Turquoise

Energy Ltd. News #65

Victoria BC

by Craig Carmichael - July 5th, 2013

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries)

- Next Projects possibilities, Building the Green Economy

event, Electric

Mazda, Solar 'DC grid tie', 3D printer repair (sigh!), 'Ultra-efficient

Transmission' work, new chemie batteries - MnMn still looks best

In Passing (Miscellaneous

topics, editorial comments & opinionated rants)

- extended supply chain breakdown

Electric Transport - Electric

Hubcap Motor

Systems

* PGTC Transmission: Clutch mechanism figured out and built. Now motor

controller has quit - sigh!

* Idea: A simple 2-speed transmission with one clutch pedal shifting? -

pedal down is low; pedal up is high; pedal centered is neutral.

* Electric Weel motor design change: 24 coils as 2 sets of 12, 2 motor

controllers @ 48V, 150+amps.

* Homemade "Segways"! from Germany - with schematics, source

code, ...

* Mazda RX7 stuff - maximum range 13Km, individual battery float

charging system, NiMH

batteries are charging more slowly than lead-acids - and not to very

full

Other "Green" Electric Equipment Projects

* Solar PV main distribution panel things & lead-acid batteries

Electricity Generating (no reports)

Electricity Storage - Turquoise

Battery Project etc.

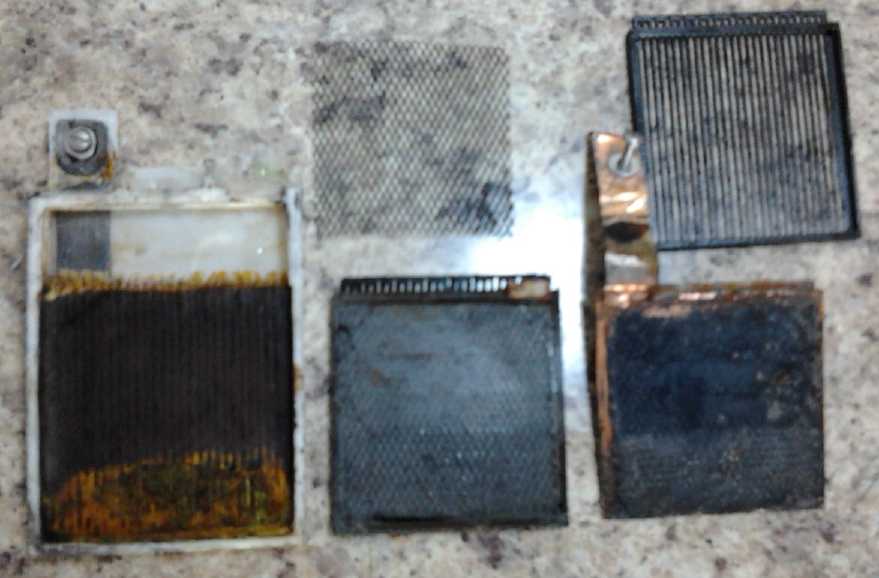

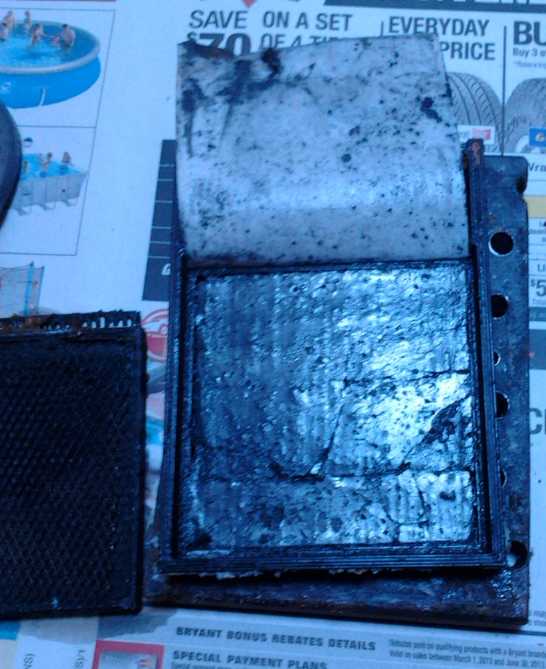

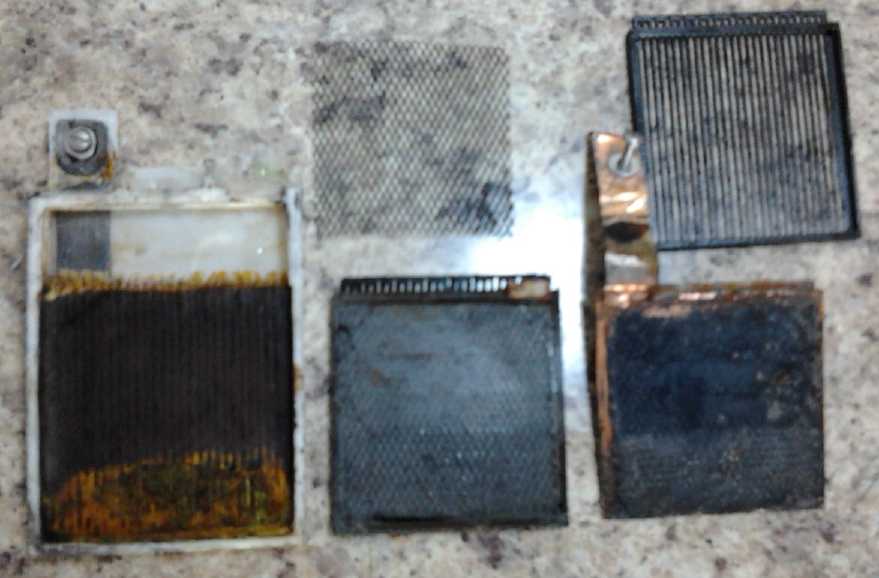

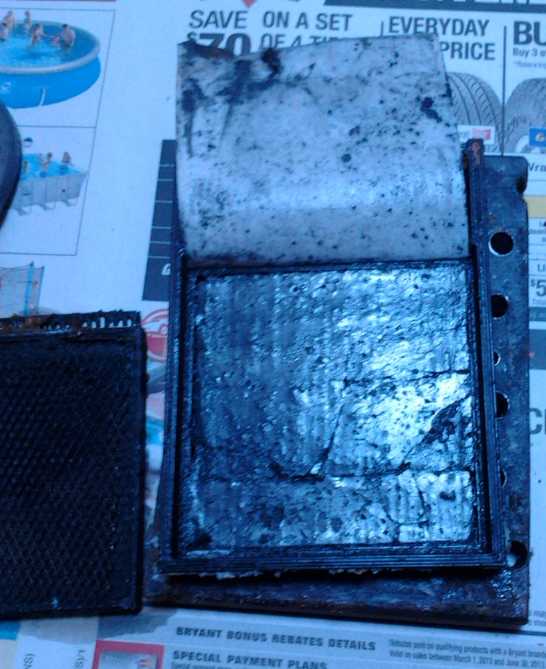

* Production Prototype Cell #4 (PP#4): MnNi - a nickel negode to try to

isolate MnMn electrode/cell problems

* Worked crappy - rebuilt.

* Low pH (6) causes high self discharge! (Well, duh!)

* PP#5: Ni-Ni. Even with "traditional" Ni(OH)2 posode and pH (near?)

14,

same self-discharge problem and even lower conductivity.

* Carbon fiber cloth separator sheets to improve electrode conductivity

* Mn-Mn is better. I'm returning to it - with carbon fiber cloth, paper

and nylon separator sheets, and any other new tricks I can think of.

With a 5-fold improvement (over PP#3) it would be a practical battery,

whereas the NiNi would need a 20-fold improvement over PP#5 - and even

then it would be just 1/2 the voltage.

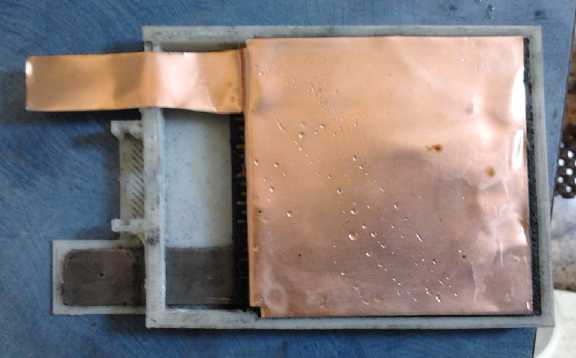

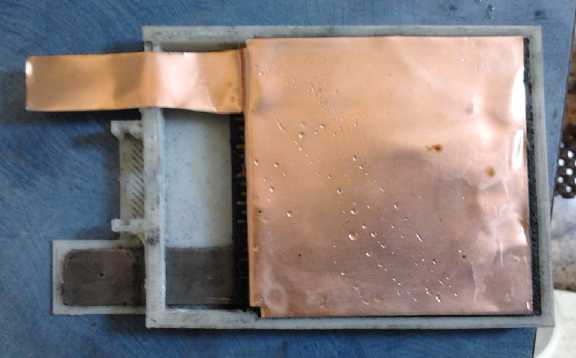

* Perforating metal for 'porous' electrode conductors: a silkscreen

with tiny holes and acid? ...and faster PCB etching?

No Project Reports on: DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic

Motion Machine,

CNC Gardening/Farming Machine (sigh, maybe summer 2014?),

Woodstove/Thermal Electricity Generator, Peltier & vacuum pipe heat

pumping.

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater (say, this heater is now obsolete! Use Peltier module heat

pump!)

