Turquoise Energy News Report #174

Covering

November

2022 (Posted December 5th 2022)

Lawnhill BC Canada - by Craig Carmichael

(CraigXC at Post dot com)

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- I Want a Better Camera? - Improving a Peltier Cooler: "New"

Experiments - New Battery Experiments

- Magnetic Variable

Torque

Converter: Better than The Best! (making for Miles Truck) - Axial

Flux

Unipolar BLDC Motor (5KW? - Magnet rotor cut)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Amazon: A Den of Thieves! -

Car Key FOB Hidden Health Hazard - Smol Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Magnetic Variable Torque Converter with Planetary Gear: The

Future of the Automotive Industry! (Building one for Miles Truck)

* Axial Flux Unipolar BLDC Motor - 5KW? - Magnet Rotor

Other "Green"

& Electric Equipment Projects

* Peltier Cooler Performance: Greatest Cooling is running at

9-10 volts

* Indoor & LED Gardening

Electricity Storage:

Batteries

* Gelled Ni-Zn Salt Cell - A.K.O. New Experiment Details

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

On the afternoon of December 5th, I was walking toward

home on the left shoulder of the highway, having found that the upper

beach was very rocky today and it was near high tide. There was very

little traffic. A vehicle came up from behind, slowed, and the

Purlolator van stopped beside me. "I have a box for you." Through the

driver's window he handed me a box that said "Westlab" - my KCl salt!

"Thanks!" "Only on Haida Gwaii, eh?" he said and continued on his way.

I Want a Better Camera?

I had been trying to get a better camera. In my earliest

wave power tests (2008) the wind had blown over my 2005 Centrios

DVD/camera on a tripod and about 1/3 of the display's LCD liquid leaked

out,

leaving the already tiny display barely showing what I'm taking a

picture of, much less whether it's blurred or out of focus. A button

clicks to 'near', 'portrait' and 'far'. If it was wrong, too bad. For

close-ups I have to try at about 9, 10 and 11 inches and use the best

one. My old cell

phone had been good but the 'new' one doesn't focus close up. I bought

a

camera on AliExpress that likewise disappointed me. Somebody gave me

one from a thrift shop that took good pictures but the display was

still too

small for my liking and worse, I couldn't find a cable with its odd

plug to

connect it to

USB. Somebody told me to try "Best Buy". Just before I went on

line I looked at my 7 year old RCA Android 'tablet with keyboard' that

I

never use. Hmm, it has two cameras. I removed the keyboard, powered it

up and discovered that it seemed to take focused close-ups! And the

screen is of

course huge to view the scene and the result. Problem solved? (If only

its internal lithium battery lasted longer, or it took regular "AAA"

cells that could be swapped! If you leave it a week without plugging it

in, it's dead. Unless you turn it right off, after which it takes a

coon's age to boot.)

Sigh! When I went to use the first set of pictures I had

taken with the tablet, I found that they weren't nearly as sharp and

clear as from my

2005 camera, to the point where I couldn't compare 'before' and 'after'

images of an electrode that might reveal changes, one from

each camera. Back to square one! Or maybe my old camera isn't so bad

after all? Hmm. Or maybe I should try Best Buy after all?

Quality images?

Quality images?

Improving a Peltier Cooler: "New" Experiments

Perry gave me

a Peltier module camping cooler he found at

the thrift store. It didn't seem to work. I checked the module by

itself and it cooled. After some frustrating sessions trying to figure

out what was

wrong, I reversed the polarity of the fan motor, which spun both the

outside and the inside fan at opposite ends of the same shaft. It

cooled!

Someone had wired the fan and the module oppositely. (The odd-shape

blades seemed to be right, but they just didn't work that way

around.)

Perry gave me

a Peltier module camping cooler he found at

the thrift store. It didn't seem to work. I checked the module by

itself and it cooled. After some frustrating sessions trying to figure

out what was

wrong, I reversed the polarity of the fan motor, which spun both the

outside and the inside fan at opposite ends of the same shaft. It

cooled!

Someone had wired the fan and the module oppositely. (The odd-shape

blades seemed to be right, but they just didn't work that way

around.)

From looking at graphs on Peltier module datasheets long

ago, I had noticed

that the COP (Coefficient of Performance) was better and better (a) the

less the temperature spread was between the hot and cold sides of the

module and (b) the lower the current drive. The current drive is

reduced by reducing the voltage. That provides less wattage of actual

cooling, but the cooling losses from heating of the hot side are

greatly reduced.

From those

specs I have long thought that "12

volt"

Peltier modules (unless trying to attain the most extreme temperature

drop) would cool much more efficiently at a lower voltage.

With a "properly" working cooler now, I could give the theory a good

test. I ran it off a DC to DC converter from the 36VDC solar power

system and turned the adjustment pot to various output voltages over

the day. The table

shows the results. At the nominal rated 12 volts it used 45 watts and

got the

cooler down to about 11°C cooler than the room. Much as I had

surmised, at 7 volts it used 1/3 the power (15W) to provide

approximately the

same temperature drop! Peak cooling effect seemed to be attained at

about 9-10 volts and 25-30 watts power draw.

From those

specs I have long thought that "12

volt"

Peltier modules (unless trying to attain the most extreme temperature

drop) would cool much more efficiently at a lower voltage.

With a "properly" working cooler now, I could give the theory a good

test. I ran it off a DC to DC converter from the 36VDC solar power

system and turned the adjustment pot to various output voltages over

the day. The table

shows the results. At the nominal rated 12 volts it used 45 watts and

got the

cooler down to about 11°C cooler than the room. Much as I had

surmised, at 7 volts it used 1/3 the power (15W) to provide

approximately the

same temperature drop! Peak cooling effect seemed to be attained at

about 9-10 volts and 25-30 watts power draw.

If you're trying to run it off your car battery overnight,

15 or 20 watts is much better than 45! Running off a solar panel only

in the

daytime, 25 or 30 watts provides the maximum cooling to keep the cooler

coolest. I'd call a cheap DC to DC converter to

reduce the voltage an excellent asset for running a Peltier

camping

cooler! I'm surprised makers of both Peltier modules and camping

coolers haven't caught on. A Peltier rated for about 18V instead of 12V

would

cool better with less power at 12 volts. (Extra

details under Other "Green" & Electric Equipment Projects.)

There was snow on the ground the day I did these tests. I

won't be camping any time soon.

Cooler

Supply

(Volts)

|

Power to

Cooler

(Watts)

|

Cooler

Temperature

Drop (~°C)

|

13

|

53

|

11.7

|

12

|

45

|

11

|

11

|

39

|

11

|

10

|

30

|

12.5

|

9

|

25

|

12.4

|

8

|

20

|

11.7

|

7

|

15

|

11

|

6.5

|

13

|

10

|

The other improvement to Peltier performance is to

minimize the temperature difference between the hot and the cold faces.

Among other things, both faces should contact with the best possible

heat conductor to reduce the temperature loss/gain in the junctions.

This would mean using silver, copper or at least pure alume in

the heatsinks. This seems to never be done. Alume alloy is fine

for keeping transistors from roasting, but it's not

as good a heat conductor as pure alume and has higher thermal

resistance at those

critical junctions. Pure copper is even better. Reducing the heat

loss/gain in both junctions by just

one degree would mean the same cooler could cool by 14.5° instead

of 12.5°. (Maybe I should try my "superinsulated Peltier chest

fridge" again with copper on the hot side as well as the cold side? It

certainly seemed to perform better than most Peltier coolers even with

just the one fat copper bar, on the cold side. It froze water in the

ice tray.)

(Hint for Peltier cooler camping: cool the food in a regular fridge or

freezer, maybe throw in a block of ice, before you leave. The cooler

will take a long time to get food cool, expecially at low watts.)

New Battery Experiments

I finally got back into these experiments with some crappy

weather when I didn't want to do any outside work. I improved my

techniques and learned a lot about things I've been "stuck" on for

ages. I think am much closer to making good cells.

Key findings:

1. The nickel-manganates powder electrodes work and repeatedly

recharge. (It should have at least twice the energy per kilogram of the

beta

nickel oxyhydroxide presently used in typical rechargable alkaline

cells.)

2. The nano-powders from that electrode penetrate separator papers and

make a low resistance path across the cell, slowly deteriorating the

performance. This seems to be cured simply by

wetting the paper with Varsol first. (it must close or reduce larger

pores?)

3. Other than that, my perennial self-discharge problems are evidently

caused by soluble impurities which have to be diluted out in baths of

water or electrolyte.

4. Including that the "99.9% KCl" electrolyte salt itself seems to be

contaminated. Solved by drying out a salt solution and collecting the

purest crystals off the sides of the tray.

5. Cupro-nickel current collectors seem to work in the positive

electrode. (better than graphite sheets.)

