Turquoise Energy News #139

covering

December

2019 (Posted January 5th 2020)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- 12/36 Volt DC CAT/HAT plugs and sockets - Woodstove Steam Engine

Generator - Power outage and running 230 V well pump on an inverter -

Ground

Effect Vehicle - New Chemie Batteries - A Solar Kayak

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Hair Loss: the Demodex Folliculorum Mite / Helpful

Methods for Keeping (& Restoring?) Hair - Social and

Political

Evolution - Small Thots: "5G"≠"5 GHz", Supercorder, Nuclear waste -

Disaffected Generation - How food shortages anywhere become a global

problem - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Ground Effect Vehicle (Still the Prototype 1/4 scale R/C

Model... continued)

* EV Transmissions: 5 to 1 planetary gear for the Miles

electric cargo truck

Other "Green"

Electric Equipment Projects

* HAT & CAT Plugs & Sockets

Electricity Generation

* My Solar Power System: - Monthly

Solar Production log et cetera - Notes.

* Woodstove Stirling Engine "Carmichael's

Woodstove Engine" (& generator)

- Rapid design metamorphosis - Design Arrival: A "Closed Cycle

Steam Engine"

- Noted in passing: Woodstove or Stirling Engine as a potentially

very high COP Refrigerator or Heat

Pump

Electricity Storage

* Turquoise Battery Project

(Mn-Zn or Ni-Zn in Mixed Alkaline Salt electrolyte)

- "layed down" flat case - Gold electroplating copper current collector

- Natural Resources

Canada's Charge The Future Battery Challenge Rejection Notice

The Weather

Here I am at 53-1/2° north latitude, same as Edmonton

where we left when I was 17. What's notable about winter in this

moderately far north? I'm only 5'8" tall (maybe 5'9" with shoes and

tuque), but at the start of December around noon, my shadow was about

23 feet long. This also explains how it is that spruce tree shadows,

even from 200-300 feet away on the next acreage to the south, shade the

solar collectors (especially the ones down on the lawn) so much of the

short day.

Luckily the climate is very different from Edmonton. None

of that -20°c lasting for weeks stuff. In fact, being a Pacific

Island not

so close to the mainland, the winters seem hardly colder than in

Victoria, about 48° north. But it's not the tropics either. When I

went outside on a starry night, I discovered the lawn suffered from

"crunchy ground syndrome" and the wooden deck was very slippery. It

stayed down around 0°C day after day, and soon there was hard water

in every shady area. And my firewood started

evaporating - I had to buy a cord since I didn't want to burn wet or

green wood. (But I checked on the 15th and at 8 to 9°C at night, we

were Canada's 'hot spot', above Victoria and Comox with 5°.)

But summer here isn't hot. In fact, two out of three so

far

haven't been very nice with a lot of clouds. (As part of the global

climate chaos I look forward to more nice summers like 2018 when I grew

quinoa.)

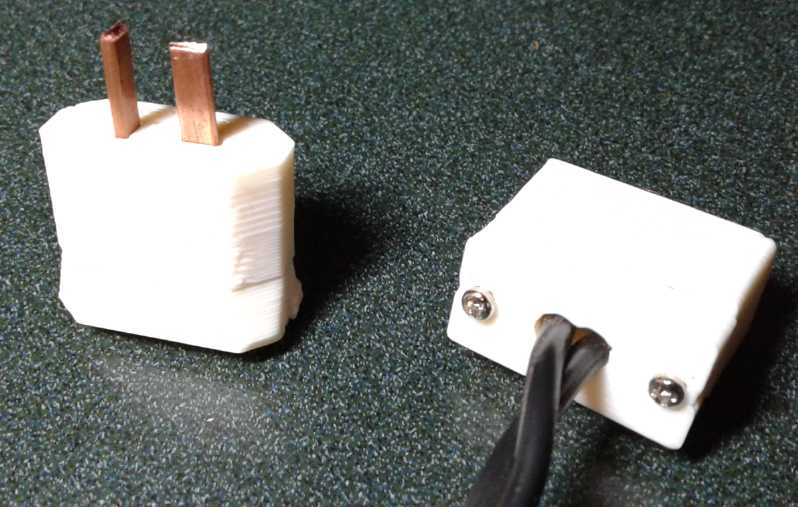

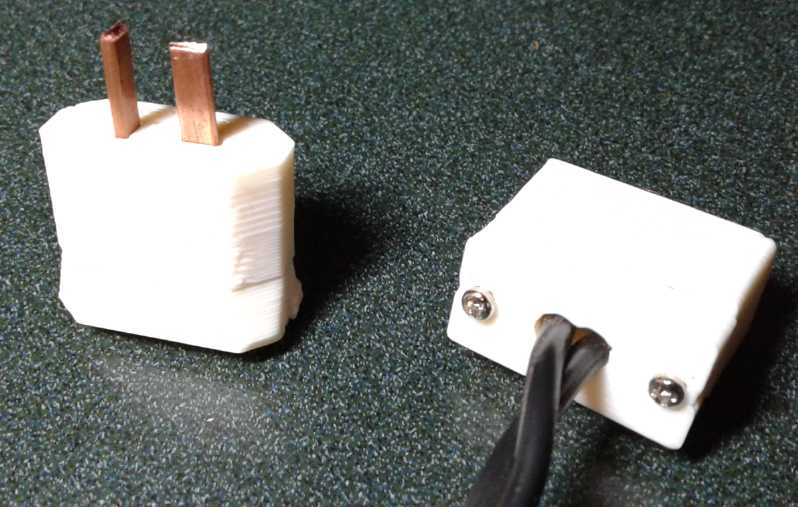

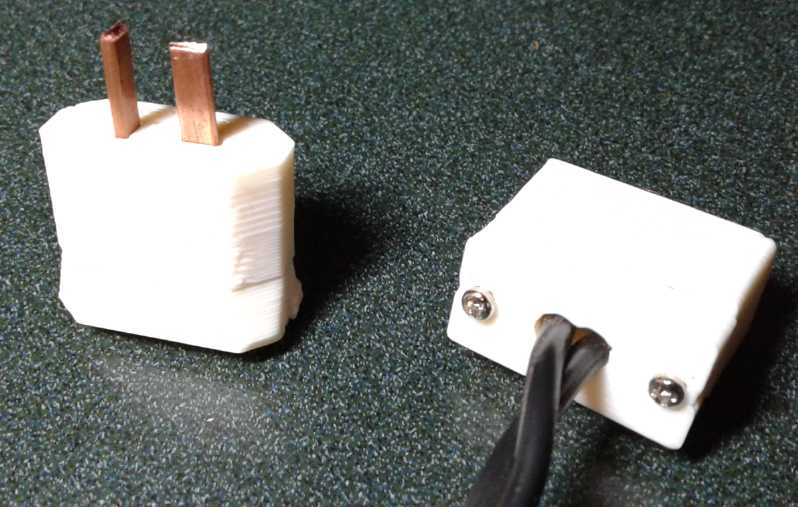

Commercializing CAT and HAT Components (plugs, inline sockets,

connectors, 3 or 4 socket wall plates, "cigarette lighter" adapters,

click-lock plugs and sockets, 50 amp plugs and sockets... for

solder-on, crimp-on & screw-on connections)

In

keeping

with

frustration

in making myself a new 36VDC HAT

plug I decided that it was high time I tried to find ways to make CAT

and HAT plugs and sockets easy to produce, and then to commercialize

them. I talked about them with Mike on Saturdays when I went into QC to

check my mail and he would be in his new (now almost completed) shop.

Between us we came up with some good solutions, and I started designing

new shells to accommodate the new pin/blade and blade receptacle

designs. This wasn't any change to any specs, just to the insides of

the plugs and sockets. The old ones and the new ones will still plug in

together.

In

keeping

with

frustration

in making myself a new 36VDC HAT

plug I decided that it was high time I tried to find ways to make CAT

and HAT plugs and sockets easy to produce, and then to commercialize

them. I talked about them with Mike on Saturdays when I went into QC to

check my mail and he would be in his new (now almost completed) shop.

Between us we came up with some good solutions, and I started designing

new shells to accommodate the new pin/blade and blade receptacle

designs. This wasn't any change to any specs, just to the insides of

the plugs and sockets. The old ones and the new ones will still plug in

together.

With me using 36 volts, it suddenly me occurred to me:

that's just me. I may (or may not) convince people that 36 volts is

better for DC house wiring than 24 or 48, but by far the most

common DC power

is 12 volts. The 12 volt CAT parts will surely outsell the 36 volt HAT

ones by 10 to 1. "More." said Mike. So once I had done a decent new

shell for HAT, CAT will definitely be the thing to focus on for

commercialization. With the new techniques like the "Z-fold" blade

receptacles, they'll connect better - more reliably - than with those

crappy Pico ones.

Somehow it's ironic that I designed the CAT system to use the same pins

and receptacles as AT fuses so as to not have to make pins and sockets

myself, but now every piece will be made from scratch.

And I hope to bring out a good line of mutually supporting

products with CAT and HAT connectors besides just plugs and sockets.

