Turquoise Energy News #138

covering

November

2019 (Posted December 2nd 2019)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- 12/36 Volt DC Infrastructure - WIFI/5G Countermeasures - Ground

Effect Vehicle - 100% Efficient Infinitely Variable Torque Converter -

Woodstove Stirling Steam Engine Generator - New Chemie Batteries

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Gardening - Winter Cabbage, Sugar Beets - Hearing Improvement Further

Notes - 5G Countermeasures: Biologically Harmful - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle (Still Prototype R/C Model... continued)

* EV Transmissions: 100% efficient infinitely variable torque

converter.

Other "Green"

Electric Equipment Projects

* Working with the Handheld Bandsaw Mill (& Alaska Mill)

Electricity Generation

* 5 Blade Windplant - Windplant Ducts

- Clarkson University Experiments with Windplant Ducts

* My Solar Power System: - Monthly

Solar Production log et cetera - Notes.

* Woodstove Alternator with Stirling Steam Engine?

Electricity Storage

* Turquoise

Battery

Project

(Mn-Zn or Ni-Zn in Mixed Alkaline Salt electrolyte)

November seemed to pass in

something of a blur with day after day going by seemingly with little

to no accomplishment. But somehow I had a lot of writing to do. And it

wasn't a whole loss. I inched forward on various projects.

I started

making the DC/Solar charging system for the Sprint car, but making a

HAT plug for the charge controller (to plug it into a solar panel(s))

took so long I diverted into looking for ways to make them easy to

produce and didn't get it finished.

I started

making the DC/Solar charging system for the Sprint car, but making a

HAT plug for the charge controller (to plug it into a solar panel(s))

took so long I diverted into looking for ways to make them easy to

produce and didn't get it finished.

Between me and Mike in QC we worked out to make the plug

blades simply straight pieces of flat copper, and to put a ring around

the inner end made of small copper tube. The ring then crimped a piece

of wire to the pins.

Somehow I had never conceived that the pipe, even 1/4

inch, could be small enough. And it doesn't make a 'clean' crimp - it

squashes out. But I got on line and found some still smaller, 6mm and

5mm (and under). One of those will probably be just about right.

The next week we tackled the sockets, studying some 120VAC

electrical socket innards, and Mike came up with a simple "Z" fold,

with the same copper pipe crimp at the wire end. I never think of

things that would waste an extra milligram of metal myself, but these

will be practical -

easy to make and easy enough to use. At least they won't need

soldering. And they will probably be model "A". Later will be some

(bulkier ones) with screw connections - easiest to wire.

Instead of copper, the AC sockets seemed to use brass. We

figured that must be springier, and they need to grip the plug blades.

I had nickel silver, which is still stronger than brass. I would

however note that pure copper is by far the better conductor. Brass is

likely to be better than nickel silver too - sigh, another thing I

should check out before deciding what material to use in production!

Copper plug blade (ring crimped)

and "Z-fold"

nickel-brass socket

receptacle (ring uncrimped).

Copper plug blade (ring crimped)

and "Z-fold"

nickel-brass socket

receptacle (ring uncrimped).

They seemed to grip each other quite well.

The next task will be to design shells to hold these pins

and sockets.

And, my fiber optic internet

having come at last, I realized it had both regular 2.4 GHz WIFI and 5

GHz - the notorious "5G". Furthermore it was only a few feet from where

I sit.

And, my fiber optic internet

having come at last, I realized it had both regular 2.4 GHz WIFI and 5

GHz - the notorious "5G". Furthermore it was only a few feet from where

I sit.

Nobody mentioned the "5G" when they were putting it in. I

only noticed the light later. I should have had it mounted somewhere

far from where I usually am.

We are all guinea pigs in the 5G experiment. It's a very

penetrating wavelength (~6 mm) transmitted with considerable power, and

it has never had the slightest testing to ensure that it's safe

long-term. There are already troubling signs that regular WIFI can in

fact cause people serious problems.

No one should imagine that transmitted microwave radiation

somehow goes around their body. Suing someone for criminal negligence

later won't help anyone who has developed cancer or who has had a

defective baby(s) in the coming years. I expect eventually "5G" will be

scaled back in power of even abandoned as being too unhealthy.

Even in front of this grounded piece of metal, the cell

phone still shows four bars WIFI from it. How strong are the signals

without the protection?

Ground Effect Vehicle - to open up the BC north coast

and other rugged, isolated and island territories

I modified the canard to hold the ducted fans and then

mounted them. I put in a heavier (1/4" dowel) pivot since all the

thrust will go through it. I redid the rear of the wing (ex "elevator")

after melting the covering with the heat gun, and screwed it onto the

back of the wing. I mounted the servo to move the canard up and down,

and by the end of the month I tested it.

It was starting to look like it might be finished some day.

It works!

It works!

Moving the "elevator" control on the handheld transmitter

moves the canard up and down. With the ducted fans mounted

on it, aiming it up for take-off blows the air under the wing

for more lift, a highly desirable ground effect craft feature

"incidentally" incorporated by putting them on the canard.

100% Efficient Infinitely Variable Torque Converter - for

improved efficiency of road and rail transportation

After all these years muddling around, and finally having

a very clear concept of how everything should go together last summer,

and then having found a piece of pipe just right for a spinnable

housing for the planetary gear, I couldn't help but start working on

it. This month I got and mounted on the shafts two strong double row

sealed

ball bearing units that seemed the ideal type for this application.

(ordered in October)

I found some aluminum disks that were usable. But I was

unable to readily turn them as desired. I'll need to go to some

contortions to mount them on so they fit "in the gap" of my "too small"

lathe.

Instead I focused on making a coupler to couple the motor

to the planetary gear. Somehow turning a little piece of pipe to exact

size was an all day job, and I still need to weld it to the end of the

splined shaft stub that fits the planets gear.

Shaft coupler pipe.

Shaft coupler pipe.

It'll be "pound it onto the motor shaft and put in set screws",

and "weld the pipe onto the splined shaft stub".

I got it to pound onto the shaft aligned, so hopefully

I can weld it on still solidly held straight.

Now having all these pieces I could start trying to put things

together. From the left (below):

* The shaft to connect the motor (Motor mounting off to left to be

created).

* A gear to connect the assembly to the car's differential (which will

hold the large gear).

* Aluminum end plate.

* Planetary gear housing (to be oil filled - the end plates seal the

gear housing.)

* The other end plate.

* The big centrifugal clutch drum.

All the parts seen here are tied together and turn

together as the car moves except the motor shaft, which is connected to

the planets assembly inside the planetary gear. Since they are, both

end rings and the plate of the clutch drum will all be bolted through

from left to right with long bolts, ensuring everything is held solid

and squeezing the oil seals tight.

Sizes and spacings conspired to insist that the drive gear

had to go on the left end without touching the motor shaft. (There's

more to do to mount it to the end plate. I may use sprockets and a

chain instead of my perhaps dubious gears.)

Seen in the second image from the other end (below):

* The centrifugal clutch inside part (with UHMW centrifugal shoes to

contact the aluminum drum.)

* An end bearing to hold it all in line. (Mounting to be created.)

Some may ask how any mechanical mechanism could be 100%

efficient. To review the operation, the ring gear/outer drum of the

planetary gear is attached to the car's differential by gears or a

drive chain. The motor turns the planets assembly. Since the car isn't

moving, the ring is stationary and the sun gear spins. The sun gear's

shaft connects to the inside element of the centrifugal clutch, which

is thus turned at three times the speed of the motor.

As the shoes fly out and engage the drum, it turns it and

the car starts to move.

As the car starts moving, there actually are losses. Even

a

planetary gear is only around 97% efficient, bearings turning have

small losses and the centrifugal clutch is an unknown. But as it all

gets

up to speed and less torque is needed, the clutch shoes lock to the

drum and then everything spins at once: motor, centrifugal disk/shoes

and the drum, and both sides of the bearings are turning together.

There is no relative motion, so nothing to cause losses. (The end

bearing turns, but some shaft bearing would doubtless be needed anyway.

And I suppose one might count air friction...)

Woodstove Stirling Steam Engine Generator - Reliable winter

electrical generation at home

Stirling

Engine

Animation

from

Wikipedia

Owing to lack of sunlight to make electricity, and with a woodstove TEG

(thermo electric generator) seeming to be not much bang for the buck,

and with steam engines needing too high of a temperature, I thought of

Stirling engines. I didn't understand how they worked, but I knew that

like TEGs, they ran off the difference in temperature between a hot and

a cold side.

