Turquoise Energy News #157

covering June

2021 (Posted July 7th 2021)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- Ultra Efficient Chevy Sprint Revival: Direct Drive to CV

Shaft With 96%

Efficient Reduction Gear - New Motor design - "Plug & Play?" DC

Power Components

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Public Committees - Small

Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Making & Driving 96% Efficient Direct "Motor to Planetary

Reduction to CV Shaft Drive"

for

Chevy Sprint: - Coupling the components - Mounting them - Torque

improvement - Driving (on acreage only) - Conclusions

* Designing "car drive size", unipolar, outrunner, BLDC, "Electric

Hubcap" type motor

Other "Green"

& Electric Equipment Projects

* Off grid infrastructure: "Plug-and-Play Solar"

* Greenhouse, Gardening

* Innovative Beekeeping for the BC Coast

Electricity Generation

* My Solar Power System: - Daily/Monthly

Solar Production log et cetera - Monthly Summaries and

Estimates (27 months)

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte) (No

Report)

This month I did a notable electric transport project:

an "ultra-efficient" fixed reduction electric car drive train (below

& in Electric Transport). Also surely worthy of note in In

Passing is the idea of volunteer "Public Committees" to advise

elected government on best directions for society in any and every

field, and in any and every issue that arises within that field. It's

an idea mentioned before, but I think put more understandably herein.

Last month with one thing and another I didn't finsh TE

News

#156 until the 9th.

I hoped to do better this month by doing much

editing before the the next month started, but there were many

distractions and with firewood on order I really needed to make a

second firewood shed. With just one shed, even if it's big enough to

hold all the firewood you need, you inevitably end up stacking fresh,

green firewood in front of the remaining seasoned firewood. Even this

second one will be split into two smaller ones side by side to make it

easier to stack fresh wood in a vacant space. I had the floor done by

the 26th and started putting up the walls.

I

finished my

"Bee Barn" on the night of the 8th and

set

it outside the next morning. (to get it out of the workshop!) I made

special frames edges into which one would slide the "nuc" frames with

the new bees, brood and honey into, making them into tall frames for

the tall space. The last feature was a little roof over the entrance so

the bees would stop getting wet in damp weather even before they

alighted instead of entering the hive.

(But still no bees! Looks like it'll be next year now. I put a plastic

"tarp" over it.)

I

finished my

"Bee Barn" on the night of the 8th and

set

it outside the next morning. (to get it out of the workshop!) I made

special frames edges into which one would slide the "nuc" frames with

the new bees, brood and honey into, making them into tall frames for

the tall space. The last feature was a little roof over the entrance so

the bees would stop getting wet in damp weather even before they

alighted instead of entering the hive.

(But still no bees! Looks like it'll be next year now. I put a plastic

"tarp" over it.)

After I made it, I mentioned it to Al, and he directed me

to a website called "ApiHex.ca" where they already make plastic well

insulated beehives. If I had known, I'd probably have bought one.

It had some great features, seemingly well thought out. The two things

it didn't have were that it took standard Langstroth frames rather than

"bee barn" tall ones, and it didn't have a roof over the entry. I could

no doubt have hacked it to meet my specifications more easily than

building from scratch if I had known about it, but what I've built is

just as good if not as "stylish". Bees won't care.

Chevy Sprint Revival: 96% Efficient

Direct Drive to a CV Shaft Via

Reduction Gear

With the schedule more or less cleared for a moment and

the Yun Duan 5:1

planetary gearset ordered through AliExpress.com having at last

arrived, I was eager to

start

on the Sprint and see what the performance would be like. Somehow it

didn't

matter that it wasn't a special sort of groundbreaking project or even

original, or that I had

many better, more urgent or more important things to do. Or that it was

really just an experimental demo of an ultra-efficient drivetrain and

wouldn't, even working well, replace the Nissan Leaf.

The 96+% efficient, 5 to 1 reduction planetary gearbox,

coupled directly to the car's right side CV drive shaft, are the only

components between the motor and the wheel - ie, there are almost no

losses. If a typical vehicle transmission is only 60-70% efficient as

I've always heard (with driving the differential gears to the wheels

presumably imposing a further penalty), this means perhaps a 50%

efficiency boost over a "typical" car conversion to EV, which almost

invariably seems to use the original transmission and differential.

Thus the motor can be 2/3 the size to provide the same performance, and

the batteries will take the car 50% farther.

So at the expense of other things, I spent most of my

available time for two weeks on it, and then did a few "finishing

touches"

here and there over the next days. For once a project didn't stretch

out

interminably into the future. The motor controller was already in the

car, and all that was needed was to mount the motor and gearbox... and

put in some batteries, of which I didn't have quite enough for

everything any more.

So at the expense of other things, I spent most of my

available time for two weeks on it, and then did a few "finishing

touches"

here and there over the next days. For once a project didn't stretch

out

interminably into the future. The motor controller was already in the

car, and all that was needed was to mount the motor and gearbox... and

put in some batteries, of which I didn't have quite enough for

everything any more.

I had the drive assembly mounted in the car in

a week. I hooked up a battery to the motor and ran some quick tests. It

appeared to have more torque than in the previous incarnation with the

original transmission. This seemed remarkable as the reduction ratio

had gone from 8.9 to 1, down to 5 to 1. More torque in a "higher gear"

instead of less? But actual driving showed that the quick tests without

actual figures must have been deceptive. It was no doubt better than 5

to 1 with the old transmission (and with the differential) would have

been, but it wasn't "twice as good".

As a rough estimate, the

car with the drive system and

batteries under the hood probably weighs only about 1570 pounds plus

the driver. (Empty Car 1400 [est], Motor 51, Gearbox 15, Batteries

about 100 pounds, misc.) The motor

controller was still mounted on the center hump behind the firewall

between the driver and passenger. Everything else to do with the

compact drive fit under the hood, including two 36 volt stacks of

lithium-ion batteries providing 36V, 240AH or 8640WH. So the entire car

was free for its original uses. One could of course fill the spare tire

space and part of the cargo space with more batteries to give it very

substantial driving range.