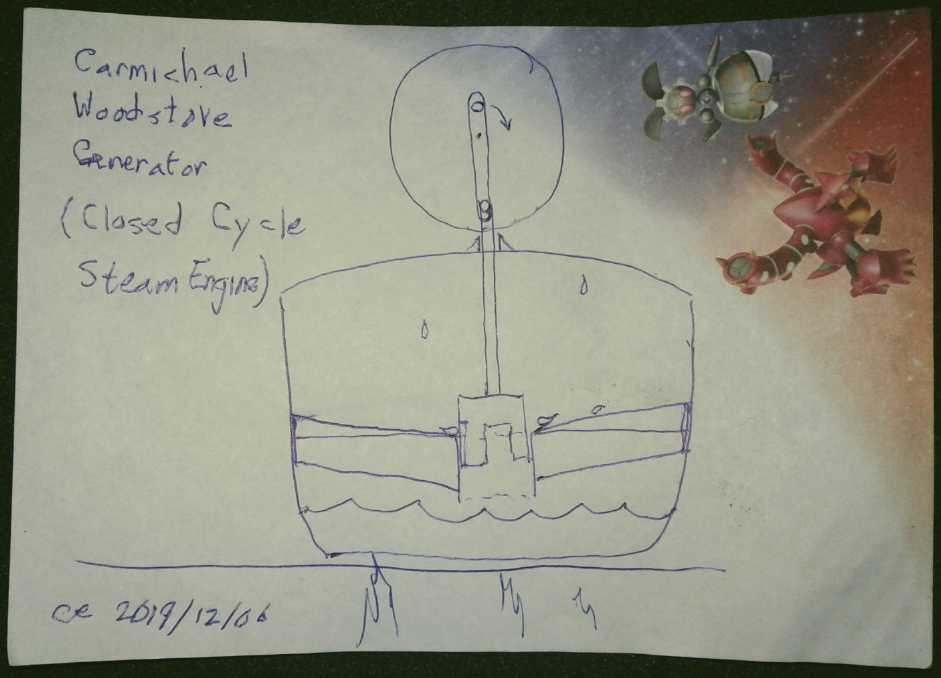

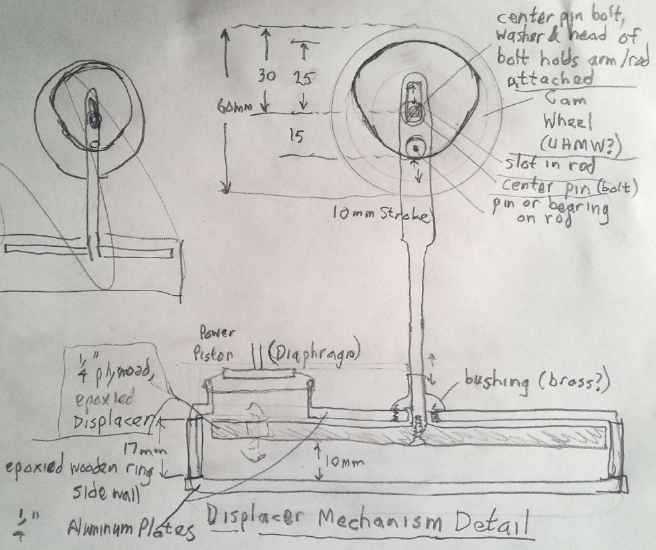

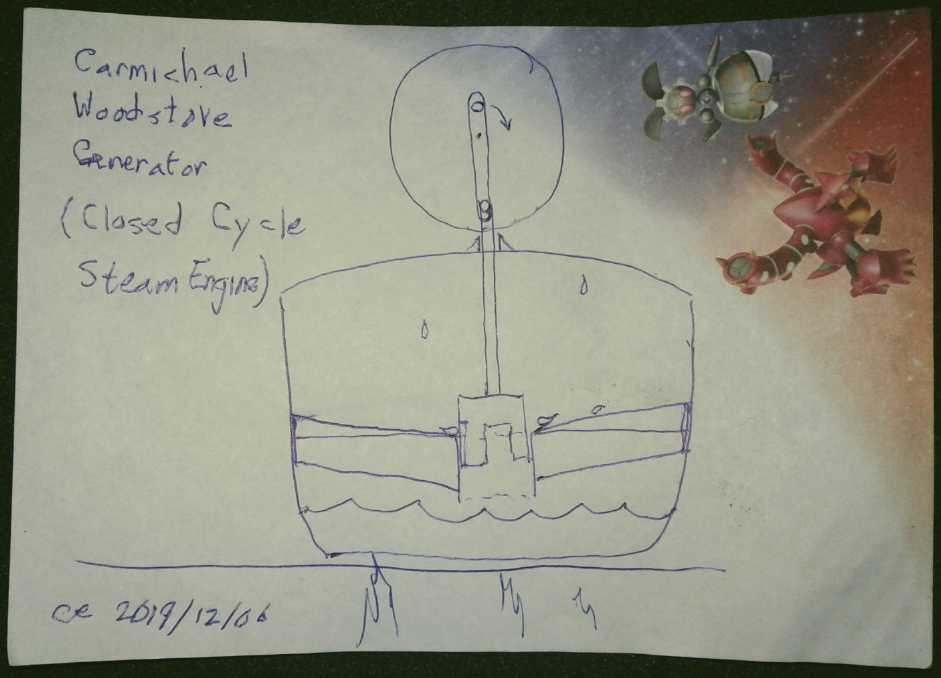

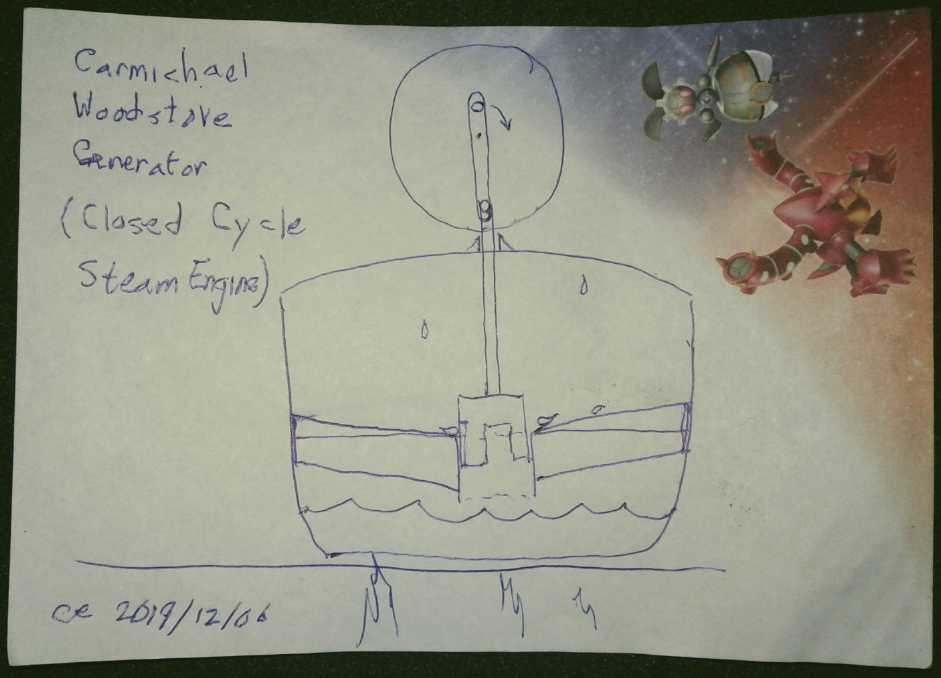

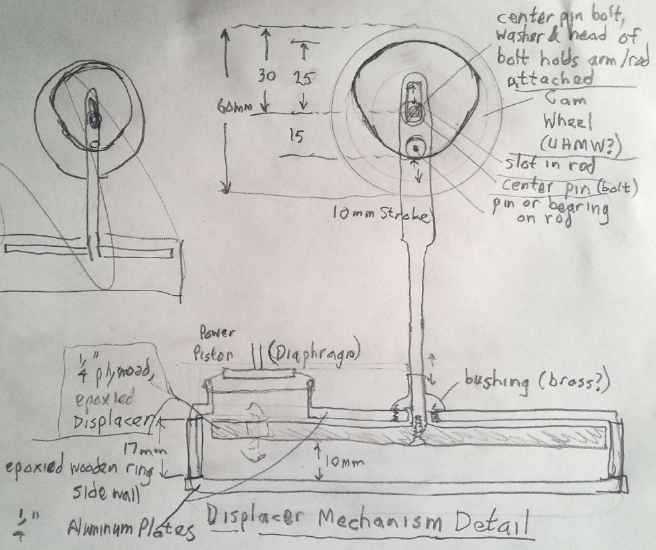

Carmichael Woodstove Steam Engine?

With the solar collectors not making much juice in the

winter and the windplant sitting motionless for 3 or 4 weeks, I thought

again about making electricity from the heat of the woodstove. But TEG

modules didn't seem to have much "bang for the buck". So I thought of

Stirling engines, and looked into them for the first time.

"Exploring Stirling Engine for the

woodstove" concepts.

"Exploring Stirling Engine for the

woodstove" concepts.

When the lid is tightened on the pressure cooker pot on the woodstove,

the formerly cool open air (+ water/steam) inside expands with the heat

and partly

fills the balloon, which in the engine would become the stroke of a

power

piston.

I started drawing one up, but it rapidly metamorphosed

into a simpler engine

especially for the woodstove (or of course any "stove burner" heat

source): a

"closed cycle steam engine". My target is 100 watts

continuous electricity from a moderate fire, and I collected parts to

build it.

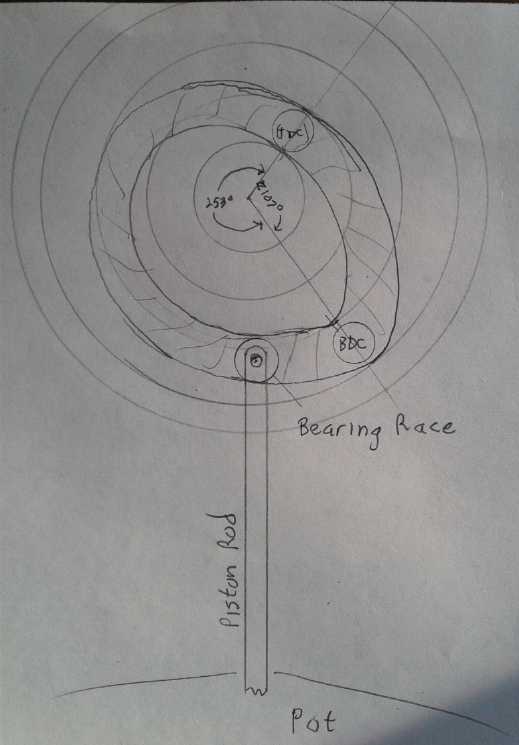

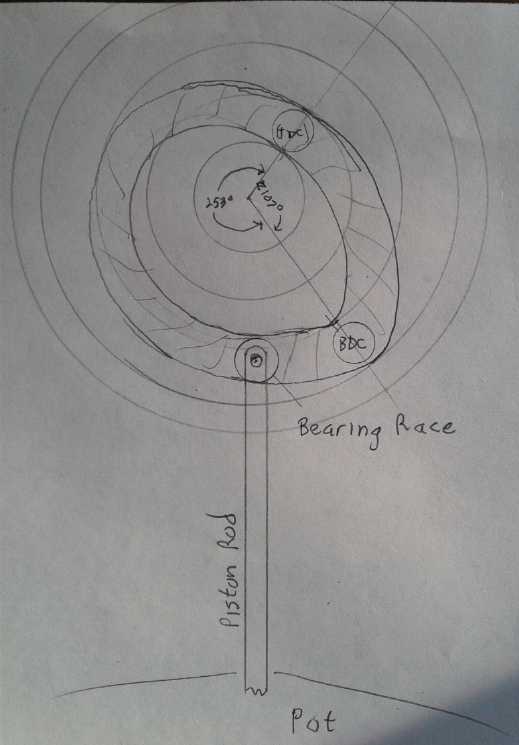

I did some work on one hard part: the flywheel/magnet

rotor and its mountings. It sits above the pot to connect the piston

rod to.

