Turquoise Energy News #159

covering

August

2021 (Posted September 9th 2021)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month

In

"Brief"

(Project Summaries etc.)

- Ground Effect Vehicle - Peltier Cooler Experiments - Handheld

Bandsaw Mill Kit - Unipolar "Electric Hubcap" Motor New Thought: a

Higher-RPM-Safe Flat Magnet Rotor for Axial Flux? - Cabin Wall

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Institutions of Governance - Smol Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Preliminary testing of the Ground Effect Vehicle RC model

Other "Green"

& Electric Equipment Projects

* Peltier Cooler Experiments: Lower Voltages for Greater Efficiency Etc.

* Handheld Bandsaw Mill Kit progress

* Greenhouse, Gardening

* Attracting a Swarm of Honeybees?

Electricity Generation

* My Solar Power System: - Daily/Monthly

Solar Production log et cetera - Monthly Summaries and

Estimates

Electricity Storage

* Turquoise Battery Project

(NiMnOx-Zn in Mixed Alkali-Salt electrolyte)

- There may be No further reports on this subject: Hey, I tamed zinc,

and I even tamed manganese as a negative electrode! Anybody who does

batteries should be able to take it from there!

My plan was to focus on the handheld bandsaw mill kit this

month and it is coming along, but with other priorities I didn't get it

finished to where I could run it.

Aside from trying to get better at

growing food, working on the greenhouse and running

or improving the acreage, I seem to have somehow also touched on the

ground effect vehicle RC model -- and on solid state peltier module

refrigeration again.

The month's gardening is under Other Green Projects

in the detailed reports. (Some may be interested that I found an easier

way to shell peas -- at least, it's faster than the way I've done it

all my life.)

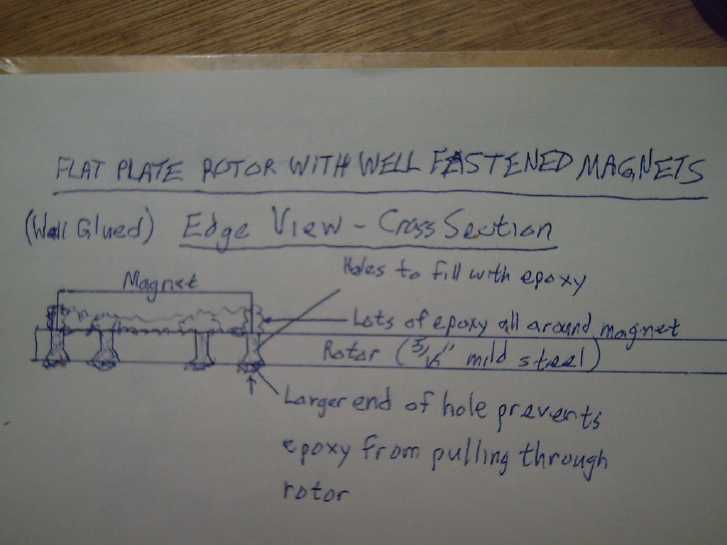

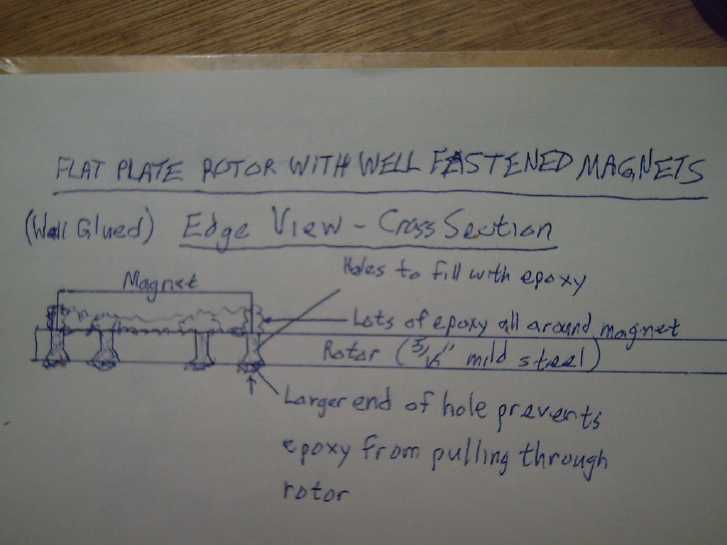

And I have a refinement to the idea of a flat plate magnet

rotor with holes for "plugs" of epoxy to help hold the magnets more

securely.

After putting the south door on, I also finally got just a

bit more done on my cabin walls after neglecting it all summer.

[September 8th] This newsletter seems to be taking forever

to finish up! It's eating into September's project times - 1/4 of the

month is gone!

Ground Effect Vehicle

I couldn't seem to get at the programming for the

left-right motor steering controls, and I decided to at least run the

model without steering and see what happened. I made a "splitter" plug

and cord that let me plug both motors into the one "throttle" output

from the receiver. After a few glitches I got both motors to run

simultaneously when I pulled back the throttle stick. Although I hadn't

put on the bottom skin of the wing or the vertical steering fin, I took

it outside. (I haven't glued the fin on yet because it sticks out

adding a third dimension that will make the model hard to carry around

the house and to store. Maybe I should make it bolt on? ...at this

point, how?)

Sorry, no new pictures. It still

looks much the

same as in (ouch!) December 2019.

Sorry, no new pictures. It still

looks much the

same as in (ouch!) December 2019.

I aimed the canard up with the radio control, to aim the

ducted fans to blow their air under the

wing. On the first try on my freshly cut lawn, it seemed to be off in a

few feet and then it spun around. One fan had sucked in a big clump of

the cut grass and was clogged. I pulled the grass out through the

blades one lump at a time with needlenose pliers.

I took it over to the edge of my property by my neighbor's

and flew it onto his lawn, which hadn't been cut so recently. I got

in a few short flights and got some impressions of the operation. They

were short because with no steering, it would soon veer off to the left

or right, and with no fin, if not stopped it would at some point spin

around even facing back the way it came.

The ducted fans were amazingly powerful, as they had

advertised. In fact I didn't like to be very close to them without

hearing protection on. So there was no question but that the craft

would move. That it went off so fast said it was flying - or at least

skimming along the grass - almost

immediately. So the first conclusion was that the ducted fans blowing

air under the wing made for fast, low speed take-offs as intended,

expected and hoped.

The back end was well up, but the front was still pretty

much within the grass, leaving a trail in it and probably skimming

the ground. And that was with the canard pointed all the way up.

Pointed level, the

nose was on the ground and from a stop it wouldn't start moving.

So the second conclusion was that it was badly balanced.

The center of gravity was way in front of the center of lift. And this

really only made sense: the wing profile was designed to make a ground

effect craft more longitudinally stable. The center of lift was

substantially farther back than for a typical airplane wing, and the

wing went right to the back. (The canard is "typical airplane wing"

profile.) The weight was all near the front. Lifting it disclosed that

the

center of gravity was only about 1/5 of the way back on the wing. It's

probably wasting much of the ground effect lift with such a shallow

angle of attack by the wing.

It would seem I should position the batteries (half the

entire 5 Kg weight of the model!) farther back to get better balance,

which would make for a better overall "pitch" while flying. Then the

flight position of the canard should be more level.

(Move the center of gravity farther back: I knew I would be very glad I

had made a radio controlled model before

ever attempting a man size version, however absurdly long it's taking!)

I moved the batteries a little way back - the wires

weren't long enough to do more without rewiring. The rear was a little

lower, but it skidded along the ground even with the canard pointed

full

up and fans blowing full down under the wing. Next (whenever that may

be) I'll lengthen the wires and move them farther back. ...and hope it

can actually fly if the weight distribution is good!

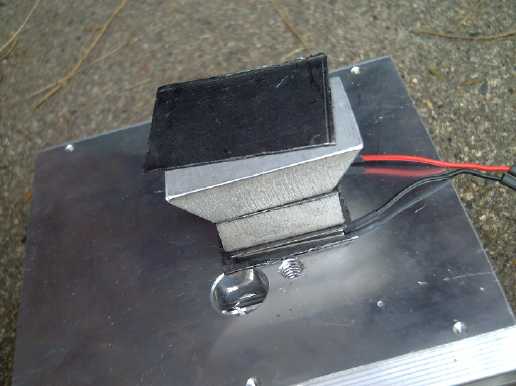

Peltier Cooler Experiments

Having got

some supposedly better peltier modules almost a

year ago, I finally got one out and tried to fix my solid state camping

cooler. (The peltier in it previously had quit. Perhaps I burned it out

with a 17 volt solar panel when camping in 2015? - it hadn't worked

except maybe near the beginning of that trip as I recall.) It didn't do

as well as the original module (TE News #54, which was larger physicly

[40x40mm versus 30x30mm] and higher current electricly ["6 amps" versus

"5 amps").

Having got

some supposedly better peltier modules almost a

year ago, I finally got one out and tried to fix my solid state camping

cooler. (The peltier in it previously had quit. Perhaps I burned it out

with a 17 volt solar panel when camping in 2015? - it hadn't worked

except maybe near the beginning of that trip as I recall.) It didn't do

as well as the original module (TE News #54, which was larger physicly

[40x40mm versus 30x30mm] and higher current electricly ["6 amps" versus

"5 amps").

But now having an adjustable DC to DC converter I got to

try

it out it at several voltages from 7 to 12, instead of being stuck at

12 (or whatever some power source gave me). Since the modules are more

efficient at lower voltages I found best cooling - at least as I had it

set up - was at about 8 or 9 volts at just 21 or 27 watts, and

increasing the voltage only used more power without making the interior

noticeably colder.

The warm side heatsink was getting up to

32-35°C in a 22° room in spite of the fan blowing air across

it, even with a plastic shroud directing the fan's air right across it.

The

cold side heatsink generally measured about 4° below the cooler's

overall temperature.

So it was cooling the cooler by just 12° to 10°,

but across a (32° - 6°) = 26° actual temperature drop

across the two heatsinks - and so even slightly more between the two

sides of the peltier module. Well, that big temperature differential

did much to explain poor performance.

How could the heat generated by the warm side, and the cold from the

cold side, be dissipated with lower temperature differences? That was

the key to better cooling with lower

input watts. (I think I was doing better than this with my "super

insulated" solid state chest fridge in 2012-2016. Its big ice tray

would at least partly freeze. But maybe it was by virtue of cooler room

temperature in my almost year round chilly kitchen in my old house in

Victoria BC! My house was most comfortable when other people around

town were

complaining about the heat!)

