Turquoise Energy News #135

covering

August

2019 (Posted September 7th 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- "Charge the Future" Challenge

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Third Stage Democracy

- Truth and Truthfulness - The Epstein Saga - Rational and Irrational

Numbers 10-99 - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle ("GEV")

Other "Green"

Electric Equipment Projects

*

Some more Handheld Bandsaw Sawmill Notes

Electricity Generation

* Wind Power: 5 Blade Windplants Better Than 3?

* My Solar Power System: - Monthly

Solar Production log et cetera - Six month summary, notes.

Electricity Storage

Turquoise Battery Project (Mn-Zn or Ni-Zn in Potassium

Hydroxide electrolyte ?)

*Re-agaring the zinc electrode - More Research Needed - The real reason

all my NiMn cells had high self discharge - Painting Parts of

Electrodes to Prevent Gas Generation - Making Nickel-Manganates '+'

Electrode - Tentative Procedure for Making Positive Electrode (Aug 22nd

2019) - "Kneader Reactor" - FWIW: Cupro-Nickel as Alkaline "+" Current

Collector -

Electrode Powders Compactor: Pneumatic-Hydraulic Bottle Jack -

Commercialization and the "Charge the Future Challenge"

Even more than July, August

came to be about battery development experiments and tests. Inevitably

there's not much other news as everything else got left behind.

In addition to the exciting recent battery research

developments

already, there was the prospect of funding to commercialize long or

everlasting life, low cost, nickel manganate-zinc batteries. The

assurance and detail with which I could write, and perhaps the odds

of getting funded, would increase by the percentage of everything that

was

already working when I applied, which had to be by mid October.

Charge the Future Challenge

As soon as I had TE News #134 out, I turned my attention

to applying for Natural Resources Canada's battery challenge. Unlike

the dysfunctional IRAP and STDC funding programs for which the biggest

qualification to qualify for funding is to have lots of money already,

this one had no specific requirements for having other funding. It also had a line for

a cash equivalent value of "in kind" support by the applicant and

by others. If working for over a decade unpaid and having spent tens of

thousands of dollars for equipment and materials, and being quite

prepared to contribute all - and space - to the cause, isn't "in kind"

value,

I don't know what is. Obviously without it I wouldn't be about ready to

make new technology batteries and there would be no application. Of

course batteries hasn't been my only and full time project, but the way

forward now is to get others involved, for which money is required.

I found my friend Mike K. was very enthusiastic about it,

and he's had a lot of experience running production businesses. His

readiness with specific ideas for how to get rapid production going to

perform critical tasks give me great confidence we'll succeed. We

talked about the amount of money to ask for. He said I was asking for

too little. that trying to do things too cheap ends up wasting a lot of

time and costs more in the end, and that everything takes longer than

you think it will - which I can only agree heartily with. And that

being a government program they would expect people to spend lavishly.

OTOH asking for a lot more than is required will probably end up

looking self-serving which might be counterproductive later.

In the battery developments of this summer, many things

which

had seemed to be side tracks in previous years, which hadn't led to

working batteries then, nevertheless started coming back as being

useful to developing, improving or producing the present working

batteries, more and better things than would have been possible without

all this accumulated knowledge.

During August I tried to make a couple of nickel-manganate

electrodes, but they didn't seem to work very well. They should have

higher amp-hours per weight, but if I can't get them going I can always

fall back on regular nickel oxyhydroxide electrodes, or manganese

dioxide. So failure in this direction isn't a project killer.

I ended the month going to a camp-out with a group of

friends and seeing my mother, who lives near the campground. But it's

sure costly getting in and out of the BC north coast.

It's great to see things happening in electric transport.

Here are a couple of pictures.

EV Bus spotted in Vancouver BC by Tom

Sawyer

EV Bus spotted in Vancouver BC by Tom

Sawyer

They're coming, gradually!

Tom also found electric trucks (left)

for sale on line, dirt cheap.

Tom also found electric trucks (left)

for sale on line, dirt cheap.

A mutual friend bought two of them and got one running. It seems

a shame that they need minor electronic work, but almost no one

knows how to do it so they're mostly going to waste.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Third Stage Democracy

Unless stopped, immoral actions by a society's leaders

will get bolder and bolder over the years and decades until the society

collapses. Civilizations spring up from relatively unorganized liberty,

then

leaders want more and more power and control over the citizens over

several generations

until people effectively become slaves who can't thrive and there is

collapse, usually with great depopulation. How many

civilizations have come and gone on this planet, at least for tens of

thousands of years if not hundreds? Violent revolution may

be necessary to win democracy, to wrest control of governance from

those who will not yield power. Even then formation of a democracy is

not assured as we have seen - it depends on those who become powerful

in the revolution wanting it and instituting it.

Once democracy has been established, change of power if

nothing else occurs peacefully. Democracy is the only form of

governance capable of adapting and growing as conditions change. But if

power is effectively seized by an immoral oligarchy of the increasingly

rich and powerful, if public choices are between Tweedledum and

Tweedledee who are both beholden to that oligarchy for their place,

democracy becomes a facade. If people find there is no way to maintain

or regain liberty and freedom in their lives, where might they turn but

violent revolution? And if there is violent revolution in a democracy,

it can only be to return to some form of dictatorship, which will

usually last at least several generations. ("They tried democracy. It

didn't work. It broke down.") Violence must be avoided at all costs.

Dialog is the way forward.

An oncoming great global depopulation is becoming

increasingly visible. Bizarre and unprecedented weather patterns are

devastating crop production and ranching worldwide and wreaking havoc

to infrastructure. The oceans seem to be virtually fished out, and per

latest findings it looks like a 3 meter (10 foot) sea level rise will

be astonishingly rapid, displacing gigantic populations. Species are

daily becoming extinct. The now global "ponzi scheme" financial system

is collapsing. When people can't afford scarce food they become

malnourished and easily susceptible to some epidemic, which with modern

travel will quickly become a pandemic.

But in this global catastrophe is opportunity for

humanity. People who would never have considered allowing (much less

promulgating) change will become far more open, perhaps even proactive,

when their own mortality is suddenly in question and it is clear that

things are already rapidly changing, one way or another, for better or

for worse; that their "status quo" is gone. With population reduction

today's competition

mentality will change to co-operation as everyone is needed to keep

modern technology and communications from collapsing. Workers'

conditions will greatly improve when corporate competition is how to

attract and keep them.

Everyone still

around by the end (around two billion?) will be saying "Well, that

didn't work." and asking "What went wrong and how do we do it

differently this time?"

Along with environmental sustainability and population

management, we must start restructuring our societies, all our social,

economic and political institutions and organizations from the family

up to attain Social Stability, then Social Sustainability which will

never break down. We need to move to a "Third Stage Democracy" where

concerned citizens form 'Social Sustainability Design Teams' to work

out solutions to each problem, in accordance with the core values of

Life, Equality, Growth, Quality of life, Empathy, Compassion and Love

for humanity. The consensus of such solutions is then passed to elected

government for enactment. Those in power today might resist efforts to

establish such a principle and practice of grassroots power by the

elite of the common citizenry, but future leaders will see that it is

in everyone's best interest. (Apparently the beginnings of such teams

are already happening in Sweden, with government sanction or

sponsorship, so the idea isn't entirely "pie in the sky".)

In the meantime, if I myself do start a company to make

batteries and perhaps other electric transport products, it must first

of course be self sustaining, but otherwise I will attempt to organize

it along new lines in accordance with such principles.

I have never understood why democratic forms and habits

are never established within companies - or even in government/civil

service work environments when the government is supposed to be

democratic. You can elect your national political representative, but

you're not qualified to periodically elect your own shop supervisor? -

he must be chosen by someone "in authority", and once chosen, good or

bad, and even in the face of some new person better qualified or with

talent and great ideas coming along, he's there until he retires and

until then no one else is allowed a chance.

Truth

and Truthfulness

One must be aware of the difference between teaching "the

truth" and teaching "truthfulness". When a truth/fact like "Pi

equals 3.14159" is taught, there is no dispute. There is no need to

argue the merits of using this particular number over any other number.

There is no need to pass a law to force math teachers to not teach that

some other number is pi, or that pi is a meaningless number.

Many other matters are not so concrete and there is room

for varying opinions. When one teaches for example that "capitalism is

better than communism", there may even be differences of opinion on

what those words mean, and what the speaker feels these words represent

could change the statement from true to false for him, or for different

listeners, with any number of shades of gray in between. But there have

been laws passed for, or in the old Soviet union against, teaching this.

One might truthfully believe the statement is true or

false. But it is an opinion, not a fact. A more truthful thing to say

might be that "Most people in this country think that...", and also to

try to define the two words. By far the best thing to teach the student

is how to think for him/her self. (...instead of in effect telling

him/her that other people have already done the thinking for them and

they should simply believe it's the truth on faith.) There are no laws

specifically forbidding teaching students how to think, but there are

usually any number of ways, including laws, that it is discouraged. The

state does not want the current "status quo" questioned. Why, something

might be changed!

It would not be amiss to feel that the state should stay

out of defining educational content beyond the very basics of reading,

writing and arithmetic. Young people - like most people - like to

learn. Beyond such basics young people should be free to learn what

interests them, rather than a set curriculum which is perhaps "ideal"

for the "average student" but not suitable for any student in

particular.

This is just one of a number of subjects related to clear

and critical thinking on social issues discussed at much greater length

in Skeptical Essays by Bertrand Russell. (Russell himself

especially resented having to learn Latin, "a language that nobody

speaks any more", in school. BTW I think the title gives little away

about the contents... an "essay" to me is a school English class

assignment, and "skeptical" has the connotation of negative thinking to

my mind, when the book as actually full of papers related to "critical

thinking" on social issues.)

