Turquoise

Energy Ltd. News #61

Victoria BC

Copyright 2013 Craig Carmichael - March 5th, 2013

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com = www.MushroomOutboard.com

Features:

* Woodstove Thermoelectric

Generator: 60-150W of free electric power from heat

* Electric Caik Outboard Motor test on the water: Great performance

& efficiency! Quiet!

* Peltier Heat Pump for House & EV Heating: 200% COP (~400W heat

for

200W electricity!)

Month In Brief

(Project Summaries)

- modified newsletter format - MnMn batteries: improving, and just 5

cells makes 12 volts!

- Electric Caik Outboard Motor on the water - woodstove thermoelectric

generator - Efficient thermoelectric heat pumping & refrigeration!

- magnetic heat pumping

crossed off the

project list.

In Passing (Miscellaneous

topics, editorial comments & opinionated rants)

- Bursting Bubbles - Upside down economy

Electric Transport - Electric Hubcap Motor

Systems

* Electric Caik Motor [Honda 7.5] Outboard motor.

- Boat Launch & tests!

* Centrifugal clutch for car PGTC transmission system (why didn't I

think of

it sooner?)

Other "Green" Electric Equipment Projects

* need for an all-inclusive hub to tie in various energy sources,

storage

devices, and loads.

* New design of Peltier module heat pumps for space heating: 200%

coefficient of

performance!

- evolving designs & COP measurement experiments

- Peltier fridges: same design principle cuts power consumption

in half!

Electricity Generating

* Woodstove Thermoelectric Generator (TEG) -

Perfect complement to solar panels!

- Picking the right TEGs

- Heat transfer with water

- Evacuated heat transfer tubes: thousands of times faster heat

transfer than copper or aluminum!

- Pressurized pipe to remove woodstove heat only if temperature

hits TEG max rating of 190ºC.

- Better Peltier fridges and Peltier heat pumps with evacuated

pipes?

* Low temperature steam turbine with evacuated pipes?

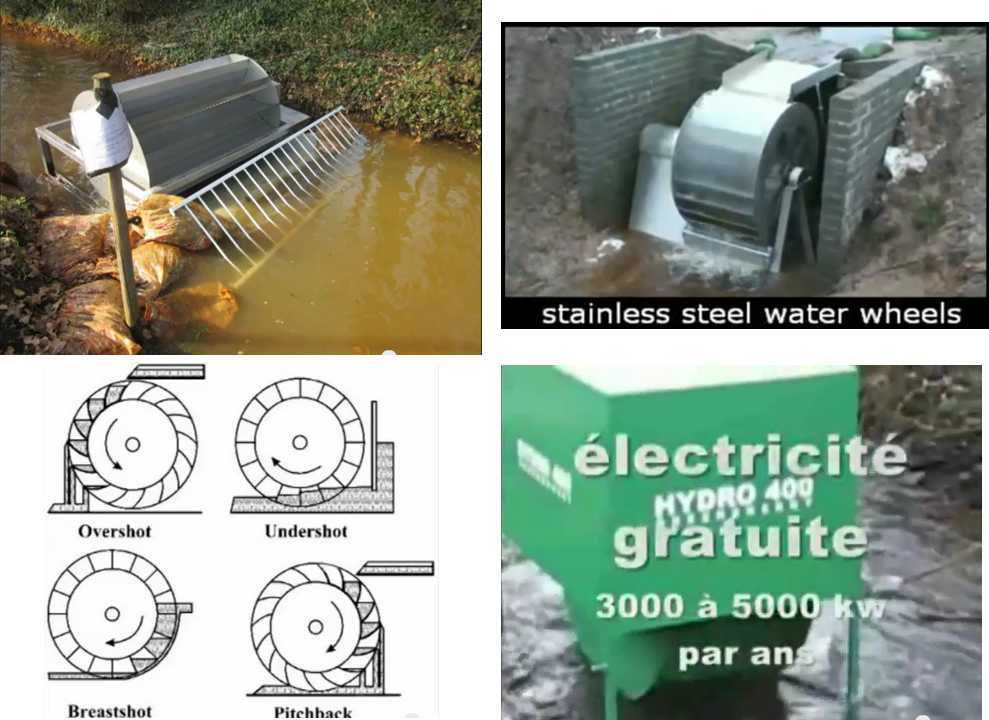

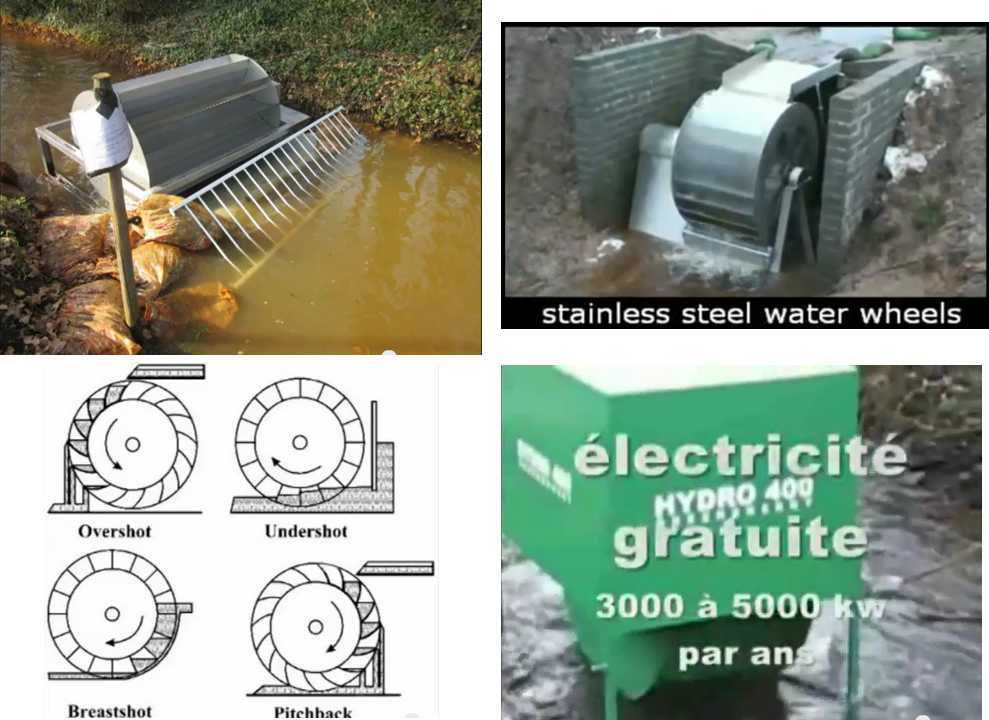

* River/stream Hydro power with surface water wheels.

Electricity Storage - Turquoise

Battery Project etc.

* Production Prototype Mn-Mn Cell #2: not great, but continues working

without leaks or deterioration.

- updated cell assembly instructions

* NiMH cells - safety issues - causes of troubles in January and

Februaury.

No Project Reports on: DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic

Motion Machine, Large

format NiMH batteries - take 3, CNC Gardening/Farming Machine.

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater (say, this heater is now obsolete! Use Peltier module heat

pump!)

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit - also please inquire about Electric

Caik

3KW Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks & Dry Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

February in Brief

I've moved a growing hodge-podge of

subject and project 'detailed reports'

that often have write-ups one month and then perhaps some brief, or

lengthy,

followups at later dates, into subheadings within four broad

categories: Electricity

Generation, Electricity Storage, Electric

Transport, and (other) Electrical Equipment, to

accommodate many and various topics. Within these, there are larger

'major subject' or 'project' headers and the usual small bold headers

for topics

within a project.

There seems to be little being done commercially to

develop new means

for generating electricity, although experiments go on on a small scale

by individuals. Means that seem costly or too small to

bother with today may get

cheaper with

development, and grid energy prices will only rise. Other means look

like

they'd be substantially less costly than present means. Where will the

world will be when these things are badly

needed, without having explored what's really practical and what isn't,

and so not knowing where to start? Wave power and in-stream hydro and

possibly tidal power have more potential for the power grid than wind

power, but are going untapped. Some solar installations have been done,

but it seems there should be more. It's a shame Canadian and US solar

PV panel makers have gone bankrupt in the midst of vast potential for

utilization. (One wonders about manipulations by 'big oil' in such

matters.)

Electricity storage is of course vital for electric

transport and for

off-grid installations, and lack of good & economical batteries is

seriously retarding

development of these fields. I'll continue to focus on battery

projects, and

especially on the MnMn/moderately alkaline batteries, which are now

entering the "production prototype" stage of development with 3D

printed cases and specialty parts.

I seem to have involved myself in further areas of

electric transport, from the initial idea of turning cars into hybrids

to marine drives and motors for two-wheeled vehicles. A large impetus

for the newer projects has been the failure so far to put any car on

the street, which is in turn owing to failure so far to create an

ultra-efficient vehicle transmission. But the marine and electric

cycling

are potentially very good markets for my motors and controllers, and

presently there is interest in them. The Electric Caik at least has

just proven itself to work well as an outboard on a boat. I haven't got

a transmission for cycles either, but I think the (as yet unbuilt) "rim

motor" has good potential as a direct wheel drive system.

"Other electric equipment" projects focus on products to

improve infrastructure and improve efficiency of electricity

utilization. The LED Globe Lighting, improved Peltier Heat Pump, and

the now reduced power Peltier Fridge

unit are examples of improving efficiency.

The Peltier module heat pump for space heating in

particular, initially more costly than electric resistance heaters but

not prohibitively so, can be installed by homeowners and uses half the

electricity.

It will soon pay for itself in electricity savings. Adding good LED

lighting to that gives the potential to substantially reduce electrical

consumption on a global scale.

The "CNC

Gardening/Farming Machine" will

be

a great

infrastructure investment that will increase areas gardened and hence

local food production everywhere.

