Turquoise Energy News #134

covering July

2019 (Posted August 5th 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Feature: Batteries: "Everlasting" Zinc Electrodes! √

(See

Month in Brief, Electricity Storage)

Month In "Brief"

(Project Summaries etc.)

- All the Answers at Once! - Picking Up Steam -

CNC Table - More Things - The Covered Wagon (solar E-Bike) -

Donation

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Stop Colds Fast with OJ - Homegrown, Homemade Quinoa Flour Bread:

Mmm! -

Another Hair Loss Preventative - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle ("GEV") - only slight progress as usual - wing

shape

and stability

- Testing Ducted Fans, Radio and Motor Controllers -

Revised Ducted Fan

positions: Outboard, in line with wing

* More Unipolar BLDC Motor and Motor Controller Ideas - ? Turns per

coil - Sizing

- Permanent Magnet Assist, Magnet Fitting - Tuned Circuit

Coil Drive - Rotor Design - Figuring Out Activation Sequences

* More Variable Torque Converter Ideas

Other "Green"

Electric Equipment Projects

* 36 Volt DC Wiring & Infrastructure

*

Some Handheld Bandsaw Sawmill Notes - Update

Electricity Generation

* My Solar Power System: - "Floating" Panel Voltage Grid Tie -

Combining More Panels on One Grid Tie or Charge Controller? - east-west

facing panels - Monthly

Solar Production log et cetera

Electricity Storage -

* Dried Out(?) NiMH Dry Cells

Turquoise Battery Project (Mn-Zn or Ni-Zn in Potassium

Hydroxide electrolyte ?)

* Non Dendrite-forming Nickel-Zinc Cells:

- Cost comparison and estimate - Preparing a Zinc Alkaline

Electrode - Electroplating - Egg

Albumen Coating - Assembly and testing - Antimony Sulfide or Zirconium

Silicate? - 14th - Duck Eggs - Electroplating Rack - A Positive

Electrode - Parchment Paper Separator - 3D Printed Positive Electrode

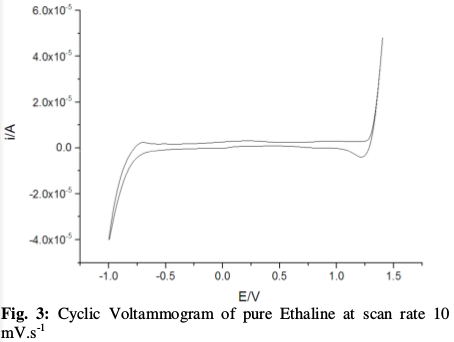

Shells - Ethaline Deep Eutectic Solvent (DES) - Ethaline Electrode Jell

for Zinc? (nope) - Agar Jell (seems to work, including in KOH, but low

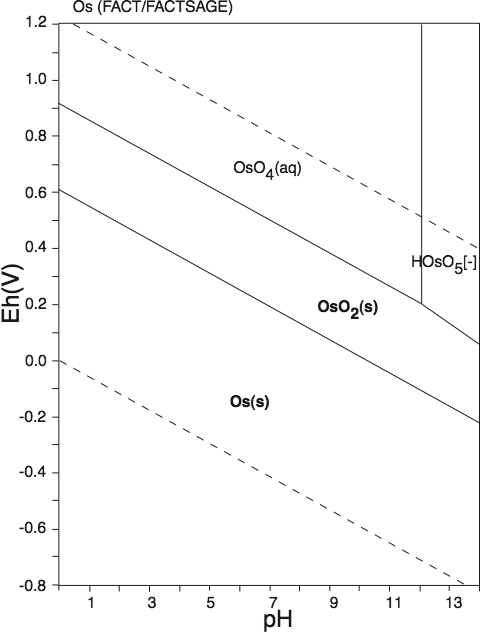

currents) - Getting Current - Osmium Doped Film Again + Agar? - Apparently

Successful

and Practical

'Fuzzy' Electroplated, Osmium Filmed and Agar Jelled Zinc Negative

Electrode! - Microcontroller for Cycle Tests and Cycling Cells? -

How Many Ni-Zn Cells for 12 Volt Battery? (Seven.) - Positive

Electrodes and 3D Printers

All the Answers at Once!

Omitting the previously started original wave power

project (from

2006-2007) which I soon ceased to pursue, the inspirations of June

and July bring the original goals of Turquoise Energy in

January 2008 right back and into clear focus:

1. A highly efficient electric car motor, mounted on the outside of a

car wheel.

2. An efficient, friendly, repairable and reliable motor controller for

said motors.

3. Better, cheaper batteries for electric cars.

And when I finally decided a motor small enough to fit

directly on a car wheel at 1-to-1 ratio (at least any in line with how

I was making them) couldn't have the torque to drive it:

4. An efficient variable torque converter to couple the motor to a

wheel - spring 2009.

I made great axial flux BLDC motors by 2012 or 2013. My

BLDC motor controllers work but usually end up with blown transistors

when stressed too hard. (A 300 amp Kellycontroller BLDC controller

finally put the Electric Hubcap motor to work and showed its power.) A

lasting battery cell was elusive until this

June, and I stumbled around in the dark trying various things

mechanical and magnetic to make a torque converter. (I finally had all

the right parts for a mechanical one, but I wasn't putting them

together in a way that worked. The "Magnetic Impulse" torque converter

idea should work, but it needs too many magnets and rotors with too

much copper

to be practical in a car - and it would probably make too much

vibration.)

In 2016 I came up with or ran across concepts for

"unipolar" motors where each coil is activated in only one magnetic

direction instead of opposite directions at different points in the

rotation. From my point of view, the biggest benefits were simplicity

and ruggedness of the high power electronic circuits of the motor

controller. A

unipolar controller couldn't short straight from B+ to B- if a

transistor turned on for an instant at the wrong time, and so the

chance it would blow transistors in heavy use was greatly reduced.

For reluctance motors a 3-phase unipolar controller would

work

because the rotor iron is attracted to either polarity. But (limiting

my imagination to 3-phase motor controllers) I couldn't figure out a

"unipolar BLDC" configuration that would work right and well.

Reluctance motors were however a new type for me, very different from

the ultra-efficient BLDC motors I already knew how to build well. I did

get

a sample reluctance motor (the "ARM" axial reluctance motor) running,

but it needed a lot of changes to be effective, and a reluctance motor

would probably never have the "ultra-efficiency" of my axial flux BLDC

motors (~95%).

An additional potential advantage of the unipolar motor is

that it is amenable to a type of permanent magnet assist that adds the

flux of a permanent [super]magnet, seemingly for free "two for the

[energy] price of one", to that of the coil electromagnet. I would very

much like to try this out and see what actually happens.

Suddenly in July 2019 I have answers for what seem to be

excellent batteries, for rather simple and effective variable torque

converters, and for unipolar BLDC motors that will allow me to make

reliable unipolar motor controllers that won't blow up. Since I already

build great BLDC motors and simply need to create a (4/3 larger)

variant

of the Electric Hubcap motor, this means that I quite suddenly

have answers to all the thorny design questions I've beat my head

against for so many years, in all my main projects.

If the time I have lavished on these projects over the

years had been spent building them in the right or optimal way from the

start, I'd have had them all done long ago. But with the inspirations

finally coming now and having further valuable projects on the go as

well, I wonder when and even if I'll ever be able to build these

marvelous concepts and put together the fabulous, ultra-efficient,

longer range electric car that I now, quite abruptly, see just how to

create.

They will each take a lot of work.

Of course things progress from a beginning, and for new

technology ideas - inventions - from something of a blank slate,

as puzzles with pieces missing. If it wasn't so, the invention would

already exist. I learned as I went. The designs and principles I now

present seem pretty simple (that is to say, easily grasped by those in

the relevant fields), but if it seems like I was really slow off the

mark to take so many years stumbling around to get to such simple

places, it must also be considered that no one else has come up with

any of these things, from any past time to the present day. If they

had, the thing would be out there and I could have just copied the work

-- or perhaps have just gone into a store and bought finished products.

Instead here are some new concepts and designs that never existed

before, for anyone to use to create working models. (I acknowledge of

course all those things developed by previous inventors that I can

just go into a store and buy, or order on line, and which my own new

work is built on top of!)

Picking up Steam

In June I was lamenting that I didn't have time for

projects. In July, with so many answers to imponderables suddenly there

in front of me, I made time. The garden was mostly planted and I did

the minimum watering and almost no weeding. I cut way down on milling

wood.

I skipped naps. I skipped trips to town, where it seemed sometimes the

only purpose to the trip was to check the mail anyway (but I usually

buy a couple of pieces of fresh fruit). Seeing real progress I did

battery experiments and

developments one after another instead of weeks apart.

CNC Table

From a far corner in the shop I brought in the new

Geckodrive, the old CNC table controller box and the CNC table. If I

was to build a new design of motor, this had to work - at least the

router to make the molds. I put

them in my 3D printer alcove (clean, uncluttered... was) and started

putting things together for the CNC router and CNC plasma cutter.

(15th, 16th) I disassembled the stepper motor/limit switch assemblies

to trace out the connections to the DE-9 connectors. (I tried months

ago to get the DE-9 pinouts from "Techno", the company that made it, to

no avail. Too old, I guess. But they were easily traced once opened.)

The CNC table was one "hi-tech" item that wasn't obsolete after 30

years. Then I made up cables to connect them to the "Gecko", which also

used DE-9 connectors but with a completely different pinout. Having got

that far, on the 17th I ripped the old electronics out of the box,

keeping just the power supply, and installed the Geckodrive on the back

panel. I started in on the instructions, testing that the unit worked

properly - the right lights came on, and the CNC table stepper motors

had holding torque.

The Geckodrive mounted on the back of the

original controller box for the CNC table.

The Geckodrive mounted on the back of the

original controller box for the CNC table.

In 1990 the whole box was choc full of electronics to do the same job.

I

wasn't confident

of getting it to work as I couldn't get info on it, and anyway it only

had

two stepper

motor drives and I would need at least three. (The Gecko has four.) Now

I'm just

using the box's power supply with its on-off switch and emergency stop

button.

(and the fan... that loud fan has got to go!)

Front View

Front View

Then I reached the part about "using your software"

to step the motors and found that LinuxCNC was a 1.1 gigabyte

download. Oops. With my internet, that put an end to that for the time

being. On the 23rd I went to town to the library to use the WIFI and

try to download some short version, but I

spent much of that day and the next in frustration unable to get

anything I'd downloaded to work.

Later I phoned a friend in Victoria, Jim Lawrence. He

downloaded the

1.1 gigabyte disk image (in a minute and a half!) and sent it to me on

a DVD, which arrived August 3rd. I look forward to

getting the software, the CNC table and (at least) the CNC router to

work. Getting the

plasma cutter going (to do steel motor rotors and make equipment for

recycling plastic) will need additional work - a separate project. (Oh

boy, another project!)

More Things

In the meantime I did battery experiments. Doing the

batteries is a given. The osmium doped film and agar seems able to make

'everlasting' zinc electrodes, so in principle I seem to have

everything needed for nickel-zinc or manganese-zinc "prismatic cell"

batteries, with zinc sheet and plastic shelled Ni/Mn electrodes simply

stacked in a row filling the cell end to end. These would be "liquid

filled" but would require only a small amount of liquid.

