Turquoise Energy News #137

covering

October

2019 (Posted November 5th 2019)

Lawnhill BC Canada

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- House - New Chemie Batteries - Ground Effect Vehicle - Two Lithium

Battery Charger Circuits; AC and DC Sources - Internet! - Planetary

Gears!: Miles Truck & Chevy Sprint

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Gardening, Growing Barley, Processing Grains into Flour With

Common Kitchen Appliances - Hair Preservation with Recap - Continuing

Fatal Financial Flops - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle (R/C Model)

- Ultimate Key to Longitudinal Stability and Pitch Control: a Canard -

Modern Fabrics and Paints

* EV Transmissions: Off-the-Shelf Planetary Gears, More. (Miles

Truck & Chevy Sprint)

Other "Green"

Electric Equipment Projects

* Working with the Handheld Bandsaw Mill (& Alaska Mill)

Electricity Generation

* 5 Blade Windplant

* My Solar Power System: - Monthly

Solar Production log et cetera - 8 months! Notes.

Electricity Storage

Turquoise Battery

Project

(Mn-Zn or Ni-Zn in Mixed Alkaline Salt electrolyte)

* Electrolyte to Depassivate Discharged Manganese Oxides? - Air Leaks?

- Bleach - Nickel Oxides Electrode - Making NiOOH - Better Technique -

Paste Electrodes? - 3D Printer Insulated Surround

-- Other Battery Related Projects --

* Honda NiMH Hybrid Car Batteries (installed in solar system)

* Two Lithium Battery Charger Circuits: for AC and DC Power

I note on November 1st that

this is the third anniversary of my viewing of the house at Lawn Hill

on Haida Gwaii where I now reside. While it's an odd layout, I

certainly lucked out getting this particular spacious, well built and

still pretty new place, with its big workshop and a storage room the

same size under it, two garages, on five acres and with a lovely sandy

ocean beach.

South side of house with new

5-blade windplant,

porch,

South side of house with new

5-blade windplant,

porch,

livingroom bay window, last section of spruce log

to mill (debarked, with metal roof pieces cover ...and

some remaining bits of clutter from the 2nd last section),

small bedroom windows, back door of garage and workshop,

solar panels on roof and on lawn, 'double' greenhouse.

The white painted wall behind the garden gives

more much needed light to the plants near the wall.

(There's a wire fence. The deer haven't figured out they

could go up and across the porch into the garden.)

And here's the north side as seen from my neighbor's yard.

(My fence with rotting posts blew down in a high wind.)

[...and what was with my camera that day? Fog on the lens?]

I think my angels must have

worked overtime to get it for me because I was somewhat clueless at the

time and thought I wanted a much cheaper but older and inferior

"fixer-upper" place 15 Km north of it. I would have had far more money

left over, but I would have been spending my time fixing it up instead

of doing more valuable projects. It would have been notably farther

from town and is so low lying as to be in jeopardy if - when - sea

levels rise. (What was I thinking?) But it had just been sold and this

place was the only acreage left on the east coast where I wanted. From

viewing it, I knew it was nice, but it was just a quick look and I

didn't have all the details. Once here I gradually recognized how ideal

a place it is to live and work.

On October 7th and 8th I finally did a last polish on the application

to the "Charge the Future" battery challenge and sent it off. Not that

it was very polished. In January we'll hear whether those who have been

awarded some funding includes Turquoise Energy.

According to the information on line, they are expecting

funding recipients to just be starting with a concept for a better

battery, and hoping the recipients will be able to use the funds to

make a working prototype by the end of the project. I am starting with

essentially working prototypes after already working on the R & D

for 12 years unpaid, and I hope to use the funding not only to improve

them via more R & D, but to start actually producing batteries by

the end of the project. I hope they are thrilled with that prospect.

After that, if manufacture and sales can be made viable as I hope, it

should fund itself and even provide some funding for other projects.

New Chemie Batteries

I'm not very ready to manufacture batteries yet, but every

month brings improvements. The lagging item now is better positive

electrodes. At this point I don't care about the exact chemistry.

Nickel oxides electrodes work even if nothing else I try does. The

other components all seem to work well except for the warping,

ever-leaking cells, and that's just a matter of getting and installing

the proper software for the new 3D printer - or maybe even just turning

up the extruder temperature another 10 or 20 degrees.

Nickel oxyhydroxide

electrode on a graphite

foil current collector in a 3D printed "test

size" battery

cell case.

At the start of October the only cell that had worked and

recharged reasonably well was the nickel oxides-zinc one in alkali,

using nickel oxide electrode chunks taken from a commercial NiMH cell.

The

difference between it and any other nickel-zinc battery was the jelling

of the zinc that should make it very long cycle life instead of very

short. So it would be something of special value to produce, even if

none of

the other experiments and ideas were to work out.

At the start of October the only cell that had worked and

recharged reasonably well was the nickel oxides-zinc one in alkali,

using nickel oxide electrode chunks taken from a commercial NiMH cell.

The

difference between it and any other nickel-zinc battery was the jelling

of the zinc that should make it very long cycle life instead of very

short. So it would be something of special value to produce, even if

none of

the other experiments and ideas were to work out.

But before the end of the month I had made a cell with my

own gelled nickel oxides electrode, and proven that it works with

chloride salt in the electrolyte as well as with just hydroxide. The

amp-hours is low, and this must be the nickel "+" side's problem,

because the zinc (even the very same electrode) has worked better with

other "+"es. I am confident of being able to make further chemical

improvements as well as to get decent overall performance from whatever

chemistry is used.

The chemical improvement I really want to get working is

the nickel manganates positive electrode. It should have higher

currents than nickel oxides, more amp-hours, and recharge properly,

which plain manganese oxides don't seem to do. The other item is the

calcium-copper oxide coated copper positive current collector. If it

works it should allow substantially higher currents than graphite based

current collectors. Those items will be the November (and maybe

December) battery research focus.

Ground Effect Vehicle

But at last I got to some other projects besides new chemie batteries

this month. I came up with yet another exciting new idea for the ground

effect vehicle: a front canard replacing the rear elevator of all

previous ground effect craft. Flying so low, a ground effect craft has

great need of being able to respond instantly to gain and loss of

ground effect lift as it goes over waves, without gain or loss of

altitude. A rear elevator can only respond indirectly by lowering the

tail even more than the wing is already dropping. That's not okay when

flying so close to the water.

But at last I got to some other projects besides new chemie batteries

this month. I came up with yet another exciting new idea for the ground

effect vehicle: a front canard replacing the rear elevator of all

previous ground effect craft. Flying so low, a ground effect craft has

great need of being able to respond instantly to gain and loss of

ground effect lift as it goes over waves, without gain or loss of

altitude. A rear elevator can only respond indirectly by lowering the

tail even more than the wing is already dropping. That's not okay when

flying so close to the water.

The canard can itself gain or decrease lift at the bow

almost even before altitude is gained or lost, keeping the height

steady and level. I visualize a microcontroller operated canard, so the

human operator only has to control the throttle and steering controls.

Liftoff and setdown will (maybe) be handled automatically as the speed

is increased or dropped. It is said that ground effect craft have been

restricted to flying over pretty calm water. With a canard I expect

this one will be much more seaworthy.

Perhaps I should have thought of this much sooner - after

all the only airplane I've ever flown was a Vari-Eze with a rear

propeller, swept back wings and a front canard. (Okay, I only kept it

level and on course for a while while the pilot smoked his pipe. In

1985.)

And I even did a little actual work on the R/C model. I

made and mounted the canard and made the rear elevator (which now will

just be a fixed rear end of the wing - maybe adjustable for trim). I'll

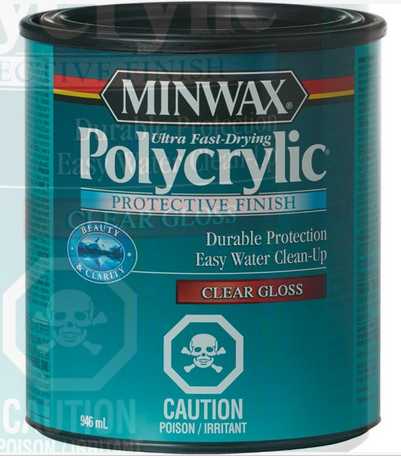

seal all the fabric with Minwax "Polycrylic", which model airplane

makers have been raving about recently as a superior replacement for

nitrate/cellulose dope - and even for products specifically made to

replace that dope.

The position of the canard (pretty much the only place I

could have put it at this point in the construction) seems ideal: not

only does it deflect air up and down as it is lowered and raised, but

it deflects it right over or under the main wing, magnifying its lift

changing effect.

And on November 5th before posting this, I realized that a

better place for the ducted fans would be to mount them on the canard.

I'll make that change. Better and better!

The potential to really open up the BC north coast, isolated

islands and other hard to get to places is more there than ever.

Windplant

I

installed my windplant the day before a huge storm. I

wired it up after finally figuring out what to do, on a day with enough

wind to test it. I used the MPT-7210A boost charge controller that had

once been running my DC solar system. It looked good and spun well, but

the output wasn't a lot. In the storm if things had been configured it

might have hit 100 watts.

I

installed my windplant the day before a huge storm. I

wired it up after finally figuring out what to do, on a day with enough

wind to test it. I used the MPT-7210A boost charge controller that had

once been running my DC solar system. It looked good and spun well, but

the output wasn't a lot. In the storm if things had been configured it

might have hit 100 watts.

On the evening of the 21st a chair blew off my porch, the

power went out almost all night, and a section of my fence blew over.

The posts had rotted away at ground level. Wind! Great - more work! I

decided

to leave it down. Firewood!

But the next day I finally came up with a plan for

connecting the windplant into the DC power system to charge the

batteries: with an MPT7210A boost solar charge controller. It could

take the lower voltages from the windplant and boost them to charge the

36 volt DC battery system. It was about right to handle the range of

voltages I was getting from the windplant.

