Turquoise Energy Newsletter #156 - May 2021

Turquoise Energy News #156

Covering

May

2021 (Posted June 9th 2021)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- Roofing Screws the Easy Way! - Ground Effect Craft:

Promotion

of the Designs -

Sundry - Plastic Recycling - "Plug & Play?" DC plugs, sockets,

circuits

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Tinnitus Treatment - World: Dangerous Phase? - Small

Thots: (Reader/viewer comments under articles; Rudeness and

Intolerance; Toxic Vanilla?) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (no

reports)

Other "Green"

& Electric Equipment Projects

* Off grid infrastructure: "Plug-and-Play Solar"

* Greenhouse, Gardening, Chickens

* Innovative Beekeeping for the BC Coast

Electricity

Generation

* My Solar Power System: - Daily/Monthly

Solar Production log et cetera - Monthly Summaries and

Estimates (26 months)

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte)

- Assembling C Cell - Tests (ug!) - Drawing Copper Pipes

into

C-Cell Cans?

May in Brief

Looking at my house -

somewhere

in there - from

low tide.

Looking at my house -

somewhere

in there - from

low tide.

(This camera has a much wider angle of view than the old one.)

Roofing Screws the Easy Way!

I put up another piece of

sheet metal siding on my cabin. (one piece for the whole month!)

You

can't push hard enough to penetrate

the sheet metal easily without the drill suddenly jumping sideways

and

the screw coming out of the driver with its flimsy magnetic

holder.

You spin it and spin it and spin it trying to get the screw to

start

penetrating, even using two hands to try to press and keep it

centered

(when one

hand should be holding you on the ladder). I take plenty of extra

screws

up the ladder to replace the ones that fall to the ground below.

Some

people punch a hole in the roof metal first for the screw to go

into,

but that too is extra work.

After all the many years of frustration with this

unsatisfactory process, this time I suddenly came up with the idea

that

the hex screwdriver bit for sheet metal roofing screws had a

hexagonal

base to fit securely in the drill chuck... but so did the roofing

screws

themselves! Why not just put the screw straight into the drill

chuck?

With a keyless chuck it's easy to tighten it in, and then loosen

it off

once the screw is in. Bingo! It stays in the drill chuck securely

and

goes in like a charm, ending all the extra effort, time and

frustration. This should work for any hex-head screw that fits in

the

chuck.

I was excited enough by how easy it was to quit

working

and make a short, clumsy video of it to share it with everybody on

Youtube.

https://www.youtube.com/watch?v=ipMVx4AkwZo

Ground Effect Craft: Promotion of the Designs

I have been too busy to get at the programming

for the thrust/steering on my ground effect vehicle. But on the

10th

there

was a new video from RCTestFlight, one of the people whose models

I

originally watched when I was designing the ground effect vehicle.

He

had now tried out in model form the "airfish" inverted-delta wing

design and the old

Russian ecranoplan layout. Neither of them seemed very

satisfactory. An

interesting aspect was that he used a height sensor to to

automaticly

control the motor power to try and maintain a steady altitude. I

was

going to potentially use inertial sensors to make for a smooth

flight

even over a rough sea, but even his altitude sensor might have

worked

well over flat ground if it controlled the angle of a canard

rather than motor power.

One of his problems was that the propeller was well

above

the center line and increasing the power made the craft's nose

drop

instead of rise. This was one reason I went with ducted fans: the

small propellers can be more in-line with the wing without hitting

the

water.

I put in a substantial comment with details of my

design

under the video. If he sees it amidst the other 1000+ comments,

perhaps

he may get excited by the ideas? If so, he seems to put together

and

try out

cheap models pretty rapidly. (Well, actually I guess it's been

over 4

years since his previous ground effect tests. Still faster than

I'm

getting there, and I wasn't able to get to it this month.)

Soon there was a related video by someone who had

been in

contact with RC Test Flight and I more or less repeated myself

there.

Both times with links to TE News. If only there weren't SO many

useless

comments, mine might get seen.

Sundry

On the 13th I drove to Masset airport, but my bees

weren't

on the flight. Way to go Hiveworld, who almost never return my

e-mails

or phone messages! But this may have worked out serendipitously:

later

I saw a video of a guy who just this month invented a new type of

beehive that I realized would be much better for the BC west coast

and

especially Haida Gwaii, and having no bees yet, I combined parts

of my

two hives and built it. But it now depends on them finally sending

me

the bees. Details in "Other Green & Electric Equipment

Projects"

(which category I have to expand from just "Other Green Electric

Equipment Projects").

The new insulated, tall,

beehive

box with

plywood and insulation end spacer inserts,

The new insulated, tall,

beehive

box with

plywood and insulation end spacer inserts,

and the first matching "tall" frame - two "deep" frames cut and

glued

together.

I bought a nice metal door at Co-op Home Centre in

Masset while I was there. On this island I could only find doors

complete with frames/casings around them. What? Can't buy just a

door?!? And because it did have a frame around it, I'll have to

redo

my opening and make it a little taller. Yuk! And the price floored

me -

with tax it was over 500$! I almost decided to build a wooden door

myself

after all. I hope there are no more similar unpleasant price

surprises

in building supplies that I still need. (It's looking more like

we're

headed into the long predicted hyperinflation, and shortages of

all

kinds.)

Expanding

the Greenhouse

Expanding

the Greenhouse

On the 9th I went to prepare to plant the corn I had

started in a tray of

toilet paper roll centers "seedling pots".

I was going to make a big

"cold frame" to plant it in and give it a head start, similar to

last year. But I ended up deciding to expand the greenhouse

instead,

which I had wanted to do anyway, and plant the corn inside

it. Corn grown in the open around here most commonly doesn't

produce.

Once I had straightened out the formerly curved roof, which made

it

about 4-5 usable feet

wider, I realized I should put in a concrete footing to keep the

grass

and weeds - and slugs - from creeping in under the wall. And

before

doing that I really needed to fix my cement mixer. Project creep

to

prevent creeping!

The corn meanwhile was badly outgrowing the little containers.

So...

the seemingly simple act of planting corn took all working my time

for

well over a week. Everything these days is eating into energy

project

time. But the corn is looking good! The roots were already growing

out

through the soggy tubes, so I just planted them with the tube.

Better

than "peat pots". (More under "Other ... Projects".)

I finally put together

the

"C" cell nickel-manganates / zinc. But it suffered my usual

problem of

self discharge, and didn't perform very well current-wise either.

Then

I had to clear off the top of the washing machine for laundry and

didn't set it up again. Not much of a chem lab! (More under

"Electricty

Storage".)

As I drove to Masset one day I reflected on

"hybridizing"

the Echo, that it would probably be much better to mount the motor

in a

fixed position and put in an idler sprocket mechanism with a

strong

spring to jump up and down with wheel suspension travel, instead

of

having the whole motor bounce around. (Is that as far as I get

with a

project in a month these days?)

Plastic Recycling

The food oil expeller, which seemed to have all the

same

parts as a plastic extruder and for which I hoped to use it,

arrived.

Having also ordered a few other plastic recycling

related

things on AliExpress, I told Mike I had pipe heaters and

temperature

controllers suitable for the plastic injector he had made before I

knew

him, and had shown me a year or two ago. I got the injector from

him to

add the heaters to it. (Then I started working on the greenhouse

and it

sat helping to clutter up the garage. Sigh!)

I kept thinking about how to make flat or

"corrugated"

panels from recycled clear plastic for greenhouses. I thought

about

something that would extrude a thin sheet of stiff plastic

hopefully a

couple of feet wide, but that seemed like a process that would be

too

involved and that I knew little about. The alternative would be to

press entire panels at once into greenhouse "window panes", with

or

without "corrugations" to stiffen them.

But how would one melt an expanse of plastic much too

big

to fit in an oven? On PreciousPlastic.com they had made a one

meter

square

sheet press. It was huge and had a lot of metal in it. Very

industrial

in nature, occupying a lot of shop floor space. And at least 2

meters

would be a better length. It had a bunch of flat

cartridge heaters.

Surely something simpler could be done? For the bed:

two

sheets of aluminum (can we just call this common metal "alium"?),

thick

enough to spread the heat, with a wooden frame under and on top.

Stack

dispersed weights on top instead of making it super rigid and

using a

press.

A pile of heaters would cost a lot. What about just

heating elements? What about just resistance wire? I ordered a

couple

of spools of ni-chrome resistance

wire, which can be used to make heat. These might be strung back

and

forth on insulated hangers along the length of the press. I could

make

a mold and cast the hangers in porcelain. Or ceramic inserts going

through holes in wood. (Good old "knob and tube" wiring!) The

underside of the lower aluminum plate would be insulated with

fiberglass and some bottom plywood. The top too. That way the

energy to

make the heat could be minimal, and slow heating would allow

thinner

alium plates to spread the heat through the plastic. Maybe I could

get away with 1/8" (3mm) sheets? I asked Steve to order me a 4 by

8

foot sheet of 1/8" next time he was getting alium.

Then it occurred to me that smaller greenhouse panels

might be overlapped at the edges and "glued", either with a cement

suitable for the type of plastic used, or melted together either

with a

clothes iron or a special heater that could do a whole seam at

once.

Then the individual sheets wouldn't have to be huge to be useful.

Now...

what about my plastic shredder kit? I finally

checked on it. No information or tracking. I e-mailed the maker

and

inquired. A few days later, the 18th, I got a message that it had

now

been

shipped. Sigh! But once shipped, it arrived on the 31st - just 13

days,

from Czech republic in Europe! I had a motor and a 50:1 reduction

worm

gear. But I recently heard someone had had their shredder jam, and

that

burned out their motor. What about a safety clutch? Or maybe a

V-belt

that would slip if the going got too tough? Yes, I think that's a

good

idea.

