Turquoise

Energy Ltd. News #62

Victoria BC

Copyright 2013 Craig Carmichael - April 4th, 2013

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com = www.MushroomOutboard.com

Features: Electric Mazda RX-7 &

a Better Battery Strategy for EV's

Month In Brief

(Project Summaries)

- New Electrode Edge Compactor & MnMn Battery #3, Thermoelectric

heat pump & fridge, Evacuated Pipe "Heat Diode" radiators, Mazda

& EV battery strategy.

In Passing (Miscellaneous

topics, editorial comments & opinionated rants)

- Inequitable Wealth Distribution - Banking System Suicide - Magnetic

Projectile Launcher Idea - Poland Attacks Germany Replay?

Electric Transport - Electric Hubcap Motor

Systems

* Lead-acid battery renewal & better battery charging system for Mazda

RX-7

* Better clutch idea for Sprint transmission

Other "Green" Electric Equipment Projects

* Peltier module tests & research for making a heat pump for space

heating

* Peltier fridge uses 1/2 as much power for the same cooling: Max

efficiency!

* Evacuated water/steam tube radiators - "heat diodes"

Electricity Generating (nada)

Electricity Storage - Turquoise

Battery Project etc.

* New edge-feed electrode compactor

* "Production Prototype" Cell #3 - assembly - testing:

- Much better than #2... and gradually improving with charging.

No Project Reports on: DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic

Motion Machine, Large

format NiMH batteries - take 3, CNC Gardening/Farming Machine,

Woodstove Electricity Generator.

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater (say, this heater is now obsolete! Use Peltier module heat

pump!)

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit - also please inquire about Electric

Caik

3KW Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks & Dry Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

March in Brief

I

couldn't upload the February newsletter to the web for at least a week.

The server

just kept closing the connection. I went to enquire on about

the 13th, but first I tried it yet again... and everything worked fine!

This month's 'short' e-mail version newsletter is somehow almost 1/2 as

long as the web version with the ad nauseum detailed project reports.

For a while I couldn't seem to settle down and get at my taxes, nor

concentrate too long on anything else. I picked away at various things.

MnMn Turquoise Battery Project: Production Prototype Cell #3

One of the things I worked at fitfully was the

battery project, 2 or 3 hours now and then. I made the improved

electrode compactor box, and finally put together 'production prototype

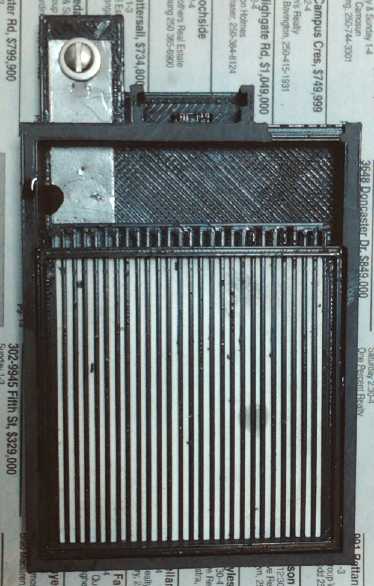

cell #3' by the 17th. Edge compaction of the electrodes seems to work

out well, using pressures that are easy to attain. It does preclude

putting a conductive grill in the electrode, but I haven't found any

zinc or graphite 'screens' anyway. Except for a couple of glitches to

work out in the case design for #4, it went together well, and I had

fair hopes for it. One thing - maybe the only thing - that was still

going poorly was the negative electrodes - they seemed poorly

conductive, and were probably also the culprit for very low amp-hours

capacity. But the cell initially had double the capacity of #2, and it

doubled again over the rest of the month. If it continues to improve,

after 3 or 4 months it may be a fine battery!

In order to get flat electrodes instead of ones that bulge in the

middle, I put together a new electrode compactor.

The faces are 3/8" thick stainless steel, sanded and polished up as

best I could on the inside.

Two sets of sides (new, old with new holes) make electrodes 2.3 or

3.1mm thick - or I suppose 5.4mm.

Compacting electrode powder into the box, using the book press center

screw as a fulcrum,

and a steel bar like a lever or arbor press handle to press the die

into the box.

Compacted negative electrode, about to be covered by perforated zinc

foil current collector.

After that, the front face was glued on and the cell was ready to fill.

(Underneath at back is positive electrode laid on flexible graphite

current

collector. Top end of vertical bar separator grille is visible.)

"Production Prototype" Cell #3 after a couple of weeks.

At the left crystals are growing from a small leak around the positive

terminal.

Peltier Fridge Improvements &

Thermoelectric Heat Pump

Another thing I picked away

at was the idea of flattening a larger diameter pipe to mount

peltier modules on so they could have flowing water right behind them.

But having made a couple, I fear the pipe may "cup" a bit in the center

when they're clamped on, preventing good thermal contact of the entire

module. And the evacuated tube system being developed may eliminate

having water behind the modules.

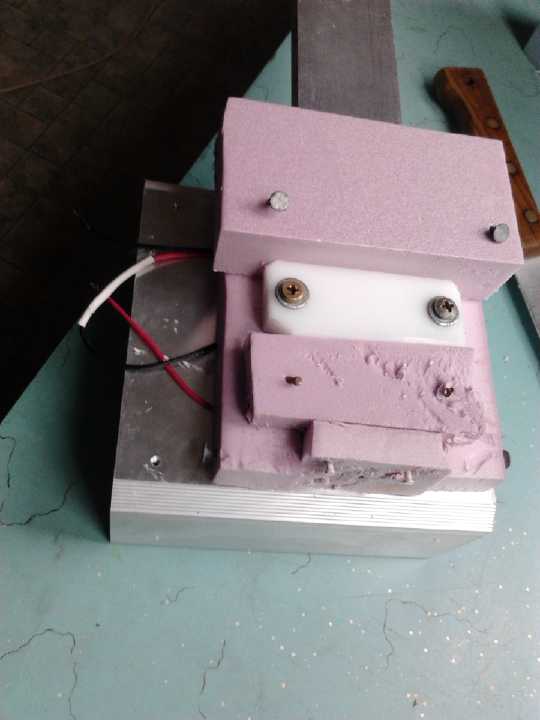

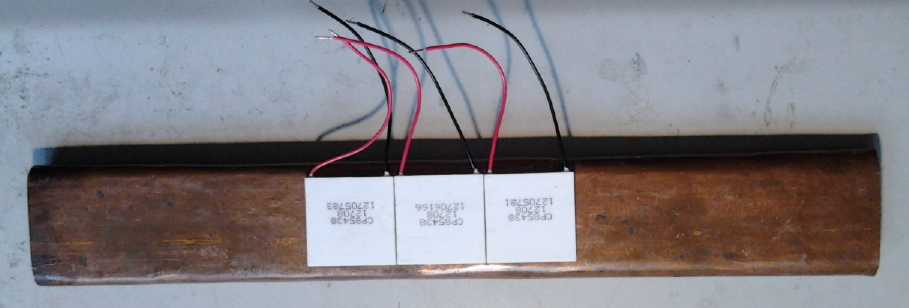

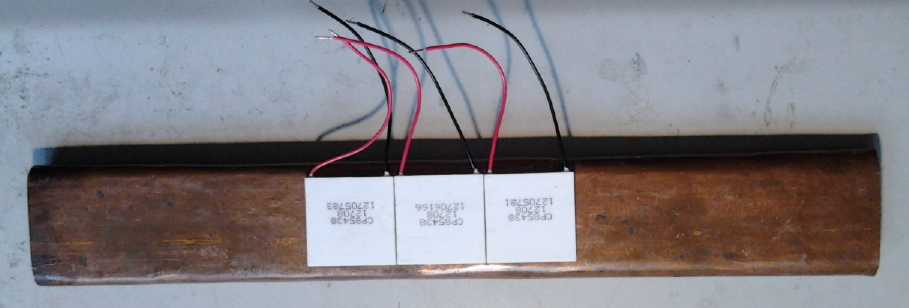

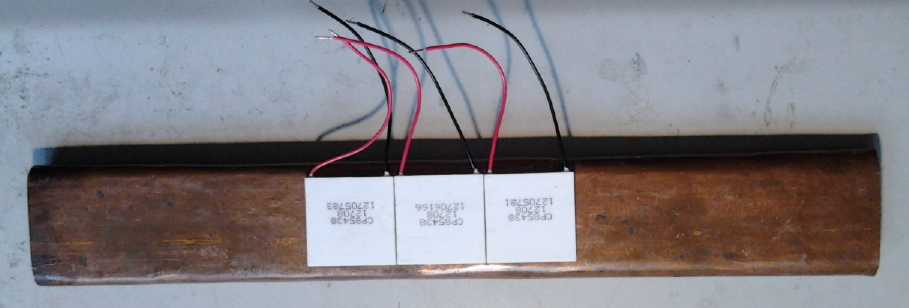

1.5" copper pipe, flattened to form a "water box" to hold and

dissipate heat or cold from peltier modules.