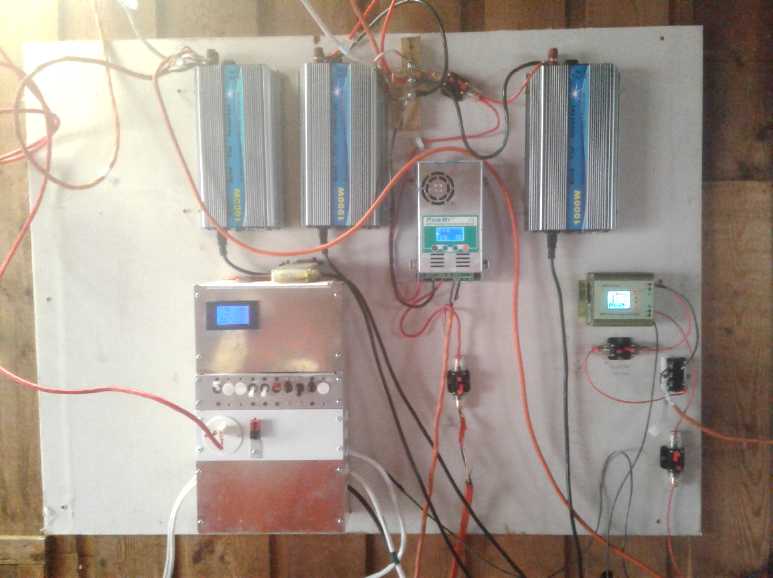

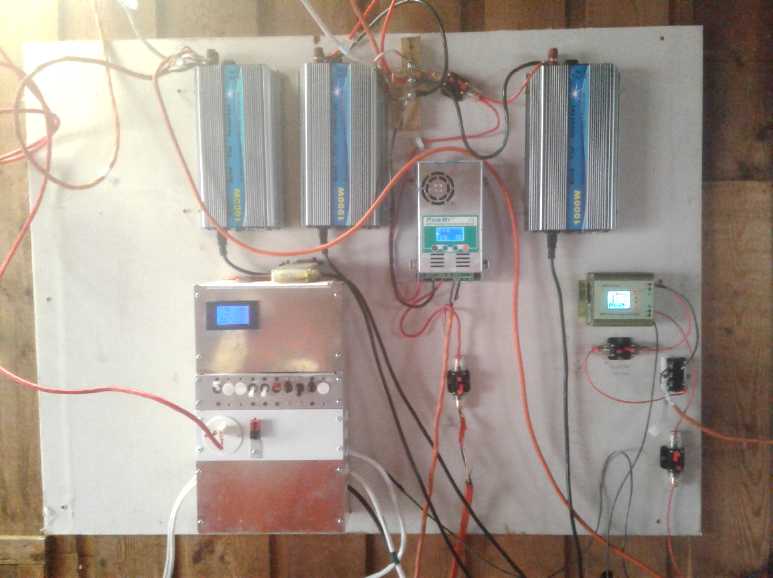

The new

windplant components

on the solar power board wall:

Boost 36 volt charge controller; circuit breaker on input, 3-phase

diode bridge from 3-phase windplant, and circuit breaker on output

to batteries. (I think it says 20.16 VDC on input from windplant

via

the diode bridge, 37.65 V out, .43 A, and 16.10 W output to batteries.

In moderate wind the next day I wired it (23rd). It put out 10 to 20

watts. Then it sat motionless for the rest of the month and beyond.

There were maybe 5 or 6 days in October it would have done much of

anything. Getting

occasional moderate and high winds and being in a "normally windy"

place are two

different things. Masset gets more wind, but tidal power is by far the

best bet for this island.

In moderate wind the next day I wired it (23rd). It put out 10 to 20

watts. Then it sat motionless for the rest of the month and beyond.

There were maybe 5 or 6 days in October it would have done much of

anything. Getting

occasional moderate and high winds and being in a "normally windy"

place are two

different things. Masset gets more wind, but tidal power is by far the

best bet for this island.

The front of the house roof was the best available

place (failing putting up a huge tower above the trees), but windspeeds

there were only half what they were on the beach at low tide away from

all obstacles. Since power depends on the cube of the wind speed, 1/2

the speed means just 1/8th of the power. In "no wind" there's no

difference.

This also meant my worries about it over-revving in a

storm were doubtless unfounded. It didn't need any high wind

protection. It was rated for 160(?) Km/Hr winds anyway, and 200 Km/Hr

winds would only be 100 owing to its sheltered location.

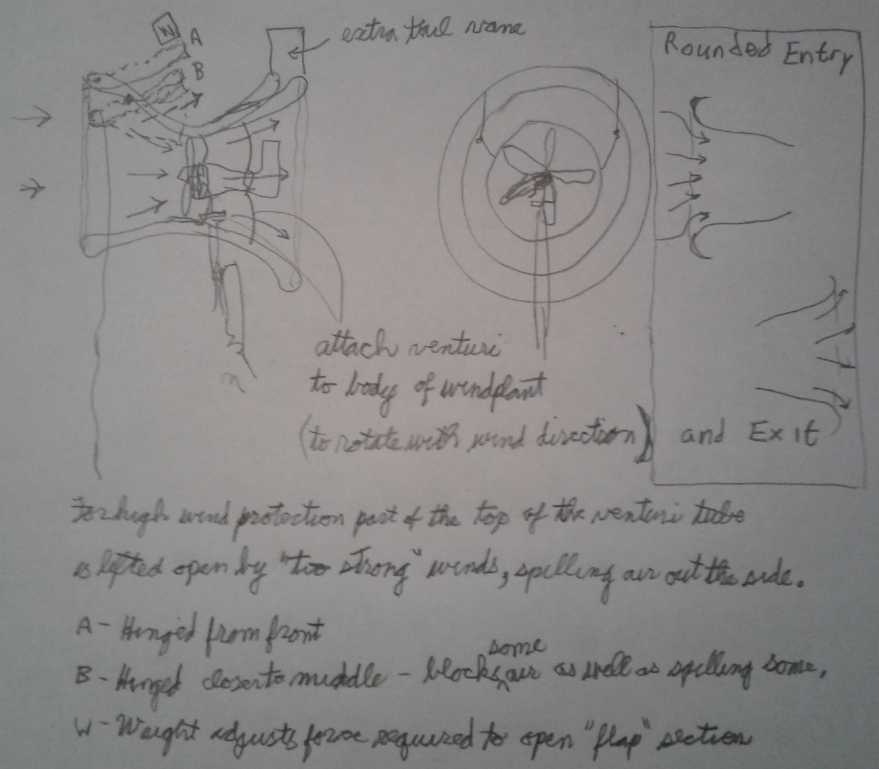

The one thing that might

drastically perk up its performance in the lower winds it does get

would be a venturi duct, but building that would be too much of a

sideline at the moment.

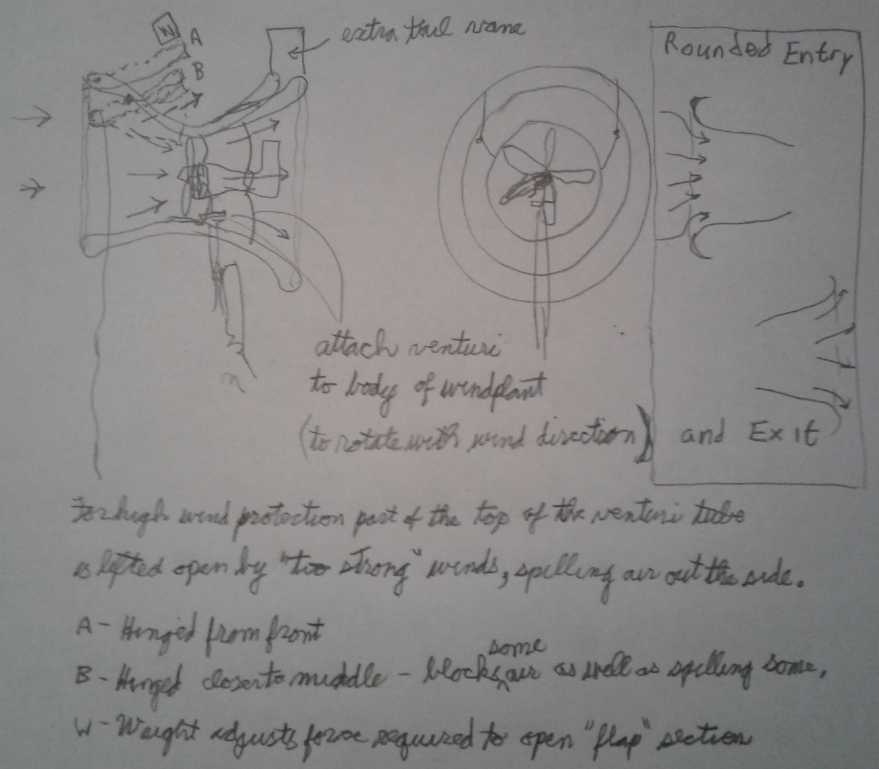

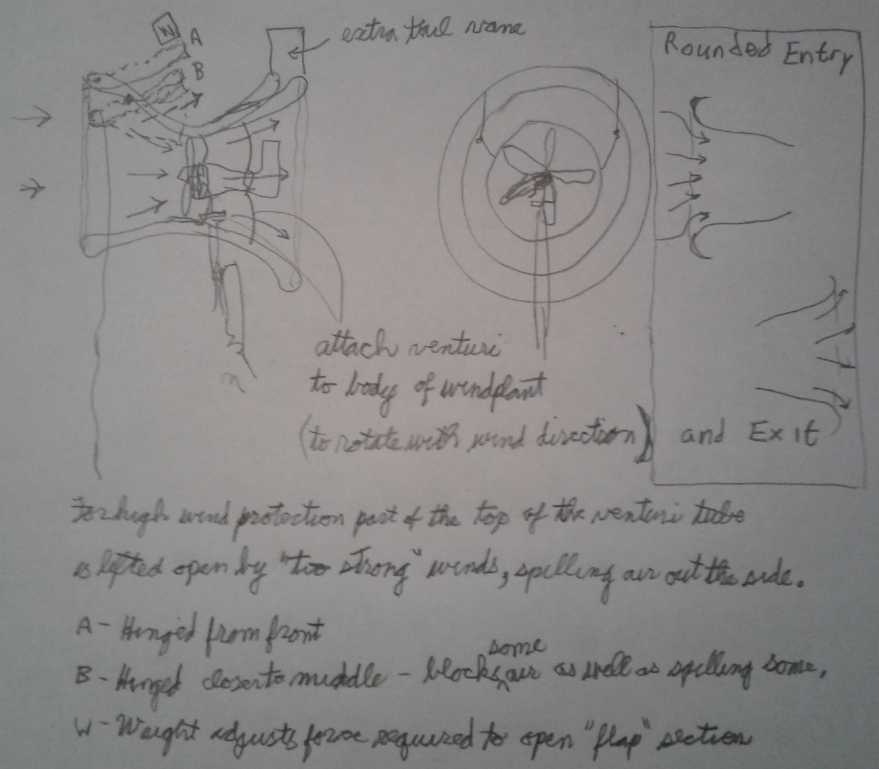

The venturi duct idea.

