Turquoise Energy News #163

covering

December

2021 (Posted January 4th 2022)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Highlight: The Best Vertical

Axis Windplant Blades & Rotor

Month

In

"Brief"

(Project Summaries etc.)

- "Wind Wall" VAWT Windplant Development & Research - Solar

Panels

Connection & Switching Board - Cross-Current Tidal Power

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Smol

Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* (A few measurements for me for later: Planned Unipolar Electric

Hubcap

Motor

Diameters)

Other "Green"

& Electric Equipment Projects

* CNC Table (still not working)

Electricity Generation

* Wind Wall Windplant: Mold & recycled polypropylene rotor

blade development/production -- and some more design research

* My Solar Power System:

- Improvements: Switches to switch panels between AC

and DC systems, and Another Grid Tie

- Daily/Monthly

Solar Production log et cetera - Monthly Summaries,

Estimates, Notes

December in Brief

The low noontime sun of winter

solstice at 53.4° north.

The low noontime sun of winter

solstice at 53.4° north.

HAPPY NEW YEAR TO ALL!

This month I continued on the windplant I somehow started

last month. Last month was the idea, then mostly "research", online and

then by

experimenting with forms and ideas after making the "mini wind tunnel"

box. This month surely it was all "forge ahead" "development" now? But

I ended up

thinking... surely three blades would be better than two? More quick

fabrications and wind tunnel experiments showed it was a 35-40%

improvement. (So, why do so many people just use two?)

Altogether the experimenting brought about performance way

beyond my expectations, so I am encouraged to continue to develop it

into a product.

The development aspect of the project mainly centered

around trying out and experimenting with what seems a rather simple

but probably unused or little used technique for molding plastic, which

seems especially good for recycling larger pieces of plastic without

having to shred them. It uses alium. box molds with fitted lids. Chunks

of plastic measured by weight (eg, salvaged PP rope or fishnet) are

thrown into the box and the box into an oven, with heavy weights on

top. As the plastic melts, the weights push the lid down to a bottom

position and spread the plastic to fill the mold. Naturally I've

started with the hardest part - the elaborately shaped windplant rotor

blades. If I can get it to work for those, it'll work for anything.

The devil has been in the details so far with promising

but not quite satisfactory results. But I think perseverance will get

it to work well. If so I plan to use an oven element or two, some

sheets of steel, and some rock wool insulation to create an oven long

and wide enough for every mold I wish to make, including one 2 feet

wide by up to 6 or 7 feet long to make flat greenhouse wall panels from

transparent PETE food containers. (And maybe 6 foot long plastic

"boards" or "posts"?)

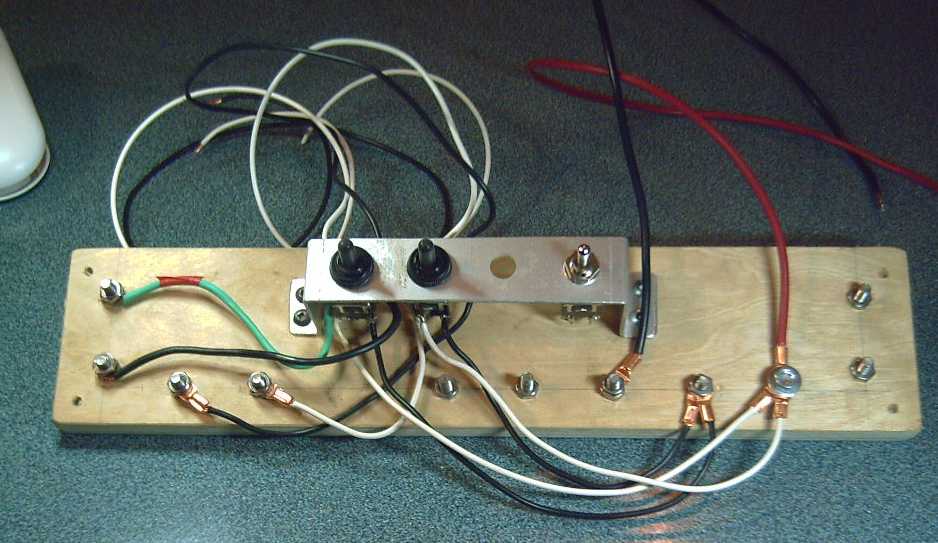

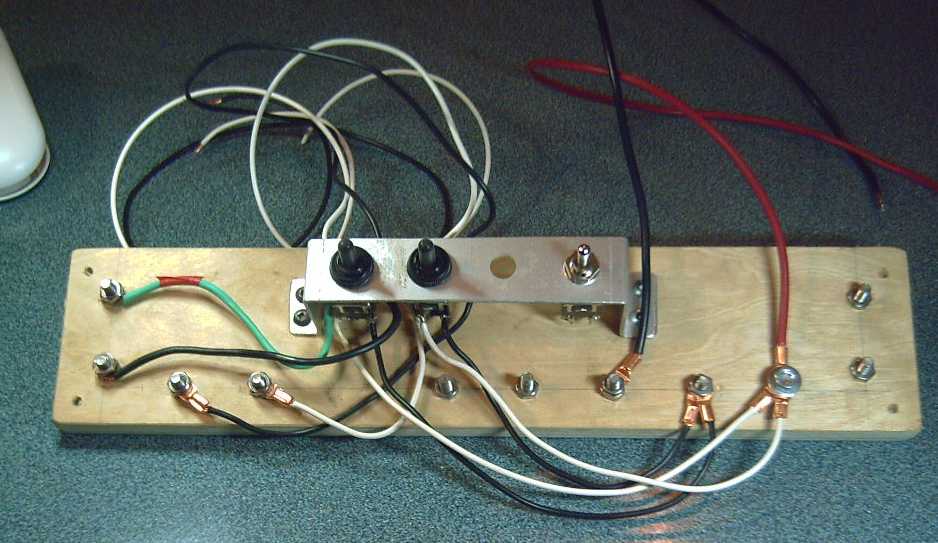

Aside from that main two-headed project, I made and

mounted a board

(plywood) with some terminal posts and switches on my solar equipment

wall and can now quickly switch 5 or 7 panels between the grid tie

inverters and the DC charge controller.

VAWT (Vertical Axis Wind Turbine) - "the Wind Wall"

I put small pieces of polypropylene rope and fishnet into

the kitchen oven and heated them. At over 420°F the rope pieces

melted into blobs. At 450° the net still looked the same. I

pressed on it with an alium. bar and that spot compacted into

a solid piece. I guess as my brother said, fishnets are nylon. They

seem to have a higher melting point. I may try them later, but for now

I'll go with PP ropes.

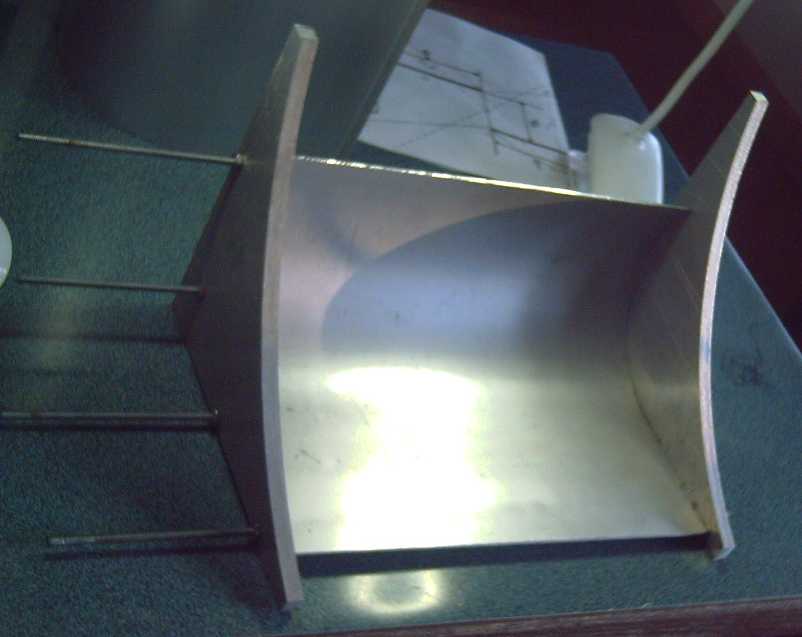

Rotor blade

mold minus top & weights: some new rope + a "too small" piece to

remelt

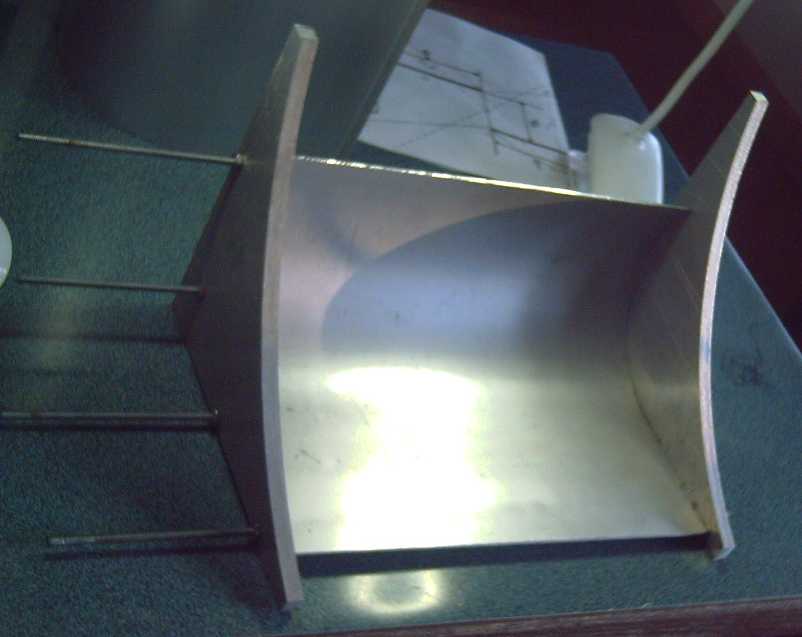

I made a "box" mold to cast plastic rotor blades in.

It had a curved top face of 2mm alium, a bottom face that matched to

make the rotor shape, and two straight side pieces. Threaded rods

between the sides held the bottom piece in place. The plastic chunks

are set on this bottom piece and the top loosely placed over it. Then

very heavy weights are placed on top to press everything together. As

the plastic melts, the weighted top piece presses everything together

until either it's full and the plastic has nowhere to go, or else until

it hits end stops and won't go down any farther. Naturally, one wants

to hit the end stops at the same time as the plastic is full, so that

there are no gaps and no excess plastic is oozing out every crack in

the mold. To accomplish this one weighs the plastic being put in to get

the right amount each time.

