Turquoise Energy Newsletter #158 - July 2021

Turquoise Energy News #158

covering

July

2021 (Posted August 4th 2021)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- The Everlasting Zinc Electrode: Why Am I

Just

Sitting On the Gold Mine? - Firewood Shed - Vehicle

Transmission

Efficiencies -

Chevy

Sprint: Forward-Reverse Switch, Bicycle Speedometer - Lithium Ion

Battery Charge Voltage - Solar Installations in Qinghai - Another

Floating Tidal Flow Power Unit

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Food Security: A Constitutional Right to Grow and

Trade

Food? - Small

Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Programming for the Ground effect Vehicle RC model

* Chevy Sprint Add-ons: Forward-Reverse Switch, Speedometer,

De-clunking the Motor Mounting

Other "Green"

& Electric Equipment Projects

* Off grid infrastructure (T12 sockets deficiency)

* Handheld Bandsaw Mill Kit progress

* Greenhouse, Gardening

Electricity

Generation

* My Solar Power System: - Daily/Monthly

Solar Production log et cetera - Monthly Summaries and

Estimates

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte)

- poor performance testing continued - Trying to make a one-piece

copper can from copper pipe

The Everlasting Zinc Electrode: Why Am I Just Sitting On the

Gold

Mine?

I got the "everlasting zinc electrode" side of the

battery

chemistry working using bits of nickel [NiOOH] electrode from a

commercial Ni-MH dry cell for the other electrode - in fact quite

a

while back now. A zinc electrode that doesn't degrade with cycling

has

been a "holy grail" of battery making for at least 150 years.

Countless experiments have been done and dozens if not hundreds of

papers and semi-effective patents have been written on the

subject. And

most researchers have long since given up and looked for other

metals.

After that was going (using positive electrodes from

commercial Ni-MH cells), I started working on my "new

chemistry" positive electrode: nickel manganates. And at the same

time,

on making cells with higher conductivity than the experimental

flat

ones that couldn't stop the electrodes from bulging and losing

conductivity. I expected rapid success. But that hasn't come. The

nickel manganates formula just doesn't seem to be working the way

I

expected. (There are still more things to be tried!)

Finally I've started thinking, that whatever adverse

thing(s)

is happening in the positive electrodes, nobody else has managed

to

tame the zinc dendrite problem in the negative electrode for any

sort

of simple battery cell. Is that not already a success? Is it not

already worth a fortune?

The combination of an osmium doped film on the zinc

and a

layer of agar gel proved to be the winner. The agar layer prevents

the

vexing and previously intractable problem of dissolved zinc ions

forming dendrites that migrate through the separator sheet and

short

out the cell. But the current flow was pathetic. Painting the

osmium

doped acetal ester film on the surface of the zinc brings back the

high

current capacity zinc had before the agar. (I confess I don't

really

understand how.) The cell is "moderately alkaline" using potassium

chloride electrolyte or a mix of that and weak potassium

hydroxide.

Since the time

I started experimenting with gels,

experimental gelled electrodes by others have now reputedly lasted

20,000 cycles without deterioration. This one too should last for

ages,

not just for the 500 recharges advertised in the one brand of

available

nickel-zinc "AA" cells I'm aware of. So why am I beating my head

over

trying to do entire batteries where I'm having trouble with other

parts,

while just sitting on the "mother lode"?

Since the time

I started experimenting with gels,

experimental gelled electrodes by others have now reputedly lasted

20,000 cycles without deterioration. This one too should last for

ages,

not just for the 500 recharges advertised in the one brand of

available

nickel-zinc "AA" cells I'm aware of. So why am I beating my head

over

trying to do entire batteries where I'm having trouble with other

parts,

while just sitting on the "mother lode"?

So the layers of the

negative part of the cell are:

1. Copper (or ?) current collector (copper can?)

2. The Zinc (suggested: Zinc paste in graphite foam or graphite

foil?

1-3% Zirconium silicate to raise hydrogen overvoltage.)

3. A film of acetal ester doped with osmium powder

4. A layer of gelled agar. I don't know how thick it needs to be.

I'm

thinking as little as an "eggshell" thickness could work.

5. The separator paper or sheet. Beyond that is the positive

electrode

and its current collector.

With 820 amp-hours per kilogram at about -1.25 volts,

zinc

has substantially better energy by weight than metal hydride. And

it's

cheap. In fact, typical construction single use manganese-zinc "D"

cells are said to hold 12 to 18

amp-hours (or even 20) depending on rate of discharge. (18 * 1.5V

= 27

watt-hours), whereas nickel-metal hydride "D"

cells only have 8 to 10 amp-hours (10 * 1.2V = 12 watt-hours).

Rechargeable nickel-zinc is nominally 1.6 volts (if not 1.7+), so

potentially 18AH * 1.6V = 29 watt-hours.

That means for a 12 volt battery 8 Ni-Zn cells (maybe

even

7) are needed instead of 10 Ni-MH, and it'll have over twice the

energy

storage. If (as is likely) the rechargeable cells weighed about

the

same as Mn-Zn single use alkaline dry

cells:

29 WH/D-cell (Ni-Zn) / .144 Kg/cell (typical Mn-Zn alkaline

D-cell) =

200

watt-hours/kilogram.

That is on a par with lithium-ion cells. Assuming 15

AH

gives 167 WH/Kg - still an impressive figure. In quantity it

would be much lower cost than either lithium types or nickel-metal

hydride - probably not a whole lot more than throw-away dry cells.

That

provides much potential for utility level electrical storage and

load

leveling. (eg, saving solar energy for evening cooking hours.)

So surely the "forever" rechargeable zinc electrode

formula should be worth a fortune all by itself! (So... now what

do I

do with it?)

Firewood Shed

I

continued making the double sided firewood shed I

started in June. With just one firewood space, one ends up

stacking new

green wood on top and in front of the older dry wood. It wasn't

so much that I was enthusiastic about it as a project as that I

had

ordered 2 cords of firewood*. Next winter might be cold. I might

well

need it and I needed

somewhere to put it. Othen than things like some old metal roofing

and

concrete blocks, I used

entirely the spruce lumber I had cut with the handheld bandsaw

mill I

made in

2018, including one inch siding boards, which took

a lot longer to cut and screw on than plywood. But I put gaps in

the

siding for air

circulation to help the firewood dry out.

I

continued making the double sided firewood shed I

started in June. With just one firewood space, one ends up

stacking new

green wood on top and in front of the older dry wood. It wasn't

so much that I was enthusiastic about it as a project as that I

had

ordered 2 cords of firewood*. Next winter might be cold. I might

well

need it and I needed

somewhere to put it. Othen than things like some old metal roofing

and

concrete blocks, I used

entirely the spruce lumber I had cut with the handheld bandsaw

mill I

made in

2018, including one inch siding boards, which took

a lot longer to cut and screw on than plywood. But I put gaps in

the

siding for air

circulation to help the firewood dry out.

* In addition there's 2-1/2 cords now in the

original

firewood shed: a remnant from last winter and the rest variously

acquired, cut, split and stacked this spring and summer.

Shed finished except for the

doors. Prefab

front porch.

Shed finished except for the

doors. Prefab

front porch.

Each side holds almost two cords of firewood.

Escapee chickens came to see.

Of course the piles of

the

sizes of lumber I

was using (mostly 12 foot 1x6, 2x6) dwindled some, but it wasn't

1/5 of

the spruce I had cut with the handheld bandsaw mill in 2018 to

2020. I

finished it except for the doors, which are lower

priority. The firewood can go in.

The firewood arrived in three pickup truck loads on

the

31st. It got stacked before a day of wind and rain. A little

dampness

blew in the open doors, but not bad.

Expecting to be warm

whatever the

weather!

Expecting to be warm

whatever the

weather!

Vehicle Transmission

Efficiencies

I am guilty of not

having checked out information - "givens" I was operating under -

in a

long time and hence I have been working with outdated info. Back

in the

1970s(?) someone told me that manual car transmissions were about

70%

efficient, and automatics were around 60%. Four-wheel drives

(always

manual!) also lost an extra 10%, so 60%. (There was of course no

such

thing as an

internet back

then to readily check out information one has been given.) Those

rough

figures

were probably for the whole drive train. Probably they

were valid at the time, but there have been considerable

improvements

in recent decades, especially in the last 15 years or so, and

especially to automatic transmissions. Car companies certainly had

a

low bar to jump over for making improvements!

In some ways, automatic transmissions have an edge

because

they use inherently efficient planetary gears instead of two "corn

cobs" full of helical spur gears all churning and squeezing oil

through

the

gear tooth spaces by rotating against each

other at different speeds. These spur gears are all permanently

engaged

against each other, one fixed

to its shaft

and the other free-spinning, except the selected gear (only) is

locked

on both

shafts. The faster the engine is spinning, the faster the ones

fixed to

the input shaft are spinning, and the faster the car is moving,

the

faster the ones on the

output shaft are spinning. And these helical spur gears have

unproductive "side loading" forces causing still more wasted

fluid

friction to the oil on the bearings.

The killer for automatics was mostly the "slush box"

fluid

torque

converter. (How anyone conceived of churning up liquid as a way to

propel a vehicle is beyond me.) However, now those apparently have

a

clutch to lock them up and are no longer a loss in steady driving.