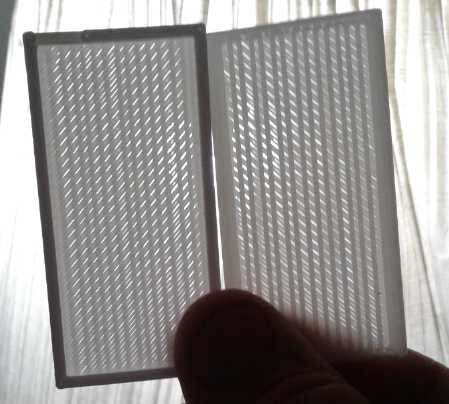

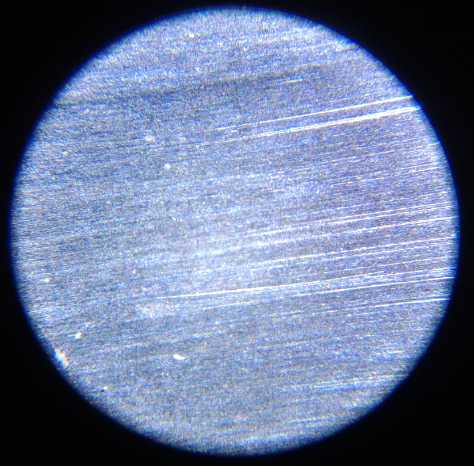

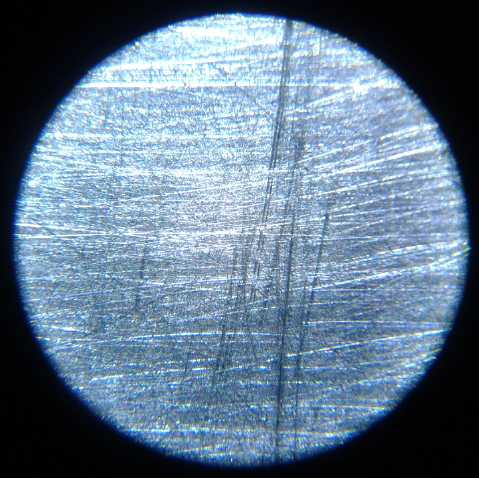

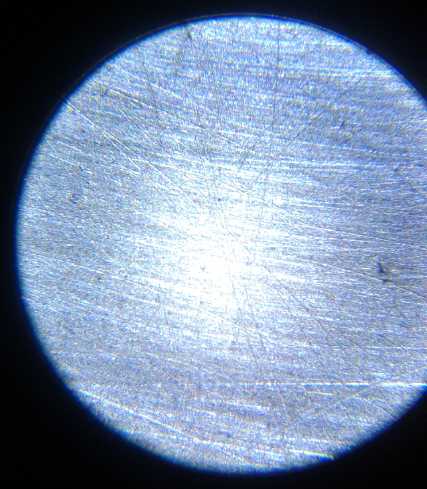

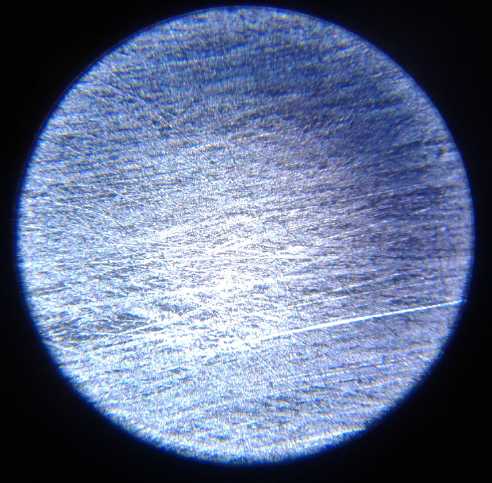

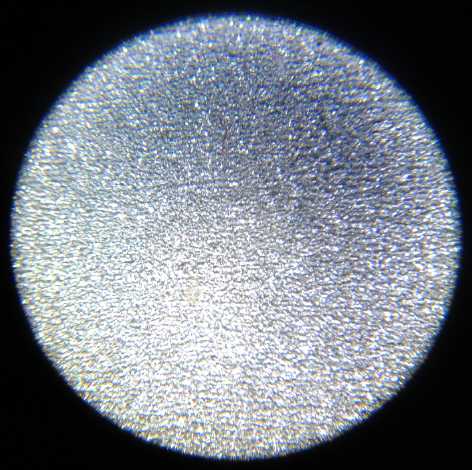

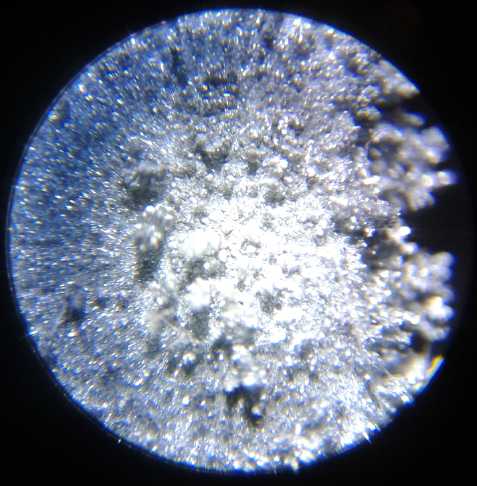

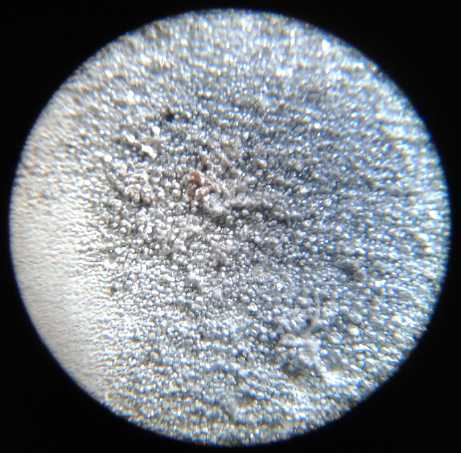

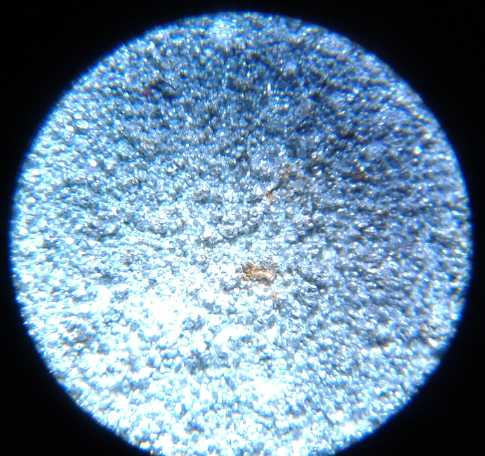

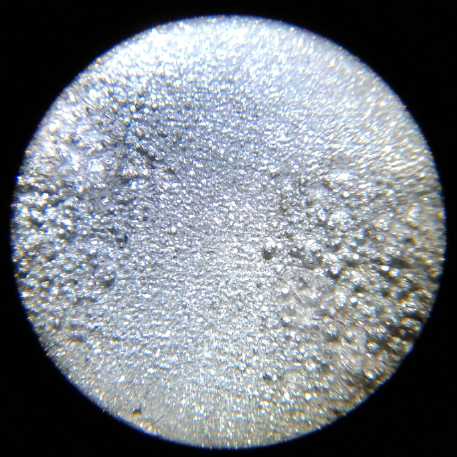

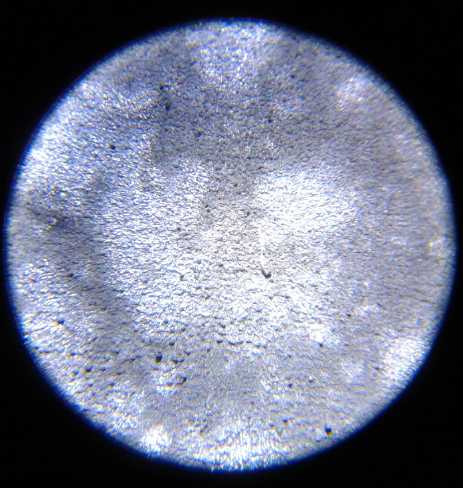

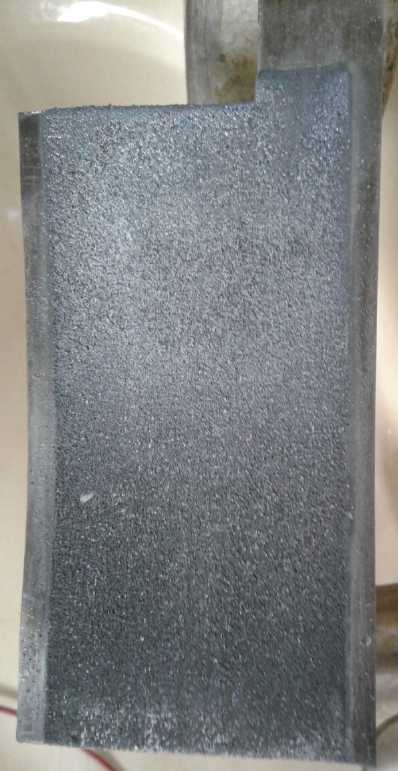

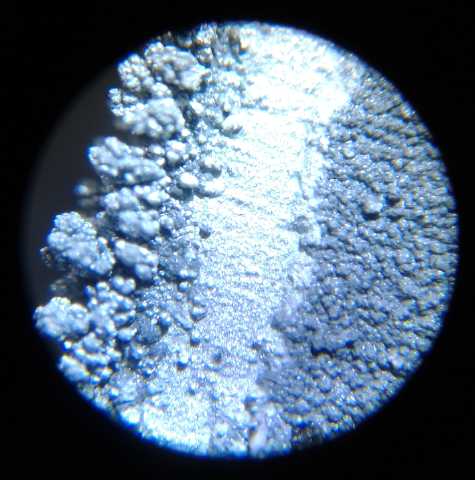

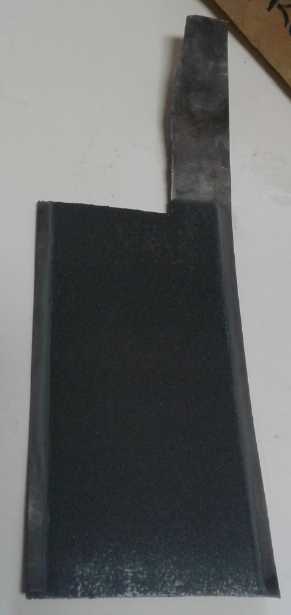

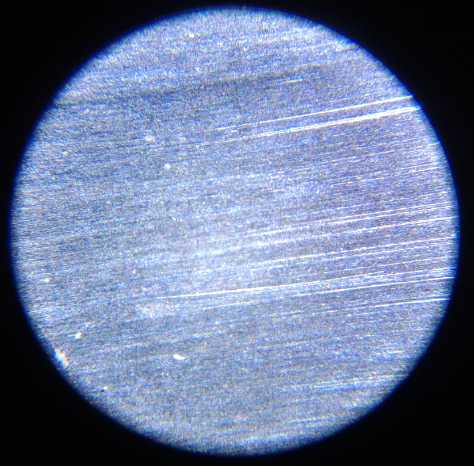

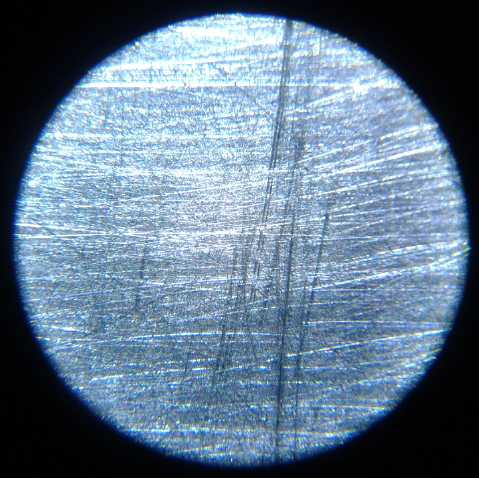

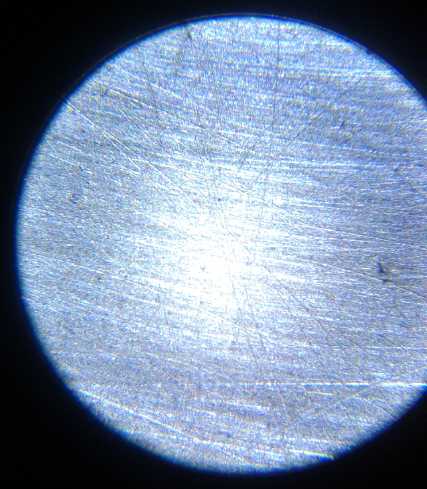

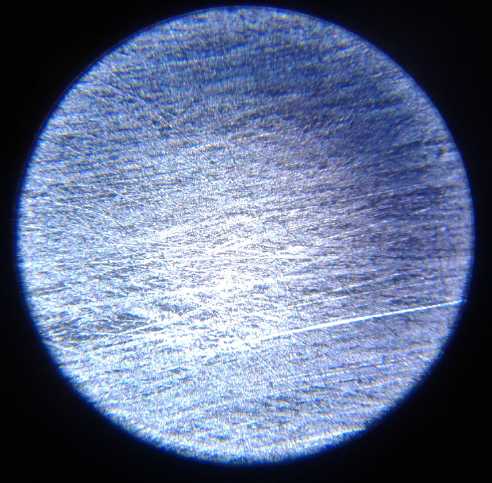

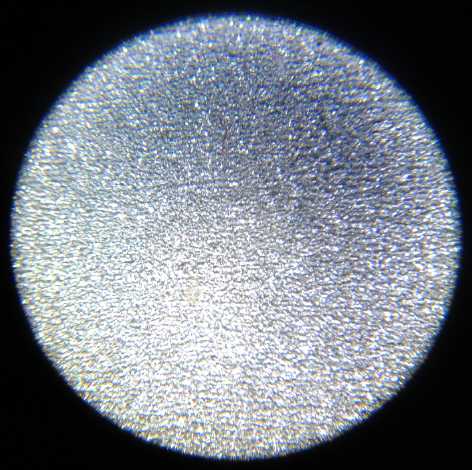

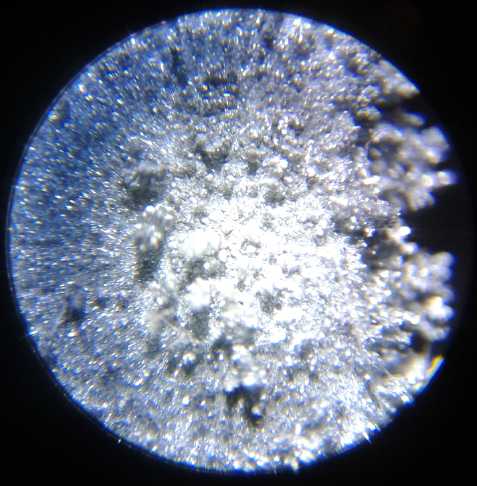

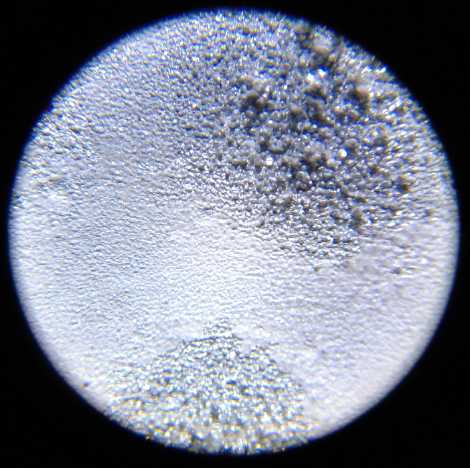

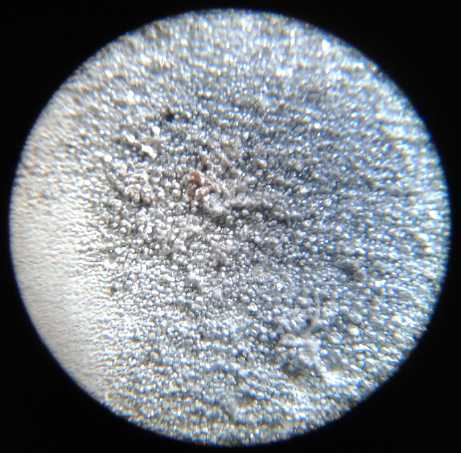

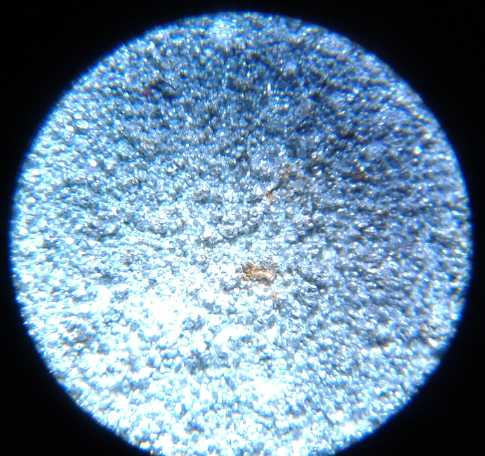

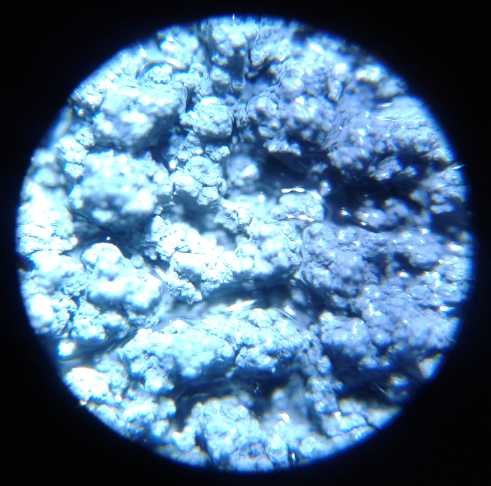

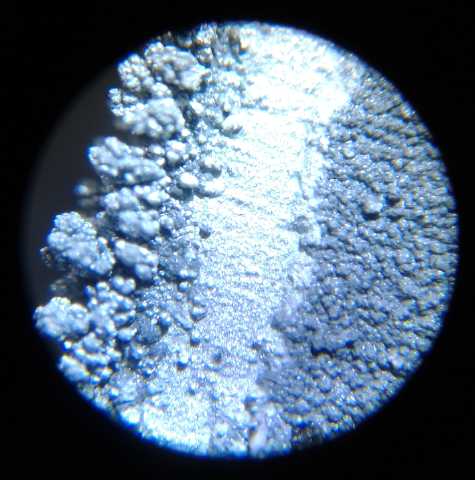

L: Sheet Zinc Electrode with "fluffy" zinc

electroplating giving it high surface area per volume for high

amp-hours. ("full size")

L: Sheet Zinc Electrode with "fluffy" zinc

electroplating giving it high surface area per volume for high

amp-hours. ("full size")

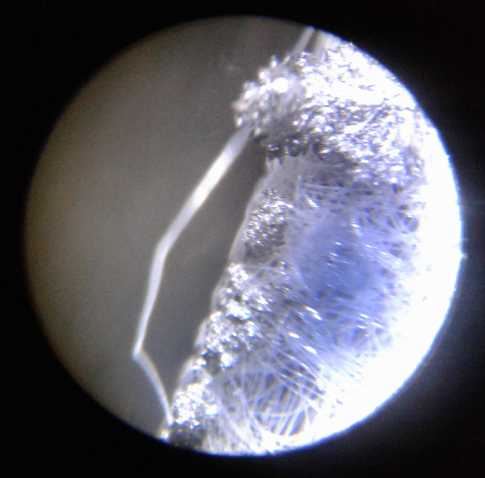

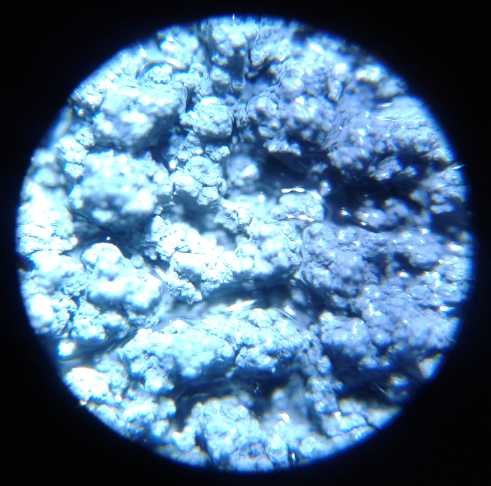

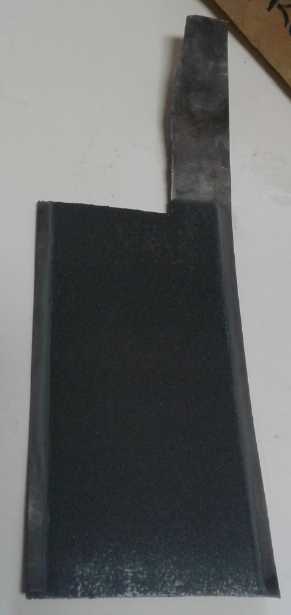

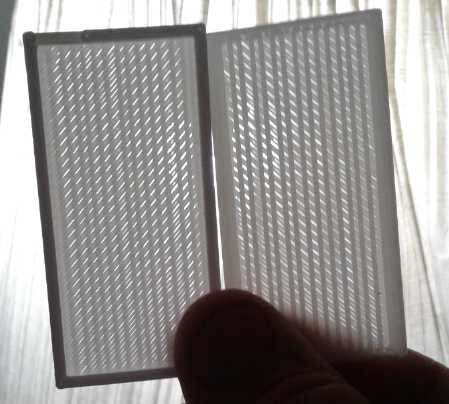

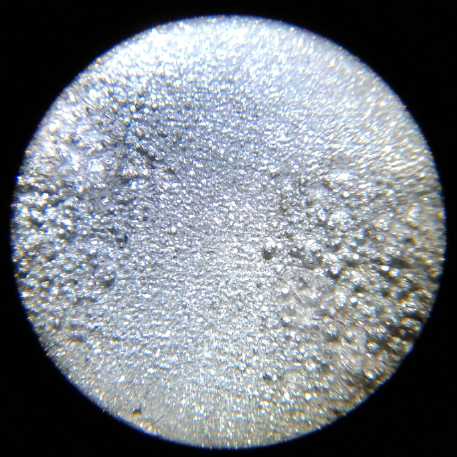

