Turquoise Energy News #140

covering

January 2020 (Posted February 8th 2020)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Features:

* Open Loop, Free Air Heat Pumping: COP > 10? - or: How to

Heat a

Building Really, Really

Cheap! (see: Month in Brief, Other Projects)

* 12 Years of Green Energy Projects in Review (see "In Passing")

Month

In

"Brief"

(Project Summaries etc.)

- Brr!

- Free Air Heat Pumping - Theory - Heat Pumping Experiments - Meanwhile

in Other News - Bringing a Dead NiMH Battery Back to Life

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Von Braun and the Apollo Moon Landing Project - 12 Years of

Energy Projects in Review - Reversing Desertification - Small Thots:

Columnating out-of-line binoculars, Hair mites, Earth heat... - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (No Reports)

Other "Green"

Electric Equipment Projects

* HAT & CAT Plugs & Sockets

* Very High COP Open Air Heat Pumping

- Cooling - Heat Pump Heating - Some Simple Tests - Experiments -

Copper Pipe, Soldered Copper Fins - A Test - More Compressed Air Piping

and Test 2 - Outer Ducting and Test 3 - Building-to-Outdoor Heat

Exchanger and Tests #4 - Michelin Air Compressor Tests - Air Compressor

Noise Solutions? - Custom Air Pumps? - Refrigerator Air Pump

Electricity Generation

* My Solar Power System: - Monthly

Solar Production log et cetera - Notes. (December & January:

trivial power output!)

* "Carmichael's

Woodstove Engine" (& generator) -- Called off for now for

greener pastures & easier projects.

* An Experiment: Woodstove Electricity with Thermoelectric

Generators

(TEGs)

Electricity Storage

* Turquoise Battery Project

(Mn-Zn or Ni-Zn in Mixed Alkaline Salt electrolyte)

- Thinner copper current collector - nickel electrode - pure zinc

electrode - Nickel-manganates Again - Low Currents - Back to Graphite

Felt? - Chemistry seems fine but Mushy Electrodes Don't Conduct Well

January in Brief

House with some snowed-over solar

panels on

the roof.

House with some snowed-over solar

panels on

the roof.

Some snow had melted or slid off the bottoms, but

they don't produce unless the whole panel is clear.

Best Laid Plans and all that: It's

the Weather

After returning from my Christmas holiday I had intended

to

carry on with the model of the ground effect vehicle, but I came back

with a nasty chest cold. I put heat and steam on

in my bedroom at night for some days. (yet more electricity!) I sat

down and

looked into the Stirling engine heat pumping idea. This led to thinking

of

an exciting way to refrigerate, followed by an even more exciting way

to heat a building, for exceptionally low cost. These dominated my

creative thoughts.

And the weather was cold, varying from -5 to -10°C for

a couple of weeks. I could hear 2 or 3 chainsaws in the neighborhood, I

thought

to cut more firewood in the unexpected cold. Luckily I was already

short of it and I had bought a cord of fairly dry firewood just before

Christmas. (On the night of the 13th-14th it dropped to -10.2. That's

the coldest I've ever been in in 47 years on the west coast - if only

by a degree or so and I'm farther north now.) I left the kitchen sink

running a bit to make sure the pipes coming in from the well through

the unheated garage didn't freeze. (Some other peoples' water did

freeze.)

ACK! My potatoes! Since it doesn't usually get so cold I

had

left them in the ground, digging them up as needed. Now they were in

danger of freezing! I went outside for a couple of short sessions,

throwing off big slabs of frozen dirt about 3-4 inches thick and then

digging through the soft sandy soil underneath. There were too many in

the frozen top layer, and I sliced through too many with the shovel,

and doubtless I missed too many. (Weapon of choice for potatoes is

normally a pitchfork: you'll skewer a few, but you'll turn them up

without slicing a bunch of them in half.) I wasn't a day too soon as

there was thick snow the nest day. It would have gone better in

December - if I had guessed what was coming. I only got the main patch

- there were still others. Oh well, 6 Kg of potatoes is 6 Kg of

potatoes. Some had been frozen and went mushy, but most were good.

Sitting anywhere but the livingroom where the woodstove

was - and preferably next to it - wasn't comfortable. So

I dabbled at things that didn't require going outside or into the

workshop much... or even into the kitchen. Especially things for which

I could sit near the stove to do some of the work. On the 13th I

noticed that electricity consumption had gone WAY up that day, from 40

KWH

to 90. I finally realized the house baseboard heaters, set to 10°,

must have come on at night when the fire was low. They were

using far, far more electricity, to keep the house less warm, than my

new plan for heat pumping would have if it had been already working

instead of

just a concept.

On the 15th I checked my "root cellar" storage room. It

usually maintains a nice, cool temperature but now the thermometer said

35°f... 2°! I put a 425 watt heater down there to keep the room

with its many gallons of paint and some food from freezing. I can only

be glad I'm not on the prairies. Edmonton where I grew up was almost

-40°c (= -40°f), even colder than the coldest day when I was

going to

school in the 1960s, -30°f or -34°c -- "-90 [°f] with

wind chill". (I remember it well. That was before

Canada went metric)

We have by no means seen the end of unprecedented weather

and broken all-time records. It's global. IMHO there are three main

forces at work: Unnatural high stratospheric cloud cover being caused

by jet aircraft which are heavily disrupting the global wind

circulations and precipitation patterns (TE News #109 etc), global

warming, and the grand solar minimum ("GSM") with the

sun being slightly dimmer than usual for a period of (hopefully only) 2

or 3 decades. It seems to me that the first of these is the most

disruptive.

Things improved for some days in the later part of the

month, but there was just one sunny day where it was nice to be

outside, and on the night of the 31st it snowed again, with the

temperature around freezing.

Free Air Heat Pumping: How to Heat a Building Really, Really Cheap

Reading in a paper that Stirling engines might potentially

get a Coefficient

Of

Performance (COP) of 8 to 10, that is, pump 8 to 10

times as much heat from a cool place to a warm place as the electricity

being used to pump it with a 30° temperature

rise or fall, was really exciting. Why didn't we already have such

equipment, then? I just

couldn't drop the subject in my mind. Then I thought, why a Stirling

engine? When powered by a motor, all it did was shuffle air around, and

perhaps not even as effectively as it might. One could shuffle air

around in simpler ways. What about just a plain air compressor using

open air?

On the 6th I started writing ideas down, and the more I

looked into it, and the

more thought I gave to it, the more exciting it seemed. I started

thinking

of refrigeration, but soon turned to building heating. It was

so much

simpler than a refrigerant gas/liquid heat pump system that even if the

COP wasn't higher, it should be cheaper and so would have broader

application. And the COP

looked like it could be substantially higher. If a 'regular' heat pump

had a

COP of 2 to 4 depending on temperature differentials, might free air

(at this point based

solely on the Stirling engine paper and expecting similar) be 6

to 12, using 1/2 or 1/3 as much energy to do just as much heating of

cooling? But it turned out the Stirling engine paper seemed to have

been

quoting almost theoretical maximum COP, not what was likely to be

attained by

actual heat pumping equipment, especially pumping air and with amateur

homemade

equipment.

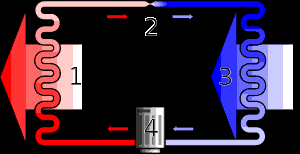

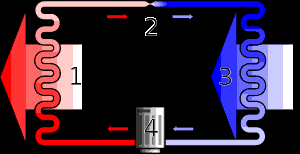

In a typical closed-loop heat

pump, a

refrigerant

In a typical closed-loop heat

pump, a

refrigerant

is pumped between outdoors and the building.

The cooled refrigerant must be reheated from

below the outdoor temperature to above

room temperature to heat the building.

By the time I realized that, I had also realized that

by

using open loop heat pumping with air instead of a closed loop

refrigerant based system, one might

actually get a real COP above 10 - even 15 to 20 or more

by further heating indoor air instead of heating

air from outdoor

temperature! The lower the temperature rise, the higher the COP. So

one might perhaps get (eg) 1200 watts of heat

from

each 100 watts used to run the compressor. This was the essential

conceptual

breakthrough. Soon a few more bits fell into place to enable that to

work well.

In northern latitudes heating is the great energy

consumer, in winter exceeding all other energy uses combined including

transport. The possibility of attaining "unheard of" COPs by

doing just a small temperature rise seemed

unbelievable at first, but I didn't see

a flaw in it. It seemed like such an exciting idea, to be achieved with

such potential simplicity, as to be a game changer for home energy use

- the energy equivalent of going from incandescent light bulbs to LEDs,

but for the much larger energy use of space heating.

How could I not look into it? I learned more. (What a

fantastic resource the internet is, and accessible from home!)

The Theory

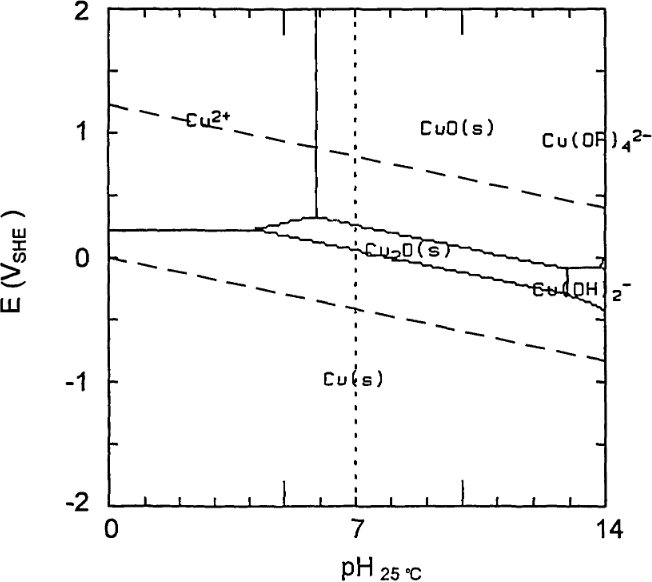

I finally found the essential, simple formula for theoretical

maximum COP. Temperature units must be in

absolute temperature (°Kelvin, °K = °C+273):

Thot

COP = ----------

(Thot

Tcold )

The denominator is known as the "lift", the number of

degrees (here °K or °C are the same) by which one wishes to

raise a

temperature. To pick a simple round number for Thot, Earth's

temperature is around 300°K. (That's 27°C.)