(This locking up

is similar to my concept for a 100% efficient variable torque

converter

but very differently implemented.) And evidently even these are

lately

being

replaced entirely by a "dual clutch" or even "triple clutch"

mechanism

(which items I haven't looked

up). And there have been other improvements to them as well:

electronic

controls, linked to electronic engine controls, adjusting

everything

together and shifting gears optimally. The result is that

automatic transmissions have become more efficient than manuals,

and so

manuals have become almost extinct.

Today's automatic transmission drive trains, it

seems, are

well over 80% efficient. An article mentioned 84%.

This doesn't change my essential thrust toward "ultra

efficient" electric motors and drive trains. The Sprint's simple

drive

train should be almost 96%. But I should at least be

more familiar with what else has been going on!

Chevy Sprint: Forward Reverse Switch, Bicycle speedometer

With the

car

running and using it for odd hauling around

the acreage, and also for showing it to people, it was a nuisance

and

something of an embarrassment to have to push it to back it up. I

didn't

want to buy a costly high power DPDT contactor relay for a motor

that was (presumably) only temporary. But one day I made a special

high

current "DPDT" sort of switch and wired it in to reverse the

armature

coils polarity. It worked quite well (somewhat to my surprise),

and now

by yanking or shoving hard enough on the push-pull rod under the

dash,

the direction can be changed. The copper pieces do get warm.

With the

car

running and using it for odd hauling around

the acreage, and also for showing it to people, it was a nuisance

and

something of an embarrassment to have to push it to back it up. I

didn't

want to buy a costly high power DPDT contactor relay for a motor

that was (presumably) only temporary. But one day I made a special

high

current "DPDT" sort of switch and wired it in to reverse the

armature

coils polarity. It worked quite well (somewhat to my surprise),

and now

by yanking or shoving hard enough on the push-pull rod under the

dash,

the direction can be changed. The copper pieces do get warm.

There was a notable "clunk" from the

motor supports the first time one presses the electron pedal after

reversing direction. (Motor assembly supports were revised on

August

4th to eliminate it.)

Then on the 20th the bicycle speedometer I ordered

arrived, and I installed it. With the wheel jacked up in the

garage it

hit about 55 KmPH. Nice to see what the speed is, but on the

short,

bumpy trail across the lawn I only got it up to 25 KmPH. I

hesitate to

try it on the road. (If only it was a side street instead of the

main

highway!)

Then on the 20th the bicycle speedometer I ordered

arrived, and I installed it. With the wheel jacked up in the

garage it

hit about 55 KmPH. Nice to see what the speed is, but on the

short,

bumpy trail across the lawn I only got it up to 25 KmPH. I

hesitate to

try it on the road. (If only it was a side street instead of the

main

highway!)

In installing it, the tire circumference is measured

in

millimeters, and that number is entered as the setting to

calibrate the

unit. Here I realized in that that a figure I'd been roughly

estimating, "10 RPM for each 1 KmPH", can be exactly calculated.

The

Sprint's tires measured about 1670mm in circumference. That can

also be

expressed as .001670 kilometers. 1 / .00167 = almost exactly 600

revolutions to travel 1 Km. So with 60 minutes in an hour, 1 KmPH

is

almost exactly 600 / 60 = 10.0 RPM. My rough estimate was closer

than I

ever suspected!

(I've ordered an identical speedometer for the Miles

truck.)

Speedometer Sensor: Magnet

spinning on CV shaft

coupler,

Speedometer Sensor: Magnet

spinning on CV shaft

coupler,

Magnet sensor hanging from planetary gearbox is wired to

speedometer on

dash.

(Gosh, wouldn't it be nice to enclose under the entire hood area

to

keep rain & rocks out?)

A friend

came

along one day and looked under the hood

while I drove back and forth a bit. He showed me by pulling on it

how

much the motor assembly was rotating under torque pressure, and

the

"clunk" backing up was something hitting the edge of the battery

shelf.

I also noticed there was a simple way to improve it with a short,

fat

steel "L" bar to another spot on the plate, making the connections

form

a triangle instead of just a line and holding the rear

rubber-cushioned

support itself at the right angle.

A friend

came

along one day and looked under the hood

while I drove back and forth a bit. He showed me by pulling on it

how

much the motor assembly was rotating under torque pressure, and

the

"clunk" backing up was something hitting the edge of the battery

shelf.

I also noticed there was a simple way to improve it with a short,

fat

steel "L" bar to another spot on the plate, making the connections

form

a triangle instead of just a line and holding the rear

rubber-cushioned

support itself at the right angle.

Much better, but even after all that there still

seemed to

be a "clunk"! My friend was over again and looked in. It seemed

the

rear cushion support was still tilting with torque, and the rubber

cushioned part was

hitting an end stop in reverse, so the metal parts connected -

clunk.

(BTW the wooden spindle and base on the right is the lamp.)

[August 4th] I looked

at

the original transmission bracket and saw it

had held the rear cushion mounting at about 45░. Mine was pulling

it over to more like 70░, nearer vertical.

[August 4th] I looked

at

the original transmission bracket and saw it

had held the rear cushion mounting at about 45░. Mine was pulling

it over to more like 70░, nearer vertical.

I disassembled the rear mount pieces. I drilled new

holes

and bent the pieces to sit at a

better angle on the mount.

If it didn't end up at the "ideal" 45░ slope, it

was at least closer to 50░ than 70░.

That seemed to eliminate the main "clunk". There was

still

a smaller, sharp "tink", always just once after changing from

forward

to reverse and pressing the pedal. I guessed it was something in

the

drive shaft, but found nothing. Perhaps

this remaining "tink" is in the actual CV joint, or something in

the

suspension? It hardly seems worth further investigation.

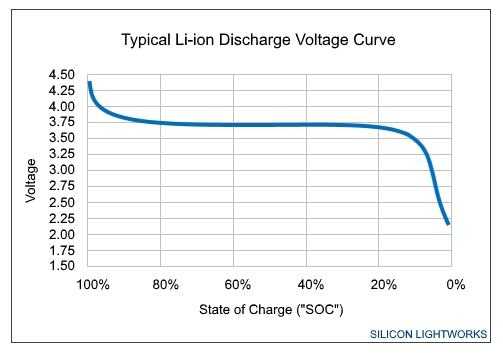

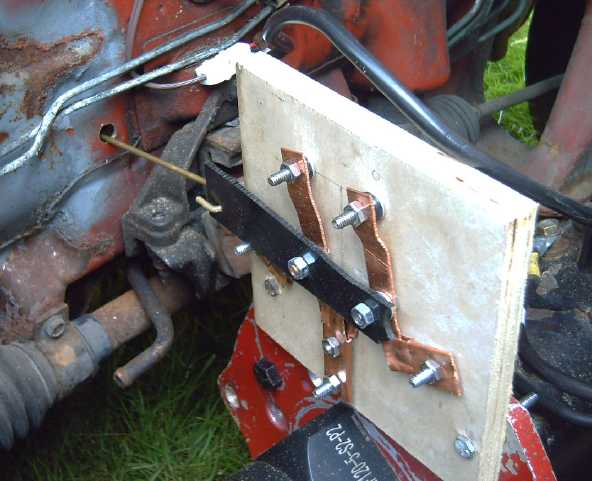

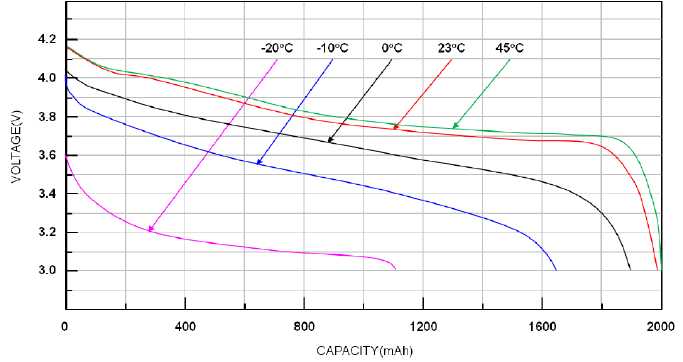

Lithium Ion Battery Charge Voltage

For some reason after putting the Sprint on charge I

looked this up again. I wondered why people were so insistent

about

charging to the absolute limit voltage of 4.2 volts per cell if

3.95

volts was virtually a full charge. It's so important not to exceed

that

limit, and some cheap voltmeters, for example on the charge

controller,

aren't all the precise. I get readings from "39.0" to "39.7" from

different displays at the same time. It's nice to have a safety

factor.

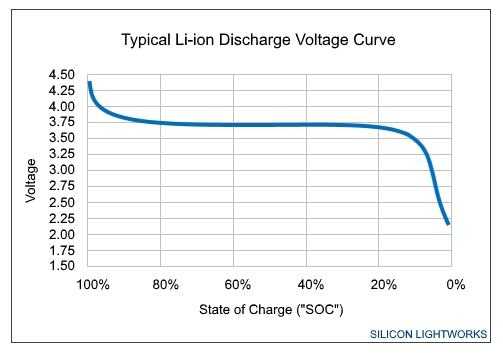

But it appears that I may have been looking at a

battery discharge

curve graph rather than one of open circuit voltage, and

charging to only 3.95 open circuit volts per cell could after all

be as

little as 80% of the full charge potential. OTOH, if one doesn't

need

the full capacity, charging to a bit less than 100% full is likely

to

extend the life of the cells. If I need the capacity I may up the

charge voltage. That might be if the Sprint goes on the highway,

or if

there's a long power failure and I'm having trouble running

fridge,

freezer and lights overnight from its batteries.