I made a "box" mold to cast plastic rotor blades in.

It had a curved top face of 2mm alium, a bottom face that matched to

make the rotor shape, and two straight side pieces. Threaded rods

between the sides held the bottom piece in place. The plastic chunks

are set on this bottom piece and the top loosely placed over it. Then

very heavy weights are placed on top to press everything together. As

the plastic melts, the weighted top piece presses everything together

until either it's full and the plastic has nowhere to go, or else until

it hits end stops and won't go down any farther. Naturally, one wants

to hit the end stops at the same time as the plastic is full, so that

there are no gaps and no excess plastic is oozing out every crack in

the mold. To accomplish this one weighs the plastic being put in to get

the right amount each time.

I conceive that the curved rotor blades must be the

hardest

parts to cast. All the straight pieces should be pretty simple - just

boxes with lids - so if the technique works for the rotors, everything

else should work fine. An advantage of this whole "primitive" casting

arrangement is that one can just put in pretty big chunks of plastic to

recycle it, and not have to shred the material into little bits.

A friend talked me out of

trying to cast the first rotor

vane in my kitchen oven. (Just as well!) So a couple of days later I

hooked up the stove I'd got at the refuse station. The digital controls

didn't seem to work, so I rewired the long cord (off my old 2006

sawmill) straight to the oven element. I got out a ladder and put it

through the laundry room window to plug into the dryer socket.

I tried casting quite a few blades. It's been a learning

experience. For the first one I just put it in the oven, put weights on

top, and plugged in the oven. The product came out much darker than the

original rope, which I attribute to it having a long time to oxidize as

the oven gradually heated. It took 55 minutes.

The first one

wasn't too bad except one area was too

thick, and the polypropylene rope plastic didn't make it into any of

the four corners. I thought it was because the edges were uphill in the

curved rotor.

The first one

wasn't too bad except one area was too

thick, and the polypropylene rope plastic didn't make it into any of

the four corners. I thought it was because the edges were uphill in the

curved rotor.

I modified the mold sides and turned it upside down for

the second attempt so the

corners were the low points, and used less plastic. It needed to be

hotter than I had

thought (~250°C?) and so the mold was still in the preheated oven

for almost 1/2 an hour and the part still came out notably darker than

the original rope.

This time the thickness was good, but there wasn't enough

plastic and it still was all in the middle - it didn't get into the

corners and mostly not even to the edges.

So it seems the melted PP plastic wants to contract into a

single fat blob, regardless of where the pieces of rope are placed, and

only sufficient

weight will force it to thin out and spread. This turned out to be a very

heavy amount of weight. At 28 pounds I don't think it's really there

yet. (And if there is any fair gap along the edge it will ooze

out there before it goes into the corners.)

It needed a new bottom piece with wide lips to stop any

potential drips. Also I had decided to cast them as one solid blade

instead of two pieces that bolted together, so it needed a modified

shape having the blades' outer curve instead of flat. But at least

there would be no second mold to make. By Christmas eve I had trimmed

the original lips off the top piece and was rolling up the new bottom

piece.

In the meantime I had been

going with the essential layout

as it had been presented: two blades or vanes on opposite sides of the

shaft, with two pairs top and bottom at 90 degrees to each other.

That's how Savonius had done it a century ago and countless people

since. It seemed like The way to do his "two half barrels"

design. But then, in the middle of thinking what I was doing was

"optimum" and the design was settled and fixed, I had the thought that

two vanes or blades are across the wind nicely for part of the

rotation, but in line with it 90 degrees later. Surely it was letting

some of the wind pass by unused and 3 (or more) blades would be better?

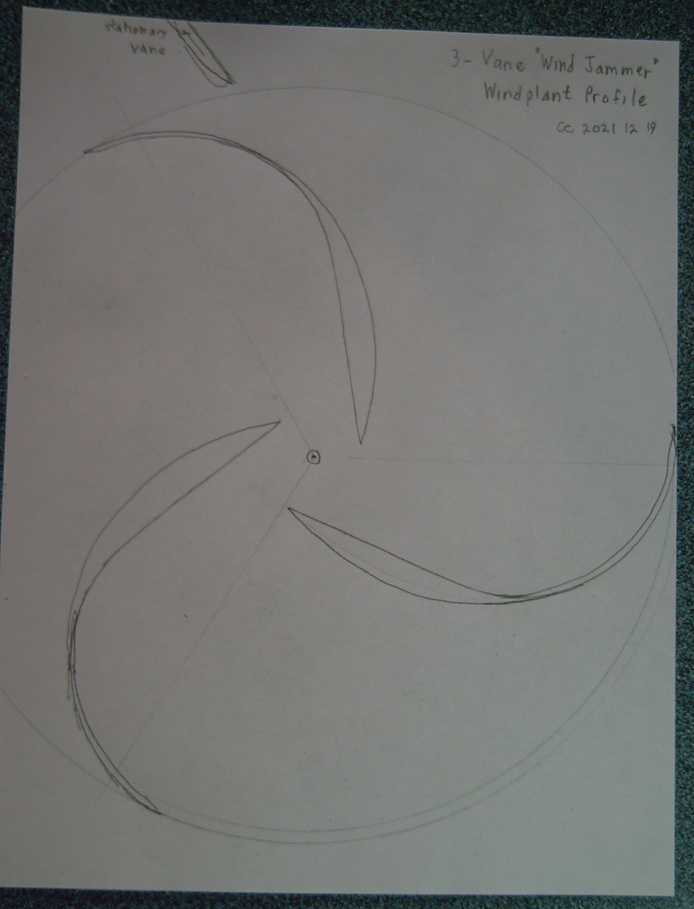

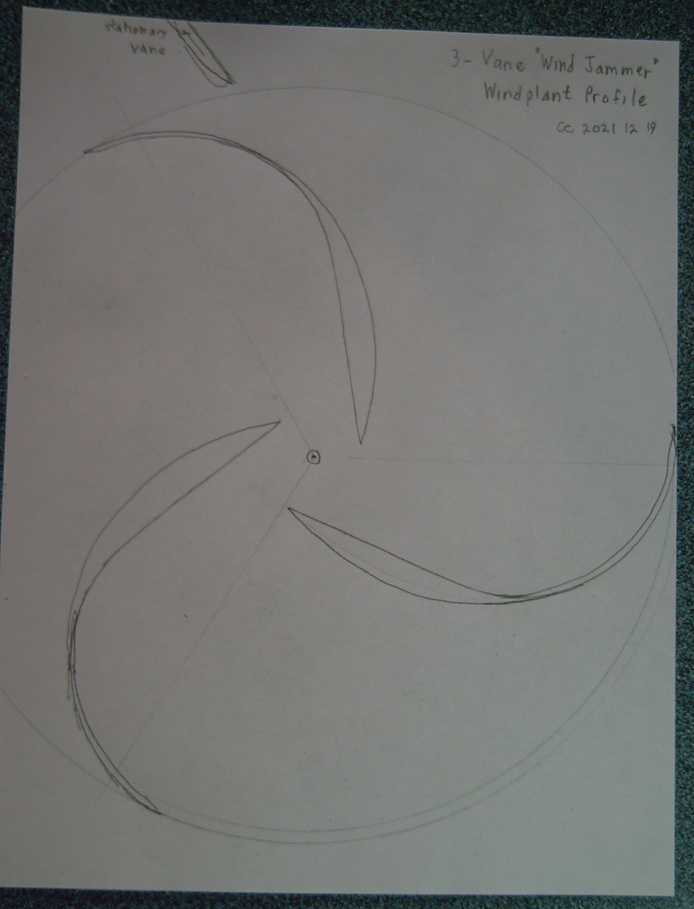

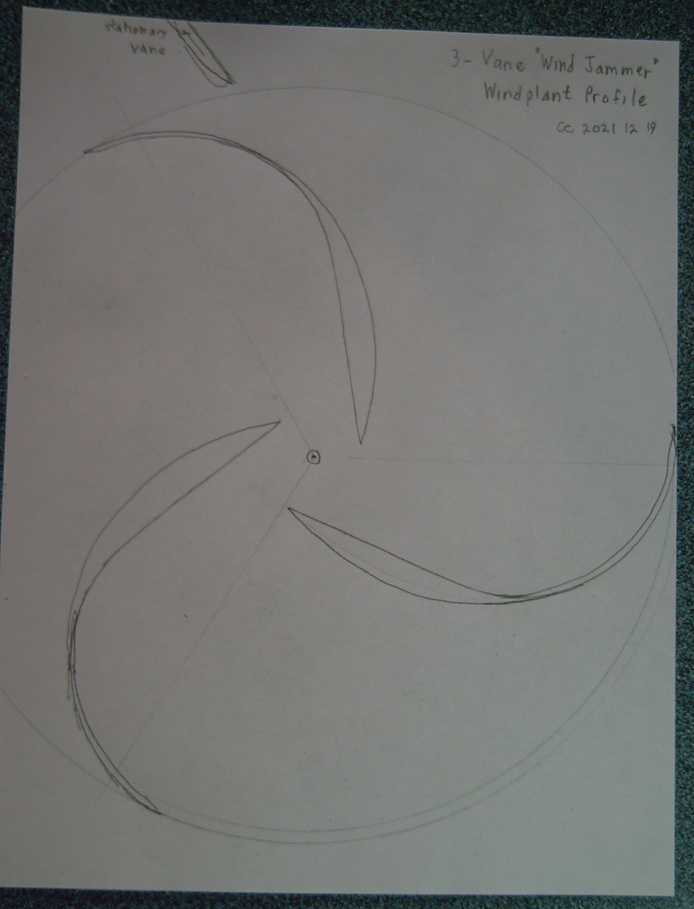

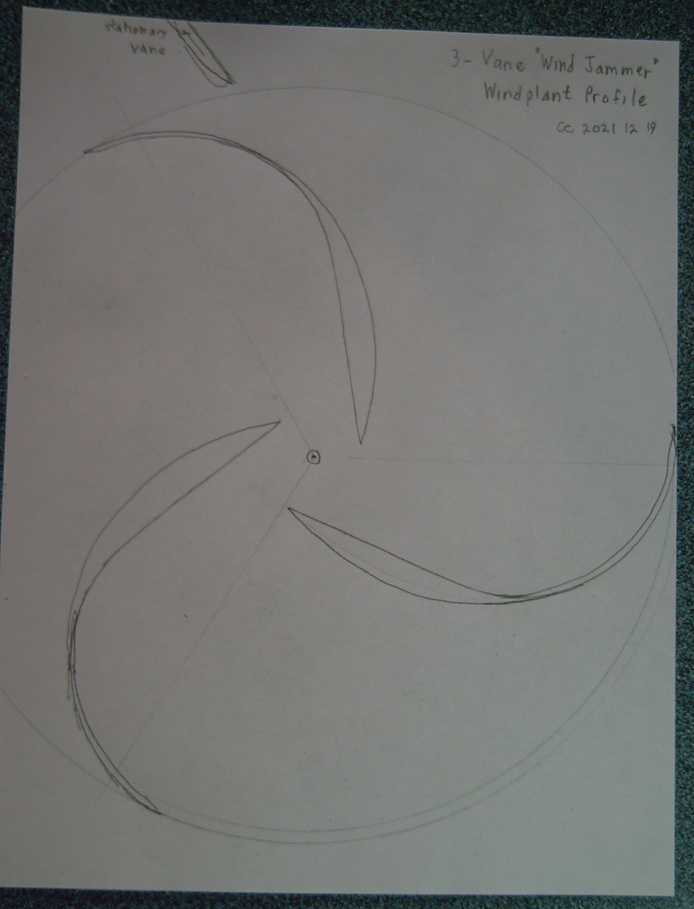

So I diverted

from "development" back to "research" for 3

days. First I did a top view drawing. It just instinctively looked

far superior! It's funny the things one starts with and takes as

"givens" because that's what others did, and then one may (or may not)

realize one or more of the "givens" has no special basis for being done

that way and in fact can be done better, maybe even much better.

