Turquoise Energy Report #176

Covering

January 2023 (Posted February 12th 2023)

Lawnhill BC Canada - by Craig Carmichael

(CraigXC at Post dot com)

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

- Magnetic Variable Torque Converter for ZX40 truck - Soldering

Alume: Wow, easy! - Another Peltier Module Heatsink Idea - Battery

chemie, design, experiments... not without some Success - Living Titan

(the planet orbiting Saturn)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Scattered Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Magnetic Variable Torque Converter with Planetary Gear: The

Future of the Automotive Industry! Assembling/Installing one for

Miles Truck: Almost working.

Other "Green"

& Electric Equipment Projects

* Indoor & LED Gardening

* Plastic recycling 2.0 - No smells at 500° in kitchen oven; PETE

failure; PE Bleach bottle melt... not long enough in the oven.

Electricity Storage:

Batteries

* Oodles of eperiments: Gelled Co(OH)2 + Zn Salt Cells - Theoretical

about cobalt & its

oxides - Didn't work as expected but the lower voltage redox reaction

that does work has double amp-hours: 3 to 5 times the amp-hours of

nickel! - Cobalt electrode conductivity additive: copper powder - Zinc

grit from alkaline 'D' cells - Super lightweight "packaging tape" cell:

over 100 WH/Kg - 35 WH rechargeable 'D' cells? - A Ni-Zn cell

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

The day after posting my lamentations (under "batteries")

that I couldn't seem to get a good camera, I went to the thrift shop in

town and got a great Fuji camera for 2$ that takes fabulous, sharp

pictures at any focus/distance. I just had to put in an SD memory card

and four new AA batteries. (Ni-MH rechargeable, of course. And I had 4

crappy cameras to donate to the thrift shop!)

What were my project priorities for the month? Although

the 6mm shank router bits had arrived, I decided to set aside the

project of making a magnet placement jig for the new motor project. I

had been working on new chemie batteries for two months, had a new idea

or two, and I decided they took priority.

On the 14th the bearing for the truck arrived - presumably

the last piece needed to make the "road-worthy" version of the magnetic

variable torque converter conceived last August which "jury rigged"

experiments in September had shown seemed to work so well. But there's

always plenty to do and I'm trying to avoid plunging off in all

directions so I stuck with the battery experiments.

Then on the 28th my friend Tom called from Victoria. There

was a second Miles ZX40 truck sold later by Burnaby Repo [.com] back in

2017 which my friend Jim had purchased, charged up and sold again. (It

went for a song - 1800$ or something. I had paid way over 5000!) Tom,

who is now really into making battery packs for electric vehicles, was

working with the person who bought it from Jim to make it an effective,

roadworthy vehicle. I had told him that the magnetic torque converter

would make it fantastic. Apparently they've been waiting for me to get

my Miles truck working to see how it goes! So I decided I'd better get

back to doing the truck. I thought I'd have it going very early in

February so I put off doing this newsletter pending that, but success

was elusive mostly for readily solvable mechanical reasons.

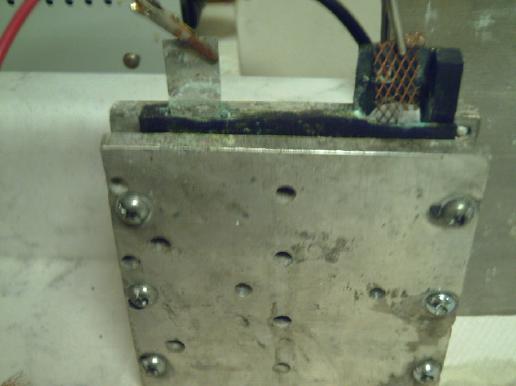

Magnetic Variable Torque Converter/Miles Truck

Wooden housing to avoid

interference with

magnets (to be well epoxied, and closed off from road dirt)

Wooden housing to avoid

interference with

magnets (to be well epoxied, and closed off from road dirt)

RIGHT to LEFT: * Curtis AC35(?) 72 volt, high RPM induction motor

- with splined socket shaft

* Motor end of motor-to-planetary-gear shaft (just visible) - turns

alume disk & sun gear

* Plywood wall holds bearing to steady the long shaft

* 10 inch Alume rotor/disk - spins with motor

* 10 inch Magnet rotor (from a brake disk) - Hallbach configuration -

spins with planetary gear body

* 10:1 magneticly spun planetary gearbox

* Black metal "U" bracket strap holds rear end of housing up to truck

frame (Motor holds front end)

* Front end of drive shaft to rear differential, a socket fitted to

planetary's output shaft (planets assembly)

* Drive shaft, U-joint & with safety guard so if it somehow slips

off, front of drive shaft can't drop to ground.

(I don't think there's any way it can possibly come off, but if somehow

it dropped it could "pole vault" the rear axle of the truck.)

Almost at the end of the month I finally got back to the

magnetic variable torque converter. I had hoped to quickly have a

glowing report about first tests of the "working model" to put the

truck on the road, even tho it isn't finished. Alas things didn't go as

planned. First the join between the output of the planetary gear and

the rear drive shaft started slipping trying to go up slope, and took a

day or two to fix once I realized what all the vibration was.

Then it seemed to work better for a bit until I pressed

too hard on the pedal. I thought the input shaft junction was

now slipping. I have found it to be a frustrating join because it has

only one allen screw and a clamp affair that is supposed to clamp

around the skinny 19mm input shaft. No key slot, no splines, nothing. I

had roughened up the shaft before I put it together to make it

un-slippery. How hard can one reef on a 6(?)mm screw with a vise grip

on the end of an allen wrench before something strips? How is it supposed

to work? By the 6th of February I finally gave up.( If I had a paved,

level driveway instead of lumpy gravel slopes and grass I'd have had at

least something good to show. Instead, just doing a loop around the

driveway is a challenging mechanical test!) The first and longest test

ended up with the truck finally only going level or downslope and

having to be levered uphill by hand, with a peevee and planks, just to

get it back in front of the garage.

Then I remembered (duh!) there was one more component that

can slip: the alume rotor. The SDS taper lock hub had no shaft key. I

had tightened it pretty well, but not to the ultimate - I thought I

might want to adjust the position. But the plywood wall to hold the

bearing was now in the way of tightening the bolts. I thought to go

under the truck and tighten its set screw. That might just do it. But

it was between the two rotors and needed a really long allen wrench.

The only way to get that was to put a magnetic bit in a long

"screwdriver" handle. And the magnet that held it in wasn't nearly as

strong as the rotor magnets. After a couple of tries, and fishing out

the allen bit with forceps, it got around behind a magnet and I lost

it. It might jam between disks and break magnets, so I now do have to

remove the whole thing to get at it. That ended any hope of having it

running well for this report, even well into February.

A second and perhaps more troubling problem is that the

alume disk got too hot on the longest test. Clothes ironing hot. I

could smell it from in the cab. The whole thing should be high

efficiency once the vehicle is up to driving speeds, but at high torque

at "crawl" speeds trying to go upslope in a lumpy driveway it's much

lower. And whatever loss there is, however small as a percentage,

mostly goes straight into heating up that disk. (But it might also be

heating from friction if it's slipping.)

I had initially realized that it might need a heatsink -

perhaps two or three finned heatsinks spinning on the back of the disk,

but I neglected to make a place for them in the design of the housing.

I found 3 small heatsinks I had bought for LED COB lights. Those would

probably do it since the spinning disk would move a lot of air past the

fins, and I think I'll be "proactive" and add them to the design rather

than have to change it later.

If the disk does get pretty warm in normal driving, one

might profitably put in ducts and a fan from the rotor space to the

cab: could be good supplementary "free" heat for windshield defrosting?

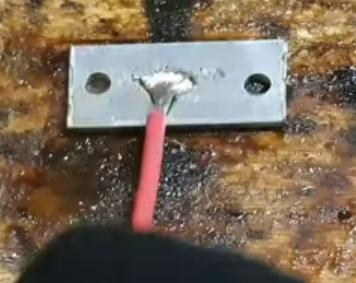

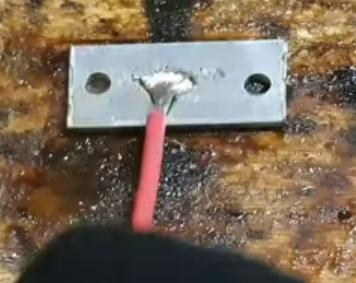

Soldering Alume - Wow, easy!

You've been told it can't be done? You've tried and never

been successful? I guess nobody told this Russian guy (youtube channel

"Lithium Master"). He showed how to solder to aluminium, with a regular

soldering iron (60W)

and solder. He was a bit surprised that people said he should make a

video about such a simple thing!

The first

trick is to put a drop of

oil on the spot to be soldered. He used motor oil but said any, even

olive oil would work. That's the flux! It keeps oxygen away from the

surface. The surface of alume oxidizes in an instant in air, a one

molecule thick layer, and that's what prevents soldering to it.

The first

trick is to put a drop of

oil on the spot to be soldered. He used motor oil but said any, even

olive oil would work. That's the flux! It keeps oxygen away from the

surface. The surface of alume oxidizes in an instant in air, a one

molecule thick layer, and that's what prevents soldering to it.

The second

trick, after getting it hot, is to rub it (quite a

bit) with the soldering iron as you tin it. This scrapes off the

existing oxide layer to expose the actual metal to the solder. After

tinning a spot on a small plate of alume and a fat stranded wire, he

soldered the wire to the plate.

The second

trick, after getting it hot, is to rub it (quite a

bit) with the soldering iron as you tin it. This scrapes off the

existing oxide layer to expose the actual metal to the solder. After

tinning a spot on a small plate of alume and a fat stranded wire, he

soldered the wire to the plate.

When it was

cool he pulled and twisted until the wire actually broke - the solder

joint and the ends of the wire

stayed put on the plate.

When it was

cool he pulled and twisted until the wire actually broke - the solder

joint and the ends of the wire

stayed put on the plate.

BTW in the comments some said the technique hadn't worked

for them. I suspect from what was said that they were trying to solder

anodized alume, which has a very thick layer of oxide. You would have

to sand/grind it down to the metal first. OTOH perhaps some alloys

might not work.

(I wonder if you can solder to stainless steel with this

method? or to zinc?)

I tried it

myself, with the soldering station set to

600° and the big tip on it, and a small piece of alume. (I usually

use 400°, but I figured the Al sheet would conduct much heat away.)