Writing almost 100 years ago in the early to mid 1920s,

Russell hits upon many of the evils which started perhaps with the

industrial revolution or before, and which have only - as he predicted

would happen if no action was taken - become more exacerbated in the

intervening century. (Indeed he seems to have loosely predicted most of

the future century - even the alignment of forces involved in what

became "the cold war" - short of the rise and fall of Nazi Germany,

nuclear weapons, and much further on, computers and the internet.)

Perhaps it's time to look at corrective actions for the

social problems and failings he so clearly identifies. After all, it's

not the things civilizations do that cause them to fail, it's doing

nothing and letting wrong thinking and dysfunctional methods fester and

grow over generations until they overwhelm reality.

The

Epstein Saga

First Jeffrey Epstein is

arrested for child sex and human trafficking, after flaunting it in

everyone's face for most of his life. (Arrested again... after getting

off with some sort of "plea deal" years ago that no lesser placed

person would have got, instead of being forcibly removed from the

planet. The judge that signed that deal has just resigned.) Since he's

the "king" of it all, and since it's known that he knows everyone

involved at all the highest levels [of depravity], everyone starts

speculating how many rich, famous and even royal persons will be named.

Then it starts circulating on youtube that because he

knows so much about so many highly placed people, he'll surely be

murdered before he can testify - and that they'll surely say he

committed suicide. A week(?) later, amid some very strange anomalies in

the workings of the prison system (especially for such a high profile

prisoner), Epstein "commits suicide." This time the "conspiracy

theories" preceded and predicted the actual event.

And even with all that suspicion even well in advance of

the event, the bought-off 'main stream' media makes no suggestion that

it was anything but: It wasn't "apparently by suicide", "said to be

suicide" or "alleged suicide" or "was found dead". All the stations

just said "Epstein committed suicide." And why did no one say how it

was done? Did he "hang himself" with a bedsheet (for "plausible

deniability" of murder), or was it one of those "three bullets to the

back of the head" sorts of suicide? The guards were said to have been

asleep(?...or did it for pay or were blackmailed?... who else could get

in? They were uncooperative with investigators.) and people had heard

screams coming from Epstein's cell.

A couple of days after I wrote the above, the coroner

reported that the broken hyoid bone in the throat was usually (not

invariably) indicative of homicidal strangulation rather than suicide.

Combine that with the screams... Oops! (Hilarious! As usual the MSM is

caught looking like either idiots [Hah!] or bald faced liars spouting

fake news.) But it must be noted that evidently one of the usual worst

offenders, the Washington Post, broke the coroner story. It could as

easily have promulgated the same lie as the rest of the media and kept

quiet about the coroner's report, which would then only have been

circulated among "conspiracy theorists" on youtube and on zerohedge.

Yay WaPo! Maybe things are changing?

Rational

and Irrational Numbers 10-99

In French, numbers from 20 to 60 follow a logical pattern

(I must use it as an example because it's the only other language I can

count above 4 in. I definitely don't guarantee my spellings, either.):

20 Vingt

30 Tronte

40 Quarante

50 Cinquante

60 Soixante

Above that the system breaks down, reminding one somewhat of

Roman numerals:

70 Soixante-dix (sixty-ten)

80 Quatre-vingt (four-twenty)

90 Quatre-vingt-dix (four-twenty-ten)

(I don't understand why they wouldn't use

70 Septante

80 Huitante

90 Neuvante)

In English we fare better:

20 Twenty

30 Thirty

40 Forty (Fourty)

50 Fifty

60 Sixty

70 Seventy

80 Eighty

90 Ninety

The numbers from 10 to 19 are another case. In both languages they

start off irregularly with a single word as if they were another single

digit number:

10 ten / dix

11 eleven / onze

12 twelve / douze

In French this continues:

13 trez

14 quatorze

15 quinze and then I think it's:

16 seize (but I'm not sure of that, It could be dix-six, ten-six)

finally the few remaining:

17 dix-sept (ten-seven)

18 dix-huit (ten-eight)

19 dix-neuf (ten-nine)

In English the rest of the numbers after 12 are called the "teens",

which follow a strange reverse pattern, thir-teen (three-ten),

four-teen, ... , nine-teen. If we wanted to rationalize them, however,

we run into a bit of trouble. "tenty-three" just sounds too much like

"twenty-three" and would be bound to be misheard occasionally.

Mishearing numbers can have bad consequences. We'd have to drop the

standard "_ty" ending.

We could turn the teens around and add "y": teeny-three, teeny-four,...

, teeny-nine. These should be fairly easily to understand even if the

hearer hasn't heard them before. Of course, "teeny" by itself has

another quantitative meaning. But if shortened to "tenny-three",

"tenny-four"..., again it sounds too close to "twenty". That might

leave the shortest and perhaps the most obvious: "ten-three",

"ten-four"..., "ten-nine" ...which could actually work. It does in

French.

(Hmm... or how about "tenna-three, tenna-four, tenna-five...")

Or we could just leave it the way it is. We managed to learn it and we

never think about its oddness, why should future generations have it

any easier?

Small

Thots

* Duralex Impact Resistant, Tempered Glass Drinking Glasses -

Info Update. As soon as he got my last newsletter my friend Rick

Peterson sent me a

page from Amazon.ca, a search for Duralex glasses. They have been made,

in France, since 1939! There were many selections - far more styles,

sizes

and colors than were (rather briefly) available in Canada in the 1970s.

Sometimes I remember one can find most anything on line these days,

sometimes I don't think of it. I ordered a set of four 8.75 oz glasses.

It's just taken

an extra 42 years. I still think their absence from store shelves is

deliberate - to keep people buying easily broken glasses, again and

again.

Whether this is a distributor's or individual stores' idea or both is

less

certain.

* A piece of fuzzy logic that causes so much trouble in the

world: "I can think, therefore I am right."

* I am SO good at losing or misplacing things. I decided

(having been out for a couple of months) that it was time to make

another batch of white wine. (Last batch was August 2017.) I went to

the coat closet and got out the

primary fermenter bucket, lid and the hydrometer. Where was the

long-handle stir spoon? Nowhere to be seen. I checked another closet.

Nope. I went back to the first closet and in a space of no conscious

thought, I leaned into it and reached my fingers around the door frame

to

the right - a tiny space only 2 inches wide, surely too small to hide

anything - and felt the handle of the spoon, standing there utterly

vertical. I

would never have found it by looking. I might almost say I'd never have

found it by myself.

This isn't the first time something like this has

happened. I remember the first time I became consciously aware of

finding something this way. Back in Victoria a few years ago I was

missing a car key. Not urgent. A day or two later I was wandering

around the house for some reason, and without any conscious thought, I

suddenly "snapped awake" as I found myself standing facing sideways in

front of a narrow set of open shelves along the side of the kitchen

doorway, staring at the "missing" key in an ashtray on a shelf.

One can only give thanks to one's guardian angels for

their guidance as one tries to live in harmony with the unfolding of

the universe.

* Perhaps if one buys "tall telephone pole" variety peas, one should

put up 6 foot tall pea netting instead of just 3 foot. (I used chicken

wire.) Predictably some of these stems folded over as they grew taller

and as the peas grew heavier. But I must say I've had a much better

crop from these (in spite of the short netting and the cloudy summer

with generally poor vegetable harvests) than from any other variety

I've grown in recent years. I have almost a pound of them in the

freezer besides all the ones I've eaten - mostly raw. Mmm, garden peas!

"Tall Telephone Pole" variety Peas, two short

rows (left planted earlier), August 13th

"Tall Telephone Pole" variety Peas, two short

rows (left planted earlier), August 13th

ESD

(Eccentric Silliness Department)

* Yeasterday: When the dough rose from the dead, so there's fresh bread

and buns today.

* An engineer runs a boring bar, but his clients are never bored. Only

pieces of metal are bored. On a lathe. Bored stiff.

[from my high school Chemistry teacher, 1971... I think

there were three, but I don't remember the other one.]

* BaNa2 : Some students (who had apparently learned

something)

howled that that is an impossible compound - all cations and no anions.

The teacher replied that it was very important in the diet of

anthropoid apes.

* BaAuH2O : Probably only the elders might remember this guy

now**.

* Cipate: unforeseen, unpredicted, a surprise, to not see something

coming. (opposite of Anticipate.)

** Barry Goldwater

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency and

completeness before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground

Effect

Vehicle

(first

the

R/C

Model)

On the 14th I needed a bit

of epoxy. I make a bit extra and cut a piece of the thin PP cloth to

cover the bottom of one of the hulls. But the 20 grams of epoxy only

glued it down for about 1/3 of the way from the back. It would need

another 40+. And (as I

expected) it didn't visually cover things over. Every irregularity

showed, and the writing on the foam showed through. A thin coat of

spray paint later could help, but I

started sanding the foam cuts and the joins much smoother.

That was as far as I got. I can't believe the whole summer

has slipped by without finishing the model and trying it out. But the

battery research has taken precedence.

Other

"Green"

Electric

Equipment

Projects

Handheld

Bandsaw

Sawmill

Notes

The saw didn't seem to be

cutting at all well. I should have been dicing up the big log into

cants with the chainsaw mills, but I was too busy with battery

development to cut much anyway. It became evident that the big log was

going to sit until September. I ordered 5 new bands and awaited their

arrival.

They came on the 17th. I put one on and started cutting

the 8" wide x 5' long spruce cant into 1" x 8" boards. Is spruce hard

to mill? I ticked off the seconds that I had the saw trigger pressed

with my tongue. I'm

very good at that, and I'll say I should have been well within 10%. The

time for each cut in seconds was roughly:

52, 63, 75, 75, 86, 100, 88, 89, 120. I sharpened the band. As best I

remember the next ones took something like: 75, 90, 100, 88. Then I

stopped

counting.

