Turquoise Energy News #164

covering

January 2022 (Posted February 6th 2022)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Special Features:

• Plastic

Recycling 2.0 - remanufacturing/recycling plastics a simpler way!

(Month in Brief, Electricity Generation)

• Water Wall ! the Wind Wall repurposed for

stream, river, tidal power! (Month in Brief, Electricity Generation)

Month

In

"Brief"

(Project Summaries etc.)

- "WindWarp" VAWT Windplant... and waterplant Development &

Research

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Smol

Thots: Fertilizer & Food Shortages; Trucks Tied Up; Excess Deaths

2021; Land Living Frogs (Permian evolution); A Local Environmental

Collapse? - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems [no reports]

* Unipolar Electric Hubcap Motors: Cast PP Bodies?

* Potential Driving Range of the Chevy Sprint EV with the Ultra

Efficient Drivetrain

* Unfairly Maligning the Low Rolling Resistance Tires? - Sticking Brakes

Other "Green"

& Electric Equipment Projects

* CNC Table

* Winter Gardening

Electricity Generation

* Windrap™ VAWT Windplant (& Waterplant) & Plastic Recycling

2.0: - Plastic

Recycling 2.0: General Discussion - Some more casting rotors from PP

ropes - Brushless generators arrive, test - Failure of the "Transparent

PETE Greenhouse Panels" idea - Water Power Plant ! - Casting

Disks

* My Solar Power System:

- Daily/Monthly

Solar Production log et cetera - Monthly Summaries,

Estimates, Notes

For the third month now,

the main project focus has been the "Wind Wall" VAWT windplant with an

outer frame and the new rotor blade shape. Within that has been the new

way of recycling polypropylene plastic for making larger, not very

intricate parts - which after all uses up a lot of the best waste

plastic, potentially making really useful things. Later in the month

there was a big shift in what it was all about and the project assumed

far greater potential for higher and more steady power generation (read

on).

On the 11th it occurred to me to give the type of rotor a

new name. It really wasn't a "Savonius" or a "Darrieus". Rather than

"Carmichael" (which would have been in the tradition), I tentatively

came up with "Windwarp™ ".

I improved my mold

and was getting

good blades except that too often the outer/back corners weren't quite

filled in.

I improved my mold

and was getting

good blades except that too often the outer/back corners weren't quite

filled in.

I had 15 by the end of the month.

I did some wind tunnel tests on

the "full size"

rotors with good results.

I did some wind tunnel tests on

the "full size"

rotors with good results.

I screwed the blades in at various angles and distances from center to

see what worked best.

They ended up right where I had first, intuitively, placed them, but

variations in performance at various reasonable positions were not

large.

I made a mold to make a top and

bottom circle

for "spool" form rotors.

I made a mold to make a top and

bottom circle

for "spool" form rotors.

The first circle piece - after 3

tries.

The first circle piece - after 3

tries.

(Why does it take SO long to melt plastic in the hot, hot oven? I

bought a remote laser temperature

sensor and got readings of 262 and 266°C [511°F] on the top of

the mold when I pulled the latest piece out.

In future I can check it and make sure it's up to that to guess whether

the plastic has fully melted yet.)

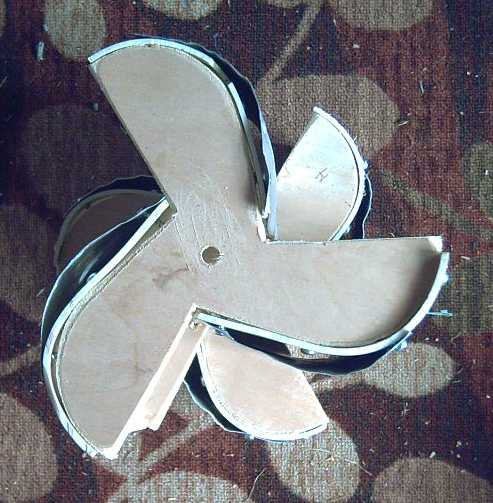

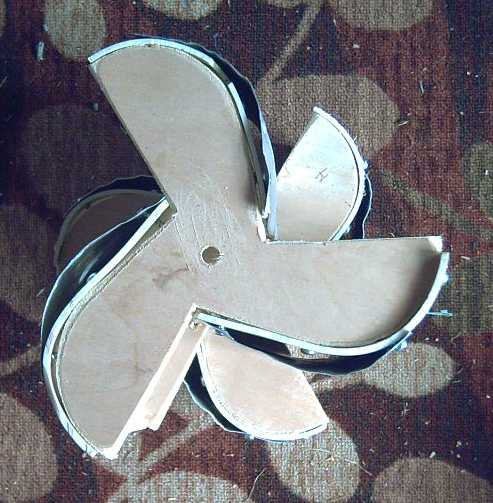

The real thing - the ROTOR !

(mostly still

needing bolting together).

The real thing - the ROTOR !

(mostly still

needing bolting together).

Water Power Plant !

On the 21st something completely new and different struck

me. But amazingly this time, not something that would have me delving

off onto yet another project! I had off and on since moving here been

thinking about tidal flow power, and possibly of power from shallow,

fast flowing creeks. There's a lot more power, and more consistent

power, in flowing water than in fickle wind. On a trip to Masset as I

passed by Masset Inlet with the tide flow ripping along, it occurred to

me that the "Wind Wall", almost exactly as already designed, seemed in

several fortuitous ways to be a perfect "Water Power Unit" that could

be deployed or installed in many and various ways wherever there was

flowing water.

First, it was a vertical axis with the generator at the

top, right under the roof to keep it driest in the weather. As a

flowing water power unit that would also put it in the air above the

water. One of the most impractical aspects of most tidal power units

I've looked at is that the generator is under the water, in line with

the propeller. Here, vertical axis rocks!

Second, I was already making it out of polypropylene

plastic - impervious to fresh or salt water! If it had a stainless

steel or alium. shaft and a UHMW-PE lower bushing, that would last well

even in salt water, and it would be the only part of concern actually

in the water.

Third, I was already designing it for power in minimal

winds, which is similar speeds to good flowing water.

Then, it's actually better: in a stream the flow is all in

one direction with no need or use for the whole unit to pivot into the

wind, the mounting for which which will likely be tricky for rotors in

a structured enclosure. For tidal flow it's two opposite directions,

and for a fixed aim mounting, a bi-directional "Water Wall" can

probably be as effective as a unidirectional (or close enough).

In addition for the Wind Wall I was going to start with a

"wall" having maybe two shafts of 3 rotor sets each. Water has so much

more power than air that one would gain more power than than wind

provides except in storms, even with a single rotor - maybe even cut

shorter for use in shallow water. And flowing water is guaranteed to

flow most of the time, quite unlike wind except in the most favorable

of locations. Even tides flow much of the time with only short slack

periods gently entered and exited.

Maybe I'll title it the "VAWP" - Vertical Axis Water Plant

24V inverters

I swear I

ordered two 12 volt DC to 120 volt AC inverters and on spec, one 24

volt DC to 120 volt AC. One was pure sine wave and two were "modified

sine wave", all 3000W, 6000W peak. Somehow all three were 24 volts!

I swear I

ordered two 12 volt DC to 120 volt AC inverters and on spec, one 24

volt DC to 120 volt AC. One was pure sine wave and two were "modified

sine wave", all 3000W, 6000W peak. Somehow all three were 24 volts!

Indignantly I went to the AliExpress site to complain, but

checking my order they all said 24 volts. I still don't know how that

happened.

I used one, with two batteries, to run my angle grinder at

the refuse station. Then I sold one. I guess I should use the money to

order a 12 volt one. (They didn't have 36V.)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Smol

Thots

* Fertilizer & Food Shortages Nitrogen, potassium and

phosphorus compounds are the fertilizers that are required in great

quantity to provide good crop yields on 'modern' farms. In 2019 some

big phosphate mines closed. According to "Financial Argument" on

youtube, ammonia (nitrogen) fertilizer created using 'natural gas'

(methane) has kept crops flourishing and almost 4 billion people from

starving. That's right: we're that overpopulated that half the world is

in effect at least partly living off consumption of non-renewing

chemicals stored in the Earth for millions of years. (I might also add

that it shows the broken link in our food chain: human excrement is not

recycled to fertilize new crop growth, and is instead considered a

waste product needing "disposal". This is not sustainable at any

population level.) With rising gas prices, major ammonia producers have

shut down and the price for nitrogen fertilizer too is skyrocketing.

