Turquoise

Energy Ltd. News #63

Victoria BC

Copyright 2013 Craig Carmichael - May 6th, 2013

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features: - NiMH Compact, stackable 12V D

cell battery cases (12V, 10AH per case) - CAT standard click-lock 12V

plugs & sockets

Month In Brief

(Project Summaries)

- CAT Standard click-lock plugs & sockets - Getting the Mazda RX7

& renewed batteries going - Compact, stackable, 12 volt NiMH "D"

cell battery cases with 3D printer - Programming microcontrollers -

Fridge

In Passing (Miscellaneous

topics, editorial comments & opinionated rants)

- Investing in the future - "Cold fusion" (catalytic fusion) evidently

works, was suppressed... by universities, MIT.

Electric Transport - Electric Hubcap Motor

Systems

* Getting the Mazda RX7 going

* Superior battery charging and automatic battery monitoring

* Ungrounded "floating" high voltages are less hazardous

Other "Green" Electric Equipment Projects

* Fridge: 15v + 8v Peltier modules in series for more efficient and

effective operation

* Getting Started with TI MSP430 microcontroller (µC, uC)

software

development (under Ubuntu): µC controls are wanted for fridge,

heat

pump, EV

battery monitoring, motor controller overcontrol, and still other

projects

Electricity Generating (no reports)

Electricity Storage - Turquoise

Battery Project etc.

* Lead-acid Battery Renewal with Sodium Sulfate - New Techniques

* NiMH compact, stackable 12V battery cases for making large

batteries from D cells (first one is 12V, 60 AH for electric RX7) -

a more compact alternative where "handy battery sticks" don't fit well.

* "Super battery stick" proves less than super.

No Project Reports on: DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic

Motion Machine, Ultra efficient vehicle transmission/torque converter,

CNC Gardening/Farming Machine (sigh, maybe summer 2014!),

Woodstove Electricity Generator, Peltier heat pump, Turquoise (MnMn)

battery.

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater (say, this heater is now obsolete! Use Peltier module heat

pump!)

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit - also please inquire about Electric

Caik

3KW Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks & Dry Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

Now accepting BITCOIN

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

April in Brief

Having bought the 1981

Mazda RX7

electric converted car, R & D priorities shifted to making it work,

as I intended with "any old mix of batteries" to reduce costs and not

waste good batteries. I didn't want to pour thousands

of dollars into this old car, but I could certainly spend a week

or two renewing PbPb

batteries to get it back on the road. Two of them didn't

work out and I traded

them for another, and a couple more didn't seem to perform well, so by

month's end I had

spent a considerable amount of time on them.

AGO Environmental had

a big splurge of orders and the owner Jim Harrington (who sold me the

RX7 for irresistible terms) asked if I could work there for a few days,

wiring cables for motor controller devices. I did, which naturally ate

away at my own project time.

Other than the Mazda, which I chipped away at (cleanup

&

minor adjustments, chargers, windshield wipers, LED light bulbs and the

batteries), projects got neglected owing to lack of time. Up to the

22nd, I didn't find even

bits of time to do much of anything including Turquoise Energy's income

tax, which should have been done in March. The thermoelectric projects

other than trying

another peltier configuration on the fridge were pushed aside,

perhaps for the summer, and MnMn battery test

cell #4 didn't get made. On the other hand, some previously neglected

items came

to the fore and got done: click-lock CAT Standard 12 volt plugs &

sockets,

and the

3D printed cases to make large capacity compact, stackable, 12V NiMH D

cell batteries.

The "Edible Everything Landscaping" [goedible.com] person

who wanted the

electronic soil moisture probe switch (no point watering if it's

rained) came back as gardening season

approached, and put the parts on the PCB. After we did a bit of

troubleshooting and found his several cold solder joints, it worked to

his satisfaction.

This was gratifying.

Here are the schematic and the PCB layout, done in Eagle PCB.

I've been saying my Electric Hubcap motors seem like

they're around 95% peak efficiency. But I haven't

definitively tested them, and probably many people think I must be

overestimating. But this month I see a company claiming their new

motors are 97% peak efficiency. They also claim an amazing 2600 W per

Kg, which make the Electric Caik's ~400 W/Kg

and the Electric Hubcap's ~300 seem pretty pale, tho these figures are

themselves quite good and would

doubtless be much higher for short bursts of power.

Click-Lock CAT Standard 12V Plugs & Sockets

In order to connect up the individual 12 volt chargers to

each

battery in the Mazda, I created "click-lock" CAT standard sockets and

plugs to put

on each battery and charger. I had had these in mind for quite a while,

and

now that I needed them I designed and 3D printed them. To my surprise,

the design and a $1.50 each price quickly made them popular - I sold a

couple of sets to one person I showed them to, and traded 3 more to

someone else for other trinkets. Yellow was definitely the popular

color.

CAT click-lock sockets on batteries and plugs on 13.9V, 5A power

adapters/battery chargers, in the RX7.

Half the batteries have two sockets: the second is for the battery

monitoring system, yet to be made.

I had been putting the CAT plugs' blade folding tool in a vise.

This time I asked myself why not use it freehand? Sure enough it's

easier.

Mazda, Mixed Batteries & Battery Renewal

Under the RX7 hood: batteries, main breaker box (grey/silver)

with

"kill" lever by steering wheel, DC to DC converter provides

12 volts, a

couple of dangling 'click-lock' power adapter chargers,

and the front end of the motor just

visible below.

Talking on the

VEVA electric car list I learned that the

problems

with using mixed batteries extend not only to the need to charge them

individually, but to monitor them individually as well, so the weaker

or lower capacity batteries - or if a charger quits working - don't get

overdischarged or even driven into reverse charge (and hence weakened

or damaged) before the driver

notices. A gauge to show the overall voltage is insufficient,

especially in a typical higher voltage system.

Talking on the

VEVA electric car list I learned that the

problems

with using mixed batteries extend not only to the need to charge them

individually, but to monitor them individually as well, so the weaker

or lower capacity batteries - or if a charger quits working - don't get

overdischarged or even driven into reverse charge (and hence weakened

or damaged) before the driver

notices. A gauge to show the overall voltage is insufficient,

especially in a typical higher voltage system.

In order to not impose such a difficult task on the driver

while

he's driving, I decided it would have to be an automatic

microcontroller based monitoring system that would alert the driver

when any battery started getting low (yellow alert), and then again

(red alert) when it was definitely time to stop. The alerts would also

say which battery(s) it was. Or maybe colored bar graphs (green,

yellow, red) showing all the batteries at once.

This, with 12 volt chargers, should make it much more

practical for

EV owners to buy batteries on an as-needed basis instead of doing bulk

replacements costing several thousand dollars at a crack and

doubtlessly wasting batteries that still have good life in them. So,

unexpectedly, taking on the "mundane" already converted car has led to

yet another new innovative product idea!

Various battery issues and an unknown wire held up running

the Mazda until the 16th, when I got it to move up and down Jim's

driveway. After borrowing a couple more batteries and putting them in

as well as buying license plates and insurance, I drove it the short

distance home on the

17th, where I could wash it and start attending to the many minor

problems of an old vehicle that had been sitting unused for some time.

I also had to convert a bunch more 12V, 5A power adapters from 12.0 to

13.8 or 13.9V for

use as battery float chargers for each battery in the car.

In the rear end of the Mazda. (Plastic & carpet stripped out for

washing.