The times show how the band dulls quickly cutting spruce.

and

the 8" width seems much harder than 6". On the last board the band hit

a knot hole full of sap 1/3 of the way along. The band and wheels

gummed up, and I had to wedge the cut end open to un-jam the saw. After

I picked up the board and tossed it with the others, the palms of my

hands were likewise thoroughly wet with sap/gum. I went inside to clean

my hands with varsol. After I finished these two little cants I had

another whole large log to mill and get off my lawn. (I got it started

in early September.) After that, I hope

I can do some alder instead, or some other tree specie.

I did finish them - 24 more 1"x8" x 5' boards, with the

new band getting sharpened once. Only the very first cut with the brand

new

band was under 60 seconds. Naturally I wish they were all that fast,

but I don't know how to achieve it. The automatic band sharpener isn't

bad, but I had to modify it myself to do finer toothed bands, and I

note that it flattens the angle of the tooth a bit behind the cutting

edge. Perhaps that's a reason they aren't quite as good as new after

sharpening.

Again I would note that spruce is tough stuff to mill, and

that 6" wide boards cut twice as fast as 8". I think the wide cuts have

just too

much drag on the band as it goes through the wood, even without

cutting. I cut alder up to 12(?) inches, a whole small log with (as

best I recall) one band sharpening if any. I don't think I'll make any

more 8" wide spruce cants to be cut into lumber. (I can probably use

some 2"x4"s for interior walls. Those should go pretty easily.)

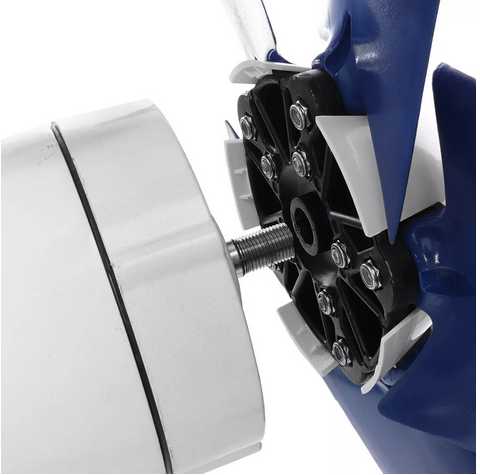

Wind

Power: 5 Blades Better than 3?

Jim Harrington pointed me to a 5-blade wind turbine (horizontal axis)

link from BangGood.com . There was a question/discussion space and

someone asked why 5 blades, and someone answered it. Apparently the

slower turning 5 blade types are quieter than 3-blades, and in light

winds deliver up to around 60% more output. Here I had always

understood that 3 blades was "the ultimate"... but apparently that's

only in sufficient wind.

Jim Harrington pointed me to a 5-blade wind turbine (horizontal axis)

link from BangGood.com . There was a question/discussion space and

someone asked why 5 blades, and someone answered it. Apparently the

slower turning 5 blade types are quieter than 3-blades, and in light

winds deliver up to around 60% more output. Here I had always

understood that 3 blades was "the ultimate"... but apparently that's

only in sufficient wind.

Since a chief objection to (3-blade) windplants is the

noise, and since winds are far more often light than strong, I decided

to swallow my gradually improving ideas for making a VAWT (like I have

time anyway?) and try one of them. It is on order.

Another point was that the extra air friction of 5 blades

in heavier winds reduces over-revving. But I do wonder what will happen

in a really heavy gale.

I don't understand why no one seems to use Hugh Piggott's

fabulous tail design. The propeller is slightly off center compared to

the pivot axis. As the wind strength exceeds safe limits, the

increasing off-center pressure on the propeller causes the weighted

tail to climb up a ramp and pivot, allowing the off center windplant to

turn away from the wind, until it can be almost sideways to it in

powerful blasts. This prevents the unit from over-revving and

over-powering. As the wind lightens, the tail swings it back into the

wind. The tail weight and the ramp steepness governs the process, so

there's nothing to wear out and start changing the response.

The output of the windplant was rated as 24 volts. That wouldn't do for

charging 36 volt batteries, so at the same time I ordered a DC to DC

up-converter of substantial power, also at BangGood, to bring it up to

about 40 volts.

The output of the windplant was rated as 24 volts. That wouldn't do for

charging 36 volt batteries, so at the same time I ordered a DC to DC

up-converter of substantial power, also at BangGood, to bring it up to

about 40 volts.

My

Solar

Power

System

Month of August Log of Solar

Power Generated [and grid power consumed]

I decided to log daily power for at least one more month

and have a half a year's data. But I'd be away camping with friends the

last week.

(All

times are in PST: clock 48 minutes ahead of sun, not PDT which is an

hour and 48 minutes ahead. DC power readings - mostly the kitchen hot

water heater - are reset to zero daily, while the others are

cumulative.)

Date House solar KWH(Grid+DC), +Trailer Roof solar KWH - day

total KWH

made [power

co. meter readings] weather, usage...

July 31st 49.85+.53, 629.39 - 14.46 [67202@ 20:30; Br.Heat] Early:

rain,

Most of day: Sun w. scattered clouds, very light haze, no jet trails.

---

August 1st 57.62+.53, 634.98 - 13.89 [67207@11:00; bath; 67208@21:00]

Mostly Sunny, no jet trails. Forgot I had turned 2 inverters off

previous evening, until late morning.

2nd 66.90+.44, 641.21 - 15.95 [67213@20:30] Sunny

3rd 75.19+.43, 646.98 - 14.49 [55Km,chj.car slow(oops, into

evening); 67222@20:30] Mostly sunny

4th 84.59+.52, 653.39 - 16.33 [55Km,mor car chj.@1500W; bath;

67233@20:00] Sunny, warm day for the Tlell "Fall" Fair!

5th 91.79+.45, 659.80 - 13.76 [finish car chj; 67240@21:30]

Sunny. Oops, left the 2 grid ties turned off again. (Wouldabin ~16 KWH)

6th 100.86+.55,666.03 - 15.84 [bath(solar!); 67246@23:30] Lo &

behold, another sunny day!

7th 104.74+.51,668.77 - 7.13 [55 Km,3.8 KW chj.;

67258@21:00] Overcast! (Summer iz over? but, but... ther wuz sun in QC!)

8th 108.00+.50,671.08 - 6.07 [67262@20:00] castover

9th 111.57+.59,673.56 - 6.64 [85Km,Chj.car@3.8KW; Laundry;

Chj.someone's Chevy Bolt @3.8KW(~45 KWH?) and, 44Km,chj.my car

again@1500W 67295@20:00; 2 cars still charging; 67313@23:00] abovecast

10th 116.63+.50, 677.22 - 9.22 [BR heat, 2 car fini. chj. overnight;

67355@8:30; 55Km,chj car@3.8KW; 67367@22:30] overcast, w. sunny breaks

AM.

11th 120.93+.42, 680.31 - 7.81 [67372@10AM; 67373@20:30] light overcast

12th 123.50+.42, 682.17 - 4.85 [67371@20:00; bath] Heavy overcast &

(gasp) Rain! (A tourist said it was sunny most of the day at

Masset/North Beach!)

13th 132.37+.49, 688.39- 15.58 [55Km,part Chj.car@1500W; 67392@21:00]

Sunny and warm. (what a contrast!)

14th 141.23+.43, 694.58- 15.48 [Finish chj.car@1500W; 67397@21:30;

bath] Sunny and warm.

15th 144.77+.49, 697.15 - 7.60 [40Km,chjd.@1500W; 67409@19:00]

overcast.

16th 147.47+.59, 699.30 - 5.44 [85Km drv,chj.@1500W (not much

solar); 67426@21:00] overcast. 2 inverters (4 250W panels) were turned

off 2/3 of the day.

17th 153.16+.53, 703.31- 10.23 [55Km,chj@1500W; 67444@20:00] Sunny with

drifting clouds.

18th 161.90+.45, 709.41- 15.29 [67450@21:30] Sunny & warm.

19th 163.90+.61, 711.12 - 4.32 [Laundry; 67462@21:30] Cold &

wet. Clouds - light - heavier & finally torrential rain over the

day.

20th 164.66+.45, 711.76 - 1.85 [55Km,chj'd@3800W; bath;

67478@20:30] Overcast, wind & rain. I had to turn 2 inverters off

so those panels could feed only the kitchen hot water tank, which they

barely did with minimal hot water use. (Someone got a sunburn in

Vancouver area today.)

21st 4.46 + .64, 715.21 - 8.55 [50Km&chjd.@1500W;

67491@20:00] Alt. sun & clouds. Power bump in night - meter reset

itself

22nd 6.18 + .48, 716.60 - 3.59 [bath; 67500@20:00; BR heat]

Clouds & rain. This is summer?

23rd 12.66+ .42, 721.21 - 11.51 [67508@19:30] Clouds and some sun.

On Holydays, returned Sept. 2nd.

Sept.

2nd 69.46+.71, 759.99 - 96.29 (10 days) [67543@20:00] Sunny until late

afternoon.

3rd 71.99+.51, 762.06 - 5.11 [55Km:chj.car1500W;

67558@20:00] Overcast, later rain. Not much solar for car!

4th 1.98+.32, 763.73 - 3.97 [76568@20:00] Part

Cloudy AM, Sunny PM. I turned off the inverters and unplugged them

while the electric line crew were working replacing the power pole

& transformer outside (~10:30 - ~14:30), so the day's collection

was way down. And of course the power break reset the one meter so

earlier AM collection recording was lost. During the outage I moved the

two panels on the lawn in order to mow the lawn. They had also been

more and more in the lengthening tree shadows until mid day, and the

new position should be a little better for the autumn.

5th 6.24+.52, 766.76 - 7.81 [55Km,chj@3800W;

76582@19:00] Mostly overcast.

6th 8.55+.53, 768.77 - 4.85 [85Km,chj@3800W; 76604@19:00]

Mostly overcast, rain. 2 inverters were off quite a while.

7th 13.42+.46, 772.27 - 8.83 [laundry; bandmill; 76618@19:00] AM

overcast PM sunny periods.

