12 VDC outlet by the "solar fridge", nearby a 120 VAC outlet

(Ironically, the AC outlet has a 12 VDC power adapter plugged in for the LED globe light that lit the corner for the foto!)

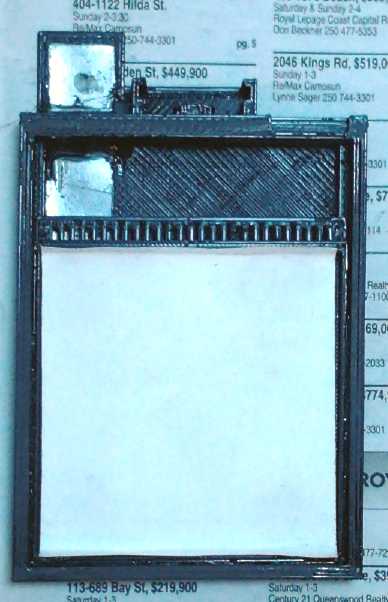

I'd also

read some people used glossy magazine paper instead of

acetate. One web site finally explained why: you can soak the paper

off, so it

won't lift any of the toner from the copper board. Aha! Finally I saw

the

glimmer of potential good results! (And here I

thought people were just using

it because they were being cheap!)

Trying it

revealed more details: thin magazine paper transfers the heat to the

toner and board better, and there seems to be less smear. On the minus

side, you can't see through it to see any spots of toner that haven't

transferred.

I'd also

read some people used glossy magazine paper instead of

acetate. One web site finally explained why: you can soak the paper

off, so it

won't lift any of the toner from the copper board. Aha! Finally I saw

the

glimmer of potential good results! (And here I

thought people were just using

it because they were being cheap!)

Trying it

revealed more details: thin magazine paper transfers the heat to the

toner and board better, and there seems to be less smear. On the minus

side, you can't see through it to see any spots of toner that haven't

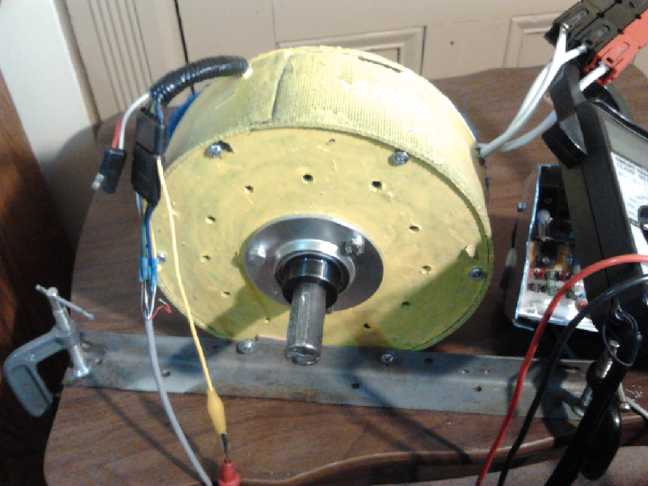

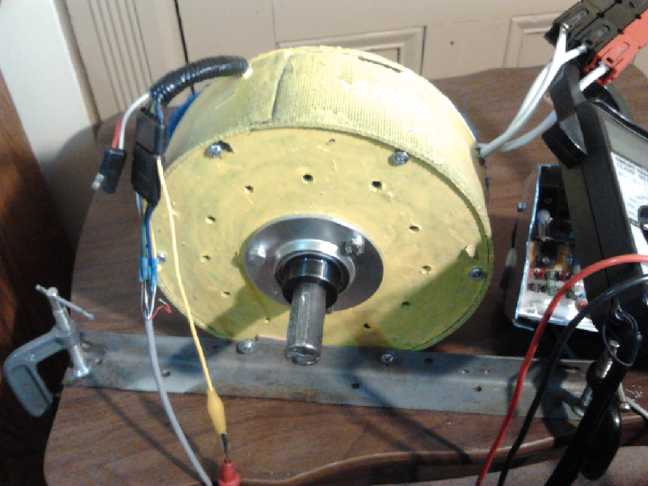

transferred. * I fitted the pressed

shell

bearings to the motor bells on

the 5th, using hex bolts and "T" nuts since the intended carriage bolt

system was too bulky to fit in at either end. Theoretically the motor

could be thinner and slightly smaller diameter, but in practical terms

it was as thin and small as I could make it and I almost made the rotor

compartment too thin to fit everything. On the rotor bushing I had to

drill recesses and use flat

head bolts to eliminate the normally protruding hex heads.

