7th one on the lawn) were

making 1550 watts! Gotta love those cool panels. By the time I got to

the trailer to see what new record it might hold, the clouds had

returned. And that was it for sun for the day.

But the next morning it was sunny and well before noon the

trailer was putting out upwards of 940 watts. That's slightly above the

75% "realism factor" for 1220 rated watts of panels, and more than ever

before. The

maximum with one grid tie microinverter seemed to be 860-870, so

having two with two panels each was helping more than last month's few

readings would have indicated. It was at least 70 watts or 7.5% extra

and a 5 year payback on the second microinverter. Later it was

down to 915 - still more than before.

Another consideration besides simple electrical payback

math is that if the microinverters are more lightly loaded the thermal

stress will be less, so the cooling fans will run less often and they

may last longer. And if one does fail, the system is still putting out

lots of power. I don't think I'd put more than ~900 watts of solar

panels on one of these 1000 watt rated microinverters again. (I suppose

I should install the second one properly in the trailer. The freezer

can't be used with the open door and wires coming out of it!)

OTOH, if the majority of days are cloudy anyway as they

were in June, one microinverter or charge controller could run more

panels and have higher output without being pushed to its limits on all

those cloudy days.

Month of June Log of Solar Power Generated [and grid power consumed]

(All

times are in PST: clock 48 minutes ahead of sun.)

As I had been logging them, the power consuming activities

noted didn't always give an

indication of whether they occurred before or after a power meter

reading. On the 20th I got the idea to put them in the square brackets

with the power readings, before or after them. I backdated this to the

15th but didn't attempt to reorder the whole month.

Note: On the 7th I thought to start including the DC power as

well as that to the grid. DC power measured is that consumed - usually

under one kilowatt hour per day - mostly by the 36 volt kitchen

water heater with a bit by LED lights. The DC "power produced" reading

disappears when the sun

goes down and restarts the next day. I virtually never look at it at

right before dark, so I can't use it. I reset the "consumed" meter each

evening after reading it.

Note FWIW: On July 2nd I turned the battery charge controller

voltage down from 40.35 volts to 39.6 volts. That's 13.2 volts for each

12 volt section or 1.32 volts per cell. That's probably only about

80-85% charge, but it should be easy on the NiMH "D" dry cell

batteries.

One can float charge them as high as 42.0/14.0/1.40 volts, but

experience with them in the Mazda RX7-EV says not to push them so hard.

It's probably a reason some had dried out. (With 5000 watt-hours of

refurbished battery storage, under 1000 watt-hours from DC loads

doesn't draw them down too far. Long winter nights may need

conservation measures like turning the water heater off.)

Date House solar KWH(Grid+DC), Trailer Roof solar KWH - day

total KWH

made [power

co. meter readings] weather, usage...

May 31st 53.10, 393.27 - 5.26 KWH [66469 KWH @9:00, 485@20:30]

Lt.Rain. (no BR heat) 85 Km drv. fast charged.

June 1st 56.94, 397.18 - 7.75 [66502@20:30] cloudy, occasional sunny

spots in PM. 60 Km drv.Fast Chj.

2nd 58.56, 399.19 - 3.63 [66517@19:30] RAIN, more RAIN!

(We REALLY needed rain!) 49 Km Drv.- chjd.after meter reading.

The 4 older poly panels went to the DC system only, to keep kitchen hot

water hot, so real total might be ~4.4 KWH (with a little power going

to waste

from the 4 panels).

3rd 61.14, 401.68 - 5.07 [66537@20:30] Rain AM, cloudy PM.

55 Km Drv, fast Chj.

4th 64.08, 404.41 - 5.67 [66557@21:00] Rain, clouds.

5th 70.02, 409.40 - 10.93 [66570@24:00] Sun & clouds.

6th 75.29, 413.34 - 9.21 [66573@10:00, 581@21:00] Clouds,

Lt.clouds. 55Km drv.& fast chj.

7th 79.08+.60, 415.90 - 6.93 [66587@10:30, 592@20:30] Clouds. 55Km slow

chj.

8th 83.00+.65, 418.93 - 7.60 [66603@20:00] Cloudz.

9th 86.20+.42, 421.88 - 6.57 [66614@11:30 & 21:00] Cloudy, some

rain.