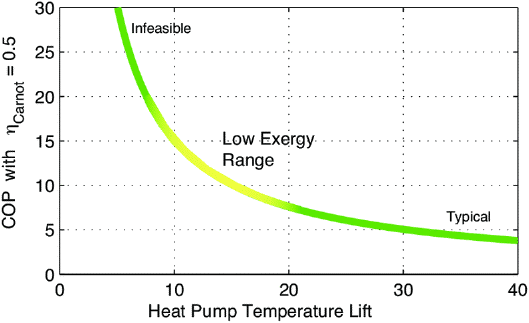

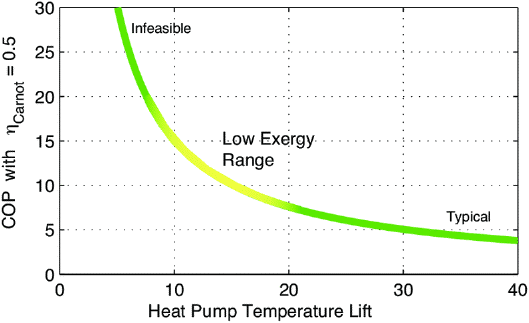

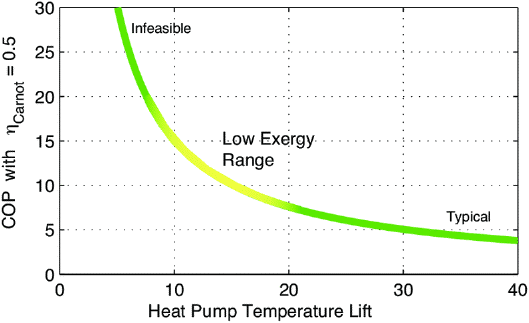

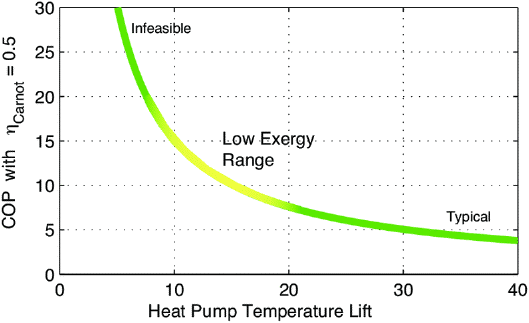

Graph showing COP potential for

heat pumping at various temperature "lifts",

assuming 50% efficient heat pumping. But: "Infeasible"

looks feasible!

So

if

one

wants to heat ("lift") outdoor air by 30°K (=

30°C), eg, to heat from freezing air temperature up to 30°C

to be warm enough to radiate heat into the building to get a

comfortable 23°C or so room temperature, 300 / 30 = 10 theoretical

COP. Inefficiencies in closed loop, refrigerant based heat pumping

apparently reduce

the actual COP to around 2 if it's below freezing outside, to 3, or

often 4 or higher if it's not very cold outside. (When the most heat is

needed

the COP is lowest. Note: Could newer equipment do a little better

than my old statistics?)

So

if

one

wants to heat ("lift") outdoor air by 30°K (=

30°C), eg, to heat from freezing air temperature up to 30°C

to be warm enough to radiate heat into the building to get a

comfortable 23°C or so room temperature, 300 / 30 = 10 theoretical

COP. Inefficiencies in closed loop, refrigerant based heat pumping

apparently reduce

the actual COP to around 2 if it's below freezing outside, to 3, or

often 4 or higher if it's not very cold outside. (When the most heat is

needed

the COP is lowest. Note: Could newer equipment do a little better

than my old statistics?)

If instead we can merely heat the indoor air from

23 to 30

at the radiators, that's only a 7° "lift". 300 / 7 = 43

theoretical COP. Given even just 25% equipment efficiency

overall, we still get an actual COP of 11: eg, 1100 watts of

heat for

100

watts of electricity. If the equipment is more efficient, it may go up

from there. With a fabulous radiator system one might need a lift of

just

3°, giving a theoretical maximum COP of 100: 10,000 watts of heat

from 100 watts of electricity!

The questions arose, and then the answers. How can one

just

heat pump the indoor air? Doesn't the air finally come out of the

system at room pressure, chilled as it decompresses? The heat pumped is

chilled again! That's where the open loop system has the advantage: it

can discharge the cooled air to the outdoors. So overall heat from the

outdoors is transferred into the building.

That is the essential, but there's still another

improvement to be had. Since

outside air is drawn into the building to replace what the compressor

uses, one can add a building-to-outdoor heat exchanger (or just

"outdoor heat exchanger") instead of just letting it suck cold air

through

the cracks. The

outgoing air warms

the incoming air, while the incoming air cools the outgoing air. Then

when the outgoing air, now cooled to almost outdoor temperature, is

decompressed to the outdoors, it will be colder than the outdoor air.

But the heat exchanger passively raises the temperature,

and the heat pump only heats room temperature air up a little

warmer.

So the open loop, free air heat pump system has three main

components.

1. The prime mover

is an air compressor. It is (at least thermally speaking) inside the

building

being heated. As air is

compressed, it contains the same thermal energy but in a smaller and

smaller space. If it's compressed into half the space at double the

pressure, it theoretically doubles in absolute temperature. But the

much denser solid materials of the compressor cylinder, piston and

pressure tank

quickly absorb this excess thermal energy and warm up, so it takes a

lot of air to warm things a little. But it is heat that came from the

already warm building air, not from the electricity running the

compressor.

2. The second component is the radiator - a heat

exchanger between the warmed, compressed air and the room air. This (at

least in

my prototype) is copper pipe with copper

fins, all inside a thin walled aluminized flexible dryer hose. The

compressed (and

hence a little warmed) air flows continually from the compressor

through the

pipe, under full pressure all the way. Its warmth is transferred from

the pipe via the fins into the dryer hose around it. The dryer hose

is thin walled and not insulated, and a small fan also blows the air

through the

hose/duct and out the end. Moving air transfers heat to the

room air much better than just passive convection and radiation from

the pipes,

minimizing the

"lift" needed to heat the radiator enough to heat the indoor air, and

hence maximizing the COP.

3. The third component is the building-to-outdoor heat exchanger. The

workings of these are long and well known since the 1970s(?). (Thanks

ASHRAE trade shows!) Inch by inch as the air comes in, it gets a little

warmer until it's (almost) room temperature, and inch by inch the

outgoing air gets cooler until it's (almost) outdoor temperature as the

two exchange their heat. (I've seen manufacturer's claims of 90%

efficiency.)

The unit should work without an outdoor heat exchanger,

but cold air being

sucked in from outside would add to the heating load. "Portable" single

duct air conditioners also work, but similarly the outside air they

draw in as the duct expels building air, adds to the cooling load and

they lose efficiency.

The unit in

this case is like the radiator pipes

except its outer duct is insulated. The compressed air, having heated

the living space, is down (almost) to room temperature. The pipe is now

routed through the outdoor heat exchanger, where it is cooled to

(almost) outdoor temperature. The pipe ends outdoors and pointed away

from the incoming air. The

compressor is using air from inside the building and exhausting it

outside, and so air is

drawn in from outdoors through the outdoor heat exchanger's outer duct.

So as the compressed air is exiting the building, it is warming the

incoming air to (about) room temperature while itself being cooled.

The unit in

this case is like the radiator pipes

except its outer duct is insulated. The compressed air, having heated

the living space, is down (almost) to room temperature. The pipe is now

routed through the outdoor heat exchanger, where it is cooled to

(almost) outdoor temperature. The pipe ends outdoors and pointed away

from the incoming air. The

compressor is using air from inside the building and exhausting it

outside, and so air is

drawn in from outdoors through the outdoor heat exchanger's outer duct.

So as the compressed air is exiting the building, it is warming the

incoming air to (about) room temperature while itself being cooled.

At the very end of the long compressed air pipe, outdoors,

is a nozzle where

the air is decompressed, which further cools it, and released. Thus the

air actually exits the

system below the surrounding outdoor air temperature. So the building

is heated while the outdoors is cooled just

like with other heat pumps. But here the pump itself only heats indoor

air. The outdoor heat exchanger has pre-warmed the air to help make an

extreme COP possible - regardless of outdoor temperature.

(I used square aluminum fin pipes I had already made.

Probably

not optimum. And the outer duct ended up being a bit narrower than I

had intended.)

Heat Pumping Experiments

I ordered a "highest flow capacity" plug-in 120 volt air

compressor: over 4 CFM at 90 PSI. (MORE money going out, ahrg!) I had

hoped

for a quieter one

than the piston type, but

the quieter and supposedly more efficient (now I have my doubts)

helical screw, scroll and

centrifugal types seem to be made only in very

large sizes.

