Turquoise Energy News #141

covering

February 2020 (Posted March 7th 2020)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- Carrying Heat Uphill: A way to look at heat pumping - Open Loop

Air Heat Pumping Experiments - Another Higher COP Device -

Nickel-manganate/Zinc Battery

Developments - High Efficiency Titanium Dioxide Solar Cells and

"Pebble" Surface Cover Glass - NiMH D Cell Refill

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Permian Period Amphibian Evolution (continued) -

Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (No Reports)

Other "Green"

Electric Equipment Projects

* End of the Solar Hot Water Tank (the mineral rich water stank) - Hot

Water Tank Protective Anodes

* Very High COP Open Loop Air Heat Pumping - With Water Cooler

Pump

- Means for Improvement? - New Heating Unit - Compressors Today Are Not

Made For Air Heat Pumping (& compressor design ideas) - Value of

the outdoor heat exchanger - Install & test of that - A Better Way

to join PVC Pipes to Copper Pipes (no pipe fittings) - The

Grand Potential - Additional Heat Pumping/Air Compressing Info Gleaned

From Web

Electricity Generation

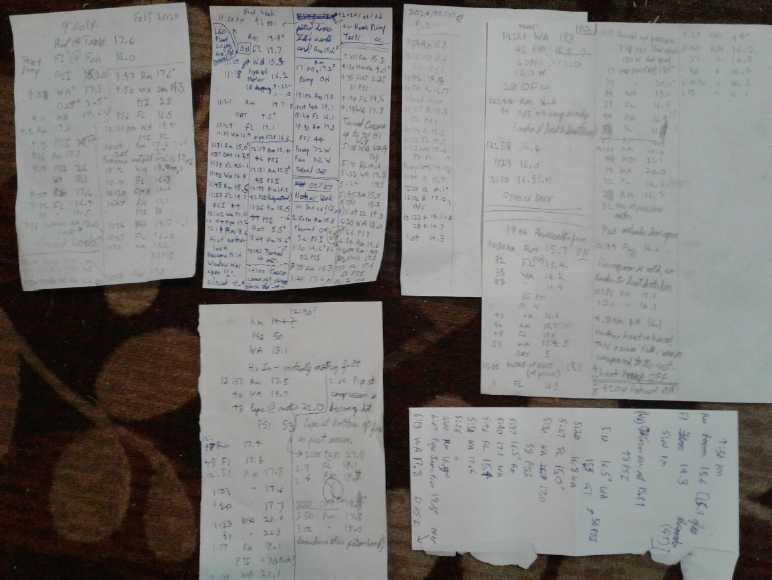

* My Solar Power System: - Monthly

Solar Production log et cetera - Notes. - Analysis of a Whole

Year's Figures

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkaline Salt electrolyte)

- Powder Electrodes Conductivity - Solid Porous Electrode

Briquettes; Plaster - Some theory/ideas - 50x50mm Electrode Compactor -

tests - Cylindrical Cells? - Okay, How About Flat With "Rebars"? -

Cupro-Nickel Current Collector

February is a short month,

but somehow this is anything but a short newsletter, and it has taken

me some time to complete it.

This month I continued

experimenting with the open loop air heat pumping (hoping to save

myself electricity and money and have a warmer kitchen as well as it

seeming to be an exciting and highly

valuable project anyway).

And I did some more work here and there on the new

chemie batteries. They're getting close! (...How many times have I

thought

that and had to stop and try a new tack?)

Aside from that I did just a couple of little things

- some paint and plastic battery holders - for the ground effect

vehicle model. Its two powerful ducted fan motors need about 2750 grams

of lithium batteries to get full power, almost doubling the entire

weight of the model.

Aside from that I did just a couple of little things

- some paint and plastic battery holders - for the ground effect

vehicle model. Its two powerful ducted fan motors need about 2750 grams

of lithium batteries to get full power, almost doubling the entire

weight of the model.

There was no pipe into which two rows of the lithium cells

fit, or even one row fit nicely. I used pieces of the '1.25 inch

sprinkler system' PVC pipes, slit

them open and then shaped them by softening them in the oven.

And of course I did a little garden

raking/weeding/cultivating to prep the soil for spring. The 2019 crop

failures were staggering all over the world, shipping is way down, and

a few shortages have been reported in the USA with some large groceries

starting to limit the amounts of some items like flour, sugar and rice,

albeit to "5 bags" - more than most of us would buy anyway... so far.

"Ice Age Farmer" on youtube said hardly anyone he talked to was taking

the coronavirus threat seriously, so if just 3% of the population

trying to stock up was causing shortages, imagine what will be left

when everyone starts trying. So I want to grow more. At least I get

good potatoes and most of my fresh vegetables. Maybe it's time to build

that chicken enclosure?

The Fake and the Real

McCoy:

The Fake and the Real

McCoy:

The four prong implement on the right/top has been

my favorite gardening implement since I bought

it around 1980. I even put a new handle on it

when the old one rotted off. It's a rake, hoe and

cultivator, and one can pick up weeds with it,

shake off the dirt, and dump them in a bucket.

There's less bending

down, and when there is, it's a

loose weed, not a tug and break the root off.

The tines have never bent or broken. Maybe

a good tool to wield on a CNC gardening machine?

The imposter on the left/bottom is less useful, so

it just sits in the garage and its original handle

is still pristine.

Daylight started returning over the month and the solar

panels came at least somewhat back to life as the monthly tallies show.

But tops was under 6 KWH per day. March 6th and 7th made a dramatic

rise to

about 9 KWH - it was at last sunny (except for a couple of small - ugh

- snow flurries), and although it's still quite cold, the sun is

getting higher and the days are lengthening.

The end of February marks a year of logging solar PV

collection daily performance, and I made some notes on the annual

figures obtained. Overall the sun made 22% of my power, but it was 35%

in the seven best months. As expected the winter months were very low

collection, with high electricity use for heating. Even with the

woodstove doing most of it, 500 watts of heat in the trailer to keep it

from going mouldy added a big chunk to the total, as did bedroom heat

at night. And the electric car added some to the bill in all months.

Carrying Heat Uphill: A way to look at heat pumping?

Here's a visualization if we need to take some of the

seeming

magic out of the workings of a "conventional" refrigerant based heat

pump: There's a hill. It's not as high (as warm) as the occupants want

it. Instead of getting new dirt from elsewhere to make the hill taller,

they shovel dirt from the bottom of the hill and bring it to the top.

The work done by a heat pump may be seen as similar to the work being

done to bring the dirt up the hill. There's dirt (thermal energy)

everywhere, but

to make the top of the hill comfortably tall (warm), work must be done.

But it's less work and expense to "concentrate" existing, nearby dirt

into a hill than to get

all-new dirt delivered direct from the distant quarry (power company)

to make a hill.

Now, obviously the higher the ground is around the hill

(the less cold it is outside), the less work it is to bring up the

additional dirt, and higher COP ('coefficient of performance') is

obtained, and vise-versa: if the

hill towers above the frozen countryside, much more work has to be done

to carry it up and the equipment has more trouble doing it, too. The

work increases, but the COP gets lower.

The analogy is incomplete without noting that the sides of

the hill are continuously slumping off into the surroundings - the heat

gradually leaks out of the building, so more and more dirt has to be

brought up to keep the hill from shrinking until it's level with the

surroundings.

The analogy rather breaks down with the open loop air heat

pump. Here the compressor brings dirt from near the top of the hill and

piles it up a little taller in one spot. From there it spreads around

pretty much to where it came from. It doesn't take much work to do

that, so the COP is (in principle) very high.

But this misses the open loop and outdoor parts of the

system: the 'spent dirt' (room temperature compressed air) from the

radiator pipes exits to the outside, goes down the hill, but through

the outdoor heat exchanger. The exchanger is like a ski lift circuit.

As the dirt goes down, and ideally gets carried down into a valley

below the base of the hill (is refrigerated below outdoor temperature

as it is released and expands), its weight carries an equal weight of

fresh dirt up from the base of the hill virtually for free, passively,

effortlessly, regardless

of the height of the hill. So the compressor gets its fresh dirt from

the top of the ski lift instead of from the bottom of the hill and only

has to lift it a little higher.

A house still needs more heating as outdoor

temperature drops, but here the COP in principle remains the same -

potentially very high - or at least drops only a little.

Open Loop Air Heat Pumping Experiments

First I tried out the small water cooler (fridge type)

compressor I got February 1st in the same piping setup as last month's

experiments. It seemed to work about as well as the lab

vacuum/compressor pump - not a real improvement. But a coefficient of

performance ("COP") of 4 or 5 is the maximum today's heap pumps can

manage, and that in weather well above freezing, where this was only a

little above 0°C. Obtaining roughly those levels of COP at that

outdoor temperature would seem to make the technology better even with

my jury-rigged experimental equipment. And I'm sure the potential is

there to do much

better yet.

