Turquoise Energy News #142

covering March

2020 (Posted April 6th 2020)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- Open Loop Air Heat Pumping - Better Peltier Modules for Solid

State Heat Pumping? - Lawn Tractor Electric Conversion

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Catastrophes Galore (and gardening) - Curing Eye Floaters with

Pineapple?: Bromeliads, Bromelaine - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Lawn Tractor as "Rototiller"?

Other "Green"

Electric Equipment Projects

* Very High COP Open Loop Air Heat Pumping -

Electricity Generation

* My Solar Power System: - Monthly

Solar Production log et cetera - Notes.

* Stirling Engine Electric Generator with Hot Water Solar Energy

Storage? (Concept)

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte)

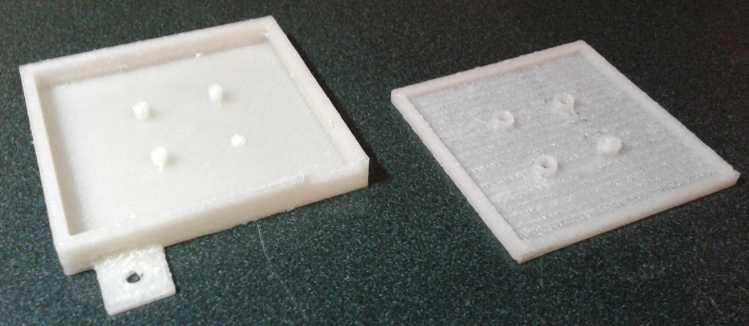

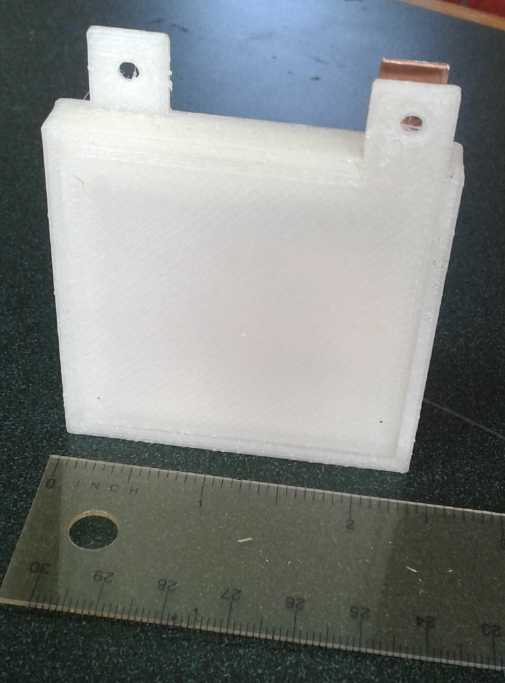

- New Case, 3D Printed from PVB - Base for electrode Compactor

(I Can't believe it's April

6th. I could have put out this newsletter by the 3rd. Some strange

lethargy has come over me.)

The first half of March

stayed cold, with heavy frosts every night, snow now and then and a

couple of good windstorms. When I found time to work on anything, it

was the open loop air heat pumping.

When it finally started warming up after about the 15th

and one could spend time outside, I looked around and felt overwhelmed

by all the projects I'd set aside waiting for warmer weather. Not for

the most part energy projects, but gardening, greenhouse improvements,

making a "chicken sled" enclosure that I could pull around the yard for

a few chickens to forage in safety from hawks and eagles (for

eggs of course), and then there was that roof over the travel trailer

to put walls on and turn into a house. Then there were optional

projects like a rabbit enclosure and plowing a field to try out

growing different strains of wheat. (Barley grew well even in the

cloudy summer

of 2019. Quinoa did well in sunny 2018, but poorly in 2019. Potatoes

always do well. I think I got 4 Kg of them just digging the compost

pile.) And

I either have to cut more

firewood than last year (by thinning out some of those scrawny alders

so the others have more room) or buy some more.

Then after a pretty decent week or so, the weather turned

cold again and stayed that way into April. It didn't feel like spring.

Having started some seeds and seedlings indoors, in spite

of the cold some had to get planted, so I started transplanting them

into the greenhouse. I had meant to fill one area with corn since it

won't grow outside here, but I'm not sure there'll be room. With the

cold I planted a potted cherry tree I bought last year inside the

greenhouse, in the shadiest end. I figure I'll have about 2 years

before it gets too tall and I need to remove that part of the

greenhouse so that that (not very

productive) area is outside. Cherries do grow around here. In the

meantime, unless the summer gets warmer than last year, it'll probably

give more cherries in there than out in the cold. And the birds won't

get them.

There's plenty of work for the whole summer - assuming

there is one. So now I have

to find time for energy projects in the midst of all that. Perhaps the

next battery experiments and the (almost ready to fly) ground effect

vehicle should get priority. For that last project I put in some brass

tubes for hinges in conjunction with the wooden dowels that went

through each hull into the ends of the canard. But that was it.

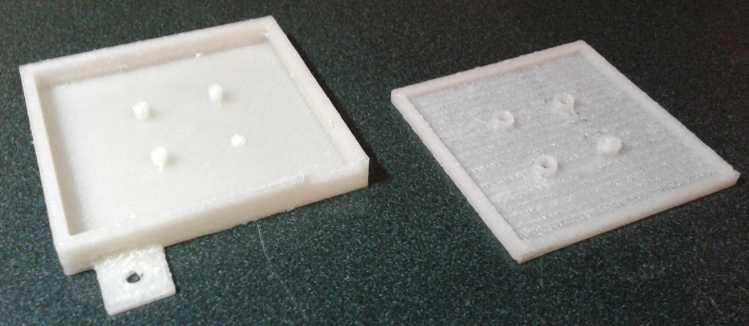

On the batteries I made a little progress on cases, and

made the base for the 50x50mm electrode compactor.

But mostly, although I was pretty busy, somehow other

things besides energy projects seemed to be getting priority,

especially in the letter part of the month.