The venturi duct idea.

Capturing twice the frontage area into the same size propeller means

double the wind speed at the propeller and hence 8 times the power.

(To actually capture twice the wind the opening must be more

than double the area to account for inevitable friction losses.)

In conjunction with testing the windplant I added a

switch to the kitchen hot water heater. The third element can either be

shorted out by the switch, or in series with the other two to reduce

the power demand. In the DC system, that makes it either around 250

watts or 160 watts. In the low winter sun, I wish I could turn it down

even more! (Hmm... a DC to DC converter could do that by lowering the

voltage.)

Two Lithium Battery Charger Circuits - AC and DC Sources

Since my NiMH batteries weren't perfoming well in the

solar power system, and since I had some lithiums, I gave thought to

how to effectively charge that type without risk of some of them going

over-voltage, since they have almost no tendency to balance each other.

Lithium open circuit cell voltages are very specific:

* under 2.8 volts is deleterious

* 3.29 volts or less is pretty low or discharged

* 3.32 volts is fairly well charged

* 3.34 volts and above to 4.2 is fully charged

* above 4.2 risks failure

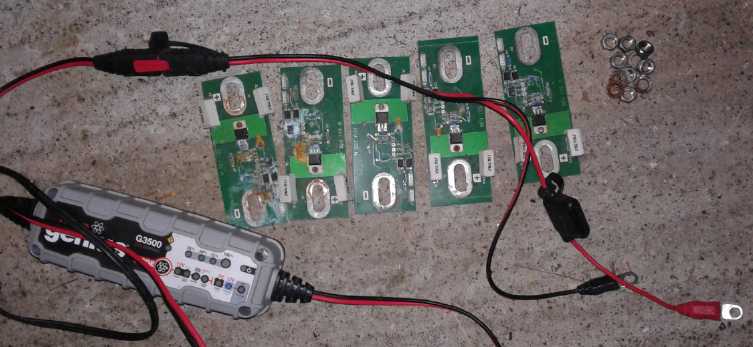

Once they are charged they can go to very high voltages without

drawing any appreciable current, but they are at risk of failure if

they go over 4.2 volts. I didn't want to use the power wasting voltage

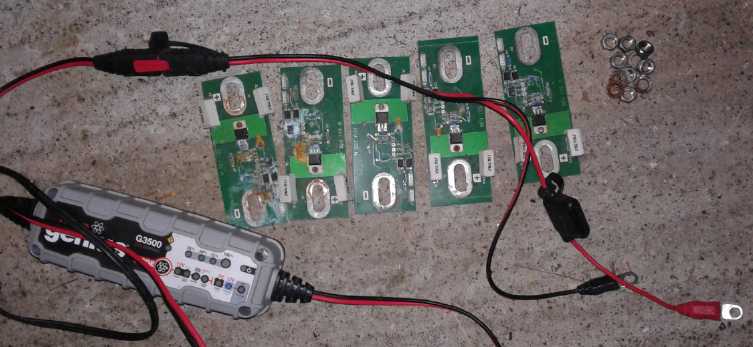

shunt boards that can be placed on each cell to keep it below 4.2

volts. (I have some from the Swift, but some of them are quite

corroded.)

I started by thinking of charging each cell separately

with a 3.4 to 3.6 volt source. Then I realized one could charge two

cells in series at 6.8 to 7.2 volts without any risk of the better one

rising to the 4.2 volt maximum limit, since the low one will never be

under about 3.3 volts. That would cut the number of chargers in half -

much better. Then I determined that even if three cells in series are

charged at up to 3.6 maximum volts each or less (10.8 volts maximum),

none will go overvoltage. When 12 volts (four series cells) is reached,

the danger of imbalance causing overvoltage on the stronger cells

begins, and it gets worse from there as the number of cells and voltage

increases.

So instead of charging a 36 volt bank with one charger,

one can charge it as four 9 volt banks of three cells, at 10.5 volts or

less, without any "Battery Management System" ("BMS"). (The generally

recommended 3.6 volts per cell is the very maximum for three cells in

series - 10.8 volts total: a little less is better. To go any higher

than 3.6 per cell, only two cells can safely be charged in each string.)

(Nov. 3rd... Hmm, actually for trickle charging (eg,

solar) 12 volts/4 cells in series per charger would be all right at

under about 3.35 to 3.50 volts per cell, total 13.4 or even up to 14.00

volts.)

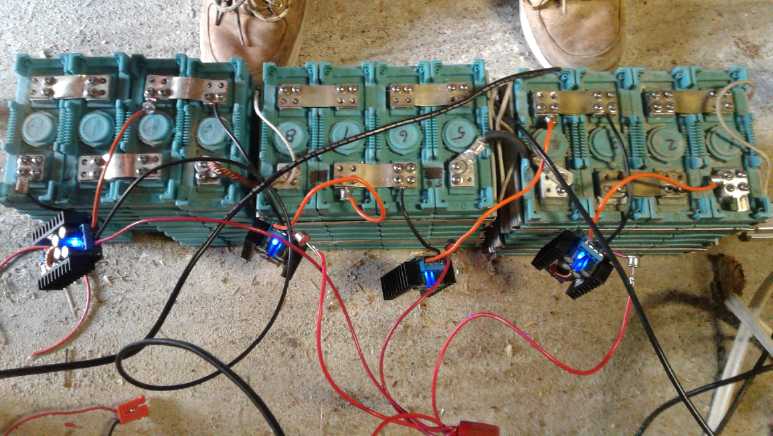

Three 100 amp-hour, 12.8 volt

lithium batteries

in parallel.

Three 100 amp-hour, 12.8 volt

lithium batteries

in parallel.

The two 5 amp chargers each charge a 6.4 nominal volt, two

series cells section up to 7.2 volts: [0 to 7.2], and [7.2 to 14.4].

Details in detailed report under "Electricity Storage".

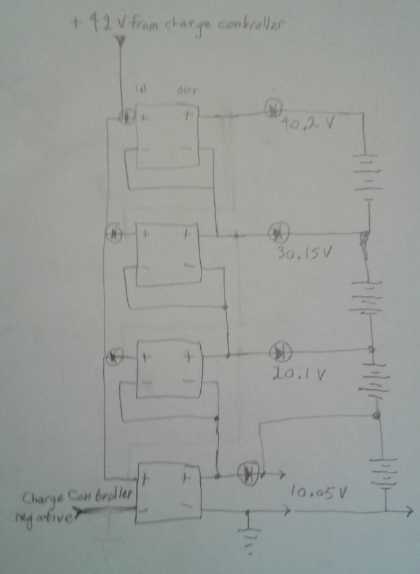

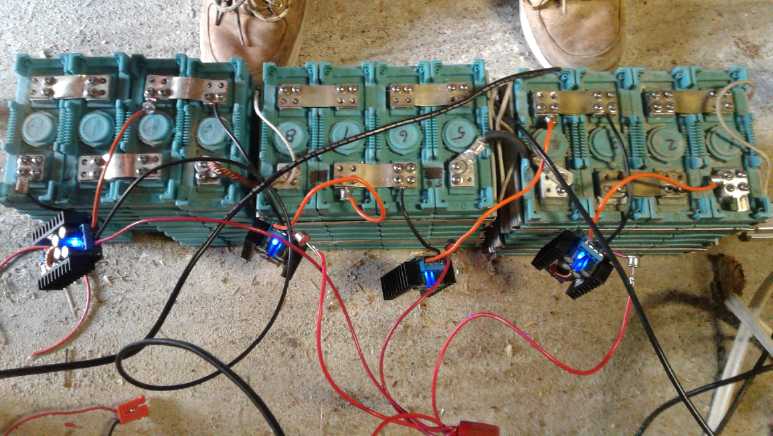

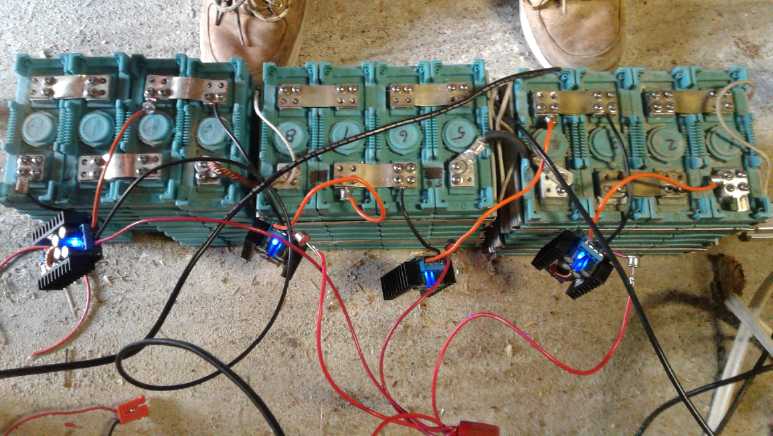

Four DC to DC buck converters

adjusted to 10.05

volts each, charging a nominal

Four DC to DC buck converters

adjusted to 10.05

volts each, charging a nominal

36 volt lithium battery as four 9 volt sections. Note the diodes

soldered on in

many places: see circuit diagram under "Electricity Storage".

