Turquoise Energy News #144

covering March

2020 (Posted June 4th 2020 AD / 25 AI - After Internet)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- Attributions - Bugs and More Gardening - Miles Mini Cargo Truck

- OLAHP: Open Loop Air Heat Pumping

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Dimetrodon & Edaphosarus Finally Explained: Aquatic swimmers! -

Gardening and Chickens - Seaweed Shredder? - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Miles Truck: 5:1 Planetary Gear replaces 40 pound transmission, much

improves performance

Other "Green"

Electric Equipment Projects

* Very High COP Open Loop Air Heat Pumping

Electricity Generation

* My Solar Power System: -

Monthly

Solar Production log et cetera - Notes.

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte) - No

Report

* Miles mini cargo truck battery restoration

* Set of 144 Lithium Cylinder Cells (recovery of some cells)

I note that May 1st to 8th marked the 3rd anniversary of

my leaving my deteriorating 1879 coach house in Victoria after 40 years

and moving into my lovely new 1988 house on Haida Gwaii.

Attributions?

When people send me interesting material (generally by

e-mail) that I use or write about, I always wonder whether I should put

their name in the newsletter. I don't mean to slight valuable

contributions and not give credit where it's due. On the other hand,

perhaps some people might not want their names published in what some

might consider to be an unorthodox or unprofessional series of

newsletters. I think (after all these years) I will make it my policy

that if I haven't asked

and no preference has been stated, I will reference first names only.

Bugs and More Gardening

Just a couple

of days into

May the first wave hatched: Blackflies. Midges. Mosquitos. Mostly

blackflies at first. Why was it I wanted warmer weather to work outside

in,

again? They and soon the "no-see-ums" continued to be a big nuisance

for the rest of the month whenever I tried to work outside. But I got

my new garden plot prepared, fenced and planted.

Just a couple

of days into

May the first wave hatched: Blackflies. Midges. Mosquitos. Mostly

blackflies at first. Why was it I wanted warmer weather to work outside

in,

again? They and soon the "no-see-ums" continued to be a big nuisance

for the rest of the month whenever I tried to work outside. But I got

my new garden plot prepared, fenced and planted.

I didn't spend

this whole month on gardening but I pretty

much finished planting everything, and I did (more or less) finish the

chicken sled and moved the little chicks into it. It would appear I

have two roosters and three hens. (Which rooster do I want to keep, the

white leghorn or the brown one?) After a couple of weeks they were out

foraging on the lawn and I move the sled frequently to fresh ground.

(More in In Passing)

I didn't spend

this whole month on gardening but I pretty

much finished planting everything, and I did (more or less) finish the

chicken sled and moved the little chicks into it. It would appear I

have two roosters and three hens. (Which rooster do I want to keep, the

white leghorn or the brown one?) After a couple of weeks they were out

foraging on the lawn and I move the sled frequently to fresh ground.

(More in In Passing)

Miles Mini Cargo Truck

I spent quite

a lot of time on my electric "mini cube van"

truck. In fact, much more than I had expected. It became the month's

project, always looking almost done.

I spent quite

a lot of time on my electric "mini cube van"

truck. In fact, much more than I had expected. It became the month's

project, always looking almost done.

I did my best to restore the batteries, boiled completely

dry by

the truck's insane "Delta-Q" charger running at full blast for two

weeks last winter, which I had plugged in just to top them up and then

forgotten about.

Over a couple of weeks I managed to get 6 of the 12 - 180

amp-hour "golf cart" batteries going again. The other 6 still had at

least one dead cell.

I took my spare 100 amp-hour lithium battery and

two more out of the Sprint to replace them. (The Sprint is now down to

200 amp-hours, 36 volts instead of 300 amp-hours. Those should still

supply sufficient current to run it, so it's not too significant until

I have it driving nicely on the highway and want to go places. Since it

seems that may still be a while, who knows what will develop

battery-wise in the

meantime. Maybe I'll be making the NiMnO-Zn cells by then?) On the

bright side each pair of golf cart batteries weighed about 145 pounds,

and the lithium ones were 30 pounds. So the 3 pairs removed dropped the

weight of the truck by 345 pounds. It would be down 690 pounds if I

replaced

them all - not insignificant!

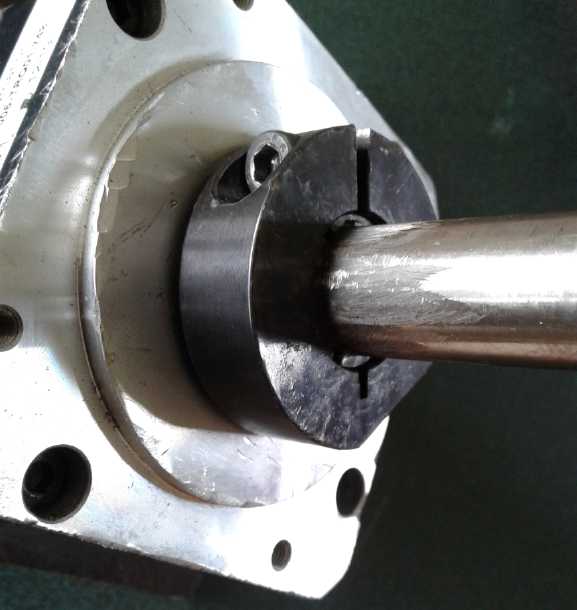

Planetary Gearbox & the

driveshaft, and the old transmission in 3 pieces.

After I had it

running again, I decided to replace the

transmission with the little 5 to 1 planetary gearbox I bought for it

last winter. Surely that would only take a few days? I got the ~42

pound transmission out and and discovered that contrary to my

expectations of it being 6 to 1 speed reduction or higher, it was just

under 2 to 1. (There had been no simple way to determine it when it was

installed.) With the rear differential also providing 2.16 to 1

reduction, the total was only about 4.3 to 1.

After I had it

running again, I decided to replace the

transmission with the little 5 to 1 planetary gearbox I bought for it

last winter. Surely that would only take a few days? I got the ~42

pound transmission out and and discovered that contrary to my

expectations of it being 6 to 1 speed reduction or higher, it was just

under 2 to 1. (There had been no simple way to determine it when it was

installed.) With the rear differential also providing 2.16 to 1

reduction, the total was only about 4.3 to 1.

Now it made sense that

the poor truck didn't have much hill climbing ability. Essentially, it

was geared for running at highway speeds, but was limited by the motor

controller programming to 40 KmPH, so the motor was loafing along and

its available power was little utilized. The planetary gear would have

the motor running 2-1/2 times faster. If I had known, I might have

picked 4 or 3.5 to 1, so it could go faster on the highway without

over-revving the motor than at 5 to 1. It still would have had more

pick-up and hill climbing ability at low speeds than it had before. Now

it was really more optimized for lower speed city driving - and for

carrying cargo. I could also be confident of it climbing even the

steepest hills.

Most of it went well, but there was no such thing as the

right shafts to match everything. I managed to grind down the gearbox's

square key so it fit into the

drive shaft. The shaft from the motor to the gearbox was another story.

I thought I could pound a 3/4 inch threaded rod into the splined motor

tenon and the splines would "notch" the threads so it wouldn't slip.

That seemed to work, but the other end was just slightly small for the

compression fitting on the gearbox and seemingly regardless of anything

including sheet metal sleeves I couldn't get it tight. It always

slipped.

My neighbor Ron gave me a 19mm shaft from some washing

machine. That was the exact right diameter for the compression fitting

on the

gear. I roughed up its slick polished surface at that end to make sure

it wouldn't slip. But it had a spline on the other end that was just a

bit too small for the motor. I worked in a sheet metal sleeve. It

wasn't easy assembling. That lasted 300 yards, then it started

slipping. The splines had simply munched up the sleeve. I pounded in a

thin nail and managed to drive it back into

the garage and up onto the ramps, clunking all the way. I finally

thought that what it needed was two pairs of set screws through the

motor tenon and set against the shaft, two in line and two more 90°

off. I've seen that sort of arrangement to hold shafts in place before,

and the splines would prevent any possible slippage that a smooth shaft

might have. (I just hope that the front end of the shaft being a

millimeter off center doesn't make vibration. That shaft turns 10.8

times as fast as the wheels.)

That last job should have put a quick end to what had

become an annoyingly long saga, but I couldn't do it. After working

eight days under the truck, lifting the heavy assembly in and out in an

awkward position, time after time, I had done something to my shoulder.

It was in agony and I had to stop for some days.

I noticed that (when it wasn't slipping) the truck was

much more responsive. It had no problem going over tree roots in the

driveway, and the front wheels easily climbed up the ramps, where

before it sometimes needed a bit of a run at it.

When I let off the pedal, with the 2.5 times lower gearing

it was like slamming the brakes on, which force was transferred through

the shafts from the motor to the wheels like an "instant stop" power

tool. That showed up the weaknesses and loosened set screws.

The month ended with the truck still not behaving itself

and me sorry I had started this "a few days" project and finally

finding that

the left rear wheel's brake was leaking too badly to want to drive the

truck on the road anyway. Yet another job to do!

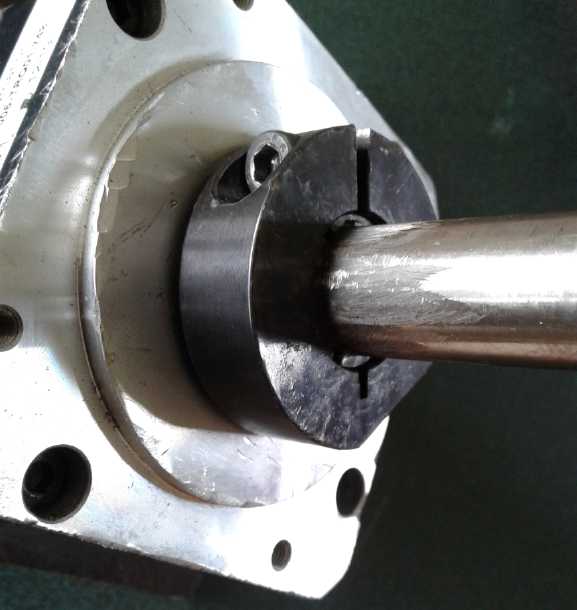

The offending shaft from the motor to the

planetary gearbox.

The offending shaft from the motor to the

planetary gearbox.

(All the space between motor and driveshaft (far left) was formerly

occupied by the inappropriately geared, heavy, fixed reduction

transmission.)