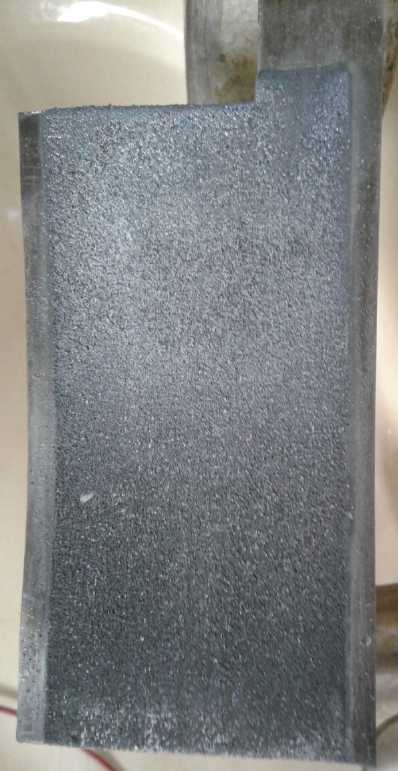

R: 3D printed Porous Plastic Electrode Shell to encase positive oxide

electrodes. ("test size" shell/electrode bits)

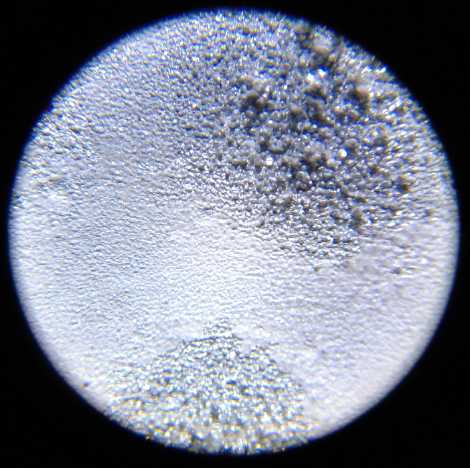

Test cell in use. It didn't look much different

Test cell in use. It didn't look much different

from test "A" to "Z", but the things inside

definitely got better!

By the end of the month I had the makings of what should

be an "everlasting" zinc electrode with good performance, and "porous"

plastic shells for positive electrodes. The detailed writeup on all

this under Electricity Storage is about 1/2 of this newsletter,

which may be the longest one yet.

Of special note in this connection, Jim Harrington sent me

a link to a Canadian battery design challenge. It looks much more

promising than NRC's IRAP offerings. Instead of asking you to supply

over half of the money yourself in order to qualify for funding with

many strings attached (why bother?), it was sponsored by multiple

organizations who seemed more interested in getting better batteries

developed and made in Canada than in delving into every petty detail

about exactly what the future is expected to hold. (The future is

always changing as it unfolds, as even the last couple of months of

battery development in these newsletters abundantly discloses.) There

is more than one "prize" for promising sounding projects. If this

project doesn't sound promising at this point, I don't know what would.