Owing to lack of sunlight to make electricity, and with a woodstove TEG

(thermo electric generator) seeming to be not much bang for the buck,

and with steam engines needing too high of a temperature, I thought of

Stirling engines. I didn't understand how they worked, but I knew that

like TEGs, they ran off the difference in temperature between a hot and

a cold side.

So I studied them. Youtube has many working examples.

They're pretty simple, but they aren't very powerful for their size.

I'm sure they can be improved.

It seemed to me, first, that the stroke of the displacer

is wasteful. It creates the most heating and cooling effect, the most

propulsion, when it's at either end of the cylinder. Instead it spends

too much time in the middle and never actually quite gets to the ends.

That could certainly be improved by having it sit right on either end

for almost 1/2 the stroke.

Second, woodstove tops often operate just in the region

where water boils - a low simmer. If a large diameter cylinder had

water in the bottom, and if there was a phase change from water to

steam in the heat part of the cycle, and back from steam to water in

the cooling part, the volume of gas in the cylinder would change far

more than just with heating and cooling air, giving the stroke much

more power for the size.

By turning an efficient alternator, perhaps as part of the

required flywheel assembly, I thought a good goal would be making 100

watts of electricity - day and night for as long as the stove had a

moderate fire going.

Just what I need, another project!

New Chemie Batteries - Better,

cheaper

mass

electricity storage

I didn't do an awful lot on these this month. What I did

do led me to I re-think a few things.

At the start of the month I had another zinc tab corrode

off from the rest of the electrode. I decided I should order some zinc

that was at least said to be pure - there were no claims to

purity on the "rooftop moss killer", and there was all always that

black crud left over when I used up a sacrificial electrode for

electroplating. How could it be pure? Would pure zinc work better?

Probably!

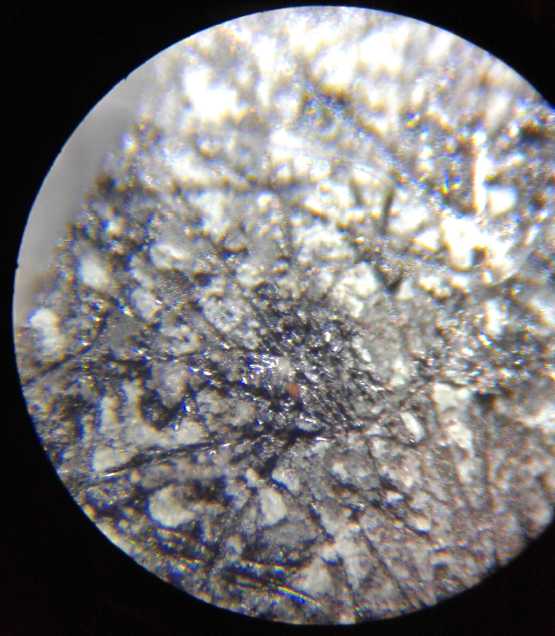

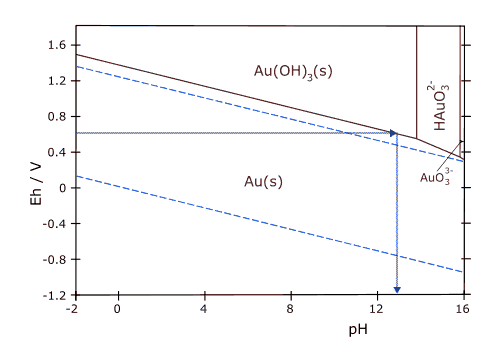

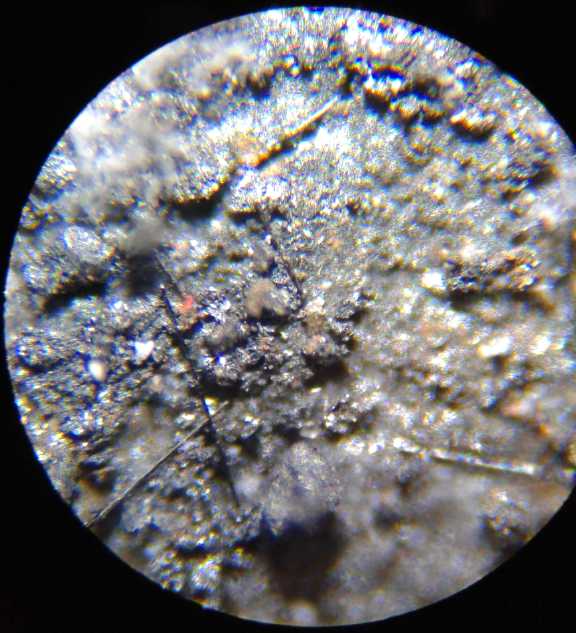

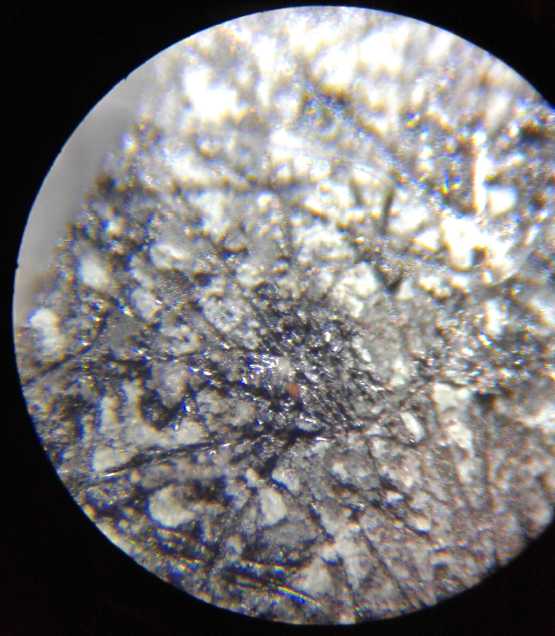

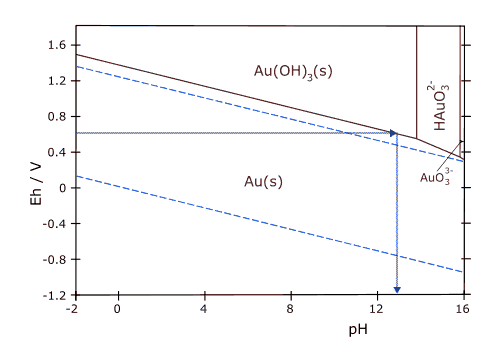

The experimental copper electrode with calcium oxide on it

had also corroded away, but apparently radiating from one point on the

tab. So I was left wondering whether that was just where it (probably)

got scraped at that point when putting it into the cell, or not, and so

whether the idea worked or not. But then I also thought that gold

plating the copper might be a better plan. It wouldn't have to be very

thick - hardly enough to see - and it would probably protect the copper

nicely. (especially at manganese dioxide voltage, which is below the

gold-to-gold-oxide voltage.) My old gold brush plating solution (from

2004) didn't seem to be working any more, so I ordered a bottle of

"proper" gold tank electroplating solution. (Almost 200 dollars - Ouch!)

If no metal works there's still graphite. Metal would give

higher current capacity.

Finally I also decided it would probably be practical to

make the cells to lie down flat instead of standing up. That'll need a

new (3D printer) case design. It will also allow very large but thin

individual cells that won't keep falling over.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Gardening - Winter Cabbage, Sugar Beets

In the spring I had planted cabbage in the garden. By fall, just like

last

year, it hadn't formed heads. Somebody said cabbage had to go in the

greenhouse. Certainly the ones in there seemed to grow better. On

November

8th I decided to try taking a greenhouse to

the cabbage. I put some walls of scrap styrene foam and glass

around them, another scrap window on top plus three 12"x12", 45 watt

LED grow lights. I covered over the top of the lights with a piece of

plastic. It was pretty slipshod (removed for picture), but we'll see

how they do - if it

doesn't get too cold.

In the spring I had planted cabbage in the garden. By fall, just like

last

year, it hadn't formed heads. Somebody said cabbage had to go in the

greenhouse. Certainly the ones in there seemed to grow better. On

November

8th I decided to try taking a greenhouse to

the cabbage. I put some walls of scrap styrene foam and glass

around them, another scrap window on top plus three 12"x12", 45 watt

LED grow lights. I covered over the top of the lights with a piece of

plastic. It was pretty slipshod (removed for picture), but we'll see

how they do - if it

doesn't get too cold.

Toward the end of the month it was almost surely too cold. I started

leaving the lights on full time to keep them from freezing. I'm not

sure I see any growth. Perhaps

if I had done it a month earlier? or two? I'll persevere for a couple

more weeks, but it doesn't look promising.