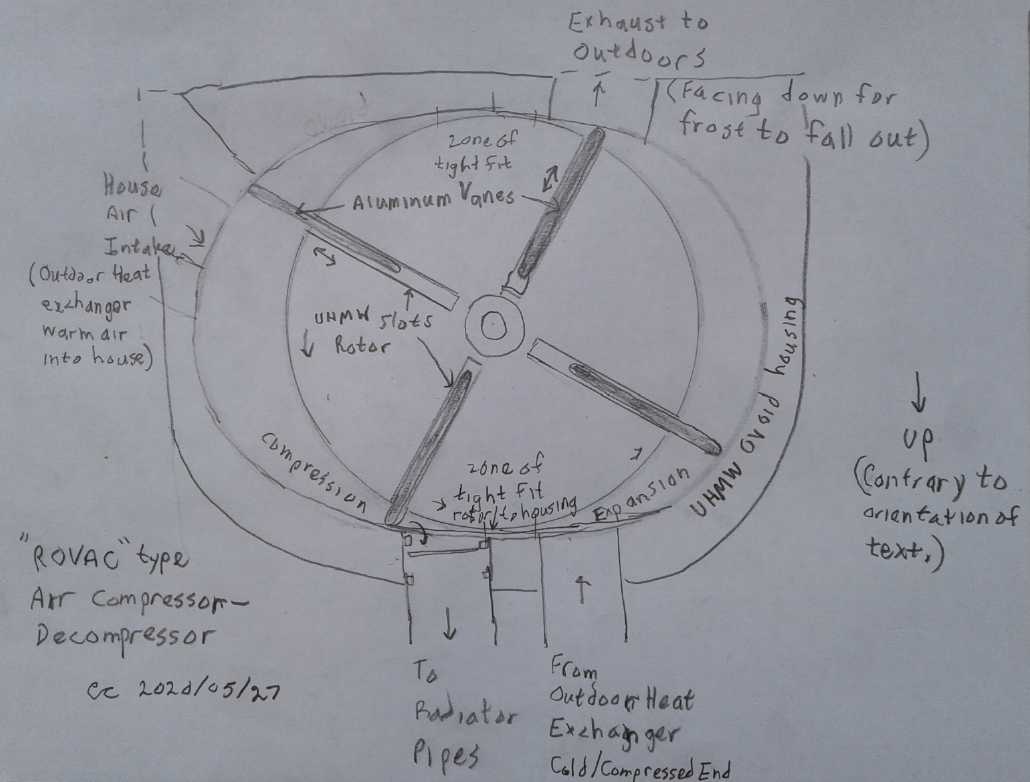

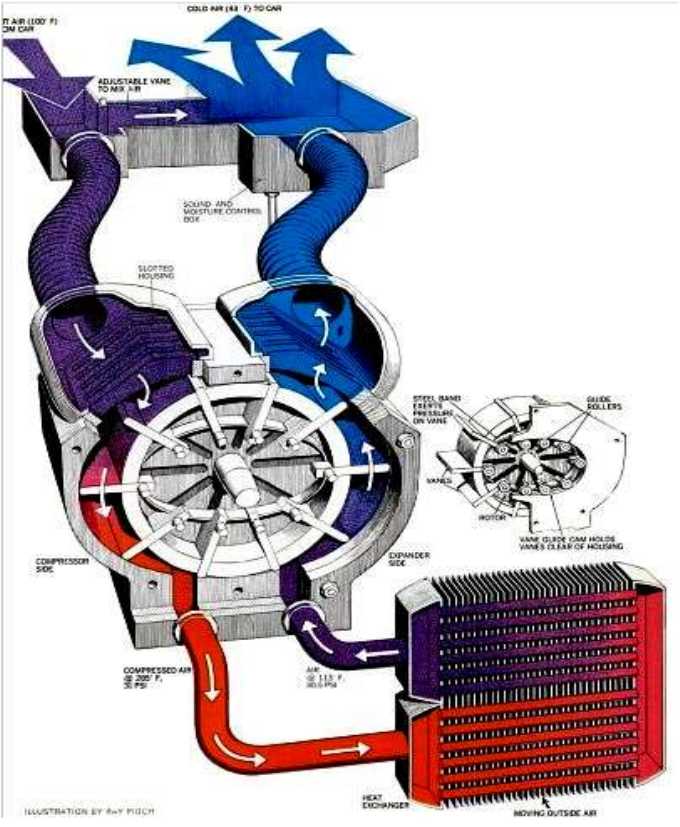

"OLAHP": Open Loop Air Heat Pumping

With the hurt shoulder I went back to studying this

subject. I learned some more and got a better feel for proportions and

what was happening in the processes of compressing, cooling and

decompressing air. In particular, if one pushes twice as much air into

a space, the pressure and the temperature both double, giving

it four times as much energy. This seems obvious once you realize it.

So the amount of air needed to double the energy is thus square root of

2, or 1.414 times as much air.

The book was about air engines, and it pointed out that as

the air cooled it lost the heat energy and pressure, so that by the

time the engine used it, it only had .707 (1 ÷ root 2) of the

energy spent in compressing it. 29.3% was thus wasted. Of course, since

it's the heat we want, we get the 29.3% and if the compressed air is

simply vented after radiating its heat away, much of the other 70.7% is

wasted. (Not quite all since the outdoor heat exchanger cools it below

its starting temperature.) Hence the low COPs obtained with regular air

compressors. Logically using the cooled but still compressed air to

help drive the compression should then roughly triple the COP over

simply venting the compressed air.

