Turquoise Energy News Report #175

Covering

December

2022 (Posted January 5th 2023)

Lawnhill BC Canada - by Craig Carmichael

(CraigXC at Post dot com)

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- Magnetic Variable Torque Converter for ZX40 truck - Battery

chemie, design, experiments... and some Success!

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Smol Thots (Fraud &

corruption... corporate & individual; Ukraine) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Magnetic Variable Torque Converter with Planetary Gear: The

Future of the Automotive Industry! Assembling/Installing one for

Miles Truck

* Axial Flux Unipolar BLDC Motor - 5KW? - Magnet Rotor

Other "Green"

& Electric Equipment Projects

* Indoor & LED Gardening

Electricity Storage:

Batteries

* Gelled NiMn2O4+n - Zn Salt Cell - A.K.O. New Experiment Details -

NiMn2O4(+n) apparently has low reaction voltage but high amp-hours

- Zinc

dendrite problem solved! by sodium dodecylbenzenesulfonate gel

& osmium doped film - Cobalt Oxides "+"?

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

By the evening of the 9th it seemed like everything I had

been trying to do was on hold. For the variable torque converter for

the truck, I was awaiting a 10 to 1 planetary gearset. For the new

battery

R & D I had just ordered some seemingly vital sodium

dodecylbenzenesulfonate [herein "SDBS" or "sulfonate"] that had to make

it way across the country, and

for the magnet rotor for the new design unipolar axial flux BLDC motor,

I had just discovered that instead of 1/4 inch, the CNC router's only

collet chuck took

only 6mm shank router bits, which are not sold around here, and which

are going to take 2 months to come from China.

I'm sure I'd have been

far and away better to have simply thrown out this CNC table and

ordered from China a complete, ready assembled and tested new unit with

all parts and

the

computer components & applicable software - almost

regardless of cost. Instead I have a cludged unit with limited

capabilities, a computer that occasionally crashes and jury-rigged this

and that, and I spent many hours getting it working. Hindsight! Anyway

it seems to be working now... almost there!

I contrived to

scrape some of what I hoped was the sulfonate

out of Sunlight dishsoap (the stuff that didn't flow down the sheet to

the bottom - it seems to work but the purity is highly suspect), and

the month became

mostly about continuing the battery experiments from last month -

opening cells and replacing

components, and long hours of charging and tedious testing.

I contrived to

scrape some of what I hoped was the sulfonate

out of Sunlight dishsoap (the stuff that didn't flow down the sheet to

the bottom - it seems to work but the purity is highly suspect), and

the month became

mostly about continuing the battery experiments from last month -

opening cells and replacing

components, and long hours of charging and tedious testing.

My biggest discovery was that my cells have all along

seem to have worked much better than I thought - but at lower voltage

than I was expecting.

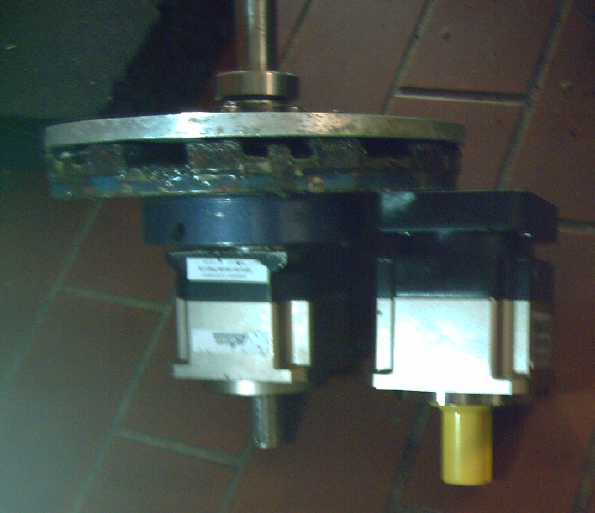

Magnetic Variable Torque Converter

for Miles ZX40 Truck

When the new

10 to 1 planetary gear arrived before Christmas and the bitter weather

warmed up, I did get just a bit of work done on this project.

When the new

10 to 1 planetary gear arrived before Christmas and the bitter weather

warmed up, I did get just a bit of work done on this project.

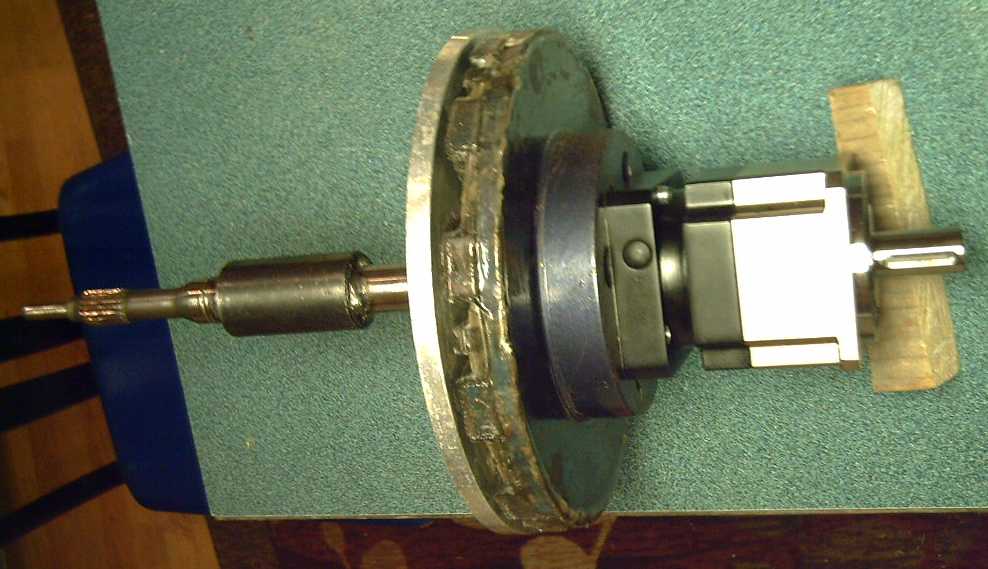

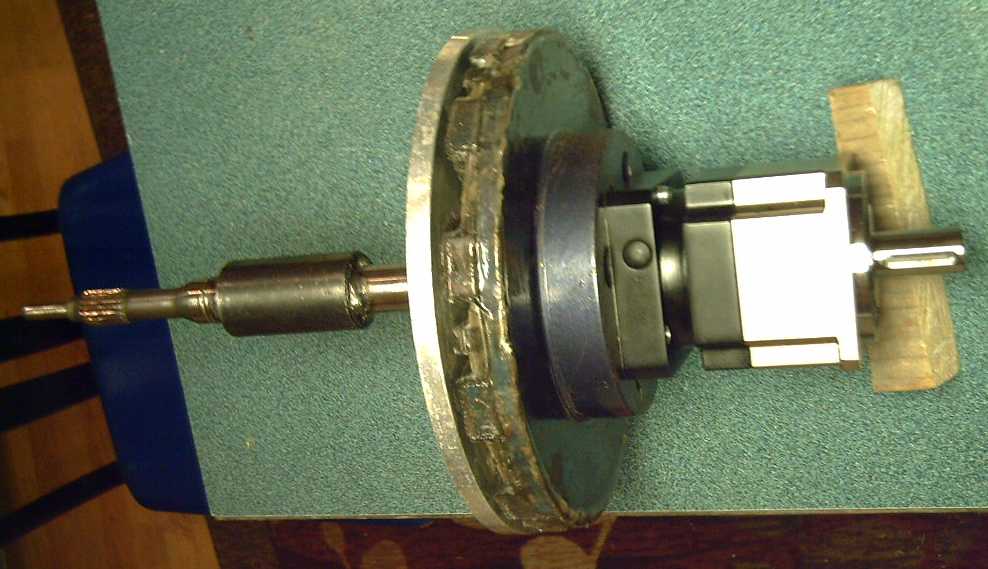

* I coupled the magnet rotor to the new

gearset with 3/8 inch bolts. (A fabulous fit with just a little work

for two things that were never made to go together - Yay!)

* I coupled the magnet rotor to the new

gearset with 3/8 inch bolts. (A fabulous fit with just a little work

for two things that were never made to go together - Yay!)

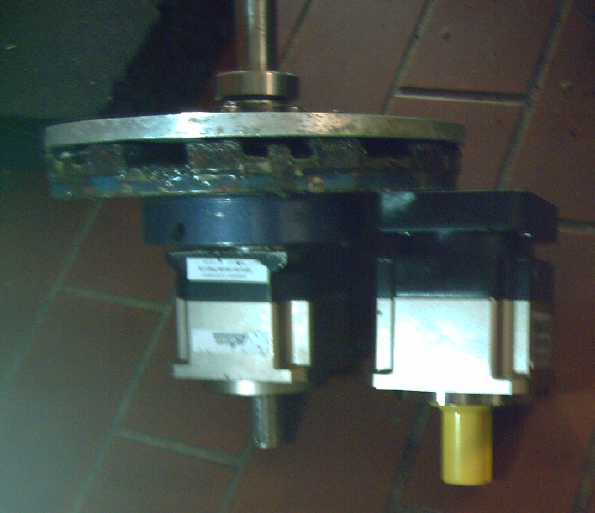

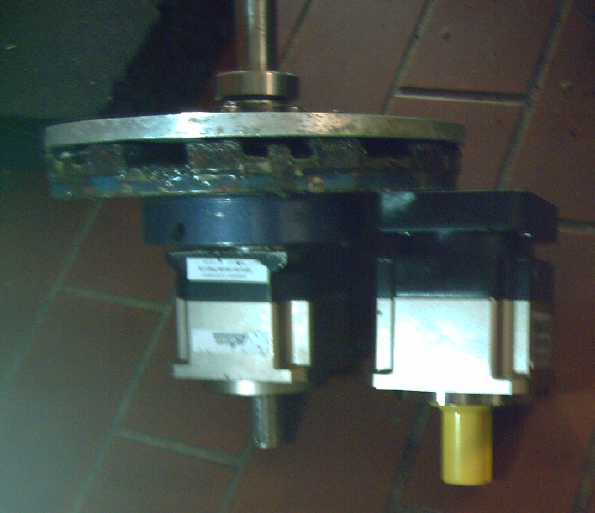

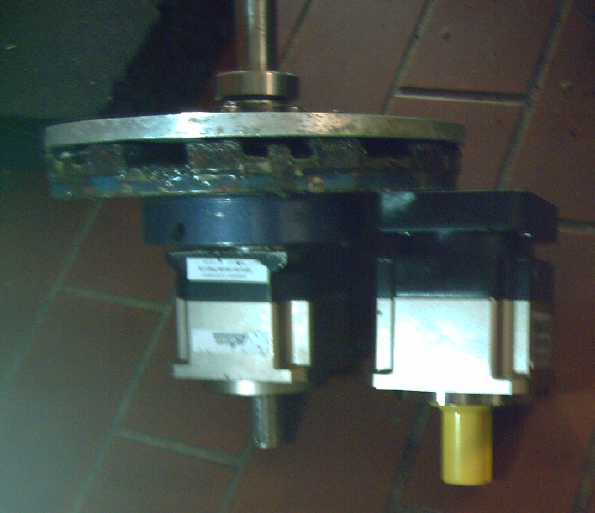

The converter shaft assembly

refitted with the

new planetary

The converter shaft assembly

refitted with the

new planetary

* I shaped the upper pieces of wood to

miss projections under the truck - the parking brake cable and a couple

of brackets.

* I fitted the assembly under the truck. Seeing how it fit I changed

the way I'll do it a bit. Now I need a 32mm I.D. roller bearing for the

truck's drive shaft.