Daily-

KWH- # of Days (August)

Made

1.xx - 1

2.xx -

3.xx - 1

4.xx - 2

5.xx - 1

6.xx - 2

7.xx - 3

8.xx - 1

9.xx - 1 (9**)

10.xx- 1

11.xx- 1

12.xx-

13.xx- 2

14.xx- 1

15.xx- 5

16.xx- 1

** The "9" days includes the 8 days of August pro-rated average of the

10 days I was away.

Monthly Tallies: Generated KWH [Power used from grid KWH] ("April 0"

starts

March 31 after solar hours.)

March 1-31: 116.19 + ------ + 105.93 = 222.12 KWH [786 KWH - used from

grid]

April - 0-30: 136.87 + ------ + 121.97 = 258.84 KWH [608 KWH]

May - 0-31: 156.23 + ------ + 147.47 = 303.70 KWH [543 KWH] (11th

solar panel connected on lawn on 26th)

June - 0-30: 146.63 + 15.65 + 115.26 = 277.54 KWH [374 KWH] (36V, 250W

Hot Water Heater installed on 7th)

July - 0-31: 134.06 + 19.06 + 120.86 = 273.98 KWH [342 KWH]

August 0-31:127.47 + 11.44 + 91.82 +(8/10)*96.29 = 307.76 KWH [334 KWH]

(12th panel 'installed' on lawn Aug. 1)

6

month total March 1 to August 31: 1643.94 KWH made; [2987 KWH consumed

from grid]

Things Noted

* With the 12th panel added, [estimated] August solar power production

beat all

previous months, slightly above May. Tree shadows definitely got longer

and reduced the light as the month went on, especially to the two

panels down on the lawn. (Not to mention the garden.) Soon they'll be

hitting the house roof too.

* The August total assumes 8 days of the 10 I was away at the average

of those 10 days, 9.63 KWH/Day. (The other 2 days were September 1

& 2.)

* Power on fully sunny days in August with the 12 panels (~3440W total)

seemed to be just under 16 KWH near the start of the month, dropping a

bit as the month went on. And mostly either it was sunny or it wasn't -

there were few "mostly sunny" days giving close to full output.

* Cloudy days averaged perhaps a little under 8 KWH from the 3440W of

panels - around half of what sunny days give. That didn't stop a few

rainy days from having very low output. Again at present prices it

seems worth it. If we weren't get electricity at a subsidized rate

here, the economy over diesel would be large and obvious.

* Power going to the grid isn't counted by the utility company meter -

it won't run backward. But since the power generated and used in the

house does subtract from that used from the grid and slow down or stop

the meter, the total consumption is somewhere between the grid power

and the grid power plus the power generated. (Depending how much the

grid was being subsidized - probably not very much except on sunny

days.)

* For the 6 months of spring and summer, on average about half as much

solar power was made as was used from the grid. So comparing power

generated to that used from the grid suggests that twice as many solar

panels (20-24 instead of 10-12) would be required to make the house

"power neutral" in spring

and summer (and early autumn) but the situation is complicated by not

knowing the total consumption.

Four or five winter months will have

much less collection (not to mention far heavier power usage). I really

ought to raise the tops of the

panels to get them to a steeper angle, since at only 15° south

slope they'll get less than half power in December. Even in June

30° would be an improvement and at winter solstice would give 70%

output instead of 50%. At 45° they would be weighted well for

spring and fall while still giving 86% in winter (short days anyway,

and except in very favorable locations full of long shadows too) and

97% in

summer.

* On sunny days during the summer more solar power was usually made

than the amount consumed from the power grid. Much less power was used

from the grid was when I was away on holidays. (No EV car charging,

etc. I unplugged the kitchen solar hot water. Hmm, I could have turned

off the main water heater, too.)

* Months that had sunny days (March, April, May, August) had better

collection than those that didn't (June, July), yet the totals

generated in the cloudy months were not so much lower than the better

months. Of course, in June and July the sun was highest, so they had

the potential to exceed any other months if they had had more sun. So

perhaps we are measuring ~275 as against ~350 if the weather had been

nicer,

or even more had most of the days been sunny.

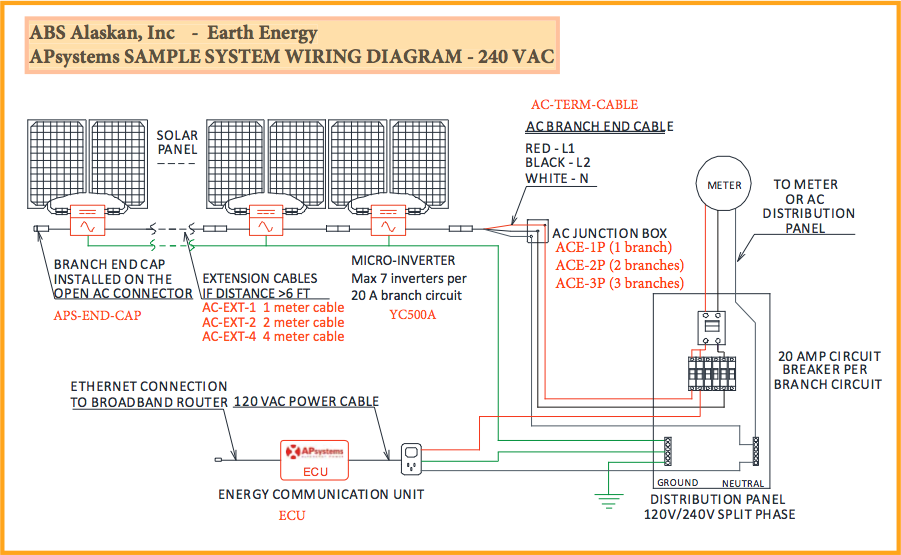

Improving the System

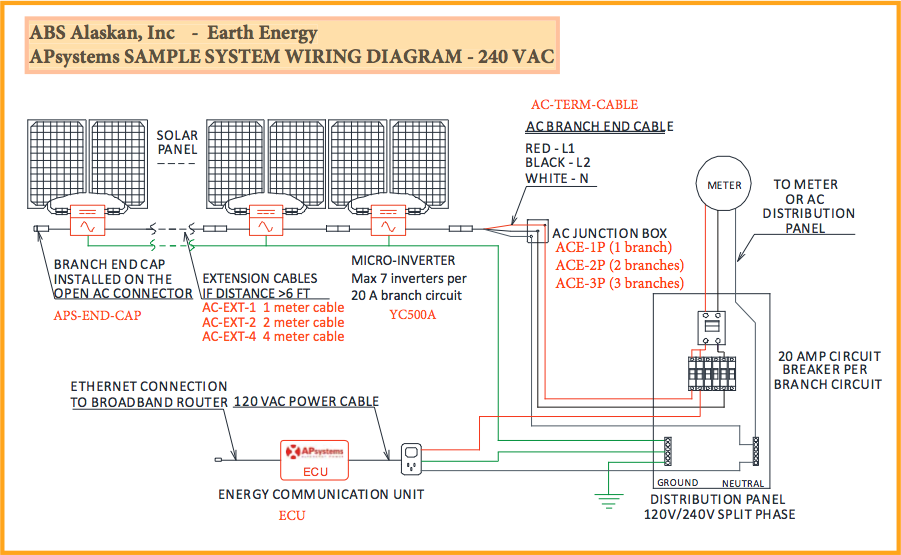

I decided to improve the grid tie arrangement and get it

inspected, with some 240 volt wired-in grid tie inverters. In some ways

it seems a little silly, since the plug-in grid tie inverters work

fine. They also cost 75-150 $C for a nominal 1000 W - but which rarely

give over 850 or so.

The "AP" wired-in grid ties I'm planning on getting have

four separate panel inputs (that's a slight improvement) and are rated

at 1200 W (also somewhat better). Since they will be wired into the

circuit breaker panel one can't read the power figures directly.

Instead one buys a communications unit that can be connected to a

computer or to WI-FI. The costs add up: Inverter 500 $ each, comm unit

350 $, double circuit breaker and wiring maybe another hundred,

bringing it to almost 1000 $ plus the panels. Hmm... I may have just

talked myself out of it for now. 100 $ and "plug it into an outlet" is

a lot cheaper and easier. Anyway here's a sample circuit/wiring diagram

(with 2-panel inverters, from the web).

Electricity Storage (Batteries)

Turquoise

Battery

Project:

Ni-Zn

or

Mn-Zn in KOH ? or in KCl ?

Tokudo et al Nickel-Zinc Battery Patent (2001)

I had looked at this years ago. Beneficiary was listed as

"Sanyo". The first problem was that all the tables were completely

disordered. Their structure had been erased and they were just jumbled

text and virtually indecipherable. Different words of each heading had

been

on different lines and words of other headings now appeared between

them. The

second was that I had printed it double sided and the printer had

messed up. The pages were mixed up all over, the flip side having no

page relation to the front. I had to jump all over to find the next

page. Between these two factors it was almost impossible to read it.

But now that I was doing zinc myself, I got interested

enough that I downloaded a new copy and set about fixing the tables,

copying the scattered bits of text into initially blank tables I

created in the HTML editor. That made it far more useful and I learned

some new things, mostly not because of the (arguably) patentable things

but because they had described their procedures in creating the

battery. These were no doubt similar to how they already created

production batteries, and it was the first time I'd seen much on how

batteries are made. There are occasional references to this patent

below.