Other "electrical equipment" projects seem to boil

mostly down to means to tie

in various electrical sources into one system, utilize all the

electricity generated, and wire dwellings with low voltage DC in

addition to, or as an

alternative to, 120/240 VAC.

The main focuses of February were on

getting the electric outboard going,

and exploring a new idea - the woodstove thermoelectric generator

(TEG). Other items included assembly of 'production prototype MnMn cell

#2 and subsequent testing that seems to indicate I finally have a long

lasting cell. Later came substantial improvements to the Peltier Heat

Pump

and the Peltier Fridge designs. The Peltier developments were first

spurred on by heat radiator ideas for the TEG, which has closely

related

construction. That led to re-examination of the Cui Peltier module

datasheets, which led

to realization that if they're run at 2/5 to 3/5 of full rated current

(1/2

current is 1/4 power), Peltier efficiency rises dramatically. Peltier

heat pumps for space and EV heating can be made that'll have a heating

coefficient of performance of around 2 in typical west coast winter

weather. (They do get worse in below freezing weather. So do

compressor/refrigerant heat pumps.) At the start of March I ran an

experiment which roughly verified these higher efficiency potentials of

Peltier module heat pumping.

MnMn Battery: just 5 cells for 12 volts!

I made MnMn 'production prototype' cell #2 near the start

of the month. In some ways

it seemed like a flop. It charged, but had high internal resistance

(substantially higher than the first one), still

too much self discharge overnight, and seemed to hold only 2 or 3% of

the capacity it should have had, under .1 amp-hour. It didn't want to

drive much more than a couple of mA/sq.cm (10-20mA/sq.cm with a 1 ohm

load

at much too low a voltage) instead of 30 to 50.

On the other hand, it didn't seem to leak except when

overfilled or when suds

came out the filler hole, and it continued to work similarly over the

whole month (it even improved) showing no signs of trouble or

deterioration except when

seriously overcharged. That makes it a winner of sorts: my first

lasting cell.

Another thing that came to light was that it charges up to

about 2.6 volts instead of the expected 2.2 or so, and (except for

continuing gradual self discharge over the hours, which stopped

nowhere) it

held the voltage. I won't complain about 2.6 volts!

For a while I wasn't letting the charging voltage rise high enough to

charge it properly. Even 2.5 volts to charge a single cell just seemed

silly, but finally I tried more and got results.

The problems it has including the self discharge appear to

be related to construction and implementation problems rather than to

the chemistry. (When I shook out the electrolyte and replaced it with

fresh, electrode powders that had escaped from an electrode(s) somehow

came out with it, and self discharge went up instead of down. The new

electrolyte was at least no less pure than the old.)

Perhaps (assuming the internal resistance is reduced to an

acceptable figure) one might call it 2.4 volts nominal under load. With

such high voltages it'll only take 5 cells

to make a 12 volt battery. That contrasts well with 10 NiMH cells or

even 6 PbPb cells, especially when it theoretically has more amp-hours

per weight than any other type. Only Li-ion takes fewer

cells, 4.

They may be under 11 volts (2.2 volts/cell) towards the

end of their useful charge, and they'll need about 13.5 to 15 volts to

charge (2.8 to 3 volts per cell), rather similar to other 12 volt

types. They'll probably be quite tolerant of various chargers with

differing characteristics.

I didn't put any calcium hydroxide in this cell, and the

pH started out low, perhaps 7.5. It rose gradually to seemingly about

13 on its own. I guess it's self regulating, just as lead acid will

always acidify any chemicals added to maintain pH 1. It won't hit 14

because the Mn negode will spontaneously absorb excess OH- ions,

discharging until that lowers the pH again.

When it was overcharged at about 3.5 volts for a few hours

(testing the limits!), the smell of chlorine became evident in the

room,

and yellow and orange crystal growths that may have been sulfates and

sulfonates from the Sunlight dishsoap, or

possibly Fe(OH)3 from the rusting ball bearing filler cap, grew

profusely around the filler cap area. I probably won't repeat that

charge level.

Overcharging (at 3.5 volts) caused this crystal growth... whatever it is

Toward the end of the month I inched forward again

(amongst all the other things) by doing a new 3D plastic case with a

couple more improvements, to be complemented by an improved compactor

and some improved procedures.

Electric Caik Outboard Motor

Setting up, Friday. I managed to finish and even scrub off the boat

before launch.

Setting up to run the motor in the Honda 7.5 outboard

shell on the water took first place in construction efforts until the

16th. Starting at the VEVA electric transport meeting on the 6th I had

told

people I would launch the Electric Caik Outboard in my 14'

aluminum boat at 1:30 PM on that date. I finally got everything set up

except an appropriate

speedometer by the afternoon before, and went for a couple of test runs

on schedule. It performed well. The 24 volt motor drew up to 60 amps or

so, about 2 horsepower, and reached over 2000 RPM. In the 2010 tests

the early version of the Electric Hubcap motor drew up to 30

amps at 36 volts (1.5 HP), and only reached about 1750 RPM.

I

must have been going faster this time since the RPM was higher and the

boat was 100 pounds lighter (3 heavy lead-acids versus a NiMH dry cell

battery weighing less than one), but with a strong wind blowing

the boat around it was hard to tell. Someone shot some short video

clips:

I was pleased that the temperature rise in the motor

(after 2 short trips) was

only about 17°C. That means the air flow is good, it's running

efficiently and hence making little heat, and that it'll probably take

the full 3KW I tentatively rated it at continuously without

overheating. That's all the more remarkable when the maximum

temperature is just 65ºC for this motor with all the epoxy

construction. It's an efficient, compact, cool, lightweight powerhouse.

And

it was all but silent. I might be inspired to go out fishing some time!

Perhaps I should mention that the Caik motor can easily be

made as 36 volts, 82 amps instead of 24 volts, 127 amps. (or of course

12 volts, 254 amps. Find your own motor controller for

that!)

Woodstove Thermoelectric Generator

Radioisotope ThermoElectric Generators (RTEGs) powered by

a hot chunk of plutonium (self heated by its

radioactivity) have long been used in spacecraft going out to Jupiter

and beyond, where solar power from the sun is feeble.

I have just

discovered that TEGs are readily

available in a usable format, after buying a new woodstove and a

Caframo "Eco Fan" that

sits on the stove and runs off the heat of the stove... using a TEG. In

fat, TEG modules look just like peltier

modules, but are optimized for making electricity from temperature

difference (the Seebeck effect) instead of temperature difference from

electricity (Peltier effect). For those who

burn

wood for

winter heat, as is relatively common in this area, it appears a

woodstove thermoelectric generator (TEG) could be a good complement to

solar

PV, since it runs most of the winter when there's little sun -

including at

night.

But it appears TEGs made for wood stoves have been

designed

for surviving peak temperatures rather than for good output with

typical average temperatures of modern low emissions stoves with smoke

igniting baffles, and average

electricity output suffers greatly. This would be a natural tendency of

a TEG device designer who doesn't himself burn wood for daily

heating... or

who perhaps lives in a colder climate where fires are kept hotter. My

design innovates by

using lower temperature TEGs that will produce much more electricity

under typical west coast operating conditions.

The boiling point of water rises with air pressure. My

plan to protect the TEGs when the stove is too hot for them is for a

185 PSI pressurized radiator pipe loop. That will boil

water at 190º, their maximum rating. The steam will rise to a

radiator where it cools and condenses, then runs back down. Below

190º the water will sit in the hot side box unit on the stove, so

no generating capacity is wasted.

Where I get the first impression that most other woodstove

TEG units make up to

around 50 watts with quite a hot fire, I'm expecting up to about 150

watts of electricity from 16 of the 190º TEGs with a moderate

fire. And the stove top could easily fit two such units if more

elecricity was desired. All the heat that isn't made into electricity

(most of it) just

goes out to the room as usual, so conversion efficiency is immaterial

except for defining the overall size and number of parts, and hence

cost, to get "X" amount of electrical capacity.

Peltier Heat Pump for individual room, EV heating: 200% COP!

Peltier Fridge: 1/2 the power for the same cooling!

I got going again on

the heat pump by thinking of potentially better heat radiating

mechanisms with no fan noise. Then I re-read the Cui Peltier Module

datasheets. I multiplied 1/2 times 1/2 and got 1/4 instead of 1/2.

The graph showed (typically) that if the current was half,

the watts of heat pumped

was a little over half. But that's comparing apples and oranges. Then

I related the

current chart to the voltage chart and suddenly realized that half

current comes at about half voltage, and so it was actually one

quarter as much

input power! This suddenly made

Peltier module performance look much better - at lower currents and

voltages. I had heard that they worked better at low power, but I

wasn't seeing the extent until on the 22nd I realized my

error in

thinking. I'd been sucked in by the misleading graph!

The detailed report shows that the heat pump can attain

around 200% coefficient of performance for heating by

driving 15 volt peltier modules with between about 6 to 9 volts, and

how in a fridge, simply putting two of the same peltier elements in

series to drive

them at 6 volts and half the current each will cool it

about as much as a single one (drawing twice the total current) at 12

volts. My 85 watt fridge will drop to under 50 watts!

Driving the Peltiers at lower power means using more of

them, and somewhat larger interface surfaces (more materials), to

attain a given

heating or cooling objective, but that investment will soon be made up

in electricity savings.

Cutting heating energy and cost by 25 or 30% was one thing

-

nice, but not compelling. Cutting it in half, 50% - to replace 400 watt

heaters with 200 - has a lot more appeal. Now I'm really getting

enthused about improving the fridge, and getting peltier heat pumps in

my house in the rooms that use the most electric heat -- and probably

even

working them into professional products, offering them for sale and

making a small enterprise out of it. (Wait, I thought I was doing that

with motors... I'd have to hire someone for this.)