To do it with DC from a

solar charge controller proved to be a different kettle of fish. There

don't seem to be any adjustable or 'right voltage' isolated output DC

to DC power adapters. I contrived to make a "totem pole" arrangement

with non-isolated DC to DC buck (voltage reducing) converters, but I

had to try several variations, and they ended up needing 7 isolation

diodes, on both inputs and outputs, and if the charging voltage is

insufficient, the top bank won't get charged. (If that insufficient

charge voltage rises as the lower ones charge, the top ones will charge

last.) In a variation, if the voltage to the top set of cells is too

low, one might use a DC to DC voltage boost converter instead of a buck

converter for that top set. (or even 2 or 3 or all sets - a wide range

of charge voltages could thus be accommodated.)

In trying to do it with the PowMr solar MPPT charge

controller, thorny problems cropped up and I finally realized it simply

couldn't be done with a charge controller that gets its own power off

the batteries on the same connection that is also its charging power

output (almost all of them). A battery can't charge itself when there's

no solar coming in, but the voltage has to be there and they will try,

which can only run them down. However the MPT7210A boost charge

controller draws its power from the solar panels instead. It should

work with that one - I hope - but I didn't get to actually trying it so

far.

Internet!

On the 27th was an event which will be most helpful: the

fiber optic internet was at long last hooked up! That was supposedly to

have happened shortly after the time I moved up here from Victoria. It

took over 2 extra years, but it's here at last. That still doesn't give

the whole island a truly good connection to the mainland, but that's

supposed to be coming too. Already it's far better than the

"connection: poor" pirate WiFi from a very slow satellite link. (I went

to a page and waited for it to reload... it seemed awfully slow. Then I

realized it had already reloaded in the time it took me to glance back

at the window after clicking the mouse. What a change after typically

waiting 15-45 seconds for it to maybe load a page!)

Handheld Bandmill

I was still, very gradually, milling my last spruce log in

October. (As of November 3rd I'm finally cutting into the last 12 foot

section.) I had lately noticed the bandmill seemed slower than usual.

But why? It finally turned out to be the new smaller V-belt pulley on

the saw - the band was actually going too slow.

And I had had about enough of re-welding washers onto the "railway

wheel" band guides, so I ordered some alternatives. See the 'detailed

report' under "Other Equipment Projects" for more.

New "yoke roller" and "thrust

bearing" band

guide

New "yoke roller" and "thrust

bearing" band

guide

I am planning to make and post a video of a take-apart of

my fine bandsaw mill to help those who would like to build one

themselves. After I'm finished milling those last big lumps of spruce!

Planetary Gears! Miles Truck & Chevy Sprint

I found something I've somehow never managed to find

before (but probably available all along): planetary gear gearsets

already fully assembled -- ready to use drive components. (at "Anaheim

Automation") To say the least they weren't cheap. But I had decided to

replace the big, ugly, lossy transmission in the Miles truck with a

simple efficient planetary reducing gearbox. A helical gears unit

promising up to 97% efficiency seemed like just the thing. I knew

planetary gears must be more efficient but I was surprised that it was

so high. There's the "ultra efficiency" I'm always after for EVs.

GPBS90

Planetary Gearbox

I

worked out that a 5 to 1 reduction unit should be about

right for the Miles mini cargo truck, with the rear differential

contributing a further ~ 2.16 to 1 for a total of 10.8 to 1 from motor

to wheels. I picked a model to order and have been in touch for

details. Having the Curtis programmer I can increase the maximum motor

RPM a little, and with the extra efficiency 10.8 is surely a slightly

reduced overall reduction ratio. It still wouldn't turn the truck into

a highway speeds vehicle, but it would be up to at least 60(?) Km/Hr

instead of 40 with less waste of battery power over distance, and so it

would be much more useful than at present.

I

worked out that a 5 to 1 reduction unit should be about

right for the Miles mini cargo truck, with the rear differential

contributing a further ~ 2.16 to 1 for a total of 10.8 to 1 from motor

to wheels. I picked a model to order and have been in touch for

details. Having the Curtis programmer I can increase the maximum motor

RPM a little, and with the extra efficiency 10.8 is surely a slightly

reduced overall reduction ratio. It still wouldn't turn the truck into

a highway speeds vehicle, but it would be up to at least 60(?) Km/Hr

instead of 40 with less waste of battery power over distance, and so it

would be much more useful than at present.

I don't have enough lithium batteries at present to do

both the truck and the Sprint to desired capacity, but if I put 2/3 of

them into the truck for 7200 watt-hours I'd have a useful range

vehicle. (IE, it could at least make it into town from here. It would

surely be useful around town.)

And then, here I've been fiddling around all this time

with planetaries from auto transmissions trying to do the variable

torque converter in the Sprint, and trying to figure out how to fit the

components together outside of a proper case, with much trouble and

limited success. But starting to think of the cast housings of the

ready-made units, why could I not make my own suitable enclosed

housing, out of pieces of pipe big enough to enclose the entire gear

and shafts, and turn internal and end bearing plates, and a mounting

for a chain sprocket, on the lathe?

On November 1st I happened to visit someone who had scraps of pipe in

his shop and got a piece of heavy steel pipe that would be ideal for

the housing. And with custom turned end pieces enclosing it, I could

put proper gear oil inside. Suddenly the planetary gear + centrifugal

clutch infinitely variable torque converter seemed much closer and more

promising.

Free Outboard

Earlier I had looked at the

"refuse transfer station" for a pipe. Instead I found discarded

outboard motors. I took a smaller one for a potential electric outboard

conversion. Just in case. Sometime. Maybe. I also 'scored' a big chunk

of 1/2" thick stainless steel plate. That could be good for battery

electrode punches and dies.

Not bad, but where is its hat?

Not bad, but where is its hat?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Gardening - Growing Barley

- Processing Grains into Flour With Common Kitchen Appliances

In the spring I planted barley. It was one of the few things outside

the greenhouse (besides potatoes and peas) that did well in the clouds

and cool weather this northern summer. It probably wasn't much more

than 50-60 square feet in all (ie, something like 7' x 8'). I threshed

the heads in a blender. That broke up most of the chaff from the seeds.

Then I winnowed them in a mixing bowl, shaking the bowl and with a hot

air hair dryer blowing the light chaff out. There were still husks on

some. I rubbed the grains between my hands and blew again, but it

didn't help much. Now what? I suppose I could grow barley sprouts,

which are said to be very good for you - and for which I had originally

bought the seeds.

In the spring I planted barley. It was one of the few things outside

the greenhouse (besides potatoes and peas) that did well in the clouds

and cool weather this northern summer. It probably wasn't much more

than 50-60 square feet in all (ie, something like 7' x 8'). I threshed

the heads in a blender. That broke up most of the chaff from the seeds.

Then I winnowed them in a mixing bowl, shaking the bowl and with a hot

air hair dryer blowing the light chaff out. There were still husks on

some. I rubbed the grains between my hands and blew again, but it

didn't help much. Now what? I suppose I could grow barley sprouts,

which are said to be very good for you - and for which I had originally

bought the seeds.

Anyway I ended

up with 270 grams of seeds, over 1/2 a pound. If I want there should be

enough grow a much larger patch next year. (The original seeds will be

about 4 years old.)

Anyway I ended

up with 270 grams of seeds, over 1/2 a pound. If I want there should be

enough grow a much larger patch next year. (The original seeds will be

about 4 years old.)

To complete the grains processing plot, while I haven't

used the barley, I have ground quinoa into meal or coarse flour, and

wheat grain into coarse flour, with a coffee grinder. Less grain in the

grinder makes a finer grind. Grinding a bigger batch longer, even a lot

longer, doesn't make it fine. (I've just made a nice applesauce

cake with the wheat flour. I'm going to try planting winter red wheat

today (Oct. 10th). Done.)

I often add quinoa flour to bread in place of some of the

wheat flour. (Too much makes the bread rather crumbly - I'm just now

trying 1/2 cup out of 4 total cups of flour instead of a whole cup, so

a hamburger won't fall apart. Yes, that's better.)

So there it is: grains can be grown in the garden and

processed into flour with common household small appliances. There's no

need to buy anything more special than these three common items. Of

course this was just a "test" and one would want a much bigger plot to

get a really useful amount. (The quinoa gave the most grain from the

same small plot.)

And here are some

gratuitous pictures of some of my greenhouse produce, which did

surprisingly well, eventually, after the all-cloudy July we had.

Greenhouse Produce mid October

Greenhouse Produce mid October

Beans, peas, cherry tomatoes, cherry hot peppers...

and a foot long cucumber that cleverly hid behind 3 leaves.

And "coastal star" romaine

lettuce seeds,

cabbage, hot red peppers, leek,

And "coastal star" romaine

lettuce seeds,

cabbage, hot red peppers, leek,

cauliflower, cherry tomatoes, pole beans and a more reasonable

cucumber.

(Only decent cauliflower I've ever grown! it was delicious.)

A single cabbage, left to grow

for a second

year, filled a greenhouse bed.

A single cabbage, left to grow

for a second

year, filled a greenhouse bed.

Earlier it sprouted several branches and grew enough seeds for a whole

farm. In the fall it grew some funny clusters of leaves and two more

very nice (if smallish) heads of cabbage. (with a third one maybe

coming.