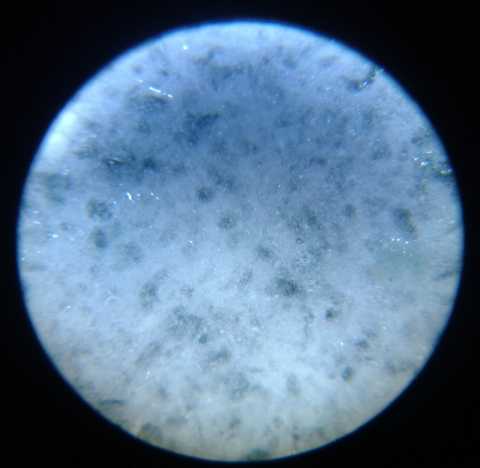

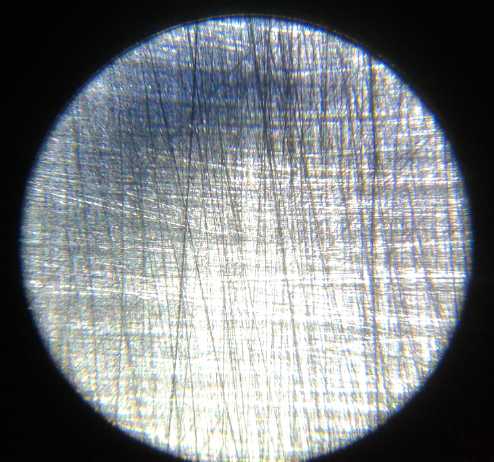

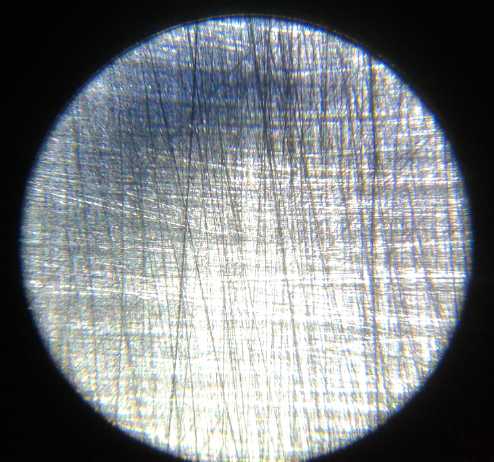

Electrode ReAgaring

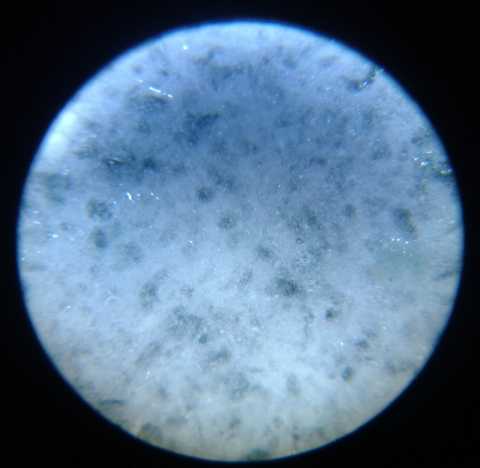

Microscope images of the agared electrode

surface and a 'fuzzy' zinc plated edge. 40x

Microscope images of the agared electrode

surface and a 'fuzzy' zinc plated edge. 40x

I had put the cell back together without fixing the bare zinc edges,

and I did a couple of quick load tests around the time I put out the

last TE News. (August 5th, 6th) With each test, performance seemed to

improve. The short circuit tests generally started out 3.5 to under 4

amps, but at first held 1.5 amps for 10 seconds, then 1.75 amps, then

over 2 amps. Driving a 1 ohm load (more like 1.2 with the wiring

losses) it held over 1.00 volts for 2.5 minutes, then the next time

just over 4.5, and the 5 watt resistor got quite warm.

Next I took the cell apart again to paint agar around the

bare edges of lumpy zinc. I discovered that while the jell was still

good, much of one side (having an open edge) had come loose from the

zinc, like wallpaper come loose from a wall. Being unattached would be

acceptable as long as the zinc was totally encapsulated. It would be

pretty much pressed against the electrode anyway. The jell was also

flaking off the stem from the top down. (Ah... It was drying out

there.) It looks like getting a good solid coat of jell is going to be

a rather critical part of the manufacturing.

(7th) I left the electrode overnight to dry. I had cleaned it as best I

could, but I wanted as little potassium hydroxide left on the electrode

as possible, seeing it interferes with the jelling. Here I discovered,

or

probably rediscovered, that if there's one thing a jell can't stand

it's being dried out. It was all loose, dry flakes. I rubbed them off

along with much of the fragile fuzzy plating, and wondered how many

milliamp

hours and how much current drive it would have left. Nevertheless, I

prepared a new batch of jell, a bit 'stiffer' than last time with 50 cc

less water. (What's optimum? I have no idea.)

200 cc distilled water

10 grams agar powder

5 grams zirconium silicate powder (AKA 'zircon', 'ultrox')

I heated the

water to boiling in a bread pan and sprinkled

the agar powder in. This made a lumpy mixture. Probably better to stir

the powder in and then heat the water. Then I added the zircon. (I

doubtless could better have done that before the heating, too.) I used

a bread pan because it's a good size and shape to dip an entire full

size electrode into to coat it. It's not easy to heat uniformly on a

burner, however.

I heated the

water to boiling in a bread pan and sprinkled

the agar powder in. This made a lumpy mixture. Probably better to stir

the powder in and then heat the water. Then I added the zircon. (I

doubtless could better have done that before the heating, too.) I used

a bread pan because it's a good size and shape to dip an entire full

size electrode into to coat it. It's not easy to heat uniformly on a

burner, however.

I dipped in the small one. Then I painted around the edges

with a small brush. After a couple of minutes the electrode had cooled

and I ran my finger around the edges. They all felt like smooth jell

except one top corner. I brushed a bit more onto that to build it up.

I took my somewhat lumpy coated but well encapsulated

'trode and put the cell back together again. Somehow it seemed to need

charging.

On the next load test (#12, @ 10 Ω) the voltages were a

bit lower, but it ran almost the same length of time as the previous 10

Ω test; just a couple of minutes less over an hour. My take is that the

nickel side is what's been limiting the mA-hours, but with some of the

plating (and obviously some of the osmium film, too) rubbed off, the

zinc side has a bit less current capacity and is letting the voltage

down a little. It gave 129 mA-hours instead of 137 because the slightly

lower voltages meant slightly lower currents throughout. Overall the

performance was down just a little. Would it stay there or start

improving again?

On the 10th performance seemed to have dropped a bit more.

I wondered if maybe the nickel was coming apart a bit, or if the two

electrodes weren't pressed together well enough. I managed to insert a

thin strip of metal behind a piece of spacer plastic. It was certainly

tight after that and I hoped I wasn't squashing the agar. But somewhat

to my surprise the currents (short circuit and charging) went up

substantially. It started charging at 300 mA instead of 200, and

delivered over 200 mA after 10 seconds of being shorted. On the 11th, a

10 ohm load test started with slightly higher voltages and current, but

went down faster, to 1.2 volts in 40 minutes instead of closer to an

hour, giving a capacity of only 87 mAH. On the bright side, the zinc

tab hadn't fallen off after almost 20 cycle tests (over double any

other zinc tab electrode I've made), and the charging current still

drops under 20 mA

once the cell is charged and the voltage sits at over 1.8 volts or so

overnight, which indicates no zinc dendrites are trying to short out

the electrodes.

Then next question was, was it the zinc electrode or the

nickel oxide one degrading? It could certainly be the nickel - I was

running it down pretty low. In fact if the zinc was still at 1.24 volts

when the cell was down to 1.2, the nickel must be dropping down to

nothing and maybe even into reverse charge. I needed to replace the

nickel electrode chunks with others as similar as possible and see if

it improved or not.

On the 12th I took the cell apart. One corner of the lower

back side of the agar had been peeled away from the zinc trode, surely

either on insertion or (perhaps more likely) on pulling it out again.

All electrodes are to be inserted together, but perhaps a backing sheet

should slide in with the zinc electrode that's against the end wall of

the cell so that the agar itself isn't sliding along something. Or

perhaps wrap a sheet of cellophane - or just polyethylene - around the

outside of the end electrodes and the bottom when inserting.

The agar I had jelled didn't really liquify when I heated

it up. That may be why it was so lumpy the first time, too. I added

around as much distilled water as jell in the tiny pot, and painted

some on the electrode. I consider that 10 grams of agar in 200 cc of

water made it too thick. I might try about 5 next time (if not less).

So:

Water - 200 cc

Agar - 5 g

Zircon - 5 g

Or I might just heat it up and add another 200 cc of water to the

present batch. (More zircon?)

I remembered the Tokuda et al (Sanyo) Ni-Zn AA cells

patent. I looked up their discharge tests. They ran them from a

charge of 1.95 volts all the way down to .9 volts! Hmm... they didn't

seem to have degrading cycle capacity, at least not for reason of

over-discharge,

over 10 cycles. ???

PAA Jell

They also jelled their zinc electrode. Herein may lie a

buried secret. Some of their cells didn't degrade at all over ten

cycles. If they could make a zinc electrode that wouldn't

degrade, they would be manufacturing them, right? They must have all

degraded over a somewhat longer number of cycles with disappointing

performance, right? Or else we'd already have Sanyo very long lasting

nickel-zinc "AA" cells and probably many other size Ni-Zn batteries.

Right?

But it wouldn't be the first time a company cast away a

superior product in favor of continuing to market and sell their

existing product line, which would be made obsolete by the new product.

Existing companies - at least at the management level - rarely have a

culture of creation or

vision for new technologies. They are generally reactive rather than

proactive. They are usually pushed into advances from behind rather

than leading them. I could easily see the executives just look at its

potential to cut into their ongoing sales of non-rechargeable

batteries, instead of seeing potential for a whole broad new

battery market opening up before them with themselves at the head of

it. Or, it wouldn't be the first time someone 'in charge' was bribed or

threatened by petroleum industry people to shelf a product, and those

for

higher

efficiency, 'free energy' and better batteries have always been the

prime targets. I suspect Sanyo's research team had come up with a

fabulous

advance but Sanyo, notwithstanding apparently having a battery factory

already set up, simply didn't make them, so no one was the wiser. (The

almost illegible patent couldn't have helped spread the word?)