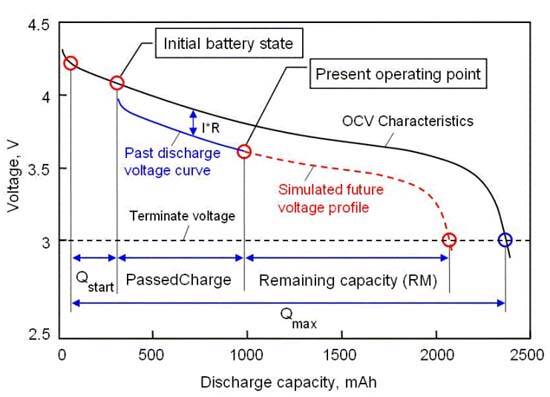

The voltages in a discharge

graph will

be lower than the open circuit voltages.

The voltages in a discharge

graph will

be lower than the open circuit voltages.

A graph showing both open circuit voltages and discharging

voltages.

(of course the heavier the load, the lower the discharge voltage

will

be.)

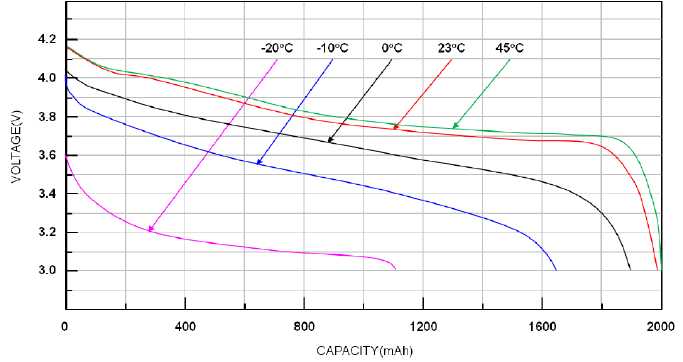

But lest it all seem too cut

and

dried, the

voltages (seemingly open circuit voltages)

But lest it all seem too cut

and

dried, the

voltages (seemingly open circuit voltages)

also change markedly with temperature.

(which shows one factor decreasing vehicle energy economy in

cold

weather - and

another reason to leave a safety margin! 3.95V is evidently 100%

charge

at

-10░C!)

---

On the 16th, the middle of the month having come, I started

thinking

about my project priorities.

* Firewood shed was almost finished to the point where it could be

filled with the firewood

* Cabin hadn't been worked on since early May

* Ground effect craft just needed some more programming before

trying

to fly it.

* The new chemie battery was about dry enough to try adding some

salt

electrolyte.

* The bandsaw mill kit idea seemed to have fallen by the wayside

for

some time.

* So had documenting how to make my Supercorders.

* And then there's assembling the third li-ion battery stack. That

would be what was needed to run the truck at this point.

The list could go on and on, but that was already too

much

to even think about!

I figured a couple of good programming sessions for

the

craft, but it might easily stretch into a week. Could I work a few

battery tests in somewhere? Then the bandsaw mill kit, which might

bring in some revenue, beckoned.

By the end of the day the firewood shed was in

operating

shape. It still needed one piece of wood put up and doors. Then it

should keep raccoons out unless they can squeeze through a smaller

gap

than I think. In the evening for the first time in a while, it

really

rained. No sign of "wet" anywhere inside or around the walls,

except

just inside the open doorways. As it seems to be staying "wettish"

out,

I finished just in time. I know the seller has the

firewood outside, now getting wet. Time to get it delivered!

By the 26th somehow all I had done was another

programming

session on the craft (and then decided it should be done a

different

way) and tried out the salt electrolyte in the battery with my

typical

disappointing results, along with trying to make a one-piece

copper

battery can from copper pipe.

But that's when I gave it some more thought and

realized

that since I already had the really significant result, an

everlasting

zinc electrode (as I wrote about above), perhaps concentrating on

the

frustrating nickel-manganates positive electrodes that just

weren't

cooperating was rather a waste of my time and I should drop the

battery

work.

---

Below to end are a couple of interesting sustainable

power

projects people have pointed me to this month. There was a video

somewhere on Youtube about the Qinghai solar installations. Later

I

located

satellite images of them via Google Maps.

Solar Installations in Qinghai

Here are a few [Google Maps] satellite images of

stupendous Chinese solar power installations - in a northwestern

desert

in Qinghai [southeast of Shingjiang (or Xingjiang, AKA East

Turkestan)]

at about 37.3░ north. The area of the broad view is about 17-1/2

Km

by 7-1/2 Km.

These apparently supply much of the power for the

entire

region. They wash off the panels (monthly?) and the water plus the

shade from the panels has caused vegetation to grow, which started

to

grow over the panels. So they got a rancher (multiple

ranchers?) to graze sheep in the installations among the panels.

The

rancher interviewed thinks it's marvelous: win-win!

Each tiny black strip below is a row of about 16

solar

panels (hard to count at any scale). If that count is correct,

there

are 768 one meter wide panels from left to right. There seem to be

almost 60 rows, which would be 46,000 solar panels in this one

field.

If they were 300 watts each, that would be over 13 megawatts

rating.

(Over double the BC Site-C dam project, IIRC, from this one

field.)

While most fields go

east-west to get the maximum daily collection, a few fields have

rows

oriented north-south, surely to maximize evening (supper cooking

time?)

or early morning collection.

Below is a solar concentrating collector (near the right

end of

the broad first image). Typicly in such installations, mirrors

direct

sunlight to a concentrating point at the top of the huge central

tower,

where steam is made to run a steam turbine generator. The mirrors

have

to automaticly move continually to maintain their aim over the day

and

through the seasons. With the falling price of solar PV panels

this is

complex system is probably an obsolete idea. (I understand they're

also

good for frying passing birds.)

(The small tower at the lower right may have been the

"proof of concept" prototype installation?)

Another Floating Tidal Flow Power

Unit

This Sustainable Marine Tidal System tidal

power

unit from Nova Scotia seems unique in using multiple

smaller propellers, which should make it usable in much shallower

waters than the 'two huge propellers' Orbital Marine ones in the

Orkney

Islands. It looks like it could be a winner. They might be just

the

thing for Masset inlet on Haida Gwaii. If they don't chop up fish.

One trusts that each

propeller/generator can be

raised, removed

One trusts that each

propeller/generator can be

raised, removed

and serviced individually without it being a really major

operation

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Food

Security:

A

Constitutional

Right

to

Grow and Trade Food

Here is the summary of a declaration recently

proposed in

the State of Maine, USA, legislature.

"Section 25. This constitutional resolution

declares that all individuals have a natural, inherent and

inalienable

right to acquire, produce, process, prepare, preserve and

consume, and

to barter, trade and purchase the food of their own choosing

for their

own nourishment, sustenance, bodily health and well being."

(The full statement continues with provisos to exclude unlawful or

harmful acts to acquire food. It also contains a phrase that says

everyone has the right to

eat well, which is likely to be proven unattainable in the next

few

years. - still the whole act is all in one sentence!)

It seems to me that such a declaration enshrined into

a

constitution or bill of rights would go a long way to correct

legal

imbalances that in many subtle or coercive ways favor the mass

production and centralized distribution of food by a small number

of

"mega" corporations, which block individuals and families from the

potential of making their own local food for their own locality.

This

impoverishes rural communities financially and increases

vulnerability

of the food supply everywhere.

That such a thing is happening may be puzzling to the

majority. Can we not plant and harvest our own vegetables? (Even

this

seems to be under threat these days!) But garden produce is not

the

only food group. I will revert to a couple of examples I've

mentioned

before.

* Milk Products Ostensibly to protect public health,

in

the early 1970s BC outlawed sale of raw milk. Furthermore,

pasteurizing

milk had to be done at a government inspected facility where it is

done

in vast quantities in programmed processes with chart recorders

available for government inspection.

The result was predictable: One cow produces too much

milk

for a single family, and is too much work and expense to keep one

just

to throw out most of the milk. So the entire rural population all

across BC had to get rid of their dairy cows. Family producers all

over

the province were prevented from earning local income from their

cow or

small herd. I recall this being enforced against a family who was

selling us delicious raw milk in 1972, from which we were also

making

butter and ice cream. Today as far as I know there are only a

handful

of dairy cattle in all of northern and rural BC, mostly owned by

Mennonites. All our milk is shipped from 2 or 3 big processors in

the

big cities, across the entire province, and the processed milk

can't be

made into butter, cheese, sour cream or buttermilk - making

everyone

still more dependent on the "factory" dairy processors. And of

course,

the dairy farms are clustered around the big cities near the

processing

plants. One presumes that the cattle herds are much too

concentrated to

graze on their own pastures and so feed must be grown and

processed

here, there and everywhere, then purchased and transported in.

This,

instead of grazing the cattle on that land to "harvest" and

"process"

it themselves, with more local and direct distribution of the end

product. From an economic standpoint, what makes more sense?