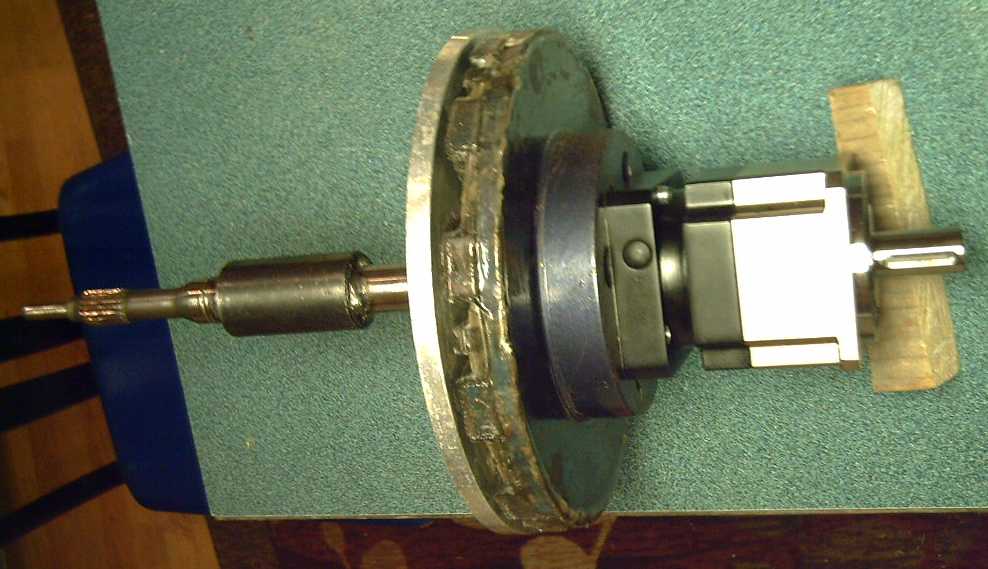

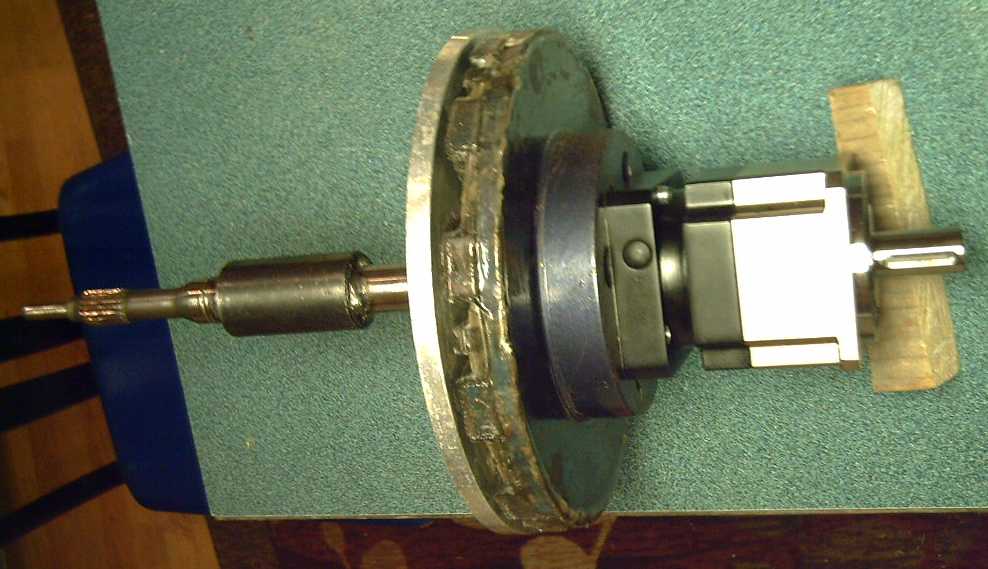

Magnetic torque converter

assembly under truck

(less 'shaped' upper 2 by 6'es),

Magnetic torque converter

assembly under truck

(less 'shaped' upper 2 by 6'es),

attached to Curtis AC35 motor at right.

Far left the front end of the drive shaft to the rear

differential fits (poorly) over the planetary gear's output shaft.

Shaft & rear end of converter to be steadied by

roller bearing (to replace cone bearing in foto).

Discussion of Nickel-Zinc Battery Chemie

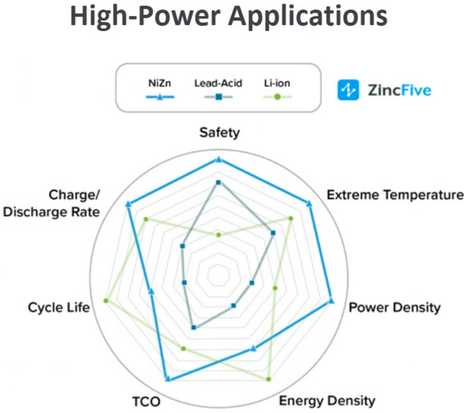

I did a bit of reading on nickel-zinc (seeing how I'm

trying to

make a fairly similar chemistry). The big weakness of course is the

rated 300 cycles recharging life (if you're lucky), which I hope to

change to "indefinitely rechargeable".

Of presently available small cylindrical alkaline batteries

(considering Ni-Cd as obsolete: low energy and usually short life):

Ni-Zn: 1.6+ volts (they charge to almost 2 volts. 1.7V might be a

better nominal rating. Short cycle life compared to others.)

Mn-Zn: 1.5V (not rechargeable. Highest energy storage matching lithium

types on a single (and only) charge.)

Ni-MH: 1.2V (Longest cycle life)

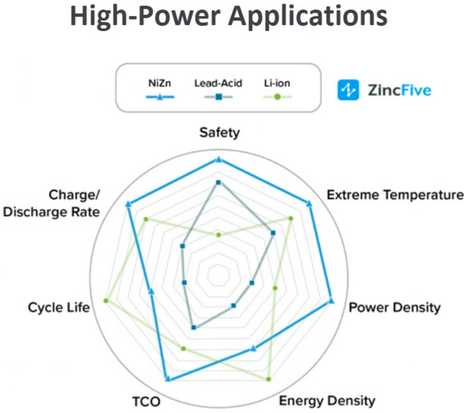

"ZincFive.com"

touts Ni-Zn for uninterruptable backup

power supplies. The reason they are especially applicable in that

particular application is that they can replace even worse lead-acid

power and

they are little cycled - only during power failures, hence may give

long service life.

"ZincFive.com"

touts Ni-Zn for uninterruptable backup

power supplies. The reason they are especially applicable in that

particular application is that they can replace even worse lead-acid

power and

they are little cycled - only during power failures, hence may give

long service life.

Someone bought some "AA"

and "AAA" size Ni-Zn cells and

reviewed them on line. He didn't get many cycles out of them (15

instead of

300) and the higher voltages fried some of his appliances. But he also

showed his charger, including opened up, and it was a cheap piece of

crap.

It's funny how for battery tools with lithium cells, such

careful

attention is paid

to proper "intelligent" chargers which work "just so", but

for alkaline batteries any piece of garbage that puts out a voltage

will do - including the many chargers that never shut off and just keep

on

charging fully charged cells full bore. Unless these are watched

closely the cells are

inevitably left in too long, get hot and lose their internal moisture

out the seams. (I guess the companies care about being sued because

their lithium product exploded and injured or killed someone or burned

a house down, but they could care less about any other batteries

failing and shortening their product's life.)

This is a typical story of zinc rechargeable batteries so

far. In spite of their high energy density by weight they are little

wanted as they are today. This is a 150 year old story I have been

wanting to change in my battery research.

A special use for Ni-Zn dry dells even as they are is in

devices that claim

"the battery is low" and won't operate, or operate properly, with

Ni-MH's. One of each type, or one Ni-Zn and two Ni-MH instead of all

Ni-MH can make them operate. So I bought a few.

My New Chemistries: The Plus Sides

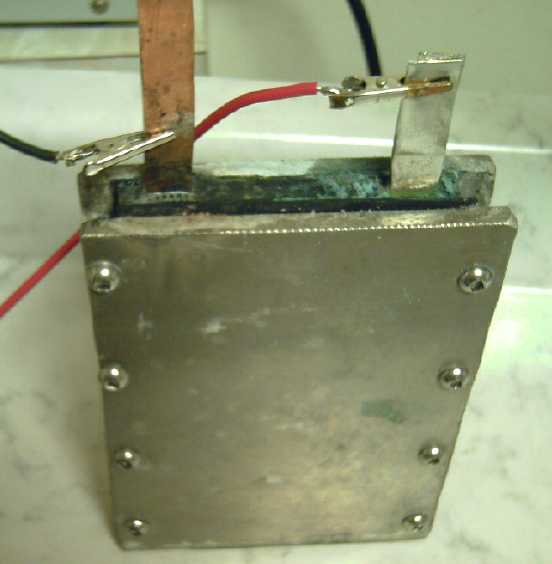

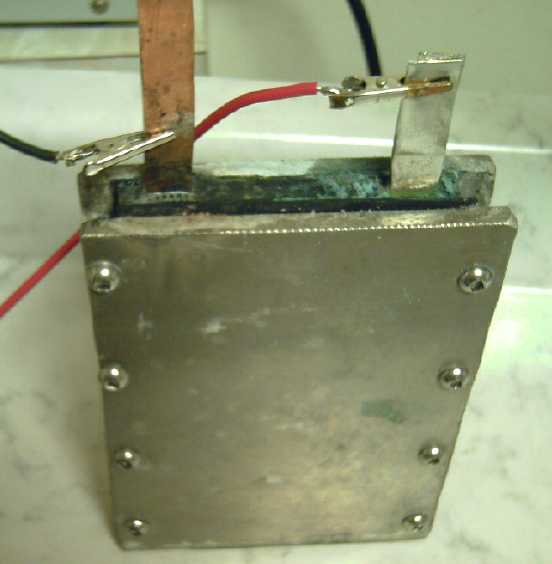

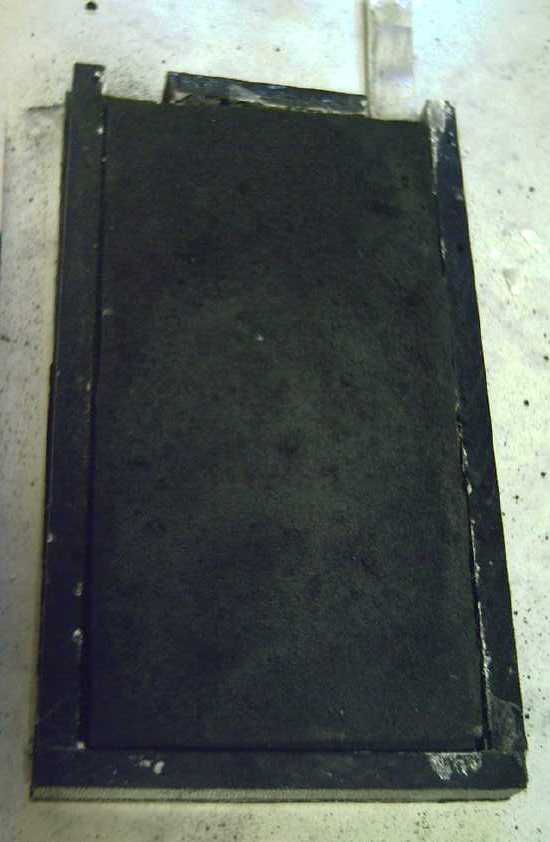

External

clamps battery.

Entire groups of cells are

to be sandwiched together.

The

theoretical energy by weight of beta nickel oxyhydroxide in

a cell is 289 amp-hours per kilogram. But in practice in an electrode,

it actually only manages about 90 AH/Kg. Replacing the nickel oxides

electrode (the "Ni-" in "Ni-Zn" etc) with mixed

nickel-manganese oxides (AKA "nickel manganates" ... AKA "NiMn-" for an

abbreviation?) should more than double this to around 200 AH/Kg and

increase available current capacity. But I [at long last] have

discovered that the reaction voltage is so much lower than I

expected that I kept giving up, thinking something was wrong. And what

I had thought was "high self discharge" was merely the overcharged

cells drifting down toward their actual reaction voltage.

The

theoretical energy by weight of beta nickel oxyhydroxide in

a cell is 289 amp-hours per kilogram. But in practice in an electrode,

it actually only manages about 90 AH/Kg. Replacing the nickel oxides

electrode (the "Ni-" in "Ni-Zn" etc) with mixed

nickel-manganese oxides (AKA "nickel manganates" ... AKA "NiMn-" for an

abbreviation?) should more than double this to around 200 AH/Kg and

increase available current capacity. But I [at long last] have

discovered that the reaction voltage is so much lower than I

expected that I kept giving up, thinking something was wrong. And what

I had thought was "high self discharge" was merely the overcharged

cells drifting down toward their actual reaction voltage.

The low voltage has led me to some dissatisfaction with

this chemistry that I've pursued for so long, as a NiMn-Zn cell turns

out to

be seemingly only about .75 to .9 volts. But still given the higher

amp-hours, as a rough estimate the 85

WH/Kg of present Ni-MH cells would increase to maybe 125 WH/Kg for

NiMn-Zn.

If cells with "dirt cheap" materials costs are mass

produced economicly and easily interconnected, it doesn't matter how

many there are if there is less total mass of cells for a given storage

capacity.

While the NiMn-Zn combo might be okay in EV's, it might be

better suited to mass storage. Manganese and zinc are cheap and they

can contain much less nickel than Ni-Zn, so the cells should be

less than half the price of lithium types and safer, environmentally

benign, and they should be extremely long lasting and highly

recyclable if no longer wanted.

I started thinking again of using nickel oxides to make

higher voltage cells. They work, even if the amp-hours per weight is

rather low. (Manganese oxides alone evidently don't recharge properly

because the discharged state (Mn2O3 or Mn(OH)3) is an electrical

insulator.)

