Turquoise Energy News #155

covering April

2021 (Posted May 5th 2021)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- More Snow! ...then nice weather - Zinc Plating the C Cell -

Sodium Sulfate lead-acid Battery Life Extender - Toyota Echo Plug-in

Hybrid Conversion? - The Low Rolling Resistance Tires - Handheld

Bandsaw

Mill Kit - Solar PV: Cheapest Energy Ever - Supercorder Making

Instructions

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Titan's Elliptical Orbit - Auroras of Ganymede - Small

Thots (CoViD again (sigh!) - Hair Loss Recovery) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Improved Configuration for a 100% Efficient Torque Converter

* Miles Electric Mini-Cargo Truck: Chargers?: Killer Battery

Dischargers! - Shaft balanced,

reinstalled

* Toyota Echo Plug-in Hybrid Conversion?

Other "Green"

Electric Equipment Projects

* Handheld Bandsaw Mill Kit

Electricity Generation

* My Solar Power System: -

Annual Summaries and Estimates (2 years) - Daily/Monthly

Solar Production log et cetera - Monthly Summaries and

Estimates (26 months)

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte)

- Zinc Plating Onto Graphite Felt

It Snew - Again!

But on the 12th, after almost no sunshine all dreary

winter, it was suddenly

sunny, for most of the rest of the month with a small gap, and it

started warming up. As the days were

rapidly getting longer and the shadows shorter, about one day out of

two set a new daily record for 2021 of

solar electricity generated: 11, 12, 13, 14 KWH. (It never hit 14 in

April 2020!) Total for the month was virtually the same as April last

year, with a greater spread between 'least' and 'most'.

After I finished the final writeup of the last newsletter,

I spent a couple of days making a crossword puzzle for the May-June

issue of Haida Gwaii Trader magazine. And having someone test play it,

then fixing up a final version. AFAIK there's no good computer software

for creating crossword puzzles (but then I've never looked) and I make

them on a piece of graph paper. I then enter the blank and the answer

key

(rather laboriously) into HTML tables so they look nice, and do .PNG

screen grabs to send to the magazine. The clues are just text, but

that's the part that I need to conscript a neighbor for to test play it

and make sure it all works properly and see if any clues are too

indecipherable. I think this is the fifth one I've done. HaidaGwaiiTrader.com covers

many local topics and can be

read on line.

With the good weather I feel blessed to hear the

continuing chorus of frogs from a nearby small swamp, as well as

occasional flocks of gaggling geese going north overhead. It gives one

the sense that "all is well" with the world.

Zinc Plating the C Cell (at last!)

I

put some conductive graphite felt around the inside rim of the larger

"C" cell

and got about 3 grams of zinc plated into it, and surely enough onto

the cleaned copper can to make a solid zinc trail to conduct from the

felt to the copper can. So the cell is almost ready to assemble. I was

surprised how much the remaining diameter is reduced.

I

put some conductive graphite felt around the inside rim of the larger

"C" cell

and got about 3 grams of zinc plated into it, and surely enough onto

the cleaned copper can to make a solid zinc trail to conduct from the

felt to the copper can. So the cell is almost ready to assemble. I was

surprised how much the remaining diameter is reduced.

Then I got onto other things.

Thinking about it: if you have ten or a dozen projects,

either you set some aside month after month, or

you're lucky to be able to spend 2 days a month on each one. That'd be

20-24 days and various other

things always come up. I always spend some time writing, including

TE News. I've done just a little gardening, firewood collection,

construction and so on, but make my meals, shop, and I still look after

5 chickens who the raccoons want for late night snacks if I get

careless.

Miles Truck & Killer Battery

Dischargers

I went to add three more lithium iron phosphate batteries

to the Miles electric mini cargo truck and remove the remaining

lead-acids. But when I went in I found the ones already in the truck

were swollen up. It turned out that unsuspected by me, something was

rather heavily discharging them even with the truck turned off - enough

to drain the whole set of drive batteries seemingly in 2 or 3 weeks.

I'm pretty sure it was the "Delta-Q" battery charger. They were ruined!

They would not charge.

If you were using the truck regularly you wouldn't

notice, but being idle for some time it killed batteries. That also

explains why the original lead-acid 'golf cart' batteries had degraded

so badly over time for no apparent reason, too.

I also found another charger, likewise still connected to

a battery but unplugged from the wall, had almost discharged a lithium

battery in the Sprint car that I was taking for the truck. It took many

hours to recharge. If I had left that one too much longer, it would

doubtless have been ruined too.

It's hard to believe that companies selling supposedly

professional battery chargers obviously intended to remain connected to

the batteries would be so cavalier with customers' batteries when they

could easily put in protection diodes so that the chargers wouldn't

gradually discharge them when not plugged into the wall. ...And not

even mention it to the customers! Replacing those batteries with new

ones would be around 1800$C. Being used, I was selling them for 250$,

and now I'm sorry I was because I only have 5 out of the 6 needed for

the truck. I had to change the plan.

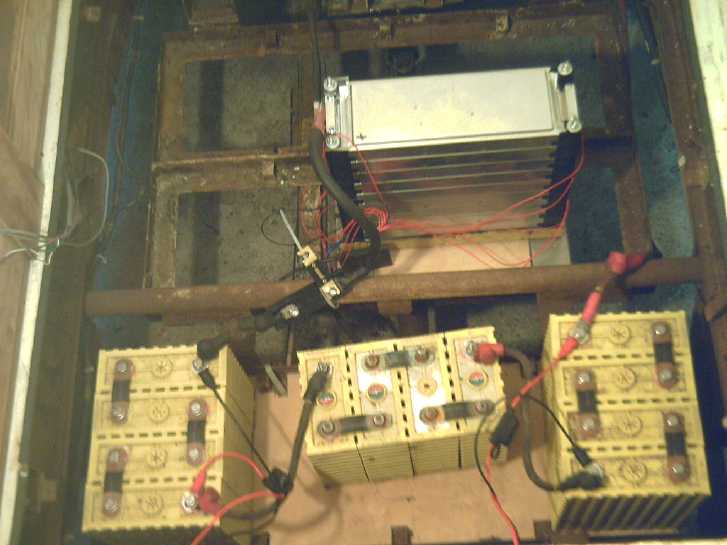

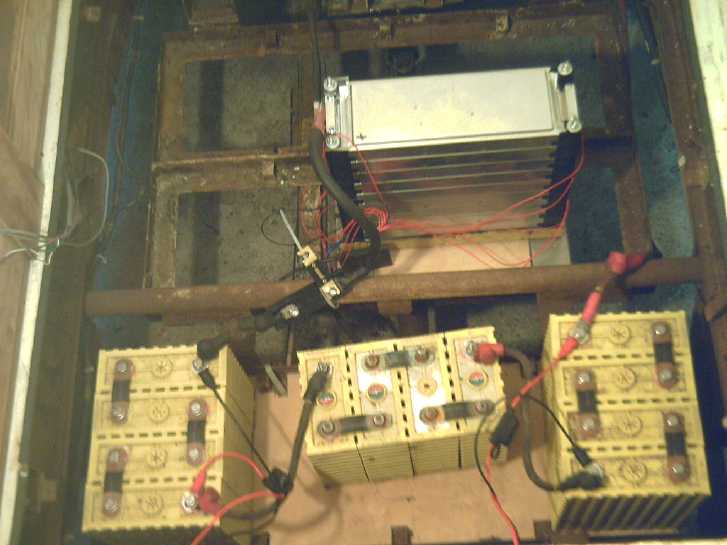

Three Ruined 12V batteries; twelve 100 AH

lithium iron phosphate cells.

Three Ruined 12V batteries; twelve 100 AH

lithium iron phosphate cells.

The new set: three of the five remaining yellow

lithium iron phosphate batteries (100 AH, 36V)

The new set: three of the five remaining yellow

lithium iron phosphate batteries (100 AH, 36V)

and one of the new stacks of ten lithium ion batteries (120 AH, 36V -

later bolted down).

So the truck gets 100 AH (if that - the middle yellow one is well used)

at its required 72 volts.

One observes that they occupy much less than 1/2 the space of the 12

golf cart batteries,

and their weight is about 132 pounds instead of 840 - a reduction of

about 710 pounds.

Back on the actual project... I reinstalled the

balanced, welded drive shaft from the Curtis AC35 motor (right)

Back on the actual project... I reinstalled the

balanced, welded drive shaft from the Curtis AC35 motor (right)

to the 5:1 planetary gearset (shiny box) under the truck. The front of

the drive

shaft (black) to the rear wheels with its "U joint" can be seen at the

left.