So I diverted

from "development" back to "research" for 3

days. First I did a top view drawing. It just instinctively looked

far superior! It's funny the things one starts with and takes as

"givens" because that's what others did, and then one may (or may not)

realize one or more of the "givens" has no special basis for being done

that way and in fact can be done better, maybe even much better.

I made new plywood rotor end pieces to hold three blades

at

120 degrees instead of two at 180, and two more test blades since

it now needed 6. Then I screwed it all together. Sure

enough, it performed 35-40 percent better than with two blades!

Luckily this rather significant design

change didn't change much else. The shape of the blades I was trying to

mold was unchanged, and nothing else was done yet anyway.

Later I checked the performance of a single blade in the

mini wind tunnel, turning it by hand to see how it fared at different

angles of its

rotation. It had strong forward thrust for around 145°, over 3

times the 60° arc that

had substantial - but considerably weaker - reverse thrust.

Here are the chief

conclusions from my tests (in the "detailed report"):

CONCLUSIONS

Here is a new

fixed VAWT blade design that has

excellent

forward thrust through a wide arc, and much lower reverse thrust

through a small arc while returning upwind. A 3-blade rotor

made with

these blades has strong torque at all points of rotation and will turn

even in the lightest of winds. Air directed toward the axle by

the thrusting blade(s) is used by the others to assist rotation.

Furthermore the rotor runs near the

speed of the wind instead of the Darrieus (or propeller) type's 4 or 6

times faster,

and so it will have much less noise as well as less stress

and wear on the

components, yet the experiments indicate it should extract a similar

good percentage of

the power of the wind - much more than a typical Savonius design.

Here is a new

fixed VAWT blade design that has

excellent

forward thrust through a wide arc, and much lower reverse thrust

through a small arc while returning upwind. A 3-blade rotor

made with

these blades has strong torque at all points of rotation and will turn

even in the lightest of winds. Air directed toward the axle by

the thrusting blade(s) is used by the others to assist rotation.

Furthermore the rotor runs near the

speed of the wind instead of the Darrieus (or propeller) type's 4 or 6

times faster,

and so it will have much less noise as well as less stress

and wear on the

components, yet the experiments indicate it should extract a similar

good percentage of

the power of the wind - much more than a typical Savonius design.

FURTHER

When a stationary vane (or vanes) is (are) added

to concentrate the wind and direct it to the power stroke side of the

rotor,

significantly more power can be obtained, including from lighter winds.

The rotor

turning only at the speed of the wind is less susceptible to

damage from very high winds than rotors that turn much faster than the

wind. Making it as a "Wind Wall" unit with a mesh to keep

birds out, it will be a simple box that sits and effectively and pretty

quietly generates electricity when a wind is blowing. One expects it

should prove acceptable even in close residential neighborhoods where

other types of windplants have not.

After the

additional research I went back to trying to

make blades. After making the new bottom, I still was making minor

adjustments to the mold for quite a while. It probably took me several

more tries than it should have to get good results, but I finally

started to get decent ones... sometimes.

After the

additional research I went back to trying to

make blades. After making the new bottom, I still was making minor

adjustments to the mold for quite a while. It probably took me several

more tries than it should have to get good results, but I finally

started to get decent ones... sometimes.

Even to make a 2 foot tall rotor takes six

1 foot tall blades, and each one has to be in the oven for an hour, so

once I "have it" I'll be making them day

after day.

Next I need to make the other parts starting with the

rotor end

pieces that connect the blades to the axle. To do a good job of that I

really need the CNC router table to be working, so it comes to the fore

again.

But even into January I wasn't getting the best or

consistent results making blades. It seems it needs EVEN MORE weight to

really press the top down to the bottom! (Probably over 30 pounds on

the poor little box!)

I did note in the December

cold that the wind was coming

from the north

instead of blowing straight up my driveway from the east - an arctic

outflow coming down from the USA (Alaska) into Canada. I'm starting to

think the "Wind Wall" does really need to be able to pivot. (Maybe a

big pipe

at the front for a foot?) On January 3rd a good wind was blowing up the

driveway again. I took the anemometer-on-a-pole out and measured. Down

in front of the gate the wind was 4 to 6 meters per second, but if I

stuck it up a few feet, it was more like 5.5 to 7.7 - about 1.5 m/s

faster. 7.6^3 / 6.0^3 = 2.0... double the power!

This suggests that the "wind wall", if it is to be mounted there,

should at least be on top of the gate rather than in line with it.

Going up even higher didn't seem to help. That was apparently getting

above

the funneling effect of the driveway slopes.

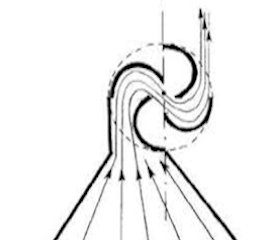

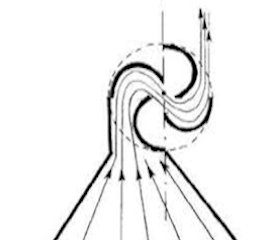

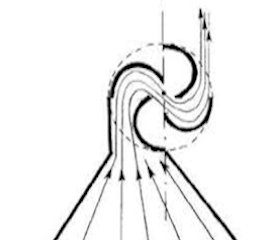

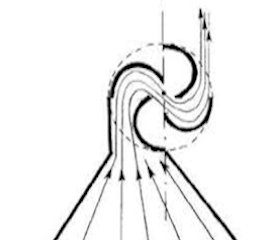

Among

the rotor profiles I searched, I found this drawing showing fixed vanes

concentrating and directing the wind at the 'power stroke' side of a

4-vane Savonius type VAWT. It also shows the extra benefit of the air

flow between vanes. (But the flow pattern with the inside-flat blades

is

better.)

Among

the rotor profiles I searched, I found this drawing showing fixed vanes

concentrating and directing the wind at the 'power stroke' side of a

4-vane Savonius type VAWT. It also shows the extra benefit of the air

flow between vanes. (But the flow pattern with the inside-flat blades

is

better.)

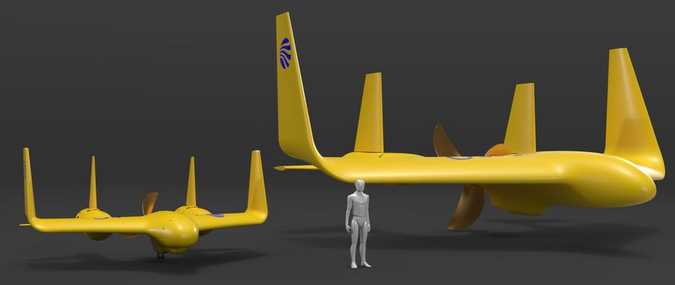

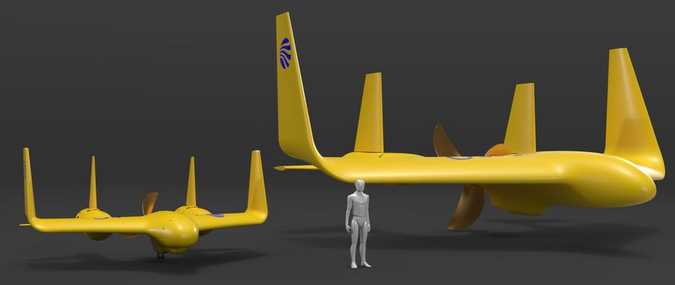

I also found a video of

this ducted propeller windplant. I have said before that a venturi duct

should greatly increase the airflow by the propeller and hence the

power.

I also found a video of

this ducted propeller windplant. I have said before that a venturi duct

should greatly increase the airflow by the propeller and hence the

power.

Even with just half of a venturi, the authors claim the

unit has double the power over having no duct. (Wouldn't having both

halves be even better?)