(One peltier module, a thin white square, is shown sticking out a

little.

These are clamped between the copper bar cold side and the

aluminum heatsink warm side.)

At about mid month I tried to use two peltiers each at 1/2

voltage to

make the fridge more efficient. I spent several days on that instead of

the

intended 2 hours, determined to make it work well in spite of various

setbacks. Finally it was refrigerating just as well at about half power

- around 3 amps instead of 6 amps, 40 watts instead of 80. It looks

like a winner!

At about mid month I tried to use two peltiers each at 1/2

voltage to

make the fridge more efficient. I spent several days on that instead of

the

intended 2 hours, determined to make it work well in spite of various

setbacks. Finally it was refrigerating just as well at about half power

- around 3 amps instead of 6 amps, 40 watts instead of 80. It looks

like a winner!

It demonstrates that Peltier modules are currently being

employed in less than efficient ways.

I had previously been

thinking of a peltier fridge as a niche market item, and thought that I

was to some extent wasting my time on it. But a quiet or

even silent fridge might be considered an "up-scale" appliance, even

worth paying extra for. It might be attractive to many homeowners, and

especially to apartment dwellers where the fridge's compressor noise

often

permeates the whole living space.

A new thing I tried was an evacuated pipe "heat diode"

radiator with a

bit of water in

the bottom to replace the warm side heatsink and fan. When the water at

the bottom is heated by the peltiers, it immediately boils. The steam

rises up the cool tube and condenses as it cools, and runs back down.

Quickly the heat at the bottom is transferred throughout the whole

pipe, and is radiated off by the cooling fins. Cold at the bottom

doesn't get transferred up the pipe except gradually by the copper pipe

walls.

This

wasn't immediately successful owing to insufficient vacuum, resulting

in a boiling point of about 38°c instead of under room temperature,

but it has much

promise for a most effective

and completely silent (well, except for some 'pinging' bubble noises)

fridge.

Evacuated Pipe "Heat Diode" Radiator with aluminum fins,

and aluminum block peltier module thermal interface.

(Oops, I didn't get a picture when I had it installed.)

Then I decided the

heat pump should take priority and

really should be built and tested this month. I worked on it a while

and installed a cold side radiator loop on the outside wall, but didn't

get it there. The

closely related work on the fridge continued and led to great ideas

about evacuated tubes for better heat radiation, with conduction loss

reductions when the heat is off. Thermoelectric heat pump potential for

saving as much

as 1/2 the electricity used in electric heat and the consequent

potential reduction in total power grid consumption seemed

valuable. And like the fridge it

would have advantages over compressor & refrigerant heat pumps in

being quiet or almost silent, plus it would be installable by a home

owner without special skills.

A switch to thermoelectric heat pumps and LED lighting

would

surely save more electricity than the total amount of increase that

would accompany

converting all road vehicles to electric drive. There is interest from

both potential customers and investment. Improving the fridge really

was a precursor to it.

The TEG2.0 thermoelectric generator modules tested out

very well as peltier modules, providing good coefficients of

performance at low voltages. I decided to use eight of them in the

liquid based TEG unit, as designed, as the first prototype

heat pump instead of as a woodstove electricity generator. (Did I

mention that all these thermoelectric things

are very closely related?) I'll cut the woodstove generator in half

from 16 modules to 8 for the time being.

Just before the end of the month the weather warmed up

dramatically. Unless there are some cold spells it may be hard to test

the woodstove electrical generator and heat pump units under "real

life"

conditions until next fall. That doesn't preclude heating a room up

like a sauna just to test.

Electric Mazda, Battery Renewal and Superior Charging System

On the 23rd I was offered excellent terms and a very low

price - 2500$ - for a 1982 electrified Mazda RX-7 that no one else

seemed to want. In addition to being old, it needed at least "3000$"

worth of lead-acid batteries

to put it back on the street. Since none of my car electrifying

projects are on the road yet (sigh!), I took it. I figured I could

scrounge some "deep cycle"

batteries to renew with sodium sulfate without spending a lot of money.

I had 3 and needed at least 8. I obtained 6 more before month's end and

emptied out the acid.

My "set" of miscellaneous batteries for the electric RX-7.

The second key to making this work will be to charge each

battery with a separate 12 volt

charger. That's far superior to charging them all in series from one

charger: a weak or misbehaving battery can't damage the others during

charging. Any assortment of batteries will work fine, with driving

range of

course dictated by the one with least capacity. When a battery gets

weak, it can be replaced individually, avoiding the need to replace

them all at once... which is what took this electric car (and seemingly

many others) off the road in the

first place. (After a long drive, the batteries can readily be tested

with a

voltmeter to see which one(s) lost the most charge.) I may even use

some

NiMH D cells for a battery or two, just to show the point. (Who's ever

heard of mixing PbPb's with NiMH's?)

On the 27th I went out to hunt down some old 'deep cycle'

PbPb batteries. One place that used to sell them would only buy them,

and that proved almost universal. However, Battery Doctor was willing.

I got 4 there, and they said they'd have another one the next day. With

the 3 I already had, that gave me the minimum number (8) for the main

cost of a long session of dumping out 'pants eating' acid, neutralizing

it and disposing of the lead crap (feeding it into dead batteries going

for recycling), and refilling with sodium sulfate solution.

A couple of the batteries were size "24" instead of "27".

Those will be the ones that limit the car's range and will probably be

replaced first when and as I find better ones.

Another one for the road?

Someone hopes to buy a one of a kind 1970's electric jeep.

Evidently it has some odd switches and levers for speed control, which

ought to be updated to a modern PWM controller. It's a 36 volt drive

system. That's the voltage of my Turquoise Motor Controllers, so I just

may be supplying the control to make it really drivable. It's

interesting to realize how far power semiconductors have come that a

PWM controller for a powerful motor was impractical in the 1970's.

Chev Sprint Transmission

I also came up with another new plan for the Sprint

clutch. I

started losing confidence in the centrifugal clutch idea without having

tried it, as it began to sink in that it probably won't engage at the

RPMs the shaft will attain, and also that I might want it to engage at

various RPMs and torques depending on driving conditions.

Then it occurred to me that instead of adding two idler

pulleys (for forward and reverse) to engage the clutch, I could mount

the whole lightweight motor and torque converter assembly on a

pivotting mounting. To engage, the whole assembly would pull away from

the lower side with the differential and its pulley, tightening the

flat drive belt. It sounds like a big deal, but I think it would

actually be easier to do this than the idler pulley assembly, and it

should work more smoothly.

Now if I just could find any time to build it! I don't see

how I can do the CNC Gardening Machine this spring, either, along with

the several other potentially valuable things listed under "No Project

Report On:".

Fine Print

On the 24th someone had the nerve to tell me the text font

I've been using in my newsletters was absurdly large. Well, I think

some website text is absurdly small. It's as if everybody wants to

continue to use the same number of pixels per character no matter how

much finer the pixels have become, and fit an inch of text into 2/3 of

an inch no matter how much more viewing space there is with bigger

displays -- and then make big margins with flashing pictures to spoil

the reader's concentration. (Text also seems to continue to shrink as I

get older.) I

figure I'd rather sit back and look at the monitor from a couple of

feet away than have my breath fogging it up while I go more and more

shortsighted. Okay, probably I swung the pendulum too far in reaction

to all the needlessly fine print and then never gave it any more

thought... so this is the next common size down, still larger than

most. (which I've already been using lately in the e-mail short

version.) If this text was too small to read and so you didn't get this

far,

let me know.