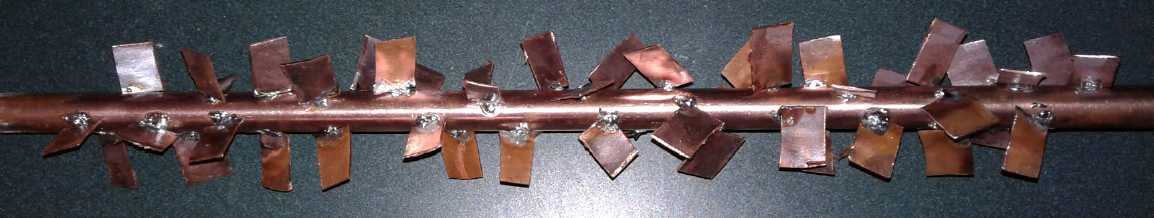

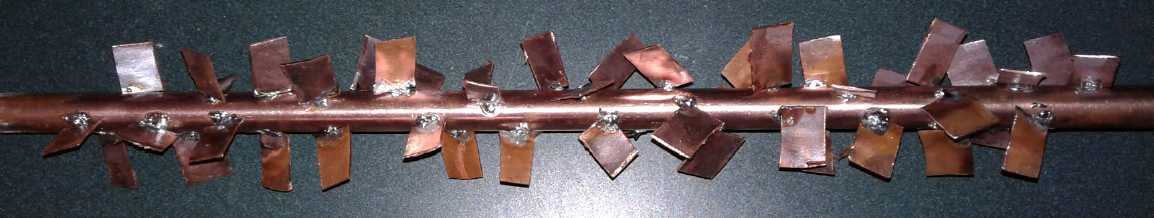

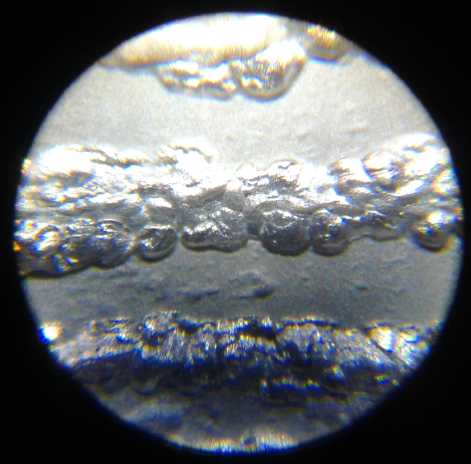

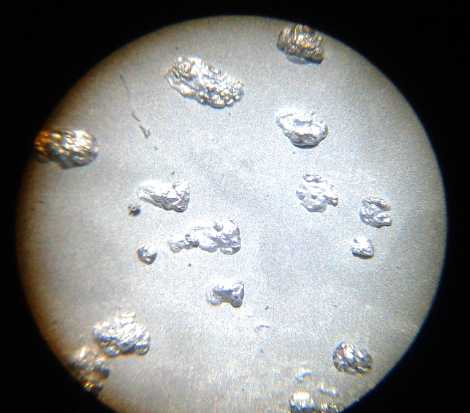

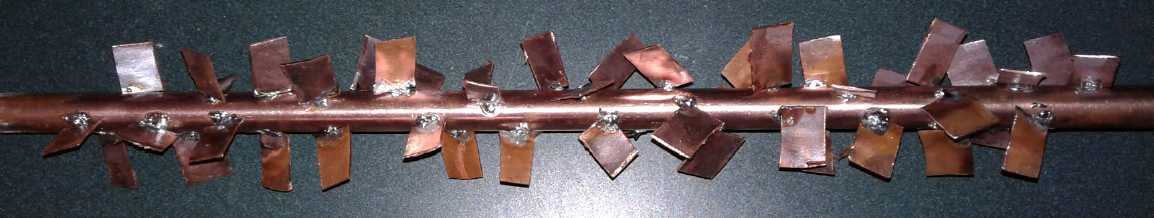

And I made a short "stegosaur" finned radiator pipe with

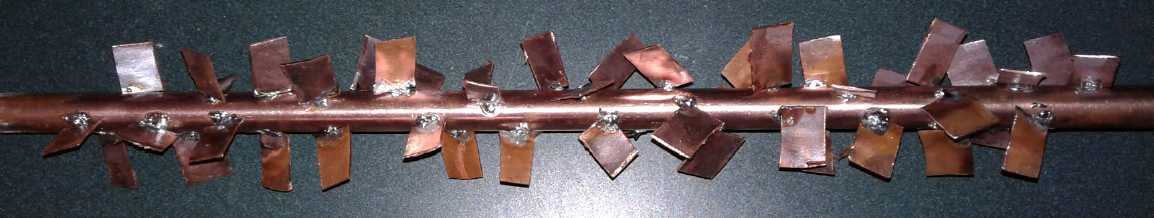

diagonally oriented, soldered-on copper fins to catch the air going

along in the duct outside the pipe, about 2 feet long. This

proved very tedious and they had less than an optimum grip (a few fell

off) and thermal connection, so I decided I had to make a jig(s) to

simplify and

improve the

process before I did any more.

"Stegosaur" finned pipe

"Stegosaur" finned pipe

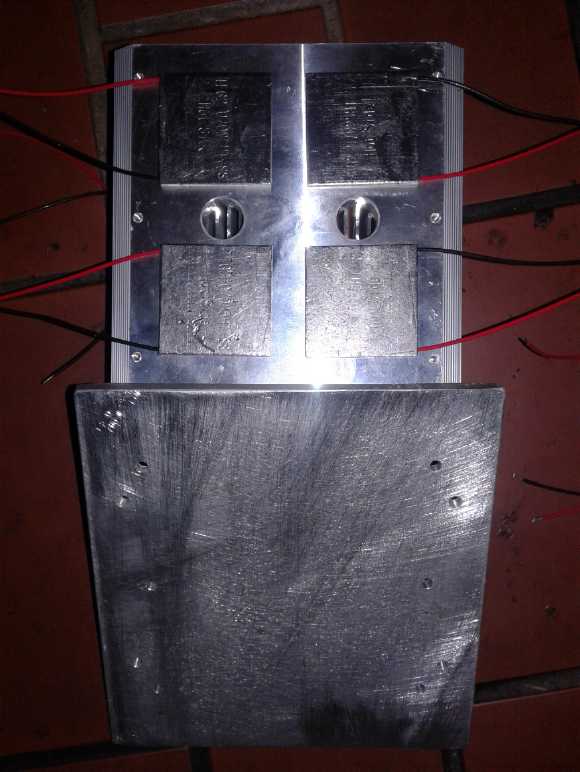

The "Star Wars Cannon" setup. It doesn't much

matter whether the body of the outdoor heat

exchanger is inside or outside, so I just set

the end up against the window, opened a bit.

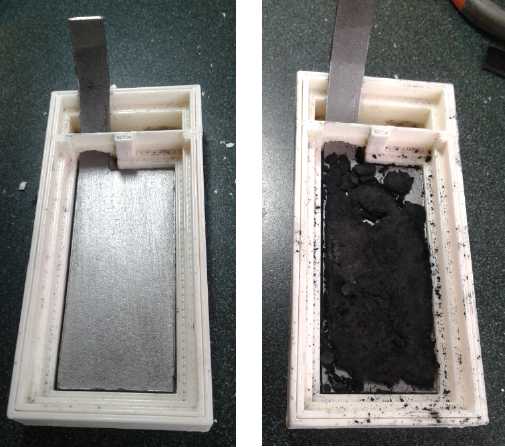

Later

in

the

month I thought of my small lab

vacuum/pressure pump.

I bought various pipe fittings, and made a mini heat pump unit with it,

making and testing one component at a time. The heart was a plywood box

with the compressor and a fan to blow air through the duct. (I plugged

the 36 volt fan into my DC solar power system outlet.) On the 26th I

completed the

last one, the building to outdoor heat exchanger, and in the evening I

tried it out in the kitchen/dining area with no other heat on and both

doors closed so it wasn't just being heated from other areas through

the doors.

Later

in

the

month I thought of my small lab

vacuum/pressure pump.

I bought various pipe fittings, and made a mini heat pump unit with it,

making and testing one component at a time. The heart was a plywood box

with the compressor and a fan to blow air through the duct. (I plugged

the 36 volt fan into my DC solar power system outlet.) On the 26th I

completed the

last one, the building to outdoor heat exchanger, and in the evening I

tried it out in the kitchen/dining area with no other heat on and both

doors closed so it wasn't just being heated from other areas through

the doors.

It was hard to tell what the effect was. The air coming

out the indoor radiator hose hose was only

2-3 degrees above the air going in, but it was a fair amount of air

being moved. The room temperature wasn't rising. But then it was

cold out, 4°C, and the space was mostly exterior

walls/floor/ceiling. How

effective was it really? I ended up by running several tests measuring

only the room temperature, one after another, with each test for one

hour:

Test

|

Start Temp.

(degrees C)

|

End Temp.

(after 1 hour)

|

Rise/-Drop |

Heat Pump

|

17.1

|

17.0

|

-.1

|

No Heat

|

17.0

|

16.0

|

-1.0

|

Heat Pump

|

16.0

|

15.9

|

-.1

|

425W Radiant heater

|

15.9

|

16.1

|

+.2

|

No Heat

|

16.1

|

15.5

|

-.6

|

It can be seen that without heat, room temperature

dropped. The heat pump almost kept it steady, so it was obviously

having some effect. The 425 watt radiant

heater managed to bring it up slightly. By comparing it with the

radiant

heater result, I conclude that the heat pump with the 75 watt

compressor must have been pumping in around 300 to 375 watts of heat.

That's a COP of 4

to 5. That's just a prototype with a compressor that works but is

probably not very efficient. (It keeps running but won't rise above

25 PSI. I was using

17 PSI to get some flow and still have some pressure. A substantially

higher pressure would probably be more ideal.)