The fourth, farthest right in the cluster, is actually

a separate

cabbage, planted this year, which has yet to make a head.)

After getting three lovely big

boletus

mushrooms at the edge of the

After getting three lovely big

boletus

mushrooms at the edge of the

highway in early October (and cooking and freezing them), now all I

find is a couple of wormy ones,

...and oodles of deadly poisonous amaneta muscaria

Hair

Preservation

with

Recap

I started putting a towel on the pillow on my bed, and I

pulled it

down

to cover my scalp. This kept my head warmer at night, which evidently

should

help prevent thinning hair and baldness. It didn't always stay when I

rolled around, and usually got lost somewhere before morning. But it

was much better than nothing. (Now I think I know where the term "night

cap" came from. Before good house insulation and heating, probably lots

of

people wore them in bed. Probably something like a light tuque or

beanie.)

Later in the month, I tried putting a pillow up on edge,

above and

behind my regular pillow, sort of between it and the wall, so the top

of my head goes against it. I used a down/feather pillow - smaller and

easily shaped. That seems to work pretty well.

So now to recap, to fight thinning

hair we have:

- tuques, beanies, caps and hats for wearing in cool and cold

temperatures (indoor and out)

- extra pillow 'overhead' or a nightcap for sleeping in cool to cold

bedrooms

- frequent shampooing/showers, leaving shampoo on scalp for a couple of

minutes or more (and some shampoos are evidently better than others)

- at least a daily hair brushing for more scalp stimulation than using

a comb

- once a month spraying or rubbing of ethyl alcohol on the scalp to

kill any deleterious bacteria, perhaps clean out pores and hair

follicles, and perhaps cause some

vaso-dilation. Ethyl rubbing alcohol and vodka have both been used.

Vaso-constriction of scalp blood vessels, usually from

cold scalp, is evidently the biggest culprit that causes

hair follicles to become "dormant" and stop growing hair. But there

seems to sometimes be some sort of bacterial or perhaps mite infection

component or cause, too, and or possibly just accumulation of dead skin

in hair follicles. (I think I had some sort of mite infection once -

little scabby bumps here and there all over my scalp. They could be

scraped off with a fingernail. Daily shampoo eventually cleared them

out.)

Continuing Fatal Financial Flops

* Well... The US "Fed"s incredible volume of money printing didn't end

after a few days or on October 11th as they promised. Instead the

amounts are growing. (along with those of the ECB, Japan and China. In

fact one or more of these institutions has always been printing money

since 2008, serially. Now it's all together.) Now they're saying it may

be a "permanent" fixture of the financial system. What kind of fairness

is it that the banks and the banking system give themselves free money

while the rest of us get more and more poor? Where are the bailouts for

the average person? Where are the low interest rates on our

debts? These everlasting, ever growing central bank balance sheet

expansions can't end well.

Be prepared for some big eruption of the financial system.

It has for some time now been strongly advisable to pull some cash out

of your account to cover at least a couple of weeks' groceries, gas and

so on. And if you've become used to paying for everything with a debit

card, you may be astonished to discover how fast cash evaporates from

your wallet these days. A couple of hundred bucks can easily be gone in

a day - even in one gas fill-up for some, or just stocking up a few

groceries.

Small

Thots

* Energy Equivalencies [Below: Canadian dollars, BC residential

electric rate ~12 ¢/KWH,

imperial gallons.]

-

Diesel is said to contain 3.65 KWH/Liter when burned in an efficient

generator. Diesel should then cost about 43¢/liter to be

competitive

with power grid electricity.

-

It is said that a boat outboard motor burns about 1 gallon of

gasoline per hour per 10 horsepower.

-

One horsepower is about 750 watts, so 10 HP for an hour is 7.5 KWH. Per

liter, that's less than 2 KWH, when burned in an outboard. So to be

competitive a liter of gasoline should cost under 24¢. (Probably

cars are somewhat more efficient than outboards, so they added road

tax.)

* Only 41% of US corn has been harvested instead of the average of 61%,

and now record cold temperatures and snow in the continental USA are

finishing it off. With this, combined with many other crop and food

losses globally, global food scarcities seem inevitable. Prepare.

* Some say China has culled 130 million pigs owing to African Swine

Fever. The USA has 75 million pigs. Others put the death

estimate much higher, at up to 300 million pigs - half of the total

population. Some say this won't end until 70% of the entire Chinese pig

population has been wiped out. There is no vaccine and no cure and it

is contagious. Just kill the pigs and try to keep the remaining herd

healthy. Pigs in China have become seriously overpopulated in

attempting to feed the human overpopulation. It is now spreading across

Asia and Europe. Will it hit the Americas? Some estimate 1/4 of the

world's pigs have died.

"This is a global plague unlike anything we've ever seen before." --

Michael Snyder, zerohedge.com

Not to underplay the seriousness of that situation in and

of itself, the parallel to the human situation is unnerving: we are

likewise overpopulated. A disease that preys on humans and spreads like

African Swine Fever certainly could have the potential to wipe out 2/3

of the human population (especially a malnourished population) before a

vaccine can be developed, and these days it won't stop at any national

border or (with air travel) ocean.

* I solved the mystery of the red spots on my legs. They would seem

to be from mites that live in the spruce or spruce bark in the wood

shed. Apparently they think human legs (or at least mine) are a good

substitute and they contrive to 'get on board' when I bring in

firewood. I bring it in in big garbage pails because they don't drop

bits and the handles are high up so you don't have to stoop down to

pick them up - great for when you have to set them down in front of the

door to

open it. If I spray the buckets off with water frequently, and don't

leave them out in the wood shed, and rest the pail only against my knee

and not my thigh as I carry it, I get very few of them, and only on the

knees.

Witch hazel remains by far the most effective way to get

rid of them once acquired, one wetting of the skin where it is usually

being enough.

When I've finished milling the spruce (soon!) and run out

of spruce firewood (not so soon!) I'll gladly switch to burning alder.

ESD

(Eccentric Silliness Department)

* I've always liked to call a bunch of crows a "crew" because they go

strutting about, inspecting and pecking at things, like workers on a

job site. Recently I've seen a couple of what I could only describe as

"crow conventions" there were so many of them. Or maybe they were "crow

trade

shows".

But someone told me a group of crows was called a

"murder of crows". A little bizarre! I guess people only notice crows

when

they're cawing angrily. According to that analogy, these must have been

"massacres of crows" or perhaps even "genocides of crows"!

* Conpare: to make an unfavorable comparison.

* Discover: to remove the cover to see what's inside.

* The cougher coughed upon the coughee. No one else wanted it after

that, so he added the tin of coughee to his coughers. Having thus "won"

it, he had little incentive to quit coughin' for next time.

* Counting on Puns:

owe - won - too - free - fore - fife - sicks - savin' - ate - nein* -

ton

- all even - doesn'

*nein: the number of words of German I speak.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency and

completeness before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground

Effect

Vehicle

(first

the

R/C

Model)

Recap of Design Details

In case there are new readers and in general, I'd like to

go over the whole project and put everything that's been so gradually

"accruing" in one place.

I first learned of ground effect craft in March 2017 from

a video 'suggestion' on youtube. From there I found some more info and

soon found a video of a 2011 radio controlled "catamaran" style one,

which seemed impressively stable -- flying just over a paved road. It

seemed to have spawned a few more similar models also to be seen on

youtube. What I gradually came up with as highly valuable design

features were these:

1. The catamaran shape. Two hulls

prevents spilling air off the ends of the wings, increasing the lift

efficiency. The single wing between the two hulls can be smaller, and

longer front to rear than it is wide. The height of the ground effect

depends on the front-back length of the wing(s), so this should give

the highest-up ride for its size. In addition, it's an easy shape to

dock and to maneuver at low speeds. (I made the hulls flat bottomed

(yet with a "step") because I know it takes less power to get a flat

bottom boat planing. We shall see if this proves better for takeoffs.)

2. The central "dorsal fin" vane instead of a rear tail. A

negative 'feature' of ground effect craft in general is that with

little or no banking for turns, tighter turns are difficult. The

catamaran in particular tends to simply fly diagonally on its original

course when turned, before gradually straightening out. The center vane

should counteract this tendency without banking. (If it is tall enough

it will automatically cause banking into the turn.)

3. The special wing profile. The designer of the profile I've

adopted for the 1/4 scale radio controlled model, John Ryland of Ryland

Research, says that unlike typical airplane wings, the suction lift

from above is more to the stern, while the compression lift beneath is

more forward, and that this improves longitudinal stability. (His

little model seemed quite stable as he changed its weight distribution.

Computer modelling assisted with determining the profile.) Whether the

lift to drag ratio is as good I'm not sure.

4. The forward "canard" elevator -- this month's design change:

see below. The canard near the front can respond positively to changes

in pitch - a dipping or rising nose - virtually as they start to

happen. As the front loses lift going over the trough of a wave (it's

suddenly "higher" over the surface and so the ground effect is reduced)

and the nose starts to dip, aiming the canard up adds lift and directly

pulls the nose back up to maintain level flight. Vise versa with a wave

crest.

A rear elevator can only respond to a falling nose by

pushing the tail down, which will level the craft but with a loss of

altitude. To regain the altitude, the tail must be pushed down further

to get the nose up. So the tail loses even more altitude. That's okay

in an airplane even at 100 feet. It's not okay in a ground effect craft

at 1 or 2 or feet. It might hit the next wave crest.

Previous ground effect craft have worked poorly except

over calm water. I expect the front canard will make the ground effect

vehicle considerably more "seaworthy". I plan that it will be computer

controlled for instant response and automatic trim, for a smooth, level

ride without effort from the operator.

5. Ducted Fan propulsion. A ducted fan provides the maximum

static thrust for takeoff from water with the lowest horsepower. My

original idea was one fan - perhaps a gasoline engine in the full size

vehicle.

