Turquoise Energy News #147

covering

August

2020 (Posted September 21st 2020 AD / 25 AI - After Internet)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- CAT, HAT and "T-Plug" Connectors - Low Voltage Shocks?!? -

Winston/Thundersky Batteries: Tight strapping and Failures? - The New

Lithium-Ion 3.7V Batteries - Culvert Hydro? - A 12V LED Light

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Cure for COVID19 (Why does nobody seem to care?) - Telling

Fake News from Real News -

Gardening and Chickens - Small Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Miles Mini Cargo Truck - Shaft works but vibrates

* Ground Effect Vehicle - working on the model: Sigh, battery &

Control issues!

Other "Green"

Electric Equipment Projects

* "T-Plug-12V" Connector System Replaces "CAT-12V" System

Electricity Generation

* My Solar Power System: -

Monthly

Solar Production log et cetera - Notes.

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte) - No

Report

Here again is a "filler

inner" issue without a lot happening in the way of sustainable

electrical projects. For now, there just seems to be too much else that

needs doing. Of course winter will make it hard to do things outdoors.

And I look forward to quieter times for myself, but they may be a year

or two off.

I got half a wall for my

outbuilding done except for throwing up some of the plywood, which is a

pretty small part of it. (We won't mention the door and window, much

less insulation, wiring and gyproc.) I figure I've done about 3/7ths of

the way around

now. The concrete footing is done for the next section. This is this

month's biggest excuse for not getting a lot of renewable energy

projects going.

East half of the South wall of

the outbuilding

as of Sept. 1.

East half of the South wall of

the outbuilding

as of Sept. 1.

(Somebody noted "No cripples around the window?" But it's

post and beam, so even the outside walls aren't bearing walls.)

The 'model airplane' batteries for the model ground effect

vehicle arrived on the 4th. On the 11th I belatedly ordered "6S balance

chargers" for them. (Why have I been farting around with separate

chargers? Oh well. Why am I farting around with lithiums instead of

getting my own nickel-manganate-zinc cells going?)

CAT, HAT and "T-Plug" Connectors

In doing that I ran across something called "T-Plugs", or

"Deans Connectors". The batteries had a "T-Socket" as the main load

connector for however many zillion

amps to the propeller motor. They looked very similar to my own "HAT

36V"

connectors. In fact, a HAT plug actually fit into the T-socket on the

battery and the lamp worked.

It occurred to me that these ready-made, "dime-a-dozen"

connectors would be perfect for 'off-grid' wiring. I trust that they

would be fine for 15 or 20 amp circuits, 40 and even 60 amps being

mentioned for model aircraft use. Since 12 volts is by far the most

common, I decided to drop CAT 12V connectors in favor of them. Then I

would modify HAT 36V connectors so they wouldn't fit. But I might use

the T-plug pins in the new 36V design and just change the spacing by a

couple of millimeters.

It seems to me that it's a big advantage from a market

acceptance point of view to use existing suitable connectors, even if

they've only been used for model aircraft in the past. And while in

that application any voltages may be connected, their use in 12 volt

off grid wiring would soon so eclipse model use that they would come to

be viewed as "for 12 volts" connectors, and replace those silly

"cigarette lighter" connectors.

It's also a big advantage, at least for starting up

production, not to have to make the connection

blades. I will probably make nylon shells for safety anyway, as the

usual ones

they come with are cheap low temperature plastic. (Or perhaps I can

find some

better quality ones?) The blades push out of their shells easily enough

from the back.

Very few HAT plugs, sockets and wall

receptacles have ever been made. All that will be lost by modifying

them to not fit with T-plugs is a little design time.

So I ordered 50 pairs of the basic T-Plugs and

T-Sockets on the 11th, the same day I found them, and a few plugs with

wire-enclosing shells for appliance cords and extension cords.

Additional

"T-Plug-12V" components to be created:

* wall receptacle plates for fixed wiring (to hold, eg, duplex,

triplex (DONE!), fourplex T-Sockets)

* Plug shells that enclose the wires, for appliance cords

* "cigarette lighter" adapters with a T-Plug socket

* wire crimp-on and or screw-on T-plugs and T-sockets (consumer

alternatives to

soldering)

* outer shells incorporating strain reliefs for the wires for appliance

and extension cords

* click-lock outer shells for automotive and marine use.

If I get these done then it'll all be ready for general consumption. If

I can market them could they bring in actual revenue?

My white HAT plug plugged into

the battery's

red

T-Socket, powering the DC to DC buck

My white HAT plug plugged into

the battery's

red

T-Socket, powering the DC to DC buck

converter, which powered my 12 volt LED table lamp, which lit

the scene for the picture

The order arrived on the 31st and that very evening I

modified the triplex wall receptacle plates to take T-Plug sockets. I

got it very close and after tweaking, a second version was a great

working model. The sockets friction-fit tightly in their housings and

the plugs plugged in perfectly. I wired it up, and printed a couple

more of them without further modification.

[Sept. 3rd] It occurred to me that for 36 volt connectors all I needed

to do was change (widen) the pin spacing a couple of millimeters to

render them incompatible with the 12 volt type, and use the same plug

and socket pins. With this simplification I wouldn't have to design a

new spec, and variety of inventory would be reduced. Designing

receptacle plates and other surrounding paraphernalia would also be

quite simple changes to the 12 volt versions.

(T-Plugs are Covered in more detail under Other "Green" Electric

Equipment Projects.)

Low Voltage Shocks!?!

I've written that people don't usually get shocks (still

less, electrocutions) from under around 40 volts. It doesn't break down

skin resistance. In disconnecting some batteries in the Sprint car, I

got a mild shock from 24 volts. Then from 18 volts.

What had happened?

Both shocks were at the same place on the same thumb. I had been

working on the lathe and had had a tiny metal sliver there. I

had thought I had pulled it out with cuticle cutters (my favorite

sliver removing tool). It no longer hurt. But apparently I had merely

cut it off at the skin line, and it conducted electricity through my

skin resistance.

Winston/Thundersky Batteries: Tight strapping and Failures?

Quite a while back, I wrote that someone had given me a

couple of Winston/Thundersky 100 amp-hour lithium-iron-phosphate

batteries that

refused to charge above about 3.29 volts. Usually when charged the

voltage will rise to whatever is supplied (max 4.2 volts). These just

kept drawing current, without the voltage rising further. I found more

and more that did it after I had taken the same type of batteries out

of the

Suzuki Swift EV.

I wrote of getting some new 120 amp-hour 3.7 volt lithium

cells this month. The problem for selling them as solar components was

that the most common voltage is 12 volts, and they aren't close enough:

three makes 11.1 volts (various 12 volt equipment items will balk at

that), and four makes 14.8 volts. If those are being charged the

voltage would be even higher and would risk "frying" 12 volt

appliances. So I decided to use the new cells in 36 volt configurations

(3.7*10=37V - pretty close) and I could sell the used 3.2V

(3.2*4=12.8V) batteries instead.

And as it happened, in August someone wanted a 12 volt

solar panel system. I pulled another battery out of the Sprint. But it

wasn't well balanced, with two of the four cells refusing to rise above

3.29 volts. I checked the car and found a well balanced one. It was one

I had taken the aluminum end plates and stainless steel strapping off

of to change the layout (to reverse "+" and "-").

I went to put the end plates and straps back on. They were

too tight and wouldn't go on. I brushed them off to make sure there was

nothing holding the cells apart a little. I thought "This should have

been a 5 minute job. Aren't these the same cells the strapping came off

of?"

Then I had another thought.

Originally the straps had fit.

Now they were too tight. The straps couldn't have changed, so it must

be that the battery cells had swelled just a little. Furthermore... none

of

the

cells

that

weren't

bound

tightly with straps had the problem.

And

a battery I'd been given that wouldn't rise above 3.29 originally

had worked fine when I tested it about a year later. It seemed the

cells were having trouble when they were jammed in and couldn't

swell up, just a very little bit. If they had just a bit of room,

they

didn't have a problem. And one I'd been given had even seemed to "fix

itself"

after being left loose for a while.

Then I had another thought.

Originally the straps had fit.