The next evening I tried

again with my big compressor, but I only found a thin tube (~1/8 inch

ID?) to connect it to the piping. The compressor got hot instead of the

piping, and the pipe was substantially warmer than the air it was

supposed to be heating so it didn't transfer even that heat to the air

very well, and the result was unsatisfactory. The 800 watt compressor

seemed to heat the room less than 900 watts worth of radiant heaters. A

second experiment connecting straight to the compressor tank with 1/2

inch copper pipe wasn't noticably better. If I hadn't tried the

previous experiment, I might have concluded the whole thing didn't

really work. But it was pretty obvious that most of the heat was

somehow trapped inside the compressor, from which it simply radiated.

(Now I think the pressure inside

the compressor cylinder was much higher than what I was allowing in the

pipe, and so there was far too much flow. I should have run with much

higher pressure to match the compressor, with less flow.)

The next step will be to make a jig for making copper

finned radiator pipes, and then to try again with much more radiator

pipe and duct.

What about compressor noise? That will have to be dealt

with before the system is commercially acceptable. (I discuss it a bit

in the 'detailed report'.) On February 1st I got an 80 watt fridge

compressor at the scrapyard. It's quiet enough to use. If I can really

get 800 watts or more of heat from it, that will be great! (It should

work, but it's still hard to imagine!)

As a side note, in doing a little further investigation I

found where someone suggested on a discussion list that instead of just

venting compressed air to the outdoors to decompress it, it could

be decompressed through a turbine to generate electricityas it goes! I

don't know

how worthwhile this would be with a small home system, but it would

recover even some of the little energy used to compress the air.

Factoring this in

would further raise the overall effective COP - could it really hit 100?

Meanwhile in Other News

On the 10th I

noticed that nearly 1/3 of the month was

already gone on heat pumping theory and I turned to other projects,

starting with trying out

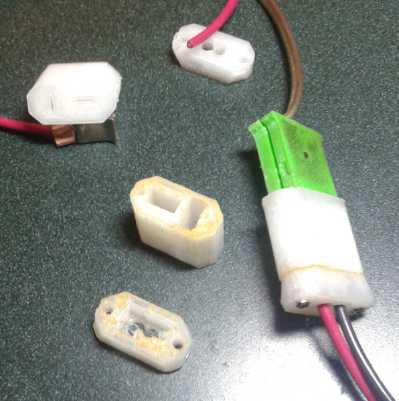

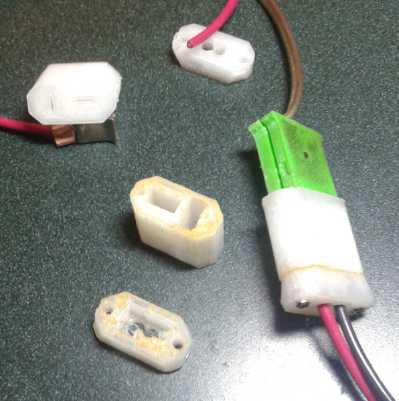

the higher temperature nylon printing filament for CAT and HAT

electrical sockets. That went well. Mike pointed out that if I 3D

printed a few plugs and sockets, they could be mass produced by making

a silicone rubber mold and casting them in epoxy. And that epoxy was

probably high temperature enough, or perhaps could be with

an additive. Now we're talking real, low cost production! Perhaps for

battery cases, too?

On the 10th I

noticed that nearly 1/3 of the month was

already gone on heat pumping theory and I turned to other projects,

starting with trying out

the higher temperature nylon printing filament for CAT and HAT

electrical sockets. That went well. Mike pointed out that if I 3D

printed a few plugs and sockets, they could be mass produced by making

a silicone rubber mold and casting them in epoxy. And that epoxy was

probably high temperature enough, or perhaps could be with

an additive. Now we're talking real, low cost production! Perhaps for

battery cases, too?

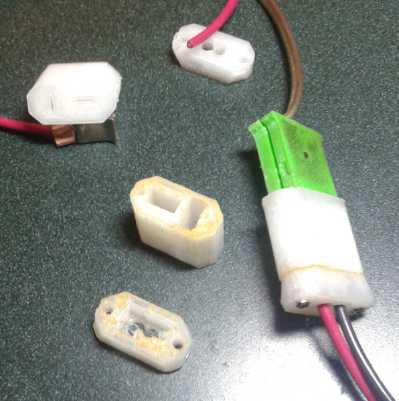

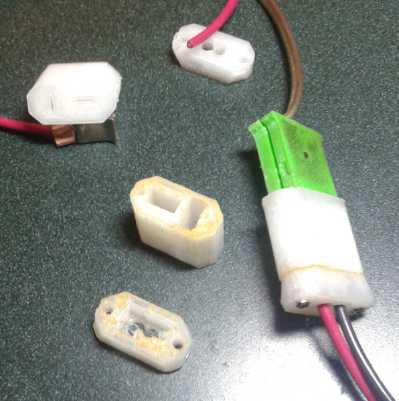

What didn't go very well was putting in and connecting the

pins. The crimp rings bulged out too far to the sides after crimping

the wires to the pins. I widened the recesses a bit to make more room.

This was however making the whole socket thicker and wider.

Later in the month I did a plug.

It still didn't go together so easily, so I further adjusted the design

for next time. And another adjustment in the cap - a larger hole for

the exit for heavier wire. They're getting better. But fatter. The

earlier plugs and sockets for soldered-on wires (green, above) are

considerably

smaller.

Later in the month I did a plug.

It still didn't go together so easily, so I further adjusted the design

for next time. And another adjustment in the cap - a larger hole for

the exit for heavier wire. They're getting better. But fatter. The

earlier plugs and sockets for soldered-on wires (green, above) are

considerably

smaller.

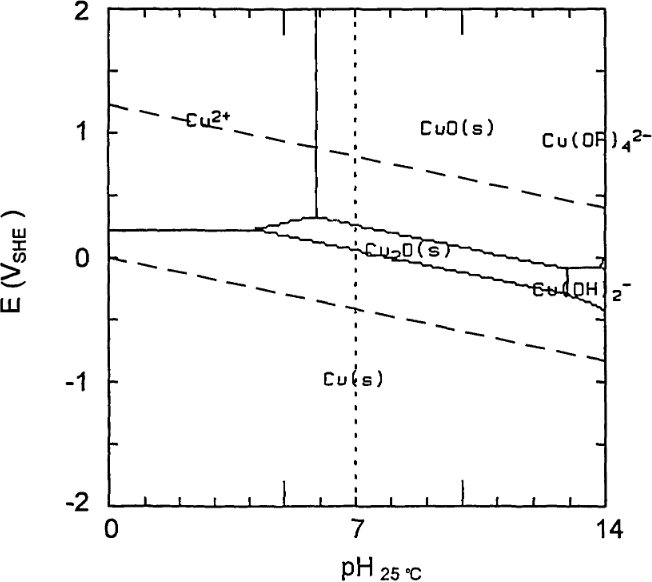

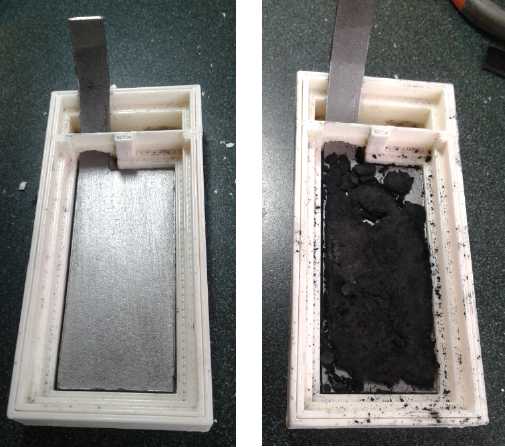

On the 12th I decided that

funding rejection or not, I should put

together another battery cell with the gold plated copper and the new

pure zinc sheets and try it out. This zinc behaved quite differently in

hydrochloric

acid, which showed what impure crap the old stuff I'd been using was. I

had trouble with the cell leaking - again! Sigh! That's

disheartening and I set it aside.

On the 12th I decided that

funding rejection or not, I should put

together another battery cell with the gold plated copper and the new

pure zinc sheets and try it out. This zinc behaved quite differently in

hydrochloric

acid, which showed what impure crap the old stuff I'd been using was. I

had trouble with the cell leaking - again! Sigh! That's

disheartening and I set it aside.

But I planned a new 106 x 106 mm flat battery case. The

new Cura slicer would doubtless make cases that wouldn't leak. The pure

zinc sheets came in 100x100 and 140x140mm. (4"x4", ~5.5"x5.5") So

(counting

outer walls) 106x106 should be a good small production size. The zinc

sheets would be on the bottom, so if graphite felt was used it could be

on top and wouldn't have to bend up much to make a terminal. They

should turn out about 7mm (just over 1/4") thick/tall.

Then I tried a copper oxide electrode in the plus side, then two of

nickel manganates again. In all cases conductivity was poor. Under load

the voltages were low and it didn't last long. The last one with the

powder in graphite felt, wasn't much better than the others. But with

it if I put weights on the cell, everything improved, and it improved

markedly if I leaned on it. It supplied load for much longer at higher

voltages. It seemed the chemistry was fine in each case. It was the

mechanical aspect that needed something.

I looked at some old issues of TE News and found that I

had been getting much better results in 2013-2014, probably from

torching the positive electrodes before I put them in. That presumably

"sintered" many of the particles together so the whole piece (even if

it stayed crumbly and fragile when handling) didn't just swell up and

everything lose connectivity once it was immersed in the electrolyte.

How easy it is to forget things after enough time goes by. If that

works I should finally be able to put together real, working batteries

now. I suppose if I had stuck solely or at least more heavily to

battery development I might have had it all working years ago and not

had time to neglect and then forget various details between experiments

sometimes months apart. But I hadn't really "connected all the dots"

and I confess I got rather discouraged for

quite a while.

