Turquoise Energy News #136

covering

September

2019 (Posted October 3rd 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- More Battery Experiments - Handheld Bandmill, Milling Lumber -

Polyurethane Paint on Polypropylene Cloth: Modern version of cellulose

dope on canvas for aircraft? - Five Blade Windplant

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Hearing Improvement? - Fatal Financial Flops - Insane Acts: a Hint of

Twisted Rational Purpose? - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle (R/C Model)

Other "Green"

Electric Equipment Projects

* Working with the Handheld Bandsaw Mill (& Alaska Mill)

Electricity Generation

* 5 Blade Windplant

* My Solar Power System: - Monthly

Solar Production log et cetera - Six month summary, notes.

Electricity Storage

Turquoise Battery Project (Mn-Zn or Ni-Zn in Potassium

Hydroxide electrolyte ?)

* Nickel Manganates Electrode Toasting - Backing Up: What Works? -

Experiment #1 - Printing An ABS Electrode Shell - Experiment #2: Nickel

NiOOH electrode - Extracting MnO2 from old dry cells - Experiment #3:

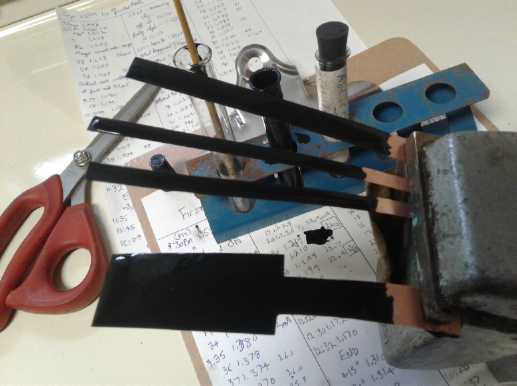

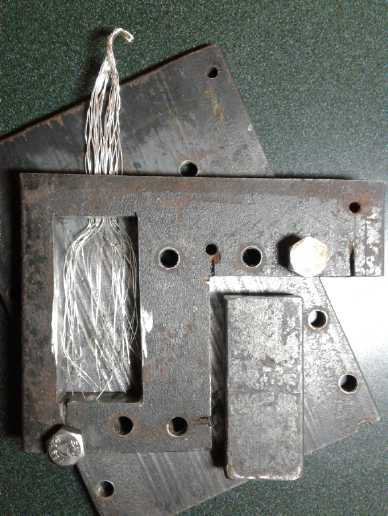

Jelled MnO2 - New Electrode Compactor, Punch and Die - Sewing Carbon

Fiber Cloth - The Electrode - 3D Printed Battery Cases (Deja Vue?) -

Compactor Die Slit for Graphite Foil Terminal Tab - MnO2 Electrode with

Loose Carbon Fibers - Painted Zinc Electrode - A Better MnO2 Current

Collector: Conductive Graphite Painted Copper Fingers - It's a Product!

- Cell with Graphite Coated Copper Current Collector (canceled) -

Second Cell with Calcium Oxide instead: Assembly & Testing

The beach that changes with every tide

sometimes gets some unusual formations.

The beach that changes with every tide

sometimes gets some unusual formations.

Here calm weather at a quite high tide deposited much sand high up on

the beach.

On another day rough waves washed it away to expose rocks underneath,

but the

tide wasn't as high - the waves only got up 'so far', leaving a foot

tall sand 'cliff'

above high water. It was there for several days until a higher tide

rearranged it

all again.

More Battery Experiments

As one might expect with good progress and the possibility

of funding, yet another month has been almost wholly devoted to battery

experiments, design and construction. The cells weren't exactly giving

high currents but I decided that anyway the simple and ready market to

enter into was economical bulk electricity storage rather than try and

break into the electric vehicle market, which requires extreme currents

of the batteries. As someone showing zinc-bromide flow batteries in

Australia said of his, these would be marathon runners, not sprinters.

Unless I could come up with a fabulously conductive positive current

collector that wouldn't oxidize away. That may be a last major research

goal. (In fact, after some experiments with graphite paint on copper, I

tried something novel in a cell on October 1st - copper calcium oxide.)

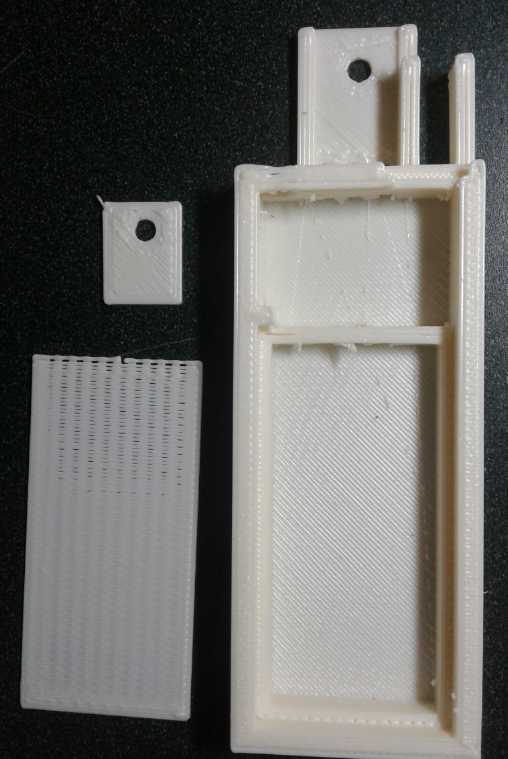

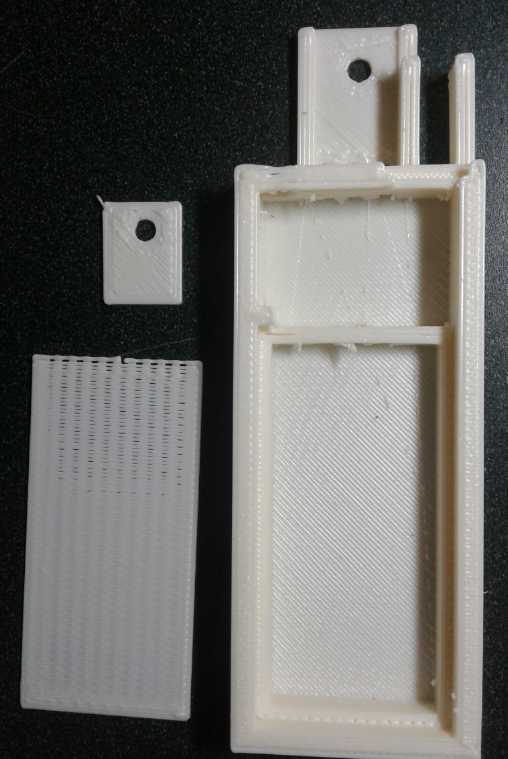

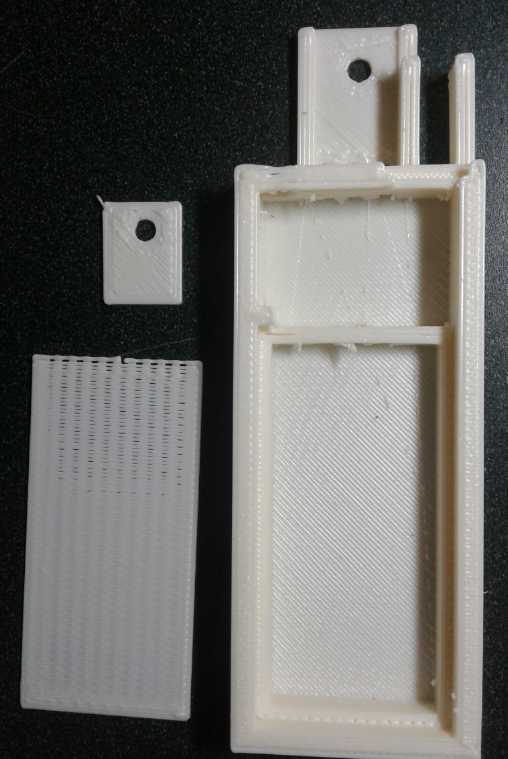

Cell Case with "porous"

plastic separator and a glue-in terminal piece

I

went from glued together cell cases of ABS sheets to custom 3D printed,

but I had problems with them leaking. I thought I hadn't sealed it

around the seam, and I made the next lip wider. It wasn't until October

1st I put together a second cell. I hoped this would be "the" cell,

which would go on working, with good current flow, for as long as I

cared to test it. But it seemed to leak too. This time some calcium

oxide patches on the back face which could only have come from inside,

made me realize the liquid was actually seeping right through the 3D

printed face of the cell! (I 'glued' a piece of ABS sheet right over

the whole face to stop the leaking, but it didn't work. They must leak

around the edges too.)

I

went from glued together cell cases of ABS sheets to custom 3D printed,

but I had problems with them leaking. I thought I hadn't sealed it

around the seam, and I made the next lip wider. It wasn't until October

1st I put together a second cell. I hoped this would be "the" cell,

which would go on working, with good current flow, for as long as I

cared to test it. But it seemed to leak too. This time some calcium

oxide patches on the back face which could only have come from inside,

made me realize the liquid was actually seeping right through the 3D

printed face of the cell! (I 'glued' a piece of ABS sheet right over

the whole face to stop the leaking, but it didn't work. They must leak

around the edges too.)