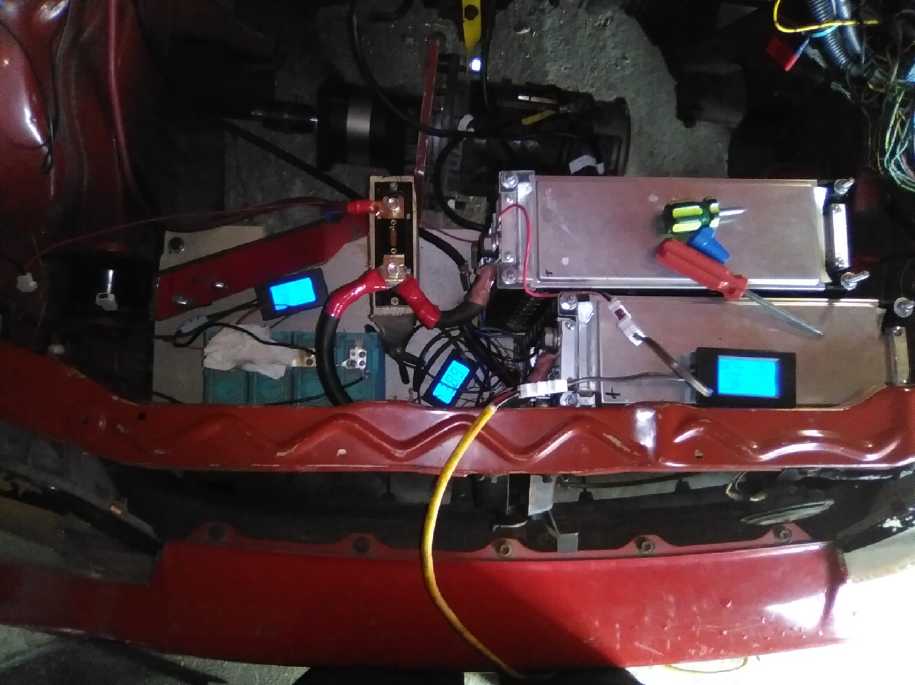

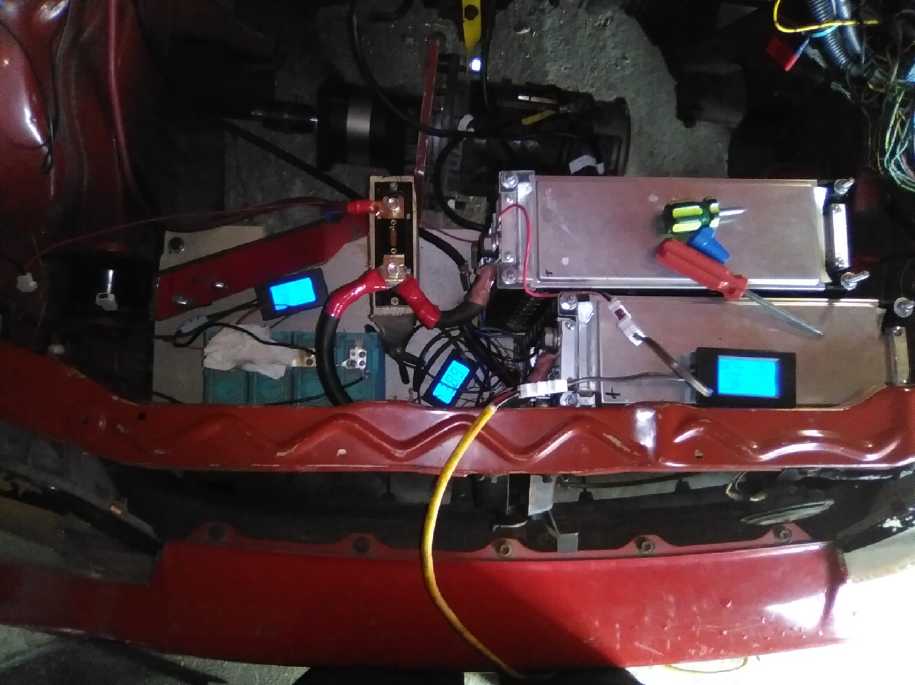

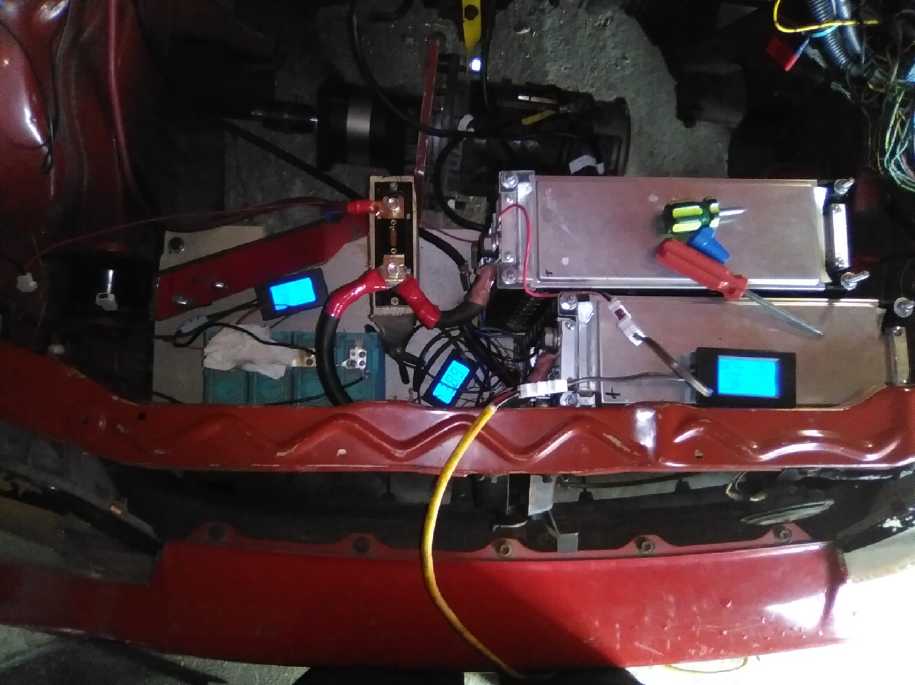

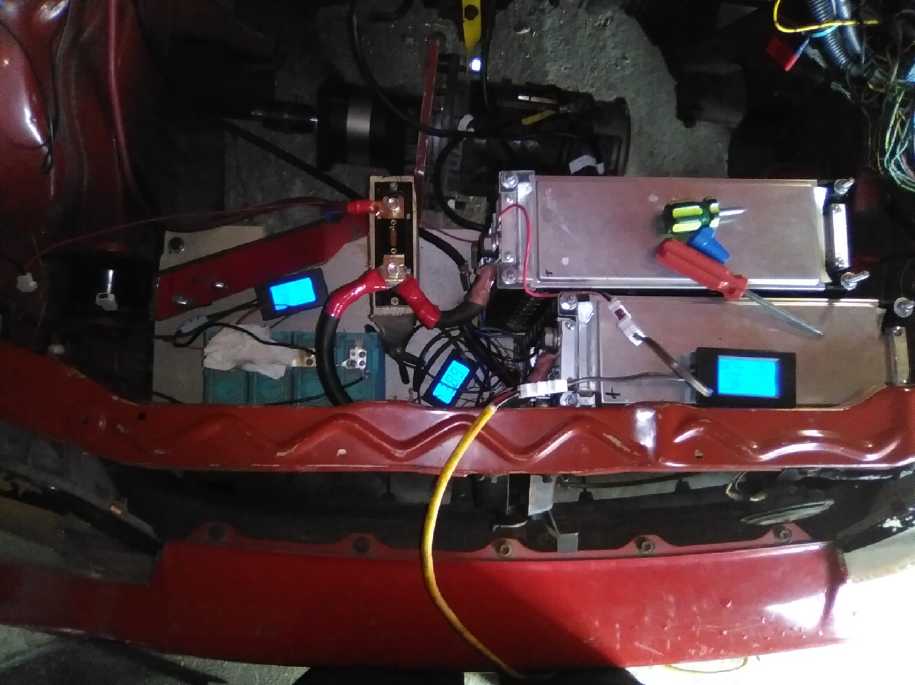

Rear/Top: Forklift motor to 96%

efficient

planetary gear reducer to starboard side CV shaft.

Rear/Top: Forklift motor to 96%

efficient

planetary gear reducer to starboard side CV shaft.

Red rectangular steel tube running diagonally from below Motor to

Frame higher up

replaced previous "flimsy" yellow bar to hold drive assembly against

high torque loads.

(had to cut into 3/4" plywood battery shelf to fit it.)

There's also a 1/4" plywood front wall. Can't accidently short

batteries to wood, keeps out flying debris!

Ctr: 500 amp fuse in holder, mounted on top of a piece of 2"x6" to

raise it near to "+" at top of batteries

Right (port): 2 stack assemblies of 10 "LG" li-ion batteries, total 240

AH, 36 V

Left (stbd): Green 12 V, 40 AH li-FePO battery for car electrical,

stereo. (Car plugs in to battery!)

Yellow cord: Charging car from 36V DC solar system; panels on house

roof.

Illegible here, meters show voltages, current and total energy of

charging.

What was to be determined with this experimental project:

* With the high efficiency, would a mere 5 to 1 ratio gear be enough

speed

reduction to give the car sufficient torque for decent acceleration

from a stop and for climbing hills?

* How would driving a single wheel perform? Would it pull to one side?

Would it slip?

* How fast would the car go on level road? (This could be estimated in

advance from the difference in ratios from the 2018 trials with the

"cludged" original transmission: 8.9/5 * 25 KmPH = 44.5 KmPH. Since it

doesn't have a speedometer and hasn't been on the road so far, we'll

just estimate "45 KmPH".)

On the summer

solstice I drove the car across the acreage... and got it stuck there.

One of my motor supports was too flimsy and bent - almost folded -

under high torque. (Oops, no picture!) And the coupler to the CV shaft

started slipping. I fixed these problems that day and the

next. Luckily the weather was finally nice for a change.

When I got to the base of the hill rising to the main

driveway I stopped. (mistake! Here I must note that the car still

doesn't

back up except by pushing it, or by rewiring the motor to change the

direction, and then again to go forward again.) The car didn't make it

up the hill. It was going very slowly when the

new supposedly 300 amp circuit breaker (more like 100!) blew 3/4 of the

way up. When I tried

to start on the hill, with the added weight (motor, batteries, driver)

nearly all

on the left and the lightweight car also leaning to the left on the

hill, the drive

wheel - the right front - slipped on the grass. I shoveled in a little

pea gravel,

When I got to the base of the hill rising to the main

driveway I stopped. (mistake! Here I must note that the car still

doesn't

back up except by pushing it, or by rewiring the motor to change the

direction, and then again to go forward again.) The car didn't make it

up the hill. It was going very slowly when the

new supposedly 300 amp circuit breaker (more like 100!) blew 3/4 of the

way up. When I tried

to start on the hill, with the added weight (motor, batteries, driver)

nearly all

on the left and the lightweight car also leaning to the left on the

hill, the drive

wheel - the right front - slipped on the grass. I shoveled in a little

pea gravel,

and finally put a ramp

under the left rear wheel so one wheel was going downhill. I thought

that would get it going, but I had to repeat it. It didn't get up any

speed

and it kept slipping whenever it reached the end of the pea gravel. And

finally there was a last little dip where the wheel would neither slip

nor rise out of. It was stalled. 5 to 1 just was close to but not

quite enough reduction to give satisfactory hill climbing torque with

this motor and controller.

and finally put a ramp

under the left rear wheel so one wheel was going downhill. I thought

that would get it going, but I had to repeat it. It didn't get up any

speed

and it kept slipping whenever it reached the end of the pea gravel. And

finally there was a last little dip where the wheel would neither slip

nor rise out of. It was stalled. 5 to 1 just was close to but not

quite enough reduction to give satisfactory hill climbing torque with

this motor and controller.