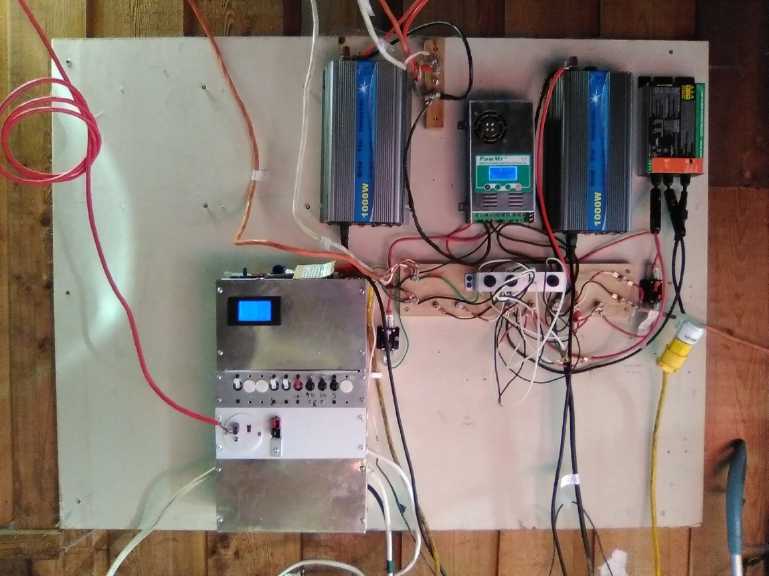

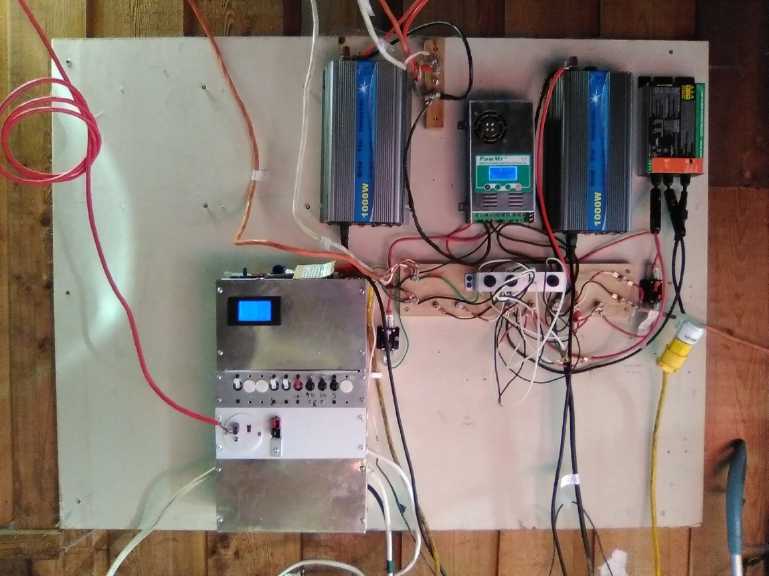

Solar Panels Connection & Switching Board

For the house system with the 36 V DC "off grid" battery I added

a set of switches with lots of bolt terminals around the edges for

securely

connecting solar panels and equipment. Now of the 11 panels around the

house,

I can switch 0 to 7 of them from the grid ties to the DC battery system

as needed. The original four ~250W panels on the roof still just go to

the top left grid tie. (Now if the six panels on the roof weren't

covered with snow, I might get just a little power from them!) A third,

new, grid tie inverter ([black, orange, green] 700W model GMI700/120V)

is at the upper right to divide the panels up better and give the

system more capacity in the summer. (So far I'm not sure if it is any

better - or worse - than the Y-Solar 1000W grid ties.)

The solar collection in

December dropped to "not much". Only the 5 panels I could reach to

sweep the snow off did much of anything for much of the month. On

January 1st things finally started to thaw. (Then more snow and cold on

3rd!)

Cross-Current Tidal Power

A friend

pointed me to an article about tidal power in the Faroe islands.

Undersea "kites" with wings and rudders are being programmed to "swim"

back and forth in a figure 8.

A friend

pointed me to an article about tidal power in the Faroe islands.

Undersea "kites" with wings and rudders are being programmed to "swim"

back and forth in a figure 8.

The flows aren't that strong in this north Atlantic

archipelago southeast of Iceland, and power is proportional to the cube

of the flow speed. So the idea was to increase the apparent speed of

the water flowing past the turbines.

A propeller itself is always "tacking" into the wind

faster than the wind (or water) speed. With thin blades it captures all

the flow going through its

cross sectional area. Then, a land based sailing

vehicle on a "reach" across the wind can also travel much faster than

the wind speed. This would also apply underwater with ocean currents.

If

a vessel is traveling across the flow faster than the flow and coupled

with a propeller, the

gain is multiplied by going across the flow in both ways, as the

'kites' fly back and forth behind their tether and electrical

connection. (I've shown these computer models but there are photos of

real ones.)

I don't think underwater units would last long deployed in

the ocean environment, but the concept seems brilliant. They are

talking about getting a megawatt from each unit. I would think a vessel

on the

surface would be more reliable and easier to maintain. A special big

"wing" rudder - or mulitple rudders? - might replace the 'kite' wings.

Floating 1MW tidal power units have already proven

themselves in the Orkneys and they are improving the designs. My own

design of a couple of years ago would have had a rudder to steer it out

into the highest current or back to shore at high tide for maintenance

at low tide. But there is no reason that same rudder couldn't get it to

tack back and forth. If one could tack sideways until the speed through

the water was even just 1.26 (cube root of 2) times as fast as just

dragging out behind the mooring, the potential power would be doubled.

Not trivial, especially during those times when the tide is running

more slowly - during every tide anywhere as well as in the Faroes.

(Hmm, 1.26 x... at what angle would that be?).

Original article:

https://www.goodnewsnetwork.org/faroe-islands-looks-to-tidal-power-with-tis-underwater-kites/?utm_campaign=newsletters&utm_medium=weekly_mailout&utm_source=05-12-2021

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Smol

Thots

* Many millions of Muslims have

converted to Christianity in recent years, spurred by a dream or vision

of or about Christ, Jesus or "a being of light" who they identified

with him. This is unprecedented in Muslim history. For more info about

Jesus and his teachings see "The Gospels", meaning the first four

chapters of

the "New Testament" in the Bible: Mathew, Mark, Luke and John. For more

complete coverage, see the Urantia Book, Part 4, "Jesus' Life and

Teachings". (It's available on line too, eg, at TruthBook.org )

* More odd weather news on the 11th: 30 tornados have swept across the

central-eastern USA, leaving unprecedented devastation. One went

through 4 states, over 200 miles, apparently leaving a swath of

destruction all the way.

December is usually the quietest month for tornados. On the same day my

brother said it hit +18°C in Toronto, Ontario. Here, and in recent

days on Vancouver Island, we had light snow. There has also been snow

on the BC mainland on top of the record floods, and heavy snows in

Europe including even Spain. (Climate Change Channel and others

on youtube bring us the daily dramas of cataclysms and "unprecedented"

weather around the world.)

* I don't understand why the virus responsible for the present problems

isn't called the "Fauci Virus". Although it is said to have originated

in

the Wuhan Institute of Virology, it seems Anthony Fauci funded the

research there and at several other institutions with what must

have been

hundreds of millions of dollars over a 20 year period. (And without the

knowledge of his superiors.) In his work emails obtained by Freedom of

Information requests he is said to have said that doing the "gain of

function" research

to

make a bat virus transmissible among humans was "worth the risk of a

global pandemic." Usually when someone sponsors the development of

something they get their name on it. He seems shy but credit where

credit is due - why

is Fauci's name not all over this

virus?

* Government of Canada death stats for British Columbia (copied from an

open letter to the BC government by many prominent physicians), from or

with Covid by age group for the entire 18 month duration of the

disease as of September 2021 are shown below. The total population of

BC was given as 5,145,851.

Age

Bracket

|

Total

Deaths

|

0-19

|

2 |

20-29

|

0

|

30-39

|

2

|

40-49

|

16

|

50-59

|

30

|

60-69

|

77

|

70-79

|

178

|

80+

|

1117

|

So 0.028% of the BC population died over 18 months, mostly

people over 80. Of the

population under 80, it's 305 individuals, 0.0059% of the population.

Assuming an average lifespan of 70, it can be expected that 2.1% of a

population will die in any given 18 months. So all else being equal

make that 2.128% of the

population who would have died in the 18 months of Covid to the time of

the figures. Percentages for the whole country are similar. In other

words, the percentage of deaths with or from Covid are statisticly

insignificant, and even more so among those below retirement age.

Over this "nothing burger" we have a continuing "fear

blitz", insinuations of mass illness, death and mayhem by the mass

media. We

have shut down our society, our schools, our production and our

economy, and severely restricted the freedoms and activities of each

citizen. We have been imprisoned within our nations, our communities

and sometimes even in our own homes. Indications are that deaths from

other causes such as depression leading to dangerous drug use and

suicide as well as from actual problems resulting from restrictions on

movements and illnesses that went untreated far outnumber Covid deaths.

And we are now in danger of many problems resulting from the shutdowns

including educational deficit, food shortages and breakdowns of un- or

poorly-maintained infrastructure as well as the whole supply chain.

* An anagram of "omicron" is "moronic". Is that intentional? Where did

that name come form? 0 microns is nothing. Is omicron, however

contagious, a big deal when

its symptoms are less severe and shorter than a typical cold? If we get

it do we become immune to the more serious forms as well? That could be

a good thing!

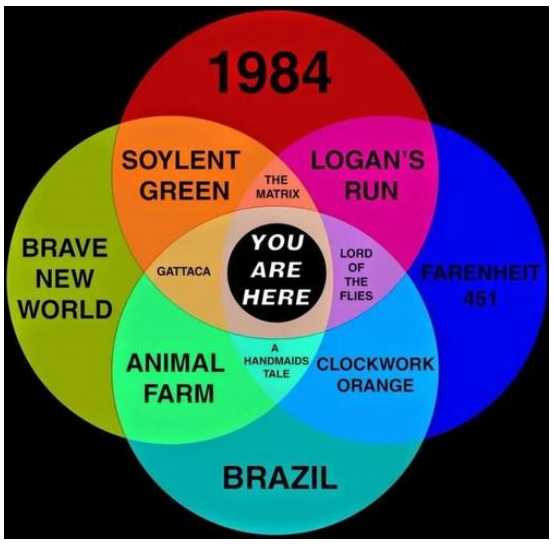

* Many have tried to classify what they see as "the present dystopia"

with one of those

those envisioned in literature. But someone suggests it is a

combination of all of them with a venn diagram.

(I wonder what happened to "Atlas Shrugged?")

ESD

(Eccentric Silliness Department)

* A man went west from China and became disoriented.

* After you found a city, if you leave and have a compass, you can

refind it and return. If it is refined it will have higher culture than

when you originally founded it.

* Make sure you buy only inspired food. Expired food isn't as good.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Planned Unipolar Electric Hubcap

Motor Diameters

[14th] Really this is just for my own reference. If I write things on

paper I can lose track, but I can always check my previous newsletters.

I got out 12 coils again (same ones as for the last 10

years) and arranged them in a circle. I closed the circle in until I

thought they were as close together as would easily fit and measured

diameters. It seemed to work out a bit smaller than the last time I

tried it, when I got 370mm. That time I had only measured the outer

diameter. Later I realized I wanted the rotor diameter and other

diameters, and that the diameter from the windings (of uncertain,

inexact thickness) probably wasn't a good thing to take other diameters

from.

350mm - Outside of coil windings, inside of outer case

330mm - Rotor diameter (outside edge of magnets, outside edge of

coil cores)

280mm - Centerline of coils & magnets

139mm - outside of trailer wheel hub (for case)

63mm - raised center of hub (stator end of case bolts against flat area

from 63 to 139, with 63mm hole in center.)

Notes:

1. Just 45mm radius from inside of magnets to outside of metal hub.

...How much magnetic drag will that cause?