If ever an invention was "drawn on a napkin

over coffee", this was it.

If ever an invention was "drawn on a napkin

over coffee", this was it.

But this simple concept drawing was the culmination

much thought over some days of

rapid design evolution.

Weather and Power and Running the Well Pump on an Inverter

Winds off the ocean had warmed it back up to +7°C. On

the morning of the 11th it was blowing very strongly. The mostly idle

windplant came to life and started delivering record power, around 100

watts, with much fluctuation. (I think I saw over 170 at just one

point.) And my gold plating solution arrived. I decided that was what

to do that day. Then the power went out. Why had I not expected that

some tree would blow down across the power lines? Of course one doesn't

know how long a power outage will last.

Last December it was out for 25 hours after a windstorm -

I think three trees in different places had broken the lines. (I found

2 of the stumps when I drove into town a day or two later. That should

be, um, TE News #127.) Toward the end of that I had plugged in an

inverter and ran my fridge and then the freezer, which were getting

pretty un-cold. Since then - and partly because of it - I had got

serious and hooked up the solar system and more panels than my original

four - eventually 8 more.

2500

watt inverter plugged into kitchen 36 volt water heater's power socket

in

order to run fridge & freezer

(both here unplugged as the power had come back on.)

Since there was almost no solar power to the DC system in

the winter overcast (and of course none to the dead power grid), the

heretofore seemingly useless windplant was just what was needed. This

time I just plugged the inverter in to the 36 volts in the kitchen by

unplugging the water heater under the sink. It was making enough power

to keep one or the other, fridge or freezer, running much of the time

without too much drawing down batteries.

Since there was almost no solar power to the DC system in

the winter overcast (and of course none to the dead power grid), the

heretofore seemingly useless windplant was just what was needed. This

time I just plugged the inverter in to the 36 volts in the kitchen by

unplugging the water heater under the sink. It was making enough power

to keep one or the other, fridge or freezer, running much of the time

without too much drawing down batteries.

Since I ran it through the DC

solar (& wind) equipment and its meter, I discovered that the new

2500W and the older 1800W "pure sine wave" power inverters themselves

used

30 and 55 watts, eg, 150W was being used but just 120 was going to the

freezer. No wonder inverters kill batteries if you forget to turn them

off! But they let me run the fridge and freezer enough in case the

power failure became long.

And then, what project for

the afternoon instead of gold

electroplating with no power? I had purchased a 2500W, 230V inverter

(...looks identical to the 120 V one above!) so

I

could run my well pump if the power was off, and a 230V AC plug and

socket. But I hadn't done the wiring. The pump was hard wired to the

breaker box. So I shut off the (dead anyway) power to the whole shop

and garage sub panel and rewired the pump. Now it can be easily

unplugged from the mains and plugged into the inverter.

Then somehow I didn't have the courage to test it. The

power came back at 6:30 PM after just 5-1/4 hours and the pressure tank

still hadn't dropped to where the pump would come on. (I was

conserving.) I could have run a garden

hose until the pump came on but I didn't.

I plugged the pump back into the

mains. Then I ran enough water to get it to come on to verify

that I hadn't made a mistake wiring the plug or socket. But I really

ought to test it on the inverter!

(I also baked an applesauce cake while the power was off

on top of the woodstove by arranging firebricks for an "oven" and

putting the small pan inside. It took over twice as long, well over an

hour. It wasn't well done, but the bottom had a crust. I wished I

hadn't given my old, even

smaller pan to the thrift shop, because it was hard fitting the new

smallest one

into the bricks. (It sat for many many years unused, and I gave it away

a month ago. OTOH it was just one of many items cluttering the

cupboards, and I wouldn't want the rest back.)

The 12th was calm again.

On the 16th I decided it was stupid not to test the well

pump on the inverter when it wasn't needed, instead of during some

power failure when it was. It worked, but it sure was a heavy load. It

drew the Sprint car batteries down as low as 36.3 volts from about 40,

and the drop fluctuated. When it was lowest I could hear the sound of

the flow change a bit, so the 230 volts from the inverter must have

dropped a bit too. It kept running, but no doubt it was pushing the

limits.

Let's see... The well pump has to draw the water up about

66 feet. That's 30 PSI. I had neglected to measure the DC current, but

I didn't want to repeat everything. So later I measured the pump's AC

current with two

amp probes by opening the breaker panel. They said 5.7 and 5.4 amps -

not as bad as I had feared. If the pump drew 5.7 amps at 240 volts,

that would be 1368 watts (almost 2 horsepower), and 38 amps at 36

volts. With what the inverter drew for itself, it would probably be a

little over 40 amps. I'm glad it wasn't higher, and I would probably

restrict my water use to essentials during a power failure. I wouldn't

for example grab a shower in the first hours while there's still hot

water in the tank. I'm not confident this pump power offers complete,

satisfactory service. Of course one must remember it takes a lot of

power to pump water up over 60 feet. I keep a couple of 200 liter

barrels of rain water around just in case, too.

Before departing the "windplant" subject, here are some

windplant flared exit

ducts that might be easier to make than the one with more compound

curves shown

last month. (Youtube) Like them, these probably put out at least twice

the power of an unducted propeller. I still can't help but think that

adding a flared entrance as well to create a full venturi effect would

be even better.

(On the 4th of January at 11 PM, just as I was thinking if I stayed up

late enough I might get this newsletter out, the power went out again

while I was typing. It was only off for 1/2 an hour, but it reminded

that I still hadn't got the solar charging to the Sprint car's lithium

batteries done, which I had started in November but stalled out on in

December to make HAT plugs and sockets instead.)

Power Co. Troubles

On the 13th I heard BC Hydro was having equipment trouble

around

here. Surprisingly in the high wind, the power failure wasn't a tree

across

the lines. Evidently all the diesel generators in the Sandspit power

station are at or beyond service life or time for maintenance shutdown,

but

apparently it was some insulator or something that failed. What

happened to the hydro plant? What a spur to get a

woodstove powered electrical generator working!

On the 16th there was a Hydro crew working on the pole in

front of my house. (They were actually putting a transceiver for the

nearby smart meters on the next pole over. Out here in the country it's

too far between meters for them to talk to each other direct. I wonder

what will happen now about my 'stealth' solar tie-in?) When they were

finished I talked to one named Rob. He had noticed my windplant and I

told him about my wind and solar, the woodstove steam engine and the

idea for a floating tidal power project. I asked about the diesel

generators. The reason maintenance is behind is because the main power

transformer from the small river hydro plant blew last summer and it

hasn't been replaced yet, so the plant has been running on the

'auxillary' diesel generators ever since. (The new transformer has

arrived at and is being tested in Vancouver.) I've seen a few big ones

blow with a blue arcing glow on youtube and it was mentioned how the

power grid could be down for a long time if more than one or two blew

at once because they take so long to replace.

Evidently also, the load on our little grid is much

greater since since everyone in Skidegate Village (technically a Haida

Indian reserve) got heat pumps a year or two ago - and mostly threw out

their woodstoves. (Your federal tax dollars at work.)

Ground Effect Craft/Vehicle (RC Model)

I had been trying to get around to more battery work and

experiments (not very successfully - waiting for supplies) and had been

working on the torque

converter, the new woodstove electricity generator, and the ground

effect craft. Sometime on the 13th it occurred to me that if I did get

funding, I might be doing little but batteries, ad nauseum, for quite

some

time. And working on too many projects meant little steps with nothing

getting finished. I decided to try and get the ground effect craft

model into shape before Christmas. or at least in January. So from that

evening I did some thing or other on it most every day - mostly gluing

and painting fabric. It was very near Christmas when I painted the

second side of the vertical fin and the cloth sagged and became loose

and baggy. (Evidently I hadn't "primed" that side with polycrylic.) It

would have to be stripped off and redone. That meant I wouldn't get it

flying before Christmas and it would be January.

I figured out that each of the powerful ducted fans would

need its own set of batteries - better, two sets each - and set about

mounting small lithium cells as "flashlight tube" batteries in oversize

ABS plumbing pipes. From the specs it appeared they were strong enough

to lift the craft straight up like a rocket if I applied full power.

New Chemie Batteries

I

received the gold plating solution I had ordered and

plated a copper current collector sheet with a thin layer. If it works

(as I hope and seems likely) it will make for much lower internal cell

resistance than a graphite sheet. The pure zinc to make a new cell

arrived just before Christmas, too late to start anything.

I

received the gold plating solution I had ordered and

plated a copper current collector sheet with a thin layer. If it works

(as I hope and seems likely) it will make for much lower internal cell

resistance than a graphite sheet. The pure zinc to make a new cell

arrived just before Christmas, too late to start anything.