In Passing

Incidental news, editorial comments & opinionated rants

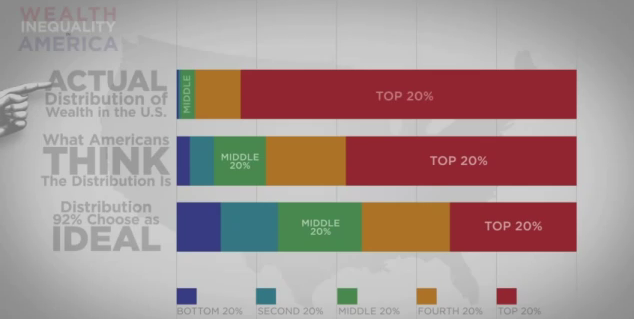

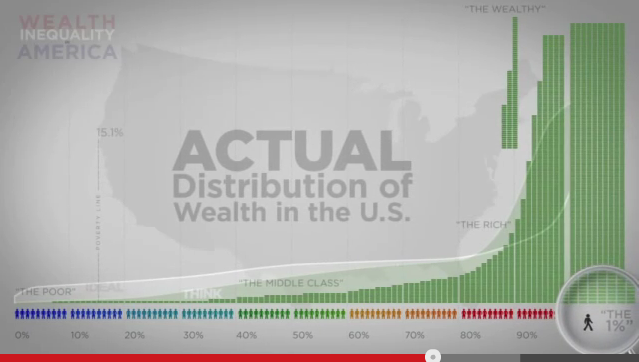

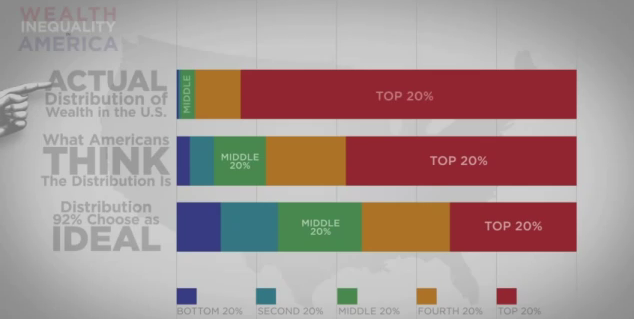

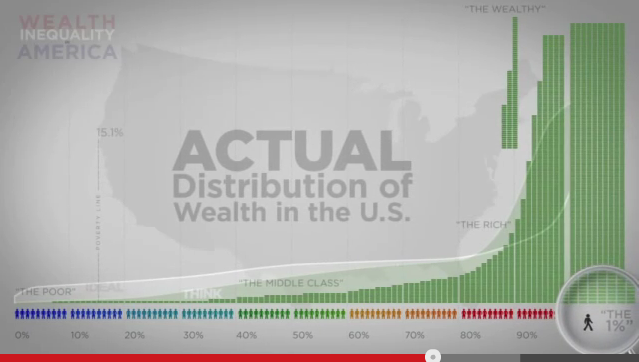

I saw a video on youtube called Wealth

Inequality in America. You already know it's bad, but even so it's

shocking almost beyond belief:

http://www.youtube.com/watch?v=QPKKQnijnsM

1% of Americans have 40% of the nation's wealth. 80% have only 17% of

it

between them. And the figures used were from 2009 - it's worse now. And

broken down further, "the 1% of the 1%" in fact have much of the wealth

attributed to "the 1%". At that point we can virtually start naming the

individuals who

have the bulk of the wealth, and many of the names will be

familiar.

It then starts to become obvious why some things never

seem to change: those few with wealth and power don't want

change. To finance major production of, say, an electric vehicle

conversion system or themoelectric heat pumps, those few who could

easily dig into their spare change and make the needed investment are

the same few who maintain their vast fortunes and power off

selling gasoline and

operating power generating facilities. They would rather manipulate

such underfunded enterprises out of business whenever they manage to

germinate, lest they take root and free people from their control. At

least, that was the situation for a century, before the banksters

started outscamming all the other scammers.

Worldwide, we are arriving at the point where a large

percentage of people

under 30 have no real economic or political stake in their society -

they have no control and it's done

little or nothing

for them except order them around, put them in debt, and supply paltry

handouts. It appears they may never buy a home or raise a family. And

in fact the

remaining wealth is being stolen from everyone of all ages wherever

"the 1%" gangsters can manipulate any

slight opening. A huge disconnect has arisen, and societal breakdown

seems

inevitable. Since we live

on an evolving world in an evolving universe, since "All things work

together for the progress of men and angels", we may surmise that a

major evolutionary step of some sort is imminent.

Whether it's a sudden leap of progress or whether some new

dark age will have to intervene between today and a better world will

depend on us collectively and even on individuals. One individual can

alter the whole course of evolution. Jesus reformed religious thought

and insight around the

world. Joan of Arc rescued France. Winston Churchill rescued Europe.

Werner von Braun inspired John Kennedy and sent men to the moon - an

idea that could still be a science fiction dream. The Beatles, a

band of four, inspired a generation. Zillions of examples of

individuals who were inspired to do something and changed history could

be cited if one

wanted to dig.

Suicide by the banking system

About mid month, the "bond bubble" hinted it was starting

to burst. In

California, municipal bonds are falling and interest rates are rising.

The financial system is starting to unravel.

Debts everywhere are so absurdly huge that

rising rates will bring everything down.

Then on the 19th I heard the

IMF and ECB wanted to charge 6 to 10% to every bank account in Cypress

as part

of 'bailing out' this small economy. They even said the Cypress

parliament was

taking

too long to decide and that they would start taking out the money. The

next day, the parliament unexpectedly (but rationally) voted against

this theft - the first time an EU country stood up to the banksters.

It seemed like a citizens' triumph of sorts - leave the EU and let the

bankster/gamblers pay the price.

But Russia wouldn't bail Cypress out, and two days later

the account

theft was enacted in perhaps even more sinister form, leaving smaller

accounts but stealing far higher percentages - like 40% - of money from

accounts

worth over 100,000 Euros. Although the banks in Cypress were closed,

mainland branches of the same banks remained open, allowing the large

international account holders to get their money out. So mostly what

was confiscated was the life savings of older

people who had retired to Cypress for its sunny Mediterranean climate.

Toward month's end Cypress banks still wouldn't allow anyone to

withdraw more than 300 Euros a day after being closed for almost two

weeks.

Can they ever actually fully reopen?

Serious damage to the

viability of the whole world's banking system has been done. A

precedent has been set and trust is on the

wane. One repetition anywhere else or even the threat of one will

probably finish it. It may even sink even without one. Without

trust, there will be no

customer deposits. Without deposits, there will soon be no banks.

Without

accumulated capital, there is no

'capitalism'. Financial guru

Reggie Middleton

(BoomBustBlog.com) speaking on Keiser Report #421 (RT.com), reminds us

of

the basics: the purpose of banks is to

be a safe place to keep your money, and to pay you interest for the

privilege of using that money. The banks have failed to pay interest

for some years now,

and if they're not even a safe place to keep money, what are they good

for? Why would anyone make new deposits beyond enough to cover

immediate

transactions and monthly bills?

And even if people were so complacent as to allow their

life savings to be eroded away without trying to withdraw them, it's

difficult to imagine that Cypress' banks will somehow have the money in

cash after the bank run by the big investors - they will only be in

less debt. They are are surely doomed and

will soon need

bailouts to pay out their every liability.

At the end of the month I learned that withdrawals were

limited to 300 Euros a day, holding not only individuals' money

hostage, but companys' as well. As a result, companies in Cypress can't

pay their employees and must lay off their staff. How could anyone

cause a swifter collapse of Cypress' whole economy?

One effect of this hit me in a financial

transaction of my own: I downloaded a "Bitcoin Wallet" program about

the 14th. (bitcoin.org) It took it 3 days to "synchronize with the

web", where all bitcoin transactions ever made are recorded on all the

'anonymous'

Bitcoin Wallets everywhere with no central server, so Bitcoin can't be

counterfeited, fooled or usurped. Then I found "NanaimoGold.com"

digital

currency exchange. (Yes it's in Nanaimo BC) The price of each bitcoin

was 51$, up from 11$ a few months ago when I first figured I should

pick some up but didn't, which was up from 5$ a year ago. Since I

hadn't been

following it, this was quite a shock. It

took two days of e-mails where I got all the details figured out and a

test transmission to my 'wallet' (.01 BTC) before I sent him some money

and received a few bitcoins on the 20th.

In those two days, the Cypress banks had closed and the

crisis

was in full swing. Evidently people in Cypress and maybe

elsewhere

were buying bitcoin as a safer place to put their money, and

the price had gone up to 67$. I got 30% less Bitcoin for my money than

I would have just a day or two before! The next day it was up another

4$ to 71$. Then it lost a couple of dollars, but a week later it was

89$. This near doubling in 10 days of an experimental currency based on

ideas of almost free money transfers for online commerce and trust in

computer programming and math, shows the level of distrust in 'regular'

currencies and institutions. Now the world's first Bitcoin ATM has

opened - yes, in Cypress. On April 3rd bitcoin was 123$. The total

value of all bitcoins hit a billion dollars.

But in other lands, account money is being continually

raided indirectly by having the central banks simply print money,

eroding the value of everyones' savings. It was just estimated that in

the UK, a value of 200 B pounds (as close as I recall) was eroded from

people's total bank account savings of a little over 1 T pounds - an

indirect

theft of about 20% of everyones' wealth. This is by no means unique.

For example the USA figure is considerably higher (34% IIRC), and the

"Fed" is printing 85 B$ a month - a trillion dollars a year. That's

likely to rise.