Obviously this is just a minor glitch. I already know I

need to get new software running to print better. Some time soon I'll

have worked out all the glitches and can start thinking of production.

It didn't happen in September. October is the month to apply for the

"Charge the Future Challenge" from Natural Resources Canada, and I'll

have to do that without having every detail wrapped up.

Handheld Bandmill, Milling

I

finally, months late according to my schedule but at least a year late

according to the amount of rot and bug tunnels in the spruce log, I got

back to milling the last spruce log from the four trees I had cut down

in summer 2017 when I moved here. I made wood and learned a bit more,

and came up with a small change to make (detailed report).

I

finally, months late according to my schedule but at least a year late

according to the amount of rot and bug tunnels in the spruce log, I got

back to milling the last spruce log from the four trees I had cut down

in summer 2017 when I moved here. I made wood and learned a bit more,

and came up with a small change to make (detailed report).

I showed the mill working to a neighbor. He was impressed

and thought he would like to make one himself. I think I should do some

sort of instruction guide on how to build these saws. There have been

enquiries about doing so, and it would be a lot easier if a person

knew, for example, the dimensions of various parts, and how they went

together. Somehow I can't see trying to set up a business of making and

selling them from scratch. I'm just not "DeWalt", "Husqvarna" or even

"Yardworks".

Polyurethane Paint on Polypropylene

Cloth - Modern version of cellulose dope on canvas for aircraft?

I

had been planning on epoxying the fabric, but my brother said he was

making a canoe and he was going to try painting varathane on PP cloth.

I thought that might be worth a try myself.

I

had been planning on epoxying the fabric, but my brother said he was

making a canoe and he was going to try painting varathane on PP cloth.

I thought that might be worth a try myself.

Varathane (I believe) is polyurethane. I had a pretty full

spray can of it. I cut a piece of featherweight PP fabric and pinned it

on the top of the wing on the model ground effect craft. Then I sprayed

it. It didn't seem to do much. 7 or 8 sprayings later, I could feel my

breath warmth much less when I put my hand behind and blew through it.

But the spray can was empty. A few more coats and it will probably be

airtight. I wasn't expecting to have to go on day after day, and the

month ended with me still waiting for paint to dry. And will it really

be lighter than epoxying it?

I would note that the varathane doesn't shrink the cloth

like dope does to organic fabric, and it doesn't glue the fabric to the

model, either to the styrene foam or to the wood. I still have a piece

of loose cloth simply pinned to the model. At least if I decide I don't

want it, it'll be no problem at all to remove and discard.

I cut and shaped pieces of wood to mount one of

the "outboard" ducted fans.

I cut and shaped pieces of wood to mount one of

the "outboard" ducted fans.

Five Blade Windplant

The 15th was sunny and warm. I milled some lumber. The next two days

were cloudy and windy and cold. I lit a fire, looked at the waves and

wondered where my 5 blade windplant was. Tracking said it was en route

from China to Canada.

The 15th was sunny and warm. I milled some lumber. The next two days

were cloudy and windy and cold. I lit a fire, looked at the waves and

wondered where my 5 blade windplant was. Tracking said it was en route

from China to Canada.

Finally an e-mail on the 30th said it was at the post

office, and I got it, assembled it and tried it out on October 1st,

which happened to be quite windy. It spins well and looks like it

should put out some power - how much will remain to be seen after it's

installed and some metering is put on it.

To slow it down and to keep it from spinning up, I moved

the meter from AC Volts (18~20 volts between two phases) to AC Amps.

This shorted the output, which hit about 3 amps as the blades braked.

I keep thinking of not bothering to record my solar power

collection (now having logged it for 6 months - the best 6 of the

year), but adding the windplant, and moving or adding solar panels,

might bring some new 'revelations', so I've decided to keep going.

Finally, Dr. Evans sent me another very generous donation of $500

US. And an interesting (patented) circuit diagram that may have

application in switching coils in unipolar motors. Thank you Dr. Evans!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Hearing Improvement?

We hear that hearing, once lost, doesn't improve. But on a

short time scale we know that's not entirely true: after being exposed

to loud noise for a while - a noisy work environment or a loud concert

- our hearing is dulled and our ears may ring, but the next day it has

recovered (except maybe for some of the tinnitus) and we hear better

again.

In the long term, our hearing doesn't seem to completely

recover. I've lost hearing in concert bands and orchestras, sawmilling

and workshop work, and especially I lost some making alto recorders

from 2003 to 2007, testing the sound and getting the tuning just right

over three octaves. Except once (~1991) I have never had a hearing test

with results better than the previous one.

But, our environment is never very quiet. There are noisy

cars and traffic, noisy heating and ventilation systems, noisy computer

fans, humming or buzzing electrical equipment, refrigerator, heat pump

and air conditioning compressors, radio or other music sources, and so

on. Our hearing just doesn't get that truly quiet time in which to

fully recover, and over the years we lose more and more, especially of

the high frequencies that surround us seemingly all the time.

I looked on the web to see if anybody had anything or any

technique that might help, and I came across the idea of putting

vegetable oil in your ears - olive oil, peanut oil or whatever - with

an eyedropper. At first glance that sounded silly. But it was from more

than one source. I started dripping it in my left ear to try it out.

(Then I just let it drain. A bit of tissue in the ear for a minute

soaks up the drop or two that comes out.)

After a few months I went to an audiologist and had my

hearing tested. He couldn't see any reason it would help either. The

only effect should be to help loosen and expel wax buildup.

For whatever reason I had continued to put in the oil even

on the morning of the appointment. First he looked and said he could

only see the center of my left eardrum because the oil and wax was

built up around the sides. The right eardrum was clear. Then the test

showed my left ear as being worse than my right ear instead of better,

in fact, it had degraded into the mildly impaired range at (??) 2 to 8

kilohertz. In 2012 it was on the edge of impaired. (He said he'd e-mail

me a copy of the results. Where is it?)

I left his office disappointed, but gradually I started

realizing how it works. With the oil built up around the sides, the

eardrum is less responsive, especially to high pitches. So basically it

acts like a high-frequency selective "earplug" to reduce the noise

level that you hear, in effect to make the environment with all those

fans and things quieter. Hence my 'impaired' range test results. It was

as if I was hearing through an "earplug". The quiet environment helps

give the ear quiet time to recover (very, very gradually).

This says that the efficacy of the treatment is probably

timing dependent. There's little point putting the oil in before bed If

your bedroom is quiet - no noise is present to be filtered out. The

better time would be in the morning, and more especially before doing

anything noisy, and probably more than once a day if you are, or if

your environment is noisy.

But results will also depend on your noise environment(s)

- when and how much and what sort of "background" noise you are daily

exposed to. Of course if there's a fan in your bedroom or noisy traffic

right outside or other conditions, before bed might be a good time to

put in oil after all. And personally, I would settle for a fridge that

used twice as much electricity if it didn't have a compressor. (and two

noisy fans. Something or other is running about 3/4 of the time.) I've

always felt that fridges make a kitchen from a quiet space into an

unpleasant noisy one. (In fact sometimes I close the kitchen door to

keep the sound out of the livingroom.) If you haven't noticed your

fridge, could it be there's more noise in your environment than you

have been aware of?

Insane

Acts - a Hint of Twisted Rational Purpose?

Around 1970(?) someone put poisoned pills in tylenol

bottles in a grocery store or two. The people who bought those bottles

were poisoned and died. (Ever since that, all packages sold in stores

have had some sort of "safety seal" that has to be broken to open the

bottle or get into the package.)

What was the motive behind this mad act? It plays on the

mind because one can't come up with anything more than "Whoever did it

was nuts." Could there be any meaning at all behind the madness?

But tylenol (acetaminophen) is said to cause 50,000 deaths

per year. It is contained in various different pain killers with

different names, and those who don't bother to read the fine print

often don't realize they've exceeded the maximum dose by many times,

getting it in several "different" pills. It also evidently damages the

liver if taken when there is alcohol in one's system.

Here's my theory: The poison pill pusher had a loved one

who died as a result of tylenol overdose. In order to highlight to the

world the dangers of tylenol, he would have people die of it until

"they" were forced to withdraw it from the market. His evil act was

miscalculated because it was quickly realized that the poison wasn't

the tylenol. (AFAIK the culprit was never caught.)

Then there was the other devious, seemingly insane thing I

was going to write about... didn't involve murder... I had them both

clearly in my mind when I started... now what was it?

(I'll decline to comment on false flags, and on mass shootings.)

Fatal

Financial Flops

In 2008 in the

"TARP" bailouts a staggering amount of money was spent bailing out the

banks. Lehman Brothers failed for want of a half a billion dollars

(well, 620 million). Foreclosing on mortgages (even illegally in a

spree of bankster lawlessness) the banks then ended up owning much of

America's real estate. not just owning the mortgage, but actually

owning it outright. which they kept off the market to prevent house

prices from going back to pre-bubble levels. People everywhere lost an

average of 30% of their wealth in a short time. No one bailed the

citizens out. The big bankers took their usual annual bonuses of tens

or even hundreds of millions of dollars each - now paid for directly by

taxpayers who were losing everything.