The patent specified polyacrylic acid gel. I found (or was

pointed to) two researchers in the news, a year or two apart but in the

latter part of the current decade, who both claimed to have created a

jelled

electrode that lasted 20,000 cycles without deterioration. At least one

of them mentioned "acrylic" and "jelled" which probably also means

polyacrylic acid gel. Agar seems to work fine, but it's certainly

possible some other jell such as PAA might work better or will be

easier

to work with in production. It certainly bears investigation.

OTOH agar does seem to work well. I ordered a kilogram for

a lower cost from China. The package said "Health Products". (Why they

didn't just write "Agar" I don't know. It seems no one wants to tell

customs agents just what's really in a box.) Customs opened the package

and slit open one of the bags inside. First they were probably looking

for someone trying to buy "prescription" medication, ordered from

abroad because their doctor here wasn't permitted to prescribe it, and

then on opening it and seeing white powder they were suspecting maybe

cocaine.

As long as there are laws against most everything,

senseless or not, the government will suspect its citizens of

lawbreaking. But they didn't challenge the "$5" stated price when as I

recall it was more like 35$. They were probably just disappointed to

have found nothing interesting.

More Research Needed

About at this point, there were too many questions about

what I would actually use for a positive electrode in commercial cells,

and the many options that each might or might not work were muddying

the proposals. Nickel manganates? Nickel oxyhydroxide? Manganese

Dioxide? With graphite or without? In salt or mixed electrolyte, or

must we use concentrated potassium hydroxide? (Samarium oxide to raise

oxygen overvoltage is a given.) Should they be 'jelled' with

sulfonates? something else?, or at least would it be advantageous?

I decided that since I had until late October to submit

the application, I should try to do this research beforehand, which

would make the application much simpler - more clear and direct. The

trouble with salt is that I've never been able to get a positive

electrode to hold its charge in salt electrolyte. It just might devolve

to using KOH or else using manganese dioxide with its lower voltage,

definitely known to hold charge well in salt. Somehow I don't think

that ought to be or will be necessary, but it seems to me I haven't

shown

otherwise in the past. Self discharge has been my greatest bugaboo.

Wait a minute!...

The real reason all my NiMn cells had high self discharge

Then I figured it out at long last! On the 13th I realized

I was probably wrong and that my test for which electrode was

discharging was somehow faulty - that there was a good reason for

gradual self discharge in the negative side in my nickel

manganate-manganese cells. In fact, the zinc sheet current collectors

were fine where they were in contact with the manganese electrode

substance with its overvoltage raising additives, but they degraded

where they weren't: mainly at the terminal tab connection, which would

finally corrode off.

I didn't understand at the time that hydrogen

bubbling off it would affect the zinc. It changes it to brittle zinc

hydride (not mentioned

in battery literature or electrochemistry charts), and being held

at -1.5 volts by the manganese electrode, even tho they weren't the

active substance themselves, the metallic zinc would have been bubbling

hydrogen wherever it wasn't in contact with the hydrogen overvoltage

raising electrode additives, and whether or not the cell was being

charged. (Well duh, of course it would!) There was the gradual self

discharge, slow but relentless, not

from the electrode itself but from the zinc terminal tab. And even when

I switched from zinc to 'flexible graphite' current collectors, the

graphite

didn't decay but most probably it also bubbled hydrogen at such a high

voltage.

SO! That was probably the reason my extra high voltage

cells always had 'overnight' self discharge instead of holding charge

properly. To make such a high voltage electrode hold its charge, the

hydrogen overvoltage ingredients - or an insulating paint - would have

to coat the entire exposed current collector inside the cell. Now that

I think I understand that, I could probably make the 2.4 volt cells.

Well,

some other time!

Painting Parts of Electrodes to Prevent Gas Generation

Overnight it dawned on me that that idea of painting the

terminal tab would also be very good for a plain zinc electrode. The

hydrogen overvoltage substance (zirconium silicate) is in the agar and

it can't extend up the tab right to the outer case. Paint can. The

terminal strip should be painted or epoxied, and the whole back side of

single sided electrodes could also be painted, although the agar with

the zircon should do the job.

This also reminds that likewise the oxygen overvoltage

substance (samarium oxide/hydroxide) is in the powder mix, but not in

the carbon fibers running up to the top to form the "tab". It might be

necessary or at least advantageous to paint these, too, or perhaps

better for those to epoxy them into a solid piece.

Making Nickel-Manganates '+' Electrode in a plastic shell

Zinc electrodes will be easier to work with - and if the

nickel manganates side is indeed working at the high "+" voltage it

seemed to have in those earlier cells, they may still be around 2 volts

in salt - as high as lead-acid and just six cells for a 12 volt battery.

I may experiment with nickel manganates-manganese 2-1/2

volt cells again (just 5 cells for 12 volts), but the coated zinc

electrodes are working well, and at this point I'm going with that.

So the next experiment would be a nickel manganates "+"

electrode... and it would probably work.

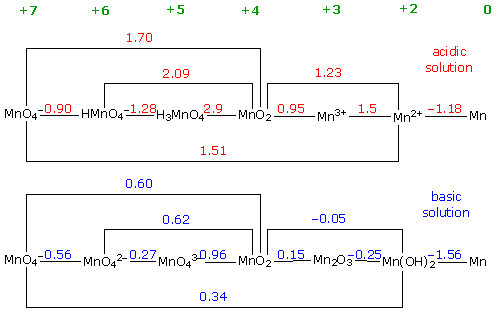

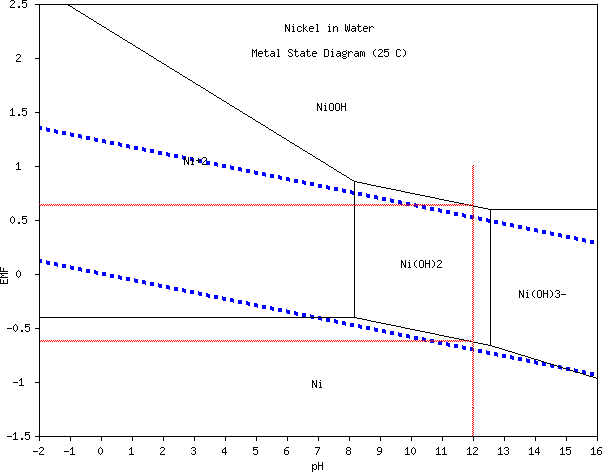

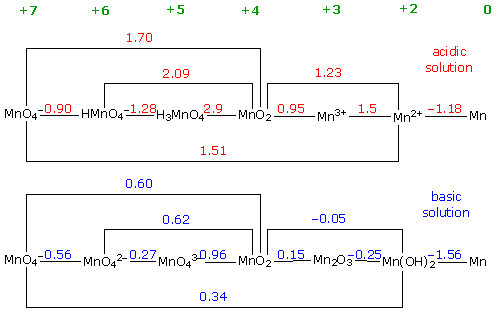

![[graf]](MnPourbaix2.png) I

may have found a potential reason voltages seemed higher than I

had expected in my nickel manganates-manganese cells too: the voltage

of MnO4- would be around +.75 volts at pH 12. It was KMnO4 I put into

the cells to react and form the manganates. Perhaps that voltage also

applies to the manganates, rather than the nickel oxyhydroxide voltage

(~+.65) that I had expected. Add +.75 to -1.5 for metallic manganese

and you have about 2.25 volts. Even so they charged even higher, to 2.6

or so (dropping quickly to 2.4 volts under load), but most cells charge

somewhat higher than theoretical.

I

may have found a potential reason voltages seemed higher than I

had expected in my nickel manganates-manganese cells too: the voltage

of MnO4- would be around +.75 volts at pH 12. It was KMnO4 I put into

the cells to react and form the manganates. Perhaps that voltage also

applies to the manganates, rather than the nickel oxyhydroxide voltage

(~+.65) that I had expected. Add +.75 to -1.5 for metallic manganese

and you have about 2.25 volts. Even so they charged even higher, to 2.6

or so (dropping quickly to 2.4 volts under load), but most cells charge

somewhat higher than theoretical.

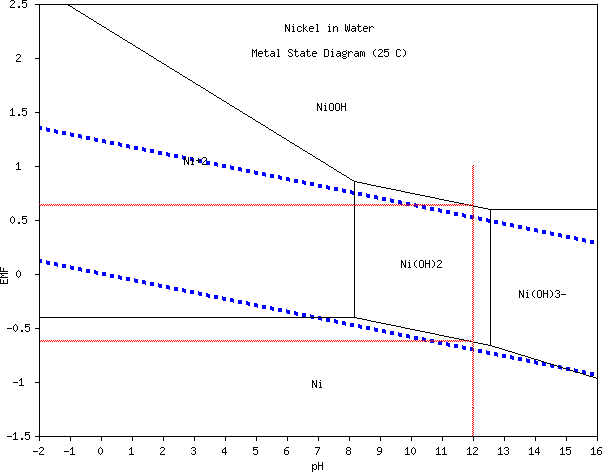

But there's also the CRC Book graph at

pH 1 and pH 14:

If perhaps in

nickel manganates the form MnO4--- might for some reason

prevail, that would give +.15v + +.96v = +1.11V. That plus the roughly

-1.4v provided by the Mn negative would better explain cells that

charged up to 2.6 and even 2.7 volts. Was that the case?

If perhaps in

nickel manganates the form MnO4--- might for some reason

prevail, that would give +.15v + +.96v = +1.11V. That plus the roughly

-1.4v provided by the Mn negative would better explain cells that

charged up to 2.6 and even 2.7 volts. Was that the case?

The experiment, now with a zinc negative, is the thing!

The experiment, now with a zinc negative, is the thing!

[Ahead of the narrative: The experiment showed that, for all this

speculation, the voltage was initially about the same as nickel

oxyhydroxide,

+.65 volts at pH 12. Then with some short circuiting and recharging it

seemed to get lower... perhaps to the voltage of MnO2+Zn, under 1.5.