It came without a rear seat - instead the black hole at the top.) 3

power adapter

chargers are unseen behind the batteries and one regular charger is

employed.

The battery well was installed where the spare tire, and perhaps the

gas tank,

used to sit. (If there's a spare tire, I haven't found it yet.)

After this procedure, the batteries would jump to 14.4

volts when the charger was connected without drawing much current. I

did some higher voltage short pulses with the "charge/start" switch on

the charger, which would probably overpower little differences between

cells. Finally I tried a "smart" lead-acid charger instead of a "dumb"

one. I generally prefer the predictability of the "dumb" ones, but the

"smart" charger proved its worth for this purpose: it raised the

voltage to well over 15 volts to get the battery to start taking charge.

As a couple of weeks and 3 or 4 test drives and recharges

went by, the renewed batteries in the car went from holding about 11.5

volts to 11.8 and then 12 volts. This seemed promising. While some on

the web say to do about 3 charges and discharges, then they're good to

go, someone told me in person they would take many charge-discharge

cycles to develop good capacity after renewal, which seemed to match my

previous and present experience. The number of

chargers went from 3 (done previously for 36 volt Electric Hubcap

systems) to 5 and I could charge the batteries in two groups, front and

rear, after a drive. But one per battery (9 or 10) will eliminate

plugging,

unplugging and moving things around.

The car had problems other than the batteries. Pressing

the clutch pedal had no effect. With an EV there's no need to use the

clutch to start moving, so for test drives I just stayed in 2nd gear. I

had filled the

empty hydraulic clutch cylinder, but it still didn't work, so I thought

I'd have to bleed it. But with all the electrical equipment above and a

metal guard below, I couldn't reach or even see the lower end of the

line. Finally I thought "most clutch pedals go down farther than this

one." I pressed

it really really hard and suddenly it broke free and dropped to the

floor. The mechanism had simply seized up from sitting too long! (and

with

no fluid.) The clutch worked after that without having to do anything

more.

The battery voltage display never came on, and several

times the car had momentarily cut out as I started

driving, but always started again. Finally it cut out and just wouldn't

go, across the street from my driveway, blocking a side street. Home

was close but uphill. I

said "Well, this

is just great!" to my neighbor who was nearby mowing her front

boulevard. She

got someone else from the house, and just then two joggers came along

and she flagged them down. The five of us pushed the car back into my

driveway. Whew, thanks Kathy!

I found a couple of very loose small wire terminals - one

had fallen off its terminal and the other - from the 'electron pedal'

to

the motor controller - dropped off when I touched it. It was the

culprit. I tightened them

with pliers and put them back on, and the car

didn't cut out any more. The drive battery voltage meter worked for the

next two trips and then cut out again - and I found and fixed yet

another

loose wire.

Near the end of the

month I decided I should put in a couple of batteries made of NiMH D

cells, and I started making cases for them (see below). I figured I

should stack at least 6 banks to replace a

lead-acid in the Mazda to handle the currents - up to about 125 amps

even on

my leisurely

test drives. That would make for 60 amp-hours (and ~500$). Each bank

beyond 6 would

decrease the stress per bank and add driving range, but each bank costs

me around 80$.

Whether I convert the whole car to NiMH's (quickly or

slowly) will depend on how much money I have, how easy or troublesome

it is to renew and maintain the PbPb's, how much I drive the car, and

whether the PbPb's give the sort of driving ranges I need. And if I get

the Sprint running it would have priority since it would give

inherently more range per battery. Still, the car with all NiMHs would

definitely outperform lead-acids and it would lose 200-250 pounds. This

would be all the better as the front springs are nearly bottomed out

with 5 lead-acids under the hood.

Even knowing this is a "regular" electric conversion,

working through a typical lossy automotive transmission, and knowing

what people consider to be adequate power for such vehicle systems, it

still surprises me to see the car using 50 to 125 amps at around 100

volts, 5 to 12.5KW, just to putter down a side street at 30KmPH. (From

what the previous owner says, that sounds typical - in fact,

light-footed.) I'm

just as sure now as I was to start with that substantially better

performance

and hence range is possible (I'll stick with my 1.5x figure). But five

years down the road, I have yet to demonstrate it. Hopefully a clutch

mechanism is the last operative piece that'll get the Sprint going.

When I do, the experiences with the Mazda will help me do

a more streetworthy overall job of the Sprint.

12V NiMH D Cell Battery Cases!

I have to keep reminding people who claim they saw

"Who Killed the Electric Car?" that the batteries that made the EV-1,

RAV4-EV, et al so good were nickel-metal hydride. I don't know how

after that movie the corrupt have waved the magic curtain and somehow

not only prevented the manufacture of large NiMH cells but

made everyone forget they exist, last many years, and perform - and

this in spite of their outstanding performance in hybrids like the

Toyota Prius!

On the

26th I

redesigned the

12V NiMH D cell battery case I'd

had poor 3D printing results with earlier in order to be easily able to

fit in a 60+ amp-hour NiMH dry cell battery or two in the Mazda instead

of lead-acids, to better

illustrate the potential for mixing batteries. The first 5 hour print

was a success, notwithstanding the inevitable somewhat curled up

corners. I separated the cells within by 3mm

so that if they got hot (serious overcharging or overcurrent) and the

plastic labels/sleeves melted, the

cases wouldn't short together and everything go up in smoke.

On the

26th I

redesigned the

12V NiMH D cell battery case I'd

had poor 3D printing results with earlier in order to be easily able to

fit in a 60+ amp-hour NiMH dry cell battery or two in the Mazda instead

of lead-acids, to better

illustrate the potential for mixing batteries. The first 5 hour print

was a success, notwithstanding the inevitable somewhat curled up

corners. I separated the cells within by 3mm

so that if they got hot (serious overcharging or overcurrent) and the

plastic labels/sleeves melted, the

cases wouldn't short together and everything go up in smoke.

Then I cut the metal bits to connect all the cells (after

which I discovered all the D cells on the shelf very much needed a

recharge). Thick copper is best for the high

currents of an EV drive, and I switched to that from nickel-brass.

Tinned or nickel plated is doubtless best for preventing corrosion.

(Here is an advantage of the battery tubes: no extra connections

between cells.)

I

made further

improvements and printed more cases in the

next few days. Then I decided that notwithstanding the warped corners I

had a product to add to the Turquoise

Energy Product Catalog, and that the introductory price would be

25$. (Naturally I'd like to make them cheaper and better, but at the

moment, they're a 4.5 hour 3D printout and then the copper bits have to

be

cut and shaped by hand.)

I

made further

improvements and printed more cases in the

next few days. Then I decided that notwithstanding the warped corners I

had a product to add to the Turquoise

Energy Product Catalog, and that the introductory price would be

25$. (Naturally I'd like to make them cheaper and better, but at the

moment, they're a 4.5 hour 3D printout and then the copper bits have to

be

cut and shaped by hand.)

The plastic irrigation pipe first made it possible to make

reliable big NiMH batteries out of D cells. The new case makes such a

battery much more compact, able to fit where a lead-acid battery fits

with space to spare, with lighter weight, better performance, and

much

longer life. ...all at a much higher initial cost, one not dissimilar

to equivalent lithiums.

An attractive idea

in using small NiMH cells (and 13.8 to 13.9 volt float charging) is

that to increase capacity (as in vehicle

driving range), one can add new

batteries incrementally one 10AH bank at a time without removing old

ones - a lower capital investment at any one time - until the

maximum space or weight limit is reached.