Then it was a big scandal in Canada, retroactively, when

accountants discovered later that from 2009 to 2012 the big Canadian

banks had likewise been bailed out to the tune of 112 Billion $. (So

much for "Canada's sound banking system", which effectively disappeared

in about 1972, according to former cabinet minister from those times,

Paul Hellier.)

Then there was "QE3", the US Federal Reserve's ("Fed") big

free money printing program to the tune of 80 BILLION DOLLARS PER

MONTH! For comparison, the total "base currency" in circulation in

about Y2K was 820 billion. They were now printing more money than that

each year! That money was used drive up the prices of assets and thus

further dilute the value of people's savings - those that still had

savings.

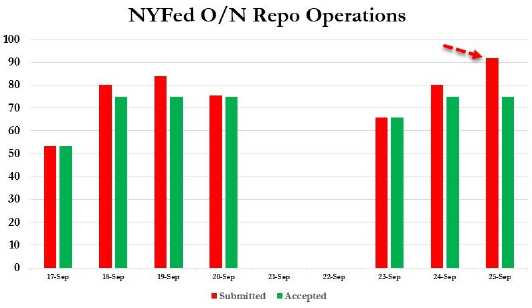

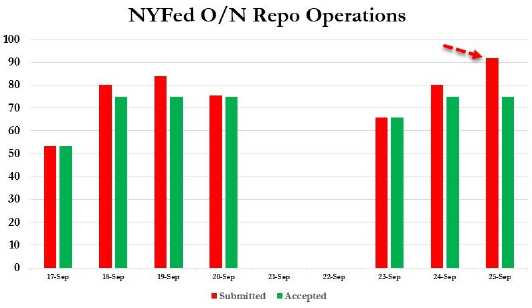

Then along comes September 2019. The "Fed" quietly starts printing 75

BILLION DOLLARS PER DAY to bail out the again failing banks. (Really

they've been insolvent since 2008. I imagine that since the huge bubble

was blown up, failing businesses, failing stores, a failing housing

market and consumer credit defaults have all contributed to an ever

worsening income picture) They said they would continue printing

$75,000,000,000 - per day - "until October 10th". That totals to far

more money than all that was in circulation in 2000. It's as much money

as in a year and a half of "QE3", which people feared would by itself

destroy the value of the US$. All in 3 weeks. And a few days into it

the banks were asking for even more. (Can I get a loan at the Fed

"Discount Window" at 2% too?)

Then along comes September 2019. The "Fed" quietly starts printing 75

BILLION DOLLARS PER DAY to bail out the again failing banks. (Really

they've been insolvent since 2008. I imagine that since the huge bubble

was blown up, failing businesses, failing stores, a failing housing

market and consumer credit defaults have all contributed to an ever

worsening income picture) They said they would continue printing

$75,000,000,000 - per day - "until October 10th". That totals to far

more money than all that was in circulation in 2000. It's as much money

as in a year and a half of "QE3", which people feared would by itself

destroy the value of the US$. All in 3 weeks. And a few days into it

the banks were asking for even more. (Can I get a loan at the Fed

"Discount Window" at 2% too?)

What happens after October 10th? Will the banks

miraculously need no more, printing will stop, and the "Fed" will be

able to close out its mushrooming balance sheet? Hah!

How huge will the toxic balance sheets of the

central banks mushroom out to?

How huge will the toxic balance sheets of the

central banks mushroom out to?

[This is a huge (10"?) poisonous amanita muscaria. If it was a central

bank

it might just keep inflating until it blocked the whole highway!]

Have they gone off the deep end this time? How much longer

can the whole pyramid scheme financial system carry on? Will there be

hyperinflation, or will the banks simply close their doors? If the

latter, there may be no money except the paper in peoples' wallets (and

in odd on-line places like Paypal accounts), which would cause sudden

drastic deflation. But how can it possibly end except in chaos?

One financial analyst, Rob Kirby, said that if the "Repo"

printing ends in a few days things could go smoothly for a while

longer. (and looking at it again later, it just might. Maybe!) But he

also points out that this is what they did just prior to the 2008

crash, and he thinks they'll keep doing doing "whatever it takes" -

whatever they can - to keep everything going even a few more months.

Below is what another well known financial expert had to

say about it. Bear in mind that both of these financial people are (or

have come to be) firm believers in gold as money, but I doubt if

they're too far off. Timing of events is always anyone's guess.

Amazingly things have held together so far for over a decade since the

"financial crisis" even though none of the problems were fixed:

[Via Greg Hunter's USAWatchdog.com & Zerohedge.com]

Financial and precious metals expert Egon

von Greyerz (EvG) says the signs abound that we are nearing the end of

this global fiat money experiment, while central bankers are befuddled.

EvG explains, "The central banks are panicking..."

"They don't know what to do anymore. They are just

starting to print money and with the euro on a daily basis...

Europe is starting QE ["quantitative

easing", AKA money printing] again with $20 billion a month, but

that's nothing compared to what is coming. . . . The panic that started

with central banks in the summer in late July and August was, to me,

the first step towards total chaos in the world that we will be seeing

in the months and years to come. They (central bankers) see it

clearly.

They know the banking system is absolutely on the

verge of collapse. They know Deutsche Bank (DB) and CommerzBank,

too, are down 95%. If you show this chart to a child and ask

where is that likely to go, it is likely to go to zero. DB, with their

$50 trillion in derivatives, there is no chance they will survive. Of

course, Germany and the ECB [European central bank] is panicking

because that will affect the whole banking system worldwide. This

is why they have started to print money now because there is a massive

liquidity problem, and that's Germany, which is the best country in the

EU from the point of economics. Then you take Italy, Spain,

France and Greece and they are in a real mess.

This is why the whole system is on the verge of

disappearing into a black hole... With the U.S., there is massive

liquidity pressure there too."

The massive amount of money printing to keep the fiat system afloat is

just starting. EvG contends, "This is just a practice round..."

"This is just more money at this point. The

balance sheet . . . of the Fed is going to go from around $4 trillion

to $40 trillion. It is going to go to $100 trillion before this

is over. So, right now, they are just practicing a bit because they are

going to put the pedal down to the bottom very soon...

There is no other way to save this system, it has

gone too far. I am not a pessimist. I don't want to see the end of the

world, but you can see their actions. You can see that now there is

absolutely no way out. The only thing they know is to print money. They

have already reduced rates to zero or negative, which is a disaster in

and of itself."

EvG predicts, "All of these bubble assets that are based on just credit

and credit expansion are going to implode measured in real terms,

measured in gold."

Of course, most of these experts are saying one should

have precious metals (the actual metal, in your possession - and very

well hidden I would add) in one's portfolio, since whatever happens to

fiat currency, those coins and bars will retain some real value. (I

wish I had bought some rhodium 5 years ago. It's gone from what? 1500

$CA/ozt, to 5000 $. Silver and gold have gone up a little, and will

probably go up more, platinum has been flat, palladium has doubled...

but rhodium... ooh! But one rarely can predict such specifics very far

in advance. As usual I digress.)

Small

Thots

* I found my fourth 'impact resistant' 6 oz Duralex glass from the set

of four bought in 1977. It wasn't broken or gone after all. (It was a

lone item 'abandoned' in the dishwasher, which I hardly ever use.)

* On the 18th I noticed a battery recycling bin outside a thrift store.

I found 5 good looking alkaline "D" cells and a couple of "C", to

extract the manganese oxide from. I tested them at home. The 5 "D"

cells were all like new: ~1.59 volts and they put out over 7 amps

shorted! Maybe I'm in the wrong business... I could probably get 2 or 3

dollars each for them, and if some of the big stash of "AA" and "AAA"

cells were likewise good, maybe a buck or more. Move over, pop bottle

collectors!

* The "C" cells were rather interesting. One was only 1.47 volts but

put out almost 4 amps when shorted. The other was 1.53 volts but put

out less than an amp. I tried it a few more times to be sure and it

started doing around 1.5 amps.

* With the idea of recycling waste clear plastic into greenhouse

panels, I had started saving clear packages, and getting the labels off

them. Soon I had a surprisingly large mound. Finally I decided saving

them was dumb: If I created a means to turn them into panels, all that

would be needed would be a recycling bin for each type and volunteers

would put more in in a day than my whole pile of clutter, being glad it

would go to a good cause. I threw them into the woodstove on a good

fire (a couple at a time) and incinerated it all - and got back the far

corner of the kitchen to set up the LED indoor garden for the winter.

* Concerning the weather these days, someone put it this way in a

comment on Youtube to a Video by Paul Beckwith:

Our New Normal Since 2000

Record Rain has been 29 - 600 % Increase in Rain

Record Rain, Record Snow,

Record Highs Record Lows

Record Winds, Record Waves

Record Fires, Record Floods,

Record Volcanic Eruptions.