I decided to try growing carrots indoors. I hooked up the "LED indoor

garden" in the corner of the kitchen. But only lettuce seems to be

doing very well so far. I think the corner if not the whole kitchen is

just not warm enough. I think I'll insulate around the lights and maybe

even turn on the electric heat just so it heats that space. (Maybe

replace one LED with a 100 watt incandescent bulb in one socket, with

the small fan near it, just

for the heat?)

I decided to try growing carrots indoors. I hooked up the "LED indoor

garden" in the corner of the kitchen. But only lettuce seems to be

doing very well so far. I think the corner if not the whole kitchen is

just not warm enough. I think I'll insulate around the lights and maybe

even turn on the electric heat just so it heats that space. (Maybe

replace one LED with a 100 watt incandescent bulb in one socket, with

the small fan near it, just

for the heat?)

We've heard about the

staggering global crop losses in

corn, wheat, soy and even potatoes (almost nothing easier to grow at

home than potatoes!), and the staggering devastation of vast herds of

porkers and beefers. Now here's another whammy: as fall turns to winter

the summer's stats from sugar beet farming have come in and the crops

are way down: grand disaster in southern Alberta and south of the

border too. People trying to source sugar simply can't get it. Rogers

has apparently declared "Force Majeur" on contracts and put its usual

customers on allocation: there just isn't enough to go around. So

places report sugar cane crop failures, but Louisiana had a bumepr crop.

And NASA's predictions for the next solar cycle indicate

we're in for a grand solar minimum like the Dalton minimum: 30 years of

cold, rainy weather - worse next year than 2019. The conditions for

that grand depopulation of the

planet by mid

century are really starting to take form!

So I looked up sugar beets. I've never seen them in stores

in the spring, but there are some seed suppliers who have them

available. I should look further to see if growing them here sounds the

least bit feasible. (back to youtube!)

Later I heard that the phenomenon is being called

"farmageddon" in the USA. Farms are going bankrupt en masse (in Europe,

too), there's an unprecedented wave of farmer suicides, and food

companies are going bankrupt when they can't get inputs at prices they

can pass on - especially dairies because the price for milk is "fixed"

by the government. ("Fixed"? Don't they mean "Broken"? How about

"Rigged"?)

http://www.iceagefarmer.com/2019/11/07/food-system-collapsing-actively-rapidly-urgent-warning/

https://electroverse.net/in-the-last-30-days-the-u-s-set-7112-new-all-time-low-temperature-records-vs-just-the-1605-max/

And in the face of this, a NASA temperature map shows

globally slightly warmer average temperatures for 2019 as a whole most

everywhere except a big, dark "cold hole" over most of North America.

Not that farming has done well anywhere. The staggering losses

everywhere have

different causes in different places.

Hearing Improvement Further Notes

In TE News #136 I wrote of improving hearing by dripping vegetable oil

in one's ears. It's also supposed to help reduce or eliminate tinnitus.

I found this idea from more than one source. But how could it help?

This month I read an article saying we lose hearing

because of our noisy environment. It mentioned things like hair blow

dryers, shavers, food processors, blenders and coffee grinders, many of

which are pretty loud for short periods. In #136 I also mentioned

noises that persist over long periods like refrigerators, fans and

heating and air conditioning systems, traffic, and music or continuous

babble - radios, TVs and so on. Since the noise is ubiquitous we pretty

much stop noticing it, but I suspect that both types of noise have long

term deleterious effect.

The article went on to say that with indigenous people who

don't have all these electrical noises around them all the time, old

people hear as well as young people. This tends to validate the idea

that QUIET is what one needs to retain hearing, or to recover it if

[that's an IF in a mechanized society?] if it has been lost. And that

the way the oil works is as a high-frequency selective "earplug" that

works for hours, reducing the levels of noise entering the inner ear

mechanism, perhaps by 10 dB.

This is obviously a very slow acting, long term treatment

- a reversal of the slow, long term loss of hearing. And obviously of

course it must be done along with all other sensible hearing protection

precautions one may take. And eliminating environmental noise as much

as possible.

5G

Countermeasures:

Biologically Harmful

(Oops, I've written this up twice)

My fiber optic internet

finally came in late October. I had the fiber cable end and the

interface box put in near my computer desk. It's great to have good

internet again! It came with WIFI.

When I finally

bothered to look at it, I was shocked to see that it also came with the

controversial 5 GHz as well as 2.4 GHz WIFI. (now I finally know

why they call it "5G".) This is getting up into a biologically

destructive range and I'm sorry it's there. Even 2.4 GHz WIFI can be a

damaging level of radiation if, for example, you hold a cellphone to

your ear for hours per day, or there is a cell phone/WIFI station too

close where you are routinely present... or sit too close to the WIFI

box in your house for too many hours a day. (I have heard stories -

rumours - that brain cancers have been observed from the first, and

other fatal cancers from the second.) Does anybody imagine that these

rays somehow go around people instead of through them? I hardly care if

I have WIFI at all. Why would I want to subject myself to even more

penetrating radiation? I wish I could just turn it all off. I wish I

had had it installed in some far corner of the garage I rarely go into.

I'd have run any length of ethernet cable in preference!

When I finally

bothered to look at it, I was shocked to see that it also came with the

controversial 5 GHz as well as 2.4 GHz WIFI. (now I finally know

why they call it "5G".) This is getting up into a biologically

destructive range and I'm sorry it's there. Even 2.4 GHz WIFI can be a

damaging level of radiation if, for example, you hold a cellphone to

your ear for hours per day, or there is a cell phone/WIFI station too

close where you are routinely present... or sit too close to the WIFI

box in your house for too many hours a day. (I have heard stories -

rumours - that brain cancers have been observed from the first, and

other fatal cancers from the second.) Does anybody imagine that these

rays somehow go around people instead of through them? I hardly care if

I have WIFI at all. Why would I want to subject myself to even more

penetrating radiation? I wish I could just turn it all off. I wish I

had had it installed in some far corner of the garage I rarely go into.

I'd have run any length of ethernet cable in preference!

"5G" is a very considerable radiation and there have never

been tests done on it to assure that it's safe. It is down to 6

millimeters wavelength, even shorter than "microwaves" (centimetric

waves) and headed toward the infra-red band. In fact we are guinea pigs

in a vast experiment. I put a piece of sheet metal (cupro-nickel, but

steel would work too) in front of it and connected it to a ground with

a 3-prong electrical plug, only using the ground pin. That way the

radiation can't come directly toward my computer desk where I sit a

lot. Even so my cell phone shows four bars if I turn on its WIFI. (I

had been cutting pieces from this sheet. It had a convenient "tab" that

I simply bent over to hang it from the unit itself.)

It won't help you to say, when you have terminal cancer,

"Nobody told me it wasn't safe!" Anyway "they" will deny that the 5G by

your desk could have had anything to do with it and you won't be

absolutely 100% certain yourself. But then, "they" told you that

smoking was safe, that thalidomide was safe, that glyphosate ("round

up") weed killer was safe, that GMO wheat was safe (that's when

widespread "gluten intolerance" started), ...

Small

Thots

* I noticed a title from "Provident Preppers" on youtube, who grow

their own gardens. I didn't watch it, but it said something about that

they had lived for 90 days on their stored food and garden produce,

without going to the grocery. Of all the crazy ideas, testing to find

out how you actually make out and finding any deficiencies in your

preparations!

* CDC Director Robert Redfield said people should stop referring to "a

coming time" when antibiotics won't work: "It's already here." Many

microscopic threats are "urgent", "serious" or "concerning".

Along with suddenly developing food scarcity, we are

setting up for the global pandemic or pandemics which will end the

unsustainable "population bubble" humanity is now in. The African Swine

Fever epidemic is a foretaste of how an entire species population can

drop dramatically and rapidly. (I'd say globally but it hasn't hit the

Americas yet. We are desperately trying to keep it out. But if some

European pork tour group books a flight to vacation to

Disneyworld, look out!)

* Freedom of Speech is not about being agreeable. Freedom of speech is

about freedom of thought. It is about being willing to hear things and

ideas that you don't want to hear. It is about letting people express

themselves even if you don't agree with them - and even if you think no

one agrees with them. Even if you think they are wrong and what they're

saying is idiotic. It's about allowing things to be said that you

fervently hope others don't believe or agree with. If what someone says

really is wrong, they will gain few adherents. If it is right, you've

avoided putting yourself in the wrong by arguing against it or worse,

preventing people from hearing it.

When freedom of speech is infringed by authority, it is a

case of "might versus right". If we don't believe might makes right, we

should want no part in suppression of free speech. Whether you like or

dislike Alex Jones and what he says, when he was almost simultaneously

banned from Youtube, Facebook, Twitter et al, it was a sad day and a

sad precedent for free speech for all. "First they came for the

Jews..." ... First they came for Alex Jones, then a whole pile of other

people you won't find videos or articles from any more (even their old

ones), and they're subtly going after the whole of alternative media -

keeping them out of all but the most direct search results,

demonetizing

their videos until everybody interested has already watched them, and

so on.