6-stack NiMH D cell battery: 12V, 60AH, 180A, 300A intermittent.

The need to program microcontrollers to automate

the

fridge and the heat pump systems, set motor controller RPM limits, and

now for the Mazda battery monitoring

system, led to considering

setting up to do such work, and getting familiar with it, as a

priority.

TI's integrated MSP430 development system took more

computer

hardware than any one computer of mine had, but there was a basic

"MSP430-GCC" C

compiler, utilities, and header data files at the Ubuntu Software

Centre and I used web

searches to help figure out how previously successful people had got

things to work. (...and I started to suspect the majority haven't

succeeded.)

There were some 'non obvious' tricky bits like an obscure

file that had to be placed in an

obscure directory (/etc/udev/rules.d/) to enable USB

communication to the MSP430 Launchpad board, a command

line with specific 'options' to type in to make the compiler

generate the program (msp430-gcc -mmcu=msp430x2553 -o

hello.elf hello.c), and a command

line

'debugger' with another obscure 'option' to run that could erase the

previous program and load the

new finished program to the MSP430 chip on the

Launchpad board. (mspdebug rf2500) Luckily one

person had spelled out these few vital details on his web page. After a

second learning session, I managed to compile, download and run a

couple of programs before midnight (ie before 1AM DST) on the last day

of April.

I'd like to make a graphical program with Python language

so one can just click buttons to get these things to happen instead of

typing them in a terminal program.

Fridge

The two 15 volt peltier modules in series didn't seem to

make ice fast enough to avoid needing considerable evening battery

capacity - and not at all if the power was below about 12.5 volts.

On the 22nd I put 15 and 8 volt peltiers (both 8.5 amp) in

series to cool the fridge, raising the daytime voltage on the 15 volt

one from about 6.7 to 8.4 volts. The voltage on the 8 volt unit was

then

about 4.8. Both were still in the better efficiency area of their

specs.

Typical daytime current went up from 3.1 amps to 4.0. But the warm side

temperature rose from about 26 to 30 - partly it was the kitchen

warming with the weather. The cold side was -5 making a 35 degree

spread instead of the 30 I had with the 15:15 volt units, and the heat

pumping didn't

seem to increase a whole lot. I raised the speed of the fan, but it

only

lowered the warm side a degree or two. But after a couple of weeks, it

did seem to me there was generally more ice by evening.

On the 22nd I put 15 and 8 volt peltiers (both 8.5 amp) in

series to cool the fridge, raising the daytime voltage on the 15 volt

one from about 6.7 to 8.4 volts. The voltage on the 8 volt unit was

then

about 4.8. Both were still in the better efficiency area of their

specs.

Typical daytime current went up from 3.1 amps to 4.0. But the warm side

temperature rose from about 26 to 30 - partly it was the kitchen

warming with the weather. The cold side was -5 making a 35 degree

spread instead of the 30 I had with the 15:15 volt units, and the heat

pumping didn't

seem to increase a whole lot. I raised the speed of the fan, but it

only

lowered the warm side a degree or two. But after a couple of weeks, it

did seem to me there was generally more ice by evening.

But one thing I noticed in changing the peltiers: I rubbed

at the heatsink compound on the copper bar with the peltiers gone with

my fingers, and rubbed off a small lump or grain of some sort. This may

have been preventing optimal surface contact of one peltier for quite a

while, which might explain why I thought it was working as well as the

single peltier at first, and then I changed my mind and decided it

seemed to make ice too slowly. Now I'll have to try the two 15V

peltiers

configuration again.

Another thing that finally dawned on me was that the ice

was melting faster at night with the new setup, which included the fat

copper

bar and two peltiers to transfer cold from the ice tray to the improved

warm side heatsink, to better dissipate it into the room. With the

first assembly, the ice in the fridge would last 10 or 11 hours but now

it would only last 8 or 9. If I put a foam box over the outer assembly,

it got fridge cold inside, and the ice in the fridge lasted 11 or 12

hours.

The remedy for this, I hope, will be the water-ammonia

evacuated radiators instead of the solid heatsink and fan. The "heat

diode" evacuated radiator has

more advantages than immediately meet the eye. It'll only radiate heat,

not coldness. It can

be well insulated at the bottom end without affecting "ON" heat

radiation along its length, and something close to the 11-12 hour ice

melting figure

should apply.

As May started, night time temperatures rose fast after a

chilly April. I was uncomfortably warm for the first time this year.

The fridge had to work much longer to make any ice, and stay off for

fewer hours at night to keep its cool, in spite of insulated boxes or

anything I'd done with it. Occasionally leaving it on all night became

necessary. (I want that automatic control!) Four inch foam insulation

at least for the top, bottom and back, and an octagon shape, now seem

like even better ideas for minimizing heat gain.

In Passing

Incidental news, editorial comments & opinionated rants

Investing in the Future

The "5 gallon flush" has become the "5 liter flush" these

days,

and the city has continued summer water rationing for no apparent

reason despite building a larger dam. (So just what was the new dam for

then?) As less water is used, the city water rates keep rising to

maintain

revenues - less and less water costs more and more. I replaced my two

old toilets with new low

flush toilets last year.

They cost about 400$. The first four-monthly water bill with them only

(admittedly for winter - no gardening) arrived in April and was around

25$ less than usual - 1/3 off, suggesting a total 75$/year savings. So

at

present

water rates it'll take about 5 years to pay for

them (ignoring my labour installing them). The toilets should of course

last pretty much as long as they're wanted (just as the decades old

ones were still perfectly good) and will continue to save.

Let's see...

if I had put them in in 1981 when I originally redid the plumbing, how

much would I have saved over the years? Of course, I don't think there

were low flush toilets back then.

The case is similar for many home improvements that

gradually pay for themselves, the latest one being the new woodstove

that uses a little less wood. Investing in the future takes a bit of

money and effort, and generally only pays back gradually. But it's

worth it, and the sooner it's done, the

sooner it starts to pay back. And usually it's better for the

environment.

Unfortunately if you're paying over 1000 $/month on a

mortgage, and 300 $/month on property taxes even after you "own" your

house, doing real things that make real differences to Earth's ecology

may seem trivial compared to doing artificial financial things that can

make a big difference to your financial ecology. Along with much else,

this will change when the pyramid scheme global financial system

collapses.

Catalytic Fusion (AKA "Cold Fusion") - suppressed technology?

Someone sent me a link to a documentary about the

so-called cold fusion that got everyone excited about 25 years ago, but

then seemed to "go away" with other labs "unable to duplicate the

results" of the two inventors. It seems this last claim is simply

untrue, and that palladium has been used as a "nuclear catalyst" to

convert heavy

water into helium, tritium and other heavier elements not present

before the reactions - and lots of

heat. ...even in labs which then claimed it didn't work. Perhaps the

alchemists weren't so far off after all - one of the heavier elements

found was silver. How the discoverers hit on the process I don't know,

but it was the product of many years of research.

http://www.forbiddenknowledgetv.com/videos/suppressed-technology/cold-fusion-a-story-of-suppressed-technology.html

It appears to be yet another story of vested interests

sweeping promising new technologies under the carpet in order to

maintain the status quo - this time especially including universities

and MIT getting massive ongoing funding for "hot fusion" research.

Not all questions

about how it works have been answered, but the documentary

concluded that we may soon power most

everything by catalytic fusion, and that the power grid may disappear.