But that's okay if it moves 2 or 3 electrons instead of 1. The

amp-hours would go way up in the same size cell.]

(13th) On the old RepRap Mendel 3D

printer I had always got the bed up to at least 95°C, preferably

100, before I tried printing ABS. The new printer only heated the bed

to 80° for ABS. I didn't and don't consider that anything like hot

enough. While the PLA shells had printed very nicely in the new printer

if the extruder temperature was increased to 200°C (a miracle!),

when I tried in ABS the bottom printed fine but the ends started

lifting on only the second row and the pieces broke away from the

glass. So I had to give up and go with a PLA shell.

The only electrode compactor I could find was the one made

as an edge-fed compactor. Either I've let the others slip away somehow

after I moved here (probably), or I wasn't looking in the right places.

The edge one will do.

I used the powders already mixed in July:

Monel Powder - 16 g

Ni(OH)2 - 17 g

KMnO4 - 40 g

Conductive Carbon Black Powder - 5 g

Sm2O3 - 5 g

I wetted these with a few drops of "Lemon Fresh Sunlight" dishsoap. The

ingredients in that, especially the sulfonates, are there to form a

jell. (Hmm... Sanyo had a "kneader" to help mix things. I must go on

line and see just what that is and look for one. Hmm... does it replace

the "compactor"?)

I

used a flat rod to tamp the powder/soap mix with. It

seemed to get very solid as I tamped. I added just a bit at a time and

tamped some more. When I took the front off the compactor, it looked

just about how I wanted it. I trimmed off a couple of bulging corners.

I started to slide it off the back and it immediately cracked into 3.

Hmm... not really very solid after all. Maybe I should have used the

hydraulic press after all?

I

used a flat rod to tamp the powder/soap mix with. It

seemed to get very solid as I tamped. I added just a bit at a time and

tamped some more. When I took the front off the compactor, it looked

just about how I wanted it. I trimmed off a couple of bulging corners.

I started to slide it off the back and it immediately cracked into 3.

Hmm... not really very solid after all. Maybe I should have used the

hydraulic press after all?

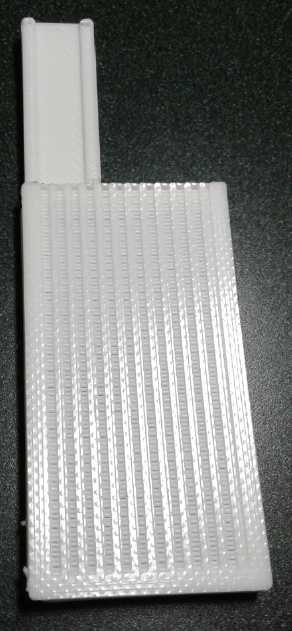

But if the mountain

wouldn't move, maybe put

the cap over the mountain? That worked quite well. The piece was

actually a bit long, but the edge of the shell just cut it off. So I

had a pretty much intact (if extremely fragile) briquette that filled

the shell, with an unbroken section of PP cloth in front of it to make

sure none could come out to short against the zinc.

But if the mountain

wouldn't move, maybe put

the cap over the mountain? That worked quite well. The piece was

actually a bit long, but the edge of the shell just cut it off. So I

had a pretty much intact (if extremely fragile) briquette that filled

the shell, with an unbroken section of PP cloth in front of it to make

sure none could come out to short against the zinc.

(I knew I was forgetting something. I forgot to paint the

inner surface of the electrode with calcium oxide/hydroxide. It's a

useful layer.)

I put the carbon fiber 'cloth' over that and wrapped it

all up in the PP cloth.

Methylene chloride won't 'glue' PLA, but on youtube I

found out that cyanoacrylate (Krazy glue) would. So I broke open a tube

of that and put it around the edges. I didn't trust it to stay together

while setting, so I put the 'trode in the hydraulic press and squeezed

it pretty lightly (but heavier than just setting some metal weight on

it) and left it a while to set. (How long does that take, anyway? It

was trying to stick my skin on pretty fast.) Later I removed it. The

whole thing seemed pretty solid.

I had a great picture of the open face with the cloth but

without the current collector. It was the last one I had been looking

at; where on Earth did it go? I suspect my cell phone of turning itself

on in my pocket and spuriously deleting it. When I'm outside working I

repeatedly pull it out and find it turned on with all kinds of stuff

running. There's been a message on it for weeks that I need to take

"account action" at "Google Play Store", where (as far as I remember) I

have never been. I suppose it's been trying to buy things. (surely not

some scam?) Other peoples' phones just redial the last called number

from their pocket.

I wasn't at

all fussy about the terminal connection.

Something had to be done about that. It came to me that I could make a

hollow rectangular plastic tube, a terminal extension to the shell that

would contain the strands of graphite fiber and guide them up through a

hole in the lid. (In the next shell I ended up making a shallow trough

for the strands.)

I wasn't at

all fussy about the terminal connection.

Something had to be done about that. It came to me that I could make a

hollow rectangular plastic tube, a terminal extension to the shell that

would contain the strands of graphite fiber and guide them up through a

hole in the lid. (In the next shell I ended up making a shallow trough

for the strands.)

Then perhaps at the exposed top, it could have one face

open, and a graphite block would be inserted in front of the mess of

fibers. The external connections would be made to this. This would

imply that each '+' electrode would have its own external pillar on the

top. They would have to be joined with a bar or piece of wire. (The

graphite strands might also have to be coated with Sm2O3 - or

insulating paint - to prevent oxygen generation. Epoxied maybe? That

will have to be seen.)

(For the zinc side I conceive that all the tabs will bend

over and come out one "slit" hole. Either that or they will each come

out their own slit and be bent over above the case to join externally

on top.)

(14th) For the present I gathered all the

loose strands of graphite

into a short piece of plastic drinking straw. I found a piece of

graphite rod and sanded it down so it fit into the straw. Then I mixed

some epoxy and painted it in to fill the straw before I jammed the

graphite bit in. I put a weight on it to flatten the straw where it

would come out the slit in the lid of the cell. I hope the connection

is good.

(14th) For the present I gathered all the

loose strands of graphite

into a short piece of plastic drinking straw. I found a piece of

graphite rod and sanded it down so it fit into the straw. Then I mixed

some epoxy and painted it in to fill the straw before I jammed the

graphite bit in. I put a weight on it to flatten the straw where it

would come out the slit in the lid of the cell. I hope the connection

is good.

I tried to warm up my kitchen oven to set the epoxy faster

than free air temperature, and found my new oven wouldn't warm. It

either wanted to be off or baking hot. The digital control would only

go down to 170°F (75°C)! 65°C is the tops for curing epoxy.

I'd have preferred 50°. But it was even worse than that. While the

oven measures the temperature in 5°F steps and is perfectly capable

of displaying it to the operator, it will only show the actual

temperature in two conditions:

1) While the oven is warming up and

2) The oven timer is off

So to set the timer for just a few minutes so it won't get

up to the (minimum) setting of 170°, means it simply will not show

the temperature. No way to see it! There's cause for alarm bells

already. So after a few minutes I canceled the heating entirely. When I

then selected "cook" and turned the oven on again (not that I wanted it

on), it showed the temperature. It was already 230°F! S**T!

I grabbed the electrode with the metal weight pieces and

pulled it out. It had heated so fast that the metal weights weren't hot

enough yet to burn my hands, but the plastic had become quite soft and

was bulging out. I set the weights on top and squeezed it flat again.

(Now it bulged a bit at the sides.)

Now, one might think "But

that's not what kitchen ovens are

intended for." But I might want a just-warm oven for other things. For

rising bread dough for example. That is a common oven use, and if it

wasn't for having a bread machine I would

discovered the problem long ago. Or what about for just keeping food

warm

for a while? My disgust with the shoddy programming, so poorly thought

out and so typical of so many electronically controlled products,

remains. (And: why have an ultra-fast magnetic induction hotplate

burner

that warms water for yeast in 40 seconds and boils it in 90 seconds...

and is only programmable, and only displays, to the nearest minute -

did you want 0, 1 or

2? I did far better than that with my own stove burner control in 1986.

And: why make a delicate

weigh scale so that it keeps zeroing itself as the user slowly adds

epoxy trying to

get an accurate and exact weight, so that he has no idea how much he's

actually poured in? You can't pour the gooey stuff back and try

again! The list goes on... I know we all have to forgive others in

order to have the capacity to forgive ourselves and move on. I have a

peculiar

resentment with "whoever" does this sort of thing,

being such a good programmer myself. And I don't even know the person!

Or maybe it's with management for

rushing a new product out the door without allowing the programmer

enough time to work out the finer points? Whenever I've worked on any

such

product I would try to anticipate all the uses to which

it might be put, and make the software that runs it as versatile and as

user friendly as

possible. Allowing an electronically controlled oven to be warmed up

and stay warm seems like a no-brainer to me.)

Sorry for the diatribe. (Perhaps I should have grabbed my all-time

favorite kitchen stove with its digital display but oven temperature dial

when I moved, and left some other one in its place.)

Back to the plot... at least the oven episode showed me

that if I have assembled a warped electrode shell, or wish to press it

together better, I could heat it to soften the plastic. But the next

electrode showed the printed plastic breaks easily.

While I waited for the epoxy to set (very slowly at room

temperature), I started in on designing an improved electrode shell.

One of the last ones hadn't fit well - it took a bit of a snap to get

it together (sometimes it would stay), and that gave me the idea. If I

could make them so they would snap together properly, they shouldn't

need to be glued. That would mean I could print them from PLA and avoid

the problems I was having with ABS. And besides, once all the bits had

been delicately placed within, snapping it together at once would give

much less chance for things to shift around, and one wouldn't have to

hold it until the glue set. And it would be done - much better for

production.