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit - also please inquire about Electric

Caik

3KW Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

Will accept BITCOIN digital currency

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

June in Brief

Mazda RX7 parked at Westburne Electric, early June

They had another one of those fancy EV charging stations that I

can't use

Tom did a video here of me driving it:

www.youtube.com/v/vSX3JQWIKng

The electric Mazda RX7

continued to occupy time into mid month. Now I'm

driving it and with most of its

components now functional, where should I next turn my attention? The

possibilities

were and are endless:

* Fix the 3D Printer (sigh!)

* the Referendum Web Site to be developed

* some exciting new ideas as well as unexplored old ones for new

chemistry battery making

* the Chev Sprint ultra efficient electric transmission/planetary gear

torque converter... that sat idle all winter after exciting progress in

September

* then, a variant of that transmission to finally make the Electric

Hubcap

car hybridizing system

* motors and motor controllers to be made including:

- the 13.5KW high torque Electric Weel motor that must be

about 3 years old and hasn't been finished

- the wheel rim/arc motor for bikes

- more Electric Hubcap and Electric Caik motors, to have

kits on hand to sell or to use

- more BLDC motor controllers. It also makes me nervous

that only the V1 controller and not the V2 is running reliably.

- Optimize

component values to make the V2 more reliable and robust.

- other motor controllers such as VFD for AC motors, and

controllers for DC motors with brushes. These can be variants of the

existing

controllers, but some high power ones, like 300 or 400 amps at 36 or

48 volts, would be good to have for cars, even with very high

efficiency.

* The "Outboard from Scratch" - and casting the more efficient-looking

prop (plastic prop from a scuba unit).

* lots more 12 volt DC house wiring, LED globe lighting and other solar

equipment projects that could be done. I should make a production

version of the circuit board for the LED globe lights: with CAT plug

pins - the little round power adapter plugs are frustratingly

unreliable, especially

if you have to wire one yourself, and of course you can freely plug in

the

wrong voltage or polarity of adapter.

* the peltier/thermoelectric heat pumping and thermoelectric

electricity generator projects (All these projects use almost exactly

the same

components.)

* now having reliable means to do simple circuit boards and now also

microcontroller programming, there's various microcontroller-electronic

projects:

- the fridge control

- peltier heat pump control

- solar PV system 'dump load' and other ancilliary

equipment control

- motor controller 'overcontrollers' with RPM limiting

- the individual battery monitor for EVs of all types

...and in case those weren't enough possibilities, then moving just a

little farther afield I could try getting back to other projects I

haven't had time for in quite some time or haven't got very much

started on:

* high refraction, low reflection 'pebble glaze' (nanocrystalline

titanium dioxide borosilicate glaze) solar panel cover glass and DSSC

solar panels

* pulsejet steel plate cutter

* magnetic motion machine

* the ocean wave powered electrical generator of the recently described

type

* CNC gardening/farming machine

On the 4th I decided that with the onset of good summer

weather, I should 'make hay while the sun shines' and do the things

with outdoor activity. That means physical EV things, and

especially the PGTC transmission/Sprint. That car has now sat over two

winters in one place, and I fear things may start seizing up like on

the Mazda.

Also, I decided to work on the long 'overdue' Electric

Weel, which a couple of people are interested in, and try and make

molds to cast the stator body parts. Of course, people have expressed

interest

in my other motors too and yet no one has bought any kit yet. I got as

far as a 'life size' drawing of an octagonal section.

And I also decided to try a few battery chemistry things,

because surely it's pretty close, and the short range Mazda shows the

glaring need for better yet economical batteries. Other things could be

worked on

on occasional evenings or put off until inclement

weather. Even if one achieved only the 50 watt-hours per kilogram of

nickel-iron flooded cells - with of course high current capacity and

long cycle life - they'd be better than lead acid. With modern

techniques and materials one could certainly make much more

economical and better performing NiFe batteries than Edison did 100

years ago. But MnMn seems to be the superior choice.

Electric Mazda

The first thing I actually did, on the 4th, was to put in

a plywood and carpet cover over the battery well in the rear of the

Madza RX7, with a few more bits of matching carpet surround. It looks

nice, provides a cargo space, and muffles the noise coming through the

battery well from the rear axle and wheels.

The next day was the VEVA electric car club, and I finally

got to show off something besides semi-functional battery prototypes,

and once the electric outboard motor, even if the car wasn't using

motors and components I'd made myself. But there was a free, outdoor

Buffy

St. Marie concert that evening. Everyone rushed off to that and paid

little attention to the car, except I gave someone a ride.

After it was over we went to his place and he showed me

his 'new' Morris Minor, a 1960's British car produced with a 948cc

engine, that he wanted to make electric. (See Morris Minor)

On the 14th, I swapped out the weakest lead-acid battery

in the RX7 for a new one Tom Sawyer loaned me. With that and upping the

NiMH charger voltages a bit, the car's range went up to about 8 miles

(13Km)

or better, with the somewhat undercharged NiMHs becoming the limiting

factor. It's a long way

from the 70Km or so the original owner got with 18 new 8-volt high

current golf cart

batteries.

Later Tom came over and insisted on helping me wash

the RX7 (which he doubtless realized I would never have gotten around

to myself) in preparation. The car works better through my efforts;

that it

looks rather good must largely be credited to Tom's enthusiastic

'detailing' efforts.

Finally, after some great black 'rubber' texture paint (bumper, rusty

battery well steel under),

we had seen "Electric" nameplates on a converted car at the April VEVA

meeting.

Tom ordered a couple from Canadian Electric Vehicles and we put one on

the back.

Not only many conversions but the manufactured electric cars seem to

want to hide the fact that they're electric, giving the general

public the impression as they travel that there are essentially no

electric cars on the road even when there's one here, one there...

I think I want to paint the black parts between letters white, because

it doesn't show up very well.

Two of the NiMH batteries were below 12 volts, eg 11.8.

They surely had little life left. The other two were just over 12v, eg

12.10. The lead-acids were all above 12.2 volts. If I beefed up the

charging of the NiMHs to get them up to 14.0 volts it should surely be

good for 10 miles/16Km. Then again running lead-acids down too far

with no sodium sulfate in them is worse than running down NiMHs.

The best battery

appeared to be the

"reconditioned" one I had purchased at Battery Doctor. It was still at

12.6 volts and so apparently could well have driven at least as far

again,

total 16 miles/26Km or more.

Of course, while the ever decreasing voltages can be seen

by glancing at the CycleAnalyst while driving, there's no indication of

which batteries are dropping by how much when you hit the pedal. Is it

mostly the NiMHs are at

the end of their charge and going way down?, or are they doing okay

while the

weaker lead-acids are going down to 8 or 9 volts?, or are they all

dropping more or less equally? These are the sort of questions my

individual battery monitor is intended to answer.

Solar House Equipment

Also that day I repaired a 20 amp,

13.8 volt power supply I'd been given some months ago. (blown

transistor from foolishly placed, clamped, output wires that melted and

shorted together.) It's exactly what

I've been wanting for the

solar PV system as the backup "DC grid tie" power supply. I fit it in,

replacing a 12 amp

battery charger I'd been using. It gets pretty hot doing 100-200 watts

if the car is plugged in and it's cloudy. It has its own 20 amp breaker

in the main panel.

Building the Green Economy

Event

Showing EV mixed battery system to Murray Rankin, MP.

On Saturday the 15th, I had a display table at Building

the

Green

Economy, an event put on by Murray Rankin, member of

parliament for Victoria BC. Before the event started, I presented him

with a printed copy of my booklet Fundamental Principles of

Democratic Government - Towards Utopian Systems of Governance,

which he seemed interested in. He said he would read it, and asked me

to e-mail him to discuss it later. There was an hour long panel talk

with short talks by several people. Guy Dauncey, who started the BC

Sustainable Energy Association, spoke last and gave

a surprising, brilliant talk mainly about about one of the broadest

issues that nobody talks about except on youtube:

"locally has to be in a global

context", the impoverishment of people and nations by the bloated

financial sector's intrigue

and fraud, the need for more local, accountable public financial

institutions and for local or regional currencies, and the need for

everyone to

learn more about how finances work - and how they ought to work. I just

hope many of the audience of perhaps 130 understood the background of

systemic, unsustainable global financial problems which he was

addressing. Sustainability has to begin with sustainable societal

institutions, and we ain't got 'em.

On Saturday the 15th, I had a display table at Building

the

Green

Economy, an event put on by Murray Rankin, member of

parliament for Victoria BC. Before the event started, I presented him

with a printed copy of my booklet Fundamental Principles of

Democratic Government - Towards Utopian Systems of Governance,

which he seemed interested in. He said he would read it, and asked me

to e-mail him to discuss it later. There was an hour long panel talk

with short talks by several people. Guy Dauncey, who started the BC

Sustainable Energy Association, spoke last and gave

a surprising, brilliant talk mainly about about one of the broadest

issues that nobody talks about except on youtube:

"locally has to be in a global

context", the impoverishment of people and nations by the bloated

financial sector's intrigue

and fraud, the need for more local, accountable public financial

institutions and for local or regional currencies, and the need for

everyone to

learn more about how finances work - and how they ought to work. I just

hope many of the audience of perhaps 130 understood the background of

systemic, unsustainable global financial problems which he was

addressing. Sustainability has to begin with sustainable societal

institutions, and we ain't got 'em.