6. Multiple Ducted Fans. Having left and right propulsion

greatly improves maneuverability when docking. I hope to use electric

propulsion not only in the model but (probably) in the full size

vehicle, and that

would allow reverse as well as forward thrust for maneuvering. There

are new aircraft designs with many small electric ducted fans, and this

might serve well in the full size vehicle as a safety factor - one fan

failure of 6 or 8 fans won't end the flight in the middle of the water

somewhere, necessitating rescue.

A Burt Rutan Vari-Eze two person airplane with front

canard is said to get 40 miles per US gallon at 150 to 180 knots.

That's a very efficient aircraft. A ground effect craft should be even

more efficient. Thus a battery that would fly some other plane 30

minutes might last on the ground effect vehicle for 60 or 90 minutes,

making electric propulsion more practical than for high-flying aircraft.

Ultimate Key to Longitudinal

Stability and Pitch Control: a Canard

Strange how thoughts develop. As I was getting up on the

morning of the 10th my wandering thoughts crossed by the name "Faeroe

Islands", which had been mentioned in an ad on youtube. I wasn't quite

sure where those were (somewhere around Scotland), so then I thought of

the Orkney Islands, off the north coast of Scotland, where powerful

floating tidal flow units are already generating megawatts. Scapa Flow,

the harbor in the middle between the several islands, had been the home

base of the main British fleet in both world wars.

Early in World War Two a daring U-boat commander had

sallied into Scapa Flow underwater in a shallow, narrow channel between

two islands, thought to be unnavigable, and with a torpedo sank a

battleship in the midst of the fleet. No one at first understood what

could have caused the explosion in this "safe" place where the larger

channels were all mined against just such an incursion, and the

submarine got away the way it came.

Then I thought of the bow planes, the "dive planes" on a

submarine that gave it such vertical maneuverability. Then I thought

that if there were "bow planes", front rudders, on a ground effect

craft, it could be more stable. But those would be something else

sticking out the sides, making docking the craft more difficult. (It's

already the one concern I have with the two 'offside' ducted fan

motors.) Then, why should those "bow planes" be separate? Why not have

an elevator on the front of the wing? As the front of the wing rose up

or veered down, its motion or even the tendency toward such motion

could more easily and quickly be compensated for by an elevator

directly pushing the front of the wing up or down. The rear follows the

front. An elevator at the back can only more indirectly respond to the

rise or fall of the wing that has already happened.

Our imagination is always limited by what we already know,

and airplanes we know all have a certain familiar design -- they just

don't have control surfaces on a leading edge anywhere. Even birds have

similarly shaped wings and a rear tail/elevator. Instinctively, control

surfaces at the rear of

an airfoil have negative feedback. They will "return to center" if the

control stick is released. A front control surface, if hinged at the

back, would prefer to jam full up or full down. But the similarity of

the airplane to the bird is deceptive. The bird can minutely maneuver

and aim its whole wing. It can move it forward or back to change its

center of lift. A front control surface, wherever it is hinged, would

seem to be just what is needed for the ground effect craft.

And come to think of it, on a 'canard' aircraft the

elevator is actually in front of the wing. Those fly quite nicely -

in fact I've actually flown one, a Vari-eze that won the 1979

Oshkosh airshow for "best homemade aircraft of the year". (The only

thing I've ever flown. Admittedly I only held it level and on course

while the pilot had a smoke.) Since I already knew of it and had

experience with it, perhaps I should have thought of this design much

sooner and skipped the submarine, but that's how the thought stream

progressed! A youtube video says the Vari-eze gets 40 miles per [US?]

gallon at

150-180 knots. If the ground effect craft is even better, we should

expect amazingly low energy use.

Vari-eze, a popular homebuilt

front canard,

rear swept wing, rear propeller aircraft.

Vari-eze, a popular homebuilt

front canard,

rear swept wing, rear propeller aircraft.

(designed by Burt Rutan long before he made the "space plane" that won

the "X-Prize".)

I can visualize a front elevator, probably controlled by

computer, responding in real time to the aerodynamic forces that would

cause the craft to rise and fall, a tendency to "hobby horse" in large

wave crests and troughs. Inertial sensors can detect the slightest

change in motion when the nose of the craft starts to rise or fall and

the control would compensate. It could maintain an ideal height with

little variation. Passengers would enjoy a smooth flight even over a

stormy sea. (Even I wouldn't get seasick! ...except maybe in big swells

over larger areas, which it would probably have to follow up and down.)

Here then would seem to be the ultimate key to

longitudinal stability of ground effect craft! This missing key is what

has kept them restricted to smooth water, and from being safe and

practical in real world conditions. Even an intrinsically less stable

craft design could doubtless be made to work quite well, again,

particularly with a microcontroller doing the up-down trimming.

The next question was whether or not I could add some sort

of front control surface or canard to my half-built model. If it made

more lift at the front, it would just be necessary to move the weight

(mainly the batteries) forward in the craft to keep the center of

gravity in line with the lift. Or it could be made "lift neutral" in

center position.

I decided a 'canard' between the two hulls looked doable,

and would be best and most stable. The idea of a front elevator with a

rear hinge as part of the main wing somehow is unappealing. The

previously planned rear elevator, somehow not made yet, could just

become a fixed part of the wing (or for the model could be "trimmed",

adjusted to different positions, to see where it worked best for any

insights that might be gleaned for optimizing the full size vehicle). I

looked at the model. It could either be a very narrow canard (front to

back) very near the front, or it would have to be raised above the

level of the wing. Would a narrow one have enough control surface? The

whole thing could pivot. And it would be well to the front, giving it

maximum up-down aim leverage. I decided that was what I would try.

When people see it, the front canard on a 'catamaran'

ground effect craft will seem so natural -- that is the "obvious" way

to build them. How can it be that no one has thought of it before?

Wright brothers first aircraft had a front canard, and there has been a

century

of not-very-satisfactory ground effect craft. And yet, look at the

circuitous route my thoughts took to suddenly "get it", 2-1/2 years

after first hearing of ground effect craft myself and even having

already had personal experience with canard design aircraft.

Well! (Of all the nerve!) Having mentioned "canard" and

"ground effect" in an e-mail or two, on November 4th ever-ready

Google/Youtube came up with a video suggestion of a very large radio

controlled model ground effect craft with a canard from November 2010

that it had never shown me before even in searches. The maker said it

was made lightweight and went so slowly so they could observe it better

and keep radio control over it without having a high speed chase boat.

The planned heavier human carrying version "will take off" at 120-140

Km/Hr. Call me chicken but my intended cruising speed is around 80-100.

(The intended human carrying craft was to be the same size as the 7.2

meter long model but was apparently never built, for the usual reason:

no funding or partners to be had for a promising new design. There were

some Japanese characters in the video title, but it also included

"Fugure-8 Flight of WISES Model". With the spelling it should be easy

to find.)

His design predates (by only months) the first "catamaran"

model shown (so far) on youtube, but it had wingtip features to

accomplish the same thing. It looks quite viable, but I like mine

better.

And I too am wondering about keeping the model within a good range for

radio control. At least mine is 1/4 scale, so it won't take up quite so

much of the small lake I intend to try it on. His model weighed 57 Kg.

The

1.23 x .76 meter bare body of mine so far is just 1.35 Kg, but it needs

more fabric and more paint and hull decks, and when the motors and

batteries and electronics are added it'll be lots heavier.

Once again, the lack of progress on this project seems to

have miraculously worked out to allow yet another important and

beneficial idea to improve the final design. At some point, it has to

get built and flown, but in the meantime the more improvements that

have come to light, the more confident I am of getting a fabulous,

efficient, stable and practical craft for rapid transportation over

water!

Modern Fabrics and Paints

Having used up a can of varathane spray paint on the wing

fabric and yet it still wasn't airtight, I decided to simply try some

other paint. I used white 'rustoleum'. One coat (on top of all that

varathane) seemed to make it pretty much airtight. and white. It also

had the opposite effect of cellulose dope on canvas: instead of the

featherweight polypropylene fabric tightening and stretching, it

loosened and went slack. It sagged between the supporting pieces.

Having used up a can of varathane spray paint on the wing

fabric and yet it still wasn't airtight, I decided to simply try some

other paint. I used white 'rustoleum'. One coat (on top of all that

varathane) seemed to make it pretty much airtight. and white. It also

had the opposite effect of cellulose dope on canvas: instead of the

featherweight polypropylene fabric tightening and stretching, it

loosened and went slack. It sagged between the supporting pieces.

This suggests another technique should be used. Next thing

was to take a big piece of fabric and lay it out flat on an even bigger

sheet of polyethylene plastic. Then it would be cut and glued (still

using epoxy, I think) to the airframe in flat sheets. (Luckily there

don't seem to be any compound curves.)

...or could the paint itself glue it to the model? That

might be worth a try! (Actually it seemed to "melt" the polystyrene and

I ended up glad I had done no more.)

(20th) I cut and shaped pieces of wood

for the canard. As I did so I

thought of paints again. I looked up "model airplane dope" on line and

found that there are more modern alternatives. There's one called

"Eze-Dope", and on a seller's website some model builders were saying

how great it was, without odor and fast drying. (No wonder the hobby

store I was in a while back didn't sell aircraft dope any more.) One

customer

commented to that effect in 2014, but then he added a note in

September of this year, barely a month ago. He said after reading

something in a model

aircraft magazine, he had tried MinWax "Polycrylic" and found it was

even better.

"-----Updated

9/17/2019 After reading an article in Model Aviation, I decided to try

Minwax Polycrylic (satin finish) thinned with water to 33% Polycrylic.

One coat with a wide (1" brush) gave me better results than I got with

two or three coats of Eze Dope. See photo. So, while Eze Dope gave me a

good enough alternative to nitrated dope as a tissue sealer, Polycrylic

is a decidedly better one."