I drove it around on the more level driveway area, but it

still slipped pretty easily on the grass going uphill. Other than that

it seemed to

have enough pickup and drove quite nicely. It didn't pull to one side

when I "booted" it that I could notice. But then it wasn't a very

powerful "boot". I didn't take it out on the road because I doubt that

it

would make it back up my longer steep driveway into the yard at the end

of the trip. (Rats!)

I put the old 135 amp breaker back in and had no further

trippings. From then on I always took a run at the hill and always made

it up - by early July, numerous times including with loads of lumber.

Even with 96% drivetrain efficiency, one can only push a

motor so far. With this motor, 7 to 1 instead of 5 to 1 probably would

have

climbed hills from a stop fine even with 'potholes' - wheel slipping

aside. It would also limit the potential speed to 32KmPH instead of 45.

I didn't get to see how it would go on level pavement, but I think it

would have gone a long way per unit of energy consumed, even if not

very fast.

And I concluded (no surprise!) that a single

wheel drive really isn't for "off road"!

A motor with more torque

and a higher maximum RPM should

put the car on city streets. It would have to be 4500 RPM for 90 KmPH

on the highway.

My thought is that I should try and make the long planned

"Electric Hubcap unipolar outrunner" BLDC motor. It would probably meet

the torque requirements and have RPM at least for 60 KmPH (3000 RPM).

If I do of course it'll be ultra efficient throughout and use the least

electricity in any situation.

On the 23rd, I made up some plugs and cables, and connected every

second cell between the two parallel batteries for the balance

charging, and started charging the Sprint - which now had both of my

assembled 36 volt

lithium ion battery stacks in it - from the DC solar power system, for

which the equipment is already in the garage and the panels on the

house roof. Thus my recorded solar DC

power figures jumped up this month from almost 0, and the 13th solar

panel was being used a bit more than trivially. (If I could drive on

the

highway and really work the batteries it would be much higher!)

Firewood Shed July 5th. 100% my

own cut lumber.

Roof of scrap sheet metal with old screw holes caulked.

By the 26th,

if I couldn't use it on the highway, I found

I could at least use it for hauling lumber from the piles where I had

stacked the wood I cut with the handheld bandsaw mill over the last 3

years, to the shop to it cut up for the new firewood shed. It actually

saved me considerable heavy hauling by hand.

By the 26th,

if I couldn't use it on the highway, I found

I could at least use it for hauling lumber from the piles where I had

stacked the wood I cut with the handheld bandsaw mill over the last 3

years, to the shop to it cut up for the new firewood shed. It actually

saved me considerable heavy hauling by hand.

A problem with not using the original transmission was that there was

no way to hook up the speedometer/odometer. I ended up ordering a

bicycle speedometer, which comes with all the required parts. A magnet

"in the spokes" (or on the shaft) triggers a sensor that counts wheel

revs. The wheel diameter is a programmable numeric setting, which gives

it the flexibility to use with the car, presumably up to 99.9 KmPH.

A problem with not using the original transmission was that there was

no way to hook up the speedometer/odometer. I ended up ordering a

bicycle speedometer, which comes with all the required parts. A magnet

"in the spokes" (or on the shaft) triggers a sensor that counts wheel

revs. The wheel diameter is a programmable numeric setting, which gives

it the flexibility to use with the car, presumably up to 99.9 KmPH.

I may yet take the car out on the road for a few tests

once I can measure speed and distance. (Even if I have to tow it back

up to the top of my steep driveway on the return!)

Outrunner "Electric Hubcap" Motor

Layout?

Thinking about making that new type of motor, I did a bit of figuring

and checking. It looked like a trailer stub axle and machined-down hub,

which I had made a couple of in my earliest motor experiments, could

make a great center for such a motor.

Thinking about making that new type of motor, I did a bit of figuring

and checking. It looked like a trailer stub axle and machined-down hub,

which I had made a couple of in my earliest motor experiments, could

make a great center for such a motor.

And I spaced out some of my my "standard" independent-mount motor coils

with iron powder centers and ilmenite magnetic circuits around a 300mm

rotor and found that that seemed like just about the right diameter for

the outside of the stator.

And I spaced out some of my my "standard" independent-mount motor coils

with iron powder centers and ilmenite magnetic circuits around a 300mm

rotor and found that that seemed like just about the right diameter for

the outside of the stator.

Adding the "outrunner" rotor would make the outer diameter

just over 360mm. With the flux gap at about 156mm radius, and with 12

coils and 16 supermagnets (2"x1"x.5" or 2"x1"x.375"), the potential

torque for this layout of motor should be quite high - I expect

substantially higher than the forklift motor.

[a few more details in detailed report] Now, about when

I'll be able to get to it...?

"Plug & Play?" DC Power Components

I

started making good use of my DC "T-Plug" plugs, sockets, and power

monitors to see if the remaining golf cart batteries from the truck

would come back to life. I connected a 305W solar panel through a power

monitor, a DC to DC converter, another power monitor and a PWM lead

acid battery solar charge controller to two (6V) batteries in series at

a time.

I

started making good use of my DC "T-Plug" plugs, sockets, and power

monitors to see if the remaining golf cart batteries from the truck

would come back to life. I connected a 305W solar panel through a power

monitor, a DC to DC converter, another power monitor and a PWM lead

acid battery solar charge controller to two (6V) batteries in series at

a time.

I could see

the solar voltage and current, the DC to DC converter output voltage

and current, and the battery voltage via the charge controller.

I could see

the solar voltage and current, the DC to DC converter output voltage

and current, and the battery voltage via the charge controller.

With this setup I determined that the idea of using the DC

to DC converter in the charging circuit to reduce the 30+ volts solar

panel to 17 volts instead of using a 17 volt one doesn't work properly.

As long as the panel could supply whatever current the DC

to DC converter was set to, everything was fine. One would see (eg)

36V, 1A on the high voltage side and after the converter to the

batteries, 13.3V, 2.5A.

But as soon as there wasn't enough light, the converter

would "short" the solar panel down to the low voltage level, and so the

current to the batteries would drop to (eg) the 1A figure.

Owing to this wasting of low sunlight, one would set the

converter's current limit to a lower current than could be supplied by

bright sunlight, wasting the highest energies as well.

Apparently the charge controller can't figure out that if

it backs off its demand a bit, it gets way more current. Presumably an

MPPT charge controller would do better... but if it's really an MPPT

controller, one can simply feed the higher voltage solar panel straight

to it. But the pulse charging from PWM controllers makes lead-acid

batteries last longer.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Public

Committees

I had been seeing the works of Daniel Raphael on "Social

Sustainability Design Teams" and "Third Stage Democracy" and I was sure

he was onto something special, but I was also sure that the name he had

given the former didn't make

it an easy "sell". To me it conjured up virtually no picture

of what it was all about. I had been trying to come up with some

better name for quite a long time without thinking of anything

promising.

On the 12th I woke up in the morning with the term "Public

Committee" floating ever so faintly in my head. What was that? Random

words drifting through my mind? But when I brought this shadow

of an echo of a thought to consciousness, I immediately realized it was

the name I had been searching for, yet totally unlike anything I had

come up with. My thanks to my angels, the indwelling spark of the

Universal Father, the cosmic mind or whoever it

was!

The name "Public" implies of course that the public is

involved. Of, for and by "the people"! The name "Committee" immediately

gives a sense of what it is:

a small, perhaps temporary, internally organized group with a defined

hierarchy and positions, brought into existence to study or focus on a

specific issue or topic. Thus the intent is readily understood.

Every detail of the organization might be just as Raphael has defined

it, but a committee is exactly what it is. What do governments set up

to study an issue and make recommendations? What do they listen to (or

ignore)

besides the mega-corporations whining loudly in their ears? Committees!