First I tried out the small water cooler (fridge type)

compressor I got February 1st in the same piping setup as last month's

experiments. It seemed to work about as well as the lab

vacuum/compressor pump - not a real improvement. But a coefficient of

performance ("COP") of 4 or 5 is the maximum today's heap pumps can

manage, and that in weather well above freezing, where this was only a

little above 0°C. Obtaining roughly those levels of COP at that

outdoor temperature would seem to make the technology better even with

my jury-rigged experimental equipment. And I'm sure the potential is

there to do much

better yet.

The next week

I got another refrigerator pump from the refuse

station, this time a bigger one from a large fridge. (I had to make a

larger box.)

The next week

I got another refrigerator pump from the refuse

station, this time a bigger one from a large fridge. (I had to make a

larger box.)

On the same trip, Mike gave me two four-foot long finned

copper

pipes. These would save me from having to make more copper finned pipes

before I could do more experiments.

The compressor blew lots more air than the previous one

and the power consumed went up with the output pressure, from 100 to

150 watts, instead of staying pretty much stationary. I had high hopes.

I had to make a bigger box for it, and I made a new radiator piping

loop across the dining area and out through a wall. Not wanting to make

a big hole in the wall, I dispensed with the outdoor heat exchanger.

I was disappointed that this one didn't seem to work any

better than the previous, if as well. It was drawing more power (120

watts instead of 75) and still only heating as well as the 420 watt

radiant heater - if that well. That suggested a COP of 3 to 4, tops.

It seemed that perhaps the outdoor heat exchanger was more

effective and more necessary than I had thought. I soon installed one

on the side of the house.

Outdoor heat exchanger: Tall box on the outside

wall (same box), and duct and pipe

Outdoor heat exchanger: Tall box on the outside

wall (same box), and duct and pipe

through wall into house for incoming (warmed) and outgoing (still

compressed) air.

It seemed obvious that air compressors weren't being made

with heat pumping in mind. I thought about what an ideal air compressor

for heat pumping would be like.

Then I cut the first (water cooler) compressor apart with

an angle grinder and a hacksaw. It was immediately apparent that there

was a major bottleneck to the air flow, in the form of a 16 inch long

copper pipe of only 1/16" inside diameter. All my efforts to make the

airflow as free as possible once the air was out of the unit were

annulled by that.

I improved it by cutting off that pipe

and putting in a 1/8" one at the compressor body. That's 4 times the

cross section

-- and I only made that pipe 1/2 inch long before it "telescoped" out

into a

bigger one.

Then I (finally) had a look at

the big new Makita air compressor. If it wasn't made for the job, at

least it seemed closer than anything else I had so far. It drew 550

watts with no air compression (drain valve open) which increased to

1100+ watts at 120 PSI. (Does that make it 50% efficient at compressing

air? Anyway it indicates at least 550 watts of energy (and probably

more) is going into actually pumping and compressing air, above and

beyond simply spinning the motor and oscillating the piston.) The

motor's fan also blew air under a shroud to cool the compressor, which

didn't get too hot while I had it running. If I made a large box and

put it inside, where a fan would blow its heat into the heating duct

(as with the fridge compressors), and attached the radiator pipe

directly to the bottom of the air tank, it should work better than any

other other unit I had.

Then I (finally) had a look at

the big new Makita air compressor. If it wasn't made for the job, at

least it seemed closer than anything else I had so far. It drew 550

watts with no air compression (drain valve open) which increased to

1100+ watts at 120 PSI. (Does that make it 50% efficient at compressing

air? Anyway it indicates at least 550 watts of energy (and probably

more) is going into actually pumping and compressing air, above and

beyond simply spinning the motor and oscillating the piston.) The

motor's fan also blew air under a shroud to cool the compressor, which

didn't get too hot while I had it running. If I made a large box and

put it inside, where a fan would blow its heat into the heating duct

(as with the fridge compressors), and attached the radiator pipe

directly to the bottom of the air tank, it should work better than any

other other unit I had.

But it had so much power

that it (surely) needed much more

radiator pipe, and surely I would have to install the outdoor heat

exchanger. And it needed a large new box with a fan on the side. I

wouldn't finish all that in February. So I tried

out my "improved" water cooler compressor first to see how it worked

and what lessons might be gained. It already had a box with a fan and

the fittings. All it needed was some pipe fittings and lots of PVC

("electrical") tape to close up the housing. It should last long enough

for an experiment of two. If eventually the oil leaked out and it

seized up... oh well. It was free.

I thought about the amount of power being used by these

various compressors. Ideally, if there was no radiator pipe or if the

end of the pipe was wide open, and no pressure would build up in the

system, the compressor is just blowing air like a fan. The duct fans

were drawing about 3-1/2 watts. Running with open ducts the compressors

started at 75 watts and went up from there to 750. (750 - one

horsepower - was for the

Michelin. The larger Makita was a little better at 550 W.)

This means that all the compressors are wasting huge

amounts of energy. Of course it takes some energy to turn a motor, and

to slide piston rings back and forth in a cylinder. But that should be

small, almost trivial compared to the energy needed to compress air,

where real work is being done.

One can literally feel the truth of this

when pumping up a bicycle tire with a hand pump. Disconnected or at no

pressure, the lightweight pump

handle, shaft and piston assembly plunges freely, almost effortlessly.

It may slide down the cylinder just from gravity. (Of course the more

pressure there is

in the tire, the harder it is to push the handle to the end of the

stroke to pump it up further because then it's doing actual work.) Why

do electrically powered compressors use so much power - or even any

significant amount of power - in free air?

One can see this is at least partly owing to internal

restrictions to the air flow: they are compressing air, but it is

decompressing before it even comes out of the compressor. Nowhere was

this more obvious than in the 1/16th inch, 16 inch long pipe in the

water cooler compressor. It was heavily compressing air in the cylinder

and making heat there regardless of whether the air outlet was wide

open or almost completely closed off. And thus the power consumed (75

W) didn't change much with external load, since most of the load was

internal. (After I put a larger pipe in, it used as

little as 55 watts pumping 20 PSI; 50 watts at 0 PSI.)

In a compressor designed for heat pumping, designed for

optimum efficiency, I would hope that the watts consumed would go up

with pressure by

a factor of 5 to 10 when pumping to it operating pressure. and also

that

much of the heat would go out in the air being pumped. The heat

starts in the compressed air. The "bicycle pump" air compressor with

effective (copper) radiator fins and a one-way valve would also be the

start of the radiator piping inside the opening of the duct, a

continuous solid copper finned pipe with no obstructions. (I am

presently thinking of how to make a "rotary" compressor using a screw

mechanism of some sort to move a rather large piston with a long stroke

in and out. That should have less vibration and noise than one with a

short crank arm flying

back and forth.)

In a test at the end of the month the outdoor heat

exchanger's performance was disappointing, raising the outdoor

temperature air barely half way to room temperature. It may need to be

made substantially longer to gain more heat exchange area between the

outgoing warm air and the incoming cold air. Or it needs to exchange

better over the same length. However, the performance was better than

without a heat exchanger. It really does seem to be a key component of

the system and I'm sure a better one will raise the COP. (I improved

it. It helped.)

On March 3rd I put together a configuration with the

larger fridge pump. The warm air came out the end of the heating duct 4

to 5 degrees higher than the room temperature instead of 2 to 3.

Drawing 115 watts it seemed to heat a little better than the 420 watts

radiant heater, suggesting a COP of at least 4. So the COP wasn't

higher but as the compressor was more powerful it was pumping more

watts of heat. But the temperatures at night weren't much above

freezing and it was quite inadequate for the amount of heat needed.

Time for the bigger compressor!

As March started I had a pretty good setup with

the large fridge compressor in a box with a fan,

As March started I had a pretty good setup with

the large fridge compressor in a box with a fan,

finned pipes and a duct with air blowing through it, and the outdoor

heat exchanger, improved with

some thermal breaks in the copper pipes and some reductions to the

incoming air flow space.

(Here including a piece of foam partly blocking the inner opening in a

strong wind.)

When efforts are made to

create really high efficiency

equipment for air heat pumping, we will start to see the ultra-high

COPs dangling in front of us.

Another Higher COP Device

A reader sent me a link to another interesting device that

uses similar principles to get more energy performance out of heating

and cooling. This one is used to desalinate sea water. As well as

making drinking water at sea, this process will doubtless someday be

highly valuable for helping to turn deserts into fertile lands.

