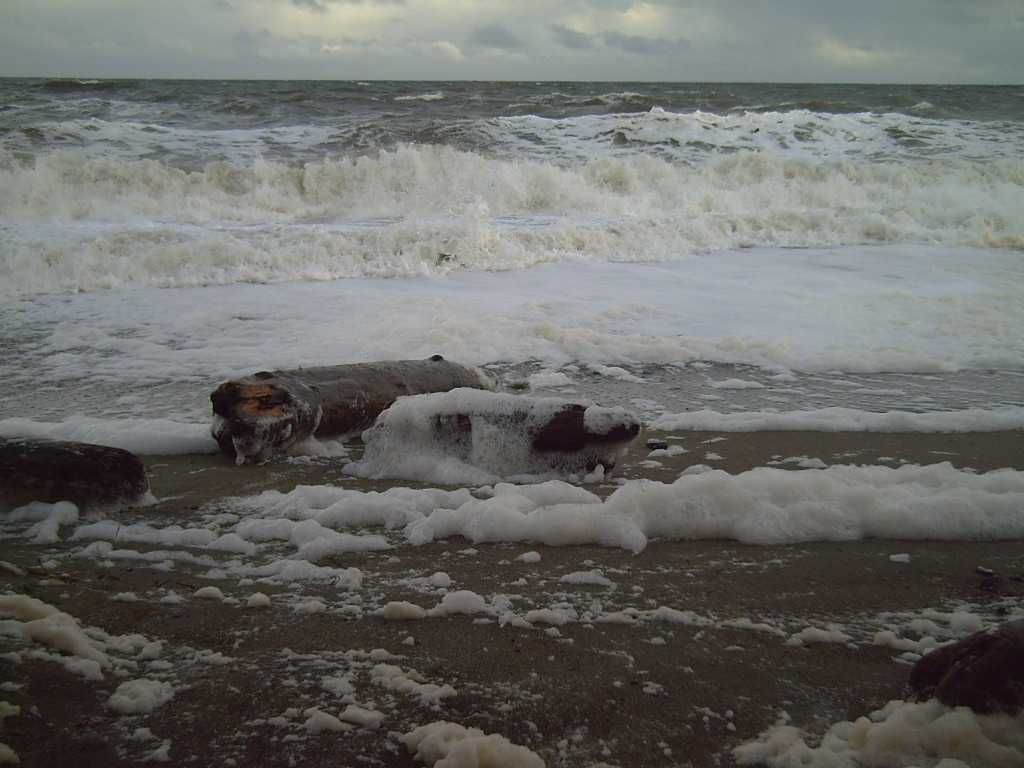

I've shown views of the broad beach below my home at low tide before.

This time I thought I'd try for high tide in a storm with a new moon, November

5th. (Drying foam says I missed highest tide by a 1/2 an hour or so.)

Big logs were rolling and tossing around. Surely there is power in waves!

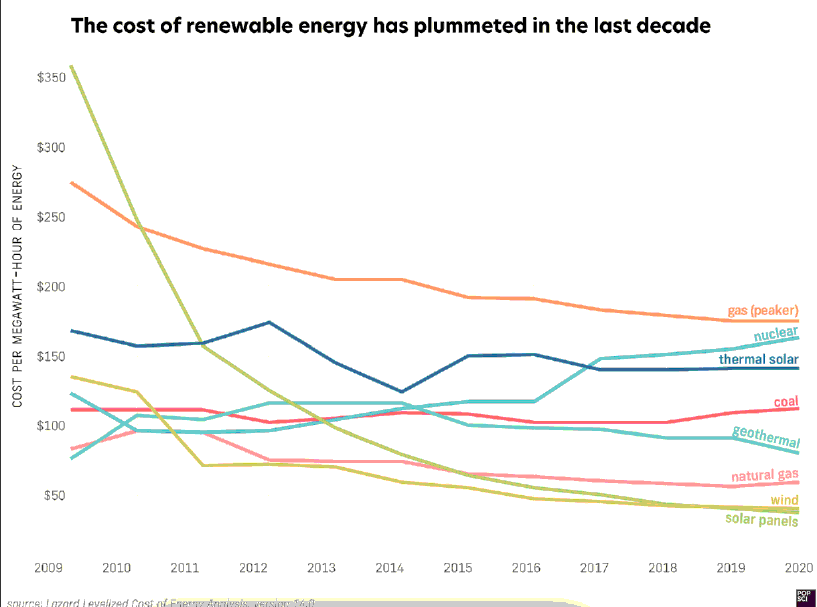

It's nice to know that in all the inflation some things have been getting cheaper:

Solar PV, Wind and maybe Geothermal power.

(When I was a kid in Edmonton, CH4 "natural" gas was dirt cheap. Now it's gassing out of the

former permafrost in the Arctic, but in Europe the winter heating supply is in question.

But it was never "sustainable".)

Of course I had some ideas of my own tucked away in the back of my

mind too, and I thought again after the power failure of how little

solar power there is here in the winter. So somehow I got sucked into

this new project, unwanted and

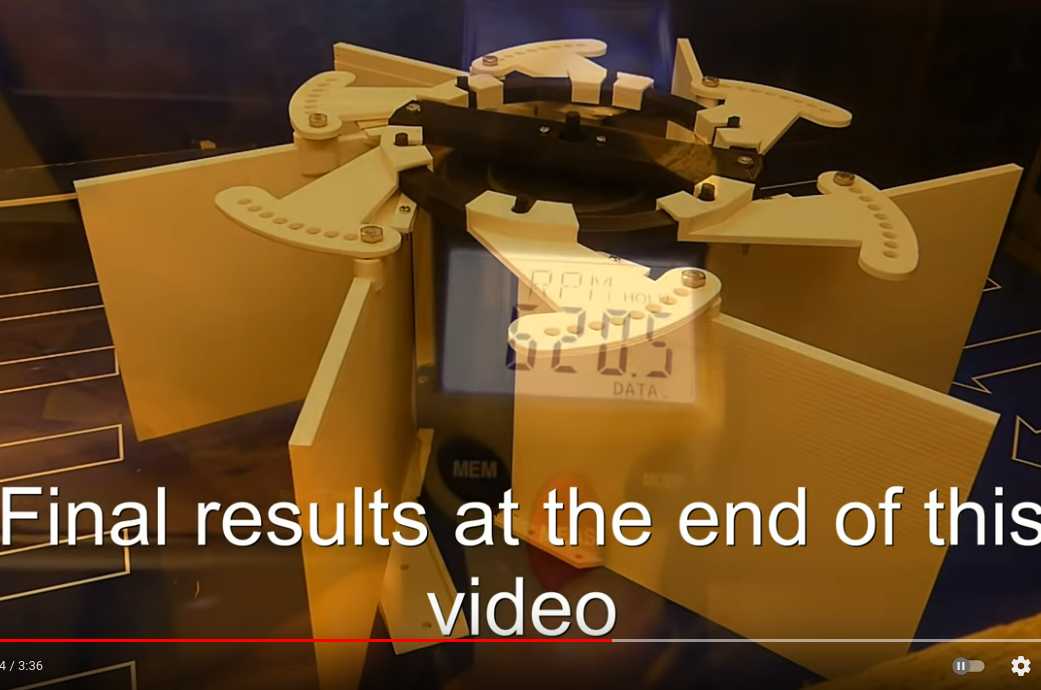

seemingly not very promising in the big picture. I made a tall,

thin Savonius rotor (why a bunch of short ones?) and stood it in front

of my big box fan. Of course it turned, more or less.

Of course I had some ideas of my own tucked away in the back of my

mind too, and I thought again after the power failure of how little

solar power there is here in the winter. So somehow I got sucked into

this new project, unwanted and

seemingly not very promising in the big picture. I made a tall,

thin Savonius rotor (why a bunch of short ones?) and stood it in front

of my big box fan. Of course it turned, more or less. Then I cut it

down to half the height and I made a mini wind tunnel: a box the size

of the fan from

scraps of plywood,

open at both ends. I put a bearing in a hole at the bottom and drilled

a hole for the shaft to stick through at the top. Every rotor tested

would then be mounted in exactly the same place relative to the fan and

tunnel.