A

public committee thus becomes a volunteer extension of the government.

"Off the cuff" hypothetical examples:

Public Committee on Dairy Product Production and Distribution

Public committee for New Parent Education

Public Committee Concerning Private Residential Property Rights

and Responsibilities

Public Committee on Bylaw Interpretation and Application

Public Committee on Provincial Electoral Procedures

Public committee on Public Educational Goals

and so on and so on and so on. Many of these would probably have a

place name

in front of them, so "Victoria Public Committee on Sewage Treatment and

Nutrient Recycling"

might determine better solutions for that particular city, which is

surrounded on three sides by sea.

I hope this shows with the variety of examples that all

sorts of

social and societal issues might be - and eventually will be - the

focus of attention with the intent of improving on present day

practices. Once the idea takes hold, it should spread exponentially.

The first ones that are formed will probably have the greatest impact

and stir the most excitement, but in the aggregate they will soon

(decades) utterly transform human civilization - doubtless for the

better in every area.

And many such local committees would

connect together on the internet to discuss issues to be presented to

larger governments than local. Again, as elected officials

who represent the public realize that submissions and reports from such

groups represent the

thinking and wishes of the more intelligent, more thoughtful segments

of society who are the most involved with the issue they are

presenting, they will realize it is their place to give them

legislative or other governance effect. Representative government will

therefore continue, but it will become much more representative of the

public will, and it will start to attract a different sort of people

and become more of a coordinative function.

Thus the combined talent and creative thought of all,

instead of that of just a few elected to positions of representation of

all, will go toward improving the human condition. This will create a

new age, a new chapter in the history of human evolution, the journey

toward Light and Life, toward Utopia, or whatever one terms it.

Note: Presently and for some time, the term "committee" has had

something of a "bad rap".

Something poorly thought out with dubiously useful or even conflicting

components is sometimes said to have been "designed by a committee" -

everything a compromise overall perhaps satisfying to no one.

(The very spelling of the word "committee", versus something like, say,

"commity" seems to have been formulated to be as awkward as possible.)

Most

committees visible to the public are put together for political

purposes and they may come to conclusions not always agreeable to the

public. More often, they seem to come to good conclusions, which are

then usually

ignored by the government in full session for political reasons.

However, any committee does put together several minds in

an organized manner to focus on something specific, and the coordinated

creative thoughts of multiple

people can multiply together rather than just add, especially if the

structure lends itself to it. Raphael seems to have put much thought

into the structure of the "Public Committee" idea that he calls the

"Social Sustainability Design Team". And a Public Committee is likely

to generate ideas and plans agreeable to the general public, on many

topics of interest to various groups, and in the long term best

interests of society. A "committee of public committees" communicating

over

the internet on a regional, national or global level, is likely to come

up with the best solutions presently thought of by anyone and

acceptable to many, in their area of study.

And when those solutions have had their day and are

becoming obsolete, whether 1, 10 or 100 years later, when they are no

longer enhancing the universal core values of being human, members of

the public will recognize the disharmony and

organize new committees to update solutions and keep them current.

Updating of obsolete solutions is a rare occurrence today, and no such

organized planning groups except as affiliated with special interest

groups, exist

today.

Gardening

Plantings

It being the end of spring and

finally some good weather toward the end of June, I filled in the

garden with what few seedlings I had started and

whatever else I could come up with. Somehow I have 5 potato patches. If

a crop that feeds many people is going to grow like weeds, why argue?

Wherever I threw sods of grass to get rid of them, I also threw in a

few potatoes. They outgrow everything else.

Free Wheat - Chicken Feed

Near where I have the chicken pen, I hadn't mowed the lawn

because it was panicing the chickens. The grass and ferns were tall and

lush. As I pulled some out to give the chickens some greens, I realized

some of it was wheat. It was already forming heads bigger than grass

seeds. Huh? Hmm... I was feeding the chickens sprouted wheat. They're

messy eaters. The chicken pen is semi-portable and I shift it over to

fresh lawn now and then, and to let the previous section recover. The

wheat was growing where it had been in the spring.

If the lawn was growing wheat instead of just grass, it

would be free chicken feed. Inspired, I took the chickens' next meal

(sprouted kamut) and sprinkled it around where the pen had more

recently been and the grass was still short, then watered it. July 5th

is a rather late start, but perhaps there'll be grain there come

autumn? (The next day, two chickens got out somewhere and were eating

it!)

Slugs & Sawdust

Having good fences to keep the deer out,

slugs are the number one concern. It's disheartening to have a row of

beans, chard, quinoa or something and come back and find a couple of

plants savaged, and a couple of days later a few more, until you

finally realize they're all gone.

Zucchini transplanted into ground

and just

about to take

Zucchini transplanted into ground

and just

about to take

off, when its first real leaf was bit off at the stem by a slug.

By the time it recovered and started some new

leaves, others started later were much larger.

Someone said broken oyster shells would keep them out.

Then someone else said clam shells or egg shells were just as good. I

put some clam shells around some quinoa, but I suspected it was just a

rural myth. Or rather that one needed a wide layer of them. Gardeners I

asked about slug control kind of rolled their eyes. They had ideas and

things they did, but no magic bullet.

Then I came up with the idea of sprinkling sawdust around.

That seemed to work quite well in many places. (It's spruce sawdust,

since that's what I'm cutting. I don't know if the type is important.)

The weather being cold, windy and wet when I transplanted

them out, I also put up some boards as wind guards.

After the sawdust the slugs seemed to leave the quinoa

alone and it was growing well by July 4th (below).

I did space

out on one fence... Since my apple trees bloomed at different times

there was no cross pollination and so no apples. So finally I bought a

third one. When I planted it, I did everything else "by the book". I

looked at it the next day and a deer had eaten all the foliage except

near the top. (I saw there was one still for sale outside the store,

and a deer had got at that one too.)

I did space

out on one fence... Since my apple trees bloomed at different times

there was no cross pollination and so no apples. So finally I bought a

third one. When I planted it, I did everything else "by the book". I

looked at it the next day and a deer had eaten all the foliage except

near the top. (I saw there was one still for sale outside the store,

and a deer had got at that one too.)

The small corn plot in the

greenhouse seemed to

be growing nicely by July 4th.

The small corn plot in the

greenhouse seemed to

be growing nicely by July 4th.

(The broccoli (left) is growing heads - and shading other things out,

so I'm plucking

them out to make room. The chickens love the leaves from any cabbage

family plant.)

Small

Thots

* We Canadians pay high rates for our

telecomm services, and the government seems to abet overcharging and

makes regulations designed to stifle competition. Recently the Trudeau

government appointed "ex" executive Ian Scott from Telus, just one of

the telecomm companies with a corporate culture of greed,

misrepresentation and fraud, as the head of the Canadian Radio and

Television Commission (CRTC), the watchdog agency regulating such

industries. This, like the USA's "revolving door" of high personnel

between the federal government and the big banks, is a clear conflict

of interest, a betrayal of public trust by our government as they put

the wolf in charge of tending the sheep. No doubt the telecomm

companies have used some of their excessive profits - our money - to

induce the government to make this appointment.

To cement his reputation as inappropriately representing

the interests of the "big telecomm" rather than those of the public

entailed in his position, someone recently snapped a photo of him in a

bar having a private beer with Mirco Bibic, the CEO of Bell Telephones.

When this is how the public interest is "represented" in

the last decade or two and if it can't be corrected, the society we

have known is doomed.

* In Japan after about 1750(?) deforestation was becoming recognized as

a huge problem. Rather than cut down the rest of the forests, it was

decided that a peasant could own one big beam post, the next higher

class 10, and a shogun could have 100. Or something along those lines.

As inequitable as this sounds, today those raking in the big money

could buy thousands or millions of beam posts, leaving none for anyone

else, and the forests would be cut down for money.

Which system then is actually more equitable - one based

on "money is power", or one that regulates how much it is reasonable to

own? And which saves the environment? Japan also started an aggressive

reforestation program, and today in spite of its dense population is

said to have more percentage of forested land than any other

industrialized nation.

ESD

(Eccentric Silliness Department)

* Some people think the grass is greener on the other side of the

fence, and they're likely to be wrong. The chickens think that too, but

they are right. They've already eaten it all on their side.

* Our organizations have become too complex and too many. We have

become too overorganizated.

* Why does the word "wrench" have an extra, silent letter? Is it

accordingly pronounced "wench"?

* Why does "island" have an extra, silent letter? (Bob: "That speck way

over there?