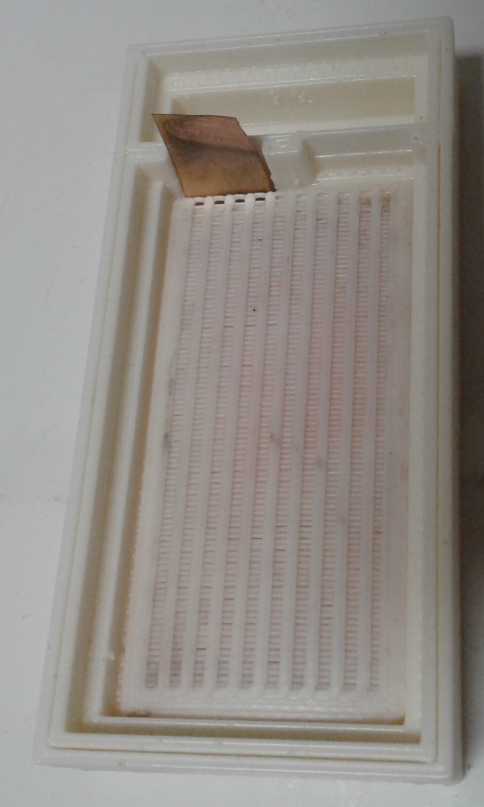

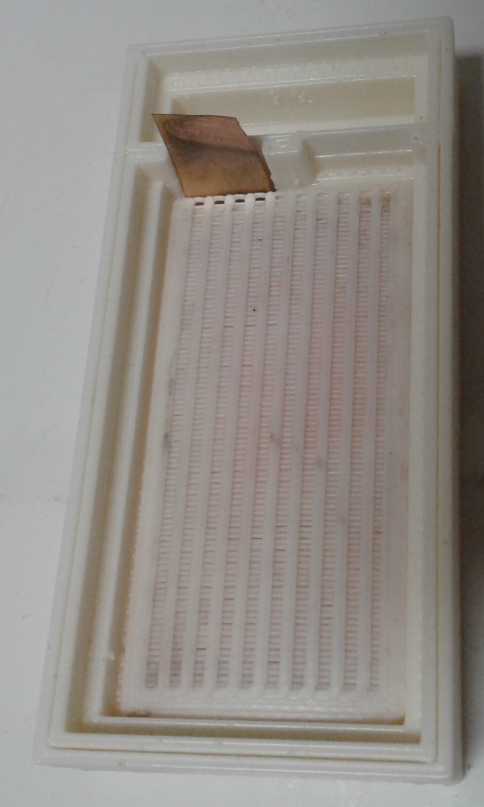

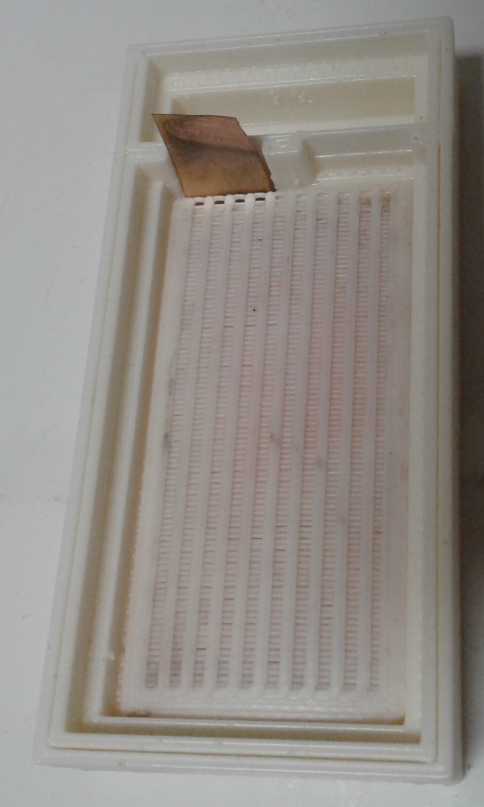

Before doing a current collector I printed the new "lay

down" battery case I've been intending. It has a electrolyte reservoir

on one end instead of on top. Whether or not it's a final configuration

for production,

it'll make experimenting easier because I won't have to glue the front

- now top - cover on to keep it from leaking. That of course makes

disassembly for inspection and electrode replacement much easier.

On the 20th an e-mail said

the application to the "Charge

the Future Battery Challenge" for funding to finish the research and

then hopefully get the batteries into production had been rejected.

They were awarding funding for up to five projects. I had only asked

for

1/2 the maximum amount. I was planning to use that to not just create a

prototype but to get to initial battery production. What was it about

this that it wasn't their dream project? Of course I won't abandon it

since I think the batteries will prove to be both better and cheaper

than lithiums,

but it is certainly disappointing to get no help for getting to

production stage.

Plain copper, gold plated copper, pure gold

anode for electroplating.

Plain copper, gold plated copper, pure gold

anode for electroplating.

A Solar Kayak

It doesn't have to be complicated... Here is an

interesting kayak that is powered by the sun, which runs the white

motor and propeller on the side. No batteries. In the video the power

would cut out whenever he went under the shadow of a bridge, and he

would coast through. (I was guessing he was on the Danube river but I

don't remember why and I've misplaced the URL.)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Hair

Loss:

the

Demodex Mites

I came across a word, "alopecia". On Wikipedia it redirected to "hair

loss". There is a considerable article. But I think Wikipedia and many

others err in the belief that little can be done about it - and about

its prime cause.

One point which wasn't stressed but that grabbed

my

full attention, is that an almost microscopic mite is 'sometimes'

involved. I had

so

strongly suspected some mite as the prime cause of hair loss as to be

virtually sure of it. But until now,

I've never seen any mention of one anywhere. So I had thought, well,

surely it would be known if there was one... Maybe it was an unknown

bacteria then? But that didn't seem to fit the observations.

But such a mite is known (apparently not by very

many people!) and

it is called Demodex folliculorum. Apparently many or

most people

have it on their skin. It lives only on human skin. It multiplies in

the hair follicles 'especially on an oily scalp' and its food includes

essential hair nutrients (sebum) secreted in the follicles. (One

expects the scalp is the oiliest skin, with extra from infrequent

shampooing, or maybe a poor shampoo.) I would

say they must also live quite well on a perennially cold scalp.

Related

Demodex species cause "mange" - loss of fur in dogs and cats with

weak immune systems. Perhaps one might ask: Why would they not

be the cause of human hair loss? Perhaps our hair thins as we get older

because

parts of our immune systems weaken? Where would it be weakest? Where

the blood flow is least, in top-of-scalp blood vessels, especially when

vaso-contracted and with the pores closed off

in cool to cold air? I suspect this mite plays a far larger role in

hair loss than is apparently suspected, either by its immediate or its

long term effects or both. In fact I think it is central to

the whole topic - the primary cause of hair loss.

On January 5th I did another web search and discovered

that there is another species: demodex brevis is half the size,

(about .15 to .2mm long) and also feeds off sebum. It is the mite that

inhabits eyelashes, but it can be found anywhere on the body including

the head and may cause scaly skin and other skin conditions. Demodex

mites are more common in men than in women... and which sex is it that

often becomes bald?

How is it these mites are never mentioned, even in

writings and studies

about hair loss? The Wikipedia article was the only place I'd seen it

mentioned until my web search, and the couple of articles I looked at

about Demodex weren't about hair loss but skin conditions.

Surely all this should be common knowledge... but evidently it isn't!

At least the mites seem to have never been taken seriously as related

to hair loss.

The existence of mites explains the likely reasons the

several methods I've unearthed for helping to keep hair work: they

eliminate or reduce populations of these critters to harmless levels

or keep them from multiplying and thriving - much as I was suspecting

but had no real evidence for.

I now

wet my scalp with ethyl alcohol just before a shower, once a month.

(Over Christmas I discovered once a week should be much better. The

shower is because once it has killed the mites it seems to have no

further purpose

for being on one's scalp and I would rather wash it off, after having

apparently got shingles from it by the daily use experiment without

washing it off, a few months ago after 3 or 4 (?) weeks.)

And the reason letting shampoo sit on the scalp for a

couple of minutes is helpful would also be so that it penetrates the

pores and hair follicles where the mites are living.

In fact it would seem that all the things I

mentioned in

TE News #137 (updated list below) are helpful, and that the things that

are helpful to keeping or regrowing hair are things that eliminate

mites or make it harder for them to thrive and multiply.

For me the extra pillow to keep the top of the head

warm at night (or a nightcap, as well as a tuque or hat in the daytime

in winter) seemed to be the last missing piece, as my hair seems to be

getting noticeably thicker again in the areas where it had become so

thin.

Unfortunately as ideas and treatments regarding this topic

gradually came to me, I

didn't have the thought to take any "before" pictures months ago or any

previous time, so once again it's just an impression that is hard to

verify. (I've taken a couple of pictures now. I was going to wait

another month or two before revisiting

this topic to be quite certain it's thicker if not back to

full thickness, but learning about the nearly microscopic (.3mm long,

thin) mite I thought surely must exist, has prompted me to write.)

The mite is doubtless easily spread by contact. For

example, someone with it

rests their head against the back of a sofa, or on a cushion. Another

person occupies the same seat or uses the same cushion... Small wonder

"most" people have them!

During my Christmas holiday I had other things to do than

think

about it. I took a comb and no brush. I also had no shampoo except in

one shower. There were no light, formable pillows to pull over my head.

By the time I was returning home, I could scratch little

bumps off my scalp, which are surely an indication of 'robust' mite

activity and conditions for hair loss. (Shall I call them "scabbies"? -

flakes like little scabs. It seems the mites prefer closing off a door

between them and the outside.)

The very few days it took them to multiply and become so

active suggests a more frequent ethyl alcohol treatment is desirable. I

think I'll go for once a week just before a shower, instead of once a

month. From my own experience one wouldn't want to do it much more

often than that, and I'll wash it off soon after.

Helpful Methods for Keeping (& Restoring?) Hair

- tuques, beanies, caps and hats for keeping the head warm and the

pores and follicles open in cool and cold temperatures. (indoor and out)

- lightweight, "shapeable" extra pillow 'overhead' or a nightcap,

likewise for keeping the head warm, in cool to cold bedrooms.

- frequent shampooing/showers, leaving shampoo on the scalp for a

couple of minutes or more to soak into the hair follicles where the

mites are living. (Some shampoos are evidently considerably better than

others. It would seem there's a reason the most popular brands are

popular.)

- at least a daily hair brushing for more scalp stimulation than using

a comb. Some brushes offer much more stimulation than others. It seems

to get the blood flowing more, which would boost the effect of the

immune system on the scalp.

- weekly spraying or rubbing of ethyl alcohol on the scalp to wet it

all over and kill the mites, before a shower. Ethyl rubbing alcohol and

vodka have both been used. Once applied for (?) a couple of minutes it

is desirable to wash (shower) it off.

- I understand cutting the hair very short or shaving it off is

helpful. I'm not sure why. Perhaps the mites have nothing to cling to

or climb on as they try and spread from follicle to follicle?

I suspect that these methods just might bring back hair to

a bald person or at least one with very thin hair, perhaps only

eventually, but that's not a promise.

Here's a perhaps humorous aside: When I was first

suffering from itchy scalp and the probable beginnings of hair loss in

about 2004, I knew little about it and I went to the clinic to see a

doctor. The doctor that saw me was bald! This seemed ironic. All I

could think was that whatever advise he gave me, I should do the

opposite. After that I began looking for my own information.

DISCLAIMER: I

am not a medical professional.

Any use made of this information is by your own judgment and at your

own risk.