I put the electric Mazda RX7 on display with the hood up

out in the parking lot, with a sign on my table saying it was there. I

showed it and explained what I was doing

with mixing non-identical batteries and separate charging to a number

of people. Jim

Harrington brought some economical LED house light bulbs to add to my

small 12V collection, but as usual no one bought any, even once the

amazing electrical savings were explained. Perhaps everyone's been made

skeptical by the claims of compact fluorescent bulbs, which were

heralded as

being better than they proved to be in most peoples' experience.

At the end of the event, Rankin's assistant Edward, who

had invited me to the event after we chanced to meet earlier in the

week, asked if he could get some pictures of me and Rankin out by my

electric RX7. So when we (Rankin too!) had stacked up the chairs

and tables, and I had packed up the Electric Caik Outboard and my boxes

of

stuff, we did the pictures and they watched me drive off burning no

fossil fuel.

Magnetic Control with Light?

Jim Harrington

and his Ecosat Satellite team have taken

lasers - one violet or UV and the other IR, both in the

x100's of milliwatts range - and shone them on a round disk of

pyrolytic

graphite floating by magnetic repulsion just above a "checkerboard" of

cubic supermagnets. If

the laser is shone near one edge of the graphite, it jumps in that

direction, right over the magnetic boundaries between magnet cubes to

the next corner boundary. Shine at the other side, it jumps back.

There's recent research on the reciprocal relationship between light

and

magnetism, but I don't think it's ever been graphically seen and

demonstrated before. Jim says it could revolutionize space flight.

Jim Harrington

and his Ecosat Satellite team have taken

lasers - one violet or UV and the other IR, both in the

x100's of milliwatts range - and shone them on a round disk of

pyrolytic

graphite floating by magnetic repulsion just above a "checkerboard" of

cubic supermagnets. If

the laser is shone near one edge of the graphite, it jumps in that

direction, right over the magnetic boundaries between magnet cubes to

the next corner boundary. Shine at the other side, it jumps back.

There's recent research on the reciprocal relationship between light

and

magnetism, but I don't think it's ever been graphically seen and

demonstrated before. Jim says it could revolutionize space flight.

I

can see a potential use for it in magnet machines to generate

electricity, where the effect might help generate larger circular

magnetic

imbalances to get more power from a smaller magnet machine. And I'm

probably not even scratching the surface of the possibilities.

3D Printer Repair

My RepRapPro Mendel 3D printer hadn't worked since I

started programming the TI MSP430 using the Launchpad board. I've had

ongoing

converse with their tech support. Out best guess (theirs and mine) is

that somehow programming the MSP430 was also programming the

AT-mega1284 chip on the printer's Melzi board, and it had wiped out the

firmware and the bootloader for uploading new firmware, via the USB

port. We figured I'd need a

USB "AVR" "ISP" programmer to reprogram the boot loader so the Melzi's

AT-Mega firmware could be reprogammed. The Arduino Uno board I got as a

possible alternative to the MSP430 Launchpad appeared to have the right

header pin plug on it, labeled "ICSP".

I spent most of the 23rd on the problem. The Uno's port

proved to be an input programming port rather than an output. However,

only one wire was different. I cut the trace and converted it, and made

a short cable to go to the Printer's identical port.

The software was another problem. Following the

instructions on the reprappro & reprap web site, I got "Burn

Bootloader" to work. (Apparently.) That was a big step. However, the

LED on the

printer board still didn't light, and I couldn't upload the firmware. I

must be very close, but something isn't quite right.

Once it's working again, I have the 3D '.STL' design for a

J1772 car charging plug. I intend to try using the 'ground' wire in the

sockets as a 'neutral' to use with 120 volt charging systems - or at

the very least with my charging system where I can roughly balance the

load by putting 1/2 the chargers on each side of the 240V line.

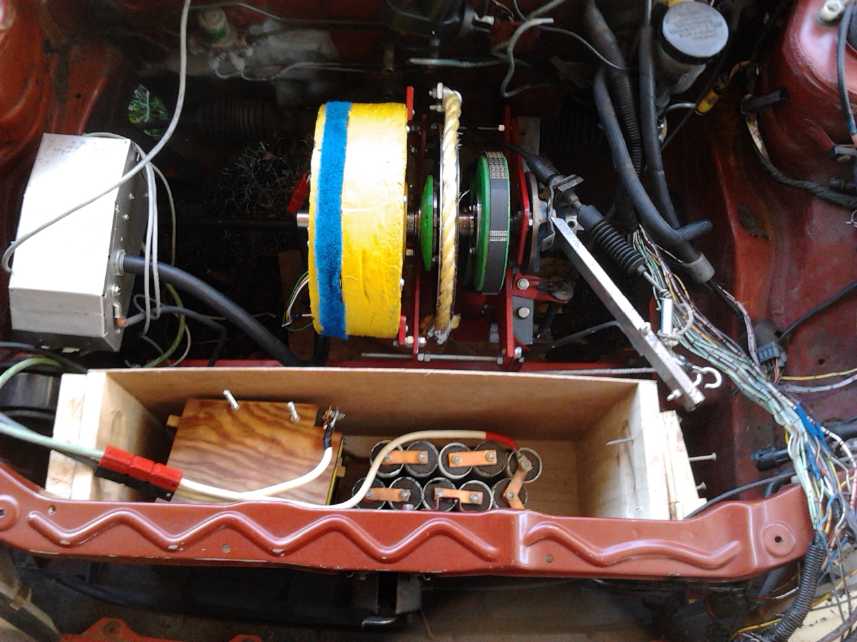

Ultra Efficient Transmission/Chevy Sprint - motor controller blowout

(sigh!)

Then I went out and made the clutch linkage for the Sprint

'ultra efficient planetary gear torque converter' transmission, having

done a spring loaded belt tensioner the previous day. After assembling

the mechanism properly on the 25th, it seemed ready to attach the motor

controller and batteries, and test.

But now I'd used the previous battery in the Mazda and

would have to find a new arrangement for that. I could use 100 more

NiMH D cells, but am uncomfortably far in debt. I decided to settle for

50 D cells, and to pull the seven-3D-printed-trays battery from the

Mazda, and simply have one less battery in it for now. By

changing the bus bars in the tray, I made it 24 volts, 30 amp-hours.

I added 3 'quintos' pipe batteries taken from the solar PV system for

the third battery. That could certainly run the Sprint

around the yard if it could be coaxed into moving at all.

On the 28th I made a new wooden box to hold the batteries

in the Sprint

radiator area, the original one for long pipe batteries having proven a

little too wide to get in and out with the motor/transmission in place,

and the second one having lost its short pipes battery into the Mazda.

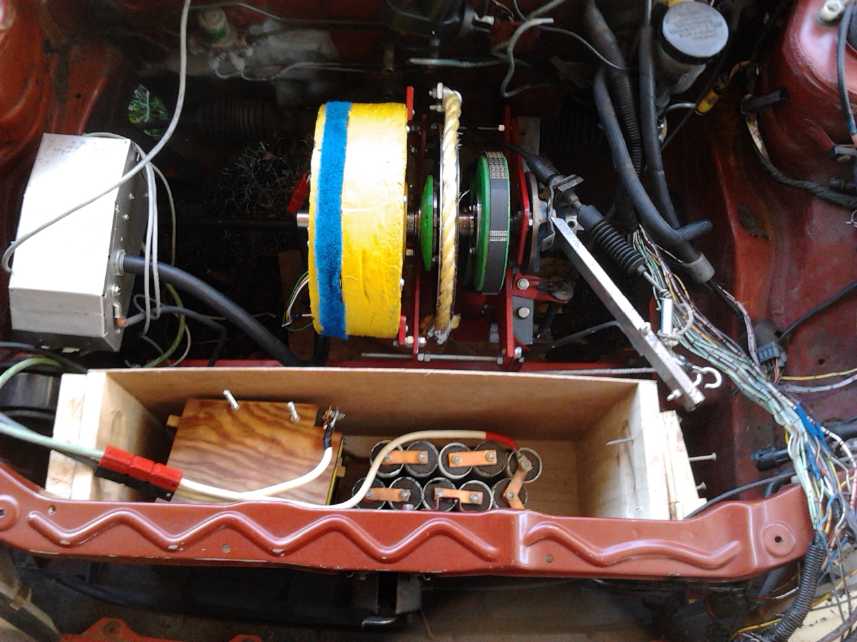

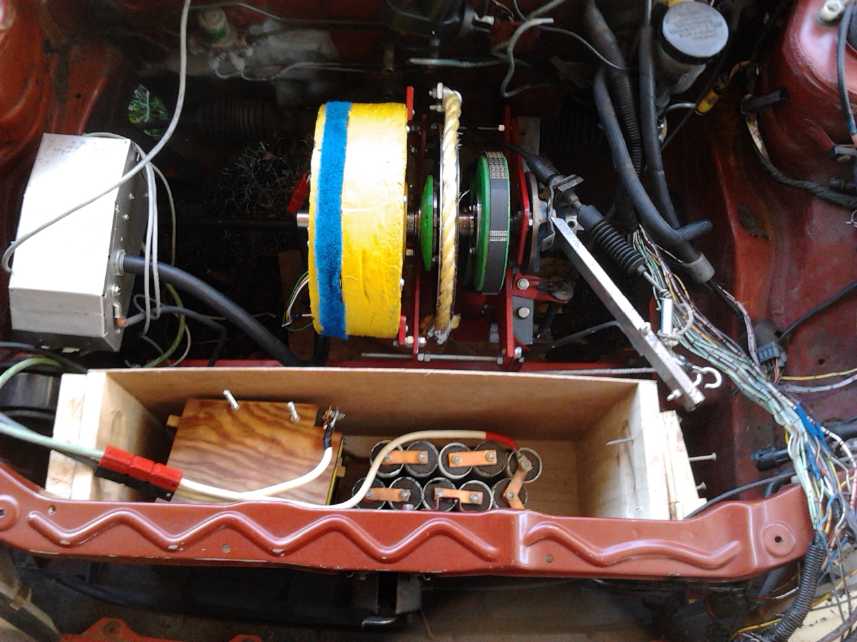

Under Sprint Hood

Front: 36v battery in open box,

Left: motor controller

Center: yellow motor, PGTC with slip pulley, flat belt on green pulleys,

To the right: friction cable & pulleys that tension yellow rope

(from automatic gear shift lever)

Right, under: clutch linkage to slip flat belt (from clutch pedal)

New Chemie Batteries

I tried out a couple of other combos of battery

chemistries to see if I could isolate the causes of self-discharge and

poor conductivity in my NiMn-Mn in KCl ("MnMn" for short) cells to one

electrode or the other. Earlier, an Fe electrode had undergone capacity

decay with each cycle in slightly less than pH 14 solution and I gave

up on that. MnNi (PP#4) didn't seem to work any better than MnMn

including having high self discharge, so the suspect was the Mn posode.