"-----Updated

9/17/2019 After reading an article in Model Aviation, I decided to try

Minwax Polycrylic (satin finish) thinned with water to 33% Polycrylic.

One coat with a wide (1" brush) gave me better results than I got with

two or three coats of Eze Dope. See photo. So, while Eze Dope gave me a

good enough alternative to nitrated dope as a tissue sealer, Polycrylic

is a decidedly better one."

It was nice of the store selling "Eze-Dope" to let him

post that, years later! (I suppose they didn't know.)

I looked that up and some common stores had it, but they

all wanted the customer to pick it up and wouldn't ship it. Then I

found that "Home Hardware" had it. There was one of those in Masset.

That was 85 Km away, but at least driving there didn't involve ferries

and motels and 1000 $. They didn't have any but would order it. It

seemed it would take until the end of the month to arrive. Nothing is

fast when it has to come across BC and then catch the ferry to this

island.

To finish this, I drove up to Masset on November 1st and

picked it up. Then I went down the street to "Co-op Home Centre". They

had it sitting on the shelf - no need to have ordered it at all! Oh

well, Home Hardware was 50¢ cheaper. The co-op also had the

elusive #10-24 threaded rod I had previously been unable to find.

(22nd) I cut and shaped pieces of wood

for the rear elevator, which will now simply be pinned into one

position before each flight. Different positions will be tried along

with different weight distributions front to rear to see what works

best.

I found a 2017 youtube video about fabric and coverings by

a model aircraft builder 'of 40 years experience'. He himself was

trying Polycrylic for the first time. He did three different fabrics

and three different fabric fillers. Here was someone of long experience

with fabric aircraft materials, and he was more than a little impressed

with Polycrylic. It would seem it must be the best! He said he used a

heat gun to tension the fabrics but I don't know if that was before or

after applying the finish.

He also gave the weights per yard of his fabrics. I

measured and weighed a piece of the light PP cloth and found it was 20%

lighter than his lightest fabric: 28 grams per square yard versus 34.

And being PP, it was probably stronger too.

At some point I started gluing fabric onto the canard and the elevator

with ordinary white carpentry glue, which was suggested in the same

video. It dries a LOT slower on styrene foam than on wood!

At some point I started gluing fabric onto the canard and the elevator

with ordinary white carpentry glue, which was suggested in the same

video. It dries a LOT slower on styrene foam than on wood!

(31st) I finished the canard and elevator, and I mounted the canard on

the craft with a 1/8 inch dowel that ran right through everything from

the left edge to the right. Now it just needed the radio control servo

hooked up to the radio receiver... or to an inertia sensor and a

computer control to automatically adjust the canard for level flight

even in wavy conditions. But that can come later.

Another profile

With wing recovered November 2nd

(I was going to do the starboard motor mount properly,

but my mini milling machine was again "on strike".)

(Egads, what's with my cell-phone camera today? "foggy")

I am very pleased with the position of the canard. It

could hardly have worked out better if it had been planned from the

beginning. It extends the lifting surface almost to the front of the

hulls, which will in itself improve the ground effect. It also seems to

give some meaning (besides floatation in water) to the hulls extending

so far forward from the wing. Now the whole craft seems like a lifting

body.

And its position just in front of the main wing gives it

another effect: If it is aimed up, not only does it increase its own

lift and raise the nose, but its slipstream will deflect more air under

the main wing, increasing the main wing's lift. If it is aimed down, it

deflects air over the main wing, decreasing lifting pressure beneath

and increasing pressure above, which decreases lift. I expect the

altitude control to be very responsive.

If there's any tendency to tip sideways and dip one hull

into the water, as some of the 'catamaran' models on youtube had, the

canard for the full size vehicle can be broken into left and right

"aileron" sections - which will again both probably be computer

controlled.

A late thought came to me on November 5th: The ducted fans

might be mounted on the canard, instead of sticking out the sides.

They'd still be vertically in line with the wing. And the air thrust

would be

aimed up or down with the canard. It could be aimed under the wing for

"inflation" of the largely trapped airspace, making for a lower takeoff

speed. The canard would be even more effective at maintaining desired

attitude and altitude. The height of the canard with respect to the

wing height could be optimized for best effect. (least drag?) And

there'd be nothing

sticking out the sides to impede docking. For the model I'd need to

redesign and rebuild a suitable and stronger canard and pivot - and

preferably on the model the height of the canard pivot should be

adjustable to find

where it works best. Doable! I think I will! It may be proceeding at a

snail's pace, but this project just keeps getting more and more

exciting!

EV

Transmissions:

Off-the-Shelf

Planetary

Gears,

More.

(Miles Truck & Chevy Sprint)

Once before, years

ago, I had looked on line for planetary gears, but I don't remember

finding much, and later the ones I had found were gone. They were

pretty costly and came without cases. I got almost the same thing from

auto transmissions much cheaper. Now I looked again and found some

already fully assembled in cases from "Anaheim Automation" - ready to

use drive components. To say the least they weren't cheap. But they

were no doubt just the thing.

So here I've been fiddling around all this time with

planetaries from auto transmissions and trying to figure out how to

house them and fit the components together outside of their intended

transmission case, with much trouble and limited success. Was it worth

1000$ to get one ready made? If I knew exactly what I wanted, probably.

If I got one and it turned out it really needed a different ratio, if I

ended up ordering multiples, it could get expensive really fast.

But starting to think of cast housings, could I instead

make my own suitable enclosed housings, out of pieces of pipe big

enough to enclose the entire gear and shafts, and turn internal and end

bearing plates on the lathe? Now if I had a real R & D budget I

wouldn't even consider such a thing - I'd just order one ready made to

try out, from those who are already all set up and experienced with

making them! OTOH this way I'd get a custom unit to my requirements.

But starting to think of cast housings, could I instead

make my own suitable enclosed housings, out of pieces of pipe big

enough to enclose the entire gear and shafts, and turn internal and end

bearing plates on the lathe? Now if I had a real R & D budget I

wouldn't even consider such a thing - I'd just order one ready made to

try out, from those who are already all set up and experienced with

making them! OTOH this way I'd get a custom unit to my requirements.

I decided the thing to do would be to order a stock one

for the

truck to see how it's made

(to get any useful construction tips) before I install it, and then

make the custom one for the Sprint.

I lucked out November 1st visiting Lawrence of Drifttech Mechanical in

his garage. He had a selection of pipe pieces, and we found a piece of

thick walled pipe that when I got it home looked perfect. Boring out

the inside just

slightly on the lathe will make the ring gear fit in perfectly. And

then it could butt up against the unbored part inside - a solid end

stop. Perfect! Next: a bearing for the planets assembly (odd size -

1.20" or 30.5 mm). While not having everything figured yet, it looks

like I should turn two ends with centers to hold a bearing on each

side, perhaps from aluminum plate. But it needs some way to hold the

drive chain sprocket.

Anaheim Automation speaks

of the 'reduction ratio' from the input to the output

shaft, from 3 up to very high numbers. It would seem then that the

'input' shaft (actually a recess/tenon to fit an input shaft) is the

sun

gear, the 'output' shaft is the planets

assembly, and the case between is the ring gear.

Planetary Gearbox GPBS90

I

had recently decided on the Miles truck I should use a simple

5 to 1(?) reduction planetary of that configuration, simply replacing

the present bulky and doubtless lossy transmission with this small

part. These ones boast

'up to 97% efficiency', and anywhere near that would of course be

excellent - I'm sure much better than the hacked standard transmission

now in the truck. Interestingly the helical gear models were also rated

as being "up to 97%". I have instinctively always assumed they would be

lower because of the sideways pressure. Having the Curtis programmer I

can increase the maximum motor RPM a little, and with extra efficiency

I can surely reduce the overall reduction ratio a little (not a lot -

10%?).

That still wouldn't turn the truck into a highway speeds vehicle, but

it should be up to about 60(?) Km/Hr instead of 40, and with less waste

of

battery power over distance, which would make it much more useful than

at present.

I

had recently decided on the Miles truck I should use a simple

5 to 1(?) reduction planetary of that configuration, simply replacing

the present bulky and doubtless lossy transmission with this small

part. These ones boast

'up to 97% efficiency', and anywhere near that would of course be

excellent - I'm sure much better than the hacked standard transmission

now in the truck. Interestingly the helical gear models were also rated

as being "up to 97%". I have instinctively always assumed they would be

lower because of the sideways pressure. Having the Curtis programmer I

can increase the maximum motor RPM a little, and with extra efficiency

I can surely reduce the overall reduction ratio a little (not a lot -

10%?).

That still wouldn't turn the truck into a highway speeds vehicle, but

it should be up to about 60(?) Km/Hr instead of 40, and with less waste

of

battery power over distance, which would make it much more useful than

at present.

I don't have enough

lithiums at present to do both the

truck and the Sprint to desired capacity, but I could put 2/3 of them

in the truck for 7200 watt-hours and have a useful range vehicle. (IE,

it could make it into town from here. Coming back... well, it wouldn't

be 'empty' when it hit town, and the small capacity should charge

faster. And with two

solar panels on the roof, always charging...)

For the Sprint of course I want to do the variable

transmission. But a complete, enclosed planetary gear still seems like

just the thing for that. The whole case can be made to rotate to give

effect to

the desired motions. A five times faster output to the special

centrifugal clutch component should get it spinning nicely - 1/5 torque

and 5 times speed for good centrifugal grip. (I hope that's not too

fast.)

(Nov 1st) I checked the reduction ratio of the truck's differential by

jacking up a back wheel. For 2 turns of the drive shaft, the wheel

turned about 1.85 turns. If both rear wheels had been turning equally,

that would have been .925 turns, or .4625 turns for one turn of the

driveshaft, or 2.16 to 1 reduction. That's not far from the 2.4 I was

figuring. The 5 to 1 planetary would then make it 10.8 to 1 reduction

from motor to wheels. That's probably just about right. A 6 to 1

planetary would make it 13 to 1 - 20% more torque but 20% lower top

speed. I think I'll gamble on the higher speed (since the speed is at

the bottom end of "useful" anyway) and order the 5:1 unit.