10th 88.10+.91, 424.04 - 4.97 [66637@21:00] Clouds, rain. Car part

chj.@1500W after 55Km. (Left BR heat on & door open, so it was

heating house - yowr!)

11th 92.27+.70, 427.57 - 9.40 [66643@13:30] Light Clouds &

chemtrails. Finished chj.car. Didn't turn off water heater for night.

12th 96.38+.50, 430.88 - 7.92 [66646@10:00; 66655@20:30] Lt.cloud AM,

Cloud rain PM. Bath AM; car slow chj. from 15:30-20:30 (How did the

water heater use LESS power by being left turned on all night? Ah...

the water isn't as hot. The top fell off the thermostat yesterday and

it must have turned the dial. I'm only turning it part way back up

because the water was really too hot - scalding.)

13th 98.86+.74, 433.28 - 5.62 [66661@20:00] Cloudy.

Finished slow

charging car during day.

14th 103.88+.58 , 437.16 - 9.48 [66666@10:30, 66671@21:00] Clouds 85Km

drv.

slow chj. 2-6 PM. HWH was off for night.

15th 106.65+.71, 439.21 - 5.53 [66698@21:30] Lt.Rain. Car not

full, but 55Km drv. 4 KW car charge.

16th 108.80+.66, 441.42 - 5.02 [ Laundry; 66710@20:30] Cloudy all

day -- again.

17th 113.57+.69, 444.77 - 8.81 [66716@20:00] Cloudy with a short

sunny break.

18th 116.16+1.09,446.95- 5.86 [Laundry, Part car chj.slow after

55Km; 66734@26:30(2:30)] Cloudy. (did extra dishes)

19th 121.68+.53, 451.11- 10.21 [66739@11:30, Finish car chj;

66742@20:30] Cloudy, some rain, couple short sunny breaks.

20th 128.61+.75, 456.18 - 12.75 [a little BR heat, bath; 66749@19:30]

Sunny AM (Yay!), cloudy PM

21st 138.88+.52, 463.74 - 18.27 [66753@10:30; 85 Km drv. & fast

chj; 66762@21:00] Sunny; jets making cloud trails all day from one end

of the sky to the other.

22nd 142.65+.61, 466.66 - 7.30 [55 Km-Chj car slow

56%=>80%-not much solar; 66775@20:30] Cloudy

23rd 147.77+.73, 470.35 - 9.54 [bath, br heat;66783@10:00;finish

chj.car;66785@20:30] Cloudy, some rain later

24th 154.21+.57, 475.26 - 11.92 [BR heat; 66791@10:00; slow chj car;

66797@22:00; bath] Cloudy AM; Sunny PM (not even any jet trails).

25th 164.52+.57, 482.60 - 18.22 [NO heat,finished car chj;66804@20:00]

Sun. No jet trails. But warmer than 21st - solar panels don't like

heat. And, the 21st was the solstice, the longest day of the year.

26th 174.57+.55, 489.83 - 17.83 [NO heat,laundry,bath; 66810@22:30]

Sun, warm, some jet trails.

27th 184.55+.60, 497.11 - 17.86 [chj.car slow in sun; 66815@22:00]

Sunny, warm again! Slow car chj: I plugged it into the house solar

outputs outlet for a while. (less than an hour?) Then I walked by and

noticed that the meter read ~500 W instead of 1100-1200...then I

realized that was extra going IN to charge the car (1500 W), and that

the solar output was going straight to the car without being recorded.

I plugged the car in elsewhere. So actual production was surely well

over 18 KWH - maybe a record? Only 5 KWH from the power grid for the

whole day [surely at night], when charging the car alone would have

used almost 10.

28th 187.91+.50,499.60- 6.35 [66820@21:00; then charge car @3.8 KW

after 85 Km] Cloudy

29th 3.71+.69, 502.54 - 7.34 [bath; 55Km part

chj.car@1500W; 66845@20:30] Cloudy.House meter reset in 9-10AM power

failure

30th 11.82+.68,508.53 - 14.78 [laundry; 45Km, finish chj;

66860@22:00] Cloudy AM, Sunny PM

July1st 15.90+.63,512.76- 8.94 [66866@21:30] Clouds, dim sun all day...

or are those heavy chemtrails? Oops, grid tie on 1000 W panels was

turned off until afternoon. (shoodabin over 10 KWH!)