(Ni negodes don't work in pH 14 BTW - but 10-13 seems okay.) Then I

tried NiNi

in another cell with the same negode (PP#5), and that didn't work any

better either despite its low voltage.

Since PP#3 (MnMn) had been

gradually improving with each cycle both in capacity and with gradually

dropping self-discharge, further improving the construction and using

MnMn chemistry seems like the best bet. If it had had about 10 times

more

capacity and if the self discharge had continued to drop (and also if

it

hadn't suddenly quit holding any charge, with electrode powder leakage

evident) it could have been a practical cell - and over 2 volts. It

might have even got there simply with enough cycling. While the NiNi

also seemed to improve with cycling, it would seemingly need a

substantially larger improvement, and even if that was obtained it's

just over 1 volt and

twice as many cells would be needed.

Two things I meant to do in June and didn't were to finish

the CAT standard 12 VDC plug & socket promo video, and to evacuate

a pipe with

ammonia as the fluid, to get lowered boiling and freezing points. You'd

think I could have got to those rather short projects! But projects

once started seem to have a habit of growing.

In Passing

Incidental news, editorial comments & opinionated rants

Warnings from the spirit

beings that oversee this planet have been coming over the ether then

through e-mail lists (1111progress, TML, CCC, CWM...) for at least a

couple

of years now that we're headed for a very rough time. This month it was

stated that when the main crisis hits, the disruption to global supply

chains is likely to last about 3 years, and almost nobody has put away

enough

food to tide them over for so long. Plus, many people have left

important things out of their supplies, like salt or whatever.

It seems reminiscent of what I've heard

of the Irish potato famine. When potatos came to Europe from the new

world, they grew great, and they supported a large population

increase in Ireland. Then the potato crops got a blight. It spread

across the

island and people went hungry. Nobody actually starved in the first

year. But by the second and third potatoless year, everybody had run

through everything they had and mass starvation ensued. There was a

great exodus of Irish people desperate to go anywhere on any outbound

ship. Many went to America. 2 million people, perhaps 25% of the

population, died or fled. As with today's crisis, there were a host

of political, ethnic, religious, social and economic factors

exacerbating the problem.

Accompanying the financial fraud that's impoverishing the world today,

we also see

increasing levels of natural(?) disasters occurring around the globe.

And there are all those new, antibiotic resistant diseases as well as

old diseases which will likely strike as diseases usually do - when

populations are in hunger and want. It sounded like perhaps five

billion people are

likely to ascend prematurely to the mansion worlds in the coming years

or perhaps in the next decade or two, reducing the global population to

two billion. It's surprising how global it all is, with even China

suddenly and unexpectedly facing a "credit crunch" similar to that of

so many other lands.

Although the crisis is essentially man-made, with the

worst aspects being

generated by the machinations of those in economic and political power,

something fairly

drastic has evidently become necessary in any event owing to an

overpopulation of unthinking, uncaring and unspiritual materialistic

people who are destroying the planet. The horrific crisis and its

outworkings

will however lead to tremendous quickening of individual thought and

consciousness, and rapid planetary progress. The world will be a

different

place, just as pre- and post-famine Ireland were different places in

just a few years.

Things that will still have currency value after people

lose confidence in fiat currency (which always collapses in a few

decades if you look

back into history) include silver and gold (which are now being bought

up at record rates), and I expect bitcoin and other digital currencies.

With internet transactions, digital currencies may be the only form of

money that can be sent to another place quickly and without risk of

theft in transit. Bitcoin is 'fiat', but it can't be inflated away to

nothing: no more than 22 million bitcoins can ever be created because

the program was written that way. If it catches on, people will be

using milli- micro- and perhaps even nano-bitcoins for transactions.

And even by itself it may be the beginning of the end for the financial

system as we know it since most transactions will require no

"middleman".

We can see a crescendo of calamity

rising around the world, but we don't know exactly how the collapse

will

unfold or

the timing (everyone asks the economists on youtube "how?" and "when?",

and the usual and honest answer is "I don't know."). One of the

motivations for getting the electric Mazda is that it just might

give me a way to get around in case extreme fuel prices or shortages

develop before I've got my own

'ultra-efficient' vehicle drive on the street.

As to those "natural" disasters, there's substantial

evidence some of them are being generated by HAARP projects. When HAARP

antennae aim millions of watts of radio wave power at an area of

Earth's ionosphere, the ions heat up. They rise and are dispersed,

being replaced by non-ionic air that wells up from the stratosphere.

This causes low and high pressure zones directly and severely affecting

weather, and also brings unfiltered sunlight with all its UV radiation

down to ground level, which is a possible reason for otherwise

unexplained big die-offs of plants and animals. Weather control was one

of the ideas behind the system, as claimed in its 1990s patent. It's

even being said HAARP

effects can trigger earthquakes. I don't really follow that part.

Fracking can almost doubtless create earthquakes. Then there's "seeded"

jet "chemtrails" supposedly with stuff in them. I don't follow the

rationale for

those either and suspect the whole story is just vapor, but one

theory says the alleged chemicals react with the HAARP radio waves to

magnify the effect.

Some are asserting that

HAARP and or its sister antenna arrays are responsible for generating

global warming (makes more sense than CO2, a so-far fairly small

increase to a trace gas), for hurricane Katrina increasing in

size and being

steered directly onto New Orleans, Hurricane Sandy hitting New York,

the

Indian Ocean earthquake and tsunami, the Japan earthquake and tsunami

and earlier recent earthquakes in Japan and China, dead dolphins with

burned flesh washing up on beaches in the Persian Gulf after a bizarre

"fire tornado" over the water, and the extreme US drought of summer

2012. Much of this stretches credulity. But then, so would some of

these

extreme weather and geologic events if we didn't have clear proof that

they did happen.

The celestials say the people running HAARP and fracking

programs have

no idea what effects they're causing and that the repercussions of

these disturbances will take thousands of years to completely settle

back to equilibrium.

Aside from personal and family physical preparations to

tide us over an extended supply failure, what

can we do? Some may at some time find themselves in some position to

make a big

difference by a courageous personal act, like Julian Assange, Bradley

Manning, Ed Snowden... or millions of unsung people doing what they

think is right in spite of implicit or explicit negative consequences

to their

career or person. For the rest of us, the answer is to improve ourself.

This

seems too paltry, too insignificant, too mundane, to be the means for

changing a world: but the whole world is

made up of people like us, and only better people make a better

world. Education is vital - learn what's going on, how things work in

our screwy society, and think of better systems. We need to invent new

and sustainable systemic tools and institutions to prevent people from

relieving the citizenry of power by usurping it themselves and ruling

instead of leading. Clear separation of executive and legislative

powers and the choice ranking vote will help politically, and the

citizenry also needs to control its monetary systems.

And there's one thing the

celestials repeat time and again - "hit us over the head" with, as it

were: take 10 minutes a day out of your

busy schedule and meditate, or take a quiet, meditative walk. Still

your mind to make it receptive to the leadings of your

own guiding spirit. These mentally quiet times are when you grow in

spirit and advance in psychic status. Even if nothing seems apparent,

it's happening.

And while making whatever preparations you feel are

prudent and applicable, hopefully without unwarranted disruption to

your life, fear not! The universes are evolving towards

perfection according to the Universal Father's grand plan. The 'local'

Lucifer

rebellion is over (ca. 1986), and our world along with several others

is now, somewhat swiftly

and

painfully, being yanked back into the regular circuits before we

destroy ourselves with the leftover products of his ways of thinking,

which has greatly delayed our evolution towards the eventual 'era of

light and life'.

Electric

Hubcap Motor Systems - Electric Transport

Chevy Sprint: Ultra-efficient variable "PGTC" Transmission... and

the next blown motor controller

The biggest draw to 'ultra-efficiency' is the substantial

range improvement to be had with any given set of batteries. Another

is with the Mazda burning 160 to almost 200 watt-hours per kilometer,

or 1.6 to 2¢ [at 10¢/KWH], _assuming_ high charging

efficiency (which I don't really think I've got), lower energy use

would reduce the fuel cost, or the load on the solar collectors,

notwithstanding that it's already so much cheaper than say 14¢/Km

for gasoline.

A while

back, I came up with the idea that moving the

whole motor and pulley shaft up and down might be easier, and would

probably be better, than having an idler wheel to tension the belt.