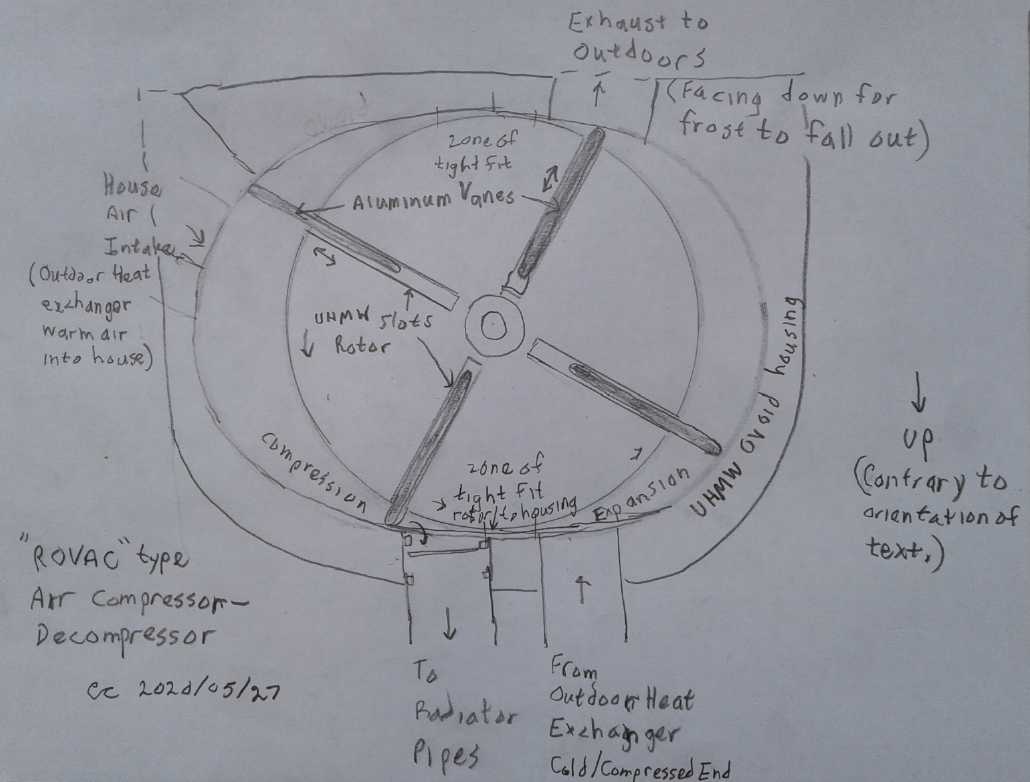

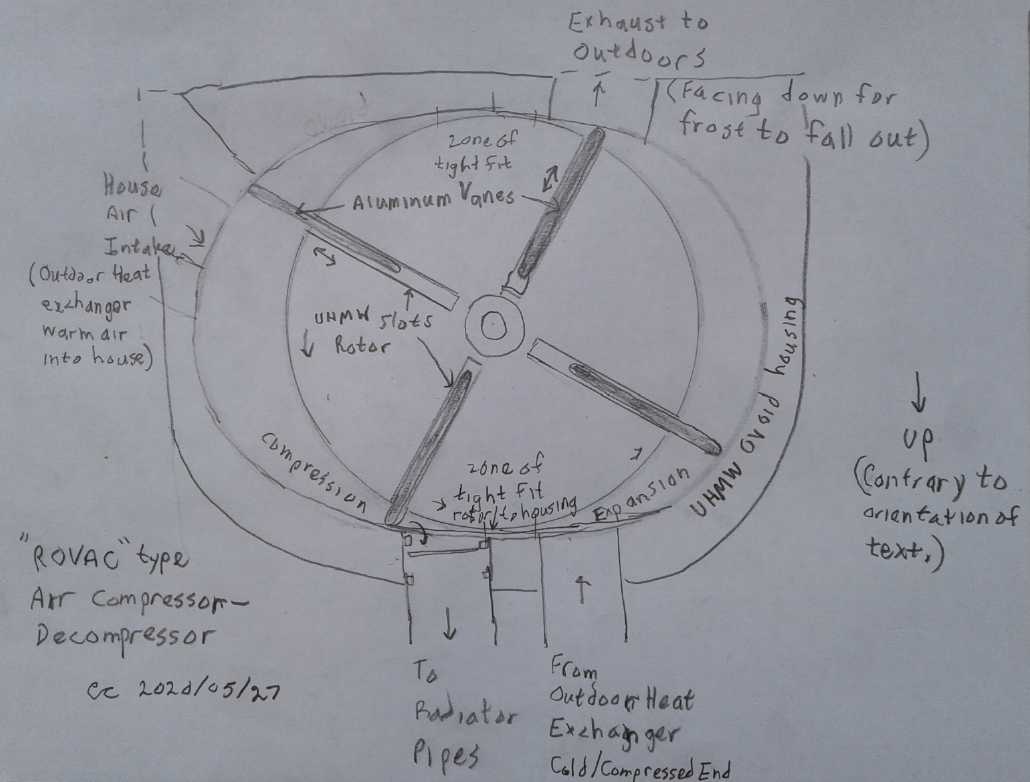

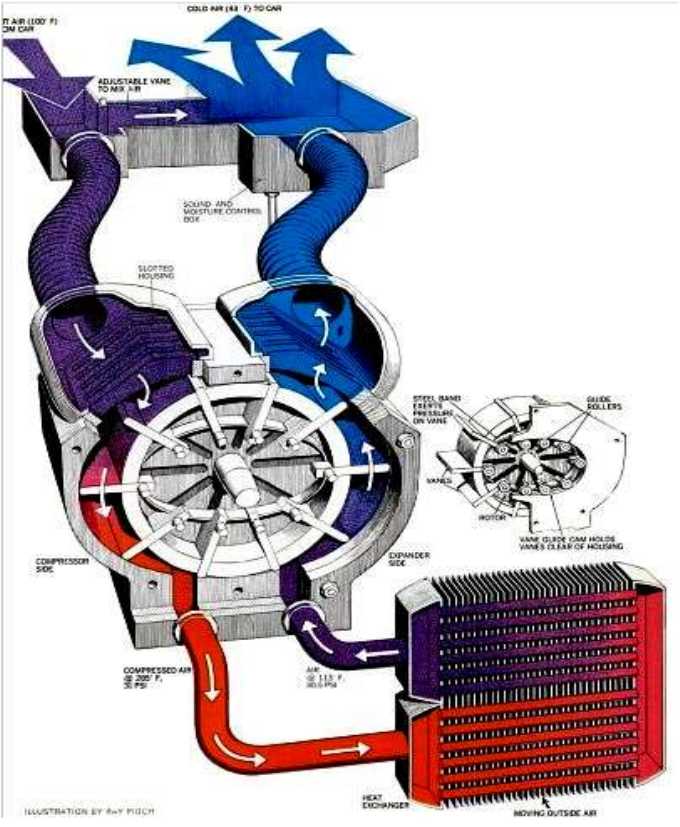

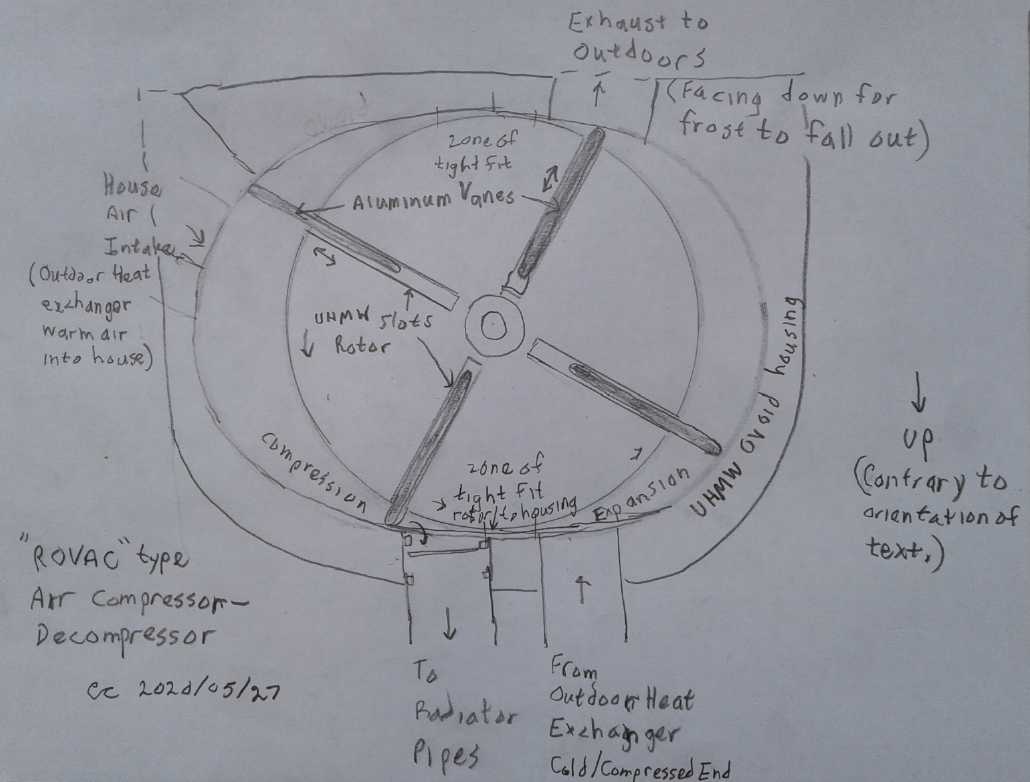

I had come up with some designs for double ended cylinders

with a piston in the middle for compressing and decompressing air, but

thinking of how little friction there is between UHMW-polyethylene and

polished aluminum I started thinking those specific materials could

make for a much simpler and easier to build ROVAC type rotary

compressor-decompressor than the original 1970s model. In principle it

was certainly an elegant concept. Now instead of complex guides and a

steel belt to move the vanes in and out, the unit could simply be spun

at an RPM sufficient to have them slide out by centrifugal force, but

not spinning so fast as to create excess drag against the elliptical

outer rim. It would also probably be reasonably quiet - quieter than a

piston type.

There is a further advantage: As already cold air is

decompressed, moisture in it can freeze out. If the exhaust port of a

slick UHMW housing faces down, the ice crystals or frost will probably

just fall out. It could potentially be arranged that they simply fall

on the ground underneath the unit if it is situated outside. (Any ice

crystals adhering to the aluminum vanes would melt again in the

compression cycle - or simply not freeze.)

Another potential improvement would be to make the inside

of the rim an ovoid (egg) shape rather than a simple ellipse. This

could be beneficial because the cooler decompressing air will have

slightly less volume than that being compressed, also because seemingly

inevitable leakages around the vanes will slightly reduce the

compression and waste a bit of expanding air.

Still another thought was that the original's 10 vanes

were surely overkill. It seemed to work in quarter rotations, so why

not 4 vanes? That would be another substantial simplification in

construction.

My "modern materials" version of a ROVAC air

compressor-decompressor for OLAHP

My "modern materials" version of a ROVAC air

compressor-decompressor for OLAHP

As I didn't find any "ROVAC" type compressors available

(notwithstanding a recent or current research project in India), this

would surely be the better component to develop for "OLAHP" rather than

a piston type.

I could say "When could I possibly find the time to do

this?" as with so many other potential projects, but given the impact

it could have on heating my own house next winter, I just might make

the time for it. To an extent it could be in place of making time to

cut and stack firewood.

Things are looking pretty good going forward here. I think

I'm about as well set up as I can be to weather the economic storm

that's brewing and still pursue the green energy and electric transport

work. Hopefully in June I can get back to the battery development. Then

I really should complete the model ground effect vehicle -

notwithstanding that nobody seems to be going anywhere lately anyway.

(I'm actually thinking about how to put together a full size one later

- extruded styrene foam sheets with polypropylene-epoxy skin

construction - but first, flying the model may point the way to

improvements.)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Dimetrodon &

Edaphosarus Finally Explained: Aquatic swimmers!

Someone commenting on a youtube video (whose name and what

video I can't remember), and noting that Spinosaurus was

evidently aquatic, may have been the first to come up with the "fish

fin" idea, in 2019 or early 2020. It made sense to me, and it fit in

with the similar "sails" of also known-to-be-aquatic Dimetrodon and

Edaphosaurus.

Now, still more new fossils of this aquatic dinosaur with

a "sail" on its

back were recovered this year from the Sahara

desert, which was long ago (and many multiple times) a swampy wetland

full of lakes and rivers. Long bones protruding upward from

the tail vertebrae revealed it had a long, tall, slender tail that was

obviously made for propulsion underwater. (BTW apparently it was indeed

a theropod dinosaur, having hollow theropod bones as well as three

toed

feet. Evidently it doesn't need to walk up on its rear legs like the

others to qualify.)

It would seem it freely went swimming underwater to catch

fish. The "sail" then is of the nature of a "dorsal fin"

such as Ichthyosaurs had, and of course as most fish have always had,

for stability underwater. But

it obviously still walked around on land too to lay eggs, and able to

travel between bodies of water. An Icthyosaur-like

"fish-fin" tail would have hampered walking.

Tadpoles and salamanders have similar tail shapes, albeit

they are so much smaller they probably don't need "fin" bones in the

tail.

This gives us the obvious explanation for the

similarly configured Permian creatures such as Dimetrodon and

Edaphosaurus.

I am still sure they were amphibians and that reptiles had not yet

evolved in the Permian period. (There are no hard-shelled egg shells

from before about the mid Triassic.) However, my idea that the sails

were to provide

extra skin surface to assist primitive amphibian buccal respiration was

wrong or at least secondary.

An examination of a few pictures of Edaphosaurus fossils

clearly shows that somewhat like Spinosaurus they had taller,

thinner swimming tails. Thus again the "sail" is akin to a "dorsal fin"

to provide stability and agility underwater. That they were fins for

swimming explains the similar form in both amphibians and repiles.

In the fossils I looked at of Dimetrodon, the thin tails

didn't seem so tall as those of Edaphosaurus, but a more vertical

form was still still evident.

It is possible that taller tail

bones simply haven't been found because of the generally poor quality

of fossils - mostly just fragments of skeletons and bones - from so

long ago. It

was long believed their tails were very short, until some better

preserved ones were unearthed. As recently as 2019 the idea the much

later (prehistoricly speaking) Spinosaurus had a tall, thin "swimming"

tail wasn't even imagined. Many scientists had concluded it couldn't be

a good swimmer.

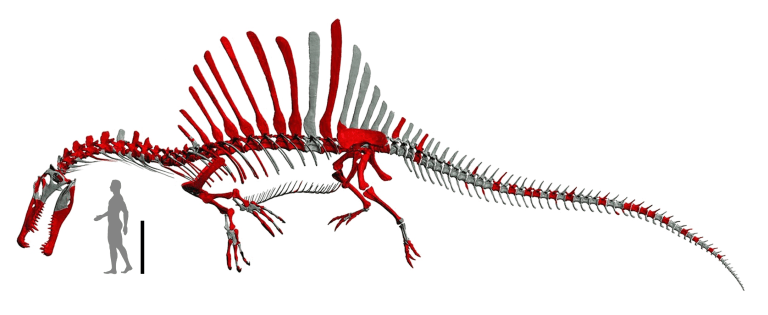

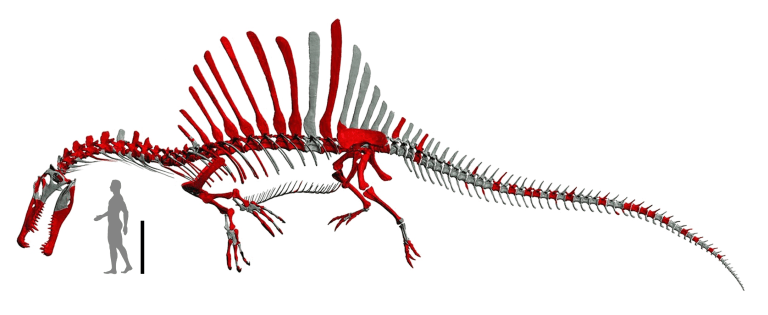

Spinosaurus skeletal reconstruction from

shortly before the "fin" tail bones finding.