As far as public health is concerned, all the

transported

product is less fresh. I occasionally get migraines from milk

direct

from the store on the day I bought it (less often than I used to)

and

have to take a migraine pill, dump the whole gallon of one cup

serving

bottles I've just frozen, and re-wash the bottles. And I

understand

that while there have very occasionally been hospitalizations owed

to

raw milk products, there have been no deaths at all in modern

times. Is

that sufficient health concern to prohibit what people have done

for

thousands of years? Even if one considers raw milk unsafe, there

are

now economical counter-top milk pasteurizers, and doubtless there

would

be many more and better choices if there was a legal market for

them in

larger countries.

* Meat At some time (probably also in the 1970s), it

became a requirement that domestic meat be butchered only at a

registered government facility. A small grocer I knew in Victoria

BC

used to butcher his own and always had fresh meat. You could buy

your

week's groceries there. He closed the meat section and gradually

the

selection of everything shrank. They sold lottery tickets instead.

On

this island I'm told Richardson Ranch used to butcher grass fed

cattle

annually in the fall. Now the cattle must be trucked to a facility

on

the mainland (just the long ferry ride costs hundreds of dollars

and a

round trip takes several days), butchered doubtless by others for

which

the ranch must pay instead of earn, and then (hopefully) the meat

is

shipped back to the island. How is it that the amateurs who

butcher

their own deer meat are no longer permitted to trust the

experienced

ranchers to sell them beef they've butchered?

A key word missed was "sell". One has the right to

buy

food, and to barter or trade it for one's own use, but not

necessarily

to sell it outright to others. That was probably as far as the

proposer

of the amendment wanted to or dared to go. Still, if the things

listed

were considered to be "rights", it would be much harder to argue

for

monopolistic food industries and against local food production and

distribution, and laws such as these examples that shut it down by

making local production and sale impractical or uneconomic might

start

to be thought of as government overreach and would be much harder

to

argue for.

Small

Thots

* Obviously my little gardens even with

the no-fruit problems are doing better than a lot of commercial

farming

right now. Practicly every major wheat exporting country's crops

are

way down this year. Droughts, floods, locusts, mice...

With corn and soy production down so much in the last

couple of years, meat producers have been switching to wheat to

feed

their herds. Now that too is becoming prohibitively expensive and

and

the remaining choice is to drasticly reduce the herds so they

don't

starve outright. And the supply

chain is having

problems delivering even what there is. Ukraine has wheat but

can't get

it out to export.

Railroads in the US west are shutting down because they're afraid

of

potentially starting yet more forest fires. Every year the

situation

looks worse than the year before, and we must be getting close to

some

tipping point.

* Some in the grocery business are commenting under youtube videos

that

warehouses are looking rather spacious, grocery store orders are

being

short shipped owing to shortages and some products are becoming

hard to

get or have been discontinued. This has in fact been a growing

trend

for a year or two now. Some are even worried about August; some

think

things will last until after Christmas. Is it all just

fearmongering?

Where in the world is there any big

breadbasket of crops growing "as usual" this year?

* I just ran across a French word: "Liberticides" - killers of

liberty.

In my meager understanding of French it usually seems to be

applied to

what are considered to be unjustified authoritarian laws and

edicts.

According to an online translator "Liberticide" is an English

word,

too, but I'm not sure the translator actually knows what it means,

or

if it's just copying an unknown word straight into the [one word]

translation. It seems an apt word to describe some things that

have

been happening.

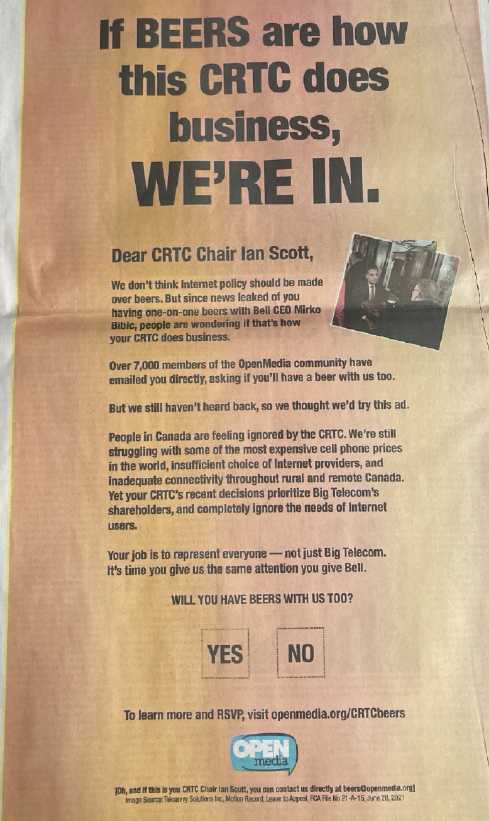

* In a

today typical piece

of oligarchic corruption, a former head of Telus, a monopolistic

telecomm company with a corporate culture of greed, fraud and

deceit

was appointed head of the Canadian Radio and Television Commission

(CRTC), the federal government agency assigned as the watchdog

over

such companies. (He seems to have ordered things done to enrich

Telus

for which a private citizen would have gone to jail.) This is of

course

having a wolf for the shepherd. Canadians pay more than any other

people for our telephone, TV and internet services, and rules are

rigged to keep other service providers out.

* In a

today typical piece

of oligarchic corruption, a former head of Telus, a monopolistic

telecomm company with a corporate culture of greed, fraud and

deceit

was appointed head of the Canadian Radio and Television Commission

(CRTC), the federal government agency assigned as the watchdog

over

such companies. (He seems to have ordered things done to enrich

Telus

for which a private citizen would have gone to jail.) This is of

course

having a wolf for the shepherd. Canadians pay more than any other

people for our telephone, TV and internet services, and rules are

rigged to keep other service providers out.

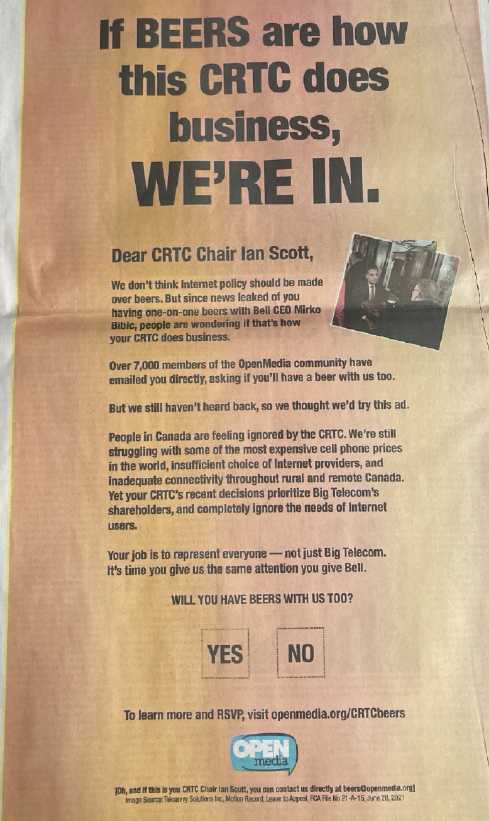

Someone recognized him in a bar, having a beer with

the

CEO of Bell, a telecomm company with an even worse reputation. We

can

be pretty sure he wasn't "laying down the law" to Bell but rather

they

were plotting together how to continue to keep competition out and

extract still more money from Canadians. The organization OpenMedia

has called him out on it in a full page ad in the capital's

newspaper,

the Ottawa Citizen.

If he doesn't respond favorably I hope they ask the

government to fire him and suggest a replacement. Can the corrupt

be

ousted without pitchforks and torches coming out? That's not

supposed

to be necessary in a democracy - of course, such people should

never be

considered for holding a position of public trust in the first

place.

ESD

(Eccentric Silliness Department)

* In any court case there are two sides: the Defense and the

Persecution.

* A good Offense requires the best Defense - or the offender will

be

persecuted.

* The bank lacked liquidity, so we dug a trench around it and

filled it

with paint thinner. Now it's just another insolvent bank.

* Orders of magnitude as applied to financial currency: one -

thousand

- million - zillion - gazillion - quazillion ...

* A typical bungalow worth a million dollars today may be worth a

gazillion by this time next year.

* A quazillion dollars in 10,000$ bills would stack to the moon

and

back.

* Food worth 100$ today may be 10,000$ by this time next year.

* It was once feared one could sail off a waterfall over the edge

of

the world. That was dismissed as ignorance, but I recently found

this

Google 360░ photo image that proves it's real. (Apparently one

edge

of the

world is in the West Falklands):

* I bought a bag of rock wool insulation to have on hand for when

I

(theoreticly, some day) get around to making my plastic sheet

press,

which will (I hope!) probably get too hot for fiberglass. What I'd

really like to know is, how do they fleece the rocks to get their

wool?

:( All the rocks I find are already fleeced. ):

* Once spawn has been spawned, doesn't responding just increase

the

quantity?

* Burrito: A baby burro

"in depth reports" for

each project are below. I hope they may be useful to anyone who

wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or

just

thought

of and not tried... and even of how not to do something -

why

it didn't

work or proved impractical. Sometimes they set out inventive

thoughts

almost as they occur - and are the actual organization and

elaboration

in writing of those thoughts. They are thus partly a diary and are

not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths

and

avoid potential pitfalls and dead ends.