A while

back, I came up with the idea that moving the

whole motor and pulley shaft up and down might be easier, and would

probably be better, than having an idler wheel to tension the belt.

Now I considered that given the tiny amount of travel

needed to tighten or slip the belt, perhaps the motor could be fixed in

place

after all, and only the other side, where the belt pulley was close to

the end of the shaft, needed to pivot. That seemed much more doable.

The slight twist of the pulley and shaft could be accepted.

I also considered that if my plastic flat belt pulleys

didn't hold up under the pressure or couldn't be tightened enough to

prevent slipping when tight, I would swap them for metal V-belt

pulleys and link belt.

With these ideas I got back to the long-stalled project.

On the evening

of the 17th I put the shaft and pulley set back together with some

adjustments, and figured out where and how to mount the spring to hold

the belt tensioned, and how to position and apply the clutch cable from

the pedal to compress that spring and slip the belt. On the 22nd I made

the spring part and on the 23rd the clutch linkage.

Not until the 30th did I put in the new battery box with a

36v, 30AH NiMH battery in it, and try it out. As soon as I tried

reverse, the motor controller blew. A video from a camera showed that

the belt had slipped off the pulley before that, so it not only blew,

it did so with no load.

This was quite unsettling, as this was the one controller

with an impeccable record. It had run the Electric Caik outboard in

February just fine. Did I have decent controllers, or were there still

circuit problems? But as I disassembled it, I discovered a loose wire

clamping screw, which held the output wires for phase "B", which was

where the blown mosfets were. With any loose connection in the high

power circuits, no further explanation of the failure is necessary...

except for why it might have been loose and how it might be prevented

in the future. The area was a bit cluttered with wires, and messes abet

accidents - could it be made cleaner? A better question might be

whether I should put in the TVS (transient voltage spike) back-to back

protection diodes that I bought for the purpose quite a while ago.

Further, when I took it apart and did the repair, I found

two sense wires attached only at one end. They should have been removed

long ago but went unnoticed in the wiring 'clutter'. If either bare end

had touched the case or some other wrong place that too would probably

have explained the failure. I don't think I'll look for some unknown

design problem at this point.

The drive belt will need a guide to keep it from going

sideways. Another thing I found was that the clutch guide slot bolt had

tightened itself up as the clutch went in and out a few times, so the

mechanism no longer moved freely. I had already thought of tightening a

nylock nut on the end to prevent it from turning. Evidently it's a

necessity even for a little testing.

A Simple 2-Speed Transmission? - Morris Minor

In thinking about the

Sprint

transmission, there are so

many ways a transmission could be made that my mind goes off on

tangents at times. This process was abetted by seeing a Morris Minor

that was to be made electric, and hearing that another one had been

done simply by putting an electric motor straight onto the drive shaft,

and putting in a higher gear ratio rear differential. This got around

many inefficiencies of a regular automotive transmission. But the motor

was probably bigger than would have normally been necessary, and

evidently it was sluggish getting rolling - not a surprise. It probably

also ran at a rather high RPM on the highway.

So I started thinking the Minor should work a lot better

and need a smaller motor with

even a two speed transmission. And, that any belt transmission would be

far

more efficient

than a geared transmission oozing oil around. Also, a belt transmission

with reducing pulleys

would eliminate the need to change the differential.

Then there's that

clutch pedal idea. On pressing a clutch pedal, a belt-clutch system

could

loosen belt tension... or tighten it. ...Or, it could loosen one

belt and tighten another. When the clutch pedal was pressed 1/2 way

down, both belts could be loose - neutral. When it was fully pressed,

the pressure of the foot could tension a belt (or pair of belts)

providing a very large reduction ratio - a low 'gear'. Thus to start

up, the right foot would press the electron pedal to start the motor

turning, and the left foot, already part way down, would gradually

press harder on the clutch

pedal to engage low gear. Once the car had sufficient speed, the foot

would be lifted, smoothly shifting the car into high gear to allow

driving at higher speeds without undue motor RPM.

Or we might conceive that this clutch pedal could be

replaced by a lever similar to an automatic transmission lever, which

would lock into place wherever the lever's button was released. Then

the car could be kept in either gear effortlessly.

And then we can conceive of having the lever tighten still

another belt and pulley in the middle of its stroke and having a

3-speed transmission with two neutral positions, at 1/4 and 3/4 of the

travel.

Somehow, this seems simple compared to a variable torque

converter, and still highly efficient. Perhaps

the variable torque converter could be done with belts instead of a

planetary gear, too... tho I can't see how to make something that

functions like a planetary gear out of belts and pulleys.

A final note: The front wheel drive has an efficiency advantage. In a

'regular' rear wheel drive, the differential must always be turned by

a 90 degree driveshaft gear, creating losses, whereas in the

front differential Sprint, the entire

differential and both drive shafts are (will be) turned in unison by

the drive belt except when

cornering: the gear teeth don't move, so it's essentially lossless.

The Electric Weel Motor & the 4-Runner Truck

Of course, one way to avoid

a transmission is to have a motor with stupendous torque that can turn

vehicle wheels directly. One simple thought I've had for the still

unmade Electric Weel motor is to make the stator in eight octagonal

sections. What escaped me in that idea is that with 27 coils, 3-3/8

coils would go on each section. That might be awkward! If instead 3

coils

went on each section, the motor would have 24 coils, spaced slightly

farther apart. The rotor would

have 32 magnets instead of 36.

Then the easiest way to accommodate those coils would be

to use two 48 volt motor controllers each running 12 coils (4 in series

in each phase), instead of three 36 volt controllers each running 9

coils. It thus reduces the cost by one motor controller - 500$ at my

present prices. I'll probably want to raise the voltage specs on a few

of the controller components to have safe margins. However, I now

consider that if 48 volts was plus 24 volts and minus 24 volts, or if

the drive system was floating ground compared to the chassis, it would

be virtually safe as far as electrical shocks. 200 amps times 2

controllers at 48 volts would be 19200 watts. 400 amps - 200 from each

controller and four battery set - would provide around 240 foot-pounds

of torque. (down from 270.)

It is of course one thing to have a plan, but there are

some other things that have higher

construction priority for now. but I drew out the design for one

octagon piece on a piece of legal size paper, using the actual metal

center, a ruler and a triangle. It seemed surprisingly small and pretty

simple. Simple and straightforward raises priority!

A problem does arise in the inability of the CNC router...

any router... to cut a sharp inside corner. Maybe I'll try finishing

them with a chisel?

Homemade Segway Clones!

On the 30th someone e-mailed me with a link to his

homemade "Segway" pages after

seeing one of my motors on a discussion list. Very

cool to make your own if you like that

form of

transport! His write-up details the "Kalman Filter", microcontroller

and gyro sensors used to give self-balance to the system, and his

first,

second and projected third "Segway" projects: Runner I, the improved

Runner II, and Runner III - a project for some rainy weather.

| Runner II |

Die Plattform wurde dabei aus Alu-Riffelblech angefertigt. Die Motoren

mit integriertem Getriebe und direkt montierten Rädern

sorgen für eine größere Stabilität.

Z.Z. ist noch keine Elektronik eingebaut (15.1.12).

Hurra, Runner II läuft.

|

His site has schematics,

circuit board layouts, complete program source code for the ATMega in

'C', and

even a PDF book about the operational concepts, Das Programm-

und Filterkonzept für meinen selbstbalancierenden

Runner. - von W. Schmidt. I must confess to not understanding much

of it. (The language was beyond me!)

Even more surprisingly, it turns out this German person

had no idea where I live when he wrote me, but he's coming to see

western Canada including Victoria this July.

A Superior EV Charging System... a superior battery monitoring

system...

and an old "Derelectric" car: the 1982 Mazda RX7

J1772 EV Charging Plugs & Sockets

It seemed galling that "EV charging Stations" were being

installed all over town, but I couldn't take advantage of them - the

Mazda has an

ordinary 120V plug, and no ordinary socket was present at any of these

charge stations. (Nor have I seen any EVs using the stations except

those belonging to the owners of the station, eg, an Esquimalt

municipal vehicle at the Esquimalt public library.)

It seemed galling that "EV charging Stations" were being

installed all over town, but I couldn't take advantage of them - the

Mazda has an

ordinary 120V plug, and no ordinary socket was present at any of these

charge stations. (Nor have I seen any EVs using the stations except

those belonging to the owners of the station, eg, an Esquimalt

municipal vehicle at the Esquimalt public library.)

It's like they're really just being installed for show:

"Look what we're doing for the environment - but hey, it's not for YOU

- Get your low-life EV out of here or we'll have it towed!"

But after getting a good look

at one at Westburne Electric [picture], I began to hope that they maybe

weren't very complex after all and could be used.

Also I realized that probably there's no line

voltage present on the main pins unless the plug and socket were mated,

for electrical safety outdoors in rain, dew or frost. This is in fact

the case: it's simple enough and the voltage is shut off until it's

plugged in.

There is however one huge problem: while the J1772

claims it allows for 120 volt charging, there is in

fact no neutral pin to get 120 volts from. I'm trying to make EV's more

practical with separate chargers on each battery. I have yet to see a

240 volt battery charger in any store, and yet

this so-called standard doesn't allow for 120 volt charging. Evidently

for the

sake of one pin on the plug, it shuts out smaller and much more common

vehicles like e-bikes and scooters, handicapped scooters, and converted

EV's such as

mine.

Naturally Wikipedia had an article on them. There was a

diagram of what circuits were needed for both the plug and the socket.

(It doesn't make sense - surely pin 4 and 5 are reversed on one

end... but which end?)