As best I understand the operation, the initial heat comes

from

the sun to vaporize sea water. But instead of simply letting the

evaporated water cool to re-condense, its heat in cooling and

condensing is used to heat more water up to near vaporization

temperature. Then (if I have this right), still pretty hot, it warms

the next 'batch' of water

part way. This is done, apparently in several steps, making it akin to

my outdoor heat exchanger using the heat of the outgoing air to warm

incoming air for the compressor. The water will be cool for drinking

sooner, too.

https://www.pv-magazine.com/2020/02/10/recycling-heat-for-a-385-efficient-solar-desalinator/

February 10, 2020 Mark Hutchins

February 10, 2020 Mark Hutchins

MIT scientists have developed a solar desalinator which transports heat

from the sun through a ten-stage process of evaporation and

condensation. The group estimates a $100 device employing their

innovation could provide the daily drinking water needs of a family.

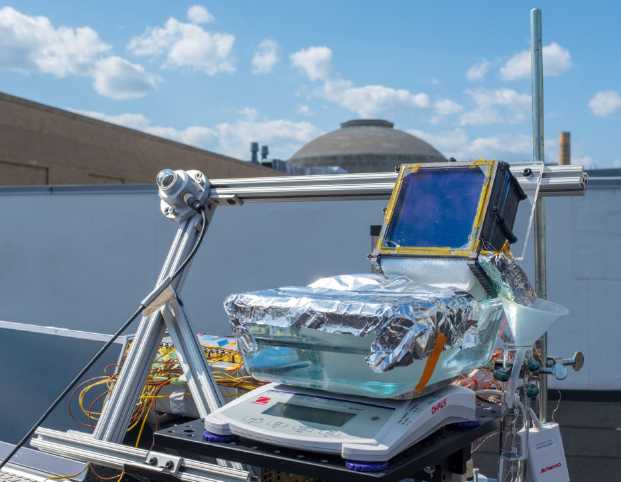

Scientists at the Massachusetts Institute of Technology (MIT) have

developed a prototype solar-powered water desalinator which they say

achieved solar-to-vapor efficiency of 385% through a multi-stage

process where the heat released as water condensed was recycled,

flowing into the next layer to power the next stage of evaporation.

Rather than using photovoltaics to power electrically-driven

desalination - a method which has been used in large scale applications

already - MIT's process uses solar absorbers to gather heat from the

sun and evaporate the saltwater.

A prototype on an MIT rooftop delivered water which exceeded local

drinking water standards at a rate of 5.78 liters per hour, per square

meter of solar collecting area. The university said that was more than

double the previous record for water produced by passive solar

desalination. By optimizing and adding further stages to the

desalination process, the group estimates devices based on the concept

could reach efficiencies as high as 800% - meaning that eight times as

much energy as is initially collected from the sun would be available

for the conversion of water into vapor.

Nickel-manganate/Zinc Batteries

An enthusiast

with casting equipment in Oregon is making

copper sheet electrodes with cast zinc on one face. This is likely

better than electroplating on the zinc. With the degrading zinc tabs

and

after the last very thin zinc sheet got holes in it, I think the copper

sheet is needed to make a solid, changeless base for the zinc which

oxidizes and reforms with discharging and charging.

An enthusiast

with casting equipment in Oregon is making

copper sheet electrodes with cast zinc on one face. This is likely

better than electroplating on the zinc. With the degrading zinc tabs

and

after the last very thin zinc sheet got holes in it, I think the copper

sheet is needed to make a solid, changeless base for the zinc which

oxidizes and reforms with discharging and charging.

He is sending me samples.

I

also found

that in pH 13 electrolyte (even with salt in

it) cupro-nickel doesn't seem to degrade in the positive electrode, so

it can

be used instead of graphite for the current collector. That will be

better - yay! And monel or cupro-nickel powder can probably be used for

conductivity additive in the electrode. That too may be better than

graphite or 'acetylene black'

powder. Or better in conjunction with it.

I

also found

that in pH 13 electrolyte (even with salt in

it) cupro-nickel doesn't seem to degrade in the positive electrode, so

it can

be used instead of graphite for the current collector. That will be

better - yay! And monel or cupro-nickel powder can probably be used for

conductivity additive in the electrode. That too may be better than

graphite or 'acetylene black'

powder. Or better in conjunction with it.

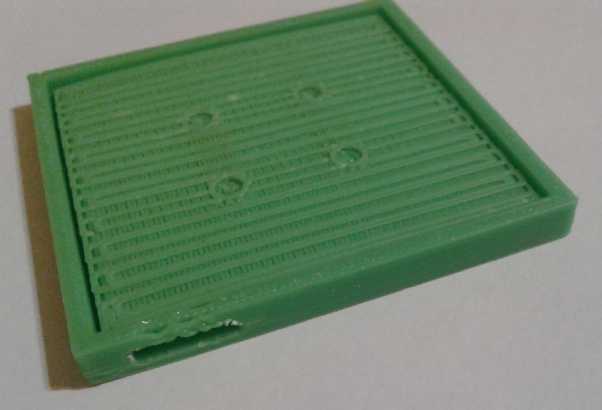

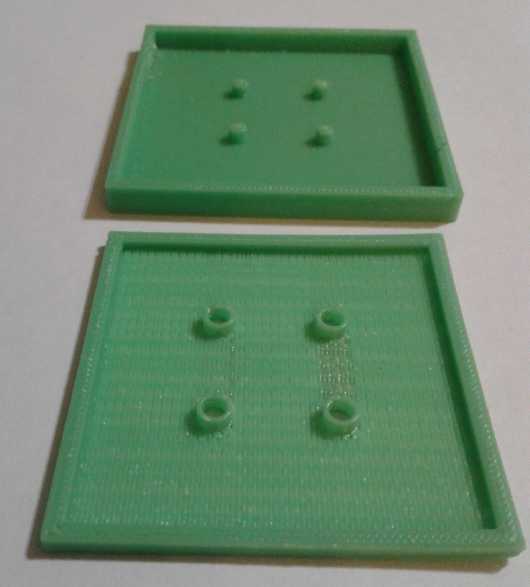

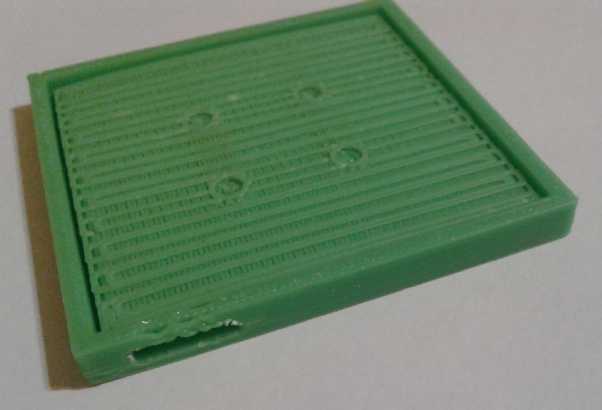

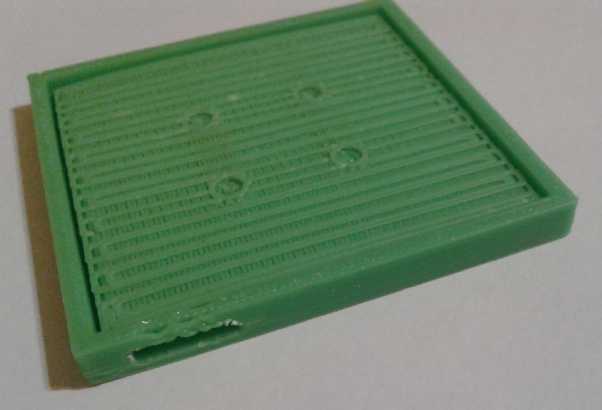

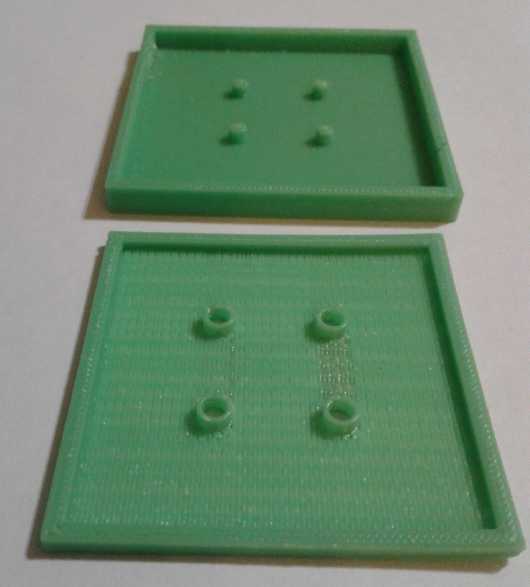

I designed a

50x50 mm flat cell case that would hold the

positive electrode compacted by having some glued support points in the

middle of a "porous" plastic separator as well as a glued-down outside

edge. (The nickel-manganate electrode is installed under the porous

grid with its tab sticking out the slot; the zinc electrode goes above

it. The sides will be a little taller, with an upper slot, an a cover

will be glued on top.)