Farmers - many of whom have been having a very hard time

in the last few years especially owing to weather calamities and who

have already been bankrupted in the millions - will no longer be able

to afford these manufactured fertilizers. (Where are the lavish

bailouts for our most essential industry?) Corn crop yields will be

hard hit - US corn is output expected to drop by 40% this year. Other

crops' productions will also suffer and soon they'll all be in short

supply if they aren't already. Some want to switch from corn to soy

beans (less fertilizer intensive), but as a result soy bean seeds are

in short supply.

In addition supply chains have been breaking down,

hindering maintenance and repair of farm machinery and trucks for

deliveries. Major ports are now locking out older trucks for

climate/pollution considerations, adding to the bottlenecks.

* Trucks Tied Up And with the ending of the month tens of

thousands of trucks and farm tractors have been in Ottawa, and more in

other places around North America and the world, protesting government

overreach all supposedly related to some virus. How has a medical

concern become a political reason for imposing sweeping dictatorship?

The obstinacy of our prime minister in his refusal to respond to

people's widespread and ever growing concerns about the destruction of

freedom, the economy and society in general is surely contributing to

empty store shelves for the duration which doubtless will last weeks or

months beyond. The outlook for 2022 and beyond for crop production and

distribution to grocery stores is rather bleak - especially in the

absence of caring and competent leaders in our positions of power.

Where are the big bailouts for the destitute farming community?

Ensuring our food supply is more important than bailing out the banks

was in 2008.

* Excess Deaths 2021 According to Greg Hunter (USA Watchdog -

1st program of 2022), who got it from Robert Malone (perhaps the

leading mRNA vaccine researcher), who got it from new life insurance

actuarial tables, deaths from all causes of working age people 18 to 64

were up by 40% in later 2021. Apparently it is still rising.

In another video Scott Davison, CEO of One America Life

Insurance company, says a 10% rise in this number would indicate some

huge "once in 200 years" disaster had occurred. It was up by 20% in the

second quarter. The 40% in the third and fourth quarters of 2021

(ending in October) is "off the charts". In addition claims on short

and long term disability insurance are way up. He says these figures

are consistent across the industry and that most of the excess deaths

weren't attributed to Covid. Some of the timeline was before the mild

"omicron variant" appeared, and mostly it's the elderly who die of

Covid. What was so different in 2021 from all previous years? Please

draw your own conclusions.

* Land Living Frogs When some time ago (TE News #100, #112,

#141) I wrote about the unlikelihood that there were any reptiles until

well into the Triassic period and still less in in the Permian or

prior, the biggest question mark in my mind was that if the Listrosaurs

(or more generally genus Lystrosauridae as there were several species)

were a sort of "pre-reptilian frog" or "toad" (and my take from the

skeletal features, having advanced costal (diaphragm) breathing instead

of primitive buccal "frog" breathing), so different from other and

previous Carboniferous and Permian period amphibians, and seemed to be

a land dweller, how did they reproduce? No egg shells have been found

until after the first perhaps 10 million years of the Triassic. A land

dwelling creature couldn't have laid soft eggs in water and had

tadpoles. I was left to suspect that they must have borne live young,

but as far as I knew there was nothing similar to compare it with.

But this month I learned of some "ovoviviparous" genera of

toads, Nectophrynoides and Nimbaphrynoides, that give birth to live

young - little "froglets", rather than laying eggs in water that become

tadpoles. So! There is an extant "precedent" (can that be the right

word?) for what I have been assuming (in the absence of other options)

probably must have been the Lystrosaur's mode of reproduction: land

living frog family creatures that bore live young.

* A Local Environmental Collapse? I watched a documentary of an

anthropological dig in Cornwall (Youtube), The Buried Bronze Age

Ruins of Bodmin Moor | Time Team | Odyssey, presented by Tony

Robinson. (Apparently just one of a Time Team archeological TV

series.) Cornwall is the southwest corner peninsula of Great Britain.

There are many farms and towns, but the moor and its promontory Rough

Tor (somehow pronounced "Roe Tor") is a desolate, wind swept area with

more rocks than soil. There were stone footing walls and burial relics

of neolithic and bronze age peoples. Why had people chosen to live in

such a forbidding place, where no one lives now?

As the video went on, they analyzed pollen in ancient soil

underneath stones laid down way back in the bronze age, if not in

neolithic times. They concluded that the area had been an oak and hazel

forest. As usual with prospering human civilizations, forest got cut

down for firewood and to clear land for grazing animals, then for

farming. Until, as usual, after enough generations of degradation there

was no forest left and the wind and rains swept through, possibly

blowing or eroding away the forest soil. Then acidification of the soil

prevented the forest from growing back. However, there are farms all

around Cornwall (Google maps) so the area so ruined way back then

seemed to be limited to the area of the hillsides and higher grounds

around the Tor where winds were strongest and regrowth slowest. So

maybe in this case it was more a limited local environmental collapse

than a societal or civilizational one.

But again, if only locally, we are left with the saying

"Civilization starts with a forest and ends with a desert."

ESD

(Eccentric Silliness Department)

* "Foreign businesses are leaving China in droves." What is a

drove? I haven't heard of these before. Can a drove

hold an entire business? Factory equipment, offices and all? Is it

bigger than a bus? Or maybe it's some odd plural form of "drove"? In

that case, they may have all droven off in private vehicles, en

masse.

* I couldn't find the metric equivalent of a "drove" anywhere. How many

droves in a liter? or kilometers in a drove? Looking for

it drove me nuts.

* In a dictionary I actually found that a "drove" refers to having

driven a herd of cattle, so "in droves" alludes to moving large groups

or "herds". (Well, duh!)

* The old adage says: "Don't take any wooden nickels!" Wow, a carved

wooden nickel would be an amazing work of art! I'd give anybody 20$ for

a well made wooden nickel!

* What is the difference between a caregiver and a caretaker?

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Unipolar

Electric

Hubcap

Motors:

Cast PP Bodies?

About mid month it occurred

to me,

now that I was melting and molding parts for the windplant, that I

could also do the same for motor body parts! Instead of making UHMW

molds and casting polypropylene cloth-epoxy with the set epoxy making

it

hard, I could make alium. molds and simply cast pure [recycled] PP

parts in the oven. I've had electric lawnmowers with bodies made of

solid PP.

It's tough stuff, and I could make it quite thick without adding much

percentage weight to the copper and iron of a motor. (After all, it

floats!) And seeing how

much heat it takes to melt it, perhaps pure PP could run a little

warmer than PP-epoxy?

Well, I may not be getting it built in all this time, but

the design details

keep improving. The CNC table is finally

working and the HHO torch for cutting metal with it looks doable. It's

looking like when and if I get to them, the building should go

smoothly and they'll be great motors. (I hope the 330mm [13.0"] magnet

rotors aren't too big to manage when mounted on solid trailer stub

axles, and that the 6 phase unipolar

motor controllers they'll need won't be too difficult to create!)

Potential

Driving

Range

of the Chevy Sprint with the Ultra Efficient Drivetrain

Since I got the Sprint

running last summer with the highly efficient drivetrain (motor to 96%

efficient planetary gear straight to right wheel CV shaft), I have idly

wondered what its potential range might be on paved road and (more

especially) whether it could potentially be driven to town and back.

Since it didn't go fast enough to actually drive on the highway in

traffic - and almost surely wouldn't make it back up my steep driveway

because of its low torque with only the 5 to 1 reduction ratio - I

didn't dare try it out.

Now it occurred to me that I have enough info to calculate

at least theoretical potential ranges.

* I know the theoretical capacity of the battery: 240 amp-hours (at 36

volts nominal - about 9 KWH).

* I know the distance to town: about 27.5 Km.

* I know vaguely how much current the car drew driving at a constant

speed on the bumpy lawn where it was some approximation of level: In

the June 2021 trials in TE News #157 I said "30 to 70 amps" and later

"30 to 50 amps". (In spring 2018 I had noted around 70 amps average on

the highway in short tests. The speeds were even lower, but the

transmission would have been less efficient.)

* I know the rough speed range from trials after getting the bicycle

speedometer for it in July (TE News 158). On the bumpy lawn over the

short run it could accelerate, it never got much over 25 Km/Hr. But I

estimated it should pick up speed to average 35 to 40 Km/Hr on level

pavement. My earlier hopes of 45 were probably overly optimistic. (Even

40 might need a bit of down slope. The 55 it got up to free-spinning

the tire jacked up would only be going downhill.)

Let's take what would likely be the worst case for driving

to town and back:

27.5 Km * 2 = 55.0 Km

55 Km / 35 Km/hr = 1.57 hours of driving

70 amps * 1.57 hours = 110.0 amp-hours

Wow! That says it should make it to town and back even if I took out

one of the two battery stacks and had only 120 amp-hours!