Sure enough - worked great - solid join! There was

some smoke from the machine oil. Maybe olive oil next time?

I tried it

myself, with the soldering station set to

600° and the big tip on it, and a small piece of alume. (I usually

use 400°, but I figured the Al sheet would conduct much heat away.)

Sure enough - worked great - solid join! There was

some smoke from the machine oil. Maybe olive oil next time?

Another Peltier Module Heatsink

Idea

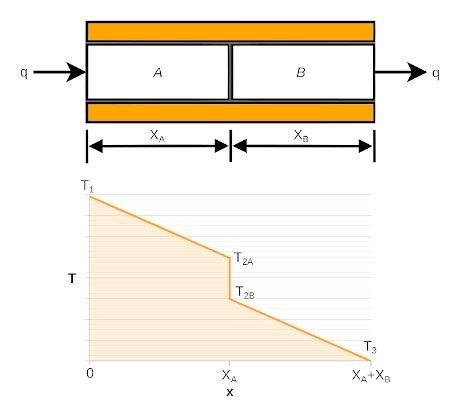

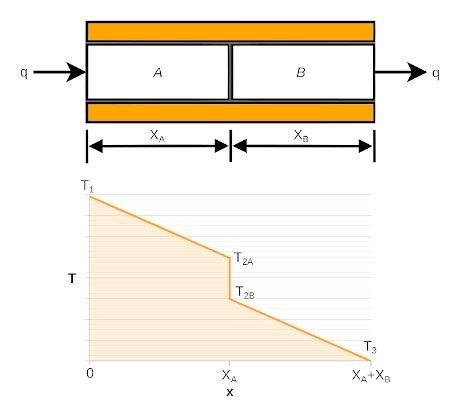

The above brings to mind, as I have noted, perhaps ad nauseum, that one

thing that degrades the

performance of Peltier modules is the loss or gain of temperature

at the junction between the body of the module and the heatsink, and

here's an

illustration I found.

The above brings to mind, as I have noted, perhaps ad nauseum, that one

thing that degrades the

performance of Peltier modules is the loss or gain of temperature

at the junction between the body of the module and the heatsink, and

here's an

illustration I found.

The closer in temperature the two sides are, the higher

the COP and the lower the heat transfer across the module. If you want

to cool a cooler by 15°, and 3° is lost on each side before the

heatsinks "T2A to T2B" times 2),

the module has to cool by 21°. That's just for starters of course.

Then there's the heat loss/gain going through the heatsinks: "T1 to

T2A" for two

heatsinks, and the final temperature of the heatsink fins (T1)

above/below the air temperature, which is mostly mitigated by fans.

To be complete the picture there's the loss/gain "T2B to

T3" from the actual components within the module to each ceramic

surface. (the Peltier manufacturer's concern!)

In my homemade "superinsulated" Peltier module fridge I was freezing

the ice tray through the copper bar (Cu = lowest junction heat gain)

and a second junction from the bar to the alume tray of water (but this

one with much more surface area than the Peltier module). The outside

"hot side" alume alloy heatsink was often around 35°. So the module

was probably about 40° between sides - with the bulk of the "extra"

5° being the module to alume alloy heatsink junction. 40° (when

you're trying to cool by only 20°!) leaves a lot of room for

improvement. Every degree counts until you've made the fan(s) too noisy

and so the unit is put aside or discarded by the user.

Now, if I could solder copper to alume over a broader

area, I could make the heatsink for Peltier modules have a lower

junction

temperature between the module and the copper section of the heatsink,

without

creating a second high thermal resistance junction where the two metals

meet. The trick would be tinning the heatsink over that large area so

the copper would thermally bond as well as just electricly.

Some had suggested in the alume soldering video's comments

putting oil

on and then wire brushing it before heating. Perhaps that would allow

tinning the required

broad area?

Here are some thermal conductivity figures I dug up

on line. (Presumably valid at or around room temperature.)

Boron arsenide (BAs): 1300

W/m*°K -- Looks tricky

Diamond: 1000 -- but can this

help us? (Graphite: 1000 'along the grain'? see comments below.)

Pure silver: 418 -- Most conductive element

Pure copper: 401 -- almost as good, cheaper, not quite as heavy

Pure Alume: 237 -- a big step down but cheaper and lighter than

copper. Soft and easily bent.

Al - 6160 T6 alloy: 167 -- the worst one - and the one usually used for

heatsinks. Another big step down. Fine for preventing transistors from

cooking. Not good for Peltier cooler COP! Substantially harder than

pure alume.

Thoughts on those best ones... We can't make a BAs or diamond heatsink.

Hmm... Diamond powder on copper? But that doesn't expand the surface

area from the Peltier module. A substance called boron arsenide (BAs)

is rated as 1300 - much more thermally conductive than any single

element! It turned out that was for a pure, flawless crystal, so unless

huge flawless crystals can be grown, like the diamond it is of little

use for peltier modules. (Unless again it could be made as a flat

powder "sheet", fused to copper.)

Looking for "boron arsenide powder", it is in fact

available. Perhaps (if it is quality crystals, however tiny) it could

be used as, or in, a heatsink compound in place of silicone compound,

flexible graphite or graphite powder, to make a better thermal

connection between the ceramic surface of the peltier and the heatsink

itself. But...

Graphite Heatsink?

Then again, graphite sheets are rated at 1000 W/m*°K

along the grain similar to diamond, although they are much lower (said

to be 1% as much?) between layers. Exactly the wrong way! Still, with

flex graphite gasket one can feel rapid heat transfer through the

thickness as if it was a metal like copper, so I think the 1% is a

mistaken or at least misleading figure at least for that material.

Anyway a thin sheet of flex graphite seems to conduct heat between

module and metal (across the grain) better than silicone heatsink

compound. (And it's not ucky!) Hmm... What about graphite sheet

heatsink fins?... could they be better than alume? or copper? and flex

graphite is really lightweight! What about a whole flex graphite

heatsink? Maybe with sideways stacked sheets bolted together so the

module's heat is going up along the grain to yield that "1000" figure?

At least in theory that could be much better even than copper! Oh dear,

this train is picking up speed... time to jump off! (For now!)

Battery Chemies

Despite having discovered several chemical "firsts" or

"bests" for batteries over the years including this latest, all my

cells are still plagued by very low current capacity. Other problems

were leaks of electrolyte and material getting around the edges of

separator sheets causing electrical paths between electrodes and

preventing them from holding their charge.

By mid month I was almost ready to think of giving up on

the possibility of making workable batteries. Voltage readings

suggested that the bottleneck was likely to be poor conductivity

through the positive electrodes. (Seemingly no matter what I made them

of!)

But there must be answers. And additional chemical

possibilities seem to be presenting themselves. So I'll persevere.

(After all, Edison spent over 30 years on battery research before he

came out with his successful alkaline nickel-iron 'pocket electrode'

batteries first in 1908 - I saw a picture of a lab note of his from

1875.)