* I fitted the pressed

shell

bearings to the motor bells on

the 5th, using hex bolts and "T" nuts since the intended carriage bolt

system was too bulky to fit in at either end. Theoretically the motor

could be thinner and slightly smaller diameter, but in practical terms

it was as thin and small as I could make it and I almost made the rotor

compartment too thin to fit everything. On the rotor bushing I had to

drill recesses and use flat

head bolts to eliminate the normally protruding hex heads. After

completing the second magnet installation, I tried the motor again and

ran a few tests. It ran great, smooth and well balanced. I got nervous

about turning the RPM up too high and chickened out at 2700 RPM - and

at only about 1/4 or 1/3 "throttle". My instinct said it'd be safer to

call it a 2000 or at most 2500 RPM motor instead of the planned 3000. I

also thought it was using too many watts to turn with no load, but the

power needed went down considerably as (presumably) the bearings warmed

up. I was then in essence happy with the motor, barring a few ideas for

improvements that could wait for another occasion or the next motor.

(One idea in particular is to add a microcontroller control to

limit such motors to safe RPMs

- but that's the domain of the motor controller rather than the

motor.)

After

completing the second magnet installation, I tried the motor again and

ran a few tests. It ran great, smooth and well balanced. I got nervous

about turning the RPM up too high and chickened out at 2700 RPM - and

at only about 1/4 or 1/3 "throttle". My instinct said it'd be safer to

call it a 2000 or at most 2500 RPM motor instead of the planned 3000. I

also thought it was using too many watts to turn with no load, but the

power needed went down considerably as (presumably) the bearings warmed

up. I was then in essence happy with the motor, barring a few ideas for

improvements that could wait for another occasion or the next motor.

(One idea in particular is to add a microcontroller control to

limit such motors to safe RPMs

- but that's the domain of the motor controller rather than the

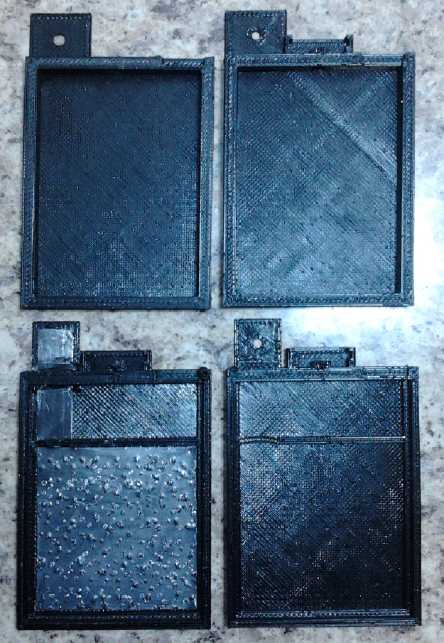

motor.) All the test

battery cells I've made able to open for

trying various things and inspection have leaked and become encrusted

in salt from the electrolyte around the seams. The leaks cause

self-discharge and loss of

electrolyte, making any longer period test results questionable at

best. On the 20th I decided that, having a proven

chemistry, workable materials, and now a plan in my head for what ought

to be good, working cells, it was time to put together a production

battery design that would be securely glued shut, and a much faster

means for producing electrodes - as simple, highly compacted briquettes.

All the test

battery cells I've made able to open for

trying various things and inspection have leaked and become encrusted

in salt from the electrolyte around the seams. The leaks cause

self-discharge and loss of

electrolyte, making any longer period test results questionable at

best. On the 20th I decided that, having a proven

chemistry, workable materials, and now a plan in my head for what ought

to be good, working cells, it was time to put together a production

battery design that would be securely glued shut, and a much faster

means for producing electrodes - as simple, highly compacted briquettes.