110 amp-hours * 36 volts = 3960 WH of Energy consumed. (The Nissan Leaf

uses double that [in summer] or more.)

That's worst case. Now let's assume things are more

favorable (probably closer to a "best case" than a "medium" one.):

55Km / 40 Km/Hr = 1.375 hours of driving

50 amps * 1.375 hours = 69 amp-hours.

69 amp-hours * 37 volts = 2544 WH

So with the 240 amp-hours, the minimum (pessimistic)

potential range would be 120 Km. In the more favorable scenario it

would be 190 Km to "dead batteries". The farthest town on the island,

Masset, is 170 Km round trip from my place. (The scenic north coast is

a little farther.) Getting there and back with just 9 KWH of battery

would be amazing. The Nissan Leaf can't do the round trip with 24 KWH.

Well, theoretical is fine. The real proof would be in the driving. But

of course even if it was safe on the highway, it would be frustrating

to drive so long so slowly. One might fall asleep at the wheel!

I was wishing I knew the actual RPM rating of the present

motor under load. But let's see... another simple calculation: With

10.0 wheel RPM for each 1 Km/Hr, and 5 to 1 reduction from the motor,

at 35 Km/Hr the motor would be turning 1750 RPM, and at 40, 2000 RPM.

At the top speed the car got to on the lawn of 25 Km/Hr, it would only

have been doing 1250 RPM. With the free-spinning jacked up wheel in the

garage it hit "54 Km/Hr" or 2700 RPM. It seems to very much depend on

the load.

If I ever get that new unipolar BLDC "Electric Hubcap"

motor made (probably safe max ~3500 RPM limited in the controller

instead of 1750~2200) the Sprint should probably get up to maybe 60-70

Km/Hr. Still not fast, but I would license it and try it out. It might

not be much different in power consumption: an ultra-efficient motor

replacing a rather inefficient series wound motor... but the car would

be driving considerably faster and get to town in pretty fair time.

Then again, if I took out one of the two battery stacks

(to have two for the 72 volt Miles mini-cargo truck), seemingly I could

make it to town and back with either vehicle. (I keep assuming I can

reprogram the Miles to go about 60 Km/Hr. I suspect a broken or cut

connection from the motor controller to the programmer is what kept me

from doing so earlier, and I didn't look at it last summer or since.)

Unfairly

Maligning

the

Low Rolling Resistance Tires? - Sticking Brakes

I discovered this month

that the rear brakes were sticking on the Nissan Leaf. With the gravel

and salt on the highway in freezing winter weather, they started making

a considerable grinding noise, at first when I used the brakes, but

then it seemed to be more and more, and the energy economy got worse.

(I then remembered it helps to wildly jerk the car from side to side to

flex the assemblies to retract the brake pads & pistons from the

disks a bit.)

Did this perhaps begin last fall and only lately get

noticeable? Now I'm not sure whether or how much of the poorer economy

I've been having has been due to the brake pads rubbing on the disks

and not to the Bridgestone Ecopia "low rolling resistance"

tires. Are the tires actually not even part of the problem?

I finally took a wheel off and looked. The brake rotor

disk was shockingly worn considering how rarely one uses the brakes

driving the highways around here. There are few crossroads and no

traffic lights, and one mostly uses just the 'gas' pedal until arriving

at one's destination. (except when encountering kamikaze birds that sit

on the highway until the last instant and then fly up in front of the

car, and of course insolent deer and the very occasional bear.) Of

course, I did buy the car used, so maybe they were already considerably

worn. I didn't notice when I had a rear wheel off before.

I've bought new rotors. I'm not sure whether to put them

on now or wait until maybe March and hope that's the end of

graveling/salting the roads until next fall. After they're on we may

see whether the energy efficiency markedly improves.

Other "Green" & Electric Equipment Projects

CNC Table

[8th] The "PCI Express" parallel port

arrived. It fit in the computer! I screwed it in and found a parallel

to parallel cable. Linux CNC started up instead of exiting with a "no

parallel port found"

error message. I went to "manual control", selected "X" and hit "+".

It

moved!

"X" and "Y" moved the carriage across the table. "Z" would

only

go down. Somehow there wasn't enough torque for it to lift the router

and its mountings up. But I was well satisfied. The machine plus the

computer interface was, at long last,

working!

YAY!

[9th] If I lifted a bit on the router, "Z" would go up. Once it was up

a bit, it continued by itself. It only "stuck" down when it was down

very near the bottom - probably lower than it would be with any bit or

tool in its chuck. I tried stopping the "X" and "Y" motors from moving,

but they seemed to have a fair bit of torque. (Not that I couldn't

stop them.)

Then I went into the "step configuration" program and

found how fast the motors could reliably drive each axis. Not very

fast, and "X" was slower than "Y".

It seemed good enough to try out. What was I going

to try making? Without the HHO torch working, metal was out. (Yes, I

bought a plasma cutter a while back. But I suspect the HHO torch will

prove much

superior and make cleaner cuts.) I didn't want to hack up valuable

plastic, or to attempt routing alium, so that left plywood. Am I going

to do it in the house and get sawdust everywhere, or take it all out

through the pouring rain to the unheated shop? And set it up where?

First I had to design something, and then convert it to

G-code. In OpenSCAD I designed a test hub with 3 spokes to try out the

PP windplant rotors at different angles and distances from the axle.

In the evening I managed to send a few G-Code commands

from the computer and have the motors move, and I got it to run the

default test program. I was however unsuccessful trying to get

"DXFToGCode" to run properly on my desk computer. It would start, but

hang or crash whenever I tried to load a DXF file. So I am so far

unable to get the shapes I've designed to LinuxCNC to run the machine.

Am I going to have to write direct G-Code to make this work? Well, I

did it that way before. What are my other options?

Winter

Gardening:

¡

Sterilize

the

potting soil !

Sometime around the start

of December I planted carrots in a big deep bucket. I set it near the

woodstove with a one foot square LED grow light propped up on "stilts"

over it. In a week or more they were sprouting... and soon after

falling over, losing their leaves and wilting.

Sometime around the start

of December I planted carrots in a big deep bucket. I set it near the

woodstove with a one foot square LED grow light propped up on "stilts"

over it. In a week or more they were sprouting... and soon after

falling over, losing their leaves and wilting.

I've had bad results with carrots before, but these were

indoors and getting lots of water. Could there be something in the

garden soil I had used, eating the tender sprouts? I thought back to 50

years ago when my dad had once been putting soil in the oven to

sterilize it. I looked it up on youtube. Fungus gnats! They're

everywhere. That's why you sterilize soil before planting seedlings in

it. Duh! How long have I been gardening or trying to garden, and often

not knowing why I was having problems? More often I bought potting soil

in bags - pre-sterilized! It must be whenever I didn't that I had

problems.

I saved my remaining carrots with insecticidal soap, and

again a week later. Later I watered with about .75% hydrogen peroxide.

It's supposed to kill the larvae in the soil. That doubtless helped too.

At first they were growing taller and spindly, and I

lowered the light panel. Then at the start of January I traded the red

and blue LEDs 'grow light' for a 4000K light panel on the 36V DC power

system. (With a 10 ohm resistor this one had a whopping 12 watts over 2

square feet, instead of 28 watts in

half that.) By early January the carrots weren't very tall. Maybe they

just stopped bolting for light because they were getting enough? and

instead growing their roots? If so, in spite of it being just 3 inches

above the leaves,

that's pretty impressive for so few watts.

I had also planted lettuce and spinach in my usual long

narrow

pot. In spite of the soap, mostly the fungus gnats must have cut them

down, then I neglected to water for a day (was it two?) and the last

lettuce seedling

wilted.

Since the new light was wider than the carrot pot, I tried

lettuce again at the start of January, filling two smaller square pots

with a

mix of dirt -- this time all sterilized in the oven. Two broke the dirt

on the 8th and several by the 10th.

But they seemed to be getting too long and spindly, so I

went back to the 40W grow lights. By early February the carrots were

growing well and looking like they would be a good crop.

But soon I gave the lettuce too much nitrogen, too

concentrated. They wilted and I had to start over again.

Electricity

Storage

(Batteries)

[No Reports]

Electricity

Generation

Wind Wall ...& Plastic Recycling 2.0

...& VAWP: Vertical Axis Water Plant

Plastic Recycling 2.0: General

Discussion

I'm calling my

plastic recycling method "Plastic Recycling 2.0" to differentiate it

from "typical" plastic recycling methods. In "Plastic Recycling

1.0" techniques for example at PreciousPlastic.com , one first shreds

the

original plastic items to break them down into bits that can be heated

in

an injector or extruder.