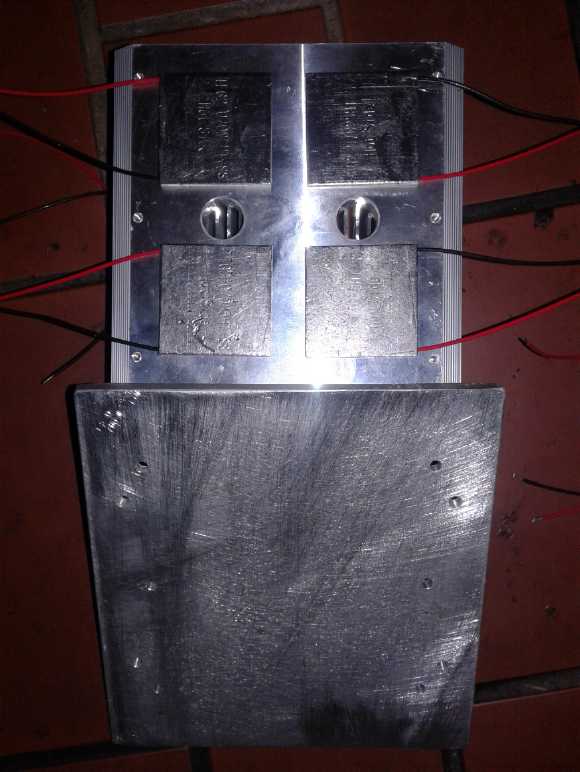

Having put the

woodstove closed cycle steam engine generator on hold in favor of the

heap pump project, I decided to (at long last) try a thermo-electric

generator (TEG) on the woodstove idea, little promise tho it seemed to

have. I could make four modules with four TEGs each, wire them in

series, use a DC to DC voltage boost converter to get a regulated

output, and feed that into the solar power system through the 36 volt

HAT receptacle near the woodstove.

Having put the

woodstove closed cycle steam engine generator on hold in favor of the

heap pump project, I decided to (at long last) try a thermo-electric

generator (TEG) on the woodstove idea, little promise tho it seemed to

have. I could make four modules with four TEGs each, wire them in

series, use a DC to DC voltage boost converter to get a regulated

output, and feed that into the solar power system through the 36 volt

HAT receptacle near the woodstove.

But I put one together and found that it was much harder

than expected to keep the upper heatsink cool. The TEGs passed a lot of

heat through from the stove. And anyway the output seemed pretty dismal

- 3 or 4 watts, so it would have been under 20 watts with all four. I

was hoping for 50 and I gave up on the idea again.

Bringing a Dead NiMH "D" Cell Back to Life

I was ready to post this newsletter on the night of

February 2nd, but the internet was down, apparently to the whole of

northern BC owing to landlides in the Fraser canyon and or high winds

and blizzard conditions and or damaged equipment that was hard to

replace - for over a week. (Without internet I only hear rumors of what

happened! I suppose the landslides will be on Nared King on Youtube!)

And everybody just in the last couple of months has canceled their

satellite internet accounts since the fiber optic system was hooked up.

Satellite internet may be slow and glitchy, but it would be a good

backup.

Okay, someone tells me that the microwave link on a

mountain on the mainland was hit by high winds and a blizzard. It broke

off the two dish antennas (one was never found) and wrecked the

equipment shack. To get internet back, on the 6th one of the two dishes

on the island side was taken to the mainland and a half-speed link was

restored. It will be months before new dishes are built and installed.

It may be a bit slow, but it's better than satellite and at least we're

on line again.

So here is another tidbit, February 3rd: I had been

virtually certain that the nickel-metal hydride dry cells lost capacity

and finally quit working not due to any fault of the chemistry, but

rather because they dried out inside. After all, lots of the flooded

NiMH batteries used in the 1997-2001(?) EVs like the GM EV1 and the

Toyota RAV4-EV were still working after 20 years and much hard EV use.

I had previously tried dumping some of the dead "D" cells

into a 200 liter barrel of water, but none of them revived. Now I cut

the top button off one with the angle grinder. (It was a very dead cell

with the plastic label melted off the outside in the Swift fire in

2017.) Under the button was a rubber sealing piece. Under the rubber

piece, dead center, was a small hole into the cell. That must be where

the water hisses out if there's much pressure in the cell, for example

if it was being overcharged, pressing the rubber seal out of the way.

Or seemingly it eventually came out anyway.

I found that if I dripped distilled water onto it, it just

sat there on top. But if I put the eyedropper against the hole and

squeezed, the water went in. I squirted in 2 or 3 CC, and then hooked

it to the power supply at 1.4 volts overnight to charge it. It took a

charge and held it!

It put out half the short circuit current of a good cell I

grabbed for comparison, but still over 5 amps. I squirted in another

1/2 a cc. That's all for now. More tests in February to see how

'restored' they can really be.

If it works I could in theory drill through the center of

each cap and use

a sharp syringe to poke through the rubber and add a measured optimum

amount of water, and restore my NiMH solar power batteries that have so

little capacity left in them. (I would want to set the tubes of cells

on end so the holes then faced up.)

New Hybrid Ferries being

delivered to BC

Ferries on a huge semi-submersible cargo ship, the Sun Rise.

New Hybrid Ferries being

delivered to BC

Ferries on a huge semi-submersible cargo ship, the Sun Rise.

It is a bit disappointing after seeing pure electric ferries in service

in Europe since 2015.

It is said there isn't any charging infrastructure for them yet where

they're to be put

into service, on the Port McNeil-Alert Bay-Sointula (Malcolm Island)

run and um... where

was that again... Campbell River to Quadra Island? Anyway it's a step

in

the right direction.

Hopefully the infrastructure will be upgraded soon so they don't need

to run the diesels.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Werner

Von

Braun

and

the

Apollo

Moon

Landing

Project

Of course, the idea of going to the moon had always intrigued people,

especially after Jules Verne's early science fiction story From the

Earth to the Moon well before such a flight was really conceivable.

The young Werner Von Braun probably read it.

I watched a documentary on Von Braun. In judging him

morally on his early days in Nazi Germany one must remember he was

still pretty young. He and his group were trying to build rockets on

the usual sort of shoestring

research and development budget, and suddenly (before the war) the

government came along

and pressed on his group virtually unlimited funds to do so. The

alternative was

probably to be drafted into the army. Even

then

his great talents both scientific and for managing other creative

workers were definitely manifested. His privately expressing regret

that they weren't building a spaceship, and thinking the war wasn't

going well, in early 1944, was reported to the authorities, which

"defeatism"

led his arrest. But he was indispensable and had to be released

("unpalatable though it is" said Hitler) for the

V2 rocketry program to continue.

There was footage of him in early flights of fancy

(1948-1955?) even before the Soviet Union had actually launched the

first

satellite into Earth orbit, showing how space exploration could be

done, and I was surprised to see pretty much the same designs I'd seen

in magazines when I was young. I hadn't realized they were mostly his

conceptions. I

was unaware of just how much it was Von Braun that had primed everyone

for taking

the dream and turning it into an actual program.

In the actual Apollo project, Von Braun showed what a

master manager he was, with thousands of talented people

enthusiastically and effectively working under him. In 1977 he died of

kidney cancer at my present age, 65. (The vitamin D, Luke! Use the

vitamin

D!) He never got to fly in space himself, but he and his vision, with

Kennedy's presidential backing and vision, did get men to the moon.

There was a point to this narration: Few will ever have

both the inspiration and ability to inspire others plus the

scientific/technical and the managerial talent of Von Braun. Visiting

the moon might still be a dream without him. Myself I

have uncovered and pursued some very exciting technologies, but I

haven't managed to inspire anyone with major resources and I haven't

had the experience of supervising more than a person or

two for single work sessions. But if somehow Turquoise Energy had a

real

budget to commercialize the various products I've developed or half

developed, I think I could hold my own.

But I think of the Avro Arrow, and I think of the Apollo

project, and even Glen Clarke's catamaran ferries, and think that in

Canada today, about the most effective way

to really pursue a large project that needs some research in the

course of product development would be with the prime minister or

provincial premier actively on your side, brushing away red tape and

doubting naysayers and helping with funds. Or maybe some very wealthy

philanthropist. But perhaps that's an exaggeration -

getting these things started would be a far smaller project than those,

and soon there should be revenues. Elon Musk got SpaceX and

Tesla EV companies going without such backing... didn't he?

What would this need? Tens of millions of dollars, or

maybe hundreds if it was to be scaled up fairly rapidly. Not billions.

Not thousands of employees. Not to start with.

12

Years

of

Green

Energy

Projects

in

Review

Here is a quick recap of some of

the perhaps more significant projects I've undertaken since January

2008. Most of the unfinished/unproven ones would surely be done/proven

by now except one person can only do one thing at a time and there are

only so many hours in a year.

* Electric Hubcap & Electric Caik 95% efficient BLDC motors for

electric transport - these work well (I converted an outboard motor to

electric with Electric Caik motor.)

* Motor controllers for above - haven't been very reliable. (Electric

Hubcap motor

ran great with a Kelly 300A/36V BLDC controller.)

* Switched reluctance motors - I got enthused about these, and made one

that ran, but finally I decided BLDC is

better - it will surely give the longest range in an EV.

* Concept for unipolar BLDC motors (potentially with permanent magnet

assist for ultimate performance) - should be pretty simple to go from

the above motors to these since the construction techniques are the

same.

* Motor controllers for above would be inherently more reliable. (I

made one for the reluctance motor. It worked.)

* Infinitely variable automotive torque converters - after long

stumbling about I finally have a complete design of what should be a

fabulous unit - now 3/4 built. 100% efficiency (once vehicle is moving

at

driving speeds all the converter's parts rotate together in unison 1:1

- no friction or losses).