Now...

what about my plastic shredder kit? I finally

checked on it. No information or tracking. I e-mailed the maker

and

inquired. A few days later, the 18th, I got a message that it had

now

been

shipped. Sigh! But once shipped, it arrived on the 31st - just 13

days,

from Czech republic in Europe! I had a motor and a 50:1 reduction

worm

gear. But I recently heard someone had had their shredder jam, and

that

burned out their motor. What about a safety clutch? Or maybe a

V-belt

that would slip if the going got too tough? Yes, I think that's a

good

idea.

Anyway... that's for later. My plate is more than

full!

(And... what about the planetary gear I ordered in

March

for the Chevy Sprint project?... It was taking forever. Turned out

FedEx had auto-dialed my old cell phone number, and getting no

reply

was now in the process of returning it to China owing to a trivial

customs charge. Sigh!

It arrived on June 7th. It's much larger and heavier,

and

seemingly more skucum, than the one I bought before. It's just

short of

15 pounds. I expect it'll have no problems direct driving a wheel

via a

CV shaft on the car.)

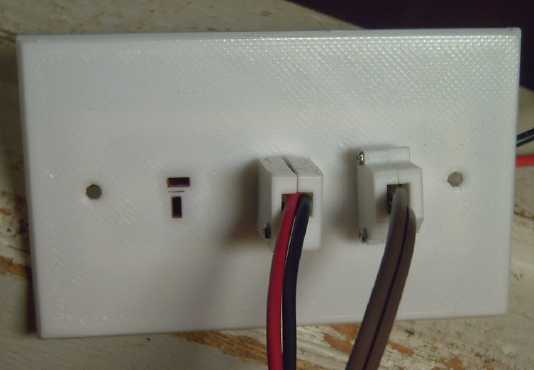

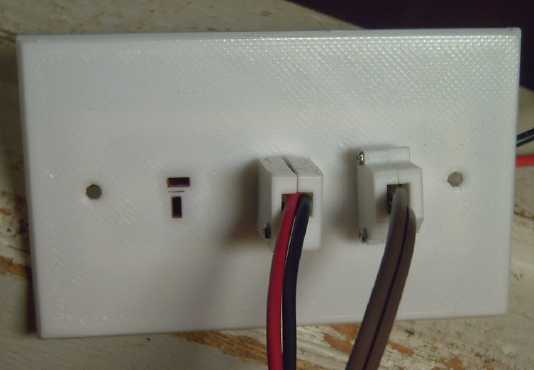

"Plug & Play?" DC Power

Components

Improved

T-Plug (right)

works better, holds

better

I

designed and

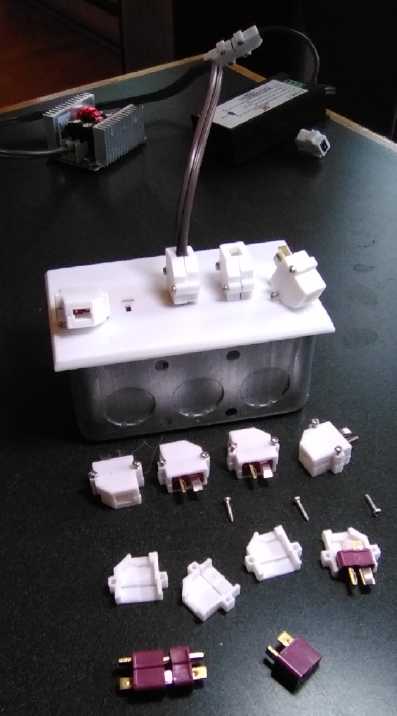

3D printed more of the planned T-plug (36V, 15A) and mini T-plug

(12V,

10A) wiring shells. And using these I connected some devices

together.

I gave these the names "T36" and "T12", so a 36V plug is a T36P.

Eventually I hope there will be screw and crimp type connections

as

well as solder-on, and high current versions for heavy loads,

which

will need other shells and variant names. And plugs and sockets

that

lock together. But this is enough for now.

I

designed and

3D printed more of the planned T-plug (36V, 15A) and mini T-plug

(12V,

10A) wiring shells. And using these I connected some devices

together.

I gave these the names "T36" and "T12", so a 36V plug is a T36P.

Eventually I hope there will be screw and crimp type connections

as

well as solder-on, and high current versions for heavy loads,

which

will need other shells and variant names. And plugs and sockets

that

lock together. But this is enough for now.

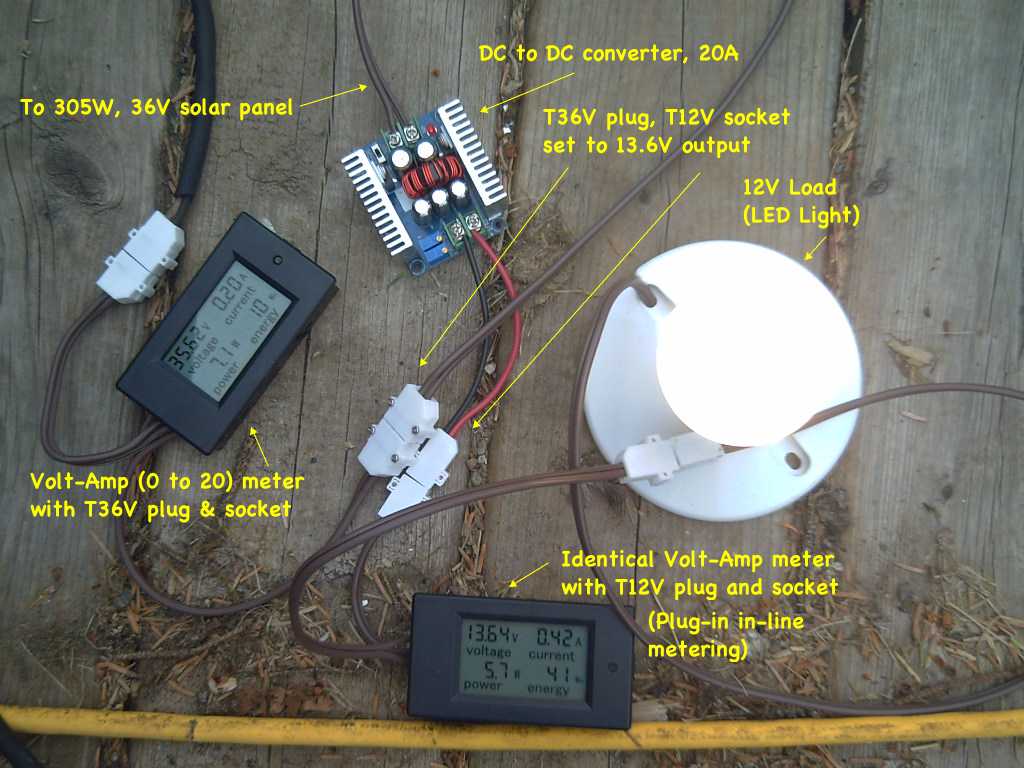

The first plug-in device I did was in-line LCD power

meters (9-100V, 0-20A) with T36 plugs and sockets, and a identical

meter with T12's. Using two of them you can see all the things you

most

want to know such as solar panel and battery voltages, current in

and

out, and accumulated totals of power made and used. And being

plug-in,

they can easily be unplugged to measure somewhere else, and the

plug

and socket of the circuit connected together without the meter. I

had

only bought two of these power meters/monitors, but having all

these

readings, independent of any other equipment, seemed so useful

that I

ordered some more of them to sell with solar systems. To go above

20

amps requires identical looking ones with an external current

measuring

shunt. I also got some straight LCD volt meters, 8 to 30V and I

put T12

plugs on them. Also some for up to 80V for T36 plugs.

Not seeing what's going on can be costly: After all,

if I

had had low power LCD voltmeters on the batteries in the truck -

or

even on one of them - I'd have seen at a glance the truck was

draining

all those batteries before it ruined them all.

Next I put a T36 plug and a T12 socket on a DC to DC

converter and set it to 13.6 volts, 10 amps max. to make a plug-in

charger for 12V Ni-MH or lithium-iron phosphate batteries.

I also made up a cable with MC4 solar panel

connectors on

one end and a T36 socket on the other, a T12 socket to a 12V

battery,

and a T12 plug to alligator clips for batteries and a 12V cord on

a

light fixture for a DC "light bulb", then connected them all out

on the

porch. (The arrow straight to the DC to DC converter input is a

...typo? The solar panel cord is right under the words - Solar

power

goes through the meter, then to the DC to DC.)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Tinnitus

Treatment?

I have terrible tinnitus. The ringing in my ears

started

when I was

very young, perhaps either because of going duck hunting with my

dad

when I was 4-5 (which just very recently came back to my memory),

or because the TV we kids used to sit in front of and watch had a

very

loud 15,750 Hz flyback transformer. (IIRC the frequency correctly.

It

seemed to me that was also the original frequency of my whistling

tinnitus. OTOH,

the audiologist thought the duck hunting would have been the

culprit:

single very loud noises -

"It doesn't matter who was firing the shotgun.")

It got worse over the years along with my hearing as I hammered

together additions to my house, played in a concert band, and so

on.

Notably it got worse 2003-2007 while I was making my "Supercorder"

modern recorders, and playing them and playing them, loud and

soft,

high and low to get each note in tune by scraping away bits from

the

inside around the finger holes. And then 2017-2019 probably from

running a very large, powerful chainsaw to break up logs into

cants for

milling lumber. Even 'earmuffs' ear protection probably wasn't

enough.