Spinosaurus skeletal reconstruction from

shortly before the "fin" tail bones finding.

The red bones are actual findings. The gray parts are anatomical

guesses.

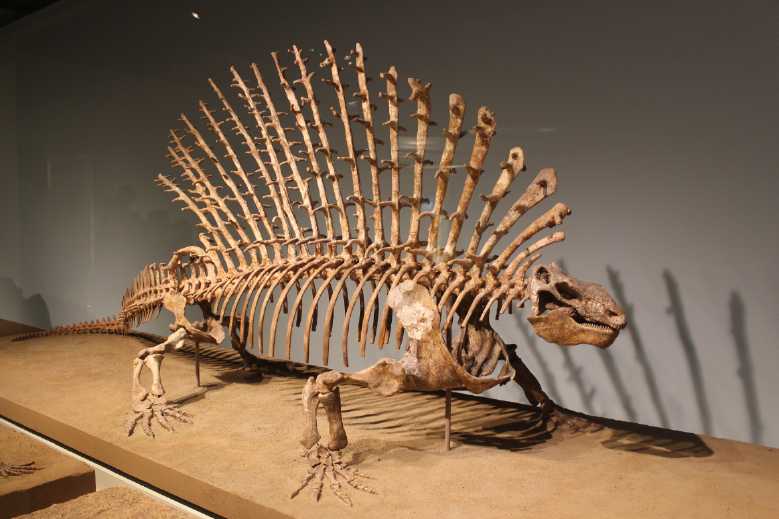

This year's reconstruction shows the long, tall

finned tail.

This year's reconstruction shows the long, tall

finned tail.

(Hmm, not at a very good angle!

BTW there are still plenty of missing bones - no complete skeleton.)

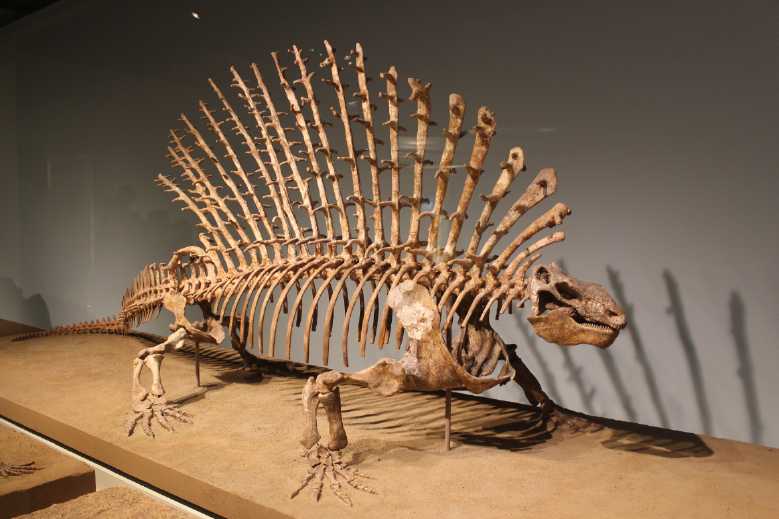

The tall, thin swimming tail of the Edaphosaur

is evident in these skeletal reconstructions.

The tall, thin swimming tail of the Edaphosaur

is evident in these skeletal reconstructions.

The bone protrusions in the "dorsal fin" (upper image) probably

attached muscles related to swimming.

The vertical forms of the tails evident in the skeletons

doesn't carry

over into most artists' renderings of these creatures, in which they

are

usually depicted on dry, open ground, and with a round tail - yet with

the bone

microanatomy saying "aquatic". It shows

how much the artists' renderings depend on

their perceptions of what the animal was, at times even to

ignoring features of the actual skeletons upon which these assumptions

are based.

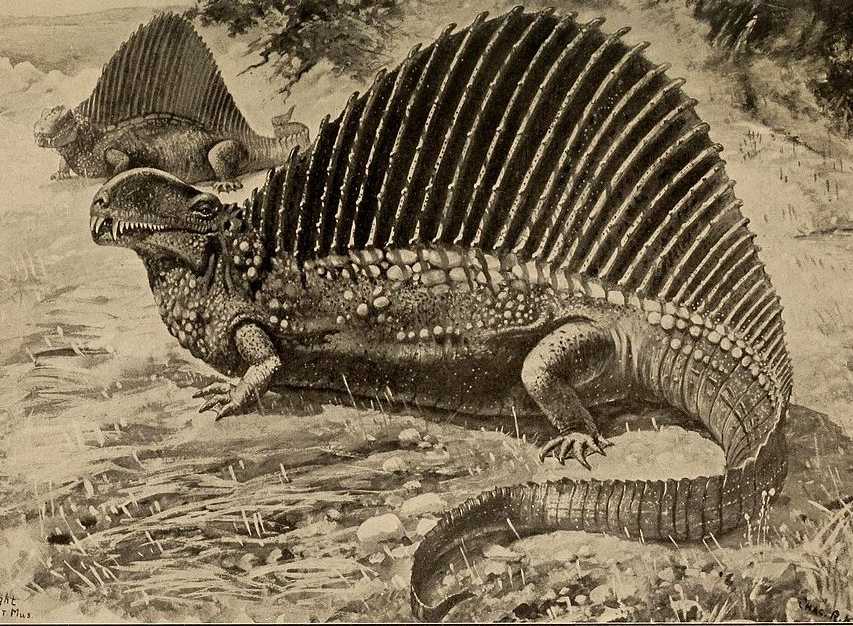

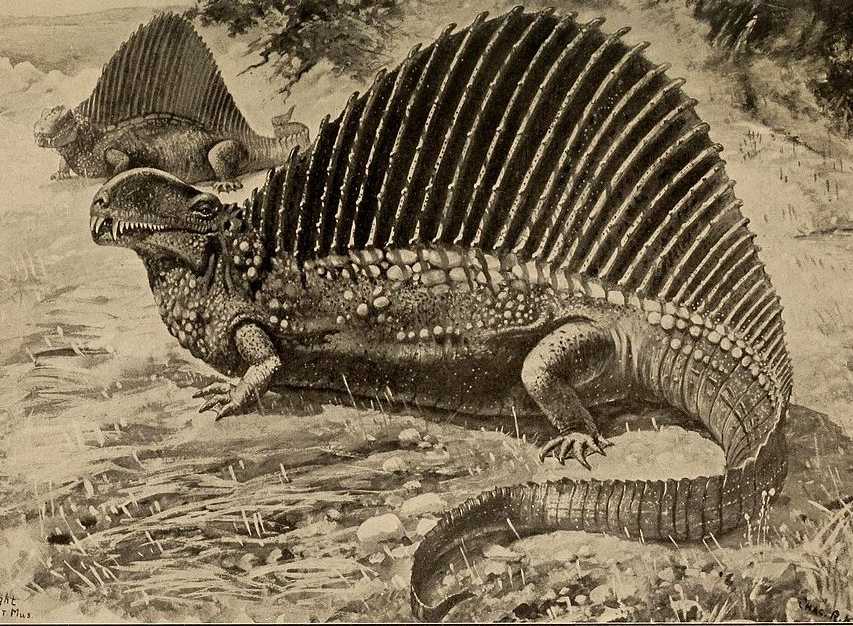

This very early drawing of a Dimetrodon shows a

'swimming', rather alligator-

This very early drawing of a Dimetrodon shows a

'swimming', rather alligator-

like tail form (and webbed feet) much better than more recent ones.

But the belief that it was a land dwelling reptile rather than a large

salamander (based on expectation rather

than evidence) shows through clearly in the "scaly" instead of smooth,

moist

skin texture and especially in the

"skeletal" sail, which actually must have been fleshed out to be

smooth and streamlined in the water.

We may part with thoughts that perhaps Dimetrodon tail fin bones simply

haven't been discovered yet, or the creature being smaller than

gigantic Spinosaurus, perhaps they were made up of cartilage that

didn't fossilize, and also the possibility that Dimetrodon also kicked

its webbed back feet like a frog to help propel it through the water.

It must be remembered that in those distant times, seed

plants had

not yet developed and there would have been little food to base an

advanced dry land ecosystem on. Dry land creatures were initially

limited to

arthropods - scorpions, insects, millipedes and so on - some of which

grew to enormous sizes. The larger ones would die out as seed plants

developed and more advanced animals colonized dry land.

I think that seeing such "giant salamander" creatures in

the flesh, swimming through the warm pools and swamps of that time and

crawling out onto the land, would have been an astonishing sight.

Gardening & Chickens

I soon noted that the wheat, Kamut and Red Fife, had

sprung up. I have high hopes for the Kamut. The kernels are much larger

than the other types so it will be easier to process with a blender,

hair dryer and coffee grinder if I grow enough of

it to actually use, and it is said to have a "corn-like" flavour. (Red

fife: "nutty" flavour.) I didn't like the "Alaska Spelt" because the

seeds came with the husks

still on and they seemed very difficult to peel off. That's probably

okay if you have automated equipment. And I got a fence around the new

plot. Some

deer was already trampling through it repeatedly. Soon enough it would

be eating

things.

Someone was criticizing my gardening methods. I'm doing

what seems to work around here. I decided "no dig" was great for

established beds, but I found last year that if I didn't get the mass

of roots out of the new bed the weeds would completely take it over

again during the winter. And even if I had scratched out the

muskeg-like upper mass without digging out the fern roots a few inches

down, it would have soon overgrown with ferns. Grass mulch is great

except I found it attracts or hides slugs, which keep eating all my

seedlings before they get a chance to grow much. It's disheartening to

see a promising young plant growing well one day is missing its leaves

or is lying loose on the ground separated from its roots the next day.

(And (gasp!) mice ate my 45 $ worth of slug bait!) Most of the

gardening ideas were probably good depending on climate and conditions.

I liked grass mulch in Victoria.

I am thrilled with this new long-thin-blade

shovel!

I am thrilled with this new long-thin-blade

shovel!

One can dug a deep post hole or a trench removing far less dirt than

with a typical wider shovel.