6. Improved cell constructions.

I must say that

doing battery chemistry experiments has been worse than watching paint

dry. It occupies much time. I suspect

some of the things I've been trying haven't been tried before simply

because people have run out of patience for ideas with markedly

uncertain outcomes. Especially salt electrolyte rechargeable battery

chemistry and

techniques don't seem to have been very well explored. Everybody jumped

on the KOH alkaline electrolyte bandwagon when Jungner found that

nickel (and only nickel) didn't corrode in the plus electrode, while

graphite/carbon was the only thing so far found to work in salt, and it

limited currents and cell forms. (And now, with zinc still not properly

tamed and the low effective watts per gram energy of beta nickel

oxyhydroxide, 'everyone' has jumped on the lithium bandwagon.)

Perry imported a 6 foot arborite/melamine countertop with

a backsplash for me from Home Depot on the mainland, something I've

wanted for ages

to set on top of my washer and dryer and short sink counter - at last,

a decent work surface

at standing height, that won't stain and can be wiped clean, for my

very meager "chem lab"!

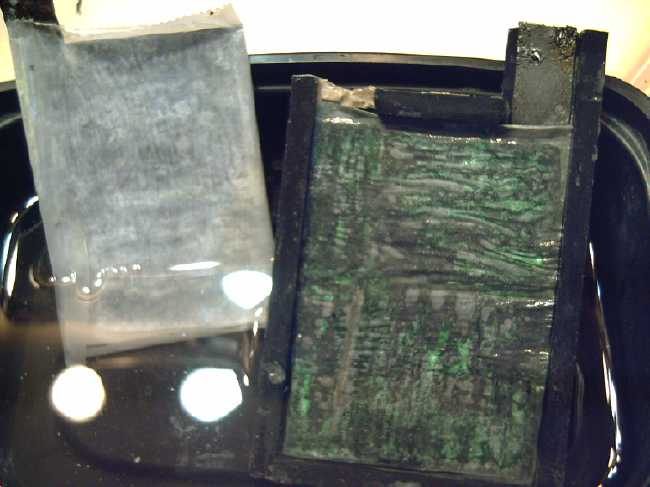

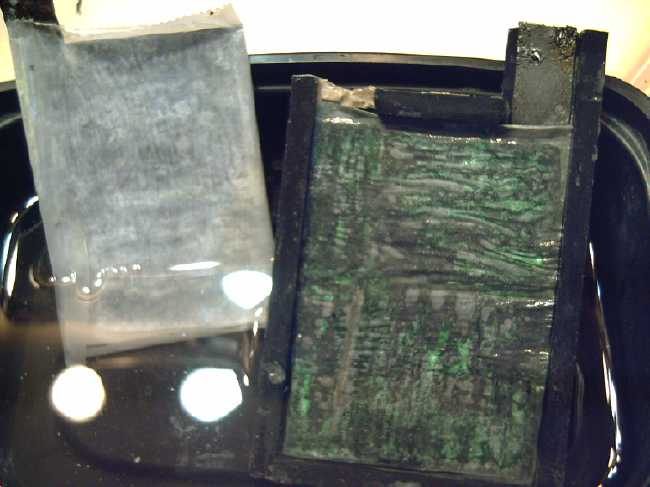

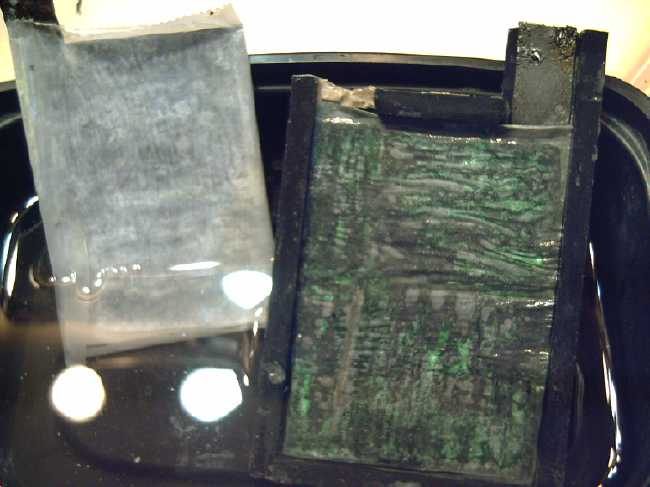

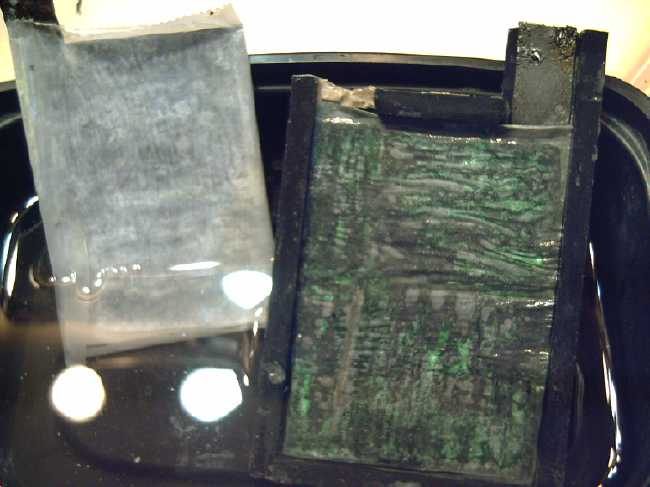

Externally

Clamped Cell,

under charge. L: mA; R:

V

With the

externally clamped cell(s) system I found I could use a sheet of rubber

for the front face of the cell and not glue it. This was

revolutionary in my experiments as I could now seal and reopen the cell

any time. I can replace each any any component as desired. (Why didn't

I have anything like this, if not in 2008, at least by 2012 or 2013?

Duh!)

With the

externally clamped cell(s) system I found I could use a sheet of rubber

for the front face of the cell and not glue it. This was

revolutionary in my experiments as I could now seal and reopen the cell

any time. I can replace each any any component as desired. (Why didn't

I have anything like this, if not in 2008, at least by 2012 or 2013?

Duh!)

I also finally

got tired of having a dozen alligator clip test and voltmeter probe

leeds all falling off or making poor connections, and wired a bunch of

connections to a terminal block to reduce their number. If it looks

cluttered, it has nothing on just a pile of loose wires.

I also finally

got tired of having a dozen alligator clip test and voltmeter probe

leeds all falling off or making poor connections, and wired a bunch of

connections to a terminal block to reduce their number. If it looks

cluttered, it has nothing on just a pile of loose wires.

As of

this writing I it appears my cells have been performing poorly because

of a combination of small things:

* Traces of soluble

materials in the electrode powders, which then dissolve in the

electrolyte. Especially nitrate ions will travel back and forth

becoming nitrate at one electrode and nitrite at the other, stealing

the electrons from the one and releasing them into the other to make a

continual self discharge. The solution seemed to be to bathe the

materials or electrode in water about 3 times before using them and

then drain the water, to dissolve and dilute out soluble impurities

beforehand.

* Traces of soluble

materials in the electrode powders, which then dissolve in the

electrolyte. Especially nitrate ions will travel back and forth

becoming nitrate at one electrode and nitrite at the other, stealing

the electrons from the one and releasing them into the other to make a

continual self discharge. The solution seemed to be to bathe the

materials or electrode in water about 3 times before using them and

then drain the water, to dissolve and dilute out soluble impurities

beforehand.