* Ground Effect Vehicle: A rather radical design of ground effect craft

with many new features, for riding a cushion of air just over the waves

at aircraft speeds with very low fuel consumption. This project expects

to make such a craft practical: much more seaworthy than any previous

and easy to 'drive'. In personal transport or "sea bus" sizes it would

really open up islands and isolated rugged coastlines. - Radio

Controlled model almost completed.

* New Chemistry Batteries. Found a lot of good chemical and

construction techniques. (I think I can now at long last make

working, very long life nickel manganate + zinc cells.)

* Peltier module refrigerator - worked well. Used a lot of power for

the amount of cooling. (There are some somewhat improved Peltier

modules now available.)

* Magnetic refrigeration - Had a novel concept that probably would have

worked well. I started but didn't go very far. Decided other means of

refrigeration were better regardless of whether it worked or not. (Air

heat pumping may prove more effective.)

* Have worked out the theory for getting "free" electricity from High

Energy (HE) rays, which come from all directions but especially from

the plane of the Milky Way and seem to be by far the most abundant

radiant "background" energy in the electromagnetic spectrum. - Theory

has not yet been demonstrated.

* Have (in this very issue!) conceived of and demonstrated open loop

air

heat pumping for space heating. It works - potential for incredible

coefficients of performance and very cheap electric space

heating.

* Solar power system components:

* Made LED lighting before it was available to buy.

* Made various good plugs, sockets and wall plates for

house wiring of DC power systems, 12 volt and 36 volt. These should be

commercialized.

* Various battery/solar power infrastructure components -

mostly unbuilt conceptions.

* A fine handheld bandsaw mill for milling lumber (use similarly to

alaska mill). It incorporates several features including self

correcting band guides to make it simple, easy to use, and low power.

(It cuts lumber from smaller logs or cants with just a plug-in skillsaw

motor: the least power, thinnest kerf and least sawdust of any mill.) -

prototype works great!

Somehow many of these projects seem ripe or almost ripe to

explode into commercial activity to produce fabulous new products that

have never been available before. Will it ever happen?

Reversing

Desertification

It has been said that the amount of arable land in the

world is actually dropping. More and more turns to desert. People have

various ideas on causes and

cures.

"Around the planet, you see the same pattern -- People cleared the land

to farm, then they raise sheep and/or goats, the grazers eliminate

every vestige of vegetation, the soil erodes, and a desert

results. You see this in Scotland, Ireland, Spain, Greece, the

fringes of the Sahara, the Loess plateau of China, Australia, ... the

list is endless." -- Kevin Byrne (Youtube Video Comment)

===

Restoring the ancient Caledonian Forest Alan Watson Featherstone:

TEDxFindhorn

"The most predominant feature in the picture of the planet from space

is desertified areas."

https://www.youtube.com/watch?v=nAGHUkby2Is

How Peter Andrews rejuvenates drought-struck land | Australian Story

https://www.youtube.com/watch?v=-4OBcRHX1Bc

Then Allan Savory has a completely different idea: have

herds of grazing animals, but keep them moving so they can't overgraze

one spot before moving on.

How to green the world's deserts and reverse climate change | Allan

Savory

https://www.youtube.com/watch?v=vpTHi7O66pI

Of course it is known that the migratory cattle ranchers

in the USA of the old west (1800s I suppose?) hated the sheep farmers

because while cattle left some grass stubble to grow back, the sheep

would eat it to the ground and wreck the land. (I think it was some

teacher in grade school who told us that. Probably Mrs. Husby.)

Small

Thots

Columnating out-of-line binoculars

Ever

had

binoculars

where

the

two images didn't line up? I just had a

problem with one pair (dropped them) and discovered something new. The

objective lenses screw in. If you loosen the threads on one or both and

rotate them a bit, the alignment changes. I got two pairs lined up,

including a 12x70mm pair that had never been in line.

In theory this should have no effect, but apparently the

lenses are not entirely straight and centered, and it worked for me.

* Gold and silver used to be used as currency. Until 1933 gold was 20

$US/ozt, and there were coins to that effect, even in circulation,

until 1933. So a 1 oz gold coin actually said 20 $ on it and could be

spent in a store. (Not in a grocery store unless you were stocking up

on food for several months.) Now the 20 $US coin costs over 2000 $C to

buy,

and the 1/4 oz, 5$ coin is now over 500 $C. (One expects that soon

they'll be over that in $US too, as the demand for actual physical gold

has become unprecedented in the last 2-3 years. There is enough printed

money in circulation to buy all the gold in the world hundreds of times

over if not thousands.)

* Last month (TE News #139) I was hopeful that lost hair could be

restored (as well as further loss prevented) if one could eliminate or

greatly curtail the activity of the widespread demodex mites the

majority of people have, with the techniques

mentioned. But I'm not confident my thin hair areas are getting

thicker, that full normal growth has immediately returned. It may well

be that these

supposedly harmless mites

permanently damage the hair follicles, or that they take a very long

time to recover after a sufficient infestation. I

suppose I'll just be thankful I caught it and found good tools to deal

with them before it got any thinner or I became bald.

* I also showered and put shampoo in my hair to be left to soak in for

a couple of minutes... and then (my eyes already being closed) I

shampooed my eyebrows and eyelashes and let them soak for a bit too.

Why give the [choice of expletive] things a free ride and a free lunch?

* I should also note that I read that the older a person is the more

likely they are to have the mites, and to have greater concentrations

of them. Every 90 year old tested had them. That supports my idea that

parts of our immune systems

probably weaken as we get older, and explains why more older people

have thinning hair or are bald. (I can still hardly believe people

don't seem to have connected these common mites with hair loss as being

a

cause-effect relationship.)

* I expect that some day people will recognize these critters are in

fact a problem and

sooner or later will deal with them and, rather like lice of past

generations, they will plague people no more.

* Where is the heat inside the Earth coming from to activate so many

volcanoes, and to make so many earthquakes all at the same time? Could

rising ocean temperatures have anything to do with it?

Could cutting down the cooling forest canopies have anything to do with

it? Could thousands of square miles of dark asphalt road surfaces

absorbing sunlight have anything to do with it?

The Earth's core is so hot compared to the surface, how

could dark roads cause volcanoes? But there is a continual outward flow

of heat. Hotter ground surfaces will reduce that flow and make it even

hotter inside. So could it be that even these seemingly most natural

and unfathomable of cataclysms are mainly of our own making?

* Alberta's highways are a much lighter color than most others. They

would absorb much less sunlight. How do they do that?

ESD

(Eccentric Silliness Department)

* Why is an "outside the box" solution more innovative than an "out of

the box" solution?

* Which drugs are cheaper, over the counter or under the counter?

* Chimneys weep for a chimney sweep. (must be some "woodchuck chuck"

line in there somewhere.)

* Daylight Savings Date: US congress has just passed the new

"Daylight Savings Date" bill. Canada, as we are a sovereign nation,

will follow suit automatically. On the first Sunday in March, from now

on the date will be moved ahead one week. Just think, school will get

out

a week earlier, and there'll be a whole week with more daylight in the

fall just when the farmers need it to bring in the crops! On the last

Sunday in December dates will revert to normal calendar time (NCT),

making an extra week of Christmas holidays.

It's a win-win for most everyone. I'm sure. except for calendar makers,

future historians, people with the wrong birthdays, the easily

confused, ordinary people...

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

no reports

Other

"Green"

Electric

Equipment

Projects

Easier CAT Plugs and

Sockets

(10th) I removed the ABS filament from the 3D printer and inserted the

6/66 nylon higher temperature, which should be high enough "temperature

resistant" to use for electrical sockets. Then I printed another of the

HAT 36V/15A sockets designed last month. Oddly bed temperature is just

60°C where ABS is 100°, but the extrusion temperature was a

little higher: 245 where I had been using 230 for ABS. (ABS just slides

the bed off below about 95° but the nylon stuck well at 60.)

Did it need the heat gun on it while printing, like the

ABS? I decided to try with the same g-code file, which set the

temperature to 230°, and gave it a try. After a few layers, the

print shrank and one end pulled away from the bed. Then of course the

whole thing came loose. But it didn't seem as bad as ABS. I tried again

with

the heat gun on it, and got a good socket.

Then I made

small

modifications and made a CAT 12V/15A socket. This time I edited the

file

to read "245" and I tried again without the heat gun. This time

it worked - no unsticking, a good socket! If that result proves

consistent (next two worked fine too), it will make printing them a

heck of a lot easier. It could be told to print, eg, 4 rows x 4

columns, 16

sockets or plugs at a time and just left alone for hours to do it and

who cares how long it takes. (It would have to be somewhere safe if

left unattended - eg, in a shed away from the house, in case of the

worst. Or, a smoke detector might be an alternative idea as long as

someone was in the house. Or maybe place the printer well back on the

woodstove hearth bricks so that even if it somehow made a fire it

couldn't spread. Yes, I think I like that.)

Then I made

small

modifications and made a CAT 12V/15A socket. This time I edited the

file

to read "245" and I tried again without the heat gun. This time

it worked - no unsticking, a good socket! If that result proves

consistent (next two worked fine too), it will make printing them a

heck of a lot easier. It could be told to print, eg, 4 rows x 4

columns, 16

sockets or plugs at a time and just left alone for hours to do it and

who cares how long it takes. (It would have to be somewhere safe if

left unattended - eg, in a shed away from the house, in case of the

worst. Or, a smoke detector might be an alternative idea as long as

someone was in the house. Or maybe place the printer well back on the

woodstove hearth bricks so that even if it somehow made a fire it

couldn't spread. Yes, I think I like that.)

Next I cut two strips of cupro-nickel and made the

"Z-fold" connection sockets. Then I cut pieces of the 6 mm copper pipe

with 1 mm walls for crimp rings. One was a bit long for the socket

height, so I made the fold shorter on the other one and the ring

shorter too. That one fit in.