So far, bank runs have been restricted mainly to Greek and

Spanish banks, and these banks have been propped up by [the people of]

Europe

in general. But when confidence in the

financial system somewhere is finally lost, everyone everywhere will

try

to pull their

money out of the banks. They'll all collapse, since they all retain

only a few percent of depositors' money and lend the rest out... or

worse, have lost it in risky investments. Inflating the currency is

sneaky and

hasn't led to panic yet. I can't think of any

trigger quite so likely to precipitate the banking collapse as stealing

money

directly out of peoples' bank accounts.

Sometime I started to become aware that greed had struck

at

my own credit union, Coast Capital Savings, now the second largest

credit union in Canada and no longer controlled locally on Vancouver

Island. I've banked there or at its predecessors (Westcoast Savings,

then Pacific Coast Savings) since 1977. A letter came to members asking

them to vote on a "special resolution" that 'members must approve of

the

annual salaries

and benefits of the board of directors'. The directors 'were required

to

put forward the member's special resolution', but advised the members

to vote 'no'. In other words, they don't want the members to know what

they're giving themselves.

The proponent states that the CCS board has

been paying themselves more than double what the board of the largest

credit union earns, and that they decide their

own benefits without members knowing about them. With uncontrolled

greed evident, can

fraud, corruption and probably insolvency be absent? I voted 'yes' on

the

resolution, but I closed my Turquoise Energy account and have only

petty cash left in my personal account. I don't have much more than

that to

my name at this time anyway, but I certainly don't want my annual tax

refund money (to pay off my debts!) in the hands of a shaky

institution. BC credit union deposits are 'insured' by the province,

but does BC have

the money to pay out if its second largest credit union collapses? I

opened an account

at Island Savings Credit Union, a much smaller institution whose head

office

is within driving distance. A first impression perhaps, but I felt a

welcome difference in atmosphere in the branch.

On the 28th, I was tipped off about unwelcome Canadian

news in a

silverdoctors.com article, which was spreading widely around the

youtube financial news community in connection with Cypress within a

day or two. I print the most salient points about the government

authorising itself to steal customer account money to prop up any

"systemically important" banks if they should happen to fail, buried on

page 144-145 of the 2013 national budget:

"...it appears

that the Cypriot bail-in is anything but a one-off event, and is in

fact

the new collapse template for the entire Western banking system, and

not just the ECB/ Eurozone!

SD has been alerted to an alarming provision that has been buried deep

inside the official 2013 Canadian Budget that will result in depositor

haircut bail-ins jumping to this side of the pond during the next bank

crisis!"

A subsequent CBC article on the subject ended with a piece

of good advice:

"The fact is, if Ottawa is seriously contemplating the failure of a

Canadian bank, ordinary Canadians might want to do the same, and govern

themselves accordingly."

Wherever the next theft of

peoples' savings occurs, the

third country probably won't have to worry about what to do, because

worldwide bank runs will have already happened. (Ha! -- One youtube

video was

titled "How to Survive a Bank Run". It began: "What, you still have

your

money in a bank!?! <LOL> Get it out now while there's

still time!" And that was before Cypress.)

Magnetic Gun Design Idea?

I watched a documentary (youtube) on 3D printed guns. It

was interesting, but I thought they were doing it the hard way. They

were 3d printing fairly complex parts for traditional explosive shell

guns, with a less than common laser/resin bath 3D printer.

It seemed the problem with a magnetic gun might just be a

barrel. It's quite a different proposition, since everything works

differently. It seems that the projectile (eg, ball bearing?) doesn't

touch the barrel, but is held centered by the magnetic forces. But the

succession of coils accelerating the ball has to be held in a straight

line. Another consideration is that the projectile must interrupt

an optical sensor in order to know when to turn each coil's mosfet on

and off for best acceleration.

So I thought of a stiff acrylic plastic tube... better

still a lexan tube. It's transparent. Lexan is very strong. Then the 3D

printer can print two simple parts. Part one is one side and the center

part of a bobbin/spool to wind the coils onto, just big enough to slip

over the 'barrel'. Part 2 is the other side of the bobbin with places

in which to mount an LED and a phototransistor. This is

glued to the first section to form a complete accelerator coil/sensor

section.

As many of these as might be deemed useful are wound, the optics

installed, and slipped over the barrel. And then probably just glued to

it. It just seems so simple. (Circuits to control the firing

sequence

are readily available on line.) Conceivably I could see an effective

projectile launcher powered by nothing more than a D cell or two.

Doubtless one would run into various construction considerations if

one actually attempted building one.

So far I have no use for such a thing myself, unless

grizzly bears are spotted in towns on the south end of Vancouver

island. (Well, I'm not very fond of cougars, either, and once there was

one in a tree across the street. but that was 3 decades ago.) I'd

rather

make axial flux car motors and thermoelectric heat pumps to save

electricity and make life more pleasant for all. Those who need to

shoot pesky rabbits or grizzly bears, put down a revolution by unruly

peasants, fight a brutal government to regain lost liberty, or put a

molten

blob of steel into orbit, can work out the details for themselves.

Poland Attacks Germany Replay?

On the 25th I went to youtube and found a bunch of new

videos saying that Iran's "supreme leader" (apparently not the

president) has 'vowed to wipe out Tel Aviv and Haifa', while Obama was

in Israel - probably conferring with Nettenyahu on the invasion of

Iran. This was so

ridiculous, so contrary to anything the host country of last year's

NAM ("non aligned nations") conference has actually been saying and

anything it's in their interest to say, that I didn't even look at any

of them. Even if such provocative words were used (in contrast

with Abadiminijad's moderate, cool-headed statements that get twisted

into "threats to annihilate Israel" in translation to English for the

American

public), it would obviously have been prefaced with "If we are

attacked by Israel..." It's a pretext for the gullible, to "justify" a

war for control of Iran's oil, so obviously long planned by the USA and

Israel. (As Greggory Mannarino (TradersChoice.com, youtube) says, "Iran

has a

target painted on it.")

It's a close parallel to Hitler's Germany saying Poland

had attacked on September 1st 1939 -- a couple of hours before the

German war machine predictably rolled over Poland as had been

obviously

planned for some time, crushing it in a very few weeks and incidentally

starting world war two. Germany killed some people they didn't care

about after dressing them up in Polish uniforms, to have pictures for

the newspapers of the 'vile invaders who had stormed over the border',

to "justify" their attack.

Anything Hitler could do, Obama can do better. It's also

reminiscent of GW Bush claiming there were "weapons of mass

destruction" to justify his long planned attack on Iraq. With Syria,

Iraq,

Iran and Afghanistan all lined up plus a Libyan entry point into

Africa, the USA would

control through the Mediterranean a huge empire of oil-rich states

whose former

leaders (Saddam Hussein, Moamar Qadafy) each tried to get away from

using the USA "petrodollar"

for trading oil. (Iran has been forced off it by US sanctions.)

The funny thing is, tho, that it would appear Iran may

well be able to beat off

the attack unless the USA and Israel use nuclear weapons against them.

It would be little consolation then that that would show Iran

would

have been fully justified in making nuclear weapons

themselves as a deterrent.

And what of North Korea, which actually has

nuclear weapons and missiles, and not only that, is actually is

threatening to use them in a first strike against the USA (in

retaliation for US led sanctions)? Well... there's no oil in North

Korea, and it doesn't lie between Iraq

and Afghanistan, so who cares? Some youtube skeptics think the North

Korean

"threat"

is a just a decoy inspired by the US government to distract the

public's attention from the plan for war with Iran and ever growing

control of the USA by the gestapo, er... DHS, et al.

Electric

Hubcap Motor Systems - Electric Transport

Lead-Acid Battery Renewal and a Superior Charging System:

Low Cost Ideas to put Idle Electric Mazda Back on the Road

On the 23rd I was offered irresistable terms and a very

low

price - 2500$ - for a 1982 Mazda RX-7 converted to electric in 2003 and

driven until 2010, now for sale by

Jim Harrington. He

bought it simply to see what went into an electric conversion. He

already has a nice new Mitsubishi iMiEV, so after checking it over, he

had no further use for it except an idea to transfer the motor and

drive system to a Mazda

pickup

truck for deliveries, which naturally would have been a lot of work.

Surprisingly, no one else seemed to want it - I guess

because

it was so old and it needed "at least 3000$" worth of lead-acid

batteries

(or maybe 6-7000$ for equivalent(?) NiMH dry cells, or still more for

lithiums)

to put it back on the street after 3 years. Well, my Chev Sprint isn't

on the road

yet (much less the Toyota 4runner), and I haven't managed to

"hybridize" a gas car with a hubcap motor. So I thought about

it overnight, and decided that even as a "conventional" conversion, a

bird on the road would save more gas and pollution than two in the back

yard. And it couldn't hurt someone trying to create improved EV's to

have some first hand experience with a 'conventional' converted EV.

Furthermore, I have a plan to potentially make electric

cars, even with lead-acid batteries, more practical. Typically,

all the batteries are replaced at once with an entire complement of

identical, new batteries. The overall budget is substantially less than

buying

gasoline (if I had it worked out right 4 or 5 years ago), but it's a

sudden great expense that tends to remove EV's from the street.