My left ear is somewhere in the "mildly impaired" hearing range in

the

mid to high frequencies and

always has a loud, high pitched whistle to it. My right ear is

just

above "impaired" range.

On the evening of the 26th I heard that someone who

works

in a hospital said

tinnitus can be cured by taking magnesium and calcium for a year.

If

there's a way to end tinnitus I wasn't putting it off!: the next

morning I ran to a store and

found "Jamieson: calcium-magnesium+D3, 100+100 pills, 333mg,

167mg, 200

IU" and

bought two bottles to get a year's supply (400 pills). I took one

in

the in the car as I left the store. In case some deficiency of

magnesium is

contributing to the ringing, I'll take two daily for a while to

build

up the levels and (i trust) eliminate the deficiency, then one a

day

for the next

year. The amount of vitamin D3 is almost trivial, so

I'll continue taking daily vitamin D pills (1000 IU) to ward off

potential cancer. (And CoViD, I hear, but I'm not convinced of

that.)

If it works I'll certainly mention it in an upcoming

TE

News! If I run out of pills with little or no apparent effect I'll

also

write about it. (In the meantime, writing it here gives the date

for

when I started.)

World:

Dangerous

Phase?

While some still hope

for a

return to "normal", the world is moving on. It is very much

overpopulated and the time seems to be upon us that things are

primed

for collapse. Every civilization of the past collapsed, and while

each

collapse was unique they shared some typical features. The

population

grew too large in good years to maintain in bad, and the high

population and or poor practices degraded the environment.

(Reading

"Collapse" by Jared Diamond is eye opening. Easter Island lost all

its forest - every tree. The Anasazi turned the pine and juniper

woodland they built on into a desert, which it still is. There are

a

few presently successful stories too. Japan stabilized its

population

and reversed its deforestation by 1700, before it was too late. A

key

take-away in the many failures is that no one seriously thought

there

was a systemic problem - or that a developing problem was their

problem - until it was much too late and the population much too

large

to do anything about it.) The institutions

became self-serving: concerned with self-aggrandizement and

finally

self-preservation rather than societal service. As soon as a few

years

of drought (self inflicted from deforestation?) or other bad

weather reduced agricultural output people started starving. Chaos

ensued. The organizations and institutions couldn't cope and

simply

ceased to function, and finally ceased to exist. Usually there was

great loss of life and people were thrown on their own resources

until

a new order eventually started to emerge. A thousand year "Dark

Age"

ensued from the collapse of the Roman empire before things started

being well organized again. (Why did Alaric sack Rome? Looking for

food. But there wasn't any. The Romans were starving too.)

This time such effects look like they will be global,

not

limited to any one nation or region. There are many factors.

Healthy,

vibrant societies with stable, sustainable population levels would

be

resilient and

weather adversities easily. But most societies so far have never

even

tried to address population growth, and our social mentality (at

least

in the west) has to a

significant extent moved from being society serving and

cooperative to

being separative and self serving and this is reflected in our

institutions, creating a dysfunctionality where even the most

blatant

and severe of societal problems go unaddressed and unresolved.

* With the population growth, poverty and want is rather suddenly

becoming widespread. We think of that as being a "third world"

phenomenon, but it is now everywhere. Rents and mortgages gobble

up

everyone's paycheque. Shortages of housing and land are so far the

most

observable effect. Individual homelessness, which started around

1980

(pop. 4+ billion), has reached the point of tent cities

and refugee camps full of people, tens of millions, to which there

seem

to be no

solutions, nowhere for them to go unless they displace others or

occupy

land already in use for something else. There are more displaced

people

today than during World War II. And suddenly the price of lumber

(hey,

it grows on trees!) and other building materials has shot way up.

* We have had 2 years of generally very poor crops, globally, and

2021

is looking like a third. Supplies of

grains are now increasingly tight. The largest nations that

usually

export

a major crop are now often trying to import it. If the weather

doesn't

get the crops, plagues of locusts or mice do.

* The global distribution system seems to be having increasing

trouble

moving goods around. Delays are becoming widespread and costs are

rapidly rising. Many cargo ships have been scrapped for their

steel in

recent years decreased shipping, which has lately risen

substantially.

Shipping containers badly needed elsewhere are sitting

empty at other ports. It is said that things have been continuing

to

get worse instead of better since the Evergiven was cleared from

the

Suez canal. By early June the situation has been looking chaotic.

Shipping a 20 foot container that cost 2000 $ in 2019 is now over

10,000 $ -- but only if the shipper can book a space at all.

* Owing to the cost of housing and rising prices for most

everything,

food is becoming an unaffordable "extra" for some who are still

managing to keep a roof over their heads, to be obtained at food

banks.

Such services, now often with long lineups, have staved off

disaster so

far, but they will surely

soon be overwhelmed. Everyone trying to stockpile food is

competing

with everyone else: food banks, groceries and state governments

that

have decided they should stock up are all finding that larger

quantities have become hard to get.

* We are told "the young today don't want to work", but is that

not

because the average salaries being offered are insufficient to

live on?

What is the solution? Life, not to denigrate anyone, is becoming

"cheap".

* The financial system and the banks have been "on life support"

since

2008. Ever increasing money printing has kept them afloat. Yet the

underlying problems haven't been addressed. The value of your

dollar

denominated assets has been shrinking as the currency supply

balloons,

and hyperinflation seems inevitable and now much closer. Then all

the

fiat currencies, all

your monetary savings, will become worthless. Advice to get out of

currency and into real, tangible assets is increasing from many

quarters, and when enough people actually do that, currency

finally

becomes a "hot

potato" to be spent as soon as available, not accumulated as

savings,

and finally no one will

accept it any more. In some areas, houses are now selling not just

for

a million dollars, but for a million dollars over the asking

price.

But it will surely be a rapidly rising price of food

that

will start getting everyone buying "tangible assets" - extra food

-

"today" since we all need to eat and it will only cost more next

month.

The

crisis will probably be sudden and will catch the majority

unawares. It

is said that in Wiemar Germany "One week no one knew what

hyperinflation was. The next week everyone knew."

* New, worse strains of CoViD seem to be emerging. But whether it

is

these or some other disease that next crosses over from animals to

overcrowded populations of humans, predictions indicate that

disease

will

almost inevitably strike down billions of people in the next

decade or

two. And then this new disease(s) will continue to be a scourge

until

we learn enough about biology to eradicate it - that could be many

decades or a century or more. (Early June: WION reports a new

strain of

avian influenza in China (H10N6?) has infected a person. Might

that one

spread human to human? If not, might the next one?)

* The weather disasters not only destroy crops and livestock, but

have

become a large nuisance in their own right. Especially, high winds

are

wreaking havoc in many areas. Also seemingly random "rivers from

the sky" unprecedented floods, snow and cold to the horse

latitudes,

and giant hailstones

that can kill even large animals and destroy cars are causing

major

damages. They seem to be getting even worse. A snowstorm in the

southern USA bought Texas to a halt last winter, and in more

recent

storms there a few hailstones even bashed through house roofs. One

triangular

shaped hailstone measured 8 inches across.

* There are worrisome and credible predictions of a rapid, almost

sudden, 3 meter sea level rise before mid century, saying that it

is

already too late to prevent it. (It may not be too late to prevent

further disastrous rises over the next couple of centuries.) Many

present

day port cities and facilities will be flooded out, which will

not help supply distribution. These predictions would also involve

hundreds of millions of refugees from low lying areas seeking to

find

higher ground. (In Bangladesh alone 100 million people would or

will be

flooded

out!)

For those who manage to weather the worst of the

storms,

the world by

2050 will obviously look very different than it does today. After

the

now inevitable cataclysmic events have run their course, the

exponential learning curve we are on especially since the printing

press and now the recent advent of the

internet will continue, and we (or for many of us it will be

"they")

will start understanding our major

problems better - societal as well as technical - and learning how

to

solve them. For everyone to understand the need to limit

population is

the key to the future. (Best estimates to enable high quality

lives are

around 3 billion globally with cities of 1/2 a million or less.)

The

smaller, less dense populations will be more secure and contented,

and much more cooperative inter-person and inter-nation instead of

competitive and suspicious, and a better prosperity and solutions

for

sustainable societies will emerge. It won't be utopia at that

point,

but

it'll be the start of the road toward it.

Should our democracies finish failing, those who take

power may tell us "Democracy didn't work." And they won't want to

try

it again. Could we see a new dark age before there's another

chance?

But what is failing? It may soon be that democracy as it is

currently framed may be said to have failed. But if so, why? Did

it not

become ossified, stuck in time when constitutions were framed, and

failed to evolve to meet human and social needs?

Why did that happen?

It is said that when citizens don't participate in

governance, that society is already doomed. When populations were

tiny,

person to person contact was sufficient. One of the people at

dinner

candidly and openly discussing an issue was probably an elected

representative whose voice would be heard if he brought it up in a

government house. But as they grew, those governing became aloof.

Listening to everyone with a concern probably just left them

confused

and indecisive from

hearing multiple incompatible ideas, and occupied their productive

time, so they gradually stopped listening. This process started

very

gradually around 150 years ago. Citizens today have almost zero

opportunity for effective input into governance. Think of all the

talent, ideas and potential plans and social designs that

continually

go to waste in every

direction and sphere because those everywhere who are involved in

something, and who see and foresee problems and solutions in

their areas, have no voice in their governance. How can a few

elected

representatives be expected to come up with good answers to all of

the

many multiple issues society faces? A leader is given

responsibility

for everything. He probably picks a few major topics he's familiar

with; the rest are

never dealt with. The potential solutions of countless thoughtful

people are scattered to the winds. And into that vacuum of input

and

thought step in ever more powerful special interest groups who

eventually gain impunity to start paying politicians to pursue

their

specific agendas quite apart from - and hence inimical to - the

general

societal good. So:

essentially no input from the public except the occasional letter

to a

representative (and where does that go?); daily input from

lobbyists,

who also bear gifts for those who listen to them. Who is going to

be served?