I chafe that

no one wants to make and sell heatsinks of pure aluminum, since it has

better heat transfer than any alloy. I think manufacturers don't like

it because it's so soft and so the fins are easily bent. Fine for

transistors, but it would be very beneficial for peltier modules where

it's hard to get the heat away and every degree counts.

I chafe that

no one wants to make and sell heatsinks of pure aluminum, since it has

better heat transfer than any alloy. I think manufacturers don't like

it because it's so soft and so the fins are easily bent. Fine for

transistors, but it would be very beneficial for peltier modules where

it's hard to get the heat away and every degree counts.

Pure copper and silver transfer heat better than aluminum

(and still better than aluminum alloy), and I used a copper bar to good

effect transferring the cold into the fridge. Now I've come up with the

idea of a copper or silver plate with tapered edges to spread the heat

from the surface of the peltier module to a larger area before it

contacts the aluminum heatsink.

I also remembered to use thin graphite gasket instead of

"heatsink grease". The gasket has enough flex or "sponge" to contact

the whole of the two surfaces together, and transfers heat much better

than the paste.

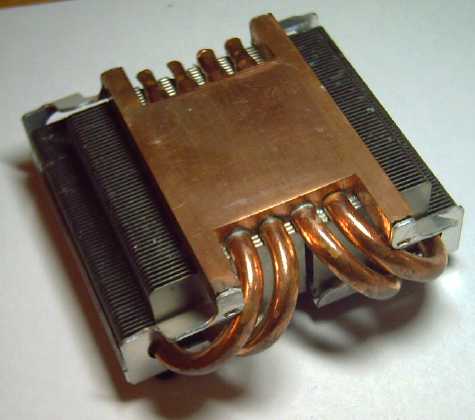

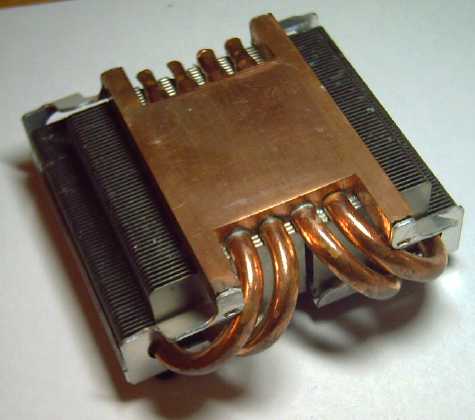

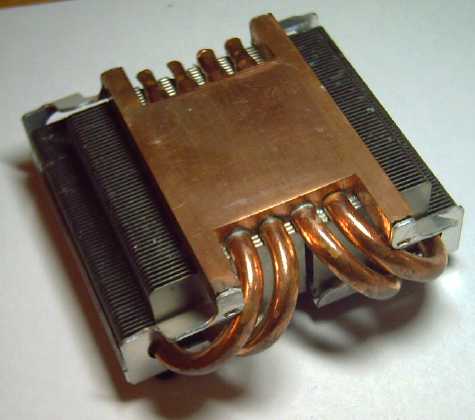

Sitting inside the cooler when I got it out was

a seemingly well designed

CPU heatsink someone had given my some years ago. It seemed to have a

copper block as the bottom of the heatsink.

I thought I would try it and see how

much the warm side temperature could be reduced toward room

temperature. But it didn't really seem to work as well as either the

biggest heatsink (which I also tried) or the one that came with the

cooler.

In the end I put it back as close to factory condition as

I could manage (having lost the original aluminum heat transfer block

somewhere). I don't think it works quite as well, cooling by just 11 or

12° below room temperature. According to Canadian Tire who still

sell it, 16 or 18° should be possible, but I don't think mine ever

cooled that much - maybe by 14°. And this peltier module is

physicly smaller and has a lower current rating (~4.5 amps at 12 volts)

than the original (6 amps). It does get the cooler just as

cold running at 8 or 9 volts as it does at 12 volts, using far less

power - as little as 20 watts instead of over 50. Peltier module

performance graphs indicated this might be the case, and seeing how

that would actually work was the biggest original point to the

experiments.

Having spent far too much time on such a trivial project

for which I had no immediate use (much more detail in "Other

projects"), I put the cooler away again.

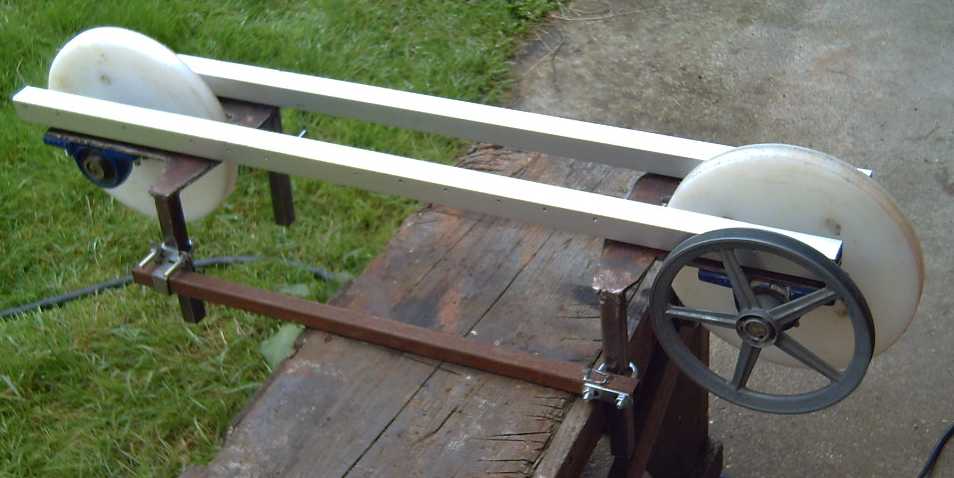

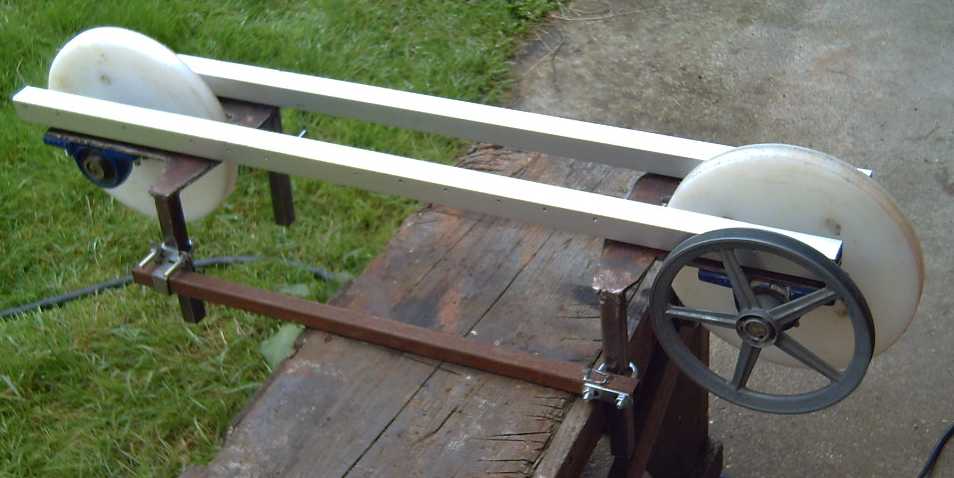

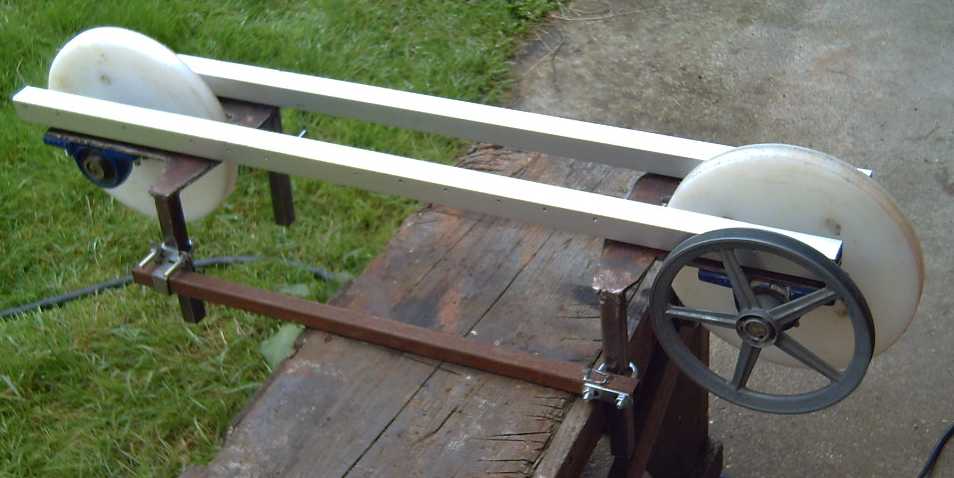

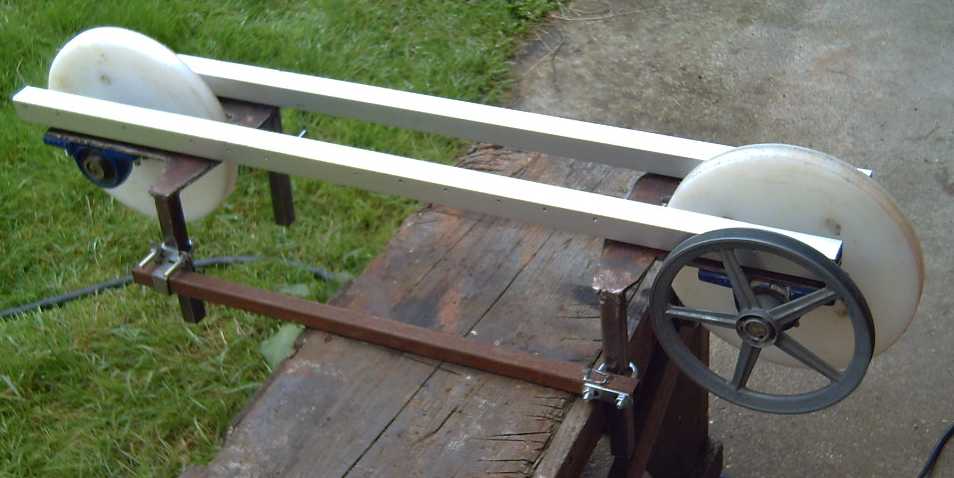

Handheld Bandsaw Mill Kit

I continued working on this. I made a few changes and

revisions, and it's looking promising. After several tries I finally

silver soldered a blade band together that didn't quickly break. Even

if it doesn't stand up to cutting, it has to be there to set things up

and the ones that broke didn't help.