2. Unsupported end plate from 70mm radius to outside of end plate 175mm

= 105mm. ...How thick PP/epoxy so it doesn't bend with pull of magnets

on rotor? Reinforce?

(WHEN am I going to get that CNC table running? With the HHO torch to

cut the rotors?)

Other "Green" & Electric Equipment Projects

CNC Table

[5th,6th] Given that I seemed to want it

for most every project now, I (finally) installed LinuxCNC and

connected the 'Gekkodrive' stepper motor driver, and then spent the

rest of two days trying to get it to run the motors on the CNC table.

At the end of the second day I discovered the file names it was

offering me to select from were "simulation" files that didn't run any

hardware, and that to see the real file I had created in the "setup

wizard", I had to click a tiny "-" sign in a tiny box and turn it into

a "+" sign. Then the real info file name appeared. When I had done that

and tried to run it again, it finally quit with an error that divulged

it 'couldn't find the parallel port'.

Parallel ports have been obsolete for 18-19 years now. The

one on the computer went out the window with the old malfunctioning

motherboard. So mine was a 'USB to Parallel port' adapter cable. These

are said to have problems and mostly can't run the old parallel port

printers they are supposed to be for. I only need for it to output 6

bits, "direction" and "step" for each motor. Using USB to Parallel

isn't recommended because there can be delays in USB systems in sending

the real-time signals, causing jittery motor operation. But options are

limited.

Other than actually installing LinuxCNC on the first

morning, the only real progress was that at the end of the second day I

wired up the "Z axis" motor to raise and lower the router carriage.

Great, that made 3 connected stepper motors that wouldn't run instead

of 2.

Perhaps more time spent reading would result in less time

spent in futility and frustration? I'm not entirely convinced in this

case, but I'll see if I can dig anything up on 'configuring a USB port

as a Parallel port' in Linux.

[7th] Spent some hours in frustration trying to find out how to run a

USB to Parallel adapter as a parallel port. Info on line is sketchy and

way out of date. There's something called "parport" which has to be

installed and activated. One thing said to enter a string of text into

"the "LILO" file. There are around 20 files called "lilo" on my desktop

computer. The CNC computer has all kinds of needed user stuff stripped

out of the system including no "file finder", no "power manager" (so I

have to log in again every time I leave for a few minutes and can't

change the settings) and no "software center" to go look for missing

items (which I see on my other computer are not available on Ubuntu

"software center" anyway).

[8th] It occurred to me to check out the thing I had done in 2013 to

get the MSP430 "Launchpad" board to talk to the computer over the USB

bus. I found the issue (TE News #63). In it I had linked to the site

with the info... but the site wasn't there any more! Why had I not put

the info into the newsletter? Oops!

I went to the old laptop with the MSP430 stuff on it and

started vainly searching through the thousands of mostly empty

directories that make up the Linux system. Then I went to the MSP430

assembler directory. I had made a copy of the command lines as a file.

Then I remembered a name, "rules.d". /etc/udev/rules.d/ directory

turned out to be where the command lines had been typed in, in a file

named "46-TI_launchpad.rules". Except that it had been renamed

"46-TI_launchpad.rales". Why on Earth did it still work? (Or at least,

it worked last time I tried running the assembler and debugger.) No

matter. Was getting the USB to Parallel port a matter of putting some

configuration line(s) into the /etc/udev/rules.d/ directory (as opposed

to any of the other 5 "rules.d" directories in the system folders)?

That didn't do the trick. Still have nothing nothing

except "You can't use a USB to parallel converter with LinuxCNC." But

for a typical CNC table or whatever, all it needs to do is output 4, 6

or 8 bits (2 per axis), and the for that hardware IS THERE! If the

software can't do it, it's because something is missing.

So now I'm into the 650 page manual for "HAL" (Hardware

Abstraction Layer). (Good God am I going to have to C compile a new

piece into the Linux system? YETCH! I can't help but think that's

really not my department and it will probably come with a steep

learning curve to do what for someone "into" linux programming should

be a simple if not trivial job. If I do it it's not just for myself,

it's to make what they're saying on line "can't be done" into "plug and

play" for everyone in the future.)

Then I thought to write to the Ubuntu developers. I'm

pretty sure this would be a trivial task for those already "into" the

core of the Linux system.

[12th] Having had no answer from Ubuntu, I gave up and ordered a

parallel port that would fit my computer off AliExpress in case

(seemingly like everybody else) I can't get the USB to parallel to

work. It'll run the

CNC table smoothest anyway.

Electricity

Storage

(Batteries)

[31st] I had thought somewhere in there

to get back to trying to

make a working, usable battery. I was frustrated with the cylinder

cells (although if I kept at them long enough I just might succeed). So

I started thinking of flat cells again. Could I make them with

reinforced PVB tops and bottoms so they couldn't bulge? Now I had a new

idea as to form: What about a giant button cell? Copper is the metal

for the negative. Surely one could take a disk of copper, sandwich it

between a headstock and tailstock on the lathe, and push the edges over

a cylinder to form it into a shallow cup? Then sand it even on top.

Coat the copper inside with zinc for a flat plate -ode and paint it

with the osmium dopant and then the agar layer. Another shallow dish of

paper would make a tray for the paste +ode.

Hmm... a nice sheet of graphite for a current collector

over that... and then? How about a lid of PVB with...

Okay, how about a dish of PVB with a reinforced bottom

(turned over to be the top of the cell) that fits inside the copper

rim? It would have a slit for a flat piece of cupro-nickel terminal

that sits flat across the inside of the top of the dish. Under that is

the graphite sheet. Under that, still within the PVB rim, is the paste

electrode. Then a sheet of separator paper whose edges fold outside

the PVB rim, but inside the copper rim. After wetting with electrolyte,

this assembly is inserted into the copper cup, and the edges of the cup

can be crimped over to keep it all together.

Maybe I should think a little more? Isn't there any easier

way?

Electricity

Generation

Wind Wall

[5th] I printed out the template for the

cross pieces for the

rotors at the full size that I wanted: 16 inches outer diameter. One

end was longer to the center than the other: 183mm versus 178mm. Since

it was printed on two pieces of paper, I spread them apart a bit so

they were the same. Were they perfectly straight?

I thought,it was one thing cutting pieces of wood for test

rotors in the wind tunnel. But now, every imperfection of form when I

cut it out with scissors and traced it out for the mold would be

duplicated in every piece on every rotor produced. And the rotors spin;

they should be perfectly balanced.

How to get relative perfection? It keeps coming back to

the same thing: get the CNC table working, and the HHO torch for

cutting metal with it. Then the patterns can be described mathematicly

and cut by machine to perfection. And the generator rotors will need to

be cut out in quantity to exact specifications too.

I wanted to make a mold and try melting PP fishnets into

rotor pieces. It seems it would be better to get the CNC table going.

The mighty, 90

pound sheet

metal machine -- Mighty feeble!

Still, I could

make an alium. sheet mold piece

for one

face of the rotor... Trouble at the pass with this, too! I had bought a

sheet metal cutter/bender/roller back in Victoria before I moved. It

had proven pretty useless for folding and cutting anything but very

small pieces. Maybe its forte was rolling? I had never had occasion to

try that before. When I tried rolling the sheet of 2mm thick alium. it

wouldn't do it! It seemed 2mm was too thick, and the roller gears just

barely meshed - sometimes - so one roller wouldn't push and it would

just slip. This was probably ruining the gears, too. And it was really

hard pushing on the handle... as with everything I've done using this

machine. I only got it slightly curved and just couldn't go any

farther. I am officially disgusted with this 300$ combo unit - it

doesn't do anything well.

Still, I could

make an alium. sheet mold piece

for one

face of the rotor... Trouble at the pass with this, too! I had bought a

sheet metal cutter/bender/roller back in Victoria before I moved. It

had proven pretty useless for folding and cutting anything but very

small pieces. Maybe its forte was rolling? I had never had occasion to

try that before. When I tried rolling the sheet of 2mm thick alium. it

wouldn't do it! It seemed 2mm was too thick, and the roller gears just

barely meshed - sometimes - so one roller wouldn't push and it would

just slip. This was probably ruining the gears, too. And it was really

hard pushing on the handle... as with everything I've done using this

machine. I only got it slightly curved and just couldn't go any

farther. I am officially disgusted with this 300$ combo unit - it

doesn't do anything well.

[11th] The 4 little

generators I'd ordered arrived (already?!?) and I

checked them out. The reason they were "low RPM" was because they had a

double planetary gear reduction to the output shaft. This inevitably

meant there was a lot of friction turning the shaft to get the motor to

spin. It didn't look like they would start turning without a

considerable wind blowing, even with high-torque "wind jammer" rotors.

(In fact I couldn't turn the shaft except by sticking a screwdriver

through the hole for leverage.) One of them was much harder to turn

than the others. I suspect a

shorted winding in the motor. Not very confidence inspiring, but what

do you expect for 16$ each? (Hmm, perhaps I could have rigged them up

without one or both planetaries, if that was feasible. Let's see...

direct on the motor shaft in the drill press at 3100 RPM: 1.6 volts.

Forget it!)

[11th] The 4 little

generators I'd ordered arrived (already?!?) and I

checked them out. The reason they were "low RPM" was because they had a

double planetary gear reduction to the output shaft. This inevitably

meant there was a lot of friction turning the shaft to get the motor to

spin. It didn't look like they would start turning without a

considerable wind blowing, even with high-torque "wind jammer" rotors.

(In fact I couldn't turn the shaft except by sticking a screwdriver

through the hole for leverage.) One of them was much harder to turn

than the others. I suspect a

shorted winding in the motor. Not very confidence inspiring, but what

do you expect for 16$ each? (Hmm, perhaps I could have rigged them up

without one or both planetaries, if that was feasible. Let's see...

direct on the motor shaft in the drill press at 3100 RPM: 1.6 volts.

Forget it!)

[12th] I had

drawn up a plan for a device to bend the metal and looked for some

pipes to make it from. But I thought I'd try again to bend the alium.

This time I rolled it

into the machine as best I could and then used brute force: I pushed

the sheet with both hands to

bend it a little farther than the roller would by itself, then moved it

along a bit and pushed repeatedly. Of course it wasn't

perfect. I did much adjusting over an hour and more trying to get it to

match the simple round curve of the drawing. But eventually I had it

close enough. Better than having to make a whole new machine specificly

to make a couple of bends! Then I put my polishing wheel on the drill

press and did what I could to polish it up so the melted plastic would

flow smoothly and not stick.

[12th] I had

drawn up a plan for a device to bend the metal and looked for some

pipes to make it from. But I thought I'd try again to bend the alium.