Record Hurricanes, Record Tsunamis,

Record Typhoons, Record Earthquakes,

Record Mud-Slides, and Record Sea Surges.

Record High Tides, Record Sea Level Rise.

I thought he must surely have covered it all... then I

noticed he had missed record tornadoes, record droughts and record

hailstones.

ESD

(Eccentric Silliness Department)

* Okay, I'm always behind the times if I'm not ahead. Totally out of

sync. I never did get a pet rock.

- Where do you get a pet rock? In a pet rock quarry.

- Where do you keep a pet rock? In a rock garden.

- What do you get when two pet rocks rub together? Gravel.

* A vice is supposedly used to hold things. I find mine are devious

de-vices, always letting things slip out no matter how tightly closed.

* The density of the Earth is about 6. The other planets are under

density 4. Most of the spheres orbiting Saturn are only about 2 while

Saturn itself is less than one. Could Saturn be placed in water, it

would float. The Earth is the densest thing in the solar system except

for the density of we who inhabit it.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried or thought

of... and even of how not to do something - why it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency and

completeness before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground

Effect

Vehicle

(first

the

R/C

Model)

On the (ahem) 24th I

finally got back to this project. Luckily it seemed pretty

straightforward - no vital details to forget by setting it aside for a

while (repeatedly). And somehow with every delay has come some new idea

for it. The plan until now had been to use the thin but strong

polypropylene cloth and coat it with epoxy, and I had done part of the

bottom of one hull. That was my idea of a modern version of the

cellulose based dope (lacquer) on canvas or cotton of early aircraft

coverings. The epoxy was much heavier than the cloth it was

impregnating.

But my brother had called some days previously, saying he

was going to make a foam core canoe. For the skin he was planning to

use polypropylene cloth with varathane. Instead of epoxy, varathane? As

I recalled, varathane was in fact a polyurethane paint.

The idea took hold. I had a can of varathane spray paint.

What would happen? If it worked, it would probably be the lightest wing

covering imaginable. At first I was just going to try out a small

piece, then I decided I might as well do the whole top surface of the

wing. (I trusted that I could rip it off again if I didn't like it.) I

cut a piece of the paper thin white PP cloth (with some extra margins)

and pinned it in place, then I sprayed it.

A while later I tried to blow through it. I could feel my

breath on the other side. I sprayed on another coat. After 7 or 8 daily

coats the month ended. The spray can was about empty and I could still

feel my breath, although much reduced. A few more coats should do it.

HOW many coats of varathane to make the

lightweight fabric airtight?

HOW many coats of varathane to make the

lightweight fabric airtight?

I am thinking it might be better to epoxy the cloth,

sitting loose on a piece of plastic (LDPE), squeegeeing out all

possible excess, and then pinning it onto the model. The epoxy would

glue it on. (Maybe add some epoxy to the contacting surfaces of the

model to be sure there's lots there?)

While I was at it, I shaped a couple of pieces of wood to mount one of

the ducted fans on. I cut similar pieces for the other side but didn't

get them shaped up. I cut/milled slots in the pieces with my milling

machine, which had decided it would work fine on this occasion.

(Nothing to see here... but next time I tried it it wouldn't run again.)

While I was at it, I shaped a couple of pieces of wood to mount one of

the ducted fans on. I cut similar pieces for the other side but didn't

get them shaped up. I cut/milled slots in the pieces with my milling

machine, which had decided it would work fine on this occasion.

(Nothing to see here... but next time I tried it it wouldn't run again.)

Other

"Green"

Electric

Equipment

Projects

Working with the

Handheld Bandsaw Mill (& Alaska Mill)

I wasn't going to write up anything about this, but it

seemed I had taken a few pictures while I was milling and had just a

couple of little things to say.

This big spruce log, still 48 feet long (after

about 22' was milled off the top in 2018),

This big spruce log, still 48 feet long (after

about 22' was milled off the top in 2018),

the last one cut down in 2017, is rotting! Bug holes riddle the sapwood.

It can't be allowed to lie out on the ground a third winter.

Log Tip: Way back in 1972 someone showed us how

to peel bark with a sharpened square shovel.

Log Tip: Way back in 1972 someone showed us how

to peel bark with a sharpened square shovel.

This spruce bark seems to dull the saws rather quickly, so it can be

worth peeling it off.

(I've had this shovel since about 1978.)

A 12' section, an 8' section, and now just 28

more feet to go!

A 12' section, an 8' section, and now just 28

more feet to go!

(a 16' and a 12' - from the fat but end)

...as the weather heads into fall. Rain & clouds started on October

1st.

I buck the log segments into 4", 6" or 8" thick

slabs (cants) with the Alaska mill,

I buck the log segments into 4", 6" or 8" thick

slabs (cants) with the Alaska mill,

then slice those into boards of those widths with the handheld

bandmill, 1", 1.5" or 2" thick.

The thin-band electric bandmill utilizes the whole of the wood

with negligable sawdust and waste, using no gasoline and oil.

I still had a lot of milling to do by the time October

rolled around. On October 2nd I sharpened a band and cut three 16 foot

2 by 4s, but it still didn't cut very well and it was hard going.

Wasting my time... Time to toss it and break out a new one! The next

day a new band was somewhat faster. But part of the problem had been

the V-belt slipping because the skillsaw was at its maximum height

adjustment. Removing a couple of links from the link belt so it could

be tightened properly surely helped too. (Maybe I won't throw out that

old band just yet.)

I've decided I want to change the guide wheels - the

little 22mm ball bearing units are plain crappy and I've used them all

up or worn them out. Maybe I can make them instead with larger diameter

bearings, wide enough to be the wheel. Then there'd be a thrust

bearing behind between two washers, to get the "railroad wheel" edge

since the washers gradually wear out and it's a pain welding new ones

onto the wheels. Then again, bearing rims won't have sawdust relief

slots in them.

Someone suggested mounting a brush or wooden block to

brush or scrape off sawdust off the inside face of the band. That's

probably a good idea.

5

Blade Windplant

On the evening of September 30th there was (at long last) a notice in

my e-mail that 'a package' had arrived at the post office. The

windplant was the only thing I was expecting and I picked it up the

next day. (Call it September 31st.) I opened it and put the blades on.

On the evening of September 30th there was (at long last) a notice in

my e-mail that 'a package' had arrived at the post office. The

windplant was the only thing I was expecting and I picked it up the

next day. (Call it September 31st.) I opened it and put the blades on.

Then, as it was a blustery day (and spitting rain), I took

it out to the porch, where fitful gusts didn't start it turning.

Location is everything!

At the top of my driveway where the wind funnels in, I set

it on a stool and held it upright. Here it ran. It seemed to barely

start, but as it sped up, it became more and more energetic.

Windplant propellers are designed for spinning "at speed",

and are not very effective for starting up. When they're stopped, only

the air passing very close to each blade has much push on them, and at

a poor angle of attack. That would explain why they are reluctant to

start up in low winds, and why a 5 blade would be better than a 3. At

speed, all the wind passing the area swept by the propeller blades, the

whole circle, is utilized. The 3 blade has to spin fastest to catch it

all, while the 5 blade (all else being equal) is just 3/5 of that

speed. The five blades have more drag, which is said to limit the power

in higher winds. (Come to think of it, why should that be: since the

five blades are only spinning 3/5 as fast, shouldn't each blade have

less drag by virtue of going slower? Anyway I would rather have a

little power in lower winds than extra power in high winds, because low

winds are much more frequent.)

Soon the tips were making a furious whizzing noise that

said "I dare you to put your fingers in here!", and the voltmeter

across two phases reached 20 volts AC. (If it's quieter than a 3 blade,

it's only by degree, not a big jump. One expects 6, 7, 9 and 11 blades

should have progressively less high pitched "whizz".) To slow it down I

moved the meter leads to 'current', which shorted the two phases. It

put out up to 3 amps AC or so as it lost its speed. I could estimate

that the "1200 watt" windplant might do 40 or 50 watts if the

controller had been connected and there was a load, but I could be way

off. The good part was that it could do it whenever it was windy, day

and night. Several solar panels weren't doing any better in the rain

and clouds that afternoon.

That was all I had time for. I'd have liked to install it

and wire it in, because the solar was (for the second time) so poor

that I couldn't run the kitchen hot water heater with four panels

dedicated to the DC system. In addition to it getting late in the day,

I didn't want to climb up on the roof in the wind and rain, and I

didn't want to run the wiring from one end of the long, low attic to

the garage at the other end (ever, really). (And I only came up with a

good plan for mounting it on October 3rd.)

One could also estimate theoretically by size. The radius

from the hub to the blade tips is .64 m. The area is pi * R^2

or 1.29 sq. meters. (Ooh, more than a toy!) The formula is:

P = 1/2 * Rho * A * V^3.

1/2: from the general formula: e = 1/2 * M * V^2

P: power (in watts)

Rho: weight (of air in Kg/m^3)

A: area (square meters)

V: velocity (in meters per second)

(How metric makes all that work with no weird conversion constant "K"

except times 1/2, I don't know. Whoever designed some of these units

evidently knew just what they were doing!)