But in the last week of the month (not to mention the first one in

September) there were other priorities and I had to set it aside. It

won't take a lot more before it's running again, and then I can start

on the CNC cutting CAD/CAM files. And milling some 2" by 4"s from 6" by

6"s that I need for the cabin wall. More depth in the detailed report

in "Other Projects".

Early in the month, the cutting

depth bars

Early in the month, the cutting

depth bars

(If there was a band, it would be cutting the bench.)

Later, the band guide wheels

Later, the band guide wheels

Right wheel: tensioning and

tracking adjustment

screw

Right wheel: tensioning and

tracking adjustment

screw

(one on each side of the wheel)

Various lengths of cutting bands can be accommodated

by sliding these assemblies along the rail.

Band guide wheels. The right

wheel can be moved

anywhere

Band guide wheels. The right

wheel can be moved

anywhere

along the track to optimally cut different widths of lumber.

(I'm still using the old design guide wheels and assemblies

for present convenience - one more thing to update later!)

Unipolar "Electric Hubcap" Motor New

Thought: a Higher-RPM-Safe Flat

Magnet Rotor for Axial Flux?

The idea of making the new model of Electric Hubcap motor

as an outrunner (rotor outside from the stator with the magnets facing

in) instead of axial flux (magnets on rotor side by side with stator)

has only one special appeal: being on the inside of a steel rim, it

would be harder for centrifugal forces to break the magnets off the

rotor. That's the weak point of flat plate rotors and axial flux.

Other than that, the outrunner drum rotor is heavier and

making all the

magnetic surfaces with the ideal curves would be a parts nightmare (at

least for

prototyping and limited production), plus the molds for the PP-epoxy

body parts get more complicated. I figured I could get away with flat

components anyway, but there would be some things I

haven't tried before and adjusting the flux gap (and finding the

optimum gap) would be difficult to impossible.

So... if I could come up with a more secure and less labor

intensive means of mounting the magnets on a flat plate rotor to make

them safe at higher RPMs, in every other way I'd surely be farther

ahead. I would build it just the same way as my previous motors.

But I have had my fill of magnets breaking off rotors and

stators. So far: a lawnmower motor (stator), where it appears the glue

failed, early electric hubcap motors that I put rust primer on the

rotor before the magnets: the rust paint broke away from the rotor

steel, an

electric hubcap motor that I over-revved, and my lawn tractor (stator)

where the glue failed on one magnet and two other cheap sintered

(ceramic?) magnets actually fractured internally just inside the glue -

the glue itself didn't fail. The magnet on the over-revved motor

actually went through the thin outer shell (teaching me to make them

thick for safety!) and a 3/4 inch particle board tabletop.

So... How can safety be assured? Putting a PP-epoxy strap

all the way around each magnet is extra work and adds to the physical

height of the magnet and the thickness of the rotor plate. And if the

glue comes loose, it will vibrate and need repair anyway even if it

doesn't fly apart. Something

that occurred to me a while back would be to make holes in the rotor

plate behind the magnets, and fill them with epoxy "plugs". Thus the

epoxy

behind the magnet doesn't end at the plate surface. Still the magnet

itself could delaminate - it's corrosion protective skin could break

away from the inner magnet.

Now it occurs to me to put such "plug" holes in the plate around

the edges of the magnet, and to paint epoxy around the magnet's edges

as well as onto the rear to fill the holes. This extra support around

the edges would to

an extent mean the magnet was effectively attached on 3 or even 5 sides

out of 6 instead of just on the back. The more epoxy there was around

the edges, extending back through the plate holes for a good grip, and

of course the more holes there were (within reason), the more secure it

would be. (One might even stuff some PP cloth into the holes? Thicker

epoxy would be better held in place while it set. Or two+ coats of

epoxy could accomplish the same thing?)

Now it occurs to me to put such "plug" holes in the plate around

the edges of the magnet, and to paint epoxy around the magnet's edges

as well as onto the rear to fill the holes. This extra support around

the edges would to

an extent mean the magnet was effectively attached on 3 or even 5 sides

out of 6 instead of just on the back. The more epoxy there was around

the edges, extending back through the plate holes for a good grip, and

of course the more holes there were (within reason), the more secure it

would be. (One might even stuff some PP cloth into the holes? Thicker

epoxy would be better held in place while it set. Or two+ coats of

epoxy could accomplish the same thing?)

Might I hope 3500 RPM would prove safe? That would (eg)

put the Sprint on the road, and adding the zero losses variable torque

converter would optimally couple the motor to the load for the best

performance from the smallest motor.

I'm hoping these new motors

wouldn't overheat running at 150

amps (5400 watts, over 7 HP). That is perhaps a bit of a tall order.

(and still not a

"muscle car" by any means!) I would note that

with all the plastic parts, the motors are not only very light by

traditional motor standards, but they also have very low thermal mass.

And the plastic can't take really high temperatures.

With the Kelly controller delivering over 100 amps (so 3600 watts) with

heavy loads in Chevy Sprint trials around 2016, the electric hubcap

motor coils had heated up quite quickly. And with the Electric Caik

outboard having shown that at least that small version doesn't cool

very well, I may incorporate ducts to connect a blower fan for

additional

forced air cooling independent of the spinning of the motor itself.

That's still a minimal addition in lieu of the radiator and liquid

cooling found in most commercial cars, even electric ones.

By making the new motor so similar to my previous ones,

and using a trailer stub axle and hub as a solid, robust rotary center

for

everything, I should think that once the CNC router table is running to

make molds for the body shell parts, the new model could actually come

together very quickly.

Then, at what point might the whole thing (95% efficient

motor, controller, 100% efficient variable torque converter) become a

simple kit to

convert fuel burning cars? That's farther off in dreamland.

Cabin Wall

I finally got back to the cabin, after neglecting it since

early May - all summer! At some point I put the door on. Then I could

finally move on with the alium* siding. Near the end of the month I

finally got started framing the west half of the wall. Maybe I can

finish the south wall (exterior) before winter sets in? One excuse for

procrastination on the framing: I wasn't sure where I would put the

windows. I'll want probably one more small one somewhere toward the far

left. (Now... where... and how big? I should have been checking at the

refuse transfer station now and then for a suitable window! Windows are

a lot cheaper if you scrounge them before you frame the wall

and

can make the openings to size!) (I finished the siding up to the center

post on September 5th-6th.)

* The names 'aluminum' or 'aluminium' are just too long for

this most commonly used light metallic element!

Now I'm running short of 2" by 4"s. I have no logs ready

to mill, but there are some 6" by 6" beams. I can cut each into one

2" by 6" and three 2" x 4"s. (Otherwise I'd be cutting 2" by 6"s (still

have quite a lot) into 2" by 4"s and 2" by 2"s. I don't have any use

for 2" by 2"s at present.) To cut the beams means I have to get the

handheld

bandsaw mill running again, as nothing else will nicely reduce them.

Finishing the cabin is just another project whose

completion looks farther and farther off. But it would be really nice

just to frame it in and have an interior space. First the travel

trailer inside will have to go. I've made precious little use of it

over 4+ years.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Institutions

of

Governance

I recently gave some thought after watching a youtube

video concerning Canada and the present election, and I tried to go

deeper than the various usual comments of "in the moment" hatred for

whoever is

presently in power. Few people ever seem to consider why it is we

repeatedly get governments that don't live up to our expectations or

their own stated objectives (promises) and

we soon come to hate. For that to happen, is there not something

fundamentally wrong with the systems under which the land is governed?

I will further elaborate here.

I noted that "minority governments" - those where the most

popular party has less than half the votes - always only last 2 years -

just long

enough to give a bunch of the members pensions after their 6 years. The

leaders aren't happy with having to compromise with other points of

view than their own, and want to end such a situation ASAP.

This is contrary to the original point of electing a

legislative body that is supposed to be a cross section representing

the society that elected it. Instead it is a rubber stamping authority

of uniform members all elected exactly the same way. For a time the

biggest universities in England each had their own member of

parliament. This could be expanded upon: members elected from

districts, and

apart from districts: from academia, from industry, from trades, from

professions, social and religious groups, and so on. That way we would

elect knowledgeable people qualified to speak about and propose

legislation on different subjects, instead of the government listening

to unelected lobbyists. Hopefully these members would also be in better

touch with their own specific electorate and their needs and wishes.

And a body composed of various interests and specialties, all chosen

from specific fields by groups of specially qualified voters, would be

harder to manipulate and corrupt from "behind the scenes" than a

uniform body where no member needs to have any special knowledge or

qualifications except to be a good politician.

Some other things we most need:

1. Elect our national/provincial leader separately from our member of

parliament instead of casting one schizophrenic vote to select two

different

people to two different offices. Any high school textbook says there

are three branches of

government. Why do we try to cram two of them into one? It hampers both

legislative and executive work.

Having a leader outside of parliament as in some other

countries prevents paralysis of executive governing action while

parliament deliberates over passage of laws instead of the legislature

merely rubber stamping

things already decided behind closed executive office doors.

2. Rank our choices on the ballot instead of the Illiterate's 'X'

ballot, which far too often elects a less desired candidate by "vote

splitting" -- and also by scaring off talented potential candidates.

This would make third parties and independent thinkers much more

electable, and perhaps avoid power block 'majorities' altogether. Why

should we have to vote "strategicly" for someone other than who we

really like in order to keep the one we like the least from winning by

a "vote split"?

3. Local volunteer "Public Committees" or topical "Design Teams"

focused on one topic, to study

it and make recommendations to government for legislative enactment.

The more of these there are,

connected by the internet, making unified recommendations

on a multitude of subjects, essentially coming from the whole of the

concerned public, the more

governments will listen to the involved public instead of to big

corporations and pressure groups. The talent of thousands of people

would be set to work to solve society's problems, instead of it all

falling on a few elected representatives who can't possibly have

expertise in all those subjects.