Social

and

Political

Evolution

Just as scientific and technical progress comes about

through experimentation with new ideas and concepts, so does social

evolution. Somehow while we experiment freely with physical sciences

and technologies, we have been conditioned to be exceedingly timid with

social experimentation. To an extent this is probably good, but if we

are so blind as to attribute longstanding and developing social

structural problems to individuals and think things will go 'back to

normal' once they are gone and someone else is in charge, if we are so

timid as to refuse to face facts

and experiment when

changes are clearly needed, if we too much fear any slight possibility

of making things worse, we end up with an unprogressive "status quo"

whereby the few rich and influential increasingly have hijacked our

democratic social processes and have been converting them into a shell,

a

facade of democracy that they control for their own benefit behind the

scenes.

It has become almost impossible to win an election in

western nations without

being beholden to these special interests. Vast numbers of people,

especially older people, don't understand that there has been an

ongoing shift away from meaningful democracy and toward it being merely

a façade for hidden totalitarianism - so far by an

oligopoly rather than a single dictator. But many - especially those

specifically wronged - are coming to recognize that the government at

present is

no longer their friend but their enemy. "I'm from the government, I'm

here to help." is a phrase that strikes terror into many hearts rather

than assurance.

I say social experiments can only very temporarily

make things worse, because once people start to recognize that the

worst problem of all is fear of changing

existing systems and institutions, they become unafraid of social

experimentation and there evolves a culture of social experimentation

(and not only political but in family, education, economics, health -

all

social areas and institutions), whole

new arrays of possibilities will open up from each experiment. The

better

models will be chosen and the poorer ones will be dropped. Even

failures may illuminate the way toward a bright future - if they don't

become "the new normal" that is too sacred to change like so many

long-ago-failed experiments or utterly outdated techniques and

procedures in

use today.

For a parallel, the whole vast internet with

all its intricacies has opened up in just around 30 years because of

people with vision and ideas, and some pretty wild experimentation.

Things that

didn't work well have dropped away, and things that did have opened up

more and more realms for exploration. Even the failures, the "wastes of

money" and the "dot com bubble" have paid back a millionfold in

progress. The changes we've seen and have

so quickly taken for granted weren't even imagined in science fiction

when I was young.

It has been stated that if one asked an audience to list

50 technical advances in the last 50 years, most could come up with a

fair list. If one asked the same people to list 5 social advances in

the last 500 years, few would complete the task.

Why are we terrified to experiment socially? Why do we

stick with

what used to work 100 or 200 years ago in preference to trying anything

new? - just in case it might not work out? But what worked

for a while back then isn't working any more.

The most damaging and dangerous thing to democracy and the

continuing evolution of

peaceful civilization is unwillingness or inability to change when

society and the

whole world

is continually changing. If a democracy has finally become disrupted

and bankrupt, if violence and riots instead of peaceful and working

processes become the

only effective method of voicing distress and getting change, there is

a reversion to

dictatorship where there is no active social participation by the

public, and it may be 50, 100, 150 years before democracy is able to

emerge

again.

We must act to evolve our social mechanisms in all areas,

progress instead of reverting. While social experiments should be

cautious to a point, we should not be starved of them just because not

all of them will prove to be the ultimate in nutrition.

"Those who make peaceful revolution impossible will make violent

revolution inevitable." - John F. Kennedy

"Riots are the voice of the unheard." - Martin Luther King Jr.

Here is a very pertinent present political example to take this from

the abstract to the

concrete. I have no doubt many readers will take strong exception to my

view of the situations, but they are as I see them and I know many

others hold similar views:

Virtually the whole social decision making body in the

USA, which

includes (at least) the strongly intermingled members of the upper

civil service, the justice system, the largest corporations, and the

propagandizing oligopoly (virtually monopoly) major news media, had

become

almost completely corrupt - self serving, for sale to the highest

bidder, and filling all the posts with more like themselves. Political

party

matters not. With their own corrupt people heading the justice

system, they have felt - and have been - more and more safe to do

whatever they please without fear of prosecution. They have pillaged

the society they supposedly work for until most of the population is in

overwhelming debt and 50% of Americans say in surveys that they

couldn't come up with 500 $ in an emergency.

Those in all the high places universally

detest and fear the new

president because he won in spite of all their machinations and

whatever else he is doing, he is

indeed attempting to 'drain their swamp' as he would put it. Before

that they had everything their own way. Those behind the scenes bought

the elected

'leaders'. The public was 'free' to pick anyone, but from a slate of

the gangster "elite's" behind the scenes choosing - Tweedledum or

Tweedledee. No one got

into high

government or corporate offices without first proving they were corrupt

and would play along.

A great many people realized that government had become

their enemy instead of their friend, but there was no avenue of

expression for it until someone - anyone - from outside that "club" was

able to run for the presidency and have a serious chance of

winning. It seems incredible how bad it has become. Laws were passed to

protect the 'cleptocracy' from the public instead of the other way

around, not excluding permanent

suspension of the centuries old and hard-won rights of Habeus Corpus

(innocent until proven guilty) and the right to a fair and speedy

trial. No such safeguards for "terrorists!" -- to be defined as

expedient. Forget the fair trial: Take a plea bargain sentence or we'll

throw the

book at you. Many people, often America's real elite of creative

problem solvers and thinkers, have been thrown in

prison without trial, died

"accidentally", been murdered or "suicided" with no investigation over

the last two decades. How many political and social prisoners does the

USA now hold?

Their chosen figurehead for 2016, Clinton, early and

clearly indicated her willingness to take orders from them rather than

to exercise leadership against their wishes if she won the election.

Her astonishing statement to that effect to the Council of Foreign

Relations (the "CFR", perhaps the heart

of the "club"?), "I'm so glad we have you to tell us what to do!" (I'm

not sure those were her exact words. There was a smile on her face.),

from

the lady who wanted to "lead" the nation, made it onto Youtube. They

have done their utmost to prevent democracy from working against

themselves, or for the people, not short of illegal acts (to brag

about at the CFR) and a continuing barrage of unsubstantiated

allegations and a false narrative - not excluding

outright lies - on television and in print, repeated over and over a la

Goebbels/Hitler, which unfortunately are swallowed by so many with no

inkling that they might not be true or that the media is biased.

Perhaps most famously "Saddam has

weapons of

mass destruction.", repeated over and over and over on the news, was

used to justify invading Iraq. None were found.

Well, let's blow some other minor story(s) out of proportion for a week

or

two that will make the public indignant and distract attention from

that.

Or how about:

Media: 'Worthless Trump is playing golf over Christmas [2018] and

ignoring the many things that need to be done.'

Actual: Trump was in Iraq visiting the troops, and trying to figure

out how to extract them from Syria.

To be fair Trump doubtless didn't tell anybody where he

was going until he was there, and the white house may have even put out

misleading hints. Saying he was traveling to the Middle East would

have invited planning for an attack on himself.

(It was Obama who was always off playing golf. That wasn't

a criticism then as "Mr. Teleprompter Reader" was pretty much doing

whatever they wanted. ...But I do credit him with calling off the

imminent US invasion of Syria in October 2013 after George Galloway in

parliament caused Britain to back out of the operation against prime

minister Cameron's plans and wishes, and Syrian

leader Assad offered to dispose of all Syrian chemical weapons under

international supervision. What a relief that was! It then degenerated

into a poorly coordinated proxy war

supported by USA and Soggy Arabia. At one point Pentagon backed rebels

and CIA backed rebels were even fighting each other. ...Hmm...

notice

all the US drone strikes seem to have stopped since 2016?)

Frequent floods covering

seemingly vast areas

are why I now call it "Soggy Arabia".

Frequent floods covering

seemingly vast areas

are why I now call it "Soggy Arabia".

Here is yet another bunch of camels up to their necks with someone

trying to lead them to higher ground.

(Nared King Youtube videos show the various unprecedented cataclysms

happening all over the

world.) But I digress.

Social media telling a wholly different story than the

"sanctioned narrative" - with prompt reporting on attempts to rig

ballot

boxes - probably turned the tide in 2016. And polarized the nation and

other

nations - and even families - as never before, because the two "visions

of reality" (as my grade 9 English teacher in California would put it)

were so different

and so utterly opposed.

Since 2016 some of the worst of the corrupt have

resigned, 'not run for re-election', retired or been fired, and some of

the many pedophiles in high places are being weeded out. A great many

in high places know the many crimes they have committed, never

expecting to be called to account in their mortal lifetimes, and are

now in fact terrified of

being sent to prison. That's why they they fought so hard against an

honest judge being appointed to the supreme court.

(H. Clinton saying "If that

___ing Trump wins, we'll all hang!" ...was that a clean conscience

speaking?) Whatever one thinks of Trump as a person, his almost

miraculous election - and the fact that he

has so far avoided being murdered or deposed - in fact gives hope that

democracy may be salvaged. But what happens when the

billionaire they can't control is gone, and the corrupt go back to work

to restore their hidden influences and "refill the swamp"?

They have done nothing but demonize, fight and obstruct

everthing the president tries to do, and to try to find - or falsely

create - any grounds for having him dismissed. Agendas given strong

approval in lip service but no action in the past (like a Mexico border

wall) are suddely "pure evil" when the new white house tries to

actually implement them. (After all, it interferes with their highly

profitable drug running and human smuggling.) Having failed for almost

four years, they now presume to impeach the president on (groan)

"Trumped Up"

allegations amounting to nothing.

(The corrupt who may well have had Bobby Kennedy shot, and

got

Nixon elected, behaved similarly when

he turned about-face and ended their "profitable" Vietnam war,

diplomatically recognized China, and started nuclear arms limitation

talks with the Soviet Union. Until then he was immune. Anyone trying to

expose him would have been silenced. After he "double crossed" them by

doing things for the nation and the world instead of for them, the

dirty laundry was

brought out and he was forced to resign.)

How can things be "brought back to normal" without the

house burning down besides by making social advances toward a new and

improved "normal" - a society which will ever be adaptable - flexible

and able to change with human progress, and in which concerned citizens

- or 'social sustainability design teams' of concerned citizens - have

a say in the operation of the government instead of just a vote

every few years for someone whom they then have no control over?

Small

Thots

* I'm sorry no virtuoso player was ever

able to take up the "Supercorder" instrument I created and made over 20

of between September 2003 and sometime in 2006. In order that a fine

instrument with such a gorgeous sound may not be forgotten (and perhaps

may even be produced by someone?) I (at long last) made a video of me

playing

Vivaldi's Recorder Concerto in A minor RV445, and put it on Youtube.