Now they were too tight. The straps couldn't have changed, so it must

be that the battery cells had swelled just a little. Furthermore... none

of

the

cells

that

weren't

bound

tightly with straps had the problem.

And

a battery I'd been given that wouldn't rise above 3.29 originally

had worked fine when I tested it about a year later. It seemed the

cells were having trouble when they were jammed in and couldn't

swell up, just a very little bit. If they had just a bit of room,

they

didn't have a problem. And one I'd been given had even seemed to "fix

itself"

after being left loose for a while.

The seemingly growing

number of cells in the Sprint (some

of them now in the Miles truck) that had been misbehaving were making

me

uneasy. I took all the strapping off all of them. It was less

convenient for carrying them, but it maybe they would stop "going

rogue", and perhaps some more might even "get better" again.

The 60 amp-hour batteries had similar straps on them. On

one set one of the extruded aluminum end plates was actually bulged

out, bent, indicating considerable pressure on the cells to expand.

When I undid the screws, the strapping sprang off. (There were a couple

too few good ones of these to use them for 36 volts or I would have

been employing them. Unless I use them for 12 or 24 volts for

something, they don't seem to have much purpose.)

The New Lithium-Ion 3.7V Batteries

These needed just 10 cells for 120 amp-hours, 36 volts

(actually 37V). Ten of them in a cardboard box weighed just 44 pounds.

Thirty of them would provide the Sprint car (should I ever get it going

- anyway it's my house/solar battery backup power) with 360 amps-hours

at 37 volts: 13,320 watt-hours for just 150 pounds weight.

With the old ones it was 36 cells giving ~38 volts and 300

amp-hours: 11,400 watt-hours for 270 pounds weight.

To get 12 volts for the car lights and all, instead of

another battery I would simply use a DC to DC down converter. That will

also provide an even drain on the whole 36 volts, instead of the

previous setup which ran the lights off the lowest 12 volts of the 36.

Culvert Hydro?

I'll preface this theoretical topic by saying that the

only way I

would undertake such a project would be (a) if the regular power was

down with no reasonable prospect of it coming back on line any time

soon, (b) with permission (or in the absence of anyone to say "no"),

and

(c) if the local neighborhood was solidly behind it to the point that

they would volunteer to do most of the work. I would supply the overall

plan, the improved Piggott alternator and probably a few mechanical

parts.

These conditions might be met if things were bad enough

for long enough. Here the power would likely go off, or be off for

extended intermittent periods, if supplies of diesel fuel were cut off.

(The small hydro plant can only run when sufficient rains have kept the

lake full, and now it may not be enough to supply everywhere at once

anyway.) As times are getting rather chaotic for the coming decades,

such contingencies may be thought of. But then again they may never

occur.

I went for a walk, and I decided to look at Lawn Creek,

thinking, what sort of hydro project might work on it? There were many

drops of a few inches, maybe even a foot. But not close together and no

real waterfall. Those might be amenable to some sort of undershot wheel

with

its own "scoop" base to direct the flow across the blades. But to get

very much, one would either need a dam or else a very long pipe to

bring water from higher up to a lower place.

Then I thought of the culvert where the creek went under

the highway. It was three 6-foot diameter metal culvert pipes. Most of

the time the water just ran along the bottom of two of them and didn't

reach the third one, a foot or so higher up. In heavy and constant

winter rain storms, it probably filled the two lower pipes and came

part way

up the third.

If one blocked the entries to the pipes, the water would

rise up and flood a very small area. So the highway would be an instant

dam. One might block, say, the

bottom 5/8 of the lowest pipe, 1/2 the next one and 1/4 of the third,

perhaps with plywood.

Then the water would build up to the 1/2 closed and 1/4 closed pipe and

start spilling over into those culverts, but not quite to the top of

the 5/8 blocked. That one would have a nozzle spraying on a pelton

wheel just inside. The shaft would come out and up so that the

(improved Piggott) alternator was above the culvert pipe. It would be

attached to the wooden cover, as would the bearing for the pelton

wheel. I think that would give sufficient power for LED lights and

fridges in a few nearby houses. It would be consistent power as any

excess

water would just spill over the other gates. (The other two, at least,

would probably have to be removable for heavy rains to prevent flooding

the highway.)

If one blocked the entries to the pipes, the water would

rise up and flood a very small area. So the highway would be an instant

dam. One might block, say, the

bottom 5/8 of the lowest pipe, 1/2 the next one and 1/4 of the third,

perhaps with plywood.

Then the water would build up to the 1/2 closed and 1/4 closed pipe and

start spilling over into those culverts, but not quite to the top of

the 5/8 blocked. That one would have a nozzle spraying on a pelton

wheel just inside. The shaft would come out and up so that the

(improved Piggott) alternator was above the culvert pipe. It would be

attached to the wooden cover, as would the bearing for the pelton

wheel. I think that would give sufficient power for LED lights and

fridges in a few nearby houses. It would be consistent power as any

excess

water would just spill over the other gates. (The other two, at least,

would probably have to be removable for heavy rains to prevent flooding

the highway.)

Since the highway runs up and down the coast there would

be a number of culverts that might be suitable for this simple sort of

"neighborhood micro hydro" system.

I speculate that 208/240 volts AC would be the desired

output - assuming one can derive 120 from it. (Else 120/139. It's a 3

phase alternator, so those are the choices.) Running lower voltages

along roads even to nearby houses

would entail heavy losses. Pelton wheel diameter (and hence speed) and

the number of winds of wire in

the stator windings would determine the voltage and frequency.

A later thought was that a box with the pelton wheel

should be on the outside of the plywood covering the culvert pipe (but

with an open side spilling out to the inside), with

the generator shaft going straight up to the generator box above.

Nothing would be inside the culvert pipe. That should simplify

everything.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Cure

for & Prevention of COVID19

With all the hype, societal

distress and economic disruption over COVID19, which is for sure an

insidious and dangerous disease, it is quite a surprise that finding an

effective treatment and preventative for it in the spring wasn't all

over the news in

May or June, or at least by July.

It is perhaps a sign of how dysfunctional western society has become

that while the lab tests were done in Australia in March, and patients

were treated in a hospital in Florida in April, it is being adopted in

places like Peru, Bangladesh,

Dominican Republic and Brazil rather than in Canada, USA, EU and

Australia. Instead we're still enduring dictatorial lockdowns,

isolations, "social

distancing", face masks, hand sanitizers whenever we go into public

places, and immense overall economic turmoil - all apparently

needlessly.

"Big Pharma" wants to develop a costly new vaccine (a

company trying has already said they would charge a fortune for it).

Simple pills of an existing, low cost and well known medication with

few side effects simply aren't what anybody expected - or 'big pharma'

wanted to see.

Nevertheless

that's just what has been found. It's had no publicity in the

corrupt "mainstream" media while people everywhere continue to suffer

and a few die of the virus - now, it would seem, needlessly. (But

perhaps doctors are using it quietly - a recent chart shows the number

of deaths from CV19 dropping off dramatically.)

The medication is called Ivermectin (AKA "Stromectol"). It

is almost 40 years old. It was developed to cure people of parasites

such as nematodes and worms. It was also known to be effective against

certain viruses. It was a surprise that it

seems

remarkably effective against the COVID19 virus. Improvement

even in very ill patients is evident within 48 hours, and they test

negative for the virus within 10 days. It's not perfect, but it can be

used at any stage of the disease, from prevention to even to severe and

critical - where it cuts mortality roughly in half.

!!! [Inserted at time of posting] Warning: Doctor

Mobeen Syed (DrBeen.com - youtube video titled "Ivermectin Remdesivir

Leronlimab") warns that ivermectin should not be used by pregnant or

lactating women (it crosses the placenta and might cause brain damage

to the fetus or baby), nor by meningitis patients or anyone else whose

blood/brain barrier is compromised.

Orthodox medical journals are viewing it cautiously or

skeptically to say the least. Doctors treating patients, however, are

enthusiastic. It has been spread among doctors' social media groups,

and there are a number of interviews with doctors at the forefront of

it on youtube. (This shows the value of social media, morally polluted

as it may be on certain topics. How else would the knowledge have

spread

"virally" between doctors?)