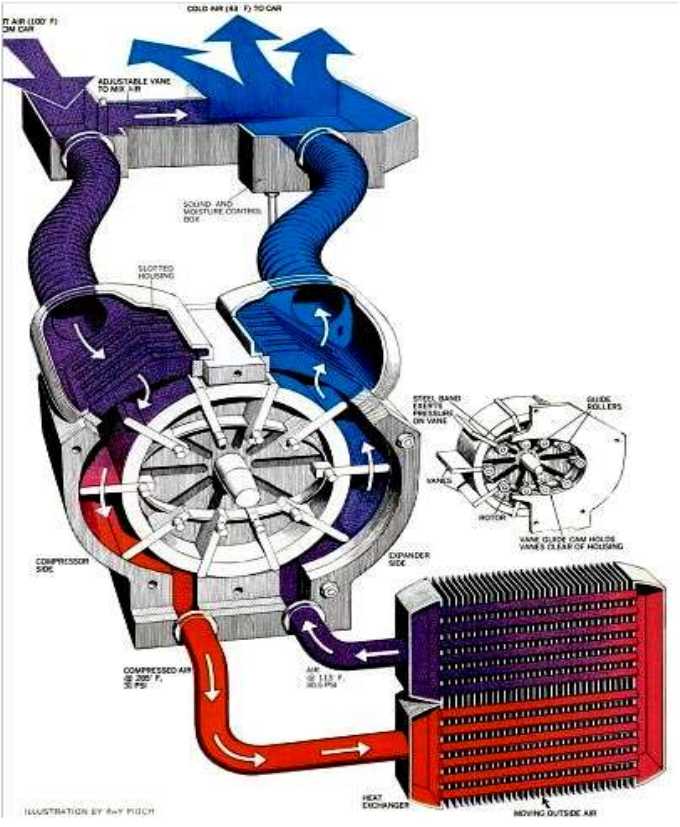

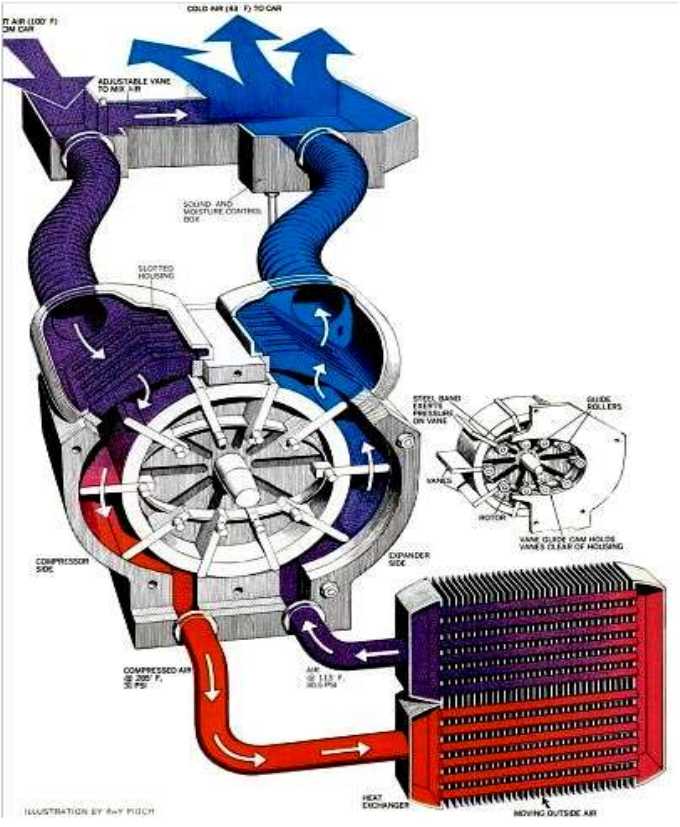

Open Loop Air Heat Pumping

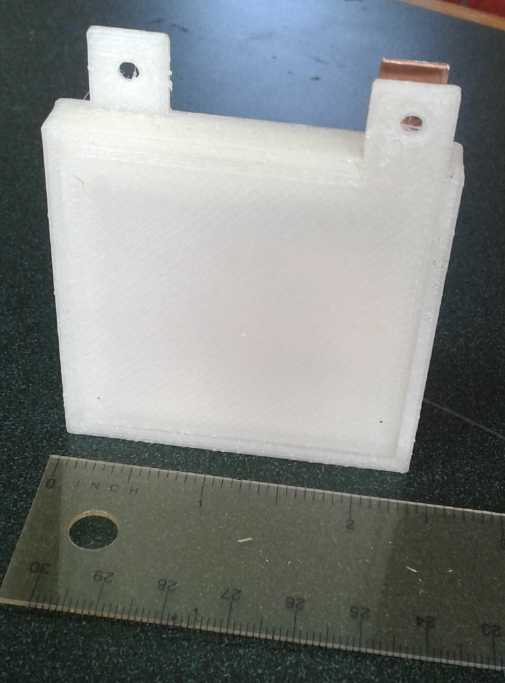

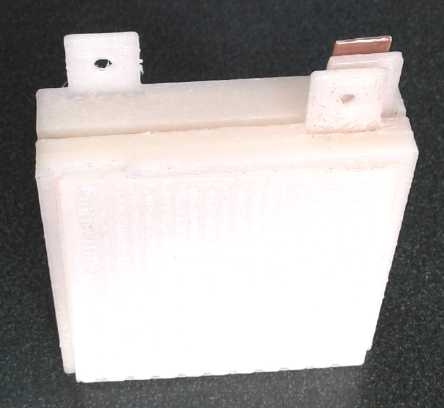

Enclosure with Makita air

compressor (as first

made);

Enclosure with Makita air

compressor (as first

made);

ducts at right loop back to outdoor heat exchanger underneath

compressor box.

It seems there are potentially two main ways to do the

heat pumping.

One is to cludj it with an existing air compressor. This has the

advantage that the heart of the system is ready made. Here one get's

what I've been getting: from COP of perhaps 2 to - maybe, or

seemingly - about 4 or 5, tops, which I seemed to get with the

refrigerator type compressors. But a regular compressor, regardless of

efficiency, expects the compressed air to be used by some other

destination. In heat pumping, the compressed air is simply allowed to

hiss out at the end of the pipes. That is quite a lot of wasted energy.

The

other and far more effective way would be to make an air compressor

designed

especially for heat pumping. Thanks to some great info sent in by a

couple of readers after my last two newsletters, I discovered how to do

it: after the compressed air has done everything else, given up its

heat to the house and then to heat the incoming cold air in the outdoor

heat exchanger, it can still be used by its decompression to assist the

compressor.

The

other and far more effective way would be to make an air compressor

designed

especially for heat pumping. Thanks to some great info sent in by a

couple of readers after my last two newsletters, I discovered how to do

it: after the compressed air has done everything else, given up its

heat to the house and then to heat the incoming cold air in the outdoor

heat exchanger, it can still be used by its decompression to assist the

compressor.

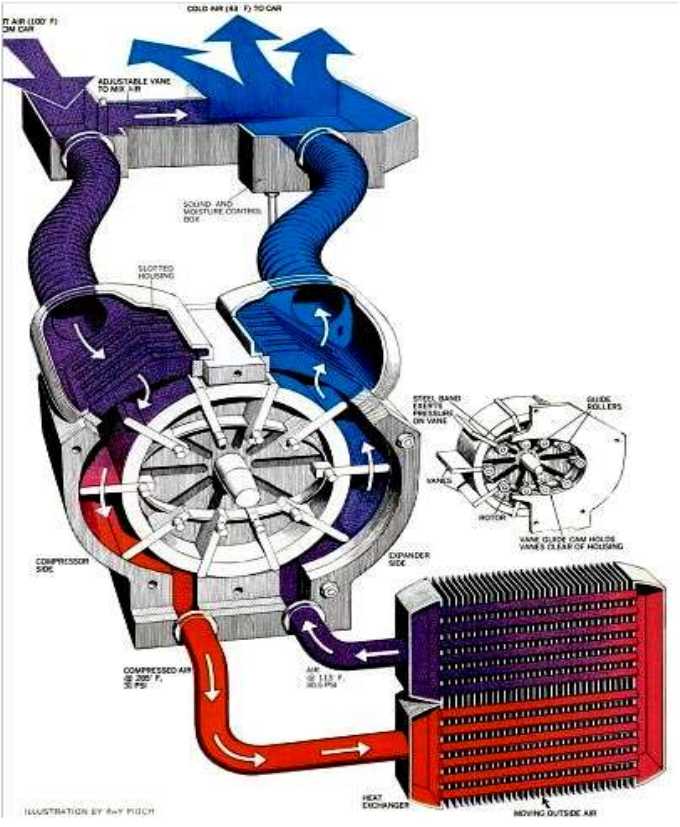

This ROVAC (Rotary Vehicle Air Conditioner - or it could

as easily heat instead) design from the 1970s uses the cooled,

decompressing air to help compress the incoming air. That gave me the

idea, but my simpler way of doing the same thing would be with two

pistons. The outgoing air would fill the second, in-line cylinder

that has a rod connected to the compression cylinder. When the

same amount of air has filled the outgoing cylinder as is being

compressed in the incoming cylinder, it will have compressed it most of

the way to the desired pressure. This now cold air will have slightly

less volume at the same pressure because colder air is denser, but the

motor is only needed

for (eg) the last 10% and is pumping, and to only 10% additional

pressure over the other cylinder's, rather than all the way up from

atmospheric pressure.

Imagine a COP even of 2 being raised closer to 20 because

so much less additional energy is needed by the compressor. 100 watts

to heat instead of 2000: there's the very cheap building heating!

Better Peltier Modules for Solid

State Heat Pumping?

In January or February I checked on line to see if there

were and better Peltier modules with higher COPs. The Wikipedia article

said some were under development with COP as high as 3. I found some

"high performance" peltier modules

that looked better than most. (A COP of 3 appeared on the graph

lines, but that was with only a 10° temperature differential. The

fridge needed 30° or more.)

Another change from 2012 is all the low cost DC to DC

converters now available on line. One isn't "stuck" with using 12-14

volts from a battery or

putting two modules in series for 6-7 volts. If the best choice looks

like 9.5

volts, that's now a simple screwdriver adjustment.

They were from USA rather than China and hence quite

pricey and pricey to ship. Typically US companies refuse to use the

post office even for the smallest things.

This month I finally ordered four small ones. To my

surprise they arrived on the day a UPS e-mail said they would, instead

of weeks later. (But: 40 $US shipping for 80 $US of parts, and a

further bill for 33$ UPS collect charges (far more than the

tax itself - 6$) came in the mail.) That's certainly how to make your

product uneconomical for the purchaser!

I'd like to say I tried them out, but I threw them inside

the solid state fridge and there they sit. I'm sure I'll get around to

trying them, uh... soon!

Lawn Tractor Electric Conversion

I started looking on youtube for some reasonable way to

break up the grass on part of the mossy turf lawn, in order to turn it

into a garden to try growing grains. Instead I found a conversion of a

lawn tractor to

electric. Then another one. The second one was a guy, Brian Edmund

Electric in Ontario, who had done more than one and who offered a

conversion kit.

Much as I had idly thought of converting mine with my

forklift motor and controller on the cheap, the kit had a 24 volt

motor[, reduction gear for sure] and differential already mounted with

axles for the lawn tractor rear wheels, a one-piece assembly. That

should be quite an efficient drive. And of course all the required

parts for the conversion. That got me. I ordered it (1400$; so much for

"cheap"). In addition it had

two more motors for the two mower blades. No drive belts anywhere.

(Later I

thought the motor/reduction/differential/axles assembly might be

made for some model of mobility scooter. That would have been the place

to find that finished assembly. Oh well!)

The message from all sides was that I wouldn't be ripping

up turf with a lawn tractor. For that I should go up to a garden

tractor - and a 48 volt motor - and "tractor" tread tires instead of

"turf savers", which tend to slip even going up hills. Unless I can

find an old dead one, those cost real money.

But I got the

idea (thinking of "tractor tread tires") that instead of pulling a

plow,

I could weld up steel wheels with protruding (bars or spikes?). The

(side to side) bars

would go down vertically at the front of the wheel as it rolled,

digging in. They would rip up the turf and twist to horizontal as they

came back up behind, scooping up clods of dirt. It should take less

power to drive, or at least, the power (and

tilling depth) would depend on the length of the bars and they could be

made any reasonable length. I could call them "turf ripper" wheels.

The tractor place had thrown out their old

rims. ("Try the dump?" Nope, none to be seen in the vast pile of tires

at the refuse transfer station.) Rats!