Having to shred the source material greatly complicates

the entire process, even if it's light food containers. But what about

old PP ropes? fishnets? 200 liter plastic drums? Fishing floats? Tote

boxes? Other big plastic items? Without at all disparaging the

recycling of the continuous barrage of food containers and other small

packages, larger, heavier items contain much more plastic material than

small, light items, and "1.0" with a typical plastic grinder has no

ready means for dealing with them.

"2.0" can deal with all of them, and more easily.

Everything is simpler. To recap:

Advantages of "2.0"

1. The range of plastics that can be easily employed is greatly

extended, and there is much less processing of the raw material.

Imagine trying to shred a 2 inch polypropylene rope? The regular

plastic package shredding machine surely won't manage it. Here the rope

is only cut roughly into lengths that will fit into the mold. (A zip

disk makes

short work of cutting thick PP rope. Pull on the rope while

cutting.) How about fishnet? surely

it would jam the shredder. Cut it to the right weight of material and

fold or scrunch it into the mold. There are thousands of pounds of

fishnets cleaned off of beaches sitting at a property just down the

road.

Bulky packages and bottles can either be cut into chunks

or thrown into the oven in a box to collapse them.

2. In general, the plastic for forming larger objects doesn't have to

be totally clean. If there are grains of sand or small bits of organic

matter still embedded after it is rinsed, as long as the end product is

not to be used for food or a waterproof container, it's doubtless good

enough. This is a big advantage in reusing material salvaged from the

environment.

3. The equipment required is lower cost, lighter weight, non-precision,

and uses just one special item: an oven. (A scrap kitchen oven will do

for many molds, or a longer, wider one may need to be created for large

"boards", "posts" and sheets.)

4. The molds, having to contend only with tens of pounds of weights on

top rather than with the high pressures of injection or extrusion

molding, can be much easier to make. Sheet or plate alium. can be used

to cover

large, flat areas, perhaps with stronger pieces such as bars, plates or

"angle

iron" (all alium.) reinforcing. They can be bolted (or even

spring-clipped) together, and

un-bolted if required to remove the part. (Note that steel expands less

than alium as it heats. This can warp the alium. so it is recommended

that all the larger/longer mold parts be alium. or use springs) Plastic

shrinks more than

alium. as it cools and also doesn't adhere to it, so it's generally

easy to get the part out of the mold. (It may be advantageous to spray

the mold with, eg, silicone lube.)

Disadvantages of "2.0"

Never much of a salesman, here also are the weaknesses I

can see in the "2.0" system.

1. It is for larger parts, not fine detailed ones. Forget keyboard keys

and plastic feet for electronics! Think boards, posts, beams, big

sheets, tiles, "giant lego blocks", "cutting boards", plates...

and of course windplant blades, rotor pieces and enclosure parts!

2. The parts produced will in general be less precise than injection

molded parts. This does depend considerably on the skill and attention

to detail of the mold maker.

3. Ability to mix colored plastics to get cool patterns is more limited.

4. It is not always appropriate for making complex part shapes. (Forget

making PP electric lawnmower bodies?)

Equipment:

1. The only special piece of equipment, used for everything, is an oven

large enough to hold the biggest mold for the biggest pieces it is

desired to make: No shredder, no injector, no extruder, no large sheet

press. The oven should be capable of reaching somewhere around

260°C (500°F). For health and safety this oven should ideally

be located outdoors and sufficiently far away from flammable structures

when in use. But it is the plastic melting heater for all molding and

it has to plug in, usually to 220V. A larger oven may need two or even

more "regular oven" heating elements.

A regular kitchen stove with oven may be serviceable for

smaller parts. I note however that I connected the plug straight to the

oven element on mine so with no temperature control it surely gets

hotter than most, and that the inner glass has cracked in several

places, probably from the heat.

2. A simple alium. box mold with a fitted lid for each and every

desired part. No matter how you are going to form plastic into new

things, each unique part will need a unique mold. Simple box molds can

be made with sheets and various thicker pieces of alium. instead of

welded steel or milled parts of heavy alium. They don't have to take as

much pressure as molds for injection or extrusion and so don't need to

be as strongly built. They do have to take the heat of the oven, so

(eg) wooden pieces are "out".

3. A temperature control is desirable, but simply timing the melt can

also be serviceable. (I found a "laser thermometer" at the end of the

month: point it at the object whose temperature is to be measured and

press the trigger. I'm sure it will be valuable.)

Procedure:

Note: In the windplant making section below are examples of the

components of making molds and parts.

1. The mold is filled with chunks of the desired plastic to the desired

weight or the amount of weight that will fill the mold.

2. Heavy (steel - lead might melt?) weights are distributed on the lid

of the box. (These replace the high pressure needed for injecting or

extruding.) Typically it seems 25-40 pounds are required for "kitchen

oven size" molds. (Support the oven rack.)

The lid will not fit into place on the box with all the lumps of

plastic in it. The sides of the box must be tall enough or otherwise

arranged so that as the plastic melts, the lid will end up in its final

position as it lowers.

3. The oven is plugged in or turned on and left on for the amount of

time required to melt the plastic and have the mold's lid drop down to

its final position to correctly shape the part. This depends on the

type of plastic, how fast the oven heats, and how long the pieces of

plastic take to heat up and melt down, so no hard and fast rules can be

made.

4. When the time is up, the oven is turned off and the door opened. The

mold and part are left to cool for the desired length of time until the

plastic is solid again and the mold is considered safe to handle. If

there are screws going through the part and setting the

depth/thickness, they should be unscrewed before it cools too much, as

the plastic shrinks a bit and will probably crack around or between the

screws.

5. The mold is opened and the part removed.

In the early trials, if the plastic hasn't completely melted, the

process is tried again for a longer time. If it has and perhaps seems

"overdone", a shorter time time may be tried for the next similar piece.

Now back to the windplant development.

I'm not sure why these pictures didn't make the December

newsletter, tho the tests were near the end of that month. There I

wrote of trying out a single blade in the wind tunnel to see where it

had positive and negative turning force. It was largely positive:

stronger forces over a broader angle of rotation than the counter

forces as the blade returned upwind.

"Top dead center" where

resistance is turning to positive rotational force

"Top dead center" where

resistance is turning to positive rotational force

Midway down the power

stroke, which doesn't end until well past "bottom dead center"

Midway down the power

stroke, which doesn't end until well past "bottom dead center"

Last month I wrote about this: "[It] had positive force, measuring from

the axle to the outside edge of the blade, from about 350° (just

before it reached the fan end) to about 230° (well past where it

pointed straight away from the fan). Thus it was providing thrust for

2/3 of the circle and resistance for only 1/3.

Moreover, subtracting the areas where there wasn't much

force either way, the thrust was reasonably strong from about 45 to

190°, a 145° range. As the blades are 120° apart, one blade

will always be in the strong thrust area. The resistance was strong

from about 270 to 330°, a 60° range. So the region of good

thrust was over twice as large as the region where it was really

resisting." and "the forward force around the maximum area felt

substantially stronger than the resistive force around its strongest

area."

It was a good thing to test and it showed how the rotor

shape works quite well.

[5th] I went to the refuse

station looking for weights and instead found a big steel "box" to use

for the inner shell of a long,

wide, low oven. It didn't look quite as big as I had wanted, but it

seemed about right otherwise. It looked like it could save me a whole

bunch of work making my own. It had two hinged doors or lids on top.

(The tail of the car already having a 45 gallon drum of planer shavings

from a woodworker in it for the chickens, I put it across the

folded-down back seat

and drove home with the rear right door open. Funny there seemed to be

a lot more road noise than usual from the snowy, gravelly highway. and

it didn't

make the car any warmer. At least with the electric car there was no

chance of exhaust gas coming in.)

The box measured about 19" * 58" * 10" (inside) - not

quite the 2 feet wide and 5 feet long I had hoped for. Oh well! It had

a "step" in the length and was shorter, 52", for the bottom 5-1/2". It

looked sufficient for a couple of oven elements and tall enough for the

windplant blade mold. It was probably sufficient for making all the

parts for

the wind wall if I didn't get too carried away as to size. Wind Wall

1.0, anyway!

My idea for greenhouse wall panes from transparent PETE

will have to be shrunk to about 16 or 17 inches by 56 inches (4' 8")

max. Likewise, beams or boards longer than 4' 8" will likely be

problematic.