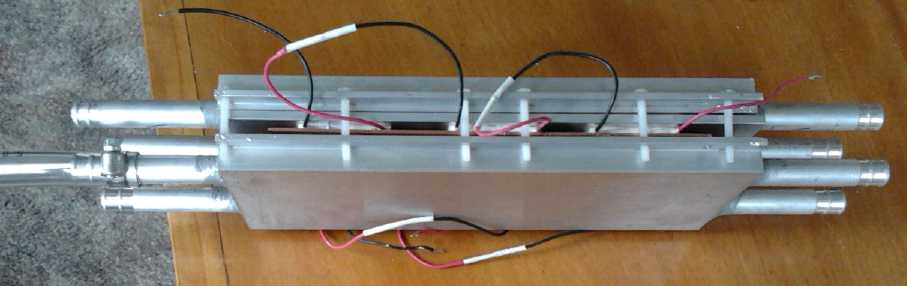

Heat pump with cold side air radiator, warm side liquid.

Then somebody suggested antifreeze would allow a liquid cold side.

This got changed to water radiators for both sides - with anti-freeze

in the cold outdoor side.

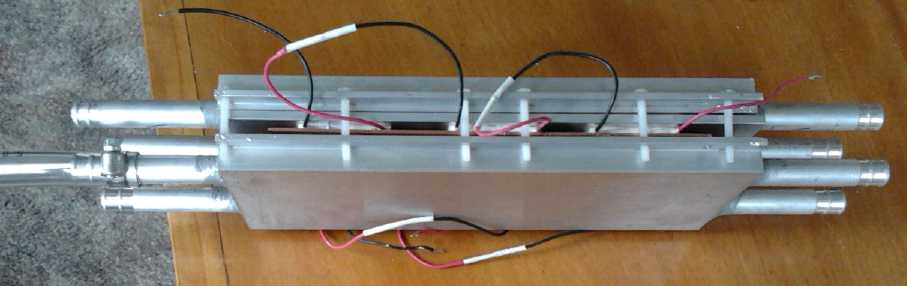

This looks about the same as the woodstove electricity generator.

Next: 3D plastic printed cases with copper plates facing the peltiers.

I made the left radiator first. The punch was the perfect size - good

friction fit.

So I decided I needed a proper sheet metal sheer to cut the same size

fins repeatedly

and a jig to get the holes centered (right). Later came fin spacing

clips in 3D

printed plastic.

On the 26th I got on youtube and looked for videos of

Peltier fridges and heat pumps as well as thermoelectric generators.

The words were there in the titles, but when you viewed the videos, a

"fridge" was just a peltier

unit frosting up on a table, and a "heat pump" just meant the basic

Peltier module operating principle. There were a couple of videos where

the ideas sounded good

but the authors didn't seem to quite understand what they

were doing. There was a nicely made beer cooler, a roughly made larger

cooler (beady styrofoam, no hinges) and one guy worked out the

COP for heating up 100cc of water by 22.5ºC (about 2.65! - IIRC)

in 2009, and that was

about as interesting as it got.

So I thought I'd put a video of my fridge up, even tho I

haven't enclosed the heatsink and fan, made the solar day-night

control, or tried out the half power idea. I shot it that evening.

Youtube's 'enhancement' of the rather dim scene is probably an

improvement

but still less than perfect. (The patterned melamine top looks like

rocks at

first!) Anyway it's hi-rez, and it's the only practical thermoelectric

fridge I saw on Youtube. [ http://youtu.be/iCuNBY3hMwI

]

Quitting Magnetic Heat Pumping project

I've decided to abandon the magnetic heat pumping idea in

favour of the Peltier system, which can provide better performance than

I had realized. It's not that it was a bad idea, or that it might not

have a higher coefficient of performance, or

that I feel I might not get there if I persevered. I did get gadolinium

to change temperature with a magnet, and I feel my 'solid state'

magnetic heat pump designs (with moving parts but no liquid or gas)

have pointed to a new

direction for future research and potential product development.

(Perhaps I'll do a youtube video.) It's just that I have far too many

projects. I can make magnetic prototypes, or I can make working Peltier

heat pumps as products that might start saving homeowners electricity

next winter. If the whole thing wasn't just one area of many I'd try to

do

both.

There's one further consideration: if someone should come

up with a Peltier module with better thermocouples - perhaps find some

junction materials superior to bismuth-telluride, performance could

rise to a point where the simplicity and longevity of a solid state

device would simply make magnetic and compressor based heat pumping

redundant except in (or even in?)

large systems. Achieving a 'typical' COP of 3 would accomplish that. I

don't know that that'll happen but if it did probably my existing

designs, or modified versions of them, would simply work better with

the improved parts.

In Passing

Incidental news, editorial comments & opinionated rants

In discovering that the world isn't the

stable, stately place I used to think is was, in a couple of my recent

newsletter editorials I got pretty excited about what might happen, and

how soon. The population is in a bubble and looks like it'll shrink,

the financial

system is bound to crash, and the USA obviously can't go on as it's

going. One sees what must happen in broad outline, and yet the

sequences and timings and

what straw breaks what camel's back, or if the camels just lie down or

something,

are pretty unpredictable.

Viewed in retrospect, these things will no doubt seem to

have occurred in the blink of an eye, but in the present, event follows

upon event in an unforeseeable sequence that may take a decade or more

to play out - we have only to

look

at the protracted woes of Greece or Palestine and think they must

surely end, but they go on and on. Hopefully the population drop will

be gentle and trouble may largely overlook

less crowded regions, tho one suspects not. Money will have to

be recreated in some form - hopefully as an honest, sustainable system

without institutionalized robbery built into it. And the nation that

brought us the silicon chip, went to the moon, and created the internet

is as likely to

reinvent itself in new form as to break up. Only the financial crash is

almost certain to be a sudden, full blown crisis, because everything

that's being done to put off the day is making it so it'll be worse

when it happens.

Viewing the facts, a few negative circumstances do stand

out:

* The population seems to be "in a bubble". Perhaps not so much in the

Americas or Australia, but other regions on other continents seem

seriously

overpopulated. All financial and economic bubbles burst, and this

bubble seems

poised

to do so as well. China's one child policy has

doubtless had considerable beneficial effect there, and India has been

overtaking China as the most populous country in the world. But

together they have 1/3 of the world's people. Almost

everywhere, there seem

to be too many cities that are too large and with tenuous supply lines,

vulnerable to any interruption.

A small number of nations such as Indonesia and Nigeria are still

procreating prolifically. This can't work out well. It's said that when

people are spending 40% or more of their income on food, revolutions

break

out, and that this has been an under-reported factor in the "Arab

Spring" uprisings. And when conditions

get bad enough, disease epidemics are almost bound to break out and

wreak

havoc too. In an

increasing number of "more advanced" lands, family size has shrunk to

or under replacement levels, but owing to increased life spans

the

effects of this are slow of realization.

* The world economy has also been "in a bubble", the need for goods and

services growing with the expanding population. This is now collapsing,

in large part part owing to extreme inequitable

distribution of

wealth (youtube: "Wealth Inequality in America"), but it will get worse

regardless. When the population

starts to shrink,

there'll probably be more than enough material goods for everyone, and

so much less

need for new goods, and especially for new housing and expansion of

civic infrastructure. Except for food, energy and clothing,

improved technologies and superior products may become - if they aren't

already - the only flourishing areas of production.

A possible exception might be large scale investments in

infrastructure (such as

electric rail transport and 'green' electric power)

if those who wish to build a better future are able to grasp the reins

of governance. But for progressive people to get into decision making

positions gets into improving our social and economic governing

structures, which won't happen before a big crash.

* The financial system is in some bubbles of its own making, and it is

one area where a sudden and probably global crisis is likely to strike.

There was the "dot

com"

bubble, then the "housing bubble", now the "bond bubble" is global, and

currency

itself is inflating itself to oblivion and will soon need drastic

revisions.

Having privately owned central banks print money on behalf

of

countries and then lend it to them and charge interest on the

money they simply conjured up, is a huge pyramid scheme that was

foisted

on

everyone long ago by greedy people, corrupt or indifferent leaders, and

a complacent

public. It's been perpetrated by cunning and persistent schemers to

make themselves fabulously wealthy. It was and is enabled by general

lack of education about how finance works and even about what money is,

and it's largely to

blame for present day ills.

---

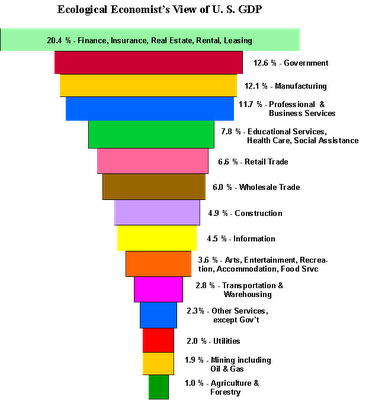

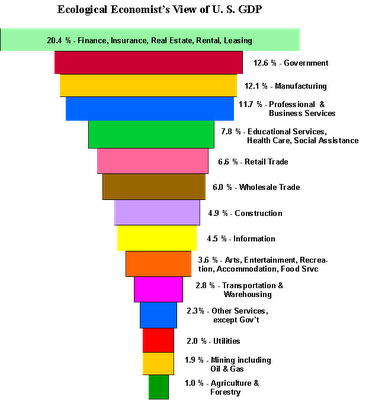

Usually economic charts are pie graphs, where everything

is "equal" except in percentage. Someone sent a

link to

the interesting one below, which shows how food and energy production,

natural resource extraction and transportation and storage of goods,

the parts of the economy essential to the maintenance of all else,

forms

an inverted pyramid. Without that seemingly trivial food sector at the

bottom, less than 1% of the economy, we all die, so the thin edge of

the wedge - the farmers - holds the rest of

the pyramid up. The fact that oil and gas are vital to food production

and distribution shows why we need to get on to electric farming with

CNC farming and gardening machines, electrify the railroads for freight

and passenger transport, and finally move to electrify all vehicles

and

vessels. At the "top" of the pyramid, the financial sector should only

exist at all to serve the rest of the

economy. It sector should be as small as is consistent with

that mandate. The government should be at least large enough to

ensure no one can take advantage of anyone else. But those in charge,

using the "revolving door" between corrupt government and finance, have

figured out how to extort so much wealth from everyone else that they

have become cancerous parasites that dominate the economy.