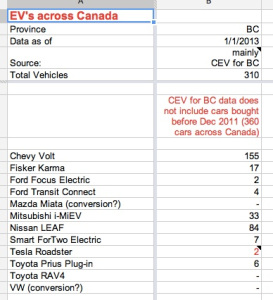

Also of interest, the first ever 120 car, 360

passenger, 80 meter catamaran

electric ferry is said to be going into operation in Norway in 2015.

(So far, it looks like it's a computer graphic judging by all the

identical cars.)

Also of interest, the first ever 120 car, 360

passenger, 80 meter catamaran

electric ferry is said to be going into operation in Norway in 2015.

(So far, it looks like it's a computer graphic judging by all the

identical cars.) All the

subheadings here

this month are about the "Mini Electric Hubcap Motor", now

titled the Electric Caik Motor ("ElectricCake.com" was taken).

It continues - and essentially concludes - the motor development story

started in December, including the

making of the molds and jigs to produce the motors, and the making and

initial testing of the first one, which runs great.

All the

subheadings here

this month are about the "Mini Electric Hubcap Motor", now

titled the Electric Caik Motor ("ElectricCake.com" was taken).

It continues - and essentially concludes - the motor development story

started in December, including the

making of the molds and jigs to produce the motors, and the making and

initial testing of the first one, which runs great. It runs great,

and the rotor is the best balanced one I've

made, thanks to the new magnet placement jig below. I had thought that

if the regular Electric Hubcap was 0 to 2000 RPM with a 10" magnet

rotor, the new one should be about 0 to 3000 RPM with a 7.5" rotor, but

as I increased the speed, despite running smoothly the energy seemed so

ominous that I stopped at 2700 RPM and headed down again, and decided

that maybe it should be rated 0 to 2000 RPM as well, or not a lot more.

The back EMF (Kv) seemed quite low at 5.1 mV/RPM and it attained those

RPMs with quite low control settings. This would be partly because I

used thinner supermagnets, .375" instead of .5", in spite of the fact

that the flux gap is probably down to 10 or 11 mm instead of 14 to 16.

I think that if I turned it right up with the 24 volt supply and no

load, the motor speed would increase until it self destructed, even if

that didn't happen until 5000 or more RPM. I'm starting to think that a

microcontroller overseeing operation is really a necessity if only to

set an RPM limit at a

safe maximum regardless of flux gap and load.

It runs great,

and the rotor is the best balanced one I've

made, thanks to the new magnet placement jig below. I had thought that

if the regular Electric Hubcap was 0 to 2000 RPM with a 10" magnet

rotor, the new one should be about 0 to 3000 RPM with a 7.5" rotor, but

as I increased the speed, despite running smoothly the energy seemed so

ominous that I stopped at 2700 RPM and headed down again, and decided

that maybe it should be rated 0 to 2000 RPM as well, or not a lot more.

The back EMF (Kv) seemed quite low at 5.1 mV/RPM and it attained those

RPMs with quite low control settings. This would be partly because I

used thinner supermagnets, .375" instead of .5", in spite of the fact

that the flux gap is probably down to 10 or 11 mm instead of 14 to 16.

I think that if I turned it right up with the 24 volt supply and no

load, the motor speed would increase until it self destructed, even if

that didn't happen until 5000 or more RPM. I'm starting to think that a

microcontroller overseeing operation is really a necessity if only to

set an RPM limit at a

safe maximum regardless of flux gap and load.

Sometime I

heard that iron-on transfers printed on a laser

printer

worked better if the sheet was repeatedly printed with the same

pattern, thickening the toner on the acetate sheet. Although not

optimistic about the probable results, I decided to give this a try,

with the LED constant current board I designed last summer.

Sometime I

heard that iron-on transfers printed on a laser

printer

worked better if the sheet was repeatedly printed with the same

pattern, thickening the toner on the acetate sheet. Although not

optimistic about the probable results, I decided to give this a try,

with the LED constant current board I designed last summer.