(Now, about all that clutter by the garage far wall...)

Sodium Sulfate Lead-Acid Battery Life

Extender & Toyota Echo

I bought 3 months insurance for the Toyota Echo (gasoline

car)

as I would soon have to drive to Masset and pick up my nuc (nucleus

hive) of Carniolan bees. (There's nothing much available in BC between

a

"day

pass" and 3 months car insurance.) On the 17th I

couldn't get it to start. In this car too, something drains the battery

slowly but continually. I'd disconnect it when the car isn't

licensed/used except

the heavily corroded terminals with rusty bolts were a great

disincentive to wanting to touch it. It's happened before, but this

time charging it, even overnight, didn't seem to help. The

charger claimed it was charged, but the engine would barely turn over.

Twisting the battery terminals around to get a better connection didn't

help. Adding

distilled water didn't help - the level wasn't down too far anyway.

(I'm glad I didn't wait for the day I needed it to try starting the

car!)

I thought, hey!, I've never put sodium sulfate in this

battery - never

had the caps off it before. So I funneled a tablespoon of it into each

cell. Then I turned on the headlights to start cycling the battery. Was

it 3+ discharges and then recharges? It's been a long time since I was

doing this.

(And when I was into investigating PbPb battery

renewal some years ago, it was a fiasco... In acid (pH 1) the reaction

voltage of PbO2

=> PbSO4 is +1.7V. Owing to a wrong figure on a chart that said PbO2

=>

PbSO4 was +2.5V instead of +0.5V at neutral/alkaline pH, I was totally

confused for a couple of years as to why the voltage would drop instead

of either rise or else completely cease to work if I added enough

sodium sulfate to raise the pH. I thought

cells must be going bad inside the batteries to explain the lowered

voltages. Being

unable to measure individual cells and figure out what was going on,

the confusion was a

big waste of time and a whole pile of doubtless perfectly useful

batteries! If the pH rose, they needed a charger that would stop at

(eg) 11.5 volts

instead of frying it by trying to drag it up to 13+.

All because of a simple typo or

copying error in a book on the most critical number, one I didn't find

shown elsewhere correctly for a long, long time! Moral: Don't

believe

everything you read?)

Back to the story... I drew it down for well over an hour until the

voltage

dropped under 11.5V. I figured that was far enough and put it back on

slow charge with the best restorative high-frequency "miracle" slow

rate pulse charger. The car engine would still

hardly turn over. Then I did a second draw-down to 11.5V with the

lights, and another recharge. No better. The next morning, I went down

to 11.3V and back up again.

But it was no dice on starting the car. Finally I bought

another battery. That didn't help either. What was going on?

I tried to start the Echo by letting out the clutch in 3rd

gear

while it was rolling down a small hill on my back drive. But it was

almost like

putting on the brakes! There were squealing noises. No way the car

would start. So! It wasn't the battery or the starter: the engine

wasn't seized, but it really didn't want to turn!

I loosened the alternator (breaking the head off the

seized

adjustment bolt to get it loose!) and discovered the alternator was

seized. With the belt off, the car started easily.

I got the alternator off. The housing was cracked and

bulging out. Probably from corrosion. That settled any idea of trying

to repair it. I put the old battery back in and (after making sure it

started the car) drove to the auto parts store. They took the battery

back (yay! 150$!), but the alternator was about 335$. I put it in

and went for a test drive. Everything seemed fine.

The 2014 battery, drained to nothing several times and now

"restored" with the sodium sulfate and pulse charging, still starts the

car no problem, time after time. Next time I'm going to leave the car

sit for months, I'll disconnect it.

Toyota Echo Plug-in Hybrid Conversion?

I started thinking again about the idea of turning the

Echo into a plug-in hybrid with an electric drive on the right rear

wheel. It's a good car. In some ways I like it better than the Nissan

Leaf. I'm short of EV batteries now, but if I could make it work - and

work

well including on the highway - I could sell the Leaf and have a lot of

money for more batteries!

Then I started thinking about all the little things it needed if it was

to become a "nice" project car. What about the cracked windshield? And

the broken tail light? And the non-functional parking brake (ever since

I changed rear brake shoes)? And then how about that intermittent and

noisy cab air fan? And the dash lights that only work sometimes? And

the much pitted, fogged-up plastic headlights? It could use some

cleanup and a vacuuming, too! With 420 Mm* on it, it could hardly be

expected to be like new. I dealt with a few of these things, and they

occupied several days of the month.

Then I started thinking about all the little things it needed if it was

to become a "nice" project car. What about the cracked windshield? And

the broken tail light? And the non-functional parking brake (ever since

I changed rear brake shoes)? And then how about that intermittent and

noisy cab air fan? And the dash lights that only work sometimes? And

the much pitted, fogged-up plastic headlights? It could use some

cleanup and a vacuuming, too! With 420 Mm* on it, it could hardly be

expected to be like new. I dealt with a few of these things, and they

occupied several days of the month.

* That's "Megameters" for all those who don't know the

scalable metric system quite as well as they thought they did.

I dug out the 120 tooth, #40 chain sprocket that would fit

on the rear wheel, and a 20 tooth one that would give it 6

to 1 reduction. Then I pulled out the stiff, formed upholstery

obscuring the right

wall of the trunk, and began to think that if I simply mounted a motor

in the trunk and put a really heavy spring on it to tension the chain,

it could propel the car. It would need one large hole through the sheet

metal

and the plastic bumper for the shaft with the sprocket on it.

The only motor I'd want to try this with at this time

(without making the long planned unipolar BLDC and a controller for it)

is probably the 36 volt forklift motor, for which I already have the

motor controller. Wait, that motor was for the Sprint! It looks like I

have to pick one project or the other.

I got out the motor, got the other half of the lovejoy

connector out of the original Sprint transmission, and rounded up a few

more potential parts. The idea is simple; exactly how to actually do

everything is going to get complicated.

Perhaps the most needed thing is a paint job on

the motor.

Perhaps the most needed thing is a paint job on

the motor.

It works fine as is, but it'd have a better "aura".

There are concerns with the whole idea. A motor in the

trunk will be well above the center of the wheels. So as the car wheel

bounces over bumps, the chain will want to slacken and tighten quite a

bit, and the motor and shaft will have to bounce around a lot to

accommodate that. Mounting it to allow that is surely going to be

the biggest headache. (Toyota is to blame for not making the trunk

lower to

the ground on this side.)

The other big one is that it wouldn't be able to go very

fast with this (2000? RPM) motor; nothing like highway speeds. So

really either this or the Sprint

project would be just a "proof of concept" in anticipation of another

motor - either higher RPM (5000?) or with much more torque so the

reduction ratio can be reduced. (For this it would be nice to still be

living in the city where a car that went 55 KmPH would be adequate for

the streets. 80 is minimal for the highway.)

As to that Sprint direct "motor => planetary reducer

=> CV drive shaft" project: By May 6th the planetary

gear I ordered in mid March had still not arrived. "Departed country of

origin" at last in early April, and nothing more since on the tracking.

I did

ask them to mail it, but oh no, "Things get lost in the mail." It had

to be courier delivery. The mail would have been cheaper than 125$

for no slower delivery. A number of items I ordered through AliExpress

later have arrived in the mail.

I did lose an important parcel in the mail in 2006

(insured), and I know before everything was tracked crooked employees

used to steal things, and the post offices in Canada and USA became

notorious

for losing valuables. That's decades ago now. I think times have

changed since everything more than "small packet" started being

tracked, and corrupt employees are gone. Today nothing an employee

could steal from the mail would be worth the high risk of losing a rare

good job for!

The Low Rolling Resistance Tires

In my trips into town in the Leaf with the new tires (the

four Bridgestone "Ecopia 422+") and in warming weather "mileage" seemed

to be

getting better than ever.

Instead of .9, 1.0, 1.1 or 1.2 kilometers for each percent of battery

charge, I was now getting at least

1.0 or more commonly 1.1 to 1.4. I was getting back

home with around 55 to 60% charge remaining instead of 52 to 56%, or 45

to 50% in

cold weather. And in spite of mostly driving a little faster. My

estimate for the tires' efficiency is still

between 10 and 15% better. And tires improve a little more once they're

"broken in".

But warmer weather is substantially better with both

types of tires. I have noted that sunshine on the pavement (heat!)

gives the best results, while any amount of wetness on the road

(preventing the tires from warming up) is the worst. I'm thinking it

must be possible to formulate tires

that would have their lowest rolling resistance on our usually cool to

cold

roads, around say -5 to 20°C, even if such tires might simply not

be

suitable for (eg) California or Mexico heat.