Seven posts and six long boards to help keep them upright

(The cross bracing boards idea came from a youtube gardening video)

I wrapped about 90 feet of a 100 foot roll of 5

foot tall fence wire around it all.

That should keep out our small island deer. (3 staples so far. Must add

a few more!

I got the metal gate from the dump station a year ago. Finally I've

used

it.)

The corn I

grew in cloudy, cool 2019 was a wipeout. The tallest

stalks only grew tassels to barely chest high without a ripe, edible

kernel anywhere by fall. This year I've tried putting plastic over them

to help them start out in early spring, and planted them against the

south wall of the house.

The corn I

grew in cloudy, cool 2019 was a wipeout. The tallest

stalks only grew tassels to barely chest high without a ripe, edible

kernel anywhere by fall. This year I've tried putting plastic over them

to help them start out in early spring, and planted them against the

south wall of the house.

In a store looking for other seeds I saw packages of corn

seeds: "Peaches and Cream Early". It sort of registered, but it wasn't

until later that I thought "Wait a minute! The growing season is too

cool and too short, and I'm

growing regular season corn? There being nothing called "Cool Season

Corn", why on earth should I be trying anything but "Early"? By the

time I went back to that store again it was early May, and the corn

moved out of seedling pots into the ground was 6 inches high. They

still had some of the seeds and I decided to start a flat of the

"Early",

indoors, anyway. Boom! They germinated in a couple of days. Maybe by

the time to put them out I would have made a

decent plastic frame that the wind didn't blow away?

I put them down in the new

plot. The frame I made was good, but the packaged sheet of plastic I

found was so thin it was soon badly ripped up. How long had this

useless package of plastic been sitting around this house? No web site.

No bar

code. Price printed on the package in felt pen... followed by a

"¢" sign! The price gave an idea

of how long it must have been sitting around (and how much everything

has gone up):

The thin plastic "protecting" the corn has

shredded badly.

The thin plastic "protecting" the corn has

shredded badly.

Yes, this was once a typical price for a small item. Early 1970s?

(The "$" sign traditionally goes on the left instead of the

right because "¢" was the more common unit. $0 49¢)

Last month I wrote of my neighbor having

a small

Last month I wrote of my neighbor having

a small

backhoe attachment for his tractor. Remarkable!

I didn't get a picture of him using it in April, but I

saw it sitting at his place in May and took this one.

Penthouse Suite in the chicken sled. (Nesting

box is off to the left at close end.)

Penthouse Suite in the chicken sled. (Nesting

box is off to the left at close end.)

It's not very big. I planned to just have 2 or 3 hens, but having to

buy "unsexed"

chicks you want to get enough to be pretty sure you do get those hens.

Five 7 week old chicks

The whole chicken sled at the end of the month.

I move it frequently. The chickens scratch around

for bugs and weeds, and the chicken feed

consumption seems to have

dropped.

(It's pretty light but I think wheels would be an asset.)

Seaweed Shredder?

Being in an opportune location for it, I had been getting

seaweed from the beach in buckets as garden fertilizer - eel grass,

kelp, some sort of polyps and so on - whatever was there, mostly in the

spring before planting. I mostly took

dried out material lying along some high tide line. I figured it had

mostly the same minerals as the freshly washed in stuff but it was all

shrunk down - both more concentrated and lighter to carry. However, wet

or dry it's like a mass of strings. You can bury it with a shovel, but

then when you rake the ground it catches and you pull big wads of it up

again. So much of it is always on sitting top instead of mixed into the

soil, and being up there it doesn't rot and blend in its nutrients. The

handheld rototiller somewhat chops it up, but it winds around the tines

and clogs it up.

I figured what was needed was some sort of

giant "Vegomatic", maybe 18 inches square, with criss-cross blades and

a plunger, to cut it all into little squares. Probably with long

handles

for leverage to push the stuff through. (Either that or make it to be

hammered down with a maul.) Heavy steel blades.

A doubtless more practical (easier to make) version could

have blades just going one direction. After pushing a clump through,

turn it sideways and do it again to get squares.

Later, on trying to slice through a mat of it with a

sharp, flat end shovel, it was almost impossible - too tough - and so I

don't think the "vegomatic" approach would work well. unless it was very

heavily built.

Perhaps a better thought would be to make the plastic

shredder for

recycling plastic instead. That could equally shred seaweed, and it

would be much finer! It could perhaps even be a "money maker" for

someone who wanted to sell shredded seaweed for organic gardeners. (And

it'd shred plastic as well for remanufacturing! Ooh, aah!)

Oh wait... the seaweed usually has wood bits, sand and

sometimes small rocks in it. That might be a fast way to wear out

plastic shredder blades.

Back to square one!

Small

Thots

* According to "Epic Economist" channel on Youtube, UN world food

program executive director David Beasley has warned that we are facing

the "worst humanitarian crisis since world war two." He says that we

could soon see 300,000 people starve to death every day over a three

month period. This estimate didn't even include any extra owing to

economic

problems caused by the CV19 pandemic. Unfortunately it wasn't clear

whether this was in India, Africa or both, but I've seen ads pleading

for people to send money for food to India.

In the USA, people are lining up for hours - in nice cars

- at food banks. Those arriving too late get nothing. It would seem

shortages, and poverty, are spreading. Perhaps some of those people

would have sold their cars to have grocery money, but the bottom has

dropped out of the used car market.

* In the 1930s Hitler's SA, SS and gestapo murdered and tortured many

people.

One could not turn to authority for justice when the police were the

criminals with sanction from the highest levels. Stalin's Russia was

probably worse. In the 1970s Pinochet overthrew Chile's president and

suspended human rights, and his thugs burned books and

"disappeared" 30,000 people - those in power feared anyone who dared

speak up or who entertained thoughts for improving society. The active

and idealistic young were special targets.

Now in the USA a policeman stuck his knee into an unarmed

man's neck on the ground, suffocating him. Three other police stood by.

Bystanders were

not permitted to give aid. He died. Apparently he had passed a

counterfeit 20 $ bill. There is a lot of counterfeit money in the USA,

so without knowing more of the story, one can't be at all sure he did

it knowingly.

(Interestingly, according to a nightclub owner, both the

victim and the killer had previously worked security at his

establishment, but probably(?) hadn't known each other.)

In any of the above mentioned

states and times, and in many previous complaints about this same

police officer's violence, it would have simply been presumed (by the

authorities) that the officer must have been doing the right thing, and

there would have been no action or investigation. The difference?

This one was caught on video and made it onto the internet. It seemed

clear that the officer and his companions had used entirely

unwarranted force with no compassion or mercy and with utter distain

for human life.

The outrage led to protests and violent uprisings in various cities

across

the nation. Could a brutal dictatorship where such things were routine

establish itself in North America or Europe in this day and age? I

wouldn't say no, but I hope it

would be substantially harder. Even Hermann Goering was taken aback at

the Nuremberg trials when films were shown of concentration camps and

the

suffering caused by the anti-Jewish program he had played such a

leading part in.

* Someone once said something to the effect that riots are

the voice of those who have no voice. The gross inequalities in western

societies are coming home to roost. Someone else has said that rule of

law has been gone for years in "upper" circles. It started with the

"sub prime mortgages" (whose crazy idea?!?) which ended in the 2008

debacle where banks essentially stole something like 1/3 of America's

wealth and real estate from people everywhere. Rule of law didn't

apply to them. No one went to jail or even lost their job, and the

government didn't

make the banks give back or give up all that ill-gotten real estate.

(for which the banks were double paid: they got the mortgage insurance

money plus the houses, with all that had already been paid off the

mortgages.) They simply kept it off the market, often vacant, to

prevent property

prices from dropping back to a natural level. With the above spark now

lawlessness is descending from the rich and powerful to

levels of the general poverty stricken public owing to the pent-up

anger of so many who have lost everything with so little hope of ever

getting anything back.

* Some economist on Youtube in a video titled The Government is

Broke said that the USA owes 20,000,000,000,000 (trillion) dollars.

Then he said that if you went into every country, and into every store

in each country, in all of Europe, and bought everything off every

shelf, you'd have spent about

that amount. Then he said that with all the government's unfunded

obligations (pensions, food stamps, and so on), the actual debt is

around 140 trillion. (And I've heard others give figures in the same

ballpark.) Tax revenues are grossly inadequate. There is no

way to pay it except to inflate the money supply, stealing the value of

everyone's savings. (And in my opinion and that of many others, and

with all the currencies linked together, at this point that's going to

end rather soon in hyperinflation - the devaluation of all fiat

currency

to zero.)

ESD

(Eccentric Silliness Department)

* Hitler's favorite alligator has died in a Moscow zoo, age 84.

* My "pullet surprise" chicks seem to be two roosters and three hens.

Pessimists' Club

* Every silver lining conceals a dark cloud.

* Murphy was an optimist thinking one might get as far as a

demonstration before something went wrong.

* Philosophers may debate whether the glass is "half empty" or "half

full", but whatever it is it's probably stale by now if not utterly

rancid.

* If alcohol, tobacco, cocaine and marijuana are such bad drugs, why do

people

lose so much more sleep over coffee?

* Pronunciation debate settled: With the ambiguity of English spellings

people have long been confused whether the "Celtic" people were

actually called "Kelts" or Selts". The "C" is actually pronounced the

same as in "cycle" or "concert".

* The ones from Wales were probably Welts.

* Pooey, the right front door on my Toyota Echo won't unlock or open!

(Jiggling the lock lever while repeatedly pulling the inside door

handle has quit working.)

SIDE DOORS - DISASSEMBLY AND REPAIR INSTRUCTIONS

1. Unlock door and open it wide.

2. Undo screws from.....

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Miles Electric Truck: New Planetary Gearbox

(I got the batteries working or replaced in the first part of the

month. (See under Electricity Storage) Then I decided I might

as well put in the planetary gear I bought to replace the transmission.

A short, simple project... Ha Ha!)

What am I doing with this little electric cargo truck,

anyway? I haven't had a real use for it so far. The paint is crappy so

it's rusting unless it's taking up a garage, and it's not worth

insuring it at this time.

I just have this

feeling that it'll be much wanted during some of the coming hard times.

Haida Gwaii is at the end of a long, tenuous supply chain.

Infrastructure here was late developing - someone said the paved

highway was only

finished in (?)1979. If gasoline becomes scarce for a while, a few

electric vehicles and bicycles may be the main things running.