I designed a

50x50 mm flat cell case that would hold the

positive electrode compacted by having some glued support points in the

middle of a "porous" plastic separator as well as a glued-down outside

edge. (The nickel-manganate electrode is installed under the porous

grid with its tab sticking out the slot; the zinc electrode goes above

it. The sides will be a little taller, with an upper slot, an a cover

will be glued on top.)

I still worried that a

thin

ABS grille is too flexible and will let the electrode swell and

lose contact with the current collector somewhat between the posts. But

on

line I found a new 3D printing filament: PVB. It sounds better -

stronger and stiffer than either ABS or PLA. (And unlike PVC, its

environmentally

benign.) Of course I ordered a roll to try it.

I

also made a very exact fit 50x50 mm electrode compactor

punch and die from 1/2 inch steel plate. After I put a base on it, it

should press good electrodes for my planned 50x50 and (eg) 100x100,

150x150 and 200x200

mm (by ~8 mm) flat cells.

I

also made a very exact fit 50x50 mm electrode compactor

punch and die from 1/2 inch steel plate. After I put a base on it, it

should press good electrodes for my planned 50x50 and (eg) 100x100,

150x150 and 200x200

mm (by ~8 mm) flat cells.

High Efficiency Titanium Dioxide Solar Cells and "Pebble" Surface

Cover Glass

[This probably belongs in some "detailed project report", but it's not

something I'm actively pursuing at this time.]

Longtime readers of this newsletter may recall that I did

some abortive experiments with dye sensitized titanium dioxide solar

cells a decade

ago. (eg, TE News #29) I was trying tartrazine (yellow food color) as a

dye. It has just the right light absorption spectrum. And I

developed a special glaze with a high refractive index (nanocrystalline

titanium dioxide borosilicate glaze). It could be ground up into a

"frit" (sandy grains) and melted into the front surface of solar panel

glass as little "pebbly" grains, tiny lenses that would aim angled

light more straight into the glass and hence increase the power gained

from light coming from steep angles and scattered sky light. I didn't

get that far.

Really

this was two separate solar cell projects both using titanium dioxide

and I

confused myself as to what I was doing and what my objectives were. At

the time I didn't even have any solar panels. If I had known where to

buy "raw" solar cells, I could have tried out the pebbly cover glass

idea separately with them, but at the time I didn't, and my TiO2 cells

weren't working. And it seemed more and more

like a lengthy diversion - wasn't I doing electric transport?

And as to titanium dioxide solar cells I thought, "So

what, even if they work?" I read about

the almost "problematic" tendency of titanium dioxide based solar cells

with liquid electrolyte

to leak. Could I solve that? And I had no shortage of other projects. I

threw up my hands for the time being, but I never got back to either

project.

Now some researchers have come out with "24% efficient"

titanium dioxide solar cells, a higher efficiency than today's

best silicon based cells and much higher than those being made at the

time I was experimenting. I hadn't realized the potential of TiO2 for

actually

being significantly better than silicon, or I might have continued.

Probably a non-liquid electrolyte that would work could be (or has

been) found, too.

First: Cover Glass (In)Efficiency:

In an article in PV Magazine, researchers studied the effects of

creating microfractures in glass to assess how they deteriorated panel

performance. It shows that the surface

of the glass is important.

https://www.pv-magazine.com/2020/02/17/assessing-the-impact-of-micro-cracks-in-solar-glass/

By deliberately stressing

glass to simulate years of wear and weather exposure, and with all

other factors being the same:

By deliberately stressing

glass to simulate years of wear and weather exposure, and with all

other factors being the same:

"The Turkish team ascertained reduction in both exergy and energy

efficiencies were attributable to a large number of micro-cracks

and

deformations on the glass surfaces, which were responsible for

considerably affecting the absorbance, transmittance and reflectance

properties of the materials." [my italics]

Those little pits and cracks, causing reduced performance, appear to

affect performance pretty much

the opposite of what I hoped to achieve with the convex 'pebbly'

surface. Those little lenses would aim angled light more directly onto

the

active

collector surface, whereas pits would do the opposite and cracks would

also scatter the light.

Well, I still have the formula and method: TE News #29,

June 2010, "Glaze Mix 9". I also still have no shortage of other

projects. Solar panels are a big industry. It would be one more

exciting thing that could be developed

and commercialized if there were some more people in on the act.

Second: 24% Efficient Dye-Sensitized Titanium Dioxide Solar Cells

https://www.pv-magazine.com/2020/02/13/a-titanium-solar-cell-with-24-efficiency/

In 2010 silicon solar panels were maybe 12% efficient. Now

they have hit and passed 20% efficiency in the best new panels. But if

a solid electrolyte is or has been found, dye sensitized TiO2 panels

might still be

cheaper and easier to make and are said to be more environmentally

friendly.

With higher efficiency, fewer solar panels need to be

installed, reducing the materials and installation costs for putting in

solar energy. A typical house roof that might today be covered in about

as many panels as it can hold might be only 2/3 full instead, or if

filled would supply more energy.

The Australian research team which developed the device said the higher

efficiency was achieved through a nanowire design which eliminates the

interface

inside the titanium dioxide band.

['interface': usually a transparent, conductive tin-antimony oxide

"current collector" layer behind the glass - but in front of the TiO2.

In my trials I was having trouble getting a good layer.]

February 13, 2020 Emiliano Bellini

Titanium dioxide forms the basis of the cell, with efficiency lifted by

a nanowire structure.

A delicious looking dish of titanium dioxide

nanopowder accompanies the article

A delicious looking dish of titanium dioxide

nanopowder accompanies the article

Scientists at Australia's Queensland University of

Technology have developed a quantum dot, titanium dioxide (TiO2) solar

cell they claim offers better efficiency more cheaply than traditional

crystalline silicon cells, as well as being more eco-friendly.

The researchers claim the cell boasts 24% efficiency, more than double

the 8-11% lab-level performance observed in standard TiO2 quantum dot

devices.

Some photons become trapped in the interface between nanocrystals in

typical TiO2 quantum dot cells but the Queensland team claim to have

removed the problematic interfaces.

"Our nanowire design eliminates the interface inside the

TiO2 band, as it's just a single layer of QD [quantum dot]

-coated TiO2," said research coordinator Ziqi Sun. "If we can remove

this disordered interface, we can

improve efficiency."

Commercial production

The nanowire crystal used for the cell was assembled in China with an

advanced transmission electron microscope.

The research group said their cell concept could be expanded to bring

the technology to production.

Most dye-sensitized - Grätzel - solar

cells are based on titanium dioxide thin film - a cheap

and harmless, water-insoluble inorganic material which is commercially

available and widely used in industrial applications.

Low efficiency has remained the chief obstacle preventing such

materials competing with crystalline silicon cells to date.

Titanium has also been used recently to raise the efficiency of

perovskite cells. Research projects of that nature have been carried

out by Japan's Kanazawa University and scientists from

Russia's National University of Science and Technology and

Rome's Tor Vergata University.

And maybe some solid electrolyte can be (or is being) employed to

eliminate the

leakage problem. There would be a pretty rapid switch to this type of

panel if it was available, cheaper, reliable and anything like 24%

efficient.

(What efficiency might I have achieved if I had kept working on it?

These people have a much better idea of what they're doing and some

fancy equipment. But I still suspect tartrazine would be the best dye.

Might it boost efficiency even farther?)

NiMH D Cell Refill

Finally, here

is a picture of the long dead nickel-metal hydride battery I cut the

top button off of, drilled through a rubber seal beneath it, and

refilled with some distilled water (amount not measured). (as mentioned

at the end of January in the previous issue) It then took a charge -

but didn't seem to hold it overnight. Some cycling might or might not

help, but I didn't get around to doing anything more with it.

Finally, here

is a picture of the long dead nickel-metal hydride battery I cut the

top button off of, drilled through a rubber seal beneath it, and

refilled with some distilled water (amount not measured). (as mentioned

at the end of January in the previous issue) It then took a charge -

but didn't seem to hold it overnight. Some cycling might or might not

help, but I didn't get around to doing anything more with it.