The first and at the time unknowing or "accidental" use

seems to have been in a Toronto nursing home where there was an

outbreak of scabies in February (2020). Owing to that, the residents

were all given Ivermectin.

In the next couple of months CV19 was killing the elderly

in nursing homes in droves. Not at this one! Many staff came down with

it, but very few residents. This was a great effective blind study.

https://www.youtube.com/watch?v=8XCYzpHBEkI

Then in March was the lab study in Australia.

Perhaps the first doctor to knowingly try it on a patient

was Dr. Rajter in

Broward county, Florida. He had just read of the Australian test tube

study a couple of days previously. He had to phone the son of a patient

who was getting worse and seemed likely to die. The man asked, wasn't

there anything that could be done for his mother? Finally the doctor

hesitantly mentioned the study, but said he

didn't know the dose used or how much was safe for humans. The son

asked how

much was used for the treatment of parasites, and the doctor told him.

Why not try that amount, known to be safe, then, asked the son? The

doctor and the patient agreed, it was done and she recovered. Some of

the doctors in the four hospitals of Broward county went on to treat

other serious cases with ivermectin, cutting the mortality roughly in

half in several hundred patients. Especially at first, Dr. Rajter could

hardly publish the findings as a "study",

but he posted to a doctors' social media group, and soon ivermectin was

being used in many countries.

https://www.youtube.com/watch?v=nzqnAIfEbv4&t=618s

The presenter of the video notes that in spite of the

"carefully controlled off-label observational study" which was approved

by Broward County, a major US county health board, no medical peer

review journal seems willing to publish it. The mainstream media, for

all its hype about CV19, seems equally uninterested in hearing of what

appears to be a cure.

Dr. Pete Ellis, "at the epicenter" of the infections in

Brazil, has been treating patients with ivermectin with great results

and also taking it himself as a preventative. Here is his excellent

video, in which there is much information including suggested dosages:

https://www.youtube.com/watch?v=9gApbQlSIAA

(Dr. Ellis is 78? years old and was in intimate contact with people who

were catching or who had the virus including family members - a prime

candidate for catching it

and dying from it. If I was an elderly doctor treating CV19 patients I

would surely take it, too!)

Here' an Ivermectin Study that claims 100% success curing

CV19 in 6 days. Other clinical trials in other countries, shortened

CV19 from 20 to 10 days.

https://www.youtube.com/watch?v=VfTvViI8IKI

Of course I am not a medical professional. I am just

reporting something I've found that seems very interesting and

relevant. I'm sure results of any treatment will vary with every case.

Some people test positive for the virus without having any symptoms.

Only a few percent of cases (4%?) result in death.

And there may be something more effective, too.

Remdesivir, touted by many professionals, also seems to help

significantly shorten the disease's stay. Is it better?

Lest we rejoice too much over cures for CoViD-19, it seems

a new (or not new?)

virus initially spread by ticks has been claiming victims in China.

(Only a few so far.)

https://www.youtube.com/watch?v=llpv1BNhoGg

A school bus driver here said he thought Haida Gwaii had

already had CoVid-19, because in February a lot of people were quite

ill. That was of course just before it was hitting the news.

That reminded me... I flew to Comox BC to see my own

mother for Christmas 2019. CoViD-19 was not yet known. In a 6 hour

stopover at YVR on the way there, I seem to have caught something that

made me quite ill for a few days after New Years day. (Looking back, I

described it as "a nasty chest cold" in TE News #140, for which I had

put steam on in my bedroom.) And my 94 year old mother caught it in

early January, probably from me. (She was needlessly sent to hospital

by ambulance by a concerned friend in her building. She said she would

have gladly gone to hospital the day before, but had been feeling a

little better by that day and after seeing a doctor, went home (by taxi

I presume).)

Perhaps what we had was CoViD, and perhaps more people on

this island caught it in January and February from me and other

Christmas travelers? Then with our low population density here and and

the later containment measures, by the time there were tests for it, it

had disappeared.

That is of course idle speculation. As far as I know, no

one died from whatever it was. And the later 26 cases stemming from a

Haida man who went to the USA by car to pick up his daughter, and then

they both went to a funeral immediately on return, didn't spread any

further and it died out - perhaps again.

Wall

Building

Here are some pictures

showing the progress on making the wall.

Thin concrete footing walls. The

posts

(on concrete footing blocks) and beams

Thin concrete footing walls. The

posts

(on concrete footing blocks) and beams

support the roof, so no wall is a bearing wall. So the main objective is that the

wood of the

walls not be in contact with the ground. (With the rising ground,

I'm

going to have to

dig some more dirt away from near the walls.)

2x4 frame around the outside.

2x4 frame around the outside.

Wall Partly framed with 2x4s.

Wall Partly framed with 2x4s.

Framing Done. The window frame is

a bit

unorthodox.

Framing Done. The window frame is

a bit

unorthodox.

It must be remembered that with the post and

beam construction, no walls are bearing walls.

First two sheets of plywood.

First two sheets of plywood.

With 15-1/2 feet of length, the

only place to

put the plywood joins is

With 15-1/2 feet of length, the

only place to

put the plywood joins is

"all at the same stud". (Except at the bottom row.)

(Drizzle wetted the sheet as I cut it, temporarily changing the color.)

Telling

Fake

News

from

Real

News?

I think I've found a good

indicator of

"fake" versus "real" news on Youtube. When the comments are turned off

by the video producer, it's a good indication that the video is pushing

a narrative -- or at least that they don't want other views or opinions

on the

subject to be aired under their video.

I found a CBC video, The controversial push to

fast-track a COVID-19

vaccine. I thought I would look at it, mostly to see what people

were saying underneath. And if no one (or the video itself) had

mentioned ivermectin (AKA "Stromectal") -- the low

cost, "at hand", apparently safe and effective, oral treatment (and

even preventative) that is getting no publicity while "they" have

everyone vainly hoping for an injectable vaccine, I was going to do so

myself.

And I might find other unsuspected, enlightening facts or ideas

that people had posted.

The comments were turned off. I was disgusted and didn't

watch very

much of it. As far as I did watch there was some hype for vaccines in

general (yes, yes, there's no question but that smallpox vaccine

virtually eliminated that horrendous disease), and no indication they

would mention

any possibility for treatment but the "holy grail" CV19 vaccine (which

may still be many years away) -- a

very narrow focus and perspective, certainly not the "big picture".

What are you scared of, CBC? Truth? (Note: Not all CBC

videos have the comments turned off.)

Gardening &

Chickens

In all the following gardening writeup, it must be

remembered that summer

2020, and especially August, had very little sun. Where the solar

panels had made 307 KWH in 2019 - which itself wasn't a very nice

summer - they only made 205 KWH in August this year. Perhaps it's

surprising there was much of anything besides potatoes.

Wheat Growing Experiment

This spring I ordered small packets of 5 different

varieties of wheat, "ancient grains?" from Saltspring Seeds. I wanted

to try wheat growing

in general, and I wanted to see what grew well on these islands. On the

14th I plucked a few heads. It had been raining for a couple of days

and was pretty cool, not to say cold for "summer".

First thing of

note from the main garden was that much of

the Red Fife had fallen over in the rain. Much of the Kamut was

bent over randomly, but not fallen.

First thing of

note from the main garden was that much of

the Red Fife had fallen over in the rain. Much of the Kamut was

bent over randomly, but not fallen.

The second thing was that

the wheat in the garden by the

south side of the house, in spite of having a head start by virtue of

being planted indoors in flats earlier in the spring and then

transplanted, didn't fare as well as that simply planted outdoors in

the open field a

little later. That side garden just didn't get as much sun, and most of

the wheat there was drooping over by the 14th. (The more so as some

Elderberry bushes grew up rapidly over the summer next to the wheat and

cast a lot of shade. They were cut back on the 11th FWIW.) So we'll

make allowances for the smaller side-garden heads. Since I grew Kamut

in both locations, it makes for some comparison.

The Alaska Spelt grew the tallest of the ones in the

side-garden, and seemed to stand up best to the rain, but it seemed to

have the smallest kernels and obviously it was difficult to get them

out of their chaff - the seeds right from Saltspring Seeds were still

in the chaff, whereas all the other varieties were just bare kernels. I

won't plant them again just because they are harder to process. Emmer

is apparently similar.