At a cut-in speed of about 10(?) Km/Hr:

P = .5 * 1.2 Kg/cubic meter * 1.29 sq.m * 2.78 m/sec ^3 = 16.6 watts.

That would be the total power in the breeze. A propeller

should capture a bit less than 1/2 of that. Gosh, we're down to 8

watts. Of course, a 20 KmPH wind would have 8 times as much, over 60

watts, and 30 KmPH would be 27 times - around 200 watts. Well, we knew

stronger winds were a lot better. It'd take a 50 KmPH blow to get up

near the 1200 watt rated power of this unit. That does happen -

thankfully rarely.

Here again we might do much better with a venturi. If we

made one with a mouth and or an exit that was say 3 meters diameter and

shrinking down to 1.29 meters at the (?)throat, in theory over 5 times

as much air would be going past the propeller. To do that it would have

to go 5 times faster? No doubt there would be a lot of frictional

losses and it wouldn't be 5 times the air speed, but there should be

substantial power to harvest in a 10 KmPH breeze instead of almost

nothing. Then too, one could place shutters in front of the opening so

that if the wind was too strong, it would lift them against gravity (or

against a spring) and blow them shut, reducing the opening and

protecting the windplant. An experiment with some lumber and sheets of

plywood or just plastic might be worthwhile.

---

In my observations of two small (3 blade) windplants, I

would see them start up, start whizzing, and then stop again. Hmm, just

like when I shorted the output? Trees were blamed, but the same effect

might be had if their control systems ask a bit too much, overloading

them, and so the blades stall. We'll see what happens with this one!

My

Solar

Power

System

Y-Solar Grid Tie Inverters

Someone on youtube put out a video expressing concerns

that these Chinese grid tie inverters, technically not approved by UL

or CSA, might be dangerous to electrical linemen. Obviously if the

inverter is working right, it is perfectly safe. Like all grid tie

inverters, it only puts out electricity each 120th of a second if it

senses voltage is already present. Then it synchronizes its own output

to that signal, adding current. I have given it considerable thought,

and I can't imagine a scenario where the inverter was malfunctioning

and yet would put out a working signal into a dead line.

But I have another complaint with them: lack of

performance. It's not that they don't effectively utilize the panel

energy... under ideal conditions.

The way they try to put out power seems to be to assume

they can put out "X" watts. Then when there isn't enough power from the

panels for that, they only put out the power for a brief period and

their capacitors become discharged. Instead of adjusting, they stop

entirely and then come on again trying out a lower power level. When at

last they are very near the correct level, they will adjust up or down

a bit at a time. That's fine on a perfect sunny day. In a minute the

inverter is (we presume) putting out what the panels can supply.

But when a bit of cloud drifts in front of the sun,

instead of adjusting down they turn off again, and start the process of

finding the right level all over again. By the time they've done so,

the cloud gets a little thicker and boom - they're turned off again.

Then the cloud passes by and it takes them a while to ramp up to full

power again. Then the next bit of cloud hits and boom - off again. Thus

on days with scattered clouds, they waste quite a lot of sunshine,

forever alternately ramping up and shutting down.

The PowMr 60 amp (36 V) DC to DC buck charge controller by

contrast seems to make the most of whatever sunlight hits the panels,

moment by moment. It's not without its quirks, but it seems to be a

very effective unit. (The fact that it decides by itself when turned on

the a system is 48 volts if the 36 volt batteries are over 40 volts,

when it itself may charge them to (eg) 42 volts, is dangerous. If it

tries to charge a 36 volt battery to 48 volts, it will at the very

least ruin it - at worst burn a house down. I wish there was a manual

battery voltage setting.)

Month of September Log of Solar

Power Generated [and grid power consumed]

One more month!

(All

times are in PST: clock 48 minutes ahead of sun, not PDT which is an

hour and 48 minutes ahead. DC power readings - mostly the kitchen hot

water heater - are reset to zero daily, while the others are

cumulative.)

Date House solar KWH(Grid+DC), +Trailer Roof solar KWH - day

total KWH

made [power

co. meter readings] weather, usage...

23rd 12.66+ .42, 721.21 - 11.51 [Utility co. meter showed: 67508@19:30]

Clouds and some sun.

On Holydays, returned Sept. 2nd.

Sept.

1st (& 2nd are estimated) -> 9.63 KWH for the day. [est. 3.5 KWH

from grid on 1st; 3.5 KWH 2nd while I was away.]

2nd 69.46+.71, 759.99 - 9.63 (10 days Aug24-Sept2) [67543@20:00] Sunny

until late

afternoon.

3rd 71.99+.51, 762.06 - 5.11 [55Km:chj.car1500W;

67558@20:00] Overcast, later rain. Not much solar for car!

4th 1.98+.32, 763.73 - 3.97 [67568@20:00] Part

Cloudy AM, Sunny PM. I turned off the inverters and unplugged them

while the electric line crew were working replacing the power pole

& transformer outside (~10:30 - ~14:30), so the day's collection

was way down. And of course the power break reset the one solar meter

so

earlier AM collection recording was lost. During the outage I moved the

two panels on the lawn in order to mow the lawn. They had also been

more and more in the lengthening tree shadows until mid day, and the

new position should be a little better for the autumn.

5th 6.24+.52, 766.76 - 7.81 [55Km,chj@3800W;

67582@19:00] Mostly overcast.

6th 8.55+.53, 768.77 - 4.85 [85Km,chj@3800W;

67604@19:00]

Mostly overcast, rain. 2 inverters were off quite a while.

7th 13.42+.46, 772.27 - 8.83 [laundry; bandmilling

(<1500W); 67618@19:00] AM

overcast, PM sunny periods.

8th 15.17+.53, 773.81 - 3.82 [BR heat, bandmilling;

67627@19:30] Overcast, dull.

9th 22.03+.66, 778.46 - 12.17 [BR heat; 55Km,part chj@1500W while

sun out; 67640@23:00] Mostly sunny. The tree shadows are definitely

getting longer, starting to hit the house roof panels.

10th 28.97+.50, 783.29 - 12.27 [BR heat; finish car chj in sun; band

milling; 67647@19:00] Mostly sunny.

11th 29.88+.23, 784.08 - 1.93 [55Km,chj@3800W; 67663@20:00]

Heavy overcast. This was the first day since I installed it that there

wasn't enough power from 4 panels to heat the kitchen water tank. I

kept turning it off as the battery voltage dropped, and then forgetting

to turn it on again. (If the panels had been feeding the tank directly

it would have been enough.)

12th 33.86+.59, 787.09 - 7.58 [bath; 67671@19:00 ] Sunny periods.

13th 35.57+.42, 788.45 - 3.49 [85Km,late chj@3800W; 67685@21:00;

still charging] overcast, rain

14th 38.51+.66, 790.86 - 6.03 [Car@3800W,55Km; 67710@19:30; bath,

BR heat] Overcast, bit of rain

15th 43.81+.69, 794.64 - 9.77 [67722@19:30] Sunny, scattered

clouds. Tree shadows are hitting over top of house roof.

16th 44.95+.55, 795.62 - 2.67 [67733@18:30] Overcast. windy.

miserable. Again 2 inv. off = 4 panels -> kitchen HW tank. Where is

my 5-blade windplant?

17th 47.43+.55, 797.75 - 5.16 [67741@19:00] AM-same as yesterday.

PM-clearer with some sun. 4 panels -> K HW.

18th 52.56+.51, 801.52 - 9.41 [55Km,3800Wchg; 67759@23:30; bath;

BR Heat] Sunny. Daylight hours and solar collection are shrinking!

19th 55.75+.86, 804.08 - 6.61 [67769@21:00] light overcast.

20th 57.71+.42, 805.88 - 4.18 [90Km,chj@1500W daytime;

67783@20:30] overcast.

21st 61.09+.41, 808.41 - 6.32 [continue chj,55Km; 67801@19:40;

laundry, bath] Scattered sunny breaks.

22nd 66.88+.40,812.35- 10.13 [continue,finish chj.in sunlight;

67816@18:00] Sunny, scattered clouds.

23rd 70.23+.53, 815.33- 6.86 [67826@20:00] mixed sun & clouds.

24th 74.82+.50, 818.71 - 8.47 [BR Heat left on all day (oops- BR door

open heats whole house); bath; 55Km,chj@3800W; 67846@19:30] AM clouds

& some sun, PM mostly sunny.

25th 75.64+.50,819.33 - 1.94 [bath; 67863@19:00] Rain and heavy

clouds ugh! I liked yesterday better.

26th 77.83+.51, 821.39 - 4.79 [60Km,chj@3800W; 67882@20:30] Light

clouds, sprinkles, bit of sun.

27th 82.74+.59, 824.63 - 8.74 [90Km,partChj@1500 while sunny;

67896@18:30] Sunny!

28th 87.04+.45, 828.74 - 8.86 [55Km,Mor car chj.@1500W; 67912@18:00]

Sunny

29th 92.10+.58, 832.89 - 9.79 [more car chj.; Laundry; 67933@18:30]

Sunny.