I had planned

to test the magnet sensor board before

bolting the

stator together. On the 19th, I was ready to close it up. First I

tested the board and was glad I did: a solder

blob across two traces kept one of the sensors from working (and

seemingly blew it), and like the previous motor, the temperature sensor

didn't work. The previous motor was also the first time it had occurred

to me to try reading the temperature, since I haven't run any of the

motors long enough to get very warm since designing the PC board with

the

temperature as well as the hall sensors. Investigation disclosed that

the AD590

temperature sensor part in the Eagle PCB components 'library' was

defined mirror image. (I probably defined it myself.) Turning it around

fixed it, and I'll redo the PCB design for next time.

I had planned

to test the magnet sensor board before

bolting the

stator together. On the 19th, I was ready to close it up. First I

tested the board and was glad I did: a solder

blob across two traces kept one of the sensors from working (and

seemingly blew it), and like the previous motor, the temperature sensor

didn't work. The previous motor was also the first time it had occurred

to me to try reading the temperature, since I haven't run any of the

motors long enough to get very warm since designing the PC board with

the

temperature as well as the hall sensors. Investigation disclosed that

the AD590

temperature sensor part in the Eagle PCB components 'library' was

defined mirror image. (I probably defined it myself.) Turning it around

fixed it, and I'll redo the PCB design for next time.

I took

a piece of 1/2" square steel rod and stuck it into

the splined socket of the leg drive shaft in the Honda. To my surprise

it was virtually a perfect fit. I took a Joy coupling I had lying

around and realized that if I rounded the corners a bit, the square

steel would fit it perfectly. So, one 2-1/2" piece of steel and a bit

of grinding and filing later, I had a fitting in the outboard. On the

24th I bought the rubber center piece and the Joy coupling to fit the

motor

shaft, and it's done. (Amazing how a shopping trip can eat up a whole

morning or afternoon.)

I took

a piece of 1/2" square steel rod and stuck it into

the splined socket of the leg drive shaft in the Honda. To my surprise

it was virtually a perfect fit. I took a Joy coupling I had lying

around and realized that if I rounded the corners a bit, the square

steel would fit it perfectly. So, one 2-1/2" piece of steel and a bit

of grinding and filing later, I had a fitting in the outboard. On the

24th I bought the rubber center piece and the Joy coupling to fit the

motor

shaft, and it's done. (Amazing how a shopping trip can eat up a whole

morning or afternoon.)

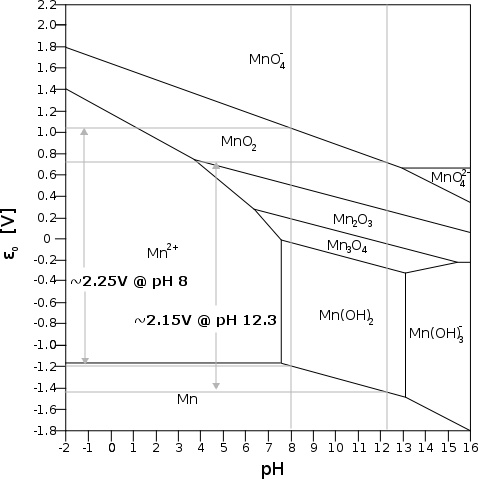

The new cell,

supposedly Mn-Fe, would charge up to well over 2 volts, the voltage for

Mn-Mn, instead of maybe 1.6 or so. I consider that the posode initially

loses a little unchelated KMnO4 into the electrolyte. The MnO4- ion

finds its

way to the negode and discharges to

MnO2->Mn2O3->Mn3O4->Mn(OH)2->Mn (all solid, the last

metallic), coating the negode with Mn as a higher voltage surface

charge.