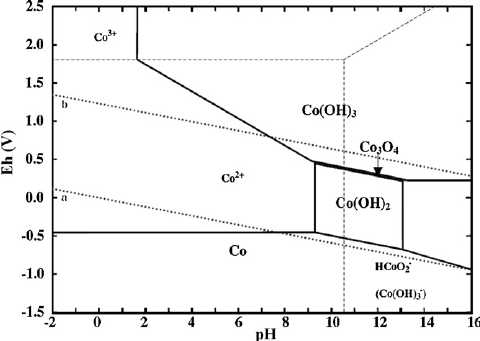

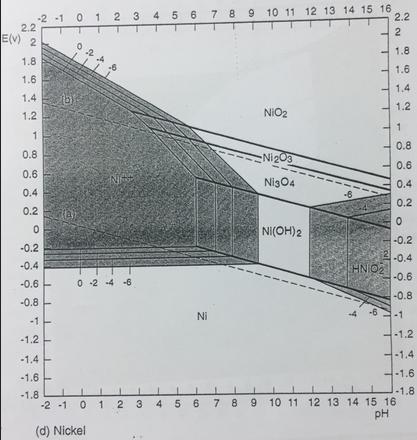

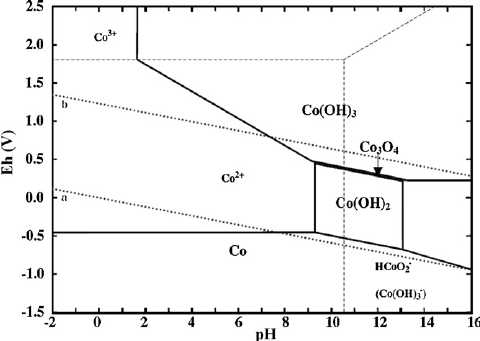

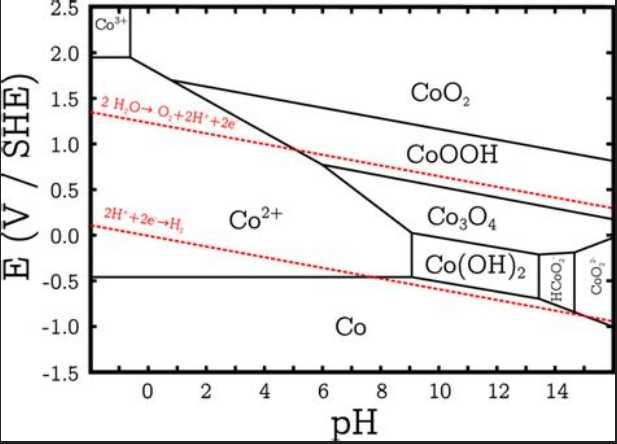

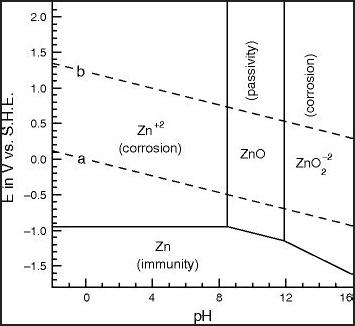

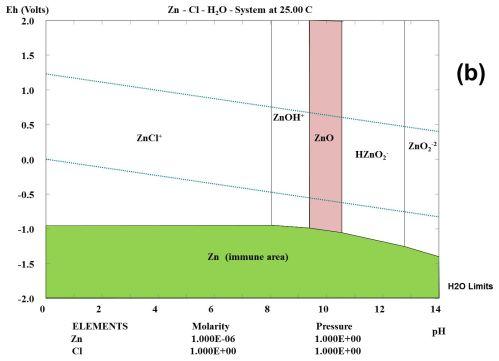

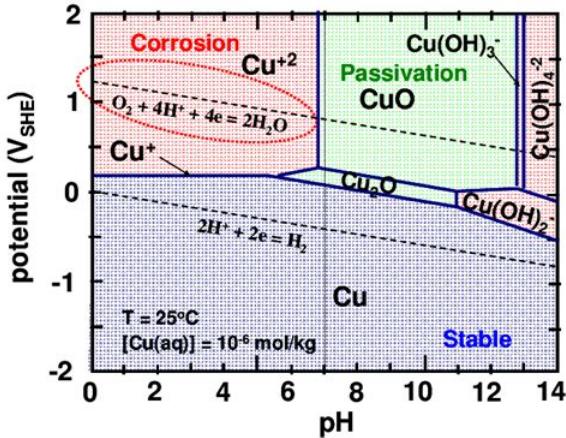

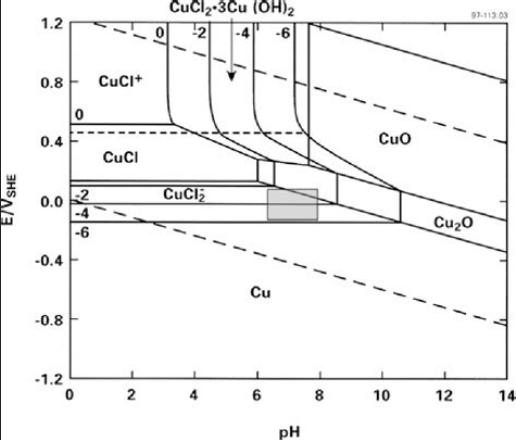

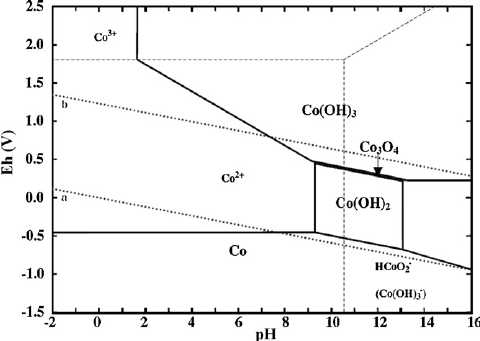

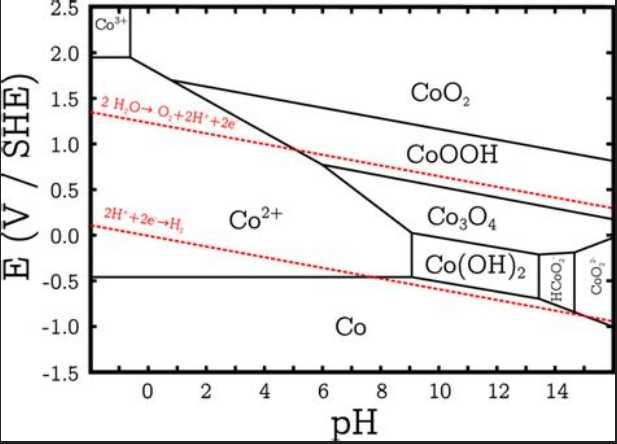

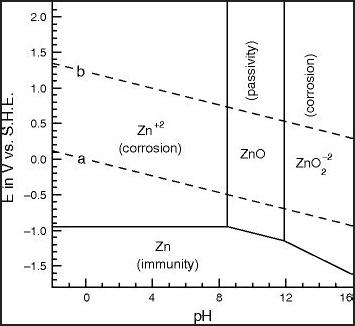

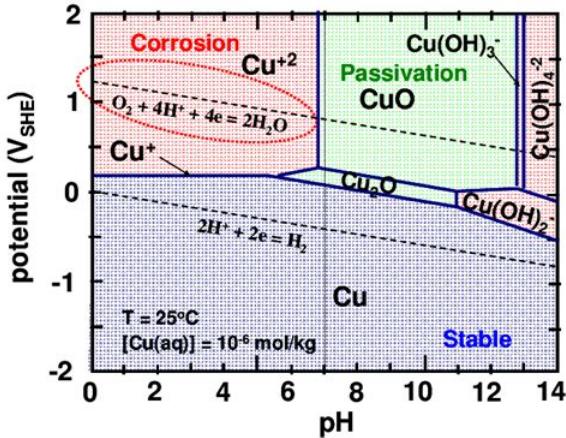

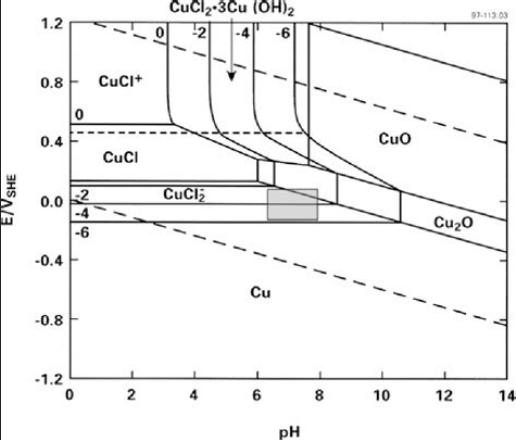

Looking at some Pourbaix diagrams I conceived that cobalt

oxyhydroxide CoOOH or "Co3O4" and Co(OH)2 could make a great electrode

- better

than nickel oxyhydroxide NiOOH. Puzzlingly (at least to me) neither of

the indicated redox reactions seemed to work. It just didn't hold the

expected charge. Is that why no one has used cobalt, or was I

doing something wrong? But the

lowest voltage reaction, between Co(OH)2 and metallic cobalt, did work.

Looking at some Pourbaix diagrams I conceived that cobalt

oxyhydroxide CoOOH or "Co3O4" and Co(OH)2 could make a great electrode

- better

than nickel oxyhydroxide NiOOH. Puzzlingly (at least to me) neither of

the indicated redox reactions seemed to work. It just didn't hold the

expected charge. Is that why no one has used cobalt, or was I

doing something wrong? But the

lowest voltage reaction, between Co(OH)2 and metallic cobalt, did work.

Cobalt-zinc cells made that way would be under a volt, but

this reaction moved two

electrons per reaction instead of one, so it was double the amp-hours

of the other two reactions together. And the metallic form should be

highly conductive for high currents. Despite the seemingly ridiculously

low

voltage, this would mean that far less cobalt was required to balance

the

zinc's amp-hours: it would take more cells to attain a given voltage

but each cell would store more energy instead of less - an overall gain

in watt-hours per kilogram.

In checking out redox

potentials of some elements I realized I could use copper powder as a

conductivity enhancement for the cobalt hydroxide electrode. With the

low reaction voltage it wouldn't turn to copper oxide and dissolve.

Could that turn tens of milliamps into amps, the required two orders of

magnitude improvement in current capacity?

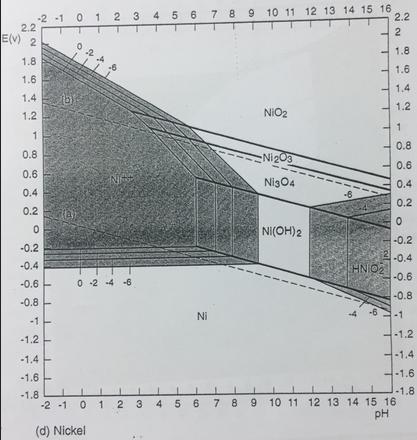

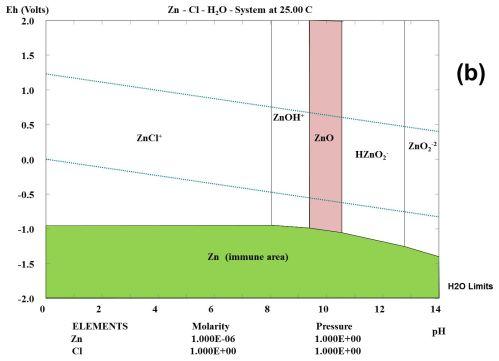

The Role of pH

I tried copper chloride as a potentially better

electrolyte than potassium chloride, and discovered that it has an

acidic pH rather than neutral. One cell with no calcium hydroxide ended

up having an acidic pH and I'll have to try cobalt over again. I

finally realized (after all these years) that pH can play an important

role in making different substances and chemistries work well in a

cell. (For example the cobalt diagram above shows that cobalt oxides

should be most stable at around pH 11... although they are added to

nickel oxide cells to enhance conductivity at pH 14, which is not

intuitive.) I read up on "pH buffers". By using the basic calcium

hydroxide and acidic copper chloride, the cell's pH can be somewhat set

into a desired range and not drift too much.

Since it was discovered that nickel metal, and only

nickel, won't oxidize at pH 14, everyone went with caustic KOH

electrolyte and different pH'es for cells seems to be an almost

unstudied area of battery research.

And yet, from

appearances, even nickel oxides should work better at a lower pH than

14 - eg at 10 or 11.

And yet, from

appearances, even nickel oxides should work better at a lower pH than

14 - eg at 10 or 11.

After a couple

of different cells and chemistries with perplexing results, near the

end of the month I made a nickel-zinc cell just because I know the

combo works, and the sodium dodecylbenzenesulonate in the separator

sheet should stop zinc dendrites from sooner or later shorting out the

cell. (usually quite soon, in my experience.) Except for leaking around

the edges somewhere and having to keep adding water it continued

performing about the same for a couple of weeks after gradually

improving some during the first few days. Stability!

After a couple

of different cells and chemistries with perplexing results, near the

end of the month I made a nickel-zinc cell just because I know the

combo works, and the sodium dodecylbenzenesulonate in the separator

sheet should stop zinc dendrites from sooner or later shorting out the

cell. (usually quite soon, in my experience.) Except for leaking around

the edges somewhere and having to keep adding water it continued

performing about the same for a couple of weeks after gradually

improving some during the first few days. Stability!

Then I decided to take it out of its ABS

case and just wrap it up with packaging tape, to cure the leak. That

seemed to get some material crossing an edge of the separator sheet

somewhere and it didn't work right after that. Sigh!

Then I decided to take it out of its ABS

case and just wrap it up with packaging tape, to cure the leak. That

seemed to get some material crossing an edge of the separator sheet

somewhere and it didn't work right after that. Sigh!