I was never a virtuoso player and not in my prime either, but perhaps

the qualities

of the instrument itself may be heard here and there in the playing.

https://youtu.be/MErSlx1luuQ

(Yes "youtu.be" is a valid Youtube URL.)

* When I saw a "5GHz" light on my fiber optic router I naively

assumed

that was the same as "5G" cellphone system - and that that must be why

it was called 5G. Sorry, my mistake. Apparently they are completely

different entities.

I do however still maintain that microwaves go

though people rather than around them and that you're better off if

they don't, and the more powerful and the closer they are, the worse it

is. There is various evidence for and stories about this even tho no

proper long term studies have ever been conducted. Sumsung brand

cellphones have one of the lowest radiations, but I usually put it on

"louder" and hold it away from my head when I'm talking.

...I also still don't understand why the new cellphone

system is called "5G" instead of "G5".

* What kept me from designing the flat battery cases and new HAT

plug and socket shells? ...The "notebook" computer I use and 3D printer

were in about the coldest little alcove of the house. I didn't just

move

it because it was attached to a big video monitor for doing the

graphical work, and it was next to the 3D printer. Being winter the

situation could persist for months.

Say... how about setting a small electric radiant heater there just for

when I want

to work? Duh!

* USA nuclear reactors produce about 2200 tons of radioactive waste per

year, with an accumulated total of 88,000 tons so far. One of the waste

byproducts, plutonium, needs to be stored for 30,100 years. (or is that

just the half life when it becomes only 1/2 as radioactive?) Nobody

wants it stored in their state, even in a hollowed out mountain. (in

which some tunnels have already collapsed.) In 30,100 years of nuclear

power, 66,220,000

tons of spent fuel would need to be stored. Then in the year 32040

(maybe) the first fuel from the 1940s can be released from storage.

Yup, nuclear power is a great, sustainable solution! New solar plants

are much cheaper to build and to operate. It seems to me that for

anyone to propose a new nuclear power plant today betrays either

willful

ignorance or vested personal financial interest or both. Fusion or

thorium reactors too would create radioactive waste - perhaps less of

it, perhaps shorter lived, but that would just be reducing a still

seemingly unsolvable problem.

* Every generation since world war two has been poorer than the one

before it. This is in large part due to dilution of resources -

their being

spread between more and more people, including with older generations

that "already have", on average living and retaining their resources

longer.

Adults under 40 in North America today command only about

3% of the GNP instead of 25 or 30%. The generalization is that they are

still living

in their parents' basements. They mostly have low paying jobs while

everything needed to live (especially housing) costs more and more.

They can't afford homes and a large percentage don't have and will

never have their own families. (Of course the gap has not gone

unnoticed. This article speaks of organizations trying connect old and

young people together for mutual benefit: https://getpocket.com/explore/item/the-real-trick-to-staying-young-forever?utm_source=pocket-newtab

[hmm... had to type that in - hope it's right])

They have developed a disdain for the societies that

nurtured them in youth but provide them so little for life in

adulthood. Most of

them have no idea of the societal collapse that is soon to happen, but

those who do say "Yay, it's all going to end!" (As an accomplished

inventor

with so much to offer who has been repeatedly spurned and has got so

little from - and been able to contribute so little to - our society, I

have over the decades come to share their disdain. Apparently I am now

much more valuable to our government for having reached the magic age

of 65 on January 1st 2020 than for a lifetime of inventing new or

improved things to try to improve the world, and I will finally get

some funding: old age pension. It'll be more money, and how each penny

is spent won't even be scrutinized, audited and disallowed! How much

longer currency will be worth anything is another question.)

But

soon the younger people will be inheriting everything as older

generations die off,

and will occupy the seats of power and influence. Then as they don't

have the same values and ideals as their parents, rapid social change

is not only possible but inevitable. The various calamities we are

starting to face will propel this change.

If change is channeled in positive directions, social

evolution may take a great leap toward sustainability.

* Notwithstanding all the global crop failures, South America's crops

did well. China bought corn from Brazil this fall. USA also bought corn

from Brazil. Now a Brazilian company has bought corn form Argentina

because Brazilian corn has become too expensive. Now Argentina is

putting very large tariffs on corn and other grains for export,

probably fearing there soon won't be enough for Argentinians. China

will probably just pay the tariffs.

Unlike in past times, crop failures in some countries have

become everybody's problem worldwide and if the 2019 and 2020 forecast

crops continue to fail, hunger threatens to be global. Some have noted

on youtube hints that governments are planning for potentially

rationing food.

ESD

(Eccentric Silliness Department)

* Which salad has the darkest

color?

- Coalslaw

(Okay, I admit that's pretty juvenile!)

* Apparently it wasn't "cake" that Marie Antoinette commended to the

peasants. It was "brioche"(SP?), a favored bread of the French upper

classes.

Squire: "Majesty, the peasants have no bread!"

Marie: "Then let them eat brioche!"

Squire: "Majesty, have you lost your head?"

* A Title for the accelerating collapse of glaciers and rapid melting

of the ice: "Antarctica, the Incontinent Continent"

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency and

completeness before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Ground Effect Vehicle (...first the 1/4 scale R/C Model)

State of the model before

Christmas

State of the model before

Christmas

It occurs to me that at

least one of the RC catamaran models on Youtube could fly up way above

the ground. Its

motor seemed perhaps strong enough to almost lift the lightweight craft

straight up, and it flew at a high angle of attack, the propeller

almost dragging along the body as a dead weight. And the Wises craft

had gone a ways above the water. It's possible the two ducted fans,

each rated at over 3 Kg of thrust, might likewise be able to pull this

craft up out of ground effect and higher up (if not straight up like a

rocket). If so, it should have

ailerons to prevent tipping over sideways! (Split the canard in half as

two independent airfoil

surfaces? - yikes!)

Flying up high is not a design aim, but it might have

value

for

avoiding, say, a whale that suddenly jumped up in the path, or a

deadhead bobbing up from the waves. Or to fly over ice or a protruding

sand bar. Or even a boat or ship. But it would require substantially

more skill to drive it... Hmm.

Another thing that occurs to me is there are all these

radio controlled(?) drones with GPSes that can be programmed for

various things like to fly a specific path, maintain an altitude,

return to their starting point and land, and so on. I'm not much into

trying to duplicate that sort of programming, but somebody might be.

Then even the model could be programmed to deliver something somewhere

or to take video along a route.

(15th) Controlling the two ducted fan motors remotely in order to steer

seemed to pose a considerable extra problem because the radio control

wasn't set up for it and its options were so limited, but I have

thought to use the "ailerons"(?) control, sideways on the same stick as

the motor control, and take out the springs that return it to center.

OFF would be bottom right, FULL power would be top left.

If I found when I removed the cover that I could somehow

twist the whole control 45 degrees so "up" was full and left and right

varied each motor to turn the craft, so much the better.

In connection with this whole thought, perhaps I should

look on line for a different handheld remote control transmitter? Just

because I bought this one am I stuck with it? Maybe there's one already

made with the "two throttles" configuration I need? Nope - they all

seem to have the same left-right-hand, two-simple-joysticks

arrangement. If the canard was computer controlled I could use the left

and the right joystick as 'throttles'. But for the first model it's not

and I don't fancy having the canard be a sideways motion on the same

stick as a throttle.

On January 4th I opened up the controller/transmitter and

took the spring out. Trying it then, it didn't seem it should be too

hard to control.

Canard & Ducted Fans Mounted on Canard

(8th) Having mounted the ducted

fans I started painting the "Minwax Polycrylic" on the fabric now and

then. For all that the model airplane builders raved about it, it

seemed to be taking a lot of coats. From 75% thinned I went to 67% and

then 50%. And I turned the craft vertical so 'drips' ran along

the

fabric instead of through it. That and more coats seemed to help - it

started to get

harder to blow through it. And I cut and shaped two pieces of styrene

foam for top covers for the hulls.

Nothing fast, but the snail had picked up a little

speed. I'd like to get it done and try flying this thing!

(13th) I decided to concentrate on it. Could I try to fly it before

Christmas? If not, perhaps in early January? Unrealistic? How about

"Sometime in January"? I had already done a

couple more coats of polycrylic "dope" on the fabric.

That evening I did a bit of epoxying on some flakes of

foam to fill in

some low spots on the bottom. Then I could put the fabric on the other

hull.

Then I cut and shaped pieces of wood for the "dorsal fin"

lateral stabilizer. Then I epoxied them together. (14th) I

added some triangle gussets and more epoxy to strengthen it. But I was

still wondering how to attach it securely. I decided to more or less

epoxy it into the wing.

Then I got out the thinned carpenters' glue, spread it

around, and glued the light fabric onto the other hull. The styrene

foam needs at least some protection. I'm bound to fly it

into something or run it across some gravel. It took a long time to do

the whole hull in one go.

(15th) Covered the fin. Later gave it and the wind a coat of polydrylic.

(16th) In spite of the model aircraft builders raving about it, I got

fed up with doing coat after coat of polycrylic - and it was still

transparent and still had the grain of the cloth. I really wanted a

smooth, solid, white finish. I dug out a can of Tremclad oil based

white rust paint that I had got at the recycling center a couple of

years ago. (4L, almost unused and still like new - hardly even needed

stirring! Probably cost somebody 60$.) I filled a large ointment jar

and painted the underside of the rear 'elevator'. It didn't seem to sag

the way the wing fabric had when spray painted, whether because it was

primed with the polycrylic or because it was a different paint, I don't

know. Then, not wanting to wash the brush with paint thinner after such

a small job, I did the bottoms of the hulls. The fabric being glued to

the styrene foam, it couldn't sag.

On the 19th I found out: I painted the second side of the

fin and it stretched and sagged badly. I guess I hadn't 'primed' that

side with polycrylic. But later both sides looked just as baggy. After

that I decided I shouldn't have just bare

fabric anywhere in the full size vehicle. Instead I would put the

fabric over styrene foam, even very thin foam, to keep it flat and

smooth. (Score one for learning by making a model first!)

Wiring

The "ESC" motor controllers seemed to have awfully heavy

power wires - about #8 AWG. I looked at the motor specs again: 112

amps. Okay, they probably needed at least #8 wire. To go across

the wing from the battery to the other motor would need two wires over

3 feet long. I got out a scrap piece of #8-3 electric stove wire

about 4-1/2 feet long. 600 grams. Then I weighed the batteries.

* 40 inches #8 AWG copper wire: ? 200-250 grams.