My biggest conclusion is that I should now start spending

less

time glancing down at readings on the dash and more time watching the

scenery as well as the road.

Handheld Bandsaw Mill Kit

From the 19th I got some work done on this. I cut out two

3/16" steel plates as the bases for

the main wheels at each side of the saw. I got

the idea to mount the guide wheel assembly on the end stop piece so it

won't need its own (third) post at the powered end. Then I welded two

8" posts of 3/4" steel onto each plate. These also hold the guide rails

that determine the depth of the cut.

The guide wheel on the right side has to be free to move

back and forth to set different widths of cuts, so it needs its own

mounting assembly with a post.

I put it together on the "backbone" rails. It looked

pretty good.

Bandsaw mill mock-up, upside-down.

Bandsaw mill mock-up, upside-down.

The thin bar represents the end stop that buts up against the log or

cant.

The 1 inch tubes (resting on wooden blocks) represent the cut-depth

setting rails,

which must be able to slide up and down and attach securely to the four

posts.

I sized it up for blade bands. With an 82 inch blade, the

two main wheels fit entirely within the length of the backbone rails,

and the

maximum cut width - the distance between the posts - is about 15

inches. With the maximum 93 inch blade that I have been using, the

wheels

stick out past the ends and the maximum possible cut is about 20

inches.... But perhaps more

like 13-14 and 18-19 inches when all is assembled.

A 13 or 14 inch cut width doesn't seem very wide for a

sawmill, but the widest I've ever cut, siding boards on the alder log,

was only

12 or 13 inches at the widest point. I've never needed a wider cut than

that so far. (Of course I diced up the large spruce logs with an alaska

mill and only

tackled the cants, 6 or 8" wide, with the bandsaw mill. Being spruce,

that was plenty to ask of a plug-in powered bandmill and thin bands.)

There's a certain amount of technique that may be employed

to avoid needing a chainsaw mill on logs up to a certain size, even

with a shorter available cut. A 20 inch diameter log is only wide that

at

its center. If having only a 14" cut width, one cuts say a 3 inch strip

off the top, flips it and takes another off the bottom, these cuts

(each narrower than 14 inches we trust) would leave a cant only 14

inches wide when turned sideways, which can then be further sliced up

as desired. (The tricky part is placing the guide board on an angle so

the two cuts are parallel as the log gets thicker toward one end.

Cutting parallel both width and length is an asset!)

If one uses such a technique with a 19" available cut

width, the

low power of the motor will probably become the size limiting factor

unless one is cutting balsa wood.

Cheap Energy

The

International Energy Association has said that solar PV is now the

cheapest energy the world has ever seen, and that we are moving into an

era of "insanely cheap" energy. And that's even without HE ray "free

energy"!

The

International Energy Association has said that solar PV is now the

cheapest energy the world has ever seen, and that we are moving into an

era of "insanely cheap" energy. And that's even without HE ray "free

energy"!

In the earlier stages it wasn't thought that solar PV

would be a serious contender in the global energy market, but the

Australian "Father of Solar Energy" took it from an observed effect of

sunlight hitting silicon chips to a practical energy source, and

continually improved it over three(?) decades. (Here I am telling a

story without even remembering his name!) A city in China lured away

his brilliant Chinese engineer with several million dollars to build a

solar panel factory in that town, and soon it "went big" in China and

elsewhere.

By 2010 new solar installations became cheaper to make per

kilowatt-hour of energy than other types of energy such as nuclear, and

they are perhaps a third of that price now while the cost for other

types has only risen.

Nighttime storage of the very large amounts of energy

obtained is

now the biggest bottleneck to still greater adoption.

I've made some comments about the poorer effectiveness of

solar energy here on the northern west coast with its cloudy weather,

low sun and short winter days under Electricity Generation. Yet

if the power on this island wasn't subsidized to make it a uniform

price across all of BC, the price would be quadruple and solar would be

springing up all over, rapidly.

Supercorder Making Instructions

I wanted to get back to the new chemie batteries, the

Miles EV truck programmer, and the ground effect craft programming.

(Not to mention planting the garden, finishing the carport, working on

the cabin, making another firewood shed and cutting next winter's

firewood.)

A Supercorder in African Blackwood with

Nickel-Brass Keys

A Supercorder in African Blackwood with

Nickel-Brass Keys

Instead I suddenly got the idea to put instructions for

making my Supercorder on line on about the 28th, and I spent

the whole 29th making a start at writing those up. I don't know why I

didn't think of doing that years ago! I wasn't writing anything like

Turquoise Energy News back in 2003-2006 when I created them, so there's

no "how-to", and I would like to see them being made - by anyone,

anywhere - rather than the whole grand design for a beautiful

instrument that should be making wonderful music everywhere being lost.

So between that and the handheld bandsaw mill kit, I've

been spending time working on old "finished" inventions, to give them

value. And company arrived for a few days and the month came to an end.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Titan's

Elliptical

Orbit

Titan is not just some

"oid", being between Mercury and Mars in size and having a nitrogen

atmosphere of similar pressure to Earth's. By itself it is 96% of the

mass of all the things in orbit around Saturn. I have long wondered

about Titan's slightly

elliptical orbit about Saturn. It has been said that it should have

circularized long ago over the age of the solar system, but it hasn't.

This 2% eccentricity makes for Titan's fascinating once daily tides (16

Earth days) with a powerful 9 meter impulse, compared with Earth's

twice

daily tides with a .5 meter impulse. These tides drive Titan's shallow

seas

of relatively pure liquid methane into a complex geometric pattern

around the equator, with areas of undersea "dunes" that extend for

hundreds of kilometers, from 400 meters depth to the surface. The

inevitable and

obvious conclusion is that something is keeping the orbit elliptical.

Two other worlds worlds seem to be involved in this:

Iapetus, Saturn's next and outermost regular moon out from Titan, and

tiny "potato" Hyperion with an irregular orbit between them.

Hyperion, in a complex resonance that brings it very near

Titan, makes 3 orbits of Saturn for every 4 of Titan. (Its extreme

tidal bulge "potato" shape is probably a result of passing very close

to Titan at some point, plus having little gravity to draw itself back

into a sphere. It is known to rotate to point at Titan when it gets

close to it,

causing it to "tumble" instead of always keeping its long axis pointed

toward Saturn.)

Iapetus also has a 2% elliptical orbit with 5 times the

period of Titan. Yet not exactly 5 times:

Titan: 15.94542 Earth Days

Hyperion: 21.27661 E.D.

Iapetus: 79.33018 E.D.

Titan * 4/3 = 21.26056

Titan * 5 = 79.7271

Discrepancies:

Hyperion: 21.27661 / 21.26056 = +.000755

Iapetus: 79.33018 / 79.7271 = -

Although the Titan/Hyperion 4/3 ratio isn't 100% exact,

scientists say a gradual precession of orbits (over a 20 Earth year

cycle) accounts for the difference. However, they say the same isn't

true of Iapetus - that its orbit isn't resonant with Titan's;

precession can't account for the difference. (I remember once trying to

work

it out for myself (I don't remember how), and that seemed to be true.)

And yet we have the undeniable fact that all their orbits stay

elliptical

and there is simply nothing else that can account for it. And Iapetus

is so close to exactly 1 orbit per 5 of Titan as to be more than

slightly suspicious. We must be missing something, some subtle

complexity to the relationship that we haven't figured out.

But I have just learned something I hadn't known before:

Iapetus' orbit is inclined 15.5° from Saturn's equatorial plane,

where the other moons orbit pretty closely to it. Without knowing how

to calculate the orbital mechanics, I say AHA! Something in that

orbital inclination must

explain that Titan, Hyperion and Iapetus are somehow in resonance after

all and causing each others' orbits to remain elliptical. Perhaps

Iapetus' inclination precesses in resonance with Hyperion and or Titan?

We may find there's another resonance over a still longer period of

time, maybe even hundreds or thousands of Earth years. After all, Earth

has some extremely long known cycles such as the wobble of its orbital

inclination. (11,000 years, was it?)

An interesting note is that Iapetus can be closest to the

others when it is crossing the equatorial plane where Titan and

Hyperion are, twice per orbit. One suspects the interactions are

probably somehow also tugging Iapetus into its relatively steep orbital

inclination as well as causing the slight orbital eccentricities. The

clues of what's going on are doubtless there for us to figure out.

(my writings on this fascinating world ~ 2005-2008: Living Titan: https://www.saers.com/recorder/craig/titan

)

Auroras

of

Ganymede

Ganymede has

a magnetic field rather similar

to Earth's. Lately astronomers have used one o' them fancy new

telescopes to image its auroral displays. (Well, I can't remember the

details.)