4. Public Boards of Appeal with Recommendations on Bylaw Interpretation

and Application, composed of volunteer citizens in good standing. (For

each level of government) This

would give people who feel regulations (or those enforcing them) are

being applied to things they weren't meant for, a place to appeal

without having to launch a court case, which is costly and seldom worth

any one

individual's time and effort, even tho many people many be

similarly aggrieved, and even then is not necessarily going to provide

a fair outcome, with judges who may be bound to say "Well, that's what

the law says, so..." in spite of misapplication or other unfairness.

The Board of Appeal would be free to recommend any

resolution whether

or not it is in strict accordance with a bylaw, and may also recommend

to government the modification or repeal of bylaws causing trouble.

Today, it is rare for a bylaw ever to be repealed. (In one US state

(Arizona?) a few years ago someone, on release from a prison, demanded

a horse and a gun. His right to be given these upon release were still

in some old law of the state from bygone days of a century ago, never

repealed.)

The appeal board takes the place of writing one's member

of

parliament with a complaint. An MP's hands are usually tied too, so

that

seldom leads to a satisfactory resolution.

When people don't take a hand in their own governance, we

get the sorts of things that are happening today. But as things are

managed

today we can't participate: people are virtually unrepresented by their

"representative" governments and unable to have input into the

governing processes. Numbers 3 and 4 are new ideas for how we may do

so. Then

we will start to get politicians who are in it to coordinate the

various needs of society instead of for their own power and money as

most of them now are.

Smol

Thots

* It was somewhere around 1985-1988 when "mass-production" of children

seemed to come to a rather abrupt end in Victoria BC where I was

living, and probably throughout much of the western world, and small

families became the norm. (We were then over 5 billion people and using

resources faster than nature can replenish them, so it was

already too late to alleviate the present severe overpopulation

crisis.) I was working for the school district as an electronic

technician and control systems computer designer and programmer.

The facilities manager, Keith Hawkins P.Eng, who had an

active and reasoning mind, was having portable classrooms placed in

school yards. Some people were upset and asked why there weren't new

schools being made instead, or proper additions to existing schools.

Surely the need would only grow in the coming years? Why this makeshift

solution? He replied "That would be a waste. Have you seen

the population statistics for ages newborn to five years old? In five

years you'll be hauling away the portables and then you'll be closing

schools." And that is what happened. Soon many of the portables were

removed and they are mostly long since gone. At least two (of 54)

schools closed in about the next ten years that I remember hearing

about in the news. I wasn't following it any more by then. Most of

those remaining are probably not operating anywhere near full capacity.

* Just when we thought things were starting to get back to normal...

New South Wales (or was it Victoria?) in Australia has locked down

the entire state, again, on account of what I understand was 84

cases of corona virus and one death. "Don't leave your home!" The army

has been employed to crack down on the widespread protests -- their own

friends, neighbors and relatives. New Zealand locked down the entire

country for just one case - no deaths! The mass media reported

wildly on the horrendous epidemic of cases in Uttar Pradesh in recent

months, but uttered not a peep about its very sudden end when the state

government distributed "home health kits" containing (among other

things) iver mectin to everyone. And now it has apparently said the BC

north is flooded with virus cases. Masks in public places have been

demanded again - province wide, and even if you've been vaccinated. But

with a profusion of summer tourists coming and going from all over, we

have had zero cases for months on Haida Gwaii in the BC north. Where is

this "epidemic"?

* Many governments everywhere want to impose "vaccine passports",

supposedly owing to a disease that has really not killed a large number

of people except among the most aged and infirm population, to which

there are now several known and well tested non-vaccine cures, and to

which billions already have immunity to owing to their genetic makeup

or to having already had the disease or a related corona virus disease.

What is the medical motivation for insisting on vaccination for all (in

spite of all the available vaccines being unapproved, highly

experimental products with serious known side effects including having

killed tens of thousands of people). What reason besides big pharma

profits and the gaining of authoritarian political power and control?

Without the passport, one will not be able to travel or do business.

People who have no medical reason to risk the vaccine are anyway,

trying to regain their liberties and freedoms of movement. It won't

work. At every point, perhaps even the grocery store: "Papers please!"

are soon to be demanded. Is this worse than Nazi Germany? How far is it

from the Biblical "Mark of the Beast?"

* How far awry have things become when a government identifies its own

concerned citizens as "domestic terrorists"? Are we going to see a

firestorm of elimination of "domestic terrorists" similar to the

disappearance of perhaps 30,000 people in Pinochet's Chile?

* With the globally terrible harvests of the last 3 years owing to all

the weather cataclysms, the supply chain becoming ever more chaotic and

everything being repeatedly shut down owing to the draconian reactions

to the virus, how long will it be until grocery store shelves empty

out? This happens suddenly in a matter of hours whenever people realize

they need to stock up for any reason. How trivial will the present

virus seem when real want and starvation are all around us?

* We don't do thresh on dirt floors any more. We have nicely finished

floors in various materials. Thresh is for chicken coops! So why do we

still have thresholds? If the floor under the door is flush, you can

just sweep dirt out the door with a broom. With a threshold there

is nowhere it can go, and one must use a dustpan and several sweeps

into it,

moving it back each time and never quite getting it all to

lift the

dirt off the floor. (or a vacuum cleaner - I suspect brooms would be

more popular if the dirt can be swept out the door instead.) "What are

you

supposed to do with the last line?"

asked a lady as she finished sweeping. "Snort it?"

* Quinoa has long been a staple of peoples of south America. Now the

rest of the world has "discovered" it and will pay top dollar for it.

And harvests of many crops - notably corn, soy, wheat, rice - have been

globally poor since 2019 (with 2021 looking to be much the worst yet).

So now the quinoa gets exported and the people living where it grows

can't afford it.

* The Great Awk was a flightless bird of the Arctic, very similar to,

tho not closely related to, the Penguin. People treasured their soft,

thick, downy pelts and they became all the rage. This "Arctic Penguin"

was hunted to extinction for money, not even the last breeding pair

being spared. Attempts to introduce penguins into the Arctic have been

unsuccessful to date.

* I saw an audiologist a couple of years ago. I mentioned my tinnitus,

ringing in the ears, that I've had from an early age. He said I had

probably been exposed to some very loud noise, perhaps a gunshot from

close range. I said I couldn't think of anything like that. I thought

it was probably from the loud flyback transformer whistle (15,734 Hz)

in the old

tube TV set we kids watched when I was little.

But I went again this past summer, and somewhere in there

I remembered that my dad used to take me duck hunting when I was 4 or 5

years old. All I remember from these trips was it was fall in Alberta

and usually being shivering cold as we sat around keeping still,

waiting for birds. But of course whatever I can't consciously bring to

mind about these trips of so long ago, 1959 and or 1960, obviously I

was near my

dad when he was shooting. "It doesn't matter who fired the gun." said

the audiologist. Now I'm convinced he's right. (I wonder if my dad had

or got tinnitus? Back in those days it wouldn't have been "macho" to

use hearing protection. "Earplugs? What a Wuss!" Hmm... I don't

think "wuss" was a word back then either. What was the equivalent?)