Alternate plan... maybe my neighbor with a real tractor

and plow will do it for me?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Catastrophes Galore

(and gardening)

I think I've spoken of all or most of these things before,

other than the "black flamingo" corona virus event.

Many have been

expecting some sort of

"Black Swan" event, but...

Many have been

expecting some sort of

"Black Swan" event, but...

"No one expects the Black Flamingo!" (...a la Monty

Python)

Now, suddenly, some of the problems anticipated for some

years now are getting real, looming right in front of us.

How bad is the corona virus? Predictably, it is worst in

crowded cities. New York is a prime example. That doesn't mean it isn't

spreading everywhere via air travel, or that one will be entirely safe

even out in the countryside. Much depends on proximity to others and

much depends on careful sanitary measures after being where people are,

or when people come to the door and touch your doorbell, doorhandles,

and so on. Keeping 6 feet distance from others is a big help,

apparently. (It figures that the drug store here is closed and the

groceries are out of sanitation products. Earlier I had asked about

masks but they were already sold out. No one has been the least bit

prepared!) Evidently the almost universal wearing of masks in public

has greatly blunted the spread in Korea. Someone has said that if no

protective measures were being put into place, there would be 40

million deaths. That is almost equivalent to the Spanish Flu of

1918-1919. (50 to 80 million dead, from a global population then under

2 billion) Hopefully it is also wildly exaggerated. This virus, while

wildly contagious, has only a 3-4% mortality rate. (A nephew of mine

who works at a hotel in Victoria had it. Apparently he had one very bad

day with a high fever, but he recovered. I didn't ask, but no doubt he

had very good medical care.)

Many expect this epidemic is likely to abate in warmer

months while people are outside in the

sun, and return for winter 2020-2021. The Spanish flu was also worse in

its

second season.

It has been warned by more than one source that with the

present density of the human population, inevitably some disease will

come along that will kill billions of people. This virus is, then, just

a foreshadow of what's to come. Or perhaps it will mutate and become

more lethal itself. Hopefully that's a decade off, maybe even two, but

we have no

guarantees.

On top of the corona virus two other catastrophes are

looming. One is potential - now seemingly inevitable - famine. This too

has

been warned of for some years. We are so used to having an abundance of

food this seemed - still seems - inconceivable to the majority. But

kicking it off rather suddenly, agricultural production globally was

devastated in 2019. (EG, go over some of the video reports of the past

year

and more on youtube by "Ice Age Farmer". Real figures and articles from

credible sources.) For 2020 we again face outrageous predicted (and

already actual) weather, widespread shortages of seed of many types

owing to drops that didn't grow last year, and even shortages of farm

equipment and repair parts owing to the virus related shutdowns, plus

farmers everywhere who are now bankrupt after last year, and so many

farms won't be

planted this year regardless. And each foolish edict from governments

seems exactly calculated to make a bad matter worse. (I'm sure it's not

deliberate, but no kidding: for example even many retail and mail

order garden seed outlets stopped taking orders in March or they are

out of product. Then at the start of April, some US state governments

had also banned sale of "non-essential" items... which included garden

seeds already sitting on store shelves! As scarcities begin to

manifest, food, seeds and the spring planting season are going to

waste. Milk is being poured down the drain at dairy farms owing to

shortage of labor at the dairy plants and in the UK eggs are rotting

simply because of an egg carton shortage. All while purchase quantities

are being limited in the groceries.)

People wanting to get a little ahead on food for whatever

emergencies are now being called "hoarders", and they are being blamed

along with the virus, but if the warehouses weren't getting empty

already the supply lines could handle these things.

The other catastrophe (along with economic collapse) is

financial

collapse. In Y2K, US dollar base currency was something like 850

billion dollars total. Now the US central bank is nonchalantly printing

6 TRILLION dollars almost overnight to prevent collapse? That's over

18,000 $ for every

American man, woman and child, on top of all its other egregious money

printing. Bank of Canada is now also going to purchase assets - in

accord with all the other central banks. As the central banks print

enough money to buy every investable asset, everywhere, from everybody,

and the

price of food keeps going up, how long will confidence in the currency

remain? And how do banks make money with negative interest rates?

And now that I've hit 65 and have received just two

fabulous monthly pension deposits of 1200 $, the Canadian government is

going to give lots of people all over of any age (excluding the

retired) over 2000 $/month "pensions" owing to the virus.

Unless some very different directions are suddenly chosen,

the banks are

going to collapse and the money will hyperinflate and become worthless.

In what order those happen or with what speed I won't try to guess.

But even these may not be all the troubles that we

experience in the coming seasons. Volcanic activity and earthquakes

have seen a steep increase in recent years. Some places are already

suffering from such activities. If a huge volcano like Yellowstone were

to go off in a major eruption, anywhere 100 miles around it could be a

death zone, and with the ash clouds it could disrupt life in much of

the continental USA and probably not leave Canada untouched.

And recent measurements of the ocean water temperatures

and undercutting of ice sheets in Antarctica and Greenland are warning

us that 3 meters or more of sea level rise may come much more rapidly

than any past predictions.

And if the ice is thinned substantially over Antarctica

and

Greenland, they are sure to rise up in compensation as the immense

weight of

the ice is reduced. When they do, other areas will have to subside. So

probably some continental lands and coastlines will sink by still more

than the 3

meters of actual ocean rise. Along with storm surges and tsunamis,

hundreds of millions could be displaced and become internal or migrant

refugees. Maps or satellite images of the world are likely to look

visibly different by the middle of the century.

Through all these causes, the population will be much

reduced - to under three billion, perhaps even under two. In the middle

of what looks like unmitigated

disaster, the silver lining is that if and as much of the façade

of today's

civilization is ripped away, it is only in order that it be replaced

with something much better - a world and society more humane and

equitable, without wars, with a higher quality of life and plenty for

everyone, stable and

sustainable. In order to renovate, some of the old and inferior aspects

of the dwelling must be torn down in advance to make room for the new

and superior construction to come.

Addendum: Here's another aspect to the farm production crisis

that has "cropped up". Plants need phosphate, the "P" of the three main

"N-P-K" fertilizers. It is mined, and it's getting harder to extract.

(What about that is sustainable in the first place?) Last year with the

bad growing season, demand from US farmers was down, and so costly

phosphate mining operations shut down. Now there isn't enough available

in the USA for this year. China, a very large producer, has banned

exports owing to their own needs. It has been said that US farm yields

could be down as much as 50% from low phosphate levels in the soil

alone. (And they banned phosphates in laundry detergents because the

fertilization effect caused algal blooms in a very few streams or

rivers!)

And to bring that down to the practical level:

* I call nitrogen, the "N" of the above main fertilizers, "vitamin P

for plants". Actually that's spelled "Pee". While I wouldn't add it to

growing garden plants, it's the easy and free way to fortify garden

soil in the winter and when and where there's nothing planted.

* Here on the BC north coast where it's deficient in soils, lime

(calcium compounds) can be added as broken or crushed seashells.

* Potassium ("potash" - the "K") compounds can come from wood ashes.

* Other than buying "bone meal" (pricey) I don't know where to get

phosphates.

* Seaweed is a great fertilizer. (Maybe it has phosphates?)

Fertilizers aside, if it would just warm up above near

freezing with frost at night and occasional snow flakes in the cold

rain (this is April?), I could put some of my seedlings out in the

garden. Now I'm wondering if I should concentrate on greens in the

house. Here's some of my indoor gardening work.

Some seedlings. They have become

"leggy" - tall

and scrawny - owing to

Some seedlings. They have become

"leggy" - tall

and scrawny - owing to

insufficient light before I finished the "LED wall garden".

Here are some quinoa seedlings

where the lack

of light earlier really shows.

Here are some quinoa seedlings

where the lack

of light earlier really shows.

(The onion bulbs quickly became rootbound and had to be planted in

the greenhouse. They didn't died of exposure and are growing. Yay!)

The coffee bushes lost a lot of lower leaves owing to having light

coming

only from straight above.

Some readers will remember my old

"LED garden":

a table with

Some readers will remember my old

"LED garden":

a table with

lights underneath (here turned off) and some rolling dollies for

planters.

I started trying to put some shelves on the wall in the corner, with

some real "grow light" panels. It wasn't as wide to the window as

I had been visualizing - not enough room for two columns of shelves.

(Under window are heat pumping radiator pipes.)

I ended up taking the legs off

the 'light

table' and mounting it up high on the wall.

I ended up taking the legs off

the 'light

table' and mounting it up high on the wall.

I can't help but think the 20 LED "light bulbs" (~170 watts) look like

a lot more

light than the three grow lights beneath (84 watts).

The setup by the start of April.

The setup by the start of April.

The kitchen/dining area is pretty cold if it's cold out,

so the curtains help keep heat from the lights in.

(They meet quite nicely, but the left end has a gap

caused by the "U" end of the heat pump pipes. But it's a

couple of degrees warmer inside when the lights are on.)

The cherry tomato on the left in the square pot, left over

from last spring, pollinated with a brush, and draping over

the spinach box on the table, is producing enough for salads.

Here it is open to view with the

curtains open

and the lights out.

Here it is open to view with the

curtains open

and the lights out.

There are now three levels of lights with plants under them.

(More light panels are to be added under the middle shelf.)