And I think it must be an old chart. Evidently the

unregulated

shadow

banking system is now much larger than the rest of the economy combined

(notwithstanding that the big banks are insolvent, ie, they have more

liabilities than assets). Governments have swelled, and in the

west manufacturing has much shrunk, making the pyramid even more top

heavy and parasite ridden than shown. The pyramid is probably a good

indication of the symptoms of what's wrong with our unsustainable

society.

Now back to that trivial little part of the economy, food

production. If - when - Monsanto's patented GMO pollen blows into your

field and contaminates your crop seeds, you have to pay royalties to

Monsanto for using their patent. That means most all farmers,

everywhere, are paying Monsanto royalties on the unwanted

contamination, and unhappily growing GMO foods to boot.

There was a big court case about it in Canada (15-20

years ago?) - Monsanto detected their GMO genetics in the crops of a

farmer who had never ever had any dealings with them and hardly knew

their name, whose family had grown their own seeds for generations -

and Monsanto won. The farmer, a well-spoken and articulate man, lost

the family farm. This set the precedent for this tyranny. In India

farmers had to fight a huge court battle to regain the "right" to grow

their own seeds at all.

I've heard that some farmers lately - even in India - have

given up and even committed suicide because they're all pressed under

the thumb of Monsanto and their global GMO experiment. And yes, it

seems those GMO foods are causing at least a few people serious health

problems (allergies at least). How many health problems then are being

caused

by them but the link hasn't been discovered - or admitted - yet?

Evidently over 1/2 of

US children now have chronic health problems. ...Well, here's an

alarming piece in my e-mails just as I'm finishing up this newsletter:

it says

"An Italian study found that Monsanto's NK603 genetically-modified (GM)

corn causes serious organ damage and tumors in mammals."

and

"Based on earlier research involving the link between viral genes and

plant and human health, the new discovery raises serious concerns about

the safety of many GMOs in commercial production today."

http://www.ubalert.com/bwwb?open_ctab=1

http://www.naturalnews.com/038998_GMO_crops_viral_gene_organ_damage.html

This probably won't hit the US news at all. They know Monsanto will sue

them if they broadcast it.

And I hear Monsanto has recently purchased every major

garden seed company. It may get very hard to avoid GMO foods even in

your own garden. Latest news is that while bugs are adapting to thrive

on GMO foods that were immune to existing pests, Monsanto is blaming

the

farmers for recent poor

GMO crop yields.

---

Ever think of a good "comeback" or response just after, or

long after,

the time to say it has passed? (There was one that kept annoyingly

popping into my mind for a decade, until one day I finally thought of

the

perfect response for what was said ten years previously that I had

answered so lamely. Ever since then, I can't even remember what the

subject

was.) Now I've thought of a great ending to last

month's

little piece on arms: "Guns don't kill people, Americans kill people."

Of course, most people everywhere including the Americans are good

hearted...

but that's where

so

many violent death stories in the news originate, from shooting sprees

by depraved individuals to drone strikes killing hundreds (4700+ so

far

according to a senator supporting the strikes) by the present

administration.

Electric

Hubcap Motor Systems - Electric Transport

Electric Caik Motor

'Honda 75' Outboard Conversion

(a motor with many scratches but not made from scratch)

Flexible 'joy coupling' connects motor shaft to outboard drive shaft.

Luckily, a 1/2" square steel rod fit in the drive shaft's socket, and

with

the corners a little ground off, in the joy coupler.

On the evening of the 2nd I discovered how little work would be needed

to mount the Electric Caik motor in the Honda 7.5 outboard shell. On

the morning of the 4th I had it in. It wasn't my idea of ideal,

but the shafts lined up well and in a retrofit it's often far simpler

to go with the flow and cludj things in than to do it in an ideal way.

(In other words, I don't think it'll fall apart on the water.

In the event it seemed pretty solid.)

Theoretically I could have thrown things together and

taken it out that very day. But I decided to be more methodical. I

wanted the controls right on the outboard this time - a twist speed

control on the arm and the forward/reverse switch on the case - instead

of in the motor controller on the seat. (Later I measured and it looked

like I could (just) fit a controller under the hood with the motor.)

In addition, the plywood motor

mounting board on my boat's transom was virtually rotted off. I cut a

new one after the trip in 2010 but hadn't painted it or put it on.

(It's all the

newer now.) And I wanted RPM, current, temperature and voltage meters

nicely set up.

On the 6th I tried running it dry, and then in a garbage

pail of water. It seemed quite solid and smooth. Forward was pretty

quiet (unlike in 2010 when the motor shaft was pressing downward on the

leg drive shaft), but in reverse (motor running backwards) there was

notable gear noise. So what? Turning at 2000 RPM dry took about 16 amps

- 1/2 a

horsepower. The motor alone took 5.7 amps last month, showing the

friction in the outboard drive mechanism is eating about 1/3 of a

horsepower.

It was pathetic seeing how slowly the prop turned with the

motor racing away. To eliminate that nasty gearing down is of course

the main reason I want to build the 'outboard from scratch'. And maybe

it

could eliminate most of that 1/3 of a horsepower of wasted energy.

Hitting 2000 RPM wet took around 40 amps - 24 more than

dry - showing it took 3/4 of a horsepower to churn up a storm in the

water in the pail. After a few moments of this, I felt the MOSFETs in

the motor controller. They were actually slightly warm.

Then I took it to the VEVA electric transport meeting in

the evening and ran it (dry) in the parking lot as a demo. I announced

that I'd launch it at 1:30 PM on Saturday the 16th, and I told a few

other people in the next few days. I spent a good portion of the next 9

days getting things ready.

I painted and put the new piece of plywood on the back of

the boat, installed a potentiometer in

the outboard's steering handle to replace the throttle cable and a

Fwd-Off-Rev switch on the front of the case, made a box with plexiglass

to hold meters for amps, volts, motor temperature and RPM, got a pitot

tube with a speedometer, reconfigured the batteries from 20 AH at 36 V

to 30 AH at 24 V, licensed the trailer, put a circuit breaker in the

motor controller and fixed the RPM signal trace (long overdue), wired

the necessary plugs and cables, and made two labels for the motor. I

meant to make a housing and tie in two 100 amp-hour lead-acid

batteries, but I ran out of time. The 30 AH NiMH, 60 D cells, would be

enough for a

test.

Friday prep.

On Friday I

put it all together in the boat. I

found I had

managed to wire three of the cables wrong, but nothing blew up and I

got it all running before the afternoon ran out.

On Friday I

put it all together in the boat. I

found I had

managed to wire three of the cables wrong, but nothing blew up and I

got it all running before the afternoon ran out.

One unsatisfactory feature was the speedometer. It read

from about 15 to 60 'mph', with lower speeds hardly moving the needle,

and the boat wasn't going to hit 15. Evidently they're only made for

high speed speedboats. Blowing into the tube I couldn't make enough

pressure to get the needle up to the first mark -- there must be some

transducer to work with much lower air pressures in the tube. Aircraft

pitot tubes also must surely work at much lower pressures, since

they're in air and not water. There were paddlewheel speed indicators

available, but they were too costly to consider.

Saturday had a lot of weather. It started out as a

beautiful morning with (gasp!) full sunshine, but clouds rolled in and

around noon another unusual phenomenon, strong wind, sprung up. When I

got to the boat launch at 1 PM, everybody was bringing in their boats.

I was still planning to launch in the sheltered little bay, but someone

thought it was too windy. There was some discussion and we talked for a

while. We shot a little video where I showed the various components.

[http://youtu.be/zrtE6yHSFRw]

Finally I decided the launch had to go ahead. It was a small,

light boat, and four of us could surely manhandle it around regardless

of wind.

The wind

pushed the bow of the boat

around and nearly blew it back against the jetty as I headed out.

[http://youtu.be/jen-WpfaM4k]

When I finished concentrating on that I glanced at meters. I

was surprised to see the motor over 2000 RPM and drawing almost 60

amps. I had meant to keep it under 30 amps for the first trip, which

was the maximum value I'd used in the November 2010 trip with the

primitive version of the Electric Hubcap motor. (That one used the

second

stator ever made - oblong nail strip core coils on a lossy steel rotor,

and a 9" rotor that *just* fit inside the Honda hood.)

The wind

pushed the bow of the boat

around and nearly blew it back against the jetty as I headed out.

[http://youtu.be/jen-WpfaM4k]

When I finished concentrating on that I glanced at meters. I

was surprised to see the motor over 2000 RPM and drawing almost 60

amps. I had meant to keep it under 30 amps for the first trip, which

was the maximum value I'd used in the November 2010 trip with the

primitive version of the Electric Hubcap motor. (That one used the

second

stator ever made - oblong nail strip core coils on a lossy steel rotor,

and a 9" rotor that *just* fit inside the Honda hood.)

I cringe because I've had so many of my motor controllers

blow up at high amps, but this one has been very faithful and has done

100, tho only momentarily. And

running 24 volts instead of 36 should be easier on it. At 30

amps, I could hardly keep the boat headed into the wind, and I had to

up it to 40. It seemed the motor had less push per amp. It finally

dawned on me that the previous motor was 36 volts and this one was 24,

so the current to match the previous 30 amps was now 45, power being

volts

times amps.

With the strong wind it was hard to compare speed mentally

with

the 2010 trip, and I was disappointed - I thought the boat was going

slower. But it was the

same outboard shell and the same prop, and the same boat was about 100

pounds lighter with the NiMH battery instead of 3 big lead-acids, so

the same RPM had to be at least

the same speed on average, and probably a little faster. Last time the

motor was

about 1700-1750 RPM max, and

this time it was over 2000, so it had to be going somewhat faster.

