Turquoise Energy News/Report #171

covering

August

2022 (Posted September 1st 2022)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Feature:

Simplest Concept Automatic Variable Torque Converter - using planetary

gear and

magnetic disks (see under August in Brief, Electric

Transport)

Month In "Brief"

(Project Summaries etc.)

- Cabin Construction - Ground Effect Craft Model: test (ESC) failed -

Chevy Sprint Shenanigans (Smaller tire = Performance!) - Variable

Torque Converter, Take 123 - Bandmill Use & and Improvement -

Plastic Recycling 2.0 - Dual EV Boat Motors - The Wuling HongGuang

"Mini EV" - Lithium Gripes (Sponsored by Petroleum Industry as usual?)

- Grid-Down Necessities: Well Pump!

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

-

Smol

Thots (Big Bust, Ignoring Symptoms, Mincing Words) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* More Chevy Sprint Shenanigans (Smaller tire = Performance!)

* Variable Torque Converter with Planetary Gear: a Magnetic Method

* Axial Flux EV Motors Discussion (from Youtube Video Comments) &

putting Brakes Inside Car Idea

Other "Green"

& Electric Equipment Projects

* Plastic Recycling 2.0

* Gardening

Electricity Storage:

Batteries [no

reports]

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

Cabin

Construction

Cabin

Construction

Early in the month I planed some of the 2 by 4s I cut from

the dead spruce in the spring to a uniform 3-13/16 inches wide for wall

studs. I framed the next section; the north

wall, east end of the cabin. I framed around the outside: posts, beams

and concrete footing, then put

in a nice steel door that I got at the refuse station (in excellent

condition except the paint - even that wasn't bad after cleaning), then

studs across, then plywood. Then I took some plywood off.

I stopped because Perry still had his RV in there, which

he has been planning to redo the caulking on for a couple of years

since arriving here. (It leaks.) I should have been urging him on

sooner so I could do these walls while the weather was nice. Ah well,

he started a new business and was very busy, and it's not like I've had

nothing else to do either.

Finally he decided he needed scaffolding to get up there,

so I made him an "A" frame scaffold, with an extension 'fence rail' to

hang onto when standing on the top cross of the "A" making it more a "λ" cross section. And a half step ladder (refuse

station again) screwed on to climb up.

Now that he's working and making good money, instead of

doing it, he's trying to hire someone else to do it. I've given him

until the end of September to finish. I want to get on with the

building and there's a huge garage space he can rent in town if he's

still not done.

I'll have to pull out my own travel trailer too before

doing the fourth wall. I think I'll wait for next spring, since I'm not

going to get to that wall in the next few weeks before cold, wet

weather sets in.

North wall: door, a little window

to look out.

North wall: door, a little window

to look out.

Ground Effect Craft

It seemed to me I had read that currents to the motor

controllers could be up to 115 amps, so it didn't seem unreasonable

that a 100 amp circuit breaker was blowing when I "floored" it. I now

had some breakers rated for

150 amps, and I replaced them with those. [9th] I took the ground

effect craft model to Meyer Lake. I borrowed a kayak from a neighbor in

case I had to go out on the lake to retrieve it. Surely it would take

off now? I put it at the edge of the boat launch ramp and ran it out. I

maneuvered it around a bit. When it was aimed into a clear lane through

the water lilies I gave it the gas. Almost at once the right motor

quit again - this time without blowing the breaker. This time the motor

controller seemed dead - no little tune when it was powered up,

nothing. Battery voltage good, connections good, breaker good. Oh crap!

A little sealed black box. I guess I'll have to order a new one. This

is an unexpected setback. Successful flight seemed imminent. Now it's

far off.

I managed to retrieve the model without the kayak by

wading out into the water and catching it with a 10 foot stick. Just as

well - the neighbor had helped me get the kayak onto the car roof

racks, and when I did take it off by myself later at home I found it

was too heavy for me and I re-injured my weak back for about the third

time since March.

It occurs to me that the one thing I had done since it

seemed to work fine last summer was to lengthen the wires by about 7 or

8 inches to about 2 feet, so the batteries could sit farther back for

better weight distribution. That would increase the inductance and

these very high current things can be really finnicky as I found when

making my own motor controllers. "Every bit of wire is an antenna" as

they say. Could the left one be on the edge of

failure too?

I had meant to get some pictures and video. When I went to

grab my cameras they both needed charging, so I plugged them in and

then forgot to put them in the car. I had my cell phone but it doesn't

go on the tripod and it's so wide angle the craft would have

disappeared into the distance almost before it had taken off. Not that

it took off.

...

I ordered a new 120 amp "ESC" motor controller to replace

the apparently blown one. The store I bought from before seemed to be

gone, and I ordered a different model from a different store. It's good

for 28.8 [nominal] volts so hopefully it will be more robust at 21.6

volts.

At the same time, I saw sets of two joysticks for remote

controls. It occurred to me to make a mounting and attach two side by

side for dual motors throttles - the right way up for intuitive

steering and power to the two motors. And glue or screw them to onto

the left side of the R/C transmitter. Then I would disconnect the

regular left hand potentiometers and wire in the new ones instead. I'm

not totally confident about doing it, but the craft is almost

impossible to steer as it is, and they didn't cost much.

Chevy Sprint Shenanigans (Smaller tire = Performance!)

On the 15th I went to cut an alder log into lumber. I

decided to use the electric Sprint to carry the bandmill and boards

across the acreage. And for that I decided to try using the smaller

diameter "emergency spare" tire on the drive wheel, an idea I had

thought of

last month. It was only 18 inches diameter compared to the 20 inch ones

on the car, giving it a theoretical 11% more torque. Would it just slip

more on the grass? Would the performance difference even be perceptible?

If there was any difference in slipping on the grass, it

seemed it was slightly better. This surprised me. After I had

finished with milling and carting some rocks around, I did some more

driving around without a load.

If there was any difference in slipping on the grass, it

seemed it was slightly better. This surprised me. After I had

finished with milling and carting some rocks around, I did some more

driving around without a load.

The best "max. speed" (corrected for tire size) said 25.65

KmPH" instead of just over 20. That indicated better acceleration from

one end of the short field to the other. Climbing the small hill from

the low road back up to the house/shop/garage area usually took

something of a run, or the car would slip and or stall on the way up,

without enough torque to keep going to the top. This time I made it up

from stopped at the bottom! (I expect then it could make it up my steep

driveway from the highway if I dared to try taking it on the road.)

The odometer hit 11 Km - I probably drove 3+ this day. The

next day in the garage I noticed the tire was low. 5 PSI. I put in 40

PSI ("max 60"). It drove about the same.

Who'd have thought that

putting on a 10% smaller diameter

tire could possibly make such a difference? It actually seemed to be

"the" difference between "a bit too feeble" and "just sufficient".

Substantial! And to think, I almost didn't bother to

try it!

I didn't find any promising looking smaller diameter tires

on line. Racing, golf cart or trailer tires, and nothing looked quite

right. (Later I discovered a new car that uses 12 inch tires close

enough to the Sprint's regular size - I was starting to wonder if I'd

be able to get new 12 inch tires at all and the sidewalls are

cracking!) But I got a new idea for a variable torque converter and I

don't think I'll need to bother looking for "low profile" 12 inch car

tires.

Variable Torque Converter - Take 123

This new idea is surely the simplest and potentially the

smoothest and most effective one I have thought of. It combines a

planetary gear and magnetic disks. Two disks replace the special

centrifugal clutch. This time the motor

drives the sun gear (the regular planetary gearset configuration) and

the output rotation to the car wheels is

the planetary assembly (also normal). I picked a 7 to 1 reduction

gearbox and ordered it. All else being equal, the wheels would have a 7

to 1 speed reduction from the motor, which is sufficient for the car to

start moving and accelerate well in most circumstances.

But instead of being held, the ring gear (gearset body) is

free to rotate. If there were no other components the whole body of the

gearset would simply spin freely backward instead of the the car

starting to move forward.

The other part of the equation consists of an alume or

copper disk that spins on the motor shaft, and a disk

of supermagnets positioned next to it attached to the case, the ring

gear. As

the motor starts turning with the car stopped, its alume disk also

turns. Owing to electromagnetic friction, the body/ring gear with the

magnet disk next to it

wants to follow it (forward) instead of spinning freely backward. The

planets assembly then tries to turn forward with 7 times the torque of

the motor at 1/7th of its speed (per normal) while the gearset body

tries to turn backward with 6 times the torque of the motor at 1/6 of

its speed.