The article said:

J1772 signaling circuit

The signaling protocol has been designed so that:

- supply equipment signals presence of AC input power

- vehicle detects plug via proximity circuit (thus the vehicle can

prevent driving away while connected)

- control pilot functions begin

- supply equipment detects plug-in electric vehicle [PEV]

- supply equipment indicates to PEV readiness to supply energy

- PEV ventilation requirements are determined

- supply equipment current capacity provided to PEV

- PEV commands energy flow

- PEV and supply equipment continuously monitor continuity of

safety ground

- charge continues as determined by PEV

- charge may be interrupted by disconnecting the plug from the

vehicle

The technical specification was described first in the 2001 version

of SAE J1772 and subsequently the IEC 61851. The charging station puts

12 volts on the contact pilot CP and the proximity pilot PP (also "Plug

Present") measuring the voltage differences. This protocol allows it to

skip integrated circuit electronics as they are required for other

charging protocols like the CAN Bus used with Chademo or – the SAE

J1772 is considered robust enough for a range of

−40 °C to +85 °C.

The bare car side J1772

plugs cost over 100$ (ouch!) on the web, but I found a 3D printer

design to print the body for one. In the absence of any other way to

make it work, I'm going to make up a plug for the car that uses the

ground pin as neutral. I can plug the front chargers into one phase and

the rear chargers on the other to roughly balance the load - which is

under 5 amps anyway. According to the spec, the ground wire has 'ground

fault detection'. So the question is, will the breaker trip out with

the slightest inevitable load imbalance, or will it tolerate a certain

amount? I certainly intend to find out. And I'll try everywhere.

Hopefully owners will disable or somewhat desensitize the ground fault

circuit if it keeps getting tripped by people trying to charge. A

"standard" that only works with 40,000$+ cars is of little use to many

of the few EV'ers actually driving around. And the 40,000$ EV's

generally have a long range and little need to plug in everywhere they

go, whereas the 120 volters are the vehicles that really need to plug

in everywhere.

I'm somewhat hopeful that the 'ground fault' detectors

won't be very sensitive, because the body of the car is supposed to be

grounded to the wire, and that therefore the idea will work if the load

is anywheres near balanced. Cars get dusty and dirty, and they would be

almost bound to trigger a sensitive circuit in the rain. This would be

a nuisance to the charging station owners. The above Wikipedia spec

also says the car ('PEV') monitors the ground continuity, as

well as the supply equipment. This leaves a lot open to interpretation

about what the car is expected, or permitted, to do with the ground

wire.

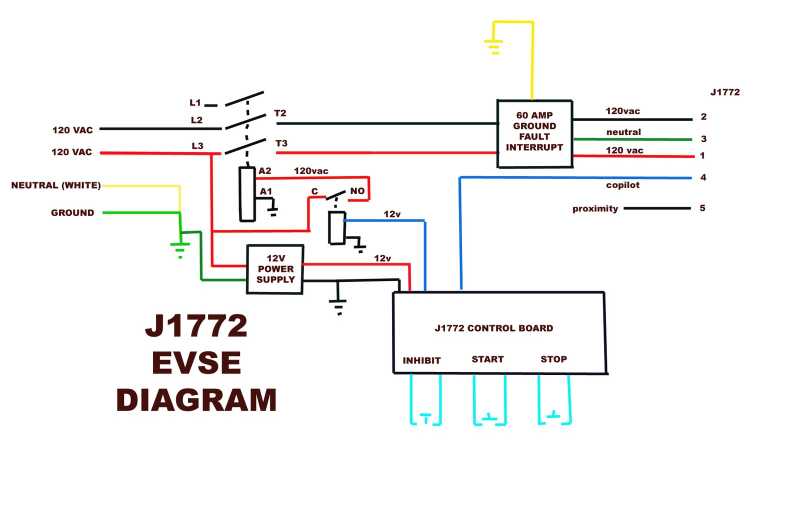

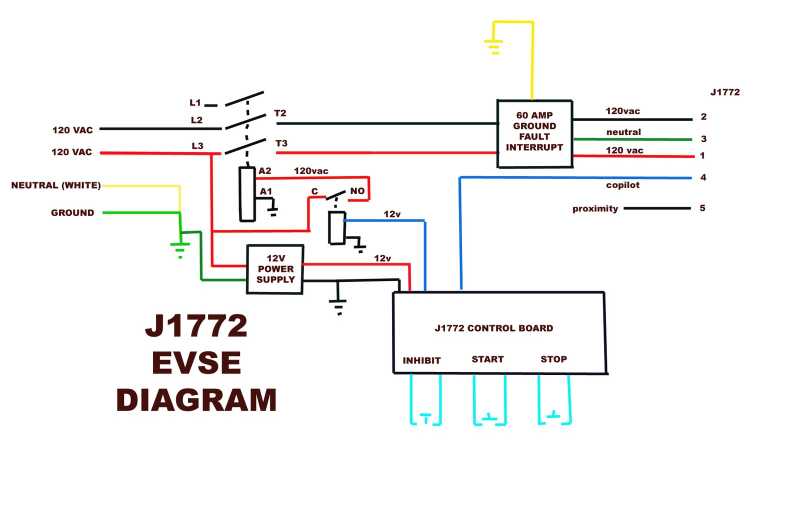

Later I found the following diagram, which shows inside

the charging unit, with neutral and ground tied together... and on the

car socket, pin 3 is labeled neutral instead of ground.

If this isn't a mistake, current flow is permitted in a neutral

wire, and one can get 120V. That would seem more reasonable than

excluding 99.9% of battery chargers in North America, but I'm not sure

how the ground fault breaker would work, and it can't be both 'neutral'

and 'ground' in conformity with normal North American

electrical practices. But it's also unusual that neutral and ground are

tied together inside the charging unit. Who can really tell - maybe

using 120V chargers will work fine, maybe it won't. It's certainly

worth a try, since these stations are popping up all over the place.

On a final note, regular 120VAC sockets out in the rain

are dangerous

electrocution hazards. The intent of this charging system to leave the

power disconnected by a contactor until activated when a vehicle is

sensed is good. A similar system could be made for regular outlets by

having a socket with a pushbutton on it, which is pressed by the plug

on the cord as it's pushed home. However, the cord would become 'live'

whether or not the cord was plugged in at the other end, and users

would have to remember to plug the car end in first, then the cord into

the charging plug. This would still be dangerous and people would have

accidents. The button could be on a special charging cord that plugs

directly into the car, with the note "no extension cords!" or somesuch

on it.

With somewhat more effort (walking back and forth), I can

operate as safely by plugging one end of the cord in indoors where it's

dry, and plug the car end in first and unplug it last.

A "trick" that could make a safer 120 volt charger from

regular parts would be to have no actual ground wire, but instead tie

neutral to 'ground' in the car. A contactor in the charger unit would

have its coil activated when the "ground" wire in the cord was pulled

to neutral by plugging in the car. But this would be an unorthodox use

of plugs and cords that might lead to unanticipated problems, obviously

no ground fault breaker could be employed... and like regular sockets,

they probably won't be found at EV charging places.

More Mazda Miscellany

On the 4th I put in a both-sides carpeted plywood cover

over the battery well in the rear of the Madza RX7,

with a few more pieces of matching carpet surround. In addition to

looking nice and providing a cargo space, this muffled the

noise coming through the battery well from the rear axle and wheels. I

was a little disappointed by the sonic results. The rear was audibly

muffled, much quieter. But I seemed to be hearing all the same

unmuffled sounds now coming from the front, as if they had simply moved

forward to compensate. But no

doubt the sound level is

down a few dB.

Later on I noticed that it was quieter in third gear than

in second, and even quieter out of gear. That makes it transmission

noise, probably entering the car from both the front and rear end of

the driveshaft. Not much to be done about that besides insulate. People

outside the car say it's

quiet. The silence when stopped at red lights is great!

Sometime I'd like to

get the

car up on a hoist, or over a pit, to grease the suspension and steering

(it's 31 years old!). But Tom Sawyer and I managed to crawl underneath

and spray zinc "galvanizing compound" and then textured black paint on

the

rusting angle iron battery well supports at the rear, on flat pavement.

Then Tom sprayed the bumper black as well, which had various white

scrapes on it and looked pretty ugly. Another day we sprayed over the

flaking black paint at the sides of the windshield. I've done the

mechanical and electrical stuff to make it work. Tom has supplied a

couple of batteries to up the range and has done a lot of what's making

it look presentable! I presume I'll be helping him out when he gets an

electric car or a car to convert to electric, which he very much wants.

I bought an 11th

power adapter, for the 11th battery, and

on the 7th I wired it up as a float charger. It was only 3.3 amps

instead of 5, and 25$ + taxes - including a discount. I'm now paying

for having bought only 10 of the 3.95$ ones at XS Cargo instead of 30

or 40! But one can do better (than 25$) pricewise and also get more

ideal 14 volt,

6 amp

adapters, by shopping on line - worth it for several for a car charging

system.

This adapter was 15 volts, and instead of opening it, I

simply

cut the plug off the end and soldered on two diodes on the end of the

"+" wire to give a 1.2 volt

drop to the 13.8V float voltage (another 8% charging efficiency loss

right there), and then a .82 ohm resistor to limit the current when

the battery was low (more loss). I used the larger resistor since it

was only a 3.3 amp charger.

Captain's log

On the 10th I put columns on a piece of paper for date,

mileage and trip meter, amp-hours, watt-hours and comments, and I

started keeping track of my driving. Short as the trips were (the

longest one being 13 Km), I went

171 Km by the end of June, using about 32 KW of electricity - 3.20$

worth if charging was 100% efficient, but also if none of it had been

done 'for free' from the solar PV panels.