Ganymede has

a magnetic field rather similar

to Earth's. Lately astronomers have used one o' them fancy new

telescopes to image its auroral displays. (Well, I can't remember the

details.)

One may observe that the more equatorial area is darker

than the more polar regions beyond the auroras, perhaps indicating that

the fluffy layer of reddish complex organic materials thrives better

where

protected by the magnetic field from "cosmic rays" (high energy charged

particles) and Jupiter's ionizing radiation.

Thus Ganymede (diameter ~5260 Km) would be friendlier to

space visitors than Mars (diameter 6787 Km), where "cosmic rays" are

free to blast right in to the surface.

Outside of magneticly protected areas, there is also a

hemispheric difference where Jupiter's ionizing radiation, swept around

with its 12 hour rotation, blasts the trailing hemisphere but not the

leading one.

This is most noticeable on Callisto and especially

Saturn's small moon Iapetus, where astronomers have long noted that the

rear is almost as reflective as ice, but the front is "as dark as

coal", and from the Cassini probe, "very fluffy".

Small

Thots

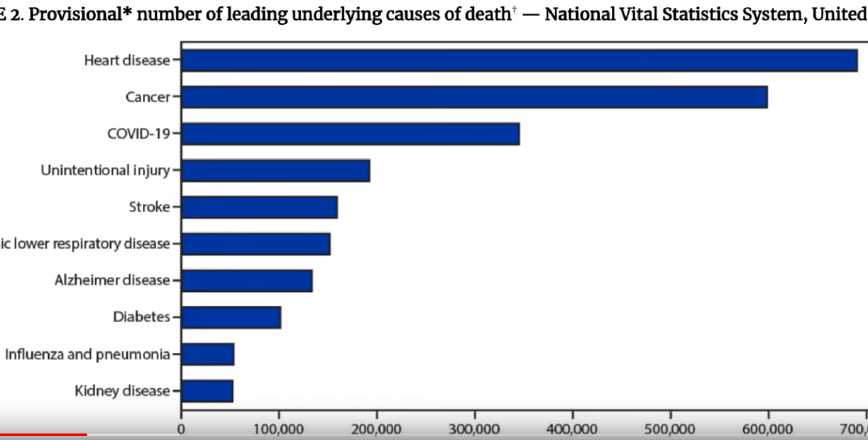

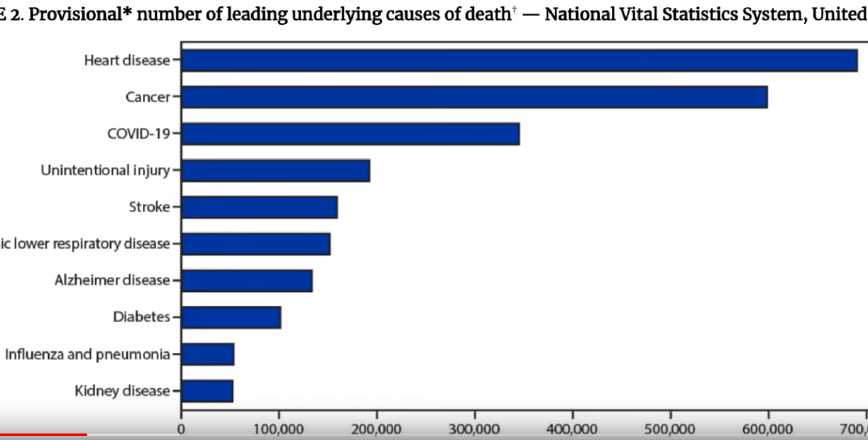

* It seems that new CDC statistics

indicate that as few as 6% of those in the USA said to have died of

CoViD had CoViD and nothing else. The other 94% had at least

potentially fatal co-morbidities that were at least major contributing

factors if not the actual cause of death. Hospitals have been getting

substantial extra money to handle "CoViD deaths", so they have a strong

incentive to report every death possible as "CoViD" regardless of the

actual cause. Hospitals have admitted to misleadingly counting at least

130,000 deaths as "CoViD" which were actually from other causes such as

pneumonia, flu and heart attack. Herein is no doubt a main reason the

USA has been

reporting a much higher incidence of "CoViD" deaths than other

countries. (And why flu seems to have almost died out?) The original

number of deaths said to be from CoViD was 345,000. 6% of this is just

21,000, or even 33% is just 115,000 - more in line with many other

nations' CoViD death rates and - not to minimize the seriousness or

contagiousness of CoViD - rather similar to regular seasonal influenza.

Even so, both heart disease and cancer each killed almost

twice as many people as were previously reported to have died of the

virus. Yet there is no big push being made to eliminate these "more

epidemic" causes of death. Society isn't being disrupted and shut down

- not even the "worst culprit" foods and drinks are being pointed out.

No one is being lectured about healthier diets or the need to

take vitamin D to be resistant to cancer if you're not getting out in

the sunshine.

Even so, both heart disease and cancer each killed almost

twice as many people as were previously reported to have died of the

virus. Yet there is no big push being made to eliminate these "more

epidemic" causes of death. Society isn't being disrupted and shut down

- not even the "worst culprit" foods and drinks are being pointed out.

No one is being lectured about healthier diets or the need to

take vitamin D to be resistant to cancer if you're not getting out in

the sunshine.

* Local statistics as far as I have

heard (accuracy is by no means guaranteed) from Haida Gwaii, pop. 4500

or so:

Deaths from Covid: 0

Deaths from Covid Vaccine: 4.

Of course one must note that that is out of two or three

thousand vaccine doses, and also that if the vaccine is 100% effective,

it only makes sense that all of very few deaths among those vaccinated

must be from the vaccine, which has prevented the disease. And

statisticly it is said that rates of CoViD are down substantially among

the vaccinated.

I wonder how many deaths there have been here from other

causes

in the last year? If we all live to age 100, and all else being equal

(but of course there are many factors), one would expect around

45 deaths per year here total.

* A head person at CNN was secretly filmed while saying (among other

disturbing things) that fear

gets ratings, and nothing gets ratings like CoViD, so they've been

hyping it

for all it's worth. He said next they plan to hype global warming

again.

But mass media viewership has declined substantially in the last year.

* There seem to be a growing number of new strains of CoViD. As with

influenza,

vaccination for the original one is unlikely to confer immunity to

others. Someone was saying that the efforts to slow the disease -

lockdowns and vaccines - are helping it to mutate much faster. I

didn't really follow the logic behind this assertion.

* Sign at the ferry terminal, in lights like a highway construction

sign: "Essential travel only" - blink - No recreational travel" - blink

- stay local - (back to 1st)

This isn't a good way to advertise to get business!

Apparently the public is marooned on this

island, and also on Vancouver Island! And wherever else they are! One

might hope the insanity would

end. Instead, so far, it has been getting worse and worse.

* Texas however has reopened everything, and now (after many dire

warnings from politicians and the media of the doom and gloom and mass

death that

would follow such a reckless move) their rate of new covid cases is

lower than locked-down states. Statistics are now

starting to show that none of the lockdowns, shutdowns, masks and other

measures

tying everyones' hands have had any significant effect on the spread of

the virus. It has spread virtually the same in nations and states with

or without such craziness.

* Is it time to call the whole thing off? And give out Ivermectin pills

to cure the ill as some Eastern European countries have now started

doing, instead?

...and vitamin D to improve resistance to both CoViD and cancer?

---

* My hair has definitely gotten thicker since writing about hair loss

in (at least) TE News #139, 137, 140 and 141. If I part it in the

middle it now looks like an ordinary part instead of a very wide part

showing lots of skin. The top-back area is much improved too, although

it doesn't seem like "full thickness" yet.

I think the weekly scalp spray and rub with (ethyl)

alcohol before

a shower keeps the Demodex mites at bay to prevent further hair loss,

and stimulation of the scalp by fairly gently rocking a hair brush back

and forth on it (not a brush with a little ball on the end of

each bristle). I've only been doing that for 3 or 4 months, and it

seems to have really

helped get it growing again where it was thin. (In lieu of that,

perhaps a "scalp roller", eg from AliExpress.com, is probably a good

stimulator? I ordered one once to try it out, but it never came.)

Now, why is my hair starting to get so much gray in it?

I'm only 66!

* Having mirrors placed in your bathroom so you can see your back side

is really helpful. (In my bathroom a "full length" mirror hanging on

the door works great combined with the three medicine cabinet door

mirrors

across from it, which each must be aimed at the best angle to give rear

views at good angles with the door mirror.)