That's not land!" Al: "It island, I tell you!")

* Some cats have nine lives. Some have nine tails. Some have eight wavy

arms and live under the sea.

* Favorite cat method for a surprise pounce: use a catapult.

* Cats are mighty hunters that kill lots of little birds and they

surely all deserve to die, but they are also blamed for a lot that

isn't [always] their fault:

- Catnaps

- Catnappings (Actually these are mostly carried out by dogs.)

- Floggings

- Catarrh

- Cataracts

- Catalepsy

- Catastrophes

- Cataclysms

- TEOTWAWKI (or was that bats?)

...and there are probably a lot more uncategorized categories in the

grand catalog of catatonic catechisms.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

96% Efficient "Motor

to

Planetary Reduction to CV Shaft" Drive for Chevy Sprint

[9th] Somehow I felt this project would be exciting, not just fantastic

in theory but to actually do even if it was nothing Earth

shattering or commercially useful. And I've had the car kicking around

so long now it's become a "vintage" car over 30 years old. So ignoring

all other projects with more potential, and higher priority jobs...

Since the motor controller

was already in the car and it was pretty much set up, the tasks for

making this drive work were:

1. the mounting and interconnections of the motor and 5:1 planetary

gearset to the wheel end of a chopped off CV shaft.

2. Figuring out what batteries to use. I would probably have to borrow

some from the truck.

3. If it worked well and I decided it was a keeper, making a proper

charging system for the batteries.

I confess I don't expect to replace the Nissan Leaf with

this configuration. It is a test of the principle of having an "ultra

efficient" drive train, and a lower reduction ratio thereby. With the

fixed 5 to 1 reduction this motor from a forklift is too low RPM to do

50 KmPH even for town driving, and perhaps not powerful enough to put

it on the highway even if RPM permitted. However the same 5:1 gearbox

would be good for trying out the 100% efficient infinitely variable

torque converter idea in the future. Or the motor could be replaced

with one capable of higher RPM.

BTW the 96+% efficient Yun Duan PLF120-5-S2-P2 planetary

gearset I ordered via AliExpress.com seems great. It weighs all but 15

pounds and seems to be good quality, heavy duty. According to its

output torque specs it's only "adequate", but so far it's been be

plenty strong enough to turn

the car wheel. It won't be going half its rated RPM (which would take

the car up to about 120 KmPH) and higher speeds are at lower

torques.

Cut CV shaft (w. paper

towel) sticking

into hood area from wheel

I started

sizing things up. The one obvious connection

would be a shaft coupler to make a solid connection between the gearset

output (25mm) and the CV shaft (~23mm). The gear body would essentially

become the end of the CV shaft. It would have to pivot slightly as the

wheel suspension bounced and changed.

I started

sizing things up. The one obvious connection

would be a shaft coupler to make a solid connection between the gearset

output (25mm) and the CV shaft (~23mm). The gear body would essentially

become the end of the CV shaft. It would have to pivot slightly as the

wheel suspension bounced and changed.

At first I thought I would

make a plate to hold the motor

and gearset solidly together. It seemed like the logical way. But I

wasn't quite sure how I would attach the 22mm splined motor shaft to

the 24mm socket on the gear. And that arrangement meant the motor would

also have to pivot with the suspension. I visualized the plate on a

front-rear pivot, holding the motor and gearset up and from twisting

but allowing the up-down pivot. But it seemed like it would be a lot of

inertia with the motor attached. The gear body was longer than I had

expected, and the motor was no pancake motor. (Turned out to be fine.)

Then for a while I

had decided

instead to use the Lovejoy connectors

between the motor and gear. The motor would be mounted solidly, and the

gearset would do its pivoting by slightly flexing the rubber Lovejoy

connection. That was less strong than the regular inner CV coupling,

but it also only had 1/5 as much torque being applied owing to the

reduction being after the connector. The rubber might (or might not)

wear out prematurely, but it should work well.

When I measured the length of this whole assembly, I was

surprised that it was a whole meter, 100cm. There was about 95cm

available width under the hood. It looked like I might have to cut a

few centimeters off the CV shaft. Doable.

Thinking of attaching some shock

mounting at

front of hood (right).

Thinking of attaching some shock

mounting at

front of hood (right).

There's already one at rear (center left).

[10th] Of course mounting the motor on shock mountings would be best -

smoother and quieter. I sized the existing ones up. (Nicer if I don't

have to do any welding.) I didn't come to any firm conclusions about

what to do except that the motor placement depended on the planetary

gear placement, so that had to come first.

To connect the CV shaft and planetary gear output shaft, I

found "weld-on sprocket hubs" in a box, 7/8 inch and 1.0 inch. I welded

them together to make a shaft coupler for the two different shaft

sizes. (A

few of my usual crappy tack welds. I left it at that just in case I had

to take it apart again.) The gear shaft was 25mm rather than 25.4mm so

it was a bit of a loose fit, but I put the keyed coupling on anyway.

7/8 inch is 22.2mm and the CV shaft was 23mm. The hub wrecked a drill

bit and I figured it would do the same to a boring bar. The shaft

wouldn't fit on my lathe, and my neighbor with a bigger lathe didn't

seem to be around, so I ground a bit off it with the bench grinder,

being as even as I could. I left it a bit large so I had to pound it

into the hub/coupler (solid fit and not quite to the end). No shaft

key. (There was a slot in the hub/socket. It seemed like a really tight

friction fit and there were two set screws done up, but theoreticly I

should probably at least grind a slot into the shaft and put in a key.

Later.

With those fitted together, I plugged the CV shaft into

the car wheel. (Hmm, it needs some new boot clamps!)

(To retrieve the gearbox later I just loosened the set

screws and pulled it from the coupler.)

How to mount things?

How to mount things?

A bar from the rear/firewall shock mounting?

A bar left to right?

A way to hang a shock mounting?

Now... back to how to mount everything. I went out to the

car and pondered this long into the night. Perry had suggested welding

two supports across left to right to hold everything. But of course,

rubber shock mounts would eliminate vibration. I came up with another

way, to mount one between the right shock mounting (actually port or

driver's side, but I'm looking in from the front) and a new left

(starboard) side one. The third one on the firewall would add the

needed stability and resistance to turning torque.

Looking at it again, the shaft and all were long enough

that up-down motion of the suspension would cause only slight pivoting

at the motor end of the shaft, and I decided to couple the motor and

gearbox right together after all... if I could figure out how to

connect the shafts. The 22mm splined shaft on the motor was a tough

one. The 24mm socket on the gearbox wasn't a problem. I needed

something very short with a 22mm socket on one end and a 24mm shaft on

the other. I had just used my 7/8" (22.2mm) weld-on sprocket hub for

the other join. That left me with 7/8" taper lock shaft hubs, SD or H

type.

Assuming that would work out, the CV shaft and solid

couplings would hold the gearbox and motor straight out from the wheel.

So then the challenge would be to hold the plate between motor and

wheel in the desired position, and to not rotate with the torque from

turning the wheel. If there were two arms holding the motor, one at the

front and one at the back of the plate, forces would be up and down and

especially the front arm would be quite hard to brace against those

forces. The assembly would be prone to twisting with wheel torque. But

if there was one arm at the top and one at the bottom of the plate, the

forces would be toward and away from - horizontal instead of vertical.

I could bolt on a shock mounting and run an arm (channel or angle iron)

to under the motor from the front bar under the former radiator. There

was a support just above and behind where the motor would be, for the

top bar which could also hold up the whole 70 pound or so assembly. All

of a sudden mounting it all looked a lot simpler.

[11th] Well, I couldn't ignore everything else for long. But I figured

I could get something done on it every day. I picked "how to connect

the motor shaft to the planetary gear input socket." The motor had the

22mm splined shaft output. The gearbox had the 24mm socket. (I could

have got the one with a 22mm socket, but they weren't made to fit

together and with an interface plate between them the motor shaft

wasn't long enough anyway. or the gearbox socket was too far recessed -

take your pick.)

I had dug out the plate from previous conversion versions. It seemed

needlessly big and ugly, but I set it on

the motor and put in the two bolts that tie them together.

I had dug out the plate from previous conversion versions. It seemed

needlessly big and ugly, but I set it on

the motor and put in the two bolts that tie them together.

After much puzzling (a couple of hours?) I took a 7/8 inch

"H" taper lock shaft hub (AKA shaft "bushing") and put it on the motor.

It stuck up about 3/8" past the end of the shaft. And it fit within the

recess in the gearbox, so the gearbox would sit flat on the plate.