Many think that the alternative media is "just a bunch of

nuts" anyway. But some of the better channels provide a link to a page

with the mostly credible sources of their information - which you

virtually never get from the "mainstream media". From them its "experts

say", "scientists say" (unspecified experts), stock or other footage

pawned off as being news, even outright lies, with no provision for

checking for yourself. And on Youtube and Zerohedge (at least) comments

may be entered below the video, so if others have more information or

disagree with the content, you can find out quickly by reading a few of

them. And you can enter your own comment.

Those who are in corporate and government and "mainstream

media" power are afraid of truth. They don't want you to hear other

opinions than their "narrative", and they use their bureaucratic power

to stifle

their airing, without being so obvious about it that there is a huge

and immediate backlash that exposes their dictatorial habits.

"The truth never suffers from honest examination." - Jesus

* If humans try to go to Mars without protection against cosmic "rays",

they may arrive blind if at all. Recall that the lunar astronauts

reported seeing flashes of light with their eyes closed once they were

outside of Earth's Van Allen Belts of protective magnetic shielding.

Later some of them got cataracts early in life. That's from being just

a week outside Earth's magnetic protection.

Vegetation might grow outside the protective zone. It

doesn't have delicate eyes or nervous systems. It seems like Ganymedean

vegetation has spread to many spheres (even little "oids") without air,

as long as there is good soil and no special harsh radiation such as

Jupiter and Saturn sweep around with their rotation. (This is why

Callisto and Iapetus are covered with "dark", "fluffy" complex

polycyclic aromatic hydrocarbons organic matter (scientists' findings),

plant life (my interpretation), but on their

leading hemispheres only.)

ESD

(Eccentric Silliness Department)

* We used to have "television sets". Now with flat screens they are too

thin to set anything on top of. It will fall off. Should we still call

them "sets"?

* "Zero" and "seven" are single digit numbers. Why do they, alone, rate

two syllables? Especially "seven" grates on my mind when counting to

ten.

Sometimes used "oh" is easily confused with the letter

"O" - which also looks the same when written**. (or the word "owe", as

in "I 0 1 2 thee 4 fine help.") Maybe we could shorten "zero" to "zo"?

That's pretty unambiguous. Or use the British words, "naught", "aught"

and

"nill"?

We could perhaps shorten "seven" to "sev"? The French word

"sept" with the silent "p" - unlike "sept-ember", the 7th, er, 9th

month] might be good except it is already much used as, in

"television set". Okay maybe better, "sept" but sound the "p"? That has

good precedent in language.

** I've seen a scanned book with a strange word, "loomm". It was

really "100mm". And in the same book I think "ydmrn" was probably

"92mm" (or 93 or 96).

* There's something funny about the flavor of wry bread.

* Lifting 100 grams is easy. Lifting 100 killergrams is hard.

* Earthly vegetation that might grow on Mars: Marzipan, Marsmallows.

* Algorithms: The daily comings and goings of Al Gore.

* Bacon supplies that may be in short supply owing to the "pig

apocalypse": bacon powder, bacon soda.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency and

completeness before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground

Effect

Vehicle

(first

the

R/C

Model)

Canard & Ducted Fans Mounted on

Canard

Having decided to have a front canard to replace the rear

elevator and never having seen such a thing, I found the "WISES" ground

effect model video. It seemed to

fly quite well with much more positive response when put to climb or

descend.

The "WISES" ground effect craft -

Full size

model test prototype 2011. (Why does it keep

The "WISES" ground effect craft -

Full size

model test prototype 2011. (Why does it keep

buzzing that poor guy in that boat? ...Yes, the one holding that, um...

radio control... unit?)

Although it was "full size", 7

meters long, he

built it lightweight and graceful,

Although it was "full size", 7

meters long, he

built it lightweight and graceful,

so it would quite fly slowly. Why? Because he didn't have a high speed

chase

boat. A faster version such as is planned for the manned craft would

have

quickly flown out of control range. (I wonder how mine will fare?)

Then, having decided to move the ducted fans to the

canard, I looked at the "WISES"

ground effect video again. I had been trying to see where the propeller

was but it seemed invisible. I had thought it must be at the front of

that long thin nose. Finally I noticed there was (sure enough) one on

each side on

the canard, faintly visible in some of the footage. Essentially the

same place as my own new plan!

So while both my reconfigurations were already made, the

high-performing WISES craft provided strong reinforcement that I was

probably making the best choices. At least I was in good company.

And I believe the ducted fans are a better choice than

open propellers: higher static thrust, and higher above the water, so

they can be mounted lower. Around the 12th to 15th I picked away at the

canard,

ripping off some of the cloth, adding two ribs for mounting the fans,

and filing the front and back edge spars to more streamlined inside

shapes. Of course the canard was made without the fans in mind, but

even so it needed to have the lengthwise strength that the famous Haida

Gwaii aircraft spruce provided.

I changed the dowels from 1/8 to 1/4 inch as they would

now be taking all the propulsion thrust force along with lift. I

couldn't have the canard with the motors break off and fall into the

water!

And of course, the "ESC" motor controllers had to go in

near the bows beside the canard - the one part of the hulls I had

covered over on top! (Won't need to get in there, oh, no!)

(23rd) I finally decided to

try heat shrinking the covering, which seemed to be recommended by all

the modelers for all the coverings they used. I had started to make a

test piece, a short version of the canard, but then I tried on the top

of the rear elevator (now to be a fixed part of the wing, but already

made separate). Instead of shrinking and getting taut, the PP cloth

stretched and sagged. I moved the heat gun in a little closer - not

close - and a

hole appeared and spread too quickly to react. I would have to

sand it off and redo it.

(23rd) I finally decided to

try heat shrinking the covering, which seemed to be recommended by all

the modelers for all the coverings they used. I had started to make a

test piece, a short version of the canard, but then I tried on the top

of the rear elevator (now to be a fixed part of the wing, but already

made separate). Instead of shrinking and getting taut, the PP cloth

stretched and sagged. I moved the heat gun in a little closer - not

close - and a

hole appeared and spread too quickly to react. I would have to

sand it off and redo it.

Okay! No heat for PP cloth/landscaping fabric! Either

it'll shrink a bit and become more taut when the finish is applied, or

it will stay as-is.

I had dabbled in it just

occasionally, and eventually got the ducted fans mounted in/on the

canard. By the 30th I had mounted and was able to attach the

servomechanism to the canard.

It works! As the "elevator"

control is

moved up and

It works! As the "elevator"

control is

moved up and

down on the handheld transmitter, the tiny receiver

picks up the position info and the servo twists,

pushing the rod, and the canard aims down and up.

With the canard pointed up, the air from the fans is blown

down under the wing. With the sides and back largely "boxed in", this

somewhat "inflates" underneath like a hovercraft, allowing takeoff at

lower speeds. This is an advantage built into the propeller angle of

some of the radio controlled models. But in this design that steep

downward air angle is obtained as part of the vertical control, and

only when it's useful.

There is one part I haven't gotten to yet:

turning and maneuvering. There is no provision on the motors (or the RC

control) for going in reverse. It would seem the only way is to swap

two of the

three power wires. For the model, at least for the first run, I think I

will just have to say "if it was the real thing you could easily

maneuver up to a wharf or float."

My present plan for turning has been to turn one motor

down and

the other one up. But once again there is no provision for that, which

would have to be a "double" throttle stick in the control transmitter.

I'm thinking I need to make a special circuit board to "reinterpret"

the signals from the motor speed control and the "rudder" control, and

use the "rudder" control to speed one up, and slow the other one down.

The other alternative is to put an actual rudder on the

craft, and power both fans equally. As with inability to edge up to a

wharf, I'm not fussy about the idea, but it may be a good stopgap for

initial testing.

EV

Transmissions:

Off-the-Shelf

Planetary

Gear (for Miles Truck),

100% Efficient Infinitely Variable Torque Converter

(5th)

In spite of it not being high on my priority list and trying to get out

the October newsletter, having a plan for making a planetary gear

enclosure and the parts to do it, I was inspired to not bother waiting

for the

stock gearbox and start putting together the custom one for the Sprint.

I didn't have a bearing the right size for the

motor/planets side. It was 30.5 mm/1.20". There were lots of 30 mm

bearings, but none 30.5 and none 1.20 inches. I had a couple that were

1.375 inches. I found a brass plumbing piece that was a perfect fit to

hammer into the bearing center, and I cut a short piece off and did so.