This time I rolled it

into the machine as best I could and then used brute force: I pushed

the sheet with both hands to

bend it a little farther than the roller would by itself, then moved it

along a bit and pushed repeatedly. Of course it wasn't

perfect. I did much adjusting over an hour and more trying to get it to

match the simple round curve of the drawing. But eventually I had it

close enough. Better than having to make a whole new machine specificly

to make a couple of bends! Then I put my polishing wheel on the drill

press and did what I could to polish it up so the melted plastic would

flow smoothly and not stick.

Okay, great. That's one face of one mold. Of one element

of a rotor. Of how many for the whole wind wall? Anyway, one more face

and then I could start figuring out how to do the edges and the spring

assemblies for the first one.

Then I went on AliExpress and ordered some new polishing

wheels and some various bars of polishing ("buffing") compound. While I

was there I saw a 20 pole brushless motor that looked like a better bet

for a generator than the ones I had just received. I had reduced my

"wind wall" expectations to 2 rotors wide, since each rotor means more

axles, bearings... and generators. Let's keep the duplication of parts

to a minimum! So I ordered two of those too (and there went another

couple of hundred dollars). I would have to gear the wind turbines'

outputs up to get maybe 1000-3000 RPM from turbines turning 150-750 -

of course all depending on the wind.

The day wasn't done. I went out to the shop and made the

inner face. I needed to make some sharp bends on the ends of this as

well as the curved face. I suppose I did as well as could be expected

when none of my sheet metal folding and bending tools were adequate for

the job. It would have to be good enough. I needed much heavier duty

sheet metal tools perhaps worth 10 times what mine had cost. (In spite

of the little roller/bender/cutter weighing 90 pounds!)

Now it's all in making the frame with the edges and the

springs

to hold the faces "perfectly" aligned while pressing the plastic

together into a solid piece as it melts, to get rotor faces that aren't

just misshapen lumps of plastic maybe full of voids.

[13th] Moving on to the

sides! I only had vague ideas how I might do them. I was thinking of

angle iron, and welding bits and pieces into place. Or maybe cutting

1/4" plate steel to fit? Then I thought of some outside 1/4 circles of

alium. I had got from Jim at AGO in about 2014 when I was trying to

cast metal. I found two remaining in 3/8" thickness. To my surprise

they were big enough. In fact, just about right. And plastic wouldn't

stick to alium.

[13th] Moving on to the

sides! I only had vague ideas how I might do them. I was thinking of

angle iron, and welding bits and pieces into place. Or maybe cutting

1/4" plate steel to fit? Then I thought of some outside 1/4 circles of

alium. I had got from Jim at AGO in about 2014 when I was trying to

cast metal. I found two remaining in 3/8" thickness. To my surprise

they were big enough. In fact, just about right. And plastic wouldn't

stick to alium.

Then I thought I would connect across between the end

plates with threaded rod. I had picked up some 3 foot sections of

#10-24 when I discovered the Coop Home Centre in Masset had them, a

couple of years ago. (And people wonder why my place is cluttered. But

I had them!) I cut off the sharp ends and drilled holes in the plates

to fit the rotor outside face piece. I threaded one end and made the

other end slip-through. I cut two rods in half into four shorter and

threaded them in, set in the face piece, and tightened the end pieces

together over it with 4 nuts.

How simple! It

all fit and looked way better than anything I had expected I would come

up with. The cracks at the edge joins were so small I don't think

they'll ooze much if any plastic.

How simple! It

all fit and looked way better than anything I had expected I would come

up with. The cracks at the edge joins were so small I don't think

they'll ooze much if any plastic.

The inner

piece was just a bit wider and didn't fit in. The belt sander soon took

care of that. There was a slight gap along the left edge around the

middle. Maybe .04"? If much plastic oozes out there, I'll sand or file

the outer piece just in that area to close it up. Most of the rest was

less than half that.

The inner

piece was just a bit wider and didn't fit in. The belt sander soon took

care of that. There was a slight gap along the left edge around the

middle. Maybe .04"? If much plastic oozes out there, I'll sand or file

the outer piece just in that area to close it up. Most of the rest was

less than half that.

The last piece is the spring assemblies to press the

plastic into a single sheet as it melts. I was thinking of 2 or 3 sets,

but maybe I'll try just one first. What works best will depend on how

easily the plastic flows, which will probably depend a lot on oven

temperature. (And the type of plastic. Hmm, my brother says fishnets

are not polypropylene but nylon. Whatever -- if it works I'll take it!)

Looking some more, the top and bottom are pretty open

until the plastic has melted. (I should have put the upper and lower

lips on the lower piece. But I had enough trouble bending it as it was!)

But It's a concave shape. If I stood it at an angle so the

top and bottom were both even and highest, it would be a "bowl" and

minimize loss of plastic through those edges. And when I set it up that

way, it looked like the spring assembly could be replaced simply by

weights on the upper piece, in the "bowl"! - perhaps some bits of

steel. And discovering how much weight to use will be much easier than

trying to adjust springs. Suddenly it's almost ready to try out!

[14th] I finished up the mold by cutting

some angles to help it sit with the two ends level, and added a couple

of "feet" that should hold the upper mold just the right distance from

the lower whe the plastic melted regardless of how much weight was on

top. while I had it apart I sanded the edges of the face pieces just a

bit for a more perfect fit with the tiniest edge gaps.

I tried

putting a piece of fishnet in the oven in a throw-away alium. pie pan,

and gradually increasing the temperature. It got to 350°F without

doing anything. I cut a couple of bits of rope - polypropylene for sure

- and put them in the pot too. They didn't do anything either. I raised

it to 400° again with no effect that I saw. I raised it again and

at 420° the two ropes had shriveled up into lumpy pieces and could

be easily squashed down when pressed. The fishnet still sat there, but

could be squashed into a solid by pressing hard enough.

I tried

putting a piece of fishnet in the oven in a throw-away alium. pie pan,

and gradually increasing the temperature. It got to 350°F without

doing anything. I cut a couple of bits of rope - polypropylene for sure

- and put them in the pot too. They didn't do anything either. I raised

it to 400° again with no effect that I saw. I raised it again and

at 420° the two ropes had shriveled up into lumpy pieces and could

be easily squashed down when pressed. The fishnet still sat there, but

could be squashed into a solid by pressing hard enough.

I decided to pass on the fishnet for now and cut up the

5/8" PP rope, about 8 or 10 feet long, into short sections of plastic

to put in the mold. The pieces weighed 382 grams. I'll go by weight: if

there are voids it needs more, if it's oozing out and too thick, less.

(I cut them with a nice pair of one-handed branch loppers that work

really well for fat cable, too.)

I was going to put it in the kitchen oven and open some

windows1 to quickly see the result, but a friend talked me out of it.

Well, no doubt it's not the healthiest thing to do. I guess I'll have

to wire up the oven I got at the dump to use outside. (If it wasn't

freezing, snowing and raining out there I would have done it without

hesitation.

[16th] I tried to wire up my "new" stove

from the dump. The solid state controls didn't work properly. No

warranty; can't complain! I rewired it to just power the oven element

whenever it was plugged in. (The oven element drew ~9.2 amps, so 240V *

9.2A = 2200 watts. ...Just 2200? At the freezing point outdoors? No

wonder it took so long to heat! How long will it take if I cut out the

back and extend the oven to 5 feet long, even with rock wool

insulation? It may need two elements.)

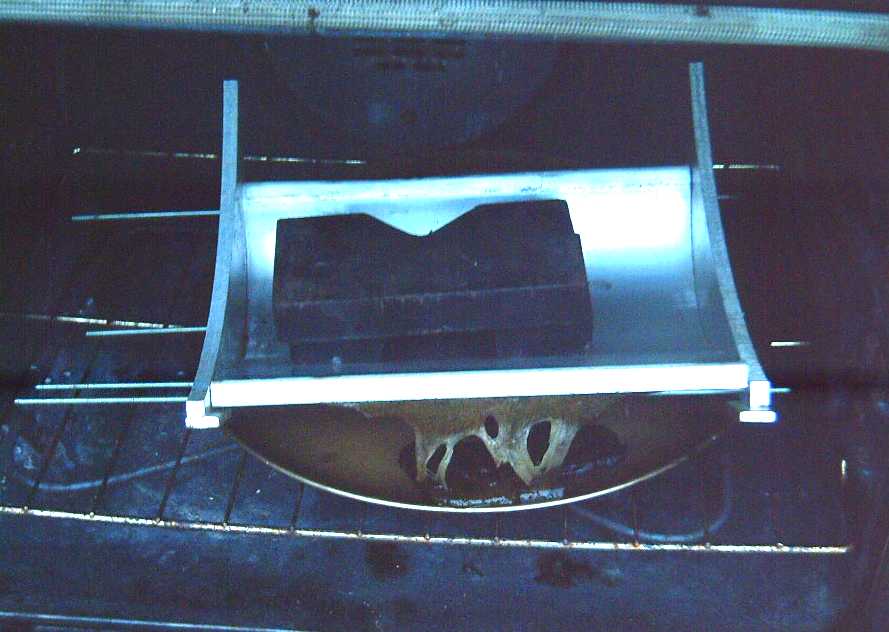

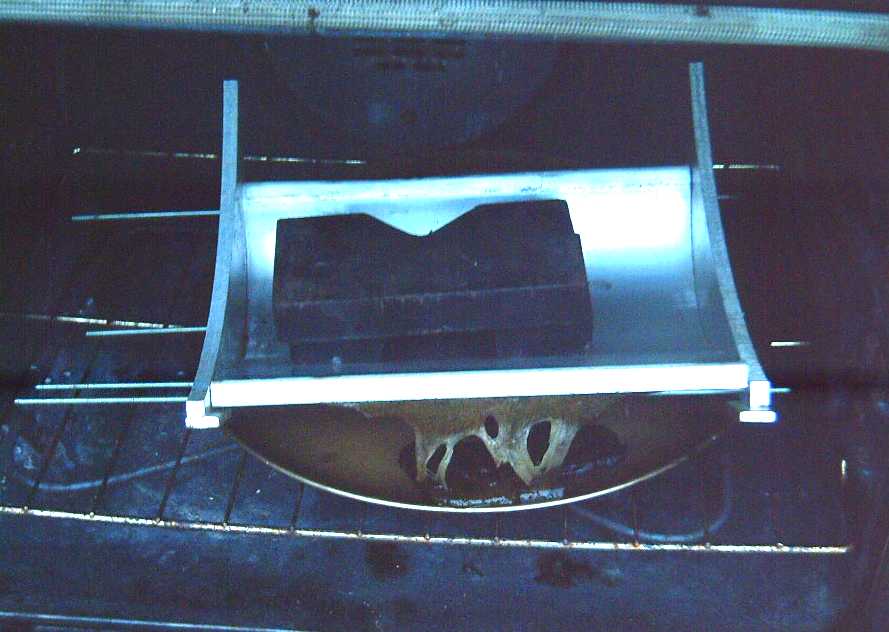

Mold in oven with weights to

press the top and

bottom together. Plastic is oozing out the front onto the drip pan.