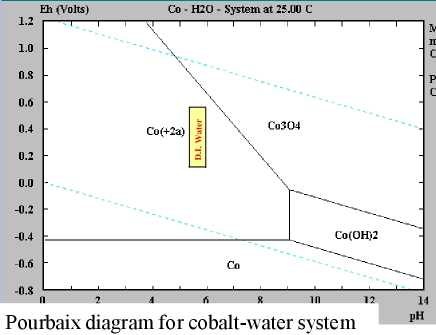

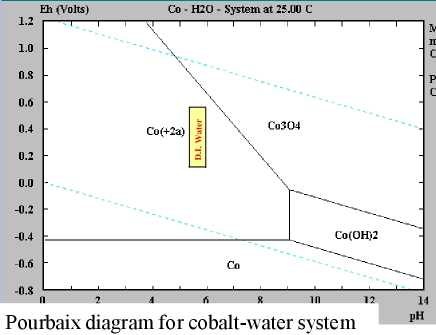

But as 2023 began I had a fresh look at cobalt oxides and

recognized they seemed to have some subtle but important advantages

over nickel oxides. Although superficially the redox formulas and

numbers for nickel and cobalt oxides look very similar except for

cobalt having a lower reaction voltage, cobalt oxides are more dense,

more conductive, and likely to provide in actual practice much more of

their theoretical 288

amp-hours per kilogram than nickel oxides (@~90 AH/Kg).

If it provides high amp-hours by weight like nickel manganates do, at a

higher voltage, then it should really be the very best plus electrode.

To my surprise it only costs around 1.5 times more than nickel oxide.

I don't know if others have missed this, if it

isn't as good as it looks, or if others just thought cobalt was too

costly to consider. Three different sources give three very different

pH14 alkaline reaction voltages: -.2, +.17, +.42. I'm rather expecting

the center figure is close, but it could be anywhere from about +.2 to

+.45 in

salt. I have some cobalt oxide powder from a pottery supply store to

experiment with, so I'll soon find out how it works and what cell

voltage is attained!

Assuming cobalt works well, there might be a place for

both

types: nickel manganates + zinc for economical bulk, even utility scale

storage, and cobalt oxides + zinc for high performance and light weight

per KWH - as in EVs.

But here I am seriously trespassing into January territory.

And the Minus Sides

Zinc is high energy at 820 AH/Kg. Until now, no one seems

to have been able to make a long lasting zinc electrode because the

molecules have a temporary soluble state as it discharges before they

turn into zinc oxide, and these dissolved ions are free to migrate

through the electrolyte. During recharge, these migrant ions turn back

into zinc where they touch the zinc sheet, but can build the sheet out

in fine threads instead of plating smoothly. Soon these zinc

"dendrites" penetrate the separator paper. They stick the zinc sheet

and separator solidly together, then they go on right through the paper

and short to the positive electrode, killing the cell. (Similar to but

worse than

nickel cadmium.) I seem to have a solution to this problem -- the "holy

grail" of battery making for 150 years now -- in SDBS, enabling

potentially "everlasting" higher energy aqueous battery chemistries

with zinc negatives.

Also I might get back to

the metallic manganese negative

electrodes I was experimenting with 10 years ago. [People thought

manganese

couldn't hold a charge in water, but I got it to work with trace

additives. More under

"Detailed Project Reports" - "Electricity Storage".] The

cells (Ni-Mn) charged to about 2.6 volts, so theoreticly only five

would be needed for a

nominal 12 volt battery. (Take that, lead-acid!) If further experiments

prove them practical,

Ni-Mn would provide highest available aqueous battery voltage, and

perhaps higher energy density cells

than zinc, possibly as high as 200 WH/Kg and hitting the density range

of lithium-ion cells. It depends on how much of the

theoretical capacity potential the Mn <=> Mn(OH)2 reaction

provides in actual use.

I went from writing about the theoretical

possibility to realizing I had eventually figured out or recently

solved self discharge and degradation problems I had been having

with them so long ago now and deciding to give it

another try. But I remain unsure whether they will actually perform as

well as zinc - there's nothing like a solid sheet of metal for high

current capacity.

I may well

try electrodes of both cobalt oxides (+), and metallic manganese (-).

Grand new Cell Design & Experiments

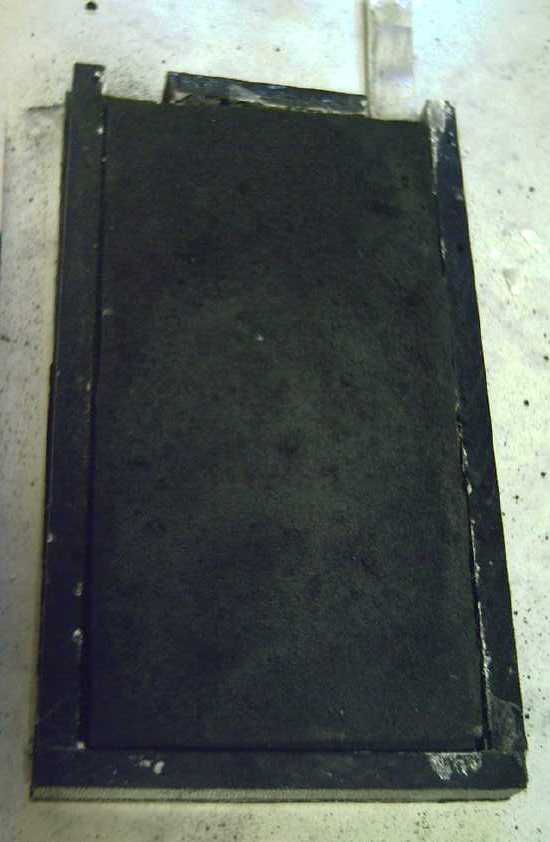

Graphite felt

electrode in

ABS plastic

shell

Among other things, I came up with what

seems like a fantastic plan for externally clamped, flat plate cell

construction, potentially with manganese negatives: use graphite felt

for both current collectors, and impregnate the appropriate

nasty nano-powders into the felts by vibration, using (eg) a palm

sander. Since there is no solid sheet between the faces, the electrodes

are bi-facial. Stack as many alternating electrodes together as desired

for a cell of any capacity, with (of course) a separator paper at each

face. And the more faces, the higher the current capacity will be.

Connection to each electrode is external at the felt terminal tabs.

Each cell could be wrapped with (eg) packaging tape and the cells put

into a common case, then all clamped together with the external

clamping plates to compact the electrodes. With nickel manganese oxide

and metallic manganese, assuming one can put substantially more grams

of powder in than there are grams of felt, excess weight of

non-reacting material would be minimal. That could yield

similar energy density to lithium cells!

Among other things, I came up with what

seems like a fantastic plan for externally clamped, flat plate cell

construction, potentially with manganese negatives: use graphite felt

for both current collectors, and impregnate the appropriate

nasty nano-powders into the felts by vibration, using (eg) a palm

sander. Since there is no solid sheet between the faces, the electrodes

are bi-facial. Stack as many alternating electrodes together as desired

for a cell of any capacity, with (of course) a separator paper at each

face. And the more faces, the higher the current capacity will be.

Connection to each electrode is external at the felt terminal tabs.

Each cell could be wrapped with (eg) packaging tape and the cells put

into a common case, then all clamped together with the external

clamping plates to compact the electrodes. With nickel manganese oxide

and metallic manganese, assuming one can put substantially more grams

of powder in than there are grams of felt, excess weight of

non-reacting material would be minimal. That could yield

similar energy density to lithium cells!

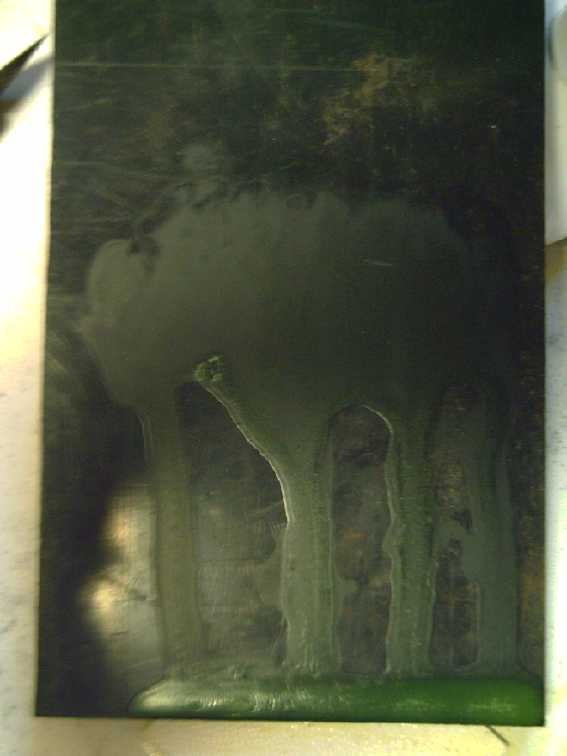

With the

separator paper

treated with SDBS, in disassembly after two weeks the

zinc

electrode and the paper still come apart cleanly. (barring a few small

patches)

This is a "game changing" result promising potentially everlasting

zinc cells.

So I spent most of the month on

batteries again. I tilted a plastic plate and let Sunlight dishsoap

trickle down it, and I made the assumption that the sodium

dodecylbenzenesulfonate was the film left behind that didn't flow down

to the bottom of the sheet with the rest. I scraped it off and painted

it into the separator sheet. It seemed to work quite well at keeping

the zinc from

growing dendrites into the paper, which normally soon sticks the paper

solidly onto the electrode. (A few small spots were stuck - the

sulfonate extracted from the dishsoap may not have been very pure.)

So I spent most of the month on

batteries again. I tilted a plastic plate and let Sunlight dishsoap

trickle down it, and I made the assumption that the sodium

dodecylbenzenesulfonate was the film left behind that didn't flow down

to the bottom of the sheet with the rest. I scraped it off and painted

it into the separator sheet. It seemed to work quite well at keeping

the zinc from

growing dendrites into the paper, which normally soon sticks the paper

solidly onto the electrode. (A few small spots were stuck - the

sulfonate extracted from the dishsoap may not have been very pure.)

With this problem solved, zinc should be better than most

any

other water-based negative electrode.

Also seen in cell disassembly,

the graphite

felt NiMn2O4 electrode

Also seen in cell disassembly,

the graphite

felt NiMn2O4 electrode

Generation of gas bubbles as the

nickel & manganese oxides convert

to the mixed oxide

Generation of gas bubbles as the

nickel & manganese oxides convert

to the mixed oxide

I got some performance out

of the new test cell, but not a lot. I discovered that the reaction

voltage of nickel-manganese oxides is substantially lower than I had

expected, and in fact in forming them by charging and discharging

nickel hydroxide and manganese dioxide, the voltages dropped as the

amp-hours improved to the point where I suddenly realized I had had

working cells (NiMn2O4+n and Mn [metal]) way back in 2013 or 2014, but

because of the falling voltages and reducing charge retention at the

higher voltages as I proceeded, I had thought they had

deteriorated and I gave up on them. So the dual oxide

has been perplexing and frustrating to work with. And the range of

voltages, the

slope as it discharges, is a little disheartening. So I was thinking of

going for straight "Ni-" (nickel oxyhydroxide) cells notwithstanding

that it has only around 90 effective amp-hours per kilogram instead of

the 200 of the dual metal substance.