30th 96.93+.48, 836.90 - 9.32 [Finish car chj; BR Heat; 67944@18:30;

Bath] sunny.

October 1st 97.69+.25, 837.43 -> 2.54 KWH [Car 60 Km, chj@3800W;

67969@20:30] heavy clouds & rain. I found the (ground fault)

circuit breaker to the trailer blown, so the 4 panels on the trailer

were off-line for an unknown length of time.

2nd 98.89+.43, 838.66 - 2.86 [BR Heat; 67980@20:30] Cloudy.

3rd 103.50+.54,832.07 - 8.56 [67990@19:00] mostly sunny

Daily-

KWH- # of Days (Sept)

Made

1.xx - 2

2.xx - 1

3.xx - 3

4.xx - 3

5.xx - 2

6.xx - 4

7.xx - 2

8.xx - 4

9.xx - 6

10.xx- 1

11.xx-

12.xx- 2

13.xx-

14.xx-

15.xx-

16.xx-

Monthly Tallies: Generated KWH [Power used from grid KWH]

March 1-31: 116.19 + ------ + 105.93 = 222.12 KWH [786 KWH - used from

grid]

April - 1-30: 136.87 + ------ + 121.97 = 258.84 KWH [608 KWH]

May - 1-31: 156.23 + ------ + 147.47 = 303.70 KWH [543 KWH] (11th

solar panel connected on lawn on 26th)

June - 1-30: 146.63 + 15.65 + 115.26 = 277.54 KWH [374 KWH] (36V, 250W

Hot Water Heater installed on 7th)

July - 1-31: 134.06 + 19.06 + 120.86 = 273.98 KWH [342 KWH]

August 1-31:127.47 + 11.44 + 91.82 +(8/10)*96.29 = 307.76 KWH [334 KWH]

(12th panel 'installed' on lawn Aug. 1)

[Egads! I'm posting this newsletter now. If I start doing calculations

for September it won't be until tomorrow.]

6

month total March 1 to August 31: 1643.94 KWH made; [2987 KWH consumed

from grid]

Things Noted

* On the 19th I did a bunch of dishes in mid afternoon, clearing up

accumulated clutter. Austere as I am with hot water use, the extra is

visible in the figure recorded for that day, and the hot water in the

little kitchen tank actually ran out, becoming just warm, and finally

almost cold. Here's where the slow recovery of the small 36V, 200W

heating element showed. And not being sunny, the battery voltage

dropped notably too.

* All this time I have noticed that the "smart" utility power meter

wouldn't run backward when the house was (surely) making more power

than it was using. I have assumed I was just giving the power to the

utility for free. It isn't a big portion of what I'm making - the bulk

of it gets used here.

In late September I got my regular 2 month's bill. It also

had two pages of adjustments, in my favor, going back to last March

when I had started making solar power. The meter readings on the bill

didn't match the actual meter readings on the days given. Egads! That

means that at least their meter knows I'm making power. Somewhere

inside it is recording actual use and gain, even if it doesn't show it

on the display.

However, the meter reading given for August-September is

the one on the face of the meter, so they have charged me for an extra

248 KWH this time. Perhaps that's the same amount I got credit for for

past months. I guess I'll see what the next bill holds, or if I get a

call complaining that my system hasn't been approved. Since the diesels

cost them about 50 ¢/KWH and our rates are subsidized (we pay

about 12¢), I'm doing them a favor.

Hopefully some time I'll have lots of battery storage and

perhaps I'll disconnect the solar stuff from the power grid.

* As autumn progresses the sun gets lower and the days get shorter.

This is more visible in September than in any other month. There were

no more days of 13 to 16 KWH collection, and in fact only 3 days hit 10

KWH. By the end even sunny days were giving under 10. Tree shadows

reduce the sunlight to the solar panels. So does the too-flat angle of

the panels (other than the two sitting propped up on the lawn) - about

15° south slope while the sun is at 53° on the equinox. That's

38° off (even at noon) for a 21% reduction even without shadows.

Electricity Storage (Batteries)

Turquoise

Battery

Project:

Long lasting, high energy batteries

Nickel Manganates Electrode Toasting

I swapped the 1st electrode for the 2nd one, which I had

dunked in DieselKleen just before leaving on holidays, so it had lots

of time to evaporate. But in spite of having more conductive carbon

black, it didn't seem to work any better.

On the 7th I remembered the technique of toasting the

substance with a propane torch. The back had broken off the shell

anyway, so I took it apart, dried it in the oven, and toasted it very

briefly with the extra hot "swirljet" propane torch, which can even

braze small objects. I can't think that it's a very exactly controlled

procedure.

It may have been a bit better, but basically it didn't

seem to solve the problems. Okay then, let's back up.

Backing Up: What Works?

Experiment #1

Manganese dioxide is well known to work well in either salt or alkali.

If it doesn't, I'm doing something wrong. So on the 10th I put 20 grams

of MnO2 mix from an alkaline dry cell, into a PLA plastic shell with a

carbon fiber current collector & connection. I just crunched the

powder down into the shell with a short 3/4" x 3/4" bar of metal with a

square end. Then I fitted a piece of carbon fiber behind that and

closed it up.

Manganese dioxide is well known to work well in either salt or alkali.

If it doesn't, I'm doing something wrong. So on the 10th I put 20 grams

of MnO2 mix from an alkaline dry cell, into a PLA plastic shell with a

carbon fiber current collector & connection. I just crunched the

powder down into the shell with a short 3/4" x 3/4" bar of metal with a

square end. Then I fitted a piece of carbon fiber behind that and

closed it up.

There was some positive

result: The voltage dropped to the expected Mn-Zn voltage of around 1.5

pretty quickly when charge was removed, and it recovered to 1.5 pretty

quickly after being shorted. My 'nickel manganate' electrodes so far

had been much less stable in voltage, and had recovered above a volt or

1.1 volts extremely slowly after being shorted.

But currents were the lowest yet - under half of what the

previous unsatisfactory cell did - around 100 mA short circuited,

although it maintained that current for 10 seconds without falling off

at all. But that's only 5% of 2 amps, which the Ni-MH dry cell nickel

oxide electrode had supplied. Surely that is the area to aim for.

Apparently either I should have re-compacted the dry cell

powder in a press, or the carbon fiber cloth wasn't making very good

connection to the electrode powder? I started thinking maybe the carbon

fiber had to be compressed into the electrode material to get better

contact along all points, rather than just laid on top with the lid put

on to hold them together. OR, the number and fineness of strands coming

up to the terminal wasn't enough "wire" to carry much current. I

decided to check these out. I didn't get very far. I started 'munching'

the carbon fiber into the powder with the bar. But the PLA shell

started breaking up. It would seem PLA deteriorates in alkali, and then

falls apart entirely.

PLA plastic electrode shell, disintegrated in

alkaline environment.

PLA plastic electrode shell, disintegrated in

alkaline environment.

But the currents, shattered shell and all, went up to

around 170mA shorted (10 seconds) and it held 1.525 volts overnight.

That current was in the same neighborhood as my nickel manganate

attempts. I started to suspect the connection of the electrode material

to the carbon fiber current collector really was the bottleneck.

I tried a load test (after it had sat overnight) with 60

ohms. Voltage was soon down to 1.25. But there the drop slowed and it

ran for an hour and 20 minutes before it was down to 1.000 volts

(exactly), having delivered around a whopping 23 mA-Hours of electrons.

(I didn't add salt to the electrolyte, so it was weak KOH, pH 13. Some

salt(s) (or more KOH) probably would have improved the result

somewhat.) It recovered quickly (45 seconds) to 1.25 volts, then more

slowly (9 minutes) to 1.35 and 1.36 (13 minutes). It was still rising

slowly but I had things to do and put it on to recharge.

I would like to make a similar electrode and compact the

carbon fiber cloth into the middle of the mix for better contact, but

if I couldn't make a shell, that was going to be tricky. In fact it was

starting to hold up all the experimentation.

Printing An ABS Electrode Shell

Somehow I would have to get ABS shells to print out nicely

after all. As to that... Why on earth would the printer not set the bed

warm enough to make ABS stick to it in the setting for ABS? (Just one

more stupid piece of programming to sabotage good operation of an

otherwise fine product - see my diatribe on this subject last month

also under 'batteries'!) Now what do I do? I hadn't been able to get

the old printer to work again, and I hadn't been able to get it to

print "porous" well at any time. One number... why did they change it?

Maybe move the heat sensor away from the bed so it didn't think it was

at 80° yet? Too much disassembly and too uncertain. Was I going to

have to give up on the whole electrode shells idea because PLA didn't

work and the printer bed ABS temperature setting was wrong and not

changeable by the owner? The old printer let you enter any temperature.

Did I have to come up with a whole new plan because of that? All too

discouraging! Must be time to go eat ice cream, stack today's lumber

milled on the band mill (twelve 12 foot 1x6es) and do a sudoku.

I returned to the charge late at night with a web search.