2nd 22.47+.78, 417.66 - 13.25 [66872@20:30] cloudy, dim sun. again.

(not chemtrails, I think?)

3rd 25.74+.66, 420.24 - 6.61 [65 Km, chj.car 3.8KW;

66886@21:00] cloudy

Daily-

KWH- # of Days (in June)

Made

3.xx - 1 (Now that's HEAVY overcast!)

4.xx - 1

5.xx - 6 days

6.xx - 3

7.xx - 5

8.xx - 1

9.xx - 4

10.xx- 2

11.xx- 1

12.xx- 1

13.xx- 0

14.xx- 1

15,16- 0

17.xx- 2

18.xx- 2 (just four sunny-all-day days in June!)

June was certainly a good month to see how solar power

does in

clouds and rain. Production was under 8 KWH on 16 of the 30 days, and

under 10 KWH on 21 of 30. One might say half the month was at 1/3

production and only 9 days were over 1/2 production. Until the 21st I

really didn't even know how much the system should be

giving in full sunlight because there was hardly a day with much sun,

let alone a full sunny day.

In May it was over 16 KWH on rare sunny days. All the clouds and cool

certainly didn't help

for growing vegetables either. Oh well, there are plenty of worse

places to be

living these days! There's been no flooding, snow, giant hail, tornados

or hurricanes.

The morning of the 20th, and the whole day of the

summer solstice (June 21st) were sunny. But even then, jets filled the

sky with a thin haze of trails all day. The 11 panels (with the one

still propped up on the lawn) made a record 18.27 KWH of energy that

day - the day

with the most daylight of the entire year. (What would it have been

without the jets? 20 KWH? How much climate chaos does there have to be

before this madness

ends? I'm sure that much of the cataclysmic weather and the horrendous

destruction of the whole 2019 crop season globally is owed to it. Well,

not to mention... 7.5 billion people, burning fossil fuels, surely has

a lot to do with it, too.) On the

22nd it went back to being cloudy and sprinkling rain, with some sun on

remaining days as noted in the log.

Low light Performance

I tried again to measure lower-light performance of the old

polycrystalline panels compared to the new and supposedly

better-in-low-light

monocrystalline ones. This time there were still the 4 polys (~1000W),

and now there was the 3rd mono sitting on the lawn - at a steeper angle

than the 2 on the roof (total 915 nameplate watts). And I added the

watts going to the

DC system from the polys to the total watts. The lesser reading is just

the 3 mono panels, which go only to the grid tie, after turning off the

polys' grid tie. All the readings jump around by 10-20 watts, so they

are an average as I estimated it at the time.

All else being equal, 915/1915=46.7%, so theoretically

46.7% of the power should come from the monocrystalline panels. If the

percentage is higher in low light compared to in full sunlight, then it

would seem they perform better in low light. The amount of load on the

grid tie inverters affects their efficiency, and it would be difficult

to compensate for that. However, if the DC load (via the charge

controller) is 10% of the grid

load, which is not unusual, then the mono and poly inverters should be

doing rather similar power output. Then again, as little as a couple of

percent to the DC isn't unusual either.

6th cloudy morning 10AM PST: 460W, 212W, 212/460=46%

7th more cloudy 10:20: 340 157, 46%

24th 15:50: SUN! 1175W, 594W 51%

25th 9AM Sun, 55°(?) angled sunlight: 865, 412 - 47.6%

11AM still sunny 1137, 575 - 50.5%

If anything, the monocrystalline panels seemed to give more in higher

light. We saw last month that a

light load made a significant improvement to the efficiency of the grid

tie

microinverter. Perhaps another possible conclusion is that in lower

light, the less

loaded inverters performed more equally. and more

efficiently. This would contribute to a somewhat higher output in

cloudy skies per

the actual percentage of light coming through. Or more accurately, to a

lower output proportional to light on bright days. Then again, the 305

watt panels are only a few months old, whereas the ~250 watt ones are

from 2012 and may have slightly reduced output at maximum light

levels(?) Heating of the

panels also reduces their output on warm sunny days. All the panels are

thus in fact operating at higher efficiency in lower light levels, and

higher in cold winter than in warmer summer.