The "up to" amount of each prize, apparently intended for

research, should be enough to start some small Everlasting Ni-Zn

battery factory -- and up the pace of more of my other research as

well. The grand prize of a million dollars to be awarded later would be

enough to expand on that factory and perhaps move it to a more central

location than "the edge of the world".

And I worked out some of the basic details for a unipolar

BLDC motor for an EV (etc): configuration, size, PM assist, coil

sequencing and rotor magnet sensing, and a new "resonant drive" system

to replace PWM for driving the coils. (More is under Electric

Transport.)

And I thought I might manage to do the variable torque

converter

in less than geologic time if I could contrive to use the same

basic "experimental transmission box" for the Chevy Sprint that has

housed all such experiments, and fit everything in using all the

existing parts including the 'forklift' drive motor. I cut a new steel

plate to

mount the motor on. I took out the motor and transmission to see what

could be fitted. The motor wouldn't fit the way I had hoped, but I

figured out another configuration (the second of two possibilities that

looked good to me) that should work equally or almost as well.

I'll do my very best to make the whole thing sturdy enough not to bust

or slip instead of moving the car. (In fact, for once I think I'll do a

drawing first, to make sure everything actually fits exactly where I

vaguely expect it to, and to know exactly how to make each part.) (more

under Electric Transport)

And I thought I might manage to do the variable torque

converter

in less than geologic time if I could contrive to use the same

basic "experimental transmission box" for the Chevy Sprint that has

housed all such experiments, and fit everything in using all the

existing parts including the 'forklift' drive motor. I cut a new steel

plate to

mount the motor on. I took out the motor and transmission to see what

could be fitted. The motor wouldn't fit the way I had hoped, but I

figured out another configuration (the second of two possibilities that

looked good to me) that should work equally or almost as well.

I'll do my very best to make the whole thing sturdy enough not to bust

or slip instead of moving the car. (In fact, for once I think I'll do a

drawing first, to make sure everything actually fits exactly where I

vaguely expect it to, and to know exactly how to make each part.) (more

under Electric Transport)

![[pitcher]](GEV-Sparred-Front.jpg) I

didn't need any special new insights to continue (at glacial pace) the

radio controlled model for the ground effect vehicle. But it did occur

to me that if the ducted fans were in-line with the wing, that they

would have no tendency to push the nose down or need to be angled to

where they would be less efficient. So I re-made a couple

of longer,

'streamlined' spars so I could mount them solidly at the sides. They

should still be above the water there. (more under Electric

Transport)

I

didn't need any special new insights to continue (at glacial pace) the

radio controlled model for the ground effect vehicle. But it did occur

to me that if the ducted fans were in-line with the wing, that they

would have no tendency to push the nose down or need to be angled to

where they would be less efficient. So I re-made a couple

of longer,

'streamlined' spars so I could mount them solidly at the sides. They

should still be above the water there. (more under Electric

Transport)

And I continued to monitor and record the performance of

my electric solar panel system. It has been cutting 1/3 or more off my

electricity bill (which is pretty good considering it includes the cost

of driving my electric car all over the place). Even with a month of

nothing but clouds and overcast it put out about 55% of what it would

have in full sunlight, which makes such installations worthwhile at

today's solar equipment prices. I look forward sometime to being able

to store a couple of days worth of electricity in the new batteries.

By the end of the month I had some lengthy project reports

and a ton of pictures on my cellphone (camera) all to be edited and put

together, and I could see this newsletter wasn't going to be out in a

day or two. And there seemed to be one thing or another taking up much

of each of the first few days in August, too.

The Covered Wagon: E-Bike

My friend Tom Sawyer sent me pictures of a three wheeled

solar electric cycle he ran across. He said it was made by a homeless

person in Vancouver. If so the guy has a lot of talent, imagination,

drive and for sure someplace to work. It would be long enough to sleep

in (it seems to be insulated), and assuming a reasonable battery

capacity the 600 watts of solar panels that unfold would allow

considerable daily travel distance with (two?) typical e-bike motors of

500+ watts, especially as it would continue to charge at 300 watts

while riding. I imagine as long as one can afford to eat, one could get

to most anywhere, slowly but almost for free, with this unit. (Tom's

pinstriped electric Nissan Leaf with "Tesla" logos is in the

background.)

Donation

Someone sent me a very generous donation in July. I've

been

meaning to ask if he wanted his name and or the amount in the

newsletter, but somehow I didn't get to it. He said he has been reading

TE News for years with interest, and has made use of the ideas of

ilmenite for magnetic circuits and molded

polypropylene-epoxy composite material. Thank you

again, it is much appreciated!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Stop Colds Fast

Ever wake up and feel that unpleasant sensation at the

back of your throat that says you're getting a cold? I used to feel

helpless, knowing that it was taking hold and that in a few hours

it would spread and I'd be stuck with it, perhaps for weeks, until it

decided to leave.

Then I found a secret weapon: orange juice. by itself,

with no other food or drink. I woke up and had that nasty "cold

starting" feeling in the early morning hours of the 27th. I thought,

"Uh-oh! Surely this

has progressed too far to be stopped?" But I got up and rummaged

through the freezer and finally found a small container of orange juice

I had frozen, probably 3 years ago. (At the bottom, at the back. I knew

it was there somewhere! I split big containers of OJ into small ones so

I can use some and save the rest. Somehow I had stopped drinking it as

a regular drink, so the last couple had been just sitting in the

freezer. BTW this freezer is around -25° C -- that keeps things

much better for much longer than say -15°.)

I put the bottle into a larger container of hot tap water

so some would thaw quickly. I took that into my bedroom and managed to

get a couple of swigs before I lay down, and another couple before I

got to sleep again. Drinking too much too quickly isn't good anyway.

And I took the juice bottle out of the warm water. In the morning there

was no sign of a cold. I poured the thawed juice into a glass for

breakfast, but most of it was still frozen and I put it back in the

freezer for next time. When there's no more, I'll buy another bottle

and freeze it in smaller containers again, just for this purpose.

Something related that many aren't aware of (but may be

subconsciously aware of through experience of colds and flus): your

digestive system wants to do somewhat different things with alkali

reacting foods than with acid reacting foods. Citrus fruits don't go

well with starches, and they especially don't go well with milk

products. The digestive system can't optimally handle both at once, and

the environment is more conducive to viruses. Drinking fruit juice,

especially orange juice, with milk (eg, with cereal) is a ticket

to getting colds and flus. They're all good, but not together. Juice

and milk should be spaced hours apart.

[The source for this information is (if I remember the title right)

"The Edgar Cayce Handbook for Health Through Drugless Therapy" by Dr.

Harold J. Reilly (or was it Riley?) who Cayce referred a lot a patients

to. I read it decades ago. I can vouch that most any of the things I've

tried in it work. I seem to have lost it in my house move.]

Quinoa

Bread...

Mmm!

On the one hand I had been

baking my own whole wheat bread in a bread machine. On the other, in

spite of finding a better way it was a bit heavy and dense. ("knead

dough" cycle and then "bake only" cycle works better than "whole wheat

bread cycle", which makes it extra heavy and low rising.) Then on the

other hand, I had a big sack of quinoa I bought at a health food store

in Victoria over two years ago when I lived there. And again on the

other hand, I also had a couple of liters of quinoa that I grew myself

last year. (Mentioned in TE News #...123-125?)

I had used quinoa in bread. But it was grainy and not much

of an addition. Why wasn't there quinoa flour?

There's a lot of bitter stuff, little bits of chaff, in

with the home-grown quinoa. That's how it protects itself from being

eaten by bugs. (The store bought is all nicely cleaned.) It was

said to just rinse it in a collander under the tap, but that just

didn't work. I put some in a small mixing bowl, got a hair dryer, took

it out on the porch, and blew the hair dryer into the bowl. Shake the

bowl as you blow. When you have it right, most of the bitter and

lighter chuff comes out. Bingo!

Some is in clumps that still have some seeds in them. To

get those, rub a bunch of it between your palms, dropping it into the

mixing bowl. That breaks it up and then the chaff can be blown out

without the seeds.

So I took 1/2 cup of that and ground it in the coffee

grinder. Then I did the same with 1/2 cup of the store-bought quinoa.

The store bought ground finer, easier. The home-grown was somewhat of

"quinoa meal" while the store bought was definitely "quinoa flour".

(They may have been different varieties?)

Then I made bread as usual except using 3 cups of whole

wheat flour and 1 cup of quinoa flour instead of 4 of the wheat

flour. It rose to the lid of the breadmaker. It was delicious! The

texture was ideal and the flavor was great! 100% whole wheat flour is

now "out". 25% quinoa flour is "in". Now I'll seriously be using up the

quinoa instead of just a bit now and then. I may actually finish it all

some day. ...I bet it would be great

in pie crust! - a bit of a "graham wafer"-like effect? (Yup, it's quite

nice. Mmm, delicious pie from thimbleberries picked along the edge of

the highway! You wouldn't want to do that near a very busy highway, but

this is Haida Gwaii.)

It's great that 1/8 of the makings (potentially 1/4) of

the best bread came

from a small patch in my own garden. It seems pretty impractical to

grow

wheat, although I did grow a little once along with a few oats, and

this summer I have a small patch of barley. As well as corn, which just

might produce a few palatable ears. Some "volunteer" quinoas in the

barley patch (last year's quinoa patch) are growing well. (They're not

in a greenhouse, but the main garden is along the south wall of the

house, so it's a bit warmer and calmer than out in the open. Growing a

garden here this cloudy, cool July reminded me I'm not so far south of

Alaska.)

Another

Hair

Loss

Preventative

Using a brush on the scalp

instead of a comb didn't seem to be the whole answer. At the top at the

back, it gradually started getting thinner again anyway, and then I

realized I had lost some all along the top, too. Hardly noticeable

without looking carefully - I'm sure baldness creeps up on people that

way. I saw some "Rogaine" in the drug store and on impulse I bought

some. There was some patented ingredient, but I looked and it seemed

the main constituents were ethyl alcohol and propylene glycol. I

thought, "Wow! They've sure found a good way to sell alcohol and

antifreeze for a really high price!"

So I started looking on the web, and some clues seemed to

indicate that putting ethyl alcohol on your head is a very good way to

help prevent hair loss. Not just a little bit on the thinning patch as

Rogaine recommends, but over the whole scalp. In my enthusiasm and

experimentative nature I started spraying ethyl rubbing alcohol on

daily. (The squirter from the Rogaine fit on the alcohol bottle - the

one real benefit to the Rogaine besides triggering the search for

information.) But that must have been seriously overdosing - it's how I

gave myself shingles.

Maybe once or twice a month may be about right. The

ostensible reason for it is that it seems a primary cause of hair loss

is the hair follicles going "dormant". The reason for that is lack of

blood flow in the scalp. (That's why the stimulation of a brush helps.)

The reason for the poor blood flow is more or less continual

vaso-constriction because of cold - the sort of cool conditions many of

us in northern climes get used to all winter. (Hmm, how prevalent is

baldness in the tropics?)

Most people don't wear hats any more. Is your house warm?

Do you go around in the cool to cold all day? Is your bedroom cold at

night too? What part of your head is against the warm pillow? What part

goes bald?

Alcohol is a vaso-dilator when drunk. Apparently it

dilates the blood

vessels as well or better if sprayed directly on the whole scalp.

But I have a suspicion that there may be more to it.

Perhaps some bacteria or something that get growing in the cold scalp

that are part of why the hair follicles quit working. Not the shingles

(which bacteria never go away entirely once you've had chicken pox),

but something that persists along those lines and spreads over the poor

circulation areas of the scalp. If that is the case, killing them off

once a month with alcohol may go much farther than expected to prevent

hair loss in the first place whether or not it restores lost hair. But

that's just my present theory. It may simply be periodic

vaso-dilation.

I can see one can't expect miracles once hair has been

lost. Hair isn't lost in day, either. But maybe, eventually, it will

get thicker again? (<= wishful thinking alert!)