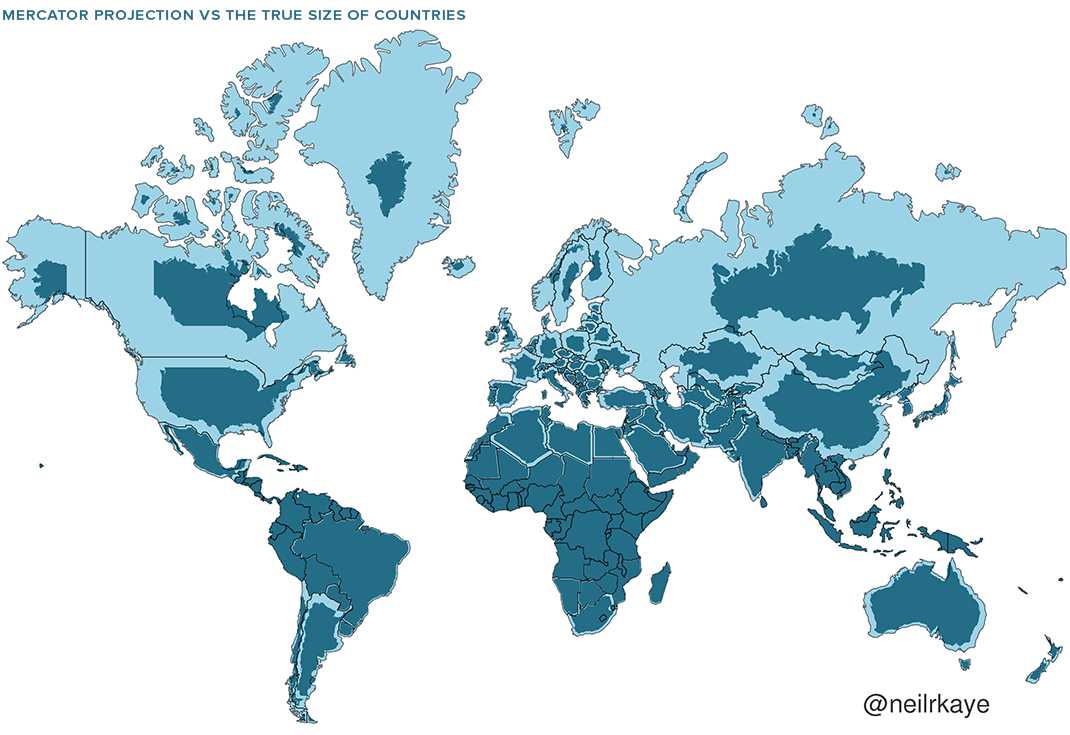

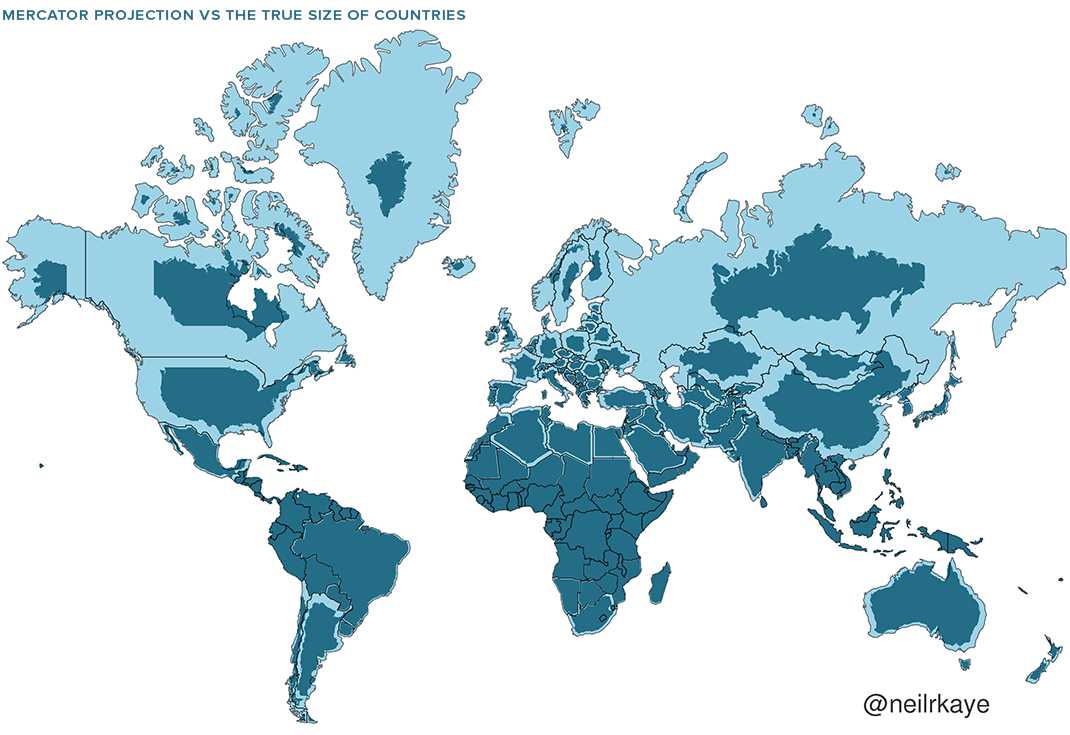

* The distortions of the Mercator Projection world map are well

understood

in principle. But do we really realize just how distorted the sizes of

lands farther from the equator are? Despite knowing "Greenland isn't as

big as it looks", this map will probably surprise many people as it did

me. (Look at Canada's and Russia's arctic islands! And where did

Svalbard go? Antarctica (not shown) is a little bigger than Canada,

smaller than Russia. I note that Canada, USA, China, Brazil and

Australia are all very similar in size.)

"TheTrueSize.com" has an interactive map where one can

drag countries around and see them change apparent size with latitude.

ESD

(Eccentric Silliness Department)

* The world is deeply affected by rising sea levels.

* Corn can hear because it has ears.

* Potatoes can see because they have eyes.

* Venus fly traps can feel because they need to close to trap flies.

* Do Venus fly traps taste? I'm not sure about that one.

* Skunk cabbages smell because... well, they just do!

* Pheromones are scent chemicals given off by living things, especially

bees and wasps, for various communication purposes. The little iron

garden statues are ferrognomes.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Ground Effect Craft

(R/C Model)

Why is nothing happening?

[20th] I looked at the computer I was programming the motor controls

with. It had been weeks since I had felt I had time to do any of the

programming. And maybe a year? since I had done any construction on the

model. I decided to try it and see what would happen if I tried to fly

it on the lawn: even without any steering, even with no bottom on the

wing or vertical fin, and without putting the covers on the hulls.

(They block access to the circuit breakers.)

Build

I made a

"splitter" connector so I could connect both

ducted fan motors to the one motor output on the receiver. I cut the

wire from the right (far side) motor and made it a plug and socket

there, so I could plug it into either the receiver or the computer

board connections. After a few fits and starts, I had both motors

running simultaneously when I moved the "throttle" stick on the

transmitter.

I made a

"splitter" connector so I could connect both

ducted fan motors to the one motor output on the receiver. I cut the

wire from the right (far side) motor and made it a plug and socket

there, so I could plug it into either the receiver or the computer

board connections. After a few fits and starts, I had both motors

running simultaneously when I moved the "throttle" stick on the

transmitter.

Tests

[Sorry I didn't take pictures. I took some video but didn't post it.]

I took it out to where I had just mowed the lawn

yesterday, aimed the canard up because then the fans blow air under the

wing, and pulled the throttle lever from 'off' to 'max'. In a few feet

the craft seemed to be up, then it spun around. One fan had sucked in a

load of the fresh grass clippings and was clogged. I removed it clump

by clump with needlenose pliers.

So I took it over to my property line and onto my

neighbor's lawn where there was more space and it hadn't been mowed

recently. There I did a few more runs, with video recording. I made a

very short movie. But was it flying or just sliding across the grass?

It was supposed to be up at least to grasstop height. On reflection I

decided to wait for better results before posting anything. Then it

could be used to show the progress.

A while later I put the bottom on the wing and the tops on

the hulls, but it didn't seem to make much difference to the flying.

Some Observations - Conclusions

All up (with the central fin) the weight was 5235 grams -

over 5 kilograms. The center of gravity was only about 1/5 of the way

along the main wing from the front, hardly behind the step in the hull.

Having the ducted fans on a front canard and able to aim

to blow air under the wing for a quick, easy takeoff seemed to work

admirably. But with the motors and the heavy batteries all near the

front, it seemed notably front heavy in flight. The light rear easily

lifted into the air, but the fronts of the hulls were barely off the

ground - still in the grass - even with the canard pointing well up. If

I leveled the canard the nose grounded. With this design and wing

profile there's substantially more lift toward the back of the wing and

toward the back end than in a typical aircraft, so the weight

distribution needs to be redistributed to account for that. Then it

should fly with the canard more centered, and at a better pitch overall

with the front higher off the ground. I'll have to lengthen the thick

wires and move the heavy batteries farther back.

Even with that, the longitudinal stability seemed good. It

seemed to "float" over the lawn as hoped, albeit with the canard

pointing well up and the fans blowing air under the wing, and the tail

higher up than expected as well. With the weight distribution improved

I expect it'll fly well. The front was so low to the ground, maybe

supported a bit by the grass, that lateral stability couldn't really be

judged.

Without having programmed a means to vary the two motors

separately yet, there was no directional control. The craft inevitably

veered left or right (almost equally, at random), and with no fin in

the middle and the light back end, when it veered it flew diagonally

and then (if I didn't stop it there) spun around. The flights pretty

much all ended that way. (I think I should have made the fin to screw

in. I'm reluctant to glue it on because it'll add a third dimension and

make it quite bulky to store when I'm not using it.)

For a manned version I was hoping the people could sit at

the hull step, which could make a natural "chair". It looks like either

they should be farther back or some other weight (batteries? cargo?)

should be behind them toward the tail end. OYOH, perhaps if that's the

weight and lift distribution the step(s) should be farther back too?

The canard is already almost at the front.

[21st] I cut out the rear foam battery holders. There was enough wire

length that I could move them back a little way. Not as far as I

wanted. But I tried it out, also across a patch with no grass. This

time the tail end didn't rise up into the air. But I still had to keep

the canard pointed full up, and it didn't really fly, but rather slid

along the ground. Was it too heavy for those ducted fans to lift,

powerful as they were? And how could that be improved when the

batteries to power them were half the entire weight of the model? I

hadn't expected the lightweight foam model to be so heavy when I was

making it.

I surmise that it needed to get up more speed to really

fly, but that ground contact was making drag that was preventing the

needed acceleration. But before trying anything else, I should rewire

the batteries and move them still further back so the nose could lift,

and in lifting would make for a steeper angle of attack for takeoff.

Also the tufts of grass sucked into the propellers

couldn't be helping their performance and should be cleaned out! (They

lodge in the stationary blades behind the spinning ones.)

Other "Green" & Electric Equipment Projects

Peltier Cooler

Experiments: Lower Voltages for Greater Efficiency Etc.

Warning: Long boring subject with

a lot of minutae and repetitive findings. If you aren't extremely

interested in the subject, you might just want to look at the orange

table, then skip down to the last paragraphs above "Latest Conclusions"

at the bottom.

[8th] I was planning on checking

out the freezer in my refrigerator. The freezer defrost kept filling

the bottom with ice until water started running onto the floor, at

which point I would pry out the ice layer and it would start over

again. In thinking about emptying the freezer I thought of coolers and

the peltier cooler. (and the peltier chest fridge - but I didn't want

to empty the fridge of whatever junk was in it and bring it into the

house from storage.) The cooler's peltier module hadn't been working

since my camping trip in 2015. Perhaps I had fried the 12 volt module

with 17 volts or so from the solar panel?

(In the end I didn't put any food into the cooler. Instead it

was starting to melt by the time the drain hole in the freezer had been

unearthed, the ice obscuring it thawed, located and un-clogged, with

some liquid observable in frozen milk containers - ouch. I hope they

don't give me migraines! But I had the cooler running before doing the

fridge, and I carried on with some tests.)

I had bought 4 peltier modules a couple of years ago that

were supposed to be better. I got one of them out and installed it in

the cooler. I hooked up a "20 amp" DC to DC converter from my 36V solar

supply, and following that, in line, one of my power monitors (volts,

amps, watts, watt-hours). These were things I didn't have in 2012(?)

when I was originally experimenting. I could adjust the voltage instead

of taking whatever the supply gave, and I could see the currents at

different voltages and as they changed with temperature and time. Also

I have faster reacting digital temperature meters [supposedly] precise

to 0.1°C.