Then I cut it

down to half the height and I made a mini wind tunnel: a box the size

of the fan from

scraps of plywood,

open at both ends. I put a bearing in a hole at the bottom and drilled

a hole for the shaft to stick through at the top. Every rotor tested

would then be mounted in exactly the same place relative to the fan and

tunnel. Then I thought

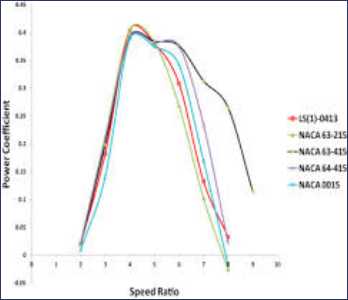

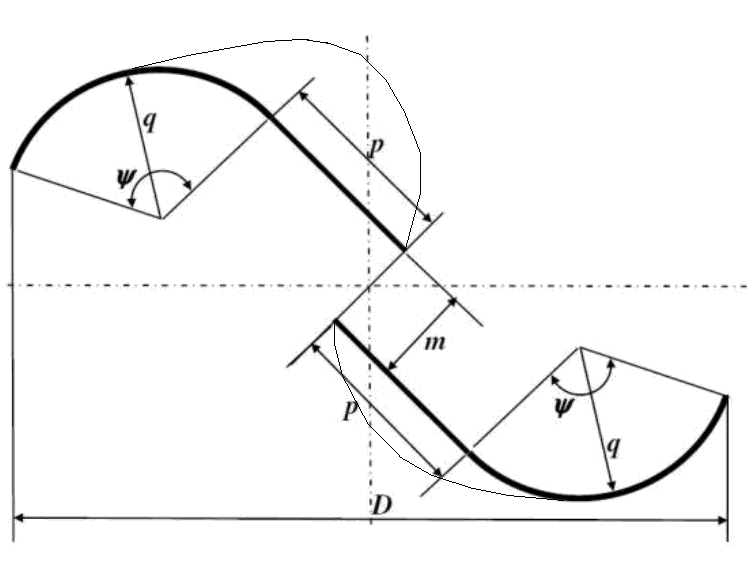

I'd search on line and see if there was anything better. I found a

paper that mentioned a "slightly better" shape and had a diagram of it.

I printed the diagram. "Full page" was just the right size for the

plastic PVC pipe I was using. I heated the pipe in the oven and bent it

to the right shape to fit on the pieces of wood I cut by cutting out

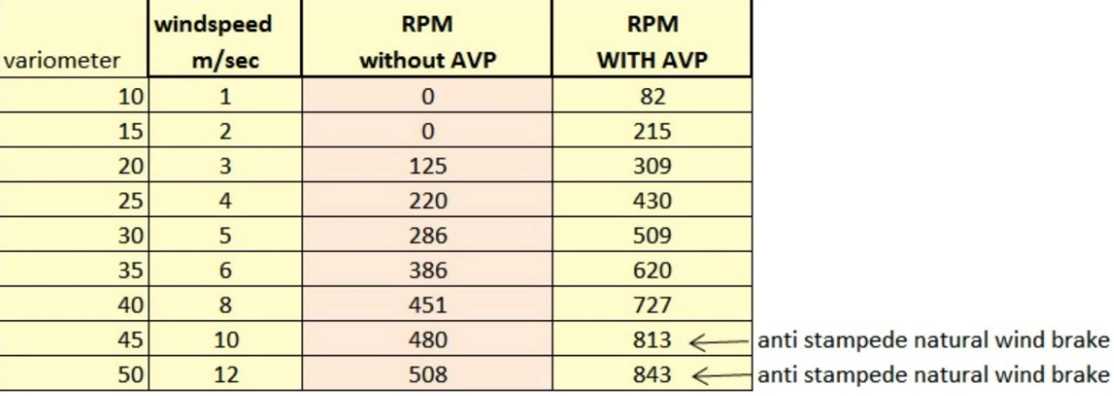

and tracing the drawing. It turned at 82 RPM. But the first rotor was

only 7 inches diameter while the new one was 10 inches, so the same RPM

actually represented considerably more outer rim speed and more power.