Small

Thots

* The whole world is fully populated (and then some). Very large

families have had their purpose, but may now be considered immoral.

Even 3 child families will continue to grow the population, albeit at a

much slower rate than with so many couples, so often in poor

circumstances, having

5 or more children.

The best and most effective aid more developed

nations could send to the "third world" is free birth control products,

freely proffered but with the notice "We can't take any more of your

ever-growing crowds of

desperate refugees. However many kids you have, you'll have to house

them and feed them yourselves." There is now, too little and much too

late to stave off the coming disaster, the beginnings of a backlash

against large families and in favor of birth control in the world's

most crowded countries such as Bangladesh.

* How the financial system is ruining everybody. Charles Hugh

Smith explained it all on Zerohedge.com one day in July. Central bank

prints money galore and lends it almost 'free' to other financial

institutions. They use it to speculate in investment assets. One of

these is real estate.

So say a mall cost 1 million dollars. The stores in it pay

1000 $/month rent. (just for nice round numbers.) Now an entity comes

along and buys it for 3 million - the free money for some is pushing

all

real estate prices up. Now they have to charge the stores 3000 $/m

because of their large mortgage. The stores have very little room to

raise prices in the declining market where the consumer isn't getting

proportionate increases in salary/income. Stores go out of business and

become empty. If the mall can't charge the

stores 3000, then the whole mall goes under. Here we have the makings

of the retail apocalypse which has been underway for a decade.

Smith explains it much better:

Main

Street Melancholy - Small Business On The Precipice

--

Authored

by Charles Hugh Smith via OfTwoMinds blog

-- Small businesses on the precipice need only one small shove to

go over the edge, and there won't be replacements filling the

fast-multiplying empty storefronts.

https://www.zerohedge.com/news/2019-07-30/main-street-small-business-precipice

* In the early to mid 1970s one could buy "Duralex" ("Made in France")

unbreakable glass drinking glasses. (I think they were associated with

the new "Corelle" by Corning dishware that is so much better than the

old thick, heavy, easily broken ceramic dishes. At least, they became

available at about the same time.) As with the Corelle dishes they were

very popular and everyone assumed they were here to stay.

I had (have) an 8 oz. Duralex glass that I somehow got

from my Mom. When I bought my house in 1977 I looked for some more in

the stores. I have a vague recollection of

at least one person saying then that they had looked all over but

hadn't been able to find any. I wanted the 8 oz glasses, but all I

could find was a set of four 6 oz. ones. I bought those "for now"...

but I have never again seen any Duralex glasses in any store. They were

the last ones.

You already know I'm the suspicious type... I think

someone of means deliberately got rid of them (one way or another) so

they could continue selling their regular easily broken glasses. But

that's only the same suspicion as other people voiced at the time.

Once you bought glasses that didn't break, you never needed any more,

so "they" got rid of them. I

have bought several sets of regular breakable glasses since then, since

6 oz is pretty small. Almost all of them are gone - bought, used and

then broken over the years. I still have three of the four Duralex I

bought in 1977 (I don't know where the other one went), and the 8 oz

one from my Mom (possibly bought 1971-1972?).

* Floating ice sheets extend variously around Antarctica. Variable

warmer sea currents are causing some of these to break up unexpectedly

fast. "Average" temperature doesn't count; it's the warmest points

causing the break-ups. New info

based on observing the collapsing Jakobshavn glacier in Greenland would

suggest that the ongoing breakup of the sea ice shelves destroys the

outer edge support and would cause the

mile to two miles thick on-land glaciers to start to collapse from the

shorelines. Since they are so thick they can't support their own weight

if the edge isn't supported, and so they will break up and flow faster

into the sea. As the Antarctic ice melt, thus far minor in global

terms,

increases, it would reach epic proportions. If it happens to the area

in the news some time back, this

would cause a very rapid global 11 foot sea level rise. It is probably

now just a matter of "when", and it didn't sound like it would be many

decades off. Say g'bye to most of the port facilities

and coastal cities around the globe. Say hello to hundreds of millions

of displaced and destitute refugees seeking higher ground. (I'm glad I

found this place, 25 feet above the present high tide mark! I could as

easily have taken one just above sea level and might then have wound up

in the refugee category in my lifetime.)

Eagles feasting on a rotting sea lion carcass

on the beach out front.

Eagles feasting on a rotting sea lion carcass

on the beach out front.

Where it came from I have no idea. It was huge. Evidently somebody

thought it was a whale.

The first day I saw it someone had skinned the accessible part, but it

was too heavy to flip over.

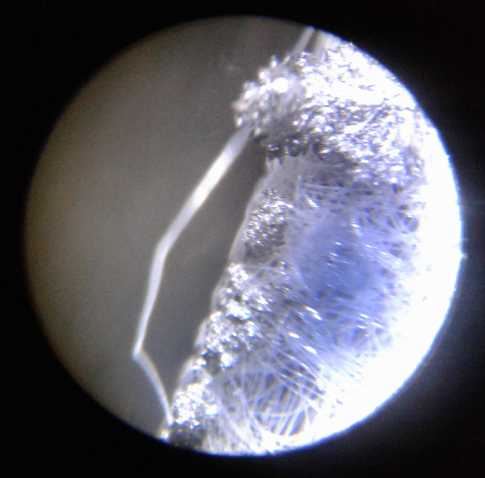

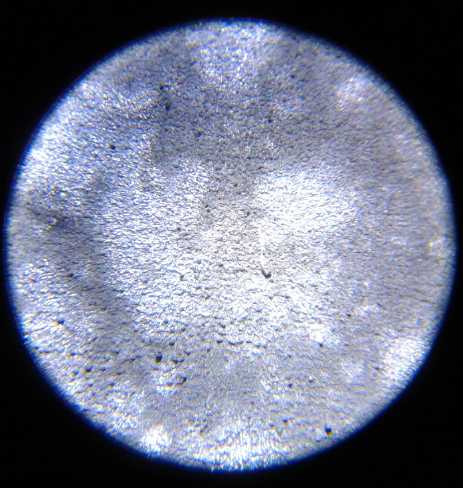

Bits of crystal(?) sponge have washed up all

over

the beach everywhere. Why?

Bits of crystal(?) sponge have washed up all

over

the beach everywhere. Why?

I've never seen more than the odd lone piece before.

I have only been here 2 years, so I don't know if this might be normal

every few years.

I hope it isn't yet another mass marine die-off - the end of the

world's only sponge reef!

ESD

(Eccentric Silliness Department)

* Conponent: That piece you got at such a great discount price, that

doesn't actually work when installed.

* Ah! I get it now! The glass labware item is called "beakers" because

they have "beaks" to pour out of. How mundane, ha ha! (How many decades

did that take me?)

* Az sumwun faymus wunss sed, "Hee iz uv smoll maend, hoo kan onlee

thingk ov wun wey tu spel u wurd."

* Rumor has it one should stay away from the bar in Epstein. You're

likely to catch something there. (...At first I thought it was just a

virus.)

* Do Linux computers have to be run in "sudo" mode to get permission to

play sudoku?

* Parachuting, like fine wine, is good 'til the last drop!

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency and

completeness before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground

Effect

Vehicle (first the R/C Model)

On the 9th I put the spars

and ribs together to form the wing, and did a bit of sanding. It

started to take on more form. Then I got onto other things.

On the 23rd

the motor controllers ("ESC"s) ordered in May finally arrived. Well,

they did

say up to 60 days delivery. There was two days to spare.

The motors had come with banana jacks on them. The

controllers came with bare wire and some bits of heatshrink to cover

the solder joins. I found a brass tube of the right diameter for the

jacks. I cut six 1 inch lengths and soldered three on the wires of one

controller, with some bigger, longer pieces of heatshrink to match.

Then I got out the radio controls and a 6 volt NiMH

battery tube to try one out. Everything worked fine. It blew a lot of

air. Then I tried 12 volts (10 NiMH AA cells tube). It blew a hurricane

and I could feel the fan want to move forward. Nothing ventured and all

that I put them both in series for 18 volts. Up to 22 volts is allowed.

This time it blew a hurricane at lowest throttle, and then sucked in

and ripped a nearby piece of paper. I think the craft will take off

with two of those on it.

(Ack, 1AM! How do I end up always staying up so late?)

---

Someone thought that the craft as configured would be

unstable, that it would "hobby horse" [in waves?]. Well, some

ground effect craft have done that. He mentioned that wings have their

center of lift at about 1/4 of the way from the front to the back. But

that was the point to to Ryland's special ground effect wing profile,

that the center of suction lift from the top would be much further

back. The wing is actually thicker toward the back than near the front.

It's a bit more like a wing "with its flaps down". Ryland says that the

compression lift from underneath, the ground effect lift, is more

toward the front. I'm not sure myself how pronounced that effect will

be.

Anyway we shall see! It may be that the batteries (the

heaviest

part) should be placed more toward the rear than the front, which would

also be unusual for an aircraft. But these questions are just more good

reasons for

making a model first. If there is anything like "hobby horsing"

instability that is hard to get rid of by physical design, my backup

plan is to take the "stealth fighter" technology route: a

microcontroller connected to inertial sensors and servo motors makes

instant microadjustments to the elevator to keep it on an even keel. If

that is done, it may be that the driver?/pilot?/captain? doesn't even

need to have an elevator control. After all, it isn't intended that the

craft fly up into the sky, only that it ride just above the wave crests.

Near the end of the month I decided the ducted fans should

go on the outside of the hulls, in line with the wing. That way they

would only be pulling/pushing forward, and not trying to push the nose

down as propellers above the wing do. That meant a couple of the spars

had to be made longer to mount them, as well as made streamlined.

Working on batteries as I was, I didn't get that done until the 30th.

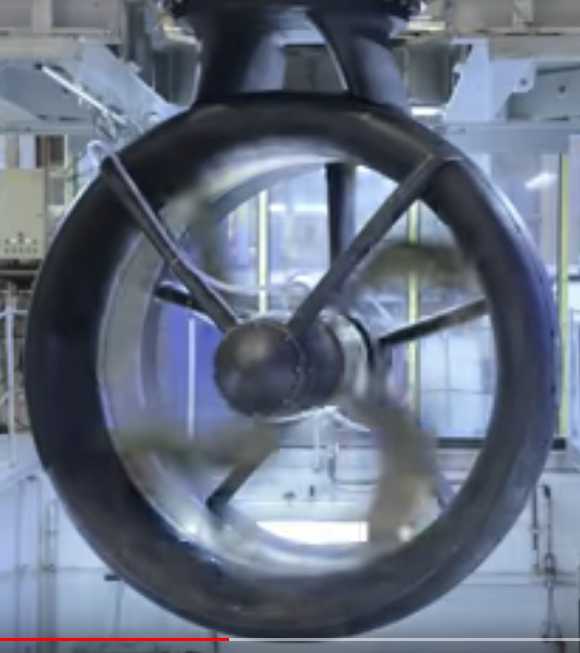

GEV with the ducted fans placed outside, in

line with the wing

GEV with the ducted fans placed outside, in

line with the wing

Finally to visualize what I have in mind, on the 31st I

pinned on a scrap of the paper-thin polypropylene cloth. (non-woven

"landscaping fabric") My intention is to epoxy this, as thinly as

possible so as to add very little weight. I expect this strong,

featherweight, cloth composite to be a modern version of the doped

canvas that early aircraft skins were made of.

Three views with the motors set in place with

sticks

and a scrap of fabric pinned on for effect.

Three views with the motors set in place with

sticks

and a scrap of fabric pinned on for effect.

(The elevator that goes behind the wing at the very back isn't made

yet.)