Populations have long been much too large for

one-on-ones

of someone with an idea explaining to the leadership, or even

making an

effective presentation at a "town hall" meeting. Again, what is

surely

needed is for those people who have considered some topic to

organize

into small local groups, probably under a dozen people who assign

themselves specific roles that discuss and formulate plans or

solutions

related to it, that are agreed upon within the group - preferably

unanimously but at least by majority consensus - as being the best

way

forward. These

can be written down and presented to government. Presently they

will

probably have the most influence at the local community level. But

once

this process has taken hold, groups will link via the internet and

pick

or formulate the best consensus plans coming from all the local

groups.

Once this has been done, the plans can be submitted to elected

government for action. Even national governments will understand

that

the submission is the collective will of the most thoughtful part

of

the citizenry who have given that specific issue a far more

thorough

"going over" than anything they would manage to formulate from the

center of power.

"Social Sustainability Design Team" Organization

What differentiates the new ideas for a design team

from a

"citizens' assembly" or a "citizens' jury" is that it is an

organization rather than a simple collective, with the team

members

fulfilling specific different roles within it. It is also smaller,

to

be composed ideally of around 5 to 9 people. A committee of 100

people

without specific functions or assignments won't necessarily

research

and compile

more ideas or have more themselves, or come up with better or even

as

good solutions as a small focused group where each person has done

some

specific homework in search of optimum answers, and everything is

thought out in an organized way as a group.

I was going to try to briefly describe the

"organizational

chart" such as it is, but I don't think I could do any better than

has

been done here:

Here is a link to the structure/members of a social design team:

http://www.7corevalues.org/values-based-design-teams.html

(It's worth starting on their main page!)

http://www.7corevalues.org/

Small

Thots

* I got a new

Ryobi skillsaw. It came with an edge guide. If I've ever seen one

of

those for a handheld circular saw before, I've never thought of it

or

used it. This time for cutting some pieces of plywood I did. Wow!

Perfect, straight cuts with a skillsaw! The big caveat is that it

only

works cutting up to about 14 inches wide. If you're making a wider

cut

you're still on your own, and I wonder how effective it would be

even

at a foot or so width.

* I got a new

Ryobi skillsaw. It came with an edge guide. If I've ever seen one

of

those for a handheld circular saw before, I've never thought of it

or

used it. This time for cutting some pieces of plywood I did. Wow!

Perfect, straight cuts with a skillsaw! The big caveat is that it

only

works cutting up to about 14 inches wide. If you're making a wider

cut

you're still on your own, and I wonder how effective it would be

even

at a foot or so width.

* I have come to look on "news" articles on major platforms that

don't

allow for comments below them as potentially being "fake news".

Such

articles often

seem to have agendas other than true information dissemination and

contain serious distortions of facts to pursue a narrative, and

apparently the authors are

not being open to hearing the views, ideas and even facts others

might

submit underneath. Just recently I've started scanning down to the

bottom first to see if comments are allowed, and sometimes

skipping

suspicious sounding articles if not.

* Come to think of it, I myself would probably get more

interesting and useful feedback if I could arrange to allow

comments

under Turquoise Energy New issues! And other readers would be

exposed

to more and doubtless often better informed opinions and ideas

than

just mine. (Awg, now I'm talking about undertaking another major

project, to set up such a thing? Way beyond my very basic HTML

skills!)

* In India CoViD seems to have suddenly spread wildly. Two states

not

using the big "I." pill were the hard hit ones. Finally it was

decided

that it should be used, and CoViD cases dropped by 92% and 84%.

Well

duh!

* In Madhra (SP?) Pradesh some village doctor or medical

practitioner

had made some herbal concoction administered as eye drops that

seemed

to be curing people - by the dozens - with notable improvement

even in

just ten minutes and no side effects that any of the treated who

were

interviewed had noticed. The villagers had quit masks and social

distancing as being no longer necessary. Thousands very ill with

CoViD

or with a family member in severe condition started coming from

all

around. They were even arriving in ambulances. The doctor said it

was a

family recipe passed down to him from his father and grandfather.

He

was arrested and the police stopped non-residents trying to travel

to

that village. A second news video treated it pretty much as a

hoax,

mainly showing the crowds and the police and (IIRC) without

interviewing patients or really asking anyone's opinion about

anything.

Viewer comments below that one were rather scathing, saying the

video

was pushing a judgment that had been decided in advance without

evidence.

Of course I have no other knowledge, but there did

seem to

be a lot of people there who didn't seem to think it was a scam or

mass

delusion.

* According to most people, rising prices are a problem. According

to

bankers, lowering prices are a terrible disaster.

* "They" say the US dollar has lost 96% of its value since 1913. I

have

thought for several years that it's more like 99%, that a dollar

now

buys what a penny would buy then. The trend toward 'worthless'

appears

to be accelerating rapidly this year.

* I have been troubled by some no longer new but more recent

"themes"

that have been put forward by authority:

- "Just say NO to drugs." I'm not a proponent of psychedelic

drugs, but what happened to common courtesy, "Yes please"

and

"No thank you"? It is implied that we should be rude

because we

dislike what is being offered. What does being offensive

accomplish

besides rubbing people the wrong way? Is it more or less likely to

generate respect for oneself? If good people rudely alienate the

person

who offers the drug will he become more or less likely to want to

have

dialogue with them, which just might result in him changing his

own

views of what's good?

- "Zero tolerance." None of us want people who are unfit to

drive

driving. Accidents happen. People are hurt and killed. Drunk

drivers

account for a lot of it. But... total intolerance? Somehow getting

the

inebriated off the

road has progressed to extremism. What is gained by besides

stress,

anxiety and a distaste for authority by almost cutting in half the

long-defined acceptable alcohol limit and giving roadside

suspensions or fines to someone who had a glass of wine or two

with

dinner or a social beer or two at a pub? Other drivers such as

tired

ones may be less safe than one with just a tiny bit of alcohol in

their

blood but nothing is said about that. When did intolerance and

extremism become good, even commendable things? (One of the women

who

started MADD said they never intended it to go so far.)

* Related: You go out for an evening drink after work/sports/band

rehearsal/evening studies/et cetera with friends at a downtown

pub. In

the interesting conversations you drink more alcohol than you had

intended. You're not flaming drunk, but you're not exactly fit as

a

fiddle either. Sure, you could take a cab home. But in the morning

rush

hour your car will be in peoples' way and it will be towed away or

at

least ticketed. (It might even indirectly contribute to an

accident

just by sitting in an awkward place when the street gets busy!)

Even if

somehow it's parked fine

in the heart of "no parking/short term parking land", you will

still

have to make your way downtown again to retrieve your car before

work,

and you're already out late. (You drove there because it was too

far to

walk in the first place, so now that's two cabs!) What do you do?

You've

accidently left yourself without an easy, right choice. "Playing

it

safe" and not socializing with one's associates has penalties

too, and there is no "one size fits all" answer.

* Of course, these days people try to avoid "downtowns" because

they

have become "too hard to park" and unpleasant, with destitute

beggars

asking the now increasingly financially stressed for (at least)

their

change. (Okay, I haven't been in a city since the pandemic

started. One suspects things will have changed again. A couple of

people have shown videos of some pretty deserted looking downtown

streets with closed businesses. In California and Ireland, IIRC.)

* My bottle of vanilla ran out. I had heard 3 or 4 years ago that

something had ruined most of the vanilla plantations in the chief

growing region, Madagascar, and soon there wouldn't be any vanilla

to

be had. (I can't remember what it was. One of the many "once in a

century" to "unprecedented" natural disasters taking place on a

daily

basis in the last few years.) So I was rather surprised that it

has

continued to be available in stores. I bought two 125ml bottles.

On the evening of the 29th I had strawberries I'd

been

given that would soon go mouldy, and carrot pulp from making 2

cups of

carrot juice that morning and the previous day. So I decided to

bake a

carrot cake (or "carrot loaf" as I call my version) and a

strawberry

upside-down cake. I opened a new bottle of vanilla and used 3

teaspoons

between the two cakes.

Of course I ate some of each cake. During the night I

developed a migraine that became more and more severe. Even 1/2 a

100mg

Sumatriptan didn't seem to do much. A half packet of Cambia seemed

to

quell it. These migraine medications last many hours, but the

migraine

outlasted them. Even without the headache I didn't feel well all

day

and by evening I wondered if I was coming down with something. The

other half Sumatriptan took me through the evening, but in the

early

morning of the 31st I had to get up and take another whole one. I

finally started feeling better in the afternoon.

I'm almost certain the vanilla was the culprit. It

had the

same list of ingredients as usual. They might as well have added

phosphoric acid or MSG! I threw out both bottles. The chickens are

getting the cakes, one piece a day from the freezer. (Do chickens

get

headaches?) It was "Western Family" brand but AFAIK it all comes

from

Madagascar and I won't trust any brand now. It would seem that

vanilla

has become toxic. (Another brand says... say, when did the first

ingredient after "water" in "pure vanilla extract" become

"propylene

glycol" - the flavoring of artificial vanilla?)

* I had been re-imagining my "ideal bathtub" (since I had never

got

around to trying to make it). A little less extreme, but still

much

less of a water hog than the typical "big square box" tub that

came

with my house. A friend wanted me to look at some leaking drain

pipes

downstairs where he was staying while he drained the bathtub

upstairs,

to see where the leaks were. (I found two spots!)