Electric

Transport

Ground Effect

Craft

(R/C Model)

[8th] I had been wondering

about the methods for programming and testing the combination

motor

thrust/steering controls. Turning my attention to the project

again at

long last, it occurred to me that instead of trying to get it all

working at once, I could check the motor outputs by simulating the

received radio control joystick commands with the

display-controller

buttons. The lower two left and right buttons could slew the

steering

"joystick position" to the left and right, while the two vertical

ones

in the middle could be throttle up and down. They would directly

increment/decrement the "ThrottlePosition" and "SteeringPosition"

variables, each 0 to 15, and the display would show the number. As

I

wrote the code I thought to do a "STOP" button too, that

immediately

turned off the motors and set 'steering' to center.

Then the output variables, the strange PWM signals

that

the receiver puts out, would be fed to the motors to hopefully

give the

desired effects, and everything tweaked until the motors ran

right.

Then the receiver end could be implemented and feed

the

same two variables and the display with the motors off, and

finally the

two could be coupled together when they both seemed to work well.

[9th,10th] I spent especially the day of the 10th trying to get

just

the pushbuttons to work. It was frustrating dealing with somebody

else's assembler and debugger instead of all the fabulous software

development tools I had made for myself in the 1980s and 1990s,

but

which aren't applicable to the new microcontrollers. The biggest

problem turned out to be the weird syntax of the "call" (AKA

"jsr")

instruction. One expects "call readbuttons" to do just that... but

no,

it's "call #readbuttons". Without the "#" it defaults to some

strange

address mode that no one would use and goes off into space, and I

forgot about that in a couple of places. Then the obtuse debugger

made

it difficult to track down the problem. But finally it worked and

the

numbers slewed up and down happily.

[17th & 20th] (Still can't seem to get to this in any hurry!)

The

model aircraft radio control signals are supposedly 1.0 (full off

or

full left) to 2.0 (full on or full right) milliseconds, in a fixed

period of 50 Hz (20 milliseconds). All very vaguely specified.

My original intent had been to have timer interrupts

to

make the output pulses to the motors be between 1 and 2

milliseconds

per these requirements, with the second half of the pulse length

divided into 16 parts, "off" to "full on". But it finally dawned

on me

that to divide a millisecond down into 16 parts would mean an

interrupt

every 67 microseconds. I hadn't paid any attention to the

processor

speed, but it was megahertz rather than gigahertz and I figured

that

such a frequent interrupt wasn't "going to fly", so to speak. It

would

have to be done another way.

I programmed "Timer A" and got its interrupt working,

but

only every 20 milliseconds for the 50 Hz, not every 67

microseconds. To

determine the speed I divided it by 50 to have a light blink on or

off,

adjusting that to once per second. I found that running Timer A

from

the fastest internal clock and dividing by 1 (instead of 8), it

only

counted to 120 to give the 20 mSec. I had expected a much larger

number. (A 67 ÁSec count would be to less than one - not even

possible!)

I decided to use a simple program delay timing loop

in the

main

event loop with a register counting down to get the 67 ÁSec

intervals. This would be triggered every 20 mSec by the timer. The

control pulses could be up to 2 mSec occupying 10% of the total

time.

This was obviously going to have to interact with the 1 to 2 mSec

receiver pulses that might (inevitably) happen concurrently. Oh

well,

one thing at a time.

[26th] I was thinking about the asynchronous nature and critical

timing

of the signals from the receiver while the equally critical timing

loops for the transmitter were running. A new strategy came to me.

There was 2 milliseconds of receive signal and 2 of transmit. But

the

period overall was 20 milliseconds. That's 16 idle seconds. What

if I

simply waited for the receive signal, decoded its length from 1 to

2

milliseconds, and then, knowing it had already occurred, there was

plenty of time to send a 1 to 2 millisecond pulse to the motors,

and

then to do anything else necessary, before the next receive

signal. The

only thing I didn't know was whether the up-down pulse was

synchronized

with the left-right pulse or if they occurred randomly (which

would

throw a monkey wrench into things), or if they were synchronous,

whether they were at the same time or occurred at different times.

The

only way to tell that would be to view the waveforms on the

oscilloscope. (Ug!) As long as they're not asynchronous with each

other

any timings can be accommodated.

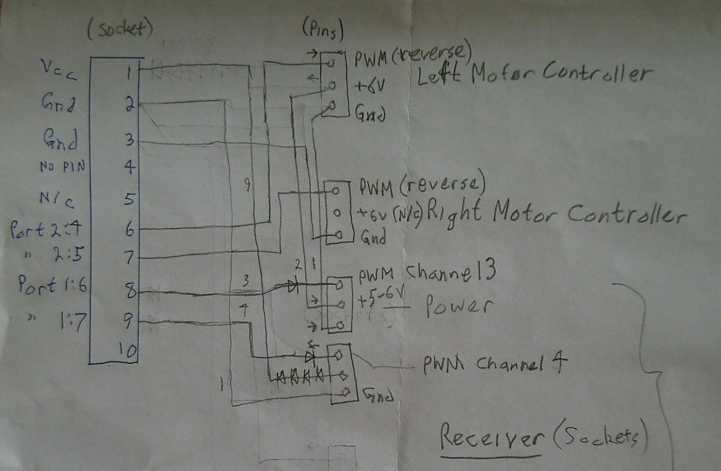

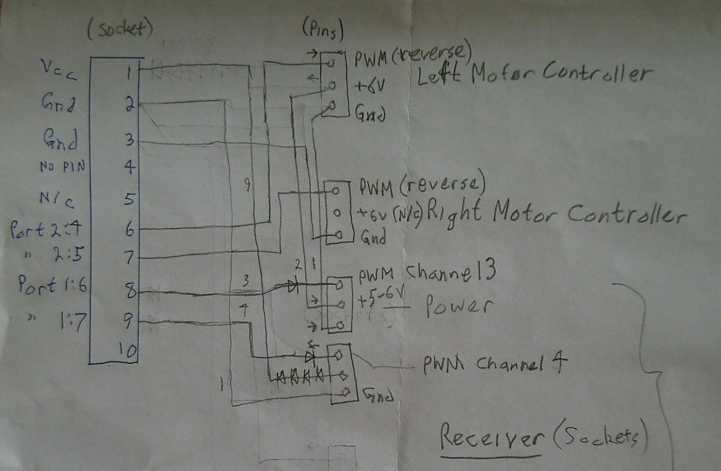

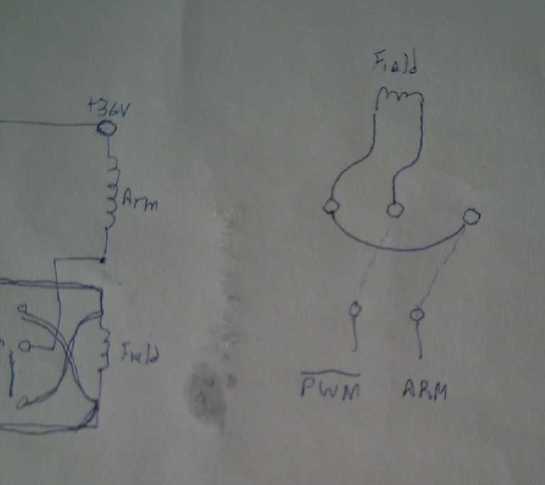

I'm copying my wiring

diagram

into this

newsletter for myself, before I lose the piece of paper.

I'm copying my wiring

diagram

into this

newsletter for myself, before I lose the piece of paper.

(The socket on the left is on the microcontroller board. The

ones on the

right are to the motor controllers and from the radio control

receiver.)

Chevy Sprint

Add-ons: Forward-Reverse, Speedometer

And at some point I had sprayed the pivots of the

windshield wipers with WD40 or something. When I thought to try

them

maybe a week later and beyond, they started wiping more easily. On

"high" they started going faster instead of slower. I didn't see

any

smoke from the controls, although I haven't dared leave them on

for

very long. (But one day it was raining and I actually had to use

the

wipers! I put in some windshield washer fluid and that worked,

too!)

---

[12th] There were some

little details yet to go on the car. First, I

moved the 12 volt charging plug arrangement so the isolation diode

was

on the

battery terminal instead of hanging perilously in mid air on a

wire by

the DC to

DC

converter. (Oops, no "after" picture?)

[12th] There were some

little details yet to go on the car. First, I

moved the 12 volt charging plug arrangement so the isolation diode

was

on the

battery terminal instead of hanging perilously in mid air on a

wire by

the DC to

DC

converter. (Oops, no "after" picture?)

But the big thing was

reverse. It seemed a bit silly

having to get out and push the car to back it up. In fact as I was

actually using the car (if only for hauling lumber and things

around

the acreage), it was getting to be a nuisance. And a bit

embarrassing

to

"proudly" show the novel, smooth-running car to people and yet

have to

do that.