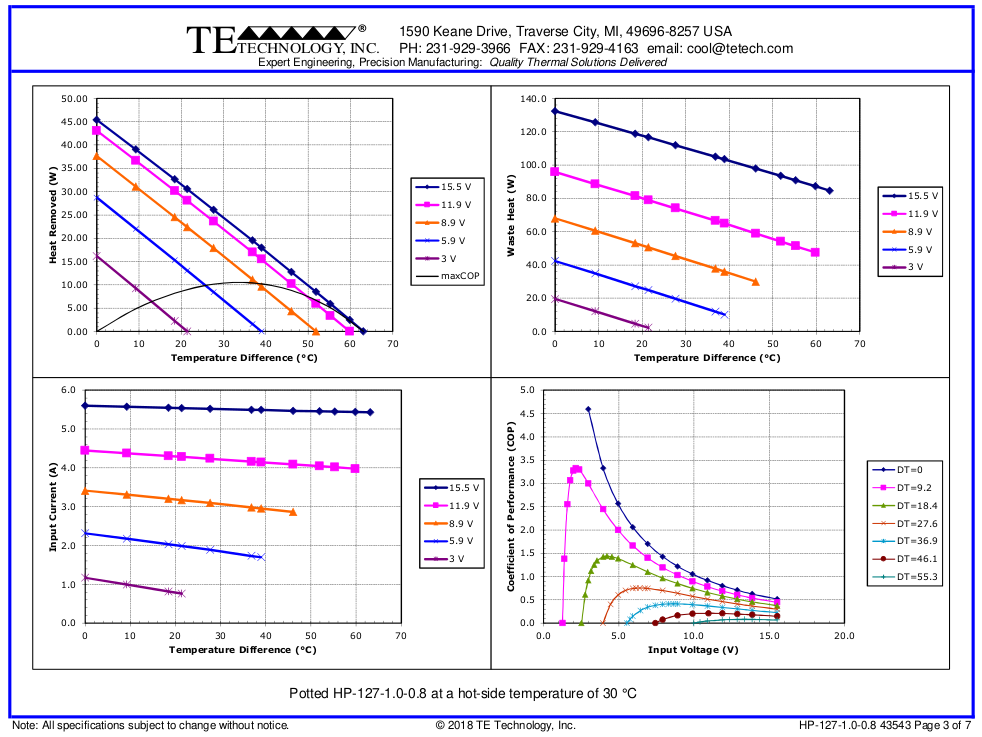

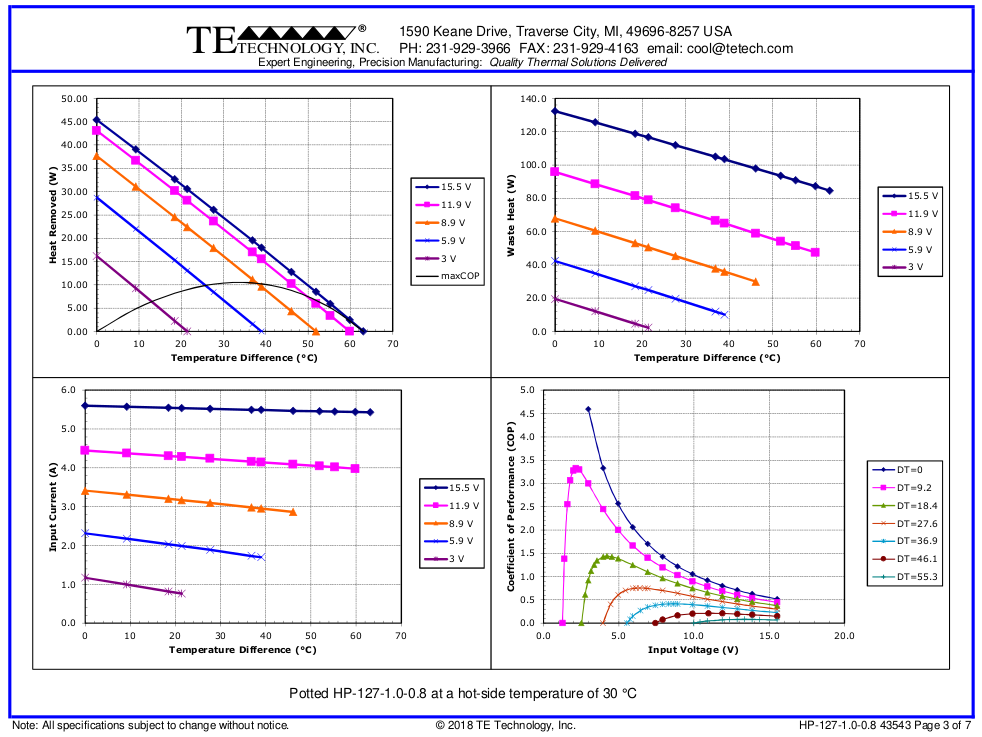

Especially the upper left graph shows the diminishing rate of

performance increase using voltages above around 9 volts,

yet peltier modules are most commonly run at 12-14 volts - double the

power or more of 9 volts - from automotive batteries,

usually via their cigarette lighter plugs. Today a 5$ DC to DC

converter can provide 9 volts efficiently from a higher voltage source.

The [empty] cooler started

off drawing about 4.7 amps at

12.0 volts, which soon dropped to about 4.0 amps/47 watts and

stabilized there as the module's temperatures rapidly changed with the

activation. It seemed to cool awfully slowly. In an hour it was only

down by 2°C from 22.0 to 20.0, although it seemed to speed up just

a bit after that. I turned the juice down to 11.0 volts. There it drew

just about 3.65 amps/40 watts. By four hours it was only down to

15.5°C. I raised the voltage back to 12, but the temperature

started going up marginally. Then I checked the room. The

afternoon sun (Yay, Sunshine!) had been beating through the windows and

the room was up to 23.7. Compared to that, 15.5° was 8.2°

cooler.

When I first bought the cooler I don't remember the time

it took, but I recall that with its original "6 amp" peltier module it

went down to about 4°, probably in about a 16° or 18° room

in winter. 4 is 12° cooler than (at least) 16°. (No doubt the

exact figures are in some old issue of TE News.) Now I'm using 40 watts

and only getting 8° cooler? I know I changed an aluminum cooling

block that the coolness passed through. In all my experiments I suspect

I've made some things in the cooler's cooling system worse rather than

better. It was probably about as well designed and made as it could be

for what it is. (I found the original block after I had reinstalled the

one I made.)

It didn't seem to matter whether it was at 11 volts or 12.

The temperature wouldn't drop below 15.5°. So I thought I'd go to

10.0 volts and see what happened. The lower the current, the lower the

losses and the higher the COP. That doesn't mean it has the same

cooling power, but between 11V and 12V evidently the extra 7 watts was

just a waste. At 10V current was down to 3.35 amps and 33.5 watts. In

an hour or so I checked and it was flashing between 15.6° and

15.3°. (I'm not sure what happened to the digits in between,

because I saw it sitting on 15.5° earlier.) But by now it was 8 PM

PST (and the fridge freezer was fixed). I thought the room had probably

cooled off, but I checked and it still read 23.2° - only 1/2 a

degree down.

The cooler had been running on solar all this time, now it

was getting dim and it was more running on the batteries. So far 12, 11

and 10 volts had all seemed to have resulted in about the same cooler

temperature.

I decided to try 9 volts for a while before I shut it off

for the night. There it drew 3.0 amps, 27 watts. After a while it was

sitting right on 15.3°. Later it hit 15.4, and still later

15.2°.

So I decided to try 8 volts. It did 2.7 amps, 21.5 watts.

The temperatures seemed to jump around a bit: 15.3, 15.4, 15.5 after

some time it seemed to settle on 15.4. It didn't seem to be rising or

falling from there. At 21:30 PST I turned it off. In ten minutes it had

climbed to 16.1, and in half an hour, to 17.5°, so clearly it

wasn't staying down at 15.5° or below without effort. Room

temperature was still 23.0°, so its range since early afternoon had

only been between 23.0 and 23.7° and its differential effects on

the various readings would have been fractions of a degree. There is a

lot of difference between 47 watts and 21.5 watts to accomplish about

the same temperature of cooling!

Volts

|

Amps

|

Watts

|

Cooler Temperature

(Room temp. 23.0 to 23.7)

|

12.0

|

4.0

|

47

|

~15.5

|

11.0

|

3.65

|

40

|

~15.5

|

10.0

|

3.35

|

33.5

|

15.3 - 15.6

|

9.0

|

3.0

|

27

|

15.2 - 15.4

|

8.0

|

2.7

|

21.5

|

15.3 - 15.5

|

Since everything down to 8 volts seemed as good as, or

almost as good as, 12 volts, perhaps I should have tried 7. I suspect

the temperature would have started rising. And I would note that with a

temperature difference from the room of only ~ 8°, lower voltages

would be more efficacious than with higher differences. If 12, 15 or

more degrees can be obtained, 8 volts and below are likely

underpowered. [8.5 to 9V proved to be pretty optimum in later tests

when 11 or 12° drop in the cooler were obtained.]

Conclusions

1. Apparently these peltiers seemed less efficient - they weren't able

to drop the temperature as much as the old one with seemingly similar

input power at 12 volts. Was it because they were smaller? Or was it my

homemade aluminum heat transfer block? (not precision machined flat

surfaces, two joined layers instead of one piece.) [actually I had

missed the warm air guide duct on reassembly!]

2. These tests did seem to demonstrate what I had been unable to show

in

2012: that the performance curves for peltier modules looked so much

better at somewhat lower voltages that they might do just as much

cooling with substantially less power. One might well use two at some

lower

voltage to get higher COP: more watts of cooling power with similar

input watts. The modules being so little

efficient, for portable power use any way to squeeze a bit higher COP

out of them is probably worth the extra initial cost.

I'm still waiting for peltier modules to be developed that

can compete with compressor based refrigerators, even at some cost in

COP and energy use, because they are so much quieter. I haven't

followed

any recent progress but having heard nothing earthshattering (in that

subject area), AFAIK they aren't there yet.

Caveats/Next tests?

There was at least one wild card: as the voltage dropped, the

fans slowed down. That meant the air cooling of the hot side was

decreasing and the cold from the cold side wasn't being blown into the

cooler as well as at 12 volts. And different arrangements of peltier

modules could also be tried.

1. A test I could potentially try was lowering the peltier module

voltages but keeping the fans at 12 volts. Or maybe just the hot side

fan at 12 volts? Any such options would take some rewiring.

2. Still another experiment would be to connect two peltiers in

parallel (electricly and physicly) and try different voltages to see

what cooling could be achieved with how many watts input.

3. The new modules were physicly smaller that the original one. 30x30mm

versus 40x40mm. I could try another one of the original size.

OTOH, this project is a sidetrack! I must get back to the handheld

bandsaw mill kit!

[9th] I went out to the shop and found (a) the manual for the cooler,

which said I bought it June 2012, and (b) an inner air guide that

routed the blown air over the heatsink fins. I had missed it in the

reassembly. That doubtless explains most of the difference in

performance between 2012 and yesterday! I decided to open it up again

and put it back in. Sigh! When I did so I put in a T12V plug and socket

on the peltier module and I left off a grille so I could reach them.

And I remembered that thin pieces of graphite gasket

seem to transfer heat from the module to the heatsinks better than

using "heatsink compound". The gasket is slightly flexible, eliminating

air gaps while itself being a very good heat conductor, whereas the

"heatsink compound" fills air gaps, but is actually a rather poor heat

conductor.