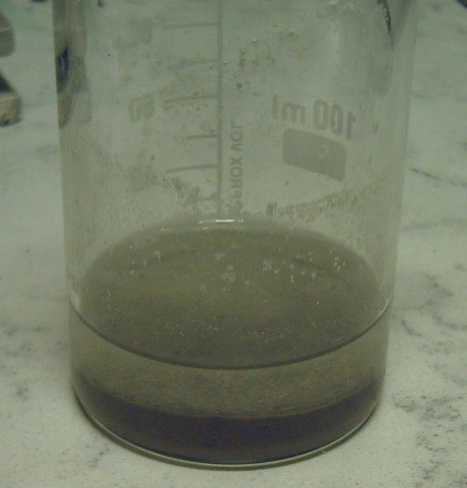

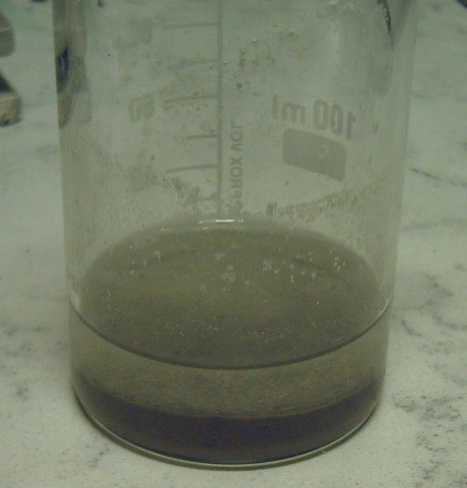

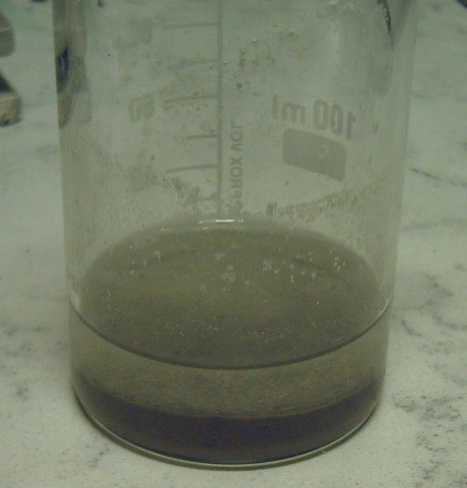

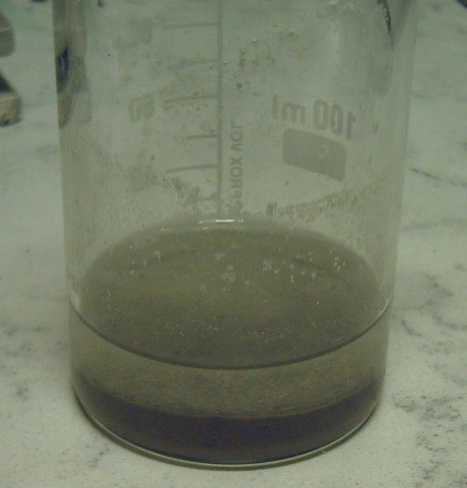

* Likewise, impure KCl electrolyte salt has

probably been causing self discharge. My "99.9% KCl" salt from a health

food store needs to be purified by dissolving it and evaporating the

water. It seems the salt that crystallizes on the side of the beaker as

the water evaporates is pretty pure, the impurities settling out last

at the bottom. Some I made (tried to make?) by combining KOH (USP

grade) and suspect purity HCl had a thick dark gray sludge on the

bottom. Yikes! (Some KCl I ordered from Westlab hasn't come yet.)

* Likewise, impure KCl electrolyte salt has

probably been causing self discharge. My "99.9% KCl" salt from a health

food store needs to be purified by dissolving it and evaporating the

water. It seems the salt that crystallizes on the side of the beaker as

the water evaporates is pretty pure, the impurities settling out last

at the bottom. Some I made (tried to make?) by combining KOH (USP

grade) and suspect purity HCl had a thick dark gray sludge on the

bottom. Yikes! (Some KCl I ordered from Westlab hasn't come yet.)

* Air needs to be kept out of the cell.

Oxygen gas will oxidize (discharge) the salty, wet zinc electrode. (And

carbon dioxide may gradually turn things irreversibly into carbonates.)

Leaks need to be sealed.

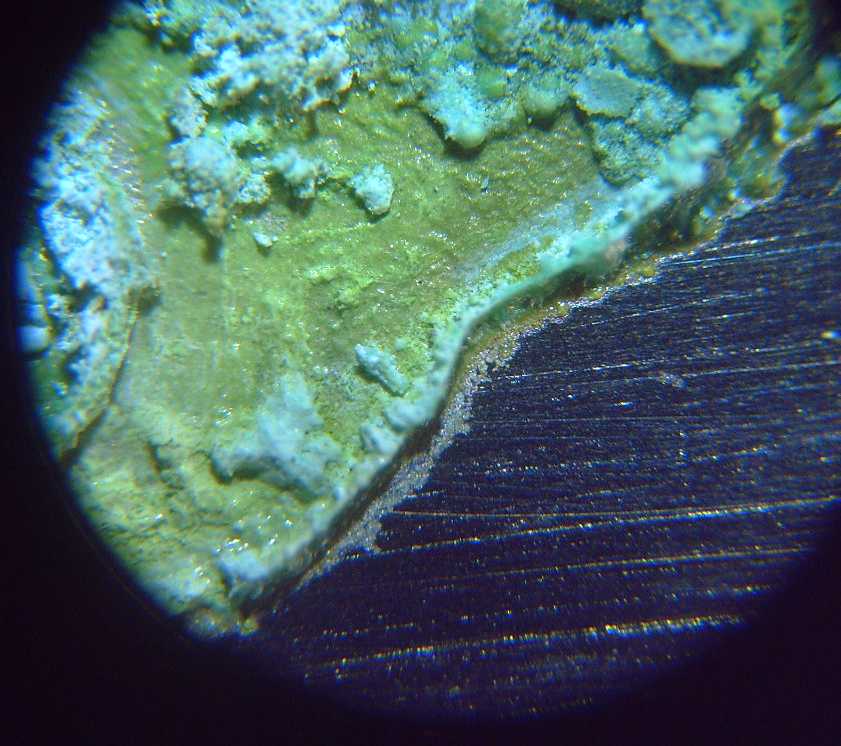

* The nano-powders of the positive electrode seemed to be seeping

through separator sheets, notably the thick watercolor mat paper, and

causing cells to fail. A recent experimental treatment of dousing the

paper with varsol and then letting it evaporate seems to have blocked

it. But it hasn't been tried for very long yet.

* The biggest thing, partly realized years ago but only fully

understood last, is that my positrodes consisting of unglued mixed

powders need to not only be held so they "don't swell up", but to be

held compacted as tightly in use in the cells as I have been compacting

them in the hydraulic press. Otherwise they lose conductivity, and this

somehow seems to prevent proper charge retention, not just limit

maximum currents. (I've only finally realized this and I'm still not

sure why.) The external heavy alume plates clamping system can do it

with enough bolts around the edges, but the materials going into the

cells will have to be very carefully measured so that everything will

be held tightly compacted and yet the cell will close and not leak

around the edges. The rubber cell fronts give just a slight amount of

tolerance to the whole thing as they will compress to some extent.

Something else that could help would be to wrap up the

electrodes with package tape. Mainly this would hold the edges together

better. (Hmm... Could tape hold multiple series cells all within one

hard case? How about shrink-wrap plastic bags?)

By December 3rd the cell was charging at the lowest

current yet (under 25mA @ 2.27V, 1Ω) and holding over 1.95V for several

minutes, and running a 20Ω load at over 1.2V for 20 minutes instead of

just 6 minutes. The nickel + manganese oxides electrode, having started

out uncharged, has charged twice to this level of discharge proving at

least that it's rechargeable (unlike MnO2 by itself). So I won't be

using any more nickel electrodes from old dry cells.

Still there's that nagging self discharge. On the 4th I

wrapped the electrodes with packaging tape. That did nothing special.

In evening I reached through the terminal holes and plucked out some

tape to expose electrode, and put the whole cell in a tray of salty

water (the purified KCl). It was soon evident that the self discharge

was slowing. A second bath was a little better yet, indicating that

"stuff" dissolved inside the cell seemed to be diluting out into the

water in the tray.

That's probably it then: the impurities in the cells have to be

diluted out by running them underwater, with some edge open to that

water, until they don't self discharge any more. (If I'm making a

bunch of cells, I'll probably have several baths from "most

contaminated" to "purest" and run them in one after another. Distilled

water and salt will start to add up!)

The final touches, which I'm evidently not quite at yet,

relate

to keeping the zinc 'trode from growing dendrites during charge and

discharge, which get through the separator(s) to the positive side and

short out the cell. (This is also the way most Ni-Cd's end.) Prime

candidate for this ion transfer barrier is sodium

dodecylbenzenesulfonate in the separator sheet pores. (as used in

"sulfonic ion exchange membranes"... also used in "Sunlight Lemon

Fresh" dishsoap.) Poly vinyl alcohol is another tempting thing to try.

What is the objective? Metallic zinc (-ode) theoreticly

has 820 amp-hours per kilogram

and the Zn is over half the mass of the electrode, using a thin copper

foil current collector. So call it 500?

I expect the nickel

manganates (+ode), with graphite conductivity enhancement et al to

have around 200 amp-hours per kilogram, which is over double what beta

nickel oxyhydroxide

effectively yields (~90). Dilute that 200 by the cupro-nickel current

collector weight, which will depend on its thickness.

If either or both of the current collectors can be made

into an expanded mesh instead of a solid sheet, they should be at least

as effective and lighter. Bunches of taped or bagged "pouch" cells all

in one case could eliminate some of the weight of the housings.

Together the electrodes will make cells of about 2.0 volts

open circuit, which might be considered to be 1.7 or 1.8 volts nominal.

The final planned size of my cells, 85 by 150 mm by 13 mm thick, should

have several tens of watt-hours each, and can all be easily clamped

together in a series string for a desired voltage. A safe, inexpensive,

everlasting production battery of this construction may hopefully be at

least 120-150 watt-hours per kilogram (or better), which matches

present lithium iron phosphate models.

Countless sordid and petty details under Electricity

Storage: Batteries

Magnetic Variable Torque Converter for Miles Mini Cargo Truck

I was working on the details and housing for this off and

on, then on the 17th, as a 10 to 1 ratio planetary gear looked like a

better mechanical match (for most any vehicle) than the 5 to 1, I

broke down and ordered one. I had a choice of ordering one identical to

the one I had

with the new ratio from Anaheim Automation for somewhere way over

1000$, or one with similar specs but a bit longer end-to-end from

"TopStock" on AliEpress for about 270$. I chose the affordable

route.

Unfortunately that means I'll have to shorten the motor

shaft a bit, and I'll wait until I have the unit before doing so to

ensure a

good fit. That means waiting for it to arrive, hopefully before

Christmas.