If I made the socket longer, the longer one would have

fit, but the shorter one would have been sloppy. Obviously some sort of

jigs or automated processes are needed to be made to get consistent

part sizes for consistent results.

But using nylon for socket shells instead of having to

make them of porcelain was a big improvement. I might say needing to

use porcelain would have been almost a show stopper.

(25th) I took a day off from the heat pump.

Having good internet again,

I downloaded a new version of OpenSCad to replace my ancient 2012

version. It was night and day simpler to create many common 3D shapes.

I designed a CAT 12V plug with rounded corners and a taper to the

shape, and an opposite taper on the cap.

(25th) I took a day off from the heat pump.

Having good internet again,

I downloaded a new version of OpenSCad to replace my ancient 2012

version. It was night and day simpler to create many common 3D shapes.

I designed a CAT 12V plug with rounded corners and a taper to the

shape, and an opposite taper on the cap.

For the first time I used the Cura slicer. In spite of

selecting "Generic Nylon", just like the "Skeinforge" it picked

200° (PLA)

print temperature and I had to edit the file to say 245°. It

printed pretty well.

I shaped some copper for the blades and cut two crimp

rings from the 6mm copper pipe with 1 mm thick walls. I wired and

crimped them. Things didn't fit

readily (even the screws were too tight) and I adjusted some dimensions

(yet again) so

the next one would be easier.

I shaped some copper for the blades and cut two crimp

rings from the 6mm copper pipe with 1 mm thick walls. I wired and

crimped them. Things didn't fit

readily (even the screws were too tight) and I adjusted some dimensions

(yet again) so

the next one would be easier.

Just for the sake of doing something with it I attached a

flat "COB" ("Chip on Board") LED light board through a resistor and

plugged it into 12 volts so the light came on. Now the light just needs

a housing... 3D printed... and a heatsink... NO! Get back! Not another

project.

Simple

Air

Compression

Heat

Pumping

- or -

How to Heat a Building Almost for Free

Warning: long, convoluted article

(6th) If, as the paper Coefficient of Performance of Stirling

Refrigerators had seemed to indicate, Stirling engines could get a

coefficient of performance ("COP") for heating or cooling as high as 8

or 10 at a 30°c temperature differential with simple gas expansion

and contraction, I wondered what society has overlooked that we are

still using ozone depleting, refrigerant phase change gas/liquid that

gets (as best I understand) COP under 4 or 5. Certainly house heat

pumps

are only around 3, and less in freezing weather.

Even having far more than enough projects, my mind just

couldn't let this rest. (Especially in the cold weather!) What

coefficient of performance was really

possible - and practical, by compressing and expanding air? If a

Stirling engine works doing nothing but sort of churning air inside a

closed cylinder, what was the ultimate? What COP could simple open loop

air compression and expansion give? And how simple could such systems

be made? Could they also be far more practical and economical to

install than refrigerant based systems? Could they simple enough to be

practical for hot water heaters, clothes dryers and maybe even cooking

ovens?

I began to think that if it really worked, such high COP

heat pumping could be central to answering energy problems by greatly

reducing the demand side of the equation. If one only needs (say) 1/4

as much energy to live just as well as before or better, the need for

energy supply is greatly reduced. Not only grid-tied solar panels

(supply side) but low energy light emitting diode ("LED") lighting

(demand side) has already reduced the loads on many utility power

grids. High COP heat pumping would do much more.

Heating and cooling are the greatest energy consumers in

most lives. Dwelling heating and cooling, followed by heating for hot

water are the greatest energy uses in a house.

Consider the effects if 5000 watts of dwelling heat could

be pumped in from outdoors using just 500 watts of electricity. I could

perhaps heat my whole house electrically with that - the amount of

energy now being used in one small electric heater to keep mold out of

my travel trailer. Or that trailer with 50 watts. Or heat (or cool) the

bedroom with 175 watts instead of 1750. Or run a fridge needing 300

watts of cooling from a 30 watt supply. Or in a hot water tank get

perhaps 3000 watts of heating from say 400 watts of electricity.

These things would make a tremendous difference -

a "game changing" difference! And is 10 the ultimate COP attainable?

Ground source heat pumping reduces the temperature differential, which

would further and substantially increase the COP from whatever was

being got from cold air in winter. Suddenly the potential for

drastically, and probably easily, reducing the total energy needs of a

home - and a whole society - comes into focus.

The load of a refrigerator and freezer might be thought

not very significant, but they run so much over each day that they use

enough that it's hard to keep them supplied from solar power, and most

every home has at least a fridge.

And new uses come into view as well. Perhaps it would

become practical to heat a greenhouse enough (as well as lit enough

with LED lighting) to grow things all winter? Perhaps the separate home

workshop can be properly heated to make working in it more comfortable

in the winter without incurring major expense?

A big advantage of an open air system in home heat pumping

is obvious: In closed system heat pumps, refrigerant sent to the

outdoor unit has been greatly cooled to heat the indoors, and must

be reheated back up toward the outdoor temperature before it is

recirculated. There is a big heat exchange pipe with radiator fins

in it, and a big fan blowing outside air onto it to try to heat it up

again. And it is still a bit colder than the outdoor air when it is

sent back into

the house to again extract heat from, increasing the thermal gradient

that the compressor must pump it against. And the cold refrigerant is

subject to

creating frost on the radiator fins, so it loses efficacy when the

weather get down near freezing, let alone when it is even colder. A

simple COP 1 "auxiliary" electric heater takes over in the colder

weather when heating costs the most - ouch!

The air expansion system would merely draw in outdoor air

at the temperature it is, and blow it out again, colder, somewhere

else. There is no outdoor unit needed at all, and it suffers nothing

from very cool or below freezing weather. (It gets better - read on!)

(9th) On the 6th and 7th I started writing a bunch of stuff, but I was

confused by the unfamiliar subject area abetted by a misleading

statement in Wikipedia -- in fact I edited the Wikipedia article.

A

graph indicated that a COP of about 10 at 30° 'lift'

(to create a 30° temperature rise or fall) was the theoretical

maximum. (Later I found there's a simple formula for maximum COP which

the graph was based on. (it's below)) Typical COP might be half of

that,

50% efficiency as indicated. I suspect it's likely 8 or above for the

Stirling was a

theoretical rather than a realistic figure. (Unfortunately, having

failed to copy the page or a link to it (Coefficient of Performance

of Stirling Refrigerators) I couldn't find it again except at a

site that wanted a ransom for permission to read it, so I

didn't.)

A

graph indicated that a COP of about 10 at 30° 'lift'

(to create a 30° temperature rise or fall) was the theoretical

maximum. (Later I found there's a simple formula for maximum COP which

the graph was based on. (it's below)) Typical COP might be half of

that,

50% efficiency as indicated. I suspect it's likely 8 or above for the

Stirling was a

theoretical rather than a realistic figure. (Unfortunately, having

failed to copy the page or a link to it (Coefficient of Performance

of Stirling Refrigerators) I couldn't find it again except at a

site that wanted a ransom for permission to read it, so I

didn't.)

What might the simple open

loop compressed air system

really achieve? Before I got far enough to be disillusioned, I had hit

on another aspect: because it was open loop instead of closed

cycle, it could be made so that instead of heating outdoor air, the

heat pump could further heat indoor air, just a little. Theoretical COP

limit for say a 10° lift was 30, and for 15°, 20. At just

7.5° it could hit 40. Now THOSE figures left a lot of room for

actually achieving a COP of around 10 - or even higher.

The more I looked, the more I found that the whole thing

was a lot more complex than simple 'ideal gas' laws. Something that

especially struck me was "isothermal" versus "adiabatic". In an

isothermal demo a piston in a poorly insulated cylinder slowly

compresses the gas to higher pressure in a smaller volume. The gas

hardly changes temperature (eg, <1°) because the heat gain is

lost into the environment. That would demonstrate "the ideal gas law"

equation perfectly - and shows why it is misleading. But the gas DID

gain heat - it merely wasn't retained! In an adiabatic demo, a piston

in a well insulated cylinder (a "fire syringe") is suddenly plunged

(hammered) down, compressing the gas so fast and with so little heat

loss that the air temperature obtained and retained for a moment can

ignite cotton in the cylinder.

[Now back to the 6th, re-edited on 9th to correct for Wikipedia error

and other misconceptions... The reader could probably skip or

skim quite a lot of the following without missing much - especially if

familiar with the subject.]

(6th) Now, what about trying to make it work? I looked up Boyle's Law

which I had heard of and ended up at the ideal gas law:

P * V = n * R * T

where:

P = pressure in Pascals

V = volume in cubic meters

n = is the number of moles of the gas

R = 8.314 Joules/(°K*n)

T = Temperature in degrees Kelvin

There was nothing in that to suggest that when the pressure is doubled,

the temperature will double too, because if a cylinder is compressed to

double, obviously the amount of gas "n" will also double and the two

sides will cancel with temperature "T" remaining the same.

Then there was the combined gas law, which doesn't specify the number

of moles but shows relationships:

P * V

------ = k

T

Where k = an arbitrary constant, and the others are as above. (This was

stated in a mistaken or at least misleading form on Wikipedia, saying

"'k' is a constant (for a given amount of gas)". [My italics]

This caused me to double "k" when I doubled pressure, since there was

now twice as much gas. That fit with what the "ideal gas law" said.

Then temperature would remain the same no matter how much the gas was

compressed or rarified. How then did one change the temperature of a

gas by heat pumping? One could change the pressure by changing the

temperature, but not the temperature by changing the pressure? It made

no sense and caused me further confusion.