Someone had made a plastic a 'tent' over the printer with

'greenhouse'-like construction, and heated the entire space with an

electric heater. He said he got great ABS prints. Someone else

mentioned some better materials than glass to print on, and an "ABS

juice" of ABS liquified in acetone.

Someone else mentioned setting the I3 Mega bed hotter. Huh? I went back

to the printer and found another menu. (I should check these things out

better - but I only want to print, not learn how to use it!) The "ABS

setting" sets the bed to 80°c, but the other menu lets you set it

to any temperature. I set it to 105°C and tried printing a shell in

ABS. This time it printed the first two layers fine, but then the

corners lifted and the prints came loose. But the gcode had set the

extruder temperature down to PLA level. Perhaps it would print okay if

increased to ABS temperature? Anyway before I retired very late, I had

something that looked like a bottom for an ABS shell, with the porous

face. It could (surely) be done! But the next morning (11th) I redid

the file with ABS extruder temperature, and it was little better.

Someone else mentioned setting the I3 Mega bed hotter. Huh? I went back

to the printer and found another menu. (I should check these things out

better - but I only want to print, not learn how to use it!) The "ABS

setting" sets the bed to 80°c, but the other menu lets you set it

to any temperature. I set it to 105°C and tried printing a shell in

ABS. This time it printed the first two layers fine, but then the

corners lifted and the prints came loose. But the gcode had set the

extruder temperature down to PLA level. Perhaps it would print okay if

increased to ABS temperature? Anyway before I retired very late, I had

something that looked like a bottom for an ABS shell, with the porous

face. It could (surely) be done! But the next morning (11th) I redid

the file with ABS extruder temperature, and it was little better.

Someone on the web had mentioned that "layer fans" were

death for printing ABS. I thought of the fan slit blowing air onto the

work. Was that a "layer fan"? Probably. I stuck modeling clay over the

opening and tried again. It went a couple more layers before it curled

up and broke loose. Too bad it was blowing cold air instead of hot,

which would have reduced the shrinkage. Basically, this printer was

awful; it just didn't print ABS. (And at 230° extruder many of the

porous holes were filled in, even whole sections. It worked better at

220° or even 200.) Well, if the worst came to the worst, it printed

the porous faces now before the prints broke loose. I could always

print the faces and make the rest of the shell out of solid ABS sheets

for test electrodes. But what a pain!

I gave it one more try. I turned the bed down to 95°C

- the lowest ABS will stick to the glass - and the extruder down to

220°, hoping it would shrink less as it cooled. And I printed a

"skirt" at the bottom to help hold it down. All to no avail! The old

RepRap was no hell, but it printed ABS way better than that. Why, when

it was such a similar setup? But at least turning temperatures

down had restored the porosity: melted plastic hadn't smeared over the

tiny holes.

I looked on line and found "7 best printers for printing

ABS". They all had enclosures, "ovens" - the thing I hadn't found when

I was looking for a printer and bought the Anycubic I3 Mega. Most of

them weren't cheap. Perhaps if/when I have funding. Or perhaps I should

make an enclosure over the whole printer, like the fellow's

"greenhouse" on youtube?

There was one more thing to try. I took the hot air gun

and heated the curled pieces until they flattened. If I had it blowing

on the printer bed as the printer worked, the parts might stay hot and

soft and not warp, and so would print okay. The trick would be to mount

it somehow where it wouldn't interfere with the printing, and then to

find the right distance and angle to blow from: not too hot, not too

cool, across the pieces being printed. Luckily the pieces for test

electrode shells were pretty small.

On 12th I made a stand to hold the heat gun so it could point at the

print bed. I printed a shell. It came out perfect - completely flat, no

warping. It seemed terribly wasteful blowing 750 watts of heat at the

printer for the duration, and I don't know how long everything

(including the heat gun) would last with this as a regular setup. I

would turn the heat down if it had more settings, or I would move it

farther from the printer if there was room on the table. But the only

casualty found on the first print was that the "warning, high

temperature" label by the print extruder curled up from the heat

of the hot air.

On 12th I made a stand to hold the heat gun so it could point at the

print bed. I printed a shell. It came out perfect - completely flat, no

warping. It seemed terribly wasteful blowing 750 watts of heat at the

printer for the duration, and I don't know how long everything

(including the heat gun) would last with this as a regular setup. I

would turn the heat down if it had more settings, or I would move it

farther from the printer if there was room on the table. But the only

casualty found on the first print was that the "warning, high

temperature" label by the print extruder curled up from the heat

of the hot air.

I noted that a hair dryer

is also 750 watts on 'low', but it blows much more air so it's not as

hot. But I tried it the next time and found it was totally inadequate.

The parts warped up the same as without heat.

Printer printing ABS with a heat gun blowing hot air

on the piece. For a printed battery case I had to get

the hot air quite close. (I held it by hand for the whole

print the second time.) But then, yay! It printed the

ABS without warping it!

Experiment 2: Nickel NiOOH electrode

The pieces of NiOOH electrode from the dry cell worked at

pH 14 and had given good high currents. Now using a less than pH 14

electrolyte, they might not. Certainly a metallic current collector

would dissolve. The fine nickel mesh inside the pieces would also turn

to nickel oxide/oxyhydroxide, which would reduce the conductivity.

Well, how about trying the dry cell pieces, but in a plastic shell with

a carbon fiber current collector?

After getting the 3D printer to print a shell on the 12th

I tried this. I had intended to throw the electrode pieces into some

bleach to oxidize them in advance, but as usual I forgot one of the

several planned steps. So the cell started very uncharged. And it

didn't seem to hold a charge, even in weak KOH electrolyte. Yet it

wouldn't take charging current very fast.

Surely the low currents must be a result from the carbon

fiber cloth current collector - nothing wanted to charge fast or drive

a heavy load since I had started using it instead of metal. But hadn't

I measured the fibers as being very low resistance? I got out a meter

and found the truth: if there were just a few fibers, a single "strand"

of the cloth, resistances were in the tens of ohms. My memory was

faulty. It was doubtless useful, but not as good as I had thought, not

"under an ohm". Making the cloth thicker, perhaps two layers, might be

better. In fact, maybe a layer of electrode, a layer of cloth, then

more electrode... maybe 2 or 3 or 4 of cloth and 3 or 4 or 5 of

electrode material, all fairly thin layers.

And then there was Diesel Kleen to soften the graphite and

reform it with better conductivity. How well might that work?

And there was one other thing to try: Since the strands

going up to the top of the terminal had too high a resistance, and yet

only graphite could be used, I could connect a piece of graphite foil

or flex graphite go up to the terminal, extending far enough into the

electrode to make lots of good contact with the strands therein. That

should make for substantially better connection from the electrode

substance to the external circuit. And it would be easier than trying

to coerce the strands to bend into the channel running up the plastic

terminal strip.

But there was another factor. The NiOOH electrode pieces

were poor at first and had gradually improved even in the best cells

with metal and KOH. Now I measured them too, and found resistances like

a megohm or more, but some much lower. I attribute the lower

measurements to the enclosed fine nickel mesh. The Ni(OH)2 was long

since completely discharged, and discharged Ni(OH)2 has very high

resistance, probably explaining the megohms.

Now that I had an electrode shell that was snapped

together (if not very well) instead of glued, and wasn't

disintegrating, I removed it from the cell and soaked it in quite

concentrated bleach for half an hour. Then I put it back. (The sodium

hypochlorite bleach, NaClO, would convert to NaCl electrolyte salt once

the "O" was used up. Right? - I get less and less sure about such

things as I go along.)

It still didn't work very well. It started at just ~1.43

volts instead of 1.7-1.8 and even when charged didn't seem to hold a

charge. So far I liked the manganese better. Could I get nickel working

somehow? It seemed silly that it wasn't going well. Maybe I need to do

the jell on the "+" electrode. Or use the Sm2O3 additive to raise the

oxygen overvoltage. Or both.

Extracting MnO2 from old dry cells

I had been puzzling over a good way to do this for the

longest time. Here is all this fine battery electrode substance freely

available, but solidly encased in tiny, tough steel cans. (or just a

zinc can in the cheapest 'standard' dry cells.) I had thought of

cutting them open with an angle grinder. But the potassium hydroxide

would be very bad to spray over things, and would blind if one got it

in one's eye(s). A power hacksaw, maybe? Still messy, and I don't have

one.

Suddenly on the 9th the answer came to me: a plumbers pipe cutter for

copper plumbing pipe! Sure enough, it sliced a "D" cell battery can in

two quite nicely, and there was no mess. (But somehow the old cell from

a box had KOH all over it and I was obliged to wash my hands repeatedly

and hold it with a pair of vicegrips. Or I could have put it in a

vice.) In fact the pipe cutter makes it easy enough I might find it

practical to open "C" and "AA" cells instead of only "D" cells. (Nope,

"AA" is harder, and for little substance. "C" maybe.) Next time I wore

nitrile "single use" gloves, and put the battery in a vice.