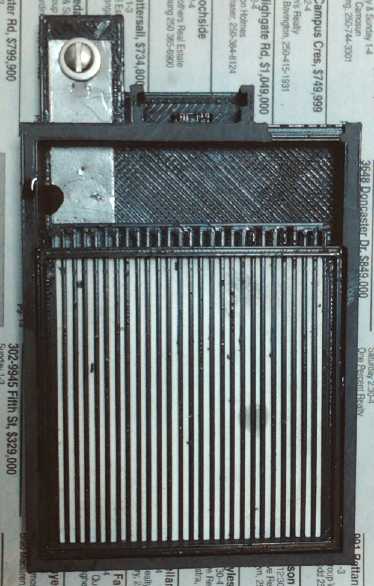

Under the hood, back when it had 18 - 8 volt batteries. The

other 10 were in the

back.

The problem is

that they are usually all charged as a single

string of batteries, and any battery that's a little different from the

rest either is stressed or stresses the rest during charging. As they

age, they may start to differ, accelerating the need for replacement.

The problem is

that they are usually all charged as a single

string of batteries, and any battery that's a little different from the

rest either is stressed or stresses the rest during charging. As they

age, they may start to differ, accelerating the need for replacement.

I plan to charge each battery with a separate 12 volt

charger. Those

are pretty cheap, and it seems to me it's a

far superior method. Any

assortment of batteries will work fine, with vehicle range of course

dictated by the one with least capacity. When a battery gets weak, it

can be replaced individually, thus avoiding the need to replace them

all at

once... which is what took this car off the road in the first place.

(After a long drive, the batteries can be checked with a voltmeter to

see which one(s) lost the most charge.) I may even use some NiMH D

cells for a battery or two, just to show the point. (Who's ever heard

of mixing PbPb's with NiMH's?) There's then the possibility of

gradually

replacing the lead-acids with a better type - even "types", again one

at a time instead having a sudden huge bill to pay. One NiMH (or

lithium) 80

amp-hour battery made of 80 dry cells in "battery stick" tubes would be

around 500-600$ - costly, but much more palatable than 6000$ or more at

one shot.

(and BTW worth perhaps 120 AH of lead-acid, and BTW that charger would

have to be adjusted or replaced with one suitable for the new type.) Or

of course, if I manage to get the MnMn cells working really well,

they'd be cheap and presumably better than anything, and again could be

substituted a section at a time.

This charging method isn't exactly an original idea - I

saw it

in a youtube video. It was a component of someone's electric car

project video(s). He had identical batteries with a charger mounted

over each one, and he didn't make any

special point of it or explain why. I thought it

seemed hoaky at the time - I figured he just got a bunch of chargers

'on sale'

somewhere. Later I started to realize its

advantages.

With separate charging in mind, I figured I could then

scrounge

some "deep cycle" batteries to renew with sodium sulfate without

spending a lot of money. It seems they last considerably longer when

renewed with

sodium sulfate than when purchased new anyway. (I did mention this

possibility to

others before I bought the car myself, but

it didn't seem to sway anybody.) I had 3 already from earlier 36 volt

Electric

Hubcap tests and battery renewal experiments, and needed at least 8

(for 96

volts). Each

additional battery beyond

that to 12 (144 volts) can

add a bit of performance and range.

On the 27th I

went out to hunt down some PbPb

batteries. A recycling place that told me a couple of years ago they'd

sell them now

will only buy them, and

that proved almost universal. Even the dump wouldn't part with an old

battery for love nor money. This seems rather uncharitable when people

to drop off these old batteries for free. You know

the original owner would just as gladly have given it to you as to

them. However,

Battery Doctor was willing. I

got 4 there, and they said they'd have another one the next day. They

got two, giving me nine. The monetary cost was low, but

they got more from me than by shipping them out for recycling. The main

cost was a long session of dumping out the 'pants eating acid' while

holding up and shaking these very heavy batteries (with my bad back -

now quite painful again after a long time without pain),

neutralizing

it (I used potassium hydroxide, making potassium sulfate salt. Baking

soda should work, but it would have taken quite a lot. Hmm... with

sodium hydroxide I could have made more sodium sulfate to renew with!

Why buy it?), and disposing of the lead crap (feeding it into a dead

battery

definitely going

for recycling, or saving it for glaze making), and refilling with

sodium sulfate solution.

On the 27th I

went out to hunt down some PbPb

batteries. A recycling place that told me a couple of years ago they'd

sell them now

will only buy them, and

that proved almost universal. Even the dump wouldn't part with an old

battery for love nor money. This seems rather uncharitable when people

to drop off these old batteries for free. You know

the original owner would just as gladly have given it to you as to

them. However,

Battery Doctor was willing. I

got 4 there, and they said they'd have another one the next day. They

got two, giving me nine. The monetary cost was low, but

they got more from me than by shipping them out for recycling. The main

cost was a long session of dumping out the 'pants eating acid' while

holding up and shaking these very heavy batteries (with my bad back -

now quite painful again after a long time without pain),

neutralizing

it (I used potassium hydroxide, making potassium sulfate salt. Baking

soda should work, but it would have taken quite a lot. Hmm... with

sodium hydroxide I could have made more sodium sulfate to renew with!

Why buy it?), and disposing of the lead crap (feeding it into a dead

battery

definitely going

for recycling, or saving it for glaze making), and refilling with

sodium sulfate solution.

A couple of the batteries were size "24" instead of "27",

and some of the "27"s had less capacity than others.

Those will

be the ones that limit the car's range and will probably be replaced

first when and as I find better ones. It still looks like a good

starter set - as long as they're charged separately!

I got the Na2SO4 into one battery on the 31st. Instead of

my usual technique of "1 gram per cell per 2 pounds of battery weight",

I

mixed the salt with warm water (Britta filtered and warmed on the

stove) to a specific gravity

of about 1.15.

Sodium sulfate isn't the most highly soluble salt, and it

couldn't be made much thicker than that. It's far more soluble in warm

water than

in cold. But in the battery, it converts into twice as much acidic

sodium bisulfate, NaHSO4, with sulfate desulfated from the plates. This

replaces the sulfuric acid, H2SO4, or some of it, and it appears to be

a

better electrolyte. I've said this before, or most of it, in

previous issues about lead-acid battery renewal quite some time ago. (I

wonder what would happen if one was to fill a brand new battery with

sodium bisulfate right from the start?)

A little black touch-up paint will spruce it up?

(The back of the new iMiEV can be seen on the right.)

Assuming the plan works,

putting an EV back on the road just got affordable. But I'm not sure I

can give up the gas

car and insure only an

e-vehicle with little cargo space, even for one rather occasional

driver. Occasionally I take a

highway trip and need the range, and occasionally I have a larger load.

But with the irregular and

often short trips I usually take, even for one car the insurance

sometimes

costs me

more than all other annual car expenses combined, and insuring two cars

will double it. This is just one of the reasons for wanting to add a

motor onto

a car wheel and "hybridize" regular cars.

PGTC Car

Transmission: clutching at a

better idea

Right after saying I'd take the Mazda, I came up with

another new plan for the Sprint clutch. I

started losing confidence in the centrifugal clutch idea without having

finished or

tried it, as it began to sink in that without modification it probably

won't even engage at the

RPMs the shaft will attain, and I suspect it might well be desirable to

engage it more gradually, and at

various RPMs and torques depending on driving conditions.

Then it occurred to me that instead of adding two idler

pulleys (needed for forward and reverse) to engage the clutch, I could

mount

the whole lightweight motor and torque converter assembly on a

pivoting mounting. To engage, the whole assembly would pull away from

the lower side with the drive shafts differential and its pulley,

tightening the

flat drive belt. It sounds like a big deal, but they already pivot at

one point (and then bolt into position) to adjust the belt. I think it

would

actually be easier to do this than the idler pulley assembly, and it

should work more smoothly.

Now, if I only had enough time to actually make it

instead of just to give it a passing thought now and then!

Electric Equipment Projects

Peltier Module

Heat Pump

I'm applying the idea of an easily installed peltier heat

pump to

mild or moderate winter weather such as we have on the Pacific coast of

North America. Here it's usually above freezing during the day with

frost some nights, highs 4 to 8, lows -1 to 5 C. Colder weather (-6 to

0) and snow happen, but it usually melts and warms up in a day or a

week. In the spring and fall, temperatures creep up but typically some

heat is still required about 8 or even 9 months of the year.

Where temperatures commonly dip to well below freezing,

a heat pump would best have a ground source heat exchanger for the

outdoor loop, with all the complications that come with that - except

the hole or trench might be small enough for an ambitious person to dig

by hand. (I think of boring a hole down from the basement in Edmonton

Alberta, where it freezes to 6 feet down and so most houses have

basements, with an auger of some sort.)