Conceptual mock-up (with a

Planetary gearset I

had handy).

Conceptual mock-up (with a

Planetary gearset I

had handy).

Right: motor shaft with 10" alume disk.

Center: gearset body with 10" magnet rotor attached.

Left: output shaft to wheel via CV shaft.

The motor holds the right end; a steady bearing holds the output end in

alignment.

(The housing that holds the motor at one end and the steady bearing

at the other should be (?)plastic where it passes by the magnets.)

Of course a center will be needed

to hold the

disk to the shaft.

Of course a center will be needed

to hold the

disk to the shaft.

I'll probably use these disks with the Miles mini-cargo truck, which

has a long motor shaft,

and a flat magnet disk for the Sprint car where the space is tight.

Depending then on the motor speed, the strength of the

magnetic interaction at that speed, and the torque needed to move the

car, the body will either turn backward, not move, or turn forward with

the motor. When the strength of the gear force and the magnetism are

equal, the body won't turn either way and the torque to the stopped

wheels is 7 to 1. If the body turns backward, the torque to the wheels

is actually increased. Perhaps it can rise to 10 to 1 or more. (This

should start the car moving even out of a pothole or up a steep hill.)

If the torque needed is less than 7 to 1, the gearbox will begin to

rotate forward in the direction of the motor as the car starts to move.

As the car picks up speed, the slip between motor and body

in "relative RPM" remains constant at a constant acceleration torque.

That means the gear body is spinning faster and faster along with the

motor and the gear reduction is dropping, until as it all speeds up it

gradually approaches 1 to 1 instead of 7 to 1. As acceleration drops

and torque reduces, the slip also reduces, until at zero torque the

reduction ratio is exactly 1 to 1. (Going downhill it will even reverse

during regenerative braking.) At 100 KmPH the gearbox body

(fortunately) is still only turning just under 1000 RPM - slower with

larger tire vehicles.)

Even the mere 2000 max. RPM of the

forklift motor at 1 to 1 reduction theorecticly allows for vehicle

speed headed toward 200 KmPH, along with up to 10(?) to 1 reduction to

start the car moving.

To be determined: the size and magnetic strength of the

disks used. With an estimated maximum 10 to 1 reduction through the

planetary, or something like 7 to 1 from the ring gear, the maximum

magnetic torque required will be correspondingly reduced (if I have it

right either way) to 10% or 14% of the wheel torque. I'm expecting to

be able to use the illustrated prototype 10 inch "electric hubcap"

magnet rotor with that matching alume disk, spinning maybe 1/8 inch

apart. If that's not enough, I have 12 inch rotors, or even (I hope

not!) could use a magnet disk on each side of the alume disk, or even a

copper disk with two magnet disks for ultimate electromagnetic

strength. But I hope not to have to go to such extraordinary lengths.

(Hmm... a bit of late figuring: it might take stronger magnetic forces

than I was thinking. However, I'm going to proceed and find out.)

The housing holding this assembly has to hold the face of the motor,

enclose the disks and the gearset body, and have a steady bearing for

the output shaft, to hold everything in place and in alignment.

I awaited the arrival of the 7 to 1 planetary gearset for

a few days. Then I looked under the truck and saw there was sufficient

room around the shaft to make the "conversion" easy using the same 5 to

1 planetary and shafts it already had, and the two magnetic disks shown

above. The next morning (29th) I pulled the parts out from under the

truck. I found all the other components required to do the job, leaving

a couple of miscellaneous things and a housing to be created to hold

everything.

Since the part of the housing near the magnet rotor is

best made of non-magnetic material, on the last evening of the month I

started thinking of a partly wooden housing, at least for the prototype

on the truck. (I'd prefer welded steel, but it's magnetic. Alume or

copper would make even worse magnetic drag.) Well, surely it can be

made strong enough, and hey!, that makes it even easier to make!

Nothing is proven until it's made and working, but I have

excellent hopes for this and I'll take simply having this new concept

as being fine progress for the month. And now the truck is on "fast

track" for fitting the first prototype. (As much as anything is "fast

track" these days. My new hot water heater took up the afternoon...)

Bandmill Use & an Improvement

[17th] All-Electric Logging and Milling Operations.

I cut down the trees with the Dolmar electric chainsaw (in March or

April).

I

milled boards with my electric handheld bandmill (sharp new band this

day).

I

milled boards with my electric handheld bandmill (sharp new band this

day).

(Building is neighbor's 'heavy equipment' shop. Orange marker is

property line.

Board on ground is guide board for the mill.)

I

hauled the equipment, boards and firewood in the converted Sprint EV.

I

hauled the equipment, boards and firewood in the converted Sprint EV.

[21st] I started the next

log, a 12 foot piece, at the base 12" x over

16" and 12" x 14" at the top, a considerable piece for a tiny mill.

[21st] I started the next

log, a 12 foot piece, at the base 12" x over

16" and 12" x 14" at the top, a considerable piece for a tiny mill.

I have been using an unusual technique for smoothing off

the log: I take off the bumps and high areas with an electric planer

until the guide board sits nicely. (Also if my guide board is a little

too short, as here, when I get near the far end I stop and push the

board until it sticks out sufficiently to hold the saw level as it

comes out the far end of the log.)

I cut 4 slices, on opposite faces, intending to make

boards with cut edges instead of slabs. (Why I thought they wouldn't be

wedge shaped, I don't know!)

The band kept coming

off the drive wheel on the last one. (Why doesn't it track evenly on

both wheels? - must figure this out.) This time however I probably had

the band tension too light. I made an extra effort to tighten it and

finished cutting the slab. It came off again just as it exited the end

and I quit for the day. Maximum cut width was about 11-3/4 inches in a

few spots. (12-1/4 counting the bark.)

So, another revision before it goes commercial: 3/8" band

tracking/tension adjustment bolts. With 1/4" I had to use a wrench on

the wing nuts, and the bolts stripped. The wing nuts on 5/16" bolts are

still too hard to turn by hand to get good band tension. 3/8" wing nuts

should be big enough. or 5/16" knobs. Bolts (carriage bolts?) that

won't turn while adjusting the nuts would also be an improvement, as

would tensioning springs.

A couple of

fat, wide

boards... and a

bench!

I measured the voltage and power

at the end of the 320 feet of extension cords. It was about 100 volts

when running the mill and 1550 to 1700 watts. (That was with the Cabin

solar panels making 650 watts at the 150 foot mark of the cords, too.)

So I was losing around 20% of the power in the long cords. Not a

surprise! Usually I'm not working so far from the house.

I measured the voltage and power

at the end of the 320 feet of extension cords. It was about 100 volts

when running the mill and 1550 to 1700 watts. (That was with the Cabin

solar panels making 650 watts at the 150 foot mark of the cords, too.)

So I was losing around 20% of the power in the long cords. Not a

surprise! Usually I'm not working so far from the house.

Wayne said he's trying to get approval for his Indonesian

engineer to come to Canada. If he's here, the bandmill is likely to get

a production version and be commercialized. It's not a fast mill, but

it's the only way to cut one or a few logs or cants into lumber with

just a 120V power cord. And easy to stow away when not in use compared

to a mill on tracks. People will love it!

Plastic Recycling 2.0

[27th] In the evening I finally wired the power cord for the oven made

from a freezer.

[28th] I put

it all together with much fiddling around. When I finally had it right,

the temperature showed and the heating element came on. At first I just

set it to 50°C. It got up to that fine and cycled rapidly on and

off to keep it right there. Then I turned it to 150°. Around

70° there was a hissing, agitated sound. Ah... water had leaked

into the lid (when I made it if not later) and was boiling off. It

seemed to take a long time going from 98° to 102°, and much

steam was coming out. Eventually it reached 150° and stayed there.

Duty cycle seemed to be around 40%. But it was steaming for over half

an hour. By 45 minutes it had subsided considerably and by an hour it

had stopped. At that point I went to the laundry room and unplugged it.

(What was I thinking not to have put a power switch on it?)

[28th] I put

it all together with much fiddling around. When I finally had it right,

the temperature showed and the heating element came on. At first I just

set it to 50°C. It got up to that fine and cycled rapidly on and

off to keep it right there. Then I turned it to 150°. Around

70° there was a hissing, agitated sound. Ah... water had leaked

into the lid (when I made it if not later) and was boiling off. It

seemed to take a long time going from 98° to 102°, and much

steam was coming out. Eventually it reached 150° and stayed there.