Then I cut another piece and cut a diagonal groove across it. I widened

the groove until it fit inside the other piece. So I had the bearing

with two shims inside. It fit perfectly onto the flange on the planets

assembly. The ring gear already had a previously made shaft on it that

took a 1.0635" ID bearing, which I had some of. So now the planetary

had a bearing on each side of the ring gear.

(6th) I cut off a 70 mm piece of the big (~4-1/2") pipe with a zip

disk. Then I put it on the lathe and squared up the cut end. Then I

used a boring bar and did some turning on the inside on one end,

extended into the middle. Then I turned it around and worked on the

other end, but inside only to 10 mm depth.

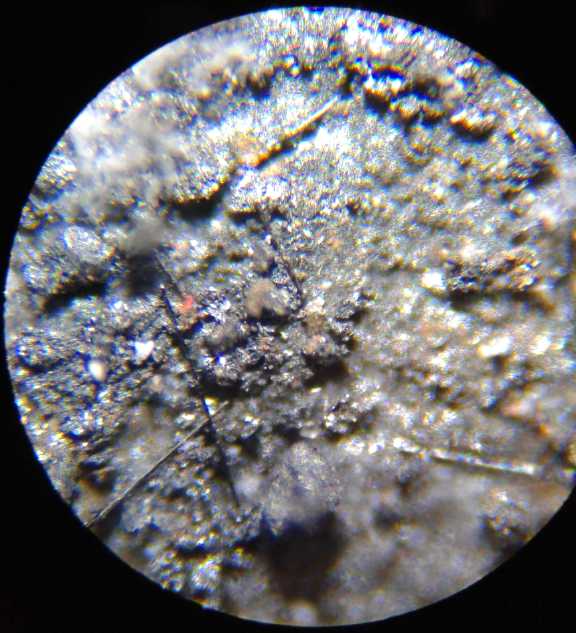

Starting to turn the inside of

the pipe to

"prfectly round" and the right size to hold the ring gear.

Starting to turn the inside of

the pipe to

"prfectly round" and the right size to hold the ring gear.

With the ring gear pounded in.

With the ring gear pounded in.

The motor end with the planets

assembly and

stub splined shaft.

The motor end with the planets

assembly and

stub splined shaft.

Soon I realized that the "cup and cone" bearings would have leaked

oil, so I replaced them with "double row sealed ball" bearings.

The centrifugal clutch end. The

long shaft on

the ring gear,

The centrifugal clutch end. The

long shaft on

the ring gear,

which was "ready made" from some previous attempt,

proved to be just long enough.

Then I turned it around again and widened the inside

diameter some more. After going a very tiny bit at a time (seemingly

far too many times), I had a fit where I could pound the ring gear into

the pipe. So it had machined ends and a solid fit. The ring gear could

have gone another 1/8" in (I was just guessing the depth to cut), but

its was wider side to side than the planets, so there was some room

for play and it all fit. The piece of pipe was about 1/4" longer than

it needed to be. (I was guessing that too, but I had left a bit extra

in case my guess was short.) Here again I was in luck because the

1.0635" section on the shaft extended out an extra 1/4", so all it

needed was a spacer. So everything fit first try without having to

pound the ring gear out and bore deeper, and without having to cut the

pipe shorter.

(7th) I noted that it was going to be very hard to get a good oil seal

with cup & cone bearings at each end. Well, not much I could do

about that! I could change to sealed needle bearings, but... but what?

I went out and looked, and while I didn't have just the right sizes, it

looked like they'd actually even be a better fit. They had side walls

and were filled with grease, but I suspected a bath of oil on the

inside would get in and seep through. But at least it would "seep" and

not "gush" through.

So I went online to vxb.com (bearings store in California

with a good online catalog and prices listed). I ended up picking two

"double row, sealed" ball bearings that I hoped would fit - and not

leak, or not much. (One might be too tight, the other loose - best I

could find.) I ended up 100 $C lighter. How much cheaper to make than

to buy, again?

I really still didn't have a complete plan. I took the

assembly out to the car. It looked like the thing to do would be to put

the chain sprocket on the motor/input end and leave the other end just

for the centrifugal clutch. Other than having to make some large

support with a bearing on the end to support the end of the clutch

inner shaft, an extender shaft adapter/coupler for the motor and maybe

cut out a recess in the sidewall for the body pipe of the planetary

assembly, everything looked like it would fit in best - would actually

fit in at all - that way.

It seemed a great pity the the chain sprocket wouldn't fit

around the pipe/planetary gearbox. That would have simplified things

immensely. But such a large sprocket would have made for a very low

reduction ratio to the differential - less than 2 to 1, when it needed

3 or 4 to 1.

At this point the impetus ran out. On the 15th I took it

to the cafe at lunch for ideas (where I was reminded that the end

plates would leak without an O-ring or a gasket). I also found some

aluminum plates I could use for the end plates. But basically it was

now "wait for the bearings to arrive".

The company selling me the 5 to 1 planetary gearbox for

the Miles truck was also dragging their heels. I had to phone to see

what was happening and give a couple of instructions to get them to get

on with it. Then on the 15th they sent a drawing of the gearbox and

asked me to sign it saying it was what I wanted! Oh well, somehow I

didn't seem to be getting a lot done on any projects anyway. On the

21st I finally got another e-mail... saying I should approve their

shipping

method (Fedex)! Do they really want to sell things?

That same day the bearings arrived. As I expected the 30mm

I.D. one wouldn't quite go onto the 30.5mm hub protruding from the

planets assembly. I put the hub on the lathe and filed it down. (I was

surprised I could - weren't these parts "case hardened"? Maybe not the

outer shell for the planets.) As

expected the other one was too loose. I started making a brass spacer.

It was going to need a lot of sanding down. Somehow when I was putting

a sanding disk onto the drill press, I glanced somewhere and saw some

old previously made steel spacer that looked about right. Sure enough

it was a perfect fit. I must have had to fit a 1-1/8" something onto a

1-1/16" shaft before - probably the same shaft in some previous attempt

at a torque converter years ago.

In the meantime I had been down to the dungeon, er, root

cellar, er, storage room, and found four 3/8" thick aluminum disks I

had made trying to do a flat belt to the differential years ago. The

centers were too big for the bearing, but they also had some bolt holes

which could be used to attach new centers. They should make good end

caps for the rotating planetary gearbox.

(22nd) I went to put one of these disks on the lathe, but it was too

big. I asked my neighbor if I could use his larger lathe (he had been

given this beautiful modern lathe and didn't know how to use it), but

the center of the 3-jawed chuck was too big to fit into my center hole,

and the outer jaws were too small to go around the outside. I went home

disappointed.

There were holes in them for SDS hub bolts, and that must

be how I had originally made them on my lathe, but SDS hubs aren't a

perfect thing to center on. Oh well...

How to connect the motor?

How to connect the motor?

Trivial in the design concept, tricky to actually do.

(24th) I left the disks for the moment.

There was a question mark

around how to connect the motor to the planets assembly of the

planetary gear. And that connection would affect the spacing and inside

size of

the drive gear going to the differential, so I wanted to do it before I

got too far on that. The motor had a short shaft. There was a short

shaft stub that fit into the spline of the gear. It seemed to need a

short

hollow shaft to couple them together. On a hunch I went into a drawer

full of scrap

copper wire, pulled out most of the wire, and found a long forgotten 2"

long, 28 mm O.D. steel pipe at the bottom. (I didn't know it was there,

honest!) It looked a bit small in diameter, but I had nothing else

close. It

turned out that if the inside was turned out a little, it would fit

over the motor shaft. I made it so I would have to bang it on, and I

would add a couple of set screws. If that didn't hold, I might have to

drill a hole through the shaft and put a bolt through it - worry about

that if it happens.

The other end was more of a puzzle. If I turned it out to

fit the shaft stub, it would be so thin it would probably split open.

There was a bit of the end of the stub shaft that was narrower, about

23 mm. I could probably turn the pipe to accept that, but it was only

about 3/16" long - not much to grip. I might turn down the outside end

of the stub shaft, but it might be a bad idea too. (Aren't those things

"case hardened"?) Lacking other

inspiration, I turned out the inside of the pipe to take the 3/16"

long narrow end of the shaft. Again I made it a "pound in" fit, but

still it

wasn't much length to grip onto.

Then I thought that with the two pieces tightly held in

perfect alignment, I could weld them together. The idea of welding

something to the shaft stub had occurred to me before, but I was sure

the two parts wouldn't be in good alignment no matter how careful I

was. This would be perfect because it would be solidly held in

alignment during the welding.