Curing

Eye

Floaters with Pineapple?: Bromeliads, Bromelain

Youtube suggested a video by a doctor whose videos I'd

seen before. He was commending a recent study where people ate

pineapple, and their eye floaters disappeared. It wasn't a large enough

sample size to wake up the AMA, but the success ratio, near 100%,

sounded very convincing.

Pineapples are a member of the recently evolved (12 MYA) bromeliad

plant family from South America. It seems the active ingredient in

pineapple is bromelain, which can be extracted from the stems.

I looked that up, and it seems bromelain can dissolve proteins. What

are eye floaters? Dead proteins ("and other debris" - Wikipedia) inside

the vitreous humor in the eyes. So this seems to make sense.

Not being much of a fan of eating pineapple (and

invariably getting cold sores in my mouth), I ordered some bromelain

capsules. (Actually they were "turmeric and bromelain" capsules from

CanadianVitaminStore.ca in Victoria just before they stopped taking

orders owing to unprecedented demand. ...And I thought that was just

garden seed companies!) I'm taking one every day. I (very much) hope to

be able to report good results in 2 or 3 months.

Small Thots

* People always matter more than things. If costly jet liners have to

sit on the ground to slow the spread of the virus, that is better than

having to raise and train new flight crews, and also to replace all the

talent and experience of the passengers who will die.

* OTOH with food already in short supply, the world can't afford

another bad harvest season. If farm labor isn't out there to plant in a

timely manner this spring, as it appears various factors are causing,

the harvests could be even worse than last year.

So, people are at risk in more

ways than one. Where is the "best compromise" line to be drawn?

* US Government: We're closing the border to Mexican migrant workers

because of the corona virus.

US Farmers: We need our trained, willing and able labor force! If we

don't have farm labor, we won't be able to plant, and Americans won't

eat next winter.

(US Government reaction?: Farmers are threatening us again! -- Actually

I think in a brief fit of realism they lifted the

ban. But if the workers have to undergo 14 days quarantine they may be

available pretty late - and will they even come?)

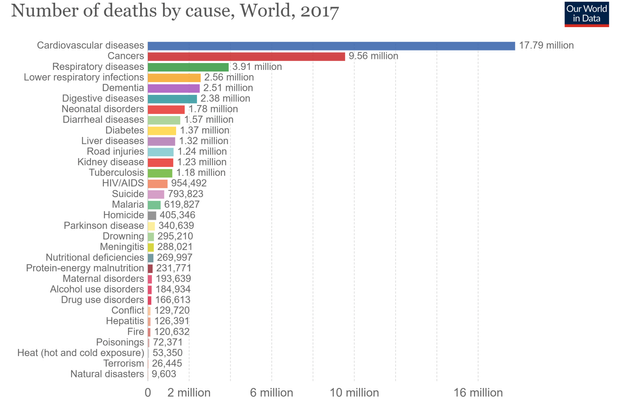

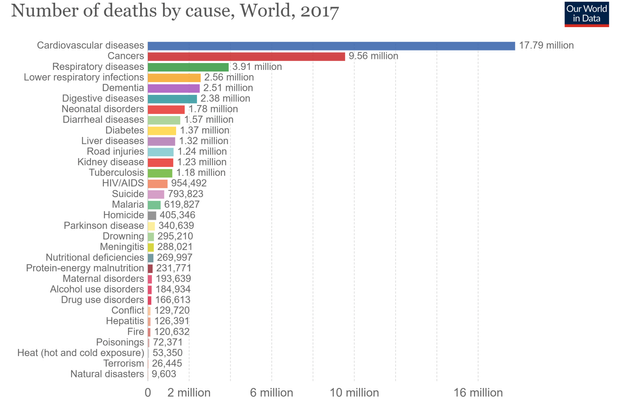

* How might corona virus rate in causes of death in the overall scheme

of things? Respiratory diseases and infections were third and fourth in

2017. Hopefully at worst the virus just might double that, reaching 5

million or

more, or it might be under a million. (300,000 people drown

every year?!?)

* Another addendum to the hair care bits

of recent months: There is a slight feeling of soreness, tenderness,

discomfort (I can't find the right word) of the scalp which I have come

to associate with scalp conditions

improving after having been poor, rather than with it getting worse. I

like to think it happens because previously dormant or damaged hair

follicles are coming back to life. I had

my hair cut very short, almost shaved (she called it "shaved") because

I

had heard it can help with hair loss (the one thing I hadn't tried in

recent years), and also to better see what hair loss I had.

I found the whole top, at the middle, from almost the

front to the back seemed thinner. (the top-back is where I had

previously noticed it in double mirrors.) With 3/4 inch at the front

being just fine, and with my hair

normally combed sideways, I might never have noticed the rest until it

was virtually bald. Without treating it, I might have been headed for

the "Telly Savalas"(sp?) look. After that, I noticed that "discomfort"

of

the scalp at times in that area. So I'm not holding my breath, but I'm

hoping it will come back to

full thickness eventually. After a month or so, it finally occurred to

me to take a couple of pictures. It's less obvious but still visible.

So if it does get noticeably thicker, I'll have "before" as well as

"after" pictures to show it. (Ug! The photos showed more thinner areas

on top than I had been aware of. They looked worse in the straight-on

images than in the mirrors.)

ESD

(Eccentric Silliness Department)

* There is not much silly this month. Swallowed overdose of "serious"

and "viral hysteria". (I thought of two good puns at some points, but I

didn't get them written down... gone. I'm sure they must have been

fantastic!)

* In a video about grid tied plus battery solar in Australia (or was it

New Zealand?) a screen flashed up "5¢ earnt". I laughed for a

moment at this weird spelling. But if money is "spent" why isn't it

"earnt"? Apparently it is in Australia. And why do we use "ed" for all

"regular" past tense verbs anyway? The "e" is often silent. Why is it

(eg) "relayed" and not "relayd"? (Not to be confused in either case

with "relaid".)

* The kitchen table was stacked with debris, largely from 3 months

worth of heat pumping builds and experiments. They being mostly

finished, one day I resolved to clear it off. I didn't get far. I would

take something out to the workshop or the greenhouse and get

sidetracked there on something else. Finally I decided to set myself a

more realistic goal: I cleared off a small but somewhat cluttered end

table in the livingroom instead.

(I did eventually finish clearing the kitchen table, some days later,

bit by bit.)

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric Transport

Lawn Tractor "Rototiller"?

I ordered a kit to turn my lawn tractor electric. 24

volts. Charge with solar panels and run it for free. Regardless, I want

to use it to turn some lawn into a garden plot.

But the message from all sides was that I wouldn't be

ripping

up turf with a silly little lawn tractor. For that I needed to go up to

a garden tractor - and if it was electric it needed a 48 volt motor -

and

"tractor" tread tires instead of "turf savers", which on the lawn

tractor tend to slip even

just going up hills.

But when I wrote the above line, it struck me: ...want to

rip up

turf ..."turf saver" tires. What's wrong with that picture? Then I

thought, in fact, maybe that's the key: instead

of just "tractor" tread tires and making an attachment to plow or till,

I could make a welded steel

rear wheel (or two?) with spikes/special blades or something to

plow/till/harrow the turf simply by driving over it. Maybe something

like diagonal "tractor tread" pieces but hard steel, longer sharp thin

"treads", angled toward the rear. They would dig down almost vertically

into the dirt, then as the tire continued to turn, the "blade" would

twist to almost horizontal at the back as it lifted out of the dirt.

That should really rip up the moss and ground simply by driving over

it. (If you drove fast clods might even be flying into the air behind!)

I would change the

regular tire(s) for the special wheel(s) after driving out to the

intended

plot. The

wheel(s) sure wouldn't slip while plowing when the plow is the wheel!

And they wouldn't tax the motor like dragging a plow. Gosh, I may have

something here!

The rims of the tires are much

smaller than the tire outer diameter. Some old regular rims that

already fit the tractor might be perfect. Instead of tires I could

attach the

ground ripping components to them.

I found a catch: the tractor place had thrown out all

their old rims. "Try the dump." I suppose I could do that. (Nope,

couldn't find any there.)

Hmm... OTOH... I found a youtube video where someone had

sprayed his overgrown gravel driveway with salt water to kill the

grass. Maybe that would be an easier way than mechanically ripping up

the dirt: just spray salt water and kill the grass, moss and weeds a

few times to prepare the soil for planting? Hopefully by the time one

was planting the old stuff would be pretty dead and a new lawn wouldn't

quickly overwhelm all attempts to weed the garden.

Other

"Green"

Electric

Equipment

Projects

Simple

Air

Compression

Heat

Pumping

- or -

How to Heat a Building Almost for Free

The fridge compressor was pretty quiet and I couldn't hear

it with the warm air "computer" fan running on the heat pump radiator

duct. I had put a 15 ohm, 5 watt resistor in series to slow it down,

but it only slowed it a bit. The fan wasn't loud but it was continuous

with an "edge" to it, and it was so cold out I left it running to help

heat whenever I was home to monitor it. By the 8th I noticed that my

tinnitus had gone wild. I was listening to a piercing tone in my ears

at all times, especially when it was quiet. A much quieter fan

arrangement was needed.

I didn't dare run the system when I wasn't there.

On one evening I had caught the air pressure rising and I turned it

off, and on another I noticed the compressor sounded labored. It had

pinned the needle on the air pressure meter. (and in fact bent it. I

had to get a new one.) It must have been well over 250 PSI - maybe 300.