Optimally, if the room was warmer than the setting, the

control

would turn down the voltage instead of switching on and off. A 5 or 6

volt supply (per peltier) would suffice with outdoor temperatures where

just a little heat was needed. With the low in-out temperature

difference and the resulting low voltages and currents, not only the

lowest heating power but the highest possible heat pumping efficiencies

would be obtained, even over 200%, further minimizing the

cost for just a little bit ot heating.

At the other end, if it was very cold out and the room

temperature

couldn't be maintained with a 7 volt supply, the unit might put 8, 9 or

10 volts into each peltier to bring it up. The unit might require 300

watts or more and only pump 150 or 200 watts of heat for a COP below

200%, but it would still keep the room warm for 60-70% of the cost of

450 or 500 watts of electric resistance heating - and the highest

actual

dollars savings. But where such temperatures are common, a unit with

more peltiers run more gently would be better.

Little Idea:

Thermoelectric heat pumps could be even more valuable for conversions

of gas cars to electric. The unit can be under the hood somewhere, and

the warm side can connect to the original heater via the original hose

fittings. This eliminates working under the dash, and hence may make

the heat pump heater easier to install than an electric resistive heat

element. (One new electric car is said to have a "heat exchanger" that

uses substantially less electricity, but the video didn't explain it.

It sounded like it might be thermoelectric, but somehow the COP was

about 300% IIRC.)

Conceivably a thermoelectric unit could be run as an air

conditioner. However this would probably depend on actively pumping

liquids, and the capacity and

COP in that role are perhaps half the figures for heating. I'm thinking

more of evacuated tubes, which wouldn't allow reversal for cooling - at

least for home heating.

More experiments and conclusions

I ran some more heat pumping tests on the 7th, after

sanding the surface of the aluminum plates, applying heatsink grease

and tightening the bolts a little harder than last time (in spite of

small crunching noises that made me nervous about breaking the peltier

module). And I thought of a bit different way to test: turn the power

on for some number of seconds and then off again, and then wait until

the maximum temperature readings were reached. That would allow time

for the slow temperature probes to catch up to the swiftly changing

temperatures.

The results weren't dissimilar to the first time. The 5

and 6 volt tests showed performances of a little over 200%. That

wasn't with high measured temperature differentials, however, the

actual temperature differentials across the peltier surfaces would have

been somewhat higher than the readings, owing to the delay of heating

the plates out to the edges plus the additional delayed

response of the two AD590 temperature sensors. With copper

peltier module mountings to provide optimum thermal

conductivity in practical units, such figures should be attained at

somewhat higher temperature differentials - those associated with our

normal weather.

7V produced just under 200%, and 8 was down at around

167%. 5V

figures were a bit better than 6V, eg 225%, but the whole scale of the

watts and heating was down to pretty low values, like 10 watts of

electricity with 13

watts pumped for a total heat of just 23 watts per peltier. At 6 volts,

these figure went up to around 16 and 17 for 33 watts each, and at 7,

22 and 20 watts for 42.

At 8 volts current and watts are around 3.4 and 27, but

watts pumped is only up a little. Above 8 or 9 volts is applying brute

force to pump only a little more heat.

I began to notice that the currents were less than I was

expecting (per the datasheets) for each voltage. It turned out the amp

meter on the lab

power supply was reading somewhat low, and the high side meter would

only read unit degrees with no decimal. And all these things are very

approximate, varying with

every

small temperature change on either side of the unit. So the figures are

corrected rough estimates.

But on reviewing

my table from last month, the test results really aren't much

different. My essential conclusions are:

1. The modules definitely do have much higher heat pumping efficiency

at around 1/2 their rated voltage.

2. 200% coefficient of performance is attainable, but not above 6 or 7

volts (with 15 volt peltiers). Overall, I think the test setup attained

COP's of probably about what the final product can be expected to

attain. A key requirement

will be that the radiators must be able to minimize the spreading of

the

temperature differential.

3. The number of peltiers required for a given capacity of heat pump

space heater will be considerably greater than expected to get a 200%

COP, as they must be run at quite a low wattage to attain it. Expect

under about 45 watts of total heat per unit.

4. The voltage they should be run at to obtain 200% efficiency is a

little lower than expected, under 7 volts rather than about 8.

5. Running at 8 or 9 volts per peltier on colder than designed days,

they would attain the required heating capacity, at a lower COP but

still using substantially less electricity than electric resistance

heating.

6. Therefore a variable voltage supply would optimize the heater for

best efficiency on merely chilly days while providing sufficient

capacity on colder (but probably not far below freezing) days.

7. To maximize performance, the variable voltage supply would best be

controlled by a

microcontroller measuring indoor and outdoor temperatures, and warm and

cold side radiator temperatures.

8. In EVs where heat reduces driving range and batteries are a huge

expense, the peltier heat pump heater/windshield defogger would be even

more cost effective than in homes.

9. All the parts cost money, but it looks like the cheaper the peltier

modules can be obtained, the more cost effective the whole thing will

be, since even a 200 watt heat pump (to get 200% COP delivering 400

watts) will need at least 9 or 10 of them. but copper is also pricey

and the radiators, variable switching power supply and a

microcontroller control system won't be trivial.

On the 8th I checked and found Peltier modules at dx.com

for 6$ (and up) instead of 16$ (Digikey), although they were 6 amps (or

less) instead of 8.5. I ordered 3 to try out. Probably there are other

more

cost effective sources as well. This will make a big difference.

Flattened copper pipe Peltier module mounting

Flattened copper pipe for peltier mounting

I had samples of 1" and 1.25" pipe, and a 3/8" x 1" steel

bar. I just hammered a small bit flat at the end of each. The 1" would

fit 32mm square peltier modules but not 40mm. But the 1.25" would just

fit the 40mm.

I went to the recycling place almost at once on the 5th

even tho I was still trying to get the February newsletter done,

because I had seen the guy slicing copper pipes up a week previously,

thinking "what a waste!" -- and they might ship the crate out any day

or hour.

They had just three pieces that were still long enough for

6

peltiers and I bought them, along with three 6" x 12" pieces of copper

plate

or sheet I saw (doubtless a rare score) and the one unsliced length of

1/2" pipe. Hopefully I'd find more another time. But even the scrap

price of copper is 6 $/pound and it's dense, so it cost far more than

loose change. (I'm sure it was just 3.50$/pound about 3 years ago!)

The next day I decided that 1.5" would be a better fit

than 1.25" because there was room for more water flow since they'd need

less flattening, and I went back and traded them in. They still had the

crate (whew!), and they had more and longer pieces of 1.5". I bought

enough for 5 lengths instead of 4... for 10$ more.

In the afternoon of the 7th I banged the short piece flat

to see the fit. It was 15" long, which proved just long enough for 9

peltier modules. (9 is the number

needed to obtain 200/400W at 200% COP with the revised lower voltage

requirements as determined by the experiments.) The following day I cut

another piece to the

same length, and after obtaining a proper piece to put inside and

flatten against, I squashed it sort of flat with the book press.

On the 9th, I finished both pipes with pieces of aluminum

to cushion the grip of C-clamps. Both pieces had to not only be 'flat'

on the peltier side, they had to match closely along their entire

length. In the end, it took several hours to get a somewhat passable

job of having two pipes that could be clamped together and all 9

peltiers would touch both pipes securely and hopefully not have some of

them simply slide out sideways. I decided not to do any more pipes for

more than 6 peltiers unless I came up with better means to ensure they

squashed down very uniformly and flatly along their length. Short

segments could be easily tied together with plastic hoses and clamps.

The 15" divided by three would give a switchable 67, 133

or 200 watt

heat pump at 20 volts, with just under 7 volts on each peltier to

deliver a nominal 133, 266 or 400 watts of heat.

By the 17th, I had decided to make the flattened pipes

shorter with just 4 peltiers each and to make a diagonal square 'grid'

of them all tied to one inlet pipe and one outlet pipe. But I had also

been

exploring "all things peltier" for improving the fridge including

evacuated radiator tubes with a bit of liquid that boils, and the whole

water filled copper face mounting idea may be history.

All the tests and figures applied to the Cui peltier

modules, but I started thinking about the possibility of improved

peltier modules with a higher COP, first as a future possibility, and

then... whether any might already be available. Just because Digikey

didn't have them didn't mean there was nothing new that word of hadn't

spread.

Peltier Research on the Web

With the above

thought in mind, I realized that the obvious first step would be to

look on the

web and see if any improved peltiers are already available.

The first spec sheets COP's I downloaded from some web

site looked

worse than my Cui ones. (and the prices were somewhat higher.) So -

there are

peltiers of differing COP qualities even now!