I fitted everything together. Somehow the images with

extensive descriptions are above in "November in Brief" and I won't

repeat them here.

Other

"Green"

Electric Equipment Projects

Handheld Bandsaw

Mill (& Alaska Mill)

(7th) Along with ordering some other bearings I ordered a couple of

needle thrust bearings that I thought would be more suitable for the

saw than the ones I just got.

Level?

(10th) I conceive that for milling narrow or misshapen boards or when

using a narrow or imperfect guideboard, it may be useful to put a level

on the mill. One can then maintain the level from one end to the other

as one goes and avoid cutting twisted boards.

I thought of this as I was cutting on top of slightly

convex "cupped" previous cuts without bothering to fasten down the

guide board. It was too easy to tilt the mill side to side, and it is

often the case one can make small adjustments by pushing down harder on

one side of the mill then the other. Just a few boards after thinking

of this, the guide board actually started tipping off one edge without

me noticing, and my cut was more and more diagonal. With a level I should

have noticed something was wrong sooner, before it was way off. Over

much of the board the two faces were nothing like parallel. (I screwed

the guide board down and put in chunks of bark to stabilize the net cut

to get back to something like level, and that next board of course also

was a wedge

shape.) Anyway I got twelve 2" by 4"s from about a 24" tall cant. (The

top and bottom ones, being sapwood, have a lot of worm holes.)

Ow! A Nail!

(12th) I cut another 6"

slab from the log, and managed to push it

aside. That went so well I decided to do another. About 4' along, and

6" inside the log, I hit a nail or something that wrecked my chain. I

don't think I could have detected metal that far inside even if I had

thought to try. A nasty expense for a job almost done! This is the

second tree near the house that has had nails, even in this country

place. It would have been over 6' up in the tree. That seemed rather

high for fence nails. Perhaps it was a hook for a clothesline or

humming bird feeder? The next question was, was there just one piece of

metal, one hook, or were others lying in wait? If it was just one, I

should be able to cut through 8 feet from the other end and just

carefully cut off the last bits of wood with a small chainsaw, then pry

it apart off the hook/screw/nail. It did seem like a spot a clothesline

might have been hung - quite a short clothesline, but there were no

other trees near the house that were more suitable for one. (It was a

straight nail. I bent it to pull it out of the wood. Naturally I had

been trying to rip the nail down its center. If I had just been cutting

through one section, the saw might have actually got through it. ...not

without lots of damage to the chain anyway.)

(12th) I cut another 6"

slab from the log, and managed to push it

aside. That went so well I decided to do another. About 4' along, and

6" inside the log, I hit a nail or something that wrecked my chain. I

don't think I could have detected metal that far inside even if I had

thought to try. A nasty expense for a job almost done! This is the

second tree near the house that has had nails, even in this country

place. It would have been over 6' up in the tree. That seemed rather

high for fence nails. Perhaps it was a hook for a clothesline or

humming bird feeder? The next question was, was there just one piece of

metal, one hook, or were others lying in wait? If it was just one, I

should be able to cut through 8 feet from the other end and just

carefully cut off the last bits of wood with a small chainsaw, then pry

it apart off the hook/screw/nail. It did seem like a spot a clothesline

might have been hung - quite a short clothesline, but there were no

other trees near the house that were more suitable for one. (It was a

straight nail. I bent it to pull it out of the wood. Naturally I had

been trying to rip the nail down its center. If I had just been cutting

through one section, the saw might have actually got through it. ...not

without lots of damage to the chain anyway.)

But if there were more pieces of metal, or if I went a bit

too far, I would just wreck another chain. Should I gamble it was just

one clothesline hook? How much is that wood worth? There was still a

lot of it. I could cut off 4+ feet and have a less than 8 foot log, but

I still might hit another piece of metal. I could cut off 6 feet and

have a 6 footer - not the most useful length boards! That would be fairly

safe. I could turn the log over and start milling again on the other

side?

Pulley and Link Belt Selections

(13th) I was sorting pulleys and I ran across a 2 inch V-belt pulley.

Then I realized the one I thought had ordered as a "1 inch pulley" was

really 1.5 inches. So it would seem that from the 5000(?) RPM skillsaw,

the 1.5" pulley turning a 9" pulley (6 to 1 reduction) made the band

run too slowly. Also it was too small for the V-belt to get a good grip

on, so it slipped when the going got tough. I estimate the variable

pulley I'm using is set to about 2.5 inches - it seems still larger

than the 2 inch pulley. (I may try the 2 inch pulley - it has the right

1/2" bore so it'd be easy enough to try out.)

2 inch and 1.5 inch V-belt

pulleys. The 1.5 was

held on the skillsaw by that bolt.

2 inch and 1.5 inch V-belt

pulleys. The 1.5 was

held on the skillsaw by that bolt.

I also note here that when I went beck to the larger

pulley, I also soon went back to the link belt. It's much better than

the regular V-belt. I don't understand why they don't make regular

V-belts with grooves in them like the "variable transmission" V-belts.

Those would have to be better too!

Moving Along - Setting Teeth

(17th) Finally got back to it. I sharpened the band. But it didn't go

well. The saw was binding in the cut. I only cut one 6" wide by 12'

long board, and it was an inverted bowl across and not very straight

lengthwise. I tried to cut a second, but the cut curved up badly and I

gave up after a foot or so. The next day I gave myself a blister

bending a 'set' into the teeth with a small pair of pliers. (That feels

hard on that finger... well there's only 279 teeth, keep going and

finish it up!)

It was night and day difference! A thick stream of sawdust

sprayed from the saw, which cut freely at about 6 feet a minute. I cut

3 more boards in no time. After that it wasn't quite as sharp and the

cutting slowed down, but I still did 9 boards in well under an hour,

finishing the whole cant.

Moral: A tool working right works WAY better than one that isn't. Also

every time the band is sharpened some of the 'set' is ground off, and

it needs to be re-set after 2 or 3 or 4 (?) sharpenings.

Next Cant

Having had my chain re-ground (losing 1/2 its life) I cut

in from the other end of the log until I got near the metal thing. Then

the log kind of went "clunk" down on the cut and jammed it. I wedged it

open and pulled the saw back out. There was still over an inch of

"hinge".

I filled the gas tank, then I cut another 6" thick slice.

This one seemed to go well until about 9 inches from the end. There the

saw ran out of gas. Hard to believe - really? Normally I'd have stopped

it at the first sign of a sputter, but it was hard to believe it could

be empty, and with such a short distance I thought it might make it.

Not another inch!

I refilled the tank, but I wore myself out trying to start

it again. Typical! I hate gasoline powered appliances more and more the

more I use them. I know the best way to get this saw to start again if

it doesn't start with a few pulls or with removing the spark plug and

giving it a few cranks is to leave it a week. Then it will usually

start right up again.

I backed it off in the cut and cut to the end freehand with the

electric Dolmar chainsaw. The cuts weren't very straight. Anyway I had

- at long last - reached the bottom piece of the last section of the

last tree cut down in 2017. The rest was bandsawing. But I didn't get

there for the whole rest of November!

Skilsaw Chain Beam Saw

Someone sent me a picture of a chain attachment for a handheld circular

saw, for "beam cutting". I'm not sure how practical it looks, but as

it's related, here it is.

Someone sent me a picture of a chain attachment for a handheld circular

saw, for "beam cutting". I'm not sure how practical it looks, but as

it's related, here it is.

One interesting feature is that like my bandsaw mill, it

uses a skillsaw as a motor to power something else.

http://www.praziusa.com/12-beam-cutter-model-pr-2700/

5 Blade Windplant - Windplant Ducts

Until the morning of the

6th no wind had blown to turn the windplant since October 23rd. Then it

made a few watts for a little while before stopping again. In the

evening it picked up and the next day there was a fair blast for a

while, creating figures of 45 to 65 watts. It was dark overcast and

that was almost as much as the DC solar power was making.

In fact, while typically things were quiet, there were

quite a few days with wind in November, and I would often see the

MPT7210A charge controller putting out 3, 15, 20 or 50 watts in the

wind. Occasionally it would hit 60s to 70 and beyond. On the 13th it

was blowing all day, with 40 to 65 watts being the most common

readings, and it went just over 100 for three brief readings. And it

would do it at times of day when there was little or no solar

collection. So it is by no means a useless appendage to the energy

system.

I don't notice the noise much. I do think it's quieter

than a 3-blade windplant. When the wind is blowing the waves are

crashing in and the level of noise is pretty high anyway. (This place,

for all its virtues, is a bit close to the sound of the ocean - a roar

on windy days - for my taste.)

On the 13th it all seemed worthwhile. Maybe I should do

some sort of venturi surround for it after all and get some higher

mileage out of it? But there wasn't much wind for the last 10 days of

the month.