ESD

(Eccentric Silliness Department)

* Year after year we celebrate Easter. When do we get to celebrate

Wester?

* I C Y. Do U C Y?

* Times change. How many houses and buildings have candles burned down?

Perhaps in this new age we should change the little rhyme:

"The butcher, the baker, the LED maker".

* Some people do very fine welding. I occasionally do astounding

welding. I am always astounded when two pieces I weld together don't

come

apart! (Another 10 years and I'll be as good as the kids in first year

trades school!)

* Some heavily processed junk foods can't really be said to have a

shelf life - rather, they have a half life. [per Perry, grocer]

* Deer hunting season is over. Garden raiding season has started. For

the deer.

* I found a Canadian Tire flyer that said "Canada's Spring Store". I

looked through all the pages but couldn't find a single spring!

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

A

Modified

100%

Efficient

Torque

Converter Assembly

[9th] For some reason I got back on AliExpress looking at planetary

gears. I noticed one with a round body. This time I also had in mind

the other

recent idea of going in-line from a planetary gear straight to a CV

drive shaft or a wheel. That got me to thinking... that instead of

driving a gear or chain sprocket to a differential from the torque

converter, one might use it in-line the same way.

I thought about it again, and came up with needing the

same gear

configuration for the torque converter, in order that the

forces all act in the same direction rather than oppose each other:

- motor drives the planet assembly gears

- sun gear drives the shoes of the centrifugal clutch (highest

speed point for centrifugal action)

- ring gear has the outer centrifugal drum, and drives the car.

(Will turn the same direction as the shoes as it starts turning.)

The trouble is I couldn't see how to arrange that. To have

the ring gear be one end to drive the wheel/drive shaft, the planets

and sun gear would both have to be concentric on the other. And somehow

the planets would have to be on the inside shaft to connect to the

motor, with the sun gear outside to turn the centrifugal shoes. It's

not

that such a thing couldn't be created, but I doubt if anyone makes one

configured that way, and I expect creating a hollow centered sun gear

with a hollow shaft (that the shaft of the planets assembly can run

through) is beyond my capability.

But Wait! Aha! The ring gear also connects to the

centrifugal drum. The drum

can have two solid faces. One is attached to the ring gear. Then the

outside face is beyond the centrifugal shoes within - it is at the very

end with nothing else sticking out past it. So the outside face can

connect to the drive shaft or wheel. Then only a regular planetary

gear is required! No custom parts except

the special centrifugal clutch. What is usually the output shaft

(planets) connects to the motor shaft. The socket that usually connects

to the motor gets a shaft to turn the centrifugal shoes, which is

inside the two-faced outer drum. This should simplify the whole idea.

Should I want to put one on the Miles mini cargo truck, it

could drive the existing rear differential, which

provides about a 2 to 1 "final reduction ratio". So with a variable

torque converter fully engaged (1 to 1 ratio) the motor

would spin twice as fast as the wheels, which seems desirable, and it

should easily attain highway speeds.

On the Sprint car the motor speed is doubtless too low

with

direct drive to the wheel (only 1000 RPM at 100 KmPH), so one might

employ a second planetary gear

in-line after the torque converter one for a fixed "final reduction

ratio", again probably about 2 to 1 or higher, depending how high one

wishes the motor to rev at highway speeds - which of course depends on

the motor.

But a lot will depend on just how the torque converter

performs at what RPM. And that depends on the ratios of the planetary

used, the output shaft speed before final (again planetary) gear

reduction,

and the performance of the centrifugal clutch.

Miles

electric

cargo

truck

delayed

project

Killer Battery Dischargers!

[8th] I decided to use six 100 amp-hour, 12 volt

lithium-iron phosphate (LiPO) batteries for the 72 volt drive. I took

out the six remaining 70 pound golf cart batteries. Between the

unwiring and the weight, that ended the afternoon.

With around 840 pounds (for all twelve) removed and six 30

pound LiPOs added, total lightening of the truck would be 660 pounds.

Not insignificant!

And given one shouldn't discharge PbPb's to less than 50%

remaining, their 180 amp-hours rating is the same as the 100 amp-hours

of the new batteries, which can be discharged to 10%. And being 660

pounds lighter the vehicle should go farther for the same energy. At

least that's

the theory: in practice, the golf cart batteries were all failing

anyway, and half the LiPO's were

as old as the truck, considerably used (the were from the Suzuki Swift)

and hence it's doubtful they had full capacity.

But I found that the LiPOs that were already in the truck

were horribly swollen up! Had they been badly overcharged too? Frozen?

(In the garage?!?) To my shock they all read 0.0 volts! The other

possibility then was

that they had been totally discharged. (They swell up if they're

discharged?) I had left them fully charged in the truck, but assuming

there was no load on them if the truck was shut off, I hadn't looked at

it for months. It had no clock, no radio, and the contactor solenoid

shut

off the motor controller when the key was off -- what on Earth would

draw current if it was shut off? Apparently there must be

something. Sh*t! That doubtless explained the deteriorations and

pretty much demise of the lead-acids over time, too. In all the time

I've had the truck I never suspected that they were always under load -

however light - rather than being idle. Why didn't I think of it? So

many newer vehicles (well, since around ?1985) draw current and drain

the battery even while they're sitting. But how much does it draw,

anyway, that it would drain several kilowatt-hours, even over a few

months? [calculating...] Well it would have to be well over a watt

rather than milliwatts. Obviously

I should have disconnected the batteries entirely when I put the truck

away. For the future I'll put a 500 amp fuse at the 36 volt point, that

I can disconnect if I'm not going to be using the truck. (By putting it

at the middle point, even if the system should become grounded

somewhere that's okay to touch.)

But I found that the LiPOs that were already in the truck

were horribly swollen up! Had they been badly overcharged too? Frozen?

(In the garage?!?) To my shock they all read 0.0 volts! The other

possibility then was

that they had been totally discharged. (They swell up if they're

discharged?) I had left them fully charged in the truck, but assuming

there was no load on them if the truck was shut off, I hadn't looked at

it for months. It had no clock, no radio, and the contactor solenoid

shut

off the motor controller when the key was off -- what on Earth would

draw current if it was shut off? Apparently there must be

something. Sh*t! That doubtless explained the deteriorations and

pretty much demise of the lead-acids over time, too. In all the time

I've had the truck I never suspected that they were always under load -

however light - rather than being idle. Why didn't I think of it? So

many newer vehicles (well, since around ?1985) draw current and drain

the battery even while they're sitting. But how much does it draw,

anyway, that it would drain several kilowatt-hours, even over a few

months? [calculating...] Well it would have to be well over a watt

rather than milliwatts. Obviously

I should have disconnected the batteries entirely when I put the truck

away. For the future I'll put a 500 amp fuse at the 36 volt point, that

I can disconnect if I'm not going to be using the truck. (By putting it

at the middle point, even if the system should become grounded

somewhere that's okay to touch.)

Totally discharged, swollen up LiPO cells.

Totally discharged, swollen up LiPO cells.

Thanks, "Delta-Q" Battery Discharger!

I had 8 sets of the LiPOs. That was supposed to do the

truck with 2 to spare. If 3 were now no good, that left me just 5 where

the truck needed 6. Oh, no! Here was a disheartening development. These

things aren't cheap, even ordered from China. Too bad I sold some of

them. I thought I had more than enough left.

Assuming they had been discharged I went to charge them

and see what would happen. I got out a lab power supply and set it to

10 volts (they might charge unevenly so I kept it low to start with)

and its maximum

of 5.5 amps. Gradually the voltage started to creep up, but painfully

slowly. and unevenly between cells. What would happen? LiPOs aren't

supposed to explode. But. They're also not supposed to be allowed to go

below 2.8 volts per cell. If they had been at zero for weeks or months,

would they recharge at all? If they did, would they have full capacity

or way less than their rating? Or would they explode anyway? After a

while it became apparent that the voltage wouldn't rise to halfway and

that the batteries were completely ruined. In fact it started dropping

again even with all the current going in. A sickening waste of what had

been good batteries.

That leaves using:

(a) three of the five good LiPO batteries and one of the new

lithium-ion stacks for the other 36 volts, or

(b) The two assembled lithium ion stacks (leaving the unassembled one),

or

(c) buying at least one new set of four LiPOs. (500-600 $) Still leaves

3 older well used sets that may not last too long in vehicle use. (The

other two sets are better)

(a) seemed the most practical. I had been hoping to

put all three of the 36V, 120AH LiIon stacks into the Sprint in

parallel. Or at least the two

assembled ones for now. I guess I'll have to assemble that third stack

sooner rather than later. (Or rob the truck when I go to try out the

car.) Let's see... a 40 pound 36V stack instead of three 30 pound 12V

batteries means another 50 pounds off the weight, so total weight

reduction from the twelve golf cart batteries is 710 pounds.