A pipe-clamped plastic-on-copper join was hissing air, which is

probably the only reason

it didn't go even higher. Air compressors compress humidity along with

air, and when it reaches the outside exit, decompresses and cools

perhaps below outdoor temperature, it condenses and the water was

apparently freezing and plugging up the outlet. I opened the tap later

and a tablespoon or more of water came out.

Ideally one would have a little pipe heater at the exit,

perhaps activated by excess pressure, to prevent freezing. Failing

that, something to shut the system off if the air pressure was too

high. Nobody in town had an air pressure switch. I ordered one from

China (3$) which... hopefully... should arrive by summer.

I rather dreaded hooking up the loud Makita compressor. I

had, or did have, a larger fan that was probably quieter, but I

couldn't find it. One advantage however is that the Makita has its own

shutoff at 120 PSI, and so can safely be left to run unattended. I

could leave it running when I went out. And it had more power. I could

close the kitchen door to block the noise and the kitchen would get

warmer instead of colder. It would (surely!) even want a thermostat

which would shut it off part of the time.

(8th) I cut the pieces of plywood to make the compressor enclosure, and

screwed the bottom and three sides together. The last side needed

cutouts for the warm air duct and the fan and the top would go on after

that.

(10th) Where was that fan? I thought I had seen it, but perhaps I thew

it out when I moved? Not finding it anywhere, I went to

Skidegate. Co-op didn't have one (no surprise), Fields didn't have one

("wrong season") but said I could go to Fields.ca and order one, to be

shipped to the store. I picked one out and got to the "checkout", where

I discovered there were shipping charges ("under 50$"). I looked again

at the choices... "oscillating pedestal fan". Maybe that would be

quieter?...

Wait! I already had an "oscillating pedestal fan"! Someone

had given it to

me a few years ago. The pedestal had broken, and the front of the fan

cage had fallen off. But somehow it hadn't got thrown out in my move.

Wasn't it sitting somewhere in the corner of the shop? Sure enough! I

guess I just couldn't see a white fan in 1/2 a cage in the clutter when

I was looking for an open black fan. So I already had one, and plugging

it in and on "low", it proved to be as quiet as a fan is going to get.

I cut a big round hole in the box and mounted it by putting screws on

the outside of the cage rim.

The motor was too fat to mount inside to blow outward, so

once again it blows into the box and from there into the duct rather

than sucking through the duct and blowing outward. Having determined

that all the pipes (and hence the duct) should gradually slope down to

expel moisture, I'm pretty sure that's backward, trying to push warm

air downward instead of pulling it upward. Maybe later I'll figure out

a mounting so it can work the other way around.

(11th) Much of

the day was occupied with making a stand for the

compressor box. (It takes longer when you're planing your own lumber

that you milled.) Like the last arrangement (with the fridge compressor

on a chair) I wanted the compressor highest up with the pipes gently

sloping down all the way so moisture would flow along them and go out

the outdoor end. Otherwise quite a lot builds up and burbles in the

pipe. I put the box on the stand and

then lifted the compressor into it.

(11th) Much of

the day was occupied with making a stand for the

compressor box. (It takes longer when you're planing your own lumber

that you milled.) Like the last arrangement (with the fridge compressor

on a chair) I wanted the compressor highest up with the pipes gently

sloping down all the way so moisture would flow along them and go out

the outdoor end. Otherwise quite a lot builds up and burbles in the

pipe. I put the box on the stand and

then lifted the compressor into it.

Then I laid out my finned pipes and found fittings to

connect them all together, and did some required soldering. There were

too many to simply have a straight line, and anyway I wanted some of

the wall space for a new LED indoor garden setup with adjustable

shelves. So the compressor is at the same end as the outdoor heat

exchanger and the pipes do a U-turn and are double along the wall.

The elbow I wanted to use didn't fit properly into the

"drain" hole in the compressor. It only went in 1/2 a turn and ended up

pointing the exact opposite to the desired direction. I got

a "1/4 inch NPT threading die" and expanded the hole in the compressor

a bit.

(12th) I uncovered a way to make a far higher performance compressor,

by making it with a decompressor to help drive the compression cycle.

Efficient

air heat pumping is possible after all! A COP of 10 started looking

minimal. It might not attain to 100, but that's the direction it's

headed I've written that up down below. But it was still frosting and

snowing and under 5°C this far into March. To have heat in the

meantime before I ran right out of firewood, I still had to get the

Makita compressor connected and pumping heat, even if it was only COP 4

or 5.

One thing I wanted was to

make the 180 degree bend at the

far end as a smooth curve without any sharp corners where the air would

make a hissing sound, as I heard in the first couple of experiments

with a 90 degree pipe bend. From the sound I had suspected a leak at

the elbow.

I wished I had some gallium. I've heard of that from brass

musical instrument makers: heat up the gallium in warm water, pour it

into the tube of the instrument, then dip it in cold water. The gallium

freezes, making the tube into a solid rod which will bend nicely. Then

dip it in warm water again and pour the gallium back into its bottle.

I

hoped the building supply would have a pipe bender. They

didn't, but someone suggested a place that did. I went there and a guy

grinding a piece of metal said he didn't think theirs would work for it

- it

would probably kink. He said to fill the pipe with water, put it in

the freezer, and with frozen ice in it, bend it around something the

diameter I wanted.

I

hoped the building supply would have a pipe bender. They

didn't, but someone suggested a place that did. I went there and a guy

grinding a piece of metal said he didn't think theirs would work for it

- it

would probably kink. He said to fill the pipe with water, put it in

the freezer, and with frozen ice in it, bend it around something the

diameter I wanted.

Brilliant! Exactly what I needed! Why did I have to

think "gallium", expensive and hard to get, when there was water and

ice? Perhaps the instrument makers are afraid of freezing water

splitting the pipes - or just that ice expanding them a bit might

change the

tuning and gallium doesn't expand when it freezes? I cut a block of

wood to

the right shape and drilled a hole in it for one end of the pipe. I

clamped it to a workbench. After I waited long enough and the ice was

solid (2nd try - and the unpressurized ice didn't split the short

pipe), I took the pipe out to the workshop and bent it around

the wood. It worked beautifully! The quite steeply bent soft (annealed)

copper pipe wasn't flattened at all, and had had no tendency to kink.

(Now I know how to make brass instruments... or maybe a shower pipe

more to my liking for the bath, aimed down a little steeper!)

The "U-turn" pipe at the middle

of the radiator

pipes.

The "U-turn" pipe at the middle

of the radiator

pipes.

I used a threaded pipe union on one end so the two

lengths could be handled separately until assembled.

(Egads, the plant grow lights really make the colors weird!)

Hooked up and running.

Hooked up and running.

With the fan that draws instead

of pushing.

With the fan that draws instead

of pushing.

(18th) I finished putting it together, and I tried it out 2 or 3

times. The compressor uses so much power it makes the plant lights

(probably on the same circuit) flicker a bit.

Before the last test I

found a different fan at the refuse transfer station. The blades and

rotation were set to draw air through the motor instead of pushing it

away, so I cut a new piece of plywood (as it was smaller than the other

one) and put it on to blow the air outward instead of inward. (It seems

to blow it out the sides more like a centrifugal fan. Perhaps it can't

get enough air through the duct - one can really feel the air sucking

into the end of the duct.) The results seem puzzling. When it's turned

on, the room temperature seems to rise quickly. That seems really

exciting. Then the rise slows dramatically. After an hour it's gone up

maybe 2 or 2.5°.

It uses around 900 watts (the fan accounting for 65). When

I put in 920 watts of electric heaters, the temperature only rose

somewhere over one degree in an hour. So it would seem the COP is at

least better than 1. But it seems more like 2 than 4 or 5.

(22nd) Similar results. It rose a full degree in 8 minutes, then slowed

down and hit 2.5° in an hour. There are any number of wild

variables:

- outdoor temperature

- temperature of the livingroom: if the livingroom is colder than

the kitchen it definitely heats slower.

- The fridge: when the fridge runs, the room temperature goes up

in a few minutes by about 1/2 a degree. (Amazing!)

- door openings and closings (livingroom door, door to cold

entryway, patio door to outside).

- wind chill.

- sunlight coming through the patio doors

- Whether or not the plant lights are turned on.

(270(?) watts of extra heat)

- trying out different air pressures

- The heat pumping blows air, while the electric radiant

heat doesn't. So the heat pump air was probably more heating all the

walls and furniture. The temperature gain might last longer than from

the radiant heaters. Or not - heating the windows is a losing

proposition.

I

thought about the air flow. I opened the top of the box

and set it slightly askew so it could pull some air through the box as

well as through he duct. Sure enough, the air started blowing out

forward from the fan instead of coming out sideways around the edges.

It must have greatly increased the flow. The compressor heat - both

from its power consumption and from compressing air - must have been

building up in the box instead of blowing into the room.

I

thought about the air flow. I opened the top of the box

and set it slightly askew so it could pull some air through the box as

well as through he duct. Sure enough, the air started blowing out

forward from the fan instead of coming out sideways around the edges.

It must have greatly increased the flow. The compressor heat - both

from its power consumption and from compressing air - must have been

building up in the box instead of blowing into the room.