Then I found a a site with a lot of info [www.tetech.com/] including a Peltier

Cooler COP Graph which seemed about like the Cui performance and is

probably generally representative:

Peltier

Cooling Coefficient of Performance (Add +1 for

Heating

COP)

It shows graphically, roughly what I read into the Cui graphs, and

found, for use in heat pumps:

Under 1/2 voltage can give over 2 (200%) COP - if the unit is optimized

and the weather's not too cold.

c) The input power for maximum efficiency of a cooler does not

correspond

to its maximum operating voltage and current. When maximum efficiency

is desired, the applied power should be typically 1/3 to 2/3 of the

Vmax and Imax specifications of the module(s) used in the assembly.

With the two series peltiers, in

the daytime (in winter - kitchen ~17°) the fridge is operating

typically with about 28 degrees spread (max: +25, -3) at 13.3 volts and

3.2 amps - just under 40% of full current rating and exactly at peak

COP of around 93% according to the graph. (For the Cui's, each .1 DT

graph unit represents about 7° since DT max is about 70°.)

TeTech.com was good general info on principles and the

current state

of the art. There appear to be some patented attempts to improve

peltiers, including to reduce their thermal conductance, and the good

old "W" has an article on the subject: en.wikipedia.org/wiki/Thermoelectric_materials

. I decided that rather than read it carefully, I would simply take it

that many

zealots are trying to make improved peltier units that I'll be able to

buy, and not risk learning enough to get an idea for an involved

materials project

myself.

Now... are there any already available? More web

searching...

Then I decided I'd try one

of the TecTeg

TEG2.0's (bought for the woodstove electric generator) as a peltier in

my same test apparatus and see how the COP

stacked up to the Cui peltiers. They were supposed to be 'optimized'

for their Seebeck effect and were unrated as Peltiers... but who knows?

They seemed quite good. The manufacturer says they're

rated for 25 amps! They draw over 10 at 4 volts, so they might

be rated at about 8-10 volts. I don't think he has attempted to graph

their performance as peltiers. For the heat pump, it's of benefit if

good COP can be attained at low amps, but they can be turned up very

high to provide adequate heat in extra cold weather, even if 2/3 of the

heat is resistive.

Evacuated "Heat Diode" Tubes

On the 30th, having succeeded in making an evacuated tube

with water in it, the idea for doing it with a mix of ammonia and water

came up. (See the topic, below the Peltier Fridge topic...

these things are all so closely related!) I now have the idea, instead

of the solid aluminum heat transfer rod through the wall to the

outdoors, that an evacuated tube of this might be put through the wall.

The ammonia would be the antifreeze, and it might transfer heat better

than

anything else. Grocery store cleaning ammonia solution might be strong

enough. (It's hard to guess since there's no indication of strength on

the bottles.)

And they would doubtless work for the indoor radiators as

well. So much for circulating liquid if this works! Thus, the design of

the heat pump has become contingent on whether or not the evacuated

pipes do what's needed, and attempting to make good ones is the next

challenge.

Peltier

Fridge Power Reduction

Experiments

I decided I should check out my ideas about getting

the lower power fridge with 2 peltiers in series. I used the test

setup for the peltier heat pump, and found that with a 6 volts supply,

currents seemed to settle down to around 2.5 amps when fridge-like

temperature differentials were reached.

This was lower than expected, and seemed puzzling when I

remembered measuring the fridge as being 7.1 amps at a little over 11

volts. So I decided to check currents on the fridge again. I did so and

found it drawing only about 5.0 amps at about 11 volts. My previous

readings must have been when the fridge was first turned on and still

warm, and I've been assuming them as "gospel" ever since, without

considering the temperature versus current factor. It probably drew

more like 6 amps during the day when voltage was higher, but by the

time I thought to measure that, I'd taken the old cooling unit apart.

The lower currents mean that the fridge is only using

55-75 watts, not

80-85, so it was already using somewhat less energy than I thought it

was! The

graphs say it should draw 5.0 amps at around 9.5 volts rather than 11.

I suspect the 'discrepancy' is further voltage drops in the fridge

wiring & PCB before it hits the Peltier module, and a considerable

temperature differential. As I recall, the warm side was typically

30-35°C. The cold side seemed to lose (gain) 3 or 4° from near

the peltier to the inside of the fridge, and probably more before the

water tray. So the differential was probably 35-40°. These figures

and the

graphs indicate it should have been pumping around 25-30 watts of

cooling power

into the fridge.

These readings didn't invalidate the idea of using 2

peltiers in series to reduce power and increase efficiency, but it

appeared that, even allowing for a cooler warm side owing to less

electrical heat generation (and slightly reduced supply voltage drop

with the lower current), they would probably pump less heat than the

single one, say 15-20 watts instead of 20-25. If the 2 peltiers were

run at 7 or 8 volts, similar or better heat pumping power might be

obtained with 2/3 the current. That seemed to imply adding a switching

power

supply, which is a lot more complicated than to simply put two peltiers

in

series across the 12 volt line for 6 volts each.

There are other ways. Perhaps the fridge might simply run

an hour, or two or three, longer each day. Then, these are 15.4 volt,

8.5 amp peltiers. I've seen 10 amp units advertised, and I think even

12's. Two of those might provide sufficient heat pumping at 6 volts.

Other combos such as four 5 or 6 amp peltiers, 2 parallel sets of 2 in

series, could provide the same cooling capacity, at around 3-3.6 amps

(instead of 5.0) with the higher efficiency of 6 volts each, for some

extra cost and fitting.

Three lower current peltiers running on 8 volts each from

a 24 volt supply could also pump just as much cold at lower power than

the single 12 volt unit at 12 volts (or two 12 volt units in series at

24 volts).

(There are good arguments for running 24 volt house

circuits. In

fact, the biggest argument for using 12 volts at all is the common

availability of existing 12 volt equipment.)

A later thought was perhaps best: use one 15 volt (AKA "12

volt"), 8.5 amp peltier and get an 8 volt, 8.5 amp peltier from

the same manufacturer. These could be expected to divide the 12+ volts

into around 8 and 4.5 for the 15 and 8 volt unit respectively, which

would up the current and heat pumping compared to two 15 volters

- hopefully making more cooling than the single 15V while still

being substantially lower current, perhaps 3/5.

I decided I'd still try

putting two of my 8.5 amp units in

series at 12 volts and see what happened. If that didn't pump enough

cold, I'd try something

else.

I built the unit on the 11th and turned it on. The current

started off around 3.4 amps - but it was daytime and the voltage was

13.5 at the fridge. That's 6.75V on each peltier, which (as the graphs

work out) should work much better than 6.0.

Having checked the single peltier at night with only 11

volts on the supply, exact comparisons between units in the daytime are

more difficult. I wish I'd thought to measure it during the day.

I wanted to try evacuated tubes or thermosiphoning water

with radiator fins for a totally silent fridge. But I also wanted to

get it running and try out the two peltiers in series idea without a

big diversion. So I used the excellent looking new heatsink from

TecTeg.com, and a 120mm square fan from Digikey.

The fridge now has none of the parts from the original

peltier camping cooler I bought when I started. (In fact, I can now

reassemble the cooler for summer camping.) For this fan, I put in a 100

ohm resistor, and turned it over to blow down instead of up, to quiet

it down.

However, the lower heat generation part seemed good,

because the highest temperature reading I could get on the heatsink

side of the peltiers was 23°C, instead of in the low 30's. So as

expected, the two peltiers were pumping from a lower warm side

temperature. (Of course, not only were the series peltiers making less

heat: the fan was blowing more air, it was a better heatsink, and the

kitchen was only 17°.)

After half an hour or so, the aluminum bar going from the

peltiers into the fridge was -3 coming off the peltiers, and +2 under

the pan, where it had cooled a cup or so of water from +7 to +4. Here

were a couple of thermal conduction inefficiencies - one would hope the

warm water's heat would keep the tray and bar warmer, and also that

there wouldn't be so much heat gain - at least five degrees - along the

length of the .5" x 1.75" bar.

According to the graphs, at 3.4 amps and 26°

temperature spread, the peltiers should be pumping about 20 watts each,

for a total of 40. That's as much as a single element at 6.8 amps, even

if the temperature differential was no more.