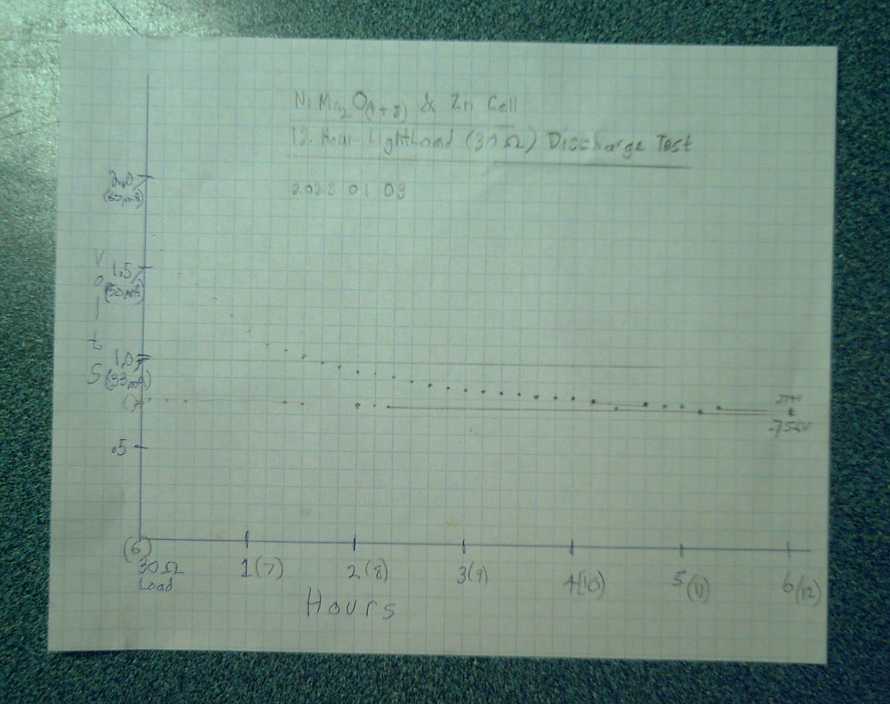

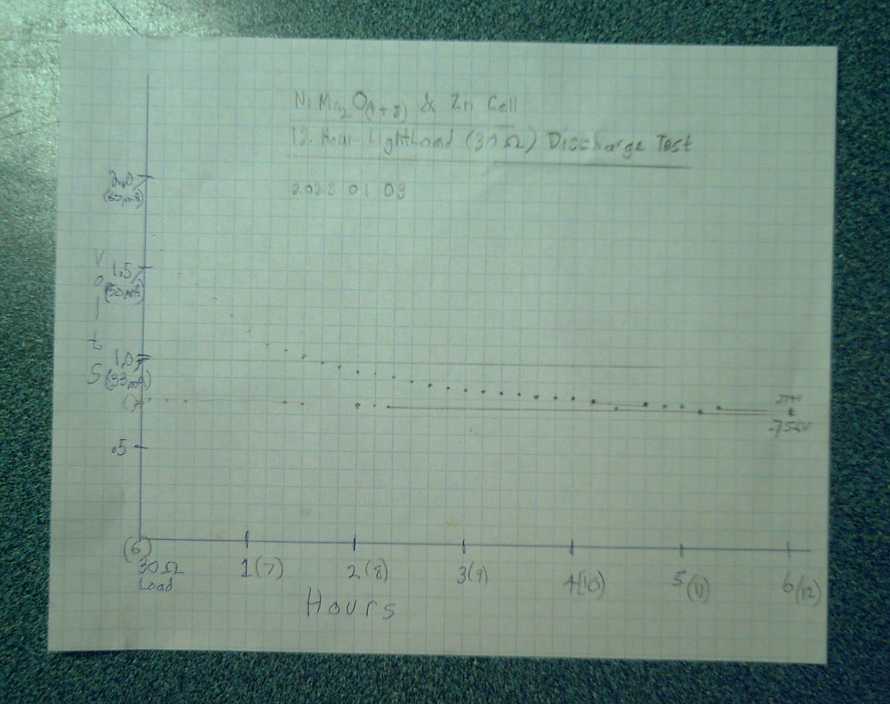

Transgressing on January, even until now I had still

misjudged

how low the reaction voltage of the nickel manganates was. On January

3rd I did a

load test with a 30 ohm resistor for 12 hours. It started with the

usual dropping voltages -- for 4 hours, until it was down below 0.8

volts. Usually I have cut off tests at well above one volt and am

distressed with the performance. Where are all the amp-hours my cells

should have? Why don't the voltages stop dropping at some flat level?

But the nickel manganates have a lower reaction voltage

than I ever suspected, seemingly around -.4 or -.5V instead of a plus

value,

actually subtracting from the -1.25V or so of the zinc. It ran for the

next 8 hours at just above .75 volts, even gaining 5 millivolts to

.756V in the

later hours. So it actually did have a particular flat voltage

it would run for a long time at! And it dawned on me that it actually

had all those amp-hours that I had thought it should - just at this

lower

voltage. And that drawing only 25 milliamps from a battery with several

amp-hours in it, and with it the flat voltage that I finally discovered

it had, the cell would probably run for 4 or 5 days or more before it

petered out. It was probably still 90% charged after 12 hours when I

stopped it! Furthermore, now that I had actually drawn that 10% of its

charge from it, it didn't need weirdly high voltages in order to absorb

at least a little charging current.

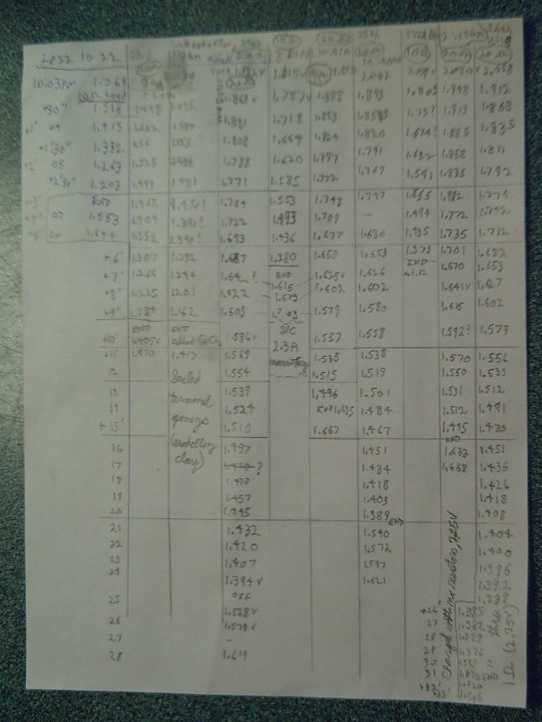

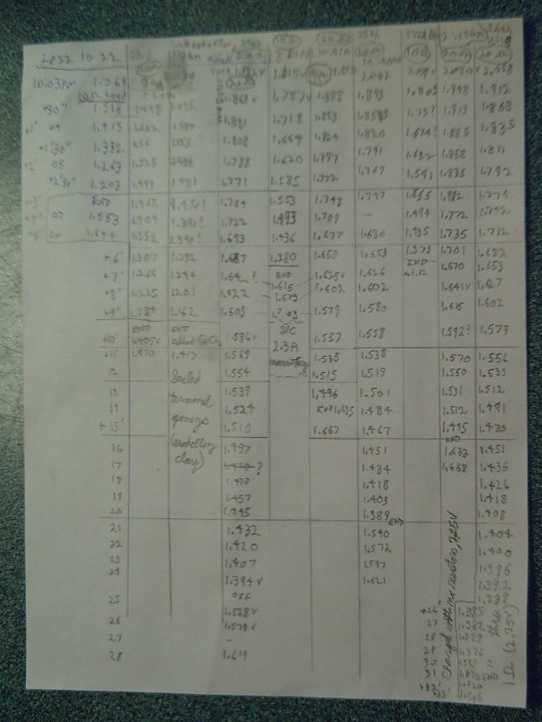

Graph of the cell's discharge

voltage with time.

Graph of the cell's discharge

voltage with time.

I only allowed for 6 hours on the paper so I had to double back to the

left for the second 6 hours,

within which time the voltage hardly changed.

Obviously it could have continued discharging at .75V, 25mA for several

days if I had left it going.

My one remaining major concern is that my cells seem to have puzzlingly

low current capacity. They're great for charging and driving a small

load slowly over days, hopeless for driving a car for an hour. In this

cell, instead of 100 or 200 mA/sq.cm of interface between electrodes

with a heavy load, it's more like 10 to 20. With the good current

capacity it should have, voltages in the above graph would

surely be a little higher. Well, I'm sure there's some cause and a fix

to be found. Hopefully it won't take another decade!

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Smol

Thots

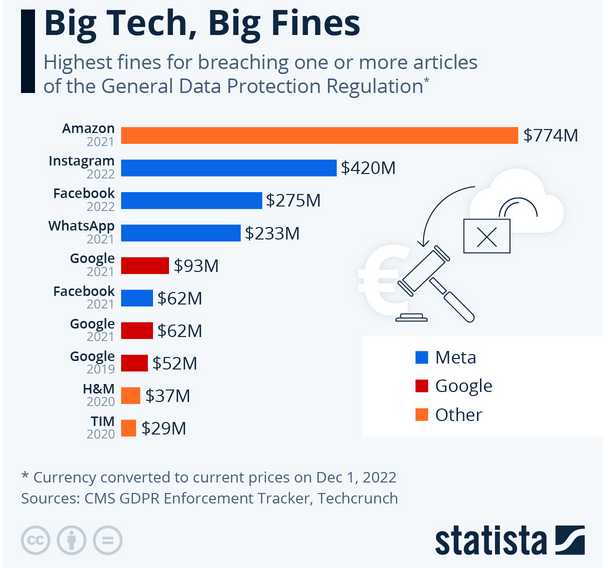

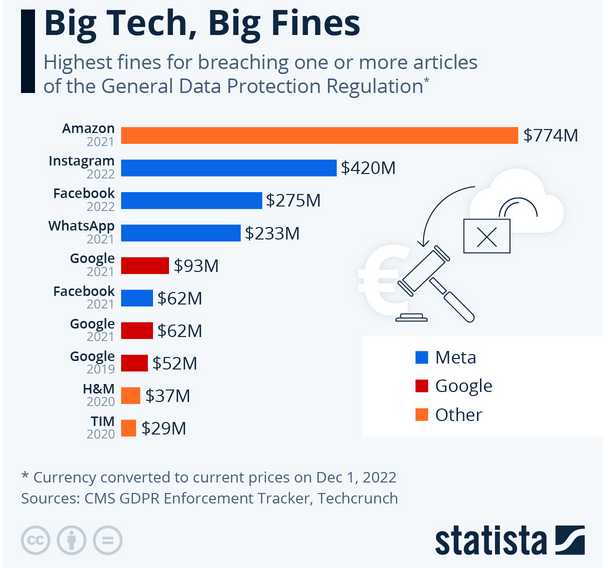

* Amazon Fraud: How?

I got another

message on my cell phone (that only a very

few friends have been given the number for and on which I had blocked

the number

Amazon had previously messaged me from): "Your Amazon account has

ended." And there was no charge on my credit card. Thank God!

I got another

message on my cell phone (that only a very

few friends have been given the number for and on which I had blocked

the number

Amazon had previously messaged me from): "Your Amazon account has

ended." And there was no charge on my credit card. Thank God!

It seems the way they sign you up is when you place an

order it says "Free shipping with Amazon Prime". Who doesn't want free

shipping? Unless you un-check the box, hey, you've signed up

for an "Amazon prime" account and for being billed 14.99 $US monthly

from

now on! (*Somewhere* I must have entered a password, but it wasn't

evident to

me, and obviously not to others either, that we were signing up for

something

with ongoing billing. We were just trying to order one item.)

Shown is fines Amazon incurred in Europe in 2021 for

breaching European laws.

* It is disturbing that so many major corporations have become gangs of

pickpockets seeking any stealthy means to extract money from people,

legal or moral or not -

especially as ongoing charges. And that they only pay fines as

"corporations": even the head pickpockets in upper "management" never

get punished, fined or even fired, or removed by government.

* And today often the CEOs and upper management pickpocket from the

company itself and from shareholders by various manipulations,

sometimes enriching themselves personally so much that the company they

manage goes bankrupt. (Eg, Kodak, Enron...) As someone said, "The best

way to rob a bank is to own it."

* Those having attained positions of power by unscrupulous means are

among those who hate truth. I understand that 67 journalists are known

to have been killed globally in 2022 (as of early December), said to be

up from 47 in 2021. There are probably more and some "disappeared",

that simply haven't been recorded as "killed journalists". Washington

still wants revenge on Julian Assange for exposing its war crimes in

Iraq almost 2 decades ago. Right now Ukraine, and the Donbas, are the

most dangerous places for a journalist to be. But as (for example)

Michael Hastings showed us in 2012, anywhere can be deadly if you have

a story about the wrongs of the wrong people or organization. Any idea

why we only hear the "fake news" that "TPTB" want us to hear on the

mass media?

* But it's not just corporations: The unfortunate tendency to look on

others outside one's own circle as "resources to be plundered" rather

than as fellow human beings has become all too pervasive with

individuals within our societies, too.

* I have been hearing that stores in some American cities are becoming

targets of organized shoplifting, where a whole group/gang connects on

social media, sets a date, and everyone comes in at once and robs the

store, saturating any store security. More and more stores are closing,

and this has been the reason in some cases. In many cases, especially

furniture stores for example, it's just that so many people have no

money for things they don't urgently need.

* With the growing level of

shortages and crop failures, fuel and energy inflation and egregious

costs for housing, even basic necessities are becoming unaffordable for

too

many people, even the greater majority. I was a bit dismayed this month

to hear someone say there

was rampant crime

in Edmonton Alberta where I grew up. That would be just about the last

major

North American city I would have expected it in. How much longer can

20th century civilization endure such growing levels of trouble and

self-serving disunity coming from every corner?

* One of a kind Lamp I have a lamp with a twist switch

that only takes one click to turn on or off instead of two. Came with

the house. Never seen one before. What an ingenious invention!