Next I cut a

short piece of shaft and turned it on the lathe. It had a short 7/8"

end that had to be pressed into the "H" hub. (I wanted to mill a keyway

into it to match that of the hub and put in a key as well for surety,

short as it was, but my fickle milling machine started fine and then

stopped running just as I was about to start milling. Click, click -

nothing happens. I would sure like to know what's intermittently wrong

with it.)

Next I cut a

short piece of shaft and turned it on the lathe. It had a short 7/8"

end that had to be pressed into the "H" hub. (I wanted to mill a keyway

into it to match that of the hub and put in a key as well for surety,

short as it was, but my fickle milling machine started fine and then

stopped running just as I was about to start milling. Click, click -

nothing happens. I would sure like to know what's intermittently wrong

with it.)

(A washer or two on the motor will set the exact spacing

with no play.)

The "H" hub

had to go flange side up, since it's the other end that squeezes in to

lock it to the shaft, while the flange side is solid to press the

stubby shaft into.

The "H" hub

had to go flange side up, since it's the other end that squeezes in to

lock it to the shaft, while the flange side is solid to press the

stubby shaft into.

The other end of that shaft, about an inch long, was

turned to 24mm until it fit into the socket in the gearbox. When I

tighten up the bolt it will hold the piece securely and not let it

slip. (Ya, like the one in the truck? - slip, slip! Anyway being 24mm

instead of 19, it should have considerably more holding power.)

For the motor end, I had to find something to tighten the

"H" taper lock hub around the splined shaft. For that I have a feeling

I'll have to make a very special very large washer with bolt holes

through it from 5/16" steel plate. For extra measure I might also put

in a specially shaped key that fits in the hub's keyslot and projects

into one of the spaces between the splines in the motor shaft.

For the motor end, I had to find something to tighten the

"H" taper lock hub around the splined shaft. For that I have a feeling

I'll have to make a very special very large washer with bolt holes

through it from 5/16" steel plate. For extra measure I might also put

in a specially shaped key that fits in the hub's keyslot and projects

into one of the spaces between the splines in the motor shaft.

So at the end of the day it

still needed something to tighten the "H" taper lock hub to the motor

shaft, and four new holes in the plate to attach the gearbox to it.

(All those sets of holes in the plate, and still none in the right

places!)

After all

that, before midnight I went to my storage room

to look for something to tighten the taper lock hub, and instead I

found a stray 7/8" weld-on sprocket hub loose in a box - the part I had

wanted in the first place. It fit on the

motor almost snugly, and it had a key slot and 2 set screws to tighten

it up. It was about 1/64" too long and held the gearbox up off the

plate, but I could easily trim it down that much on the lathe. That

should solve the problem nicely! The work of the day had mostly been

making the coupling shaft, which would still be used, so little was

lost switching the part.

After all

that, before midnight I went to my storage room

to look for something to tighten the taper lock hub, and instead I

found a stray 7/8" weld-on sprocket hub loose in a box - the part I had

wanted in the first place. It fit on the

motor almost snugly, and it had a key slot and 2 set screws to tighten

it up. It was about 1/64" too long and held the gearbox up off the

plate, but I could easily trim it down that much on the lathe. That

should solve the problem nicely! The work of the day had mostly been

making the coupling shaft, which would still be used, so little was

lost switching the part.

[12th] I got to it in the

later afternoon and made the four bolt holes

to attach and center the gearbox onto the plate. Try as I might to get

them perfect, measuring and drilling by hand 3 of the 4 holes had to be

filed out a bit so the bolts could go in the right places and the gear

be well centered (at least looking centered by eye).

[12th] I got to it in the

later afternoon and made the four bolt holes

to attach and center the gearbox onto the plate. Try as I might to get

them perfect, measuring and drilling by hand 3 of the 4 holes had to be

filed out a bit so the bolts could go in the right places and the gear

be well centered (at least looking centered by eye).

Then I started fitting the fittings. The 7/8" end of the

stub shaft proved to be a tiny bit too long, so I turned it down on the

lathe. Then the milling machine decided it was working today, so I

milled the key slot in it. I cut a 1/2" long key and after a little

filing fit it in. Then I pressed the shortened, keyed shaft back into

the weld-on hub. This time it fit great onto the motor. It also fit

great into the gearbox socket. However it seemed to hold the motor off

the plate. Later I made a couple of short steel pipe spacers to

optimally set the width of the gap.

Owing to the friction of the brush type motor being

multiplied by 5 I had to use a wrench on the planetary output to turn

everything, including the motor turning 5 times faster than the wrench.

A final point was that if the assembly was suspended by

the two bolts holding the motor, the rigid connections from motor

almost to the wheel would ensure that everything stayed in line. Still,

it would be better if the ~70 pound assembly was all balanced. [I was

unable to do as well as I wanted. It seemed fine anyway.] With the

motor and gear fitted to the plate I checked and found the balance

point (without the CV shaft) was about 2" behind the bolt holes in the

motor faceplate. Counting the CV shaft, some longer bolts and roughly

1.5 to 1.75 inch standoffs (pipes as really long washers) slid onto

them should about do it. Then the exact position and shape of the two

arms to hold everything could be determined.

[13th] The milling machine god was smiling, so I milled a tiny key slot

in

the coupler shaft stub to secure it better to the "weld-on sprocket

hub" on the motor. I made the key and it all looked good. To make sure

the motor wouldn't slip, I made a special key to fit in the hub with

the other part ground and filed to fit between two of the splines on

the motor shaft. I'm much more confident these two joins can't slip now.

I put the motor and gear assembly into the car. It looked

great except for one large annoyance: the gearbox was longer than I had

realized and the mounting plate lined up in the one place it couldn't,

right in front of the shock absorbing mount. (I should have noticed

earlier that it would be.) It seemed I could shorten the chopped CV

shaft by another 1 to 1.5 inches without causing other problems, and

that would put the plate to the side of the post. I looked for another

half hour trying to figure out some other way, but finally I just had

to take the shaft off, cut a bit off it, and do it over again.

This time I tried to mill a key slot in the CV shaft. It

seemed more like I was just dulling my titanium mill bit. (I knew those

shafts must be hard metal!) So I gave that up and tried to make it a

good "pound-on" friction fit, grinding a tiny bit of the 23mm shaft

each time and then seeing how it fit into the 22.2mm hub. (With the CV

joint flopping around on the other end, I could neither put the shaft

on the lathe nor press the coupler in with the press. But I decided

that if it slipped I could weld the coupler on.) On the last pounding

it went to about 4mm from the end and wouldn't go any further, so I did

up the set screws and barring any slips when I drive the car, it's done.

The next challenge was to get the planetary gear output

shaft into the hammered end of the coupler. Not thinking of trouble I

hadn't tried fitting them until I had put the shaft back in the car

wheel. (After all it was a 25.4mm coupler and only a 25mm shaft. Lots

of room, right?) It took a fair while leaning into the under-hood space

with files and "dremmel" type tool to get the "mushrooming" out of the

end of the socket.

Perhaps 3 hours later I had the works installed under the

hood again. This time it looked good. Well, that was more than enough

overtime for that "trivial" oversight! It was getting late and past

time for various chores, where I had hoped to be done early. Now it was

all ready except that if powered up, the unmounted motor and gearbox

would just spin until the wires broke off instead of trying to move the

car.

[14th] With the linkages

done it was time for the actual mountings. I

anticipated quite a challenge. I started out thinking of how to connect

the firewall shock mounting to the top bolt of the motor and plate.

With the position now almost ideal, it was only gonig to need a short

piece. But the two ends were 90° different orientation... actually

more like 80° since the motor assembly was at a bit of a diagonal.

Angle iron? That would give two 90° sides. Then I thought of

twisting a plain bar of steel. I used a 1 inch by 1/8 inch bar. I

twisted it with a big vise and my favorite metal bending tool: a large

crescent wrench. Then I drilled the motor bolt hole too large (5/8"

instead of 9/16") and did it over again.

[14th] With the linkages

done it was time for the actual mountings. I

anticipated quite a challenge. I started out thinking of how to connect

the firewall shock mounting to the top bolt of the motor and plate.

With the position now almost ideal, it was only gonig to need a short

piece. But the two ends were 90° different orientation... actually

more like 80° since the motor assembly was at a bit of a diagonal.

Angle iron? That would give two 90° sides. Then I thought of

twisting a plain bar of steel. I used a 1 inch by 1/8 inch bar. I

twisted it with a big vise and my favorite metal bending tool: a large

crescent wrench. Then I drilled the motor bolt hole too large (5/8"

instead of 9/16") and did it over again.