But it took much longer than expected as things just

didn't fit quite right. I guess the original aluminum thermal transfer

block got lost somewhere over the years and in the house move. (Rats!)

It worked somewhat better, dropping by about 10-11°

from the room temperature instead of 8. At any voltage from 7 to 10 it

seemed to work almost the same. The only real difference seemed to be

in the level of power: at 10 volts it used 33 watts and at 7 volts only

17 watts to achieve almost the same cooling.

Then I accessed that plug and powered the module from 7

volts but the fans from 12 volts to keep them running full speed. To my

surprise, the temperature in the cooler started rising instead of

falling. The most likely reason is that blown air is getting through

cracks between the hot side and the cold side. That's probably why it

wouldn't cool as much as when it was in new condition. Apparently I

should have taken extra care to seal it all. I put it back to "single

voltage".

[10th] After running for hours at 8 volts, it was about 11° cooler

than the room (13.8°), which was about 25°. (Wow 25°!)

[14th] I returned to the charge on this morning. I took it apart again

and filled in the cracks as best I could with bits of foam packing and

foam insulation, and put it together again. Then I connected it and set

it to 9 volts. I was disappointed that it didn't seem to cool much

better. Acoording to the graphs for the peltier module (HP127-1.0-.8)

if the warm side heatsink was at 30° and the cold side was at 15,

it should have been removing heat at about 27 watts. It was using 28.5

watts for a cooling COP just below 1. But as before the cooling got

slower and slower long before I thought it should have.

After some hours the room was 22.4° and the cooler was

11.3° - virtually the same performance as before. I am puzzled.

[15th] I tried 10 volts and it got about 12.0° cooler than the

room: 10.3° in the 22.3° room. I finally (perhaps "belatedly"?)

went back and found TE News #54, where I described the cooler when I

bought it in 2012. I noted at the time that it only cooled "by 13 or

14°". That it got down to 4° probably means the room it was in

was only about 17 or 18° - somewhat typical of my old coach house

by the harbour, even in summer. In this room 4 or 5° warmer, the

lowest the original cooler would have got would be about 8 or 9°.

That was with 12 volts and using probably around 50 watts, so getting

to 12° cooler with 10V and 33 watts, or over 11° cooler with 9

volts and 27 watts... or 10.5° cooler with 7 volts, 18 watts... is

probably almost as good as it ever was. And it's a smaller size, 5 amp

rated peltier module instead of a large 6 amps.

The only other thing I can think of to try with the cooler

would be two

of the new peltier modules in parallel, run at say 7, 8 or 9 volts.

Could that give lower temperatures with the same or less power than 50

watts? The other question is how fast any of this would cool food. For

camping, the best idea is of course to have the food cold before it

goes into the cooler.

The other idea would be to drag out the "super

insulated thermoelectric chest fridge", which I still have stored away,

and experiment with it. I have up to three of the new modules I could

put in

parallel. (The fourth one isn't coming out of the cooler!)

More Conclusions

This "high performance" peltier module is probably better

than the ones I was using before. Hopefully it will at least last

longer in use than some of them did. But it's not a big leap. Even if

these are much more durable, without a substantial leap in COP

performance, solid state refrigerators won't replace compresser based

ones except for specialty purposes like camping coolers. (Should I have

continued with my magnetic refrigeration experiments with gadolinium? I

thought I had a better and simpler idea than what other researchers had

come up with. But no! I still think that big leap in peltier module

performance is coming some day. It'll probably be done with intricate

nano scale structures inside the modules.)

Another Idea...

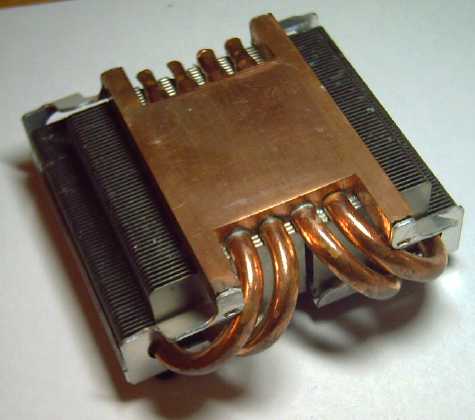

There is one other thing I could try. Some years back,

someone gave me a very sophisticated CPU cooling heatsink.

There is one other thing I could try. Some years back,

someone gave me a very sophisticated CPU cooling heatsink.

With the cooler in its regular configuration, even at 7

volts the warm side heatsink was 32° with the room at 22°, so

the peltier module was cooling from 32° to 11° -- not an

11° difference but 21°. And that's assuming the cold side of

the peltier is no colder than the cooler's air, which it will be. So in

fact the peltier itself probably has over a 25° difference between

its two sides, but it's only

getting the cooler down by 11°. Potentially then, if all heat could

be transferred perfectly, the inside of the cooler might be -3°

instead of 11. That's a lot of losses that are hard to reduce, much

less eliminate. (The colder cooler would also lose more coldness

through its insulation, so it would doubtless be somewhat warmer than

-3°... A little above freezing?)

Later: At 8.5V, the heatsink hit 34 to 35° with about

the same room temperature.

Copper conducts heat better than aluminum. (It's second

only to silver, which is only 10 to 12% better and quite costly.) The

gift heatsink has a copper plate against the top of the peltier module,

very closely spaced cooling fins that a small computer fan blows

through, and in miniature the evacuated tubes with water that steams

below room temperature that I tried so hard to make, but could never

get a sufficient vacuum in.

The heat from the peltier heats the copper with the bottom

ends of the evacuated pipes, boiling the water. There's evaporative

cooling, and the steam (which is just above room temperature) rises up

to the top end of the pipes among the heatsink fins and almost

instantly transmits the heat to them. The fan sucks air through the

fins, removing the heat to the air above. The water cools, condenses,

and drips back down in a continual heat transfer process. Assuming the

tiny and mostly horizontal water pipes work right and don't clog

(diagonal sloped is optimum), it is a masterpiece of thermal

engineering.

If the temperature of this clever heatsink is lower by say

5° than a regular aluminum heatsink can attain, that's 5°

cooler the cold side of the peltier can get to. If the cooler was at

5°C instead of 10, it would keep food a lot better. If it could do

it with under about 25 watts at 8 or 9 volts, it might even be

considered economic for a small unit.

Silver?

And having written of it... silver is 10-12% more

conductive than copper, both for electricity and for heat. For

something pretty "ultimate", one might take a pure silver coin, which

is maybe .08 inches thick, make it super flat on both sides, then pound

out the edges to spread them thus:

______________

__/_____Ag________\_ ...but with shallower slopes to expand

the area more where it contacts the heatsink.

| Cu

|

|___________________|

The peltier sits on top, and it's soldered to a larger

copper block underneath. So the heat (or cold) spreads out to a larger

area through the very best metal before it spreads further into the

second best. The finned aluminum heatsink goes under that. (That's the

cold side. The hot side goes the other way up with the heatsink on top.

PS: A copper heatsink should be better than aluminum, but I've never

seen one. And a pure aluminum heatsink would be better than aluminum

alloy, but nobody seems to make one.)

Or would the thin solder layer negate the benefit of the

silver? Probably not -- as long as the solder was thin and it had no

air bubbles. One could

have no copper on the top side. The silver would go straight to the

aluminum heatsink. The copper is just to make a decent thickness of

insulation between the two heatsinks.

But this is all effort for what is after all a pretty

trivial project. I might try out the CPU cooling heatsink. At least

it's cheap. Two 1 troy ounce silver coins is headed toward 100 $C these

days.

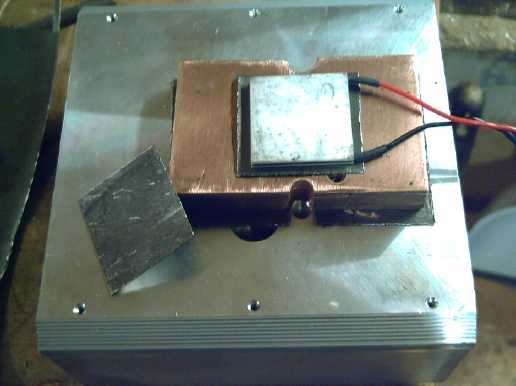

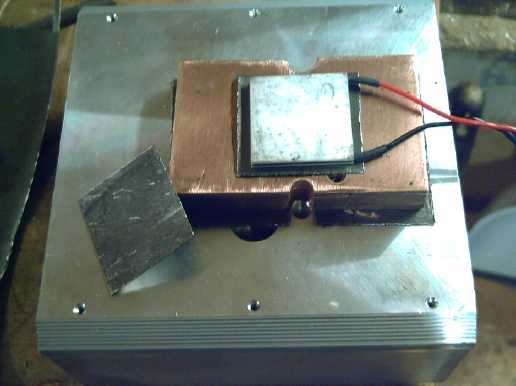

[25th] I tried out the CPU cooler. I left the top cover off and it

wasn't properly mounted, but even so it seemed disappointing. The

heatsink fins were so close together that the fan could suck very

little air through them, and it heated up pretty quickly to 30° and

more.

Then I got out one of the big heatsinks similar to the one I had

used with good results in the peltier module fridge in August 2012. It

only "sort of" fit in, but with the same fan one could feel far more

air movement. It seemed promising.

Then I got out one of the big heatsinks similar to the one I had

used with good results in the peltier module fridge in August 2012. It

only "sort of" fit in, but with the same fan one could feel far more

air movement. It seemed promising.

I decided to try everything I could think of (except

silver), and worked late into the night. On the top of course was the

fan and the big heatsink. Instead of putting the peltier module right

under the heatsink, I put in a bar of copper, about 48 by 75mm, 1/2"

thick. The peltier went under that. My thinking was that copper would

absorb heat best, and the heat from the peltier would spread more

quickly into and through the copper than the aluminum heatsink. Then

instead of the 30 x 30 mm peltier, heat would spread into the heatsink

from the larger 48 x 75 mm copper block, overall removing the heat

better from the peltier hot side.

Under the peltier was a 1/2" thick aluminum block of about

the same size as the copper one, then the cold side heatsink in the

cooler. Between each layer was a sheet of thin flexible graphite

gasket. This is better than heatsink grease for getting good contact

and conducting the heat between the two metal or ceramic surfaces. I

drilled and tapped holes and clamped it all together with 1/4" nylon

machine screws, about 2" long. I used nylon bolts so as not to conduct

heat between hot and cold sides, in large

1/4" size because nylon bolts are pretty flimsy.