Duty cycle seemed to be around 40%. But it was steaming for over half

an hour. By 45 minutes it had subsided considerably and by an hour it

had stopped. At that point I went to the laundry room and unplugged it.

(What was I thinking not to have put a power switch on it?)

The front (especially) and back had bulged out with the

metal having separated from the insulation at the inside wall. Maybe I

should stuff some fiberglass in there?

Now I'll have to think about a timer to turn everything

"off" after a prescribed length of time so I don't have to sit around

waiting for the plastic to melt properly and then turn it off.

Now I think probably I should put another whole metal skin

with fiberglass insulation inside the inner liner, to keep the hottest

heat entirely away from the foam insulation. It'll still be a plenty

big oven.

Dual EV Boat Motors

Jim at AGO

Environmental Electronics (Victoria BC) has converted several outboard

boat motors to electric. Now he has installed left and right 230V

induction motors as electric drives on his 26(?) foot Bayliner boat,

with chain drives to the propeller shafts. The gearing to the

propellers can be changed by changing sprocket sizes. "Idler" sprockets

take up the chain slack. He's planning to use an 8,000 watt inverter to

power them from a 48V battery bank. IIRC, 10 horsepower electric is

roughly equivalent to 25 HP gasoline on a boat.

Jim at AGO

Environmental Electronics (Victoria BC) has converted several outboard

boat motors to electric. Now he has installed left and right 230V

induction motors as electric drives on his 26(?) foot Bayliner boat,

with chain drives to the propeller shafts. The gearing to the

propellers can be changed by changing sprocket sizes. "Idler" sprockets

take up the chain slack. He's planning to use an 8,000 watt inverter to

power them from a 48V battery bank. IIRC, 10 horsepower electric is

roughly equivalent to 25 HP gasoline on a boat.

Performance & specs will be derived by testing (which

may not be until spring).

The Wuling Hongguang "Mini EV"

This new electric two-door hatchback from China seems to be attracting

a lot of attention and excitement, and it seemed worthy of

note here for three reasons:

This new electric two-door hatchback from China seems to be attracting

a lot of attention and excitement, and it seemed worthy of

note here for three reasons:

1) It's only around 6000$! (There are two battery options for range and

other 'options')

2) It looked like a pretty decent basic economy car - not "as cheap as

we can make it".

3) It appears one can actually order one from dealers on Alibaba.com

That said, I haven't tried to order one to see if I

actually could, and whether after buying one and getting it shipped

here one could legally license it for the streets in Canada is another

question.

2022 Wuling Hongguang Mini EV: In Depth Walkaround

https://www.youtube.com/watch?v=Vyv1aGfdVrk&ab_channel=JustCARS

Later I saw it crash tested and disassembled.

The back

seats were dangerous places in the event of a rear end collision. Other

than that, it seemed to be as good (or as poor) as could be expected

for a compact, lightweight car with a very short hood. The front seats

section of the passenger compartment held its integrity in the front

end collision.

Later I saw it crash tested and disassembled.

The back

seats were dangerous places in the event of a rear end collision. Other

than that, it seemed to be as good (or as poor) as could be expected

for a compact, lightweight car with a very short hood. The front seats

section of the passenger compartment held its integrity in the front

end collision.

In another video a special safety feature stood out: one

was floating level in a flooded street with the driver still inside.

People were laughing at it. A dump truck drove by, wheels mostly

submerged, rocking it with a big wave. Eventually the wheels touched

ground at a side street going up, and it drove up out of the water!

That's impressive. In most cars aside from quitting, it would quickly

sink and you

might drown! You would certainly have to abandon your car.

Nothing Fancy, just basic "take

us there"

transportation

Nothing Fancy, just basic "take

us there"

transportation

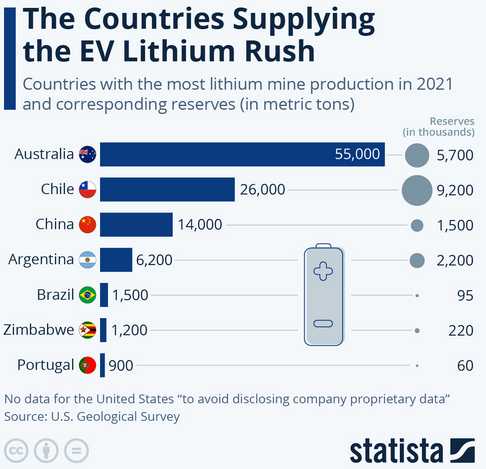

Lithium Gripes (Sponsored by Petroleum Industry as usual?)

We keep

hearing hear "Oh, lithium mining is done in poor third world countries

where there are no environmental standards and it's an environmental

catastrophe"... and "It's too rare. There won't be enough for all the

EVs people plan to make."

We keep

hearing hear "Oh, lithium mining is done in poor third world countries

where there are no environmental standards and it's an environmental

catastrophe"... and "It's too rare. There won't be enough for all the

EVs people plan to make."

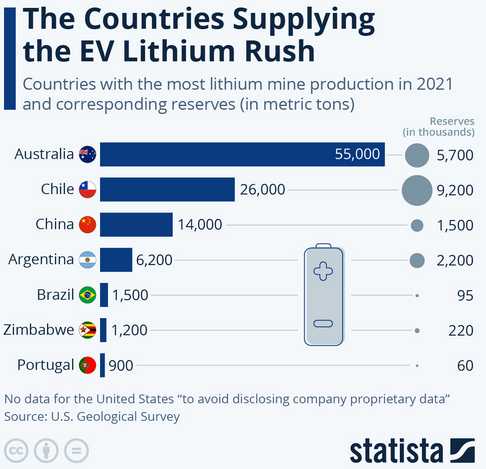

Seems like just another fabrication to justify petroleum

monopoly of transportation to the undiscerning. The chart shows where

lithium comes from. China, perhaps Chile and especially Australia are

hardly "poor third world countries" being exploited by the West.

And here is a new estimate of US reserves:

US Lithium Reserves 750 Gg (gigagrams or 750,000 metric tons - makes

USA's the 5th largest reserves)

And no mention is ever made of the nickel-metal hydride EV

batteries [no lithium] that have been kept off the market for over 20

years by they who have bought all the patents and who refuse to produce

any or allow anyone else to. (All those metal hydride patents must have

expired by now. The main ones did in 2014.)

So the overall message is "Keep using petroleum vehicles

and handing us your hard-earned income, and here's another one of our

twisted excuses why you should!"

Gelled nickel-zinc should be better and cheaper than any

of the above.

Grid-Down Necessities: Well Pump?

To my list of electrical "necessities" for an off-grid

situation - freezer, fridge, lights (,electronics?) - I must add the

well pump, not only for drinking water but for watering the gardens and

greenhouses. When it's warm and sunny out the water needs to be on for

hours at least every second day. Luckily, this is in the summer when

there is lots of sunshine to run the pump, not in December when

there's almost none. But I'd probably want to install that lower power

24V, 300W well pump if there's no mains power.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Smol

Thots

Big Bust

* Apparently the new James Webb space telescope has just shown the "big

bang" theory of the beginning of the universe to be mistaken. I have

long thought it was a mistaken idea, and there has been evidence

against it for some time.

For example, something as massive a a galaxy yet invisible

has been drawing hydrogen gas away from a young visible galaxy. But

this attractor has no spectral or other data; it emits no light and has

no stars. Only its galactic scale gravity suggests it exists. One

expects that this is ultimatonic/higgs-bosun/adamic particle matter in

process of formation into regular atomic matter from a cloud of energy.

The "big bang" theory does not propose that new matter or energy can be

coming into existence today. If that can happen, the theory is not

needed to explain the existence of energy and matter in the universe.

* People seem highly prone to "explaining" what is not understood as

being caused by some not understandable cataclysmic event rather than

by evolutionary processes. A "big bang" started the universe... an

impossible collision between two planetary bodies broke the moon away

from the Earth (It couldn't possibly have simply formed along with the

Earth?)... there was once a global ice age (before there were extensive

land elevations?!?)... huge lava flows in Siberia killed most life on

Earth - everywhere, land and seas, at the end of the Permian... an

equally impossible asteroid impact killed the dinosaurs. (They weren't

losing ground for millions of years before, and they couldn't have been

outcompeted by the rise of birds and placental mammals?)