With the change, the room temperature started rising

rapidly, degree after degree. It soon seemed to be up from 18.2° to

21.0° - notably warmer than the livingroom where I had fallen off

on tending the woodstove and there wasn't much fire. That seemed really

exciting until I realized that the fan was now blowing the warm air

across the room onto the temperature sensor 6 feet away. So that was

really the "warm air out" temperature. That was probably the same

reason as for initially getting better results than later in previous

tests, too. Still, it was blowing a large volume of warm air and could

hardly fail to be raising the room temperature. I opened the crack a

little wider and the air blew even more straight out.

The finned radiator pipes beyond the air duct actually

felt like they were probably above room temperature, too; not really

warm, but not cold either. But the far end was cooler than coming out

of the compressor, so it was radiating.

After the time spent writing this, the air coming across

the room was 22.1° instead of 21.2. That would be because the whole

room was actually warmer by that amount. I turned the noisy thing off.

After a few minutes the temperature read 19.8°. Still, it had

started off at 18.2.

In the evening I ran it again, this time with the

thermometer aside from the warm air stream. Outdoors it was +3°.

Room temperature went up by 1.2° in 45 minutes (from 17.8 to 19.0).

Then I turned it off and put on the 920 watts of electric plug-in

heaters. In 45 minutes they raised the temperature a further .5° to

19.5°. Does that make the COP 1.2 / .5 = 2.4? probably something

like that. That's disappointing, but perhaps some parts of the

compressor are still getting too hot?

It would seem

that the next thing might be to make some

strategic holes in the box - maybe even put short ducts or shrouds

inside - so that the air flow would be directed right across the

compressor elements making and having the heat. A coefficient of

performance of 4 to 5 or more from a regular air compressor just might

be in there!

It would seem

that the next thing might be to make some

strategic holes in the box - maybe even put short ducts or shrouds

inside - so that the air flow would be directed right across the

compressor elements making and having the heat. A coefficient of

performance of 4 to 5 or more from a regular air compressor just might

be in there!

On the 23rd the house was cold and I decided to run it

while I took a bath. I had taken the lid off. This time I put it back

on with a bigger gap at the back. And I realized that was the right

place:

the fan had to draw the air through the box from the back. If I also

put in a baffle or two, it would have to draw it right past the

compressor. The blow from the fan was stronger with the larger gap and

I realized I hadn't had it open wide enough previously.

I checked the initial temperature: 16.7°. After I came

out of the bath I turned off the racket, and checked again: 15.5°!

Well, it might not be super, but it couldn't be cooling instead of

heating! What was that I said about too many variables? The sliding

door was open to the cooler entryway/alcove area. I guess the fan

blowing so much air had caused more cold air to blow in faster from

there. (Okay, that particular variable should have been under my

control. But I didn't notice.) In fact, that door being open was

probably why the house was cooler in the first place. I closed it, and

soon the kitchen was reading 16.6° again.

(24th) I made the air baffles and tried it out during the day, for an

hour. The room went from 17.8° to 20.1, a 2.3° rise. Of course,

it was +7° outside and some sun was breaking through the patio

doors. Then again, the fire was out in the livingroom so it was cooler

than the kitchen. Variables!

Soon after I turned it off, I opened the lid and felt the

components. The compressor heat sink fins and its ouplet pipe's fins

were too hot to rest one's fingers on. Clearly the COP would be much

better if those could be kept cool. That meant finding some way to get

air blowing right across them at a good speed. Since they were inside a

box and under a shroud aimed sideways, that was going to be tricky. On

the 26th I fussed around and cut some pieces. I arranged them so they

would try to push air through the shroud the same way as the motor's

fan. That should be a fair reinforcement.

Outside it was +7° C. The room went from 17.8 quickly

to 17.6. Grr! Then it started to rise, and in an hour it hit 19.3°.

I was disappointed. But it felt warmer to me. Then I realized that in

spite of all the moving air, the dining area on one side seemed warmed

than the kitchen area where the temperature sensor was. I moved it and

soon it was reading 19.8°! Since I don't think the temperature - in

this single "two cubes" space - was stratified before, that was

2.0° degrees warmer than it had been - except the kitchen was only

up 1.5°. I moved it in front of the fan, five feet away, and it

soon read 22° - the warm air out, even at that distance, across the

table. I shut it off and opened the lid. The compressor fins still felt

hot, but I don't think they were as hot as before the baffles. That

might be about the best that can be done without going to great

lengths. If I'm going to go to great lengths, I might as well do so

making a heat pumping air compressor that would really perform and give

far better performance - very high COP.

I then turned on the baseboard heaters that I almost never

use. (8:47 PM) I had checked the ratings: 1250, 500 and 500: 2250 watts

total. In 1/2 an hour temperature went from 19.8 to 21.8; 21.9 or 22.0

on the dining side where the heaters were. That would have been 4°

in an hour, where the heat pump had got about 2°. So perhaps it was

heating around 1125 watts, and using about 900. 1125/900 = 1.25

COP. That was pretty disappointing - and it certainly didn't seem

as good as I had been getting from the fridge compressors. Still, with

the heat I could feel in the cast alloy fins after it was running it

was obvious it wasn't working as well as it ought to be. The cast

cylinder and fins probably didn't even transmit the heat very well, so

the cylinder and piston were running even hotter than anything that

could be felt on the outside, instead of cool.

A compressor made for the job would give far better

results. The potential to change the whole outlook for heating in the

north (and doubtless air conditioning in hot climes) is still epic and

untapped.

I noted

previously that while an electric air compressor seems to use an

amazing amount of power even to blow uncompressed air, a bicycle hand

pump takes virtually no effort until it is actually compressing. I

found one in the garage, so here it is for anyone who hasn't seen how

simple they are. The tapered rubber piston seal presses against the

cylinder wall on the power stroke, but lets air pass on the back stroke.

I noted

previously that while an electric air compressor seems to use an

amazing amount of power even to blow uncompressed air, a bicycle hand

pump takes virtually no effort until it is actually compressing. I

found one in the garage, so here it is for anyone who hasn't seen how

simple they are. The tapered rubber piston seal presses against the

cylinder wall on the power stroke, but lets air pass on the back stroke.

April 4th - Another Test

As I still haven't got this newsletter out... on chilly

April 4th morning I thought to try out the Makita system again, this

time with the large fan again, now that I had made the slot and baffles

in the compressor housing. It looked the same as originally except that

I opened the slot in the lid still wider. And it had the baffles

inside. It seemed to work better.

An improvement to the testing was that the previous day the digital

thermometers I had ordered had arrived. As one might expect, they

didn't seem to entirely agree with each other to .1°, but 3 out of

the 5 were within .2°. The others were "add .3" and "subtract .2" -

at room temperature. Things changed somewhat outdoors at around

+2°. They all read about 1° higher than the old one, so it's

probably the old one that's off. They took those horrible little button

cells instead of (rechargeable) "AA" or "AAA" cells. Those will become

an annoyance. Maybe I'll still look for some others and pay attention

to what batteries they take?

An improvement to the testing was that the previous day the digital

thermometers I had ordered had arrived. As one might expect, they

didn't seem to entirely agree with each other to .1°, but 3 out of

the 5 were within .2°. The others were "add .3" and "subtract .2" -

at room temperature. Things changed somewhat outdoors at around

+2°. They all read about 1° higher than the old one, so it's

probably the old one that's off. They took those horrible little button

cells instead of (rechargeable) "AA" or "AAA" cells. Those will become

an annoyance. Maybe I'll still look for some others and pay attention

to what batteries they take?

After some use, it seemed the amount of disagreement

between units wasn't constant. Perhaps the readings vary a bit

depending on the state of the batteries, among other things?

I started about 11 AM PDT

(9:12 AM actual local time). Outside was +3°. The kitchen was

14.9°. Once it had been running for a bit, the warm air out the

rear slot was 7° warmer than that going in: eg, 22.8° versus

15.8°. As well as saying the 900 watts was making more heat than

the 150 watts of the fridge, that higher rise cuts in half the

potential COP compared to 3° rise from the small fridge

compressors. In addition, the air coming out at the left of the rear

slot was much warmer than that from the right (around 4° warmer

than the incoming), which suggests that the airflow inside the box is

still less than even or optimum. Perhaps I should examine the baffles

carefully. Either that or... have an even bigger, faster fan? Or

another fan inside the box, blowing right on the compressor? In half an

hour the room (and intake air) was up to 16.6° or so. It didn't

seem like much performance.

I discovered that the farther into the housing I put the

sensor (even being sure it wasn't touching or right next to the

compressor), the warmer it was, until it was as high as about 9°

above the incoming air. Yes, definitely the circulation was not the

best in there, and that's partly what was killing the COP. Maximum

potential COP with 10° rise is only 30, where with 3° it's 100.

And the poor efficiency of a regular air compressor of course brought

either of those figures way, way down, but more so with 10°.

I felt the radiator pipe where it came out of the duct

(which was much shorter than the pipe - another inefficiency) and near

the end where it went out the wall into the outdoor heat exchanger. It

definitely got cooler as it went, so it was radiating some small amount

of heat. But it seemed trivial compared to the warm air blowing from

the enclosure.

In an hour the room was up to 17.1°. The kitchen area

wasn't as warm, 16.5°. In spite of an open passage and being open

between the countertop and the upper cupboards (at eye level to the

ceiling), it was taking a while to catch up to the dining area. After

about an hour and a half I turned it off. The room hadn't quite hit

18°.