Perhaps another good battery deal will come my way some

time? (Even if I get my nickel manganates - zinc cells working great I

don't have much confidence for producing enough to put into a car any

time soon. Especially not by making C cells!)

I re-installed the now

balanced (or at least

centered/straight) shaft I'd made to connect the 5:1 planetary gear to

the truck motor. It was also now welded so the two shaft coupler joints

couldn't shift and it would stay centered.

Right to Left:

Right to Left:

Back of Curtis AC35 motor; the shaft; the shiny 5:1 planetary gearset

with

angle bracket & plate - a somewhat cushioned mounting to frame;

(dark) socket and U-joint of drive shaft to rear sheels.

Then I set the batteries in, and then connected them. Then

I checked the battery voltages and found a couple were down more than I

liked. I connected some chargers using an extension cord and a power

bar and left it a while. So I cleaned up in and around the truck - long

overdue.

At the end of the day I tried it out, just in the garage.

It powered up and drove backward and forward. YAY!

When I quit for the day I disconnected the fuse that I put

in-line. Why would I trust it?

Then some proper chargers. I thought maybe I should just

get two 40 or 50 volt lab power supplies and set them to optimum

voltage for the balance chargers: maybe 42 volts for the 12S

lithium-iron phosphates and 40 for the 10S lithium-ions. (or I could

reduce the PO4s to 11S. Then 40V would be enough.)

That night I went to AliExpress, but the lab units were

uniformly "0-30V, 10A" or else "0-60V, 5A". 10 amps seems like a good

minimum. An overnight charge seems reasonable, but to charge a 100

amp-hour battery at 5 amps could take most of a whole day. After much

further searching I found an "OEM" power supply that was 40V, 10A, with

an adjustment screw plus or minus 10%, so presumably about 36 to 44

volts. Runs on 110 or 220 volts AC. They were about 45$. Perfect! I

ordered three - two for the truck and one for the Sprint.

[15th] I was wondering why the one LiPO battery from the Sprint had

been so low - 12.8 volts instead of the usual 13.5 or so. It seemed all

four of its cells were maybe 80 or 90% discharged. It was taking many

hours to

recharge. Then it occurred to me: one of them out of two had been

plugged into a "Genius" charger from Canadian Tire, set to "Lithium".

The other had the double 6 volt charging system I had made for balanced

charging. I had put in diodes to make sure it would only charge.

But the "Imbecile" charger (I'll not call it "Genius"!) must have been

drawing current from the

other battery when it wasn't powered up! It's supposed to be a charger,

not a discharger! I supposed if I'd left it very much longer this

battery would have suffered the same fate as the ones in the truck.

I'll have to watch for that with the new power supplies and if

necessary (probably) put high current diodes in series so they can't

become dischargers. (The "12S" and "10S" balance chargers might prevent

discharge, but I'm not counting on it. In fact, I hope they don't cause

discharge themselves! The charge on the stack isn't as high as it was

when I unplugged the stack from charging some time back, either. Hmm! I

disconnected the 11 pin plug just in case.)

Then I suddenly realized that's what it must be on the

truck: the "Delta-Q" 72 volt battery charger must surely be what was

discharging the batteries! The longer I go the more I hate those

chargers. First the Swift fire, then this one boiled the golf cart

batteries completely dry (probably after draining their charge entirely

more than once

first), now it has destroyed three LiPO's as well (and whatever was

left of the last six golf cart batteries) -- and it wasn't even being

used! Add "remove old charger" to the list of truck jobs. Later I put

the mulitmeter on "10 amps" scale across the disconnected fuse and

found that something was in fact drawing over .6 amps with the key not

even in the ignition! The current seemed to be dropping ever so slowly,

but at

that rate even 100 amp-hour batteries would be dead in two weeks.

With the tall stack of LiIon's too likely to fall over, I made

a couple of aluminum brackets, drilled some holes, and bolted it into

place.

This time I moved "the place" over toward the middle so I could get a

screwdriver in behind to undo the screws and connect meters on the dash

to show

battery voltages.

With the tall stack of LiIon's too likely to fall over, I made

a couple of aluminum brackets, drilled some holes, and bolted it into

place.

This time I moved "the place" over toward the middle so I could get a

screwdriver in behind to undo the screws and connect meters on the dash

to show

battery voltages.

(I should strap down the 3 LiPO's too. And the fuse holder

is just strapped down with a cable tie. And I'm not fussy about it all

being open to the road beneath. Perhaps I'll enclose it all with

plywood.)

When it was mounted and reconnected I didn't see

anything to prevent a test drive.

I backed the truck out of

the garage and started to circle

around the driveway. The drive shaft started slipping or skipping when

I tried to go uphill. I checked underneath and found the socket screw

in the planetary was loose, although I had tightened it all I could

when I assembled it. (ONE silly little socket screw to hold all that

torque??) I tightened it up and it seemed okay. I drove it back into

the garage. I had

noticed that the shaft splines were sticking out a bit from the motor

socket. I thought they were usually right inside. Had the whole shaft

slipped back too far, or was it okay? STILL not done with this cyrsid

shaft? But assuming it's fine now, next job is seeing what's up with

the

handheld programmer - why doesn't it seem to work right?

I'm not going to do much or any driving until I have

proper chargers. Or 2 x 36V solar panel chargers: Two on the roof, with

or without two 'extra' panels that swing up from the sides of the box

when the truck is parked.

Toyota

Echo Plug-in Hybrid Conversion?

I started thinking again about the idea of turning the

Echo into a plug-in hybrid with an electric drive on the rear wheel.

It's a good car. In some ways I like it better than the Nissan Leaf.

I'm short of EV batteries, but if I could make it work - and work well,

for the highway - I could sell the Leaf and have a lot of money for

more batteries!

Then I started thinking about all the little things it

needed. [Well, you can skip down from here to the next white space

below the taillight pictures from here!]

What about the cracked windshield? And the broken tail light? And the

non-functional parking brake (ever since I changed rear brake shoes)?

And then how about that intermittent and noisy cab air fan? And the

dash lights that only work sometimes? And the much pitted, fogged-up

plastic headlights? It could use some cleanup and a vacuuming, too!

With 420 Megameters on it, it could hardly be expected to be like new.

YAY! A junked car with the same tail lights as

my cracked ones!

YAY! A junked car with the same tail lights as

my cracked ones!

On the 24th I noticed the other tail light had a crack in

it as well and fine dirt was getting in. Doubtless I'd have noticed it

earlier if the broken one with all the "Tuc" tape around it didn't draw

one's attention away. I asked Paul if he might have a wrecked Toyota

Echo and got two "new" tail light assemblies at his wrecking yard in

Port Clements, from a corroded 2000 Echo (one year older than mine). I

disassembled, washed and installed them, bashed out a few dents around

the one that had been broken, and sprayed on some rust primer paint.

(Now, if I'd been prescient earlier, I could probably have got the

alternator off the wrecked Echo for a lot less than 335$! Hmm, are

there any other parts the car needs that might be had from it?)

Then I fixed the rear/parking brake. (I had

re-assembled it wrong last time - a little "self-adjustment ratchet"

was sprung out of place. I only figured it out thanks once again to

someone on youtube showing how-to!) Then I drove the car up on ramps

twice and sprayed "Fluid Film" over all the rear, and then front,

steering, springs and suspension parts and joints around the wheels to

ward off further corrosion.

Now about that windshield... There was one on the scrapped

Echo, but watching a how-to video convinced me I didn't want to do it

myself except as a last resort. And a brand new windshield is always

clearest - if costly. (Rock chips in windshields have convinced me to

slow down on the highway in winter when there's gravel on the road, and

still more whenever another vehicle is approaching. I think dropping

down to 50 KmPH saved

my Leaf windshield at least once when a big truck passed by.)

I pulled out the formed upholstery obscuring the right

wall of the trunk, and began to think that if I simply mounted a motor

in the trunk and put a really heavy spring on it to tension the chain,

it could propel the car. It would need one hole through the sheet metal

and the plastic bumper for the shaft with the sprocket on it.

The only motor I have that I'd want to try this with

(without making

the long planned unipolar BLDC and a controller for it) is probably the

forklift motor. Wait, that motor was for the Sprint! It looks like I

have to pick one project or the other. Unfortunately, I now really only

have batteries for one EV project, too. Two if I stretch it and maybe

resurrect some golf cart batteries for the house solar.