Test fitting the wooden housing

to the truck

motor. (Metal would interfere with the magnetism.)

Test fitting the wooden housing

to the truck

motor. (Metal would interfere with the magnetism.)

The top two 2 by 6es had to be unscrewed and trimmed to fit around

obstacles, leaving the center parts "sticking up".

The whole wooden assembly will be glued by epoxy and well epoxied, and

all gaps will be covered.

* *

* * *

Later in looking over some parts on the shelves for the

motor (below), I realized that having finally created a great magnetic

variable torque converter, I can scrap all kinds of parts of a lot of

the older experiments that I am definitely not ever going to use.

Since I started in 2008 I've mostly been accumulating things rather

than getting rid of them.

Everything that "just might be useful" until this

point was well kept, because when I went to make the converter that

proved successful I found all the parts I needed to put together the

prototype unit for the truck. It is marvelous now to disassemble all

these old things, return nuts and bolts to the drawers, UHMW plastic

parts into the bucket to melt down and reuse, metal pieces to bins or

the

garbage, and to clear off some shelf space!

Unipolar BLDC "Electric Hubcap" Axial Flux Motor

Someone had

told me that Sheldon had acquired a CNC plasma cutter. As I was going

to his town, Masset, on the 25th for the first time in months, I took a

piece of 1/8" steel with me and got his last name & phone# from

someone. I was directed to his impressive shop on Tow Hill Road. He had

just finished something else and to my delight immediately set about

cutting me a

330mm diameter magnet rotor from my piece. The "kerf" was taken from

the inside

of the cut and it didn't go very smoothly. It ended up 326mm with a

small gouge. He said he would chalk it up to "a learning experience"

and didn't charge me. Unlike abrasive waterjet, there was lots of

knocking off "slag" and grinding to smooth off the edges.

Someone had

told me that Sheldon had acquired a CNC plasma cutter. As I was going

to his town, Masset, on the 25th for the first time in months, I took a

piece of 1/8" steel with me and got his last name & phone# from

someone. I was directed to his impressive shop on Tow Hill Road. He had

just finished something else and to my delight immediately set about

cutting me a

330mm diameter magnet rotor from my piece. The "kerf" was taken from

the inside

of the cut and it didn't go very smoothly. It ended up 326mm with a

small gouge. He said he would chalk it up to "a learning experience"

and didn't charge me. Unlike abrasive waterjet, there was lots of

knocking off "slag" and grinding to smooth off the edges.

I now have:

(1) A place on the island to go to get pieces of metal computer cut to

my specs (I'll bring G-Code or .DXF files), and

(2) a magnet rotor plate for the long-planned motor! (It's good enough.)

New rotor size for unipolar motor (24 magnets when done halbach) versus

old 10 inch (18 m-h.)

[26th] I knocked off the "slag", ground and

filed the rim "smooth". It doesn't look as imposing as I feared - nor

at 326mm, as imposing as my original estimates of the diameter needed

to fit everything, of 400 or 370 mm diameter.

[26th] I knocked off the "slag", ground and

filed the rim "smooth". It doesn't look as imposing as I feared - nor

at 326mm, as imposing as my original estimates of the diameter needed

to fit everything, of 400 or 370 mm diameter.

Intending a Halbach magnet configuration I made this

rotor just 1/8" thick, and the new 326mm O.D. rotor weighed just 2135

grams, where an old 250mm, 5/16" thick one for an original Electric

Hubcap motor weighed 3031 grams (both without magnets). One sees that

the motor can thus be lighter for its size - another benefit of Halbach.

Checking the

326mm rotor to

make sure the planned 12 coil motor will work out well at that

diameter

I grabbed some of the coils and

set them around the rotor to see if 12 coils would actually fit within

a 326mm framework without jamming them too close together. It looked

reasonable.

I grabbed some of the coils and

set them around the rotor to see if 12 coils would actually fit within

a 326mm framework without jamming them too close together. It looked

reasonable.

[27th] In OpenSCad I drew up a jig for putting magnets on the rotor,

with a little pocket to slide each magnet into in exactly the right

place. Now to use it I have to get some DXF to GCODE program working,

then actually get my CNC router to cut it out.

[28th] Owing to plasma cutter hiccups I drilled four mounting holes by

hand - same positions as 4 inch circle car tire studs since I''m using

a 1 inch trailer hub and stub axle with flange, with the flange and hub

both having the same bolt pattern. I got them pretty well centered and

aligned and it fit right on.

I couldn't get "DXF2GCode"

to work and I gave up. Instead I spent a day with a spreadsheet and

other software putting in numbers and formulas to manually create the

required GCode! I set the paths to run the router an extra 1/8" to get

the 1/4"

router bit right into the corners. Otherwise it would have been a lot

of filing plastic to square them, so it's better.

Next: trying to get the CNC router that I've never

actually used to actually cut the template.

The next work

after that will be pieces for alume molds for the PP (non-magnetic)

stator components. (I still need to finish that plastic recycling

oven!) This flat circle PP piece for the windplant idea is just about

the

right diameter. The motor will want some more complex shapes, but

there's the idea.

The next work

after that will be pieces for alume molds for the PP (non-magnetic)

stator components. (I still need to finish that plastic recycling

oven!) This flat circle PP piece for the windplant idea is just about

the

right diameter. The motor will want some more complex shapes, but

there's the idea.

Obviously the motor won't be finished for quite some time,

and the microcontroller based 6-phase unipolar motor controller needed

to run it will stretch the project out still longer. But at last I've

started the 95% "ultra-efficient EV" motor!

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Amazon:

A Den of Thieves!

Fraud,

Espionage & Duplicity

Probably a year or so ago now I ordered a book from

Amazon.com . It was the only place I saw where I

could get that book. I noticed on a credit card statement last month

that there was

a bill from "Amazon Prime" for around 20$. It seemed like a long time

since I had made the purchase. Wasn't that already paid long since?

Hadn't I already seen the bill on a previous statement? But I ignored

it. This month there was another one for a similar but not identical

amount! I went back over my bills: ever since I ordered the book Amazon

has been billing me 14.99 $US each and every month! "Amazon Prime" it

says. I don't know why this wasn't raising red flags with me much

sooner. Once or twice it was the only charge on my card. I just wasn't

paying attention, and of course I'm annoyed with myself for being

asleep at the wheel for so long.

But I very deliberately had never, ever intentionally

opened an "Amazon Prime" account - I wanted nothing to do with it!

I don't even know what it's good for. Amazon has fraudulently been

billing me monthly ever since my order. I phoned

the credit card company and asked that the charges be reversed. This

request about Amazon Prime was by no means a new one to the lady I

talked to.

She said that somewhere in there I had accidently opened an "Amazon

Prime" account when I made the purchase, so it "wasn't fraud". She

couldn't reverse the charges. (Later someone else told me that had

happened to him too, and to someone else he knew, but that they had

caught it soon and had the charges reversed.) It was probably some

inconspicuous

checkmark in a box that I would have had to UN-check to NOT open this

so-called account when I made the purchase. Or something devious like

that.

I said maybe technicly it wasn't fraud [in some legalistic

sense] but really it was fraud, wasn't it? She agreed. It has cost me

way over 200$ for nothing - maybe more. That's probably the value of

any

and all of the two or three orders I've ever placed with Amazon - and

all at 100% pure profit for them for doing nothing. It is sad that

one of the biggest companies in the world can get away with

illegitimately, deceptively bilking unsuspecting customers month after

month. Big corporations - especially American & Western ones - have

no shame!

I went to the amazon.com web site to close the account -

sure enough the account existed, at my old email address! But searching

page

after page, if there was any option anywhere to close your account, it

was really well hidden. Finally I went to the "payments methods" page

(where three of my credit cards popped up, however many years ago I had

used them)

and found a way to cancel the one not out-of-date credit card they were

charging to as

being a valid payment method, leaving (I hope) no valid payment methods

for further charges to "my" so-called "account". (And even then, the

box to cancel it without putting in a new payment method first was

"lighted out" type and border - made

as

inconspicuous as possible as if it wasn't an available option.)

I thought that was it but soon Amazon was leaving messages

on my cell phone complaining that my account was in danger. I've never

given that cell phone number out to anyone except a very few friends. I

suppose that as soon as a friend entered my name and number on their

phone the whole world knows it. Or they just saw a phone sitting at the

location of my old phone and messaged to it. Either way they're

obviously spying with very sophisticated spyware on everyone across the

whole cell phone network. By phoning a number they should never have

had, they've admitted it!

I sent "report spam" and blocked their number.

I will never deal with Amazon again, even if I have to

forgo getting something I want. But they've already made more free

money off

me than if I had ordered 1000$ worth of actual merchandise. Someone

suggested I call them and try to have all those charges reversed, but I

doubt if they will (maybe the last one or two - I can hear it now:

"It's been too long") and I don't have the stomach for it.

(AliExpress.com has no monthly fees. You pay only when you

buy

something and it's usually cheaper. I've never had an unexpected or

fraudulent charge to a credit card there. And there's e-bay.)