The conclusion: There are too many variables that can't be

controlled to assess the actual panels.

More Panels? - Thoughts

What good is it to get 17-18 KWH on four sunny days

in

June if most days only give 5 to 9 KWH? With all the cloudy days

providing

under half the capacity of a sunny day, and knowing how much less

daylight there is in winter regardless, probably the best way to

improve things would be to have more panels. Perhaps even double - 20

instead of 10. Even just another 4 or 5 would help. If the

grid was down, the house would fare better. And one needs a full 1500

watts

to

charge the Nissan Leaf off solar only (ie, using the 2500 W inverter) -

anything less and the charger will choke. That requires more than 10

panels except on a good sunny day. One doesn't necessarily have to buy

anything but more panels - if the panels were potentially putting out

5000 watts but the equipment can only handle 2500, well, 2500 is

enough. On the cloudy days and winter days, the output would still be

under

2500 anyway, but proportionately higher. OTOH if one was properly

connected to the power grid and

selling power to the utility, one would spring for adequate equipment

to take advantage of whatever sunny summer days came along.

From videos I've seen on youtube, the Y-Solar 1000 watt

grid

tie "micro"inverter must be the world's most popular.

At least with DIYers. I wonder: even if the equipment and installation

doesn't meet standards for "approval" by the utility, what if all the

microinverters tied into one approved switching circuit with an

approved shutoff before entering the grid system?

Something I would consider with more panels is that the

new ones

should be at a steeper angle to capture more than 50% of what little

winter sun there is. That's when the least power is available and the

most is wanted. Obviously sun tracking, AM to PM left to right, and

Summer solstice to Winter solstice vertically is optimum, but the

mountings have to be very strong since the panels make a big sail in

high winds. A few extra panels is probably cheaper than an adequately

strong tracking system with sensors and motors. (I guarantee one would

very quickly get tired of moving panels around by hand for tracking AM

to PM manually. Changing winter to summer tilt angle by hand is

probably

practical.)

For a fixed mounting, the angle of latitude (here

53.4°) is the best for all year, and that's so steep here there's

probably little point in standing them even more upright. (For winter

solstice 76° would be optimum, but 53° still gives 92% as much

output

- and works better most of the year. The 15° slope of the house and

trailer roofs is much less than ideal for any time of year. A vertical

south wall is almost ideal in December!)

So I was thinking to make frames to put up on the roof(s)

to mount some new panels at latitude angle. Then I was thinking of

orienting panels on the west end of the roof to face partly eastward

and take advantage of the morning sun

with the least early morning shadows, and vice versa at the east end of

the roof, where the afternoon shadows hit last.

Then my ever scheming mind though of putting two panels,

one on each side of a single "upright" pole (at 53°) with two other

poles behind forming a tripod. This should be stronger than a single

pole with both/all panels attached to the top by an angled mounting.

The bottoms of the panels would be up off the roof so they could turn

side to side on this angle. Note that rotating systems are for panels

sufficiently separated from others, since any such panels next to each

other would cast shadows on each other at different times of day. I

have sufficient roof space not to "stuff" the whole south slope with

panels.

Entering July I noticed I had a stiff metal post with a

stout mounting at the 53.4° angle sticking out of the ground. It

was a mounting for an old 1980s era satellite TV dish. All the bolts

and joints were rusted solid, but they were already set as required.

There was just one catch: it was under the edge of the tree line west

of the house. I wondered if I could dig it up and move it to a better

location... somewhere.

These are just thoughts. Not today! Well, if I do do more

panels, it's easiest to just bolt them onto the roof, poor angle or not.