NiMH cells are known to corrode if their voltage sits at

less than 1.0 volts. Since this one had sat for probably over two years

completely dead and discharged, one suspects that refilling cells that

aren't completely dead yet, but which have become reduced in capacity

owing to drying out inside, would probably work better - perhaps even

restore them completely.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Permian Period

Amphibian Evolution (continued)

* It seems the earliest fossil eggs that

have been found were from the Triassic period (and the earliest egg shells

are from the Jurassic - so Triassic eggs must have been leathery

covered?). This has puzzled paleontologists: "One of the fossil

record's most puzzling features is the absence of preserved eggs or

eggshell of the first third of the known 315 million year history of

amniote evolution."

This is in fact excellent further support

for

my theory that there were no

reptiles before the end of the Permian period. I believe that the

creatures on

land until the Permian extinction were actually (adult) amphibians (not

amniotes) or an intermediate stage, "pre-reptiles", which have long

been misidentified

from the meager fossil remains as reptiles (or even "mammal-like

reptiles", their anatomy being atypical for reptiles). The present view

that reptiles - advanced

land life - crawled out of the sea almost contemporaneously with

amphibians - fish that later breathe air in adulthood - in the mid

Carboniferous, long before there were seed bearing land plants to

support an advanced land ecosystem and even before all the carbon

dioxide

had

been eliminated from the atmosphere (and deposited as coal), on the

face of it actually

seems pretty far fetched. It probably didn't in earlier times before

the great anatomical differences between amphibians and reptiles were

well appreciated, and in that ignorance the error was originated. (See

TE News #100)

Small Thots

* I had my hair cut short, virtually shaved off, and I discovered

perhaps what it is that may be the advantage to that for keeping or

perhaps restoring thinning hair: when you rub your scalp, you're often

pushing

the short bristles into the follicles instead of merely pulling at

them. Furthermore, you're moving them around in different directions

than with your usual hair style.

Anyway that's what I've come up with for differences very

short hair makes.

And I don't know what if anything it has to do with the demodex

follicularum mites or any damage they may have caused to the scalp and

hair follicles. (It's hard writing a coherent piece on this when the

ideas or answers come in so much piecemeal, over months and indeed

years.)

* It seems Joe Biden is having a lot of trouble just making coherent

sentences these days. Senile dementia has well set in. In choosing this

near zombie, under criminal investigation in two countries, as the next

"Democratic"

party presidential candidate, the corrupt body politic is clearly

showing it wants only a figurehead in the highest office, someone who

will

obligingly rubber stamp whatever they've decided on out of public view.

They've had far too much trouble getting that out of the current

occupant, and they've had a lot of trouble getting some of the other

candidates with their own programs and ideas off the stage. (Not with

the reasonable, honest candidates with sound ideals and sane ideas.

Those are easily disposed of. Tulsi who? She got the mic? Well, just

cut to a political commentator while she's speaking.)

ESD

(Eccentric Silliness Department)

* When is Obsolete Obsolete? It's been 2000 years since people

were

using plumbium (lead) for water pipes. Why do we still call them

"plumbers"? Enough is enough already! Shouldn't they be called

"copperers"

or "pexers" or something?

* Stragedy: A dyslexic's cunning plan that ends up very badly.

* People in China are spraying disinfectant on bank notes, or boiling

them. As the Wuhan corona virus spreads, people all

over the world will soon be laundering money.

* "I must be an athlete... I have an athlete's build... athlete's

reflexes... athlete's foot."

* Lettuce not beet about the blueberry bush. If we really carrot to

help our fellow human beans, we would have mustard up the curry to

chervilly collard up the scallions in our legislatures and insist that

they turnip their efforts for those with who have been uprooted, those

sorrel cases

who have leeked through the cracks, to help them ketchup

with the rest of us. Then there can be peas for olive us. (Vegetable

stew for dinner?)

* Biologists know that nothing in life is unavoidable except death and

taxonomy.

* The Americans invaded Syria and Afghanistan and have long been

threatening Iran. I believe I have finally figured out what they're

really after: Pistachios! They are native to these countries, and

especially Iran. If they can dominate them like they do Latin America,

and turn them into "pistachio republics", then these delicious but

costly nuts can be much cheaper in the USA. No wonder they have wanted

Iran so

badly for so long!

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

no reports

Other

"Green"

Electric

Equipment

Projects

End

of

Kitchen

Solar

Hot

Water

Tank?

(8th) With my mineral-rich well water, for whatever reason, once the

water had sat in the tank under the kitchen sink for a day or two, it

started to stink. A

sulfur smell permeated the air near the sink whenever hot water was

run. Or maybe it was straight hydrogen. I am puzzled as to why this hot

water tank would smell when the large tank has always been fine,

however long the water sits in it.

Other than that I had been very happy with the 15 liter,

36

volt water tank. I had hot water in the sink in 2 or 3 seconds, as hot

as I cared to set the thermostat to. But the stench was too much, and I

couldn't figure out why it was there or how to get rid of it. (Now I

think some mineral was causing the water to react with the tank metal,

to oxidize it

and bubble hydrogen. There was a lot of black sludge in the tank when I

removed and drained it. Or maybe it formed hydrogen sulfide. Apparently

it's a very common problem where there is mineral rich water.) I

just couldn't run a whole tankful of hot water every day to keep it

fresh. Even keeping the tank cold didn't entirely solve the problem,

tho it seemed to slow it down.

Finally I ordered a 3KW "on demand" water heater. This

huge draw just while the water is running - the total of all my solar

panels at noon on a sunny summer day - is the opposite of what one

needs with off-grid type solar power - something that can collect heat

gradually all day so it's there to be suddenly drained when you want

it. Well, I'm not off-grid as long as there's a grid.

Now I finally got

around to installing it. I picked 3 KW, the smallest power available,

because there was an electric

heater under the sink at the floor (which I had never used - I only

finally turned

it on to find out which circuit breaker it was on.) and I could (and

did)

take the 230 volt #14 AWG cable from that to use for the water heater

instead

of having to run new, heavier wire all the way from the breaker box.

I am not enamored with this unit. One must run the water

quite slowly to get it warm, it takes 20 or 30 seconds before hot water

is coming out, and I would never really call it "dishwashing hot"

except at the lowest dribble of flow rates.

Well, it did say it was for a "lavatory sink".

One major impediment was that the outlet to the hot water

faucet was at the bottom left facing down, and I had to put in a 16

inch long "U" of copper pipe with several odd fittings I had (a

frustrating piece of

plumbing) to aim it up and bring it close enough to reach the already

long (18"?) flex pipe to the faucet, which then had a further 18" spout

on it (a tall upside down "J" spout). What was especially galling was

that the hot water came out of the heating element at the top of

the unit, and there was a foot-long pipe inside bringing it down to the

fitting in the most inconvenient possible spot, the bottom left. Since

the hot water lever is usually the one on the left, in order for the

heater to be clear of the cold water pipes it will normally be mounted

on the wall under the left side of the sink. Thus the shortest run in

most situations is obviously from the top right, and just as obviously,

with the very limited flow and "on demand" heating, the run length is

very

important. I suppose they had leaks and electrical safety in mind, but

after installing and using it I can see that the setup is ridiculous.

They should have simply brought the output pipe outside the case to the

top right (even closer!) and had the join away from it.

It all made a total of almost 6 feet of piping between the

"on demand" heater right below the sink and the end of the spout. With

the tiny flow

available to get really hot water, it takes quite a while to actually

get hot water. If you run it faster, it never gets very warm. If I had

used some skinny tube instead of 1/2 inch pipe

it would have helped. But it would have been far better with the hot

water outlet at the top on the right to allow the shortest connection

to the faucet instead of forcing one to do a lot of extra work to

create a very long one. To get decently hot water, one only cracks the

tap open a little - and waits, and waits - and then if it isn't on

quite high enough, the unit doesn't

turn on and the water stays cold and all the waiting is in vain.

I'm tempted to disconnect everything, take it out,

disconnect the fitting, cut most of the pipe off, and try to bend it up

to join straight to the flex hose at the top. (I've been doing lots of

that sort of thing for the air heat pumping!) That would cut out about

2 feet of piping and so reduce the absurd wait for "on demand" warm or

hot water. In fact, then I could put in a shorter flex pipe, too, and

make it 2-1/2 feet less.

Six kilowatts would obviously not by any means be overkill

for an "on demand"

kitchen sink water heater - I would now judge it as minimal. I think a

shower or

bath would take more - 12 kilowatts?