Ignoring Symptoms

* The less people know, and the less thought they give to it, the more

they think everything is fine and that the population level is fine and

can keep on growing for the foreseeable future. Some, even some

prominent people, are even concerned that there aren't enough children

being born to keep economies expanding the way they were in previous

recent generations. This is a happy state of mind to be in because one

can carry on with life without becoming depressed or being concerned

about what is happening. Our problems are just beginning.

* Climate change and climate mayhem isn't a problem. Like a fever, it

is a symptom of an underlying problem or problems. Even ignoring the

use of non-renewable fossil fuels we overshot the Earth's sustainable

carrying capacity in the 1960s if not earlier, and we have been in

ecological overshoot ever since. As the population grows, we have used

up the resources (renewable as well as non-renewable) and polluted our

ecology faster and faster with each passing decade. At this point we

are in ecological freefall and our chances to change environmental and

ecological outcomes are mostly "in the rearview mirror". Even if all

human activity could suddenly be stopped now, it is decades too late.

Most of the dire ecological consequences of what we have been doing for

the whole of the "modern" era of civilization are "baked into the

cake". It is too late to do much besides brace for impact.

* In the conditions we have gradually created over the last 150 years

or so, with the number of people that have been created, the question

is not how many billions are going to transit prematurely to the

mansion worlds in the next two or three decades, but how many people

will remain on the planet to rebuild a new and better civilization.

Pessimists speak of half a billion. I think that would entail a new

dark age - a serious loss of human gains of the past few centuries that

would require centuries of regrowth to restore. In accord with others

more reasonable guestimates I would suggest around two billion. And

after all, it is only 98 years since the world first hit two billion

people. The process of depopulating to that sort of figure is a tragedy

for the people involved, a couple of oncoming generations filled with

awful and tragic times and events, but not a tragedy for humanity or

the world as a whole. Three billion is a common upper figure for the

planet's sustainable carrying capacity - once the ecology and

environment have been restored as well as possible in some decades or a

century following the most awful times to come. Although if the sea

level rises enough we may find the land may no longer accommodate a

whole three billion, even for thousands of years.

Mincing Words

* There's a guy on Youtube,

channel "robwords", explaining the origins of things in the English

language and alfabet.

- Eth (Ð, ð) and Thorn (Ϸ, ϸ) are now rare 'Latin' letters used

for

"th" as in "the" (ðe) and in "path" (paϸ). Another,

(Ŋ, ŋ), is for

"ng". (I even derived that lower case shape for myself.) You mean we

actually had proper letters for these phonemes and gave

them up?!? (Haven't seen one for "sh" - ?)

Some renditions of Eth looked too much like Wye (Y). So

you

see a sign "Ye Olde English Inn"? It actually says "The Olde English

Inn".

- Eð and ϸorn are still used

in [at least] Íslands (Iceland).

- After I cast off ðe prejudices of my cultural upbriŋiŋ I ϸought

ðe

American spelliŋs of "humor", "color", "labor" and so on instead of

"humour", "colour" and "labour" were good ideas. What are ðose

extra "u"s for, anyway?

What I didn't know was ðat

Webster in creatiŋ "Ðe American Dictionary" in the 1700s was ðe

one and sole instigator of ðese changes. Ðe power of one!

- And you think the silent letters in "debt", "doubt",

"island" and so on were once pronounced, or have some meaning? Never.

They weren't originally

in the words. They were spelled "det", "dout" and (?)"iland" ("ile"

also in French today). Some (or was it one?) officious middle English

scholar(s) noted that the Latin words for those items (like "debitum"?)

had contained those sounds and figured they should be included in the

English spelling even tho they weren't part of the word. Thanks a lot!

- With "knife" however, the "k" was in the early English sound of the

word, ie, "kneef".

- It seems that in Latin and early French quite a number of words

started with "es". (William the Conquerer brought the early Norman

French to England from Normandy.) So they had something

along the lines of "escule". In many if not most words in English the

"e" was dropped, giving us "scule" or "school". In Parisian French the

"s" was generally dropped and an accent mark added instead, giving

"écule", which came to be

"école". In Spanish many words still start with "es". Latin

"escule" became "escueta". (I have no idea when or where the "h" in

"school" popped in from, but in Russian it's "Шкoлa" ("Shkola"))

- From another source, it would seem the use of "ph" as an "officious"

(IMHO) way of writing "f" was based on (again, one?) medieval scholars'

mispronunciation of "ph" in ancient Greek texts, which it would seem

was just a softer "p". Thus "Phoenicians" was pronounced more like

"Punicians", and the Punic wars against Rome were instigated by the

seafaring Phoenicians (Punicians) that had voyaged to and settled in

Carthage.

- Why is "of" not spelled "uv" or at least "ov"?

ESD

(Eccentric Silliness Department)

* Enquirer: "Can pigs fly?"

Federal agent: "Ya, sure. They're not on the 'no fly' list."

FAA Agent: "Not unless they have a valid pilot's license."

Druggie: "It depends what they're smoking."

* A man broke into a food plant and destroyed the garbanzo beans,

tahini and several other ingredients. He was caught and convicted of

hummuside.

* Trying to keep things ridiculously clean... I think I'flossed my mind!

* Is a 6$ bill twice as phony as a 3$ bill?

* People aren't lazy - they're just "effort challenged".

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Some Chevy Sprint Shenanigans (Smaller tire = Performance!)

On the 15th I went to cut the rest of the alder log that

has been

lying at the far side of the acreage for months now into lumber. I

decided to use the electric Sprint to carry the bandmill & tools

across. Then

while I was at it I decided to try using the smaller ("emergency

spare") tire on a 13 inch rim on the drive wheel, an idea I had thought

of last month. (Recap: Only the right front wheel is driven, from

the 36V, 3.5KW forklift motor through a 5 to 1 reduction planetary gear

to the outer half of the original CV shaft: a highly efficient fixed

transmission, but it didn't seem to quite have the torque to climb even

"typical" hills, and it slipped rather easily in the grass.) This tire

was only 18

inches diameter compared to the 20 inch ones on the car, giving it just

a theoretical 11% more torque. Would it just slip more on the grass?

Would the performance difference be perceptible?

As expected, the 13 inch rim, having the same bolt pattern

as the 12

inch rims, fit right on. Room to spare over the brake disk.

If there was any difference in slipping - spinning the

wheel on acceleration and going up hills, it seemed it was slightly better

instead of worse. Perhaps it dug in and gripped better just because it

was so narrow? It had an easier time starting up out of low spots on

the grass. This surprised me. After I had cut a board (and dulled the

saw band badly on a hidden, broken off dead branch with sand around it)

and shortened a

couple of stumps, and carried the equipment, board and some firewood

back to the shop, and some rocks to another location, I did some more

driving around without a load.

I had got it to hit 20 KmPH before, this time the best

"max. speed"

read "28.5" (= 25.65 KmPH allowing for the speedo error with the

smaller tire/wheel). To have got it going faster indicated better

acceleration from one end of the short field to the other. Climbing the

small hill from the low road back up to the house/shop/garage area

usually took a fair run, or the car would slip and stall on the way up,

without enough torque to keep going to the top. This time I took less

of a run at it, and made it fine. Then even less. Finally I started up

the the hill from a stop - and made it up! I imagine then that I could

make it up my steep driveway from the highway if I dared to try taking

it on the road (at least with a run at it).

After all its exertions the motor was for the first time

ever

(AFAIK) quite warm, and parts of the forward-reverse switch hissed if

I touched a wet finger to them. I hadn't connected the current clamp

meter or the Curtis motor controller programmer and I had no voltage

reading. (An indication of state of charge is a poor thing to be

without

in an EV!) Odometer hit 11 Km - I probably drove almost 3

overall this day. (Later I checked the voltage: 38.5V, down from 39.6

or so full charge. 35V would

mean mostly discharged, IIRC, with 32V being the definite "stop

driving!" point.) The next day in the garage I noticed the

tire was low. 5 PSI. (...after sitting in storage for years.) It said

"max 60", but considering the light weight of the car I put in 40. I

drove around once. Seemed about the same.

Who'd have thought that putting on a 10% smaller diameter

tire could

possibly make such a difference? It actually seemed to be "the"

difference between "a bit too feeble" and "sufficient" on typical

hills. Substantially better! And to think, I almost didn't bother to

try it!

I didn't think much of my chances of finding "low profile"

12 inch tires. (Can one even buy any

12 inch rim car tires any more? Were they ever used on any other

vehicles? So, with the sidewall cracks on the present tires, it's good

to know 13 inch rims will fit.) If there are "low profile" 13 inch

tires of 18 or less inches diameter, probably that's what I should put

on the front. If they exist. Otherwise the "emergency spare" is it.