On the 12th, Rick Pitts, who had nicely converted an S10

pickup

truck came and saw the RX7. The two conversions had fairly similar

parts, so it was rather to my surprise that he was impressed by the

performance and handling. The big difference is the batteries. He lives

out of town and a 20 Km range would be inadequate. His S10 has

24 six volt golf cart batteries, which would weigh

around 1500 pounds - 3/4 of a ton. He said it's like driving a concrete

block down the road, and the brakes are only just adequate. The RX7 had

only about 450 pounds of batteries, the four NiMH'es being only about

115 pounds or so.

The weakest

lead-acid battery seemed to be getting better inch by inch - I think

with cycling, but perhaps just because of warmer weather, as suggested

by Jim Harrington. But I

wanted kilometers rather than inches, and on the 13th I changed it for

a new one that Tom brought me to use. I

put the old one outside under the wiring closet, to use with the solar

collector

system (see under 'Electric Equipment Projects').

After I got the windshield wipers working last month, I

thought they'd loosen up with use. Instead they went lethargically, had

to be pulled by hand a couple of times to get them moving again, and

then seized up again. After driving home in the rain with no wipers on

the evening of the 17th, I took the passenger's side pivot apart, with

difficulty

twisted the rod out of the pipe with vise-grips (it should have been

*loose*), filed off some rust from the outside of the rod, cleaned and

greased it,

and reassembled it all. Now they work without hesitation.

I don't get around a lot, but I drove the Mazda almost

every day and with all the electric

driving, I didn't buy gas for the Tercel from April 29th until June

22nd. Unfortunately all the money saved on gas and more is going for

extra

car insurance. It is amazing how artificial monetary factors often act

to keep us from

making the best real investments, what with having to pay extra in

order to do

the right thing, or obtaining savings, eg, energy savings, that are

trivial in monetary terms compared

to gigantic 'imposed' expenses that we may have little control over

such

as a mortgage and property taxes.

Longest drive: 13Km

On the 26th I

decided I needed the

6-tray NiMH battery from the Mazda for the Chevy Sprint experiments. I

decided to first see how much "ultimate" range the Mazda had with the

present batteries. I drove it 8.1 miles (13Km), the last mile going

around streets near home. Voltages under load went from 130's to 120's

to 110's and finally dipped down into the 100's, the lowest I've driven

them to. The CycleAnalyst showed 17.5 amp-hours - 2310

watt-hours at 132 volts. That's the most I've used in one charge. 17.5

amp-hours

doesn't seem like a lot of juice to get from batteries rated from 60 to

95 amp-hours. Part of the problem is doubtless that continuing currents

of 50 to 150 and even 200 amps are very high for regular marine-RV type

batteries. This is a less obvious reason for using golf cart batteries,

which are made to handle higher continuous currents. Battery

performance improvement with reduced currents is also a reason an

"ultra-efficient" car drive system will give a much improved driving

range.

After the trip two of the NiMH batteries were below 12

volts, eg 11.8.

They surely

had little life left. The other two were just over 12v, eg 12.1. The

lead-acids were all above 12.2 volts. If I beefed up the charging of

the NiMHs to get them up to 14.0 volts would it be good for 10

miles/16Km? Then again running lead-acids down too far with no

sodium sulfate in them is worse than running down the NiMHs. (Now 3 of

the 7 PbPb's have sodium sulfate added when new, but none presently

installed are ones 'renewed' with sodium sulfate.)

Three or four batteries were still at 12.4 volts and could

have gone a good further distance. The best battery

appeared to be the

"reconditioned" one I had purchased at Battery Doctor. It was still at

12.6 volts and so apparently could well have driven as far again to a

total of at least 16 miles/26Km.

Need for individual battery monitor

Of course, while the ever decreasing voltages can be seen

by

glancing at the CycleAnalyst while driving, there's no indication of

which batteries are dropping by how much. A manual measurement of each

battery afterwards is tedious and can only give 'after the fact'

readings. Is it mostly the NiMHs are at

the end of their charge and dropping way down under load?, or are they

doing okay

while the

weakest lead-acids are going down to 7 or 8 volts?, or are they all

dropping more or less equally? These are the sort of questions my

planned individual battery monitor is intended to answer, pretty much

automatically, while driving.

The point was acutely illustrated after a drive on the

29th. The 120 volts DC was low enough that I checked all the batteries.

I found one at 10 volts. It would obviously have been pushed much

lower while driving - into battery damage territory. In removing a

battery 3 days

previously, I had accidentally left a charger unplugged. (Wouldn't I

make a good surgeon?) The

monitor would have shown this in good time. When I turned the car on,

probably on the previous trip, I would have seen

that one battery didn't seem to be charged, and if I'd missed that, at

some point it would have

gone yellow and beeped when I stepped on the electron

pedal.

After the same drive one of the NiMHs was down farther

than the others, too. I might try to drive too far for it, too some

time -- without the monitor.

Ultrasonic Noise!

The evening after driving 13 Km, my tinnitus was loud and

piercing. Yet I had

played no music nor worked with noisy tools. It seemed to me I had

noticed this before after driving the Mazda. I looked up the PWM

frequency of the Curtis 1231C motor controller. It was 15KHz --

the same frequency as the TV flyback transformer whine that

originally caused my tinnitus when I was 6 or 7! There it was: the car

apparently makes a piercing ultrasonic sound (15KHz is ultrasonic to me

these

days) that is apparently damaging my already mediocre hearing. That

squeal would be coming off the controller, but more so as vibration of

the coils of the motor. I decided to carry earplugs in the Mazda and

use them. Another brand of controller said it was 16KHz.

In my controllers, the 'CRM' frequencies may go as high as

maybe 30 KHz. But the frequency is variable. It drops lower and lower

with motor speed and as the load decreases, and is quickly into the

audio range where its loudness can at least be heard and assessed. At

higher speeds or low loads the CRM signal may be absent. In the car

the CRM is gated on and off by PWM at around 300Hz, so it's only there

part of each second. 300Hz is audible (providing some warning to

pedestrians), but it has far less sonic energy

than 15,000.

So my controllers aren't 'innocent', and in fact the motor

coil humming will probably be heard, but they'll probably be much less

of a problem, and a less hidden problem, than fixed frequency units in

the worst "near ultra-sonic" frequency range for human ears, often more

felt as a discomfort rather than heard. With my units, no one is likely

to suffer hearing loss - without even knowing why.

120 volts better than 132?!?

The next day, the 27th, I took out the NiMH 'stack of

trays' battery to use it in the Chevy Sprint experiments. I put a size

24 battery from the back in its place. In removing one battery of

eleven, 10%, and dropping the voltage from 132 to 120 volts, one would

expect a proportional rise in the current needed to move the car.

Instead I got a surprise. When I left home, the car seemed to have more

pep, or at least no less, rather than less - if anything at slightly

lower currents. I drove 4.4 miles using

just 8.1 amp-hours - my first recorded time of using under 2 amp-hours

per mile. With the lower voltage, this translated to even more

watt-hour savings:

8.1 AH * 120 V / 4.4 miles = 221 WH/mile or 137 WH/Km.

It's hardly been below 270/170 before, and sometimes above

300/185. True, I neglected to reset the trip meter on the Cycle Analyst

before starting and the amp-hours estimate might just be slightly off,

the streets were quiet and the battery made about 30 pounds gone from

the car... but the route had the usual hills and I wasn't being

super-light with my foot.

It appeared the car had more range with 10 batteries

than with 11! Could it be that the motor or controller just runs more

efficiently at a lower voltage?

If this was verified by further 120 volt drives, I

certainly wouldn't be bothering to add another battery. Instead I might

be

trying out 108 volts again to see how the statistics stacked up. But in

the

next couple of drives I'd left a charger unplugged and couldn't trust

the rather high

figures because of the low battery. The third drive was 4.2 miles using

9.06 AH. That's 260 WH/mile, 165 WH/Km, with a very light foot on the

pedal, and the next one was 270/172. I'm guessing I made some mistake

in the first 120 volt trip's

readings. Any slight drop in watt-hours is probably explained by the

shedding of the 30 pounds of the battery.

Pipe Battery Problem (It's the chargers!... mostly)

The two newest 6-pipe NiMH 60 D cell batteries are a mix

of older batteries, some of which were in soldered together cases that

I took apart. They seemed very

good and after a drive were down to around 12.5 volts along with the

lead-acids.

But the one in the stacked cases, and the older bottom one

in the box, made of twelve 6-volt tubes, previously used in the Sprint

tests and then in the boat with Electric Caik outboard, were getting

almost as discharged as the weakest PbPb after 5 miles. The worst one

was the twelve 6-volt tubes in the bottom of the box. I suspected that

one of the sets of tubes wasn't making contact properly.

On the 7th I took the battery box apart. When I pulled out

the bottom battery I found it had not one, not two, not three, but four

end caps broken loose (two of them on the same series pair - and they

were all 'plus' ends) and only three tubes were working. Yikes! And yet

I

seem to remember testing every tube before I put the sets of 6

together, and fixing, at least, 2 or 3 of the new ones that I'd just

made. (This was the morning after thinking the voltages were getting

low

unexpectedly soon near the end of a drive, so one or two of the breaks

may have happened just within a day or so.)

I glued the caps back on and put the box together again

the other way up, with this suspicious set of 12 six volt tubes on top

where I could keep an eye on them. Some thoughts are:

- that the caps are ABS while the pipes are PVC. (There's

supposed

to be a "transition glue" for both materials in the hardware stores.)