---

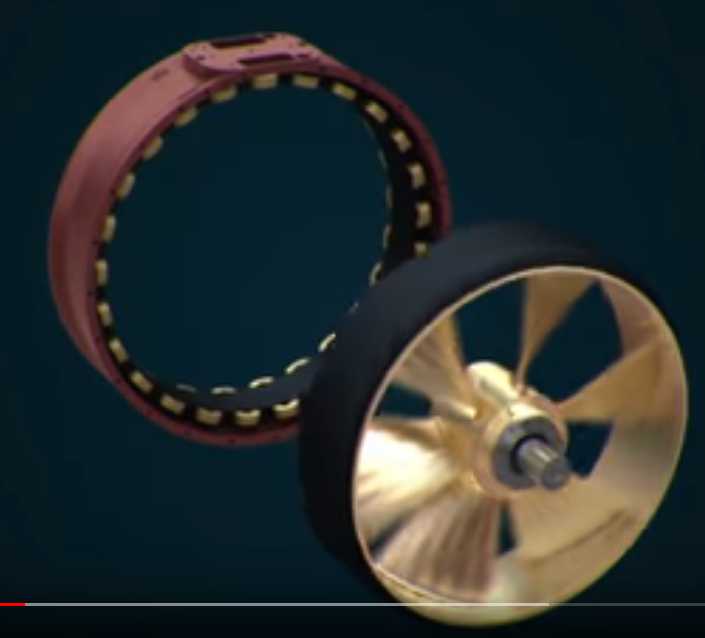

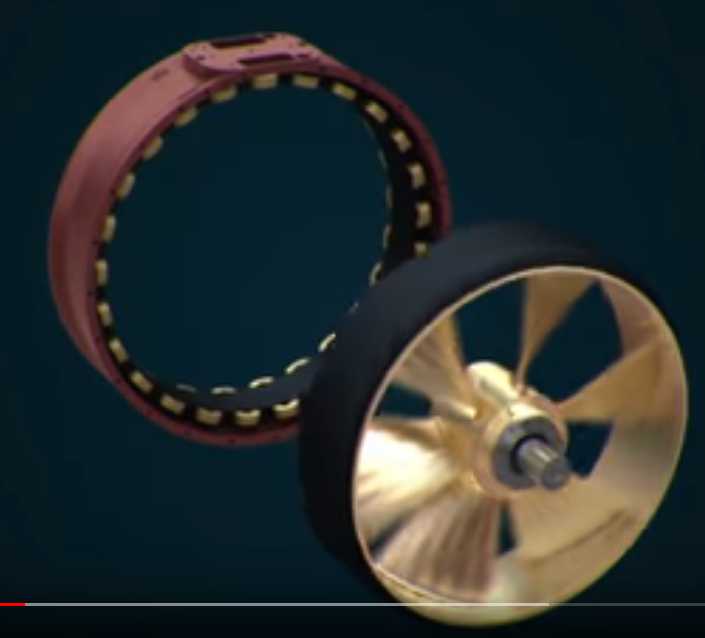

In related news... I was thinking how the unipolar

BLDC motors

(next article down) would probably make great motors for the ducted

fans on the full size ground effect craft, except for their large

"pancake" diameter taking up so much room in the middle of the duct.

Then on

the 19th

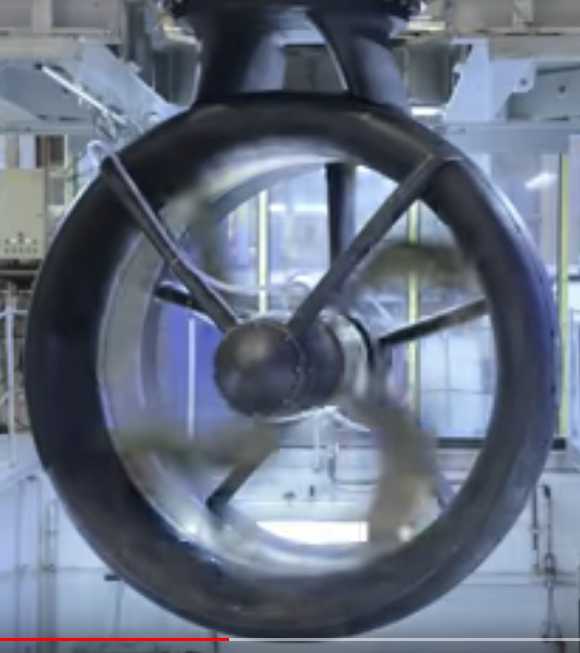

I happened across a short video on youtube: Rolls-Royce | Permanent

Magnet Technology by Rolls-Royce. They were making PM / BLDC

motors

for marine use, as underwater ducted fans.

In their configuration the stator coils were on the inside

of a drum

around the outside: in the outer duct. The magnets were on a rotor rim

inside from that. Of course that configuration would be quite

applicable to the unipolar motor. The stator was the outside of the

duct, and the rotor with propeller was almost the whole inner diameter,

with no lump bigger than the bearings on the center shaft, and of

course a few stationary spokes. It seemed

ideal.

Rolls-Royce electric ducted fan motor for

marine use.

Rolls-Royce electric ducted fan motor for

marine use.

Outside: ring of stator coils. Inside: magnet rotor with fan.

Stator ring and magnet motor rim form parts of

the duct,

Stator ring and magnet motor rim form parts of

the duct,

thus only a small center spindle is required to mount the rotor.

Somehow designing another whole new motor configuration

(and rather different than my others) wasn't quite what I had in mind

of when I thought of applying the (potential) new motor to the ground

effect vehicle.

Unipolar BLDC Motor & Motor Controller Design

![[drawing]](FigurinItOut-Roturz.jpg) On the 5th I decided to cut circles out of paper and draw

magnets and coils on them. Then I could actually rotate the "rotor" and

see which sets and sequences of coils (if any) would rotate it

consistently. I drew 8

magnets on the rotor and 12 coils on the stator. I wasn't sure that 12

and 8 would work. Rotating the rotor around the stator 1/3 of a coil at

a time disclosed that it was the same as 6 coils and 4 magnets,

doubled, and so of course it would work the same. (Duh!) What was

different was that being doubled, whatever coils were activated next to

each other was duplicated on the other side of the rotor, so the forces

were all symmetrical. Perfect!

On the 5th I decided to cut circles out of paper and draw

magnets and coils on them. Then I could actually rotate the "rotor" and

see which sets and sequences of coils (if any) would rotate it

consistently. I drew 8

magnets on the rotor and 12 coils on the stator. I wasn't sure that 12

and 8 would work. Rotating the rotor around the stator 1/3 of a coil at

a time disclosed that it was the same as 6 coils and 4 magnets,

doubled, and so of course it would work the same. (Duh!) What was

different was that being doubled, whatever coils were activated next to

each other was duplicated on the other side of the rotor, so the forces

were all symmetrical. Perfect!

It would seem that ideal conditions are: both the rotor

and stator have to have an even number of elements, and that there are

3 coils per 2 magnet poles. So, a multiple of 6 coils and 4 magnet

poles, but at least two sets so forces on the rotor are balanced

against the axle. Hence, 12 coils and 8 magnets.

So the next size up that would work so perfectly would be

18 coils and 12

magnets, which would be a triple set of 6 coils and 4 magnets, with

three sets of coils activated symmetrically 1/3 of the way

around the rotor from each other. Then 24 and 16 with four sets. I had

tried that, 24 coils with the "Electric Weel" and it was just too big

for me to make solid enough with my "Electric Hubcap" techniques. The

slightest off-angle on the axle bearings and the huge rotor would be

touching the coils at one point and too far away at the other side. I

would presume that the 18/12 size would likewise more than tax my

capabilities. It looked like the 12/8 size was thus IT! If other sizes

of motor were desired, they would have to also be made with 12 coils

and 8 magnet poles, with different size coils and magnets than the

sizes I

already have lots of.

I started with rotor magnet

"A" (north) approaching coil

"1" (north). This meant that also the opposite north magnet ("E") was

approaching

north coil 7. The other two north magnets ("C", "G") were approaching

south coils 4, 10. The coils that would drive the rotor clockwise from

this position were: 2 & 8 coming on, 3 & 9 already on, and 4

& 10 just

turning off.

Next I moved "A" just past "1". Now it was 1 & 7

coming on,

2 & 8 already on, and 3 & 9 turning off.

1/4 of a rotation thus needed this sequence of coils

driven:

2,8, 3,9

1,7, 2,8

12,6, 1,7

11,5, 12,6

10,4, 11,5

9,3, 10,4

1/4 of a rotation also brought the next set of north

magnets to coils 1,4,7 & 10, and so completed a magnetic cycle,

with four magnetic cycles to one physical rotation.

----

I then checked out the 3-4 (or "4-3") unipolar

configuration I had

conceived of in 2016, with the 8 magnet rotor and just 6 coils. Sure

enough, that could be made to run too, with the coil activation

sequence being the opposite direction to the 4 magnet, 6 coil

arrangement:

4,5

5,6

6,1

1,2

2,3

3,4 (and repeat)

Again with 12 coils (and 16 magnets) instead of 6 coils,

it would be bi-symmetrical with even forces around the rotor. But there

would be twice as many coil switchings for the same rotation. Since I

would be using 16 magnets anyway for the 8 magnet pole version, it

would be just a matter of mounting the same magnets one way or the

other:

NNSSNNSSNNSSNNSS or NSNSNSNSNSNSNSNS.

(Gosh, I actually have the unipolar Electric Caik with 6

coils and 8 magnet poles made in 2016 - asymmetrical forces

notwithstanding. That should work to test the required

6-phase motor controller that would be the same as for the 12 coils 16

magnets size. Then I can put on the regular rotor with 4 magnet poles

NNSSNNSS and try out both options. They would be sure to perform a

little differently. Might one have more torque than the other?)

Of course another new motor and controller is a very

considerable project. However, since I have already made very good

axial flux BLDC motors I am sure the unipolar one would be likewise an

excellent runner, and since the motor controller will doubtless be more

reliable, I am sure they would make a good set for an electric car. If

it wasn't for the large diameter - or maybe in spite of it - they could

also be a good set for a propeller drive - the ducted fans for the

ground effect vehicle or for a boat propeller. [See Ground Effect

Vehicle, above, for a new idea.]

And it would be great to be able to try out the "permanent

magnet assisted" coils idea, which just might bring a whole extra level

of performance per power used, perhaps somewhat akin to a heat pump

making a building warmer by an amount of energy greater than the amount

of energy supplied to pump it.

? Turns Per Coil

Now... How many winds per coil? In the Electric Hubcap there were 20 or

21 winds per coil with the three coils of the phase in series. Then

there were always 2 phases activated in series between ground and 36

volts (via the "Y" point). That's 120 (to 126) winds total. In this

unit just two coils are driven by each phase, which would suggest 60

turns per coil. But the currents will need to be higher because ony 1/3

of the coils are on at a time instead of 2/3. That might suggest using

30 turns per coil for a total of 60, which would mean #12 or #13 magnet

wire.

Which I don't have any of. Or perhaps double winding a #15 and a #16.

Then again, coils are inductors... how many winds for

double the current again? I have a feeling it's not a straight linear

relationship. I should probably be able to look it up on the web and

figure it out but my brain is rebelling. 30 turns sounds good.

Motor Sizing

I laid

out 12 coils/cores on a table. I left a bit more

room between each two than in the original Electric Hubcap for

fatter wires and better

cooling - 78 mm instead of 73. When I had what seemed like a good size

circle, it appeared the magnet rotor should be about 350 mm diameter,

and the stator inner diameter then 370. (Make it 390 and have enough

room for the wiring for a change!) That seemed very substantially

larger than the 250/280 mm of the original Electric Hubcap. I

guess saying "huge" would be an overstatement. It would probably weigh

over 40 pounds. I don't suppose such a large rotor could take much over

2000 or 2200

RPM safely.

I laid

out 12 coils/cores on a table. I left a bit more

room between each two than in the original Electric Hubcap for

fatter wires and better

cooling - 78 mm instead of 73. When I had what seemed like a good size

circle, it appeared the magnet rotor should be about 350 mm diameter,

and the stator inner diameter then 370. (Make it 390 and have enough

room for the wiring for a change!) That seemed very substantially

larger than the 250/280 mm of the original Electric Hubcap. I

guess saying "huge" would be an overstatement. It would probably weigh

over 40 pounds. I don't suppose such a large rotor could take much over

2000 or 2200

RPM safely.

I would probably make the stator plate almost an inch

thick to be sure it didn't warp. Polypropylene-epoxy is quite light, so

thick ends don't add much weight. Later it occurred to me that "spoke"

ribs on

the outside might be the best way to go, with a thick bearing mount

place at the center. (The longer the short shaft is between end

bearings, the straighter it will be. and it will need to be very

straight for such a big platter.)