On line the next day, there were some 12 inch tires, but

only one

low profile bias ply racing tire, or trailer tires. Later I found "golf

cart" tires. "Low profile"

didn't seem to be "a thing" with 13 inch tires except for golf carts,

and they seemed to be too wide. I guess that

leaves "trailer tires" (maybe) or "emergency spare" tires. I bet

there's lots of those lying around the wrecking yards! I could put two

on the front to match and

have one in the back for a spare.

Later I saw a new Chinese car (the Wuling HongGuang "Mini

EV", just 6000$!) that had 12 inch tires "close enough" in size to the

Sprint's regular tires and perhaps slightly smaller diameter:

(145/70R12

versus 144/80R12 -- 19.5 inches versus 20 ?).

Later I got another idea, which may eliminate any call

for a smaller tire - see next title.

Variable

Torque

Converter

with

Planetary

Gear:

a Magnetic Method

Ideas evolve faster than

opportunities to build them these days. Sometimes that's a shame. Other

times it's fortunate because a better idea comes along without having

spent time on the first one.

I had thought of using a planetary gear as a variable

torque converter in various ways, and the "car size" low-friction

centrifugal clutch to help effect the "variable" part of it. Or even

just the centrifugal clutch followed by a reduction gear. With a

planetary the whole gear would spin, housing and all, the interaction

between the three elements controlled by the clutch to provide a

variable rate.

I have also realized that the 'variable' part could be

effected by a motor/generator driving or creating drag to control the

rotation of the housing. But that seemed rather complicated.

And I've come up with various "magnetic impulse" variable

converter ideas over the years which never really panned out.

This month I at first thought of having the same

configuration as

with the centrifugal clutch (motor driving planets, ring gear to car,

sun gear to spin) but the sun gear would spin a copper or alume disk

(or drum) instead of the drive plate/shoes of the centrifugal clutch.

Opposite this the ring gear would have a disk (or rim) of strong

magnets. As the motor starts to turn, with the car initially not

wanting to move, the sun gear starts to spin. This puts a drag on the

magnets on the ring gear so the housing wants to follow the disk, and

the disk wants to slow down. The car starts moving. The more torque

needed, the more the slip and the higher the reduction ratio. The less

torque, the less slip.

With (eg) a 5 to 1 reduction planetary, five times the

force on the magnets acts on the output to start the car moving. If it

was 10 to 1, the magnification is ten times. Somewhere in there the

copper and magnet rotors don't have to be absurdly large and powerful

to provide a good leverage, but won't drag the motor down to too low an

RPM. And it would be silent. It wouldn't bee 100% efficient with the

magnetic slip heating the copper, but it should be quite high.

This is right in line with what I've wanted all along, but

once again, it would be another considerable project for just me to

build when I have so many other things, from scratch (while the

centrifugal clutch is already made). I'll have to think about it. (If

only I had thought of it ten or even seven years ago!)

But I have 9, 10 and even 12 inch magnet rotors kicking

around from Electric hubcap prototypes and the improved Piggott

alternator. On the 17th I noticed a 1/2

inch thick alume disk in a storage spot I happened to look in for

something else, about 9-1/2 inches. In case I ever find the time, I

ordered a 7 to 1 planetary gear (hoping that will be about right) so

I'll have all the essential components. (What, I'm spending yet another

500$ that I don't have on something I don't actually need at the

moment?!?)

[23rd] I had

the thought that the above was probably configuring it the

wrong way, or at least in a poor way. The centrifugal clutch shoes

needed to turn at the highest speed obtainable to get them to engage

strongly. But the magnets interact with a strongly conductive metal at

much

lower speeds, and (as I found with the "magnetic impulse torque

converter" quite a few years back, TE News #47-#50), above a certain

speed there's not additional force to be had. So if instead of the

above, the motor drove the sun gear (right, per normal, with alume disk

attached) and the output to the

wheel was taken from the planets assembly (left, per normal), the ring

gear

(body of the gearset, with the magnet rotor attached) would be the

free-spinning element.

[23rd] I had

the thought that the above was probably configuring it the

wrong way, or at least in a poor way. The centrifugal clutch shoes

needed to turn at the highest speed obtainable to get them to engage

strongly. But the magnets interact with a strongly conductive metal at

much

lower speeds, and (as I found with the "magnetic impulse torque

converter" quite a few years back, TE News #47-#50), above a certain

speed there's not additional force to be had. So if instead of the

above, the motor drove the sun gear (right, per normal, with alume disk

attached) and the output to the

wheel was taken from the planets assembly (left, per normal), the ring

gear

(body of the gearset, with the magnet rotor attached) would be the

free-spinning element.

Now we take the 7 to 1 gearset. When the motor starts

turning, the output wants to turn with 7x the force of the motor, at

1/7 the speed. This reduction by itself with the body stopped is enough

for even the 3.5KW forklift motor to start the car rolling under most

circumstances. Therefore we are not asking for more torque than the

motor and gearset would deliver even without any additional parts.

The body wants to turn backward with a force of -6x times

the force of the motor, at similarly -1/6x its

speed. We place the alume disk on the motor shaft and the magnet disk

on the gearset body, with a flux gap between. The gap would be

adjustable by moving the alume disk, to find the optimum coupling gap.

We now have the gears trying to turn the body backward (in

preference to pushing the whole car), but the magnetic coupling trying

to turn it forward. The gears always have the same coupling at any RPM,

but the magnetic coupling increases with the speed difference between

the disks, between motor and gearset body. As the motor speeds up and

the magnetic coupling strengthens, the force trying to slow the body's

reverse rotation down and hence to get the planets assembly to turn

instead (moving the car), increases.

As the speed of the motor and the car increases and the

torque to keep it moving decreases, the ring gear's reverse spin will

slow to zero and then it will start turning in the motor's direction.

As the car accelerates the gearset body will turn more and more along

with the motor.

The more it turns in the same direction as the motor and the wheels,

the lower the reduction ratio becomes until all are moving at almost

the same speed and everything nears 1 to 1 reduction.

One will note that the arrangement has losses because the

magnets and metal disk are always slipping WRT each other, sort of like

the notorious fluid torque converter. I'm not sure how significant the

losses will prove to be. (Hopefully much less!) The prototype should

reveal whether the loss is significant or not.

IF it is, the effect can of course be 'cured' in a number

of ways. One way would simply be to have two or more magnets on the

other disk.

If the torque and relative speed were low enough - just "slippage" -

the two disks would cog magneticly and turn in unison. The best number

of magnets and flux gap could be derived by experiment or perhaps by

calculation. (The motor has to be able to overcome the cogging from a

stop.) But this would make for vibration under higher torque when the

plates aren't cogged. Electromagnets spinning on the metal disk could

be employed to lock the disks together only under the right conditions.

Or an electric brake on the magnet disk with shoes on the metal one

could lock them. (A commutator connection would be required for either)

Another way would be... of course... a special centrifugal clutch

engaged when the assembly is spinning fast enough. (Or perhaps just a

centrifugally actuated cog on the magnet disk that would latch into a

slot on the alume disk?)

The same configuration should work with a

centrifugal clutch instead of magnet + conductive disks, but in 2016 a

motor at 1200(?) RPM didn't seem to engage the shoes of the one I made

very strongly. That's why I had wanted to configure the planetary in

reverse: to make a considerable speed-up to the clutch shoes on the

fast-spinning sun gear.

Truck Too! -- Truck First!

If this works as well as I expect it to, I'll want to

outfit the Miles Mini Cargo Truck with one, too. With the new 7 to 1 on

the Sprint, I could use either of the 5 to 1 gearsets that I already

have. Since there's a 2.2 to 1 (IIR exactly) reduction in the truck's

rear differential, that gives 11 to 1 total reduction to the wheels,

and it only has .45 times the wheel torque acting on the planetary. So

we have plenty of torque to start the truck moving and accelerate well,

and with the planetary fully engaged, a reduction approaching 2.2

to the wheels at highway speeds. The motor controller was programmed to

limit the motor RPM so the speed was only 40 KmPH, with something like

a 4 to 1 total reduction originally. So even without reprogramming the

motor

controller, the truck should attain 73 KmPH. Reprogrammed it could

certainly do 80 or 90 on level pavement and with its 10KW motor

and lightweight batteries probably even up most typical slopes on the

highway.