Then I thought

I'd search on line and see if there was anything better. I found a

paper that mentioned a "slightly better" shape and had a diagram of it.

I printed the diagram. "Full page" was just the right size for the

plastic PVC pipe I was using. I heated the pipe in the oven and bent it

to the right shape to fit on the pieces of wood I cut by cutting out

and tracing the drawing. It turned at 82 RPM. But the first rotor was

only 7 inches diameter while the new one was 10 inches, so the same RPM

actually represented considerably more outer rim speed and more power. But, I

thought, the new shape was flat both on the back (the main part of the

advantage) and the front - a disadvantage. The front would have more

air resistance returning upwind to the "top" of the power cycle. I

added a second layer (screwed on alium. sheets) that made it a rounded

front face again, which created a further improved "Savonius" rotor

that turned at 90 RPM. That seemed rather thrilling. How much - or was

it how little - creative thought had been given to Savonius rotor

shapes in the last 100 years or so?

But, I

thought, the new shape was flat both on the back (the main part of the

advantage) and the front - a disadvantage. The front would have more

air resistance returning upwind to the "top" of the power cycle. I

added a second layer (screwed on alium. sheets) that made it a rounded

front face again, which created a further improved "Savonius" rotor

that turned at 90 RPM. That seemed rather thrilling. How much - or was

it how little - creative thought had been given to Savonius rotor

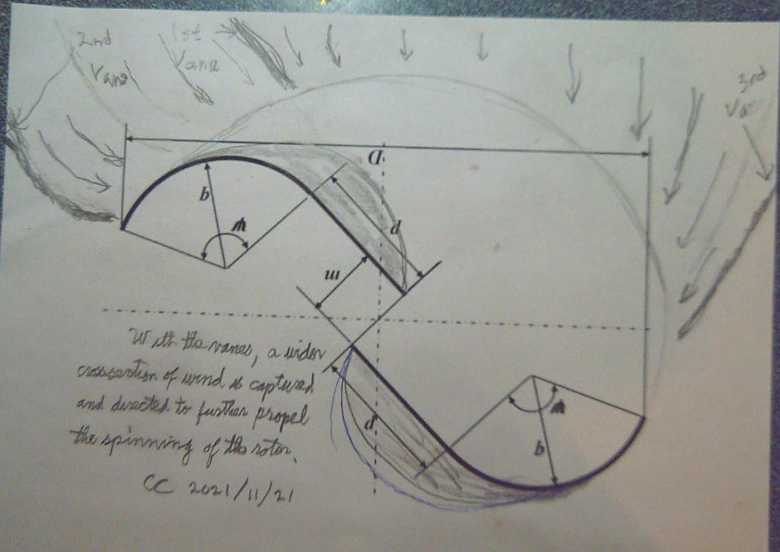

shapes in the last 100 years or so? Next I put a

stationary vane in to direct the wind toward the side of the rotor

being pushed downwind, and away from the side pushing its way back

upwind. This also concentrated the wind and increased its speed. This

time the rotor hit 160 RPM, and took some actual bit of force pinching

the shaft to slow it down much. Potential tens of watts, I think. With

a couple of vanes it hit 172 RPM. The vanes would of course be built

into the frame of the wind wall. (Further testing might optimize vane

sizes, placements and shapes, but even one flat board works wonders!)

Next I put a

stationary vane in to direct the wind toward the side of the rotor

being pushed downwind, and away from the side pushing its way back

upwind. This also concentrated the wind and increased its speed. This

time the rotor hit 160 RPM, and took some actual bit of force pinching

the shaft to slow it down much. Potential tens of watts, I think. With

a couple of vanes it hit 172 RPM. The vanes would of course be built

into the frame of the wind wall. (Further testing might optimize vane

sizes, placements and shapes, but even one flat board works wonders!)