Other

"Green"

Electric

Equipment

Projects

Handheld Bandsaw

Mill (& Alaska Mill)

Instruction Video Planned

Perhaps of particular interest to those who are interested

in making a mill like this one, I have decided to do a video of taking

it apart and reassembling it. That's in lieu of making an actual "how

to" instruction book. I hope to do it in November or December after

I've finished milling my last spruce log. (How can it be I'm not

finished yet?!?)

Working with the Mill and Latest Mods.

I finally finished the second last 16 foot cant in our

lovely indian summer up until mid October. Then rain, drizzle and more

drizzle brought cutting to a halt. Was the last section of log really

going to sit out another winter? It was rotting! In spite of the metal

roofing over it, the bark seemed to carry moisture all around - the top

was as rotten as the side down at the ground. On the 24th, again

stymied, I went out in the drizzle and de-barked it with the sharpened,

square-ended shovel. I should have done that last year!

[Warning: digression 2 paragraphs =>] Somewhere I lost

my peevee. I couldn't find it anywhere. The log sections were so heavy

I had used a jacks-all (sp?) to roll them. I considered that I might

have carelessly left it lying and rolling a log onto it, but I thought

that if I had done that I'd be able to see it underneath. Only when I

moved the last bottom slab of the 16 foot section did I find it again.

The log was so heavy it had pushed the peevee right down into the moss

and dirt so it was virtually underground. I also found I had hit it

with the chainsaw in trimming the log, but just a couple of slight

nicks.

I still remember when I bought that peevee about 1980. I

saw it in Capital Iron in the garden tool section in a bin with shovels

and rakes. I was thrilled to find one for sale and although it cost 4-5

times as much as a shovel or rake, I grabbed it. Oh boy! As I pulled it

out and started walking a store clerk stared in astonishment. "Are you

actually going to buy that?" he asked. "Well yah!" I couldn't believe

my luck finding one; he couldn't believe anyone would want one. I

hadn't seen it before so I don't think they could have had it

long, but they never got another one in. It has grabbed, pried, levered

and rolled a lot of logs and heavy things over the years. Well, I'm

really digressing here, to little cause...

On the sunny 26th I squared up the last cant with the

Alaska mill, and on the 28th I got three 2" by 6"s cut. But it had

seemed like slow going for quite a while. And the saw pulley got very

hot. My link belt started slipping, melting and breaking, and finally I

had bought a regular V-belt and now put it on.

Finally I thought "I wonder if it's the 1 inch pulley I

put on?" I got the old one and put it back on. Sure enough, it cut

faster. It was like getting my good saw back after using a crappy one!

The 1 inch pulley going to the 9 inch made the band speed

actually too slow. The skillsaw motor never labored much - instead the

belt just slipped. Looking at the 1" pulley, I saw that it had kept

getting so hot that the belt would slip, and the combo of heat and

rubbing had polished the inside slick and smooth. That's surely why I

had to tighten it so much and then the hot link belt kept breaking

(melting?) where it slipped.

The old one was a variable pulley. I'd estimate it was set

to more like 1-1/2" to 2". Now it seems more like the motor is working

- hopefully not to the point of overheating and burning out. I may get

a selection: 1.5", 1.75" and 2.0" pulleys, and try them out to find

which is "optimum".

And I found the saw getting some nasty vibration, to the

point I thought something had gone wrong. But it seemed to be the

V-belt setting up a resonance, in spite of being pretty tight. I put

the link belt back on and it stopped. It also seemed to have more power

- which is the reason for using link belts in the first place: typical

V-belts are pretty inefficient. (I wonder why they don't make them all

grooved like the ones for variable transmission pulleys?)

At the same time, I had ordered and received two "idler

bearings" and two thrust bearings whose inside diameter matched the

outside of the idlers. These replaced my "railroad car wheels" with the

rim being a pulley welded to a custom machined part. (I got them at

vxbbearings.com, part numbers:

"CY36L - 1-1/8" Heavy Duty Yoke Rollers",

"12473 - TC1828 Thrust Needle Roller Bearing 1-1/8" (ID) x 1-"?/?"

(OD).)

I've only put one set on so far. It seems to work well

enough, although the loose thrust bearings rattle around some. The

"yoke rollers" are perfect - a good diameter and a good width for

guiding the band without touching the teeth, so the guide rollers don't

start flattening out the 'set' to the teeth. (I didn't order runner

washers for the thrust bearings and had to make do. The last thrust

bearings I got, the matching washers came with them. In my experience

with my "railway wheel" welded-on washers, they gradually wear out

anyway and have to be replaced - a real pain when you have to weld

them.)

I've only put one set on so far. It seems to work well

enough, although the loose thrust bearings rattle around some. The

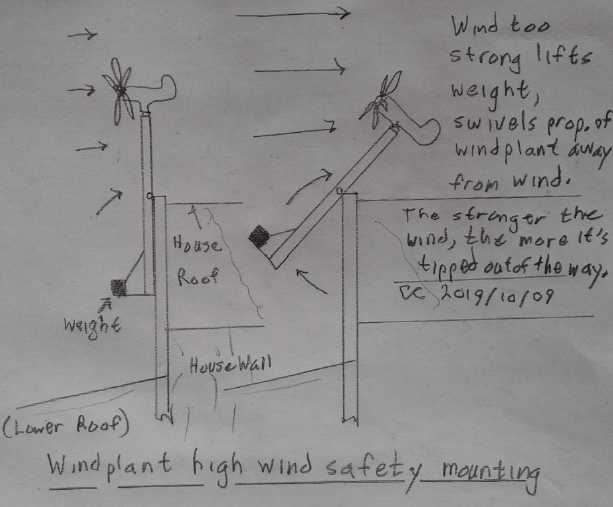

"yoke rollers" are perfect - a good diameter and a good width for

guiding the band without touching the teeth, so the guide rollers don't

start flattening out the 'set' to the teeth. (I didn't order runner

washers for the thrust bearings and had to make do. The last thrust

bearings I got, the matching washers came with them. In my experience

with my "railway wheel" welded-on washers, they gradually wear out

anyway and have to be replaced - a real pain when you have to weld

them.)

It seems to me now that I should have found thrust

bearings to fit onto the 5/16" bolts. They would go behind the "yoke

rollers". Then I would make a "shoulder washer" 5/16" x 1-3/4" to put

in between. with another washer behind the thrust bearing against the

bolt head. That should be pretty solid.

On the 31st I finished off

that last 16 foot cant. Now the

new boards need to be stickered and added to the considerable stack

under pieces of sheet metal roofing to dry. ("Stickered": Cut small

pieces of wood ("stickers", meaning "spacers") and place them across

the rows of boards to make an air space between each layer of boards so

they can dry faster and better. Hey, I don't make up these terms, I

just use them. "Cants", hmpf!)

Then there are a couple of 16 foot edge slabs that

probably have a couple of boards in them. Or should I just cut them

into firewood and get on with milling the last 12 foot section of log,

the base of the tree?

5 Blade Windplant

<

(5th) I got out the wind

meter

and tried out some spots. As I had surmised, the front corner of the

house roof seemed to be the best spot if I wasn't going to erect some

tall tower. I got readings of about 1.8 to 2.2 meters per second. (Of

course the wind is always coming and going. To most fairly compare any

two

spots, one ideally needs two anemometers and a second person on the

cell

phone or 2-way radio.) It seemed best at least 4 or

5 feet above the peak. As I walked along the peak toward the other end

of the roof, it got lower, no doubt mainly because of the tall trees

too close to the other end of the house.

(5th) I got out the wind

meter

and tried out some spots. As I had surmised, the front corner of the

house roof seemed to be the best spot if I wasn't going to erect some

tall tower. I got readings of about 1.8 to 2.2 meters per second. (Of

course the wind is always coming and going. To most fairly compare any

two

spots, one ideally needs two anemometers and a second person on the

cell

phone or 2-way radio.) It seemed best at least 4 or

5 feet above the peak. As I walked along the peak toward the other end

of the roof, it got lower, no doubt mainly because of the tall trees

too close to the other end of the house.

The top of the driveway where the wind funnels in at

ground level (at least for our typical southeasters) was a close

second, just 2 or 3 feet off the ground. Figures might have been 1.7 to

2.1. Everywhere else had too many wind shadows - mostly of trees.

Then it occurred to me to go down to the beach. In the

access path there was again that wind tunnel effect, and I got readings

up to maybe 3.5. Down on the beach itself I was getting up to over 4 -

even a 4.8. (I should probably have walked more toward the water, too,

to be sure I was out of the wind shadows of the trees.) Theoretically

the strip beween the highway and the beach is my property.

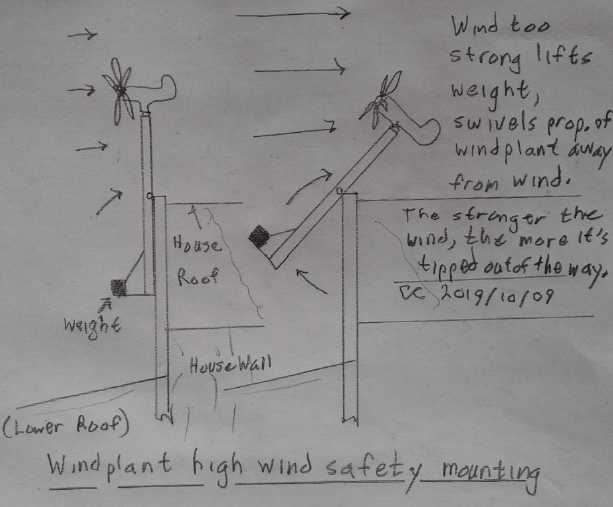

Theoretically. Hah! Even if I put the windplant in the path, and