Electricity

Storage

(Batteries)

Electrode

"Pocket" with Nafion Ion-Selective Membrane Face

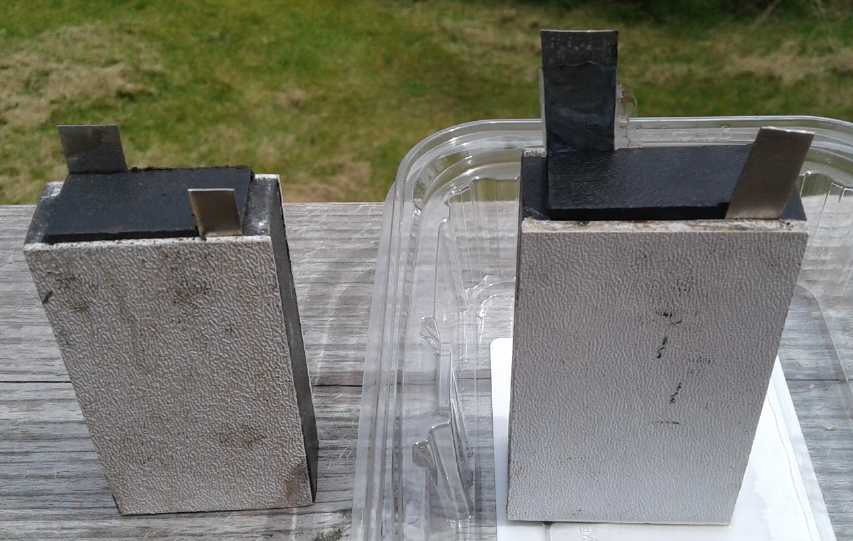

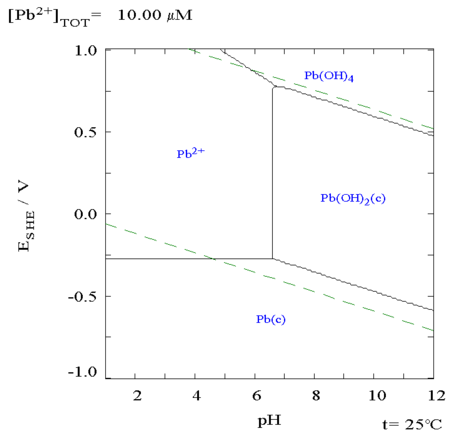

The zinc electrode

still looked pretty smooth and shiny,

so I etched it in ferric chloride and then cleaned it with varsol, then

dried it off with tissue. I put it in the nafion pocket. I looked at

the

manganese oxide electrode and didn't think much of it. It's probably

pretty heavily contaminated with zinc oxide by now. So I took a lead

positive electrode from the commercial lead-acid battery and made it

lead-zinc. I used the mixture of methyl hydroxide and potassium

hydroxide previously mixed for electrolyte.

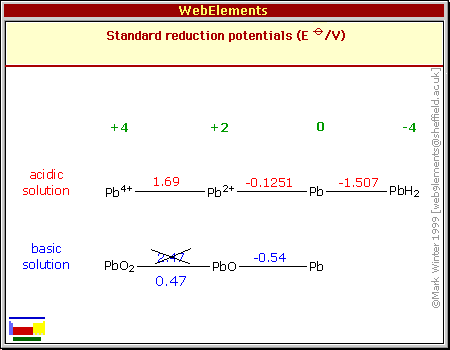

IIRC this should have yielded a theoretical 1.68 volt

cell. Both electrodes were supposedly already in their charged form.

But the cell started out just over 1.4 volts and started dropping. It

current capacity was just milliamps. With a 1000 ohm load, it held just

over 1.1 volts. And it hardly came back with the load off - just to 1.2

volts.

The cell should have worked great (perhaps with limited

cycle life) without the nafion membrane. But I took it out and it

didn't work any better. The current capacity, which one would expect to

be quite high, didn't even go up. As I tried things the voltage got

lower, but it wouldn't hold any further charge. A few milliamps would

go in, but when the charge was removed, the voltage would go back to

where it was before and continue dropping. In the morning it was

sitting at .70 volts. But the zinc sheet didn't look oxidized - hardly

changed since it was put in.

The barium carbonate "glue" was still on the plastic and

the nafion sheet stuck to it, but it hadn't set in any way and the

sheet could be slid off. If one put thin pieces of plastic over the

nafion and screwed them to the frame I could see that it might still

form a seal and block ions from getting around the edges, but it wasn't

my idea of glue.

All I could think was that perhaps the lead oxide

electrode was contaminated from some previous try, or that the barium

had added something bad to the electrolyte.