I disagree at least with the first conclusion. I think magnet powered

generators (seemingly another way of harnessing nuclear power in a

simple, environmentally friendly way) and other energy sources

including solar

and wind power are likely to claim big shares of the future energy

production pie.

Universities themselves may soon be extensively

restructured, or else go the way of the dodo. They are becoming

increasingly management heavy and self-serving, producing less and less

of value for more and more money. They do little research (and even

less development) unless big funding is attached, and deliberately

avoid teaching students too much, too soon, in order to keep them

captive for as many years as possible. This, IMHO, is despicable. Then

employers complain that university students and grads are 'clueless',

unable to complete simple tasks in their field without help. The

chemist inventors of "cold fusion", like most people doing really

valuable R & D, had to fund their own work, and were unable to

bring it to market in the absence of any support.

New ways of learning such as self directed internet

studies may soon look better on a resume than a degree from some

institution. Lectures of from the best, including nobel prize winning

professors, are evidently available for free at coursera.com, and many

students say they learn more off youtube videos than they do in

classes.

Electric

Hubcap Motor Systems - Electric Transport

Lead-Acid Battery Renewal and a Superior EV Charging System...

and a superior battery monitoring system

By April 6th I had (I thought) enough renewed lead-acid

batteries to

run the RX-7. Evidently performance would "suck" with only 96 volts,

but it would run. If all 9 batteries worked it would be 108 volts, to

which I could add as occasion served, up to 11 for 132 volts. Someone

advised me not to add the 12th one for 144 volts, as the model of

controller in the car was more reliable without it. The car had 144

volts of lead-acid batteries before, but lithiums are a substantially

higher voltage than 'nominal' with a full charge. I suspect it's after

conversion to lithium cells that the problems would usually arise.

Complications set in when I started mentioning my charging

batteries individually

idea on the VEVA electric car list. Canadian Electric Vehicles had

tried it and found there are a lot of unreliable battery chargers out

there. If any one of them doesn't work, the car will soon let you down

on the road.

Another experienced EVer said a weaker battery would go

dead

and into reverse charge, damaging it, before the driver would notice

performance degredation. (...another argument against using high

voltages?) When you step on the electron pedal, the

voltage drops, and even if noticed it's not readily apparent whether

it's all the

batteries dropping a little or if it's more just one that's dying. Now

I start to see the less obvious practical reasons why using mixed

battery sets hasn't been the normal way to run an electric car! And

yet, the

economy is much greater and the problems have nothing to do with the

performance of the actual batteries.

(The same person also mentioned they should all have an

equalization charge ("overcharge") now and then to equalize the 6 cells

within one battery. That didn't fit very well with my 13.8 volt power

adapter float charge idea. I decided to see how doing it as an

occasional

manual operation with a "real" charger works out, and this was also

suggested.)

I soon decided that the 'remedy' for all this would be a

microcontroller monitoring each individual battery, which was suggested

as an 'ideally you would...' possibility. When any battery was getting

low, a

"yellow alert"

would indicate driving range was nearing its end. When the same battery

always gives the yellow alert, that's the one to change if it's felt

range is insufficient - especially if it goes to "red alert" before any

others go to "yellow". A "red alert" would say damage could result from

driving further. Any battery that was low after charging would also

"alert" and show up any charger problem, without waiting for

the car to die on the road.

My plan for the microcontroller is essentially the same as

for the fridge and the heat pump: A TI MSP430 uC, the small color LCD

display, and a few pushbuttons for programming and status.

On May 4th I had the idea to have colored bars, green,

yellow and (flashing?) red, as the main display, showing the state of

charge of each battery. A yellow and red alert warning beeper should

also be a good feature.

Since it should make using mixed batteries far more

practical in an EV, this is another potentially great energy and money

saving product. Funny how I sometimes start things that seem fairly

mundane, and

end up with innovative product ideas to make them better! So far, I

hadn't even installed a software development system for the MSP chips,

but the need was growing and growing.

Another plan for a product to solve all the problems might

be to have the

controller both sense the voltage and charge the individual batteries.

This would

take some fairly hefty power electronics circuitry, and for 144 volts

(12 batteries), quite a lot of it. It would be more manageable for 24,

36 and 48 volt systems.

Aside from renewing batteries, the first job I did was to

design and 3D print "click-lock" CAT sockets. These would mate either

with regular CAT plugs or "click-lock" or "friction-lock" CAT plugs,

which had yet to be made. The sockets fit in a wall plate, but

they stick out 8mm. The click- and friction-lock systems address the

problems for battery system

and EV use:

1. Both the battery and the charger can be 'live'. Therefore the plug

has to be enclosed, "hooded", as well as the socket. The CAT click-lock

and

friction-lock system have this.

2. In the vibration of a vehicle, a regular plug might eventually work

its way out and come unplugged. The friction-lock system requires a

definite tug to get the plug and socket apart. The click-lock system

requires that the click latch be held unlocked to unplug it. The same

click-lock socket is used for both.

In theory the click-lock plug has a right angle catch that

won't pull away unless held open, while the friction-lock has a 45°

angle catch that will open if you simply pull hard enough. In practice,

the 3D printer rounds things off enough that the click-lock plugs can

be pulled off with a good pull unless the catches are specifically

trimmed or filed square. I consider them "good enough" for the car, so

I haven't bothered doing specifically

friction-lock plugs yet. A 3D printer with finer resolution, or maybe

small design modifications, would

probably give more exact results.

Duds!

Four of the batteries seemed to renew fine giving me 7 of

the

minimum 8, but two seemed to have self discharge in one cell each. I

thought this could be cured, surely in at least one of them.

The two that wouldn't recycle were green and white

"Megatron" (size 24) and "Interstate" (size 27), obviously both made in

the same factory. I noticed that when I shook up and then drained the

batteries, most of the battery acid was pretty clear, but the green and

white ones were grey with lead crap even after several shakings and

drainings, until I just couldn't hold them up to do another rinse. My

tentative theory is that the

plate separators are open at the top instead of accordian folded, so

that as the lead crap settles on the tops of the plates it

can create

bridges between the plates. As the battery charges, the crap is

converted to conductive (and adhering) states until it causes shorts or

high self

discharge. I tried blasting 24 volts through them from two other

batteries to burn out the shorts. It seemed to improve them but not fix

them. I tried charging them for extended periods. Nope. They would both

hold 10 volts - 5 cells out of 6, fine - but not 12V. After some days

of

frustration I

had everything else ready to go to at least put the batteries in the

car

with charger and battery monitor connectors, and I

decided I'd better trade them another battery or two and try again.

Sigh!

And when I was originally

trying to recycle lead-acid batteries with sodium sulfate over 3 years

ago, two size 24, green and white "Megatron" deep cycle batteries were

among the frustrating failures with similar results to this attempt.

I'm not convinced they can't be renewed with the right 'touch' - maybe

just a sloshing around after refilling to wash the crap to the bottom.

But the

score is 0 for 4 so far.

On the 11th I traded them for one other battery, which

seemed to work like new. After putting in the sodium sulfate, it took

about 30 hours running a headlight to wear it down to under 3 volts.

Then it needed a lot of charging. Finally on the afternoon of the 13th

I was ready to connect up all 8 to the car and try it out - with this

last battery only half charged.