Apparently I still hadn't or haven't heard the

last of them. On the 28th there was a computer call to my home phone -

the number I actually gave them. The call display said it was from a

local number, one digit different than a friend's (which on calling it

said the number wasn't in service) and started out something like "This

is Amazon... unfortunately your recent purchase was billed to your

credit card that..." At this point I assumed it was some scam to get a

credit card number from me and I hung up. Obviously Amazon doesn't have

a local Haida Gwaii office nor had I purchased anything in (?)a year.

Now I think I probably was Amazon and they were calling because

they couldn't keep billing me monthly for nothing. Calling from a

"local phone number"??? About a "recent purchase"??? (If they have

charged my card again, this time it's clearly illegal.)

Car

Key

FOB

Hidden

Health

Hazard

I noticed several times that I was feeling a small but sharp pain in my

right leg, which had no apparent explanation. It felt like it was a

little deeper in than right at the skin and there were no marks. I had

already noticed that I seemed to have lost the feeling in the skin in

the same area some time ago. Deeper down had feeling and I could feel

pressure, but if a spider was crawling across my leg hairs there, I

wouldn't have felt it.

One day it dawned on me: that was right under where the

"key fob" for the Nissan Leaf car sat in my pocket! Previously, the

cell phone had done funny things to my other leg, making it twitch and

vibrate, and I had also lost skin feeling there (which I hadn't until

now attributed to the phone - after all, it had started on the other

leg too). I had stopped carrying it.

Now here it was, another source of microwave(?) radiation

right against my skin, evidently causing trouble! I took the "fob" out

of

my pocket. I hope neither the phone nor the "fob" has started a cancer!

(Yes, people do die of cancer from cell phones.) I'll have to have it

in my pocket when I drive anywhere, but I'll keep it away from me

otherwise. Leaving it in the car would invite theft - and what if the

key is inside and the doors lock themselves, as they do if I press the

wrong button? I can see there'll be many episodes of having to go back

into the house for the FOB just after I've got into the car to drive

off. And many of forgetting to take it out of my pocket at home.

I knew I never liked the idea of "key fobs"! I just didn't

know why, other than that they need batteries, might die if they get

wet, and are costly to replace. Here is a much bigger reason. One more

thing to worry about.

Smol

Thots

* Many still rail against electric cars, saying that "they aren't the

future" and make arguments against them that don't hold water when

examined. They will say making the car itself uses "X" energy resources

and so the vehicle doesn't become "energy neutral" for many tens of

thousands of miles, and never if it's used in an area where electric

plants run off coal. But they offer no alternatives except to finish

using up the world's fast depleting petroleum deposits. And then?

Furthermore, they don't say how much energy it takes to

produce a gasoline powered vehicle to compare figures with, or how long

it

takes that to pay off the energy used in making that - which of course

it never does. And they don't consider that many homeowners with

electric cars also have rooftop solar power and produce more

electricity than their car uses, or that an electric car simply uses

less energy than a gasoline vehicle owing to its higher efficiency and

that anyway any power station burns its fuel more efficiently than a

car does.

And they complain that "there isn't enough lithium for the

batteries" and that "it's mined in third world countries where there

are no environmental regulations and slave wages." First of all, they

have no such scruples about any other metal or where it's mined or how

it's processed - only

lithium. And Australia - reputedly not a "third world country" last I

heard - is the world's leading supplier of lithium. Australia has also

just created a process that extracts twice as much of the lithium from

the ore as presently. Also the naysayers discount that there may ever

be any other

type of EV battery besides lithium. Nickel-metal hydride flooded EV

cells (that never explode) were just as good before the oil company

that ended up owning the factory shut it down, and I now (after many

experiments

this month and some conclusions that remain to be proven) fully expect

success in my attempts to create 'everlasting' gelled nickel

manganates-zinc cells that should be the safest batteries, cheap and

with a high energy density.

* How many of the people complaining about electric cars are the same

ones saying we can go on increasing the global population ad infinitum

because "new technology will always solve our problems"?

* Jesus once said "The truth never suffers from honest examination."

[Urantia Book 153:2.11]

All those who rail against freedom of speech today, is it because they

are afraid of truth or don't want it spread for one reason or another?

Do they not want to face truth themselves and want others who might, to

not be exposed to it? Some are afraid of others knowing truth because

of things they themselves have done that might become known. But many

simply hate to face change (even tho they would never want to live in

the

"unchanged" world as it was 100 or 1000 years ago) to the point that

they would try to ban new knowledge. "Know the truth, and the truth

shall set you

free." - Jesus again. [Bible, John 8:32] We should seek various

different views from diverse sources in attempting to discern the most

accurate picture of major events around us. The mass media all have

just one and the same view.

* The economists at the world economic forum in Davos have indicated

that

they've prepared for the next pandemic -- whatever it is. (As long as

it kills less than one person in a thousand who contracts it, like

statistics seem to now show covid did?) Vaccine passports mean people

won't

be locked down and unable to travel, and all is agreed on. A minor fly

in the ointment might be that we can't possibly have any clear idea

what sort of disease the next pandemic might be, or how deadly or

how contagious it will be. (Unless it's already been created in a lab

somewhere.) But from the sounds of the economists making

regulations for it, it seems there must already be an experimental mRNA

vaccine mandated for it, since they're putting the vaccine passports

into place

already. Just in case it's a virus and not something else that can't be

vaccinated against.

Next they should get some doctors and health professionals

in to mandate the economic and industrial measures for

improving our economies.

* Authoritarians are those who think they can run your society, your

economy and your own life better than anyone else including yourself.

They

don't need input from others or to gain better understandings

themselves, just to give orders and make everything fit their vision.

Peasant farmers are so ignorant... great leader Mao had

all the little birds they had been putting up with, ignoring or maybe

even liking and feeding, killed so they wouldn't eat any of the seeds

or crops. One problem solved! Instead swarms of bugs ate the crops

because there were no birds to keep their numbers in check, and China

had famine. In more recent decades people were given freedom in China

and China rose up from poverty and prospered. Now an authoritarian

leader has

come in who is jealous of prosperity and who wishes to "nationalize"

all the prosperous private businesses. And who in some strange paranoia

also has no hesitation locking down a city of 20 million people for

months

because of one case of Covid. A crash in living standards,

economy and creative progress - or a great and doubtless violent

political clash - seems inevitable. (In fact, living standards are

crashing, and after I wrote this and before the end of the month,

political confrontations have already arisen across the whole country -

masses

of people clamoring to "End the CCP!" and for Chi Jinping to "Step

Down!")

Today there seem to be far too many of these authoritarian

types of

people around and often running the show, to the detriment of society

as a whole. They make law after law, each to myopicly solve one seeming

problem but always applied zealously in unintended situations with

wider repercussions that all put together leave everyone unable to to

what is desirable or needed without contravening one ordinance or

another. Life becomes more and more complicated.

Freedom is better. Somewhere, bit by bit over the decades

and a couple of centuries after having gained it, most of the world

seems to have lost it again.

* Freedom and Responsibility go hand in hand. Freedom is dangerous and

sooner or later lost in the hands of people who abuse it - or who

don't understand what their responsibilities are. In today's case, we

are losing our freedoms not only because of people who have been

permitted to abuse the freedom given them, but because with all the

freedom-granting progress in governance, medicine, food production and

so on, we have missed the most essential thing: as more and more people

survive into adulthood and live longer and longer lives, the population

can't be

allowed to grow unchecked.

We are long past the time when calamity and a catastrophic

die-off of people could have been avoided. Probably the last and maybe

the only time that could have worked was in the early to mid 1960s

immediately following the invention and availability of the birth

control pill. At that date we were already over the 3 billion mark that

is probably about the maximum sustainable population for this

planet,

and beyond which life has become increasingly "cheap". Since then we

have been drawing down future resources (and non-renewable resources)

to feed and power the present

at an ever increasing scale as the population grows, and just now are

suddenly running out of many needful things.

EIGHT BILLION PEOPLE! Who would ever

have thought it could get so out of hand? But the measures would

have had to have been applied worldwide, not just in the developed

world, and I'm not sure the prolific peoples of the fastest growing

countries could have been convinced of the need at that time. Today

probably yes. Then... probably not. OTOH there are still plenty

of people everywhere who don't think the present population is a

problem even as the environment and ecology that sustain us are

crashing

down, one more adverse event, one more species extinction, at a time

all around us.

ESD

(Eccentric Silliness Department)

* English spellings are weird. They are created ad lib by weird and

conflicting spelling conventions. We've all eaten "ghoti" (gh as in

"enough", o as in "women", ti as in" fraction": ghoti = fish). And then

there's two completely different sounds for "c"....

How about a ckhourin pad? (scouring pad - "in" as in "sink"; "hour" as

in "hour") or a

lighn? (line) or or

or... btongcre (tinker - bt as in "debt") or or or...

* Here's the title for a new book I have no intention of writing:

"Ukraine: From Breadbasket to Basketcase". (No doubt the territory will

eventually recover and reassemble in new form(s) agreeable to the

peoples who live

there when all the authoritarians are through meddling with it!)