There it was in that house! My ideal bathtub! It had

the

sloped back and the (slightly) narrowed foot/drain end. It was a

couple

of inches narrower than mine and a little shorter. You could get a

much

deeper bath with less water. It was plastic so it wouldn't conduct

the

heat out of the water like metal does.

It was probably decades old, but if I knew where to

get

one like it I probably would, and would be happy. (If I ever got

around

to installing it.) OTOH if I was actually designing a tub I'd

change a

couple of things. I'd add "arm rests" pretty much above the water

line,

giving more space for moving the arms around. (That might make it

practical to narrow it another couple of inches down lower - 20

inches?)

And a rather new thought had occurred to me: if the

shower

was at the upper end of the tub, away from the drain, then that

end

would be where one would stand, and the foot end could be narrowed

even

more since it would be just an place for the legs in a bath. Water

pipes might be an issue: it would need a long pipe from the faucet

to

the shower nozzle and so the water temperature would respond to

adjustment only after a considerable delay. The faucet could

perhaps be

moved to the middle of the tub on one side (where it would also be

easier to reach from in the bath), but it might be more practical

to

have separate taps for the shower. (They could be placed higher up

near

the nozzle for quick response to temperature adjustment while also

being easy to reach while standing.)

ESD

(Eccentric Silliness Department)

* What is the difference between hash browns and hash brownies?

* Why are we "Marsiforming" the Earth? I thought it was supposed

to be

the other way around.

* What is the difference between a widget and a wigeon?

* I hear we're having a "V as in Venezuela" shaped recovery.

"in depth reports" for

each project are below. I hope they may be useful to anyone who

wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or

just

thought

of and not tried... and even of how not to do something -

why

it didn't

work or proved impractical. Sometimes they set out inventive

thoughts

almost as they occur - and are the actual organization and

elaboration

in writing of those thoughts. They are thus partly a diary and are

not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths

and

avoid potential pitfalls and dead ends.

Electric

Transport (no reports)

Other "Green" & Electric Equipment Projects

Off-Grid

infrastructure Components

[19th] Some desired configurations of

solar panels and battery

chargers seem perplexingly hard to come by. The variables are the

solar

panel voltage, the battery voltage, and the battery type. Each

combination has its own requirements.

1. PWM solar charge controllers for charging 12 volt lead-acid

batteries with 36 cell solar panels are very common and cheap.

2. The same ones can be used for charging 24 volt lead-acid

batteries

with 60 or 72 cell solar panels.

They can not, however, be used to charge 12 volt

batteries

from 60 or 72 cell panels, nor of course 24 volts from 36 cell

panels.

It has occurred to me that all that is needed for

many

systems to use "full size" panels is a DC to DC converter. (The

next

problem was that most of the common DC to DC converters use the

same

chip, which has an absolute maximum rating of 40 volts. This

choice by

manufacturers is very frustrating as 60 cell solar panels output

up to

(according to my panels' labels) 40.05 volts, and many 36 volt

battery

systems can also go up to about 42 volts when charging. It would

be far

better if they could take 45+ volts for solar panel and 36 volt

systems

operation. Oh well, find the pricey DC to DC converters that can

take

50+ volts!) Wait! The chip on my 20 amp DC to DC units is rated at

42

volts. A tiny margin for comfort.

Here are some combinations that I thought could be obtained

using

DC to DC

converters.

3. To charge 12 volt lead-acids from 60-72 cell panels, one would

reduce the panel voltage to about 15 volts with a DC to DC

converter,

and then a cheap 12 volt PWM charge controller would handle the

lower

voltage properly.

(June 8th: Having now tried this with varying light levels, I

found it

doesn't work well. Whatever is being fed from the solar panel has

to be

sensitive to what it can put out. The PWM controller is

insensitive to

how much power the DC to DC converter is able to supply. I thought

its

circuits would figure out the maximum power point for amps

available

the DC to DC converter, but it just drags the panel voltage way

down in

lower light levels. If the DC to DC converter's current limiting

is

turned down too much, the major power of the panel isn't available

when

the sun is strong.)

For battery types other than lead-acids, one doesn't

want

to use a PWM type controller. Most notably it will fry

nickel-metal

hydride type, which may leak, burst or even explode and cause a

fire.

And it's not good for lithium types either.

4. To charge 12 volt nickel-metal hydride or lithium, a constant

voltage is ideal. And good DC to DC converters can be adjusted

exactly

to any desired voltage, and a maximum current can be set as well.

If

the batteries are being left perpetually on charge as in a solar

installation, it's best not to push them to their maximum. This

table

is my suggestions for 12 volt systems:

Battery

Type

|

Max. constant

charge voltage (V)

|

Suggested constant

charge voltage (V)

|

Ni-MH (10S)

|

14.0

|

13.5 (1.35 volts/cell)

|

Li-FeSO4 (4S)

|

16.8 (better 14.4)

|

13.6-13.8 (3.40-3.45 volts/cell)

|

Li-ion (3S)

|

12.6

|

11.85 (3.95 volts/cell)

|

With the suggested voltages the cells will gradually

attain over 95% of their full charge with little stress, and then

the

charging current will drop to a very low value.

Nickel-metal hydride batteries will continue to draw

high

currents once charged if fed a continual voltage above about 1.40

V/cell (14.0V). If it's much more -- including with PWM charging that

says

it's

under

14.0V but where the peaks are actually much higher

-- they may gradually get hot and even burst or cause a fire. Both

lithium types will cease drawing much current once charged

(~3.35V,

~3.95V) but may be damaged if the voltage is raised to more than

4.2

volts per cell (both types).

(June 8th: Again this may not work well in low light/low solar

power

levels. I have yet to test it under various conditions. AFAIK so

far,

an MPPT controller whose output voltage can be adjusted is still

much

the best performer.)

By using

a DC

to DC converter we can get the desired

charging voltage. But we can't see it. We don't know how charged

the

batteries are or what the voltage is. For that, enter the

volts/amps/watts/watt-hours power meter/monitor. (Coming up,

below.)

By using

a DC

to DC converter we can get the desired

charging voltage. But we can't see it. We don't know how charged

the

batteries are or what the voltage is. For that, enter the

volts/amps/watts/watt-hours power meter/monitor. (Coming up,

below.)

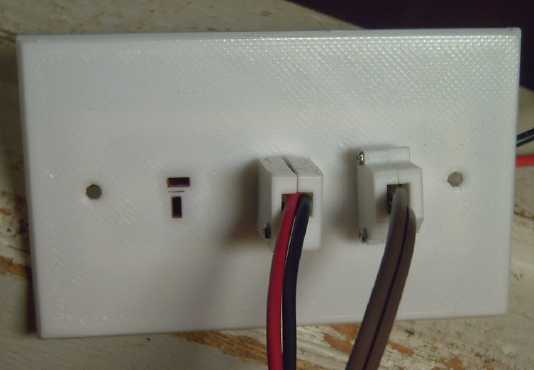

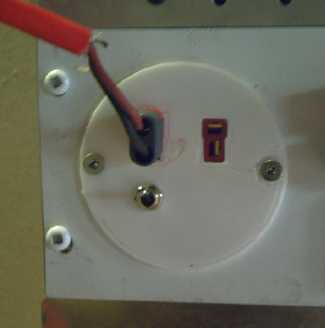

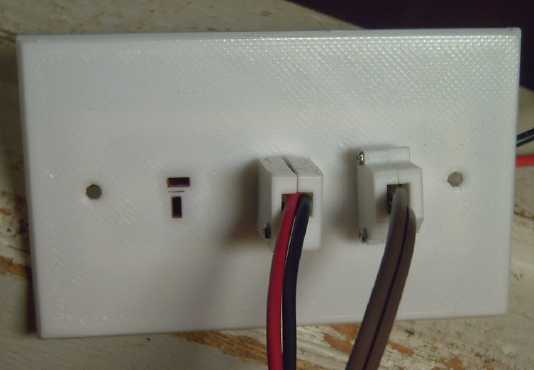

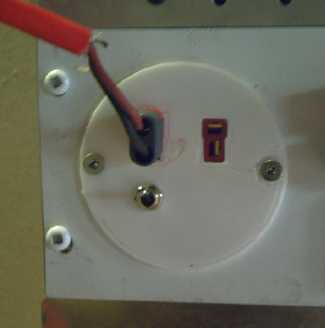

[21st] I printed a

T-Plug

socket plate for my 36V panel in the garage and changed the

"HAT" sockets and the plug on the panel light to "T" sockets and

plug.

For the light I used

one of the T-Plugs that had a little rubber boot to cover the wire

ends. It comes off easily and I don't really think much of it. A

proper

shell is much better.

[21st] I printed a

T-Plug

socket plate for my 36V panel in the garage and changed the

"HAT" sockets and the plug on the panel light to "T" sockets and

plug.

For the light I used

one of the T-Plugs that had a little rubber boot to cover the wire

ends. It comes off easily and I don't really think much of it. A

proper

shell is much better.

Gosh, no proper shell for the T-Plugs? I went to

design a

new one for the nylon T-Plugs and sockets with lips around the

upper

edge. (With lip is better: The connection is definitely better

when the

plugs and sockets mate without a bit of plastic in between them

being

needed to keep them from falling out of the shells.)

When I 3D printed it, "V1" as usual had a couple of

dimensions slightly off. "V2" was

perfect, an improvement in every way: it was smaller and held

together

better (two screws), the T-plug was firmly gripped yet flush with

the

front so it connected well, and the little ears for the screws on

the

sides made it easy to grip to unplug. I printed a second one.