It took a considerable session to wire brush off all the

posts and fat inter-battery jumper wires. When I tried on the 14th the

car

didn't go. A solenoid clunked on when I pressed the pedal, but the

motor didn't try to turn. One of the batteries dropped down in voltage

after merely running the vacuum pump, which comes on when the key is

turned. Then Jim pointed out a wire to a DC to DC converter that wasn't

connected, and later sent me a picture of it when it was connected to

"B+". It was too short for my battery arrangement. I made a longer one,

and put it on after work on the 16th.

The car ran! I drove it a few feet up the driveway and

back. There were many things still to do and to clean up, but it was

working.

I decided to borrow another battery or two to have 9 or

10, then obtain a couple more of my own. That way, if one quit on the

road, I could (hopefully) pull over somewhere and bypass it, and still

have enough voltage to run the car. And the range would be at least 10

or 20% greater.

The next day I got the license and insurance at lunch

time. A friend met me & Jim at the car at 4:40 PM. He helped put

the extra batteries in, and remove one that wasn't charging up

properly. Between the three of us, the car was 'ready to roll' within

two hours and I drove it the 3 or 4 blocks from Jim's to my home.

They'll be glad to have it out of their driveway, and I could start

cleaning and

working on the many little problems of a 32 year old car that's been

sitting for the last 3-1/2 years. And then start making the

computerized battery monitoring system.

On short test drives, several times the car had

momentarily cut out as I started

driving, but the next time I pressed on the gas, it would go.

That would be just what was needed on a busy street! Finally I tried a

drive on the 30th, and it cut out

and just wouldn't go, just across the street from my driveway, blocking

a

dead-end but somewhat busy street. Home was uphill. I said "This is

just

great!" to my neighbor who was mowing her front boulevard. She got

someone from in the house, and just then two joggers came along and she

flagged them down. The five of us pushed the car into my driveway.

Whew, thanks Kathy!

I decided I needed to see the voltage to know if low

voltage was why

it was cutting out. There was a digital monitor on the dash that hadn't

been working. I pulled things apart and got at the back of it. There

were five wires. I traced the blue one back to the main breaker box,

and found it lying next to a flat lug. It was loose and had simply

fallen off. I squeezed the connector to tighten the join and put it

back on. The car still wouldn't go, and I pulled on the wires from the

gas pedal pivot/potentiometer. They went straight across to the motor

controller at the front. Having done that, I tried the car and this

time

it went! I pulled out a battery to access the controller and found one

of the wires so loose it fell off. As with the other, I bent the

connector tight and replaced it. On the next test drive, the car

didn't cut out any more. Even when the voltage went down (from 120) to

75 volts coming home, at 100 to 125 amps.

That 75 volt figure, and not knowing which battery or

batteries were causing the drop, made me all the more sure each one

needed to be monitored individually. And all the more nervous to try to

drive the car any distance.

Adding one more insult, the voltage display quit again

after two trips. Sure enough, it had yet another loose wire.

Ungrounded

("floating") high voltage drive systems are less dangerous

I've been very concerned about the dangers of the high

voltages typically used in EV drives. In fact, I wondered why we

weren't hearing about DIY EV people being shocked or electrocuted.

But all along I've been missing a key point, and somehow

no one illuminated me on it despite all the times I voiced my concerns:

the high voltage drive systems aren't grounded to the frame of the

vehicle - they're deliberately left floating. In principle this means

that any point the grounded user touches becomes ground. In practice,

dust and grime, capacitance, and other stray leakages to the car frame

mean the user will often get a shock from accidental contact with drive

voltage wires, hidden but exposed motor terminals (I got one) or

battery terminals. But it's usually not a serious or fatal shock, just

a tingle. Somebody had a brilliant idea there - a typical grounded

system would

have the deadly dangers I've been so concerned about.

I finally learned this when I checked out some things on

the Mazda RX7. I'll stick with lower voltages for my own motors - it's

still much safer - and now I'll probably make them floating as well.

As long as cars need pretty powerful systems to move them

through lossy transmissions and gears, lower voltages need very heavy

wires. (Still good insurance IMHO.) When and if I have cars running

with

more efficient transmissions and lower power motors the wires won't be

heavier than are common now.

Another interesting common feature of many converted cars

including the Mazda, especially using lead-acid batteries, is a

contactor [heavy relay, solenoid] that only supplies main power to the

motor controller if the 'electron pedal' is pressed. The potentiometer

unit for the pedal also includes an on-off switch which activates the

contactor's coil.

If the motor controller dies, this system will stop

further damage via high power wiring from the moment the foot is off

the gas. But it will

also prevent the controller from doing regenerative braking.

Lead-acid batteries would fry if heavy regen braking was

applied. NiMH will take almost any current thrown at them, which is why

they're preferred in hybrid cars where the regen braking rapidly

charges them to save gas. So you probably wouldn't want the solenoid

with them. Many lithiums do well too, and are

used in some hybrids. The idea of "supercapacitors" to hold the charge

and feed it slowly to the batteries was essentially created for

lead-acids and earlier slower lithium types.

Electric Equipment Projects

CAT Standard 12

volt DC Click-Lock and Friction-Lock Plugs and Sockets

I've had these in mind for some time as an expansion of

the CAT connection system, foreseeing various 12V battery and mobile

system connection needs. Now

trying to wire up an electric car with many batteries and chargers, I

needed them.

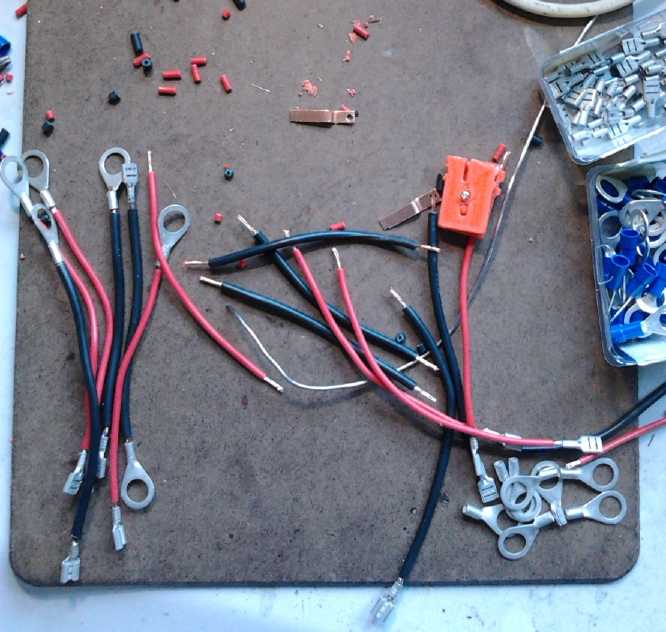

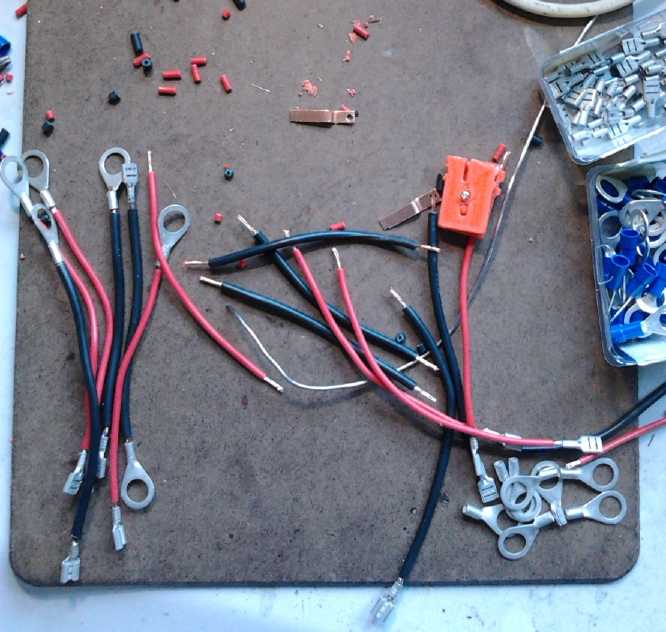

Wiring up about 15 click-lock sockets for Mazda RX7 batteries

The "click-lock" sockets

will mate either with regular CAT

plugs or with "click-lock" or

"friction-lock" CAT plugs. They

fit in a regular CAT wall plate, but they stick out 9mm to make space

for the click mechanism and the plug surround. (Flush wall plates with

slots surrounding the sockets could be designed.)