I

dug out the 120 tooth, #40 chain sprocket that I had

made to fit on a car wheel, and I pulled out a 20 tooth one (from 2016

experiments) that would give it 6 to 1 reduction. By having a gear

almost as large as the wheel (hopefully I didn't go TOO large - there's

not much ground clearance if the tire is low), the forces on the chain

are reduced. With a smaller gear a #50 or #60 chain might be a better

choice. I expect #40 chain, wrapping around larger sprockets, will have

lower losses and last longer.

I

dug out the 120 tooth, #40 chain sprocket that I had

made to fit on a car wheel, and I pulled out a 20 tooth one (from 2016

experiments) that would give it 6 to 1 reduction. By having a gear

almost as large as the wheel (hopefully I didn't go TOO large - there's

not much ground clearance if the tire is low), the forces on the chain

are reduced. With a smaller gear a #50 or #60 chain might be a better

choice. I expect #40 chain, wrapping around larger sprockets, will have

lower losses and last longer.

Another viable choice with the larger sizes might be a

poly-V or flat belt instead of chain. Those are said to be almost 99%

efficient and are very quiet - as long as they don't slip. (I'm less

sure about the efficiency of toothed belts.)

[26th] After hooking up the trailer and

driving into town to buy

enough plywood to finish the cabin (before the price goes up!), I got

out the motor,

got the other half of the lovejoy connector from the original Sprint

transmission, and rounded up a few more potential parts. The idea is

simple; exactly how to actually do everything is going to get

complicated.

My biggest concern - all along for trying out this idea -

with a motor in the trunk

is that it will be well above the center of the wheels. So as the car

bounces over bumps, the chain will want to slacken and tighten quite a

bit, and the motor and shaft will have to bounce around a lot to

accommodate that. It's almost as if Toyota's engineers never

contemplated

this sort of electric conversion when they designed the car! Somehow

I'm reluctant to chop out part of the floor of the trunk in order to

mount the

motor lower. Is that just a silly mental block? Hmm!

[May5th] Say, I should mount the motor and sprocket to a vertical plate

that can easily spring back an forth, not to a horizontal one that has

to lift and fall a ways in order to go back and forth. Or, say, not

quite vertical but perpendicular to the line from the motor to the

center of the wheel. Yes, that would be optimum!

But the real problem is that the car won't go very fast.

If the Sprint (10" tire radius) only did 25 KmPH with a 9 to 1

reduction from this motor, the Echo (11") is probably just going to hit

40 with 6 to 1. That's nothing like highway speed. And in fact one

would much over-rev the motor if one drove too fast under gasoline

power with the electric system connected. The reason for doing it then

is really just to try it out in principle and anticipate getting or

making some other motor later. But a 5000 RPM motor instead of (?)2000

would allow 100 KmPH, or a very high torque motor might deliver

sufficient thrust with a lower reduction ratio.

It would be pretty much the same with the Sprint "motor to

planetary gear reduction to wheel shaft" project. If I'm not going to

make the unipolar BLDC motors and controllers any time soon, perhaps I

should hunt around for a more suitable motor for whichever project I

pursue?

Other "Green" Electric Equipment Projects

Handheld Bandsaw

Mill Kit

[19th] I got

around to cutting out a 3/16" steel plate as the base for

the powered side of the saw. I had made marking on the wood, now used

those to size up the steel. I drilled the bolt holes and tried it out.

After a couple of small cuts to trim it, it seemed about right. I have

the idea to mount the guide wheel assembly on the end stops, so it

won't need a separate (third) post.

[19th] I got

around to cutting out a 3/16" steel plate as the base for

the powered side of the saw. I had made marking on the wood, now used

those to size up the steel. I drilled the bolt holes and tried it out.

After a couple of small cuts to trim it, it seemed about right. I have

the idea to mount the guide wheel assembly on the end stops, so it

won't need a separate (third) post.

[21st] I welded on two 8

inch posts of 3/4 inch square steel tubing to

this base for mounting the depth setting bars, the left end stop/guide

and the left side band guide wheel assembly. Then, having all the

equipment out on the lawn, I made a mirror image copy for the right

end. The plate is actually identical - just turn it over.

[21st] I welded on two 8

inch posts of 3/4 inch square steel tubing to

this base for mounting the depth setting bars, the left end stop/guide

and the left side band guide wheel assembly. Then, having all the

equipment out on the lawn, I made a mirror image copy for the right

end. The plate is actually identical - just turn it over.

This time instead of

cutting the complex shape with the

angle grinder and a jigsaw with a metal cutting blade, I remembered I

had bought a plasma cutter a while back. I got it out and cut it with

that. No doubt it was faster cutting than anything else, but it made

the ugliest cuts, with bits of slag everywhere, that I had to spend

quite some time cleaning it all up. And I used up a cutting disk on the

angle grinder doing so, so I only saved one zip disk, and probably 1/2

a

metal cutting jigsaw blade. But I may get better with practice?

Then I welded 7 inch posts to that plate. (instead of 8":

At the right end they don't hold the end stop/guide and so don't really

need to go below the blade.) And drilled the bolt holes.

I put it

together on the "backbone" rails. It looked

pretty good. Of course for production I will draw out the plates in a

CAD program and

then send them off to be CNC waterjet cut. (...unless I get my own

plasma cutter working on the CNC platform. Well, not this month.)

I put it

together on the "backbone" rails. It looked

pretty good. Of course for production I will draw out the plates in a

CAD program and

then send them off to be CNC waterjet cut. (...unless I get my own

plasma cutter working on the CNC platform. Well, not this month.)

But I noted one conceptual flaw: the flat end stop piece

will prevent the cutting depth guides from being set to thinner than

the width of the part of the stop above the band. Having cut some

myself, I just know that people will want to cut about 1/4 to 3/8 inch

thick guitar backs and bellies with this nearly zero kerf mill! (Maybe

even cut veneer?) It would probably be easier and have less waste than

with a shop bandsaw. Well, maybe I would just have to cut out offending

bits from the end stop, and hope there's enough left to impart

structural rigidity to the posts assembly. (I already have to cut out a

big notch for the band in the part of the end stop below the band,

ending a little above it. Can't thread a bandsaw band through a hole!)

I sized it up for blade bands. With an 82 inch blade, the

two main wheels fit within the length of the backbone rails, and the

maximum cut width - the distance between the posts - is about 15

inches. With the maximum 93 inch blade that I was using, the wheels

stick out past the ends and the cut is about 20 inches. The cuts are

likely to be an inch or more narrower because the right guide wheel

assembly may not travel all the way to the right wheel. So perhaps more

like 14 and 19 inches.

14 inches doesn't seem very wide for a sawmill, but:

(a) the widest I've ever cut, siding boards on the alder log, was only

12 or 13 inches. I've never needed a wider than that cut so far. (That

said, I diced up the large spruce logs with an alaska mill and only

tackled the cants, 6 or 8" wide, with the bandsaw mill. Being spruce,

that was plenty to ask of the plug-in bandmill and small bands.)

(b) 14" is plenty wide enough for cutting up cants, guitar backs, and

so on.

(c) really even a 12 inch cut, even in easy-cutting wood, is stretching

the limits of a 120V plug-in (skillsaw) motor.

(d) if someone really needs a wider cut, they will doubtless stretch it

and put on a longer band, whether recommended or not. I used 93" bands

throughout, and never felt like I was doing anything dangerous. I was

behind the blade with both hands on the mill, and if the band snapped

it would at worst fly out the end. (In fact it always just stopped.

It's a light band with little inertial force.) But if others are

working around the mill besides the sawyer, protecting them from

spinning, protruding wheels with teeth with end covers (and from the

V-belt and pulleys with a cover) is common sense.

There's a certain amount of technique that may be employed

to avoid needing a chainsaw mill on logs up to a certain size, even

with a shorter available cut. A 20 inch diameter log is only that at

its center. If having only a 14" cut width, one cuts say a 3 inch strip

off the top, flips it and takes another off the bottom, these cuts

(each narrower than 14 inches we trust) would leave a cant only 14

inches wide when turned sideways, which can then be further sliced up

as desired. The tricky part is placing the guide board on an angle so

the two cuts are parallel as the log gets thicker toward one end.

(Cutting parallel both width and length is an asset!)

If one takes such a technique with a 19" cut width, the

low power of the motor will probably become the size limiting factor

unless one is cutting balsa wood.

