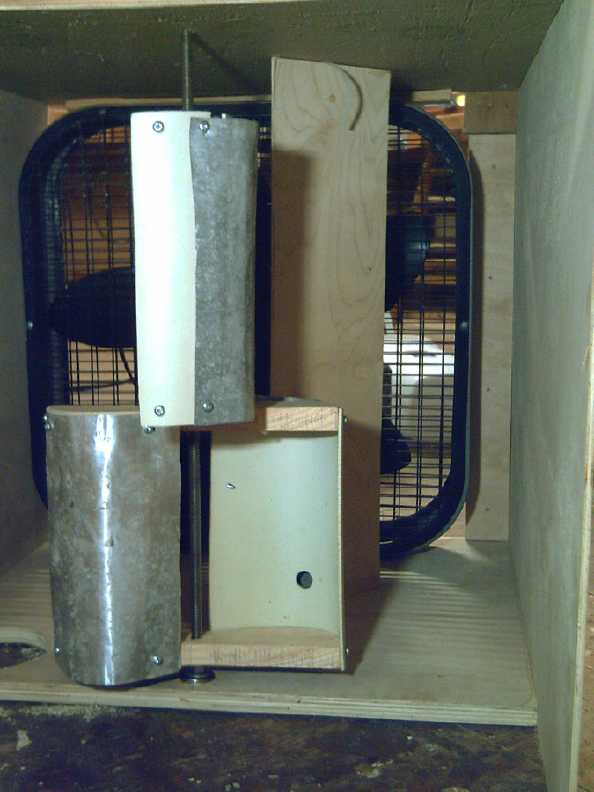

The bottom "two scoops" rotor is a superior

design to the "two half barrels" Savonius type.

The top "composite" rotor design created by the author

incorporates the best aerodynamic advantages of both types.

The new rotor shape was devised and (even as a crude prototype) proven

in a mini wind tunnel to attain a higher RPM speed than existing rotor

types in the same wind. Made with two sheets of material instead of

one, the "scoops" trailing face to catch the

wind is a different shape than the more streamlined leading face going

into the wind.

The new rotor shape was devised and (even as a crude prototype) proven

in a mini wind tunnel to attain a higher RPM speed than existing rotor

types in the same wind. Made with two sheets of material instead of

one, the "scoops" trailing face to catch the

wind is a different shape than the more streamlined leading face going

into the wind.| MINI WIND TUNNEL FAN SPEED |

AIR SPEED meters/second (max. reading with no rotor in the wind tunnel) |

1st (SAVONIUS) "OVERLAPPED HALF BUCKETS" ROTOR RPM: (OD = 7") |

2nd "FLAT SCOOPS" ROTOR RPM (OD=10") |

3rd "COMPOSITE" ROTOR RPM (OD=10") |

| LOW |

2.1 |

20 |

40 |

40 |

| MEDIUM |

2.6 |

50 |

62 |

66 |

| HIGH |

3.1 |

80 |

82 |

90 |

| FAN SPEED |

AIR SPEED meters/second (maximum reading with no rotor in wind tunnel) |

1st "OVERLY OVERLAPPED SAVONIUS" ROTOR no load RPM: (Second Tests) (OD = 7") |

2nd "FLAT SCOOPS" ROTOR no-load RPM (OD=10") |

3rd "COMPOSITE PROFILE" ROTOR no load RPM (OD=10") |

3rd ROTOR WITH WIND DEFLECTOR VANE no-load RPM ( try 2 - /21st) |

3rd ROTOR WITH TWO WIND DEFLECTOR VANES no-load RPM |

| LOW |

2.1 |

20 |

40 |

40 |

104 |

- |

| MEDIUM |

2.6 |

50 |

62 |

66 |

138 |

- |

| HIGH |

3.1 |

80 |

82 |

90 |

166 |

172 |

The generator

- really a 3-phase alternator - is to be a lightweight version of the

ultra-efficient axial flux type essentially based on the Hugh Piggott

windplant alternator design. This wastes no power and extracts every

watt available from any wind up to its power capacity. This will not be

the author's first such design and there are no important "unknowns" to

be faced in the design and construction. Building such alternators as

parts of the rotor assembly instead of buying and attaching generators

will lower costs and improve performance.

The generator

- really a 3-phase alternator - is to be a lightweight version of the

ultra-efficient axial flux type essentially based on the Hugh Piggott

windplant alternator design. This wastes no power and extracts every

watt available from any wind up to its power capacity. This will not be

the author's first such design and there are no important "unknowns" to

be faced in the design and construction. Building such alternators as

parts of the rotor assembly instead of buying and attaching generators

will lower costs and improve performance.