* And of course some have proposed to replace the US dollar in

international trade with "a basket of national currencies". But since

none of them are tied to anything physical and can be printed ad

infinitum, I would rather call it "a basketcase of national

currencies." (In 1950 10$ would buy a week's worth of groceries for a

family. Today 10$ will buy one or two small grocery items. But it's

similar everywhere.)

* Someone wrote in a comment under a video: "Only trust half of what

you see on the

internet" - Abraham Lincoln

* How does a jugglernaut keep on going and going in space, when the

jugs he's juggling just don't come back down?

* Word Jumbles, anyone?: aaabcehillpt deorr -- (If you get the

second word, the first one is intuitive.)

* If someone has "doctor" in their name, does it mean they've been

indoctorinated?

* Riddle: Where are "Satis"

made?

A:

In

a

satisfactory. (groan!)

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Magnetic Variable Torque Converter with Planetary Gear

I spent much of the month

on new chemistry battery experiments and the torque converter project

went into "low gear". But I did get a few things done on the "proper"

housing to try and get the truck on the road.

[?] At some time early in

the month cut a square of plywood for the

motor shaft bearing, and punched an "almost perfect" metal flange out

just slightly to fit that bearing, with a slightly cone shaped thing I

found and the hydraulic press.

[?] At some time early in

the month cut a square of plywood for the

motor shaft bearing, and punched an "almost perfect" metal flange out

just slightly to fit that bearing, with a slightly cone shaped thing I

found and the hydraulic press.

Just the right size to slip the

bearing into!

Just the right size to slip the

bearing into!

I put together

the transmission housing with deck

screws and tried to mount it to the motor under the truck. It didn't

quite go in, and I made some marks on the two

upper 2 by 6's to cut them to clear obstacles. It was awkward because I

couldn't get it attached to the motor. I cut the angles wrong and they

still didn't fit, so I did it again. They were closer.

I put together

the transmission housing with deck

screws and tried to mount it to the motor under the truck. It didn't

quite go in, and I made some marks on the two

upper 2 by 6's to cut them to clear obstacles. It was awkward because I

couldn't get it attached to the motor. I cut the angles wrong and they

still didn't fit, so I did it again. They were closer.

[16th] It finally occurred to me that

the second plywood bearing holder

would be identical to the first. I cut the second square of plywood.

The hole saw wandered way off my 1/8 inch pilot hole and I had to do it

all over, with a larger pilot hole. I filed it down a bit and mounted

the pressed bearing holder. I got the housing bolted to the motor with

the upper 2 by 6's removed and marked them for a bit more trimming.

Then I decided to order a 10 to 1 planetary gear instead

of the 5 to 1 as the variable ratios looked better. It has a slightly

different size so I had to stop and wait for it to arrive. (Dec. 3:

Tracking says it hasn't left China yet! ...by Christmas?)

Axial

Flux

Unipolar

BLDC

Motor - 5KW?

[25th] Someone had told me that Sheldon

(from whom I got the 36V, 3.5KW forklift motor for the Chevy Sprint in

2019) had acquired a CNC plasma cutter. As I was going to Masset for

the first time in months to look in the hardware store for something

not available in QC, I took a piece of 1/8" steel with me and got

his phone# from someone. I was directed to his impressive shop on Tow

Hill Road where there were a few other people, dead cars and much

equipment. (I'm not sure if they were employees or what.) He had just

finished something and immediately set about cutting me a 330mm

diameter magnet rotor from my piece. He cut it without making a drawing

file, just typing in some numbers and moving the arm to the starting

position. It didn't go especially well and the "kerf" was on the inside

of the cut, so it ended up 326mm with a small gouge. Then the four "lug

nut" bolt holes didn't go well either. It made two then didn't arc, and

I was left to drill the other two. He said he would chalk it up to "a

learning experience" and didn't charge me. In addition, the cuts were

nothing like as clean as those made by abrasive waterjet cutters. There

would be lots of grinding to smooth off the edges. (Hammering a

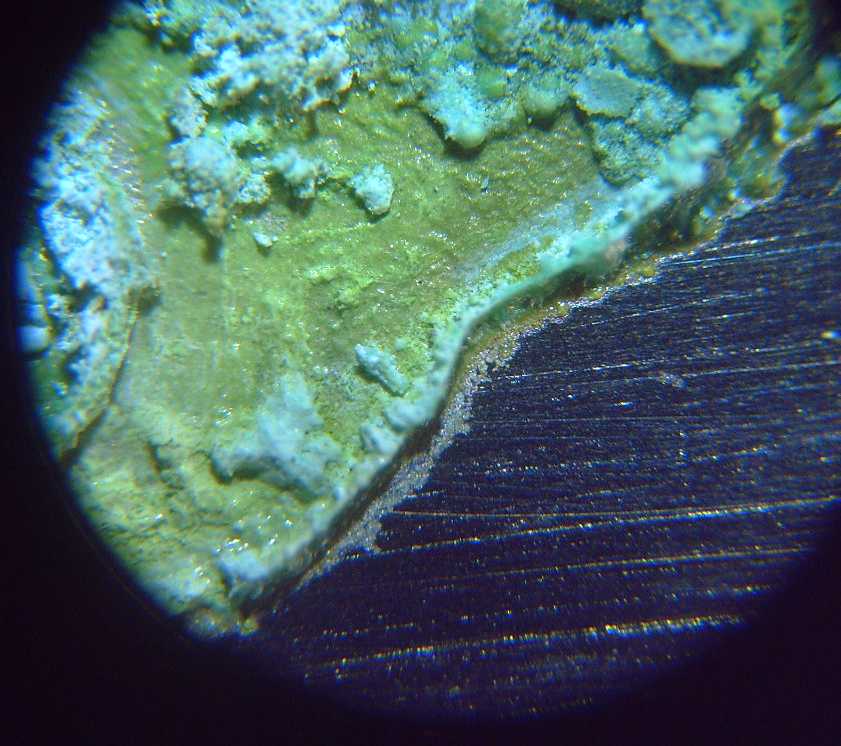

screwdriver at them broke off most of the "slag" seen in the image.)

[25th] Someone had told me that Sheldon

(from whom I got the 36V, 3.5KW forklift motor for the Chevy Sprint in

2019) had acquired a CNC plasma cutter. As I was going to Masset for

the first time in months to look in the hardware store for something

not available in QC, I took a piece of 1/8" steel with me and got

his phone# from someone. I was directed to his impressive shop on Tow

Hill Road where there were a few other people, dead cars and much

equipment. (I'm not sure if they were employees or what.) He had just

finished something and immediately set about cutting me a 330mm

diameter magnet rotor from my piece. He cut it without making a drawing

file, just typing in some numbers and moving the arm to the starting

position. It didn't go especially well and the "kerf" was on the inside

of the cut, so it ended up 326mm with a small gouge. Then the four "lug

nut" bolt holes didn't go well either. It made two then didn't arc, and

I was left to drill the other two. He said he would chalk it up to "a

learning experience" and didn't charge me. In addition, the cuts were

nothing like as clean as those made by abrasive waterjet cutters. There

would be lots of grinding to smooth off the edges. (Hammering a

screwdriver at them broke off most of the "slag" seen in the image.)

I mounted it on the axle ("trailer 1 inch stub axle with

flange") and found that even the two bolt holes that were cut were

about 2mm off center, so it wobbled. I abandoned them and

drilled four new holes at 45° to them.

But I now have two things: (1) A place on the island to go

to get pieces of metal computer cut to my specs, and (2) a rotor plate

(good enough...). Next time I'll bring a .DXF CAD file of the part(s)

to give me exactly what I want.

The next parts will be pieces

for alume molds for the PP

stator components. (Metal parts would interfere with the motor's axial

flux magnetic operation.) Finally it looks like I can start to move

forward with this long-planned motor project - and without having to

make a CNC plasma cutter (or HHO torch cutter) myself. Something I do

still need, IF I'm going to cast pure PP parts, is to finish the

plastic recycling oven. (Although, an regular kitchen oven should be

big enough for the motor mold parts!) (Shown with molded PP circle

under it. I have plans for more complex shapes for the motor housings.)

The next parts will be pieces

for alume molds for the PP

stator components. (Metal parts would interfere with the motor's axial

flux magnetic operation.) Finally it looks like I can start to move

forward with this long-planned motor project - and without having to

make a CNC plasma cutter (or HHO torch cutter) myself. Something I do

still need, IF I'm going to cast pure PP parts, is to finish the

plastic recycling oven. (Although, an regular kitchen oven should be

big enough for the motor mold parts!) (Shown with molded PP circle

under it. I have plans for more complex shapes for the motor housings.)

The other way is to make UHMW plastic molds and go back to

PP-Epoxy composite parts. (I could, I presume, make UHMW molds on my

own CNC router table... Which has never yet had a real test and which I

am rather apprehensive about using. Then again, I can get some bigger

UHMW pieces for molds by melting down some of the smaller pieces I

already have... again in the plastic recycling oven. Experience on the

phone so far suggests that might actually be more practical than trying

to buy larger pieces and have them shipped here.) But direct molding of

PP-only components would be much less labor intensive for production,

and PP is good, tough plastic.