In about 20 minutes the room had already dropped to

16.6°. At 12:36 I turned on the two portable radiant heaters

totaling 920 watts. In half an hour it was up again to 17.1°. Soon

after that it was 17.5° -- because the fridge had come on. It shut

off again having added .4°. The fridge (itself a heat pump) is a

wild card. Had it been on with the Makita heat pump? Probably, but in

the noise there was no way to hear if it was running. And the plant

grow lights had been on part of the time with the heat pump, but I had

turned them off to take a picture. When was that? I put them back on

for the last 15 minutes of the one hour radiant heating test. Also, I

had put a fire on in the livingroom (long common wall) and it was

substantially warmer, and it had gone up to 4° outside, so the

kitchen should be easier to heat. The the end of an hour, the kitchen

was 17.7°, up 1.1°.

Hmm... about 2.2° rise in an hour with the heat pump,

compared to 1.1° for the radiant heaters of very similar power that

should have had a slightly easier time heating the kitchen. That made

it better than I had thought - maybe 2.5 COP or at least over 2. It

wasn't a stupendous unit that would make the room comfortable in a

short time using just 950 watts of power. And it was very noisy.

Perhaps it's practical except for the noise, but if I want to heat the

house, the workshop, and maybe the garages and the greenhouse as

needed, all very cheaply, then creating air compressors made for heat

pumping is really the key.

Designing a High Performance Heat Pump Air Compressor/Decompressor

(11th) Could there be better ways to make an air compressor

specifically for heat pumping? A couple of readers sent me some little

known or obscure

information on compressed air systems. (Wow, thanks!) Apparently way

back, even before

1900, people were experimenting with complex air compression and

decompression systems. And there was at least one gem, and probably

some more that I didn't get as far as reading and comprehending.

In 1926 someone apparently made a car that needed gasoline

to get up

to 10 MPH, but above that it used a complex system to propel the car on

air alone, and it could get up over 60 MPH - a very high speed at the

time.

It was explained that this wasn't perpetual motion, it was

actually solar energy propelling the car. Acoustics were involved: a

complex mechanism put more air into the pressure tank when the sound

wave created a low pressure point. I didn't follow all of this document

which was

whole chapters out of a book, but I suppose - assuming it actually

worked (I'm not 100% convinced as the inventor didn't disclose all the

details) - that the air came out the end

cooler than ambient after going through three compressed air tanks and

various heating, cooling, compression and decompression cylinders in

the engine, so it was the ambient temperature and pressure of the air

that was being used to drive the car. Wow! (I wonder what happened to

him? Instead of becoming rich and famous, people who have invented such

things usually seem to have disappeared from view soon afterward with

no further news.)

Apparently Nicola Tesla was quite involved in the

technology around 1900. There were compressed air railway locomotives.

I expect they had to start with a charge of compressed air, but by

going through different stages of expansion, compression, heating and

cooling, with three tanks at changing pressures and temperatures,

evidently they got a lot more out of a tank than (eg) Tata Motors

compressed air powered vans in India do today.

Anyway, that info was a couple of chapters from a book.

I'll get around to reading it carefully sometime. Soon!

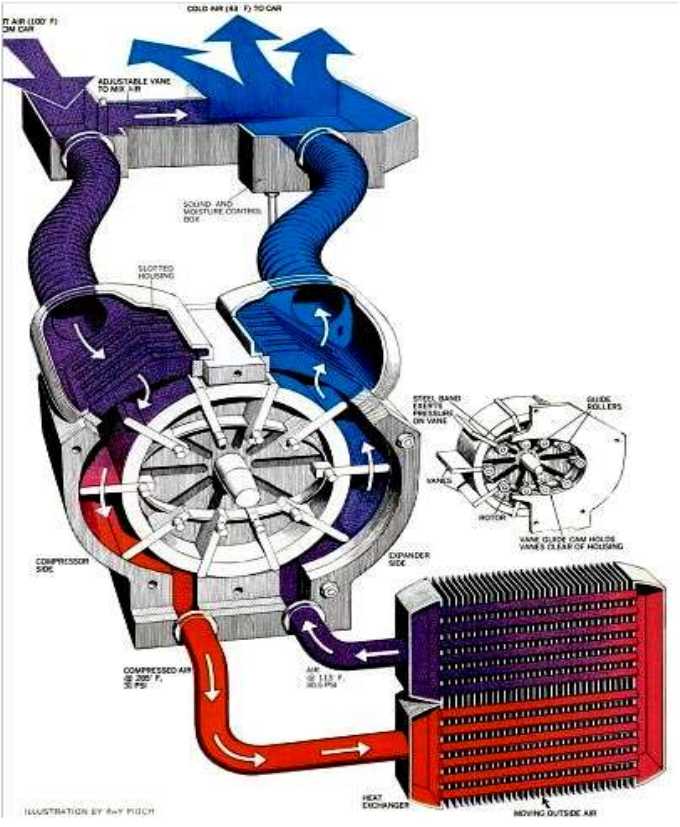

Another

reader sent a document describing "ROVAC", ROtary

Vehicle Air Conditioner from the 1970s. Since it had a heat radiator

(here outside the cab),

it could have been used either for heating or cooling. Of most interest

was the heart of the beast, the rotary compressor itself. It looked

like it would be pretty quiet. In one half, the air was compressed

(and sent to the pressurized radiator). In the other half of the

rotation that air (after cooling in the radiator) was decompressed

again (making it

even cooler than ambient, for the air conditioning).

Another

reader sent a document describing "ROVAC", ROtary

Vehicle Air Conditioner from the 1970s. Since it had a heat radiator

(here outside the cab),

it could have been used either for heating or cooling. Of most interest

was the heart of the beast, the rotary compressor itself. It looked

like it would be pretty quiet. In one half, the air was compressed

(and sent to the pressurized radiator). In the other half of the

rotation that air (after cooling in the radiator) was decompressed

again (making it

even cooler than ambient, for the air conditioning).

I thought that the design seemed needlessly complex and

lossy by friction. Air can be decompressed just by letting it out

through a valve.

Why waste half the rotary compressor mechanism to do it? Was it just to

decompress it gradually and hence quietly?

I looked at it

again in the evening (still 11th) and suddenly realized it had a huge

advantage: The decompressing air helped power the compression! If air

compression was akin to trying to lift up a heavy elevator in a shaft,

the

decompression was a counterweight dropping down on the other side,

balancing it all out. The whole system would use far less energy.

It failed to become commercial. One suspects the

compressor was just too complex mechanically to really work well. It

must have had a lot of friction with all its moving, sliding vanes

having to seal on all sides in the elliptical cylinder. And no one

thought of it potentially for building heating, owing to it being

intended "for vehicles" and "for air conditioning". On a petroleum

vehicle there's no use for heating because most of the energy from the

fuel becomes waste heat anyway, readily available to heat the cab.

Someone on a discussion list had mentioned using

decompressing air to power a turbine to recover compressor energy. This

did it all in one unit! It compressed air, which takes energy, but it

would more freely turn because it was equally decompressing it and

returning much of that energy on the way out. The main work of

compression was

done by the decompression.

There is a loss in the air

itself. Heat pumping isn't magically free. The

pressure is equalized throughout the radiator section, but cold air is

more dense than warm air at the same pressure*. To maintain pressure,

no more molecules of

air can be decompressed than were compressed, so the volume or air to

be decompressed must be less than that being compressed. How much less?

If the air temperature goes from 300°K (when compressed) to

275° (27°C to 2°) through the radiator and outdoor heat

exchanger pipes on a cold day, I expect the cooled air should be

275/300=92% of the volume of the room air at the same pressure. If I

have it right, ignoring incidental losses the compressor motor has to

provide 8% as much energy as an ordinary compressor's motor. So even if

not magically free, heat

pumping could get really cheap!

With a truly efficient air compressor made specifically

for heat pumping, suddenly a

heating COP of 10 looks puny! Suddenly the supposed "inefficiency" of

compressed air heat

pumping is exposed as misinformation, perhaps innocent owing to lack of

imaginative thought, perhaps

perpetuated by corrupt vested interests - or clumsy attempts at

implementation that were considered failures - a century ago until no

one remembered what

was possible. And there are probably more ways to do it - maybe there's

a simpler sort of mechanism - two (or more) connected pistons

compressing and decompressing simultaneously, perhaps? How is it

possible with such promising beginnings and designs dating back to the

late 1800s all this simple yet fantastic technology has been overlooked

and then forgotten for over a century?

It was getting very late. I started trying to think of

simpler ways to do the same thing. I took a clipboard, paper and pencil

into the bath, and then to bed.

(12th) Okay, how about this:

A cylinder has a piston in the middle. The two ends are

separate, and both will hold pressure. One is the compressor end,

similar to other compressors; the other end, instead of being open to

outside air, is the decompressor end.

The center piston may perhaps be screwed in and out as I

proposed last month. or some other mechanism. It pushes air into the

radiator pipe and a one-way

flap prevents the air from returning. The air intake can be a one-way

flap at the same end that only allows external air (indoor air) to come

in from outside the unit. That's pretty standard.