- That it's possible but not easy to twist an end cap off when

glued with the present methylene chloride solvent, which seems about

right in case access to the cells is needed. Having them come off by

themselves, of course, is no good.

- that this battery had the pipes oriented vertically in its

original box. The means the weight of the batteries was bouncing up and

down, eg with waves on the sea or being handled roughly or dropped,

stressing the end caps.

- These particular tubes have a "U" spring of nickel-brass on the

plus end, a supposedly advantageous feature to help hold the cells

under a bit of pressure. This may have had some odd effect - maybe

there's more pressure on the caps than with other tubes.

- I think it's the first time I've had even one cap accidentally

come loose, so I think I'll just see how they all hold out now.

The next day, the 8th, this battery seemed to do okay,

while the other low one, the one in the 6-stack of 3D printed cases,

was about empty (reading 11.99 volts) on return from a too long drive.

Without knowing what it's problem was, I decided just to replace part

of it at a time and see what happened. Before dark, I pulled it from

the car and replaced the bottom tray, and the cells in the second from

bottom one. The "-" terminal of the 2nd tray seemed quite loose when I

was removing that tray. Perhaps it may not have been connecting, but

the cells in it had the exact same voltage as the others. Then I put it

back in the car and got it on charge for the night. Ideally I'd have

replaced 1/2 the battery instead of 1/3, but I now only have 20 free

NiMH D cells.

On the 10th I took a an 8 Km drive. The same two

batteries, in spite of it all, were at the end of their charge while

the other two had a few Km left in them - about the same as before. I

started thinking about upping the low ones to 70 amp-hours to

compensate.

It would at least be simple to add one more tray to the

stack of 6 - I had made it with that in mind. But I persevered and

swapped out the middle two trays with the ones previously removed from

the bottom two which had no apparent effect. Most of the trays had a

lower voltage following the drive, but one seemed to be more fully

charged. It also seemed to have a bad connection. I suspected the bad

connection was the problem.

Naturally one bad connection drops the range to less than

5/6 - maybe to 3/4 or worse - owing to the higher currents being drawn

from the remaining five banks.

The tube batteries showed no obvious problem. With the end

cap problems, probably from the push and pull on individual tubes from

the copper "springs" in between them, I might want to break up the 6v

tubes and make 6 new 12v tubes with the same cells. Those would have

1/2 as many end caps, with no special stresses on them.

Finally I put in a 7th tray, and a 7th pipe. In spite of

the theoretical added capacity, at the end of an 8.5 Km drive, they

were down to 12.0 & 12.1 volts while the other two were still at

13.3 or so.

After all that, it finally occurred to me to check

the voltages when the car was charged, instead of only after a long

drive. On the morning of the 13th the lower ones proved to be only

about 13.7 volts while the higher ones were at 13.8. That seemed to

explain the differences, but evidently none

of them were being fully charged - at least, not in 8, 12 or 20 hours.

The chargers were putting out about 14.0 volts, but into no load. Going

through the .62 ohm resistors, the charging current drops more and more

as 14 volts is approached. At about 13.8 volts, only 300mA is flowing,

or 50mA per 10 amp-hour bank, and at 13.9 volts, it's half of that,

25mA. 50mA may not even exceed the 'idle' current once charged, and so

they won't charge up to the desired 14.0 volts at all.

I changed the resistors that set the regulated voltage in

the low

pair of chargers and got

them up to 14.11 and 14.07 as measured in the lab. (It's slightly pot

luck

with no adjustment potentiometer.) As wrote about this, I considered

that I should probably raise them all ideally to about 14.15. Without

the current limiting resistor, 14.2 would be too high, but with it, the

batteries probably won't get above 14.1 or so. The resistor will

prevent excessive currents. Or, anywhere from 14.05 to 14.15, a smaller

series resistor would bring up the voltage more quickly and closer to

the set voltage. But that would need a charger either with more amps

capacity, or one that would do constant current at its maximum capacity

until it reached its set voltage.

I decided to do more measurements on the NiMH batteries,

charged and discharged, over a few days before doing anything more.

With the weak lead-acid now out, if

the NiMH's would get up to the optimum 14.0 volts, I figure the car

should have perhaps

another 3 to 6 Km of range. 12 to 15 Km will take me a few more places

than 8 or 9. 20, 25 or 30 would start making a big difference.

Then I started thinking about the 13.8 volt float chargers

for the lead-acids... maybe for the same reason those 13.8 volt charges

should be upped to 13.9 or 14.0? Some of them already were 13.9... were

those batteries the ones that were staying highest after a long drive?

At the end of all this, the NiMHs were still only charging

to about 13.8 volts, and the lower ones to 13.75.

Lead-Acid versus NiMH Float Charging

The float charging turned out to be the opposite of what I

originally expected.

The PbPb batteries charge and attain full charge at a lower voltage,

then rise up to near the 13.8 volt float charge voltage when they're

full.

Since the chargers put out their highest current, 5 amps, at around 11

to 11.5 volts, and less and less as the voltage rises towards 13.8,

the lower voltages mean they charge more quickly, in relative terms.

The NiMHs, on the other hand, rise quickly to higher

voltages at

lower states of charge, and thus they end up charging much more slowly.

8 or 10 hours wasn't enough - they were needing a whole day, and they

only seemed to hit about 13.75 to 13.85. At that the NiMH batteries

would be only

partly charged and were being drained to 12 volts while the lead-acids

still had

plenty of range left. Thus with the weak lead-acids having been

replaced by strong ones, the NiMH batteries, which should have been

great, were definitely limiting the range of the car.

Partial workaround solutions would be to set the chargers

to a

voltage

bordering on "too high" like 14.15 instead of 14.0, and to reduce the

charging resistor to .4 ohms (at 10 watts). That would mean that at 12

volts, the chargers would be being pushed to their 5 amp limit, but

would source somewhat higher currents than before as voltages rose.

As a first step to seeing the difference, I took out my

regular 6 amp battery charger that's set to 14.2 volt cutoff for

NiMHs, and started more quickly charging up the 4 NiMHs, one at a time.

Surely having all good, full batteries would provide a 20Km range! It

helped, but it too cut off without getting them fully charged - and the

voltages actually dropped again once the cells were back on 'regular'

float charge.

13.8 volts seemed to be about all I was getting.

Nevertheless on the 19th I drove 6.9 miles/11.1 Km on a single well

charged charge. 3 of the 4 NiMHs were down to 12.0 volts as measured

afterward. They may have had another kilometer or two in them above 10

volts, but no more. This didn't get put to the ultimate test. The

lead-acids were all over 12.2 volts and mostly over 12.4, indicating a

few more kilometers were available from them.

More Amps & Motor Controllers

The Mazda uses around 25 to 95 amps cruising along the

street, depending on the slope of the road. It can easily use 150 to

250 amps when accelerating or going up a steeper hill. And that's at

over 100 volts. The Electric Hubcap seems to have pretty high torque

per amp, but noting the RX7 performance, I'm considering that pumping

200 or 300 amps

into a 36 volt Electric Hubcap motor at times will be a minimal

requirement, even with an efficient transmission and optimum motor

speeds from the torque converter. I'm putting temperature sensors into

the motors, but I'm not half so concerned about the motors overheating

(the Electric Caik Outboard hardly got more than cold at 50-60 amps) as

I am about my motor controllers blowing up. Theoretically they'll take

240 amps continuous, and higher surges for short periods...

Theoretically!

Related to this, someone looked at my controllers and

pointed out that a problem with TO220 and TO247 transistor packages is

that the screw-down hole is at one end while the actual semiconductor

inside is at the other. The active end isn't being pressed against the

heatsink very well, and if contact isn't good, the heat has to travel

across the metal tab to the area of the screw before it's dissipated

into

the heatsink, so the transistor is running hotter. And as someone keeps

pointing out on the motor controller discussion list, "Heat, not

current, is the enemy." The TO247 seems better than the TO220, but

still at very high amps, thermal runaway is possible. ...and what if

that plastic around the edges isn't exactly flush with the

metal? Potentially it could actually hold the metal off the heatsink.

My early controllers from 2008, which weren't very well current limited

and might well have pushed out a few hundred amps, often burned up,

seemingly, or so I thought, from high currents causing sudden thermal

runaway.

The thermal transfer aspect of the design may bear some

investigation and measurement - or just redesign to ensure the best

attainable heat flow from that spot on the lower right where the

silicon actually is, to the heatsink. Maybe even a copper heatsink bar

under them instead of aluminum (which is inevitably aluminum alloy,

which is less heat

conductive than hard-to-get pure aluminum).

Electric Equipment Projects

Renewed

Lead-Acids for Solar Batteries

With having the 'renewed'

PbPb batteries that didn't seem to

have enough capacity to use in the car, and which nevertheless should

have hundreds of cycles in them and might well improve with use, I

decided I should use them with the solar PV system to increase the

storage capacity, which was quite small all along and had shrunk with

the loss of most of the NiMHs, now used for cars.

I decided that rather than bring the batteries into the

house and upstairs, and having to vent the closet to the outdoors in

case of gasses, I'd run a long wire to the ground and just put them

there, outside below the 12V wiring closet. I used some #14 house wire.

Rather thin, oh well - the hole in the wall was small. The bare ground

wire would be ground, the white wire (taped red) would be to the main

house supply (which is 14.0 volts in the sun, dropping to 12 or less at

night, via a

circuit breaker), and the black wire (also taped red) would be the