I now have in mind a design

where the separator sheets are sandwiched between two 3D printed

bevelled "bread crust" edge pieces with no solid front or back, with a

small water reservoir and filler hole incorporated at the top so one

knows if the cell is drying out and can refill it. (Hopefully not more

than every few years!) The separators can even stick out the edges a

bit instead of being precision cut. The whole will be wrapped with

packaging tape as the body of the cell. (If it leaks, add some more

tape!)

Assembly would go like this: The rear "bread crust" is set down on

packaging tape and the rear current collector is placed in the cavity

thus formed with its tab coming out an indent in the crust. Then the

electrode powder/material goes on that, making sure it doesn't cover

the top of the "crust" anywhere. Then the prepared separator sheets are

placed on top, then the top "crust" goes on to form a cavity for the

front electrode. The "crusts" should be taped or pinned together to

prevent any material from seeping in toward the edges of the separator

sheets. Then the top electrode and current collector are placed, then

it's all wrapped with the tape to seal it. The height of the edges can

be adjusted so that when the electrode materials are compacted in the

clamps, there's still a slight bulge rather than the edges limiting the

pressure on the materials.

And maybe I'll make the cells taller yet, with thin (3D

printed integral) cross braces from left to right to keep the edges

from bulging. Nothing like size and more material to boost capacity,

and that would work without making them any more complicated or making

the electrodes thicker. (If they were wider as well as taller, the 1/4

inch thick alume clamp plates would probably bulge, losing compaction

in the middle area. But "any" height should be possible.)

The whole idea of being able to clamp a cell or a set of

cells between two alume plates certainly gives freedom of design for

flat plate cells, and takes away the need for strength of the large

flat front and rear surfaces of each cell itself. (I wish I had figured

this out long ago!)

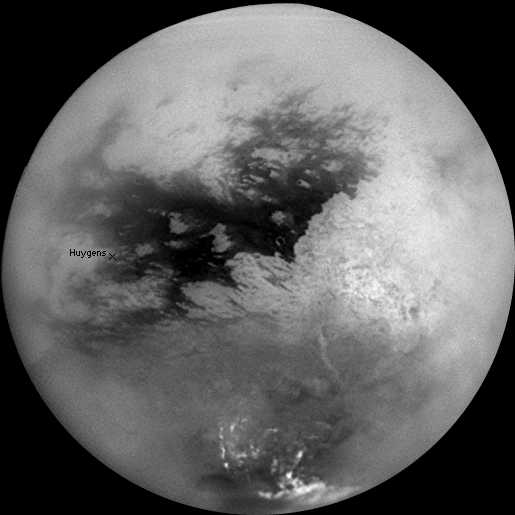

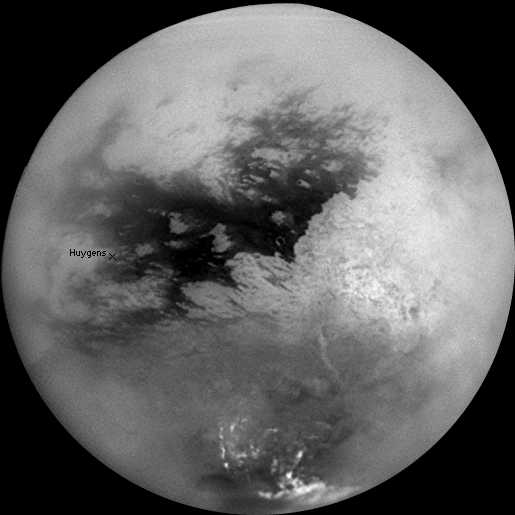

Living Titan

I finally made a start of putting back together my

"Sears.com" website after Niklas Saers, having become a computer

professional, changed the whole site to his now more mature,

professional liking and deleted all the stuff everybody else had posted

over the last 22+ years.

I got only as

far as a pile of editing of my work Living Titan (2005 -

2006) about what the Cassini-Huygens mission was finding on

this astonishing and previously unknown world somewhat smaller than

Mars that orbits Saturn.

I got only as

far as a pile of editing of my work Living Titan (2005 -

2006) about what the Cassini-Huygens mission was finding on

this astonishing and previously unknown world somewhat smaller than

Mars that orbits Saturn.

It's covered

with immense forests of giant trees, and with aquatic vegetation of a

scale unknown on Earth growing in the shallow tidal-flowing seas, lakes

and rivers of liquid methane. The low-rez monochrome and radar images

that were returned don't make these facts jump out at the casual

observer. I couldn't bring myself to just throw this "book"

back on line as it was in 2006, since the Cassini mission had continued

on for several more years and more exciting and revealing things were

discovered. And in editing I could correct some of my own early

mistaken or distorted impressions.

Earth life wouldn't last five minutes at Titan's

temperatures. That seemed to blind the mission's space scientists.

'It's like a deep-freeze Earth that must be how Earth was before life

started.' they kept saying like a mantra. They ignored "inconvenient"

instrument

returns that didn't fit their preconceived ideas. Somehow benzene,

amino acids, proteins and polycyclic aromatic hydrocarbons were just

organic "tholins, left over from the formation of the solar system."

They utterly misinterpreted the whole amazing scene that a few months

of study gradually opened my eyes to. Every new "mystery" that was

reported, every unexpected or "inexplicable" finding, the images and

radar returns, all fit right in with an Earthlike and yet very

different world, covered with alien vegetation. And many things in the

mission one after another besides Titan kept diverting scientists'

attention.

For a while they even claimed that Titan had no liquid methane!

Last I heard they were still saying that the shallow equatorial

seas so obvious in the images and SAR radar findings from both Cassini

and Huygens and reported by other instruments as well, are dry land!

How then could they see the totally unexpected verdant

plant life? The profuse aquatic vegetation itself explained why they

didn't see the reflections they had expected to get from open liquid. A

few emails with some of them revealed how closed-minded they were. And

I heard that they would never disagree publicly, whatever differences

they had in private.

One suspects that if there's plant life there are also

animals. But looking down on the Amazon rainforest from a distance,

does one expect to see monkeys and otters and birds? or just a forest

canopy? And I didn't see any sign of human works. The vegetation is all

I'm sure of.

Yet, for all the hours I put in this month and all the

details I added, the writing is still rather helter-skelter,

disorganized. I could spend weeks making it into a nice, well organized

book. I don't seem to have time. (Feb. 10th: I can't even seem to

finish this monthly report!)

Living Titan

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Scattered

Thots

*

We know that cutting down forests causes droughts. A mechanism has been

found that helps to explain this better than was previously understood.

It seems trees release "turpines" into the air. These give for example

the "fresh" smell of a pine forest. These also act as condensation

nucleation sites which help to form clouds and foster rain. In other

words, trees do their own cloud seeding. [from SciShow on Youtube.] So

the more forest is cut down, the more droughts are likely to occur.

* I had started keeping track of how much Sumatriptan I was using for

migraines, being quite susceptible to them all my adult life.

Sumatripan and occasionally Cambia have made life far more livable for

me than it used to be before they were created and somebody finally

told me about them. I was hoping one package of 6 pills per month would

be plenty. By almost the end of January I had only used 3 pills from

the December package. Then suddenly it was one migraine after another

until by February 8th I had used all 9 of the remaining December and

the January pills, sometimes half a pill, once 3 pills in two days.

They're great, but definitely not as good as simply not having a

headache.

What was it? Bad bananas? Bad cheese? Maybe the ice cream

(which package I had been eating from for months without ill effect)?

Maybe the mayonnaise had suddenly gone off? or the mustard? (I didn't

think mustard went off?) None of it seemed likely except maybe the

cheese - I had bought three small packages "on sale". I would open one

and use some then slice up the rest and put it in the freezer (with the

date [and for these, "??"] on them. I was keeping my coffee pot &

dishes clean and had a fairly new filter in the Britta pitcher. I

dumped the mayonnaise in the compost (needlessly it turns out) and

finally had stopped eating everything else on that list, and still was

getting continual headaches. What could it possibly be?

Finally it occurred to me: I was having a handful or two

of trail mix every day, just like usual except that I had opened a new

package and dumped it in the jar. I don't remember but it wasn't one I

usually bought... "Vitality Mix" or something? It had a slightly

unusual flavor. That had to be it! What in God's name could somebody

put into trail mix that would cause migraines? That odd

flavoring, no doubt. By this time I had eaten much of it. I dumped the

rest in the compost. That was one expensive little clear PETE box of

trail mix, both in terms of expense and health! The headaches stopped.

* And there is just one of many things unknowingly affecting our

health. We suffer, never suspecting the cause and sometimes die. Some

of the worst are well known, like scurvy is lack of vitamin C. Others

are known but not well known or taught in school as I think

they should be: Vitamin D cuts the chances of getting cancer at least

in half. Arthritis and osteoporosis are caused by boron deficiency.

Most thinning hair and baldness is [surely] caused by "microscopic"

Demodex Folliculorum mites on the scalp. Drinking too-hot liquids can

cause esophageal cancer (and I knew someone who always sipped boiling

hot tea while having life threatening esophageal problems and doubtless

died from it). Homogenized milk goes through blood vessel walls and can

clog arteries. (and I met someone who was proud of drinking a glass of

milk a day and who had life threatening calcium buildup in his

arteries. The doctors were about to operate... and surely all he had to

do was reduce or eliminate his milk intake!)

There are probably dozens of health things overall that

are worth learning about, except that "we don't know what it is that we

don't know" in order to find them out. And then there are the things

that would better everyone's health and lengthen our lives that just

haven't been discovered yet. They say the first person who will live

150 years is alive today. How far have medicine & health come in

150 years? By the time he is elderly still more things related to

living longer, healthier lives will be known!

* Population of Ukraine: 1990, 52 million; 2020, 44 million; 2022, 37.5

million. Millions had already fled the corruption and nazification

since the collapse of the Soviet Union and by 2022. Crimea and the

Donbass (including 1/3 of Ukraine's military) effectively split off

after the coup in 2014. Since the start

of the war another 10 million have fled mostly to avoid being drafted

into the AFU (which is considered a death sentence) and 4 million of

the population live in the Donbass, Zaparojjia and Kherson (portion

East/South of the Dnieper), which are now in Russian hands, leaving

only

an estimated 18 to 22 million in Ukraine proper.