But the water doesn't stink.

Hot Water Tank Protective Anodes

(10th) Now that I've gone to all that work - removed my under-sink tank

and installed the "on demand" hot water unit - I see on youtube that

there's something called a sacrificial anode in hot water tanks! A guy

showed four hot water tanks cut wide open with a zip disk/angle

grinder, and there they are: rods sticking down from the top.

Apparently they're magnesium or aluminum and by corroding first, they

protect the metal tank from rusting! How is it possible I have lived

this long, and even having replaced several water tanks, I've never

heard of them before? How is it possible people say a tank lasts 8

years (or whatever) and never mentioned that there's an anode inside

which eventually wears out and then stops protecting the tank? Or is

putting an anode in water tanks a "new" idea that I just never heard

about -- like newer than the 1980s when I was (too frequently)

replacing hot water tanks in my old house? I'm going to guess that

that's the case, since my last water heater lasted 19 years 11 months.

(I remember it because of something else at the time I replaced it,

December 1996. It sprung a leak in November 2016 before I moved and I

was cursing that it hadn't lasted just a few more months until it was

somebody else's problem! Probably it had needed a new anode and with

one could have lasted more decades yet! No doubt I should check my

present main water tank.)

I'm

going to guess that in my mineral rich water the anode wore out quickly

and that's when the water started to stink, because I don't remember it

smelling until it had been installed for a while. When I removed it I

unscrewed a nut attaching a bolt through the shell (whose purpose I had

wondered

about), and something fell down inside. No doubt it was the anode. In

this small tank it wasn't made to unscrew from the shell and pull out

the top. I would have to unscrew the heater element to access the

inside and really see what's up. Sometime I will get to that...

Simple

Air

Compression

Heat

Pumping

- or -

How to Heat a Building Almost for Free

I read on a "Q & A" discussion list ("Quora") that air

heat

pumping does work, but "at low efficiency" and needing to pump "quite a

high volume of air at high pressure". I understood it was lower

efficiency, but with potential Coefficients of Performance (COPs) being

so high in the open loop air system one should be able to tolerate

quite poor efficiency and still get excellent results.

And having now looked at and tried some compressors, I

think the low efficiency is in the way compressors are being made and

not

inherent in the whole process. Today's air compressors are simply not

designed for heat pumping and they care nothing about design as related

to

that purpose. Just thinking of the simplicity and efficiency of a hand

bicycle pump one can see that it's easily possible to do much better.

(3rd) With Water Cooler (Refrigerator Type) Pump

The water cooler compressor blew up a balloon

very slowly

The water cooler compressor blew up a balloon

very slowly

I unsoldered the inner 'telescoping' narrow pipe from the

larger

output pipe on the 'new' refrigerator compressor to leave a maximum

size opening with least resistance to air flow. It was a hard go,

heating virtually to red hot - must have been silver solder. I tried to

do the same with the input pipe, but the whole thinner pipe softened

and fell off without melting the solder. I cut it off shorter. A last

bit of the intake's thinner pipe was then loose inside and came out.

I note that when I first plugged it in, it sprayed out

some oil. Later I turned it sideways and more oil started dripping out

the input pipe. So it still had some oil in it. (several fluid ounces

as it turned out.) I suppose it will need

occasional or even frequent lubrication now that the oil isn't sealed

inside with the refrigerant.

When covered and turned on it also pinned my 0-60 PSI air

pressure meter in about one second!

I

went to put it into the heat pump box box and found it

was 3/4" too tall. I had to rebuild the box. I filed a pipe with 1/8"

NPT threads on one end for a

friction fit over the compressor's output pipe. I threaded another

fitting I had, to screw onto it and bring it up to 3/8" NPT to fit

another adapter to the 1/2" copper water pipe size. (In 35 years I

think that's the first time I've ever used that threading tap! But

there it was in the set. The trick with NPT threads is that they're

tapered. One must taper the end of the pipe slightly with a file,

grinder or reamer before trying to thread it. Even lots of pro metal

workers don't know that and can't figure out why it won't thread. But

it's why pipe thread joints don't leak.)

I

went to put it into the heat pump box box and found it

was 3/4" too tall. I had to rebuild the box. I filed a pipe with 1/8"

NPT threads on one end for a

friction fit over the compressor's output pipe. I threaded another

fitting I had, to screw onto it and bring it up to 3/8" NPT to fit

another adapter to the 1/2" copper water pipe size. (In 35 years I

think that's the first time I've ever used that threading tap! But

there it was in the set. The trick with NPT threads is that they're

tapered. One must taper the end of the pipe slightly with a file,

grinder or reamer before trying to thread it. Even lots of pro metal

workers don't know that and can't figure out why it won't thread. But

it's why pipe thread joints don't leak.)

(4th) I bought

a 0-160 PSI air pressure meter. I worried about setting

a 4 foot long heavy finned pipe on top of the soft, scrawny copper

output pipe on the fridge compressor. It would just bend it and fall

over, and probably kink it. I thought the least I could do was put a

steady of some sort on the pipe. It would have been easy if the air

duct didn't have to fit over the pipe and also into the hole in the

box. I cut a chunk of aluminum and rigged something up. Afterward I

thought of a better arrangement. I'll probably want to make that later,

so there's no force at all pushing on the fridge compressor's little

output pipe.

(4th) I bought

a 0-160 PSI air pressure meter. I worried about setting

a 4 foot long heavy finned pipe on top of the soft, scrawny copper

output pipe on the fridge compressor. It would just bend it and fall

over, and probably kink it. I thought the least I could do was put a

steady of some sort on the pipe. It would have been easy if the air

duct didn't have to fit over the pipe and also into the hole in the

box. I cut a chunk of aluminum and rigged something up. Afterward I

thought of a better arrangement. I'll probably want to make that later,

so there's no force at all pushing on the fridge compressor's little

output pipe.

(5th) I

changed the outdoor heat exchanger from 2 legs to 4. (Then I

had to unscrew 2 to get the height just right for the other pipes.) I

put everything together and turned it on at 21:00 PM. Now it wouldn't

go above 30 PSI. Why did I buy a new air pressure meter again?

(5th) I

changed the outdoor heat exchanger from 2 legs to 4. (Then I

had to unscrew 2 to get the height just right for the other pipes.) I

put everything together and turned it on at 21:00 PM. Now it wouldn't

go above 30 PSI. Why did I buy a new air pressure meter again?

I closed the doors and turned off the LED garden lights (~200W). It

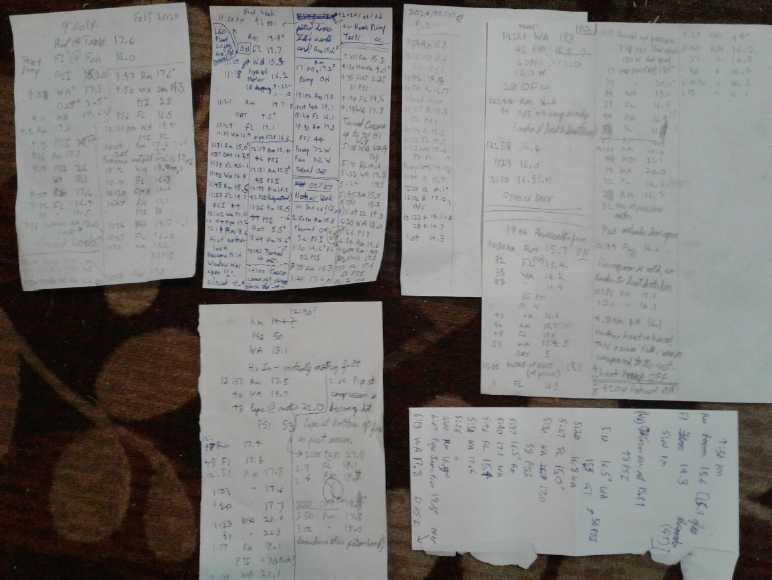

started off with the following conditions:

Outdoor air: 2.5° (°C), no wind.

Room air (at kitchen table) 17.6°

Cold air in at floor: 16.0°

Air pressure in pipes: 20 PSI

This time the compressor was so much quieter that the air

fan was most of the noise. It makes quite a whir, but with the lab air

pump I could hardy hear it, and not at all with the Michelin

compressor. A very slight waft of cool air could be felt coming in the

outdoor heat exchanger. Also unlike other tests, the compressor and its

output pipe seemed hardly warm. Then I put my hand near the pressure

meter and felt a leak at a soldered joint. I wrapped some electrical

tape around it. But the threaded joint next to it was also leaking. I

turned it off and 're-threaded' the pipe with some new teflon tape, and

while I was at it I put the old lower pressure meter back on. I turned

it back on. It seemed no matter how much tape I wound around the leak I

couldn't stop it. But it was now next to nothing.