But the Nissan Leaf requires so much power to charge that

it may be a problem: no petroleum, no mains power. It's not a question

of charging slower. Its lowest charger wants 1500 watts from a 120 VAC

plugin, and if it can't get it, the charger just chokes and it can't be

charged at all. With over 300 volts potential, and even then a computer

that probably won't recognize if it's been charged by some outside

means, it's not something I care to try and "hack". Realisticly 1500

watts is about eight or nine 305 watt solar

panels in the sun at good angles on a sunny day, all connected in

parallel to feed

(eg) my 2500 watt, 36 VDC to 120 VAC inverter - and perhaps taking days

to charge the car depending on its state, the sun and the time of year.

(November, December and January could well be entirely problematic.)

The truck, especially with three solar panels on the roof,

will charge however fast or slow the sun lets it. I'm pretty sure it

will use less power than the Leaf with the new gearbox (and lighter

batteries). Travel speed being below regular highway speed will improve

economy and (presumably) it won't matter much as long as it can deliver

cargo.

A big discovery from doing the project is that contrary to

my expectations of it having a very large gear reduction, the original

transmission was only 2 to 1. With the differential's reduction that

made only ~4.2 to 1. That explains why the truck seemed to have not a

lot of torque. Its hill climbing ability was poor. Even at 50 KmPH it

would be running the motor at just 2100 RPM - less than half its rated

continuous speed. So it was really geared for highway speeds, but was

limited by

the motor controller programming to 40 KmPH. (If I had realized that, I

might have chosen a 4 to 1 or 3.5 to 1 planetary gear to allow

higher speeds yet still improve torque.)

So dumping that low ratio transmission and changing to the

5 to 1 planetary gearbox (10.8 to 1 total reduction) has an unexpected

effect of greatly improving the performance at the lower speeds for

which the truck was intended and for carrying heavy cargo.

People have asked me if that little 7-1/2 pound planetary

gearbox is big enough. It's sure small and light compared to the

original 42 pound transmission. I reply that the torque and RPM specs

looked good enough. About 200 foot-pounds (admittedly minimal) and 8000

RPM. It won't ever be going half that RPM (and I suspect that will

increase the allowable torque somewhat). A mechanic said planetary

gears are

enormously strong. But in truth I do wonder myself if maybe I shouldn't

have gone up a size.

(14th) Having got the truck running again by battery renewal and by

replacing half of them after the Truck's "Delta-Q" charger boiled them

dry last winter - charging them at its maximum power for around 2

weeks, somehow

in preference to any other building project, I decided to go for

putting in the small planetary gearbox I had bought last December to

replace the doubtless "typical" lossy transmission in the truck. (with

only one gear ratio installed anyway.)

It should be simple, right? Just a little project, a few

days? I drove it back into the garage and the front wheels onto ramps,

which gave me enough room to work under it.

I spent 3 hours getting the ~42 pound transmission out. So

far so good. Then I thought I would probably want the splined front

shaft that fit into the motor shaft's splined tenon, so I spent a

couple more taking it apart and extracting the shaft. But the way it

was made it seemed

problematic to attach anything to the other end.

I recall when I was driving the truck around Victoria,

getting it up to 50 KmPH, it sounded like it was screaming away, and I

assumed the motor had a very high reduction ratio through the

transmission and was headed toward its 10,000 RPM 'intermittent' rated

top speed. (It only went that fast once or twice near the beginning,

when the sensor was malfunctioning - it wouldn't go much above 40 once

it was working right.)

But when I got the transmission off the truck, opened it

and checked, I discovered that the reduction ratio in the transmission

was in fact only ~1.95 to 1!

Last October/November I had figured out that the reduction

ratio of the rear axle differential was 2.16 to 1. That meant the

overall reduction from motor to wheels was just 4.21 to 1! The howling

noise must have been from the transmission gears then, since the Curtis

AC34 motor would only have been going ~2100 RPM at 50 KmPH -- less than

half its 5000 RPM continuous rated speed.

So those who made the truck had really done it "out of

whack". It had poor torque because of the low ratio, and yet it was

artificially limited to 40 KmPH so it couldn't go high speeds. It

wasn't making good use of the motor's power capacity by loafing it

along. I had assumed 5 to 1 would be lowering the reduction ratio, but

it was in fact multiplying it by 2.5! Still, with the new ratio of 10.8

to 1 the motor will stay under 5000 RPM until almost 50 KmPH, and I

expect it will really handle to 60 KmPH (~6480 RPM), if not 70 KmPH,

fine.

The truck should perform much better. Greater torque will

be wanted if it's carrying a heavy cargo. And there's a hill in Queen

Charlotte I doubt it would have gone up even empty. I wasn't confident

of getting back up my driveway, either, especially if the batteries

were low after a trip. With the greater reduction it should have no

problems.

I'm glad I have the Curtis motor controller programmer and

should be able to change the parameters to match what I'm doing.

So... I had the transmission out. The jobs to complete the

project are:

1. Match the planetary gear output shaft to the drive shaft. They fit

so closely that I think it will be a matter of 'cludjing' it by

grinding/filing the square key on the gear so it fits tightly into the

splines in the driveshaft and won't slip. (Without the grinding the

shaft with the key won't quite go in.) This should be pretty easy.

2. Mount the planetary gear in position for those shafts to match up

and connect. This will be harder.

3. Make a very straight shaft that fits the motor on one end and the

planetary gear input on the other, of the length to connect them. This

will be tricky.

Driveshaft with "missing"

splines - a place to put in a shaft key

(15th) I started in on the

first job and decided it was just a bit too

loose and needed a thin sleeve. I cut a thin piece of nickel-brass, but

it was too thick. I hammered it thinner, annealed it with a torch and

did it again. This time it almost went. Now I hammered them together,

wincing somewhat at the stress I must be putting on the bearings.

(15th) I started in on the

first job and decided it was just a bit too

loose and needed a thin sleeve. I cut a thin piece of nickel-brass, but

it was too thick. I hammered it thinner, annealed it with a torch and

did it again. This time it almost went. Now I hammered them together,

wincing somewhat at the stress I must be putting on the bearings.

The driveshaft and planetary gearbox,

The driveshaft and planetary gearbox,

and the original transmission in pieces.

I found a piece of 3/16" steel to use for a mounting plate

and cut it to size using up a zip disk on the angle grinder. Now it

needed bolt and mounting holes cut out for the planetary gearbox, and

bolt holes to attach it to the frame of the truck. (The truck had a

couple of existing mounting holes with welded on nuts.) And the hard

part would be bending this plate steel piece 90° into an "L" across

a 7 inch width. The transmission had a rubber mounting attached to that

to lessen vibration and noise. Did I need that? I decided not to bother

and see how it was.

There was an 80mm mounting ring on the gear. The hole

should fit around that. But there was a catch: with the gear and the

driveshaft together, an 80mm hole wouldn't fit over the far end

assembly of the driveshaft to slide down to the gear end. I put a fat

slot through the plate for the thin part of the shaft to pass through

to the 80mm circle.

(16th) The shaft from the motor to the gear turns 10.8 times faster

than the wheels, with 1/10.8 times as much torque. 250 foot-pounds at

the wheels would be just 23 on the motor shaft. My original thought had

been to use a piece of 7/8" 4140 HTSR steel machine shaft. But it had

to fit at both ends. A 3/4" bolt seemed to almost jam into the splined

motor tenon. That gave me the idea that if I had 3/4" threaded rod,

which was softer than

the bolt, I could pound it in and it probably wouldn't slip. That was

also the right size for the input tenon on the gearbox. I didn't have

any 3/4" rod and the hardware store was still closed, but that was what

it needed.

I also dropped by the refuse transfer station. There were

a couple of adjustable brackets. I didn't need a bracket, but I did

want one of the pieces of 2" x 3" angle iron they contained. I

could attach it to the truck, then my steel plate to that, and not have

to bend the steel plate. That would simplify things.

(17th) Cutting the welded parts off the angle iron piece used up a

couple of zip disks. With a couple of bolt holes it seemed to fit well

on the truck.

Then I went to my neighbor's and bummed a piece of 3/4"

threaded rod off him. He had one, in the last space of what he said was

the very last place we could look. Then I spent an hour there showing

him how to use a machine lathe to resurface his trailer brake drums.

(Someone had given a great machine lathe to him in exchange for work,

but he had never used one.) I was pleased to be able to pay him back in

this way for preparing up my garden plot and for the piece of rod.

Cutting the

80mm circle from the plate steel with a jigsaw was

(as expected) tedious and time consuming. I had carefully laid out the

holes for the four bolts through the gear face, but the oil from the

cutting wiped the markings off. I put the gear in the hole and used a

pencil through the actual holes to mark for the bolts. They were all

substantially off even when I drilled a size larger, and I had to file

them all to ovals in one direction or another to get the bolts through.

Cutting the

80mm circle from the plate steel with a jigsaw was

(as expected) tedious and time consuming. I had carefully laid out the

holes for the four bolts through the gear face, but the oil from the

cutting wiped the markings off. I put the gear in the hole and used a

pencil through the actual holes to mark for the bolts. They were all

substantially off even when I drilled a size larger, and I had to file

them all to ovals in one direction or another to get the bolts through.

(18th) I noticed

that on the driveshaft's tenon a couple of the splines were omitted,

making notable slots. I trimmed down the key for the gear shaft until

it fit into one of these. Then I pounded it back together again. I

don't think that can slip. Then, needing a smaller plate (owing to

finding the angle iron piece), I cut it smaller. (Yet another zip disk!)

I

cut the threaded rod to length. Then I pounded it into

the tenon on the motor shaft. As I had hoped, the splines in the tenon

cut little notches into the threads in the threaded rod to hold it from

slipping.

I

cut the threaded rod to length. Then I pounded it into

the tenon on the motor shaft. As I had hoped, the splines in the tenon

cut little notches into the threads in the threaded rod to hold it from

slipping.

After a few other nuisances

and readjustments, I put

everything together under the truck. The other end of the threaded rod

at the gearbox, from which I had expected no trouble, just slipped. It

was a "taper lock" type compression fitting with no solid splines or

keyslot. I tightened the screw more and more, finally hammering on the

Allen key to tighten it more, but it didn't fix it. The key was

starting to strip and the socket bolt in the gear might be no better.

(The truck did now actually move, but it was still slipping. I probably

could have driven it off the ramps, but that would only mean I'd have

to work under it right at ground level.) I guess the threaded rod was

just a bit too small diameter and would need a sleeve. Let's see:

socket, 19mm. shaft, 3/4" or 18.35mm. But probably even smaller being

threaded. Ug!