So here's a peaceful solution: Instead of trying to win

the Eastern regions back by throwing 16 year olds and younger, and 55

year olds and older, into bloody battle against hopeless odds and

then trying to coerce the 4 million mostly Russian speakers

there to abandon their homes and flee to some other country as

refugees, just invite all the 10-20% Ukrainian speakers in those areas

to move to vacated dwellings in the rest of the country. Let the

largely Russian speaking areas join Russia or become independent, and

sign some agreement to

end the war. There must be plenty of lebensraum in most of Ukraine now!

(Of course, while Russian has been banned in Ukrainian

territory, Ukrainian language and culture is still okay in Russian

areas. So the Ukrainian inhabitants in Russian areas may not bother to

move.)

* All dressed up and nowhere to go: Russia has mobilized a large army,

said to be for a winter offensive in Ukraine "when the ground is

solidly frozen". So far I still see on the weather maps little sign of

serious cold through most of Europe including Ukraine, and it's the end

of January. Theater commander General Surovikin must be going nuts

waiting! North America is getting it instead with record cold and snow.

I suppose the Arctic is warm too. Climate chaos! (With February Europe

has finally started to cool.)

* The "College of Psychologists of Ontario" has threatened to revoke

Dr. Jordan Peterson's license to practice psychology on a matter

unrelated to that practice - essentially for expressing his personal

views on line. He often does so in response to questions people ask him

either because they respect his thoughts - or because he has become a

public figure and they want to trick him into saying or agreeing with

something that isn't what he means. But he also called into question a

government bill that he says unduly restricts freedom of speech, in

response to its enactment.

This "college" wants him to submit to "a remedial media

training course" - to be humiliated and renounce all he believes - in

order to keep his license! Why would a regulatory body want to grossly

overstep its own regulatory bounds and hence call its own legitimacy

into question? For someone who hasn't even been practicing for years?

It smacks of political motive. When people start saying

"Jordan Peterson for prime minister!" those in power feel threatened.

Discrediting our most promising leaders over some irrelevant thing

before they just might potentially become a serious political

leadership contender is an old political dirty trick. We've lost a lot

of promising, talented leaders to trumped-up "scandals". I wonder how

much officials of

the "college" were paid by the federal government (or received "in

kind")?

* And why would the CBC support such affronts with twisted words and

innuendo? The

government today funds CBC lavishly (500 million dollars... annually?)

and it asks in return that CBC speaks for the oligarchy behind the

government. It is no longer our public network. It no longer speaks

for, represents or reports fairly to Canadian citizens. Thus in the

biggest public protest in Canadian history, the truckers' convoy to

Ottawa, the CBC parroted the prime minister's line that they were a

tiny fringe group of crazy radicals,

and a remarkably peaceful and restrained demonstration was reported as

militant and threatening to the peace.

And our august prime minister says "Canadians have a right

to protest and to be heard". These are hypocritical words from someone

who turns

a

deaf ear to the grievances of a huge mass of really upset people and

uses the "Emergencies Act" (the

"War Measures Act" renamed) to break up the first protest to come his

way.

* Canada is rapidly becoming a big disappointment in the eyes of the

world. It is earning international disgust and becoming a

laughingstock. (Along with other Western nations, unfortunately.) What

happened to the Canada of the Flag Song written

when Canada first unveiled its own flag?

...

"Take your place next to those unfurled

Spread our friendship throughout the world"

... ?

* Why did Canada have no "right to bear arms" in our constitution?

There seemed to be no need - it was implicit that Canadians would want

to hunt and when required defend themselves and their domestic animals

from predators, and that government regulations were superfluous

regarding such matters.

* "Rob Words" channel on Youtube had on someone who was trying to bring

back "Anglish" as it was before 1066 when William the conquerer

introduced all

kinds

of French and Latin words. As they went through some odd and awkward

terms that were formerly used for many and various

things, I couldn't help but reflect how much English has been enriched

by those additions. And the English of today has a plethora of new

words and terms even since a century ago. And it's still growing and

changing, although computers are increasingly enforcing "the norm" as

the world adopts English as the international language and people who

are

learning it want to conform to as not be seen as ignorant. Also I note

many new terms are often the same or

very similar in every major language as the world shrinks.

How long does a ferrocement boat

last?

How long does a ferrocement boat

last?

This is the very first one, made by the inventor Joseph Lambot, in 1848

(Okay, it doesn't look very seaworthy at this point. ...It could be

fixed!)

ESD

(Eccentric Silliness Department)

* Wheat is a flouring plant.

* I think there's a reason the words "rooster" and "roaster" are so

close together. Only the hens lay eggs.

* Is "jury rigged" the same thing as a "rigged jury"?

* OMG! If you try to type "ing" and your right hand is one key over,

you get "omg"!

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

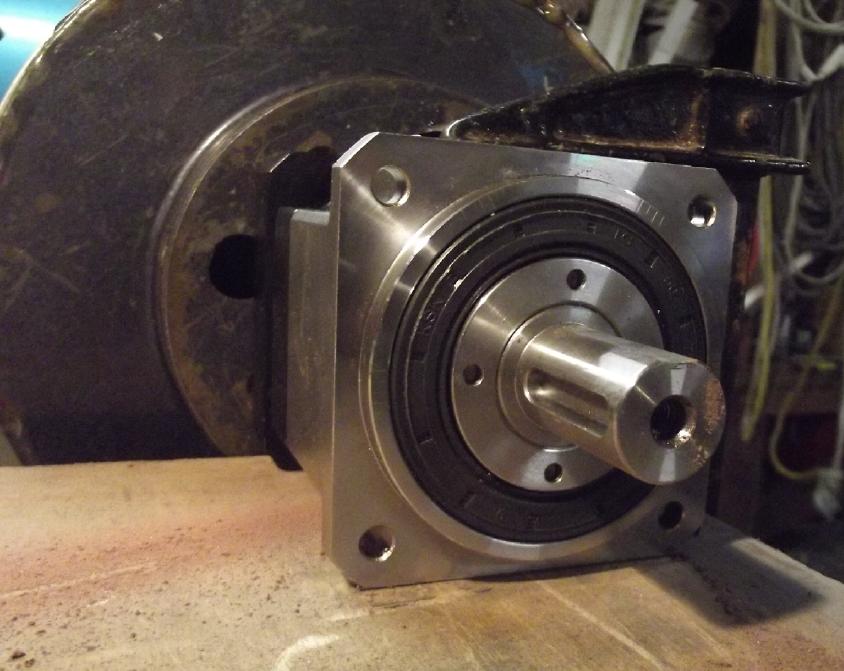

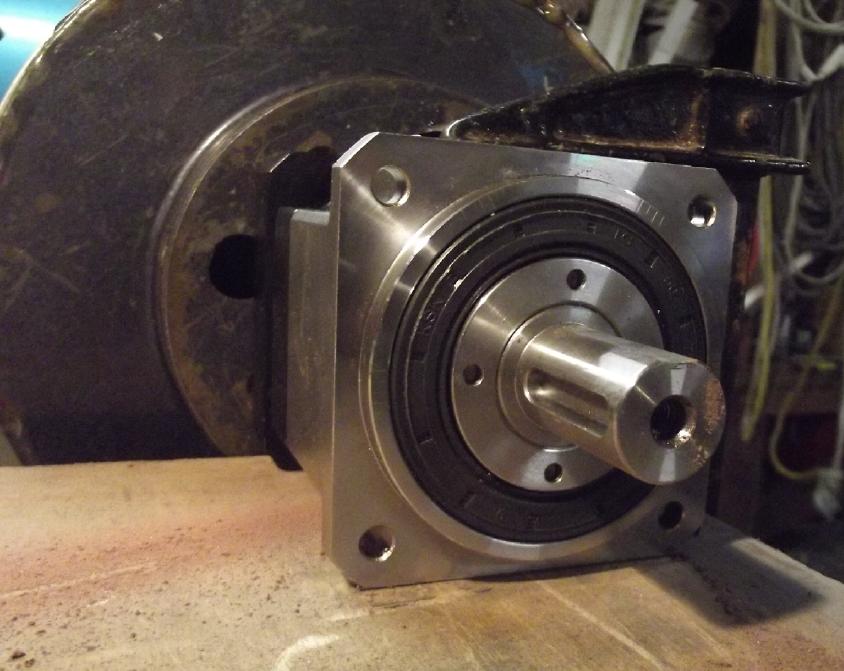

Magnetic Variable Torque Converter with Planetary Gear

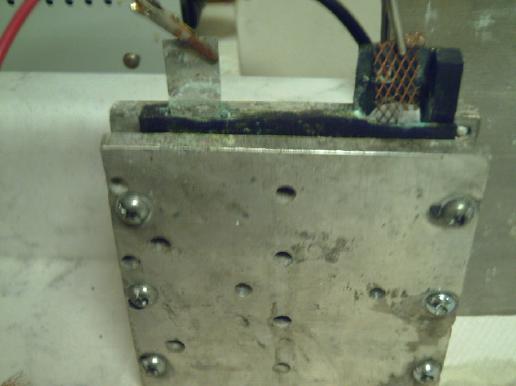

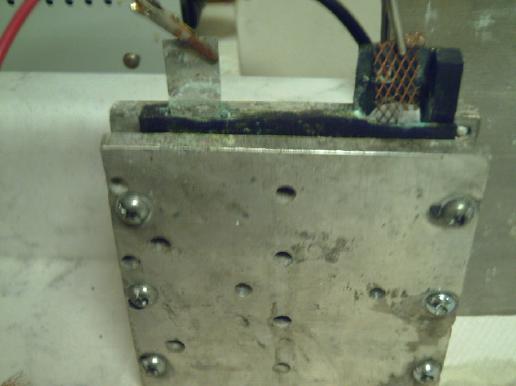

Bearing for Rear Drive Shaft

[15th] The 1-1/4 inch bearing came from Princess Auto. On the phone I

had hastily worked out that that was .009 inches larger than the 32mm

drive shaft. I goofed. It was the drive shaft end that was larger by

that amount. The bearing was in fact 31.75mm and it wouldn't quite go

on. Either the inside of the bearing had to be filed out (if that's

even possible) or the drive shaft end socket would have to be filed or

ground down. (Trying to turn the drive shaft on my small lathe - or

even on any lathe without disassembling it - seemed like a

non-starter.) The consolation was that if done well it would be a

better fit.

(Dang - if I'd realized, I would have ordered a real 32mm

bearing from VXB bearings. I've made more work for myself. OTOH while

on the website I discovered and got a very helpful flange mounting with

this one, which will save the work of making something up for it.)