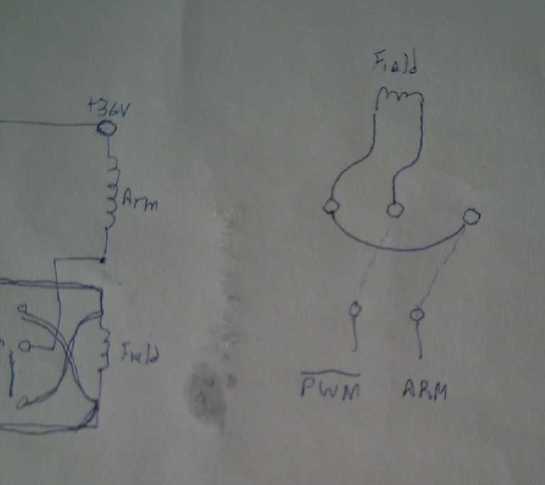

To reverse direction on a series wound DC motor, one

must

change the polarity of the field coils without changing the

polarity of

the armature coils, or vice versa. Simply changing that of the

entire

motor won't reverse it. And the field coils have the same high

currents

flowing in them as the armature coils.

As I don't intend to use this motor long term, I

didn't

want to spend

probably hundreds of dollars on a big DPDT contactor relay - or

even

order and wait for a probably cheaper one from China. But perhaps

I could make a heavy duty version of a DPDT "knife switch" with

some

lever on the dash to flip it. To handle the currents: thick copper

plate switch arms, and copper water pipe shaped into clips to

connect

to. Or maybe it could be a slide switch? I decided on a special

flat

switch on a plate of plywood.

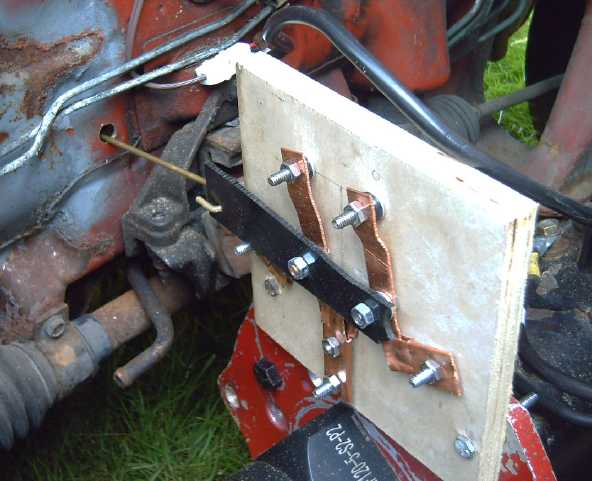

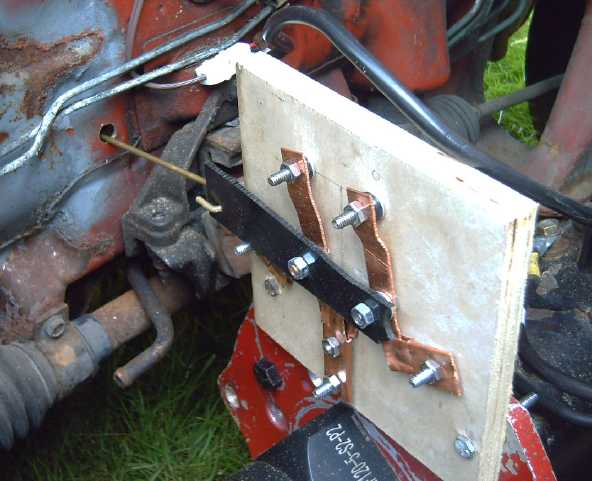

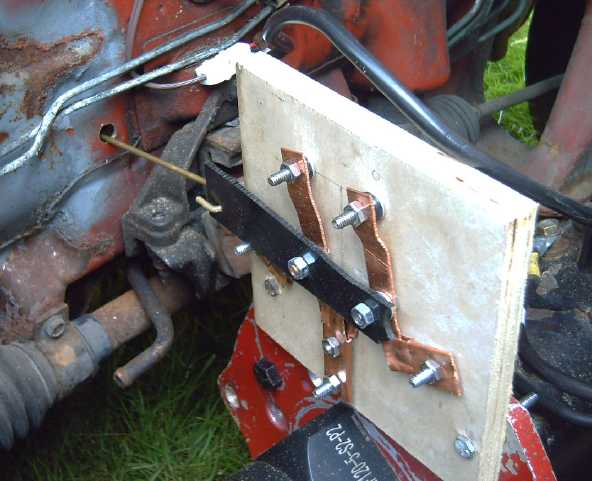

Okay, 6 bolts sticking up

through

the plywood,

heads all recessed (using flat blade drill bit).

Okay, 6 bolts sticking up

through

the plywood,

heads all recessed (using flat blade drill bit).

* Two flat copper bars pivoting in unison on bolts.

* 3 contact "clips" of copper water pipe.

Delrin plastic to couple the

two

moving bars.

Delrin plastic to couple the

two

moving bars.

Mounting it on the motor

plate

under the hood.

Mounting it on the motor

plate

under the hood.

Brass push-pull rod to "flip" the switch goes into the cab.

(inner end recessed, on passenger side of center hump.)

It was "sort of" DPDT. It did what DPDT switches are usually

wired to do: reverse the output connections when flipped. Two

moving

bars

connect to the two input wires. There are three roughly formed

output

"clips". The

center one connects to one bar in forward and the other in

reverse, and

powers one end of the field coils. One or the other of the end

ones is

connected to

a bar, to the bar not then connecting to the middle. The two end

clips

are

tied together and go to the other end of the field coils.

It was "sort of" DPDT. It did what DPDT switches are usually

wired to do: reverse the output connections when flipped. Two

moving

bars

connect to the two input wires. There are three roughly formed

output

"clips". The

center one connects to one bar in forward and the other in

reverse, and

powers one end of the field coils. One or the other of the end

ones is

connected to

a bar, to the bar not then connecting to the middle. The two end

clips

are

tied together and go to the other end of the field coils.

The bars have to move together but they can't be

electricly connected. I used a piece of delrin/acetal plastic as a

tie

bar with a protruding end to pull/push on.

At the car I noticed that if I mounted the switch on

the

motor/gearbox plate, I could arrange it so a push rod could go

through

an existing hole in the firewall, which I could reach to "flip"

the

switch from the driver's seat. (It was once the hole for the gear

shift

lever cable.)

I had it done that day and tried it out. It's not

elegant;

in fact pretty "makeshift", but it does seem to work if one pushes

and

pulls hard enough on the rod.

Then I drove it across the acreage. One bar on the

switch

got hot, the

other only warm. Backing up (starting with a clunk!), both bars

got

hot. Now I didn't

trust

driving it. Maybe I could file inside the clips to clean the

copper,

and bend them for a tighter grip? (It was running fine without a

switch... maybe I should have left well enough

alone?)

Later I brought a small file and looked again. I

discovered that one of the bolts holding a wire to its bar was

loose.

(I had checked them all before I started it up, honest!) I

drove around again. In a little backing up, nothing got hot. After

a

"fast" (read, "bouncy") drive with high currents going up the

hill,

both bars were a little

warm, but nothing was hot.

Let's see... The bars

were

~1.7mm thick by 16mm wide, or

27 square millimeters. If it was round wire:

Area = π * R^2, so R = √(Area / π)

√(27 / π) = 2.93 mm. (diameter 5.84 mm)

That would be about #3 AWG. The wires are #2 or #4,

so

that's a pretty good match. The heat must be from contact

resistance at

the connections between clips and bars when carrying 50 to 100+

amps.

But they were just warm, not hot like with the loose wire.

Considering

the roughly shaped copper contact pieces of the switch, it's

surely to

be expected. I guess everything is fine. I'll continue checking it

after driving.

And I must fasten the heavy wires down properly so

they

don't rub on anything and gradually wear off their insulation.

Maybe

even cut some shorter ones, since they're all substantially longer

than

they need to be.

I was glad to have started and essentially finished

this

project and written it up in one day. In retrospect rather

surprised.

Things that could have been time consuming like the switch design,

mounting the switch, and a way for the driver to operate it, just

fell

into place and it went amazingly smoothly. In spite of starting

with

somewhat vague ideas, nothing was puzzled over for long, and

nothing

was done that had to be undone or redone or done differently. I

don't

suppose putting in a

commercial contactor relay would have taken less time. I'd

have had to wire up power to activate it from a switch on the

dash.

(Could I even have found an appropriate one, heavy DPDT contacts

and 36

volts DC activated? or perhaps 12 V DC?)

---

I've found some of the beeps and whistles of the

Nissan

Leaf annoying (especially chiming away continually when I get out

to

open and close the driveway gate), but I'm starting to see their

utility, because I've already got out and walked away without

turning

the Sprint off a couple of times. (Only for short periods... so

far! Of

course it's not something you'd do with a petrol car.) Maybe I

actually

should install some annoying reminder beeper for when the door is

opened with it running. (Hmm... easier to do if the driver's door

switch was working. If the door is open for enough weeks, the cab

light

comes on. How do I get at that switch?)

[13th] I had a look. A plastic panel unclipped easily. When I had

it

off I discovered that the whole switch could just be pried right

out

from outside! It consisted of just one wire that connected to the

clip

that held the switch from falling out by itself, which was also

supposed to

connect to the car body. Corrosion presumably had stopped it. I

worked

it around a bit until it connected.

In that I discovered that the car already had an

annoying

beeper when the door opened and the key was in the ignition, or

the

lights were turned on. That solves that!