Improved T-Plug shell (R)

versus

old one (L)

that has a layer of plastic in front of the plug body.

Improved T-Plug shell (R)

versus

old one (L)

that has a layer of plastic in front of the plug body.

Also note the plastic in front of the T-Sockets in the older

wall plate,

versus the flush ones in the new round plate.

Cosmeticly the old is better, but flush makes better connection.

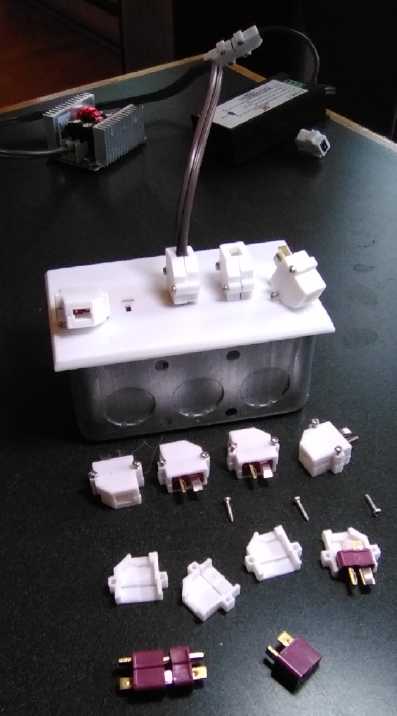

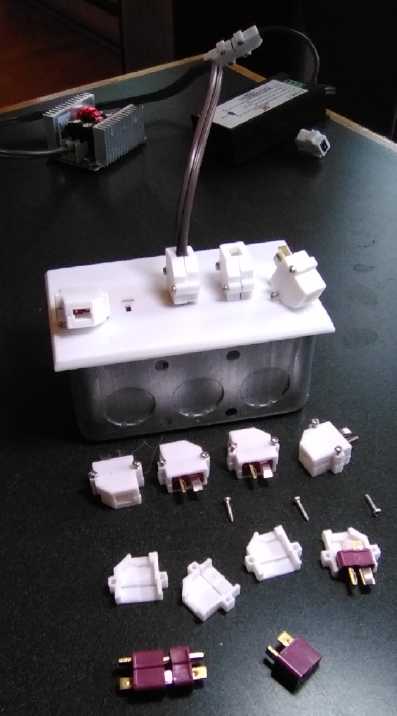

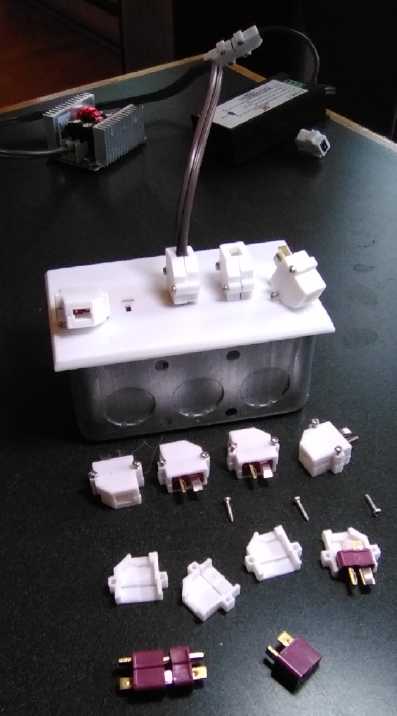

I printed a batch of T36P

shells.

I printed a batch of T36P

shells.

[25th] Next I needed to do one for

in-line sockets. But I idly put a socket into a plug shell and

realized

it was the same except it needed to be 4mm longer at the front,

the

plug and shell bodies having the same dimensions except the

front-to-back length. Change 4 numbers. 3D Print it. Perfect fit.

That

was simple! Now I have shells for both plugs and sockets in-line

for

both mini-T-Plug (12V, 10A) and 'regular'-T-Plug (36V, 15A). And

triplex wall plates for both. (The 36V ones to be improved -

should

also be simple.)

It's well the I got the newer 3D printer and the

"Cura"

slicer. It may be painfully slow printing such fine detail on

larger

objects, but it's really needed for small, detailed things like

plug

shells. Even "draft" mode is finer than the old RepRap and

"Skeinforge"

slicer, although I prefer Skeinforge for printing large objects in

less

than geologic time and it does work fine on the new printer.

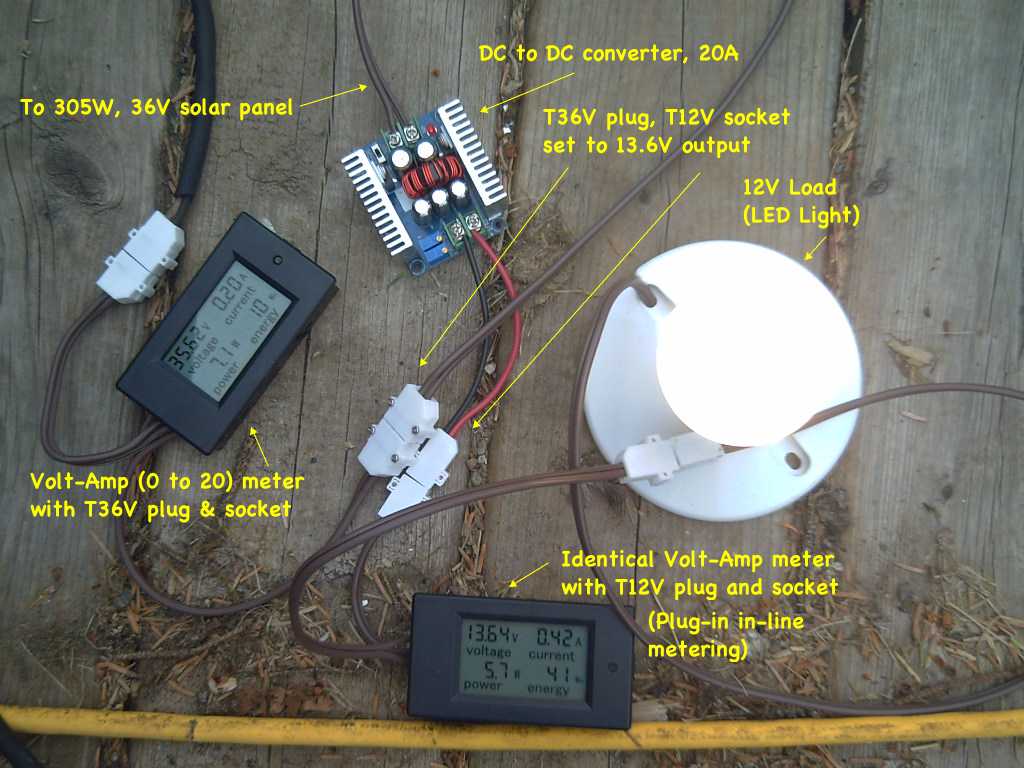

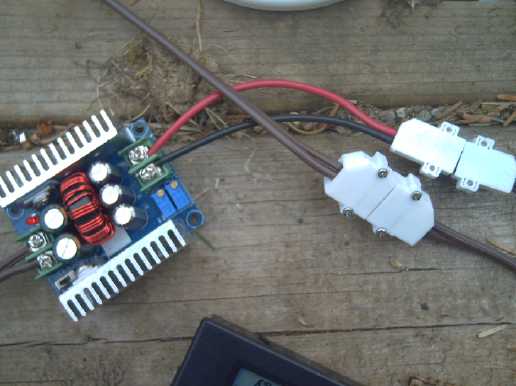

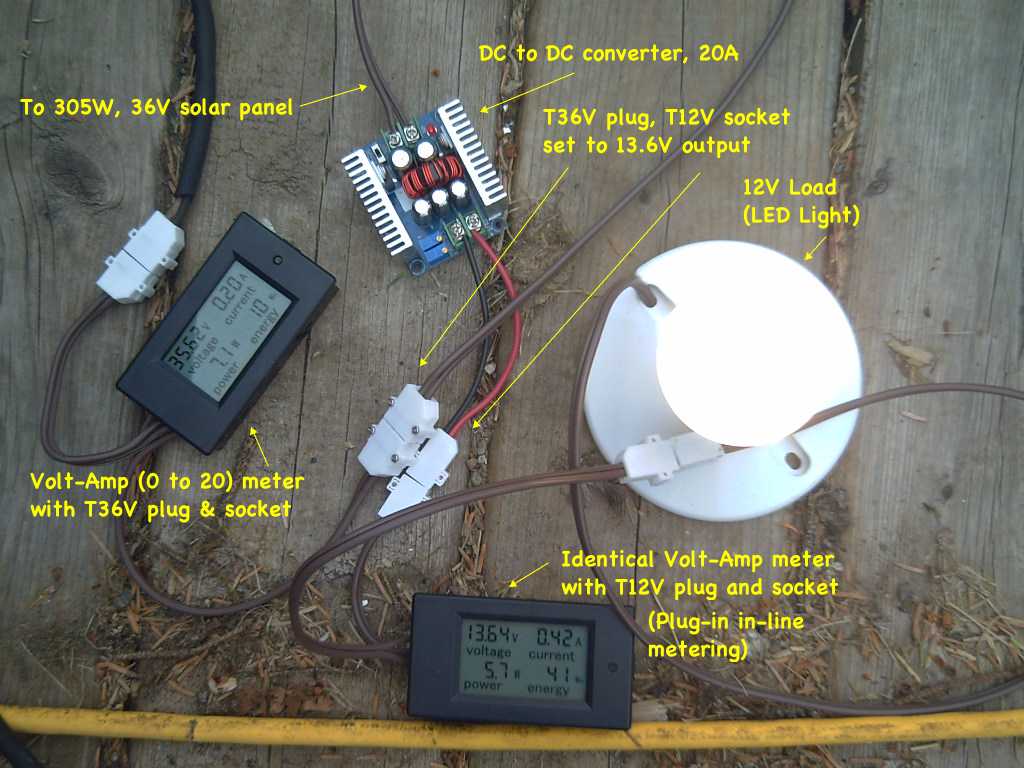

[30th] I envisoned "Plug-and-Play Solar" for off grid

systems.