Oh, wait! There's a protruding lip on the inside part of

the bearing. That means I should be able to mount it in the lathe chuck

and increase the inside size with a boring bar. (Assuming the metal

isn't too hard.)

[29th] I learned that friends in

Victoria have been waiting to see how my 'roadworthy' version of the

torque converter works out before potentially putting one into

(surprise) another Miles ZX40 truck! Must get back to it! I tried

fitting the wooden assembly under the truck and found that with the

rear plate on it was going to be nearly impossible to install it. I

decided it would have to do without the rear bearing I had waited weeks

for, and to do it without the whole rear plate that bearing was to

mount to. So I made a couple more cuts to the wooden side pieces, which

were blocking the motor bolts. (I had thought of using lag screws. I'd

rather not, and the bolts ended up being right at the edges of the

boards instead of somewhere in the middle.)

I still wasn't sure how I would hold up the back end of

the housing, but it would just be some sort of metal strap(s) to the

frame.

Flat spot ground into planetary

output shaft

for 5 set screws in a row

Flat spot ground into planetary

output shaft

for 5 set screws in a row

to go through wall of [splined] socket on vehicle's rear drive shaft

This is the drive shaft socket.

This is the drive shaft socket.

I don't know how I can mark,

center punch and

start small pilot holes

I don't know how I can mark,

center punch and

start small pilot holes

and still end up with a crooked line. But I seem to be an expert at it.

I took the rotating

assembly (27 pounds) out to the shop

and ground a flat area into the planetary output shaft at 90° to

the shaft key. Now the key would go into one of the two wider splines

in

the rear drive shaft, and setscrews would go against the flat area to

pin it down better. I drilled and tapped for 1/4 inch setscrews. Plus

two 5/16 inch opposite from the shaft key. My

confidence that the rather thin socket metal would hold them securely

increased when it was quite hard threading in the taps, and in fact I

broke one in the process.

[30th] I went under the truck and attached the housing to the motor,

then slid the rotating assembly into place. I found the set screws ware

directly over where the shaft key had to go. Fine; like that then. With

a wooden block to prop up the back of the housing I fit the shafts

together.

I bent a 3 foot long piece of 1/8" x 1" steel strap into a

sort of a "U" with tabs on top to hold it to two threaded bolt holes

into the frame above. This went under the torque converter housing and

was bolted to the lower 2 by 6'es. I left extra length on the tabs to

make it "springy" and decouple any noise it made from the truck frame.

RIGHT to LEFT: * Curtis

AC35(?) 72 volt

motor - with splined socket shaft

RIGHT to LEFT: * Curtis

AC35(?) 72 volt

motor - with splined socket shaft

* Motor end of motor-to-planetary-gear shaft (just visible) - turns sun

gear & alume disk

* Plywood wall holds bearing to steady the long shaft

* Alume rotor/disk - spins with motor

* Magnet rotor - Hallbach configuration - spins with planetary gear body

* 10:1 planetary gearbox

* Black metal "U" bracket strap holds rear end of housing up to truck

frame (Motor holds front end)

* Front end of drive shaft to rear differential, a socket fitted to

planetary's output shaft (planets assembly)

* Drive shaft, U-joint & with safety guard so if it somehow slips

off, front of drive shaft can't drop to ground.

[31st] I installed said "U". Then

I attached the video camera to the

side facing the mechanism. I ran it back and forth in the garage a

couple of times. It seemed good. With the 10 to 1 reduction plus the

magnet drive I thought it should have plenty of torque. It didn't. The

first clue was when I had to take a run to get over a little hump

coming out of the garage. I tightened the screw that couples the input

shaft inside the planetary, but I'm still not convinced it isn't

slipping. (Why do they have such a "non positive" attachment mechanism

to take all the input torque?)

I tried to drive around the driveway, but a vibration

started up whenever I pressed very hard on the pedal. Apparently the

springy back end of the housing wasn't a good idea. Then, with the

seeming low available torque the truck wouldn't go up the lumpy spots

on the lawn. Lumpy lawn is much less forgiving than smooth pavement!

Finally back backed down a bit of a slope and couldn't get up it again.

I didn't dare press too hard on the gas with the vibrations that

started. And something smelled hot. Sure enough it was the alume rotor.

When the torque converter isn't 100% efficient, the rest goes into

heating it up. I had recognized that that disk might need a heatsink.

It sure did! It was hot enough to fry french fries on. I ended up

prying the bumper forward with the peevee and kicking blocks behind the

wheels to creep it ahead to a more level spot where it would go again.

But it seemed to start vibrating more easily now and had little power.

When I swung around to get to where I could back into the garage it got

stopped again and I had to repeat the process, tho not so much uphill

or so far.

While the truck was out I swept the dusty garage floor for

the first time in ages. But it was a relief to get it safely back in. I

had expected this test to work really well. Instead I was quite

disappointed and saw there were some kinks yet to be worked out. And I

didn't leave any room between the alume plate and the bearing holder

wall for heatsinks.

Aha! On looking at the video (thank God for the "instant

replay" video looking at the mechanism!) it appears the vibration was

most likely the drive shaft slipping on the splines of the output shaft

of the planetary. No wonder there was vibration! Well, I always knew

that was the weak link. If that's the main problem (and if I can solve

it) that's actually not so bad. I can drill new holes in the drive

shaft's socket and get set screws on that flat spot I made, and maybe

I'll have to make another shaft key if that one has worn down. And

maybe the rotor won't heat up so much if everything else is working

right and the truck moves readily.

[Feb. 2nd] I pulled the rear drive shaft off. Sure enough the set

screws were no longer tight, and the shaft key was worn down from the

splines racking across it. As too often trying to make things for

vehicles, my mechanical build was too weak. It seems all too obvious

now that I should have saved the splined shaft that came out of the

transmission and fit into the rear drive shaft splined socket, to weld

onto a coupler to properly fit the planetary's output shaft. Oh well,

long gone now! (I actually checked at the yard where I discarded it,

and it's surely there somewhere, but Paul can't remember where he put

that transmission among a zillion cars and other metal things. I could

spend all day out there and still not find it.)

I'm going to put 5 set screws in a row through the socket

wall into the area I flattened on the shaft. When I have the torque

converter off again I'll grind another flat area opposite to the shaft

key slot to press the [new] key as best possible into the too-small

slot in the socket.

[Feb. 5th] I spent the day drilling and tapping the rear drive shaft

socket for 5 set screws in a row, all to cinch in to the flat side I

had made on the planetary's output shaft, then cutting and shaping a

new key to go into the too-small slot in the socket at 90° to those

screws.

After a warm-up break (after hours in the cold shop and

the woodstove had gone out while I was there), I put the drive shaft

back on the truck and did up the screws. I opened the garage door and

tried it out. But the truck's nose didn't poke out very far before I

heard some vibration. I wasn't up for another big adventure just before

dark. I backed back in and closed the door. The magnet rotor was

already slightly warm. Anyway, why didn't I have the camera on it to

see what was happening? (Oops)

[Feb. 6th] I thought the input shaft junction must now be slipping in

the planetary. I have found it to be a frustrating join because it has

only one allen screw and a clamp affair that is supposed to clamp

around the 19mm input shaft. No key slot, no splines, nothing. I

roughened up the shaft before I put it together to make it un-slippery.

How hard can one reef on a 6(?)mm screw with a vise grip on the end of

an allen wrench before something gives? How is it supposed to work?

The same vibration continued when I drove the truck out of

the garage. I didn't get very far upslope. It still wasn't right.

[Feb. 8th] I remembered there was one more component that can slip: the

alume rotor. [Duh!] The SDS taper lock hub had no shaft key. I had

tightened it pretty well, but not to the ultimate - I thought I might

want to adjust the position. I thought to go under the truck and at

least tighten its set screw - might hold it for a test or two. But it

needed a really long allen wrench. The only way to get that was to put

a magnetic bit in the "screwdriver" handle. And the magnet that held it

in wasn't nearly as strong as the rotor magnets. After a couple of

tries, and fishing out the allen bit with forceps, it got behind a

magnet. It might jam and break magnets, so I now have to remove the

whole thing to get at it. That ended any hope of having it running for

this report, even so far into February.

I then had the thought that I could have drilled a hole in

the plywood so the bolts on the SDS could be accessed and tightened

without removing it all, but now there's that allen wrench bit stuck

inside.

The perhaps more troubling problem is the alume disk

getting so hot. The whole thing should be high efficiency once the

vehicle is up to driving speeds, but at high torque at "crawl" speeds

trying to go upslope in a lumpy driveway it's much lower. And whatever

percentage loss there is mostly goes straight into heating up that disk.

I had initially realized that it might need a heatsink -

perhaps two or three finned heatsinks spinning on the back of the disk.

There was lots of space on the rotating assembly but I neglected to

make a place for them in the design of the housing. Well, possible

changes is why I didn't epoxy the whole housing solidly together yet! I

found 3 smallish heatsinks I had bought for LED COB lights. Those would

probably do it, and I think I'll be "proactive" and add them on now

rather than most likely have to re-fit it all later.

If it does get pretty warm in normal driving, something

that might be worthwhile would be to put in ducts and a fan from the

rotor space to the cab: could be good supplementary "free" heat - at

least for a windshield defrosting assist in winter?

Other "Green" & Electric Equipment Projects

Winter Gardening

Window & LED Gardening

The romaine

lettuce and spinach continued to

grow well under the bright new

"100 watt" 30x45cm/12"x18" LED light dimmed down to about 35 watts (yet

still much brighter than the old ones at 40 watts each) and I got some

salad greens out of them. I finally pulled out the center lettuce plant

of the three because they were all overlapping each other. The spinach

attracted one, a few, then a zillion flying fungus gnats and I finally

plucked the spinach leaves to eat, and took it outside.

The romaine

lettuce and spinach continued to

grow well under the bright new

"100 watt" 30x45cm/12"x18" LED light dimmed down to about 35 watts (yet

still much brighter than the old ones at 40 watts each) and I got some

salad greens out of them. I finally pulled out the center lettuce plant

of the three because they were all overlapping each other. The spinach

attracted one, a few, then a zillion flying fungus gnats and I finally

plucked the spinach leaves to eat, and took it outside.

In the bay window with a few lights and very occasional

sunshine, the "third try" cherry tomato finally started producing a

little ripe fruit. (Two sets of flowers, hand pollinated, & then

tomatos... where is the next set? The "first" and "second" try tomato

plants I managed to wreck in the fall or early winter by

underwatering.)