For the other piece I had been thinking of drilling holes

in the crosspiece at the front of the car and bolting a shock mounting

there, to run a piece of angle iron to the lower motor bolt. Then I

thought a place where there had been an original shock mounting would

be close enough and would be simple to do. I bolted that mounting back

on. The rest of the same yellow painted bar was just the right length

for a strap between the plate and the mount. After drilling, bending

and twisting it a bit, it went in nicely.

I inserted the main motor bolts and pulled out the block

of wood holding up the motor. There it sat, suspended in mid air. But

for a couple of spacers and miscellaneous... It was IN! I manged to

stop myself from going any further by 4:30 PM, instead of charging

along to complete those details and getting nothing else done. (like,

making supper, having someone test play my new crossword puzzle to find

mistakes...)

The 2018 configuration with the

"hacked"

original transmission, for visual comparison to above

The 2018 configuration with the

"hacked"

original transmission, for visual comparison to above

[15th] Having realized that if all the batteries would fit under the

hood there was no use for wiring to and in the back cargo compartment,

I pulled it all out except for a few light wires running along just

inside of the passenger doors under the carpet. It was now completely

free for cargo and a spare tire!

[16th] Well, I still had to go underneath the car and clip the cable

ties holding the power cable then pull it out. There's a few pounds of

cable removed! No more heavy transmission, this and that pulled out...

The car is getting amazingly light, but with the 75 pounds of motor,

gearbox and attachments the front suspension is no longer topped out. I

now have to lift on the bumper to hit the top end stops.

I cut two pieces of pipe (and turned them on the lathe) to

use for "just right" spacers between the motor and gearbox, and I undid

the two motor holding bolts and put them in.

Car Movement Tests

Physicly everything was ready. I got out a lithium iron

phosphate battery and jumper cables. I set the battery beside the hood

and attached the cables to the motor. With 3 volts across the motor

nothing seemed to happen. With 6 volts it crawled across the floor.

With 9 volts it crawled faster. With 12 it picked up speed and if I

hadn't disconnected it before it got there, it would have jumped over

my 2x6 "chock" and hit the garage shelves. It was all totally silent

except for the slight scrape of the brake components in the wheels that

one doesn't usually hear because other things are louder.

I went back to when I had done the car before with the

original transmission, which I had altered to give a fixed 8.9 to 1

reduction to the wheels utilizing one planetary gear and the spur gear

driving the differential. That time the car was in the same garage in

about the same place, but apparently I had connected the battery and

backed it up instead of going forward. As there was a slight and uneven

slope to the floor, going the same direction again - slightly upslope

instead of downslope - would make for a better comparison of

performance. From TE News #117:

"Using a 4-cell lithium battery and jumper cables

beside the car, it backed up a bit with 6 volts, more with 9 volts, and

up a slight incline with 12, drawing around 75 amps each time."

In reverse this time I got the following results: With 6

volts, it would back up a bit only if it was in a level spot. With 9

volts, it accelerated just a bit and slowed but made it up the same

slight incline as it did before at 12 volts. With 12 volts, it

accelerated more strongly and easily went up the rise. (I didn't check

the currents this time as they were doubtless about the same.)

While there were no precise figures for either time, these

simple voltage-performance tests seemed to show the new 5 to 1

speed

reduction to actually apply more torque to the wheel(s) than

the previous 8.9 to 1 transmission arrangement. Although 6 volts seemed

similar, in the earlier tests it sounded like the car hadn't climbed

the up-slope with 9 volts, and there was no mention of acceleration at

any voltage tested. To make sure it hadn't just got a better run at the

slope at 9 volts this time, I rolled the car to the base of it, just to

where the car stopped to rolling forward. It still went up it.

Seeming to get more torque from "n" power, instead

of

just 5/8.9=0.56 times as much, presumably indicates an increase in

efficiency of the drive train of more than 1/0.56=1.78 -- the desired

result of putting this all together and more. In fact it is a

remarkable gain. It surprised me because I thought the old transmission

was better than that. (In actual driving later it didn't seem so

amazing.)

[17th] I considered that it was

possible the battery was less

charged in 2018, but it didn't seem likely. I can't imagine having used

any battery except fully charged for tests I knew needed a lot of amps.

This time the battery hadn't been charged in months, so if anything

might have been slightly lower. But finally I got out the CD amp-clamp

meter and checked. I got around 60 amps at 6 volts, 100 at 9 and over

140 at 12. In 2018 I had been puzzled to read about 75 amps seemingly

regardless of voltage. I am still puzzled by that. Could there have

been a bad battery connection last time? Was the meter doing something

funny? Did I use the same meter? Did I in fact neglect to take a

reading at each voltage? I wish I had recorded it carefully, for each

voltage, even if they were actually similar. But let's use the figures

as given. This time it behaved more as one would expect, drawing higher

current with higher voltage. And according to theory, the torque

depends directly on the DC current.

At 6 volts it seemed to draw less current and perhaps

performed around the same, but it's hard to tell from vague

descriptions and impressions. It was very lethargic both times. So

let's forget the 6 volts.

At 9 volts it drew 100/75 amps - about 1/3 more. Instead

of rolling slowly on the level, it accelerated and went up a slight

slope. If on the 2018 tests it was actually 75 amps, then if it drew

100 amps this time it should have had 1.33 * (5/8.9) = .75, or 75% as

much torque at the wheel. Instead it performed better, climbing the

little rise that took 12 volts to climb in 2018.

At 12 volts current was (according to what I said in 2018)

almost double from 2018. By theory, torque should then have been 2 *

(5/8.9) = 1.12 times the torque. But I suspect the 2018 current at 12

volts was probably considerably higher than 75 amps and I just wasn't

paying it much attention. The motor was spinning faster so the current

drops more, but even if it wasn't near 140, perhaps it was 100? That

would make it 140/100 * 5/8.9 = 79% as much torque. Instead, rather

than either beating it by a small margin (case 75 amps) or not doing as

well (case 100A), it noticeably accelerated as it went notwithstanding

the uphill, where in 2018 it hadn't sped up - at least not enough for

me to make note of it. And

So if the new gearbox is 96% efficient and if the old one

with a higher reduction had given the same torque to the wheels, we

might guess the old transmission was around 1.4 * 5/8.9 * .96 = 76%

efficient. Since it didn't perform even that well, it was probably well

under that figure. Saying it was 70% would probably be being kind to it.

But the 17th wasn't all about theory and performance. I

cut a piece of 3/4 inch birch plywood to be a shelf for the batteries

behind where the radiator had been, then painstakingly trimmed it to

fit everywhere including a couple of cutouts to accommodate protruding

joins in the car, drilled holes, and made a steel bracket to hold up

one corner. It was in and out many times, trim a bit and see, then

again. Then I did similar with a 1/4 inch thick piece for a front

shield so nothing flying off the road could hit the batteries. (Just in

case I actually get it onto the road!) I'll paint them later.

But the 17th wasn't all about theory and performance. I

cut a piece of 3/4 inch birch plywood to be a shelf for the batteries

behind where the radiator had been, then painstakingly trimmed it to

fit everywhere including a couple of cutouts to accommodate protruding

joins in the car, drilled holes, and made a steel bracket to hold up

one corner. It was in and out many times, trim a bit and see, then

again. Then I did similar with a 1/4 inch thick piece for a front

shield so nothing flying off the road could hit the batteries. (Just in

case I actually get it onto the road!) I'll paint them later.

Then I got out some of the still loose lithium ion

batteries and positioned them on the shelf. It should be easy to fit

two stacks, more crammed to fit three, and four would be a problem

because of the long motor strap cutting across... but doable. Two

stacks should be good enough for the 300 amps max current according to

the battery specs, but would only 8640 watt-hours. All three would be a

better 12960 WH, and a fourth stack would make it 17280 WH. With lower

energy use, that should take it as far as the Nissan Leaf's 24000 WH.

And there's room for more in the rear cargo area if I want huge range.

But to go beyond a 'proof of concept' demo, if I'm actually going to

use it on the highway with everything else the same, it'll need a

higher RPM motor.

[18th] I was otherwise occupied. I just

figured out where the battery

stacks would go, and drilled bolt holes. (battery stacks... yes, that's

why the French call them "piles" - "piles electrique"!)