* Good military analysts expected that Russia's now strong mobilized

forces

would make their big attack on Ukraine once the ground was solidly

frozen so that tanks could roll across the open fields without sinking

into the mud. Somehow I suspected something would go wrong. It would be

too simple to just have some decisive action put a quick end to the

fighting. On the 17th I checked on a world weather map. Sure enough,

while we were having a cold snap here (-5°C the next morning),

temperatures in Ukraine were mild, above or near freezing except in the

northernmost parts. As temperatures here plummeted to -7° and even

-11° [a

record?] for days on end - unheard of around here and much colder

inland -

Ukraine hovered around zero to the end of December and even warmed up

into January -- hardly the usual winter deep freeze the Russians were

said to be waiting for! In fact all Europe has been wondering "What

happened

to winter?" And the American or NATO or Ukrainian side (whatever one

calls it) has been gathering forces to oppose such a move that would

have been

simple and decisive in November or December.

As Scottish poet Robbie Burns said, "The best

laid schemes o' mice an' men gang aft a-gley." From another viewpoint,

one may glimpse the workings of our governing spirit overseers: "The

Most Highs rule in the affairs of the Kingdoms of Men." and "All things

work together for the progress of men and angels."

* Instead, local Donbass militia groups with Russian

artillery support continued localized

attacks notably around the fortified transportation/communications hub

of Bakhmut

in

Donetsk while Ukrainian (and foreign mercenary?) forces continued their

8 year long artillery

terror shelling of Donetsk city from their well-dug-in nearby

fortifications. Russian speaking refugees flee East and Ukrainian

speaking refugees flee West to escape the war. As best I understand it,

10 million out of 44 million have fled so far.

* Some in authority seem to want to ban ranching and production of

meat. They seem to reason that to have a cow eat vegetation is less

efficient than having people eat vegetation directly. But it's a false

argument because many lands that are good for ranching aren't good for

crop production. And cattle poop is good for the soil. The rich

prairies of the Americas were made by kazillions of grazing bison

before the

first settlers ever looked and saw ready cleared land free for the

taking.

ESD

(Eccentric Silliness Department)

* What is the relation between a tax and attacks?

* A disgruntled worker can cause many problems. An office should hire

only gruntled workers.

* I keep seeing companies filing for Chapter 11. Dang, I always miss

the first 10 chapters!

* What gets cooked in a chicken ckichen?

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Magnetic Variable Torque Converter with Planetary Gear

Magnetic Torque Converter =

Performance!

Power equals torque times speed. With a fixed 5 to 1

planetary and 2.2 to 1 at the differential, the truck would have had 11

to 1 reduction between motor and wheels. That would be sufficient

torque to get it to start moving, even up a hill. But with the 10 to 1

planetary making it a theoretical 22 to 1, at low speeds and higer

torques the motor speed is faster with the

same torque. The truck should really accelerate fast even with

its small motor. Yet as it hits 30 or 40 or 50 KmPH and the foot is

raised on the accelerator reducing the torque, it will still head

toward 2.2 to 1 (torque converter toward 1 to 1) and the motor won't be

turning very fast. Even at 100

KmPH it won't be going much more than 2200 RPM, which is under half its

continuous speed rating.

In other words, with a well configured magnetic torque

converter even very small motors (like the 3500W one in the Sprint)

will give great lower speed performance and be able to climb steep

grades and almost jump away from stop lights.

Next this has to be assembled and demonstrated on the road...

The New Planetary Gear

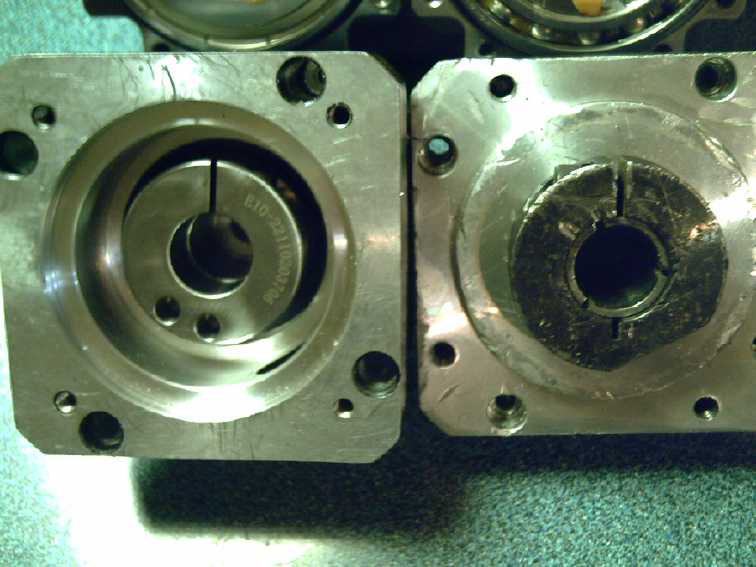

[20th] The new 10 to 1 planetary gear arrived. I had finally given up

and thought it would be after Christmas. The front half of the new gear

looked like it had come from the same mold as the old gear. Could I

swap the back halves and then not have to change the shaft? It seemed a

bit dubious, but I had wanted to see what sort of lubrication was

inside them anyway.

[21st] I opened them up. The 10 to 1 sun gear on the new unit was a

tiny red dwarf. I'm actually a little nervous about how small it is. If

it had to take too much torque, it might actually break off its shaft.

I console myself that it sees only 1/10 the torque of the output, and

that with the body 'free' to turn, it should never get a hard jarring

from a sudden force. But I'm actually wondering whether a 9 or 8 to 1

gearset might just be more robust. Either that or use a larger physical

size planetary. Anyway, this one is going in the truck now. If it's not

strong enough, I'm sure I'll find out only too soon.

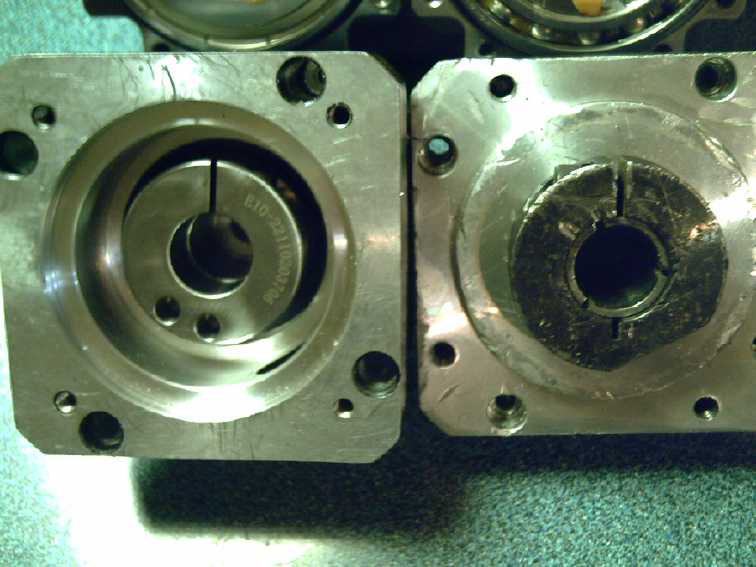

Old & New gearset.

Old & New gearset.

The box said deltaww.com .

Apparently that's the maker, with many international offices.

On the new one (L), the input is

recessed, by

making the body longer

On the new one (L), the input is

recessed, by

making the body longer

The Planets assemblies inside,

& the grease

The Planets assemblies inside,

& the grease

The sun gears (new 10:1 reduction

sun seems

awfully tiny!)

The sun gears (new 10:1 reduction

sun seems

awfully tiny!)

The new one's output shaft is a

bit longer

The new one's output shaft is a

bit longer

The lubrication was a thin grease. I figure

that it's thin enough that with the body turning it will get thrown

around inside and continually lubricate, rather than get flung away

from the gears and gradually lose lubrication as with a stationary

housing - Yay! (That's what did in the gear teeth in my first Ryobi

skill saw running the handheld bandmill when I was milling, when after

much

milling the grease was no longer where the gears were. I didn't want

that happening on the truck. (Hmm... Maybe I should open up the gears

on the present saw

on the bandmill and see how it's doing?))

Inside, the sizes were all different. There was no piece

of one that looked like it would fit in the other housing. All the snap

rings were different sizes. So much for that idea! I put them back

together as they were.

But on the old one the input clamp was external, and on

the new one it was recessed inside, making them almost the same length

from shaft end to shaft end. If the end of the motor shaft needed to be

trimmed at all it would be by just a few millimeters, such a small

amount that no more of its length would need to be reduced to 19mm.

Yay! Also the output shaft was an extra 4mm longer than the old one.

Any bit longer to insert into the tenon on the rear drive shaft is a

plus,

because there isn't much to grab onto and it carries a lot of torque.

It's surely the weakest link.

The outer housing however was an extra 27mm or so longer,

putting the magnet rotor that much farther up the shaft. So the center

bearing and alume rotor would have to move along to compensate, and for

that the motor shaft

would have to be turned to 1.0 inches for that further length. All very

doable on the lathe if it wasn't freezing cold outside and in the

workshop. The garage was also pretty chilly for lying under the truck

and struggling to fit things together. If the whole project doesn't

wait for spring, it will probably sit at least until this cold snap

ends. 2023 approaches.

[29th] It warmed up. Sometime in there I had figured out that I could

mount the alume rotor on the reverse side of the huge washer/disk it

bolted to, and changed it. This moved it up the shaft about 3/4 of an

inch. Trouble is the new planetary is over an inch longer than the old

one, so I expect it'll still be 1/2 inch or so too long between motor

and rear wheels drive shaft. But I'll try fitting it all on. If it fits

it saves me some lathe work.

There were

four new holes in this gearset body for an

allen wrench to fit through, owing to the extra length obscuring some

screw heads. They were just the right size to tap for 3/8 inch bolt

threads. The holes in the magnet rotor were just a little off and a bit

small, so I had to spend some time filing them so they fit and centered

the rotor. (Still, really nice that everything was so miraculously

close to a perfect fit!) I'm much happier with some big fat bolts to

take

the torque between magnet rotor and gearset body than the puny #10-24

holes they came with

or even the 1/4 inch bolts I drilled out the old unit for.

There were

four new holes in this gearset body for an

allen wrench to fit through, owing to the extra length obscuring some

screw heads. They were just the right size to tap for 3/8 inch bolt

threads. The holes in the magnet rotor were just a little off and a bit

small, so I had to spend some time filing them so they fit and centered

the rotor. (Still, really nice that everything was so miraculously

close to a perfect fit!) I'm much happier with some big fat bolts to

take

the torque between magnet rotor and gearset body than the puny #10-24

holes they came with

or even the 1/4 inch bolts I drilled out the old unit for.

Shaft assembly with new planetary

Shaft assembly with new planetary

[30th] I tried fitting the whole thing

under the truck. Sure enough, it

was too long... unless I didn't put the bearing on the rear shaft. But

that did make for more overlap length to connect the drive shaft to.

Could I put a bearing instead on the outside of the socket of the drive

shaft? That would be better. It was smooth. 32mm. I could probably

order a bearing for that. I could make anything to fit the length and

outer diameter of a bearing as long as it was 32mm I.D.

I found a cup & cone bearing that had a shim on the

inside from some long ago project. It was just about right. Nah! I

would be better off to find a one piece ball bearing or needle bearing

race.

I trimmed the top boards to fit around obstacles under the

truck frame, notably the parking brake cable, but haven't reattached

them.

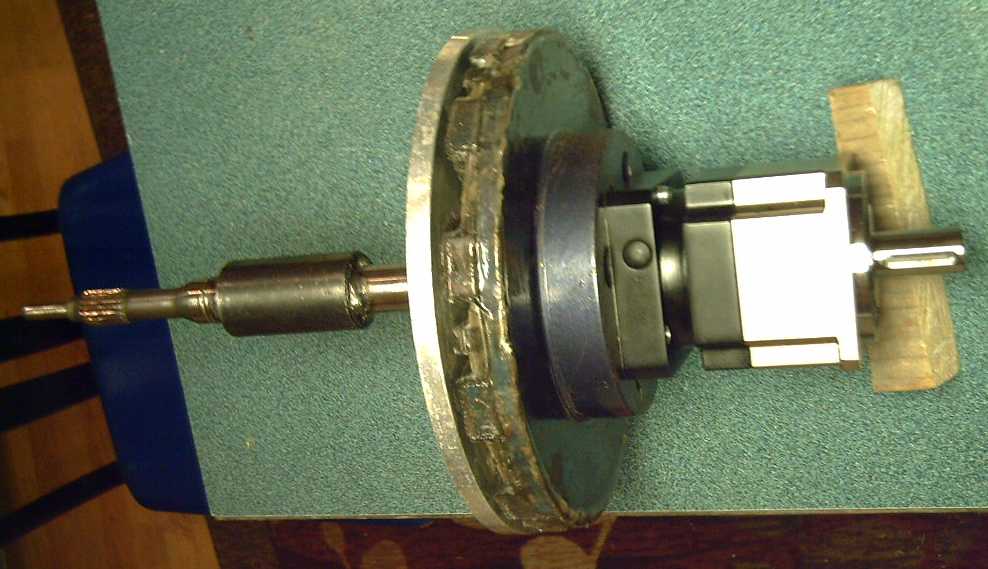

The main frame of the variable

torque converter

fitted under the truck

The main frame of the variable

torque converter

fitted under the truck

Unipolar

Axial

Flux

BLDC

Motor

I was wondering where I

would get steel plate to make molds for the PP body parts -- or should

I try alume molds again? Sheldon

had mentioned that a 4 by 8 foot sheet of 1/4 inch steel had gone up

from something like 150$ to 600$ -- plus shipping and I hate to imagine

the cost of shipping to here. Suddenly I remembered: I still have 1-1/2

of the two 80 gallon propane tanks made of 5mm and 6mm steel that I got

especially to make plastic molds from! Duh! Bending the curved pieces

straight has been a challenge, but the pieces for the motor molds will

be somewhat smaller than the big plate mold I was making - hopefully a

little easier. (And maybe I should

try cutting them with the plasma cutter this time?, instead of using up

so many angle grinder zip disks!) There was one loose piece 16" by 21",

and I "sort of" flattened that. I improved my technique with a couple

of small bars of steel to form bend points more where they were needed,

and at least I got it flatter than the previous piece. I wonder if

anyone else has a better method or some heavy steel roller (unroller?)