It would be nicer to have "boards" and greenhouse wall

panes long enough to

provide standing height. Is there any way to expand it a foot plus, to

at least 6 feet? As it is -3° and everything including the box is

covered with snow, I'll have to check the feasibility later.

---

Take 10

Then, after yet another blade came out with the right hand

side not pressed fully down to the screw, in spite of having over 30

pounds of

weight on it, I started to think that something was probably flexing

and the right-rear side of the bottom was sagging down.

The angle pieces I had used for the sides rested on two

narrow "foot" sections, rather casually cut out of the corners with the

bandsaw. I moved the two side pieces together, sliding the left one in

along the spacing rods. Aha! one had a slightly different slope than

the other. It wasn't much, but it was in the direction that might

explain it. I suspected the more weight I put on top, the harder it

would

push it out of line!

With the rods tying the pieces together, I took them out

to

the shop and ground and sanded them together to make them even. When

assembled it

seemed more solidly seated, where it had rocked back and forth before.

[6th] Take 11, 12 It didn't seem to help. Maybe what it needed

was for the weight to be more in the middle instead of some distributed

up the back as far as possible? Maybe because of the weight there the

back wouldn't flex as it needed to to sink into place? I tried again

with about 28 pounds thus positioned. None was preventing the back

portion of the "lid" piece from flexing forward. That was easier to set

up, too.

No dice. In fact, neither side went down home, and the

plastic didn't reach the left and right sides, much less the corners.

What to do next? Could all that weight really not be enough? I

hadn't been able to find more steel for weights in the snow at the

dump. Suddenly I remembered; I did have one more good weight: my

makeshift anvil was 16 pounds. That made 44 pounds. I put the same

plastic (had been ropes, now a solid blob) in the oven again for

another hour.

This time it was fully pressed down, and most of it looked

great. It really did need all that weight to work well!

At the back at the top, however, with no weights pressing against the

back, it had bulged open. Plastic had pushed out the middle instead of

filling the corners. The melted plastic must exert a very strong force

trying to form a blob instead of flowing out to fill the long, wide and

thin mold! But again, the windplant blades are the most difficult part

I want to make, and the amount of equipment this simple oven-molding

technique replaces makes it worth pursuing to the ultimate.

It seemed what it needed next was a cross support near the

back-top to stop the outside from bending back, and the cylinder

weights pressing against the back from the inside - in addition to all

those other weights pushing down. Then I thought I would start getting

the blade shape I had designed into the mold!

[7th] Take 13 Well, I tried redistributing the weights. Even

with 40 pounds, it didn't press down, not even half way! It looked like

maybe the lid had hung up on the top of the bottom at the back. So much

for pressing against the back as well as down! I couldn't seem to press

it down with a stick, either.

While waiting for it to cool down, I started thinking the

2mm / 12 gauge sheet alium. simply wasn't quite stiff enough. Not when

so much weight was needed. My idea of cheap, light box molds might need

a little revision. Thicker alium. like 10 gauge might make the

difference. But I started thinking instead, maybe thick alium. ribs

below the bottom sheet and above the top, cut to the exact curves, to

ensure they hold their exact desired shape might make the difference.

Once again this comes down to having the CNC table working

and cutting alium. (And finding some thick alium. to cut.) Maybe I

should give up on trying to make blades until I have the CNC table and

the HHO torch cutter working? Ug! Perhaps in answer to my (?)prayers,

the parallel port I had ordered had arrived at the post office.

When the mold

had cooled I opened it and found it was a

totally different problem. After an hour in the oven, the PP ropes had

only partly melted! They had shrunk to half their length, but still

looked like ropes. This could mean one of two things: either the oven

element was cutting out or, more likely, the door hadn't been quite

shut. I had noticed it not quite shut before, the door sticking out

just a 1/2 inch or an inch at the top. Sure enough, an hour with two

boards propped against the door melted it. It was still missing those

two back corners. Time for a modified plan!

When the mold

had cooled I opened it and found it was a

totally different problem. After an hour in the oven, the PP ropes had

only partly melted! They had shrunk to half their length, but still

looked like ropes. This could mean one of two things: either the oven

element was cutting out or, more likely, the door hadn't been quite

shut. I had noticed it not quite shut before, the door sticking out

just a 1/2 inch or an inch at the top. Sure enough, an hour with two

boards propped against the door melted it. It was still missing those

two back corners. Time for a modified plan!

[8th] I showed the blades to Steve. He had the idea to make mountings

for them that would let each blade move in and out from center as well

as swivel. "U" tracks or something? Thus some rapid experimentation

could narrow down the best angle and distance from center of the blades

on the rotor. That sounded worth making to me. Steve, who has plastic

molding experience, also said that having all the plastic at the same

temperature (because it was all in the oven at the same time) was

valuable - presumably over plastic that is cooling as it is being

pumped into a mold under high pressure.

The next day I realized I should just make plywood pieces,

like the test rotors but just a "leaf" for the top and bottom of each

blade. These could screw the blades onto the axle/"spokes" pieces. With

the CNC table now essentially working, should I try cutting the 6

identical pieces with it?

[10th] I couldn't get the "DXF2GCode" program to work properly.

Apparently it's written in Python but they changed Python and it isn't

compatible with Python 3.7 or 3.8. My computer had 3.8... and 2.7.

Maybe that was too old, or maybe it simply went to 3.8 regardless. I

tried installing 3.5 and 3.6 but got "not found" messages. Installing

3.9 didn't seem to help. Why do people keep changing things that are

working, and that other things depend on? Adding features is one thing.

Chopping and changing existing features just makes a mess. It will

probably work somehow - others are using it - but I haven't yet figured

out how.

Take 14 I tried another molding in the evening. With two boards

propped against the door to ensure the oven was fully closed, it still

only partly melted the ropes in an hour. It seemed to me the oven

element must be cutting out. Grr!

[11th] I suddenly thought to make a name for the windplant blades I

created. They can hardly be described as "Savonius" or "Darreius".

"Carmichael"? "Windjammer"? Something catchy... How about "Windwarp"

VAWT blades? ...or "Windwrap"? Those perhaps somewhat describe the

rotated path of the wind through the rotor? - it's not just slowed down.

I did a web search for "Windwarp". Although it did appear,

it was mostly as two words "wind warp", about winding the warp on a

loom. There was a what appeared to be a misspelling/typo of "windwrap"

in a German document. And as a title in music. Nothing related to

windplants.

And maybe the name should also be for the whole rotor?

...I'm making {3-blade} "Windwarp rotors"?

If I can't create parts in OpenSCAD and convert them to

G-Code,

the other option is to create them directly in G-Code. What a nuisance,

and I'm now pretty rusty at that! But the plywood parts for the blades

are pretty simple, and the sample program shows what codes are needed

for cutting lines and curves.

[12th] Take 15 I

went to the refuse station and found some

grader blade bottoms - an inch thick and 4 wide solid steel. I was

prepared. I had 2 large batteries and one of the 3000W/6000W(peak) 24V

to 110VAC inverters I accidently bought, an extension cord, and angle

grinder with spare zip disks and safety equipment. I cut a piece off

one blade so I could lift both pieces, and put them in my car. (I

wonder why these blades were thrown out? They looked fine to me!) At

home I cut one to fit the mold. The bevel it had let it sit in a better

position than a flat piece, covering the flat part of the blade and

then up the inside curve toward the back. And it covered all the way

from left to right evenly - it wouldn't tend to warp the alium. with

uneven side-to-side pressure. It was perfect! 10 pounds. I put the two

10 pound blocks from the shop hydraulic press on top of it and plugged

in the oven. (Now if the oven will stay on!)

[12th] Take 15 I

went to the refuse station and found some

grader blade bottoms - an inch thick and 4 wide solid steel. I was

prepared. I had 2 large batteries and one of the 3000W/6000W(peak) 24V

to 110VAC inverters I accidently bought, an extension cord, and angle

grinder with spare zip disks and safety equipment. I cut a piece off

one blade so I could lift both pieces, and put them in my car. (I

wonder why these blades were thrown out? They looked fine to me!) At

home I cut one to fit the mold. The bevel it had let it sit in a better

position than a flat piece, covering the flat part of the blade and

then up the inside curve toward the back. And it covered all the way

from left to right evenly - it wouldn't tend to warp the alium. with

uneven side-to-side pressure. It was perfect! 10 pounds. I put the two

10 pound blocks from the shop hydraulic press on top of it and plugged

in the oven. (Now if the oven will stay on!)

I looked 3 or 4 times. The oven element seemed to stay on.