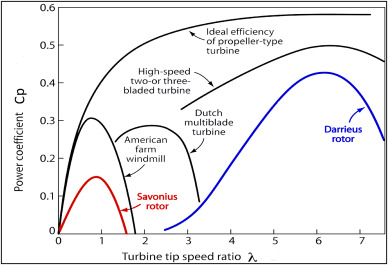

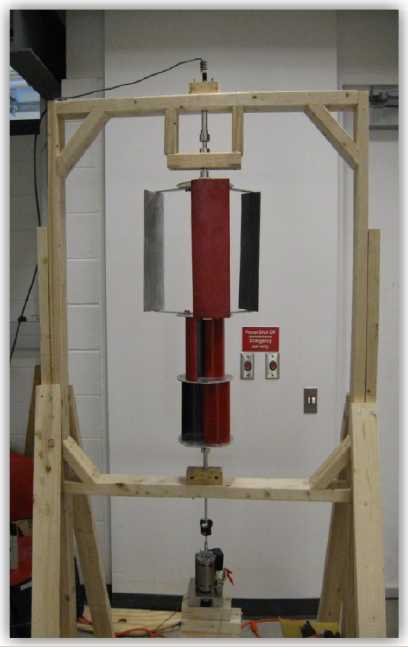

The actual subject of the same

paper was about making and testing a hybrid rotor,

where the Savonius bottom half was the means to start the Darrieus top

half spinning, even in low winds, thus harvesting power with something

toward the efficiency of a Darrieus rotor (~40%) at catching the wind's

energy. (Straight blade Darrieus rotors only work once they are

spinning, so they need some way to start them.)

The actual subject of the same

paper was about making and testing a hybrid rotor,

where the Savonius bottom half was the means to start the Darrieus top

half spinning, even in low winds, thus harvesting power with something

toward the efficiency of a Darrieus rotor (~40%) at catching the wind's

energy. (Straight blade Darrieus rotors only work once they are

spinning, so they need some way to start them.) I didn't have

enough grid ties for all the solar panels in summer sun, and I wasn't

happy with the way the present ones kept jumping back to zero and only

gradually ramping up again when a cloud came along. By the time they

were back to full power, another cloud would come and it would start

all over again. So when I ordered 3 new grid ties they were a different

brand, 700 watts rated.

I didn't have

enough grid ties for all the solar panels in summer sun, and I wasn't

happy with the way the present ones kept jumping back to zero and only

gradually ramping up again when a cloud came along. By the time they

were back to full power, another cloud would come and it would start

all over again. So when I ordered 3 new grid ties they were a different

brand, 700 watts rated. Having looked

up eelgrass, I went farther and looked at

just grass grass. Sure enough, a company is processing that into batts

for insulation, too. The "R" value is around 4.26 per inch, which is

27% better than fiberglass. (~3.3. I never did get an exact figure for

eelgrass - perhaps 3.5?) That would mean R 15 in

a "2 by 4" wall (actually 3.5 inch) and R 23.5 in a "2 by 6" wall (5.5

inch). With such an improvement, might we return to making "2 by 4"

walls as was done up until... hmm, 1980 or so, was it? Around that time

exterior walls started being made of 2 by 6es to get a higher "R" value

than R12 with fiberglass.

Having looked

up eelgrass, I went farther and looked at

just grass grass. Sure enough, a company is processing that into batts

for insulation, too. The "R" value is around 4.26 per inch, which is

27% better than fiberglass. (~3.3. I never did get an exact figure for

eelgrass - perhaps 3.5?) That would mean R 15 in

a "2 by 4" wall (actually 3.5 inch) and R 23.5 in a "2 by 6" wall (5.5

inch). With such an improvement, might we return to making "2 by 4"

walls as was done up until... hmm, 1980 or so, was it? Around that time

exterior walls started being made of 2 by 6es to get a higher "R" value

than R12 with fiberglass. What

processing does it need? Those making it

into batts

were first "de-juicing" it to extract "the cellulose". Their pictures

were pretty tiny, but to me the batts looked

like they were made of bits of straw, so I suspect the process wasn't

very involved and that simply drying it would do almost the same. Then

they added jute and PETE. It was said the PETE could be replaced by

PLA. Starch was also mentioned, and borate. (More info:

www.GrassInsulation.com/technical )