Mold in oven with weights to

press the top and

bottom together. Plastic is oozing out the front onto the drip pan.

I put the mold in the oven with a couple of heavy solid

steel weights on it and turned it on. Nothing seemed to happen for the

longest time. Finally after 45(?) minutes some plastic started changing

and some was oozing out. Then I remembered (just in time) to put a drip

tray under it.

Then I noticed the mold had warped at the front edge! The

alium. expanded more with the heat than the steel threaded rods holding

the end plates, and it had to go somewhere. Apparently alium. needs

alium. threaded rod. Since there is no such thing, I'll replace the

rods with long, thin alium. bars, and thread bolts into those.

For this session I took it out, loosened the nuts, and put

it back in. It was in the oven a total of 55 minutes. After that time

plastic was oozing out the front and the mold had, mostly in the last

minutes, squashed down on itself as planned. I opened the oven door and

unplugged it. There had been a fair bit of smoke, and I was happy that

I hadn't done it in the house. (Although, if I had, I wouldn't have put

it in until the oven was up to temperature, so the time would have been

much shorter.

After Cooling

After Cooling

After it had cooled the top of the mold pulled off easily.

It mostly came away from the bottom too, except where it had dripped

and curled around to meet the bottom surface, which I hadn't polished.

But that wasn't badly stuck either and it was a small area. It worked

off easily with a little flexing.

The rotor wasn't perfect but the plastic had filled

everywhere solidly - except that the corners were all missing. It was

also too thick in some places. My desired 3mm (1/8") had become 6mm

through an area toward the fat right edge. (It may have been partly

because of the warping of the bottom piece. Also the weights were

placed a bit too far to the left, which may have left the right side

not fully pressed down.)

First rotor vane as-is removed

from mold.

First rotor vane as-is removed

from mold.

(Sometime, considering the airfoil-like shape, I decided the

new design is better described as "blades" than as "vanes".)

Rotor blade after chiseling away

the drooled

front edge and scraping the edges.

Rotor blade after chiseling away

the drooled

front edge and scraping the edges.

A piece of the original PP rope shows the darkening of color. The

pieces on the drip

pan were quite dark and brittle - oxidized. This indicates I should

heat

the oven first,

then put in the mold with the plastic, to minimize the time it's at a

high temperature

and especially the time the PP is exposed to air before the mold starts

to close down.

(That should also minimize smoke.) (FWIW: There was one short

piece of thin yellow

rope, bottom left.)

For the next time, I would straighten the bottom out, do

the alium. bars to eliminate the differing expansions problem and put a

lip on the bottom piece along the front edge to stop - or very much

slow - plastic from coming out there. That will mean attaching a piece

of alium. to the bottom, and removing the lip from the top piece, since

the two would clash. The rear edge, at least on this first try, didn't

seem to be a problem. Away from the corners it was perfect and came to

a point as planned.

Actually instead of changing the threaded rods I'll

probably just leave the nuts somewhat loose, so they're tight when it's

up to temperature. After all, the plastic won't ooze out the cracks

until it is up to temperature and it melts, and then the nuts will have

tightened up and the cracks will be gone. I'll save the alium. rods for

the next mold.

Finally, I would have to carefully place extra plastic

near the corners to ensure they got filled. Of course, if it wasn't for

the dripping front and the extra thick area, there should have been

more than enough PP to fill the whole mold. So I'll use the same amount

(weight) next time. And more weights, better distributed, to press the

mold together.

When I get to the next mold, I'll probably get more of it

right the first try. In a way this is "pioneering" in that usually

little plastic bits are melted in a heater and extruded into a very

solid mold made with a milling machine of thick metal, under high

pressure, filled rapidly before it can freeze again. Here I'm using big

chunks

of plastic - pieces of scrap PP rope (or hopefully fishnet - nylon?) -

and gradually squeezing them down under low pressure with weights, with

the oven

keeping everything at working temperature until the process is done. If

I expand the oven I should be able to make very large shapes - like

wide 5 foot long "boards" (HDPE?) for the frame and stationary vanes of

the wind wall, and 2 foot by 5 foot transparent greenhouse panels from

scrap clear PP or PETE food containers. First, I have to "perfect"

things to get good results, consistently.

[17th] Okay the plastic didn't get into the corners, but it dripped out

one end where there was no lip. What if I flip it over? The top piece

with the front & rear lips becomes the bottom, and it's downhill to

the ends where the corners are. The plastic would then fill the

corners, and drain away from the center part that was too thick --

hopefully not leaving any voids there. I can put a couple of bolts

through near the sides to set the desired thickness at the front, and

the holes they make can become bolt holes for the final rotor. Worth a

try! So first I needed to drill new holes in the sides to reposition

the threaded rods since the mold faces would now be on the other side

of them.

[18th] Someone suggested that the "stationary" vanes might move to be

less effective in high winds, to prevent over-revving of the rotor. If

the wind aiming vane could pivot, it might be held by a spring that

would be overpowered by sufficient wind. Or perhaps the old inclined

ramp trick: to pivot away, the vane must climb a sloping ramp. A very

strong wind would be sufficient to push it up, and it would slide back

down into its usual position when the wind weakens. This is maybe

getting more involved than I had meant to get, but if the ramp is built

into the mold, it's little extra to manufacture.

Late at night

I drilled the holes and moved the rods. It's

ready

to try again tomorrow.

Late at night

I drilled the holes and moved the rods. It's

ready

to try again tomorrow.

[19th] This time I used

some fat green rope I had salvaged off the

beach a couple of years ago. The first attempt coming out too fat, I

tried just 200 grams. I plugged in the oven. I decided to wait 50

minutes and then put the mold in. At 48 minutes the power went off.

When it came back on I plugged it back in, but of course the heat-up

timing was screwed up. I got out a meter with a thermocouple to measure

the actual oven temperature. Just as well - I learned from that. The

plastic didn't seem to melt below about 250°C, if then. The oven

was preheated to that temperature. But when I opened the door and put

it in, the temp. dropped to ~180°C and had to warm up again from

there.

[19th] This time I used

some fat green rope I had salvaged off the

beach a couple of years ago. The first attempt coming out too fat, I

tried just 200 grams. I plugged in the oven. I decided to wait 50

minutes and then put the mold in. At 48 minutes the power went off.

When it came back on I plugged it back in, but of course the heat-up

timing was screwed up. I got out a meter with a thermocouple to measure

the actual oven temperature. Just as well - I learned from that. The

plastic didn't seem to melt below about 250°C, if then. The oven

was preheated to that temperature. But when I opened the door and put

it in, the temp. dropped to ~180°C and had to warm up again from

there.

Twice the weights slid off the back, and once slid down to

the front, so I had to keep opening it and replacing them, cooling the

oven again. But by the end of 35 minutes with the mold in, it read

around 275°C, and it looked like the plastic had squashed down. I

opened the door and let it cool a short while. When I pulled it out and

saw it it was apparent I hadn't waited long enough. Or something. The

left hand edge hadn't fully squashed down. And when I pulled it apart,

I found the idea of inverting it so the plastic would flow downhill to

the corners hadn't worked at all. Instead, it seemed the plastic just

wanted to pull itself together into as compact a blob as it could even

against gravity, and only the heavy weights on top made it spread out

at all. It was about the right thickness, however, so obviously it

wasn't enough plastic. The only solution I could think of was MORE

WEIGHTS. But if inverting it did nothing to spread the plastic out, I

could at least turn it the other way up again so the weights sat in a

valley instead of skiing down from a hilltop. Then I could use a big

lead ball fishing weight. (Oops, no! The oven must get awfully close to

the melting point of lead if not exceed it! More bars of steel, then!)

Twice the weights slid off the back, and once slid down to

the front, so I had to keep opening it and replacing them, cooling the

oven again. But by the end of 35 minutes with the mold in, it read

around 275°C, and it looked like the plastic had squashed down. I

opened the door and let it cool a short while. When I pulled it out and

saw it it was apparent I hadn't waited long enough. Or something. The

left hand edge hadn't fully squashed down. And when I pulled it apart,

I found the idea of inverting it so the plastic would flow downhill to

the corners hadn't worked at all. Instead, it seemed the plastic just

wanted to pull itself together into as compact a blob as it could even

against gravity, and only the heavy weights on top made it spread out

at all. It was about the right thickness, however, so obviously it

wasn't enough plastic. The only solution I could think of was MORE

WEIGHTS. But if inverting it did nothing to spread the plastic out, I

could at least turn it the other way up again so the weights sat in a

valley instead of skiing down from a hilltop. Then I could use a big

lead ball fishing weight. (Oops, no! The oven must get awfully close to

the melting point of lead if not exceed it! More bars of steel, then!)

Re-inverting it meant going

back to the plan of putting a

lip on the outer (again the bottom) piece to keep plastic from dripping

out the front. And removing the lip from the inner one.

Then I had the thought that perhaps I should make them one

piece. They weren't so thick in the thick area that it would take a

whole lot of extra plastic. In that case maybe I should make a new

outer (lower) mold piece anyway, because it would need to be a bit

longer. OTOH I could just add the extra plus the lip. (By the 21st I

had decided to do a new mold bottom with the "bulging" cross section

and large front and rear lips to prevent any plastic from drooling out.)

Back to the Design (Wait, what? Oh No!)

Thinking I had "the ultimate" and with the plans all set

in my mind, I now conceived that 3 rotor blades might be better than 2.

With 2, they were alternately across the wind and then in line with it.

How could they be capturing the full potential of the wind? With 3 they

would go from 1.5 rotor blades width across the wind to 1.73 and back

as it spun - much more constant.

On the negative side of adding blades there is the drag of

each blade to consider. But with rotors going about the speed of the

wind, that would be less notable than for "Darieus" blades moving 4 or

6 times faster. For the one(s) going downwind it's more power being

caught. Only coming back upwind is there additional drag. For 3 blades

it's probably

less than the extra power obtained.