But the plastic was again only partly melted after an hour. I left it

in another 10 minutes, and then another 10 minutes. Finally I saw

plastic oozing out the edges. Why so long? The weather is a little

warmer than it was, not colder. But then, a small piece had fallen out

of the inside oven glass, so it is double glass now instead of triple.

Maybe I should just screw a piece of metal over it? The only thing I

can see through the glass anyway is whether the element is glowing.

Maybe that, with some insulation, would cut down on the original 60

minutes, too?

It still came out like

others: plastic oozing out the top

in the middle but not filling to the back corners. And a lower corner

wasn't quite full. Because of the curved shape making the two pieces of

the mold vertical at the back instead of horizontal, it really needed

something to push the lid backward in the top area and not just

downward. And maybe I should put in another 25 or 50 grams of plastic

(to 525 or 550 grams) and accept the overflow as long as everything

gets filled?

A typical blade

casting: everything great except the outer/back corners.

A typical blade

casting: everything great except the outer/back corners.

Typical molding out of

the oven.

Typical molding out of

the oven.

Potential Rotor

Layouts: Variation #1

Potential Rotor

Layouts: Variation #1

#2

#2

#3 (not a very likely

looking setup!)

#3 (not a very likely

looking setup!)

It ended up

somewhere between 1 and 2.

[14th] I finished breaking out the innermost (of 3) piece of glass in

the oven door, put some fiberglass insulation in the ~1 inch space to

the next piece, cut a piece of steel to fit over it, and screwed it on.

I could hardly see into the oven anyway. Hopefully, if melting plastic

took longer because of the missing piece of glass, it would now be

shorter with the insulation.

In the evening I e-mailed the people doing the beach

cleanups with an update on my plastic molding. They replied saying that

the thousands of pounds of ropes and nets were all going to be removed

from the island Monday, so I had better get what I wanted Saturday -

tomorrow! Egads!

[15th] I hooked up the utility trailer to the Toyota Echo and picked up

a few hundred pounds of ropes. I hadn't tried the nets yet, but I knew

the ropes worked, and either way I could get all I would care to carry.

Operations yard for

cleanup of plastic off remote Haida Gwaii beaches.

Operations yard for

cleanup of plastic off remote Haida Gwaii beaches.

Contractors have picked it up with boats and brought it all here.

(My blue car and big "utility trailer" [hacked up tent trailer] at

left.)

Forklift sized

bags of plastic - at leat one huge flatbed truck load had already been

removed.

Forklift sized

bags of plastic - at leat one huge flatbed truck load had already been

removed.

The bags are at least sorted into different materials. A forklift is

filling the blue bin (far right).

I am pleased to be making (hopefully) good use of some bit of this

mountain of waste material.

But the real mountain of waste plastic, with huge excavators crawling

like ants around on top of it, is on the BC lower mainland.

I essentially emptied one of their big white forklift

bags. Short bits and rope frayed ATRS are just as good as any other,

and

actually need less (or no) cutting to fit into the mold.The rest (and I

saw a truckload already on its way as I drove down) is going to

Vancouver on the North Arm barge from Masset. In 6 months or a year I

may be sorry I didn't take more and that it's all left the island, but

in case I don't actually produce windplants I already sure have a lot

of bits of rope.

After that I went into town. Two little BLDC motors I'd

ordered thinking they might make good generators for the windplants,

were in the mail. I did some quick tests.

RPM (with

Multi-speed

drill press)

|

VAC

(any

phase)

|

Load

|

Watts =

V^2 / R

|

Notes

|

620

|

3.2

|

open

|

-

|

Easy to

hold stator

|

1100

|

6.0

|

open

|

-

|

(with rotor

turning in drill

press chuck)

|

1100

|

5.7

|

10 Ω |

3.2

|

Resistance to

holding stator

from turning

|

1100

|

5.5

|

5 Ω |

6.1

|

More

|

1100

|

5.4

|

3 Ω |

9.7

|

and |

1100

|

4.0

|

1 Ω

|

16.0

|

more |

1100

|

3.2

|

.5 Ω

|

20.5

|

resistance/pull |

| 1720 |

9.7

|

open |

-

|

|

| 1720 |

8.7

|

3 Ω |

25.2

|

|

| 1720 |

6.4

|

1 Ω |

41.0

|

|

| 1720 |

5.4

|

.5 Ω |

58.3

|

greatest

resistance to

holding stator

|

I didn't care about frequency because I'm just going to

rectify it with a 3-phase bridge. To run a DC to DC up converter it has

to be over 8.5 volts. While that needs to be modified to the DC value

from all 3 phases, let's just say I should be aiming at around 1500 RPM

from say 200 RPM from the windplant rotor as a starting point in low

winds. The voltage can go through the DC to DC converter to say 13.5VDC

for charging 12V batteries or to about 40.5VDC for 36V. No doubt the

converter will manage whatever power it is getting from the windplant.

(or maybe an MPS7210A boost charge controller? But they need about 15

volts in. DC to DC and then MPS71210?)

So it needs about a 7.5 x mechanical speedup. How?

Anything is going to have some friction. How to get such a large

speedup in one step? I have those poly-V belts and ~2" pulleys. the

rotor part could run on a 15" flat or 'barrel' pulley of plywood

(prototype) or molded PP on the rotor axle. Or maybe a simple rubber

wheel running on a big PP wheel? Like, 1" and 7.5"? or something like

that. (Preferably that won't slip in a strong wind & generating say

100 watts.)

[16th] I drilled and threaded holes and put an alium. bar across the

back of the mold to support horizontal force pressing backward. The

other part to that is... how to get that force? Maybe I should cut a

piece to what I hope will be the exact length to supply it?

Fat alium. bar across

back to help hold curved form upright

Fat alium. bar across

back to help hold curved form upright

Take 16 I put 525 grams of rope in the mold and put it in the

oven. I used some yellow and some blue rope too. The resulting colors

were visible but not very bright.

I had hoped the door insulation would reduce the time

needed in the oven, and I set the timer for 55 minutes instead of 60.

But it wasn't melted. Another 10... and another 10... and another 10.

It took almost 1-1/2 hours! The element looks the same brightness

AFAICT by eye, so my best guess is that I'm getting it so hot that the

insulation around the oven is withering. Maybe I need to replace the

(surely) fiberglass insulation with rock wool? I'll take a side off the

stove and see what I can see. I don't see why it shouldn't be possible

to melt the plastic in maybe 30 to 40 minutes. (After 15 minutes

cooling with the oven door open, the "oozed" plastic was still quite

soft to the touch of a screwdriver. So it's obviously not going to heat

up and cool down in 5 or 10 minutes.)

There was a little more edge oozing. The top corners were

still not filled, but the unfilled area was smaller. Maybe I

should try 550 grams? Or, if I could get thinner cracks between

the top and the sides, and more force against the back, less plastic

should ooze out around the edges. Since it would be hard to expand the

top piece, I should probably sand the bottom piece just slightly

narrower. Another thing that might be abetting poorer results is that

except for the first 2 or 3 times, I have repeatedly forgotten to spray

on the silicone lubricant. The ones that filled the corners best

probably had been sprayed. Maybe the problem will magicly go away if I

do? I put the can in the mold so I don't forget next time.

[17th] I did a bit of sanding on the edges to narrow the bottom piece a

trifle. It had been about 1.5mm(?) wider than the top. I probably got

it below 1mm max. (But if the top is Any wider than the bottom, it will

probably jam instead of sinking down as the plastic melts!)

I looked at the oven. The far side had sprung away at the

front, leaving a gap. (Remember where I got this free stove.) That had

to be letting cold air in! The insulation inside of it looked all

right. So I just sprung it back on and put a stake next to it to stop

the bottom from springing out again.

Take 17 I put in 525 grams of PP again, hoping less would ooze

out the sides and it would go into the outer corners instead, and

sprayed the mold with silicone lube. I set the oven timer for an hour.

Nope. Add 10 minutes (looked like it was close) and add 10 minutes

again. Then, still not seeing anything coming at the top corner edges,

I unplugged it but left the door closed for another 10.

Another Mold (something

of a sideline!)

Another Mold (something

of a sideline!)

I also wanted to try something besides rotor

blades. The idea of greenhouse wall and roof panels or panes was

enticing. There are clear PS and PP packages, but most "display" food

comes in clear PETE, so I chose that. I looked around for scraps of

alium. and picked some small pieces to make a simple box mold about 157

by 212 mm. Just a test size. I can't see such small pieces being of

much use. I suppose because it was small, it seemed proportional to

make it with low walls. In doing that, I neglected a key "Plastic

Recycling 2.0" point. That is, that whatever the size of the mold, if

you're going to throw in chunks of plastic, the sides have to be high

enough to contain them. To accommodate bulky transparent food

containers, the sides should have probably been about 3 inches tall.