The Emmer grew next best to the Spelt (and was next to

it), and was riper than any others in mid August, with the sheaves

starting to turn brown. For that reason it might be worth further

trials, especially if the others aren't ready by, say, mid September.

The Kamut next to the Emmer didn't grow as well as that in

the open field. It still did not bad and still had the biggest kernels.

The Brazilian Lavras didn't grow very well, but it was the

most shaded by the Elderberry bushes, so it might not have had a very

fair trial. Still the fairly similar Emmer had bigger and more golden

heads, so I think I'd go with the Emmer over the Lavras. But I don't

expect I'd grow either again.

The Red Fife from the main field had formed good heads

with good green kernels inside, but it had fallen over. We get a lot of

rain and cool cloudy days here, and it didn't fare as well as the Kamut.

I'll drop the Spelt and Emmer. I might

give Red Fife another chance, and perhaps a small patch of Brazilian

Lavras, which didn't get much of a chance in the shade of the

Elderberries. But the Kamut was looking like much the best

choice.

From left to

right:

From left to

right:

* Kamut (Chorazin) and Red

Fife (from the larger sunny garden, planted

direct later)

* Kamut, Alaska Spelt, Emmer,

and Brazilian Lavras (planted in flats

early and transplanted to the side garden)

But the heads of wheat weren't at all mature yet. The

husks had developed, but the kernels inside were still tiny and

unformed.

(24th) I checked on the wheat again this day. Some of the kernels were

much better formed but were still soft and green. One could at this

point open individual kernels and eat them like green peas, but it

wouldn't be worth the effort. The most developed ones were again the

Red Fife and the earliest planted Kamut in the big garden.

The Emmer, for all the early golden color, was

disappointing as was the Brazillian Lavras. The Alaska Spelt were still

pretty small - and why bother with it when they seem so hard to

de-husk? Admittedly these three varieties weren't grown in the best

conditions, but they still didn't match the Kamut in the same patch,

planted about the same time.

On September 3rd I checked the earliest planted Kamut and

Red Fife in the field again. The kernels were probably about full size

now, but still green and "chewy" soft.

The outstanding performer seemed to be the

Kamut in the open field. Most of it was still upright. The kernels were

developing well in spite of the cool, cloudy, wet weather. Remote Haida

Gwaii will never be a breadbasket of wheat, but if growing an acre or

two here and there of wheat for local consumption should seem like a

good

idea, Kamut would seem to be the choice. Red Fife comes in second. It

too had decent size kernels ripening, and had bent up again after

pretty much falling over in heavy rain.

Peas

Peas are one of my favorite garden vegetables. Of three times and

places I planted peas this year, the largest one did great!

Peas are one of my favorite garden vegetables. Of three times and

places I planted peas this year, the largest one did great!

Home grown

peas are delicious -- much better than frozen store-bought peas. The

store-bought ones are blanched in case anything has started growing on

them. I shell peas and immediately freeze them - I figure they're fine

that way and taste much better, retaining more nutritional value, and I

have never got sick from them yet (AFAIK).

With the new larger garden space, this year I planted a 4

meter row of "tall telephone pole" peas. (with a narrow gap for a path

through the middle.) It produced well even through cool, cloudy August.

On the 25th after leaving them perhaps a week, I picked, shelled and

added another 300 grams to the freezer bag, for a total of 900 grams of

frozen peas. It all took maybe half an hour. I had used a few and there

were still plenty left, so it must have yielded over a kilogram.

By the end of

the month I had harvested a Kg of

peas and

put them in the freezer, not counting what I had eaten plus some to

plant next year. And there were still some more ripening on the plants.

I picked some of that on September 3rd, putting another 95g of what

I'll call "late season peas" (less tender and sweet) in the freezer and

drying almost as many for next year's seed.

By the end of

the month I had harvested a Kg of

peas and

put them in the freezer, not counting what I had eaten plus some to

plant next year. And there were still some more ripening on the plants.

I picked some of that on September 3rd, putting another 95g of what

I'll call "late season peas" (less tender and sweet) in the freezer and

drying almost as many for next year's seed.

Inevitably one misses some until the plants have died and

dried up, but that's good as the old dry peas become more next year's

seeds.

(If there are more than needed, one can store them dried anyway, and

use them in soups. With solar panels et al, I'm counting on being able

to keep

the freezer going regardless of anything.)

Other Vegetables

I grew quinoa again, but it didn't seem to do very well.

Something was eating holes all through the leaves. Three red colored

plants started to flower early and then died. The tops were eaten off.

A deer had got in and I attributed it to that. But in late August

flower

tops on the other plants started to turn red, and then they too were

being eaten off.

I'd seen a couple of birds fly up from the garden when I

came out, little brown wrens or something, but they were down on the

ground, not up at the flowering

tips. Then I figured it out: they pecked off large chunks of the tops,

which fell to the ground. Then they spent most of their time on the

ground eating them down there. At least, that's my surmise.

Swiss Chard and Zucchini -

planted to replace

young quinoa that the slugs ate.

Swiss Chard and Zucchini -

planted to replace

young quinoa that the slugs ate.

Behind them, a whole bare patch where carrots were replanted at least

twice

but eventually grew only a single good carrot. Why did they not come up?

Why did they all gradually disappear when they did come up, instead of

growing?

Garden by the south wall of the house, with the corn that was under

cover during

the spring and actually had edible (but not large) cobs, and some bushy

quinoa behind

it before the birds (? - or mice) got to it.

First two cobs. Many were a

little better, but

none were full.

First two cobs. Many were a

little better, but

none were full.

Birds (at least I think it was

birds)

decapitated the quinoa and

Birds (at least I think it was

birds)

decapitated the quinoa and

left it in ruins as the flowers started to turn red.

Very disappointing! (This was September 1st. It got worse until whole

plants

were dying or dead. No crop - including from those in the greenhouse.)

Soon after, they got this one,

too.

Soon after, they got this one,

too.

Onions by house were okay, not

spectacular but

as well as I've ever done with onions.

Onions by house were okay, not

spectacular but

as well as I've ever done with onions.

Garlic from same place seemed good, if a bit small. More peas and some

wheat.

The corn I planted indoors and then put under plastic by

the house grew and matured. When I picked the cobs they were

disappointing. One cob had just 20 kernels on it. A couple of others

were about half full. This indicates poor pollination, notwithstanding

that I had taken some tassels and shaken them onto the silks. A bigger

patch would obviously be much better if it can be protected from the

weather until it's growing tall. Nevertheless, it's the first edible

corn I've grown up here and it tasted great!

The cover plastic over the other corn out in the new

garden had ripped early and in several places, and I didn't get around

to replacing it until late. It never matured, having cobs just starting

at the end

of August.

The Chickens

The chickens on August first (and

some

freeloading deer).

The chickens on August first (and

some

freeloading deer).

The only trouble was... four out of five were roosters.

I had already culled one rooster, still at least two more had to go.

The survivors. (The hen started

laying small

greenish eggs in mid September.)

The survivors. (The hen started

laying small

greenish eggs in mid September.)

I did the 'lesser' white one early in the month. On the 16th my friend

Perry killed the boisterous (not to say cocky) big

black rooster for me. (It's not my favorite sport.) I had meant to take

a picture of the three, but

when I thought of it it was too dark, and I didn't think of it again

until he was gone. With the lesser white one having been consumed early

in the month, it's down from 4 roosters to one off-white leghorn, and

the hen with the fluffy cheek feathers.

The chicken feed consumption has dropped dramatically. I'm

not sure they get a whole lot from foraging at wherever I move the

chickenmobile to, but ferns, garden weeds and trimmings, and food

scraps, stretch out the supply. (If chickens liked slugs, it would be

great! But to eradicate slugs one evidently needs ducks, who think

they're a delicacy. Evidently they are not only gross but poisonous to

humans.)

The 3 roasters tasted great, but I'd rather have had at

least two hens. Egg supply was what the project was about! And my

timing was poor: they're 4 months old now, another month or two until

she starts laying, and the days are quickly getting shorter. Chickens

lay by the light - when the days are long. Better to have got chicks in

the fall to start laying in the spring. Or maybe I should put an LED

light in the coop on a timer. Any light works.