The "click-lock" sockets

will mate either with regular CAT

plugs or with "click-lock" or

"friction-lock" CAT plugs. They

fit in a regular CAT wall plate, but they stick out 9mm to make space

for the click mechanism and the plug surround. (Flush wall plates with

slots surrounding the sockets could be designed.)

The click-lock and friction-lock plugs will only mate with

the click-lock sockets. The pins on the plugs have the same dimensions

and spacings as regular CAT plugs, but they're enclosed by an 8mm deep

surround, with a center rib of that same length separating the two

blades. The center rib fits into a slot in the click-lock socket.

These new CAT plugs and sockets address needs of battery

connections and any use where there's vibration:

1. Both the battery and the charger can be 'live'. Therefore the plug

blades are enclosed - "hooded" - as well as the socket receptacles. (I

recommend

putting the socket on the

battery and the plug on the charger.)

2. With vibration (as in a vehicle or any moving object), a regular

plug might eventually work

its way out and come unplugged. The friction-lock type requires a

definite tug to get the plug and socket apart. The click-lock type

requires that the click latches be held open to unplug it. The socket

is the same for both plug types.

To elaborate, the click-lock plug has a right angle or

steeper catch that

won't pull away from the socket's catch unless deliberately held open.

The friction-lock has a 45° angle

catch that will open if you simply pull hard enough. In practice, as

presently printed on my 3D printer, the click-lock plugs can be pulled

apart with a good pull without pressing the releases. But they won't

pull apart from vibration.

The first two sockets went into a 24 volt cordless electric lawnmower

so it could

be charged as two separate 12 volt batteries, for the same reasons as

the car.

At this point I didn't have the click-lock plugs yet, but the

'ordinary' plugs can

mate with the click-lock socket. (...Yuk, what gutless machines these

things

are!)

The rear battery compartment of the Mazda with CAT click-lock sockets

across each battery.

Two black 13.8V, 5A power supply/chargers with CAT click-lock plugs at

the lower left

are float-charging the left side batteries.

The heavy wired thing with the white ceramic center strip (upper right)

is a

450 amp fuse.

It would probably blow before the batteries melt down or explode in the

event of a short in the heavy wiring.

Fridge

The two 15 volt

peltier modules in

series didn't seem to make ice fast enough to avoid needing

considerable evening battery capacity - and none at all if the power

was

below about 12.5 volts.

On the 22nd I put 15 and 8 volt (both 8.5 amp) peltiers in

series to

cool the fridge, raising the daytime voltage on the 15 volt one from

6.7 to 8.54 volts. The voltage on the 8 volt unit was then about 4.81

from the total 13.35 volts. Both were still in the good efficiency area

of their charts. Typical

daytime current went up from 3.1 amps to 4.0. But the warm side

temperature rose from about 26 to 31. Partly it was the warming

weather, partly more heat generated from the higher current - in fact

the unit would be consuming 4.0A*13.35V=53.4W. Previously it would have

been 3.1A*13.4V=41.5W. With a single Peltier it had been around 85

watts with little additional cooling. The cold side was about -5 making

a 36 degree

spread instead of the 30 I had earlier, and with the higher spread the

increase in heat pumping didn't seem marked, although there was

definitely more ice after 12 hours or so. I raised the speed of the

fan. It lowered the warm side a couple of degrees. (I really want to

try out the evacuated tube radiator with ammonia-water. It has the

promise of quiet (no fan), best cooling, and lowest loss of cold when

the fridge is turned off.)

The cooling unit will be less voltage sensitive. Two 15

volt peltiers have nearly 7 volts each and over 3 amps during the day,

and cooling is decent. But with about 6 volts at night & well under

3 amps they can only barely attain a 45°C spread even with nothing

carrying away the coldness, so they can hardly keep a 30° spread

cooling a fridge. Whereas with one at 8 volts (at night) & 3.5 amps

it can hit 55° with no load, giving it more pumping ability at a 30

or 35°

spread.

The 8V, 8.5A peltier module at 4.8 volts would be

proportional and also have a 55° limit. It just has 8/15ths of the

same thermocouples in series as the 15 volt. They can be viewed

together as

being the same as a single 23 volt, 8.5 amp Peltier module.

But I noticed an unsettling detail in changing the

peltiers: I rubbed at the

heatsink compound on the copper bar while the peltiers were removed

with my

fingers, and felt a small lump or grain of some sort, which I

rubbed/brushed off. This may

have been preventing optimal surface contact of one peltier... which

just might explain why I thought it was working as well as the

single peltier at first, and then I changed my mind and decided it

seemed to make ice too slowly. Perhaps I'll try the two 15V peltiers

again sometime and see if the results are better than before.

Another factor appeared to be that the new cooling

arrangement with the new heat sink and fan and copper bar appeared to

bleed off cold (when the fridge was off) faster than the original one.

Whereas a tray with more ice than water would last 10 or 11 hours at

night, with the new cooling setup it only lasted 8 or 9. If a foam box

cover was placed over it at night, it would last around 11 or 12 hours.

This

shows how much coldness leaks out via the cooling mechanism. The

evacuated tube radiator, conducting heat at the bottom but not cold,

should presumably be much better, especially if its base block is

insulated. Unfortunately I didn't find time to try to make one in April.

12V versus 24V

Perhaps it's worth noting that the solar supply was

actually over

13.8V, not 13.35 volts, at the breaker panel. So at least .45V was

being lost in the wiring with the 4 amp draw. A 24V supply would use

1/2 the

current for the same device, so the voltage drop

would be .24, and so the losses would be a smaller percentage of the

total voltage - in fact, less than 1% versus 3.4%.

On the other hand, the fridge specifically would have

needed 3 or 4 peltier elements instead of 1 or 2 (rated 4A instead of

8.5A), which would each take heatsink space and leak cold from the

fridge when off. And LED lights are more easily run off 12 volts if a

standard is to be applied.

So I keep thinking of having both 12 and 24 volts. On the

other hand, for high power devices, 120 VAC from the street would

appear to be quite a good and very popular option to minimize wire

sizes and losses. An inverter by the batteries would take little heavy

wiring, and the 120 VAC wiring from it would be light.

Mini LED

Voltage Display

Someone had some mini LED voltage displays for 12 volt

batteries, from China. I bought one (3$?) and put it on the solar panel

system batteries, and wondered why I'd bothered mounting the analog

panel meter.

MSP430

Software Development Suite

MSP430

Software Development Suite

I figured a "Linux guru" friend would have figured out how

to get the

MSP430 Launchpad development board connected to a PC via Ubuntu Linux

for programming,

but he hadn't been able to get the computer to 'talk' to the Launchpad.