To review the figures: a 13

inch car wheel turns about 10

RPM for every kilometer per hour it's traveling. So to do 100 KmPH (63

MPH) the wheels are turning around 1000 RPM. I was counting on 3000 RPM

motor speed to be able to have two such motors, one on each front

wheel, to provide sufficient torque to get a car moving at 3 to 1

reduction yet do 100 KmPH on the highway, in case the variable

transmission didn't pan out. But at just 2200 RPM, the vehicle wouldn't

go much over 70 KmPH. I'd call that a success as a town vehicle, but

I'm not sure

other traffic on the highway would appreciate it. A reduction of only

2.2 to 1 to the wheels is asking for a lot of motor torque.

(...at least 35 foot-pounds each or better. At 3 to 1 it's 25 - still a

lot, but just a minimal 150 foot-pounds at the wheels.)

Now... about that 6-phase unipolar motor controller!

Permanent Magnet Assist - Magnet Fitting

I had found in 2016(?) that I could machine the iron

powder toroid cores on the lathe - I had done one. A typical washer for

a 1/2 inch

bolt could fit perfectly, flush with the top end of the core. The

purpose of the washer was as a "keeper" for a permanent magnet assist

cylinder magnet placed in the center of the toroid. But I had never

tried to fit one.

![[imidj]](CorWiPM.jpg) On the 11th I

dug out some 3/4 inch and 1 inch PVC water

pipe. The 1" one was too big for the core center and the magnet rattled

around loose in it. The 3/4" one telescoped inside the 1". It was too

small for the magnet and was very loose inside the core. I thought I

could probably shrink the 1" in the oven. Then I thought of cutting a

slit

in the 3/4". It could open up a bit to fit the magnet. It was too

stiff. I heated it to over 200°F in the oven and it was much more

compliant. I put it over the magnet. Then it looked a little too big

for the core, but I tried it anyway. It was a perfect, fairly tight

friction

fit. No looseness, no jamming anywhere! There was a gap where the slit

was, but that didn't matter.

On the 11th I

dug out some 3/4 inch and 1 inch PVC water

pipe. The 1" one was too big for the core center and the magnet rattled

around loose in it. The 3/4" one telescoped inside the 1". It was too

small for the magnet and was very loose inside the core. I thought I

could probably shrink the 1" in the oven. Then I thought of cutting a

slit

in the 3/4". It could open up a bit to fit the magnet. It was too

stiff. I heated it to over 200°F in the oven and it was much more

compliant. I put it over the magnet. Then it looked a little too big

for the core, but I tried it anyway. It was a perfect, fairly tight

friction

fit. No looseness, no jamming anywhere! There was a gap where the slit

was, but that didn't matter.

![[imidj]](CorForPMAssist.jpg) Then I put the washer on the end and

everything was just right. (The washer stuck out just a bit but the

depth of the machined space could easily be made a little deeper.) The

other end was still open, and predictably a second core was far more

attracted to

the open end than the closed end.

Then I put the washer on the end and

everything was just right. (The washer stuck out just a bit but the

depth of the machined space could easily be made a little deeper.) The

other end was still open, and predictably a second core was far more

attracted to

the open end than the closed end.

All was going just as according to theory! Now, if the

coil on the core was energized so as to have the same strength as the

magnet, the magnet and the coil should project their united magnetic

field at twice the strength the electricity being applied to the coil

alone would make. How could it not make more torque than just the coil

alone, yet without using more electrical energy?

My prime concern was that the magnet and the washer would

make for substantially higher iron losses than the miniscule losses of

the iron powder core and would thus warm the cores. The next day it

occurred to me I could machine the washer and magnet in at least a

little deeper, recessed in instead of flush with the top of the core.

That would help a little.

There was another takeaway from this little trial: in

order to allow for later addition of permanent magnets into the cores,

the 12 cores should be machined to

take the washers before winding them, and the stator plate

should be designed to lock down

the open end - i.e. the core center mounting "buttons" shouldn't be too

tall to accommodate the magnets. Easy to do and shouldn't make any

substantial performance difference if the magnets weren't put in, or if

they were put in and then removed. Simply adding the

magnets to the same cores in the same motor after initial tests, should

allow some very

fair performance comparisons!

Tuned Circuit Coil Drive

(20th) I came up with an idea for a new sort of coil driver,

especially appropriate to 'permanent

magnet assisted' technology. The permanent magnet assist, according to

sources I've run across, reduces currents at higher currents, but

doesn't do much at lower levels of magnetic flux. The assistance is

probably maximum

when the permanent magnet and the electromagnetic coil are magnetized

to the same strength. So even if lower power is needed from the motor,

it would pay to have the flux strength at a high level. So instead of

applying high frequency PWM to get less overall flux in the coil, short

bursts

of full strength coil activation would be used to gain high flux, with

rests between since full torque isn't needed. In other words, a very

slow PWM, perhaps measured in tens of hertz or even ones, instead of 16

KHz. (This would also eliminate what surely must be an [ultra]sonic

noise irritant.)

First I thought to put a capacitor in series with each

coil. That seemed ideal for turning on the coil and holding it on

for the resonant period. But then I couldn't see how to discharge the

capacitor when the coil was turned off.

So the tuned circuit would be created by putting a

capacitor in

parallel with the coil. Three B+ power line chokes (per 2016 unipolar

designs) for the six phases would be placed in series with the coils

so that the capacitor doesn't present an initial short circuit to the

driver. (I expect we can get away with 3 instead of 6 because an

oppositely timed coil is off when the active one is being

switched, and for a period before and after, so the one motor coil

isn't affected

by the switching of the other one.) In a coil, current rises with pulse

on time. In a

capacitor it drops. Thus the current, for the given resonant frequency

period, stays somewhat even instead of simply rising with time, and a

magnetically high level of flux is maintained at a relatively even

strength while the mosfet remains on.

When the mosfet switches off, the coil voltage continues

to be supplied by the capacitor. Decreasing flux continues to be

supplied until

the capacitor (and coil) voltage is exhausted.

No flyback diodes are needed in this configuration,

because the coil loses voltage "gradually" as the capacitor discharges

instead of being suddenly

switched off. Likewise, the main power line choke suddenly has a

voltage across it when any coil switches on, but as it is a

lower inductance this recovers

rapidly during the coil's on period and there is no significant

flyback effect. (I should check this out to make sure.) The saving of

energy usually wasted in flyback diodes

through their forward voltage drop is not insignificant, without

recourse to "active rectification" that means turning on mosfets that

just

might short across the power supply. (improved reliability.)

Based on the component values, the microcontroller (ie the

programmer writing the code)

must determine how long each resonant pulse should be, and the time

between pulses, and based on the "throttle" control and RPM, how many

pulses to apply and when, as a magnet passes between two coils.

Rotor Design

I decided that wrapping each magnet with PP

webbing/strapping is probably a waste of time. Maybe in a dirty

environment it protects the magnets better. But if the epoxy came

loose, the magnet might not fly out, but the rotor would still need

repair. I saw one youtuber (making a generator, was it?) who cast his

magnet rotor in epoxy, but he simply didn't fill it full, in order that

each magnet protruded and provided some "centrifugal fan" action for

cooling. That would surely be simpler and cleaner than the strapping.

Could the whole cast epoxy disk come loose from the steel

rotor? I had the thought that putting some smaller holes through the

rotor for the epoxy to put "roots" through would be a good improvement

to strength. Especially if they were drilled out on the back side with

a "V", so the plugs of epoxy would look like flat-head bolts. With

that, might I even dare push the max. up a couple of hundred RPM? 2400

or 2500 RPM sounds so much better than 2000 or 2200. OTOH 350 mm,

almost 14", is a big disk to spin! Also I'm thinking 1/4" steel rotor

might

be just as good as 5/16", and 20% lighter. (If only I had that plasma

cutter working... OTOH I could just have Victoria Waterjet do the rotor

and mail it to me. OTOH I have to get the CNC table working to make the

stator molds anyway.)

Activation Sequence

![[drawing]](FigurinItOut.jpg) (16th) In

3-phase motors, one uses 3 hall effect sensors each midway

between two coils to determine magnet positions - the rotation of the

rotor. Would the 6-phase controller need 6? Obviously one will be using

a microcontroller as the brain. There are no 6-phase motor controller

chips (much less unipolar ones). Three hall sensors do in fact provide

six different polarity combinations, and there are 6 phases. But with

unipolar coils it seemed lopsided - two sensors would be between N-S

coils and only one between a S-N pair. I put three hall sensor

positions between three coils on my paper 'motor' to figure it out.

Somehow it all worked out. Each of the six combos of three "norths" and

"souths" corresponded to one of the six coil activations. The

microcontroller could easily be programmed to pick the right ones. Only

three hall sensors are required.

(16th) In

3-phase motors, one uses 3 hall effect sensors each midway

between two coils to determine magnet positions - the rotation of the

rotor. Would the 6-phase controller need 6? Obviously one will be using

a microcontroller as the brain. There are no 6-phase motor controller

chips (much less unipolar ones). Three hall sensors do in fact provide

six different polarity combinations, and there are 6 phases. But with

unipolar coils it seemed lopsided - two sensors would be between N-S

coils and only one between a S-N pair. I put three hall sensor

positions between three coils on my paper 'motor' to figure it out.

Somehow it all worked out. Each of the six combos of three "norths" and

"souths" corresponded to one of the six coil activations. The

microcontroller could easily be programmed to pick the right ones. Only

three hall sensors are required.

Variable

Torque

Converter

Having groped around in the dark for a way to do this from

2009 to 2016, I gave it a rest after I moved to Haida Gwaii. I thought

maybe making reluctance motors that could freely do very high RPMs and

so not need a variable converter was a better answer - at least for me.

But

during June I had thought of a couple of fixed 3-speed gear designs,

and somehow started to realize that for a variable torque converter,

just two main components had to work together:

1. A three element gear set such as a planetary with one of the

elements being tied to the driving motor and the second one to the

output - the car

wheels or the differential. If the motor turned but the car didn't

move, the third gear had to spin.

2. The third gear's turning had to be controlled; obviously it couldn't

just free-spin. Controlling its turning would control the coupling

ratio between the other two. If it spun near its free-spinning speed,

the RPM reduction between the other two would be very great. If all

three elements spun together, the drive ratio (regardless of the number

of teeth on each) would be 1 to 1.

Furthermore:

3. If the control element ran around the same speed as the other two,

then the torque needed to adjust the control element would be as high

as that needed to move the car. The faster the control element spun,

the less the torque that would be needed to modify its speed. This was

driven home to me by the large control forces needed for the

experiments of 2016, driving one wheel and using the car's differential

itself as a 3-element variable torque converter gear set. A control

gear spinning 3 times as fast as the motor would need 1/3 the torque.

4. If the control element ran opposite to the motor, then the force

required to slow it would also try and slow the motor down. If the

control element ran the same direction as the motor but free-spun

faster, then the force needed to slow it down would add to the motor's

force instead. The losses incurred that way would be [I presume] lower.

I was

trying to accomplish that in the 2016 designs. But now I realize they

were needlessly complicated and less able to supply good results than

just (1) a planetary gear with ratios that would lend themselves to the

job, and (2) a centrifugal clutch (or a flat belt & pulleys

"clutch") to control the spin of the control element - both correctly

configured of course. (The way I was doing it before 2015, a clutch

that tried to halt the control gear entirely, was simply wasting

energy.)

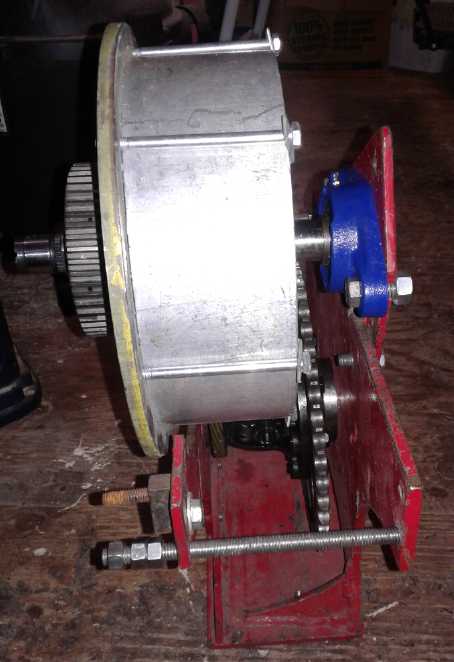

It also seemed to me that the large centrifugal clutch I

made in 2016 (2015?) was an ideal means to couple the motor to the

control element. As the motor started the shoes would be retracted, and

the drum on the control gear would spin up freely. The car wouldn't

move. When the motor started imparting force to the drum via the shoes,

pressure would be put on the output gear and the car would want to move.