Because they are so short I had to cut

the containers way down into

pretty flat bits, and even then I had to scrunch them down and put the

weight on top to get them "contained" - more or less.

Because they are so short I had to cut

the containers way down into

pretty flat bits, and even then I had to scrunch them down and put the

weight on top to get them "contained" - more or less.

[18th] Oven: I took the back off and checked the oven element.

Still 9.33

amps: 2240 watts. No change there. I put in the little tray of PETE

with a single 8 pound weight on it. In just 10 minutes the lid had sunk

into the box. I left the oven on another 10 and took it out. I was too

early. And it looked a little thin, so I added some more bits.

Perhaps the insulation just under the floor of the oven

and the heater element was burned or melted? Could I open it? I tipped

the oven

on its side. Water came out. It looked like nearly everything would

have to disassemble before the underneath panel, but there was one

little

finger hole and I could feel that the oven floor insulation was soaking

wet! That would certainly ruin its insulating capacity, and explain why

it seemed to be taking longer and longer to melt the plastic. Of course

I should have the stove under cover. Easier said than done.

Perhaps I could put something over it? What? I ended up with a piece of

PE for a tarp, held down by a couple of boards. Well! I could have done

that easily in the first place!

Take 18 #17 had less PP oozed out the cracks, but it hadn't

fully pressed home on the right side again. And I noticed later that

#16 hadn't pressed quite down at the left-front corner. It was a little

thicker there. The extra

thickness in each could explain why there still wasn't enough plastic

to fill the top corners. Need more weights, again? I had dropped it

down to 30 pounds again. It seemed so absurdly heavy for what it was

doing. Maybe it really needed 35 or 40? Then maybe part of the reason

for long times was insufficient pressure to squash the PP into place

until it was hotter than just "melted"? Maybe that was adding 5 or 10

minutes?

I cut another 30cm, 10 pound piece of grader blade, which

also

left an end that was 6.6 pounds. Then I cut a bunch more pieces of the

green PP rope. I put in about 535g of rope and about 35 pounds worth of

weights on top. At the same time I put the little PETE test mold in

again with 9 pounds on it, and set the timer for 30 minutes. The oven

rack was sagging even with a piece of brick supporting the middle.

After 30

minutes the sheets of PETE had all squashed down

pretty flat, but they hadn't actually melted: they were still separate

sheets that didn't stick to each other and merge into one thick piece.

I put it back in and set the timer to 30 more.

After 30

minutes the sheets of PETE had all squashed down

pretty flat, but they hadn't actually melted: they were still separate

sheets that didn't stick to each other and merge into one thick piece.

I put it back in and set the timer to 30 more.

By this time the sheets were at least merging into each

other. They also seemed to be turning from transparent to gray. I hoped

and thought they would become clear again once fused into a single

sheet between the alium sheets.

I gave it

another 15. That was apparently too much. I hadn't

put stoppers inside, counting on the viscosity of the melted plastic to

stop the weight. But the PETE was so much thinner than the PP that it

came out every tiny crack around the top and bottom. And turned light

gray.

I gave it

another 15. That was apparently too much. I hadn't

put stoppers inside, counting on the viscosity of the melted plastic to

stop the weight. But the PETE was so much thinner than the PP that it

came out every tiny crack around the top and bottom. And turned light

gray.

And it stuck to the

alium pretty hard. I had to unscrew all 4 corners and hit them with a

screwdriver handle, at which point the side pieces would snap off

suddenly, like glass.

(I had again neglected the silicone lube spray on this one.) I put it -

the top and

bottom with the PETE sandwiched between, gluing them together - in the

freezer. That didn't coax them to separate, but a chisel and a hammer

did so without bending up the alium. sheets.

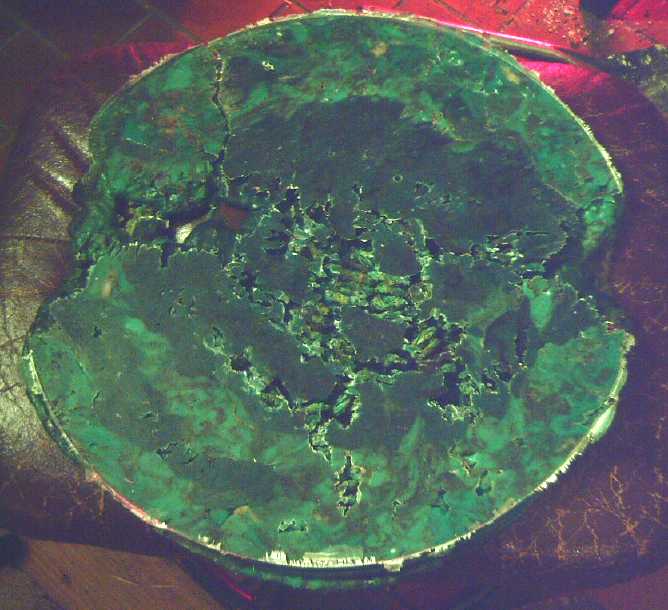

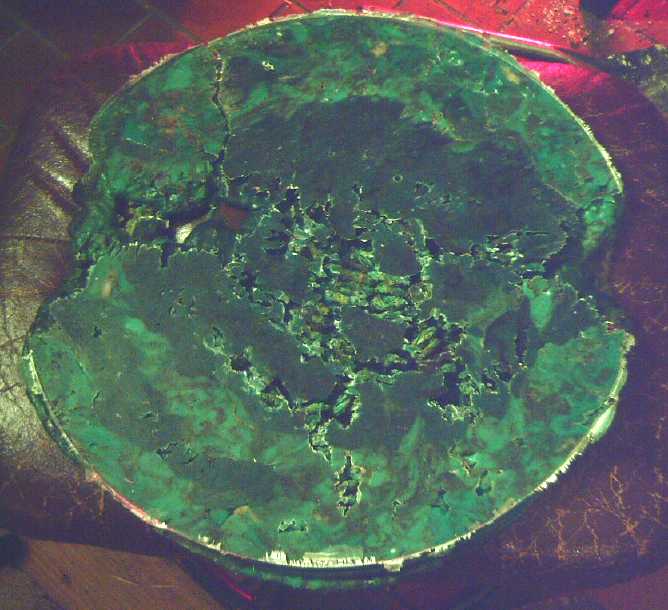

Clear PETE Not Transparent!?!

Some of the

thin layer (< 1 to 2 mm thick) still inside stuck to each face. It

was useless, and quite a challenge to chisel off in little bits. Along

with becoming brittle as glass, the PETE

including inside the mold had lost its transparency and become a light

gray color. In fact it seemed to

be doing that even before it had completely melted. I could hardly see

light through a 1.5 to 2.0mm thick shard. So much for PETE! I don't

think I'll try it again.

Some of the

thin layer (< 1 to 2 mm thick) still inside stuck to each face. It

was useless, and quite a challenge to chisel off in little bits. Along

with becoming brittle as glass, the PETE

including inside the mold had lost its transparency and become a light

gray color. In fact it seemed to

be doing that even before it had completely melted. I could hardly see

light through a 1.5 to 2.0mm thick shard. So much for PETE! I don't

think I'll try it again.

That shattered my dream of making

transparent PETE greenhouse panels - at least with my technique. The

brittleness merely

underscored the unsuitability. Just as well I did a small mold and not

a big "greenhouse panels" size one to test the idea out!

There are transparent PP and PS food containers, but they

are rare compared to PETE. Even if one or both of them work, it's hard

to imagine collecting enough scraps to make a good part of a

greenhouse, let alone make it an enterprise.

When I scraped

them off, the pieces made an interesting jigsaw puzzle. The clues were

the thickness and general shade of the pieces. (It helped that the

bottoms were darker than the tops.) The smaller pieces usually looked

like they just couldn't be the right fit until they were actually in

place and the cracks disappeared.

When I scraped

them off, the pieces made an interesting jigsaw puzzle. The clues were

the thickness and general shade of the pieces. (It helped that the

bottoms were darker than the tops.) The smaller pieces usually looked

like they just couldn't be the right fit until they were actually in

place and the cracks disappeared.