I tried it out with the peltier at 9.0 volts and the fans

at 12 volts. I discovered that the top heatsink stayed a little cooler

if the fan was raised up off the top 5 mm or so by a couple of pieces

of clothespin. And it took the "edge" off the sound. It sat at about

27.3° - quite a lot cooler than 35! But the cooler didn't seem to

cool very fast. As it was very late I turned it off and went to bed.

[26th] In the morning I put everything at 9 volts and tried it again.

The top heatsink went up to 27.9° -- 2.9° warmer considering

the room was over 2° cooler. So the slower fan certainly wasn't

helping the hot side to stay cool. (It did make it a lot quieter!). It

seemed I had gone to a lot of work for what I thought should have been

a great improvement, instead for not much result.

Hmm... it now occurs to me that there is no real point to

the cold side block being a lot bigger than the module. Maybe that

applies to both sides, and it would be better to have more insulation

instead of a cold block and a hot block 4mm apart, radiating heat/cold

at each other? Well duh, of course it would!

One more time! I didn't want to chop up the piece of

copper, so I cut two 1/2" thick aluminum pieces, one about 32 by 32 mm,

the other that size and angled so it had a bigger surface on the cold

side heatsink, as per the idea with the silver piece. This time the

peltier went right against the hot side heatsink. I cut hole in the

main insulation to a rectangle, and cut out a block of insulation to

fit that. Then I cut that in half and cut out the middle to fit the

aluminum blocks and peltier module. I did it all more carefully than on

previous tries -- still not a great seal but no big gaps either.

One more time! I didn't want to chop up the piece of

copper, so I cut two 1/2" thick aluminum pieces, one about 32 by 32 mm,

the other that size and angled so it had a bigger surface on the cold

side heatsink, as per the idea with the silver piece. This time the

peltier went right against the hot side heatsink. I cut hole in the

main insulation to a rectangle, and cut out a block of insulation to

fit that. Then I cut that in half and cut out the middle to fit the

aluminum blocks and peltier module. I did it all more carefully than on

previous tries -- still not a great seal but no big gaps either.

It didn't seem to work even

as well as before. Alright!

I've wasted a lot of time on this stupid project to little effect! I

can't even get it to cool as well as when I bought it.

It did seem to show that using lower voltages on the

peltier module made a big difference to the power consumed to little

difference in coldness, but even that is suspect: if it's not going to

get very cold, lower voltages are going to be more effective than if it

actually gets down to refrigerator-like temperatures.

If I'm going to to any more I should either get out my

superinsulated peltier fridge and perhaps use 3 of these little modules

on it, or buy a new camping cooler with the insulation and everything

intact. And maybe it would already have the latest and greatest peltier

module already in it?

Anyway I might as well run it... After 3(?) hours at 9

volts, room 20°, hot side heatsink 27.5°, cooler 12.3°,

3.35 A, 30.1 W. I turned it up to 10V. After not very long, the hot

heatsink was 28.3 and the cooler was up to 12.6°. Good grief!

[31st] I decided to put it back as close to original as I could, and if

it still didn't work very well maybe to buy another one -- or someone

says one can just buy a cooling unit by itself. I looked on AliExpress.

There indeed were some. They looked like about what I had made except

that some were double or triple, 3 fans on each side and 3 peltiers on

one long heatsink. They went up to hextuple units together and hundreds

of watts.

Then I looked at Canadian Tire's website. The "Mobicool"

that I

already have had the best reviews of all their models. (The price has

gone up since 2012.) And some scathing ones. They went from "fabulous!"

to "died in 2 weeks" to "doesn't get very cold" to "drains battery in

no time". No doubt much depended on expectations. We know peltier

cooling uses a lot of power for a little cooling, and I've found they

seem to have have a very limited life expectancy quite unlike most

solid state components. That's better for occasional camping than for

daily use. They seemed to be quite popular in Quebec. Someone actually

got it to the advertised 20°C cooler than the outside, after 9

hours. And they gave a table in their 2015 review:

Température

d'extérieur: 27°

Aprés 2 heures: 13°

Aprés 4 heures: 10°

Aprés 6 heures:

9°

Aprés 9 heures: 7°

(Hmm... Did their outside temperature go

down during the test? Might help explain the exceptional results.

Evidently the manufacturer says it'll drop by 18°.)

At 8.5 volts mine got down to 8.1° in a 19.7° room

overnight - only 11.6° down. The temperature of the air coming out

from the cooling fan and cold side heatsink starts out at about

13°, and the cooler starts cooling quickly. But once the cooler is

down by 9 or 10° from outside, the cooling air was only about

2.5° colder, so about 6.6°. (I still don't see why it doesn't

continue cooling with even just 2.5° cooler air still wafting out.

It seems pretty well insulated. I guess it shows that "super"

insulation is a key to getting good results.) On turning it up to 10

volts, the temperature went marginally up instead of down. So I turned

it down to 7.5 volts instead, where it was using just 20 watts. It went

up a bit more. At 9 volts it went up a little more. But then over that

time, so did the room.

[Sept. 2nd]

Something I finally thought to do was to leave a

temperature sensor directly in the flow of the air coming off the

cooling fan. That way a change in the amount of cooling could

rapidly be measured as a drop or rise in the cooling air temperature

without waiting hours to see what temperature the whole cooler got down

to. I quickly verified what had been taking a long time to figure out.

(It would have been even easier except that while the 3 identical

temperature sensors indicated to .1°C, they would jump around by up

to .3°, giving a slightly different reading each second. This is

not helpful when you actually want to measure such fine divisions.)

[Sept. 2nd]

Something I finally thought to do was to leave a

temperature sensor directly in the flow of the air coming off the

cooling fan. That way a change in the amount of cooling could

rapidly be measured as a drop or rise in the cooling air temperature

without waiting hours to see what temperature the whole cooler got down

to. I quickly verified what had been taking a long time to figure out.

(It would have been even easier except that while the 3 identical

temperature sensors indicated to .1°C, they would jump around by up

to .3°, giving a slightly different reading each second. This is

not helpful when you actually want to measure such fine divisions.)

In some further tests I had sensors on both the cold

side heatsink (or at least the air coming right off of it... was it

actually touching the heatsink? Can't tell.), and near the bottom of

the cooler. Whatever the temperatures (once it was all fairly cold), it

seemed the cold side air was very close to 4°C colder than the

cooler itself. So the peltier had to run at 4° colder than if there

was no difference. (...and why wouldn't 4° cooler air further

cool the unit?...) That large difference indicated to me that perhaps

the cold

side fan wasn't strong enough. If so this was of course largely due to

running it at the lower voltages. Perhaps just that fan should

be run at 12 volts at all times? But then, the warm side heatsink is

even more warm than the ambient temperature - maybe by 7 to 10°.

Latest Conclusions

I knew from the manufacturers' graphs that peltier modules

should work more efficiently at lower powers, and using a DC to DC

converter to easily change the supply voltage, it was a major part of

this experiment to show that. Going between 20 and 50 watts of

input power, from say 8 to 12 volts supply, seem to make very

little difference to the

temperature of the cooling air coming off the cold side fan and

heatsink, or to the lowest temperature attained inside the unit. The

cold

air

temperature

coming

out of the fan hardly seemed to change at

different voltages. In my tests with this module and this cooler as set

up (indeed with several setup variations), about 8 to 9.5 volts

instead of 12 seemed to be a good supply voltage for both low power and

attaining low temperature. It should be noted that the speed of the

fans also changed with voltage. Also somewhat higher voltages might

have worked better than 8-9.5 if greater temperature drop had actually

been attained.

But I still wonder about better optimizing heat transfer from the

peltier module including changing the fans voltages of both fans with a

DC to DC converter. (Hey! I could easily have done that when I had the

unit open! I was after all using two DC to DC converters and could have

tried different fan voltages independently of peltier voltages! NO!

DON'T get it out again! Awrgh!)

This "high performance peltier module" may work a little

better or perhaps live longer than others, but it's not the quantum

leap in performance I'm still hoping will someday soon be made. I think

I'll just put the cooler back in storage and pretend I never got it

out. If you use a peltier cooler for camping, put the food in already

cold to help it out.

Handheld Bandsaw Mill Kit

[6th] I went to Masset and at

Co-op

Home Centre I found some pieces of metal that were about what I needed

for continuing with the bandsaw kit project.

[7th] I had found one inch square steel tube, and I cut two pieces

rather elaborately to make the "P" brackets to hold the cutting guide

rails, bending out outer "ears" and drilling holes to attach the

U-bolts to. I had wanted 1.25 inch tube to fit over the 1 inch square

aluminum guide rails that I had, but 1 inch was the largest. So I cut

out two 3/4 inch rusty steel guide rails from some old assembly I had

lying around. I don't suppose they would slide across wood very easily,

but for sizing things up it all fit together.

I note that the vertical posts really need to be very

straight vertical, and square on, not twisted, to hold the guide rails

properly and so they slide easily in the "d" brackets. ("d"... or "b"

or "p", as seen from the end of the saw.)

The "d" Brackets to allow the

right assembly to

slide for band

The "d" Brackets to allow the

right assembly to

slide for band

adjustments/replacement without unfastening the cutting depth rails

The cutting guide rails in place,

rear and

front views, as if cutting the bench.

The cutting guide rails in place,

rear and

front views, as if cutting the bench.

* I noticed that if the plates stuck out past the posts, they could in

theory reduce the maximum cutting depth by about 1/2 an inch. It would

be good if at least the driven side plate didn't. (Oh, it doesn't

matter -

the depth guides prohibit it anyway.)

* And come to think of it, the fact that the driven depth guides stop

below the plate will limit it even more. On the undriven side, the "d"

brackets can be inverted to be "p" brackets so the guide bar can go

above the plate. I tried inverting the brackets and found the ears

stick into the potential cutting width. It can still be done on the

undriven end for cuts less than absolute maximum width, but not on the

driven end. So there's no point putting "p" brackets on the driven end.

If no welds are in the way of the driven end U-bolts, potential cutting

depth measures about 6 inches. With a 2 inch guide board on top of the

piece being cut, that makes it 4 inches. That will have to do. It's a

lot thicker than I could cut with the prototype, which

was only about 2 inches with a 1.5 inch guide board.

* I had also noted that if the hollow of the driven side posts went

through the plate, supports could be inserted to mount it to a bench as