[23rd] I took the saw and showed it to Wayne. He suggested that to save

labor, one might put 8 inch extensions on the metal base and bend them

up instead of welding 8 inch posts on. It might be a good idea. But I'm

wondering, with long spidery arms along both X and Y axes, how much

steel will be wasted in cutting them out of a piece of plate?

[25th] I had at one point thought of putting extensions on the left

posts in order to attach the saw to a workbench as a shop bandsaw. But

that would have the saw over the bench with the body in the operator's

way. I had a small "eureka" moment when I thought that if the hollow

posts went through the plate instead of butting against the solid

plate, extensions to clamp it to a bench could be inserted from the

other side, from the top, leaving the blade exposed for use. Now I see

a glimmer of the dual-use idea, handheld mill plus shop bandsaw (that

can easily be put away on a shelf when not in use), being practical and

relatively simple to make. (I suppose supports could also be mounted to

bent-up flat 'posts'.)

Electricity

Generation

My Solar Power System

Annual Summaries and Estimates

March 2019-Feb. 2020: 2196.15 KWH Solar [used 7927 KWH from grid]

March 2020-Feb. 2021: 2069.82 KWH Solar [used 11294 KWH from grid]

Haida Gwaii is probably one of the worst places in the world to harvest

solar energy. The low sun, long shadows and usual clouds in the winter

mean very little solar energy is available for six months of the year.

Nevertheless, summer is much better and the overall result isn't

trivial, and most of whatever power is made reduces the amount having

to come from diesel generators. (There is also a small hydro plant on

the south grid, contribution from which depends mainly on how much rain

there has been lately.)

- Counting 2100 KWH annually from 11 panels, apparently about 52 panels

would account for my roughly 10 MW total annual electricity usage.

(There is an uncertainly factor here as some of the solar power

generated goes to the grid, and some is consumed in the house.)

- But four of my panels are now older 250W panels and the others 305W.

The newest ones are around 325W, so for a new installation one can

probably lop off about 6-7 panels. And my cheap grid tie inverters lose

a lot in variable clouds, dropping to nothing when the sun dims and

then taking tens of seconds to build gradually back up to what's

available. So call it maybe 43 new panels using better inverters.

- If tree shadows didn't reduce daily collection by... call it 25% (a

very conservative estimate) that would then be 32 panels.

- A sunnier climate might easily add 25% (or more) again, making it 24

panels.

- One sees from the monthly totals above that with the low sun, long

shadows and clouds, there is very little solar energy here in the

winter months. A more southern latitude (than 53.4°N) would not

only have less shading but with longer days and higher sun angles, the

solar energy would be much greater in the winter. (And - maybe -

somewhat less in the summer.)

Of course, these numbers are just based on my electricity

use, and usage will vary drasticly by household. The electric car uses

some. In a warmer climate (and without a travel trailer to keep at

least somewhat warm so it won't go moldy) one might use less electric

heat. OTOH, much of my house heat is from the woodstove (which many

don't bother with even in this climate), so the heating part of the

bill will very wildly. If the open loop air heat pumping were to be

manufactured and live up to its promise of COPs of 10+, it would make a

gigantic difference to electric consumption everywhere.

Daily/Monthly Log of Solar

Power Generated [and grid power consumed]

(All times are in PST: clock 48 minutes ahead of sun, not PDT which

is an hour and 48 minutes ahead. DC power output readings - mostly

the kitchen hot

water heater for some months, since its removal mostly just lights -

are reset to zero

daily (mostly for just lights, occasionally), while the others are

cumulative.) Note that the DC is actually power used since there's

nothing totaling up the amount incoming to the batteries, which is

(unless it's a lot and there's little sun) replaced the following day.

Solar: House, Trailer => total KWH [grid power meter

reading(s)@time] Sky conditions

Km = electric car drove distance, then car was charged.

March

31st 1316.28, 434.73 => 3.61 [55Km; 83769@19:30] Clouds and rain.

April

01st 1319.68, 437.19 => 5.86 [83792@19:30] Snow, downpour, clouds,

snow & hail, sunshine, clouds, drizzle, yetch!

02nd ?? Oops, what happened? (Estimate: 6.25 2nd, 8.35 3rd) [?] Cloudy.

03rd 1328.57, 442.90 =>14.60 [60Km; 83850@20:00] Some sun in AM,

later rain, hail, clouds.

04th 1332.53, 445.44 => 6.50 [83882@19:30] Alternating sun and

clouds.

05th 1336.16, 447.68 => 5.87 [83909@19:00] Clouds, bit of sun now

and then.

06th 1339.24, 449.62 => 5.02 [55Km; 83940@20:00] mostly overcast.

07th 1343.13, 452.14 => 6.41 [55Km; 83975@19:00] Occasional

sunshine. (also hail, snow, rain)

08th 1345.15, 453.35 => 3.23 [45Km; 84021@21:00] Overcast.

09th 1350.86, 457.07 => 9.43 [84040@22:00] AM: clouds, "blizzard",

PM:

sun, sun and snow. High +5°C, dropped to +2 later PM. Frost, stars

& snow late night.

10th 1354.84, 459.89, .2 DC => 7.00 [40Km; 84062@22:00] More like

yesterday but less sun, very light snow - no blizzard

11th 1357.52, 461.53 => 4.32 [84094@20:00] Mor cold and overcast.

12th 1364.64, 466.31 => 11.90 [55Km; 84124@20:00] The first SUNNY

DAY this year!

13th 1371.90, 471.16 => 12.11 [84057@25:00] Sunny again!

14th 1379.51, 476.71 => 13.16 [84172@19:00] Three in a row!

15th 1386.42, 482.36 => 12.56 [84187@21:00] Four! Awesome, spring is

here! The daily KWH from the grid is dropping. (9.6 KWH less per day

when the 400W travel trailer heater is shut off!)

16th 1394.06, 488.05 => 13.33 [55Km; 84219@19:00] Sunny! Turned off

heater in travel trailer. Shut off "indoor LED garden" lights for

summer.

17th 1401.77, 493.76 => 13.42 [84226@19:00] Sunny day #6 in a row!

Wow! What a difference in electrical consumption.

18th 1409.08, 499.42,.03 DC => 13.01 [84244@21:00] #7!

19th 1415.80, 503.99 => 11.35 [50Km; 84262@20:00] Hazy cloud/sun

20th 1423.46, 509.80 => 13.47 [55Km; 84271@20:30] Sunny AGAIN!

21th 1430.96, 514.96 => 12.66 [84281@19:30] Pretty sunny or very

light overcast.

22th 1437.92, 519.60 => 11.60 [55Km; 84309@20:30] very light

overcast.

23th 1440.50, 521.22 => 4.20 [84323@18:30] Clouds &

Rain. (Rats, there goes the nice weather!)

24th 1447.86, 526.39 => 12.53 [84335@19:30] Light overcast, then

sometime in the morning the sun came back!

25th 1456.13, 532.32 => 14.20 [84350@21:00] Beautiful sunny day!

26th 1464.52, 538.18,.13DC => 14.38 [84359@20:00] Sunny day, a few

jet trails.

27th 1468.83, 540.92 => 7.15 [55Km; 84381@20:00] Cloudy,

windy. But no rain. 13°c

28th 1471.12, 542.42 => 3.79 [50Km; 84402@21:00] Cloudy

again, no wind, 10°.

29th 1474.02, 544.39 => 4.87 [84418@20:00] mostly rain,

cleared off later PM.

30th 1478.11, 547.08,.08 DC => 6.89 [55Km; 84449@19:30]

similar to yesterday.

May

01st 1481.93, 549.53 => 6.27 [55 Km; 84499@29:30] For third day rain

AM,

cleared off later afternoon.

02d 1484.99, 551.65,.21 DC => 5.39 [84528@22:00] Clouds, later

rain & wind. Power was off in AM until (?)12:00 PDT. (Used DC

system with inverter to make coffee.)

03rd 1490.40, 555.32 => 9.08 [84548@19:30] Another day of clouds

& rain then sunshine in later PM.

04th 1496.70, 559.76 => 10.74 [55Km; 84571@21:00]

05th 1499.66, 561.71 [55Km; 84595@20:00] cloudz an drain.

Daily KWH from solar panels. (Compare April 2021 with March

2021

& with April 2020.)

|

March 2021 (11 Panels)

|

April 2021 (11 panels)

|

April 2020 (12 Panels)

|

0.xx

|

3

|

|

-

|

1.xx

|

2

|

|

-

|

2.xx

|

-

|

|

-

|

3.xx

|

8

|

2

|

-

|

4.xx

|

7

|

3

|

3

|

5.xx

|

4

|

3

|

3

|

6.xx