Moving on, the PP Wind Wall

was still a "go"... The "Take 18" blade had a lot of overflow in

the top middle, so much and so thick I had to cut it off on the bandsaw

rather than just breaking it off. And one top corner had filled. The

other one was almost filled. Maybe 550 grams of PP next time? Or, what

if anything could I do about the overflow? It also had not quite

flattened out at the front left, like #16. Maybe with so much

weight on top, it's bending the mold? (It's certainly bending the oven

rack! So the two mold 'feet' are probably not even.)

A wind wall with two 3 foot tall rotors will take 18

blades, so for the prototype I'll be using most of the ones I've made

regardless of flaws. Not to mention 3 of the best for the test rotor.

Finally Some Tests

I cut two 16"

diameter circles out of plywood (3/4" and 1/4") and measured off

120° positions. Then I found 8 and made 4 more small angle

brackets. (never mind making complex plywood shapes on the CNC router!

or by hand again.) I drilled holes and mounted three blades between the

two circles, at the positions and angles I thought would be about

optimum. It was 16" (OD) by 12" effective height.

I cut two 16"

diameter circles out of plywood (3/4" and 1/4") and measured off

120° positions. Then I found 8 and made 4 more small angle

brackets. (never mind making complex plywood shapes on the CNC router!

or by hand again.) I drilled holes and mounted three blades between the

two circles, at the positions and angles I thought would be about

optimum. It was 16" (OD) by 12" effective height.

I put it in the wind tunnel and got the

following results (Shop & OAT = +5°c):

Low: 50-58 RPM

Med: 84-88 RPM

High: 100-104 RPM

From last month, the 9.75" (OD) by 14" (effective blade height)

3-bladed test rotor gave:

Low: 56-57

Med: 86-90

High: 108-118

Being 16" diameter instead of 10", the similar RPMs

represent 1.6* more linear speed at the outer rim, which surely

represents more torque from the wider rotor better overcoming bearing

friction. And, putting some finger friction on the axle, it did seem to

have more torque.

Then I put the stationary vane in front at 45° to aim

the wind. With the larger diameter rotor it was a little too narrow to

deflect all the wind from the returning side to the power stroke side,

but it still gave a good boost:

Low: 68-78 RPM

Med: 96-106 RPM

High: 128-136 RPM

Again the torque seemed at least marginally substantial.

It may only be a few watts, but again, the 3.1 m/s wind speed from the

fan on high is still below the 4 m/s cut-in speed of most windplants.

And if the rotor was 3 feet tall instead of 1 foot, I'm pretty sure it

would prove to be well over 10 watts, and with two rotors in the wind

wall, 20 or 30. It's the cube of the wind speed from there up. Double

the speed to a good stiff breeze (6.2 m/s): 160 or 240 watts.

[20th] I started thinking that if plywood would eat 1.5 inches out of

each 12 inch blade (12.5% power loss!), maybe I should make the blade

supports differently than I had planned. Well, they will be PP, so

there's time to design them differently than a flat slab.

Generator Coupling

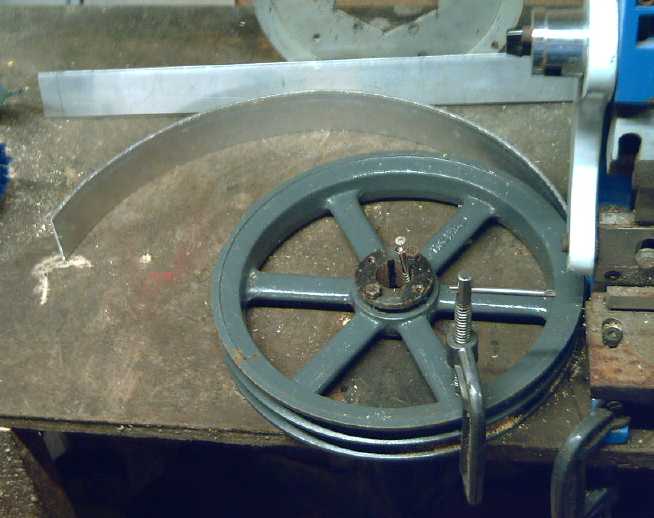

I had been wondering how to connect the generators to the

axle of the rotor with a speed-up. A flat belt might be good, but PP

strapping was too heavy for this. Where to find a light one? Then I

thought of just using fat string or thin rope. It might be tricky, but

the ends could be melted together to make a loop, and an idler wheel

could apply tension. And it might even be arranged that it would slip

with sufficient resistance before it burned out the generator in a

storm? I would need some pretty ordinary pulleys for thin rope! I

decided to lay it all out on a small piece of plywood that could be set

on top of the wind tunnel to test it.

I took a piece of fat string and melted the ends together.

There was a bump every time the join passed the small pulley, but it

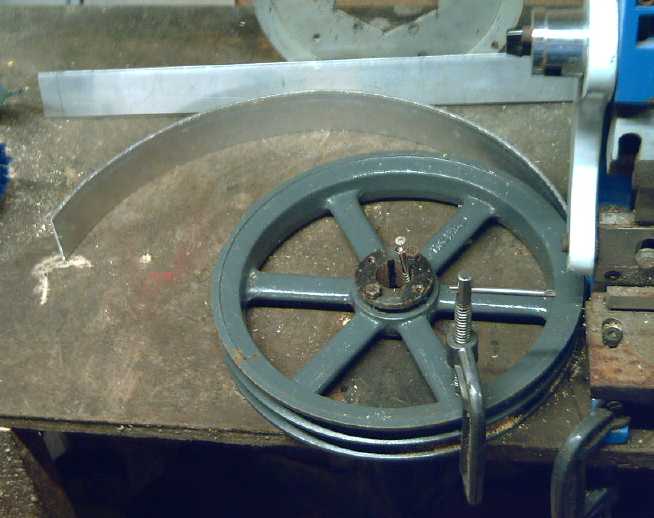

didn't break apart. I found a 9" V-belt pulley and added some brass

tubes to shim it down from 1/2" to the 3/8" rotor axle. I couldn't find

two small V-belt pulleys I bought a while ago for the bandmill project.

So on the generator I tried a round piece of wood, which I turned on

the lathe to what I thought would be suitable, but the cogging and

friction of the generator, multiplied by 10+ by the speed increase

ratio, prevented the rotor from spinning. And if I started it by hand,

it soon came to a stop. I tried the other end of the piece with a

somewhat larger diameter, but it still wouldn't start. (If the rotor

had been 3 times taller, it might have.)

Then I tried a 3+" V-belt pulley I had on hand. That

turned, and gave 0.2 VAC out. The rotor wasn't turning very fast. I

really think I want magnets right on the rotor axle and a non-cogging

stator -- a low speed generator that has no effect on the rotation

until one tries to draw power out of it.

smallest pulley

smallest pulley

a bit larger

a bit larger

3" V-belt pulley

3" V-belt pulley

The poles and magnets

construction of this small motor

The poles and magnets

construction of this small motor

Wind Wall... or WATER Wall ?!?

[21st] I drove to Masset to buy some machine screws no one seemed to

have in QC. As the highway passed by Masset Inlet with its strong tidal

flow running, it suddenly occurred to me that the wind turbine should

also make a great low-speed water turbine, and that the wind wall could

also be a great water wall! There seemed to be a some 'fortuitous'

features that could make it a great fit for marine use:

1. With the generators at the top end of the axles as planned, they

could be out of the water while the turbines were in it.

Counter-rotating turbines would neutralize (or at least limit) any

tendency to pull to one side.

2. I had designed for torque and power at the lowest possible wind

speeds, but obviously a 2 meters per second wind doesn't have enough

force to do much more than charge a cell phone or light an LED.

However, a 2 meters per second water flow would certainly have a lot of

power! Air = 1.25 Kg/m^3. Water = 1000 Kg/m^3. So

power at the same flow rate is 800 times more.

3. It's mostly made of polypropylene plastic! With, say, UHMW (& ?)

bushings instead of ball bearings, it would last a long time

underwater. The metal shaft could be replaced with PP or stainless

steel.

4. Having low-speed turbines with blunt faces, it would probably allow

small fish to pass through without harm. With a "cow-catcher" to

deflect surface logs and debris, and the turbines underwater, it

probably wouldn't be very prone to getting clogged. (If necessary,

grilles can be deployed in front.)

In addition, the fixed "wall" enclosure allows for diverse

deployment options. For example: attached to any sort of floating

vessel, or placed in a creek with ropes to hold it in position. It

could be fixed in place underwater, with tall sides on the wall and

long shafts holding the generators far in the air for varying water

depths including for tides. With floats attached to the sides, it could

be tethered in a river or other flowing water (eg, Masset inlet) either

from shore (with the programmable rudders), from a fixed anchor or from