The other end of the cylinder is the decompressor. Here

the

one-way air flaps seem to be backward and I haven't thought of a way to

make them automatic, so they will have to be some sort of activated

valves. It works like this:

On the compression stroke, a valve opens and this cylinder

gets its air from the compressed air radiator pipes. The compressed air

helps

push the piston to compress the next 'batch' of air in the compression

end. In fact, for most of the stroke it will power the piston forward.

When the decompression cylinder has filled with as many molecules of

air as are being compressed, the valve closes. A microcontroller

controls the timing of this based on the desired air pressure. Then in

the last bit the

motor needs to power the piston in, and then only against the pressure difference,

not

all

the

way

from

ambient air pressure. It is going to compress the

same air as any compressor, but using much less power!

At the end of the power stroke, the piston pauses for a

moment. The air inlet valve to the decompression cylinder closes, and

then the air outlet valve opens, releasing the compressed air to the

outdoors. After the air is decompressed the piston does its return

stroke, with both sides of the cylinder open to ambient air pressure.

The return stroke expels the remaining uncompressed cold air from the

decompression piston. The compression side is refilled with new

(indoor) air.

In a short pause at this end the outlet valve is closed

and then the inlet valve is opened to allow more compressed air into

the decompression end. Then the next compression cycle starts. (I am

imagining that somehow the shaft and piston just freely slip to where

the compressor motor needs to cut in and push, toward the end of the

stroke.)

The compressed and hence heated air enters the ducted

radiator pipes, where it radiates away its excess heat ideally down to

room temperature. Still compressed it then goes through the outdoor

heat exchanger, warming the air coming into the house (to feed the

compressor) from outdoors. But the still compressed air, instead of

being directly expelled to the outdoors, is then routed to the

decompression cylinder. It's already cold, perhaps not much above

outdoor temperature, and it gets even colder in the decompression

cylinder before it is exhausted outdoors.

I should think this compressor would be much quieter than

a 'regular' one:

1. The outgoing compressed air pushes the compression cylinder most of

the way to the end even before the motor does any work. That surely has

to be quieter.

2. Because it does far less work, the motor would be much smaller and

hence (presumably) quieter.

3. The planned screw piston moving mechanism should be quieter than a

crank arm type.

4. Large cylinders with long strokes will move a greater volume of air

per stroke, so the speed is much less. That just has to be way quieter.

For a bit I thought maybe if the air had to be routed back

into the house and then out again anyway, the compressor could be

situated outdoors and make its noise (however much or little) out

there. That would actually shorten the piping. But then the warm air

ducts would have to go out through the wall and back in again. That

would make for two big holes through the wall, and the

compressor noise would inevitably come right through those holes anyway.

There may be a more optimum way: Put the compressor

through the wall. Have the compression cylinder indoors, linked by a

push rod in a thin cylinder to the decompression cylinder outside the

wall. Then the outgoing pipes don't have to come back into and out of

the house again to get to the decompression cylinder.

And if that rod in a cylinder were positioned next to the

outgoing air pipe to the outdoor heat exchanger, it would also be in

the same incoming air duct, so there would still be only one hole to

drill through the wall. Of course if the compressor's (small!) motor

was on the outside, it might pay for noise minimization to position the

compressor away from the open air duct with a separate small, sealed

hole for the rod connecting the two halves.

The blower fan will still make noise.

Two concerns will be:

1. elimination of moisture in the pipes, which can't all slope

gently down when they must return to the same compressor/decompressor

unit they started from. A big manual drain (or with an automatic drain

mechanism) water catcher container at the lowest part of the pipes may

be necessary.

2. lubrication of the piston, which being in the middle of two air

cylinders can't have oil sloshing against one side. For this the most

practical solution might be a really long piston with sealing rings at

both ends, whose center is never in the air cylinders, so it can be in

oil. Or it could equally be two separate in-line cylinders with a rod

between them, so that one end of each cylinder is exposed. (That could

fit with the indoor-outdoor, through wall, idea.)

* On Earth the air pressure is ~15 PSI. On Titan it is

~22.5 PSI. But Titan is 1/3 of Earth's temperature, under 95°K

versus 285°. So the air would be 3x denser at same pressure, then

times 1.5x pressure, so Titan's air has 4.5 times as many molecules per

cubic meter as Earth's. In the heat pumping differences are of course

much less extreme: unit percentage differences like 95% or 105%, rather

than 450%.

My

Solar

Power

System

Month of February Log of Solar

Power Generated [and grid power consumed]

(All

times are in PST: clock 48 minutes ahead of sun, not PDT which is an

hour and 48 minutes ahead. DC power output readings - mostly the

kitchen hot

water heater for some months, then just lights - are reset to zero

daily (for just lights, occasionally), while the others are

cumulative.)

Solar: House+DC, Trailer => total KWH [grid power meter

reading(s)@time] Sky conditions

February 29th 09.00,-, 972.49 => 4.33 [55Km,chj; 72475@19:00] At one

point,

the sun came out.

March

1st 10.36, 973.25 => 2.12 [40Km,charging; 72500@19:00] Heavy

overcast, rain: dull.

2nd 14.06, 975.32 => 5.77 [72528@18:30] Mostly SUNNY!

3rd - Power failure and huge windstorm brewing. I decided to

unplug the grid tie inverters and leave them off for now. I don't want

them damaged by power bumps.

4th --

5th -- I turned them back on mid-late PM on the 5th. I

also put a "watch" battery in the house power logger so it wouldn't

lose

readings during power failures (they did again start at 0). Probably

about

3/4 KWH attributed to the 6th was actually collected on the 5th.

6th 05.88, 979.21 => 9.77 KHW [35Km,Chj; 72665@18:30] Sunny (with a

few light

snow

flurries). (Includes ~3/4 KWH from 5th PM.)

7th 11.13, 983.09 => 9.13 [55Km,chj; 72695@18:30] Sunny.

8th 15.68, 986.18 => 7.64 [72715@18:00] Sunny AM, cloudy later.

9th~17.10,~987.05=>2.29 [70Km,chg; ~72750@---] Cloudy. (~estimated

AM of 10th)

10th 21.00, 989.57 =>6.42 [40Km,chg; 72782@18:30]

Clouds, a bit of sun in PM.

11th 23.86, 991.32 =>4.61 [72804@18:30] Cloudy. A bit of sun.

12th 26.39, 992.79 =>4.00 [60Km,charging; 72835@18:30] Clouds &

snow. (Soon after last snowfall at dusk, clear - stars & moon for

whole night.)

13th 31.35, 997.35 => 9.52 [~72915] Sun. Very cold 0°.

Discovered one inverter of 3 at the house wasn't working. Looking at

readings, the house started producing less than the trailer on the

11th. It probably quit then. Everything LOOKED great, the lights were

blinking normally, but it was contributing 0 watts and not loading down

the panels at all. (The manual said if that happened it had probably

failed, to "return it for analysis".) So the house system was running

on 4 panels, the older 250 watt ones, instead of all eight. I swapped 3

new ones and disconnected 2 old ones on another inverter so it had 5.

Apparently I need another inverter... or perhaps two more would be

better, to keep the load on each down.

14th 34.20, 1002.03 => 7.53 [55Km,Chj; 85Km Charging; 72941@18:30]

15th 38.35, 1006.52 => 8.64 [72975@20:00] Sun! 6°. Sometime in

the afternoon I hooked up the two other panels from the DC system to

the grid tie inverter. Now making good use of the two remaining

inverters, with 7 panels of 8 connected. Somehow I was reluctant to

attach the 4th 305 watt panel since that inverter had (?)blown. OTOH

that was the same arrangement as at the trailer - four 305 W panels on

one inverter, still working fine. Instead I hooked the last panel to

the DC system in series to get the PowMr solar input to over 50 volts.

I opened up the dead inverter. With lights blinking normally, it seemed

to me it was probably a blown power transistor. I tested them with a

meter. It was hard to be sure, but they all seemed okay except a couple

I couldn't get at. I couldn't see how to get it the rest of the way

apart. All the screws were out but the board wouldn't slide out. I gave

up and put it back together. Then there were some powerline light

dimmings and I turned the other two inverters off. (Turned trailer

heater down from 500W to 250. Should reduce daily power consumption by

6 KWH/day.)

16th 41.56, 1010.92 => 7.61 [55Km,chj; 73016@19:00] Sunny. (Pattern

is setting in: Frost AM -2° but warmer during day) I didn't turn

the house inverters back on until afternoon and missed some power

collection. I tried the non-functional one again but it still didn't

seem to work. But, but, but... nothing seems to be wrong with it!

17th 46.77, 1015.40 => 9.69 [73033@18:30] Sunny. I had left the

non-working inverter on and in the morning the cooling kept cycling on

as if it was getting too warm, but it was stone cold, no watts output.

It's certainly pretending it's working!

18th 50.69, 1018.25 => 6.77 [55Km,chj; 73063@19:30] Sunny AM, cloudy

PM.

19th 56.23, 1022.62 => 9.91 [73084@20:00] Sunny... and (gasp!)

somewhat warm!

20th 62.10, 1027.39 => 10.64 [85Km,Chj; 73113@19:30] Sunny, rather

warm.

21st 66.52, 1030.63 => 7.66 [50Km,Chj; 73134@19:30] Sun

& clouds.

22d 70.08, 1033.21 => 6.14 [73155@18:30] Clouds &

sun ending with rain.

23rd 74.37, 1036.36 => 7.44 [55Km,chj; 73184@19:30]