[26th] I knocked off the "slag", ground

and filed the rim "smooth". It

doesn't look as imposing as I feared - nor at 326mm, as imposing as my

original estimates to fit everything, of 400 or 370 mm diameter.

Intending a Halbach magnet configuration I made this

rotor just 1/8" thick, and the new 326mm O.D. rotor weighed just 2135

grams, where an old 250mm, 5/16" thick one for an original Electric

Hubcap motor weighed 3031 grams (both without magnets). One sees that

the motor will be lighter - one benefit of Halbach.

[27th] In OpenSCad I drew up a jig for putting magnets on the rotor; a

little slot to put each magnet into in exactly the right place. Now to

use it I have to get some DXF to GCODE program working, then actually

get my CNC router to cut it out. In spite of testing the stepper motors

and getting them to move the carriage across the CNC table and move the

router up and down, I haven't actually tried the router out yet. I have

little confidence that it will be made to work flawlessly without much

work.

[28th] I drilled the four mounting holes (12mm) - same positions as 4

inch circle car tire studs since I''m using a 1 inch trailer hub and

stub axle with flange, with the flange also having the same bolt

pattern.

A new idea occurred to me: to integrate the motor and the

magnetic torque converter. The rotor would have the motor magnets on

one side and the converter magnets on the other. The alume disk would

be on the adjacent planetary gearset body. A PP housing could

accommodate both with a bearing at the end on the output shaft of the

converter, to go straight to a drive shaft or CV shaft as desired. This

would make the most compact unit.

This would be for a production unit. It would be pretty

hard to use that end of the "trailer axle with flange" as the motor

output shaft - almost no shaft sticks out past the flange to attach to

the planetary input. If it were to be produced, there

would be a need for at least 2 or 3 different models. One would be for

"straight to CV shaft" which would need a large planetary to handle the

full torque of the wheel. A smaller planetary is needed if there is a

subsequent gear reduction, as in the 2.2 to 1 differential in the

truck, or some other gear to add further reduction to increase the

motor speed. This is desirable because even at 150 KmPH the motor speed

would be only around 1500 RPM, whereas it should be capable of over

double that and would deliver more power at higher speed.

A variant of the "straight to CV shaft" one would also

incorporate my recent idea of having a mechanical brake away from the

wheel. Instead it could be on the output of the planetary, ie, at the

CV shaft. This would remove the brake mechanism from inside the wheel

where it is unsprung weight and subject to moisture, dirt and grit from

the road. The wheel would be lighter and so the vehicle would have the

best possible handling. The brakes would last far longer. (This would

assume there was one unit driving each front (or rear) wheel (if not

all four wheels) to make braking symmetrical side to side.)

[30th] I downloaded the latest version of .DXF to .GCode ("DXF2GCODE").

Whenever I tried to open a .DXF file, it hung with a little spinning

wheel. Same as before, IIRC. I'm not paying a hefty annual license fee

for another product to use it once every 2 years. I give up! I'll have

to generate the g-code manually, using a spreadsheet to do the angles,

as I did before for previous motors et al. Yetch, manual labor!

[Dec. 1st] I spent the day with spreadsheets [instead of editing this

report], putting in numbers and formulas, and repeating everything ad

infinitum (for 24 magnets!) for each mistake or change. Even with "fill

down" in the spreadsheet things were less than automatic when every

third magnet is different from the other two. Then I had to pass the

numbers through Libre Office Writer to delete all the tabs the

spreadsheet inserted, then used a simple text editor, and a program

called "CAMotics" that would nicely display what the router would cut

on the CNC machine (but could not edit the GCode). CAMotics wouldn't

take multiple commands on a line, so I had to insert 144 "RETURN"s each

time I changed something to separate the figures, into one X,Y point

per line. It could have been so simple with something to convert a .DXF

file to GCode. Well, it's done now.

Next: trying to get the router that I've never used to

actually cut the template.

Other "Green" & Electric Equipment Projects

Peltier Cooler Performance: Greatest Cooling & Lower Power

is attained by running them at 9-10 volts

[6th] Someone brought me a

Coleman

peltier camping cooler from the thrift shop. It didn't seem to work. I

spent a couple of frustrating sessions fiddling with it and wondering

why I was wasting my time on it. It was a mystery: the peltier module

was working and drawing tens of watts, and everything seemed in order,

but it didn't cool. I rearranged the heatsinks and module more than

once, thinking it somehow wasn't making good thermal connection.

[6th] Someone brought me a

Coleman

peltier camping cooler from the thrift shop. It didn't seem to work. I

spent a couple of frustrating sessions fiddling with it and wondering

why I was wasting my time on it. It was a mystery: the peltier module

was working and drawing tens of watts, and everything seemed in order,

but it didn't cool. I rearranged the heatsinks and module more than

once, thinking it somehow wasn't making good thermal connection.

Finally I disconnected the fan motor and reversed the

wires. It worked! The motor runs both the inside and the outside fan

with one on each end of the axle, which sticks through the cooler's

wall. Someone had apparently switched the fan motor polarity WRT the

peltier polarity, and it just didn't cool the outer heatsink well

enough to let the inner one get cool.

Now that it was working... going back a way I had noticed

from Peltier module performance charts that the higher the voltage the

more heat the hot side made, and even with excellent heatsinks the heat

transferring across the unit made it harder for the cold side to cool.

The coefficient of performance (COP) went up as the voltage and power

went down. So I had surmised that they might work just as well at lower

voltages and powers. I even thought 6 volts instead of 12. I'm not sure

why I didn't try different voltages

with a lab power supply back in 2012 to check this out, but I only used

the 12V solar power. And I rather hacked up my old Mobicool peltier

cooler from Canadian Tire.

So now I had a properly working peltier cooler, and a DC

to

DC converter plugged into my 36V DC solar power system. I had a patch

cord from the 12V "Mini T-Plug" to alligator clips, which I clipped

easily to the cooler plug's flat pins.

Tests & Measurements

I hooked it up and tried running it at 12, 11, 10, 9, 8,

7, 6.5 and 13 volts. This applied to whole unit including the fans as

well,

which were rather noisy but not as bad at lower voltages. The tests

occupied much of the day and evening. Vexingly I

only found two of my digital thermometers and in one the batteries were

dead, so tabulating inside versus outside temperatures with the room

temperature fluctuating with woodstove heat was a bit tricky. The

cooler

takes a long time for the temperature to 'stabilize' and the

thermometer reading takes a long time to stabilize at a new temperature

each time it's moved between inside and out. But I can say the

following:

* 12 volts (45 watts) or even 11 volts (39 watts) didn't seem to work

as well as slightly lower voltages. I was finding temperature drops of

around

11°C. (eg, 18 in the room / 7 in the cooler.)

* A couple of hours later at 10 volts (30 watts) I read 20° /

7.5°, which is a 12.5° spread - seemingly about as good as

Peltier coolers get.

* At 9 volts (just 25 watts) it stayed at about 7.6° but I didn't

measure the room again. (Finally I remembered I had another digital

thermometer hanging outside the front door and brought it in.) Best

estimate drop was just under 12.5°.

* At 8 volts and 20 watts the cooler temperature crept up to 8.1°.

The room may have cooled slightly (by ~.3°?) Difference: 11.7°.

* At 7 volts and 15 watts it gradually rose to 8.4°. The room had

cooled a bit (to 19.5°?) so the spread was down to 11° or so.

(That's 1/3 the power of 12V to get the same temperature drop!)

* At 6.5 volts, 13 watts, after a while it had risen to 8.9°, while

the room had cooled to just over 19° - spread about 10°.

* I raised it to 13 volts, 53 watts, last. The temperature quickly rose

to 9.1°, probably related to the fans speeding up. Over the course

of an hour it was down to 8.3°. That small, gradual drop from what

6.5 volts had kept it at didn't say much for running it at higher

voltages.

Cooler

Supply

(Volts)

|

Cooler

Power

(Watts)

|

Cooler

Temperature

Drop (~°C

below room)

|

13

|

53

|

11.7

|

12

|

45

|

11

|

11

|

39

|

11

|

10

|

30

|

12.5

|

9

|

25

|

12.4

|

8

|

20

|

11.7

|

7

|

15

|

11

|

6.5

|

13

|

10

|

(Watt figures are rounded to the nearest watt. Believe it or not.)

Conclusions

Expanding

slightly on prior theoretical expectations, I

conclude (similar to my previous cooler tests), that a "12 volt"

Peltier element and cooler cools best at 9 to 10 volts. Certainly if

one has limited energy available (eg, solar in winter, car battery) 8

or 9 volts is

a good choice. To ultimately minimize power consumption while still

having it cooling, it can go down to 7 or 8 volts - maybe even 6 (and

probably just over 10 watts) if the fan(s) keep running. (My "8.5 to

100 VDC" power meter craps out below 7V. At 6.5 I could barely read the

display even with the backlight turned off.) Running it at 12 volts -

or 13 to

14 as in a running car - seems to be nothing but a waste of energy

unless you're trying to make heat in the room or vehicle.