* 6 of my intended lithium cells: 640 g

Adding a second set of 6 batteries in the other wing would

save having to install the heavy wires, so they would only add an extra

440-390 grams instead of their full weight. And they would double the

potential travel distance. Besides... Oh wait! 100+ amps was an awful

lot to

ask of these little cells. 200+ was much worse. In fact, the motor

sheet recommended larger cells. So I should probably put in, not one

set, but two sets in parallel for each motor - four

sets, 24 individual cells, 2560 grams! That would about double the

entire weight. Without giving it too much thought, I had expected the

batteries, for short test flights, would be pretty trivial. Like my

quadcopter drone. Well, it

won't fly without power. And if the motors really do put out over 3

Kg of thrust each, in theory they should still lift it straight up if

it was launched like a rocket.

Obviously then it should also be easily capable,

power-wise, of flying above ground effect. But if it did, it would need

ailerons. I decided to forget about that for now. If it didn't need

anything like full power at any time to fly in ground effect -- Good!

Low power is supposed to be a big benefit of flying in ground effect.

And I don't want to get into aircraft regulations or

needing

pilot skills to drive the vehicle. OTOH... being able to fly up higher,

even tho using more energy, could be a safety feature if a stormy sea

with very big waves blows up during a trip. It would be fantastic to at

least be able to stay safely above those notorious 4 meter wave crests

on stormy Hecate strait. Or I suppose, on a vessel intended to travel

between open Pacific (Hawaii...) or Atlantic (Canaries...) islands, to

be able to go up as high as necessary whatever the sea. That would be

the ultimate in seaworthiness. And one could, of course, computerize

the elevator and aileron controls to minimize the skill

level required. The driver just tells it the desired height. ...Then of

course there's 'just program the entire travel path via GPS' and the

driver merely watches for obstacles, then taxis it to the wharf and

ties it up. But I'm looking far ahead here.

I took apart the battery pack I was to take the cells

from.

It didn't lend itself to any reconfigurations. The cell voltage was

higher than I'm used to for lithiums, almost 4 volts. But I don't know

the chemistry of these ones. Would they drop to 3.2 as soon as there

was a load? I discovered that 6 in series read 23.05 volts. The motor

said 22.8 max. No doubt as soon as there was a load the voltage would

drop

under 22.8, and maybe under 20. But I didn't want to exceed any specs

at any time. The motor controllers said 22.2. So for now the series

sets would be of 5, which read 19.2 volts. I'm pretty sure there's lots

of excess power. If it won't take off, or if the voltage drops a lot

once they're in use, I'll go to 6 cells.

So how to mount the batteries? I decided putting them in

tubes of 5 (or 6) sounded like the best option. For that I needed to

find (or make) a plastic tube of the right diameter. I didn't have any.

Shopping list... I couldn't find anything different than what I already

had. I decided to use the smallest I had that would hold them: 1.25"

ABS drain pipe. I could put in a bar or two to hold them at one side of

the tube. Or maybe I could heat and stretch a 1.25" PVC "sprinkler

system" tube into an oval shape, and put two sets in each tube?

EV

Transmissions:

Off-the-Shelf

Planetary

Gearbox

for

Miles

Truck

The 5:1 planetary gear. The input is a

socket instead of a shaft.

The 5:1 planetary gear. The input is a

socket instead of a shaft.

It is intended that a motor's shaft insert into the socket and that the

gearbox bolt onto the motor,

but it will be ~18" away from the motor and the socket is too small for

the shaft anyway.

(18th) The 5 to 1 reduction

planetary gear finally arrived. It looks pretty tiny for a vehicle

transmission and the shafts are pretty small, but the torque specs

looked adequate, and then much of most transmissions is the housing.

This was the innards in a small shell. (It was sent by Federal Express,

but I picked it up at the post office. On January 3rd I got a bill for

101$ from FedEx, of which 37$ was tax. The rest was FedEx collect

charges. Total FedEx bill for one small (albeit heavy) item: ~ 125 $.

Distraction!?! The ground effect craft model that I was

focusing on could be done in a month. Could the truck be done in a

week?

It was tempting. Well, I didn't even have a week before Christmas.

Presently the motor is bolted to a bracket which holds it

in place under the vehicle. The front of the transmission bolts to the

motor, and another bracket holds the rear end under the truck, which of

course holds the driveshaft steady.

Now I have to figure out:

a) How to attach the gearbox to the truck where the back end of the

transmission was.

It will need some sort of mounting plate. It needs

to hold up itself and

the driveshaft securely, the body not twisting (in any

direction) with torque or axial forces.

b) How to attach the motor to the gear. It will need to be some sort of

adapter shaft,

with an extension to take the place of the removed

transmission (~18 inches).

c) How to attach the driveshaft to the gear. Doubtless it too will need

to be

some sort of adapter.

But perhaps the first thing to do is to get the truck

running again after the "Delta Q" battery charger boiled at least some

of the cells dry. I hate to look! If I can't get those working again,

even temporarily just to move the vehicle, I'll have to put in 2/3 of

the lithiums from the Sprint. (That's the plan anyway for once it's

running well. Can I make batteries before I just really really need

to buy more?) And then work out a charging setup that won't do what the

charger that came with the truck has done to the batteries that came

with the truck.

At the start of January I looked under the truck in the

cold garage again. I had the thought that it would be much nicer

crawling under it in the summer when it was warm.

Other

"Green"

Electric

Equipment

Projects

Easier HAT Plugs and

Sockets

On the night of the 3rd I did up a "simpler"(?) shell to

hold the 36V, 15A HAT plug pins described in the previous issue. Owing

to the fat 1/4" pipe squashing out so far - to at least 9 mm long, they

were rather large. I'd even say "clunky". Very square. I can only hope

the 5 mm or 6 mm pipes allow for smaller shells. I'm even thinking I

should have ordered some 4 mm. One could always squash them down to an

oval to fit over the pin before completing the crimp.

At this size one might almost put screw connections on the

blades. Perhaps I could move the screws to the sides instead of the

ends. The would make it shorter but fatter.

Of course there were teething troubles. Even on "take 2"

The crimps were still hard to fit in - must have squashed out to 10 mm

instead of 9, and the machine screws didn't hold well. (What, specify

even smaller holes? Usually I have to ream them out with a tiny

screwdriver to get the screws in at all.)

(8th)

After

talking

with

Mike

the previous day, we decided the new

shell for the "crimp-on connection" type HAT plugs was nice, but that

rounded corners would make them nicer. I did beveled corners thinking

that would be easier in OpenSCad, and "3D" beveled the back part to

make

the corners

protrude a bit, to make it a little easier to grip to pull the plug

out. I had thought it was awfully bulky, but Mike liked it that way.

There can be more than one type and style. I think a smaller shell for

"solder

on" wire connections would be nice to offer.

(8th)

After

talking

with

Mike

the previous day, we decided the new

shell for the "crimp-on connection" type HAT plugs was nice, but that

rounded corners would make them nicer. I did beveled corners thinking

that would be easier in OpenSCad, and "3D" beveled the back part to

make

the corners

protrude a bit, to make it a little easier to grip to pull the plug

out. I had thought it was awfully bulky, but Mike liked it that way.

There can be more than one type and style. I think a smaller shell for

"solder

on" wire connections would be nice to offer.

I also noted that with the "front-back" two piece shell,

the "crimp connect" sockets could be quite similar to the plugs, with

just a couple of dimension tweaks. I verified this by sticking in a

couple of "Z-fold" blade receptacles (they stuck out the back) and

trying to plug in a plug. It worked, depending on the exact sheet metal

and fold. So, longer shell and slightly wider spaces for the "Z-fold"

pieces. (9th) I designed it and made a socket. (No pic - looks about

like the plug without pins.)

Small Screws

Something I've always been on the lookout for - and never seen anywhere

- is a

source of small "self tapping" screws for plastic. All the local

dealers stop at "#4" screws, and trying to find anything smaller has

been frustrating. If you only want a few you can take apart some old

cassette deck or computer. The hobby shop in Victoria had a few, priced

"each". Sometimes one can find an "eyeglass screw assortment" with a

several, of various sizes. But where were the bags of 100 for actually

making things?

It started to get really frustrating when I started making

CAT plugs and sockets. I ended up using 2mm "machine screws" (tiny pan

head bolts) for them because they were the closest thing I could find.

(And I was doubtless lucky the local electronic parts store even had

those.)

But the fine threads don't hold in plastic very well.

Now I got on line and looked for them. That didn't look

very promising either. And if I order anything from USA they always

insist on shipping any little thing by courier and then there'll be

"brokerage fees" and tax - all for a few stupid little screws? And

still no bags of 100 the same anyway.

Finally I gave up Amazon and e-bay and went to China, to

AilExpress.com .

Sure enough there they were. Several stores, good selection, great

prices, cheap or "free shipping" by mail for small things. I ordered

about 300 from one store in a small assortment of sizes close to what I

think I want: 30$C.

YAY!

I could have ordered just 4$ worth (50 screws), and paid

4$. How can North America compete? Just the obligatory courier shipping

- or even postage for a bubble envelope - is more than that. And then

if you buy enough quantity or "extras" to get up to most

companys' "minimum order" purchase, it's also enough to trigger customs

brokerage fees and taxes, for which the minimum is only 20$, doubling

the

price again. You're up to 40-50$ for one little bag of a few screws.

The Chinese rarely have a minimum order, and they usually write a lower

value on the package so customs won't bother it. And we mostly don't

have the selection - virtually nothing for small screws. Even when we

do, the prices are much higher.

Of course once I had ordered, the system showed me even

better bargains from other stores, that hadn't shown up in my original

search. Maybe next time.

Cura Slicer

Now that I finally have high speed internet I downloaded

Cura (perhaps not the first time?). The file called itself a

".AppImage". That sounded like some sort of archive file, like an Apple

".DiskImage" but there was no suggested application for it and I

couldn't get anything to open it. (I think that's about where I got to

last time.)

Finally I just double clicked on it - again, I think.

After several seconds a small window opened. It was a "ready to run"

application program. That's something I probably missed too: with the

delay when nothing seemed to happen, I didn't wait long enough. Well

[your choice 4 letter word]! Why couldn't they just call it ".app"?