And there

was, if not a wake, more turbulence behind the transom than I

remembered.

[http://youtu.be/-L3yHhgoFmE]

Towards the end of the second little trip, with two of us

on board, while drawing a high current like 60 amps, the 30 amp-hour

battery was down to 20.8 volts. I'll want more cells in parallel next

time to handle the currents better, which will improve the range more

than simple addition of the amp-hours adds up to. And before I head out

on a real trip (fishing?), I'll want to see how long it really will run.

I seemed hard to gauge efficiency. But on the second trip

I looked at the the motor temperature a few times. It sat at about

300-301ºK (27-28ºC) and wasn't rising. Since it was around

10ºC out, that's a rise of just 17-18º, pushing 40-60 amps or

up to 1.44 KW (2 HP). The low rise indicates (besides good airflow) not

much heat generation, which indicates little power is being wasted

inside

the efficient motor.

"Best under" temperature for the coil cores and the epoxy

is 65ºC. If it was 20º ambient, that's an allowable rise of

45º. So it looks like the motor could probably run continuously at

my originally estimated rating of 3 KW without overheating, except

perhaps in

hotter weather. And I could always drill some more airflow holes in the

rotor end - they're pretty few and small as built. I couldn't try

higher current and power on this trip without over-revving the motor -

and probably over-stressing the battery.

Next I'll want to try one of the scuba unit design

propellers to see how much difference that might make to performance.

I'm expecting lower amps to achieve the same boat speed. Now, about

measuring boat speed...

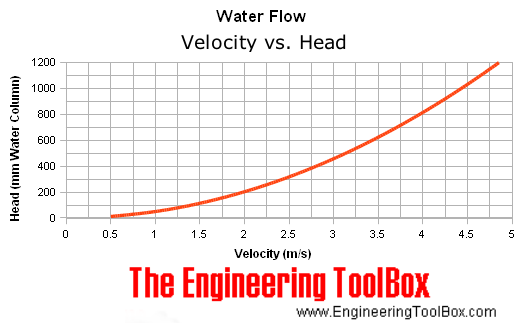

Measuring Boat Speed

I found a pitot tube that should give boat waterspeed, but

the speedometers went from 0 to 60 miles per hour, and the first

marking was at 10 and the next at 15. I had to blow awfully hard to

move the needle at

all, suggesting that the problem wasn't the pitot tube but the

insensitive speedometer. In the rush of events, I didn't even mount it

during the boat test, and I doubt I'd have seen much on it if I had.

I looked everywhere for a chart of the Faria pitot tube's

speed versus pressure, but found nothing. Finally at

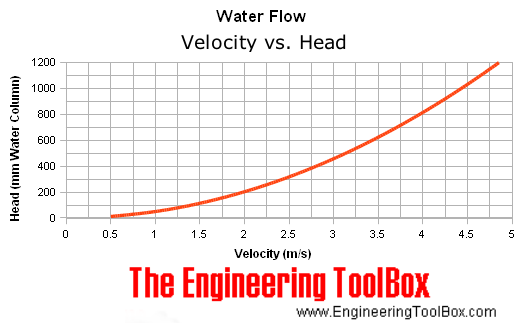

"EngineeringToolBox.com" were some graphs and tables.

I was

thinking that every pitot tube design would be different, but that's

really not the case. If there's a hole in the front end, the dynamic

pressure must depend only on the speed, so the figures would apply to

all. Hence any speedometer will go on any front-end pitot tube. The

size of the hole and piping behind it would only make a

difference in how fast that pressure equalizes when the front end

pressure changes, not to how high the water finally rises in a vertical

column tube. (Let's see...

there's 3600

seconds/hour and 1000 meters/kilometer, so 1 m/s = 3.6 Km/h.)

The table below shows the head obtained at different velocities

(conveniently in feet & feet/sec,

contrasted to their two graphs in meters & meters/sec, and in

inches

& feet/minute). Evidently, all

one needs to do is use transparent tube, make it into an open topped

vertical column

from the waterline up, do the

necessary conversions, and mark off the velocities on the tube or a

white surface behind it. Then it should be possible to get pretty

accurate velocity readings down to maybe 2 or 3 miles per hour,

depending on the accuracy of the height readings. This can go up to the

speed of however high the tube is, above which speed water will spew

out the top. Of course one could plug the top end and get a

more linear scale, but column height versus air pressure above the

column would all have to be worked out for each speed.

The one catch to this is to keep the measuring stick base

at the

waterline level, which naturally varies considerably. Perhaps one way

to do that is to put a 'trim tab' with a float out the

back, which would go up and down with the water level.

The tube could attach directly to this and be situated

behind the transom, but then you'd have to lean over the back of the

boat to read it. (How many people have drowned from peeing off the

back of their boat and falling in?) A better way might be to have

something like a coat hanger wire bent in an upside down "U", with the

outside end on the float, coming over the transom, and down again at

the rear of the boat. The base of the measured tube section attaches to

the inside end. No doubt there are a zillion possible variations on

this theme.

Velocity Velocity Head

- v - - v^2/2g -

(ft/sec) (ft of Water)

0.5 0.004

1.0 0.016

1.5 0.035/10.6mm (1 MPH = 1.46667 ft/sec)

2.0 0.062

2.5 0.097

3.0 0.140 (2 MPH, 29.6mm)

3.5 0.190

4.0 0.248

4.5 0.314 (3 MPH, 95.7mm)

5.0 0.389

5.5 0.470

6.0 0.560 (5.86f/s=4MPH, 171mm)

6.5 0.657

7.0 0.762

7.5 0.875 (7.3333f/s=5MPH, 267mm)

8.0 0.995

8.5 1.123 (5.8MPH, 342mm)

9.0 1.259

9.5 1.403

10.0 1.555 (6.8 MPH, 474mm)

11.0 1.881 (7.5 M/Hr)

12.0 2.239 (8.2MPH, 682mm)

13.0 2.627 (8.9MPH, 801mm)

14.0 3.047

15.0 3.498 (10.2MPH, 1066mm)... Wow, after

converting units, this actually agrees with the graph above!

16.0 3.980 (10.9MPH, 1213mm)... I'd probably be

doing really well to hit these speeds?

17.0 4.493

18.0 5.037

19.0 5.613

20.0 6.219

21.0 6.856

22.0 7.525 (15 miles/hour, 2294mm)

My take at the moment is that for speeds of about 2 or 3

up to 10 MPH, the system with a vertical tube a meter or more long

would work well. Above 10 or 15 MPH (if I get there - probably with the

'outboard from scratch') a stock speedometer could be used and the

waterline is of little consequence. Hovering around 10MPH might be

annoying to measure. I think you'd want a tube with a stopper on top,

and would have to do (or find) the calculations for height water for

each speed.

Future Caik Outboard Runs

The outboard with the Caik motor seems like a keeper, and

I'll be taking it out again and checking out the speeds attained... and

a 9" shortened cast aluminum or PP-epoxy version of the scuba unit

propeller, assuming I make one successfully. With some more amp-hours

of batteries on board, and perhaps a couple of large 12V solar panels

forming a roof at the front, I might even go out fishing!

A final note: It would be surprisingly easy to over-rev the Electric

Caik motor

and the gearing down of the prop prevents being able to use full power

without over-revving, but I do have one safety in the outboard as done:

I put a 50 amp circuit breaker in the motor controller. It didn't blow

at 50 to 60 amps and

somewhat over 2000 RPM, but it surely would have by about 70 amps

before

hitting 2500 RPM or so. I had the Caik running up to 2700 on the bench

and that didn't bust it. So I probably have a boat that won't

blow up

with the first mistake on the throttle. But I keep thinking I should

come up with some way

to strengthen the rotor so I'll feel comfortable taking the motor up to

at

least 3000 RPM.

Before the end of the month it occurred to me I might try

reducing the supply voltage to 18 volts from 24. That would drop the

maximum RPM, probably to a reasonable level. Currents would be 4/3

higher, but it wasn't drawing near the limit anyway. (Of course, I'd

have to find a higher rated circuit breaker.) Or, the potential 36 volt

Electric Caik version could be run at lower voltage... like

24... really, I want that outboard that isn't geared down!

PGTC

Car Transmission

Centrifugal Clutch for Sprint

Car Torque Converter Transmission

System

Suddenly on the morning of the 14th, I had the idea of

using a centrifugal clutch instead of the manual clutch system I was

making for the Sprint car. That seemed to hold the promise of magically

leaping over a number of hurdles. Why hadn't I thought of it sooner? -

perhaps it was just as well I hadn't

gotten any farther than I had on the clutch construction?

I found the centrifugal I tried on the motorbike a while

back. The idea was right, but the shaft size was wrong. So as I was

going shopping to buy a breaker for the motor controller for the boat

anyway, I made the trip out to Princess Auto, and indeed I found a

somewhat heftier looking one with 1" shaft bore, 'on sale' for 30% off

- 70$ plus tax. It said "1800 RPM". Doubtless that was the RPM where it

engaged rather than a performance limit. I'll probably have to do

something to reduce the 'engage' speed. Half might be good. Could I

simply take out two of the four spring clips on the shoes?

It was also pretty wide, sporting a fat V-belt pulley

instead of a narrower chain sprocket. It started to look like

I'd have to change the mountings to accommodate it.