Small

Thots

* Some have been calling birds "avian

dinosaurs". Obviously they evolved from dinosaurs, but that would seem

to be stretching the point considerably. So did placental mammals. Does

that make mammals "non avian

dinosaurs"? (Bats excepted of course.) Kangaroos even look like

dinosaurs. Then, reptiles evolved from

amphibians. Does that make dinosaurs "non avian frogs"? And are frogs

"extra-aqueous fish"? Does that make birds "avian fish"?

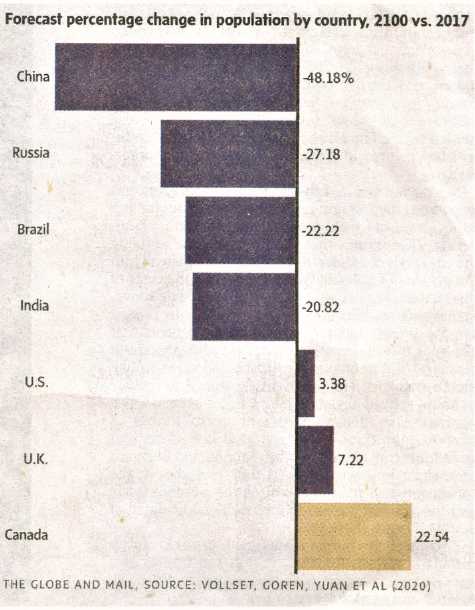

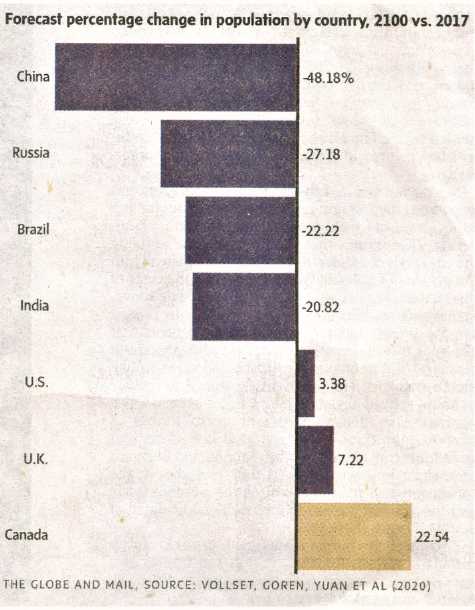

* Here is a

graph projecting future populations. These are mostly going the right

direction, but it's too little, too late to prevent upcoming

catastrophes.

* Here is a

graph projecting future populations. These are mostly going the right

direction, but it's too little, too late to prevent upcoming

catastrophes.

I have the impression our food supply chain is thinning

out and will soon be largely empty, inaugurating a great population

reduction by hunger and poor nutrition. On top of economic and

financial disintegration, the flooding in China this year has been just

as staggering as that of the heartland of the USA last year. Now we

have locusts decimating various regions, droughts, winds, hail, cold,

CoViD-19 shutdowns... and fires ravaging the western USA, especially

California where so much of our food is grown.

Still, it's a good sign that population growth is slowing

so much before people are hurting. When things settle down, and birth

control products are available everywhere, it looks like the world

should have little trouble keeping a stable population at a size where

in future generations everyone can have a prosperous and fulfilling

life and grow into their full potential. (under 3 billion, perhaps?) No

more marginalized, homeless and economic refugees searching for

anywhere they can settle and make ends meet, contrasting with the

outrageous wealth of a few, and everyone in fear of and in competition

with everyone else for what limited resources there are.

ESD

(Eccentric Silliness Department)

* Quiz: Do dinosaurs have gizzards? (Rest assured there are no answers

known to be entirely wrong. Except maybe "(e)".)

a) Probably

b) Unlikely

c) Maybe some did

d) Who cares, dinosaurs are extinct

e) None of the above

* I think Brazil is the only country named after a nut. Except for

countries named after certain people...

Chemical Elements Spotlight

Sb: Antipathy is next to Te and also to Sn, sandwiched between As and

Bi

in column 15 of the periodic table (N, P, As, Sb, Bi). It doesn't like

any of them.

P: Prosperous is near the top of the same column. There's plenty of it.

Te: Delirium is the last element found sleeping in column 16: O, S, Se,

Te, Po. (Po never sleeps, being highly radioactive and also a river in

northern Italy. O2 is always active, too.)

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Miles Electric Truck: New Planetary Gearbox

Around the 20th to 23rd, I put the planetary gear end of the shaft in

my lathe. It wobbled as it turned. How on Earth was I going to make a

"steady" for it? I idly tried to mill a little... and it centered

itself! What happened was that the one inch shaft pressed itself into

the one inch hole in the 3-jaw chuck, and that centered it perfectly. I

still had a hard time. It was very hard metal, and I actually spent

several hours of trying to sharpen lathe tools/bits and cutting the

25mm down to 19.0mm. (For some reason the last millimeter seemed easier

than all the rest.) I had to take the chuck off the lathe and hammer

the shaft out of it.

I then pressed it into the other end of the shaft coupler

with about 4 tons of force. I don't think this shaft will come apart

without a lot of persuasion. Next, to put it into the truck, which

wasn't up on ramps and couldn't be driven onto them until the shaft was

in!

Two shafts pressed into shaft

coupler to get

the two proper ends for

Two shafts pressed into shaft

coupler to get

the two proper ends for

splined motor socket and 19mm compression socket on planetary gear.

[28th] I finally went under the truck and dismounted the old shaft. I

took the planetary gear with the rear drive shaft right off the truck,

as there was no easier way to fit the assembly together. The planetary

gear end of the new shaft was just marginally too big to fit into the

socket. I tried to pound that end of the shaft out of the shaft coupler

with a big vise and a hammer. It wouldn't budge. Then I tried putting

it in the lathe, gripped from the very end of the join and with the

motor end in the drill chuck at the other end of the lathe to hold it

steady. Contrary to my expectations, the shaft wasn't straight.

Nevertheless I took a file and started filing it down until it was all

under 19mm diameter. I hope the wobble wouldn't be noticable on the

truck.

It still wouldn't go in, so I just filed it down a bit

more until it did, and worked it in. Then I pushed the front into the

motor and put it all back together.

One of the lithium batteries had a cell that was dying

before all the rest, and I took it out. I sold the best 8 cells for

Steve's solar project, making two 100 amp-hour, 12 volt batteries.

There seemed to be a lot of misbehaving cells left over (see under Electricity

Storage). I would have to pick 4 cells to put back into the truck

before I could drive it.

Other bad news was that Randy of Canadian Electric

Vehicles (retired) said he had never run across a Curtis motor

controller that wouldn't 'talk' properly to the programmer. He did

suggest I contact "HPEV", who he thought had done the components for

the Miles EVs.

[29th] I put

in another lithium battery (misbehaving or not), and then

ran the truck around the driveway. Contrary to my hopes, the vibration

from the unbalanced shaft was pronounced with even a little speed. I

put the truck away, exasperated with the whole thing. Why had

I started this? Then I thought, with unbalanced tires they add

counterweights until they are balanced. Why couldn't I do that with the

shaft? And I had found a strange clamp that went on a pipe, and had

thrown it in a box just days before. It might be just right, or at

least it was the right idea. I dug it out again.

[29th] I put

in another lithium battery (misbehaving or not), and then

ran the truck around the driveway. Contrary to my hopes, the vibration

from the unbalanced shaft was pronounced with even a little speed. I

put the truck away, exasperated with the whole thing. Why had

I started this? Then I thought, with unbalanced tires they add

counterweights until they are balanced. Why couldn't I do that with the

shaft? And I had found a strange clamp that went on a pipe, and had

thrown it in a box just days before. It might be just right, or at

least it was the right idea. I dug it out again.

But that might not be a

satisfactory fix. The planetary

gear, if not the motor, would wobble back and forth a bit and might

still make for a lot of vibration. It occurred to me

that even tho I hadn't been able to budge the shaft from the coupler

with hammer and vise, if I stuck it in the hydraulic press sideways and

pressed down on the shaft coupler with the two ends supported, it would

doubtless "bend". That is, one shaft would pull loose a bit on one side

to straighten it. And I could test the straightness the same way,

putting

it in the lathe with both ends supported, and turning it to see any

wobble. (Repeat until it seemed good.)