Soon the warm air out was 19.3° (instead of

18.3°), almost 3 degrees warmer than the 16.5° air being drawn

in by the fan at floor level. That had to be doing some heating. Later

the temperatures were down a bit (disappointing but not surprising

given it was 2° outside.) Warm air 19.1, Floor air back down to

16.0, and the room air 17.1. I went in and did some dishes and they

came up marginally - about .2 degrees - a warm human, hot dish water

and vapor.

At 23:00 PM I finished and I turned off the pump and fan.

Within 15 minutes the temperature was down 1/2 a degree, and .7 or

.8° in half an hour. The heat pump had definitely been doing some

good pumping to keep it from dropping much for two hours. Then I went

to run the 425W electric heater for 1/2 an hour, but the temperature

rose .4° in a very few minutes - in fact, when I turned the heater

on and looked again it was already up by .1°. Perhaps I had left

the livingroom door open for a few minutes? Or maybe it was because the

fridge had come on? Then after I left the room the loose "tip over"

switch decided to cut the heater off and the temperature dropped. I

decided to ignore that test entirely and run it another 1/2 hour. The

thermometer read 16.9° the whole time until just before 00:30 it

went up to 17.0. At that time I turned it off and turned the heat pump

back on.

I put my hand on the tape and managed to squeeze off the

leak. It didn't seem like much, but the air pressure rose from 35 PSI

to 46. That was surely a substantial loss, having that air

decompressing into the room instead of outside. It was too late at

night to stop and fix it. Manñana! The temperature dropped a bit

over 40 minutes by 01:10 AM, but not as much as with no heat. or with

just 75 watts of it.

(6th) In the morning I returned to the charge. I re-soldered the pipe

fitting and put it together again. An hour later, thinking I still

heard hissing air, I found another leak, inside the box. It was hard to

get into and I had only tightened it by hand. (There was oil from

inside the compressor all over the fitting.) I took the wall with the

fan off the box and got two wrenches in and tightened it up. The

compressor motor outer case was just a little warm. It seemed the heat

transfer

was very good, especially compared to the previous compressors. I was

now running it at about 45 PSI. It seemed to be getting the room slowly

warmer. Then I realized a window was open 1-1/2 inches for fresh air

and I closed it.

It was quite something, because nothing much seemed to be

happening. What heat? There was noise, and a fan was blowing cold air

out the end of a dryer hose duct. How could that heat a room? Yet that

air was a couple of degrees warmer than the air coming in at floor

level and just a bit warmer than the temperature of the room, and would

continue to be a bit warmer than the room regardless of room

temperature. A low temperature rise is just what is wanted for high

heating COP. I went away for an hour and the room temperature had risen

by about 1/4 of a degree. That would make it about the equal of the 425

watt radiant heater... except that the outdoor temperature had risen to

5.5° and the LED lights (200w) were on. (Too many variables!) At

13:45 I turned the unit off, but at 14:00 (for once) the sun came out,

heating the room through the patio doors and making further comparisons

of temperature changes useless.

Here are some typical readings, obtained in the evening

after running the unit for a couple of hours:

Outdoor air: +2° (dropped from +5° earlier)

Room air: 17.3° (at table height - livingroom door was open

allowing woodstove heated air in, so this temperature is meaningful

only in comparison with the two below.)

Cold air into duct: 16.1° (room air at floor level)

Warm air out of duct: 19.1° (so the air was being raised by

3.0°, to 1.8° above room temperature, as it blew through the

box and duct past the compressor and stegosaur pipe. With a faster fan

it would have been even less rise - but at least as much heat.)

Top of Pipes°: not measured in this instance. (It seemed to be

typically only 1/4 of a degree above the warm air temperature, so it

would seem the "stegosaur" radiator pipe (now with about 30 inches of

fins) was quite effective, and or that the pipe wasn't being warmed

very fast by the mere 75 watt compressor.

Compressor Body°: Not measured, but felt like 35+°. (Here is

where there may be some important losses and COP drop.)

Pressure in pipes: 44 PSI

Pump power: 72 watts (Varied from ~78W cold to ~72W once well warmed)

Duct Fan power: 3.2 watts

Means for Improvement?

This time I didn't see (feel) any major "hot spots" on the

compressor where the pumped heat is being wasted. But it was definitely

warm, and there may still be one or more bottlenecks inside the outer

body of the compressor. The real compressor flops around inside when

you tip it, "clunk clunk", so it's obviously just a

refrigerant-leak-proof outer shell that's seen. (It probably cuts down

the noise quite a lot.) Does it restrict air flow? I suspect something

in there is reducing efficiency. (It sure was!) If I get up the nerve,

I may cut open

the compressor body and see what further gain might be had by using

just the actual bare bones compressor from inside the housing. Actually

I think I'll get another one to do that to.

Also I'm not sure how effective my outdoor heat exchanger

is. With the small compressor there's almost no air to be felt coming

in through it, and what it does need may be coming in through other

leaks in the room. One of the doors, a sliding door to a very cool room

with lots of free air flow, has big gaps under it and on the side. It

could draw air through that perhaps more easily than through the heat

exchanger. If this is in fact the case, an effective COP rise - and

some air definitely coming in through the exchanger - might be observed

in a tighter space.

I've heard it said that plain air heat pumping is less

efficient than with refrigerant. No doubt that's why everyone has gone

with refrigerant until now. But reducing the pumping 'lift' required

from 20 or 30 or 40° (depending on weather) to 10° and maybe

even well under that (independent of weather), makes allowances for

even very low efficiency of equipment and technique to nevertheless

attain high real COPs.

If the 75 watt air compressor only does about as well as

the 425 watt electric heater, that indicates an effective COP of about

5.5. Or it may be a bit less. Even if COP 20 or 10 can't really be

attained in practice, at least not without a specially made air pumping

unit, 5 or higher (no matter how cold it is outside) is still better

than anything else out there. I can replace the 250/500 watts radiant

heater in the travel trailer with the 75 watt heat pump - 1.8 KWH per

day to keep it from getting cold and mouldy* instead of 6 or 12 (and I

won't care about the noise). But I'm sure that if I can't improve them

myself at home, once this goes commercial great efforts will be made to

attain those juicy potential COPs.

At one point I thought to check the temperature of the

decompressing air at the nozzle outside. It was 4.0°, while the

outdoor temperature was 2.2°. The fact that it was about the

outdoor temperature instead of below indicates the outdoor heat

exchanger wasn't doing well. I'm pretty sure the compressor had an

easier time drawing in air from elsewhere, as one couldn't feel much

air movement coming in from the exchanger. However, 4° is way

colder than the radiator pipes it was coming from. The unit was

definitely compressing and heating the indoor air, and decompressing

and discharging it outside much cooler.

At one point I thought to check the temperature of the

decompressing air at the nozzle outside. It was 4.0°, while the

outdoor temperature was 2.2°. The fact that it was about the

outdoor temperature instead of below indicates the outdoor heat

exchanger wasn't doing well. I'm pretty sure the compressor had an

easier time drawing in air from elsewhere, as one couldn't feel much

air movement coming in from the exchanger. However, 4° is way

colder than the radiator pipes it was coming from. The unit was

definitely compressing and heating the indoor air, and decompressing

and discharging it outside much cooler.

That the leaks in the house were drawing in a bit of cold

air only added a bit to the heating load. They didn't negate the

overall heat pumping effect. (hmm, a couple of windows at the far end

of the house were cracked open for fresh air.)

*On the 5th someone living 'off grid'

told me a horror story of how his

unheated travel trailer quickly got damp and went mouldy inside, and

became unlivable and useless.

New & Improved Compressor

(8th) I went

back to the refuse transfer station and got another fridge

compressor. This one was from a large fridge instead of an office water

cooler.

(8th) I went

back to the refuse transfer station and got another fridge

compressor. This one was from a large fridge instead of an office water

cooler.

(9th) It seemed to put out far more air. It was around 100

watts running open, but if one covered the air outlet, it quickly ran

up to 150 watts and even 185, and plenty of air really wanted out! My

immediate impression was that it was far superior to the other one.

Twice the power and more, and seemingly at least 10 times as much air.

And it even was quieter! The power of the other one stayed pretty much

constant at 75 watts regardless, while this one changed markedly if it

had to compress the air more, indicating that its power was being much

more fully harnessed to the work, not just into turning itself.