Clarkson University Experiments with Windplant Ducts

Of course I'm not the only one to think of improving the

performance of a propeller type windplant. At Clarkson university they

have been experimenting and found they could literally double the

performance simply with a flaring exit to the fan, similar to the one I

drew last month as the exit to the venturi duct.

"Ducted" wind turbine (2017):

just a short

flared exit

"duct" doubles power -

"Ducted" wind turbine (2017):

just a short

flared exit

"duct" doubles power -

without doubling the price. What would a whole venturi duct do?

(On the left wall louvered fans blow controlled air at the unit under

test. Many of us only dream of having such test facilities!)

Other windplant duct experiments

by Clarkson.

Other windplant duct experiments

by Clarkson.

Putting together the flared exit of the previous photo

and the "back end of a venturi" configuration of the

right side unit, they'd probably hit around 2/3 of the

effect of a complete front-to-back venturi duct.

(Or, they just might be doing better than I think

with those clever vane arrangements.)

https://www.youtube.com/watch?v=EXxA-RkwuRY

My

Solar

Power

System

Water Heater, Sprint Car &

Lithium Batteries

I noted last month that I had put a switch on the water

heater, hoping I could leave it on on dull days. Opening the switch

puts

the third heating element in series with the two already in series,

bringing the watts down from ~250 to ~160. When I did that the weather

doubled down and got duller and cloudier so that not even 100 watts was

being produced at midday. With the very weak NiMH dry cells battery,

turning on the water heater in either mode quickly brought down the

voltage.

By the 7th I was tired of nothing more than luke-warm

water and a sink full of dishes.

Last month I had made a DC/solar charging circuit to

charge lithiums without danger of any one cell hitting too high a

voltage, and connected to some 40 amp-hour blue colored lithium

batteries I had bought used about 4 years ago. I had always tried to

keep them charged up. Now at the end of October I tried to power the

solar system with them, and discovered that 3 of the 14 cells were

useless. They had voltage until one tried to use them, then they

instantly went to zero. A fourth cell was very weak. So there weren't

enough good ones to make 36 volts. This was unexpected. Perhaps they

were bad when I bought them? I might contrive to use some completely

different lithium cells in series to make up the last two, but for now

it seemed impractical to try and use them.

Other than the inaccessible 24 KWH Nissan Leaf battery,

that left the ~11400 rated watt-hours of lithiums in the Sprint car, at

36 volts. I thought I had made everything so I could connect the car to

the solar power with 70 amp Anderson connectors except the final

"extension cord" to connect them together. Connector in

car... Connector to panel... presently plugged into the NiMH batteries.

I now made

that cord, unplugged the increasingly unsatisfactory NiMHes and plugged

in

the car/lithiums, and turned on the water heater with the full 260

watts

setting. The lithiums quickly dropped from just over 40 volts to

39-1/2, but only gradually continued down to 39.14. The next time I

checked, the water heater had shut off and it was back up to 39.68

(eventually to 39.81 and overnight about 40 volts). Time to wash dishes!

I now made

that cord, unplugged the increasingly unsatisfactory NiMHes and plugged

in

the car/lithiums, and turned on the water heater with the full 260

watts

setting. The lithiums quickly dropped from just over 40 volts to

39-1/2, but only gradually continued down to 39.14. The next time I

checked, the water heater had shut off and it was back up to 39.68

(eventually to 39.81 and overnight about 40 volts). Time to wash dishes!

(8th) Even with high capacity batteries that actually work one can't go

on too long without recharging them. For charging from 120 VAC I had

done the first two 6-volt chargers each on 2 series cells under the

hood last month. (putting out a constant 7.0-7.2 volts) Since I hadn't

yet done the rear, I connected my two Canadian Tire 'trickle' chargers

on the two 12 volt sections of the 36 volt total in the rear of the

car, ran a 120 VAC extension cord from the front to the back (under the

trim and next to the doors), and put an AC power bar in the back. I

plugged in all the chargers and put an AC power meter on the main cord.

The two old chargers in the rear drew just 15 watts each -

hardly over 1 amp at 14 volts. The new front ones started out at 135

watts,

indicating charging at almost 10 amps, and gradually dropped from

there. That's faster than the water heater discharges them. It's hardly

a guess which 12 volt section will be charged first! After a while

(well over an hour), the front was down to 45 watts while the rear two

were still at 15 each.

At first I still turned the water heater off at night, and

I

unplugged the chargers to the front of the car. I note that these are

not very well regulated - the voltage changes over time probably with

temperature. Furthermore the knob is much too easy to turn accidentally

an hard to get just where you want. Adapters with screwdriver 10 turn

trim pots - and better regulated - would be much better if they can be

found. A plus of these ones is that the AC input can be 100 to 240

volts. That means they could be plugged into a 240 volt J1772 car

charging

station - although there is no need or use for plugging them into more

than a

regular 120 volt outlet. (With 5 amp chargers at 36 volts it won't be a

fast charging car by any means. 10 or 20 amp power adapters would be

better if I could find them.)

Sprint Car & Solar Lithium Battery Chargers

(Now, should this be under batteries, solar power, or electric

transport?)

At this point, I had done nothing to recharge the lithiums

from the solar. I decided I should put an MPT7210A right into the

Sprint and connect it straight from the solar panels. (a second,

lighter extension cord.) That would be compatible with my DC lithium

charging circuit, and when I put the long-planned solar panel on the

car roof, it would be all ready to hook up. And since I had determined

that slow-charging 12 volt sections from solar was safe, I would use

just 3 DC to DC converters for the 36 volts. As I thought about it, I

would use two of them and adjust the 7210 to the exact voltage for the

uppermost section, 40.2 volts, from which the middle and bottom

sections would be subtracted leaving 13.4 volts per section.

How to connect? I wasn't going to hard-wire any part of a

car to a stationary wire. The solar panels were about 36 volts...

How about my 36 volt HAT connectors? I decided a 15 amp one should be

adequate. I had a couple of the 3D printed shells.

I

took an absurd amount of time to wire up the plug - a

couple of hours. I had to make the pins by flattening a piece of #10

AWG wire and notching and drilling them per TE News 129, and then

soldering the wires

to them. It didn't go smoothly. I pulled out the wrong size pins in the

drawer but didn't realize it. Redo. For some reason the first drill I

tried

simply wouldn't drill through copper. Then the holes were too small for

the

wires. I soldered a wire on the wrong side of a pin and it mattered:

redo. I dropped a box of 100 tiny screws on the carpet. They wouldn't

go through the holes in the plastic shell so I had to drill those out

bigger.

I

took an absurd amount of time to wire up the plug - a

couple of hours. I had to make the pins by flattening a piece of #10

AWG wire and notching and drilling them per TE News 129, and then

soldering the wires

to them. It didn't go smoothly. I pulled out the wrong size pins in the

drawer but didn't realize it. Redo. For some reason the first drill I

tried

simply wouldn't drill through copper. Then the holes were too small for

the

wires. I soldered a wire on the wrong side of a pin and it mattered:

redo. I dropped a box of 100 tiny screws on the carpet. They wouldn't

go through the holes in the plastic shell so I had to drill those out

bigger.

I'm convinced now that the thing to do is to do injection

molds for CAT and HAT plugs and molds for putting clay in to make

porcelain sockets, as well as molds for wall plates and everything else

needed or useful, and to make stamps that will stamp out the various

pins and receptacles... and to manufacture and sell them to all the

places that sell solar and low voltage equipment. Maybe Amazon? That

way when anyone - including me - wants to do 12 or 36 volt wiring it'll

be simple and straightforward. Somehow no one else seems to have done

anything like it yet. (If they did and used my pin size and spacing

specs, I could just buy them and my problem would be solved.)

Next I thought about the steering diodes. The "car

alternator" diodes lost over .8 Vf. Recently I had uncovered

some 60 volt, 30 amp Schottky rectifier diodes I had lost track of.

(And I now put all my diodes into some plastic part drawers all in one

place.) These had actual part numbers so I could look up the specs!

They only lost .49 V max at 15 amps - only about 60% as much wasted

power - and even less since the MPT71210A only puts out max 10 amps.

(15th) I soldered four of them to little pieces of copper to screw to

battery terminals at the 12, 24 and 36 volt levels, with the anode

inputs from the DC to DC converter outputs. I mounted the MPT7210A in

the back of the car and ran a ground wire from under the hood to the

back.

That was about as far as I got. Owing to the time it took

to make a plug, I started thinking about making them easier to make,

and about how to produce them for sale. I enlisted Mike's help and we

at least came up with easier to make and use pins for the plugs and

almost equally simple "Z Fold" receptacles for the sockets. The small

writeup on that process is in "November in Brief".