Then one could select print material, printer, and item

to print, and it would "slice" it into layers of print filament in a

G-code file for the printer. There were also "settings". My RepRapPro

usually did .4mm

per layer. Cura defaulted for the AnyCubic I3 Mega (which was on its

list of printers - yay!) to .2mm per layer, optionally .3mm. The

default

print time for a battery cell case was something over 2 hours instead

of 40 minutes - ouch!

I may wish to use some lower rez settings for many items.

After all, the printer printed from the old Skeinforge slicer decently.

And using the low rez print at slightly low

temperature allowed me to print the "porous" separator grilles which

had previously been so elusive.

High Temperature 3D Printing Filaments

While exploring Cura I noted various filaments and their

settings. "PC" was supposed to be good up to 110°C. I thought that

would be a hot enough rating to print electrical sockets from, instead

of going to labor intensive porcelain. With a bit more

exploration starting on the Ultimaker (Cura) website, I found 6/66

nylon (PA, polyamide), which was also high temperature but didn't look

unprintable. (And if "666" is the number of the beast from hades, it

should withstand very high temperatures.)

It claimed detail when printing with this material was

almost as good as with injection molded parts. I ordered some from a

Canadian source because the ones on AliExpress didn't specify what type

of nylon they were and for once they didn't seem much cheaper. (Got it

January 3rd.)

Sufficiently high temperature printable plastic, plus

proper screws, and the metal part designs, should at last

enable commercial production of the redesigned 36 volt HAT plug and

socket items. Next I need to redesign the wall outlet plates and all

the 12 volt CAT plug and socket items.

Essentials For Commercialization:

* CAT plugs and sockets (crimp wires)

* CAT Click-Lock plugs and sockets (crimp wires)

* CAT Wall (triple or more) socket plates (Pigtails or crimp wires)

* CAT Cigarette Lighter adapter socket (CL to CAT only... or both

directions?)

* Same items for HAT 36V. (Lower Priority)

But I would like to come out with a broad range of related

products. It would be best to have at

least some of them on offer at the first launch.

Desirables:

* Wall sockets with built in switches.

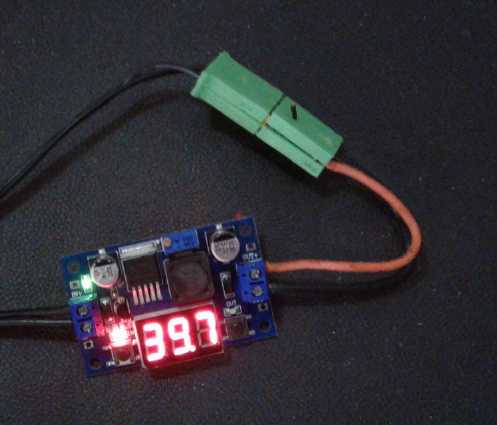

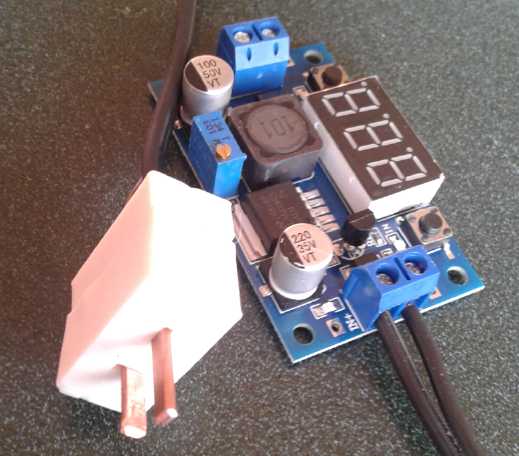

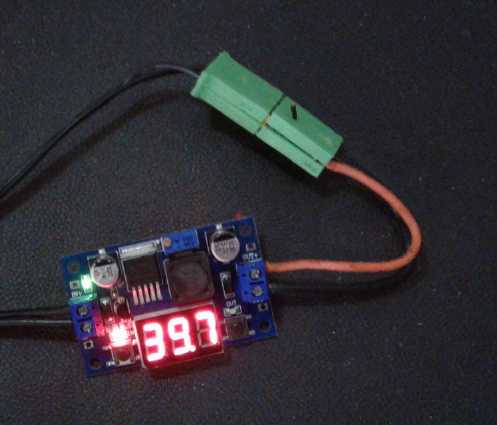

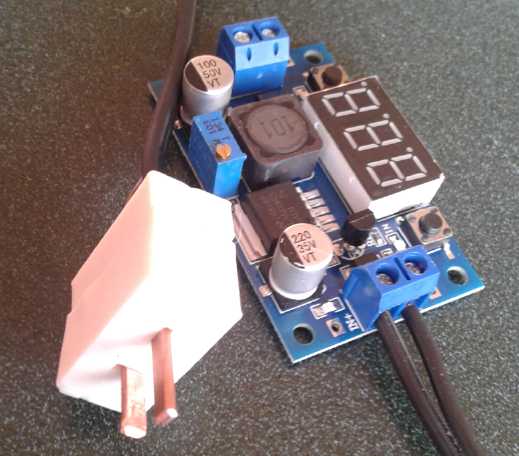

* DC to DC Down Converter, in a housing with HAT plug and CAT socket

for running 12 volt items from 36 volts supply.

* Meter box with CAT plugs and sockets to check voltage and current,

and maybe count up watt-hours used.

* Similar

converters that also show the voltages.

* Similar

converters that also show the voltages.

(Unfortunately I have

two such converters out of two that seem to have quit working -

Vout~=Vin. I

either need to find better ones, or figure out why they're blowing.)

One

of them worked for a few days, and it was very nice to be able to read

the state of the batteries from the livingroom, as well as adjust the

12.0 volt

output. I was running a 12 volt LED light with it. A "production" one

needs a 3D printed housing with integrated CAT socket.

The HAT input plug

The HAT input plug

* CAT and HAT Programmable voltage and time delay switches (eg, to turn

on

loads when solar or wind is available, and off when it's not.) Ideally

this would have many programmable features and monitor voltage, current

and watt hours consumed.

* 12 volt LED lamps with CAT plugs.

* 36 volt LED lamps with HAT plugs. (the 12 to 72 volt DC LED 'bulbs'

that fit regular E27 sockets, and some regular lamps might be good.)

* CAT and HAT 'electric heater' dump loads. (Probably to be used with

the voltage switches.)

My

Solar

Power

System

Month of December Log of Solar

Power Generated [and grid power consumed]

(All

times are in PST: clock 48 minutes ahead of sun, not PDT which is an

hour and 48 minutes ahead. DC power output readings - mostly the

kitchen hot

water heater - are reset to zero daily, while the others are

cumulative.)

Solar: House+DC, Trailer => total KWH [grid power meter

reading(s)@time] Sky conditions

November

30th 18.12,(1.11),915.01-1.30 [55Km,Charging; 69232@17:00; 50Km,Chj.]

Not sunny.

December

01st 18.84, (.71),915.41=> 1.12 [69276@18:30] Even more not

sunny.

02nd 19.58, (.63), 915.84 = 1.17 [55Km drive,Car chjd; 69306@21:00]

Clouds and

Rain.

03rd 21.26. (.52), 916.77 = 2.61 [69319@17:00; laundry] Am? - PM

Sunny.

04th 22.58, (.56), 917.60 = 2.15 [69342@17:00] Mostly sunny.

05th 23.04, (.64), 917.82 = 0.68 [69367@17:00] Mostly cloudy.

06th 24.23, (.62), 918.36 = 1.75 [85Km,Charging; 69401@17:30]

Cloudy AM, sunny later PM.

07th 25.93, (.67), 919.49 = 2.83 [69438@17:00; 55Km,charging]

Sunny except overcast with jet trails

08th 27.10, (.56), 920.15 = 1.83 [69482@18:30] Earlier AM cloudy,

then similar to yesterday

09th 27.34, (.88), {.3}, 920.28 = 0.37 [69514@16:30] Clouds,

wind, bit of rain. {windplant - not added to total}

10th 28.79, (.75), 921.00 = 2.17 [69543@16:30; 55Km,chjng] Some

sun, clouds

11th Power fail,(.45).52*,921.10(est)=0.62 [? - Power fail and I didn't

read the meters] Gloomy, high winds. There would have been hardly any

solar anyway. *DC power from windplant

12th 00.00, (.00), 921.52 = 0.42 [69595@17:00] Mostly cloudy, a

little sun with obscuring jet trails. I forgot to turn the inverters in

the garage back on. I had neglected to turn the one in the trailer off,

so it was on.

13th 00.64, (.04), 922.10 = 1.22 [90Km,chjng; 69621@16:30] Rain,

later PM sun.

14th 01.08, .05, 922.38 = 0.77 [60Km,chjng;

69665@16:30] Fog, mist, overcast.

15th 01.20, .19, 922.45 = 0.38 [69714@23:30] Yikes!

Might we just call it "gloomy" again? OTOH apparently at +8 to 9°C

at midnight we are the "hot spot" for Canada, most of which is at zero

or much colder. (2nd place: Victoria & Comox @ 5°.)

16th 01.92, .08, 922.96 = 1.31 [69735@18:00] Pretty

dreary again.

17th 02.52,(.53), 923.36 = 1.00 [69764@16:00] Mostly

overcast, a bit of sun.

18th 03.80,(.91), 923.94 = 1.86 [69804@22:00] A little sun,

but more rain and clouds.

19th 04.44,(.49), 924.31 = 1.01 [69825@16:00; 50Km,chj.]

About the same as yesterday.

20th 05.24,(.45), 924.69 = 1.18 [85Km,charging; 69867@17:00]

21st 06.79,(.85), 925.67 = 2.53 [60Km,chj; 69908@17:00]

mostly sunny, a bit of rain. WINTER SOLSTICE.

22nd 08.05,(.75), 926.55 = 2.14 [69940@18:30] neutral to sunny.

23rd 08.31.(.53), 926.71 = 0.42 [69987@17:00] dull.

I turned off the grid tie inverters while I was away over

Christmas and New Year's Day - just in case there might be any trouble.

(While I can't believe they could somehow put power into a dead line

and be dangerous to BC Hydro crews, I am slightly concerned about the

potential for an inverter(s) to be damaged by some bad power spike

while unattended for 10 days in winter winds. Perhaps it might even

even cause trouble to my buildings, although it's also pretty unlikely

no fuse would blow - each of them has three fuses. The power was in

fact off just long enough sometime in there to start a clock blinking,

altho it still kept the right time.)

Jan 02 08.31,(0), 926.71 = 0000 [70401@18:30] sleet, rain,