I could use?

[8th] I spent the evening with the CNC router. After some of the usual

frustrations with unfamiliar software that worked differently than what

I'd used before, I had it work correctly for a dry run with the router

turned off. It went through all the motions of moving the carriage

around through all the steps for cutting out the magnet placement jig.

I learned a bit about setting default parameters and feed rates, which

had all been pre-set in the old drill-router I had had in Victoria

until 2017. I must say a stepper motor on the vertical "Z" axis seems

much better than than the compressed air plunger that lowered that

one's router. (Why, one could even make cuts to different depths -

right through the material or only various indents. A 3D un-printer.

What a concept!)

One thing I realized to my annoyance in setting "max.

travel X" and "Y" was that although the table was 29" by 29", the

workpiece cuts could only be 19" by 22" max. One inch legs in the

corners underneath kept the 8 inch wide left and right gantry pillars'

mobility to 10" less than the depth, and the router carriage was about

7 inches wide. and hit end stops on the gantry pillars. Perhaps if I

ever need more depth I could extend the tracks beyond the back of the

table. How feasible that would be I'm in doubt. Taking the legs off and

devising an alternate mounting could bring it up to 21" deep.

Anyway, 19" is plenty for the present motor project, and

maybe for anything I'm likely to do with it.

Once the machine had run the course flawlessly I called it

a night and was happy to have got that far.

[9th] I mounted a piece of 1/4" plywood on a center of 3/4" plywood. I

ran the course again and discovered that the whole pattern was running

about 2/3 of actual size. I ended up running the configuration software

again and telling the software that the motors were 324 steps per

revolution instead of 200, which must be some standard. The "Z" motor

said "200" on top. But apparently the pitch of the screws moved things

by an an inch over more than one revolution of each motor. or something

equivalent.

Finally I went to put a router bit in the collet chuck...

and discovered that it, the only collet I had received with it, was 6mm

instead of 1/4" or any other shank diameter one might readily find in

North America. My other collet chucks from other machines were all too

big for this one. I put in a 1/4" bit but it wouldn't go in all the

way. It drilled the five holes in the center, but predictably it fell

out after butchering an inch of the plywood when asked to cut sideways.

I got on line to AliExpress. Sure enough, 6mm is a

standard size router bit shank in the rest of the world, and I ordered

some bits. "February 10th" is the estimated delivery date. Knowing how

deliveries are going today, I'll be lucky to see them by spring. If

ever. So close to being able to route, yet so far! The other option

would be to make a carriage for my regular handheld router. That would

be a considerable project in itself.

Well, I could work on designing the chassis of the motor.

(Instead I went back to battery chemistry & design.)

(The bits arrived January 7th.)

Other "Green" & Electric Equipment Projects

Winter Gardening

Window & LED Gardening

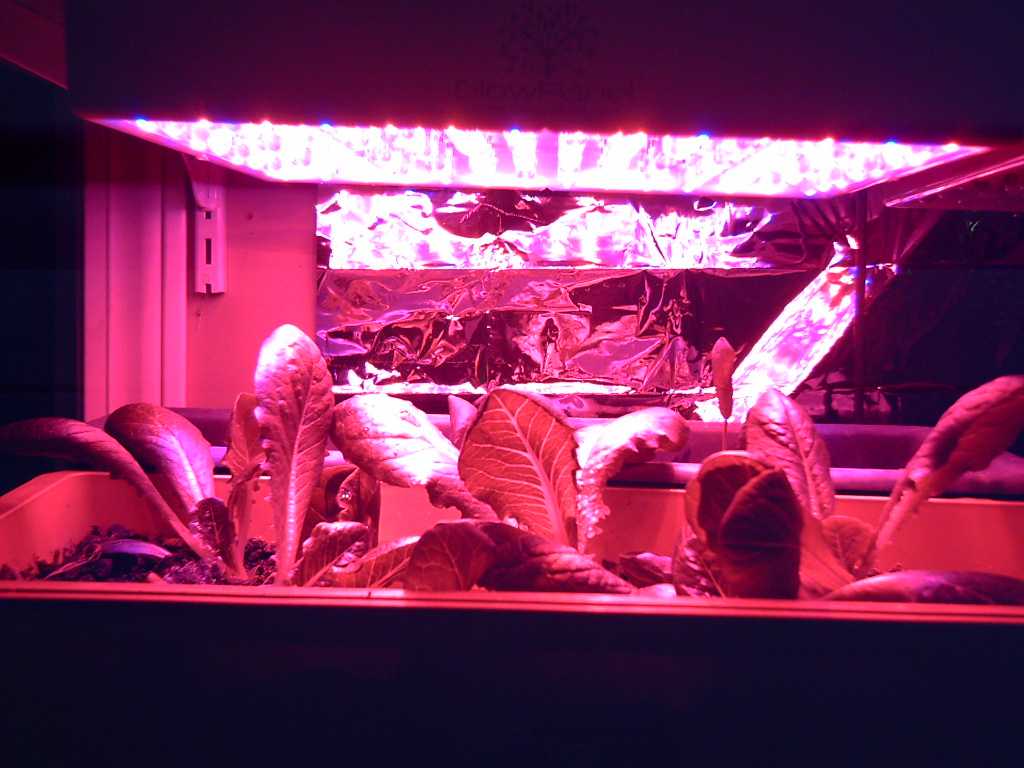

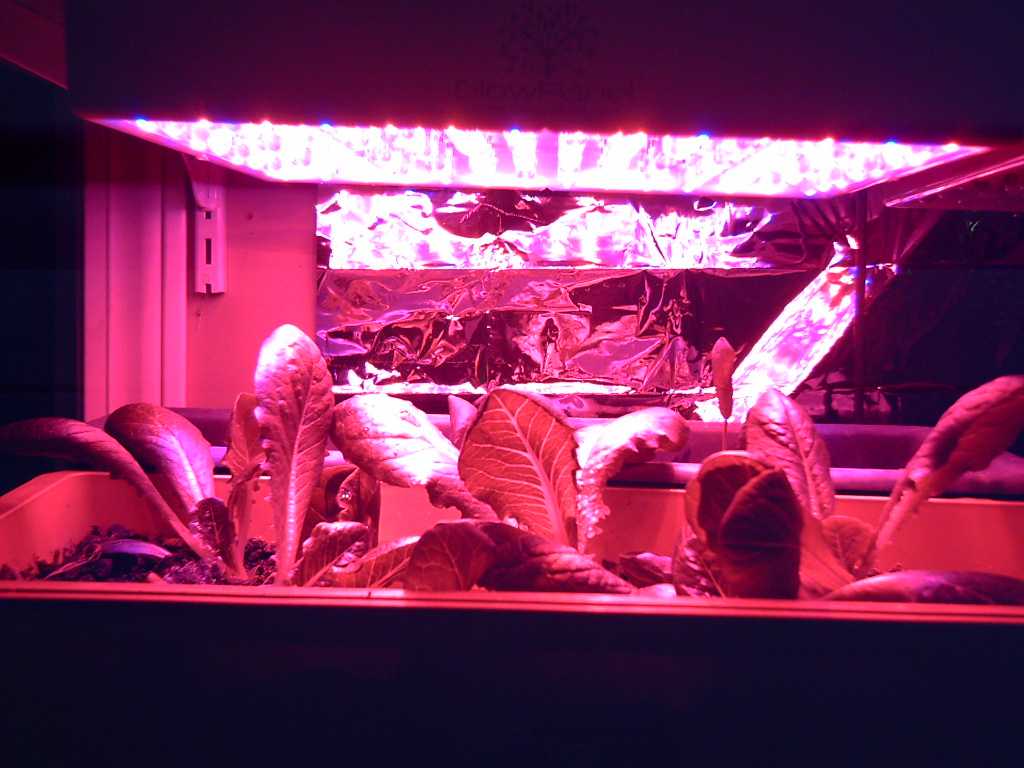

The romaine lettuce and spinach planted in two rectangular

pots under two 40W red-blue LED grow lights in November started growing

well once they were very close to the lights and so were getting enough

in 9-11 hours a day of the lights. One light quit. (They're quite old

now.) I've ordered a new 100 watt 30 x 45 cm light The lettuce

has been yielding leaves for burgers and salads. I had to seed more

spinach as only a couple came up, and I've only had a couple of small

leaves. But finally the first two are growing bigger.

The lettuce must be worthwhile, because I saw a head of

romaine in the grocery at 9.99$ !

Lettuce and spinach under LED

light.

Lettuce and spinach under LED

light.

They had to be this close to the lights to survive.

Seen in normal light.

Seen in normal light.

In the bay

window with added lights, a pepper died from

having water always in a tall drip tray around it (overwatered) and the

other three peppers have aphids, but I'm still using the peppers that

started in the summer and ripened over the fall - a few are left if

only because I don't eat them very often. After 3 months with no

flowers, one banana pepper has a couple. The larger "restarted" cherry

tomato has a couple that should be ripe soon, more to follow, and

continues to flower. The other one isn't doing much.

I grew more onions last summer than I'm ever going to use

up, even keeping them in a cold place. After all these years with so

little success growing onions, I planted a lot. How was I to know

they'd all make nice big bulbs? And plenty of garlic.

Electricity

Storage

Manganese Negative Electrodes (~ -1.5V)

This is the "too

technical"

part of the discussion of batteries in "Month in Brief", about my

experiments 10 years ago wherin I created chemicly successful metallic

manganese electrodes that might still make higher voltage, higher

energy density water based cells.

People said it couldn't be done, that the reaction voltage

of manganese (~-1.5V) was a little too high and that in water it would

spontaneously convert to Mn(OH)2 and bubble H2 gas from the water

without the electrons bothering to flow through an external electrical

circuit. I reasoned that if trace substances could be added to zinc

electrodes to raise the hydrogen overvoltage so they could charge

better without bubbling hydrogen, then for the extra .3 volts or so of

manganese (Zn -1.24V vs. Mn -1.57 in alkali), one might find additives

that would take it from "doesn't quite work" to "does work". First 1%

antimony sulfide got it to work, yay! ...but only if the room was below

18°C. Next summer that didn't work any more, to my considerable

puzzlement for a while. Then I put the cell in the fridge and it worked

again - Aha! Adding 3% zinrconium silicate as well got it to work into

the upper 30's° (I tested up to 39° IIRC). I only got it to

work in KCl salt electrolyte, pH up to 13, not in pH 14 KOH.

So my Mn negative electrodes held a charge! ...mostly. The

first one I tested (Sb2S3 only, in winter) had a graphite rod current

collector, and it seemed to hold its charge. I was mostly using zinc

sheets as current collectors, as well as zinc powder conductivity

enhancement. But (which I didn't figure out until much later) with the

high voltage, the zinc plate bubbled hydrogen and formed zinc hydride

continuously where it wasn't near the Mn electrode mix with the

overvoltage ingredients. So the self discharge never completely stopped

and it wasn't so long before the terminal tabs on the zinc plates would

corrode completely away around the water line and the cell would be

disconnected. I had thought zinc should work because with the higher

reaction voltage of manganese the zinc would remain in metallic form. I

don't know why didn't think it would bubble hydrogen, also I was

unaware that zinc could form a hydride and degrade, so didn't

understand the degradation, the hydride being similar light color

powder as zinc oxide.