So I spent some time looking for info on the web.

Texas Instruments had an 'integrated development

environment' for programming them. I downloaded versions for Windoze

and Linux but somehow the theoretically simple functions of a

microcontroller software development kit took more computer than any

one I have to run it. There were text command line files at Ubuntu

Software

Centre... but how to get them working?

Finally I ran across this web page: dbindner.freeshell.org/msp430/

. The author uses essentially the software at the Ubuntu center, but he

describes setting up a couple of critical things in Ubuntu needed to

get the computer to recognize the Launchpad board/MSP430 as a USB

device, and

command line commands with the options needed to successfully compile a

program and send it to the board. Those are

the sort of initial setup things that most documentation and

tutorials take for granted you already know or have set up, but without

which you're dead in the

water.

After a second learning session on the morning of the 30th

I went at it that night and after a few hickups (like an MSP430 chip I

plugged in backwards) compiled and sent a couple of programs to the

board and ran them. Yay!

I have the idea in mind to write a 'front end' GUI program

in Python that composes the more common compile and debug command lines

for you - so you just click the buttons.

Electricity Storage - Turquoise Battery Project (etc.)

Unfortunately, I didn't get any chance to look at the MnMn Turquoise

Battery Project in April. Other battery types did get more than looked

at since I had an immediate need for batteries for the electric Mazda

RX7.

Lead-acid Battery Renewal with Sodium Sulfate: new technique

One of the batteries I renewed for the electric Mazda RX7

didn't stay charged. When the car was turned on, it would drop to 10 or

8 volts just from running the vacuum pump. I removed it.

Later, I discharged it with a halogen headlight bulb and

then shorted it with a wire, not only to 0.0 volts, but until all the

little noises of outgassing seemed to cease - about a whole day shorted.

Then I charged it up and got graph 1. [Oops, I didn't make

the graph!] It ran the headlight

(~3.5 amps) for a little over an hour at over 11 volts before dropping

to 10.5 volts. This was much better than quickly dropping to 10 or 8.

In the manner of battery renewal, I expected the next discharge to last

somewhat longer at a somewhat higher voltage. I charged it overnight.

It went on and off of charge in a cycle of less than a minute.

The next morning it was sitting at about 12.2 volts. I put

the headlight on with it... and it dropped to under 4 volts in a couple

of seconds! Perplexed, I left it sitting for a day or two. Then I tried

again, and this time from 11.8V it only dropped to about 8 volts

running the headlight. I left it another day. The voltage again sat at

11.8. When the headlight was connected it dropped to about 11.4 and

started an apparently normal discharge. I wasn't into running a long

test, so I left it a couple of hours. When I returned, it was 12.0v,

and running the light it started dropping slowly from 11.6. The

headlight was bright. In all this, it hadn't been charged since the

first time. I almost put it back into the Mazda.

Three hours later I tried again. Sitting voltage was 11.9,

and when it lit the headlight, the voltage almost immediately dropped

to about 4.5 volts! The next day, the the 26th, it was 11.8V and

started dropping from 11.4 with the headlight. After 40 minutes the

voltage dropped under 10.5. After 3 hours charging, it immediately

dropped to 8.4 volts when the headlight was connected. Was this really

the same battery each time, or was some gremlin swapping them around

while I wasn't looking?

NiMH 12 volt D

cell Battery Cases

Most people don't seem to think of NiMH batteries for much

of anything they want batteries for. They're excellent batteries, but

first, the economical wet cells have been kept off the market by the

corrupt, and the dry cells cost about as much as lithiums. The second

problem is how to make a bunch of individual dry cells into a reliable

large battery.

I would suggest one ideal use for NiMH dry cell

batteries: it appears to be a better drop-in replacement for a

lead-acid battery than lead-acid in regular gas cars, with the 13.8

(13.8 up to about 13.95) volt alternator being an optimum float charge

voltage for NiMH as well as lead-acid. In addition to lasting a decade

or two or maybe longer, it's maintenance free, much less damaged by

accidental discharge (ie, lights left on), and it drops the vehicle

weight by 15 or 20 pounds to continually save a little gas.

Mine has now been in the Tercel over two years, has run

down a few times, just once to too low to start the car (yes, always

from lights left on), and it still works like new. And this is in spite

of the fact that I often turn the engine off at long red lights and

then restart, and I have the idle set so low that the battery is also

discharging when idling at traffic lights, coasting, etc. -- practices

that killed my last 2 or 3 lead-acid batteries in a year or two. (The

gas saved paid for the batteries, but there's no sign I'll ever need

another battery now.)

Mine was made with plastic pipe "battery sticks", which

aren't a good fit in a space intended for a square lead-acid battery.

The new cases solve this problem.

The last time I tried making compact 12V NiMH cases, I had

3D printer troubles

and frustration. Perhaps luckily, I didn't get back to it for some

months.

Meanwhile I discovered that if the cases of the cells are touching

and they get hot, the plastic sleeves melt, the metal cases connect,

and as they're at different voltage levels, it's a short circuit and

everything goes up in smoke. That meant for safety and reliability the

case design should be modified to put some space between the cells.

L: First new printed case.

R: Subsequent improved cases. The half-height inside ribs prevent

spreading of the walls with the pressure of the contacts.

I stretched the

design by 12mm, putting 3mm between each pair of cells so their cases

couldn't short together, which is a potentially dangerous situation.

The first 5 hour print

was a success, notwithstanding somewhat curled up corners - I had moved

the

main multi-battery case stacking supports away from the corners. It

seems corner warping is inevitable with a printer lacking an oven to

keep the plastic heated.

Then I cut the metal bits to connect all the cells. (after

which I discovered the D cells on the shelf very much needed a

recharge.)

I made a few improvements and printed more cases in the

next few days. I figured I shouldn't use less than 6 cases to replace a

lead-acid in Mazda, having seen currents over 100 amps even on slow

test drives. Theoretically they'll handle 50

amps intermittently and 30 amps continuous: 6*50=300 and

5*30=150 amps. But I wouldn't want them over about 20 amps most of the

time, and 6*20=120, and the currents while driving are usually under

that.

Battery with 6 stacked cases: 12V, 60AH, 180A, 300A intermittent.

Wooden spacers for extra ventilation.

(I'll tape some slit hose over those exposed copper bars.)

The plastic irrigation pipe made it possible to make

reliable big

NiMH batteries out of D cells (and they're still easiest); the new case

makes such a battery much

more compact, able to fit where a lead-acid battery fits with space to

spare, 3/5 of the weight, better performance, and much longer life.

...all at a much higher initial cost.

An attractive possibility in using small NiMH

batteries is that to increase capacity (as in vehicle driving range),

one can add new

batteries one 10AH bank at a time without removing old ones, until the

maximum space, weight or cost limit is reached. I left extra height on

the threaded rods to add a 7th case to the stack.

Tips for NiMH Battery Cases (preliminary)

(At the risk of providing far too much nit-picky detail and making

something simple seem complex...)

* Cases may be stacked to obtain a higher capacity battery with #10

threaded rod through the mounting holes. The top battery case needs a

cover to hold the cells in place.

* Long strips can be run through all the cases vertically for the plus

and minus terminals. If the currents are to be very high, connecting

each case to an external point or bus bar may be better.

* Spacers between stacked cases will improve ventilation. Place strips,

eg, of wood, so they hold the cells in place.