This one was taller yet than the first and second ones and

bigger around, so I would have to rebuild the box yet again with more

changes. I decided to leave the present box and make a new one. Making

and assembling 6 plywood sides into a box took the afternoon.

I went to dinner at Mike & Heather's on board their

boat. Mike was replacing the heating system on a neighboring boat and

gave me two four foot radiator pipes of 3/4" copper with aluminum fins

from the old system being discarded. What a great score! That would

save me from having to make a bunch more stegosaur radiator pipes

before trying out the new compressor - I was sure it would need more

radiators than the old one.

A parameter I thought of later was that the pipes might be more

effective per foot if there were heat exchange fins inside the

pipe so the compressed air would yield its heat more readily to the

copper pipe. How much improvement that would make I have little idea,

but it sounds hard to do. Perhaps here is a place for aluminum: short

lengths of 'fin assembly' can be inserted and pushed into the pipe with

a plunger of some sort until it's as full as desired. OTOH might it be

noisy with compressed air running by little pieces inside? It seems to

have enough hiss going around a sharp corner that I ended up making the

corners rounded.

New Heating Unit

12 foot finned radiator pipe

(16th) With

these new components I got a couple more pipe fittings and

another piece of dryer duct and started putting together a new unit.

Since the 9th I had unsoldered the two new finned pipes and reassembled

them in line so I could get the dryer duct over them. And I put in a

pipe union and added the stegosaur. I had enough confidence to drill an

11/16 inch hole through the house wall so the compressed air radiator

pipe would end outside.

(16th) With

these new components I got a couple more pipe fittings and

another piece of dryer duct and started putting together a new unit.

Since the 9th I had unsoldered the two new finned pipes and reassembled

them in line so I could get the dryer duct over them. And I put in a

pipe union and added the stegosaur. I had enough confidence to drill an

11/16 inch hole through the house wall so the compressed air radiator

pipe would end outside.

It seemed to me at the time that the outdoor heat

exchanger didn't really

do a lot, and I didn't bother with it for this build. The compressor

just didn't draw that much air, and it seemed to get it from other gaps

anyway - windows cracked open or whatever.

Now I fitted out the

plywood box and mounted the

compressor and another fan in it. After I mounted the fan it occurred

to me to wonder whether it should blow air from the compressor end, or

from the far end and then through the compressor. If it blew from the

compressor end the unheated air would hit the compressor and the

warmest part of the radiator. But then it still had to blow it out the

far end. That meant that warmed air would hit the coolest end of the

radiator pipe, and it might not cool it any further.

Now I fitted out the

plywood box and mounted the

compressor and another fan in it. After I mounted the fan it occurred

to me to wonder whether it should blow air from the compressor end, or

from the far end and then through the compressor. If it blew from the

compressor end the unheated air would hit the compressor and the

warmest part of the radiator. But then it still had to blow it out the

far end. That meant that warmed air would hit the coolest end of the

radiator pipe, and it might not cool it any further.

If on the other hand the air blew the other way, the

coldest air would hit the coolest end of the pipes, and the pipe would

be coolest when it when outdoors and hit the end. The somewhat warmed

air would flow past the warmest end of the pipes and the compressor.

And the warmer air would come out at floor level where the fan was

blowing it out.

I decided the second way was better. That seemed

convenient, because I had accidentally mounted the fan on the wrong

face of the plywood - on the outside. Now I wouldn't have to turn it

around. (I may put it inside it later.)

The larger fridge compressor in its

The larger fridge compressor in its

box and all connected, fan pulling out

(17th, 18th) I got

everything together and fired it up. It didn't seem

to perform very well. The warm air out wasn't even as warm as the

smaller compressor. I thought that since warm air rises it might

circulate more slowly because of being pulled down instead of pushed

up. Later I remembered that the uninsulated aluminized duct was now 15

feet long instead of 5, and that warmth would be radiating from it all

the way along. So the air at the end should be cooler.

(17th, 18th) I got

everything together and fired it up. It didn't seem

to perform very well. The warm air out wasn't even as warm as the

smaller compressor. I thought that since warm air rises it might

circulate more slowly because of being pulled down instead of pushed

up. Later I remembered that the uninsulated aluminized duct was now 15

feet long instead of 5, and that warmth would be radiating from it all

the way along. So the air at the end should be cooler.

Still, it didn't seem to be warming the room very much.

Again it seemed less effective than the 420 watt electric heater. Why?

(19th) I turned the fan around. Then I turned up the air pressure from

60 to 80. (actually from 63 to 77, by closing the faucet on the outside

end the the pipe a bit more. It's hard to set exactly.) One or both of

these measures seemed to help. Temperature readings including room

temperature slowly started rising.

There was a join between the two sections of dryer duct,

and I had closed it with alligator clips. I could remove one and put

the temperature sensor in there. It was at least a degree warmer than

at the warm air outlet, proving that a lot of the heat radiated out

before it reached the far end.

I ran the unit for about 6 hours. Initially it warmed the

room a little, but it failed to get it above about 16.5 degrees at any

time. This was however the warmest part of the house as I had tried to

do something with the woodstove and then it smoked horribly. (I had to

wait for it to pretty much go out so I could take the stovepipe off.)

After that I ran the 420

watt radiant heater for a couple

of hours. Once again it seemed to do about the same as the heatpump or

maybe a little better. The good part was that the heatpump was 120

watts where the radiant heater was 420, suggesting a COP of at least 3

to 1. This at least seems to indicate that

open loop air heat pumping works and is worth pursuing - it can save

energy and money over simple electric radiators, and the performance is

on a par with refrigerant based heat pumps but it's simple to install

and cheaper.

Along the way I noted that fridge compressors seem to burp

oil out the compressed air outlet. I thought it would drain back inside

since the outlet air pipe goes up, but even when it's turned off, the

oil just sits and builds up in the pipe. It burbles more and more the

longer it has run. One might drain it, but of course the compressor

eventually needs the oil.

So apparently, to accommodate in an open air system this

type of compressor, which is made to run continuously and last a long

time but in a closed loop of refrigerant, it needs a very tiny

connecting pipe to bleed the oil back into the air inlet and hence back

into the pump. Ug! That should pretty much solve the problem, at the

cost of wasting a bit of the compressed air. I hope.

But it would be nice to know where the bottleneck(s) is

and be able to do something about it. It is said that air heat pumping

is less efficient than using refrigerant. But why is that?

Then, if piston compressors in general are inefficient

perhaps something else could pump air? Where is the inefficiency in a

piston and cylinder? The piston rings against the cylinder walls must

surely be a significant source of friction. What about some sort of

bellows type of device instead? The walls of the bellows themselves

move, so nothing is sliding against anything else. Or what about the

"balloon" type of power "cylinder" found in some Stirling engines --

might that have lower losses than piston and cylinder? (The internet is

out again. Otherwise I would be looking this up and seeing for myself.)

In the other end, how can the transfer of the heat to the

room air be optimized? Obviously the bigger the radiators and the

harder the fan or fans blow on them, the better the heat exchange from

the radiator pipe to the duct air.

What about the transfer of heat from the compressed air to

the radiator pipes?

Compressors Today Are Not Made For Air Heat Pumping

The Ideal Case

(24th) I thought about the amount of power being used by these

various compressors. Ideally, if there was no radiator pipe or if the

end of the pipe was side open, and no pressure would build up in the

system, the compressor is just blowing air like a fan. The duct fans

were drawing about 3-1/2 watts. Running with open ducts the compressors

started at 75 watts and went up from there to 750. (750 was for the

Michelin - the larger Makita was better at 550 W.)

What is wrong with this picture? It means that all the

compressors are wasting huge amounts of energy. Of course it takes some

energy to turn a motor, and to slide piston rings back and forth in a

cylinder. But that should be small, almost trivial compared to the

energy needed to compress air, where real work is being done. One can

literally feel this when pumping up a bicycle tire with a hand pump.

Disconnected, the pump handle plunges freely, almost effortlessly. If

it's upright, it may descend by itself. The more pressure there is in

the tire being inflated, the harder it is to push the handle to the end

of the stroke to pump it up further. Why don't motorized compressors

use so little power in free air?

One can see this is at least partly (if not mainly) owing

to internal restrictions to the air flow: they are compressing air, but

it is decompressing before it even comes out of the compressor. Nowhere

is this more obvious than in the 1/16th inch, 16 inch long pipe in the

water cooler compressor. It was heavily compressing air in the cylinder

and making heat there regardless of whether the air outlet was wide

open or almost completely closed off - because it was almost completely

closed off anyway. And thus the power consumed (75 W) didn't change

much with external load, since most of the load was internal. When I