The components just plug in to each other with the T-Plugs and

Mini

T-Plugs. Which I think I'll call:

T36P (T-Plug 36 volts)

T36S (T-Socket 36 volts)

T36WP-3 (T-Sockets Wall plate 36 volts, triplex)

T12P (Ditto for the 12 volt series)

T12S

T12WP-3

T12CLA (Cigarette lighter adapter... TBA)

The plugs and sockets are of course to

plug together the actual system components:

Power meter/monitor

with

T36 plugs, connected to solar panel (and DC to DC converter)

Power meter/monitor

with

T36 plugs, connected to solar panel (and DC to DC converter)

One with blueish backlight On

One with blueish backlight On

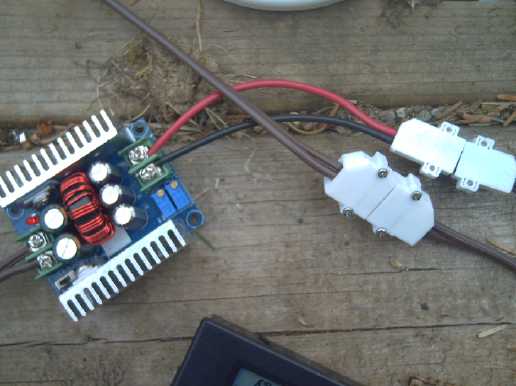

The DC to DC converter

(9-42V in, screw adjust out, screw adjust 0-20 amps out max).

The DC to DC converter

(9-42V in, screw adjust out, screw adjust 0-20 amps out max).

Operating these things so close to the

absolute maximum rating of 40V always makes me nervous. "36V"

batteries

can charge to a little over that, and the 60 cell Hanwha solar

panels

say "40.2V open circuit". Why didn't they make the XL4015 DC to DC

chip

- that

they virtually all use - 45 or 50 volts just to be on the safe

side?

Wait! I just looked and I see the 0-20 amp ones use an LM25116

instead.

It's rated 42 volts max! Just enough. Yay!

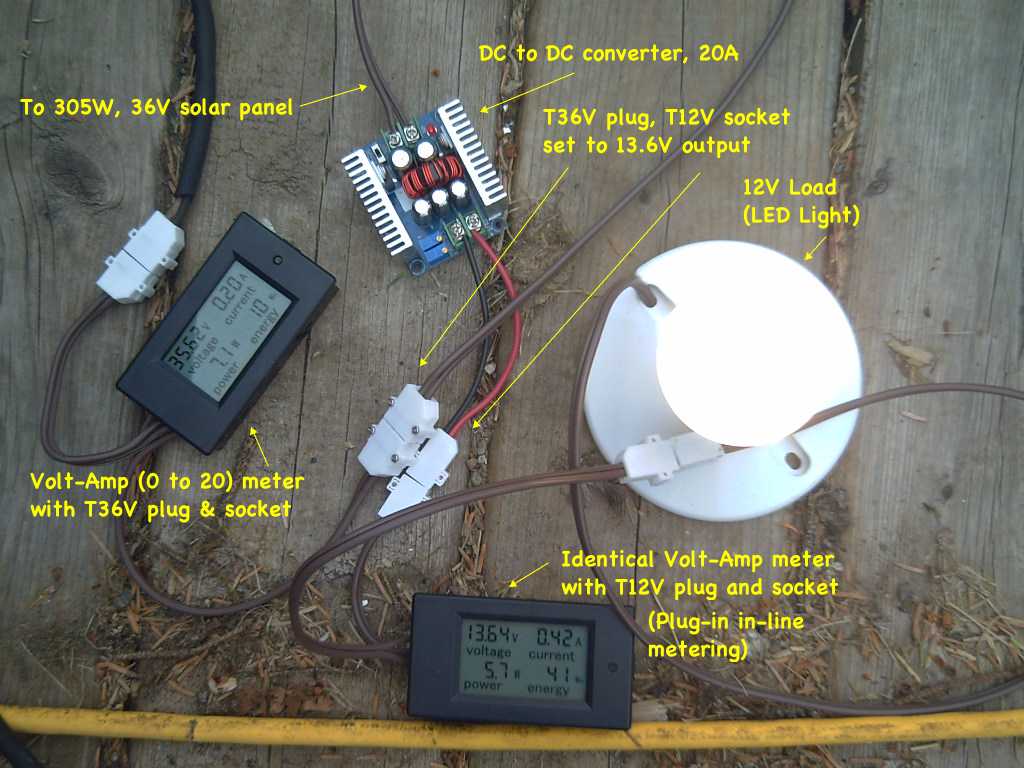

Charging

a

battery. The battery has a T12S socket to plug loads into and so

does

the DC to DC converter, so there's a male-male coupler between

them.

It's always a bit weird connecting two power sources together.

Charging

a

battery. The battery has a T12S socket to plug loads into and so

does

the DC to DC converter, so there's a male-male coupler between

them.

It's always a bit weird connecting two power sources together.

(Top left arrow is wrong.

The

cable from the

solar panel is the one under the words.

(Top left arrow is wrong.

The

cable from the

solar panel is the one under the words.

The cord to the DC to DC Converter comes out of this first power

monitor.)

I made a cable with MC4 solar panel connectors on one

end

and a T-socket on the other. Then I wired up a voltage/current

meter

with T-plug and socket. So now for the charging side a 12 volt

system

with a large (33-40V) solar panel, one plugs the solar meter into

the

collector, the DC to DC converter into that (amps up to 20 with

the

ones I have), and the battery into the DC to DC converter. (set it

to

about 13.5V output for lithium iron phosphate type 4S, NiMH 10s.

Set to

about 11.85V for 3S lithium ions.)

For lead-acid, the DC to DC converter will bring the

panel

voltage down to 15 volts (must check optimum voltage), then a

cheap PWM

controller intended for a low voltage solar panel feeds the

battery the

pulses that lead-acids like.

By one of these methods I expect one can feed 12V

batteries including lead-acid from a 30+ volt panel instead of a

~17V

one. With two low power LCD current and voltage meters one can see

just

what's happening both to the charging and the loads. Considering

the

cost of batteries, it's worth a few dollars to be able to see

exactly

what's going on. (If I had had them on the Miles truck I would

have

noticed that they were getting low - both the original golf cart

batteries and the lithium iron phosphate ones - before they were

all

ruined. I would have seen that they were being continually

discharged

instead of being oblivious.)

In fact, to

that end I had found and purchased self powered, low power LCD

voltmeters on line, and I wired up some 7-30 volt ones (T12P plug)

and

some 18-80 volt ones (T36P) to leave connected to the batteries in

the

truck. I used the power meters to check how much power they used.

They

read .00A, meaning less than 10mA. The old LED ones I had been

using

before read .02A, ie somewhere around 20mA. I figure the new ones

I

should be able to leave on for ages without them draining the

battery

they're supposed to be measuring. (If I could turn off their blue

backlights I'd be even happier.)

In fact, to

that end I had found and purchased self powered, low power LCD

voltmeters on line, and I wired up some 7-30 volt ones (T12P plug)

and

some 18-80 volt ones (T36P) to leave connected to the batteries in

the

truck. I used the power meters to check how much power they used.

They

read .00A, meaning less than 10mA. The old LED ones I had been

using

before read .02A, ie somewhere around 20mA. I figure the new ones

I

should be able to leave on for ages without them draining the

battery

they're supposed to be measuring. (If I could turn off their blue

backlights I'd be even happier.)

Greenhouse,

Gardening,

Chickens

[9th] People have little success

growing

corn in the open around here. Last

year I got some 1/2 decent corn (good tasting even if only 1/2

filled

cobs) by placing an improvised wooden frame with LDPE sheet around

the

little patch and on top. It was all below my waist and when the

corn

got that tall I took it off. But by that time it had had a good

head

start. I did some hand pollinating, shaking tassels over the

silks.

Right wall

plastic shows

where roof used to bend down to to also form the front

wall,

and how much new space has been added from the lawn (within the

cement

footings).

Being [just] standing height instead of under the sloped wall,

the

increase in usable space

is much more, and will be still more usable with the

cement to

keep weeds and slugs out.

I

started to do similar this year and had a somewhat

bigger and better frame half made. But I went into the greenhouse,

and

had

the thought that if I extended it as I had planned to do anyway,

it

would have

as much room for the planned corn patch as the frame.

I

started to do similar this year and had a somewhat

bigger and better frame half made. But I went into the greenhouse,

and

had

the thought that if I extended it as I had planned to do anyway,

it

would have

as much room for the planned corn patch as the frame.

I started by

raising the roof, intending to put up walls the next day. Then I

thought I

should put a cement footing around it to keep the seemingly

unstoppable

grass, weeds and slugs from creeping in from all around. Before

doing

that, I really had to fix the cement mixer so I wasn't mixing it

all by

hand. That was going to increase project scope - all that just to

plant

some corn! But that evening I cut my finger and decided to be nice

to

it for a day or two. So I did other and 'office' things on the

10th and

11th. I got the cement mixer fixed, and I dug and got a few feet

of the

footing done on the 12th. On the 13th I dug more trench and

finished

another 6 feet of the footing. The blackflies were horrible and I

finally put on a mesh helmet. At least a couple still got in under

my

left glove and my wrist was still

itchy 3-4 days later. I could only look forward to finishing so

I'd be

working inside the greenhouse instead of out in the open.