So the truck didn't run on the 18th. It also needed some

rubber vibration stoppers on the bolts holding the gearbox plate and

angle bracket to the truck, but I'd have been happy to drive it around

the driveway once even with the plate rattling.

Planetary gear mounted with plate and

angle iron

Planetary gear mounted with plate and

angle iron

(shafts are as later configured - still later thick rubber

washers were

added to the mounting bolts for cushioning)

(19th) I disconnected the (3/4" threaded) motor shaft from the

planetary gearbox. I made a sleeve but couldn't get it in. I pounded it

thinner and still couldn't. Then I took a file to the threads and filed

them down a bit. Then I managed to get it started, and I used a hammer

on the other side of the gearbox to work the shaft in to its proper

depth. Then I tightened up the locking screw and clamp. I got in the

truck. It still just slipped. I put visegrips on the allen key and

really torqued it in. (It's only a poor little ~m5 socket bolt!) This

time it seemed to hold. I backed the truck off the ramps and out the

garage door, but as soon as it hit a bump it started slipping again,

and wouldn't move. I crawled under and torqued it down until the allen

key stripped. It still slipped. This gearbox is supposed to be rated

for that sort of torque - it wasn't even that much. If it's that hard

to get the grip with a compression fitting, why would it not have a key

or splines? Now what? I pushed the truck back into the garage and

closed the door.

After a bit I thought that maybe it could get a better

grip if the clamp wasn't fully closed up to the gearbox. I pried the

clamp away. Now I could turn the motor & shaft by hand - it slipped

freely. Then I realized what was happening: the clamp was tightening up

fully until its slot was closed. Then of course it could tighten no

more, no matter how hard I turned the screw. In spite of my sleeve, the

shaft was still a little too small.

By this time, after days of crawling under the truck, I

was feeling somewhat crippled. My left shoulder and upper arm ached and

burst into pain if I moved it the wrong way.

(20th) I tried inserting thin steel shims, but the results didn't

inspire confidence. And after backing the truck out of the garage, I

stepped on the electron pedal a bit harder and it started slipping and

spinning again. I pushed it back into the garage. In fact, once again

it was so loose I could turn it and slip it by hand.

My Neighbor Ron

had a washing machine shaft whose end he said looked similar to the

original splined shaft. On close inspection, verified by a micrometer,

it wasn't quite the same. However the smooth end was 19mm - the exact

proper size for the compression-fit gearbox end. Now during disassembly

the pounded-on driveshaft slipped off of the gearbox shaft just by

gravity!

I came up with a new plan. I could cut the original

splined shaft off and machine it so there was a short 19mm shaft end

and fit the splines into the motor splines, and use a piece of the

smooth 19mm shaft at the gearbox end. (I would rough up the surface to

help ensure it didn't slip.) Connecting those I would need a piece of

steel pipe machined to 19mm I.D. at the ends. This could have a couple

of pins or bolts with nuts, right through the pipe and shaft at both

ends to ensure they couldn't slip. It would be a three piece shaft.

Since it seemed I couldn't stop the threaded 'ready rod' from slipping

at the gearbox,

this sounded like a more workable plan, and I would feel more confident

having the original splined shaft end in the motor.

Hmm... Maybe instead of a pipe I should buy a 3/4" keyed

shaft coupler. (If I need to I can bore that out to 19mm on the lathe.)

(How *do* they cut those inside keyslots, anyway? ...And inside

splines?)

(21th) I got the threaded

rod out of the motor shaft by screwing a nut

all the way on until it was turning against the motor shaft socket. I

tried the splined shaft, even knowing it wasn't the right spline. It

seemed to fit solidly enough anyway... just trying to turn it by hand.

I cut

the shaft to length.

(21th) I got the threaded

rod out of the motor shaft by screwing a nut

all the way on until it was turning against the motor shaft socket. I

tried the splined shaft, even knowing it wasn't the right spline. It

seemed to fit solidly enough anyway... just trying to turn it by hand.

I cut

the shaft to length.

After I roughed the polished shaft up to help keep

the gearbox end from slipping, I had to pound the 19mm shaft into the

19mm opening intended for that size. I did up the clamp bolt quite

tight, but without hammering on the allen key. Hopefully that

wouldn't slip! Eventually I got the whole thing together and tried it.

The splined shaft in the motor tenon just spun freely. So much for my

"by hand" assessment and wishful thinking that it wouldn't. I could

either try with a sleeve or go for the two-coupled-shafts idea. The

sleeve was of course the easier and worth a try. But I was really

getting tired of this whole exercise in frustration. If I

could just go into some store and buy a shaft coupler I'd probably have

gone for that. But I didn't want to order one and then wait for it to

come.

And I didn't want to spend time turning shafts and milling keyslots.

(But it turned out that might have been faster!)

This project was supposed to be done days ago! It was

getting frustrating. At 10 PM I cut and curled up a sleeve piece and by

11 I had managed to get it in place. It formed to the shape of the

splines and it worked. I drove the truck a foot forward and back in the

garage, and I pressed a little extra on the pedal and it didn't slip.

But to what press on the pedal, and for how long? I didn't really trust

it farther than I could throw it.

(22nd) I drove around the driveway in the morning. The truck was very

responsive to the pedal, and I didn't have to push it half so far to

get acceleration from a stop. It easily climbed over a tree root on a

rise that had stopped it when I was testing the batteries (albeit with

poor battery power). It was definitely an improvement. So I decided to

drive across the acreage and back. I got around back and there was an

obstacle. I took my foot off the pedal and the sudden very heavy

braking torque

(multiplied by 2.5 times!) must have bent or squished the sleeve. Once

again it just spun. (Great!

Now it was blocking the drive at the narrowest point.)

The lacerated sleeve let the shaft & socket

just slip.

The lacerated sleeve let the shaft & socket

just slip.

(Somehow not obvious: many of those indents have or are actual air

gaps.)

I decided to try

driving some bit of metal into the join to see if I could get it to

move again. I found a nail. It wouldn't pound in very far and only got

me 40 feet before it fell out. I found & pounded in a couple of

smaller ones, and managed to drive it back into the garage - and even

back up onto the ramps - clunking all the way. (But with the new 5 to 1

planetary gear it went easily up onto the ramps, whereas before it was

dicey whether it had the 'oompf' to go up them without taking a run at

it.)

Another idea had occurred to me in this: sometimes shaft

sockets have setscrews put in at right angles to grip the shaft inside.

The tenon seemed plenty thick to hold set screws. I could put in four,

two in line and two more at 90° to that. Since the shaft inside was

splined (and the contact points could be ground down a bit),

the setscrews wouldn't just slip around the shaft. This of course meant

taking it apart again. And then getting underneath to drill and tap the

holes. I was really getting sick of this project. At least the

compression joint, and the driveshaft, didn't seem to be

slipping or clunking.

(24th) I not only had other things I had to do, but my arm hurt too

much to consider crawling under the truck again for a few days. All -

presumably - within an ace of having it running well. Now 10 days of a

project I had hoped might take 3 or 4.

I spent two nights in agony with no sleeping position

where my upper arm wasn't in pain. I reached over with my other arm and

started feeling out the sore spots around the back of the "ball and

socket" shoulder joint. Finding sore spots and pressing on them a bit,

moving the finger around a little, seems to do wonders for many soft

tissue injuries. The next three nights got better.

(27th) I unthinkingly lifted the heavy end of the chicken sled and my

arm exploded into pain again. It didn't seem to last, but I thought I

might not be ready yet to resume. The day was fine. That evening I

drilled just one of the holes, but that night I woke up with my arm in

considerable pain again. Was it the day's stresses, or did I just twist

the wrong way sleeping? Yikes! (I thought this was about a truck

project?)

(28th) I

decided I just had to finish this up. Over the course of the

day I drilled and tapped the four holes and put in set screws. (I hung

a visegrips and on that an actual vise, to keep the shaft from spinning

while I worked. I had to turn the tap with a crescent wrench because

the motor body was in the way for the regular 2-ended tapping handle.)

One at a

time and I gave myself lots of rests, but my shoulder was aching again

before I was finished. I put two set screws in each position to hold

the shaft along the length of the coupling. As the shaft was splined

and it couldn't slip if the set screws simply pressed a couple of

splines between three other splines (although mismatched) on the other

side, I decided to put the set screws 30° apart instead of 90°.

That way when there was pressure on them it would be more on both sets

instead of each set alternately.

(28th) I

decided I just had to finish this up. Over the course of the

day I drilled and tapped the four holes and put in set screws. (I hung

a visegrips and on that an actual vise, to keep the shaft from spinning

while I worked. I had to turn the tap with a crescent wrench because

the motor body was in the way for the regular 2-ended tapping handle.)

One at a

time and I gave myself lots of rests, but my shoulder was aching again

before I was finished. I put two set screws in each position to hold

the shaft along the length of the coupling. As the shaft was splined

and it couldn't slip if the set screws simply pressed a couple of

splines between three other splines (although mismatched) on the other

side, I decided to put the set screws 30° apart instead of 90°.

That way when there was pressure on them it would be more on both sets

instead of each set alternately.

Front shaft from motor to planetary gearbox

Front shaft from motor to planetary gearbox

(29th) I pulled off the drive shaft and put four set screws in it, too.

That gave me much more confidence than the sheet metal sleeve,

especially seeing one had already failed. I put it all together and,

after tightening the set screws on the motor a couple of times (splines

finding the grooves, I assume), it worked and I drove it around the

driveway a bit.

But there was a lot of vibration. I attribute that mainly

to the motor-gearbox shaft being just 1mm(?) off-center at the motor

end, since it

seemed too rapid to be the drive shaft. That would wobble the gearbox

and motor slightly. I was rather surprised it was so noticeable as to

be serious. I also had everything bolted solidly together. I conceive

that putting some rubber bumpers in the mountings (as the original

transmission had) would decouple those vibrations from the body of the

truck. Hopefully that would make it acceptable. I might also try a

sleeve plus the setscrews, to put the shaft more centered. But my

experience with sleeves in this project has also been poor.

(30th) I got a chunk of high pressure line - thick rubber tube with a

3/8" hole - and cut some short chunks for cushioned spacers. I got some

longer bolts and put them in with a spacer on each side of the angle

plate. When I started the truck, the brake pedal went to the floor. The

left rear brake was leaking so badly that the reservoir, which had been

full when I started the project, was empty. I refilled it. (I know it

was the left rear because there was brake fluid all over the garage

floor there. The vibration seemed a little better, but after a couple

of trips around the driveway somehow the set screws seemed to have come

loose and the shaft started slipping again at the motor. It was just

outside the garage door. I closed it and left it. I am officially

discouraged with this project.