What

processing does it need? Those making it

into batts

were first "de-juicing" it to extract "the cellulose". Their pictures

were pretty tiny, but to me the batts looked

like they were made of bits of straw, so I suspect the process wasn't

very involved and that simply drying it would do almost the same. Then

they added jute and PETE. It was said the PETE could be replaced by

PLA. Starch was also mentioned, and borate. (More info:

www.GrassInsulation.com/technical ) [10th & 11th - Rememberance day! "The

Great War", "WW I", "The War to End All Wars", ended 103 years ago this

month. I'll bet that no one alive today ever met and would remember

anyone who died in that war.]

[10th & 11th - Rememberance day! "The

Great War", "WW I", "The War to End All Wars", ended 103 years ago this

month. I'll bet that no one alive today ever met and would remember

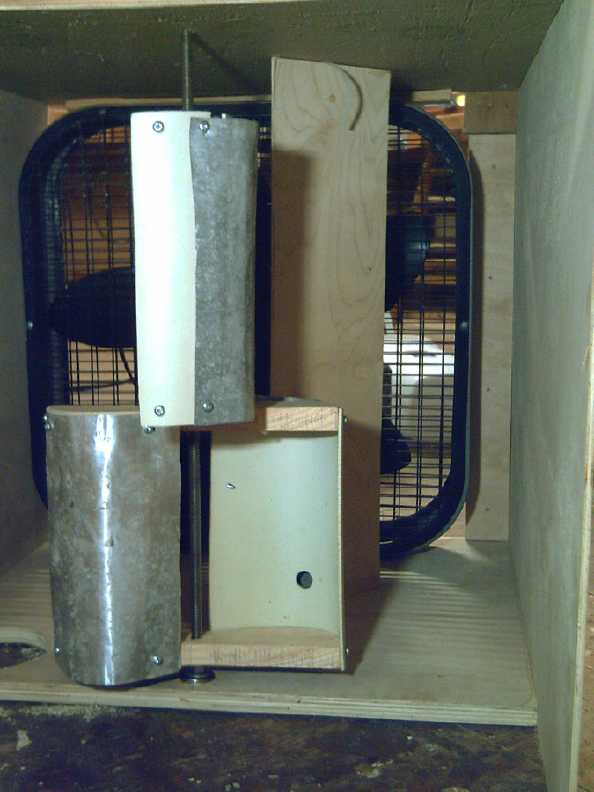

anyone who died in that war.] [16th] "In for a penny, in

for a pound..." I went out to the shop (Brr - freezing out!) and made a

plywood box with open ends to blow the fan into. That strengthened the

air flow and made a mini wind tunnel with fairly "linear" air flow to

allow better comparisons of different diameter rotors. I put a hole to

mount a bearing at the bottom and another at the top to stick a shaft

through. That was convenient and also ensured that every rotor would be

in the same place for every test.

[16th] "In for a penny, in

for a pound..." I went out to the shop (Brr - freezing out!) and made a

plywood box with open ends to blow the fan into. That strengthened the

air flow and made a mini wind tunnel with fairly "linear" air flow to

allow better comparisons of different diameter rotors. I put a hole to

mount a bearing at the bottom and another at the top to stick a shaft

through. That was convenient and also ensured that every rotor would be

in the same place for every test. Thus it has the "scoop" profile when the wind is pushing it, and a

"rounded" profile when it's pushing up through the wind to the front

side again. This might even give it better "airplane wing" lift to pull

it forward through some parts of the rotation.

Thus it has the "scoop" profile when the wind is pushing it, and a

"rounded" profile when it's pushing up through the wind to the front

side again. This might even give it better "airplane wing" lift to pull

it forward through some parts of the rotation.