Sure enough, I milled the keyslot in the

shaft to the end so it, with its built-in keyshaft, could slide onto

it, and found it was a bit too wide. Thus an impass was created where I

wasn't sure what I should do next, and I worked on other projects. Only

on the last day of the month did I think that I should go back and

trade the clutch for one with a chain sprocket - it would be just that

little bit narrower that it should fit. Furthermore, the one with the

V-belt pulley (that I wasn't going to use) had no solid way to prevent

a plastic flat belt pulley from slipping. However, the pulley could be

printed with a shape that fit between the chain sprocket teeth and so

lock it to the clutch rotation. With either one, there was no provision

for attaching anything, and I'd have to open the clutch and put in flat

head bolts from the inside sticking out the side. Somehow I still had

the package, intact, so I could take it back and do the swap, which I

did on March 1st. The one with the sprocket was 45$ more, but trying to

use one that was causing headaches was false economy. The new one fit

on. It was just as long, but thin at one end, which protruded into a

hole just far enough to replace a couple of spacers, placing it just

that bit farther along the shaft that it fit.

Getting the Sprint car going is definitely on my short

list of things to do. It's sat out there immobile for two winters now,

while the day of petroleum shortages and high prices draws on apace!

And the weather to work outside is ahead.

Electric Equipment Projects

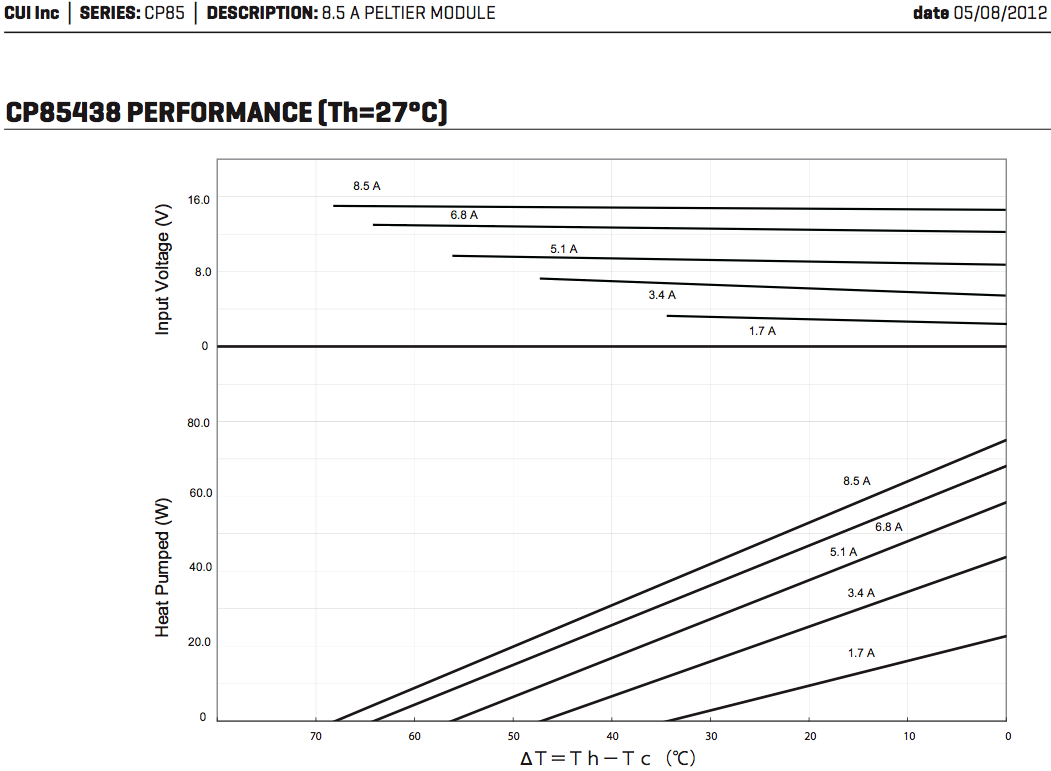

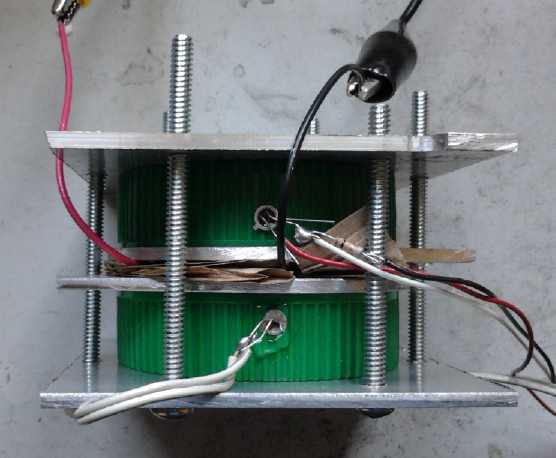

Peltier Element Heat Pump: Good COP (200%) is attainable!

A re-reading of the charts in the Cui Peltier Module

datasheets led to a reassessment of the potential for a peltier heat

pump to save electricity. It now appears that if optimally designed, it

might put out twice the heat of an electric resistive heater for the

same electricity input, at outdoor temperatures somewhat above

freezing. This is a very significant cost and energy savings for

the many people who heat with electric heat, and doubly so for electric

vehicles, whose range is decreased by the electricity used in heat and

window defogging.

Furthermore, a peltier fridge can be made to use half the

electricity mine presently uses for the same cooling power.

The key, as detailed below, is to run the peltiers at

about 40 to 60% of their maximum voltage, such as 6 to 9 volts for a 15

volt rated

unit.

The construction of the heat pump being somewhat

frustrating as it was made, not to say problematic, I hadn't done

anything more on

it since fall, while the heating season has come and is now gradually

going. But in considering the makings of the thermoelectric generator,

so

closely related in makeup, I had the idea to use a hot water pipe

radiator with thermoconvection circulation instead of heatsinks and a

fan. I'm not a big fan of fan noise - I wouldn't put one in my bedroom

where I often use the most electric heat - and a pipe seemed very

adjustable.

Then longer the radiator pipe - which could easily be any

length - the lower the temperature would be returning to the unit, even

down to room temperature. Total heat pumped per watt of electricity is

highest when the temperature spread between hot and cold is least.

My original idea for doing water was that if the

outdoor side temperature was 5ºc and the water

kept the warm side down to 25ºc in a 20º room, the spread

would only be 20ºc and each 8.5A Cui Peltier unit would deliver

about 50 watts of heat pumping while drawing about 7.2 amps at 12 volts

- 85 watts of electricity. That would be 135 watts of heat to the

heated space for 85 input watts, or about 160% COP. Expanding on

that: 1500 watts of heat for just 950 watts of electricity. (with about

12 Peltiers in series if it's to run off 120 VAC. 3 per set in a 36V EV

would each be just under 400W of heat for 245W in.) This contrasted

well with a warm

side temperature of 35ºc for the heatsink and fan, resulting in

about 140% COP.

Those figures seemed like the best that would be

attained... before I realized that the higher efficiency of running

Peltier modules well below their ratings allows for 200% COP's.

Either way, I'm making a

considerable assumption that the water in the pipe will exit the unit

at 25ºc and not need to be warmer to generate enough flow

thermally. There's always a small pump...

Ideally from a thermal point of view, one would use copper

for all the heatsink parts and piping. It's the best heat conductor of

any element (except silver - slightly better but rare), and it can be

soldered to. But it's costly

and heavy.

The construction I had in my head at that moment would use

a

fat aluminum main warm side plate. Some copper plate strips, maybe

1.25" x .064", would be each soldered along one side of a copper pipe.

The

strips are then bolted to the aluminum plate to transfer the heat from

it to the water in the pipes.

Alternatively, square, rectangular or oval copper pipes

(if available) could be sandwiched between two pieces of aluminum. That

was when I flattened a copper pipe for this purpose:

An idea for flat copper pipes. (3/4" pipe)

This looked very good after sanding the flat part flat.

Say!... This still might be a productive idea - but as a one-piece

replacement for a water box

if a pipe wide enough to mount a Peltier module on when flattened

(ie 40+ mm) was employed.

Hmm... 1-1/4" works! Must get more than this one 9" piece!

Peltier Heat Pump Efficiency is much better if driven softly - over

200% COP!

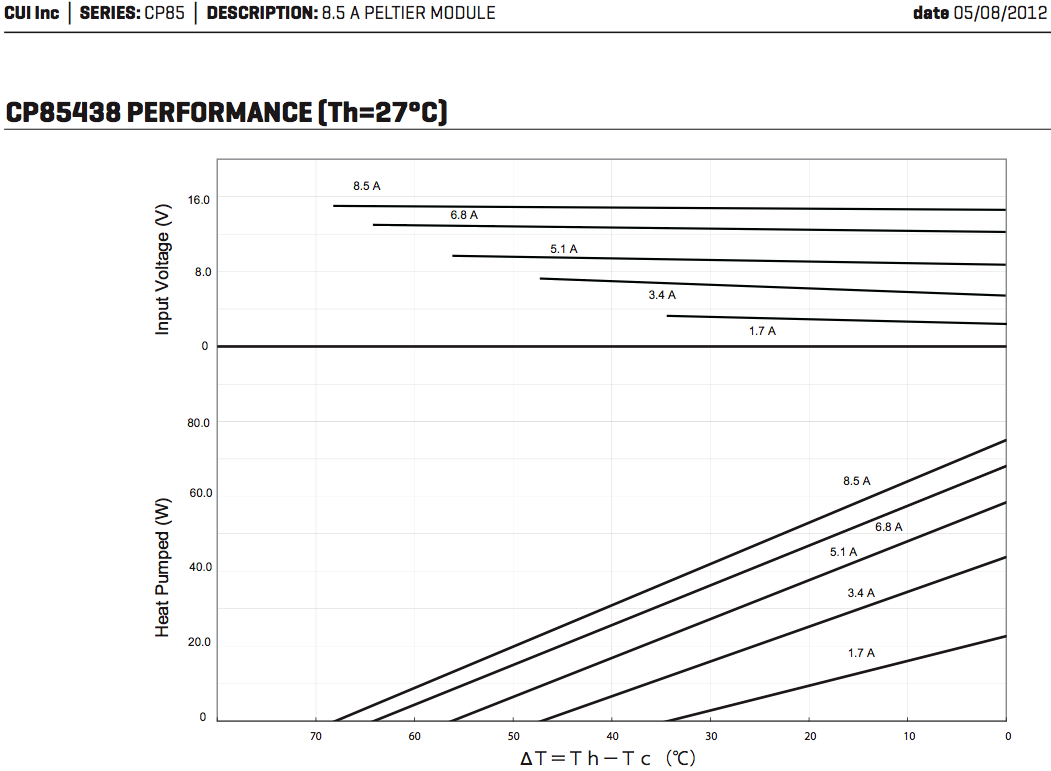

On inspecting the performance curves of the Cui Peltier

modules again, for the first time I related the voltage graphs to the

current graphs, which are shown separately, and working out the input

powers, came up with quite

different ideas of the efficiency a Peltier module could have than I've

previously held. The performance at lower currents is better than I had

believed, and the idea of Peltier heat pumps and fridges becomes more

attractive.