While the

power was off I did a little drawing and rather

liked it. I decided it was worth trying out in the wind tunnel. And

since 3 rotor blades would be bound to be self starting at any angle of

attack, why would one want to separate them into two or more vertical

sections at different angles? Why not just one tall rotor of the entire

desired height? The only thing having two vertically in-line sets might

do was even out torque ripple a bit. And the only problem with that was

my 12 inch wide sheet metal roller still wasn't any wider. Also a maybe

20 inch tall max. rotor would fit in the oven until the oven was

enlarged. I want to undertake things one step at a time. Now I'm into

more experiments (research), trying to change the mold to do the whole

blade at once, and still trying to get it working right in the oven.

Looks like too many things to do at the same time already! (How did I

get into this?)

While the

power was off I did a little drawing and rather

liked it. I decided it was worth trying out in the wind tunnel. And

since 3 rotor blades would be bound to be self starting at any angle of

attack, why would one want to separate them into two or more vertical

sections at different angles? Why not just one tall rotor of the entire

desired height? The only thing having two vertically in-line sets might

do was even out torque ripple a bit. And the only problem with that was

my 12 inch wide sheet metal roller still wasn't any wider. Also a maybe

20 inch tall max. rotor would fit in the oven until the oven was

enlarged. I want to undertake things one step at a time. Now I'm into

more experiments (research), trying to change the mold to do the whole

blade at once, and still trying to get it working right in the oven.

Looks like too many things to do at the same time already! (How did I

get into this?)

As the RPM seemed to have gone up with use, I ran the wind

tunnel with the original rotor (#3) and no stationary vane. It had

rather inexplicably gone from 90 RPM up to about 102(?) with use of the

mini wind tunnel. Now that the tunnel hadn't been used for a while

(plus the temperature was down to about freezing every day) it was back

down to 86! I'm glad I checked this detail. I'm using the blades from

this rotor (+ 2 new blades) to make the new one, so I won't have it any

more to compare with. I'd have made the new rotor and thought 95 RPM

was lower performance instead of higher. (I should really have checked

it with

a stationary vane, too.)

[20th] One point in the drawing was bothering me. With 3 blades, the

gaps in the center were smaller, presumably by cosine 120 degrees or to

.866 of the original gap. That would restrict the air blowing through

the center area, which now also had two exit paths to take instead of

one. That would surely have some effect on the efficiency. Moving the

inside of the blades farther from the center should be better. Because

of the angles it would also decrease the outer diameter a bit with the

same blades. It would also be a hard thing to try and adjust to find

"optimum" because I would have to make new center pieces to hold the

blades for each try. Unless I came up with some new system. It would

also

be hard to measure the results without an actual generator (or

dynamometer) connected: since the diameter would change a bit, the RPM

reading would have a slightly different meaning. I decided to just use

my sense of judgment. It should look like there was enough room

between the blades at the center to pretty freely pass the amount of

air being scooped in, but no more. And I figured that if in theory

changing the inner space would change the blade shape, it was by such a

tiny amount as to be negligible, so I wouldn't (didn't) change it.

Before I went any farther... that reality check that is so

easily forgotten in the excitement of discovery: Was my work really

original, or could I possibly be duplicating or coming very close to

what someone else had already done? and maybe was already for sale

somewhere? I did a web search and went through 20 pages of thumbnails

of windplant rotors. Nope. Nothing close. There were Savonius rotors

with 3 or 4 semicircle "blades" and with air spaces in the middle, and

even shaped "Savonius" blades something like the drawing I had found,

and there

were airfoil section blades for Darrieus rotors, but nothing close to

the highly curved blade shape having wing-like thickness to it that I

had come up with. So my design seems to be a first. Probably worth

developing, then. And hopefully producing!

Using the same

paper template one blade at a time and a

30-60-90 drafting triangle,

I outlined an end piece of the test rotor size on a piece of 3/4"

plywood and cut it out. I sanded it

smooth and cut 3 more. It was a pretty good job because when I turned

one

on top of another by 120 or 240°, they still lined up almost

perfectly with each other. By evening (in spite of a 2 hour diversion)

I had made two additional blades and put it all together. I

assembled it like the others with the top section blades offset midway

between those of the bottom section. The diameter measured about 9.75".

Using the same

paper template one blade at a time and a

30-60-90 drafting triangle,

I outlined an end piece of the test rotor size on a piece of 3/4"

plywood and cut it out. I sanded it

smooth and cut 3 more. It was a pretty good job because when I turned

one

on top of another by 120 or 240°, they still lined up almost

perfectly with each other. By evening (in spite of a 2 hour diversion)

I had made two additional blades and put it all together. I

assembled it like the others with the top section blades offset midway

between those of the bottom section. The diameter measured about 9.75".

Results: Measuring just the 3

blade rotor with no stationary

vane, two 30 second counts said 118 RPM and one said 116. That compared

really well with 86 RPM for the same design with 2 blades in each

section - and 4 of the 6 were the very

same blades. I then tried putting in a

stationary vane and

got it up to 152 RPM. (I didn't run the 2-blade rotor with

the vane before

disassembling it.) After running a while at low and medium speed, it

would only do 108 RPM on high. I still didn't understand why the RPM.s

should vary at different times. Perhaps the grease in the lower bearing

stiffens up in cold weather? - it certainly is colder this month than

last.

The most enthusiastic case for three blades over two (and

seemingly the most likely to be the most accurate) would be 118/86 RPM

= 1.37 times the speed. The worst case, taking the lower speed achieved

by the 3-blade and the best ever with the 2-blade (both with the fan on

"high"), is 108/102 = 1.06 times. Even that suggests the 3-blade is 6%

better, but it would seem to be unreasonable to use those figures given

that the 2-blades one wouldn't even get back up to 90 RPM in its last

trial.

Here is the table of results extended with the new rotor's

figures:

FAN SPEED

|

AIR SPEED

meters/second

(maximum

reading with

no rotor in

wind tunnel)

|

1st "OVERLY

OVERLAPPED

SAVONIUS"

ROTOR RPM:

(Second Tests)

(OD = 7")

|

2nd "FLAT

SCOOPS"

ROTOR RPM

(OD=10")

|

3rd

"COMPOSITE"

ROTOR RPM

(OD=10")

|

3-BLADE

"COMPOSITE"

ROTOR RPM

(OD= 9.75")

(later trial)

|

LOW

|

2.1

|

00 (20)

|

40

|

40

|

57 (56)

|

MEDIUM

|

2.6

|

30 (50)

|

62

|

66

|

90 (86)

|

HIGH

|

3.1

|

60 (80)

|

82

|

90 (102, 86)

|

118 (108)

|

The fan "low" and "medium" figures ("very low wind") as

well as the "high" round off to 1.4 times better. Everything is saying

"more watts in lower winds" with the 3-blade design. With everything

else that goes into producing and selling a useful product it would

seem silly to not produce the 3-blade design.

Taking a couple of days for this new bit of research thus

seems to have paid off. But again, what about a 4-blade rotor? Would it

be a further improvement? No doubt there's the law of diminishing

returns. But would it be NO significant return? I think... I'm just not

going to go there at this time! The designs have far surpassed simple

Savonius rotors and my expectations. I think I'd rather get the project

developed and into production

than experiment to perhaps squeeze out what would likely be just a few

more percent of power.

[21st - Winter Solstice] I decided to investigate why the wind tunnel

test results would vary with the same rotors at the same fan speeds at

different times - seemingly identical conditions. The chief

environmental

factor I could think of was the temperature, since the shop was

unheated.

With a stationary vane to aim the wind I got "before"

readings with the new 3-blade rotor. Then I popped out the lower

bearing and warmed it up by the

woodstove in the house. It was very warm, almost hot, in my hand as I

took it back out and replaced it. It had felt free-turning enough when

it was

cold, quite unlike some very stiff bearings, but it seemed to have

almost no friction hot. I immediately

turned on the fan and got a second set of readings. The difference was

so impressive (and the bearing so easy to pop out and put back) that I

reheated the bearing for each fan speed for maximum results on each:

Fan

|

RPM "Before":

Bearing

Cold (~ 1°c)

|

RPM "After":

with bearing

very warm

|

High

|

140

|

200 even

|

Med.

|

108

|

158

|

Low

|

72

|

106

|

So! The bearing indeed has a great bearing on the

situation. It was probably a warm day when the 2-blade rotor (with no

wind aiming vane) got up to 102 RPM, but it would have been around

freezing when it only got up to 86.

In comparing the 3-blade rotor with the 2, we should use

figures obtained at identical temperatures. The two readings closest

together in time (tho not on the same day) and at least similar

weather, and both at the start of testing with the fan not having run

for long in either case (I'm not sure why that seems to make a

difference either), are the 86 and the 118 RPM figures, which also are

the ones to show the 3-blade rotor to be the most improved over the

2-blade.

So to get entirely consistent results the mini wind tunnel

should be run at a consistent temperature. I can't get that. (And I

should check the wind speed each time in case the fan output varies?)

Two things are clear: (1) Results will vary widely in actual use. Lab

tests only mean so much. (2) It doesn't take much friction to slow the

rotor a lot. That surely means it won't put out a lot of watts at low

wind speeds. Well, there isn't much energy in a low wind. This design

should do better than most. But when there's the weight of the

generator on the bearings, what wind speed will it take to get it going

and actually making electricity? Evidently everything should be built

lightweight: small shafts and bearings, small light generators. But

then, they also have to stand up to high winds. It'll be useless if

things just break or overheat when there is a good gale blowing. And

that's just when one gets more significant power - maybe even like a

solar panel.

Getting more from light winds... Since bearing friction

effects seem significant, if (eg) I make the wall just two rotor

sections high, I could use 3/8" threaded rod for shafts and turn the

end down to use smaller bearings causing less friction, eg, 6mm or

1/4". A thrust bearing could help minimize friction from the weight of

the generator or its rotor(s).

[28th] Still in the realm of research, I had thought of one other thing

to measure: over what angles was there positive force turning the

blades versus counteractive force? I took one blade off the 3-blade

rotor and screwed it back onto two of the 2-blade rotor blade holders,

and put a straight shaft through it. It seemed to have positive turning

force through all 360 degrees! Wherever I set it the rotor started

spinning. For a moment this seemed incredible. But the one-blade rotor

was off balance, and the mini wind tunnel box wasn't quite level (or at

least, the shaft wasn't quite plumb). The blade wanted to point toward

the fan when it wasn't running. So when it was going upwind, it was

also going "downhill".

I put some shims under the box until the rotor stayed in

whatever position it was placed without trying to turn somewhere else,

and turned the fan on again. This time it had positive force, measuring

from the axle to the outside edge of the blade, from about 350°

(just before it reached the fan end) to about 230° (well past where