I used up most of the ripe peppers which had started

mostly in the summer, and the plants became infested with aphids. I

wiped them off the leaves by hand now and then. The aphids spread to

the coffee plants. Hopefully when I set these all out in the spring the

aphids will vanish.

Plastic

Recycling

2.0

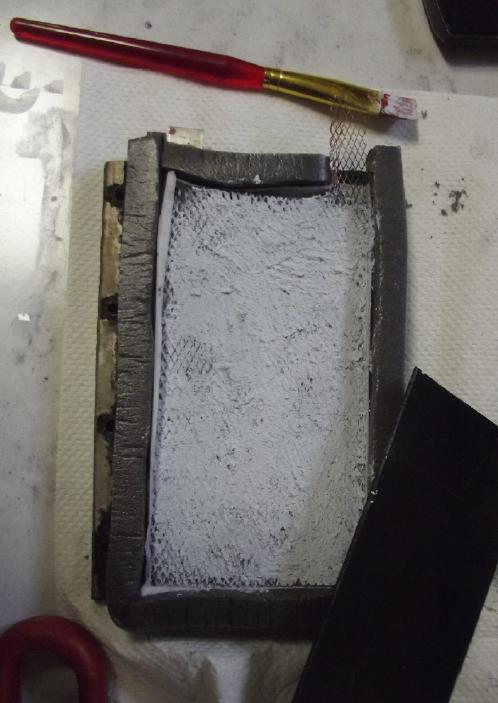

Another try melting PETE

"Sample Plate"

size alume

box mold coming out of the oven with the plastic

sagged down. 9 pound weight. On an old cookie sheet in case of

drips.

I had long been meaning to try melting clear PETE again. I

suspected that when it had fused solidly onto the alume mold I may have

just got it too hot for its chemistry.

I had long been meaning to try melting clear PETE again. I

suspected that when it had fused solidly onto the alume mold I may have

just got it too hot for its chemistry.

I (finally) cleaned off the

little "sample sheet" box mold, repolished the plates and reassembled

it. (I found that a polishing disk and a stick of rouge polish on the

angle grinder does a really fast but not very smooth polish. I used a

polishing disk on the drill press to further smooth the surface, but it

still has grooves from the angle grinder.)

In the trials below I must note that because of the low

sides on the mold, I had to cut the "3D" shaped pieces of plastic much

too fine with scissors to get the lid below the top of the sides. The

moral is that the higher the sides are on the mold, the easier the

whole thing is. That's a key part of the idea of doing it this way:

throw big chunks of plastic in the mold instead of having to shred it.

I cut some pieces of clear PETE

and put them in the mold,

and an 8 pound steel weight on top. Since it was small and I wasn't

expecting to get it too hot I just used the kitchen oven. I tried 275,

300, 325, 350, 375, 400 and 425°F. At even the lowest temperature

the crinkly pieces flattened out. Only at the highest did they even

start to melt, and at 400 and 425°F they started turning from clear

to white, and shrinking down. Yet they still didn't stick together.

Each piece was still separate. If I went to 450° would they all

melt and fuse solidly to the mold like last time? Since they had

already turned white and let much less light through, the whole point

to melting clear PETE into a sheet - to make transparent greenhouse

panels -

was already lost.

I cut some pieces of clear PETE

and put them in the mold,

and an 8 pound steel weight on top. Since it was small and I wasn't

expecting to get it too hot I just used the kitchen oven. I tried 275,

300, 325, 350, 375, 400 and 425°F. At even the lowest temperature

the crinkly pieces flattened out. Only at the highest did they even

start to melt, and at 400 and 425°F they started turning from clear

to white, and shrinking down. Yet they still didn't stick together.

Each piece was still separate. If I went to 450° would they all

melt and fuse solidly to the mold like last time? Since they had

already turned white and let much less light through, the whole point

to melting clear PETE into a sheet - to make transparent greenhouse

panels -

was already lost.

So I decided it would be relatively pointless to continue

even if it did make a nice white sheet that wasn't stuck to the mold.

It took so long to fix up the mold that I had put it off for months and

months and I was reluctant to risk a repeat. I suppose I should have

tried anyway. They're not completely opaque. Yet.

But later I tried 475°, with no better results - every

piece was shrunk and sagged flat, but still separate. And turning white.

If they didn't stay at least reasonably clear, the whole

idea of using it for greenhouse panels wasn't viable, so there seemed

no point continuing.

Then I tried a polyethylene

bleach bottle, warmer and warmer, finally at 500°. It was somewhat

better than the PETE - at least the pieces were fusing together. 1/2 an

hour instead of just 5 minutes probably would have made it into a

single sheet. Needs more time! - a lesson I keep relearning about

melting plastic.

Then I tried a polyethylene

bleach bottle, warmer and warmer, finally at 500°. It was somewhat

better than the PETE - at least the pieces were fusing together. 1/2 an

hour instead of just 5 minutes probably would have made it into a

single sheet. Needs more time! - a lesson I keep relearning about

melting plastic.

This was in the kitchen oven indoors, but I didn't notice

any smell.

The bottom side picked up

polishing compound

from repolishing the mold surfaces.

The bottom side picked up

polishing compound

from repolishing the mold surfaces.

Electricity

Storage

New Chemistry Batteries: Cobalt Oxide Positive Electrode

Cobalt Oxides Electrode Theoretical Discussion & More Electrode

Theory

I could find no references on line to cobalt oxide

electrodes except in connection with lithium ion batteries,

supercapacitors or sodium ion batteries. Has no one ever tried cobalt

for a regular alkaline or salt battery before? Maybe any rare

references were obscured by the oodles of hits related to

those other three topics? It isn't mentioned in the "definitive" book, Alkaline

Storage

Batteries (1969) which covers battery history as well as

then present chemistries. No one, apparently, has ever done

"cobalt-zinc", "cobalt-iron" etc, or "cobalt-metal hydride".

Perhaps because it superficially looks so much like nickel oxides

but with lower reaction voltage and higher price, it's readily

passed over by the researcher?

What about conductivity? CoOOH (= Co2O3) is often used to

raise the conductivity of NiOOH electrodes. It must be pretty

conductive to be so employed in spite of its extra weight lowering the

effective amp-hours of the nickel oxide. But one source said the Co3O4

form (or is it Co(OH)2:CoOOH?) was a "poor conductor". This is at least

better than manganese where Mn2O3 (or Mn(OH)3) is "an insulator" and so

won't recharge properly to MnO2. I found no clues about Co(OH)2. One

suspects it's the most conductive form since it is the least oxidized,

but then that manganese, Mn2O3 or MnOOH (valence 3), was an insulator

when the other

forms aren't certainly caught me by off guard and I didn't understand

my "won't recharge" problem. (Otherwise MnO2 would be the simple and

cheap "+" electrode.)

NiOOH loses 2/3 of its theoretical amp-hours mostly

because of its low conductivity. For CoOOH to have high conductivity

means that with (eg) just 5% graphite conductivity additive, the

transition

CoOOH to "Co2O3" form (probably in water actually Co(OH)2:CoOOH) has in

effect almost as many amp-hours. Then the further transition to all

Co(OH)2 doubles that, so with (surely) almost three times

the amp-hours per kilogram cobalt should yield a much higher energy

density than nickel in spite of lower voltage.

And what is the voltage or voltages?

Every source of redox chemistry said something different, so I didn't

know for

sure what voltage to expect, and I didn't know if there would be a

serious step or steep slope in voltage as it charged through Co(OH)2 to

Co3O4 and then

from Co3O4 to CoOOH.

The most optimistic forecast was

the CRC

diagram showing +.42V going valence 2 to 3. This is the one that

recently struck me while "idly" going through diagrams for different

elements one more time for some reason, and started me considering

cobalt. It suddenly

looked to me too good to be true, and sure enough it's an

oversimplification, ignoring the mixed 2-2/3 valence state "Co3O4".

The most optimistic forecast was

the CRC

diagram showing +.42V going valence 2 to 3. This is the one that

recently struck me while "idly" going through diagrams for different

elements one more time for some reason, and started me considering

cobalt. It suddenly

looked to me too good to be true, and sure enough it's an

oversimplification, ignoring the mixed 2-2/3 valence state "Co3O4".

If the zinc was -1.20V, the

cell should be 1.62 volts according to this. (Of course these are never

exact figures - as shown by the fact that a low charged cell has a

lower voltage than with a full charge, and of course the voltage drops

when drawing current.)

But the CRC charts are pretty old and not really done

thoroughly. The Pourbaix diagrams are better, but even they are made

under varying conditions and concentrations for various purposes and

don't necessarily agree with each other, as seen below.

I'm quite certain that the cell would bubble oxygen before

the valence state of the cobalt was 4 to make CoO2, even with any

overvoltage raising additives that might be found. And the CRC's +.7V

becomes +1.0V (@pH12.7) in one Pourbaix diagram (below) and just

"doesn't happen" in the other.

Half a volt in the 'plus' direction in

an alkaline environment seems to be about the limit. The dotted lines

in the Pourbaix diagrams show the potentials where oxygen (+) and

hydrogen (-) can start bubbling out of the water. The limits can be

stretched depending on the substance, and further with overvoltage

additives, but only so far. Well known nickel oxyhydroxide (+.49V

@pH14) self-discharges above 40°C if there are no oxygen

overvoltage raising additives with it. (In fact I tried charging the

first Co-Zn cell using 2.15 volts and there was no sign of it staying

anywhere up

there once taken off charge.)

Continuing on the subject, zinc stretches the limits in

the negative direction but does hold a charge. A hydrogen overvoltage

raising additive helps it not bubble hydrogen when under charge. (I'm

using a little ZrSiO4, painted onto the electrode a

parchment paper separator.) Manganese (as fine powder) stretches the

limits even further and it won't retain its charge and metallic form

without some good overvoltage raisers. (I found mixing in 1% Sb2S3, 3%

ZrSiO4 powders works.)

I thought the one Pourbaix

diagram showing both reactions at about +.25V was more likely to be

correct or closer. That would make the cell about +.25 - -1.20 = 1.45

volts.

I thought the one Pourbaix

diagram showing both reactions at about +.25V was more likely to be

correct or closer. That would make the cell about +.25 - -1.20 = 1.45

volts.