(Something I

really miss about Victoria is the almost complete absence of

biting

insects, at least in my old neighborhood.)

On

the 15th and 16th I got things pretty much closed in,

and I started digging up clods of grass to get down to dirt

without

grass roots.

On

the 15th and 16th I got things pretty much closed in,

and I started digging up clods of grass to get down to dirt

without

grass roots.

Then I dug up some clayish soil from an old garden

(too shady with alder trees to use since long before I bought the

house) and

dumped in a few inches of that. Then I finally transplanted the

corn

that

had badly needed it even before I started. Smaller

seedlings went in the next day [17th].

I could

now

dig out the rest of the grass at leisure...

except that it was now the latter half of May and time to plant

most

everything. I had some broccoli in seedling pots go to out ASAP or

sooner, and a considerable garden space to fill. By the 20th I had

the

rest of the grass out and the garden soil in, and the greenhouse

was

pretty much planted - not that I didn't squeeze in a few more

things

here and there over the next couple of weeks.

I could

now

dig out the rest of the grass at leisure...

except that it was now the latter half of May and time to plant

most

everything. I had some broccoli in seedling pots go to out ASAP or

sooner, and a considerable garden space to fill. By the 20th I had

the

rest of the grass out and the garden soil in, and the greenhouse

was

pretty much planted - not that I didn't squeeze in a few more

things

here and there over the next couple of weeks.

19th. The greenhouse is

still

rather "cobbled

together".

19th. The greenhouse is

still

rather "cobbled

together".

I hope to be making my own clear plastic panels to replace the

6mil

LDPE roll plastic

and the not-so-transparent roof material... "soon". (Ya right!)

20th. Later I stuck in a

fifth

row of corn next

to the broccoli.

20th. Later I stuck in a

fifth

row of corn next

to the broccoli.

Who needs broccoli?

Egads, there's a snake in

the

asparagus!

Egads, there's a snake in

the

asparagus!

(The aluminum trays are for light reflectors on the house wall -

the "not very transparent" greenhouse roof makes it all too

dark.

There are no snakes around here!)

Last year plastic "walls" - wall sections of

polyethylene

milk

cartons - seemed to have stopped the slugs from killing vulnerable

plants and I managed to grow some. This year I made a slightly

raised

bed with 8 inch walls. I covered the wood with coroplast

(polypropylene). But it didn't seem to work. On the evening of the

30th

I found about 15 slugs decimating the vegetables in that raised

bed!

Regardless of eliminating those soon the broccoli was eaten to

stems. I

guess polyethylene and polypropylene don't have the same deterrent

effect. I also planted carrots at one end, but after seeing a few

sprout they vanished and only fine grass, I assume from seed,

seemed to

be growing. I planted carrots in the expanded greenhouse and hope

they

fare better.

I saw some mesh bags of tiny onions in a grocery last

winter. They

looked just like planting onion sets and I bought three bags

(white,

red and an larger type whose name escapes me at the moment) to

plant in

the spring. But nothing came up. I wetted some indoors in a tray

and

kept them moist, but very few of them would grow. Most of them

just

seemed to rot and not root or sprout. Someone suggested that they

may

have been irradiated. What a horrifying thought! What is happening

to

our food supply? Of course by then it was too late to buy planting

onion sets at seed places.

I put out my quinoa

seedlings

next to the house.

I put out my quinoa

seedlings

next to the house.

Someone said sea shells would keep slugs away. Seems to be just

a

superstition!

But later I sprinkled on some spruce sawdust all around the

patch...

and that actually seems to be doing the trick!

(Must cut wood, make more sawdust, for other garden beds!)

The auricana chickens gang,

seemingly safe with

a net above and when the

door is closed

The auricana chickens gang,

seemingly safe with

a net above and when the

door is closed

at night. (These chickens are late partyers and some day I'll

forget to

close it at dark

and there'll be mayhem. In the meantime, 3 or 4 eggs a day.)

Innovative

Beekeeping

Sometime later in the month I watched a video on a

new

type of

beehive, the larger cubic, insulated "Bee Barn", created earlier

this

very month, May 2021, by Jim of "Vino Farm" youtube channel. And

someone who had kept bees said I should add a roof to keep the

landing

and hive entrance area dry in blowing rains. I became sure that

such an

improved hive is just what is needed in this cool, damp climate

with

its cool to cold

nights. Combined with Carniolan bees that can forage in "cool" and

"damp" better than most, I finally see how one might make a

reliable

success of raising honey bees here other than by praying for very

good

summer weather.

Funny how things can work out: if I had got the

Carniolan

bees earlier when I was supposed to, I

wouldn't have seen the video in time and wouldn't have been able

to

make this new type of hive for them. But I really need to get

Hiveworld

to send the nucleus hive ("nuc") now, from their own last order of

the

year from Chile! (Where I hope there are no varoa mites!)

Only one person on all Haida Gwaii, in an especially

favored spot,

keeps bees. Others have said it just doesn't work around here. A

warm,

dry hive for the queen, the

brood and for the bees laden with pollen to return to after their

strenuous foraging trips must be key in a cool climate. The fellow

in

Alaska who was keeping bees had

actually put his hive inside a garage, with a "tunnel" through one

wall

to the hive entrance.

And in fact, nights are cool up and down the whole BC coast from

Vancouver Island to Alaska. I think it would make for a more

reliable

and more productive way to keep honey bees. There'd be more honey

for

harvest if the bees aren't spending their energy and eating more

to

keep warm. It seems like a worthwhile

inventive project, and, in anticipation of getting the bees, I

went

ahead with building it.

The standard Langstroth beehive components in

ubiquitous

use are built around two sizes of internal "frames", about 18

inches

long, 1.5 inches thick and 6 or 10 inches tall. These hang from

upper

lips in the "supers" (superstructures?), simple four sides pine

(or ?)

crates with open top and

bottom. The frames usually have a sheet of some material, often

plastic

laid out in a hexagonal pattern on both sides, sometimes pre-waxed

with

beeswax, for the bees to build

their combs on. Simple wire frames for the bees to build over

works too.

The width of the box is sized to hold 4 or 5 frames

(for nucleus hives, sold as "nucs"), or 8 to 10 frames, 10 being

the

most

common. There are various options for the top lids and bottoms,

and

additional optional or accessory pieces that go inside the tops

and

bottoms - vents and feeders.

Knowing so little about beekeeping I simply assumed

that

all these

must be optimal and that much thought must have been given to

choosing

the designs. Apparently it's more a case of somebody (named

Langstroth,

IIRC) slapped something together that worked, and everybody else,

having no original ideas, simply copied it. Of course at the time

it

was a huge

improvement, an exciting technical breakthrough: for the first

time,

one could raise a honey bee hive and

then extract honey from frames without destroying the hive. And it

works well in warm climates.

I was planning on getting Carniolan bees, which were

said

to fare better in cool summers and damp weather, so typical here,

but

Al was ordering two packages of live bees from Australia for the

end of

March, and he added another package to his order for me. Once the

package of bees was dumped in and the queen released, I understood

I

wasn't supposed to open the hive for 3 weeks. The weather was cold

(it

even snowed again!) and my bees all died in a few days or a week

or so.

(Who knows exactly, when you're "not supposed to open it" and

look!?!)

What went wrong? I had just taken Al's advice on a hive entrance

feeder. Apparently the bees, in trying to keep warm and keep the

queen

warm, don't come down to the hive entrance. I should have had a

hive

top feeder system. Also, did I mention it was cold? How were they

supposed to keep warm in an uninsulated wooden box? I had heard

something about wrapping a hive, but it looked almost problematic

to

start with, and especially once there were bees in it.

[17th] Ah... Here's when I watched that video. The presenter, Jim,

had

just had most of his

hives die off over the winter in spite of his precautions. It

wasn't

his only problem, but he felt the Langstroth was a poor design on

several counts and contributed to the problem. So he had (just in

April

and May 2021 -- this very month!) developed

a new layout, the "bee barn" with a larger, well insulated main

brood

box and some

features to require less lifting and disassembling, with less

stress

and dislocation for the bees during hive inspections and

disassemblies. Instead of stacking a 10 inch and 6.5 inch super

with

their separate frames on top of each other, the box was made that

tall

(16.5"), "the Goldilocks size" he thought, and the frames were

made

taller to match - "more like a

[hollow] tree". He made taller frames and used the same plastic

'hexagons' inserts as

usual for those two sizes, which left a gap between 'for the bees

to

fill in as they saw fit', eg, with drone and queen cells. And

because

it was taller, he had only 7 of

these larger frames, that being the equivalent of 12 ten inch

frames.

(Mine will hold up to 10 of these 'tall' frames, equivalent to 17

or 18

regular 'deep' frames.) And there were also several details for

end

spacers and end insulators, vents and

feeders, that sounded well thought out.

I decided that little experience tho I had had, this

design

sounded like an improvement in several ways - especially in being

insulated like a house instead of needing to be "wrapped" - and I

would

try it out. It sounded especially suitable for our climate here

where

heating would be wanted at night for most of the year, and in the

day

for much of it. Thus

insulation should save the bees a lot of energy expenditure (of

buzzing

to keep the hive warm) and could

well make the difference between "practical" and "impractical" to

keep

honey bees in this climate. (Camille, an experienced beekeeper,

earlier

said to me that

Langstroth hives were "no good". He was carving out some hollow

tree

stumps to use for hives himself, but then decided his location was

just

too cold, shady and windy regardless. Mine is more favorable - and

I'd