(31st) I pushed the truck back into the garage. I shall have to return

to the charge sometime later.

(June 2nd/3rd) I tightened the setscrews and drove a small distance,

just out of the garage and back in. It seemed fine going that far, but

I left the key turned on, and the brake leak aided by the vacuum assist

pump left brake fluid all around the wheel and the master cylinder

empty again. (Yuk!)

Well, not an Earth-shaking project, but nonetheless

illuminating. The infinitely variable torque converter (100% efficient

at higher speeds) would of course be more interesting, but I wasn't

about to try it on the truck. And perhaps I've learned a little toward

making that a better unit. (At least I can see that any "off center" or

"off balance" is a problem big enough to merit scrutiny and not brush

it off during construction.)

It's too bad I don't have some "before" measurements both

of torque or hill climbing ability and of range. Those might have

revealed how the performance has improved, and whether and how much the

driving range has improved. But even if I had chosen target hills for

later comparison, they would have been in Victoria, and even if I had

done any driving range tests with which I might now compare

transmission efficiency, they would be changed with some new batteries

and 345

pounds of battery weight removed.

Other

"Green" Electric Equipment Projects

Simple

Air

Compression

Heat Pumping

- or -

How to Heat a Building Almost for Free

Further Reading

I continued my readings of the PDF books sent me by Bruce and Marc.

The units in Bruce's old book were in BTUs, degrees

Farenheit,

feet and pounds instead

of metric units. That kept reminding me of the

original "Murphy's Law" pages in about 1971 which read (roughly):

"Formulae will always be given in the most obscure, least practical

units. For example, a velocity might be given as 'Furlongs per

Fortnight'."

On reading a bit more theory I did gain a bit further

understanding and feel for air compression and heating. It also

occurred

to me that there isn't anything that's a constant in the process: as

the air goes

through the system the pressure, temperature, volume, density and

quantity of air are

all changing at the same time. The "textbook" formulas I'd

first been reading implicitly assumed temperature was

held constant by compressing so slowly that the heat all dissipated --

so I was looking for what happened to the temperature and they were

claiming implicitly by omission "no change"! No wonder it all seemed

impossible! This book made a lot of how these incomplete

'textbook' formulae explains why 'modern engineers don't understand

pneumatics' and think compressing air is "inefficient".

Also, because of cooling the air in the outdoor heat

exchanger on the way out, and the additional cooling created by its

own final decompression, the outgoing air was likely to to have a bit

less

energy yet for compressing the next batch of incoming air, and it was

likely to have 'freeze-up' problems with water.

It turned out the compressed air locomotives effectively

used something akin to an "outdoor heat exchanger". In

their case, when

the air was decompressed though the cylinder, it also cooled, and so it

was being expelled at ambient pressure and colder than the outdoor air.

Instead of simply venting it outside, this cold air was expelled into

another

tank, and outdoor air going through heat exchange

pipes inside that tank was used

to warm it up again. As it warmed it its pressure rose, so it became

compressed again, and the locomotives had a second cylinder and piston

that used this secondarily compressed air, which also helped drive it.

That was how

they got 30% more "bang for the buck" out of the air than (eg, per the

claims) Tata

motors compressed air minivans in India. (OTOH in India the occupants

appreciate the 'free' air conditioning this cooled air provides, and

I'm not sure it doesn't in fact use some of these tricks itself.) Then

3-stage locomotives were made in Britain that got about 55% more than

single stage.

All these locomotives were used mostly in mining - I

assume

because they vented no noxious fumes into confined underground spaces.

They would have been replaced with electric units. Not to mention

that noxious exhaust is of little immediate concern in open pit

mining, so

fossil fuel machines have been used there.

Then the reading got down to "Maxwell's Demon". This was

that if there was some little imp (or nanomachinery, or ???) that could

open a door to let individual molecules of air through, it could

selectively let the fastest moving ones pass from left to right and

build up temperature or pressure

"for free" in the right hand compartment.

Then they went on to jets, pulsejets and sound waves to

accomplish this amazing feat with pressure resonances. It sounded too

much like "perpetual motion" to me. Being quite

dubious that such a phenomenon could be made to actually work by

material human

means without consuming more energy than it made, I decided to leave

that for others. (And that meant I didn't

have to read the last 2/3 of the book! Maybe I'm just lazy?) If someone

can get it to work, or has done so, more power to them!

I went on to other documents sent by Marc and by Bruce. In

one there was an article written by one Nicola Tesla in 1900 and

published in a magazine, where he was trying to get energy out of

ambient energies in the environment. One hears various rumors of

various things he had been trying to do, but cutting through to the

reality shows he didn't always have some vision beyond the rest of us.

He wasn't the first or the last inventor to look for a

"perpetual motion" machine, and the more complicated an convoluted

something gets, the more promising it sounds and the harder it is to

see that it won't work. And then there's the plain impractical: Yes, a

thermocouple with its ends at different temperatures will produce

power, but things in the same vicinity tend to be at similar

temperatures and his ideas for miles long thermocouples weren't going

to do much for solving energy needs. Even my woodstove TEG tests showed

only a few watts of electricity, from a hot woodstove. (Doubtless they

could be markedly improved. So what - a few tens of watts?)

He had at this point already contributed the AC motor and

generator systems that gave us the power grids everywhere. Around this

time he also came up with the ingenious bladeless "Tesla Turbine". The

future

still held his radio work which was successfully utilized by Marconi to

send the first radio signal across the Atlantic (and then the first

vital use: the sending of distress signals from the sinking Titanic in

1912). And then there's his atmospheric electricity work and the rumors

of his pulling high power out of thin air by electromagnetic means. At

least for this latter we now know there is actually a High Energy (HE

ray) radiation band 10 octaves above gamma rays as a plausible source

for the energy. Did he really tap it to light a bank of light bulbs as

rumor has it, or was T H Moray the first to do so 2 or 3 decades later?

I ran across more mentions of the ROVAC system. It keeps getting

referenced as a theoretical type of air conditioning without it seeming

to have actually been constructed except as a prototype decades ago.

One article said it "needed more research". The author

wanted to be able to ascertain characteristics of operation under

various conditions. I think it needs development before such research

can be undertaken. It's already great in principle. One can't start

measuring real world parameters too far without actually having a

working unit.

Another said it was great in principle but it needed

materials that could work without lubrication. We now have those

materials. Polished aluminum and UHMW can rub against each other with

virtually no friction, without lubrication.

I had started to come up with a double ended piston based

compressor-decompressor, but the more I looked the better the ROVAC one

looked, imagining said materials could make for a simple design and

construction of the vanes and the sealing between the vanes, the rotor

and the outer housing.

ROVAC Rotary Compressor?

(25th) I was again looking into how to make a good

compressor-decompressor for heat pumping, and came up with some fair

ideas. But I kept thinking of the ROVAC.

The idea was abandoned technology from the 1970s, but the date in

Bruce's PDF article was 2016-2017. Evidently a new ROVAC was an R &

D project being done in India, where vehicle air conditioning is vital

more than a luxury. There were names and places given, and it

occurred to me that I might actually find that they were available. It

might be worth a considerable price if I found such a thing could

simply be purchased. And if it was now available, it would probably be

better than anything an amateur could design and make. And it might

well make the Open Loop Air Heat Pumping (OLAHP?) project into a

working house heating system before next winter.

The idea was abandoned technology from the 1970s, but the date in

Bruce's PDF article was 2016-2017. Evidently a new ROVAC was an R &

D project being done in India, where vehicle air conditioning is vital

more than a luxury. There were names and places given, and it

occurred to me that I might actually find that they were available. It

might be worth a considerable price if I found such a thing could

simply be purchased. And if it was now available, it would probably be

better than anything an amateur could design and make. And it might

well make the Open Loop Air Heat Pumping (OLAHP?) project into a

working house heating system before next winter.

On line I found mentions of the ROVAC as a theoretical

possibility from the 1980s and 1990s saying in effect that it deserved

and needed "more research" with newer materials. I emailed the lead

author of the Indian paper to see what the status might be. But there

had been no new drawings in that, just the 1970s one, and even as I

wrote I started feeling that probably nothing had come of it. I got no

reply.

Assuming the ROVAC

compressor isn't available - is still in development or hasn't/didn't

become commercial - is there a way to make something similar but

mechanically simpler than the 1970s build?

TITLE Dr. Edwards' air conditioner: ROVAC update

AUTHOR(S) Lindsley, E. F.

PUB. DATE September 1983

SOURCE Popular Science;Sep83, Vol. 223 Issue 3, p64

SOURCE TYPE Periodical

DOC. TYPE Article

ABSTRACT

The article provides information on the revamped Rotary-Vane Air Cycle

(ROVAC) invention of Thomas Edwards in Florida. It states that Edward's

rotary-vane compressor produces more than 15 Btu of cooling per watt

with few working parts and little mechanical friction. However, the

requirement for larger air compressors and the unavailability of

materials that can work without lubrication had hindered its

manufacturing and marketing processes.

My Take on this tidbit:

* 15 BTUs/hour = 4.4 watts. 4.4 W / 1 W = COP 4.4. Temperature details

of where this figure applies aren't given, but given any sort of

typical conditions, that sort of cooling

power per watt input is surely an excellent figure. Employing an

outdoor heat exchanger for doing house heating, it is bound to be

considerably higher.

* I am surprised and impressed that it claims the ROVAC

compressor-decompressor was considered "low friction". I was expecting

serious friction losses. (Then again, would the friction be worse than

piston rings rubbing on a cylinder?)

* So, what materials can work without lubrication? Plastics. More

especially, UHMW interfacing with polished aluminum. UHMW is as

slippery as teflon, and aluminum carries away any bit of heat generated

by plastic and metal sliding across each other. We could have polished

aluminum

fins and a UHMW cylinder and rotor, or vise versa. (In the 1970s we

were still using paper grocery bags and plywood-veneer stereo cabinets.

Whether UHMW existed then or not, plastics were less familiar and

common.)

It seemed to me that if one

used flat pieces of slippery UHMW-polyethylene for the vanes, one could

pick an RPM at which they would slide out of their slots by centrifugal

force until they were "solidly" set against the inside of the outer rim

of the elliptical housing to prevent air escape, but without too much

pressure causing excessive friction. The vanes would also have to fit

pretty snugly against the sides, also without much friction. It would

be required that that the rim, and the sides, be accurately machined

and highly polished aluminum to have the vanes go by with minimum

friction and also low compressed air leakage.

I also conceive that rather than having high pressure with