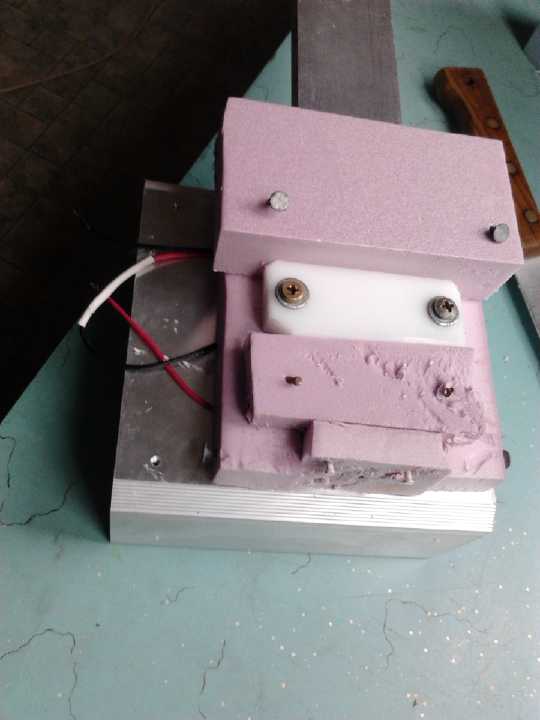

Peltier/outside end of the aluminum bar.

The bar went through the fridge wall and the pan was bolted on inside.

Later that evening, I was less sure about the efficacy of

the system. The voltage was still 12.5 and the amps 3.15 (39

watts), but temperatures seemed almost static. The warm side heat sink

was just

21-22°C. There was frost on the "cold transfer bar" towards the

source end and it was still -4 or -5°C coming off the peltiers. The

fridge

had dropped from 6.5° to 5.

Ice had been starting to form earlier in the 1 cup of water I had

initially put in, but after adding another 3 or 4 cups at 5 or 6 PM, by

9:30 there was still no ice. I went to bed late, but there was still

only a little ice. Was I reading the graphs wrong? I turned it off

anyway, and by morning the fridge was up to 9°.

The next morning, before trying to get onto the battery

project, I decided to cut the hole through the fridge wall bigger and

clamp another .5" x 1.75" aluminum cold conducting bar under the

existing one to improve the coldness flow from the peltiers to the

water tray. This seemed better, with the warm side pushed up to 26°

but the cold side not getting so cold. It was 1° going into the

fridge (where the water was 12). But then I managed to get the probe

right behind the peltiers. It read -6, just 3" away from +1 on the same

thick bar!

When aluminum isn't aluminum!

At this point, I was pretty sure I had some aluminum alloy

bar instead of pure aluminum, and that that was the chief problem with

the whole unit. It was gaining at least 5° in the first 3" and

3° in the next 3", headed for 10° from one end to the other. So

instead of 25°, the temperature spread across the peltiers was

perhaps 35°, and there'd have been, as observed, not much heat

pumping wih the lower currents. Was that what came of buying aluminum

at a

scrap place... or would brand new "aluminum" stock be likewise impure?

I found out the next day, the 12th. Almost all "aluminum"

sold is actually one alloy or another, made to machine more easily and

be stronger. Any alloy (elaborate superconductive combos

excepted) is much less conductive of electricity and heat than the pure

element. This was doubtless why my "aluminum" heat transfer rod for the

heat pump didn't seem to work very well either, which led me directly

to the copper pipe and water/anti-freeze convection based idea. For the

motor

controllers and other heat sink items, distances are short and alloy is

"good enough". The real thing would be better in all cases.

It then occurred to me that my "copper", which I've also

purchased for copper's great electrical and thermal conductance, might

have the same problem. So I thought I'd also have to view plumbing

pipe, rod, plate and other sources of "copper" with suspicion despite

their high cost, but I've been assured that copper is usually pretty

pure.

Otherwise it's considered to be some variety of "brass", "bronze" or

whatever. And the color is noticably different.

I did some phoning around on the 13th. I could look on the

web, but it started to sound like pure aluminum bars or plate wouldn't

be an easy thing to get hold of. Trying to melt down aluminum wire or

pure aluminum "1050" or "1100" sheet to try and make a bar had little

appeal. I decided I'd just have to redesign the unit with the shortest,

fattest alloy bar I could find. Or a copper bar, but that would be

heavy and costly. Gee, putting everything in line on one bar seemed so

simple!

After spending two

days on the fridge instead of a couple

of hours, I was a bit fed up with it. I meant to leave it, working and

at lower power, but having to run considerably longer hours to freeze

ice instead of about the same (or wishfully, shorter). But a short,

pricey copper plate

heat conduction

arrangement started to sound like an appealing way to quickly solve the

problem, and on the 15th I went down to

Smith Bros Foundry to see what they had. I ended up with a 3" x .5"

copper bar, 9" long. That was just a bit too narrow to mount 2 40mm

square peltiers

side

by side. Annealing it with a torch and pounding one end to 'wide

enough', and then trying to get it perfectly flat again, seemed

daunting. So I found a piece of .25" thick copper plate at home, left

over

from a magnetic torque converter idea. Bolting a .25" x .5" x 2" piece

onto the big bar made it just wide enough, 3.25", to hold both.

Heatsink with copper bar... I realized after installing that the air

could only vent out one end of the fins.

Sideways pan on short copper bar freezing ice.

Pan is now mounted near top for better cold air circulation,

to better keep the whole fridge cooler.

Bottom view showing copper bar sticking in through the wall.

Installing, with ice pan attached to copper bar,

Peltiers sitting on copper bar outside,

and heatsink and fan sitting on wall.

Installed, but showing one peltier sticking out.

In the 17°C kitchen,

the warm side stayed down at

23° with -3° on the cold side feeding the tray of ice-water - a

peltier temperature differential of just 26° or so and only about a

3 or 4 degree gain along the copper and into the tray. The current

stayed at 3 to 3.2 amps. This all seemed excellent. But it didn't seem

to freeze the water much faster than with the aluminum.

I realized at some point that I could easily disconnect

one peltier and run full voltage on the other. I decided to try it and

see how well the improved layout worked with just one at 'normal'

power. The fridge drew 6.4 amps instead of 3.2. The warm side

temperature rose to over 30°. Everything seemed good and I waited

to see how fast the ice blob would grow. Instead, much to my surprise,

the frost on the copper bar melted, and it stopped making ice in the

tray. It sat at about the freezing level. I tried the other peltier

instead and

got the same result. The ice that had been made by the two in series

earlier now floated up - it was no longer even frozen to the source of

cold

at the bottom!

It seemed to me there could be just one cause: the

unpowered peltier module was electrically but not thermally removed

from the system. It was conducting the heat from the warm side to the

cold side fast enough to seriously reduce overall system performance.

Here then was demonstrated a major cause of Peltier module

inefficiency: direct heat conduction across the module.

(As a TEG, the unpowered peltier module had about 1.25

volts open circuit, and would supply about an amp if shorted. A bigger

temperature difference would have made more useful electricity.)

Soon I started to realize that when it's turned off, the

fridge must radiate a lot of its cold from the ice tray, along the cold

side bar, through the peltier(s), to the warm side heatsink, and thence

to the air in the room. This would negate the efficacy of a

considerable portion of the excellent foam insulation, and it was

considerably worse with two peltiers.

An evacuated tube with water in the bottom radiator would

not only eliminate the fan noise, but much of this unwanted loss of

coldness as well, since only heat and not cold would transfer up the

pipe and radiate off - the "heat diode" effect. This devide is covered

in its own topic section, below.

After discovering how much heat was transferring across the peltier

modules when they were off,

I made a foam box to cover the entire cooling unit.

Sure enough, the temperature in the box dropped to 5°c, the fridge

temperature. When the fridge was off,

the ice tray coldness was being radiated straight out into the room

from the warm side heatsink!

I set the fridge back to 'two in series' operation. At

least whatever losses were inherent were theoretically accounted for in

the graphs. At midnight there seemed to be enough ice and I turned it

off. There was still a bit the next morning at 10 AM.

On the 17th, the first full day of normal operation, I

noted that ice seemed to be forming reasonably quickly (faster than had

I expected), but the pattern of ice buildup seemed to indicate only a

few good points of connection from the copper bar to the tray. This was

understandable as I was only able to put two of the three bolts into

the copper, since the tray was turned sideways to it for the minimum

bar length. (Did I mention copper is expensive?) So I decided to put a

thinner copper strap from the second to the unused third bolt the next

morning when the second bolt wasn't encased in ice.

When I went to look I found a small piece of 1/2" thick

copper bar left over from another project (magnetic torque converter),

so I used that instead.

Second bar of copper to cool the pan better.

Main conclusions:

* For daytime solar power with over 13 volts, my idea of cooling with

half the current does seem to have worked. The

fridge is now around 40 watts instead of 70, and cools roughly as well

- and the peltiers don't even seem to be making the best contact with

the heatsinks.

* It makes ice somewhat more slowly, but rather than this being caused

by reduced cooling, it appears to be because in the changes, the tray

was moved upwards from about the middle (too low!) to near the top. The

cold air flows better and over the food to the far side, reducing

temperature stratification and keeping the whole fridge a little

cooler. The ice also melts more rapidly overnight, which doubtless has

little to do with the peltiers. (This leads to the thought, tho, that