---

There

were

nasty clunks when changing direction. I thought this must be the

hollow

rectangular

tube motor mount strut. One can't do up the bolts very tightly on

flat

tubes - they

simply

start to crush the tube. (I had used locking nuts to ensure they

wouldn't

gradually unwind.) So with the reversing torque the bolts were

probably slipping up or down or left or right in their slotted

holes on

the car

mount. (That's why I had started with a solid bar. But it bent. A

tube

has the push strength.) Short pipe piece "washers" for spacers

across

the inside

the tube might (or might not) allow tightening the bolts enough to

stop

the slipping and clunking.

There

were

nasty clunks when changing direction. I thought this must be the

hollow

rectangular

tube motor mount strut. One can't do up the bolts very tightly on

flat

tubes - they

simply

start to crush the tube. (I had used locking nuts to ensure they

wouldn't

gradually unwind.) So with the reversing torque the bolts were

probably slipping up or down or left or right in their slotted

holes on

the car

mount. (That's why I had started with a solid bar. But it bent. A

tube

has the push strength.) Short pipe piece "washers" for spacers

across

the inside

the tube might (or might not) allow tightening the bolts enough to

stop

the slipping and clunking.

I cut 2 pieces of heavy steel pipe to fit just inside

the

square tube

motor strut. I could well imagine them falling to the bottom end

of the

tube where they would be virtually inaccessible and I'd have to

take

the bar off to get them out, so I made them just a

bit too long. The tube had to expand slightly and I had to tap

them

into place with a screwdriver and a hammer. I did up the bolts

quite

tightly.

But the car still had the "clunk" going into reverse

when

the

pedal was pressed. Now, after pushing and pulling on the motor, I

think

the rear shock mounting isn't stiff enough. Maybe it doesn't have

the

same support to keep it from twisting that it had with the

original

transmission attachments? A little video would be nice since I

can't

see

under the hood when I'm driving. Or I could take the hood right

off and

set up a mirror like I did once before? (Ug!)

Anyway it was nice to drive across the acreage and

back

without getting out of the car. (After all, it was evening and the

midges were

getting pretty thick!) The next day I hauled a couple more loads

of

lumber (all done now, I think!) and after four days of

miscellaneous

trips around the acreage the batteries were down from 39.3 V to

38.6.

"Discharged" is way down at 35 volts or so, but I drove back into

the

garage and connected to the DC solar system to recharge. (used 640

watt-hours - down 7.4% from 8640 watt-hours.)

---

Some annoyances keeping it from being really nice are

typical of

old cars... The rocker panels under the doors are badly rusted,

even

tho the rest of the car is mostly pretty good. I could see wanting

to

do a bit

of welding on the frame along there, and perhaps replacing the

outer

surface with plastic - maybe polypropylene-epoxy. And the

"Armorall"

plastic coating is off half

the hood and bubbling up here and there. Aside from rust and

damage,

nothing looks worse than shiny

with a big dull patch and flaking edges.

The front left wheel looked a bit funny with a hole

in the

middle instead of a CV drive shaft end nut, and I belatedly

realize

that I've lost the two front hubcaps somewhere along the way,

perhaps

when I moved. It looks better with them, but where might I find

hubcaps

for 12 inch rims these days? So I put both hubcaps on the left

side.

---

[21st] The bicycle

speedometer arrived on the 20th, and I set to work

installing it in the car. At first I thought of putting it inside

the

original instrument panel somewhere, and I took the whole thing

out of

the dash.

and removed the original speedometer cable that no longer went

anywhere. I thought, what good is the original panel anyway? The

speedometer/odometer didn't work, and the engine temperature and

fuel

gauge were equally useless. Then I remembered it did have the

brake

light, the useless seatbelt light (who would drive somewhere

without

doing up their seatbelt?!?) and maybe another light or two on the

sides. Another problem was that the two buttons at the bottom of

the

speedometer had to be

accessible, so it couldn't be mounted behind the glass. So that

seemed

like

a whole waste of time, and finally I put it all back together and

made

an aluminum "L" bracket to mount it on top of the dash, but still

below

the driver's view.

[21st] The bicycle

speedometer arrived on the 20th, and I set to work

installing it in the car. At first I thought of putting it inside

the

original instrument panel somewhere, and I took the whole thing

out of

the dash.

and removed the original speedometer cable that no longer went

anywhere. I thought, what good is the original panel anyway? The

speedometer/odometer didn't work, and the engine temperature and

fuel

gauge were equally useless. Then I remembered it did have the

brake

light, the useless seatbelt light (who would drive somewhere

without

doing up their seatbelt?!?) and maybe another light or two on the

sides. Another problem was that the two buttons at the bottom of

the

speedometer had to be

accessible, so it couldn't be mounted behind the glass. So that

seemed

like

a whole waste of time, and finally I put it all back together and

made

an aluminum "L" bracket to mount it on top of the dash, but still

below

the driver's view.

I tried my best to route the wire to the sensor by

the CV

shaft. Both ends were molded in plastic and inaccessible. But it

just

wasn't quite long enough. So finally I cut it and used some

small "XT30" model airplane plugs and sockets to add a two foot

extension cord in the middle. Next, how to mount the sensor and

the

magnet?

The magnet had

to go on the CV shaft and spin.

At the

coupler I had drilled holes and made the setscrews 3/8 inch

instead of

the 1/4" and 5/16" ones they came with. I had run out of

appropriate

length 3/8" setscrews, and one that was too long stuck out. That

gave

me the idea to put a nut on it to clamp down a mounting. The

two-piece

magnet was

made to screw onto a wheel spoke. I found a brass rod of suitable

diameter. Using jeweler's ring pliers I bent one end into a

ring/loop

to go under the 3/8" nut, and the other around to fasten the

magnet

onto.

The magnet had

to go on the CV shaft and spin.

At the

coupler I had drilled holes and made the setscrews 3/8 inch

instead of

the 1/4" and 5/16" ones they came with. I had run out of

appropriate

length 3/8" setscrews, and one that was too long stuck out. That

gave

me the idea to put a nut on it to clamp down a mounting. The

two-piece

magnet was

made to screw onto a wheel spoke. I found a brass rod of suitable

diameter. Using jeweler's ring pliers I bent one end into a

ring/loop

to go under the 3/8" nut, and the other around to fasten the

magnet

onto.

The sensor was made to tie-wrap to the bicycle fork.

I

pounded the end of another piece of the brass rod flat until it

fit

in the slot where a cable tie was supposed to go. Being flat it

kept

the sensor

from turning and seemed to hold it pretty well, so I extended it

and

made another loop. I

put an 8mm bolt through an unused hole in the

planetary gearbox and fastened down the loop end. That held the

sensor

next to where the magnet turned.

(I should make something to prevent the sensor from

sliding off the end of the rod. But the wire going the other way

stops

it. Later it twisted away from the magnet and became intermittent,

so I

wrapped some tape around it.)

Then I set the tire

circumference to my estimated 1630mm

in the speedometer unit. (I measured it as about 1670mm later with

a

tape measure - 2.3% off. That's .001670 kilometers, giving almost

exactly 600 wheel revolutions per kilometer - and 10.0 RPM per

each 1

KmPH.) It being night by this time I didn't

want to take the car out. Instead I got the idea to jack up the

drive

wheel and let it spin. I turned the car on and pressed the

electron

pedal. I thought since the parking brake only held the rear

wheels,

brakes on should be good. I didn't really trust the jack not to

slip

and put the

wheel in contact with the floor, so I put my left foot on the

brake

pedal

just in case. Somehow it didn't occur to me immediately that the

pedal

also operated the front brakes. Duh! The wheel turned, but instead

of

freewheeling it seemed labored and the currents were very high,

like I

was driving around the yard. The speedometer gave readings, even

up to

30 KmPH. Once it occurred to me to take my foot off the brake, the

currents dropped way down and "wide open" got the reading up to 54

KmPH. (If it would actually go that fast on the road, it'd be

great!)

At highest speeds there was some vibration, which I tentatively

attribute to the off-center weight of the long set screw, nut, and

magnet assembly. Perhaps I should try putting a weight on the

opposite

side, held on by a pipe clamp?

I had

assumed

that with a backlight in the speedometer, it

would be visible in the dark up on top of the dash with no light

on it.

Nope! The backlight only stayed on for a few seconds after a

button was

pressed, with no options to keep it on. I guess you're not

supposed to

go bike riding at night. I'd have preferred AAA battery(s) and

being

able to keep the light ON to a single use button cell and

"conserve all

possible power!" owing to that.

I had

assumed

that with a backlight in the speedometer, it

would be visible in the dark up on top of the dash with no light

on it.

Nope! The backlight only stayed on for a few seconds after a

button was

pressed, with no options to keep it on. I guess you're not

supposed to

go bike riding at night. I'd have preferred AAA battery(s) and

being

able to keep the light ON to a single use button cell and

"conserve all

possible power!" owing to that.

I wonder if I can find something a little more

appropriate

for the Miles mini cargo truck, which also needs one? (I ended up

ordering another one the same rather than spending time on line to

check out others. At least I know they work.)

Back of speedometer from the

outside

Back of speedometer from the

outside

The next day I did go for a

drive across the acreage. It only hit about 19.4 KmPH bouncing

across

the rough lawn path. After this I stopped a while. I cleaned and

vacuumed the inside of the Nissan Leaf, then the Sprint. (Now it

can't

haul lumber!)