Suddenly on the 9th the answer came to me: a plumbers pipe cutter for

copper plumbing pipe! Sure enough, it sliced a "D" cell battery can in

two quite nicely, and there was no mess. (But somehow the old cell from

a box had KOH all over it and I was obliged to wash my hands repeatedly

and hold it with a pair of vicegrips. Or I could have put it in a

vice.) In fact the pipe cutter makes it easy enough I might find it

practical to open "C" and "AA" cells instead of only "D" cells. (Nope,

"AA" is harder, and for little substance. "C" maybe.) Next time I wore

nitrile "single use" gloves, and put the battery in a vice.

I

pulled out and saved the "bags" of zinc electrode, too. I did more on a

couple of occasions because it just seemed more satisfying than

experiments and 3D printing that weren't going well.

I

pulled out and saved the "bags" of zinc electrode, too. I did more on a

couple of occasions because it just seemed more satisfying than

experiments and 3D printing that weren't going well.

I could also see automating the process and taking all the

recycled cells I can get as free material for battery production.

To anybody who does this:

wear safety glasses (or just glasses) and gloves. DON'T get it in your

eyes. Don't rub your eyes while working. Wash your hands after. Any

"slimy" or "soapy" feel means there's potassium hydroxide there, eating

into your skin and flesh. If you don't wash it off, it can do a lot of

tissue damage. (This, after all, is why I've been trying to find a less

hostile electrolyte.)

The hollow cylinder manganese dioxide electrodes were:

CAN: 32.92 mm OD; .33 mm thick metal

MnO2 Electrode:

5.7 mm thick,

52 mm tall

32.26 mm OD (32.92-.33-.33)

(and hence 20.86 mm ID.)

= 476 sq.mm (OD-ID area) * 52 mm (length)

= 24.7 cc of MnO2 (+graphite, + KOH, +H2O)

I was surprised to find the MnO2 outer electrode was only 5.7mm thick.

That's a very thick electrode, pretty much the maximum but not as I had

supposed "ridiculously" thick. It also explains why "D" cells are the

largest diameter made - any larger and the thickness would be

ridiculous.

The mass for two "D" cells was 141 grams. For the few flakes I lost,

I'll call it 78 grams per cell. If such cells are said to be 12-18

amp-hours, that suggests the MnO2 must supply 153-230 AH/Kg.

Theoretical total value is about 309 AH/Kg, so it's being pretty

decently utilized.

So the density of the MnO2 mix was 78g / 24.7cc = 3.16 g/cc. IIRC the

density of 'fluffy' nickel oxyhydroxide 'trode substance is only about

2.1 . (?)

This gives a figure to aim for when compacting a manganese electrode.

If it's very far under 3, it must be poorly compacted.

What do we know about Mn-Zn dry cells? The alkaline "D"

size will put out over 8 amps if shorted. That's with those thick

electrodes and... how much interface area? 52 mm tall *

(πD=π*20.86=about 65 mm circumference) = 34 sq.cm .

8 / 34 = 235 mA/sq.cm. Actually that's very impressive. If I can get

1/2 of that with carbon fiber current collectors, or maybe even 1/4,

I'll be happy.

The wetness of the cell seems much higher than that of

nickel-metal hydride. Since the cells don't recharge, they don't need

to worry about oxygen being blocked to the zinc side during charge.

This will allow them much longer life without drying out than

rechargeables. (That's why I don't want to make dry cells for mass

storage. Adding a bit of water every few years is better than having

them dry out.)

And we know they aren't very rechargeable. But is that

just because of the zinc dissolving (presumably solved with the agar)

or are there problems with the manganese side as well? A paper by

Polish researchers hints that Mn2O3 or Mn3O4 may not be electrically

conductive. I thought all oxides of manganese were conductive. That

would make for a non-reversible component of the reactions. They used

zinc sulfate electrolyte to get two electrons moving at once,

converting the MnO2 directly into Mn(OH)2 without creating the

intervening compounds above. These are real battery researchers, so

they're probably right. But I note that another electrolyte besides

sulfate for the two electron move would be potassium oxalate. Either

there's some problem with it I'm still unaware of, or they (more

probably?) never thought of it.

The discharge graphs in the Polish study also weren't very

flat. Voltage kind of meandered down gradually as the cell discharged.

That may perhaps excuse own my nickel-zinc tests for behaving that way.

My other take is that MnO2 needs an extra .45 volts or so

to charge to KMnO4. If Mn2O3 or Mn3O4 aren't a problem, then as long as

the charge voltage is kept under 1.9 volts per cell (max!), the

manganese side should be okay. Also, the dry cell electrodes aren't

jelled. A working jell should make them indefinitely(?) rechargeable.

And hopefully obviate the problems noted by the Polish team. That was

probably the next thing to try, to jell my electrodes, which didn't

seem to be working very well whether MnO2 or NiOOH.

Experiment #3: Jelled MnO2

The nickel oxyhydroxide electrode hadn't performed. The

nickel manganates electrodes hadn't performed. Manganese had at least

worked. The low currents in all of them were explained by the carbon

fiber current collector high resistances as well as probably the

connections between the electrode substances and the fibers.

One choice would be to go back to straight alkali

electrolyte, and use a nickel (or cupro-nickel or monel) current

collector. But first there were improvements that could be tried. They

might make the nickel work, or they might make the manganese work

better - even work well.

(13th) The MnO2 had seemed to charge up and hold a good charge the

first time, but after that it didn't charge as well and didn't stay

charged overnight. Perhaps it was time to try the jelled electrode

plan? Would it work at least as well at least once when jelled - and

then hopefully continue working every time thereafter - or was my Lemon

Fresh Sunlight dishsoap (having sulfonates like nafion membrane) a poor

choice of jell?

I took apart the non-performing NiOOH 'trode and cleaned

out the shell. I got a piece of graphite foil. It wasn't perfect

either. It seemed its internal resistance was pretty low, but surface

contact resistance was high. It got lower with (a) the more area of

metal in contact with the surface and (b) the higher the pressure was

between them. At first I was having trouble getting a reading under

2000 ohms with just meter probe points digging into it. Pressing down

hard on chunks of sheet metal set on top of it, I got it down to under

an ohm. That still seems pretty poor compared with any piece of metal.

I guess the answer is lots of carbon fiber in contact with it inside

the electrode (and some diesel kleen?), and a big fat washer bolting

the graphite foil solidly to the plastic at the top. Maybe a washer on

each side of the foil? I note that on standard dry cells, the metal

button piece is crimped pretty hard onto the graphite rod, for the same

reason.

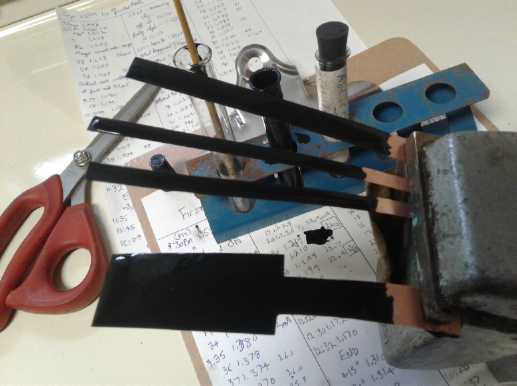

"D" Cell Graphite Rod Experiment

Perhaps this is a good place to mention my little experiment with

standard "D" cells. I bought a couple at the dollar store. My idea was

that if there was a metal rod inside the carbon rod, one might get

lower resistance and hence be able to draw more current from these

cells. The cells only weighed 78 grams - hardly 1/2 the weight of the

alkaline ones. I suspected they weren't even full - the "AA" cell in a

"D" package sort of thing. Anyway, they managed to put out about 5 amps

when shorted, which seemed very good.

Perhaps this is a good place to mention my little experiment with

standard "D" cells. I bought a couple at the dollar store. My idea was

that if there was a metal rod inside the carbon rod, one might get

lower resistance and hence be able to draw more current from these

cells. The cells only weighed 78 grams - hardly 1/2 the weight of the

alkaline ones. I suspected they weren't even full - the "AA" cell in a

"D" package sort of thing. Anyway, they managed to put out about 5 amps

when shorted, which seemed very good.

I drilled a hole into the end of the rod on one of them. I

was afraid of coming out the side of the rod so I didn't go very deep.

How to get good connection? I threaded it, and screwed in a bolt.

Instead of going through the whole rod or even a lot of it, it only

went in 5/8 of an inch or so. When shorted via my bolt, the current

was, if anything, just marginally lower than when shorted to the button

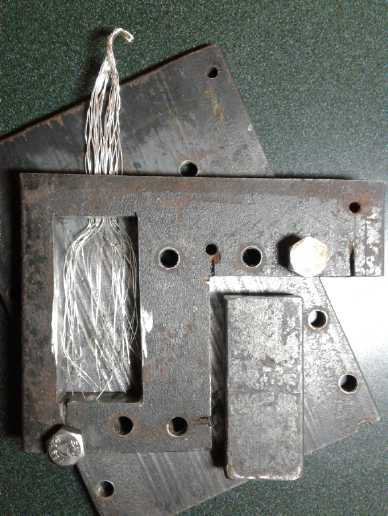

(they were presumably shorted together anyway), both still about 5