So once again perhaps it's well I didn't get around to

working further on the truck's transmission yet, since this totally

changes it.

Perhaps it's worth noting that while the planetaries one

orders on line are quite long end to end, they could easily be made

only a couple of inches thick, with the alume magnetic disk adding just

a bit more. Along with axial flux "pancake" motors, it should be pretty

easy to fit two motors and variable torque converters, one for each

wheel, rather than using one motor with a differential gear, for

ultimate efficiency. And there's extra reliability: if one motor quits,

the other can still drive you to a repair shop.

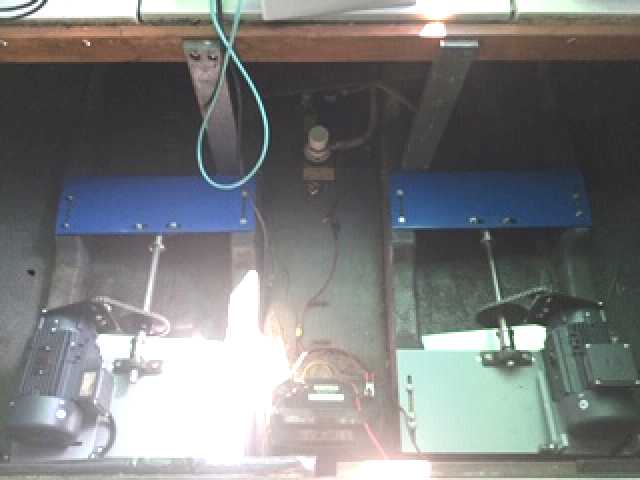

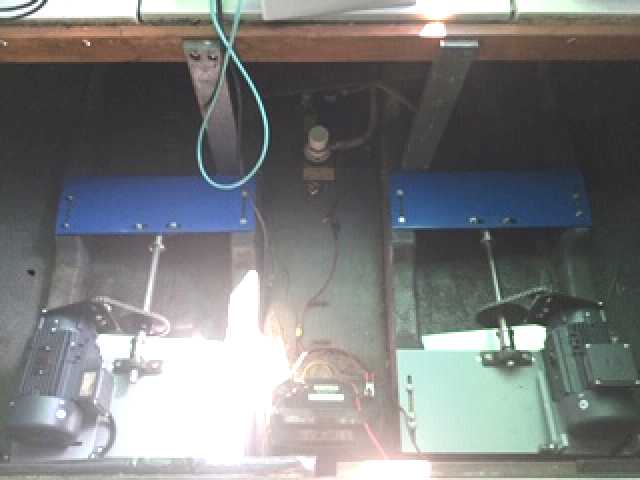

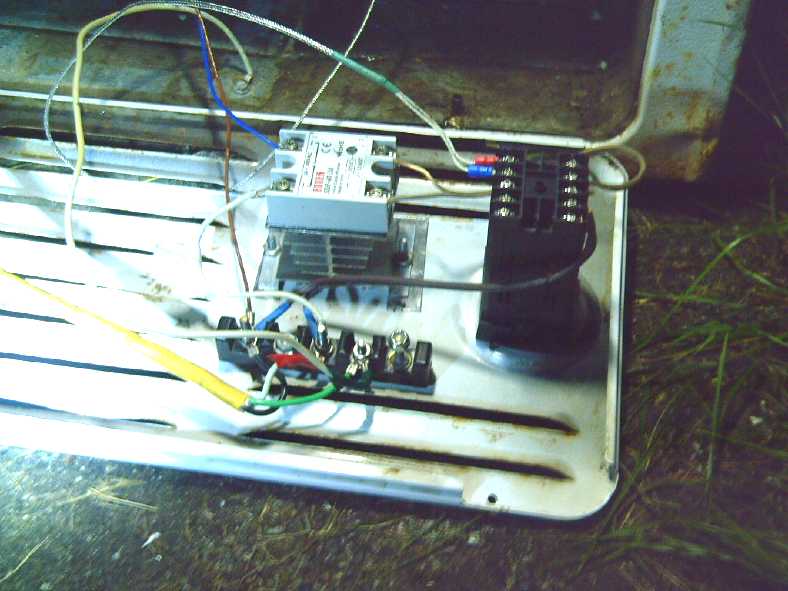

[28th] If I used the same (5:1) planetary all connected the same way as

presently, the conversion should be simple. I figured there wouldn't be

room for the rotors, but I looked under the truck, and there was! That

would be the simple first one to make then. I would have to put the

steady bearing on the original drive shaft to the rear wheels, which

had a "machine smooth" 32mm section at the front. So I had the

planetary, the magnet rotor and the alume rotor. Only a 32mm bearing

was lacking. Hmm... perhaps the steady bearing could be mounted on the

body of the gearset instead of the output shaft? (I found I had a 35mm

cup and cone ("trailer wheel") bearing... that might just work?) Why do

they make most motor and gearset shafts so * short?

(Apologies for the lighting!)

(Apologies for the lighting!)

Drive train under the truck.

The magnetic disks would be just right of the planetary on the left,

which would no longer be bolted to a plate to the truck frame but

"free" (except magneticly) to spin.

Output end - truck's drive shaft.

The mounting

plate will

Output end - truck's drive shaft.

The mounting

plate will

need to attach to a steady bearing on that short output shaft.

The steps then would be:

1. Make a center to fit the alume disk to the 19mm(?) shaft from the

motor. If it can slide up and down the shaft, the magnetic gap can

easily be adjusted without disassembly.

2. Attach the magnet disk to the body of the planetary. I think all it

needs are 4 bolt holes.

3. Fit a steady bearing to the output shaft. (or to the output end of

the body?)

4. Make a case/housing of some sort to tie the motor to the output of

the planetary (the steady bearing) to hold everything rigid and in a

straight line. It would also attach the steady bearing end to the truck

frame.

Each of these tasks will be something of a challenge, but they should

all be doable. I should probably order a 32mm roller bearing ASAP.

Suddenly it went from "I should get around to getting the

truck running again sometime" to an exciting, cutting edge R & D

project with huge potential!

[29th] In the morning I pulled the shaft and planetary out of the truck.

1. The shaft near the planetary was one inch, and I found a 1" SDS hub

and a giant washer I could use to attach it to the alume disk.

2. Four holes in the magnet rotor lined up with with the four #10-32

threaded holes on the input side of the planetary gear. Little pipes

for spacers around the bolts will ensure it stays centered. (Seems like

pretty small bolts to me, but it's the lower torque side and it'll only

turn up to around 1200 RPM.)

3.Much to my surprise I found a needle bearing that fit on the

planetary's output shaft, and a flange for it to hold the stationary

part to the housing.

Not bad for a morning's work! That left fiddling around with those, and

of course the hard part - the housing. There was an alume flange on the

face of the motor with three holes, not quite at 120° to each

other. There were the mounting holes for attaching that end.

Later, thinking about magnetic drag on the magnet rotor, I

thought of making some of the housing from wood. Hmm... That could

speed construction up some more! finally I'm wondering if the whole

thing might need considerably more magnetic interaction than I've been

thinking... double rotors, bigger diameter, copper instead of alume for

more conductivity. Well, I guess I'll find out!

Axial Flux EV Motors Discussion

(from Youtube Video Comments)

& putting Brakes Inside Car Idea

I watched a video about some new axial flux EV motors. The

presenter thought they were going to be "game changers". It sounded

like they had some features in common with mine (did they get ideas

from TE News?), but technical details weren't the focus of the video.

More interesting were some of the many comments under the video, some

seemingly quite knowledgeable. I copied some of the more interesting

and enlightening ones. Since they were published and were intended to

enlighten people, I'll feel free to re-post them here. Of course, it is

gratifying to see some that reinforced my own views on the subjects as

well as broadening them.

Axial flux motors are great and might fit in a car wheel

hub, but I (after some experiments) and others have tended to frown on

in-wheel motors because they add to un-sprung weight. My old Tercel

felt something like a truck when I had mounted extra weight on the

wheel and axle. I would rather put the motors inside the hood and

connect them with single-joint CV shafts, as I have done with the

Sprint (TE News #168, 169). Short axial flux motors should be good for

this because two might be fitted within a car's width. The

forklift radial flux motor extends well over into the other side of the

car.