* These cases are intended for use within a protected space, not out in

the open. Likewise, it isn't intended that the cells be inserted and

removed on any regular basis, especially since the cells hold the

connector tabs in place.

* Be sure all cells are well connected. If they move back and forth

loosely when pushed, bend a metal connection tab 'V' out a bit more

with pliers. If they pop out when installed or are hard to put in, bend

the 'V's shallower.

* Be sure all cells are correct polarity when installing - measure the

voltage after inserting cells.

* Be sure the battery is the right way around - double check everything

before

connecting. (Remember, 3 of these batteries ganged together will start

a car! ...or maybe a fire.)

* 3D printer people: Don't eliminate the space between the cells. If

the

cells get hot, the sleeves will melt, the cases will touch, and

everything will go up in smoke, perhaps starting a fire. (In fact,

pieces of something heat resistant between cells and between cases

isn't a bad idea. Mylar or acetate, motor slot paper, wooden tongue

depressors...)

* Badly overcharged NiMH dry cells survive best if they are upright.

Level isn't bad. Upside down, they tend to lose too much electrolyte if

they build up enough heat and pressure to vent. They can't all be

upright, but they can be placed to minimize damage or the number of

cells damaged if it seems like a useful thing to do. A reliable charge

system is better.

* We know the the case bottom corners and edges are warped. The cases

are considered 'good enough' to use. (If it was a 20000$ printer

instead of an 800$ one, results might be improved - for a higher price.)

NiMH "Super Battery Stick" not so

super

I made the "Super Battery Stick", a single 4" PVC plumbing

pipe which turned out to be a good size to hold 7 banks NiMH cells, a

year or more ago. It seemed like a great idea at the time. With no EV

running, I had been using it in the 12

volt solar PV system. I had put a spring clip on one end for each row

of

cells

to press the cells in each row together for good connection. But some

springs might be a little looser than

others, and there was no way to test the connection of individual rows.

So ever since making it, I've been worried that all 7 rows of 10

cells might not be making good connection. With all the new battery

cases I was

making, I

decided to take it apart and use the batteries in the new cases.

Sure enough, 30 of the 70 cells weren't well charged, 15

being about 1.2 to 1.25 volts, and 15 down around 1 volt, the minimum

that NiMH's should be allowed

to drop to to avoid corrosion of the negative (metal alloy with fast

corroding lanthanum) electrode. (I don't know why it wasn't an even 10

or 20 cells at each level.) I won't use the "multi-rows in a tube" idea

again.

I am however still considering that I'll probably use the

older single 12V battery stick designs in situations where there's

sufficient

space and no need to have the "square" format of the printed battery

cases, which take 4-1/2 hours to print, extra labor to assemble, and 6$

of plastic filament and copper plate.

http://www.TurquoiseEnergy.com

Victoria BC

Talking on the

VEVA electric car list I learned that the

problems

with using mixed batteries extend not only to the need to charge them

individually, but to monitor them individually as well, so the weaker

or lower capacity batteries - or if a charger quits working - don't get

overdischarged or even driven into reverse charge (and hence weakened

or damaged) before the driver

notices. A gauge to show the overall voltage is insufficient,

especially in a typical higher voltage system.

Talking on the

VEVA electric car list I learned that the

problems

with using mixed batteries extend not only to the need to charge them

individually, but to monitor them individually as well, so the weaker

or lower capacity batteries - or if a charger quits working - don't get

overdischarged or even driven into reverse charge (and hence weakened

or damaged) before the driver

notices. A gauge to show the overall voltage is insufficient,

especially in a typical higher voltage system.

On the

26th I

redesigned the

12V NiMH D cell battery case I'd

had poor 3D printing results with earlier in order to be easily able to

fit in a 60+ amp-hour NiMH dry cell battery or two in the Mazda instead

of lead-acids, to better

illustrate the potential for mixing batteries. The first 5 hour print

was a success, notwithstanding the inevitable somewhat curled up

corners. I separated the cells within by 3mm

so that if they got hot (serious overcharging or overcurrent) and the

plastic labels/sleeves melted, the

cases wouldn't short together and everything go up in smoke.

On the

26th I

redesigned the

12V NiMH D cell battery case I'd

had poor 3D printing results with earlier in order to be easily able to

fit in a 60+ amp-hour NiMH dry cell battery or two in the Mazda instead

of lead-acids, to better

illustrate the potential for mixing batteries. The first 5 hour print

was a success, notwithstanding the inevitable somewhat curled up

corners. I separated the cells within by 3mm

so that if they got hot (serious overcharging or overcurrent) and the

plastic labels/sleeves melted, the

cases wouldn't short together and everything go up in smoke. I

made further

improvements and printed more cases in the

next few days. Then I decided that notwithstanding the warped corners I

had a product to add to the Turquoise

Energy Product Catalog, and that the introductory price would be

25$. (Naturally I'd like to make them cheaper and better, but at the

moment, they're a 4.5 hour 3D printout and then the copper bits have to

be

cut and shaped by hand.)

I

made further

improvements and printed more cases in the

next few days. Then I decided that notwithstanding the warped corners I

had a product to add to the Turquoise

Energy Product Catalog, and that the introductory price would be

25$. (Naturally I'd like to make them cheaper and better, but at the

moment, they're a 4.5 hour 3D printout and then the copper bits have to

be

cut and shaped by hand.)

On the 22nd I put 15 and 8 volt peltiers (both 8.5 amp) in

series to cool the fridge, raising the daytime voltage on the 15 volt

one from about 6.7 to 8.4 volts. The voltage on the 8 volt unit was

then

about 4.8. Both were still in the better efficiency area of their

specs.

Typical daytime current went up from 3.1 amps to 4.0. But the warm side

temperature rose from about 26 to 30 - partly it was the kitchen

warming with the weather. The cold side was -5 making a 35 degree

spread instead of the 30 I had with the 15:15 volt units, and the heat

pumping didn't

seem to increase a whole lot. I raised the speed of the fan, but it

only

lowered the warm side a degree or two. But after a couple of weeks, it

did seem to me there was generally more ice by evening.

On the 22nd I put 15 and 8 volt peltiers (both 8.5 amp) in

series to cool the fridge, raising the daytime voltage on the 15 volt

one from about 6.7 to 8.4 volts. The voltage on the 8 volt unit was

then

about 4.8. Both were still in the better efficiency area of their

specs.

Typical daytime current went up from 3.1 amps to 4.0. But the warm side

temperature rose from about 26 to 30 - partly it was the kitchen

warming with the weather. The cold side was -5 making a 35 degree

spread instead of the 30 I had with the 15:15 volt units, and the heat

pumping didn't

seem to increase a whole lot. I raised the speed of the fan, but it

only

lowered the warm side a degree or two. But after a couple of weeks, it

did seem to me there was generally more ice by evening.

The "click-lock" sockets

will mate either with regular CAT

plugs or with "click-lock" or

"friction-lock" CAT plugs. They

fit in a regular CAT wall plate, but they stick out 9mm to make space

for the click mechanism and the plug surround. (Flush wall plates with

slots surrounding the sockets could be designed.)

The "click-lock" sockets

will mate either with regular CAT

plugs or with "click-lock" or

"friction-lock" CAT plugs. They

fit in a regular CAT wall plate, but they stick out 9mm to make space

for the click mechanism and the plug surround. (Flush wall plates with

slots surrounding the sockets could be designed.)