So I started trying to minutely adjust dimensions (more

trying to adjust for the vagaries of the 3D printer(s) and 'Skienforge'

'slicer' program than for theoretical dimensions) to make a slot in the

base and a lip in the top that would snap into it when they were

pressed together. (If the first shell had snapped together not only

would it not have needed krazy glue, but I could have pried it open

again

and painted in the forgotten Ca(OH)2 layer by the current collector.)

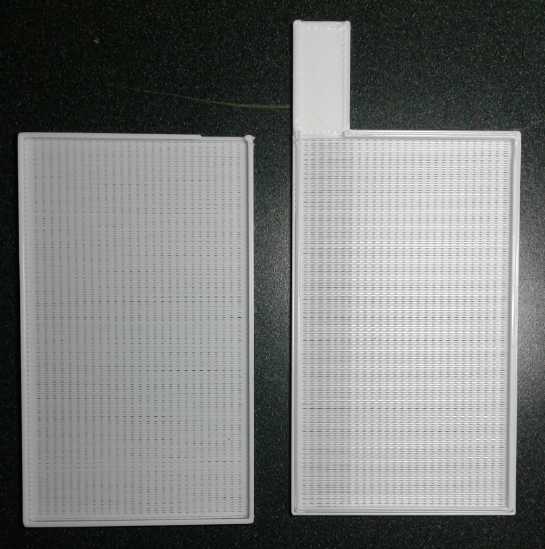

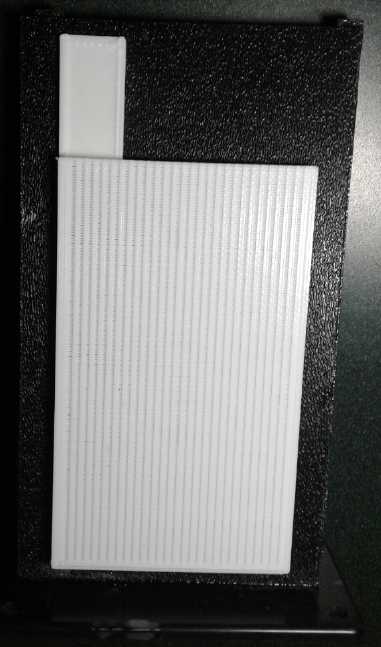

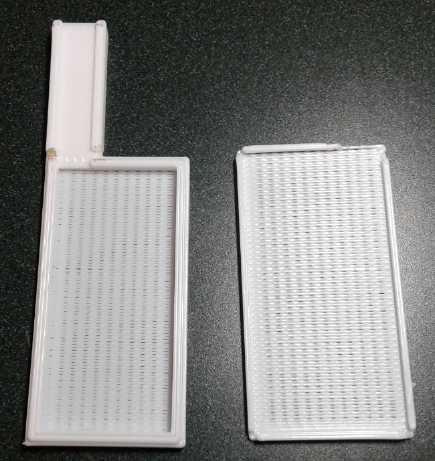

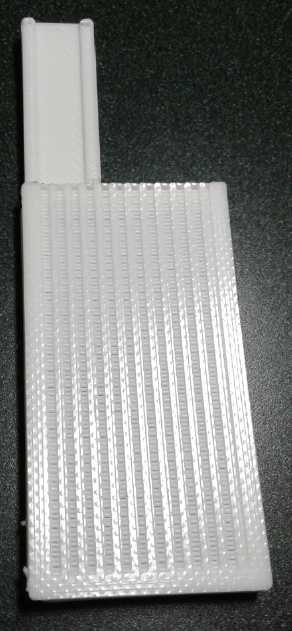

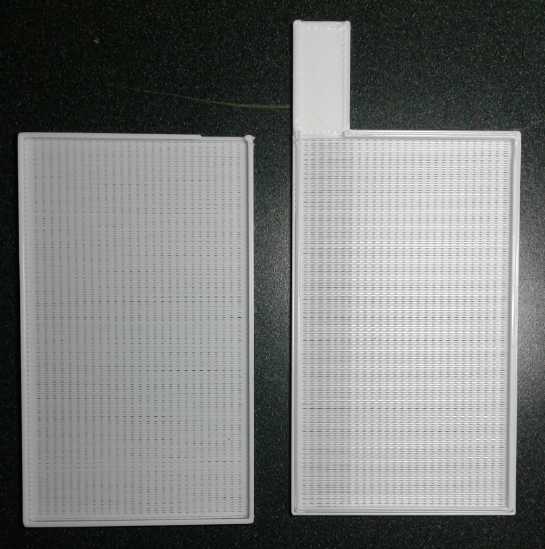

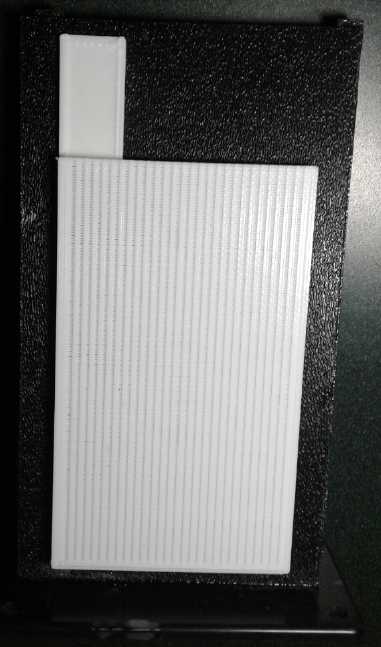

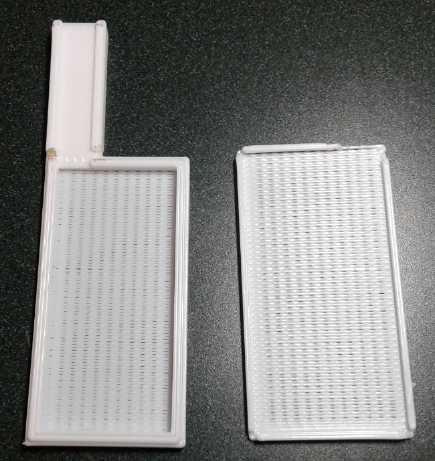

Later I

returned to it and decided to do the "full size"

electrode shell. All the minute adjustments would have to be done over

for it. I printed one. It looked pretty good. But I made the grille

bars

on 2.2 mm centers instead of 2.0, and without any change in the 1 mm

bar width, it printed them as two beads instead of one. Then instead of

printing the second layer as diagonals, it printed them square across

in the other direction. Those things were both notable improvements...

but who

would have guessed they would happen? Or... Aha! It was because I made

them

open at the top (for bubbles to escape). Just where the terminal tab

was on one side so the tops weren't open, it did them the old way. I'll

have to fix that. And I

want to make them still wider apart since the double trace actually

narrowed the bubble slots instead of widening them. And it didn't

"snap" together - it was a sloppy fit. And somehow I'd made it too

short.

Later I

returned to it and decided to do the "full size"

electrode shell. All the minute adjustments would have to be done over

for it. I printed one. It looked pretty good. But I made the grille

bars

on 2.2 mm centers instead of 2.0, and without any change in the 1 mm

bar width, it printed them as two beads instead of one. Then instead of

printing the second layer as diagonals, it printed them square across

in the other direction. Those things were both notable improvements...

but who

would have guessed they would happen? Or... Aha! It was because I made

them

open at the top (for bubbles to escape). Just where the terminal tab

was on one side so the tops weren't open, it did them the old way. I'll

have to fix that. And I

want to make them still wider apart since the double trace actually

narrowed the bubble slots instead of widening them. And it didn't

"snap" together - it was a sloppy fit. And somehow I'd made it too

short.

It was 1 AM PDT (23:12 by the sun) and that was about it

for that day. But I was on the case. It looked like it would work great

and they ('perfected' ones) could be used for production!

Hmm, somehow an inch short for the 'full size'

battery case

Hmm, somehow an inch short for the 'full size'

battery case

Cell Assembly and Tests

On the 15th I mixed some potassium chloride solution, 35 g

of KCl in 100 cc/ml/g of H2O. I put a new piece of plastic in as a

slightly thinner case filler than before since the plastic shell

electrode was fatter than the other ones. It took a little under 20cc

to fill the test cell. The solution turned purple from the potassium

permanganate. But only a few grams per 100 cc will dissolve into water.

The rest should remain solid - and jelling it should help make it

permanent, too. (Perhaps in times past this purple herring distracted

me from realizing it was my negative electrode causing the self

discharge.)

On the 15th I mixed some potassium chloride solution, 35 g

of KCl in 100 cc/ml/g of H2O. I put a new piece of plastic in as a

slightly thinner case filler than before since the plastic shell

electrode was fatter than the other ones. It took a little under 20cc

to fill the test cell. The solution turned purple from the potassium

permanganate. But only a few grams per 100 cc will dissolve into water.

The rest should remain solid - and jelling it should help make it

permanent, too. (Perhaps in times past this purple herring distracted

me from realizing it was my negative electrode causing the self

discharge.)

I put it on charge and was disappointed by the small

currents. Short circuit wasn't much either. Well, I had only compacted

the electrode by tamping down the powder... perhaps it wasn't well

enough compacted to have good internal contact? But that wasn't it.

There was a poor connection at the zinc electrode - again. I should

have put a bolt through that zinc tab sometime!

After that it started taking a charge and shaping up. I

had to go over 2 volts to get much charging current.

1.9 V: 10 mA

2.0 V: <20 mA

2.1 V: <30 mA

Soon it was putting out some short circuit current, with a

spike to only .55 A when first connected and dropping to 200mA

after 10 seconds. (.50 & .290 A after leaving it a while longer.)

And when the charge was removed, the voltage kept dropping gradually.

Now it really was in a performance range that might well be a result of

poor conductivity in the "+"trode . But maybe it would improve. The

nickel hydroxide and the potassium permanganate were supposed to get

together and form nickel manganates.

I decided they could take their time doing that and left

it at 1.9 volts charge. In fact, it occurred to me that I should keep

the voltage below where more permanganate would form and 1.9 was tops.