Ground

Effect

Vehicle

(1/4

scale

model)

(11th) On discovering the main output wires of the batteries went to

"T-Plug" sockets, and that those would make a very good replacement for

my own HAT (or CAT) plugs and sockets, I ordered a bunch of those. Now

I have the excuse that I'm waiting for the plugs to arrive before

continuing on the model. (The real excuse is as usual, I'm too busy. I

even bought 2 cords of firewood for this winter because I simply

haven't got around to cutting any myself all summer.)

I'm also suspecting that it may need a tail rudder. When

the fans were to be on the outside of the hulls, they would have a lot

of turning force. Now that they are inside on the canard, that force

will be considerably less. Even with one off and the other on high the

turning radius may be very wide. OTOH the 'shark fin' pivot point being

well forward may make for sharper turns with less leverage than might

be expected. I guess I'll find out when I fly it.

One thing I think I might do immediately is make an

electronic circuit to (a) reverse the 'backward' throttle controls so

they shut off if the radio control signal is lost instead of turning on

full, and (b) so that pushing forward on the stick increases the

throttle and moving it side to side turns one engine up and the other

down for turns.

(Let's see... a 5 volt rail-to-rail dual OP-AMP... How

about a CA3260? - the same one I used in my last OP-AMP circuit design

in [egads!] 1986?)

Defining just what was wanted was a bit of a trick. With

two independent throttle sticks (as I intend on any full size craft,

including pulling back past 'zero' for reverse thrust for maneuvering

when docking) it would have been easy. Having just one stick that moved

four directions (and no reverse in the "ESC" motor controllers) was

different, and all radio controls for model aircraft seemed to be

configured the same.

1. Moving the stick from bottom to top (centered left to right)

obviously should take both

motors from fully OFF to full power.

2. Moving it left to right at the bottom should do nothing - both

motors should stay off.

3. Moving it left to right while at the top should decrease the power

of the one in the

direction of the stick motion. But by how much? Should it

turn it right OFF at the ends

of motion (cutting the total thrust in half), or

only partly?

4. What should it do in the middle of top to bottom, when moved left or

right? Still

decrease the one for sure - perhaps to OFF at the

extremities. But what should the

other one do? Should it increase (keeping the total

thrust even), or just stay the same?

The practical circuit is probably going to define some of

that. The motors can't go beyond full throttle no matter what the

control tries to do. So probably the thing to do is define what happens

going left to right in the mid throttle range. Surely it's best if the

overall thrust remains the same regardless of left-right position, so

the thrust of one motor should rise as the other goes down.

So I guess the thing is to define what voltages are

optimally wanted to the motor controls for the two motors at what stick

positions.

|

LEFT

|

MID

LEFT

|

CENTER

|

MID

RIGHT

|

RIGHT

|

TOP

|

5 - 0

|

2.5 - 0

|

0 - 0

|

0 - 2.5

|

0 - 5

|

MIDDLE

|

5 - 0

|

3.75-1.25

|

2.5 - 2.5

|

1.25-3.75

|

0 - 5

|

BOTTOM

|

5 - 5

|

5 - 5

|

5 - 5

|

5 - 5

|

5 - 5

|

So... Left motor off (off=5V) at the bottom OR stick is all the way to

the left; Right motor off at the bottom OR stick to the right.

And... if above OFF, the thrust inreases one way (left or right) and

decreases the other, hopefully to attain the MIDDLE row figures, and

also the BOTTOM row OFF condition must be met for both motors. What

happens at the TOP row in order to attain everything else is in the lap

of the gods.

So the function needed is a sort of multiply, vertical * opposite

horizontal, and then invert so off is 5V and full is 0V.

I wonder if perhaps the whole thing might be easier to do with a

microcontroller? (They most always have analog inputs... do mine have

analog outputs?)

How is it that ALL the 'green energy' and electric

transport projects seem to have got to be "on hold"?

Other

"Green" Electric Equipment Projects

New

System:

"T-Plug"

12VDC

--> Now Replacing CAT 12VDC <--

CAT, HAT and "T-Plug" Connectors

The 'model airplane' batteries for the model ground effect

vehicle arrived on the 4th. Being still busy, I set them aside. I

should have ordered "6S balance chargers" for them.

On the 11th I started looking into that on AliExpress, and

ran across something called "T-Plugs", also called "Deans

Connectors". (Apparently "Deans" was the first person or company to

make them,

although there are now other knock-offs.) The "T-Socket" was what was

on

the batteries as the main load connector for however many zillion

amps to the propeller motor. The connections all seem to be gold

plated. One place said they were rated for 40 amps. That seems pretty

optimistic. (Maybe I should double up the connectors?) I trust that

means they would be fine for 15 or 20 amp circuits. The wires from

these batteries were #10 AWG, which in house wiring is only rated for

something like 30 amps. But then they're only 5 inches long.

One minor oddity is that the 'springy' bit that presses

the blade into good contact with the socket is on the plug blade

instead of inside the socket. But that is perhaps an advantage. One is

needed somewhere. It means that the plug on the appliance cord is the

component to wear out and fit loosely instead of the socket in the

wall. And being exposed on the plug blades, one might perhaps pry them

out a bit to restore good connections.

Another oddity is that they are not quite

symmetrical, because the in-line negative metal is on one side in the

plug and on the other in the socket. Instead the contact plane

(the

socket having its contact blade only on one side of the plug blade

instead

of both sides) is centered.

There were also "XT30", "XT60" and "XT90" plugs for model

aircraft, with round pins. An exact matching unsymmetric shape of the

shell on both plug and socket is required to ensure correct polarity. I

decided that while I might make use of these as specialty connectors,

neither round pins nor the exact shell necessity fit my philosophy of

connectors for general RV/Marine/Off Grid house wiring purposes.

The T-Plugs were another matter. The top of the "T" cross

was, like on my connectors, the positive terminal, and the in line one

the negative. Noticing the similarity in form and size, I got out one

of my 36 volt "HAT" connector plugs and tried it. The sizes were so

close that it plugged in, and the lamp worked! That made for several

choices:

The T-Plugs were another matter. The top of the "T" cross

was, like on my connectors, the positive terminal, and the in line one

the negative. Noticing the similarity in form and size, I got out one

of my 36 volt "HAT" connector plugs and tried it. The sizes were so

close that it plugged in, and the lamp worked! That made for several

choices:

1. Ignore T-Plugs and continue working on the CAT and HAT plug and

receptacle systems.

2. Adopt T-Plugs in place of HAT for 36 volt systems.

3. Adopt T-Plugs in place of CAT for 12 volt systems - and re-design

HAT so it won't mate with T-Plugs.

Of course, each idea has its pros and cons.

Simply ignoring the T-Plugs would ignore the fact that HAT

and T-Plug sockets and receptacles will plug into each other anyway.

(or at least, one HAT plug fit into a T-Plug socket.) And a system has

yet to be made to produce CAT and HAT plugs in quantity, and then they

each still need to be marketed and the market has to adopt them.

Using T-Plugs as 12V or 36V specific connectors would ignore the

fact that they are already in use for multiple different voltages, so

no absolute set standard is possible - there is no "spec" that says

"this connector is only to be used for 12 [or else 36] volt systems".

However, it seems that they are only, or mainly, used for

electric radio controlled model types of equipment. That's pretty

specialized. It seems unlikely that if they came into general use for a

specific voltage, that there would be very many mistakes plugging the

wrong things together.

If they came to be used as the standard for a

specific voltage of off-grid power, that would probably eclipse its

present specialty uses, which would come to be seen as "unorthodox".

(or eventually perhaps even "improper".)

For course 2, very few HAT plugs, sockets and wall

receptacles have ever been made. I've never uploaded the 3D printer

designs to Thingiverse.com . All that is needed is a couple of very

minor size adjustments to HAT to make it virtually the same as T-Plug.

Switching it would be almost trivial.

OTOH, for course 3, 12 volt systems are incomparably the

most common today, and cheap T-Plugs with solder lugs seem to be widely

available from more than one source already. I quickly decided this was

the practical choice.