My mistake had been to unthinkingly think that half

current was half power. But half the current is attained at half the

voltage, which means it's 1/4 the power.

Cui 8.5A 15V Peltier Module -

performance at 27º hot side.

From the datasheet graphs, I worked out coefficient of

performance (COP) for different currents at 10º, 20º and

30º temperature spreads. (Voltages were read from the above graph

for 20º spread, but they only change a bit for 10 & 30º.)

Amps (given)

|

Volts

(from graf 1)

|

Input Watts

(V * A)

|

Heat Pumped @ 10º spread

(Watts, graf 2)

|

Heat Pump COP @ 10º

(heat: watts out/watts in)

|

Heat Pumped @ 20º spread (Watts, graf

2)

|

Heat Pump COP @ 20º

(heat: watts out/watts in)

|

Heat Pumped @ 30º spread (watts, graf

2)

|

Heat Pump COP @ 20º

(heat: watts out/watts in

|

1.7

|

3.2

|

5.44

|

17

|

413%

|

9

|

265%

|

3

|

155%

|

3.4

|

6.3

|

21.42

|

35

|

263%

|

26

|

221%

|

16

|

175%

|

5.1

|

9.0

|

45.9

|

48

|

205%

|

38

|

183%

|

27

|

159%

|

6.8

|

12.4

|

84.32

|

58

|

169%

|

47

|

156%

|

36

|

143%

|

8.5

|

14.7

|

124.95

|

62

|

150%

|

53

|

142%

|

42

|

134%

|

One's first impulse from this table might be to put

as many Peltier elements in series as possible to attain the highest

coefficient of performance - which looks almost as good as a

compressor/refrigerant unit. However, if the temperature difference is

increased to 30º (-7 on the outside), 1.7 amps only pumps about 3

watts, dropping to zero at about 34º spread. There 3.4 amps is

more

efficient. I'm inclined to go with 6 to 9 volts per 15Vmax peltier, say

2/5 to 3/5 of the rating.

That will up the initial expense but will pay back in electrical

savings over a heating season or two. maybe 3.

Better Peltier Fridges &

Peltier Heat Pumps with Evacuated Pipes?

The picture seemed brightened on the 21st when someone

told me how to

make an evacuated copper pipe with a bit of water in it on the 21st.

Evidently if the bottom of the pipe is heated, the instant steam

instantly

transfers the heat throughout the tube, thousands of

times faster than the copper itself.

This should mean that the warm

side of the unit can be kept only slightly above room temperature using

sufficient finned copper pipe. This augers well for getting the 160%

heating efficiency, tho the radiator pipes will hardly feel warm.

Likewise the warm

side of the Peltier fridge's unit can be kept cooler, to do more

cooling with less electricity. With the finned heatsink and

fan, it stays around 35ºC in a cool room. With sufficient

evacuated water pipe with

fins, it might be kept down around 25º and the fan noise could be

eliminated. It would need to run somewhat less time each day, or the

peltier module might be dropped to the next lower current rating.

I've written

more on this under the closely related Woodstove TEG project in

"Electricity Generation" below.

Of course

compressor refrigerant fridges and heat pumps are still higher

efficiency. The attraction to Peltier solid state units is simplicity,

robustness, portability, and reliability for 12 VDC operation. DC

compressor fridges have a reputation for short life. Magnetic heat

pumping has the potential to be at least as efficient as compressor

technology if not better, and probably more portable.

And of course, the heat transfer of evacuated pipes is

only better by degree than simply having water circulate by convection,

which is only better by degree than a finned heatsink and fan.

The Actual Peltier Heat Pump

On the 20th I

found a grungy

3/8" aluminum plate about the size I wanted (5" x 6") and sanded it

flat and smooth on the belt sander. 3/8" is a good heat

distributor, and it's thick enough the bolts on one side can thread in

securely without sticking out and being in the way of things on the

other side. Then I dug out some

pieces of

copper pipe and fittings from a 30+ year old box, from when I had

plumbed the house.

I didn't expect to take it any farther, but by the 25th I

had some basic design details firmed up in my mind. It occurred to me I

could finish a basic working unit before the end of the month, install

it in my bedroom (where I use the most electric heat), and use my lab

power supply to run and test it.

The design details (as built) were:

* The 3/8" plate as the cold side base for the whole unit.

* One or two 7/8" round aluminum rods to transfer heat from the plate

through the wall to the outside, needing only a hole (or two) drilled

through the wall, rather than cutting a large opening.

* A fat aluminum bar clamped on the outside of the rod(s), holding the

finned outside heat sinks previously made. (Water outside would freeze,

hence an air only system.)

* A copper box of water covering the unit, taking the heat from the

warm side of the 6 peltier units.

* A copper pipe radiator against the the wall above the unit, cooling

the water, which would circulate by convection from the box.

The secrets are in driving the Peltiers lightly, and in

excellent heat transfer surfaces and radiators. The better the inside

radiator is, the cooler it stays warming the room, and the better the

outside one is, the closer it is to the outdoor temperature. Such good

heat transfer keeps the temperature spread across the Peltiers to a

minimum, which as the graph shows, makes them the most efficient.

On the 25th I set up the CNC machine and made a pattern of holes. I

drilled out the 3/8" plate. I made the same mistake as with the

previous one: I put the Peltier mounting holes where they would

conflict with the heat radiator holes on the other side. Then I bought

7/8" aluminum rod. I drilled a 7/8" hole in a piece of test aluminum.

The hose had to be just right to fit the rod tightly to give excellent

transfer of coldness from the plate to the rod. I feared the rod would

fit loosely, but it was very close. I drilled out the 3/8" plate and

inserted the rod. I could still wiggle it a bit. So I took it out and

pounded on the end with a hammer for a bit to mushroom it out. Then I

had to pound it on, and it wouldn't move. Good! I sanded it flush with

the plate as peltiers would overlap it.

As for the pipe radiator fins, I couldn't find them.

Evidently they're only stocked as whole radiant wall heaters complete

with covers. I found some fins that wrap around the pipe along its

length, but that would be much less radiance per meter of pipe.

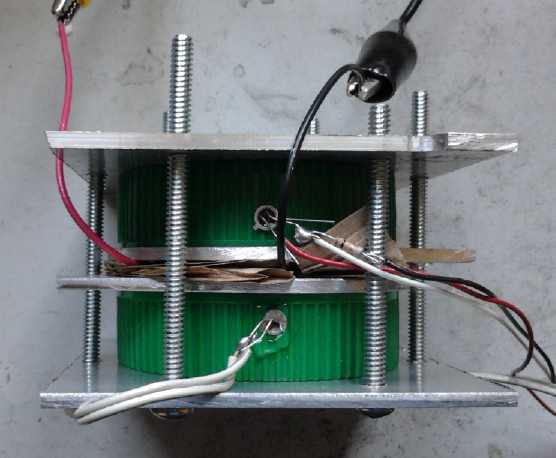

First Design, with air radiators on both sides

Assembled unit with water box warm side, air & conduction cold side.

Heat pump with inside warm side water box to go to radiators,

mounted on wall with cold side aluminum rod going through the wall.

Outside of wall with aluminum rod poking through.

& with radiator fins attached.

On the 26th, after I'd

bought a sheet of copper and as I

was working on the unit, the parts for my woodstove TEG arrived. I

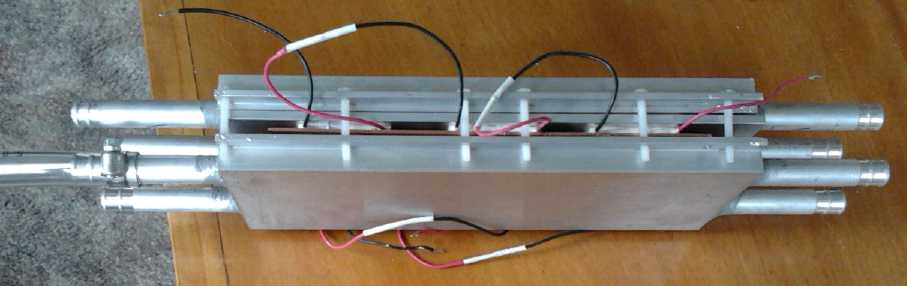

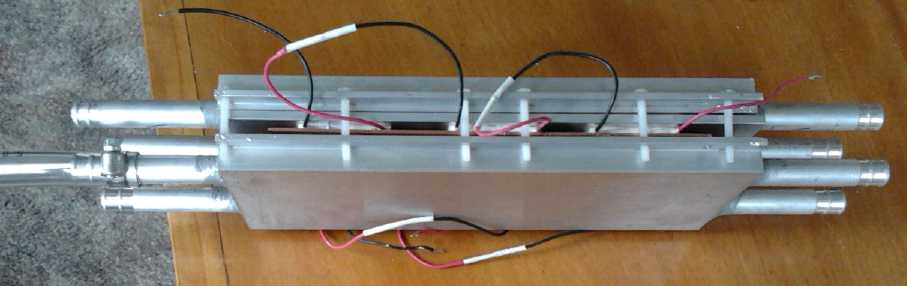

looked at the liquid plates and immediately saw that one of them would

be the ideal thing for the heat pump warm side. I exchanged the

aluminum cover plate for copper to improve the heat transfer from the

Peltier warm sides - the most critical point - and set to work on the

improved unit.