[19th] I grabbed the lithium-ion battery stacks from the truck and from

the DC solar system in the garage next to the car. (I'll have to

connect up the third stack soon, but I didn't want to divert from doing

the car.) The two stacks will provide 240 amp-hours at 36 volts (8640

WH) for the 36 volt motor and 300 amp, 36 volt motor controller, and

according to the battery specs, hundreds of amps. With some

re-positioning ("moving" mounting holes a bit), I got them mounted on

the shelf under the hood. I removed the balance charger from one stack

because with the stacks connected together in parallel, two couldn't

work right. Instead I would put wires across to parallel at least every

second cell so they all charge as one battery. I put in a holder for a

400 amp fuse. (And the breaker at the motor controller is 300 amps.)

I spent the rest of the time on the heavy wiring. In

connecting the minus cable to one stack, I noticed that it flopped over

onto the battery side of the fuse holder when disconnected. Fuse holder

+36V. Minus side 0V. Both straight from batteries - always live. Very

bad to touch together with heavy cable! I put in a piece of 2x6 wood as

a pedestal to hold the fuse holder way up high.

The battery stacks bolted to the

shelf, with

cables from "B+" at the top of the stacks to the fuse holder,

The battery stacks bolted to the

shelf, with

cables from "B+" at the top of the stacks to the fuse holder,

raised to the same height with a piece of 2"x6".

I went into town to buy some lugs for #2 AWG wires with

1/2 inch holes to fit the battery main connection bolts. Then I

realized that that cable connected to the fuse, which had smaller bolts

(Duh!), so (other than having to go into town anyway) I had wasted my

time. When I had the cable ready I found it was a little too short and

had to make a longer one. At least I had enough wire and lugs.

Then I contrived to run the heavy wires through the

firewall instead of under the floor. Yay, I can cover over that hole in

the floor between the seats, which I had used to run wires through last

time. (originally the gearshift stick hole)

Then I contrived to run the heavy wires through the

firewall instead of under the floor. Yay, I can cover over that hole in

the floor between the seats, which I had used to run wires through last

time. (originally the gearshift stick hole)

I replaced the under-rated 135 amp circuit breaker

(biggest one I could get in Victoria when I was living there with a new

300 amp breaker of the same physical size.

Finally I was left with one control wire that I wasn't

sure where it went. Only then did I notice that the wiring diagram had

vanished somewhere. I decided I should leave it all until morning and

go over everything before I powered it up and tried to run the car.

Before bed I downloaded the manual for the 1243 type motor

controller again from Curtis and found where it went. I printed out the

control plug pinout and the wiring diagram.

First Test

[20th] I wired in a ground from the battery minus to the car body - not

something to omit! In a higher voltage system one would keep the drive

power system separate and make it floating ground so as not to

electrocute anyone. With 36 volts that's not necessary. But

I didn't want to hook just some of the cells up as the 12 volt supply.

So I put in a 12 volt battery - one made of four of the 40AH LiPo cells

that have been kicking around for some years now. (That will need some

charger too.) Everything seemed to work except the headlights. (Not

those cursed headlights again! Days later I discovered, or

rediscovered, that there was nothing wrong: the headlights only come on

if the parking brake is off.) When everything seemed ready I put a

500 amp fuse in the holder on the 36 volt line and closed the circuit

breaker.

When I turned the key (drum roll... suspense...) nothing

blew up. The contactor clicked. I pressed on the gas and the car moved

forward. So I opened the garage door, moved the other cars out of the

way and pushed the Sprint out of the garage. (I still haven't done

anything about getting it to run in reverse.) The driveway being

cluttered I drove it across to the far side of the acreage. It seemed

to move well enough and climb little humps that the badly geared Miles

Truck had sometimes had trouble with. Driving so far from the garage

was a

mistake. Perry came along. We got it turned around, and he sat in the

passenger seat. But one wheel was in a hole. It took extra force to try

and move the car. And it didn't.

Something squealed and the car didn't move. We looked and

found the long yellow bar had bent. (Driving forward pushes on that

support instead of pulling on it.) Walking back and forth across the

acreage I eventually shaped a 1" x 2" steel tube into a new, stronger

motor support.

But that wasn't the end of it. Perry's eyes were valuable

to seeing the problem. The CV shaft had started

slipping in the shaft coupler. Suddenly (and belatedly) it occurred to

me that I even if the shaft was too hard to mill a keyslot into, I

could have ground one in with the angle grinder. And I should have made

a couple of flat spots for the set screws. Now, unless I was going to

tow it back, it all had to come apart again, out in the weather, at the

far end of the property.

Luckily both this afternoon and the next day the sun came

out and it was, for a change, nice weather.

[21st] Between the truck and this, I was tired of slipping shafts. I

took the mechanical parts apart. I started gouging a key slot in the CV

shaft. The hub had only a 5/32 inch keyslot. Why so small? After a

while I thought, why do it this way?

If the keyslots were inappropriate, what else was there?

For DIY mechanics, making splined shafts seemed like a more than

daunting task. But one could easily make a shaft square with a grinder.

Making a square socket was another prospect. Too bad no one seems to

sell them. But did one need to do that?

The coupler

socket had two set screws at right angles. If

they hit in an indented area instead of on the very outside of the

shaft, the shaft couldn't slip. And why settle for a small indent? I

took the angle grinder and ground the shaft to square on two faces at

right angles, matching the set screws.

The coupler

socket had two set screws at right angles. If

they hit in an indented area instead of on the very outside of the

shaft, the shaft couldn't slip. And why settle for a small indent? I

took the angle grinder and ground the shaft to square on two faces at

right angles, matching the set screws.

Then, the setscrews were 1/4 inch (1/4"). Why had

they

used such tiny ones? They might just bend, or the metal around them

bend and let them rip out. I drilled out the two holes larger and

threaded them for 5/16". Then before I did anything else I changed my

mind and drilled them out and rethreaded to take 3/8" set screws.

Then, the setscrews were 1/4 inch (1/4"). Why had

they

used such tiny ones? They might just bend, or the metal around them

bend and let them rip out. I drilled out the two holes larger and

threaded them for 5/16". Then before I did anything else I changed my

mind and drilled them out and rethreaded to take 3/8" set screws.

Squared shaft, beefy 3/8" set screws... let's have a setup commensurate

to the job! 200 or more foot-pounds on an axle is a lot of torque.

Squared shaft, beefy 3/8" set screws... let's have a setup commensurate

to the job! 200 or more foot-pounds on an axle is a lot of torque.

The gearbox end's socket was similar except 5/16" set

screws. Same hub except different shaft size - why the difference in

screws? And why did one have a 5/32" key slot and the other 1/4"? The

gearbox shaft's key slot was about 5/16ths" (8mm?) so it didn't match

the 1/4". I ground another square face into the gearbox shaft at

90° to the keyslot. I got fancier and made it so the setscrew

couldn't slide off the shaft - not that it could anyway in this setup.

I threaded that setscrew to 3/8" but left the other. The other wound

nicely into the key slot with no key in it. I figured that one wasn't

going to slip either.

The gearbox end's socket was similar except 5/16" set

screws. Same hub except different shaft size - why the difference in

screws? And why did one have a 5/32" key slot and the other 1/4"? The

gearbox shaft's key slot was about 5/16ths" (8mm?) so it didn't match

the 1/4". I ground another square face into the gearbox shaft at

90° to the keyslot. I got fancier and made it so the setscrew

couldn't slide off the shaft - not that it could anyway in this setup.

I threaded that setscrew to 3/8" but left the other. The other wound

nicely into the key slot with no key in it. I figured that one wasn't

going to slip either.

Before I put

it all back together, I beefed up my tack welds on the coupler. No

point having everything else toughened up and have the welds snap when

I drove!

Before I put

it all back together, I beefed up my tack welds on the coupler. No

point having everything else toughened up and have the welds snap when

I drove!

With replacement rectangular bar

(left:

diagonal, red) to take the torque,

With replacement rectangular bar

(left:

diagonal, red) to take the torque,

beefed up linkages to CV shaft,

and charging from solar DC supply in garage with monitors.

When I had everything back

together I got in and drove the

car back toward the garage. It seemed to have sufficient

pickup. It

rose out of the dip I couldn't push it out of by hand. There was a bit

of

vibration when I got up a little speed, but not bad. (The lawn trail is

too bumpy

to get going very fast.) I stopped at the corner at the base of a hill

just before reaching the "usual" part of the driveway. I thought I'd

see how it did up a hill from a stop. In the winter the Echo and the

Leaf had slipped on the wet grass and in the mud (and barely made it

up). Now the mud was hard ground.

It was more challenge than I had expected. I had to press

the pedal pretty hard starting up the hill, and the one-wheel drive

slipped in the wet grass. Eventually I got it worked around so the tire

hit the narrow pea-gravel trail I had made up the hill. Now I had to

push the pedal a long way down to go anywhere, but it started climbing