Later after I had adjusted the tire circumference

number I

went around again 3 separate times. I "booted it", and hit a "Max

Speed" reading of 25.6. The lane was too rough and too short to

pick up

more speed. (Hitting the corner to go up the hill at such speeds

got

exciting!) How much faster would it get up to on level pavement?

45

KmPH started to seem less likely. 35 or 40?

Since the car as configured with this motor surely

couldn't make it up my

steep driveway from the highway, I had come up with a "cunning

plan" to

drive out on the highway and go a short distance to my neighbor's

(they're usually away) and go up his shallower driveway, then

across

his long drive and then through his rough grass back to the far

side of

my own place, linking up with where I've been driving. But did I

really

want to do it? That section of highway wasn't level anyway, so not

the

ideal for a "level pavement" speed test. And it would surely leave

a

track on their lawn for quite a while. Maybe better to just say

"project complete" and put it away until I need it around the

acreage

again -- or can make that new motor at some hypothetical future

date.

De-clunking the Motor Mounting

[24th] A friend came

over

and I took him for the ride

across the acreage. When we got back he thought he'd investigate

the

"clunk" in reverse, so we opened the hood and he looked in while I

went

forward and back as bit. He showed me by pulling on it that the

motor

assembly was rotating more than I had realized, in both

directions. In

reverse, a protrusion in the plate was actually hitting the

plywood

battery shelf - the "clunk". I could also see what looked like an

easy

fix: as he moved it, a bolt on the plate upper edge moved almost

directly toward and away from the nearby rear mounting. I could

just

add one

more short steel joiner bar from there to the rear

support. That would make it form a triangle instead of just a

line,

virtually eliminating rotation of the assembly.

[24th] A friend came

over

and I took him for the ride

across the acreage. When we got back he thought he'd investigate

the

"clunk" in reverse, so we opened the hood and he looked in while I

went

forward and back as bit. He showed me by pulling on it that the

motor

assembly was rotating more than I had realized, in both

directions. In

reverse, a protrusion in the plate was actually hitting the

plywood

battery shelf - the "clunk". I could also see what looked like an

easy

fix: as he moved it, a bolt on the plate upper edge moved almost

directly toward and away from the nearby rear mounting. I could

just

add one

more short steel joiner bar from there to the rear

support. That would make it form a triangle instead of just a

line,

virtually eliminating rotation of the assembly.

Later I went out and made it. Since it would be

pushing

when driving forward rather than pulling, I used a heavy, thick

"L"

bracket piece. After expanding its end hole, drilling a new one

for the

plate bolt and

cutting a bit off the bottom side at the end, it fit great. Trying

to

shove the motor

around showed it was much more solidly fixed into place than

before.

But it still had a "clunk". It seems to be coming

from

movement in the rear shock mounting itself. Apparently the rubber

reaches an end stop and the metal parts hit. The attachment angles

of

the steel straps bears further investigation.

[August 4th] (As this

may

be the last write-up about the Sprint for some time, I'll put this

in with July.)

[August 4th] (As this

may

be the last write-up about the Sprint for some time, I'll put this

in with July.)

I looked at the original transmission bracket and saw

it

had held the rear cushion mounting at about 45░. Mine was pulling

it over to more like 70░, nearer vertical.

I put a block under the motor to hold it up, and

disassembled the rear mount pieces. I drilled a new hole in the

lower

piece that made it effectively a bit longer, and bent it to sit at

a

better angle on the mount.

On the upper piece I

drilled an end hole by the corner, higher up and more to the

outside to

improve

the angles and reduce twisting a bit. Then I tried to bend the end

across the face to get a more horizontal mounting angle, but the

metal

was too hard, too thick and too wide and it only bent a bit

striking it

with a 6 pound maul. Mostly it just jumped around or came loose in

a

vise. I almost gave up, then thought to cut the whole end narrower

with

the angle grinder, cutting in half the width to be bent. Then I

managed

to pound it around with the maul. A couple of other bends through

the

thickness helped line it up. If it wasn't sitting at the "ideal"

45░ slope, it

was at least closer to 50░ than 70░.

That seemed to eliminate the main "clunk". There was

still

a smaller, sharp "tink", always just once after changing from

forward

to reverse and pressing the pedal, that I'd probably missed

hearing

before. I figured this must be coming from

the drive shaft somewhere. I tried tightening set screws on the

shaft

coupler and found one (the one holding the speedometer magnet!)

wasn't

properly tight. And I tightened the wheel nut on the CV shaft a

bit

tighter. These things were to no avail. The sound was the same.

Perhaps

the remaining "tink" is in the actual CV joint, or in the

suspension?

(Hey, not my

fault?)

Other "Green" & Electric Equipment Projects

Off-Grid

infrastructure Components

T12V socket problem

I had managed to eliminate

putting anything covering the ends of the plugs and sockets of the

T-plug and mini-T-plugs, because they didn't mate well with even a

.8mm

end cover on each. But as I was using them, I started getting a

bit

nervous. With the mini plugs (12V) the blades in the sockets were

so

little recessed that, while they couldn't be plugged in backward,

inevitably people would inadvertently get them wrong occasionally,

and

the pins might actually make contact. Equipment was likely to get

fried.

Sure enough... I had made the Sprint car plug into

its 12V

battery so I could easily unplug it and the radio (and whatever?)

wouldn't gradually drain it if I

wasn't using it.

One day when I went to plug in the battery, as I was trying to

line up

the plug and socket, the plus pin from the battery socket touched

the

minus pin on the car plug (battery "-" and plug "-" both grounded

separately to car body)

and there was a spark. It wasn't backward, and I was still trying

to

line them up, not push them together, but they touched. (No

damage.)

(Technicly I should disconnect the separate ground wire from the

battery - it makes a "ground loop".)

I decided that after all there had better be some

thin

sheet of plastic covering the sockets, to recess the pins a bit.

So I

should redesign the socket shells and the wall plates. Even 1/2 a

millimeter should prevent accidental contact. Hopefully it

wouldn't

notably weaken the fit once plugged in. (But I didn't get around

to

doing any new socket shells yet.)

I don't think the T36 larger sockets suffer from this

problem, but I should probably try to deliberately connect them

wrong

in

various ways and find out.

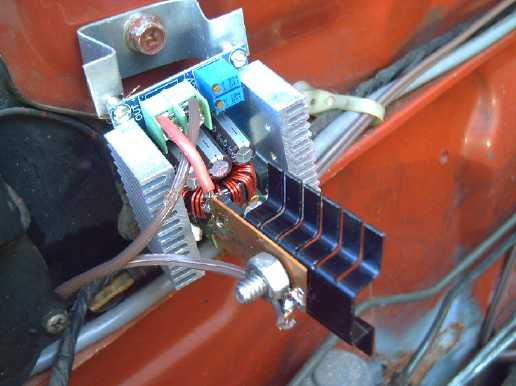

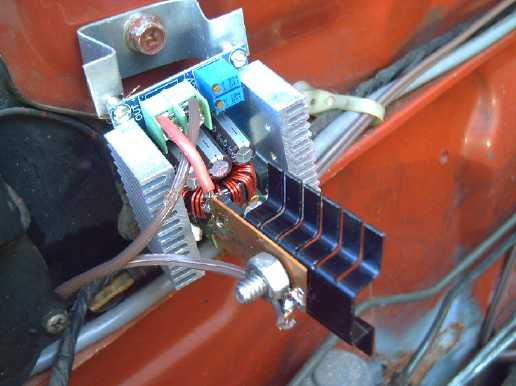

MPPT Solar Charge Controllers for Lead-Acid

I

finally found a low cost charge controller that could

take the 35-40 volts from a full size solar panel and charge a 12

volt

lead-acid

battery from it. All the ones I had managed to uncover before that

said

"12-24V" would only work with a 12 volt battery if the solar panel

was

under 20 volts - in other words, only with small panels. The

description of the the "UEIUA CPY-2420" was pretty vague. It

sounded

like it might do the job, but didn't specificly say so. It

might be just like all the rest.

I

finally found a low cost charge controller that could

take the 35-40 volts from a full size solar panel and charge a 12

volt

lead-acid

battery from it. All the ones I had managed to uncover before that

said

"12-24V" would only work with a 12 volt battery if the solar panel

was

under 20 volts - in other words, only with small panels. The

description of the the "UEIUA CPY-2420" was pretty vague. It

sounded

like it might do the job, but didn't specificly say so. It

might be just like all the rest.

Two of them arrived weeks ago. (Ordered April 14th.)

At

last I got around to testing one, connected to a 305W panel and

two 6

volt golf cart batteries for 12 volts. It translated 36 volts from

the

panel to 12 volt charging voltages fine. I had feared it might

either

want a 24 volt battery or else put out high voltage spikes (ie, 36

volts) into the 12 volt battery, but the oscilloscope showed that

it

didn't and its lights showed the battery as "full", or as "low",

when

it was. And my power monitor showed that it seemed to find the

maximum

power point of the panel in the late afternoon clouds, current and

voltage changing some as I picked up the panel and pointed it in

different directions, or if I stood over it and darkened it.

I didn't want to sell them without checking one out

first.

Now that summer is getting old, I can advertise 305W panels with

charge

controllers for 12 volt systems that don't cost an arm and a leg,

for