Month of November Log of Solar

Power Generated [and grid power consumed]

(All

times are in PST: clock 48 minutes ahead of sun, not PDT which is an

hour and 48 minutes ahead. DC power output readings - mostly the

kitchen hot

water heater - are reset to zero daily, while the others are

cumulative.)

October 31st 2.98+.24, 888.72 => 2.78 KWH

[68579@17:30]

mostly cloudy, a bit of sun in the afternoon.

November

Solar: House+DC, Trailer => total KWH [grid power meter

reading(s)@time] Sky conditions

1st 4.00+.19, 889.33 => 1.82 KWH [68598@18:00]

light

overcast.

2nd 5.41+.56, 890.50 => 3.14 [55Km.chj.car;

68627@17:00] cloudy AM, sunny PM.

3rd 7.20+.42, 891.87 => 3.58 [68648@19:00] Mostly

sunny.

4th 8.08+.39, 892.65 - 2.05 [68666@17:30] cloudy.

5th 8.79+.11, 893.28 - 1.45 [68684@20:00]

cloudy.

6th 9.11+.19, 893.54 - 0.77 [68712@19:00]

Clouds rain and light winds (2-5 watts from windplant)

7th 9.82+.72, 893.84 - 1.73 [68732@17:30]

Dull,

windy (up to 45-65 W at one point from windplant)

8th 10.86+.50, 894.76 - 2.46 [85 Km,car charging;

68762@17:00] Mostly overcast.

9th 12.52+.05, 895.75 - 2.70 [60 Km,charging car; 68797@21:30]

Largely Overcast, a little sun.

10th 13.65,(.61*),896.58- 1.96 [68818@19:00] Mostly overcast.

(*Recharging lithiums on 36 volts system from wall not solar, so it

doesn't count

for solar collected.)

11th 14.95,(.95*),897.41- 2.13 [68835@19:00]

12th 16.40+.33, 898.37 - 2.74 [68849@17:00]

13th 16.77+.35, 898.87 - 1.22 [68864@16:30] (there's some wind

power in the DC .35, .62 KWH figures)

14th 18.00+.62, 899.69 - 2.77 [55Km,charging car; 68883@17:30]

Some sun.

15th 19.80+.07, 901.07 - 3.25 [85Km,ChjdCar; 68914@22:30] Quite a

bit of sun. (But quite short days now!)

16th 20.16+.15, 901.33 - 0.77 [55Km,Chj; 68931@17:30] Clouds

& rain.

17th 21.37+.42, 902.33 - 2.63 [68950@18:00] some clouds, rain,

sun.

18th 01.83+.37, 903.58 - 3.45 [68968@19:00] mostly sunny (power

fail during night)

19th 03.47+.30, 905.28 - 3.64 [68983@18:30] Sunny!

20th 04.74,(1.28),906.14-2.13 [69000@21:00] Some sun. I ran out

all the hot (hardly warm) water in the sink because it stank, until it

ran completely cold. Then I turned on the heater and later with water

that didn't stink I did a good load of dishes. Thus the high usage -

which came mostly from the car lithiums, from the power grid. I turned

down the temperature a couple of times, but if the water is in the tank

a couple of days, (ie if I don't use most of it, daily) it starts to

stink. (sulfur?) I know the well water is mineral rich, but why does

the kitchen hot water smell, but the water in the main hot water tank

tank never does? And I con't remember any smells last summer when I put

the tank in.

21st 05.64+.35, 906.99 - 2.10 [69026@17:30] Mainly sunny, rained

a bit anyway (sun from way south, rain from above.)

22nd 05.68+.01, 907.01 - 0.06 [85Km&Chjd; 69064@23:00] Clouds &

Rain. Holy Nothings! Could a day's collection get any closer to

'gooseegg' than that?!? From a full 15 KWH in summer that's ~.04%. One

could do 100x better in space way out near Jupiter! PS: One can see I

didn't turn the kitchen water heater on this day - just lights on the

DC power.

23rd 06.51+.01, 907.52 - 1.35 [55Km&Chjd; 69076@17:30] Mor cloudz

and rain. Left KHW off again.

24th 08.21,(1.04),908.71-2.89 [69098@24:00] Sunny, rain before dark.

Left KHW heater On, on the car/lithiums.

25th 09.77,(.60),909.88 - 2.73 [89109@17:00] Mostly sunny.

26th 10.58,(.62),910.81 - 1.74 [89131@17:00] Snow, then sunny.

27th 13.71,(.92),912.35 - 4.67 [69153@16:00; 55Km,ChgCar] Sunny. (Extra

sunny - No jet trails)

28th 15.33,(.14),913.18 - 2.45 [69184@19:30] Mainly sunny.

29th 17.33,(.18),914.60 - 3.42 [90Km,Charging; 69205@17:00] Sunny. (Sky

full of jet trails by sunset)

30th 18.12,(1.11),915.01-1.30 [55Km,Charging; 69232@17:00; 50Km,Chj.]

Not sunny.

December

01st 18.84, (.71), 915.41 - 1.12 [69276@18:30] Even more not

sunny.

02nd 19.58, (.63), 915.84 - 1.17 [55Km,Chjd; 69306@21:00] Clouds and

Rain.

Daily-

KWH- # of Days (Nov)

Made

0.xx - 3

1.xx - 8

2.xx - 12

3.xx - 6

4.xx - 1

5.xx -

6.xx -

7.xx -

8.xx -

9.xx -

10.xx-

11.xx-

12.xx-

13.xx-

14.xx-

15.xx-

16.xx-

Monthly Tallies: Solar Generated KWH [Power used from grid KWH]

March 1-31: 116.19 + ------ + 105.93 = 222.12 KWH - solar [786 KWH -

used from

grid]

April - 1-30: 136.87 + ------ + 121.97 = 258.84 KWH [608 KWH]

May - 1-31: 156.23 + ------ + 147.47 = 303.70 KWH [543 KWH] (11th

solar panel connected on lawn on 26th)

June - 1-30: 146.63 + 15.65 + 115.26 = 277.54 KWH [374 KWH] (36V, 250W

Hot Water Heater installed on 7th)

July - 1-31: 134.06 + 19.06 + 120.86 = 273.98 KWH [342 KWH]

August 1-31:127.47 + 11.44+91.82+(8/10)*96.29 = 307.76 KWH [334 KWH]

(12th panel connected on lawn Aug. 1)

Sept.- 1-30: 110.72 + 15.30 + 84.91 = 210.93 KWH [408 KWH]

(solar includes 2/10 of 96.29)

Oct. - 1-31: 55.67 + 13.03 + 51.82 = 120.52 KWH - solar

[635 KWH - from grid]

Nov. - 1-30: 36.51 + 6.31 + 26.29 = 69.11

KWH - solar [653 KWM - from grid]

9

month total March 1 to November 30: 2044.50 KWH made; [4683 KWH

consumed

from grid]

Things Noted

* At some point in October I gave up trying to charge the car at 1500

watts during the day in order to use power from the solar, and just

used the 3800 W charging station. There just wasn't enough of it for it

to help. What solar power there was would have been taken by other

loads around the house anyway - easily by the 250 W travel trailer

heater and the 175 W(?) LED grow lights for the indoor winter garden.

And the sunny hours were too short to bother even if there had been

enough power during

the day.

* On the 10th to 13th (and various other days) I didn't drive anywhere.

This is reflected in

markedly lower electrical consumption on those days.

* Owing to the low winter collection I looked up Stirling engines (see

article below). I think I can make a better one for the woodstove,

"sort of" a low pressure steam engine! A generator would be attached.

100 Watts?

Woodstove

Alternator

with

Stirling Steam Engine?

(apologies for poorly written rambling article. I want to get this

newsletter out tonight!)

(22nd) In the winter weather and low sunlight, and with the windplant

only very occasionally firing up, I thought again occasionally about

using the woodstove for generating electricity, and how the seemingly

promising TEGs (thermoelectric generators - sort of a special Peltier

module - had in the end seemed like "not much bang for the buck" and I

didn't build it. I thought that boiling water on the stove and running

a steam turbine could give a heck of a lot more power. But realisticly

the top of the woodstove is rarely hot enough - unless the steam was in

some sort of closed loop in a partial vacuum to reduce the temperature

water would boil at. That would make it a very complicated project.

I have also

thought off and on about Stirling engines, also called "external

combustion engines", invented by Robert Stirling in about 1816, after

Guillaume Amontons' "Fire Mill" hot air engine in 1699. (over a century

earlier!) They run off any amount of heat, in fact off the temperature