Since there has been no HAT equipment sold yet (and an

insignificant amount of CAT), if T-Plugs are to replace CAT for 12

volts, the HAT 36 volt type can be changed with virtually no loss

except a little design time to make it so it won't fit with T-Plugs and

making a few new prototypes. That design time will be more than

compensated for by using the ready-made T-Plugs for 12 volts instead of

making and wiring CAT connectors.

I ordered over fifty each of the basic T-Plugs and

T-Sockets on the 11th, the same day I found them, and some with

enclosed shells for appliance cords and extension cords. Additional

"T-Plug-12V" components should be created:

* wall receptacle plates for fixed wiring (to hold, eg, duplex,

triplex, fourplex T-Sockets)

* "cigarette lighter" adapters with a T-Plug socket

* wire crimp-on and or screw-on T-plugs and T-sockets (alternatives to

soldering)

* other alternative shells incorporating strain reliefs for the wires.

* click-lock outer shells(?)

Then it'll all be ready for general consumption. Here are approximate

dimensions for T-Plugs (as measured from the sockets on the batteries):

Blade Spacing ('+' contact plane to middle of negative pins):

6.7 mm

Blade Size (Plugs):

T: ~1.1 mm

W: ~4.0 mm

L: 8 mm

(Sockets):

T: ~1.1 mm

W ~5.0 mm

L: 8 mm

Outside of [Solder Tabs] Shell:

13.6 mm x 7.8 mm ('+' side), 6.4 mm ('-' side); each 6.8 mm + 6.8

mm = 13.6 mm)

Since the contact/interface area is flat, shells can be

made as appropriate for larger wire connection areas (crimp, screw,

enclosed) and may be wall plates or any other flat surface shape. I

hope it isn't a dangerous assumption that the plastic used for the

shells is higher temperature resistant for electrical/fire safety. The

currents in model aircraft can be very high, and even in a model

airplane one doesn't want the plug to melt and short the wires, which

could certainly cause a fire.

For making further 3D printed surrounds around those

shells, I would then assume it should be safe to use ordinary PLA,

which prints easily and is sufficiently stiff and strong.

It's always amazing to find that something you've been

working on for years already exists in some obscure, unrelated corner,

and you

never suspected.

At first I thought I'd jump right in and redesign the HAT

36 volt plugs and sockets to make them incompatible with

the T-plug 12 volt ones. Then I decided I'd wait until my order arrived

to see what design wisdom might be gleaned from those first. I have the

T-Sockets on the batteries, but not the plugs with the interesting

looking blades.

Notwithstanding that I heard "60 amps" go by in a couple

of youtube videos, it would seem the cheap plastic melts easily so care

must be taken when soldering. There didn't seem to be any with higher

quality shells being produced, which seemed a bit of a surprise and

disappointment for something so generic and simple to produce. But

then, they're only being used for model aircraft at this point... and

apparently are being phased out even for that - partly because of the

cheap easy-melt shells! I wonder if I might have to 3D print higher

temperature nylon shells after all? If the pins can be slipped out of

the cheap shells and inserted into better ones, that wouldn't be so

bad, I suppose. But the wires are just soldered onto the flat of the

blades, which stick out the back. No holes for better stability. No

crimp-on or screw terminal types.

I pushed the gold plated pins out

of a socket

(left) and

I pushed the gold plated pins out

of a socket

(left) and

a plug (right) with small pliers. (I lost one spring piece.)

(If I was designing them, for off-grid wiring use,

the pins' interconnection length would be longer -

about 10mm instead of 8 - so the plugs wouldn't

pull out so readily if the cord is tugged. But I

think here I'll just work with what's available.)

T-Plug Triplex Wall Receptacle

(31st) The sets of 50 T-Plugs

and 50 T-Sockets arrived. They seemed to mate nicely and securely.

While the model airplane people seemed to think they were good for 40

or 60 amps, I decided a good rating for household use would be about 20

amps. (20 amps times 12 volts is only 240 watts. Oh well. It should

work great for small appliances such as LED lighting and charging small

device batteries.)

It's unfortunate that they didn't use a high temperature

plastic for fire safety - then they would be perfect. I decided to

ignore that for prototyping. I might have to push the pins out of the

shells and insert them into nylon ones. (They proved to slide out of

the shells pretty easily when pushed from the [clean, unsoldered]

solder end. They should insert as easily into nylon shells. Shoulders

on the pins prevent them from inserting too far in.) And anyway there

should be other wiring types besides solder-on: crimp-on and screw-on,

which will need their own pin stamps and shells. (Those will be made

10mm, even if the existing plug blades only insert to 8mm.)

T-Socket Triplex Wall Receptacle

Plate

T-Socket Triplex Wall Receptacle

Plate

with a couple of loose T-Plugs plugged in.

In

the

late

evening

I opened my "3D printed wall

receptacle plate" file and modified it in OpenSCAD so the T-Sockets

would slide in,

and a simple screw with a washer could hold them in place.

In

the

late

evening

I opened my "3D printed wall

receptacle plate" file and modified it in OpenSCAD so the T-Sockets

would slide in,

and a simple screw with a washer could hold them in place.

Then I sliced it with Skeinforge (fastest to print) and

printed it in PLA. I seemed to have got it pretty good on the first

try. The spaces to insert the socket shells were so close as to be a

great friction fit on all four sides. I didn't bother with the screws.

The blade holes were slightly off

relative to that and their positions had to be adjusted.

Skeinforge had as usual made my thin and critical supports

hollow, deciding everywhere that there wasn't quite enough

width to print a line through the middles - which would have made them

good and strong. The worst was a gap all the way around the hold-down

screws, which also seemed to make the holes larger so the screws fit

loosely. (The user pushes the plug in while the screw keeps the socket

from popping backward out of its slot in the plate, so [except that

they fit so tightly] strength is

needed.)

Having thus disposed of "wall receptacle plates" on the

first evening, the next item will be [was] nylon shells that enclose

the

wires for appliance cord plugs. With that plus higher temperature nylon

shells for the sockets as well, I should think they'll be about ready

for the off-grid market.

[Sept. 4th] I designed and printed

shells for the sockets. I made

prototypes from PLA, but the end products are to be made from higher

temperature nylon for fire safety. Having carefully measured

everything, and having used "Cura" slicer for highest accuracy, when

printed the pins wouldn't fit in. I had to do another one adding .2 to

.5 mm to each inner dimension, and they were still too tight.

In lieu of a real supply, the pins are obtained from the

original shells, which are discarded. The nylon sockets can be inserted

into the PLA wall receptacle plates. Thankfully the whole plate

shouldn't need to be high temperature, just the individual socket

inserts. I found that trying to make wall plates out of nylon was a

wasted exercise: they come loose from the bed during printing, and

anyway are flexible to the point of being floppy. PLA is at least

pretty stiff, and prints well. [In mid September I finally found T-Plug

connectors that claimed to be made with nylon, and ordered some.]

The plugs should be okay with their existing plastic,

because however hot things get, the plug pins are held in place in the

socket until they are unplugged. After the plug is pulled, the

appliance is, well, unplugged. So the thing needed for them is an outer

shell to enclose the ends of the wires.

My

Solar

Power

System

Month of August Log of Solar

Power Generated [and grid power consumed]

(All

times are in PST: clock 48 minutes ahead of sun, not PDT which is an

hour and 48 minutes ahead. DC power output readings - mostly the

kitchen hot

water heater for some months, then just lights - are reset to zero

daily (for just lights, occasionally), while the others are

cumulative.)

Solar: House, Trailer => total KWH [grid power meter

reading(s)@time] Sky conditions

Km = electric car drove distance, then car was charged.

July

31st 798.46, 115.35 => 12.64 [75736@20:00] Sunny with cloudy periods.

August

01st 801.67, 117.33 => 5.19 [oops, left water on (well

pump) for hours; 75748@21:00] Clouds, rain and wind. Welcome to Autumn!

The wind was so steady that the windplant had made about 400 watt-hours

over a 19 hour period when I looked. (I didn't add this to the solar

total.)