I found a planetary that looked about right - one I had

used before, early on. If the motor drove the planet gears assembly,

and the ring gear (connected to the car wheels) wasn't moving, the sun

gear (centrifugal

drum) would turn 2.8 times as fast and in the same direction. If the

sun gear was slowed toward the motor speed, the ring gear would have to

start turning and

speed up toward the motor speed - the car would move. If I have it

right, the torque to move the car would be (at most!) 1 / 2.8 times the

torque needed to slow the drum, or just over 1/3 as much. This would be

similar to having a 2.8:1 gear reduction. Multiply that by 3:1

reduction to the differential gear and it's the equivalent of 8.4:1

total reduction, which should be sufficient to start the car rolling

with a fairly small motor. The difference is that as the torque

requirement drops, so does the ratio. When all three gears are spinning

together with the shoes locked to the drum, the 1:1 ratio from the

variable section has dropped the overall ratio to 3:1, which will

prevent the motor from over-revving on the highway. If that loaded a

small motor too heavily, a 3.5:1 at the differential would give 9.8:1

overall reduction at low speed and still allow ~87.5 KmPH (instead of

~100).

Or if that wasn't good enough, I should look for a

suitable planetary gear with a higher ratio from the planets to the sun

gear, such as 4 or 5 to 1.

![[desired config]](TqCvrtDesiredConfig.jpg) After

working

all that out on the night of the 5th, on the

6th I showed the gear and explained the concepts to a friend, and as I

did so, I realized it still wasn't the best arrangement. I was putting

the centrifugal shoes on the motor because that was the only part that

was surely driven at a known speed. But until the car started moving,

the sun gear would actually spin 2.8 times as fast as the motor. There

was the part to fling the shoes outward with maximum force! The drum

could be on the motor (planets assembly) and the shoes on the sun gear

instead.

After

working

all that out on the night of the 5th, on the

6th I showed the gear and explained the concepts to a friend, and as I

did so, I realized it still wasn't the best arrangement. I was putting

the centrifugal shoes on the motor because that was the only part that

was surely driven at a known speed. But until the car started moving,

the sun gear would actually spin 2.8 times as fast as the motor. There

was the part to fling the shoes outward with maximum force! The drum

could be on the motor (planets assembly) and the shoes on the sun gear

instead.

And it appeared this configuration

would simplify construction. When laid out, it appeared that

the ring gear that had to drive the chain to the differential would be

off to the left of the 'experimental transmission box' entirely.

![[config 2]](TqCvtrConfig1.jpg) Still later I

realized that the drum could be either on the

motor or on the output (ring) gear with quite similar effect. Which was

better? At the start, if the drum was on the motor, it would be turning

1/3 of the speed of the centrifugal shoes, and in the same direction.

If it was on the output gear, it wouldn't be turning at all. Which way

made for higher torque to the output? Probably the latter? Either way,

as the shoes took more hold and the car accelerated, everything would

end up rotating at the same speed, 1 to 1 ratio.

Still later I

realized that the drum could be either on the

motor or on the output (ring) gear with quite similar effect. Which was

better? At the start, if the drum was on the motor, it would be turning

1/3 of the speed of the centrifugal shoes, and in the same direction.

If it was on the output gear, it wouldn't be turning at all. Which way

made for higher torque to the output? Probably the latter? Either way,

as the shoes took more hold and the car accelerated, everything would

end up rotating at the same speed, 1 to 1 ratio.

It looked like this might work well, but only if the motor

was on the port side of the box instead of the starbord. It looked

close, so at this point I wanted to fit the box into the car to see.

Just how

many ways were there to configure one planetary gear, anyway? It seemed

there were 6 possible ways to connect the 3-element gear to the 3

external components:

Motor

|

Differ-

ential

|

Ratio

Control

|

sun

|

ring

|

planets

|

sun

|

planets

|

ring

|

planets

|

ring

|

sun

|

planets

|

sun

|

ring

|

ring

|

planets

|

sun

|

ring

|

sun

|

planets

|

For each of those, one part of the centrifugal clutch

(either one) had to go to the ratio control, and the other part could

go to either the motor or to the output. So by picking which gear (x

3), and picking which element of the clutch went to which gear (x 2

again), that made 36 possible ways, each with its own advantages or

disadvantages. But putting the centrifugal shoes on the output

obviously won't work. And any configurations that cause reverse motion

of any of the elements is probably counterproductive. Without checking,

that's likely to be over half of them. Of the remainder, only one can

be optimum so the rest are relatively counterproductive by comparison.

I wonder how many counterproductive ways I've already

tried? The two options mentioned above the table seem likely to be the

best.

---

It looked like I could contrive to cludj everything

together mostly with parts and pieces I already had, perhaps

fabricating and welding up a couple more things. The next question was,

what to use for a motor? I had the Electric Hubcap, but the Kelly motor

controller was blown, and I had dismantled the surrounding parts and

used them for the forklift motor controller. So the simple thing would

be to use the forklift motor, already wired in to the car.

And... amid all the other fabulous projects, when on Earth

was I going to find time to put this together? But of course it was

easy to dig out the transmission box and various parts just to see how

they all fit together. When I did so on the 9th there seemed to be one

very big fly in the ointment: There seemed to be no way to arrange it

to fit the ring gear anywhere where a chain or belt or whatever from it

could turn the differential. The ring gear would be right outside the

box.

I turned the shaft around. It looked like it just might

work with the motor on the right instead fo the left. That seemed

preposterous, but measurements showed that it just might work. Maybe!

Just! To check it out I would have to disassemble the present (fixed

ratio) transmission, install the box, make careful measurements, and if

it could work, some new pieces for mounting things - the motor and a

steady bearing at the far end. There would sure be a lot of empty space

under the hood on the other side. One could easily place more batteries

there.

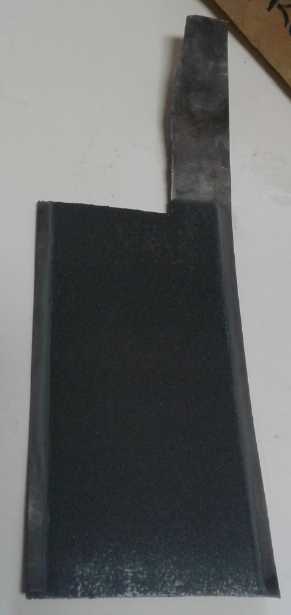

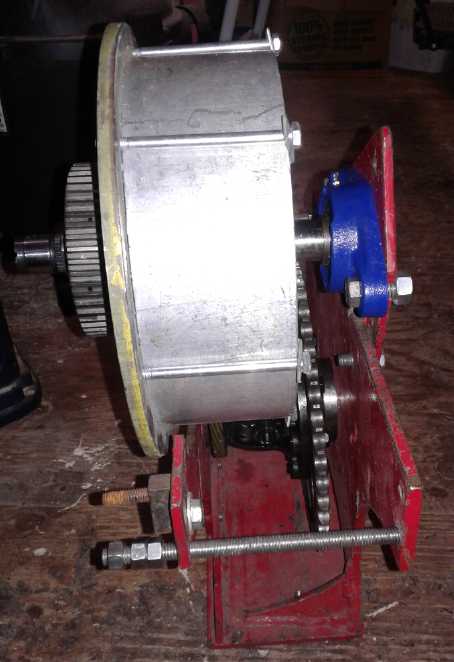

![[imidj]](TqCvrtConfig2.jpg) On the 22nd I took out the forklift motor and the

transmission, and put in the 'transmission experiments box'. It didn't

seem the motor could be fitted on the narrow side of the box. I

would have to rebuild the box as a sort of mirror image of itself. Or

would I? There were after all two similar configurations. My

plan was to place the centrifugal drum on the motor shaft. But if

instead I placed it on the output shaft, and reversed the car's

differential (chain sprocket on the other side), and made a couple of

new mounting plates with spacers, it

looked

like the motor could go in the larger space of the starboard side after

all. It might even be easier to mount things, and maybe even get a

bearing on to help stabilize the drum/ring/drive sprocket.

On the 22nd I took out the forklift motor and the

transmission, and put in the 'transmission experiments box'. It didn't

seem the motor could be fitted on the narrow side of the box. I

would have to rebuild the box as a sort of mirror image of itself. Or

would I? There were after all two similar configurations. My

plan was to place the centrifugal drum on the motor shaft. But if

instead I placed it on the output shaft, and reversed the car's

differential (chain sprocket on the other side), and made a couple of

new mounting plates with spacers, it

looked

like the motor could go in the larger space of the starboard side after

all. It might even be easier to mount things, and maybe even get a

bearing on to help stabilize the drum/ring/drive sprocket.

Finally on August 4th,

editing this newsletter, I looked at the first photo again. If the drum

was shifted way over to the right by making an offset mounting for the

steady bearing and maybe cutting a bit of a dish into the top of the

right side, the sprockets could line up and everything should fit that

way. I went out to the car where I had already set 'the box' in place

and checked it out. It looked like the drum could just clear everything

if it was all done just right. That should actually be the most

practical. (I couldn't place it there to take a photo without making

changes.)

---

In any event, (way premature of course) for something

besides a prototype I might look at something with larger

plastic gears that don't need to be immersed in oil, since it would be

at least difficult if not impossible to seal oil into a regular

planetary with

the external clutch components attached to it.

The "all spur gears" differential or planetary gear

might be a good choice for that. I had come up with that (derived from

a sketch in Wikipedia) in October 2016 - the last month before I got

involved in buying a house on Haida Gwaii and moving. I think the sizes

of all the gears could be adjusted to provide any desired ratios.

The "all spur gears" differential or planetary gear

might be a good choice for that. I had come up with that (derived from

a sketch in Wikipedia) in October 2016 - the last month before I got

involved in buying a house on Haida Gwaii and moving. I think the sizes

of all the gears could be adjusted to provide any desired ratios.

Then

one could probably drive gear "D" from the shaft going out the back

and attach the centrifugal shoes to it on the motor side of the drum.

The

outer drum (planets) could extend behind to engage the shoes,

all on the motor's side of the planetary. The output would then come

out the front on a shaft from "C" (attached to "C" and not with a

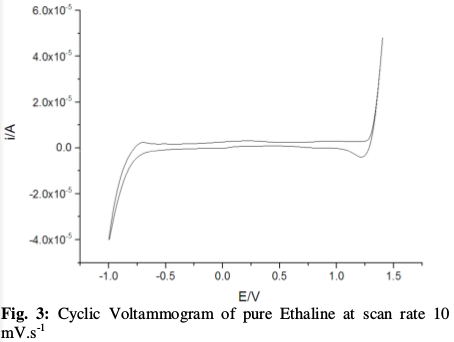

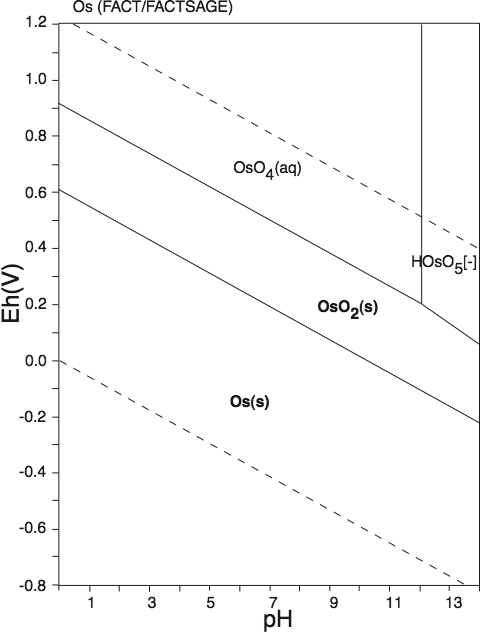

bearing there as shown, of course).