Less desirable would be if it

works like in this diagram, which shows the first reaction at around

-.2V and the second at +.35 (at pH 12.7). If it worked like this, there

would be a 'step' or at least a steep slope in voltage during charge

and discharge. If the cell was less than 2/3 charged voltage might be

around:

Less desirable would be if it

works like in this diagram, which shows the first reaction at around

-.2V and the second at +.35 (at pH 12.7). If it worked like this, there

would be a 'step' or at least a steep slope in voltage during charge

and discharge. If the cell was less than 2/3 charged voltage might be

around:

-.2V - -1.20V = 1.00V

If more than 2/3 charged, it would be closer to:

+.35V - -1.20V = 1.55V

These might be similar enough for motors and electronics to cope with

the changing voltages, but it certainly wouldn't be very desirable.

OTOH if the cobalt yields anything like its full amp-hours, it's got

almost as many amp-hours as nickel oxides at the higher voltage, and

then as much again at the lower. And a simple voltmeter will certainly

show when a battery is getting low!

There is yet one more

possibility: The transition from Co(OH)2 to Co metal at around -.65V.

This is a double change in valence from +2 to 0, so the theoretical

amp-hours per kilogram is doubled to 576. Considering the cobalt alone

it reaches 910 AH/Kg. If in practice it attains 2/3 of 576 it's still 4

times the effective amp-hours of nickel. But the cell voltage with zinc

would only be:

-.65 - -1.2 = .55V. That seems pretty crazy to me. OTOH the

amp-hours is huge.

Zinc is all but free. However it works, if cobalt oxides

are 1-1/2 times as expensive as nickel oxides, but less than 1/2 as

much is required to obtain the same energy, it is not only going to

make higher energy density per weight but the cost per unit of energy

will actually be lower.

On another note, cobalt is quite toxic. Precautions should

be taken not to breathe the dust or get it on your skin or in your

eyes. It is also toxic to aquatic life. (So is zinc.)

Experiment

I had been getting things ready for the new cobalt-zinc

cell.

The Cobalt Oxides Mix

- 46.5g CoO and or Co3O4 and or Co2O3(?) (93% cobalt oxide active

redox ingredient)

- 2.5g CCB (5% conductivity raiser)

- 1.0g Sm2O3 (2% oxygen overvoltage raiser)

On the 8th I assembled everything. I put 15 grams of the

cobalt oxide mix into/onto a graphite felt. (Less went in than sat on

top.) If this gives 200 AH/Kg that should be 3 amp-hours. The mix might

up to 268 (theoretical @ 93% cobalt oxides), which would be 4.0 AH.

(This is far better than the effective 90 AH/Kg for nickel, NiOOH.)

I painted the deerskin heavily with SDBS in water. It

absorbed a lot of it. I was very excited to see the cell work and

neglected to add the osmium dopant and the zircon hydrogen overvoltage

raising layer to the zinc, and to paint the cupro-nickel with calcium

oxide on the plus side. Anyway I will be able then to first check the

performance without it, and later paint it on and see what happens with

it.

I took the old (nickel manganates "+") cell out of the

clamp set and bolted the new one in.

Initial voltage was 1.046V.

I started charging at 1.75V through 10Ω at 40 or 50 mA. Soon the

current was below 15mA and I switched to 1Ω. After a while the current

was again down and I raised the charge voltage to 1.85V. Then I

squirted in a bit more electrolyte and the cell voltage dropped below

1.8

and the currents went up. It went quite a while at 1.798V and 40mA.

I was thinking nothing needed to change except the cobalt to higher

oxides, but in fact there was bound to be oxidation of the cupro-nickel

- especially without the calcium oxide on it.

In the evening I opened the cell.

I painted

Ca(OH)2 onto the cupro-nickel, which by now had a couple of spots that

looked like bare copper. Not to worry there's still more nickel inside

the sheet. (Picture before painting.) The fact that there were only odd

spots like that wouldn't seem to say much for the connection between

the graphite felt and the metal sheet.

I painted

Ca(OH)2 onto the cupro-nickel, which by now had a couple of spots that

looked like bare copper. Not to worry there's still more nickel inside

the sheet. (Picture before painting.) The fact that there were only odd

spots like that wouldn't seem to say much for the connection between

the graphite felt and the metal sheet.

(Why can't I get, for love nor money, a camera that focuses? A

gift camera, 45$ and now 95$ down the tubes for this newest blurry

wonder. Sigh! Back to my 2005 Radio Shack video/camera with the tiny

half dead display and 3-place manual focus setting 'switch'.

[9th] Yay, a great Fuji camera that takes marvelous pictures - and

simple Ni-MH 4x "AA" cells - from the Thrift shop for 2$! Hmm...

Actually it wants 3 Ni-MH cells and at least one Ni-Zn cell, or it says

"low batteries" and shuts off just a day after cells were fresh

charged. Still, it works!)

Then I painted the osmium doped

layer onto the "expanded copper mesh" zinc electrode and let it dry.

(Again a "before" image.) I thought I saw the fine osmium powder at the

bottom of the little test tube when I started and I put the stopper on

it and shook it up 3 or 4 times to mix it in while I was brushing it

on. Osmium is after all the densest of all elements.

Then I painted the osmium doped

layer onto the "expanded copper mesh" zinc electrode and let it dry.

(Again a "before" image.) I thought I saw the fine osmium powder at the

bottom of the little test tube when I started and I put the stopper on

it and shook it up 3 or 4 times to mix it in while I was brushing it

on. Osmium is after all the densest of all elements.

It didn't look much

different until I painted on the zirconium silicate to raise the

hydrogen overvoltage. When that was dry (image) I reassembled the cell.

Before the treatments when I short circuited the cell

through the ampmeter leeds a couple of times, it hardly supplied 1.5

amps, and the next reading (after 1/2(?) a second) was 1 amp, then

under 1. I hoped for improvement with the osmium but afterward it

seemed no better. Why do just my cells have such abyssmal

current capacity. I have never heard of such poor performance from

water based cells as mine seem to always have.

I upped the charge voltage to 2.0 volts in case it was

really not getting enough charge. Then to 2.15 before bed. It was

drawing well over 100mA, and still 70 by morning. Headed for an

amp-hour of charge

overnight? Out of 3 or 4? That should in theory be 1/4 charged.

[9th] I disconnected the charge and let the voltage drop. It finally

started definitely slowing at around 1.3 volts, suggesting (considering

it's only 1/4 to 1/3 charged) that the upper Pourbaix diagram is the

operative one or at least the closest. Then I ran a load test for an

hour with a very light load (60Ω). It started just below 1.2V after 30

seconds, was at 1.1V in 15 minutes, and hit 1.046V after an hour. In

the last half hour it was dropping a little over a millivolt per

minute. It never seemed to stop dropping anywhere, but it probably

would have if I had let it run longer. Afterward it only recovered to

1.111V in 30 seconds, and 1.160V in 10 minutes. These fairly steady but

low voltage readings throughout suggest that the lower chart is more

correct, and that the cell is running in the lower region. More

charging will tell if it will rise up to the upper voltage level or

not. I put it back on charge at 1.85V with no series resistor.

[10th] The voltages started higher in a load test but after 1/2 an hour

were a bit lower than the previous. I suspect conductivity, already

poor, has dropped.

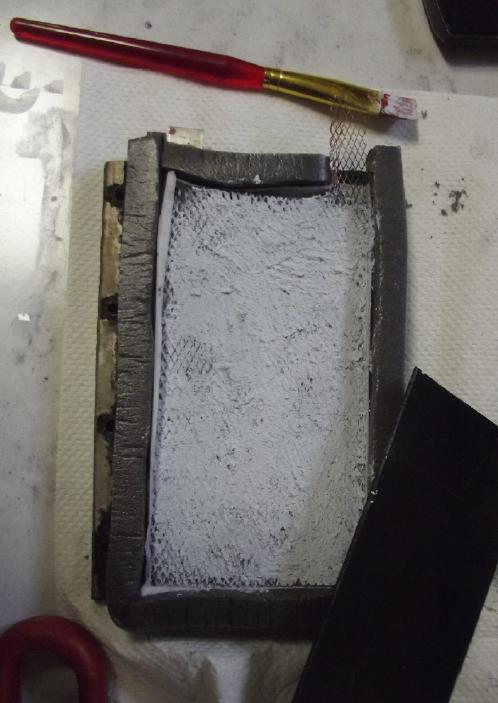

Cell Design

The ABS cell shells seem like a good design, but

they have a flaw or two. One is that they have weight and bulk - fairly

trivial. The other is that with the solid edge walls, one can only

clamp them flat to a certain extent. Unless there's just the right

amount of material inside, the powders will be compressed too little or

alternatively the cell will leak around the edges. Furthermore there's

no way to tell how compressed it is.

I'm leaning toward modifying the design - maybe even just

wrapping up the electrodes with packaging tape.

Another way to infuse powder into the graphite felt?

I got another

idea related to conductivity: It was hard to

get powder, however fine, to go into the conductive graphite felt.

Porous as it is, the surfaces seem made to prevent penetration.

Vibrating it in had worked rather poorly and spread a lot of dust, and

cobalt is toxic - I don't want it floating in the air even outdoors.

Putting the powder on top of the felt seemed like mostly a waste of

time, even if a certain amount did rub in. I had tried to punch some

holes in the felt with a pin frog (used in flower arranging) for the

powder to go into, but they seemed to just close up again. How about

putting the powder on the felt and then punching it in with a pin frog?

Surely that should infuse a fair quantity within the felt and very

close to the conductive fibers? (And could I dampen it first so it

wouldn't raise dust?)

I got another

idea related to conductivity: It was hard to

get powder, however fine, to go into the conductive graphite felt.

Porous as it is, the surfaces seem made to prevent penetration.

Vibrating it in had worked rather poorly and spread a lot of dust, and

cobalt is toxic - I don't want it floating in the air even outdoors.

Putting the powder on top of the felt seemed like mostly a waste of

time, even if a certain amount did rub in. I had tried to punch some

holes in the felt with a pin frog (used in flower arranging) for the

powder to go into, but they seemed to just close up again. How about

putting the powder on the felt and then punching it in with a pin frog?

Surely that should infuse a fair quantity within the felt and very

close to the conductive fibers? (And could I dampen it first so it

wouldn't raise dust?)

I took the

cell apart and measured the conductance of the

"+"ode. I "knew" that as it was damp I would get the ionic conductivity

rather than the electronic conductivity. I "knew" I would have to dry

out the electrode to measure its real electronic conductivity, which

was too much hassle. But I touched one electrode to the cupro-nickel

terminal tab. It was hundreds of ohms! Of course: the terminal was dry!