Expanding

slightly on prior theoretical expectations, I

conclude (similar to my previous cooler tests), that a "12 volt"

Peltier element and cooler cools best at 9 to 10 volts. Certainly if

one has limited energy available (eg, solar in winter, car battery) 8

or 9 volts is

a good choice. To ultimately minimize power consumption while still

having it cooling, it can go down to 7 or 8 volts - maybe even 6 (and

probably just over 10 watts) if the fan(s) keep running. (My "8.5 to

100 VDC" power meter craps out below 7V. At 6.5 I could barely read the

display even with the backlight turned off.) Running it at 12 volts -

or 13 to

14 as in a running car - seems to be nothing but a waste of energy

unless you're trying to make heat in the room or vehicle.

Peltier coolers always suffer from comparisons to

compressor refrigeration. At 9 volts and 25 watts this one cubic foot

cooler maintains about a 12.5° temperature reduction from ambient.

At 60 watts my (pretty new) 5 cubic foot freezer maintains somewhere

around 30-40°. And it only runs half the time to do it, making it

around 30 watts. And with this particular peltier unit, the buzzy fan

is more

annoying than freezer's compressor.

I still await some superior Peltier modules with higher

COPs made by some novel new technique or materials. (10 years so far...

Is there anything that transmits electricity but insulates heat?

Electromagneticly induced current across a thermal barrier? How might

that be employed inside a Peltier module? Probably not.)

Repeat Remarks: Heat Sinking Peltier

Modules

I will again say that to my mind pure alume or

copper (or even silver) are heatsinks of choice for peltier modules

rather than the common alume alloy heatsinks. Pure alume

conducts heat much better than any alloy and pure copper is still

better. If you are trying to keep a

transistor below 100°C, alloy is fine. But in a peltier module

every degree is critical and any difference in the junction

temperatures between the ceramic surface of the module and the

contacting surface of the heatsink are dead loss. Think that if a

better heasink can keep the hot side one degree cooler, and the cold

side one degree warmer, the Coleman cooler would go from cooling by the

maximum temperture drop I found of 12.5°, to 14.5°. If the

outdoor temperature was 21°, the food inside would stay at 6.5°

instead of 8.5°. Furthermore, the heat transfer across the module

would be reduced, perhaps making a higher voltage work better, which

just might (and I haven't worked this out or tried it) further increase

the potential cold side drop.

If I didn't have other projects I'd still be tempted to

make copper block contacts to the module, expanding to a larger contact

area attached to pure alume heatsinks. (The copper bar that connected

the module cold sides to the ice tray in my "super insulated" peltier

shallow chest

fridge [10 years ago TENews #??] certainly seemed to work well. Now

that I think about it, I should have had another big, fat copper bar

connecting the hot sides to the outer heatsink, too!)

Winter

Gardening

Window & LED Gardening

It seems a shame to give up pepper and tomato plants after spending all

summer growing them, so this year I put some cherry tomatos and "orange

mini bell" and "banana" peppers in pots instead of in the ground. And I

still have the coffee plants. (I wish I had put a large tomato plant in

a pot to bring in - I got great tomatos into October when it got too

cold. Well, next year!)

It seems a shame to give up pepper and tomato plants after spending all

summer growing them, so this year I put some cherry tomatos and "orange

mini bell" and "banana" peppers in pots instead of in the ground. And I

still have the coffee plants. (I wish I had put a large tomato plant in

a pot to bring in - I got great tomatos into October when it got too

cold. Well, next year!)

As the weather got cool I brought them in

and made a shelf under the bay window. Now as the days got short and

dull I took some of my "indoor LED garden lights and mounted them at

the top of the window. I put up some reflectors and some white

tablecloth "curtains" to make it brighter. It seems very satisfactory,

making use of what little daylight does shine in as well as 8 hours of

bulbs.

But I was trying to water every second day, and I must

have missed a day. Possibly two. My biggest cherry tomato withered and

didn't come back; another (far left) had a single small live branch

left. I

brought in the third one, that had been in the kitchen. It had a single

flower now starting to turn into a fruit, and now a couple more. But it

drooped and almost died too. All the peppers looked like they had been

through some drought too. Now I don't dare miss a single day watering.

The banana peppers turn yellow first, then red. They're sweeter than

the orange ones.

And I planted

a rectangular pot of romaine lettuce and one of spinach about 6 inches

under two 40 watt red and blue LED "grow light" panels. The lettuce was

soon getting tall and spindly, and on December 3rd all of them fell

over. There just wasn't enough light. I piled some dirt around them

them to prop them up and then raised the pot so they were within 3

inches of the lights, which I then left on all day and night. and I put

up some alume foil at the front to reflect the light back in. (The back

was already reflective. The next day they survived and all started

their first leaf. I'd say they're just barely getting enough light now.

I'm certainly not impressed by these "grow lights"! But they are old

ones.

And I planted

a rectangular pot of romaine lettuce and one of spinach about 6 inches

under two 40 watt red and blue LED "grow light" panels. The lettuce was

soon getting tall and spindly, and on December 3rd all of them fell

over. There just wasn't enough light. I piled some dirt around them

them to prop them up and then raised the pot so they were within 3

inches of the lights, which I then left on all day and night. and I put

up some alume foil at the front to reflect the light back in. (The back

was already reflective. The next day they survived and all started

their first leaf. I'd say they're just barely getting enough light now.

I'm certainly not impressed by these "grow lights"! But they are old

ones.

Now a couple of spinach have come up and and are also

getting tall and spindly. I'd better find some more props and also get

that pot up to the lights before they keel over too!

(Now there isn't room to water them in place, and they're

quite heavy to move - ug!)

Electricity

Storage

Gelled Nickel-Zinc Batteries

[7th] I figured that for testing as I

was doing, the cell didn't need to be perfectly sealed. That could come

when things were basicly behaving as expected. And I figured that with

the external clamp plates, the beeswax on the joins should make a fair

seal when firmly pressed together, too. That meant I could now screw

the cell open and closed and try a lot more things faster. This is what

I should have done long ago.

Previously I

had broken open another NiMH "D" cell and

taken out the NiOOH electrode (broken pieces). I put it in bleach to

charge it up.

Later I saw some tiny oxygen bubbles. Now I made it into a new

electrode which I painted with a mix of KCl solution, Sunlight soap and

a bit of SmO3. I used parchment paper as a separator paper and put in a

plastic spacer as well.

Previously I

had broken open another NiMH "D" cell and

taken out the NiOOH electrode (broken pieces). I put it in bleach to

charge it up.

Later I saw some tiny oxygen bubbles. Now I made it into a new

electrode which I painted with a mix of KCl solution, Sunlight soap and

a bit of SmO3. I used parchment paper as a separator paper and put in a

plastic spacer as well.

When I put it on it read under a volt again. It

charged up at 30mA to about 1.485 volts and didn't seem inclined to go

any higher. Could it be that at neutral pH the NiOHOH didn't stay

charged to NiOOH? That was what I was doing differently: I had

previously been using 20%:20% KOH:KCl to raise the pH. I'm trying to

avoid corrosive KOH. But I needed to do something to raise the pH. How

about some Ca(OH)2 to raise it to 12-13 but not to the "dangerous to

handle" pH 14?

I opened the top of the cell, wetted the electrode with

salt water and dabbed some calcium oxide onto it. It didn't seem to

have much if any effect, even over a few hours to let some dissolve.

Hmm... When I was doing the manganese negative electrodes

long ago

I had used a mix of NiOOH and MnO2 in the plus. I supposed it was

forming

nickel manganates, but I found found it didn't seem to recharge

properly, which is (I later found out) a characteristic of manganese -

Mn2O3 or Mn(OH)3 [valence 3] are insulators and so don't

recharge electricly to MnO2 [valence 4]. The cells that "should have

been" great got weaker and weaker with each cycle - and not from the

metallic Mn negatives. (Also the negative voltage was so high my

negative current collectors were bubbling hydrogen wherever they were

exposed to the electrolyte, a source of continual overnight

self-discharge, which I also didn't realize/understand until much

later.)

On a whim I opened the cell again, pulled off the top

current collector and dropped 3% hydrogen peroxide onto the NiOOH

pieces. IIRC this should DIScharge them. A fine froth bubbled up with

each drop until I had covered pretty much all of it. Then I put it back

together and onto charge again - 50mA instead of 30, and the voltage

came up to 1.9 volts. It still dropped rapidly when the charge was

removed. I worried that the zinc must be getting overcharged and making

hydrogen/zinc hydride. It still didn't stay up to voltage.

Back to basic basics!

[9th] Once upon a time, 11 to 10 years ago, I was getting better

results than I have been recently. Let's see... with no protection, the

zinc forms dendrites rapidly and the cell dies. The osmium doped acetal

ester layer helps. Agar... PVA... did I ever try using just the

dishsoap as the gel for the negative side? Or was that back when I was

making metallic manganese negative electrodes, before I started using

zinc? Far too much time between battery experiments: I lose my

continuity and forget just what I've done, time after time.

- I heated up the zinc electrode to 90° to dissolve off the PVA (in