Someone had an interesting idea: there is already

considerable un-sprung weight in a wheel in the brake components,

notably the brake drum or disk. If that disk can be replaced by a

magnet rotor disk that weighs little or no more, the weight of the hub

motor is offset to a degree. If the magnets are on one side and the

reverse remains smooth, brake cylinders and pads can be placed front

and rear on the smooth side. Of course much of the braking will be

regenerative by electromagnetic force, but the vehicle still needs to

come to a complete stop and 'lock' there mechanicly. And the stator

with iron cores and copper coils adds more weight than just the

magnet rotor.

But then I looked at it the idea other way around: if the

each

motor connects to its wheel via an outer-joint end of a CV shaft, the

entire

brake

assembly

can

also be at the inner end of the shaft, inside the vehicle

or under the hood, and will be

sprung weight instead of un-sprung. This would reduce the

un-sprung weight considerably. For example while most cars are heavier

all around than the Sprint, we might attempt to guestimate for its

wheel:

Brake Disk: 8 pounds? (Nissan Leaf's is 10 pounds)

Brake piston assembly with brake pads: 4 pounds?

Other parts holding the wheel on the car (axle, unsprung portions,

incl. cut CV shaft): 12 pounds?

Typical 12 inch wheel with tire: 20 pounds (I weighed one. Again I

remember the Tercel's (13 inch) as being about 25 pounds)

Total unsprung weight: 44 pounds.

If one eliminated the brake components:

Total unsprung weight: 32 pounds.

A 25%-30% percentage reduction of wheel weight would make

for more nimble handling cars! Indeed, it might be almost in a class of

its own, and it would be a great selling feature. The idea does assume

that the CV shaft and bearings can take the force of hard braking -

even of skidding the wheels on dry pavement. That might mean increasing

the thickness and weight of the CV shaft - shall we add 2 pounds and

(counting half as 'unsprung') make it 33 instead of 44?

An additional benefit is that the brakes would be inside

rather than exposed to the grime and salt from the road, kicked up by

the wheels. They would last far longer with a correspondingly

reduced maintenance cost.

There might - just possibly - be yet one more benefit: if wheel rims

don't have to be designed to fit over a brake disk or drum, the design

might be improved. Their weight might be lightened (yet more weight

reduction) or they might (somehow) provide less rolling resistance.

* * * * *

Well, here's some of the actual comments from under the video, below.

https://www.youtube.com/watch?v=SyqBQhKsoP8&ab_channel=TheElectricViking

I found them more interesting than the video itself.

Paul

Axial flux motors are a big deal, yes. Not a total game changer, but a

significant improvement nevertheless. And yes, there were around before

the radial flux motor we all know, being the first electric motors

invented. Nicola Tesla actually had a patent on a version he designed.

All thin CD players use axial flux motor because the radial does not

fit in that tight of a space. Some elevator use large ones, for

example, due to their higher torque and efficiency. Their issue has

been that the machinery for mass manufacturing hasn't been there

because radial are easier to design for simple applications like

ceiling fans and power tools, and other similar applications, the main

uses of electric motors until now. After the mass manufacturing is in

place, the issue remaining is heat dissipation. Especially in the

yokeless design.

This was

something I found. The Electric hubcap motor in the Sprint in 2015-2016

heated up surprisingly fast under heavy load at low RPMs. And the

Electric Caik in the outboard didn't dissipate heat well. It took a

while, but it just kept getting warmer.

As far as efficiency, they are absolutely more efficient than radial

because their power/electric mechanism is stationary being axial as

opposed to radial because by design they use alternating current to

induce the rotation, therefore use a little less electricity/power to

do the same job. Their efficiency is obviously not more than 100%,

that's idiotic to even mention, however, they do reach above 96% on

average. So they are at least 6 to 7% more efficient than radial, while

still having 30 to 35% more torque. And they can be much smaller, so

much so that, yes, Ford actually tried using them inside the tire's

rims for the Mach-E and Lightning, but their efforts obviously failed

due to the fact that you mentioned -- there is no suspension there to

take the shocks of the road. Perhaps in the future tiny suspension

designs that fit inside the rim can allow it. But for now, that's out

of the question.

In spite of

never having done proper tests and getting hard figures, I was finding

that the last version of the Electric hubcap motors seemed to require

almost nothing to keep them going with no load, and seemed still quite

efficient under heavy load (notwithstanding heating up). I was

estimating they were about 95% peak efficiency and people didn't seem

to believe me. (It was quite a contrast to the very first version that

was only around 50% efficiency.) Now we see "above 96%" as an average

peak efficiency, which makes my claim modest.

They are so efficient and light that Rolls Royce is using them for

their electric airplane motors they are working on now. In fact, they

are actually currently testing them on actual small airplanes. So yes,

axial flux motors will absolutely enter the EV world soon. <snip>

John Boen

Thoughts on efficiency... from a class I took on windings motors...

Typical motors operate better in one direction ... they also have to

operate like a generator, meaning they have to absorb power. The design

for maximum output efficiency makes generator efficiency pretty

low.

There is a certain amount of tuning to turn an efficient motor into an

efficient generator.

But these are highly symmetric - they should work equally well as

motors and generators.

It could be recovering 2x as much energy as older designs.

If they are 2/3 the weight... if they are smaller... if they produce

less heat... and they recover 2x as much energy...

Hidden

benefits not immediately obvious from the printed specs!

Mike l

Denis T / Yes, but you forget one important thing: higher torque coming

from an electric motor, in any physical package smaller or bigger of

the electric motor, comes with higher necessary amps meaning higher

current consumption.

Torque formula for electric motors is like this:

Torque ( N-m ) = 9.5 X Power ( KW ) / Speed ( RPM )

Or practically : Tq= 9.5 X UI / RPM

Do you see that multiplication of the 2 terms UI? Those are U=voltage

and I=current.

To have more torque you can use higher voltage, higher Amps or both.

At the same voltage, more Torque means more Amps.

And don't forget that more Amps means higher temperature.

All OK, now?

I hadn't seen

this formula and constant before. Cool!

Bill Gaytes

I was working with Axial flux (pancake motors) in the 70's and they

were around long before then. The biggest disadvantage is there is no

thermal inertia so when you dump a huge amount of current into them

(torque) they get hot very quickly as they don't have a big armature

mass to soak up the heat.

Once again,

the rapid heating issue that I was having with the Electric Hubcap

motor.

Chris G

Axial flux motors are a way of squeezing more out of given energy

inputs. That is the case primarily because axial flux motors are

lighter than their radial flux cousins and because energy losses to

rotational impediments are reduced. Taken together those two factors

mean that torque and power density (which are measured relative to

motor weight) can go up a lot even as the efficiency rating of the

motor only increases by a modest amount.

I suspect there might also be a degree of difficulty in calculating

motor efficiency precisely or in an indisputable fashion. Year after

year more efficient radial flux motors are making their way to

production. These new motors have consistently improved on the current

state of the art in electric motor design. I am not sure that

calculated efficiency always fully reflects the degree to which these

motors have improved.

It is worth noting that not all electric motors are based on magnetic

drive principles. So how does one rate the efficiency of a motor based

on electrostatics against magnetic motors? It seems to me everything

must finally reduce to some distance output/charge input calculation

(with certain test conditions, e.g. driving conditions and vehicle

weight, controlled/equalised) but short of that the technical factors

playing a leading role in motor design mightn't look alike (across

different motor types) and could even generate pictures of motor

efficiency that aren't easily commensurable.

Sam, you would be doing those who follow your vlog a great service if

you set about trying to answer some of the questions you have raised.

Of course, a dyno will tell us a lot about the performance

characteristics of a motor but that doesn't mean motor design is based

on what the dyno tells us - ideally, the dyno will confirm the motor

designers assumptions about how best to design a motor. Also, it would

be nice to know whether motor designers work with highly generalisable

accounts of efficiency or whether their work requires them to look at

things in a unique way more applicable to the type of motor that they

are developing.

Well, there

are certainly some of the finer details to take into account! Of

course, two motors might both boast "88% peak efficiency", but graphs

of efficiency under varying loads and varying RPMs might look quite

different for each motor. Someone (youtube somewhere) took a 1000W

bicycle hub motor, and then a tiny 1000W model airplane motor, and said

"Why can't I gear the airplane motor down and use it as a bicycle

motor?" He tried it. The model airplane motor indeed ran the bicycle,

but it got smoking hot quickly. Same watts figure, but they were rated

quite differently. And in the bicycle application there was no

propeller blowing cold air onto the motor - an unspoken condition that

would simply be "assumed" for aircraft models.