The new cell,

supposedly Mn-Fe, would charge up to well over 2 volts, the voltage for

Mn-Mn, instead of maybe 1.6 or so. I consider that the posode initially

loses a little unchelated KMnO4 into the electrolyte. The MnO4- ion

finds its

way to the negode and discharges to

MnO2->Mn2O3->Mn3O4->Mn(OH)2->Mn (all solid, the last

metallic), coating the negode with Mn as a higher voltage surface

charge. I've sung the

praises of manganese as a battery ingredient

for both electrodes before, but here's another perspective. A great

beauty of manganese is that in every state of

oxidation from Mn metal to MnO4- (valence 7), it has electrical

conductivity. It can electrically charge or discharge all the way from

one end to the other; it can't be passivated, which is the chief factor

limiting the life of most batteries. All the states except permanganate

are also insoluble.

I've sung the

praises of manganese as a battery ingredient

for both electrodes before, but here's another perspective. A great

beauty of manganese is that in every state of

oxidation from Mn metal to MnO4- (valence 7), it has electrical

conductivity. It can electrically charge or discharge all the way from

one end to the other; it can't be passivated, which is the chief factor

limiting the life of most batteries. All the states except permanganate

are also insoluble. On the 20th,

since I thought I pretty much knew in almost

every detail what I wanted to do to make production MnMn flooded cells

(along the lines of last month's writing), I decided it was time to

bite the bullet, make all the needed tools to make them and design the

3D plastic pieces, and try making some. This seems something of a

gamble, but with yet another test

cell oozing salt out the seams and discharging itself, it seems making

test cells has been something of a losing proposition and isn't

providing any more especially useful results.

On the 20th,

since I thought I pretty much knew in almost

every detail what I wanted to do to make production MnMn flooded cells

(along the lines of last month's writing), I decided it was time to

bite the bullet, make all the needed tools to make them and design the

3D plastic pieces, and try making some. This seems something of a

gamble, but with yet another test

cell oozing salt out the seams and discharging itself, it seems making

test cells has been something of a losing proposition and isn't

providing any more especially useful results. It seemed to me that rough material would contact the

briquettes far batter than the smooth sheets of flexible graphite and

zinc. But what rough material? I've never seen a zinc mesh or grill. I

dislike working with carbon (graphite) fiber, but perhaps that would be

an option to make a "grill" for the positrode? Of course, there would

be no way to electrically bind it to the current collector except by

random contact.. or perhaps by winding it around the whole sheet.

It seemed to me that rough material would contact the

briquettes far batter than the smooth sheets of flexible graphite and

zinc. But what rough material? I've never seen a zinc mesh or grill. I

dislike working with carbon (graphite) fiber, but perhaps that would be

an option to make a "grill" for the positrode? Of course, there would

be no way to electrically bind it to the current collector except by

random contact.. or perhaps by winding it around the whole sheet. On the evening

of the 29th I made a positrode. I used about

the same permanganate-nickel-graphite mix as last time, with a bit more

graphite added to it. I removed the top plate from the book press to

get more pressing height, making a very nice screw press except that

the screw had no

non-turning end piece on it. But it was good enough and the compactor

seemed to compact very well. I added more and more of the powder until

20 grams had been consumed. (From which one might estimate 5 to 8

amp-hours capacity if utilization is good.) Even then it wasn't quite

full size. Because I had made one side of the compactor exactly the

63mm electrode

height, it was hard to add powder to get it right to the top without it

spilling. If I pressed it

hard enough, the 2.6mm stainless steel bulged. (.1" was the thickest

piece of flat stainless steel the recycling place had at the time.)

On the evening

of the 29th I made a positrode. I used about

the same permanganate-nickel-graphite mix as last time, with a bit more

graphite added to it. I removed the top plate from the book press to

get more pressing height, making a very nice screw press except that

the screw had no

non-turning end piece on it. But it was good enough and the compactor

seemed to compact very well. I added more and more of the powder until

20 grams had been consumed. (From which one might estimate 5 to 8

amp-hours capacity if utilization is good.) Even then it wasn't quite

full size. Because I had made one side of the compactor exactly the

63mm electrode

height, it was hard to add powder to get it right to the top without it

spilling. If I pressed it

hard enough, the 2.6mm stainless steel bulged. (.1" was the thickest

piece of flat stainless steel the recycling place had at the time.)