02nd 807.42, 120.57 => 8.99 [75759@22:00] A little brighter

but still mostly cloudy. (But any rain has been light - Jungle Creek

has stopped flowing above ground on the beach.)

03rd 814.57, 124.59 => 11.17 [75767@25:00(1 AM)] Mainly cloudy AM,

mainly sunny PM.

04th 817.09, 126.17 => 4.10 [55Km; 75782@22:00] Clouds

& rain.

05th 821.77, 128.82 => 7.33 [55Km; 75797@22:00] Clouds

and no rain.

06th 827.12, 131.85 => 8.38 [75806@24:00] Mostly

cloudy, a bit of rain.

07th (est) => 7.0 -- Cloudy.

08th (est) => 7.5 -- Didn't hit "save" (since 6th) and there was a 1

hour power failure on the 9th. Mostly cloudy.

09th 842.30, 140.75 => 9.58 (est)(=24.08 for all 3

days) [65Km+55Km; 75836@21:00] Mixed sun and clouds.

10th 846.17, 142.92 => 6.04 [75846@21:00] Cloudy. Again.

11th 851.43, 145.87 => 8.21 [25Km; 75857] A few sunny

breaks.

12th 855.56, 148.19 => 6.45 [75862@21:00] Clouds.

13th 858.01, 149.63 => 3.89 [100Km; 75889@21:30] Clouds

& some rain. (Farthest I've driven without recharging. I was taking

it very easy on the highway both trips 55Km+45Km - forgot to plug in

car after trip on 12th.)

14th 860.71, 151.23 => 4.30 [75896@20:30] Mor uv thu

same.

15th 863.00, 152.61 => 3.67 [55Km; 75918@21:00] Rain

rain.

16th 868.64, 154.35 => 8.38 [75927@21:00] Thinner clouds.

17th 872.48, 156.54 => 6.03 [75933@20:00] Surprise

weather: Clouds!

18th 876.62, 158.94 => 6.54 [55Km; 75950@20:00] Mostly

rain.

19th 877.74, 159.56 => 1.74 [75966@20:30] Dark, windy

and rainy.

20th 883.04, 162.52 => 8.26 [75973@20:30] An actual bit

of sun now and then!

21st 889.59, 166.36 => 10.39 [55Km; 75993@20:30] Wow, sun in the

afternoon!

22d 893.59, 168.62 => 6.36 [76000@21:00] Cloudy,

again?!?

23rd 896.72, 170.40 => 4.91 [76009@19:00] Light Clouds, then

Deluges!

24th 900.49, 172.59 => 5.96 [76018@20:30] Cloudy again.

Wither summer? Feels like fall.

25th 902.93, 173.94 => 3.79 [76027@22:30; 55Km]

Clouds, Rain. Sigh. (Car charger "fault", charged next day)

26th 908.75, 177.46 => 9.34 [76042@20:30] mixed sun and

clouds.

27th 910.82, 178.58 => 3.19 [55Km; 76064@21:30] Clouds

and rain... again! (I've started turning on bedroom baseboard heater at

night.)

28th 915.02, 181.04 => 6.66 [85Km; 76092@20:00] Some sunny

breaks in AM, then... clouds and rain.

29th 920.27, 184.18 => 9.39 [76103@20:30] Some sun, some

clouds.

30th 924.37, 186.55 => 6.47 [76113@20:30] Cloudy and

damp, then some sun mid afternoon.

31st 928.45, 188.97 => 6.50 [76121@20:30; 55Km (plugged

in later) Mostly cloudy, a bit of sun.

September

01st 930.38, 190.07 => 3.03 [76141@24:30] Mor cloudz and rain.

02d 932.56, 191.29 => 3.40 [55Km; 76156@20:00] Yet

mor uv thu same.

03rd 937.41, 194.09 => 7.65 [76169@20:00; 35Km] Clouds but no

rain

04th 939.93, 195.45 => 3.88 [25Km; 76192@19:30] same

only darker.

05th 943.57, 197.53 => 5.72 [35+60+35 Km; 76220@20:00]

mor cloudz

Daily KWH from solar panels. (Compare August 2020 with July

2020 & with August 2019.)

KWH

(Each Day)

|

July 2020 (12 panels)

|

August 2020 (12 panels)

|

August 2019 (12 Panels)

|

0.xx

|

-

|

-

|

-

|

1.xx

|

-

|

1

|

1

|

2.xx

|

-

|

-

|

-

|

3.xx

|

1

|

4

|

1

|

4.xx

|

4

|

3

|

2

|

5.xx

|

4

|

2

|

1

|

6.xx

|

1

|

8

|

2

|

7.xx

|

3

|

3

|

3

|

8.xx

|

3

|

5

|

1

|

9.xx

|

1

|

3

|

1

|

10.xx

|

-

|

1

|

1

|

11.xx

|

2

|

1

|

1

|

12.xx

|

3

|

-

|

-

|

13.xx

|

3

|

-

|

2

|

14.xx

|

1

|

-

|

1

|

15.xx

|

4

|

-

|

5

|

16.xx

|

-

|

-

|

1

|

17.xx

|

-

|

|

|

18.xx

|

1 (ONE really sunny

day, a few pretty

sunny, in July!)

|

0 (ZERO really sunny

days in August!)

|

|

Total KWH

|

300.18

|

205.43

|

307.76

|

Monthly Tallies: Solar Generated KWH [Power used from grid KWH]

2019

March 1-31: 116.19 + ------ + 105.93 = 222.12 KWH - solar [786 KWH -

used from

grid]

April - 1-30: 136.87 + ------ + 121.97 = 258.84 KWH [608 KWH]

May - 1-31: 156.23 + ------ + 147.47 = 303.70 KWH [543 KWH] (11th

solar panel connected on lawn on 26th)

June - 1-30: 146.63 + 15.65 + 115.26 = 277.54 KWH [374 KWH] (36V, 250W

Hot Water Heater installed on 7th)

July - 1-31: 134.06 + 19.06 + 120.86 = 273.98 KWH [342 KWH]

August 1-31:127.47 + 11.44+91.82+(8/10)*96.29 = 307.76 KWH [334 KWH]

(12th panel connected on lawn Aug. 1)

Sept.- 1-30: 110.72 + 15.30 + 84.91 = 210.93 KWH [408 KWH]

(solar includes 2/10 of 96.29)

Oct. - 1-31: 55.67 + 13.03 + 51.82 = 120.52 KWH, solar

[635 KWH - from grid]

Nov. - 1-30: 36.51 + 6.31 + 26.29 = 69.11

KWH, solar [653 KWH - from grid]

Dec. - 1-23: 18.98 + .84* + 11.70 =

31.52

KWH, solar + wind [711 KWH + 414 (while away) = 1125 from grid]

2020

Jan. - 6-31: 17.52 + ------* + 10.61 = 28.13 KWH,

solar+

wind [1111 KWH from grid]

Feb. - 1-29: 56.83 + ------* + 35.17 = 92.00 KWH,

solar + wind [963 KWH from grid]

* Now the solar DC system is only running a couple of

lights - not worth reporting. So there's just the 2 grid tie systems:

house and "roof over travel trailer".

One year of solar!

March - 1-31: 111.31 + 87.05 = 198.37 KWH solar total

[934 KWH from grid]

April - 1-30: 156.09 + 115.12 = 271.21 [784 KWH

from grid]

May - 1-31: 181.97 + 131.21 = 313.18 KWH

Solar [723 KWH from grid]

June - 1-30: 164.04 + 119.81 = 283.82 KWH Solar [455 KWH

from grid]

July - 1-31: 190.13 + 110.05 = 300.18 KWH Solar [340

KWH from grid]

August- 1-31: 121.81 + 83.62 = 205.43 KWH Solar [385KWH

from Grid]

Things Noted - August 2020

* Even early in the month, the days were getting notably shorter. By

the 10th it was getting dark at 9:45 (PDT) instead of 10:45 near the

summer solstice; by the 31st it was 9:00 PM.

* There were a lot of clouds and a few sprinkles, but rarely enough

rain to obviate the need for garden watering. (Later in the month the

rains got heavier.)

* But as the month went on, the ground was staying moister - a prelude

to plants going mouldy in the garden and greenhouse in the fall.