Edward De Jong

@IncognitoTorpedo theoretically, if you can make the hub

motors light enough, that will be a superior arrangement, as the

knuckles and universal joints cost you in various ways. When you have

very powerful motors those shafts are non-trivial in weight and

inertia. I have no doubt in my mind that eventually some company

will ship hub motors. [clipped]

This is the

comment that got me thinking about where the motors and brakes are. If

a CV shaft is straight, there should be no losses. The more it bends at

the joint, the higher the losses will be. So for non-hub motor

efficiency it's a question of being able to position the components so

the shafts are pretty straight unless the car is turning.

zmavrick

To understand axial flux motors requires a completely different

mindset. There are different types of electrical motors that work very

differently and we are used to trying to understand them by comparing

them to ICE engines and that doesn't work. I have been building these

motors and generators as a home hobbyist for years and they are very

efficient, especially for RPM's less than 2,200. Above that you

get field latency problems in the the cores which causes heat buildup.

The easiest way to think of their method of operation is that instead

of current driven the current is used for field switching.

This isn't a revolutionary game changer, but it does open

up some real possibilities for system performance efficiencies. At a

time when battery materials supply is having problems keeping up with

demand increases this is important. Even a slight performance increase

could result in a slight reduction in batteries required. Multiplied by

thousands of cars this could have a significant reduction in overall

batteries needed. Reductions in weight of both the drive train and

battery pack could also give a significant improvement on tire wear.

Here the new

variable torque converter will come into play. It keeps the motor RPMs

low even on the highway, so that a 95% peak efficiency BLDC axial flux

motor is always operating in its most efficient speed range. This

eliminates the value of high speed reluctance motors unless they can be

as efficient on the road as the BLDC-torque converter combo. (In which

case, being cheaper is an advantage.) "My money" is on the BLDC with

variable torque converter - which one expects (also favorable comment

somewhere above) is also better at regenerative braking.

Other "Green" & Electric Equipment Projects

Plastic Recycling 2.0

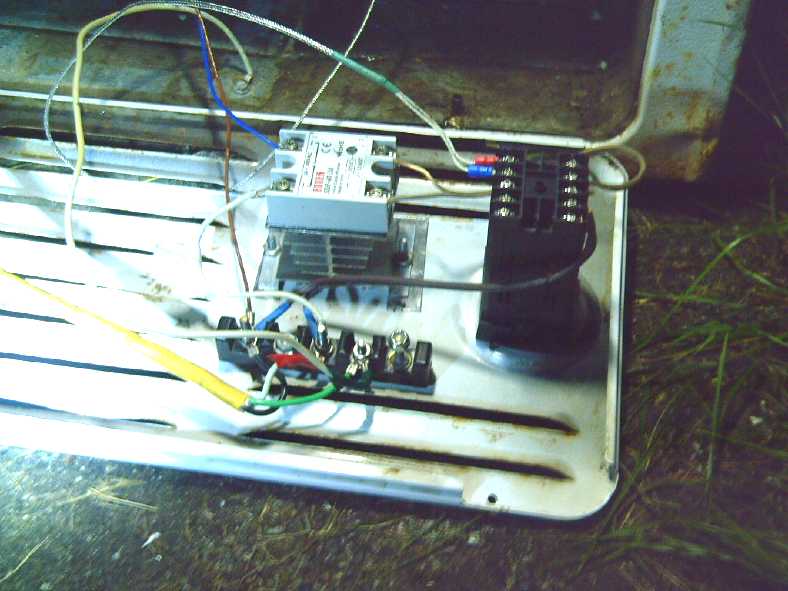

[27th] In the evening I finally

wired the power cord for the oven made from a freezer. Sounds simple

enough... the delay was partly from indecision. It only needed a 15 amp

breaker as the heating element was only about 9 amps. One could do that

9 amps with a simple #16 AWG extension cord instead of the heavy wire I

had run to the stove. But this being North America, the power outlets

are all 120V, not 240. Should I put the heavy "dryer" plug on the end

of a light power cord, and run it through the window into the laundry

as I had done with the original oven? Or, use a 15A, 240V plug and plug

it into the water pump supply? But if I used a 15A plug and plugged it

into the water pump supply, I would surely forget and run the water

pressure down to nothing and get air in the lines and hot water tank.

Or should I do some house wiring and add a proper new 240V, 15A socket?

I finally went with the path of least resistance and connected the

light extension cord to the bulky "dryer" plug via an in-line

electrical box.

[28th] I put it all

together with much fiddling around. I got the confusing temperature

sensor wiring wrong several times and it kept flashing "error". (Which

was which? Is TC the 'temperature compensation' or the 'thermo

couple'?) I finally went to youtube and looked at a video. Hey, it

doesn't even need that second "temperature compensation" thermocouple

(that wasn't supplied)! Some versions of the controller don't even have

the third terminal to connect one. That simplified things!

[28th] I put it all

together with much fiddling around. I got the confusing temperature

sensor wiring wrong several times and it kept flashing "error". (Which

was which? Is TC the 'temperature compensation' or the 'thermo

couple'?) I finally went to youtube and looked at a video. Hey, it

doesn't even need that second "temperature compensation" thermocouple

(that wasn't supplied)! Some versions of the controller don't even have

the third terminal to connect one. That simplified things!

When I had it

right, the temperature showed up instead of a blinking error code and a

clicking alarm relay. And the heating element came on. At first I just

set it to 50°C. It got up to that fine and cycled rapidly on and

off to keep it there.

When I had it

right, the temperature showed up instead of a blinking error code and a

clicking alarm relay. And the heating element came on. At first I just

set it to 50°C. It got up to that fine and cycled rapidly on and

off to keep it there.

Then I turned it to 150°. Around 70° there was a

hissing, agitated sound. Ah... water had leaked in (when I made it if

not later) and was boiling off. It seemed to take a long time going

from 98° to 102°, and much steam was coming out. Eventually it

reached 150° and stayed there. Duty cycle seemed to be around 40%.

But it was steaming for over half an hour. By 45 minutes it had died

down and by an hour it had stopped. At that point I went to the laundry

room and unplugged it.

(What was I thinking not to have put a power switch in?)

The front

(especially) and back had bulged out with the metal having separated

from the insulation at the inside wall. I was worried that might happen

at plastic melting temperatures, not at 150°. Obviously the foam

insulation is inadequate.

The front

(especially) and back had bulged out with the metal having separated

from the insulation at the inside wall. I was worried that might happen

at plastic melting temperatures, not at 150°. Obviously the foam

insulation is inadequate.

In a comment under a video

someone mentioned that solid state relays usually fail "on", and that

that would leave your heating element on. I'm not sure having the

element left "on" will raise the temperature much higher than that

desired anyway. It may depend on whether I can seal the door well or

not. I'll have to think about it, and about a timer to turn everything

"off" after a prescribed length of time so I don't have to sit around

waiting for it.

Now I think probably I should put another whole metal skin

with fiberglass insulation inside the inner liner, to keep the hottest

heat entirely away from the foam insulation. Or maybe if I heat it up

and the foam gets soft or melts, I can unplug the heating element and

pull the whole inner liner right out? (Nothing else holds it in?) Then

it might be simple to replace the insulation with fiberglass or rock

wool?

Gardening

Sunflowers!

3 in the south wall garden were

the most

successful: 2 'giant', 1 'dwarf'.

3 in the south wall garden were

the most

successful: 2 'giant', 1 'dwarf'.

28th - The 'dwarf' always looked

somewhat

pathetic with ever-drooping leaves,

28th - The 'dwarf' always looked

somewhat

pathetic with ever-drooping leaves,

but it grew a 10 inch head in July that matured near the end of August.

The 'petals' on each seed (left half) could be easily brushed away

(right half).

I picked it after this picture and took it in to dry. The weather

turned rainy.

28th - The largest of the 'giant'

ones grew a

head about 14 inches across, but rather late.

28th - The largest of the 'giant'

ones grew a

head about 14 inches across, but rather late.

The seeds weren't ripe and in general the little 'petals' on each seed

weren't ready to drop off.

31st - The 'petals' were easier

to brush off

the seeds, but they

31st - The 'petals' were easier

to brush off

the seeds, but they

still need some warm weather to ripen. 50-50 whether they get it.

It would seem the 'dwarf' are more the reliable variety to grow around

here.

This year, for the first time I had planted sunflowers in

trays indoors in the spring. For some reason I had always thought of

them as "flowers" rather than a food plant, notwithstanding all the

sunflower seeds I've eaten in my time. And I wasn't sure they'd grow