I drilled the hole through my bedroom wall in the evening

and hooked things up with plastic tubes. It leaked at the copper plate,

I had the peltiers the wrong way around, and worse, the heat from the

outer plate hardly seemed to come through the wall to the outside. (I

had put it under a window so I could reach out and touch it or get

temperature readings without standing on a ladder outside.) I was

disappointed by this evidently poor heat transfer.

Then on the 27th I had coffee with my friend who had

worked with the evacuated tubes, and I brought the heat pump along. He

suggested liquid in pipes for the cold side instead of big aluminum

rods through the wall. I said water would freeze. He said use

antifreeze, perhaps (edible) propylene glycol. This seemed obvious. Why

it had never occurred to me, I'm not sure. Except that I had thought

the aluminum rods would be good enough. After all, the warm side was

400

watts, but the cold side was only 200.

The obvious thing to do was to use another of the water

piped plates for the cold side as well. Now the whole design was using

the parts TecTeg had made for a liquid TEG device!, with 6 Peltiers

replacing the 8 TEGs. Or I could add two more Peltiers and use around

32 volts instead of 24 (or 4 circuits of 16 volts).

I did some shopping and found some plastic hose that would

fit over the heat block end pipes, some fittings, and some copper pipe

(from a scrap dealer).

I got another

idea for the pipe heat/cold radiator fins:

Cut a bunch of pieces of aluminum sheet the desired fin size (~3" x

3"), then use the jeweller's 5/8" hole punch to punch an exactly

pipe-sized hole in the center of each piece. That seemed to work fairly

well for a rough trial, and I did a foot of pipe.

I got another

idea for the pipe heat/cold radiator fins:

Cut a bunch of pieces of aluminum sheet the desired fin size (~3" x

3"), then use the jeweller's 5/8" hole punch to punch an exactly

pipe-sized hole in the center of each piece. That seemed to work fairly

well for a rough trial, and I did a foot of pipe.

Another thought occurred to me before bed: TecTeg had done

a lot of work to make those aluminum channel blocks, and I was told

they each took about an hour's machining. I had replaced the aluminum

cover of one with copper to improve the heat flow. Heat rapidly

transferred to the water and the rest of the box had no special

requirement to heat or

cool.

Suitable boxes - in some respects better - could as easily be made on

the 3D printer out of plastic, in not so much more time. Cheap and

replicable. I'd definitely have only one pipe coming out each end, and

save considerable plumbing.

They'd still be given copper covers, and the heat or cold

would transfer 'instantly' across the copper between the peltier unit

and the water.

Of course, such materials are good only for low

temperature Peltier units, not for TEGs. For those the aluminum blocks

will be vital.

On the 28th, Jim Harrington of AGO Environmental

Electronics made a financial contribution to the project. At this time

of year I can use it! He also mentioned a nearby potential source of

surplus copper radiators. But the one I saw had narrow, back and forth

piping for pumped systems. It would fare poorly in thermosyphoning.

Maybe it'll want a small pump(s) anyway to minimize temperature gain

(and loss) in the water box(es) and keep the Peltier modules operating

at best efficiency... but not until I've tried with convection flow and

no moving parts!

I bought a mini sheet metal shear to cut fins with, made a

little template to get the holes centered, and later, on March 3rd, 3D

printed a couple of plastic clips to evenly space the fins.

Performance Tests

Jim wanted me to measure the performance. I came up with a

quick plan: mount peltiers to identical aluminum blocks on the hot and

cold sides, take the room temperature, and measure the hot side and

cold side block temperatures as they changed, with various target

supply voltages on the peltiers. The temperature of the hot side is the

heat pumped plus the heat from the electrical power. While the hot side

gets hotter less than twice as fast as the cold side got colder, more

of its heat is from the heat pumping than from the electrical energy

supplied. When it drops to double the temperature change, that's the

average 200% COP point. Ideally both blocks would be insulated from the

room air to minimize radiative temperature change. Temperature change

should be slow enough that the temperature sensors would keep up with

it, suggesting a fair mass of aluminum.

Jim wanted me to measure the performance. I came up with a

quick plan: mount peltiers to identical aluminum blocks on the hot and

cold sides, take the room temperature, and measure the hot side and

cold side block temperatures as they changed, with various target

supply voltages on the peltiers. The temperature of the hot side is the

heat pumped plus the heat from the electrical power. While the hot side

gets hotter less than twice as fast as the cold side got colder, more

of its heat is from the heat pumping than from the electrical energy

supplied. When it drops to double the temperature change, that's the

average 200% COP point. Ideally both blocks would be insulated from the

room air to minimize radiative temperature change. Temperature change

should be slow enough that the temperature sensors would keep up with

it, suggesting a fair mass of aluminum.

I found a couple of irregular chunks of 3/8" aluminum

plate that weighed 454 & 453g. I figured that with just one peltier

at 8 volts, the temperature changes might be slow enough I could keep

up with them. On the first test I got such poor results that I tried it

again, and got the same thing. Then I realized that the aluminum plates

were so large that the warm plate had a large surface area one peltier

thickness from the cold, so that it was heating it up appreciably.

Aluminum cubes would have been better.

I may not have gotten the measurements I wanted, but it

was a good reminder that the hot and cold sides have to be as separate

as possible, and I came up with a couple of new points:

1. The copper or aluminum hot and cold plates should be only just large

enough to fit the peltiers and conduct their heat to the water. (Any

surplus metal "looking at" the other side should be insulated - as well

as possible with only 3mm thickness.)

2. Plastic water boxes might well be better than aluminum as they don't

transmit heat well. They'd be all plastic except for the heat

conductive metal faces the Peltier modules mount on. That means no

direct radiation of heat from the boxes, but also no radiation towards

each other or in proximity to each other. And clamping the two boxes

together with the peltiers in between could be done with metal screws

instead of nylon, as the temperature won't transmit through them.

Metal backs, perhaps with heat sink fins, could be

employed. I think I'd rather have solid plastic, providing fewer seams

that might leak. 1/2" copper pipe fittings, or plastic hose fittings,

and interior supports for the metal plate which would also stir up the

flow, would be 'molded' (printed) into the plastic part.

I cut out a peltier square hole in a thin piece of foamy

packaging material and stuck it in between the plates. I tried at just

6 volts, but that just gave more time for heat transmission between the

plates. I started to think that if I had to go to a lot of trouble to

make a test rig, I might just as well do the real thing. And point 1

above suggested that since 8 peltier modules would fit on the TecTeg

plates, I should fit 8 instead of 6. Less extra to need insulation.

That should

have been it for the month, but on March 3rd, having been distracted

from finishing this newsletter by various things on the 2nd, I awoke

with the rather ambitious idea that I should test the 200% performance

idea and put the results in this newsletter.

That should

have been it for the month, but on March 3rd, having been distracted

from finishing this newsletter by various things on the 2nd, I awoke

with the rather ambitious idea that I should test the 200% performance

idea and put the results in this newsletter.

I thought the best way to

do that might be to build and install the whole heat pump unit, and

compare performance with a 400 watt electric radiant heater. I had

decided to do the 3D printed plastic

boxes with copper sheet/plate faces. I spent the morning cutting

aluminum fins

and putting them on copper pipes, then fitting the pipes up. I 3D

printed two plastic spacer clips to space the fins evenly.

In the

afternoon I started designing the boxes. Naturally it took quite a

while; pretty much the afternoon. To my surprise, they turned

out to be too long for the 3D printer's 200mm maximum size, so I re-did

them a little shorter. They would also be 2-1/2 hour prints. But I'd

been having trouble with the temperature readings from the extruder,

and I tried to tighten the connections. I had nothing but trouble with

the printer after that, and finally gave up at 10 PM with the plastic

not sticking to the glass and smoke coming

out the extruder nozzle, which must have been considerably hotter than

the reading on the computer.

Parts for test #2 on March 4th.

Top: clamp

Left: one of the lids and plates

Right: the other plate with peltier & cardboard insulator on top,

lid under.

I "discovered" that

water expands as it's heated when a little water came out the warm

side hole after the first test, and on a test I continued to

50ºC, there was a small puddle underneath, and not enough water

inside to reach the sensor (in the top hole in the edge of the jar lid

during that test) after it cooled. (I

allowed for expansion in the heat pump radiator pipes.)

Assembled tester in use. Temperature probes are in the water filler

holes in the jar lids.

The lids were filled with a syringe with about 65cc of water.

| Volts |

Elapsed Time

(seconds, approx) |

Amps |

Hot Side ºK

(º read at aluminum

Peltier face plates)

|

Cold Side ºK |

Hot, Cold, COP |

| 8.0 |

0 |

0 -> 5 |

290 |

289.5 |

|

| 8.0 |

20 |

3.3 |

299 |

287 |

+9, -2.5, 138%

|

| 8.0 |

40 |

3.2 |

304

|

285

|

+5, -2, 167%

|

| 8.0 |

60 |

3.1 |

306

|

284.7

|

+2, -.3, 118%

|

| 8.0 |

80 |

3.1 |

307

|

284.3

|

+1, -.4, 167%

|

I took more readings, but the cold side stopped getting colder and the

hot side rose slowly. There's heating and cooling the aluminum plates,

and then there's heating and cooling the water behind the plates, and

then there's the caps radiating back to room temperature. Measuring in

the water showed little change in the cold side and huge change in the

hot side. You'd have never guessed the module would freeze water.

I decided to try again, at 6 volts, measuring temperature at the plates

again. This is the voltage the Peltiers of the fridge will have if two

are in series with the 12V supply.

| Volts |

Elapsed Time

(seconds, approx) |

Amps |

Hot Side ºK

|