Finally I realized that the temperature simply must double

if the pressure is doubled regardless of what the formulas seemed to

say, and if the gas is doubled the pressure must

double. "k" can NOT describe the amount of gas. (It's not very often I

see need to edit Wikipedia, but I removed those words. I also rewrote

several equations & text below.)

Solving for "T", replace all values with "1" in arbitrary units.

1(P) * 1(V)

------------- = 1(T)

1(k)

If we compress air into a fixed size tank until the pressure is

doubled, the temperature is doubled.

2(P) * 1(V)

------------- = 2(T)

1(k)

Of course the gas soon heats the pressure vessel walls and

cools, and the pressure vessel walls eventually cool to ambient. Then

if we open a valve and let out the extra air, the pressure is halved

(back to "1" again) and "k" is halved:

.5(P) * 1(V)

T = -------------- = .5 (half temperature)

1(k)

Since the solid pressure vessel quickly absorbs the temperature

of the gas and since it is far more massive than the air, the actual

temperature rise and fall are only a little. Thus to attain significant

heating or cooling the process must be (a) far higher pressures, (b)

incrementally repetitive or (c) continuous. Or of course a combination

of these.

Then I thought

that compressed gas hissing out

through a valve would rapidly cool. It was said that it doesn't. Again

this appeared to be misinformation, but the cooling isn't really

perceptible because the decompressing air is so quickly dispersed into

the surrounding air. But I got a good cooling result from air hissing

out through

the water drain spigot. Why? I could feel moisture there when I did

that test. The water was vaporizing into the thinning, moving air,

causing evaporative cooling.

Then I thought

that compressed gas hissing out

through a valve would rapidly cool. It was said that it doesn't. Again

this appeared to be misinformation, but the cooling isn't really

perceptible because the decompressing air is so quickly dispersed into

the surrounding air. But I got a good cooling result from air hissing

out through

the water drain spigot. Why? I could feel moisture there when I did

that test. The water was vaporizing into the thinning, moving air,

causing evaporative cooling.

Cooling

Maybe the project should be separated into its two halves:

the compression of the air and the decompression. I could use the air

compressor to fill a tank with compressed air, then consider just the

cooling half of the cycle, the refrigeration.

What about taking a compressed air tank and feeding that

compressed air through a thin pipe that runs through a fridge? It might

hiss through a narrow valve into the pipe (both inside the fridge), and

then the coldness would radiate through the pipe walls.

For using air compression and decompression, which as seen

in the Stirling heat pumping figures can give a very high COP, would

completely decompressing the compressed air within the fridge not give

the ultimate cooling COP? The expanding air should continuously cool

the pipe with the utmost efficacy possible from compressed air, however

efficiently or inefficiently it was compressed, right? Proving (or

disproving) that should be an easy experiment!

Then the overall COP would be directly proportional to the

efficiency with which the compressor compressed the air. And with

"ultimate" COP on the cooling side, if a Stirling engine could manage a

COP of 8 or 10, it should be possible to attain an even higher COP. Is

there anything wrong with this picture?

That reminded me of the Tata Motors compressed air vans:

they have free air conditioning from the cooling of the expanding air

coming out of the engine cylinders. Great thing for hot climes, I'm

sure! Of course, they are unconcerned with the COP because the main

purpose of the compressed air is to move the vehicle. (It was well over

100 Km range from a carbon fiber compressed air tank under the van

(that would rip, not explode); I don't remember - Was it even 200 or

300 Km? Wow!)

If the "hissing valve" released depressurized cold air

into the pipe, a length of pipe could radiate that coldness into the

fridge. I looked for and found three 1/2 inch copper pipes with

aluminum fins that I made some years back in connection with peltier

modules and low pressure boiling water heat transfer. (I was amazed I

found them all quickly and easily in the first 3 different places I

looked - they had been carelessly tossed here and there when I moved.)

I also had a 120(?) liter brass water tank. (Had it for

almost 40 years, originally intending to make a solar hot water system

that would last.) Surely it would take at least 60 pounds of pressure.

Refrigeration shouldn't need 1/2 that much, and such a large tank would

probably run a fridge for many hours before refilling it.

Let's see, how much pressure would it take?: If we want (eg) 40°c

cooling for a freezer (from +20 to -20 or in real scale terms from

293° to 253°K) we have to have at least that much gas

expansion, so we have to compress it that much.

293 / 253 = "x" PSI / 14.7 PSI

or

x = (293/253) * 14.7 = 17.0 PSI

So we need at least 2.3 PSI (above regular atmospheric pressure) to get

40° cooling.

Gosh, that seems like nothing! It doesn't take

much to compress air that much. Of course it'll need to be considerably

higher than that (or an awful lot of actual air) to cool a real freezer

with finite insulation, but the potential for very high COP seems to be

there.

(7th) Can everyone really have missed something this simple

that sounds this good for this long? I can't believe I'm the first to

come up with it. One thing I could potentially believe is it just isn't

as good in real life as it sounds before calculating or testing it out

- but not without trying it out! Another is that someone invented it

and patented it long ago, and a company making 'conventional'

refrigerators bought the patent and threw it in a drawer, just like the

car companies have always done with better car inventions. Since

someone held the patent, no one was able to build them and eventually

the whole technology was forgotten. Western civilization is replete

with examples of this practice.

I didn't see how to easily calculate exactly what to

expect in advance, but checking it out just looked easier and easier...

I could connect the three 1/2 inch copper radiator pipes

together in series and to a valve, and mount the assembly to the

underside of the lid of the shallow chest fridge, with an inlet and an

outlet to the outside air.

Then I could just connect the air compressor to the fridge

inlet pipe, and set its output to (say) 10 PSI.

Initial testing would be a matter of cracking open the

valve until air was hissing through it and seeing how fast the fridge

got cold and what temperature it got down to, and connecting a power

monitor to see how much power the air compressor used.

To get the roughest of ideas:

1. My fridge-freezer is around 150 watts and runs 60%(?) of the time.

Call that 2.16 KWH/day. (Well, less in winter when the kitchen is

cold.) I should monitor that and record it, too.

2. My shallow chest fridge is maybe 1/3 the size and has no freezer.

Energy parity then might be around .5 KWH/day. If over some days it

used substantially less than that, it would doubtless be owing to a

higher COP. If it was around parity, it might be compressor

inefficiency compensated for by higher COP, or it might be just similar

COP.

It all depends how far open the valve has to be cracked to

get the requisite cooling to keep the small fridge cold. That air flow

will determine how often the compressor has to come on. And that will

determine how much energy is used. An important point is that the

compressor runs until it hits 120 PSI or so. If it only hit (eg) 20 and

shut off, it might run more efficiently and use a lot less energy, even

while running much more often to supply the same amount of air overall.

Air compressors are probably not designed to maximize efficiency in the

first place. People are simply happy if they work. (Perhaps at some

point I could try opening the control box and adjusting it to have it

shut off at a much lower pressure?)

If it proves worthwhile, the next step would be

thermostatic control. This could be on-off, or analog with an air valve

that can be minutely adjusted to pass more or less air, depending on

the temperature and heat loading. Then one has a real fridge or

freezer. (In the 1980s doing computerized controls for Victoria schools

I had an electrically activated variable pneumatic valve. Where did I

get it? Accutemp? Are they still available?)

There would be a second advantage to such a fridge: The

compressor could be somewhere else besides in or at the fridge,

connected by a single pipe. It could be in the basement underneath. And

it would only run occasionally. Kitchens - and many cafes - could be

quiet places again!

By evening of the 7th I had convinced myself that this

project was more worth pursuing than the woodstove electricity

generator. Furthermore, the first experiments with the fridge were so

simple to set up (given that I had an air compressor and most of the

parts) it seemed foolish not to do so.

Heat Pump Heating

But what about the heating side of the equation? Soon this

replaced cooling in my thoughts because a fantastic potential came into

view. Logic said that if a Stirling engine could manage COP up to 10,

that unless the compressor was very inefficient, the heat being put

into the air tank - the thermal energy of the air going into the tank -

must be much greater than the amount of electricity it took to pump it

in. In the tank was the thermal energy to heat a house, if radiated out

through pipes and probably with a fan. Once the heat radiates out along

the air pipe, it is routed outside the house and decompressed at a

spigot to cool the great outdoors. More air has to be compressed from

the inlet side to keep pressure in the pipe and pumping in thermal

energy from outdoors. Once again the pressure doesn't have to be very

high to gain a 30, 40 or 50 degree differential from the outside air to

the radiator pipe.

I had no idea how efficient or inefficient my compressor

was. It was 99 $ at Rona with a plethora of attachments. It's a light

duty unit intended to be used once in a while to blow off dust or pump

up a car tire. Okay for limited testing, but not much more.

For house heating one would want a unit designed for

continuous service in a building, and optimized for efficiency. and as

quiet as they come. And it needs to move air volume, but not with a

high pressure buildup. But! such units are doubtless already available.

I started off thinking that if it became a project, I would have to

build some pumping unit from scratch, but (excluding controls) really

there are only three components: compressor, radiaators and

decompressor valve. Only the compressor is complex and uses power.

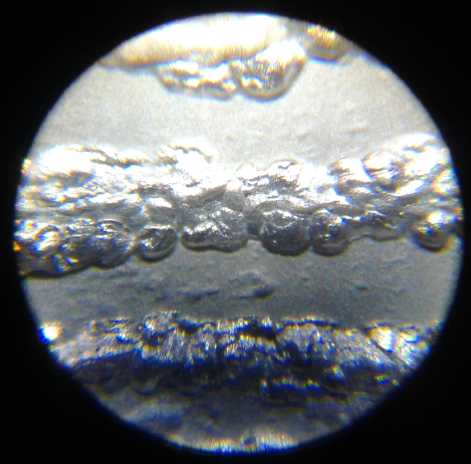

Unlike with