Some other metal (lead, bismuth?) or graphite might work

for the negative current collector, or else perhaps a protective

(non-conductive) coating could be applied to the exposed zinc. Or the

overvoltage ingredients would need to be everywhere - perhaps in the

protective coating? Come to think of it, my last experiments, using

graphite sheets instead of zinc, did seem to be working better. But I

think that one may have been when I tried MnO2 in the positive, and I

didn't understand why that wasn't recharging. Then I probably went onto

something else and didn't seriously get back to batteries for a long

time. So: a graphite sheet current collector and maybe graphite powder

instead of zinc for conductivity additive. Graphite is much lighter

than using a metal anyway, further upping the amp-hour per kilogram of

the electrode and cell. If needed a paint/coating impregnated with

the overvoltage raising substances could coat all exposed surfaces

including the terminal tab up to the connection level. Why did I stop?

Oh yes -- because I didn't understand why it kept self-discharging. In

fact, these earlier cells would have had the same problem I've just

(apparently) solved of nano powders penetrating through the separator

sheet, degrading their performance over a couple of weeks, which always

seemed to happen. Having at long length figured out some answers,

perhaps it's time to try again?

Between the nickel-manganese oxide which I was

experimenting with even back then and the manganese negative, the cells

charged to 2.6 or even 2.7 volts. They might be considered "2.4V

nominal", of which just five cells would would be required to make 12

volts. (They even lit a 2.9V LED; not brightly, but no other single

cell water based battery will!) This should be similar to lithium ion

cell energy density, by weight and maybe by volume.

And yet, if zinc can be contained and not grow dendrites

across the separator sheet, the solid metal has very high current

capacity and will yield most of its theoretical amp-hours. I suspect

manganese probably won't perform as well. So I remain torn about which

to make.

Hidden Culprit Found!

[15th] The more thought I gave to my early results, the more I thought

I would try this chemistry again. I went looking for my antimony

sulfide, which I hadn't wanted at any time since I moved here from

Victoria, and ran across a nearly empty plastic jar of KCl - USP

grade! This solved a mystery. Since I've discovered that my KCl

electrolyte salt has been a cause of self discharge all along, why was

I getting better results early on in my experiments, and then I could

never again duplicate such good results? That was it: the first

KCl I had bought at the health food store was that jar and it was pure.

After that they had switched and had [contaminated] KCl in bags. I had

switched to using the next bag I had bought, and didn't notice that it

was after that that all my cells of any kind seemed to have

serious - and mysterious - self discharge. Of course I should have

figured it out long ago, but I didn't. Instead, frustration, time after

time after time! Amazing how some little thing can throw one off track

for years - or even maybe never be suspected and change the whole

course of life. How far along would I have got years ago without this

setback?

In a lengthy search - of everything twice - I never did

find the antimony sulfide. Hopefully antimony oxide will do the job,

because I found a small bag of that and will try it. I'll certainly

know if the electrode won't charge.

New

Chemistry Batteries

[6th] Nothing seemed to

completely stop

the self discharge, but I did note that higher charging voltages (2.3

vs 2.25 vs 2.2 vs 2.1) gave better results. It still only powered a 20Ω

load for 16-19 minutes. Was it really charging fully or properly? I set

it to 2.4V. That seemed to give somewhat better results. A load test in

the evening went a little over 19 minutes.

Owing to the fact that it can take 10 minutes to recover

its voltage after a load test, it seems to me that the conductivity of

the plus electrode must be quite low.

[7th] Hours and hours on charge, and it gets incrementally better over

time. Will more charge and more charge and more charge over many days

or weeks eventually make it perform well? Should I be chemicly

pre-charging with bleach?

Positive Electrode Mix

Speaking of which, I would think that using MnO2 (or

Mn2O3) from old dry cells and mixing in the Ni(OH)2, and then putting

it in bleach, should give about the same effect as using Ni(OH)2 and

KMnO4 and water. The dry cell has graphite already in it and it all

must be pure enough already to hold a charge. The trace Sm2O3 or

Sm(OH)3 to raise oxygen overvoltage can be added any time. It won't

react.

I don't think the monel powder (which I spent so much

money, time and effort on) is needed at all. That was a left-over in

thinking from trying to do it in a similar manner to how NiOOH alkaline

cells are done with cobalt hydroxide in the mix to improve

conductivity. The graphite or conductive carbon black (herein "CCB")

takes its place. A little more Ni(OH)2 is added to replace what the

monel would have formed? The mix using KMnO4 is thus simply:

Ni(OH)2 - 25 g

KMnO4 - 40 g

Graphite Powder - 5 g

Sm2O3 - 5 g

The mix using old dry cells is a bit less certain. How

much is graphite or CCB? And was it charged (MnO2), Discharged (Mn2O3

or Mn(OH)3), or somewhere in between? Each substance has a different

amount of oxygen in proportion to the Mn. Hmm, perhaps pre-bleaching

can ensure that it's all charged to MnO2?

The mix to be bleached and purified then becomes (wt% for 100g product):

Ni(OH)2 - 29 g

Dry cell Powder (MnO2 + CCB) - 63g

Sm2O3 - 3 g

Additional Graphite or CCB power - 5 g

(proportions of Ni to Mn are approximate)

This is pretty cool as the largest ingredient is the

powder from old dry cells, which can be had for free anywhere where

they are turned in for recycling. I suppose one could get nickel and

nickel compounds out of rechargeable dry cells too, but in my

experience the "D" cells have a heavy metal case and are a bit tough to

open and extract the spiral electrode from. (If I didn't have a whole

tub of Ni(OH)2, however...) But, also: since the negative electrode of

NiMH is mostly nickel (with some lanthanum and cobalt: Ni:La:Co 10:2:1

ration IIRC), it too could be oxidized to Ni(OH)2 and used for the

positive. The La(OH)3 would substitute for Sm(OH)3 - I think it should

work well enough, especially as there is quite a lot of it. I expect

the Co(OH)2 would have little effect - perhaps raise conductivity a

bit, otherwise pretty benign.

Thus, both electrodes from NiMH cells could be used to

make the nickel compounds for the new cells. The metallic nickel would

have to be turned into hydroxide first in order to react it with the

MnO2. (HCl + H2O2, or mildly alkaline salt electrolyte and a "+"

charge?)

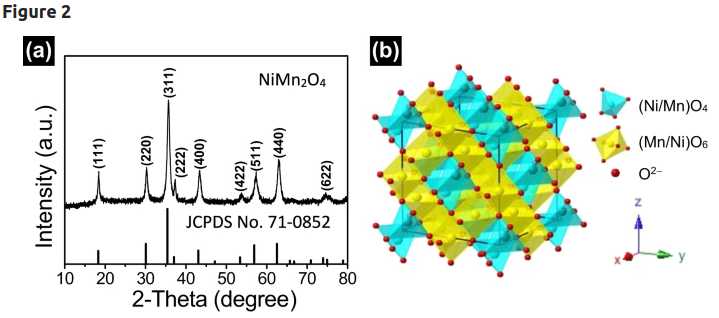

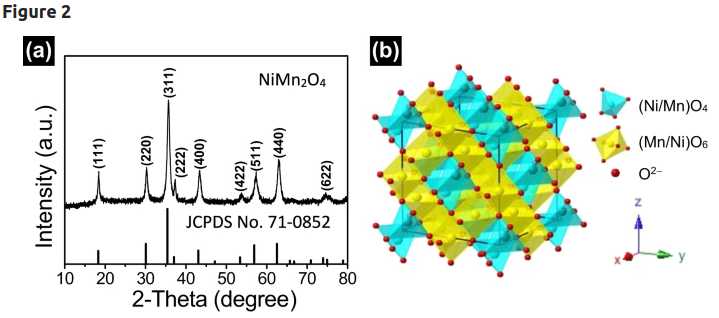

Spinel crystalline structure of

nickel manganates.

Spinel crystalline structure of

nickel manganates.

It is easy to see how oxygen ions can attach or detach, or

attach/detach a

hydrogen ion, to provide many potential oxidation states for redox

reactions.

[8th] On disconnecting, the

voltage dropped to 2.100 volts in 85

seconds instead of 50-60. But a 20Ω load test down to 1.200 volts had

somewhat lower voltages throughout and only ran 18 minutes where

yesterday morning it went for 22. What drives these changes? Maybe a

lack of salt? I had added water with weak salt to 'top it up', which

might decrease the concentration. Or the tiny filler hole I left open

to the air after that? (Oops)

I pulled the modeling clay off a terminal and spooned some

salt onto it. It didn't seem to entirely absorb, but I put on another

piece of modeling clay to (hopefully) restore the seal.

[9th] I'm convinced I still need to somehow hold the "+" electrodes

more heavily compacted. Same pressure in the cell as when I compact

them in the hydraulic press. I think that even with the extra pressure

I've added to the clamped cell, 95% of the electrode material isn't

being utilized. As well as far more current drive and fast recovery

after running a load [presently takes many minutes!], I think the

amp-hours would go way up and the self discharge would become trivial

in proportion to the charge held.

But even the 1/4 inch plastic sides are likely to bulge

out and 1/4 inch alume end plates to bend under the pressures I think

are really needed. I could use steel end plates, or 3/8+ inch alume.

What about those sides? Wrap the cell innards in lots of winds of

packaging tape to keep the sides from bulging? Hmm, that just might be

the best answer! Maybe I need to re-think cell construction.

Or has it got lots of pressure and the problem is

something else entirely? the cell went downhill after a couple of

weeks. Probably in this case it's zinc dendrites, since it doesn't have

anything to inhibit them or restrict their growth from the separator

sheet.

Positive Electrode Chemistry

[11th] I mixed a double batch (200g) in the above proportions. I gave

some thought to what the actual redox chemical reactions might be. I'm

going way out on a limb here, as I'm not a chemist and I haven't found

much info on "nickel manganese oxides" on line. In fact, I created the

page on Wikipedia and the first paragraph is what I wrote. Someone has

added a second paragraph about magnetic properties, but it doesn't

answer many of my questions. It may be that someone who knows the art

would have to use x-ray diffraction or similar technologies to actually

isolate the molecules. I'm only going to say that the small amount of

previous research I've found makes it look promising, and it's probably

more promising in salt electrolyte than in pH14 alkali.

Compounds seen in passing in the literature on line (mostly abstracts

of research papers hidden behind a paywall):

NiMnO3

NiMn2O4

NiMn2O(4+δ)

Ni6MnO8

Ni2MnO4

(derived from "NixMn(3-x)Oy")

Here I'm going to assume that the best ratio of Mn to Ni

atoms is 2 to 1, as in NiMn2... In water, I expect some of

the "oxide"

is replaced by "hydroxide" making it "oxyhydroxide". Nickel can have a

valence of +2 or +3, and manganese can be +2, +3 or +4. If we assumed

it was in a "maximally charged" (oxidized: Ni@+3, 2 Mn@+4) state, it

might be Ni2Mn4O11. Possible oxidation

states abound (Valence in Roman numerals):

XI - NiMn2O5OH

X - NiMn2O5 or (eg) NiMn2O4(OH)2

IX - NiMn2O4OH

VIII- NiMn2O3(OH)2 (or NiMn2O4)

VII - NiMn2O2(OH)3

VI - NiMn2O(OH)4

(Later I found a lengthy molecular formula with many variables showing

that the molecules and spinel crystal structure of mixed nickel

manganates/nickel-manganese oxides can be quite complex.)

I suggest that (a) the substance overall will probably

change valence states by 3 or 4 during charging and

discharging, and (b) that the changes will mostly be between O-- and

OH- ions, so the

spinel structured substances will be largely stoichiometric, that is,

they won't swell or contract much during charge and discharge.

Again these are only somewhat educated guesses. I don't

have either the costly specialty equipment (XRD, SEM, Raman

spectography, ICP emission spectrography...) nor the

training to use them to make definite assertions. The only

things I can say for certain so far are that the electrode successfully

charges and discharges repeatedly (unlike MnO2 by itself).

I had thought that the cell would be around 2 volts open

circuit, but that was a guess at a wild card and it turned out to be

quite wrong. The cell starts out near 2 volts, but after the nickel

hydroxide has been converted into nickel manganates it's under 1 volt.

But one very good plus is that with all the available

oxidation sates it probably has 200 amp-hours per kilogram of charge

capacity where nickel oxyhydroxide (in actual use) only has around 90.

In terms of overall energy storage, the lower voltage is more than

compensated for by the higher amp-hours.

Varsol (or Toluene?) Treatment of Separator Paper

I wetted one piece of the watercolor paper with varsol and

left another plain. When the one was dry I examined them under a

microscope, half on each side of the view, to see if I could see any

difference. The only clear thing was that I couldn't focus on both of

them at once. So I measured the thickness with a micrometer and found

that the

solvented piece was .45mm and the plain one .50mm. The solvent had

shrunk the thickness by 10%, probably uniformly through the fibers

within the sheet. So they were at least a bit more horizontally

oriented, which might explain why they seemed to stop the nano powders

from penetrating through.

If there was any lateral or longitudinal shrinkage it was

so little as to be unnoticeable. Later I measured another piece with a

micrometer and then varsoled it.

141.12mm / 141.50mm = 99.73% or .27% longitudinal shrinkage, and

78.63mm / 78.87mm = 99.70% or .3% lateral shrinkage.

Yup, not very significant.

Sodium Dodecylbenzenesulfonate (herein "SDBS")

On the 7th I opened an account with SigmaAldrich.com and

put in an order for SDBS that hardly anyone had for sale that I thought

I wanted. On the 14th they sent me an e-mail asking where was the

address that this would be used at? I had said to ship it (by personal

agreement) to Westpoint Auto Parts in town, since I was sure they

wouldn't ship to a rural or residential address. After a week I had

hoped the substance was already well on its way here, but they hadn't

shipped it yet! (At the end of the month I had still had no further

contact with them!)

In the meantime I had mentioned it to someone and he

mentioned "making a chromatograph" as a potential means to separate it

from the dishsoap. Apparently if one dissolves something like that in

water and puts a piece of paper sticking out of it, the water will wick

up the paper and the different substances in it will wick up to

different levels in the paper, making horizontal layers. Often the

substances are different colors, which gave rise to the misleading name

of "chromatography". (To me that sounds more like something to do with

color photography.) That sounded like the hard way to get not much of a

substance, but I looked it up and found "column chromatography" wherein

much more substance could be separated in a glass tube with a drain and

spiggot at the bottom, with some tricks involving a cotton wad, silica

and a solvent (water). I didn't have such a tube.

I

poured some of the "Lemon Fresh Sunlight" dishsoap onto a smooth

plastic plate tilted at a shallow angle (15°?), and poured on a

little distilled water on the sheet above it to push it down (as in the

column chromatography). When I came back some time later, the bulk of

the liquid had run down to the bottom and off the edge, making a pool

of soap on the counter. However, there were some trails of dried up

substance left on the plastic sheet that hadn't flowed down to the

bottom with the rest. Since SDBS is probably the highest molecular

weight and the least mobile substance in the dishsoap, I assume this

was the desired chemical. There was probably more in the residual

drying blob at the bottom of the sheet that hadn't run off over the

edge, but probably that was more mixed with other things. I scraped up

the (presumably more pure) trails with a small spatula and into a small

ointment jar. (It seemed to work in the cell.)

I

poured some of the "Lemon Fresh Sunlight" dishsoap onto a smooth

plastic plate tilted at a shallow angle (15°?), and poured on a

little distilled water on the sheet above it to push it down (as in the

column chromatography). When I came back some time later, the bulk of

the liquid had run down to the bottom and off the edge, making a pool

of soap on the counter. However, there were some trails of dried up

substance left on the plastic sheet that hadn't flowed down to the

bottom with the rest. Since SDBS is probably the highest molecular

weight and the least mobile substance in the dishsoap, I assume this

was the desired chemical. There was probably more in the residual

drying blob at the bottom of the sheet that hadn't run off over the

edge, but probably that was more mixed with other things. I scraped up

the (presumably more pure) trails with a small spatula and into a small

ointment jar. (It seemed to work in the cell.)

However, just about this same time I was starting to think

of my other abandoned negative chemie that didn't need an ion exchange

layer. It made higher voltage cells than zinc. Why didn't I try that

one again?

Metallic Manganese Negative Electrode

Mn(0) + 2(OH)- <==> Mn(OH)2 + 2 e- @~ -1.5V

[15th] Having just written about this chemistry again [above, December

in Brief], I recalled that I had finally understood and had solutions

to the problems I had been having when I was trying this chemie long

ago. As I have found from much experience, nothing says "it works

great!" until it is actually demonstrated to work great, but I think it

will. It's worth trying again. Compared to zinc, metallic manganese has

substantially more energy. It's about -1.5V instead of -1.2 (@ ph 13)

and its molecular weight is almost 20% lighter:

820 AH/Kg (zinc) * 1.189 (65.40/54.94 atomic weights Zn/Mn) = 976 AH/Kg

Zn: 820 * 1.2V (~ reaction voltage Zn) = 1104 WH/Kg

Mn: 975 * 1.5V (~ reaction voltage Mn) = 1464 WH/Kg (32.6% extra)

I looked over some earlier newsletters (TENews #67, 68, 73

...) when I had been experimenting with this chemie. Although zinc

powder had worked as a conductivity enhancement, it seems to me it was

a weaker choice, and that graphite should be better and lighter. I

formulated the following mixture to make a "half charged" manganese

powder electrode:

35g Mn (Manganese metal powder <325 mesh - Atlantic Equipment

Engineers)

56g Mn(OH)2 (Manganese Dioxide powder - common old dry cells, pottery

supplies ...contains 35g Mn)

5g CCB (Conductive Carbon Black - Barite World - or graphite

powder - art supplies)

3g ZrSiO4 (Zirconium Silicate - pottery supplies: purest is "Ultrox")

1g Sb2S3 (Antimony Sulfide - Fireworks "sparkle" pyrotechnics, eBay)

------

100g: 1g = 1%

Before bedtime I weighed these out and poured them all

into a plastic jar. I had to use Sb2O3. The 5 grams of CCB seemed to

have more volume than everything else put together, the Mn ingredients

being very dense. I labelled the jar and referenced it to this TE

Report #175. That's both electrodes now.

There was another possibility for a current collector than

zinc or graphite: expanded copper mesh. It could be in the middle of

the powders, protected by the overvoltage additives within it.

Including the terminal strip all the way up through the cell case to

the exterior, even if the additives there were poorly compacted -- or

within (say) epoxy paint.

Then I thought of graphite felt. According to an early TE

News (#73?) graphite didn't bubble hydrogen even without an overvoltage

additive. It was the lightest choice at about 4 grams (copper foil 11g;

expanded copper mesh 5g, graphite foil 8g; my piece of felt 3.85g) and

impregnating it with the powders mix would ensure high conductivity

throughout the electrode. I decided to try it. The hard part with it is

impregnating the powders into it. All I've ever thought of is vibration

- lots of vibration to percolate them in. How? And would they go in

evenly, or separate by density or particle size? Can one get 10 or 15

grams of the powder in? Only one way to find out! 10 grams of powder -

itself only 70 wt% active Mn atoms - in 4 grams of felt would be a

weight penalty of 7/14=50%, reducing the electrode to 732 WH/Kg. If one

could squeeze in 15 grams, that would be 10.5/19=55% Mn, 45% loss. 808

WH/Kg. Hmm, not so much difference! And of course these figures are if

all the Mn in the electrode is effectively utilized.

Ah... I suddenly (and finally, after many years of thinking

of using graphite felts and trying a couple of times) thought of a good

way to get the powders into the felts. Dang! I sold my buzzy "palm"

(reciprocating) sander 25 years ago, preferring the belt sander for

most everything. Now this would be a great special use for one. Turn it

upside down and strap a sealed box with the felt and powders onto it.

It's probably just the thing to shake them in!

And if they're sufficiently dense, I don't think there'll

be a need to pre-press it in a compactor. Just use the the alume clamps

and screw them down inside the cell, along with the plus side. At any

reasonable level of compaction, conductivity through the electrode

should be pretty much guaranteed by the conductive graphite felt.

...I wonder if that's the best thing to use for the plus side as well?

Wouldn't that make it simple! And the electrodes, having no solid sheet

inside, would automaticly be bifacial! One could stack as many

alternating electrodes as desired into a cell (with separators at each

face of course)! It doesn't matter if the current capacity of graphite

is lower: just add more plates to compensate and get more energy

storage at the same time. If this (or some other) "shakedown" idea

works well, using graphite felts - for both electrodes - seems like

both much the best and much the easiest-to-make idea ever! My head is

swimming in the possibilities!

(Conductive Porous Graphite Felt "Sigracell" - source "SGL Group - The

Carbon Company")

Finally I had the thought that maybe the MnO2 oxide should

be initially discharged to Mn(OH)2 for use in the negative electrode? I

wouldn't want it to passivate at electricly insulating valence 3, Mn2O3

or MnOOH, on the way down to valence 2. Hmm... Bedtime!

Copper Chloride

[16th] Seeing my hydrochloric acid seemed so impure, I drove to Masset

where Co-op home Center said they had some and bought a new bottle. I

cut 3 more felts and a couple of separator papers, which I also

varsoled. I tried to order a "King Canada 1/4 sheet palm sander" from

Rona's web site but it said "can't ship to your area". WTH? I think

postal "flat rate boxes" are shipped anywhere in Canada for the same

price. I'll check to make sure before I contact Rona's customer service

to complain about discrimination. I inquired and was told that Haida

Gwaii was listed by Canada post as a "remote location", which term

usually means that all mail has to be flown in and costs more. Instead,

we don't have any air mail here and all the mail comes by ferry (3

times a week). It just means that stated delivery times are not

guaranteed. But stores have us on their "extra cost, do not ship" list

- despite there being no extra cost.

[17th] I dumped some

copper

oxide into some of the new acid and added

some water. There was still some black oxide in the bottom and I left

it and went into town. When I came back it had dissolved, and I set the

beaker of green liquid on the woodstove to evaporate off the water. It

left a brown powder: CuCl2 anhydrous. Turns turquoise in water per

Wikipedia. (Hmm, it didn't take long. When I went to get a picture it

was already dry!)

[17th] I dumped some

copper

oxide into some of the new acid and added

some water. There was still some black oxide in the bottom and I left

it and went into town. When I came back it had dissolved, and I set the

beaker of green liquid on the woodstove to evaporate off the water. It

left a brown powder: CuCl2 anhydrous. Turns turquoise in water per

Wikipedia. (Hmm, it didn't take long. When I went to get a picture it

was already dry!)

I put a little in the cell, into the electrode hole with tweezers. If

it made any differenceto maximum currents it wasn't apparent. Maybe

I'll try more some time.

Vibrating Electrode Powders Into Graphite

Felt

Vibrating Electrode Powders Into Graphite

Felt

In town I chanced across a woodworker, Gary. He had an old vibrating

"1/4 sheet palm sander" that he didn't use any more (having two newer

ones). I bought it for 10$.

At the Farmers Market I had a talk with Neil, member of an

off-grid farming family, about batteries and someone he knew in

Tennessee who made diesel fuel from wood with graphene as a waste

product. The graphene was supposed to be 10 times as conductive as

copper and when Neil had seen the plant (10 years ago now), they were

trying out conductive plastic for 3D printing and using the graphene

for circuit breaker contacts.

It sounded like it might be a good replacement for

conductive carbon black or graphite powder to improve conductivity

inside the electrodes.

I got a contact name. "Proton Energy".

(But the question is: What is actually causing low current rates in my

cells? Does it have anything to do with the conductivity of the

electrodes? Or is it the electrolyte? or what?)

Another view

Another view

In the

evening

I made an ABS box to mount onto it. Basicly it was my battery cell box

with no terminal openings. For a lid I saw a 1/4" thick piece of

acrylic plastic that just needed one cut to fit it - a clear lid!

In the

evening

I made an ABS box to mount onto it. Basicly it was my battery cell box

with no terminal openings. For a lid I saw a 1/4" thick piece of

acrylic plastic that just needed one cut to fit it - a clear lid!

Weatherstripping foam around the edges should keep it

closed. (If it's not sealed, this is likely to be a very dusty

operation.

The box on the "vibro"

The box on the "vibro"

I'll mount it this way up in the big vise, with the box level.

It'll need some special little C-Clamps to hold the box in place.

Loading the box: conductive

felt plus active

electrode powder.

Loading the box: conductive

felt plus active

electrode powder.

Assuming it works well,

there will need to be two boxes and lids, one for minus 'trodes and one

for plus, so as to not cross contaminate them. I'll know when I've

tried one whether to make the second or if the idea doesn't work well.

[18th] I started thinking that zinc is known to perform really well,

while manganese is still poorly tested. It would seem I could now make

a nickel-manganate zinc cell, and I had the zinc electrode in the

drawer. I could try impregnating one felt with the positive mix and put

together a cell. Hopefully it would perform better than

previous attempts with the graphite felt to improve conductivity in the

positrode, and maybe some copper chloride in the electrolyte?

I dissolved the SDBS in some water and painted it

onto/into a piece of the watercolor paper separator. It absorbed it

all. Then I went to bleach the nickel & manganese powder. The 100

gram jar of it needed somewhere over 1/4 liter of water, and I used 1/2

a teaspoon of bleach. Then I tried to stir it and it was still full of

lumps of the dry cell manganese. It took quite a while. If I ever use

dry cell MnO2 again I'll be sure to crush it up well into powder before

I mix it in with anything else. Finally I had a jar of soaking wet

stuff. If I poured it through a filter the nano-fine powders would have

clogged the filter after about 3 drops of water. I waited over an hour

for it to settle and poured off only 75cc of water - surely only 1/4 of

it, leaving a slurry. Evidently diluting out soluble impurities from